Page 1

现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

________________General Description

The MAX3263 is a complete, easy-to-program, single

+5V-powered, 155Mbps laser diode driver with complementary enable inputs and automatic power control

(APC). The MAX3263 accepts differential PECL inputs

and provides complementary output currents. A temperature-stabilized reference voltage is provided to

simplify laser current programming. This allows modulation current to be programmed up to 30mA and bias

current to be programmed from up to 60mA with two

external resistors.

An APC circuit is provided to maintain constant laser

power in transmitters that use a monitor photodiode.

Only two external resistors are required to implement

the APC function.

The MAX3263’s fully integrated feature set includes a

TTL-compatible laser failure indicator and a programmable slow-start circuit to prevent laser damage. The

slow-start is preset to 50ns and can be extended by

adding an external capacitor.

________________________Applications

Laser Diode Transmitters

155Mbps SDH/SONET

155Mbps ATM

____________________________Features

♦ Rise Times Less than 1ns

♦ Differential PECL Inputs

♦ Single +5V Supply

♦ Automatic Power Control

♦ Temperature-Compensated Reference Voltage

♦ Complementary Enable Inputs

_______________Ordering Information

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

________________________________________________________________

Maxim Integrated Products

1

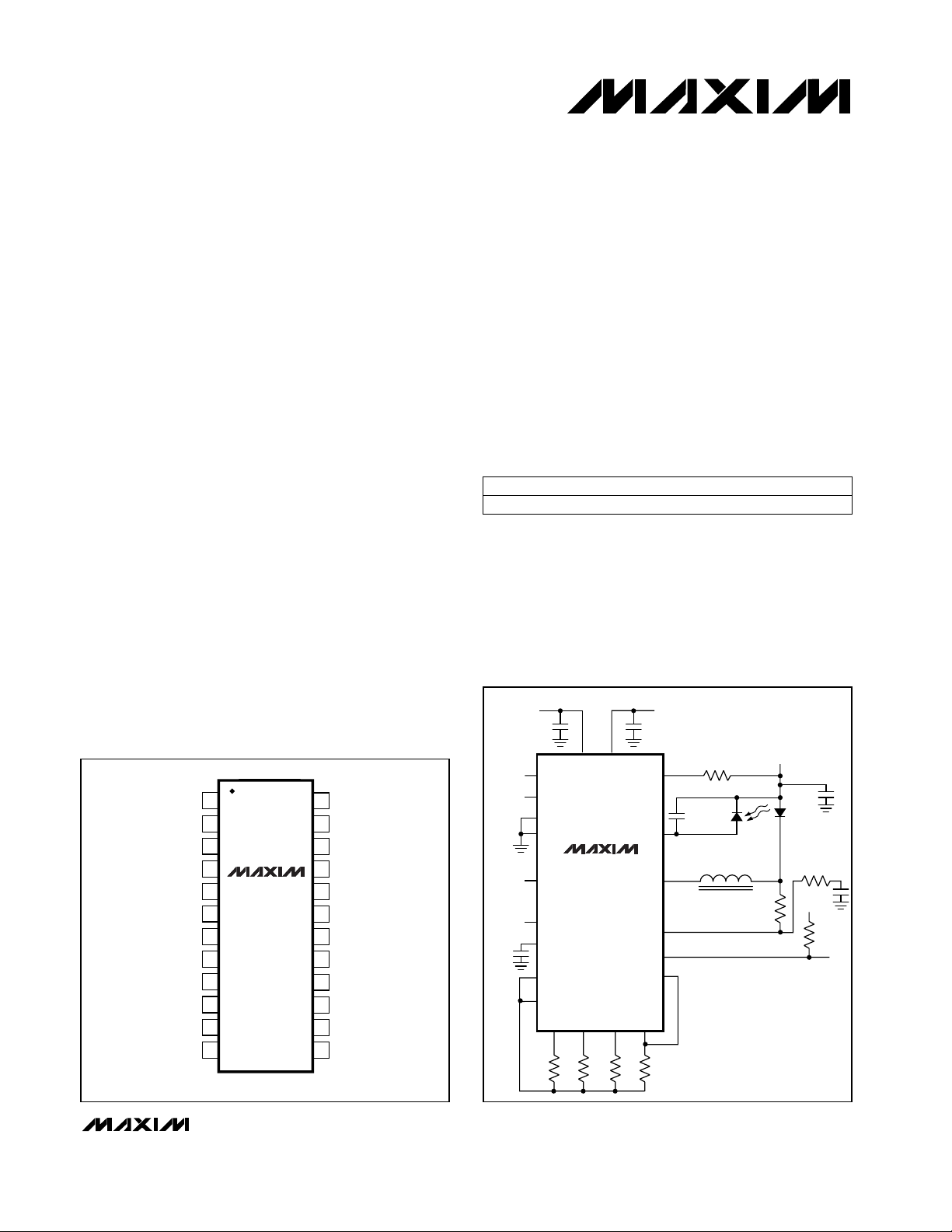

___________________Pin Configuration

19-0432; Rev 1b; 4/98

PART

MAX3263CAG 0°C to +70°C

TEMP. RANGE PIN-PACKAGE

24 SSOP

MAX3263

+5V

0.01µF 0.01µF

+5V

+5V

+5V

OUT+

IBIASOUT

IPIN

PECL

INPUTS

OUT-

FAILOUT

IBIASFB

OSADJ

IMODSET

IPINSET

IBIASSET

VCCA VCCB

VIN+

VIN-

ENB+

GNDB

GNDA

ENB-

SLWSTRT

VREF1

VREF2

LASER

2.7k

PHOTO-

DIODE

FERRITE BEAD

_____________Typical Operating Circuit

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

TOP VIEW

VREF2

1

IPINSET

2

FAILOUT

3

GNDB

4

VIN+

VIN-

GNDB

VCCB

ENB-

ENB+

VREF1

OSADJ

MAX3263

5

6

7

8

9

10

11

12

SSOP

24

23

22

21

20

19

18

17

16

15

14

13

SLWSTRT

IPIN

VCCA

GNDA

OUT+

GNDA

OUT-

GNDA

IBIASOUT

IMODSET

IBIASSET

IBIASFB

Page 2

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

2 _______________________________________________________________________________________

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

TA = +25°C

(Note 1)

CONDITIONS

mA12I

REF

Available Reference Current

V3.15 3.3 3.45V

REF

mA60I

BIAS

Range of Programmable Laser

Bias Current

Reference Voltage

VV

IL

TTL Low Input

mA50I

VCC

Supply Current

