General Description

The MAX19588 is a 3.3V, high-speed, high-performance analog-to-digital converter (ADC) featuring a

fully differential wideband track-and-hold (T/H) and a

16-bit converter core. The MAX19588 is optimized for

multichannel, multimode receivers, which require the

ADC to meet very stringent dynamic performance

requirements. With a -82dBFS noise floor, the

MAX19588 allows for the design of receivers with superior sensitivity requirements.

At 100Msps, the MAX19588 achieves a 79dB signal-tonoise ratio (SNR) and an 82.1dBc/97.7dBc single-tone

spurious-free dynamic range performance (SFDR1/

SFDR2) at f

IN

= 70MHz. The MAX19588 is not only optimized for excellent dynamic performance in the 2nd

Nyquist region, but also for high-IF input frequencies. For

instance, at 130MHz, the MAX19588 achieves an

82.3dBc SFDR and its SNR performance stays flat (within

2.3dB) up to 175MHz. This level of performance makes

the part ideal for high-performance digital receivers.

The MAX19588 operates from a 3.3V analog supply

voltage and a 1.8V digital voltage, features a 2.56V

P-P

full-scale input range, and allows for a guaranteed sampling speed of up to 100Msps. The input track-and-hold

stage operates with a 600MHz full-scale, full-power

bandwidth.

The MAX19588 features parallel, low-voltage CMOScompatible outputs in two’s-complement output format.

The MAX19588 is manufactured in an 8mm x 8mm,

56-pin thin QFN package with exposed paddle (EP) for

low thermal resistance, and is specified for the extended

industrial (-40°C to +85°C) temperature range.

Applications

Cellular Base-Station Transceiver Systems (BTS)

Wireless Local Loop (WLL)

Multicarrier Receivers

Multistandard Receivers

E911 Location Receivers

High-Performance Instrumentation

Antenna Array Processing

Features

♦ 100Msps Conversion Rate

♦ -82dBFS Noise Floor

♦ Excellent Low-Noise Characteristics

SNR = 79.4dB at f

IN

= 10MHz

SNR = 79dB at fIN= 70MHz

♦ Excellent Dynamic Range (SFDR1/SFDR2)

93.2dBc/102.5dBc at fIN= 10MHz

82.1dBc/97.7dBc at fIN= 70MHz

♦ Less than 0.1ps Sampling Jitter

♦ 1275mW Power Dissipation

♦ 2.56V

P-P

Fully Differential Analog Input Voltage

Range

♦ CMOS-Compatible Two’s-Complement Data

Output

♦ Separate Data Valid Clock and Over-Range Outputs

♦ Flexible Input Clock Buffer

♦ Small 56-Pin, 8mm x 8mm x 0.8mm Thin QFN

Package

♦ EV Kit Available for MAX19588

(Order MAX19588EVKIT)

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

________________________________________________________________

Maxim Integrated Products

1

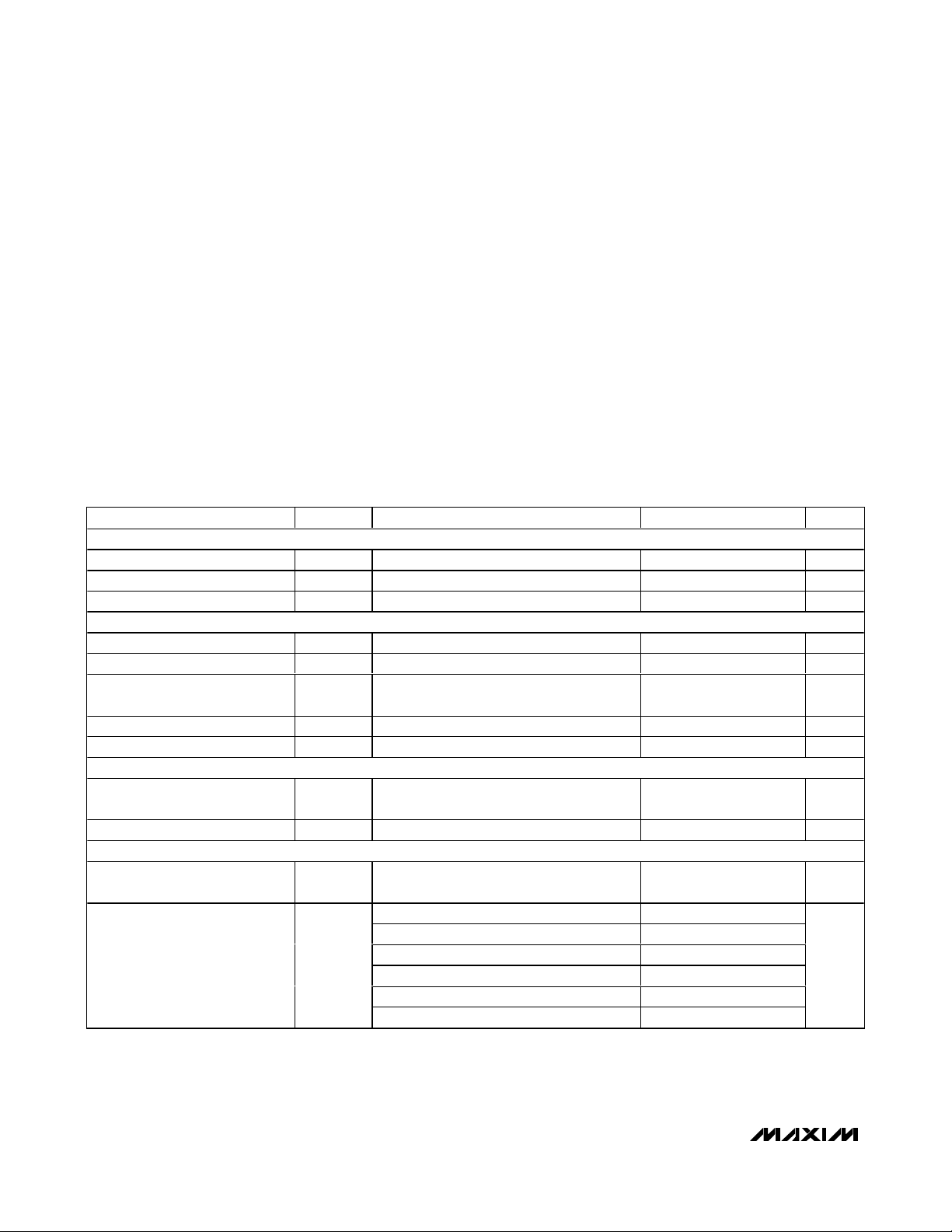

Pin Configuration

Ordering Information

19-0513; Rev 0; 5/06

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

+

Denotes lead-free package.

D = Dry pack.

*

EP = Exposed paddle.

PART

MAX19588ETN-D

MAX19588ETN+D

RANGE

-40°C to

-40°C to

TEMP

+85°C

+85°C

PIN-PACKAGE

56 Thin QFN-EP* T5688-2

56 Thin QFN-EP* T5688-2

PKG

CODE

TOP VIEW

DD

DVDDDV

42 41 40 39 38 37 36 35 34 33 32 31 30 29

D9

43

D10

44

D11

45

D12

46

D13

47

D14

48

D15

49

DAV

50

DV

51

DD

DGND

52

53

DOR

54

N.C.

55

AV

DD

56

AV

DD

1 2 3 4 5 6 7 8 91011121314

MAX19588

EP

DDAAVDDA

CLKP

CLKN

AGND

AGND

AGND

AV

THIN QFN

8mm x 8mm

AGND

AGND

INP

DD

DGND

DGND

DV

D0D1D2D3D4D5D6D7D8

28

AGND

27

REFIN

26

REFOUT

25

AV

DD

24

AV

DD

23

AV

DD

22

AGND

21

AGND

20

AGND

19

AV

DD

18

AV

DD

17

AV

DD

16

N.C.

15

N.C.

INN

AGND

AGND

AGND

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

2 _______________________________________________________________________________________

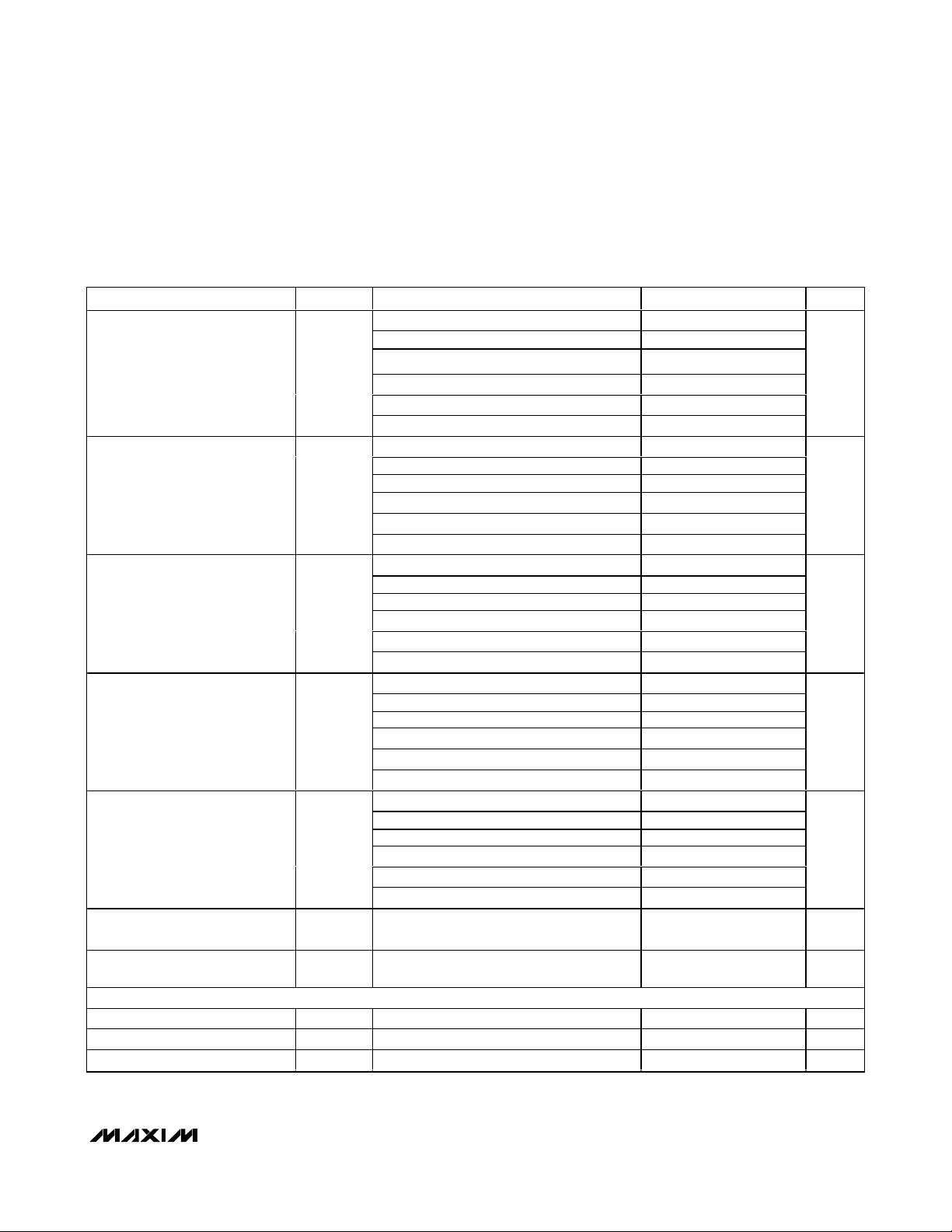

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(AVDD= AV

DDA

= 3.3V, DVDD= 1.8V, AGND = DGND = 0, internal reference, INP and INN driven differentially, CLKP and CLKN driven

