General Description

The MAX6643/MAX6644/MAX6645 monitor temperature

and automatically adjust fan speed to ensure optimum

cooling while minimizing acoustic noise from the fan.

Each device measures two temperature locations.

The MAX6643/MAX6644/MAX6645 generate a PWM

waveform that drives an external power transistor, which

in turn modulates the fan’s power supply. The

MAX6643/MAX6644/MAX6645 monitor temperature and

adjust the duty cycle of the PWM output waveform to control the fan’s speed according to the cooling needs of the

system. The MAX6643 monitors its own die temperature

and an optional external transistor’s temperature, while the

MAX6644 and MAX6645 each monitor the temperatures

of one or two external diode-connected transistors.

The MAX6643 and MAX6644 have nine selectable trip

temperatures (in 5°C increments). The MAX6645 is factory programmed and is not pin selectable.

All versions include an overtemperature output (OT).

OT can be used for warning or system shutdown. The

MAX6643 also features a FULLSPD input that forces the

PWM duty cycle to 100%. The MAX6643/MAX6644/

MAX6645 also feature a FANFAIL output that indicates

a failed fan. See the Selector Guide for a complete list

of each device’s functions.

The MAX6643 and MAX6644 are available in a small

16-pin QSOP package and the MAX6645 is available in

a 10-pin µMAX®package. All versions operate from

3.0V to 5.5V supply voltages and consume 500µA (typ)

supply current.

Applications

Networking Equipment

Storage Equipment

Servers

Desktop Computers

Workstations

Features

♦ Simple, Automatic Fan-Speed Control

♦ Internal and External Temperature Sensing

♦ Detect Fan Failure Through Locked-Rotor Output,

Tachometer Output, or Fan-Supply Current

Sensing

♦ Multiple, 1.6% Output Duty-Cycle Steps for Low

Audibility of Fan-Speed Changes

♦ Pin-Selectable or Factory-Selectable Low-

Temperature Fan Threshold

♦ Pin-Selectable or Factory-Selectable High-

Temperature Fan Threshold

♦ Spin-Up Time Ensures Fan Start

♦ Fan-Start Delay Minimizes Power-Supply Load at

Power-Up

♦ 32Hz PWM Output

♦ Controlled Duty-Cycle Rate-of-Change Ensures

Good Acoustic Performance

♦ 2°C Temperature-Measurement Accuracy

♦ FULLSPD/FULLSPD Input Sets PWM to 100%

♦ Pin-Selectable OT Output Threshold

♦ 16-Pin QSOP and 10-Pin µMAX Packages

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

________________________________________________________________ Maxim Integrated Products 1

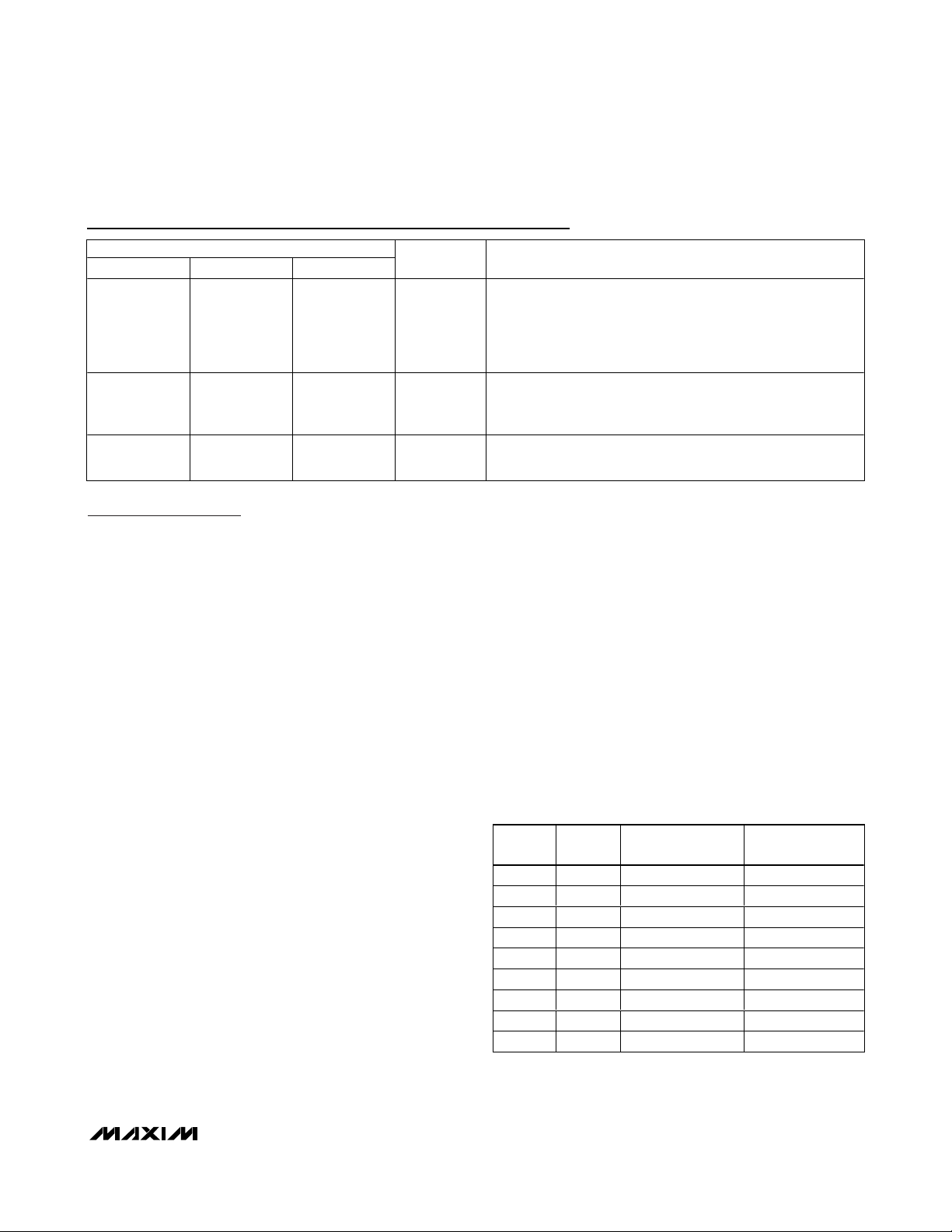

Ordering Information

19-3305; Rev 2; 3/07

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Pin Configurations, Typical Operating Circuit, and Selector

Guide appear at end of data sheet.

µMAX is a registered trademark of Maxim Integrated Products, Inc.

