Page 1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

General Description

The MAX3669 is a complete, +3.3V laser driver with automatic power control (APC) circuitry for SDH/SONET applications up to 622Mbps. It accepts differential PECL

inputs, provides bias and modulation currents, and operates over a temperature range from -40°C to +85°C.

An APC feedback loop is incorporated to maintain a

constant average optical power over temperature and

lifetime. The wide modulation current range from 5mA

to 75mA and bias current of 1mA to 80mA are easy to

program, making this product ideal for use in various

SDH/SONET applications. Two pins are provided to

monitor the current levels in the laser: BIASMON with

current proportional to laser bias current, and MODMON with current proportional to laser modulation.

The MAX3669 also provides enable control and a failuremonitor output to indicate when the APC loop is unable to

maintain the average optical power. The MAX3669 is

available in a 5mm 32-pin TQFP package as well as in

dice.

Applications

622Mbps SDH/SONET Access Nodes

Laser Driver Transmitters

Section Regenerators

Features

♦ +3.3V or +5.0V Single-Supply Operation

♦ 40mA Supply Current at +3.3V

♦ Programmable Bias Current from 1mA to 80mA

♦ Programmable Modulation Current from

5mA to 75mA

♦ Bias Current and Modulation Current Monitors

♦ 200ps Rise/Fall Time

♦ Automatic Average Power Control with Failure

Monitor

♦ Complies with ANSI, ITU, and Bellcore

SONET/SDH Specifications

♦ Enable Control

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

________________________________________________________________ Maxim Integrated Products 1

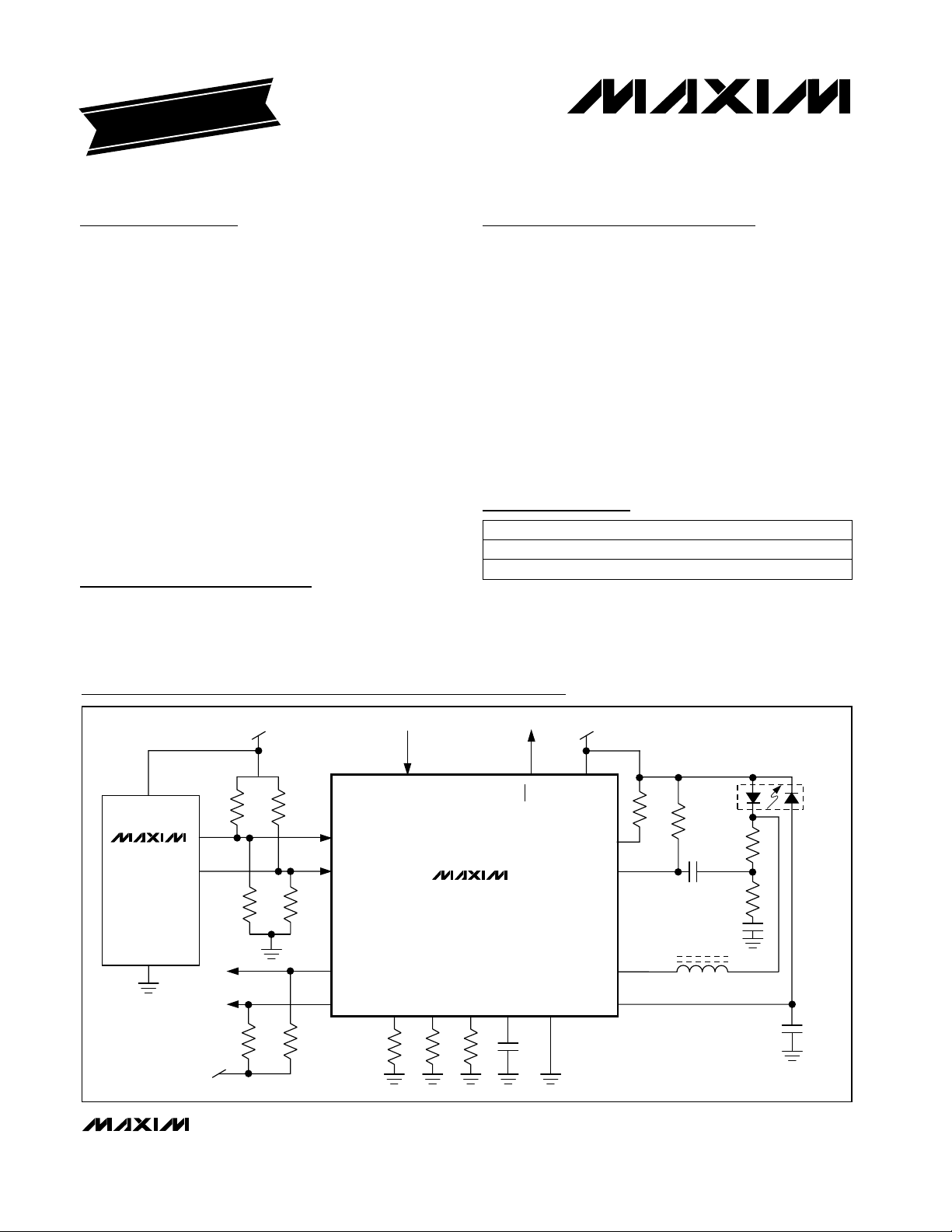

Typical Application Circuit

19-1575; Rev 0; 10/99

PART

MAX3669EHJ -40°C to +85°C

TEMP. RANGE PIN-PACKAGE

32 TQFP (5mm x 5mm)

EVALUATION KIT

AVAILABLE

Ordering Information

Pin Configuration appears at end of data sheet.

MAX3669E/D (Note A) Dice*

Note A: Dice are designed to operate over a -40°C to +140°C

junction temperature (T

j

) range, but are tested and guaranteed

at T

A

= +25°C.

