________________General Description

The MAX3766 is a complete, easy-to-program laser

driver for fiber optic LAN transmitters, optimized for

operation at 622Mbps. It includes a laser modulator,

automatic power control (APC), and a failure indicator

with latched shutdown.

Laser modulation current can be programmed up to

60mA at 622Mbps. A programmable modulation temperature coefficient can be used to keep the transmitted extinction ratio nearly constant over a wide

temperature range. The modulator operates at data

rates up to 1.25Gbps at reduced modulation current.

APC circuitry uses feedback from the laser’s monitor

photodiode to adjust the laser bias current, producing

constant output power regardless of laser temperature

or age. The MAX3766 supports laser bias currents up

to 80mA.

The MAX3766 provides extensive laser safety features,

including a failure indicator with latched shutdown and

a smooth start-up bias generator. These features help

ensure that the transmitter output does not reach hazardous levels. The MAX3766 is available in a compact

20-pin QSOP and dice.

________________________Applications

622Mbps ATM Transmitters

1.25Gbps Fiber Optic LAN Transmitters

1.25Gbps Ethernet Transmitters

____________________________Features

♦ 60mA Modulation Current

♦ 80mA Bias Current

♦ 200ps Edge Speed

♦ Modulation-Current Temperature Compensation

♦ Automatic Power Control

♦ Laser-Fail Indicator with Latched Shutdown

♦ Smooth Laser Start-Up

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

________________________________________________________________

Maxim Integrated Products

1

19-1249; Rev 0b; 10/97

PART

MAX3766EEP

MAX3766E/D -40°C to +85°C

-40°C to +85°C

TEMP. RANGE PIN-PACKAGE

20 QSOP

Dice*

EVALUATION KIT

AVAILABLE

Ordering Information

*

Dice are designed to operate over this range, but are tested and

guaranteed at T

A

= +25°C only. Contact factory for availability.

Typical Application Circuits appear at end of data sheet.

Pin Configuration

20

19

18

17

16

15

14

13

1

2

3

4

5

6

7

8

REF1

POWERSET

MD

GNDOUTMOD

REF2

TC

BIASMAX

TOP VIEW

BIAS

OUT+

OUTV

CCOUT

GND

IN+

IN-

GND

12

11

9

10

FAIL

SAFETYENABLE

V

CC

MAX3766

QSOP

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 408-737-7600 ext. 3468.

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

2 _______________________________________________________________________________________

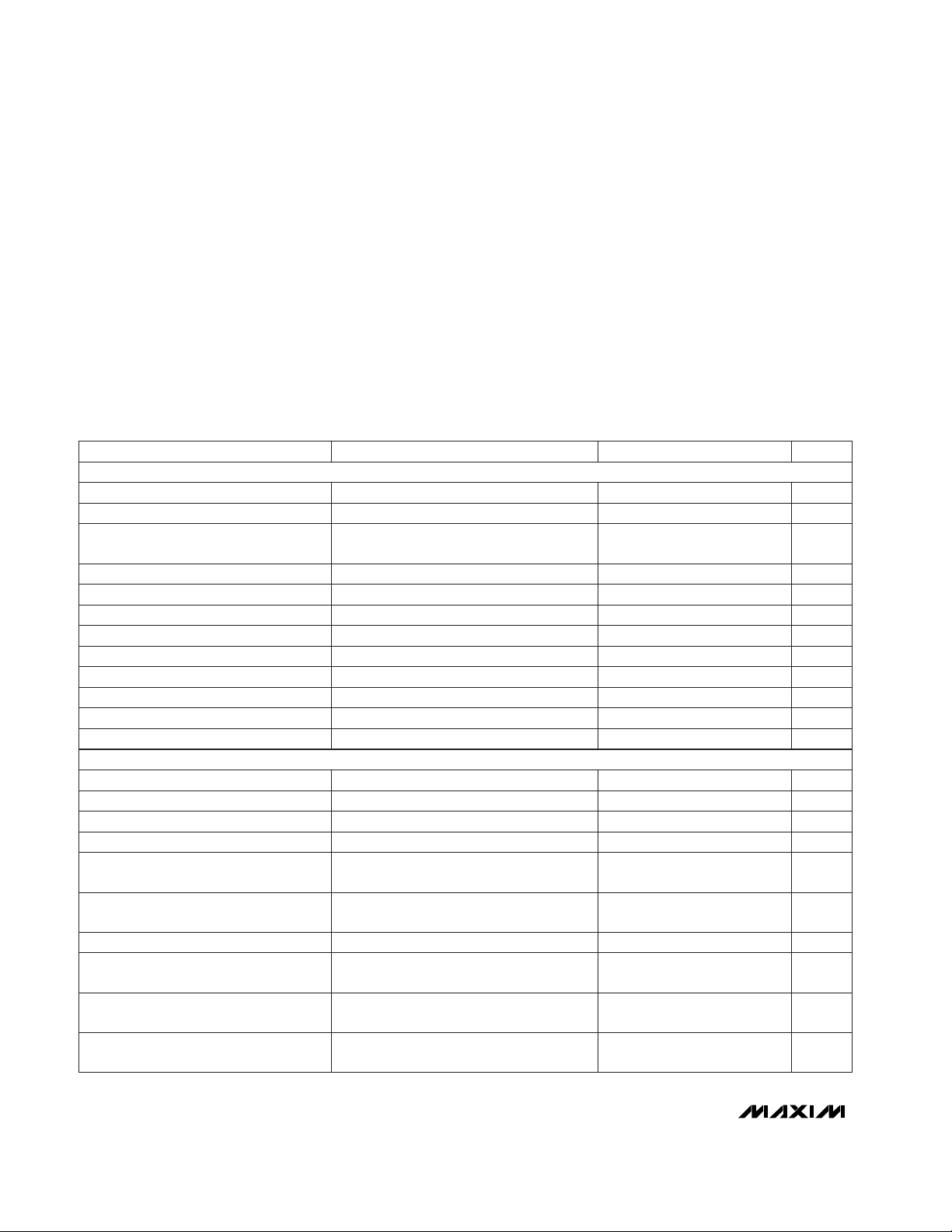

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Supply Voltage, VCC, V

CC

OUT

.................................-0.5V to 7.0V

Voltage at IN+, IN-, ENABLE,

SAFETY,

FAIL ...........................................-0.5V to (VCC+ 0.5V)

Voltage at MOD, BIASMAX, POWERSET, TC..........-0.5V to 4.0V

Current out of REF1, REF2 .................................-0.1mA to 10mA

Current into OUT+, OUT- ....................................-5mA to 100mA

Current into BIAS.................................................-5mA to 130mA

Current into MD.......................................................-5mA to 5mA

Current into FAIL ...................................................-5mA to 30mA

Current into SAFETY..............................................-5mA to 10mA

Continuous Power Dissipation (T

A

= +85°C)

QSOP (derate 9.1mW/°C above +85°C).......................590mW

Operating Junction Temperature Range...........-40°C to +150°C

Processing Temperature (dice).......................................+400°C

Storage Temperature Range.............................-55°C to +150°C

Lead Temperature (soldering, 10sec).............................+300°C

CONDITIONS UNITSMIN TYP MAXPARAMETER

V4.5 5.0 5.5Supply Voltage, V

CC

(Note 1) °C-40 25 85Ambient Operating Temperature

Referenced to V

CC

V-1.4 -1.3 -1.19Input Common-Mode Voltage

V0.8Enable Input Low

V

IN+

- V

IN-

, common-mode input =

VCC- 1.3V, Figure 1

V2.0Enable Input High

mV500 1000 1800Differential Input Signal Amplitude

VVCC- 2.5Voltage at BIAS

While using APC %50Data Duty Cycle

GbpsDC to 1.25Data Rate

VVCC- 2.5Voltage at OUT+, OUT-

Not tested mA/mA0.001 to 0.1Laser to PIN Coupling

R

F AIL

= 5.1kΩ V4.3

FAIL Output High

(Note 3) mA0.5 80Bias-Current Range

ICC(Note 2)

IMD> 15µA, R

F AIL

= 5.1kΩ V0.33 0.44

FAIL Output Low

mA21 25 32Supply Current

µA0.1 10

Bias Current when Driver is

Disabled or Shut Down

Input data low (Note 2) µA1 200Modulation Current

Input data high (Note 3) mA2 60

Modulation-Current Programmable

Range

RTC= 0Ω ppm/°C-50

Minimum Modulation-Current

Temperature Compensation

µA10

Modulation Current when Driver is

Disabled or Shut Down

All DC testing uses 5.1kΩ load kΩ2.7 to 20

FAIL Load

RTC= open ppm/°C5600

Maximum Modulation-Current

Temperature Compensation

RECOMMENDED OPERATING CONDITIONS

DC PARAMETERS

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

Note 1: Dice are tested at room temperature only (TA= +25°C).

