General Description

The MAX6715–MAX6729 are ultra-low-voltage microprocessor (µP) supervisory circuits designed to monitor two or three

system power-supply voltages. These devices assert a system reset if any monitored supply falls below its factorytrimmed or adjustable threshold and maintain reset for a

minimum timeout period after all supplies rise above their

thresholds. The integrated dual/triple supervisory circuits significantly improve system reliability and reduce size compared to separate ICs or discrete components.

These devices monitor primary supply voltages (VCC1) from

1.8V to 5.0V and secondary supply voltages (VCC2) from

0.9V to 3.3V with factory-trimmed reset threshold voltage

options (see Reset Voltage Threshold Suffix Guide). An

externally adjustable RSTIN input option allows customers to

monitor a third supply voltage down to 0.62V. These devices

are guaranteed to be in the correct reset output logic state

when either VCC1 or VCC2 remains greater than 0.8V.

A variety of push-pull or open-drain reset outputs along with

watchdog input, manual reset input, and power-fail input/output features are available (see Selector Guide). Select reset

timeout periods from 1.1ms to 1120ms (min) (see Reset

Timeout Period Suffix Guide). The MAX6715–MAX6729 are

available in small 5, 6, and 8-pin SOT23 packages and operate over the -40°C to +85°C temperature range.

Applications

Multivoltage Systems

Telecom/Networking Equipment

Computers/Servers

Portable/Battery-Operated Equipment

Industrial Equipment

Printer/Fax

Set-Top Boxes

Features

♦ VCC1 (primary supply) Reset Threshold Voltages

from 1.58V to 4.63V

♦ VCC2 (secondary supply) Reset Threshold

Voltages from 0.79V to 3.08V

♦ Externally Adjustable RSTIN Threshold for

Auxiliary/Triple-Voltage Monitoring

(0.62V internal reference)

♦ Watchdog Timer Option

35s (min) Long Startup Period

1.12s (min) Normal Timeout Period

♦ Manual Reset Input Option

♦ Power-Fail Input/Power-Fail Output Option

(Push-Pull and Open-Drain Active-Low)

♦ Guaranteed Reset Valid Down to VCC1 or

VCC2 = 0.8V

♦ Reset Output Logic Options

♦ Immune to Short VCCTransients

♦ Low Supply Current 14µA (typ) at 3.6V

♦ Small 5, 6, and 8-Pin SOT23 Packages

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

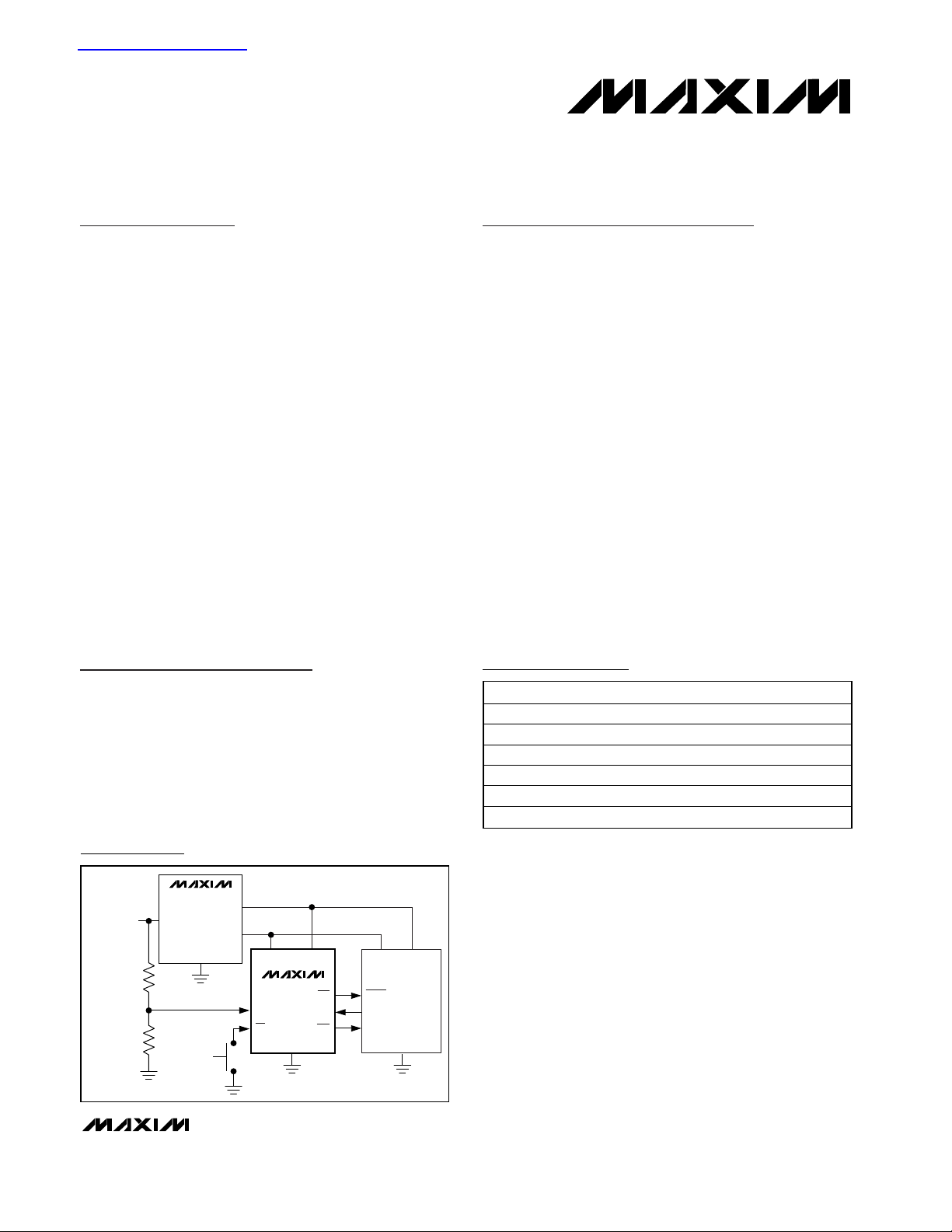

IN

OUT2

OUT1

DC/DC

CONVERTER

UNREGULATED

DC

R1

R2

VCC1VCC2

RSTIN/PFI

MR

RST

WDI

PFO

MAX67_ _

PUSHBUTTON

SWITCH

I/O

SUPPLY

CORE

SUPPLY

RESET

I/O

NMI

µP

1.8V 0.9V

Typical Operating Circuit

19-2325; Rev 3; 6/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Pin Configurations appear at end of data sheet.

Selector Guide appears at end of data sheet.

Note: The first “_ _” are placeholders for the threshold voltage

levels of the devices. Desired threshold levels are set by the part

number suffix found in the Reset Voltage Threshold Suffix Guide.

The “_” after the D is a placeholder for the reset timeout delay

time. Desired delay time is set using the timeout period suffix

found in the Reset Timeout Period Suffix Guide. For example the

MAX6716UTLTD3-T is a dual-voltage supervisor V

TH

1 = 4.625V,

V

TH

2 = 3.075V, and 210ms (typ) timeout period.

Ordering Information continued at end of data sheet.

