Page 1

现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

General Description

The MAX5060/MAX5061 pulse-width modulation (PWM)

DC-DC controllers provide high-output-current capability

in a compact package with a minimum number of external components. These devices utilize an average-current-mode control that enables optimal use of low

R

DS(ON)

MOSFETs, eliminating the need for external

heatsinks even when delivering high output currents.

Differential sensing (MAX5060) enables accurate control

of the output voltage, while adaptive voltage positioning

provides optimum transient response. An internal regulator enables operation with 4.75V to 5.5V or 7V to 28V

input voltage ranges. The high switching frequency, up

to 1.5MHz, allows the use of low-output inductor values

and input capacitor values. This accommodates the use

of PC-board-embedded planar magnetics.

The MAX5060 features a clock output with 180° phase

delay to control a second out-of-phase converter for

lower capacitor ripple currents. The MAX5060 also limits

the reverse current if the bus voltage becomes higher

than the regulated output voltage. The MAX5060 is

specifically designed to limit current sinking when multiple power-supply modules are paralleled. The

MAX5060/MAX5061 offer an adjustable 0.6V to 5.5V output voltage. The MAX5060 offers an overvoltage protection, power-good signal, and an output enable function.

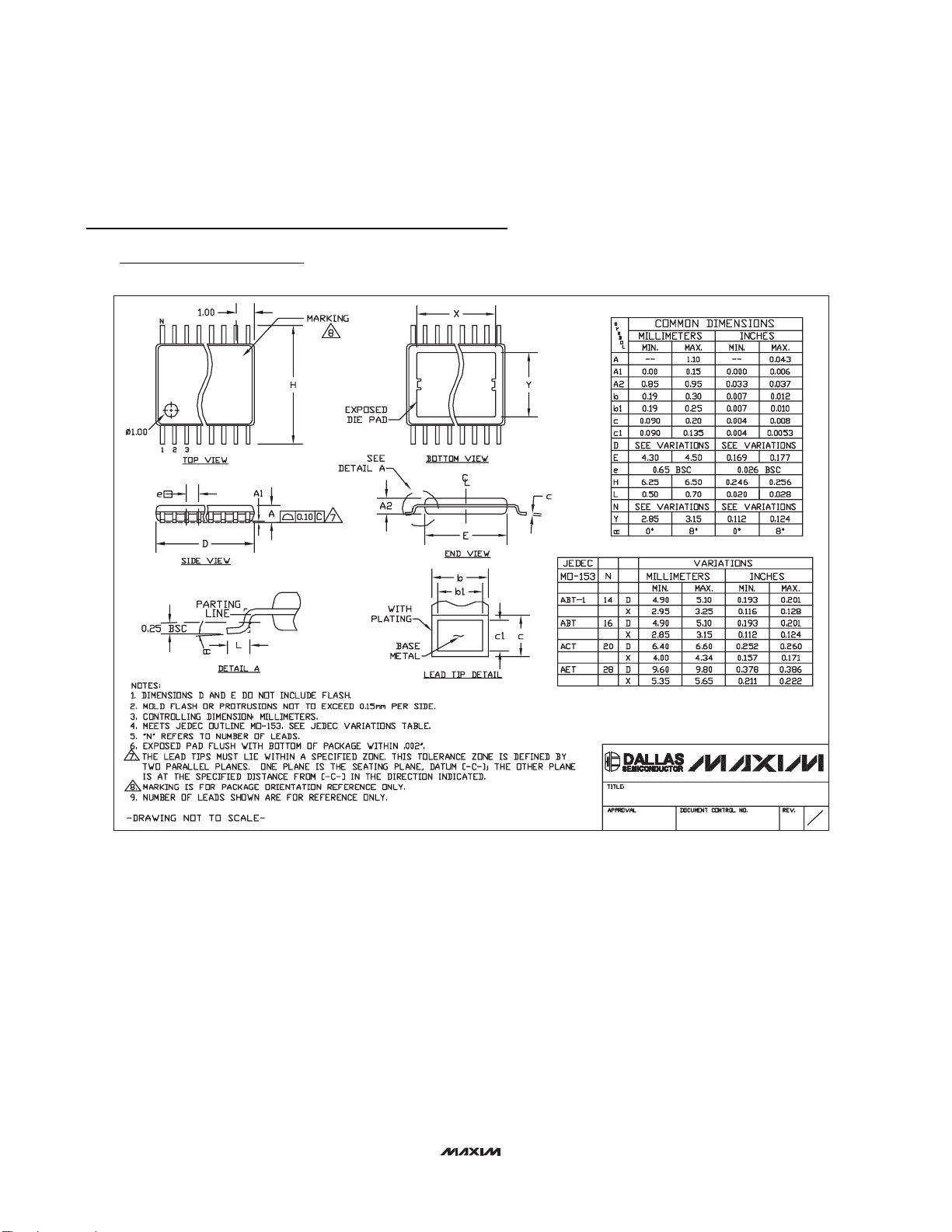

The MAX5060/MAX5061 operate over the automotive

temperature range (-40°C to +125°C). The MAX5060 is

available in a 28-pin thin QFN package while the

MAX5061 is available in a 16-pin TSSOP package.

Applications

Servers and Workstations

Point-of-Load Telecom DC-DC Regulators

Networking Systems

RAID Systems

High-End Desktop Computers

Features

♦ 4.75V to 5.5V or 7V to 28V Input Voltage Range

♦ Adjustable Output Voltage from 0.6V to 5.5V

♦ Up to 30A Output Current

♦ Can Parallel Outputs For Higher Output Current

♦ Programmable Adaptive Output Voltage

Positioning

♦ True-Differential Remote Output Sensing

(MAX5060)

♦ Average-Current-Mode Control

• Superior Current Sharing Between Paralleled

Modules

• Accurate Current Limit Eliminates MOSFET

and Inductor Derating

♦ Limits Reverse Current Sinking in Paralleled

Modules (MAX5060)

♦ Programmable Switching Frequency from 125kHz

to 1.5MHz

♦ Integrated 4A Gate Drivers

♦ Clock Output for 180° Out-of-Phase Operation

(MAX5060)

♦ Voltage Signal Proportional to Output Current for

Load Monitoring (MAX5060)

♦ Output Overvoltage Crowbar Protection

(MAX5060)

♦ Programmable Hiccup Current-Limit Threshold

and Response Time

♦ Overtemperature Thermal Shutdown

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

________________________________________________________________ Maxim Integrated Products 1

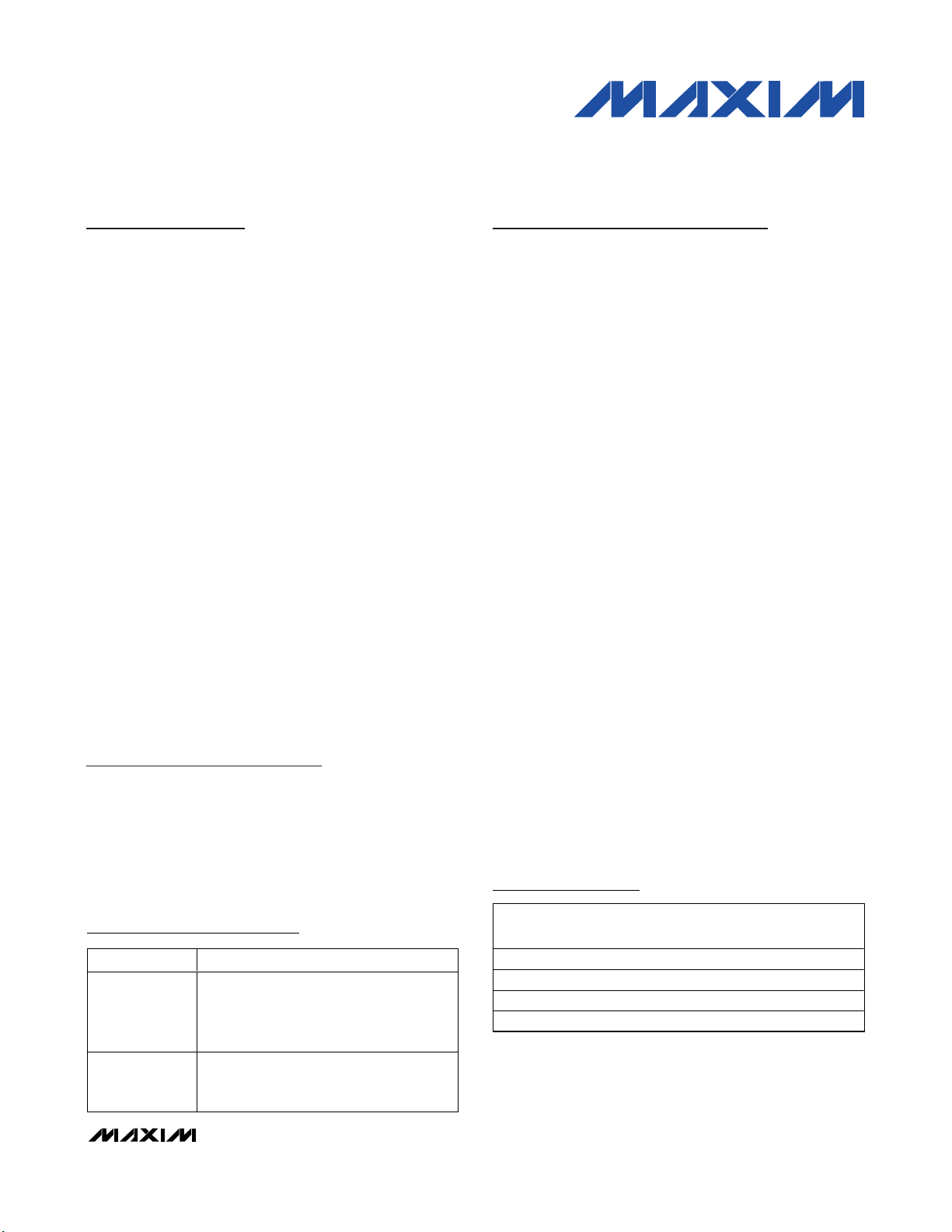

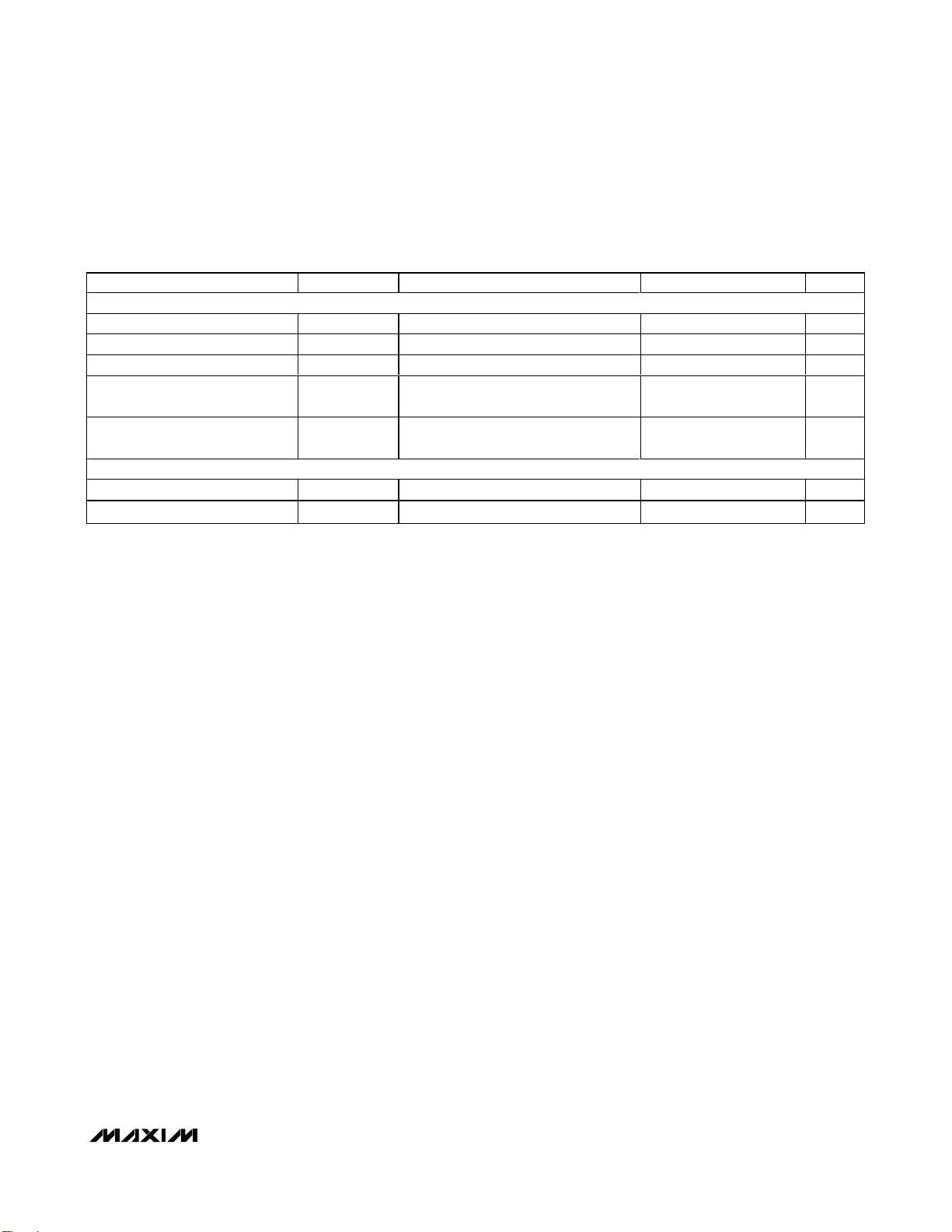

Ordering Information

Selector Guide

PART TEMP RANGE

PKG

CODE

MAX5060ATI

28 TQFN-EP*

T2855-3

MAX5060ETI

28 TQFN-EP*

T2855-3

MAX5061AUE

U16E-3

MAX5061EUE

U16E-3

PART OUTPUT

MAX5060

Average-Current-Mode DC-DC Controller

for 5V/12V/24V Input Bus with CLKOUT,

Load Monitoring, Overvoltage, EN Input,

SYNC Input, and PGOOD Output

MAX5061

Average-Current-Mode DC-DC Controller

for 5V/12V/24V Input with SYNC/ENABLE

Input

19-3583; Rev 2; 7/05

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Pin Configurations appear at end of data sheet.

