Page 1

现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

General Description

The MAX5035 easy-to-use, high-efficiency, high-voltage, step-down DC-DC converter operates from an

input voltage up to 76V and consumes only 350µA quiescent current at no load. This pulse-width modulated

(PWM) converter operates at a fixed 125kHz switching

frequency at heavy loads, and automatically switches

to pulse-skipping mode to provide low quiescent current and high efficiency at light loads. The MAX5035

includes internal frequency compensation simplifying

circuit implementation. The device uses an internal lowon-resistance, high-voltage, DMOS transistor to obtain

high efficiency and reduce overall system cost. This

device includes undervoltage lockout, cycle-by-cycle

current limit, hiccup mode output short-circuit protection, and thermal shutdown.

The MAX5035 delivers up to 1A output current. External

shutdown is included, featuring 10µA (typ) shutdown

current. The MAX5035A/B/C versions have fixed output

voltages of 3.3V, 5V, and 12V, respectively, while the

MAX5035D features an adjustable output voltage from

1.25V to 13.2V.

The MAX5035 is available in space-saving 8-pin SO

and 8-pin plastic DIP packages and operates over the

industrial (0°C to +85°C) temperature range.

Applications

Consumer Electronics

Industrial

Distributed Power

Features

♦ Wide 7.5V to 76V Input Voltage Range

♦ Fixed (3.3V, 5V, 12V) and Adjustable

(1.25V to 13.2V) Versions

♦ 1A Output Current

♦ Efficiency Up to 94%

♦ Internal 0.4Ω High-Side DMOS FET

♦ 350µA Quiescent Current at No Load, 10µA

Shutdown Current

♦ Internal Frequency Compensation

♦ Fixed 125kHz Switching Frequency

♦ Thermal Shutdown and Short-Circuit Current

Limit

♦ 8-Pin SO and PDIP Packages

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-2988; Rev 0; 9/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

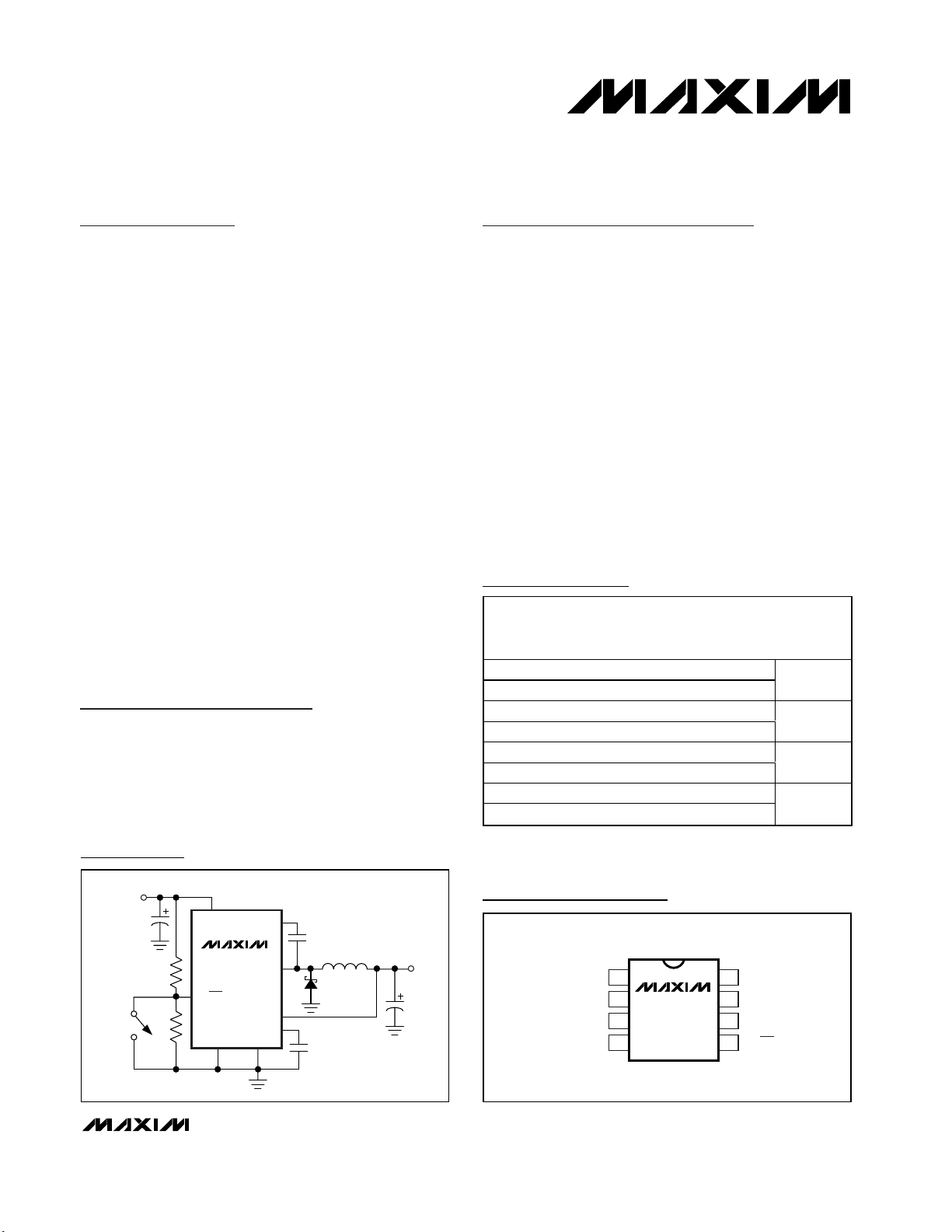

Pin Configuration

MAX5035

GND

BST

LX

V

IN

SGND

FB

D1

50SQ100

VD

100µH

V

OUT

5V

V

IN

7.5V TO 76V

68µF

0.1µF

0.1µF

68µF

ON

OFF

R1

R2

ON/OFF

Typical Operating Circuit

PART TEMP RANGE

MAX5035AUSA 0°C to +85°C 8 SO

MAX5035AUPA 0°C to +85°C 8 PDIP

MAX5035BUSA 0°C to +85°C 8 SO

MAX5035BUPA 0°C to +85°C 8 PDIP

MAX5035CUSA 0°C to +85°C 8 SO

MAX5035CUPA 0°C to +85°C 8 PDIP

MAX5035DUSA 0°C to +85°C 8 SO

MAX5035DUPA 0°C to +85°C 8 PDIP

PINPACKAGE

OUTPUT

VOLTAGE

(V)

3.3

5.0

12

ADJ

TOP VIEW

1

BST

VD

2

SGND

FB

MAX5035

3

4

SO/PDIP

8

7

6

5

LX

V

IN

GND

ON/OFF

Page 2

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

(Voltages referenced to GND, unless otherwise specified.)

V

IN

.........................................................................-0.3V to +80V

SGND ....................................................................-0.3V to +0.3V

LX.................................................................-0.8V to (V

IN

+ 0.3V)

BST ...............................................................-0.3V to (V

IN

+ 10V)

BST (transient < 100ns)................................-0.3V to (V

IN

+ 15V)

BST to LX................................................................-0.3V to +10V

BST to LX (transient < 100ns) ................................-0.3V to +15V

ON/OFF........................................................-0.3V to (V

IN

+ 0.3V)

VD...........................................................................-0.3V to +12V

FB

MAX5035A/MAX5035B/MAX5035C ...................-0.3V to +15V

MAX5035D .........................................................-0.3V to +12V

V

OUT

Short-Circuit Duration...........................................Indefinite

VD Short-Circuit Duration ..............................................Indefinite

Continuous Power Dissipation (T

A

= +70°C)

8-Pin PDIP (derate 9.1mW/°C above +70°C)...............727mW

8-Pin SO (derate 5.9mW/°C above +70°C)..................471mW

Operating Temperature Range

MAX5035_U_ _ ...................................................0°C to +85°C

Storage Temperature Range .............................-65°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10s) .................................+300°C