Note 2: V

CC

= +5.5V, R

BIASMAX

= 887Ω, R

MOD

= 887Ω, R

POWERSET

= 287Ω, RTC= 0Ω, V

BIAS

= V

OUT+

= V

OUT-

= 3.0V. Supply

current excludes I

BIAS

, I

OUT+

, I

OUT-

, and I

FAIL

.

Note 3: Total output current must be reduced at high temperatures with packaged product to maintain maximum junction

temperature of T

j

= +150°C. See the

Design Procedure

section.

Note 4: All AC parameters are measured with a 25Ω load. I

MOD

is the AC current amplitude at either OUT pin. The AC voltage at

OUT is greater than V

CC

- 2.5V.

Note 5: Pulse-width distortion is measured at the 50% crossing point. Data input is a 155MHz square wave, with tR≈ 300ps.

Note 6: AC specifications are guaranteed by design and characterization.

V

CC

- V

MD

V1.5 2.1 2.3Monitor-Diode Bias Voltage

Referenced to V

CC

V-2.8Lower MD Voltage for Failure

Referenced to V

CC

V-1.2Upper MD Voltage for Failure

Referenced to nominal V

REF1

V0.5REF1 Voltage for Failure

TA= +25°C, V

REF2

V2.1 2.4 2.7REF2 Reference Voltage

Width of operating window, centered at

nominal V

MD

TA= +25°C, V

REF1

V

CONDITIONS

2.8 3.1 3.4REF1 Reference Voltage

mV300Range of MD for No Failure

I

MOD

= 60mA 210 400

Output Edge Speed (20% to 80%)

I

MOD

= 10mA

ps

125 250

I

MOD

= 30mA 160 300

I

MOD

= 30mA %10Output Aberrations

µA15 2000

Monitor-Diode Current

Programmable Range

UNITSMIN TYP MAXPARAMETER

I

MOD

= 60mA 5 80

I

MOD

= 30mA 20 80

I

MOD

= 10mA

ps

80 120

Pulse-Width Distortion

RMS, TA= +25°C, VCC= +5V, I

MOD

= 30mA ps2 3Random Jitter

AC PARAMETERS (Notes 4, 5, and 6)

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

4 _______________________________________________________________________________________

