Page 1

General Description

The MAX6638 thermal-management sensor includes

internal (local) and external (remote) digital temperature

sensors and two independent SMBus™ serial ports. The

remote temperature accuracy is ±1.0°C, and the local

temperature accuracy is ±2°C. The MAX6638 also features extended temperature resolution data available in

0.125°C increments.

The MAX6638 provides three system alarms: channel 1

alert (ALERT1), overtemperature (OVERT1), and channel 2 alert (ALERT2) that contain programmable thresholds set independently by each of the SMBus serial

ports (SMBus1 and SMBus2). Each alert output asserts

when any of four temperature conditions is violated:

local overtemperature, remote overtemperature, local

undertemperature, or remote undertemperature. The

overtemperature signal asserts when the temperature

rises above the value in the overtemperature limit register. Use the OVERT1 output to activate a cooling fan or

trigger a system shutdown.

Each of the 2-wire serial-interface ports accepts standard System Management Bus (SMBus) write byte, read

byte, send byte, and receive byte commands independently of one another with total collision avoidance handled by the MAX6638. Each SMBus can operate its own

unique serial-data rate to access any register in the

MAX6638 for data reads or data writes. The MAX6638

manages all dual-port data register access functions

providing a seamless, conflict-free integration into a

multimaster architecture for thermal management.

The MAX6638 performs measurements autonomously,

at the programmed conversion rate, or in a single-conversion mode. Each SMBus port can set the conversion

rate with the higher conversion and update rate dominating the average power-supply current. Single-conversion requests have a maximum delay of two

conversion cycles with channel-conversion management and cycling regulated by the dual-port controller.

The MAX6638 operating temperature range is -40°C to

+125°C and measures temperatures between 0°C and

+145°C. The MAX6638 is available in a 16-pin, 4mm x

4mm TQFN with exposed paddle package.

Applications

Graphics Cards

Notebook Computers

Computer Motherboard Systems

Desktop Computers

Workstations

Features

♦ Two Independent SMBus/I2C-Compatible

Interfaces with Collision Avoidance

♦ High Accuracy

±1.0°C from +85°C to +100°C (Remote)

♦ Remote and Local Temperature Measurements

♦ Three Programmable Output Alarms: ALERT1,

OVERT1, and ALERT2

♦ Programmable Conversion Rates

♦ 11-Bit Low-Noise Integrating ADC

♦ No Calibration Required

♦ Autoscan Conversions

MAX6638

Temperature Monitor with

Dual Serial Interface

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-3895; Rev 1; 1/06

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

PART

TEMP

RANGE

PINPACKAGE

PKG

CODE

MAX6638ATE+

16 TQFN-EP*

(4mm x 4mm)

T1644-4

SMBus is a trademark of Intel Corporation.

Typical Operating Circuit appears at end of data sheet.

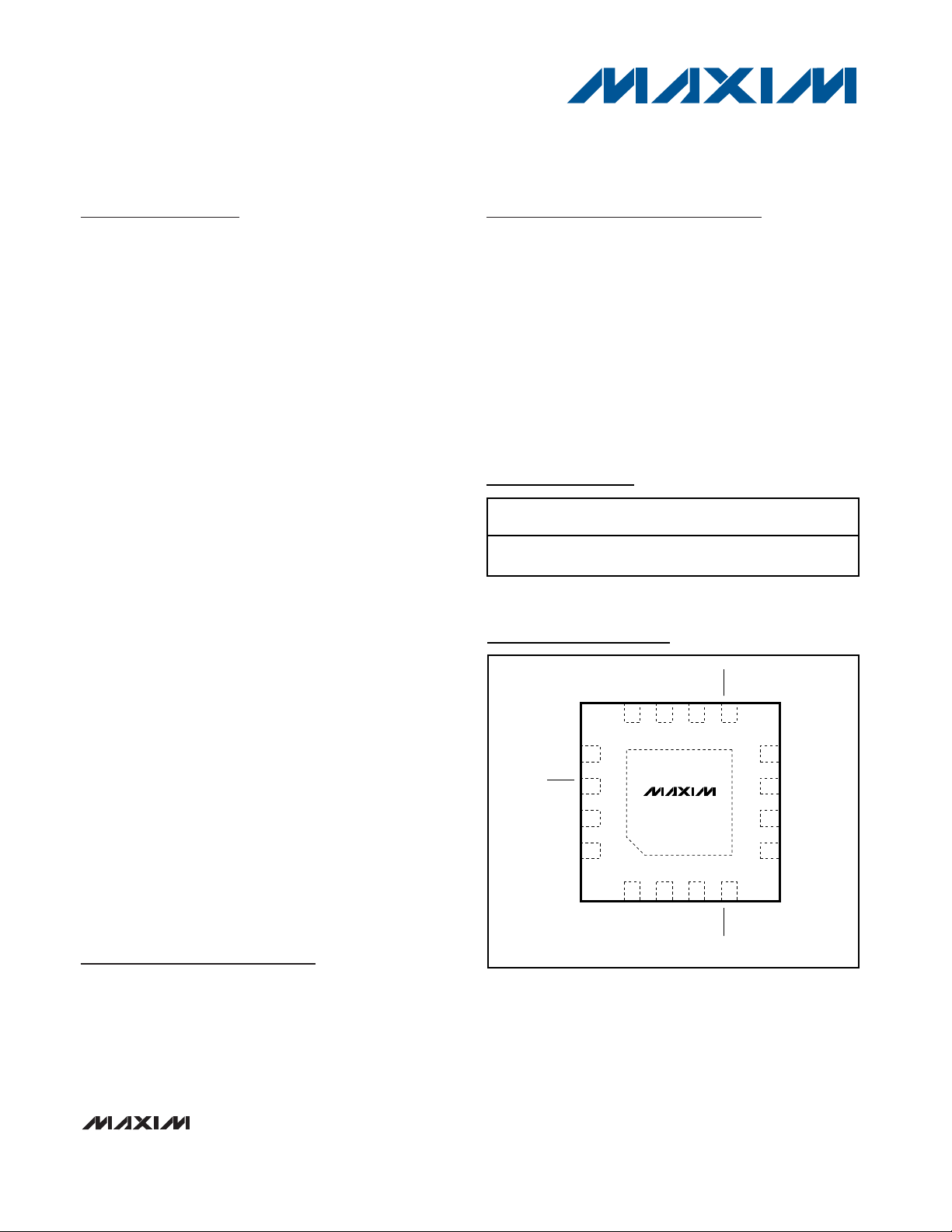

15

16

14

13

6

5

7

DXP

8

V

CC

SCK1

N.C.

12 4

12 11 9

SDA2

SCK2

GND

N.C.

I.C.

N.C.

MAX6638

DXN SDA1

3

10

N.C.

TQFN-EP

TOP VIEW

OVERT1 ALERT1

ALERT2

+

Pin Configuration

*EP = Exposed paddle.

+Denotes lead-free package.

-40°C to +125°C

Page 2

MAX6638

Temperature Monitor with

Dual Serial Interface

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC= 3.0V to 5.5V, TA= -40°C to +125°C, unless otherwise noted. Typical values are at VCC= 3.3V and TA= +85°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

(All voltages referenced to GND, unless otherwise noted.)

V

CC ....................................................................................

-0.3V to +6.0V

DXP.............................................................-0.3V to (V

CC

+ 0.3V)

DXN .......................................................................-0.3V to +0.8V

SCK1, SDA1, SCK2, SDA2, ALERT1,

OVERT1, ALERT2 .....................................................-0.3V to +6V

SDA1, SDA2, ALERT1, OVERT1, ALERT2 ..........-1mA to +50mA

DXN Current .......................................................................±1mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin TQFN (derate 16.9 mW/°C above +70°C) ....1349 mW

ESD Protection (all pins, Human Body Model) ................±2000V

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Supply Voltage V

Operating Current

Standby Supply Current SMBus1 and SMBus2 static 3 10 µA

TEMPERATURE MEASUREMENT

Remote Diode-Source Current I

Remote Temperature Error

Local Temperature Error

Supply Sensitivity of Temperature

Error

POWER-ON RESET

Power-On-Reset Threshold VCC falling 1.9 V

POR Threshold Hysteresis 90 mV

Undervoltage-Lockout Threshold VCC falling 2.30 2.60 2.95 V

Undervoltage-Lockout Hysteresis 90 mV

ANALOG-TO-DIGITAL CONVERTER

Conversion Time

ALERT1, OVERT1, ALERT2, SDA1, SDA2

Output Low Voltage V

Leakage Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

RJ

OL

LEAK

During conversion 600 950

ADC not converting 80

High level 80 100 120

Low level 8 10 12

VCC = 3.3V, TA = +85°C to +100°C,

T

= +85°C to +145°C

RJ

VCC = 3.3V, TA = +25°C to +100°C,

T

= +25°C to +145°C

RJ

= 3.3V, TA = +0°C to +125°C,

V

CC

T

= 0°C to +145°C

RJ

VCC = 3.3V, TA = +25°C to +85°C -2.0 +2.0

= 3.3V, TA = 0°C to +125°C -3.5 +3.5

V

CC

Nonoverlapping single conversion from

stop bit to conversion complete

IOL = 6mA 0.6 V

VOH = 5.5V ±1 µA

3.0 5.5 V

-1.0 +1.0

-2.0 +2.0

-3.0 +3.0

±0.2 °C/V

23 32 39 ms

µA

µA

°C

°C

Page 3

MAX6638

Temperature Monitor with

Dual Serial Interface

_______________________________________________________________________________________ 3

Note 1: All parameters are tested at a single temperature. Specifications over temperature are guaranteed by design.