PART TEMP RANGE

MAX6643LBFAEE -40°C to +125°C 16 QSOP E16-1

MAX6643LBBAEE -40°C to +125°C 16 QSOP E16-1

MAX6644LBAAEE -40°C to +125°C 16 QSOP E16-1

MAX6645ABFAUB -40°C to +125°C 10 µMAX U10-2

PINPACKAGE

PKG

CODE

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

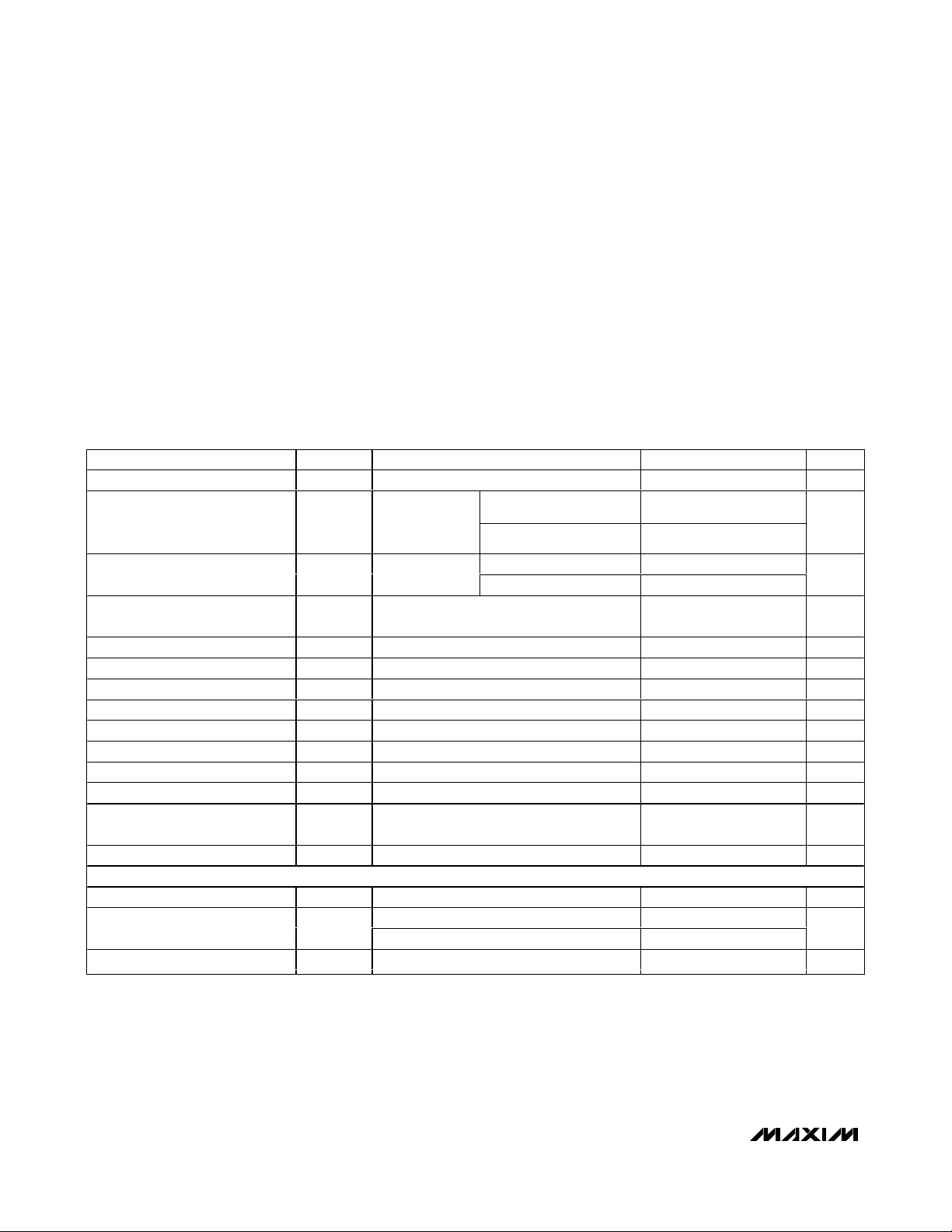

ELECTRICAL CHARACTERISTICS

(VDD= +3.0V to +5.5V, TA= -40°C to +125°C, unless otherwise noted. Typical values are at VDD= +3.3V, TA= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto GND..............................................................-0.3V to +6V

PWM_OUT, OT, and FANFAIL to GND.....................-0.3V to +6V

FAN_IN1 and FAN_IN2 to GND...........................-0.3V to +13.2V

DXP_ to GND.........................................................-0.3V to +0.8V

FULLSPD, FULLSPD, TH_, TL_, TACHSET,

and OT_ to GND ..................................-0.3V to +(V

DD

+ 0.3V)

FANFAIL, OT Current..........................................-1mA to +50mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.3mW/°C above +70°C).......... 667mW

10-Pin µMAX (derate 5.6mW/°C above +70°C) ...........444mW

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range ............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Operating Supply Voltage Range V

Remote Temperature Error

Local Temperature Error VCC = +3.3V

Temperature Error from Supply

Sensitivity

Power-On-Reset (POR) Threshold VDD falling edge 1.5 2.0 2.5 V

POR Threshold Hysteresis 90 mV

Operating Current I

Average Operating Current Duty cycle = 50%, no load 0.5 mA

Remote-Diode Sourcing Current High level 80 100 120 µA

Conversion Time 125 ms

Spin-Up Time MAX664_ _B_ _ _ _ 8 s

Startup Delay MAX664_ _B_ _ _ _ 0.5 s

Minimum Fan-Fail Tachometer

Frequency

PWM_OUT Frequency F

DIGITAL OUTPUTS (OT, FANFAIL, PWM_OUT)

Output Low Voltage (OT)V

Output Low Voltage

(FANFAIL, PWM_OUT)

Output-High Leakage Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DD

= +3.3V,

S

PWM_OUT

OL

V

OL

OH

V

DD

+20°C ≤ T

+100°C

During a conversion 0.5 1 mA

I

SINK

I

SINK

I

SINK

VOH = 3.3V 1 µA

RJ

= 1mA 0.4 V

= 6mA 0.5

= 1mA 0.4

TA = +20°C to +60°C ±2

≤

= 0°C to +125°C ±3

T

A

TA = +10°C to +70°C ±2.5

T

= 0°C to +125°C ±3.5

A

+3.0 +5.5 V

±0.2 °C/V

16 Hz

32 Hz

°C

°C

V

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

_______________________________________________________________________________________ 3

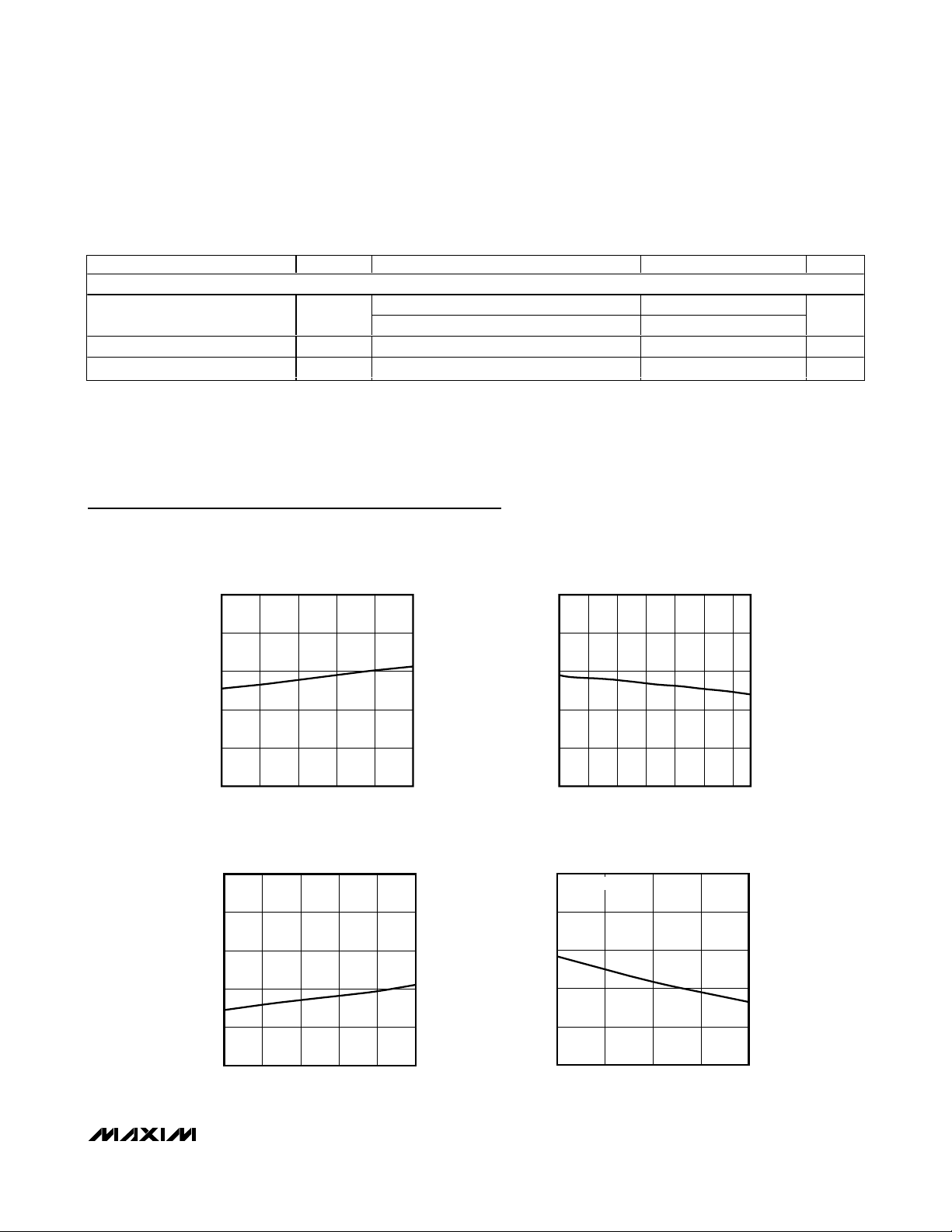

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +3.0V to +5.5V, TA= -40°C to +125°C, unless otherwise noted. Typical values are at VDD= +3.3V, TA= +25°C.) (Note 1)

Note 1: All parameters tested at TA= +25°C. Specifications over temperature are guaranteed by design.