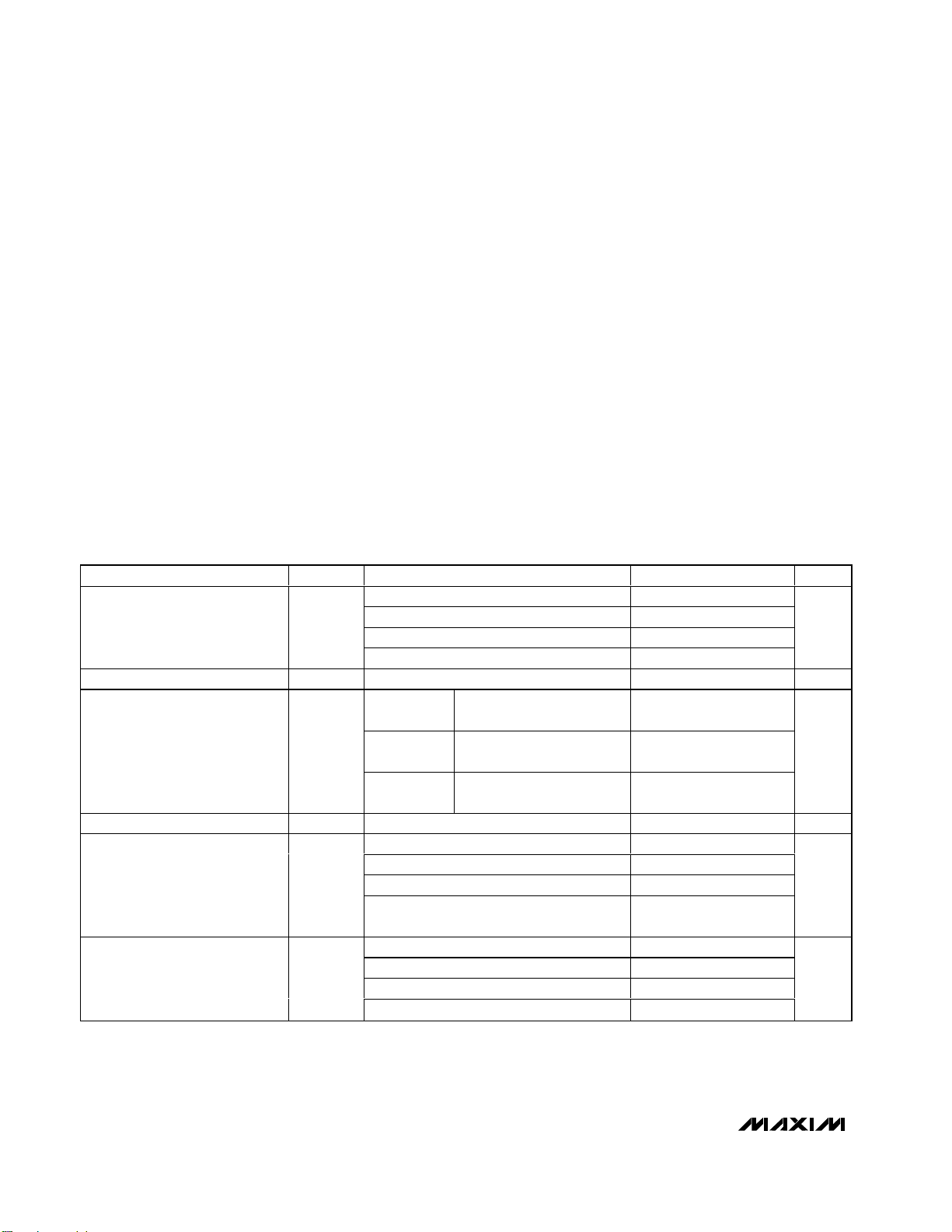

ELECTRICAL CHARACTERISTICS

(VIN= +12V, V

ON/OFF

= +12V, I

OUT

= 0, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C. See the

Typical Application Circuit.)

Input Voltage Range V

Undervoltage Lockout UVLO 5.2 V

Output Voltage V

Feedback Voltage V

Quiescent Supply Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

MAX5035A 7.5 76.0

MAX5035B 7.5 76.0

IN

MAX5035C 15 76

MAX5035D 7.5 76.0

V

IN

I

OUT

V

IN

I

OUT

V

IN

I

OUT

= 0.5A, MAX5035A 86

LOAD

= 0.5A, MAX5035B 90

LOAD

= 0.5A, MAX5035C 94Efficiency η

LOAD

= 5V, I

OUT

OUT

FB

Q

MAX5035A

MAX5035B

MAX5035C

VIN = 7.5V to 76V, MAX5035D 1.192 1.221 1.250 V

VIN = 12V, I

VIN = 12V, I

VIN = 24V, I

V

= 12V, V

IN

MAX5035D

VFB = 3.5V, VIN = 7.5V to 76V, MAX5035A 350 460

VFB = 5.5V, VIN = 7.5V to 76V, MAX5035B 350 460

VFB = 13V, VIN = 15V to 76V, MAX5035C 350 460

VFB = 1.3V, MAX5035D 350 460

= 7.5V to 76V,

= 20mA to 1A

= 7.5V to 76V,

= 20mA to 1A

= 15V to 76V,

= 20mA to 1A

= 0.5A,

LOAD

3.185 3.3 3.415

4.85 5.0 5.15

11.64 12 12.36

90

V

V

%

µA

Page 3

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

_______________________________________________________________________________________ 3

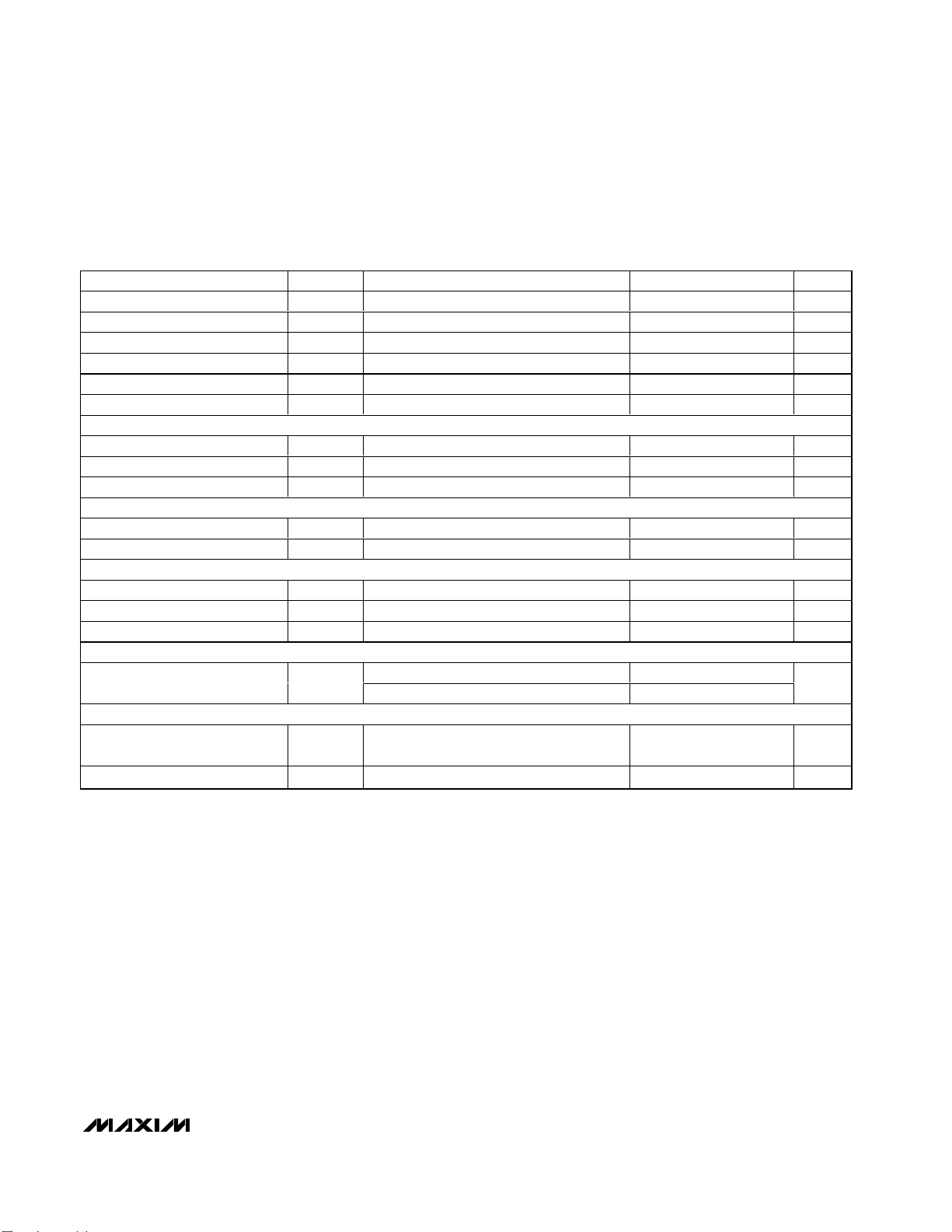

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +12V, V

ON/OFF

= +12V, I

OUT

= 0, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C. See the

Typical Application Circuit.)