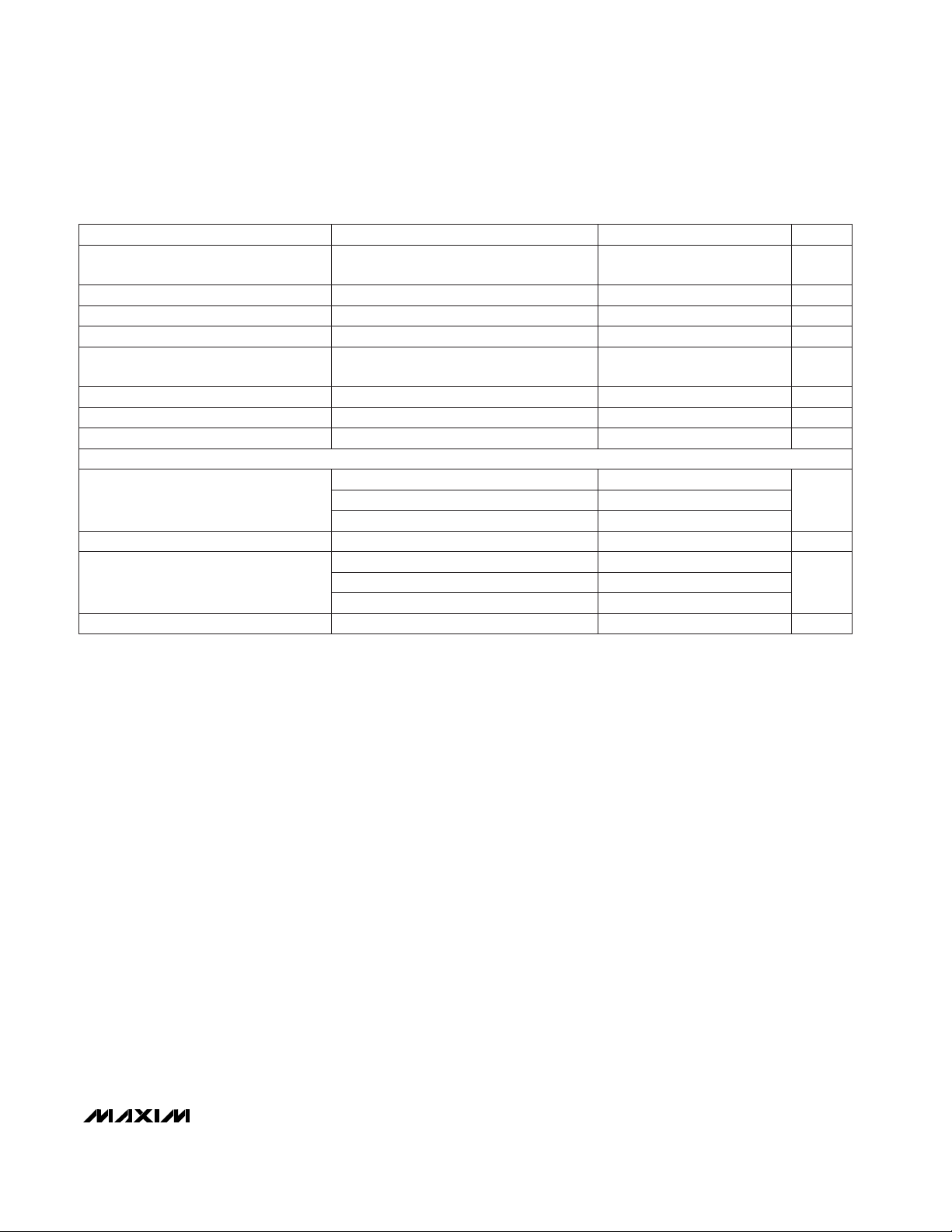

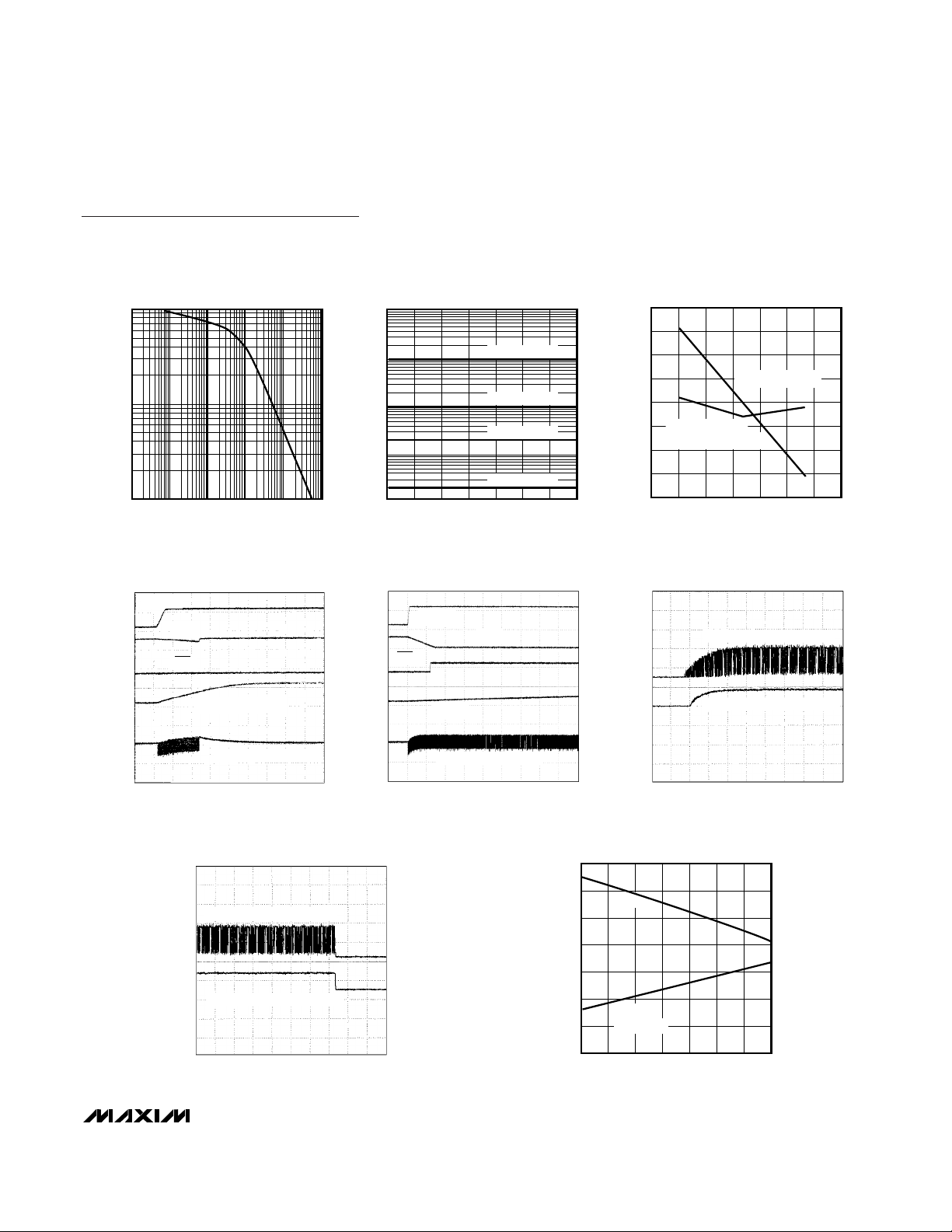

Typical Operating Characteristics

(Typical Operating Characteristics are measured on the MAX3766 evaluation kit, VCC= +5.0V, TA = +25°C, unless otherwise noted.)

0

20

10

30

40

-40 0

20

-20 40

60

80 100

SUPPLY CURRENT vs. TEMPERATURE

(EXCLUDES OUTPUT CURRENTS AND I

FAIL

)

MAX3766-01

AMBIENT TEMPERATURE (°C)

SUPPLY CURRENT (mA)

6000

4000

1 1k10 100 10k 100k 1M

MODULATION CURRENT TEMPCO

vs. R

TC

MAX3766-02

RTC (Ω)

TEMPCO (ppm/°C)

0

2000

100

1

1 1k10

100

10k

100k

DIE MODULATION CURRENT vs. R

MOD

(TJ = +25°C)

MAX3766-03

R

MOD

(Ω)

LASER MODULATION CURRENT (mAp-p)

10

TEMPCO = 0ppm/°C

TEMPCO = 5600ppm/°C

TEMPCO = 3000ppm/°C

100

1

1 1k10 100 10k 100k

MODULATION CURRENT vs. R

MOD

(20 QSOP, TA = +25°C)

MAX3766-04

R

MOD

(Ω)

LASER MODULATION CURRENT (mAp-p)

10

TEMPCO = 0ppm/°C

TEMPCO = 3000ppm/°C

TEMPCO = 5600ppm/°C

125µW/div

161ps/div

EYE DIAGRAM

(622Mbps, 1300nm LASER, 470MHz FILTER)

MAX3766-07

231- 1 PRBS

20

30

40

50

60

70

-40 0

20

-20 40

60

80 100

MODULATION CURRENT

vs. TEMPERATURE

MAX3766-05

AMBIENT TEMPERATURE (°C)

MODULATION CURRENT (mAp-p)

RTC = 100Ω

RTC = 330Ω

RTC = 1kΩ

RTC = 3.3kΩ

RTC = 10kΩ

RTC = 100kΩ

0

50

100

150

200

250

0 3010 20

40

50 60

MODULATION EDGE SPEED AND

PWD vs. AMPLITUDE

MAX3766-06

MODULATION CURRENT (mAp-p)

20% TO 80% EDGE SPEED (ps)

TA = +85°C

TA = +25°C

TA = -40°C

PULSE-WIDTH

DISTORTION (ps)

60mA/div

81ps/div

EYE DIAGRAM

(1.244Gbps, 25Ω LOAD, I

MOD

= 60mA)

MAX3766-08

231- 1 PRBS

0.01

10.1 10 100 1000

MONITOR CURRENT vs. R

POWERSET

MAX3766-09

R

POWERSET

(kΩ)

MD CURRENT (mA)

