Page 1

19-6264; Rev 0; 3/12

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

General Description

The MAX31826 digital thermometer provides 12-bit

temperature measurements and communicates over a

M

1-Wire

bus that by definition requires only one data line

(and ground) for communication with a central microcontroller. It has a -55NC to +125NC operating temperature

range and is accurate to Q0.5NC over the -10NC to +85NC

range. In addition, the device can derive power directly

from the data line (“parasite power”), eliminating the

need for an external power supply.

Each device has a unique 64-bit serial code, which

allows multiple devices to function on the same 1-Wire

bus. Therefore, it is simple to use one microcontroller

(the master device) to control many devices distributed

over a large area. The device includes 128 bytes (1Kb)

of EEPROM for storage of system data. The EEPROM

can be locked to permanently prevent any further data

writes. Four location address inputs simplify mapping of

individual devices to specific locations.

Applications

Industrial Systems

Building Automation

Consumer Equipment

System Calibration

Module Identification

Benefits and Features

S Unique 1-Wire Interface Requires Only One Port

Pin for Communication

S Integrated Temperature Sensor and EEPROM

Reduce Component Count

Measures Temperatures from -55NC to +125NC

(-67NF to +257NF)

±0.5NC Accuracy from -10NC to +85NC

12-Bit Temperature Resolution (0.0625NC)

1Kb EEPROM Can Be Locked to Prevent Further

Writes

S Multidrop Capability Simplifies Multisensor

Systems

Each Device Has a Unique 64-Bit Serial Code

Stored in On-Board ROM

Four Pin-Programmable Bits to Uniquely

Identify Up to 16 Sensor Locations on a Bus

S Can Be Powered from Data Line (3.0V to 3.7V

Power-Supply Range)

S 8-Pin µMAX® Package

Ordering Information appears at end of data sheet.

For related parts and recommended products to use with this part,

refer to www.maxim-ic.com/MAX31826.related.

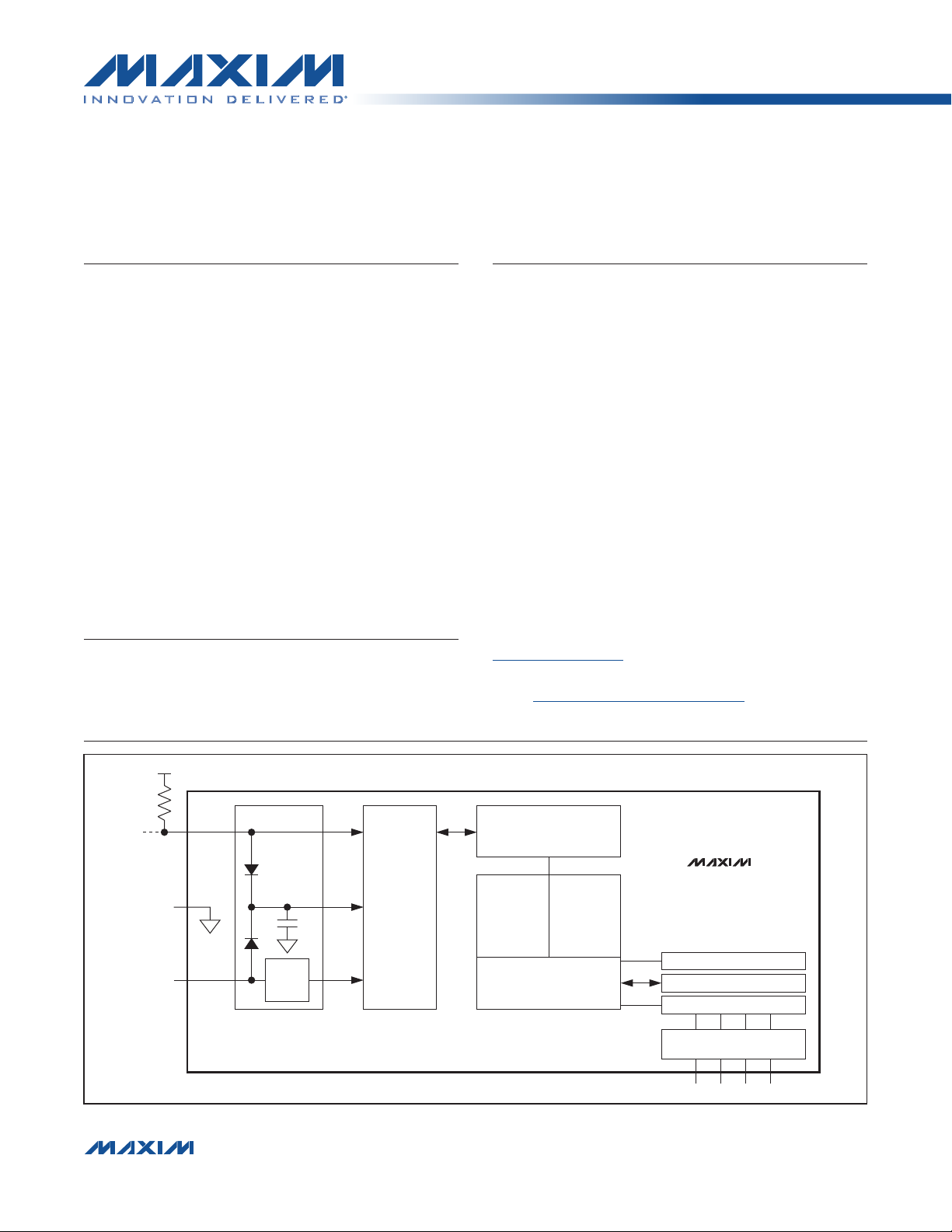

Block Diagram

V

PU

4.7kΩ

MEMORY

DQ

GND

V

DD

1-Wire and µMAX are registered trademarks of Maxim Integrated Products, Inc.

����������������������������������������������������������������� Maxim Integrated Products 1

PARASITE-

POWER

CIRCUIT

POWERSUPPLY

SENSE

64-BIT ROM

AND

C

PP

1-Wire PORT

CONTROL LOGIC

1Kb

EEPROM

SCRATCHPAD 1

MAX31826

SCRATCHPAD 2

16-BIT TEMPERATURE REGISTER

8-BIT CRC GENERATOR

8-BIT CONFIGURATION REGISTER

ADDRESS PIN

INPUT LATCH

AD0 AD1 AD2 AD3

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

ABSOLUTE MAXIMUM RATINGS

Voltage Range on Any Pin Relative to Ground .... -0.5V to +4.5V

Continuous Power Dissipation (TA = +70NC)

FMAX (derate 4.5mW/NC above +70NC) .....................362mW

Operating Temperature Range ........................ -55NC to +125NC

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

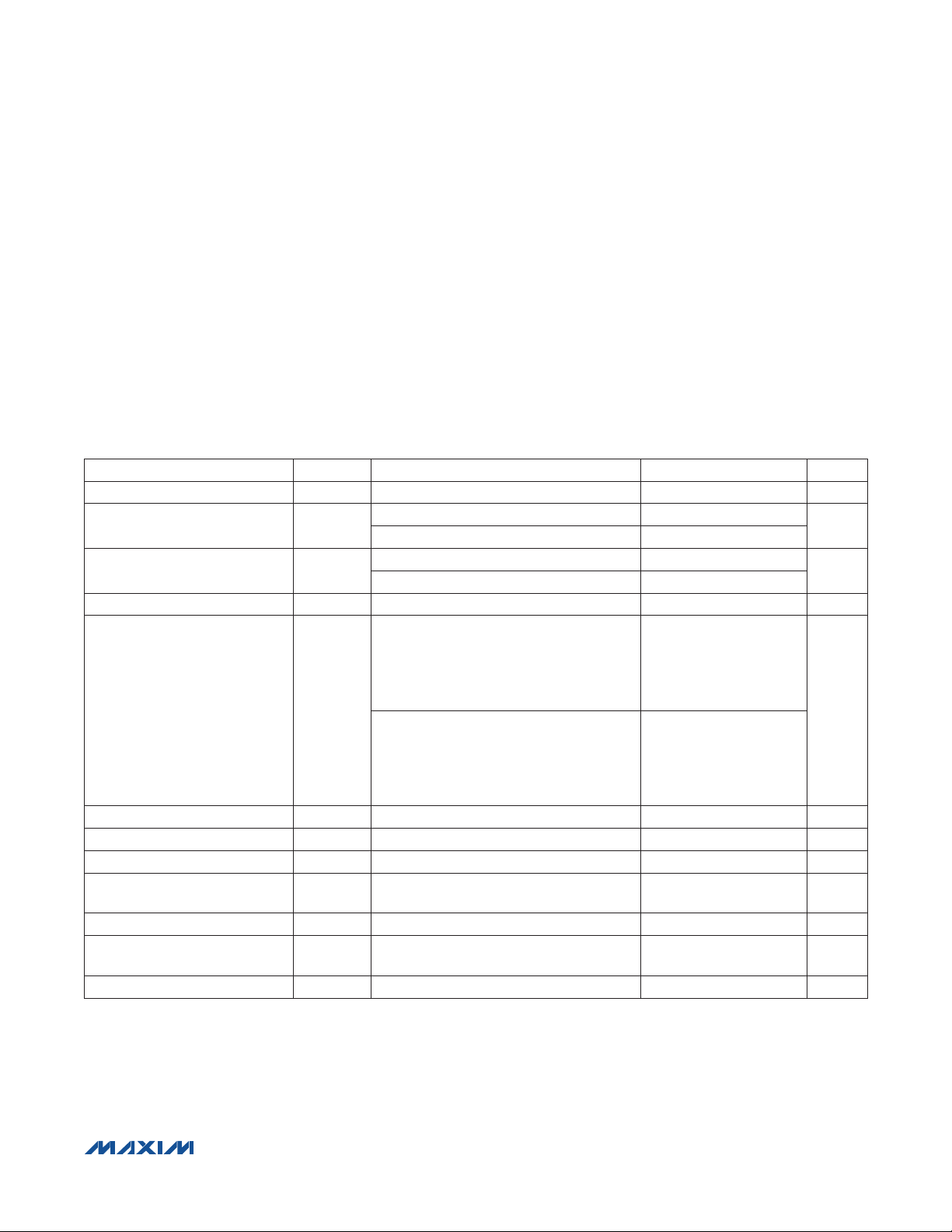

DC ELECTRICAL CHARACTERISTICS

(TA = -55°C to +125°C, unless otherwise noted.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage V

