Page 1

19-3185; Rev 2; 8/04

________________________________

MAX5417/MAX5418/MAX5419

是非易失、线性数字电位

概述

器,与机械电位器功能相似,但可通过简单的2线数字接

口控制,允许多个器件进行通信。每个器件具有分离电

位器或可变电阻的功能,具有

这些器件内置非易失

EEPROM

上电时进行初始化处理。快速模式

400kbps

的通信速率,在许多应用场合可有效减小电路板

个抽头点。

256

,用于存储滑动端的位置,

TM

兼容接口允许

I2C

面积,简化电路连接。每个器件有一个工厂预置地址,

有四种地址选择(见

选择指南

,配合地址选择输入,共

)

提供八个唯一的地址组合。

MAX5417/MAX5418/MAX5419

(MAX5417)、100kΩ (MAX5418)和200kΩ (MAX5419)

标称电阻的端到端温度系数为

为

5ppm/°C

,非常适合低温漂可变电阻的应用,如低漂移、

提供了三个标称阻值:

35ppm/°C,

比率温度系数仅

50kΩ

。

可编程增益放大器。

MAX5417/MAX5418/MAX5419

封装,工作在

TDFN

-40°C至+85°C

采用

3mmx 3mm、8

扩展级温度范围。

________________________________

引脚

应用

替代机械电位器

低漂移可编程增益放大器

音量控制

液晶显示屏

(LCD)

对比度控制

256

抽头、非易失、

I2C

接口

数字电位器

________________________________

上电后从非易失存储器调用滑动端位置

♦

微型

♦

♦

♦

♦

♦

♦ 500nA (

♦

♦ 256

♦

♦

3mm x 3mm、8

端到端电阻温度系数:

比率温度系数:

阻值:

50kΩ/100kΩ/200kΩ

快速

兼容串行接口

I2C

典型值)静态电流

单电源

+2.7V至+5.25V

抽头

分压模式下

分压模式下

DNL

INL为:±0.5 LSB

______________________________

定义的

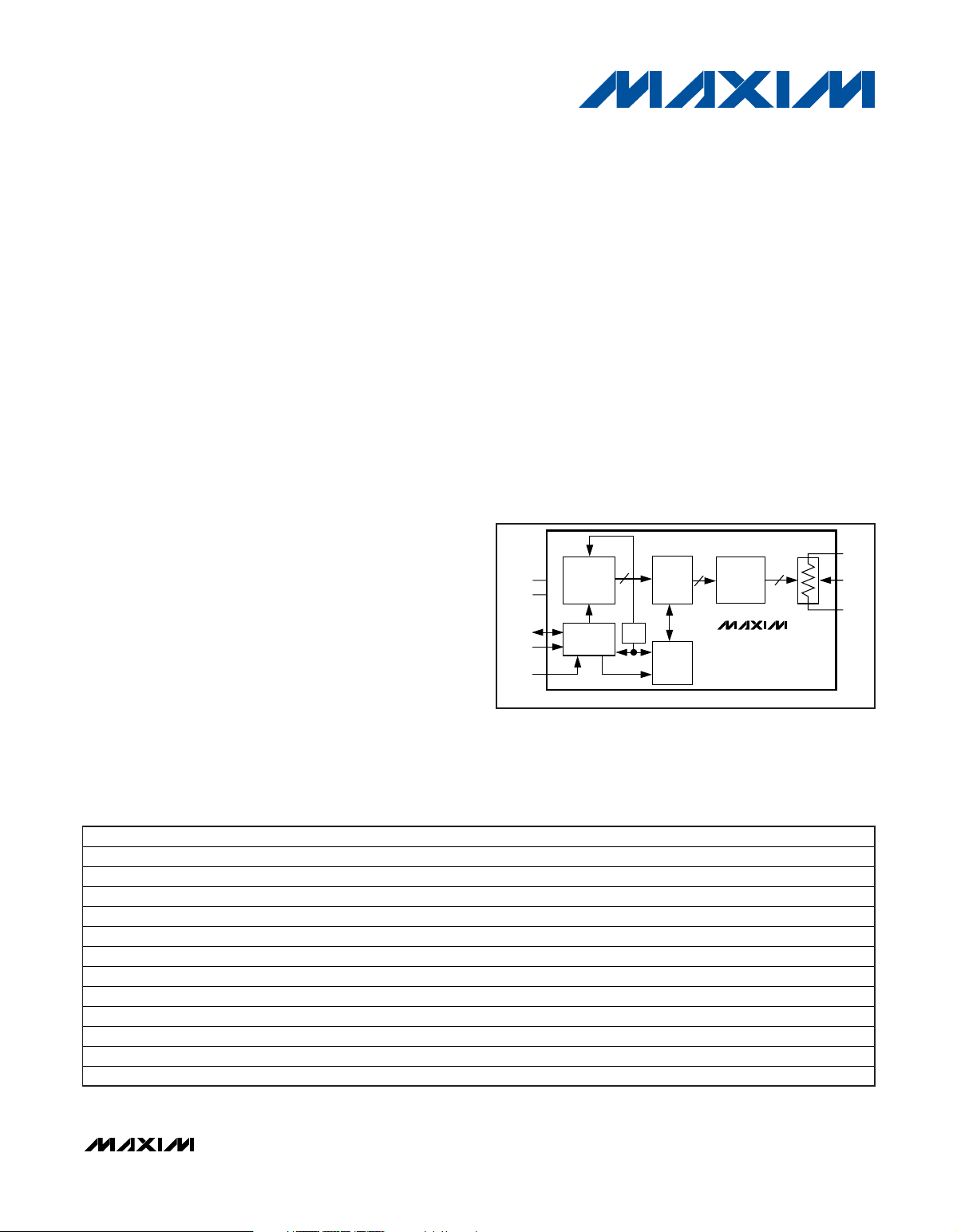

8-BIT

SHIFT

REGISTER

I2C

INTERFACE

Philips I2C

标准规范的系统。

I2C

V

DD

GND

SDA

SCL

A

0

I2C是Philips Corp.

购买

Maxim Integrated Products, Inc.

产品,即得到了

Philips

引脚

TDFN

封装

35ppm/°C

5ppm/°C

供电

为:

±0.5 LSB

8

8-BIT

LATCH

POR

8-BIT

NV

MEMORY

的一个商标。

的专利许可、将这些产品用于符合

256-

8

POSITION

DECODER

MAX5417

MAX5418

MAX5419

或其从属授权公司的

功能图

256

特性

MAX5417/MAX5418/MAX5419

H

W

L

I2C

___________________________________________________________

PART TEMP RANGE I2C ADDRESS R (kΩ) PIN-PACKAGE TOP MARK

MAX5417LETA -40°C to +85°C 010100A

MAX5417META* -40°C to +85°C 010101A

MAX5417NETA* -40°C to +85°C 010110A

MAX5417PETA* -40°C to +85°C 010111A

MAX5418LETA -40°C to +85°C 010100A

MAX5418META* -40°C to +85°C 010101A

MAX5418NETA* -40°C to +85°C 010110A

MAX5418PETA* -40°C to +85°C 010111A

MAX5419LETA -40°C to +85°C 010100A

MAX5419META* -40°C to +85°C 010101A

MAX5419NETA* -40°C to +85°C 010110A

MAX5419PETA* -40°C to +85°C 010111A

*Future product—contact factory for availability.

**Exposed pad.

________________________________________________________________ Maxim Integrated Products 1

本文是

翻译错误,如需确认任何词语的准确性,请参考

索取免费样品和最新版的数据资料,请访问

正式英文资料的译文,

Maxim

不对翻译中存在的差异或由此产生的错误负责。请注意译文中可能存在文字组织或

Maxim

Maxim

提供的英文版资料。

Maxim

的主页:

0

0

0

0

0

0

0

0

0

0

0

0

引脚配置见本文的最后部分。

www.maxim-ic.com.cn

50 8 TDFN-EP** AIB

50 8 TDFN-EP** ALS

50 8 TDFN-EP** ALT

50 8 TDFN-EP** ALU

100 8 TDFN-EP** AIC

100 8 TDFN-EP** ALV

100 8 TDFN-EP** ALW

100 8 TDFN-EP** ALX

200 8 TDFN-EP** AID

200 8 TDFN-EP** ALY

200 8 TDFN-EP** ALZ

200 8 TDFN-EP** AMA

。

定购信息/选择指南

Page 2

256

抽头、非易失、

I2C

接口

数字电位器

ABSOLUTE MAXIMUM RATINGS

VDDto GND...........................................................-0.3V to +6.0V

All Other Pins to GND.................................-0.3V to (V

Maximum Continuous Current into H, L, and W

MAX5417......................................................................±1.3mA

MAX5418......................................................................±0.6mA

MAX5419......................................................................±0.3mA

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

DD

+ 0.3V)

Continuous Power Dissipation (T

8-Pin TDFN (derate 24.4mW/°C above +70°C) .........1951mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

ELECTRICAL CHARACTERISTICS

(VDD= +2.7V to +5.25V, H = VDD, L = GND, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +5V, TA= +25°C.)

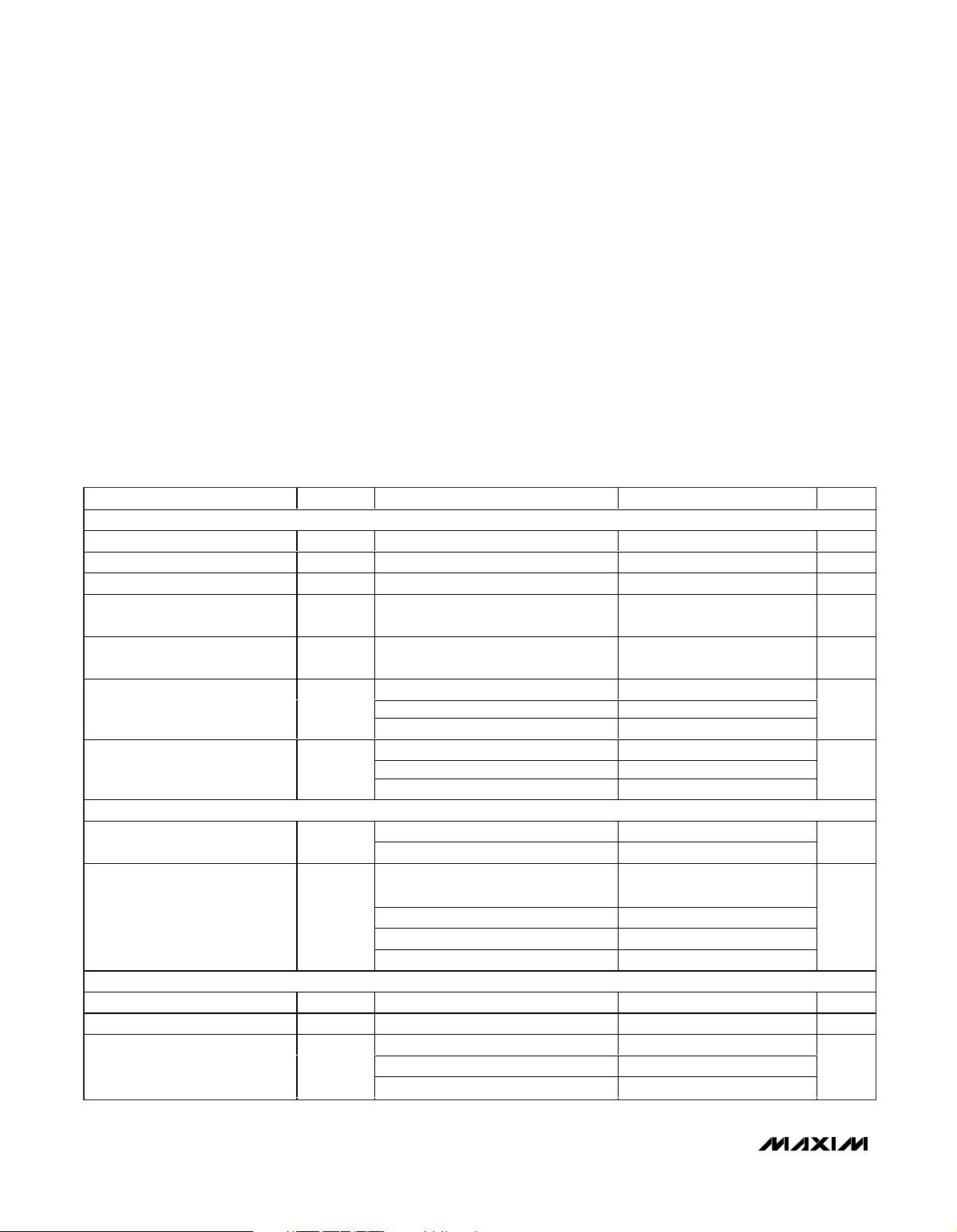

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DC PERFORMANCE (VOLTAGE-DIVIDER MODE)

Resolution 256 Taps

Integral Nonlinearity INL (Note 1) ±0.5 LSB

Differential Nonlinearity DNL (Note 1) ±0.5 LSB

End-to-End Temperature

Coefficient

Ratiometric Temperature

Coefficient

MAX5417/MAX5418/MAX5419

Zero-Scale Error

DC PERFORMANCE (VARIABLE-RESISTOR MODE)

Integral Nonlinearity

(Note 2)

Differential Nonlinearity

(Note 2)

DC PERFORMANCE (RESISTOR CHARACTERISTICS)

Wiper Resistance R

Wiper Capacitance C

TC

INL

DNL

W

W

HL

R

MAX5417_, 50Ω -0.6

MAX5418_, 100kΩ -0.3Full-Scale Error

MAX5419_, 200kΩ -0.15

MAX5417_, 50kΩ 0.6

MAX5418_, 100kΩ 0.3

MAX5419_, 200kΩ 0.15

V

= 3V ±3

DD

V

= 5V ±1.5

DD

V

= 3V, MAX5417_, 50kΩ,

DD

guaranteed monotonic

VDD = 3V, MAX5418_, 100kΩ ±1

MAX5419_, 200kΩ ±1

V

= 5V ±1

DD

VDD = 3V to 5.25V (Note 3) 325 675 Ω

MAX5417_ 37.5 50 62.5

MAX5418_ 75 100 125End-to-End Resistance R

MAX5419_ 150 200 250

-1 +2

= +70°C)

