Page 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim's website at www.maxim-ic.com.

General Description

The MAX6639 monitors its own temperature and one

external diode-connected transistor or the temperatures

of two external diode-connected transistors, typically

available in CPUs, FPGAs, or GPUs. The 2-wire serial

interface accepts standard System Management Bus

(SMBusTM) write byte, read byte, send byte, and

receive byte commands to read the temperature data

and program the alarm thresholds. Temperature data

can be read at any time over the SMBus, and three programmable alarm outputs can be used to generate

interrupts, throttle signals, or overtemperature shutdown signals.

The temperature data is also used by the internal dualPWM fan-speed controller to adjust the speed of up to

two cooling fans, thereby minimizing noise when the

system is running cool, but providing maximum cooling

when power dissipation increases. Speed control is

accomplished by tachometer feedback from the fan, so

that the speed of the fan is controlled, not just the PWM

duty cycle. Accuracy of speed measurement is ±4%.

The MAX6639 is available in 16-pin QSOP and 16-pin thin

QFN 5mm x 5mm packages. It operates from 3.0V to 3.6V

and consumes just 500µA of supply current.

Applications

Desktop Computers

Notebook Computers

Projectors

Servers

Networking Equipment

Features

o Two Thermal-Diode Inputs

o Up to 25kHz PWM Output Frequency

o Three Selectable SMBus Addresses

o Local Temperature Sensor

o 1°C Remote Temperature Accuracy

o Two PWM Outputs for Fan Drive (Open Drain; Can

be Pulled Up to +13.5V)

o Programmable Fan-Control Characteristics

o Automatic Fan Spin-Up Ensures Fan Start

o Controlled Rate-of-Change Ensures Unobtrusive

Fan-Speed Adjustments

o ±3% Fan-Speed Measurement Accuracy

o Temperature Monitoring Begins at POR for Fail-

Safe System Protection

o OT and THERM Outputs for Throttling or

Shutdown

o Measures Temperatures Up to +150°C

o MAX6639F is Optimized for n = 1.021 for Penryn

Compatability

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

________________________________________________________________

Maxim Integrated Products

1

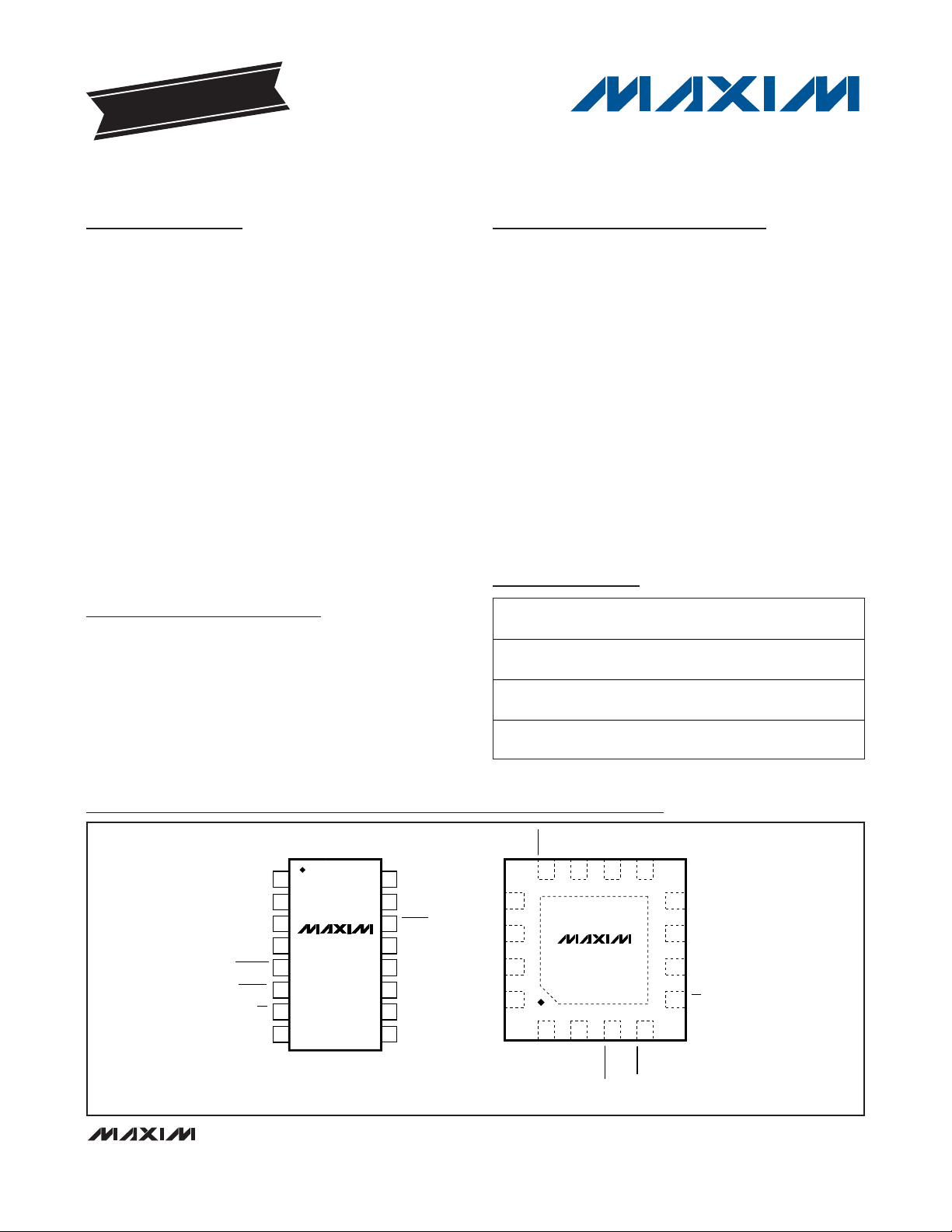

Ordering Information

19-3682; Rev 2; 4/08

EVALUATION KIT

AVAILABLE

PART

O PER A T IN G

RANGE

M EA SU R EM EN T

RANGE

PIN-

PACKAGE

MAX6639AEE

-40°C to

+125°C

16 QSOP

MAX6639ATE

-40°C to

+125°C

16 TQFN E P *

M AX6 639FAEE +

-40°C to

+125°C

16 QSOP

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

PWM1

SCL

SDA

ADD

DXP2

DXN

GND

DXP1

TOP VIEW

MAX6639

QSOP

TACH1

PWM2

TACH2

V

CC

FANFAIL

THERM

OT

ALERT

MAX6639

*CONNECT EXPOSED

PAD TO GND.

V

CC

GND

DXP1

OT

PWM1

SDA

SCL

TACH1

PWM2

TACH2

FANFAIL

THERM

ADD

DXP2

DXN

ALERT

15

16

14

13

6

5

7

8

12 4

12 11 9

3

10

THIN QFN

5 mm x 5 mm

Pin Configurations

SMBus is a trademark of Intel Corp.

Typical Application Circuit appears at end of data sheet.

+

Denotes a lead-free package.

*

EP = Exposed pad.

0°C to +150°C

0°C to +150°C

0°C to +150°C

Page 2

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

2 _______________________________________________________________________________________

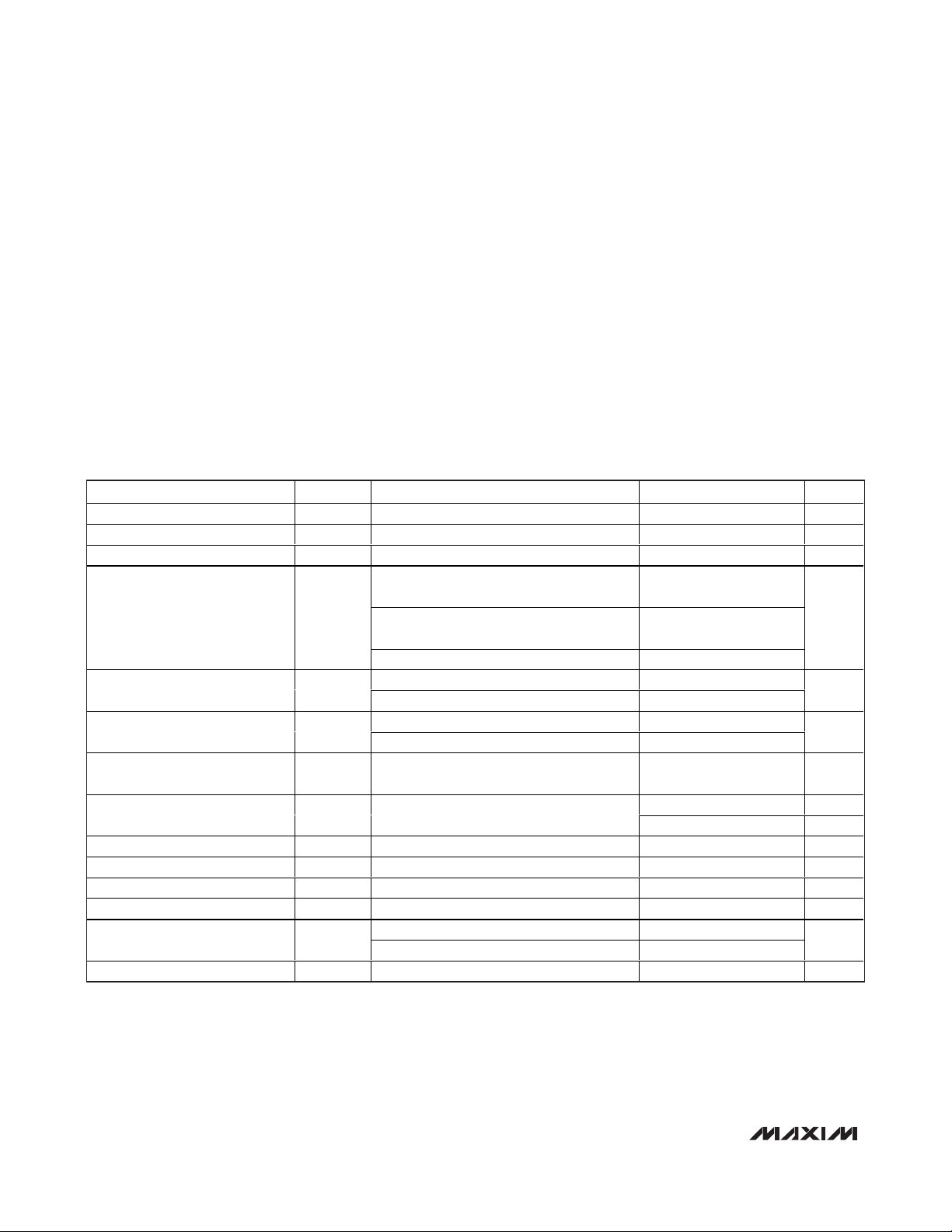

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC= +3.0V to +3.6V, TA= 0°C to +125°C, unless otherwise noted. Typical values are at VCC= +3.3V, TA= +85°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCCto GND..............................................................-0.3V to +4V

