Page 1

现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

_______________General Description

The MAX5018 is a monolithic, 8-bit digital-to-analog

converter (DAC) capable of accepting video data at

165Msps or 275Msps. Complete with video controls

(sync, blank, reference white (force high), and bright),

the MAX5018 directly drives doubly terminated 50Ω or

75Ω loads to standard composite video levels.

Standard setup level is 7.5IRE. The MAX5018 is pin

compatible with the HDAC10180 and the TDC1018,

with improved performance. The MAX5018 contains

data and control input registers, video control logic, reference buffer, and current switches.

Two performance grades of the MAX5018 are available.

Both are packaged in a 24-pin PDIP in the -20°C to

+85°C industrial temperature range.

________________________Applications

High-Resolution Color or Monochrome Raster

Graphics Displays to 1500 x 1800 Pixels

Medical Electronics: CAT, PET, and MRI Displays

CAD/CAE Workstations

Solids Modeling

General-Purpose, High-Speed Digital-to-Analog

Conversion

Digital Synthesizers

Automated Test Equipment

Digital Transmitters/Modulators

____________________________Features

♦ 275Msps Conversion Rate (MAX5018A)

165Msps Conversion Rate (MAX5018B)

♦ TDC1018 and HDAC10180 Compatible with

Improved Performance

♦ RS-343-A Compatible

♦ Complete Video Controls: Sync, Blank, Bright,

and Reference White (force high)

