Page 1

General Description

The MAX6620 controls the speeds of up to four fans

using four independent linear voltage outputs. The

drive voltages for the fans are controlled directly over

the I

2

C interface. Each output drives the base of an

external bipolar transistor or the gate of a FET in highside drive configuration. Voltage feedback at the fan’s

power-supply terminal is used to force the correct output voltage.

The MAX6620 offers two methods for fan control. In

RPM mode, the MAX6620 monitors four fan tachometer

logic outputs for precise (±1%) control of fan RPM and

detection of fan failure. In DAC mode, each fan is driven with a voltage resolution of 9 bits and the tachometer outputs of the fans are monitored for failure.

The DAC_START input selects the fan power-supply

voltage at startup to ensure appropriate fan drive when

power is first applied. A watchdog feature turns the

fans fully on to protect the system if there are no valid

I

2

C communications within a preset timeout period.

The MAX6620 operates from a 3.0V to 5.5V power supply with low 250µA supply current, and the I

2

C-compatible interface makes it ideal for fan control in a wide

range of cooling applications. The MAX6620 is available in a 28-pin TQFN package and operates over the

-40°C to +125°C automotive temperature range.

Applications

Consumer Products

Servers

Communications Equipment

Storage Equipment

Features

♦ Controls Up to Four Independent Fans With

Linear (DC) Drive

♦ Uses Four External Low-Cost Pass Transistors

♦ 1% Accuracy Precision RPM Control

♦ Controlled Voltage Rate-Of-Change for Best

Acoustics

♦ I

2

C Bus Interface

♦ 3.0V to 5.5V Supply Voltage Range

♦ 250µA (typ) Operating Supply Current

♦ 3µA (typ) Shutdown Supply Current

♦ Small 5mm x 5mm Footprint

MAX6620

Quad Linear Fan-Speed Controller

________________________________________________________________

Maxim Integrated Products

1

×

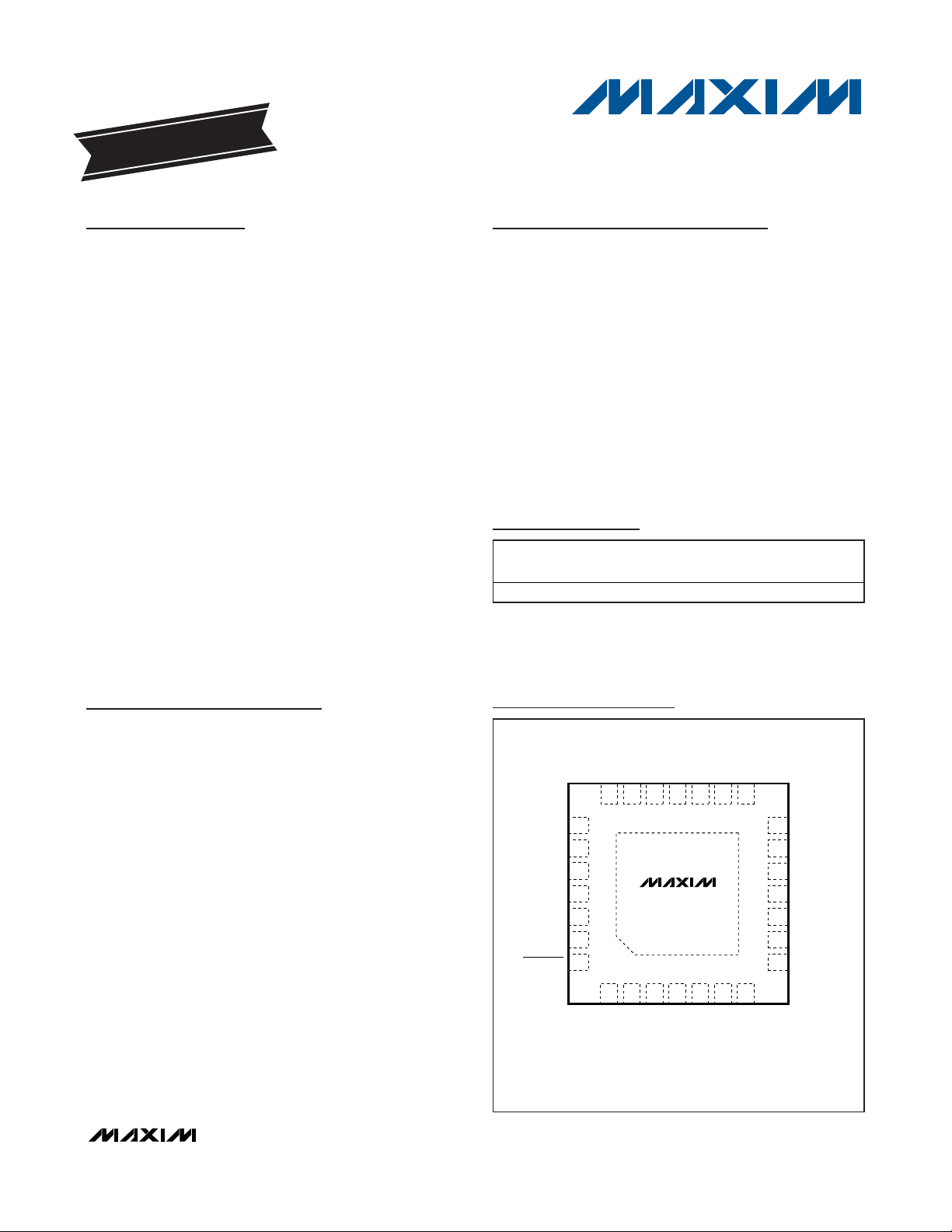

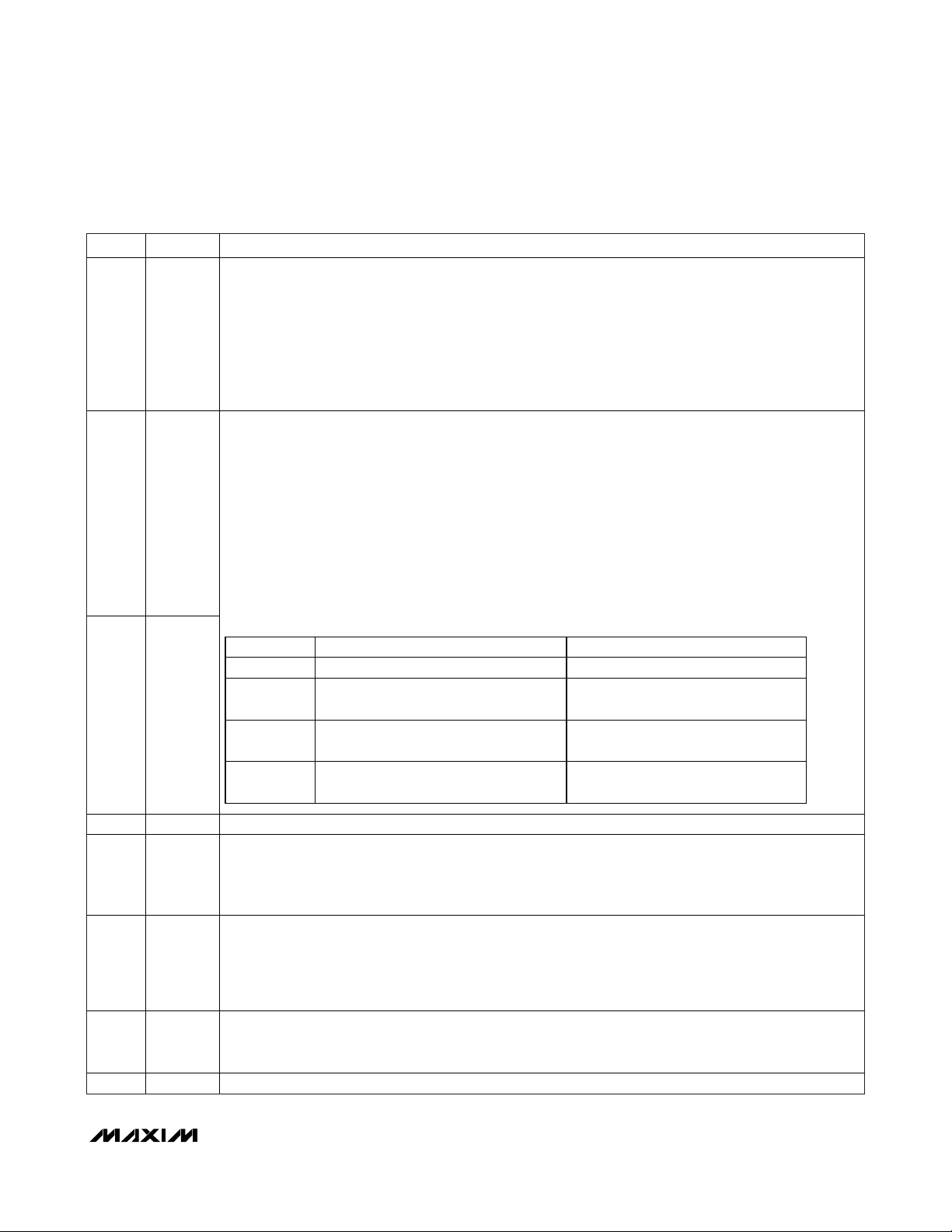

Pin Configuration

Ordering Information

19-4039; Rev 0; 3/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

+

Denotes a lead-free package.

*

EP = Exposed paddle.

PART

PINPACKAGE

PKG

CODE

MAX6620ATI+

T2855-8

Typical Application Circuit appears at end of data sheet.

TEMP RANGE

-40°C to +125°C 28 TQFN-EP*

TOP VIEW

TACH1

DACFB1

DACOUT1

GND

FAN

VCC

FAN_FAIL

22

23

24

25

26

27

28

DACFB2

TACH2

2021 19 17 16 15

+

12

SCL

(5mm

GND

DACOUT2

18

MAX6620

4567

3

SDA

GND

WD_START

THIN QFN

5mm × 0.8mm)

DACOUT3

DACFB3

ADDR

DAC_START

TACH3

14

TACH4

DACFB4

13

12

DACOUT4

GND

11

10

GND

X2

9

8

X1

SPINUP_START

Page 2

MAX6620

Quad Linear Fan-Speed Controller

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(TA= -40°C to +125°C, VCC= 3.0V to 5.5V, unless otherwise noted. Typical values are at TA= +25°C, VCC= 3.3V.) (Note 3)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCC to GND ..........................................................-0.3V to +6.0V

FAN_FAIL, SDA, SCL to GND ...............................-0.3V to +6.0V

ADDR, SPINUP_START, DAC_START, WD_START,

X1, X2 to GND ........................................-0.3V to (V

CC

+ 0.3V)

All Other Pins to GND..........................................-0.3V to +13.5V

Input Current at DACOUT_ Pins (Note 1) ...............+5mA/-50mA

Input Current at Any Pin (Note 1)..........................................5mA

ESD Protection (all pins, Human Body Model) (Note 2) ...±2000V

Continuous Power Dissipation (T

A

= +70°C)

28-Pin TQFN (derate 34.5mW/°C above +70°C) ....2758.6mW

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. DC and AC electrical specifica-

tions do not apply when operating the device beyond its rated operating conditions.

Note 2: Human Body Model, 100pF discharged through a 1.5kΩ resistor.

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS

Operating Supply Voltage V

Operating Supply Current I

Quiescent Supply Current

V

Supply Voltage

FAN

DACOUT_ Output Current I

DACOUT_ Output Voltage V

DAC Feedback Voltage at Half

Scale

DAC Feedback Voltage at Full

Scale

Drive Voltage Resolution 9 Bit

DACFB_ Impedance R

TACH Minimum Input Pulse Width 25 µs

Internal Reference Frequency

Accuracy

TACH Count Accuracy (Note 4)

CC

CC

VCC = 5.5V 0.25 0.60 mA

I2C inactive 0.2 0.5 mA

Shutdown mode 3 20 µA

V

FANHI

V

FANLO

V

GND

V

DACOUT_

DACOUT_IDACOUT_

V

V

FAN

GND

FAN

At DACFB_,

FBHS

FBFS

code = 0x100,

I

DACOUT_

At DACFB_,

DAC

DAC

code = 0x1FF,

I

V

DACFB511

DACFB

DACOUT_

(Note 4) -3 +3 %

Using 32.768kHz crystal -0.1 +0.1

Using on-chip oscillator -2 +2

+ 10V < V

DACOUT_

< 11.5V,

= 12V

+ 3V < V

DACOUT_

< 10V,

= 12V

= 5mA 0.05

V

= V

FAN

FANHI

V

= V

FAN

FANLO

V

= 12V 5.54 5.74 5.94

= 5mA

= 5mA

FAN

V

= 5V 2.05 2.25 2.45

FAN

V

= V

FAN

FANHI

V

= V

FAN

FANLO

V

= 12V 11.25 11.45 11.65

FAN

= 5V 4.3 4.5 4.7

V

FAN

3.0 5.5 V

10 12 13.5

4.0 5.0 5.5

-18

-16

V

-

FAN

0.1

256/535

256/567

511/535

511/567

1MΩ

V

mA

V

V

V

%

Page 3

MAX6620

Quad Linear Fan-Speed Controller

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(TA= -40°C to +125°C, VCC= 3.0V to 5.5V, unless otherwise noted. Typical values are at TA= +25°C, VCC= 3.3V.) (Note 3)

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS

Fan Control Accuracy (Note 4)

Using 32.768kHz crystal, test at 850RPM -1 +1

Using on-chip oscillator -3 +3

%

XTAL Oscillator Startup Time 2s

X1 Input Threshold 0.7 V

POR Threshold

V

V

CC

FAN

2

3.5

V

LOGIC (SDA, SCL, FAN_FAIL, WD_START, TACH_)

Input High Voltage V

Input Low Voltage V

Input High Current I

Input Low Current I

IH

IL

IH

IL

VCC x

0.7

VCC x

0.3

1.0 µA

-1.0 µA

V

V

Input Capacitance All digital inputs 6 pF

Output High Current 100 µA

Output Low Voltage IOL = 3mA 0.4 V

LOGIC (DAC_START, SPIN_START, ADDR)

