For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

General Description

The MAX5003 high-voltage switching power-supply

controller has all the features and building blocks needed for a cost-effective flyback and forward voltagemode control converter. This device can be used to

design both isolated and nonisolated power supplies

with multiple output voltages that operate from a wide

range of voltage sources. It includes a high-voltage

internal start-up circuit that operates from a wide 11V to

110V input range. The MAX5003 drives an external Nchannel power MOSFET and has a current-sense pin

that detects overcurrent conditions and turns off the

power switch when the current-limit threshold is

exceeded. The choice of external power MOSFET and

other external components determines output voltage

and power.

The MAX5003 offers some distinctive advantages: softstart, undervoltage lockout, external frequency synchronization, and fast input voltage feed-forward. The

device is designed to operate at up to 300kHz switching frequency. This allows use of miniature magnetic

components and low-profile capacitors. Undervoltage

lockout, soft-start, switching frequency, maximum duty

cycle, and overcurrent protection limit are all adjustable

using a minimum number of external components. In

systems with multiple controllers, the MAX5003 can be

externally synchronized to operate from a common system clock.

Warning: The MAX5003 is designed to operate with

high voltages. Exercise caution.

The MAX5003 is available in 16-pin SO and QSOP packages. An evaluation kit (MAX5003EVKIT) is also available.

Applications

Telecommunication Power Supplies

ISDN Power Supplies

+42V Automobile Systems

High-Voltage Power-Supply Modules

Industrial Power Supplies

Features

♦ Wide Input Range: 11V to 110V

♦ Internal High-Voltage Startup Circuit

♦ Externally Adjustable Settings

Output Switch Current Limit

Oscillator Frequency

Soft-Start

Undervoltage Lockout

Maximum Duty Cycle

♦ Low External Component Count

♦ External Frequency Synchronization

♦ Primary or Secondary Regulation

♦ Input Feed-Forward for Fast Line-Transient

Response

♦ Precision ±2.5% Reference over Rated

Temperature Range

MAX5003

High-Voltage PWM

Power-Supply Controller

________________________________________________________________ Maxim Integrated Products 1

19-1555; Rev 0; 12/99

PART

MAX5003CEE

MAX5003CSE

MAX5003EEE -40°C to +85°C

0°C to +70°C

0°C to +70°C

TEMP. RANGE PIN-PACKAGE

16 QSOP

16 Narrow SO

16 QSOP

EVALUATION KIT

AVAILABLE

Note A: Dice are designed to operate over a -40°C to +140°C

junction temperature (T

j

) range, but are tested and guaranteed at

TA= +25°C.

Pin Configuration

Ordering Information

MAX5003ESE -40°C to +85°C 16 Narrow SO

MAX5003C/D (Note A) Dice

TOP VIEW

1

V+ V

INDIV

2

ES

3

4

FREQ

SS

5

REF

6

CON

7

COMP

8

QSOP/Narrow SO

16

DD

V

15

CC

NDRV

14

MAX5003

13

12

11

10

9

PGND

CS

AGND

MAXTON

FB

MAX5003

High-Voltage PWM

Power-Supply Controller

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

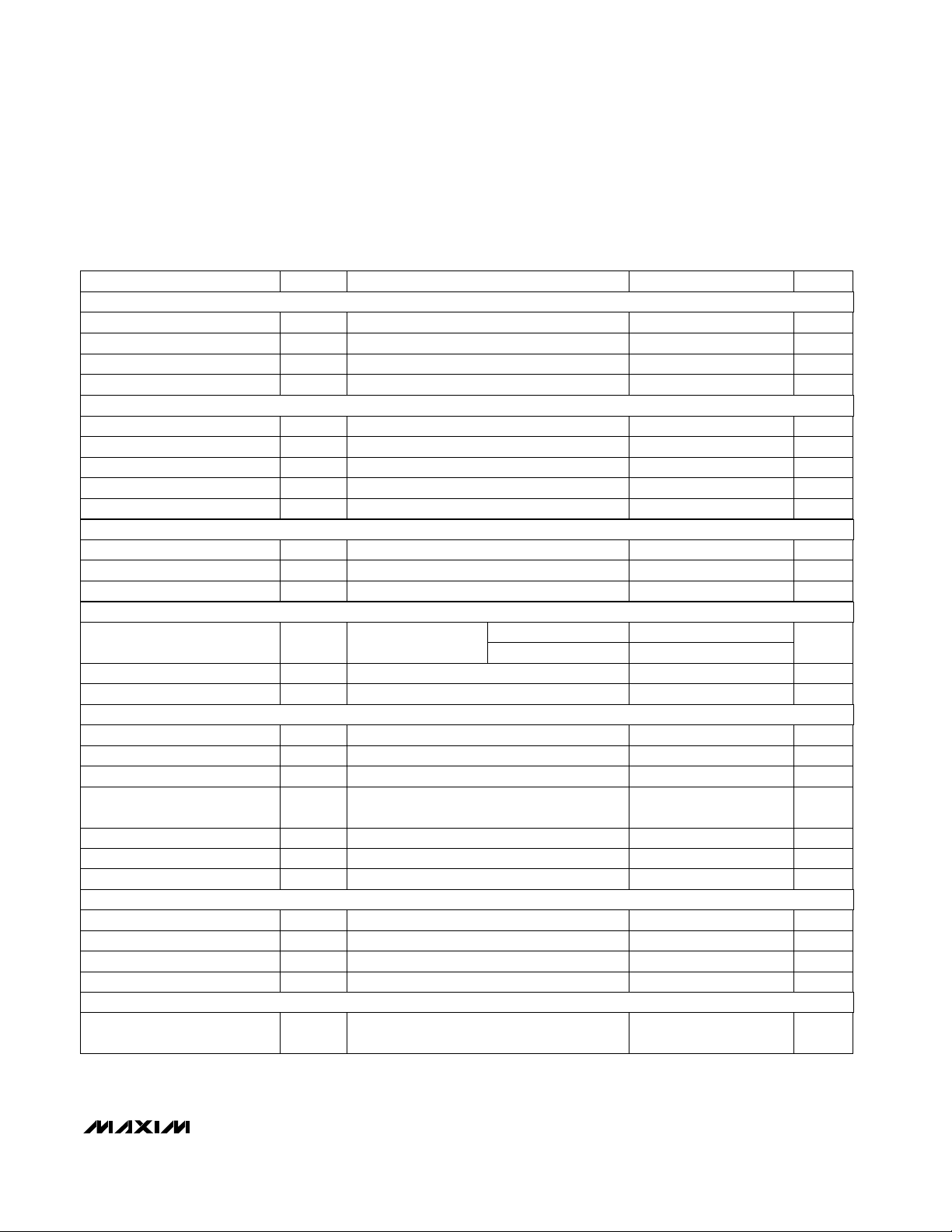

ELECTRICAL CHARACTERISTICS

(V+ = VES= VDD= +12V, V

INDIV

= 2V, V

CON

= 0, R

FREQ

= R

MAXTON

= 200kΩ, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical

values are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

V+ to GND ............................................................-0.3V to +120V

ES to GND ..............................................................-0.3V to +40V

VDDto GND............................................................-0.3V to +19V

VCCto GND.........................................................-0.3V to +12.5V

MAXTON, COMP, CS, FB, CON to GND..................-0.3V to +8V

NDRV, SS, FREQ to GND...........................-0.3V to (V

CC

+ 0.3V)

I

NDIV

, REF to GND.................................................-0.3V to +4.5V

VCC, VDD, V+, ES Current ................................................±20mA

NDRV Current, Continuous...............................................±25mA

NDRV Current, ≤ 1µs .............................................................±1A

CON and REF Current ......................................................±20mA

All Other Pins ....................................................................±20mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin SO (derate 9.5mW/°C above +70°C)...............762mW