查询MAX6715供应商

PART TEMP RANGE PIN-PACKAGE

MAX6715UT_ _D_ -T -40°C to +85°C 6 SOT23-6

MAX6716UT_ _D_ -T -40°C to +85°C 6 SOT23-6

MAX6717UK_ _D_ -T -40°C to +85°C 5 SOT23-5

MAX6718UK_ _D_ -T -40°C to +85°C 5 SOT23-5

MAX6719UT_ _D_ -T -40°C to +85°C 6 SOT23-6

MAX6720UT_ _D_ -T -40°C to +85°C 6 SOT23-6

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

2 _______________________________________________________________________________________

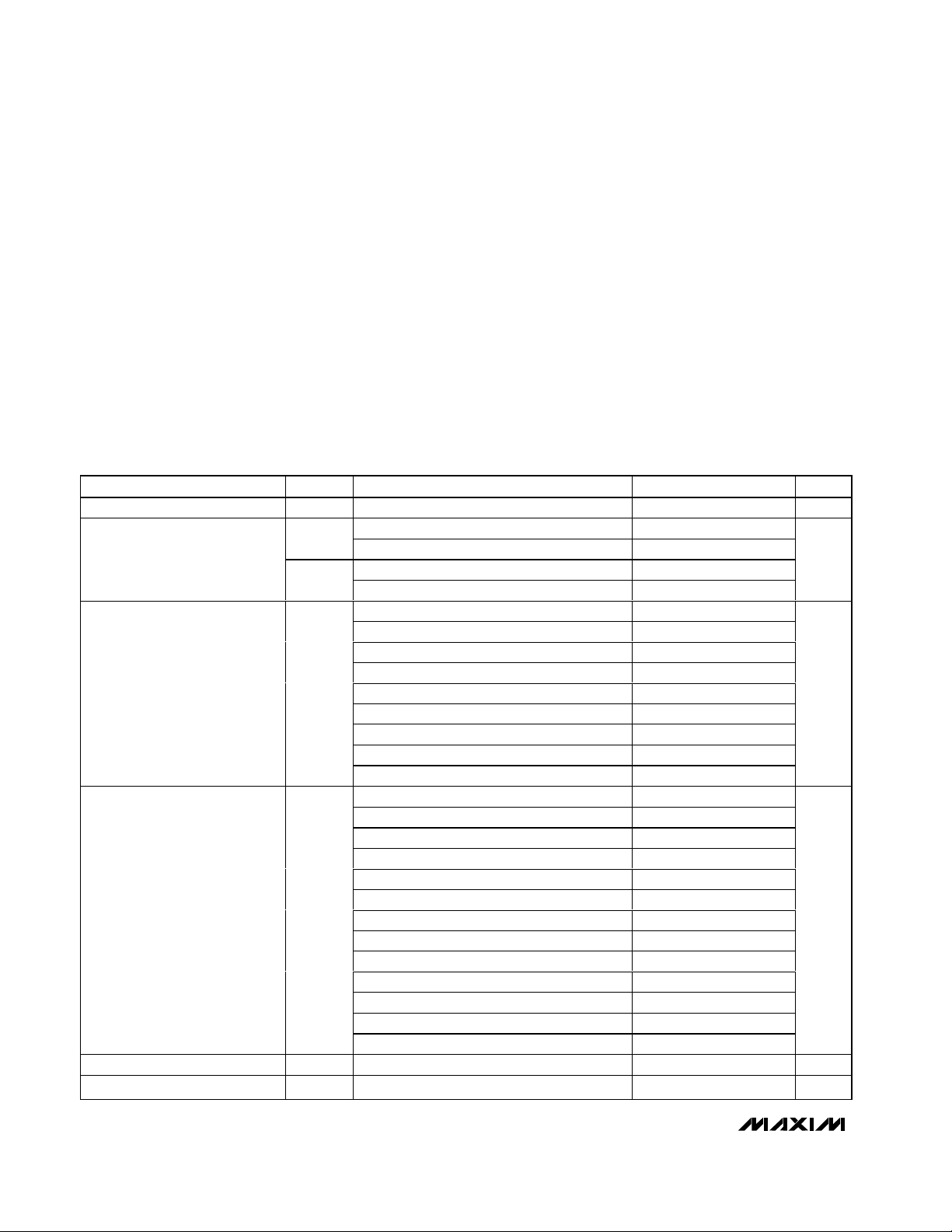

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC1 = VCC2 = 0.8V to 5.5V, GND = 0, TA= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Terminal Voltage (with respect to GND)

VCC1, VCC2 ..........................................................-0.3V to +6V

Open-Drain RST, RST1, RST2, PFO, RST ................-0.3V to +6V

Push-Pull RST, RST1, PFO, RST...............-0.3V to (V

CC

1 + 0.3V)

Push-Pull RST2 .........................................-0.3V to (V

CC

2 + 0.3V)

RSTIN, PFI, MR, WDI ................................................-0.3V to +6V

Input Current/Output Current (all pins) ...............................20mA

Continuous Power Dissipation (T

A

= +70°C)

5-Pin SOT23-5 (derate 7.1mW/°C above +70°C) ........571mW

6-Pin SOT23-6 (derate 8.7mW/°C above +70°C) ........696mW

8-Pin SOT23-8 (derate 8.9mW/°C above +70°C) ........714mW

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range .............................-65°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10s) .................................+300°C

Supply Voltage V

Supply Current

VCC1 Reset Threshold V

VCC2 Reset Threshold V

Reset Threshold Tempco 20 ppm/°C

Reset Threshold Hysteresis V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