VVCC- 1.165V

IH

PECL Input High

VVCC- 1.475V

IL

PECL Input Low

V2 0.8V

IH

TTL High Input

UNITSMIN TYP MAXSYMBOLPARAMETER

Minimum differential input swing is 1100mVp-p

(Note 3)

CONDITIONS

mA30I

MOD

Range of Programmable

Modulation Current

UNITSMIN TYP MAXSYMBOLPARAMETER

I

BIAS

= 25mA, I

MOD

= 12mA, 4ns unit interval;

measured from 10% to 90%

ns1tR, t

F

Modulation-Current Rise and

Fall Time

I

MOD

= 12mA, TA= +25°C %±15OS

Aberrations, Rising and Falling

Edge

I

BIAS

= 25mA, I

MOD

= 12mA, 8ns period ps100PWD

Modulation-Current PulseWidth Distortion

ABSOLUTE MAXIMUM RATINGS

Terminal Voltage (with respect to GND)

Supply Voltages (V

CC

A, VCCB).............................-0.3V to +6V

VIN+, VIN-, FAILOUT ................................................0V to V

CC

OUT+, OUT-, IBIASOUT ......................................+1.5V to V

CC

ENB+, ENB- ......................VCCor +5.5V, whichever is smaller

Differential Input Voltage (

|

VIN+ - VIN-|).........................+3.8V

Input Current

IBIASOUT ............................................................0mA to 75mA

OUT+, OUT- ........................................................0mA to 40mA

IBIASSET ........................................................0mA to 1.875mA

IMODSET...............................................................0mA to 2mA

IPIN, IPINSET, OSADJ...........................................0mA to 2mA

FAILOUT..............................................................0mA to 10mA

IBIASFB................................................................-2mA to 2mA

Output Current

VREF1, VREF2.....................................................0mA to 20mA

SLWSTRT ..............................................................0mA to 5mA

Continuous Power Dissipation (T

A

= +70°C)

SSOP (derate 8mW/°C above +70°C) ..........................640mW

Operating Temperature Range...............................0°C to +70°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-55°C to +175°C

DC ELECTRICAL CHARACTERISTICS

(VCC= VCCA = VCCB = +4.75V to +5.25V, TA= 0°C to +70°C, unless otherwise noted. Typical values are at VCC= +5V and

TA= +25°C.)

AC ELECTRICAL CHARACTERISTICS

(VCC= VCCA = VCCB = +4.75V to +5.25V, R

LOAD

(at OUT+ and OUT-) = 25Ω connected to V

CC

, TA= 0°C to +70°C, unless other-

wise noted. Typical values are at VCC= +5V and TA= +25°C.) (Note 2)

Loaded with 2.7kΩ pull-up resistor to V

CC

Loaded with 2.7kΩ pull-up resistor to V

CC

V0.5V

OL

FAILOUT Output Low

V4.5V

OH

FAILOUT Output High

Note 2: AC characteristics are guaranteed by design and characterization.

Note 3: An 1100mVp-p differential is equivalent to complementary 550mVp-p signals on VIN+ and VIN-.

