Page 1

现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

General Description

The MAX2055 evaluation kit (EV kit) simplifies the evaluation of the MAX2055 high-linearity, digitally controlled,

variable-gain analog-to-digital converter (ADC)

driver/amplifier (DVGA). The EV kit is fully assembled

and tested at the factory. Standard 50Ω SMA connectors are included on the EV kit for the input and output

to allow quick and easy evaluation on the test bench.

This data sheet provides a list of equipment required to

evaluate the device, a straightforward test procedure to

verify functionality, a circuit schematic for the kit, a bill

of materials (BOM) for the kit, and artwork for each

layer of the PC board.

Features

♦ Fully Assembled and Tested

♦ 30MHz to 300MHz Frequency Range

♦ -3dB to +20dB Variable Gain

♦ Output IP3: 40dBm (All Gain Settings at 70MHz)

♦ -76dBc 2nd Harmonic

♦ -69dBc 3rd Harmonic

♦ Noise Figure: 5.8dB at Maximum Gain

♦ Digitally Controlled Gain with 1dB Resolution and

±0.2dB Accuracy

♦ Adjustable Bias Currents

Evaluates: MAX2055

MAX2055 Evaluation Kit

________________________________________________________________ Maxim Integrated Products 1

19-2888; Rev 0; 5/03

Component List

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Ordering Information

*EP = Exposed paddle.

Component Suppliers

Note: When contacting these component suppliers, please

specify you are using the MAX2055.

SUPPLIER PHONE WEBSITE

Coilcraft 847-639-6400 www.coilcraft.com

Johnson 507-833-8822 www.johnsoncomponents.com

Murata 770-436-1300 www.murata.com

TOKO 800-745-8656 www.tokoam.com

PART TEMP RANGE IC PACKAGE

MAX2055EVKIT -40°C to +85°C 20 TSSOP-EP*

DESIGNATION QTY DESCRIPTION

C1, C3–C6, C8,

C9, C10, C12

C2, C11 2

C7 1 Not used

R1 1 1.13kΩ ±1% resistor (0603)

R2–R6 5 47kΩ ±5% resistors (0603)

R7 1 10Ω ±5% resistor (0603)

L1, L3 2

L2 1

1000pF ±5%, 50V C0G ceramic

9

capacitors (0603)

Murata GRM1885C1H102J

100pF ±5%, 50V C0G ceramic

capacitors (0603)

Murata GRM1885C1H101J

330nH ±5%, wire-wound inductors

(0603)

Coilcraft 0603LS-331XJBC

100nH ±5%, wire-wound inductor

(0603)

Coilcraft 0603LS-101XJBC

DESIGNATION QTY DESCRIPTION

L4, L5 2

J1, J2 2

J3 1

J4, J5, J6 0 Not installed

T1, T2 2 MiniCircuit TC1-50-4 transformers

U1 1 MAX2055EUP-T

680nH ±5%, wire-wound inductors

(1008)

Coilcraft 1008CS-681XJBC or

TOKO FSLM2520-R68J

PC board edge-mount SMA RF

connectors

(flat-tab launch)

Johnson 142-0741-856

Header 5 x 2 (0.100 spacing for

0.062in thick board)

Molex 10-88-1101 or equivalent

Page 2

Evaluates: MAX2055

MAX2055 Evaluation Kit

2 _______________________________________________________________________________________

Quick Start

The MAX2055 EV kit is fully assembled and factory tested. Follow the instructions in the Connections and

Setup section for proper device evaluation. Table 1 lists

the attenuation setting vs. gain-control bit.

Test Equipment Required

• DC supply capable of delivering 5.25V and 400mA

of continuous current

• HP 8648 (or equivalent) signal source

• HP 8561E (or equivalent) spectrum analyzer capa-

ble of covering the MAX2055’s frequency range, as

well as a few harmonics

• Two digital multimeters (DMMs) to monitor VCCand

ICC, if desired

• HP 8753D (or equivalent) network analyzer to measure return loss and gain

• Filters to attenuate harmonic output of signal sources,

if harmonic measurements are desired

Connections and Setup

This section provides a step-by-step guide to testing

the basic functionality of the EV kit. As a general precaution to prevent damaging the outputs by driving

high-VSWR loads, do not turn on DC power or RF

signal generators until all connections are made.