A

35 ppm/°C

5 ppm/°C

10 pF

LSB

LSB

LSB

LSB

kΩ

2 _______________________________________________________________________________________

Page 3

256

抽头、非易失、

I2C

接口

数字电位器

MAX5417/MAX5418/MAX5419

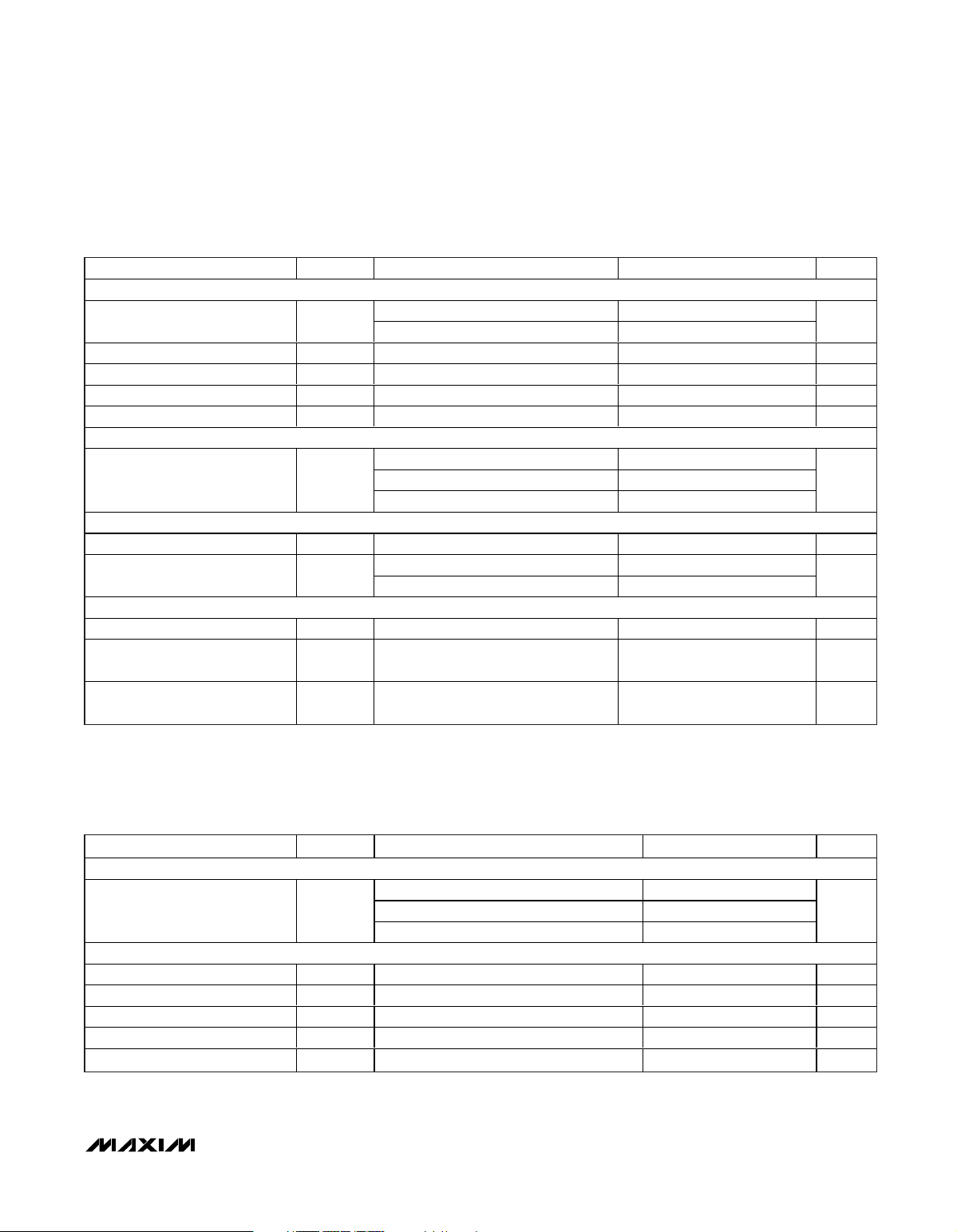

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +2.7V to +5.25V, H = VDD, L = GND, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +5V, TA= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DIGITAL INPUTS

Input High Voltage (Note 4) V

Input Low Voltage V

Low-Level Output Voltage V

Input Leakage Current I

Input Capacitance 5pF

DYNAMIC CHARACTERISTICS

NONVOLATILE MEMORY

Data Retention TA = +85°C 50 Years

Endurance

POWER SUPPLY

Power-Supply Voltage V

Standby Current I

Programming Current

LEAK

DD

DD

VDD = 3.4V to 5.25V 2.4

IH

VDD < 3.4V 0.7 x V

V

IL

OL

= 2.7V to 5.25V (Note 4) 0.8 V

DD

3mA sink current 0.4 V

MAX5417_ 100

MAX5418_ 50Wiper -3dB Bandwidth (Note 5)

MAX5419_ 25

TA = +25°C 200,000

= +85°C 50,000

T

A

Digital inputs = V

= +25°C

T

A

During nonvolatile write;

digital inputs = V

or GND,

DD

or GND (Note 6)

DD

DD

2.70 5.25 V

0.5 1 µA

200 400 µA

V

±1 µA

kHz

Stores

TIMING CHARACTERISTICS

(VDD= +2.7V to +5.25V, H = VDD, L = GND, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +5V, TA=

+25°C. See Figures 1 and 2.) (Note 7)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ANALOG SECTION

MAX5417_ 500

ns

DIGITAL SECTION

SCL Clock Frequency f

Setup Time for START Condition t

Hold Time for START Condition t

CLK High Time t

CLK Low Time t

_______________________________________________________________________________________ 3

IL

SCL

SU-STA

HD-STA

HIGH

LOW

MAX5418_ 600Wiper Settling Time (Note 8) t

MAX5419_ 1000

400 kHz

0.6 µs

0.6 µs

0.6 µs

1.3 µs

Page 4

256

抽头、非易失、

I2C

接口

数字电位器

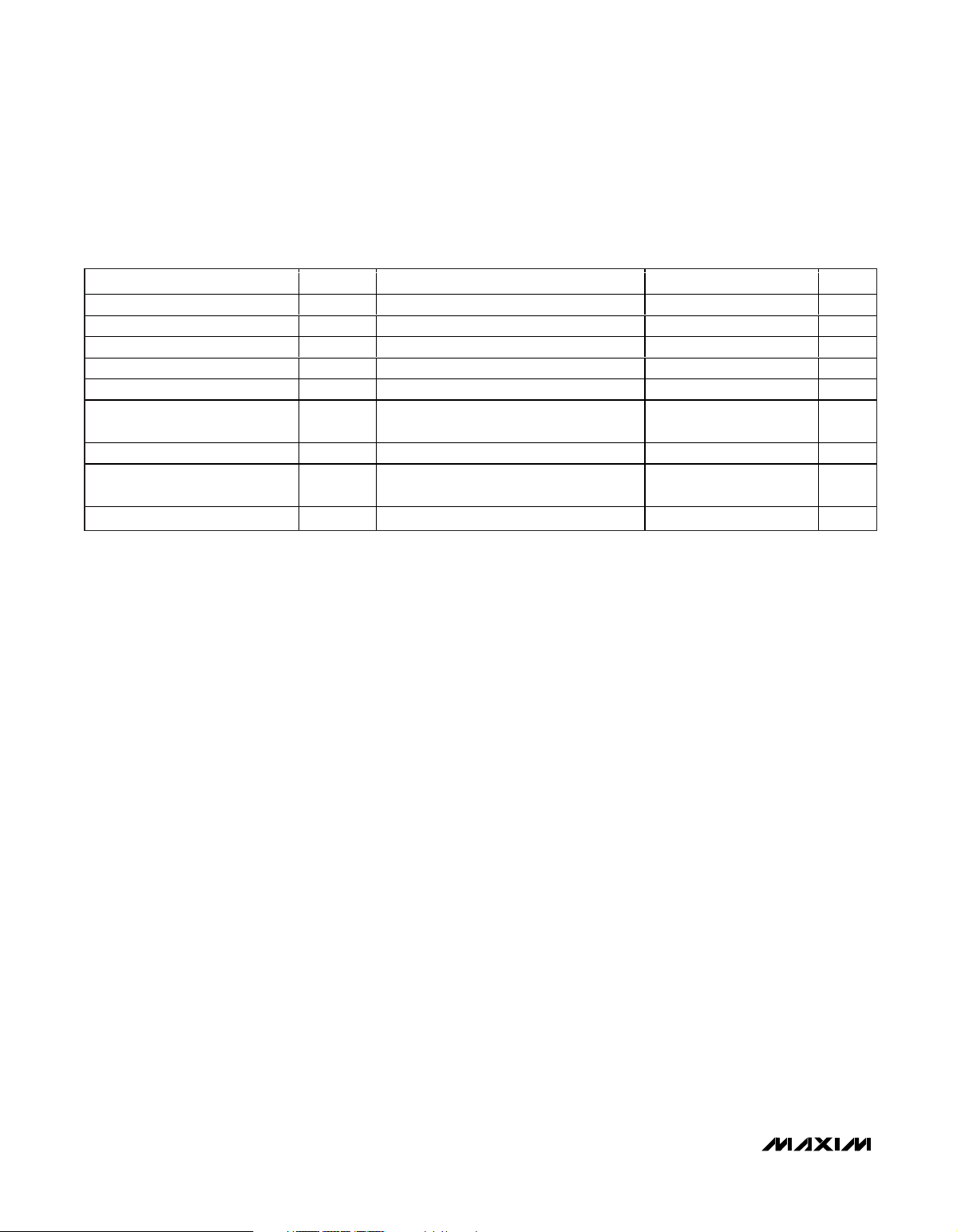

TIMING CHARACTERISTICS (continued)

(VDD= +2.7V to +5.25V, H = VDD, L = GND, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +5V, TA=

+25°C. See Figures 1 and 2.) (Note 7)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Data Setup Time t

Data Hold Time t

SDA, SCL Rise Time t

SDA, SCL Fall Time t

Setup Time for STOP Condition t

Bus Free Time Between STOP

and START Condition

Pulse Width of Spike Suppressed t

Maximum Capacitive Load for

Each Bus Line

Write NV Register Busy Time t

Note 1: The DNL and INL are measured with the potentiometer configured as a voltage-divider with H = VDDand L = GND. The

Note 2: The DNL and INL are measured with the potentiometer configured as a variable resistor. H is unconnected and L = GND.

Note 3: The wiper resistance is measured using the source currents given in Note 2. For operation to V

Note 4: The device draws higher supply current when the digital inputs are driven with voltages between (V

MAX5417/MAX5418/MAX5419

Note 5: Wiper at midscale with a 10pF load (DC measurement). L = GND; an AC source is applied to H; and the W output is mea-

Note 6: The programming current operates only during power-up and NV writes.

Note 7: SCL clock period includes rise and fall times t

Note 8: Wiper settling time is the worst-case 0% to 50% rise time measured between consecutive wiper positions. H = VDD,

Note 9: An appropriate bus pullup resistance must be selected depending on board capacitance. Refer to the document linked to

Note 10: The idle time begins from the initiation of the stop pulse.

wiper terminal is unloaded and measured with a high-input-impedance voltmeter.

For the 5V condition, the wiper terminal is driven with a source current of 80µA for the 50kΩ configuration, 40µA for the

100kΩ configuration, and 20µA for the 200kΩ configuration. For the 3V condition, the wiper terminal is driven with a source

current of 40µA for the 50kΩ configuration, 20µA for the 100kΩ configuration, and 10µA for the 200kΩ configuration.

Resistance vs. Temperature in the Typical Operating Characteristics.

0.5V). See Supply Current vs. Digital Input Voltage in the Typical Operating Characteristics.

sured. A 3dB bandwidth occurs when the AC W/H value is 3dB lower than the DC W/H value.

from a voltage level of (V

L = GND, and the wiper terminal is unloaded and measured with a 10pF oscilloscope probe (see the Typical Operating

Characteristics for the tap-to-tap switching transient).

this web address: www.semiconductors.philips.com/acrobat/literature/9398/39340011.pdf.

SU-DAT

HD-DAT

SU-STO

+ VIH) / 2.