V

-

Input High Voltage V

Input Low Voltage V

Input High Current I

Input Low Current I

IH

IL

IH

IL

CC

0.5

V

0.5 V

1.0 µA

-1.0 µA

Input Capacitance All digital inputs 6 pF

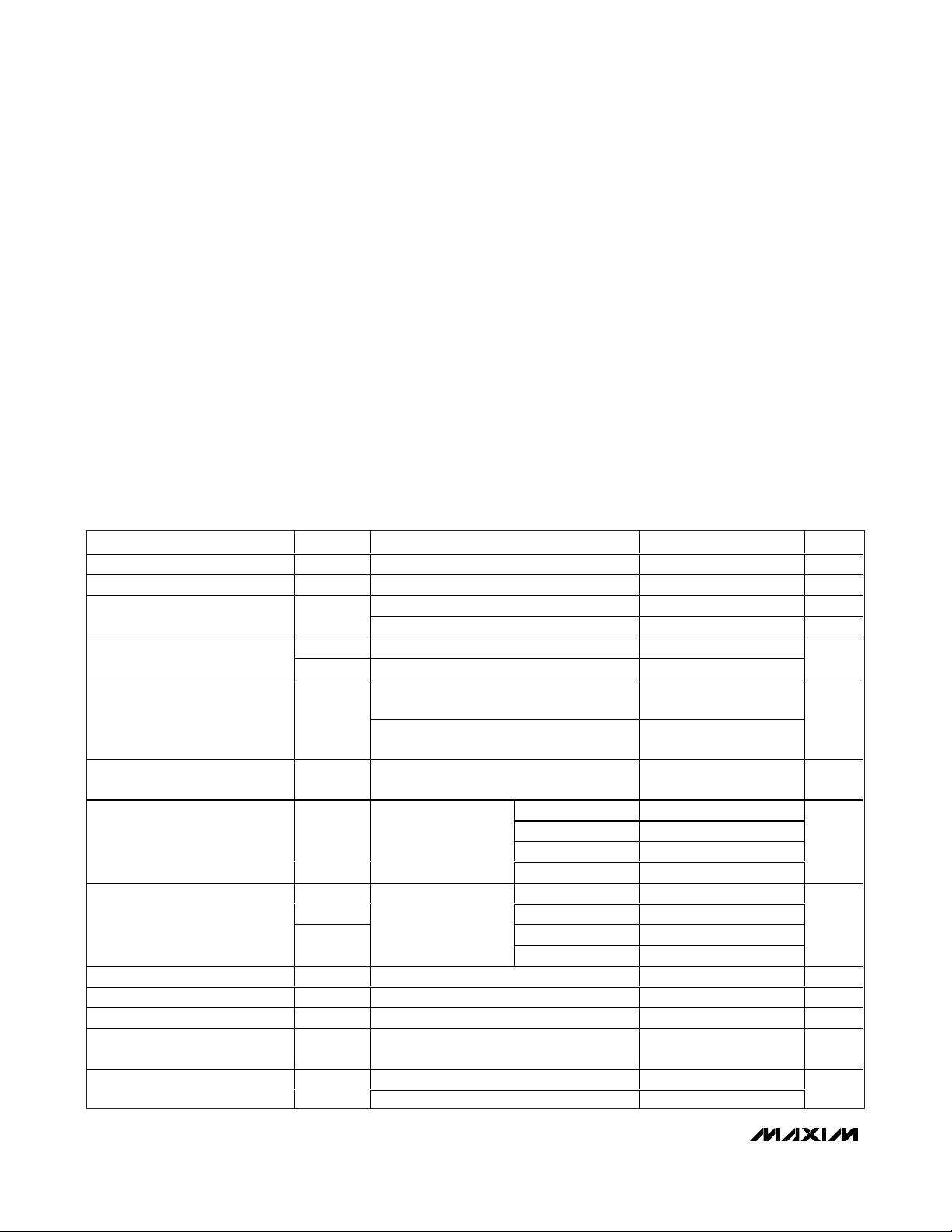

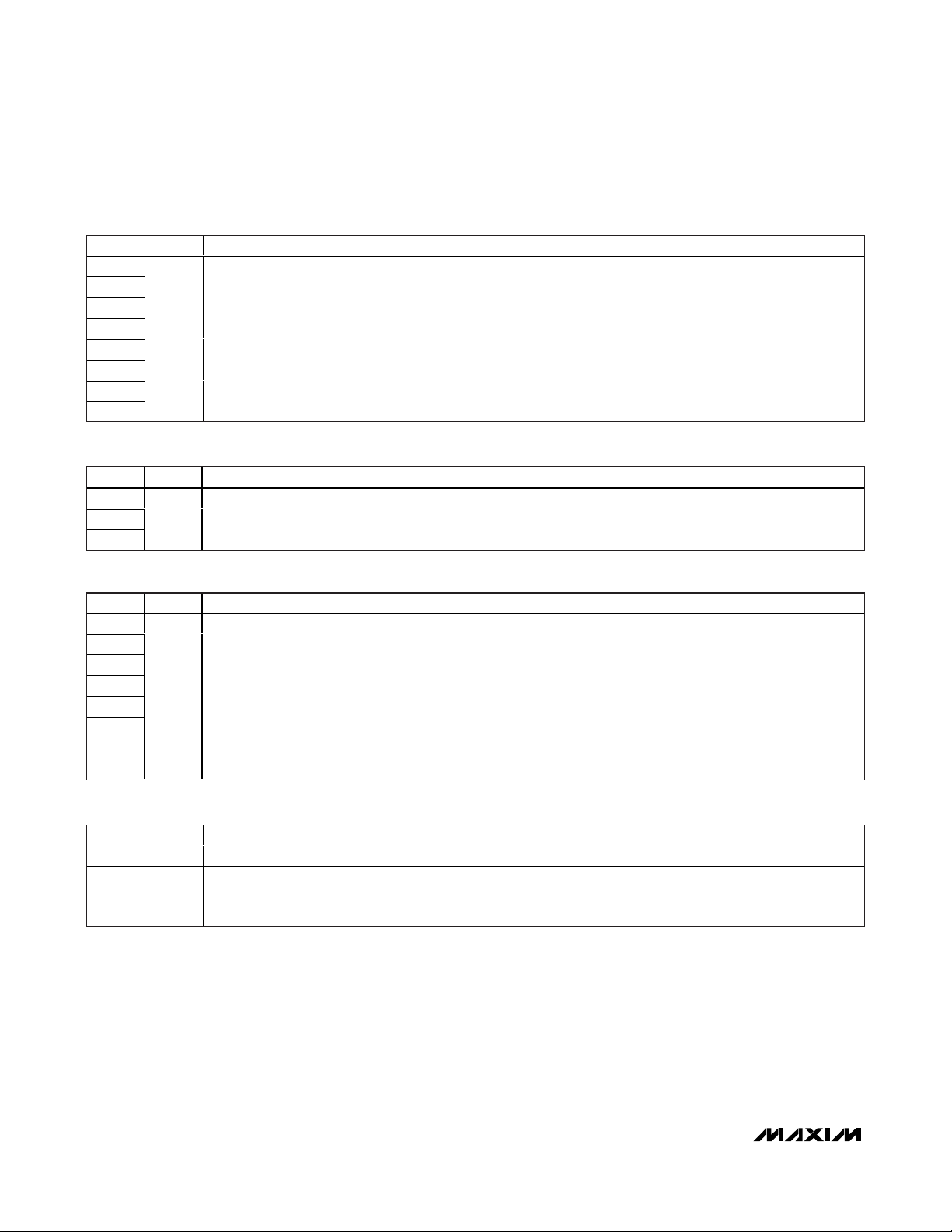

I2C-COMPATIBLE TIMING (Notes 5, 6)

Serial Clock Frequency f

Bus Free Time Between STOP

and START Conditions

START Condition Hold Time t

STOP Condition Setup Time t

Clock Low Period t

Clock High Period t

START Condition Setup Time t

Data Setup Time t

Data Out Hold Time t

Data In Hold Time t

Maximum Receive SCL/SDA Rise

Time

Minimum Receive SCL/SDA Rise

Time

SCL

t

BUF

HD:STA

SU:STO

LOW

HIGH

SU:STA

SU:DAT

DH

HD:DAT

t

R

t

R

1.3 µs

0.6 µs

600 ns

1.3 µs

0.6 µs

600 ns

100 ns

100 ns

(Note 6) 0 0.9 µs

(Note 8) 300 ns

(Note 7)

20 + 0.1

x C

B

400 kHz

ns

Page 4

MAX6620

Quad Linear Fan-Speed Controller

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(TA= -40°C to +125°C, VCC= 3.0V to 5.5V, unless otherwise noted. Typical values are at TA= +25°C, VCC= 3.3V.) (Note 3)

Note 3: All parts will operate properly over the VCCsupply voltage range of 3.0V to 5.5V.

Note 4: Guaranteed by design and characterization.

Note 5: All timing specifications are guaranteed by design.

Note 6: A master device must provide a hold time of at least 300ns for the SDA signal to bridge the undefined region of SCL’s falling edge.

Note 7: C

B

= total capacitance of one bus line in pF. Tested with CB= 400pF.

Note 8: Input filters on SDA and SCL suppress noise spikes less than 50ns.

Note 9: Holding the SDA line low for a time greater than t

TIMEOUT

will cause the devices to reset SDA to the idle state of the serial

bus communication (SDA set high).

t

HD,STA

t

HIGH

t

R

t

F

t

HD,STA

S Sr A

SCL

SDA

t

SU,STA

t

SU,STO

t

R

t

F

t

BUF

t

LOW

t

SU,DAT

t

HD,DAT

PS

Figure 1. I2C Serial Interface Timing

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS

Maximum Receive SCL/SDA Fall

Time

Minimum Receive SCL/SDA Fall

Time

Transmit SDA Fall Time t

Pulse Width of Suppressed Spike t

Output Fall Time CL = 400pF, I

SDA Time Low for Reset of Serial

Interface

t

F

t

F

F

SP

t

TIMEOUT

(Note 7)

(Note 7)