differentially, C

L

= 5pF at digital outputs (D0–D15, DOR), CL= 15pF for DAV, f

CLK

= 100MHz, TA= T

MIN

to T

MAX

, unless otherwise noted.

Typical values are at T

A

= +25°C, unless otherwise noted.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

AVDD, AV

DDA

to AGND ........................................ -0.3V to +3.6V

DV

DD

to DGND..................................................... -0.3V to +2.4V

AGND to DGND.................................................... -0.3V to +0.3V

INP, INN, CLKP, CLKN, REFP, REFN,

REFIN, REFOUT to AGND....................-0.3V to (AV

DD

+ 0.3V)

D0–D15, DAV, DOR to GND....................-0.3V to (DV

DD

+ 0.3V)

Continuous Power Dissipation (T

A

= +70°C)

56-Pin Thin QFN-EP

(derate 47.6mW/°C above +70°C).........................3809.5mW

Operating Temperature Range ..........................-40°C to +85°C

Thermal Resistance θ

JA

..................................................21°C/W

Thermal Resistance θ

JC

.................................................0.6°C/W

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

DC ACCURACY

Resolution N 16 Bits

Offset Error V

Gain Error GE -3.5 +3.5 %FS

ANALOG INPUTS (INP, INN)

Input Voltage Range V

Common-Mode Voltage V

Differential Input Resistance R

Differential Input Capacitance C

Full-Power Analog Bandwidth BW

REFERENCE INPUT/OUTPUT (REFIN, REFOUT)

Reference Input Voltage Range REFIN

Reference Output Voltage REFOUT 1.28 V

DYNAMIC SPECIFICATIONS (f

Thermal Plus Quantization Noise

Floor

Signal-to-Noise Ratio

(First 4 Harmonics Excluded)

(Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

OS

DIFF

CM

IN

IN

-3dB

= 100Msps)

CLK

NF A

SNR

Fully differential input, VIN = V

Internally self-biased 2.4 V

-3dB rolloff for FS Input 600 MHz

< -35dBFS -82 dBFS

IN

fIN = 10MHz, AIN = -2dBFS 79.4

fIN = 70MHz, AIN = -2dBFS, TA = +25°C 77.5 79

fIN = 70MHz, AIN = -2dBFS 75.3 79

fIN = 105MHz, AIN = -2dBFS 78.3

fIN = 130MHz, AIN = -2dBFS 77.5

= 168MHz, AIN = -2dBFS 76.6

f

IN

- V

INP

01020mV

INN

2.56 V

10

±20%

7pF

1.28

±10%

P-P

kΩ

V

dB

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

_______________________________________________________________________________________ 3

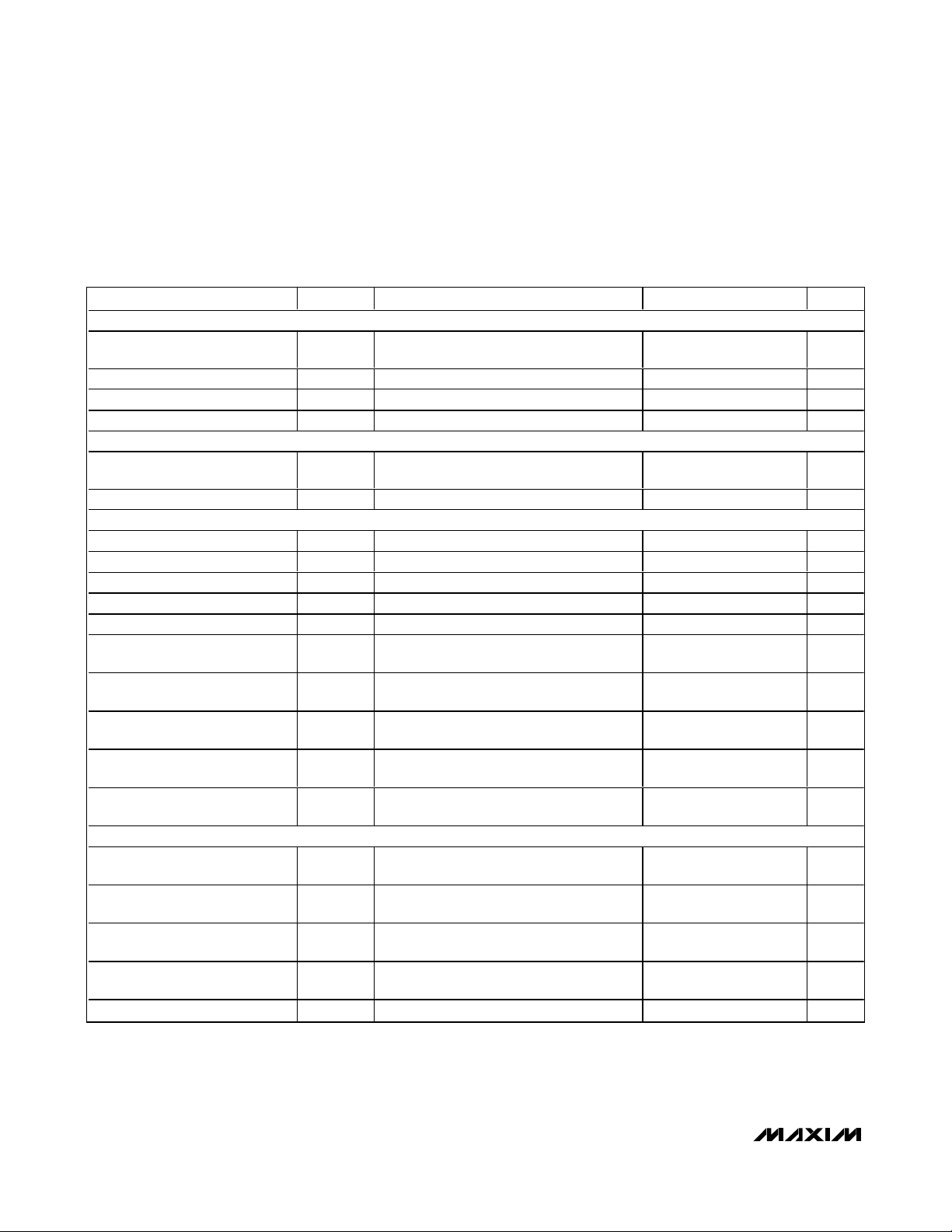

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= AV

DDA

= 3.3V, DVDD= 1.8V, AGND = DGND = 0, internal reference, INP and INN driven differentially, CLKP and CLKN driven

differentially, C

L

= 5pF at digital outputs (D0–D15, DOR), CL= 15pF for DAV, f

CLK

= 100MHz, TA= T

MIN

to T

MAX

, unless otherwise noted.

Typical values are at T

A

= +25°C, unless otherwise noted.) (Note 1)

Signal-to-Noise Plus Distortion

(Note 2)

Spurious-Free Dynamic Range

(Worst Harmonic, 2nd and 3rd)

Spurious-Free Dynamic Range

(Worst Harmonic, 4th and Higher)

(Note 2)

Second-Order Harmonic

Distortion

Third-Order Harmonic Distortion HD3

Third-Order Intermodulation

Distortion

Two-Tone SFDR TTSFDR

CONVERSION RATE

Maximum Conversion Rate f

Minimum Conversion Rate f

Aperture Jitter t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

fIN = 10MHz, AIN = -2dBFS 79

fIN = 70MHz, AIN = -2dBFS, TA = +25°C 75 77.1

SINAD

SFDR1

SFDR2

HD2

IM3

CLKMAX

CLKMIN

fIN = 70MHz, AIN = -2dBFS 73.5 77.1

fIN = 105MHz, AIN = -2dBFS 77.1

fIN = 130MHz, AIN = -2dBFS 75.8

f

= 168MHz, AIN = -2dBFS 70.8

IN

fIN = 10MHz, AIN = -2dBFS 93.2

fIN = 70MHz, AIN = -2dBFS, TA = +25°C 79.6 82.1

fIN = 70MHz, AIN = -2dBFS 79.3 82.1

fIN = 105MHz, AIN = -2dBFS 86.6

fIN = 130MHz, AIN = -2dBFS 82.3

f

= 168MHz, AIN = -2dBFS 75.4

IN

fIN = 10MHz, AIN = -2dBFS 102.5

fIN = 70MHz, AIN = -2dBFS, TA = +25°C 90.4 97.7

fIN = 70MHz, AIN = -2dBFS 85 97.7

fIN = 105MHz, AIN = -2dBFS 94.2

fIN = 130MHz, AIN = -2dBFS 94.1

= 168MHz, AIN = -2dBFS 91.5

f

IN

fIN = 10MHz, AIN = -2dBFS -94.3

fIN = 70MHz, AIN = -2dBFS, TA = +25°C -93 -83

fIN = 70MHz, AIN = -2dBFS -93 -78.3

fIN = 105MHz, AIN = -2dBFS -88

fIN = 130MHz, AIN = -2dBFS -82.3

f

= 168MHz, AIN = -2dBFS -77.6

IN

fIN = 10MHz, AIN = -2dBFS -94.3

fIN = 70MHz, AIN = -2dBFS, TA = +25°C -82.1 -79.6

fIN = 70MHz, AIN = -2dBFS -82.1 -79.3

fIN = 105MHz, AIN = -2dBFS -87.4

fIN = 130MHz, AIN = -2dBFS -92.5

f

= 168MHz, AIN = -2dBFS -75.4

IN

f

= 65.1MHz, A

IN1

f

= 70.1MHz, A

IN2

f

= 65.1MHz, f

IN1

< A

< -10dBFS

IN

J

= -8dBFS

IN1

= -8dBFS

IN2

= 70.1MHz, -100dBFS

IN2

100 MHz

-87.7 dBc

98 dBFS

20 MHz

85 fs

dB

dBc

dBc

dBc

dBc

RMS

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= AV

DDA

= 3.3V, DVDD= 1.8V, AGND = DGND = 0, internal reference, INP and INN driven differentially, CLKP and CLKN driven

differentially, C

L

= 5pF at digital outputs (D0–D15, DOR), CL= 15pF for DAV, f

CLK

= 100MHz, TA= T

MIN

to T

MAX

, unless otherwise noted.