Note 1: I

VCC

= I

VCCA

+ I

VCCB

, I

BIAS

= 60mA, I

MOD

= 30mA, and I

PIN

= 140µA.

Page 3

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

_______________________________________________________________________________________

3

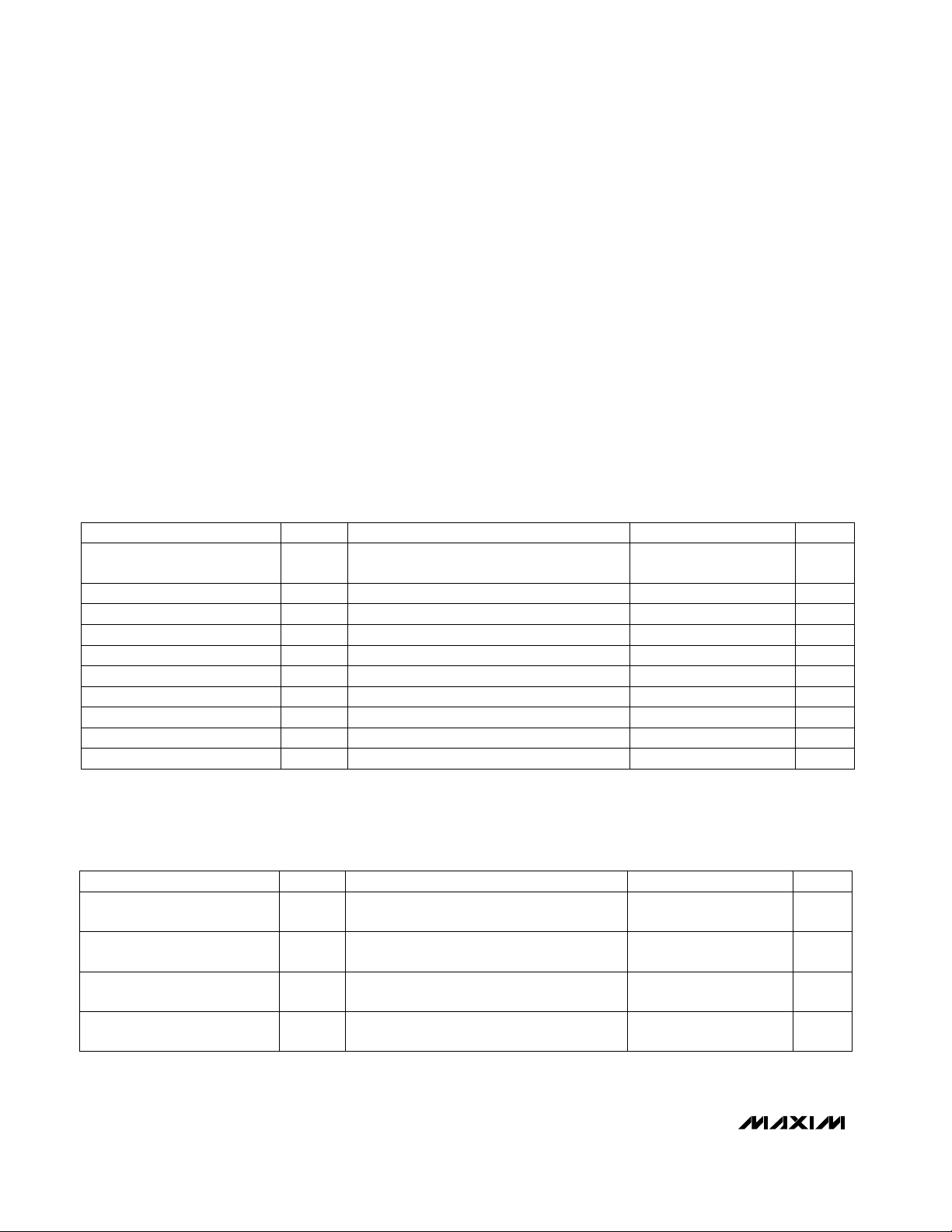

__________________________________________Typical Operating Characteristics

(MAX3263CAG loads at OUT+ and OUT- = 25Ω, V

CC

= VCCA = VCCB = +5V, TA= +25°C, unless otherwise noted.)

