General Description

The MAX1964/MAX1965 power-supply controllers are

designed to address cost-sensitive applications

demanding voltage sequencing/tracking, such as

cable modem consumer premise equipment (CPE),

xDSL CPE, and set-top boxes. Operating off a low-cost,

unregulated DC supply (such as a wall adapter output),

the MAX1964 generates three positive outputs and the

MAX1965 generates four positive outputs and one negative output to provide an inexpensive system power

supply.

The MAX1964 includes a current-mode synchronous

step-down controller and two positive regulator gain

blocks. The MAX1965 has one additional positive gain

block and one negative regulator gain block. The main

synchronous step-down controller generates a highcurrent output that is preset to 3.3V or adjustable from

1.236V to 0.75 ✕VINwith an external resistive-divider.

The 200kHz operating frequency allows the use of lowcost aluminum-electrolytic capacitors and low-cost

power magnetics. Additionally, the MAX1964/MAX1965

step-down controllers sense the voltage across the lowside MOSFET’s on-resistance to efficiently provide the

current-limit signal, eliminating the need for costly current-sense resistors.

The MAX1964/MAX1965 generate additional supply

rails at low cost. The positive regulator gain blocks use

an external PNP pass transistor to generate low voltage

rails directly from the main step-down converter (such

as 2.5V or 1.8V from the main 3.3V output) or higher

voltages using coupled windings from the step-down

converter (such as 5V, 12V, or 15V). The MAX1965’s

negative gain block uses an external NPN pass transistor in conjunction with a coupled winding to generate

-5V, -12V, or -15V.

All output voltages are externally adjustable, providing

maximum flexibility. During startup, the MAX1964 features voltage sequencing and the MAX1965 features

voltage tracking. Both controllers provide a powergood output that monitors all of the output voltages.

Applications

xDSL, Cable, and ISDN Modems

Set-Top Boxes

Wireless Local Loop

Features

♦ 4.5V to 28V Input Voltage Range

♦ Master DC-DC Step-Down Converter:

Preset 3.3V or Adjustable (1.236V to 0.75 x V

IN

)

Output Voltage

Fixed Frequency (200kHz) PWM Controller

No Current-Sense Resistor

Adjustable Current Limit

95% Efficient

Soft-Start

♦ Two (MAX1964)/Four (MAX1965) Analog Gain

Blocks:

Positive Analog Blocks Drive Low-Cost PNP

Pass Transistors to Build Positive Linear

Regulators

Negative Analog Block (MAX1965) Drives a

Low-Cost NPN Pass Transistor to Build a

Negative Linear Regulator

♦ Power-Good Indicator

♦ Voltage Sequencing (MAX1964) or Tracking

(MAX1965)

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

________________________________________________________________ Maxim Integrated Products 1

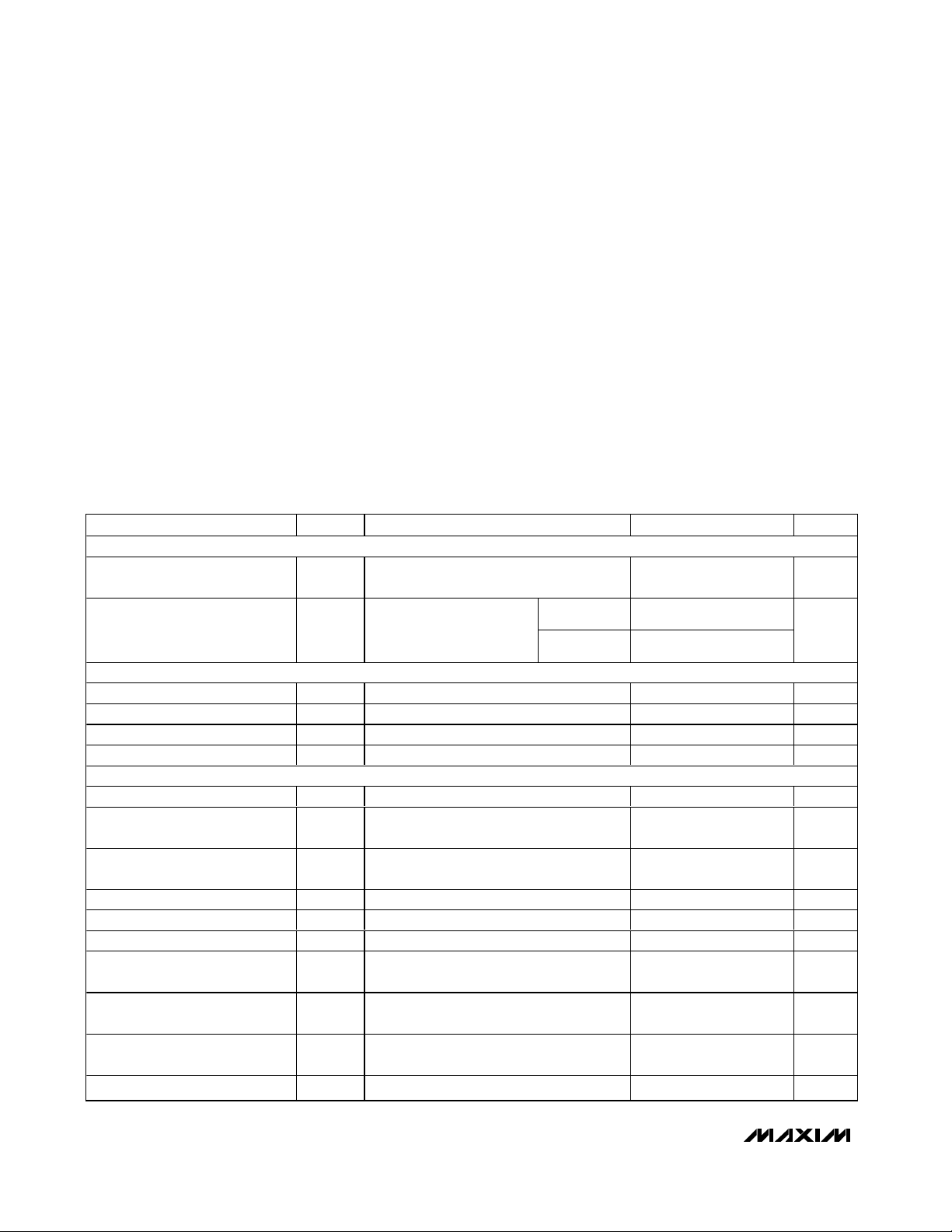

Pin Configurations

19-2084; Rev 0; 7/01

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Typical Operating Circuit appears at end of data sheet.

Ordering Information

PA RT

MAX1964TEEE

MAX1965TEEP

TEMP.

RANGE

-40°C to +85°C

-40°C to +85°C

PINPACKAGE

16 QSOP 200

20 QSOP 200

TOP VIEW

1

POK IN

COMP

2

OUT

3

MAX1964

4

FB

B2

5

FB2

6

B3

7

FB3

8

16-Pin QSOP

16

15

VL

14

BST

13

DH

12

LX

DL

11

10

GND

9

ILIM

POK

COMP

OUT

FB2

FB3

1

2

3

4

FB

5

B2

6

7

B3

8

9

B4

10

MAX1965

20-Pin QSOP

f

OSC

(kHz)

20

19

18

17

16

15

14

13

12

11

IN

VL

BST

DH

LX

DL

GND

ILIM

FB5

B5FB4

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, B2, B3, B4 to GND............................................-0.3V to +30V

B5 to OUT...............................................................-20V to +0.3V

VL, POK, FB, FB2, FB3, FB4, FB5 to GND ...............-0.3V to +6V

LX to BST..................................................................-6V to +0.3V

BST to GND ............................................................-0.3V to +36V

DH to LX....................................................-0.3V to (V

BST

+ 0.3V)

DL, OUT, COMP, ILIM to GND......................-0.3V to (V

L

+ 0.3V)

VL Output Current ...............................................................50mA

VL Short Circuit to GND..................................................≤ 100ms

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.3mW/°C above +70°C)...........666mW

20-Pin QSOP (derate 9.1mW/°C above +70°C)...........727mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

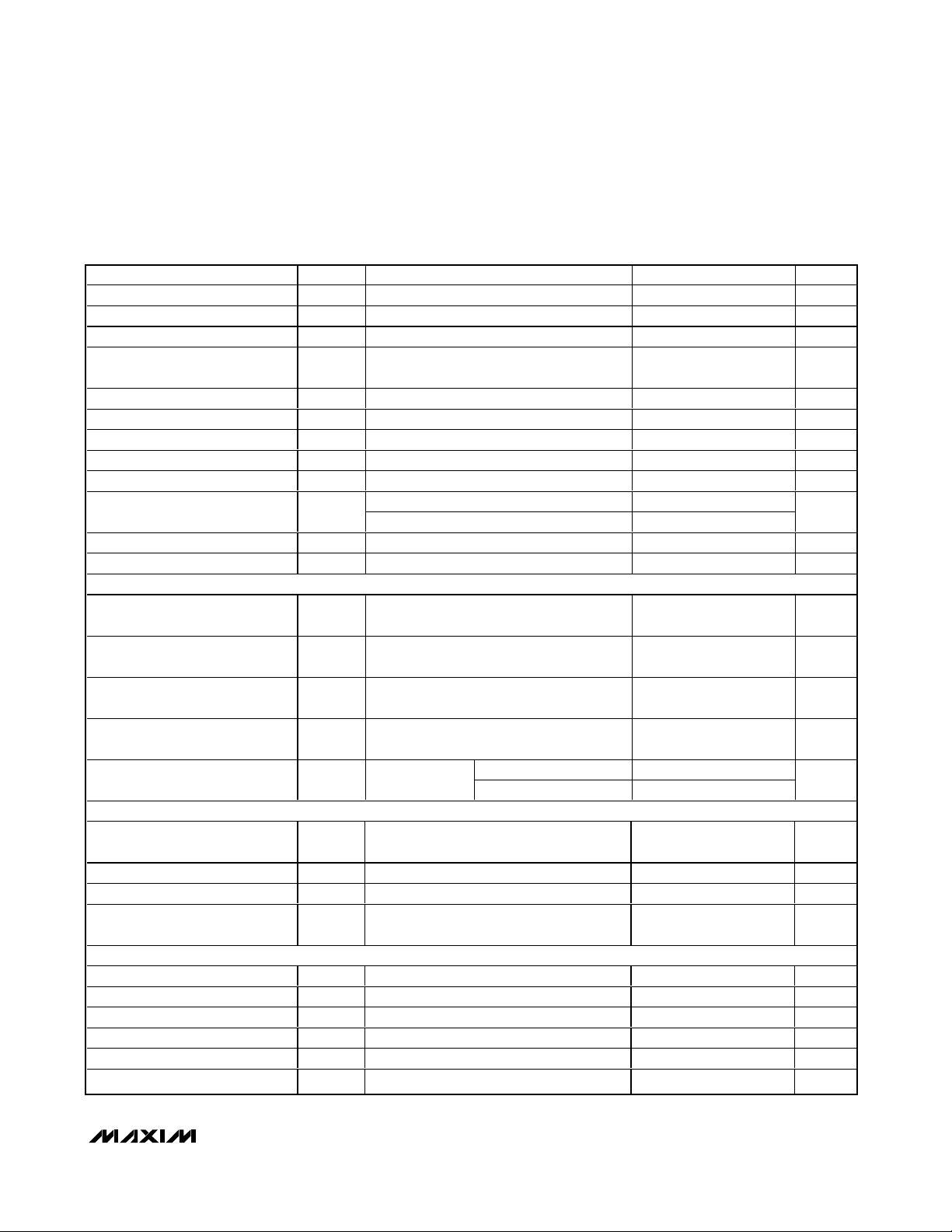

ELECTRICAL CHARACTERISTICS

(VIN= 12V, ILIM = FB = GND, V

BST

- VLX= 5V, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

)

Dual Mode is a trademark of Maxim Integrated Products, Inc.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

GENERAL

Operating Input Voltage Range

(Note 1)

