General Description

The MAX6657/MAX6658/MAX6659 are precise, twochannel digital temperature sensors. Each accurately

measures the temperature of its own die and one

remote PN junction, and reports the temperature in digital form on a 2-wire serial interface. The remote junction

can be a diode-connected transistor like the low-cost

NPN type 2N3904 or 2N3906 PNP type. The remote

junction can also be a common-collector PNP, such as

a substrate PNP of a microprocessor.

The 2-wire serial interface accepts standard System

Management Bus (SMBus™) commands such as Write

Byte, Read Byte, Send Byte, and Receive Byte to read

the temperature data and program the alarm thresholds

and conversion rate. The MAX6657/MAX6658/

MAX6659 can function autonomously with a programmable conversion rate, which allows the control of supply current and temperature update rate to match

system needs. For conversion rates of 4Hz or less, the

temperature is represented in extended mode as 10

bits + sign with a resolution of 0.125°C. When the conversion rate is faster than 4Hz, output data is 7 bits +

sign with a resolution of 1°C. The MAX6657/

MAX6658/MAX6659 also include an SMBus timeout

feature to enhance system reliability.

Remote accuracy is ±1°C between +60°C and +100°C

with no calibration needed. The MAX6657 measures

temperatures from 0°C to +125°C and the MAX6658/

MAX6659 from -55°C to +125°C. The MAX6659 has the

added benefit of being able to select one of three

addresses through an address pin, and a second overtemperature alarm pin for greater system reliability.

Applications

Desktop Computers Workstations

Notebook Computers

Servers

Features

o Dual Channel Measures Remote and Local

Temperature

o 11-Bit, +0.125°C Resolution

o High Accuracy ±1°C (max) from +60°C to +100°C

(Remote)

o No Calibration Required

o Programmable Under/Overtemperature Alarms

o Programmable Conversion Rate

(0.0625Hz to 16Hz)

o SMBus/I

2

C-Compatible Interface

o Two Alarm Outputs: ALERT and OVERT1

(MAX6657 and MAX6658)

o Three Alarm Outputs: ALERT, OVERT1,

and OVERT2 (MAX6659)

o Compatible with 65nm Process Technology

(Y Versions)