Note 2: Timing specifications are guaranteed by design.

Note 3: Each serial interface resets when its SCK_ is low for more than t

TIMEOUT

.

Note 4: A transition must internally provide at least a hold time to bridge the unidentified region (300ns max) of SCK_’s falling edge.

ELECTRICAL CHARACTERISTICS (continued)

(VCC= 3.0V to 5.5V, TA= -40°C to +125°C, unless otherwise noted. Typical values are at VCC= 3.3V and TA= +85°C.) (Note 1)

SMBus INTERFACE (SCK1, SCK2, SDA1, SDA2)

Logic Input Low Voltage V

Logic Input High Voltage V

Input Leakage Current I

Input Capacitance C

SMBus-COMPATIBLE TIMING (Figure 5) (Note 2)

Serial-Clock Frequency f

Bus Free Time Between STOP and

START Condition

START Condition Setup Time 4.7 µs

Rep eat S TART C ond i ti on S etup Ti m et

START Condition Hold Time t

STOP Condition Setup Time t

Clock Low Period t

Clock High Period t

Data Setup Time t

Data Hold Time t

SMBus Rise Time t

SMBus Fall Time t

SMBus Timeout t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IL

IH

LEAK

IN

SCK

t

BUF

SU:STA

HD:STA

SU:STO

LOW

HIGH

SU:DAT

HD:DAT

R

F

TIMEOUT

2.1 V

VIN = GND or V

(Note 3) 100 kHz

90% of SCK_ to 90% of SDA_ 50 ns

10% of SDA_ to 90% of SCK_ 4 µs

90% of SCK_ to 90% of SDA_ 4 µs

10% to 10% 4.7 µs

90% to 90% 4.0 µs

(Note 4) 300 ns

SDA_ low period for interface reset 30 45 60 ms

CC

5pF

4.7 µs

250 ns

0.8 V

±1 µA

1µs

300 ns

Page 4

MAX6638

Temperature Monitor with

Dual Serial Interface

4 _______________________________________________________________________________________

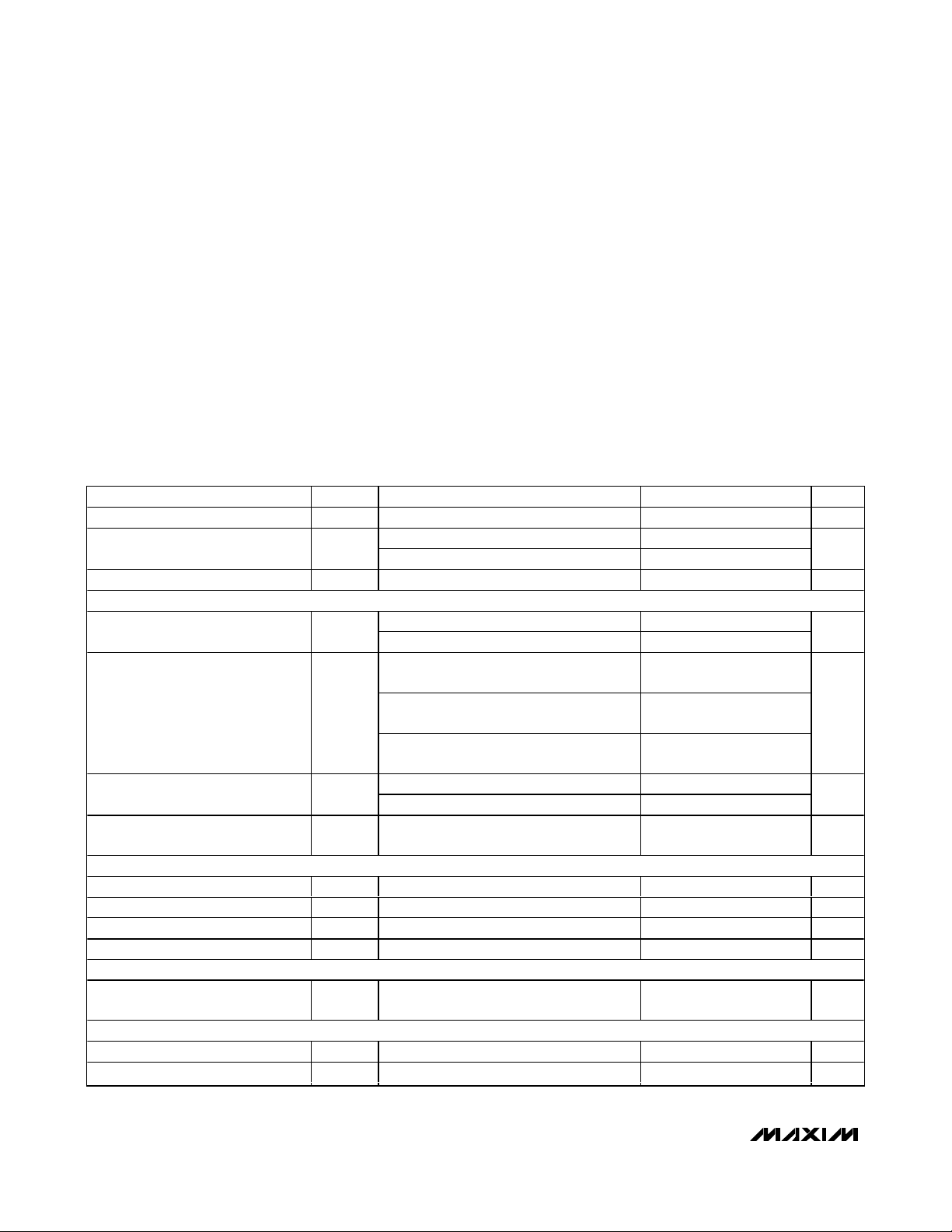

Typical Operating Characteristics

(VCC= 3.3V, TA= +25°C, unless otherwise noted.)

STANDBY SUPPLY CURRENT

vs. SUPPLY VOLTAGE

7

6

5

4

3

SUPPLY CURRENT (µA)

2

1

0

TA = +85°C

3.0 5.5

SUPPLY VOLTAGE (V)

REMOTE TEMPERATURE ERROR

vs. REMOTE DIODE TEMPERATURE

0.8

0.6

0.4

0.2

0

-0.2

-0.4

REMOTE TEMPERATURE ERROR (°C)

-0.6

-0.8

0406020

REMOTE DIODE TEMPERATURE (°C)

TA = +25°C

TA = -40°C

100 120 140

80

AVERAGE SUPPLY CURRENT

vs. CONVERSION RATE

600

500

MAX6638 toc01

400

300

200

SUPPLY CURRENT (µA)

100

0

5.04.54.03.5

020

CONVERSION RATE (Hz)

15105

MAX6638 toc02

SUPPLY CURRENT (µA)

LOCAL TEMPERATURE ERROR

vs. DIE TEMPERATURE

0

MAX6638 toc04

-0.5

-1.0

-1.5

-2.0

LOCAL TEMPERATURE ERROR (°C)

-2.5

-3.0

0608020 40 100 120 140

DIE TEMPERATURE (°C)

MAX6638 toc05

OPERATING SUPPLY CURRENT

vs. SUPPLY VOLTAGE

700

TA = +85°C

650

600

550

500

450

400

3.0 5.5

TA = -40°C

SUPPLY VOLTAGE (V)

TA = +25°C

5.04.54.03.5

TEMPERATURE ERROR

vs. POWER-SUPPLY NOISE FREQUENCY

6

LOCAL

4

2

TEMPERATURE ERROR (°C)

0

-2

0.01 100.1 1 100 1,000 10,000

POWER-SUPPLY NOISE FREQUENCY (kHz)

REMOTE

MAX6638 toc03

MAX6638 toc06

LOCAL TEMPERATURE ERROR

vs. COMMON-MODE NOISE FREQUENCY

0

-1

-2

-3

-4

LOCAL TEMPERATURE ERROR (°C)

-5

-6

0.01 1 100.1 100 1,000 10,000

COMMON-MODE NOISE FREQUENCY (kHz)

MAX6638 toc07

REMOTE TEMPERATURE ERROR

vs. DXP-DXN CAPACITANCE

2

0

-2

-4

-6

REMOTE TEMPERATURE ERROR (°C)

-8

0.01 10.1 10 100

DXP-DXN CAPACITANCE (nF)

MAX6638 toc08

Page 5

Detailed Description

The MAX6638 temperature monitor features dual-port

SMBus access for use in thermal management of

graphics processing unit (GPU) and CPU systems.