DIGITAL INPUTS (FULLSPD, FULLSPD, TACHSET)

Logic-Input High V

Logic-Input Low V

Input Leakage Current VIN = GND or V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

VDD = 5.5V 3.65

IH

VDD = 3.0V 2.2

VDD = 3.0V 0.8 V

IL

DD

-1 +1 µA

OPERATING SUPPLY CURRENT

vs. SUPPLY VOLTAGE

400

360

MAX6643 toc01

32.0

31.8

PWMOUT FREQUENCY

vs. DIE TEMPERATURE

MAX6643 toc02

V

320

280

SUPPLY CURRENT (μA)

240

200

3.0 5.5

SUPPLY VOLTAGE (V)

PWMOUT FREQUENCY

vs. SUPPLY VOLTAGE

35

34

33

32

PWMOUT FREQUENCY (Hz)

31

30

3.0 5.5

SUPPLY VOLTAGE (V)

31.6

31.4

PWMOUT FREQUENCY (Hz)

31.2

5.04.54.03.5

31.0

-40

10085603510-15

TEMPERATURE (°C)

TRIP-THRESHOLD ERROR

vs. TRIP TEMPERATURE

1.0

MAX664_L VERSIONS

MAX6643 toc03

5.04.54.03.5

0.6

0.2

-0.2

TRIP-THRESHOLD ERROR (°C)

-0.6

-1.0

20 100

TRIP TEMPERATURE (°C)

806040

MAX6643 toc04

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

4 _______________________________________________________________________________________

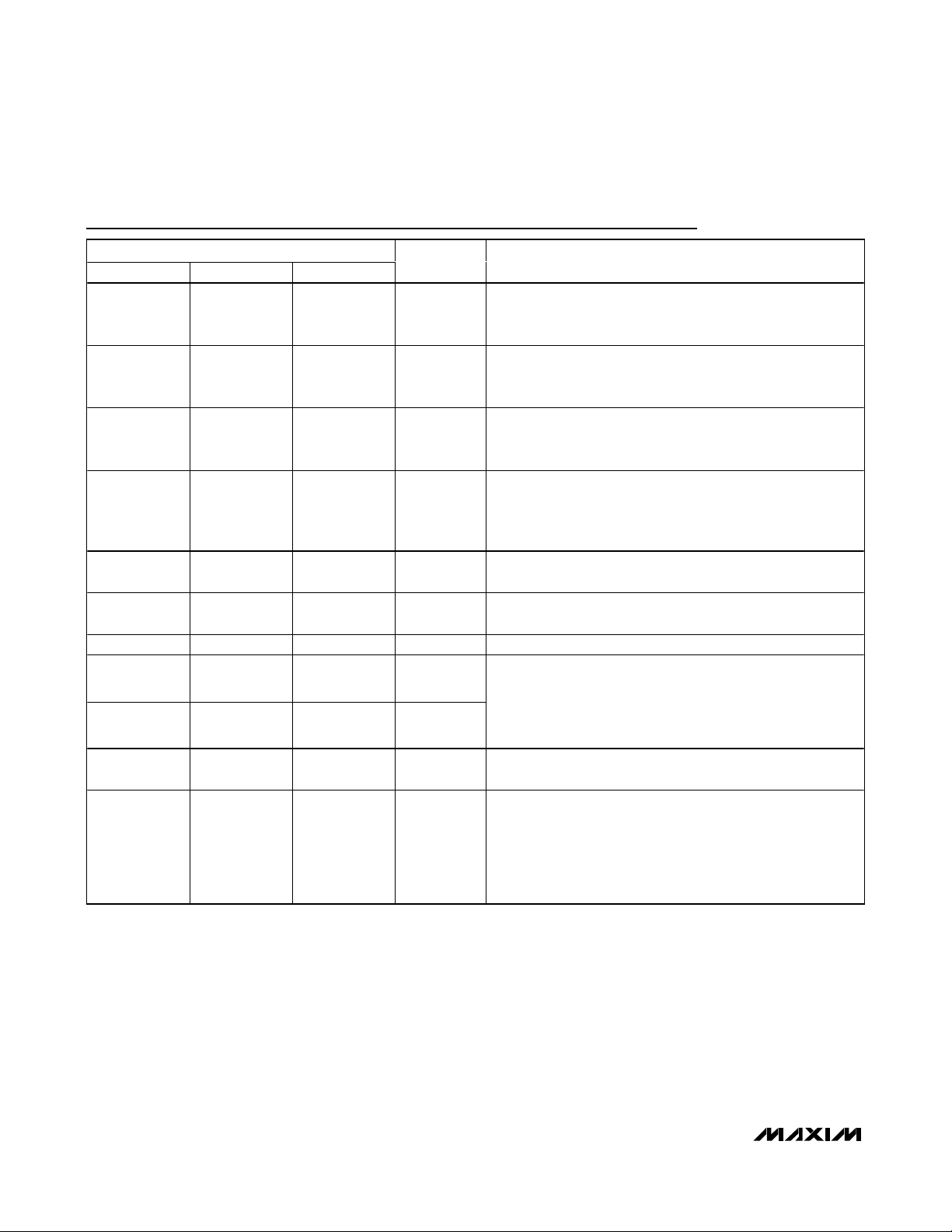

Pin Description

PIN

MAX6643 MAX6644 MAX6645

1, 15 1, 15 — TH1, TH2

NAME FUNCTION

High-Temperature Threshold Inputs. Connect to V

leave unconnected to select the upper fan-control trip

temperature (T

), in 5°C increments. See Table 1.

HIGH

DD

, GND, or

Low-Temperature Threshold Inputs. Connect to V

2, 3 2, 3 — TL2, TL1

441FANFAIL

5 5 2 TACHSET

6 — — FULLSPD

———FULLSPD

7 7 4 GND Ground

8 — — DXP

— 6, 8 3, 5 DXP2, DXP1

996OT

10, 11 10, 11 7, 8

FAN_IN2,

FAN_IN1

leave unconnected to select the lower fan-control trip

temperature (T

Fan-Fail Alarm Output. FANFAIL is an active-low, open-drain

output. If the FAN_IN_ detects a fan failure, the FANFAIL output

asserts low.

FAN_IN_ Control Input. TACHSET controls what type of fan-fail

condition is being detected. Connect TACHSET to V

or leave floating to set locked rotor, current sense, or

tachometer configurations (see Table 3).

Active-High Logic Input. When pulled high, the fan runs at

100% duty cycle.

Active-Low Logic Input. When pulled low, the fan runs at 100%

duty cycle.

C om b i ned C ur r ent S our ce and A/D P osi ti ve Inp ut for Rem ote

D i od e. C onnect to anod e of r em ote d i od e- connected

tem p er atur e- sensi ng tr ansi stor . C onnect to G N D i f no r em ote

d i od e i s used . P l ace a 2200p F cap aci tor b etw een D X P _ and

G N D for noi se fi l ter i ng .

Active-Low, Open-Drain Overtemperature Output. When OT

threshold is exceeded, OT pulls low.