R

vs. BIAS CURRENT

BIASSET

02040

I

(mA)

BIAS

MAX3263-01

(kΩ)

R

60

(kΩ)

BIASSET

R

8

7

6

5

4

3

2

1

0

PERCENT CHANGE IN MODULATION

CURRENT vs. TEMPERATURE

10

8

6

4

2

0

-2

-4

% CHANGE (w.r.t. +25°C)

-6

-8

-10

02040

TEMPERATURE (°C)

MAX3263-04

8060

R

vs. MODULATION CURRENT

MODSET

12

10

8

6

MODSET

4

2

0

0 5 10 15 20 25

MODULATION CURRENT (mAp-p)

DIFFERENTIAL INPUT

SWING = 1100 mVp-p

30

MAX3263-02

1,000,000

100,000

(Ω)

10,000

PINSET

R

1000

100

PERCENT CHANGE IN BIAS

CURRENT vs. TEMPERATURE

3

APC DISABLED

2

1

0

% CHANGE (w.r.t. +25°C)

-1

-2

02040

TEMPERATURE (°C)

MAX3263-05

806010 30 7050

50

48

46

44

42

40

SUPPLY CURRENT (mA)

38

36

34

R

vs. MONITOR CURRENT

PINSET

0 500

MONITOR CURRENT (µA)

SUPPLY CURRENT

vs. TEMPERATURE

02040

TEMPERATURE (°C)

1000

8060

MAX3263-03

MAX3263-06

ALLOWABLE R

vs. MODULATION CURRENT

12

10

(kΩ)

OSADJ

ALLOWABLE R

8

6

ALLOWABLE

4

2

0

RANGE

0 5 10 15 20 25

MODULATION CURRENT (mAp-p)

OSADJ

RANGE

30

MAX3263-07

MAXIMUM MODULATION CURRENT

vs. MINIMUM DIFFERENTIAL

INPUT SIGNAL AMPLITUDE

40

R

= 1.2kΩ

MODSET

R

35

(mAp-p)

30

25

20

15

10

5

MAXIMUM MODULATION CURRENT

0

= 2kΩ

OSADJ

0 400 800 1200 1600

MINIMUM DIFFERENTIAL

INPUT SIGNAL AMPLITUDE

(mVp-p)

MAX3263-08

2000

Page 4

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

4 _______________________________________________________________________________________