Gain Setting

Connect the header pins for B4–B0 to GND for maximum gain (20dB typ). See Table 1 for other gainsetting configurations. To set a logic high on B4–B0,

leave the respective header pin unconnected as onboard resistors pull up the logic to +5V. To control

B4–B0 using external logic (voltage limits per the data

sheet), ensure that +5V is applied to the chip. Failure

to do so can cause the on-chip ESD diodes to draw

significant current and can damage the part.

Testing the Supply Current

1) Connect 50Ω terminations to RF_IN and RF_OUT.

2) With the DC supply disabled, set it to +5.0V (through

a low internal resistance ammeter, if desired) and

connect to the +5V and GND terminals on the EV kit.

If available, set the current limit to 400mA.

3) Enable the DC supply; the supply current should

read approximately 250mA.

Testing the Power Gain

1) Connect the RF signal generator to the RF_IN SMA

connector. Do not turn on the generator’s output. Set

the generator to an output frequency of 70MHz, and

set the generator power level to -15dBm.

2) Connect the spectrum analyzer to the RF_OUT SMA

connector. Set the spectrum analyzer to a center frequency of 70MHz and a total span of 1MHz.

3) With the DC supply disabled, set it to +5.0V (through

a low internal-resistance ammeter, if desired) and

connect to the +5V and GND terminals on the EV kit.

If available, set the current limit to 400mA.

4) Connect B4–B0 to GND for 0dB attenuation.

5) Enable the DC supply, and then activate the RF generator’s output. A 70MHz signal shown on the spec-

