General Description

The MAX6618 PECI-to-I2C translator provides an efficient, low-cost solution for PECI-to-SMBus

TM

/I2C protocol conversion. The PECI-compliant host reads

temperature data directly from up to four PECI-enabled

CPUs.

The I2C interface provides an independent serial communication channel to communicate synchronously with

peripheral devices in a multiple master or multiple slave

system. This interface allows a maximum serial-data

rate of 400kbps.

The MAX6618 is designed to operate from a +3.0V to

+3.6V supply voltage and ambient temperature range

of -20°C to +120°C.

Applications

Servers

Workstations

Desktop Computers

Features

♦ 400kbps I2C-Compatible, 2-Wire Serial Interface

♦ +3V to +3.6V Supply Voltage

♦ PECI-Compliant Port

♦ PECI-to-I

2

C Translation

♦ Programmable Temperature Offsets

♦ -20°C to +120°C Operating Temperature Range

♦ V

REF

Input Refers Logic Levels to the PECI

Supply Voltage

♦ Automatic I

2

C Bus Lockup Timeout Reset

♦ Lead-Free, 10-Pin µMAX

®

Package

MAX6618

PECI-to-I2C Translator

________________________________________________________________

Maxim Integrated Products

1

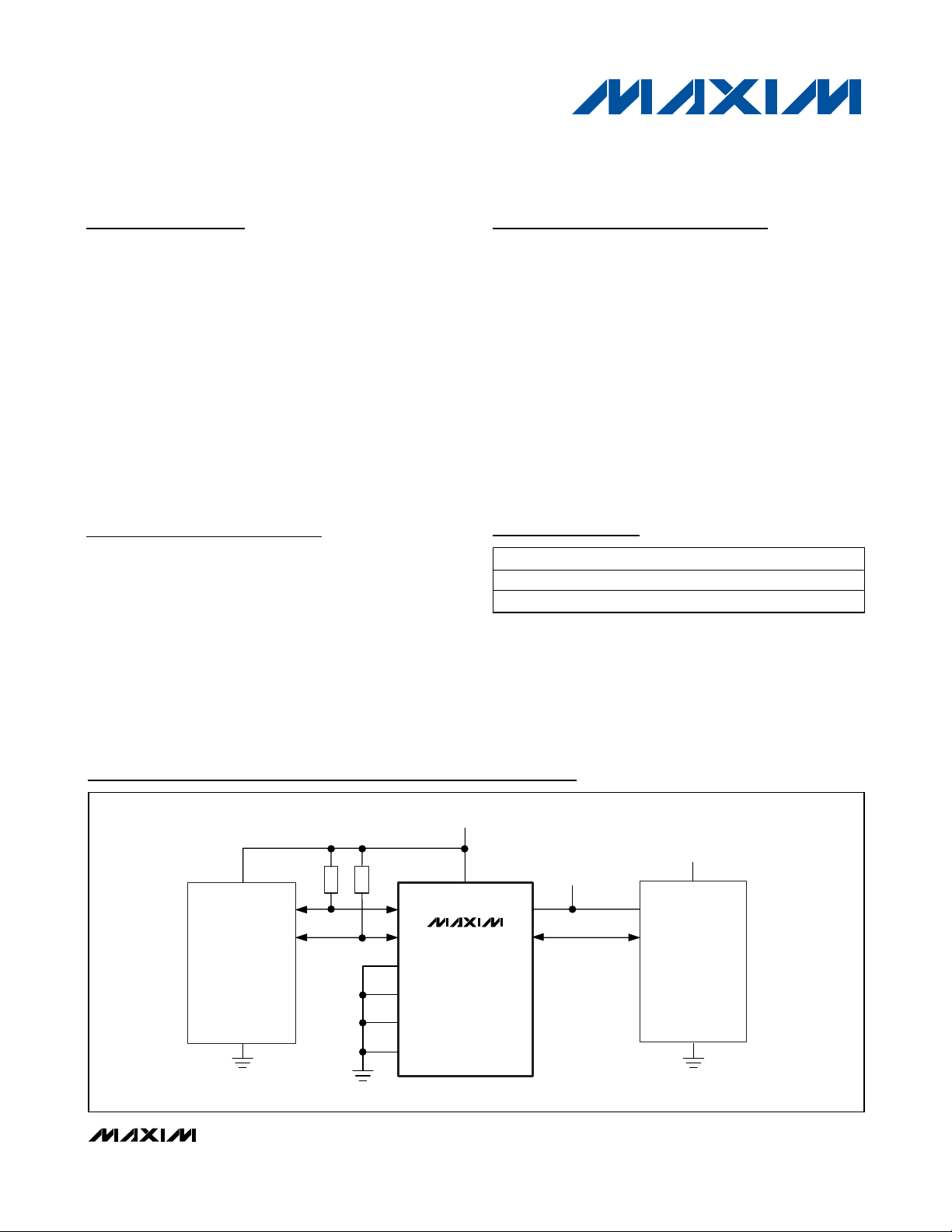

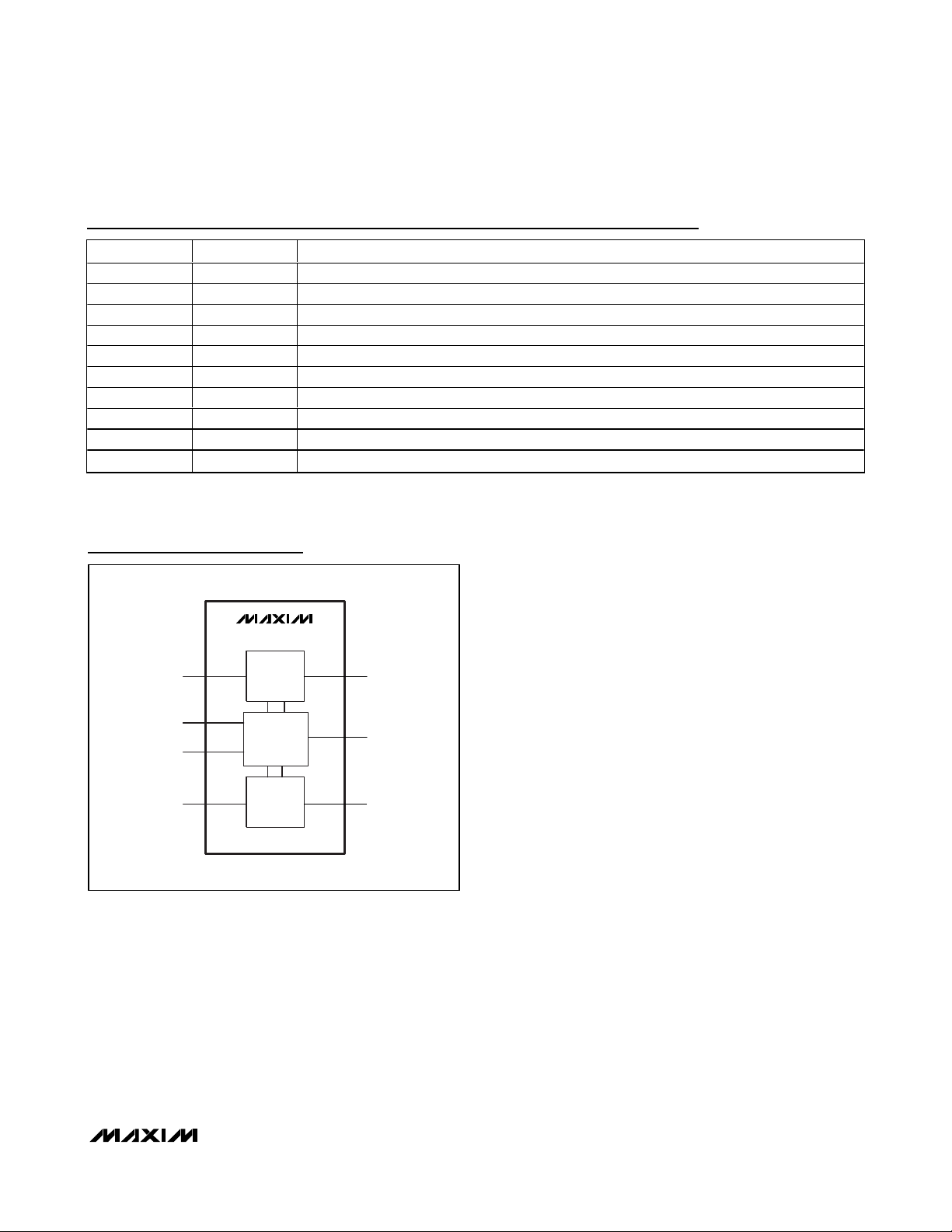

Typical Application Circuit

19-0730; Rev 0; 1/07

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Pin Configuration appears at end of data sheet.

Ordering Information

T

= Tape and reel package.

+

Denotes a lead-free package.

SMBus is a trademark of Intel Corp.