*Contact factory for availability.

+3.3V

+3.3V

LASER

V

GND

CC

OUT-

OUT+

BIAS

MD

R-

6.3Ω

R+

20Ω

C

D

1µF

FERRITE

BEAD

R

D

5Ω

R

FILT

20Ω

C

FILT

5pF

C

MD

1000pF

MAX3693

4:1

SERIALIZER

WITH

CLOCK GEN

124Ω

PECL

84.5Ω

+3.3V

124Ω

84.5Ω

DATA+

DATA-

BIASMON

MODMON

ENABLE

BIASMAX

MAX3669

MODSET

APCSET

FAIL

CAPC

0.1µF

Page 2

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

DC ELECTRICAL CHARACTERISTICS

(VCC= +3.14V to +5.5V, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VCC= +3.3V, TA= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Supply Voltage, VCC.............................................-0.5V to +7.0V

Current into BIAS ............................................-20mA to +150mA

Current into OUT+, OUT- ............................... -20mA to +100mA

Current into MD....................................................-5mA to +5mA

Voltage at DATA+, DATA-, ENABLE,

FAIL, BIASMON, MODMON..................-0.5V to (V

CC

+ 0.5V)

Voltage at OUT+, OUT-.............................+1.5V to (V

CC

+ 1.5V)

Voltage at MODSET, APCSET, BIASMAX,

CAPC............................................................... -0.5V to +3.0V

Voltage at BIAS .........................................+1.0V to (V

CC

+ 0.5V)

Continuous Power Dissipation (T

A

= +85°C)

32-Pin TQFP (derate 14.3mW/°C above +85°C)........ 929mW

Operating Junction Temperature Range...........-55°C to +150°C

Processing Temperature (Die).........................................+400°C

Storage Temperature Range ............................ -65°C to +165°C

Lead Temperature (soldering, 10s) .................................+300°C

MODMON to I

MOD

Gain A

MOD

29 mA/mAI

MOD/IMODMON

BIASMON to I

BIAS

Gain A

BIAS

38 mA/mAI

BIAS/IBIASMON

35IMD= 18µA (Note 5)

IMD= 1mA

815I

BIAS

= 1mA

I

BIAS

= 80mA

PARAMETER SYMBOL MIN TYP MAX UNITS

Common-Mode Input Voltage V

ICM

V

CC

-V

CC

-V

CC

-

1.49 1.32 V

ID

/4

V

Differential Input Voltage V

ID

200 1600 mVp-p

Bias Current Absolute Accuracy -15 15 %

Bias Current Stability

255

ppm/°C

DATA+, DATA- Input Current I

IN

-1 10 µA

Monitor Diode Current Stability

-480 -50 480

ppm/°C

Monitor Diode Current

Absolute Accuracy

-15 15 %

DC Monitor Diode Current I

MD

18 1000 µA

Bias Current Range

Supply Current 40 60 mA

I

BIAS

180mA

Bias Off Current 100 µA

Monitor Diode Input Voltage

(MD pin)

V

MD

0.8 V

TTL Input High Voltage V

IH

2.0 V

TTL Input Low Voltage V

IL

0.8 V

TTL Output High Voltage (FAIL)

V

OH

2.4 V

CC

- 0.3 V

CC

V

TTL Output Low Voltage (FAIL)

V

OL

0.1 0.44 V

CONDITIONS

PECL compatible

Figure 1

APC open loop

APC open loop

(Note 4)

Sourcing 50µA

Sinking 100µA

(Note 2)

V

BIAS

= V

CC

- 1.6V

ENABLE = low (Note 3)