*EP = Exposed pad.

-40°C to +125°C

-40°C to +85°C

-40°C to +125°C 16 TSSOP-EP*

-40°C to +85°C 16 TSSOP-EP*

PIN-PACKAGE

Page 2

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN to SGND.............................................................-0.3V to +30V

BST to SGND..........................................................-0.3V to +35V

DH to LX .......................................-0.3V to [(V

BST

- V

LX_

) + 0.3V]

DL to PGND (MAX5060).............................-0.3V to (V

DD

+ 0.3V)

DL to PGND (MAX5061).............................-0.3V to (V

CC

+ 0.3V)

BST to LX..................................................................-0.3V to +6V

V

CC

to SGND............................................................-0.3V to +6V

V

CC

, VDDto PGND ...................................................-0.3V to +6V

SGND to PGND .....................................................-0.3V to +0.3V

Current Sink in PGOOD ........................................................6mA

All Other Pins to SGND...............................-0.3V to (V

CC

+ 0.3V)

Continuous Power Dissipation (T

A

= +70°C)

16-Pin TSSOP (derate 21.3mW/°C above +70°C)* ......1702mW

28-Pin TQFN (derate 34.5mW/°C above +70°C)*......2758mW

Operating Temperature Range

MAX5060A_ _ and MAX5061A_ _ .................-40°C to +125°C

MAX5060E_ _ and MAX5061E_ _....................-40°C to +85°C

Maximum Junction Temperature .....................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

*Per JEDEC 51 standard.

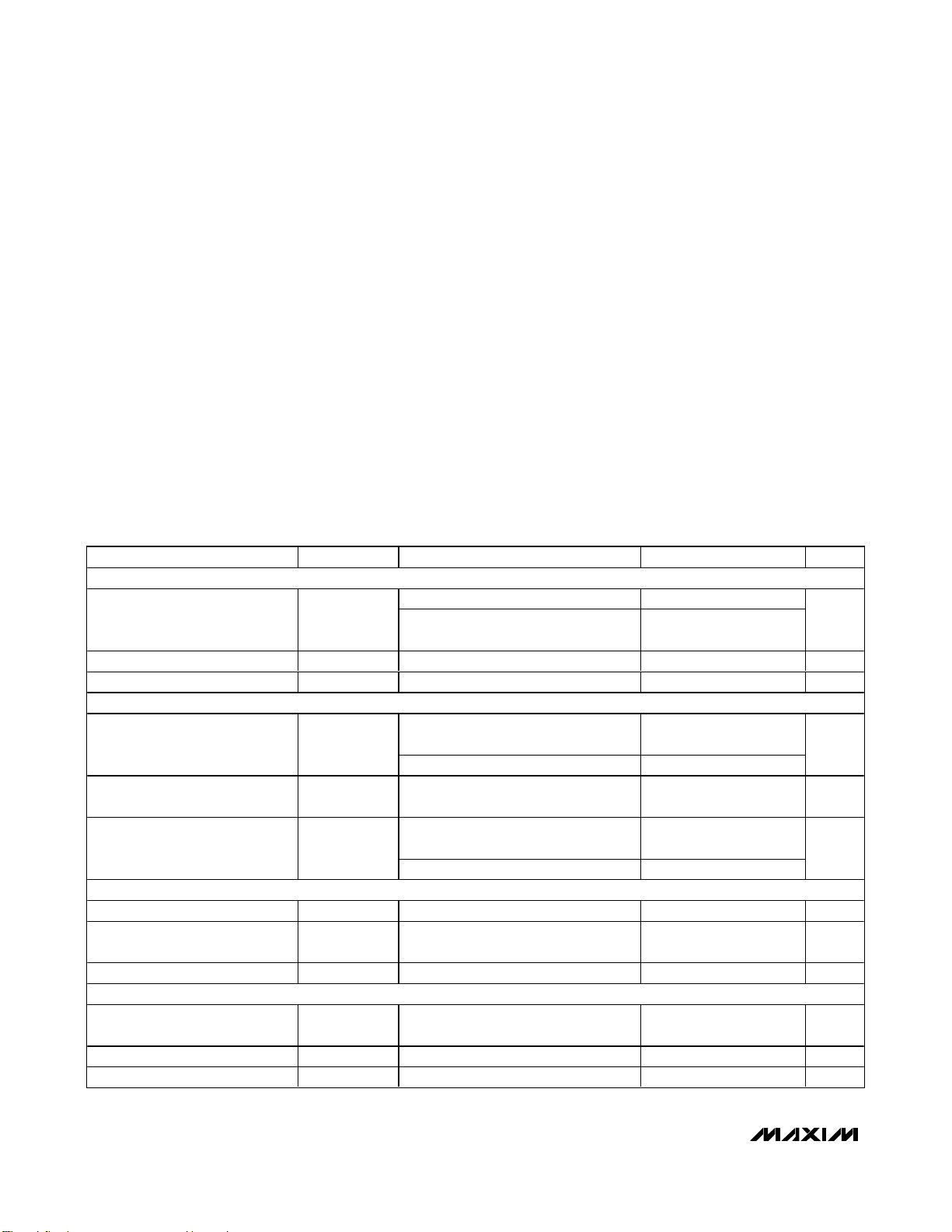

ELECTRICAL CHARACTERISTICS

(VCC= 5V, VDD= VCC(MAX5060 only), TA= TJ= T

MIN

to T

MAX

, unless otherwise noted. Typical specifications are at TA= +25°C.)

(Note 1)

PARAMETER SYMBOL CONDITIONS

MIN

TYP

MAX

UNITS

SYSTEM SPECIFICATIONS

728

Input Voltage Range V

IN

Short IN and VCC together for 5V input

operation

V

Quiescent Supply Current I

Q

EN = VCC or SGND, not switching 2.7 5.5 mA

Efficiency η I

LOAD

= 20A, VIN = 12V, V

OUT

= 3.3V 90 %

OUTPUT VOLTAGE

No load, VCC = 4.75V to 5.5V,

f

SW

= 500kHz

0.6

SENSE+ to SENSE- Accuracy

(MAX5060) (Note 2)

0.6

V

Soft-Start Time t

SS

Clock

Cycles

No load, VCC = 4.75V to 5.5V,

no switching

0.6

EAN Reference Voltage

(MAX5061)

V

REF

0.6

V

STARTUP/INTERNAL REGULATOR

VCC Undervoltage Lockout UVLO VCC rising 4.1 4.3 4.5 V

VCC Undervoltage Lockout

Hysteresis

mV

VCC Output Voltage

5.1

V

MOSFET DRIVERS

Output-Driver Impedance R

ON

Low or high output,

I

SOURCE/SINK

= 20mA

1.1 3 Ω

Output-Driver Source/Sink Current

I

DH_

, I

DL_

4A

Nonoverlap Time t

NO

C

DH/DL

= 5nF 35 ns

4.75 5.50

No load, VIN = 7V to 28V, fSW = 500kHz 0.594

No load, VIN = 7V to 28V, no switching 0.591

VIN = 7V to 28V, I

= 0 to 60mA 4.85

SOURCE

0.594

1024

0.591

200

0.606

0.606

0.606

0.606

5.30

Page 3

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

_______________________________________________________________________________________ 3

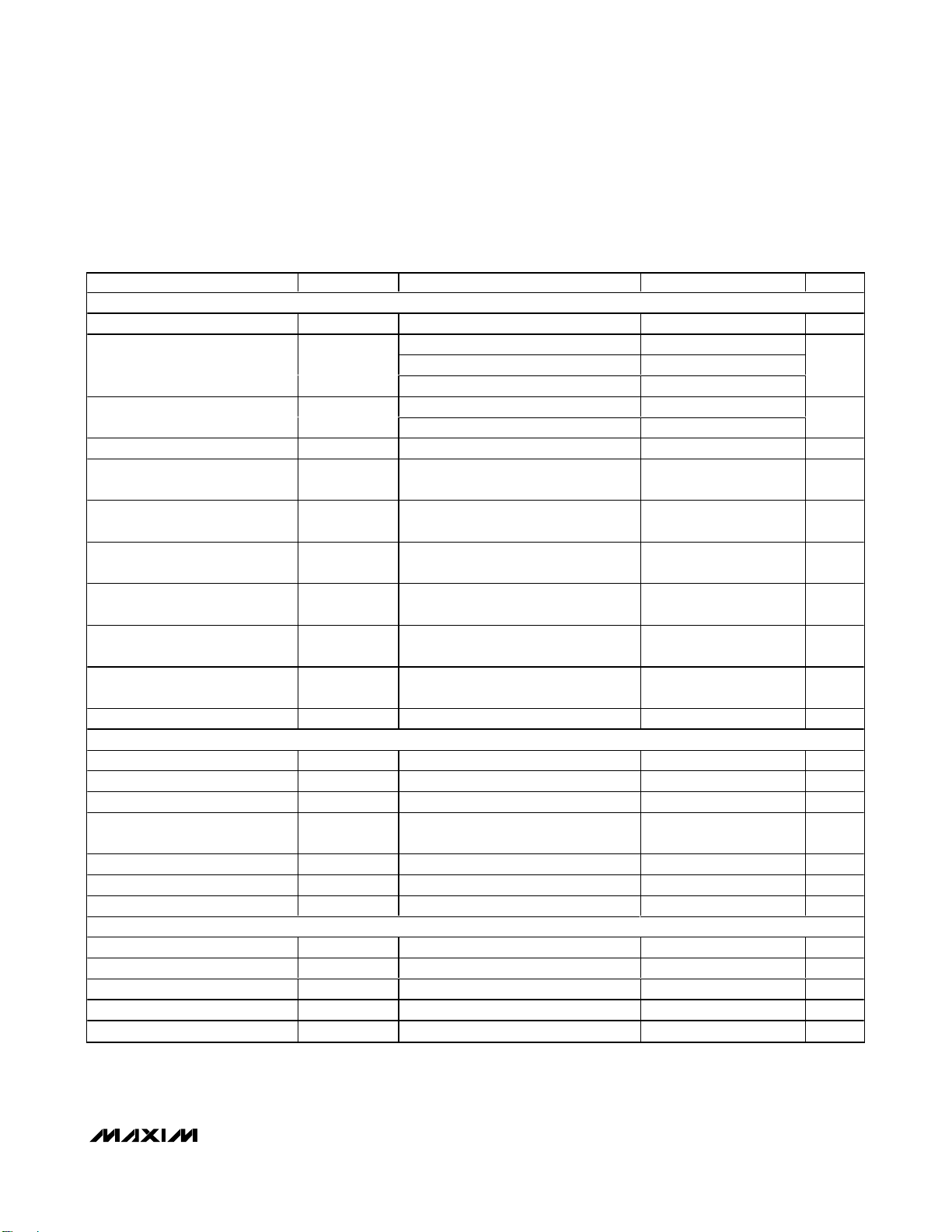

ELECTRICAL CHARACTERISTICS (continued)

(VCC= 5V, VDD= VCC(MAX5060 only), TA= TJ= T

MIN

to T

MAX

, unless otherwise noted. Typical specifications are at TA= +25°C.)

(Note 1)

PARAMETER SYMBOL CONDITIONS

MIN

TYP

MAX

UNITS

OSCILLATOR

Switching Frequency Range 125

kHz

RT = 500kΩ 121

RT = 120kΩ 495

Switching Frequency f

SW

RT = 39.9kΩ

kHz

120kΩ ≤ RT ≤ 500kΩ -5 +5

Switching Frequency Accuracy

40kΩ ≤ R

T

≤ 120kΩ -8 +8

%

CLKOUT Phase Shift (MAX5060)

φ

CLKOUT

fSW = 125kHz

degrees

CLKOUT Output Low Level

(MAX5060)

V

CLKOUTLISINK

= 2mA 0.4 V

CLKOUT Output High Level

(MAX5060)

V

CLKOUTHISOURCE

= 2mA 4.5 V

SYNC Input-High Pulse Width t

SYNC

RT/SYNC (MAX5060), RT/SYNC/EN

(MAX5061)

200 ns

SYNC Input Clock High Threshold

V

SYNCH

RT/SYNC (MAX5060), RT/SYNC/EN

(MAX5061)

2.0 V

SYNC Input Clock Low Threshold

V

SYNCL

RT/SYNC (MAX5060), RT/SYNC/EN

(MAX5061)

0.4 V

SYNC Pullup Current I

SYNC_OUT

V

RT/SYNC

= 0V (MAX5060),

V

RT/SYNC/EN

= 0V (MAX5061)

µA

SYNC Power-Off Level V

SYNC_OFF

0.4 V

CURRENT LIMIT

Average Current-Limit Threshold

V

CL

CSP to CSN

mV

Reverse Current-Limit Threshold V

CLR

CSP to CSN (MAX5060)

mV

Cycle-by-Cycle Current Limit CSP to CSN 60 mV

Cycle-by-Cycle Overload

Response Time

V

CSP

to V

CSN

= 75mV

ns

Hiccup Divider Ratio LIM to VCM, no switching

V/V

Hiccup Reset Delay

ms

LIM Input Impedance LIM to SGND

kΩ

CURRENT-SENSE AMPLIFIER

CSP to CSN Input Resistance R

CS

4kΩ

Common-Mode Range V

CMR(CS)

VIN = 7V to 28V 0 5.5 V

Input Offset Voltage V

OS(CS)

0.1 mV

Amplifier Gain A

V(CS)

V/V

3dB Bandwidth f

3dB

4

MHz

1515 1620 1725

24.0 26.9 28.2

-3.2 -2.3 -0.1

0.547 0.558 0.565

125 129

521 547

180

250 750

260

200

55.9

34.5

1500

Page 4

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

4 _______________________________________________________________________________________