IL

R

F

t

BUF

SP

C

B

BUSY

Minimum power-up rate = 0.2V/ms 1.3 µs

(Note 9) 400 pF

(Note 10) 12 ms

and tF. All digital input signals are specified with tR= tF= 2ns and timed

R

100 ns

0 0.9 µs

300 ns

300 ns

0.6 µs

50 ns

= 2.7V, see Wiper

DD

- 0.5V) and (GND +

DD

4 _______________________________________________________________________________________

Page 5

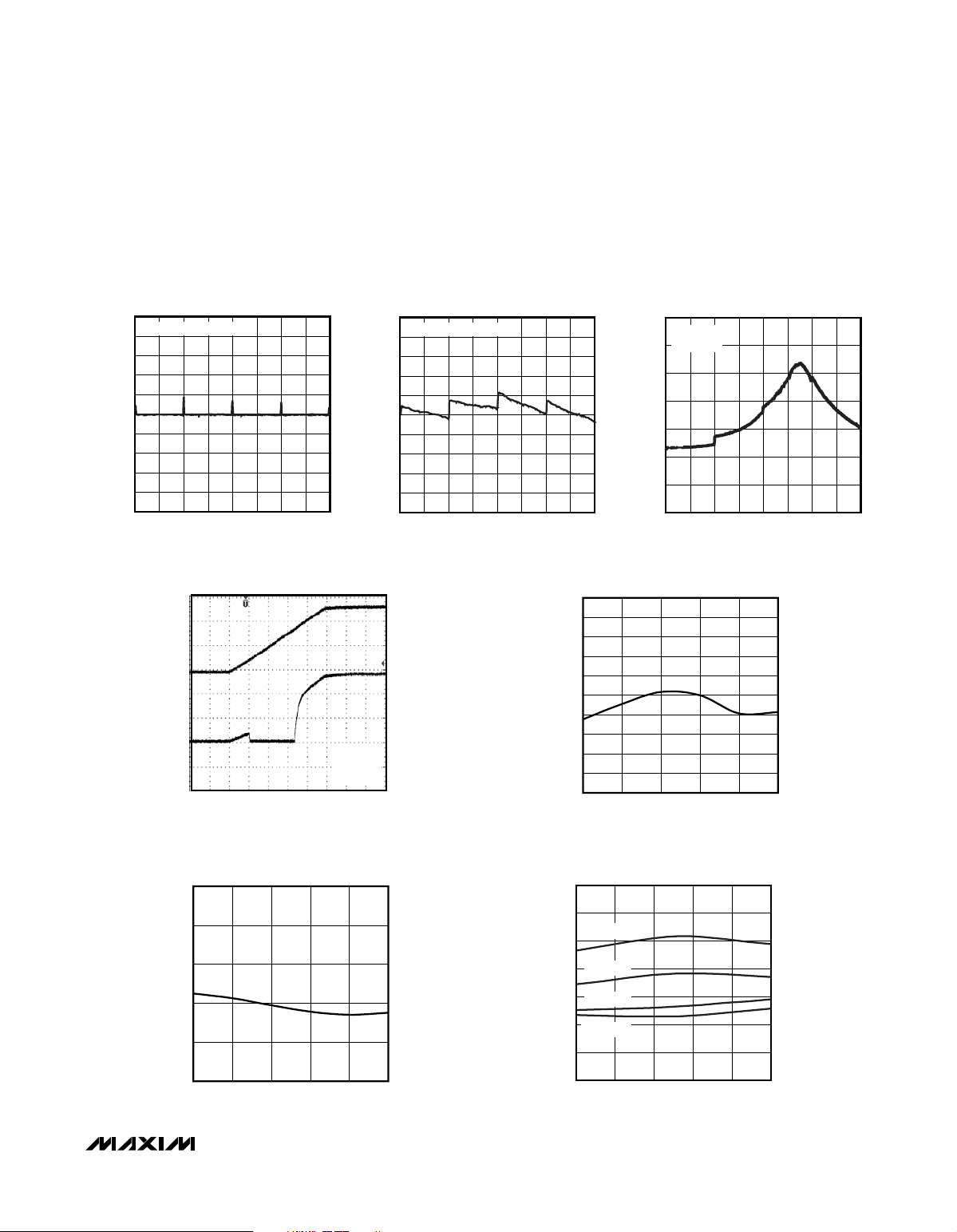

WIPER TRANSIENT AT POWER-ON

MAX5417 toc04

W

1V/div

V

DD

2V/div

4µs/div

CL = 10pF

TAP = 128

H = V

DD

END-TO-END RESISTANCE % CHANGE

vs. TEMPERATURE

MAX5417 toc05

TEMPERATURE (°C)

END-TO-END RESISTANCE % CHANGE

603510-15

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

-40 85

DNL vs. TAP POSITION

MAX5417 toc01

TAP POSITION

RESISTANCE DNL (LSB)

224192160128966432

-0.20

-0.15

-0.10

-0.05

0

0.10

0.20

0.05

0.15

0.25

-0.25

0256

VOLTAGE-DIVIDER MODE

TAP POSITION

RESISTANCE INL (LSB)

224192160128966432

-0.20

-0.15

-0.10

-0.05

0

0.10

0.20

0.05

0.15

0.25

-0.25

0 256

INL vs. TAP POSITION

MAX5417 toc02

VOLTAGE-DIVIDER MODE

WIPER RESISTANCE vs. TAP POSITION

MAX5417 toc03

TAP POSITION

RESISTANCE (Ω)

224192160128966432

100

200

300

400

500

600

700

0

0 256

VDD = 2.7V

I

SRC

= 50µA

STANDBY SUPPLY CURRENT

vs. TEMPERATURE

MAX5417 toc06

TEMPERATURE (°C)

STANDBY SUPPLY CURRENT (µA)

603510-15

0.2

0.4

0.6

0.8

1.0

0

-40 85

WIPER RESISTANCE vs. TEMPERATURE

MAX5417 toc07

TEMPERATURE (°C)

RESISTANCE (Ω)

603510-15

100

200

300

400

500

600

700

0

-40 85

VDD = 2.7V

VDD = 3.0V

VDD = 4.5V

VDD = 5.25V

256

抽头、非易失、

数字电位器

_______________________________________________________________

(VDD= +5V, TA= +25°C, unless otherwise noted.)

I2C

接口

典型工作特性

MAX5417/MAX5418/MAX5419

_______________________________________________________________________________________ 5

Page 6

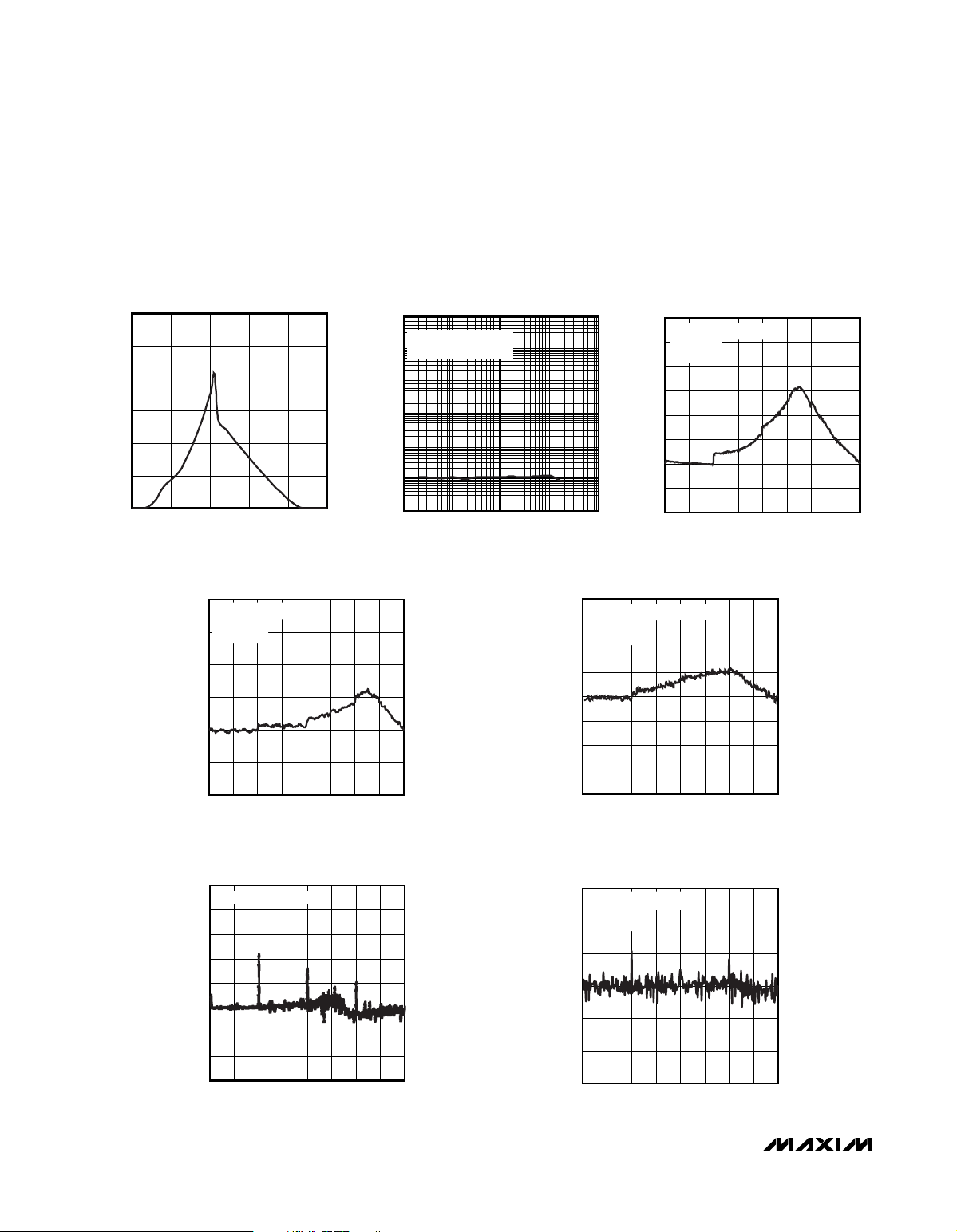

SUPPLY CURRENT

vs. DIGITAL INPUT VOLTAGE

MAX5417 toc08

DIGITAL INPUT VOLTAGE (V)

SUPPLY CURRENT (µA)

4321

100

200

300

400

500

600

0

05

10k1k100

0.001

0.01

0.1

1

10

100

0.0001

10 100k

THD+N RESPONSE

MAX5417 toc09

FREQUENCY (Hz)

THD+N (%)

1:1 RATIO

20Hz TO 20kHz BANDPASS

INL vs. TAP POSITION

(MAX5417)

MAX5417 toc10

TAP POSITION

RESISTANCE INL (LSB)

224192160128966432

-0.5

0

0.5

1.0

1.5

2.0

2.5

3.0

-1.0

0256

VARIABLE-RESISTOR MODE

V

DD

= 2.7V

I

SRC

= 50µA

256

抽头、非易失、

数字电位器

I2C

接口

___________________________________________________________

(VDD= +5V, TA= +25°C, unless otherwise noted.)

INL vs. TAP POSITION

(MAX5418)

2.0

VARIABLE-RESISTOR MODE

= 2.7V

V

DD

1.5

= 20µA

I

SRC

1.0

MAX5417/MAX5418/MAX5419

0.5

INL (LSB)

0

-0.5

-1.0

0256

TAP POSITION

MAX5417 toc11

224192160128966432

1.00

0.75

0.50

0.25

0

INL (LSB)

-0.25

-0.50

-0.75

-1.00

INL vs. TAP POSITION

VARIABLE-RESISTOR MODE

= 2.7V

V

DD

= 10µA

I

SRC

0256

(MAX5419)

TAP POSITION

典型工作特性(续

MAX5417 toc12

22419232 64 96 128 160

)

DNL vs. TAP POSITION

(MAX5417)

0.5

VARIABLE-RESISTOR MODE

0.4

0.3

6 _______________________________________________________________________________________

0.2

0.1

DNL (LSB)

0

-0.1

-0.2

-0.3

0256

TAP POSITION

DNL vs. TAP POSITION

(MAX5418)

0.3

VARIABLE-RESISTOR MODE

= 2.7V

V

DD

MAX5417 toc13

224192160128966432

0.2

= 20µA

I

SRC

0.1

0

DNL (LSB)

-0.1

-0.2

-0.3

0 256

TAP POSITION

MAX5417 toc14

224192160128966432

Page 7

256

抽头、非易失、

___________________________________________________________

(VDD= +5V, TA= +25°C, unless otherwise noted.)

I2C

接口

数字电位器

典型工作特性(续

MAX5417/MAX5418/MAX5419

)

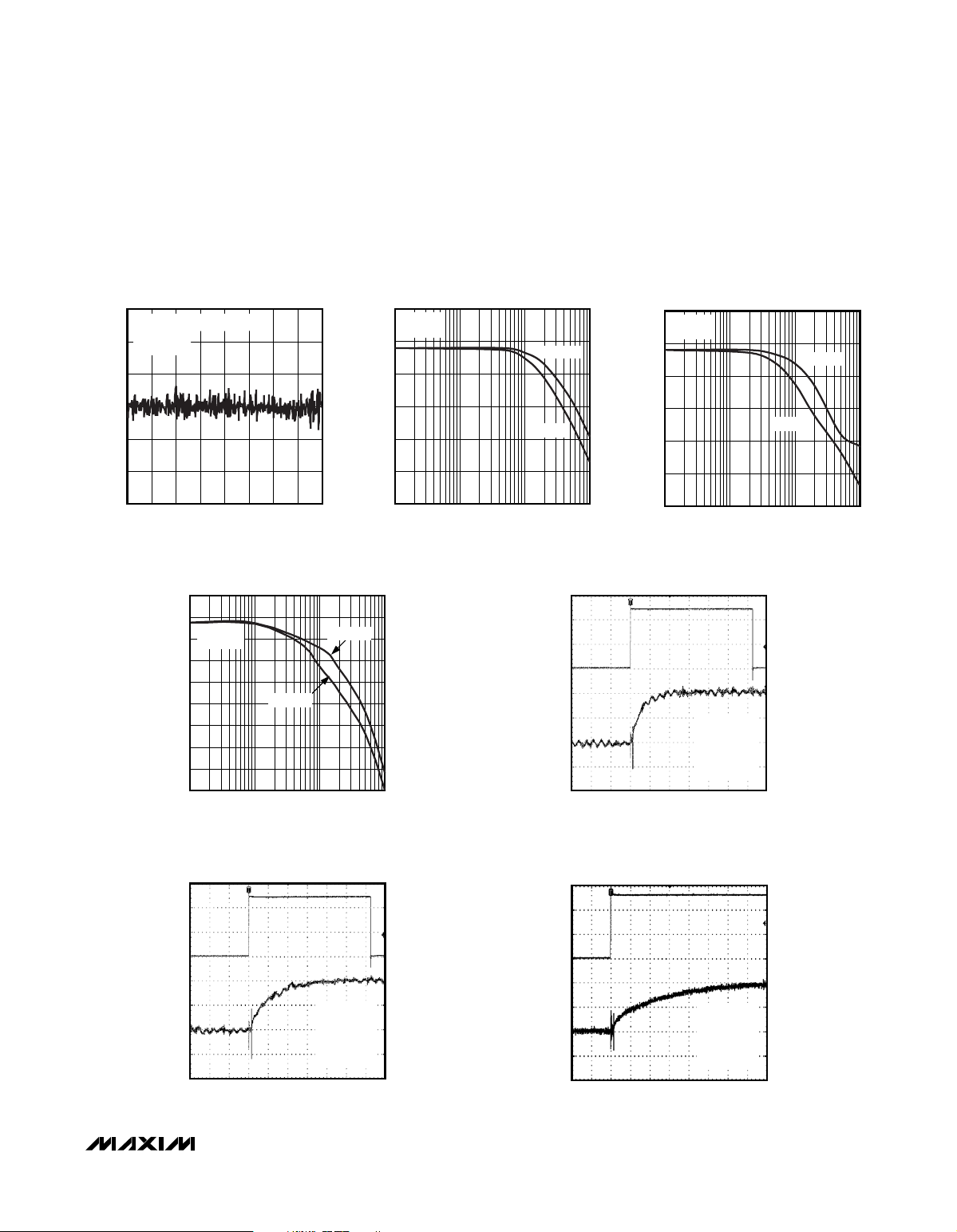

0.3

VARIABLE-RESISTOR MODE

V

DD

0.2

I

SRC

0.1

0

DNL (LSB)