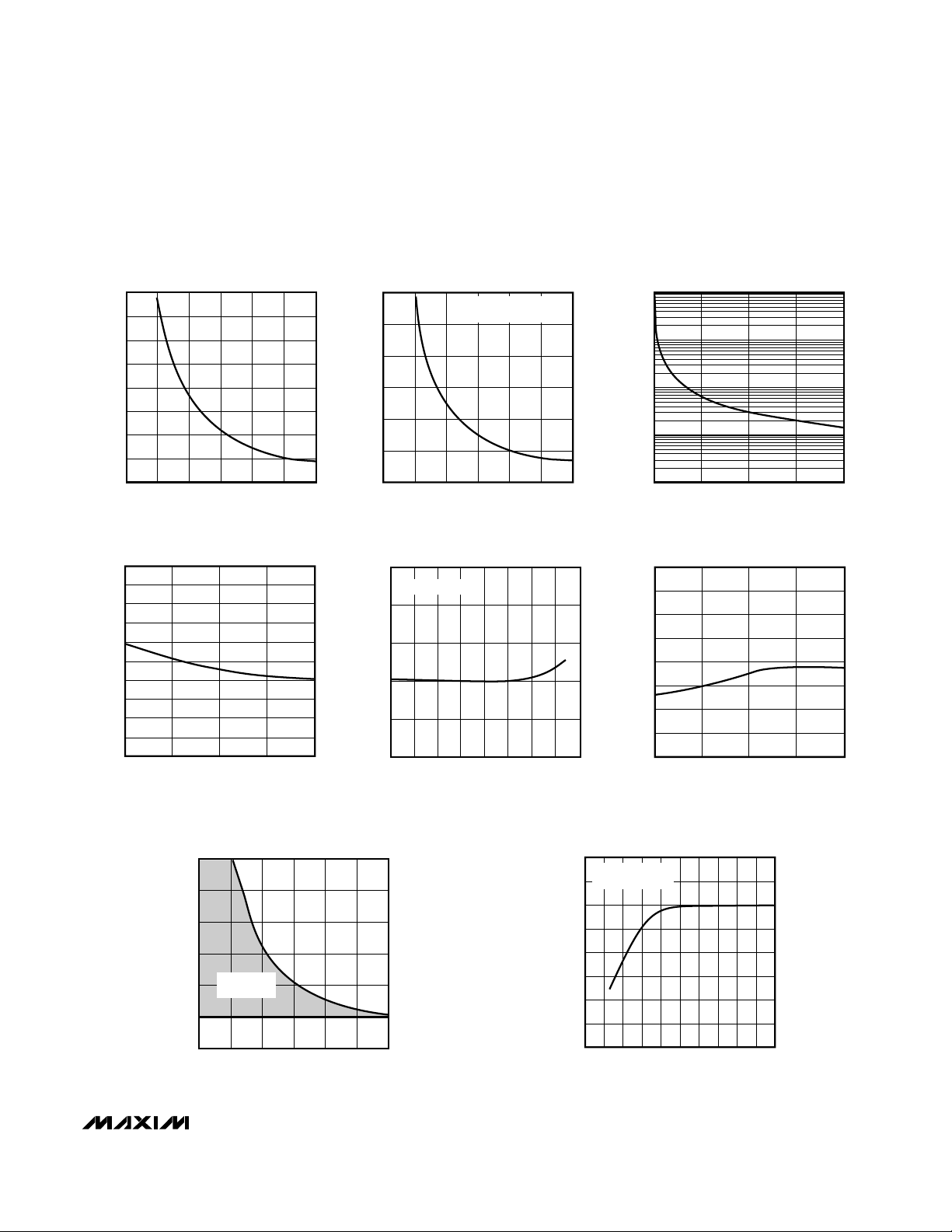

______________________________________________________________Pin Description

NAME FUNCTIONPIN

10 ENB+

Noninverting Enable TTL Input. Output currents are enabled only when ENB+ is high and

ENB- is low.

1 VREF2 Temperature-Compensated Reference Output. VREF2 is internally connected to VREF1.

12 OSADJ

Overshoot-Adjust Input. Connect to internal voltage reference through a resistor to adjust the

overshoot of the modulation output signal (see

Typical Operating Characteristics

).

11 VREF1 Temperature-Compensated Reference Output. VREF1 is internally connected to VREF2.

13 IBIASFB

Bias-Feedback Current Output. Output from automatic power-control circuit. Connect to

I

BIASSET

when using APC.

14 IBIASSET

Laser Bias Current-Programming Input. Connect to internal voltage reference through a resistor to set bias current (see

Typical Operating Characteristics

).

I

BIASOUT

= 40 x (I

BIASSET

+ I

BIASFB

).

15 IMODSET

Laser Modulation Current-Programming Input. Connect to internal voltage reference through

a resistor to set modulation current (see

Typical Operating Characteristics

).

I

MOD

= 20 x I

MODSET

.

16 IBIASOUT

Laser Bias Current Output. Connect to laser cathode through an R-L filter network (see the

Bias Network Compensation

section).

17, 19, 21 GNDA Ground for Bias and Modulation Current Drivers

22 VCCA

+5V Supply Voltage for Bias and Modulation Current Drivers. Connect VCCA to the same

potential as VCCB, but provide separate bypassing for VCCA and VCCB.

20 OUT+ Modulation Output. When VIN+ is low and VIN- is high, OUT+ sinks I

MOD

.

9 ENB- Inverting Enable TTL Input. Output currents are enabled only when ENB+ is high and ENB- is low.

8 VCCB

+5V Supply Voltage for Voltage Reference and Automatic Power-Control Circuitry. Connect

VCCB to the same potential as VCCA, but provide separate bypassing for VCCA and VCCB.

6 VIN- Inverting PECL Data Input

5 VIN+ Noninverting PECL Data Input

4, 7 GNDB Ground for Voltage Reference and Automatic Power-Control Circuitry

3 FAILOUT

Failout Output. Active-low, open-collector TTL output indicates if automatic power-control

loop is out of regulation due to insufficient monitor-diode current (when VPIN is below the

2.6V threshold). Connect FAILOUT to VCC through a 2.7kΩ pull-up resistor.

2 IPINSET

Monitor Photodiode Programming Input. Connect INPINSET to VREF1 or VREF2 through a

resistor to set the monitor current when using automatic power control (see

Typical Operating

Characteristics

).

18 OUT- Modulation Output. When VIN+ is high and VIN- is low, OUT- sinks I

MOD

.

23 IPIN Monitor Photodiode Current Input. Connect IPIN to photodiode’s anode.

24 SLWSTRT

Slow-Start Capacitor Input. Connect capacitor to ground or leave unconnected to set start-up

time, t

STARTUP

= 25.4kΩ (C

SLWSTRT

+ 2pF).

Page 5

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

_______________________________________________________________________________________ 5

_______________Detailed Description

The MAX3263 laser driver has three main sections: a

reference generator with temperature compensation, a

laser bias block with automatic power control, and a

modulation driver (Figure 1).

The reference generator provides temperature-compensated biasing and a voltage-reference output. The

voltage reference is used to program the current levels

of the high-speed modulation driver, laser diode, and

PIN (p+, intrinsic, n-) monitor diode.

The laser bias block sets the bias current in the laser

diode and maintains it above the threshold current. A

current-controlled current source (current mirror) programs the bias, with IBIASSET as the input. The mirror’s

gain is approximately 40 over the MAX3263’s input

range. Keep the output voltage of the bias stage above

2.2V to prevent saturation.

The modulation driver consists of a high-speed input

buffer and a common-emitter differential output stage.

The modulation current mirror sets the laser modulation

current in the output stage. This current is switched

between the OUT+ and OUT- ports of the laser driver.

The modulation current mirror has a gain of approximately

20. Keep the voltages at OUT+ and OUT- above 2.2V to

prevent saturation.