Page 3

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

_______________________________________________________________________________________ 3

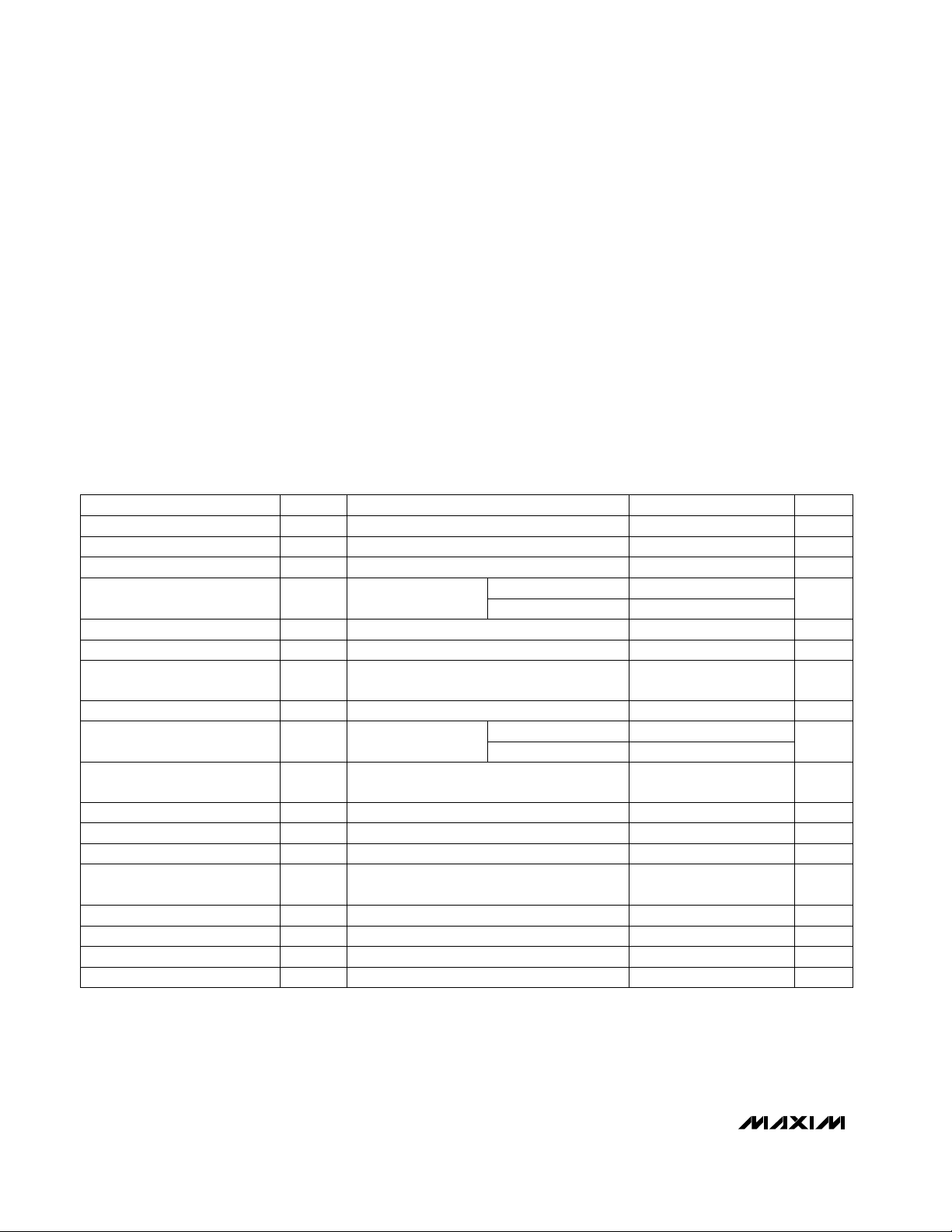

AC ELECTRICAL CHARACTERISTICS

(VCC= +3.14V to +5.5V, load as shown in Figure 2, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VCC= +3.3V,

T

A

= +25°C.) (Note 6)

Note 1: Dice are tested and guaranteed at TA= +25°C only.

Note 2: Tested with R

MODSET

= 5.11kΩ (I

MOD

≈ 38mA), R

BIASMAX

= 4.56kΩ (I

BIAS

≈ 52mA), excluding I

BIAS

and I

MOD

.

Note 3: Both the bias and modulation currents will be disabled if any of the current set pins are shorted to ground.

Note 4: Guaranteed by design and characterization. This assumes that the laser to monitor diode transfer function does not change

with temperature.

Note 5: See Typical Operating Characteristics for worst-case distributions.

Note 6: AC characteristics are guaranteed by design and characterization.

Note 7: Total I

MOD

out of OUT+. See the Design Procedure for information regarding current delivered to the laser.

Note 8: Input signal is a 622Mbps, 2

13

- 1 PRBS with 80 inserted zeros.

Note 9: Input signal is a 622Mbps, 11110000 pattern.

Note 10:PWD = (wider pulse – narrower pulse) / 2.

Figure 1. Required Input Signal and Output Polarity

Figure 2. Output Termination for Characterization

10 135I

MOD

= 75mA

Maximum Consecutive Identical

Digits at 622Mbps

CID 80 Bits

I

MOD

= 5mA

I

MOD

= 75mA

Jitter Generation (peak-to-peak) 100 ps(Note 8)

205I

MOD

= 5mA (Note 5)

I

MOD

= 5mA

(Notes 9, 10)

PARAMETER SYMBOL MIN TYP MAX UNITS

230 375

psOutput Rise/Fall Time t

R, tF

100 200

Modulation Current Absolute

Accuracy

-15 15 %

Pulse-Width Distortion

(peak-to-peak)

70 155

ps

Enable/Start-Up Delay 250 ns

Modulation Current Stability

-620 -165 620

ppm/°C

CONDITIONS

20% to 80%,

R

L

= 10Ω||20Ω load

Open loop

I

MOD

= 75mA

Modulation Current Range I

MOD

575mA(Note 7)

Modulation Off-Current 200 µAENABLE = low (Note 3)

V

CC

DATA+

DATA-

(DATA+) - (DATA-)