V

IN

4.5 28 V

VFB = 0, V

Quiescent Supply Current I

VL REGULATOR

Output Voltage VL 6V < VIN < 28V, 0.1mA < I

Line Regulation VIN = 6V to 28V 3.0 %

Undervoltage Lockout Trip Level V

Minimum Bypass Capacitance C

DC-DC CONTROLLER

Output Voltage (Preset Mode) V

Typical Output Voltage Range

(Adjustable Mode) (Note 2)

FB Set Voltage (Adjustable

Mode)

FB Dual-Mode™ Threshold 50 100 150 mV

FB Input Leakage Current I

FB to COMP Transconductance g

Current-Sense Amplifier Voltage

Gain

Current-Limit Threshold

(Internal Mode)

Current-Limit Threshold

(External Mode)

Switching Frequency f

IN

UVLO

BYP(MIN

OUT

V

OUT

V

SET

FB

A

LIM

V

VALLEYVILIM

V

VALLEYVILIM

OSC

V

= V

FB2

= -0.1V

V

FB5

VL rising, 3% hysteresis (typ) 3.2 3.5 3.8 V

10mΩ < ESR < 500mΩ 1 µF

FB = GND 3.272 3.34 3.355 V

FB = COMP 1.221 1.236 1.252 V

VFB = 1.5V 0.01 100 nA

FB = COMP, I

m

VIN - VLX = 250mV 4.46 4.9 5.44 V/V

= 5.0V 190 250 310 mV

= 2.5V 440 530 620 mV

FB3

OUT

= 4V,

= V

= 1.5V,

FB4

= ±5µA 70 100 140 µS

COMP

MAX1964 1.25 2.5

MAX1965 1.5 3.0

<20mA 4.75 5.00 5.25 V

LOAD

V

SET

160 200 240 kHz

0.75 ✕ V

mA

IN

V

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

_______________________________________________________________________________________ 3

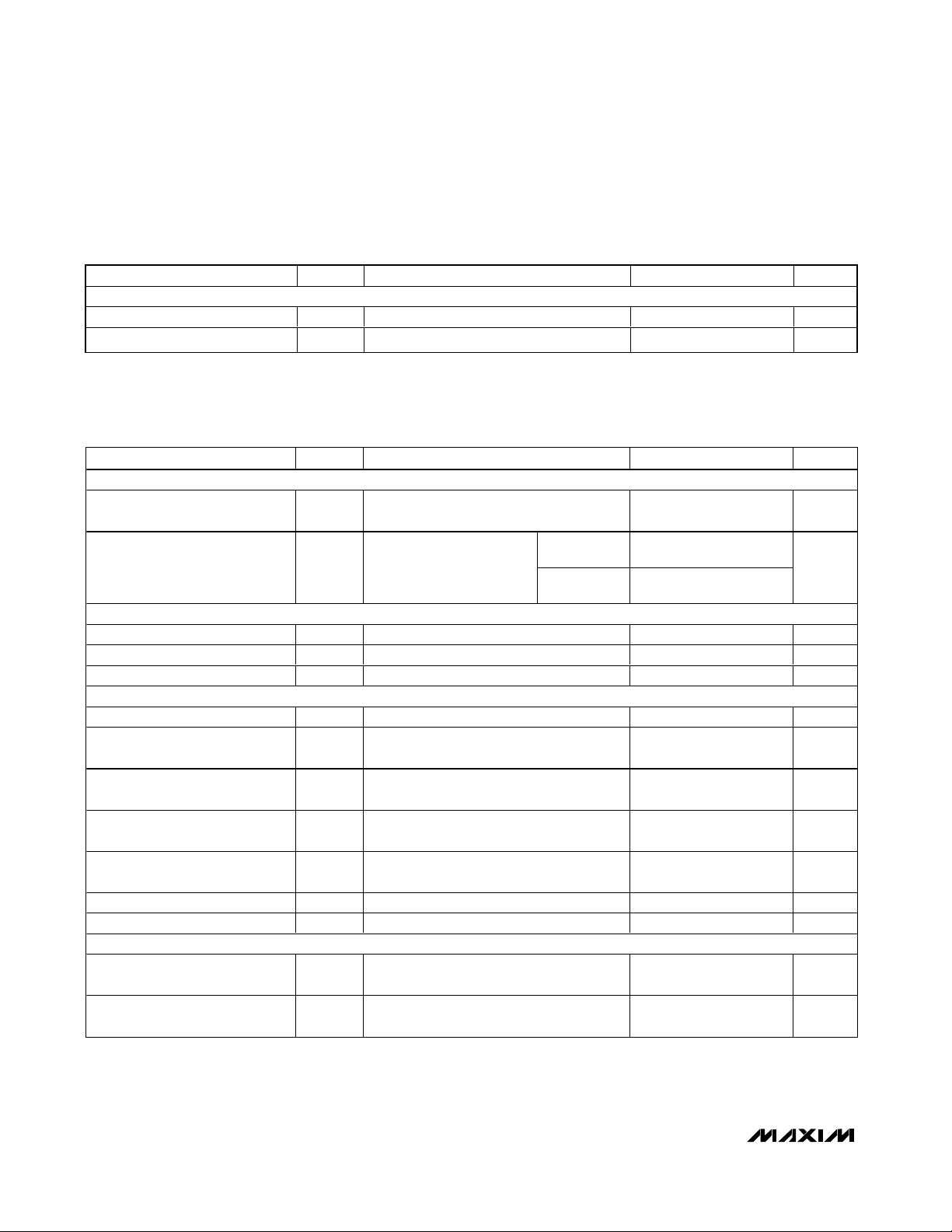

ELECTRICAL CHARACTERISTICS

(VIN= 12V, ILIM = FB = GND, V

BST

- VLX= 5V, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Maximum Duty Cycle D

Soft-Start Period t

Soft-Start Step Size V

FB Power-Up Sequence

Threshold

DH Output Low Voltage I

DH Output High Voltage I

DL Output Low Voltage I

DL Output High Voltage I

DH On-Resistance High (DH to BST) and low (DH to LX) 1.5 4 Ω

DL On-Resistance

Output Drive Current Sourcing or sinking, VDH or VDL = VL/2 0.5 A

LX, BST Leakage Current V

POSITIVE ANALOG GAIN BLOCKS

FB2, FB3, FB4 Regulation

Voltage

FB2 Power-Up Sequence

Threshold

FB2, FB3, FB4 to B_

Transconductance Error

Feedback Input Leakage

Current

Driver Sink Current IB_

NEGATIVE ANALOG GAIN BLOCK

FB5 Regulation Voltage

FB5 to B5 Tr anscond uctance E r r or ∆V

Feedback Input Leakage Current I

Driver Source Current I

POWER GOOD (POK)

OUT Trip Level (Preset Mode) FB = GND, falling edge, 3% hysteresis (typ) 2.88 3.0 3.12 V

FB Trip Level (Adjustable Mode) Falling edge, 3% hysteresis (typ) 1.070 1.114 1.159 V

FB2, FB3, FB4 Trip Level Falling edge, 3% hysteresis (typ) 1.070 1.114 1.159 V

FB5 Trip Level Rising edge, 35mV hysteresis (typ) 368 530 632 mV

POK Output Low Level I

POK Output High Leakage V

MAX

SOFT

77 82 90 %

1024 1/f

/64 V

REF

MAX1964, FB rising, B2 turns on 1.145 V

= 10mA, measured from DH to LX 40 mV

SINK

= 10m A, m easur ed fr om BS T to D H 40 mV

S OU RC E

= 10mA, measured from DL to GND 20 mV

SINK

= 10m A, m easur ed fr om D L to GN D VL - 0.1 V

S OU RC E

High (DL to VL) 4.3 10

Low (DL to GND) 0.7 2

= VLX = VIN = 28V, VFB = 1.5V 0.04 10 µA

BST

VB2 = VB3 = VB4 = 5V,

= IB3 = IB4 = 1mA (sink)

I

B2

1.226 1.24 1.257 V

MAX1964, FB2 rising, B3 turns on 1.145 V

= VB3 = VB4 = 5V, IB2 = IB3 = IB4 =

V

∆V

FB

I

_V

FB

FB5

FB5

B5

B2

_

0.5mA to 5mA (sink)

= V

FB2

V

= V

FB2

V

= 1.188V

FB4

V

= V

B5

(source)

FB3

FB3

OUT

= V

= 1.5V 0.01 100 nA

FB4

VB2 = VB3 = VB4 = 2.5V 10 21

=

V

= VB3 = VB4 = 4.0V 24

B2

- 2V, V

= 3.5V, IB5 = 1mA

OUT

-20 -5 +10 mV

13 22 mV

VB5 = 0, IB5 = 0.5mA to 5mA (source) -13 -20 mV

V

= -100mV 0.01 100 nA

FB5

V

= 200mV, VB5 = V

FB5

3.5V

= 1mA 0.4 V

SINK

= 5V 1 µA

POK

OUT

- 2.0V, V

OUT

=

10 25 mA

OSC

Ω

mA

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS

(VIN= 12V, ILIM = FB = GND, V

BST

- VLX= 5V, TA= -40°C to +85°C, unless otherwise noted.) (Note 4)

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 12V, ILIM = FB = GND, V

BST

- VLX= 5V, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

THERMAL PROTECTION (NOTE 3)

Thermal Shutdown Rising temperature 160 °C

Thermal Shutdown Hysteresis 15 °C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

GENERAL

Operating Input Voltage Range

(Note 1)

Quiescent Supply Current I

VL REGULATOR

Output Voltage VL 6V < VIN < 28V, 0.1mA < I

Line Regulation VIN = 6V to 28V 3.0 %

Undervoltage Lockout Trip Level V

DC-DC CONTROLLER

Output Voltage (Preset Mode) V

Feedback Set Voltage

(Adjustable Mode)

Current-Sense Amplifier Voltage

Gain

Current-Limit Threshold

(Internal Mode)

Current-Limit Threshold

(External Mode)

Switching Frequency f

Maximum Duty Cycle D

POSITIVE ANALOG GAIN BLOCKS

FB2, FB3, FB4 Regulation

Voltage

FB2, FB3, FB4 to B_

Transconductance Error

V

IN

VFB = 0, V

IN

UVLO

OUT

V

SET

A

LIM

V

VALLEYVILIM

V

VALLEYVILIM

OSC

MAX

∆V

FB

V

V

VL rising, 3% hysteresis (typ) 3.0 4.0 V

FB = GND 3.247 3.38 V

FB = COMP 1.211 1.261 V

VIN - VLX = 250mV 4.12 5.68 V/V

VB2 = VB3 = VB4 = 5V,

I

V

_

0.5mA to 5mA (sink)

= 4V,

OUT

= V

= V

FB2

FB3

= -0.1V

FB5

= 5.0V 150 350 mV

= 2.5V 400 660 mV

= IB3 = IB4 = 1mA (sink)

B2

= VB3 = VB4 = 5V, IB2 = IB3 = IB4 =

B2

FB4

= 1.5V,

MAX1964 2.5

MAX1965 3.0

<20mA 4.75 5.25 V

LOAD

4.5 28 V

160 240 kHz

74 90 %

1.215 1.265 V

mA

28 mV

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

_______________________________________________________________________________________ 5

Note 1: Connect VL to IN for operation with VIN< 5V.

Note 2: See Output Voltage Selection section.

Note 3: The internal 5V linear regulator (VL) powers the thermal shutdown block. Shorting VL to GND disables thermal shutdown.

Note 4: Specifications to -40°C are guaranteed by design, not production tested.