µMAX is a registered trademark of Maxim Integrated Products.

PART TEMP RANGE PIN-PACKAGE

MAX6618AUB+ -20°C to +120°C 10 µMAX

MAX6618AUB+T -20°C to +120°C 10 µMAX

SDA

SCL

I2C

MASTER

SDA

SCL

AD2

AD1

AD0

GND

MAX6621

+3.3V

V

CPU

V

V

CC

V

REF

PECI

TT

CPU

INTERNAL

TEMP

SENSOR

MAX6618

PECI-to-I2C Translator

2 _______________________________________________________________________________________

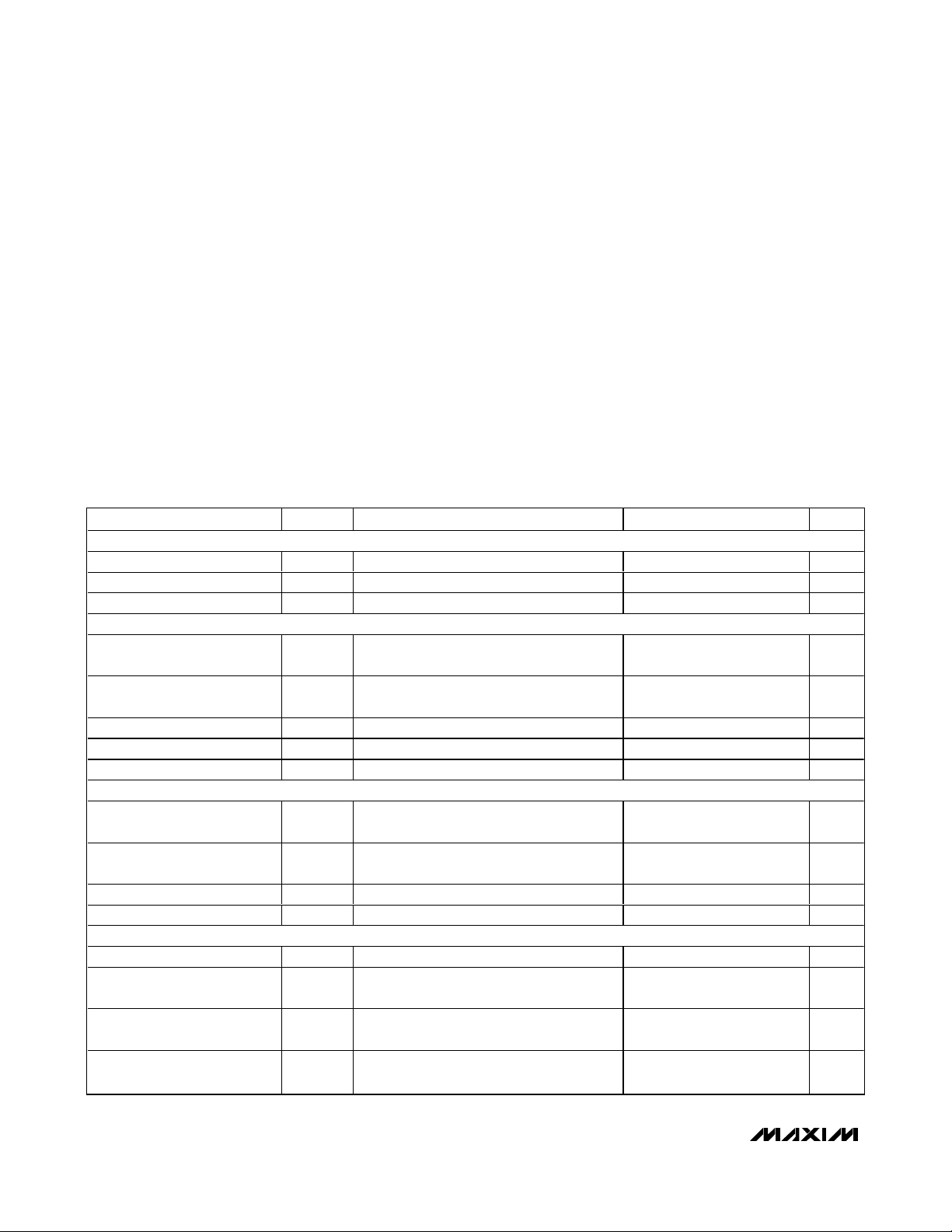

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(

Typical Application Circuit

, VCC= +3V to +3.6V, V

REF

= +0.95V to +1.26V, TA= -20°C to +120°C, unless otherwise noted. Typical

values are at V

CC

= +3.3V, V

REF

= +1.0V, TA= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

(All voltages with respect to GND.)

V

CC

..........................................................................-0.3V to +4V

AD0, AD1, AD2,..........................................-0.3V to (V

CC

+ 0.3V)

SCL, SDA .................................................................-0.3V to +6V

V

REF

.........................................................................-0.3V to +4V

PECI .........................................................-0.3V to (V

REF

+ 0.3V)

DC Current through SDA ...................................................10mA

Continuous Power Dissipation (T

A

= +70°C)

10-Pin µMAX (derate 5.6mW/°C over T

A

= +70°C)......444mW

Operating Temperature Range .........................-20°C to +120°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SUPPLY