+

I

OUT

100mV MIN

800mV MAX

200mVp-p

MIN

1600mVp-p

MAX

I

MOD

20Ω

1µF

OUT-

10Ω

BIAS

I

OUT+

V

20Ω

1µF

12.4Ω

15Ω

CC

MAX3669

OUT+

OSCILLOSCOPE

50Ω

Page 4

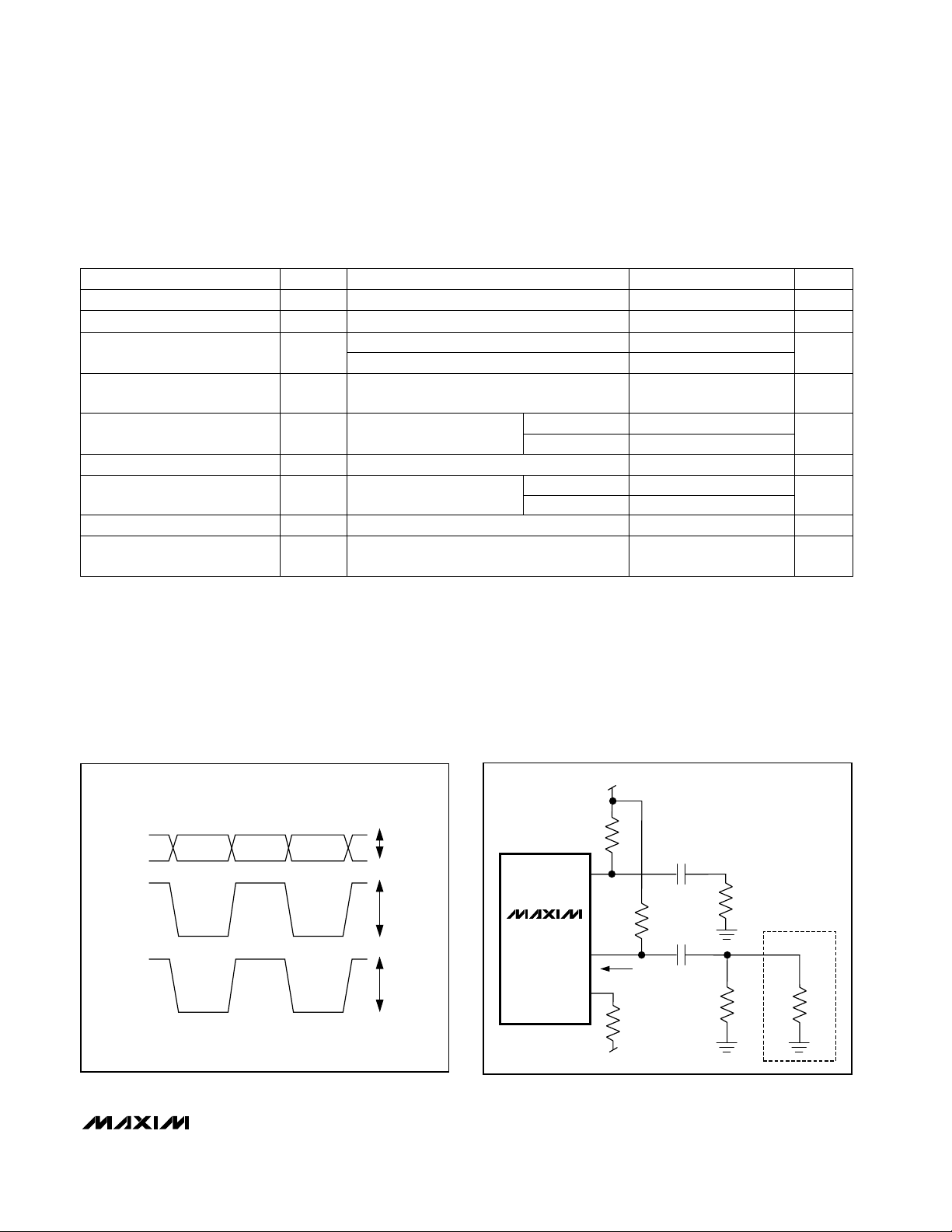

ELECTRICAL EYE DIAGRAM

(I

MOD

= 35mA)

MAX3669 TOC02

200ps/div

PATTERN = 213 - 1 + 80 CID

I

MOD

= 35mA

622Mbps DATA RATE

ELECTRICAL EYE DIAGRAM

(I

MOD

= 75mA)

MAX3669 TOC03

200ps/div

PATTERN = 213 - 1 + 80 CID

I

MOD

= 75mA

622Mbps DATA RATE

EYE DIAGRAM

(622Mbps, 1300nm LASER

WITH 467MHz FILTER)

MAX3669 TOC01

200ps/div

223–1 PRBS

10

0.01

1 10 100

MONITOR DIODE CURRENT

vs. APC SET RESISTOR

0.1

1

MAX3669 TOC04

R

APCSET

(kΩ)

I

MD

(mA)

1000

1

0.1 101 100

BIAS CURRENT vs.

MAXIMUM BIAS SET RESISTOR

10

100

MAX3669 TOC05

R

BIASMAX

(kΩ)

I

BIAS

(mA)

100

1

0.1 100 1000

MODULATION CURRENT

vs. MODULATION SET RESISTOR

10

MAX3669 TOC06

R

MODSET

(kΩ)

I

MOD

(mA)

101

16

17

19

18

20

21

04020 60 80

RANDOM JITTER

vs. MODULATON CURRENT

MAX3669 TOC07

I

MOD

(mA)

RANDOM JITTER (ps

p-p

)

INCLUDES RANDOM JITTER

DUE TO MEASUREMENT

EQUIPMENT

0

15

10

5

20

25

30

35

40

45

50

04020 60 80

PULSE-WIDTH DISTORTION

vs. MODULATION CURRENT

MAX3669 TOC08

I

MOD

(mA)

PWD (ps)

-40 10-15 35 60 85

MAX3669 TOC09

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

0

20

10

40

30

50

60

SUPPLY CURRENT

vs. TEMPERATURE

I

BIAS

= 48mA

I

MOD

= 27mA

VCC = 5.0V

VCC = 3.3V

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

4 _______________________________________________________________________________________

Typical Operating Characteristics

(VCC= +3.3V, TA= +25°C, unless otherwise noted.)

Page 5

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

_______________________________________________________________________________________ 5

Typical Operating Characteristics (continued)

(VCC= +3.3V, TA= +25°C, unless otherwise noted.)

0

10

5

20

15

30

25

35

RATIO OF I

MOD

vs. I

MODMON

MAX3669 toc13

I

MOD

(mA)

I

MOD

/I

MODMON

(mA/mA)

0 204060

80

TA = -40°C

TA = +85°C

TA = +25°C

0

10

15

20

25

30

35

40

45

0 20406080

RATIO OF I

BIAS

vs. I

BIASMON

MAX3669 toc14

I

BIAS

(mA)

I

BIAS

/I

BIASMON

(mA/mA)

5

TA = -40°C

TA = +25°C

TA = +85°C

DISTRIBUTION OF MODULATION CURRENT

STABILITY (WORST CASE)

35

TA = -40°C TO +85°C

= 5mA

I

MOD

30

25

20

15

PERCENT OF UNITS (%)

10

5

0

-125 75 175-25 275 375 475 575

MODULATION CURRENT STABILITY (ppm/°C)

MAX3669-11

DISTRIBUTION OF MONITOR DIODE CURRENT

STABILITY (WORST CASE)

25

TA = -40°C TO +85°C

= 18µA

I

MD

20

15

10

PERCENT OF UNITS (%)

5

0

MONITOR DIODE CURRENT STABILITY (ppm/°C)

-100-500 100 300 500

-300

MAX3669-12

Page 6

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

6 _______________________________________________________________________________________

NAME FUNCTION

1, 2, 6, 15,

17, 20, 24

V

CC

Positive Supply Voltage

29 APCSET

APC Set Resistor. A resistor connected from this pad to ground sets the desired average optical power. The resulting current is equal to the desired DC monitor diode current. Connect a

100kΩ resistor from this pad to ground if APC is not used.