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 12V, ILIM = FB = GND, V

BST

- VLX= 5V, TA= -40°C to +85°C, unless otherwise noted.) (Note 4)

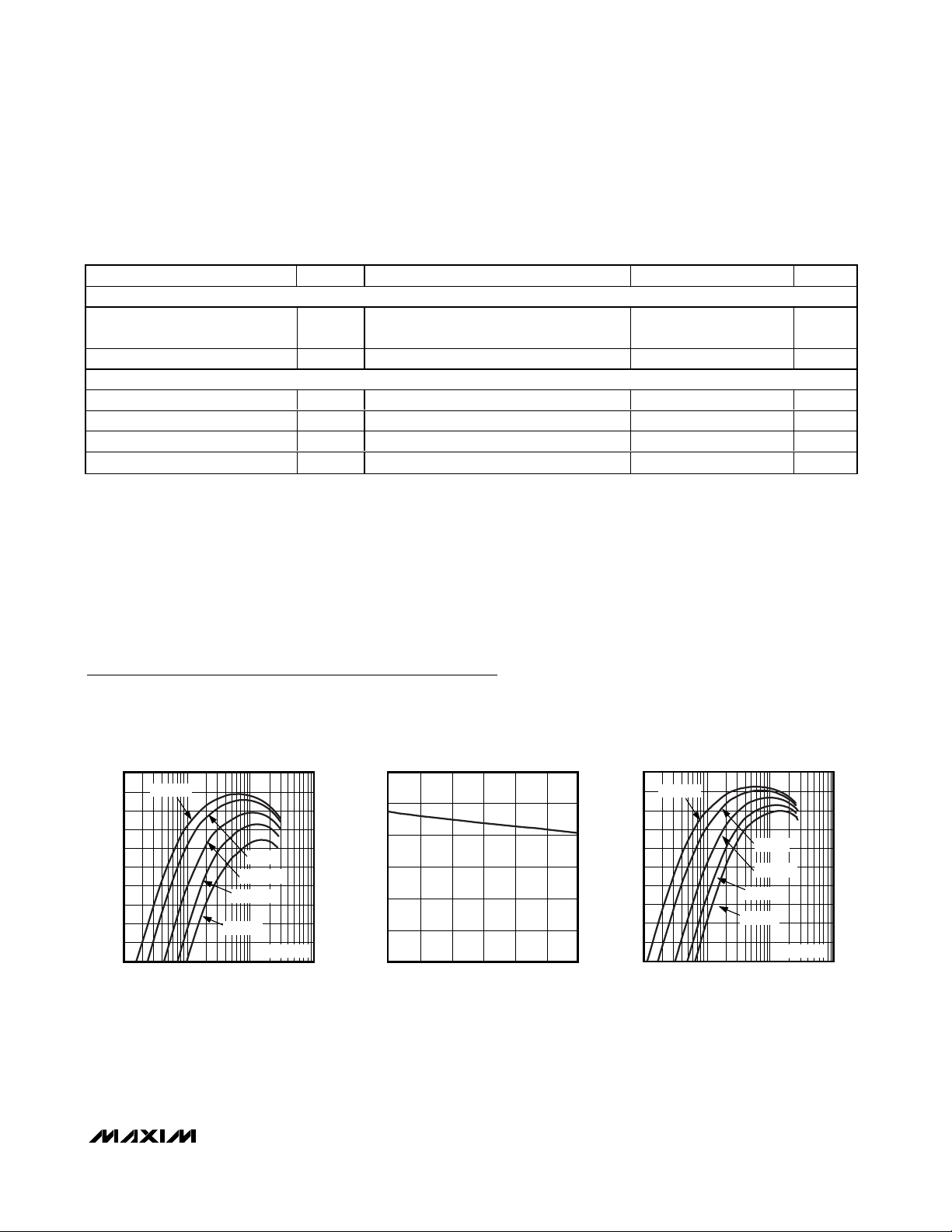

Typical Operating Characteristics

(Circuit of Figure 1, VIN= 12V, V

OUT

= 3.3V, TA= +25°C, unless otherwise noted.)

50

0.01 1010.1

EFFICIENCY vs. LOAD CURRENT

(PRESET MODE)

100

70

60

90

80

MAX1964/65 toc01

LOAD CURRENT (A)

EFFICIENCY (%)

VIN = 6.5V

VIN = 8V

VIN = 12V

VIN = 18V

VIN = 24V

V

OUT

= 3.3V

3.27

3.29

3.28

3.31

3.30

3.32

3.33

0 1.0 1.50.5 2.0 2.5 3.0

OUTPUT VOLTAGE vs. LOAD CURRENT

(PRESET MODE)

MAX1964/65 toc02

LOAD CURRENT (A)

OUTPUT VOLTAGE (V)

50

0.01 1010.1

EFFICIENCY vs. LOAD CURRENT

(ADJUSTABLE MODE)

100

70

60

90

80

MAX1964/65 toc03

LOAD CURRENT (A)

EFFICIENCY (%)

VIN = 6.5V

VIN = 8V

VIN = 12V

VIN = 18V

VIN = 24V

V

OUT

= +5.0V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

NEGATIVE ANALOG GAIN BLOCK

FB5 Regulation Voltage

FB5 to B5 Tr anscond uctance E r r or ∆V

POWER GOOD (POK)

OUT Trip Level (Preset Mode) FB = GND, falling edge, 3% hysteresis (typ) 2.85 3.15 V

FB Trip Level (Adjustable Mode) Falling edge, 3% hysteresis (typ) 1.058 1.17 V

FB2, FB3, FB4 Trip Level Falling edge, 3% hysteresis (typ) 1.058 1.17 V

FB5 Trip Level Rising edge, 35mV hysteresis (typ) 325 675 mV

V

= V

B5

= 1mA (source)

I

B5

VB5 = 0, IB5 = 0.5mA to 5mA (source) -30 mV

FB5

OUT

- 2V, V

OUT

= 3.5V,

-25 +10 mV

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

6 _______________________________________________________________________________________

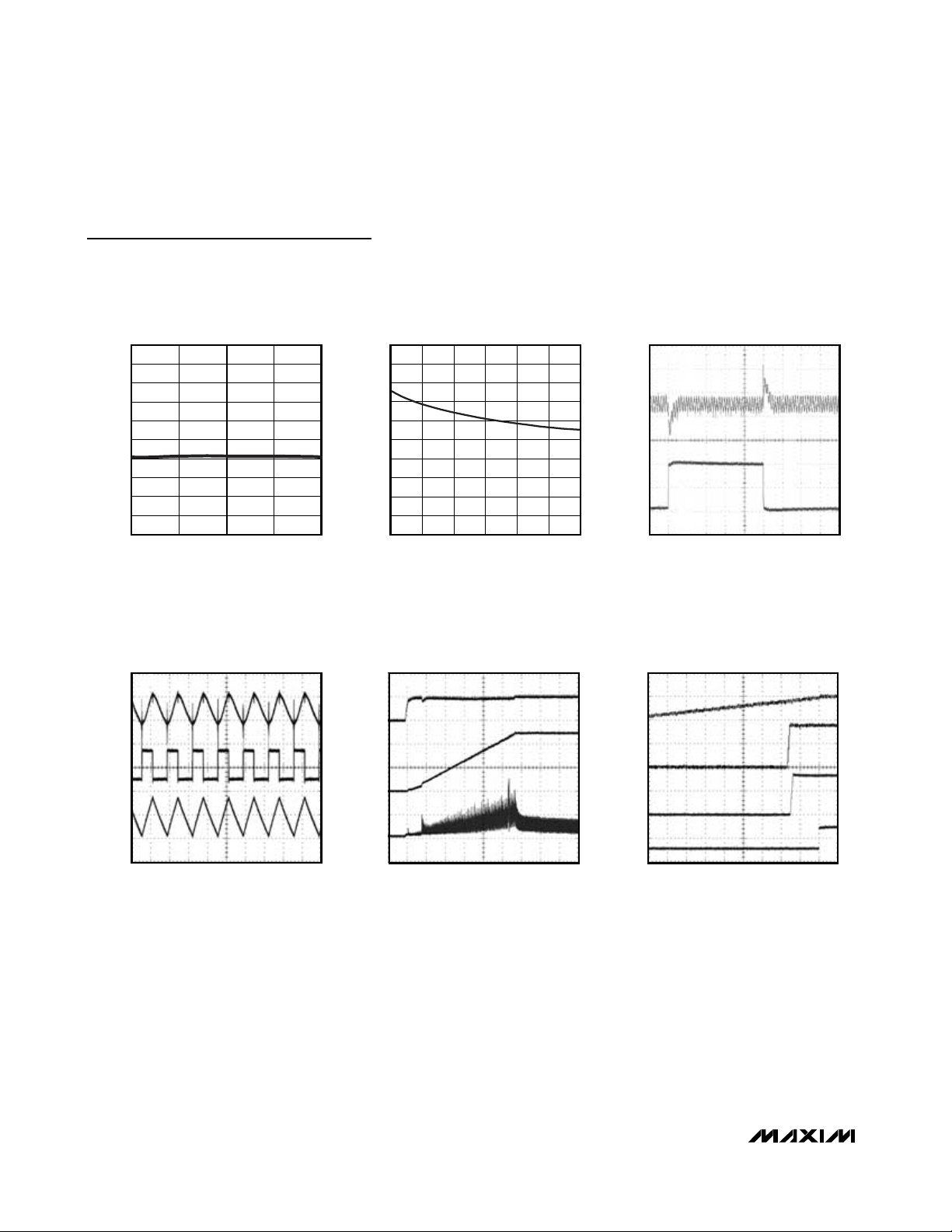

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= 12V, V

OUT

= 3.3V, TA= +25°C, unless otherwise noted.)

1.00.50 1.5 2.0

OUPUT VOLTAGE vs. LOAD CURRENT

(ADJUSTABLE MODE)

MAX1964/65 toc04

LOAD CURRENT (A)

OUTPUT VOLTAGE (V)

4.97

4.99

5.01

4.95

5.03

5.05

4.95

4.97

4.99

5.01

5.03

5.05

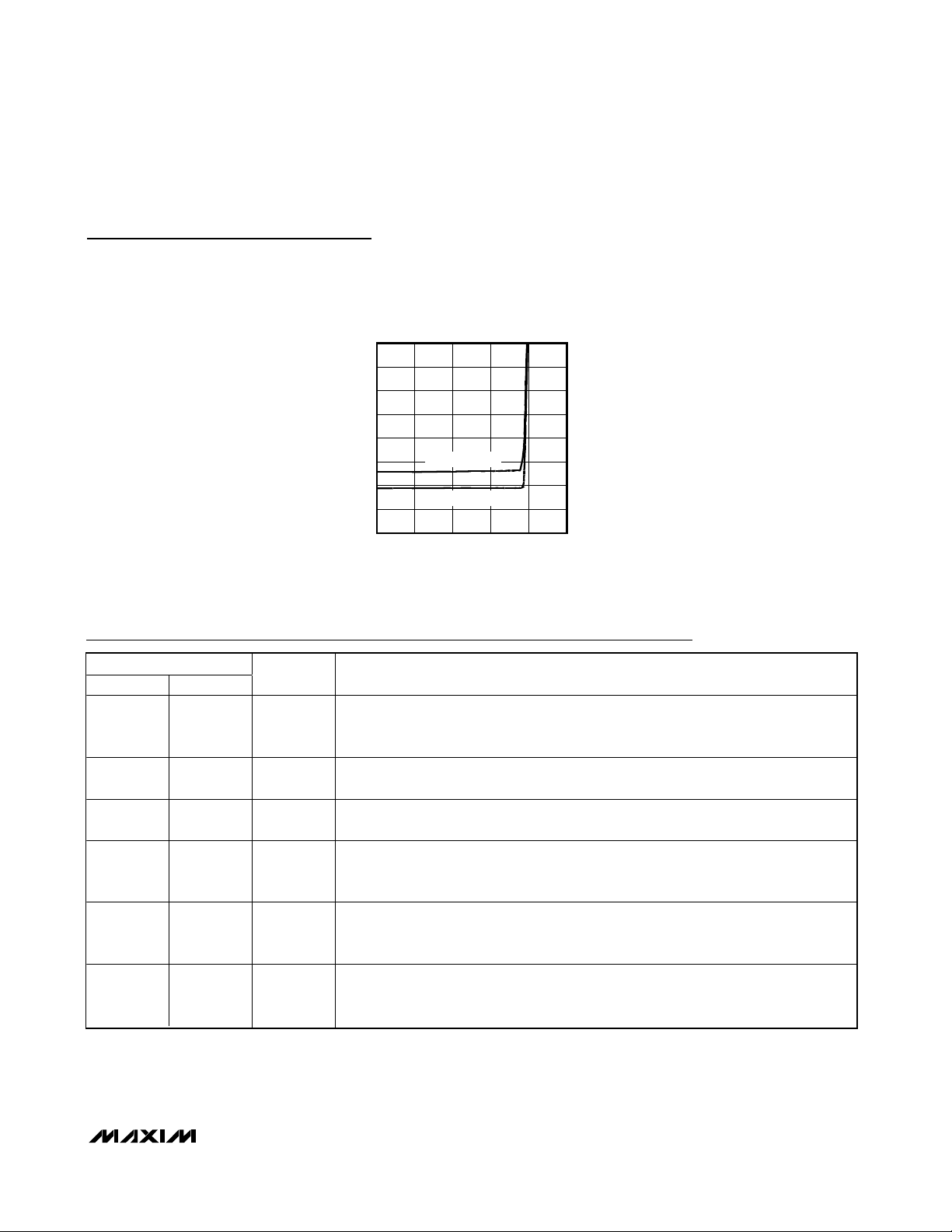

0105 15202530

INTERNAL 5V LINEAR REGULATOR

vs. LOAD CURRENT

MAX1964/65 toc05

LOAD CURRENT (mA)