Fan- S ense Inp ut. FAN _IN _ can b e confi g ur ed to m oni tor ei ther a

fan’ s l og i c- l evel l ocked - r otor outp ut, tachom eter outp ut, or senser esi stor w avefor m to d etect fan fai l ur e. The M AX 6643’ s FAN _IN _

i np ut can m oni tor onl y tachom eter si g nal s. The M AX 6644 and the

M AX 6645 can m oni tor any one of the thr ee si g nal typ es as

confi g ur ed usi ng the TAC H S E T i np ut.

), in 5°C increments. See Table 2.

LOW

, GND, or

DD

DD

, GND,

Detailed Description

The MAX6643/MAX6644/MAX6645 measure temperature

and automatically adjust fan speed to ensure optimum

cooling while minimizing acoustic noise from the fan.

The MAX6643/MAX6644/MAX6645 generate a PWM

waveform that drives an external power transistor,

which in turn modulates the fan’s power supply. The

MAX6643/MAX6644/MAX6645 monitor temperature and

adjust the duty cycle of the PWM output waveform to

control the fan’s speed according to the cooling needs

of the system. The MAX6643 monitors its own die temperature and an optional external transistor’s temperature, while the MAX6644 and MAX6645 each monitor

the temperatures of one or two external diode-connected transistors.

Temperature Sensor

The pn junction-based temperature sensor can measure temperatures up to two pn junctions. The

MAX6643 measures the temperature of an external

diode-connected transistor, as well as its internal temperature. The MAX6644 and MAX6645 measure the

temperature of two external diode-connected transistors. The temperature is measured at a rate of 1Hz.

If an external “diode” pin is shorted to ground or left

unconnected, the temperature is read as 0°C. Since the

larger of the two temperatures prevails, a faulty or

unconnected diode is not used for calculating fan

speed or determining overtemperature faults.

PWM Output

The larger of the two measured temperatures is always

used for fan control. The temperature is compared to

three thresholds: the high-temperature threshold (T

HIGH

),

the low-temperature threshold (T

LOW

), and the overtem-

perature threshold, OT. The OT comparison is done once

per second, whereas the comparisons with fan-control

thresholds T

HIGH

and T

LOW

are done once every 4s.

The duty-cycle variation of PWM_OUT from 0% to 100%

is divided into 64 steps. If the temperature measured

exceeds the threshold T

HIGH

, the PWM_OUT duty cycle

is incremented by one step, i.e., approximately 1.5%

(100/64). Similarly, if the temperature measured is below

the threshold T

LOW

, the duty cycle is decremented by

one step (1.5%). Since the T

HIGH

and T

LOW

comparisons are done only once every 4s, the maximum rate of

change of duty cycle is 0.4% per second.

Tables 1 and 2 show the °C value assigned to the TH_

and TL_ input combinations.

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

_______________________________________________________________________________________ 5

Pin Description (continued)

Table 1. Setting T

HIGH

(MAX6643 and MAX6644)

High-Z = High impedance.

PIN

MAX6643 MAX6644 MAX6645

12 12 9 PWM_OUT

13, 14 13, 14 — OT2, OT1

16 16 10 V

NAME FUNCTION

DD

PWM Output for Driving External Power Transistor. Connect to

the gate of an n-channel MOSFET or to the base of an npn.

PWM_OUT requires a pullup resistor. The pullup resistor can

be connected to a supply voltage as high as 5.5V, regardless

of the supply voltage.

Overtemperature Threshold Inputs. Connect to V

leave unconnected to select the upper-limit OT fault output trip

temperature, in 5°C increments. See Table 4.

Power-Supply Input. 3.3V nominal. Bypass VDD to GND with a

0.1µF capacitor.

, GND, or

DD

TH2 TH1

0 0 20 40

0 High-Z 25 45

0 1 30 50

High-Z 0 35 55

High-Z High-Z 40 60

High-Z 1 45 65

1 0 50 70

1 High-Z 55 75

1 1 60 80

T

HIGH

L SUFFIX

(°C)

T

(°C)

HIGH

H SUFFIX

MAX6643/MAX6644/MAX6645

There are two options for the behavior of the PWM outputs at power-up. Option 1 (minimum duty cycle = 0):

at power-up, the PWM duty cycle is zero. Option 2

(minimum duty cycle = the start duty cycle): at powerup, there is a startup delay, after which the duty cycle

goes to 100% for the spin-up period. After the startup

delay and spin-up, the duty cycle drops to its minimum

value. The minimum duty cycle is in the 0% to 50%

range (see the Selector Guide).

To control fan speed based on temperature, T

HIGH

is

set to the temperature beyond which the fan should spin

at 100%. T

LOW

is set to the temperature below which

the duty cycle can be reduced to its minimum value.

After power-up and spin-up (if applicable), the duty

cycle reduces to its minimum value (either 0% or the

start duty cycle). For option 1 (minimum duty cycle = 0),

if the measured temperature remains below T

HIGH

, the

duty cycle remains at zero (see Figure 1). If the temperature increases above T

HIGH

, the duty cycle goes to

100% for the spin-up period, and then goes to the start

duty cycle (for example, 40%). If the measured temperature remains above T

HIGH

when temperature is next

measured (4s later), the duty cycle begins to increase,

incrementing by 1.5% every 4s until the fan is spinning

fast enough to reduce the temperature below T

HIGH

.

For option 2 (minimum duty cycle = start duty cycle), if

the measured temperature remains below T

HIGH

, the

duty cycle does not increase and the fan continues to

run at a slow speed. If the temperature increases

above T

HIGH

, the duty cycle begins to increase, incrementing by 1.5% every 4s until the fan is spinning fast

enough to reduce the temperature below T

HIGH

(see

Figure 2). In both cases, if only a small amount of extra

cooling is necessary to reduce the temperature below

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

6 _______________________________________________________________________________________