PIN

3 DATA+ Positive PECL Data Input

4 DATA- Negative PECL Data Input

32 BIASMAX

Maximum Bias Set Resistor. A resistor from this pad to ground sets the maximum laser bias

current. The APC function can subtract from this maximum value but cannot add to it. This

resistor controls the bias-current level when the APC loop is not used.

31 MODSET Modulation Set Resistor. A resistor from this pad to ground sets the laser modulation current.

5, 10, 14, 21,

22, 30

GND Ground

12, 13, 26,

27, 28

N.C. No Connection. Leave unconnected.

11

FAIL

TTL Output. Indicates APC failure when low. Internally pulled high through a 6kΩ resistor.

9 ENABLE

TTL/CMOS Enable Input. High for normal operation, low to disable laser bias and modulation

currents. Internally pulled high.

16 BIAS Laser Bias Current Output. Isolate from laser with a ferrite bead.

19 OUT-

Negative Modulation Current Output. I

MOD

flows into this pad when the input signal is low.

Connect this pad to VCCthrough a 6.3Ω resistor.

18 OUT+

Positive Modulation Current Output. I

MOD

flows into this pad when the input signal is high.

Connect this pad to AC-coupling network.

23 MD

Monitor Photodiode Connection. Connect this pad to the monitor photodiode anode. A capacitor to ground is required to filter high-speed AC monitor photocurrent.

25 CAPC

APC Compensation Capacitor. A 0.1µF capacitor connected from this pad to ground controls

the dominant pole of the APC feedback loop.

Pin Description

7 BIASMON Sink Current Source—proportional to the laser bias current.

8 MODMON Sink Current Source—proportional to the laser modulation current.

Page 7

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

_______________________________________________________________________________________ 7

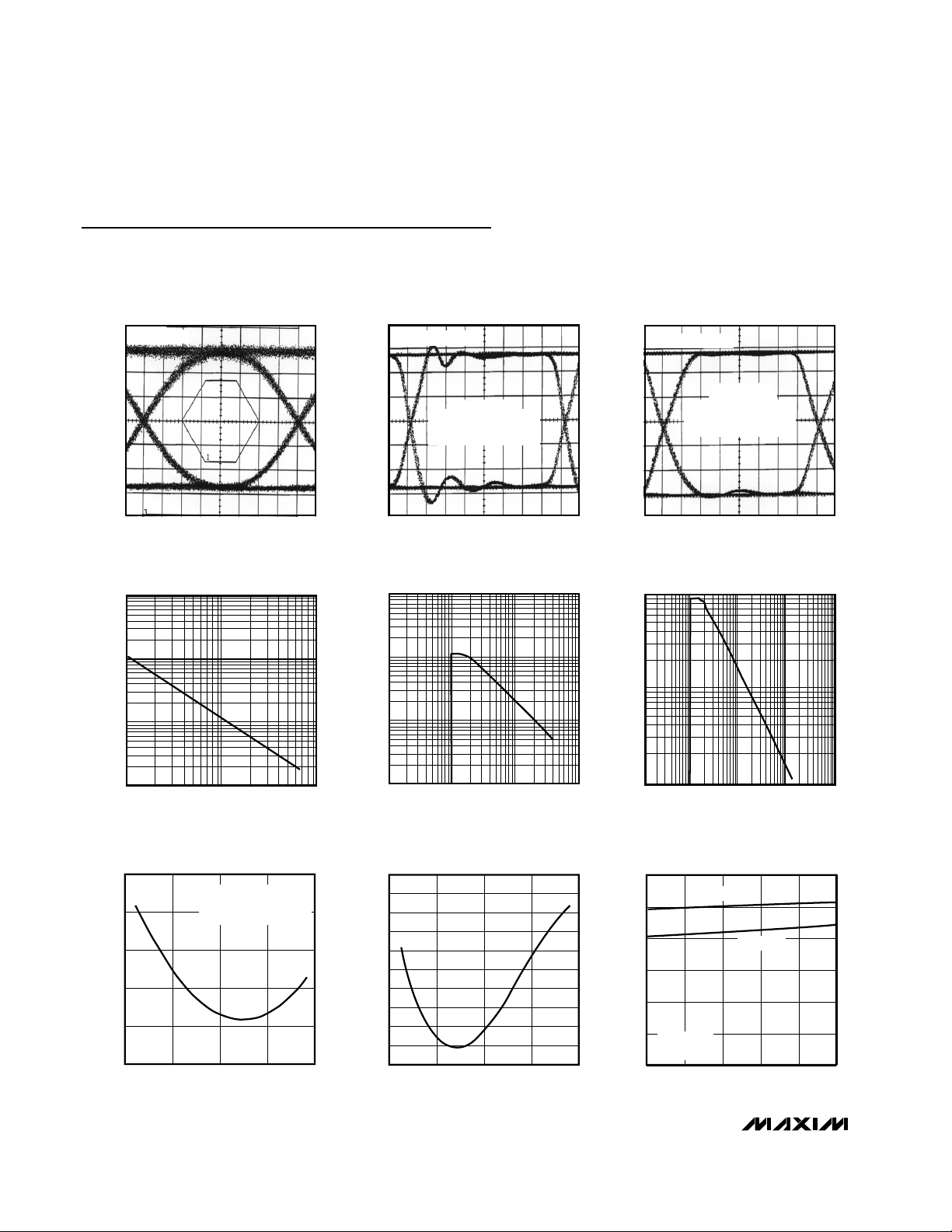

Figure 3. Functional Diagram

Detailed Description

The MAX3669 laser driver consists of three main parts:

a high-speed modulation driver, a laser-biasing block

with automatic power control (APC), and bias current

and modulation current monitors. The circuit is optimized for low-voltage (+3.3V) operation.