VL (V)

LOAD TRANSIENT

(STEP-DOWN CONVERTER)

MAX1964/65 toc06

5.0V

0

1A

A. V

OUT

= 5V, 100mV/div

B. I

OUT

= 10mA TO 1A, 500mA/div

V

IN

= 12V

B

A

40µs/div

SWITCHING WAVEFORMS

(STEP-DOWN CONVERTER)

MAX1964/65 toc07

5.00V

A. V

OUT

= 5.0V, 50mV/div

B. V

LX

,10V/div

C. INDUCTOR CURRENT, 500mA/div

V

IN

= 12V, R

OUT1

= 5V

B

A

40µs/div

C

4.95V

12V

0

1A

0.5A

SOFT-START

(STEP-DOWN CONVERTER)

MAX1964/65 toc08

5V

A. V

L

= 5V, 5V/div

B. V

OUT1

=

5V (ADJ),2V/div

C. INDUCTOR CURRENT, 1A/div

V

IN

= STEPPED FROM 0 TO 12V, R

OUT1

= 10Ω

B

A

1ms/div

C

0

5V

0

1A

0

MAX1964 STARTUP WAVEFORM

(VOLTAGE SEQUENCING)

MAX1964/65 toc09

5V

A. V

OUT1

= 5V (ADJ), 2V/div

B. V

OUT2

=

1.8V, 1V/div

C. V

OUT3

=

3.3V, 2V/div

D. V

POK

, 5V/div

V

IN

= STEPPED FROM 0 TO 12V, R

OUT1

= 5Ω

B

A

200µs/div

C

1.8V

3.3V

D

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

_______________________________________________________________________________________ 7

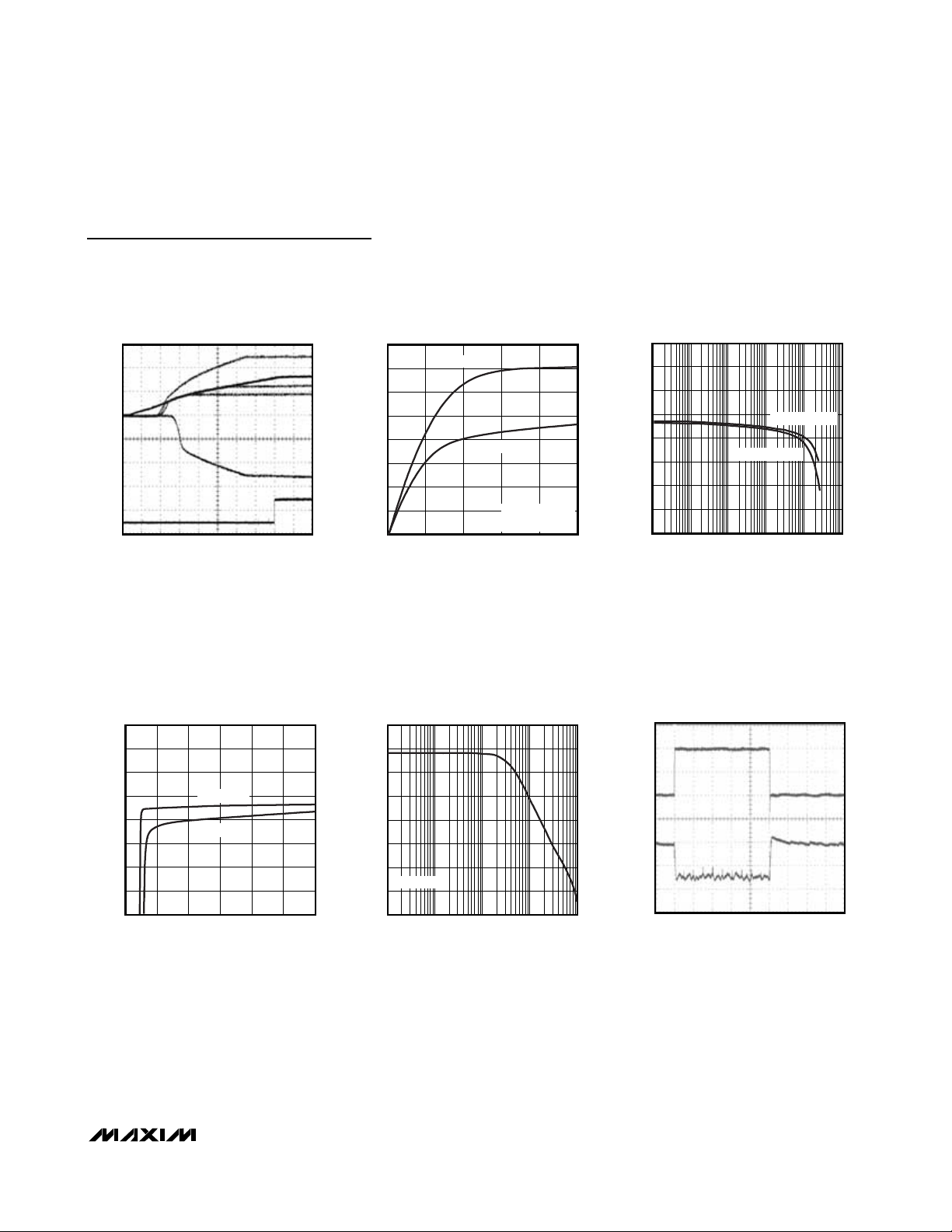

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= 12V, V

OUT

= 3.3V, TA= +25°C, unless otherwise noted.)

MAX1965 STARTUP WAVEFORM

(VOLTAGE TRACKING)

MAX1964/65 toc10

4V

A. V

OUT4

= 5.0V, 2V/div D. V

OUT3

=

1.8V/div

B. V

OUT1

=

3.3V, 2V/div E. V

OUT5

=

-5.0V, 2V/div

C. V

OUT2

=

2.5V, 2V/div F. V

POK

, 5V/div

V

IN

= STEPPED FROM 0 TO 12V,

R

OUT1

= 6.6Ω

CIRCUIT OF FIGURE 6

B

A

400µs/div

C

2V

0

D

E

F

-2V

-4V

5V

0

0

5

10

15

20

25

30

35

40

0246810

POSITIVE LINEAR REGULATOR BASE-

DRIVE CURRENT vs. BASE-DRIVE VOLTAGE

MAX1964/65 toc11

BASE VOLTAGE (V)

BASE-DRIVE SINK CURRENT (mA)

V

FB_

= 1.0V

V

FB_

= 0.96V

REF

B2, B3 AND B4

(MAX1965) ONLY

2.50

0.01 10.1 100

POSITIVE LINEAR REGULATOR

OUTPUT VOLTAGE vs. LOAD CURRENT

(Q

LDO

= 2N3905)

2.42

2.44

2.46

2.48

MAX1964/65 toc12

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

10 1000

V

SUP(POS)

= 5.0V

V

SUP(POS)

= 3.3V

POSITIVE LINEAR REGULATOR

OUTPUT VOLTAGE vs. SUPPLY VOLTAGE

(Q

2.50

2.48

2.46

OUTPUT VOLTAGE (V)

2.44

LDO

I

OUT2

2.42

243 5678

SUPPLY VOLTAGE (V)

POSITIVE LINEAR REGULATOR

POWER-SUPPLY REJECTION RATIO

= 2N3905)

80

70

MAX1964/65 toc13

I

= 1mA

OUT2

= 100mA

60

50

40

PSRR (dB)

30

20

I

= 50mA

OUT2

10

0

0.1 10 10011000

= 2N3905)

(Q

LDO

FREQUENCY (kHz)

100mA

MAX1964/65 toc14

2.467V

2.457V

POSITIVE LINEAR REGULATOR

LOAD TRANSIENT

= 2N3905)

(Q

LDO

0

10µs/div

A. I

= 1mA TO 100mA, 50mA/div

OUTZ

= 2.5V, 5mV/div

B. V

OUTZ

= 10µF CERAMIC, V

C

LDO(POS)

CIRCUIT OF FIGURE 1

SUP(POS)

MAX1964/65 toc15

= 3.3V

A

B

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

8 _______________________________________________________________________________________

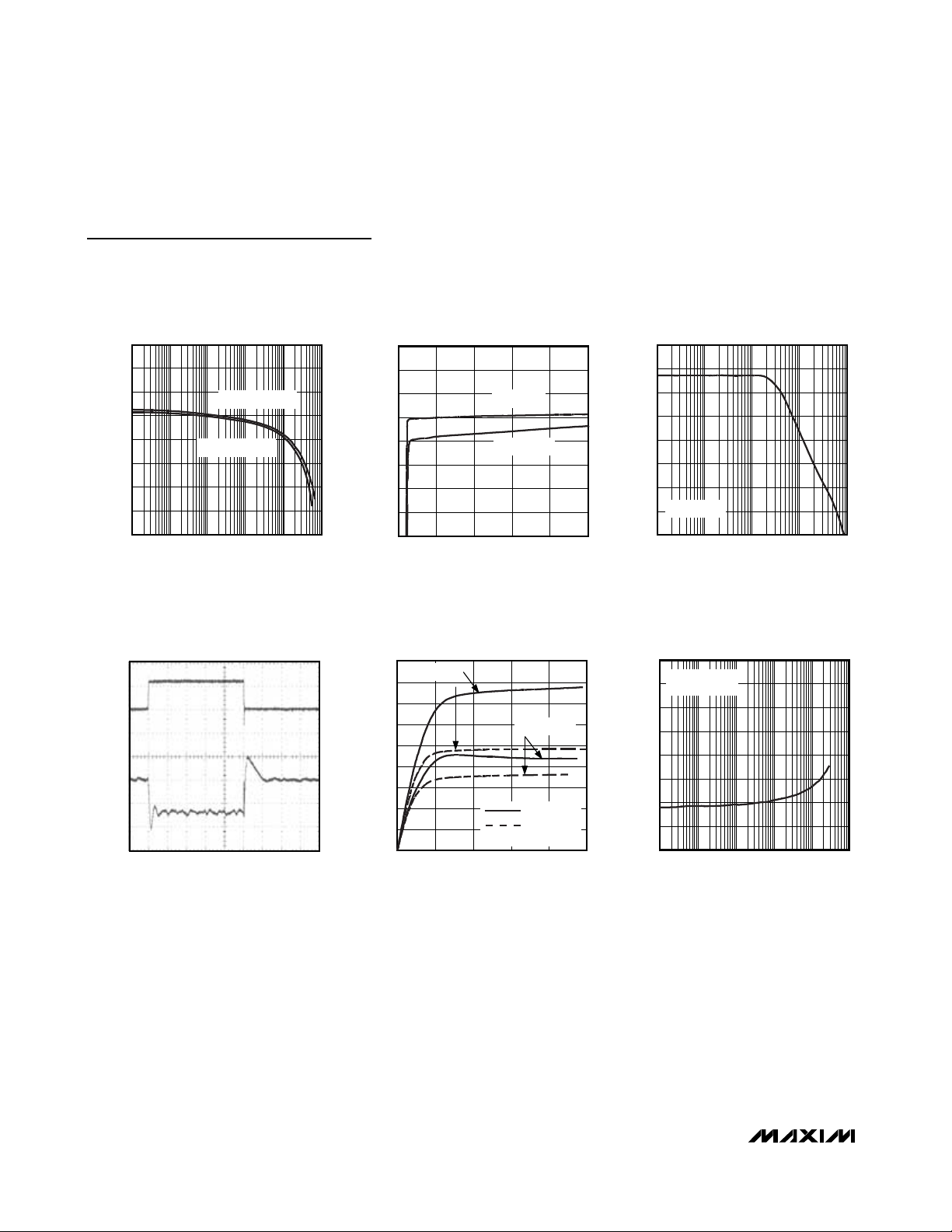

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= 12V, V

OUT

= 3.3V, TA= +25°C, unless otherwise noted.)