Each of the two SMBus serial ports can be accessed

independently by two thermal-monitoring systems with

all dual-port collision-avoidance logic controlled by the

MAX6638. Each SMBus thermal-monitoring channel

(channels 1 and 2) has a corresponding over/undertemperature ALERT_ open-drain output with independently configurable limit registers. Channel 1 includes

an overtemperature indicator (OVERT1) with an initial

set-point limit that is always activated after a power-on

reset (POR). The initial OVERT1 set point can be overwritten after POR by SMBus1 serial programming. The

overtemperature alarm OVERT1 asserts if the set-point

limit is exceeded.

ADC and Multiplexer

The MAX6638 converts temperatures to digital data

either at a programmed rate or in single conversions.

Either SMBus controller can set the programmed rate

with the higher rate setting taking precedence. The

MAX6638 begins conversions at the maximum rate

after POR to provide the OVERT1 output signal assertion for temperatures exceeding the set-point limit. The

temperature conversion results of the two temperature

channels are in integer format. The MSBs of the temperature data are in 8-bit registers (addresses 00h and

01h; see Table 1) that represent the data as 8 bits with

the full-scale reading to indicate a diode fault. The

remaining 3 bits of temperature data are available in

the extended data-registers format with the LSB equal

to +0.125°C (addresses 11h and 10h; see Table 2).

The converted readings are stored in SMBus reading

registers along with the limit-value registers and other

control functions.

MAX6638

Temperature Monitor with

Dual Serial Interface

_______________________________________________________________________________________ 5

Pin Description

Table 1. Temperature Data Format

(RLTS1, RRTS1, RLTS2, RRTS2)

PIN NAME FUNCTION

1V

2 DXP

3DXN

4 OVERT1 Digital Open-Drain Output. OVERT1 indicates an overtemperature condition on channel 1.

5, 7, 12, 13 N.C. No Connection. Not connected internally.

6 I.C. Internally Connected. I.C. must be connected to GND.

8 GND Power-Supply Ground

9 ALERT1 Digital Open-Drain Output. ALERT1 indicates alert condition on channel 1.

10 SDA1 SMBus Data Channel 1. Open-drain output.

11 SCK1 SMBus Clock Channel 1

14 ALERT2 Digital Open-Drain Output. ALERT2 indicates alert condition on channel 2.

15 SDA2 SMBus Data Channel 2. Open-drain output.

16 SCK2 SMBus Clock Channel 2

EP GND Ground. Connect to ground.

CC

Supply Voltage. Bypass VCC to GND with a 0.1µF capacitor. A 47Ω series resistor is recommended for

additional noise filtering, but not required.

Combined Current Source and ADC Positive Input for Remote Diode. If a remote-sensing junction is not

used, connect DXP to DXN.

Combined Current Sink and ADC Negative Input for Remote Diode. DXN is internally biased to a diode

voltage above ground.

TEMPERATURE

(°C)

+145 91 1001 0001

+130 82 1000 0010

+128 80 1000 0000

+25 19 0001 1001

0 00 0000 0000

< 0 00 0000 0000

Diode fault FF 1111 1111

DIGITAL OUTPUT

(hex)

DIGITAL OUTPUT

(bin)

Page 6

MAX6638

Temperature Monitor with

Dual Serial Interface

6 _______________________________________________________________________________________