Pullup Supply Voltage

(Notes 2, 3)

Thermometer Error (Note 4) T

Input Logic-Low V

Input Logic-High (Notes 2, 6) V

Sink Current I

Standby Current I

Active Current I

Active Current with

Communication

POR Time t

Input Leakage Current

(AD0–AD3 Pins)

DQ Input Current I

DD

V

PU

ERR

DDS

DD

POR

DQ

Local power (Note 2) +3.0 +3.7 V

Parasite power +3.0 +3.7

Local power +3.0 V

-10NC to +85NC

-55NC to +125NC

(Notes 2, 5) -0.3 +0.8 V

IL

Local power +2.4

IH

Parasite power +3.0

V

L

= 0.4V (Note 2) 4.0 mA

I/O

(Notes 7, 8) 350 1000 nA

VDD = 3.7V (Note 9) 650 1200

Local or parasite power 4 7.8 ms

(Note 10) 5

Storage Temperature Range ............................ -55NC to +125NC

Lead Temperature (soldering, 10s) ................................+300NC

Soldering Temperature (reflow) ......................................+260NC

V

NC

V

FA

FA

FA

FA

-0.5

Q0.25

-2 +2

lower

of 3.7V

(VDD +

0.3V)

lower

of 3.7V

(VDD +

0.3V)

800 1500

-1 +1

DD

+0.5

or

or

����������������������������������������������������������������� Maxim Integrated Products 2

Page 3

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

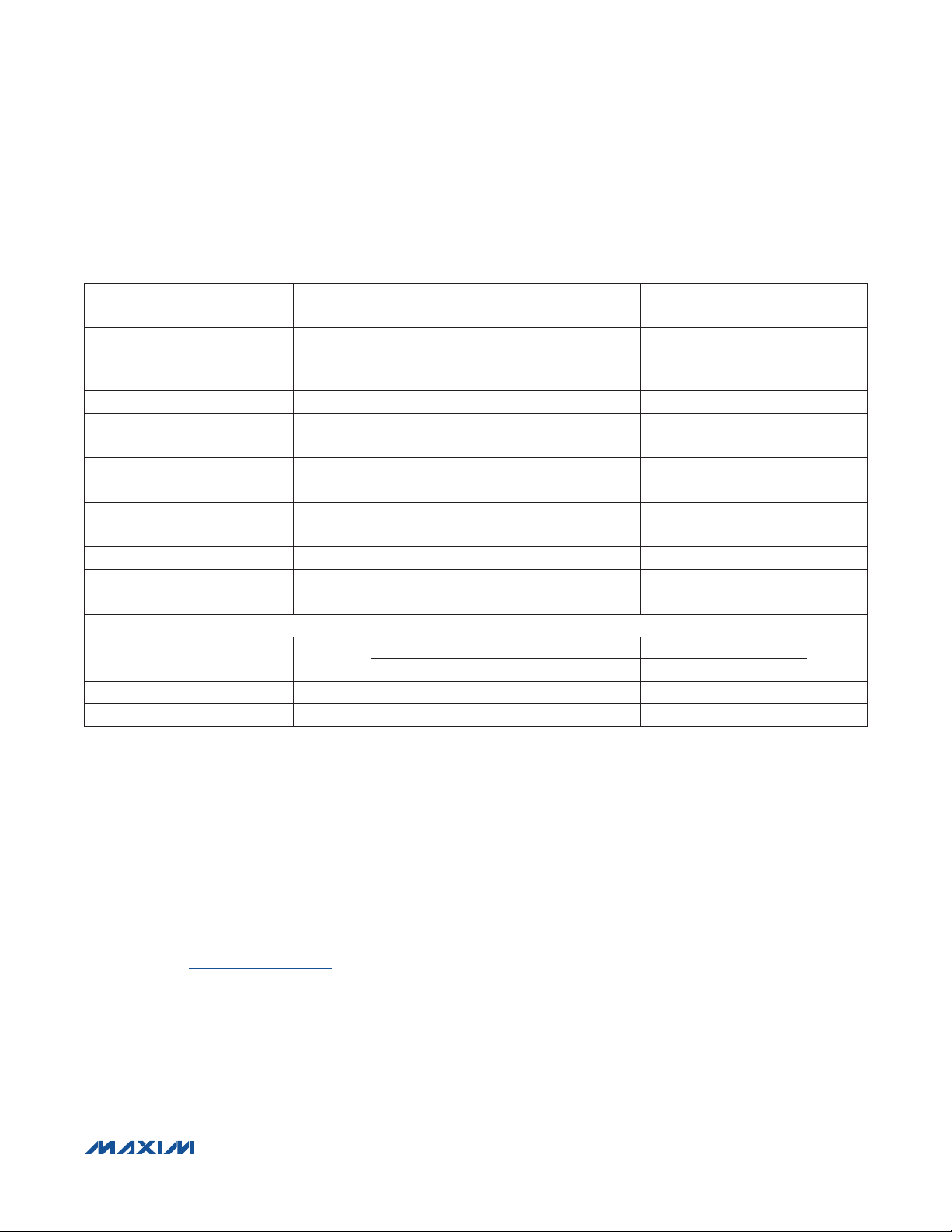

AC ELECTRICAL CHARACTERISTICS

(VDD = 3.0V to 3.7V, TA = -55°C to +125°C, unless otherwise noted.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Temperature Conversion Time t

Time to Strong Pullup On t

Time Slot t

Recovery Time t

Write-Zero Low Time t

Write-One Low Time t

Read Data Valid t

Reset Time High t

Reset Time Low t

Presence-Detect High t

Presence-Detect Low t

DQ Capacitance C

AD0–AD3 Capacitance C

NONVOLATILE MEMORY

EEPROM Write/Erase Cycles N

EEPROM Data Retention t

EEPROM Write Time t

Note 1: Limits are 100% production tested at TA = +25°C and/or TA = +85°C. Limits over the operating temperature range and

relevant supply voltage range are guaranteed by design and characterization. Typical values are not guaranteed.

Note 2: All voltages are referenced to ground.

Note 3: The pullup supply voltage specification assumes that the pullup device is ideal, and therefore the high level of the pullup

is equal to VPU. To meet the device’s VIH specification, the actual supply rail for the strong pullup transistor must include

margin for the voltage drop across the transistor when it is turned on; thus: V

Note 4: Guaranteed by design. These limits represent a three sigma distribution.

Note 5: To guarantee a presence pulse under low-voltage parasite-power conditions, V

as 0.5V.

Note 6: Logic-high voltages are specified at a 1mA source current.

Note 7: Standby current specified up to TA = +70NC. Standby current typically is 3FA at TA = +125NC.

Note 8: To minimize I

Note 9: Active current refers to supply current during active temperature conversions or EEPROM writes.

Note 10: DQ line is high (high-impedance state).

Note 11: See the 1-Wire Timing Diagrams.

Note 12: Under parasite power, if t

, DQ should be within the following ranges: V

DDS

CONV

SPON

SLOT

REC

LOW0

LOW1

RDV

RSTH

RSTL

PDHIGH

PDLOW

IN/OUT

IN_AD

EEWR

EEDR

WR

> 960Fs, a power-on reset (POR) can occur.

RSTL

12-bit resolution 150 ms

Start Convert T command, or Copy

Scratchpad 2 command issued

(Note 11) 60 120

(Note 11) 1

(Note 11) 60 120

(Note 11) 1 15

(Note 11) 15

(Note 11) 480

(Notes 11, 12) 480

(Note 11) 15 60

(Note 11) 60 240

At TA = +25°C

At TA = +85°C (worst case)

At TA = +85°C (worst case)

GND

P VDQ P V

PU_ACTUAL

GND

200k

50k

40 Years

20 25 ms

= V

PU_IDEAL

might need to be reduced to as low

ILMAX

+ 0.3V or VDD - 0.3V P VDQ P VDD.

10

25 pF

50 pF

+ V

TRANSISTOR

Fs

Fs

Fs

Fs

Fs

Fs

Fs

Fs

Fs

Fs

.