PWM1, PWM2, TACH1, and TACH2 to GND ......-0.3V to +13.5V

DXP1 and DXP2 to GND ..........................-0.3V to +(V

CC

+ 0.3V)

DXN to GND ..........................................................-0.3V to +0.8V

SCL, SDA, THERM, OT, FANFAIL, ADD,

and ALERT to GND ..............................................-0.3V to +6V

SDA, OT, THERM, ALERT, FANFAIL,

PWM1, and PWM2 Current .............................-1mA to +50mA

DXN Current .......................................................................±1mA

ESD Protection (all pins, Human Body Model) ..................2000V

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derated 8.3mW/°C above +70°C) ....... 667mW

16-Pin TQFN 5mm x 5mm

(derated at 33.3mW/°C above +70°C)................2666.7mW

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range ............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER

CONDITIONS

Operating Supply Voltage Range

V

CC

V

Standby Current SMB static, sleep mode 3 10 µA

Operating Current Interface inactive, ADC active 0.5 1 mA

VCC = +3.3V, +60°C ≤ TA ≤ +100°C and

+60°C ≤ T

R

≤ +100°C

VCC = +3.3V, +40°C ≤ TA ≤ +100°C and

0°C ≤ T

R

≤ +145°C

External Temperature Error

MAX6639AEE, MAX6639ATE:

n = 1.008

MAX6639FAEE: n = 1.021

V

CC

= +3.3V, 0°C ≤ TR ≤ +145°C

°C

VCC = +3.3V, +25°C ≤ TA ≤ +100°C

Internal Temperature Error

MAX6639AEE, MAX6639ATE

V

CC

= +3.3V, 0°C ≤ TA ≤ +125°C

°C

VCC = +3.3V, +25°C ≤ TA ≤ +100°C

Internal Temperature Error

MAX6639FAEE

V

CC

= +3.3V, 0°C ≤ TA ≤ +125°C

°C

Supply Sensitivity of Temperature

Measurement

°C

Temperature Resolution

11 Bits

Conversion Time

ms

Conversion-Rate Timing Error -10

%

PWM Frequency Error -10

%

Tachometer Accuracy TA = +60°C to +100°C ±3 %

High level 70

130

Remote-Diode Sourcing Current

Low level 7.0 10

µA

DXN Source Voltage 0.7 V

SYMBOL

MIN TYP MAX UNITS

+3.0 +3.6

-1.0 +1.0

-2.5 +2.5

-3.8 +3.8

-2.0 +2.0

-4.0 +4.0

-7.7 -2.5

-10.4 -0.1

±0.2 °C/V

+0.125

125

100

+10

+10

13.0

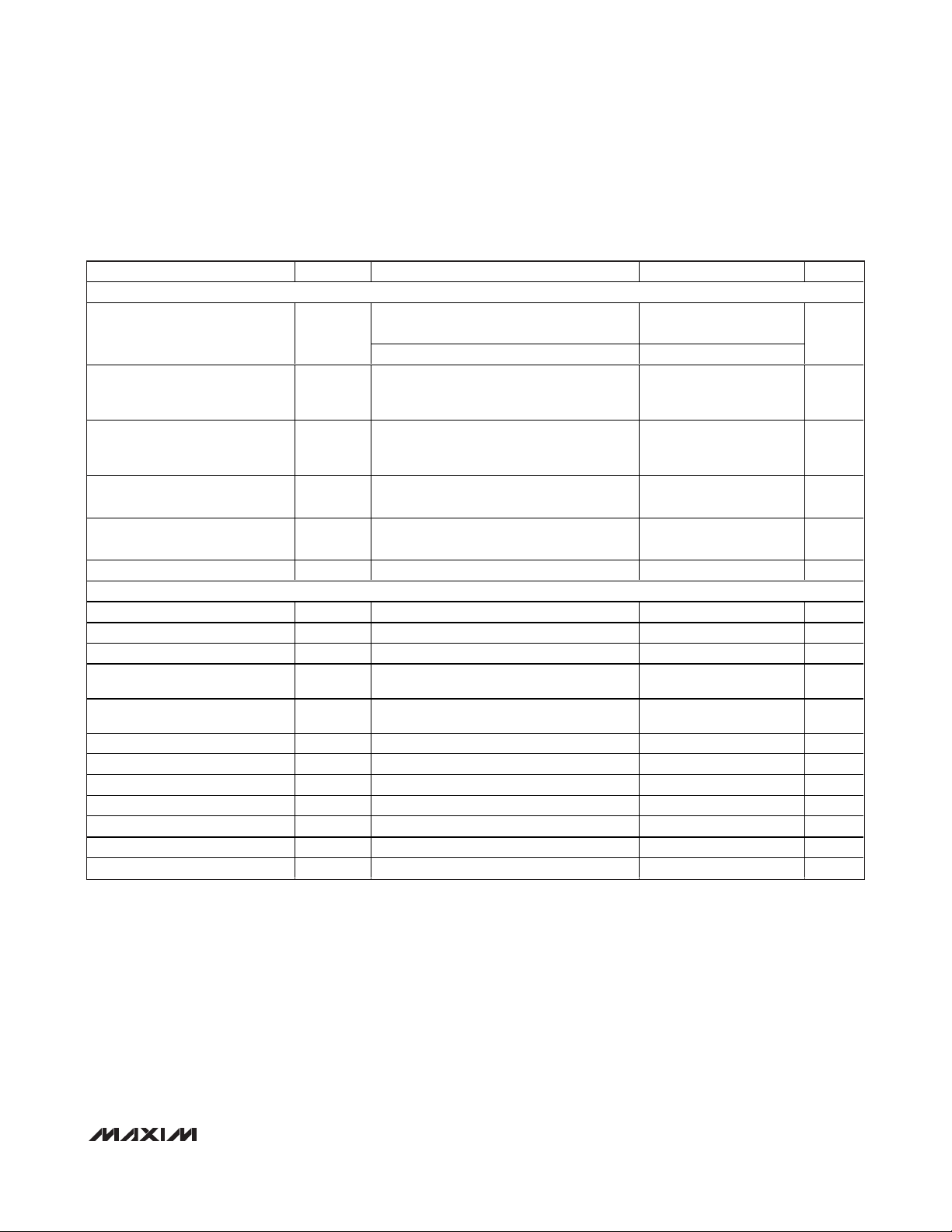

Page 3

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +3.0V to +3.6V, TA= 0°C to +125°C, unless otherwise noted. Typical values are at VCC= +3.3V, TA= +85°C.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

DIGITAL INPUTS AND OUTPUTS

ALERT, FANFAIL, THERM, OT, SDA

I

SINK

= 6mA

0.4

Output Low Voltage (Sink

Current) (OT, ALERT, FANFAIL,

THERM, SDA, PWM1, and PWM2)

V

OL

PWM1, PWM2, I

SINK

= 4mA 0.4

V

Output High Leakage Current

(OT, ALERT, FANFAIL, THERM,

SDA, PWM1, and PWM2)

I

OH

1µA

Logic-Low Input Voltage (SDA,

SCL, THERM, TACH1, TACH2)

V

IL

0.8 V

Logic-High Input Voltage (SDA,

SCL, THERM, TACH1, TACH2)

V

IH

VCC = 3.3V 2.1 V

Input Leakage Current (SDA,

SCL, THERM, TACH1, TACH2)

V

IN

= VCC or GND 1 µA

Input Capacitance C

IN

5pF

SMBus TIMING (Note 2)

Serial Clock Frequency f

SCL

(Note 3) 10 100 kHz

Clock Low Period t

LOW

10% to 10% 4 µs

Clock High Period t

HIGH

90% to 90% 4.7 µs

Bus Free Time Between STOP

and START Conditions

t

BUF

4.7 µs

SMBus START Condition Setup

Time

t

SU:STA

90% of SMBCLK to 90% of SMBDATA 4.7 µs

START Condition Hold Time

10% of SDA to 10% of SCL 4 µs

STOP Condition Setup Time

90% of SCL to 10% of SDA 4 µs

Data Setup Time

10% of SDA to 10% of SCL

ns

Data Hold Time

10% of SCL to 10% of SDA (Note 4)

ns

SMBus Fall Time t

F

300 ns

SMBus Rise Time t

R

ns

SMBus Timeout

58 74 90 ms

Note 1: All parameters tested at a single temperature. Specifications are guaranteed by design.

Note 2: Timing specifications guaranteed by design.

Note 3: The serial interface resets when SCL is low for more than t

TIMEOUT

.