MAX6657/MAX6658/MAX6659

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

________________________________________________________________

Maxim Integrated Products

1

19-2034; Rev 5; 10/10

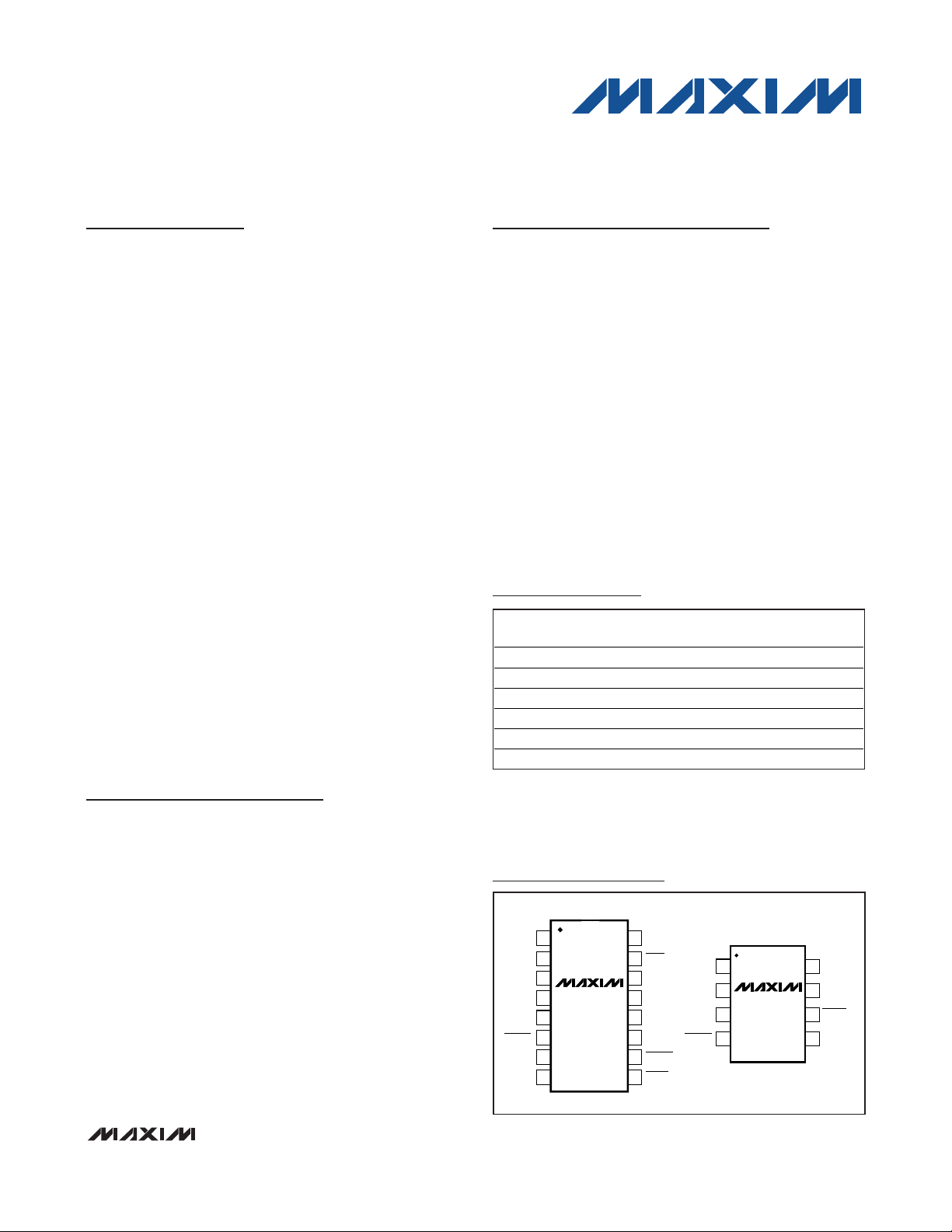

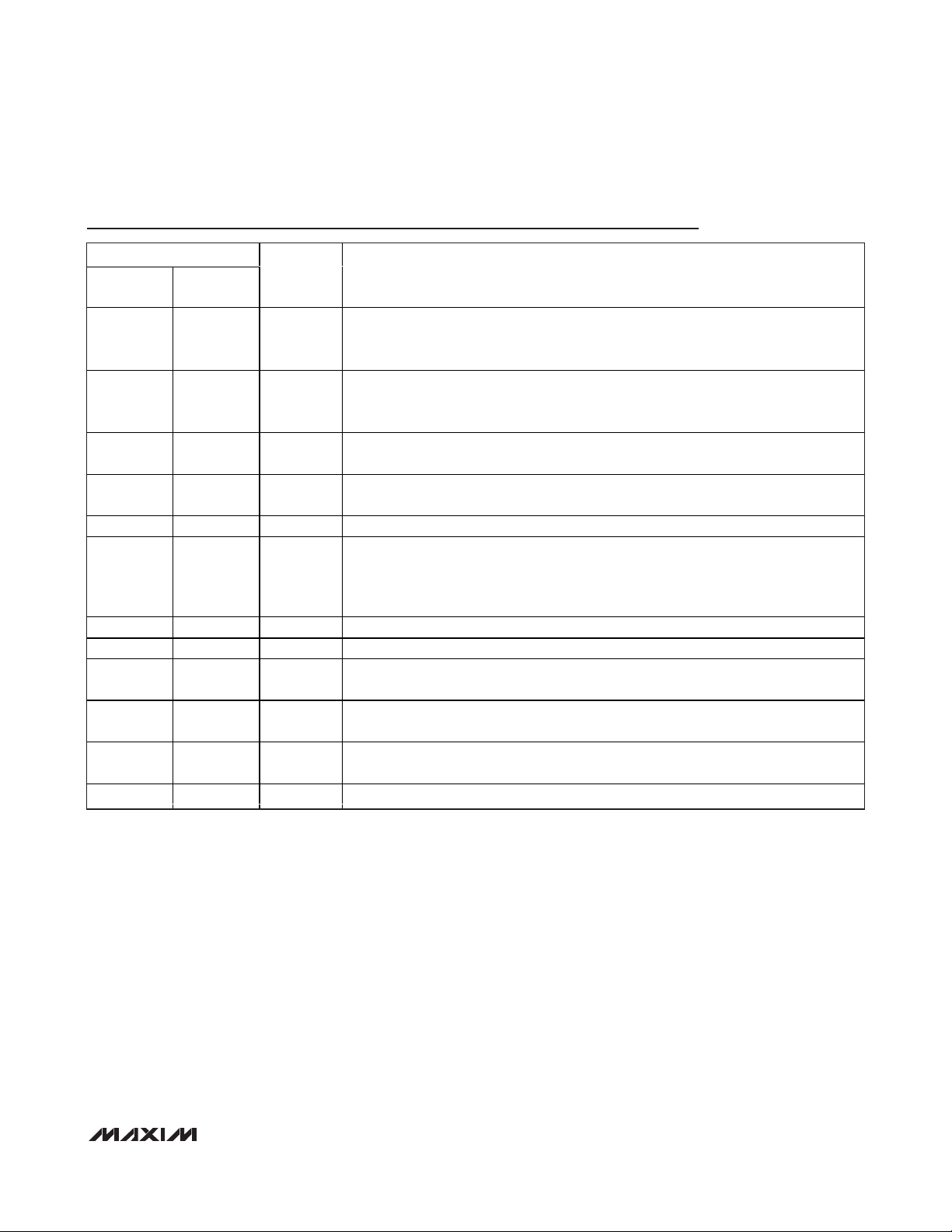

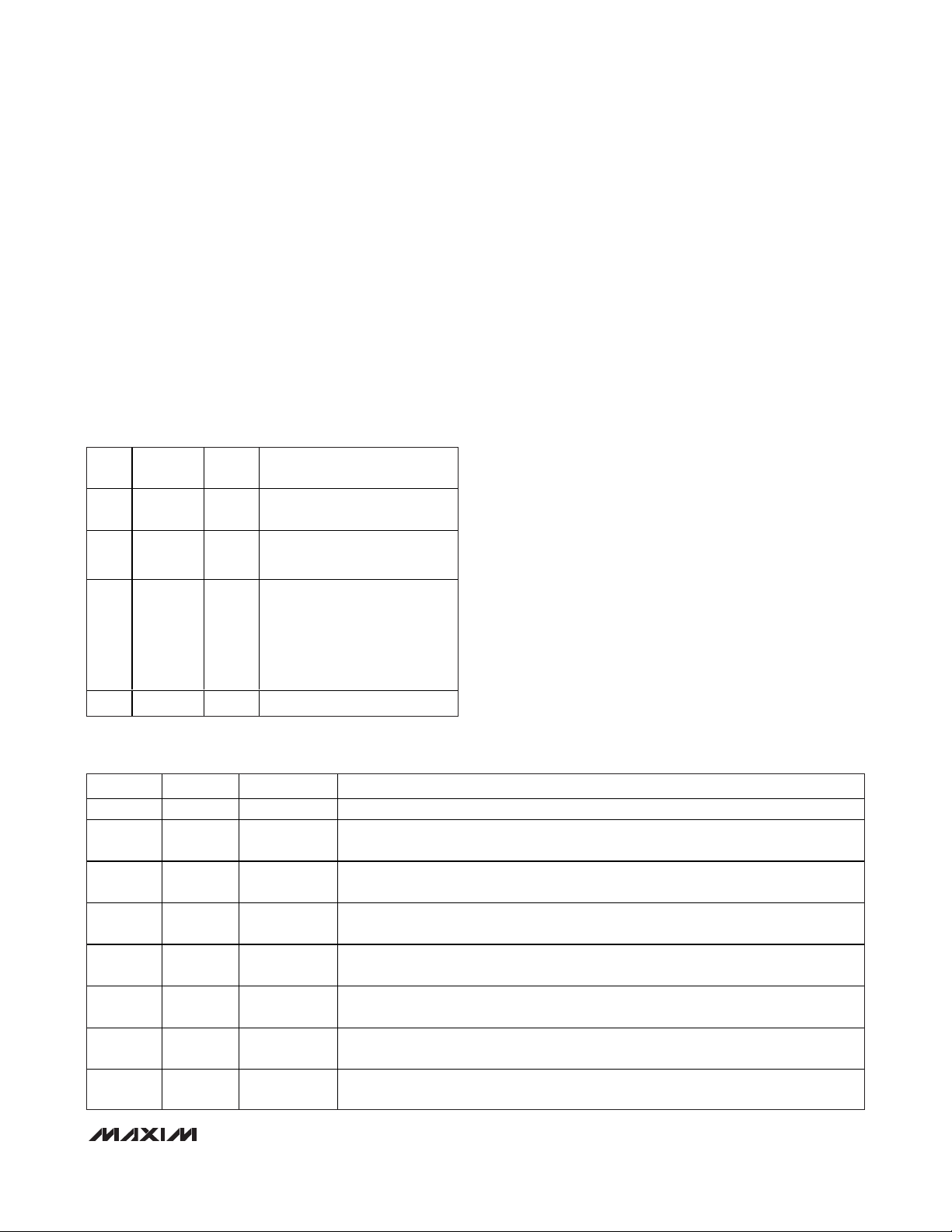

Ordering Information

SMBus is a trademark of Intel Corp.

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

V

CC

N.C.

STBY

SMBCLK

N.C.

SMBDATA

N.C.

OVERT2

ALERT

TOP VIEW

MAX6659

QSOP

N.C.

DXP

OVERT1

DXN

ADD

GND

GND

ALERT

GNDOVERT1

1

2

87SMBCLK

SMBDATADXP

DXN

V

CC

SO

3

4

6

5

MAX6657

MAX6658

Pin Configurations

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Typical Operating Circuit appears at the end of the data

sheet.

Ordering Information continued at end of data sheet.

Note: All devices are specified over the -55°C to +125°C oper-

ating temperature range.

+

Denotes a lead(Pb)-free/RoHS-compliant package.

T = Tape and reel.

PART

MAX6657MSA 0°C to +125°C 8 SO

MAX6657MSA+ 0°C to +125°C 8 SO

MAX6657MSA-T 0°C to +125°C 8 SO

MAX6657MSA+T 0°C to +125°C 8 SO

MAX6657YMSA+ 0°C to +125°C 8 SO

MAX6657YMSA+T 0°C to +125°C 8 SO

MEASURED TEMP

RANGE

PIN-PACKAGE

MAX6657/MAX6658/MAX6659

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

(All voltages referenced to GND.)

V

CC

..........................................................................-0.3V to +6V

DXP ............................................................-0.3V to (V

CC

+ 0.3V)

DXN ......................................................................-0.3V to +0.8V

SMBCLK, SMBDATA, ALERT, OVERT1,

OVERT2 ..............................................................-0.3V to +6V

SMBDATA, ALERT, OVERT1, OVERT2

Current ..........................................................-1mA to +50mA

DXN Current ......................................................................±1mA

Continuous Power Dissipation (T

A

= +70°C)

8-Pin SO (derate 5.9mW/°C above +70°C) .................471mW

16-Pin QSOP (derate 8.3mW/°C above +70°C) ..........664mW

Junction Temperature .....................................................+150°C

Storage Temperature Range ............................-65°C to +150°C

Lead Temperature (soldering, 10s) ................................+300°C

Soldering Temperature (reflow)

Lead(Pb)-free ..............................................................+260°C

Containing lead(Pb) ....................................................+240°C

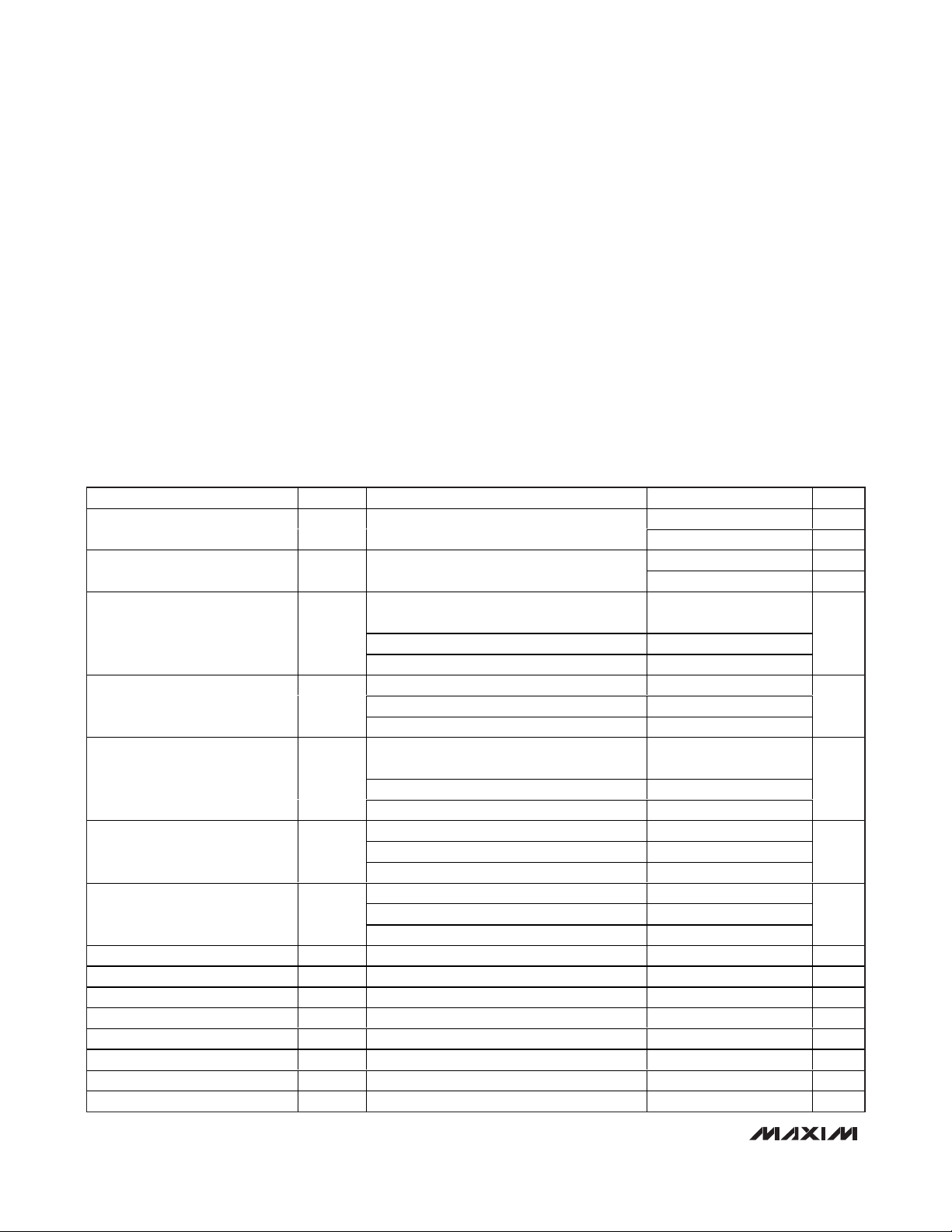

ELECTRICAL CHARACTERISTICS

(VCC= +3.0V to +5.5V, TA= 0°C to +125°C, unless otherwise specified. Typical values are at VCC= +3.3V and TA= +25°C.)