♦ ECL Compatible

♦ Single Power Supply

♦ Registered Data and Video Controls

♦ Differential Current Outputs

♦ ESD-Protected Data and Control Inputs

MAX5018

8-Bit, High-Speed DAC

________________________________________________________________

Maxim Integrated Products

1

19-1204; Rev 0; 3/97

For the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

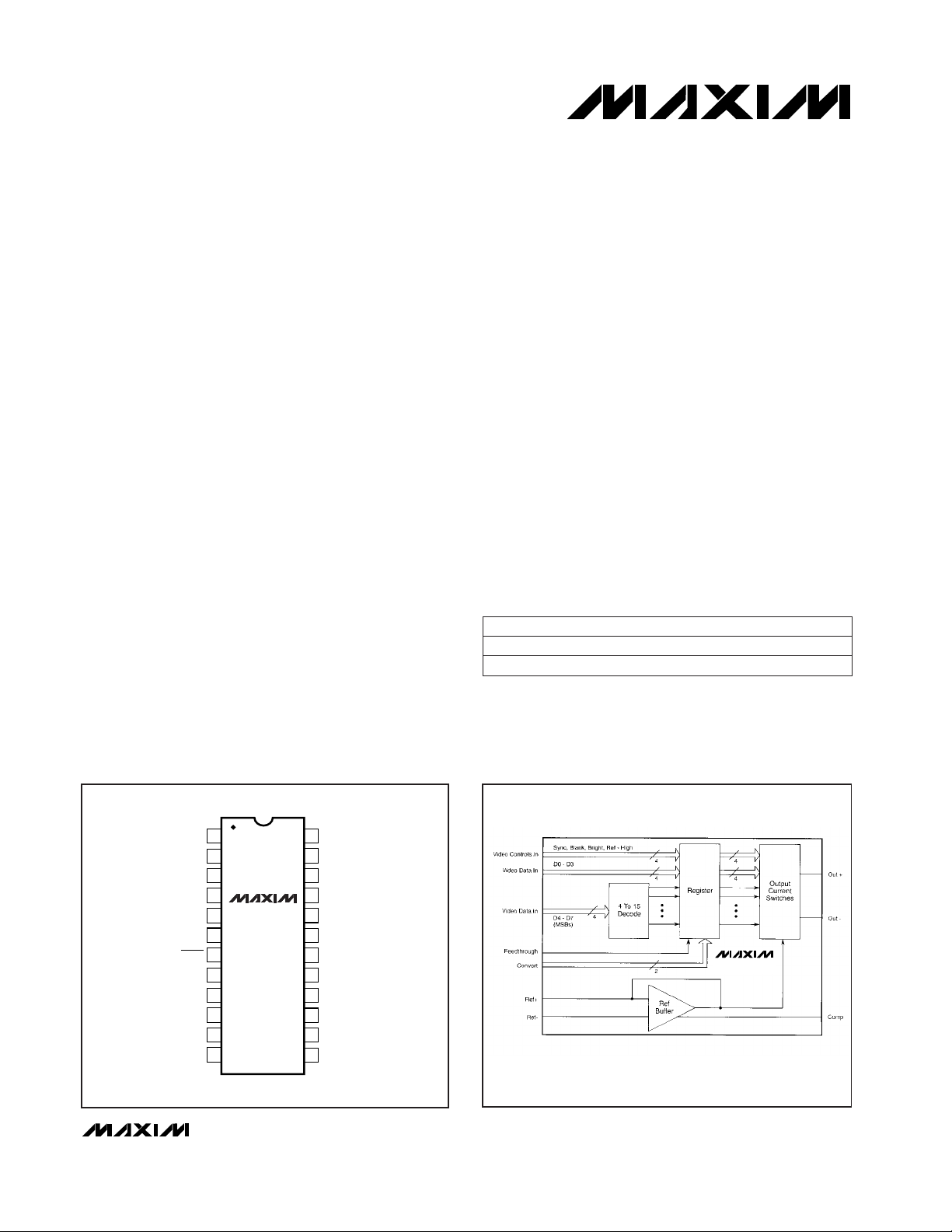

__________________Pin Configuration

24

23

22

21

20

19

18

17

1

2

3

4

5

6

7

8

D4

D5

D6

D7D0

D1

D2

D3

TOP VIEW

V

EE

Out+

OutV

CC

FT

CONV

CONV

V

EE

16

15

14

13

9

10

11

12

COMP

Ref+

RefSyncBRT

Blank

FH

V

CC

DIP

MAX5018

________________Functional Diagram

______________Ordering Information

PART

MAX5018BIPG

MAX5018AIPG

-20°C to +85°C 24 Plastic DIP

-20°C to +85°C

TEMP. RANGE PIN-PACKAGE

24 Plastic DIP

MAX5018

Page 2

MAX5018

8-Bit, High-Speed DAC

2 _______________________________________________________________________________________