2.50

0.01 0.1 1000100

POSITIVE LINEAR REGUALTOR

OUTPUT VOLTAGE vs. LOAD CURRENT

(Q

LDO

= TIP30)

2.42

2.44

2.46

2.48

MAX1964/65 toc16

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

110

V

SUP(POS)

= 5.0V

V

SUP(POS)

= 3.3V

2.42

2.44

2.46

2.48

2.50

2 4 6 8 10 12

POSITIVE LINEAR REGULATOR

OUTPUT VOLTAGE vs. SUPPLY VOLTAGE

(Q

LDO

= TIP30)

MAX1964/65 toc17

SUPPLY VOLTAGE (V)

OUTPUT VOLTAGE (V)

I

OUT2

= 1mA

I

OUT2

= 100mA

80

70

60

50

40

30

20

10

0

0.1 10 1001 1000

POSITIVE LINEAR REGULATOR

POWER-SUPPLY REJECTION RATIO

(Q

LDO

= TIP30)

MAX1964/65 toc18

FREQUENCY (kHz)

PSRR (dB)

I

OUT2

= 150mA

POSITIVE LINEAR REGULATOR

LOAD TRANSIENT

(Q

LDO

= TIP30)

MAX1964/65 toc19

250mA

2.453V

2.473V

A. I

OUT2

= 10mA TO 250mA, 200mA/div

B. V

OUT2

= 2.5V, 10mV/div

C

LDO(POS)

= 10µF CERAMIC, V

SUP(POS)

= 3.3V

CIRCUIT OF FIGURE 1

0

B

A

10µs

0

10

5

25

20

15

40

35

30

45

0426810

NEGATIVE LINEAR REGULATOR BASE-

DRIVE CURRENT vs. BASE-DRIVE VOLTAGE

MAX1964/65 toc20

V

OUT

- VB5 (V)

BASE-DRIVE SOURCE CURRENT (mA)

V

FB5

= 250mV

V

FB5

= 50mV

V

OUT

= 5.0V

V

OUT

= 3.3V

B5 (MAX1965) ONLY

-12.00

-12.06

-12.12

-12.18

-12.24

0.01 1

10

1000.1 1000

NEGATIVE LINEAR REGULATOR

OUTPUT VOLTAGE vs. LOAD CURRENT

(Q

LDO

= TIP29)

MAX1964/65 toc21

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

V

SUP(NEG)

= -15V

V

OUT3

= 5V

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

_______________________________________________________________________________________ 9

Pin Description

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= 12V, V

OUT

- 3.3V, TA= +25°C, unless otherwise noted.)

PIN

MAX1964 MAX1965

1 1 POK

2 2 COMP

3 3 OUT

NEGATIVE LINEAR REGULATOR

OUTPUT VOLTAGE vs. SUPPLY VOLTAGE

-12.00

-12.06

-12.12

OUTPUT VOLTAGE (V)

-12.18

-12.24

-20 -18 -16 -14 -12 -10

NAME FUNCTION

Open-Drain Power-Good Output. POK is low when any output voltage is more than

10% below its regulation point. POK is high impedance when all the outputs are in

regulation. Connect a resistor between POK and VL for logic-level voltages.

Compensation Pin. Connect the compensation network to GND to compensate the

control loop.

Regulated Output Voltage High-Impedance Sense Input. Internally connected to a

resistive-divider and negative gain block (MAX1965).

= TIP29)

(Q

LDO

I

= 100mA

LDO(NEG)

I

= 1mA

LDO(NEG)

SUPPLY VOLTAGE (V)

MAX1964/65 toc22

Dual-Mode Switching-Regulator Feedback Input. Connect to GND for the preset 3.3V

44FB

55B2

6 6 FB2

output. Connect to a resistive-divider from the output to FB to GND to adjust the output

voltage between 1.236V and 0.75

Open-Drain Output PNP Transistor Driver (Regulator 2). Internally connected to the

drain of a DMOS. B2 connects to the base of an external PNP pass transistor to form a

positive linear regulator.

Analog Gain Block Feedback Input (Regulator 2). Connect to a resistive-divider

between the positive linear regulator’s output and GND to adjust the output voltage.

The feedback set point is 1.24V.

✕ V

. The feedback set point is 1.236V.

IN

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

10 ______________________________________________________________________________________

Pin Description (continued)

PIN

MAX1964 MAX1965

77B3

8 8 FB3

— 9B4

— 10 FB4

NAME FUNCTION

Open-Drain Output PNP Transistor Driver (Regulator 3). Internally connected to the

drain of a DMOS. B3 connects to the base of an external PNP pass transistor to form a

positive linear regulator.

Analog Gain Block Feedback Input (Regulator 3). Connect to a resistive-divider

between the positive linear regulator’s output and GND to adjust the output voltage.

The feedback set point is 1.24V.

Open-Drain Output PNP Transistor Driver (Regulator 4). Internally connected to the

drain of a DMOS. B4 connects to the base of an external PNP pass transistor to form a

positive linear regulator.

Analog Gain Block Feedback Input (Regulator 4). Connect to a resistive-divider

between the positive linear regulator’s output and GND to adjust the output voltage.

The feedback set point is 1.24V.

Open-Drain Output NPN Transistor Driver (Regulator 5). Internally connected to the

— 11 B5

drain of a P-channel MOSFET. B5 connects to the base of an external NPN pass

transistor to form a negative linear regulator.

Analog Gain Block Feedback Input (Regulator 5). Connect to a resistive-divider

— 12 FB5

9 13 ILIM

10 14 GND Ground

11 15 DL Low-Side Gate-Driver Output. DL swings between GND and VL.

12 16 LX

13 17 DH High-Side Gate-Driver Output. DH swings between LX and BST.

14 18 BST

15 19 VL

16 20 IN

between the negative linear regulator’s output and a positive reference voltage,

typically one of the positive linear regulator outputs, to adjust the output voltage. The

feedback set point is at GND.

Dual-Mode Current-Limit Adjustment Input. Connect to VL for the default 250mV

current-limit threshold. In adjustable mode, the current-limit threshold voltage is 1/5 th

the voltage present at ILIM. Connect to a resistive-divider between VL and GND to

adjust V

default value is approximately VL - 1V.

Inductor Connection. Used for current-sense between IN and LX, and used for currentlimit between LX and GND.

Boost Flying Capacitor Connection. Connect BST to the external boost diode and

capacitor as shown in the Standard Application Circuit.

Internal 5V Linear Regulator Output. Supplies the IC and powers the DL low-side gate

driver and external boost diode and capacitor. Bypass with a 1µF or greater ceramic

capacitor to GND.

Input Supply Voltage. 4.5V to 28V. Bypass to GND with a 1µF or greater ceramic

capacitor close to the IC.

between 500mV and 2.5V. The logic threshold for switchover to the 250mV

ILIM

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

______________________________________________________________________________________ 11

Detailed Description

The MAX1964/MAX1965 power-supply controllers provide system power for cable and xDSL modems. The

main step-down DC-DC controller operates in a current-mode pulse-width-modulation (PWM) control

scheme to ease compensation requirements and provide excellent load and line transient response.

The MAX1964 includes two analog gain blocks to regulate two additional positive auxiliary output voltages,

and the MAX1965 includes four analog gain blocks to

regulate three additional positive and one negative auxiliary output voltages. The positive regulator gain blocks

can be used to generate low voltage rails directly from

the main step-down converter or higher voltages using

coupled windings from the step-down converter. The

Figure 1. MAX1964 Standard Application Circuit

C

COMP1

470pF

TO LOGIC

R

COMP

5MΩ

1µF

1µF

C1

C2

100kΩ

C

COMP2

R

47pF

POK

IN

VL

ILIM

POK

COMP

D1

CENTRAL CMPSH-3

MAX1964

BST

OUT

GND

FB2

INPUT

9V TO 18V

C

IN

470µF

R

GATE(NH)

DH

LX

DL

FB

B2

10Ω

C

BST

0.1µF

R

GATE(NL)

10Ω

C

2200pF

R

BE2

220Ω

4.64kΩ

10kΩ

BE2

Q1

R3

TIP30

R4

INTERNATIONAL

RECTIFIER

N

H

IRF7101

N

L

C3

1µF

V

OUT2

1.8V AT 300mA

C4

10µF

L1

33µH

R1

30kΩ

R2

10kΩ

C

OUT

1000µF

V

OUT1

5V AT 1A

B3

FB3

: 1000µF, 10V SANYO (CZ SERIES)

OUT

C

BE3

1000pF

R

BE3

220Ω

R5

4.99kΩ

R4

3.0kΩ

Q2

TIP32

C5

1µF

V

OUT3

3.3V AT 750mA

C6

10µF

POWER GROUND

ANALOG GROUNDC

MAX1964/MAX1965

negative gain block can be used in conjunction with a

coupled winding to generate -5V, -12V, or -15V.

DC-DC Controller

The MAX1964/MAX1965 step-down converters use a

pulse-width-modulated (PWM) current-mode control

scheme (Figure 2). An internal transconductance amplifier establishes an integrated error voltage at the COMP

pin. The heart of the current-mode PWM controller is an

open-loop comparator that compares the integrated

voltage-feedback signal against the amplified currentsense signal plus the slope compensation ramp. At

each rising edge of the internal clock, the high-side

MOSFET turns on until the PWM comparator trips or the

maximum duty cycle is reached. During this on-time,

current ramps up through the inductor, sourcing current

to the output and storing energy in a magnetic field.

The current-mode feedback system regulates the peak

inductor current as a function of the output voltage error

signal. Since the average inductor current is nearly the

same as the peak inductor current (assuming that the

inductor value is relatively high to minimize ripple current), the circuit acts as a switch-mode transconductance amplifier. It pushes the output LC filter pole,

normally found in a voltage-mode PWM, to a higher frequency. To preserve inner-loop stability and eliminate

inductor stair casing, a slope-compensation ramp is

summed into the main PWM comparator.

During the second-half of the cycle, the high-side MOSFET turns off and the low-side N-Channel MOSFET

turns on. Now the inductor releases the stored energy

as its current ramps down, providing current to the output. Therefore, the output capacitor stores charge when

the inductor current exceeds the load current, and discharges when the inductor current is lower, smoothing

the voltage across the load. Under overload conditions

when the inductor current exceeds the selected current-limit (see the Current Limit section), the high-side

MOSFET is not turned on at the rising edge of the clock

and the low-side MOSFET remains on to let the inductor

current ramp down.

The MAX1964/MAX1965 operate in a forced-PWM

mode, so even under light loads, the controller maintains a constant switching frequency to minimize crossregulation errors in applications that use a transformer.

So the low-side gate-drive waveform is the complement

of the high-side gate-drive waveform, which causes the

inductor current to reverse under light loads.