16-Pin QSOP (derate 8.3mW/°C above +70°C)..........667mW

Maximum Junction Temperature (TJ) ..............................+150°C

Operating Temperature Ranges

MAX5003C_E ....................................................0°C to +70°C

MAX5003E_E ..................................................-40°C to +85°C

Operating Junction Temperature (T

J

) .............................+125°C

16-Pin SO θJA.................................................................105°C/W

16-Pin QSOP θ

JA

............................................................120°C/W

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

I

REF

= 0 to 1mA

No load

V+ = VES, VDD= 18.75

I

NDRV

= 50 mA

V

INDIV

= 0, V+ = 110V, VES= VDD=

unconnected

I

NDRV

= 50 mA

V

NDRV

= V

CC

V

NDRV

= 0, VCCsupported by VCCcapacitor

V+ = 36V, ES = unconnected,

VDD= 18.75V

VCCfalling

V+ = 36V, IV+< 75µA,

ES = unconnected

V+ = VES= 36V, I

NDRV

= 7.5mA

V+ = 110V, VDD= unconnected

V+ = 36V, IDD= 0 to 7.5mA,

ES = unconnected

mV

520

∆V

REF

REF Voltage Regulation

V

2.905 3.000 3.098

V

REF

REF Output Voltage

Ω

1

R

OL

NDRV Resistance Low

Ω

412

R

OH

NDRV Resistance High

mA

1000

Peak Sink Current

mA

570

Peak Source Current

V

6.3

V

CCLO

VCCUndervoltage

Lockout Voltage

V

CC

VCCOutput Voltage

mA

1.2

I

DD

µA

35 75

I+Shutdown Current

Supply Current

V

7.4 12

V

10.75

V

TO

VDDRegulator Turn-Off Voltage

V

10.75 18.75

V

DD

VDDInput Voltage Range

V

25

V

10.8 36

V

ESI

ESInput Voltage (Note 1)

V

36

V

ESO

ESOutput Voltage

V

9 9.75 10.5

V

DD

VDDOutput Voltage

CONDITIONS UNITSMIN TYP MAXSYMBOL PARAMETER

VDD= unconnected, V+ = VES, I

NDRV

= 7.5mA

V110

V+V+ Input Voltage (Note 1)

ES= VDD= unconnected

REFERENCE

OUTPUT DRIVER

CHIP SUPPLY (VCC)

PREREGULATOR/START-UP

SUPPLY CURRENT

I

NDRV

= 2mA

I

NDRV

= 5mA

MAX5003

High-Voltage PWM

Power-Supply Controller

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(V+ = VES= VDD= +12V, V

INDIV

= 2V, V

CON

= 0, R

FREQ

= R

MAXTON

= 200kΩ, TA= T

MIN to TMAX

, unless otherwise noted. Typical

values are at T

A

= +25°C.)

(Note 2)

V

FREQ

= 5V, V

CON

= 3.0V

V

CON

= 3.0V

V

CON

= 3.0V

From end of blanking time 25mV overdrive

0 < VCS< 0.1V

V

INDIV

= 1.28V

FB = COMP, V

CON

= 1.5V

V+ = VES= VDD=

10.8V and 18.75V

At COMP

At COMP

I

COMP

= 5µA; V

COMP

= 0.5V, 2.5V

R

LOAD

= 200kΩ, C

LOAD

= 100pF

A

VOL

= 1V/V, C

LOAD

= 100pF

VFB= 1.5V

kHz

200 1200

f

FREQ

FREQ Range

µs

813

t

EXT

External Oscillator Maximum

Low Time

µA

1

I

OL

FREQ Output Low

V

2.7

V

IH

FREQ Input High

V

0.8

V

IL

FREQ Input Low

µA

-1 0.01 +1

INDIV Bias Current

mV

125

V

HYST

INDIV Hysteresis

1.23 1.32 1.45

V

1.15 1.20 1.25

V

INDIVLO

INDIV Undervoltage Lockout

ppm/°C

100

TC

FB

FB V

SET

Tempco

µA

-1 0.1 +1

I

FB

FB Bias Current

ns

70

t

B

CS Blanking Time

ns

240

t

D

µA

-1 +1

I

CS

CS Input Bias Current

Overcurrent Delay

V

1.448 1.485 1.522

V

SET

FB Regulation Voltage

V

3.00

V

COMPH

Output Clamp High

V

0.25

V

COMPL

Output Clamp Low

dB

60 80

A

V

Voltage Gain

MHz

1.2

BWUnity-Gain Bandwidth

degrees

65

φ

Phase Margin

fS = 1/4 f

FREQ

ns

150

FREQ HI/LO Pulse Width

kHz

50 300

f

S

Frequency Range

CONDITIONS UNITS MIN TYP MAXSYMBOLPARAMETERS

V

FREQ

= 1.5V

V

FREQ

= 0

µA

1

I

OL

FREQ Output Current Low

µA

300

I

OH

FREQ Output Current High

kHz

80 100 120

Oscillator Frequency

kΩ

50 500

R

FREQ

FREQ Resistor Range

V

INDIV

= 1.25V %

75

Maximum Programmable

Duty Cycle

V

CON

= 1.25V mV

80 100 120

V

CS

CS Threshold Voltage

MAXIMUM DUTY CYCLE (MAXTON)

MAIN OSCILLATOR—INTERNAL MODE

MAIN OSCILLATOR—EXTERNAL MODE

UNDERVOLTAGE LOCKOUT

FEEDBACK INPUT AND SET POINT

ERROR AMPLIFIER

CURRENT LIMIT

V

INDIV

falling

V

INDIV

rising

0.8

-0.4

-0.6

0

-0.2

0.6

0.4

0.2

0.8

0-20 20 40 60 80 100

FB SET-POINT VOLTAGE CHANGE

vs. TEMPERATURE

MAX5003-01

TEMPERATURE (°C)

FB SET-POINT VOLTAGE CHANGE (%)

-0.100

-0.050

-0.075

0

-0.025

0.075

0.050

0.025

0.100

11 1312 14 15 16 17 18

FB SET-POINT VOLTAGE CHANGE

vs. SUPPLY VOLTAGE

MAX5003-02

VDD (V)

FB SET-POINT VOLTAGE CHANGE (%)

-1.20

-0.80

-1.00

-0.40

-0.60

0.20

0

-0.20

0.40

-40 0-20 20 40 60 80 100

SWITCHING FREQUENCY CHANGE

vs. TEMPERATURE

MAX5003-03

TEMPERATURE (°C)

FREQUENCY CHANGE (%)

