Page 1

General Description

The MAX3891 evaluation kit (EV kit) is an assembled

surface-mount demonstration board that provides easy

evaluation of the MAX3891 2.5Gbps, 16:1 serializer with

clock synthesis and single-ended, low-voltage PECL

inputs.

The MAX3891 EV kit is optimized for +3.3V operation.

Total current consumption at 3.3V is 570mA. The EV kit

provides PECL terminations and controlled 50Ω imped-

ances on all input and output data lines.

Features

♦ +3.3V Single Supply

♦ Selectable Reference Clock Frequencies

(155.52MHz, 51.84MHz, 77.76MHz, 38.88MHz)

♦ Fully Assembled and Tested Surface-Mount

Board

Evaluates: MAX3891

MAX3891 Evaluation Kit

________________________________________________________________ Maxim Integrated Products 1

19-1969; Rev 0; 2/01

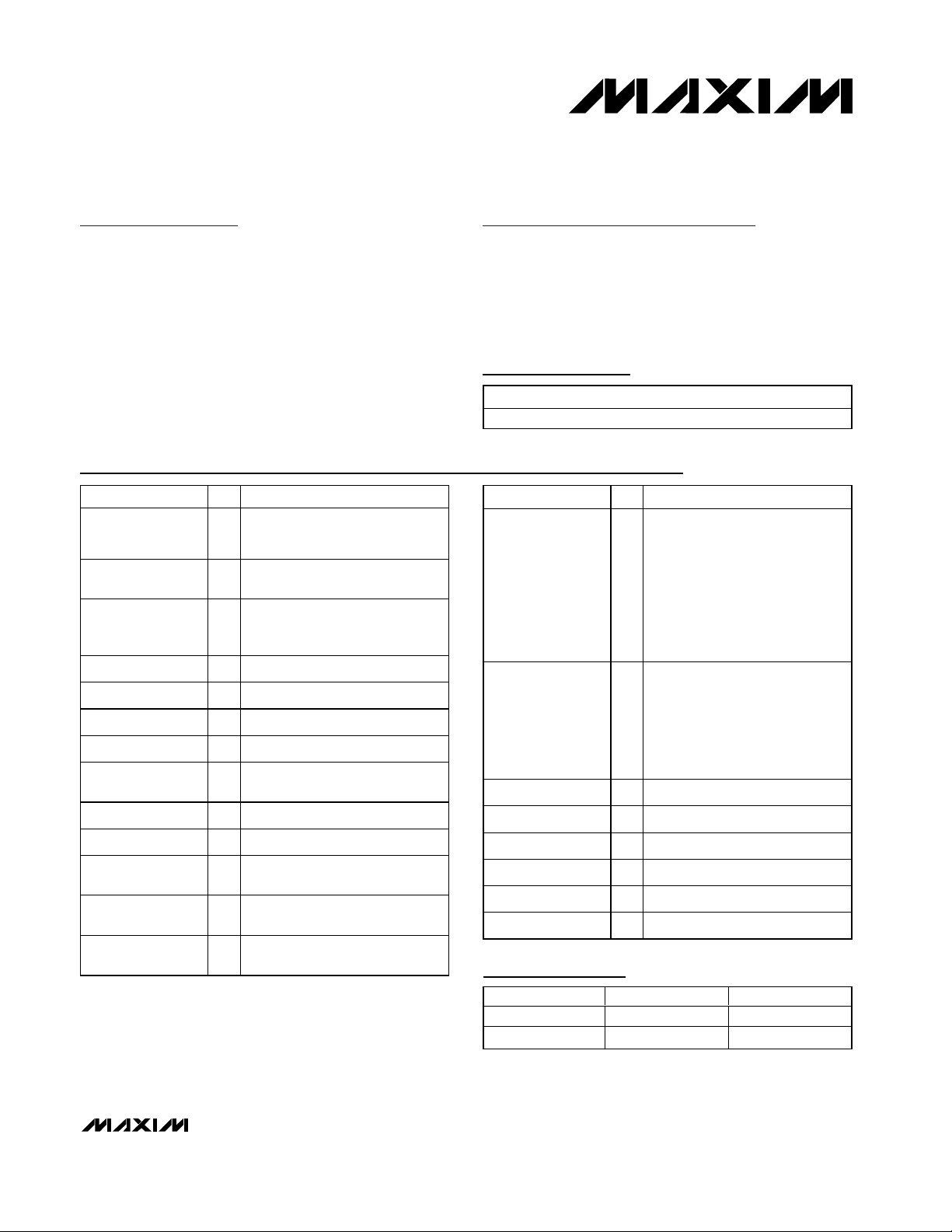

Component List

Ordering Information

Component Suppliers

Note: Please indicate you are using the MAX3891 when contacting the suppliers.