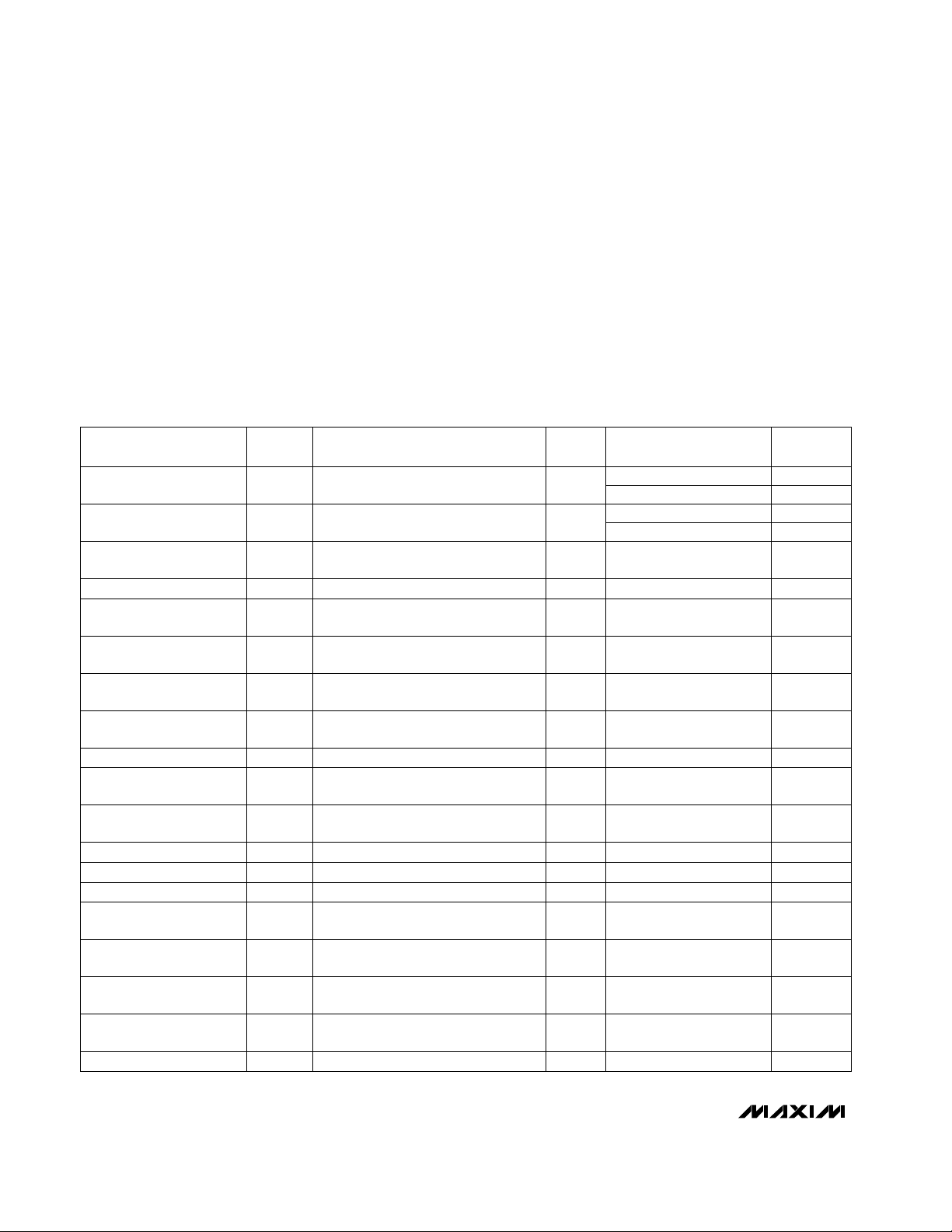

ABSOLUTE MAXIMUM RATINGS

DC ELECTRICAL CHARACTERISTICS

(VCC= ground, VEE= -5.2V ±0.3V, CC= 0pF, I

SET

= 1.105mA, TA= T

MIN

to T

MAX

, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Supply Voltage

V

EE

(measured to VCC)..........................................-7.0V to 0.5V

Input Voltages

CONV, Data, and Controls (measured to V

CC

)........VEEto 0.5V

Ref+ (measured to V

CC

) ..........................................VEEto 0.5V

Ref- (measured to V

CC

)............................................VEEto 0.5V

Operating Temperature Ranges

Ambient .............................................................-20°C to +85°C

Junction..........................................................................+175°C

Lead Temperature (soldering, 10sec).............................+300°C

Storage Temperature Range.............................-60°C to +150°C

µA35 120I

IL

Input Current, Logic Low,

Data and Controls

-0.95 0.95

VI

-0.5 0.5

CONDITIONS

µA40 120I

IH

Input Current, Logic High,

Data and Controls

VI

µA2 60I

CONV

Input Current, Convert VI

1.0mA < I

SET

< 1.3mA

% Full Scale-0.37 0.37

ILEIntegral Linearity Error VI

1.0mA < I

SET

< 1.3mA

% Full Scale-0.2 0.2

DLEDifferential Linearity Error

V0.4 1.2

Convert Voltage,

Differential

V-0.5 -2.5

Convert Voltage,

Common-Mode Range

V-1.5V

IL

Input Voltage, Logic Low

V-1.0V

IH

Input Voltage, Logic High

LSB0.05 0.5I

OS

Output Offset Current

mA-45IO-

(MAX)

Maximum Current,

Negative Output

% Full Scale-6.5 6.5Gain Error

mA45IO+

(MAX)

