Page 1

19-5723; Rev 1; 2/11

SPI/I2C UART with 128-Word FIFOs in WLP

General Description

The MAX3108 small form factor universal asynchronous

receiver-transmitter (UART) with 128 words each of

receive and transmit FIFOs is controlled through a serial

I2C or SPI™ controller interface. Auto-sleep and shutdown modes help reduce power consumption during

periods of inactivity. A low 500FA (max) supply current

and tiny 25-bump WLP (2.1mm x 2.1mm) package make

the MAX3108 ideal for low-power portable devices. The

MAX3108 operates from a supply voltage of 1.71V to 3.6V.

Baud rates up to 24Mbps make the MAX3108 suitable for

today’s high data rate applications. A phase-locked loop

(PLL), predivider, and fractional baud-rate generator allow

high-resolution baud-rate programming and minimize the

dependency of baud rate on reference clock frequency.

Four GPIOs can be used as inputs, outputs, or interrupt inputs.

When configured as outputs, they can be programmed to be

open-drain outputs and sink up to 20mA of current.

The MAX3108 is ideal for portable and handheld devices, is available in a 25-bump (2.1mm x 2.1mm) 0.4mm

pitch WLP package, and is specified over the -40NC to

+85NC extended temperature range.

Applications

Portable Communication Devices

Mobile Internet Devices

Low-Power Handheld Devices

Medical Systems

Point-of-Sale Systems

SPI is a trademark of Motorola, Inc.

IrDA is a service mark of Infrared Data Association Corporation.

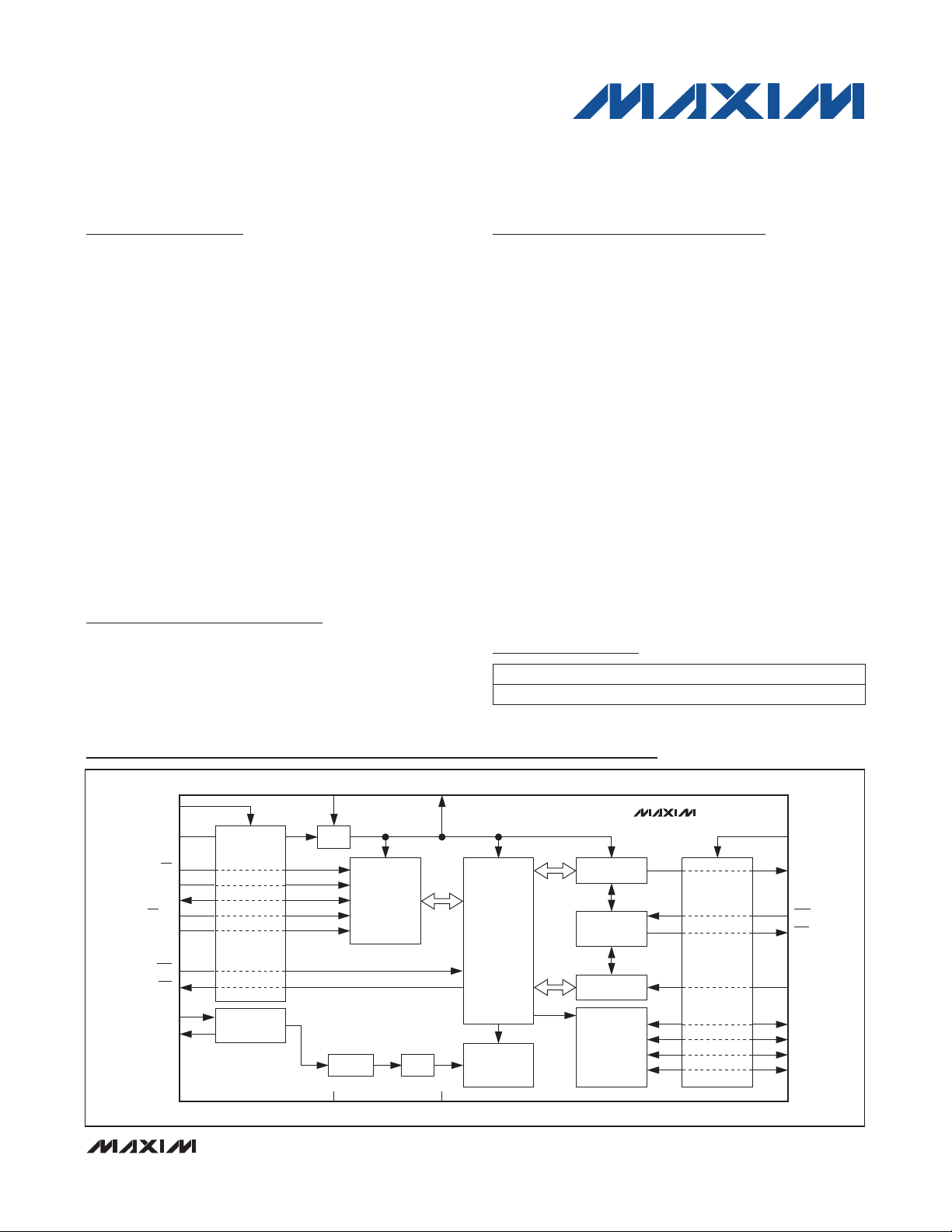

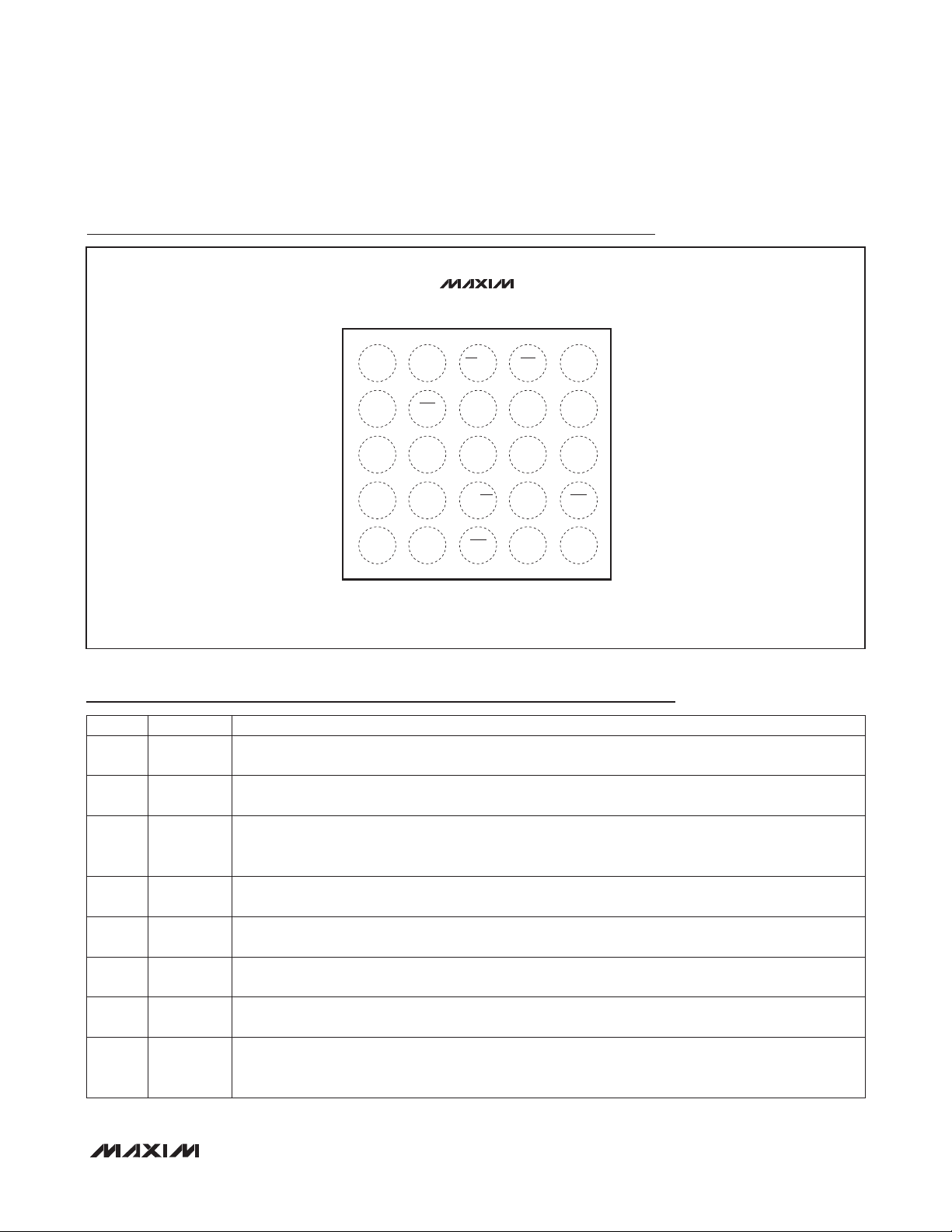

Functional Diagram

Features

S 24Mbps (max) Baud Rate

S Integrated PLL and Divider

S 1.71V to 3.6V Supply Range

S High-Resolution Programmable Baud Rate

S SPI Up to 26MHz Clock Rate

S Fast Mode Plus I

S Automatic RTS and CTS Hardware Flow Control

S Automatic XON/XOFF Software Flow Control

S Special Character Detection

S 9-Bit Multidrop Mode Data Filtering

S SIR- and MIR-Compliant IrDA

S Flexible Logic Levels on the Controller and

2

C Up to 1MHz

SM

Encoder/Decoder

Transceiver Interfaces

S Four Flexible GPIOs

S Line Noise Indication

S Shutdown and Auto-Sleep Modes

S Low 35µA (max) V

S Register Compatible with the MAX3107

S Tiny, 25-Bump WLP Package (2.1mm x 2.1mm)

Shutdown Current

CC

Ordering Information

PART TEMP RANGE PIN-PACKAGE

MAX3108EWA+

-40NC to +85NC

+Denotes a lead(Pb)-free/RoHS-compliant package.

25 WLP

MAX3108

LDOEN

SPI/I2C

MOSI/A1

MISO/SDA

CS/A0

SCLK/SCL

RST

IRQ

XIN

XOUT

V

CC

V

L

LDO

SPI/I2C

LOGIC-LEVEL

TRANSLATION

CRYSTAL

OSCILLATOR

DIVIDER

PLL

V

18

MAX3108

Tx AND FIFO

REGISTERS

AND

CONTROL

FRACTIONAL

BAUD-RATE

GENERATOR

DGNDAGND

FLOW

CONTROL

LOGIC-LEVEL

TRANSLATION

Rx AND FIFO

GPIO

V

EXT

TX

CTS

RTS

RX

GPIO0

GPIO1

GPIO2

GPIO3

_______________________________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

SPI/I2C UART with 128-Word FIFOs in WLP

TABLE OF CONTENTS

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Package Thermal Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DC Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AC Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Timing Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

MAX3108

Typical Operating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bump Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Bump Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Detailed Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Register Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Receive and Transmit FIFOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Transmitter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Receiver Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Line Noise Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Clock Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Crystal Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

External Clock Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PLL and Predivider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fractional Baud-Rate Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2x and 4x Rate Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Multidrop Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Auto Data Filtering in Multidrop Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Auto Transceiver Direction Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Echo Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Auto Hardware Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AutoRTS Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AutoCTS Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Auto Software (XON/XOFF) Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Receiver Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Transmitter Flow Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FIFO Interrupt Triggering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Low-Power Standby Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Forced-Sleep Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Auto-Sleep Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Shutdown Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power-Up and IRQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Interrupt Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 ______________________________________________________________________________________

Page 3

SPI/I2C UART with 128-Word FIFOs in WLP

TABLE OF CONTENTS (continued)

Interrupt Enabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Interrupt Clearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Detailed Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Serial Controller Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SPI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SPI Single-Cycle Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SPI Burst Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

I2C Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

START, STOP, and Repeated START Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Slave Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Bit Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Single-Byte Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Burst Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Single-Byte Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Burst Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Acknowledge Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Applications Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Startup and Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Low-Power Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Interrupts and Polling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Logic-Level Translation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Power-Supply Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Connector Sharing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

RS-232 5x3 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Typical Application Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chip Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Package Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

MAX3108

_______________________________________________________________________________________ 3

Page 4

SPI/I2C UART with 128-Word FIFOs in WLP

LIST OF FIGURES

Figure 1. I2C Timing Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2. SPI Timing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 3. Transmit FIFO Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 4. Receive Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 5. Receive FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MAX3108

Figure 6. Midbit Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 7. Clock Selection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 8. 2x and 4x Baud Rates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 9. Auto Transceiver Direction Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 10. Setup and Hold times in Auto Transceiver Direction Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 11. Half-Duplex with Echo Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 12. Echo Suppression Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 13. Simplified Interrupt Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14. PLL Signal Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 15. Single-Cycle Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 16. Single-Cycle Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 17. I2C START, STOP, and Repeated START Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 18. Write Byte Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 19. Burst Write Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 20. Read Byte Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 21. Burst Read Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 22. Acknowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 23. Startup and Initialization Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 24. Logic-Level Translation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 25. Connector Sharing with a USB Transceiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 26. RS-232 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 27. RS-485 Half-Duplex Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

LIST OF TABLES

Table 1. StopBits Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 2. Lengthx Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 3. SwFlow[3:0] Truth Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 4. PLLFactorx Selection Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 5. I2C Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4 ______________________________________________________________________________________

Page 5

SPI/I2C UART with 128-Word FIFOs in WLP

LIST OF REGISTERS

Receive Hold Register (RHR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Transmit Hold Register (THR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

IRQ Enable Register (IRQEn) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Interrupt Status Register (ISR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Line Status Interrupt Enable Register (LSRIntEn). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Line Status Register (LSR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Special Character Interrupt Enable Register (SpclChrIntEn) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Special Character Interrupt Register (SpclCharInt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

STS Interrupt Enable Register (STSIntEn) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Status Interrupt Register (STSInt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

MODE1 Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

MODE2 Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Line Control Register (LCR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Receiver Timeout Register (RxTimeOut) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

HDplxDelay Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

IrDA Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Flow Level Register (FlowLvl) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

FIFO Interrupt Trigger Level Register (FIFOTrgLvl) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Transmit FIFO Level Register (TxFIFOLvl) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Receive FIFO Level Register (RxFIFOLvl) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Flow Control Register (FlowCtrl). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

XON1 Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

XON2 Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

XOFF1 Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

XOFF2 Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

GPIO Configuration Register (GPIOConfg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

GPIO Data Register (GPIOData) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

PLL Configuration Register (PLLConfig). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Baud-Rate Generator Configuration Register (BRGConfig) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Baud-Rate Generator LSB Divisor Register (DIVLSB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Baud-Rate Generator MSB Divisor Register (DIVMSB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Clock Source Register (CLKSource) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

MAX3108

_______________________________________________________________________________________ 5

Page 6

SPI/I2C UART with 128-Word FIFOs in WLP

ABSOLUTE MAXIMUM RATINGS

(Voltages referenced to AGND.)