Typical values are at T

A

= +25°C, unless otherwise noted.) (Note 1)

Note 1: TA≥ +25°C guaranteed by production test, TA< +25°C guaranteed by design and characterization. Typical values are at TA=

+25°C.

Note 2: AC parameter measured in a 32,768-point FFT record, where the first 2 bins of the FFT and 2 bins on either side of the carrier

are excluded. For SNR and SINAD measurements, bins dominated by production test system noise are excluded.

Note 3: Parameter guaranteed by design and characterization.

CLOCK INPUTS (CLKP, CLKN)

Differential Input Swing V

Common-Mode Voltage V

Differential Input Resistance R

Differential Input Capacitance C

CMOS-COMPATIBLE DIGITAL OUTPUTS (D0–D15, DOR, DAV)

Digital Output High Voltage V

Digital Output Low Voltage V

TIMING SPECIFICATIONS (Figures 4, 5), CL = 7.5pF (D0–D15, DOR); CL = 35pF (DAV)

CLKP - CLKN High t

CLKP - CLKN Low t

Effective Aperture Delay t

Output Data Delay t

Data Valid Delay t

Pipeline Latency t

CLKP Rising Edge to DATA Not

Valid

CLKP Rising Edge to DATA

Guaranteed Valid

DATA Setup Time Before Rising

DAV

DATA Hold Time After Rising

DAV

POWER SUPPLIES

Analog Power-Supply Voltage

Digital Output Power-Supply

Voltage

Analog Power-Supply Current

Digital Output Power-Supply

Current

Power Dissipation P

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DIFFCLK

CMCLK

INCLK

INCLK

OH

OL

CLKP

CLKN

AD

DAT

DAV

LATENCY

t

DNV

t

DGV

t

t

H

AV

A

VDDA

DV

I

AVDD

I

AVDDA

I

DVDD

DISS

Fully differential inputs

Self-biased 1.6 V

DV

I

I

= 200µA

SOURCE

= 200µA 0.2 V

SINK

DD

0.2

(Note 3) 4 ns

(Note 3) 4 ns

(Note 3) 2.5 4 5.2 ns

(Note 3) 1.1 ns

(Note 3) 7.5 ns

Clock duty cycle = 50% (Note 3) 2 ns

S

Clock duty cycle = 50% (Note 3) 2.5 ns

,

DD

DD

3.13 3.3 3.46 V

1.7 1.8 1.9 V

+

1.0 to

5.0

V

P-P

10 kΩ

3pF

V

-300 ps

3.4 ns

7

Clock

Cycles

369 450 mA

31 42 mA

1275 1561 mW

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

_______________________________________________________________________________________

5

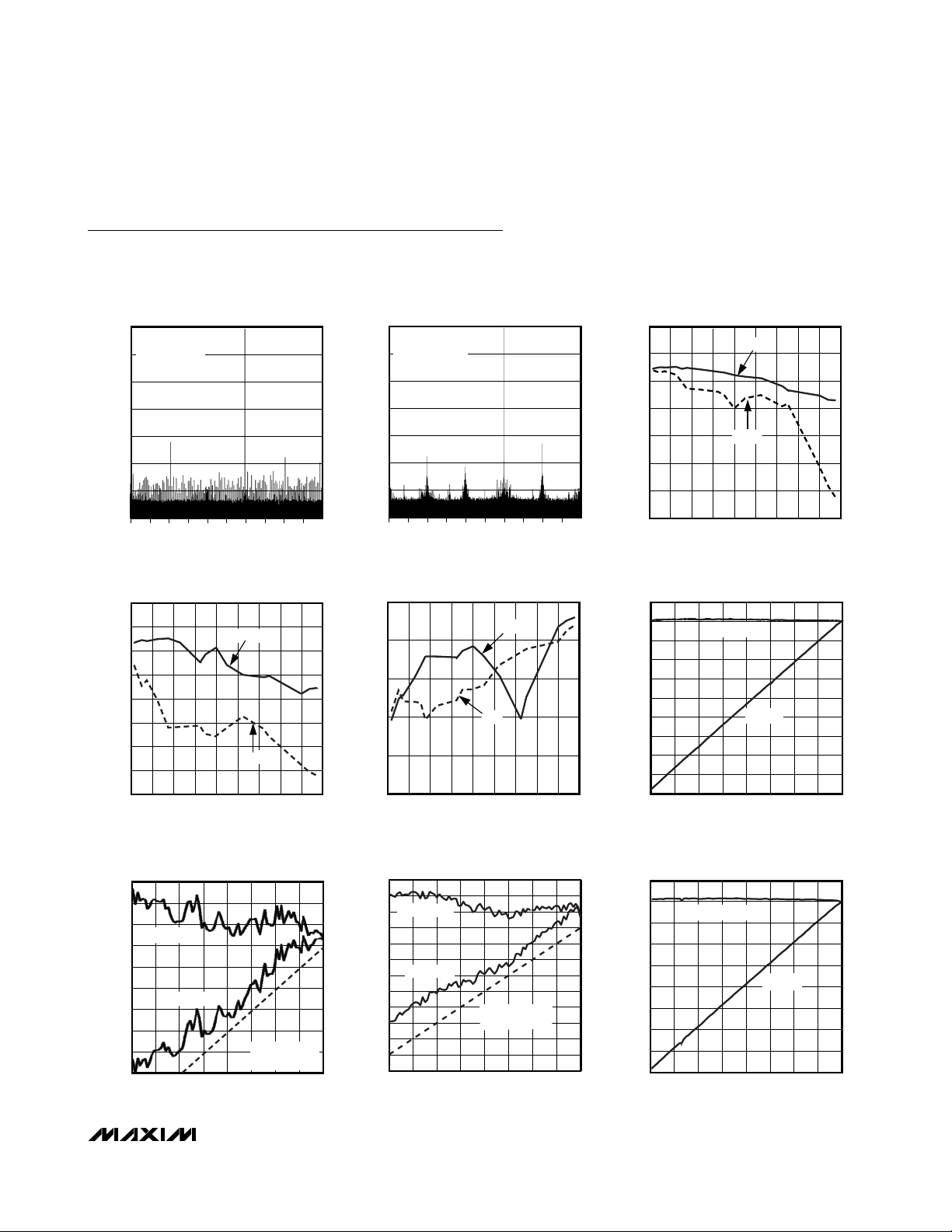

Typical Operating Characteristics

(AVDD= AV

DDA =

3.3V, DVDD= 1.8V, INP and INN driven differentially, internal reference, CLKP and CLKN driven differentially, CL=

7.5pF at digital outputs (D0–D15, DOR), C

L

= 35pF for DAV, f

CLK

= 100MHz, TA= +25°C. Unless otherwise noted, all AC data based

on 32k-point FFT records.)

FFT PLOT

(524,288-POINT DATA RECORD)

0

f

= 100MHz

CLK

= 70.164MHz

f

IN

-20

= -1.94dBFS

A

IN

-40

-60

-80

AMPLITUDE (dBFS)

-100

-120

-140

3

0105 152025 35 4530 40

ANALOG INPUT FREQUENCY (MHz)

2

SFDR1/SFDR2 vs. ANALOG INPUT FREQUENCY

= 100MHz, AIN = -2dBFS)

(f

110

105

100

95

90

85

SFDR1/SFDR2 (dBc)

80

75

70

CLK

SFDR2

SFDR1

0 40608020 100 120 140 160 180

fIN (MHz)

0

f

CLK

f

IN

-20

A

MAX19588 toc01

IN

-40

-60

-80

AMPLITUDE (dBFS)

-100

-120

-140

0105 152025 35 45

HD2/HD3 vs. ANALOG INPUT FREQUENCY

-70

MAX19588toc04

-80

-90

-100

HD2/HD3 (dBc)

-110

-120

0 40608020 100 120 140 160 180

(524,288-POINT DATA RECORD)

= 100MHz

= 130.001MHz

= -1.98dBFS

(f

FFT PLOT

3

30 40

ANALOG INPUT FREQUENCY (MHz)

= 100MHz, AIN = -2dBFS)

CLK

HD3

HD2

fIN (MHz)

SNR/SINAD vs. ANALOG INPUT FREQUENCY

82

80

MAX19588 toc02

78

76

MAX19588toc05

74

SNR/SINAD (dB)

72

70

68

04020 60 80 100 120 140 160 180

90

80

70

60

50

40

SNR (dB, dBFS)

30

20

10

0

-80 -60 -50 -40-70 -30 -20 -10 0

2

= 100MHz, AIN = -2dBFS)

(f

CLK

SNR

SINAD

fIN (MHz)

SNR vs. ANALOG INPUT AMPLITUDE

= 100MHz, fIN = 10MHz)

(f

CLK

SNR (dBFS)

SNR (dB)

ANALOG INPUT AMPLITUDE (dBFS)

MAX19588 toc03

MAX19588toc06

SFDR1 vs. ANALOG INPUT AMPLITUDE

= 100MHz, fIN = 10MHz)

(f

120

110

100

90

80

70

SFDR1 (dBc, dBFS)

60

50

40

30

CLK

SFDR1 (dBFS)

SFDR1 (dBc)