I

CC1

I

CC2

TH1

TH2

HYST

VCC1 < 5.5V, all I/O pins open 15 39

VCC1 < 3.6V, all I/O pins open 10 28

VCC2 < 3.6V, all I/O pins open 4 11

VCC2 < 2.75V, all I/O pins open 3 9

L (falling) 4.500 4.625 4.750

M (falling) 4.250 4.375 4.500

T (falling) 3.000 3.075 3.150

S (falling) 2.850 2.925 3.000

R (falling) 2.550 2.625 2.700

Z (falling) 2.250 2.313 2.375

Y (falling) 2.125 2.188 2.250

W (falling) 1.620 1.665 1.710

V (falling) 1.530 1.575 1.620

T (falling) 3.000 3.075 3.150

S (falling) 2.850 2.925 3.000

R (falling) 2.550 2.625 2.700

Z (falling) 2.250 2.313 2.375

Y (falling) 2.125 2.188 2.250

W (falling) 1.620 1.665 1.710

V (falling) 1.530 1.575 1.620

I (falling) 1.350 1.388 1.425

H (falling) 1.275 1.313 1.350

G (falling) 1.080 1.110 1.140

F (falling) 1.020 1.050 1.080

E (falling) 0.810 0.833 0.855

D (falling) 0.765 0.788 0.810

Referenced to VTH typical 0.5 %

0.8 5.5 V

µA

V

V

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

_______________________________________________________________________________________ 3

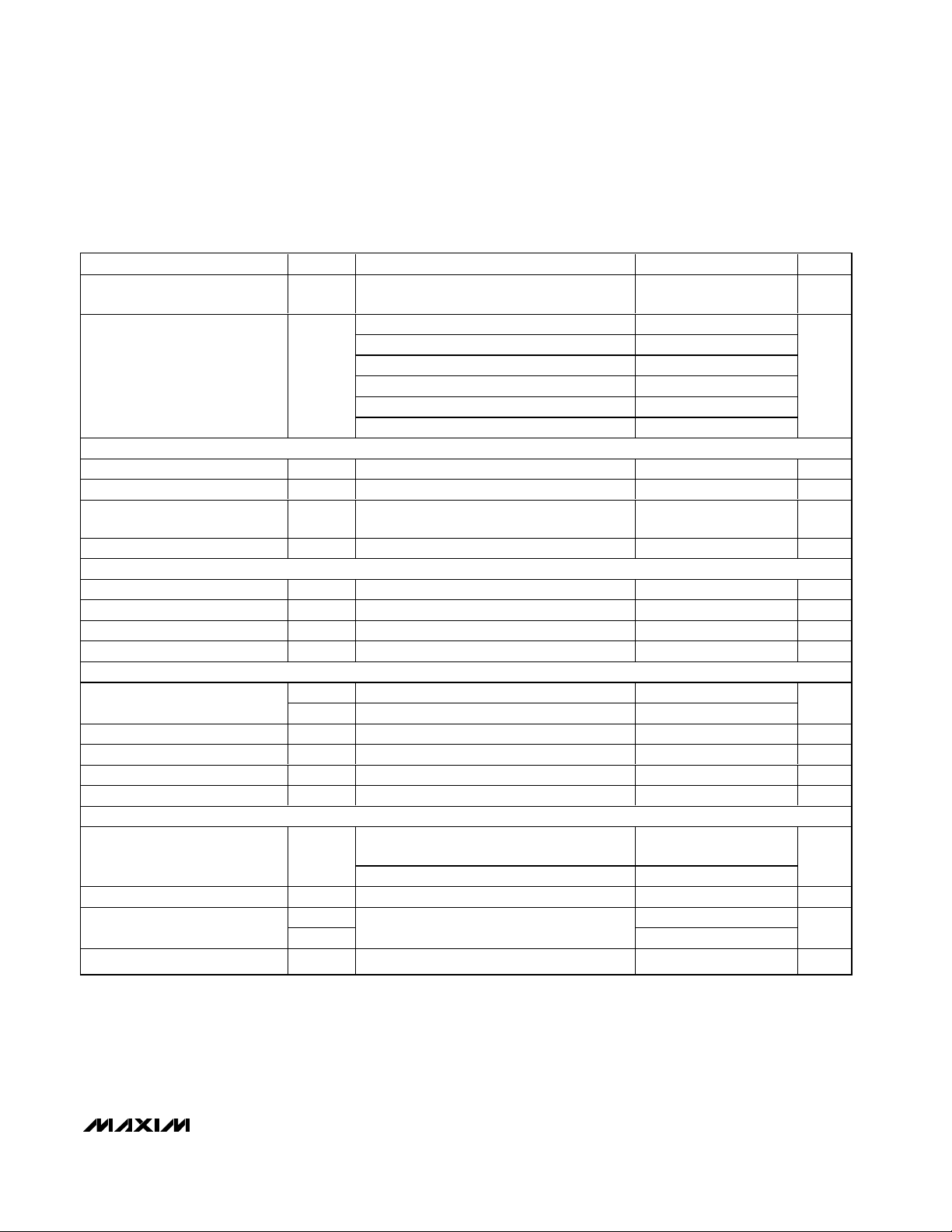

ELECTRICAL CHARACTERISTICS (continued)

(VCC1 = VCC2 = 0.8V to 5.5V, GND = 0, TA= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

VCC to Reset Output Delay t

Reset Timeout Period t

ADJUSTABLE RESET COMPARATOR INPUT (MAX6719/MAX6720/MAX6723–MAX6727)

RSTIN Input Threshold V

RSTIN Input Current I

RSTIN Hysteresis 3mV

RSTIN to Reset Output Delay t

POWER-FAIL INPUT (MAX6728/MAX6729)

PFI Input Threshold V

PFI Input Current I

PFI Hysteresis V

PFI to PFO Delay t

MANUAL RESET INPUT (MAX6715–MAX6722/MAX6725–MAX6729)

MR Input Voltage

MR Minimum Pulse Width 1µs

MR Glitch Rejection 100 ns

MR to Reset Delay t

MR Pullup Resistance 25 50 80 kΩ

WATCHDOG INPUT (MAX6721–MAX6729)

Watchdog Timeout Period t

WDI Pulse Width t

WDI Input Voltage

WDI Input Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

1 = ( V

RD

RP

RSTIN

RSTIN

RSTINDVRSTIN

PFI

PFI

PFH

DPF

V

IL

V

IH

MR

WD

WDI

V

IL

V

IH

WDI

C C

2 = ( V

V

C C

D1 1.1 1.65 2.2

D2 8.8 13.2 17.6

D3 140 210 280

D5 280 420 560

D6 560 840 1120

D4 1120 1680 2240

(V

PFI

First watchdog period after reset timeout

period

Normal mode 1.12 1.68 2.24

(Note 2) 50 ns

WDI = 0 or VCC1-1+1µA

1 + 100m V ) to ( V

TH

2 + 75m V ) to ( V

TH

to (V

RSTIN

+ 30mV) to (V

- 30mV) 22 µs

PFI

1 - 100m V ) or

TH

2 - 75m V )

TH

611 626.5 642 mV

-25 +25 nA

611 626.5 642 mV

-25 +25 nA

- 30mV) 2 µs

0.7 ✕ VCC1

35 54 72

0.7 ✕ VCC1

20 µs

ms

3mV

0.3 ✕ VCC1

200 ns

0.3 ✕ VCC1

V

s

V

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

4 _______________________________________________________________________________________

Note 1: Devices tested at +25°C. Overtemperature limits are guaranteed by design and not production tested.

Note 2: Parameter guaranteed by design.

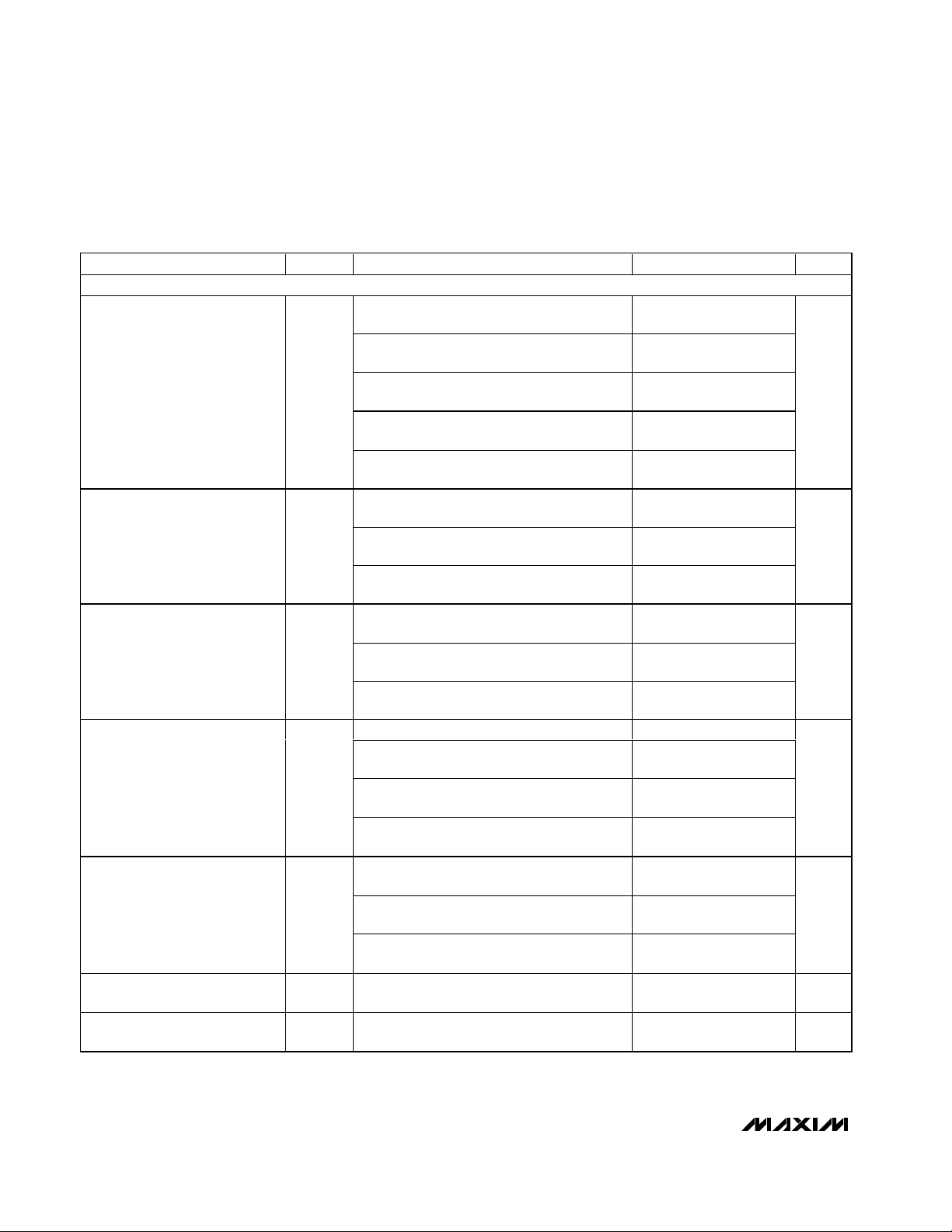

ELECTRICAL CHARACTERISTICS (continued)