Note 4: A transition must internally provide at least a hold time to bridge the undefined region (300ns max) of SCL's falling edge.

t

HD:STO

t

SU:STO

t

SU:DAT

t

HD:DAT

250

300

t

TIMEOUT

1000

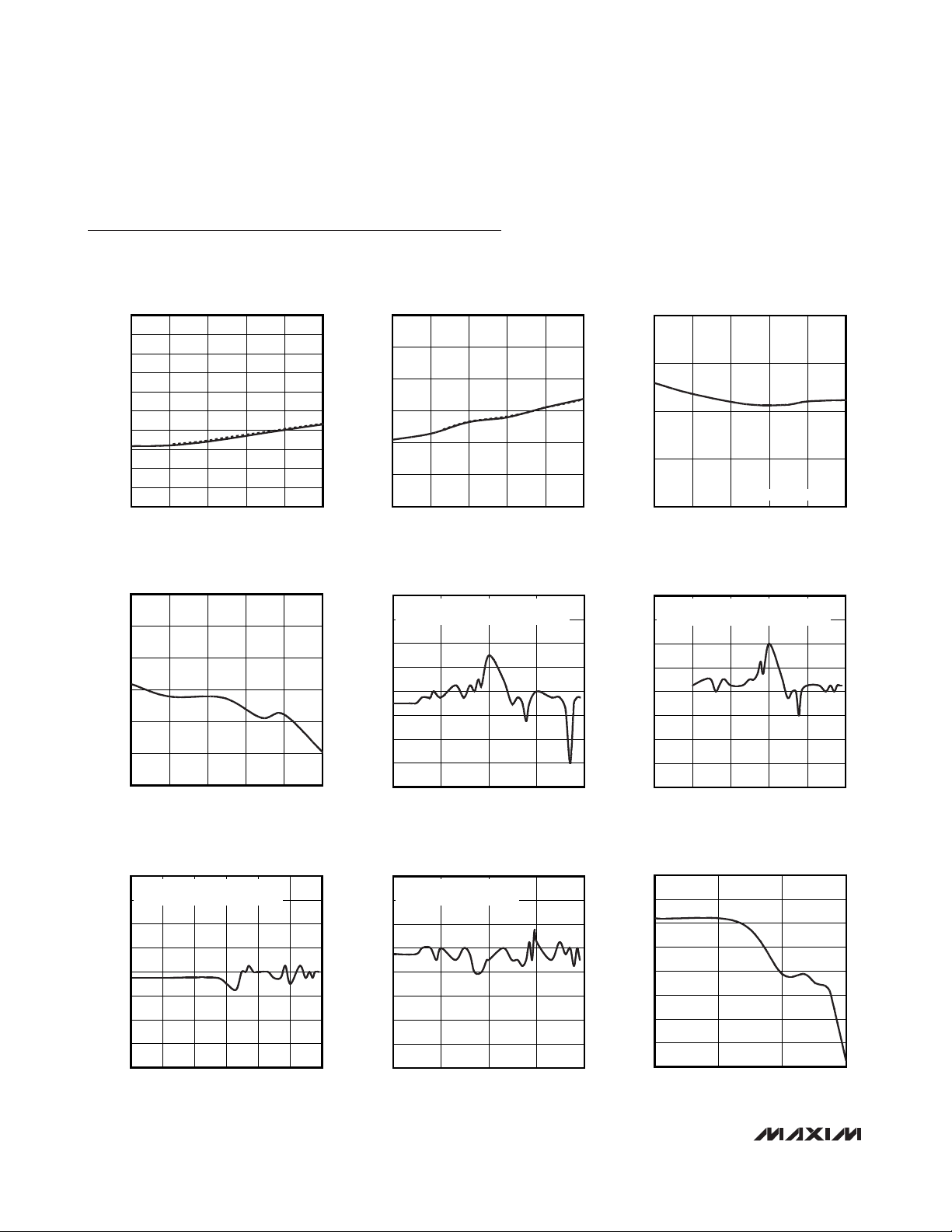

Page 4

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

4 _______________________________________________________________________________________

Typical Operating Characteristics

(VCC= 3.3V, TA= +25°C.)

STANDBY SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX6639 toc01

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (μA)

5.04.54.03.5

1

2

3

4

5

6

7

8

9

10

0

3.0 5.5

OPERATING SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX6639 toc02

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (μA)

5.04.54.03.5

300

400

500

600

700

800

200

3.0 5.5

REMOTE TEMPERATURE ERROR

vs. REMOTE-DIODE TEMPERATURE

MAX6639 toc03

TEMPERATURE (°C)

TEMPERATURE ERROR (°C)

100755025

-1

0

1

2

-2

0125

FAIRCHILD 2N3906

LOCAL TEMPERATURE ERROR

vs. DIE TEMPERATURE

MAX6639 toc04

TEMPERATURE (°C)

TEMPERATURE ERROR (°C)

100755025

-0.5

-1.0

-1.5

0

0.5

1.0

-2.0

0125

LOCAL TEMPERATURE ERROR

vs. POWER-SUPPLY NOISE FREQUENCY

MAX6639 toc06

FREQUENCY (Hz)

TEMPERATURE ERROR (°C)

10k1k100

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

-2.0

1 10 100k

VIN = 250mV

P-P

SQUARE WAVE APPLIED TO

V

CC

WITH NO BYPASS CAPACITOR

REMOTE TEMPERATURE ERROR

vs. COMMON-MODE NOISE FREQUENCY

MAX6639 toc07

FREQUENCY (Hz)

TEMPERATURE ERROR (°C)

10k1k100

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

-2.0

0.1 1 10 100k

VIN = AC-COUPLED TO DXP AND DXN

V

IN

= 100mV

P-P

SQUARE WAVE

REMOTE TEMPERATURE ERROR

vs. DIFFERENTIAL NOISE FREQUENCY

MAX6639 toc08

FREQUENCY (Hz)

TEMPERATURE ERROR (°C)

10k1k100

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

-2.0

10 100k

VIN = AC-COUPLED TO DXP

V

IN

= 100mV

P-P

SQUARE WAVE

TEMPERATURE ERROR

vs. DXP-DXN CAPACITANCE

MAX6639 toc09

DXP-DXN CAPACITANCE (nF)

TEMPERATURE ERROR (°C)

101

-5.0

-4.0

-3.0

-2.0

-1.0

0

1.0

2.0

-6.0

0.1 100

REMOTE TEMPERATURE ERROR

vs. POWER-SUPPLY NOISE FREQUENCY

MAX6639 toc05

FREQUENCY (Hz)

TEMPERATURE ERROR (°C)

10k1k100

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

-2.0

10 100k

VIN = 250mV

P-P

SQUARE WAVE APPLIED TO

V

CC

WITH NO BYPASS CAPACITOR

Page 5

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

_______________________________________________________________________________________ 5

PIN

T Q FN - EP

FUNCTION

1, 15 3, 1

PWM2,

Open-Drain Output to Power-Transistor Driving Fan. Connect to the gate of a MOSFET or base of a

bipolar transistor. PWM_ requires a pullup resistor. The pullup resistor can be connected to a

supply voltage as high as 13.5V, regardless of the MAX6639’s supply voltage.

2, 16 4, 2

TACH2,

Tachometer Inputs. Connect to the tachometer output of the fan. TACH_ requires a pullup resistor.

The pullup resistor can be connected to a supply voltage as high as 13.5V, regardless of the

MAX6639’s supply voltage.

35

Active-Low, Open-Drain, Fan-Failure Output. Open circuit when VCC = 0.

46

Active-Low, Open-Drain Thermal Alarm Output. Typically used for clock throttling. Open circuit

when V

CC

= 0.

57OT

Active-Low, Open-Drain Overtemperature Output. Typically used for system shutdown or clock

throttling. Can be pulled up to 5.5V regardless of V

CC

. Open circuit when VCC = 0.

68VCCPower-Supply Input. 3.3V nominal. Bypass VCC to GND with a 0.1µF capacitor.

7 10 GND Ground. Connect to a clean ground reference.

8, 10 9, 12

DXP1,

C om b i ned C ur r ent S our ce and A/D P osi ti ve Inp ut for Rem ote D i od e. C onnect to anod e of r em oted i od e- connected tem p er atur e- sensi ng tr ansi stor . D o not l eave unconnected ; connect to D X N i f no

r em ote d i od e i s used . P l ace a 2200p F cap aci tor b etw een D X P _ and D X N for noi se f i l ter i ng .

911DXN

11 13 ADD

Address Input. Sets device slave address. Connect to GND, V

CC

, or leave unconnected to give

three unique addresses. See Table 1.

12 14

Active-Low, Open-Drain SMBus Alert Output

13 16 SCL

SMBus Serial-Clock Input. Can be pulled up to 5.5V regardless of V

CC

. Open circuit when VCC =

14 15 SDA

SMBus Serial-Data Input/Output, Open Drain. Can be pulled up to 5.5V regardless of V

CC

. Open

circuit when V

CC

= 0.

——EP

Exposed Pad (TQFN package only). Internally connected to GND. Connect EP to a large PCB pad

for optimum performance and enhanced thermal dissipation. Not intended as an electrical

connection point.

Pin Description

Typical Operating Characteristics (continued)

(VCC= 3.3V, TA= +25°C.)

PWMOUT FREQUENCY

vs. DIE TEMPERATURE

MAX6639 toc10

TEMPERATURE (°C)

PWMOUT FREQUENCY (Hz)

85603510-15

31

32

33

34

35

30

-40 110

PWMOUT FREQUENCY

vs. SUPPLY VOLTAGE

MAX6639 toc11

SUPPLY VOLTAGE (V)

PWMOUT FREQUENCY (Hz)

5.04.54.03.5

31

32

33

34

35

30

3.0 5.5

QSOP

NAME

PWM1

TACH1

FANFAIL

THERM

DXP2

Rem ote D i od e C ur r ent S i nk Inp ut. C onnect C athod e of the Rem ote- D i od e- C onnected Tr ansi stor to D X N

ALERT

Page 6

MAX6639/MAX6639F

Detailed Description

The MAX6639 monitors its own temperature and a

remote-diode-connected transistor or the temperatures

of two external-diode-connected transistors, which typically reside on the die of a CPU or other integrated circuit. The 2-wire serial interface accepts standard

SMBus write byte, read byte, send byte, and receive

byte commands to read the temperature data and program the alarm thresholds. Temperature data can be

read at any time over the SMBus, and a programmable

alarm output can be used to generate interrupts, throttle signals, or overtemperature shutdown signals.

The temperature data is also used by the internal dualPWM fan-speed controller to adjust the speed of up to

two cooling fans, thereby minimizing noise when the

system is running cool, but providing maximum cooling

when power dissipation increases. RPM feedback

allows the MAX6639 to control the fan’s actual speed.