Operating Supply Voltage V

Operating Supply Current I

Power-On-Reset Voltage V

INPUT SCL, INPUT/OUTPUT SDA

Low-Level Input Voltage V

High-Level Input Voltage V

Low-Level Output Voltage V

Leakage Current I

Input Capacitance C

ADDRESS INPUT A0

Low-Level Input Voltage V

High-Level Input Voltage V

Leakage Current I

Input Capacitance C

PECI

Supply Voltage to PECI Cell V

Input Voltage Range V

Low-Level Input Voltage

Threshold

High-Level Input Voltage

Threshold

CC

CC

POR

REF

V

V

SCL = 400kHz 4 7 mA

IL

IH

IOL = 6mA 0.4 V

OL

L

I

IL

IH

L

I

IN

IL

IH

x V

x V

0.275

x V

0.550

x V

3.0 3.6 V

2.60 2.95 V

0.3

x V

CC

0.7

CC

5.5 V

-1 +1 µA

10 pF

0.3

x V

CC

0.7

CC

V

CC

+ 0.3

-2 +2 µA

10 pF

0.95 1.26 V

V

-0.3

REF

+ 0.3

0.500

REF

x V

REF

0.725

REF

x V

REF

V

V

V

V

V

V

MAX6618

PECI-to-I2C Translator

_______________________________________________________________________________________ 3

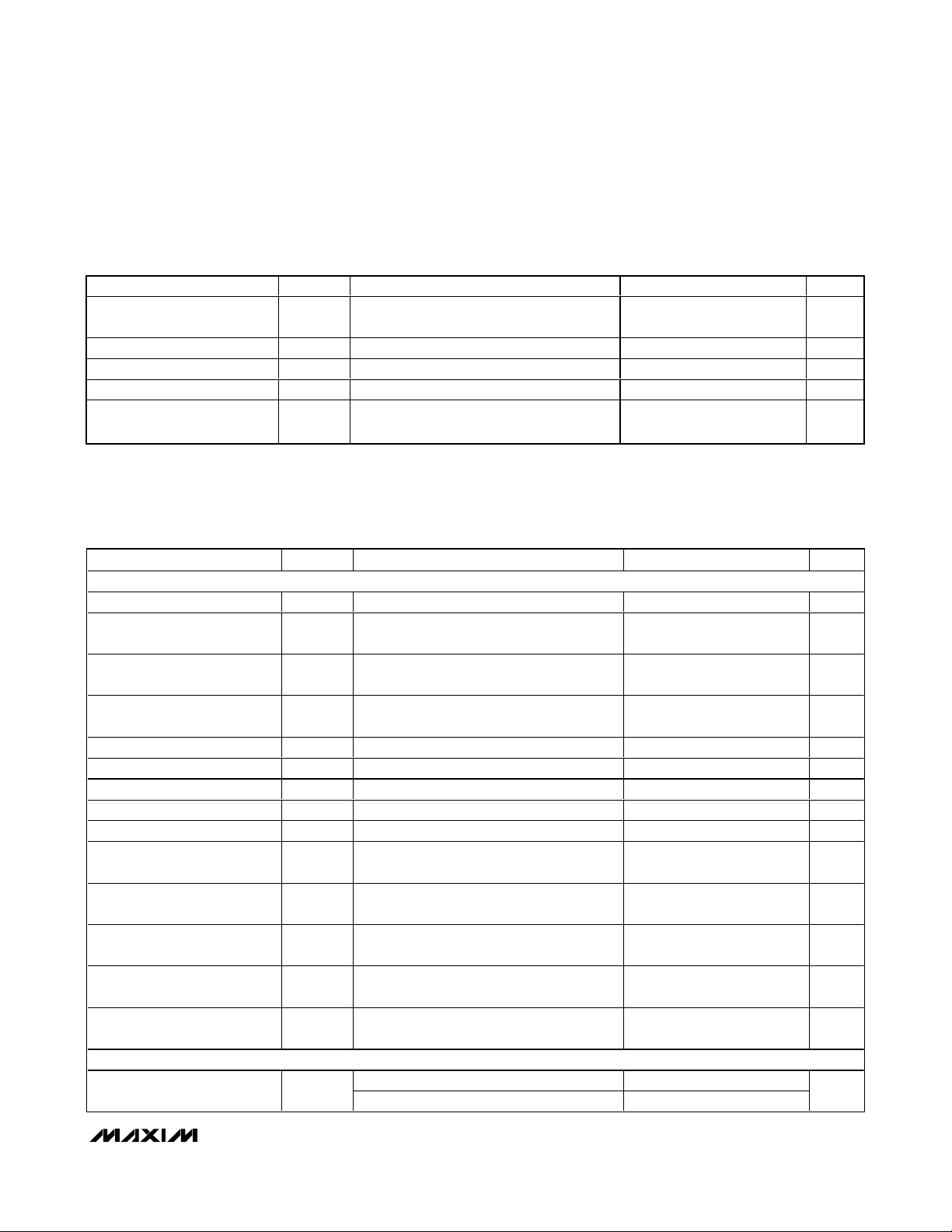

ELECTRICAL CHARACTERISTICS (continued)

(

Typical Application Circuit

, VCC= +3V to +3.6V, V

REF

= +0.95V to +1.26V, TA= -20°C to +120°C, unless otherwise noted. Typical

values are at V

CC

= +3.3V, V

REF

= +1.0V, TA= +25°C.) (Note 1)

TIMING CHARACTERISTICS

(

Typical Application Circuit

, VCC= +3V to +3.6V, V

REF

= +0.95V to +1.26V, TA= -20°C to +120°C, unless otherwise noted. Typical

values are at V

CC

= +3.3V, V

REF

= +1.0V, TA= +25°C.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Hysteresis V

Low-Level Sinking Current I

High-Level Sourcing Current I

Input Capacitance C

Signal-Noise Immunity Above

300MHz

H

IL

IH

(Note 2) 10 pF

I

V

(Note 2)

N

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I2C INTERFACE

Serial-Clock Frequency f

Bus Free Time Between a

STOP and a START Condition

Hold Time, (Repeated) START

Condition

Repeated START Condition

Setup Time

STOP Condition Setup Time t

Data Hold Time t

Data Setup Time t

SCL Clock-Low Period t

SCL Clock-High Period t

Rise Time of Both SDA and

SCL Signals, Receiving

Fall Time of Both SDA and

SCL Signals, Receiving

Fall Time of SDA Transmitting t

Pulse Width of Spike

Suppressed

Capacitive Load for Each

Bus Line

PECI INTERFACE

Bit Time (Note 7) t

SCL

t

BUF

t

HD, STA

t

SU, STA

SU, STO

HD, DAT

SU, DAT

LOW

HIGH

t

F.TX

t

C

BIT

(Note 3) 0.9 µs

(Notes 4, 5)

R

t

(Notes 4, 5)

F

(Notes 4, 5)

(Notes 2, 6) 50 160 ns

SP

(Notes 2, 4) 400 pF

b

Overall time evident on PECI 0.495 500

Driven by MAX6618 0.495 250

0.1

x V

REF

0.5 1.0 mA

-6 mA

0.1

x V

REF

400 kHz

1.3 µs

0.6 µs

0.6 µs

0.6 µs

120 ns

1.3 µs

0.6 µs

20

+ 0.1C

20

+ 0.1C

20

+ 0.1C

b

b

b

300 ns

300 ns

250 ns

V

V

P-P

µs

MAX6618

PECI-to-I2C Translator

4 _______________________________________________________________________________________

Note 1: All parameters are tested at TA= +25°C. Specifications over temperature are guaranteed by design.

Note 2: Guaranteed by design; not production tested.

Note 3: A master device must provide a hold time of at least 300ns for the SDA signal (referred to V

IL

of the SCL signal) to bridge

the undefined region of SCL’s falling edge.

Note 4: C

b

= total capacitance of one bus line in pF. tRand tFmeasured between 0.3 x VCCand 0.7 x VCC.

Note 5: I

SINK

≤ 6mA. Cb= total capacitance of one bus line in pF. tRand tFmeasured between 0.3 x VCCand 0.7 x VCC.

Note 6: Input filters on the SDA and SCL inputs suppress noise spikes less than 50ns.

Note 7: The MAX6618 must drive a more restrictive time to allow for quantized sampling errors by a client yet still attain the mini-

mum time less than 500µs. t

BIT

limits apply equally to t

BIT-A

and t

BIT-M

.

Note 8: The minimum and maximum bit times are relative to t

BIT

defined in the timing negotiation pulse.