Maximum Current,

Positive Output

pF12C

OUT

Output Capacitance

kΩ20R

OUT

Equivalent Output

Resistance

V-1.2 1.5

Compliance Voltage,

Negative Output

ppm/°C150Gain-Error Tempco

pF5C

REF

Input Capacitance,

Ref+, Ref-

V-1.2 1.5

Compliance Voltage,

Positive Output

UNITSMIN TYP MAXSYMBOLPARAMETER

VI

VI

IV

IV

IV

V

VI

VI

VI

VI

V

V

VI

VI

IV

TEST

LEVEL

LSB

LSB

Page 3

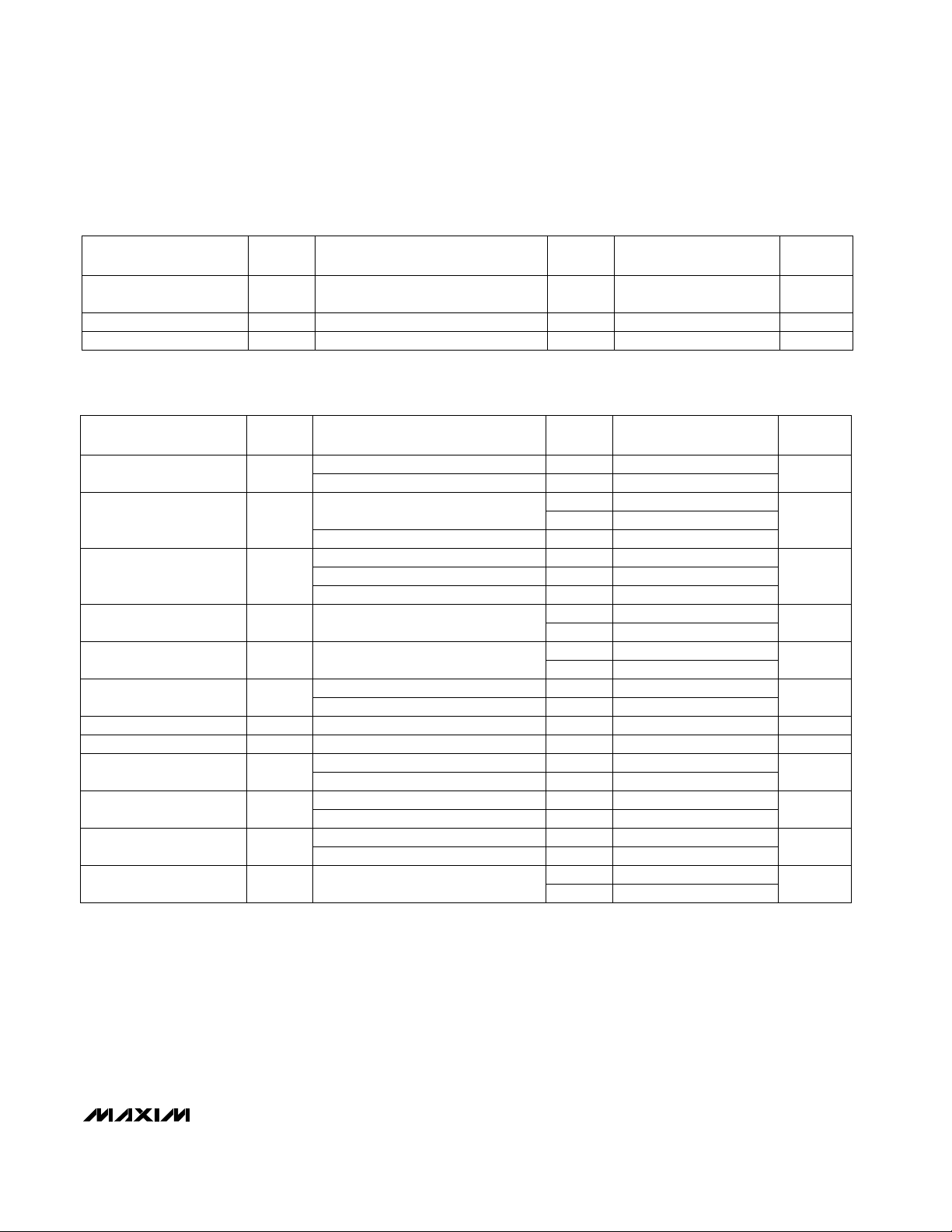

Msps

MAX5018

8-Bit, High-Speed DAC

_______________________________________________________________________________________ 3

To 0.2% G.S., RL= 25Ω 4.5

MAX5018B

V

MAX5018A 275

t

S

III

10% to 90% G.S., RL= 25Ω 1.0

2.0

IV

V

CONDITIONS

10% to 90% G.S., TA= T

MIN

to T

MAX

ns

1.6

t

R

Rise Time

III

To 0.8% G.S. 5.5V

IV

TA= T

MIN

to T

MAX

4.5

t

H

TA= T

MIN

to T

MAX

ns

2.2 4.0

t

DSC

Clock to Output Delay,

Clocked Mode

III

IV

To 0.2% G.S. 7.0V

TA= T

MIN

to T

MAX

ns

6.0

t

DST

IV

Area = 1/2VT pV-s

Msps

165

Maximum Conversion Rate

4

A Grade 1.8

Glitch Energy

Convert Pulse Width,

(low or high)