����������������������������������������������������������������� Maxim Integrated Products 3

Page 4

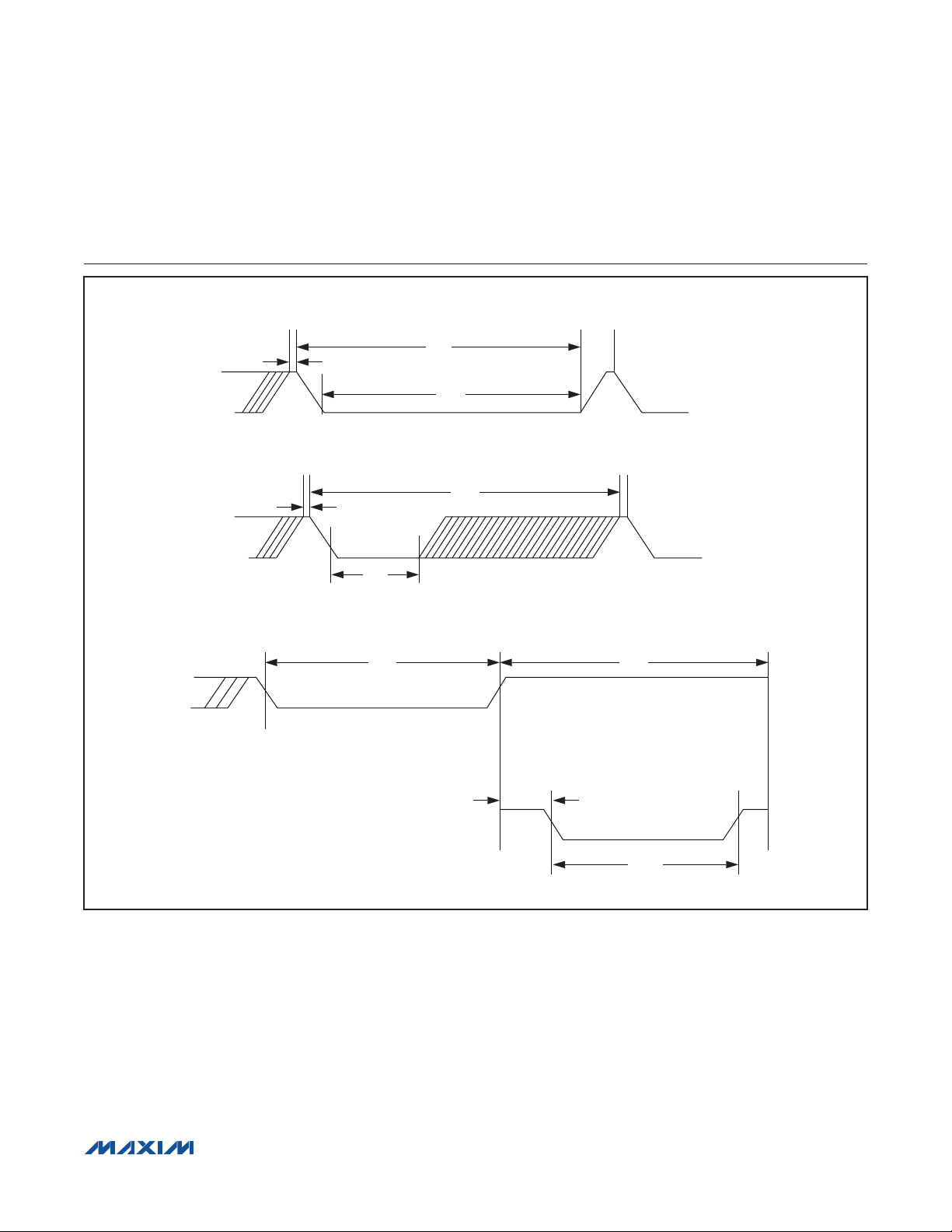

1-Wire WRITE-ZERO TIME SLOT

1-Wire READ-ZERO TIME SLOT

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

1-Wire Timing Diagrams

t

t

REC

SLOT

t

LOW0

START OF NEXT CYCLE

1-Wire RESET PULSE

1-Wire PRESENCE DETECT

t

REC

t

RDV

RESET PULSE FROM HOST

t

RSTL

t

SLOT

t

PDHIGH

START OF NEXT CYCLE

t

RSTH

PRESENCE DETECT

t

PDLOW

����������������������������������������������������������������� Maxim Integrated Products 4

Page 5

1-Wire Digital Temperature Sensor

(VCC = 3.3V, TA = -40°C, unless otherwise noted.)

THERMOMETER ERROR (˚C)

with 1Kb Lockable EEPROM

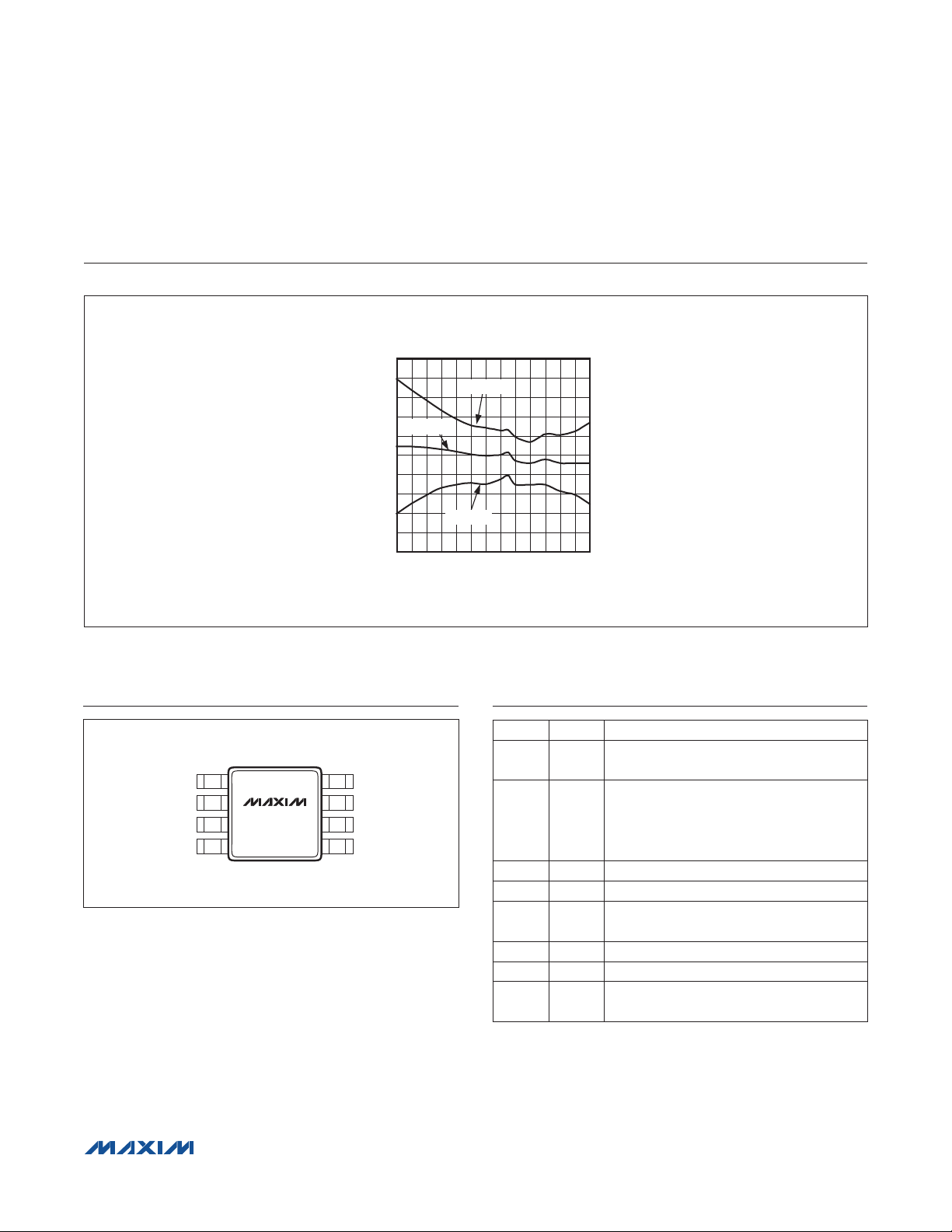

Typical Operating Characteristics

MAX31826 TYPICAL ERROR CURVE

0.5

0.4

0.3

0.2

MEAN ERROR

0.1

0

-0.1

-0.2

-0.3

-0.4

-0.5

-40 90

+3s ERROR

-3s ERROR

TEMPERATURE (˚C)