(VCC1 = VCC2 = 0.8V to 5.5V, GND = 0, TA= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

RESET/POWER-FAIL OUTPUTS

RST/RST1/RST2/PFO

Output LOW

(Push-Pull or Open-Drain)

RST/RST1/PFO

Output HIGH

(Push-Pull Only)

RST2

Output HIGH

(Push-Pull Only)

RST

Output HIGH

(Push-Pull Only)

RST

Output LOW

(Push-Pull or Open Drain)

RST/RST1/RST2/PFO Output

Open-Drain Leakage Current

RST Output Open-Drain

Leakage Current

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

VCC1 or VCC2 ≥ 0.8V, I

output asserted

VCC1 or VCC2 ≥ 1.0V, I

output asserted

V

OL

VCC1 or VCC2 ≥ 1.2V, I

output asserted

VCC1 or VCC2 ≥ 2.7V, I

output asserted

VCC1 or VCC2 ≥ 4.5V, I

output asserted

VCC1 ≥ 1.8V, I

SOURCE

asserted

V

OH

VCC1 ≥ 2.7V, I

asserted

VCC1 ≥ 4.5V, I

SOURCE

SOURCE

asserted

VCC2 ≥ 1.8V, I

SOURCE

asserted

V

OH

VCC2 ≥ 2.7V, I

asserted

VCC2 ≥ 4.5V, I

SOURCE

SOURCE

asserted

VCC1 ≥ 1.0V, I

VCC1 ≥ 1.8V, I

SOURCE

SOURCE

reset asserted

V

OH

VCC1 ≥ 2.7V, I

SOURCE

reset asserted

VCC1 ≥ 4.5V, I

SOURCE

reset asserted

VCC1 or VCC2 ≥ 1.8V, I

reset not asserted

V

OL

VCC1 or VCC2 ≥ 2.7V, I

reset not asserted

VCC1 or VCC2 ≥ 4.5V, I

reset not asserted

= 1µA,

SINK

= 50µA,

SINK

= 100µA,

SINK

= 1.2mA,

SINK

= 3.2mA,

SINK

= 200µA, output not

= 500µA, output not

= 800µA, output not

= 200µA, output not

= 500µA, output not

= 800µA, output not

0.8

0.8

0.8

0.8

0.8

0.8

✕ V

✕ V

✕ V

✕ V

✕ V

✕ V

CC

CC

CC

CC

CC

CC

= 1µA, reset asserted 0.8 ✕ VCC1

= 150µA,

= 500µA,

= 800µA,

= 500µA,

SINK

= 1.2mA,

SINK

= 3.2mA,

SINK

0.8

0.8

0.8

✕ V

✕ V

✕ V

CC

CC

CC

0.3

0.3

0.3

0.3

0.4

1

1

1

2

2

2

1

1

1

0.3

0.3

0.4

Output not asserted 0.5 µA

Output asserted 0.5 µA

V

V

V

V

V

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

_______________________________________________________________________________________ 5

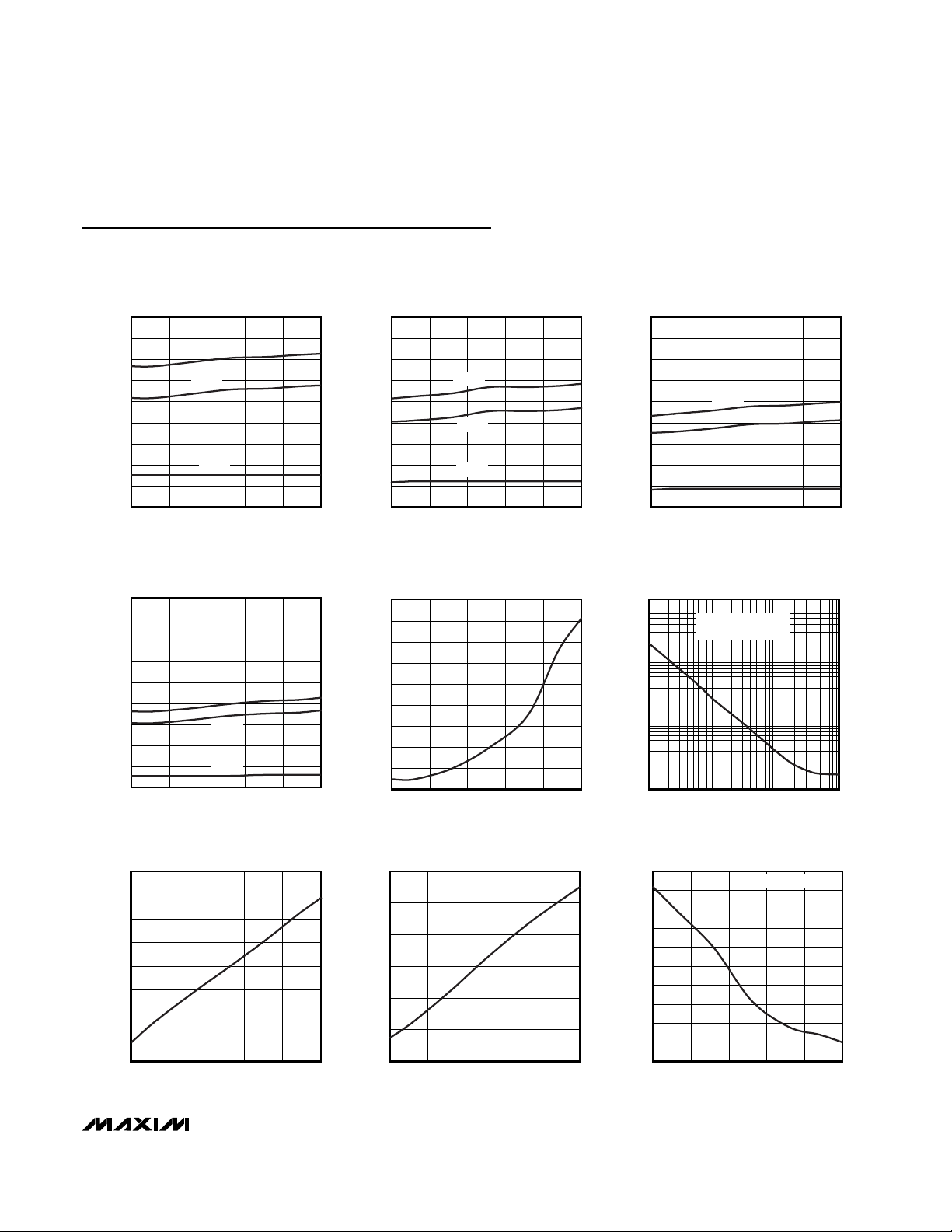

Typical Operating Characteristics

(VCC1 = 5V, VCC2 = 3.3V, TA= +25°C, unless otherwise noted.)