VIN+

Figure 1. Functional Diagram

MAX3263

V

CC

OUT+

LASER

VIN-

VCCA

VCCB

GNDA

GNDB

ENB+

ENB-

SLWSTRT

MAIN

BIAS

GENERATOR

BANDGAP

REFERENCE

IOSADJ

VREF1, VREF2

OSADJ

R

IMODSET

MODSET

R

20 x I

IBIASSET

BIASSET

R

MODSET

40 x I

BIASSET

TRANSCONDUCTANCE

AMPLIFIER

IBIASFB

+2.6V

IPINSET

OUT-

I

BIASOUT

FAILOUT

COMPARATOR

IPIN

V

x 3/5

CC

1 x I

PINSET

R

PINSET

PHOTO-

DIODE

BIAS

COMPEN-

SATION

LOOP-

STABILITY

CAPACITOR

0.1µF

Page 6

The overshoot mirror sets the bias in the input buffer

stage (Figure 2). Reducing this current slows the input

stage and reduces overshoot in the modulation signal.

At the same time, the peak-to-peak output swing of the

input buffer stage is reduced. Careful design must be

used to ensure that the buffer stage can switch the output stage completely into the nonlinear region. The

input swing required to completely switch the output

stage depends on both R

OSADJ

and the modulation

current. See Allowable R

OSADJ

Range vs. Modulation

Current and Maximum Modulation Current vs. Minimum

Differential Input Signal Amplitude graphs in the

Typical

Operating Characteristics

. For the output stage, the

width of the linear region is a function of the desired

modulation current. Increasing the modulation current

increases the linear region. Therefore, increases in the

modulation current require larger output levels from the

first stage.

Failure to ensure that the output stage switches completely results in a loss of modulation current (and

extinction ratio). In addition, if the modulation port does

not switch completely off, the modulation current will

contribute to the bias current, and may complicate

module assembly.

Automatic Power Control

The automatic power control (APC) feature allows an

optical transmitter to maintain constant power, despite

changes in laser efficiency with temperature or age. The

APC requires the use of a monitor photodiode.

The APC circuit incorporates the laser diode, the monitor

photodiode, the pin set current mirror, a transconductance amplifier, the bias set current mirror, and the laser

fail comparator (Figure 1). Light produced by the laser

diode generates an average current in the monitor photodiode. This current flows into the MAX3263’s IPIN

input. The IPINSET current mirror draws current away

from the IPIN node. When the current into the IPIN node

equals the current drawn away by IPINSET, the node

voltage is set by the V

CC

x 3/5 reference of the transconductance amplifier. When the monitor current exceeds

IPINSET, the IPIN node voltage will be forced higher. If

the monitor current decreases, the IPIN node voltage is

decreased. In either case, the voltage change is amplified by the transconductance amplifier, and results in a

feedback current at the IBIASFB node. Under normal

APC operation, IBIASFB is summed with IBIASSET, and

the laser bias level is adjusted to maintain constant output power. This feedback process continues until the

monitor-diode current equals IPINSET.

If the monitor-diode current is sufficiently less than IPINSET (i.e., the laser stops functioning), the voltage on the

IPIN node drops below 2.6V. This triggers the failout

comparator, which provides a TTL signal indicating laser

failure. The FAILOUT output asserts only if the monitordiode current is low, not in the reverse situation where

the monitor current exceeds IPINSET. FAILOUT is an

open-collector output that requires an external pull-up

resistor of 2.7kΩ to V

CC

.

The transconductance amplifier can source or sink currents up to approximately 1mA. Since the laser bias generator has a gain of approximately 40, the APC function

has a limit of approximately 40mA (up or down) from the

initial set point. To take full advantage of this adjustment

range, it may be prudent to program the laser bias current slightly higher than required for normal operation.

However, do not exceed the I

BIASOUT

absolute maxi-

mum rating of 75mA.

To maintain APC loop stability, a 0.1µF bypass capacitor may be required across the photodiode. If the APC

function is not used, disconnect the IBIASFB pin.

Enable Inputs

The MAX3263 provides complementary enable inputs

(ENB+, ENB-). The laser is disabled by reducing the reference voltage outputs (VREF1, VREF2). Only one logic

state enables laser operation (Figure 3 and Table 1).

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

6 _______________________________________________________________________________________

Figure 2. MAX3263 Modulation Driver (Simplified)

OUTPUTS

V

CC

MAX3263

280Ω 280Ω

INPUTS

2(I

OSADJ

)

400Ω

2(I

OSADJ

9Ω

)

I

MOD

9Ω

INPUT BUFFER OUTPUT STAGE

Page 7

Temperature Considerations

The MAX3263 output currents are programmed by current mirrors. These mirrors each have a 2VBEtemperature

coefficient. The reference voltage (V

REF

) is adjusted 2V

BE

so these changes largely cancel, resulting in output currents that are very stable with respect to temperature (see

Typical Operating Characteristics

).