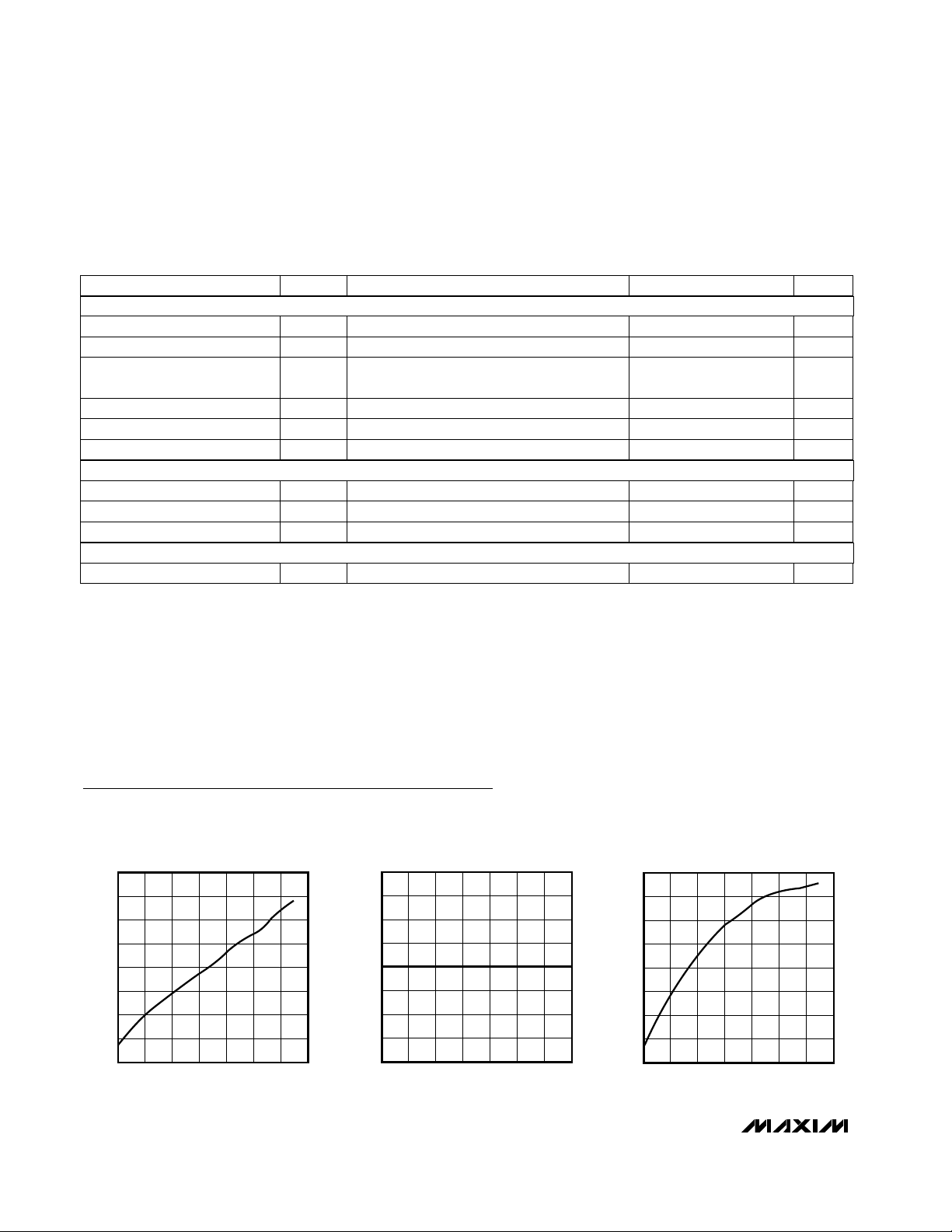

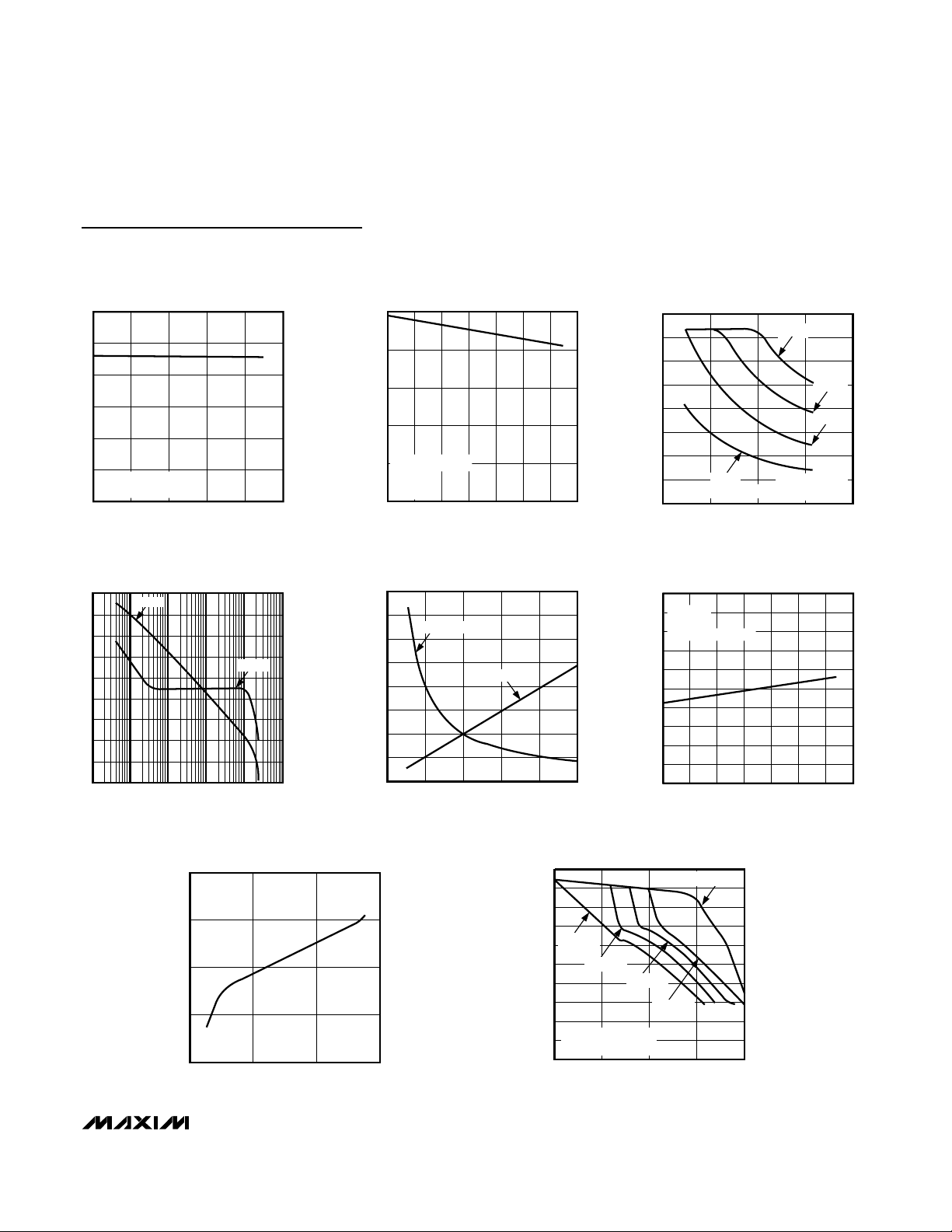

Typical Operating Characteristics

(VDD= +12V, R

FREQ

= 200kΩ, R

MAXTON

= 200kΩ, TA= +25°C, unless otherwise noted.)

MAX5003

High-Voltage PWM

Power-Supply Controller

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V+ = V

ES

=

VDD= +12V, V

INDIV

= 2V, V

CON

= 0, R

FREQ

= R

MAXTON

= 200kΩ, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical

values are at T

A

= +25°C.)

Note 1: See the Typical Operating Characteristics for preregulator current-to-voltage characteristics.

Note 2: Maximum time FREQ can be held below V

IL

and still remain in external mode.

Note 3: Feed-forward Ratio = Duty cycle at (V

INDIV

= 1.5V)/Duty cycle at (V

INDIV

= 1.875V)

Note 4: Occurs at start-up and until V

REF

is valid.

CONDITIONS UNITS MIN TYP MAXSYMBOLPARAMETERS

Minimum On-Time

200

ns

SS Source Current VSS= 0.5V, VDD= unconnected, V

CON

= 1.5V

3.4 5.5 9

µA

SS Sink Current V

SS

= 0.4V (Note 4)

10

mA

SS Time

0.45

s/µF

CON Bias Current I

CON

V

CON

= 0.5V and 2.5V

-1 0.01 1

µA

R

MAXTON

= 200kΩ, V

INDIV

= 1.25V µs

7.5

t

ON

Maximum On-Time Range

V

INDIV

= 1.875V V

0.48 0.5 0.53

RAMP Voltage Low

V

2.5

RAMP Voltage High

V

INDIV

stepped from 1.5V to 1.875V, V

CON

=

3.0V (Note 3)

0.72 0.8 0.88

Input Voltage Feed Forward

Ratio

kΩ50 500R

MAXTON

MAXTON Resistor Range

PWM COMPARATOR

SOFT-START

PWM OSCILLATOR

MAX5003

High-Voltage PWM

Power-Supply Controller

_______________________________________________________________________________________ 5

Typical Operating Characteristics (continued)

(VDD= +12V, R

FREQ

= 200kΩ, R

MAXTON

= 200kΩ, TA= +25°C, unless otherwise noted.)