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Temperature Resolution,

Legacy Mode

Temperature Resolution,

Extended Mode

TRJ = +60°C to +100°C, VCC = +3.3V

Remote Temperature Error

(MAX6657, MAX6657Y)

Local Temperature Error

(MAX6657)

Remote Temperature Error

(MAX6658/MAX6659/

MAX6658Y/MAX6659Y)

Local Temperature Error

(MAX6658/MAX6659)

Local Temperature Error

(MAX665_Y)

Line Regulation 3.0V ≤ VCC ≤ 5.5V 0.2 0.6 m°C/V

Supply Voltage Range V

Undervoltage Lockout Threshold UVLO Falling edge of VCC disables ADC 2.60 2.80 2.95 V

Undervoltage Lockout Hysteresis 90 mV

Power-On Reset (POR) Threshold VCC, falling edge 1.5 2.0 2.5 V

POR Threshold Hysteresis 90 mV

Standby Supply Current SMBus static 3 10 µA

Operating Current During conversion 0.5 1.0 mA

(Note 1)

TRJ = 0°C to +100°C, VCC = +3.3V (Note 1) -3.0 +3.0

= 0°C to +125°C, VCC = +3.3V (Note 1) -5.0 +5.0

T

RJ

TA = +60°C to +100°C, VCC = +3.3V -2.0 +2.0

TA = 0°C to +100°C, VCC = +3.3V -3.0 +3.0

= 0°C to +125°C, VCC = +3.3V -5.0 +5.0

T

A

TRJ = +60°C to +100°C, VCC = +3.3V

(Note 1)

TRJ = 0°C to +100°C, VCC = +3.3V (Note 1) -3.0 3.0

T

= -55°C to +125°C, VCC = +3.3V (Note 1) -5.0 +5.0

RJ

TA = +60°C to +100°C, VCC = +3.3V -2.0 +2.0

TA = 0°C to +100°C, VCC = +3.3V -3.0 +3.0

= -55°C to +125°C, VCC = +3.3V (Note 2) -5.0 +5.0

T

A

TA = +60°C to +100°C, VCC = +3.3V -3.8

TA = 0°C to +100°C, VCC = +3.3V -4.0

T

= 0°C to +125°C, VCC = +3.3V -4.4

A

CC

1°C

8 Bits

0.125 °C

11 Bits

-1.0 +1.0

-1.0 1.0

3.0 5.5 V

°C

°C

°C

°C

°C

MAX6657/MAX6658/MAX6659

_______________________________________________________________________________________ 3

Note 1: TA= +25°C to +85°C.

Note 2: If both the local and the remote junction are below T

A

= -20°C, then VCC> 3.15V.

Note 3: For conversion rates of 4Hz or slower, the conversion time doubles.

Note 4: Timing specifications guaranteed by design.

Note 5: The serial interface resets when SMBCLK is low for more than t

TIMEOUT

.

Note 6: A transition must internally provide at least a hold time to bridge the undefined region (300ns max) of SMBCLK's falling edge.

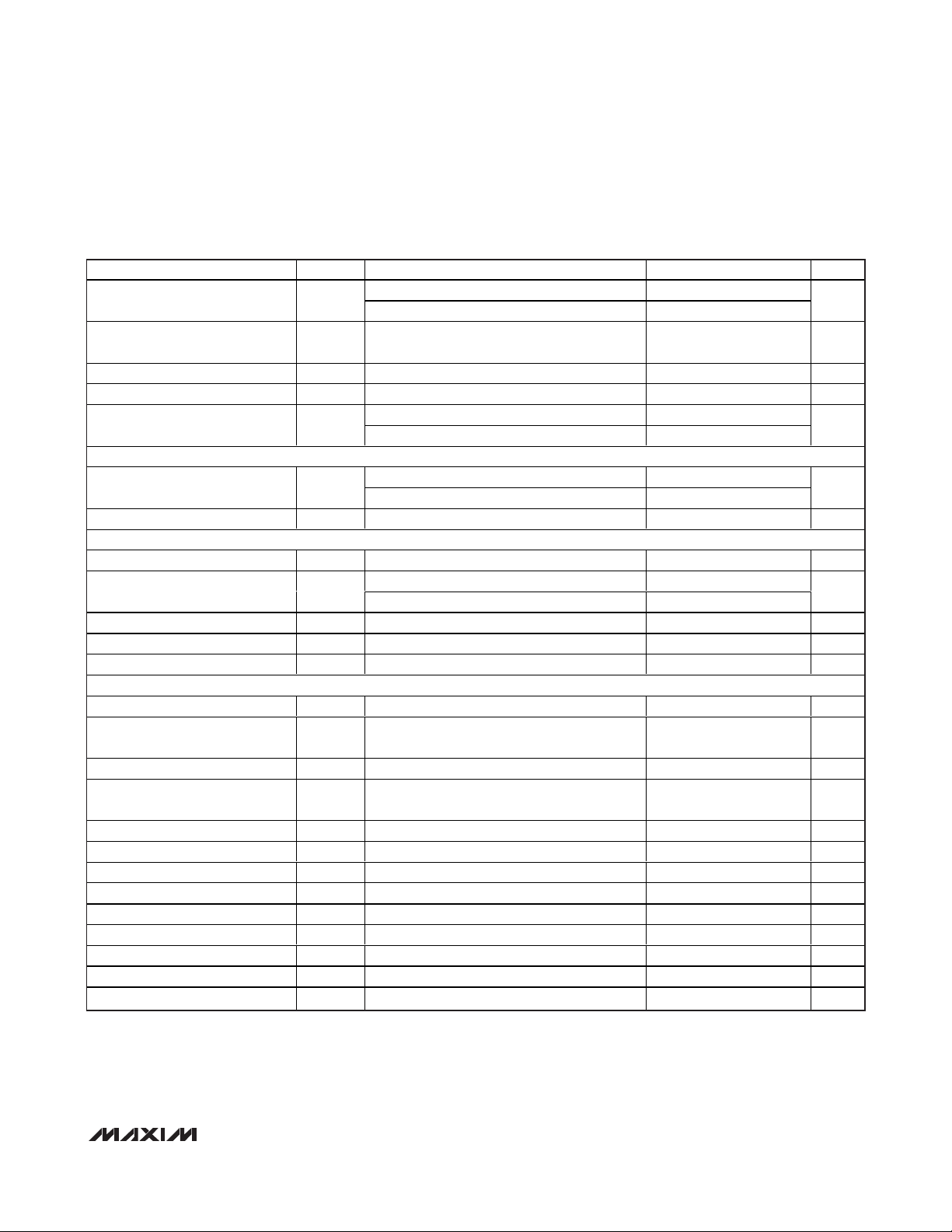

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +3.0V to +5.5V, TA= 0°C to +125°C, unless otherwise specified. Typical values are at VCC= +3.3V and TA= +25°C.)

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

Average Operating Current

SMBus-COMPATIBLE INTERFACE (SMBCLK, SMBDATA, STBY)

SMBus-COMPATIBLE TIMING (Note 4)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

0.25 conversions/s 40 70

2 conversions/s 150 250

Conversion Time t

Conversion Timing Error ±25 %

DXP and DXN Leakage Current In standby mode 100 nA

Remote-Diode Source Current I

(ALERT, OVERT)

Output Low Sink Current

Output High Leakage Current VOH = 5.5V 1 µA

Logic Input Low Voltage V

Logic Input High Voltage V

Input Leakage Current I

Output Low Sink Current I

Input Capacitance C

Serial-Clock Frequency f

Bus Free Time Between STOP

and START Condition

START Condition Setup Time 4.7 µs

Repeat START Condition Setup

Time

START Condition Hold Time t

STOP Condition Setup Time t

Clock Low Period t

Clock High Period t

Data Setup Time t

Receive SCL/SDA Rise Time t

Receive SCL/SDA Fall Time t

Pulse Width of Spike Suppressed t

SMBus Timeout SMBDATA low period for interface reset 25 37 45 ms

CONV

LEAK

SCL

t

BUF

t

SU:STA

HD:STA

SU:STO

LOW

HIGH

HD:DAT

From stop bit to conversion completed

(Note 4)

High level 80 100 120

RJ

Low level 8 10 12

VOL = 0.4V 1

V

= 0.6V 6

OL

IL

VCC = +3.0V 2.2

IH

VCC = +5.5V 2.4

VIN = V

VOL = 0.6V 6 mA

OL

IN

(Note 5) 100 kHz

90% to 90% 50 ns

10% of SMBDATA to 90% of SMBCLK 4 µs

90% of SMBCLK to 90% of SMBDATA 4 µs

10% to 10% 4.7 µs

90% to 90% 4 µs

(Note 6) 0 µs

R

F

SP

GND

or V

CC

95 125 156 ms

0.8 V

±1 µA

5pF

4.7 µs

1µs

300 ns

050ns

µA

µA

mA

V

MAX6657/MAX6658/MAX6659

4 _______________________________________________________________________________________