VL, VCC, V

XOUT ........................................................ -0.3V to (VCC + 0.3V)

V18 ...................... -0.3V to the lesser of (VCC + 0.3V) and 2.0V

RST, IRQ, MOSI/A1, CS/A0, SCLK/SCL,

MISO/SDA, LDOEN, SPI/I2C .................... -0.3V to (VL + 0.3V)

TX, RX, RTS, CTS, GPIO_ ....................... -0.3V to (V

, XIN ...............................................-0.3V to +4.0V

EXT

EXT

+ 0.3V)

DGND ...................................................................-0.3V to +0.3V

Continuous Power Dissipation (TA = +70NC)

WLP (derate 19.2mW/NC above +70NC) ................... 1536mW

Operating Temperature Range .......................... -40NC to +85NC

Maximum Junction Temperature .....................................+150NC

Storage Temperature Range ............................ -65NC to +150NC

Soldering Temperature (reflow) ......................................+260NC

MAX3108

PACKAGE THERMAL CHARACTERISTICS

WLP

Junction-to-Ambient Thermal Resistance (BJA) ...........52NC/W

Junction-to-Case Thermal Resistance (BJC) ................11NC/W

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial.

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

DC ELECTRICAL CHARACTERISTICS

(VCC = 1.71V to 3.6V, VL = 1.71V to 3.6V, V

VCC = 2.8V, VL = 1.8V, V

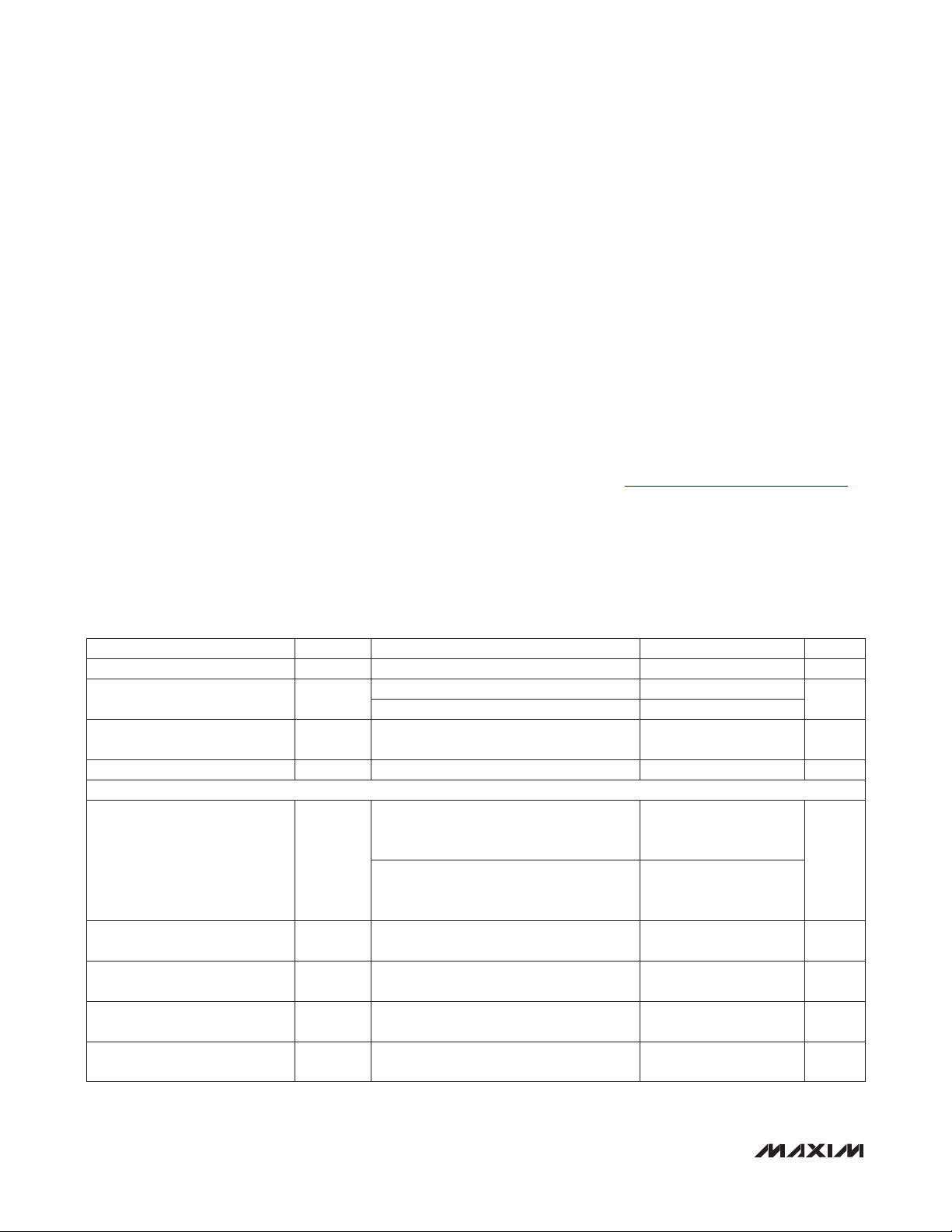

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Digital Interface Supply Voltage V

Analog Supply Voltage V

UART Interface Logic Supply

Voltage

Logic Supply Voltage V

CURRENT CONSUMPTION

VCC Supply Current I

VCC Shutdown Supply Current I

VL Shutdown or Sleep Supply

Current

V

Shutdown Supply Current I

EXT

V18 Input Power-Supply Current

in Shutdown Mode

= 2.5V, TA = +25NC.) (Notes 2, 3)

EXT

V

CCSHDN

I

18SHDN

= 1.71V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at

EXT

L

CC

EXT

CC

I

EXT

Internal PLL disabled and bypassed 1.71 3.6

Internal PLL enabled 2.35 3.6

18

1.8MHz crystal oscillator active, PLL

disabled, SPI/I2C interface idle, UART

interfaces idle, LDOEN = high

Baud rate = 1Mbps, 20MHz external clock,

SPI/I2C interface idle, PLL disabled, UART

in loopback mode, LDOEN = low

Shutdown mode, LDOEN = low, RST = low,

all inputs and outputs are idle

Shutdown or sleep mode, all inputs and

L

outputs are idle

Shutdown mode, RST = low, all inputs and

outputs are idle

Shutdown mode, LDOEN = low, RST = low,

all inputs and outputs are idle

(Note 1)

1.71 3.6 V

1.71 3.6 V

1.65 1.95 V

500

500

35

15

10

50

V

FA

FA

FA

FA

FA

6 ______________________________________________________________________________________

Page 7

SPI/I2C UART with 128-Word FIFOs in WLP

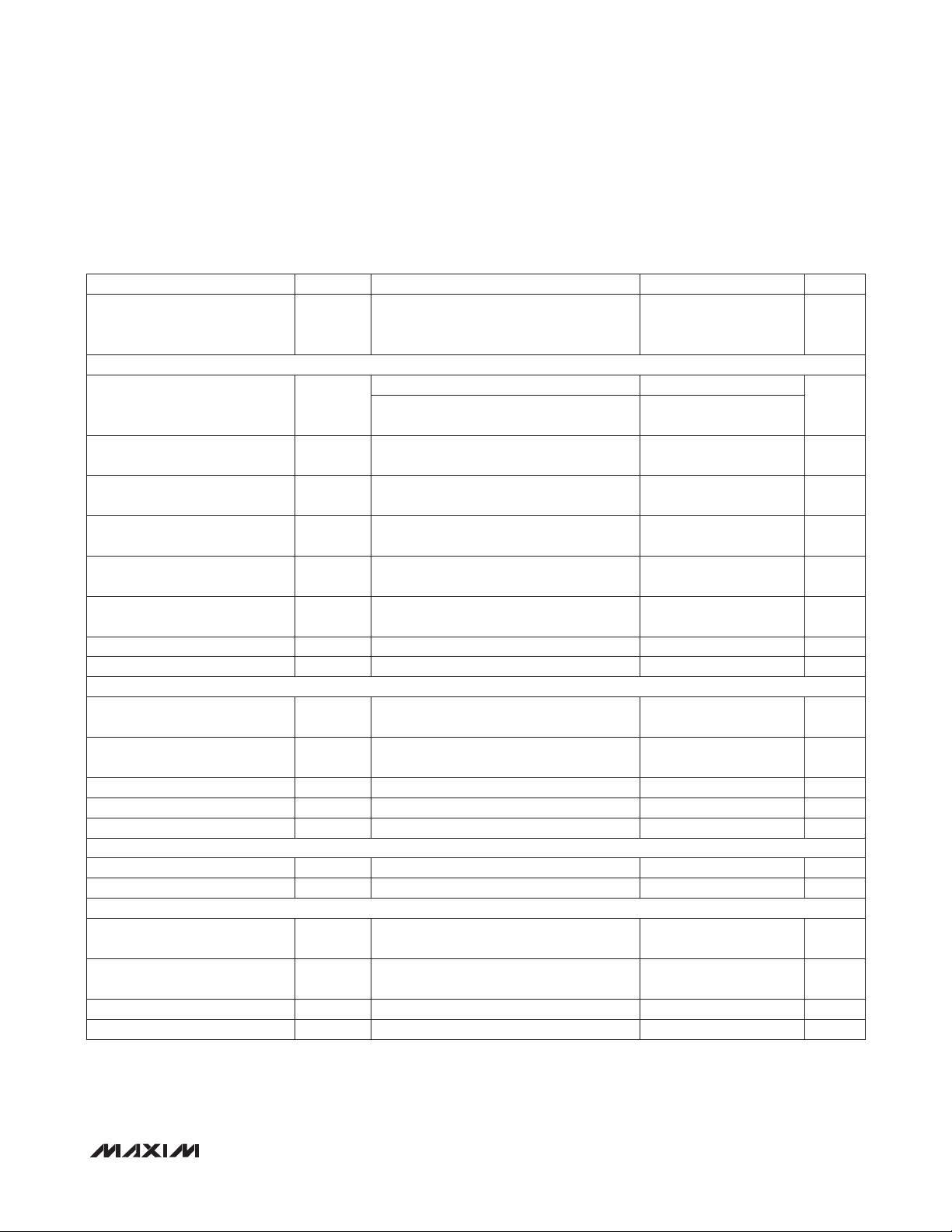

DC ELECTRICAL CHARACTERISTICS (continued)

(VCC = 1.71V to 3.6V, VL = 1.71V to 3.6V, V

VCC = 2.8V, VL = 1.8V, V

= 2.5V, TA = +25NC.) (Notes 2, 3)

EXT

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V18 Input Power-Supply Current I

SCLK/SCL, MISO/SDA

MISO/SDA Output Logic-Low

Voltage in I2C Mode

MISO/SDA Output Logic-Low

Voltage in SPI Mode

MISO/SDA Output Logic-High

Voltage in SPI Mode

V

V

V

OHSPI

Input Logic-Low Voltage V

Input Logic-High Voltage V

Input Hysteresis V

Input Leakage Current I

Input Capacitance C

SPI/I2C, CS/A0, MOSI/A1 INPUTS

Input Logic-Low Voltage V

Input Logic-High Voltage V

Input Hysteresis V

Input Leakage Current I

Input Capacitance C

IRQ OUTPUT (OPEN DRAIN)

Output Logic-Low Voltage V

Output Leakage Current I

LDOEN AND RST INPUTS

Input Logic-Low Voltage V

Input Logic-High Voltage V

Input Hysteresis V

Input Leakage Current I

= 1.71V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at

EXT

Baud rate = 1Mbps, 20MHz external clock,

18

PLL disabled, UART in loopback mode,

LDOEN = low (Note 4)