MAX31826

MAX31826 toc01

807050 60-10 0 10 20 30 40-30 -20

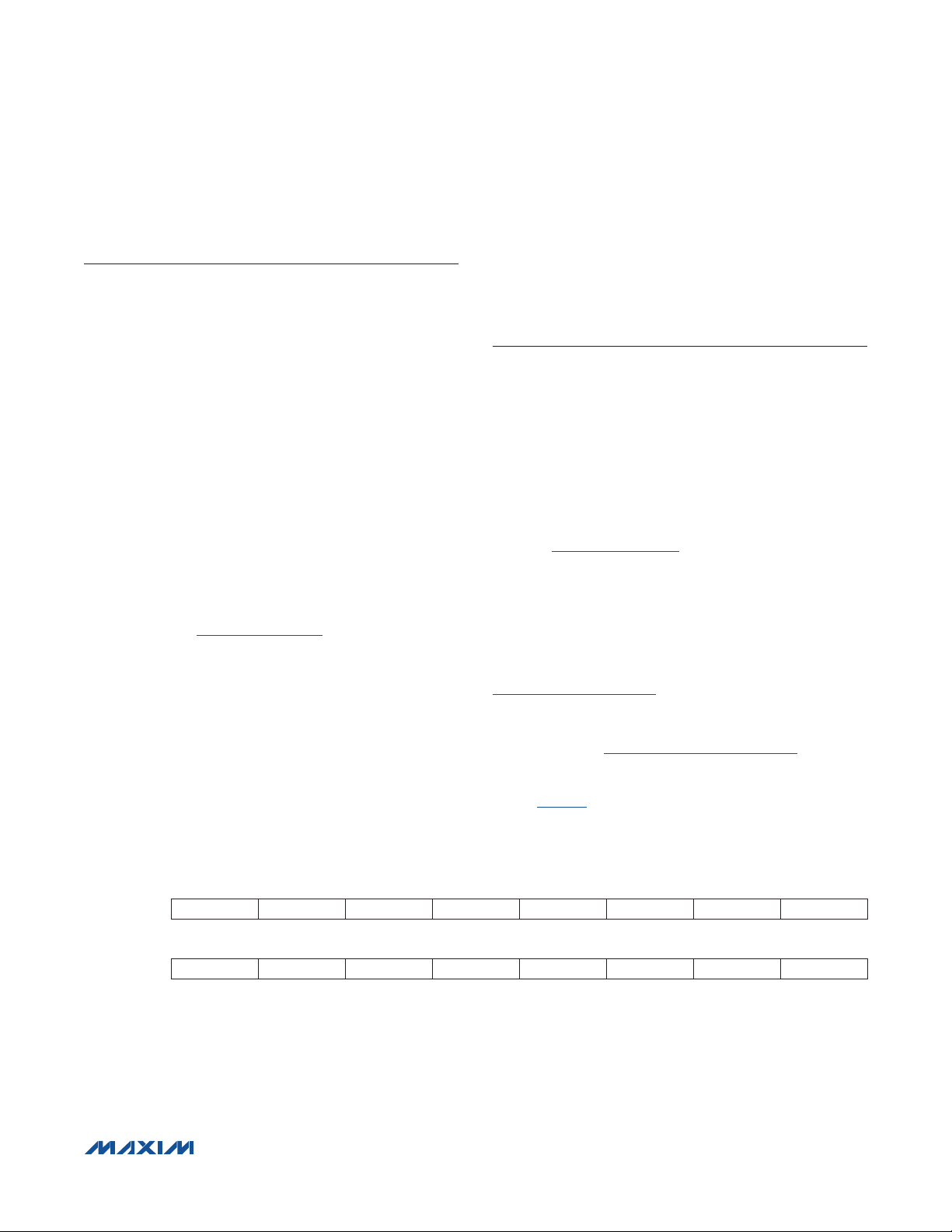

TOP VIEW

V

DD

Pin Configuration Pin Description

+

18AD3

27AD2DQ

MAX31826

µMAX

AD1N.C. 36

AD0GND 45

PIN NAME FUNCTION

1 V

Optional VDD. VDD must be grounded for

DD

operation in parasite-power mode.

Data Input/Output. Open-drain 1-Wire

2 DQ

interface pin. Also provides power to

the device when used in parasite-power

mode (see the Parasite Power section.)

3 N.C. No Connection. Not internally connected.

4 GND Ground

5 AD0

Location Address Input (Least Significant

Bit)

6 AD1 Location Address Input

7 AD2 Location Address Input

8 AD3

Location Address Input (Most Significant

Bit)

����������������������������������������������������������������� Maxim Integrated Products 5

Page 6

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

Detailed Description

The MAX31826 digital thermometer provides 12-bit

temperature measurements and communicates over a

1-WireM bus that by definition requires only one data line

(and ground) for communication with a central microcontroller. The data line requires a weak pullup resistor since

all devices are linked to the bus through a three-state

or open-drain port (i.e., the MAX31826’s DQ pin). Four

location address inputs simplify mapping of individual

devices to specific locations.

Each device has a unique 64-bit serial code, allowing

multiple devices to function on the same 1-Wire bus.

Therefore, it is simple to use one microcontroller to control many devices distributed over a large area. In this

bus system, the microcontroller identifies and addresses

devices on the bus using each device’s unique 64-bit

code. Because each device has a unique code, the

number of devices that can be addressed on one bus

is virtually unlimited. The 1-Wire bus protocol, including

detailed explanations of the commands and time slots, is

described in the 1-Wire Bus System section.

The Scratchpad 1 memory contains the 2-byte temperature register that stores the digital output from the

temperature sensor. An additional 128 bytes (1Kb) of

general-purpose EEPROM is included for storage of system data. The EEPROM can be locked to permanently

prevent any further data writes.

The device can also operate without an external power

supply. Power is instead supplied through the 1-Wire

pullup resistor through DQ when the bus is high. The

high bus signal also charges an internal capacitor (CPP),

which then supplies power to the device when the bus is

low. This method of deriving power from the 1-Wire bus

is referred to as parasite power. Alternatively, a power

supply on VDD can also power the device.

Measuring Temperature

The device’s core functionality is its direct-to-digital temperature sensor. The resolution of the temperature sensor

is 12 bits, corresponding to a least significant bit value

of 0.0625NC. The device powers up in a low-power idle

state. To initiate a temperature measurement, the master

must issue a Convert T command. Following the conversion, the resulting thermal data is stored in the 12-bit temperature register in the Scratchpad 1 memory and the

device returns to its idle state. If the device is powered by

an external supply, the master can issue read time slots

(see the 1-Wire Bus System section) after the Convert T

command, and the device responds by transmitting 0

while the temperature conversion is in progress and 1

when the conversion is done. If the device is powered

with parasite power, this notification technique cannot be

used because the bus must be pulled high by a strong

pullup during the entire temperature conversion. The

bus requirements for parasite power are explained in the

Powering the MAX31826 section.

The temperature data (in NC) is stored as a 16-bit signextended two’s complement number in the temperature

register (see the Temperature Register Format). The sign

bits (S) indicate if the temperature is positive or negative;

for positive numbers S = 0 and for negative numbers

S = 1. Table 1 gives examples of digital output data and

the corresponding temperature readings.

BIT 15 BIT 14 BIT 13 BIT 12 BIT 11 BIT 10 BIT 9 BIT 8

MSB

LSB

1-Wire is a registered trademark of Maxim Integrated Products, Inc.

S S S S S 2

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

3

2

����������������������������������������������������������������� Maxim Integrated Products 6

2

2

1

2

2

Temperature Register Format

6

0

-1

2

-2

2

5

2

-3

2

4

2

-4

2

Page 7

1-Wire Digital Temperature Sensor

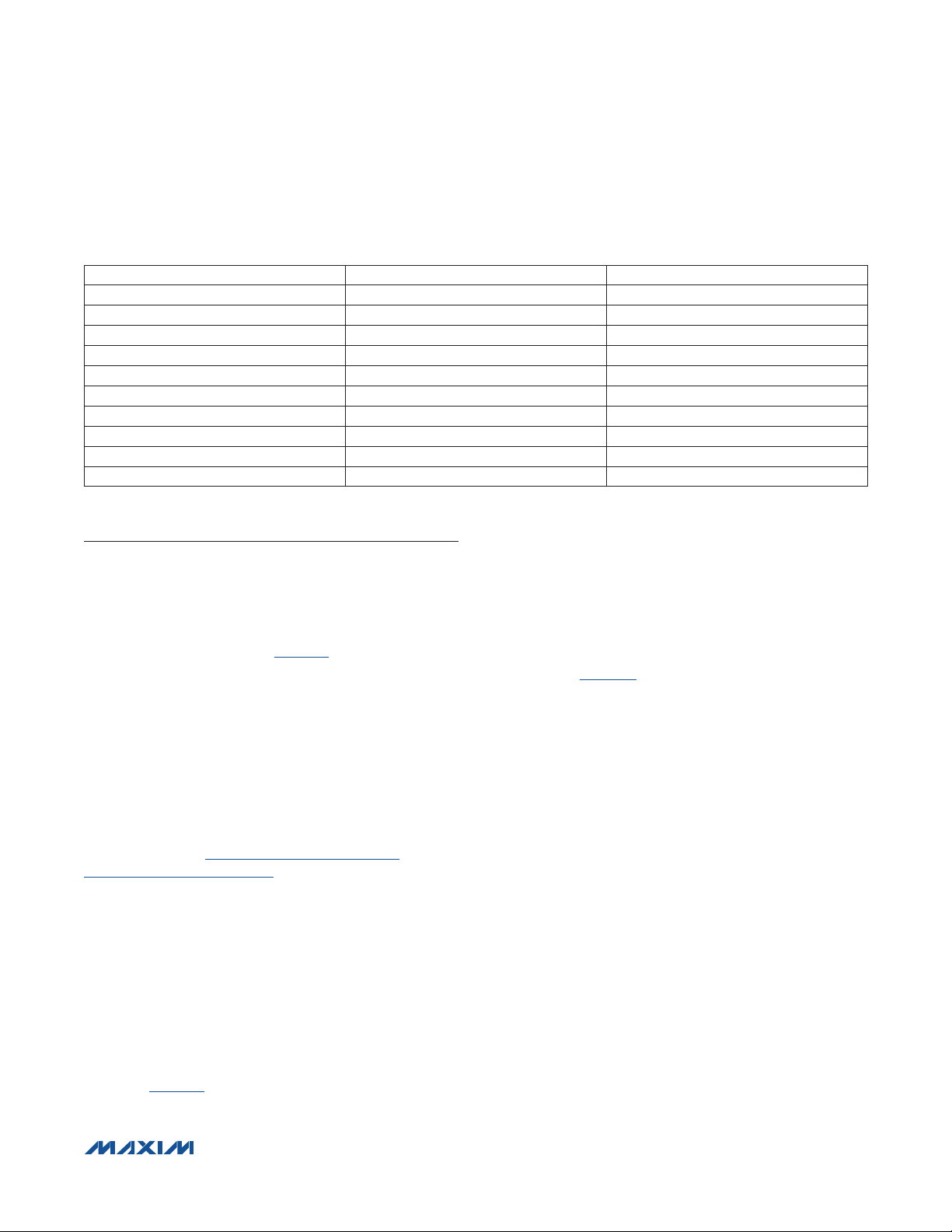

Table 1. Temperature/Data Relationship

MAX31826

with 1Kb Lockable EEPROM

TEMPERATURE (NC)

+125 0000 0111 1101 0000 07D0h

+85 0000 0101 0101 0000 0550h

+25.0625 0000 0001 1001 0001 0191h

+10.125 0000 0000 1010 0010 00A2h

+0.5 0000 0000 0000 1000 0008h

0 0000 0000 0000 0000 0000h

-0.5 1111 1111 1111 1000 FFF8h

-10.125 1111 1111 0101 1110 FF5Eh

-25.0625 1111 1110 0110 1111 FE6Fh

-55 1111 1100 1001 0000 FC90h

DIGITAL OUTPUT (BINARY) DIGITAL OUTPUT (HEX)

Powering the MAX31826

The MAX31826 can be powered by an external supply

on the VDD pin, or it can operate in “parasite power”

mode, which allows the device to function without a local

external supply. Parasite power is useful for applications

that require remote temperature sensing or those that

are very space-constrained. Figure 1 shows the device’s

parasite-power control circuitry, which “steals” power

from the 1-Wire bus through DQ when the bus is high.