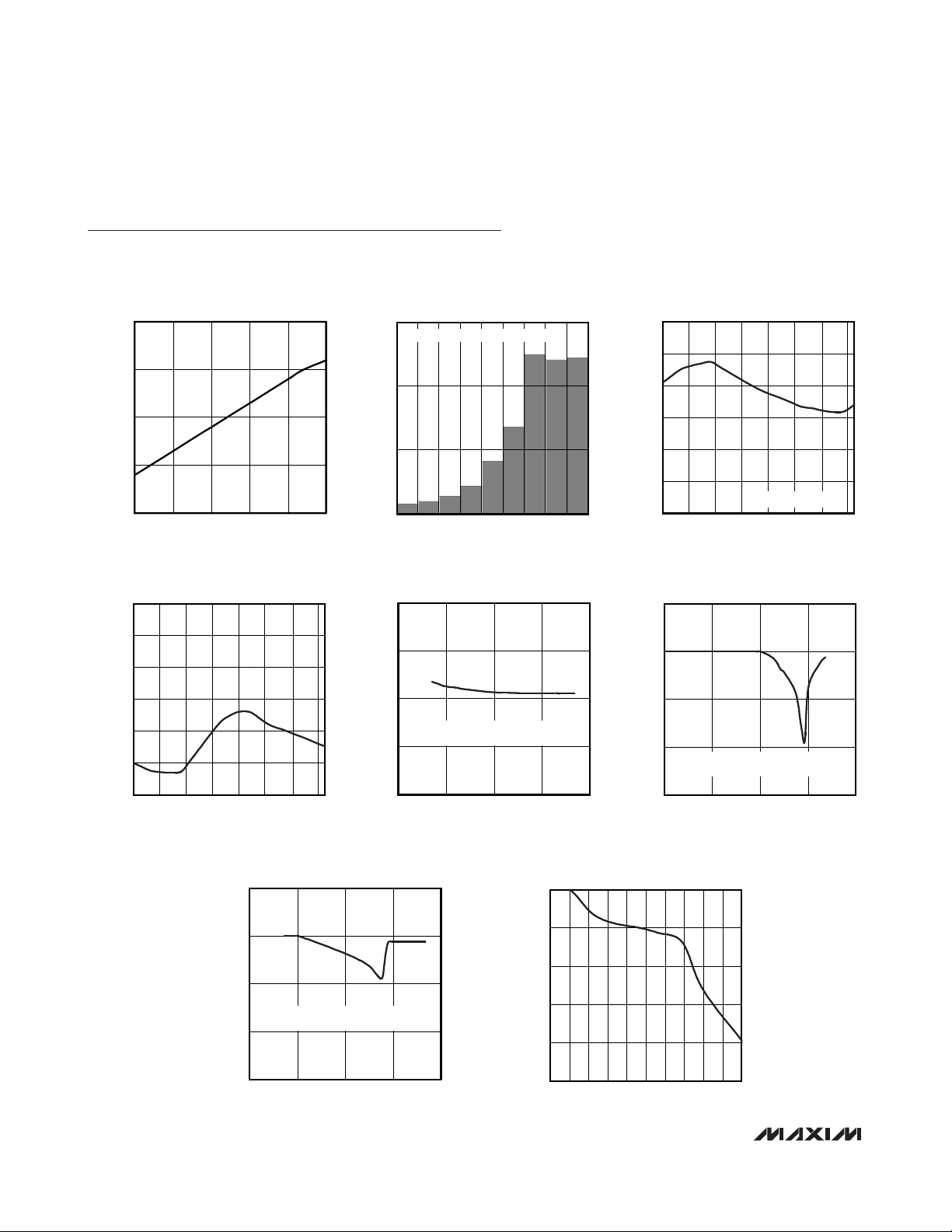

Typical Operating Characteristics

(VCC= +3.3V, TA= +25°C, unless otherwise noted.)

4.5

4.0

3.5

3.0

2.5

3.0 4.03.5 4.5 5.0 5.5

STANDBY SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX6657 toc01

SUPPLY VOLTAGE (V)

STANDBY SUPPLY CURRENT (µA)

0.063 0.5 10.125 0.25 2 4 8 16

OPERATING SUPPLY CURRENT

vs. CONVERSION RATE

MAX6657 toc02

CONVERSION RATE (Hz)

OPERATING SUPPLY CURRENT (µA)

0

200

400

600

8Hz AND 16Hz ARE 1°C RESOLUTION

-3

-2

-1

0

1

2

3

-55 -5-30 20 45 70 95 120

MAX6659

REMOTE TEMPERATURE ERROR

vs. REMOTE-DIODE TEMPERATURE

MAX6657 toc03

TEMPERATURE (°C)

TEMPERATURE ERROR (°C)

FAIRCHILD 2N3906

-3

-2

-1

0

1

2

3

-55 -5-30 20 45 70 95 120

LOCAL TEMPERATURE ERROR

vs. DIE TEMPERATURE

MAX6657 toc04

TEMPERATURE (°C)

TEMPERATURE ERROR (°C)

1

0

-1

-2

-3

10k 1M100k 10M 100M

TEMPERATURE ERROR vs.

POWER-SUPPLY NOISE FREQUENCY

MAX6657 toc05

FREQUENCY (Hz)

TEMPERATURE ERROR (°C)

VIN = SQUARE WAVE APPLIED TO V

CC

WITH NO 0.1µF VCC CAPACITOR

1

0

-1

-2

-3

0.01k 100k1k 10M 1G

TEMPERATURE ERROR vs.

COMMON-MODE NOISE FREQUENCY

MAX6657 toc06

FREQUENCY (Hz)

TEMPERATURE ERROR (°C)

VIN = AC-COUPLED TO DXN

V

IN

= 100mVp-p

1

0

-1

-2

-3

10k 1M100k 10M 100M

TEMPERATURE ERROR vs.

DIFFERENTIAL-MODE NOISE FREQUENCY

MAX6657 toc07

FREQUENCY (Hz)

TEMPERATURE ERROR (°C)

VIN = 10mV

P-P

SQUARE WAVE

APPLIED TO DXP-DXN

-5

-4

-3

-2

-1

0

0405020 3010 60 70 80 90 100

TEMPERATURE ERROR vs.

DXP-DXN CAPACITANCE

MAX6657 toc08

DXP-DXN CAPACITANCE (nF)

TEMPERATURE ERROR (°C)

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

MAX6657/MAX6658/MAX6659

_______________________________________________________________________________________ 5

Pin Description

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

PIN

MAX6657

MAX6658

11V

2 3 DXP

34DXN

46OVERT1

5 7, 8 GND Ground

69ALERT

7 12 SMBDATA SMBus Serial-Data Input/Output, Open-Drain

8 14 SMBCLK SMBus Serial-Clock Input

— 5 ADD

—10OVERT2

—15STBY

— 2, 11, 13, 16 N.C. Not internally connected. Do not make connections to these pins.

MAX6659

NAME FUNCTION

Supply Voltage Input, +3V to +5.5V. Bypass to GND with a 0.1µF capacitor. A 200Ω

CC

series resistor is recommended but not required for additional noise filtering. See

Typical Operating Circuit.

Combined Remote-Diode Current Source and A/D Positive Input for Remote-Diode

Channel. DO NOT LEAVE DXP UNCONNECTED; connect DXP to DXN if no remote

diode is used. Place a 2200pF capacitor between DXP and DXN for noise filtering.

Combined Remote-Diode Current Sink and A/D Negative Input. DXN is internally

biased to one diode drop above ground.

Overtemperature Active-Low Output, Open-Drain. Output is logic low only when

temperature is above the software programmed threshold.

SMBus Alert (Interrupt) Active-Low Output, Open-Drain. Asserts when temperature

exceeds user-set limits (high or low temperature). Stays asserted until acknowledged

by either reading the Status register or by successfully responding to an Alert

ALERT

Response address. See

SMBus Address-Select Pin. The MAX6659 is set to one of three available addresses

(connect to V

Overtemperature Active-Low Output, Open-Drain. Output is logic low only when

temperature is above the software programmed threshold.

Hardware Standby Input. Temperature and comparison threshold data are retained in

standby mode. If STBY is low, the IC is put into standby mode.

, GND, or leave open). See Slave Addresses section.

CC

Interrupts.

MAX6657/MAX6658/MAX6659

Detailed Description

The MAX6657/MAX6658/MAX6659 are temperature

sensors designed to work in conjunction with a microprocessor or other intelligence in thermostatic,

process-control, or monitoring applications. Communication with the MAX6657/MAX6658/MAX6659

occurs through the SMBus serial interface and dedicated alert pins. Two independent overtemperature alarms

(OVERT1 and OVERT2) are asserted if their software

programmed temperature thresholds are exceeded.

OVERT1 and OVERT2 can be connected to fans, a system shutdown, or other thermal management circuitry.

The MAX6657/MAX6658/MAX6659 convert temperatures to digital data either at a programmed rate or a

single conversion. Conversions have a 0.125°C resolution (extended resolution) or 1°C resolution (legacy resolution). Extended resolution represents temperature as

10 bits + sign bit and is available for autonomous conversions that are 4Hz and slower and single-shot conversions. Legacy resolution represents temperature as

7 bits + sign bit and allows for faster autonomous conversion rates of 8Hz and 16Hz.

ADC and Multiplexer

The averaging ADC integrates over a 60ms period

(each channel, typically, in the 7-bit + sign legacy

mode). Using an averaging ADC attains excellent noise

rejection.

The multiplexer automatically steers bias currents

through the remote and local diodes. The ADC and

associated circuitry measure each diode’s forward voltage and compute the temperature based on this voltage. If the remote channel is not used, connect DXP to

DXN. Do not leave DXP and DXN unconnected. When a

conversion is initiated, both channels are converted

6 _______________________________________________________________________________________

Functional Diagram

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

V

CC

MAX6657

MAX6658

MAX6659

2

DXP

DXN

ALERT

Q

OVERT1

Q

(OVERT2)

Q

MUX

REMOTE

LOCAL

DIODE

FAULT

S

R

S

R

S

R

MAX6659 ONLY

ADC

REGISTER BANK

COMMAND BYTE

REMOTE TEMPERATURE

LOCAL TEMPERATURE

ALERT THRESHOLD

ALERT RESPONSE

ADDRESS

OVERT1 THRESHOLD

(OVERT2 THRESHOLD)

8

8

CONTROL

LOGIC

SMBus

READ

WRITE

7

ADDRESS

DECODER

( ) ARE FOR MAX6659 ONLY

(STBY)

SMBDATA

SMBCLK

(ADD)

whether they are used or not. The DXN input is biased

at one VBEabove ground by an internal diode to set up

the ADC inputs for a differential measurement.

Resistance in series with the remote diode causes

about +1/2°C error per ohm.

A/D Conversion Sequence

A conversion sequence consists of a local temperature

measurement and a remote temperature measurement.