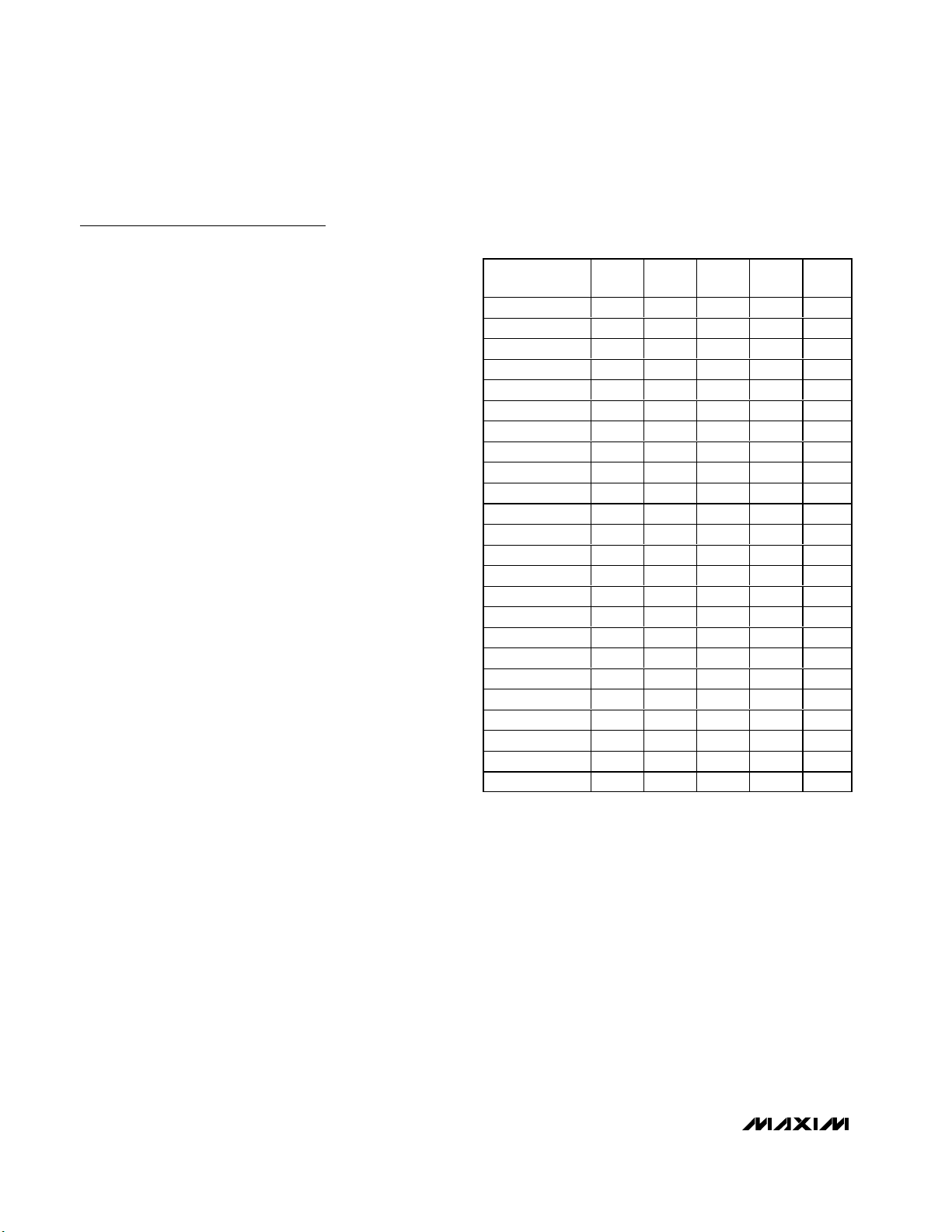

Table 1. Attenuation Setting vs. GainControl Bits

*Enabling B4 disables B3 and the minimum attenuation is

16dB.

ATTENUATION

(dB)

0 00000

1 00001

2 00010

3 00011

4 00100

5 00101

6 00110

7 00111

8 01000

9 01001

10 0 1 0 1 0

11 0 1 0 1 1

12 0 1 1 0 0

13 0 1 1 0 1

14 0 1 1 1 0

15 0 1 1 1 1

16 1X 000

17 1X 001

18 1X 010

19 1X 011

20 1X 100

21 1X 101

22 1X 110

23 1X 111

B4

(16dB)

B3*

(8dB)B2(4dB)B1(2dB)B0(1dB)

Page 3

trum analyzer display should indicate a magnitude

of approximately 5dBm. Be sure to account for

external cable losses.

6) (Optional) Gain can be determined with a network

analyzer. This has the advantage of displaying gain

over a swept frequency band, in addition to displaying input and output return loss. Refer to the network

analyzer manufacturer’s user manual for setup

details.

Detailed Description

Figure 1 shows the schematic for the MAX2055 EV kit.

The EV kit is matched for operation up to 300MHz.

Capacitors C1, C4, C5, C8, and C9 are DC-blocking

capacitors for the RF_IN, ATTN

OUT

, and RF_OUT ports.

To reduce the possibility of noise pickup, capacitors

C2, C3, C10, C11, and C12 form the VCCdecoupling

network. Inductors L1–L5 provide a method of biasing.

Inductor L2 needs to handle the total IC current and

have a DC resistance that is less than 0.2Ω. If the DC

resistance is higher than 0.2Ω, the value of R1 may

need to be adjusted down to maintain the nominal

operating current. Inductors L4 and L5 are nonmagnetic coils that provide the output supply bias for the

amplifier. Transformer T1 is used to convert the singleended attenuator output to a differential signal. This

technique results in an improved 2nd harmonic performance for the device. The amplifier can be driven single

ended if the improved 2nd harmonic is not required

(see Modifying the EV Kit section). Output transformer

T2 enables single-ended measurements, in addition to

providing common-mode rejection for the 2nd harmonic. Resistor R7 helps reduce video leakage during

switching. Replace R7 with a 0Ω resistor if video leakage is not a concern.

Modifying the EV Kit

The EV kit is easily configured for other topologies.