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

6 _______________________________________________________________________________________

GND

SMBus

INTERFACE AND

REGISTERS

LOGIC

PWM

GENERATOR

BLOCK

V

CC

TEMPERATURE

PROCESSING

BLOCK

SDA

SCL

ADD

DXP1

DXN

PWM1

PWM2

TACH1

TACH2

DXP2

OT

THERM

FANFAIL

ALERT

MAX6639

Block Diagram

Write Byte Format

Read Byte Format

Send Byte Format

Receive Byte Format

Slave Address: equivalent to chip-select line of

a 3-wire interface

Command Byte: selects which

register you are writing to

Data Byte: data goes into the register

set by the command byte (to set

thresholds, configuration masks, and

sampling rate)

Slave Address: equivalent to chip-select line

Command Byte: selects

which register you are

reading from

Slave Address: repeated

due to change in dataflow direction

Data Byte: reads from

the register set by the

command byte

Command Byte: sends command with no data, usually

used for one-shot command

Data Byte: reads data from

the register commanded

by the last read byte or

write byte transmission;

also used for SMBus alert

response return address

S = START CONDITION SHADED = SLAVE TRANSMISSION

P = STOP CONDITION /// = NOT ACKNOWLEDGED

Figure 1. SMBus Protocols

S ADDRESS RD ACK DATA /// P

7 bits 8 bits

WRS ACK COMMAND ACK P

8 bits

ADDRESS

7 bits

P

1

ACKDATA

8 bits

ACKCOMMAND

8 bits

ACKWRADDRESS

7 bits

S

S ADDRESS WR ACK COMMAND ACK S ADDRESS

7 bits8 bits7 bits

RD ACK DATA

8 bits

/// P

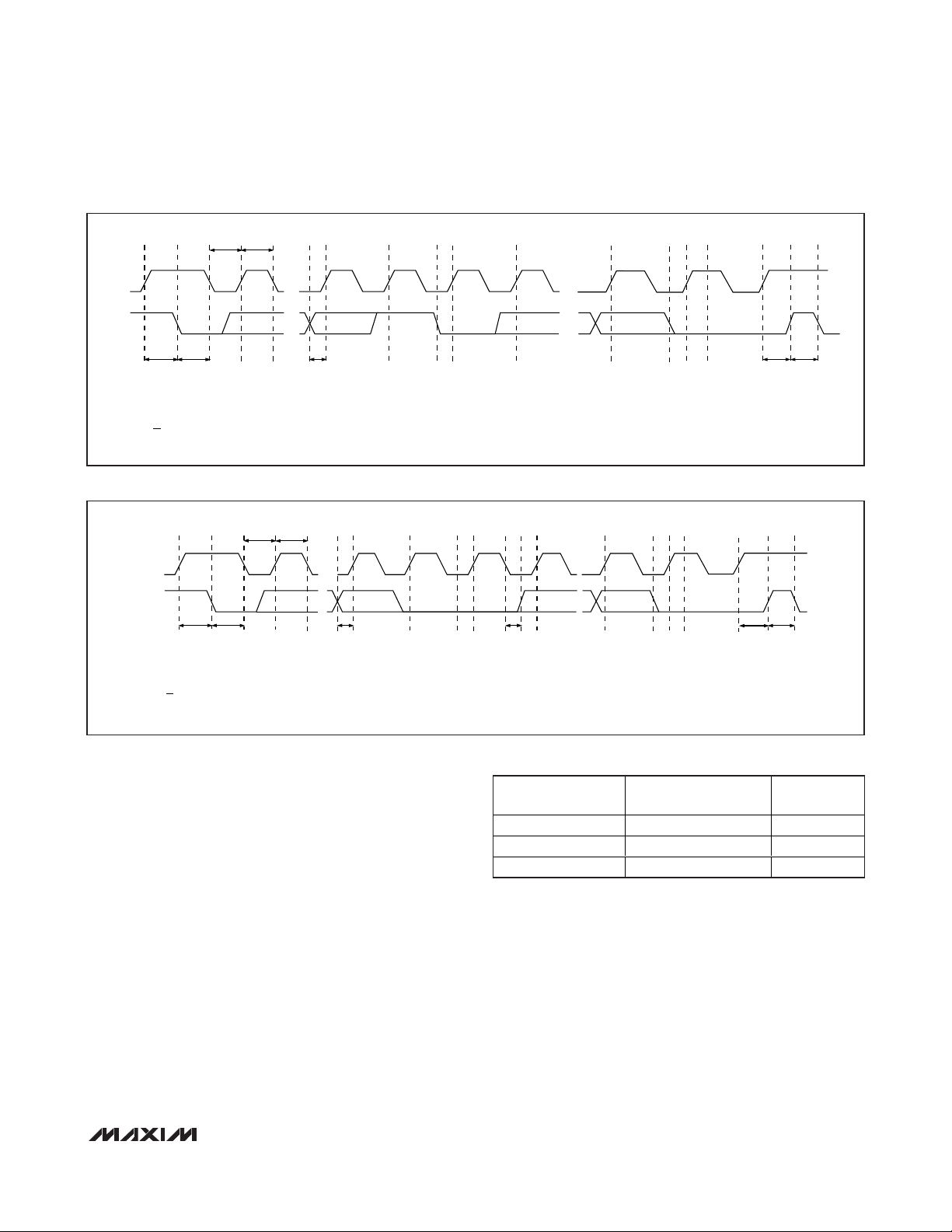

Page 7

SMBus Digital Interface

From a software perspective, the MAX6639 appears as

a set of byte-wide registers. This device uses a standard SMBus 2-wire/I2C-compatible serial interface to

access the internal registers.

The MAX6639 features an address select input (ADD)

that allows the MAX6639 to have three unique addresses

(see Table 1).

The MAX6639 employs four standard SMBus protocols:

write byte, read byte, send byte, and receive byte

(Figures 1, 2, and 3). The shorter receive byte protocol

allows quicker transfers, provided that the correct data

register was previously selected by a read byte instruction. Use caution with the shorter protocols in multimaster systems, since a second master could overwrite the

command byte without informing the first master.

Table 4 details the register addresses and functions,

whether they can be read or written to, and the power-

on reset (POR) state. See Tables 5–9 for all other register functions and the

Register Descriptions

section.

Temperature Reading

Temperature data can be read from registers 00h and

01h. The temperature data format for these registers is

8 bits, with the LSB representing 1°C (Table 2) and the

MSB representing +128°C. The MSB is transmitted first.

Three additional temperature bits provide resolution

down to 0.125°C and are in the channel 1 extended

temperature (05h) and channel 2 extended temperature

(06h) registers. All values below 0°C clip to 00h.

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

_______________________________________________________________________________________ 7

SCL

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

AB CDEFG

HIJ

SDA

t

SU:STAtHD:STA

t

LOW

t

HIGH

t

SU:DAT

t

SU:STOtBUF

LMK

E = SLAVE PULLS SMBDATA LINE LOW

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO SLAVE

H = LSB OF DATA CLOCKED INTO SLAVE

I = MASTER PULLS DATA LINE LOW

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

Figure 2. SMBus Write Timing Diagram

SCL

AB CDEFG HIJ

K

SDA

t

SU:STA

t

HD:STA

t

LOWtHIGH

t

SU:DAT

t

HD:DAT

t

SU:STO

t

BUF

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SMBDATA LINE LOW

L

M

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO MASTER

H = LSB OF DATA CLOCKED INTO MASTER

I = MASTER PULLS DATA LINE LOW

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

Figure 3. SMBus Read Timing Diagram

ADD INPUT STATE

I2C SLAVE ADDRESS

BINARY

EQUIVALENT

V

CC

5Eh 0101 111

Floating 5Ch 0101 110

GND 58h 0101 100

Table 1. I2C Slave Address

Page 8

MAX6639/MAX6639F

The MAX6639 employs a register lock mechanism to

avoid getting temperature results from the temperature

register and the extended temperature register sampled at two different time points. Reading the extended

register stops the MAX6639 from updating the temperature register for at least 0.25s, unless there is a temperature register read before the scheduled update. This

allows enough time to read the main register before it is

updated, thereby preventing reading the temperature

register data from one conversion and the extended

temperature register data from a different conversion.

The MAX6639 measures the temperature at a fixed rate

of 4Hz immediately after it is powered on. Setting bit 7

of the configuration register (04h) shuts down the temperature measurement cycle.

OT

Output

When a measured temperature exceeds the corresponding OT temperature threshold and OT is not

masked, the associated OT status register bit sets and

the OT output asserts. If OT for the respective channel

is masked, the OT status register sets, but the OT output does not assert. To deassert the OT output and the

associated status register bit, either the measured temperature must fall at least 5°C below the trip threshold

or the trip threshold must be increased to at least 5°C

above the current measured temperature.

THERM

When a measured temperature exceeds the corresponding THERM temperature threshold and THERM is

not masked, the associated THERM status register bit

is set and the THERM output asserts. If THERM for the

respective channel is masked, the THERM status register is set, but the THERM output does not assert. To

deassert the THERM output and the associated status

register bit, either the measured temperature must fall

at least 5°C below the trip threshold or the trip threshold

must be increased to at least 5°C above the current

measured temperature. Asserting THERM internally or

externally forces both PWM outputs to 100% duty cycle

when bit 6 in address 13h (fan 1) or bit 6 in address

17h (fan 2) is set.

ALERT

The ALERT output asserts to indicate that a measured

temperature exceeds the ALERT trip threshold for that

temperature channel. The status bit and the ALERT out-

put clear by reading the ALERT status register. If the

ALERT status bit is cleared, but the temperature still

exceeds the ALERT temperature threshold, ALERT

reasserts on the next conversion, and the status bit sets

again. A successful alert response protocol clears

ALERT but does not affect the ALERT status bit.

TACH1 and TACH2 Inputs

To measure the fan speed, the MAX6639 has two

tachometers. Each tachometer has an accurate internal

clock to count the time elapsed in one revolution.