Current-Sense Amplifier

The one MAX1964/MAX1965’s one current-sense circuit

amplifies (A

V

= 4.9) the current-sense voltage

generated by the high-side MOSFET’s on resistance

(R

DS(ON)

✕

I

INDUCTOR

). This amplified current-sense

signal and the internal slope compensation signal are

summed together (V

SUM

) and fed into the PWM comparator’s inverting input. The PWM comparator turns off

the high-side MOSFET when the V

SUM

exceeds the

integrated feedback voltage (V

COMP

). Place the highside MOSFET no further than 5mm from the controller

and connect IN and LX to the MOSFET using Kelvin

sense connections to guarantee current-sense accuracy and improve stability.

Current-Limit Circuit

The current-limit circuit employs a unique “valley” current-limiting algorithm that uses the low-side MOSFET’s

on-resistance as a sensing element (Figure 3). If the

voltage across the low-side MOSFET (R

DS(ON)

✕

I

INDUCTOR

) exceeds the current-limit threshold at the

beginning of a new oscillator cycle, the MAX1964/

MAX1965 will not turn on the high-side MOSFET. The

actual peak current is greater than the current-limit

threshold by an amount equal to the inductor ripple current. Therefore, the exact current-limit characteristic

and maximum load capability are a function of the lowside MOSFET on-resistance, inductor value, input voltage, and output voltage. The reward for this uncertainty

is robust, lossless overcurrent limiting.

In adjustable mode, the current-limit threshold voltage is

approximately one-fifth the voltage seen at ILIM (I

VALLEY

= 0.2 ✕V

ILIM

). Adjust the current-limit threshold by connecting a resistive-divider from VL to ILIM to GND. The

current-limit threshold can be set from 106mV to

530mV, which corresponds to ILIM input voltages of

500mV to 2.5V. This adjustable current limit accommodates MOSFETs with a wide range of on-resistance

characteristics (see the Design Procedure section). The

current-limit threshold defaults to 250mV when ILIM is

connected to VL. The logic threshold for switchover to

the 250mV default value is approximately VL - 1V.

Carefully observe the PC board layout guidelines to

ensure that noise and DC errors don’t corrupt the current-sense signals seen by LX and GND. The IC must

be mounted close to the low-side MOSFET with short

(less than 5mm), direct traces making a Kelvin sense

connection.

Synchronous Rectifier Driver (DL)

Synchronous rectification reduces conduction losses in

the rectifier by replacing the normal Schottky catch

diode with a low-resistance MOSFET switch. The

MAX1964/MAX1965 also use the synchronous rectifier

to ensure proper startup of the boost gate-driver circuit

and to provide the current-limit signal.

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

12 ______________________________________________________________________________________

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

______________________________________________________________________________________ 13

Figure 2a. MAX1964 Functional Diagram

COMP

OUT

BIAS

MAX1964

ENABLE

OK

THERMAL

SHDN

V

REF

1.114V

3.5V

FB2

FB3

FB

SOFTSTART

100mV

0.9V

REF

B2

0.9V

REF

V

REF

1.24V

CLK

∑

= 4.9

A

V

SLOPE

COMP

= 5

A

V

100kΩ

400kΩ

VL LDO

5V

IN

VL

BST

DH

LX

DL

GND

ILIM

B3

0.9V

0.9VL

250mV

REF

ENABLE

POK

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

14 ______________________________________________________________________________________

Figure 2b. MAX1965 Functional Diagram

BIAS

OK

THERMAL

SHDN

COMP

OUT

MAX1965

ENABLE

V

REF

1.114V

3.5V

FB

FB_

FB5

100mV

0.9V

REF

B_

0.9V

REF

B5

OUT

SOFTSTART

V

REF

1.24V

CLK

∑

IN

= 4.9

A

V

SLOPE

COMP

= 5

A

V

250mV

100kΩ

400kΩ

VL LDO

5V

VL

BST

DH

LX

DL

GND

ILIM

0.9VL

POK

500mV

ENABLE

The DL low-side drive waveform is always the complement of the DH high-side drive waveform (with controlled dead time to prevent cross-conduction or

“shoot-through”). A dead-time circuit monitors the DL

output and prevents the high-side FET from turning on

until DL is fully off. In order for the dead-time circuit to

work properly, there must be a low-resistance, lowinductance path from the DL driver to the MOSFET

gate. Otherwise, the sense circuitry in the MAX1964/

MAX1965 will interpret the MOSFET gate as “off” when

gate charge actually remains. Use very short, wide

traces (50mils to 100mils wide if the MOSFET is 1 inch

from the device). The dead time at the other edge (DH

turning off) is determined by a fixed internal delay.

High-Side Gate-Drive Supply (BST)

Gate-drive voltage for the high-side N-channel switch is

generated by a flying-capacitor boost circuit (Figure 1).

The capacitor between BST and LX is alternately

charged from the VL supply and placed parallel to the

high-side MOSFET’s gate and source terminals.

On startup, the synchronous rectifier (low-side MOSFET) forces LX to ground and charges the boost

capacitor to 5V. On the second half-cycle, the switchmode power supply turns on the high-side MOSFET by

closing an internal switch between BST and DH. This

provides the necessary gate-to-source voltage to turn

on the high-side switch, an action that boosts the 5V

gate-drive signal above the input voltage.

Internal 5V Linear Regulator (VL)

All MAX1964/MAX1965 functions, except the currentsense amplifier, are internally powered from the onchip, low-dropout 5V regulator. The maximum regulator

input voltage (VIN) is 28V. Bypass the regulator’s output

(VL) with a ceramic capacitor of at least 1µF to GND.

The VIN-to-VL dropout voltage is typically 200mV, so

when VINis less than 5.2V, VL is typically VIN- 200mV.

The internal linear regulator can source up to 20mA to

supply the IC, power the low-side gate driver, charge

the external boost capacitor, and supply small external

loads. When driving particularly large FETs, little or no

regulator current may be available for external loads.

For example, when switched at 200kHz, a large FET

with 40nC total gate charge requires 40nC x 200kHz, or

8mA.

Undervoltage Lockout

If VL drops below 3.5V, the MAX1964/MAX1965

assumes that the supply voltage is too low to make

valid decisions, so the undervoltage lockout (UVLO)

circuitry inhibits switching, forces POK low, and forces

the DL and DH gate drivers low. After VL rises above

3.5V, the controller powers up the outputs (see Startup

section).

Startup

Externally, the MAX1964/MAX1965 start switching when

VL rises above the 3.5V undervoltage lockout threshold. However, the controller is not enabled unless all

four conditions are met: 1) VL exceeds the 3.5V undervoltage lockout threshold, 2) the internal reference

exceeds 92% of its nominal value (V

REF

> 1.145V), 3)

the internal bias circuitry powers up, and 4) the thermal

limit is not exceeded. Once the MAX1964/MAX1965

assert the internal enable signal, the step-down controller starts switching and enables soft-start.

The soft-start circuitry gradually ramps up to the reference voltage in order to control the rate of rise of the

step-down controller and reduce input surge currents

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

______________________________________________________________________________________ 15

Figure 3. “Valley” Current-Limit Threshold Point

INDUCTOR CURRENT

-I

PEAK

I

LOAD

I

VALLEY

(VIN - V

)

V

OUT

OUT

+

[

()

L

VINƒ

OSC

]

TIME

I

PEAK

= I

VALLEY

MAX1964/MAX1965

during startup. The soft-start period is 1024 clock

cycles (1024/f

OSC

), and the internal soft-start DAC

ramps up the voltage in 64 steps. The output reaches

regulation when soft-start is completed, regardless of

output capacitance and load.

Output Voltage Sequencing (MAX1964)

After the reference powers up, the controller begins a

startup sequence. First, the main DC-DC step-down

converter powers up with soft-start enabled. Once the

step-down converter reaches 92% of its nominal value

(VFB> 1.145V) and soft-start is completed, the controller powers up the first positive linear regulator. Once

the first linear regulator reaches 92% of its nominal

value (V

FB2

> 1.145V), the second linear regulator powers up. Once all three output voltages exceed 92% of

their nominal values, the active-high ready signal (POK)

goes high (see Power-Good Output section).

Output Voltage Tracking (MAX1965)

After the reference powers up, the controller simultaneously powers up all five output voltages. The main DCDC step-down converter powers up with soft-start

enabled while the linear regulators are fully activated.

However, the linear regulators’ inputs are typically connected to or derived from the step-down converter output voltage. Since the linear regulators are fully active,

the pass transistors immediately saturate, allowing

these output voltages to track the step-down converter’s slow rising output voltage (see Typical Operating

Characteristics). Once all five output voltages exceed

92% of their nominal values, the active-high ready signal (POK) goes high (see Power-Good Output section).

Power-Good Output (POK)

POK is an open-drain output. The MOSFET turns on

and pulls POK low when any output falls below 90% of

its nominal regulation voltage. Once all of the outputs

exceed 92% of their nominal regulation voltages and

soft-start is completed, POK goes high impedance. To

obtain a logic voltage output, connect a pullup resistor

from POK to VL. A 100kΩ resistor works well for most

applications. If unused, leave POK grounded or unconnected.

Thermal overload Protection

Thermal overload protection limits total power dissipation in the MAX1964/MAX1965. When the junction temperature exceeds TJ= +160°C, a thermal sensor shuts

down the device, forcing DL and DH low, allowing the

IC to cool. The thermal sensor turns the part on again

after the junction temperature cools by 15°C, resulting

in a pulsed output during continuous thermal overload

conditions. If the VL output is short-circuited, thermal

overload protection is disabled.

During a thermal event, the main step-down converter

and the linear regulators are turned off, POK goes low,

and soft-start is reset.

Design Procedure

DC-DC Step-Down Converter

Output Voltage Selection

The step-down controller’s feedback input features dual

mode operation. Connect the output to OUT and connect FB to GND for the preset 3.3V output voltage.

Alternatively, the MAX1964/MAX1965 output voltage

may be adjusted by connecting a voltage-divider from

the output to FB to GND (Figure 4). Select R2 in the

5kΩ to 50kΩ range. Calculate R1 with the following

equation:

where V

SET

= 1.236V and V

OUT

may range from 1.236V

to approximately 0.75 ✕VIN(up to 20V). If V

OUT

> 5.5V,

connect OUT to GND (MAX1964) or to one of the positive linear regulators (MAX1965) with an output voltage

between 2V and 5V.

Inductor Value

Three key inductor parameters must be specified:

inductance value (L), peak current (I

PEAK

), and DC

resistance (RDC). The following equation includes a

constant LIR, which is the ratio of inductor peak-to-peak

AC current to DC load current. A higher LIR value

allows smaller inductance, but results in higher losses

and higher output ripple. A good compromise between

size and losses is a 30% ripple-current to load-current

ratio (LIR = 0.3). The switching frequency, input voltage, output voltage, selected LIR determine the inductor value as follows:

where fSWis 200kHz. The exact inductor value is not

critical and can be adjusted in order to make trade-offs

among size, cost, and efficiency. Lower inductor values

minimize size and cost, but they also increase the output ripple and reduce the efficiency due to higher peak

currents. On the other hand, higher inductor values

increase efficiency, but at some point resistive losses

due to extra turns of wire will exceed the benefit gained

from lower AC current levels.

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

16 ______________________________________________________________________________________

V

RR

12 1=

L

=

VVV

VI LIR

IN SW LOAD MAX

OUT

V

SET

()

OUT IN OUT

ƒ

-

-

()

Find a low-loss inductor having the lowest possible DC

resistance that fits in the allotted dimensions. Ferrite

cores are often the best choice, although powdered

iron is inexpensive and can work well at 200kHz. The

chosen inductor’s saturation rating must exceed the

peak inductor current:

Setting the Current Limit

The minimum current-limit threshold must be high

enough to support the maximum load current at the

minimum tolerance level of the current-limit circuit. The

valley of the inductor current occurs at I

LOAD(MAX)

minus half of the ripple current:

where R

DS(ON)

is the on-resistance of the low-side

MOSFET (NL). For the MAX1964/MAX1965, the minimum current-limit threshold is 190mV (for the typical

250mV default setting). Use the worst-case maximum

value for R

DS(ON)

from the MOSFET NLdata sheet, and

add some margin for the rise in R

DS(ON)

over tempera-

ture. A good general rule is to allow 0.5% additional

resistance for each °C of the MOSFET junction temperature rise.