For a single-ended amplifier input:

1) Remove T1 and place a low-inductance short circuit

between the T1 surface-mount pads that connect

capacitors C4 to C5.

2) Add a 1000pF 0603 case style capacitor for C7.

3) Change L2 to the same style and value inductor as

L1 (330nH) noted in the Component List.

4) Change R1 to 909Ω (to adjust the DC current to

compensate for the higher L2 resistance).

Note: In this configuration, C6 is not required.

The EV kit also provides the ability for additional methods

of testing by adding in the option for an interstage RF

connection along with differential RF output connections.

Layout Considerations

The MAX2055 evaluation boards can be used as a guide

for your board layout. Give close attention to thermal

design and close placement of parts to the IC. The

MAX2055 package exposed paddle (EP) conducts heat

out of the part and provides a low-impedance electrical

connection. The EP must be attached to the PC board

ground plane with a low thermal and electrical-impedance contact. Ideally, this is provided by soldering the

backside package contact directly to a top metal ground

plane on the PC board. Alternatively, the EP can be connected to a ground plane using an array of plated vias

directly below the EP. The MAX2055 EV kit uses eight

evenly spaced, 0.016in-diameter, plated through holes to

connect the EP to the lower ground planes.

Depending on the RF ground plane spacing, large surface-mount pads in the RF path may need to have the

ground plane relieved under them to reduce shunt

capacitance.

Evaluates: MAX2055

MAX2055 Evaluation Kit

_______________________________________________________________________________________ 3

Page 4

Evaluates: MAX2055

MAX2055 Evaluation Kit

4 _______________________________________________________________________________________