*Exposed pad

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

DESIGNATION QTY DESCRIPTION

C1–C6, C8–C11,

C13–C32,

C34–C37

C7 1

C12 1

J1–J6 6 SMA connectors (side mount)

J7–J24, J27, J28 20 SMB connectors (PC mount)

J25, J26 2 SMA connectors (PC mount)

JU1, JU3–JU9 8 2-pin headers (0.1in centers)

L1–L5 5

R1, R2 2 49.9Ω ±1% resistors (0402)

R3 1 10kΩ ±1% resistor (0402)

R4, R8, R12, R16,

R28, R29

R5, R9, R13, R17,

R24, R25

R6, R10, R14, R18,

R89, R93

0.1µF ±10%, 10V min ceramic

34

capacitors (0603)

0.33µF ±10%, 25V min ceramic

capacitor (0603)

33µF ±10%, 10V min tantalum

capacitor

Sprague 293D336X0010C2

56nH inductors

Coilcraft 0805CS-560XKBC

6 27.4Ω ±1% resistors (0402)

6 24.3Ω ±1% resistors (0402)

6 221Ω ±1% resistors (0402)

PART TEMP. RANGE IC PACKAGE

MAX3891EVKIT -40°C to +85°C 64 TQFP-EP*

DESIGNATION QTY DESCRIPTION

R7, R11, R15,

R19, R20, R26,

R30, R32, R33,

R34, R36, R38,

R42, R46, R50,

R54, R58, R62,

R66, R70, R74,

R78, R81, R85,

R91, R95

R21, R27, R31,

R35, R37, R39,

R40, R41, R43,

R47, R51, R55,

R59, R63, R67,

R71, R75, R79,

R83, R87

R22, R23 2 20kΩ ±1% resistors (0402)

U1 1 MAX3891ECB (64-pin TQFP-EP)

VCC, GND 2 Test points

None 8 Shunts

None 1 MAX3891 EV kit circuit board

None 1 MAX3891 data sheet

SUPPLIER PHONE FAX

Coilcraft 847-639-6400 847-639-1469

Sprague 207-324-4140 603-224-1430

26 130Ω ±1% resistors (0402)

20 82.5Ω ±1% resistors (0402)

Page 2

Evaluates: MAX3891

MAX3891 Evaluation Kit

2 _______________________________________________________________________________________

Detailed Description

The MAX3891 EV kit contains all components needed

to simplify the evaluation of the MAX3891 16:1 serializer. The completely assembled and factory-tested EV kit

operates from a single +3.3V supply and includes all

external components necessary to interface with standard 50Ω test equipment. On-board termination and

AC coupling is provided for the MAX3891’s singleended LV PECL parallel data inputs. The differential LV

PECL serial data outputs are also terminated on-board

with resistive networks optimized for forward and

reverse 50Ω termination. The evaluation kit also provides AC coupling and 50Ω terminations for the CML

system loopback outputs. Control functions and operating parameters are programmed with jumpers. The reference clock rate is programmed with JU3–JU5, the

PLL loop filter capacitor can be shorted by shorting

JU6, and the system loopback outputs can be selected

for diagnostic testing by setting JU1 appropriately.

Layout Considerations

All differential signal outputs are of equal length and

use coupled 50Ω transmission lines so that propagation

delay skew is minimized. The on-board impedance

matching resistive networks provided for the PECL outputs allow easy interface of the EV kit to standard test

equipment with 50Ω terminations to ground. These minimum loss pads are optimized for both forward and

reverse 50Ω impedance and attenuate the MAX3891’s

output signal by 0.46V/V (6dB). SMA connectors are

provided for all high-speed differential outputs (SDI±,

SLBI±, and SCLKO±) and for the differential reference

clock input (RCLK±). SMB connectors are provided for

the single-ended input data signals (PDI_) parallel input

clock (PCLKI±) and parallel output clock (PCLKO±)

Supply power is routed to the MAX3891 through five

separate, independently filtered voltage supplies:

VCCDIG, VCCO, VCCPLL, VCCVCO, and VCCPECL.

Care must be taken when designing power-supply filtering as the VCCVCO supply is most susceptible to

power-supply noise. Noise on the VCO supply causes

the VCO to generate phase noise, which could degrade

the MAX3891’s jitter performance. Inductive filtering is

recommended for the VCO supply. Noise on the VCCO

supply is effectively rejected; however, because of the

external PECL biasing, significant noise is coupled

back onto the VCCO supply pin. Ideally, this supply

should be isolated from all the others. At the least, isolate the VCCO supply from the VCCVCO supply. The

single-ended PECL inputs could be affected by noise

on the VCCPECL supply. Since PECL signal swings are

much larger than the expected supply noise, the PECL

inputs require relatively simple filtering. Decoupling

capacitors placed close to the IC should be adequate

in most cases. The VCCPLL and VCCDIG supplies

power the rest of the IC. These supplies have moderate

supply noise rejection and contribute moderately to

total supply-induced noise. In most cases, VCCPLL and

VCCDIG can also be decoupled with capacitors placed

close to the IC.

Jumpers and Test Points

The MAX3891 EV kit provides jumpers to allow easy

configuration of the MAX3891’s mode of operation.

Table 1 gives a brief description of the MAX3891’s

jumper functions. The SOS jumper, JU1, configures the

data output path. For normal operation, short pins 1

and 2 of JU1 to disable the SLBO outputs. For system

loopback diagnostic testing, remove the shunt from

JU1 to enable the system loopback outputs.