20 + 0.1

x C

(Note 8) 0 50 ns

= 3mA 250 ns

OUT

(Note 9) 20 50 ms

300 ns

20 + 0.1

x C

B

B

250 ns

ns

Page 5

MAX6620

Quad Linear Fan-Speed Controller

_______________________________________________________________________________________ 5

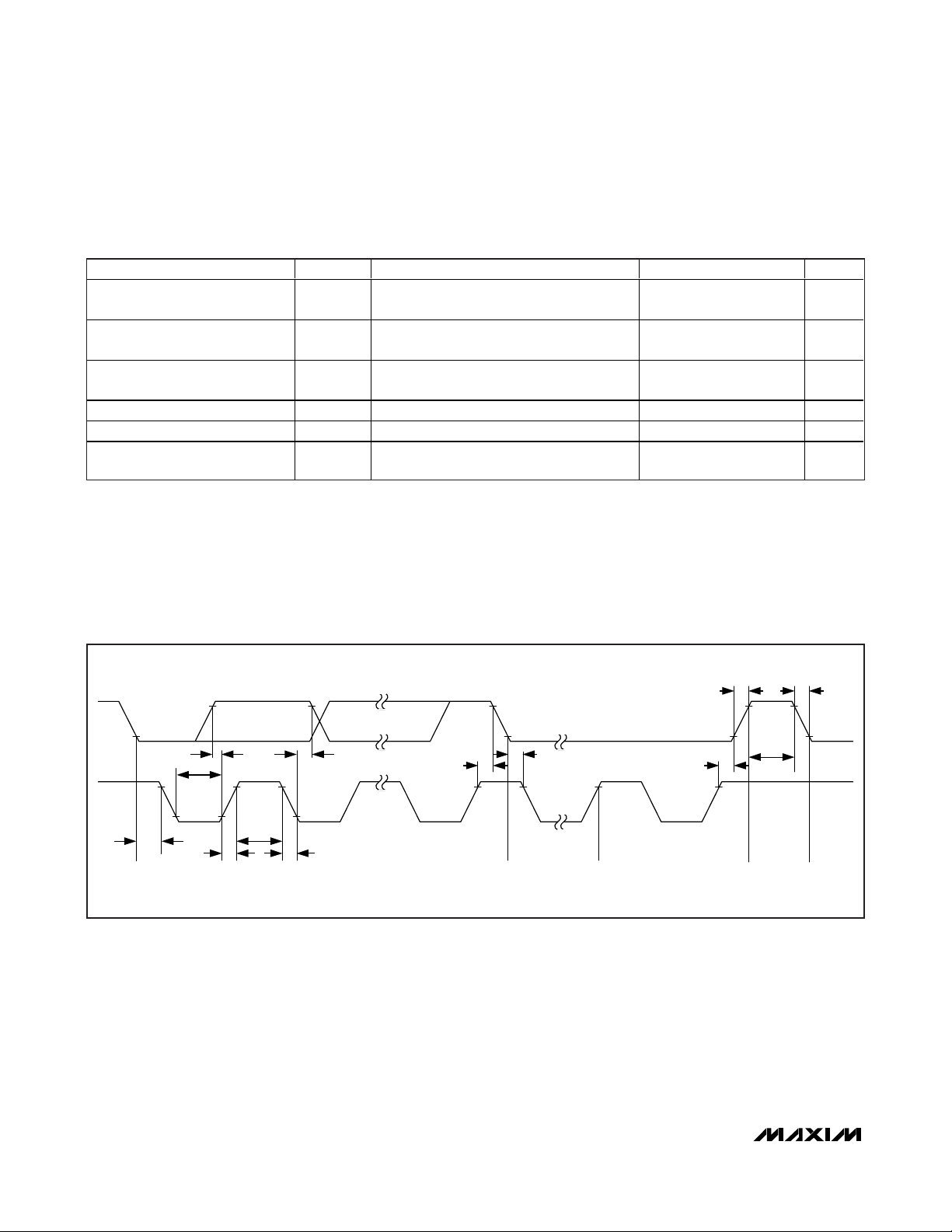

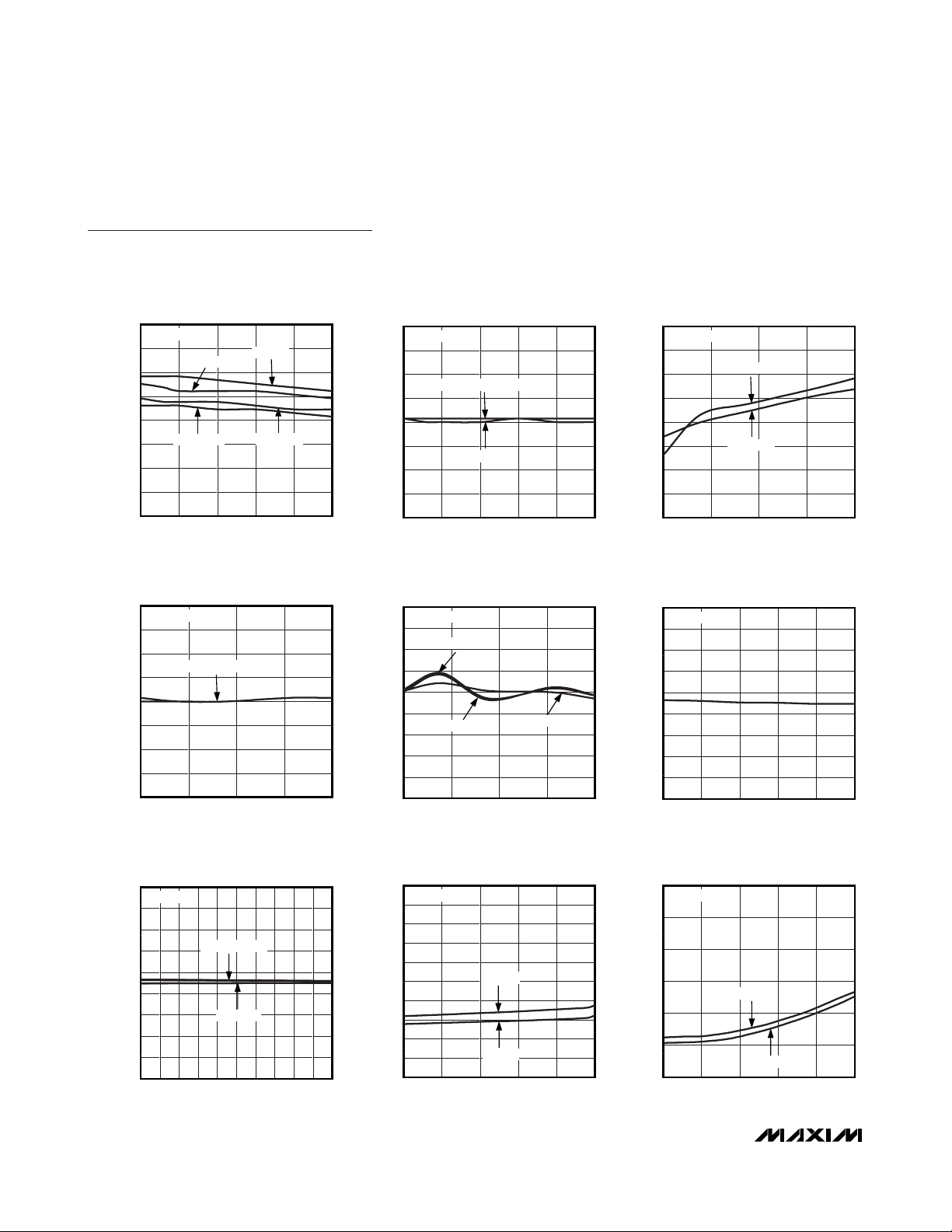

Typical Operating Characteristics

(VCC= 3.3V, V

FAN

= 12V, TA= +25°C, unless otherwise noted.)

TACH COUNT ACCURACY WITH INT CLK

vs. SUPPLY VOLTAGE

2.0

V

= 12V

FAN

1.5

1.0

0.5

TA = +25°C

0

-0.5

-1.0

-1.5

TACH COUNT ACCURACY WITH INT CLK (%)

-2.0

3.0 5.5

TA = 0°C

TA = +125°C

SUPPLY VOLTAGE (V)

TACH COUNT ACCURACY WITH EXT CLK

vs. TEMPERATURE

2.0

V

= 12V

FAN

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

TACH COUNT ACCURACY WITH EXT CLK (%)

-2.0

-55 125

VCC = 3.3V, 5.0V

TEMPERATURE (°C)

TA = +70°C

TACH COUNT ACCURACY WITH EXT CLK

vs. SUPPLY VOLTAGE

2.0

V

= 12V

FAN

1.5

MAX6620 toc01

1.0

0.5

0

-0.5

-1.0

-1.5

TACH COUNT ACCURACY WITH EXT CLK (%)

-2.0

5.04.53.5 4.0

3.0 5.5

TA = 0°C, +70°C, +125°C

TA = +25°C

5.04.53.5 4.0

SUPPLY VOLTAGE (V)

MAX6620 toc02

DACFB_ VOLTAGE ACCURACY

vs. TEMPERATURE

2.0

V

= 12V

FAN

1.5

MAX6620 toc04

1.0

0.5

0

-0.5

-1.0

DACFB VOLTAGE ACCURACY (%)

-1.5

-2.0

8035-10

-55 125

VCC = 3.0V, 3.3V, 5.0V

TEMPERATURE (°C)

MAX6620 toc05

8035-10

TACH COUNT ACCURACY WITH INT CLK

vs. TEMPERATURE

2.0

V

= 12V

FAN

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

TACH COUNT ACCURACY WITH INT CLK (%)

-2.0

-55 125

VCC = 5.0V

VCC = 3.3V

TEMPERATURE (°C)

DACFB_ VOLTAGE ACCURACY

vs. SUPPLY VOLTAGE

2.0

V

= 12V

FAN

1.5

1.0

0.5

0

-0.5

-1.0

DACFB VOLTAGE ACCURACY (%)

-1.5

-2.0

3.0 5.5

SUPPLY VOLTAGE (V)

MAX6620 toc03

8035-10

MAX6620 toc06

5.04.54.03.5

DACFB_ VOLTAGE ACCURACY

vs. OUTPUT CURRENT

2.0

V

= 12V

FAN

1.5

1.0

0.5

0

-0.5

-1.0

DACFB VOLTAGE ACCURACY (%)

-1.5

-2.0

5.0 10.08.57.56.55.5 9.5

VCC = 3.0V, 3.3V

VCC = 5.5V

OUTPUT CURRENT (mA)

STANDBY SUPPLY CURRENT

vs. SUPPLY VOLTAGE

500

V

= 12V

FAN

450

MAX6620 toc07

400

350

300

250

200

150

100

STANDBY SUPPLY CURRENT (μA)

50

0

9.08.07.06.0

3.0 5.5

INT CLK

EXT CLK

5.04.54.03.5

SUPPLY VOLTAGE (V)

MAX6620 toc08

OPERATING SUPPLY CURRENT (mA)

OPERATING SUPPLY CURRENT

vs. SUPPLY VOLTAGE

0.6

V

= 12V

FAN

0.5

0.4

0.3

0.2

0.1

0

3.0 5.5

INT CLK

EXT CLK

5.04.54.03.5

SUPPLY VOLTAGE (V)

MAX6620 toc09

Page 6

MAX6620

Quad Linear Fan-Speed Controller

6 _______________________________________________________________________________________

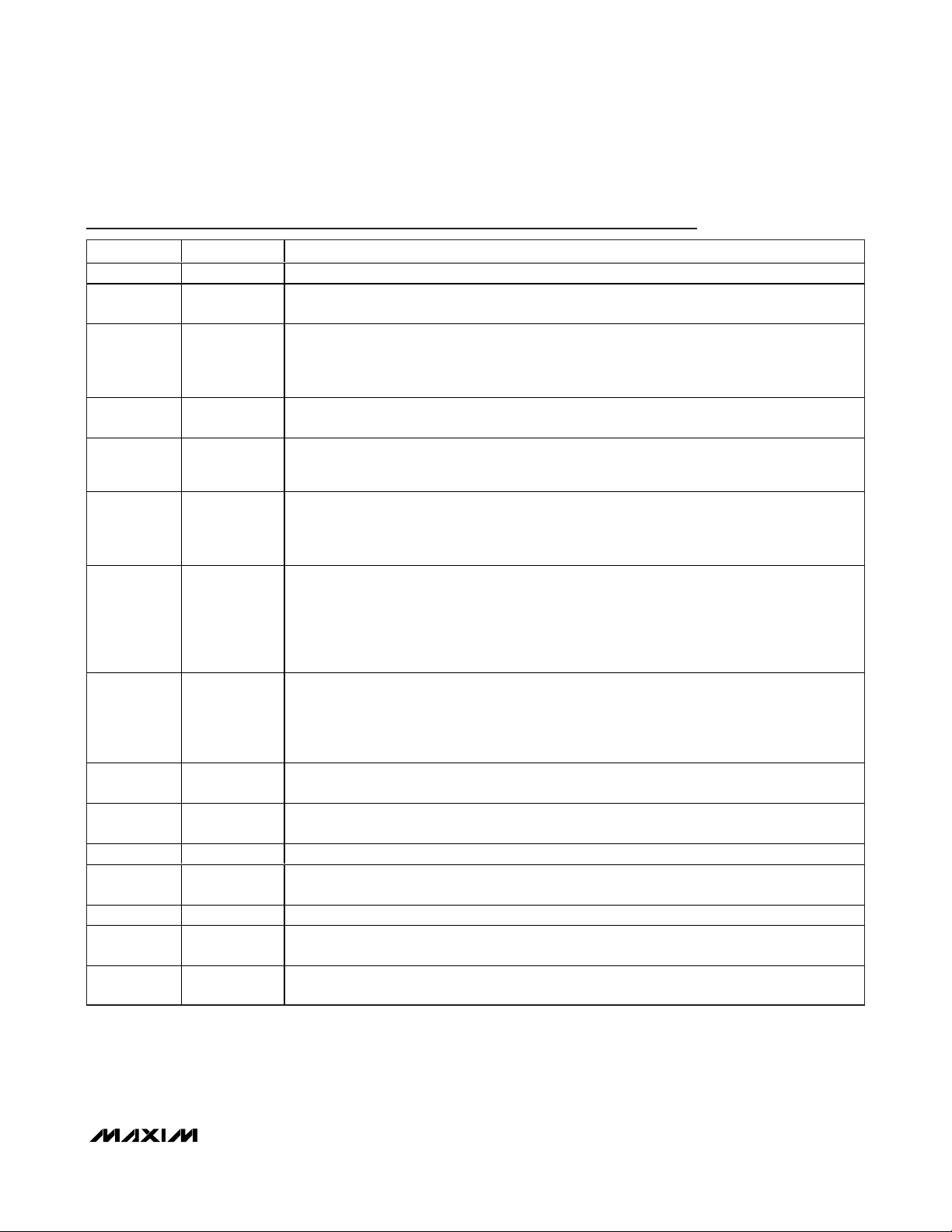

Typical Operating Characteristics (continued)

(VCC= 3.3V, V

FAN

= 12V, TA= +25°C, unless otherwise noted.)

TACH COUNT ACCURACY WITH INT CLK

vs. SUPPLY VOLTAGE

2.0

V

= 5.0V

FAN

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

TACH COUNT ACCURACY WITH INT CLK (%)

-2.0

3.0 5.5

TA = +25°C

TA = +125°C

SUPPLY VOLTAGE (V)

TACH COUNT ACCURACY WITH EXT CLK

vs. TEMPERATURE

2.0

V

= 5.0V

FAN

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

TACH COUNT ACCURACY WITH EXT CLK (%)

-2.0

-55 125

VCC = 3.3V, 5.0V

TEMPERATURE (°C)

TA = 0°C

TA = +70°C

TACH COUNT ACCURACY WITH EXT CLK

vs. SUPPLY VOLTAGE

2.0

V

= 5.0V

FAN

1.5

MAX6620 toc10

1.0

0.5

0

-0.5

-1.0

-1.5

TACH COUNT ACCURACY WITH EXT CLK (%)

5.04.54.03.5

-2.0

TA = 0°C, +70°C, +125°C

TA = +25°C

3.0 5.5

SUPPLY VOLTAGE (V)

5.04.54.03.5

MAX6620 toc11

DACFB_ VOLTAGE ACCURACY

vs. TEMPERATURE

4.5

V

= 5.0V

FAN

3.5

MAX6620 toc13

2.5

1.5

0.5

-0.5

-1.5

-2.5

DACFB VOLTAGE ACCURACY (%)

-3.5

8035-10

-4.5

VCC = 3.0V

VCC = 3.3V

-55 125

TEMPERATURE (°C)

VCC = 5.5V

8035-10

MAX6620 toc14

TACH COUNT ACCURACY WITH INT CLK

vs. TEMPERATURE

2.0

V

= 5.0V

FAN

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

TACH COUNT ACCURACY WITH INT CLK (%)

-2.0

-55 125

VCC = 3.3V

VCC = 5.0V

TEMPERATURE (°C)

DACFB_ VOLTAGE ACCURACY

vs. SUPPLY VOLTAGE

4.5

V

= 5.0V

FAN

3.5

2.5

1.5

0.5

-0.5

-1.5

-2.5

DACFB VOLTAGE ACCURACY (%)

-3.5

-4.5

3.0 5.5

SUPPLY VOLTAGE (V)

MAX6620 toc12

8035-10

MAX6620 toc15

5.04.54.03.5

DACFB_ VOLTAGE ACCURACY

vs. OUTPUT CURRENT

4.5

V

= 5.0V

FAN

3.5

2.5

1.5

0.5

-0.5

-1.5

-2.5

DACFB VOLTAGE ACCURACY (%)

-3.5

-4.5

5.0 10.08.57.56.55.5 9.5

VCC = 3.0V, 3.3V

VCC = 5.5V

OUTPUT CURRENT (mA)

STANDBY SUPPLY CURRENT

vs. SUPPLY VOLTAGE

500

V

= 5.0V

FAN

450

MAX6620 toc16

400

350

300

250

200

150

100

STANDBY SUPPLY CURRENT (μA)

50

0

9.08.07.06.0

3.0 5.5

INT CLK

EXT CLK

5.04.54.03.5

SUPPLY VOLTAGE (V)

MAX6620 toc17

OPERATING SUPPLY CURRENT (mA)

OPERATING SUPPLY CURRENT

vs. SUPPLY VOLTAGE

0.6

V

= 5.0V

FAN

0.5

0.4

0.3

0.2

0.1

0

3.0

SUPPLY VOLTAGE (V)

MAX6620 toc18

INT CLK

EXT CLK

5.0 5.54.54.03.5

Page 7

MAX6620

Quad Linear Fan-Speed Controller

_______________________________________________________________________________________ 7

Pin Description

PIN NAME FUNCTION

1 SCL I2C Serial-Clock Input. Can be pulled up to 5.5V regardless of VCC. Open circuit when VCC = 0V.

2 SDA

3 WD_START

4, 10, 11, 18,

25

5 ADDR

6 DAC_START

7S P IN U P _S TART

8, 9 X1, X2

12, 17, 19, 24

13, 16, 20, 23

14, 15, 21, 22 TACH4–TACH1 Fan Tachometer Logic Inputs. These inputs accept input voltages up to V

26 FAN

27 VCC Power-Supply Input. 3.3V nominal. Bypass VCC to GND with a 0.1µF capacitor.

28 FAN_FAIL

—EP

GND Ground

DACOUT4–

DACOUT1

DACFB4–

DACFB1

Open-Drain, I

circuit when V

Startup Watchdog Set Input. This input is sampled when power is first applied and sets the initial

2

C watchdog behavior. When connected to GND, the watchdog function is disabled. When

I

connected to V

fan drive goes to 100%.