)

Note 1: Switch current at which current limit is activated.

Shutdown Current I

Peak Switch Current Limit I

Switch Leakage Current I

Switch On-Resistance R

PFM Threshold I

FB Input Bias Current I

ON/OFF CONTROL INPUT

ON/OFF Input-Voltage Threshold V

ON/OFF Input-Voltage Hysteresis V

ON/OFF Input Current I

OSCILLATOR

Oscillator Frequency f

Maximum Duty Cycle D

VOLTAGE REGULATOR

Regulator Output Voltage VD VIN = 8.5V to 76V, IL = 0mA 6.9 7.8 8.8 V

Dropout Voltage 7.5V ≤ VIN ≤ 8.5V, IL = 1mA 2.0 V

Load Regulation ∆VD/∆IVD0 to 5mA 150 mV/mA

PACKAGE THERMAL CHARACTERISTICS

Thermal Resistance

(Junction to Ambient)

THERMAL SHUTDOWN

Thermal-Shutdown Junction

Temperature

Thermal-Shutdown Hysteresis T

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SHDN

LIM

OL

DS(ON

PFM

ON/OFF

HYST

ON/OFFVON/OFF

OSC

MAX

θ

JA

T

SH

HYST

V

(Note 1) 1.80 2.40 A

VIN = 76V, V

I

Minimum switch current in any cycle 55 85 110 mA

MAX5035D -12 +0.01 +12 nA

B

Rising trip point 1.53 1.69 1.85 V

MAX5035D 95 %

SO package (JEDEC 51) 170

DIP package (JEDEC 51) 110

= 0V, VIN = 7.5V to 76V 10 45 µA

ON/OFF

= 0V, VLX = 0V 1 µA

ON/OFF

= 1A 0.40 0.80 Ω

SWITCH

100 mV

= 0V to V

IN

109 125 135 kHz

10 150 nA

+160 °C

20 °C

°C/W

Page 4

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

4 _______________________________________________________________________________________