Sink current = 3mA, VL > 2V 0.4

OLI2C

OLSPI

Sink current = 3mA, VL < 2V

Sink current = 2mA 0.4 V

Source current = 2mA

SPI and I2C mode

IL

SPI and I2C mode

IH

HYST

HYST

OL

OL

HYST

SPI and I2C mode

VIN = 0 to VL, SPI and I2C mode -1 +1

IL

SPI and I2C mode 5 pF

IN

SPI and I2C mode

IL

SPI and I2C mode

IH

SPI and I2C mode 50 mV

VIN = 0 to VL, SPI and I2C mode -1 +1

IL

SPI and I2C mode 5 pF

IN

Sink current = 2mA 0.4 V

V

= 0 to VL, IRQ is not asserted

IRQ

IL

IH

VIN = 0 to V

IL

L

VL -

0.4

0.7 x

V

L

0.05 x

V

L

0.7 x

V

L

-1 +1

0.7 x

V

L

50 mV

-1 +1

2 mA

0.2 x

V

L

0.3 x

V

L

0.3 x

V

L

0.3 x

V

L

MAX3108

V

V

V

V

V

FA

V

V

FA

FA

V

V

FA

_______________________________________________________________________________________ 7

Page 8

SPI/I2C UART with 128-Word FIFOs in WLP

DC ELECTRICAL CHARACTERISTICS (continued)

(VCC = 1.71V to 3.6V, VL = 1.71V to 3.6V, V

VCC = 2.8V, VL = 1.8V, V

= 2.5V, TA = +25NC.) (Notes 2, 3)

EXT

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

UART INTERFACE

RTS, TX OUTPUTS

Output Logic-Low Voltage V

MAX3108

Output Logic-High Voltage V

Input Leakage Current I

Input Capacitance C

CTS, RX INPUTS

Input Logic-Low Voltage V

Input Logic-High Voltage V

Input Hysteresis V

CTS Input Leakage Current

RX Pullup Current I

Input Capacitance C

GPIO_ INPUTS/OUTPUTS

Output Logic-Low Voltage V

Output Logic-High Voltage V

Input Logic-Low Voltage V

Input Logic-High Voltage V

Pulldown Current I

XIN

Input Logic-Low Voltage V

Input Logic-High Voltage V

Input Capacitance C

XOUT

Input Capacitance C

= 1.71V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at

EXT

OL

OH

HYST

I

PU

Sink current = 2mA 0.4 V

Source current = 2mA

Output is three-stated, V

IL

High-Z mode 5 pF

IN

IL

IH

RTS

= 0 to V

EXT

0.7 x

V

EXT

-1 +1

0.7 x

V

EXT

50 mV

V

IL

CTS

= 0 to V

EXT

-1 +1

VRX = 0V -7.5 -5.5 -3.5

IN

5 pF

Sink current = 20mA, push-pull or open-

OL

OH

IL

IH

PD

IL

IH

XIN

XOUT

drain output type, V

Sink current = 20mA, push-pull or opendrain output type, V

Source current = 5mA, push-pull output

type

GPIO_ is configured as an input 0.4 V

GPIO_ is configured as an input

V

= V

GPIO_

, GPIO_ is configured as an

EXT

input

EXT

EXT

> 2.3V

< 2.3V

V

-

EXT

0.4V

2/3 x

V

EXT

3.5 5.5 7.5

1.2 V

16 pF

16 pF

0.3 x

V

EXT

0.45

0.55

0.6 V

V

FA

V

V

FA

FA

V

V

V

FA

8 ______________________________________________________________________________________

Page 9

SPI/I2C UART with 128-Word FIFOs in WLP

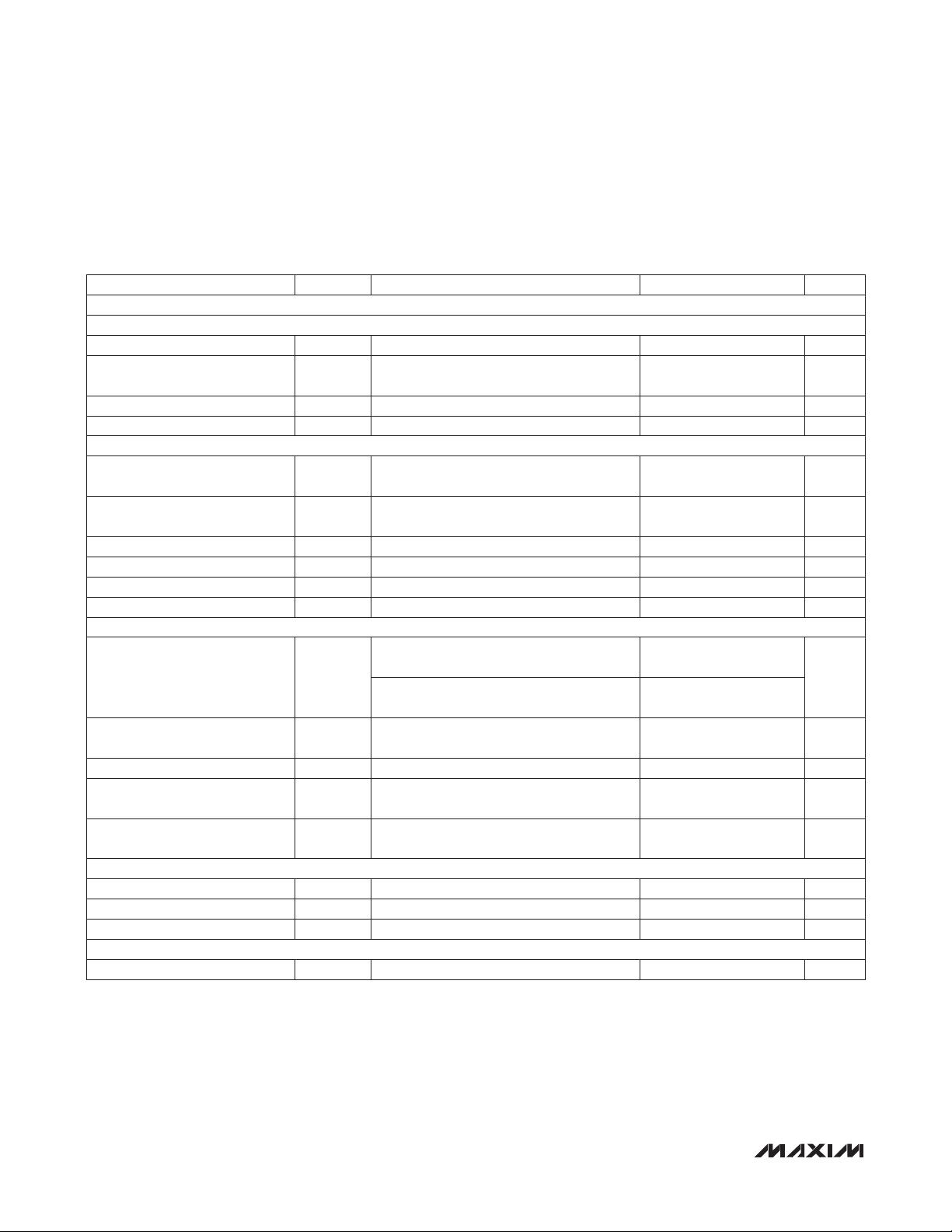

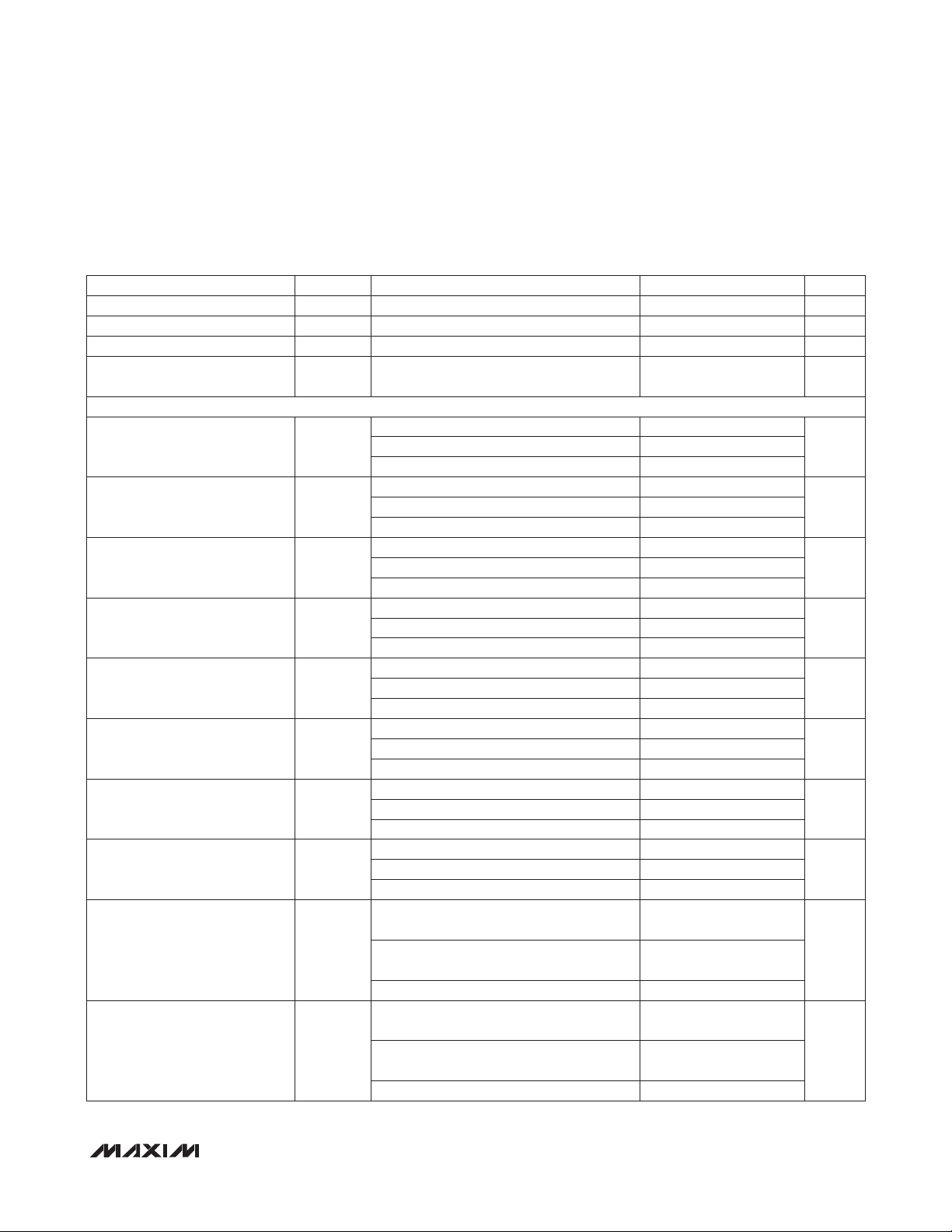

AC ELECTRICAL CHARACTERISTICS

(VCC = 1.71V to 3.6V, VL = 1.71V to 3.6V, V

VCC = 2.8V, VL = 1.8V, V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

External Cystal Frequency f

External Clock Frequency f

External Clock Duty Cycle (Note 5) 45 55 %

Baud-Rate Generator Clock

Input Frequency

I2C BUS: TIMING CHARACTERISTICS (Figure 1)

SCL Clock Frequency f

Bus Free Time Between a STOP

and START Condition

Hold Time for START Condition

and Repeated START Condition

Low Period of the SCL Clock t

High Period of the SCL Clock t

Data Hold Time

Data Setup Time t

Setup Time for Repeated START

Condition

Rise Time of Incoming SDA and

SCL Signals

Fall Time of SDA and SCL

Signals

= 2.5V, TA = +25NC.) (Note 2)

EXT

XOSC

t

HD:STA

t

HD:DAT

SU:DAT

t

SU:STA

= 1.71V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at

EXT

1 4 MHz

CLK

f

REF

SCL

t

BUF

LOW

HIGH

t

R

t

F

Standard mode 100

Fast mode plus 1000

Standard mode 4.7

Fast mode 1.3

Fast mode plus 0.5

Standard mode 4.0

Fast mode 0.6

Fast mode plus 0.26

Standard mode 4.7

Fast mode 1.3

Fast mode plus 0.5

Standard mode 4.0

Fast mode 0.6

Fast mode plus 0.26

Standard mode 0 0.9

Fast mode 0 0.9

Fast mode plus 0

Standard mode 250

Fast mode plus 50

Standard mode 4.7

Fast mode 0.2

Fast mode plus 0.26

Standard mode (0.3 x VL to 0.7 x VL)

(Note 6)

Fast mode (0.3 x VL to 0.7 x VL) (Note 6)

Fast mode plus 120

Standard mode (0.3 x VL to 0.7 x VL)

(Note 6)

Fast mode (0.3 x VL to 0.7 x VL) (Note 6)

Fast mode plus 120

0.5 35 MHz

20 +

0.1C

20 +

0.1C

20 +

0.1C

20 +

0.1C

B

B

B

B

1000

1000

96 MHz

300

300

MAX3108

kHzFast mode 400

Fs

Fs

Fs

Fs

Fs

nsFast mode 100

Fs

ns

ns

_______________________________________________________________________________________ 9

Page 10

SPI/I2C UART with 128-Word FIFOs in WLP

AC ELECTRICAL CHARACTERISTICS (continued)

(VCC = 1.71V to 3.6V, VL = 1.71V to 3.6V, V

VCC = 2.8V, VL = 1.8V, V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Setup Time for STOP Condition t

= 2.5V, TA = +25NC.) (Note 2)

EXT

SU:STO

MAX3108

Capacitive Load for SDA and

SCL

SCL and SDA I/O Capacitance C

Pulse Width of Spike Suppressed t

SPI BUS: TIMING CHARACTERISTICS (Figure 2)

SCLK Clock Period t

SCLK Pulse Width High t

SCLK Pulse Width Low t

CS Fall to SCLK Rise Time

MOSI Hold Time t

MOSI Setup Time t

Output Data Propagation Delay t

MISO Rise and Fall Times t

CS Hold Time

Note 2: All units are production tested at TA = +25NC. Specifications over temperature are guaranteed by design.