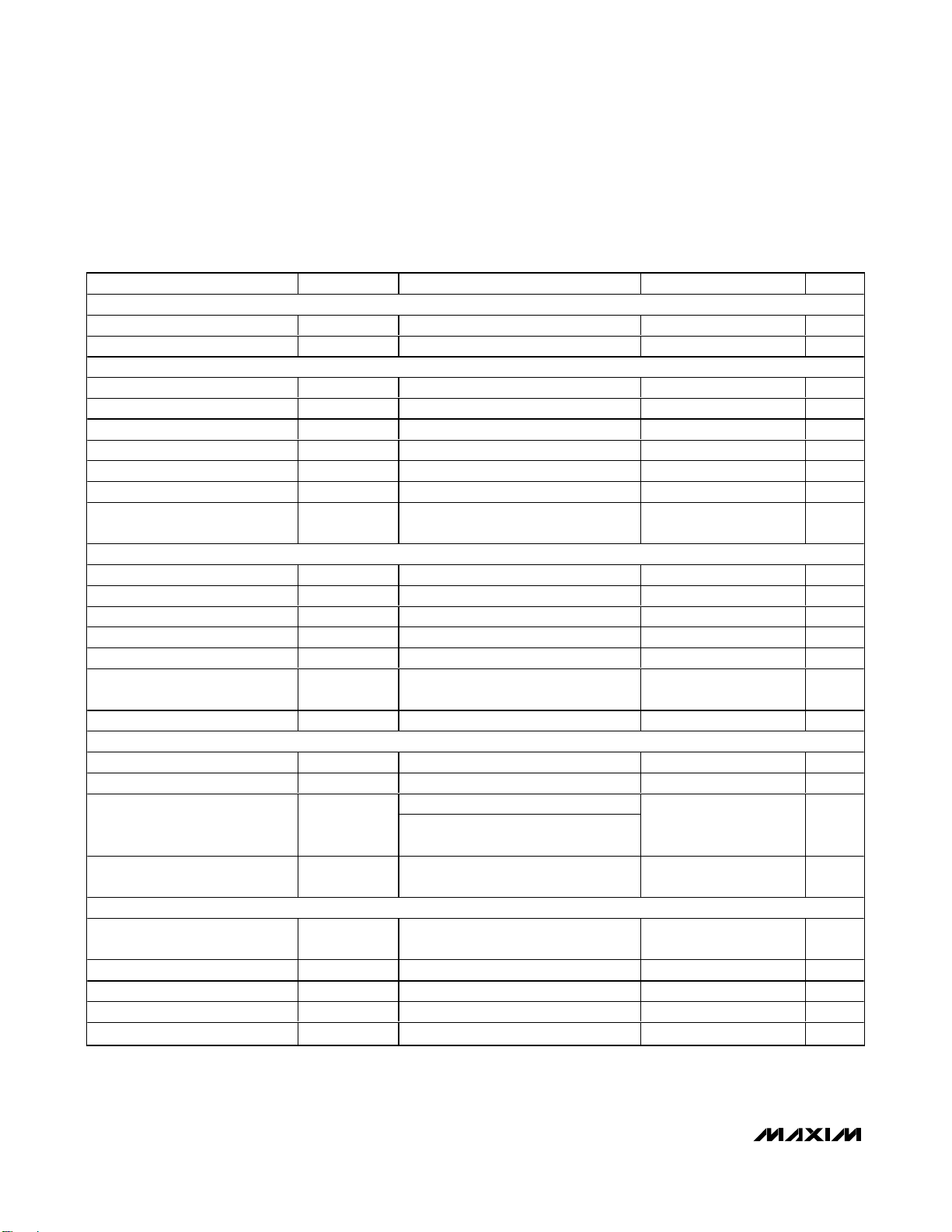

ELECTRICAL CHARACTERISTICS (continued)

(VCC= 5V, VDD= VCC(MAX5060 only), TA= TJ= T

MIN

to T

MAX

, unless otherwise noted. Typical specifications are at TA= +25°C.)

(Note 1)

PARAMETER SYMBOL CONDITIONS

MIN

TYP

MAX

UNITS

CURRENT-ERROR AMPLIFIER (Transconductance Amplifier)

Transconductance g

C

µS

Open-Loop Gain A

VOL(CE)

No load 50 dB

DIFFERENTIAL VOLTAGE AMPLIFIER (DIFF, MAX5060 only)

Common-Mode Voltage Range V

CMR(DIFF)

0

V

DIFF Output Voltage V

CM

V

SENSE+

= V

SENSE-

= 0V 0.6 V

Input Offset Voltage V

OS(DIFF)

-1 +1 mV

Amplifier Gain A

V(DIFF)

1

V/V

3dB Bandwidth f

3dB

C

DIFF

= 20pF 3

MHz

Minimum Output-Current Drive I

OUT(DIFF)

4mA

SENSE+ to SENSE- Input

Resistance

R

VS

V

SENSE-

= 0V 50

kΩ

V_IOUT AMPLIFIER (V_IOUT, MAX5060 only)

Gain-Bandwidth Product V

V_IOUT

= 2.0V 4

MHz

3dB Bandwidth V

V_IOUT

= 2.0V 1.0

MHz

Output Sink Current 30 µA

Output Source Current 90 µA

Maximum Load Capacitance 50 pF

V_IOUT Output to I

OUT

Transfer

Function

R

SENSE

= 1mΩ,

100mV ≤ V_IOUT ≤ 5.5V

mV/A

Offset Voltage 1mV

VOLTAGE-ERROR AMPLIFIER (EAOUT)

Open-Loop Gain A

VOLEA

70 dB

Unity-Gain Bandwidth f

GBW

3

MHz

V

EAN

= 2.0V (MAX5060)

EAN Input Bias Current I

B(EA)

V

EAN

= 0.4V, V

EAOUT

= GND

(MAX5061)

µA

Error-Amplifier Output-Clamping

Voltage

V

CLAMP(EA)

With respect to VCM (MAX5060),

with respect to SGND (MAX5061)

883

mV

POWER-GOOD AND OVERVOLTAGE PROTECTION (MAX5060 only)

PGOOD Trip Level V

UV

PGOOD goes low when V

OUT

is below

this threshold

90

%V

OUT

PGOOD Output Low Level V

PGLO

I

SINK

= 4mA 0.4 V

PGOOD Output Leakage Current

I

PG

PGOOD = V

CC

1µA

OVI Trip Threshold OVP

TH

With respect to SGND

V

OVI Input Bias Current I

OVI

0.2 µA

550

+1.0

0.994

1.006

100

132.3 135 137.7

-0.2 0.03 +0.2

930 976

87.5

1.244 1.276 1.308

92.5

Page 5

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VCC= 5V, VDD= VCC(MAX5060 only), TA= TJ= T

MIN

to T

MAX

, unless otherwise noted. Typical specifications are at TA= +25°C.)

(Note 1)

PARAMETER SYMBOL CONDITIONS

MIN

TYP

MAX

UNITS

ENABLE INPUTS

EN Input High Voltage (MAX5060)

V

EN

EN rising

2.5

V

EN Input Hysteresis (MAX5060)

V

EN Pullup Current (MAX5060) I

EN

15

µA

RT/SYNC/EN Input High Voltage

Enable (MAX5061)

1.6 V

RT/SYNC/EN Input Low Voltage

Disable (MAX5061)

0.4 V

THERMAL SHUTDOWN

Thermal Shutdown Temperature rising

°C

Thermal-Shutdown Hysteresis 30 °C

Note 1: Specifications at TA= +25°C are 100% tested. Specifications over the temperature range are guaranteed by design.

Note 2: Does not include an error due to finite error amplifier gain (see the Voltage-Error Amplifier section).

V

RT/SYNC/EN_H

V

RT/SYNC/EN_L

2.437

0.28

13.5

+150

2.562

16.5

Page 6

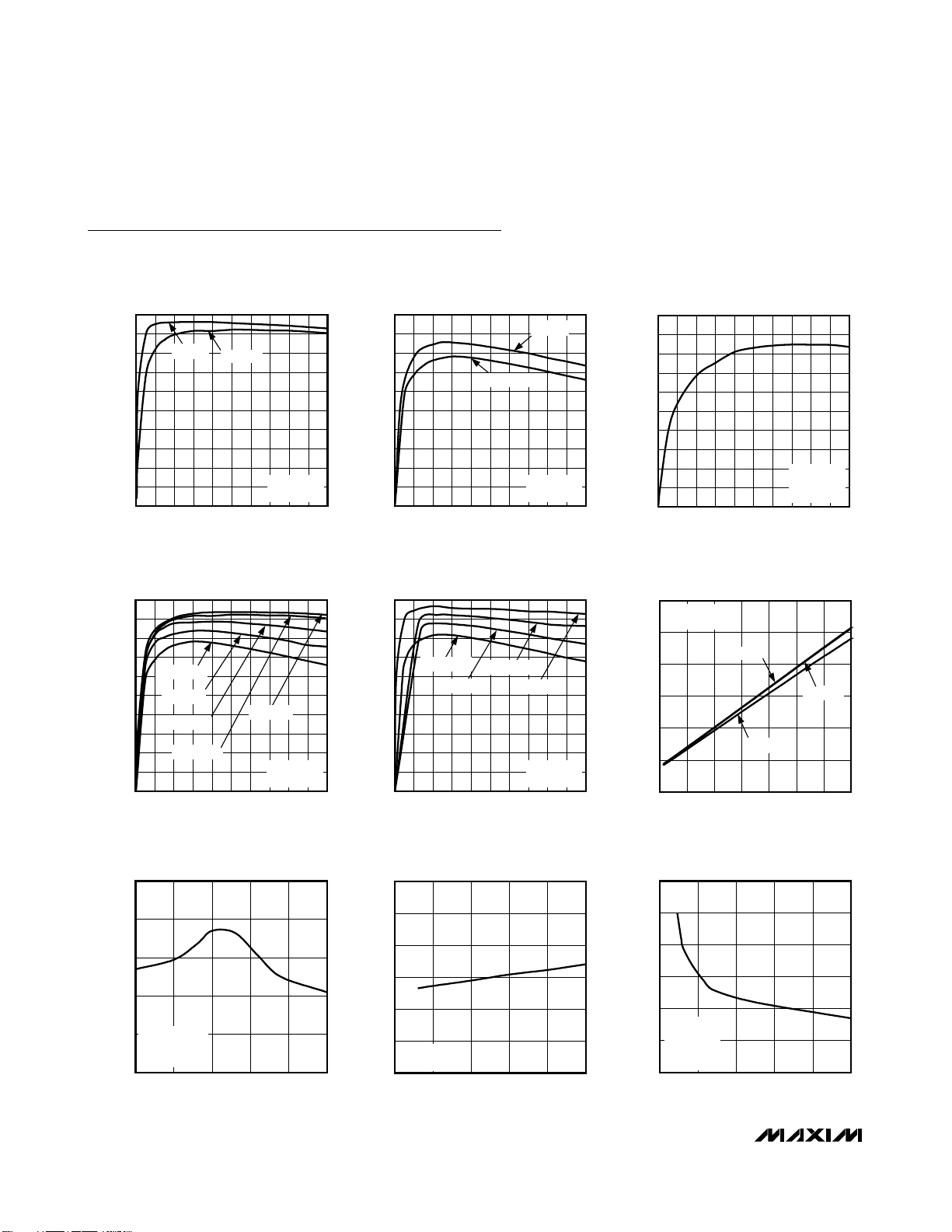

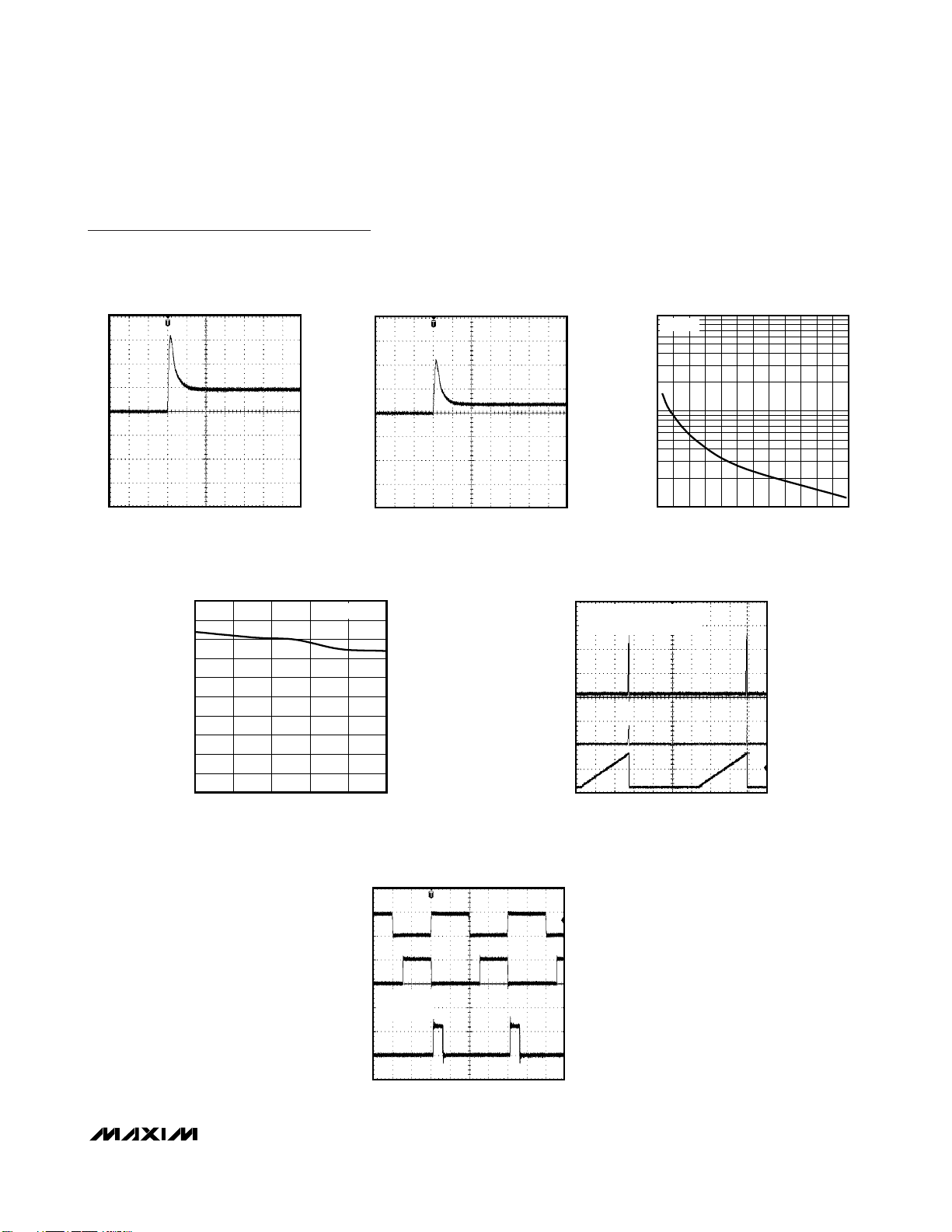

EFFICIENCY vs. OUTPUT CURRENT

AND INPUT VOLTAGE

MAX5060 toc01

OUTPUT CURRENT (A)