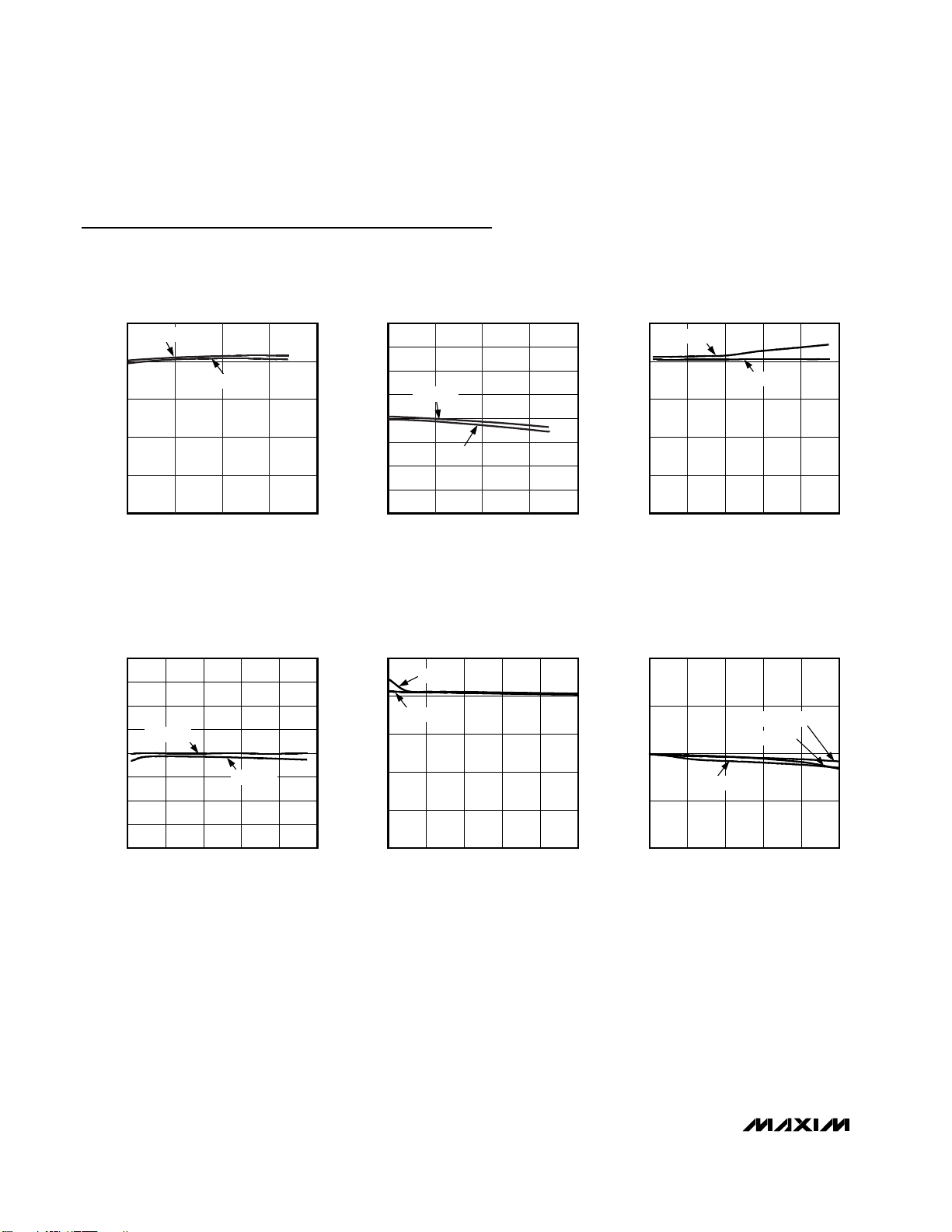

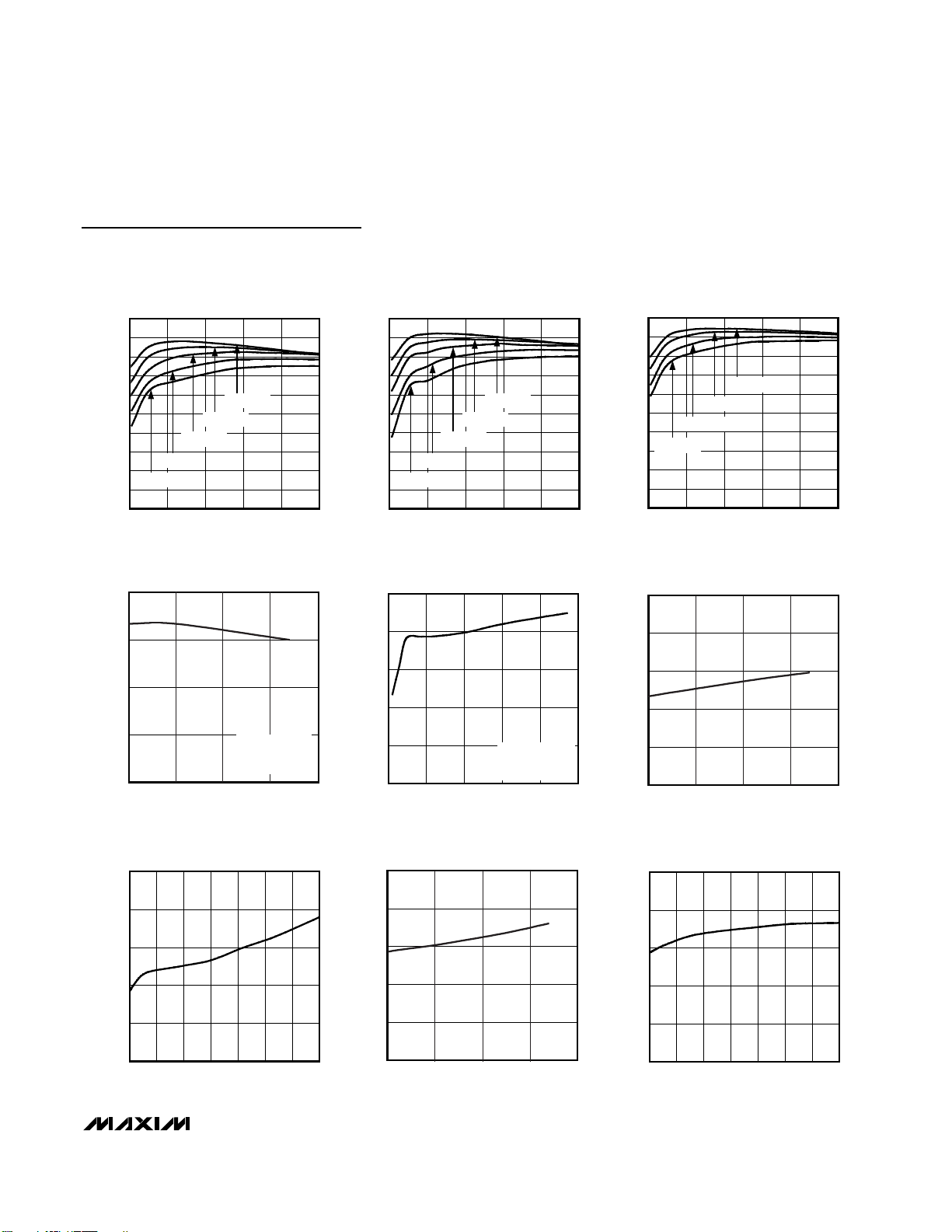

Typical Operating Characteristics

(VIN= 12V, V

ON/OFF

= 12V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C. See the Typical Application

Circuit, if applicable.)

OUTPUT VOLTAGE vs. TEMPERATURE

(MAX5035AUSA, V

3.40

I

= 0.1A

OUT

3.36

3.32

(V)

OUT

V

3.28

3.24

3.20

0 100

OUTPUT VOLTAGE vs. TEMPERATURE

OUT

I

= 1A

OUT

5025

TEMPERATURE (°C)

= 3.3V)

75

MAX5035 toc01

5.20

(MAX5035DUSA, V

5.15

5.10

I

= 0.1A

OUT

I

= 1A

OUT

0 100

25 50

TEMPERATURE (°C)

(V)

V

OUT

5.05

5.00

4.95

4.90

4.85

4.80

OUT

= 5V)

MAX5035 toc02

75

LINE REGULATION

I

OUT

OUT

= 1A

= 3.3V)

MAX5035 toc03

65503520

3.40

(MAX5035AUSA, V

I

= 0.1A

OUT

3.36

3.32

3.28

OUTPUT VOLTAGE (V)

3.24

3.20

580

INPUT VOLTAGE (V)

LINE REGULATION

5.20

(MAX5035DUSA, V

5.15

5.10

5.05

I

= 0.1A

OUT

5.00

4.95

OUTPUT VOLTAGE (V)

4.90

4.85

4.80

580

INPUT VOLTAGE (V)

= 5V)

OUT

MAX5035 toc04

(V)

OUT

I

= 1A

OUT

655020 35

V

(MAX5035AUSA, V

3.40

VIN = 76V

3.36

VIN = 7.5V, 24V

3.32

3.28

3.24

3.20

0 1000

LOAD REGULATION

OUT

I

(mA)

LOAD

= 3.3V)

800600400200

MAX5035 toc05

LOAD REGULATION

5.10

(MAX5035DUSA, V

5.05

(V)

5.00

OUT

V

VIN = 76V

4.95

4.90

0 1000

I

LOAD

OUT

VIN = 24V

VIN = 7.5V

(mA)

= 5V)

MAX5035 toc06

800600400200

Page 5

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

_______________________________________________________________________________________ 5

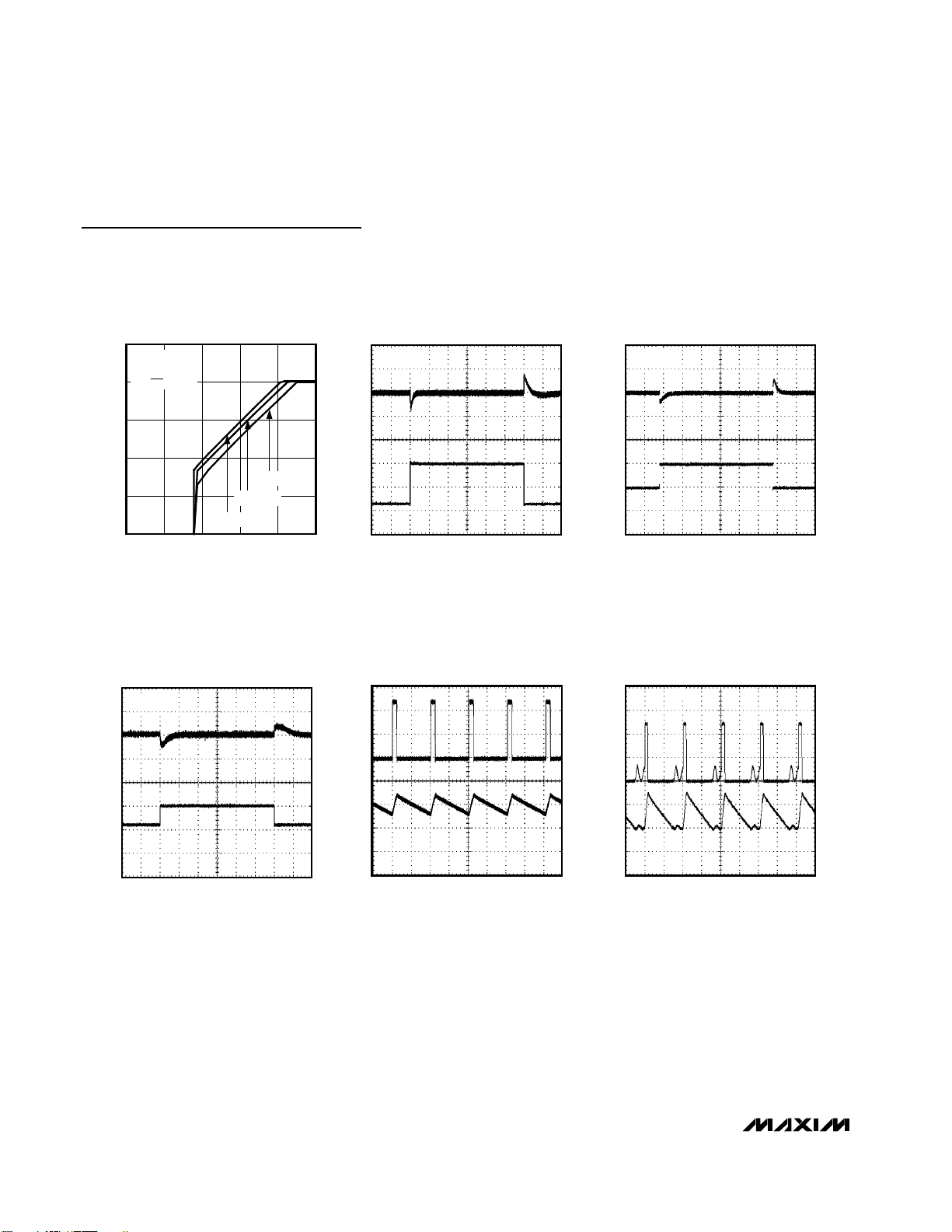

Typical Operating Characteristics (continued)

(VIN= 12V, V

ON/OFF

= 12V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C. See the Typical Application

Circuit, if applicable.)