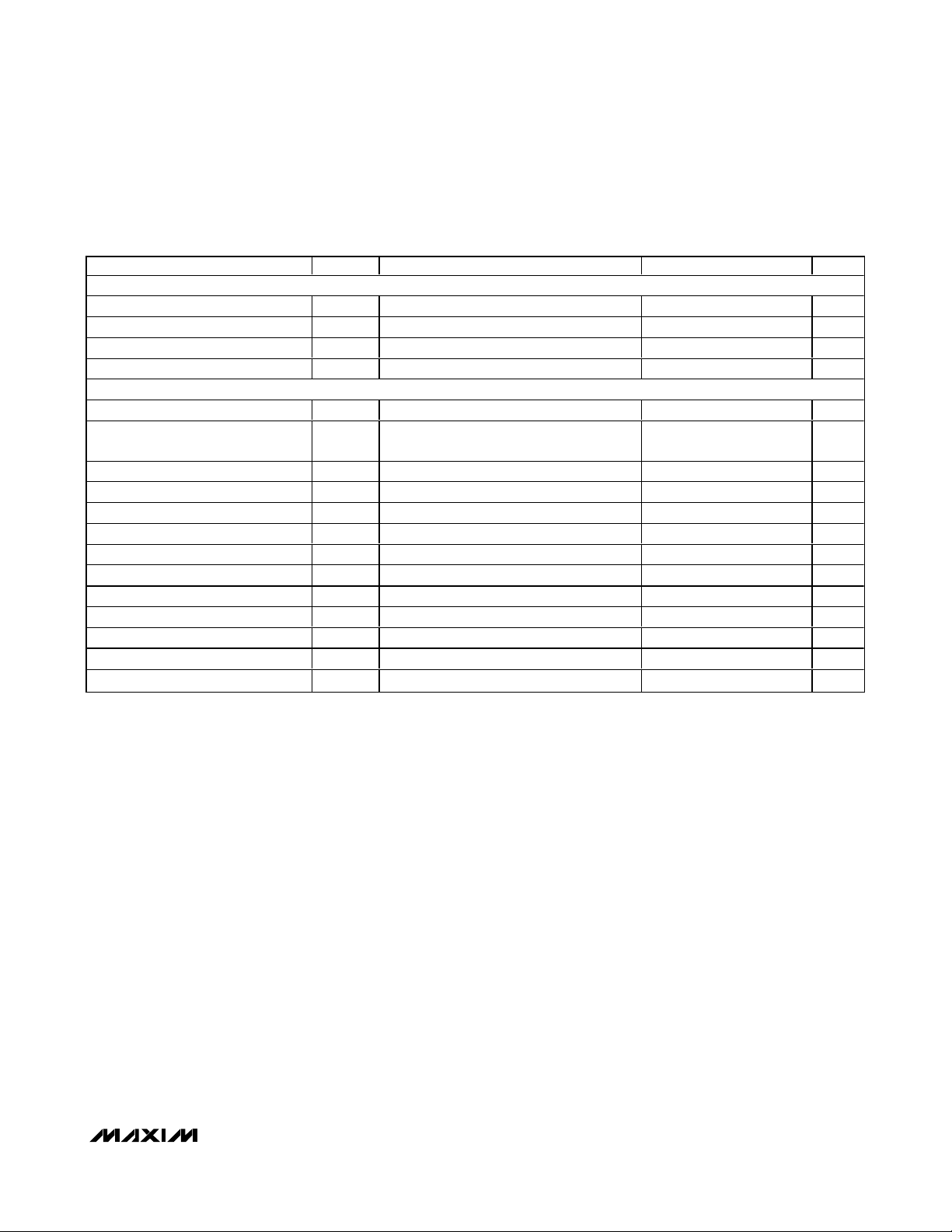

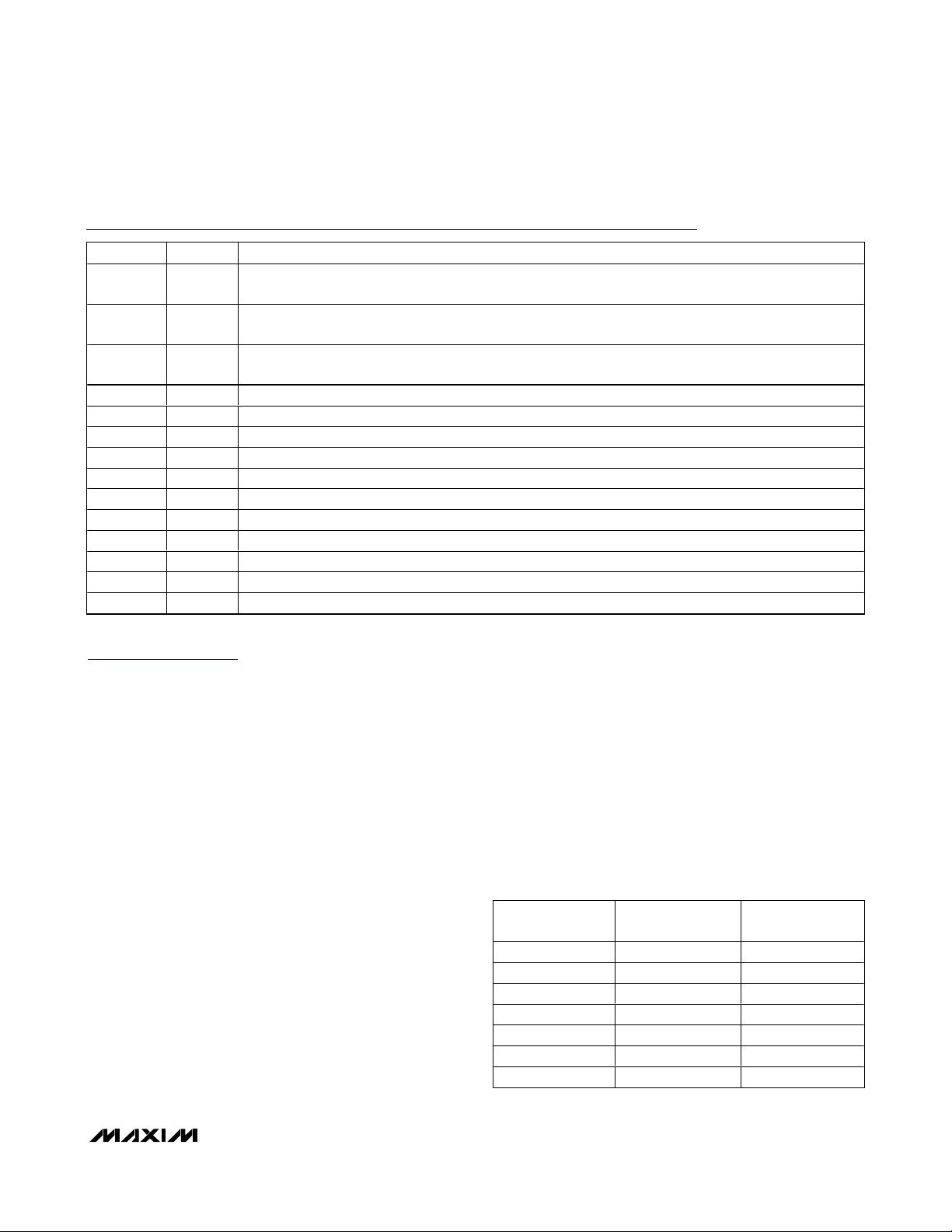

Functional Diagram

V

CC

DXP

DXN

ALERT1

OVERT1

ALERT2

S

Q

R

S

Q

R

S

Q

R

MAX6638

MUX

REMOTE

LOCAL

ADC

REGISTER BANK1

COMMAND BYTE

REMOTE TEMPERATURE

LOCAL TEMPERATURE

ALERT THRESHOLD

ALERT-RESPONSE ADDRESS

OVERT THRESHOLD

REGISTER BANK2

COMMAND BYTE

REMOTE TEMPERATURE

LOCAL TEMPERATURE

CONTROL

LOGIC

SMBus

8

READ

8

WRITE

7

ADDRESS

DECODER

SMBus

8

READ

8

WRITE

7

ADDRESS

DECODER

SDA1

SCK1

SDA2

SCK2

ALERT THRESHOLD

ALERT-RESPONSE ADDRESS

Page 7

The averaging ADC integrates over a 16ms period

(each channel, typical) with excellent noise rejection.

The multiplexer automatically steers bias currents

through the remote and local diodes. The ADC and

associated circuitry measure each diode’s forward voltage and compute the temperature based on this voltage. Both temperature sensors automatically convert

once the conversion process starts, either in free-running (RUN = 0) or single-shot mode. A BUSY status bit

in the status byte indicates that the device is performing

a new conversion. The results of the previous conversion are always available even when the ADC is busy. If

one of the two temperature sensors is not used, the

MAX6638 still performs both measurements and ignores

the results of the unused channel. When not using the

remote-diode temperature sensor, connect DXP to DXN.

The DXP-DXN differential input voltage range is 0.25V to

0.95V. Excess resistance in series with the remote diode

causes a +0.5°C (typ) error per ohm.

The MAX6638 initiates conversion cycling after POR,

after exiting standby mode from either SMBus channel,

and upon one-shot request from either SMBus channel.

One conversion cycle consists of two ADC conversions

(one for the local temperature, one for the remote temperature), a diagnostic check on the remote temperature sensor, loading of data into the read registers,

setting diagnostic flags, and setting ALERT1, ALERT2,

and OVERT1, as required. Figure 1 shows the simplified

timing sequence.

MAX6638

Temperature Monitor with

Dual Serial Interface

_______________________________________________________________________________________ 7

Table 2. Extended Temperature Data

(RLET1, RRET1, RLET2, RRET2)

Figure 1. One Complete ADC Conversion Cycle

Figure 2. Repeating ADC Conversion Cycles for Various Conversion Rate Settings

FRACTIONAL

TEMPERATURE (°C)

0.000 000X XXXX

0.125 001X XXXX

0.250 010X XXXX

0.375 011X XXXX

0.500 100X XXXX

0.675 101X XXXX

0.750 110X XXXX

0.875 111X XXXX

DIGITAL OUTPUT (bin)

ONE CONVERSION CYCLE

ADC LOCAL TEMPERATURE ADC AND DIAGNOSTIC REMOTE TEMPERATURE

START CONVERSION UPDATE REGISTERS DATA AVAILABLE TIME

START

CRCn

CONVERSION

06h

05h

04h

03h

02h

250 500 750 1000 1250 1500 1750 2000

ONE CONVERSION CYCLE

TIME (ms)

Page 8

MAX6638

The MAX6638 allows conversion rates that are 2x multiples of the minimum rate of 0.0625Hz. Figure 2 shows

several different conversion rate settings.

The ADC converts at the higher rate of the two conversions set by SMBus1 and SMBus2 controllers. The controller that sets the higher rate receives a new

conversion at the higher conversion-rate time. The controller that sets the lower rate receives the most recent

conversion result at the lower conversion-rate timing.

Figure 3 shows an example of this. SMBus1 initiates the

ADC converter by selecting conversion rate 06h (4Hz)

prior to SMBus2 initiating a conversion. Then SMBus2

initiates conversions of 05h (2Hz) independent of the

process initiated by SMBus1. The controller accesses

data at its programmed time set by the initiated conversion time. The data presented to SMBus2 is always

ready at the anticipated time, but the data is actually

the result of a previous conversion sequence driven by

the higher conversion rate set by SMBus1.

The first SMBus channel that activates a conversion

sequence always establishes the MAX6638 conversion

cycling. The ADC conversion rates increase and

decrease as set by each of the SMBus controllers with

the higher conversion rate always dominating.

Increasing the conversion rate with the ADC cycling

increases the rate the MAX6638 performs cycles without losing sync of the previously established cycle timing. A decrease in conversion rate reduces the ADC

cycling to the lower rate without losing sync with the

previously set cycle pattern. The ADC cycling pattern is

only reset following a POR event or upon exiting the

standby mode through one of the SMBus controllers’

initiation of cycling or single-shot conversion.

Low-Power Standby Mode

Standby mode reduces the supply current to 3µA (typ)

by disabling the ADC and timing circuitry when both

SMBus controller channels enable standby mode.

Standby mode is enabled only when both SMBus controllers request standby mode. Set each of the RUN bits

to 1 in each corresponding configuration register (see

Tables 3 and 5) to enter standby mode. When one

SMBus controller channel is set to standby mode, the

other conversion rate is automatically set to the active

channel’s conversion rate and mode. The MAX6638

retains all data in the registers and each SMBus interface is active and listening for SMBus commands.

