Page 1

General Description

The MAX6642 precise, two-channel digital temperature

sensor accurately measures the temperature of its own

die and a remote PN junction and reports the temperature data over a 2-wire serial interface. The remote PN

junction is typically a substrate PNP transistor on the

die of a CPU, ASIC, GPU, or FPGA. The remote PN

junction can also be a discrete diode-connected smallsignal transistor.

The 2-wire serial interface accepts standard system

management bus (SMBus™), Write Byte, Read Byte,

Send Byte, and Receive Byte commands to read the

temperature data and to program the alarm thresholds.

To enhance system reliability, the MAX6642 includes an

SMBus timeout. The temperature data format is 10 bit

with the least significant bit (LSB) corresponding to

+0.25°C. The ALERT output asserts when the local or

remote overtemperature thresholds are violated. A fault

queue may be used to prevent the ALERT output from

setting until two consecutive faults have been detected.

Measurements can be done autonomously or in a single-shot mode.

Remote accuracy is ±1°C maximum error between

+60°C and +100°C. The MAX6642 operates from -40°C

to +125°C, and measures remote temperatures

between 0°C and +150°C. The MAX6642 is available in

a 6-pin TDFN package with an exposed pad.

Applications

Desktop Computers

Notebook Computers

Servers

Thin Clients

Test and Measurement

Workstations

Graphic Cards

Features

o Dual Channel: Measures Remote and Local

Temperature

o +0.25°C Resolution

o High Accuracy ±1°C (max) (Remote) and

±2°C (Local) from +60°C to +100°C

o Measures Remote Temperature Up to +150°C

o Programmable Overtemperature Alarm

Temperature Thresholds

o SMBus/I

2

C-Compatible Interface

o Tiny TDFN Package with Exposed Pad

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

________________________________________________________________

Maxim Integrated Products

1

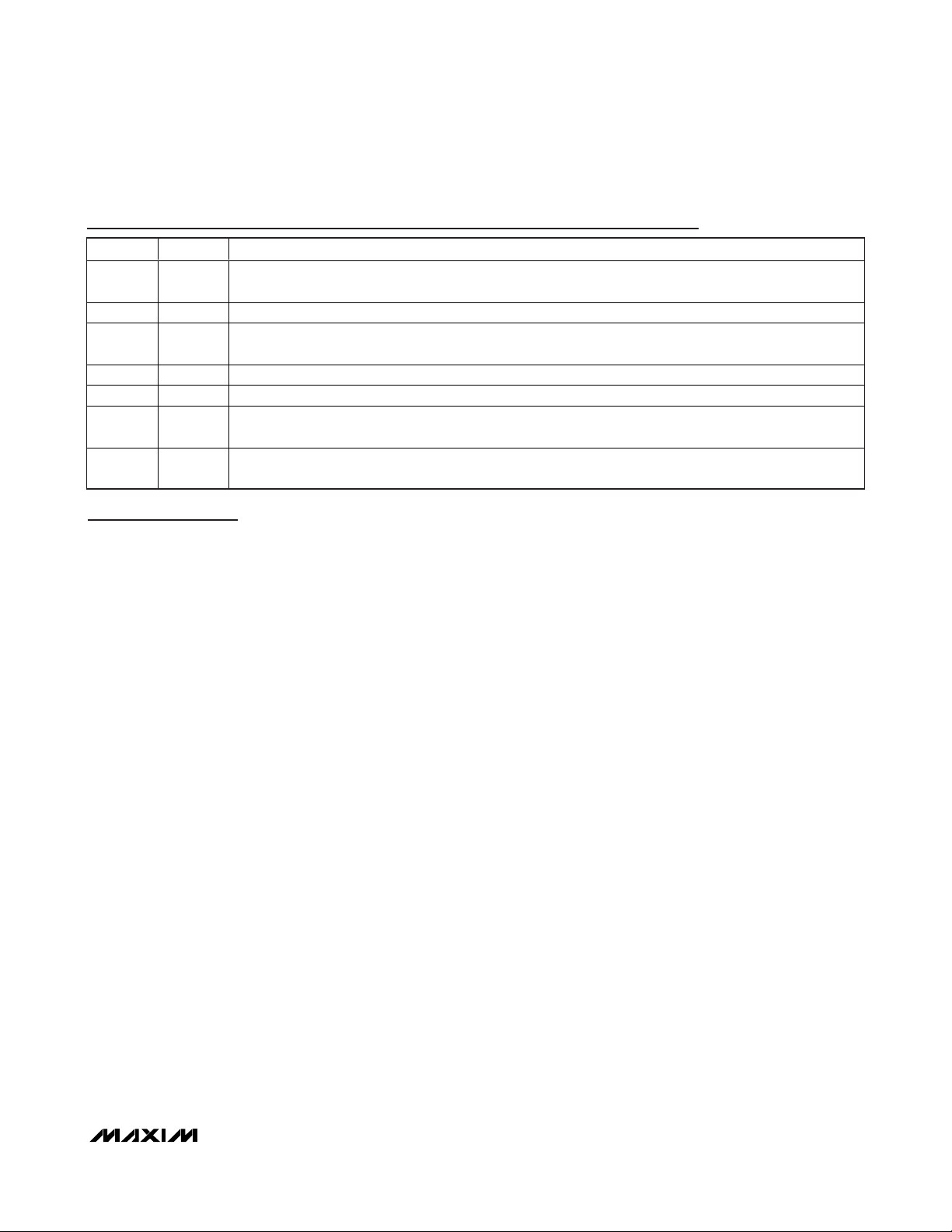

Ordering Information

19-2920; Rev 3; 10/09

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Typical Operating Circuit

PART

MEASURED TEMP RANGE

TOP

MARK

MAX6642ATT90-T 0°C to +150°C

AFC

MAX6642ATT92-T 0°C to +150°C

AFD

MAX6642ATT94-T 0°C to +150°C

AFE

MAX6642ATT96-T 0°C to +150°C

AFF

MAX6642ATT98-T 0°C to +150°C

AEW

MAX6642ATT9A-T 0°C to +150°C

AFG

MAX6642ATT9C-T 0°C to +150°C

AFH

MAX6642ATT9E-T 0°C to +150°C AFI

Selector Guide

T = Tape and reel.

*

EP = Exposed pad.

Pin Configuration and Functional Diagram appear at end of

data sheet.

SMBus is a trademark of Intel Corp.