V+ INPUT CURRENT vs. VOLTAGE

3.0

2.5

2.0

1.5

+ (mA)

V

I

1.0

0.5

V

= V

COMP

SWITCHING

= V

FB

V+ (V)

CON

0

20 6040 80 100 120

ERROR AMP FREQUENCY RESPONSE

70

60

50

40

30

20

GAIN (dB)

10

0

-10

-20

0.1k 1k 10k 100k 1M 10M

GAIN

FREQUENCY (Hz)

MAX5003-07

PHASE

MAX5003-04

0

-20

-40

-60

-80

-100

-120

-140

-160

-180

2.50

2.00

1.50

+ (mA)

V

I

1.00

0.50

0

400

350

300

250

200

150

PHASE (degrees)

FREQUENCY (kHz)

100

50

0

V+ INPUT CURRENT vs. TEMPERATURE

V

= V

CON

SWITCHING

V+ = 110V

-40 0-20 20 40 60 80 100

= V

COMP

FB

TEMPERATURE (°C)

SWITCHING FREQUENCY AND PERIOD

vs. R

FREQ

FREQUENCY

PERIOD

0 100 200 300

(kΩ)

R

FREQ

400

MAX5003-08

500

MAX5003-05

40

30

20

PERIOD (µs)

10

0

MAXIMUM DUTY CYCLE vs. V

80

70

60

50

40

30

DUTY CYCLE (%)

20

V

CLAMPED HIGH

CON

100kΩ

V

INDIV

10

0

123

V+ SHUTDOWN CURRENT

vs. TEMPERATURE

40

V+ = 110V

39

38

37

36

35

+ (µA)

V

I

34

33

32

31

30

= 0

V

INDIV

= UNCONNECTED

V

DD

-40 0-20 20 40 60 80 100

TEMPERATURE (°C)

400kΩ

(V)

INDIV

300kΩ

200kΩ

PARAMETER IS

R

MAXTON

4

MAX5003-06

5

MAX5003-09

V+ CURRENT IN BOOTSTRAPPED

OPERATION vs. TEMPERATURE

28.0

V+ = 110V

= 1.5V

V

INDIV

27.5

27.0

+ (µA)

V

I

26.5

26.0

-50 0 50 100

TEMPERATURE (°C)

MAX5003-10

(V)

V

10

9

8

7

6

5

CC

4

3

2

1

0

VCC LOAD REGULATION

V+ = 50V TO 110V

V+ = 12V

V+ = 13V

V+ = 14V

V+ = 15V

ES = UNCONNECTED

= UNCONNECTED

V

DD

0 5 10 15 20

ICC (mA)

MAX5003-11

MAX5003

High-Voltage PWM

Power-Supply Controller

6 _______________________________________________________________________________________

Pin Description

Typical Operating Characteristics (continued)

(VDD= +12V, R

FREQ

= 200kΩ, R

MAXTON

= 200kΩ, TA= +25°C, unless otherwise noted.)

NAME FUNCTION

1 V+

Preregulator Input. Connect to the power line for use with 25V to 110V line voltages. Bypass V+ to ground

with a 0.1µF capacitor, close to the IC. Connects internally to the drain of a depletion FET preregulator.

2 INDIV

Undervoltage Sensing and Feed-Forward Input. Connect to the center point of an external resistive divider

connected between the main power line and AGND. Undervoltage lockout takes over and shuts down

the controller when V

INDIV

< 1.2V. INDIV bias is typically 0.01µA.

PIN

3 ES

Preregulator Output. When V+ ranges above 36V, bypass ES to AGND with a 0.1µF capacitor close to

the IC. When V+ is always below 36V, connect ES to V+.

4 FREQ

Oscillator Frequency Adjust and Synchronization Input. In internal free-running mode, the voltage on this

pin is internally regulated to 1.25V. Connect a resistor between this pin and AGND to set the PWM frequency. Drive between V

IL

and VIHat four times the desired frequency for external synchronization.

8 COMP Compensation Connection. Output of the error amplifier, available for compensation.

7 CON Control Input of the PWM Comparator

6 REF Reference Voltage Output (3.0V). Bypass to AGND with a 0.1µF capacitor.

5 SS

Soft-Start Capacitor Connection. Ramp time to full current limit is approximately 0.5ms/nF. Limits duty

cycle when VSS< V

CON

.

10 MAXTON

Maximum On-Time Programming. A resistor from MAXTON to AGND sets the PWM gain and limits the

maximum duty cycle. The voltage on MAXTON tracks the voltage on the INDIV pin. Maximum on-time is

proportional to the value of the programming resistor. The maximum duty cycle is limited to 75%, regardless of the programming resistor.

9 FB Feedback Input. Regulates to VFB= V

REF

/ 2 = 1.5V.

(V)

CC

V

VCC LOAD REGULATION

10

9

8

7

6

5

4

3

2

V+ = V

=

ES

12V TO 36V

V

DD = UNCONNECTED

1

0

0 5 10 15 20

ICC (mA)

MAX5003-12

MAXIMUM FREQUENCY vs. INPUT VOLTAGE

AND FET TOTAL GATE-SWITCHING CHARGE

350

300

250

200

150

100

MAX SWITCHING FREQUENCY (kHz)

15nC

50

0

12 13 14

20nC

10nC

V+ (V)

30nC

25nC

15

MAX5003-13

16

MAX5003

High-Voltage PWM

Power-Supply Controller

_______________________________________________________________________________________ 7

Pin Description (continued)

NAME FUNCTIONPIN

13 PGND Power Ground. Connect to AGND.

12 CS

Current Sense with Blanking. Turns power switch off if VCSrises above 100mV (referenced to PGND).

Connect a 100Ω resistor between CS and the current-sense resistor (Figure 2). Connect CS to PGND if

not used.

11 AGND Analog Ground. Connect to PGND close to the IC.

14 NDRV Gate Drive for External N-Channel Power FET

15 V

CC

Output Driver Power-Rail Decoupling Point. Connect a capacitor to PGND with half the value used for

VDDbypass very close to the pin. If synchronizing several controllers, power the fan-out buffer driving the

FREQ pins from this pin.

16 V

DD

9.75V Internal Linear-Regulator Output. Drive VDDto a voltage higher than 10.75V to bootstrap the chip

supply. V

DD

is also the supply voltage rail for the chip. Bypass to AGND with a 5µF to 10µF capacitor.

Detailed Description

The MAX5003 is a PWM controller designed for use as

the control and regulation core of voltage-mode control

flyback converters or forward-voltage power converters. It provides the power-supply designer with maximum flexibility and ease of use. The device is specified

up to 110V and will operate from as low as 11V. Its

maximum operating frequency of 300kHz permits the

use of miniature magnetic components to minimize

board space. The range, polarity, and range of output

voltages and power are limited only by design and by

the external components used.

This device works in isolated and nonisolated configurations, and in applications with single or multiple output voltages. All the building blocks of a PWM

voltage-mode controller are present in the MAX5003

and its settings are adjustable. The functional diagram

is shown on Figure 1.

Modern Voltage-Mode Controllers

The MAX5003 offers a voltage-mode control topology

and adds features such as fast input voltage feed forward, programmable maximum duty cycle, and high

operating frequencies. It has all the advantages of current-mode control—good control loop bandwidth,

same-cycle response to input voltage changes, and

pulse-by-pulse current limiting. It eliminates disadvantages such as the need for ramp compensation, noise

sensitivity, and the analytical and design difficulties of

dealing with two nested feedback loops. In summary,

voltage-mode control has inherent superior noise

immunity and uses simpler compensation schemes.

Internal Power Regulators

The MAX5003’s power stages operate over a wide

range of supply voltages while maintaining low power

consumption. For the high end of the range (+36V to

+110V), power is fed to the V+ pin into a depletion

junction FET preregulator. This input must be decoupled with a 0.1µF capacitor to the power ground pin

(PGND). To decouple the power line, other large-value

capacitors must be placed next to the power transformer connection.