0.1

1

10

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

_______________________________________________________________________________________

5

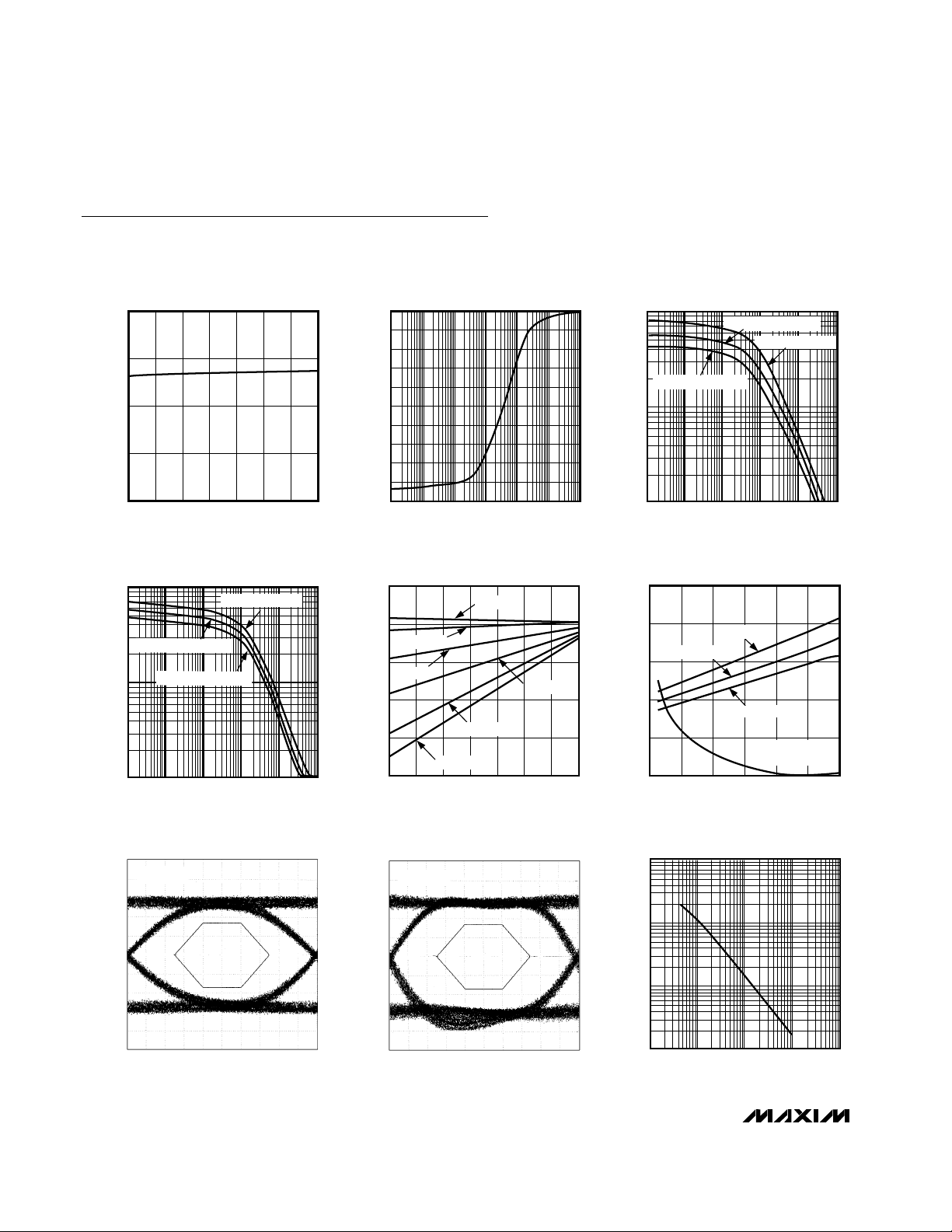

100

1 1k10 100 10k 100k

BIAS CURRENT vs. R

BIASMAX

(NO APC, OPEN-LOOP CONFIGURATION)

MAX3766-10

R

BIASMAX

(Ω)

I

BIAS

(mA)

1

10

10

0.001

-40 -20 0 20 40 60 80 100

MONITOR CURRENT vs. TEMPERATURE

0.01

MAX3766-11

AMBIENT TEMPERATURE (°C)

I

MD

(mA)

0.1

1

NOMINAL = 1mA

NOMINAL = 200µA

NOMINAL = 20µA

NOMINAL = 2µA

100

260

240

220

200

180

160

140

120

DATA-DEPENDENT JITTER

vs. TEMPERATURE (CMD = 0.1µF)

MAX3766-12

AMBIENT TEMPERATURE (°C)

DDJ (ps)

-40 -20 0 20 40 60 80 100

2

13

PRBS PATTERN

72 CONSECUTIVE ZEROS

223- 1 PRBS PATTERN

10µs/div

UNSUCCESSFUL STARTUP

MAX3766-13

V

ENABLE

V

MD

V

SAFETY

(τ = 30µs)

FAIL

DATA OUT (AC COUPLED)

5µs/div

100µW/

div

ABRUPT SHUTDOWN

MAX3766-16

OPTICAL OUTPUT WITH DATA ON

OPTICAL OUTPUT WITH DATA OFF

50µs/div

SUCCESSFUL STARTUP

MAX3766-14

V

ENABLE

V

MD

FAIL

V

SAFETY

(τ = 1500µs)

DATA OUT (AC COUPLED)

5µs/div

100µW/

div

SMOOTH STARTUP

MAX3766-15

OPTICAL OUTPUT WITH DATA ON

OPTICAL OUTPUT WITH DATA OFF

2.00

2.80

2.60

2.40

2.20

3.20

3.00

3.40

-45 -5

20

-25 40

60

80 100

REFERENCE VOLTAGE

vs. TEMPERATURE

MAX3766-17

AMBIENT TEMPERATURE (°C)

VOLTAGE (V)

RTC = OPEN

V

REF1

V

REF2

Typical Operating Characteristics (continued)

(Typical Operating Characteristics are measured on the MAX3766 evaluation kit, VCC= +5.0V, TA = +25°C, unless otherwise noted.)

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

6 _______________________________________________________________________________________

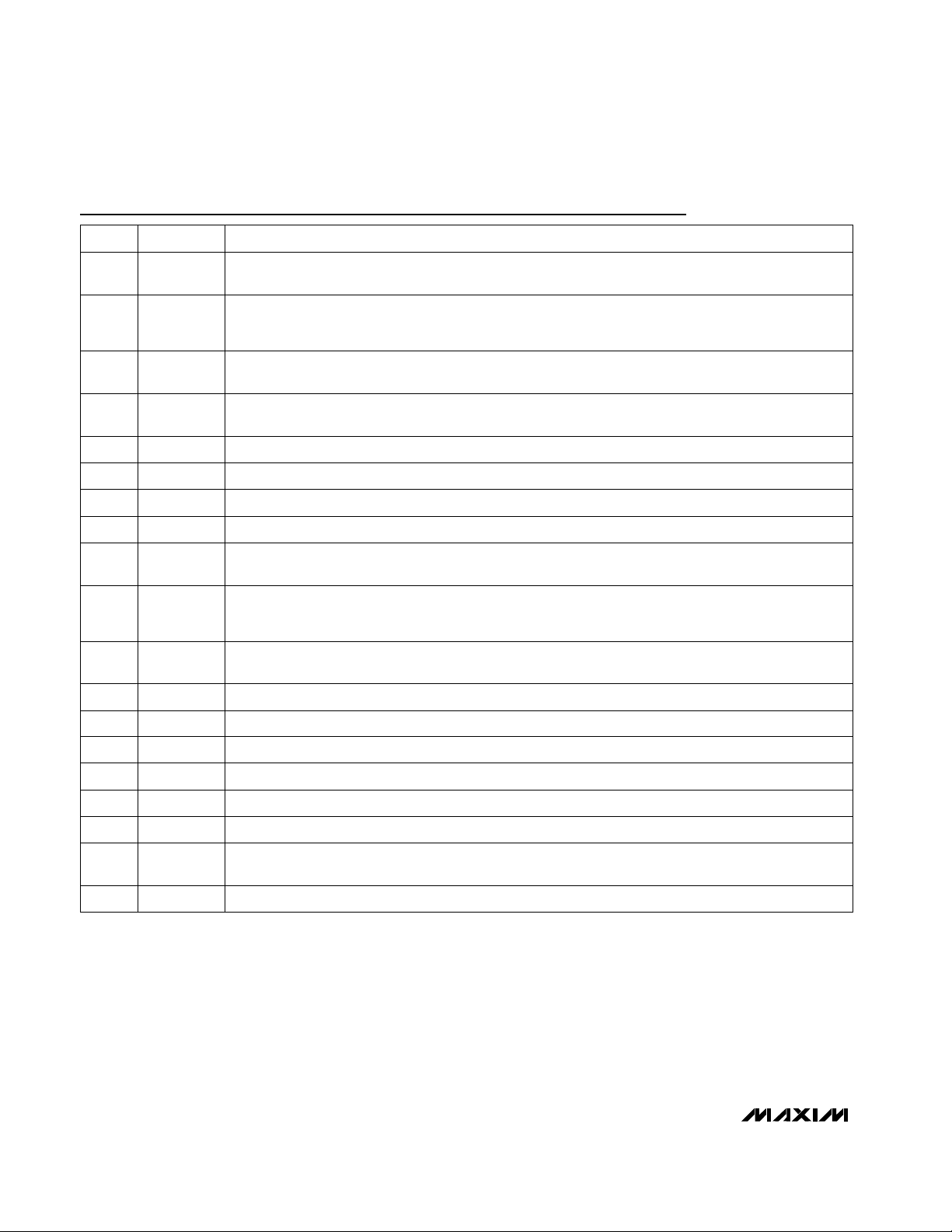

Pin Description

ENABLE is a TTL-compatible input. When low or open, this pin disables the output modulation and bias

current.