Each time a conversion begins, whether initiated automatically in the free-running autoconvert mode

(RUN/STOP = 0) or by writing a “one-shot” command,

both channels are converted, and the results of both

measurements are available after the end of conversion. A BUSY status bit in the Status register shows that

the device is actually performing a new conversion. The

results of the previous conversion sequence are still

available when the ADC is busy.

Remote-Diode Selection

The MAX6657/MAX6658/MAX6659 can directly measure the die temperature of CPUs and other ICs that

have on-board temperature-sensing diodes (see

Typical Operating Circuit

) or they can measure the temperature of a discrete diode-connected transistor. The

type of remote diode used is set by bit 5 of the

Configuration Byte. If bit 5 is set to zero, the remote

sensor is a diode-connected transistor, and if bit 5 is set

to 1, the remote sensor is a substrate or common collector PNP transistor. For best accuracy, the discrete transistor should be a small-signal device with its collector

and base connected together. Accuracy has been

experimentally verified for all the devices listed in Table 1.

The transistor must be a small-signal type with a relatively high forward voltage; otherwise, the A/D input

voltage range can be violated. The forward voltage at

the highest expected temperature must be greater than

0.25V at 10µA, and at the lowest expected temperature, forward voltage must be less than 0.95V at 100µA.

Large power transistors must not be used. Also, ensure

that the base resistance is less than 100Ω. Tight specifications for forward current gain (50 < β < 150, for

example) indicate that the manufacturer has good

process controls and that the devices have consistent

V

BE

characteristics.

Thermal Mass and Self-Heating

When sensing local temperature, these devices are

intended to measure the temperature of the PC board

to which they are soldered. The leads provide a good

thermal path between the PC board traces and the die.

Thermal conductivity between the die and the ambient

air is poor by comparison, making air temperature measurements impractical. Because the thermal mass of

the PC board is far greater than that of the MAX6657/

MAX6658/MAX6659, the devices follow temperature

changes on the PC board with little or no perceivable

delay.

When measuring the temperature of a CPU or other IC

with an on-chip sense junction, thermal mass has virtually no effect; the measured temperature of the junction

tracks the actual temperature within a conversion cycle.

When measuring temperature with discrete remote sensors, smaller packages (i.e., a SOT23) yield the best

thermal response times. Take care to account for thermal gradients between the heat source and the sensor,

and ensure that stray air currents across the sensor

package do not interfere with measurement accuracy.

Self-heating does not significantly affect measurement

accuracy. Remote-sensor self-heating due to the diode

current source is negligible. For the local diode, the

worst-case error occurs when autoconverting at the

fastest rate and simultaneously sinking maximum current at the ALERT output. For example, with VCC=

+5.0V, a 16Hz conversion rate and ALERT sinking

1mA, the typical power dissipation is:

VCCx 450µA + 0.4V x 1mA = 2.65mW

θ

J-A

for the 8-pin SO package is about +170°C/W, so

assuming no copper PC board heat sinking, the resulting temperature rise is:

∆T = 2.65mW x +170°C/W = +0.45°C

Even under these engineered circumstances, it is difficult to introduce significant self-heating errors.

ADC Noise Filtering

The integrating ADC used has good noise rejection for

low-frequency signals such as 60Hz/120Hz power-supply hum. In noisy environments, high-frequency noise

reduction is needed for high-accuracy remote mea-

MAX6657/MAX6658/MAX6659

_______________________________________________________________________________________ 7

Note: Transistors must be diode connected (base shorted to

collector).

Table 1. Remote-Sensor Transistor

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

MANUFACTURER MODEL NUMBER

Central Semiconductor (USA) CMPT3904

Fairchild Semiconductor (USA) 2N3904, 2N3906

On Semiconductor (USA) 2N3904, 2N3906

Rohm Semiconductor (USA) SST3904

Samsung (Korea) KST3904-TF

Siemens (Germany) SMBT3904

Zetex (England) FMMT3904CT-ND

MAX6657/MAX6658/MAX6659

surements. The noise can be reduced with careful PC

board layout and proper external noise filtering.

High-frequency EMI is best filtered at DXP and DXN

with an external 2200pF capacitor. Larger capacitor

values can be used for added filtering, but do not

exceed 3300pF because it can introduce errors due to

the rise time of the switched current source.

PC Board Layout

Follow these guidelines to reduce the measurement

error of the temperature sensors:

1) Place the MAX6657/MAX6658/MAX6659 as close

as is practical to the remote diode. In noisy environments, such as a computer motherboard, this distance can be 4in to 8in (typ). This length can be

increased if the worst noise sources are avoided.

Noise sources include CRTs, clock generators,

memory buses, and ISA/PCI buses.

2) Do not route the DXP-DXN lines next to the deflection coils of a CRT. Also, do not route the traces

across fast digital signals, which can easily introduce +30°C error, even with good filtering.

3) Route the DXP and DXN traces in parallel and in

close proximity to each other, away from any higher

voltage traces, such as +12VDC. Leakage currents

from PC board contamination must be dealt with

carefully since a 20MΩ leakage path from DXP to

ground causes about +1°C error. If high-voltage

traces are unavoidable, connect guard traces to GND

on either side of the DXP-DXN traces (Figure 1).

4) Route through as few vias and crossunders as possible to minimize copper/solder thermocouple

effects.

5) When introducing a thermocouple, make sure that

both the DXP and the DXN paths have matching

thermocouples. A copper-solder thermocouple

exhibits 3µV/°C, and it takes about 200µV of voltage

error at DXP-DXN to cause a +1°C measurement

error. Adding a few thermocouples causes a negligible error.

6) Use wide traces. Narrow traces are more inductive

and tend to pick up radiated noise. The 10mil widths

and spacings that are recommended in Figure 1 are

not absolutely necessary, as they offer only a minor

improvement in leakage and noise over narrow

traces. Use wider traces when practical.

7) Add a 200Ω resistor in series with VCCfor best

noise filtering (see

Typical Operating Circuit

).

Twisted-Pair and Shielded Cables

Use a twisted-pair cable to connect the remote sensor

for remote-sensor distances longer than 8in or in very

noisy environments. Twisted-pair cable lengths can be

between 6ft and 12ft before noise introduces excessive

errors. For longer distances, the best solution is a

shielded twisted pair like that used for audio microphones. For example, Belden #8451 works well for distances up to 100ft in a noisy environment. At the

device, connect the twisted pair to DXP and DXN and

the shield to GND. Leave the shield unconnected at the

remote sensor.

For very long cable runs, the cable’s parasitic capacitance often provides noise filtering, so the 2200pF

capacitor can often be removed or reduced in value.

Cable resistance also affects remote-sensor accuracy.

For every 1Ω of series resistance, the error is approximately +1/2°C.

Low-Power Standby Mode

Standby mode reduces the supply current to less than

10µA by disabling the ADC. Enter hardware standby

(MAX6659 only) by forcing the STBY pin low, or enter

software standby by setting the RUN/STOP bit to 1 in

the Configuration Byte register. Hardware and software

standbys are very similar—all data is retained in memory, and the SMB interface is alive and listening for

SMBus commands. The only difference is that in software standby mode, the one-shot command initiates a

conversion. With hardware standby, the one-shot command is ignored. Activity on the SMBus causes the

device to draw extra supply current.

Driving the STBY pin low overrides any software conversion command. If a hardware or software standby

command is received while a conversion is in progress,

the conversion cycle is interrupted, and the tempera-

8 _______________________________________________________________________________________

Figure 1. Recommended DXP-DXN PC Traces

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

GND

10MILS

10MILS

10MILS

DXP

MINIMUM

DXN

10MILS

GND

ture registers are not updated. The previous data is not

changed and remains available.

SMBus Digital Interface

From a software perspective, each of the MAX6657/

MAX6658/MAX6659 appears as a series of 8-bit registers that contain temperature data, alarm threshold

values, and control bits. A standard SMBus-compatible

2-wire serial interface is used to read Temperature Data

and Write Control bits and alarm threshold data. The

device responds to the same SMBus slave address for

access to all functions.

The MAX6657/MAX6658/MAX6659 employ four standard SMBus protocols: Write Byte, Read Byte, Send

Byte, and Receive Byte (Figures 2, 3, and 4). The shorter Receive Byte protocol allows quicker transfers, provided that the correct data register was previously

selected by a Read Byte instruction. Use caution with

the shorter protocols in multimaster systems, since a

second master could overwrite the command byte without informing the first master.

When the conversion rate is greater than 4Hz, temperature

data can be read from the Read Internal Temperature

(00h) and Read External Temperature (01h) registers.

The temperature data format is 7 bits + sign in two'scomplement form for each channel, with the LSB representing 1°C (Table 2). The MSB is transmitted first.

When the conversion rate is 4Hz or less, the first 8 bits

of temperature data can be read from the Read Internal

Temperature (00h) and Read External Temperature

(01h) registers, the same as for faster conversion rates.

An additional 3 bits can be read from the Read External

Extended Temperature (10h) and Read Internal

Extended Temperature (11h) registers, which extends

the data to 10 bits + sign and the resolution to

+0.125°C per LSB (Table 3).

When a conversion is complete, the Main register and

the Extended register are updated almost simultaneously. Ensure that no conversions are completed

between reading the Main and Extended registers so

that when data that is read, both registers contain the

result of the same conversion.