PART TEMP RANGE PIN-PACKAGE

MAX6642ATT90-T -40°C to +125°C 6 TDFN-EP*

MAX6642ATT92-T -40°C to +125°C 6 TDFN-EP*

MAX6642ATT94-T -40°C to +125°C 6 TDFN-EP*

MAX6642ATT96-T -40°C to +125°C 6 TDFN-EP*

MAX6642ATT98-T -40°C to +125°C 6 TDFN-EP*

MAX6642ATT9A-T -40°C to +125°C 6 TDFN-EP*

MAX6642ATT9C-T -40°C to +125°C 6 TDFN-EP*

MAX6642ATT9E-T -40°C to +125°C 6 TDFN-EP*

0.1μF

2200pF

V

DXP

CC

MAX6642

47Ω

SDA

3.3V

10kΩ EACH

DATA

SCLK

ALERT

μP

GND

CLOCK

INTERRUPT TO μP

Page 2

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

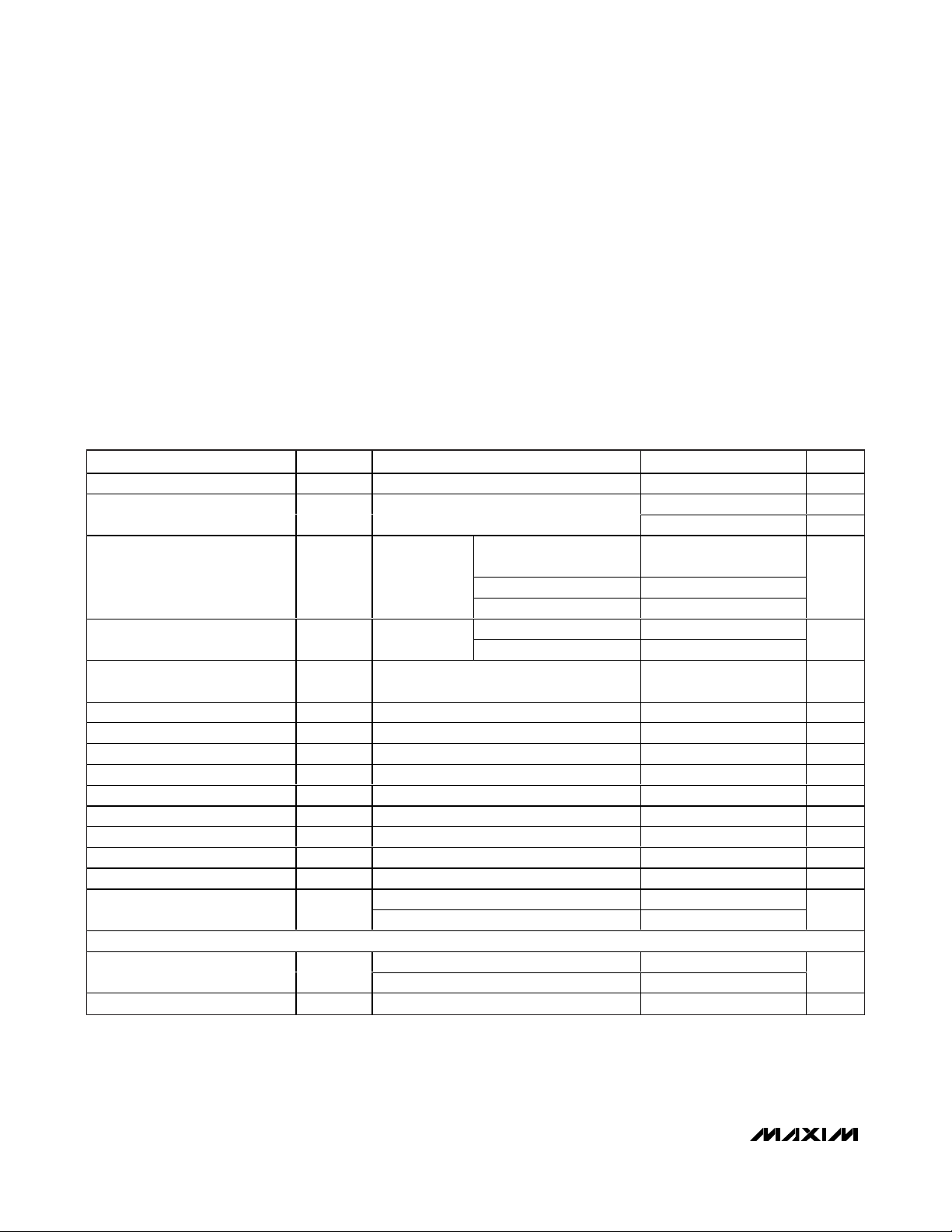

ELECTRICAL CHARACTERISTICS

(V

CC

= +3.0V to +5.5V, TA = -40°C to +125°C, unless otherwise specified. Typical values are at V

CC

= +3.3V and TA = +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

All Voltages Referenced to GND

V

CC

...........................................................................-0.3V to +6V

DXP.............................................................-0.3V to (V

CC

+ 0.3V)

SCLK, SDA, ALERT ..................................................-0.3V to +6V

SDA, ALERT Current ...........................................-1mA to +50mA

Continuous Power Dissipation (T

A

= +70°C)

6-Pin TDFN (derate 24.4mW/°C above +70°C) .........1951mW

ESD Protection (all pins, Human Body Model) ................±2000V

Junction Temperature......................................................+150°C

Operating Temperature Range .........................-40°C to +125°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage V

Temperature Resolution

Remote Temperature Error V

Local Temperature Error V

Supply Sensitivity of Temperature

Error

Undervoltage Lockout Threshold UVLO Falling edge of VCC disables ADC 2.4 2.7 2.95 V

Undervoltage Lockout Hysteresis 90 mV

Power-On-Reset (POR) Threshold VCC falling edge 1.5 2.0 2.4 V

POR Threshold Hysteresis 90 mV

Standby Supply Current SMBus static 3 10 µA

Operating Current During conversion 0.5 1.0 mA

Average Operating Current 260 µA

Conversion Time t

Conversion Rate f

Remote-Diode Source Current I

ALERT

Output-Low Sink Current

Output-High Leakage Current VOH = V

CC

CONV

CONV

RJ

= 3.3V

CC

= 3.3V

CC

From stop bit to conversion completion 106 125 143 ms

High level 80 100 120

Low level 8 10 12

VOL = 0.4V 1

V

= 0.6V 4

OL

CC

3.0 5.5 V

0.25 °C

10 Bits

TRJ = +60°C to +100°C,

= +25°C to +85°C

T

A

TRJ = 0°C to +125°C -3.0 +3.0

T

= +125°C to +150°C -3.5 +3.5

RJ

TA = +60°C to +100°C -2.0 +2.0

= 0°C to +125°C -3.0 +3.0

T

A

-1.0 +1.0

±0.2 °C/V

8Hz

1µA

°C

°C

µA

mA

Page 3

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

_______________________________________________________________________________________ 3

Note 1: All parameters tested at TA= +25°C. Specifications over temperature are guaranteed by design.