Note 9: Extended trace lengths can appear as additional nodes.

Note 10: The client may deassert its low idle drive prior to the falling edge of the first bit of the message by using the rising edge to

detect a message start. However, the time delay must be sufficient to qualify the rising edge as a true message rather than

a noise spike.

Note 11: The message stop is defined by two consecutive periods when the bus has no rising edge. Tolerance around this time is

based on the t

BIT-M

error budget.

Note 12: t

SETUP

is not additive with t

STOP

. Rather, these times may overlap.

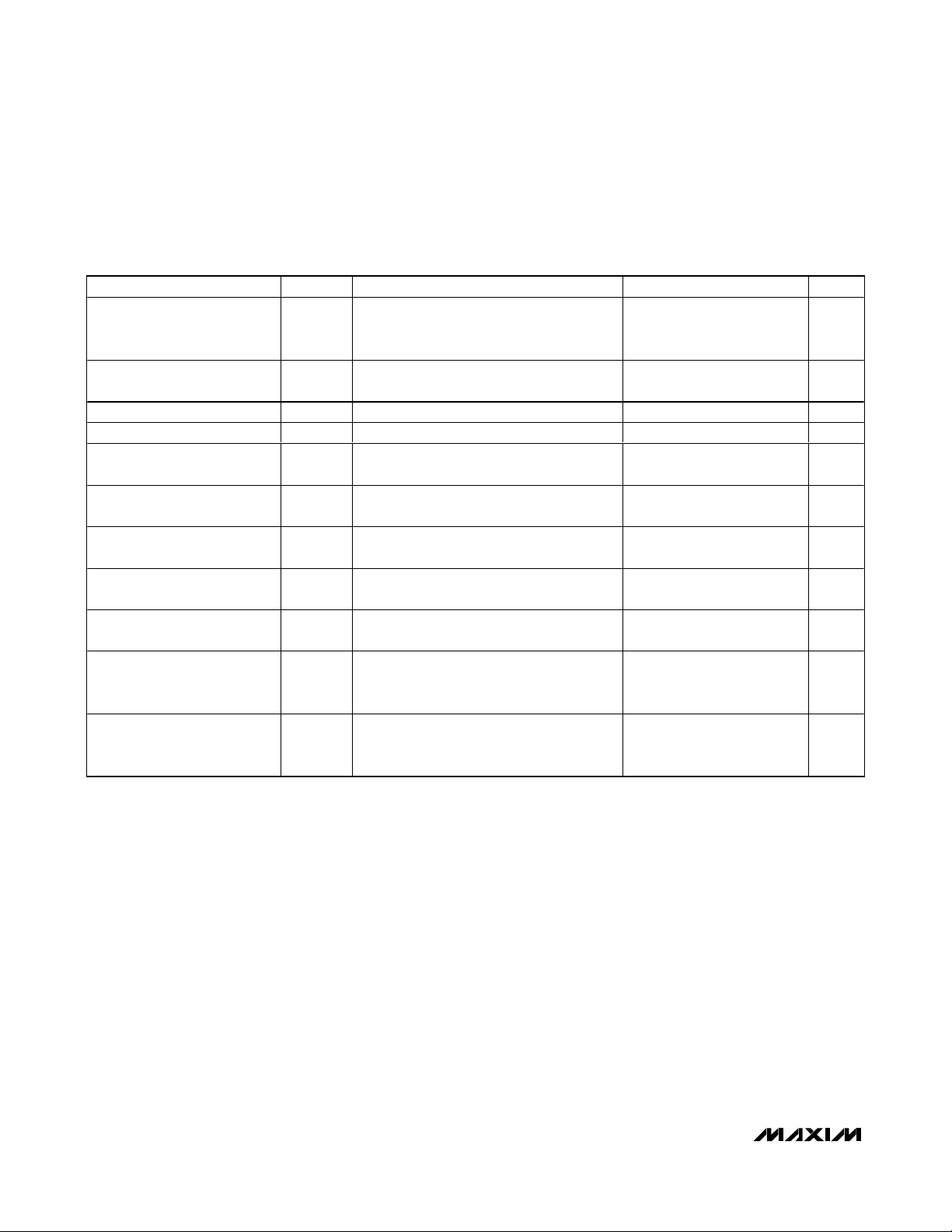

TIMING CHARACTERISTICS (continued)

(

Typical Application Circuit

, VCC= +3V to +3.6V, V

REF

= +0.95V to +1.26V, TA= -20°C to +120°C, unless otherwise noted. Typical

values are at V

CC

= +3.3V, V

REF

= +1.0V, TA= +25°C.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Bit Time Jitter t

Between adjacent bits in an PECI message

BIT, jitter

header or data bytes after timing has been

negotiated

1%

Change in Bit Time t

High-Level Time for Logic-High t

High-Level Time for Logic-Low t

Client Asserts PECI High

During Logic-High

Rise Time t

Fall Time t

Hold Time t

Stop Time t

Maximum Dwell Time of the

PECI Client

Minimum PECI Low Time

Preceding a Message

BIT, drift

H1

H0

t

SU

HOLD

STOP

t

RESET

t

SETUP

Across a PECI address or PECI message

bits as driven by MAX6618

2%

(Note 8) 0.6 0.75 0.8 x t

0.2 0.3 0.4 x t

0 0.2 x t

Measured from V

R

V

REF(nom)

Measured from VOH to VNMAX,

F

V

REF(nom)

-5% (Note 9)

+5% (Note 9)

OL

to V

MAX,

P

Time for client to maintain a low idle drive

after MAX6618 begins a message (Note 10)

A constant low level driven by MAX6618

(Notes 8, 11)

2x t

From the end of a ResetDevice command

to the next message to which the reset

client must be able to respond

If the prior t

the maximum t

t

SETUP

is not known by MAX6618,

BIT

must be assumed and

BIT

= 1ms in this case (Note 12)