To ensure valid extended data, read extended resolution temperature data using one of the following

approaches:

1) Put the MAX6657/MAX6658/MAX6659 into standby

mode by setting bit 6 of the Configuration register to

MAX6657/MAX6658/MAX6659

______________________________________________________________________________________ 9

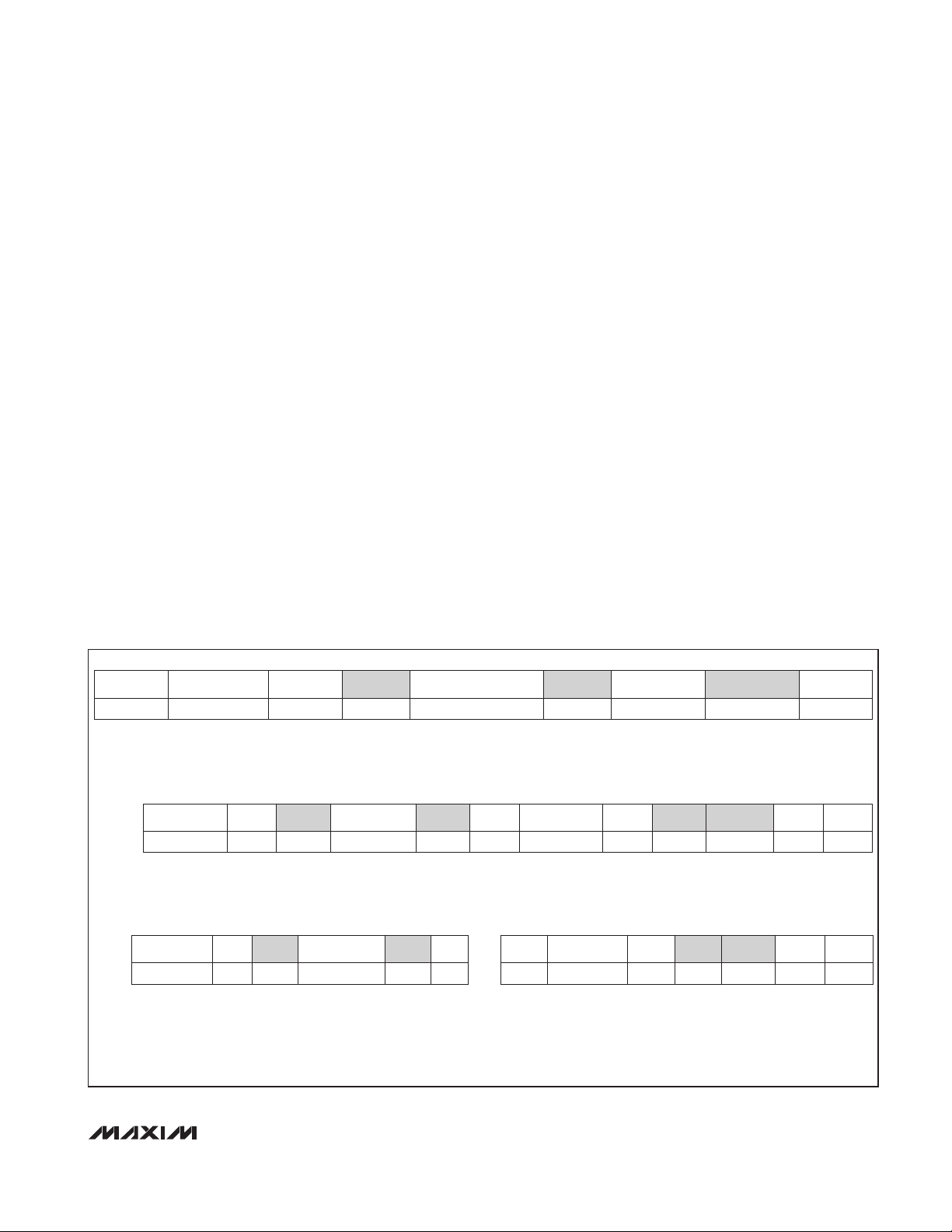

Figure 2. SMBus Protocols

ACK

7 bits

ADDRESS ACKWR

8 bits

DATA ACK

1

P

8 bits

S COMMAND

Write Byte Format

Read Byte Format

Send Byte Format Receive Byte Format

Slave Address: equivalent to chip-select line of

a 3-wire interface

Command Byte: selects which

register you are writing to

Data Byte: data goes into the register

set by the command byte (to set

thresholds, configuration masks, and

sampling rate)

ACK

7 bits

ADDRESS ACKWR S ACK

8 bits

DATA

7 bits

ADDRESS RD

8 bits

/// PCOMMAND

Slave Address: equivalent to chip-select line

Command Byte: selects

which register you are

reading from

Slave Address: repeated

due to change in dataflow direction

Data Byte: reads from

the register set by the

command byte

ACK

7 bits

ADDRESS WR

8 bits

COMMAND ACK P ACK

7 bits

ADDRESS RD

8 bits

DATA /// PS

Command Byte: sends command with no data, usually

used for one-shot command

Data Byte: reads data from

the register commanded

by the last Read Byte or

Write Byte transmission;

also used for SMBus Alert

Response return address

S = Start condition Shaded = Slave transmission

P = Stop condition /// = Not acknowledged

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

MAX6657/MAX6658/MAX6659

1. Initiate a one-shot conversion using Command

Byte 0Fh. When this conversion is complete, read

the contents of the Temperature Data registers.

2) If the MAX6657/MAX6658/MAX6659 are in run mode,

read the Status register. If a conversion is in

progress, the BUSY bit is set to 1. Wait for the conversion to complete as indicated by the BUSY bit

being set to 0, then read the Temperature Data registers. Note that the power-on reset sets the conversion rate to 16Hz, so no extended data is valid

without reducing the conversion rate to 4Hz or less.

Diode Fault Alarm

There is a continuity fault detector at DXP that detects

an open circuit between DXP and DXN, or a DXP short

to VCC, GND, or DXN. If an open or short circuit exists,

the external temperature register is loaded with 1000

0000. Additionally, if the fault is an open circuit, bit 2

(OPEN) of the status byte is set to 1 and the ALERT condition is activated at the end of the conversion.

Immediately after POR, the Status register indicates that

no fault is present until the end of the first conversion.

10 ______________________________________________________________________________________

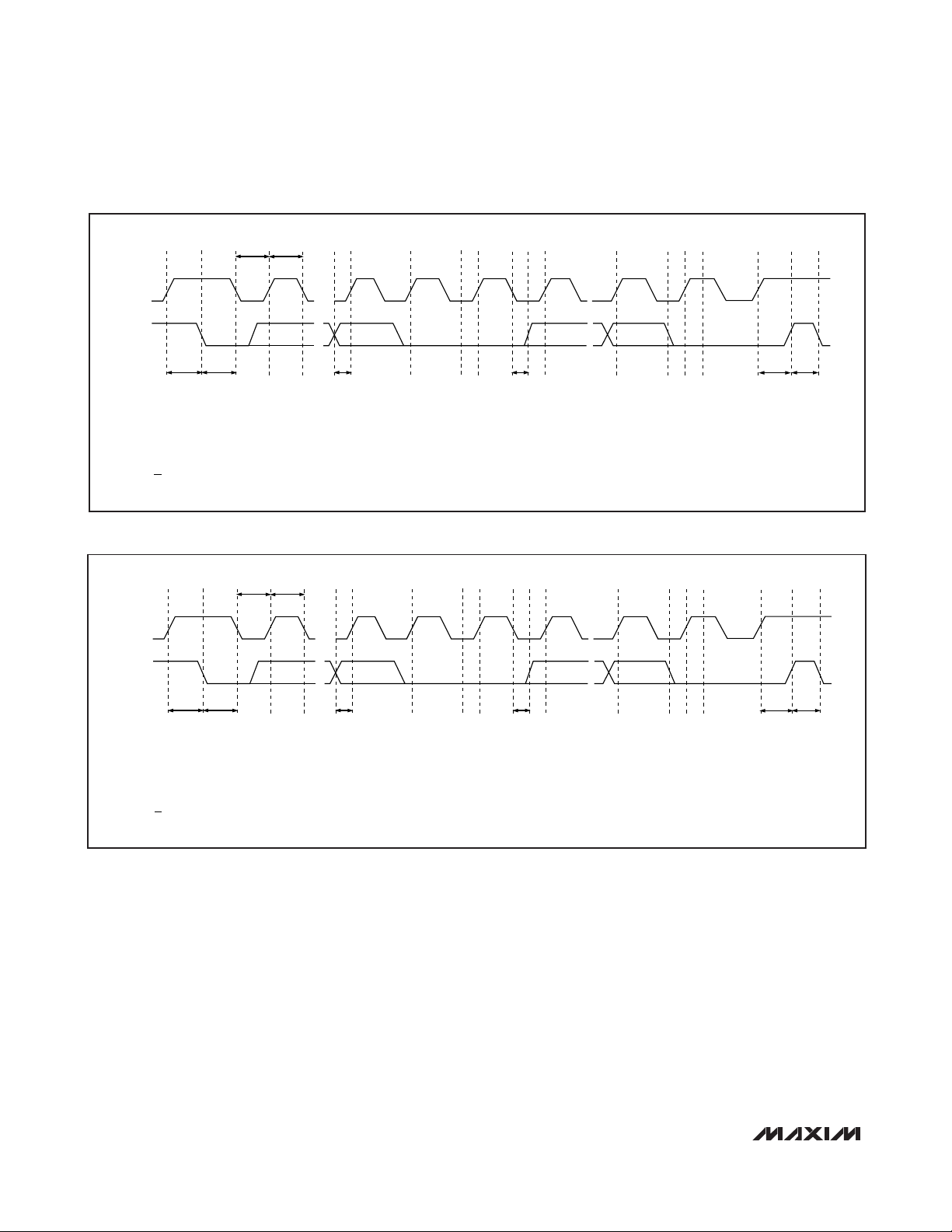

Figure 4. SMBus Read Timing Diagram

Figure 3. SMBus Write Timing Diagram

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

AB CDEFG HIJ

t

LOWtHIGH

SMBCLK

SMBDATA

t

t

HD:STA

SU:STA

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SMBDATA LINE LOW

t

SU:DAT

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO SLAVE

H = LSB OF DATA CLOCKED INTO SLAVE

I = MASTER PULLS DATA LINE LOW

t

HD:DAT

AB CDEFG HIJ

t

LOWtHIGH

SMBCLK

SMBDATA

t

SU:STA

t

HD:STA

t

SU:DAT

t

HD:DAT

K

t

SU:STO

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

K

t

SU:STO

M

L

t

BUF

M

L

t

BUF

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SMBDATA LINE LOW

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO MASTER

H = LSB OF DATA CLOCKED INTO MASTER

I = MASTER PULLS DATA LINE LOW

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

Alarm Threshold Registers

Four registers store ALERT threshold values—one hightemperature (T

HIGH

) and one low-temperature (T

LOW

)

register each for the local and remote channels. If

either measured temperature equals or exceeds the

corresponding ALERT threshold value, the ALERT output is asserted.