ENABLE10

A capacitor to ground at SAFETY determines the turn-on delay for the safety circuits. If SAFETY is

grounded or TTL low, internal safety shutdown features are disabled. A TTL high at SAFETY enables the

internal safety shutdown features.

SAFETY11

The FAIL output asserts low if the voltage at MD is above or below nominal. FAIL also asserts if REF1 is

inadvertently tied to the positive supply. FAIL has TTL-compatible output voltage levels.

FAIL

12

Supply Voltage for the Output Current DriversV

CCOUT

13

Inverting Modulation-Current OutputOUT-14

Ground. All grounds must be connected.GND5, 8

Inverting Data InputIN-6

Noninverting Data InputIN+7

Positive Supply Voltage. All VCCpins must be connected.V

CC

9

The current into MOD programs the laser modulation current. Connect MOD to REF2 with a resistor or

potentiometer.

MOD4

REF2 is the reference voltage used to program the modulation current. The tempco of REF2 is programmed by RTC.

REF23

PIN

The resistance (RTC) between TC and REF1 programs the temperature coefficient of REF2. Connecting

TC directly to REF1 produces the minimum tempco. Leaving TC unconnected produces the maximum

tempco.

TC2

The current into BIASMAX sets the maximum laser bias current. Connecting BIASMAX directly to REF1

allows the largest possible bias current.

BIASMAX1

FUNCTIONNAME

Ground for the Output Current DriversGNDOUT17

Input for the laser monitor photodiode current. MD18

The current into POWERSET programs the average optical output power when automatic power

control is used.

POWERSET19

REF1 is a voltage reference used to program laser bias current and average power.REF120

Noninverting Modulation-Current OutputOUT+15

Connection for the DC Laser Bias CurrentBIAS16

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

_______________________________________________________________________________________ 7

_______________Detailed Description

Figure 2 is a functional block diagram of the MAX3766

laser driver. The major functional blocks are the reference generator, PECL input buffer, laser-bias circuit,

modulation-current driver, automatic power control

(APC), failure detection, and safety circuit.

Reference Generator

The MAX3766 provides adjustments for maximum

laser-bias current, laser modulation current, and average laser power. To program these adjustments, simply

use the currents obtained by inserting a resistor in

series with integrated voltage references REF1 and

REF2. The temperature coefficient (tempco) of REF1

compensates for the tempco of the bias, modulation,

and APC current mirrors. Therefore, a programming

current derived from REF1 is constant with temperature. REF2 provides a positive tempco, which can be

applied to the modulation current. A positive modulation-current tempco will compensate for the thermal

characteristics of typical laser diodes. The modulationcurrent tempco is programmed by an external resistor

(RTC), which is connected from REF1 to TC. RTCand

an internal 2kΩ resistor form a weighted sum of the

temperature-compensated reference (REF1) and the

temperature-increasing reference, which is buffered

and output at REF2. REF1 and REF2 are stable with no

bypass capacitance. Bypass filtering REF1 or REF2 is

not required.

PECL Input Buffer

The differential PECL input signals are connected to the

high-speed PECL input buffer at IN+ and IN-. The input

impedance at IN+ and IN- is greater than 100kΩ, and

the input bias current is less than 10µA. The

MAX3766’s data inputs are not self-biasing. The common-mode input should be set by the external PECL

termination circuitry. To obtain good AC performance,

inputs should always be greater than 2.2V and less

than VCC.

Laser Modulation-Current Driver

The laser modulation-current driver consists of a current mirror and an emitter coupled pair. The mirror has

a gain of +30mA/mA. Modulation-current amplitude is

programmed with external resistor R

MOD

connected

from REF2 to MOD. R

MOD

can be estimated as follows:

with RTC= 0Ω.

The MAX3766 AC output drives up to 60mA of laser

current. Pulse-width distortion and overshoot are lowest

between 30mA and 60mA. However, output edge

speed increases at lower currents. When the output

current is between 2mA and 60mA, the edge speed is

suitable for communications up to 622Mbps. Edge

speeds below 30mA are suitable for communications up

to 1.25Gbps (see

Typical Operating Characteristics

).

The modulation-current tempco can be programmed

with an external resistor RTC, as described in the

Reference Generator

section. An internal 520Ω resistor

is included to limit the maximum modulation current if

MOD is connected directly to REF2.

If the MAX3766 is shut down or disabled, the modulation programming current is shunted to ground. Any

remaining modulation current is switched to OUT-.

For optimum performance, the voltage at OUT+ and

OUT- must always exceed VCC- 2.5V.

Laser Bias Circuit

The laser bias circuit is a current mirror with a gain of

+40mA/mA. Redundant controls disable the bias current

during a shutdown or disable event: the programming

current is switched off, and any remaining bias output

current is switched away from the laser. Ensure that the

voltage at BIAS always remains above VCC- 2.5V. If the

bias circuit is not used, connect BIAS to VCC.

R =

1.55V 30

I

MOD

MOD

( )

− 520Ω

V

IN+

VOLTS

250mV MIN

900mV MAX

500mV MIN

1800mV MAX

500mV MIN

1800mV MAX

I

MOD

I

OUT+

TIME

V

IN-

V

IN-

V

IN+

- V

IN-

V

IN+

RESULTING SIGNAL

SINGLE-ENDED INPUT

DIFFERENTIAL INPUT

Figure 1. Required Input Signal and Output Polarity

MAX3766

The available laser bias current is programmed by

connecting external resistor R

BIASMAX

from REF1 to

BIASMAX. The BIASMAX programming current is

adjusted by the APC circuit and amplified by the laser

bias circuit.

An internal 520Ω resistor between BIASMAX and the

mirror input at internal node APC limits the maximum

laser bias current when BIASMAX is connected directly

to REF1. BIASMAX can be directly connected to REF1

in space-constrained designs, causing the maximum

programming current (about 2.5mA) to flow into

BIASMAX. Selecting a BIASMAX resistor saves power

and limits the transmitter’s maximum light output.

R

BIASMAX

can be estimated as follows:

This equation applies to maximum bias currents above

10mA.

R =

1.55V 40

I

520

BIASMAX

BIASMAX

( )

− Ω

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

8 _______________________________________________________________________________________

SAFETY

START-UP

CIRCUIT

FAILURE

DETECTION

REFERENCE

GENERATOR

2k

V

V

TEMP

BANDGAP

POWERSET

MIRROR

1X

AUTOMATIC

POWER CONTROL

V

CC

- 2V

MONITORDIODE

AMPLIFIER

LASER BIAS CIRCUIT

BIAS

MIRROR

40X

APC

I

LBP

I

BIASMAX

I

APC

TEMP

MODULATION

MIRROR

30X

PECL

INPUT

BUFFER

ENABLE

SHDN

SAFETY

V

CC

V

CC

FAIL MOD REF2 TC REF1 BIASMAX

C

MD

V

CC

V

CC

V

CC

MONITOR

PHOTODIODE

LASER

MD

BIAS

OUT+

OUT-

POWERSET

R

POWERSET

R

BIASMAX

R

TC

R

MOD

5.1k

520Ω

520Ω 300Ω

FAILURE

SHDN

GNDOUT VCCOUT

V

CC

IN+

IN-

MODULATIONCURRENT

DRIVER

MAX3766

Figure 2. Functional Diagram

Automatic Power Control

Transmitters employing a laser with monitor photodiode

can use the APC circuit to maintain constant power,

regardless of laser threshold changes due to temperature

and aging. The APC circuit consists of the POWERSET

current mirror and the monitor diode amplifier.