2

C Address Set Input. This input is sampled when power is first applied and sets the I2C slave

I

address. When connected to GND, the slave address will be 0x50. When unconnected, the slave

address will be 0x52. When connected to V

Startup Fan Drive DAC Set Input. This input is sampled when power is first applied and sets the

power-up value for the fan drive voltage. When connected to GND, the fan drive voltage will be

0%. When unconnected, the fan drive voltage will be 75%. When connected to V

voltage will be 100%.

Startup Spin-Up Set Input. This input is sampled when power is first applied and sets the initial

spin-up behavior. When connected to GND, spin-up is disabled. When connected to V

power-up, the fan is driven with a full-scale drive voltage until two tachometer pulses have been

detected, or 1s has elapsed. When unconnected, the fan is driven with a full-scale drive voltage

until two tachometer pulses have been detected, or 0.5s has elapsed. Spin-up behavior may be

modified by writing appropriate settings to the MAX6620’s registers.

Crystal Oscillator Inputs. Connections for a standard 32.768kHz quartz crystal. The internal

oscillator circuitry is designed for operation with a crystal having a specified load capacitance

(CL) of 12pF. Connect an external 32.768kHz oscillator across X1 and X2 for operation with the

external oscillator. If no crystal or external oscillator is connected, the MAX6620 will use its

internal oscillator.

Fan Drive DAC Outputs. Connect to the gate of a p-channel MOSFET or base of a PNP bipolar

transistor.

D AC Feed b ack Inp uts. C onnect a 0.1µF cap aci tor b etw een these p i ns and GN D . C onnect to the

sup p l y p i n of the fan and to the d r ai n of a p - channel M O S FE T or col l ector of a P N P b i p ol ar tr ansi stor .

Fan Power-Supply Voltage Input. Connect to the fan power supply (V

capacitor to GND.

Active-Low, Open-Drain Fan Failure Output. Active only when fault is present; open-circuit when

= 0V. This pin can be pulled up to 5.5V regardless of VCC.

V

CC

Exposed Paddle. Internally connected to GND. Connect to a large ground plane to maximize

thermal performance. Not intended as an electrical connection point.

2

C Serial-Data Input/Output. Can be pulled up to 5.5V regardless of VCC. Open

= 0V.

CC

, the MAX6620 monitors SDA. If 10s elapse without a valid I2C transaction, the

CC

, the slave address will be 0x54.

CC

CC

.

FAN

). Bypass with a 0.1µF

FAN

, the fan drive

at

CC

Page 8

MAX6620

Quad Linear Fan-Speed Controller

8 _______________________________________________________________________________________

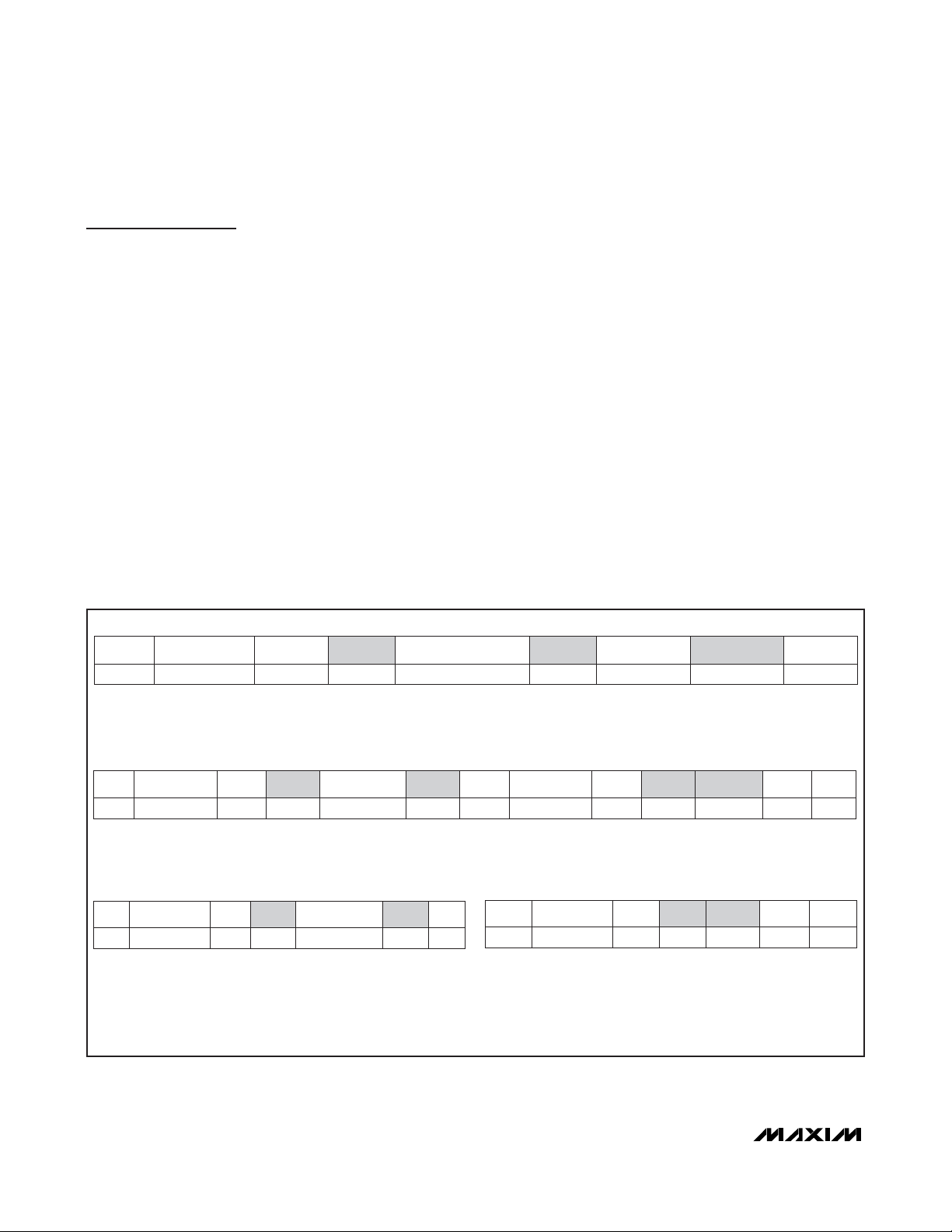

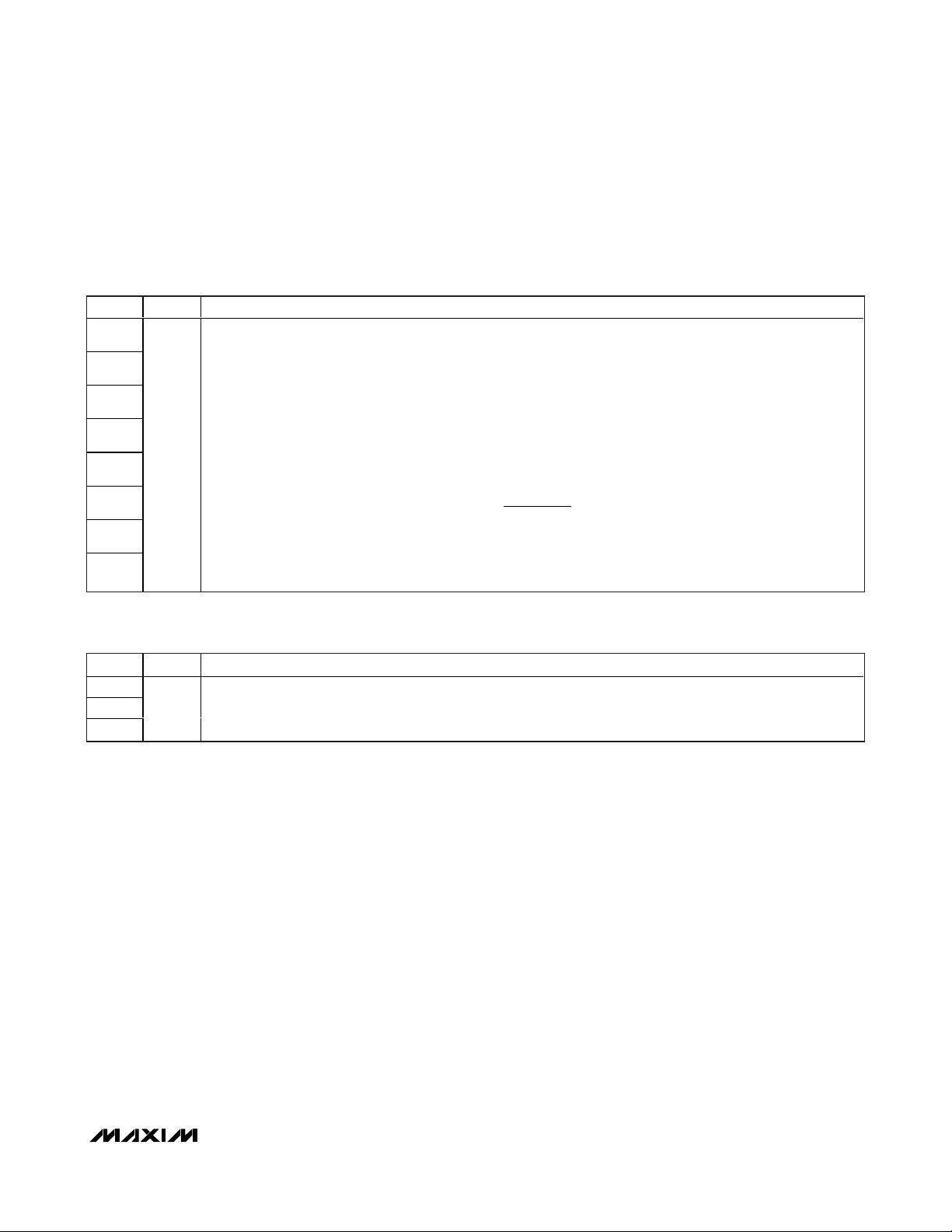

Write Byte Format

Read Byte Format

Send Byte Format

Receive Byte Format

Slave Address: equivalent to chip-select line of

a 3-wire interface

Command Byte: selects which

register you are writing to

Data Byte: data goes into the register

set by the command byte (to set

thresholds, configuration masks, and

sampling rate)

Slave Address: equivalent to chip-select line

Command Byte: selects

which register you are

reading from

Slave Address: repeated

due to change in dataflow direction

Data Byte: reads from

the register set by the

command byte

Command Byte: sends command with no data, usually

used for one-shot command

Data Byte: reads data from

the register commanded

by the last read byte or

write byte transmission;

also used for SMBus alert

response return address

S = START CONDITION SHADED = SLAVE TRANSMISSION

P = STOP CONDITION A = NOT ACKNOWLEDGED

Figure 2. I2C Protocols

S ADDRESS RD A DATA

A

P

7 bits 8 bits

WRS A COMMAND A P

8 bits

ADDRESS

7 bits

P

1

ADATA

8 bits

ACOMMAND

8 bits

AWRADDRESS

7 bits

S

S ADDRESS WR A COMMAND A S ADDRESS

7 bits8 bits7 bits

RD A DATA

8 bits

A

P

Detailed Description

The MAX6620 controls the speeds of up to four fans

using four independent linear voltage outputs. The

drive voltages for the fans are controlled directly over

the I

2

C interface. Each of the outputs (DACOUT1–

DACOUT4) drive the base of an external PNP or the

gate of a p-channel MOSFET. Voltage feedback at the

fan’s power-supply terminal is used to force the output

voltage.

The MAX6620 monitors fan tachometer logic outputs for

precise (1%) control of fan RPM and detection of fan

failure. When the MAX6620 is used with 2-wire fans,

these inputs are not used, and the fans can be driven

to the desired voltage without using tachometer feedback.

Three inputs set the fan drive status on application of

power. The DAC_START input selects the fan-supply

voltage (100%, 75%, or 0%) at startup to ensure appropriate fan drive when power is first applied. The

SPIN_START input selects whether spin-up will be

applied to the fans at power-up. WD_START selects

whether lack of I

2

C activity will force the fans to full

speed. When the watchdog function is enabled, the

fans will be driven to full speed if there is no I2C activity

for a period of 2s, 6s, or 10s.

Digital Interface

The MAX6620 features an I2C-compatible, 2-wire serial

interface consisting of a bidirectional serial data line

(SDA) and a serial clock line (SCL). SDA and SCL facilitate bidirectional communication between the MAX6620

and the master at rates up to 400kHz. The master (typically a microcontroller) initiates data transfer on the bus

and generates SCL. SDA and SCL require 4.7kΩ (typ)

pullup resistors.