-0.1

-0.2

-0.3

DNL vs. TAP POSITION

(MAX5419)

= 2.7V

= 10µA

TAP POSITION

MAX5417 toc15

22419232 64 96 128 1600 256

MIDSCALE WIPER RESPONSE vs. FREQUENCY

(MAX5419)

0

-5

MAX5419

-10

TAP = 128

-15

-20

-25

-30

WIPER RESPONSE (dB)

-35

-40

-45

1 1000

CL = 50pF

FREQUENCY (kHz)

CL = 10pF

10010

MIDSCALE WIPER RESPONSE vs. FREQUENCY

MIDSCALE WIPER RESPONSE vs. FREQUENCY

(MAX5417)

0

MAX5417

TAP = 128

-5

-10

-15

-20

WIPER RESPONSE (dB)

-25

-30

11000

FREQUENCY (kHz)

CL = 10pF

CL = 50pF

10010

MAX5417 toc16

0

MAX5418

TAP = 128

-5

-10

-15

-20

WIPER RESPONSE (dB)

-25

-30

1 1000

TAP-TO-TAP SWITCHING TRANSIENT

(MAX5417)

MAX5417 toc18

MAX5417

C

L

FROM TAP 127

TO TAP 128

H = V

1µs/div

(MAX5418)

FREQUENCY (kHz)

MAX5417 toc19

= 10pF

DD

CL = 50pF

10010

SDA

2V/div

W

10mV/div

CL = 10pF

MAX5417 toc17

TAP-TO-TAP SWITCHING TRANSIENT

(MAX5418)

1µs/div

MAX5417 toc20

MAX5418

= 10pF

C

L

FROM TAP 127

TO TAP 128

H = V

DD

SDA

2V/div

W

10mV/div

TAP-TO-TAP SWITCHING TRANSIENT

(MAX5419)

1µs/div

MAX5417 toc21

MAX5419

= 10pF

C

L

FROM TAP 127

TO TAP 128

H = V

DD

SDA

2V/div

W

10mV/div

_______________________________________________________________________________________ 7

Page 8

256

抽头、非易失、

数字电位器

I2C

接口

___________________________________________________________________

功能

电容旁路

t

HD-STA

至

GND

。

t

SU-STO

V

DD

t

SU-DAT

名称

t

LOW

t

HD-STA

电源输入,电压范围:

接口时钟输入

I2C

接口数据输入

I2C

地址输入端,设置器件ID的A0位。

地

低端

滑动端

高端

裸露焊盘

t

HIGH

t

R

t

F

2.7V至5.25V。用0.1µF

t

HD-DAT

t

SU-STA

引脚

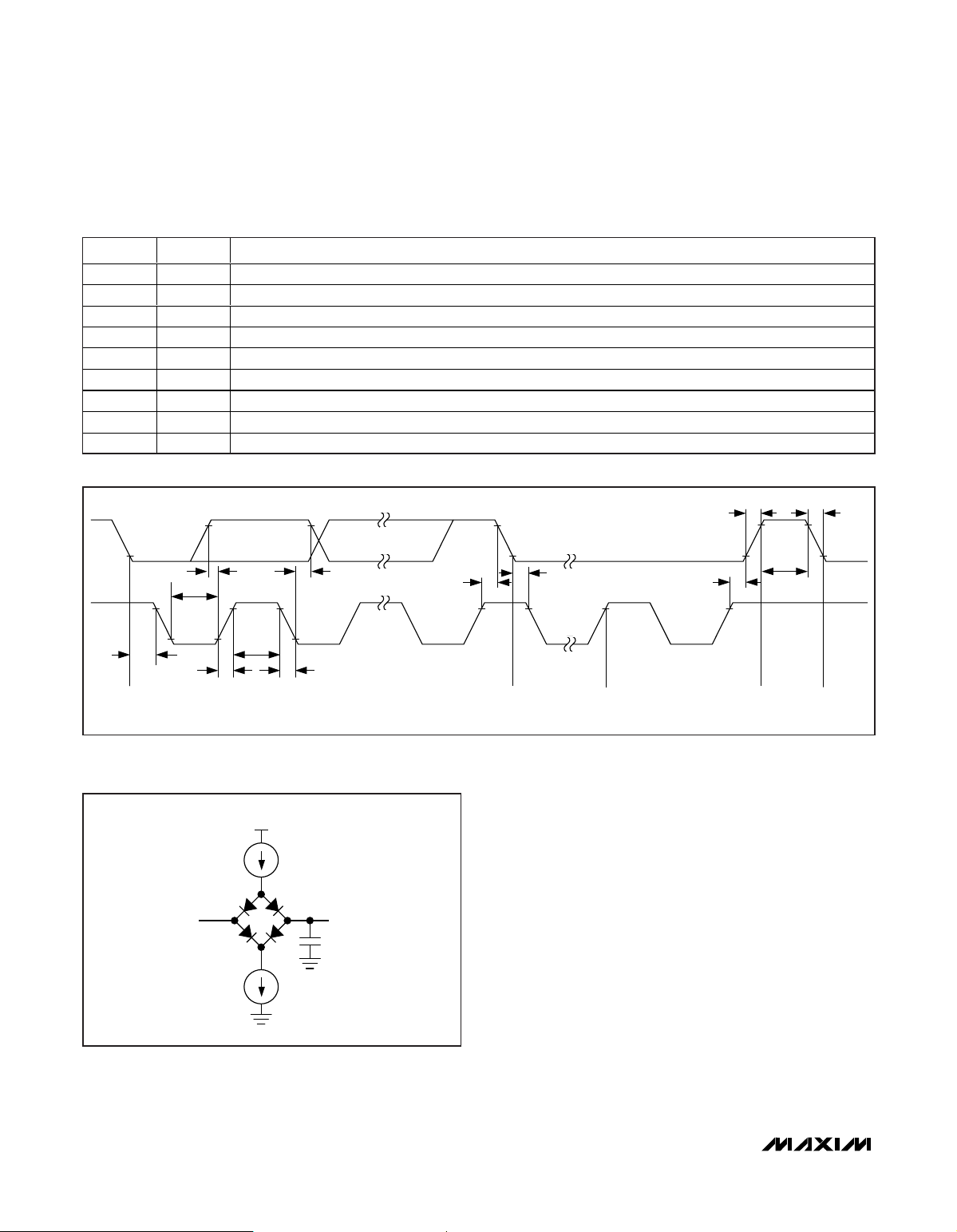

PIN NAME FUNCTION

1VDDPower-Supply Input. 2.7V to 5.25V voltage range. Bypass with a 0.1µF capacitor from VDD to GND.

2 SCL I2C-Interface Clock Input

3 SDA I2C-Interface Data Input

4 A0 Address Input. Sets the A0 bit in the device ID address.

5 GND Ground

6 L Low Terminal

7 W Wiper Terminal

8 H High Terminal

— EP Exposed Pad

SDA

SCL

MAX5417/MAX5418/MAX5419

S Sr A

PARAMETERS ARE MEASURED FROM 30% TO 70%.

引脚说明

t

R

PS

t

F

t

BUF

图

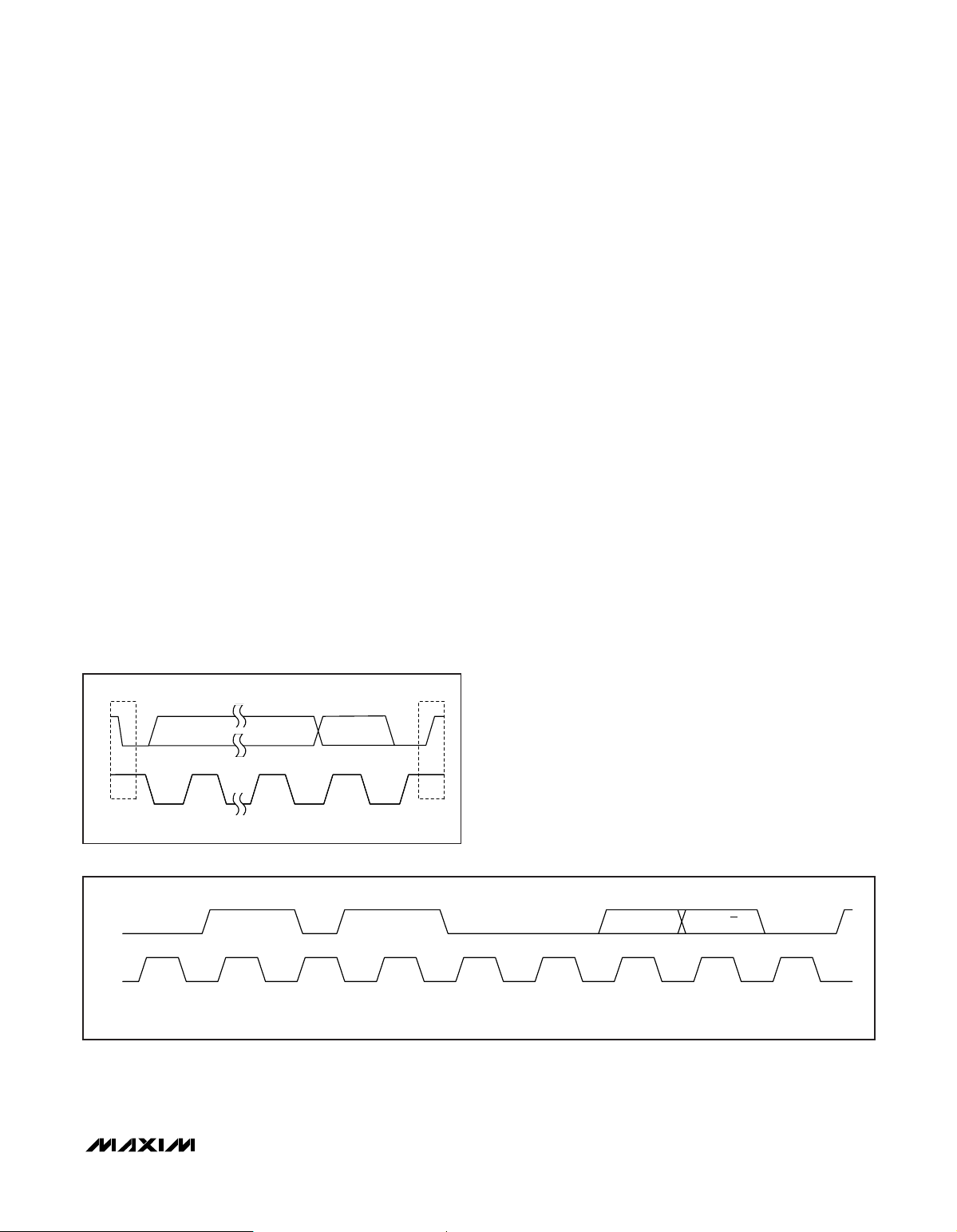

1. I2C

串行接口时序

____________________________

V

DD

I

= 3mA

OL

MAX5417/MAX5418/MAX5419

个电阻单元。

端到端阻值为

MAX5417

100kΩ,MAX5417

端到端阻值为

MAX5417/MAX5418/MAX5419

SDA

V

OUT

400pF

= 0mA

I

OH

动端可以构成标准的分压器,H、L和W端可以任意配置,

只需保证各端电压在

简单的2线

I2C

GND和V

兼容串行接口可以在

动端。非易失存储器储存并在上电时恢复滑动端的位置。

非易失存储器确保

200,000

持50年。

图

负载电路

2.