The output stage is composed of a high-speed differential

pair and a programmable modulation current source.

Since the modulation output drives a maximum current

of 75mA into the laser with a 230ps edge speed, large

transient voltage spikes can be generated due to the

parasitic inductance. These transients and the laser forward voltage leave insufficient headroom for the proper

operation of the laser driver if the modulation output is

DC-coupled to the laser diode. To solve this problem,

the MAX3669’s modulation output is designed to be

AC-coupled to the cathode of a laser diode. A simplified functional diagram is shown in Figure 3.

The MAX3669 modulation output is optimized for driving a 20Ω 10Ω load; the minimum required voltage at

OUT+ is 2.0V. Modulation current swings of 75mA are

possible. To interface with the laser diode, a damping

resistor (R

D

) is required for impedance matching. An

RC shunt network may be used to compensate for the

laser-diode parasitic inductance, thereby improving the

optical output aberrations and duty-cycle distortion.

At a 622Mbps data rate, any capacitive load at the cathode of a laser diode degrades the optical output performance. Since the BIAS output is directly connected to the

laser cathode, minimize the parasitic capacitance associated with this pin by using an inductor to isolate the BIAS

pin from the laser diode.

DATA+

I

MOD

DATA-

V

CC

100k

ENABLE

V

CC

R

BIASMON

V

CC

R

MODMON

MAX3669

I

BIAS

38

I

MOD

29

MODSET

R

MODSET

165X

BIASMAX

R

BIASMAX

FAIL

5X

DETECTOR

40X

FAILURE

I

MD

CAPC

C

APC

APCSET

R

APCSET

I

BIAS

OUT+

OUT-

BIAS

MD

Page 8

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

8 _______________________________________________________________________________________

Automatic Power Control

To maintain constant average optical power, the

MAX3669 incorporates an APC loop to compensate for

the changes in laser threshold current over temperature

and lifetime. A back-facet photodiode mounted in the

laser package is used to convert the optical power into a

photocurrent. The APC loop adjusts the laser bias current so the monitor current is matched to a reference current set by R

APCSET

. The time constant of the APC loop

is determined by an external capacitor (C

APC

). To eliminate the pattern-dependent jitter associated with the

APC loop-time constant and to guarantee loop stability,

the recommended value for C

APC

is 0.1µF.

When the APC loop is functioning, the maximum allowable

bias current is set by an external resistor, R

BIASMAX

. An

APC failure flag (FAIL) is set low when the bias current can

no longer be adjusted to achieve the desired average

optical power.

APC closed-loop operation requires the user to set three

currents with external resistors connected between

ground and BIASMAX, MODSET, and APCSET. Detailed

guidelines for these resistor settings are described in

the Design Procedure section.

Bias and Modulation Monitors

The MAX3669 includes pins to monitor the output levels

of bias and modulation current. BIASMON and MODMON sink current proportional to laser bias current and

modulation current, respectively. By monitoring the current through R

MODMON

and R

BIASMON

, it is possible to

monitor the levels of bias and modulation current in the

laser (Figure 3).

Open-Loop Operation

If necessary, the MAX3669 is fully operational without

APC. In this case, the laser current is directly set by two

external resistors connected from ground to BIASMAX

and MODSET. Connect a 100kΩ resistor from APCSET

to ground and leave MD open for open-loop operation.

Enable Control

The MAX3669 incorporates a laser driver enable function. When ENABLE is low, both the bias and modulation

currents are off. The typical laser enable time is 250ns.

APC Failure Monitor

The MAX3669 provides an APC failure monitor

(TTL/CMOS) to indicate an APC loop tracking failure. FAIL

is set low when the APC loop can no longer adjust the bias

current to maintain the desired monitor current. This output

is internally pulled up to VCCthrough a 6kΩ resistor.

Short-Circuit Protection

The MAX3669 provides short-circuit protection for the

modulation, bias, and monitor current sources. If either

BIASMAX, MODSET, or APCSET is shorted to ground,

the bias and modulation outputs will be turned off.

Design Procedure

When designing a laser transmitter, the optical output is

usually expressed in terms of average power and extinction ratio. Table 1 gives the relationships that are helpful

in converting between the optical average power and the

modulation current. These relationships are valid if the

average duty cycle of the optical waveform is 50%.

Programming the Modulation Current

In addition to being a function of R

MODSET

, the modula-

tion current delivered to the laser (I

MODL

) also depends

on the values of the series damping resistor (RD), the

shunt compensation resistance (R

FILT

), and the laser

diode’s resistance (see Typical Operating Circuit).

The modulation current (assuming C

FILT

<<CD) into the

laser diode can be represented by the following:

Assuming RD= 5Ω and r

LASER

= 5Ω, this equation is

simplified to:

I

MODL

= I

MOD

(0.67)

For RD= 5.0Ω and a laser resistance of approximately

5Ω, see the Modulation Current vs. Modulation Set

Resistor graph in the Typical Operating Characteristics

and select the value of R

MODSET

that corresponds to

the required current at +25°C.