2x t

30 +

5/Node

30/Node ns

0.5 x t

0.4 ms

BIT

BIT

BIT-M

ns

BIT-1

BIT-M

BIT-X

MAX6618

Pin Description

PECI-to-I2C Translator

_______________________________________________________________________________________ 5

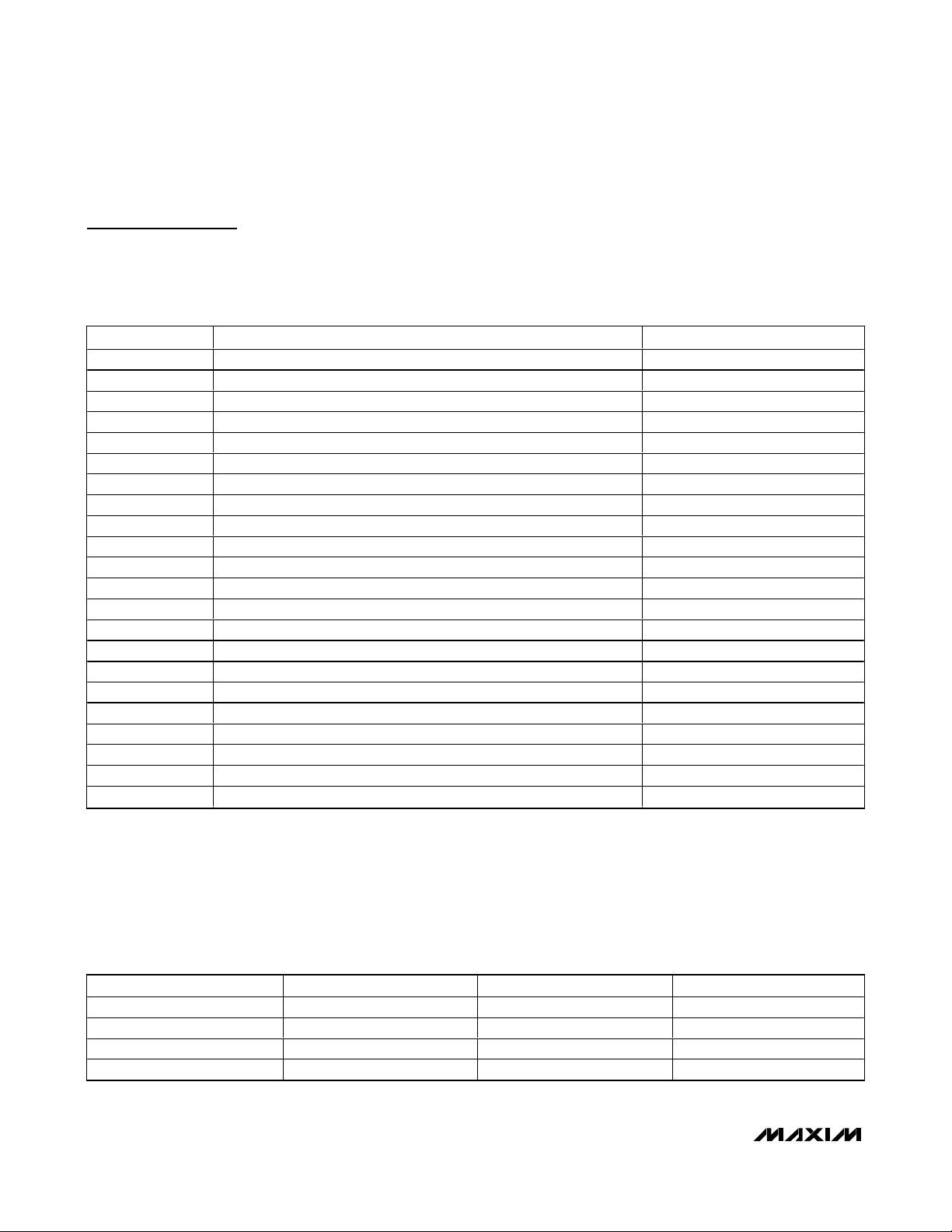

Block Diagram

PIN NAME FUNCTION

1 PECI Platform Environment Control Interface (PECI) Serial-Bus Input/Output

2 AGND Analog Ground

3 AD0 I2C Bus Device Address Selection Input AO

4 SDA I2C Bus Data Input/Output

5 SCL I2C Bus Clock Input/Output

6VCCPower Supply. Bypass to GND with a 0.1µF capacitor.

7 GND Power-Supply Ground

8 AD2 I2C Bus Device Address Selection Input A2

9 AD1 I2C Bus Device Address Selection Input A1

10 V

REF

PECI Input Supply Voltage. Bypass V

to AGND with a 0.1µF capacitor.

REF

MAX6618

SDA

2

I

PORT

C

SCL

A2

A1

PECI

PECI

TRANSLATION

ENGINE

PECI

PORT

A0

V

REF

MAX6618

PECI-to-I2C Translator

6 _______________________________________________________________________________________

Configuration

The MAX6618 has four configuration registers (Table 1).

CONFIG0 is the main configuration register that enables

the PECI sockets, I2C bus timeout, PEC, alert activation,

and polling delay. CONFIG1 sets the number of retries,

CONFIG2 sets the temperature offset, and CONFIG3

controls the temperature averaging. You can write to

the configuration registers to set the configuration or

read from the configuration registers to get the current

settings.

Detailed Description

The MAX6618 obtains temperature data from an internal temperature sensor in PECI-compliant hosts. Up to

four PECI hosts can be connected to the PECI I/O interface. The MAX6618 handles all the PECI transmissions

and uses a 2-wire, I

2

C-compatible serial interface to

communicate with the PECI host.

Registers and Commands

The following is an overview of the I2C/SMBus registers/commands supported by the MAX6618.

Table 1. Configuration Registers

ADDRESS DESCRIPTION TRANSACTION TYPE

00h Read socket 0, domain 0 temperature register ReadWord

01h Read socket 0, domain 1 temperature register ReadWord

02h Read socket 1, domain 0 temperature register ReadWord

03h Read socket 1, domain 1 temperature register ReadWord

04h Read socket 2, domain 0 temperature register ReadWord

05h Read socket 2, domain 1 temperature register ReadWord

06h Read socket 3, domain 0 temperature register ReadWord

07h Read socket 3, domain 1 temperature register ReadWord

08h Read maximum temperature for all enabled sockets/domains register ReadWord

09h Read firmware version register ReadWord

0Ah Read maximum temperature address ReadWord

0Bh Read socket and domain that caused alert ReadWord

0Ch Read/write CONFIG0 register ReadWord/WriteWord

0Dh Read/write CONFIG1 register ReadWord/WriteWord

0Eh Read/write CONFIG2 register ReadWord/WriteWord

0Fh Read/write CONFIG3 register ReadWord/WriteWord

10h Read/write alert temperature for socket 0 ReadWord/WriteWord

11h Read/write alert temperature for socket 1 ReadWord/WriteWord

12h Read/write alert temperature for socket 2 ReadWord/WriteWord

13h Read/write alert temperature for socket 3 ReadWord/WriteWord

14h Request polling SendByte

15h Clear alert SendByte

COMMAND BYTE REGISTER DESCRIPTION TYPE RESULT

0Ch CONFIG0 register ReadWord/WriteWord See the CONFIG0 section.

0Dh CONFIG1 register ReadWord/WriteWord See the CONFIG1 section.

0Eh CONFIG2 register ReadWord/WriteWord See the CONFIG2 section.

0Fh CONFIG3 register ReadWord/WriteWord See the CONFIG3 section.

CONFIG0

The CONFIG0 register holds a bit mask for PECI sockets and domains that are enabled for polling as well as

a polling delay (minimum delay between sets of polls)

and features enable/disable bits. Table 2 shows the

various options for CONFIG0.

The optional polling delay (bits 2:0) inserts after polling

the set of all sockets and domains that are enabled in

bits 15:8 with a minimal pause of 2.5ms between PECI

reads. After polling all enabled sockets and domains,

the device pauses PECI communications for the configured time before starting to poll the set of enabled

sockets and domains again. Table 3 shows the various

polling delay options.

CONFIG1

The CONFIG1 register configures the maximum number of retries before aborting a PECI temperature read

as well as the originated (suggested) PECI bit time.

Table 4 shows the various options for CONFIG1.