η (%)

181612 144 6 8 102

10

20

30

40

50

60

70

80

90

100

0

020

V

OUT

= 3.3V

f

SW

= 250kHz

VIN = 5V

VIN = 12V

EFFICIENCY vs. OUTPUT CURRENT

AND INPUT VOLTAGE

MAX5060 toc02

OUTPUT CURRENT (A)

η (%)

181612 144 6 8 102

10

20

30

40

50

60

70

80

90

100

0

020

V

OUT

= 0.6V

f

SW

= 250kHz

VIN = 5V

VIN = 12V

EFFICIENCY vs. OUTPUT CURRENT

MAX5060 toc03

OUTPUT CURRENT (A)

η (%)

181612 144 6 8 102

10

20

30

40

50

60

70

80

90

100

0

020

VIN = 24V

V

OUT

= 3.3V

f

SW

= 125kHz

EFFICIENCY vs. OUTPUT CURRENT

AND OUTPUT VOLTAGE

MAX5060 toc04

OUTPUT CURRENT (A)

η (%)

181612 144 6 8 102

10

20

30

40

50

60

70

80

90

100

0

020

VIN = 12V

f

SW

= 250kHz

V

OUT

= 5V

V

OUT

= 3.3V

V

OUT

= 0.6V

V

OUT

= 1V

V

OUT

= 1.8V

EFFICIENCY vs. OUTPUT CURRENT

AND OUTPUT VOLTAGE

MAX5060 toc05

OUTPUT CURRENT (A)

η (%)

181612 144 6 8 102

10

20

30

40

50

60

70

80

90

100

0

020

VIN = 5V

f

SW

= 500kHz

V

OUT

= 3.3V

V

OUT

= 1.8V

V

OUT

= 1V

V

OUT

= 0.6V

SUPPLY CURRENT (IQ) vs. FREQUENCY

MAX5060 toc06

FREQUENCY (kHz)

SUPPLY CURRENT (mA)

13001100900700500300

10

20

30

40

50

60

0

100 1500

EXTERNAL CLOCK

NO DRIVER LOAD

VIN = 12V

VIN = 24V

VIN = 5V

SUPPLY CURRENT vs. TEMPERATURE

MAX5060 toc07

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

603510-15

62

64

66

68

70

60

-40 85

VIN = 12V

f

SW

= 250kHz

C

DL/CDH

= 22nF

CURRENT-SENSE THRESHOLD

vs. OUTPUT VOLTAGE

MAX5060 toc08

V

OUT

(V)

(V

CSP

- V

CSN

) (mV)

4321

26.5

27.0

27.5

28.0

28.5

29.0

26.0

05

VIN = 12V

f

SW

= 250kHz

HICCUP CURRENT LIMIT vs. R

EXT

MAX5060 toc09

R

EXT

(MΩ)

CURRENT LIMIT (A)

161284

23.5

24.0

24.5

25.0

25.5

26.0

23.0

020

VIN = 12V

f

SW

= 250kHz

R1 = 1mΩ

V

OUT

= 1.5V

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

6 _______________________________________________________________________________________

Typical Operating Characteristics

(TA = +25°C, Figures 1 and 2, unless otherwise noted.)

Page 7

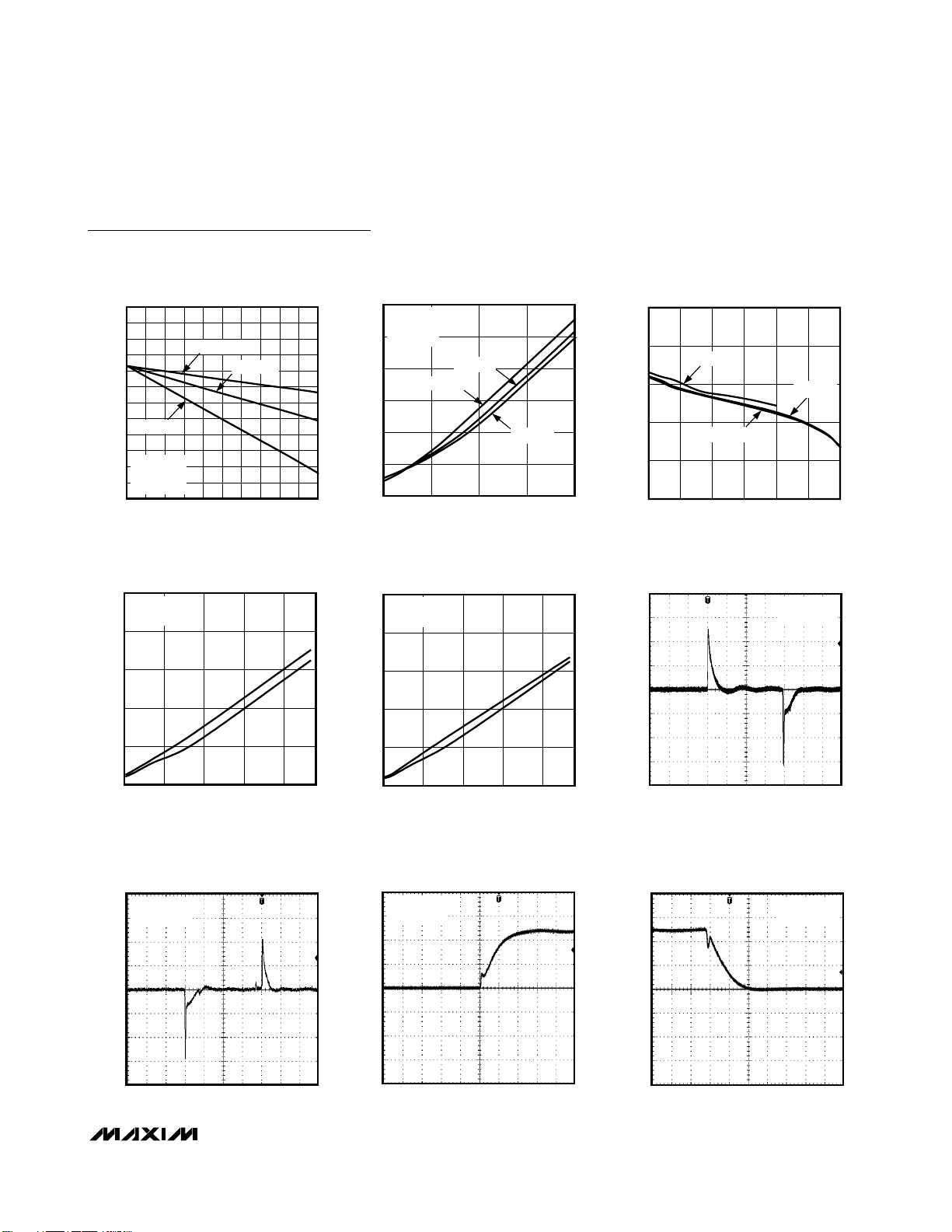

LOW-SIDE DRIVER (DL) SINK

AND SOURCE CURRENT

MAX5060 toc16

3A/div

100ns/div

C

LOAD

= 22nF

V

IN

= 12V

Typical Operating Characteristics (continued)

(TA = +25°C, Figures 1 and 2, unless otherwise noted.)

OUTPUT VOLTAGE vs. OUTPUT CURRENT

AND ERROR AMPLIFIER GAIN (R

F/RIN

)

MAX5060 toc10

OUTPUT CURRENT (A)

OUTPUT VOLTAGE (V)

181612 144 6 8 102

1.325

1.350

1.375

1.400

1.425

1.450

1.475

1.500

1.525

1.550

1.575

1.600

1.300

020

VIN = 12V

f

SW

= 250kHz

V

OUT

= 1.5V

RF/RIN = 40

RF/RIN = 10

RF/RIN = 20

V_IOUT VOLTAGE vs. LOAD CURRENT

MAX5060 toc11

LOAD CURRENT (A)

V

V_IOUT

(V)

15105

0.5

1.0

1.5

2.0

2.5

3.0

0

020

V

OUT

= 3.3V

R1 = 1m

Ω

MAX5060

VIN = 12V

VIN = 7V

VIN = 24V

VCC LOAD REGULATION

vs. INPUT VOLTAGE

MAX5060 toc12

VCC LOAD CURRENT (mA)

V

CC

(V)

125100755025

4.85

4.95

5.05

5.15

5.25

4.75

0150

VIN = 12V

VIN = 5V

VIN = 24V

DRIVER RISE TIME

vs. DRIVER LOAD CAPACITANCE

MAX5060 toc13

CAPACITANCE (nF)

t

R

(ns)

2116116

20

40

60

80

100

0

1

VIN = 12V

f

SW

= 250kHz

DH

DL

DRIVER FALL TIME

vs. DRIVER LOAD CAPACITANCE

MAX5060 toc14

CAPACITANCE (nF)

t

F

(ns)

2116116

20

40

60

80

100

0

1

VIN = 12V

f

SW

= 250kHz

DH

DL

HIGH-SIDE DRIVER (DH) SINK

AND SOURCE CURRENT

MAX5060 toc15

2A/div

100ns/div

C

LOAD

= 22nF

V

IN

= 12V

HIGH-SIDE DRIVER (DH) RISE TIME

MAX5060 toc17

2V/div

40ns/div

C

LOAD

= 22nF

V

IN

= 12V

HIGH-SIDE DRIVER (DH) FALL TIME

MAX5060 toc18

2V/div

40ns/div

C

LOAD

= 22nF

V

IN

= 12V

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

_______________________________________________________________________________________ 7

Page 8

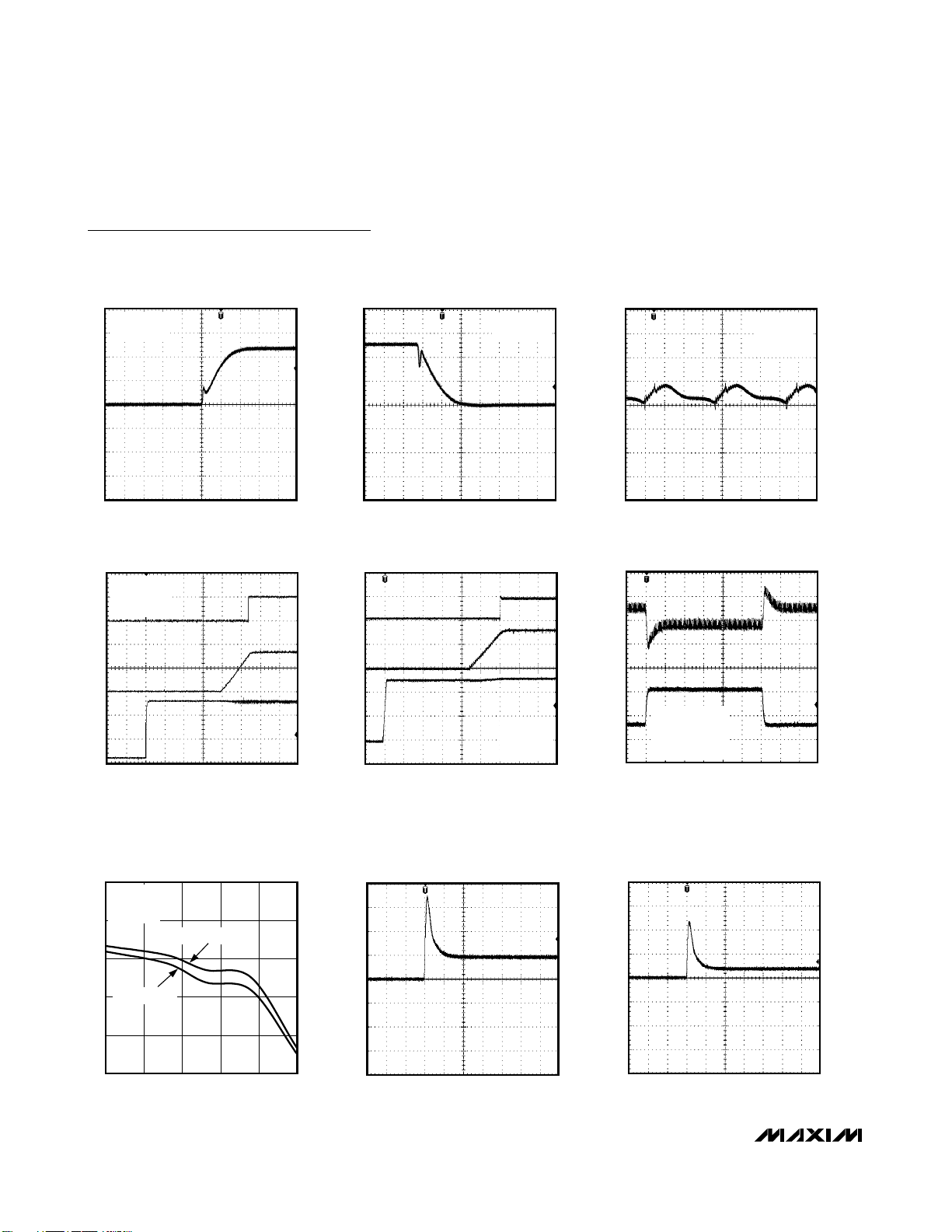

REVERSE CURRENT SINK

vs. TEMPERATURE

MAX5060 toc25

TEMPERATURE (°C)

SINK CURRENT (A)

603510-15

1.6

1.8

2.0

2.2

2.4

1.4

-40

VIN = 12V

V

0UT

= 1.5V

R1 = 1m

Ω

V

EXTERNAL

= 3.3V

V

EXTERNAL

= 2V

85

LOW-SIDE DRIVER (DL) RISE TIME

MAX5060 toc19

2V/div

40ns/div

C

LOAD

= 22nF

V

IN

= 12V

LOW-SIDE DRIVER (DL) FALL TIME

MAX5060 toc20

2V/div

40ns/div

C

LOAD

= 22nF

V

IN

= 12V

OUTPUT RIPPLE

MAX5060 toc21

50mV/div

1µs/div

VIN = 12V

V

OUT

= 1.5V

I

OUT

= 20A

INPUT STARTUP RESPONSE

MAX5060 toc22

V

OUT

2V/div

2ms/div

VIN = 12V

V

OUT

= 1.5V

I

OUT

= 20A

V

PGOOD

5V/div

V

IN

5V/div

ENABLE STARTUP RESPONSE

MAX5060 toc23

V

OUT

2V/div

2ms/div

VIN = 12V

V

OUT

= 1.5V

I

OUT

= 20A

V

PGOOD

5V/div

V

EN

2V/div

LOAD-TRANSIENT RESPONSE

MAX5060 toc24

100µs/div

VIN = 12V

V

OUT

= 3.3V

I

STEP

= 5A TO 20A

SLEW = 2A/µs

V

OUT

200mV/div

I

OUT

10A/div

0

REVERSE CURRENT SINK AT INPUT TURN-ON

(V

IN

= 12V, V

OUT

= 1.5V, V

EXTERNAL

= 2.0V)

MAX5060 toc26

200µs/div

2A/div

REVERSE CURRENT SINK AT INPUT TURN-ON

(V

IN

= 12V, V

OUT

= 1.5V, V

EXTERNAL

= 3.3V)

MAX5060 toc27

200µs/div

5A/div

Typical Operating Characteristics (continued)

(TA = +25°C, Figures 1 and 2, unless otherwise noted.)