SUPPLY CURRENT vs. TEMPERATURE

1 = 5V, VCC2 = 3.3V

V

18

16

14

12

10

8

6

SUPPLY CURRENT (µA)

4

2

0

-40 10-15 356085

CC

TOTAL

ICC1

ICC2

TEMPERATURE (°C)

SUPPLY CURRENT vs. TEMPERATURE

1 = 1.8V, VCC2 = 1.2V

V

18

16

14

12

10

8

6

SUPPLY CURRENT (µA)

4

2

0

CC

TOTAL

ICC1

ICC2

-40 10-15 356085

TEMPERATURE (°C)

NORMALIZED VCC RESET THRESHOLD

vs. TEMPERATURE

1.004

1.003

1.002

1.001

1.000

0.999

RESET THRESHOLD

0.998

0.997

0.996

-40 -15 10 35 60 85

TEMPERATURE (°C)

MAX6715-29 toc01

MAX6715-29 toc04

MAX6715-29 toc07

SUPPLY CURRENT vs. TEMPERATURE

V

18

16

14

12

10

8

6

SUPPLY CURRENT (µA)

4

2

0

CC

-40 10-15 356085

NORMALIZED RESET/WATCHDOG

TIMEOUT PERIOD vs. TEMPERATURE

1.007

1.006

1.005

1.004

1.003

1.002

1.001

RESET/WATCHDOG PERIOD

1.000

0.999

0.998

-40 10-15 356085

RESET INPUT AND POWER-FAIL INPUT

THRESHOLD vs. TEMPERATURE

631

630

629

628

THRESHOLD (mV)

627

626

625

-40 85

1 = 3.3V, VCC2 = 2.5V

TOTAL

ICC1

ICC2

TEMPERATURE (°C)

TEMPERATURE (°C)

10-15 35 60

TEMPERATURE (°C)

MAX6715-29 toc02

10,000

MAX6715-29 toc05

TRANSIENT DURATION (µs)

CC

MAXIMUM V

MAX6715-29 toc08

SUPPLY CURRENT vs. TEMPERATURE

1 = 2.5V, VCC2 = 1.8V

V

18

16

14

12

10

8

6

SUPPLY CURRENT (µA)

4

2

0

CC

TOTAL

ICC1

ICC2

-40 10-15 356085

TEMPERATURE (°C)

MAXIMUM VCC TRANSIENT DURATION

vs. RESET THRESHOLD OVERDRIVE

RESET OCCURS ABOVE

THIS LINE

1000

100

10

110010 1000

RESET THRESHOLD OVERDRIVE (mV)

VCC TO RESET DELAY

vs. TEMPERATURE

54

53

52

51

50

49

48

TO RESET DELAY (µs)

47

CC

V

46

45

44

-40 10-15 35 60 85

TEMPERATURE (°C)

100mV OVERDRIVE

MAX6715-29 toc03

MAX6715-29 toc06

MAX6715-29 toc09

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

6 _______________________________________________________________________________________

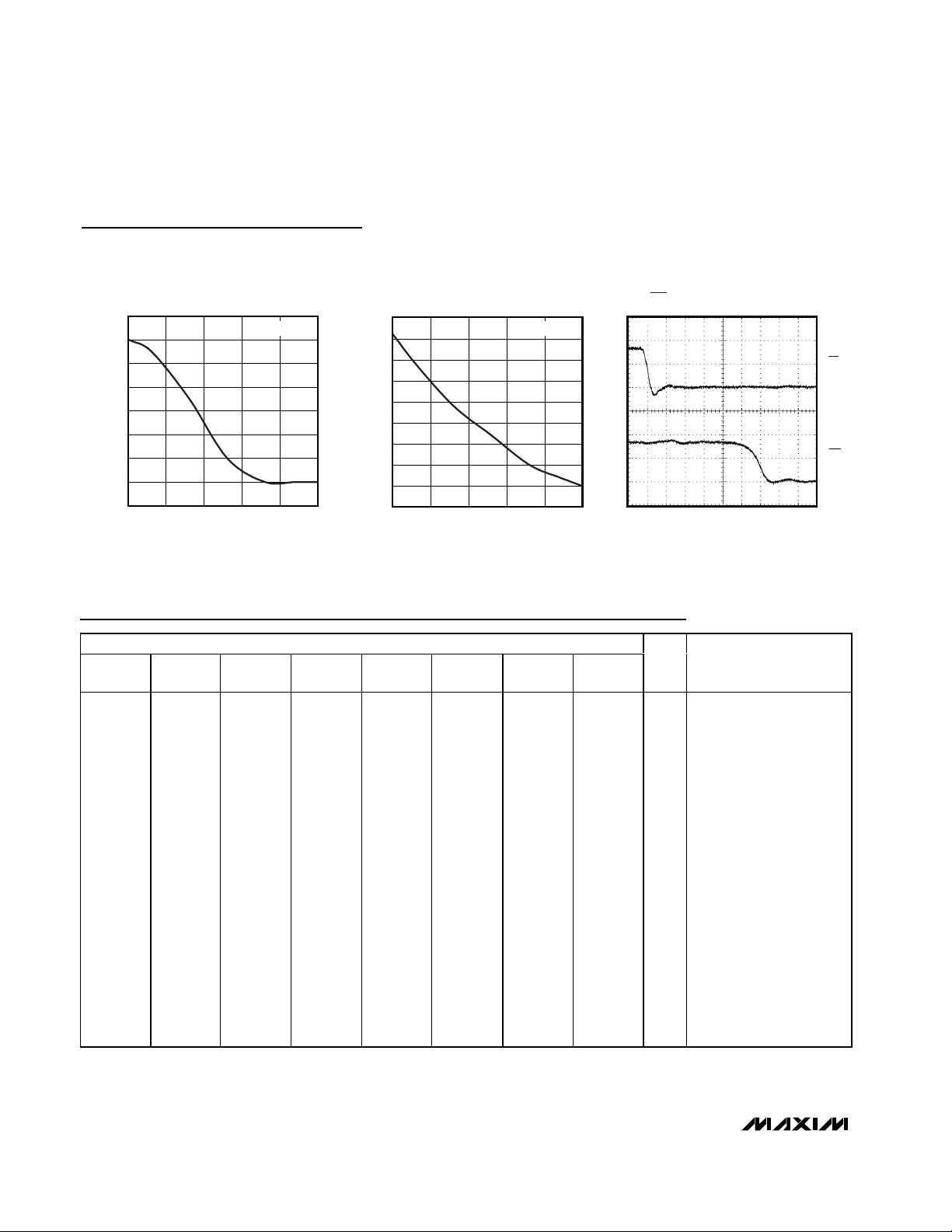

Pin Description

22.8

23.0

23.2

23.4

23.6

23.8

24.0

24.2

24.4

-40 -15 10 35 60 85

RESET INPUT TO RESET OUTPUT DELAY

vs. TEMPERATURE

MAX6715-29 toc10

TEMPERATURE (°C)

RSTIN TO RESET DELAY (µs)

30mV OVERDRIVE

2.0

2.1

2.2

2.4

2.3

-40 10-15 35 60 85

POWER-FAIL INPUT TO POWER-FAIL

OUTPUT DELAY vs. TEMPERATURE

MAX6715-29 toc11

TEMPERATURE (°C)

RSTIN TO RESET DELAY (µs)

30mV OVERDRIVE

0

0

V

RST

2V/div

MAX6715-29 toc12

50ns/div

MR TO RESET OUTPUT DELAY

V

MR

2V/div

Typical Operating Characteristics (continued)

(VCC1 = 5V, VCC2 = 3.3V, TA= +25°C, unless otherwise noted.)

MAX6715/

MAX6716

MAX6717/

MAX6718

1111111, 41

MAX6719/

MAX6720

MAX6721/

MAX6722

PIN

MAX6723/

MAX6724

MAX6725/

MAX6726

MAX6727

MAX6728/

MAX6729

NAME FUNCTION

Active-Low Reset Output,

Open-Drain or Push-Pull.

RST/RST1 changes from

high to low when V

V

2 drops below the

CC

selected reset thresholds,

RSTIN is below threshold,

MR is pulled low, or the

watchdog triggers a

reset. RST/RST1 remains

RST/

low for the reset timeout

RST1

period after V

V

2/RSTIN exceed the

CC

device reset thresholds,

MR goes low to high, or

the watchdog triggers a

reset. Open-drain outputs

require an external pullup

resistor. Push-pull

outputs are referenced to

V

1.