MAX6618

PECI-to-I2C Translator

_______________________________________________________________________________________ 7

Table 2. CONFIG0 Register

Table 3. Polling Delay

Table 4. CONFIG1 Register

BIT(S) DESCRIPTION DEFAULT

15:8 Polling enable for sockets and domains 00h

15 1 = enable socket 3, domain 1 0

14 1 = enable socket 3, domain 0 0

13 1 = enable socket 2, domain 1 0

12 1 = enable socket 2, domain 0 0

11 1 = enable socket 1, domain 1 0

10 1 = enable socket 1, domain 0 0

9 1 = enable socket 0, domain 1 0

8 1 = enable socket 0, domain 0 0

1 = enable I

7

0 = Disable timeout

1 = alternate data representation

6

0 = 16-bit data representation

1 = enable I

(PEC) on device return data

5

0 = Disable PEC

1 = mask temperature alerts

4

0 = Activate alerts

3 Reserved, set to 0 0

2:0 Poll delay, see Table 3 5

2

C bus lockup timeout

2

C packet error checksum

1

0

1

0

POLL DELAY VALUE DELAY BETWEEN POLLS (ms)

0 Polling on request only

1 2.5

25

310

450

5 100 (default)

6 500

7 Reserved

BIT(S) DESCRIPTION DEFAULT

Originated PECI bit time

(before negotiation)

15:8

7:0

01h: RESERVED

02h…0FFh: CONFIG1[15:8] + 1µs

Minimum: 02h (= 3µs / 333.3kHz)

Maximum: 0FFh (= 256µs / 3.906kHz)

Maximum number of retries for PECI

transactions

02h

03h

MAX6618

PECI-to-I2C Translator

8 _______________________________________________________________________________________

CONFIG2

The CONFIG2 register holds the offset that is added to

all temperature return values that are not error codes.

The offset is enabled in CONFIG0, bit 6; +95°C is set

as 17C0h or 005Fh, depending on the data format. To

represent +95°C in 16-bit representation, convert

+95°C to binary using two’s complement and left-shift

six times. The MAX6618 automatically converts the offset value to the equivalent value when the data format

is changed. See Table 5 for the default offset and Table

6 for some example values.

When configured in CONFIG2 and the return code is not

an error code (see the

Error Codes

section), the device

adds the offset value stored in CONFIG2 to the return

value. For example, if the CPU’s thermal control circuit

activation point is at +95°C, CONFIG2 can be set to

+95°C (005Fh or 17C0h) and all return values are converted to absolute temperatures. Note that the thermal

control circuit activation point is CPU specific. The offset

value is represented in the current data format.

CONFIG3

CONFIG3 register configures the temperature averaging

function. See the

Temperature Averaging

section for

more information. Table 7 shows the default settings.

Temperature Representation

Temperature data is formatted in 16-bit two’s complement representing a range from -512°C to +512°C in

steps of 1/64°C (Figure 1). Internally, the device always

uses the 16-bit data format. The temperature is given in

two’s complement and left-shifted so that the +1°C bit

is bit 6 (Figure 2). Temperatures can be represented

externally in alternate data format if fractional readings

are not needed. Table 8 shows some examples.

Table 5. CONFIG2 Register

Table 6. Example Offset Values in 16-Bit

Temperature Representation

Table 7. CONFIG3 Register

Figure 1. Temperature Measured in 1/64°C Steps

Figure 2. Conversion of Temperature Done in Two’s

Complement

Table 8. Example of 16-Bit Representation

with No Offset (Activation Point = +95°C)

BIT(S) DESCRIPTION DEFAULT

15:0 Temperature offset 0000h

TEMP (°C) HEX

0 0000h 0000 0000 0000 0000

+25 0640h 0000 0110 0100 0000

+50 0C80h 0000 1100 1000 0000

+75 12C0h 0001 0010 1100 0000

+95 17C0h 0001 0111 1100 0000

BINARY

RESHI RESLO

1

°C °C °C

2

RESLO

1°C

TWO'S

-50°C

COMPLEMENT

1

8

1

°C °C °C

4

00110111

1

32

1

16

01234567

1

64

RESHI

89101112131415

RESLO

BIT(S) DESCRIPTION DEFAULT

15:8 Reserved, set to 0 00h

7:0 Averaging shift count, see formula 00h

TEMP

(°C)

+94 -1 FFC0h 1111 1111 1100 0000

+85 -10 FD80h 1111 1101 1000 0000

+70 -25 FDC0h 1111 1101 1100 0000

+45 -50 F380h 1111 0011 1000 0000

+20 -75 ED30h 1110 1101 0100 0000

RELATIVE

TEMP (°C)

HEX

01234567

BINARY

RESHI RESLO

MAX6618

PECI-to-I2C Translator

_______________________________________________________________________________________ 9

Alternate Temperature Value Representation

This optional feature can be enabled using bit 6 of

CONFIG0. When the alternate data format is enabled, the

temperature value is shifted right as shown in Table 9. The

most significant bits are set to all 0s or all 1s depending on

the sign bit 15, also shown as S in Figure 3. Table 10

shows some example values. This translation is not performed for error codes (16-bit values from 8000h

through 81FFh).

Excluding error codes, the software only has to examine the RESLO data byte, as it represents an integer

value in the range from -128°C to +127°C in 1°C steps.

The RESHI byte is all 0s or all 1s for valid return codes,

and either 80h or 81h for all error codes.

Temperature Averaging

The MAX6618 can average several temperature readings and return a value as calculated by:

where T

OLD

is the previously stored temperature, T

PECI

is the new value read from PECI, and T

NEW

is the newly

stored temperature ready to be returned through I

2

C.

This calculation can cause significant bits to be lost.

Enable temperature averaging by writing the desired

averaging amount to the CONFIG3 register. Writing 00h

to the CONFIG3 register disables temperature averaging.

Figure 3. Alternate Temperature Representation

Table 9. Alternate Temperature

Representation

Table 10. Example of Alternate Representation with No Offset (Activation Point = +95°C)

DESCRIPTION RESHI RESLO

16-bit value 15:14:13:12:11:10:9:8 7:6:5:4:3:2:1:0

Alternate

representation

15:15:15:15:15:15:15:15 15:12:11:10:9:8:7:6

TxT xT

=+−

NEW

1

33

CONFIG

2

PECI

⎛

1

⎜

⎝

CONFIG

2

1

⎞

⎟

⎠

OLD

RESHI

S X X 12 11 10 9 8

S S S S S S S S S 12 11 10 9 8 7 6

RESLO

7 6 X X X X X X

INTEGER VALUE (~ 1°C)(SIGN BITS)

FRACTIONAL VALUE

TEMP (°C) RELATIVE TEMP (°C) HEX

+94 -1 FFFFh 1111 1111 1111 1111

+85 -10 FFF6h 1111 1111 1111 0110

+70 -25 FFE7h 1111 1111 1110 0111

+45 -50 FFCEh 1111 1111 1100 1110

+20 -75 FFB5h 1111 1111 1011 0101

RESHI RESLO

BINARY

MAX6618

PECI-to-I2C Translator

10 ______________________________________________________________________________________

Temperature Commands

Table 11 shows the different commands for selecting

one of the PECI hosts or getting the maximum temperature. Read commands are initiated by the MAX6618,

and the result returned is a 16-bit word with the least

significant bit (LSB) clocked in first for the selected

PECI host.

The result consists of RESLO for the 8 LSBs and RESHI

for the 8 MSBs, resulting in a 16-bit word. The 16-bit

words are temperature values read from the PECI

interface. PECI-enabled Intel microprocessors return

temperature data in fractions of 1°C below the thermalcontrol-circuit activation point, resulting in negative

return values that do not represent absolute temperatures. Absolute temperatures can be achieved by setting the temperature offset in CONFIG2.

Table 12 shows example return values for an Intel CPU.