The stolen charge powers the device while the bus is

high, and some of the charge is stored on the parasitepower capacitor (CPP) to provide power when the bus is

low. When the device is used in parasite-power mode,

VDD must be connected to ground.

In parasite-power mode, the 1-Wire bus and CPP can provide sufficient current to the device for most operations

as long as the specified timing and voltage requirements

are met (see the DC Electrical Characteristics and the

AC Electrical Characteristics tables). However, when the

device is performing temperature conversions or copying data from the Scratchpad 2 memory to EEPROM, the

operating current can be as high as 1.5mA. This current

can cause an unacceptable voltage drop across the

weak 1-Wire pullup resistor and is more current than can

be supplied by CPP. To ensure that the device has sufficient supply current, it is necessary to provide a strong

pullup on the 1-Wire bus whenever temperature conversions are taking place or when data is being copied from

the Scratchpad 2 to EEPROM. This can be accomplished

by using a MOSFET to pull the bus directly to the rail as

shown in Figure 1. The 1-Wire bus must be switched to

the strong pullup within 10Fs (max) after a Convert T or

Copy Scratchpad 2 command is issued, and the bus

must be held high by the pullup for the duration of the

conversion (t

(tWR). No other activity can take place on the 1-Wire bus

while the pullup is enabled.

The device can also be powered by the conventional

method of connecting an external power supply to VDD,

as shown in Figure 2. The advantage of this method is

that the MOSFET pullup is not required, and the 1-Wire

bus is free to carry other traffic during the temperature

conversion period or EEPROM write time.

The use of parasite power is not recommended for temperatures above 100NC because the device may not be

able to sustain communications due to the higher leakage currents that can exist at these temperatures. For

applications in which such temperatures are likely, it is

strongly recommended that the device be powered by

an external power supply.

In some situations the bus master might not know whether

the devices on the bus are parasite powered or powered

by external supplies. The master needs this information

to determine if the strong bus pullup should be used during temperature conversions. To get this information, the

master can issue a Skip ROM command, followed by a

Read Power Supply command, followed by a read time

slot. During the read time slot, parasite-powered devices

pull the bus low, and externally powered devices let the

bus remain high. If the bus is pulled low, the master

knows that it must supply the strong pullup on the 1-Wire

bus during temperature conversions or EEPROM writes.

) or the duration of the EEPROM write

CONV

����������������������������������������������������������������� Maxim Integrated Products 7

Page 8

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

V

PU

MAX31826

V

PU

GND DQ V

DD

µP

4.7kΩ

1-Wire BUS

Figure 1. Supplying the Parasite-Powered MAX31826 During Temperature Conversions

MAX31826

V

PU

µP

4.7kΩ

1-Wire BUS

GND DQ V

DD

DD

TO OTHER 1-Wire DEVICES

Figure 2. Powering the MAX31826 with an External Supply

MSb

8-BIT

CRC CODE

MSb MSbLSb

48-BIT SERIAL NUMBER

Figure 3. 64-Bit ROM Code

TO OTHER 1-Wire DEVICES

(EXTERNAL SUPPLY)V

MSbLSb

LSb

8-BIT FAMILY CODE

(3Bh)

LSb

64-Bit ROM Code

Each device contains a unique 64-bit code stored in ROM

(Figure 3). The least significant 8 bits of the ROM code

contain the device’s 1-Wire family code, 3Bh. The next 48

bits contain a unique serial number. The most significant

8 bits contain a cyclic redundancy check (CRC) byte that

����������������������������������������������������������������� Maxim Integrated Products 8

is calculated from the first 56 bits of the ROM code. See

the CRC Generation section for a detailed explanation

of the CRC bits. The 64-bit ROM code and associated

ROM function control logic allow the device to operate as

a 1-Wire device using the protocol detailed in the 1-Wire

Bus System section.

Page 9

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

SCRATCHPAD 1 (POWER-UP STATE

SHOWN IN PARENTHESES)

TEMPERATURE REGISTER LSB (50h)BYTE 0

TEMPERATURE REGISTER MSB (05h)BYTE 1

RESERVED (FFh)BYTE 2

RESERVED (FFh)BYTE 3

CONFIGURATION REGISTER*BYTE 4

RESERVED (FFh)BYTE 5

RESERVED (FFh)BYTE 6

RESERVED (FFh)BYTE 7

CRCBYTE 8

SCRATCHPAD 2 (EE SCRATCHPAD)

BYTE 0BYTE 0

BYTE 1BYTE 1

......

BYTE 7BYTE 7

*THE LOWER 4 BITS (AD[3:0]) OF THE CONFIGURATION REGISTER ARE HARDWIRED THROUGH AD0–AD3.

EEPROM

BYTES 00h−07h

BYTES 08h−0Fh

BYTES 10h−17h

...

BYTES 70h−77h

BYTES 78h−7Fh

MAX31826

Figure 4. Memory Map

Memory

Scratchpad 2 (the EE scratchpad) is used for writing to

the EEPROM. Scratchpad 2 consists of 8 bytes; write

The device’s memory is organized as shown in Figure 4. The

memory consists of two SRAM scratchpads (Scratchpad 1

and Scratchpad 2) and 1Kb of EEPROM, which can serve

as general-purpose nonvolatile memory until locked.

All memory commands are described in detail in the

MAX31826 Function Commands section.

Byte 0 and byte 1 of Scratchpad 1 contain the least

significant byte and the most significant byte of the temperature register, respectively. Byte 4 contains the configuration information. Bytes 2, 3, 5, 6, and 7 are reserved

for internal use by the device and cannot be overwritten;

these bytes return all ones when read.

Byte 8 of Scratchpad 1 is read-only and contains the

CRC code for bytes 0–7 of the scratchpad. The device

generates this CRC using the method described in the

CRC Generation section.

data to Scratchpad 2 before copying it to the EEPROM.

Configuration Register

Byte 4 of Scratchpad 1 contains the configuration reg-

ister, which is organized as shown in Configuration

Register Format. The configuration register allows the

user to read the programmed value of the address pins.

The AD[3:0] bits report the pin-programmed location

information. Pins connected to DQ (in parasite power)

or VDD (when externally powered) are reported with

logic 1, and pins connected to GND are reported as

logic 0. Pins connected to DQ (in parasite power), VDD

(when externally powered), or GND through a resistor are

valid logic 1s or logic 0s if the resistor is less than 10kI.

Unconnected or high-impedance ( > 10kI) connections

are indeterminate. Bits [7:4] are reserved for internal use

and cannot be overwritten; they return a 1 when read.

Configuration Register Format

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

— — — — AD3 AD2 AD1 AD0

Note: Bits [3:0] are programmed through the four location programming address pins, AD3–AD0. Reading the configuration register

provides location information on up to 16 individual devices.

����������������������������������������������������������������� Maxim Integrated Products 9

Page 10

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

CRC Generation

CRC bytes are provided as part of the device’s 64-bit

ROM code, in the 9th byte of Scratchpad 1, and for

Scratchpad 2 values. The ROM code CRC is calculated

from the first 56 bits of the ROM code and is contained in

the most significant byte of the ROM. The two scratchpad

CRCs are calculated from the data in each scratchpad,

and therefore changes when the data in it associated

scratchpad changes. The CRCs provide the bus master with a method of data validation when data is read

from the device. To verify that data has been read correctly, the bus master must recalculate the CRC from

the received data and then compare this value to either

the ROM code CRC (for ROM reads) or to the scratchpads’ CRC (for scratchpad reads). If the calculated CRC

matches the read CRC, the data has been received

error-free. The comparison of CRC values and the decision to continue with an operation are determined entirely

by the bus master. There is no circuitry inside the device

that prevents a command sequence from proceeding if

the device CRC (ROM or scratchpad) does not match the

value generated by the bus master.

The equivalent polynomial function of the CRC (ROM or

scratchpad) is:

CRC = X8 + X5 + X4 + 1

The bus master can recalculate the CRC and compare it

to the CRC values from the device using the polynomial

generator shown in Figure 5. This circuit consists of a

shift register and XOR gates, and the shift register bits

are initialized to 0. Starting with the least significant bit

of the ROM code or the least significant bit of byte 0 in

the scratchpad, one bit at a time should shifted into the

shift register. After shifting in the 56th bit from the ROM

or the most significant bit of byte 7 from the Scratchpad 1

or byte 10 from Scratchpad 2, the polynomial generator

contains the recalculated CRC. Next, the 8-bit ROM code

or scratchpad CRC from the device must be shifted into

the circuit. At this point, if the recalculated CRC was

correct, the shift register contains all zeros. Additional

information about the Maxim 1-Wire CRC is available in

Application Note 27: Understanding and Using Cyclic

Redundancy Checks with Maxim iButton® Products.

1-Wire Bus System

The 1-Wire bus system uses a single bus master to con-

trol one or more slave devices. The MAX31826 is always

a slave. When there is only one slave on the bus, the

system is referred to as a single-drop system; the system

is multidrop if there are multiple slaves on the bus. All

data and commands are transmitted least significant bit

first over the 1-Wire bus.

The following discussion of the 1-Wire bus system is

broken down into three topics: hardware configuration,

transaction sequence, and 1-Wire signaling (signal types

and timing).

Hardware Configuration

The 1-Wire bus has by definition only a single data line.