The MAX3891 has the ability to use multiple reference

clock frequencies. Use the CLKSET jumpers JU2, JU3,

and JU4 to program the MAX3891’s reference clock

input for 38.88MHz, 51.84MHz, 77.76MHz, or

155.52MHz (Table 2). For example, remove the shunts

from JU3 and JU5 and short pins 1 and 2 of JU4 for

operation using a 51.84MHz reference clock.

Table 1. Jumpers, Test Points,

and Connections

Table 2. CLKSET Jumper Functions

NAME TYPE DESCRIPTION

JU1

JU3,

JU4, JU5

JU6

Two-pin

header

Two-pin

header

Two-pin

header

U sed to enab l e/d i sab l e

the S LBO outp uts.

Used to program the

reference clock

frequency

Used to short the filter

(FIL ±) pins

NORMAL

POSITION

Shorted

See Table 2

Open

f

RCLK

(MHz)

155.52 Shorted (to VCC) Open Open

77.76 Open Open Open

51.84 Open

38.88 Open Open

JU3 JU4 JU5

S hor ted

( 20kΩ to g r ound )

Open

Shorted

(to ground)

Page 3

Quick Start

The MAX3891 allows the use of multiple reference

clock frequencies. Be sure to set the clockset jumpers

appropriately for your reference clock frequency. The

following procedure sets up the EV kit for a 155.52MHz

reference clock.

1) Verify that the shunts are in place on 2-pin headers

JU1 and JU3. JU1 will disable the SLBO outputs

and JU3 will select the input reference clock frequency of 155.52MHz.

2) Verify that the shunts are removed from 2-pin headers JU4, JU5, and JU6.

3) Connect the differential output of your reference

clock through 50Ω cables to the differential RCLK±

inputs.

4) Connect your single-ended signal source outputs

through 50Ω cables to the parallel data (PDI_)

inputs. If 16 separate 155.52MHz signal generators

are not available, tie the unused parallel data inputs

to either a PECL high or PECL low. To tie an input to

a PECL high, remove the 130Ω PECL biasing resistor. To tie an input to a PECL low, reverse positions

of the PECL input biasing resistors.

5) Connect the differential parallel input clock through

50Ω cables to the PCLKI± inputs.

6) Connect the serial data and clock outputs through

50Ω cables to a 50Ω oscilloscope (minimum 3GHz

bandwidth) or test equipment.

7) Power up the EV kit with a 3.3V supply and check

the signal at the output.

Exposed Pad Package

The exposed pad (EP) 64-pin TQFP incorporates features that provide a very low thermal-resistance path for

heat removal from the IC—either to a PC board or to an

external heat sink. The MAX3891’s EP must be soldered directly to a ground plane with good thermal

conductance.

Evaluates: MAX3891

MAX3891 Evaluation Kit

_______________________________________________________________________________________ 3

Page 4

Evaluates: MAX3891

MAX3891 Evaluation Kit

4 _______________________________________________________________________________________