Note 2: Timing specifications guaranteed by design.

Note 3: The serial interface resets when SCLK is low for more than t

TIMEOUT

.

Note 4: A transition must internally provide at least a hold time to bridge the undefined region (300ns max) of SCLK’s falling edge.

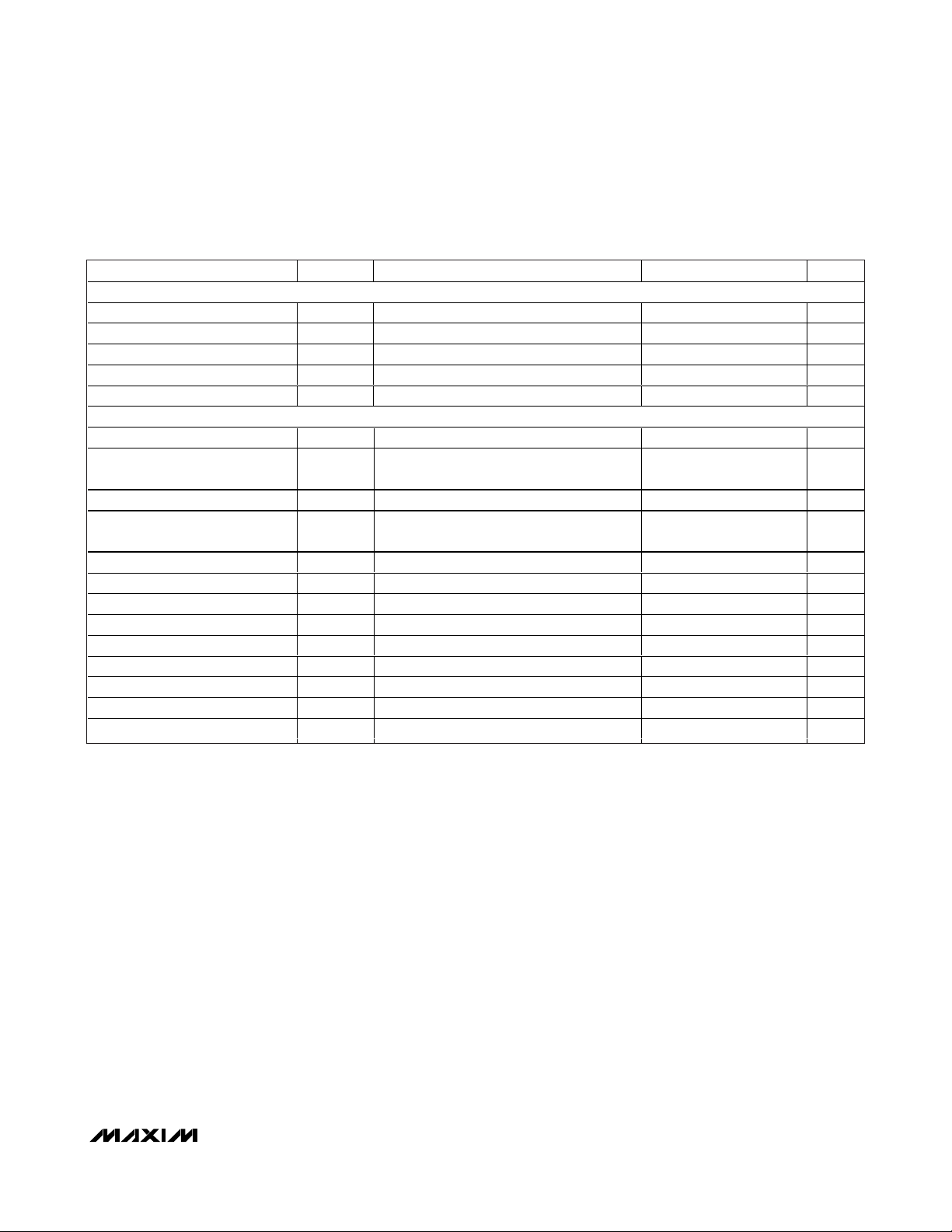

ELECTRICAL CHARACTERISTICS (continued)

(V

CC

= +3.0V to +5.5V, TA = -40°C to +125°C, unless otherwise specified. Typical values are at V

CC

= +3.3V and TA = +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SMBus-COMPATIBLE INTERFACE (SCLK and SDA)

Logic Input Low Voltage V

Logic Input High Voltage V

Input Leakage Current I

Output Low Sink Current I

Input Capacitance C

SMBus TIMING (Note 2)

Serial Clock Frequency f

Bus Free Time Between STOP

and START Condition

START Condition Setup Time 4.7 µs

Repeat START Condition Setup

Time

START Condition Hold Time t

STOP Condition Setup Time t

Clock Low Period t

Clock High Period t

Data Setup Time t

Receive SCLK/SDA Rise Time t

Receive SCLK/SDA Fall Time t

Pulse Width of Spike Suppressed t

SMBus Timeout t

IL

IH

LEAK

OL

IN

SCLK

t

BUF

t

SU:STA

HD:STA

SU:STO

LOW

HIGH

HD:DAT

R

F

SP

TIMEOUT

VCC = 3.0V 2.2 V

VIN = GND or 5.5V -1 +1 µA

VOL = 0.6V 6 mA

(Note 3) 100 kHz

90% to 90% 50 ns

10% of SDA to 90% of SCLK 4 µs

90% of SCLK to 90% of SDA 4 µs

10% to 10% 4.7 µs

90% to 90% 4 µs

(Note 4) 250 µs

SDA low period for interface reset 20 28 40 ms

0.8 V

5pF

4.7 µs

1µs

300 ns

050ns

Page 4

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

4 _______________________________________________________________________________________