The preregulator drops the input voltage to a level low

enough to feed a first low-dropout regulator (LDO)

(Figure 1). The input to the LDO is brought out at the ES

pin. ES must also be decoupled with a 0.1µF capacitor.

In applications where the maximum input voltage is

below 36V, connect ES and V+ together and decouple

with a 0.1µF capacitor.

The first LDO generates the power for the VDDline. The

VDDline is available at the VDDpin for decoupling. The

bypass to AGND must be a 5µF to 10µF capacitor.

When the maximum input voltage is always below

18.75V, power may also be supplied at VDD; in this

case, connect V+, ES, and VDDtogether.

Forcing voltages at VDDabove 10.75V (see Electrical

Characteristics) disables the first LDO, typically reducing current consumption below 50µA (see Typical

Operating Characteristics).

Following the VDDLDO is another regulator that drives

VCC: the power bus for the internal logic, analog circuitry, and external power MOSFET driver. This regulator is needed because the VDDvoltage level would be

too high for the external N-channel MOSFET gate. The

MAX5003

High-Voltage PWM

Power-Supply Controller

8 _______________________________________________________________________________________

Figure 1. Functional Diagram

V

FETBIAS

1

V+

2

INDIV

ES

3

1.2V

AGND

UV LOCKOUT

HIGH-VOLTAGE EPIFET

V

V

CC

DD

V

OK

IN

MAX5003

V

ES

V

OK

IN

V

CC

REF

REFOK

SDN

LINEAR

REGULATOR

LINEAR

REGULATOR

OK

BANDGAP

REFERENCE

AGND

V

DD

AGND

V

CC

AGND

16

V

V

DD

V

CC

DD

V

15

CC

14

NDRV

FREQ

REF

CON

COMP

“1”

V

CC

4

5

SS

6

7

8

FREQ

REFOK

SDN

INDIV

MAXTON

RAMP

SS

V

CON

PWM COMP

SDN

CLK

RAMP

AGND

V

AGND

CC

V

REF

D “D”FF

CLK Q

R

C

LIMIT

V

CC

R

R

DRIVER

CURRENT

SENSE

CS BLANK

100ns

STRETCHING

V

CC

PGND

V

CC

PGND

V

CC

PGND

NDRV

0.1V

13

PGND

12

CS

11

AGND

10

MAXTON

9

FB

ERROR AMP

AGND

VCCregulator has a lockout line that shorts the N-channel MOSFET driver output to ground if the VCCLDO is

not regulating. VCCfeeds all circuits except the V

CC

lockout logic, the undervoltage lockout, and the power

regulators.

The preferred method for powering the MAX5003 is to

start with the high-voltage power source (at V+ or ES,

depending on the application), then use a bootstrap

source from the same converter with an output voltage

higher than the VDDregulator turn-off voltage (10.75V)

to power VDD. This will disable the power consumption

of the VDDLDO. It is also possible to power the

MAX5003 with no bootstrap source from ES or V+, but

do not exceed the maximum allowable power dissipation. The current consumption of the part is mostly a

function of the operating frequency and the type of

external power switch used—in particular, the total

charge to be supplied to the gate.

A reference output of 3V nominal is externally available

at the REF pin, with a current sourcing capability of

1mA. A lockout circuit shuts off the oscillator and the

output driver if REF falls 200mV below its set value.

Minimize loading at REF, since the REF voltage is the

source for the FB voltage, which is the regulator set

point when the error amplifier is used. Any changes in

V

REF

will be proportionally reflected in the regulated

output voltage of the converter.

Undervoltage Lockout, Feed Forward,

and Shutdown

The undervoltage lockout feature disables the controller

when the voltage at INDIV is below 1.2V (120mV hysteresis). When INDIV rises higher than 1.2V plus the

hysteresis (typically 1.32V), it allows the controller to

start. An external resistive divider connected between

the power line and AGND generates the INDIV signal.

INDIV is also used as the signal for the fast input voltage feed-forward circuit.

Always connect INDIV to a voltage divider. It is not a

“don’t care” condition; the signal is used to set the fast

feed-forward circuit (see the Oscillator and Ramp

Generator section).

Choose R2 (Figure 2) between 25kΩ to 500kΩ and calculate R1 to satisfy the following equation:

where V

SUL

= system undervoltage lockout and

V

INDIVLO

= I

NDIV

undervoltage lockout.

The undervoltage lockout function allows the use of the

INDIV pin as a shutdown pin with an external switch to

ground. The shutdown circuit must not affect the resistive divider during normal operation.

Current-Sense Comparator

The current-sense (CS) comparator and its associated

logic limit the current through the power switch. Current

is sensed at CS as a voltage across a sense resistor

between the external MOSFET source and PGND.

Connect CS to the external MOSFET source through a

100Ω resistor or RC lowpass filter (Figures 2 and 3).

See CS Resistor in the Component Selection section.

A blanking circuit shunts CS to ground when the power

MOSFET switch is turned off, and keeps it there for

70ns after turn-on. This avoids false trips caused by the

switching transients. The blanking circuit also resets

the RC filter, if used. When VCS> 100mV, the power

MOSFET is switched off. The propagation delay from

the time the switch current reaches the trip level to the

driver turn-off time is 240ns. If the current limit is not

used, the CS pin must be connected to PGND.

Error Amplifier

The internal error amplifier is one of the building blocks

that gives the MAX5003 its flexibility. Its noninverting

input is biased at 1.5V, derived from the internal 3V reference. The inverting input is brought outside (FB pin)

and is the regulation feedback connection point. If the

error amplifier is not used, connect this pin to ground.

The output is available for the frequency compensation

network and for connection to the input of the PWM

comparator (CON). Unity-gain frequency is 1.2MHz,

open-circuit gain is 80dB, and the amplifier is unitygain stable. To eliminate long overload recovery times,

there are clamps limiting the output excursions close to

the range limits of the PWM ramp. The voltage at the

noninverting input of the error amplifier is the regulator

set point, but is not accessible.

Set-point voltage can be measured, if needed, by connecting COMP and FB and measuring that node with

respect to ground. The error amplifier is powered from

the V

CC

rail.

PWM Comparator

The pulse-width modulator (PWM) comparator stage

transforms the error signal into a duty cycle by comparing

the error signal with a linear ramp. The ramp levels are

0.5V min and 2.5V max. The comparator has a typical

hysteresis of 5.6mV and a propagation delay of 100ns.

The output of the comparator controls the external FET.

Soft-Start

The soft-start feature allows converters built using the

MAX5003 to apply power to the load in a controllable

soft ramp, thus reducing start-up surges and stresses.

MAX5003

High-Voltage PWM

Power-Supply Controller

_______________________________________________________________________________________ 9

RR

12 1 =−

V

SUL

V

INDIVLO

MAX5003

It also determines power-up sequencing when several

converters are used.

Upon power turn-on, the SS pin acts as a current sink

to reset any capacitance attached to it. Once REF has

exceeded its lockout value, SS sources a current to the

external capacitor, allowing the converter output voltage to ramp up. Full output voltage is reached in

approximately 0.45s/µF.

The SS pin is an overriding extra input to the PWM

comparator. As long as its voltage is lower than V

CON

,

it overrides V

CON

and SS determines the level at which

the duty cycle is decided by the PWM comparator.

After exceeding V

CON

, SS no longer controls the duty

cycle. Its voltage will keep rising up to VCC.

Oscillator and Ramp Generator

The MAX5003 oscillator generates the ramp used by

the comparator, which in turn generates the PWM digital signal. It also controls the maximum on-time feature

of the controller. The oscillator can operate in two

modes: free running and synchronized (sync). A single

pin, FREQ, doubles as the attachment point for the frequency programming resistor and as the synchronization input. The mode recognition is automatic, based on

the voltage level at the FREQ pin.