CC

CC

1/

CC

1 or

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

_______________________________________________________________________________________ 7

Pin Description (continued)

PIN

MAX6715/

MAX6716

MAX6717/

MAX6718

5 ———————RST2

22222222GNDGround

3333— 555MR

44444666V

65666888V

MAX6719/

MAX6720

MAX6721/

MAX6722

MAX6723/

MAX6724

MAX6725/

MAX6726

MAX6727

MAX6728/

MAX6729

NAME FUNCTION

2

CC

1

CC

Active-Low Reset Output,

Open-Drain or Push-Pull.

RST2 changes from high

to low when V

V

2 drops below the

CC

selected reset thresholds

or MR is pulled low. RST2

remains low for the reset

timeout period after

1/VCC2 exceed the

V

CC

device reset thresholds

or MR goes low to high.

Open-drain outputs

require an external pullup

resistor. Push-pull

outputs are referenced to

2.

V

CC

Active-Low Manual Reset

Input. Internal 50kΩ

pullup to V

to force a reset. Reset

remains active as long as

MR is low and for the

reset timeout period after

MR goes high. Leave

unconnected or connect

to V

1 if unused.

CC

Secondary Supply

Voltage Input. Powers the

device when it is above

1 and input for

V

CC

secondary reset

threshold monitor.

Primary Supply Voltage

Input. Powers the device

when it is above VCC2

and input for primary

reset threshold monitor.

CC

1. Pull low

CC

1 or

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

8 _______________________________________________________________________________________

Pin Description (continued)

PIN

MAX6715/

MAX6716

MAX6717/

MAX6718

——— 53333WDI

MAX6719/

MAX6720

MAX6721/

MAX6722

—— 5 — 577— RSTIN

——————— 7 PFI

MAX6723/

MAX6724

MAX6725/

MAX6726

MAX6727

MAX6728/

MAX6729

NAME FUNCTION

Watchdog Input. If WDI

remains high or low for

longer than the watchdog

timeout period, the

internal watchdog timer

runs out and the reset

output asserts for the

reset timeout period. The

internal watchdog timer

clears whenever a reset

is asserted or WDI sees a

rising or falling edge. The

watchdog has a long

timeout period (35s min)

after each reset event

and a short timeout

period (1.12s min) after

the first valid WDI

transition. Leave WDI

floating to disable the

watchdog timer function.

Undervoltage Reset

Comparator Input. Highimpedance input for

adjustable reset monitor.

The reset output is

asserted when RSTIN falls

below the 0.626V internal

reference voltage. Set the

monitored voltage reset

threshold with an external

resistor-divider network.

Connect RSTIN to V

V

2 if not used.

CC

Power-Fail Voltage

Monitor Input. Highimpedance input for

internal power-fail monitor

comparator. Connect PFI

to an external resistordivider network to set the

power-fail threshold

voltage (0.626V typical

internal reference

voltage). Connect to

GND, V

not used.

1, or VCC2 if

CC

CC

1 or

Detailed Description

Supply Voltages

The MAX6715–MAX6729 microprocessor (µP) supervisory circuits maintain system integrity by alerting the µP

to fault conditions. These ICs are optimized for systems

that monitor two or three supply voltages. The outputreset state is guaranteed to remain valid while either

VCC1 or VCC2 is above 0.8V.

Threshold Levels

Input voltage threshold level combinations are indicated by a two-letter code in the Reset Voltage Threshold

Suffix Guide (Table 1). Contact factory for availability of

other voltage threshold combinations.

Reset Outputs

The MAX6715–MAX6729 provides an active-low reset

output (RST) and the MAX6725/MAX6726 provides

both an active-high (RST) and an active-low reset output (RST). RST, RST, RST1, and RST2 are asserted

when the voltage at either VCC1 or VCC2 falls below the

voltage threshold level, RSTIN drops below threshold,

or MR is pulled low. Once reset is asserted it stays low

for the reset timeout period (see Table 2). If VCC1,

V

CC

2, or RSTIN goes below the reset threshold before

the reset timeout period is completed, the internal timer

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

_______________________________________________________________________________________ 9

Pin Description (continued)

PIN

MAX6715/

MAX6716

MAX6717/

MAX6718

——————— 4 PFO

————— 4 ——RST

MAX6719/

MAX6720

MAX6721/

MAX6722

MAX6723/

MAX6724

MAX6725/

MAX6726

MAX6727

MAX6728/

MAX6729

NAME FUNCTION

Active-Low Power-Fail

Monitor Output, OpenDrain or Push-Pull. PFO is

asserted low when PFI is

less than 0.626V. PFO

deasserts without a reset

timeout period. Opendrain outputs require an

external pullup resistor.

Push-pull outputs are

referenced to V

Active-High Reset

Output, Open-Drain or

Push-Pull. RST changes

from low to high when

V

1 or VCC2 drops

CC

below selected reset

thresholds, RSTIN is

below threshold, MR is

pulled low, or the

watchdog triggers a

reset. RST remains HIGH

for the reset timeout

period after V

2/RSTIN exceed the

V

CC

device reset thresholds,

MR goes low to high, or

the watchdog triggers a

reset. Open-drain outputs

require an external pullup

resistor. Push-pull

outputs are referenced to

V

1.

CC

CC

CC

1/

1.

MAX6715–MAX6729

restarts. The MAX6715/MAX6717/MAX6719/MAX6721/

MAX6723/MAX6725/MAX6727/MAX6728 contain opendrain reset outputs, while the MAX6716/MAX6718/

MAX6720/MAX6722/MAX6724/MAX6726/MAX6729

contain push-pull reset outputs. The MAX6727 provides

two separate open-drain RST outputs driven by the

same internal logic.

Manual Reset Input

Many microprocessor-based products require manual

reset capability, allowing the operator, a test technician, or external logic circuitry to initiate a reset. A logic

low on MR asserts the reset output. Reset remains

asserted while MR is low and for the reset timeout period (tRP) after MR returns high. This input has an internal

50kΩ pullup resistor to VCC1 and can be left unconnected if not used. MR can be driven with TTL or

CMOS logic levels, or with open-drain/collector outputs.

Connect a normally open momentary switch from MR to

GND to create a manual reset function; external

debounce circuitry is not required. If MR is driven from

long cables or if the device is used in a noisy environment, connect a 0.1µF capacitor from MR to GND to

provide additional noise immunity.

Adjustable Input Voltage

The MAX6719/MAX6720 and MAX6723–MAX6727 provide

an additional input to monitor a third system voltage. The

threshold voltage at RSTIN is typically 626mV. Connect a

resistor-divider network to the circuit as shown in Figure 1

to establish an externally controlled threshold voltage,

V

EXT_TH

.

V

EXT_TH

= 626mV((R1 + R2)/R2)

Low leakage current at RSTIN allows the use of largevalued resistors resulting in reduced power consumption of the system.

Watchdog Input

The watchdog monitors µP activity through the watchdog input (WDI). To use the watchdog function, connect WDI to a bus line or µP I/O line. When WDI

remains high or low for longer than the watchdog timeout period, the reset output asserts. Leave WDI floating

to disable the watchdog function.

The MAX6721–MAX6729 include a dual-mode watchdog timer to monitor µP activity. The flexible timeout

architecture provides a long period initial watchdog

mode, allowing complicated systems to complete

lengthy boots, and a short period normal watchdog

mode, allowing the supervisor to provide quick alerts

when processor activity fails. After each reset event

(V

CC

power-up/brownout, manual reset, or watchdog

reset), there is a long initial watchdog period of 35s

minimum. The long watchdog period mode provides an

extended time for the system to power-up and fully initialize all µP and system components before assuming

responsibility for routine watchdog updates.