Therefore, it is counting the time between two tachometer pulses for a fan with four poles. When the PWM signal is used to directly modulate the fan’s power supply,

the PWM frequency is normally in the 20Hz to 100Hz

range. In this case, the time required for one revolution

may be longer than the PWM on-time. For this reason,

the PWM pulses are periodically stretched to allow

tachometer measurement over a full revolution. Turn off

pulse stretching by setting bit 5 of register 13h or register 17h when using a 4-wire fan.

The tachometer count is inversely proportional to the

fan’s RPM. The tachometer count data is stored in register 20h (for TACH1) and register 21h (for TACH2).

Reading a value of 255 from the TACH count register

means the fan’s RPM is zero or too slow for the range.

Reading a value of zero in the TACH count register

means the fan’s RPM is higher than the range selected.

Table 2 shows the fan’s available RPM ranges. Use registers 10h or 14h to select the appropriate RPM range for

the fan being used.

FANFAIL

The FANFAIL output asserts to indicate that one of the

fans has failed or is spinning slower than the required

speed. The MAX6639 detects fan fault depending on the

fan-control mode. In PWM mode, the MAX6639 produces a square wave with a duty cycle set by the value

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

TEMP (°C) TEMP (°C)

DIGITAL OUTPUT

241 +241 1111 0001

240 +240 1111 0000

126 +126 0111 1110

25 +25 0001 1001

1.50 1 0000 0001

0.00 0 0000 0000

Table 2. Temperature Data Byte Format

FAN RPM

RANGE

INTERNAL CLOCK

FREQUENCY (kHz)

2000 1

4000 2

8000 4

16,000 8

Table 3. Tachometer Setting

8 _______________________________________________________________________________________

Page 9

written to the duty-cycle registers (26h and 27h). In this

mode, the MAX6639 signals a fan fault when the

tachometer count is greater than the maximum tachometer count value stored in the appropriate register (22h

and 23h). After the MAX6639 asserts FANFAIL, the fan

with a tachometer fault goes to full speed for 2s in an

attempt to restart the fan and then returns to the original

duty-cycle settings. Reading the status register clears

the FANFAIL status bits and the output. The MAX6639

measures the fan speed again after 2s. The MAX6639

asserts FANFAIL if it detects the fan fault again.

In RPM mode (either automatic or manual), the

MAX6639 checks for fan failure only when the duty

cycle reaches 100%. It asserts FANFAIL when the

tachometer count is greater than twice the target

tachometer count. In manual RPM mode, registers 22h

and 23h store the target tachometer count value. In

automatic RPM mode, these registers store the maximum tachometer count.

Fan-Speed Control

The MAX6639 adjusts fan speed by controlling the duty

cycle of a PWM signal. This PWM signal then either

modulates the DC brushless fan’s power supply or drives a speed-control input on a fan that is equipped with

one. There are three speed-control modes: PWM, in

which the PWM duty cycle is directly programmed over

the SMBus; manual RPM, in which the desired

tachometer count is programmed into a register and

the MAX6639 adjusts its duty cycle to achieve the

desired tachometer count; and automatic RPM, in

which the tachometer count is adjusted based on a

programmed temperature profile.

The MAX6639 divides each PWM cycle into 120 time

slots. Registers 26h and 27h contain the current values

of the duty cycles for PWM1 and PWM2, expressed as

the effective time-slot length. For example, the PWM1

output duty cycle is 25% when register 26h reads 1Eh

(30/120).

PWM Control Mode

Enter PWM mode by setting bit 7 of the fan 1 or 2 configuration 1 register (10h and 14h) to 1. In PWM control

mode, the MAX6639 generates PWM signals whose

duty cycles are specified by writing the desired values

to fan duty-cycle registers 26h and 27h. When a new

duty-cycle value is written into one of the fan duty-cycle

registers, the duty cycle changes to the new value at a

rate determined by the rate-of-change bits [6:4] in the

fan 1 or 2 configuration 1 register. The rate-of-change

of the duty cycle ranges from 000 (immediately

changes to the new programmed value) to 111

(changes by 1/120 every 4s). See Table 5 and the

Fan

1 and 2 Configuration 1 (10h and 14h)

section.

Manual RPM Control Mode

Enter manual RPM control mode by setting bits 2, 3,

and 7 of the fan 1 or 2 configuration 1 register (10h and

14h) to zero. In the manual RPM control mode, the

MAX6639 adjusts the duty cycle and measures the fan

speed. Enter the target tachometer count in register

22h for fan 1 and register 23h for fan 2. The MAX6639

compares the target tachometer count with the measured tachometer count and adjusts the duty cycle so

that the fan speed gradually approaches the target

tachometer count.

The first time manual RPM control mode is entered, the

initial PWM duty cycle is determined by the target

tachometer count:

where targetTACH is the value of the target tachometer

count in the target tach count register (22h or 23h).

If the initial duty-cycle value is over 120, the duty cycle

is 100%. If spin-up is enabled (bit 7 in registers 13h

and 17h) and the fan is not already spinning, the duty

cycle first goes to 100% and then goes to the initial

duty-cycle value. Every 2s, the MAX6639 counts the

fan’s period by counting the number of pulses stored in

registers 24h and 25h. If the count is different from the

target count, the duty cycle is adjusted.

If a nonzero rate-of-change is selected, the duty cycle

changes at the specified rate until the tachometer count

is within ±5 of the target. Then the MAX6639 gets into a

locked state and updates the duty cycle every 2s.

Automatic RPM Control Mode

In the automatic RPM control mode, the MAX6639 measures temperature, sets a target tachometer count

based on the measured temperature, and then adjusts

the duty cycle so the fan spins at the desired speed.

Enter this mode by setting bit 7 of the fan 1 or 2 configuration 1 register (10h and 14h) to zero and selecting

the temperature channel that controls the fan speed

using bits 2 and 3 of the configuration register.

In both RPM modes (automatic and manual), the

MAX6639 implements a low limit for the tachometer

counts. This limits the maximum speed of the fan by

ensuring that the fan’s tachometer count does not go

lower than the tachometer count specified by bits 5

through 0 of register 24h for fan 1 and register 25h for

fan 2. Typical values for the minimum tachometer count

Initial duty cycle

t etTACH

arg

=

−255

2

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

_______________________________________________________________________________________ 9

Page 10

MAX6639/MAX6639F

are 30h to 60h. Set the value to correspond to the fullrated RPM of the fan. See Figure 4.

Figure 5 shows how the MAX6639 calculates the target

tachometer value based on the measured temperature.

At T

MIN

, the fan spins at a minimum speed value corresponding to the maximum tachometer count value

stored in register 22h or 23h. Bit 0 of register 11h (fan

1) and register 15h (fan 2) selects the behavior below

T

MIN

. If bit 0 is equal to zero, the fan is completely off

below T

MIN

. When the temperature is falling, it must

drop 5°C below T

MIN

before the fan turns off. If bit 0 is

set to 1, the fan does not turn off below T

MIN

, but

instead stays at the maximum tachometer count in register 22h or 23h.

When the measured temperature is higher than T

MIN

,

the MAX6639 calculates the target tachometer count

value based on two linear equations. The target

tachometer count decreases by the tach step size

value stored in bits 7 through 4 of registers 11h and

15h each time the measured temperature increases by

the temperature step size value stored in bits 2 and 3 of

registers 11h and 15h. As the measured temperature

continues to increase, a second tachometer step size

goes into effect. Bits 3 through 0 of register 12h and

16h select the number temperature/PWM steps after

which the new step size takes effect. The new step size

is selected by bits 7 to 4 of registers 12h and 16h.

Register Descriptions

Channel 1 and Channel 2 Temperature Registers

(00h and 01h)

These registers contain the results of temperature measurements. The MSB has a weight of +128°C and the

LSB +1°C. Temperature data for remote diode 1 is in

the channel 1 temperature register. Temperature data

for remote diode 2 or the local sensor (selectable by bit

4 in the global configuration register) is in the channel 2

temperature register. Three additional temperature bits

provide resolution down to 0.125°C and are in the

channel 1 extended temperature (05h) and channel 2

extended temperature (06h) registers. The channel 1

and channel 2 temperature registers do not update until

at least 250ms after the access of the associated

extended temperature registers. All values below 0°C

return 00h.

Status Register (02h)

A 1 indicates that an ALERT, THERM, OT, or fan fault has

occurred. Reading this register clears bits 7, 6, 1, and 0.

Reading the register also clears the ALERT and

FANFAIL outputs, but not the THERM and OT outputs. If

the fault is still present on the next temperature measurement cycle, any cleared bits and outputs are set again. A

successful alert response clears the values on the outputs but does not clear the status register bits. The

ALERT bits assert when the measured temperature is

higher than the respective thresholds. The THERM and

OT outputs behave like comparators with 5°C hysteresis.

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

10 ______________________________________________________________________________________

TACH

MAX

TACH

0xFFh

TACH

MIN

TEMPERATURE

T

B

T

MIN-5TMIN

TACH

B+1

TACH

A+1

Figure 4. Tachometer Target Calculation

RPM

0

RPM

MAX

RPM

MIN

TEMPERATURE

T

MIN

-5 T

MIN

T

B

TACH

A+1

TACH

B+1

Figure 5. RPM Target Calculation

Page 11

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

______________________________________________________________________________________ 11

READ/

REGISTER

NO.