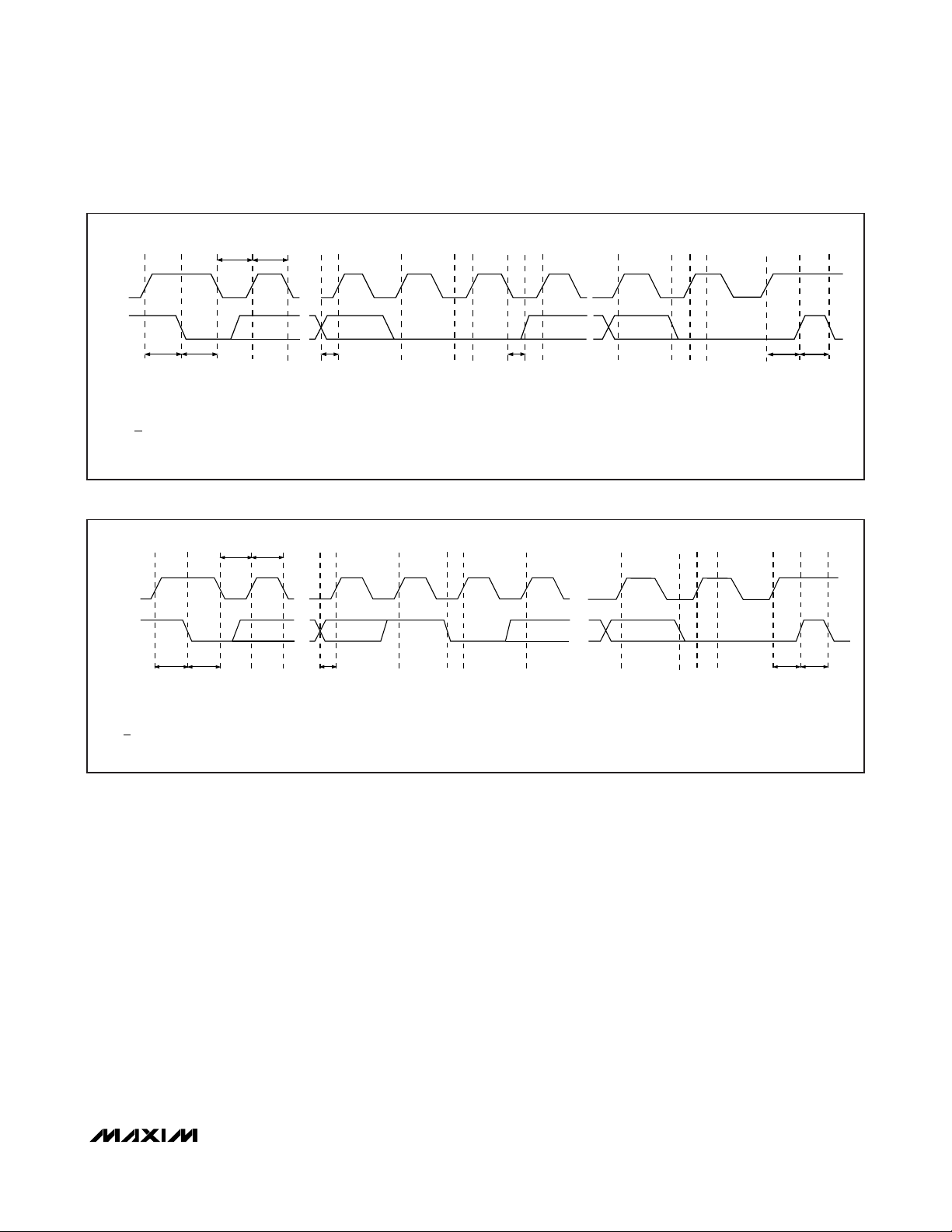

Bit Transfer

One data bit is transferred during each SCL clock

cycle. Nine clock cycles are required to transfer the

data into or out of the MAX6620. The data on SDA must

remain stable during the high period of the SCL clock

pulse, as changes in SDA while SCL is high are control

signals (see the

START and STOP Conditions

section).

Both SDA and SCL idle high.

Page 9

MAX6620

Quad Linear Fan-Speed Controller

_______________________________________________________________________________________ 9

START and STOP Conditions

The master initiates a transmission with a START condition (S), a high-to-low transition on SDA with SCL high.

The master terminates a transmission with a STOP condition (P), a low-to-high transition on SDA while SCL is high

(Figure 3). The STOP condition frees the bus and places

all devices in F/S mode (Figure 1). Use a repeated

START condition (Sr) in place of a STOP condition to

leave the bus active and in its current timing mode.

Acknowledge Bits

Successful data transfers are acknowledged with an

acknowledge bit (A) or a not-acknowledge bit (A). Both

the master and the MAX6620 (slave) generate acknowl-

edge bits. To generate an acknowledge, the receiving

device must pull SDA low before the rising edge of the

acknowledge-related clock pulse (9th pulse), and keep it

low during the high period of the clock pulse (Figure 4).

To generate a not acknowledge, the receiver allows

SDA to be pulled high before the rising edge of the

acknowledge-related clock pulse, and leaves it high

during the high period of the clock pulse. Monitoring

the acknowledge bits allows for detection of unsuccessful data transfers. An unsuccessful data transfer

happens if a receiving device is busy or if a system

fault has occurred. In the event of an unsuccessful data

transfer, the master should reattempt communication at

a later time.

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SMBDATA LINE LOW

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO SLAVE

H = LSB OF DATA CLOCKED INTO SLAVE

I = MASTER PULLS DATA LINE LOW

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

SCL

AB CDEFG HIJ

K

SDA

t

SU:STA

t

HD:STA

t

LOWtHIGH

t

SU:DAT

t

HD:DAT

t

SU:STO

t

BUF

L

M

Figure 3. I2C Write Timing Diagram

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SMBDATA LINE LOW

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO MASTER

H = LSB OF DATA CLOCKED INTO MASTER

I = MASTER PULLS DATA LINE LOW

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

SCL

AB CDEFG

HIJ

SDA

t

SU:STAtHD:STA

t

LOW

t

HIGH

t

SU:DAT

t

SU:STOtBUF

LMK

Figure 4. I2C Read Timing Diagram

Page 10

MAX6620

Slave Address

A master initiates communication with a slave device by

issuing a START condition followed by a slave address

byte. As shown in Figure 5, the slave address byte consists of 7 address bits and a read/write bit (R/W). When

idle, the MAX6620 continuously waits for a START condition followed by its slave address. The first four bits

(MSBs) of the slave address have been factory programmed and are always 0101 and the seventh bit is 0.

Connect ADDR to GND or V

CC

, or leave it unconnected

to program D2 and D1 of the slave address according

to Table 1.

After receiving the address, the MAX6620 (slave)

issues an acknowledgement by pulling SDA low for one

clock cycle.

Data Byte (Read and Write)

Single Read and Burst Read. A single read begins

with the bus master issuing a START condition followed

by the seven slave ID address bits and a zero (WR,

Figure 2), which is followed by an acknowledge bit (A)

from the slave corresponding to the slave ID. Next, the

master sends out an 8-bit register address, which is

also followed by an acknowledge bit from the slave.

The bus master issues another START condition and

the same seven slave ID address bits followed by a one

(RD, Figure 2), with the slave producing an acknowledge bit. The slave then sends out the 8-bit data corresponding to the register address previously written by

the master. The bus master sends back a not-acknowledge bit (A). This completes the single read process

and a STOP condition is issued by the bus master.

In a burst read, the process is the same as a single

read except that the bus master issues an acknowledge bit after each byte transmitted by the slave. After

each acknowledge bit, the register address increments

by one, and the data from the next register is transmitted by the slave. The process continues, with data

reads followed by acknowledges. After the register with

the highest address is read, the register pointer rolls

over to point to the first register. To terminate a burst

read, the bus master issues a STOP condition.

Single Write and Burst Write. A single write begins

with the bus master issuing a START condition followed

by the seven slave ID address bits and a zero (WR,

Figure 2), which is followed by an acknowledge bit (A)

from the slave corresponding to the slave ID. Next, the

master sends out an 8-bit register address, which is

also followed by an acknowledge bit from the slave.

After the acknowledge bit, 8-bit data is written to the

register, and the slave issues a third acknowledgement.

A STOP condition is issued by the bus master to complete the single write process.

In a burst write, the process is similar to a single write

except that the master does not issue a STOP condition

immediately after the first byte has been written. After

the first write is completed, the slave issues an

acknowledge bit, the register address increments by

one, and the data to be written to the next register is

transmitted by the master. The process continues, with

data writes followed by acknowledges. After the register with the highest available address is written, the register pointer rolls over to point to the first register. To

terminate a burst write, the bus master issues a STOP

condition.

Fan Drive

The MAX6620 uses external pass transistors to power

the fans. DACOUT1–DACOUT4 adjust the powersupply voltage for each fan by driving the base of a

PNP bipolar transistor, or the gate of a p-MOSFET. The

resulting fan-supply voltage is fed back to DACFB_.

This closes the voltage feedback loop. The system

power supply for the output devices is V

FAN

. V

FAN

is

Quad Linear Fan-Speed Controller

10 ______________________________________________________________________________________

Table 1. Slave Address Setting with

ADDR Pin

SDA

SCL

0101

1234

D2 D1 0 R/W

56789

S

A

ACKNOWLEDGE

Figure 5. MAX6620 Slave Address Byte

ADDR CONNECTION

GND 0x50 0101 000

Unconnected 0x52 0101 010

V

CC

SLAVE ADDRESS

HEX BINARY

0x54 0101 100

Page 11

MAX6620

Quad Linear Fan-Speed Controller

______________________________________________________________________________________ 11

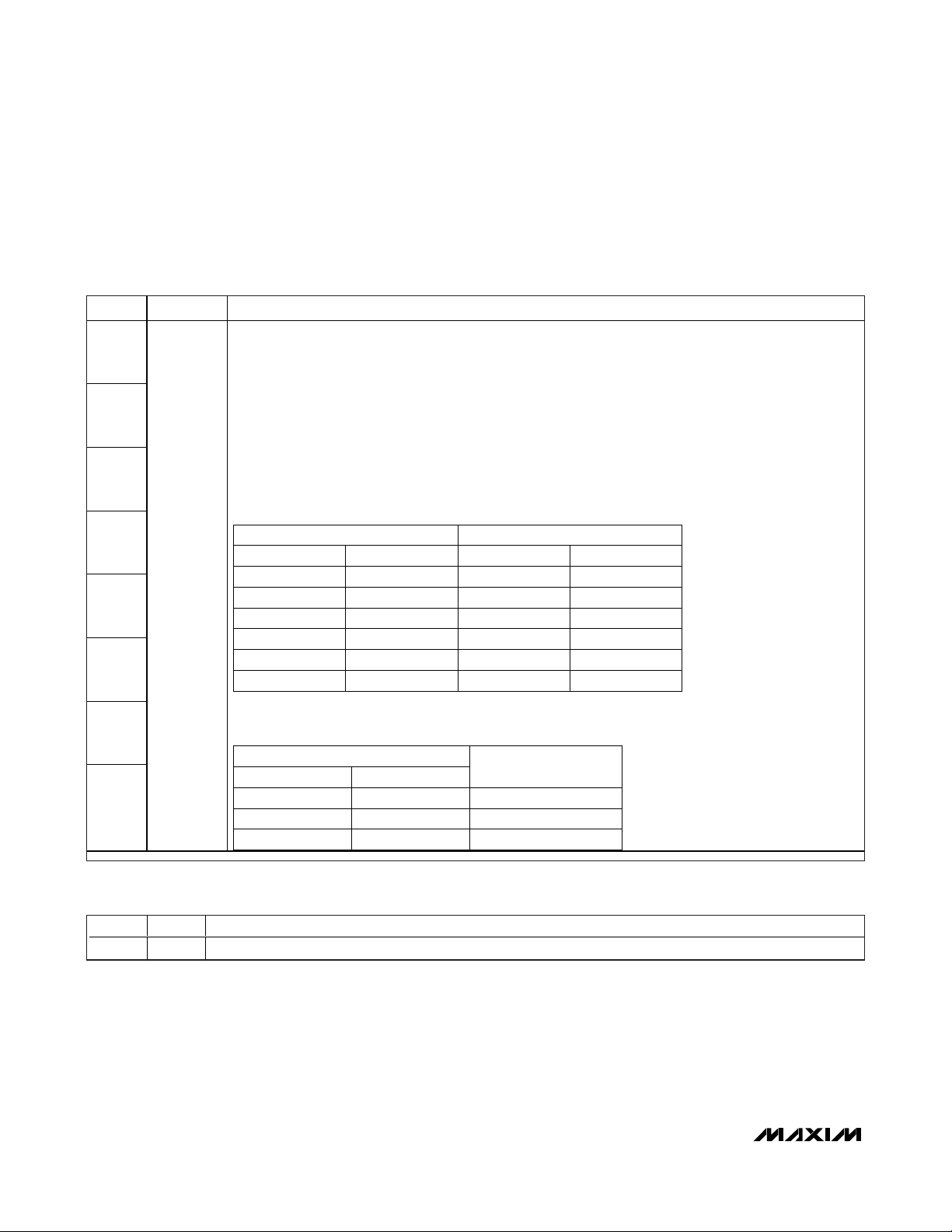

Figure 6. Read and Write Summary

P

AM

AS

8-BIT DATA

BIT 7…….…………BIT 0 ACK BIT

8-BIT DATA8-BIT REGISTER ADDRESS

BIT 7…….…….…………BIT 0 ACK BIT

1ASS P

BIT 7………….…………BIT 0 ACK BITBIT 7…………….……………BIT 0 ACK BIT

BIT 7……….…………………BIT 0 ACK BIT

LAST 8-BIT DATA AS PS

BIT 7…………….…………BIT 0 ACK BIT

AS7-BIT SLAVE ID 0 AS

AM

LAST 8-BIT DATA

BIT 7……….……………BIT 0 ACK BIT

FIRST 8-BIT DATA

AS

8-BIT REGISTER ADDRESS

8-BIT REGISTER ADDRESS

BIT 7…………….………BIT 0 ACK BIT BIT 7…………….……………BIT 0 ACK BIT

0 AS AS S 7-BIT SLAVE ID

7-BIT SLAVE ID 0 AS ASS P

BIT 7…………….……………… BIT 0 ACK BIT BIT 7…………….…………………BIT ACK BIT

7-BIT SLAVE ID

SINGLE WRITE

BIT 7…………….……….BIT 0 ACK BIT

SINGLE READ

BURST WRITE

BIT 7…………….…………BIT 0 ACK BIT

S

8-BIT REGISTER ADDRESS

BIT 7…………….…………… BIT 0 ACK BIT

0 AS AS 7-BIT SLAVE ID 1 AS FIRST 8-BIT DATA AM

7-BIT SLAVE ID

BIT 7…………….………… BIT 0 ACK BIT

BURST READ

S

S: 2-WIRE BUS START CONDITION BY MASTER

P: 2-WIRE BUS STOP CONDITION BY MASTER

AS: ACKNOWLEDGE BY SLAVE

AM: ACKNOWLEDGE BY MASTER

AM: NO ACKNOWLEDGE BY MASTER

Page 12

MAX6620

nominally 12V or 5V. The drive to the fans is proportional to V

FAN

. See the

Fan_ Target Drive Voltage Registers

and the

Applications Information

sections for more

details.