The normal watchdog timeout period (1.12s min)

begins after the first transition on WDI before the conclusion of the long initial watchdog period (Figure 2).

During the normal operating mode, the supervisor will

issue a reset pulse for the reset timeout period if the µP

does not update the WDI with a valid transition (high-tolow or low-to-high) within the standard timeout period

(1.12s min).

Power-Fail Comparator

PFI is the noninverting input to a comparator. If PFI is

less than V

PFI

(626.5mV), PFO goes low. Common uses

for the power-fail comparator include monitoring preregulated input of the power supply (such as a battery) or

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

10 ______________________________________________________________________________________

Figure 1. Monitoring a Third Voltage

Figure 2. Normal Watchdog Startup Sequence

V

EXT_TH

R1

RSTIN

R2

V

TH

V

CC

WDI

RESET

t

WDI-NORMAL

1.12s MAX

t

WDI-STARTUP

35s MAX

t

RP

MAX6719/

MAX6720/

MAX6723–

MAX6727

GND

1.12s MAX

providing an early power-fail warning so software can

conduct an orderly system shutdown. It can also be

used to monitor supplies other than VCC1 or VCC2 by

setting the power-fail threshold with a resistor-divider, as

shown in Figure 3. PFI is the input to the power-fail comparator. The typical comparator delay is 2µs from PFI to

PFO. Connect PFI to ground of VCC1 if unused.

Ensuring a Valid Reset Output

Down to V

CC

= 0

The MAX6715–MAX6729 are guaranteed to operate

properly down to VCC= 0.8V. In applications that

require valid reset levels down to VCC= 0 use a pulldown resistor at RST to ground. The resistor value used

is not critical, but it must be large enough not to load

the reset output when VCCis above the reset threshold.

For most applications, 100kΩ is adequate. This configuration does not work for the open-drain outputs of the

MAX6715/MAX6717/MAX6719/MAX6721/MAX6723/

MAX6725/MAX6727/MAX6728. For push-pull, activehigh RST output connect the external resistor as a

pullup from RST to V

CC

1.

Applications Information

Interfacing to µPs with Bidirectional

Reset Pins

Most microprocessors with bidirectional reset pins can

interface directly to open-drain RST output options.

Systems simultaneously requiring a push-pull RST out-

put and a bidirectional reset interface can be in logic

contention. To prevent contention, connect a 4.7kΩ

resistor between RST and the µP’s reset I/O port as

shown in Figure 4.

Adding Hysteresis to the Power-Fail

Comparator

The power-fail comparator has a typical input hysteresis

of 3mV. This is sufficient for most applications where a

power-supply line is being monitored through an external

voltage-divider (see the Power-Fail Comparator section).

If additional noise margin is desired, connect a resistor

between PFO and PFI as shown in Figure 5. Select the

values of R1, R2, and R3 so PFI sees V

PFI

(626mV) when

V

EXT

falls to its power-fail trip point (V

FAIL

) and when VIN

rises to its power-good trip point (V

GOOD

). The hysteresis

window extends between the specified V

FAIL

and V

GOOD

thresholds. R3 adds the additional hysteresis by sinking

current from the R1/R2 divider network when PFO is logic

low and sourcing current into the network when PFO is

logic high. R3 is typically an order of magnitude greater

than R1 or R2.

The current through R2 should be at least 2.5µA to

ensure that the 25nA (max) PFI input current does not

significantly shift the trip points. Therefore, R2 <

V

PFI

/2.5µA < 248kΩ for most applications. R3 will provide

additional hysteresis for PFO push-pull (VOH= VCC1) or

open-drain (VOH= V

PULLUP

) applications.

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

______________________________________________________________________________________ 11

Figure 3. Using Power-Fail Input to Monitor an Additional

Power-Supply a) V

IN

is Positive b) VINis Negative

Figure 4. Interfacing to µPs with Bidirectional Reset I/O

A

V

IN

R1

R2

B

V

CC

R1

R2

V

IN

PFI

PFI

MAX6728/

MAX6729

PFO

GND

MAX6728/

MAX6729

PFO

GND

V

TRIP

V

= 626.5mV

PFI

V

TRIP

= R2

R1 + R2

= V

PFI

()

R2

1R11

+-

)

(V

PFI

()

[]

R2

V

CC

R1

V

2

CC1VCC

MAX6715–

MAX6729

V

2

CC

1

V

CC

GND GND

RESET TO OTHER SYSTEM COMPONENTS

RST

4.7kΩ

RESET

µP

MAX6715–MAX6729

Monitoring an Additional Power Supply

These µP supervisors can monitor either positive or

negative supplies using a resistor voltage-divider to

PFI. PFO can be used to generate an interrupt to the µP

or cause reset to assert (Figure 3).

Monitoring a Negative Voltage

The power-fail comparator can be used to monitor a

negative supply voltage using the circuit shown in

Figure 3. When the negative supply is valid, PFO is low.

When the negative supply voltage drops, PFO goes

high. The circuit’s accuracy is affected by the PFI

threshold tolerance, VCC, R1, and R2.

Negative-Going VCCTransients

The MAX6715–MAX6729 supervisors are relatively

immune to short-duration negative-going VCCtransients

(glitches). It is usually undesirable to reset the µP when

VCCexperiences only small glitches. The Typical

Operating Characteristics show Maximum Transient

Duration vs. Reset Threshold Overdrive, for which reset

pulses are not generated. The graph was produced

using negative-going VCCpulses, starting above V

TH

and ending below the reset threshold by the magnitude

indicated (reset threshold overdrive). The graph shows

the maximum pulse width that a negative-going V

CC

transient may typically have without causing a reset

pulse to be issued. As the amplitude of the transient

increases (i.e., goes farther below the reset threshold),

the maximum allowable pulse width decreases. A 0.1µF

bypass capacitor mounted close to the V

CC

pin pro-

vides additional transient immunity.

Watchdog Software Considerations

Setting and resetting the watchdog input at different

points in the program, rather than “pulsing” the watchdog input high-low-high or low-high-low, helps the

watchdog timer to closely monitor software execution.

This technique avoids a “stuck” loop where the watchdog timer continues to be reset within the loop, keeping

the watchdog from timing out. Figure 6 shows an example flow diagram where the I/O driving the watchdog

input is set high at the beginning of the program, set low

at the beginning of every subroutine or loop, then set

high again when the program returns to the beginning. If

the program should “hang” in any subroutine, the I/O is

continually set low and the watchdog timer is allowed to

time out, causing a reset or interrupt to be issued.

Chip Information

TRANSISTOR COUNT: 1072

PROCESS: BiCMOS

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

12 ______________________________________________________________________________________

Figure 5. Adding Hysteresis to Power-Fail for Push-Pull PFO

Figure 6. Watchdog Flow Diagram

R3

A

V

EXT

R1

R2

PFI

MAX6728/

MAX6729

PFO

GND

V

IN

PFO

V

= DESIRED V

GOOD

= DESIRED V

V

FAIL

= VCC1 (FOR PUSH-PULL PFO)

V

OH

R2 = 200kΩ (FOR > 2.5µA R2 CURRENT)

R1 = R2 ((V

R3 = (R1 x VOH) / (V

GOOD VOLTAGE THRESHOLD

EXT

FAIL VOLTAGE THRESHOLD

EXT

- V

) - (V

GOOD

PFI

GOOD

V

GOOD

V

FAIL

)(V

- V

PFI

GOOD

FAIL

FAIL

)

- V

) / VOH) / V

PFI

START

SET WDI

HIGH

PROGRAM

CODE

SUBROUTINE OR

PROGRAM LOOP

SET WDI LOW

HANG IN

SUBROUTINE

COMPLETED

RETURN

SUBROUTINE

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

______________________________________________________________________________________ 13

Functional Diagram

VCC1

VCC2

RSTIN/PFI

V

1

MR

PULLUP

CC

V

CC

1

RESET

OUTPUT

DRIVER

VCC2

RST

RST

MR

VCC1

V

REF

RESET

TIMEOUT

PERIOD

V

REF/2

V

REFVCC

PFO

VCC1

1

WATCHDOG

TIMER WITH

FLOAT DISABLE

WDI

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

14 ______________________________________________________________________________________

Selector Guide

Ordering Information (continued)

Note: The first “_ _” are placeholders for the threshold voltage

levels of the devices. Desired threshold levels are set by the part

number suffix found in the Reset Voltage Threshold Suffix Guide.