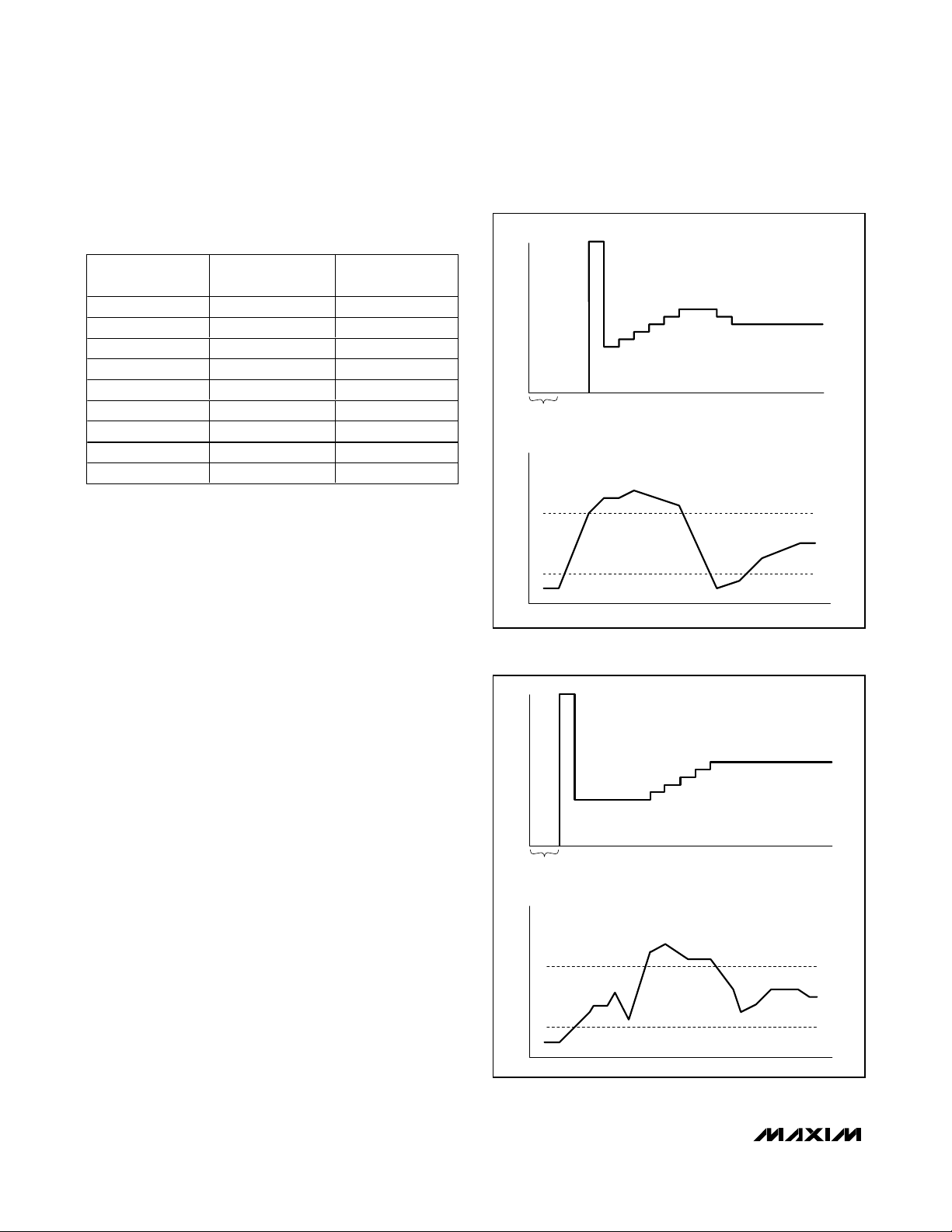

Table 2. Setting T

LOW

(MAX6643 and MAX6644)

Figure 1. Temperature-Controlled Duty-Cycle Change with

Minimum Duty Cycle 30%

Figure 2. Temperature-Controlled Duty-Cycle Change with

Minimum Duty Cycle 30%

High-Z = High impedance.

(°C)

T

TL2 TL1

0015

0 High-Z 20

0125

High-Z 0 30

High-Z High-Z 35

High-Z 1 40

1045

1 High-Z 50

1155

LOW

L SUFFIX

DUTY CYCLETEMPERATURE

DUTY CYCLETEMPERATURE

SPIN-UP

STARTUP

SPIN-UP

STARTUP

MAX664_B HAS 30% PWM_OUT DUTY CYCLE DURING STARTUP.

TIME

TIME

TIME

TIME

T

HIGH

T

LOW

T

HIGH

T

LOW

T

HIGH

, the duty cycle may increase just a few percent

above the minimum duty cycle. If the power dissipation or

ambient temperature increases to a high-enough value,

the duty cycle may eventually need to increase to 100%.

If the ambient temperature or the power dissipation

reduces to the point that the measured temperature is

less than T

LOW

, the duty cycle begins slowly decrementing until either the duty cycle reaches its minimum

value or the temperature rises above T

LOW

.

The small duty-cycle increments and slow rate-ofchange of duty cycle (1.5% maximum per 4s) reduce

the likelihood that the process of fan-speed control is

acoustically objectionable. The “dead band” between

T

LOW

and T

HIGH

keeps the fan speed constant when

the temperature is undergoing small changes, thus

making the fan-control process even less audible.

Fan-Fail Sensing

The MAX6643/MAX6644/MAX6645 feature a FANFAIL

output. The FANFAIL output is an active-low, opendrain alarm. The MAX6643/MAX6644/MAX6645 detect

fan failure either by measuring the fan’s speed and recognizing when it is too low, or by detecting a lockedrotor logic signal from the fan. Fan-failure detection is

enabled only when the duty cycle of the PWM drive signal is equal to 100%. This happens during the spin-up

period when the fan first turns on and whenever the

temperature is above T

HIGH

long enough that the duty

cycle reaches 100%.

Many fans have open-drain tachometer outputs that

produce periodic pulses (usually two pulses per revolution) as the fan spins. These tachometer pulses are

monitored by the FAN_IN_ inputs to detect fan failures.

If a 2-wire fan with no tachometer output is used, the

fan’s speed can be monitored by using an external

sense resistor at the source of the driving FET (see

Figure 3). In this manner, the variation in the current

flowing through the fan develops a periodic voltage

waveform across the sense resistor. This periodic

waveform is then highpass filtered and AC-coupled to

the FAN_IN_ input. Any variations in the waveform that

have an amplitude of more than ±150mV are converted

to digital pulses. The frequency of these digital pulses

is directly related to the speed of the rotation of the fan

and can be used to detect fan failure.

Note that the value of the sense resistor must be

matched to the characteristics of the fan’s current

waveform. Choose a resistor that produces voltage

variations of at least ±200mV to ensure that the fan’s

operation can be reliably detected. Note that while

most fans have current waveforms that can be used

with this detection method, there may be some that do

not produce reliable tachometer signals. If a 2-wire fan

is to be used with fault detection, be sure that the fan is

compatible with this technique.

To detect fan failure, the analog sense-conditioned

pulses or the tachometer pulses are deglitched and

counted for 2s while the duty cycle is 100% (either during spin-up or when the duty cycle rises to 100% due to

measured temperature). If more than 32 pulses are

counted (corresponding to 480rpm for a fan that produces two pulses per revolution), the fan is assumed to

be functioning normally. If fewer than 32 pulses are

received, the FANFAIL output is enabled and the PWM

duty cycle to the FET transistor is either shut down in

case of a single-fan (MAX6643) configuration or continues normal operation in case of a dual-fan configuration

(MAX6644/MAX6645).

Some fans have a locked-rotor logic output instead of a

tachometer output. If a locked-rotor signal is to be used

to detect fan failure, that signal is monitored for 2s while

the duty cycle is 100%. If a locked-rotor signal remains

active (low) for more than 2s, the fan is assumed to

have failed.

The MAX6643/MAX6644/MAX6645 have two channels

for monitoring fan-failure signals, FAN_IN1 and

FAN_IN2. For the MAX6643, the FAN_IN_ channels

monitor a tachometer. The MAX6643’s fault sensing can

also be turned off by floating the TACHSET input.

For the MAX6644 and MAX6645, the FAN_IN1 and

FAN_IN2 channels can be configured to monitor either

a logic-level tachometer signal, the voltage waveform

on a current-sense resistor, or a locked-rotor logic signal. The TACHSET input selects which type of signal is

to be monitored (see Table 3). To disable fan-fault

sensing, TACHSET should be unconnected and

FAN_IN1 and FAN_IN2 should be connected to VDD.

OT

Output

The MAX6643/MAX6644/MAX6645 include an overtemperature output that can be used as an alarm or a

system-shutdown signal. Whenever the measured temperature exceeds the value selected using the OT programming inputs OT1 and OT2 (see Table 4), OT is

asserted. OT deasserts only after the temperature

drops below the threshold.

FULLSPD Input

The MAX6643 features a FULLSPD input. Pulling FULLSPD high forces PWM_OUT to 100% duty cycle. The

FULLSPD input allows a microcontroller to force the fan

to full speed when necessary. By connecting FANFAIL

to an inverter, the MAX6643 can force other fans to

100% in multifan systems, or for an over-temperature

condition (by connecting OT inverter to FULLSPD).

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

_______________________________________________________________________________________ 7

MAX6643/MAX6644/MAX6645

Applications Information

Figures 3–6 show various configurations.

Remote-Diode Considerations

When using an external thermal diode, temperature

accuracy depends upon having a good-quality, diodeconnected, small-signal transistor. Accuracy has been

experimentally verified for a variety of discrete smallsignal transistors, some of which are listed in Table 5.

The MAX6643/MAX6644/MAX6645 can also directly

measure the die temperature of CPUs and other ICs

with on-board temperature-sensing diodes.

The transistor must be a small-signal type with a relatively high forward voltage. This ensures that the input

voltage is within the ADC input voltage range. The forward voltage must be greater than 0.25V at 10µA at the

highest expected temperature. The forward voltage

must be less than 0.95V at 100µA at the lowest expected temperature. The base resistance has to be less

than 100Ω. Tight specification of forward-current gain

(+50 to +150, for example) indicates that the manufacturer has good process control and that the devices

have consistent characteristics.