Each device (master or slave) interfaces to the data line

by using an open-drain or three-state port. This allows

each device to “release” the data line when the device

is not transmitting data so the bus is available for use by

another device. The device’s 1-Wire port (DQ) is open

drain with an internal circuit equivalent to that shown in

Figure 6.

POLYNOMIAL = X8 + X5 + X4 + 1

1ST

STAGE

0

X

Figure 5. CRC Generator

iButton is a registered trademark of Maxim Integrated Products, Inc.

2ND

STAGE

1

X

���������������������������������������������������������������� Maxim Integrated Products 10

3RD

STAGE

2

X

4TH

STAGE

3

X

4

X

5TH

STAGE

6TH

STAGE

5

X

7TH

STAGE

6

X

8TH

STAGE

7

X

INPUT DATA

8

X

Page 11

Rx

BUS MASTER

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

V

PU

4.7k

Ω

MAX31826 1-Wire PORT

DQ

Rx

Tx

OPEN-DRAIN

PORT PIN

Figure 6. Hardware Configuration

Rx = RECEIVE

Tx = TRANSMIT

The 1-Wire bus requires an external pullup resistor of

approximately 5kI; thus, the idle state for the 1-Wire bus

is high. If for any reason a transaction needs to be suspended, the bus must be left in the idle state if the transaction is to resume. Infinite recovery time can occur between

bits so long as the 1-Wire bus is in the inactive (high) state

during the recovery period. If the bus is held low for more

than 480Fs, all components on the bus are reset.

Transaction Sequence

The transaction sequence for accessing the device is as

follows:

1) Step 1: Initialization

2) Step 2: ROM Command (followed by any required

data exchange)

3) Step 3: MAX31826 Function Command (followed by

any required data exchange)

It is very important to follow this sequence every time the

device is accessed, as the device does not respond if

any steps in the sequence are missing or out of order.

An exception to this rule is the Search ROM command.

After issuing this ROM command, the master must return

to step 1 in the sequence.

Initialization

All transactions on the 1-Wire bus begin with an initialization sequence. The initialization sequence consists of a

reset pulse transmitted by the bus master followed by

presence pulse(s) transmitted by the slave(s). The presence pulse lets the bus master know that slave devices

(such as the MAX31826) are on the bus and are ready

5µA

TYP

100

Ω MOSFET

Tx

to operate. Timing for the reset and presence pulses is

detailed in the 1-Wire Signaling section.

ROM Commands

After the bus master has detected a presence pulse, it

can issue a ROM command. These commands operate

on the unique 64-bit ROM codes of each slave device

and allow the master to single out a specific device if

many are present on the 1-Wire bus. These commands

also allow the master to determine how many and what

types of devices are present on the bus. There are four

ROM commands, and each command is 8 bits long. The

master device must issue an appropriate ROM command

before issuing a MAX31826 function command. Figure 7

shows a flowchart for operation of the ROM commands.

Search ROM [F0h]

When a system is initially powered up, the master must

identify the ROM codes of all slave devices on the

bus, which allows the master to determine the number

of slaves and their device types. The master learns

the ROM codes through a process of elimination that

requires the master to perform a Search ROM cycle (i.e.,

Search ROM command followed by data exchange) as

many times as necessary to identify all the slave devices.

If there is only one slave on the bus, the simpler Read

ROM command can be used in place of the Search ROM

process. For a detailed explanation of the Search ROM

command procedure, refer to Application Note 937: Book

of iButton® Standards. After every Search ROM cycle,

the bus master must return to step 1 (initialization) in the

transaction sequence.

���������������������������������������������������������������� Maxim Integrated Products 11

Page 12

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

Read ROM [33h]

This command can be used only when there is one slave

on the bus. It allows the bus master to read the slave’s

64-bit ROM code without using the Search ROM command procedure. If this command is used when there is

more than one slave present on the bus, a data collision

occurs when all the slaves attempt to respond at the

same time.

Match ROM [55h]

The Match ROM command followed by a 64-bit ROM

code sequence allows the bus master to address a

specific slave device on a multidrop or single-drop bus.

Only the slave that exactly matches the 64-bit ROM code

sequence responds to the function command issued by

the master; all other slaves on the bus wait for a reset

pulse.

Skip ROM [CCh]

The master can use this command to address all devices

on the bus simultaneously without sending out any ROM

code information. For example, the master can make all

devices on the bus perform simultaneous temperature

conversions by issuing a Skip ROM command followed

by a Convert T function command.

Note that the Read Scratchpad 1 command can follow the

Skip ROM command only if there is a single slave device

on the bus. In this case, time is saved by allowing the

master to read from the slave without sending the device’s

64-bit ROM code. A Skip ROM command followed by a

Read Scratchpad 1 command causes a data collision on

the bus if there is more than one slave because multiple

devices attempt to transmit data simultaneously.

MAX31826 Function Commands

After the bus master has used a ROM command to

address the MAX31826 with which it wishes to communicate, the master can issue one of the MAX31826 function

commands. These commands allow the master to read

from the device’s scratchpad memories, initiate temperature conversions, and determine the power-supply mode.

The MAX31826 function commands are summarized in

Table 2 and illustrated by the flowchart in Figure 8.

Convert T [44h]

This command initiates a single temperature conversion. Following the conversion, the resulting thermal

data is stored in the 2-byte temperature register in the

Scratchpad 1 memory and the device returns to its low-

power idle state. If the device is being used in parasite-

power mode, within 10Fs (max) after this command is

issued, the master must enable a strong pullup on the

1-Wire bus for the duration of the conversion (t

described in the Powering the MAX31826 section. If the

device is powered by an external supply, the master can

issue read time slots after the Convert T command, and

the device responds by transmitting 0 while the tempera-

ture conversion is in progress and 1 when the conversion

is done. In parasite-power mode, this notification tech-

nique cannot be used because the bus is pulled high by

the strong pullup during the conversion.

CONV

) as

Read Scratchpad 1 [BEh]

This command allows the master to read the contents of

Scratchpad 1. The data transfer starts with the least sig-

nificant bit of byte 0 and continues through the scratch-

pad until the 9th byte (byte 8, CRC) is read. The master

can issue a reset to terminate reading at any time if only

part of the scratchpad data is needed. The CRC is com-

puted while data is read from bytes 0–7, and is shifted

out as byte 8.

Read Scratchpad 2 [AAh]

This command allows the master to read the contents of

Scratchpad 2. The command must be issued followed

by the start address to initiate a data transfer. The data

transfer always starts with the least significant bit of the

byte pointed to by the address bits [2:0], and the data

transfer continues through the scratchpad until 8 bytes

have been read. The [2:0] address bits wrap when

address [2:0] = 0x7 to [2:0] = 0x0. The master can issue

a reset to terminate reading at any time if only part of

the scratchpad data is needed. The CRC is computed

dynamically and includes the command, address, and all

the data bytes 0–7 for a total of 10 bytes. The computed

CRC is shifted out at the end of data byte 7. Because

the CRC contains the start address, the CRC value com-

puted can vary with different start addresses.

Note: After the Read Scratchpad 2 command, an address

of 00h returns the scratchpad contents correctly. This is

true regardless of the address sent during a preceding

Write Scratchpad 2 command transaction. However, the

address used during a preceding Write Scratchpad 2

command is necessary here to ensure that future Copy

Scratchpad 2 commands are copied to the correct row.

If 00h is used instead, a future Copy Scratchpad 2 com-

mand copies the contents to address 00h as opposed to

the row addressed by the Write Scratchpad 2 command.

���������������������������������������������������������������� Maxim Integrated Products 12

Page 13

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

Write Scratchpad 2 [0Fh]

This command allows the master to write 8 bytes to the EE

scratchpad. After issuing the Write Scratchpad 2 command,

the master must first provide the 1-byte address for the first

byte of the target EEPROM page, followed by the 8 bytes of

data to be written to the scratchpad for the EEPROM. The

three lower bits [2:0] of the target address byte must be set

to 0. The device automatically increments the address after

every byte it receives. The device computes the CRC of

the received data, including the command (0Fh), the target

address byte, and the 8 data bytes. After having received

a data byte for address 07h, the device shifts out (back to

the master) the computed CRC of the 10-byte stream just

received, allowing the master to verify that the data was

received correctly. Note that, because the device switches

direction from receive to transmit, writes to Scratchpad 2

must start with address bits [2:0] set to 0 and proceed from

0h–7h and not beyond.

Copy Scratchpad 2 [55h]

This command allows the master to copy the contents of

an 8-byte page of data from Scratchpad 2 to the 1Kb user

memory. The command is followed by the byte A5h. After

the master writes A5h, the device enters the programming

cycle, saving the data to nonvolatile memory, and does not

respond to further communication for the duration of the

EEPROM write time (tWR). During nonparasitic-power mode,

communication with other devices can continue. If the

device is being used in parasite-power mode, within 10Fs

(max) after A5h is issued, the master must enable a strong

pullup on the 1-Wire bus for the duration of the EEPROM

write time (tWR) as described in the Powering the MAX31826

section. No other activity can take place on the 1-Wire bus

while the strong pullup is enabled.

Changing only 1 byte of EEPROM is not natively supported

on the device. To achieve this, the master must first read the

8-byte block that contains the single byte to be changed,

and the three lower bits [2:0] of the target address byte

must be 0. The master must then modify the single byte

and write back the 8 bytes with Write Scratchpad 2 and the

same target address. Finally, the master must issue a Copy

Scratchpad 2 command.

Note: The Copy Scratchpad 2 command uses the more

recent of the two 8-bit addresses provided by either the

Write Scratchpad 2 or Read Scratchpad 2 commands as

the EEPROM destination address. The recommended procedure for writing to EEPROM starting at address 08h is as

follows:

1) Write Scratchpad 2 (address = 08h, 8 data bytes).