V

B Grade

ns

3.0

t

PWL

,

t

PWH

III

TA= +25°C

ns

1.0

MHz1.0Reference Bandwidth, -3dB V

TA= T

MIN

to T

MAX

ns

0.5IV

TA= +25°C 0.5

Hold Time, Data and

Controls

III

III

UNITSMIN TYP MAXSYMBOLPARAMETER

1.0

III

Setup Time, Data and

Controls

III

3.2 6.0

Data to Output Delay,

Transparent Mode

III

dB

-48

Clock Feedthrough

III

TA= T

MIN

to T

MAX

325IV

TEST

LEVEL

TA= T

MIN

to T

MAX

-48IV

20% to 80% G.S., TA= +25°C

V/µs

390

Slew Rate

III

CONDITIONS

mA155 220I

EE

Supply Current

pF3C

IN

Input Capacitance, Data

and Controls

µA/V-120 20 120Power-Supply Sensitivity

UNITSMIN TYP MAXSYMBOLPARAMETER

VI

V

VI

TEST

LEVEL

DC ELECTRICAL CHARACTERISTICS (continued)

(VCC= ground, VEE= -5.2V ±0.3V, CC= 0pF, I

SET

= 1.105mA, TA= T

MIN

to T

MAX

, unless otherwise noted.)

AC ELECTRICAL CHARACTERISTICS

(RL= 37.5Ω, CL= 5pF, I

SET

= 1.105mA, TA= +25°C, unless otherwise noted.)

t

SI

ns

Current Settling Time,

Clocked Mode

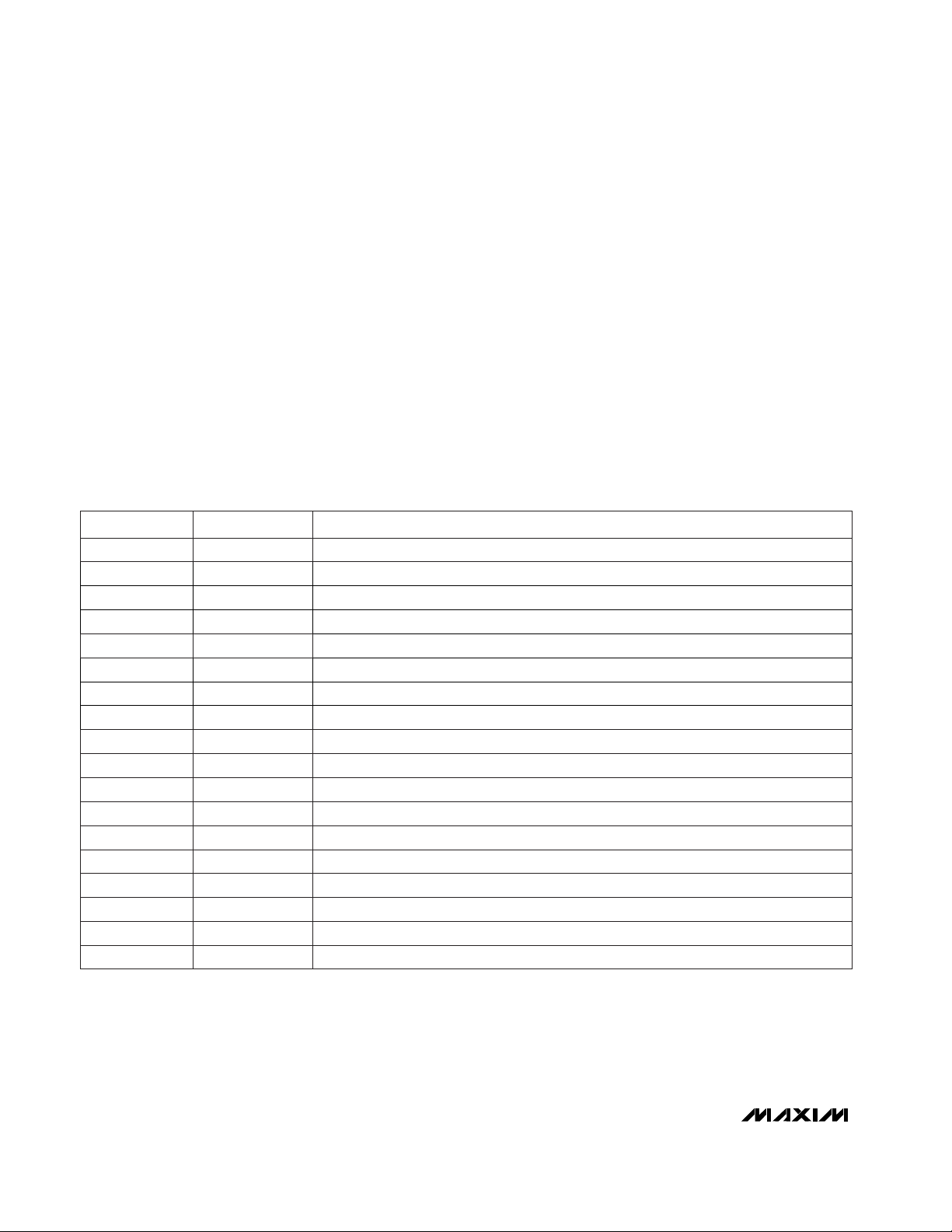

Page 4

MAX5018

8-Bit, High-Speed DAC

4 _______________________________________________________________________________________