Note that the MAX6618 does not interpret the return

Table 11. Read Temperature

Table 12. Return Temperature Values

ADDRESS REGISTER TYPE RESULT

00h Socket 0, domain 0

01h Socket 0, domain 1

02h Socket 1, domain 0

03h Socket 1, domain 1

04h Socket 2, domain 0

05h Socket 2, domain 1

06h Socket 3, domain 0

07h Socket 3, domain 1

08h

Read maximum temperature for all enabled

sockets/domains

ReadWord 16-bit words

RELATIVE

TEMPERATURE (°C)

-1

-36

-37

-38

-39

-40

-41

-42

-43

CONFIG2 OFFSET RESHI:RESLO RESULT

16 BITS ALTERNATE 16 BITS ALTERNATE

0000 0000 FFC0 FFFF

17C0 005F 1780 005E

0000 0000 F700 FFDC

17C0 005F 0ec0 003B

0000 0000 F6C0 FFDB

17C0 005F 0E80 003A

0000 0000 F680 FFDA

17C0 005F 0E40 0039

0000 0000 F640 FFD9

17C0 005F 0E00 0038

0000 0000 F600 FFD8

17C0 005F 0DC0 0037

0000 0000 F5C0 FFD7

17C0 005F 0D80 0036

0000 0000 F580 FFD6

17C0 005F 0D40 0035

0000 0000 F540 FFD5

17C0 005F 0D00 0034

MAX6618

PECI-to-I2C Translator

______________________________________________________________________________________ 11

data (with the exception of error codes) and the relative

temperatures are listed for reference only. Table 12

shows the values with 16-bit and alternate word format.

The read maximum temperature command from Table 11

returns the highest temperature that is not an error

code from the enabled PECI sockets and domains. This

operation works on signed numbers only and does not

give information as to what socket the temperature

result comes from. To find the socket and domain, use

the read maximum temperature address command as

shown in Table 13.

The read maximum temperature address command

returns the register that had the highest temperature

when read maximum temperature was last called. An

error is returned if the read maximum temperature has

not been called or when the read maximum temperature itself returns an error.

Return Value Flow Chart

Figure 4 shows the operations performed on temperature data read through PECI.

Table 13. Read Maximum Temperature

Address

Figure 4. Operational Flowchart

COMMAND DESCRIPTION TYPE RESULT

Read address of

0Ah

socket/domain with the

maximum temperature

ReadWord 16-bit

DATA FROM PECI

YN

ERROR?

N

ADD OFFSET

RETURN DATA ON I2C

AVERAGING

ALT.

FORMAT?

CONVERT

DATA

FORMAT

Y

MAX6618

Error Codes

Error codes are represented as 16-bit words in the

range 8000h–81FFh as shown in Table 14.

Version Information Command

Table 15 shows the command to read the firmware version.

The result is a 16-bit word (low byte transmitted first,

high byte second), e.g., 0100h for the MAX6618

firmware version 1.0.

Bus Lockout Timeout Reset

If an I2C transaction starts and gets locked up for

greater than 20ms, the MAX6618 asserts the internal

bus lockup reset that restarts itself in the default startup

condition.

Serial Interface

The MAX6618 operates as a slave that sends and

receives data through an I

2

C-compatible, 2-wire interface. The interface uses a serial-data line (SDA) and a

serial-clock line (SCL) to achieve bidirectional communication between master and slave. A master (typically

a microcontroller) initiates all data transfers to and from

the MAX6618 and generates the SCL clock that synchronizes the data transfer (Figure 5).

PECI-to-I2C Translator

12 ______________________________________________________________________________________

Table 14. Error Codes

Table 15. Firmware Command

Figure 5. 2-Wire Serial-Interface Timing Details

ERROR

CODES

8000h–

80FFh

8100h

8101h Polling disabled for requested socket/domain.

8102h

8103h

8104h

Refer to Intel PECI specification.

PECI transaction failed for more than the

configured number of consecutive retries.

First poll not yet completed for requested

socket/domain (on startup).

Read maximum temperature requested, but no

sockets/domains enabled or all enabled

sockets/domains have errors; or read maximum

temperature address requested, but read

maximum temperature was not called.

Get alert socket/domain requested, but no alert

active.

DESCRIPTION

COMMAND DESCRIPTION TYPE RESULT

09h

Get firmware

version

ReadWord 16-bit word

SDA

t

HD, STA

SCL

START

CONDITION

t

LOW

t

SU, DAT

t

HD, DAT

t

HIGH

t

R

t

F

t

SU, STA

REPEATED START

CONDITION

t

HD, STA

t

SU, STO

STOP

CONDITION

t

BUF

START

CONDITION

The MAX6618 SCL and SDA lines operate as both

inputs and open-drain outputs. A pullup resistor is

required on SCL and SDA.

Each transmission consists of a START condition sent

by a master, followed by the MAX6618 7-bit slave

address, plus an R/W bit, one or more data bytes, and

finally a STOP condition (Figure 6). To write to a

MAX6618 register, a write transmission consists of a

START condition, followed by the MAX6618 7-bit slave

address plus R/W = 0, a register address byte, one

data byte, and finally a STOP condition. To read from a

MAX6618 register, a combined write and read transmissions are required. The first write transmission consists of a START condition, followed by the MAX6618

7-bit slave address plus R/W = 0, a register address

byte, and finally a STOP condition that sets the register

to be read. The second read transmission consists of a

START condition, followed by the MAX6618 7-bit slave

address plus R/W = 1, one or more data bytes, and

finally a STOP condition that reads the data from the

specified register. These write and read transmissions

can be joined using a repeated START even though the

MAX6618 7-bit slave address needs to be present preceding the R/W bits.

Start and Stop Conditions

Both SCL and SDA remain high when the interface is

not busy. A master signals the beginning of a transmission with a START (S) condition by transitioning SDA

from high to low while SCL is high. When the master

has finished communicating with the slave, it issues a

STOP (P) condition by transitioning SDA from low to

high while SCL is high. The bus is then free for another

transmission (Figure 6).

Data Transfer and Acknowledge

One data bit is transferred during each clock pulse.

The data on SDA must remain stable while SCL is high

(Figure 7).

MAX6618

PECI-to-I2C Translator

______________________________________________________________________________________ 13

Figure 6. Start and Stop Conditions

Figure 7. Bit Transfer

SDA

SDA

SCL

S

SCL

START

CONDITION

P

STOP

CONDITION

DATA LINE STABLE;

DATA VALID

CHANGE OF DATA

ALLOWED

MAX6618

The acknowledge bit is a clocked 9th bit that the recipient uses to handshake receipt of each byte of data

(Figure 8). Thus, each byte transferred effectively

requires 9 bits. The master generates the 9th clock

pulse, and the recipient pulls down SDA during the

acknowledge clock pulse so that the SDA line is stable

low during the high period of the clock pulse. When the

master is transmitting to the MAX6618, the MAX6618

generates the acknowledge bit because the MAX6618

is the recipient. When the MAX6618 is transmitting to

the master, the master generates the acknowledge bit

because the master is the recipient.

Slave Address

The MAX6618 has a 7-bit long slave address (Figure 9).

The 8th bit following the 7-bit slave address is the R/W

bit. The R/W bit is low for a write command and high for

a read command.

The first 4 bits of the MAX6618 slave address (A6–A3)

are always 1, 0, 0, and 1. The MAX6618 slave address

bits A2, A1, and A0 are selected by the address inputs

AD2, AD1, and AD0. They can be connected to GND or

VCC. The MAX6618 has eight possible slave addresses,

and therefore, a maximum of eight MAX6618 devices

can be controlled independently from the same interface

(see the

I2C Address Range

section).

Message Format for Writing to the MAX6618

A write to the MAX6618 consists of the transmission of

the MAX6618’s slave address with the R/W bit set to

zero, followed by at least 1 byte of information. The first

byte of information is the command byte. The command byte determines which register of the MAX6618

is to be written to by the next byte or read from during

the next read transmission. If a STOP condition is

detected after the command byte is received, then the

MAX6618 takes no further action beyond setting the

register address.