Programming the Bias Current

When using the MAX3669 in open-loop operation, the

bias current is determined by the R

BIASMAX

resistor. To

select this resistor, determine the required bias current

at +25°C. See the Bias Current vs. Maximum Bias Set

Table 1. Optical Power Definition

I

MODL

= Pp-p / η

I

MOD

Laser Modulation

Current

η = Pp-p / I

MODL

η

Laser Slope

Efficiency

Pp-p = 2P

AVG(re

- 1) / (re+ 1)Pp-pOptical Amplitude

P0= 2P

AVG

/ (re+ 1)P

0

Optical Power Low

P1= 2P

AVG

· re/ (re+ 1)

P

1

Optical Power High

re= P1/ P

0

r

e

Extinction Ratio

P

AVG

= (P0+ P1) / 2P

AVG

Average Power

RELATIONSYMBOLPARAMETER

I = I

MODL MOD

2 + R+ r

Ω

00Ω

2

()

D LASER

Page 9

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

_______________________________________________________________________________________ 9

Resistor graph in the Typical Operating Characteristics and select the value of R

BIASMAX

that corre-

sponds to the required current at +25°C.

When using the MAX3669 in closed-loop operation, the

R

BIASMAX

resistor sets the maximum bias current available to the laser diode over temperature and life. The

APC loop can subtract from this maximum value but

cannot add to it. See the Bias Current vs. Maximum

Bias Set Resistor graph in the Typical Operating

Characteristics and select the value of R

BIASMAX

that

corresponds to the end-of-life bias current at +85°C.

Programming the APC Loop

When the MAX3669’s APC feature is used, program the

average optical power by adjusting the APCSET resistor. To select this resistor, determine the desired monitor current to be maintained over temperature and life.

See the Monitor Diode Current vs. APC Set Resistor

graph in the Typical Operating Characteristics and

select the value of R

APCSET

that corresponds to the

required current.

Interfacing with the Laser Diode

To minimize optical output aberrations due to the laser

parasitic inductance, an RC shunt network may be

used (see Typical Operating Circuit). If RLrepresents

the laser diode resistance, the recommended total

resistance for RD+ RLis 10Ω. Starting values for coaxial lasers are R

FILT

= 20Ω and C

FILT

= 5pF. R

FILT

and

C

FILT

should be experimentally adjusted to optimize

the output waveform. A bypass capacitor should also

be placed as close to the laser anode as possible for

best performance.

Pattern-Dependent Jitter (PDJ)

When transmitting NRZ data with long strings of consecutive identical digits (CIDs), LF droop can contribute to

PDJ. To minimize this PDJ, two external components

must be properly chosen: capacitor C

APC

, which dominates the APC loop time constant, and AC-coupling

capacitor CD.

To filter out noise effects and guarantee loop stability,

the recommended value for C

APC

is 0.1µF. This results

in an APC loop bandwidth of 20kHz. Consequently, the

PDJ associated with an APC loop time constant can be

ignored.

The time constant associated with the DC blocking

capacitor on I

MOD

will have an effect on PDJ. It is

important that this time constant produce minimum

droop for long consecutive bit streams.

Referring to Figure 4, the droop resulting from long time

periods without transitions can be represented by the

following equation:

AC-coupling of I

MOD

results in a discharge level for τ

that is equal to P

AVG

. An overall droop of 6% relative to

P

p-p

equates to a 12% droop relative to P

AVG

. To

ensure a droop of less than 12% (6% relative to P

p-p

),

this equation can be solved for τ as follows:

If t1equals 80 consecutive unit intervals without a transition, the time constant associated with the DC blocking capacitor needs to be longer than:

τAC≥ RACCD= 7.8 (80 bits) (1.6ns/bit) = 1.0µs

R

FILT

can be ignored for C

FILT

<< CD; therefore, the

estimated value of RACis:

RAC= 20Ω (RD+ r

LASER

)

Assuming RD= 5Ω, and r

LASER

= 5Ω:

RAC= 6.7Ω

with CD= 1µF, τAC= 6.7µs.

Input Termination Requirement

The MAX3669 data inputs are PECL compatible.

However, it is not necessary to drive the MAX3669 with

a standard PECL signal. As long as the specified common-mode voltage and differential voltage swings are

met, the MAX3669 will operate properly.

Figure 4. Droop

(100% - DROOP) = e

τ = = 7.8t

-t

(1 - 0.12)

ln

-t

τ

τ = ∞

P

P

AVG

p-p

τ << τ

τ

AC

AC

t

1

DROOP

t

Page 10

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

10 ______________________________________________________________________________________

Calculate Power Consumption

The total power dissipation of the MAX3669 can be estimated by the following:

P = V

CC

· I

CC

+ (VCC- Vf) · I

BIAS

+ I

MOD(VCC

- 20Ω · I

MOD

/ 2)

where I

BIAS

is the maximum bias current set by R

BIAS-

MAX

, I

MOD

is the modulation current, and Vfis the typi-

cal laser forward voltage.

Applications Information

The following is an example of how to set up the

MAX3669.

Select Laser

A communication-grade laser should be selected for

622Mbps applications. Assume the laser output average power is P

AVG

= 0dBm, the minimum extinction

ratio is re= 6.6 (8.2dB), the operating temperature is

-40°C to +85°C, and the laser diode has the following

characteristics:

Wavelength: λ = 1.3µm

Threshold Current: ΙTH= 22mA at +25°C

Threshold Temperature

Coefficient: βTH= 1.3%/°C

Laser to Monitor Transfer: ρ

MON

= 0.2A/W

Laser Slope Efficiency: η = 0.05mW/mA

at +25°C

Determine R

APCSET

The desired monitor diode current is estimated by

IMD= P

AVG

·

ρ

MON

= 200µA. The Monitor Diode Current

vs. APC Set Resistor graph in the Typical Operating

Characteristics shows that R

APCSET

should be 6kΩ.