8 _______________________________________________________________________________________

内置电阻阵列,包含

端到端阻值为

通过连接高端、低端和滑

之间。

DD

次抽头读写,寄存器数据可保

详细说明

50kΩ,MAX5418

200kΩ

个触点间调节滑

256

255

。

Page 9

模拟电路

MAX5417/MAX5418/MAX5419

个电阻单元;

255

串接至滑动端

口对数字电位器编程实现。8位数据,一个地址字节,和

一个控制字节设置抽头位置。

MAX5419的H、L

MAX5417/MAX5418/MAX5419

电时从非易失存储器自动装载滑动端的位置。

个抽头点可以沿着H、L之间的电阻

256

。滑动端的位置选择通过2线

(W)

端与机械电位器的两个端点相同。

内置一个电阻阵列,包含

接

(I2C)

MAX5417/MAX5418/

带有上电复位电路,在上

数字接口

MAX5417/MAX5418/MAX5419

用于存储滑动端的位置,以便上电时的初始化处理。移

位寄存器对控制位和地址位进行解码,将数据写入适当

的数据寄存器。数据可以写入易失存储寄存器,立即更

新滑动端的位置,也可以写入非易失寄存器存储。

易失寄存器在系统加电期间能够保持数据。一旦系统断

电,易失寄存器的内容被清除。非易失寄存器在系统断

电时仍能保存数据。一旦上电,上电复位电路将非易失

存储器的内容自动传送到易失寄存器中,更新滑动端的

位置。

内置非易失

EEPROM

256

抽头、非易失、

I2C

数字电位器

MAX5417/MAX5418/MAX5419

TM

SMBus

(SDA)

主设备通常是微控制器,启动

MAX5419

传输(见图1)。

MAX5417/MAX5418/MAX5419的SDA

开路输出,

MAX5417/MAX5418/MAX5419的SCL

若2线接口挂接有多个主机,或者是具有

出的单主机系统,

,

阻。

每次数据传输先由主机发送启动

然后发送

8位(图4),1

停止

接口不工作时

始数据传输,即

降沿。当主机完成与从机的通信后发送停止条件,即在

SCL

总线,进行另外的传输(图3)。

兼容的2线接口接收数据,该接口采用串行数据线

和串行时钟线

的全部数据传输,并产生

线上需要一个典型值为

SDA

SCL

MAX5417/MAX5418/MAX5419的7

个命令字节(图7)和1个数据字节,最后是

(STOP)

为高电平时

条件

(P) (图3)

SCL和SDA

SCL

SDA

实现主、从设备之间的通信。

(SCL)

线上需接典型值为

。

均为高。主机发送启动条件开

为高电平时

出现由低至高的上升沿。然后释放

作为从设备从

MAX5417/MAX5418/

时钟,同步数据

SCL

可作为输入或漏极

4.7kΩ

只能作为输入端。

SCL

4.7kΩ

(START)

条件

启动条件和停止条件

出现由高至低的下

SDA

接口

串行寻址

或

I2C

的上拉电阻。

漏极开路输

的上拉电

(S) (图3)

位从地址和第

MAX5417/MAX5418/MAX5419

,

SDA

SCL

S

START

CONDITION

图

启动条件和停止条件

3.

SDA

SCL

*See the Ordering Information/Selector Guide section for other address options.

图

4.

SMBus是Intel Corporation

01

MSB LSB

从地址

的一个商标。

_______________________________________________________________________________________ 9

0 1 0* 0*

P

STOP

CONDITION

每个时钟传输一个数据位。

需保持稳定(图5)。

A0

为高时,

SCL

NOP/W ACK

上的数据必

SDA

位传输

Page 10

256

抽头、非易失、

数字电位器

I2C

接口

表1.

应答位是第9个时钟位,它是收到每个数据字节的应答握

手信号(图6)。因此,每个字节的有效传输需要9位。主

机产生第9个时钟脉冲,接收端在应答时钟周期内将

低电平。当主机向

据时,

为它们是数据的接收者。

MAX5417/MAX5418/MAX5419

PART SUFFIX A6 A5 A4 A3 A2 A1 A0 NOP/W

L 0 1 0 1 0 0 0 NOP/W

L 0 1 0 1 0 0 1 NOP/W

M 0 1 0 1 0 1 0 NOP/W

M 0 1 0 1 0 1 1 NOP/W

N 0 1 0 1 1 0 0 NOP/W

N 0 1 0 1 1 0 1 NOP/W

P 0 1 0 1 1 1 0 NOP/W

P 0 1 0 1 1 1 1 NOP/W

拉低,所以,在时钟为高电平期间

SDA

MAX5417/MAX5418/MAX5419

MAX5417/MAX5418/MAX5419

产生应答信号,因

必须稳定在

SDA

的地址码

ADDRESS BYTE

应答信号

传输数

MAX5417/MAX5418/MAX5419

MAX5417/MAX5418/MAX5419

接下来的2位由工厂设置(见表1)。将A0输入接

,可以在两个唯一地址中为器件选择做出选择。只

V

DD

有具有唯一地址的器件才能共享总线。因此,最多可以

有8个

线上。

从地址

MAX5417/MAX5418/MAX5419

MAX5417/MAX5418/MAX5419

紧随7位从地址的第8位是

示写操作,置高表示空操作。

具有7位从地址(图4)。

NOP/W

位,

NOP/W

位置低表

提供四种从地址(表1)。

的高4位地址始终为

MAX5417/MAX5418/MAX5419

0101

或

GND

挂接在同一总

,

SCL

SDA

图

START

CONDITION

应答信号

6.

1

289

NOT ACKNOWLEDGE

ACKNOWLEDGE

SDA

SCL

DATA STABLE,

DATA VALID

图

位传输

5.

10 ______________________________________________________________________________________

CHANGE OF

DATA ALLOWED

CLOCK PULSE FOR

ACKNOWLEDGMENT

Page 11

256

抽头、非易失、

数字电位器

I2C

接口

MAX5417/MAX5418/MAX5419

CONTROL BYTE IS STORED ON RECEIPT OF STOP CONDITION

S A0SLAVE ADDRESS CONTROL BYTE

图

接收到的命令字节

7.

HOW CONTROL BYTE AND DATA BYTE MAP INTO

MAX5417/MAX5418/MAX5419 REGISTERS

ACKNOWLEDGE FROM

MAX5417/MAX5418/MAX5419

S AA

NOP/W

图

接收到的命令和单个数据字节

8.

D15 D14 D13 D12 D11 D10 D9 D8

ACKNOWLEDGE FROM

MAX5417/MAX5418/MAX5419

AP

NOP/W

ACKNOWLEDGE FROM

MAX5417/MAX5418/MAX5419

D15 D14 D13 D12 D11 D10 D9 D8 D1 D0D3 D2D5 D4D7 D6

0SLAVE ADDRESS CONTROL BYTE DATA BYTE

ACKNOWLEDGE FROM

MAX5417/MAX5418/MAX5419

MAX5417/MAX5418/MAX5419

ACKNOWLEDGE FROM

1 BYTE

A

P

写数据格式

向

MAX5417/MAX5418/MAX5419

包括器件从地址字节(第8位置零)和至少一个字节的信息

。第1个信息字节为命令字节,命令字节之后是数

(图7)

据字节。第一个数据字节按照命令字节的选择写入内部

寄存器(图8)。

写入数据时,传输内容

命令字节

命令字节用于选择滑动端数据的源地址和目的地址(非易

失或易失存储寄存器),或在非易失或易失存储寄存器之

间交换数据(见表2)。

______________________________________________________________________________________ 11

:数据字节写入易失存储寄存器,滑动端位置更

VREG

新为易失存储寄存器中的数据。

NVREG

:数据字节写入非易失存储寄存器,滑动端位置

保持不变。

NVREGxVREG

:数据从非易失存储寄存器传送到易失

寄存器(滑动端位置更新)。

VREGxNVREG

:数据从易失寄存器传送到非易失存储

寄存器。

命令说明

Page 12

256

抽头、非易失、

数字电位器

表2. 命令字节

I2C

ADDRESS BYTE CONTROL BYTE DATA BYTE

接口

SCL CYCLE

NUMBER

VREG 0 1 0 1 A2 A1 A0 0 0 0 0 1 0 0 0 1 D7 D6 D5 D4 D3 D2 D1 D0

NVREG 0 1 0 1 A2 A1 A0 0 0 0 1 0 0 0 0 1 D7 D6 D5 D4 D3 D2 D1 D0

NVREGxVREG 0 1 0 1 A2 A1 A0 0 0 1 1 0 0 0 0 1 D7 D6 D5 D4 D3 D2 D1 D0

VREGxNVREG 0 1 0 1 A2 A1 A0 0 0 1 0 1 0 0 0 1 D7 D6 D5 D4 D3 D2 D1 D0

12345678 9 1011121314151617 18 19 2021 22 232425 26 27 P

S

A6 A5 A4 A3 A2 A1 A0 ACK

TX

NV V R3 R2 R1 R0 ACK D7 D6 D5 D4 D3 D2 D1 D0 ACK

非易失存储器

内置

EEPROM

写入的数据。非易失寄存器在工厂预置为零值。

上电时,

寄存器的数据装入易失寄存器内,并随之更新抽头位置。

初始化过程需要

MAX5417/MAX5418/MAX5419

件没有编程时,进入待机模式,电流消耗典型值为

。

500nA

MAX5417/MAX5418/MAX5419

____________________________

MAX5417/MAX5418/MAX5419

系统,如

度),可调增益和/或截止频率的可编程滤波器等。

包含一个8位非易失寄存器,保留断电前

MAX5417/MAX5418/MAX5419

。

10µs

将存储在非易失

具有低功耗待机模式。器

用于需要数控调节电阻的

对比度调节(利用偏置电压调节显示器对比

LCD

上电

待机

应用信息

图9和图10显示了用分压器或可变电阻调节

置电压的应用电路图。运放提供电阻分压电路的缓冲和

放大,电阻分压电路可以由电位器构成(图9),或由一个

固定电阻串联一个可变电阻构成(图

图11为一阶可编程滤波器电路。滤波器的增益由R2调节,

截止频率通过R3调节。利用下式计算增益

止频率

:

)

(f

C

1

R

1

=+

G

=

f

C

2

R

1

××

23π

RC

LCD

。

10)

可编程滤波器

正偏置控制

正向偏

LCD

(G)和3dB

截

5V

H

MAX5417

MAX5418

MAx5419

图

用分压器实现

9.

12 ______________________________________________________________________________________

LCD

W

L

正偏调节

30V

V

OUT

MAX5417

MAX5418

MAX5419

图

用可变电阻实现

10.

5V

H

L

LCD

W

正偏调节

30V

V

OUT

Page 13

图

11.

V

IN

H

MAX5417

MAX5418

MAX5419

可编程滤波器

256

抽头、非易失、

I2C

接口

数字电位器

MAX5417/MAX5418/MAX5419

W

L

R3

C

R1

H

R2

W

L

V

OUT

W

L

R2 R1

图

失调电压与增益调节电路

13.

5V

MAX5417

MAX5418

7

1

3

8

MAX410

2

4

-5V

H

MAX5419

6

+5V

V

图

12.

MAX5417

MAX5418

MAX5419

可调电压基准

MAX6160

V0 = 1.23V

R

V0 = 1.23V

R

V0 = 1.23V

R

IN

OUT

ADJ

GND

50kΩ

FOR THE MAX5417

(kΩ)

2

100kΩ

FOR THE MAX5418

(kΩ)

2

200kΩ

FOR THE MAX5419

(kΩ)

2

V0 REF

H

W

L

可调电压基准

图12所示为使用

多级可调电压基准应用中的反馈电阻。通过改变

MAX5418/MAX5419

VIN- 0.2V

的范围内独立调节

MAX5417/MAX5418/MAX5419

滑动端的位置,可在从

MAX6160

的输出电压。

作为

MAX5417/

至

1.23V

____________________________

TOP VIEW

V

SDA

1

DD

2

MAX5417

3

MAX5418

MAX5419

4

TDFN

87H

6

5

WSCL

L

GNDA0

失调电压和增益调节

将

MAX5417

的

NULL

度范围内调节失调电压。另一个电位器用在

馈回路上以调节其增益。

中一个电位器的高端和低端分别接

输入,滑动端接运放的正电源,可在整个工作温

____________________________

TRANSISTOR COUNT: 4637

PROCESS: BiCMOS

引脚配置

MAX410

MAX410

芯片信息

的反

______________________________________________________________________________________ 13

Page 14

256

抽头、非易失、

数字电位器

I2C

接口

___________________________________________________________________

(本数据资料提供的封装图可能不是最近的规格,如需最近的封装外型信息,请查询 www.maxim-ic.com.cn/packages。)

D

N

PIN 1

INDEX

AREA

E

DETAIL A

A

E2

C

L

L

e

C

L

L

e

封装信息

6, 8, &10L, DFN THIN.EPS

MAX5417/MAX5418/MAX5419

PACKAGE OUTLINE, 6, 8, 10 & 14L,

TDFN, EXPOSED PAD, 3x3x0.80 mm

NUMBER OF LEADS SHOWN ARE FOR REFERENCE ONLY

14 ______________________________________________________________________________________

21-0137

1

F

2

Page 15

256

抽头、非易失、

I2C

数字电位器

_______________________________________________________________

(本数据资料提供的封装图可能不是最近的规格,如需最近的封装外型信息,请查询 www.maxim-ic.com.cn/packages。)

封装信息(续

接口

MAX5417/MAX5418/MAX5419

)

COMMON DIMENSIONS

SYMBOL

A 0.70 0.80

D 2.90 3.10

E 2.90 3.10

A1 0.00 0.05

L

A2 0.20 REF.

PACKAGE VARIATIONS

PKG. CODE

T833-1

T1033-1

MIN. MAX.

0.25 MIN.k

0.40

1.50±0.10

1.50±0.10

1.70±0.10 2.30±0.1014T1433-1

1.70±0.10

2.30±0.101.50±0.106T633-1 0.95 BSC MO229 / WEEA 1.90 REF

2.30±0.108

2.30±0.1010

0.65 BSC

0.50 BSC

0.40 BSC

0.40 BSC

0.20

N D2 E2 e

JEDEC SPEC

MO229 / WEEC

MO229 / WEED-3

- - - - 0.20±0.03 2.40 REFT1433-2 14 2.30±0.10

b

0.40±0.05

[(N/2)-1] x e

1.95 REF0.30±0.05

2.00 REF0.25±0.05

2.40 REF0.20±0.03- - - -

PACKAGE OUTLINE, 6, 8, 10 & 14L,

TDFN, EXPOSED PAD, 3x3x0.80 mm

21-0137

2

F

2

MAXIM

北京

8328

免费电话:

电话:

010-6201 0598

传真:

010-6201 0298

Maxim不对Maxim

北京办事处

信箱 邮政编码

800 810 0310

产品以外的任何电路使用负责,也不提供其专利许可。

100083

保留在任何时间、没有任何通报的前提下修改产品资料和规格的权利。

Maxim

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 15

© 2004 Maxim Integrated Products Printed USA

是

Maxim Integrated Products, Inc.

的注册商标。

Page 16

MAX5417, MAX5417L, MAX5417M, MAX5417N, MAX5417P, MAX5418, MAX5419 256抽头、非易失、 I²C接口数字电位器 - 概述

Temp.