The POWERSET current mirror provides an accurate

method of programming the back facet monitor photodiode current, which is assumed to be proportional to

laser output power. An external resistor from REF1 to

POWERSET programs the current in the unity-gain current mirror. R

POWERSET

can be estimated as follows:

The monitor-diode amplifier senses the current from the

monitor photodiode at MD, provides gain, and adjusts

the laser bias programming current (I

LBP

). The monitordiode amplifier forces the monitor-diode current to

equal the current programmed at POWERSET. The

monitor-diode amplifier can reduce the laser bias programming current, but cannot increase it. Therefore,

the APC circuit can adjust laser bias current between 0

and the setting determined by R

BIASMAX

.

When the APC feedback loop is closed, the voltage at

MD is approximately 2V below VCC. If the loop cannot

close due to excess or insufficient photocurrent, a failure is detected by the failure-detection circuit. Internal

circuitry prevents the voltage at MD from dropping

below VCC- 3.2V.

The stability and time constant of the APC feedback

loop is determined by an external compensation

capacitor (CMD) of at least 0.1µF. Connect the compensation capacitor from VCCto MD, as shown in

Typical Application Circuits

, to ensure a smooth start-

up at power-on or transmitter enable.

If a monitor diode is not available, the APC feature can

be disabled by connecting R

POWERSET

to GND and

leaving MD unconnected.

Failure Detection

Figure 3 shows a simplified schematic of the failuredetection circuit. The failure-detection circuit senses

two conditions. First, if the APC control loop cannot

control the monitor current due to laser undercurrent,

overcurrent, or a fault condition, a window comparator

detects that VMDis above or below VCC- 2V and

asserts the failure signal. Second, if REF1 is shorted to

the positive supply (or any another voltage above the

normal operating level), a comparator detects this condition and asserts the failure signal. If left undetected,

the reference voltage would rise, the current at POWERSET would increase, and the APC loop would attempt to

add laser current beyond the intended value.

Either failure condition causes the FAIL output to assert

TTL low. The FAIL output buffer is an open-collector

output and is designed to operate with a 5.1kΩ external

pull-up resistor.

Safety/Start-Up Circuit

The safety circuit includes the digital logic needed to

provide a latched internal shutdown signal (SHDN) for

disabling the laser if a failure condition exists. The

MAX3766 produces less than 20µA of total laser current when disabled by safety features or by the

ENABLE input. Figure 4 is a simplified schematic of the

safety circuit.

If ENABLE is low or open, the laser bias and modulation outputs are disabled by SHDN, regardless of the

state of the safety logic. The TTL-compatible ENABLE

input is internally pulled low with a 100kΩ resistor.

There are two useful safety configurations: failure

indication and latched shutdown.

Failure-Indication Configuration

Select the failure-indication configuration by connecting

SAFETY to ground. In this configuration, a failure condition is reported at FAIL, but does not cause a latched

shutdown. This configuration requires no additional circuitry for start-up.

R =

1.55V

I

POWERSET

MOD

− 300Ω

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

_______________________________________________________________________________________ 9

V

MD

FAILURE

(INTERNAL)

200mV

200mV

2V

V

CC

0.5V

V

REF1

V

BANDGAP

Figure 3. Failure-Detection Circuit (Simplified)

MAX3766

Latched Shutdown Configuration

This configuration is shown in the

Typical Application

Circuits

(configured for best performance), and can

be selected by connecting a capacitor (C

SAFETY

) to

ground at SAFETY. In this configuration, the transmitter

is shut down when a failure is detected. It can be

restarted only by a power-on cycle or a toggle of the

ENABLE input.

During start-up, FAIL is asserted until laser power reaches the programmed level. The safety circuit must be disabled at power-on or at transmitter enable, providing

enough time for the APC circuit to reach the programmed

laser power level.

In space-constrained designs, C

SAFETY

can be selected to provide a shutdown delay. When power is initially

applied, or when the ENABLE signal is toggled from a

logic 0 to a logic 1, the voltage at SAFETY is low, and

rises with a time constant set by C

SAFETY

and an internal 200kΩ pull-up resistor. The SAFETY signal is inverted and resets the input of a reset-dominant RS flip-flop.

The internal signal FAILURE from the failure-detection

circuit is connected to the set input of the flip-flop. After

SAFETY has gone high (allowing time for the APC feedback loop to settle) and if internal signal FAILURE is low,

the flip-flop output is low, and the bias and modulation

outputs are allowed to remain on. Refer to Figure 5 for

a timing diagram of start-up in the latched shutdown

configuration.

The duration of t

SAFETY

must be about 10 times t

APC

for

a successful start-up. After start-up, the transmitter

operates normally until a failure is detected, causing

the output currents to be shut down. The laser-current

outputs remain off until the failure condition is eliminated and the ENABLE input is toggled, or until the power

is cycled. A potential problem with this transmitterenable method is that a slow-rising power supply may

not enable the transmitter.

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

10 ______________________________________________________________________________________

S

RESET DOMINATE

RS FLIP-FLOP

OPEN

COLLECTOR

FAIL

Q

ENABLE

C

SAFETY

SAFETY

OPEN

COLLECTOR

100k

200k

V

CC

FAILURE

(INTERNAL)

SHDN

(INTERNAL)

SIMPLIFIED

OPEN-COLLECTOR

OUTPUT CIRCUIT

OUT

IN

R

Figure 4. Simplified Safety Circuit Schematic

V

CC

VCC ON (OR ENABLE SWITCHED TO ON STATE)

LASER BIAS AND

MODULATION CURRENT

t

ON

t

APC

t

SAFETY

OUTPUT CURRENTS ENABLED AFTER A FIXED DELAY

FAIL DEASSERTS WHEN THE APC LOOP SETTLES

SAFETY FEATURES START CHECKING

THE FAILURE SIGNAL AFTER A TIME SET

BY A CAPACITOR ON THE SAFETY INPUT.

AFTER THIS TIME, THE LASER DRIVER IS

DISABLED IF A FAILURE OCCURS.

FAIL

OUTPUT

SAFETY

Figure 5. Start-Up Sequence Timing

If PC board space is not a constraint, Maxim recommends enabling the transmitter with a reset-pulse generator, such as the MAX809, which generates a reset

signal after VCCreaches 4.5V (Figure 6). This method

ensures that the transmitter starts correctly, even if the

supply ramps very slowly.

__________________Design Procedure

Select Laser

Select a communications-grade laser with a rise time of

0.5ns or better for 622Mbps applications. The voltage

swing at the OUT+ pin affects the output waveform,

and is largely determined by the laser resistance,

inductance, and modulation current. To obtain the

MAX3766’s AC specifications, the output voltage at

OUT+ must remain above VCC- 2.5V at all times.

An approximation for the minimum voltage at OUT+ is

given by the following equation (Table 1):

Select a laser that meets the output voltage criteria. A

high-efficiency laser requires low modulation current

and generates low voltage swing at OUT+. Laser package inductance can be reduced by trimming leads.

Typical package leads have inductance of 25nH per

inch (1nH/mm). A compensation filter network can also

be used to reduce ringing, edge speed, and voltage

swing.