Effect of Ideality Factor

The accuracy of the remote temperature measurements

depends on the ideality factor (n) of the remote diode

(actually a transistor). The MAX6643/MAX6644/MAX6645

are optimized for n = 1.01, which is typical of many discrete 2N3904 and 2N3906 transistors. It is also near the

ideality factors of many widely available CPUs, GPUs, and

FPGAs. However, any time a sense transistor with a different ideality factor is used, the output data is different.

Fortunately, the difference is predictable. Assume a

remote-diode sensor designed for a nominal ideality factor n

NOMINAL

is used to measure the temperature of a

diode with a different ideality factor, n

1

. The measured

temperature T

M

can be corrected using:

where temperature is measured in Kelvin.

As mentioned above, the nominal ideality factor of the

MAX6643/MAX6644/MAX6645 is 1.01. As an example,

assume the MAX6643/MAX6644/MAX6645 are configured with a CPU that has an ideality factor of 1.008. If

the diode has no series resistance, the measured data

is related to the real temperature as follows:

For a real temperature of +60°C (333.15K), the measured temperature is 59.33°C (332.49K), which is an

error of -0.66°C.

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

8 _______________________________________________________________________________________

Table 5. Remote-Sensor Transistor

Manufacturers

Table 4. Setting the Overtemperature

Thresholds (T

OVERT

) (MAX6643 and MAX6644)

Table 3. Configuring the FAN_IN_ Inputs with TACHSET

High-Z = high impedance

TACHSET

MAX6643 Tachometer Tachometer

MAX6644 Tachometer Tachometer Current sense Current sense Locked rotor Locked rotor

MAX6645 Tachometer Tachometer Current sense Current sense Locked rotor Locked rotor

FAN_IN1 FAN_IN2 FAN_IN1 FAN_IN2 FAN_IN1 FAN_IN2

VDD GND UNCONNECTED

Do not connect

to GND

Do not connect

to GND

Disables fan-

failure detection

Disables fan-

failure detection

OT2 OT1

0060

0 High-Z 65

0170

High-Z 0 75

High-Z High-Z 80

High-Z 1 85

1090

1 High-Z 95

1 1 100

T

(°C)

OVERT

L SUFFIX

Central Semiconductor (USA) CMPT3906

Rohm Semiconductor (USA) SST3906

Samsung (Korea) KST3906-TF

Siemens (Germany) SMBT3906

TT

ACTUAL M

MANUFACTURER MODEL NO.

n

1

1.01

⎛

⎜

⎝

1.008

⎞

⎟

⎠

⎞

=

T

()

⎟

⎠

TT

=

M ACTUAL

⎛

n

=

NOMINAL

.1 00198

⎜

n

⎝

⎛

⎜

n

⎝

NOMINAL

⎞

T

=

MM

⎟

⎠

1

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

_______________________________________________________________________________________ 9

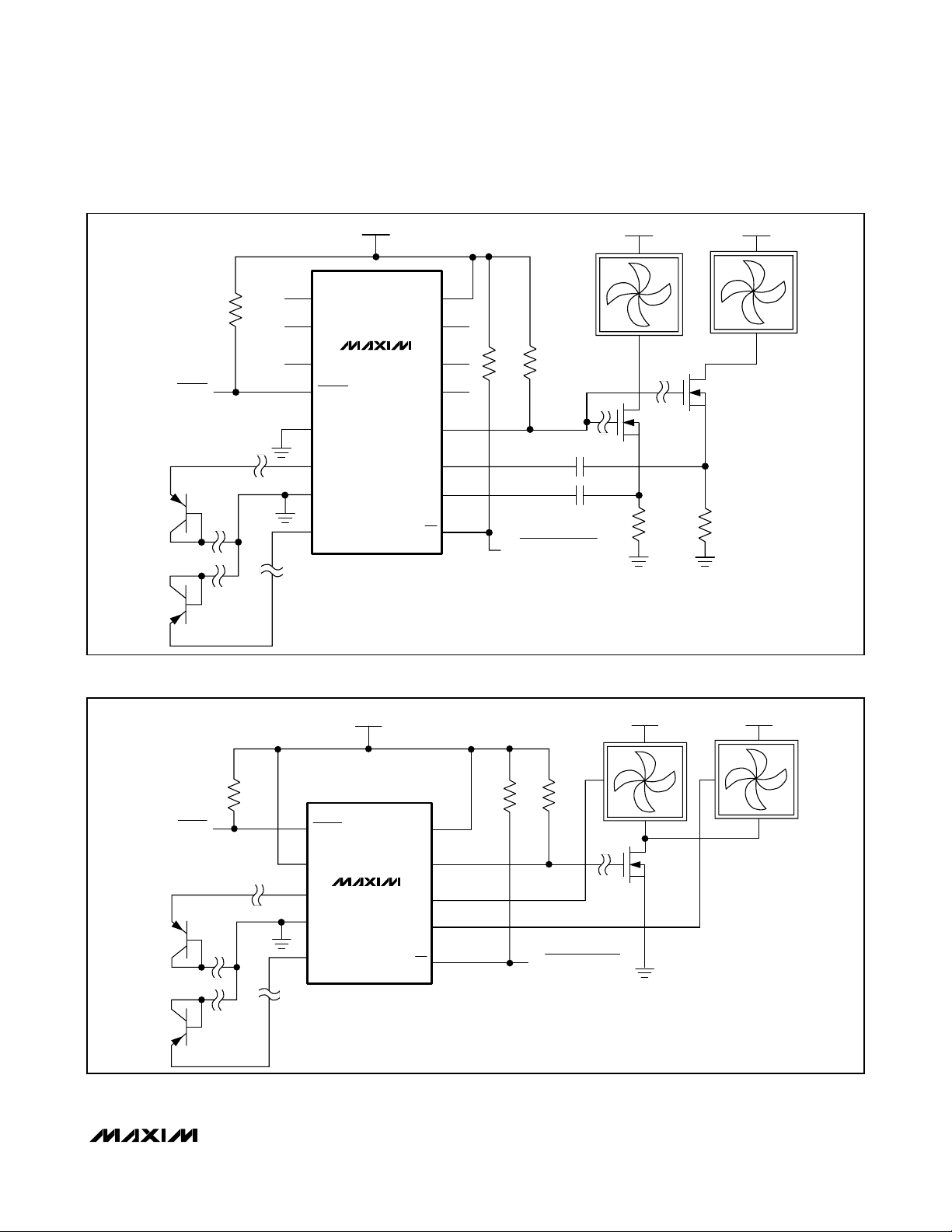

Figure 3. MAX6644 Using Two External Transistors to Measure Remote Temperatures and Control Two 2-Wire Fans. The fan’s powersupply current is monitored to detect failure of either fan. Connect pin 10 to pin 11 if only one fan is used.

Figure 4. MAX6645 Using Two External Transistors to Measure Remote Temperatures and Control Two 2-Wire Cooling Fans. The

fan’s power-supply current is monitored to detect failure of either fan. Connect FAN_IN1 to FAN_IN2 if only one fan is used.