SFDR = 90dB

REFERENCE LINE

-80 -60 -50 -40-70 -30 -20 -10 0

ANALOG INPUT AMPLITUDE (dBFS)

MAX19588toc07

SFDR2 (dBc, dBFS)

SFDR2 vs. ANALOG INPUT AMPLITUDE

= 100MHz, fIN = 10MHz)

(f

120

110

100

90

80

70

60

50

40

30

20

10

CLK

SFDR2 (dBFS)

SFDR2 (dBc)

SFDR = 90dB

REFERENCE LINE

0

-80 -60 -50 -40-70 -30 -20 -10 0

ANALOG INPUT AMPLITUDE (dBFS)

MAX19588toc08

SNR vs. ANALOG INPUT AMPLITUDE

= 100MHz, fIN = 70MHz)

(f

90

80

70

60

50

40

SNR (dB, dBFS)

30

20

10

CLK

SNR (dBFS)

SNR (dB)

0

-80 -60 -50 -40-70 -30 -20 -10 0

ANALOG INPUT AMPLITUDE (dBFS)

MAX19588toc09

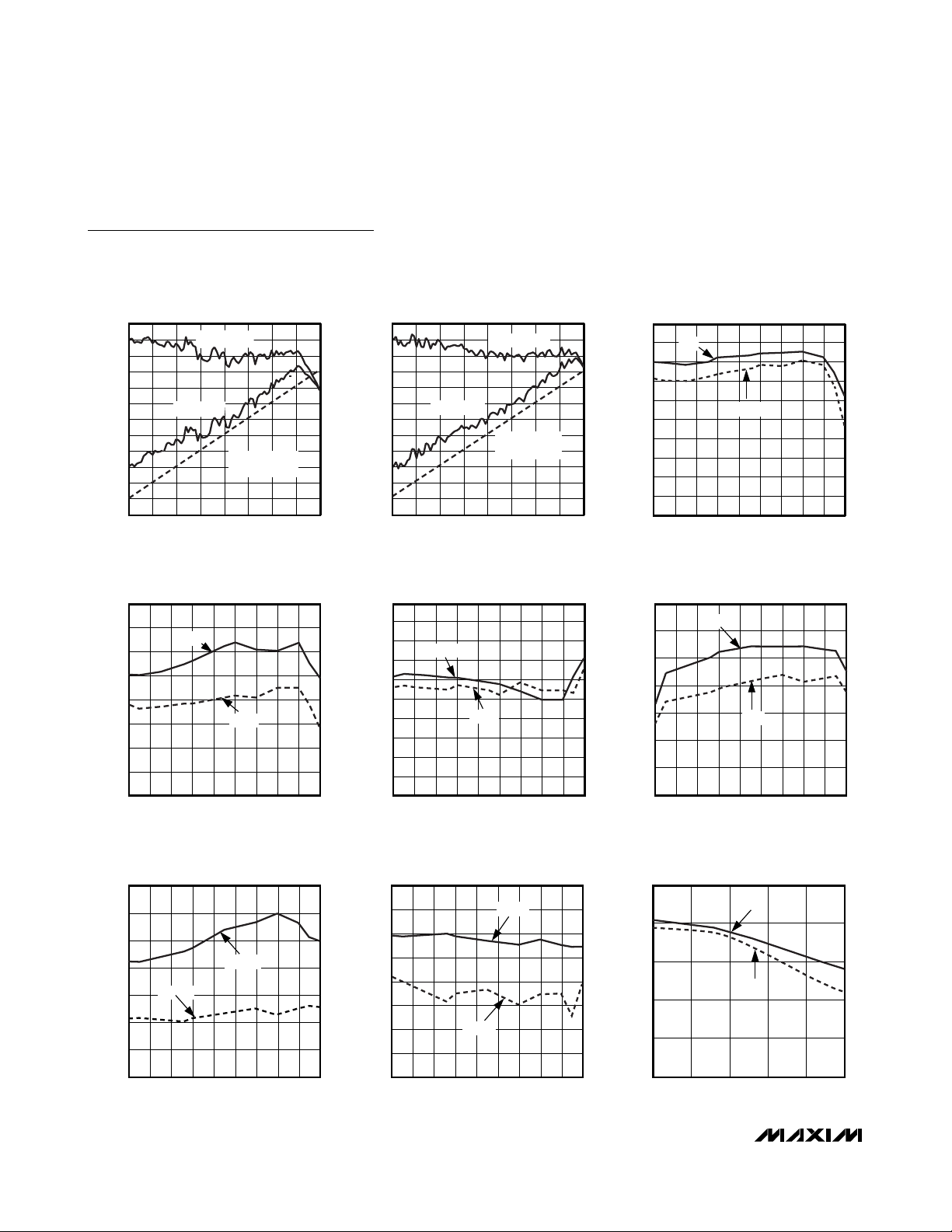

Typical Operating Characteristics (continued)

(AVDD= AV

DDA =

3.3V, DVDD= 1.8V, INP and INN driven differentially, internal reference, CLKP and CLKN driven differentially, CL=

7.5pF at digital outputs (D0–D15, DOR), C

L

= 35pF for DAV, f

CLK

= 100MHz, TA= +25°C. Unless otherwise noted, all AC data based

on 32k-point FFT records.)

70

80

95

75

85

100

90

105

20 40 50 6030 70 80 90 100 110

SFDR1/SFDR2 vs. SAMPLING FREQUENCY

(f

IN

= 70MHz, AIN = -2dBFS)

MAX19588toc16

f

CLK

(MHz)

SFDR/SFDR2 (dB)

SFDR2

SFDR1

-110

-100

-90

-105

-95

-70

20 40 50 6030 70 80 90 100 110

HD2/HD3 vs. SAMPLING FREQUENCY

(f

IN

= 70MHz, AIN = -2dBFS)

MAX19588toc17

f

CLK

(MHz)

HD2/HD3 (dBc)

-80

-85

-75

HD3

HD2

72

74

76

82

-40 -15 10 35 60 85

SNR/SINAD vs. TEMPERATURE

(f

CLK

= 100MHz, fIN = 10.1MHz, AIN = -2dBFS)

MAX19588toc18

TEMPERATURE (°C)

SNR/SINAD (dB)

78

80

SNR

SINAD

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

6 _______________________________________________________________________________________

SFDR1 vs. ANALOG INPUT AMPLITUDE

120

110

100

90

80

70

60

50

SFDR1 (dBc, dBFS)

40

30

20

10

0

-80 -60 -50 -40-70 -30 -20 -10 0

= 100MHz, fIN = 70MHz)

(f

CLK

SFDR1 (dBFS)

SFDR1 (dBc)

SFDR = 90dB

REFERENCE LINE

ANALOG INPUT AMPLITUDE (dBFS)

SFDR2 vs. ANALOG INPUT AMPLITUDE

120

110

100

MAX19588toc10

90

80

70

60

50

40

SFDR2 (dBc, dBFS)

30

20

10

0

-80 -60 -50 -40-70 -30 -20 -10 0

SNR/SINAD vs. SAMPLING FREQUENCY

= 100MHz, fIN = 70MHz)

(f

CLK

SFDR2 (dBFS)

SFDR2 (dBc)

SFDR = 90dB

REFERENCE LINE

ANALOG INPUT AMPLITUDE (dBFS)

MAX19588toc11

81

80

79

78

77

76

75

SNR/SINAD (dB)

74

73

72

71

20 40 50 6030 70 80 90 100 110

= 10MHz, AIN = -2dBFS)

(f

IN

SNR

SINAD

f

(MHz)

CLK

MAX19588toc12

SFDR1/SFDR2 vs. SAMPLING FREQUENCY

= 10MHz, AIN = -2dBFS)

(f

110

105

100

95

90

85

SFDR1/SFDR2 (dBc)

80

75

70

IN

SFDR2

20 30 40 50 60 70 80 90 100 110

HD2/HD3 vs. SAMPLING FREQUENCY

= 10MHz, AIN = -2dBFS)

(f

-70

-75

MAX19588toc13

-80

-85

-90

-95

SFDR1

f

(MHz)

CLK

-100

HD2/HD3 (dBc)

-105

-110

-115

-120

IN

HD3

HD2

20 30 40 50 60 70 80 90 100 110

f

(MHz)

CLK

MAX19588toc14

SNR/SINAD vs. SAMPLING FREQUENCY

= 70MHz, AIN = -2dBFS)

(f

82

80

78

76

74

SNR/SINAD (dB)

72

70

68

IN

SNR

SINAD

20 30 40 50 60 70 80 90 100 110

f

(MHz)