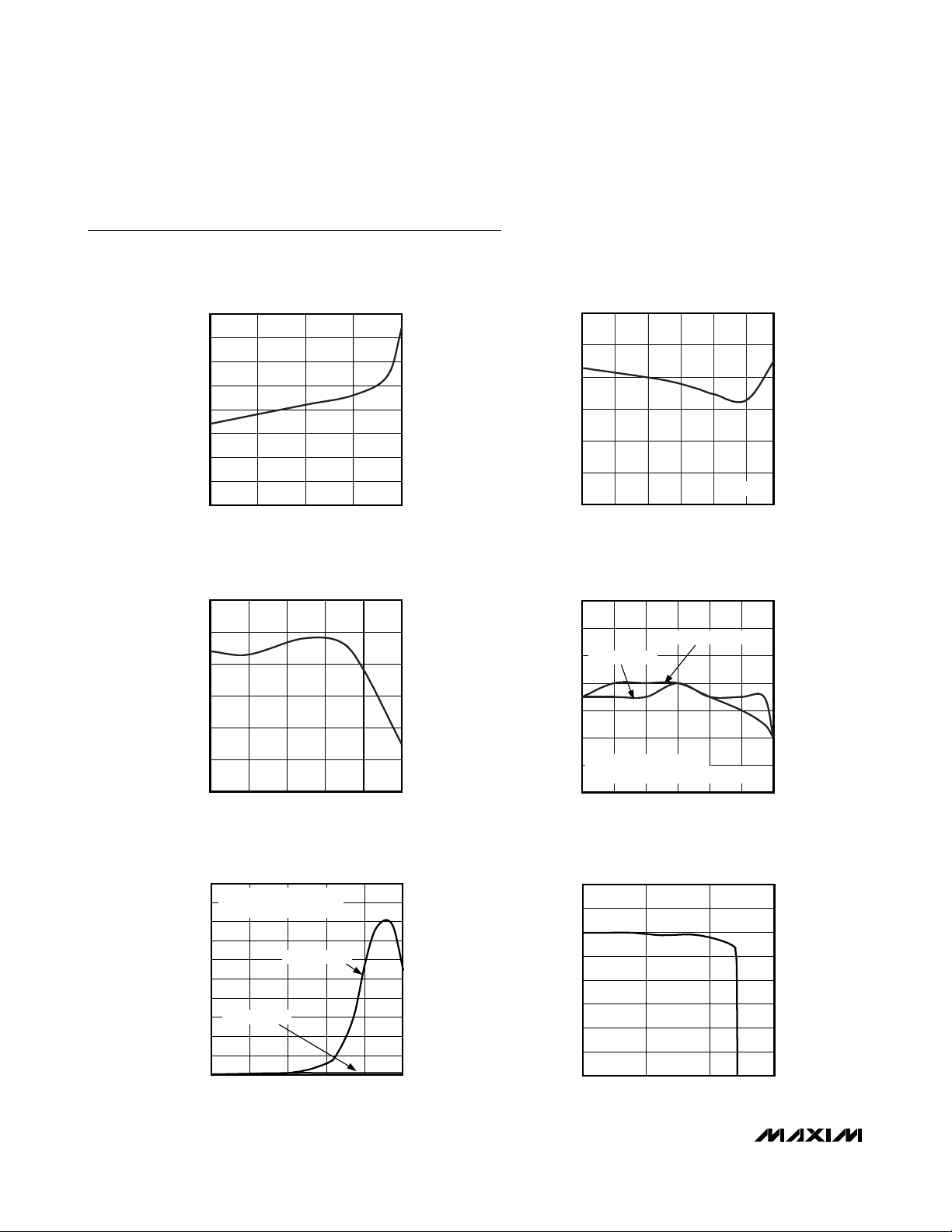

Typical Operating Characteristics

(VCC= 3.3V, TA= +25°C, unless otherwise noted.)

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

0.01 0.1 1 10 100

STANDBY SUPPLY CURRENT

vs. CLOCK FREQUENCY

MAX6642 toc01

CLOCK FREQUENCY (kHz)

SUPPLY CURRENT (μA)

-4

-2

-3

0

-1

1

2

REMOTE TEMPERATURE ERROR

vs. REMOTE-DIODE TEMPERATURE

MAX6642 toc02

TEMPERATURE (°C)

TEMPERATURE ERROR (°C)

0507525 100 125

2N3906

-3

-1

-2

1

0

2

3

0 125

LOCAL TEMPERATURE ERROR

vs. DIE TEMPERATURE

MAX 6642 toc03

TEMPERATURE (°C)

TEMPERATURE ERROR (°C)

5025 75 100

-1.5

-0.5

-1.0

0.5

0

1.5

1.0

2.0

0.0001 0.01 0.10.001 1 10 100

TEMPERATURE ERROR

vs. POWER-SUPPLY NOISE FREQUENCY

MAX6642 toc04

FREQUENCY (kHz)

TEMPERATURE ERROR (°C)

VIN = 100mV

P-P

SQUARE WAVE

APPLIED TO V

CC

WITH NO BYPASS CAPACITOR

LOCAL ERROR

REMOTE ERROR

0

30

20

10

40

50

60

70

80

90

100

0.001 0.10.01 1 10 100

TEMPERATURE ERROR

vs. DXP NOISE FREQUENCY

MAX6642 toc05

FREQUENCY (kHz)

TEMPERATURE ERROR (°C)

LOCAL ERROR

REMOTE ERROR

VIN = AC-COUPLED TO DXP

V

IN

= 100mV

P-P

SQUARE WAVE

-6.0

-5.0

-4.0

-3.0

-2.0

-1.0

0

1.0

2.0

0.1 1 10 100

TEMPERATURE ERROR

vs. DXP-GND CAPACITANCE

MAX6642 toc06

DXP-GND CAPACITANCE (nF)

TEMPERATURE ERROR (°C)

Page 5

Detailed Description

The MAX6642 is a temperature sensor for local

and remote temperature-monitoring applications.

Communication with the MAX6642 occurs through the

SMBus-compatible serial interface and dedicated alert

pins. ALERT asserts if the measured local or remote

temperature is greater than the software-programmed

ALERT limit.

The MAX6642 converts temperatures to digital data

either at a programmed rate of eight conversions per

second or in single conversions. Temperature data is

represented by 8 data bits (at addresses 00h and 01h),

with the LSB equal to +1°C and the MSB equal to

+128°C. Two additional bits of remote temperature data

are available in the “extended” register at address 10h

and 11h (Table 2) providing resolution of +0.25°C.

ADC and Multiplexer

The averaging ADC integrates over a 60ms period

(each channel, typ), with excellent noise rejection.