Note 3: Currents entering the IC are positive and currents exiting the IC are negative.

Note 4: When V18 is powered by an external voltage supply, it must have current capability above or equal to I18.

Note 5: Guaranteed by design; not production tested.

Note 6: CB is the total capacitance of either the clock or data line of the synchronous bus in pF.

CH+tCL

= 1.71V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at

EXT

Standard mode 4.7

Fast mode 0.6

Fast mode plus 0.26

Standard mode (Note 5) 400

C

B

Fast mode plus (Note 5) 550

(Note 5) 10 pF

I/O

SP

38.4 ns

CH

t

CSS

DH

DO

t

CSH

CL

DS

FT

16 ns

16 ns

0 ns

3 ns

5 ns

30 ns

Fs

pFFast mode (Note 5) 400

50 ns

20 ns

10 ns

10 _____________________________________________________________________________________

Page 11

SPI/I2C UART with 128-Word FIFOs in WLP

Timing Diagrams

MAX3108

START CONDITION

(S)

SDA

t

HD:STA

SCL

Figure 1. I2C Timing Diagram

CS

t

CSH

SCLK

t

CSS

t

HD:DAT

t

t

DS

t

SU:DAT

HIGH

t

DH

REPEATED START CONDITION

t

SU:STA

t

R

t

CL

t

F

t

CH

(Sr)

t

R

t

HD:STA

t

LOW

t

SU:STO

t

F

STOP CONDITION

t

CSH

(P)

t

BUF

START CONDITION

(S)

MOSI

MISO

t

Figure 2. SPI Timing Diagram

______________________________________________________________________________________ 11

t

DO

FT

Page 12

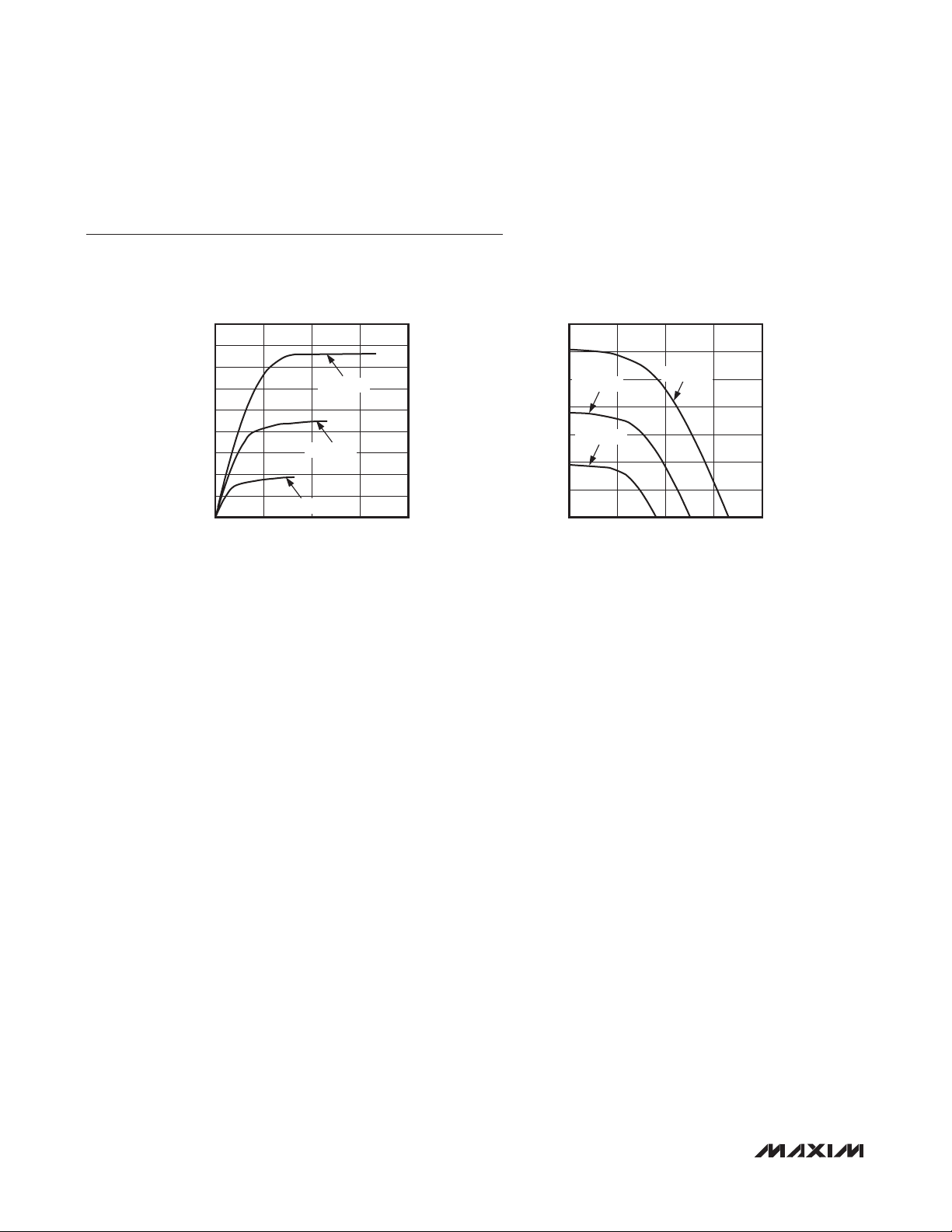

SPI/I2C UART with 128-Word FIFOs in WLP

Typical Operating Characteristics

(VCC = 2.5V, VL = 2.5V, V

= 2.5V, V

EXT

= VL, TA = +25°C unless otherwise noted.)

LDOEN

180

160

MAX3108

(mA)

SINK

I

140

120

100

80

60

40

20

0

SINK CURRENT (OPEN DRAIN)

vs. GPIO_ OUTPUT LOW VOLTAGE

V

= 3.6V

EXT

V

= 2.5V

EXT

V

= 1.71V

EXT

0 4

VOL (V)

321

MAX3108 toc01

SOURCE CURRENT (PUSH-PULL)

vs. GPIO_ OUTPUT HIGH VOLTAGE

70

60

V

= 3.3V

50

V

= 2.5V

EXT

40

(mA)

30

V

= 1.8V

EXT

SOURCE

I

20

10

0

0 4

EXT

VOH (V)

MAX3108 toc02

321

12 _____________________________________________________________________________________

Page 13

SPI/I2C UART with 128-Word FIFOs in WLP

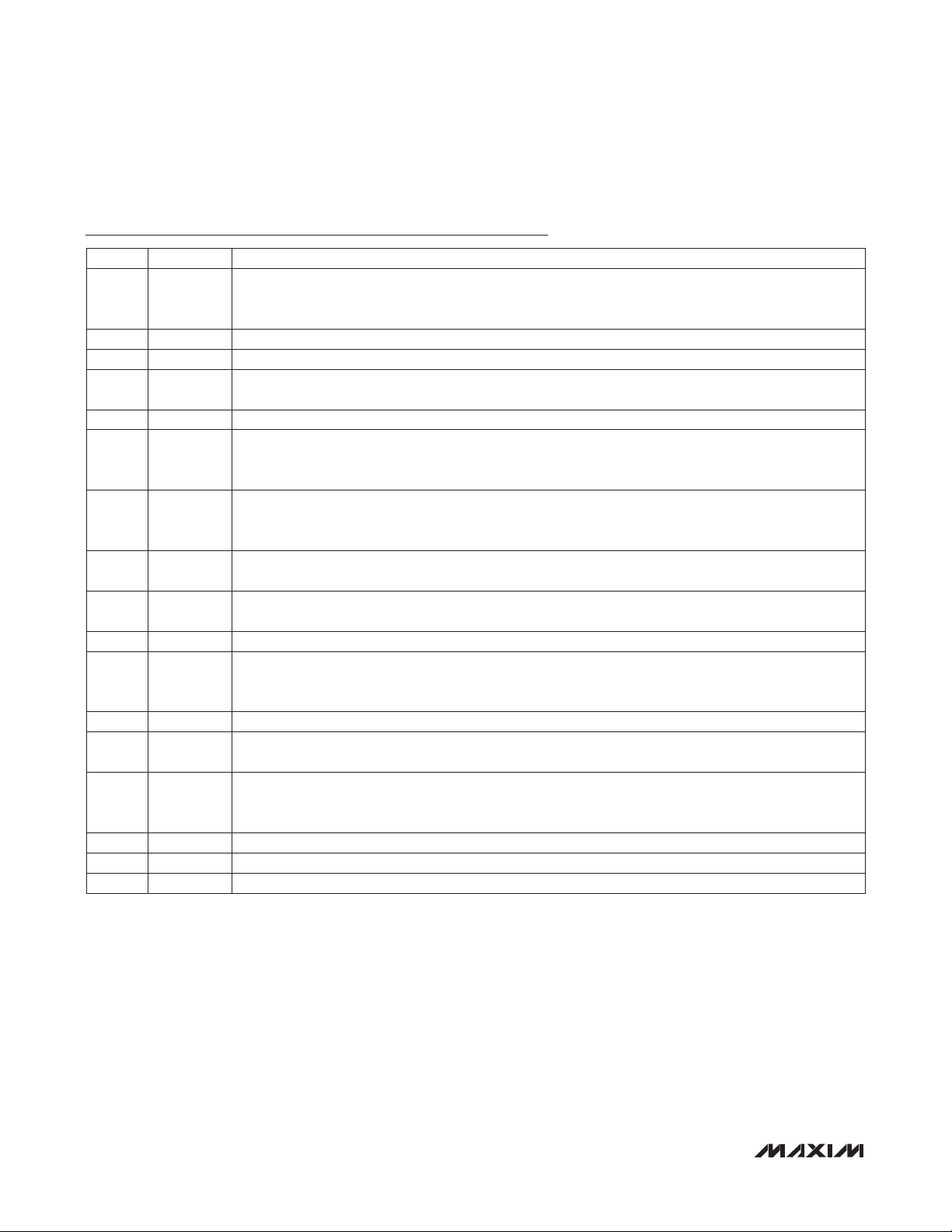

Bump Configuration

TOP VIEW

(BUMPS ON BOTTOM)

+

A

CC

2 3 41

MISO/

SDA

MAX3108

CS/A0 IRQV

5

V

L

MAX3108

B

V

C

D

E

RST

18

LDOEN N.C.

XOUT SPI/I2C GPIO3 CTSXIN

GPIO2 RTS TX

EXT

SCLK/

SCL

MOSI/

A1

GPIO0

DGND

GPIO1AGND

RXV

WLP

(2.1mm × 2.1mm)

Bump Description

BUMP NAME FUNCTION

A1 V

CC

A2 MISO/SDA

A3

A4

A5 V

B1 V

B2

CS/A0

IRQ

L

18

RST

B3 SCLK/SCL

Analog Power Supply. VCC powers the PLL and internal LDO. Bypass VCC with a 0.1FF ceramic capacitor to AGND.

Serial-Data Output. When SPI/I2C is high, MISO/SDA functions as the SPI master input, slave output

(MISO). When SPI/I2C is low, MISO/SDA functions as the SDA, I2C serial-data input/output.

Active-Low Chip-Select and Address 0 Input. When SPI/I2C is high, CS/A0 functions as the CS, SPI

active-low chip-select. When SPI/I2C is low, CS/A0 functions as the A0 I2C device address programming input. Connect CS/A0 to DGND, VL, SCL, or SDA when SPI/I2C is low.

Active-Low Interrupt Open-Drain Output. IRQ is asserted when an interrupt is pending and during initial

power-up.

Digital Interface Power Supply. VL powers the internal logic-level translators for RST, IRQ, MOSI/A1, CS/A0,

SCLK/SCL, MISO/SDA, LDOEN, and SPI/I2C. Bypass VL with a 0.1FF ceramic capacitor to DGND.

Internal 1.8V LDO Output and 1.8V Power-Supply Input. Bypass V18 with a 0.1FF ceramic capacitor to

DGND.