Standby mode is not a shutdown mode. With activity on

either SMBus, the device draws more supply current

(see the Typical Operating Characteristics). In standby

mode, the MAX6638 performs an ADC conversion

sequence through the one-shot command, regardless

of either of the RUN bit statuses, upon receipt of a oneshot command from either SMBus controller.

If the device receives standby commands from both

SMBus controllers during a conversion, the conversion

cycle truncates, and the data from that conversion is

not latched into a temperature register. The previous

data does not change and remains available.

Supply current drawn during the 32ms conversion period

is 800µA (typ). Slowing down the conversion rate reduces

the average supply current (see the Typical Operating

Characteristics). Between conversions, the conversion

rate timer consumes 40µA (typ) of supply current.

SMBus Interface

From a software perspective, the MAX6638 appears as a

set of byte-wide registers that contain temperature data,

Temperature Monitor with

Dual Serial Interface

8 _______________________________________________________________________________________

Figure 3. An Example of ADC Cycling for Two Conversion Rates Set by Each Controllers on SMBus1 and SMBus2

SMBus1 START

CONVERSION

SMBus1 CRC1 = 06h

SMBus2 CRC2 = 05h

ACTUAL DATA

READY FROM

ADC CONVERSIONS

ACTUAL DATA READ

BY SMBus2

CYCLE CYCLE CYCLE CYCLE CYCLE CYCLE CYCLE CYCLE CYCLE

250 500 750 1000 1250 1500 1750 2000

SMBus1 DATA AVAILABLE

CYCLE CYCLE CYCLE CYCLE

SMBus2 START

CONVERSION

SHADED BOXES INDICATE EXPECTED ADC CONVERSION CYCLING AND DATA READINGS OF SMBus2 FROM START CONVERSION

TIME

(ms)

Page 9

threshold limit values, and control. A standard SMBus

2-wire serial interface is used to read temperature data,

write control bits, and set threshold data. The MAX6638

employs four standard SMBus protocols: write byte, read

byte, send byte, and receive byte (Figure 4).

Read the temperature data from the read internal temperature (00h) and read external temperature (01h)

registers of each SMBus channel. The temperature

data format for these registers is 8 bits for each temperature-sensor channel, with the LSB representing 1°C

(Table 1). The temperature data transmits MSB first.

The external extended-temperature register (10h) provides additional 3 bits, extending the data to 11 bits

and the resolution to 0.125°C per LSB (Table 2).

The main temperature register and the extended temperature registers update simultaneously upon completion

of a conversion. To ensure the registers contain the

results of the same conversion of the main temperature

data (MSBs) and the extended temperature data (LSBs),

read the data before a new conversion completes.

Alarm-Threshold Registers

Four registers store ALERT threshold values: one high

temperature (THIGH_) and one low temperature

(TLOW_) limit register each for the local and remote

temperature sensors. If either measured temperature

equals or exceeds the corresponding ALERT_ threshold value, the ALERT_ output asserts.

The MAX6638 local ALERT_ THIGH_ register POR state

is 0101 0101, which corresponds to +85°C, while the

remote ALERT_ THIGH_ register POR state is 0101

1111, which corresponds to +95°C. The POR state of

the local and remote TLOW_ registers for all devices is

0000 0000, corresponding to 0°C.

Two additional registers store remote and local alarm

threshold data corresponding to the OVERT1 output

accessible only through SMBus1. The MAX6638 stores

high-temperature thresholds in these registers. If either

of the measured temperatures equals or exceeds the

corresponding alarm threshold value, the OVERT1 out-

put asserts. The MAX6638 local OVERT1 register POR

state is 0101 0101, corresponding to +85°C, while the

remote OVERT1 register POR state is 0111 1101, corre-

sponding to +125°C.

Diode Fault

A continuity fault detector at DXP detects an open circuit between DXP and DXN, or a DXP short to VCC,

MAX6638

Temperature Monitor with

Dual Serial Interface

_______________________________________________________________________________________ 9

Write Byte Format

Read Byte Format

Send Byte Format

Receive Byte Format

Slave Address: equivalent to chip-select line of

a 3-wire interface

Command Byte: selects to

which register you are writing

Data Byte: data goes into the register

set by the command byte (to set

thresholds, configuration masks, and

sampling rate)

Slave Address: equivalent to chip-select line

Command Byte: selects

from which register you

are reading

Slave Address: repeated

due to change in dataflow direction

Data Byte: reads from

the register set by the

command byte

Command Byte: sends command with no data, usually

used for one-shot command

Data Byte: reads data from

the register commanded

by the last read byte or

write byte transmission;

also used for SMBus alert

response return address

S = Start condition Shaded = Slave transmission

P = Stop condition /// = Not acknowledged

S ADDRESS WR ACK COMMAND

7 bits 8 bits

ACK DATA

8 bits

ACK P

1

S ADDRESS WR ACK COMMAND ACK S ADDRESS RD ACK DATA /// P

8 bits7 bits8 bits7 bits

S ADDRESS WR ACK COMMAND ACK P

7 bits 8 bits

S ADDRESS RD ACK DATA /// P

8 bits7 bits

Figure 4. SMBus Protocols

Page 10

MAX6638

GND, or DXN. If an open or short exists, each of the

external temperature registers contains 1111 1111.

When an open-circuit fault occurs, bit 2 (OPEN) in the

status byte sets to 1. If a fault is present upon powerup, the fault is not indicated until the end of the first

conversion cycle.

ALERT_

Interrupts

The ALERT_ interrupt occurs when the internal or exter-

nal temperature reading exceeds a high- or low-temperature limit (programmed). The ALERT_ output signal

latches and can only clear by either reading the status

register or by successfully responding to an alertresponse address. In both cases, the alert clears if the

temperature fault condition no longer exists. Asserting

ALERT_ does not halt automatic conversion. The open-

drain ALERT_ outputs allow multiple devices to share a

common interrupt line.

The MAX6638 responds to the SMBus alert-response

address, an interrupt pointer return-address feature.

Prior to taking corrective action, always check to ensure

that an interrupt is valid by reading the current temperature.

Alert Fault-Queue Register

In some systems, it is desirable to ignore a single temperature measurement that falls outside the ALERT_

limits. Bits 1 and 2 of the fault queue register (address

22h) determine the number of consecutive temperature

faults necessary to set ALERT_.

Alert-Response Address

The SMBus alert-response interrupt pointer provides

quick fault identification for simple slave devices that

Temperature Monitor with

Dual Serial Interface

10 ______________________________________________________________________________________

Figure 5. SMBus Write Timing Diagram

Figure 6. SMBus Read Timing Diagram

AB CDEFG

t

LOW

SMBCLK

SMBDATA

t

SU:STAtHD:STA

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

AB CDEFG HIJ

t

SMBCLK

SMBDATA

t

t

HD:STA

SU:STA

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SMBDATA LINE LOW

t

HIGH

LOWtHIGH

t

SU:DAT

E = SLAVE PULLS SMBDATA LINE LOW

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO SLAVE

H = LSB OF DATA CLOCKED INTO SLAVE

t

SU:DAT

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO MASTER

H = LSB OF DATA CLOCKED INTO MASTER

I = MASTER PULLS DATA LINE LOW

t

HD:DAT

HIJ

I = MASTER PULLS DATA LINE LOW

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

K

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

t

SU:STOtBUF

L

t

SU:STO

LMK

M

t

BUF

Page 11

lack the complex logic needed to be a bus master.

Upon receiving an ALERT_ interrupt signal, the host

master can broadcast a receive-byte transmission to

the alert-response slave address (0001 100). Following

such a broadcast, any slave device generating an

interrupt attempts to identify itself by putting its own

address on the bus.

The alert response can activate several different slave

devices simultaneously. If more than one slave

attempts to respond, bus arbitration rules apply, and

the device with the lower address code wins. The losing device does not generate an acknowledge

response and continues to hold the ALERT_ line low

until cleared. Successful completion of the read alertresponse protocol clears the interrupt latch, provided

the condition that caused the alert no longer exists.

Overtemperature Limit Output

OVERT1 asserts when the temperature rises to a value

stored in one of the OVERT1 limit registers (19h and

20h). It deasserts when the temperature drops below

the stored limit, minus hysteresis. OVERT1 can be used

to activate a cooling fan, send a warning, invoke clock

throttling, or trigger a system shutdown to prevent component damage.

Command-Byte Functions

The 8-bit command-byte register (Table 3) is the master index that points to the various other registers within

the MAX6638. The register’s POR state is 0000 0000,

so a receive-byte transmission (a protocol that lacks

the command byte) that occurs immediately after POR

returns the current local-temperature data.