__________________Design Procedure

Interfacing Suggestions

Use high-frequency design techniques for the board

layout of the MAX3263 laser driver. Adding some damping resistance in series with the laser raises the load

impedance and helps reduce power consumption (see

Reducing Power Consumption

section). Minimize any

series inductance to the laser, and place a bypass

capacitor as close to the laser’s anode as possible.

Power connections labeled VCCA are used to supply the

laser modulation and laser bias circuits. VCCB connections supply the bias-generator and automatic-power

control circuits. For optimum operation, isolate these supplies from each other by independent bypass filtering.

GNDA and GNDB have multiple pins. Connect all pins

to optimize the MAX3263’s high-frequency performance. Ground connections between signal lines

(VIN+, VIN-, OUT+, OUT-) improve the quality of the

signal path by reducing the impedance of the interconnect. Multiple connections, in general, reduce inductance in the signal path and improve the high-speed

signal quality. GND pins should be tied to the ground

plane with short runs and multiple vias. Avoid ground

loops, since they are a source of high-frequency interference.

The MAX3263 data inputs accept PECL input signals,

which require 50Ω termination to (V

CC

- 2V). Figure 4

shows alternative termination techniques. When a termination voltage is not available, use the Theveninequivalent termination. When interfacing with a

non-PECL signal source, use one of the other alternative termination methods shown in Figure 4.

Bias Network Compensation

For best laser transmitter performance, add a filter to the

circuit. Most laser packages (TO-46 or DIL) have a significant amount of package inductance (4nH to 20nH),

which limits their usable data rate. The MAX3263 OUT

pin has about 1pF of capacitance. These two parasitic

components can cause high-frequency ringing and

aberrations on the output signal.

If ringing is present on the transmitter output, try

adding a shunt RC filter to the laser cathode. This

limits the bandwidth of the transmitter to usable levels

and reduces ringing dramatically (Figure 5).

L = Laser inductance

C = Shunt filter capacitance

R = Shunt filter resistance

A good starting point is R = 25Ω and C = L / 4R.

Increase C until aberrations are reduced.

The IBIASOUT pin has about 4pF of parasitic capacitance. When operating at bias levels over 50mA, the

impedance of the bias output may be low enough to

decrease the rise time of the transmitter. If this occurs,

the impedance of the IBIASOUT pin can be increased by

adding a large inductor in series with the pin.

Reducing Power Consumption

The laser driver typically consumes 40mA of current for

internal functions. Typical load currents, such as 12mA of

modulation current and 20mA of bias current, bring the

total current requirement to 72mA. If this were dissipated

entirely in the laser driver, it would generate 360mW of

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

_______________________________________________________________________________________ 7

Table 1. MAX3263 Truth Table

ENB- ENB+

0 0

0 1

1 0

1 1

VREF

Off

On

Off

Off

Figure 3. Enable/Disable Operation

ENB+

DATA OUT

(LOAD = 1300nm

LASER AT OUT-)

2µs/div

Page 8

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

8 _______________________________________________________________________________________

Figure 4. Alternative PECL Data-Input Terminations

PECL

SIGNAL SOURCE

a) THEVENIN-EQUIVALENT TERMINATION

5V

5V

82Ω82Ω

VIN+

120Ω

MAX3263

b) DIFFERENTIAL NON-PECL TERMINATION

c) SINGLE-ENDED NON-PECL TERMINATION

d) ECL TERMINATION

THIS SYMBOL REPRESENTS

A TRANSMISSION LINE

WITH CHARACTERISTIC

IMPEDANCE Z

NON-PECL

SIGNAL SOURCE

NON-PECL

SIGNAL SOURCE

SIGNAL SOURCE

= 50Ω.

o

ECL

50Ω

50Ω

50Ω

VIN-

120Ω

VIN+

5V

50Ω

680Ω

MAX3263

50Ω

68Ω

5V

5V

680Ω

1.8k

0V

50Ω

5V

1.3k

3.6k

1.8k

VIN-

VIN+

180Ω

MAX3263

VIN-

1.3k

VIN+

MAX3263

-2V

VIN-

50Ω

-2V

3.6k

Page 9

heat. Fortunately, a substantial portion of this power is

dissipated across the laser diode. A typical laser diode

drops approximately 1.6V when forward biased. This

leaves 3.4V at the MAX3263’s OUT- terminal. It is safe to

reduce the output terminal voltage even further with a

series damping resistor. Terminal voltage levels down to

2.2V can be used without degrading the laser driver’s

high-frequency performance. Power dissipation can be

further reduced by adding a series resistor on the laser

driver’s OUT+ side. Select the series resistor so the

OUT+ terminal voltage does not drop below 2.2V with the

maximum modulation current.