CLK

MAX19588toc15

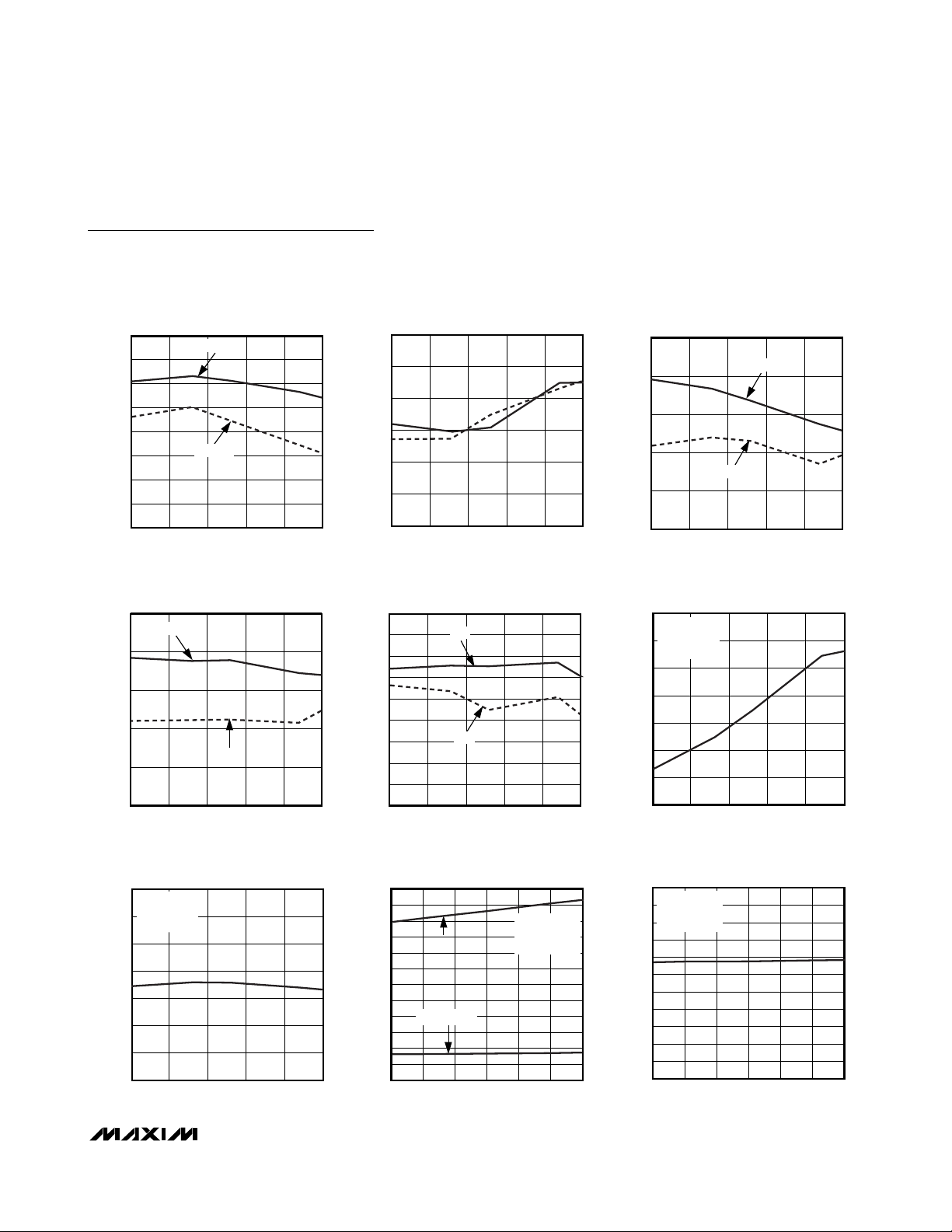

Typical Operating Characteristics (continued)

(AVDD= AV

DDA =

3.3V, DVDD= 1.8V, INP and INN driven differentially, internal reference, CLKP and CLKN driven differentially, CL=

7.5pF at digital outputs (D0–D15, DOR), C

L

= 35pF for DAV, f

CLK

= 100MHz, TA= +25°C. Unless otherwise noted, all AC data based

on 32k-point FFT records.)

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

_______________________________________________________________________________________

7

SNR/SINAD

(dB)

HD2/HD3

(dB

)

REFERENCE

VOLTAGE

(V)

SFDR1/SFDR2 vs. TEMPERATURE

= 100MHz, fIN = 10.1MHz, AIN = -2dBFS)

(f

CLK

110

105

100

95

90

85

SFDR1/SFDR2 (dBc)

80

75

70

-40 -15 10 35 60 85

SFDR2

SFDR1

TEMPERATURE (°C)

SFDR1/SFDR2 vs. TEMPERATURE

= 100MHz, fIN = 70.1MHz, AIN = -2dBFS)

(f

CLK

110

SFDR2

100

90

80

SFDR1/SFDR2 (dBc)

70

60

-40 -15 10 35 60 85

SFDR1

TEMPERATURE (°C)

REFERENCE VOLTAGE

vs. TEMPERTURE

1.31

f

= 100MHz

CLK

= 70.1MHz

f

IN

1.30

1.29

1.28

1.27

1.26

REFERENCE VOLTAGE (V)

1.25

1.24

= -2dBFS

A

IN

-40 -15 10 35 60 85

TEMPERATURE (°C)

= 100MHz, fIN = 10.1MHz, AIN = -2dBFS)

(f

CLK

-80

-85

MAX19588toc19

-90

-95

HD2/HD3 (dBc)

-100

-105

-110

-40 -15 10 35 60 85

= 100MHz, fIN = 70.1MHz, AIN = -2dBFS)

(f

CLK

-70

-75

MAX19588toc22

-80

-85

c

-90

-95

-100

-105

-110

-115

-40 -15 10 35 60 85

1400

1300

1200

MAX19588toc25

1100

1000

(mA, mW)

900

DISS

800

, P

700

AVDDA

600

+ I

500

AVDD

I

400

300

200

3.15 3.20 3.25 3.30 3.35 3.40 3.45

HD2/HD3 vs. TEMPERATURE

vs. ANALOG SUPPLY VOLTAGE

HD2/HD3 vs. TEMPERATURE

HD2

HD3

TEMPERATURE (°C)

MAX19588toc20

SNR/SINAD vs. TEMPERATURE

= 100MHz, fIN = 70.1MHz, AIN = -2dBFS)

(f

CLK

82

80

78

76

74

72

-40-1510356085

TEMPERATURE (°C)

SNR

SINAD

POWER DISSIPATION

vs. TEMPERATURE

1300

f

= 100MHz

HD3

MAX19588toc23

HD2

TEMPERATURE (°C)

POWER DISSIPTATION

CLK

= 70.1MHz

f

IN

1290

= -2dBFS

A

IN

1280

1270

1260

1250

POWER DISSIPATION (mW)

1240

1230

-40 -15 10 35 60 85

TEMPERATURE (°C)

REFERENCE VOLTAGE

vs. ANALOG SUPPLY VOLTAGE

1.280

f

= 100MHz

CLK

P

DISS

I

AVDD + IAVDDA

ANALOG SUPPLY VOLTAGE (V)

f

= 100MHz

CLK

= 70.1MHz

f

IN

= -2dBFS

A

IN

MAX19588toc26

1.279

1.278

1.277

1.276

1.275

1.274

1.273

1.272

1.271

1.270

= 70.1MHz

f

IN

= -2dBFS

A

IN

3.15 3.20 3.25 3.30 3.35 3.40 3.45

ANALOG SUPPLY VOLTAGE (V)

MAX19588toc21

MAX19588toc24

MAX19588toc27

Typical Operating Characteristics (continued)

(AVDD= AV

DDA =

3.3V, DVDD= 1.8V, INP and INN driven differentially, internal reference, CLKP and CLKN driven differentially, CL=

7.5pF at digital outputs (D0–D15, DOR), C

L

= 35pF for DAV, f

CLK

= 100MHz, TA= +25°C. Unless otherwise noted, all AC data based

on 32k-point FFT records.)

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

8 _______________________________________________________________________________________

81

f

80

f

A

79

78

77

76

SNR/SINAD (dB)

75

74

73

3.15 3.20 3.25 3.30 3.35 3.40 3.45

SNR/SINAD

vs. ANALOG SUPPLY VOLTAGE

= 100MHz

CLK

= 70.1MHz

IN

= -2dBFS

IN

SNR

SINAD

ANALOG SUPPLY VOLTAGE (V)

0

-20

-40

-60

AMPLITUDE (dBFS)

-80

-100

f

IN1

vs. ANALOG SUPPLY VOLTAGE

110

f

= 100MHz

CLK

105

= 70.1MHz

f

MAX19588toc28

SFDR1/SFDR2 (dBc)

IN

= -2dBFS

A

IN

100

95

90

85

80

75

70

3.15 3.20 3.25 3.30 3.35 3.40 3.45

ANALOG SUPPLY VOLTAGE (V)

TWO-TONE SFDR PLOT

(32,786-POINT DATA RECORD)

f

= 100MHz

CLK

= 10.098MHz

f

IN1

= -7.95dBFS

A

IN1

= 14.871MHz

f

IN2

= -8.01dBFS

A

IN2

IM3 = -104.1dBc

f

IN2

f

- f

IN2

IN1

2f

- f

IN2

IN1

SFDR1/SFDR2

-70

f

CLK

-75

= 70.1MHz

f

MAX19588toc29

SFDR2

HD2/HD3 (dBc)

SFDR1

IN

A

IN

-80

-85

-90

-95

-100

-105

-110

3.15 3.20 3.25 3.30 3.35 3.40 3.45

TWO-TONE SFDR PLOT

(32,786-POINT DATA RECORD)

0

f

= 100MHz

CLK

= 70.102MHz

f

IN1

-20

= -8.03dBFS

A

MAX19588 toc31

IN

= 65.097MHz

f

IN2

= -8.13dBFS

A

IN2

-40

IM3 = -87.7dBc

-60

AMPLITUDE (dBFS)

-80

-100

f

IN1

2f

- f

IN1

IN2

vs. ANALOG SUPPLY VOLTAGE

HD2/HD3

= 100MHz

= -2dBFS

HD3

HD2

ANALOG SUPPLY VOLTAGE (V)

MAX19588 toc32

f

IN2

2f

- f

IN2

IN1

MAX19588toc30

-120

0105 152025 35 4530 40 50

ANALOG INPUT FREQUENCY (MHz)

TWO-TONE SFDR vs. ANALOG INPUT

AMPLITUDE (f

= 10.1MHz, f

f

IN1

120

110

100

TTSFDR (dBFS)

90

80

70

60

50

TTSFDR (dBc)

40

TTSFDR (dBc, dBFS)

30

20

10

0

-100 -80 -70 -60-90 -50 -40 -30 -20 -10 0

ANALOG INPUT AMPLITUDE (dBFS)

= 100MHz,

CLK

= 15.1MHz)

IN2

TTSFDR = 90dB

REFERENCE LINE

MAX19588toc33

-120

0105 152025 35 4530 40 50

ANALOG INPUT FREQUENCY (MHz)

TWO-TONE SFDR vs. ANALOG INPUT

AMPLITUDE (f

= 65.1MHz, f

f

IN1

120

110

100

TTSFDR (dBFS)

90

80

70

60

50

TTSFDR (dBc)

40

TTSFDR (dBc, dBFS)

30

20

10

0

-100 -80 -70 -60-90 -50 -40 -30 -20 -10 0

ANALOG INPUT AMPLITUDE (dBFS)

= 100MHz,

CLK

= 70.1MHz)

IN2

TTSFDR = 90dB

REFERENCE LINE

MAX19588toc34

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

_______________________________________________________________________________________ 9

Pin Description

PIN NAME FUNCTION

1, 2 AV

3, 6–9, 12,

13, 14, 20,

21, 22, 28

4 CLKP Differential Clock, Positive Input Terminal

5 CLKN Differential Clock, Negative Input Terminal

10 INP Differential Analog Input, Positive Terminal

11 INN Differential Analog Input, Negative Terminal

15, 16, 54 N.C. No Connection. Do not connect to this pin.