The bytes received after the command byte are data

bytes. The data bytes go into the register of the

MAX6618 specified by the command byte. Only the last

data byte or word transmitted before a STOP condition

is stored by the device (Figure 10).

PECI-to-I2C Translator

14 ______________________________________________________________________________________

Figure 9. Slave Address

Figure 8. Acknowledge

CLOCK PULSE

FOR ACKNOWLEDGEMENT

SCL

SDA BY

TRANSMITTER

SDA BY

RECEIVER

START

CONDITION

S

12 89

SDA

SCL

1

MSB

00

A2

1

A0

A1

R/W

LSB

ACK

Message Format for Reading the MAX6618

The MAX6618 is read using the MAX6618’s internally

stored command byte as an address pointer the same

way the stored command byte is used as an address

pointer for a write. The pointer autoincrements after

each data byte is read. Thus, a read is initiated by first

configuring the MAX6618’s command byte by performing a write. The master can now read N consecutive

bytes from the MAX6618 with the first data byte being

read from the register addressed by the initialized command byte (Figure 10).

MAX6618

PECI-to-I2C Translator

______________________________________________________________________________________ 15

Figure 10. Typical Read/Write Word Command

TYPICAL READ WORD COMMAND

PEC (PACKET ERROR CHECKSUM) ENABLED

MASTER

MAX6618 ADDR:7 R A RESLO:8 A RESHI:8 A PEC:8

PEC (PACKET ERROR CHECKSUM) DISABLED

MASTER

MAX6618 ADDR:7 R A RESLO:8 A RESHI:8

TYPICAL WRITE WORD COMMAND

COMMAND WITH PEC (PACKET ERROR CHECKSUM)

MASTER

ADDR:7 W A CMD:8 A

ADDR:7 W A CMD:8 A

S

ADDR:7 W A CMD:8 A

NA

P

P

NA

INLO:8 A INHI:8 A

PEC:8 A

P

COMMAND WITHOUT PEC (PACKET ERROR CHECKSUM)

MASTER

THE RESULT CONSISTS OF RESLO FOR THE 8 LEAST SIGNIFICANT BITS (LSBS) AND RESHI FOR THE 8 MOST SIGNIFICANT BITS (MSBS), RESULTING IN A 16-BIT WORD.

TEMPERATURE DATA AND ERROR CODES ARE GIVEN AS 16-BIT WORDS.

ADDR:7: 7-BIT ADDRESS FOLLOWED BY A READ (R = 1) OR WRITE (W = 0) BIT TO FORM THE 8-BIT ADDRESS USED IN THE I

2

C STOP CONDITION. SEE FIGURE 6.

P: I

S: I2C START CONDITION. SEE FIGURE 6.

A: ACK. THE PULSE ON THE 9th CLOCK CYCLE TO INDICATE ACKNOWLEDGE TRANSFER. SLAVE PULLS LOW TO GND AND MASTER PULLS TO SLAVE'S V

NA: NOT ACKNOWLEDGE

CMD: COMMAND BYTE

RESLO: LEAST SIGNIFICANT 8-BIT RESULT

RESHI: MOST SIGNIFICANT 8-BIT RESULT

ADDR:7 W A CMD:8 A INLO:8 A

S

INHI:8 A P

2

C/SMBUS PROTOCOL.

.

OL

MAX6618

Packet Error Checksum (PEC)

All MAX6618 I2C packets have an optional packet error

checksum (PEC). The PEC is implemented in accordance with the SMBus specification, versions 1.1 and

2. The MAX6618 accepts commands with or without

PEC. The PEC for device responses is optional and can

be disabled in the CONFIG0 register.

Applications Information

Operation with Multiple Masters

If the MAX6618 is operated on a 2-wire interface with

multiple masters, a master reading the MAX6618

should use a repeated START between the write that

sets the MAX6618’s address pointer, and the read(s)

that takes the data from the location(s) (Table 16). This

is because it is possible for master 2 to take over the

bus after master 1 has set up the MAX6618’s address

pointer, but before master 1 has read the data. If master 2 subsequently changes the MAX6618’s address

pointer, master 1’s delayed read can be from an unexpected location. The use of multiple masters is not recommended.

I2C Address Range

The I2C device address is configurable using address

inputs AD0 and A1. Using the address inputs A0 and

A1, the base address can be configured from 48h to

4Bh (Table 16).

Choosing Pullup Resistors

I2C requires pullup resistors to provide a logic-high

level to data and clock lines. There are tradeoffs

between power dissipation and speed, and a compromise must be made in choosing pullup resistor values.

Every device connected to the bus introduces some

capacitance even when the device is not in operation.

I2C specifies a minimum 300ns rise time to go from low

to high (30% to 70%) for fast mode, which is defined for

a date rate of 400kbps (refer to the I2C specifications

for details). To meet the rise time requirement, choose

pullup resistors so that the rise time t

R

= 0.85R

PULLUP

x C

BUS

< 300ns. For typical low bus capacitances, a

4.7kΩ resistor can be used. For a bus capacitance of

400pF, choose a pullup resistor less than 880Ω. Many

I2C devices work when the minimum specified rise time

is not met. However, if the time it takes for the waveform

to rise becomes too slow, these waveforms are not recognized by the master.

PECI-to-I2C Translator

16 ______________________________________________________________________________________

Table 16. MAX6618 Slave Addresses

2

I

1001: A2:A1:A0 I2C ADDRESS

0:0:0 48h 90h, 91h

0:0:1 49h 92h, 93h

0:1:0 4Ah 94h, 95h

0:1:1 4Bh 96h, 97h

1:0:0 4Ch 98h, 99h

1:0:1 4Dh 9Ah, 9Bh

1:1:0 4Eh 9Ch, 9Dh

1:1:1 4Fh 9Eh, 9Fh

C ADDRESS

INCLUDING R/W BIT

MAX6618

PECI-to-I2C Translator

______________________________________________________________________________________ 17

Pin Configuration

Chip Information

PROCESS: CMOS

TOP VIEW

PECI

AGND

AD0

SCL

+

1

2

3

MAX6618

4

5

μMAX

V

10

REF

9

AD1

8

AD2

7

GNDSDA

6

V

CC

MAX6618

PECI-to-I2C Translator

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

18

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Heaney

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

e

10

0.6±0.1

1

A2

FRONT VIEW

Ø0.50±0.1

0.6±0.1

TOP VIEW

D2

D1

4X S

10

DIM

A1

A2 0.030 0.037 0.75 0.95

D1

H

1

BOTTOM VIEW

D2

E1

E2

H

L

L1

b

e

S

α

E2

GAGE PLANE

A

b

A1

α

E1

L

L1

INCHES

MAX

MIN

0.043

-A

0.006

0.002

0.120

0.116

0.118

0.114

0.120

0.116

0.118

0.114

0.199

0.187

0.0275

0.0157

0.037 REF

0.0106

0.007

0.0197 BSC

0.0035

c

c

0.0078

0.0196 REF

6°

0° 0° 6°

MILLIMETERS

MAX

MIN

-

1.10

0.15

0.05

3.05

2.95

3.00

2.89

2.95

3.05

2.89

3.00

4.75

5.05

0.40

0.70

0.940 REF

0.177

0.270

0.500 BSC

0.090

0.200

0.498 REF

10LUMAX.EPS

SIDE VIEW

PROPRIETARY INFORMATION

TITLE:

PACKAGE OUTLINE, 10L uMAX/uSOP

REV.DOCUMENT CONTROL NO.APPROVAL

21-0061

1

1

Loading...

Loading...