ENGLISH • 简体中文 • 日本語 • 한국어

Login | Register

请输入关键词或器件型号

最新内容 产品 方案 设计 应用 技术支持 销售联络 公司简介 我的Maxim

Maxim > 产品 > 数字电位器(pot) > MAX5417, MAX5417L, MAX5417M, ...

MAX5417, MAX5417L, MAX5417M, MAX5417N, MAX5417P, MAX5418,

MAX5419

256抽头、非易失、 I²C 接口数字电位器

业内尺寸最小的256抽头电位器,3mm x 3mm TDFN 封装

概述 技术文档 定购信息 用户说明 (0) 所有内容

状况

状况:生产中。

概述

MAX5417/MAX5418/MAX5419为非易失性、线性变化的数字电位器,实现机械电

位器的功能,采用简单的2线数字接口就取代了机械调节,且允许控制多个器件。

每个器件具有分立电位器或可变电阻等相同功能,提供256级抽头。

完整的数据资料

提供更新的英文版数据资料

这些器件内置非易失性EEPROM,用来存储中心抽头的位置,以便在上电期间进

行初始化。快速模式的兼容I²C串行接口允许以400kbps的数据速率进行通讯,为

多数应用尽可能减小了电路板尺寸,简化了布线。每个器件提供四个工厂预置地

址之一(参阅完整数据资料中的选型指南),和一个地址输入端,以实现总共8个唯

一地址的组合。

MAX5417/MAX5418/MAX5419提供三种标称电阻值:50kΩ (MAX5417)、100kΩ (MAX5418)及200kΩ (MAX5419)。标称

端对端的电阻温度系数为50ppm/°C,比例系数仅5ppm/°C。以上特性使这些器件尤其适合于要求低温漂系数的可变电阻

应用,如可编程增益放大器电路结构。

MAX5417/MAX5418/MAX5419采用3mm x 3mm、8引脚TDFN封装,工作在-40°C至+85°C的扩展级工作范围内。

现备有评估板:MAX5417LEVCMODU, MAX5417LEVKIT

关键特性 应用/使用

上电时由非失性存储器设定中心抽头位置

微型3mm x 3mm、8引脚TDFN封装

35ppm/°C端到端电阻温度系数

5ppm/°C比例温度系数

50kΩ/100kΩ/200kΩ电阻值

快速的兼容I²C串行接口

500nA ( 典型值)的静态电源电流

单电源工作:+2.7V至+5.25V

256抽头位置

在分压器模式下,达到±0.5 LSB 的DNL

在分压器模式下,达到±0.5 LSB 的INL

可提供评估板

英文

中文

下载

Rev. 3 (PDF, 288kB)

下载

Rev. 2 (PDF, 536kB)

液晶显示器(LCD)对比度控制

低偏差可编程增益放大器

替代机械电位器

音量控制

Key Specifications: Digital Potentiometers

http://china.maxim-ic.com/datasheet/index.mvp/id/4205[2010-8-19 9:06:35]

Page 17

MAX5417, MAX5417L, MAX5417M, MAX5417N, MAX5417P, MAX5418, MAX5419 256抽头、非易失、 I²C接口数字电位器 - 概述

Smallest

R

Part

Number

Taper POTs

Control

Interface

Wiper

Memory

Steps

MAX5418

MAX5419 200

Linear 1

2-Wire

Serial

Non-

Volatile

256

END-

TO-END

(kΩ)

100

MAX5417 50

查看所有Digital Potentiometers (128)

图表

Coeff.

(ppm/

°C)

Wiper

Resistance

(Ω)

I

CC

Available Pckg.

@5V

(µA)

(mm

typ typ max max w/pins

50 325 1 9.6

2

)

See

Notes

$1.25

@1k

$1.25

@1k

$1.16

@5k

Price

功能框图

相关产品

MAX5417LEVCMODU,

MAX5417_、MAX5418_、MAX5419_评估板/评估系统

MAX5417LEVKIT

类似产品:浏览其它类似产品线

查看所有Digital Potentiometers (128产品)

更多信息

顶标 MAX5417L

顶标 MAX5417M

顶标 MAX5417N

顶标 MAX5417P

顶标 MAX5417L

顶标 MAX5417M

顶标 MAX5417N

顶标 MAX5417P

顶标 MAX5417L

顶标 MAX5417M

顶标 MAX5417N

顶标 MAX5417P

顶标 MAX5417L

顶标 MAX5417M

顶标 MAX5417N

http://china.maxim-ic.com/datasheet/index.mvp/id/4205[2010-8-19 9:06:35]

Page 18

MAX5417, MAX5417L, MAX5417M, MAX5417N, MAX5417P, MAX5418, MAX5419 256抽头、非易失、 I²C接口数字电位器 - 概述

MAX5417P

顶标

顶标 MAX5417L

顶标 MAX5417M

顶标 MAX5417N

顶标 MAX5417P

顶标 MAX5418L

顶标 MAX5418M

顶标 MAX5418N

顶标 MAX5418P

顶标 MAX5419L

顶标 MAX5419M

顶标 MAX5419N

顶标 MAX5419P

新品发布 [ 2004-03-29 (English only) ]

没有找到你需要的产品吗?

应用工程师帮助选型,下个工作日回复

参数搜索

应用帮助

概述 技术文档 定购信息

概述

关键特性

应用/使用

关键指标

图表

注释、注解

相关产品

联络我们:信息反馈、提出问题 • 对该网页的评价 • 发送本网页 • 隐私权政策 • 法律声明

© 2010 Maxim Integrated Products 版权所有

数据资料

应用笔记

评估板

设计指南

可靠性报告

软件/模型

参考文献: 19-3185 Rev. 3; 2009-04-24

本页最后一次更新: 2009-10-08

价格与供货

样品

在线订购

封装信息

无铅信息

http://china.maxim-ic.com/datasheet/index.mvp/id/4205[2010-8-19 9:06:35]

Page 19

General Description

The MAX5417/MAX5418/MAX5419 nonvolatile, lineartaper, digital potentiometers perform the function of a

mechanical potentiometer by replacing the mechanics

with a simple 2-wire digital interface, allowing communication with multiple devices. Each device performs the

same function as a discrete potentiometer or variable

resistor and has 256 tap points.

The devices feature an internal, nonvolatile EEPROM

used to store the wiper position for initialization during

power-up. The fast-mode I

2

C-compatible serial interface

allows communication at data rates up to 400kbps, minimizing board space and reducing interconnection complexity in many applications. Each device is available with

one of four factory-preset addresses (see the

Selector

Guide

) and features an address input for a total of eight

unique address combinations.

The MAX5417/MAX5418/MAX5419 provide three nomi-

nal resistance values: 50kΩ (MAX5417), 100kΩ

(MAX5418), or 200kΩ (MAX5419). The nominal resistor

temperature coefficient is 35ppm/°C end-to-end, and

only 5ppm/°C ratiometric. This makes the devices ideal

for applications requiring a low-temperature-coefficient

variable resistor, such as low-drift, programmable gainamplifier circuit configurations.

The MAX5417/MAX5418/MAX5419 are available in a

3mm x 3mm 8-pin TDFN package, and are specified

over the extended -40°C to +85°C temperature range.

Applications

Mechanical Potentiometer Replacement

Low-Drift Programmable-Gain Amplifiers

Volume Control

Liquid-Crystal Display (LCD) Contrast Control

Features

o Power-On Recall of Wiper Position from

Nonvolatile Memory

o Tiny 3mm x 3mm 8-Pin TDFN Package

o 35ppm/°C End-to-End Resistance Temperature

Coefficient

o 5ppm/°C Ratiometric Temperature Coefficient

o 50kΩ/100kΩ/200kΩ Resistor Values

o Fast I

2

C-Compatible Serial Interface

o 500nA (typ) Static Supply Current

o Single-Supply Operation: +2.7V to +5.25V

o 256 Tap Positions

o ±0.5 LSB DNL in Voltage-Divider Mode

o ±0.5 LSB INL in Voltage-Divider Mode

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

________________________________________________________________

Maxim Integrated Products

1

Ordering Information/Selector Guide

Functional Diagram

19-3185; Rev 4; 4/10

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Pin Configuration appears at end of data sheet.

+

Denotes a lead(Pb)-free/RoHS-compliant package.

**

Exposed pad.

V

GND

SDA

SCL

8-BIT

8

POR

8-BIT

LATCH

8-BIT

NV

MEMORY

DD

A

0

SHIFT

REGISTER

I2C

INTERFACE

256-

POSITION

DECODER

MAX5417

MAX5418

MAX5419

256

8

H

W

L

PART TEMP RANGE I2C ADDRESS R (kΩ) PIN-PACKAGE TOP MARK

MAX5417LETA+ -40°C to +85°C 010100A

MAX5417META+ -40°C to +85°C 010101A

MAX5417NETA+ -40°C to +85°C 010110A

MAX5417PETA+ -40°C to +85°C 010111A

MAX5418LETA+ -40°C to +85°C 010100A

MAX5418META+ -40°C to +85°C 010101A

MAX5418NETA+ -40°C to +85°C 010110A

MAX5418PETA+ -40°C to +85°C 010111A

MAX5419LETA+ -40°C to +85°C 010100A

MAX5419META+ -40°C to +85°C 010101A

MAX5419NETA+ -40°C to +85°C 010110A

MAX5419PETA+ -40°C to +85°C 010111A

0

0

0

0

0

0

0

0

0

0

0

0

50 8 TDFN-EP** AIB

50 8 TDFN-EP** ALS

50 8 TDFN-EP** ALT

50 8 TDFN-EP** ALU

100 8 TDFN-EP** AIC

100 8 TDFN-EP** ALV

100 8 TDFN-EP** ALW

100 8 TDFN-EP** ALX

200 8 TDFN-EP** AID

200 8 TDFN-EP** ALY

200 8 TDFN-EP** ALZ

200 8 TDFN-EP** AMA

Page 20

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VDD= +2.7V to +5.25V, H = VDD, L = GND, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +5V, TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto GND...........................................................-0.3V to +6.0V

All Other Pins to GND.................................-0.3V to (V

DD

+ 0.3V)

Maximum Continuous Current into H, L, and W

MAX5417......................................................................±1.3mA

MAX5418......................................................................±0.6mA

MAX5419......................................................................±0.3mA

Continuous Power Dissipation (T

A

= +70°C)

8-Pin TDFN (derate 24.4mW/°C above +70°C) .........1951mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Soldering Temperature (reflow) .......................................+260°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DC PERFORMANCE (VOLTAGE-DIVIDER MODE)

Resolution 256 Taps

Integral Nonlinearity INL (Note 1) ±0.5 LSB

Differential Nonlinearity DNL (Note 1) ±0.5 LSB

End-to-End Temperature

Coefficient

Ratiometric Temperature

Coefficient

Zero-Scale Error

DC PERFORMANCE (VARIABLE-RESISTOR MODE)

Integral Nonlinearity

(Note 2)

Differential Nonlinearity

(Note 2)

DC PERFORMANCE (RESISTOR CHARACTERISTICS)

Wiper Resistance R

Wiper Capacitance C

End-to-End Resistance R

TC

INL

DNL

W

HL

R

MAX5417_, 50Ω -0.6

MAX5418_, 100kΩ -0.3Full-Scale Error

MAX5419_, 200kΩ -0.15

MAX5417_, 50kΩ 0.6

MAX5418_, 100kΩ 0.3

MAX5419_, 200kΩ 0.15

V

= 3V ±3

DD

V

= 5V ±1.5

DD

V

= 3V, MAX5417_, 50kΩ -1 +2

DD

VDD = 3V, MAX5418_, 100kΩ ±1

VDD = 3V, MAX5419_, 200kΩ ±1

V

= 5V ±1

DD

VDD = 3V to 5.25V (Note 3) 325 675 Ω

W

MAX5417_ 37.5 50 62.5

MAX5418_ 75 100 125

MAX5419_ 150 200 250

35 ppm/°C

5 ppm/°C

10 pF

LSB

LSB

LSB

LSB

kΩ

Page 21

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +2.7V to +5.25V, H = VDD, L = GND, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +5V, TA= +25°C.)

TIMING CHARACTERISTICS

(VDD= +2.7V to +5.25V, H = VDD, L = GND, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +5V, TA=

+25°C. See Figures 1 and 2.) (Note 7)

DIGITAL INPUTS

V

= 3.4V to 5.25V 2.4

Input High Voltage (Note 4) V

Input Low Voltage V

Low-Level Output Voltage V

Input Leakage Current I

Input Capacitance 5pF

DYNAMIC CHARACTERISTICS

Wiper -3dB Bandwidth (Note 5)

NONVOLATILE MEMORY

Data Retention TA = +85°C 50 Years

Endurance

POWER SUPPLY

Power-Supply Voltage V

Standby Current I

Programming Current

IH

IL

OL

LEAK

DD

DD

DD

VDD < 3.4V 0.7 x V

V

= 2.7V to 5.25V (Note 4) 0.8 V

DD

3mA sink current 0.4 V

MAX5417_ 100

MAX5418_ 50

MAX5419_ 25

TA = +25°C 200,000

T

= +85°C 50,000

A

Digital inputs = V

T

= +25°C

A

During nonvolatile write;

digital inputs = V

or GND,

DD

or GND (Note 6)

DD

DD

±1 µA

kHz

Stores

2.70 5.25 V

0.5 1 µA

200 400 µA

V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ANALOG SECTION

MAX5417_ 500

ns

DIGITAL SECTION

SCL Clock Frequency f

Setup Time for START Condition t

Hold Time for START Condition t

CLK High Time t

CLK Low Time t

IL

SCL

SU-STA

HD-STA

HIGH

LOW

MAX5418_ 600Wiper Settling Time (Note 8) t

MAX5419_ 1000

400 kHz

0.6 µs

0.6 µs

0.6 µs

1.3 µs

Page 22

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

4 _______________________________________________________________________________________

Note 1: The DNL and INL are measured with the potentiometer configured as a voltage-divider with H = VDDand L = GND. The

wiper terminal is unloaded and measured with a high-input-impedance voltmeter.