POR

D7 D6 D5 D4 D3 D2 D1 D 0

R 00h

Temperature

MSB

——————

LS B

R 01h

Temperature

MSB

——————

LS B

R 02h

Fan 2

faul t

03h

0000

OT

Fan 2

faul t

04h

0011

Global

Run

SMBus

0 =

1 =

Tem p

channel 2

2

PWM

output

R 05h

0000

Channel 1

extended

MSB

—

LSB

D i od e

faul t

R 06h

0000

Channel 2

extended

MSB

—

LSB

D i od e

faul t

08h

0101

Channel 1

MSB——————

LS B

09h

0101

Channel 2

MSB——————

LS B

0Ah

0110

limit

MSB——————

LS B

0Bh

0110

limit

MSB——————

LS B

0Ch

0101

Channel 1

MSB——————

LS B

0Dh

0101

Channel 2

MSB——————

LS B

10h

1000

Fan 1

configuration

1

PWM

Rate of

change

Rate of

Rate of

change

Fan 1

channel 1

Fan 1

channel 2

RPM

range

RP M

r ang e

11h

0000

Fan 1

2a

RPM step-

size A

RPM step-

RPM step-

RPM step-

size A

Temp

step-size

Temp

step-size

PWM

fan

0 = 0%,

1= val ue

Table 4. Register Map

WRITE

R/W

R/W

R/W

R/W

R/W

R/W

ADDRESS

STATE

0000

0000

0000

0000

0000

0000

0011

0000

0000

0000

0101

0101

1110

1110

FUNCTION

channel 1

channel 2

Status byte

Output mask

configuration

temperature

temperature

ALERT limit

ALERT limit

Channel 1 OT

Channel 2 OT

(+128°C)

(+128°C)

Channel 1

ALERT

Channel 1

ALERT

0 = run,

1= stby

(0.5°C)

(0.5°C)

Channel 2

ALERT

Channel 2

ALERT

POR:

1 = reset

Channel 1OTChannel 2OTChannel 1

THERM

Channel 1

timeout:

enabled,

disabled

(0.125°C)

(0.125°C)

Channel 2OTChannel 1

THERM

sour ce:

1 = l ocal ,

0 = r em ote

Reserved Reserved Reserved Reserved

Reserved Reserved Reserved Reserved

frequency

Channel 2

THERM

Channel 2

THERM

Reserved Reserved Reser ved

range

Fan 1 fault

Fan 1 fault

( 1° C )

( 1° C )

( 1° C )

( 1° C )

( 1° C )

( 1° C )

R/W

R/W

R/W

R/W

0101

0101

0010

0000

THERM limit

THERM limit

Configuration

mode

(MSB)

(MSB)

size A

change

size A

(LSB)

(LSB)

control

A (MSB)

control

A (LSB)

select

Polarity

( 1° C )

( 1° C )

sel ect

M i ni m um

sp eed :

Page 12

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

12 ______________________________________________________________________________________

READ/

NO.

POR

D7 D6 D5 D4 D3 D2 D1 D 0

12h

0000

Fan 1

2b

RPM step-

size B

RPM step-

RPM step-

Start

B

Start step-

S tar t step -

si ze B ( LS B)

13h

0100

Fan 1

3

Spin-up

Pulse

stretching

Fan PWM

Fan P WM

fr eq uency

( LSB)

14h

1000

Fan 2

1

PWM

mode

Step-size

delay

Step-size

delay

delay

Fan 2

Fan 2

RPM

range

RP M r ang e

select

15h

0000

Fan 2

2a

RPM step-

size A

RPM step-

RPM step-

Temp

Temp

PWM

duty

M i ni m um fan

sp eed :

0 = 0%, 1=

value in 22h

16h

0000

Fan 2

2b

RPM step-

size B

RPM step-

RPM step-

Start

B

Start step-

S tar t step -

si ze B ( LS B)

17h

0100

Fan 2

3

Spin-up

Pulse

stretching

Fan PWM

Fan P WM

fr eq uency

( LSB)

R 20h

1111

Fan 1

tachometer

count

MSB — — — — — — LS B

R 21h

1111

Fan 2

tachometer

count

MSB — — — — — — LS B

22h

1111

Fan 1 start

target tach

count

MSB — — — — — — LS B

23h

1111

Fan 2 max

target tach

count

MSB — — — — — — LS B

24h

0100

Pulses per

revolution/

fan 1

minimum

Pulse per

revolution

Pulse per

revolution

Fan 1 min

tach

tach

tach

tach

Fan 1 mi n

tach count

( LSB)

25h

0100

Pulses per

revolution/

fan 2

minimum

Pulse per

revolution

Pulse per

revolution

Fan 2 min

tach

tach

tach

tach

Fan 2 mi n

tach count

( LSB)

R 26h

0000

MSB — — — — — — LS B

Table 4. Register Map (continued)

REGISTER

0000

0001

0010

0000

0000

0001

FUNCTION

RPM

configuration

(MSB)

configuration

configuration

configuration

configuration

configuration

disable

(MSB)

(MSB)

disable

size B

THERM to

full-speed

enable

(MSB)

size A

size B

THERM to

full-speed

enable

size B

disable

size A

size B

disable

step-size

B (LSB)

Reserved Reserved Reserved

Step-size

(LSB)

RPM

step-size

A (LSB)

RPM

step-size

B (LSB)

Reserved Reserved Reserved

Start

step-size

B (MSB)

channel 1

control

step-size

A (MSB)

Start

step-size

B (MSB)

step-size

channel 2

control

step-size

A (LSB)

step-size

WRITE

R/W

R/W

R/W

R/W

R/W

R/W

ADDRESS

STATE

size B

frequency

(MSB)

select

100%

cycle

size B

frequency

(MSB)

R/W

R/W

R/W

R/W

1111

1111

1111

1111

0000

0000

0000

count

count

Fan 1 min

count

Fan 2 min

count

Fan 1 min

count

Fan 2 min

count

tach count/

tach count/

tach count

tach count

Fan 1 cur r ent

d uty cycl e

(MSB)

(MSB)

(LSB)

(LSB)

tach count

(MSB)

tach count

(MSB)

Fan 1 min

Fan 2 min

Fan 1 min

count

Fan 2 min

count

Page 13

Mask Register (03h)

This register masks the ALERT, OT, THERM, and

FANFAIL outputs. A 1 prevents the corresponding fail-

ures from being asserted on these outputs. The mask

bits do not affect the status register.

Global Configuration Register (04h)

The global configuration register controls the shutdown

mode, power-on reset, SMBus timeout, and temperature channel 2 source select:

• D7: Run/Standby. Normal operation is run (0).

Setting this bit to 1 suspends conversions and puts

the MAX6639 into low-power sleep mode.

• D6: Software POR. Writing a 1 resets all registers to

their default values.

• D5: SMBus Timeout Disable. Writing a zero enables

SMBus timeout for prevention of bus lockup. When

the timeout function is enabled, the SMBus interface

is reset if SDA or SCL remains low for more than

74ms (typ).

• D4: Temperature Channel 2 Source. Selects either

local or remote 2 as the source for temperature chan-

nel 2 register data. Writing a zero to this bit selects

remote 2 for temperature channel 2.

• D3: PWM Output Frequency Range. Selects either

the 20Hz to 100Hz range or the 5kHz to 25kHz range

for the PWM outputs (see Table 9).

Extended Temperature Registers (05h and 06h)

These registers contain the extended temperature data

from channels 1 and 2. Bits D[7:5] contain the 3 LSBs

of the temperature data. The bit values are 0.5°C,

0.25°C, and 0.125°C. When bit 0 is set to 1, a diode

fault has been detected.

Channel 1 and Channel 2 ALERT, OT, and THERM

Limits (08h Through 0Dh)

These registers contain the temperatures above which

the ALERT, THERM, and OT status bits set and outputs

assert (for the temperature channels that are not

masked). The data format is the same as that of the

channel 1 and channel 2 temperature registers: the

LSB weight is +1°C and the MSB is +128°C.

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

______________________________________________________________________________________ 13

READ/

NO.

POR

D7 D6 D5 D4 D3 D2 D1 D 0

W 26h

0011

Fan 1 target

MSB——————LS B

R 27h

0000

Fan 2 current

MSB——————LS B

W 27h

0011

Fan 2 target

MSB——————LS B

28h

0100

Channel 1

fan-start

MSB——————LS B

29h

0100

Channel 2

fan-start

MSB——————LS B

R 3Dh

0101

Read device

ID

01011000

R 3Eh

0100

Read

manufacturer

ID

01001101

R 3Fh

0000

Read device

revision

00000000

Table 4. Register Map (continued)

REGISTER

WRITE

R/W

R/W

ADDRESS

STATE

1100

0000

1100

0000

1000

1101

FUNCTION

duty cycle

duty cycle

duty cycle

minimum

000

temperature

minimum

temperature

0000

Page 14

MAX6639/MAX6639F

Fan 1 and 2 Configuration 1 (10h and 14h)

The following registers control the modes of operation

of the MAX6639:

• D7: PWM Mode. D7 = 1 sets the fan into manual

PWM duty-cycle control mode. Write the target duty

cycle in the fan duty-cycle register. D7 = 0 puts the

fan into RPM control mode. To set RPM manually, set

both fan-control temperature channels (bits D2 and

D3) to zero and write the desired tachometer count

into the TACH count register.

• D[6:4]: Fan Duty-Cycle Rate-of-Change. D[6:4]

sets the time between increments of the duty cycle.

Each increment is 1/120 of the duty cycle. By adjusting the rate-of-change, audibility of fan-speed

changes can be traded for response time. Table 5

shows the effect of D[6:4] and, for reference, the time

required for the fan speed to change from 33% to

100% duty cycle as a function of the rate-of-change

bits.

• D[3:2]: Temperature Channel(s) for Fan Control.

Selects the temperature channel(s) that control the

PWM output when the MAX6639 is in automatic RPM

control mode (PWM mode bit is zero). If two channels are selected, the fan goes to the higher of the

two possible speeds. If neither channel is selected,

then the fan is in manual RPM mode and the speed

is forced to the value written to the target tach count

register 22h or 23h.

• D[1:0]: RPM Range. Scales the tachometer counter

by setting the maximum (full-scale) value of the RPM

range to 2000, 4000, 8000, or 16,000. (Table 3

shows the internal clock frequency as a function of

the range.)