Connect ILIM to VL for the default 250mV (typ) currentlimit threshold. For an adjustable threshold, connect a

resistive-divider from VL to ILIM to GND. The external

adjustment range of 500mV to 2.5V corresponds to a

current-limit threshold of 106mV to 530mV. When

adjusting the current limit, use 1% tolerance resistors

and a 10µA divider current to prevent a significant

increase in the current-limit tolerance.

MOSFET Selection

The MAX1964/MAX1965’s step-down controller drives

two external logic-level N-channel MOSFETs as the circuit switch elements. The key selection parameters are:

1. On-resistance (R

DS(ON)

)

2. Maximum drain-to-source voltage (V

DS(MAX)

)

3. Minimum threshold voltage (V

TH(MIN)

)

4. Total gate charge (Q

g

)

5. Reverse transfer capacitance (C

RSS

)

The high-side N-channel MOSFET must be a logic-level

type with guaranteed on-resistance specifications at

V

GS

≤ 4.5V. Select the high-side MOSFET’s on-resis-

tance (R

DS(ON)

) so I

PEAK

✕

R

DS(ON)

≤ 225mV for the

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

______________________________________________________________________________________ 17

Figure 4. Adjustable Output Voltage

MAX1964

IN

MAX1965

VL

ILIM

POK

COMP

C1

C2

R

POK

R

COMP

C

COMP1

* FOR OUTPUT VOLTAGES > 5V, SEE "OUTPUT VOLTAGE SELECTION."

C

COMP2

LIR

II

=+

PEAK LOAD MAX LOAD MAX

() ()

I

2

V

VALLEY LOW

R

DS ON

()

()

>−

I

LOAD MAX LOAD MAX

() ()

LIR

2

I

INPUT

D1

BST

DH

C

BST

OUT

GND

LX

DL

FB

4.5V TO 28V

C

IN

N

H

L

N

L

OUTPUT

1.25V TO 5V*

C

OUT

R1

R2

MAX1964/MAX1965

current-sense range. For a good compromise between

efficiency and cost, choose a high-side MOSFET (NH)

that has conduction losses equal to the switching losses at the optimum input voltage. Check to ensure that

the conduction losses at minimum input voltage don’t

exceed the package thermal limits or violate the overall

thermal budget. Check to ensure that the conduction

losses plus switching losses at the maximum input voltage don’t exceed package ratings or violate the overall

thermal budget.

The low-side MOSFET (NL) provides the current-limit

signal, so choose a MOSFET with an R

DS(ON)

large

enough to provide adequate circuit protection (see the

Setting the Current-Limit section):

Use the worst-case maximum value for R

DS(ON)

from

the MOSFET NL data sheet, and add some margin for

the rise in R

DS(ON)

over temperature. A good general

rule is to allow 0.5% additional resistance for each °C of

the MOSFET junction temperature rise. Ensure that the

MAX1964/MAX1965 DL gate drivers can drive NL; in

other words, check that the dv/dt caused by NHturning

on does not pull up the NLgate due to drain-to-gate

capacitance, causing cross-conduction problems.

MOSFET package power dissipation often becomes a

dominant design factor. I2R power losses are the greatest heat contributor for both high-side and low-side

MOSFETs. I2R losses are distributed between NHand

N

L

according to duty factor as shown in the equations

below. Generally, switching losses affect only the highside MOSFET, since the low-side MOSFET is a zerovoltage switched device when used in the buck

topology.

Gate-charge losses are dissipated by the driver and do

not heat the MOSFET. Calculate the temperature rise

according to package thermal-resistance specifications

to ensure that both MOSFETs are within their maximum

junction temperature at high ambient temperature. The

worst-case dissipation for the high-side MOSFET (PNH)

occurs at both extremes of input voltage, and the worstcase dissipation for the low-side MOSFET (PNL) occurs

at maximum input voltage.

I

GATE

is the average DH driver output current capability

determined by:

where R

DS(ON)DH

is the high-side MOSFET driver’s on-

resistance (4Ω max), and R

GATE

is any resistance

placed between DH and the high-side MOSFET’s gate

(Figure 5).

To reduce EMI caused by switching noise, add a 0.1µF

ceramic capacitor from the high-side switch drain to the

low-side switch source or add resistors (max 47Ω) in

series with DL and DH to increase the switches’ turn-on

and turn-off times (Figure 5).

The minimum load current should exceed the high-side

MOSFET’s maximum leakage current over temperature

if fault conditions are expected.

Input Capacitor

The input filter capacitor reduces peak currents drawn

from the power source and reduces noise and voltage

ripple on the input caused by the circuit’s switching.

The input capacitor must meet the ripple current

requirement (I

RMS

) imposed by the switching currents

defined by the following equation:

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

18 ______________________________________________________________________________________

Figure 5. Reducing the Switching EMI

V

R

DS ON

()

=

I

VALLEY

VALLEY

QQ

+

PVI

NH SWITCHING IN LOAD OSC

()

=ƒ

GS GD

I

GATE

I

=

GATE

2

RR

()

VL

()

DS ON DH GATE

+

PIR

NH CONDUCTION LOAD DS ON NH

()()

PP P

NH TOTAL NH SWITCHING NH CONDUCTION

()( )( )

PI R

=

NL LOAD DS ON NL

2

=

=+

()

2

V

OUT

1-

V

IN

V

OUT

V

IN

MAX1964

MAX1965

TO VL

BST

GND

R

GATE

(OPTIONAL)

DH

C

LX

DH

BST

R

GATE

(OPTIONAL)

N

H

L

N

L

I

RMS

has a maximum value when the input voltage

equals twice the output voltage (VIN= 2V

OUT

), so

I

RMS(MAX)

= I

LOAD

/2. For most applications, nontantalum capacitors (ceramic, aluminum, polymer, or OSCON) are preferred due to their robustness with high

inrush currents typical of systems with low impedance

inputs. Additionally, two (or more) smaller value lowESR capacitors can be connected in parallel for lower

cost. Choose an input capacitor that exhibits less than

+10°C temperature rise at the RMS input current for

optimal circuit long-term reliability.

Output Capacitor

The key selection parameters for the output capacitor

are the actual capacitance value, the equivalent series

resistance (ESR), and voltage-rating requirements

which affect the overall stability, output ripple voltage,

and transient response.

The output ripple has two components: variations in the

charge stored in the output capacitor, and the voltage

drop across the capacitor’s equivalent series resistance (ESR) caused by the current into and out of the

capacitor.

V

RIPPLE =VRIPPLE(ESR) + VRIPPLE(C)

The output voltage ripple as a consequence of the ESR

and output capacitance is:

where I

p-p

is the peak-to-peak inductor current (see

Inductor Selection section). These equations are suitable for initial capacitor selection, but final values

should be set by testing a prototype or evaluation circuit. As a general rule, a smaller ripple current results in

less output ripple. Since the inductor ripple current is a

factor of the inductor value and input voltage, the output voltage ripple decreases with larger inductance,

but increases with lower input voltages.

With low-cost aluminum electrolytic capacitors, the

ESR-induced ripple can be larger than that caused by

the charge into and out of the capacitor. Consequently,

high quality low-ESR aluminum-electrolytic, tantalum,

polymer, or ceramic filter capacitors are required to

minimize output ripple. Best results at reasonable cost

are typically achieved with an aluminum-electrolytic

capacitor in the 470µF range, in parallel with a 0.1µF

ceramic capacitor.

Since the MAX1964/MAX1965 use a current-mode control scheme, the output capacitor forms a pole that

affects circuit stability (see Compensation Design).

Furthermore, the output capacitor’s ESR also forms a

zero.

The MAX1964/MAX1965’s response to a load transient

depends on the selected output capacitor. After a load

transient, the output instantly changes by ESR x

∆I

LOAD

. Before the controller can respond, the output

will sag further depending on the inductor and output

capacitor values. After a short period of time (see

Typical Operating Characteristics), the controller

responds by regulating the output voltage back to its

nominal state. For applications that have strict transient

requirements, low-ESR high-capacitance electrolytic

capacitors are recommended to minimize the transient

voltage swing.

Do not exceed the capacitor’s voltage or ripple-current

ratings.

Compensation Design

The MAX1964/MAX1965 controllers use an internal

transconductance error amplifier whose output allows

compensation of the control loop. Connect a series

resistor and capacitor between COMP and GND to

form a pole-zero pair, and connect a second parallel

capacitor between COMP and GND to form another

pole. The external inductor, high-side MOSFET, output

capacitor, compensation resistor, and compensation

capacitors determine the loop stability. The inductor

and output capacitor are chosen based on performance, size, and cost, while the compensation resistor

and capacitors are selected to optimize control-loop

stability. The component values shown in the Standard

Application Circuit (Figures 1 and 6) yield stable operation over a broad range of input-to-output voltages.

The controller uses a current-mode control scheme that

regulates the output voltage by forcing the required

current through the external inductor, so the

MAX1964/MAX1965 use the voltage across the highside MOSFET’s on-resistance (R

DS(ON)

) to sense the

inductor current. Using the current-sense amplifier’s

output signal and the amplified feedback voltage, the

control loop determines the peak inductor current by:

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

______________________________________________________________________________________ 19

VVV

II

=

RMS LOAD

V I ESR

RIPPLE ESR P P

V

RIPPLE C

=

I

PP

-

OUT IN OUT

=

()

=

()

8

-

VVLV

IN OUTSWOUT

ƒ

−

()

V

IN

-

I

PP

-

ƒ

C

OUT SW

V

IN

MAX1964/MAX1965

where V

REF

= 1.24V, A

VCS

is the current-sense amplifi-

er’s gain (4.9 typ), A

VEA

is the DC gain of the transconductance error amplifier (2000 typ) set by its DC output

resistance, and V

OUT(NOMINAL)

is the output voltage

set by the feedback resistive-divider (internal or external). Since the output voltage is a function of the load

current and load resistance, the total DC loop gain

(A

V(DC)

) is approximately:

The first compensation capacitor (C

COMP1

) creates the

dominant pole. Due to the current-mode control

scheme, the output capacitor also creates a pole in the

system which is a function of the load resistance. As

the load resistance increases, the frequency of the output capacitor’s pole decreases. However, the DC loop

gain increases with larger load resistance, so the unitygain bandwidth remains fixed. Additionally, the compensation resistor and the output capacitor’s ESR both

generate zeros which must be canceled out by corresponding poles. Therefore, in order to achieve stable

operation, use the following procedure to properly compensate the system:

1) The crossover frequency (the frequency at which

unity gain occurs) must be less than 1/5th the

switching frequency:

2) Determine the series compensation capacitor

(C

COMP1

) required to set the desired crossover fre-

quency:

where the error amplifier’s transconductance (g

m

)

is 100µS (see Electrical Characteristics) and A

V(DC)

is the total DC loop gain defined above.

3) Before crossover occurs, the output capacitor and

the load resistor generate a second pole:

4) The series compensation resistor and capacitor

provide a zero which can be used to cancel the

second pole in order to ensure stability:

5) For most applications using electrolytic capacitors,

the output capacitor’s ESR forms a second zero

that occurs before crossover. Applications using

low-ESR capacitors (e.g., polymer, OS-CON) may

have ESR zeros that occur after crossover.

Therefore, verify the frequency of the output capacitor’s ESR zero:

6) Finally, if the output capacitor’s ESR zero occurs

before crossover, add the parallel compensation

capacitor (C

COMP2

) to form a third pole to cancel

this second zero:

For example, the MAX1964 Standard Application

Circuit shown in Figure 1 requires a 5V output that supports up to 2A. Using the above compensation guidelines, we can determine the proper component values:

• First, select the crossover frequency to be 1/5th the

200kHz switching frequency.