Active-Low Reset Input. Drive RST low to force the UART into hardware reset mode. In hardware reset

mode, the internal PLL is shut down and there is no clock activity.

Serial-Clock Input. When SPI/I2C is high, SCLK/SCL functions as the SCLK SPI serial-clock input (up to

26MHz). When SPI/I2C is low, SCLK/SCL functions as the SCL, I2C serial-clock input (up to 1MHz in fast

mode plus).

______________________________________________________________________________________ 13

Page 14

SPI/I2C UART with 128-Word FIFOs in WLP

Bump Description (continued)

BUMP NAME FUNCTION

Serial-Data Input and Address 1 Input. When SPI/I2C is high, MOSI/A1 functions as the SPI master

B4 MOSI/A1

B5 DGND Digital Ground

C1 AGND Analog Ground

MAX3108

C2 LDOEN

C3 N.C. Not Connected. Internally not connected.

C4 GPIO0

C5 GPIO1

D1 XIN

D2 XOUT

D3

D4 GPIO3

D5

E1 V

E2 GPIO2

E3

E4 TX Serial Transmitting Data Output

E5 RX Serial Receiving Data Input. RX has an internal weak pullup resistor to V

SPI/I2C SPI Selector Input or Active-Low I2C. Drive SPI/I2C low to enable I2C. Drive SPI/I2C high to enable SPI.

CTS Active-Low Clear-to-Send Input. CTS is a flow-control status input.

EXT

RTS Active-Low Request-to-Send Output. RTS can be set high or low by programming the LCR register.

output-slave input (MOSI). When SPI/I2C is low, MOSI/A1 functions as the A1 I2C device address programming input. Connect MOSI/A1 to DGND, VL, SCL, or SDA when SPI/I2C is low.

LDO Enable Input. Drive LDOEN high to enable the internal 1.8V LDO. Drive LDOEN low to disable the

internal LDO. Supply V

General-Purpose Input/Output 0. GPIO0 is user-programmable as an input or output (push-pull or open

drain) or an external event-driven interrupt source. GPIO0 has a weak pulldown resistor to DGND when

configured as an input.

General-Purpose Input/Output 1. GPIO1 is user programmable as an input or output (push-pull or open

drain) or an external event-driven interrupt source. GPIO1 has a weak pulldown resistor to DGND when

configured as an input.

Crystal/Clock Input. When using an external crystal, connect one end of the crystal to XIN and the other

end to XOUT. When using an external clock source, drive XIN with the single-ended external clock.

Crystal Output. When using an external crystal, connect one end of the crystal to XOUT and the other

end to XIN. When using an external clock source, leave XOUT unconnected.

General-Purpose Input/Output 3. GPIO3 is user-programmable as input or output (push-pull or open

drain) or an external event-driven interrupt source. GPIO3 has a weak pulldown resistor to DGND when

configured as an input.

Transceiver Interface Power Supply. V

CTS, and GPIO_. Bypass V

General-Purpose Input/Output 2. GPIO2 is user programmable as input or output (push-pull or open

drain) or an external event-driven interrupt source. GPIO2 has a weak pulldown resistor to DGND when

configured as an input.

with an external voltage source when LDOEN is low.

18

powers the internal logic-level translators for RX, TX, RTS,

EXT

with a 0.1FF ceramic capacitor to DGND.

EXT

EXT

.

14 _____________________________________________________________________________________

Page 15

SPI/I2C UART with 128-Word FIFOs in WLP

Detailed Description

The MAX3108 universal asynchronous receiver-transmitter (UART) bridges an SPI/MICROWIREK or I2C

microprocessor bus to an asynchronous serial-data

communication link. The MAX3108 contains an advanced

UART, a fractional baud-rate generator, and four GPIOs.

Eight-bit registers configure and monitor the MAX3108

and are accessed through SPI or I2C, selectable by an

external pin. The registers are organized by related function as shown in the Register Map section.

The host controller loads data into the Transmit Hold

register (THR) through the SPI or I2C interface. This data

is automatically pushed into the transmit first-in/first-out

(FIFO), formatted, and sent out at TX. The MAX3108

adds START, STOP, and parity bits to the data before

transmitting at the selected baud rate. The clock configuration registers determine the baud rate, clock source,

and clock frequency prescaling.

The MAX3108 receiver detects a START bit as a highto-low transition on RX. An internal clock samples this

data at 16 times the baud rate. The received data is

automatically placed in the receive FIFO and can be

read out by the host microcontroller through the Receive

Hold register (RHR).

The MAX3108’s register set is compatible with the

MAX3107.

levels are programmed through the FIFOTrgLvl register

with a resolution of eight FIFO locations. The receive

FIFO trigger signals to the host either that the receive

FIFO has a defined number of words waiting to be read

out in a block or that a known number of vacant FIFO

locations are available and ready to be filled. The transmit FIFO trigger generates an interrupt when the transmit

FIFO fill level is above the programmed trigger level. The

host then knows to throttle data writing to the transmit

FIFO through THR.

The host can read out the number of words present in each of the FIFOs through the TxFIFOLvl and

RxFIFOLvl registers.

The contents of the TxFIFO and RxFIFO are both cleared

when the MODE2[1]: FIFORst bit is set high.

Transmitter Operation

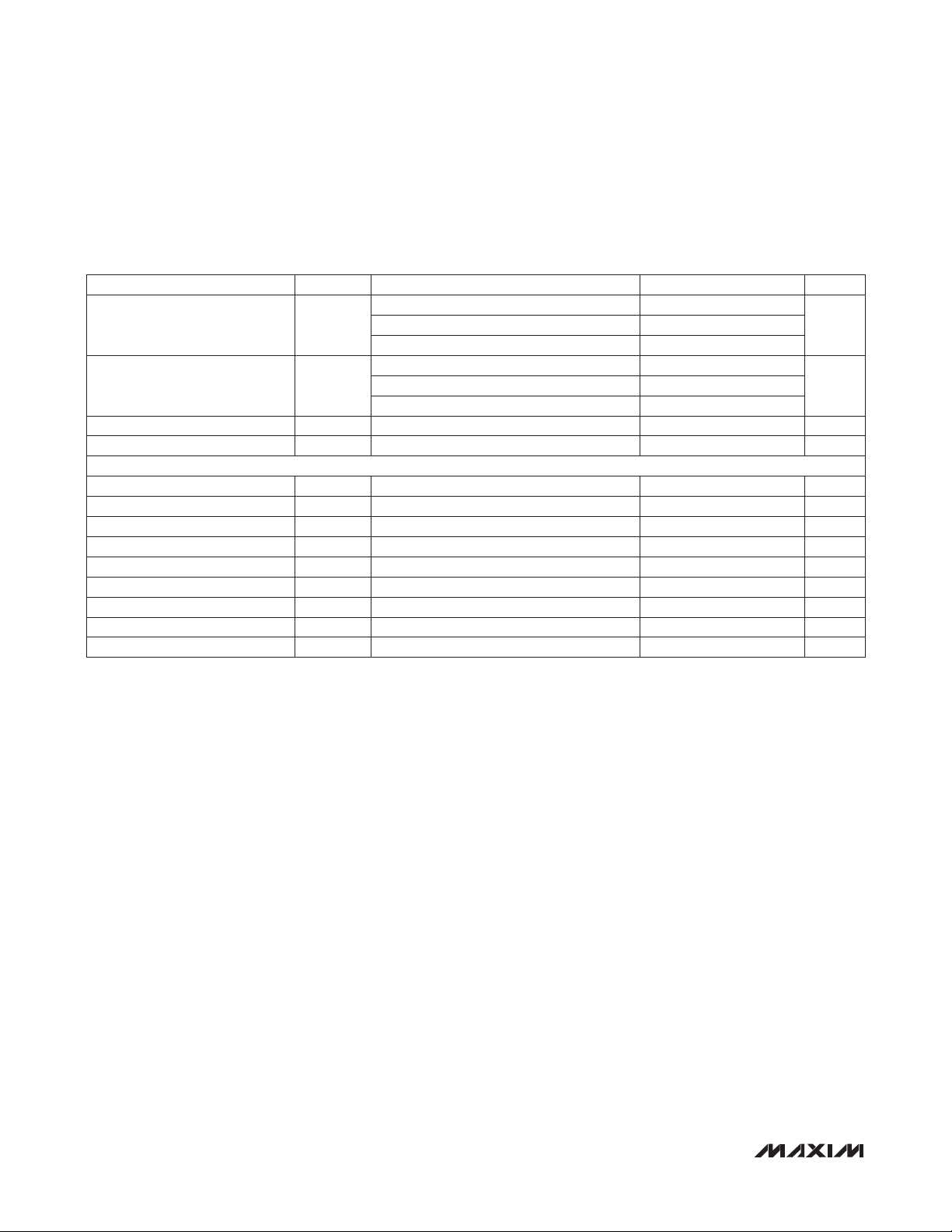

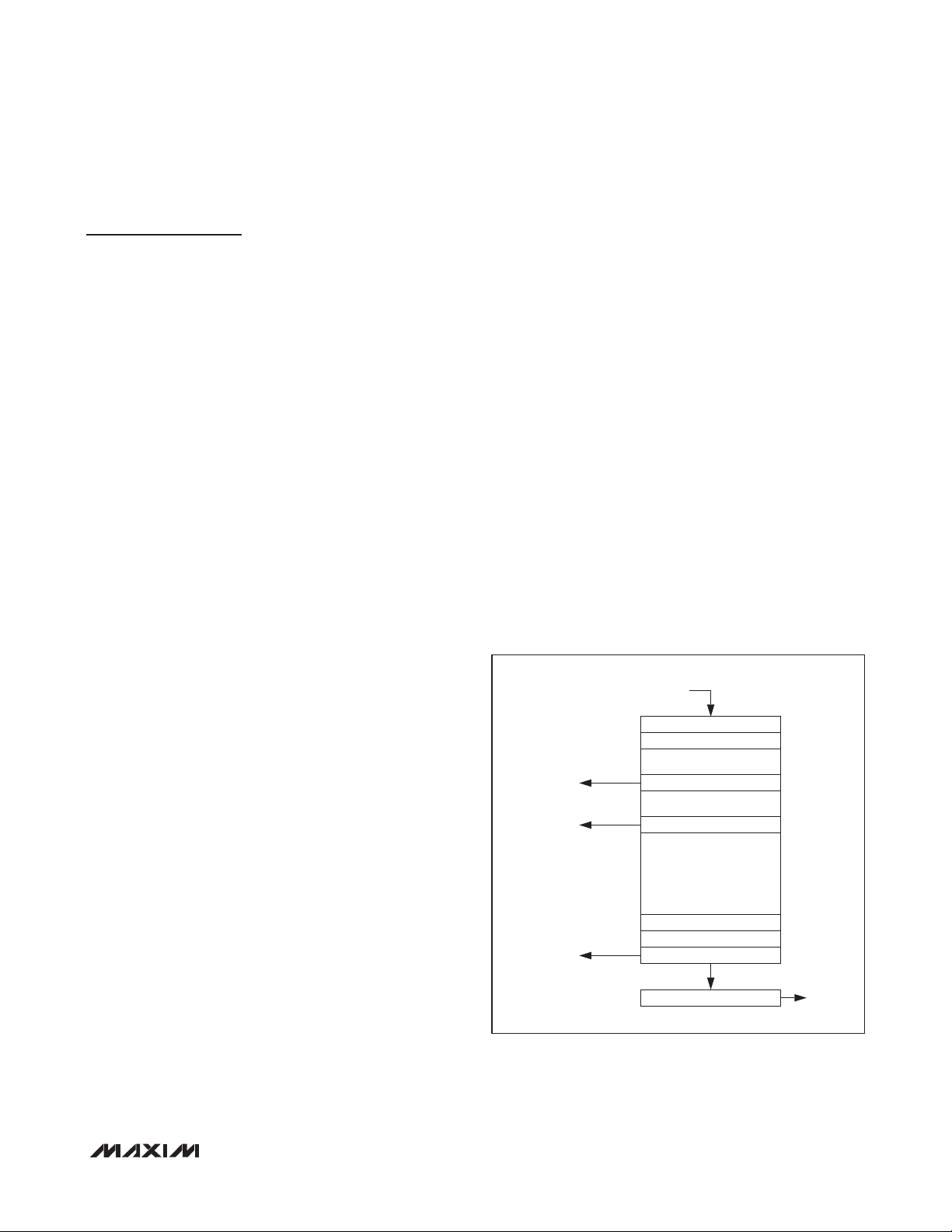

Figure 3 shows the structure of the transmitter with the

TxFIFO. The transmit FIFO can hold up to 128 words of

data that are added by writing to the THR register.

The current number of words in the TxFIFO can be

manually read out by the host controller through the

TxFIFOLvl register. The transmit FIFO fill level can be

2

DATA FROM SPI/I

C INTERFACE

MAX3108

Register Set

The MAX3108 has a flat register structure without shadow

registers. The registers are 8 bits wide. The MAX3108

registers have some similarities to the 16C550 registers.

Receive and Transmit FIFOs

The UART’s receiver and transmitter each have a

128-word-deep FIFO, reducing the number of intervals

that the host processor needs to dedicate for highspeed, high-volume data transfer to and from the device.