In free-running mode, a 1.25V source is internally

applied to the pin; the oscillator frequency is proportional to the current out of the pin through the programming resistor, with a proportionality constant of

16kHz/µA.

In sync mode, the signal from the external master generator must be a digital rectangular waveform running

at four times the desired converter switching frequency.

Minimum acceptable signal pulse width is 150ns, positive or negative, and the maximum frequency is

1.2MHz.

When the voltage at FREQ is forced above 2.7V, the

oscillator goes into sync mode. If left at or below 1.5V for

more than 8µs to 20µs, it enters free-running mode.

The master clock generator cannot be allowed to stop

at logic zero. If the system design forces such a situation, an inverter must be used at the FREQ pin.

In sync mode, the oscillator signal is divided by four and

decoded. The output driver is blocked during the last

phase of the division cycle, giving a hardwired maximum

on-time of 75%. In free-running mode, the oscillator duty

cycle is 75% on, and the off portion also blocks the output driver. The maximum on-time is then absolutely limited to 75% in either mode. Maximum on-time can be

controlled to values lower than 75% by a programming

resistor at the MAXTON pin.

The PWM ramp generated goes from 0.5V min to 2.5V

max, and the maximum time on is the time it takes from

low to high.

MAXTON is internally driven to V

INDIV

and a resistor

must be connected from MAXTON to AGND, to program the maximum on-time.

The ramp slope is directly proportional to V

INDIV

and

inversely proportional to R

MAXTON

. Since the ramp voltage limits are fixed, controlling the ramp slope sets the

maximum time on.

Changing the ramp slope while V

CON

remains constant

also changes the duty cycle and the energy transferred to

the load per cycle of the converter. The INDIV signal is a

fraction of the input voltage, so the fast input voltage feedforward works by modifying the duty cycle in the same

clock period, in response to an input voltage change.

Calculate the maximum duty cycle as:

where:

D

MAX

= Maximum duty cycle (%)

MAXTON = Maximum on-time

T = Switching period

Then:

where:

R

MAXTON

= Resistor from the MAXTON pin to ground

V

INDIV

= Voltage at the INDIV pin

ƒSW= Output switching frequency

MAXTON can then be calculated as:

N-Channel MOSFET

Output Switch Driver

The MAX5003 output drives an N-channel MOSFET

transistor. The output sources and sinks relatively large

currents, supplying the gate with the charge the transistor needs to switch. These are current spikes only,

since after the switching transient is completed the load

is a high-value resistance. The current is supplied from

the VCCrail and must be sourced by a large-value

High-Voltage PWM

Power-Supply Controller

10 ______________________________________________________________________________________

D

MAX

D 0.75 100

= ⋅

MAX

MAXTON

=

MAXTON

= ⋅ 100

T

R

MAXTON

200k

075 125

. .

k V kHz

200 100

1.25V

Ω

V

RV

⋅⋅

MAXTON

Ω

⋅⋅

INDIV

INDIV

ƒ

SW

100kHz

capacitor (5µF to 10µF) at the VCCpin, since the rail will

not support such a load. It is this current, equivalent to

the product of the total gate switching charge (from the

N-channel MOSFET data sheet), times the operating

frequency, that determines the bulk of the MAX5003

power dissipation.

The driver can source up to 560mA and sink up to 1A

transient current with a typical on source resistance of

4Ω. The no-load output levels are VCCand PGND.

Applications Information

Compensation and Loop

Design Considerations

The circuit shown in Figure 2 is essentially an energy

pump. It stores energy in the magnetic core and the air

gap of the transformer while the power switch is on,

and delivers it to the load during the off phase. It can

operate in two modes: continuous and discontinuous.

In discontinuous mode, all the energy is given to the

load before the next cycle begins; in continuous mode,

some energy is continuously stored in the core.

The system has four operating parameters: input voltage, output voltage, load current, and duty cycle. The

PWM controller senses the output voltage and the input

voltage, and keeps the output voltage regulated by

controlling the duty cycle.

The output filter in this circuit consists of the load resistance and the capacitance on the output.

To study the stability of the feedback system and

design the compensation necessary for system stability

under all operating conditions, first determine the transfer function. In discontinuous mode, since there is no

energy stored in the inductor at the end of the cycle,

the inductor and capacitor do not show the characteristic double pole, and there is only a dominant pole

defined by the filter capacitor and the load resistance.

There is a zero at a higher frequency, defined by the

ESR of the output filter capacitor. Such a response is

easy to stabilize for a wide range of operating conditions while retaining a reasonably fast loop response.

In continuous mode, the situation is different. The

inductor-capacitor combination creates a double pole,

since energy is stored in the inductor at all times. In

addition to the double pole, a right-half-plane zero

appears in the frequency response curves. This

response is not easy to compensate. It can result in

conditional stability, a complicated compensation network, or very slow transient response.

To avoid the analytical and design problems of the continuous-conduction mode flyback topology and maintain

good loop response, choose a design incorporating a

discontinuous-conduction mode power stage

To keep the converter in discontinuous mode at all times,

the value of the power transformer’s primary inductance

must be calculated at minimum line voltage and maximum load, and the maximum duty cycle must be limited.

The MAX5003 has a programmable duty-cycle limit function intended for this purpose.

Design Methodology

Following is a general procedure for developing a system:

1) Determine the requirements.

2) In free-running mode, choose the FREQ pin programming resistor. In synchronized mode, determine

the clock frequency (f

CLK)

.

3) Determine the transformer turns ratio, and check the

maximum duty cycle.

4) Determine the transformer primary inductance.

5) Complete the transformer specifications by listing

the primary maximum current, the secondary maximum current, and the minimum duty cycle at full

power.

6) Choose the MAXTON pin programming resistor.

7) Choose a filter capacitor.

8) Determine the compensation network.

Design Example

1) 36V < VIN< 72V, V

OUT

= 5V, I

OUT

= 1A, ripple

< 50mV, settling time ≈ 0.5ms.

2) Generally, the higher the frequency, the smaller the

transformer. A higher frequency also gives higher

system bandwidth and faster settling time. The

trade-off is lower efficiency. In this example, 300kHz

switching frequency is the choice to favor for a small

transformer. If the converter will be free running (not

externally synchronized), use the following formula to

calculate the R

FREQ

programming resistor:

where:

R

FREQ

= Resistor between FREQ and ground

ƒSW= Switching frequency (300kHz)

If the converter is synchronized to an external clock,

the input frequency will be 1.2MHz. The external

clock runs at four times the desired switching frequency.

R

kHz

kk

FREQ

SW

=

ƒ

=

100

200 66 7 .Ω

MAX5003

High-Voltage PWM

Power-Supply Controller

______________________________________________________________________________________ 11

MAX5003

3) The main factors influencing the choice of the turns

ratio are the switch breakdown voltage and the duty

cycle. With a smaller turns ratio, the secondary

reflected voltage and the maximum voltage seen by

the switch during flyback are reduced, which is

favorable. On the other hand, a smaller turns ratio

will shorten the duty cycle and increase the primary

RMS current, which can impact efficiency. A good

starting figure is the ratio of the input voltage to the

output voltage, rounding to the nearest integer. To

keep the flyback voltage under control, choose an 8to-1 ratio for the 48V to 5V system. The maximum

duty cycle allowed without putting the device in continuous-conduction mode can be found using the following formula:

where:

N = NP/NS= Turns ratio

V

SEC

= Secondary voltage

DC

MAX

= Maximum duty cycle

V

MIN

= Minimum power-line voltage

For a 48V to 5V system with an 8-to-1 turns ratio, the

maximum duty cycle before putting the device in

discontinuous mode is 55%. Assume that VINmin is

36V (minimum input voltage, neglecting drops in the

power switch and in the resistance of the primary

coil) and V

SEC

is 5.4V (5V plus a Schottky diode

drop). The MAX5003 maximum duty cycle is internally limited to 75%. Generally this parameter must fall

between 45% to 65% to obtain a balance between

efficiency and flyback voltage while staying out of

continuous conduction. If the value exceeds these

bounds, adjust the turns ratio.