2) Read Scratchpad 2 (address = 08h, 8 data bytes). This

reads the data correctly as expected.

3) Copy Scratchpad 2 (0xA5).

4) Data is copied to row 1, which is the correct destination

based on the Write Scratchpad 2 address.

Read Memory [F0h]

This command allows the master to read the contents of the

1Kb memory. The command is followed by the address of

the first byte to be read (00h–7Fh). The data transfer starts

with the least significant bit of the first byte and continues

through 7Fh. The master can issue a reset to terminate reading at any time.

Read Power Supply [B4h]

The master device issues this command followed by a read

time slot to determine if any devices on the bus are using

parasite power. During the read time slot, parasite-powered

devices pull the bus low, and externally powered devices

do not pull the bus low. See the Powering the MAX31826

section for more information.

Lock Low Memory and Lock High Memory

The Lock Low Memory and Lock High Memory routines

each lock the contents of eight pages of memory.

Lock Low Memory (bytes 00h–3Fh) as follows:

1) Initialize communication by issuing a reset and a ROM

command.

2) Send Write Scratchpad 2 command.

3) Send address 80h as the target address to be written.

4) Send data 55h.

5) Initialize and send Copy Scratchpad 2 command.

6) Issue write token A5h and wait tWR.

Locations 00–3Fh are now locked. Also, location 80h is

locked with value 55h. Location 80h cannot be changed to

alter the lock status of 00h–3Fh.

Lock High Memory (bytes 40h–7Fh) as follows:

1) Initialize communication by issuing a reset and a ROM

command.

2) Send Write Scratchpad 2 command.

3) Send address 81h as the target address to be written.

4) Send data 55h.

5) Initialize and send Copy Scratchpad 2 command.

6) Issue write token A5h and wait tWR.

���������������������������������������������������������������� Maxim Integrated Products 13

Page 14

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

Table 2. MAX31826 Function Command Set

MAX31826

COMMAND DESCRIPTION PROTOCOL

Convert T

(Note 1)

Read Scratchpad 1

(Note 2)

Read Scratchpad 2

(Note 2)

Write Scratchpad 2

(Note 2)

Copy Scratchpad 2

Read Memory

(Note 2)

Read Power Supply

Lock Low Memory

Lock High Memory

Note 1: For parasite-powered devices, the master must enable a strong pullup on the 1-Wire bus during temperature conversions

and copies from the Scratchpad 2 to EEPROM. No other bus activity can take place during this time.

Note 2: The master can interrupt the transmission of data at any time by issuing a reset.

Initiates temperature conversion. 44h

Reads the 9-byte scratchpad

including the CRC byte.

Reads the 9-byte EE scratchpad

including the CRC byte.

Writes to the 8-byte EE

scratchpad.

Writes the contents of the 8-byte

Scratchpad 2 to the EEPROM.

Reads data in the 1Kb user

memory.

Signals the device’s power-supply

mode to the master.

Prevents further changes to the

lower eight pages of user memory.

Prevents further changes to the

upper eight pages of user memory.

BEh

AAh

0Fh

55h

F0h

B4h The device transmits supply status to the master.

—

—

1-Wire BUS ACTIVITY AFTER COMMAND IS

ISSUED

The device transmits conversion status to master

(not applicable for parasite-powered devices).

The device transmits up to 9 data bytes to master.

The 9th byte is the CRC byte.

The master transmits the start address. The device

transmits up to 9 data bytes to the master. The 9th

byte is the CRC byte.

The master transmits the address of first byte in the

target page, and then transmits 8 data bytes. The

device then returns the CRC byte calculated from

the 10 bytes just transmitted.

The master transmits token A5h. The device enters

EEPROM write mode, during which communication

is not allowed in parasitic-power mode.

Additionally, a strong pullup is also required during

parasitic-power mode.

The master transmits the address of first byte to be

read. The device then transmits data starting with

first byte until reaching the end of the available

addresses or until the master issues a reset.

Write 55h to byte 80h of Scratchpad 2. Copy

Scratchpad 2 to EEPROM.

Write 55h to byte 81h of Scratchpad 2. Copy

Scratchpad 2 to EEPROM.

���������������������������������������������������������������� Maxim Integrated Products 14

Page 15

INITIALIZATION

SEQUENCE

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

MASTER Tx

RESET PULSE

MAX31826 Tx

PRESENCE PULSE

MASTER Tx

ROM COMMAND

33h

READ

ROM?

Y

MAX31826 Tx

FAMILY CODE

1 BYTE

MAX31826 Tx

SERIAL NUMBER

6 BYTES

MAX31826 Tx

CRC BYTE

55h

N

MATCH

ROM?

MASTER Tx

BIT 0

BIT 0

MATCH?

MASTER Tx

BIT 1

BIT 1

MATCH?

MASTER Tx

BIT 63

N

Y Y

Y Y

Y

F0h

SEARCH

ROM?

MAX31826 Tx BIT 0

MAX31826 Tx BIT 0

MASTER Tx BIT 0

BIT 0

NN

MATCH?

MAX31826 Tx BIT 1

MAX31826 Tx BIT 1

MASTER Tx BIT 1

BIT 1

NN

MATCH?

Y

MAX31826 Tx BIT 63

MAX31826 Tx BIT 63

MASTER Tx BIT 63

N

CCh

SKIP

ROM?

N

Y

Figure 7. ROM Commands Flowchart

���������������������������������������������������������������� Maxim Integrated Products 15

BIT 63

MATCH?

Y Y

FUNCTION COMMAND

NN

MASTER Tx

BIT 63

MATCH?

Page 16

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

MASTER Tx

FUNCTION COMMAND

MAX31826 BEGINS

CONVERSION

DEVICE

CONVERTING

TEMPERATURE?

Y

MASTER Rx

“0s”

B4h

READ

POWER SUPPLY?

N

MASTER Rx

“1s”

44h

CONVERT T?

Y

PARASITE

POWER?

STRONG PULLUP ON DQ

MAX31826 CONVERTS

N

YN

MASTER ENABLES

TEMPERATURE

MASTER DISABLES

STRONG PULLUP

NN

READ

SCRATCHPAD 1?

SCRATCHPAD 2 TO EEPROM

BEh

Y

DATA COPIED FROM

55h

COPY

SCRATCHPAD 2?

MASTER Tx

TOKEN A5h

PARASITE

POWER?

SCRATCHPAD 2 TO EEPROM

N

READ

SCRATCHPAD 2?

N

YN

MASTER ENABLES

STRONG PULLUP ON DQ

DATA COPIED FROM

MASTER DISABLES

STRONG PULLUP

AAh

YY

F0h

READ

MEMORY?

MASTER Tx

START ADDRESS

MASTER Rx DATA BYTE

FROM EEPROM

N

MASTER Tx

RESET?

N

0Fh

WRITE

SCRATCHPAD 2?

N

Y

Y

Y

YN

MASTER Rx

“0s”

MASTER Rx DATA BYTE

FROM SCRATCHPAD 1

N

HAVE 8 BYTES

SCRATCHPAD 1 CRC BYTE

RETURN TO INITIALIZATION SEQUENCE

MASTER Rx

“1s”

PARASITE

POWER?

Figure 8. MAX31826 Function Commands Flowchart

���������������������������������������������������������������� Maxim Integrated Products 16

MASTER Tx

RESET?

N

BEEN READ?

Y

MASTER Rx

FOR NEXT TRANSACTION

MASTER Tx

START ADDRESS

MASTER Rx DATA BYTE

FROM SCRATCHPAD 2

Y

MASTER Tx

RESET?

N

N

HAVE 8 BYTES

BEEN READ?

Y

MASTER Rx

SCRATCHPAD 2 CRC BYTE

Y

MASTER Tx EEPROM

PAGE ADDRESS

MASTER Tx 8 DATA

BYTES

MASTER Rx

CRC BYTE

Page 17

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

SEARCH ALL

ROM IDs ON BUS

AND

STORE ROM IDs

(F0h COMMAND)

BUILDING CROSS-REFERENCE TABLE

USING ROM IDs AND 4-BIT ADDRESSES

INCREMENT COUNTER

N = N + 1

Figure 9. Building a Cross-Reference Table

N > N

MASTER Tx

NEXT ROM ID

READ SCRATCHPAD 1

(USE AD3−AD0 FROM

CONFIG REGISTER)

MATCH ROM ID TO

ADDRESS AND ADD TO

CROSS-REFERENCE

TABLE

Y

?

MAX

N

MAX

OF ROM IDs FOUND

N

IS THE NUMBER

Locations 40h–7Fh are now locked. Also, location 81h is

locked with value 55h. Location 81h cannot be changed to

alter the lock status of 40h–7Fh.

Building a Cross-Reference Table

The procedure in Figure 9 uses the Search ROM command to find all MAX31826s on the 1-Wire bus (16

maximum) and then reads each configuration register to

match the ROM IDs to the hardwired addresses.

1-Wire Signaling

The device uses a strict 1-Wire communication protocol

to ensure data integrity. Several signal types are defined

by this protocol: reset pulse, presence pulse, write-zero,

write-one, read-zero, and read-one. The bus master initiates all these signals except the presence pulse.

DONE

CROSS-REFERENCE TABLE

ROM ID AD3−AD0

ROM ID(0) 0000

ROM ID(1)

ROM ID(2) 0010

ROM ID(3) 0011

ROM ID(12) 1100

ROM ID(13) 1101

ROM ID(14) 1110

ROM ID(15) 1111

NOTE: TEMPERATURE SENSORS ARE ADDRESSED

BY ROM ID, NOT BY BINARY ADDRESS.

0001

Initialization Procedure:

Reset and Presence Pulses

All communication with the device begins with an initialization sequence that consists of a reset pulse from the

master followed by a presence pulse from the device.