As the data rates of the asynchronous RX/TX interfaces

increase and get closer to those of the host controller’s

SPI/I2C data rates, UART management and flow-control

can make up a significant portion of the host’s activity.

By increasing FIFO size, the host is interrupted less often

and can use data block transfers to and from the FIFOs.

FIFO trigger levels can generate interrupts to the host

controller, signaling that programmed FIFO fill levels

have been reached. The transmitter and receiver trigger

MICROWIRE is a trademark of National Semiconductor Corp.

______________________________________________________________________________________ 15

ISR[4]

TxFIFOLvl

ISR[5]

Figure 3. Transmit FIFO Signals

TRIGGER

LEVEL

EMPTY

THR

FIFOTrgLvl[3:0]

CURRENT FILL LEVEL

TRANSMIT FIFO

TRANSMITTER TX

128

3

2

1

Page 16

SPI/I2C UART with 128-Word FIFOs in WLP

LSB

RECEIVED DATA

MIDDATA

SAMPLING

Figure 4. Receive Data Format

START D0 D1 D2 D3 D4 D5 D6 D7 PARITY STOP STOP

MAX3108

RECEIVED

RECEIVER RX

ISR[3]

ISR[6]

OVERRUN

TRIGGER

TIMEOUT

EMPTY

ERRORS

LSR[1]

CURRENT FILL LEVEL

I2C/SPI INTERFACE

LSR[0]

LSR[5:2]

Figure 5. Receive FIFO

programmed to generate an interrupt when more than a

programmed number of words are present in the TxFIFO

through the FIFOTrgLvl register. This TxFIFO interrupt

trigger level is selectable by the FIFOTrgLvl[3:0] bits.

When the transmit FIFO fill level increases beyond the

WORD ERROR 128

FIFOTrgLvl[7:4]

RECEIVE FIFO

RxFIFOLvl

RHR

4

3

2

1

DATA

MSB

programmed trigger level, an interrupt is generated in

ISR[4]: TxTrgInt.

An interrupt is generated in ISR[5]: TFifoEmptyInt when

the transmit FIFO is empty. ISR[5] goes high when

the transmitter starts transmitting the last word in the

TxFIFO. An additional interrupt is generated in STSInt[7]:

TxEmptyInt when the transmitter completes transmitting

the last word.

To halt transmission, set the MODE1[1]: TxDisabl bit

high. After TxDisabl is set, the transmitter completes the

transmission of the current character and then ceases

transmission. Turn the transmitter off prior to enabling

auto software flow control and AutoRTS flow control.

The TX output logic can be inverted through the IrDA[5]:

TxInv bit. Unless otherwise noted, all transmitter logic

described in this data sheet assumes that TxInv is set

low.

Receiver Operation

The receiver expects the format of the data at RX to

be as shown in Figure 4. The quiescent logic state is

logic-high and the first bit (the START bit) is logic-low.

The 8-bit data word expected to be received LSB first.

The receiver samples the data near the midbit instant

(Figure 4). The received words and their associated

errors are deposited into the receive FIFO. Errors and

status information are stored for every received word

(Figure 5). The host reads the data out of the receive

FIFO by reading RHR, which comes out oldest data

first. The status and error information for the word most

recently read from RHR is located in the Line Status

register (LSR). After a word is read out of RHR, LSR

contains the status information for that word.

16 _____________________________________________________________________________________

Page 17

SPI/I2C UART with 128-Word FIFOs in WLP

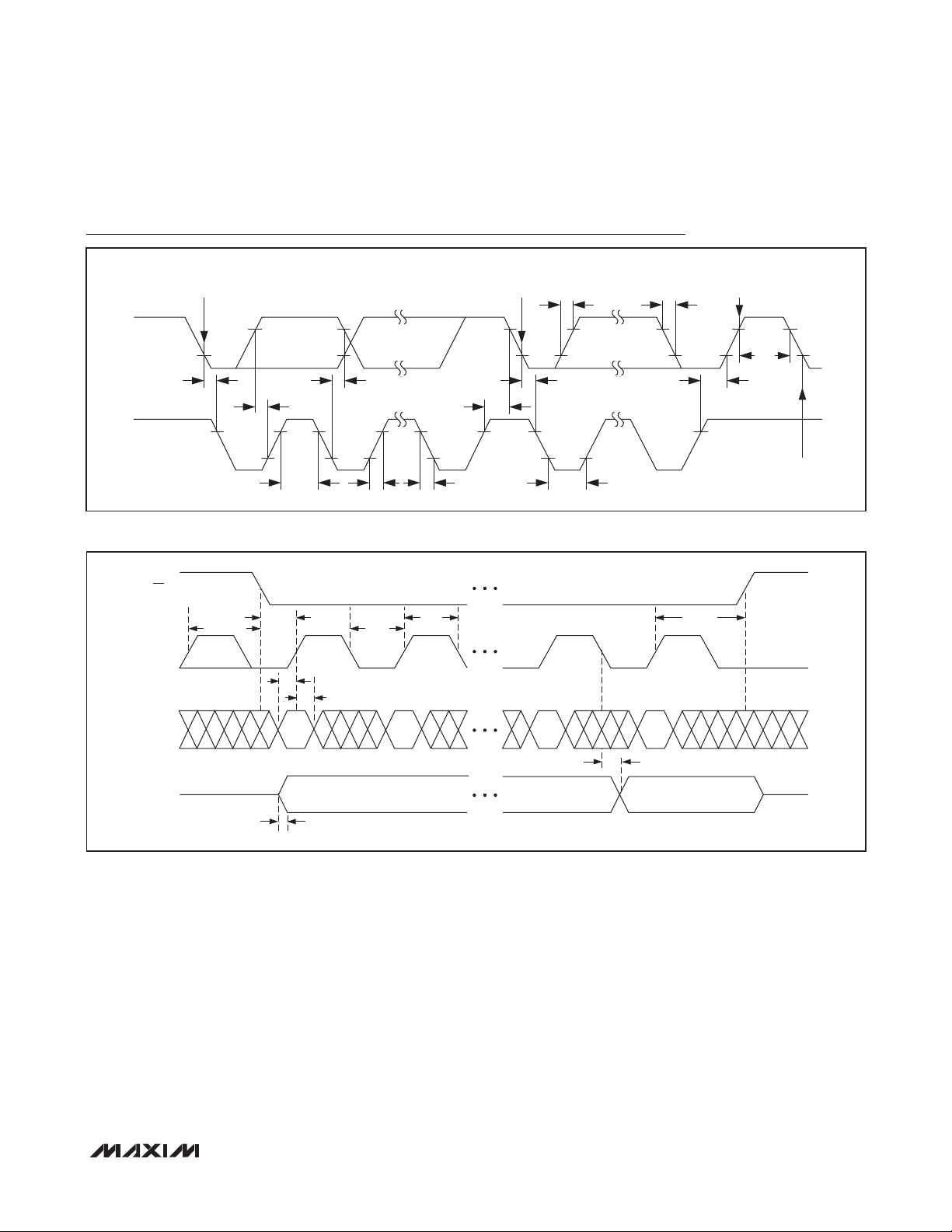

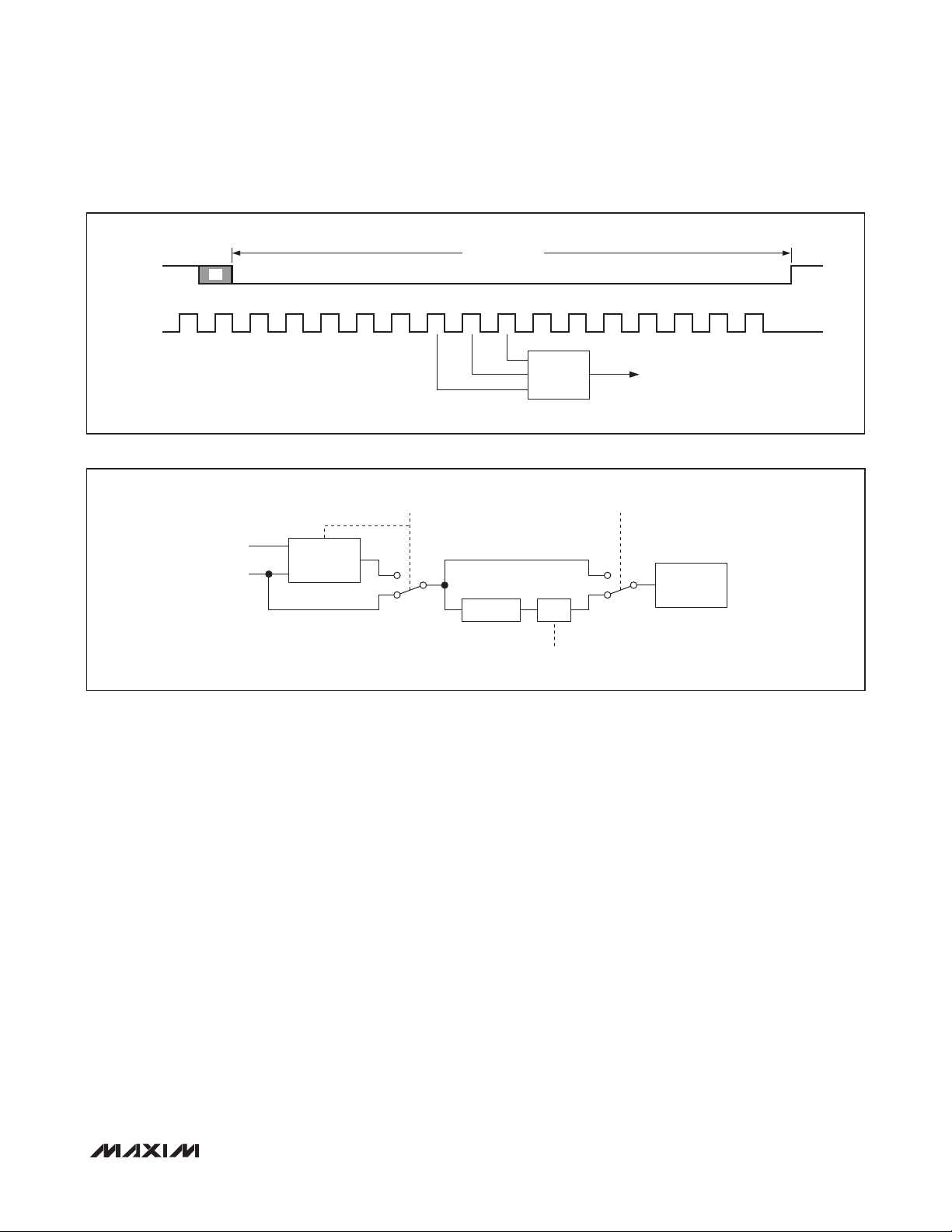

ONE BIT PERIOD

RX

A

MAX3108

BAUD

BLOCK

Figure 6. Midbit Sampling

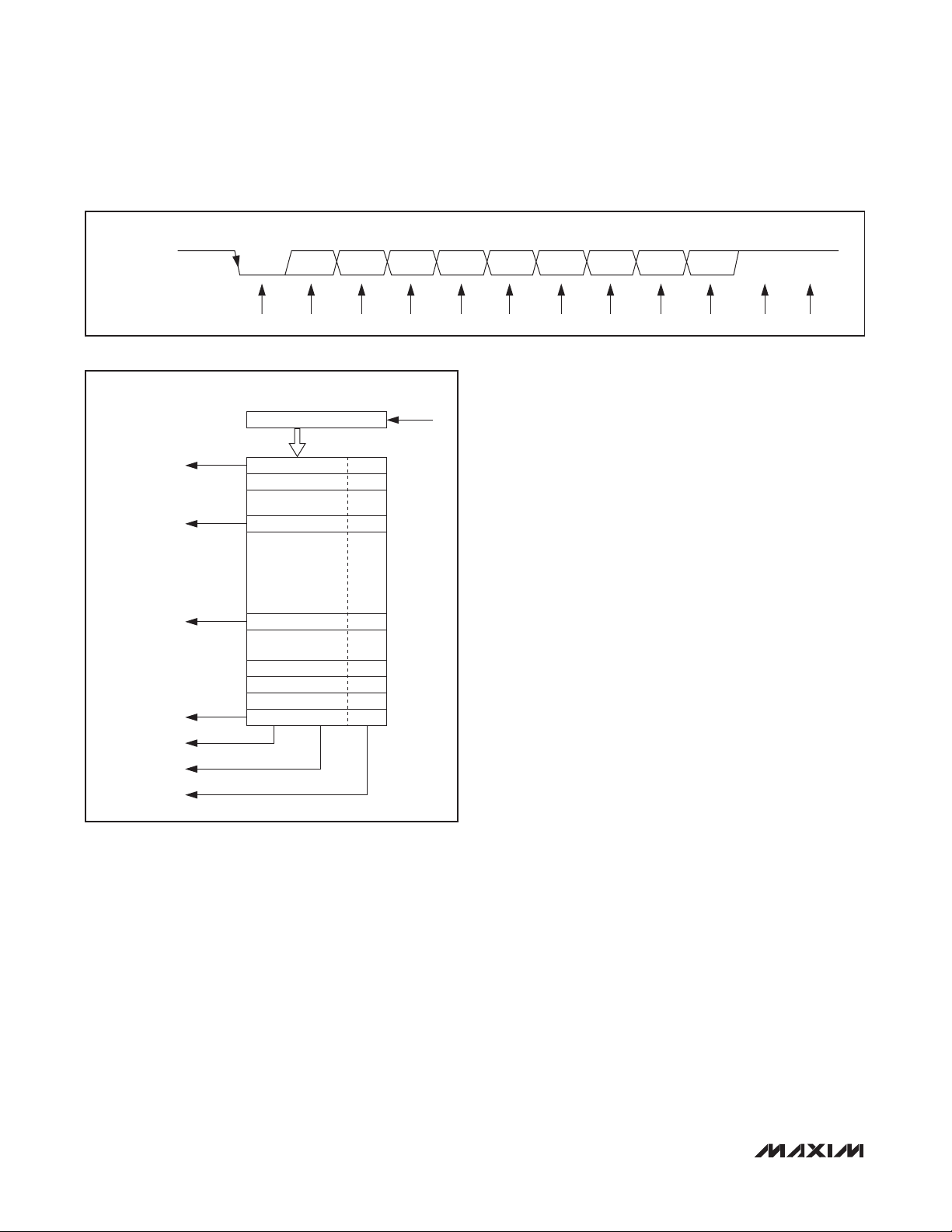

Figure 7. Clock Selection Diagram

1

2 3 4 5 6 7 8 9

CrystalEn

XOUT

XIN

CRYSTAL

OSCILLATOR

The following three error conditions are checked for each

received word: parity error, frame error, and noise on the

line. Parity errors are detected by calculating either even

or odd parity of the received word as programmed by

register settings. Framing errors are detected when the

received data frame does not match the expected frame

format in length. Line noise is detected by checking the

logical congruency of the three samples taken of each

bit (Figure 6).