4) Assuming 80% efficiency, a 6.25W input is needed

to produce a 5W output. Set an operating duty cycle

around 12% below the maximum duty cycle to allow

for component variation: 55% - 12% = 43%. Use the

following formula to calculate the primary inductance:

L

DC V

PWR

V

W kHz

H

PRI

MIN

IN SW

=

()

ƒ

=

()

≅µ

⋅

⋅⋅⋅⋅⋅

22

2

04336

2 6 25 300

65

.

.

High-Voltage PWM

Power-Supply Controller

12 ______________________________________________________________________________________

Figure 2. Application Example 1: Nonisolated +48V to +5V Converter

+48V

(36V TO 72V)

V

IN

1M

1

0.1µF

39k

0.1µF

0V

62k

470nF

0.1µF

2

3

4

5

6

7

8

V+

INDIV

ES

FREQ

SS

REF

CON

COMP

390pF

C

MAX5003

F

V

V

NDRV

PGND

AGND

MAXTON

R

F

200k

DD

CC

CS

FB

XFACOILTRCTX03

2

L

P

65µH

0.1µF

R

CS

0.1Ω

5

IRFD620S

16

15

14

10µF

13

12

11

10

9

33µF

100Ω

51k

8

CMSD4448

7

11, 12

MBRS130L

9, 10

4.7µF

22µF

22µF

R

A

41.2k

R

B

17.4k

+5V

1A

DC

MAX

=

1

V

MIN

⋅

VN

SEC

1

+

where:

DC = Duty cycle. Set to calculated minimum duty

cycle at V

MIN.

PWRIN= Input power, at maximum output power

This gives an inductance value (L

PRI

) of approxi-

mately 65µH.

5) The other parameter that defines the transformer is

peak current. This is given by:

The peak secondary current is the peak primary current multiplied by the turns ratio, or 0.8A · 8 = 6.4A.

Calculating the minimum duty cycle:

With these numbers, the transformer manufacturer

can choose a core.

6) For this application, the MAX5003 must be programmed for a maximum duty cycle of 55% at 36V.

The MAX5003 will automatically scale the limit with

the reciprocal of the input voltage as it changes. The

duty-cycle limit for an input voltage of 72V will be

27% (half of 55%). The duty cycle needed to stay out

of continuous conduction at 72V is 37%, so there is a

10% margin. The maximum duty time scales with the

voltage at the undervoltage lockout pin, V

INDIV

. The

voltage at INDIV is set by selecting the power line

undervoltage lockout trip point. The trip point for this

system, running from 36V to 72V, is 32V. Then INDIV

must be connected to the center point of a divider

with a ratio of 32/1.25, connected between the

power line and ground. Then R

MAXTON

is:

MAX5003

High-Voltage PWM

Power-Supply Controller

______________________________________________________________________________________ 13

Figure 3. Application Example 2: Isolated -48V to +5V Converter

0V

0.1µF

39k

V

IN

-48V

-36V TO -72V

XFACOILTRCTX03

CMSD4448

2

L

P

65µH

33µF

100Ω

IRFD620S

0.1µF

R

CS

0.1Ω

R1

1M

1

V+

2

INDIV

3

ES

4

MAX5003

FREQ

5

SS

6

REF

7

CON

8

R2

0.1µF

62k

470nF

1.3k

0.1µF

COMP

V

V

NDRV

PGND

AGND

MAXTON

16

DD

15

CC

14

10µF

13

12

CS

11

10

9

FB

51k

8

4.7µF

7

5

MBRS130L

11, 12

9, 10

6

5

MDC217

22µF

7

240k

22µF

1

2

TL431

51Ω

680Ω

3900pF

0.01µF

24.9k

24.9k

+5V

1A

-

I

PRI

=

2 PWR

⋅

L

⋅

PRI SW

IN

ƒ

2 6.25W

==

⋅

65 H 300kHz

⋅

µ

0.8A

DC DC

% .%===⋅⋅43

MIN MAX

() ( )

V

IN MAX

()

V

IN MIN

()

36

72

V

21 5

V

V

R

MAXTON

MIN

=

V

UVL SW

V

3632100

=

V

kHz

100

ƒ

kHz

300

kHz

DC V

55

75

MAX MIN

%

%

()

%

75

200 55

200

kk

=

ΩΩ

k

Ω

MAX5003

where:

R

MAXTON

= Resistor between the MAXTON pin and

ground

V

MIN

= Minimum power-line voltage

V

UVL

= Power-line trip voltage

DC

MAX(VMIN

) = Maximum duty cycle at minimum

power-line voltage

For this application circuit, a 10% margin is reasonable, so the value used is 50kΩ. This gives a maximum duty cycle of 50%. The maximum duty cycle

can now be expressed as:

where:

V

CON

= Voltage at the CON pin, input of the PWM

comparator

DC(V

CON

, VIN) = Duty cycle, function of V

CON

and

V

IN

0.5V and 2.5V are the values at the beginning and

end of the PWM ramp.

The term ƒSW/ ƒ

NOM

varies from 0.8 to 1.2 to allow

for clock frequency variation. If the clock is running

at 300kHz and the input voltage is fixed, then the

duty cycle is a scaled portion of the maximum duty

cycle, determined by V

CON

.

7) Low-ESR/ESL ceramic capacitors were used in this

application. The output filter is made by two 22µF

ceramic capacitors in parallel. Normally, the ESR of

a capacitor is a dominant factor determining the ripple, but in this case it is the capacitor value.

Calculating

the ripple will be a fraction of this depending on the

duty cycle. For a 50% duty cycle, the ripple due to

the capacitance is approximately 45mV.

8)The PWM gain can be calculated from:

Note that while the above formula incorporates the

product of the maximum duty cycle and VIN, it is

independent of V

IN

. For 1A output (RL= 5Ω), the

PWM gain is +3.0V/V. For a 10% load (R

L

= 50Ω),

the gain is multiplied by the square root of 10 and

becomes +10V/V. The pole of the system due to the

output filter is 1 / 2πRC, where R is the load resistance and C the filter capacitor. Choosing a capacitor and calculating the pole frequency by:

it is 723Hz at full load. At 10% load it will be 72Hz,

since the load resistor is then 50Ω instead of 5Ω. The

total loop gain is equal to the PWM gain times the

gain in the combination of the voltage divider and

the error amplifier. The worst case for phase margin

is at full load. For a phase margin of 60 degrees, this

midband gain (G) must be set to be less than:

where:

ƒU= Unity-gain frequency of error amplifier

PM = Phase margin angle

The DC accuracy of the regulator is a function of the

DC gain. For 1% accuracy, a DC gain of 20 is required.

Since the maximum midband gain for a stable

response is 16, an integrator with a flat midband gain

given by a zero is used. The midband gain is less than

16, to preserve stability, and the DC gain is much larger

than 20, to achieve high DC accuracy.

Optimization on the bench showed that a midband gain

of 5 gave fast transient response and settling with no

ringing. The zero was pushed as high in frequency as

possible without losing stability. The zero must be a

factor of two or so below the system unity-gain frequency (crossover frequency) at minimum load. With the

High-Voltage PWM

Power-Supply Controller

14 ______________________________________________________________________________________

DC(V )

CON,VIN

V 0.5V

−

CON MIN

=

2.0V

V - 0.5V

CON

≈

2.0V

V

36V

V

ƒ

SW

DC

V

ƒ

IN NOM

ƒ

50%

ƒ

INSWNOM

⋅

MAX(VMIN)

DC(V ,V ) =

CON MIN

DC(V ,V )

CON MAX

DC(2.5V,V ) 50%

DC(2.5V,V ) 25%

DC(0.5V,V ) 0

DC(0.5V,V ) 0

MIN

MAX

MIN

MAX

V 0.5V

CON

V 0.5V

CON

=

=

=

=

=

−

2.0V

2.0V

50%

−

25%

I

OUT

ƒ

SW

==

⋅⋅

C

A

1

kHz F

300 4476µ

mV

A

dV

OUT

==

PWM

dV

CON

⋅⋅

2L

=

.