Determine R

MODSET

To achieve a minimum extinction ratio (re) of 6.6dB over

temperature and lifetime, calculate the required extinction ratio at +25°C. Assuming re= 20, the peak-to-peak

optical power P

p-p

= 1.81mW, according to Table 1.

The required modulation current is 1.81(mW) /

0.05(mW/mA) = 36.2mA. The Modulation Current vs.

Modulation Set Resistor graph (see Typical Operating

Characteristics) shows that R

MODSET

should be 5kΩ.

Determine R

BIASMAX

Calculate the maximum threshold current (I

TH(MAX)

) at

TA= +85°C and end of life. Assuming I

TH(MAX)

=

50mA, the maximum bias current should be:

I

BIAS

= I

TH(MAX)

+ I

MOD

/ 2

In this example, I

BIAS

= 68.1mA. The Bias Current vs.

Maximum Bias Set Resistor graph in the Typical

Operating Characteristics shows that R

BIASMAX

should

be 3kΩ.

Determine R

BIASMON

To avoid saturating the current mirror of BIASMON, the

voltage at this pin should not drop below (V

CC

- 1.6V).

The resulting condition is:

where I

BIASMAX

is the maximum current expected for

the application.

Determine R

MODMON

To avoid saturating the current mirror of MODMON, the

voltage at this pin should not drop below (V

CC

- 1V).

The resulting condition is:

Modulation Currents Exceeding 50mA

To drive modulation currents greater than 50mA at

3.3V, external pull-up inductors (Figure 5) should be

used to DC-bias the modulation output at VCC. Such a

configuration isolates the laser forward voltage from the

output circuitry and allows the output at OUT+ to swing

above and below the supply voltage VCC.

Figure 5. Output Termination for Maximum Modulation Current

R 1.6V

BIASMON

A

I

BIASMAX

BIAS

≤

R 1V

MODMON

A

MOD

I

MOD

≤

V

CC

10Ω

OUT-

OUT+

MAX3669

BIAS

MD

FERRITE

BEADS

FERRITE BEAD

C

D

1µF5Ω

LD

R

D

R

FILT

C

FILT

1000pF

Page 11

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

______________________________________________________________________________________ 11

Chip Topography

MAX3669

TQFP

TOP VIEW

32 28

293031

25

26

27

MODSET

GND

APCSET

N.C.

BIASMAX

N.C.

N.C.

CAPC

10

13

15

14

1611 12

9

ENABLE

FAIL

GND

N.C.

N.C.

V

CC

GND

BIAS

17

18

19

20

21

22

23

MD

24 V

CC

GND

GND

V

CC

OUT-

OUT+

V

CC

2

3

4

5

6

7

8MODMON

BIASMON

V

CC

GND

DATA-

DATA+

V

CC

1V

CC

At +5V power supply, the headroom voltage for the

MAX3669 is significantly improved. In this case, it is

possible to achieve a modulation current of more than

50mA (using resistor pull-ups as shown in the Typical

Operating Circuit). The MAX3669 can also be DC-coupled

to a laser diode when operating at +5V supply; the voltage at OUT+ should be ≥2.0V for proper operation.

Wire Bonding Die

For high current density and reliable operation, the

MAX3669 uses gold metalization. Make connections to

the die with gold wire only, using ball-bonding techniques. Wedge bonding is not recommended. Die-pad

size is 4 mils (100µm) square, and die thickness is 12

mils (300µm) mils.

Layout Considerations

To minimize inductance, keep the connections between

the MAX3669 output pins and LD as close as possible.

Optimize the laser diode performance by placing a

bypass capacitor as close as possible to the laser

anode. Use good high-frequency layout techniques

and multilayer boards with uninterrupted ground planes

to minimize EMI and crosstalk.

Laser Safety and IEC 825

Using the MAX3669 laser driver alone does not ensure

that a transmitter design is compliant with IEC 825. The

entire transmitter circuit and component selections must

be considered. Customers must determine the level of

fault tolerance required by their application, recognizing

that Maxim products are not designed or authorized for

use as components in systems intended for surgical

implant into the body, for applications intended to support or sustain life, or for any other application where the

failure of a Maxim product could create a situation

where personal injury or death may occur.

Pin Configuration

Chip Information

TRANSISTOR COUNT: 1525

SUBSTRATE CONNECTED TO GND

CC

CC

DATA-

DATA+

CC

GND

GND

V

V

CC

BIASMAX

MODSET

GND

APCSET

N.C.

GND

N.C.

GND

N.C.

CAPC

V

GND

0.083"

(2.10mm)

CC

GND

ENABLE

N.C.

GND

N.C.

V

FAIL

GND

N.C.

N.C.

GND

V

BIAS

CC

GND

CC

CC

V

BIASMON

V

MODMON

GND

V

N.C.

CC

V

N.C.

OUT-

OUT+

0.070"

(1.78mm)

CC

MD

V

N.C.

GND

GND

Page 12

MAX3669

+3.3V, 622Mbps SDH/SONET

Laser Driver with Current Monitors and APC

Maxim makes no warranty, representation, or guarantee regarding the suitability of its products for any particular purpose, nor does Maxim assume any liability arising out of the application or use of any product or circuit and specifically disclaims any and all liability, including without limitation consequential or

incidental damages. “Typical” parameters can and do vary in different applications. All operating parameters, including “typicals” must be validated for

each customer application by customer’s technical experts. Maxim products are not designed, intended, or authorized for use as components in systems

intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the

Maxim product could create a situation where personal injury or death may occur.

12 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1999 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

32L,TQFP.EPS

Loading...

Loading...