The receiver can be turned off by setting the MODE1[0]:

RxDisabl bit high. After this bit is set high, the MAX3108

turns the receiver off immediately following the current

word and does not receive any further data.

10 11

MAJORITY

CENTER

SAMPLER

PLLPREDIVIDER

PLLEn

12 13 14 15 16

PLLBypass

BAUD-RATE

GENERATOR

The RX input logic can be inverted by setting the IrDA[4]:

RxInv bit high. Unless otherwise noted, all receiver logic

described in this data sheet assumes that RxInv is set

low.

Line Noise Indication

When operating in standard or 2x (i.e., not 4x) rate mode,

the MAX3108 checks that the binary logic level of the

three samples per received bit are identical. If any of

the three samples per received bit have differing logic

levels, then noise on the transmission line has affected

the received data and it is considered to be noisy. This

noise indication is reflected in the LSR[5]: RxNoise bit for

each received byte. Parity errors are another indication

of noise, but are not as sensitive.

______________________________________________________________________________________ 17

Page 18

SPI/I2C UART with 128-Word FIFOs in WLP

Clock Selection

The MAX3108 can be clocked by either an external

crystal or an external clock source. Figure 7 shows a

simplified diagram of the clock selection circuitry. When

the MAX3108 is clocked by a crystal, the STSInt[5]:

ClkReady bit indicates when the crystal oscillator has

reached steady state and the baud-rate generator is

ready for stable operation.

MAX3108

The baud-rate clock can be routed to the RTS output by

setting the CLKSource[7]: CLKtoRTS bit high. The clock

rate is 16x the baud rate in standard operating mode, 8x

the baud rate in 2x rate mode, and 4x the baud rate in 4x

rate mode. If the fractional portion of the baud-rate generator is used, the clock is not regular and exhibits jitter.

Crystal Oscillator

The MAX3108 is equipped with a crystal oscillator to provide high baud-rate accuracy and low power consumption. Set the CLKSource[1]: CrystalEn bit high to enable

and select the crystal oscillator. The on-chip crystal

oscillator has integrated load capacitances of 16pF in

both the XIN and XOUT pins. Connect only an external

crystal or ceramic oscillator between XIN and XOUT.

External Clock Source

Connect an external single-ended clock source to XIN

when not using the crystal oscillator. Leave XOUT unconnected. Set the CLKSource[1]: CrystalEn bit low to

select external clocking.

PLL and Predivider

The internal predivider and PLL allow for compatibility with

a wide range of external clock frequencies and baud rates.

The PLL can be configured to multiply the input clock

rate by a factor of 6, 48, 96, or 144 by the PLLConfig[7:6]

bits. The predivider is located between the input clock

and the PLL and allows division of the input clock by an

integer factor between 1 and 63. This value is defined

by the PLLConfig[5:0] bits. See the PLLConfig register

description for more information. Use of the PLL requires

VCC to be higher than 2.35V.

Fractional Baud-Rate Generator

The internal fractional baud-rate generator provides a

high degree of flexibility and high resolution in baud-rate

programming. The baud-rate generator has a 16-bit integer divisor and a 4-bit word for the fractional divisor. The

fractional baud-rate generator can be used either with

the crystal oscillator or external clock source.

The integer and fractional divisors are calculated by the

divisor, D:

×

f RateMode

REF

=

D

where f

rate generator, RateMode is the rate mode multiplier (1x

default), BaudRate is the desired baud rate, and D is the

ideal divisor. f

is 1 in 1x rate mode, 2 in 2x rate mode, and 4 in 4x rate

mode.

The integer divisor portion, DIV, of the divisor, D, is

obtained by truncating D:

DIV can be a maximum of 16 bits (65,535) wide and

is programmed into the two single-byte-wide registers

DIVMSB and DIVLSB. The minimum allowed value for

DIVLSB is 1.

The fractional portion of the divisor, FRACT, is a 4-bit

nibble that is programmed into BRGConfig[3:0]. The

maximum value is 15, allowing the divisor to be programmed with a resolution of 0.0625. FRACT is calculated as: FRACT = ROUND(16 x (D - DIV)).

The following is an example of how to calculate the divisor. It is based on a required baud rate of 190kbaud

and a reference input frequency of 28.23MHz and 1x

(default) rate mode.

The ideal divisor is calculated as:

hence DIV = 9.

so DIVMSB = 0x00, DIVLSB = 0x09, and BRGConfig[3:0]

= 0x05.

The resulting actual baud rate can be calculated as:

For this example: D

RateMode = 1, and

BR

ACTUAL

Thus, the actual baud rate is within 0.28% of the ideal

rate.

is the reference frequency input to the baud-

REF

must be less than 96MHz. RateMode

REF

DIV(decimal) = TRUNC(D)

D = 28,230,000/(16 x 190,000) = 9.286

FRACT = ROUND(16 x 0.286) = 5

BR

ACTUAL

= 28,230,000/(16 x 9.3125) = 189,463 baud.

×

16 BaudRate

×

f RateMode

REF

=

×

16 D

ACTUAL

= 9 + 5/16 = 9.3125,

ACTUAL

18 _____________________________________________________________________________________

Page 19

SPI/I2C UART with 128-Word FIFOs in WLP

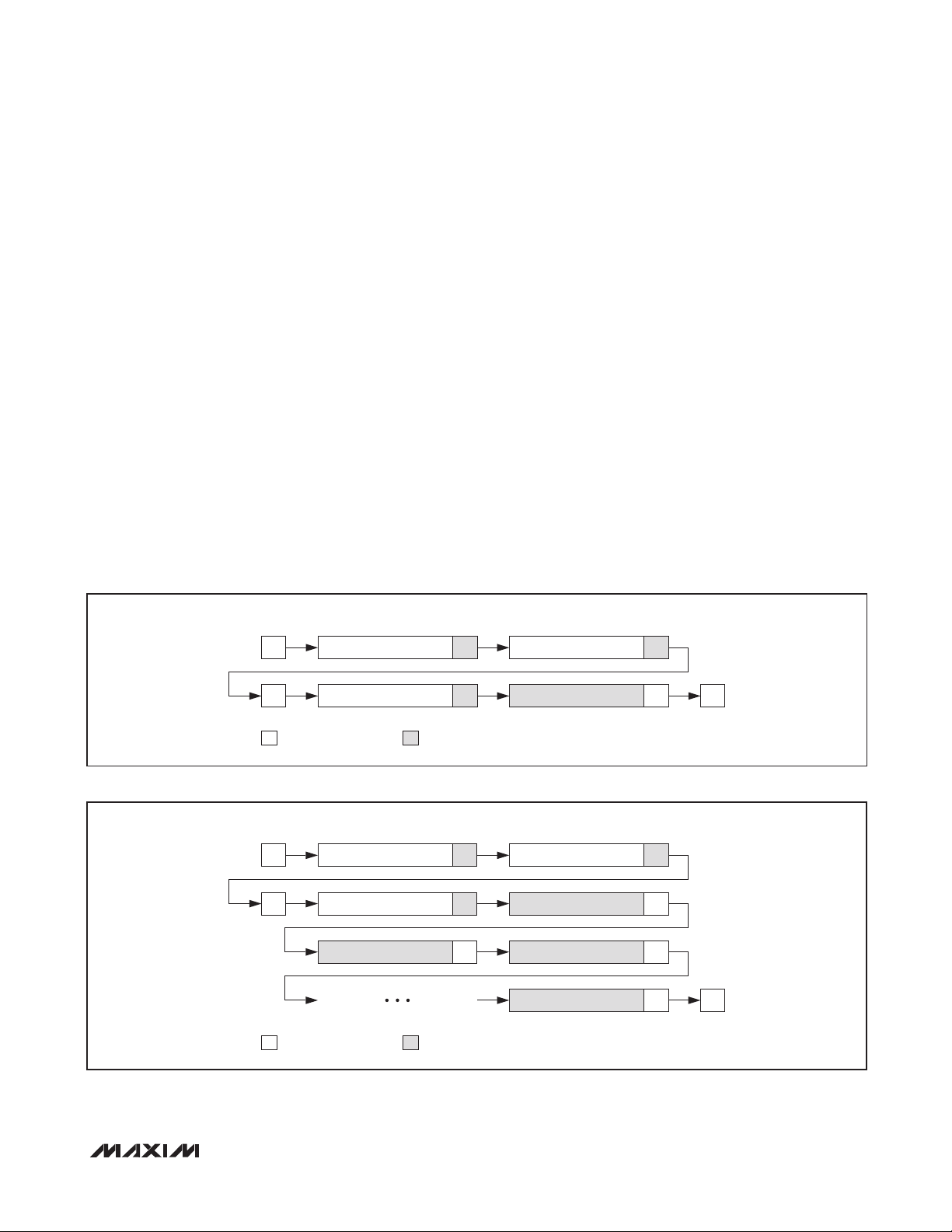

2x and 4x Rate Modes

The MAX3108 offers 2x and 4x rate modes in order to

support higher baud rates than possible with standard

operation using 16x sampling. In these modes, the reference clock rate only needs to be either 8x or 4x higher

than the baud rate, respectively. In 4x rate mode, each

received bit is only sampled once at the midbit instant

instead of the usual three samples to determine the

logic value of the received bit. This reduces the ability to detect line noise on the received data in 4x rate

mode. The 2x and 4x rate modes are selectable through

BRGConfig[5:4]. Note that IrDA encoding and decoding

does not operate in 2x and 4x rate modes.

When 2x rate mode is selected, the actual baud rate is

twice the rate programmed into the baud-rate generator. If 4x rate mode is enabled, the actual baud rate on

the line is quadruple that of the programmed baud rate

(Figure 8).

Multidrop Mode

In multidrop mode, also known as 9-bit mode, the data

word length is 8 bits and a 9th bit is used for distinguishing between an address word and a data word.

Multidrop mode is enabled by the MODE2[6]: MultiDrop

bit. The MultiDrop bit takes the place of the parity bit in

the data word structure. Parity checking is disabled and

an interrupt is generated in SpclCharInt[5]: MultiDropInt

when an address (9th bit is 1) is received while in multidrop mode.

It is up to the host processor to filter out the data intended

for its address. Alternatively, the auto data-filtering feature can be used to automatically filter out the data not

intended for the station’s specific 9-bit mode address.

Auto Data Filtering in Multidrop Mode

MAX3108

In multidrop mode, the MAX3108 can be configured

to automatically filter out data that is not meant for its

address. The address is user-definable either by programming a register value or a combination of a register

value and GPIO hardware inputs. Use either the entire

XOFF2 register or the XOFF2[7:4] bits in combination

with GPIO_ inputs to define the address.

Enable multidrop mode by setting the MODE2[6]:

MultiDrop bit high and enable auto data filtering by setting the MODE2[4]: SpecialChr bit high.

When using register bits in combination with GPIO_

inputs to define the address, the MSB of the address

is written to the XOFF2[7:4] bits, while the LSBs of

the address are defined by the GPIOs. To enable this

address-definition method along with auto data filtering, set the FlowCtrl[2]: GPIAddr bit high in addition to

the MODE2[4]: SpecialChr and MODE2[6]: MultiDrop

bits. The GPIO_ inputs are automatically read when the

FlowCtrl[2]: GPIAddr bit is set high, and the address

is automatically updated on logic changes to any GPIO

pin.