17, 18, 19,

23, 24, 25,

55, 56

26 REFOUT Internal Bandgap Reference Output

27 REFIN Reference Voltage Input

29, 41, 42, 51 DV

30, 31, 52 DGND Converter Ground. Digital output-driver ground.

32 D0 Digital CMOS Output Bit 0 (LSB)

33 D1 Digital CMOS Output Bit 1

34 D2 Digital CMOS Output Bit 2

35 D3 Digital CMOS Output Bit 3

36 D4 Digital CMOS Output Bit 4

37 D5 Digital CMOS Output Bit 5

38 D6 Digital CMOS Output Bit 6

39 D7 Digital CMOS Output Bit 7

40 D8 Digital CMOS Output Bit 8

43 D9 Digital CMOS Output Bit 9

44 D10 Digital CMOS Output Bit 10

45 D11 Digital CMOS Output Bit 11

46 D12 Digital CMOS Output Bit 12

47 D13 Digital CMOS Output Bit 13

48 D14 Digital CMOS Output Bit 14

49 D15 Digital CMOS Output Bit 15 (MSB)

50 DAV

DDA

AGND

AV

DD

DD

Auxiliary Analog Supply Voltage. Connect these pins together and connect to AVDD through a 50Ω

series resistor.

Converter Ground. Analog, digital, and output-driver grounds are internally connected to the same

potential. Connect the converter’s exposed paddle (EP) to GND.

Analog Supply Voltage. Provide local bypassing to ground with 0.01µF and 0.1µF capacitors.

Digital Supply Voltage. Provide local bypassing to ground with 0.01µF and 0.1µF capacitors.

Data Valid Output. This output can be used as a clock control line to drive an external buffer or dataacquisition system. The typical delay time between the falling edge of the converter clock and the

rising edge of DAV is 4ns.

Data Over-Range Bit. This control line flags an over-/under-range condition in the ADC. If DOR

53 DOR

— EP Exposed Paddle. Must be connected to AGND.

transitions high, an over-/under-range condition was detected. If DOR remains low, the ADC operates

within the allowable full-scale range.

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

10 ______________________________________________________________________________________

Detailed Description

Figure 1 provides an overview of the MAX19588 architecture. The MAX19588 employs an input track-andhold (T/H) amplifier, which has been optimized for low

thermal noise and low distortion. The high-impedance

differential inputs to the T/H amplifier (INP and INN) are

self-biased at approximately 2.4V, and support a fullscale 2.56V

P-P

differential input voltage. The output of

the T/H amplifier is applied to a multistage pipelined

ADC core, which is designed to achieve a very low

thermal noise floor and low distortion.

A clock buffer receives a differential input clock waveform and generates a low-jitter clock signal for the input

T/H. The signal at the analog inputs is sampled at the

rising edge of the differential clock waveform. The differential clock inputs (CLKP and CLKN) are highimpedance inputs, are self-biased at 1.6V, and support

differential clock waveforms from 1V

P-P

to 5V

P-P

.

The outputs from the multistage pipelined ADC core

are delivered to error correction and formatting logic,

which deliver the 16-bit output code in two’s-complement format to digital output drivers. The output drivers

provide 1.8V CMOS-compatible outputs.

Analog Inputs (INP, INN)

The signal inputs to the MAX19588 (INP and INN) are balanced differential inputs. This differential configuration

provides immunity to common-mode noise coupling and

rejection of even-order harmonic terms. The differential

signal inputs to the MAX19588 should be AC-coupled

and carefully balanced to achieve the best dynamic performance (see

Differential, AC-Coupled Analog Inputs

in

the

Applications Information

section for more details). ACcoupling of the input signal is required because the

MAX19588 inputs are self-biasing as shown in Figure 2.

Although the track-and-hold inputs are high impedance,

the actual differential input impedance is nominally 10kΩ

because of the two 5kΩ resistors connected to the

common-mode bias circuitry.

Avoid injecting any DC leakage currents into these analog inputs. Exceeding a DC leakage current of 10µA

shifts the self-biased common-mode level, adversely

affecting the converter’s performance.

On-Chip Reference Circuit

The MAX19588 incorporates an on-chip 1.28V, low-drift

bandgap reference. This reference potential establishes the full-scale range for the converter, which is nominally 2.56V

P-P

differential (Figure 3). The internal

reference voltage can be monitored by REFOUT.

To use the internal reference voltage the reference

input (REFIN) must be connected to REFOUT

through a 10kΩ resistor. Bypass both pins with sepa-

rate 1µF capacitors to AGND.

The MAX19588 also allows an external reference

source to be connected to REFIN, enabling the user to

overdrive the internal bandgap reference. REFIN

accepts a 1.28V ±10% input voltage range.

Figure 1. Block Diagram

CLKP

CLKN

INP

INN

CLOCK

BUFFER

T/H

MAX19588

PIPELINE

ADC

REFERENCE

REFOUT REFIN

CMOS

DRIVER

CMOS

OUTPUT

DRIVERS

16

AV

DD

AGND

DV

DD

DAV

DOR

D0–D15

DGND

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

______________________________________________________________________________________ 11

Clock Inputs (CLKP, CLKN)

The differential clock buffer for the MAX19588 has been

designed to accept an AC-coupled clock waveform.

Like the signal inputs, the clock inputs are self-biasing.

In this case, the self-biased potential is 1.6V and each

input is connected to the reference potential with a 5kΩ

resistor. Consequently, the differential input resistance

associated with the clock inputs is 10kΩ. While differential clock signals as low as 0.5V

P-P

can be used to

drive the clock inputs, best dynamic performance is

achieved with 1V

P-P

to 5V

P-P

clock input voltage levels.

Jitter on the clock signal translates directly to jitter

(noise) on the sampled signal. Therefore, the clock

source must be a very low-jitter (low-phase-noise)

source. Additionally, extremely low phase-noise oscillators and bandpass filters should be used to obtain the

true AC performance of this converter. See the

Differential, AC-Coupled Clock Inputs

and

Testing the

MAX19588

topics in the

Applications Information

section for additional details on the subject of driving the

clock inputs.

System Timing Requirements

Figure 4 depicts the general timing relationships for the

signal input, clock input, data output, and DAV output.

Figure 5 shows the detailed timing specifications and

signal relationships, as defined in the

Electrical

Characteristics

table.

The MAX19588 samples the input signal on the rising

edge of the input clock. Output data is valid on the rising edge of the DAV signal, with a 7 clock-cycle data

latency. Note that the clock duty cycle should typically

be 50% ±10% for proper operation.

Digital Outputs (D0–D15, DAV, DOR)

For best performance, the capacitive loading on the

digital outputs of the MAX19588 should be kept as low

as possible (< 10pF). Due to the current-limited dataoutput driver of the MAX19588, large capacitive loads

increase the rise and fall time of the data and can make

it more difficult to register the data into the next IC. The

loading capacitance can be kept low by keeping the

output traces short and by driving a single CMOS

buffer or latch input (as opposed to multiple CMOS

inputs). The output data is in two’s-complement format,

as illustrated in Table 1.

Data is valid at the rising edge of DAV (Figures 4, 5).

DAV may be used as a clock signal to latch the output

data. Note that the DAV output driver is not current limited, hence it allows for higher capacitive loading.

The converter’s DOR output signal is used to identify

over- and under-range conditions. If the input signal

exceeds the positive or negative full-scale range for the

MAX19588 then DOR will be asserted high. The timing

for DOR is identical to the timing for the data outputs,

and DOR therefore provides an over-range indication

on a sample-by-sample basis.

Figure 2. Simplified Analog Input Architecture

Figure 3. Full-Scale Voltage Range

T/H AMPLIFIER

INP

5kΩ

OTA

5kΩ

INN

T/H AMPLIFIER

TO FIRST QUANTIZER

STAGE

TO FIRST QUANTIZER

STAGE

2.56V

P-P

DIFFERENTIAL FSR

INP

INN

-640mV

+640mV

COMMON-MODE

VOLTAGE (2.4V)

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

12 ______________________________________________________________________________________

Figure 4. General System Output Timing Diagram

Figure 5. Detailed Timing Information for Clock Operation

N + 1

N

ANALOG INPUT

CLOCK INPUT

D0–D15

DAV

INP

INN

CLKN

CLKP

D0–D15

DOR

N - 7

N N + 1 N + 2 N + 3

t

DAT

N - 7

t

DAV

N - 6

7 CLOCK-CYCLE LATENCY (t

N + 2

N + 3

N - 5 N - 4 N - 3 N - 2 N - 1 N

t

AD

t

DNV

N - 6

t

DGV

LATENCY

t

CLKP

)

N + 4

t

N + 5

t

CLKN

N - 5

S

t

H

N + 6

N - 4

N + 7

DAV

: DELAY FROM CLKN TO DATA VALID CLOCK DAV

ENCODE AT CLKP - CLKN > 0 (RISING EDGE)

: CLKP - CLKN > 0

t

CLKP

: CLKP - CLKN < 0

t

CLKN

: EFFECTIVE APERTURE DELAY

t

AD

: DELAY FROM CLKP TO OUTPUT DATA TRANSITION

t

DAT

t

DAV

: CLKP RISING EDGE TO DATA NOT VALID

t

DNV

: CLKP RISING EDGE TO DATA GUARANTEED VALID

t

DGV

: DATA SETUP TIME BEFORE RISING DAV

t

S

: DATA HOLD TIME AFTER RISING DAV

t

H

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

______________________________________________________________________________________ 13

Applications Information

Differential, AC-Coupled Clock Inputs

The clock inputs to the MAX19588 are driven with an

AC-coupled differential signal, and best performance is

achieved under these conditions. However, it is often

the case that the available clock source is single-ended.

Figure 6 demonstrates one method for converting a single-ended clock signal into a differential signal with a

transformer. In this example, the transformer turns ratio

from the primary to secondary side is 1:1.414. The

impedance ratio from primary to secondary is the

square of the turns ratio, or 1:2. So terminating the sec-

ondary side with a 100Ω differential resistance results in

a 50Ω load looking into the primary side of the transformer. The termination resistor in this example is composed of the series combination of two 50Ω resistors

with their common node AC-coupled to ground.

Figure 6 illustrates the secondary side of the transformer to be coupled directly to the clock inputs. Since

the clock inputs are self-biasing, the center tap of the

transformer must be AC-coupled to ground or left floating. If the center tap of the transformer’s secondary

side is DC-coupled to ground, it is necessary to add

blocking capacitors in series with the clock inputs.