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

14 ______________________________________________________________________________________

REGISTER 10h

OR 14h D[6:4]

NOMINAL RATE

100Hz (s) 50Hz (s) 33.3Hz (s) 20Hz (s)

NOMINAL TIME FROM

33% TO 100% (s)

000 0 0000 0

001 0.0625 0.06 0.06 0.06 0.05 5

010 0.125 0.13 0.12 0.12 0.15 10

011 0.25 0.25 0.26 0.24 0.25 20

100 0.5 0.5 0.5 0.51 0.5 40

101 1 1 1 0.99 1 80

110 2 2 2 1.98 2 160

111 4 4 4 3.96 4 320

Table 5. Fan Duty-Cycle Rate-of-Change

REGISTER 10h OR 14h

FAN MAXIMUM RPM VALUE

00 2000

01 4000

10 8000

11 16,000

Table 6. Fan RPM Speed

MAXIMUM RPM VALUE

ACTUAL RPM

SELECTED NUMBER

OF PULSES PER

REVOLUTION

ACTUAL FAN PULSES

PER REVOLUTION

TACHOMETER COUNT

VALUE*

2000 1000 2 2 3Ch

4000 1000 2 2 78h

4000 3000 2 2 28h

4000 3000 2 4 14h

16,000 8000 4 4 3Ch

16,000 8000 4 2 78h

Table 7. RPM-to-Tachometer Count Relationship Examples

*

Tachometer count value = ((internal clock frequency) x 60) / actual RPM) (selected number of pulses per revolution / actual fan pulses)

A C T U A L R A T E O F CH A N G E AT SP EC IF I C PW M FREQUENCIES

OF CHANGE (s)

Page 15

Fan 1 and 2 Configuration 2a (11h and 15h)

The following registers apply to the automatic RPM control mode:

• D[7:4]: Fan RPM (Tachometer) Step-Size A.

Selects the number of tachometer counts the target

value decreases for each temperature step increase

above the fan-start temperature. Value = n + 1 (1

through 16) where n is the value of D[7:4].

• D[3:2]: Temperature Step Size. Selects the temper-

ature increment for fan control. For each temperature

step increase, the target tachometer count decreases by the value selected by D[7:4] (Table 8).

• D1: PWM Output Polarity. PWM output is low at

100% duty cycle when this bit is set to zero. PWM

output is high at 100% duty cycle when this bit is set

to 1.

• D0: Minimum Speed. Selects the value of the mini-

mum fan speed (when temperature is below the fanstart temperature in the automatic RPM control

mode). Set to zero for 0% fan drive. Set to 1 to determine the minimum fan speed by the tachometer

count value in registers 22h and 23h (fan maximum

TACH).

Fan 1 and 2 Configuration 2b (12h and 16h)

The following registers select the tachometer step sizes

and number of steps for step-size A to step-size B

slope changes (see Figure 1):

• D[7:4]: RPM (Tachometer) Step Size B. Selects

number of tachometer counts the target value

decreases for each temperature step increase after

the number of steps selected by D[3:0]. Value = n +

1 (1 through 16) where n is the value of D[7:4].

• D[3:0]: Selects the number of temperature/tachometer steps above the fan-start temperature at which

step-size B begins.

Fan 1 and Fan 2 Configuration 3 (13h and 17h)

The following registers control fan spin-up, PWM output

frequency, pulse stretching, and THERM to fan fullspeed enable:

• D7: Fan Spin-Up Disable. Set to zero to enable fan

spin-up. Whenever the fan starts up from zero drive,

it is driven with 100% duty cycle for 2s to ensure that

it starts. Set to 1 to disable the spin-up function.

• D6: THERM to Full-Speed Enable. When this bit is

1, THERM going low (either by being pulled low

externally or by the measured temperature exceeding the THERM limit) forces the fan to full speed. In

all modes, this happens at the rate determined by

the rate-of-change selection. When THERM is

deasserted (even if the fan has not reached full

speed), the speed falls at the selected rate-ofchange to the target speed.

• D5: Disable Pulse Stretching. Pulse stretching is

enabled when this bit is set to zero. When modulating the fan’s power supply with the PWM signal, the

PWM pulses are periodically stretched to keep the

tachometer signal available for one full revolution.

Setting this bit to 1 disables pulse stretching. The

MAX6639 still measures the fan speed but does not

stretch the pulses for measurements, so the fan’s

power supply must not be pulse modulated.

• D[1:0]: PWM Output Frequency. These bits control

the PWM output frequency as shown in Table 9.

Fan Tach Count 1 and 2 (20h and 21h)

These registers have the latest tachometer measurement of the corresponding channel. This is inversely

proportional to the fan’s speed. The fan RPM range

should be set so this count falls in the 30 to 160 range

for normal fan operation.

Fan Start Tach Count/Target Tach Count

(22h and 23h)

D[7:0]: This sets the starting tachometer count for the

fan in automatic RPM mode. Depending on the setting

of the minimum duty-cycle bit, the tachometer count

has this value either at all temperatures below the fanstart temperature or the count is zero below the fanstart temperature and has this value when the fan-start

temperature is reached. These registers are the target

tach count when in manual RPM mode.

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

______________________________________________________________________________________ 15

REGISTER 11h

OR 15h

FAN CONTROL TEMPERATURE

STEP SIZE (°C)

00 1

01 2

10 4

11 8

Table 8. Temperature Step Size

REGISTERS

13h AND 16h

LOW-FREQUENCY

(Hz) REGISTER

04h D3 = 0

HIGH-FREQUENCY

(kHz) REGISTER

04h D3 = 1

00

20 5

01

33.33 8.33

10

50 12.5

11

100 25

Table 9. Fan PWM Frequency

Page 16

MAX6639/MAX6639F

Fan 1 and 2 Pulses and Min RPM (24h and 25h)

D[7:6]: This sets the number of tachometer pulses per

revolution for the fan. When set properly, a 2000RPM fan

with two pulses per revolution has the same tachometer

count as a 2000RPM fan with four pulses per revolution.

Table 10 lists tachometer pulses per revolution.

D[5:0]: This sets the minimum allowable fan tachometer

count (maximum speed). This limits the maximum

speed of the fan to reduce noise at high temperatures.

For reasonable speed resolution, the fan RPM range

should be set so this value is between approximately

30 and 60. If a maximum RPM limit is unnecessary, this

value can be set to the full-speed tachometer count.

Fan 1 and 2 Duty Cycle (26h and 27h)

These registers contain the present value of the PWM

duty cycle. In PWM fan-control mode, the desired (target) value of the PWM duty cycle can be written directly

into this register.

Channel 1 and Channel 2 Fan-Start Temperature

(28h and 29h)

These registers contain the temperatures at which fan

control begins (in automatic RPM mode).

Applications Information

Fan-Drive Circuits

A variety of fan-drive circuit configurations can be used

with the MAX6639 to control the fan’s speed. Four of

the most common are shown in Figures 6 through 10.

PWM Power-Supply Drive (High Side or Low Side)

The simplest way to control the speed of a 3-wire (supply, ground, and tachometer output) fan is to modulate

its power supply with a PWM signal. The PWM frequency is typically in the 20Hz to 40Hz range, with 33Hz

being a common value. If the frequency is too high, the

fan’s internal control circuitry does not have sufficient

time to turn on during a power-supply pulse. If the frequency is too low, the power-supply modulation

becomes more easily audible.

The PWM can take place on the high side (Figure 6) or

the low side (Figure 7) of the fan’s power supply. In

either case, if the tachometer is used, it is usually necessary to periodically stretch a PWM pulse so there is

enough time to count the tachometer pulse edges for

speed measurement. The MAX6639 allows this pulse

stretching to be enabled or disabled to match the

needs of the application.

Pulse stretching can sometimes be audible if the fan

responds quickly to changes in the drive voltage. If the

acoustic effects of pulse stretching are too noticeable,

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

16 ______________________________________________________________________________________

REGISTERS 24h

OR 25h D[7:6]

TACHOMETER PULSES PER

REVOLUTION

00 1

01 2

10 3

11 4

Table 10. Tachometer Pulses per

Revolution

V

CC

PWM1

4.7kΩ

4.7kΩ

TACH1

3V TO 5.5V

TACH

OUTPUT

V

FAN

(5V OR 12V)

Figure 6. High-Side PWM Drive Circuit

V

CC

TACH1

4.7kΩ

4.7kΩ

PWM1

3V TO 5.5V

3V TO 5.5V

TACH

OUTPUT

V

FAN

(5V OR 12V)

Figure 7. Low-Side Drive Circuit

Page 17

the circuit in Figure 8 can be used to eliminate pulse

stretching while still allowing accurate tachometer feedback. The diode connects the fan to a low-voltage

power supply, which keeps the fan’s internal circuitry

powered even when the PWM drive is zero. Therefore,

the tachometer signal is always available and pulse

stretching can be turned off. Note that this approach

prevents the fan from turning completely off, so even

when the duty cycle is 0%, the fan may still spin.

Linear Fan Supply Drive

While many fans are compatible with PWM power-supply

drive, some are excessively noisy with this approach.

When this is the case, a good alternative is to control the

fan’s power-supply voltage with a variable DC power-supply circuit. The circuit in Figure 10 accepts the PWM signal as an input, filters the PWM, and converts it to a DC

voltage that then drives the fan. To minimize the size of

the filter capacitor, use the highest available PWM frequency. Pulse stretching is not necessary when using a

linear fan supply. Note that this approach is not as efficient as PWM drive, as the fan’s power-supply current

flows through the MOSFET, which can have an appreciable voltage across it. The total power is still less than

that of a fan running at full speed. Table 11 is a summary of fan-drive options.

4-Wire Fans

Some fans have an additional, fourth terminal that

accepts a logic-level PWM speed-control signal as

shown in Figure 10. These fans require no external

power circuitry and combine the low noise of linear

drive with the high efficiency of PWM power-supply

drive. Higher PWM frequencies are recommended

when using 4-wire fans.

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

______________________________________________________________________________________ 17

V

CC

PWM1

4.7k

Ω

4.7k

Ω

TACH1

3V TO 5.5V

3V TO 5.5V

TACH

OUTPUT

V

FAN

(5V OR 12V)

Figure 10. 4-Wire Fan with PWM Speed-Control Input

V

CC

PWM1

4.7k

Ω

4.7k

Ω

TACH1

3V TO 5.5V

TACH

OUTPUT

V

FAN

(12V OR 5V)

5V

Figure 8. High-Side PWM Drive with “Keep-Alive” Supply

V

CC

PWM1

TACH1

4.7k

Ω

3V TO 5V

4.7k

Ω

100k

Ω

91k

Ω

33k

Ω

100k

Ω

3.3V

2N3904

2.2μF

10μF

TACH

OUTPUT

V

FAN

(5V OR 12V)

TACH OUTPUT

Figure 9. High-Side Linear Drive Circuit

Page 18

MAX6639/MAX6639F

Quick-Start Guide for 8000RPM 4-Pole

(2 Pulses per Revolution) Fan in Automatic

RPM Mode Using the Circuit of Figure 7

1) Write 02h to register 11h to set the PWM output to

drive the n-channel MOSFET.