Data Bit 0 (LSB)D04

Convert Clock InputCONV6

Negative SupplyV

EE

5, 20

Register Feedthrough ControlFT8

Data Force-High ControlFH10

Positive SupplyV

CC

9, 17

Convert-Clock-Input Complement

CONV

7

Video Bright InputBRT12

Reference Current, Negative InputRef-14

Video Sync InputSync13

Compensation InputCOMP16

PIN

Output Current NegativeOut-18

Data Bits 3, 2, and 1D3, D2, D11, 2, 3

FUNCTIONNAME

Reference Current, Positive InputRef+15

Video Blank InputBlank11

Data Bits 6, 5, and 4D6, D5, D422, 23, 24

Data Bit 7 (MSB)D721

Output Current PositiveOut+19

______________________________________________________________Pin Description

TEST-LEVEL CODES

All electrical characteristics are subject to

the following conditions:

All parameters having min/max specifications are guaranteed. The Test Level column

indicates the specific device testing actually

performed during production and Quality

Assurance inspection. Any blank section in

the data column indicates that the specification is not tested at the specified condition.

Unless otherwise noted, all tests are pulsed

tests; therefore, T

j

= TC= TA.

TEST LEVEL

I

II

III

IV

V

VI

TEST PROCEDURE

100% production tested at the specified temperature.

100% production tested at T

A

= +25°C, and sample

tested at the specified temperatures.

QA sample tested at only the specified temperatures.

Parameter is guaranteed (but not tested) by design

and characterization data.

Parameter is a typical value for reference only.

100% production tested at T

A

= +25°C. Parameter is

guaranteed over specified temperature range.

Page 5

_______________Detailed Description

The MAX5018 is an ultra-high-speed video digital-toanalog converter (DAC) capable of up to 275Msps conversion rates. This high speed makes the device

suitable for driving 1500 x 1800 pixel displays at 70Hz

to 90Hz update rates.

The MAX5018 is separated into different conversionrate categories, as shown in Table 1.

The MAX5018 has ECL logic-level-compatible video

controls and data inputs. The complementary analog

output currents produced by the devices are proportional to the product of the digital control and data

inputs in conjunction with the analog reference current.

The MAX5018 is segmented so that the input data’s

four MSBs are separated into a parallel thermometer

code. From here, fifteen identical current sinks are driven to fabricate sixteen coarse output levels. The

remaining four LSBs drive four binary-weighted current

switches.

MSB currents are then summed with the LSBs that contribute one-sixteenth of full-scale to provide the 256 distinct analog output levels.

The video-control inputs drive weighted current sinks,

which are added to the output current to produce composite video-output levels. These controls (sync, blank,

reference white (force high), and bright) are required in

video applications.

A feature that similar video DACs do not have is feedthrough control. The feedthrough pin (FT) allows registered or unregistered operation of the video control and

data inputs. In registered mode, the composite functions are latched to the pixel data to prevent screenedge distortions (generally found on unregistered video

DACs).

__________Applications Information

General

Figure 1 shows a typical application using the MAX5018

in a color-raster circuit. The MAX5018 requires few external components and is extremely easy to use. The

MAX5018’s very high operating speeds require good circuit layout, supply decoupling, and proper transmissionline design. For best performance, note the following

considerations.

Input Considerations

Video-input data and controls can be directly connected to the MAX5018. Note that all ECL inputs are

terminated as closely to the device as possible to

reduce ringing, crosstalk, and reflections. Maxim recommends that stripline or microstrip techniques be

used for all ECL interfaces. A convenient and commonly used microstrip impedance is about 130Ω, which is

easily terminated using a 330Ω resistor to VEEand a

220Ω resistor to ground. This arrangement gives a

Thevenin-equivalent termination of 130Ω to -2V without

the need for a -2V supply. Standard single in-line package (SIP) 220/330 resistor networks are available for

this purpose.

Figure 2 shows equivalent input circuits.