V = V - V - I

OUT(MIN) CC(MIN) LASER MOD

( )

+ +

R R

L

t

L D

r

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

______________________________________________________________________________________ 11

MAX3766*

MAX809MEUR-T

SAFETY

C

SAFETY

RESET

V

CC

V

CC

OR

ENABLE

ENABLE

*IN LATCHED SHUTDOWN

CONFIGURATION

Figure 6. Reset Pulse Generator

Table 1. Output Voltage Approximation

Minimum power supplyV

CC(MIN)

4.5V

Laser dynamic resistanceR

L

3Ω

Laser forward voltage at operating powerV

LASER

1.3V

Any damping resistance or line termination in series with the laser

(but not in series with BIAS)

R

D

10Ω

20% to 80% rise time of the laser modulation current, filtered by a

compensation network

t

r

300ps

(20% to 80%)

Total series inductance of laser, laser package, and board traces to the

MAX3766

L 6nH

Laser modulation currentI

OUT

30mA

VARIABLE

Approximation for the lowest voltage at the OUT+ pinV

OUT(MIN)

DESCRIPTION TYPICAL VALUE

2.2V

MAX3766

Set Modulation-Current Tempco

Compute the required modulation tempco from the

slope efficiency of the laser at TA= +25°C and at a hot

temperature. Then select the value of RTCfrom the

Typical Operating Characteristics

.

For example, suppose a laser has a slope efficiency

(SE) of 0.021mW/mA at +25°C, which reduces to

0.018mW/mA at +85°C. The temperature coefficient is

given by the following:

From the

Typical Operating Characteristics

, the value

for RTC, which offsets the tempco of the laser, is 3kΩ. If

modulation temperature compensation is not desired,

connect TC directly to REF1.

Set Modulation Current

The modulation-current amplitude can be programmed

with a fixed resistor or adjusted with a potentiometer. A

small internal resistance is provided to prevent damage

if the potentiometer is adjusted to the end of its range.

The value of R

MOD

can be selected from the

Typical

Operating Characteristics

.

Example: A transmitter requires average power of

-8dBm (160µW), with an extinction ratio of 15. The optical signal output is 280µW (see

Optical Power

Relations

). If the slope efficiency is 0.021mW/mA at

+25°C, then the required modulation current is

0.280mW / 0.021mW/mA = 13.3mA. From the

Typical

Operating Characteristics

, the value of R

MOD

is select-

ed to be 3kΩ.

Set Average Laser Power

and Maximum Bias Current

When APC is used, the average power control is programmed by R

POWERSET

, which is typically a poten-

tiometer. The value of R

POWERSET

can be estimated

from the

Typical Operating Characteristics

.

Example: Suppose a transmitter’s output power will be

adjusted to -8dBm (160µW) average power during

manufacturing. The coupling efficiency from laser to

monitor photodiode varies from 0.4A/W to 0.8A/W for

the selected laser, causing monitor current to vary

between 64µA and 128µA. From the

Typical Operating

Characteristics

, R

POWERSET

should be adjustable

between 12kΩ and 24kΩ.

Select R

BIASMAX

to provide sufficient current for a hot

laser at its end of life. For example, if the expected

laser threshold at +85°C and end of life is 40mA, then

from the

Typical Operating Characteristics

, R

BIASMAX

should be 1kΩ or less.

If APC is not used, the laser bias current is pro-

grammed by R

BIASMAX

. Select R

BIASMAX

from the

Typical Operating Characteristics

.

Set APC Time Constant

Capacitor CMDdetermines the APC time constant, and

must be large enough not to cause data-dependent jitter. For 622Mbps SONET/ATM applications, Maxim recommends selecting CMD≥ 0.1µF.

Select C

SAFETY

When using the latched shutdown configuration, determine the minimum value of C

SAFETY

from the

Typical

Operating Characteristics

. Calculate C

SAFETY

as follows:

For example: If CMDis 0.1µF and typical monitor current (IMD) is 100µA, then the value of C

SAFETY

should

be 50nF or larger. This ensures that t

SAFETY

is at least

10 times the t

APC

.

Design Bias Filter

To reduce data-dependent jitter, add a filter at BIAS

(see

Typical Operating Circuit).

Maxim recommends a

1µH inductor or ferrite bead with a self-resonance frequency of 200MHz or more.

Design Laser-Compensation

Filter Network

Laser package lead inductance causes the laser

impedance to increase at high frequencies, which

leads to ringing, overshoot, and degradation of the output eye. A laser-compensation filter network can be

used to reduce the output load seen by the MAX3766

at high frequencies, thereby reducing output ringing

and overshoot.

The compensation components (R

COMP

and C

COMP

)

are most easily determined by experimentation. Begin

with a no-compensation network, and observe the ring

frequency (fn) of the laser and laser driver (Figure 7).

Begin with R

COMP

= 25Ω and C

COMP

= 1/(2πfnR

COMP

).

Increase C

COMP

until the desired transmitter eye is

obtained.

C

SAFETY

=•

C

20k I

MD

MD

Ω

Laser tempco

SE SE

SE 85 25

10

85 25

25

6

=

−

( )

• −

( )

•

= − °2380ppm C/

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

12 ______________________________________________________________________________________

Calculate Power Consumption

The MAX3766’s junction temperature must be kept

below +150°C at all times. Calculate total power dissipated on the MAX3766 by laser power as follows:

Power = VCC(ICC+ I

BIAS

+ I

MOD

)

- (I

MOD

/ 2 + I

BIAS

) V

LASER

.

where I

BIAS

is the maximum bias current allowed by

R

BIASMAX

, I

MOD

is the AC modulation current, V

LASER

is the typical laser forward voltage.

Junction temperature = power (Watts) • 110 (°C/W).

__________Applications Information

Optical Power Relations

Many MAX3766 specifications relate to output current

amplitude. When working with fiber optic transmitters,

the output is normally expressed in terms of average

optical power and extinction ratio (Figure 8). Table 2

lists relations that are helpful in converting optical

power to output signal amplitude when designing with

the MAX3766. The relations are true if the average duty

cycle of the input data is 50%.

Input Terminations

The MAX3766’s data inputs must be biased externally.

Refer to Figure 9 for common input terminations.

Laser Safety and IEC 825

The International Electrotechnical Commission (IEC)

determines standards for hazardous light emissions

from fiber optic transmitters. Specification IEC 825

defines the maximum light output for various hazard

levels. The MAX3766 provides features that aid compliance with IEC 825.

A common safety requirement is single-point fault tolerance, whereby one unplanned short, open, or resistive

connection does not cause excess light output. When

the MAX3766 is used in the latched shutdown configuration, as shown in

Typical Application Circuits

, the cir-

cuit responds as shown in Table 3.

Using the MAX3766 laser driver alone does not ensure

that a transmitter design is compliant with IEC 825. The

entire transmitter circuit and component selections must

be considered. Each customer must determine the level

of fault tolerance required by their application, recognizing that Maxim products are not designed or authorized

for use as components in systems intended for surgical

implant into the body, for applications intended to support or sustain life, or for any other application where the

failure of a Maxim product could create a situation

where personal injury or death may occur.

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

______________________________________________________________________________________ 13

500ps/div

CORRECTLY COMPENSATED

UNCOMPENSATED

OVERCOMPENSATED

Figure 7. Example Laser Compensation

TIME

P0

P1

OPTICAL

POWER

P

AVE

Figure 8. Optical Power Relations

SYMBOL RELATION

Average

Power

P

AVE

Extinction

Ratio

r

e

PARAMETER

Optical Power

of a “1”

P1

Optical Power

of a “0”

P0

Signal

Amplitude

P

INPUT

Table 2. Optical Power Definitions

P = P0 + P1

( )

AVE

r = 1 / P0

P

e

r

P P

1 21=

P P r

0 2 1= +

P P1 - P0 2P

INPUT AVE

e

AVE

r

+

e

/

( )

AVE e

= =

/2

r -1

e

r 1

e

+

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

14 ______________________________________________________________________________________

Table 3. MAX3766 Fault Response in Latched Shutdown Configuration

High voltage on REF1 causes a failure and latched

shutdown.

REF1

Normal condition for circuit operation.ENABLE

Modulation current is increased. Either the APC

circuit will reduce power levels, or an overcurrent

will be detected at MD, causing a failure signal

and latched shutdown.