2) Write 4Bh to register 22h to set the minimum RPM to

3200.

3) Write 5Eh to register 24h to set the pulses per revolution to 2 and to set the maximum RPM speed to

8000RPM.

4) Write 19h to register 28h to set the fan-start temperature to +25°C.

5) Write D2h to register 10h to start automatic

RPM mode.

Remote-Diode Considerations

Temperature accuracy depends upon having a goodquality, diode-connected, small-signal transistor.

Accuracy has been experimentally verified for all the

devices listed in Table 12. The MAX6639 can also

directly measure the die temperature of CPUs and

other ICs with on-board temperature-sensing diodes.

The transistor must be a small-signal type with a relatively high forward voltage. This ensures that the input

voltage is within the A/D input voltage range. The forward voltage must be greater than 0.25V at 10µA at the

highest expected temperature. The forward voltage

must be less than 0.95V at 100µA at the lowest expected temperature. The base resistance has to be less

than 100Ω. Tight specification of forward-current gain

(+50 to +150, for example) indicates that the manufacturer has good process control and that the devices

have consistent characteristics.

Effect of Ideality Factor

The accuracy of the remote temperature measurements

depends on the ideality factor (n) of the remote diode

(actually a transistor). The MAX6639 is optimized for n

= 1.008, for Intel®Pentium®II and AMD Athlon®MP

compatibility, and the MAX6639F is optimized for n =

1.021 for Penryn compatibiliy. If a sense transistor with

a different ideality factor is used, the output data is different. Fortunately, the difference is predictable.

Assume a remote-diode sensor designed for a nominal

ideality factor n

NOMINAL

is used to measure the temperature of a diode with a different ideality factor, n1.

The measured temperature TMcan be corrected using:

where temperature is measured in Kelvin.

As mentioned above, the nominal ideality factor of the

MAX6639 is 1.008. As an example, assume the

MAX6639 is configured with a CPU that has an ideality

factor of 1.002. If the diode has no series resistance,

the measured data is related to the real temperature

as follows:

For a real temperature of +85°C (358.15K), the measured temperature is +82.91°C (356.02K), which is an

error of -2.13°C.

TT

n

n

TT

ACTUAL M

NOMINAL

MM

=

⎛

⎝

⎜

⎞

⎠

⎟

=

⎛

⎝

⎜

⎞

⎠

⎟

=

1

1 008

1 002

1 00599

.

.

(. )

TT

n

n

M ACTUAL

NOMINAL

=

⎛

⎝

⎜

⎞

⎠

⎟

1

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

18 ______________________________________________________________________________________

FIGURE

DESCRIPTION

6 High-side PWM drive Yes Low Negative

7 Low-side PWM drive Yes Low Positive

8 High-side PWM drive with keep-alive supply No Low Negative

9 High-side linear supply No High Positive

10 4-wire fan with PWM speed-control input No High Positive

Table 11. Summary of Fan-Drive Options

MANUFACTURER MODEL NO.

Central Semiconductor (USA) CMPT3906

Rohm Semiconductor (USA) SST3906

Samsung (Korea) KST3906-TF

Siemens (Germany) SMBT3906

Table 12. Remote-Sensor Transistor

Manufacturers

Intel and Pentium are registered trademarks of Intel Corp.

AMD Athlon is a registered trademark of Advanced Micro

Devices, Inc.

PULSE STRETCHING PWM FREQUENCY PWM POLARITY

Page 19

Effect of Series Resistance

Series resistance in a sense diode contributes additional errors. For nominal diode currents of 10µA and

100µA, change in the measured voltage is:

ΔVM= RS(100µA - 10µA) = 90µA x R

S

Since 1°C corresponds to 198.6µV, series resistance

contributes a temperature offset of:

Assume that the diode being measured has a series

resistance of 3Ω. The series resistance contributes an

offset of:

The effects of the ideality factor and series resistance

are additive. If the diode has an ideality factor of 1.002

and series resistance of 3Ω, the total offset can be calculated by adding error due to series resistance with

error due to ideality factor:

1.36°C - 2.13°C = -0.77°C

for a diode temperature of +85°C.

In this example, the effect of the series resistance and

the ideality factor partially cancel each other.

For best accuracy, the discrete transistor should be a

small-signal device with its collector connected to GND

and base connected to DXN. Table 12 lists examples of

discrete transistors that are appropriate for use with the

MAX6639.

The transistor must be a small-signal type with a relatively high forward voltage; otherwise, the ADC input

voltage range can be violated. The forward voltage at

the highest expected temperature must be greater than

0.25V at 10µA, and at the lowest expected temperature,

the forward voltage must be less than 0.95V at 100µA.

Large-power transistors must not be used. Also, ensure

that the base resistance is less than 100Ω. Tight specifications for forward current gain (50 < fl < 150, for

example) indicate that the manufacturer has good

process controls and that the devices have consistent

VBEcharacteristics.

ADC Noise Filtering

The integrating ADC has inherently good noise rejection, especially of low-frequency signals such as

60Hz/120Hz power-supply hum. Micropower operation

places constraints on high-frequency noise rejection.

Lay out the PCB carefully with proper external noise filtering for high-accuracy remote measurements in electrically noisy environments.

Filter high-frequency electromagnetic interference

(EMI) at DXP and DXN with an external 2200pF capacitor connected between the two inputs. This capacitor

can be increased to approximately 3300pF (max),

including cable capacitance. A capacitance higher

than 3300pF introduces errors due to the rise time of

the switched-current source.

Twisted Pairs and Shielded Cables

For remote-sensor distances longer than 8in, or in particularly noisy environments, a twisted pair is recommended. Its practical length is 6ft to 12ft (typ) before

noise becomes a problem, as tested in a noisy electronics laboratory. For longer distances, the best solution is a shielded twisted pair like that used for audio

microphones. For example, Belden #8451 works well

for distances up to 100ft in a noisy environment.

Connect the twisted pair to DXP and DXN and the

shield to ground, and leave the shield’s remote end

unterminated. Excess capacitance at DXN or DXP limits

practical remote-sensor distances (see the

Typical

Operating Characteristics

).

For very long cable runs, the cable’s parasitic capacitance often provides noise filtering, so the recommended 2200pF capacitor can often be removed or reduced

in value. Cable resistance also affects remote-sensor

accuracy. A 1Ω series resistance introduces about

+1/2°C error.

PCB Layout Checklist

1) Place the MAX6639 as close as practical to the

remote diode. In a noisy environment, such as a

computer motherboard, this distance can be 4in to

8in, or more, as long as the worst noise sources

(such as CRTs, clock generators, memory buses,

and ISA/PCI buses) are avoided.

2) Do not route the DXP/DXN lines next to the deflection

coils of a CRT. Also, do not route the traces across a

fast memory bus, which can easily introduce +30°C

error, even with good filtering. Otherwise, most noise

sources are fairly benign.

3 0 453 1 36Ω×

°

Ω

=°. .CC

90

198 6

0 453

μ

Ω

μ

°

=

°

Ω

V

V

C

C

.

.

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

______________________________________________________________________________________ 19

Page 20

MAX6639/MAX6639F

3) Route the DXP and DXN traces parallel and close to

each other, away from any high-voltage traces such

as +12VDC. Avoid leakage currents from PCB contamination. A 20MΩ leakage path from DXP ground

causes approximately +1°C error.

4) Connect guard traces to GND on either side of the

DXP/DXN traces. With guard traces, placing routing

near high-voltage traces is no longer an issue.

5) Route as few vias and crossunders as possible to

minimize copper/solder thermocouple effects.

6) When introducing a thermocouple, make sure that

both the DXP and the DXN paths have matching

thermocouples. In general, PCB-induced thermo-

couples are not a serious problem. A copper solder

thermocouple exhibits 3µV/°C, and it takes approximately 200µV of voltage error at DXP/DXN to cause

a +1°C measurement error, so most parasitic thermocouple errors are swamped out.

7) Use wide traces. Narrow traces are more inductive

and tend to pick up radiated noise. The 10-mil widths

and spacings recommended are not absolutely necessary (as they offer only a minor improvement in

leakage and noise), but use them where practical.

8) Placing an electrically clean copper ground plane

between the DXP/DXN traces and traces carrying

high-frequency noise signals helps reduce EMI.

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

20 ______________________________________________________________________________________

MAX6639

V

FAN

(5V OR 12V)

SDA

SCL

PWM2

DXP1

DXN

TO CLOCK THROTTLE

TO SYSTEM SHUTDOWN

TO SMBus

MASTER

3.3V TO 5.5V

3.0V TO 3.6V

3.3V TO 5.5V 3.3V TO 5.5V

3.3V TO 5.5V

3.3V TO 5.5V

PWM1

5V

5V

DXP2

GPU

V

CC

CPU

GND

5V

TACH1ADD

TACH2

ALERT

THERM

FANFAIL

V

FAN

(5V OR 12V)

OT

Typical Operating Circuit

Page 21

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

______________________________________________________________________________________ 21

Chip Information

PROCESS: BiCMOS

Package Information

For the latest package outline information, go to

www.maxim-ic.com/packages

.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

16 QSOP E16-1

21-0055

16 Thin QFN-EP T1655-2

21-0140

Page 22

MAX6639/MAX6639F

2-Channel Temperature Monitor with Dual,

Automatic, PWM Fan-Speed Controller

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

22

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Revision History

REVISION

NUMBER

REVISION

DATE

DESCRIPTION

PAGES

CHANGED

0 5/05 Initial release —

1 12/07

Changed max operating voltage range from 5.5V to 3.6V; corrected TOCs 1, 2,

and 11; various style edits; and updated package outlines.

1–5, 7, 19, 20, 21, 22

2 4/08 Added MAX6639F option. 1, 2, 5, 18, 20

Loading...

Loading...