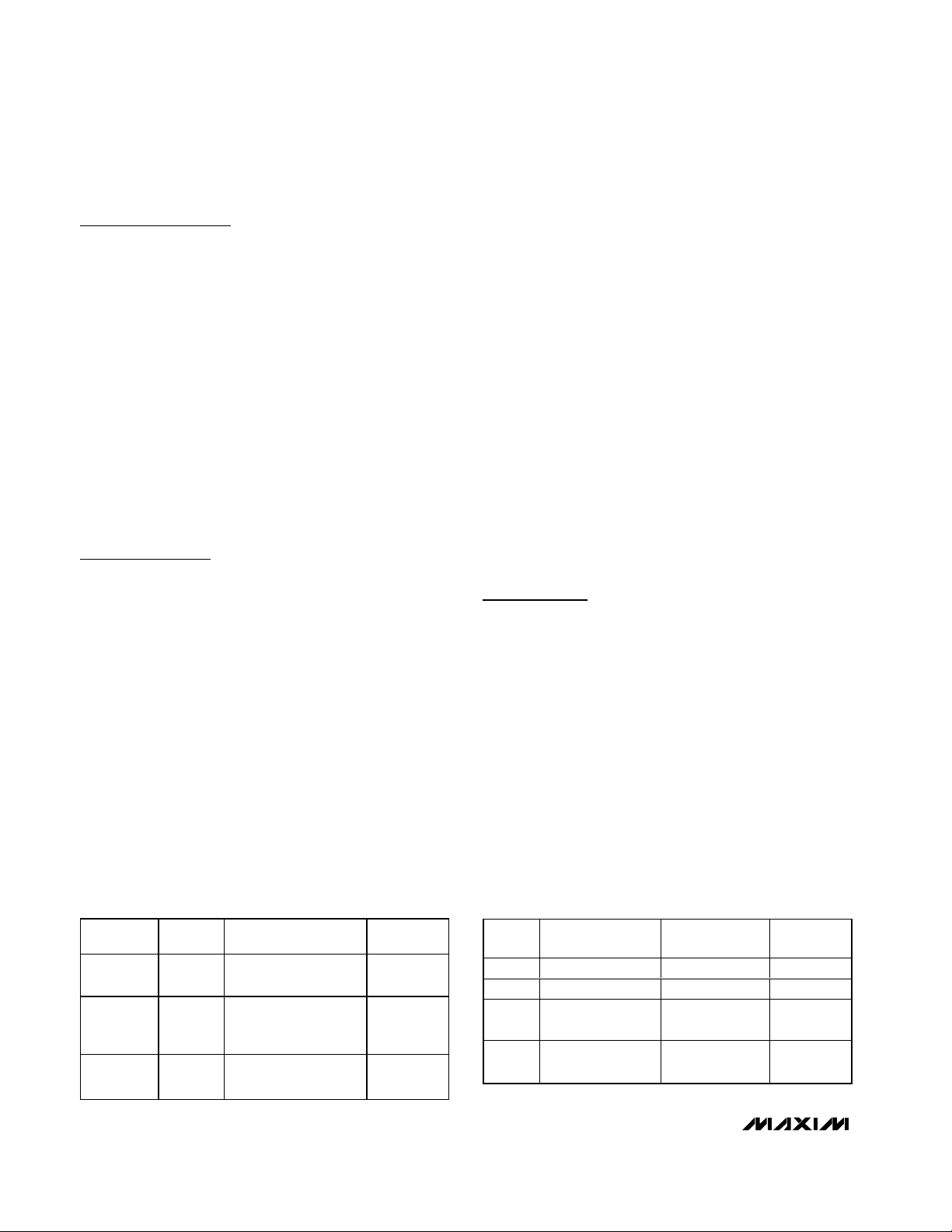

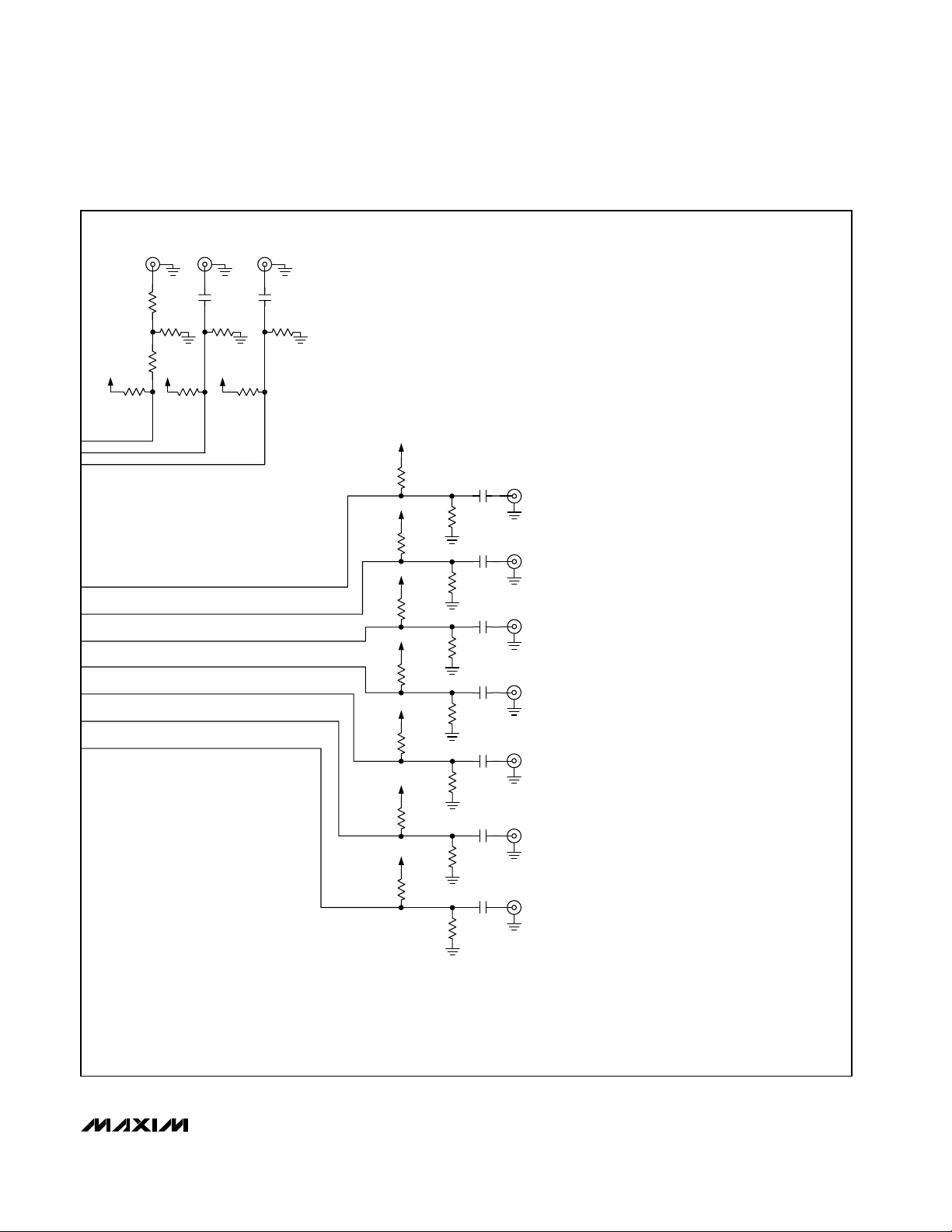

Figure1. MAX3891 EV Kit Schematic

3R3V

VCC

J46

C12

33µF

GND

J47

VCC

C1

R4

27.4Ω

R8

27.4Ω

R12

27.4Ω

R16

27.4Ω

0.1µF

C32

0.1µF

0.1µF

C2

0.1µF

C6

24.3Ω

R6

221Ω

24.3Ω

R10

221Ω

24.3Ω

R14

221Ω

24.3Ω

R18

221Ω

R32

130Ω

R5

R9

R13

R17

J1

SMA

J2

J2

SMA

SMA

J3

SMA

J4

SMA

J5

SMA

J6

SMA

J7

SMB

J8

SMB

C13

0.1µF

VCC

VCC

R1

49.9Ω

R2

49.9Ω

R40

82.5Ω

R33

130Ω

VCC

56nH

56nH

56nH

56nH

56nH

C15

0.1µF

R7

130Ω

VCC

R11

130Ω

VCC

R15

130Ω

VCC

R19

130Ω

VCC

R41

82.5Ω

L1

VCCDIG

L2

VCC0

L3

VCCPLL

L4

VCCVCO

L5

VCCPECL

GND

VCC

R3

10kΩ

JU1

VCCO

C3

0.1µF

C10

0.1µF

VCCO

VCCO

VCCDIG

C35

0.1µF

R27

82.5Ω

R26

130Ω

C16

0.1µF

VCCPLL

VCCO

VCCO

0.1µF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

VCCPECL

VCC

R22

20kΩ

C9

VCCVCO

C11

0.1µF

GND

V

CC

SLBOSLBO+

V

CC

SOS

V

CC

SCLKOSCLKO+

V

CC

SDOSDO+

V

CC

V

CC

PLKI+

PLKI-

R31

82.5Ω

R30

130Ω

C17

0.1µF

VCCDIG

JU6

64

CC

V

GND

17

18

63

GND

PDI15

VCC

JU3

JU4

JU5

C7

0.33µF

62

FIL-

FIL+

VCCPDI14

19

20

0.1µF

C8

0.1µF

61

21

R35

82.5Ω

R34

130Ω

C18

VCCPLL

60

CC

V

CLKSET

CC

V

PDI13

22

VCC

VCC

58

59

RCLK-

RCLK+

U1

MAX3891

VCCPDI12

23

24

82.5Ω

130Ω

0.1µF

C19

R38

57

R39

0.1µF

R37

82.5Ω

VCCDIGV

56

CC

CC

V

J26

SMA

C5

55

PCLKO-

PDI11

26

VCC

R36

130Ω

VCC

VCCPECL

54

V

PCLKO+

VCCPDI10