EFFICIENCY vs. LOAD CURRENT

(MAX5035AUSA, V

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

VIN = 48V

VIN = 76V

0

0 1000

VIN = 12V

VIN = 24V

LOAD CURRENT (mA)

OUTPUT CURRENT LIMIT

vs. TEMPERATURE

2.0

1.5

1.0

0.5

OUTPUT CURRENT LIMIT (A)

0

0 100

5025

TEMPERATURE (°C)

= 3.3V)

OUT

VIN = 7.5V

MAX5035DUSA

= 5V

V

OUT

5% DROP IN V

EFFICIENCY vs. LOAD CURRENT

100

(MAX5035DUSA, V

90

MAX5035 toc07

80

70

60

50

40

EFFICIENCY (%)

30

20

10

800600400200

VIN = 48V

VIN = 76V

0

0 1000

VIN = 12V

VIN = 24V

LOAD CURRENT (mA)

OUT

VIN = 7.5V

= 5V)

MAX5035 toc08

EFFICIENCY (%)

800600400200

OUTPUT CURRENT LIMIT

vs. INPUT VOLTAGE

2.0

MAX5035 toc10

1.7

1.4

1.1

OUTPUT CURRENT LIMIT (A)

0.8

OUT

75

0.5

580

INPUT VOLTAGE (V)

MAX5035DUSA

V

5% DROP IN VOUT

65503520

OUT

= 5V

MAX5035 toc11

QUIESCENT SUPPLY CURRENT (µA)

EFFICIENCY vs. LOAD CURRENT

(MAX5035DUSA, V

100

90

80

70

60

50

40

VIN = 76V

30

20

10

0

0 1000

VIN = 15V

VIN = 24V

VIN = 48V

LOAD CURRENT (mA)

OUT

= 12V)

QUIESCENT SUPPLY CURRENT

vs. TEMPERATURE

350

320

290

260

230

200

0 100

25

TEMPERATURE (°C)

7550

MAX5035 toc09

800600400200

MAX5035 toc12

QUIESCENT SUPPLY CURRENT

SHUTDOWN CURRENT

vs. INPUT VOLTAGE

MAX5035 toc13

20

16

12

8

SHUTDOWN CURRENT (µA)

4

0

0 100

350

320

290

260

230

QUIESCENT SUPPLY CURRENT (µA)

200

676

INPUT VOLTAGE (V)

665646362616

vs. TEMPERATURE

TEMPERATURE (°C)

SHUTDOWN CURRENT vs. INPUT VOLTAGE

20

MAX5035 toc14

16

12

8

SHUTDOWN CURRENT (µA)

4

755025

0

676

INPUT VOLTAGE (V)

MAX5035 toc15

665646362616

Page 6

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

6 _______________________________________________________________________________________

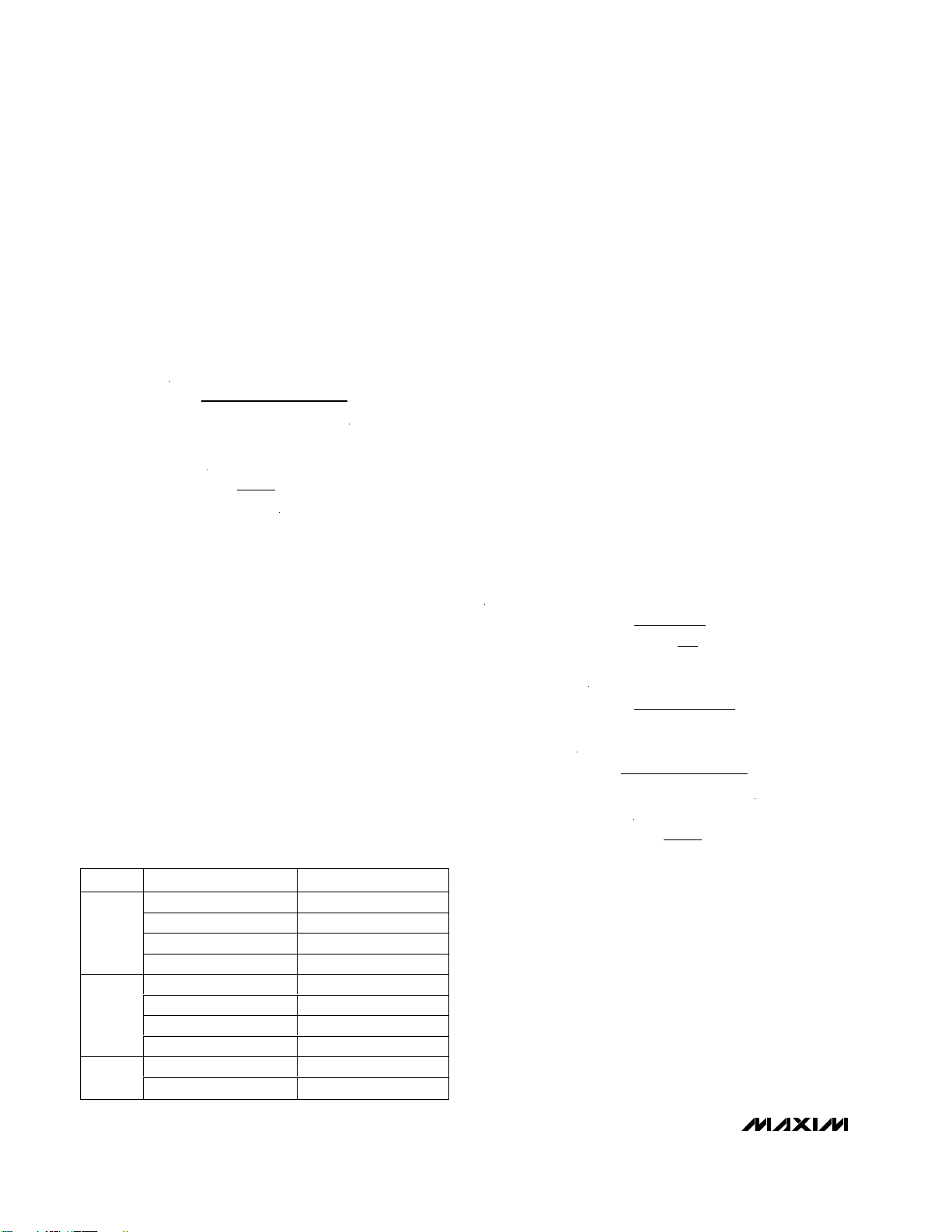

Typical Operating Characteristics (continued)

(VIN= 12V, V

ON/OFF

= 12V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C. See the Typical Application

Circuit, if applicable.)

MAX5035DUSA

LOAD-TRANSIENT RESPONSE

MAX5035 toc19

400µs/div

B

A

A: V

OUT

, 200mV/div, AC-COUPLED

B: V

OUT

, 500mA/div, 0.1A TO 0.5A

V

OUT

= 5V

MAX5035DUSA LX WAVEFORMS

MAX5035 toc20

4µs/div

B

0

A

0

A: SWITCH VOLTAGE (LX PIN), 20V/div, (VIN = 48V)

B: INDUCTOR CURRENT, 500mA/div (I

OUT

= 1A)

MAX5035DUSA LX WAVEFORMS

MAX5035 toc21

4µs/div

B

0

A

0

A: SWITCH VOLTAGE (LX PIN), 20V/div, (VIN = 48V)

B: INDUCTOR CURRENT, 200mA/div (I

OUT

= 100mA)

OUTPUT VOLTAGE

vs. INPUT VOLTAGE

15

MAX5035DUSA

= 12V

V

OUT

= V

V

12

ON/OFF

IN

9

(V)

OUT

V

6

3

0

015

I

OUT

VIN (V)