• Next, determine the total DC loop gain (A

V(DC)

) so

you can calculate the series compensation capacitance (C

COMP1

). Since the applications circuit uses

the International Rectifier IRF7101 with an R

DS(ON)

of 100mΩ, the DC loop gain approximately equals

2480 and C

COMP1

must be approximately 490pF.

Select the closest standard capacitor value of

470pF.

• Determine the location of the output pole

(f

POLE(OUT)

). With a 5V output supplying 2A and a

1000µF electrolytic capacitor, the output pole

occurs at 64Hz.

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

20 ______________________________________________________________________________________

VVA

I

=

PEAK

VRA

OUT REF VEA

OUT NOMINAL DS ON VCS

()()

A

≈≈

VDC

()

I

≈

I

PEAK

LOAD

×400

VR

OUT NOMINAL DS ON

()()

VR A

REF LOAD VEA

VRA

OUT NOMINAL DS ON VCS

()()

VR

REF LOAD

f

SW

f

≤

C

5

C

COMP

1

≥

1

2 2000

π

mVDC

()

f

C

gA

f

POLE OUT

()

==

1

CR

22ππ

OUT LOAD

I

LOAD MAX

CV

OUT OUT

R

COMP

≥

Cf

π

2

1

COMP POLE OUT

1

()

f

ZERO ESR

()

≈

1

CR

2π

OUT ESR

C

COMP

C

COMP

≈

2

RC f

21

π

()

COMP COMP ZERO ESR

Cf

COMP POLE OUT

≈

ff

()

ZERO ESR POLE OUT

1

-

() ( )

1

1

()

()

-

()

• With the output pole’s frequency and series compensation capacitor values, the required series

resistance can be determined. Based on the above

equation, select R

COMP

= 5.1MΩ.

• Now we must determine if the selected output

capacitor’s ESR generates a second zero before

crossover—the circuit shown in Figure 1 uses a

1000µF 10V Sanyo CZ-series electrolytic capacitor

with an ESR rating of 0.2Ω, so the zero occurs at

800Hz. Since crossover occurs at 40kHz, add the

second parallel compensation capacitor.

• Finally, the second compensation capacitor value

must be approximately 43pF. Select the closest

standard capacitor value of 47pF.

Boost-Supply Diode

A signal diode, such as the 1N4148, works well in most

applications. If the input voltage goes below 6V, use a

small 20mA Schottky diode for slightly improved efficiency and dropout characteristics. Do not use large

power diodes, such as the 1N5817 or 1N4001, since

high junction capacitance can charge up VL to excessive voltages.

Linear Regulator Controllers

Positive Output Voltage Selection

The MAX1964/MAX1965’s positive linear regulator output voltages are set by connecting a voltage divider

from the output to FB_ to GND (Figure 6). Select R4 in

the 1kΩ to 50kΩ range. Calculate R3 with the following

equation:

where VFB= 1.24V and V

OUT

may range from 1.24V to

30V.

Negative Output Voltage Selection (MAX1965)

The MAX1965’s negative output voltage is set by connecting a voltage divider from the output to FB5 to a

positive voltage reference (Figure 6). Select R6 in the

1kΩ to 50kΩ range. Calculate R5 with the following

equation:

where V

REF

is the positive reference voltage used and

V

OUT

may be set between 0 and -20V.

If the negative regulator is used, the OUT pin must be

connected to a voltage supply between 2V and 5V that

can source at least 25mA. Typically, the OUT pin is

connected to the step-down converter’s output.

However, if the step-down converter’s output voltage is

set higher than 5V, OUT must be connected to one of

the positive linear regulators with an output voltage

between 2V and 5V.

Transistor Selection

The pass transistors must meet specifications for current gain (h

FE

), input capacitance, collector-emitter saturation voltage, and power dissipation. The transistor’s

current gain limits the guaranteed maximum output current to:

where I

DRV

is the minimum 10mA base drive current

and RBE(220Ω) is the pullup resistor connected

between the transistor’s base and emitter. Furthermore,

the transistor’s current gain increases the linear regulator’s DC loop gain (see Stability Requirements), so

excessive gain will destabilize the output. Therefore,

transistors with current gain over 100 at the maximum

output current, such as Darlington transistors, are not

recommended. The transistor’s input capacitance and

input resistance also create a second pole, which

could be low enough to destabilize the output when

heavily loaded.

The transistor’s saturation voltage at the maximum output current determines the minimum input-to-output

voltage differential that the linear regulator will support.

Alternatively, the package’s power dissipation could

limit the useable maximum input-to-output voltage differential. The maximum power dissipation capability of

the transistor’s package and mounting must exceed the

actual power dissipation in the device. The power dissipated equals the maximum load current times the maximum input-to-output voltage differential:

P = I

LOAD(MAX)(VLDOIN - VOUT

) = I

LOAD(MAX) VCE

Stability Requirements

The MAX1964/MAX1965 linear regulators use an internal transconductance amplifier to drive an external

pass transistor. The transconductance amplifier, pass

transistor’s specifications, the base-emitter resistor,

and the output capacitor determine the loop stability. If

the output capacitor and pass transistor are not properly selected, the linear regulator will be unstable.

The transconductance amplifier regulates the output

voltage by controlling the pass transistor’s base current. Since the output voltage is a function of the load

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

______________________________________________________________________________________ 21

V

56=

OUT

V

V

V

RR

34 1=

RR

-

FB

OUT

REF

II

LOAD MAX DRV

=

-

V

BE

h

R

FE MIN() ()

BE

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

22 ______________________________________________________________________________________

Figure 6. MAX1965 Application Circuit

INPUT

D1

CENTRAL CMPSH-3

470µF

9V TO 18V

C

IN

POK

R7

15kΩ

IN

VL

ILIM

POK

FB

COMP

B5

FB5

C1

1µF

C2

1µF

R

100kΩ

TO LOGIC

C

COMP1

1500pF

D3

NIHON

EC10QS10

2200pF

Q4

TIP29

V

OUT5

-5V AT 50mA

R

COMP

412kΩ

C

COMP2

68pF

T1

N

= 2

S(NEG)

C10

47µF

C11

1µF

C

BE5

C5

10µF

R8

30kΩ

R

BE5

220Ω

MAX1965

CONNECT

TO V

OUT2

BST

OUT

GND

FB2

FB3

FB3

R

GATE(NH)

DH

LX

DL

B2

B3

B3

10Ω

C

BST

0.1µF

R

GATE(NL)

10Ω

C

BE2

2200pF

R

BE2

220Ω

R1

10kΩ

R2

10kΩ

C

BE3

2200pF

R

BE3

220Ω

R3

1.3kΩ

R4

3.0kΩ

C

BE4

4700pF

R

BE4

220Ω

R5

30kΩ

R6

10kΩ

N

N

Q1

TIP30

Q2

TIP32

Q3

2N3905

H

L

FAIRCHILD

FDS6912A

T1

NP = 1

C3

1µF

V

OUT2

2.5V AT 200mA

C4

10µF

C5

1µF

V

OUT3

1.8V AT 500mA

C6

10µF

C7

1µF

V

OUT3

5V AT 100mA

C9

10µF

V

OUT1

3.3V AT 1.4A

C

OUT

470µF

10V SANYO

(MV-AX SERIES)

N

= 1

S(POS)

D2

NIHON

EP05Q03L

C8

47µF

POWER GROUND

ANALOG GROUND

NOTE: ALL T1 TRANSFORMER

WINDINGS ARE ON THE SAME CORE

T1

current and load resistance, the total DC loop gain

(A

V(LDO)

) is approximately:

where VTis 26mV, and I

BIAS

is the current through the

base-to-emitter resistor (RBE). This bias resistor is typically 220Ω, providing approximately 3.2mA of bias current.

The output capacitor creates the dominant pole.

However, the pass transistor’s input capacitance creates

a second pole in the system. Additionally, the output

capacitor’s ESR generate a zero, which may be used to

cancel the second pole if necessary. Therefore, in order

to achieve stable operation, use the following equations

to verify that the linear regulator is properly compensated:

1) First, determine the dominant pole set by the linear

regulator’s output capacitor and the load resistor:

unity-gain crossover = A

V(LDO) ƒPOLE(CLDO)

2) Next, determine the second pole set by the base-toemitter capacitance (including the transistor’s input

capacitance), the transistor’s input resistance, and

the base-to-emitter pullup resistor:

3) A third pole is set by the linear regulator’s feedback

resistance and the capacitance between FB_ and

GND (including 20pF stray capacitance).

4) If the second and third pole occur well after unitygain crossover, the linear regulator will remain stable:

ƒ

POLE(FB)

and ƒ

POLE(CBE) >

2

ƒ

POLE(CLDO) AV(LDO)

However, if the ESR zero occurs before unity-gain

crossover, cancel the zero with f

POLE(FB)

by changing

circuit components such that:

Do not use output capacitors with more than 200mΩ of

ESR. Typically, more output capacitance provides the

best solution, since this also reduces the output voltage

drop immediately after a load transient.

Linear Regulator Output Capacitors

Connect at least 1µF capacitor between the linear regulator’s output and ground, as close to the MAX1964/

MAX1965 and external pass transistors as possible.

Depending on the selected pass transistor, larger

capacitor values may be required for stability (see

Stability Requirements). Furthermore, the output capacitor’s equivalent series resistance (ESR) affects stability,

providing a zero that may be necessary to cancel the

second pole. Use output capacitors with an ESR less

than 200mΩ to ensure stability and optimum transient

response.

Once the minimum capacitor value for stability is determined, verify that the linear regulator’s output does not

contain excessive noise. Although adequate for stability, small capacitor values may provide too much bandwidth, making the linear regulator sensitive to noise.

Larger capacitor values reduce the bandwidth, thereby

reducing the regulator’s noise sensitivity.

For the negative linear regulator, if noise on the ground

reference causes the design to be marginally stable,

bypass the negative output back to its reference voltage (V

REF

, Figure 7). This technique reduces the differ-

ential noise on the output.

Base-Drive Noise Reduction

The high-impedance base driver is susceptible to system noise, especially when the linear regulator is lightly

loaded. Capacitively coupled switching noise or inductively coupled EMI onto the base drive causes fluctuations in the base current, which appear as noise on the

linear regulator’s output. Keep the base-drive traces

away from the step-down converter and as short as

possible to minimize noise coupling. Resistors in series

with the gate drivers (DH and DL) reduce the LX

switching noise generated by the step-down converter

(Figure 5). Additionally, a bypass capacitor may be

placed across the base-to-emitter resistor (Figure 7).

This bypass capacitor, in addition to the transistor’s

input capacitance, could bring in a second pole that

will destabilize the linear regulator (see Stability

Requirements). Therefore, the stability requirements

determine the maximum base-to-emitter capacitance:

MAX1964/MAX1965

Tracking/Sequencing Triple/Quintuple

Power-Supply Controllers

______________________________________________________________________________________ 23

.

55

A

ƒ= =

POLE CLDO

()

ƒ=

POLE CBE

≈

V LDO

V

T

CR

22ππ

()

=

ƒ=

POLE FB

()

Ih

BIAS FE

+

1

I

LOAD

1

LDO LOAD

CRR

22π

BE BE IN BJT

()

RI Vh

BE LOAD T FE

CRVh

π

BE BE T FE

1

212π

CRR

FB

V

REF()

I

LOAD MAX

()

CV

LDO LDO

1

()

+

()

ƒ≈

POLE FB

()

1

CR

π

OUT ESR

MAX1964/MAX1965

where C

IN(Q)

is the transistor’s input capacitance, and

f

POLE(CBE)

is the second pole required for stability.

Transformer Selection

In systems where the step-down controller’s output is

not the highest voltage, a transformer may be used to

provide additional post-regulated, high-voltage outputs.

The transformer generates unregulated, high-voltage

supplies which power the positive and negative linear

regulators. These unregulated supply voltages are

dependent on the transformer’s turns ratio – number of

secondary turns (NS) divided by the number of primary

turns (NP). So the transformer must be selected to provide supply voltages high enough to keep the pass

transistors from saturating. For positive output voltages,

connect the transformer as shown in Figure 6 where the