272528

82.5Ω

130Ω

0.1µF

53

CC

29

R43

R42

C20

C4

0.1µF

R21

82.5Ω

VCCPECL

52

CC

V

PDI0

CC

V

30

VCC

51

J25

SMA

31

PDI1

0.1µF

R20

130Ω

50

GND

VCCVCCPDI9

32

R47

82.5Ω

R46

130Ω

C21

49

GND

PDI2

PDI3

PDI4

PDI5

PDI6

PDI7

PDI8

GND

VCC

V

CC

V

CC

V

CC

V

CC

V

CC

V

CC

V

CC

VCCPECL

VCC

J28

SMB

R29

27.4Ω

R93

221Ω

R25

24.3Ω

R95

130Ω

VCCDIG

GNDTEST

R23

JU7

20kΩ

JU8

48

JU9

VCCDIG

C34

0.1µF

VCC

VCCPECL

C36VCCPECL

C14

0.1µF

C37

0.1µF

0.1µF

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

R51

82.5Ω

R50

130Ω

C22

0.1µF

SMB

J9

J10

SMB

J11

SMB

J12

SMB

J13

SMB

J14

SMB

J15

SMB

Page 5

Evaluates: MAX3891

MAX3891 Evaluation Kit

_______________________________________________________________________________________ 5

Figure1. MAX3891 EV Kit Schematic (continued)

VCC

R28

27.4Ω

R24

24.3Ω

R91

130Ω

J27

SMB

R89

221Ω

VCC

C31

0.1µF

R87

82.5Ω

J24

SMB

R85

130Ω

VCC

C30

0.1µF

R83

82.5Ω

J23

SMB

R81

130Ω

VCC

VCC

VCC

VCC

VCC

VCC

VCC

R79

82.5Ω

R75

82.5Ω

R71

82.5Ω

R67

82.5Ω

R63

82.5Ω

R59

82.5Ω

R55

82.5Ω

R78

130Ω

R74

130Ω

R70

130Ω

R66

130Ω

R62

130Ω

R58

130Ω

R54

130Ω

C29

0.1µF

C28

0.1µF

C27

0.1µF

C26

0.1µF

C25

0.1µF

C24

0.1µF

C23

0.1µF

J22

SMB

J21

SMB

J20

SMB

J19

SMB

J18

SMB

J17

SMB

J16

SMB

Page 6

Evaluates: MAX3891

MAX3891 Evaluation Kit

6 _______________________________________________________________________________________