The multiplexer automatically steers bias currents

through the remote and local diodes. The ADC and

associated circuitry measure each diode’s forward voltage and compute the temperature based on this voltage. Both channels are automatically converted once

the conversion process has started, either in free-running or single-shot mode. If one of the two channels is

not used, the device still performs both measurements,

and the user can ignore the results of the unused channel. If the remote-diode channel is unused, connect

DXP to GND rather than leaving DXP open.

The conversion time per channel (remote and internal)

is 125ms. If both channels are being used, then each

channel is converted four times per second. If the

external conversion-only option is selected, then the

remote temperature is measured eight times per second. The results of the previous conversion are always

available, even if the ADC is busy.

Low-Power Standby Mode

Standby mode reduces the supply current to less than

10µA by disabling the ADC and timing circuitry. Enter

standby mode by setting the RUN bit to 1 in the configuration byte register (Table 4). All data is retained in

memory, and the SMBus interface is active and listening for SMBus commands. Standby mode is not a shutdown mode. With activity on the SMBus, the device

draws more supply current (see the

Typical Operating

Characteristics

). In standby mode, the MAX6642 can

be forced to perform ADC conversions through the

one-shot command, regardless of the RUN bit status.

If a standby command is received while a conversion is

in progress, the conversion cycle is truncated, and the

data from that conversion is not latched into a temperature register. The previous data is not changed and

remains available.

Supply-current drain during the 125ms conversion period is 500µA (typ). In standby mode, supply current

drops to 3µA (typ).

SMBus Digital Interface

From a software perspective, the MAX6642 appears as

a set of byte-wide registers that contain temperature

data, alarm threshold values, and control bits. A standard SMBus-compatible 2-wire serial interface is used

to read temperature data and write control bits and

alarm threshold data.

The MAX6642 employs four standard SMBus protocols:

Write Byte, Read Byte, Send Byte, and Receive Byte.

(Figures 1, 2, and 3). The shorter Receive Byte protocol

allows quicker transfers, provided that the correct data

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

_______________________________________________________________________________________ 5

Pin Description

PIN NAME FUNCTION

1V

2 GND Ground

3 DXP

4 SCLK SMBus Serial-Clock Input. May be pulled up to +5.5V regardless of VCC.

5 SDA SMBus Serial-Data Input/Output, Open Drain. May be pulled up to +5.5V regardless of VCC.

6 ALERT

—EP

Supply Voltage Input, +3V to +5.5V. Bypass V

CC

recommended but not required for additional noise filtering.

Combined Remote-Diode Current Source and ADC Input for Remote-Diode Channel. Place a 2200pF

capacitor between DXP and GND for noise filtering.

SMBus Alert (Interrupt) Output, Open Drain. ALERT asserts when temperature exceeds user-set limits. See

the

ALERT

Interrupts section.

Exposed Pad. Internally connected to GND. Connect to a PCB ground pad for optimal performance. Not

intended as an electrical connection point.

to GND with a 0.1µF capacitor. A 47Ω series resistor is

CC

Page 6

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

6 _______________________________________________________________________________________

Figure 1. SMBus Protocols

Figure 2. SMBus Write Timing Diagram

WRITE BYTE FORMAT

S ADDRESS WR ACK ACK PDATA ACKCOMMAND

7 BITS 18 BITS8 BITS

SLAVE ADDRESS: EQUIVALENT TO CHIP-SELECT LINE OF

A 3-WIRE INTERFACE

READ BYTE FORMAT

S ADDRESSADDRESS WR ACK ACK PS RD ACK ///DATACOMMAND

7 BITS 7 BITS 8 BITS8 BITS

SLAVE ADDRESS: EQUIVALENT TO CHIP SELECT LINE

SEND BYTE FORMAT

SPADDRESS WR ACK ACKCOMMAND

7 BITS 8 BITS

S = START CONDITION

P = STOP CONDITION

COMMAND BYTE: SELECTS

WHICH REGISTER YOU ARE

REDING FROM

COMMAND BYTE: SENDS COMMAND WITH NO DATA, USUALLY

USED FOR ONE-SHOT COMMAND

SHADED = SLAVE TRANSMISSION

/// = NOT ACKNOWLEDGED

DATA BYTE: DATA GOES INTO THE REGISTER

SET BY THE COMMAND BYTE (TO SET

THRESHOLDS, CONFIGURATION MASKS, AND

SAMPLING RATE)

SLAVE ADDRESS: REPEATED

DUE TO CHANGE IN DATAFLOW DIRECTION

DATA BYTE: READS FROM

THE REGISTER SET BY THE

COMMAND BYTE

RECEIVE BYTE FORMAT

SPADDRESS RD ACK ///DATA

7 BITS 8 BITS

DATA BYTE: READS DATA FROM

THE REGISTER COMMANDED

BY THE LAST READ BYTE OR

WRITE BYTE TRANSMISSION;

ALSO USED FOR SMBUS ALERT

RESPONSE RETURN ADDRESS

AB CDEFG

t

LOW

SMBCLK

SMBDATA

t

SU:STAtHD:STA

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

t

HIGH

t

SU:DAT

E = SLAVE PULLS SMBDATA LINE LOW

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO SLAVE

H = LSB OF DATA CLOCKED INTO SLAVE

HIJ

I = SLAVE PULLS DATA LINE LOW

J = ACKNOWLEDGE CLOCKED INTO MASTER

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

LMK

t

SU:STOtBUF

Page 7

register was previously selected by a Write Byte

instruction. Use caution when using the shorter protocols in multimaster systems, as a second master could

overwrite the command byte without informing the first

master.

Read temperature data from the read internal temperature (00h) and read external temperature (01h) registers. The temperature data format for these registers is

8 bits for each channel, with the LSB representing +1°C

(Table 1).

Read the additional bits from the read extended temperature byte register (10h, 11h), which extends the

data to 10 bits and the resolution to +0.25°C per LSB

(Table 2).

When a conversion is complete, the main temperature

register and the extended temperature register are

updated.

Alarm Threshold Registers

Two registers store ALERT threshold values—one each

for the local and remote channels. If either measured

temperature equals or exceeds the corresponding

ALERT threshold value, the ALERT interrupt asserts

unless the ALERT bit is masked.

The power-on-reset (POR) state of the local ALERT

T

HIGH

register is +70°C (0100 0110). The POR state of

the remote ALERT T

HIGH

register is +120°C (0111 1000).

