Page 1

General Description

The MAX19506 dual-channel, analog-to-digital converter

(ADC) provides 8-bit resolution and a maximum sample

rate of 100Msps.

The MAX19506 analog input accepts a wide 0.4V to

1.4V input common-mode voltage range, allowing DCcoupled inputs for a wide range of RF, IF, and baseband front-end components. The MAX19506 provides

excellent dynamic performance from baseband to high

input frequencies beyond 400MHz, making the device

ideal for zero-intermediate frequency (ZIF) and highintermediate frequency (IF) sampling applications. The

typical signal-to-noise ratio (SNR) performance is

49.8dBFS and typical spurious-free dynamic range

(SFDR) is 69dBc at fIN= 70MHz and f

CLK

= 100MHz.

The MAX19506 operates from a 1.8V supply.

Additionally, an integrated, self-sensing voltage regulator allows operation from a 2.5V to 3.3V supply (AVDD).

The digital output drivers operate on an independent

supply voltage (OVDD) over the 1.8V to 3.5V range.

The analog power consumption is only 57mW per channel at V

AVDD

= 1.8V. In addition to low operating

power, the MAX19506 consumes only 1mW in powerdown mode and 17mW in standby mode.

Various adjustments and feature selections are available through programmable registers that are

accessed through the 3-wire serial-port interface.

Alternatively, the serial-port interface can be disabled,

with the three pins available to select output mode,

data format, and clock-divider mode. Data outputs are

available through a dual parallel CMOS-compatible output data bus that can also be configured as a single

multiplexed parallel CMOS bus.

The MAX19506 is available in a small 7mm x 7mm, 48pin thin QFN package and is specified over the -40°C

to +85°C extended temperature range.

Refer to the MAX19515, MAX19516, and MAX19517

data sheets for pin- and feature-compatible 10-bit,

65Msps, 100Msps, and 130Msps versions, respectively.

Refer to the MAX19505 and MAX19507 data sheets for

pin- and feature-compatible 8-bit, 65Msps and 130Msps

versions, respectively.

Applications

IF and Baseband Communications, Including

Cellular Base Stations and Point-to-Point

Microwave Receivers

Ultrasound and Medical Imaging

Portable Instrumentation and Low-Power Data

Acquisition

Digital Set-Top Boxes

Features

o Very-Low-Power Operation (57mW/Channel at

100Msps)

o 1.8V or 2.5V to 3.3V Analog Supply

o Excellent Dynamic Performance

49.8dBFS SNR at 70MHz

69dBc SFDR at 70MHz

o User-Programmable Adjustments and Feature

Selection through an SPI™ Interface

o Selectable Data Bus (Dual CMOS or Single

Multiplexed CMOS)

o DCLK Output and Programmable Data Output

Timing Simplifies High-Speed Digital Interface

o Very Wide Input Common-Mode Voltage Range

(0.4V to 1.4V)

o Very High Analog Input Bandwidth (> 850MHz)

o Single-Ended or Differential Analog Inputs

o Single-Ended or Differential Clock Input

o Divide-by-One (DIV1), Divide-by-Two (DIV2), and

Divide-by-Four (DIV4) Clock Modes

o Two’s Complement, Gray Code, and Offset Binary

Output Data Format

o Out-of-Range Indicator (DOR)

o CMOS Output Internal Termination Options

(Programmable)

o Reversible Bit Order (Programmable)