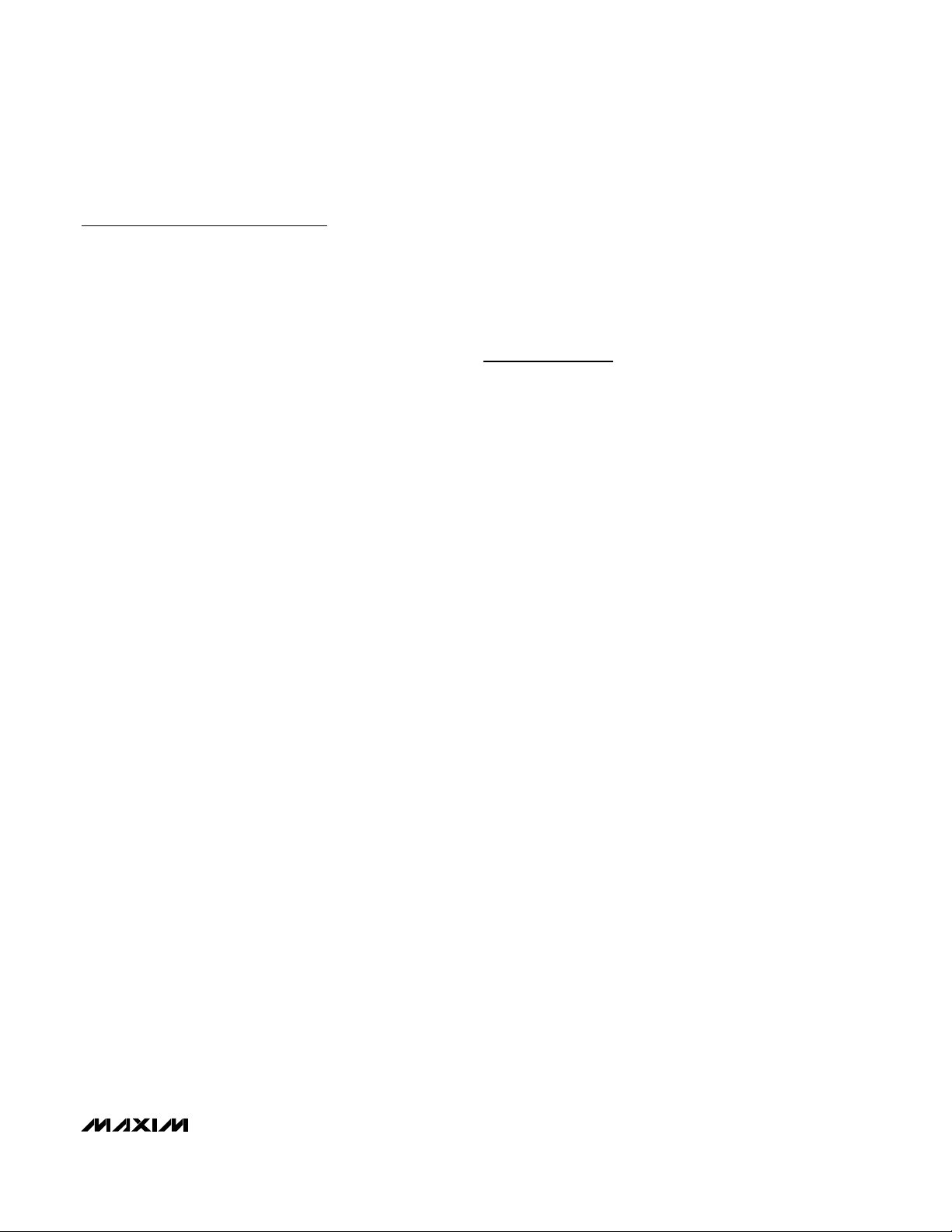

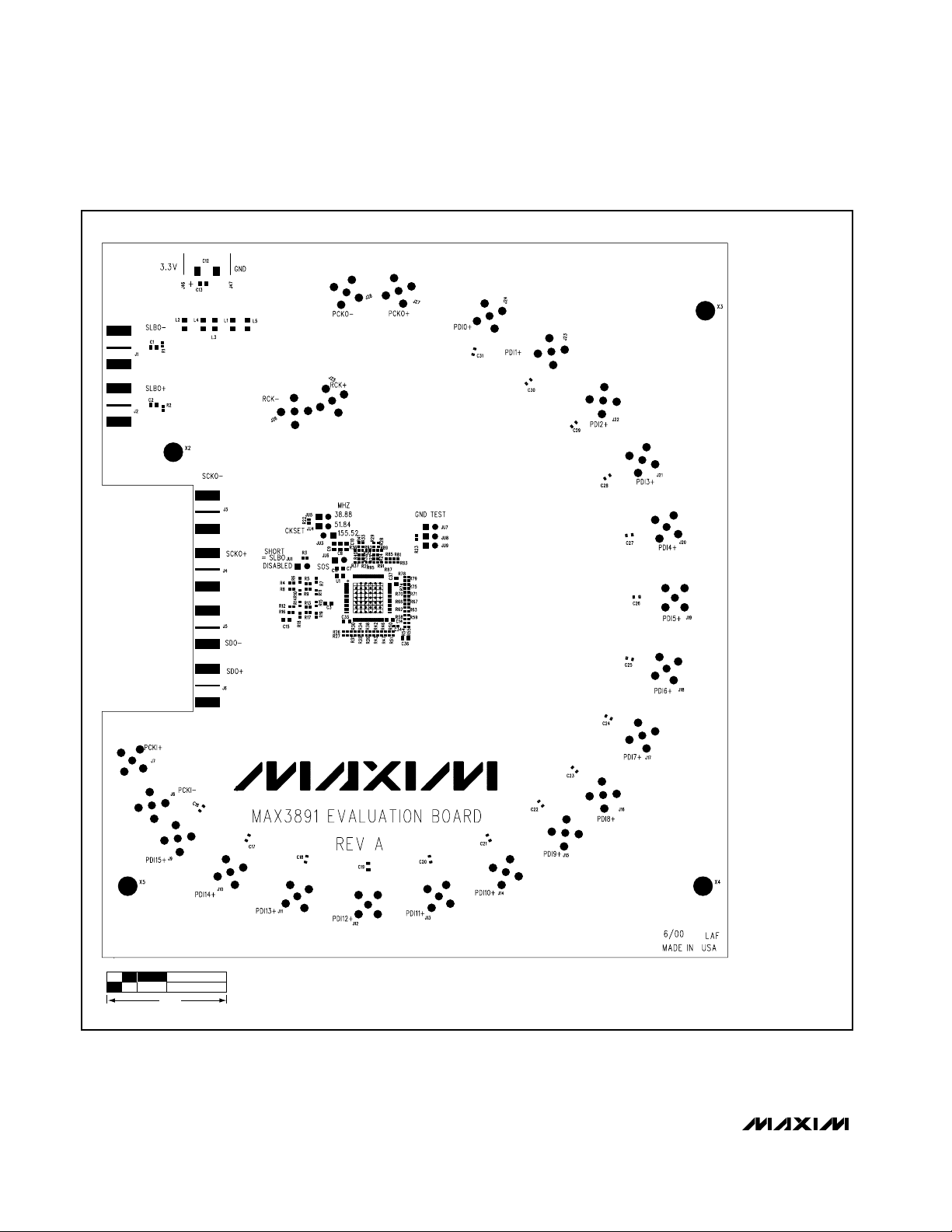

Figure 2. MAX3891 EV Kit Component Placement Guide

1.0"