Note 2: The DNL and INL are measured with the potentiometer configured as a variable resistor. H is unconnected and L = GND.

For the 5V condition, the wiper terminal is driven with a source current of 80µA for the 50kΩ configuration, 40µA for the

100kΩ configuration, and 20µA for the 200kΩ configuration. For the 3V condition, the wiper terminal is driven with a source

current of 40µA for the 50kΩ configuration, 20µA for the 100kΩ configuration, and 10µA for the 200kΩ configuration.

Note 3: The wiper resistance is measured using the source currents given in Note 2. For operation to V

DD

= 2.7V, see Wiper

Resistance vs. Temperature in the

Typical Operating Characteristics.

Note 4: The device draws higher supply current when the digital inputs are driven with voltages between (VDD- 0.5V) and (GND +

0.5V). See Supply Current vs. Digital Input Voltage in the

Typical Operating Characteristics.

Note 5: Wiper at midscale with a 10pF load (DC measurement). L = GND; an AC source is applied to H; and the W output is mea-

sured. A 3dB bandwidth occurs when the AC W/H value is 3dB lower than the DC W/H value.

Note 6: The programming current operates only during power-up and NV writes.

Note 7: SCL clock period includes rise and fall times t

R

and tF. All digital input signals are specified with tR= tF= 2ns and timed

from a voltage level of (V

IL

+ VIH) / 2.

Note 8: Wiper settling time is the worst-case 0% to 50% rise time measured between consecutive wiper positions. H = V

DD

,

L = GND, and the wiper terminal is unloaded and measured with a 10pF oscilloscope probe (see the

Typical Operating

Characteristics

for the tap-to-tap switching transient).

Note 9: An appropriate bus pullup resistance must be selected depending on board capacitance. Refer to the document linked to

this web address: www.semiconductors.philips.com/acrobat/literature/9398/39340011.pdf.

Note 10: The idle time begins from the initiation of the stop pulse.

TIMING CHARACTERISTICS (continued)

(VDD= +2.7V to +5.25V, H = VDD, L = GND, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +5V, TA=

+25°C. See Figures 1 and 2.) (Note 7)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Data Setup Time t

Data Hold Time t

SDA, SCL Rise Time t

SDA, SCL Fall Time t

Setup Time for STOP Condition t

Bus Free Time Between STOP

and START Condition

Pulse Width of Spike Suppressed t

Maximum Capacitive Load for

Each Bus Line

Write NV Register Busy Time t

SU-DAT

HD-DAT

R

F

SU-STO

t

BUF

SP

C

BUSY

Minimum power-up rate = 0.2V/ms 1.3 µs

(Note 9) 400 pF

B

(Note 10) 12 ms

100 ns

0 0.9 µs

300 ns

300 ns

0.6 µs

50 ns

Page 23

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

_______________________________________________________________________________________

5

Typical Operating Characteristics

(VDD= +5V, TA= +25°C, unless otherwise noted.)

STANDBY SUPPLY CURRENT

vs. TEMPERATURE

MAX5417 toc06

TEMPERATURE (°C)

STANDBY SUPPLY CURRENT (µA)

603510-15

0.2

0.4

0.6

0.8

1.0

0

-40 85

WIPER RESISTANCE vs. TEMPERATURE

MAX5417 toc07

TEMPERATURE (°C)

RESISTANCE (Ω)

603510-15

100

200

300

400

500

600

700

0

-40 85

VDD = 2.7V

VDD = 3.0V

VDD = 4.5V

VDD = 5.25V

DNL vs. TAP POSITION

0.25

VOLTAGE-DIVIDER MODE

0.20

0.15

0.10

0.05

0

-0.05

-0.10

RESISTANCE DNL (LSB)

-0.15

-0.20

-0.25

0 256

TAP POSITION

WIPER TRANSIENT AT POWER-ON

4µs/div

MAX5417 toc01

224192160128966432

MAX5417 toc04

CL = 10pF

TAP = 128

H = V

DD

0.25

VOLTAGE-DIVIDER MODE

0.20

0.15

0.10

0.05

0

-0.05

RESISTANCE INL (LSB)

-0.10

-0.15

-0.20

-0.25

0256

TAP POSITION

MAX5417 toc02

224192160128966432

END-TO-END RESISTANCE % CHANGE

INL vs. TAP POSITION

V

DD

2V/div

W

1V/div

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

END-TO-END RESISTANCE % CHANGE

-0.8

-1.0

-40 85

WIPER RESISTANCE vs. TAP POSITION

700

VDD = 2.7V

= 50µA

I

SRC

600

500

400

300

RESISTANCE (Ω)

200

100

0

0256

vs. TEMPERATURE

TEMPERATURE (°C)

MAX5417 toc03

224192160128966432

TAP POSITION

MAX5417 toc05

603510-15

Page 24

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VDD= +5V, TA= +25°C, unless otherwise noted.)

SUPPLY CURRENT

600

500

400

300

200

SUPPLY CURRENT (µA)

100

0

05

DIGITAL INPUT VOLTAGE (V)

4321

MAX5417 toc08

100

1:1 RATIO

10

20Hz TO 20kHz BANDPASS

1

0.1

THD+N (%)

0.01

0.001

0.0001

10 100k

vs. DIGITAL INPUT VOLTAGE

THD+N RESPONSE

FREQUENCY (Hz)

INL vs. TAP POSITION

(MAX5418)

2.0

VARIABLE-RESISTOR MODE

= 2.7V

V

DD

1.5

= 20µA

I

SRC

1.0

0.5

INL (LSB)

0

-0.5

-1.0

0256

TAP POSITION

MAX5417 toc11

224192160128966432

INL vs. TAP POSITION

(MAX5417)

3.0

VARIABLE-RESISTOR MODE

2.5

= 2.7V

V

MAX5417 toc09

10k1k100

DD

= 50µA

I

SRC

2.0

1.5

1.0

0.5

RESISTANCE INL (LSB)

0

-0.5

-1.0

0256

TAP POSITION

MAX5417 toc10

224192160128966432

INL vs. TAP POSITION

(MAX5419)

1.00

VARIABLE-RESISTOR MODE

0.75

0.50

0.25

INL (LSB)

-0.25

-0.50

-0.75

-1.00

= 2.7V

V

DD

= 10µA

I

SRC

0

0256

TAP POSITION

MAX5417 toc12

22419232 64 96 128 160

DNL vs. TAP POSITION

(MAX5417)

0.5

VARIABLE-RESISTOR MODE

0.4

0.3

0.2

0.1

DNL (LSB)

0

-0.1

-0.2

-0.3

0256

TAP POSITION

MAX5417 toc13

224192160128966432

0.3

0.2

0.1

0

DNL (LSB)

-0.1

-0.2

-0.3

DNL vs. TAP POSITION

(MAX5418)

VARIABLE-RESISTOR MODE

= 2.7V

V

DD

= 20µA

I

SRC

0256

TAP POSITION

MAX5417 toc14

224192160128966432

Page 25

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

_______________________________________________________________________________________

7

Typical Operating Characteristics (continued)

(VDD= +5V, TA= +25°C, unless otherwise noted.)

DNL vs. TAP POSITION

(MAX5419)

0.3

VARIABLE-RESISTOR MODE

= 2.7V

V

DD

0.2

0.1

0

DNL (LSB)

-0.1

-0.2

-0.3

I

SRC

= 10µA

TAP POSITION

MAX5417 toc15

WIPER RESPONSE (dB)

22419232 64 96 128 1600 256

MIDSCALE WIPER RESPONSE vs. FREQUENCY

(MAX5419)

0

-5

MAX5419

-10

TAP = 128

-15

-20

-25

-30

WIPER RESPONSE (dB)

-35

-40

-45

1 1000

CL = 50pF

FREQUENCY (kHz)

CL = 10pF

10010

MIDSCALE WIPER RESPONSE vs. FREQUENCY

(MAX5417)

0

MAX5417

TAP = 128

-5

-10

-15

-20

-25

-30

1 1000

FREQUENCY (kHz)

CL = 10pF

CL = 50pF

10010

TAP-TO-TAP SWITCHING TRANSIENT

MAX5417 toc18

MAX5417 toc16

MIDSCALE WIPER RESPONSE vs. FREQUENCY

(MAX5418)

0

MAX5418

TAP = 128

-5

-10

-15

-20

WIPER RESPONSE (dB)

-25

-30

1 1000

FREQUENCY (kHz)

(MAX5417)

1µs/div

MAX5417 toc19

MAX5417

= 10pF

C

L

FROM TAP 127

TO TAP 128

H = V

DD

CL = 50pF

10010

SDA

2V/div

W

10mV/div

CL = 10pF

MAX5417 toc17

TAP-TO-TAP SWITCHING TRANSIENT

(MAX5418)

1µs/div

MAX5417 toc20

MAX5418

= 10pF

C

L

FROM TAP 127

TO TAP 128

H = V

DD

SDA

2V/div

W

10mV/div

TAP-TO-TAP SWITCHING TRANSIENT

(MAX5419)

1µs/div

MAX5417 toc21

MAX5419

= 10pF

C

L

FROM TAP 127

TO TAP 128

H = V

DD

SDA

2V/div

W

10mV/div

Page 26

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

8 _______________________________________________________________________________________

Pin Description

Detailed Description

The MAX5417/MAX5418/MAX5419 contain a resistor

array with 255 resistive elements. The MAX5417 has a

total end-to-end resistance of 50kΩ, the MAX5418 has

an end-to-end resistance of 100kΩ, and the MAX5419

has an end-to-end resistance of 200kΩ. The

MAX5417/MAX5418/MAX5419 allow access to the high,

low, and wiper terminals for a standard voltage-divider

configuration. H, L, and W can be connected in any

desired configuration as long as their voltages fall

between GND and V

DD

.

A simple 2-wire I2C-compatible serial interface moves

the wiper among the 256 tap points. A nonvolatile memory stores the wiper position and recalls the stored wiper

position in the nonvolatile memory upon power-up. The

nonvolatile memory is guaranteed for 50 years for wiper

data retention and up to 200,000 wiper store cycles.

Figure 1. I2C Serial-Interface Timing Diagram

Figure 2. Load Circuit

PIN NAME FUNCTION

1VDDPower-Supply Input. 2.7V to 5.25V voltage range. Bypass with a 0.1µF capacitor from VDD to GND.

2 SCL I2C-Interface Clock Input

3 SDA I2C-Interface Data Input

4A0Address Input. Sets the A0 bit in the device ID address.

5 GND Ground

6 L Low Terminal

7 W Wiper Terminal

8 H High Terminal

—EP

Exposed Pad. Internally connected to GND. Connect to a large ground plane to maximize thermal

performance. Not intended as an electrical point.

SDA

t

SU-DAT

t

LOW

SCL

t

t

HD-STA

S Sr A

PARAMETERS ARE MEASURED FROM 30% TO 70%.

HIGH

t

R

t

HD-DAT

t

F

t

SU-STA

V

DD

I

OL

= 3mA

SDA

V

OUT

400pF

I

= 0mA

OH

t

HD-STA

t

SU-STO

t

R

PS

t

F

t

BUF

Page 27

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

_______________________________________________________________________________________ 9

Analog Circuitry

The MAX5417/MAX5418/MAX5419 consist of a resistor

array with 255 resistive elements; 256 tap points are

accessible to the wiper, W, along the resistor string

between H and L. The wiper tap point is selected by

programming the potentiometer through the 2-wire (I

2

C)

interface. Eight data bits, an address byte, and a control byte program the wiper position. The H and L terminals of the MAX5417/MAX5418/MAX5419 are similar to

the two end terminals of a mechanical potentiometer.

The MAX5417/MAX5418/MAX5419 feature power-on

reset circuitry that loads the wiper position from nonvolatile memory at power-up.

Digital Interface

The MAX5417/MAX5418/MAX5419 feature an internal,

nonvolatile EEPROM that stores the wiper state for initialization during power-up. The shift register decodes

the control and address bits, routing the data to the

proper memory registers. Data can be written to a

volatile memory register, immediately updating the

wiper position, or data can be written to a nonvolatile

register for storage.

The volatile register retains data as long as the device

is powered. Once power is removed, the volatile register is cleared. The nonvolatile register retains data even

after power is removed. Upon power-up, the power-on

reset circuitry controls the transfer of data from the nonvolatile register to the volatile register.

Serial Addressing

The MAX5417/MAX5418/MAX5419 operate as a slave

that receives data through an I2C- and SMBus™-compatible 2-wire interface. The interface uses a serial data

access (SDA) line and a serial clock line (SCL) to

achieve communication between master(s) and

slave(s). A master, typically a microcontroller, initiates

all data transfers to the MAX5417/MAX5418/MAX5419,

and generates the SCL clock that synchronizes the

data transfer (Figure 1).

The MAX5417/MAX5418/MAX5419 SDA line operates

as both an input and an open-drain output. A pullup

resistor, typically 4.7kΩ, is required on the SDA bus.

The MAX5417/MAX5418/MAX5419 SCL operates only

as an input. A pullup resistor, typically 4.7kΩ, is

required on the SCL bus if there are multiple masters

on the 2-wire interface, or if the master in a single-master system has an open-drain SCL output.

Each transmission consists of a START (S) condition

(Figure 3) sent by a master, followed by the

MAX5417/MAX5418/MAX5419 7-bit slave address plus

the 8th bit (Figure 4), 1 command byte (Figure 7) and 1

data byte, and finally a STOP (P) condition (Figure 3).