o Data Output Test Patterns

o Small 7mm x 7mm, 48-Pin Thin QFN Package with

Exposed Pad

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

________________________________________________________________

Maxim Integrated Products

1

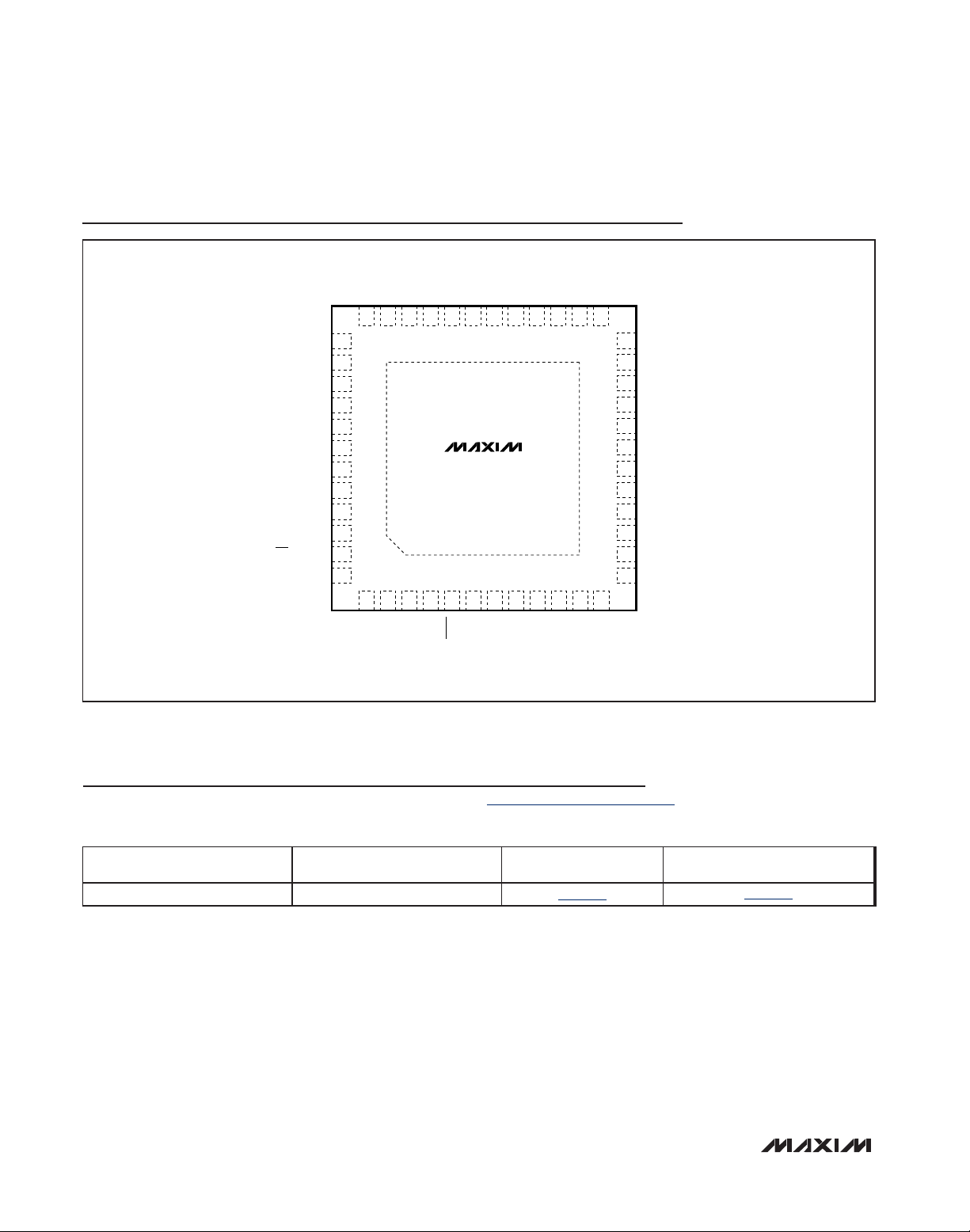

Ordering Information

19-4312; Rev 1; 9/10

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

PART TEMP RANGE PIN-PACKAGE

MAX19506ETM+ -40°C to +85°C 48 TQFN-EP*

+

Denotes a lead(Pb)-free/RoHS-compliant package.

*

EP = Exposed pad.

Pin Configuration appears at end of data sheet.

SPI is a trademark of Motorola, Inc.

Page 2

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

AVDD

= V

OVDD

= 1.8V, internal reference, differential clock, V

CLK

= 1.5V

P-P

, f

CLK

= 100MHz, AIN= -0.5dBFS, data output termina-

tion = 50Ω, T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

OVDD, AVDD to GND............................................-0.3V to +3.6V

CMA, CMB, REFIO, INA+, INA-, INB+,

INB- to GND ......................................................-0.3V to +2.1V

CLK+, CLK-, SYNC, SPEN, CS, SCLK, SDIN

to GND ..........-0.3V to the lower of (V

AVDD

+ 0.3V) and +3.6V

DCLKA, DCLKB, D7A–D0A, D7B–D0B, DORA, DORB

to GND..........-0.3V to the lower of (V

OVDD

+ 0.3V) and +3.6V

Continuous Power Dissipation (T

A

= +70°C)