Diode Fault Detection

A continuity fault detector at DXP detects an open circuit on DXP, or a DXP short to VCCor GND. If an open

or short circuit exists, the external temperature register

is loaded with 1111 1111 and status bit 2 (OPEN) of the

status byte is set to 1. Immediately after POR, the status

register indicates that no fault is present. If a fault is

present upon power-up, the fault is not indicated until

the end of the first conversion. Diode faults do not set

the ALERT output.

ALERT

Interrupts

The ALERT interrupt occurs when the internal or external

temperature reading exceeds a high temperature limit

(user programmed). The ALERT interrupt output signal is

latched and can be cleared only by reading the status

register after the fault condition no longer exists or by

successfully responding to the alert response address. If

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

_______________________________________________________________________________________ 7

Figure 3. SMBus Read Timing Diagram

Table 1. Main Temperature Register

(High Byte) Data Format

Table 2. Extended Resolution

Temperature Register (Low Byte) Data

Format

TEMP (°C) DIGITAL OUTPUT

130.00 1 000 0010

127.00 0 111 1111

126.00 0 111 1110

25 0 001 1001

0.00 0 000 0000

<0.00 0 000 0000

Diode fault (short or open) 1 111 1111

FRACTIONAL TEMP (°C) DIGITAL OUTPUT

0.000 00XX XXXX

0.250 01XX XXXX

0.500 10XX XXXX

0.750 11XX XXXX

AB CDEFG H

t

LOWtHIGH

SMBCLK

SMBDATA

t

t

HD:STA

SU:STA

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SMBDATA LINE LOW

t

SU:DAT

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO MASTER

H = LSB OF DATA CLOCKED INTO MASTER

t

HD:DAT

I

I = ACKNOWLEDGE CLOCK PULSE

J = STOP CONDITION

K = NEW START CONDITION

t

SU:STO

K

J

t

BUF

Page 8

MAX6642

the ALERT is cleared by responding to the alert

response address and the temperature fault condition

still exists, ALERT is reasserted after the next temperature-monitoring cycle. To clear ALERT while the temperature is above the trip threshold, write a new high limit that

is higher than the current temperature. The ALERT out-

put is open drain, allowing multiple devices to share a

common interrupt line.

Alert Response Address

The SMBus alert response interrupt pointer provides

quick fault identification for simple slave devices like

temperature sensors. Upon receiving an ALERT inter-

rupt signal, the host master can broadcast a Receive

Byte transmission to the alert response slave address

(0001 100). Following such a broadcast, any slave

device that generated an interrupt attempts to identify

itself by putting its own address on the bus.

The alert response can activate several different slave

devices simultaneously, similar to the I2C General Call.

If more than one slave attempts to respond, bus arbitra-

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

8 _______________________________________________________________________________________

Table 3. Command-Byte Assignments

Table 4. Configuration-Byte Bit Assignments

Table 5. Status-Byte Bit Assignments

A D D R ESS PO R ST A T EF U N C T IO N

00h 00h ( 0000 0000) Read l ocal tem p er atur e

01h 00h ( 0000 0000) Read r em ote tem p er atur e

02h N /A Read status b yte

03h 10h ( 0001 0000) Read confi g ur ati on b yt e

05h 46h ( 0100 0110) + 70° C Read l ocal hi g h l i m i t

07h 78h ( 0111 1000) + 120° C Read r em ote hi g h l i m i t

09h N /A W r i te confi g ur ati on b yte

0Bh N /A W r i te l ocal hi g h l i m i t

0D hN /A W r i te r em ote hi g h l i m i t

0Fh N /A S i ng l e shot

10h 0000 0000

11h 0000 0000

FE h4D h ( 0100 1101) Read m anufactur er ID

Read r em ote extend ed

tem p er atur e

Read i nter nal extend ed

tem p er atur e

BIT NAME POR STATE FUNCTION

7 (MSB) MASK1 0 A 1 masks off (disables) the ALERT interrupts.

6 STOP/RUN 0 A 1 puts the MAX6642 into standby mode.

5 External only 0

4

3 to 0 — 0000 Reserved.

Fault

queue

1

A 1 disables local temperature measurements so that only

remote temperature is measured. The measurement rate

becomes 8Hz.

0: ALERT is set by a single fault. 1: Two consecutive faults

are required to set ALERT.

BIT NAME POR STATE FUNCTION

7 (MSB) BUSY 0 A 1 indicates the MAX6642 is busy converting.

6 LHIGH 0

5 — 0 Reserved.

4 RHIGH 0

3 — 0 Reserved.

2 OPEN 0

1 to 0 — 0 Reserved.

A 1 indicates an internal high-temperature fault. Clear

LHIGH with a POR or by reading the status byte.

A 1 indicates an external high-temperature fault. Clear

RHIGH with a POR or by reading the status byte.

A 1 indicates a diode open condition. Clear OPEN with a

POR or by reading the status byte when the condition no

longer exists.

Page 9

tion rules apply, and the device with the lower address

code wins. The losing device does not generate an

acknowledge and continues to hold the ALERT line low

until cleared. (The conditions for clearing an ALERT

vary depending on the type of slave device.)

Successful completion of the alert response protocol

clears the interrupt latch. If the condition still exists, the

device reasserts the ALERT interrupt at the end of the

next conversion.

Command Byte Functions

The 8-bit command byte register (Table 3) is the master

index that points to the various other registers within the

MAX6642. The register’s POR state is 0000 0000, so a

Receive Byte transmission (a protocol that lacks the

command byte) that occurs immediately after POR

returns the current local temperature data.

Single-Shot

The single-shot command immediately forces a new

conversion cycle to begin. If the single-shot command

is received while the MAX6642 is in standby mode

(RUN bit = 1), a new conversion begins, after which the

device returns to standby mode. If a single-shot conversion is in progress when a single-shot command is

received, the command is ignored. If a single-shot

command is received in autonomous mode (RUN bit =

0), the command is ignored.

Configuration Byte Functions

The configuration byte register (Table 4) is a read-write

register with several functions. Bit 7 is used to mask

(disable) interrupts. Bit 6 puts the MAX6642 into standby mode (STOP) or autonomous (RUN) mode. Bit 5 disables local temperature conversions for faster (8Hz)

remote temperature monitoring. Bit 4 prevents setting

the ALERT output until two consecutive measurements

result in fault conditions.