Figure 1. MAX2055 EV Kit Schematic

5V

1

U1

20

J4

C2C3

RF_IN

5V

R3R2 R4 R5 R6

B3

B2

B1

B0

R7

5V

J1 C1

B4

C11C12

J5

10

2

3

4

5

6

7

8

9

B4

B3

B2

B1

B0

RF_OUT-

L5

ATTENUATION

LOGIC

CONTROL

EXPOSED

PADDLE

MAX2055

ATTN

19

OUT

C4

18

I

SET

AMPIN

C

BP

I

BIAS

RF_OUT+

5V

L4

R1

17

C5

16

15

L2

14

13

L3

12

11

J6

C6

T1

1

L1

C7

C8 C9

+5V GND B0 B2 B4

J3-2 J3-4 J3-6 J3-8 J3-10

J3-1 J3-3 J3-5 J3-7 J3-9

GND B1 B3

C10

1

T2

RF_OUT

J2

Page 5

Evaluates: MAX2055

MAX2055 Evaluation Kit

_______________________________________________________________________________________ 5

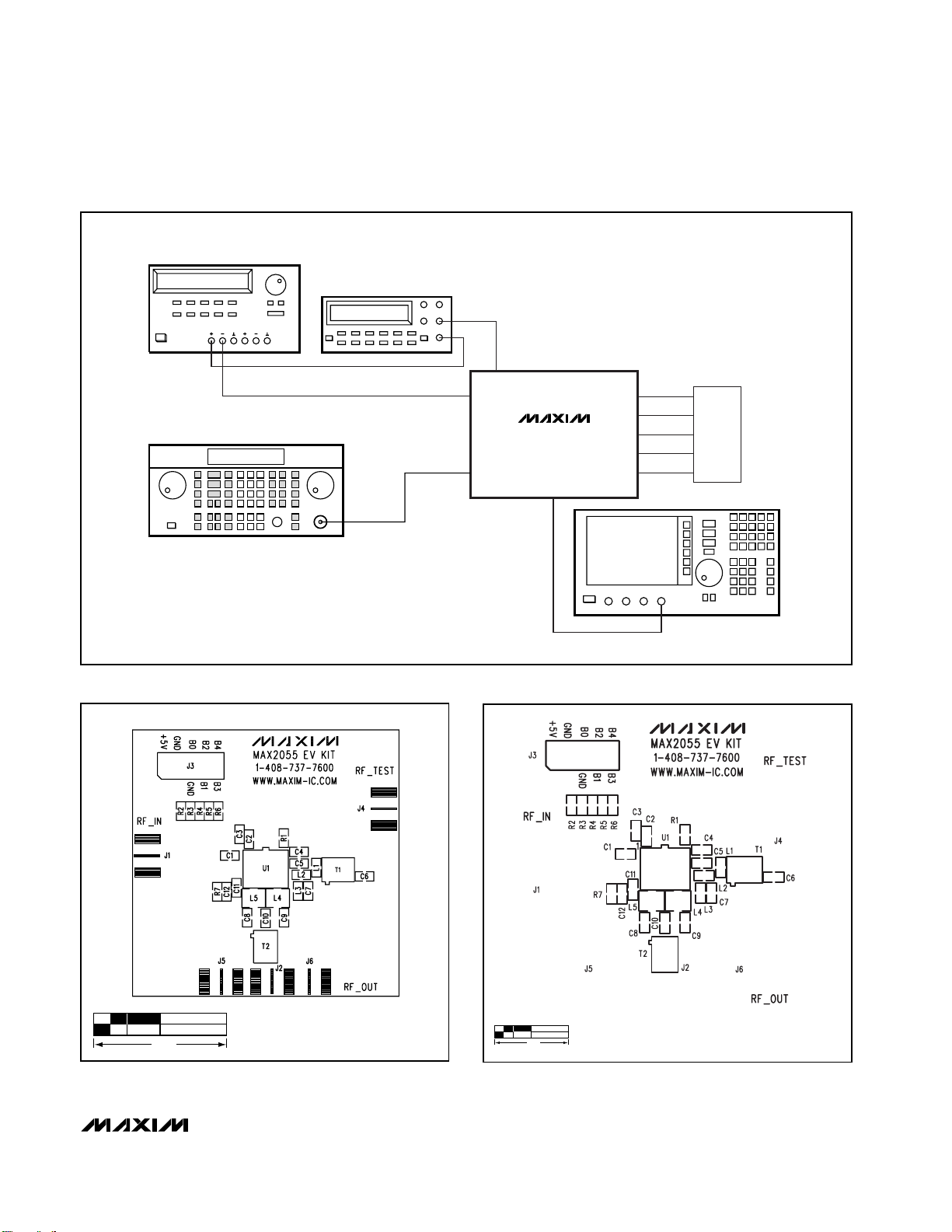

Figure 2. Test Setup Diagram

Figure 3. MAX2055 EV Kit Component Placement Guide—

Component Side

Figure 4. MAX2055 EV Kit PC Board Layout—Top Silkscreen

POWER SUPPLY

3-OUT, HPIB

(AG E3631A)

RF SIGNAL GENERATOR

(HP 8648D)

BENCH

MULTIMETER HPIB

(HP 34401A)

+5V

GND

RF_IN

MAX2055 EVKIT

RF_OUT

B4

B3

B2

B1

B0

CONTROL

INPUTS

RF SPECTRUM ANALYZER

(HP 856xE)

1.0"

1.0"

Page 6

Evaluates: MAX2055

MAX2055 Evaluation Kit

6 _______________________________________________________________________________________

Figure 8. MAX2055 EV Kit PC Board Layout—Route Layer

(Layer 3)

Figure 5. MAX2055 EV Kit PC Board Layout—Bottom

Silkscreen

Figure 6. MAX2055 EV Kit PC Board Layout—Primary

Component Side

Figure 7. MAX2055 EV Kit PC Board Layout—GND Layer

(Layer 2)

1.0"

1.0"

1.0"

1.0"

Page 7

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 _____________________ 7

© 2003 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Evaluates: MAX2055

MAX2055 Evaluation Kit

Figure 9. MAX2055 EV Kit PC Board Layout—Secondary Side

Figure 10. MAX2055 EV Kit PC Board Layout—Top Solder Mask

Figure 11. MAX2055 EV Kit PC Board Layout—Bottom Solder

Mask

1.0"

1.0"

1.0"

Loading...

Loading...