REF2, TC, MOD

Normal condition for circuit operation.SAFETY

Normal condition for circuit operation.OUT-

No effect on circuit.

FAIL

Forces output to either constant 1 or 0. APC maintains the power level at the programmed level.

IN+, IN-

PIN

Depending upon the setting of R

POWERSET

,

there is either no effect, or a latched shutdown.

BIASMAX

CIRCUIT RESPONSE TO OVERVOLTAGE

OR SHORT TO V

CC

Modulation and bias currents are reduced or off;

no hazard exists.

Modulation and bias currents are shut down.

Modulation current is reduced; no hazard exists.

Safety shutdown features are disabled, but a

hazard is not created.

Forces output to be logic 1. APC maintains the

power level at the programmed level.

No effect on circuit.

Forces output to either constant 1 or 0. APC maintains the power level at the programmed level.

Bias current reduction causes a low laser output,

resulting in a latched shutdown.

CIRCUIT RESPONSE TO UNDERVOLTAGE

OR SHORT TO GROUND

Voltage increase at these pins will turn off the

laser.

OUT+, BIAS

High laser output asserts FAIL. A complete short

will destroy the laser, eliminating the hazard. A

resistive short may cause a hazard. External

circuitry combined with the FAIL signal may be

used to protect against a resistive short (Figure 10).

Laser output increases, but is limited by the setting

of R

BIASMAX

.

POWERSET Laser output decreases.

Voltage increase at MD causes a failure and output

current shutdown.

MD

Voltage decrease at MD causes a failure and

output current shutdown.

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

______________________________________________________________________________________ 15

Layout Considerations

The MAX3766 is a high-frequency product. The performance of the circuit is largely dependent upon the layout of the circuit board.

Use a multilayer circuit board with a dedicated ground

plane. Use short laser package leads placed close to

OUT+ and OUT- to keep output inductance low. Power

supplies should be capacitively bypassed to the

ground plane with surface-mount capacitors placed

near the power-supply pins.

Solutions to Common Problems

1) Laser output is ringing and contains overshoot.

This is often caused by inductive laser packaging.

Try reducing the lead length of the laser pins. Modify

the compensation network to reduce the driver’s output edge speed (see

Design Procedure

). This problem can also occur if the voltage at OUT+, OUT-, or

BIAS is below VCC- 2.5V. Test this by increasing the

supply voltage, or reducing the modulation current.

2) Low-frequency oscillation on the bias-current

output.

Ensure C

MD

≥ 0.1µF.

3) Modulation driver is not needed.

If only the bias-current driver and safety circuits are

needed, connect IN+ to VCC, and leave IN- unconnected. Connect OUT+ and OUT- to the supply.

Leave MOD, TC, and REF2 unconnected.

4) APC is not needed.

If only the high-speed modulation driver is used,

connect BIAS to VCC, and leave POWERSET, MD,

FAIL, and BIASMAX unconnected. Connect SAFETY

to ground.

5) Laser edge switching speed is low.

Refer to the

Design Bias Filter

section. It may be

necessary to select L

BIAS

with a higher self-resonat-

ing frequency.

Wire Bonding Die

The MAX3766 uses bondpads with gold metalization.

Make connections to the die with gold wire only, using

ball bonding techniques. Wedge bonding is not recommended. Pad size is 4 mils (0.1mm) square. Die thickness is typically 15 mils (0.38mm).

Interface Models

Figure 11 shows typical models for the inputs and outputs of the MAX3766, including package parasitics. If

dice are used, replace the package parasitic elements

with bondwire parasitic elements.

PECL

OUTPUT

IN

V

CC

- 2V

V

CC

V

CC

50Ω

68Ω

R2

2.87k

R3

11.8k

R1

10kΩ

180Ω

SINGLE-ENDED TERMINATION IS SHOWN. THE OTHER INPUT SHOULD BE

TERMINATED SIMILARLY, OR CONNECTED TO V

CC

- 1.3V.

MAX3766

RF OR NON-

PECL OUTPUT

IN

MAX3766

TTL OR

CMOS OUTPUT

IN

MAX3766

Figure 9. Input Terminations

FAIL

V

CC

V

CC

RESET

FAIL

OUT+

5.1k

5.1k

100k

V

CC

LASER

MAX3766

Figure 10. External Laser Shutdown Circuit

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

16 ______________________________________________________________________________________

V

IN+

0.2pF

0.4pF

Q1

Q2

Q3

Q4

0.2pF

Q1, Q2 INPUT BIAS CURRENT ≅ 1µA

Q1, Q2 INPUT RESISTANCE ≅ 1MΩ

Q3, Q4 OUTPUT RESISTANCE ≅ 100kΩ

Q5 OUTPUT RESISTANCE ≅ 100kΩ

0.4pF

250Ω

V

CC

1.5nH

1.5nH

V

CC

V

CC

1.5nH

1.5nH

1.5nH

0.2pF

0.2pF

1pF

1pF

0.2pF

2pF

Q5

I

BIAS

I

MOD

OUT+ OUT-

PACKAGE

PACKAGE

V

CC

- 2.5 VCC - 2.5

V

CC

- 2.5

INPUT

OUTPUT BIAS

V

IN-

250Ω

V

CC

V

CC

V

CC

PACKAGE

Figure 11. Interface Models

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

______________________________________________________________________________________ 17

V

CCOUT

CONFIGURED FOR MINIMUM COMPONENT COUNT.

FAILURE-INDICATION CONFIGURATION

LATCHED SHUTDOWN CONFIGURATION

CONFIGURED FOR BEST PERFORMANCE.

R

TC

SETS THE TEMPERATURE COEFFICIENT OF THE MODULATION CURRENT.

V

CC

REF2

IN+

IN-

BIASMAX

R

POWERSET

POWERSET

REF1

TC MOD

ENABLE

R

MOD

OUT-

V

CC

0.01µF

V

CC

C

MD

OUT+

BIAS

R

FAIL

5.1k

V

CC

FAIL

SAFETY

GNDOUT

GND

MD

V

CCOUT

V

CC

V

CC

ENABLE

REF2

IN+

IN-

BIASMAX

R

POWERSET

R

TC

POWERSET

REF1

TC MOD

R

MOD

OUT-

V

CC

C

MD

R

OUT-

R

D

C

COMP

V

CC

LASER

L

BIAS

R

COMP

R

FAIL

5.1k

OUT+

BIAS

FAIL

SAFETY

C

SAFETY

(OPTIONAL—SEE TEXT)

GNDOUT

GND

MD

MAX3766

MAX3766

0.01µF

LASER

R

BIASMAX

Typical Application Circuits

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

18 ______________________________________________________________________________________

___________________Chip Topography

0.056"

(1.422mm)

0.045"

(1.143mm)

OUT- OUT+ BIAS GNDOUT

REF2

TC

BIASMAX

REF1

POWERSET

MD

IN+ IN- GND MOD

GND

V

CC

ENABLE

SAFETY

V

CCOUT

FAIL

TRANSISTOR COUNT: 725

SUBSTRATE CONNECTED TO GND AND GNDOUT.

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

______________________________________________________________________________________ 19

________________________________________________________Package Information

QSOP.EPS

Maxim makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does Maxim assume any liability arising out of the application or use of any product or circuit and specifically disclaims any and all liability, including without limitation consequential or

incidental damages. “Typical” parameters can and do vary in different applications. All operating parameters, including “typicals” must be validated for

each customer application by customer’s technical experts. Maxim products are not designed, intended or authorized for use as components in systems

intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the

Maxim product could create a situation where personal injury or death may occur.

20

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1997 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

MAX3766

622Mbps LAN/WAN Laser Driver with

Automatic Power Control and Safety Shutdown

NOTES

Loading...

Loading...