Output Considerations

The analog outputs are designed to directly drive a

dual 50Ω or 75Ω load-transmission system as shown in

Figure 1. The MAX5018 output source impedances are

high-impedance current sinks. The load impedance

(RL) must be 25Ω or 37.5Ω to attain standard RS-343-A

video levels. Any deviation from this impedance affects

the resulting video output levels proportionally. As with

the data interface, it is important that all analog transmission lines have matched impedance throughout,

including connectors and transitions between printed

wiring and coaxial cable. The combination of matched

source-termination resistor RSand load terminator R

L

minimizes reflections of both forward and reverse traveling waves in the analog transmission system.

Power Considerations

The MAX5018 has two analog power-supply pins and

operates from a standard -5.2V single supply. Proper

supply bypassing augments the MAX5018’s inherent

supply-noise-rejection characteristics. As shown in

Figure 1, each supply pin should be bypassed as

close to the device as possible with 0.01µF and 10µF

capacitors.

MAX5018

8-Bit, High-Speed DAC

_______________________________________________________________________________________ 5

PART UPDATE COMMENTS

MAX5018A 275Msps

Suitable for 1200 x 1500 to

1500 x 1800 displays at

60Hz to 90Hz update rate.

MAX5018B 165Msps

Suitable for 1024 x 1280 to

1200 x 1500 displays at

60Hz to 90Hz update rate.

Table 1. The MAX5018 Family and

Speed Designations

Page 6

MAX5018

This device also has two analog ground pins (VCC). Tie

both ground pins to the analog ground plane. All power

and ground pins must be connected in any application.

If a +5V power source is required, the VCCground pins

become the positive supply pins, while the V

EE

supply

pins become the ground pins. The relative polarities of

the other input and output voltages must be maintained.

Reference Considerations

The MAX5018 has two reference inputs (Ref+ and Ref-).

The input pins are connected to the inverting and noninverting inputs of an internal amplifier that serves as a

reference buffer amplifier.

The buffer amplifier’s output is the reference for the current sinks. The amplifier feedback loop is connected

around one of the current sinks for better accuracy.

(See Figure 3.)

Since the analog output currents are proportional to the

digital input data and I

Set

, full-scale output can be

adjusted by varying the reference current. I

Set

is controlled through the MAX5018’s Ref+ input. Figure 1

shows the method and the necessary equations for setting I

Set

. The MAX5018 uses an external negativevoltage reference. The external reference must be

stable to achieve a satisfactory output, and Ref- should

be driven through a resistor to minimize offsets caused

by bias current. To change the full-scale output, vary

the value for I

Set

with the 500Ω trimmer. A double 50Ω

load (25Ω) can be driven if I

Set

is increased by 50% for

doubly terminated 75Ω video applications.

8-Bit, High-Speed DAC

6 _______________________________________________________________________________________

Figure 1. Typical Interface Circuit

Page 7

Compensation

The MAX5018 provides an external compensation input

(COMP) for the reference buffer amplifier. To use this

pin correctly, connect a capacitor between COMP and

VEE, as shown in Figure 1. Keep lead lengths as short

as possible. Use a large capacitor (0.01µF) if the reference is to be kept as a constant. The capacitor’s value

determines the amplifier’s bandwidth. If reference modulation is required, smaller capacitance values can be

used to achieve up to a 1MHz bandwidth.

Data Inputs and Video Controls

The MAX5018 has standard, single-ended data inputs.

The inputs are registered to produce the lowest differential data-propagation delay (skew) to minimize glitching. Also, four video-control inputs generate composite

video outputs: sync, blank, bright, and reference white

(force high). Feedthrough control is also provided. All

of the controls and data inputs are ECL compatible. In

addition, all have internal pulldown resistors to leave

them at a logic low so the pins are inactive when not

used. This feature is useful if the devices are applied as

standard DACs without the need for video controls, or if

fewer than eight bits are used.

The MAX5018 is usually configured in synchronous

mode. In this mode, the controls and data are synchronized to prevent pixel dropout. This reduces screenedge distortions and provides the lowest output noise

while maintaining the highest conversion rate. With the

FT control open (low), each rising edge of the convert

clock (CONV) latches decoded data and control values

into a D-type internal register. The switched-current

MAX5018

8-Bit, High-Speed DAC

_______________________________________________________________________________________ 7

Figure 2. Equivalent Input Circuits—Data, Clock, Controls, and Reference

I

Bias

V

EE

Conv

Conv

I

Bias

V

EE

V

CC

Reference

Segment

Switch

Ref In

I

Set

I

Bias

I

Bias

80 kΩ

V

EE

V

Data and

Controls

Page 8

MAX5018

sinks convert the registered data into the appropriate

analog output. When FT is tied high, the control inputs

and data are not registered. The analog output asynchronously tracks the input data and video controls.