Fan-Speed Control

DAC (Voltage) Mode. In DAC mode, the MAX6620 sim-

ply sets the voltage that powers the fan. The fan’s

speed is related, but not precisely proportional to, the

drive voltage. The drive voltage is set by the Fan_

Target Drive Voltage registers and may be read from

the Fan_ Drive Voltage registers. Because the output

voltage can ramp to new values at a controlled rate, the

values in the two registers may be different. See the

Register Descriptions

and

Applications Information

sec-

tions for details.

RPM Mode. In RPM mode, the MAX6620 monitors

tachometer output pulses from the fan and adjusts the

fan drive voltage to force the fan’s speed to the desired

value. Fan speed is measured by counting the number

of internal 8192Hz clock cycles that take place during a

selectable number of tachometer periods. The number

of clock cycles counted (11-bit value) is stored in the

Fan_ TACH Count registers, and the desired number of

cycles is stored in the Fan_ Target TACH Count registers. See the

Register Descriptions

and

Applications

Information

sections for details.

Rate-of-Change Control. Sudden changes in fan

speed can be easily heard by users. The MAX6620

helps reduce the audibility of fan-speed changes by

controlling the rate at which the drive to the fan is incremented. Four bits in the Fan_ Dynamics registers set

the rate at which the fan drive voltage is incremented.

This allows the time required for a change in fan speed

to be varied from 0 (in DAC mode only) to several minutes. See the

Register Descriptions

and

Applications

Information

sections for details.

Monitoring Tachometer Signals. The TACH_ inputs

accept tachometer or “locked-rotor” output signals from

3- or 4-wire fans. When measuring fan speed, the

MAX6620 counts the number of internal 8192Hz clock

cycles that occur during 1, 2, 4, 8, 16, or 32 tachometer

periods. The number of tachometer periods is selectable for each fan by using the appropriate Fan_

Dynamics register. Tachometer pulses <25µs in duration are ignored to minimize the effect of noise on the

tachometer lines.

The TACH count for a given RPM can be obtained from

the following equation:

where:

NP = number of tachometer pulses per revolution. Most

general-purpose brushless DC fans produce two

tachometer pulses per revolution.

SR = 1, 2, 4, 8, 16, or 32. See the Fan_ Speed Range

information in the

Fan_ Dynamics Registers(06h, 07h,

08h, 09h)—POR = 0100 1100

section.

The tachometer count consists of 11 bits in the Fan_

TACH Count registers and is available in RPM and DAC

modes. In RPM mode, the desired fan count is written

to the Fan_ Target TACH Count registers.

Fan Failure Detection

When enabled, the MAX6620 monitors the TACH_

inputs to determine when a fan has failed. For fans with

tachometer outputs, failure is detected in various ways

depending on the fan control mode. In every case, four

consecutive fault detections are required to decide

whether the fan has failed. In DAC mode, the Fan_

Target TACH Count registers hold the upper limit for

tachometer count values; a fault condition is identified

when a TACH count exceeds the value written to the

Fan_ Target TACH Count registers for more than 1s. In

RPM mode, a fault condition is identified when any of

the following three conditions occur for more than 1s: 1)

the TACH count exceeds the value of the Fan_ Target

TACH Count registers while the fan drive voltage is at

full-scale, 2) the TACH count exceeds two times the

Fan_ Target TACH Count value, or 3) the TACH count

reaches its full count of 7FF.

Some fans have locked rotor outputs that produce a

logic-level output to indicate that the fan has stopped

spinning. These signals can be monitored by setting

D2:D1 in the Fan_ Configuration registers. D2 selects

locked rotor or tachometer monitoring and D1 selects the

polarity of the locked rotor signal. A fan fault has occurred

when a locked rotor signal has been present for 1s.

Fan failure is indicated in the Fan Fault register and

also with the open-drain FAN_FAIL output. The

FAN_FAIL output may be masked using the mask bits

in the Fan Fault register. When a fan failure is detected,

drive to the affected fan is removed. Drive may be

restored by writing a new DAC or fan count target to the

fan’s control registers. The global configuration regis-

Quad Linear Fan-Speed Controller

12 ______________________________________________________________________________________

SR

TACH count

=

60

NP

×

SR

×× =

RPM

8192

491520

×

NP RPM

×

Page 13

ter’s bit D4 can be used to cause a fan failure to force

the remaining fan speeds to 100%.

Watchdog

The MAX6620 includes an optional I2C watchdog function that monitors the I2C bus for transactions. When the

watchdog function is enabled, all fans will be forced to

full speed if no I2C transactions occur within a selected

period (2s, 6s, or 10s).

Spin-Up

When a fan is not spinning, and a voltage less than the

nominal fan-supply voltage is applied to its powersupply terminals, it may fail to start spinning. To overcome this, the full nominal supply voltage may be

applied to the fan terminals for a short time before a

lower voltage is applied. This “spin-up” period allows

the fan to overcome inertia and begin operating. Spinup is controlled using the Fan_ Configuration registers.

Spin-up can be disabled, or it can cause the fan to be

driven with the full supply voltage until it produces two

tachometer pulses, up to a maximum of 0.5s, 1s, or 2s

when the fan is started.

POR Options

Three inputs allow set up of the MAX6620’s behavior at

power-up. These inputs are sampled when power is

first applied to the MAX6620:

• WD_START. Connect WD_START to VCCto enable,

or to ground to disable, the watchdog function. When

enabled using WD_START, the timeout period is 10s.

After power is applied, the watchdog function may be

enabled or disabled through the global configuration

register.

• SPINUP_START. At power-up, spin-up operation is

controlled by the SPINUP_START pin, which can be

connected to ground (spin-up disabled), VCC(spinup for a maximum of 1s), or unconnected (spin-up for

a maximum of 0.5s).

• DAC_START. This input controls the fan drive volt-

age (for all four fans) at power-up. When connected

to ground, the initial fan drive voltage will be 0V.

When connected to V

CC

, the initial fan drive voltage

will be full scale. When unconnected, the initial fan

drive voltage will be 75% of V

FAN

.

MAX6620

Quad Linear Fan-Speed Controller

______________________________________________________________________________________ 13

Page 14

MAX6620

Quad Linear Fan-Speed Controller

14 ______________________________________________________________________________________

Register Map

Registers

C

2

I

1 =

S tatus

Watchd og

el ap sed

( r ead onl y) :

Rotor

0 = l ow

Locked

P ol ar i ty:

1 = hi g h

01 = 2s

10 = 6s

00 = N o w atchd og

OS C :

0 = i nter nal

failure:

100% on

(35ms):

Timeout

P OR:

0 = nor m al

Run:

0 = r un

11 = 10s

r otor

Rotor :

TAC H /

Locked

0 = TAC H

1 = l ocked

i np ut

TAC H

00 = N o sp i n- up

01 = tw o TAC H counts

M od e:

or 0.5s

0 = D AC

enab l e

or 1s

10 = tw o TAC H counts

1 = RP M

11 = tw o TAC H counts

or 2s

111 = 1s p er LS B

110 = 0.5s p er LS B

101 = 0.25s p er LS B

D AC Rate- of- C hang e:

0.0625s p er LS B ( RP M m od e)

000 = 0s p er LS B ( D AC m od e)

S am e as Fan 1 C onfi g ur ati on

S am e as Fan 1 C onfi g ur ati on

S am e as Fan 1 C onfi g ur ati on

000 = 1

001 = 2

S p eed Rang e ( TAC H p er i od s) :

100 = 0.125s p er LS B

011 = 0.0625s p er LS B

010 = 0.03125s p er LS B

001 = 0.015625s p er LS B

S am e as Fan 1 D ynam i cs

S am e as Fan 1 D ynam i cs

S am e as Fan 1 D ynam i cs

010 = 4

011 = 8

100 = 16

101 = 32

110 = 32

111 = 32

1 = X TAL

0 = enabled

1 = disabled

0 = enabled

1 = disabled

S p i n- U p :

1 = r eset

1 = standby

C W atchd og :

2

I

Fans to

Bus

F U N C T IO N D 7 D 6 D 5 D 4 D 3 D 2 D 1 D 0

PO R

ST A T E

R EGIST ER

N O ./A D DR ESS

R /W

Gl ob al

C onfi g ur ati on

R/W 00h 0000 0X X X

R/W 01h 0000 1111 Fan Faul t Fan 4 Faul t Fan 3 Faul t Fan 2 Faul t Fan 1 Faul t Fan 4 Mask Fan 3 Mask Fan 2 Mask Fan 1 Mask

Fan 1

C onfi g ur ati on

R/W 02h 0X X 0 0000

Fan 2

C onfi g ur ati on

R/W 03h 0X X 0 0000

Fan 3

C onfi g ur ati on

R/W 04h 0X X 0 0000

Fan 4

R/W 05h 0X X 0 0000

Fan 1

C onfi g ur ati on

D ynam i cs

R/W 06h 0100 1100

Fan 2

D ynam i cs

R/W 07h 0100 1100

Fan 3

D ynam i cs

R/W 08h 0100 1100

Fan 4

D ynam i cs

R/W 09h 0100 1100

Page 15

MAX6620

Quad Linear Fan-Speed Controller

______________________________________________________________________________________ 15

X = Depends on input states at power-up.

Register Map (continued)

S am e as Fan 1 TAC H C ount

S am e as Fan 1 TAC H C ount

S am e as Fan 1 TAC H C ount

S am e as Fan 1 D r i ve V ol tag e

S am e as Fan 1 D r i ve V ol tag e

S am e as Fan 1 D r i ve V ol tag e

S am e as Fan 1 Tar g et TAC H C ount

S am e as Fan 1 Tar g et TAC H C ount

S am e as Fan 1 Tar g et TAC H C ount

S am e as Fan 1 Tar g et D r i ve V ol tag e

S am e as Fan 1 Tar g et D r i ve V ol tag e

S am e as Fan 1 Tar g et D r i ve V ol tag e

D 2D 1D 0—————

C ount

C ount

13h 1110 0000

R

C ount

Fan 3 TAC H

15h 1110 0000

14h 1111 1111

R

Fan 4 TAC H

16h 1111 1111

F U N C T IO N D 7 D 6 D 5 D 4 D 3 D 2 D 1 D 0

Fan 1 TAC H

Fan 2 TAC H

PO R

ST A T E

11h 1110 0000

10h 1111 1111 D 10 D 9D 8D 7D 6D 5D 4D 3

12h 1111 1111

R EG IST ER

N O . /A D D R ESS

R

R /W

C ount

17h 1110 0000

R

D 0——————Ful l

V ol tag e

V ol tag e

1Bh 0000 0000

R

V ol tag e

Fan 3 D r i ve

1C h 0000 0000

1D h 0000 0000

R

Fan 4 D r i ve

1E h 0000 0000

R

Fan 1 D r i ve

Fan 2 D r i ve

19h 0000 0000

18h 0000 0000 D 8D 7D 6D 5D 4D 3D 2D 1

1Ah 0000 0000

R

D 2D 1D 0—————

V ol tag e

Fan 1 Tar g et

TAC H C ount

Fan 2 Tar g et

TAC H C ount

1Fh 0000 0000

21h 0000 0000

20h 0011 1100 D 10 D 9D 8D 7D 6D 5D 4D 3

R/W

23h 0000 0000

22h 0011 1100

R/W

Fan 3 Tar g et

TAC H C ount

25h 0000 0000

24h 0011 1100

R/W

Fan 4 Tar g et

TAC H C ount

27h 0000 0000

26h 0011 1100

R/W

D 0———————

Fan 1 Tar g et

Fan 2 Tar g et

2Ah X X X X X X X X

D r i ve V ol tag e

2Bh X 000 0000

R/W

2C hX X X X X X X X

Fan 3 Tar g et

R/W

D r i ve V ol tag e

2D hX 000 0000

28h X X X X X X X X D 8D 7D 6D 5D 4D 3D 2D 1

D r i ve V ol tag e

29h X 000 0000

R/W

Fan 4 Tar g et

2E hX X X X X X X X

R/W

D r i ve V ol tag e

2Fh X 000 0000

Page 16

MAX6620

Quad Linear Fan-Speed Controller

16 ______________________________________________________________________________________

Global Configuration Register (00h)—POR = 0000 0XXX

Register Descriptions

BIT R/W FUNCTION

Run:

7 R/W

0 = run

1 = standby

6 R/W

5 R/W

4 R/W

3 R/W

POR:

0 = norma l operation

1 = reset all registers to POR values

Thi s bit automatically re sets itself and will always return a 0 when read.

2

C Bus Timeout:

I

0 = enabled

1 = disabled

2

C interface will reset if SDA is low for more than 35ms.

The I

Fans to 100% on failure:

0 = if a fan fai lure is detected, all other fan channels immediately go to full-scale drive vo ltage to

ensure adequate coo ling

1 = disabled

Oscillator Selection:

Selects on-chip oscillator or 32.768kHz crystal/ceramic resonator. Use crystal if 1% RPM accuracy is

required.

0 = internal oscillator (default at power-on)

1 = external 32.768kHz crystal

When switching from the internal osci llator to an external crystal, the MAX6620 operates from the internal

oscillator until the crystal oscillator has started up. If the crystal is damaged or the oscillator fails to start,

the MAX6620 will continue to operate from the internal oscillator.

Page 17

MAX6620

Quad Linear Fan-Speed Controller

______________________________________________________________________________________ 17

Global Configuration Register (00h)—POR = 0000 0XXX (continued)

BIT R/W FUNCTION

I

When active, the watchdog monitors SDA and SCL for va lid I

transactions between the ma ster and the MAX6620 within the watchdog period, all fan output vo ltages

2

R/W

1

0 R

will go to full-scale drive voltage.