2L

R

PRI SW

⋅⋅

PRI SW

L

R

V

MIN

DC

2.0V

36

20

V

V

ƒ

L

ƒ

MAX VMIN

≅

50 3

%

()

ƒ=

P

⋅⋅ ⋅⋅

RC F

2

1

LL

=

1

Ω

2544ππµ

ƒ

G

<

UErrorAmp

PM A

tan( ) .

⋅⋅ ⋅⋅

ƒ

PWM P

=

MHz

1

1 7 3 723

Hz

zero at 2kHz, the crossover frequency is 4kHz and the

phase margin is 50°.

Given the above considerations, RA, RB, RF, and C

F

can be chosen (Figure 2). The sum of RAand RBis

chosen for low current drain. In the example, RAplus

RBis 58kΩ and draws 80µA. The following ratio sets

the output voltage:

RB/ (RA+ RB) = V

SET

/ V

OUT

Since V

SET

= 1.5V and V

OUT

= 5V, RAis set to 41.2kΩ

and RBto 17.4kΩ.

The midband gain is the ratio of RF/RA. RBdoes not

affect the gain because it is connected to a virtual

ground. For a midband gain of 5, the feedback resistor

equals 200kΩ. To set the zero at 2kHz, the capacitor

value is:

CF= 1 / (2π · RF· fz) = 400pF

Layout Recommendations

All connections carrying pulsed currents must be very

short, be as wide as possible, and have a ground plane

behind them whenever possible. The inductance of

these connections must be kept to an absolute minimum due to the high di/dt of the currents in highfrequency switching power converters. In the development or prototyping process, multipurpose boards, wire

wrap, and similar constructive practices are not suitable for these type of circuits; attempts to use them will

fail. Instead, use milled PC boards with a ground plane,

or equivalent techniques

Current loops must be analyzed in any layout proposed, and the internal area kept to a minimum to

reduce radiated EMI. The use of automatic routers is

discouraged for PC board layout generation in the

board area where the high-frequency switching converters are located. Designers should carefully review

the layout. In particular, pay attention to the ground

connections. Ground planes must be kept as intact as

possible. The ground for the power-line filter capacitor

and the ground return of the power switch or currentsensing resistor must be close. All ground connections

must resemble a star system as much as practical.

“Short” and “close” are dimensions on the order of

0.25in to 0.5in (0.5cm to about 1cm).

Setting the Output Voltage

The output voltage of the converter, if using the internal

error amplifier, can easily be set by the value of the FB

pin set voltage. This value is 1.5V. A resistive divider

must be calculated from the output line to ground, with

a dividing ratio such that when the output is at the

desired value, the center-point voltage will be 1.5V. The

Thevenin equivalent of the resistors must be low

enough so the error amplifier bias current will not introduce a division error. The two resistors must have similar temperature coefficients (tempcos), so the dividing

ratio will be constant with temperature.

Component Selection

CS Resistor

The CS resistor is connected in series with the source

of the N-channel MOSFET and ground, sensing the

switch current. Its value can be calculated from the following equation:

where η = efficiency and 0.5 < KTOL< 0.75.

K

TOL

includes the tolerance of the sensing resistor, the

dispersion of the MAX5003 CS trip point, and the

uncertainties in the calculation of the primary maximum

current.

The sensing resistor must be of the adequate power

dissipation and low tempco. It must also be noninductive and physically short. Use standard surface-mount

CS resistors. A 100Ω resistor is recommended between

the CS resistor and the CS pin. If the current surge at

the beginning of the conduction period is large and disrupts the MAX5003’s operation, add a capacitor

between the CS pin and PGND, to form an RC filter.

Power Switch

The MAX5003 will typically drive an N-channel MOSFET

power switch. The maximum drain voltage, maximum

R

DS(ON)

, and total gate switching charge are the parameters involved in choosing the FET. The maximum

gate switching charge is the most important factor

defining the MAX5003 internal power consumption,

since the product of the switching frequency and the

total gate charge is the IC current consumption.

R

DS(ON)

is the parameter that determines the total conduction power losses in the switch, and the choice

depends on the expected efficiency and the cooling

and mounting method. The maximum drain voltage

requirements can be different depending on the topology used. In the flyback configuration, the maximum

voltage is the maximum supply voltage plus the reflected secondary voltage, any ringing at the end of the

conduction period, and the spike caused by the leakage inductance. In the case of the forward converter,

the reset time of the core will set the maximum voltage

MAX5003

High-Voltage PWM

Power-Supply Controller

______________________________________________________________________________________ 15

R

100 100

CS

mV

I

LIM PRI

()

2

PWR

L

PRI SW

mV

OUT MAX

()

⋅⋅

η

ƒ

K

==

⋅

TOL

stress on the switch. A FET with the lowest total charge

and the lowest R

DS(ON

) for the maximum drain voltage

expected (plus some safety factor) is the best choice.

The choice of package is a function of the application,

the total power, and the cooling methods available.

Transformer

Transformer parameters, once calculated in the design

process, can be used to find standard parts whenever

possible. The most important factors are the saturation

current, primary inductance, leakage inductance turns

ratio, and losses. Packaging and EMI generation and

susceptibility are closely connected, and must be considered. In general, parts with exposed air gaps (not

contained inside the magnetic structure) will generate

the most radiated EMI, and might need external shielding. If the design is in high-voltage power supplies, the

insulation specifications are also important. Pay close

attention if the circuitry is galvanically connected to the

mains at any point, since serious safety and regulatory

issues might exist.

Capacitors

As in any high-frequency power circuit, the capacitors

used for filtering must meet very low ESR and ESL

requirements. At the 300kHz frequency (of which the

MAX5003 is capable), the most favorable technologies

are ceramic capacitors and organic semiconductor (OS

CON) capacitors. The temperature dependence of the

capacitance value and the ESR specification is important,

particularly if the ESR is used as part of the compensation

network for the feedback loop. If using through-hole-

mounted parts, keep lead length as short as practical.

Components with specifications for switching power converters are preferred. Decoupling capacitors must be

mounted close to the IC.

Diodes

The choice of rectifier diodes depends on the output

voltage range of the particular application. For low-voltage converters, the diode drop is a significant portion

of the total loss, and must be kept to a minimum. In

those cases, Schottky diodes are the preferred component for the design. At higher voltages, ultra-fast recovery diodes must be used, since Schottky components

will not satisfy the reverse voltage specification.

For all cases, the specifications to be determined

before choosing a diode are the peak current, the average current, the maximum reverse voltage, and the

maximum acceptable rectification losses. Once a type

is identified, a thermal analysis of the diode losses vs.

total thermal resistance (from junction to ambient) must

be carried out if the total power involved is significant.

Industrial-frequency (60Hz) rectifiers are not recommended for any function in these converters, due to

their high capacitance and recovery losses. If using

overdimensioned rectifiers, the junction capacitance

influence must be reviewed.

MAX5003

High-Voltage PWM

Power-Supply Controller

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1999 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

___________________Chip Information

TRANSISTOR COUNT: 1050

SUBSTRATE CONNECTED TO GND

MANUFACTURER PHONE DEVICE TYPE

Current-Sense Resistors Dale-Vishay 402-564-3131

Power FETs

Fairchild 408-822-2000

International Rectifier 310-322-3333

Motorola 303-675-2140

Diodes

Central Semiconductor 516-435-1110

Transistors Central Semiconductor 516-435-1110

FAX

402-563-6418

408-822-2102

310-322-3332

303-675-2150

516-435-1824

516-435-1824

Capacitors

Sanyo 619-661-6835 619-661-1055

Taiyo Yuden 408-573-4150 408-573-4159

AVX 803-946-0690 803-626-3123

Coils Coiltronics 561-241-7876 561-241-9339

Table 1. Component Manufacturers

Loading...

Loading...