= 0

MAX5035DUSA

LOAD-TRANSIENT RESPONSE

V

= 5V

OUT

MAX5035 toc16

I

= 1A

OUT

I

= 0.3A

OUT

12963

, 200mV/div, AC-COUPLED

A: V

OUT

, 500mA/div, 0.1A TO 1A

B: I

OUT

400µs/div

MAX5035 toc17

V

A

B

A: V

B: V

MAX5035DUSA

LOAD-TRANSIENT RESPONSE

= 5V

OUT

400µs/div

, 200mV/div, AC-COUPLED

OUT

, 500mA/div, 0.5A TO 1A

OUT

MAX5035 toc18

A

B

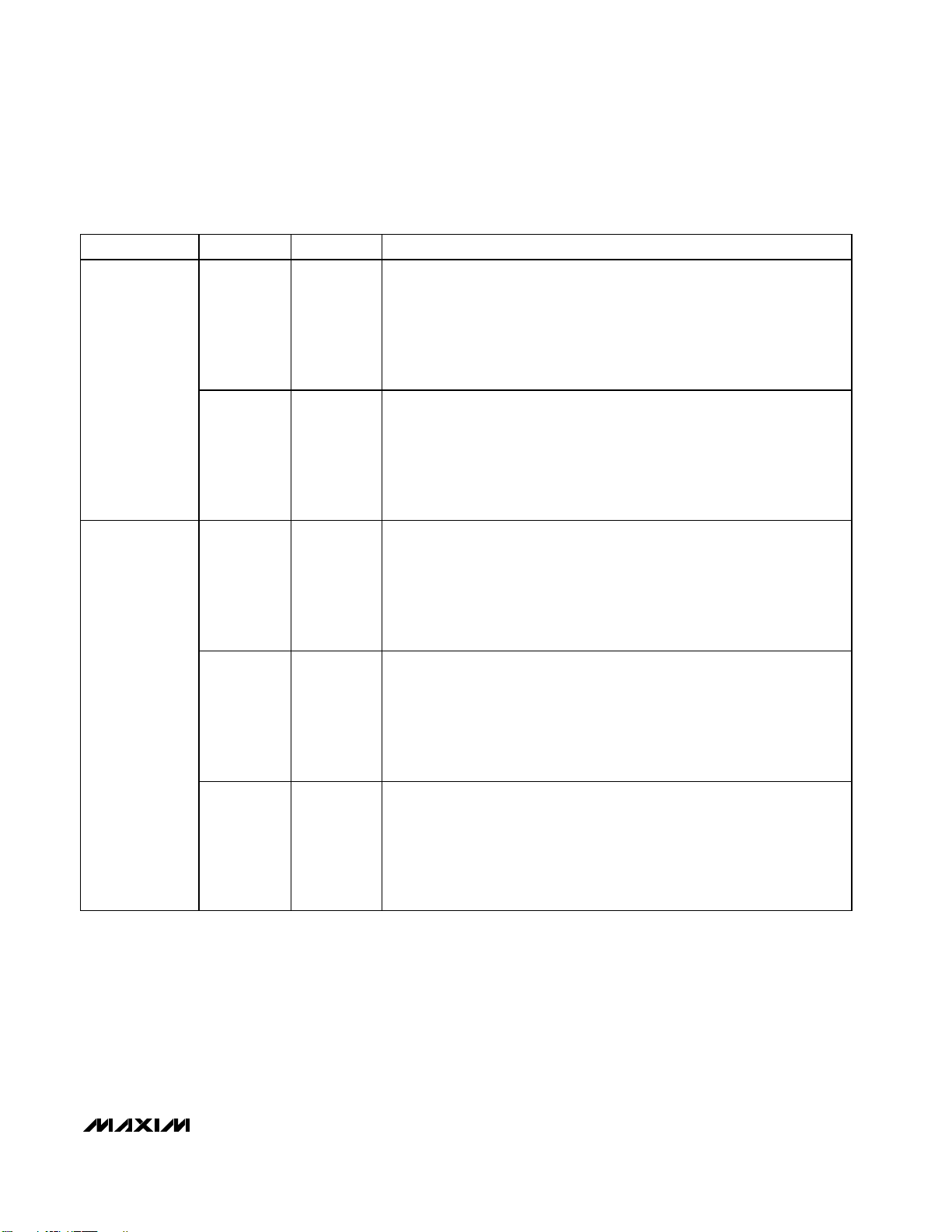

Page 7

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

_______________________________________________________________________________________ 7

Typical Operating Characteristics (continued)

(VIN= 12V, V

ON/OFF

= 12V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C. See the Typical Application

Circuit, if applicable.)

A: SWITCH VOLTAGE (LX PIN), 20V/div, VIN = 48V

B: INDUCTOR CURRENT, 200mA/div (I

MAX5035DUSA LX WAVEFORMS

4µs/div

MAX5035 toc22

= 0)

OUT

MAX5035DUSA STARTUP WAVEFORM

= 1A)

(I

O

MAX5035 toc24

MAX5035DUSA STARTUP WAVEFORM

A

0

B

0

0

0

A: V

, 2V/div

ON/OFF

, 2V/div

B: V

OUT

PEAK SWITCH CURRENT

3.0

A

2.5

= 0)

(I

O

1ms/div

vs. INPUT VOLTAGE

MAX5035 toc23

A

B

MAX5035 toc25

2.0

0

0

1ms/div

A: V

, 2V/div

ON/OFF

, 2V/div

B: V

OUT

B

1.5

PEAK SWITCH CURRENT (A)

1.0

0.5

676

INPUT VOLTAGE (V)

MAX5035DUSA

= 5V

V

OUT

5% DROP IN V

56 6646362616

OUT

Page 8

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

8 _______________________________________________________________________________________

Pin Description

Block Diagram

PIN NAME FUNCTION

1 BST Boost Capacitor Connection. Connect a 0.1µF ceramic capacitor from BST to LX.

2 VD Internal Regulator Output. Bypass VD to GND with a 0.1µF ceramic capacitor.

3 SGND Internal Connection. SGND must be connected to GND.

4FB

5 ON/OFF

6 GND Ground

7VINInput Voltage. Bypass VIN to GND with a low ESR capacitor as close to the device as possible.

8 LX Source Connection of Internal High-Side Switch

ON/OFF

1.69V

VD

Output Sense Feedback Connection. For fixed output voltage (MAX5035A, MAX5035B, MAX5035C),

connect FB to V

set V

. VFB regulating set point is 1.22V.

OUT

. For adjustable output voltage (MAX5035D), use an external resistive voltage-divider to

OUT

Shutdown Control Input. Pull ON/OFF low to put the device in shutdown mode. Drive ON/OFF high for

normal operation.

ENABLE

REGULATOR

(FOR DRIVER)

REGULATOR

(FOR ANALOG)

V

REF

OSC

RAMP

CPFM

CILIM

I

REF-PFM

I

REF-LIM

HIGH-SIDE

CURRENT

SENSE

V

IN

MAX5035

CLK

CONTROL

LOGIC

THERMAL

SHUTDOWN

SGND

GND

FB

R

h

x1

R

l

TYPE 3

COMPENSATION

V

REF

EAMP

RAMP

CPWM

BST

LX

Page 9

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

_______________________________________________________________________________________ 9

Detailed Description

The MAX5035 step-down DC-DC converter operates

from a 7.5V to 76V input voltage range. A unique voltage-mode control scheme with voltage feedforward

and an internal switching DMOS FET provides high efficiency over a wide input voltage range. This pulsewidth modulated converter operates at a fixed 125kHz

switching frequency. The device also features automatic pulse-skipping mode to provide low quiescent current and high efficiency at light loads. Under no load,

the MAX5035 consumes only 350µA, and in shutdown

mode, consumes only 10µA. The MAX5035 also features undervoltage lockout, hiccup mode output shortcircuit protection, and thermal shutdown.

Shutdown Mode

Drive ON/OFF to ground to shut down the MAX5035.

Shutdown forces the internal power MOSFET off, turns

off all internal circuitry, and reduces the VINsupply current to 10µA (typ). The ON/OFF rising threshold is

1.69V (typ). Before any operation begins, the voltage at

ON/OFF must exceed 1.69V (typ). The ON/OFF input

has 100mV hysteresis.

Undervoltage Lockout (UVLO)

Use the ON/OFF function to program the UVLO threshold at the input. Connect a resistive voltage-divider

from VINto GND with the center node to ON/OFF as

shown in Figure 1. Calculate the threshold value by

using the following formula:

The minimum recommended V

UVLO(TH)

is 6.5V, 7.5V,

and 13V for the output voltages of 3.3V, 5V, and 12V,

respectively. The recommended value for R2 is less

than 1MΩ.

If the external UVLO threshold-setting divider is not

used, an internal undervoltage lockout feature monitors

the supply voltage at VINand allows operation to start

when V

IN

rises above 5.2V (typ). This feature can be

used only when VINrise time is faster than 2ms. For

slower VINrise time, use the resistive-divider at

ON/OFF.

Boost High-Side Gate Drive (BST)

Connect a flying bootstrap capacitor between LX and

BST to provide the gate-drive voltage to the high-side

N-channel DMOS switch. The capacitor is alternately

charged from the internally regulated output voltage VD

and placed across the high-side DMOS driver. Use a

0.1µF, 16V ceramic capacitor located as close to the

device as possible.

On startup, an internal low-side switch connects LX to

ground and charges the BST capacitor to VD. Once the

BST capacitor is charged, the internal low-side switch

is turned off and the BST capacitor voltage provides

the necessary enhancement voltage to turn on the

high-side switch.