Status Byte Functions

The status byte register (Table 5) indicates which (if

any) temperature thresholds have been exceeded. This

byte also indicates whether the ADC is converting and

whether there is an open-circuit fault detected on the

external sense junction. After POR, the normal state of

all flag bits is zero, assuming no alarm conditions are

present. The status byte is cleared by any successful

read of the status byte after the overtemperature fault

condition no longer exists.

Slave Addresses

The MAX6642 has eight fixed addresses available.

These are shown in Table 6.

The MAX6642 also responds to the SMBus alert

response slave address (see the

Alert Response

Address

section).

POR and UVLO

To prevent ambiguous power-supply conditions from

corrupting the data in memory and causing erratic

behavior, a POR voltage detector monitors VCCand

clears the memory if VCCfalls below 2.1 (typ). When

power is first applied and VCCrises above 2.1 (typ),

the logic blocks begin operating, although reads and

writes at VCClevels below 3V are not recommended. A

second VCCcomparator, the ADC undervoltage lockout

(UVLO) comparator prevents the ADC from converting

until there is sufficient headroom (VCC= +2.7V typ).

Power-Up Defaults

Power-up defaults include:

• ALERT output is cleared.

• ADC begins autoconverting at a 4Hz rate.

• Command byte is set to 00h to facilitate quick

local Receive Byte queries.

• Local (internal) T

HIGH

limit set to +70°C.

• Remote (external) T

HIGH

limit set to +120°C.

Applications Information

Remote-Diode Selection

The MAX6642 can directly measure the die temperature

of CPUs and other ICs that have on-board temperaturesensing diodes (see the

Typical Operating Circuit

) or

they can measure the temperature of a discrete diodeconnected transistor.

Effect of Ideality Factor

The accuracy of the remote temperature measurements

depends on the ideality factor (n) of the remote “diode”

(actually a transistor). The MAX6642 is optimized for n

= 1.008, which is the typical value for the Intel Pentium

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

_______________________________________________________________________________________ 9

Table 6. Slave Address

PART NO. SUFFIX ADDRESS

MAX6642ATT90 1001 000

MAX6642ATT92 1001 001

MAX6642ATT94 1001 010

MAX6642ATT96 1001 011

MAX6642ATT98 1001 100

MAX6642ATT9A 1001 101

MAX6642ATT9C 1001 110

MAX6642ATT9E 1001 111

Page 10

MAX6642

III. A thermal diode on the substrate of an IC is normally

a PNP with its collector grounded. Connect the anode

(emitter) to DXP and the cathode to GND of the

MAX6642.

If a sense transistor with an ideality factor other than

1.008 is used, the output data is different from the data

obtained with the optimum ideality factor. Fortunately,

the difference is predictable.

Assume a remote-diode sensor designed for a nominal

ideality factor n

NOMINAL

is used to measure the temperature of a diode with a different ideality factor n1.

The measured temperature T

M

can be corrected using:

where temperature is measured in Kelvin and

n

NOMIMAL

for the MAX6642 is 1.008.

As an example, assume you want to use the MAX6642

with a CPU that has an ideality factor of 1.002. If the

diode has no series resistance, the measured data is

related to the real temperature as follows:

For a real temperature of +85°C (358.15K), the measured temperature is +82.91°C (356.02K), an error of

-2.13°C.

Effect of Series Resistance

Series resistance in a sense diode contributes additional errors. For nominal diode currents of 10µA and

100µA, the change in the measured voltage due to

series resistance is:

ΔVM= RS (100µA - 10µA) = 90µA R

S

Since +1°C corresponds to 198.6µV, series resistance

contributes a temperature offset of:

Assume that the diode being measured has a series

resistance of 3Ω. The series resistance contributes an

offset of:

The effects of the ideality factor and series resistance

are additive. If the diode has an ideality factor of 1.002

and series resistance of 3Ω, the total offset can be calculated by adding error due to series resistance with

error due to ideality factor:

1.36°C - 2.13°C = -0.77°C

for a diode temperature of +85°C.

In this example, the effect of the series resistance and

the ideality factor partially cancel each other.

Discrete Remote Diodes

When the remote-sensing diode is a discrete transistor,

connect its collector and base together. Table 7 lists

examples of discrete transistors that are appropriate for

use with the MAX6642.

The transistor must be a small-signal type with a relatively high forward voltage; otherwise, the A/D input

voltage range can be violated. The forward voltage at

the highest expected temperature must be greater than

0.25V at 10µA, and at the lowest expected temperature, the forward voltage must be less than 0.95V at

100µA. Large power transistors must not be used. Also,

ensure that the base resistance is less than 100Ω. Tight

specifications for forward current gain (50 < ß <150, for

example) indicate that the manufacturer has good

process controls and that the devices have consistent

V

BE

characteristics.

Manufacturers of discrete transistors do not normally

specify or guarantee ideality factor. This is normally not

a problem since good-quality discrete transistors tend

to have ideality factors that fall within a relatively narrow

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

10 ______________________________________________________________________________________

Table 7. Remote-Sensor Transistor

Manufacturers

Note: Discrete transistors must be diode connected (base shorted to collector).

TT

M ACTUAL

TT

ACTUAL M

( . )

=

=

T

⎛

n

⎜

⎝

1 00599

M

⎛

⎜

n

⎝

NOMINAL

NOMINAL

n

1

⎞

n

1

⎟

⎠

⎞

T

=

M

⎟

⎠

1 008

.

⎛

⎜

⎝

1 002

.

μ

V

90

Ω

=

μ

V

.

198 6

°

C

.

0 453

C

°

Ω

MANUFACTURER MODEL NO.

Central Semiconductor (USA) CMPT3906

Rohm Semiconductor (USA) SST3906

Samsung (Korea) KST3906-TF

Siemens (Germany) SMBT3906

Zetex (England) FMMT3906CT-ND

°

3 0 453 1 36Ω×

⎞

=

⎟

⎠

C

=+ ° ..

Ω

C

Page 11

range. We have observed variations in remote temperature readings of less than ±2°C with a variety of discrete transistors. Still, it is good design practice to

verify good consistency of temperature readings with

several discrete transistors from any manufacturer

under consideration.

ADC Noise Filtering

The integrating ADC used has good noise rejection for

low-frequency signals such as 60Hz/120Hz power-supply hum. In noisy environments, high-frequency noise

reduction is needed for high-accuracy remote measurements. The noise can be reduced with careful PCB

layout and proper external noise filtering.

High-frequency EMI is best filtered at DXP with an

external 2200pF capacitor. Larger capacitor values can

be used for added filtering, but do not exceed 3300pF

because excessive capacitance can introduce errors

due to the rise time of the switched current source.