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

8 _______________________________________________________________________________________

Page 9

Typical Operating Characteristics (continued)

(TA = +25°C, Figures 1 and 2, unless otherwise noted.)

REVERSE CURRENT SINK AT ENABLE TURN-ON

(V

IN

= 12V, V

OUT

= 1.5V, V

EXTERNAL

= 2.0V)

MAX5060 toc28

200µs/div

2A/div

REVERSE CURRENT SINK AT ENABLE TURN-ON

(V

IN

= 12V, V

OUT

= 1.5V, V

EXTERNAL

= 3.3V)

MAX5060 toc29

200µs/div

5A/div

FREQUENCY vs. R

T

MAX5060 toc30

RT (kΩ)

f

SW

(kHz)

470

430

390

350

310

270

230

190

150

110

70

1000

10,000

100

30 510

VIN = 12V

FREQUENCY vs. TEMPERATURE

MAX5060 toc31

TEMPERATURE (°C)

f

SW

(kHz)

603510-15

242

244

246

248

250

252

254

256

258

260

240

-40 85

VIN = 12V

OUTPUT SHORT-CIRCUIT WAVEFORM

MAX5060 toc32

40ms/div

V

OUT

2V/div

V

IN

= 12V CEN = 0.47µF

V

OUT

= 3.3V R

LIM

= OPEN

EN

2V/div

I

OUT

10A/div

SYNC, CLKOUT, AND LX WAVEFORM

MAX5060 toc33

1µs/div

CLKOUT

5V/div

VIN = 12V

f

SW

= 250kHz

LX

10V/div

SYNC

5V/div

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

_______________________________________________________________________________________ 9

Page 10

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

10 ______________________________________________________________________________________

Pin Description

PIN

MAX5060 MAX5061

1 3 PGND

2, 7 8 N.C. No Connection. Not internally connected.

3 4 DL Low-Side Gate-Driver Output. Synchronous MOSFET gate driver.

4 5 BST

NAME FUNCTION

Power Ground. Connect PGND, low-side synchronous MOSFET’s source, and

(MAX5060)/VCC (MAX5061) bypass capacitor returns together.

V

DD

Boost Flying-Capacitor Connection. Reservoir capacitor connection for the highside MOSFET driver supply. Connect a 0.47µF ceramic capacitor between BST

and LX.

56 LX

6 7 DH High-Side Gate-Driver Output. Drives the gate of the high-side MOSFET.

8, 22, 25 16 SGND

9 — CLKOUT

10 — PGOOD

11 — EN

12 — RT/SYNC

13 — V_IOUT

14 10 LIM

15 — OVI

Inductor Connection. Source connection for the high-side MOSFETs. Also serves

as the return terminal for the high-side driver.

Signal Ground. Ground connection for the internal control circuitry. Connect

SGND and PGND together at one point near the input bypass capacitor return.

Oscillator Output. Rising edge of CLKOUT is phase-shifted from rising edge of

DH by 180°.

Power-Good Output. PGOOD is an open-drain output that goes low when the

programmed output voltage falls out of regulation. The power-good comparator

threshold is 90% of the programmed output voltage.

Output Enable. Drive EN high or leave unconnected for normal operation. Drive

EN low to shut down the power drivers. EN has an internal 15µA pullup current.

Connect a capacitor from EN to SGND to program the hiccup mode duty cycle.

Switching Frequency Programming and Chip-Enable Input. Connect a resistor

from RT/SYNC to SGND to set the internal oscillator frequency. Drive RT/SYNC

externally to synchronize the switching frequency with system clock.

Voltage-Source Output Proportional to the Output Load Current. The voltage at

V_IOUT is 135 x I

Current-Limit Setting Input. Connect a resistor from LIM to SGND to set the

hiccup current-limit threshold. Connect a capacitor from LIM to SGND to ignore

short output overcurrent pulses.

Overvoltage Protection Circuit Input. Connect OVI to DIFF. When OVI exceeds

+12.7% above the programmed output voltage, DH is latched low and DL is

latched high. Toggle EN low to high or recycle the power to reset the latch.

LOAD

x RS.

16 11 CLP

Current-Error-Amplifier Output. Compensate the current loop by connecting an

RC network to ground.

Page 11

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

______________________________________________________________________________________ 11

Pin Description (continued)

PIN

MAX5060 MAX5061

17 12 EAOUT

18 13 EAN

19 — DIFF

20 14 CSN

21 15 CSP

23 — SENSE-

24 — SENSE+

26 1 IN Supply Voltage Connection. Connect IN to VCC for a +5V system.

27 2 V

NAME FUNCTION

Voltage-Error-Amplifier Output. Connect to the external gain-setting feedback

resistor. The error-amplifier gain-setting resistors determine the amount of

adaptive voltage positioning.

Voltage-Error-Amplifier Inverting Input. Receives a signal from the output of the

differential remote-sense amplifier (MAX5060). Connect the center tap of the

resistor-divider from the output to SGND (MAX5061).

Differential Remote-Sense Amplifier Output. DIFF is the output of a precision

unity-gain amplifier whose inputs are SENSE+ and SENSE-.

Current-Sense Differential Amplifier Negative Input. The differential voltage

between CSN and CSP is amplified internally by the current-sense amplifier

(gain = 34.5) to measure the inductor current.

Current-Sense Differential Amplifier Positive Input. The differential voltage

between CSP and CSN is amplified internally by the current-sense amplifier

(gain = 34.5) to measure the inductor current.

Differential Output-Voltage-Sensing Negative Input. SENSE- is used to sense a

CC

remote load. Connect SENSE- to V

Differential Output-Voltage-Sensing Positive Input. SENSE+ is used to sense a

remote load. Connect SENSE+ to V

difference between SENSE+ and SENSE- according to the preset reference

voltage of 0.6V.

Internal +5V Regulator Output. VCC is derived from the IN voltage. Bypass V

to SGND with 4.7µF and 0.1µF ceramic capacitors. For MAX5061, connect an

additional 0.1µF bypass capacitor from V

or PGND at the load.

OUT-

at the load. The device regulates the

OUT+

to PGND.

CC

CC

Supply Voltage for Low-Side and High-Side Drivers. Connect a parallel

28 — V

— 9 RT/SYNC/EN

—— EP

DD

combination of 0.1µF and 1µF ceramic capacitors to PGND and a 1Ω resistor to

V

CC

Switching Frequency Programming and Chip-Enable Input. Connect a resistor

from RT/SYNC/EN to SGND to set the internal oscillator frequency. Drive

RT/SYNC/EN externally to synchronize the switching frequency with system

clock. If RT/SYNC/EN is held low for 50µs, the device turns off the output drivers.

Exposed Paddle. Connect the exposed paddle to a copper pad (SGND) to

improve power dissipation.

to filter out the high peak currents of the driver from the internal circuitry.

Page 12

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

12 ______________________________________________________________________________________

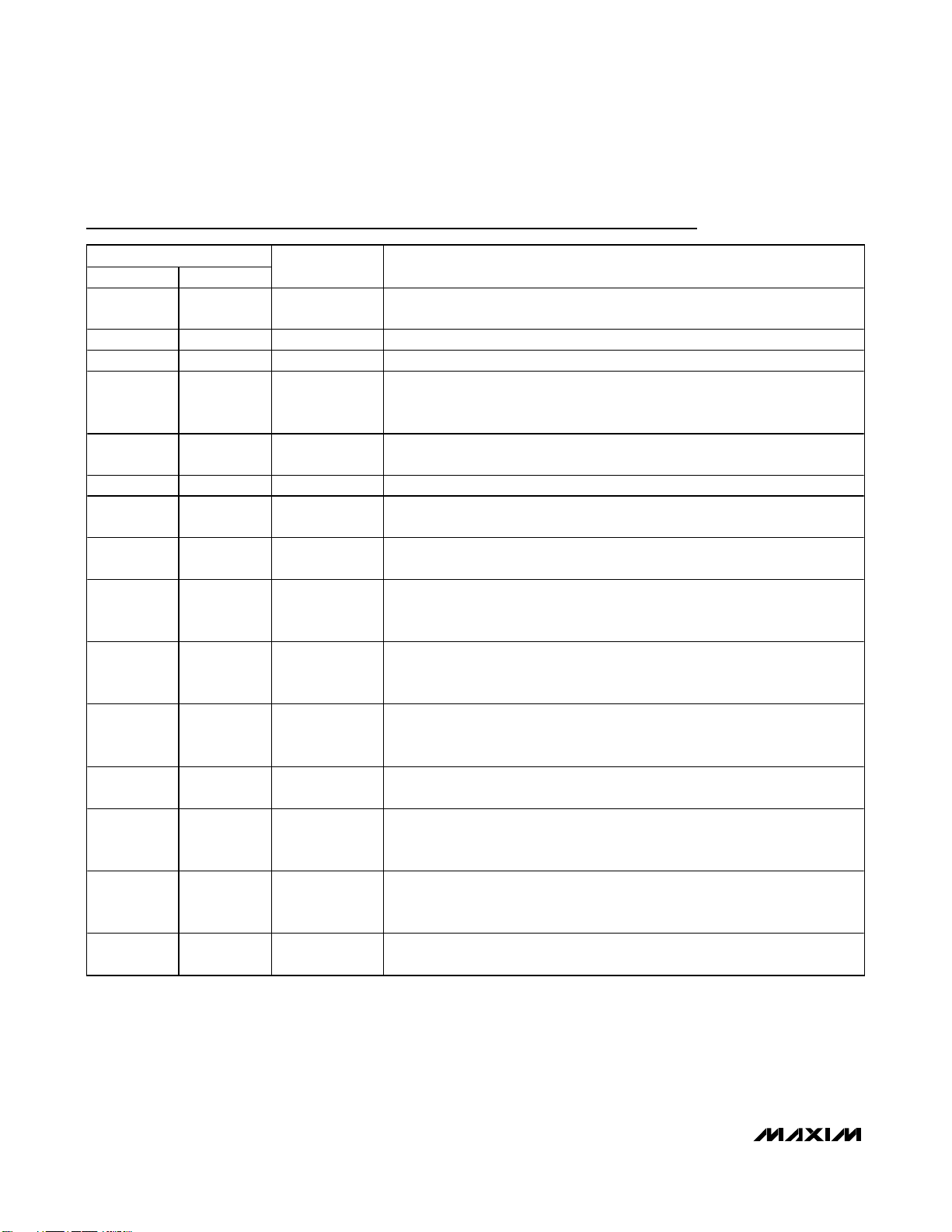

Typical Application Circuit

Figure 1. Typical Application Circuit, VIN= 12V (MAX5060)

VIN = 12V

C1, C2

C3

R

EXT

C4

ON

OFF

(VOLTAGE α I

V_IOUT

OUT

C5

)

R

IN

R

F

R13

IN

IN

SENSE- SENSE+

LIM

EN

CSN

MAX5060

V_IOUT

OVI

DIFF

EAN

EAOUT

PGNDCLP SGND

R5

C6

C7

PGOOD

CSP

RT/

SYNC

V

V

DH

BST

R

H

V

IN

R

C3–C7

Q1

LX

DL

CC

DD

Q2

D1

R3

C8

L1 R1

C12

D3

SYNC

R11

C10

C12 C13

C11

L

LOAD

V

= 0.6V TO

OUT

5.5V AT 20A

PGOOD

Page 13

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

______________________________________________________________________________________ 13

Typical Application Circuit (continued)

Figure 2. Typical Application Circuit, VIN= +12V (MAX5061)

SYNC

ON

OFF

VIN = 12V

C1, C2

C3

R

T

R

EXT

C4

C5

R5

C6

R13

IN

IN

RT/SYNC/EN

MAX5061

LIM

CLP

PGND SGND

CSN

EAN

CSP

BST

V

EAOUT

CC

C13–C16

RC1

L1 R1

C12

C9

V

V

IN

F

Q1

Q2

C7* C8

D1

DH

LX

DL

CC

R

C13*

RC2

V

= 0.6V TO

OUT

5.5V AT 20A

C10 C11

LOAD

D3

V

CC

R

H

R

L

* USE C13 = 47pf AND C7 = 4.7µF/6.3V (CERAMIC).