One-Shot Conversion Cycle

The one-shot command immediately forces a new conversion cycle to begin. If the MAX6638 receives a oneshot command while the MAX6638 is in standby mode

(RUN = 1), a new conversion begins, after which the

device returns to standby mode. If during a conversion

the MAX6638 receives a one-shot command, the

MAX6638 ignores the command; however, the results of

the conversion in progress update the data registers

accordingly.

Configuration-Byte Functions

The configuration-byte register (Tables 3 and 5) is a

read-write register with several functions. Bit 7 masks

interrupts. Bit 6 puts the MAX6638 into a standby (STOP)

mode or autonomous (RUN) mode. The MAX6638 enters

standby mode when both SMBus controllers set the corresponding configuration bits.

Status-Byte Functions

The status-byte register (Tables 3 and 4) indicates

when any temperature threshold is exceeded. This byte

also indicates whether the ADC is converting and if

there is a fault detected in the external sense diode.

After POR, the state of the flag bits are zero, assuming

no alarm conditions are present. The status byte clears

with any successful read of the status byte, after completion of a conversion and if the fault condition no

longer exists. Note that the ALERT_ interrupt latch does

not automatically clear when the status-flag bit indicating the ALERT_ clears.

Registers

The internal registers of the MAX6638 are all 8-bit data

word width and are all accessible through SMBus by

read and write operations.

MAX6638

Temperature Monitor with

Dual Serial Interface

______________________________________________________________________________________ 11

Page 12

MAX6638

Temperature Monitor with

Dual Serial Interface

12 ______________________________________________________________________________________

Table 3. SMBus1 Registers and Command-Byte Bit Assignments

R EG .

A D D R ESS

00h Read Local Tem p S ensor RLTS 1 7 6 5 4 3 2 1 0 00h

01h Read Rem ote Tem p S ensor RRTS 1 7 6 5 4 3 2 1 0 00h

02h Read S tatus Byte RS 1BU S Y LH IGH LLO WRH IGH RLO WFAU LT E OT IOT 00h

03h Read C onfi g ur ati on Byte RC 1M AS K RUN RFU RFU RFU RFU RFU RFU 00h

04h Read C onver si on- Rate Byte RC R17654321000h

05h Read Local ALE RT1 H i g h Li m i tRLAH 1 7 6 5 4 3 2 1 0 55h

06h Read Local ALE RT1 Low Li m i t RLAL1 7 6 5 4 3 2 1 0 00h

07h Read Rem ote ALERT1 H ig h Li m i t RRAH 1 7 6 5 4 3 2 1 0 55h

08h Read Rem ote ALERT1 Low Lim i t RRAL1 7 6 5 4 3 2 1 0 00h

09h Wr i te C onfi g ur ati on Byte WC 1 7 6 5 4 3 2 1 0 00h

0Ah Wr i te C onver si on- Rate Byte WC R17654321008h

0Bh Wr i te Local Al er t- H i g h Li m i tWLAH 1 7 6 5 4 3 2 1 0 55h

0C hWr i te Local Al er t- Low Li m i t WLAL1 7 6 5 4 3 2 1 0 00h

0D hWr i te Rem ote Al er t- H i g h Li m i tWRAH 1 7 6 5 4 3 2 1 0 5Fh

0E hWr i te Rem ote Al er t- Low Li m i tWRAL17654321000

0Fh One- S hot C onver si on OS C 17 6 5 4 3 2 1 0 —

10h Read Local - E xtend ed Tem p RLE T1 7 6 5 4 3 2 1 0 00h

11h Read Rem ote- E xtend ed Tem p RRE T1 7 6 5 4 3 2 1 0 00h

19h Read/Wri te Rem ote OVERT1 Limi tRWRO1765432107D h

20h Read /Wr i te Local OVE RT1 Li m i tRWLO17654321055h

21h Over tem p er atur e H yster esi sH Y S 17 6 5 4 3 2 1 00Ah

22h Wr i te Faul t Queue WFQ 1 7 6 5 4 3 2 1 0 80h

FE hRead M anufactur er ID RM ID 765432104D h

FFh Read D evi ce ID RD ID 7654321078h

R EG IST ER NA M EA B B R .

7 6 5 4 3 2 1 0

B IT

PO R

VA L U E

Page 13

MAX6638

Temperature Monitor with

Dual Serial Interface

______________________________________________________________________________________ 13

Table 4. Read Status-Byte (RS1) Bit Assignments (02h)

Table 5. Read Configuration-Byte (RC1) Bit Assignments (03h)

Table 6. Conversion-Rate Control-Byte

(RCR1 and WCR1) Bit Assignments

(04h and 0Ah)

BIT NAME POR STATE FUNCTION

7 BUSY 0 ADC is busy converting when 1.

6 LHIGH 0

5 LLOW 0

4 RHIGH 0

3 RLOW 0

2 OPEN 0

1 EOT 0 A 1 indicates the remote temperature exceeds the external OVERT1 threshold.

0 IOT 0 A 1 indicates the local temperature exceeds the external OVERT1 threshold.

Local High-Temperature Alarm. A 1 indicates a local high-temperature fault. Clears with a

POR or readout of the status byte if the fault condition no longer exists.

Local Low-Temperature Alarm. A 1 indicates a local low-temperature fault. Clears with a POR

or readout of the status byte if the fault condition no longer exists.

Remote High-Temperature Alarm. A 1 indicates a remote high-temperature fault. Clears with

a POR or readout of the status byte if the fault condition no longer exists.

Remote Low-Temperature Alarm. A 1 indicates a remote low-temperature fault. Clears with a

POR or readout of the status byte if the fault condition no longer exists.

A 1 indicates DXN and DXP are open. Clears with a POR or readout of the status byte if the

open condition no longer exists.

BIT NAME POR STATE FUNCTION

7 MASK 0 Masks ALERT1 interrupts when set to 1.

6 RUN 0

5–0 RFU 0 Reserved for future use.

Standby-Mode Control Bit. If set to 1, standby mode enables and enters if the standby-mode

control bit (RUN) for channel 2 is also set.

BIT DATA CONVERSION RATE (Hz)

7–0 00h 0.0625

7–0 01h 0.125

7–0 02h 0.25

7–0 03h 0.5

7–0 04h 1

7–0 05h 2

7–0 06h 4

7–0 07h 8

7–0 08h 16

7–0 09–FFh Reserved

Page 14

MAX6638

Temperature Monitor with

Dual Serial Interface

14 ______________________________________________________________________________________

Table 7. SMBus2 Registers and Command-Byte Bit Assignments

R EG .

A D D R ESS

00h Read Local Tem p S ensor RLTS 2 7 6 5 4 3 2 1 0 00h

01h Read Rem ote Tem p S ensor RRTS 2 7 6 5 4 3 2 1 0 00h

02h Read S tatus Byte RS 2BU S Y LH IGH LLO WRH IGH RLO WFAU LT RFU RFU 00h

03h Read C onfi g ur ati on Byte RC 2M AS K RUN RFU RFU RFU RFU RFU RFU 00h

04h Read C onver si on- Rate Byte RC R27654321000h

05h Read Local ALE RT1 H i g h Li m i tRLAH 2 7 6 5 4 3 2 1 0 55h

06h Read Local ALE RT1 Low Li m i t RLAL2 7 6 5 4 3 2 1 0 00h

07h Read Rem ote ALERT1 H ig h Li m i t RRAH 2 7 6 5 4 3 2 1 0 5Fh

08h Read Rem ote ALERT1 Low Lim i t RRAL2 7 6 5 4 3 2 1 0 00h

09h Wr i te C onfi g ur ati on Byte WC 2 7 6 5 4 3 2 1 0 00h

0Ah Wr i te C onver si on Rate Byte WC R27654321008h

0Bh Wr i te Local Al er t- H i g h Li m i tWLAH 2 7 6 5 4 3 2 1 0 55h

0C hWr i te Local Al er t- Low Li m i t WLAL2 7 6 5 4 3 2 1 0 00h

0D hWr i te Rem ote Al er t- H i g h Li m i tWRAH 2 7 6 5 4 3 2 1 0 5Fh

0E hWr i te Rem ote Al er t- Low Li m i t WRAL2 7 6 5 4 3 2 1 0 00h

0Fh One- S hot C onver si on OS C 27 6 5 4 3 2 1 0 —

10h Read Local - E xtend ed Tem p RLE T2 7 6 5 4 3 2 1 0 00h

11h Read Rem ote- E xtend ed Tem p RRE T2 7 6 5 4 3 2 1 0 00h

19h Read/Wri te Rem ote OVERT1 Limi tRWRO2765432107D h

20h Read /Wr i te Local OVE RT1 Li m i tRWLO27654321055h

21h Over tem p er atur e H yster esi sH Y S 27 6 5 4 3 2 1 00Ah

22h Wr i te Faul t Queue WFQ 2 7 6 5 4 3 2 1 0 80h

FE hRead M anufactur er ID RM ID 765432104D h

FFh Read D evi ce ID RD ID 7654321078h

R EG IST ER NA M EA B B R .