The POR state of both ALERT T

HIGH

registers is 0100

0110 or +70°C and the POR state of T

LOW

registers is

1100 1001 or -55°C.

Four additional registers store remote and local alarm

threshold data corresponding to the OVERT1 and

OVERT2 (MAX6659 only) outputs. The values stored in

these registers are high-temperature thresholds. If any

one of the measured temperatures equals or exceeds

the corresponding alarm threshold value, an OVERT

output is asserted. The POR state of the OVERT threshold is 0101 0101 or +85°C.

Alert

Interrupts

An ALERT interrupt occurs when the internal or external

temperature reading exceeds a high or low temperature limit (user programmed) or when the remote diode

is disconnected (for continuity fault detection). The

ALERT interrupt output signal is latched and can be

cleared only by either reading the Status register or by

successfully responding to an Alert Response address.

In both cases, the alert is cleared even if the fault condition still exists, but is reasserted at the end of the next

conversion. The interrupt does not halt automatic conversions. The interrupt output pin is open-drain so that

multiple devices can share a common interrupt line.

The interrupt rate never exceeds the conversion rate.

Alert Response Address

The SMBus Alert Response interrupt pointer provides

quick fault identification for simple slave devices that

lack the complex, expensive logic needed to be a bus

master. Upon receiving an ALERT interrupt signal, the

host master can broadcast a Receive Byte transmission

to the Alert Response slave address (0001100). Then,

any slave device that generated an interrupt attempts

to identify itself by putting its own address on the bus

(Table 8).

The Alert Response can activate several different slave

devices simultaneously, similar to the I2C General Call.

If more than one slave attempts to respond, bus arbitration rules apply, and the device with the lower address

code wins. The losing device does not generate an

acknowledge and continues to hold the ALERT line low

until cleared. (The conditions for clearing an alert vary,

depending on the type of slave device.) Successful

completion of the Alert Response protocol clears the

interrupt latch, provided the condition that caused the

alert no longer exists. If the condition still exists, the

device reasserts the ALERT interrupt at the end of the

next conversion.

OVERT

Overtemperature

Alarm/Warning Outputs

OVERT1 and OVERT2 (MAX6659 only) are asserted

when the temperature rises to a value programmed in

the appropriate threshold register. They are deasserted

when the temperature drops below this threshold minus

the hysteresis. An OVERT output can be used to activate a cooling fan, send a warning, or trigger a system

shutdown to prevent component damage. The HYST

byte sets the amount of hysteresis for both OVERT outputs. The data format for the HYST byte is the same for

the other temperature registers (Table 2).

MAX6657/MAX6658/MAX6659

______________________________________________________________________________________ 11

Table 3. Extended Resolution Register

Note: Extended resolution applies only for conversion rates of

4Hz and slower.

Table 2. Data Format (Two's Complement)

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

DIGITAL OUTPUT

TEMP (°C)

130.00 0 111 1111 0 111 1111

127.00 0 111 1111 0 111 1111

126.00 0 111 1111 0 111 1111

25 0 001 1001 0 001 1001

0.00 0 000 0000 0 000 0000

-1 1 000 0000 1 111 1111

-25 1 000 0000 1 110 0111

-55 1 000 0000 1 100 1001

Diode Fault

(Short or Open)

MAX6657

1 000 0000 1 000 0000

MAX6658

MAX6659

FRACTIONAL

TEMPERATURE

0.000 000X XXXX

0.125 001X XXXX

0.250 010X XXXX

0.375 011X XXXX

0.500 100X XXXX

0.625 101X XXXX

0.750 110X XXXX

0.875 111X XXXX

CONTENTS OF

EXTENDED REGISTER

MAX6657/MAX6658/MAX6659

For example, OVERT1 has a threshold set to +50°C

and is connected to a fan. OVERT2 has a threshold of

+75°C and is connected to a system shutdown. If the

system reaches +50°C, the fan turns on, trying to cool

the system. If the system continues to heat up to the

critical temperature of +75°C, OVERT2 causes the system to shut down.

Command Byte Functions

The 8-bit Command Byte register (Table 4) is the master

index that points to the various other registers within the

MAX6657/MAX6658/MAX6659. This register’s POR state

is 0000 0000, so a Receive Byte transmission (a protocol

that lacks the command byte) occurring immediately

after POR returns the current local temperature data.

One-Shot

The one-shot command immediately forces a new conversion cycle to begin. If the one-shot command is

received when the MAX6657/MAX6658/MAX6659 are in

software standby mode (RUN/STOP bit = 1), a new

conversion is begun, after which the device returns to

standby mode. If a conversion is in progress when a

one-shot command is received, the command is

ignored. If a one-shot command is received in autoconvert mode (RUN/STOP bit = 0) between conversions, a

new conversion begins, the conversion rate timer is

reset, and the next automatic conversion takes place

after a full delay elapses.

Configuration Byte Functions

The Configuration Byte register (Table 5) is a Read-Write

register with several functions. Bit 7 is used to mask (disable) interrupts. Bit 6 puts the device into software standby mode (STOP) or autonomous (RUN) mode. Bit 5

selects the type of external junction (set to 1 for a substrate PNP on an IC or set to 0 for a discrete diode-connected transistor) for optimized measurements. Bits 0 to

4 are reserved and return a zero when read.

12 ______________________________________________________________________________________

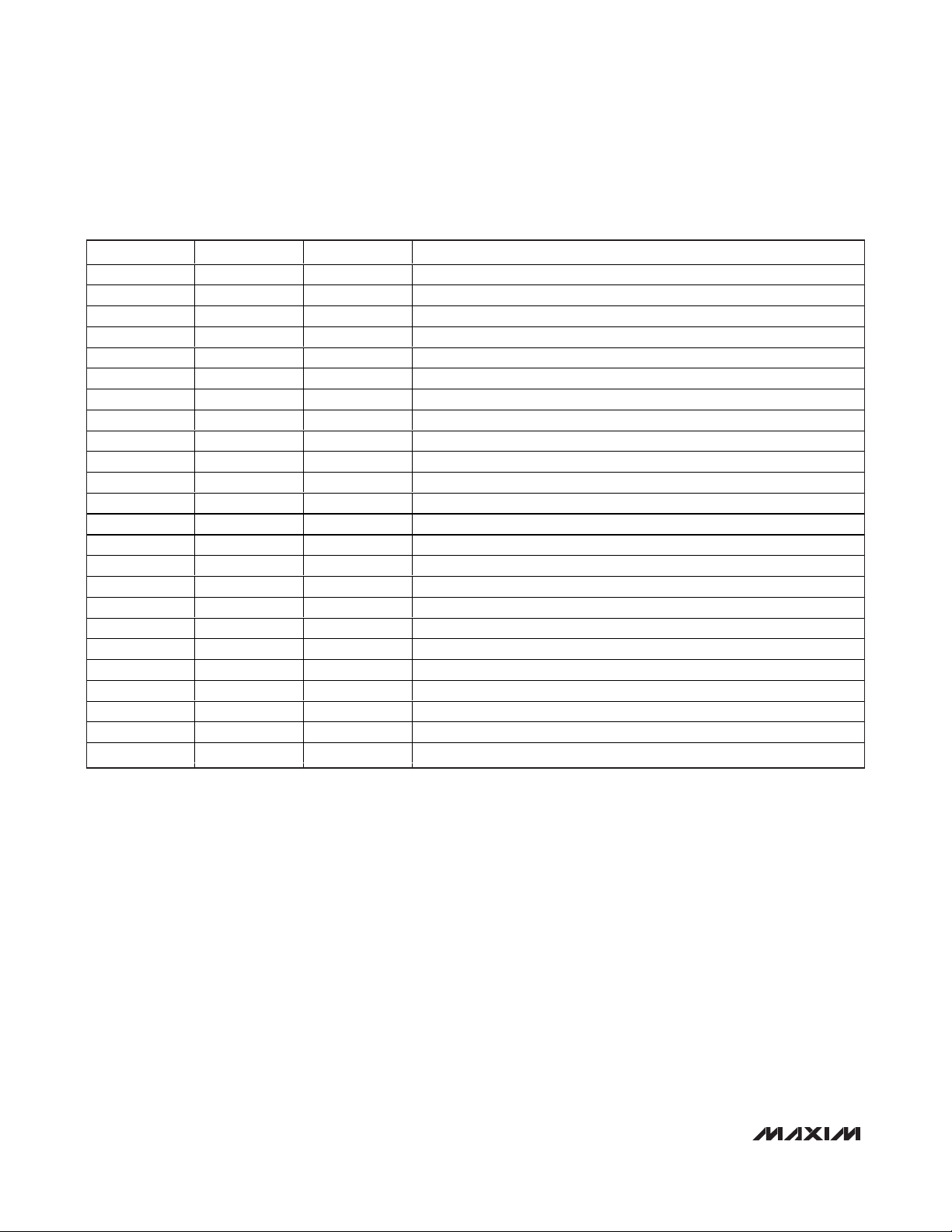

Table 4. Command Byte Register Assignments

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

REGISTER ADDRESS POR STATE FUNCTION

RLTS 00h 0000 0000 Read Internal Temperature

RRTE 01h 0000 0000 Read External Temperature

RSL 02h 1000 0000 Read Status Register

RCL 03h 0010 0000 Read Configuration Byte

RCRA 04h 0000 1000 Read Conversion Rate Byte

RLHN 05h 0100 0110 Read Internal High Limit

RLLI 06h 1100 1001 Read Internal Low Limit

RRHI 07h 0100 0110 Read External High Limit

RRLS 08h 1100 1001 Read External Low Limit

WCA 09h 0010 0000 Write Configuration Byte

WCRW 0Ah 0000 1000 Write Conversion Rate Byte

WLHO 0Bh 0100 0110 Write Internal High Limit

WLLM 0Ch 1100 1001 Write Internal Low Limit

WRHA 0Dh 0100 0110 Write External High Limit

WRLN 0Eh 1100 1001 Write External Low Limit

OSHT 0Fh N/A One Shot

REET 10h 0000 0000 Read External Extended Temperature

RIET 11h 0000 0000 Read Internal Extended Temperature

RWO2E 16h 0101 0101 Read/Write External OVERT2 Limit (MAX6659 only)