Page 14

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

14 ______________________________________________________________________________________

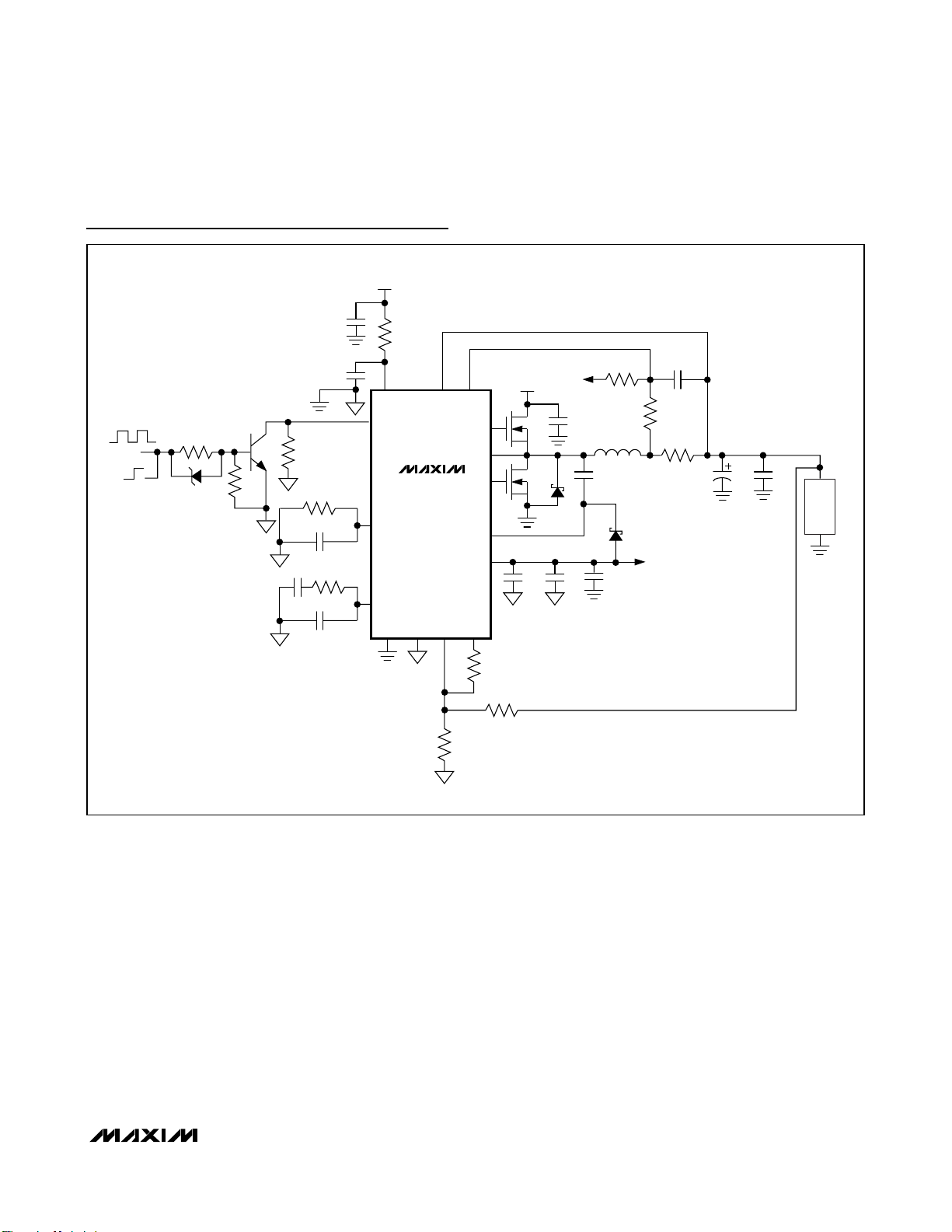

Block Diagram

Figure 3. Functional Diagram (MAX5060)

V

CC

I

S

EN

0.5V x V

CC

gm = 500µS

CEA

V

CLAMP

HIGH

UVLO

POR

TEMP SENSOR

100kΩ

0.5 x V

RAMP

2 x fS (V/s)

HICCUP MODE

CURRENT LIMIT

CLAMP

V

CM

PWM

COMPARATOR

CPWM

126.7kΩ

C

t

0.1 x V

0.12 x V

V

CM

S

R

REF

REF

MAX5060

SRQ

Q

Q

Q

N

OVP LATCH

LATCH

OVP COMP

CLEAR ON UVLO RESET OR

ENABLE LOW

R

T

IN

V

CC

LIM

5V

LDO

REGULATOR

TO INTERNAL

CIRCUITS

CLP

= 34.5

A

V

CLAMP

LOW

GENERATOR

ERROR AMP

VEA

V

= 0.6V

REF

VCM (0.6V)

V

CA

RAMP

CSP

CSN

V_IOUT

SGND

RT/SYNC

CLKOUT

DIFF

SENSE-

SENSE+

EAOUT

EAN

A

= 4

V

DIFF

AMP

SOFTSTART

OSCILLATOR

+0.6V

CLK

V

DD

BST

DH

LX

DL

PGND

PGOOD

OVI

Page 15

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

______________________________________________________________________________________ 15

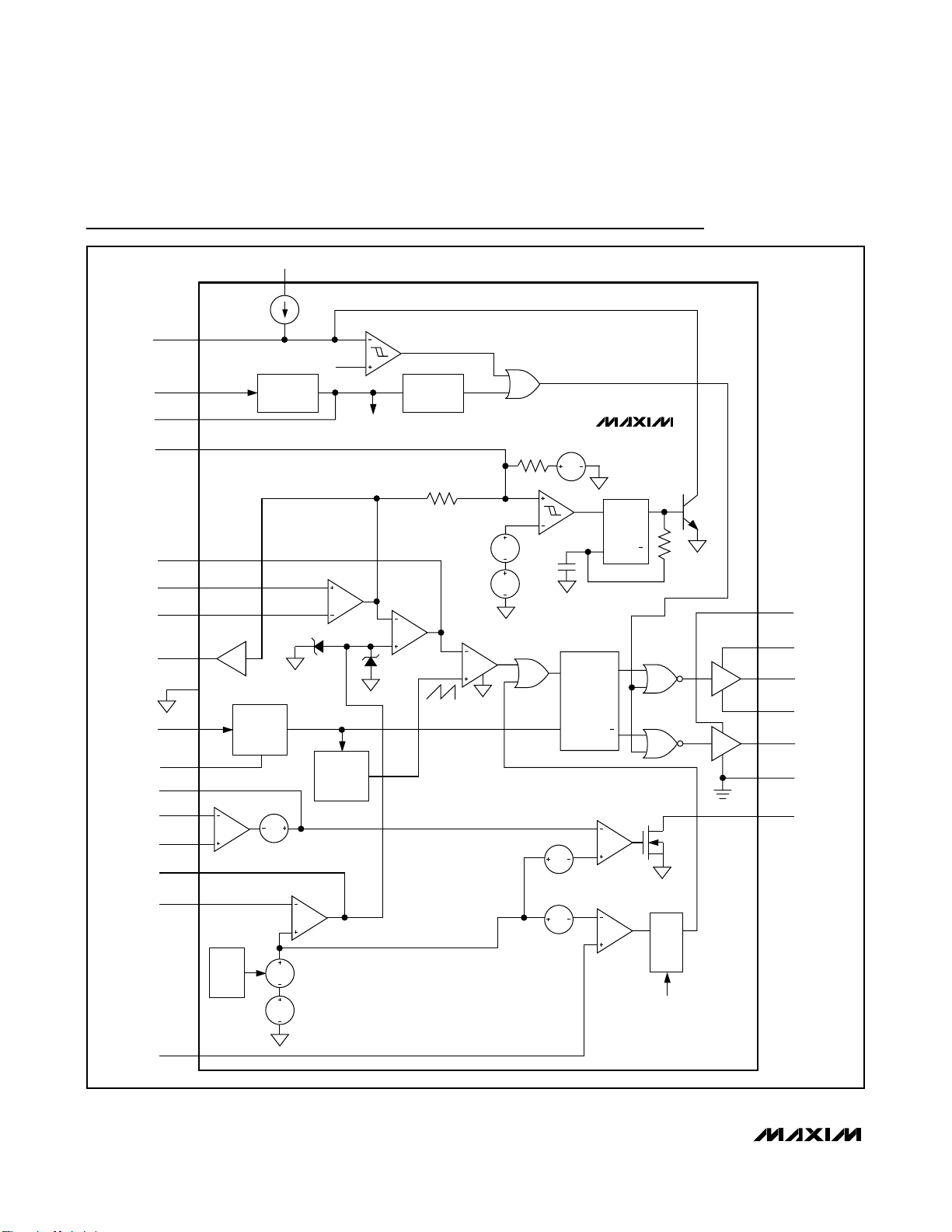

Block Diagram (continued)

Figure 4. Functional Diagram (MAX5061)

V

LIM

CLP

CSP

CSN

SGND

RT/SYNC/EN

V

CC

I

S

0.5V x V

CC

TEMP SENSOR

gm = 500µS

CEA

CLAMP

UVLO

POR

100kΩ

0.5 x V

RAMP

2 x fS (V/s)

HICCUP MODE

CURRENT LIMIT

CLAMP

V

CM

PWM

COMPARATOR

CPWM

126.7kΩ

V

CM

C

t

S

R

MAX5061

SRQ

Q

Q

R

T

Q

V

CC

BST

DH

LX

DL

IN

CC

OSCILLATOR

5V

LDO

REGULATOR

TO INTERNAL

= 34.5

A

V

CA

CIRCUITS

CLK

V

HIGH

GENERATOR

EAOUT

EAN

SOFTSTART

ERROR AMP

VEA

V

= 0.6V

REF

RAMP

PGND

Page 16

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

16 ______________________________________________________________________________________

Detailed Description

The MAX5060/MAX5061 are high-performance averagecurrent-mode PWM controllers. The average-currentmode control technique offers inherently stable

operation, reduces component derating and size by

accurately controlling the inductor current. This also

improves the current-sharing accuracy when paralleling

multiple converters. The devices achieve high efficiency,

at high current (up to 30A) with a minimum number of

external components. The high- and low-side drivers

source and sink up to 4A for lower switching frequencies

while driving high-gate-charge MOSFETs.

The MAX5060’s CLKOUT output is 180° out-of-phase

with respect to the high-side driver. The CLKOUT drives

a second MAX5060 or a MAX5061 regulator out-ofphase, reducing the input capacitor ripple current and

increasing the load current capacity. The paralleling

capability of the MAX5060/MAX5061 improves design

flexibility in applications requiring upgrades (higher load).

The MAX5060/MAX5061 consist of an inner averagecurrent-loop controlled by an outer-voltage-loop voltageerror amplifier (VEA). The combined action of the inner

current loop and outer voltage loop corrects the output

voltage errors by adjusting the inductor current. The

inductor current is sensed across a current-sense resistor. The differential amplifier (MAX5060) senses the output right at the load for true-differential output voltage

sensing. The sensed voltage is compared against internal 0.6V reference at the error-amplifier input. The output

voltage can be set from 0.6V to 5.5V (IN ≥ 7V) using a

resistor-divider at SENSE+ and SENSE-.

IN, VCC, and V

DD

The MAX5060/MAX5061 accept a 4.75V to 5.5V or 7V

to 28V input voltage range. All internal control circuitry

operates from an internally regulated nominal voltage

of 5V (VCC). For input voltages of 7V or greater, the

internal VCCregulator steps the voltage down to 5V.

The VCCoutput voltage is a regulated 5V output capable of sourcing up to 60mA. Bypass the VCCto SGND

with 4.7µF and 0.1µF low-ESR ceramic capacitors for

high-frequency noise rejection and stable operation.

The MAX5060 uses VDDto power the low-side and

high-side drivers, while the MAX5061 uses the VCCto

power internal circuitry as well as the low- and highside driver supply. In the case of the MAX5061, use

one or more 0.1µF low-ESR ceramic capacitors

between VCCand PGND to reject the noise spikes due

to high-current driver switching.

The TQFN-28 and TSSOP-16 are thermally enhanced

packages and can dissipate up to 2.7W and 1.7W,

respectively. The high-power packages allow the

high-frequency, high-current buck converter to operate from a 12V or 24V bus. Calculate power dissipation in the MAX5060/MAX5061 as a product of the

input voltage and the total VCCregulator output current (I

CC

). ICCincludes quiescent current (IQ) and

gate-drive current (IDD):

PD= VINx I

CC

ICC= IQ+ [fSWx (QG1+ QG2)]

where QG1and Q

G2

are the total gate charge of the

low-side and high-side external MOSFETs at V

GATE

=

5V, IQis 3.5mA (typ), and fSWis the switching frequency of the converter.

Undervoltage Lockout (UVLO)

The MAX5060/MAX5061 include an undervoltage lockout with hysteresis and a power-on-reset circuit for converter turn-on and monotonic rise of the output voltage.

The UVLO rising threshold is internally set at 4.35V with

a 200mV hysteresis. Hysteresis at UVLO eliminates

chattering during startup.

Most of the internal circuitry, including the oscillator,

turns on when the input voltage reaches 4V. The

MAX5060/MAX5061 draw up to 3.5mA of current

before the input voltage reaches the UVLO threshold.

Soft-Start

The MAX5060/MAX5061 has an internal digital soft-start

for a monotonic, glitch-free rise of output voltage. Softstart is achieved by the controlled rise of error amplifier

dominant input in steps using a 5-bit counter and a 5-bit

DAC. The soft-start DAC generates a linear ramp from 0

to 0.7V. This voltage is applied to the error amplifier at a

third (noninverting) input. As long as the soft-start voltage is lower than the reference voltage, the system will

converge to that lower reference value. Once the softstart DAC output reaches 0.6V, the reference takes over

and the DAC output continues to climb to 0.7V assuring

that it is out of the way of the reference voltage.

Page 17

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

______________________________________________________________________________________ 17

Internal Oscillator

The internal oscillator generates a clock with the frequency proportional to the inverse of RT. The oscillator

frequency is adjustable from 125kHz to 1.5MHz with

better than 8% accuracy using a single resistor connected from RT/SYNC to SGND (MAX5060) and from

RT/SYNC/EN to SGND (MAX5061). The frequency accuracy avoids the over-design, size, and cost of passive

filter components like inductors and capacitors. Use the

following equation to calculate the oscillator frequency:

for 120kΩ≤RT≤ 500kΩ:

for 40kΩ≤RT≤ 120kΩ:

The oscillator also generates a 2V

P-P

voltage-ramp signal for the PWM comparator and a 180° out-of-phase

clock signal for CLKOUT (MAX5060) to drive a second

DC-DC converter out-of-phase.

Synchronization

The MAX5060/MAX5061 can be easily synchronized by

connecting an external clock to RT/SYNC (MAX5060) or

RT/SYNC/EN (MAX5061). If an external clock is present, then the internal oscillator is disabled and the

external clock is used to run the MAX5060/MAX5061. If

the external clock is removed, the absence of clock for

32µs is detected and the circuit starts switching from

the internal oscillator. Pulling RT/SYNC on the MAX5060

or RT/SYNC/EN on the MAX5061 to ground for at least

50µs disables the converter.