Thermal Overload Protection

The MAX5035 features integrated thermal overload protection. Thermal overload protection limits total power

dissipation in the device, and protects the device in the

event of a fault condition. When the die temperature

exceeds +160°C, an internal thermal sensor signals the

shutdown logic, turning off the internal power MOSFET

and allowing the IC to cool. The thermal sensor turns the

internal power MOSFET back on after the IC’s die temperature cools down to +140°C, resulting in a pulsed

output under continuous thermal overload conditions.

Applications Information

Setting the Output Voltage

The MAX5035A/B/C have preset output voltages of 3.3V,

5.0V, and 12V, respectively. Connect FB to the preset

output voltage (see the Typical Operating Circuit).

The MAX5035D offers an adjustable output voltage. Set

the output voltage with a resistive voltage-divider connected from the circuit’s output to ground (Figure 1).

Connect the center node of the divider to FB. Choose

R4 less than 15kΩ, then calculate R3 as follows:

R

V

R

OUT

3

122

122

4=

−

×

(.)

.

Figure 1. Adjustable Output Voltage

V

UVLO TH()

1

R

×1

.=+

185

2

R

V

V

IN

7.5V TO 76V

68µF

V

R1

R2

IN

ON/OFF

MAX5035D

SGND

GND

LX

BST

FB

VD

0.1µF

0.1µF

100µH

D1

50SQ100

41.2kΩ

13.3kΩ

V

OUT

5V

C

OUT

68µF

R3

R4

Page 10

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

10 ______________________________________________________________________________________

The MAX5035 features internal compensation for optimum closed-loop bandwidth and phase margin. With

the preset compensation, it is strongly advised to sense

the output immediately after the primary LC.

Inductor Selection

The choice of an inductor is guided by the voltage difference between VINand V

OUT

, the required output

current, and the operating frequency of the circuit. Use

an inductor with a minimum value given by:

where:

I

OUTMAX

is the maximum output current required, and

fSWis the operating frequency of 125kHz. Use an inductor with a maximum saturation current rating equal to at

least twice the peak output current of the circuit. Use

inductors with low DC resistance for higher efficiency.

Selecting a Rectifier

The MAX5035 requires an external Schottky rectifier as

a freewheeling diode. Connect this rectifier close to the

device using short leads and short PC board traces.

Choose a rectifier with a continuous current rating

greater than the highest expected output current. Use a

rectifier with a voltage rating greater than the maximum

expected input voltage, V

IN

. Use a low forward-voltage

Schottky rectifier for proper operation and high efficiency. Avoid higher than necessary reverse-voltage

Schottky rectifiers that have higher forward-voltage

drops. Use a Schottky rectifier with forward-voltage

drop (V

FB

) less than 0.45V at +25°C and maximum load

current to avoid forward biasing of the internal body

diode (LX to ground). Internal body diode conduction

may cause excessive junction temperature rise and

thermal shutdown. Use Table 1 to choose the proper

rectifier at different input voltages and output current.

Input Bypass Capacitor

The discontinuous input current waveform of the buck

converter causes large ripple currents in the input

capacitor. The switching frequency, peak inductor current, and the allowable peak-to-peak voltage ripple that

reflects back to the source dictate the capacitance

requirement. The MAX5035 high switching frequency

allows the use of smaller value input capacitors.

The input ripple is comprised of ∆VQ(caused by the

capacitor discharge) and ∆V

ESR

(caused by the ESR of

the capacitor). Use low-ESR aluminum electrolytic

capacitors with high ripple-current capability at the input.

Assuming that the contribution from the ESR and capacitor discharge is equal to 90% and 10%, respectively, calculate the input capacitance and the ESR required for a

specified ripple using the following equations:

I

OUT

is the maximum output current of the converter

and fSWis the oscillator switching frequency (125kHz).

For example, at VIN= 48V, V

OUT

= 3.3V, the ESR and

input capacitance are calculated for the input peak-topeak ripple of 100mV or less yielding an ESR and

capacitance value of 80mΩ and 51µF, respectively.

Low-ESR, ceramic, multilayer chip capacitors are recommended for size-optimized application. For ceramic

capacitors, assume the contribution from ESR and capacitor discharge is equal to 10% and 90%, respectively.

The input capacitor must handle the RMS ripple current

without significant rise in temperature. The maximum

capacitor RMS current occurs at about 50% duty cycle.

D

V

V

OUT

IN

=

∆I

VV V

Vf L

L

IN OUT OUT

IN SW

=

−×

××

()

,

C

IDD

Vf

IN

OUT

QSW

=

×−

×

()1

∆

ESR

V

I

I

IN

ESR

OUT

L

=

+

∆

∆

2

D

V

V

OUT

IN

=

L

VV D

If

IN OUT

OUTMAX SW

=

−×

××

()

.02

Table 1. Diode Selection

where

V

IN

7.5 to 36

7.5 to 56

7.5 to 76

(V) DIODE PART NUMBER MANUFACTURER

15MQ040N IR

B240A Diodes, Inc.

B240 Central Semiconductor

MBRS240, MBRS1540 ON Semiconductor

30BQ060 IR

B360A Diodes, Inc.

CMSH3-60 Central Semiconductor

MBRD360, MBR3060 ON Semiconductor

50SQ100, 50SQ80 IR

MBRM5100 Diodes, Inc.

Page 11

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

______________________________________________________________________________________ 11

Ensure that the ripple specification of the input capacitor exceeds the worst-case capacitor RMS ripple current. Use the following equations to calculate the input

capacitor RMS current:

I

PRMS

is the input switch RMS current, I

AVGin

is the

input average current, and η is the converter efficiency.

The ESR of aluminum electrolytic capacitors increases

significantly at cold temperatures. Use a 1µF or greater

value ceramic capacitor in parallel with the aluminum

electrolytic input capacitor, especially for input voltages

below 8V.

Output Filter Capacitor

The worst-case peak-to-peak and RMS capacitor ripple

current, allowable peak-to-peak output ripple voltage,

and the maximum deviation of the output voltage during load steps determine the capacitance and the ESR

requirements for the output capacitors.

The output capacitance and its ESR form a zero, which

improves the closed-loop stability of the buck regulator.

Choose the output capacitor so the ESR zero frequency

(fZ) occurs between 20kHz to 40kHz. Use the following

equation to verify the value of fZ. Capacitors with 100mΩ

to 250mΩ ESR are recommended to ensure the closedloop stability, while keeping the output ripple low.

The output ripple is comprised of ∆VOQ(caused by the

capacitor discharge) and ∆V

OESR

(caused by the ESR

of the capacitor). Use low-ESR tantalum or aluminum

electrolytic capacitors at the output. Assuming that the

contribution from the ESR and capacitor discharge

equal 80% and 20% respectively, calculate the output

capacitance and the ESR required for a specified ripple using the following equations:

The MAX5035 has an internal soft-start time (tSS) of

400µs. It is important to keep the output rise time at

startup below tSSto avoid output overshoot. The output

rise time is directly proportional to the output capacitor.

Use 68µF or lower capacitance at the output to control

the overshoot below 5%.

In a dynamic load application, the allowable deviation

of the output voltage during the fast-transient load dictates the output capacitance value and the ESR. The

output capacitors supply the step load current until the

controller responds with a greater duty cycle. The

response time (t

RESPONSE

) depends on the closedloop bandwidth of the converter. The resistive drop

across the capacitor ESR and capacitor discharge

cause a voltage droop during a step load. Use a combination of low-ESR tantalum and ceramic capacitors

for better transient load and ripple/noise performance.

Keep the maximum output voltage deviation above the

tolerable limits of the electronics being powered.

Assuming a 50% contribution each from the output

capacitance discharge and the ESR drop, use the following equations to calculate the required ESR and

capacitance value:

where I

STEP

is the load step and t

RESPONSE

is the

response time of the controller. Controller response

time is approximately one-third of the reciprocal of the

closed-loop unity-gain bandwidth, 20kHz typically.

PC Board Layout Considerations

Proper PC board layout is essential. Minimize ground

noise by connecting the anode of the Schottky rectifier,

the input bypass capacitor ground lead, and the output

filter capacitor ground lead to a single point (“star”

C

It

V

OUT

STEP RESPONSE

OQ

=

×

∆

ESR

V

I

OUT

OESR

STEP

=

∆

C

I

Vf

OUT

L

OQ SW

≈

××

∆

∆22.