The “_” after the D is a placeholder for the reset timeout delay

time. Desired delay time is set using the timeout period suffix

found in the Reset Timeout Period Suffix Guide. For example the

MAX6716UTLTD3-T is a dual-voltage supervisor V

TH

1 = 4.625V,

V

TH

2 = 3.075V, and 210ms (typ) timeout period.

PART

NUMBER

MAX6715 2 2 ——— √ ——

MAX6716 2 —— 2 — √ ——

MAX6717 2 1 ——— √ ——

MAX6718 2 —— 1 — √ ——

MAX6719 3 1 ——— √ ——

MAX6720 3 —— 1 — √ ——

MAX6721 2 1 ——— √√—

MAX6722 2 —— 1 — √√—

MAX6723 3 1 ———— √ —

MAX6724 3 —— 1 —— √ —

MAX6725 3 1 1 —— √√—

MAX6726 3 —— 11√√—

MAX6727 3 2 ——— √√—

MAX6728 3 1 ——— √√√ (open drain)

MAX6729 3 —— 1 — √√√ (push-pull)

PART TEMP RANGE PIN-PACKAGE

NUMBER OF

VOLTAGE

MONITORS

OPENDRAIN

RESET

OPENDRAIN

RESET

PUSH-

PULL

RESET

PUSH-

PULL

RESET

MANUAL

RESET

WATCH-

DOG

INPUT

POWER-

OUTPUT

MAX6721UT_ _D_ -T -40°C to +85°C 6 SOT23-6

MAX6722UT_ _D_ -T -40°C to +85°C 6 SOT23-6

MAX6723UT_ _D_ -T -40°C to +85°C 6 SOT23-6

MAX6724UT_ _D_ -T -40°C to +85°C 6 SOT23-6

MAX6725KA_ _D_ -T -40°C to +85°C 8 SOT23-8

MAX6726KA_ _D_ -T -40°C to +85°C 8 SOT23-8

MAX6727KA_ _D_ -T -40°C to +85°C 8 SOT23-8

MAX6728KA_ _D_ -T -40°C to +85°C 8 SOT23-8

MAX6729KA_ _D_ -T -40°C to +85°C 8 SOT23-8

FAIL

INPUT/

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

______________________________________________________________________________________ 15

Table 1. Reset Voltage Threshold Suffix

Guide**

Table 2. Reset Timeout Period Suffix

Guide

**Standard versions are shown in bold and are available in a D3

timeout option only. Standard versions require 2,500 piece order

increments and are typically held in sample stock. There is a

10,000 order increment on nonstandard versions. Other thresh-

old voltages may be available, contact factory for availability.

PART NUMBER

SUFFIX

(_ _)

V

1 NOMINAL

CC

VOLTAGE

THRESHOLD (V)

V

2 NOMINAL

CC

VOLTAGE

THRESHOLD (V)

LT 4.625 3.075

MS 4.375 2.925

MR 4.375 2.625

TZ 3.075 2.313

SY 2.925 2.188

RY 2.625 2.188

TW 3.075 1.665

SV 2.925 1.575

RV 2.625 1.575

TI 3.075 1.388

SH 2.925 1.313

RH 2.625 1.313

TG 3.075 1.110

SF 2.925 1.050

RF 2.625 1.050

TE 3.075 0.833

SD 2.925 0.788

RD 2.625 0.788

ZW 2.313 1.665

YV 2.188 1.575

ZI 2.313 1.388

YH 2.188 1.313

ZG 2.313 1.110

YF 2.188 1.050

ZE 2.313 0.833

YD 2.188 0.788

WI 1.665 1.388

VH 1.575 1.313

WG 1.665 1.110

VF 1.575 1.050

WE 1.665 0.833

VD 1.575 0.788

TIMEOUT

PERIOD SUFFIX

D1 1.1 2.2

D2 8.8 17.6

D3 140 280

D5 280 560

D6 560 1120

D4 1120 2240

ACTIVE TIMEOUT PERIOD

MIN [ms] MAX [ms]

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

16 ______________________________________________________________________________________

Pin Configurations

TOP VIEW

16VCC1

RST1

GND

MR

MAX6715/

2

MAX6716

34

5

RST2

2

V

CC

SOT23-6

16VCC1

RST

GND

MR

MAX6721/

2

MAX6722

34

5

WDI GND

2

V

CC

SOT23-6

1

RST

2

MAX6727

3

WDI

RST

4

15VCC1

RST

MAX6717/

2

MAX6718

MR

34

V

CC

SOT23-5

16VCC1

RST

MAX6723/

2

MAX6724

WDI

34

RSTIN

5

V

CC

SOT23-6

87VCC1

RSTINGND

VCC2

6

MR

5

RST

WDI

PFO

1

2

3

4

2

2

MAX6728/

MAX6729

16VCC1

RST

GND

MR

MAX6719/

2

MAX6720

34

5 RSTINGND

SOT23-6

RST

1

2

87VCC1

MAX6725/

WDI

3

4

6

5

MAX6726

SOT23-8

87VCC1

PFIGND

VCC2

6

MR

5

V

CC

RSTINGND

VCC2

MRRST

2

SOT23-8

SOT23-8

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

______________________________________________________________________________________ 17

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

SOT-23 5L .EPS

PACKAGE OUTLINE, SOT-23, 5L

1

21-0057

E

1

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

18 ______________________________________________________________________________________

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

6LSOT.EPS

PACKAGE OUTLINE, SOT-23, 6L

21-0058

1

F

1

MAX6715–MAX6729

Dual/Triple Ultra-Low-Voltage SOT23 µP

Supervisory Circuits

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 19

© 2003 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

b

C

L

PIN 1

I.D. DOT

(SEE NOTE 6)

A2

A

NOTE:

1. ALL DIMENSIONS ARE IN MILLIMETERS.

2. FOOT LENGTH MEASURED FROM LEAD TIP TO UPPER RADIUS OF

HEEL OF THE LEAD PARALLEL TO SEATING PLANE C.

3. PACKAGE OUTLINE EXCLUSIVE OF MOLD FLASH & METAL BURR.

4. PACKAGE OUTLINE INCLUSIVE OF SOLDER PLATING.

5. COPLANARITY 4 MILS. MAX.

6. PIN 1 I.D. DOT IS 0.3 MM MIN. LOCATED ABOVE PIN 1.

7. SOLDER THICKNESS MEASURED AT FLAT SECTION OF LEAD

BETWEEN 0.08mm AND 0.15mm FROM LEAD TIP.

8. MEETS JEDEC MO178.

SEE DETAIL "A"

C

L

e1

D

C

L

e

C

E

A1

L

C

SEATING PLANE C

E1

SYMBOL

A

C

L

L2

e

e1

0

L

DETAIL "A"

PROPRIETARY INFORMATION

TITLE:

L2

MIN

0.90

0.00A1

0.90A2

0.28b

0.09

2.80D

1.50E1

0.30

PACKAGE OUTLINE, SOT-23, 8L BODY

21-0078

0.25 BSC.

0.65 BSC.

1.95 REF.

0

GAUGE PLANE

0

MAX

1.45

0.15

1.30

0.45

0.20

3.00

3.002.60E

1.75

0.60

SOT23, 8L .EPS

8

REV.DOCUMENT CONTROL NO.APPROVAL

1

D

1

Loading...

Loading...