Page 7

Evaluates: MAX3891

MAX3891 Evaluation Kit

_______________________________________________________________________________________ 7

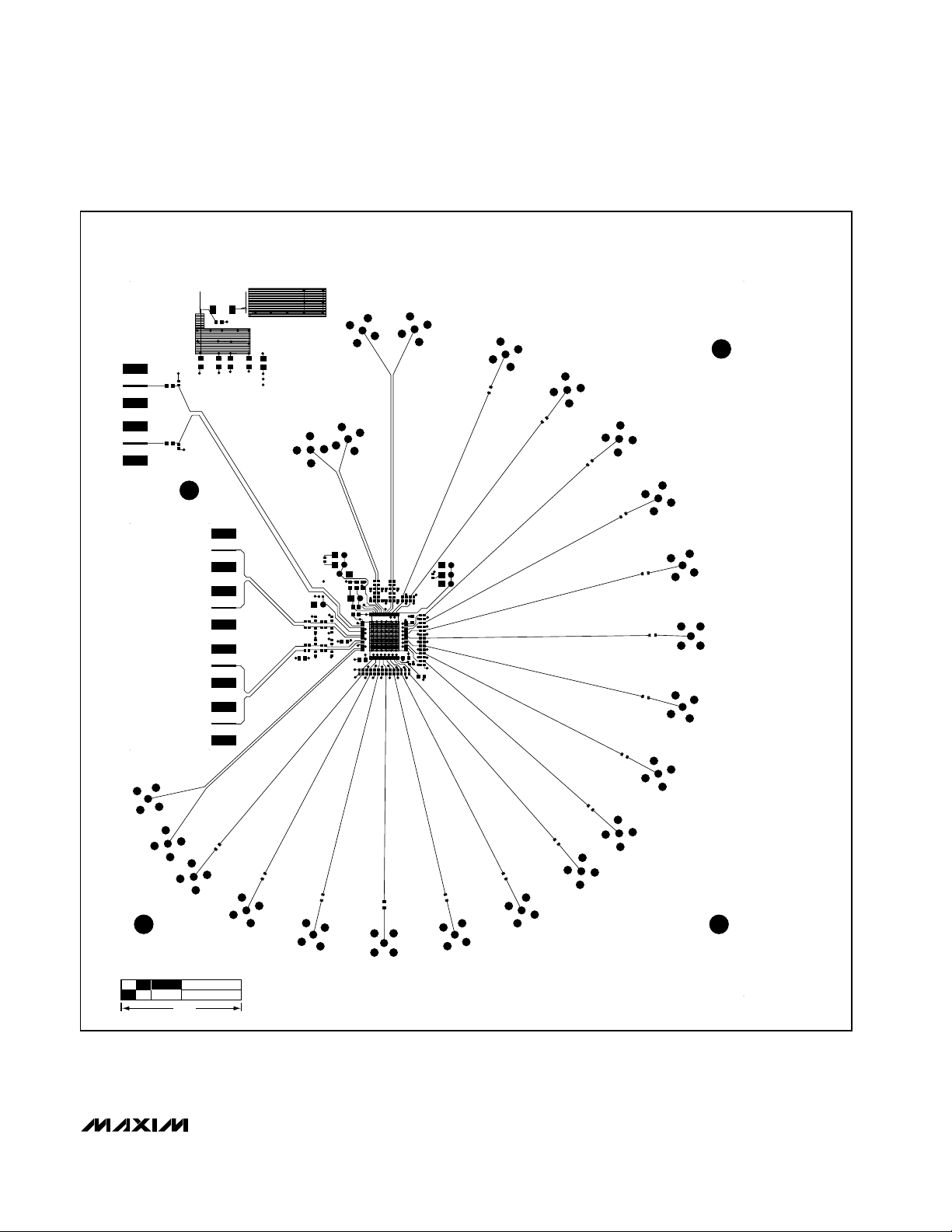

Figure 3. MAX3891 EV Kit PC Board Layout —Component Side

1.0"

Page 8

Evaluates: MAX3891

MAX3891 Evaluation Kit

8 _______________________________________________________________________________________