This is illustrated in Figure 10. When the device sends the

presence pulse in response to the reset, it is indicating

to the master that it is on the bus and ready to operate.

During the initialization sequence, the bus master transmits (Tx) the reset pulse by pulling the 1-Wire bus low for

480Fs (min). The bus master then releases the bus and

goes into receive mode (Rx). When the bus is released,

the 5kI pullup resistor pulls the 1-Wire bus high. When

the device detects this rising edge, it waits 15Fs to 60Fs

and then transmits a presence pulse by pulling the

1-Wire bus low for 60Fs to 240Fs.

���������������������������������������������������������������� Maxim Integrated Products 17

Page 18

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

MASTER Tx RESET PULSE

480µs MINIMUM

MAX31826 WAITS

V

PU

1-Wire BUS

GND

Figure 10. Initialization Timing

BUS MASTER PULLING LOW MAX31826 PULLING LOW RESISTOR PULLUP

15µs TO 60µs

Read/Write Time Slots

The bus master writes data to the device during write

time slots and reads data from the device during read

time slots. One bit of data is transmitted over the 1-Wire

bus per time slot.

Write Time Slots

There are two types of write time slots: write-one time

slots and write-zero time slots. The bus master uses a

write-one time slot to write a logic 1 to the device and

a write-zero time slot to write a logic 0 to the device. All

write time slots must have a 60Fs (min) duration with a

1Fs (min) recovery time between individual write slots.

Both types of write time slots are initiated by the master

pulling the 1-Wire bus low (Figure 11).

To generate a write-one time slot, after pulling the 1-Wire

bus low, the bus master must release the 1-Wire bus

within 15Fs. When the bus is released, the 5kI pullup

resistor pulls the bus high. To generate a write-zero time

slot, after pulling the 1-Wire bus low, the bus master must

continue to hold the bus low for the duration of the time

slot (at least 60Fs).

The device samples the 1-Wire bus during a window that

lasts from 15Fs to 60Fs after the master initiates the write

time slot. If the bus is high during the sampling window,

a 1 is written to the device. If the line is low, a 0 is written

to the device.

Read Time Slots

The device can only transmit data to the master when

the master issues read time slots. Therefore, the master

MASTER Rx

480µs MINIMUM

MAX31826 Tx PRESENCE PULSE

60µs TO 240µs

must generate read time slots immediately after issuing

a Read Scratchpad 1 command or Read Power Supply

command, so that the device can provide the requested

data. In addition, the master can generate read time

slots after issuing a Convert T command to verify the

operation status as explained in the MAX31826 Function

Commands section.

All read time slots must be 60Fs (min) in duration with a

1Fs (min) recovery time between slots. A read time slot

is initiated by the master device pulling the 1-Wire bus

low for a minimum of 1Fs (t

) and then releasing the

INIT

bus (Figure 11). After the master initiates the read time

slot, the device begins transmitting a 1 or 0 on bus. The

device transmits a 1 by leaving the bus high and transmits a 0 by pulling the bus low. When transmitting a 0,

the device releases the bus by the end of the time slot,

and the pullup resistor pulls the bus back to its high idle

state. Output data from the device is valid for 15Fs after

the falling edge that initiated the read time slot. Therefore,

the master must release the bus and then sample the bus

state within 15Fs from the start of the slot.

Figure 12 illustrates that the sum of t

, tRC, and the

INIT

master sample window must be less than 15Fs for a read

time slot. tRC is the rise time due to the resistive and

capacitive characteristics of the bus. Figure 13 shows

that system timing margin is maximized by keeping t

INIT

and tRC as short as possible and by locating the master

sample time during read time slots towards the end of

the 15Fs period.

���������������������������������������������������������������� Maxim Integrated Products 18

Page 19

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

V

PU

1-Wire BUS

GND

V

PU

1-Wire BUS

GND

START

OF SLOT

MASTER WRITE-ZERO SLOT

60µs < Tx “0” < 120µs

MAX31826 SAMPLES

MIN MAXTYP

15µs 15µs 30µs

MASTER READ-ZERO SLOT MASTER READ-ONE SLOT

MASTER SAMPLES

> 1µs

START

OF SLOT

1µs < t

REC

> 1µs

15µs 15µs 30µs

1µs < t

REC

> 1µs

MASTER WRITE-ONE SLOT

< ∞

MAX31826 SAMPLES

MIN MAXTYP

< ∞

MASTER SAMPLES

15µs 45µs 15µs

BUS MASTER PULLING LOW MAX31826 PULLING LOW RESISTOR PULLUP

Figure 11. Read/Write Time Slot Timing Diagram

V

PU

1-Wire BUS

GND

t

> 1µs t

INIT

BUS MASTER PULLING LOW RESISTOR PULLUP

Figure 12. Detailed Master Read-One Timing

���������������������������������������������������������������� Maxim Integrated Products 19

15µs

VIH OF MASTER

RC

MASTER SAMPLES

Page 20

V

PU

1-Wire BUS

GND

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

VIH OF MASTER

t

=

tRC =

INIT

SMALL

SMALL

15µs

BUS MASTER PULLING LOW RESISTOR PULLUP

Figure 13. Recommended Master Read-One Timing

Table 3. Operation Example

MASTER

MODE

Tx Reset Master issues reset pulse.

Rx Presence Devices respond with presence pulse.

Tx F0h Master issues Search ROM command

Tx Reset Master issues reset pulse.

Rx Presence Devices respond with presence pulse.

Tx 55h Master issues Match ROM command for desired address

Tx 64-bit ROM code Master sends device ROM code.

Tx 44h Master issues Convert T command.

Tx

Tx Reset Master issues reset pulse.

Rx Presence Devices respond with presence pulse.

Tx 55h Master issues Match ROM command.

Tx 64-bit ROM code Master sends device ROM code.

Tx BEh Master issues Read Scratchpad 1 command.

Rx 9 data bytes

DATA (LSB FIRST) COMMENTS

DQ line held high by

strong pullup

Master applies strong pullup to DQ for the duration of the conversion (t

Master reads entire Scratchpad 1 including CRC. The master then recalculates the CRC of

the first 8 data bytes from the scratchpad and compares the calculated CRC with the read

CRC (byte 9). If they match, the master continues; if not, the read operation is repeated.

MASTER SAMPLES

CONV

).

Operation Example

Table 3 shows an operation example in which there

are multiple devices on the bus using parasite power.

���������������������������������������������������������������� Maxim Integrated Products 20

The bus master initiates a temperature conversion in a

specific MAX31826 and then reads Scratchpad 1 and

recalculates the CRC to verify the data.

Page 21

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

1-Wire BUS

LOCATION 0

DQ

V

DD

GND

DQ

V

DD

GND

DQ

V

DD

GND

DQ

V

DD

GND

MAX31826

MAX31826

MAX31826

MAX31826

V

DD

V

DD

V

DD

V

DD

AD0

AD1

AD2

AD3

AD0

AD1

AD2

AD3

AD0

AD1

AD2

AD3

AD0

AD1

AD2

AD3

AD0 = GND

AD1 = GND

AD2 = GND

AD3 = GND

LOCATION 1

AD0 = V

DD

AD1 = GND

AD2 = GND

AD3 = GND

LOCATION 2

AD0 = GND

AD1 = V

DD

AD2 = GND

AD3 = GND

LOCATION 15

AD0 = V

DD

AD1 = V

DD

AD2 = V

DD

AD3 = V

DD

1-Wire BUS

DQ

V

DD

GND

DQ

V

DD

GND

DQ

V

DD

GND

DQ

V

DD

GND

MAX31826

MAX31826

MAX31826

MAX31826

AD0

AD1

AD2

AD3

AD0

AD1

AD2

AD3

AD0

AD1

AD2

AD3

AD0

AD1

AD2

AD3

LOCATION 0

AD0 = GND

AD1 = GND

AD2 = GND

AD3 = GND

LOCATION 1

AD0 = DQ

AD1 = GND

AD2 = GND

AD3 = GND

LOCATION 2

AD0 = GND

AD1 = DQ

AD2 = GND

AD3 = GND

LOCATION 15

AD0 = DQ

AD1 = DQ

AD2 = DQ

AD3 = DQ

NOTE: AD3–AD0 CANNOT BE LEFT UNCONNECTED; EACH PIN MUST BE

CONNECTED TO EITHER V

OR GND.

DD

NOTE: AD3–AD0 CANNOT BE LEFT UNCONNECTED; EACH PIN MUST BE

CONNECTED TO EITHER DQ OR GND.

Figure 14. Address Programming Diagram—VDD Powered Figure 15. Address Programming Diagram—Parasite Powered

Ordering Information Package Information

PART TEMP RANGE PIN-PACKAGE

MAX31826MUA+

MAX31826MUA+T

-55NC to +125NC 8 FMAX

-55NC to +125NC 8 FMAX

+Denotes a lead(Pb)-free/RoHS-compliant package.

T = Tape and reel.

���������������������������������������������������������������� Maxim Integrated Products 21

For the latest package outline information and land patterns

(footprints), go to www.maxim-ic.com/packages. Note that a

“+”, “#”, or “-” in the package code indicates RoHS status only.

Package drawings may show a different suffix character, but

the drawing pertains to the package regardless of RoHS status.

PACKAGE

TYPE

8 FMAX

PACKAGE

CODE

U8+3

OUTLINE

NO.

LAND

PATTERN NO.

21-0036 90-0092

Page 22

MAX31826

1-Wire Digital Temperature Sensor

with 1Kb Lockable EEPROM

Revision History

REVISION

NUMBER

0 3/12 Initial release —

REVISION

DATE

DESCRIPTION

PAGES

CHANGED

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time. The parametric values (min and max limits) shown in the Electrical

Characteristics table are guaranteed. Other parametric values quoted in this data sheet are provided for guidance.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 22

©

2012 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...