7 6 5 4 3 2 1 0

B IT

PO R

VA L U E

Page 15

MAX6638

Temperature Monitor with

Dual Serial Interface

______________________________________________________________________________________ 15

Table 8. Read Status-Byte (RS2) Bit Assignments (02h)

Table 9. Read Configuration-Byte (RC2) Bit Assignments (03h)

Table 11. Slave Addresses

Table 10. Conversion-Rate Control-Byte

(RCR2 and WCR2) Bit Assignments

(04h and 0Ah)

BIT NAME POR STATE FUNCTION

7 BUSY 0 ADC is busy converting when 1.

6 LHIGH 0

5 LLOW 0

4 RHIGH 0

3 RLOW 0

2 OPEN 0

1 RFU 0 Reserved for future use.

0 RFU 0 Reserved for future use.

Local High-Temperature Alarm. A 1 indicates a local high-temperature fault. Clears with a

POR or readout of the status byte if the fault condition no longer exists.

Local Low-Temperature Alarm. A 1 indicates a local low-temperature fault. Clears with a POR

or readout of the status byte if the fault condition no longer exists.

Remote High-Temperature Alarm. A 1 indicates a remote high-temperature fault. Clears with

a POR or readout of the status byte if the fault condition no longer exists.

Remote Low-Temperature Alarm. A 1 indicates a remote low-temperature fault. Clears with a

POR or readout of the status byte if the fault condition no longer exists.

A 1 indicates DXN and DXP are open. Clears with a POR or a read of the status byte if the

open condition no longer exists.

BIT NAME POR STATE FUNCTION

7 MASK 0 Masks ALERT2 interrupts when set to 1.

6 RUN 0

5–0 RFU 0 Reserved for future use.

Standby-Mode Control Bit. If set to 1, standby mode is enabled and is entered if or when the

standby-mode control bit (RUN) for channel 1 is also set.

BIT DATA CONVERSION RATE (Hz)

7–0 00h 0.0625

7–0 01h 0.125

7–0 02h 0.25

7–0 03h 0.5

7–0 04h 1

7–0 05h 2

7–0 06h 4

7–0 07h 8

7–0 08h 16

7–0 09–FFh Reserved

PART SMBus CHANNEL SLAVE ADDRESS

MAX6638ATC

1 1001 101

2 1001 101

Page 16

MAX6638

Temperature Monitor with

Dual Serial Interface

16 ______________________________________________________________________________________

Applications Information

Remote-Diode Selection

The MAX6638 can directly measure the die temperature of CPUs and other ICs that have on-board temperature-sensing diodes (see the Typical Operating

Circuit), or it can measure the temperature of a discrete

diode-connected transistor.

Effect of Ideality Factor

The accuracy of the remote temperature measurements

depends on the ideality factor (n) of the remote diode

(which is actually a transistor). The MAX6638 is optimized for n = 1.008. If a sense transistor with a different

ideality factor is used, the output data is different.

Fortunately, the difference is predictable.

Assume a remote-diode sensor designed for a nominal

ideality factor n

NOMINAL

is used to measure the tem-

perature of a diode with a different ideality factor n

1

.

The measured temperature TMcan be corrected using:

where temperature is measured in Kelvin.

The following example uses the MAX6638 with a CPU

that has an ideality factor of 1.002. If the diode has

negligible series resistance, the measured data is related to the real temperature as follows:

For a real temperature of +85°C (358.15K), the converted and quantized temperature data is +82.875°C

(356.03K), which is an error of -2.12°C. Using the correction formula above, the corrected temperature data

is +85.0°C (358.16K).

Effect of Series Resistance

Series resistance (RS) in a sense diode contributes additional errors. For nominal diode currents of 10µA and

100µA, the change in the measured voltage due to RSis:

∆VM= RS(100µA - 10µA) = 90µA x RS.

A 1°C corresponds to 198.6µV, series resistance contributes a temperature offset of:

Assume that the diode measured has a 3Ω series resistance. The series resistance contributes an offset of:

The effects of the ideality factor and series resistance

are additive. If the diode has a 1.002 ideality factor and

3Ω series resistance the total offset can be calculated

by adding error due to series resistance with error due

to ideality factor:

1.36°C - 2.12°C = -0.77°C

for a diode temperature of +85°C.

In this example, the effects of series resistance and

ideality factor partially cancel each other.

Discrete Remote Diodes

When the remote-sensing diode is a discrete transistor,

short the collector to the base. Table 12 lists examples

of discrete transistors that are appropriate for use with

the MAX6638. Avoid violating the A/D input voltage

range by using a small-signal transistor with a relatively

high forward voltage. The forward voltage at the highest

expected temperature must be greater than 0.25V at

10µA, and the forward voltage at the lowest expected

temperature must be less than 0.95V at 100µA. Do not

use large power transistors. Ensure that the base resistance is less than 100Ω. Tight specifications for forward

current gain (50 < ß < 150, for example) indicate that the

manufacturer has good process controls and that the

device has consistent VBE characteristics.

ADC Noise Filtering

The ADC is an integrating type with inherently good

noise rejection, especially of low-frequency signals, such

as 60Hz/120Hz power-supply hum. Micropower operation places constraints on high-frequency noise rejection;

3 0 453 1 36ΩΩ×

°

=°..

C

C

90

198 6

0 453

µµV

V

C

Ω

Ω

Ω

.

.=

°

TT

n

n

TT

ACTUAL M

NOMINAL

MM

=

⎛

⎝

⎜

⎞

⎠

⎟

=

⎛

⎝

⎜

⎞

⎠

⎟

=

()

1

1 008

1 002

1 00599

.

.

.

TT

n

n

M ACTUAL

NOMINAL

=

⎛

⎝

⎜

⎞

⎠

⎟

1

Table 12. Remote-Sensor Transistor

Manufacturers

Note: Discrete transistors must be diode connected (base

shorted to collector).

MANUFACTURER MODEL

Central Semiconductor (USA) CMPT3906

Rohm Semiconductor (USA) SST3906

Samsung (Korea) KST3906-TF

Siemens (Germany) SMBT3906

Zetex (England) FMMT3906CT-ND

Page 17

therefore, careful PC board layout and proper external

noise filtering are required for high-accuracy remote

measurements in electrically noisy environments.

Filter high-frequency EMI at DXP and DXN with an

external 2200pF capacitor. This value can be increased

to approximately 3300pF (max), including cable capacitance. Capacitance > 3300pF introduces errors due to

the rise time of the switched current source. Typically

noise sources cause the ADC measurements to be

higher than the actual temperature, approximately by

+1°C to +10°C, depending on the frequency and

amplitude.

PC Board Layout

Follow these guidelines to reduce the measurement

error of the temperature sensor:

1) Place the MAX6638 as close as is practical to the

remote diode. In noisy environments, such as a

computer motherboard, this distance can be 4in to

8in (typ). This length can be increased if the worst

noise sources are avoided. Noise sources include

CRTs, clock generators, memory buses, and

ISA/PCI buses.

2) Do not route the DXP-DXN lines next to the deflection coils of a CRT. Also, do not route the traces

across fast digital signals, which can easily introduce a 30°C error, even with good filtering.

3) Route the DXP and DXN traces in parallel and in close

proximity to each other, away from any higher voltage

traces, such as 12V DC. Leakage currents from PC

board contamination must be dealt with carefully since

a 20MΩ leakage path from DXP to ground causes

approximately a 1°C error. If high-voltage traces are

unavoidable, connect guard traces to GND on either

side of the DXP-DXN traces (Figure 4).

4) Route through as few vias and crossunders as possible to minimize copper/solder thermocouple

effects.

5) When introducing a thermocouple, make sure that

both the DXP and the DXN paths have matching

thermocouples. A copper-solder thermocouple

exhibits 3µV/°C, and takes approximately 200µV of

voltage error at DXP-DXN to cause a 1°C measurement error. Adding a few thermocouples causes a

negligible error.