Table 1. MAX19588 Digital Output Coding

Figure 6. Transformer-Coupled Clock Input Configuration

INP

ANALOG VOLTAGE LEVEL

VCM + 0.64V VCM - 0.64V

V

CM

VCM - 0.64V VCM + 0.64V

ANALOG VOLTAGE LEVEL

INN

V

CM

TWO’S-COMPLEMENT CODE

0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

D15–D0

(positive full-scale)

(midscale + δ)

(midscale - δ)

(negative full-scale)

AV

DDDVDD

0.1μF

T2-1T-KK81

49.9Ω

49.9Ω

BACK-TO-BACK DIODE

0.1μF

INP

INN

MAX19588

CLKP CLKN

AGND

D0–D15

16

DGND

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

14 ______________________________________________________________________________________

Clock jitter is generally improved if the clock signal has

a high slew rate at the time of its zero-crossing.

Therefore, if a sinusoidal source is used to drive the

clock inputs, the clock amplitude should be as large as

possible to maximize the zero-crossing slew rate. The

back-to-back Schottky diodes shown in Figure 6 are not

required as long as the input signal is held to a differential voltage potential of 3V

P-P

or less. If a larger amplitude signal is provided (to maximize the zero-crossing

slew rate), then the diodes serve to limit the differential

signal swing at the clock inputs. Note that all AC specifications for the MAX19588 are measured within this

configuration and with an input clock amplitude of

approximately 12dBm.

Any differential mode noise coupled to the clock inputs

translates to clock jitter and degrades the SNR performance of the MAX19588. Any differential mode coupling

of the analog input signal into the clock inputs results in

harmonic distortion. Consequently, it is important that the

clock lines be well isolated from the analog signal input

and from the digital outputs. See the

Signal Routing

sec-

tion for more discussion on the subject of noise coupling.

Differential, AC-Coupled Analog Inputs

The analog inputs INP and INN are driven with a differential AC-coupled signal. It is important that these

inputs be accurately balanced. Any common-mode signal applied to these inputs degrades even-order distortion terms. Therefore, any attempt at driving these

inputs in a single-ended fashion will result in significant

even-order distortion terms.

Figure 7 presents one method for converting a singleended signal to a balanced differential signal using a

transformer. The primary-to-secondary turns ratio in this

example is 1:1.414. The impedance ratio is the square

of the turns ratio, so in this example the impedance ratio

is 1:2. To achieve a 50Ω input impedance at the primary

side of the transformer, the secondary side is terminated

with a 100Ω differential load. This load, in shunt with the

differential input resistance of the MAX19588, results in

a 100Ω differential load on the secondary side. It is reasonable to use a larger transformer turns ratio to achieve

a larger signal step-up, and this may be desirable to

relax the drive requirements for the circuitry driving the

MAX19588. However, the larger the turns ratio, the larger the effect of the differential input impedance of the

MAX19588 on the primary-referred input impedance.

As stated previously, the signal inputs to the MAX19588

must be accurately balanced to achieve the best evenorder distortion performance.

One note of caution in relation to transformers is important. Any DC current passed through the primary or

secondary windings of a transformer may magnetically

bias the transformer core. When this happens the transformer is no longer accurately balanced and a degradation in the distortion of the MAX19588 may be

observed. The core must be demagnetized to return to

balanced operation.

Layer Assignments

The MAX19588 EV kit is a 6-layer board, and the

assignment of layers is discussed in this context. It is

recommended that the ground plane be on a layer

between the signal routing layer and the supply routing

layer(s). This prevents coupling from the supply lines

into the signal lines. The MAX19588 EV kit PC board

places the signal lines on the top (component) layer

and the ground plane on layer 2. Any region on the top

layer not devoted to signal routing is filled with the

ground plane with vias to layer 2. Layers 3 and 4 are

devoted to supply routing, layer 5 is another ground

plane, and layer 6 is used for the placement of additional components and for additional signal routing.

Figure 7. Transformer-Coupled Analog Input Configuration with Primary-Side Balun Transformer

AV

DDDVDD

POSITIVE

TERMINAL

0.1μF

ADT2-1T

T1-1T-KK81

49.9Ω

49.9Ω

0.1μF

INP

INN

MAX19588

CLKP CLKN

AGND

DGND

D0–D15

16

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

______________________________________________________________________________________ 15

A four-layer implementation is also feasible using layer

1 for signal lines, layer 2 as a ground plane, layer 3 for

supply routing, and layer 4 for additional signal routing.

However, care must be taken to ensure that the clock

and signal lines are isolated from each other and from

the supply lines.

Signal Routing

To preserve good even-order distortion, the signal lines

(those traces feeding the INP and INN inputs) must be

carefully balanced. To accomplish this, the signal traces

should be made as symmetric as possible, meaning that

each of the two signal traces should be the same length

and should see the same parasitic environment. As

mentioned previously, the signal lines must be isolated

from the supply lines to prevent coupling from the supplies to the inputs. This is accomplished by making the

necessary layer assignments as described in the previous section. Additionally, it is crucial that the clock

lines be isolated from the signal lines. On the

MAX19588 EV kit this is done by routing the clock lines

on the bottom layer (layer 6). The clock lines then connect to the ADC through vias placed in close proximity

to the device. The clock lines are isolated from the supply lines as well by virtue of the ground plane on layer 5.

As with all high-speed designs, digital output traces

should be kept as short as possible to minimize capacitive loading. The ground plane on layer 2 beneath these

traces should not be removed so that the digital groundreturn currents have an uninterrupted path back to the

bypass capacitors.

Grounding

The practice of providing a split ground plane in an

attempt to confine digital ground-return currents has

often been recommended in ADC application literature.

However, for converters such as the MAX19588 it is

strongly recommended to employ a single, uninterrupted

ground plane. The MAX19588 EV kit achieves excellent

dynamic performance with such a ground plane.

The exposed paddle of the MAX19588 should be soldered directly to a ground pad on layer 1 with vias to

the ground plane on layer 2. This provides excellent

electrical and thermal connections to the PC board.

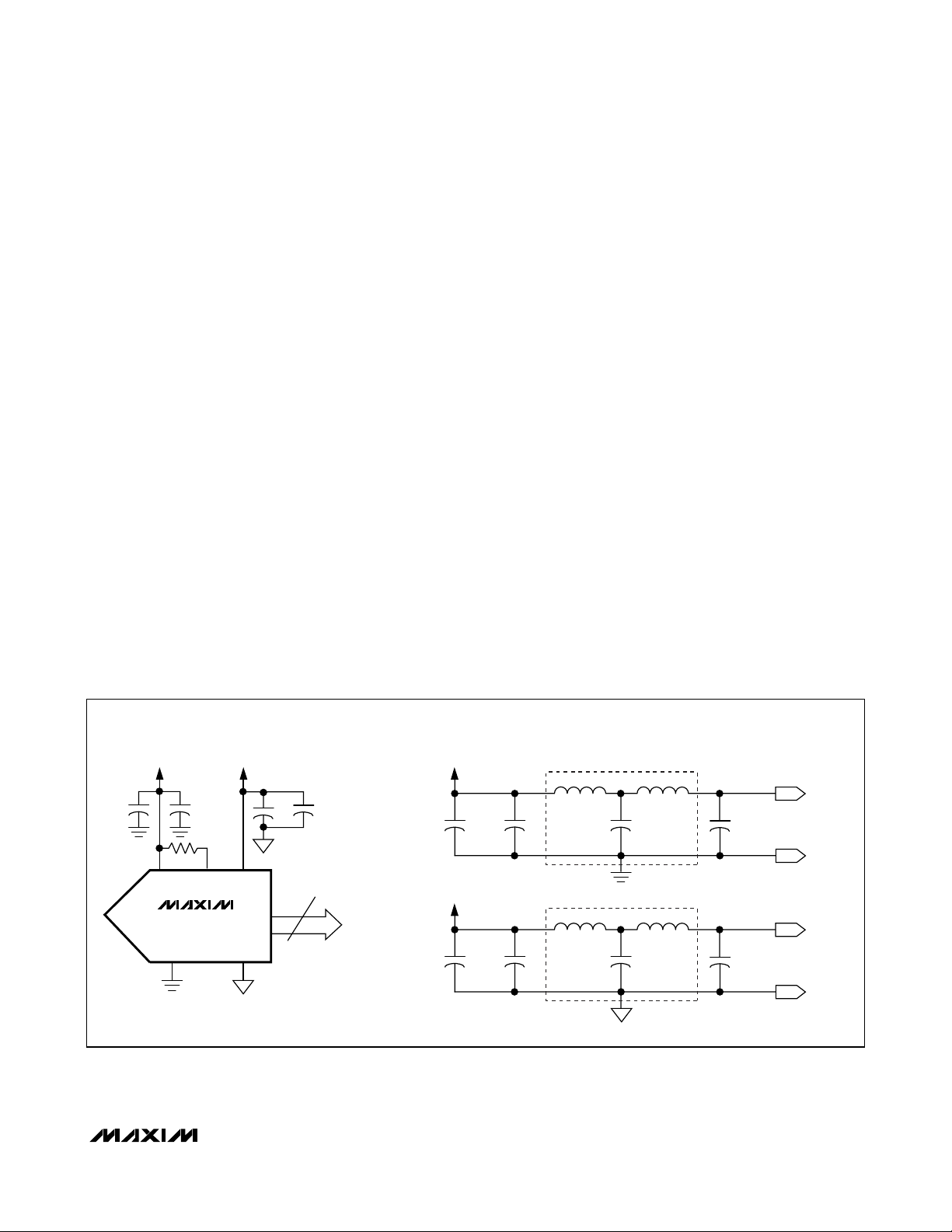

Supply Bypassing

The MAX19588 EV kit uses 220µF capacitors (and

smaller values such as 47µF and 2µF) on power-supply

lines AVDD, AV

DDA

, and DVDDto provide low-frequency

bypassing. The loss (series resistance) associated with

these capacitors is beneficial in eliminating high-Q supply resonances. Ferrite beads are also used on each of

the power-supply lines to enhance supply bypassing

(Figure 8).