ESR

V

I

OUT

OESR

L

=

∆

∆

f

C ESR

Z

OUT OUT

=

×× ×

1

2 π

IIIII

D

I

VI

V

II

I

II

I

and D

V

V

PRMS PK DC PK DC

AVGIN

OUT OUT

IN

PK OUT

L

DC OUT

L

OUT

IN

=++×

()

×

=

×

×

=+ = −

=

22

3

22

,

η

∆∆

III

where

CRMS PRMS AVGIN

=−

22

Page 12

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

12 ______________________________________________________________________________________

ground configuration). A ground plane is required.

Minimize lead lengths to reduce stray capacitance,

trace resistance, and radiated noise. In particular,

place the Schottky rectifier diode right next to the

device. Also, place BST and VD bypass capacitors

very close to the device. Use the PC board copper

plane connecting to VINand LX for heat sinking.

Figure 2. Fixed Output Voltages

Table 2. Typical External Components Selection (Circuit of Figure 2)

Application Circuits

V

IN

R1

R2

VIN (V) V

7.5 to 76 3.3 0.5

7.5 to 76 3.3 1

7.5 to 76 5 0.5

7.5 to 76 5 1

OUT

(V) I

C

IN

V

IN

MAX5035

ON/OFF

SGND

(A) EXTERNAL COMPONENTS

OUT

BST

LX

FB

VD

GND

= 68µF, Panasonic, EEVFK2A680Q

C

IN

C

= 68µF, Vishay Sprague, 594D686X_010C2T

OUT

= 0.1µF, 0805

C

BST

0.1µF

0.1µF

L1

D1

R1 = 1MΩ ±1%, 0805

R2 = 384kΩ ±1%, 0805

D1 = 50SQ100, IR

L1 = 100µH, Coilcraft Inc., DO5022P-104

C

= 68µF, Panasonic, EEVFK2A680Q

IN

= 68µF, Vishay Sprague, 594D68X_010C2T

C

OUT

C

= 0.1µF, 0805

BST

R1 = 1MΩ ±1%, 0805

R2 = 384kΩ ±1%, 0805

D1 = 50SQ100, IR

L1 = 100µH, Coilcraft Inc., DO5022P-104

V

OUT

C

OUT

C

= 68µF, Panasonic, EEVFK2A680Q

IN

= 15µF, Vishay Sprague, 594D156X0025C2T

C

OUT

C

= 0.1µF, 0805

BST

15 to 76 12 1

R1 = 1MΩ ±1%, 0805

R2 = 139kΩ ±1%, 0805

D1 = 50SQ100, IR

L1 = 220µH, Coilcraft Inc., DO5022P-224

Page 13

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

______________________________________________________________________________________ 13

Table 2. Typical External Components Selection (Circuit of Figure 2) (continued)

VIN (V) V

9 to 14

18 to 36

(V) I

OUT

3.3 1

51

3.3 1

51

(A) EXTERNAL COMPONENTS

OUT

= 220µF, Panasonic, EEVFK1E221P

C

IN

C

= 68µF, Vishay Sprague, 594D686X_010C2T

OUT

= 0.1µF, 0805

C

BST

R1 = 1MΩ ±1%, 0805

R2 = 274kΩ ±1%, 0805

D1 = B220, Diodes Inc.

L1 = 100µH, Coilcraft Inc., DO5022P-104

= 220µF, Panasonic, EEVFK1E221P

C

IN

C

= 68µF, Vishay Sprague, 594D686X_010C2T

OUT

= 0.1µF, 0805

C

BST

R1 = 1MΩ ±1%, 0805

R2 = 274kΩ ±1%, 0805

D1 = B220, Diodes Inc.

L1 = 100µH, Coilcraft Inc., DO5022P-104

C

= 220µF, Panasonic, EEVFK1H221P

IN

= 68µF, Vishay Sprague, 594D686X_010C2T

C

OUT

C

= 0.1µF, 0805

BST

R1 = 1MΩ ±1%, 0805

R2 = 130kΩ ±1%, 0805

D1 = MBRS2040, ON Semiconductor

L1 = 100µH, Coilcraft Inc., DO5022P-104

= 220µF, Panasonic, EEVFK1H221P

C

IN

= 68µF, Vishay Sprague, 594D686X_010C2T

C

OUT

C

= 0.1µF, 0805

BST

R1 = 1MΩ ±1%, 0805

R2 = 130kΩ ±1%, 0805

D1 = MBRS2040, ON Semiconductor

L1 = 100µH, Coilcraft Inc., DO5022P-104

C

= 220µF, Panasonic, EEVFK1H221P

IN

C

= 15µF, Vishay Sprague, 594D156X_0025C2T

OUT

= 0.1µF, 0805

C

BST

12 1

R1 = 1MΩ ±1%, 0805

R2 = 130kΩ ±1%, 0805

D1 = MBRS2040, ON Semiconductor

L1 = 220µH, Coilcraft Inc., DO5022P-224

Page 14

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

14 ______________________________________________________________________________________

Table 3. Component Suppliers

Figure 3. Load Temperature Monitoring with ON/

OFF

(Requires Accurate VIN)

SUPPLIER PHONE FAX WEBSITE

AVX 843-946-0238 843-626-3123 www.avxcorp.com

Coilcraft 847-639-6400 847-639-1469 www.coilcraft.com

Diodes Incorporated 805-446-4800 805-446-4850 www.diodes.com

Panasonic 714-373-7366 714-737-7323 www.panasonic.com

Sanyo 619-661-6835 619-661-1055 www.sanyo.com

TDK 847-803-6100 847-390-4405 www.component.tdk.com

Vishay 402-563-6866 402-563-6296 www.vishay.com

MAX5035

PTC*

V

IN

12V

C

IN

68µF

*LOCATE PTC AS CLOSE TO HEAT-DISSIPATING COMPONENTS AS POSSIBLE.

Ct

ON/OFF

V

IN

Rt

SGND

GND

FB

BST

LX

VD

0.1µF

0.1µF

D1

B240

L1

100µH

V

OUT

5V AT 1A

C

OUT

68µF

Page 15

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

______________________________________________________________________________________ 15

Figure 4. Dual-Sequenced DC-DC Converters (Startup Delay Determined by R1/R1’, Ct/Ct’ and Rt/Rt’)

Chip Information

TRANSISTOR COUNT: 4344

PROCESS: BiCMOS

GND

GND

FB

BST

LX

VD

0.1µF

FB

BST

LX

VD

0.1µF

0.1µF

0.1µF

L1

220µH

D1

B240

L1'

100µH

D1'

B240

V

7.5V TO 36V

MAX5035B

R1

IN

C

68µF

IN

Ct

ON/OFF

V

IN

Rt

SGND

MAX5035A

C'

68µF

R1'

IN

Ct'

ON/OFF

V

IN

Rt'

SGND

V

V'

3.3V

OUT

5V

OUT

C

OUT

68µF

C'

OUT

68µF

Page 16

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

16 ______________________________________________________________________________________

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

N

1

e

FRONT VIEW

TOP VIEW

D

INCHES

DIM

MIN

0.053A

0.004

A1

0.014

B

0.007

C

e 0.050 BSC 1.27 BSC

0.150

HE

A

B

A1

C

L

E

H 0.2440.228 5.80 6.20

0.016L

VARIATIONS:

INCHES

MINDIM

D

0.189 0.197 AA5.004.80 8

0.337 0.344 AB8.758.55 14

D

0-8

MAX

0.069

0.010

0.019

0.010

0.157

0.050

MAX

0.3940.386D

MILLIMETERS

MAX

MIN

1.35

1.75

0.10

0.25

0.35

0.49

0.19

0.25

3.80 4.00

0.40 1.27

MILLIMETERS

MAX

MIN

9.80 10.00

N MS012

16

AC

SOICN .EPS

SIDE VIEW

PROPRIETARY INFORMATION

TITLE:

PACKAGE OUTLINE, .150" SOIC

REV.DOCUMENT CONTROL NO.APPROVAL

21-0041

1

B

1

Page 17

MAX5035

1A, 76V, High-Efficiency MAXPower

Step-Down DC-DC Converter

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 17

© 2003 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

PDIPN.EPS

Loading...

Loading...