TO FANFAIL

ALARM

4.7kΩ

1

2

3

4

5

6

7

8

V

DD

TH1

TL2

TL1

FANFAIL

TACHSET

DXP2

GND

DXP1

(+3.0V TO +5.5V)

MAX6644

PWM_OUT

FAN_IN1

FAN_IN2

V

TH2

OT1

OT2

(5V OR 12V)

+V

FAN

16

DD

15

14

13

12

11

10

9

OT

4.7kΩ

4.7kΩ

CURRENT-SENSE

MODE

CURRENT-SENSE

MODE

TO OVERTEMPERATURE

ALARM

0.1μF

0.1μF

N

2.0Ω

N

2.0Ω

+V

FAN

(5V OR 12V)

(+3.0V TO +5.5V)

TO FANFAIL

ALARM

4.7kΩ

1

2

3

4

5

V

DD

FANFAIL

TACHSET

DXP2

GND

DXP1

MAX6645

V

PWM_OUT

FAN_IN1

FAN_IN2

10

DD

9

8

7

6

OT

4.7kΩ

TACHOMETER MODE

TACHOMETER MODE

4.7kΩ

TO OVERTEMPERATURE

ALARM

+V

(5V OR 12V)

FAN

+V

(5V OR 12V)

FAN

N

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

10 ______________________________________________________________________________________

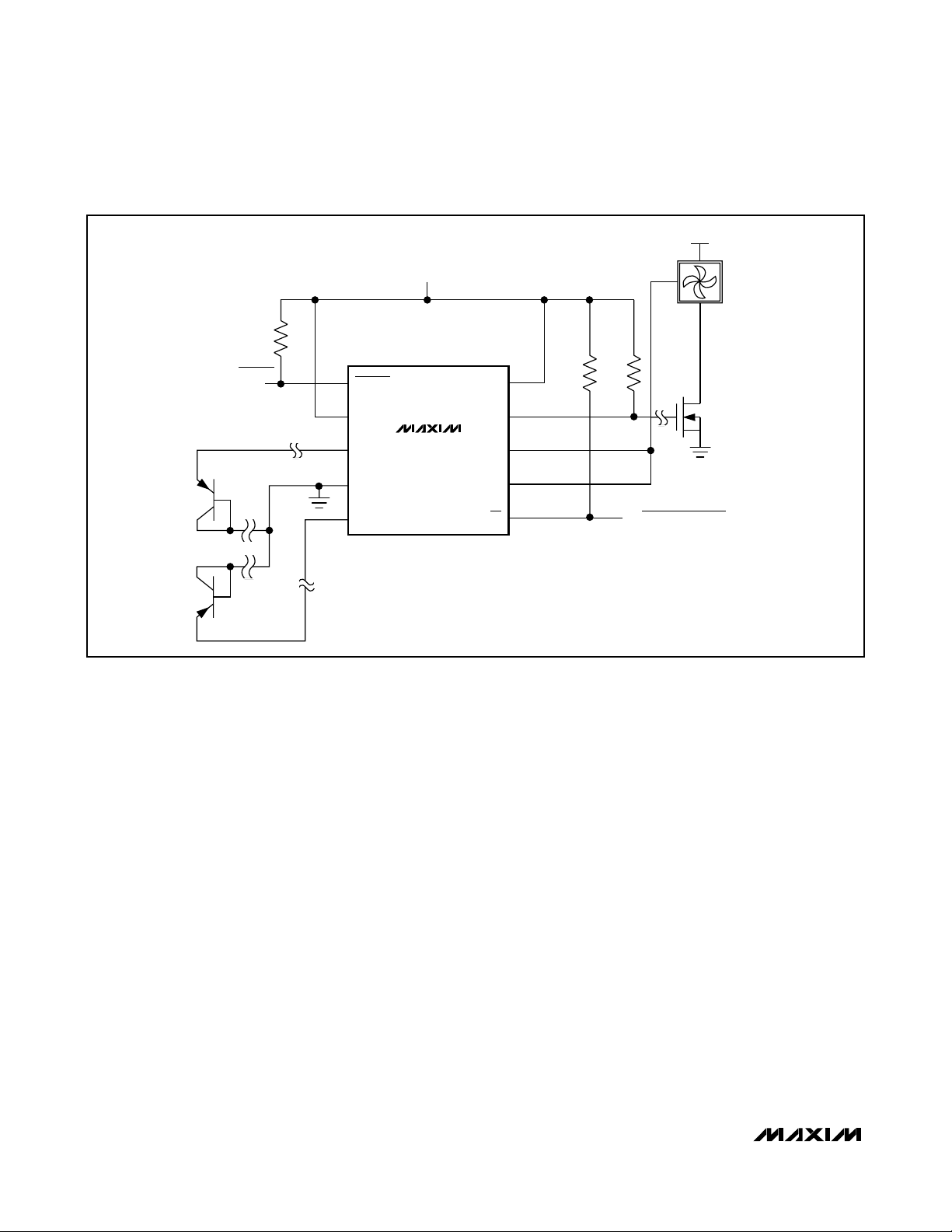

Figure 5. Using the MAX6645 to Monitor Two Fans

+V

(5V OR 12V)

FAN

V

(+3.0V TO +5.5V)

DD

4.7kΩ

TO FANFAIL

ALARM

1

2

3

4

5

FANFAIL

TACHSET

DXP2

GND

DXP1

MAX6645

PWM_OUT

FAN_IN1

FAN_IN2

10

V

DD

9

8

7

6

OT

4.7kΩ

TACHOMETER

MODE

TACHOMETER

MODE

4.7kΩ

N

TO OVERTEMPERATURE ALARM

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

______________________________________________________________________________________ 11

Figure 6. Using Two MAX6643s, Each Controlling a Separate Fan

(5V OR 12V)

+V

FAN

V

(+3.0V TO +5.5V)

DD

TO FANFAIL

ALARM

4.7kΩ

TO FANFAIL

ALARM

4.7kΩ

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

TH1

TL2

TL1

FANFAIL

TACHSET

FULLSPD

GND

DXP

TH1

TL2

TL1

FANFAIL

TACHSET

FULLSPD

GND

MAX6643

V

(+3.0V TO +5.5V)

DD

MAX6643

V

TH2

OT1

OT2

PWM_OUT

FAN_IN1

FAN_IN2

V

TH2

OT1

OT2

PWM_OUT

FAN_IN1

FAN_IN2

16

DD

15

14

13

12

11

(TACHOMETER MODE)

(TACHOMETER MODE)

10

9

OT

16

DD

15

14

13

12

11

(TACHOMETER MODE)

(TACHOMETER MODE)

10

4.7kΩ

4.7kΩ

4.7kΩ

4.7kΩ

N

TO OVERTEMPERATURE ALARM

(5V OR 12V)

+V

FAN

N

8

DXP

9

OT

TO OVERTEMPERATURE ALARM

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

12 ______________________________________________________________________________________

Effect of Series Resistance

Series resistance in a sense diode contributes additional errors. For nominal diode currents of 10µA and

100µA, change in the measured voltage is:

Since 1°C corresponds to 198.6µV, series resistance

contributes a temperature offset of:

Assume that the diode being measured has a series

resistance of 3Ω. The series resistance contributes an

offset of:

The effects of the ideality factor and series resistance

are additive. If the diode has an ideality factor of 1.008

and series resistance of 3Ω, the total offset can be calculated by adding error due to series resistance with

error due to ideality factor:

1.36°C - 0.66°C = 0.7°C

for a diode temperature of +60.7°C.

In this example, the effect of the series resistance and

the ideality factor partially cancel each other.

For best accuracy, the discrete transistor should be a

small-signal device with its collector connected to

base, and emitter connected to GND. Table 5 lists

examples of discrete transistors that are appropriate for

use with the MAX6643/MAX6644/MAX6645.

The transistor must have a relatively high forward voltage; otherwise, the ADC input voltage range can be violated. The forward voltage at the highest expected

temperature must be greater than 0.25V at 10µA, and at

the lowest expected temperature, the forward voltage

must be less than 0.95V at 100µA. Large power transistors must not be used. Also, ensure that the base resistance is less than 100Ω. Tight specifications for forward

current gain (50 < ß <150, for example) indicate that the

manufacturer has good process controls and that the

devices have consistent V

BE

characteristics.

ADC Noise Filtering

The integrating ADC has inherently good noise rejection, especially of low-frequency signals such as

60Hz/120Hz power-supply hum. Micropower operation

places constraints on high-frequency noise rejection.

Lay out the PCB carefully with proper external noise filtering for high-accuracy remote measurements in electrically noisy environments.

Filter high-frequency electromagnetic interference

(EMI) at the DXP pins with an external 2200pF capacitor connected between DXP, DXP1, or DXP2 and

ground. This capacitor can be increased to about

3300pF (max), including cable capacitance. A capacitance higher than 3300pF introduces errors due to the

rise time of the switched-current source.