Nearly all noise sources tested cause the temperature

conversion results to be higher than the actual temperature, typically by +1°C to +10°C, depending on the

frequency and amplitude (see the

Typical Operating

Characteristics

).

PCB Layout

Follow these guidelines to reduce the measurement

error of the temperature sensors:

1) Connect the thermal-sense diode to the MAX6642

using two traces—one between DXP and the

anode, the other between the MAX6642’s GND and

the cathode. Do not connect the cathode to GND at

the sense diode.

2) Place the MAX6642 as close as is practical to the

remote thermal diode. In noisy environments, such

as a computer motherboard, this distance can be

4in to 8in (typ). This length can be increased if the

worst noise sources are avoided. Noise sources

include CRTs, clock generators, memory buses,

and ISA/PCI buses.

3) Do not route the thermal diode lines next to the

deflection coils of a CRT. Also, do not route the

traces across fast digital signals, which can easily

introduce a 30°C error, even with good filtering.

4) Route the thermal diode traces in parallel and in

close proximity to each other, away from any higher

voltage traces, such as +12VDC. Leakage currents

from PCB contamination must be dealt with carefully since a 20MΩ leakage path from DXP to ground

causes about +1°C error. If high-voltage traces are

unavoidable, connect guard traces to GND on

either side of the DXP trace (Figure 4).

5) Route through as few vias and crossunders as possible to minimize copper/solder thermocouple

effects.

6) When introducing a thermocouple, make sure that

both the thermal diode paths have matching thermocouples. A copper-solder thermocouple exhibits

3µV/°C, and it takes about 200µV of voltage error at

DXP to cause a +1°C measurement error. Adding a

few thermocouples causes a negligible error.

7) Use wide traces. Narrow traces are more inductive

and tend to pick up radiated noise. The 10-mil

widths and spacing recommended in Figure 4 are

not absolutely necessary, as they offer only a minor

improvement in leakage and noise over narrow

traces. Use wider traces when practical.

8) Add a 47Ω resistor in series with VCCfor best noise

filtering (see the

Typical Operating Circuit

).

9) Copper cannot be used as an EMI shield; only ferrous materials such as steel work well. Placing a

copper ground plane between the DXP-DXN traces

and traces carrying high-frequency noise signals

does not help reduce EMI.

Twisted-Pair and Shielded Cables

Use a twisted-pair cable to connect the remote sensor

for remote-sensor distances longer than 8in or in very

noisy environments. Twisted-pair cable lengths can be

between 6ft and 12ft before noise introduces excessive

errors. For longer distances, the best solution is a

shielded twisted pair like that used for audio microphones. For example, Belden #8451 works well for distances up to 100ft in a noisy environment. At the

device, connect the twisted pair to DXP and GND and

the shield to GND. Leave the shield unconnected at the

remote diode.

For very long cable runs, the cable’s parasitic capacitance often provides noise filtering, so the 2200pF

capacitor can often be removed or reduced in value.

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

______________________________________________________________________________________ 11

Figure 4. Recommended DXP PC Traces

GND

10 mils

10 mils

10 mils

THERMAL DIODE ANODE/DXP

MINIMUM

THERMAL DIODE CATHODE/GND

10 mils

GND

Page 12

MAX6642

Cable resistance also affects remote-sensor accuracy.

For every 1Ω of series resistance, the error is approximately 1/2°C.

Thermal Mass and Self-Heating

When sensing local temperature, this device is intended to measure the temperature of the PCB to which it is

soldered. The leads provide a good thermal path

between the PCB traces and the die. Thermal conductivity between the die and the ambient air is poor by

comparison, making air temperature measurements

impractical. Because the thermal mass of the PCB is far

greater than that of the MAX6642, the device follows

temperature changes on the PCB with little or no perceivable delay.

When measuring temperature of a CPU or other IC with

an on-chip sense junction, thermal mass has virtually

no effect; the measured temperature of the junction

tracks the actual temperature within a conversion cycle.

When measuring temperature with discrete remote sensors, smaller packages, such as SOT23s, yield the best

thermal response times. Take care to account for thermal gradients between the heat source and the sensor,

and ensure that stray air currents across the sensor

package do not interfere with measurement accuracy.

Self-heating does not significantly affect measurement

accuracy. Remote-sensor self-heating due to the diode

current source is negligible. For the local diode, the

worst-case error occurs when autoconverting at the

fastest rate and simultaneously sinking maximum current at the ALERT output. For example, with V

CC

=

+5.0V, at an 8Hz conversion rate and with ALERT sink-

ing 1mA, the typical power dissipation is:

5.0V x 450µA + 0.4V x 1mA = 2.65mW

ø

J-A

for the 6-pin TDFN package is about +41°C/W, so

assuming no copper PCB heat sinking, the resulting

temperature rise is:

ΔT = 2.65mW x 41°C/W = +0.11°C

Even under nearly worst-case conditions, it is difficult to

introduce a significant self-heating error.

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

12 ______________________________________________________________________________________

Page 13

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

______________________________________________________________________________________ 13

Functional Diagram

Pin Configuration

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

6 TDFN-EP T633-2

21-0137

Chip Information

PROCESS: BiCMOS

DXP

ALERT

V

CC

2

MUX

Q

MAX6642

REMOTE

ADC

LOCAL

DIODE

FAULT

S

R

REGISTER BANK

COMMAND BYTE

REMOTE TEMPERATURE

LOCAL TEMPERATURE

ALERT THRESHOLD

ALERT RESPONSE

ADDRESS

CONTROL

LOGIC

SMBus

8

READ

8

WRITE

7

ADDRESS

DECODER

SDA

SCLK

TOP VIEW

MAX6642

1

V

CC

2GND

3

TDFN-EP

*EXPOSED PAD CONNECTED TO GND.

EP*

ALERT

6

SDA

5

4DXP

SCLK

Page 14

MAX6642

±1°C, SMBus-Compatible Remote/Local

Temperature Sensor with Overtemperature Alarm

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

14

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2009 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Revision History

REVISION

NUMBER

0 8/03 Initial release —

1 10/08

2 7/09 Corrected errors in Figures 2 and 3 6, 7

3 10/09 Corrected error in Package Information table 13

REVISION

DATE

DESCRIPTION

Added missing EP description to Ordering Information and Pin Description,

removed the transistor count on page 12, and corrected some minor style issues

PAGES

CHANGED

1, 5, 9, 10, 12

Loading...

Loading...