Figure 8. Grounding, Bypassing, and Decoupling Recommendations for the MAX19588

BYPASSING—ADC LEVEL

AV

DD

0.01μF 0.01μF

50Ω

AVDDAV

MAX19588

AGND

DV

DD

DV

DGND

DGND

DD

0.1μF

D0–D15

16

0.1μF

AGND

DDA

2μF

2μF

AV

DD

47μF

DV

DD

47μF

BYPASSING—BOARD LEVEL

FERRITE BEAD

FERRITE BEAD

220μF

220μF

ANALOG POWERSUPPLY SOURCE

DIGITAL POWERSUPPLY SOURCE

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

16 ______________________________________________________________________________________

Combinations of small value (0.01µF and 0.1µF), lowinductance surface-mount capacitors should be placed

at each supply pin or each grouping of supply pins to

attenuate high-frequency supply noise. Place these

capacitors on the top side of the board and as close to

the converter as possible with short connections to the

ground plane.

Supply/Clock Sequencing

Power up the MAX19588 (any sequence will be acceptible) and then apply the clock. If the clock is present

before the MAX19588 is powered up, ensure that DV

DD

is brought up first followed by AVDD.

Testing the MAX19588

The MAX19588 has a very low thermal noise floor

(-82dBFS) and very low jitter (< 100fs). As a consequence, test system limitations can easily obscure the

performance of the ADC. Figure 9a is a block diagram

of a conventional high-speed ADC test system. The

input signal and the clock source are generated by

low-phase-noise synthesizers (e.g., HP/Agilent 8644B).

Bandpass filters in both the signal and the clock paths

then attenuate noise and harmonic components.

Figure 9b shows the resulting power spectrum, which

results from this setup for a 70MHz input tone and a

100Msps clock. Note the substantial lift in the noise

floor near the carrier. The bandwidth of this particular

noise-floor lift near the carrier corresponds to the bandwidth of the filter in the input signal path.

Figure 9c illustrates the impact on the spectrum if the

input frequency is shifted away from the center frequency of the input signal filter. Note that the fundamental tone has moved, but the noise-floor lift remains

in the same location. This is evidence of the validity of

the claim that the lift in the noise floor is due to the test

system and not the ADC. In this figure, the magnitude

of the lift in the noise floor increased relative to the previous figure because the signal is located on the skirt of

the filter and the signal amplitude had to be increased

to obtain a signal near full scale.

Figure 9b. 70MHz FFT with Standard High-Speed ADC Test

Setup

Figure 9c. 68MHz FFT with Standard High-Speed ADC Test

Setup

Figure 9a. Standard High-Speed ADC Test Setup (Simplified

Diagram)

10dB

SIGNAL PATH

BANDPASS

FILTER

CLOCK PATH

BANDPASS

FILTER

3dB

PAD

MAX19588

AGILENT 8644B

BOTH SIGNAL GENERATORS

ARE PHASE-LOCKED

AGILENT 8644B

FFT PLOT

(524,288-POINT DATA RECORD)

0

-20

-40

-60

-80

AMPLITUDE (dBFS)

-100

-120

-140

0105 15202530 4035 45

3

ANALOG INPUT FREQUENCY (MHz)

f

= 100MHz

CLK

= 70.1MHz

f

IN

= -2.04dBFS

A

IN

2

FFT PLOT

(542,288-POINT DATA RECORD)

0

f

= 100MHz

CLK

= 67.6MHz

f

IN

-20

= -1.98dBFS

A

IN

-40

-60

-80

3

AMPLITUDE (dBFS)

-100

-120

-140

0105152025304035 45

ANALOG FREQUENCY (MHz)

2

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

______________________________________________________________________________________ 17

To truly reveal the performance of the MAX19588, the test

system performance must be improved substantially.

Figure 9d depicts such an improved test system. In this

system, the synthesizers provide reference inputs to two

dedicated low-noise phase-locked loops (PLLs), one

centered at approximately 100MHz (for the clock path)

and the other centered at 70MHz (for the signal path).

The oscillators in these PLLs are very low-noise oscillators, and the PLLs act as extremely narrow bandwidth

filters (on the order of 20Hz) to attenuate the noise of

the synthesizers. The system provides a total system

jitter on the order of 20fs. Note that while the low-noise

oscillators could be used by themselves without being

locked to their respective signal sources, this would

result in FFTs that are not coherent and which would

require windowing.

Figure 9e is an FFT plot of the spectrum obtained when

the improved test system is employed. The noise-floor

lift in the vicinity of the carrier is now almost completely

eliminated. The SNR associated with this FFT is 79dB,

whereas the SNR obtained using the standard test system is 77.2dB.

Figure 9f demonstrates the impact of test system jitter

on measured SNR. The figure plots SNR due to test system jitter only, neglecting all other sources of noise, for

two different input frequencies. For example, note that

for a 70MHz input frequency a test system jitter number

of 100fs results in an SNR (due to the test system alone)

of about 87dB. In the case of the MAX19588, which has

a -82dBFS noise floor, this is not an inconsequential

amount of additional noise.

Figure 9d. Improved Test System Employing Narrowband PLLs (Simplified Diagram)

Figure 9e. 70MHz FFT with Improved High-Speed ADC Test Setup

Figure 9f. SNR vs. System Jitter Performance Graph

AGILENT 8644B

AGILENT 8644B

REF

TUNE

PLL

SIGNAL

LOW-NOISE PLL

BOTH SIGNAL GENERATORS

ARE PHASE-LOCKED

REF

TUNE

PLL

SIGNAL

LOW-NOISE PLL

VCXO

VCXO

SIGNAL PATH

CLOCK PATH

10dB

10dB

VARIABLE

ATTENUATOR

FFT PLOT

(524,288-POINT DATA RECORD)

0

-20

-40

-60

-80

AMPLITUDE (dBFS)

-100

-120

-140

0105 15202530 4035 45

3

ANALOG INPUT FREQUENCY (MHz)

f

= 100MHz

CLK

= 70.164MHz

f

IN

= -1.94dBFS

A

IN

2

110

105

100

95

90

85

80

SNR (dB)

75

70

65

60

BANDPASS

FILTER

3dB

BANDPASS

FILTER

PAD

MAX19588

SNR vs. RMS

JITTER PERFORMANCE

INPUT FREQUENCY = 70MHz

INPUT FREQUENCY = 140MHz

10 100 1000

RMS JITTER (fs)

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

18 ______________________________________________________________________________________

In conclusion, careful attention must be paid to both the

input signal source and the clock signal source, if the

true performance of the MAX19588 is to be properly

characterized. Dedicated PLLs with low-noise VCOs,

such as those used in Figure 9d, are capable of providing signals with the required low jitter performance.

Parameter Definitions

Offset Error

Offset error is a figure of merit that indicates how well

the actual transfer function matches the ideal transfer

function at a single point. Ideally, the midscale

MAX19588 transition occurs at 0.5 LSB above midscale. The offset error is the amount of deviation

between the measured midscale transition point and

the ideal midscale transition point.

Gain Error

Gain error is a figure of merit that indicates how well the

slope of the actual transfer function matches the slope

of the ideal transfer function. The slope of the actual

transfer function is measured between two data points:

positive full scale and negative full scale. Ideally, the

positive full-scale MAX19588 transition occurs at 1.5

LSBs below positive full scale, and the negative fullscale transition occurs at 0.5 LSB above negative full

scale. The gain error is the difference of the measured

transition points minus the difference of the ideal transition points.

Small-Signal Noise Floor (SSNF)

Small-signal noise floor is the integrated noise and distortion power in the Nyquist band for small-signal

inputs. The DC offset is excluded from this noise calculation. For this converter, a small signal is defined as a

single tone with an amplitude of less than -35dBFS.

This parameter captures the thermal and quantization

noise characteristics of the data converter and can be

used to help calculate the overall noise figure of a digital receiver signal path.

Signal-to-Noise Ratio (SNR)

For a waveform perfectly reconstructed from digital

samples, the theoretical maximum SNR is the ratio of

the full-scale analog input (RMS value) to the RMS

quantization error (residual error). The ideal, theoretical

minimum analog-to-digital noise is caused by quantization error only and results directly from the ADC’s resolution (N bits):

SNR[max] = 6.02 x N + 1.76

In reality, there are other noise sources besides quantization noise: thermal noise, reference noise, clock jitter,

etc. SNR is computed by taking the ratio of the RMS

signal to the RMS noise. RMS noise includes all spectral components to the Nyquist frequency excluding the

fundamental, the first four harmonics (HD2 through

HD5), and the DC offset.

SNR = 20 x log (SIGNAL

RMS

/ NOISE

RMS

)

Signal-to-Noise Plus Distortion (SINAD)

SINAD is computed by taking the ratio of the RMS signal to the RMS noise plus distortion. RMS noise plus

distortion includes all spectral components to the

Nyquist frequency excluding the fundamental and the

DC offset.

Spurious-Free Dynamic Range

(SFDR1 and SFDR2)

SFDR is the ratio expressed in decibels of the RMS

amplitude of the fundamental (maximum signal component) to the RMS value of the next largest spurious

component, excluding DC offset. SFDR1 reflects the

MAX19588 spurious performance based on worst 2ndor 3rd-order harmonic distortion. SFDR2 is defined by

the worst spurious component excluding 2nd- and 3rdorder harmonic spurs and DC offset.

Two-Tone Spurious-Free Dynamic

Range (TTSFDR)

Two-tone SFDR is the ratio of the full scale of the converter to the RMS value of the peak spurious component. The peak spurious component can be related to

the intermodulation distortion components, but does

not have to be. Two-tone SFDR for the MAX19588 is

expressed in dBFS.

3rd-Order Intermodulation (IM3)

IM3 is the power of the largest 3rd-order intermodulation product relative to the input power of either of the

input tones f

IN1

and f

IN2

. The individual input tone

power levels are set to -8dBFS for the MAX19588. The

3rd-order intermodulation products are 2 x f

IN1

- f

IN2

and 2 x f

IN2

- f

IN1

.

Aperture Jitter

Aperture jitter (tAJ) represents the sample-to-sample

variation in the aperture delay specification.

Aperture Delay

Aperture delay (tAD) is the time defined between the

rising edge of the sampling clock and the instant when

an actual sample is taken (Figure 5).

MAX19588

High-Dynamic-Range, 16-Bit,

100Msps ADC with -82dBFS Noise Floor

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

19

© 2006 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

Freed

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

FREED

56L THIN QFN.EPS

PACKAGE OUTLINE

56L THIN QFN, 8x8x0.8mm

21-0135

1

E

2

PACKAGE OUTLINE

56L THIN QFN, 8x8x0.8mm

21-0135

2

E

2

Loading...

Loading...