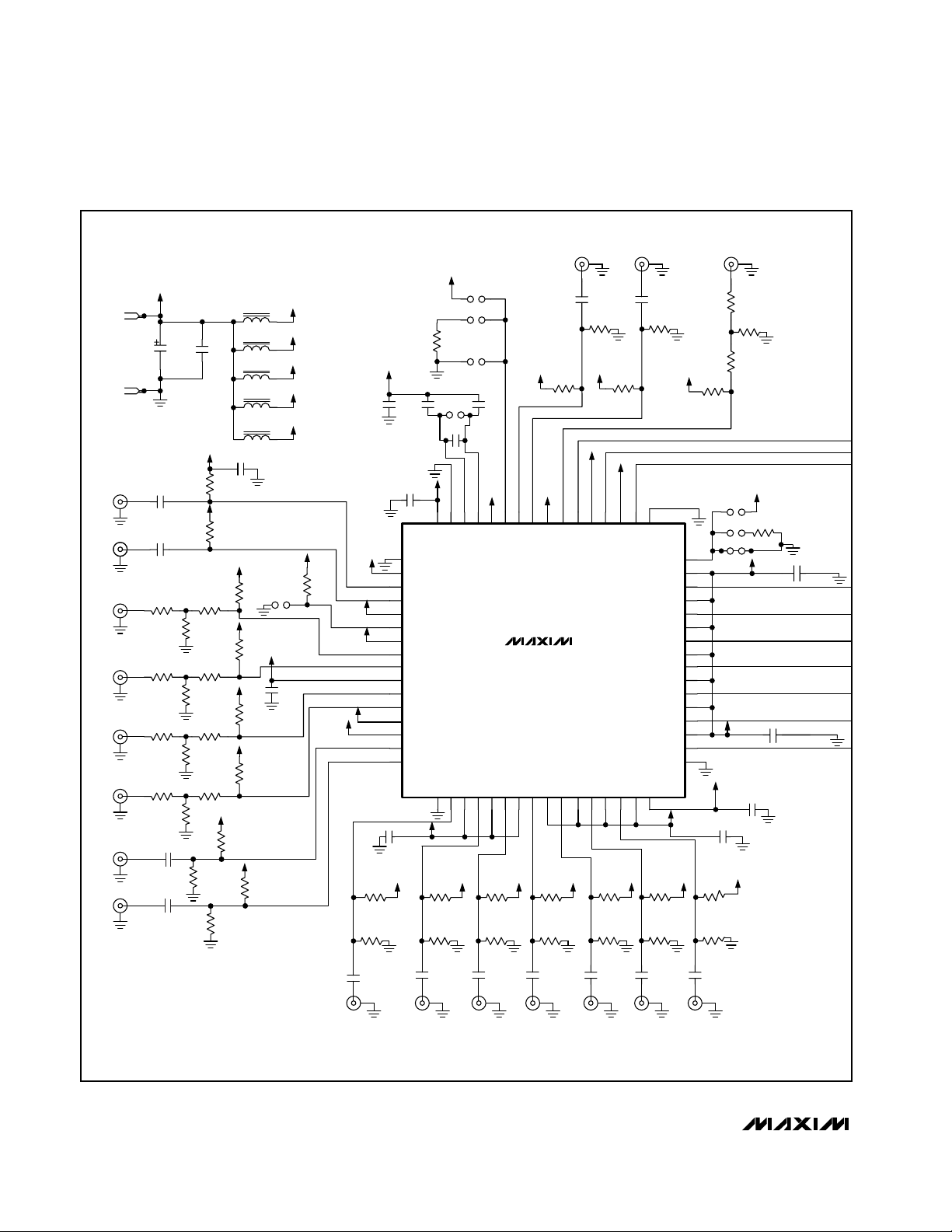

Figure 4. MAX3891 EV Kit PC Board Layout—Ground Plane

1.0"

Page 9

Evaluates: MAX3891

MAX3891 Evaluation Kit

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 _____________________ 9

© 2001 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Figure 5. MAX3891 EV Kit PC Board Layout—Power Plane

1.0"

Loading...

Loading...