RW02I 17h 0101 0101 Read/Write Internal OVERT2 Limit (MAX6659 only)

RWOE 19h 0101 0101 Read/Write External OVERT1 Limit

RWOI 20h 0101 0101 Read/Write Internal OVERT1 Limit

HYST 21h 0000 1010 Overtemperature Hysteresis

— FEh 4Dh Read Manufacture ID

MAX6657/MAX6658/MAX6659

______________________________________________________________________________________ 13

Status Byte Functions

The status byte (Table 6) indicates which (if any) temperature thresholds have been exceeded. This byte also

indicates whether the ADC is converting and if there is

an open-circuit fault detected with the external sense

junction. After POR, the normal state of the MSB is 1 and

all the other flag bits are 0, assuming no alert or

overtemperature conditions are present. Bits 2 through

6 of the Status register are cleared by any successful

read of the Status register, unless the fault persists. The

ALERT output follows the status flag bit. Both are

cleared when successfully read, but if the condition still

exists, they reassert at the end of the next conversion.

The bits indicating OVERT1 (bits 0 and 1) are cleared

only when the condition no longer exists. Reading the

status byte does not clear the OVERT1 outputs or fault

bits. One way to eliminate the fault condition is for the

measured temperature to drop below the temperature

threshold minus the hysteresis value. Another way to

eliminate the fault condition is by writing new values for

the OVERT1 threshold or hysteresis so that a fault condition is no longer present. Note that the status byte

does not provide status of OVERT2.

The MAX6657/MAX6658/MAX6659 incorporate collision

avoidance so that completely asynchronous operation

is allowed between SMBus operations and temperature

conversions.

When autoconverting, if the T

HIGH

and T

LOW

limits are

close together, it’s possible for both high-temp and lowtemp status bits to be set, depending on the amount of

time between status read operations. In these circumstances, it is best not to rely on the status bits to indicate reversals in long-term temperature changes.

Instead, use a current temperature reading to establish

the trend direction.

Conversion Rate Byte

The Conversion Rate register (Table 7) programs the

time interval between conversions in free-running

autonomous mode (RUN/STOP = 0). This variable rate

Table 5. Configuration-Byte Bit

Assignments

Table 6. Status Register Bit Assignments

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

BIT NAME

7

(MSB)

4 to 0 RFU 0 Reserved

MASK1 0 Masks ALERT interrupts if a 1.

6 RUN/STOP 0

5 SPNP 1

POR

STATE

FUNCTION

Standby mode control bit; if a

1, standby mode is initiated.

Set to 1 when the remote

sensor is a substrate or

common collector PNP. Set to 0

when the remote sensor is a

diode-connected discrete

transistor.

BIT NAME POR STATE FUNCTION

7 (MSB) BUSY 1 A/D is busy converting when high.

6 LHIGH 0

5 LLOW 0

4 RHIGH 0

3 RLOW 0

2 OPEN 0

1 EOT1 0

0 IOT1 0

Internal high-temperature alarm has tripped when high; cleared by POR or readout of

the Status register if the fault condition no longer exists.

Internal low-temperature alarm has tripped when high; cleared by POR or readout of

the Status register if the fault condition no longer exists.

External high-temperature alarm has tripped when high; cleared by POR or readout of

the Status register if the fault condition no longer exists.

External low-temperature alarm has tripped when high; cleared by POR or readout of

the Status register if the fault condition no longer exists.

A high indicates an external diode open; cleared by POR or readout of the Status

register if the fault condition no longer exists.

A high indicates the external junction temperature exceeds the external OVERT1

threshold.

A high indicates the internal junction temperature exceeds the internal OVERT1

threshold.

MAX6657/MAX6658/MAX6659

control can be used to reduce the supply current in

portable-equipment applications. The conversion rate

byte’s POR state is 08h (16Hz). The MAX6657/

MAX6658/MAX6659 use only the 4 least-significant bits

(LSBs) of this register. The 4 most-significant bits

(MSBs) are “don’t care” and should be set to zero when

possible. The conversion rate tolerance is ±25% at any

rate setting.

Valid A/D conversion results for both channels are

available one total conversion time (125ms nominal,

156ms maximum) after initiating a conversion, whether

conversion is initiated through the RUN/STOP bit, hardware STBY pin, one-shot command, or initial power-up.

Slave Addresses

The MAX6657/MAX6658 have a fixed address of

1001100. The MAX6659 can be programmed to have

one of three different addresses, allowing up to three

devices to reside on the same bus without address

conflicts. Table 8 lists address information.

The address pin state is checked at POR only, and the

address data stays latched to reduce quiescent supply

current due to the bias current needed for high-Z state

detection.

The MAX6657/MAX6658/MAX6659 also respond to the

SMBus Alert Response slave address (see

Alert

Response Address

section).

POR and UVLO

The MAX6657/MAX6658/MAX6659 have a volatile

memory. To prevent unreliable power-supply conditions

from corrupting the data in memory and causing erratic

behavior, a POR voltage detector monitors V

CC

and

clears the memory if V

CC

falls below 1.7V (typ, see

Electrical Characteristics

). When power is first applied

and VCCrises above 2.0V (typ), the logic blocks begin

operating, although reads and writes at V

CC

levels

below 3.0V are not recommended. A second VCCcomparator and the ADC undervoltage lockout (UVLO)

comparator prevent the ADC from converting until there

is sufficient headroom (VCC= +2.8V typ).

Power-Up Defaults

Power-up defaults include:

• ADC begins autoconverting at a 16Hz rate (legacy

resolution).

• THIGH and TLOW registers are set to default limits,

respectively.

• Interrupt latch is cleared.

• Address-select pin is sampled (MAX6659 only).

• Command register is set to 00h to facilitate quick

internal Receive Byte queries.

• Hysteresis is set to 10°C.

• Transistor type is set to a substrate or common col-

lector PNP.

14 ______________________________________________________________________________________

Table 8. Slave Address Decoding for

MAX6659

Note: Extended resolution applies only for conversion rates of

4Hz or slower.

Table 7. Conversion-Rate

Control Byte

Table 9. Read Format for Alert Response

Address (000 1100)

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

DATA CONVERSION RATE (Hz)

00h 0.0625

01h 0.125

02h 0.25

03h 0.5

04h 1

05h 2

06h 4

07h 8

08h 16

09h 16

0Ah-FFh Reserved

ADD CONNECTION ADDRESS

BIT NAME FUNCTION

7 (MSB) ADD7

6 ADD6

5 ADD5

4 ADD4

3 ADD3

2 ADD2

1 ADD1

0 (LSB) 1 Logic 1

GND 1001100

V

CC

Unconnected 1001101

1001110

Provide the current

MAX6659 slave address

that was latched at POR

(Table 8)

MAX6657/MAX6658/MAX6659

______________________________________________________________________________________ 15

Chip Information

PROCESS: BiCMOS

V

CC

SMBDATA

SMBCLK

DATA

CLOCK

INTERRUPTED TO µP

TO FAN DRIVER

() ARE MAX6659 ONLY

TO SYSTEM SHUTDOWN

(ADD) GND

µP

3.3V

200Ω

2200pF

10kΩ

EACH

0.1µF

DXP

DXN

ALERT

OVERT1

(OVERT2)

(STBY)

MAX6657

MAX6658

MAX6659

Typical Operating Circuit

±1°C, SMBus-Compatible Remote/Local Temperature

Sensors with Overtemperature Alarms

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages

. Note that a “+”, “#”, or “-” in

the package code indicates RoHS status only. Package drawings may show a different suffix character, but the drawing pertains to the package regardless of RoHS status.

PACKAGE

TYPE

PACKAGE

CODE

OUTLINE NO.

LAND

PATTERN NO.

8 SO S8-5

21-0041

90-0096

16 QSOP E16-5

21-0055

90-0167

Ordering Information (continued)

Note: All devices are specified over the -55°C to +125°C operating temperature range.

+

Denotes a lead(Pb)-free/RoHS-compliant package.

T = Tape and reel.

PART

MAX6658MSA -55°C to +125°C 8 SO

MAX6658MSA+ -55°C to +125°C 8 SO

MAX6658MSA-T -55°C to +125°C 8 SO

MAX6658MSA+T -55°C to +125°C 8 SO

MAX6659MEE -55°C to +125°C 16 QSOP

MAX6659MEE+ -55°C to +125°C 16 QSOP

MAX6659MEE-T -55°C to +125°C 16 QSOP

MAX6659MEE+T -55°C to +125°C 16 QSOP

MEASURED TEMP

RANGE

PIN-PACKAGE

MAX6657/MAX6658/MAX6659

1°C Remote/Local Temperature Sensors with SMBus

Serial Interface and Overtemperature Alarms

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2010 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Revision History

REVISION

NUMBER

5 10/10

REVISION

DATE

DESCRIPTION

Updated the Ordering Information table to include lead(Pb)-free parts, added the

soldering temperature to the Absolute Maximum Ratings section, replaced the

package outline drawings with the Package Information table

PAGES

CHANGED

1, 2, 15

Loading...

Loading...