Use an open-collector transistor to synchronize the

MAX5060/MAX5061 with the external system clock (see

Figures 1 and 2).

Figure 5. MAX5060 Control Loop

R

T

. =×625 10

f

SW

10

R

T

. =×640 10

f

10

SW

C

R

CF

CF

*

R

SENSE+

SENSE-

*R

AND RIN ARE EXTERNAL.

F

DIFF

AMP

IN

C

CSN

CSP

CA

RF*

CEA

VEA

V

+ V

REF

CM

MAX5060

CLP

CPWM

CFF

DRIVE

V

IN

I

L

R

S

C

OUT

V

OUT

LOAD

Page 18

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

18 ______________________________________________________________________________________

Control Loop

The MAX5060/MAX5061 use an average-current-mode

control scheme to regulate the output voltage (Figure 5).

The main control loop consists of an inner current loop

and an outer voltage loop. The inner loop controls the

output current (I

PHASE

), while the outer loop controls the

output voltage. The inner current loop absorbs the

inductor pole reducing the order of the outer voltage

loop to that of a single-pole system.

The current loop consists of a current-sense resistor

(R

SENSE

), a current-sense amplifier (CA), a currenterror amplifier (CEA), an oscillator providing the carrier

ramp, and a PWM comparator (CPWM) (Figure 6). The

precision CA amplifies the sense voltage across RS by

a factor of 34.5. The inverting input to the CEA senses

the CA output. The CEA output is the difference

between the voltage-error-amplifier output (EAOUT)

and the amplified voltage from the CA. The RC compensation networks connected to CLP provide external

frequency compensation for the CEA. The start of every

clock cycle enables the high-side drivers and initiates a

PWM ON cycle. Comparator CPWM compares the output voltage from the CEA with a 0 to 2V ramp from the

oscillator. The PWM ON cycle terminates when the

ramp voltage exceeds the error voltage.

The MAX5060 outer voltage control loop consists of the

differential amplifier (DIFF AMP), reference voltage, and

VEA. The unity-gain differential amplifier provides truedifferential remote sensing of the output voltage. The differential amplifier output connects to the inverting input

(EAN) of the VEA. For MAX5061, the DIFF AMP is

bypassed and the inverting input is available to the pin

for direct feedback. The noninverting input of the VEA is

internally connected to an internal precision reference

voltage. The MAX5060/MAX5061 reference voltage is set

to 0.6V. The VEA controls the inner current loop (Figure

4). Use a resistive feedback network to set the VEA gain

as required by the adaptive voltage-positioning circuit

(see the Adaptive Voltage Positioning section).

Figure 6. Phase Circuit

PEAK-CURRENT

COMPARATOR

A

CA

60mV

= 34.5

V

gm = 550µS

CEA

COMPARATOR

CLP

CSP

CSN

GM

RAMP

CLK

IN

2 x fS (V/s)

PWM

CPWM

V

DD

MAX5060

BST

S

R

Q

Q

DH

LX

DL

SHDN

PGND

Page 19

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

______________________________________________________________________________________ 19

Current-Sense Amplifier

The differential current-sense amplifier (CA) provides a

DC gain of 34.5. The maximum input offset voltage of

the current-sense amplifier is 1mV and the commonmode voltage range is 0 to 5.5V (IN = 7V to 28V). The

current-sense amplifier senses the voltage across a

current-sense resistor. The maximum common-mode

voltage is 3.6V when VIN= 5V. The common-mode voltage range determines the maximum output voltage of

the buck converter.

Peak-Current Comparator

The peak-current comparator provides a path for fast

cycle-by-cycle current limit during extreme fault conditions such as an output inductor malfunction (Figure 5).

Note the average current-limit threshold of 26.9mV still

limits the output current during short-circuit conditions.

To prevent inductor saturation, select an output inductor

with a saturation current specification greater than the

average current limit. Proper inductor selection ensures

that only the extreme conditions trip peak-current comparator, such as a broken output inductor. The 60mV

threshold for triggering the peak-current limit is twice the

full-scale average current-limit voltage threshold. The

peak-current comparator has only a 260ns delay.

Current-Error Amplifier

The MAX5060/MAX5061 has a transconductance current-error amplifier (CEA) with a typical gmof 550µS

and 320µA output sink- and source-current capability.

The current-error amplifier output CLP, serves as the

inverting input to the PWM comparator. CLP is externally accessible to provide frequency compensation for

the inner current loops (Figure 5). Compensate (CEA)

so the inductor current down slope, which becomes the

up slope to the inverting input of the PWM comparator,

is less than the slope of the internally generated voltage

ramp (see the Compensation section).

PWM Comparator and R-S Flip-Flop

The PWM comparator (CPWM) sets the duty cycle for

each cycle by comparing the output of the current-error

amplifier to a 2V

P-P

ramp. At the start of each clock

cycle, an R-S flip-flop resets and the high-side driver

(DH) turns on. The comparator sets the flip-flop as soon

as the ramp voltage exceeds the CLP voltage, thus terminating the ON cycle (Figure 5).

Differential Amplifier (MAX5060)

The differential amplifier (DIFF AMP) facilitates outputvoltage remote sensing at the load (Figure 5). It provides true-differential output voltage sensing while

rejecting the common-mode voltage errors due to highcurrent ground paths. Sensing the output voltage

directly at the load provides accurate load voltage

sensing in high-current environments. The VEA provides the difference between the differential amplifier

output (DIFF) and the desired output voltage. The differential amplifier has a bandwidth of 3MHz. The difference between SENSE+ and SENSE- is regulated to

0.6V for the MAX5060. Connect SENSE+ to the center

of the resistive divider from the output to SENSE-.

Connect SENSE- to PGND near the load.

Voltage-Error Amplifier

The VEA sets the gain of the voltage control loop. The

VEA determines the error between the differential

amplifier output and the internal reference voltage.

The VEA output clamps to 930mV relative to the internally generated common-mode voltage (VCM, 0.6V),

thus limiting the maximum output current. The maximum average current-limit threshold is equal to the

maximum clamp voltage of the VEA divided by the gain

(34.5) of the current-sense amplifier. This results in

accurate settings for the average maximum current for

each phase. Set the VEA gain using RFand RIN(see

Figures 1 and 2) for the amount of output voltage positioning required within the rated current range as discussed in the Adaptive Voltage Positioning section. The

finite gain of the VEA introduces an error in the output

voltage setting. Use the following equation to calculate

the output voltage at no load condition.

MAX5060:

where RHand RLare the feedback resistor network

(see the Typical Application Circuits) and V

REF

= 0.6V.

MAX5061:

The error amplifier output (EAOUT), which is compared

against the output of the current amplifier (CA), may not

reduce down to zero due to the saturation voltage of its

output stage. This requires the converter to be loaded

with a minimum load to prevent it from slipping out of

regulation. The minimum load requirement can be eliminated by adding some DC bias voltage between CSP

and CSN. See the Typical Application Circuit (Figure 2).

Use RC1 and RC2 to generate approximately 3mV DC

bias at CSP with respect to CSN. Use the following

equation to calculate the values of RC1 and RC2.

V

OUT NL

RC

1

=

⎛

=+

⎜

⎝

VV RC

()

0 002 0 25

(. ) (. )∆

⎞

⎛

R

R

CC OUT

+××

RR

IN

⎟

⎠

F

−×

HL

×

⎜

R

⎝

IR

L SENSE

+

L

2

⎞

V

×1

REF()

⎟

⎠

Page 20

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

20 ______________________________________________________________________________________

where ∆IL= peak-to-peak inductor current. Choose

RC2 = 10Ω, VCC= 5.1V, and R

SENSE

is a currentsense resistor. Note that the current limit of MAX5061 is

reduced by 3mV / R

SENSE

.

The no-load output voltage depends on the RH, RF,

V

REF

(0.6V) and the fixed DC bias voltage at CSP CSN. The following equation assumes a 3mV bias voltage at CSP - CSN.

Adaptive Voltage Positioning

Powering new-generation processors requires new

techniques to reduce cost, size, and power dissipation.

Voltage positioning reduces the total number of output

capacitors to meet a given transient response requirement. Setting the no-load output voltage slightly higher

than the output voltage during nominally loaded conditions allows a larger downward-voltage excursion when

the output current suddenly increases. Regulating at a

lower output voltage under a heavy load allows a larger

upward-voltage excursion when the output current suddenly decreases. Allowing a larger voltage-step excursion reduces the required number of output capacitors

or allows for the use of higher ESR capacitors.

Voltage positioning may require the output to regulate

away from a center value. Define the center value as

the voltage where the output drops (∆V

OUT

/2) at one

half the maximum output current (Figure 7).

Set the voltage-positioning window (∆V

OUT

) using the

resistive feedback of the voltage-error amplifier (VEA).

Use the following equations to calculate the voltagepositioning window (Figure 5):

MAX5060:

MAX5061:

R

IN

and RFare the input and feedback resistors of

VEA. GCis the current-loop transconductance and R

S

is the current-sense resistor.

MOSFET Gate Drivers (DH_, DL_)

The high-side (DH) and low-side (DL) drivers drive the

gates of external n-channel MOSFETs (Figures 1 and 2).

The drivers’ 4A peak sink- and source-current capability

provides ample drive for the fast rise and fall times of the

switching MOSFETs. Faster rise and fall times result in

reduced cross-conduction losses. For modern CPU voltage-regulating module applications, where the duty

cycle is less than 50%, choose high-side MOSFETs (Q1)

with a moderate R

DS(ON)

and a very low gate charge.

Choose low-side MOSFETs (Q2) with very low R

DS(ON)

and moderate gate charge. Size the high-side and lowside MOSFETs to handle the peak and RMS currents

during overload conditions.

The driver block also includes a logic circuit that provides

an adaptive nonoverlap time to prevent shoot-through

currents during transition. The typical nonoverlap time is

35ns between the high-side and low-side MOSFETs.

BST

The MAX5060 uses VDDto power the low- and high-side

MOSFET drivers. The low- and high-side drivers in the

MAX5061 are powered from VCC. The high-side driver

derives its power through a bootstrap capacitor and V

DD

supplies power internally to the low-side driver. Connect a

0.47µF low-ESR ceramic capacitor between BST and LX.

Connect a Schottky rectifier from BST to VDDon the

MAX5060, or to VCCon the MAX5061. Reduce the PC

board area formed by the boost capacitor and rectifier.

Figure 7. Defining the Voltage-Positioning Window

V

OUT NL

V

[(

V

REFLREF

R

.

01

R

F

RV

)]=+−×+

H REF()

∆V

V

∆V

V

CNTR

OUT

V

CNTR

OUT

CNTR

+

/2

/2

VOLTAGE-POSITIONING WINDOW

∆V

OUT

IR

×

OUT IN

=

GR

×

CF

=

.0 0289

R

G

C

×

S

RR

+

HL

R

L

IxR

=

OUT H

GxR

cF

∆V

OUT

NO LOAD

1/2 LOAD

LOAD (A)

FULL LOAD

Page 21

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

______________________________________________________________________________________ 21

Protection

The MAX5060 includes a power-good generator

(PGOOD) for undervoltage protection (UVP), and a

reverse current-limit protection; the MAX5060/MAX5061

include a hiccup current-limit protection to prevent damage to the powered electronic circuits. Additionally, the

MAX5060 includes output overvoltage protection (OVP).

PGOOD Generator (MAX5060)

A PGOOD comparator compares the differential amplifier output (DIFF) against 0.90 times the set output voltage for undervoltage monitoring (see Figure 8). Use a

10kΩ pullup resistor from PGOOD to a voltage source

less than or equal to V

CC

.

Current Limit

The VEA output is clamped to 930mV with respect to the

common-mode voltage (VCM). Average current-mode

control has the ability to limit the average current sourced

by the converter during a fault condition. When a fault

condition occurs, the VEA output clamps to 930mV with

respect to the common-mode voltage (0.6V) to limit the

maximum current sourced by the converter to I

LIMIT

=

26.9mV/RS.

The hiccup current limit overrides the average current

limit. The MAX5060/MAX5061 include hiccup currentlimit protection to reduce the power dissipation during

a fault condition. The hiccup current-limit circuit derives

inductor current information from the output of the current amplifier. This signal is compared against one half

of V

CLAMP(EA)

. With no resistor connected from the LIM

pin to ground, the hiccup current limit is set at 90% of

the full-load average current limit. Use R

EXT

to increase

the hiccup current limit from 90% to 100% of the fullload average limit (see Figures 1 and 2). The hiccup

current limit can be disabled by connecting LIM to

SGND. In this case, the circuit will follow the average

current-limit action during overload conditions.

An internal clamp (MAX5060) limits the continuous

reverse current the buck converter sinks when a higher

voltage is applied at the output. The reverse current limit

translated at the current-amplifier input is -2.3mV (typ).

The maximum reverse current the converter sinks

depends on the current-sense resistor. Normally it is

about 10% of the full load current.

Overvoltage Protection (OVP) (MAX5060)

The OVP comparator compares the OVI input to the overvoltage threshold. The overvoltage threshold is typically

+12.7% above the internal 0.6V reference voltage. A

detected overvoltage event latches the comparator output

forcing the power stage into the OVP state. In the OVP

state, the high-side MOSFET turns off and the low-side

MOSFET latches on. Connect DIFF to OVI for differential

output sensing and overvoltage protection. Alternately,

use a separate sensing network from V

OUT

to SGND.

Connect OVI to the center tap of a resistor-divider from

V

OUT

to SGND. In this case, the center tap is compared

against 1.276V. Add an RC delay to reduce the sensitivity

of the overvoltage circuit and avoid nuisance tripping of

the converter (Figure 9). Disable the overvoltage function

by connecting OVI to SGND.