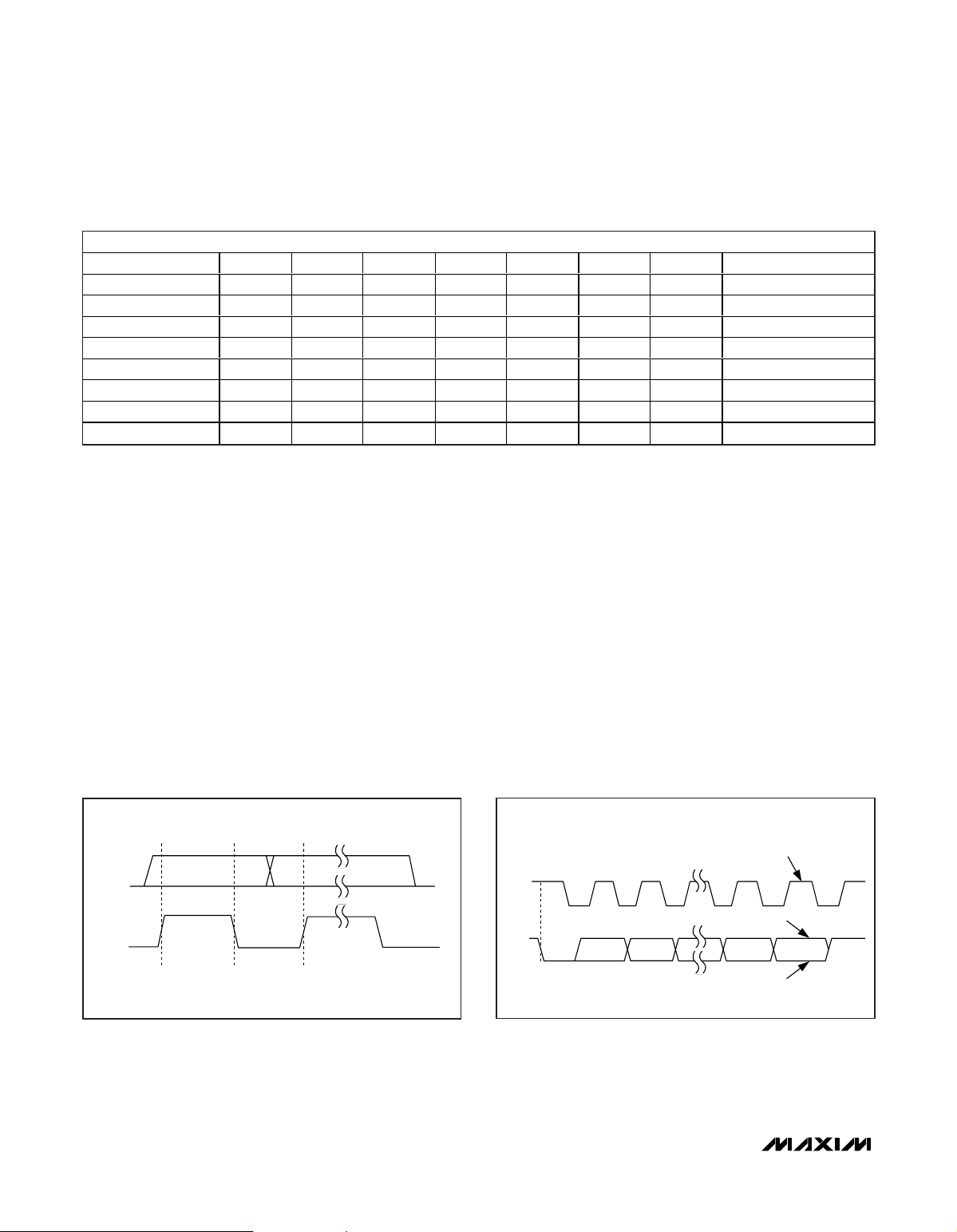

Start and Stop Conditions

Both SCL and SDA remain high when the interface is

not busy. A master signals the beginning of a transmission with a START condition by transitioning SDA from

high to low while SCL is high. When the master has finished communicating with the slave, it issues a STOP

condition by transitioning the SDA from low to high

while SCL is high. The bus is then free for another

transmission (Figure 3).

Bit Transfer

One data bit is transferred during each clock pulse.

The data on the SDA line must remain stable while SCL

is high (Figure 5).

Figure 3. Start and Stop Conditions

Figure 4. Slave Address

SMBus is a trademark of Intel Corporation.

SDA

SCL

S

START

CONDITION

SDA

SCL

*See the Ordering Information/Selector Guide section for other address options.

01

MSB LSB

P

STOP

CONDITION

A0

NOP/W ACK0 1 0* 0*

Page 28

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

10 ______________________________________________________________________________________

Acknowledge

The acknowledge bit is a clocked 9th bit that the recipient

uses to handshake receipt of each byte of data (Figure

6). Thus, each byte transferred effectively requires 9 bits.

The master generates the 9th clock pulse, and the recipient pulls down SDA during the acknowledge clock pulse,

so the SDA line is stable low during the high period of the

clock pulse. When the master transmits to the

MAX5417/MAX5418/MAX5419, the devices generate the

acknowledge bit because the MAX5417/MAX5418/

MAX5419 are the recipients.

Slave Address

The MAX5417/MAX5418/MAX5419 have a 7-bit-long

slave address (Figure 4). The 8th bit following the 7-bit

slave address is the NOP/W bit. Set the NOP/W bit low for

a write command and high for a no-operation command.

The MAX5417/MAX5418/MAX5419 are available in one

of four possible slave addresses (Table 1). The first 4

bits (MSBs) of the MAX5417/MAX5418/MAX5419 slave

addresses are always 0101. The next 2 bits are factory

programmed (see Table 1). Connect the A0 input to

either GND or V

DD

to toggle between two unique

device addresses for a part. Each device must have a

unique address to share the bus. Therefore, a maximum of eight MAX5417/MAX5418/MAX5419 devices

can share the same bus.

Table 1. MAX5417/MAX5418/MAX5419 Address Codes

Figure 5. Bit Transfer

Figure 6. Acknowledge

ADDRESS BYTE

PART SUFFIX A6 A5 A4 A3 A2 A1 A0 NOP/W

L 0 1 0 1 0 0 0 NOP/W

L 0 1 0 1 0 0 1 NOP/W

M 0 1 0 1 0 1 0 NOP/W

M 0 1 0 1 0 1 1 NOP/W

N 0 1 0 1 1 0 0 NOP/W

N 0 1 0 1 1 0 1 NOP/W

P 0 1 0 1 1 1 0 NOP/W

P 0 1 0 1 1 1 1 NOP/W

SDA

SCL

DATA STABLE,

DATA VALID

CHANGE OF

DATA ALLOWED

START

CONDITION

SCL

SDA

1

289

NOT ACKNOWLEDGE

ACKNOWLEDGE

CLOCK PULSE FOR

ACKNOWLEDGMENT

Page 29

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

______________________________________________________________________________________ 11

Message Format for Writing

A write to the MAX5417/MAX5418/MAX5419 consists of

the transmission of the device’s slave address with the

8th bit set to zero, followed by at least 1 byte of information (Figure 7). The 1st byte of information is the

command byte. The bytes received after the command

byte are the data bytes. The 1st data byte goes into the

internal register of the MAX5417/MAX5418/MAX5419 as

selected by the command byte (Figure 8).

Command Byte

Use the command byte to select the source and destination of the wiper data (nonvolatile or volatile memory

registers) and swap data between nonvolatile and

volatile memory registers (see Table 2).

Command Descriptions

VREG: The data byte writes to the volatile memory register and the wiper position updates with the data in the

volatile memory register.

NVREG: The data byte writes to the nonvolatile memory register. The wiper position is unchanged.

NVREGxVREG: Data transfers from the nonvolatile

memory register to the volatile memory register (wiper

position updates).

VREGxNVREG: Data transfers from the volatile memory register into the nonvolatile memory register.

Figure 7. Command Byte Received

Figure 8. Command and Single Data Byte Received

CONTROL BYTE IS STORED ON RECEIPT OF STOP CONDITION

ACKNOWLEDGE FROM

MAX5417/MAX5418/MAX5419

S A0SLAVE ADDRESS CONTROL BYTE

NOP/W

HOW CONTROL BYTE AND DATA BYTE MAP INTO

MAX5417/MAX5418/MAX5419 REGISTERS

ACKNOWLEDGE FROM

MAX5417/MAX5418/MAX5419

S AA

0SLAVE ADDRESS CONTROL BYTE DATA BYTE

NOP/W

D15 D14 D13 D12 D11 D10 D9 D8 D1 D0D3 D2D5 D4D7 D6

D15 D14 D13 D12 D11 D10 D9 D8

AP

ACKNOWLEDGE FROM

MAX5417/MAX5418/MAX5419

ACKNOWLEDGE FROM

MAX5417/MAX5418/MAX5419

ACKNOWLEDGE FROM

MAX5417/MAX5418/MAX5419

1 BYTE

A

P

Page 30

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

12 ______________________________________________________________________________________

Table 2. Command Byte Summary

Nonvolatile Memory

The internal EEPROM consists of an 8-bit nonvolatile

register that retains the value written to it before the

device is powered down. The nonvolatile register is

programmed with the midscale value at the factory.

Power-Up

Upon power-up, the MAX5417/MAX5418/MAX5419

load the data stored in the nonvolatile memory register

into the volatile memory register, updating the wiper

position with the data stored in the nonvolatile memory

register. This initialization period takes 10µs.

Standby

The MAX5417/MAX5418/MAX5419 feature a low-power

standby. When the device is not being programmed, it

goes into standby mode and power consumption is

typically 500nA.

Applications Information

The MAX5417/MAX5418/MAX5419 are intended for circuits requiring digitally controlled adjustable resistance, such as LCD contrast control (where voltage

biasing adjusts the display contrast), or for programmable filters with adjustable gain and/or cutoff frequency.

Positive LCD Bias Control

Figures 9 and 10 show an application where the voltage-divider or variable resistor is used to make an

adjustable, positive LCD bias voltage. The op amp provides buffering and gain to the resistor-divider network

made by the potentiometer (Figure 9) or to a fixed

resistor and a variable resistor (see Figure 10).

Programmable Filter

Figure 11 shows the configuration for a 1st-order programmable filter. The gain of the filter is adjusted by

R2, and the cutoff frequency is adjusted by R3. Use the

following equations to calculate the gain (G) and the

3dB cutoff frequency (fC):

Figure 9. Positive LCD Bias Control Using a Voltage-Divider

Figure 10. Positive LCD Bias Control Using a Variable Resistor

X = Don’t care.

SCL CYCLE

NUMBER

VREG 0 1 0 1 A2 A1 A0 0 0 0 0 1 0 0 0 1 D7 D6 D5 D4 D3 D2 D1 D0

NVREG 0 1 0 1 A2 A1 A0 0 0 0 1 0 0 0 0 1 D7 D6 D5 D4 D3 D2 D1 D0

NVREGxVREG 0101A2A1A00 01100001 XXXXXXXX

VREGxNVREG 0101A2A1A00 01010001 XXXXXXXX

S

ADDRESS BYTE CONTROL BYTE DATA BYTE

12345678 9 1011121314151617 18 19 20 2122232425 26 27 P

A6 A5 A4 A3 A2 A1 A0 ACK

TX

NV V R3 R2 R1 R0 ACK D7 D6 D5 D4 D3 D2 D1 D0 ACK

R

G

=+

=

f

C

1

1

R

2

××

23π

1

RC

5V

H

MAX5417

MAX5418

MAx5419

W

L

30V

V

OUT

MAX5417

MAX5418

MAX5419

5V

H

W

L

30V

V

OUT

Page 31

Adjustable Voltage Reference

Figure 12 shows the MAX5417/MAX5418/MAX5419 used

as the feedback resistors in multiple adjustable voltagereference applications. Independently adjust the output

voltage of the MAX6160 from 1.23V to VIN- 0.2V by

changing the wiper positions of the MAX5417/

MAX5418/MAX5419.

Offset Voltage and Gain Adjustment

Connect the high and low terminals of one potentiometer

of a MAX5417 between the NULL inputs of a MAX410

and the wiper to the op amp’s positive supply to nullify

the offset voltage over the operating temperature range.

Install the other potentiometer in the feedback path to

adjust the gain of the MAX410 (see Figure 13).

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

______________________________________________________________________________________ 13

Figure 12. Adjustable Voltage Reference

Figure 13. Offset Voltage and Gain Adjustment Circuit

Figure 11. Programmable Filter

Pin Configuration

Chip Information

PROCESS: BiCMOS

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages

. Note that a “+”, “#”, or “-” in

the package code indicates RoHS status only. Package drawings may show a different suffix character, but the drawing pertains to the package regardless of RoHS status.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

8 TDFN-EP T833-1

21-0137

W

V

IN

H

MAX5417

MAX5418

MAX5419

L

R3

MAX6160

MAX5417

MAX5418

MAX5419

+5V

V

GND

5V

87H

6

5

MAX5417

MAX5418

MAX5419

6

WSCL

L

GNDA0

C

R1

H

R2

W

L

V

OUT

7

1

3

8

MAX410

2

W

L

R1

4

-5V

H

TOP VIEW

IN

OUT

W

ADJ

V0 REF

H

L

V

SDA

+

1

DD

2

MAX5417

3

MAX5418

MAX5419

4

TDFN

Page 32

MAX5417/MAX5418/MAX5419

256-Tap, Nonvolatile, I2C-Interface,

Digital Potentiometers

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

14

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2010 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Revision History

REVISION

NUMBER

0 2/04 Initial release —

1 4/04 Adding future product —

2 8/04 Adding new part —

3 3/09 Changes to add details about exposed pad, corrections to Table 2, style edits 1, 8, 12–15

4 4/10

REVISION

DATE

DESCRIPTION

Ad d ed l ead - fr ee p ackag es to O r d er i ng Infor m ati on, ad d ed S ol d er i ng Tem p er atur e to

Ab sol ute M axi m um Rati ng s, cor r ected C ond i ti ons for D i ffer enti al Li near i ty i n E l ectr i cal

C har acter i sti cs, cor r ected A

i n P i n D escr i p ti on, cor r ected Fi g ur es 12 and 13

0

PAGES

CHANGED

1, 2, 8, 13

Loading...

Loading...