If the watchdog times out and va lid I

previous DAC va lue. The master can then program the output vo ltages, target TACH counts, or other

functions in the normal manner.

When the w atchdog function is active, ensure that the master communicates to the MAX6620

periodically, for example reading a status register.

The POR state is set by the state of the WD_START pin at power-up.

I

This bit is cleared by I

2

C Watchdog:

2

C transactions begin to occur again, operation will resume with the

D2:D1 I

00 Inactive (no watchdog) WD_START = GND

01 2 —

10 6 —

11 10 WD_START = V

2

C Watchdog Status:

2

0 = I

C transactions occurred within watchdog period

1 = time between I

2

C WATCHDOG PERIOD (s) POR CONDITION

2

C transact ion exceeds watchdog period

2

C read from this register.

2

C transactions . If there are no va lid

CC

Page 18

MAX6620

Quad Linear Fan-Speed Controller

18 ______________________________________________________________________________________

Fan Fault Register (01h)—POR = 0000 1111

BIT R/W FUNCTION

7 R

6 R Fan 3 Fault Status

5 R Fan 2 Fault Status

4 R Fan 1 Fault Status

3 R/W

2 R/W Fan 3 Fault Mask

1 R/W Fan 2 Fault Mask

0 R/W Fan 1 Fault Mask

Fan 4 Fault Status:

Indicates which fans have had faults detected. When a fan fault is detected, the drive to the fan is disabled and

the corresponding fault bit is set. The fault bits latch until they are cleared by reading, thus allowing short-term

faults to be identified. After a fault status bit is cleared by reading, the corresponding output voltage will

remain zero until a Fan_ Target Drive Voltage register or Fan_ Target TACH Register is written. Writing a

new target drive voltage or target TACH count will cause drive to be applied to the fan again, at which time a

new failure-detection cycle will begin.

Fault Conditions Are:

MODE

DAC Any

RPM

FAN_FAIL will be asserted when four consecutive faults are detected.

Fan 4 Fault Mask:

Masks faults on selected fans from asserting the FAN_FAIL output. Faults will still be indicated by the fault

status bits:

0 = not masked

1 = masked

FAN_ DRIVE

VOLTAGE REGISTER

1FF (full)

<1FF

CONDITION

TACH count exceeds value of Fan_ Target

TACH count

Locked rotor asserts

TACH count exceeds value of Fan_ Target

TACH Count

TACH count exceeds two times of Fan_ Target

TACH Count value

TACH count reaches it full count of 7FF

TIME

(s)

>1

>1

Page 19

MAX6620

Quad Linear Fan-Speed Controller

______________________________________________________________________________________ 19

Fan_ Configuration Registers (02h, 03h, 04h, 05h)—POR = 0XX0 0000

BIT R/W FUNCTION

RPM/DAC:

0 = DAC mode. The fan drive voltage is set by the value in the Fan_ Target Drive Voltage register.

1 = RPM mode. The fan drive voltage is adjusted to produce the TACH count value in the Fan_ Target

7 R/W

6 R/W

5 R/W

TACH Count regi ster.

When chang ing from DAC to RPM mode, if the current RPM value is different from the value selected in

the Fan_ Target TACH Count register, the drive voltage will start from the current va lue and increment/

decrement toward the desired value at the se lected DAC rate-of-change.

Spin-Up:

When the fan drive voltage increa se s from 0V to a value less than the ful l-s cale drive vo ltage, it may be

necess ary to drive the fan with the full-sca le drive voltage for a brief period to ensure that the fan is

spinning before reducing the drive to the selected va lue.

When spin-up is selected, the fan i s driven at the full-scale drive vo ltage until two tachometer pulses

have been detected or loc ked rotor has been cleared. A maxi mum spin-up time is a lso selectable to

ensure that the spin-up time is not excess i ve. After two tachometer pulses have been detected, or locked

rotor has been cleared or the spin-up has timed out, the drive voltage goes to the value in the Fan_ Target

Drive Voltage register.

The POR state is set by the state of the SPINUP_START pin at power-up.

D6:D5 FUNCTION POR CONDITION

00 No spin-up SPIN_START pin = ground

01

10

11

Spin-up until two tachometer pul se s or

clearing of locked rotor, or 0.5s (ma x)

Spin-up until two tachometer pul se s or

clearing of locked rotor, or 1s (max)

Spin-up until two tachometer pul se s or

clearing of locked rotor, or 2s (max)

SPIN_START pin = open

SPIN_START pin = V

—

CC

4 Reserved

TACH Input Enable:

3 R/W

2 R/W

1 R/W

0 — Reserved

Enables TACH input function and fan fault detection (automatically enabled in RPM mode).

0 = disabled. When disabled and TACH input is not used, bit 1 and bit 2 are ignored.

1 = enabled

TACH/Locked Rotor:

Selects TACH input function as TACH count or locked rotor. In locked rotor mode, the TACH count stops

and assertion of the TACH input indicates that the fan ha s stopped.

0 = TACH count

1 = locked rotor

Locked Rotor Polarity:

0 = low locked rotor. TACH input low in locked rotor mode indicates fan is stopped.

1 = high locked rotor. TACH input high in locked rotor mode indicates fan is stopped.

Page 20

MAX6620

Quad Linear Fan-Speed Controller

20 ______________________________________________________________________________________

Fan_ Dynamics Registers (06h, 07h, 08h, 09h)—POR = 0100 1100

BIT R/W FUNCTION

7 R/W

6 R/W

5 R/W

Fan_ Speed Range:

The MAX6620 determines fan speed by counting the number of internal 8192Hz clock cycles (using an 11bit counter) during one or more fan tachometer periods. Three bits set the nominal RPM range for the fan, as

shown in the table below. As an example, a setting of 010 causes the MAX6620 to count the number of

8192Hz clock cycles that occur during four complete tachometer periods. If the fan has a nominal speed of

2000RPM and two tachometer pulses per revolution, one tachometer period will be nominally 15ms, and four

tachometer periods will be 60ms. With an 8192Hz clock, the TACH count will therefore be equal to 491. With

a fan speed of 1/3 the nominal value, the count will be 1474. If the fan’s nominal speed is 1000RPM, the fullspeed TACH count will be 983. At 1/3 the nominal speed, there will be 2948 clock cycles in four tachometer

periods. This is greater than the maximum 11-bit count of 2047, so four tachometer periods is too many for

this fan; a setting of 001 (two clock cycles) is recommended instead.

The table below shows the full-speed tachometer counts for several combinations of nominal fan speeds

and D7:D5 settings. The shaded combinations will provide the best results. When setting D7:D5, the goal is

to obtain the highest tachometer count without exceeding the maximum count of 2047 when the fan is at the

minimum speed of interest. For example, if the minimum speed of interest is 1/3 of full speed, the maximum

tachometer count will be three times the value shown in the table below:

Tachometer Counts/(Counting Period) (8192Hz Clock Used):

NUMBER OF

D7:D5

TACH PERIODS

COUNTED

000 1

001 2

010 4

011 8

100 18

101,

110,

111

32

500 1000 2000 4000 8000 16000

491

(60ms)

983

(120ms)

1966

(240ms)

2047

(480ms)

2047

(960ms)

2047

(1920ms)

245

(30ms)

491

(60ms)

983

(120ms)

1966

(240ms)

2047

(480ms)

2047

(960ms)

(120ms)

(240ms)

(480ms)

RPM

122

(15ms) 61(7.5ms) 30(3.75ms) 15(1.875ms)

245

(30ms)

491

(60ms)

983

1966

2047

122

(15ms) 61(7.5ms) 30(3.75ms)

245

(30ms)

491

(60ms)

983

(120ms

1966

(240ms)

122

(15ms) 61(7.5ms

245

(30ms)

491

(60ms)

983

(120ms)

122

(15ms)

245

(30ms

491

(60ms)

Page 21

MAX6620

Quad Linear Fan-Speed Controller

______________________________________________________________________________________ 21

Fan_ Dynamics Registers (06h, 07h, 08h, 09h)—POR = 0100 1100 (continued)

BIT R/W FUNCTION

Fan_ DAC Rate-of-Change:

The fan drive voltage (at the DACFB_ inputs) varies from 0 to full scale in 512 increments. The rate-ofchange bits determine the time interval between output voltage increments/decrements. In RPM mode, a

setting of 0 would result in an unstable feedback loop, so a default value of 0.0625 is in effect when 0 is

selected.

4 R/W

3 R/W

2 R/W

Regardless of the settings, there are a few cases for which the rate-of-change is always 0:

•

When a target TACH count of 2047 (7FF) is selected, the fan drive voltage immediately goes to 0V. A

full-scale target count is assumed to mean that the intent is to shut down the fan, and going directly to 0

drive avoids the possibility of loss of control-loop feedback at high TACH counts. If a slow- speed

decrease toward 0 is desired, a target TACH count at the slowest practical value for the fan should be

chosen. Once that count has been reached, selecting a count of 2047 (7FF) will then take the drive

immediately to 0V.

• When a target fan drive voltage of 0V is selected, the drive voltage immediately goes to 0V. Again, it is

assumed that the intent is to shut down the fan. If a slow-speed decrease toward 0 is desired, a target

fan drive voltage of the slowest practical value for the fan in question should be chosen. Once that drive

voltage has been reached, selecting a target value of 0 will then take the drive immediately to 0V.

• When the current drive level is 0 in DAC mode, selecting a new target fan drive voltage will immediately

take the voltage to that value. The fan will spin-up first if spin-up is enabled.

• When the current drive level is 0 in RPM mode, selecting a new target TACH count that is less than 2047

(7FF) will immediately take the drive voltage to the value in the Fan_ Target Drive Voltage register. From

this value, the drive voltage will increment as needed to achieve the desired TACH count. The fan will

spin-up first if spin-up is enabled.

TIME BETWEEN OUTPUT VOLTAGE

D4:D2

DAC MODE RPM MODE

000 0 0.0625 0

001 0.015625 10

010 0.03125 20

011 0.0625 (default) 40

100 0.125 80

101 0.25 160

110 0.5 320

111 1.0 640

INCREMENTS (s)

TIME FROM 33%

TO 100%

(s)

1 — Reserved

0 — Reserved

Page 22

MAX6620

Quad Linear Fan-Speed Controller

22 ______________________________________________________________________________________

Fan_ TACH Count Registers (10h, 12h, 14h, 16h)—POR = 1111 1111

Fan_ TACH Count Registers (11h, 13h, 15h, 17h)—POR = 1110 0000

Fan_ Drive Voltage Registers (18h, 1Ah, 1Ch, 1Eh)—POR = 0000 0000

Fan_ Drive Voltage Registers (19h, 1Bh, 1Dh, 1Fh)—POR = 0000 0000

BIT R/W FUNCTION

7

6

5

4

3

2

1

0

BIT R/W FUNCTION

7

6

5

BIT R/W FUNCTION

7

6

5

4

3

2

1

0

R

R Fan_ TACH Count D7:D5

R

Fan_ TACH Count D10:D3:

Indicates the number of 8192Hz clock pulses counted during the counting period. The Fan_ TACH Count

consists of 11 bits contained in two bytes.

To minimize noise from spurious tachometer transitions, pulses less than 25µs are ignored.

Fan_ Drive Voltage D8:D1:

This is a 9-bit value that ranges from 0 to 511.

This register shows the actual fan drive voltage. When the value in this register is 480V, the nominal fan drive

voltage of V

is supplied to the fan, as shown in the table in the Fan_ Target Drive Voltage Registers section.

FAN

BIT R/W FUNCTION

7RFan_ Drive Voltage D0

Full-Scale Status:

0R

0 = DAC is driving with value of D8:D0 that is not at full scale

1 = DAC is driving with full scale voltage

Page 23

MAX6620

Quad Linear Fan-Speed Controller

______________________________________________________________________________________ 23

Fan_ Target TACH Count Registers (21h, 23h, 25h, 27h)—POR = 0000 0000

Fan_ Target TACH Count Registers (20h, 22h, 24h, 26h)—POR = 0011 1100

The Fan_ Target TACH Count consists of 11 bits contained in two bytes. The two bytes must be written in

order in one or two I

2

C transactions, with no other I2C

writes in between. These target registers are updated

internally at the same time when a second byte (LSB) is

written.

BIT R/W FUNCTION

7

6

5

4

R/W

3

2

1

0

Fan_ Target TACH Count D10:D3:

In RPM mode, write the desired tachometer count to this register. The MAX6620 will then adjust the fan drive

voltage to achieve this tachometer count.

In DAC mode, this register has no effect.

When changing from DAC mode to RPM mode, best results are obtained by loading this register with the

desired TACH count before changing to RPM mode. The target TACH count for a given RPM will be obtained

by the following equation:

TargetTACH

where:

NP = number of TACH pulses per revolution

SR = 1, 2, 4, 8, 16, or 32 (see the fan_ speed range information in the Fan_ Dynamics Registers (06h, 07h, 08h,

09h)—POR = 0100 1100 section)

=

NP

BIT R/W FUNCTION

7

6

5

R Fan_ Target TACH Count D2:D0

×

××608192

RPM

SR

Page 24

MAX6620

Quad Linear Fan-Speed Controller

24 ______________________________________________________________________________________

The Fan_ Target Drive Voltage consists of 9 bits contained in two bytes. The two bytes must be written in

order in one or two I

2

C transactions with no other I2C

writes in between. These target registers are updated

internally at the same time when a second byte (LSB) is

written.

Fan_ Target Drive Voltage Registers (29h, 2Bh, 2Dh, 2Fh)—POR = X000 0000

Fan_ Target Drive Voltage Registers (28h, 2Ah, 2Ch, 2Eh)—POR = XXXX XXXX

BIT R/W FUNCTION

7

6

5

4

R/W

3

2

Fan_ Target Drive Voltage D8:D1:

This is a 9-bit value that ranges from 0 to 511 and is contained in two bytes. In DAC mode, write the

desired fan drive voltage to these two registers. The MAX6620 will then ramp the fan drive voltage to

this va lue at a rate determined by the DAC rate-of-change bit s.

In RPM mode, the value contained in this register will be the vo ltage applied to the fan immed iately after

spin-up or after changing the Fan_ Target TACH Count from 2047 (7FF) to a value lower than 2047 (7FF).