Figure 8. PGOOD Generator

Figure 9. Overvoltage Protection Input Delay

DIFF

0.9 x V

V

CM

OVI

DIFF

EAN

EAOUT

REF

MAX5060

R

A

R

F

MAX5060

PGOOD

R

IN

Page 22

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

22 ______________________________________________________________________________________

Parallel Operation

For applications requiring large output current, parallel

two or more MAX5060s (multiphase operation) to

increase the available output current. The paralleled

converters operate at the same switching frequency

but different phases keep the input capacitor ripple

RMS currents to a minimum. The MAX5060 provides

the clock output (CLKOUT), which is 180° out-of-phase

with respect to DH. For the MAX5061, the out-of-phase

clock can be easily generated using a simple inverter

and driving it from the LX node. Use CLKOUT to drive

the second DC-DC converter to double the effective

switching frequency and reduce the input capacitor

ripple current (see Figure 10).

To drive multiple converters out-of-phase, use a delay

circuit to set 90° of phase shift (4 paralleled converters),

or 60° of phase shift (6 converters in parallel). Designate

one converter as master and the remaining converters

as slaves. Connect the master and slave controllers in a

daisy-chain configuration as shown in Figure 11.

Choose the appropriate phase shift for minimum ripple

currents at the input and output capacitors. The master

controller senses the output differential voltage through

SENSE+ and SENSE- and generates the DIFF voltage.

Disable the voltage sensing of the slaved controllers by

leaving DIFF unconnected (floating). Figure 11 shows a

typical application circuit using four MAX5060s. This circuit provides two phases at a 12V input voltage and a

0.6V to 5V output voltage range.

Figure 10. Parallel Configuration of MAX5060

V

IN

SENSE-

IN

DIFF

EAN

EAOUT

MAX5060

SENSE+

CSN

CSP

DH

LX

DL

V

IN

RT/SYNC

PGND SGND CLKOUT

RT/SYNC

MAX5060

IN

DIFF

EAN

EAOUT

PGND SGND

CSN

CSP

DH

V

IN

LX

DL

V

OUT

LOAD

Page 23

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

______________________________________________________________________________________ 23

Figure 11. Parallel Configuration of Multiple MAX5060s

SENSE-

V

IN

IN

DIFF

EAN

EAOUT

PGND SGND CLKOUT

MAX5060

SENSE+

CSN

CSP

RT/SYNC

V

IN

DH

LX

DL

RT/SYNC

MAX5060

IN

DIFF

EAN

EAOUT

PGND SGND CLKOUT

CSN

CSP

90° PHASE DELAY

CIRCUIT

V

IN

DH

LX

DL

RT/SYNC

MAX5060

IN

DIFF

EAN

EAOUT

PGND SGND

CSN

CSP

V

OUT

V

IN

DH

LX

DL

90° PHASE DELAY

CIRCUIT

RT/SYNC

MAX5060

IN

DIFF

EAN

EAOUT

PGND SGND

CSN

CSP

LOAD

V

IN

DH

LX

DL

Page 24

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

24 ______________________________________________________________________________________

Applications Information

Inductor Selection

The switching frequency, peak inductor current, and

allowable ripple at the output determine the value and

size of the inductor. Selecting higher switching frequencies reduces the inductance requirement, but at the

cost of lower efficiency. The charge/discharge cycle of

the gate and drain capacitances in the switching

MOSFETs create switching losses. The situation worsens at higher input voltages, since switching losses are

proportional to the square of the input voltage. The

MAX5060 can operate up to 1.5MHz, however for VIN>

+12V, use lower switching frequencies to limit the

switching losses.

Use the following equation to determine the minimum

inductance value:

Choose ∆ILequal to approximately 40% of the output

current. Since ∆ILaffects the output-ripple voltage, the

inductance value may need minor adjustment after

choosing the output capacitors. Higher values reduce

the output ripple, but at the cost of degraded transient

response. Lower values have higher output ripple but

better transient response. Also, lower inductor values

correspond to smaller magnetics.

Choose inductors from the standard high-current, surfacemount inductor series available from various manufacturers. Particular applications may require custommade inductors. Use high-frequency core material for

custom inductors. High ∆ILcauses large peak-to-peak

flux excursion, which increases the core losses at higher

frequencies. The high-frequency operation coupled with

high ∆ILreduces the required minimum inductance and

even makes the use of planar inductors possible. The

advantages of using planar magnetics include low-profile

design, excellent current-sharing between modules due

to the tight control of parasitics, and low cost.

For example, calculate the minimum inductance at

V

IN(MAX)

= 13.2V, V

OUT

= 1.8V, ∆IL= 8A, and fSW=

330kHz:

The average-current-mode control feature of the

MAX5060/MAX5061 limits the maximum peak inductor

current and prevents the inductor from saturating. Choose

an inductor with a saturating current greater than the

worst-case peak inductor current. The hiccup current-limit

circuit is masked during startup to avoid unintentional

hiccup when large output capacitors are used.

Use the following equation to determine the worst-case

inductor current:

where R

S

is the sense resistor and VCL= 0.0282V.

Switching MOSFETs

When choosing a MOSFET for voltage regulators, consider the total gate charge, R

DS(ON)

, power dissipation,

and package thermal impedance. The product of the

MOSFET gate charge and on-resistance is a figure of

merit, with a lower number signifying better performance. Choose MOSFETs optimized for high-frequency switching applications.

The average current from the MAX5060/MAX5061 gatedrive output is proportional to the total capacitance it

drives at DH and DL. The power dissipated in the

MAX5060/MAX5061 is proportional to the input voltage

and the average drive current. See the IN, VCC, and

VDDsection to determine the maximum total gate

charge allowed from the combined driver outputs.

The gate charge and drain capacitance (CV2)loss, the

cross-conduction loss in the upper MOSFET due to finite

rise/fall time, and the I2R loss due to RMS current in the

MOSFET R

DS(ON)

account for the total losses in the

MOSFET. Estimate the power loss (PD

MOS_

) caused by

the high-side and low-side MOSFETs using the following

equations:

where QG, R

DS(ON)

, tR, and tFare the upper-switching

MOSFET’s total gate charge, on-resistance at +25°C,

rise time, and fall time, respectively.

VVV

L

L

MIN

()

=

MIN

VfI

13 2 1 8 1 8

()

=

.

13 2 330 8

−

INMAX OUT OUT

∆

INMAX SW L

.. .

−

××

×

××

×

k

=

.

06µ

H

L

LPEAK

=+

V

R

CL

I

∆

L

2

S

⎛

VI ttf

IN OUT R F SW

⎜

⎝

PD Q V f

××+

=××

MOS HI G DD SW

()

4

()

−

⎞

×

⎟

⎠

+

RI

.

14

+×

()

()

DS ON

2

RMS HI

−

Page 25

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

______________________________________________________________________________________ 25

where D = V

OUT/VIN

, IDC= (I

OUT

- ∆IL/2) and IPK=

(I

OUT

+ ∆IL/2).

where C

OSS

is the MOSFET drain-to-source capaci-

tance.

For example, from the typical specifications in the

Applications Information section with V

OUT

= 1.8V, the

high-side and low-side MOSFET RMS currents are 7.8A

and 18.5A, respectively for 20A. Ensure that the thermal impedance of the MOSFET package keeps the

junction temperature at least +25°C below the absolute

maximum rating. Use the following equation to calculate maximum junction temperature:

TJ= (PD

MOS

x θJA) + T

A

where θJAand TAare the junction-to-ambient thermal

impedance and ambient temperature, respectively.

Input Capacitors

The discontinuous input-current waveform of the buck

converter causes large ripple currents in the input capacitor. The switching frequency, peak inductor current, and

the allowable peak-to-peak voltage ripple reflected back

to the source dictate the capacitance requirement.

Increasing switching frequency or paralleling multiple outof-phase converters lowers the peak-to-average current

ratio, yielding a lower input capacitance requirement for

the same load current.

The input ripple is comprised of ∆VQ(caused by the

capacitor discharge) and ∆V

ESR

(caused by the ESR of

the capacitor). Use low-ESR ceramic capacitors with

high-ripple-current capability at the input. Assume the

contributions from the ESR and capacitor discharge are

equal to 30% and 70%, respectively. Calculate the input

capacitance and ESR required for a specified ripple

using the following equation:

where I

OUT

is the output current of the converter.

For example, at V

OUT

= 1.8V, the ESR and input capacitance are calculated for the input peak-to-peak ripple

of 100mV or less yielding an ESR and capacitance

value of 1.25mΩ and 110µF.

Output Capacitors

The worst-case peak-to-peak and capacitor RMS ripple

current, the allowable peak-to-peak output ripple voltage, and the maximum deviation of the output voltage

during step loads determine the capacitance and the

ESR requirements for the output capacitors.

In buck converter design, the output-current waveform

is continuous and this reduces peak-to-peak ripple current in the output capacitor equal to the inductor ripple

current. Calculate the capacitance, the ESR of the output capacitor, and the RMS ripple current rating of the

output capacitor based on the following equations.

where ∆V

OESR

and ∆VOQare the output-ripple contri-

butions due to ESR and the discharge of output capacitor, respectively.

In the dynamic load environment, the allowable deviation of output voltage during the fast transient load dictates the output capacitance and ESR. The output

capacitors supply the load step until the controller

responds with a greater duty cycle. The response time

(t

RESPONSE

) depends on the closed-loop bandwidth of

the converter. The resistive drop across the capacitor

ESR and capacitor discharge causes a voltage drop

during a step load. Use a combination of SP polymer

and ceramic capacitors for better transient load and

ripple/noise performance.

I I DC I PK I I

RMS HI DC PK−

⎛

×××

2

⎜

⎝

IIDCIPKII

PD Q V f

MOS LO G DD SW

CVf

OSS IN SW

3

−

RMS LO DC PK

22

=++×

()

=××

()

−

2

=++×

()

⎞

+×

⎟

⎠

22

RI

.

14

()

()

DS ON

×

+

2

1

()

×

D

3

−

RMS LO

D

−

3

∆

V

()

ESR

=

IN

IDD

OUT

=

C

IN

ESR

⎛

I

⎜

⎝

∆

Vf

∆

+

OUT

×

1

()

×

QSW

I

⎞

L

⎟

⎠

2

−

∆

V

ESR

OUT

C

OUT

OESR

=

∆

I

L

∆

I

=

××

L

∆8

Vf

OQ SW

Page 26

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

26 ______________________________________________________________________________________

Keep the maximum output voltage deviation less than

or equal to the adaptive voltage-positioning window

(∆V

OUT

). Assume 50% contribution each from the output capacitance discharge and the ESR drop. Use the

following equations to calculate the required ESR and

capacitance value:

where I

STEP

is the load step and t

RESPONSE

is the

response time of the controller. Controller response

time depends on the control-loop bandwidth.

Current Limit

In addition to the average current limit, the

MAX5060/MAX5061 also have hiccup current limit. The

hiccup current limit is set to 10% below the average

current limit to ensure that the circuit goes in hiccup

mode during continuous output short circuit.

Connecting a resistor from LIM to ground increases the

hiccup current limit, while shorting LIM to ground disables the hiccup current-limit circuit.

Average Current Limit

The average-current-mode control technique of the

MAX5060/MAX5061 accurately limits the maximum output current. The MAX5060/MAX5061 sense the voltage

across the sense resistor and limit the peak inductor

current (I

L-PK

) accordingly. The ON cycle terminates

when the current-sense voltage reaches 25.5mV (min).

Use the following equation to calculate the maximum

current-sense resistor value:

where PDRis the power dissipation in the sense resistors. Select a 5% lower value of RSto compensate for

any parasitics associated with the PC board. Also,

select a non-inductive resistor with the appropriate

power rating.

Hiccup Current Limit

The hiccup current-limit value is always 10% lower than

the average current-limit threshold, when LIM is left

unconnected. Connect a resistor from LIM to SGND to

increase the hiccup current-limit value from 90% to

100% of the average current-limit value. The average

current-limit architecture accurately limits the average

output current to its current-limit threshold. If the hiccup

current limit is programmed to be equal or above the

average current-limit value, the output current will not

reach the point where the hiccup current limit can trigger. Program the hiccup current limit at least 5% below

the average current limit to ensure that the hiccup current-limit circuit triggers during overload. See the

Hiccup Current Limit vs. R

EXT

graph in the Typical

Operating Characteristics.

Reverse Current Limit (MAX5060)

The MAX5060 limits the reverse current in case V

BUS

is

higher than the preset output voltage. Calculate the

maximum reverse current based on V

CLR

, the reverse-

current-limit threshold and the current-sense resistor.

where I

REVERSE

is the total reverse current sink into the

converter and V

CLR

= 2.3mV (typ).

Compensation

The main control loop consists of an inner current loop

and an outer voltage loop. The MAX5060/MAX5061 use

an average current-mode control scheme to regulate

the output voltage (Figure 5). I

PHASE

is the inner average current loop. The VEA output provides the controlling voltage for this current source. The inner current

loop absorbs the inductor pole reducing the order of

the outer voltage loop to that of a single-pole system.

A resistive feedback network around the VEA provides

the best possible response, since there are no capacitors to charge and discharge during large-signal excursions. RFand RINdetermine the VEA gain. Use the

following equation to calculate the value of RF:

where GCis the current-loop transconductance and R

S

is the value of the sense resistor.

When designing the current-control loop ensure that

the inductor downslope (when it becomes an upslope

at the CEA output) does not exceed the ramp slope.

This is a necessary condition to avoid sub-harmonic

oscillations similar to those in peak current-mode control with insufficient slope compensation.

V

∆

ESR

=

I

STEP

×

It

STEP RESPONSE

∆

V

Q

ESR

OUT

=

C

OUT

0 0255

=

S

R

.

I

OUT

075 10

.

=

R

−

3

×

S

R

PD

V

=

CLR

R

S

I

REVERSE

IR

×

R

G

OUT IN

=

F

GV

×

C OUT

.∆0 0289

=

C

R

S

Page 27

MAX5060/MAX5061

0.6V to 5.5V Output, Parallelable,

Average-Current-Mode DC-DC Controllers

______________________________________________________________________________________ 27

Use the following equation to calculate the resistor RCF:

CCFprovides a low-frequency pole while RCFprovides

a midband zero. Place a zero (fZ) to obtain a phase

bump at the crossover frequency. Place a high-frequency pole (f

P

) at least a decade away from the

crossover frequency to reduce the influence of the

switching noise and achieve maximum phase margin.

Use the following equations to calculate CCFand C

CFF

:

Power Dissipation

The TQFN-28 and TSSOP-16 are thermally enhanced

packages and can dissipate about 2.7W and 1.7W,

respectively. The high-power packages make the highfrequency, high-current buck converter possible to