Twisted Pairs and Shielded Cables

For remote-sensor distances longer than 8in, or in particularly noisy environments, a twisted pair is recommended. Its practical length is 6ft to 12ft (typ) before

noise becomes a problem, as tested in a noisy electronics laboratory. For longer distances, the best solution is

a shielded twisted pair like that used for audio microphones. For example, Belden 8451 works well for distances up to 100ft in a noisy environment. Connect the

twisted pair to DXP and GND and the shield to ground,

and leave the shield’s remote end unterminated. Excess

capacitance at DXP limits practical remote-sensor distances (see the Typical Operating Characteristics).

For very long cable runs, the cable’s parasitic capacitance often provides noise filtering, so the recommended 2200pF capacitor can often be removed or reduced

in value. Cable resistance also affects remote-sensor

accuracy. A 1Ω series resistance introduces about

+1/2°C error.

PCB Layout Checklist

1) Place the MAX6643/MAX6644/MAX6645 as close as

practical to the remote diode. In a noisy environment,

such as a computer motherboard, this distance can

be 4in to 8in or more, as long as the worst noise

sources (such as CRTs, clock generators, memory

buses, and ISA/PCI buses) are avoided.

2) Do not route the DXP lines next to the deflection coils

of a CRT. Also, do not route the traces across a fast

memory bus, which can easily introduce +30°C error,

even with good filtering. Otherwise, most noise

sources are fairly benign.

ΔVM =μ−μ

100 10 90

()

Ss

μ

V

90

Ω

.

=

μ

V

.

198 6

°

C

C

3

°

=μ×RAA AR

C

°

0 453

Ω

=° . .0 453 1 36

CΩΩ×

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

______________________________________________________________________________________ 13

3) Route the DXP and GND traces parallel and close to

each other, away from any high-voltage traces such

as +12VDC. Avoid leakage currents from PCB contamination. A 20MΩ leakage path from DXP to ground

causes approximately +1°C error.

4) Route as few vias and crossunders as possible to

minimize copper/solder thermocouple effects.

5) When introducing a thermocouple, make sure that

both the DXP and the GND paths have matching

thermocouples. In general, PCB-induced thermocouples are not a serious problem. A copper solder thermocouple exhibits 3µV/°C, and it takes

approximately 200µV of voltage error at DXP/GND to

cause a +1°C measurement error, so most parasitic

thermocouple errors are swamped out.

6) Use wide traces. Narrow traces are more inductive

and tend to pick up radiated noise. The 10-mil widths

and spacings are recommended, but are not

absolutely necessary (as they offer only a minor

improvement in leakage and noise), but use them

where practical.

7) Placing an electrically clean copper ground plane

between the DXP traces and traces carrying highfrequency noise signals helps reduce EMI.

Chip Information

TRANSISTOR COUNT: 12,518

PROCESS: BiCMOS

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

14 ______________________________________________________________________________________

Selector Guide

Pin Configurations

TOP VIEW

TH1

TL2

TL1

FANFAIL

TACHSET

FULLSPD

(FULLSPD)

GND

DXP

1

2

3

MAX6643

4

5

6

7

8

16

15

14

13

12

11

10

9

V

DD

TH2

OT1

OT2

PWM_OUT

FAN_IN1

FAN_IN2

OT

QSOP

() ARE FOR MAX6643_A ONLY.

PART

MAX6643

LBFAEE

MAX6643

LBBAEE

TIME (s)

STARTUP

PACKAGE-PINS

SPIN-UP

DELAY (s)

START DUTY

QSOP-16 0.5 8 40 40

QSOP-16 0.5 8 30 30

TH1

TL2

TL1

FANFAIL

TACHSET

DXP2

GND

DXP1

CYCLE (%)

CYCLE (%)

MINIMUM DUTY

1

2

3

4

5

6

7

8

Remote,

Remote,

MAX6644

QSOP

CHANNELS

15 to5520 to6060 to

local

15 to5520 to6060 to

local

TL (°C)

16

15

14

13

12

11

10

9

V

DD

TH2

OT1

OT2

PWM_OUT

FAN_IN1

FAN_IN2

OT

TH (°C)

FANFAIL

TACHSET

DXP2

100

100

1

2

MAX6645

3

4

5

10

9

8

7

6

V

DD

PWM_OUT

FAN_IN1

FAN_IN2GND

OTDXP1

μMAX

OT (°C)

FULLSPD

POLARITY

FULLSPD Tach/off Tach/off

FULLSPD Tach/off Tach/off

FAN_IN1

FAN_IN2

MAX6644

LBAAEE

M AX 6645

ABFAU B

QSOP-16 0.5 8 30 0

µMAX-10 0.5 8 40 40

Remote,

remote

Remote,

remote

15 to5520 to6060 to

100

45 50 75 —

—

Locked

r otor /tach/

cur r ent

sense

Locked

r otor /tach/

cur r ent

sense

Locked

r otor /tach/

cur r ent

sense

Locked

r otor /tach/

cur r ent

sense

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

______________________________________________________________________________________ 15

Block Diagram

TO FANFAIL

ALARM

MAX6643

TH1

16

15

14

13

12

11

(TACHOMETER MODE)

(TACHOMETER MODE)

TO OVERTEMPERATURE ALARM

10

9

TL2

TL1

FANFAIL

TACHSET

FULLSPD

GND

DXP

V

DD

VDD (+3.0V TO +5.5V)

+V

FAN

(5V OR 12V)

1

2

3

4

5

6

7

8

TH2

OT1

OT2

PWM_OUT

FAN_IN1

FAN_IN2

OT

4.7kΩ

4.7kΩ

4.7kΩ

N

Typical Operating Circuit

DXP1/(DXP)

DXP2

() ARE FOR MAX6643 ONLY.

TEMPERATURE

SENSOR

TEMPERATURE

MAX6643

MAX6644

MAX6645

LOGIC

OT TH TL

THRESHOLD

SELECTION

OT1 OT2 TH1 TH2 TL1 TL2

DUTY CYCLE

FULLSPD/(FULLSPD)

PWM

GENERATOR

FAN-FAIL

DETECTION

FANFAILTACHSET

ANALOG SENSE

TACHOMETER

LOCKED ROTOR IN

ANALOG SENSE

TACHOMETER

LOCKED ROTOR IN

PWM_OUT

FAN_IN1

FAN_IN2

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

16 ______________________________________________________________________________________

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

QSOP.EPS

PACKAGE OUTLINE, QSOP .150", .025" LEAD PITCH

21-0055

1

F

1

MAX6643/MAX6644/MAX6645

Automatic PWM Fan-Speed Controllers with

Overtemperature Output

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 17

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

Revision History

Pages changed at Rev 2: 1, 2, 4–8, 11–15, 17

e

10

Ø0.50±0.1

0.6±0.1

1

0.6±0.1

TOP VIEW

D2

A2

D1

FRONT VIEW

4X S

10

DIM

A1

A2 0.030 0.037 0.75 0.95

D1

H

1

BOTTOM VIEW

D2

E1

E2

H

L

L1

b

e

S

α

E2

GAGE PLANE

A

b

A1

α

E1

L

L1

SIDE VIEW

INCHES

MAX

MIN

0.043

-A

0.006

0.002

0.116

0.120

0.114

0.118

0.116

0.120

0.114

0.118

0.187

0.0157

0.007

0.0035

c

c

0.199

0.0275

0.037 REF

0.0106

0.0197 BSC

0.0078

0.0196 REF

6°

0° 0° 6°

MILLIMETERS

MAX

MIN

-

1.10

0.05

0.15

2.95

3.05

2.89

3.00

2.95

3.05

2.89

3.00

4.75

5.05

0.40

0.70

0.940 REF

0.270

0.177

0.500 BSC

0.200

0.090

0.498 REF

10LUMAX.EPS

PROPRIETARY INFORMATION

TITLE:

PACKAGE OUTLINE, 10L uMAX/uSOP

REV.DOCUMENT CONTROL NO.APPROVAL

21-0061

1

1

Loading...

Loading...