For example, if the fan is currently stopped with spin-up disab led, and a new Fan_ Target TACH Count

corresponding to 60% of the full-sca le fan speed is to be selected, the fan voltage can be programmed

to immediately go to 60% of the full-scale drive voltage when the new Fan_ Target TACH Count is

selected from 2047 (7FF), and then clo se the RPM control loop starting from that voltage.

The register value is converted to the drive vo ltage at the fan (or voltage at DACFB _) as fol lows:

D8:D0 FAN_ DRIVE VOLTAGE (V)

DECIMAL HEX 5V RANGE 12V RANGE

0 000h 0.000 0.000

200 0C8h 1.764 4.486

300 12Ch 2.646 6.729

400 190h 3.527 8.972

480 1E0h 4.232 10.766

511 1FFh 4.506 11.462

The value of the Fan_ Target Drive Voltage at POR depends on state of the DAC_START pin, as show n

1

0

below:

D8:D0

DECIMAL HEX

0 000h GND

384 180h Open

511 1FF VCC

DAC_START

Bit R/W FUNCTION

7RFan_ Target Drive Voltage D0

Page 25

MAX6620

Quad Linear Fan-Speed Controller

______________________________________________________________________________________ 25

Applications Information

External Pass Transistors

Match external pass transistors to the fans being used.

Ensure that the pass transistor is capable of handling

the maximum fan current. For best results, the pass

transistor’s maximum current rating should be at least

50% greater than the fan’s nominal supply current.

The transistor should also be capable of dissipating the

worst-case power, which usually occurs when the fan is

being driven to approximately 50% of the nominal supply voltage. The maximum power dissipation will

depend on the thermal resistance of the transistor, its

case, and the printed-circuit board (PCB) to which it is

soldered. For example, if the worst-case transistor

power dissipation occurs when the fan current is

100mA, and the voltage across the fan is 6.5V, the

maximum power dissipation will be 650mW. A

BCP69T1-D in a SOT223-4 package is rated at 1.5W at

25°C (about 1W at 70°C) when soldered to a 0.93in

2

(6cm2) copper PCB pad, and can easily handle this

power dissipation. Larger copper pads, packages with

lower thermal resistance, or different transistors can

give significantly different results.

The MAX6620 uses an advanced output driver design

that eliminates the large external capacitors often connected across the fan’s power-supply terminals. For

stability with a variety of fans, connect a 0.1µF capacitor from DACFB_ to ground.

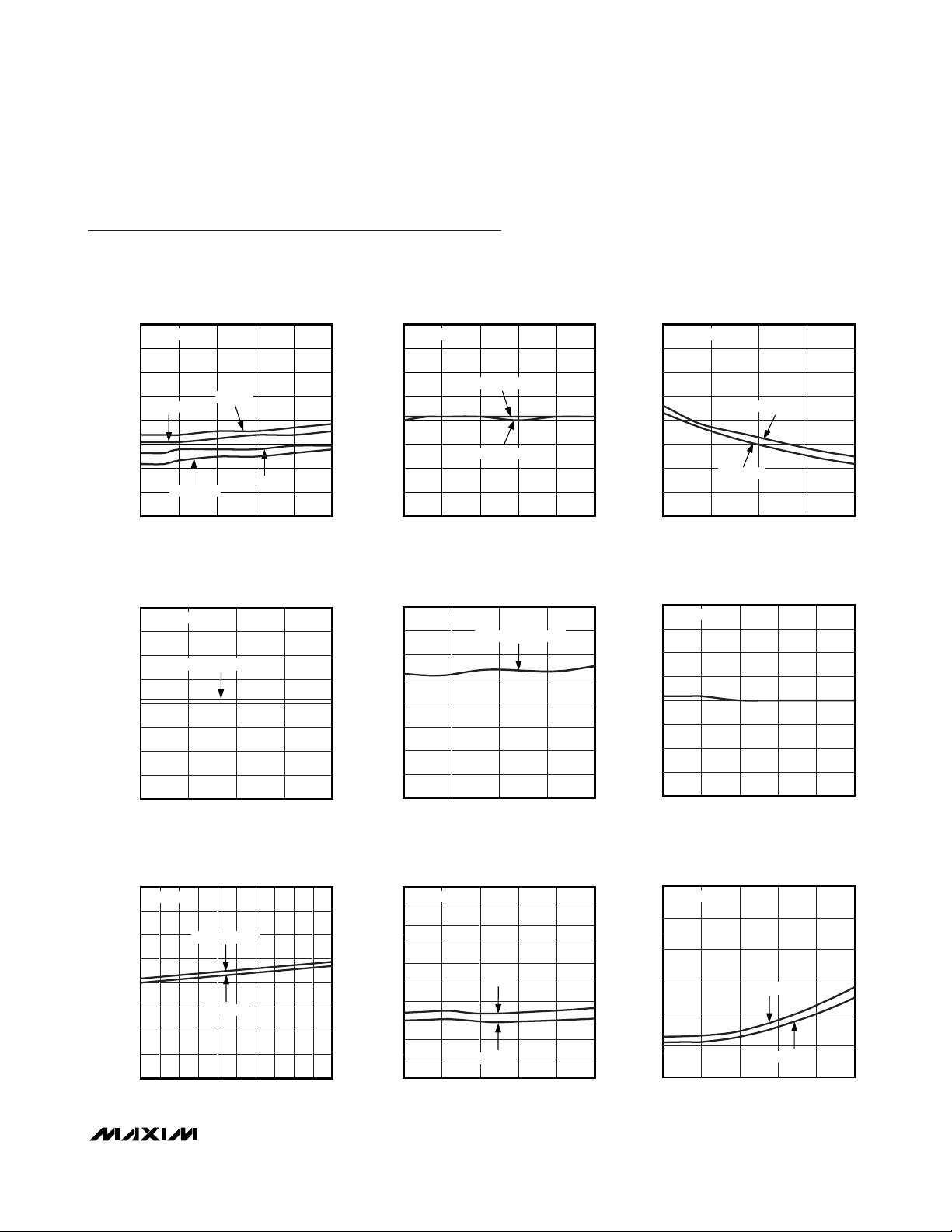

Using a Low-Dropout Voltage Regulator

(LDO) as the Pass Device

Voltage regulators can be used instead of discrete transistors to drive the fans (Figure 7). The voltage feedback loop is closed around the regulator to provide the

desired output voltage. When using a voltage regulator,

note the following:

• Most regulators require relatively large capacitors at

their inputs and outputs for stability.

• Most regulators have a lower output voltage limit that

is >0V. If removing the drive from the fan is necessary when using a regulator, choose a regulator that

has an on/off control input and drive that input from

the system microcontroller.

Fan-Speed Control (DAC and RPM Modes)

The MAX6620 has two main modes for controlling fan

speeds. In DAC mode, the MAX6620 produces an output voltage that drives the fan. This voltage is proportional to the main fan power-supply voltage (V

FAN

).

Write the 9-bit desired voltage value in the Fan_ Target

Drive Voltage register.

In RPM mode, the MAX6620 monitors the tachometer

signals from the fans through the TACH_ inputs and

adjusts the drive voltage to yield the desire tachometer

count. The tachometer count is the number of internal

8192 clock cycles that are counted during the selected

number of tachometer pulses.

Controlling 2-Wire Fans (DAC Mode)

In DAC mode, the MAX6620 sets the fan’s supply voltage to the value selected in the Fan_ Target Drive

Voltage register. Tachometer monitoring is never done

when controlling a 2-wire fan, so the TACH input enable

bit in the Fan_ Configuration register should be set to 0.

Enabling the TACH input when using a 2-wire fan will

result in an erroneous fan failure detection.

Initial Settings:

• Begin with the POR settings. The POR value of the

fan_ DAC rate-of-change bits (4:2 of the Fan_

Dynamics Register) can yield slower fan speed

changes than desired. If this is the case, choose a

faster value, such as 001.

Starting the Fan:

• Write the desired drive voltage value to the Fan_

Target Drive Voltage register.

Changing Speeds:

• Write the new desired drive voltage value to the Fan_

Target Drive Voltage register.

Stopping the Fan:

• Write a voltage value of 0 to the Fan_ Target Drive

Voltage register.

Controlling 3-Wire Fans (DAC Mode)

In DAC mode, the MAX6620 sets the fan’s supply voltage to the value selected in the Fan_ Target Drive

Voltage register. 3-wire fans with tachometer outputs

allow monitoring of the fan’s speed to detect fan failure.

To monitor a fan’s speed, the TACH input should be

enabled.

Page 26

MAX6620

Quad Linear Fan-Speed Controller

26 ______________________________________________________________________________________

Figure 7. Using Low Dropout Voltage Regulators Instead of Discrete Transistors as the Pass Devices

V

C

470Ω

DACOUT1

TO I2C MASTER

FAN_FAIL

SDA

SCL

V

CC

3.0V TO 5.5V

0.1μF

V

+12V

FAN

0.1μF

DACFB1

TACH1

DACOUT2

DACFB2

V

FAN

V

C

470Ω

V

FAN

V

FAN

+12V

V

IN

PQ20RX

V

FAN

V

IN

PQ20RX

0.33μF

V

O

V

ADJ

2.4kΩ

27kΩ

0.33μF

V

O

V

ADJ

2.4kΩ

27kΩ

47μF

FAN1

47μF

V

CC

(OPTIONAL CRYSTAL)

ADDR

DAC_START

SPINUP_START

WD_START

X1

X2

I2C INTERFACE,

REGISTERS, AND

CONTROL LOGIC

DAC OUTPUT

DRIVER

TACH MONITOR

TACH2

DACOUT3

DACFB3

TACH3

DACOUT4

DACFB4

TACH4

V

FAN

V

IN

V

470Ω

V

FAN

V

470Ω

V

FAN

V

PQ20RX

V

FAN

V

IN

PQ20RX

O

V

ADJ

2.4kΩ

27kΩ

V

O

V

ADJ

2.4kΩ

27kΩ

C

C

FAN2

0.33μF

47μF

FAN3

0.33μF

47μF

FAN3

Page 27

MAX6620

Quad Linear Fan-Speed Controller

______________________________________________________________________________________ 27

Initial Settings:

• Begin with the POR settings. The POR value of the

fan_ DAC rate-of-change bits (4:2 of the Fan_

Dynamics register) can yield slower fan speed

changes than desired. If this is the case, choose a

faster value, such as 001.

• Write the desired number of tachometer periods to

be counted in the speed range bits (7:5 of the Fan_

Dynamics register).

• Write the maximum allowable tachometer count to the

Fan_ Target TACH Count registers. Tachometer

counts greater than this value will result in a fan fault

detection. Choose a value that will not be encountered during normal operation, accounting for normal

fan speed tolerances.

Note: Setting a full-scale target count (2047) will

result in the fan drive going to 0V.

• Set the TACH input enable bit in the Fan_

Configuration register to 1.

Note: This bit can be set after the fan has been started, if desired. If the bit is set before writing a target

fan drive voltage, the target drive voltage should be

set immediately after enabling the TACH input to

avoid failure detection before the fan has started

spinning.

Starting the Fan:

• Write the desired drive voltage value to the Fan_

Target Drive Voltage register.

Changing Speeds:

• Write the new desired drive voltage value to the Fan_

Target Drive Voltage register.

Stopping the Fan:

• Write a 0 to the TACH input enable bit in the Fan_

Configuration register. This prevents the MAX6620

from deciding that the fan has failed after it has

stopped.

• Write a voltage value of 0V to the Fan_ Target Drive

Voltage register.

• If a gradual decrease in fan speed is desired, write

the lowest drive voltage at which the fan will reliably

operate. When the drive voltage reaches that value,

write 0V to the Fan_ Target Drive Voltage register.

Controlling 3-Wire Fans (RPM Mode)

Begin as in DAC mode and start the fan.

Changing from DAC Mode to RPM Mode:

• Write the desired tachometer count to the Fan_ TACH

Count registers.

• Set bit 7 of the Fan_ Configuration register to 1. This

selects RPM mode. The fan will go to the selected

speed.

Note: When the DAC rate-of-change is set to one of

the faster values, the fan drive voltage can, depending on the fan’s characteristics, undergo a slow oscillation. While this rarely has an audible impact, it can

be reduced or eliminated by selecting a slower rateof-change once the fan’s speed has reached or

approached its target value.

Changing Speeds:

• Write the desired tachometer count to the Fan_

Target TACH Count registers.

Stopping the Fan:

• Write the current drive voltage into the Fan_ Target

Drive Voltage register.

• Write a value greater than the current tachometer

count into the Fan_ Target TACH Count register.

• Write a 0 to bit 7 of the Fan_ Configuration register.

This selects DAC mode.

• Write a 0 to the TACH input enable bit in the Fan_

Configuration register. This prevents the MAX6620

from detecting a high TACH count and determining

that the fan has failed.

• Write a voltage value of 0V to the Fan_ Target Drive

Voltage register.

• If a gradual decrease in fan speed is desired, write

the lowest drive voltage at which the fan will reliably

operate. When the drive voltage reaches that value,

write 0 to the Fan_ Target Drive Voltage register.

Page 28

MAX6620

Quad Linear Fan-Speed Controller

28 ______________________________________________________________________________________

Typical Application Circuit

Chip Information

PROCESS: CMOS

TO I2C MASTER

V

CC

FAN_FAIL

SDA

SCL

ADDR

DAC_START

V

CC

0.1μF

I2C INTERFACE,

REGISTERS, AND

CONTROL LOGIC

V

FAN

0.1μF

DAC OUTPUT

DRIVER

TACH MONITOR

DACOUT1

DACFB1

TACH1

DACOUT2

DACFB2

TACH2

DACOUT3

DACFB3

TACH3

0.1μF

0.1μF

0.1μF

4.7kΩ

4.7kΩ

4.7kΩ

4.7kΩ

4.7kΩ

4.7kΩ

0.1μF

V

FAN

FAN1

0.1μF

V

FAN

FAN2

0.1μF

V

FAN

FAN3

SPINUP_START

(OPTIONAL CRYSTAL)

WD_START

DACOUT4

X1

X2

GND

DACFB4

0.1μF

TACH4

4.7kΩ

V

4.7kΩ

0.1μF

FAN

FAN4

Page 29

MAX6620

Quad Linear Fan-Speed Controller

______________________________________________________________________________________ 29

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

QFN THIN.EPS

Page 30

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

30

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Quad Linear Fan-Speed Controller

MAX6620

Loading...