6) Use wide traces. Narrow traces are more inductive

and tend to pick up radiated noise. The 10-mil withstand spacing recommended in Figure 4 is not

absolutely necessary, as it offers only a minor

improvement in leakage and noise over narrow

traces. Use wider traces when practical.

7) Add a 200Ω resistor in series with VCCfor best

noise filtering (see the Typical Operating Circuit).

8) Copper cannot be used as an EMI shield; only ferrous materials such as steel work well. Placing a

copper ground plane between the DXP-DXN traces

and traces carrying high-frequency noise signals

does not help reduce EMI.

PC Board Layout Checklist

• Place the MAX6638 close to the remote-sense junction.

• Keep traces away from high voltages (+12V bus).

• Keep traces away from fast data buses and CRTs.

• Use recommended trace widths and spacings.

• Place a ground plane under the traces.

• Use guard traces flanking DXP and DXN and connecting to GND.

• Add a 47Ω resistor in series with VCCfor best noise

filtering (see the Typical Operating Circuit).

• Place the noise filter and a 0.1µF VCCbypass

capacitor close to the MAX6638.

Twisted-Pair and Shielded Cables

Use a twisted-pair cable to connect the remote sensor

for remote-sensor distance longer than 8in, or in very

noisy environments. Twisted-pair cable lengths can be

between 6ft and 12ft before noise introduces excessive

errors. For longer distances, the best solution is a

shielded twisted pair like that used for audio microphones. For example, Belden 8451 works well for distances up to 100ft in a noisy environment. At the

device, connect the twisted pair to DXP and DXN and

the shield to GND. Leave the shield unconnected at the

remote sensor.

For very long cable runs, the cable’s parasitic capacitance often provides noise filtering, so the 2200pF

capacitor can often be removed or reduced in value.

Cable resistance also affects remote-sensor accuracy.

For every 1Ω of series resistance, the error is approximately 0.5°C.

Thermal Mass and Self-Heating

When sensing local temperature, these devices are

intended to measure the temperature of the PC board

to which the devices are soldered. The leads provide a

good thermal path between the PC board traces and

the die. Thermal conductivity between the die and the

ambient air is poor by comparison, making air temperature measurements impractical. Because the thermal

mass of the PC board is far greater than that of the

MAX6638

Temperature Monitor with

Dual Serial Interface

______________________________________________________________________________________ 17

Page 18

MAX6638

MAX6638, the device follows temperature changes on

the PC board with little or no perceivable delay.

When measuring the temperature of a CPU or another IC

with an on-chip sense junction, thermal mass has virtually no effect; the measured temperature of the junction

tracks the actual temperature within a conversion cycle.

When measuring temperature with discrete remote sensors, smaller packages, such as SC70s or SOT23s, yield

the best thermal response times. Take care to account

for thermal gradients between the heat source and the

sensor, and ensure that stray air currents across the sensor package do not interfere with measurement accuracy. Self-heating does not significantly affect

measurement accuracy. Remote-sensor self-heating due

to the diode current source is negligible. For the local

diode, the worst-case error occurs when autoconverting

at the fastest rate and simultaneously sinking maximum

current at the ALERT1 output. For example, with V

CC

5.5V, at a 16Hz conversion rate and with ALERT1 sinking

1mA, the typical power dissipation is:

5.5V x 800µA + 0.4V x 1.0mA = 4.8mW

θ

J-A

for the 16-pin, 4mm x 4mm TQFN package is

59.3°C/W, so assuming no copper PC board heat sinking, the resulting temperature rise is:

∆T = 4.8mW x 59.3°C/W = +0.283°C.

Even under nearly worst-case conditions, it is difficult to

introduce a significant self-heating error.

Temperature Monitor with

Dual Serial Interface

18 ______________________________________________________________________________________

Typical Operating Circuit

Chip Information

PROCESS: BiCMOS

3.3V

Ω

47

10k

SDA1

SCK1

2200pF

0.1µF

DXP

DXN

V

CC

Ω

Ω

Ω

Ω

10k

10k

Ω

Ω

10k

10k

Ω

10k

10k

DATA FROM/TO µP1

CLOCK FROM µP1

INTERRUPT TO µP1

TO FAN DRIVER OR SYSTEM SHUTDOWN

DATA FROM/TO µP2

CLOCK FROM µP2

INTERRUPT TO µP2

GND

ALERT1

OVERT1

SDA2

SCK2

ALERT2

µ

P

MAX6638

Page 19

MAX6638

Temperature Monitor with

Dual Serial Interface

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 19

© 2006 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

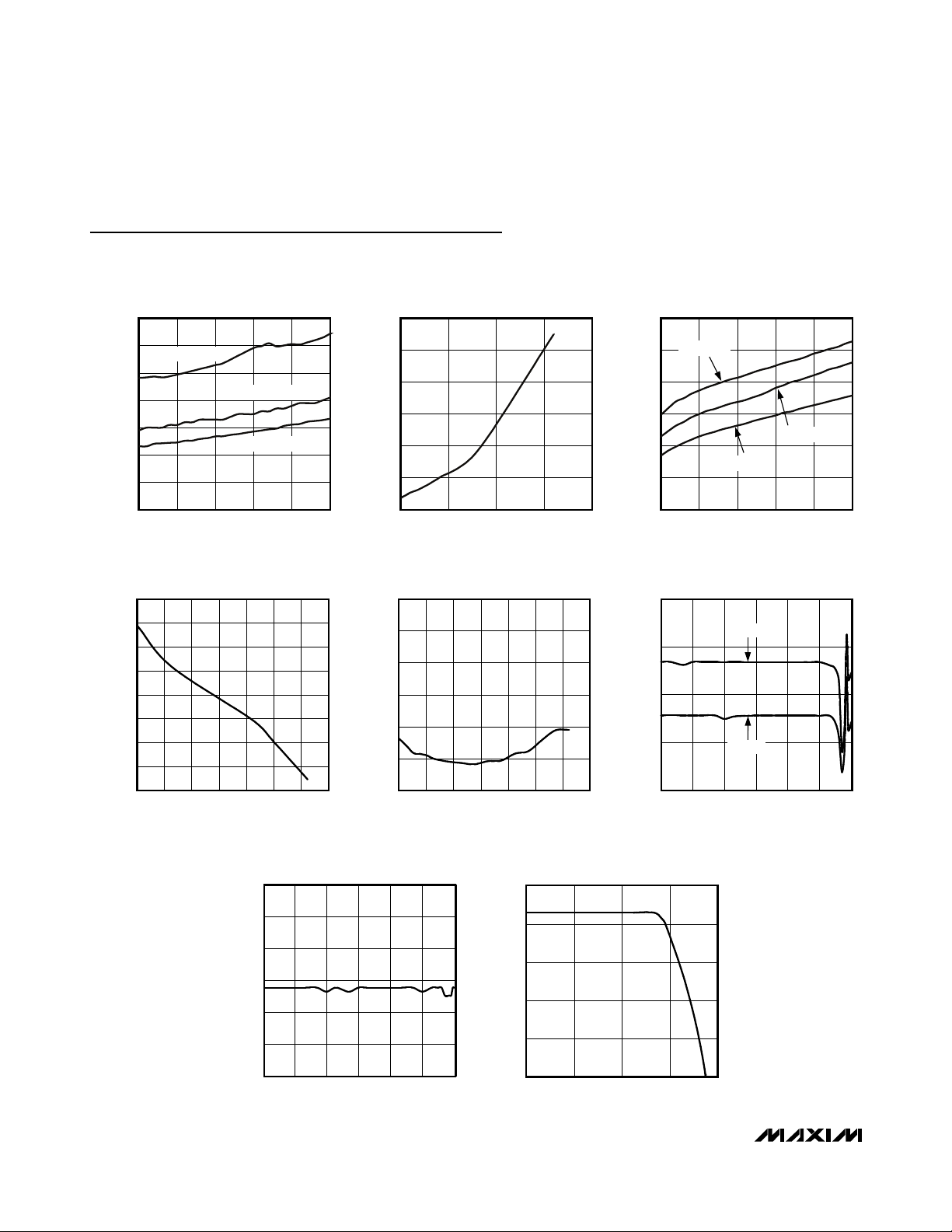

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

Springer

24L QFN THIN.EPS

PACKAGE OUTLINE,

12, 16, 20, 24, 28L THIN QFN, 4x4x0.8mm

21-0139

1

E

2

PACKAGE OUTLINE,

12, 16, 20, 24, 28L THIN QFN, 4x4x0.8mm

21-0139

2

E

2

Loading...

Loading...