When using auto data filtering, the MAX3108 checks

each received address against the programmed station

address. When an address is received that matches

the station’s address, received data is stored in the

RxFIFO. When an address is received that does not

match the station’s address, received data is discarded.

Addresses are not stored into the FIFO but an interrupt is still generated in SpclCharInt[5]: MultiDropInt

upon receiving an address. An additional interrupt is

generated in SpclCharInt[3]: XOFF2Int when the station

address is received.

Figure 8. 2x and 4x Baud Rates

______________________________________________________________________________________ 19

DIV[LSB]

DIV[MSB]

FRACT

f

REF

NOTE: IrDA DOES NOT WORK IN 2x AND 4x MODES.

FRACTIONAL

RATE

GENERATOR

BRGConfig[5:4]

1x, 2x, 4x RATE

MODES

BAUD RATE

Page 20

SPI/I2C UART with 128-Word FIFOs in WLP

Auto Transceiver Direction Control

In some half-duplex communication systems, the transceiver’s transmitter must be turned off when data is

being received in order to not load the bus. This is the

case in half-duplex RS-485 communication. Similarly, in

full-duplex multidrop communication such as RS-485 or

RS-422 V.11, only one transmitter can be enabled at any

one time while the others must be disabled. The MAX3108

MAX3108

can be configured to automatically enable/disable a transceiver’s transmitter and/or receiver at the hardware level

by controlling its DE and RE pins. This feature relieves the

host processor of this time-critical task.

The RTS output is used to control the transceivers’

transmit-enable input and is automatically set high

TRANSMITTER

TxFIFO

AUTO

MAX3108

TRANSCEIVER

CONTROL

TX

RTS

when the MAX3108’s transmitter starts transmission.

This occurs as soon as data is present in the transmit

FIFO. Auto transceiver direction control is enabled by

the MODE1[4]: TrnscvCtrl bit. Figure 9 shows a typical

MAX3108 connection in an RS-485 application using the

auto transceiver direction control feature.

The RTS output can be set high in advance of TX

transmission by a programmable time period called the

setup time (Figure 10). The setup time is programmed

by the HDplxDelay[7:4]: Setupx bits. Similarly, the RTS

output can be held high for a programmable period

after the transmitter has completed transmission called

the hold time. The hold time is programmed by the

HDplxDelay[3:0]: Holdx bits.

DI

DE

RE

D

MAX14840E

B

A

RxFIFO

RECEIVER

Figure 9. Auto Transceiver Direction Control

RTS

SETUP

TX

FIRST CHARACTER LAST CHARACTER

Figure 10. Setup and Hold times in Auto Transceiver Direction Control

RX

RO

R

HOLD

20 _____________________________________________________________________________________

Page 21

SPI/I2C UART with 128-Word FIFOs in WLP

Echo Suppression

The MAX3108 can suppress echoed data that is sometimes found in half-duplex communication networks,

such as RS-485 and IrDA. If the transceiver’s receiver

is not turned off while the transceiver is transmitting,

copies (echoes) of the transmitted data are received

by the UART. The MAX3108’s receiver can block the

reception of this echoed data by enabling echo suppression. Figure 11 shows a typical RS-485 application

using the echo suppression feature. Set the MODE2[7]:

EchoSuprs bit high to enable echo suppression.

TX

RTS

RX

TxFIFO

RxFIFO

MAX3108

TRANSMITTER

ECHO

SUPPRESSION

RECEIVER

The MAX3108 can also block echoes with a long round

trip delay by disabling the transceiver’s receiver with

the RTS output while the MAX3108 is transmitting. The

transmitter can be configured to remain enabled after

the end of the transmission for a programmable period

of time called the hold time delay (Figure 12). The hold

time delay is set by the HDplxDelay[3:0] bits. See

the HDplxDelay description in the Detailed Register

Descriptions section for more information.

Echo suppression can operate simultaneously with auto

transceiver direction control.

DI

DE

RE

RO

D

MAX14840E

R

B

A

MAX3108

Figure 11. Half-Duplex with Echo Suppression

TX

DI TO RO PROPAGATION DELAY

RX

RTS

Figure 12. Echo Suppression Timing

______________________________________________________________________________________ 21

BIT

HOLD DELAYSTOP

Page 22

SPI/I2C UART with 128-Word FIFOs in WLP

Auto Hardware Flow Control

The MAX3108 is capable of auto hardware (RTS and

CTS) flow control without the need for host proces-

sor intervention. When AutoRTS control is enabled,

the MAX3108 automatically controls the RTS handshake without the need for host processor intervention.

AutoCTS flow control separately turns the MAX3108’s

transmitter on and off based on the CTS input. AutoRTS

MAX3108

and AutoCTS flow control modes are independently

enabled by the FlowCtrl[1:0] bits.

AutoRTS Control

AutoRTS flow control ensures that the receive FIFO

does not overflow by signaling to the far-end UART to

stop data transmission. The MAX3108 does this automatically by controlling the RTS output. AutoRTS flow

control is enabled by setting the FlowCtrl[0]: AutoRTS

bit high. The HALT and RESUME programmable values

determine the threshold RxFIFO fill levels at which RTS

is asserted and deasserted. Set the HALT and RESUME

levels in the FlowLvl register. With differing HALT and

RESUME levels, hysteresis of the RxFIFO level can be

defined for RTS transitions.

When the RxFIFO is filled to a level higher than the HALT

level, the MAX3108 deasserts RTS and stops the far-end

UART from transmitting any additional data. RTS remains

deasserted until the RxFIFO is emptied enough so that

the number of words falls to below the RESUME level.

Interrupts are not generated when the HALT and

RESUME levels are reached. This allows the host controller to be completely disengaged from RTS flow control management.

AutoCTS Control

When AutoCTS flow control is enabled, the UART automatically starts transmitting data when the CTS input

is logic-low and stops transmitting data when CTS is

logic-high. This frees the host processor from managing this time-critical flow-control task. AutoCTS flow

control is enabled by setting the FlowCtrl[1]: AutoCTS

bit high. The ISR[7]: CTSInt interrupt works normally during AutoCTS flow control. Set the IRQEn[7]: CTSIntEn

bit low to disable routing of CTS interrupts to IRQ and

ensure that the host does not receive interrupts from

CTS transitions. If CTS transitions from low to high during

transmission of a data word, the MAX3108 completes the

transmission of the current word and halts transmission

afterwards.

Turn the transmitter off by setting the MODE1[1]: TxDisabl

bit high before enabling AutoCTS control.

Auto Software (XON/XOFF) Flow Control

When auto software flow control is enabled, the MAX3108

recognizes and/or sends predefined XON/XOFF characters to control the flow of data across the asynchronous

serial link. The XON character signifies that there is

enough room in the receive FIFO and transmission of

data should continue. The XOFF character signifies that

the receive FIFO is nearing overflow and that the transmission of data should stop. Auto software flow control

works autonomously and does not require host intervention, similar to auto hardware flow control. To reduce the

chance of receiving corrupted data that equals a singlebyte XON or XOFF character, the MAX3108 allows for

double-wide (16-bit) XON/XOFF characters. The XON

and XOFF characters are programmed into the XON1,

XON2 and XOFF1, XOFF2 registers.

The FlowCtrl[7:3] bits are used for enabling and configuring auto software flow control. An interrupt is generated

in ISR[1]: SpCharInt whenever an XON or XOFF character is received and details are stored in the SpclCharInt

register. Set the IRQEn[1]: SpclChrIEn bit low to disable

routing of the interrupt to IRQ.

Software flow control consists of transmit flow control

and receive flow control, which operate independently

of each other.

Receiver Flow Control

When auto receive flow control is enabled by the

FlowCtrl[7:6] bits, the MAX3108 automatically controls

the transmission of data by the far-end UART by sending XOFF and XON control characters. The HALT and

RESUME levels determine the threshold RxFIFO fill levels

at which the XOFF and XON characters are sent. HALT

and RESUME are programmed in the FlowLvl register.

With differing HALT and RESUME levels, hysteresis can

be defined in the RxFIFO fill level for the receiver flow

control activity.

When the RxFIFO is filled to a level higher than the HALT

level, the MAX3108 sends an XOFF character to stop

data transmission. An XON character is sent when the

RxFIFO is emptied enough so that the number of words

falls to below the RESUME level.

If double-wide (16-bit) XON/XOFF characters are selected by setting the FlowCtrl[7:6] bits to 11, then XON1/

XOFF1 are transmitted before XON2/XOFF2 whenever a

control character is transmitted.

22 _____________________________________________________________________________________

Page 23

SPI/I2C UART with 128-Word FIFOs in WLP

Transmitter Flow Control

If auto transmit control is enabled by the FlowCtrl[5:4]

bits, the receiver compares all received words with the

XOFF and XON characters. When an XOFF character

is received, the MAX3108 halts the transmitter from

sending further data following any currently transmitting

word. The receiver is not affected and continues receiving. Upon receiving an XON character, the transmitter

restarts sending data. The received XON and XOFF

characters are filtered out and are not stored into the

receive FIFO. An interrupt is not generated.

If double-wide (16-bit) XON/XOFF characters are selected by setting the FlowCtrl[5:4] bits to 11, then a character matching XON1/XOFF1 must be received before

a character matching XON2/XOFF2 in order to be interpreted as a control character.

Turn the transmitter off by setting the MODE1[1]: TxDisabl

bit high before enabling software transmitter flow control.

FIFO Interrupt Triggering

Receive and transmit FIFO fill-dependent interrupts are

generated if FIFO trigger levels are defined. When the

number of words in the FIFOs reach or exceed a trigger level programmed in the FIFOTrgLvl register, an

interrupt is generated in ISR[3] or ISR[4]. The interrupt

trigger levels operate independently from the HALT and

RESUME flow control levels in AutoRTS or auto software

flow control modes.

The FIFO interrupt triggering can be used, for example,

for a block data transfer. The trigger level interrupt gives

the host an indication that a given block size of data is

available for reading in the receive FIFO or available for

transfer to the transmit FIFO. If the HALT and RESUME

levels are outside of this range, then the UART continues

to transmit or receive data during the block read/write

operations for uninterrupted data transmission on the

bus.

Low-Power Standby Modes

The MAX3108 has sleep and shutdown modes that

reduce power consumption during periods of inactivity.

In both sleep and shutdown modes, the UART disables

specific functional blocks to reduce power consumption.

After sleep or shutdown mode is exited, the internal clock

starts up and a period of time is needed for clock stabilization. The STSInt[5]: ClkReady bit indicates when the

clocks are stable. When an external clock source is used,

the ClkReady bit does not indicate clock stability.

Forced-Sleep Mode

MAX3108

In forced-sleep mode, all UART-related on-chip clocking is stopped. The following blocks are inactive: the

crystal oscillator, the PLL, the predivider, the receiver,

and the transmitter. The I2C/SPI interface and the registers remain active and the host controller can access

them. To force the MAX3108 to enter sleep mode, set the

MODE1[5]: ForcedSleep bit high. To exit forced-sleep

mode, set the ForcedSleep bit low.

Auto-Sleep Mode

The MAX3108 can be configured to operate in auto-sleep

mode by setting the MODE1[6]: AutoSleep bit high. In

auto-sleep mode, the MAX3108 automatically enters

sleep mode when all the following conditions are met:

• BothFIFOsareempty.

• TherearenopendingIRQ interrupts.

• There is no activity on any input pins for a period

equal to 65,536 UART character lengths.

The same blocks are inactive when the UART is in autosleep mode as in forced-sleep mode.

The MAX3108 exits auto-sleep mode as soon as activity

is detected on any of the GPIO_, RX, or CTS inputs.

To manually exit auto-sleep mode, set the MODE1[6]:

AutoSleep bit low.

Shutdown Mode

Drive the RST input to logic-low to enter shutdown mode.

Shutdown mode consumes the least possible amount

of power. In shutdown mode, all the MAX3108 circuitry

is off except for the 1.8V LDO. This includes the I2C/

SPI interface, the registers, the FIFOs, and the clocking

circuitry.

When the RST input transitions from low to high, the

MAX3108 exits shutdown mode and a hardware reset is

initiated. The chip initialization is complete when the IRQ

output is logic-high.

The MAX3108 needs to be reprogrammed following a

shutdown.

Power-Up and IRQ

The IRQ output has two functions. During normal operation (the MODE1[7]: IRQSel bit is 1), IRQ operates as

a hardware active-low interrupt output; IRQ is asserted

when an interrupt is pending. An IRQ interrupt is only

possible during normal operation if at least one of the

interrupt enable bits in the IRQEn register is set.

______________________________________________________________________________________ 23

Page 24

SPI/I2C UART with 128-Word FIFOs in WLP

During power-up or following a hardware reset, IRQ has

a different function: it is held low during initialization and

deasserts when the MAX3108 is ready for programming. Once IRQ goes high, the MAX3108 is ready to

be programmed through the I2C/SPI interface. Set the

MODE1[7]: IRQSel bit high to enable normal IRQ inter-

rupt operation following a power-up or reset.

In polled mode, any register with a known reset value

MAX3108

can be polled to check whether the MAX3108 is ready for

operation. If the controller gets a valid response from the

polled register, then the MAX3108 is ready for operation.

Interrupt Structure

Figure 13 shows the structure of the interrupt. There are