_____________Applications Information

Programming the MAX3263 Laser Driver

Programming the MAX3263 is best explained by an

example. Assume the following laser diode characteristics:

Wavelength λ 1300nm

Threshold Current I

TH

20mA at +25°C(+0.35mA/

°C temperature variation)

Monitor Responsivity ρ

mon

0.1A/W (monitor current /

average optical power

into the fiber)

Modulation Efficiency η 0.1mW/mA (worst case)

Now assume the communications system has the following requirements:

Average Power P

AVE

0dBm (1mW)

Extinction Ratio Er 6dB (Er = 4)

Temperature Range Tr 0°C to +70°C

1) Determine the value of IPINSET:

The desired monitor-diode current is (P

AVE

)(ρ

mon

) =

(1mW)(0.1A/W) = 100µA. The R

PINSET

vs. Monitor

Current graph in the

Typical Operating Characteristics

show that R

PINSET

should be 18kΩ.

2) Determine R

MODSET

:

The average power is defined as (P1 + P0) / 2, where

P1 is the average amplitude of a transmitted “one” and

P0 is the average amplitude of a transmitted “zero.”

The extinction ratio is P1/P0. Combining these equations results in P1 = (2 x P

AVE

x Er) / (Er + 1) and P0 =

(2 x P

AVE

) / (Er + 1). In this example, P1 = 1.6mW and

P0 = 0.4mW. The optical modulation is 1.2mW. The

modulation current required to produce this output is

1.2mW / η = (1.2mW) / (0.1mA/mW) = 12mA. The

Typical Operating Characteristics

show that R

MODSET

= 3.9kΩ yields the desired modulation current.

3) Determine the value of R

OSADJ

:

Using the Allowable R

OSADJ

Range vs. Modulation

Current graph in the

Typical Operating Characteristics

,

a 5.6kΩ resistor is chosen for 12mA of modulation cur-

rent. The maximum R

OSADJ

values given in the graph

minimize aberrations in the waveform and ensure that

the driver stage operates fully limited.

4) Determine the value of R

BIASSET

:

The automatic power control circuit can adjust the bias

current 40mA from the initial setpoint. This feature

makes the laser driver circuit reasonably insensitive to

variations of laser threshold from lot to lot. The bias setting can be determined using one of two methods:

A) Set the bias at the laser threshold.

B) Set the bias at the midpoint of the highest and low-

est expected threshold values.

Method A is straightforward. In the second method, it is

assumed that the laser threshold will increase with age.

The lowest threshold current occurs at 0°C when the

laser is new. The highest threshold current occurs at

+70°C at the end of the product’s life. Assume the laser

is near the end of life when its threshold reaches twotimes its original value.

Lowest Bias Current:

I

TH

+ ∆I

TH

= 20mA + (0.35mA/°C)(-25°C) = 11.25mA

Highest Bias Current:

2 x I

TH

+ ∆I

TH

= 40mA + (0.35mA/°C)(+45°C) = 55.8mA

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

_______________________________________________________________________________________ 9

Figure 5. Typical Laser Interface with Bias Compensation

PHOTODIODE

18Ω

+5V

LASER

SHUNT RC

0.01µF

AS CLOSE TO THE

LASER ANODE AS

POSSIBLE

25Ω

AS CLOSE TO THE

LASER CATHODE AS

POSSIBLE

C

OUT+

MAX3263

IPIN

IBIASOUT

OUT-

18Ω

≥0.1µF

10µH

FERRITE

BEAD

Page 10

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

10 ______________________________________________________________________________________

______________________________________________________________________Package Information

In this case, set the initial bias value to 34mA (which is

the midpoint of the two extremes). The 40mA adjustment range of the MAX3263 maintains the average

laser power at either extreme.

The

Typical Operating Characteristics

show that

R

BIASSET

= 1.8kΩ delivers the required bias current.

Laser Safety and IEC 825

Using the MAX3263 laser driver alone does not ensure

that a transmitter design is compliant with IEC 825 safety requirements. The entire transmitter circuit and component selections must be considered. Each customer

must determine the level of fault tolerance required by

their application, recognizing that Maxim products are

not designed or authorized for use as components in

systems intended for surgical implant into the body, for

applications intended to support or sustain life, or for

any other application where the failure of a Maxim

product could create a situation where personal injury

or death may occur.

SSOP.EPS

Page 11

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

______________________________________________________________________________________ 11

NOTES

Page 12

MAX3263

Single +5V, Fully Integrated,

155Mbps Laser Diode Driver

NOTES

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

12

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1998 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Maxim makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does Maxim assume any liability arising out of the application or use of any product or circuit and specifically disclaims any and all liability, including without limitation consequential

or incidental damages. “Typical” parameters can and do vary in different applications. All operating parameters, including “typicals” must be validated for

each customer application by customer’s technical experts. Maxim products are not designed, intended or authorized for use as components in systems

intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the

Maxim product could create a situation where personal injury of death may occur.

Loading...

Loading...