Feedthrough itself is asynchronous and is usually used

as a DC control.

To be registered synchronously, control and data inputs

must be present at the input pins for a specific setup

time (ts) before and a specific hold time (tH) after

CONV’s rising edge. Setup and hold times are not important in asynchronous mode. The minimum pulse widths

high (t

PWH

) and low (t

PWL

), as well as settling time,

become the limiting factors (Figure 4).

The video controls produce the output levels needed

for horizontal blanking, frame synchronization, etc., to

be compatible with video-system standards as

described in RS-343-A. Table 2 shows the videocontrol effects on the analog output. Internal logic governs blank, sync, and force high so that they override

the data inputs as needed in video applications. Sync

overrides both the data and other controls to produce

full negative video output (Figure 5).

Reference-white, video-level output is provided by force

high, which drives the internal digital data to full-scale

output (100IRE units). Bright gives an additional 10% of

full-scale value to the output level. This function can be

used in graphic displays for highlighting menus, cursors,

or warning messages. If the devices are used in nonvideo applications, the video controls can be left open.

Convert Clock

For best performance, the clock should be differentially

ECL driven by using CONV and CONV (Figure 6).

Driving the clock in this manner minimizes clock noise

and power-supply/output intermodulation. The clock’s

rising edge synchronizes the data and control inputs to

the MAX5018. Since CONV determines the actual

switching threshold of CONV, the clock can be driven

single-ended by connecting a bias voltage to CONV.

This bias voltage sets the converter clock’s switching

threshold.

Analog Outputs

The MAX5018 has two analog outputs that are highimpedance, complementary current sinks. The outputs

vary in proportion to the input data, controls, and reference-current values so that the full-scale output can be

changed by setting I

Set

.

In video applications, the outputs can drive a doubly

terminated 50Ω or 75Ω load to standard video levels. In

the standard configuration shown in Figure 7, the output voltage is the product of the output current and

load impedance and is between 0V and -1.07V. Out(Figure 5) provides a video output waveform with the

Sync pulse bottom at -1.07V. Out+ is inverted with

Sync up.

8-Bit, High-Speed DAC

8 _______________________________________________________________________________________

Figure 3. Reference Buffer and DAC Output Circuit

Page 9

MAX5018

8-Bit, High-Speed DAC

_______________________________________________________________________________________ 9

-1.3 V

CONV

CONV

1/2 LSB

t

PWL

t

H

t

S

t

PWH

t

SI

OUT +

OUT -

1/2 LSB

-1.3 V

t

DSC

t

DST

Data Control

Inputs

Figure 4. Timing Diagram

256 Gray Levels

Normal Low (Black)

Sync

Video

Blank

Bright

Normal High (White)

110

100

7.5

0

-40

IRE

0 mV

-73 mV

-728 mV

-781 mV

-1071 mV

Figure 5. Video-Output Waveform for Standard Load

Page 10

MAX5018

8-Bit, High-Speed DAC

10 ______________________________________________________________________________________

Table 2. Video-Control Operation (output values for setup: 10IRE, 75Ω standard load)

1 X0 X X 20.83 -0.781 0 Blank Level

0 10 1 X 0.00

BLANK

X

0.000 110 Enhanced High Level

SYNC

REF

WHITE

X1

0 00 0 111... 1.95

0

-0.073 100 Normal High Level

0 00 0 000...

BRIGHT

X

19.40 -0.728 7.5 Normal Low Level

10 0 X 1.95 -0.073 100 Normal High Level

DATA

INPUT

X

0 00 1 111... 0.00 0.000 110

OUT- (mA)

28.57

Enhanced High Level

0 00 1 000... 17.44 -0.654 17.5 Enhanced Low Level

OUT- (V)

-1.071

OUT- (IRE)

-40

DESCRIPTION

Sync Level

Figure 6. CONV, CONV Switching Levels

Page 11

MAX5018

8-Bit, High-Speed DAC

______________________________________________________________________________________ 11

Figure 7. Standard Load (a) and Test Load (b)

MAX5018

a)

b)

Page 12

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

12

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

© 1997 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

MAX5018

8-Bit, High-Speed DAC

________________________________________________________Package Information

PDIPN.EPS

Loading...

Loading...