48-Pin Thin QFN, 7mm x 7mm x 0.8mm (derate 40mW/°C

above +70°C).............................................................3200mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Soldering Temperature (reflow) .......................................+260°C

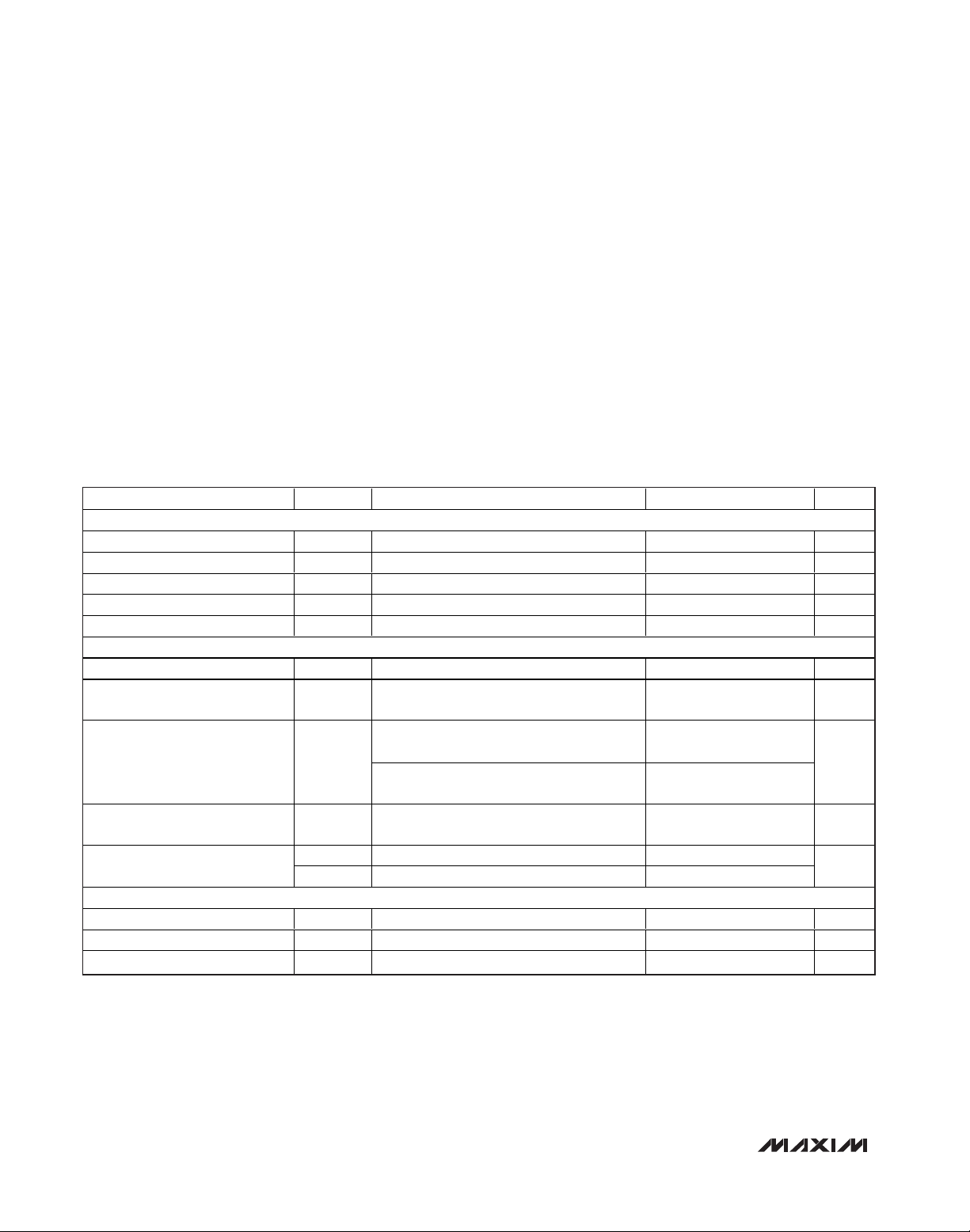

DC ACCURACY

Resolution 8 Bits

Integral Nonlinearity INL fIN = 3MHz -0.3 ±0.1 +0.3 LSB

Differential Nonlinearity DNL fIN = 3MHz -0.3 ±0.1 +0.3 LSB

Offset Error OE Internal reference -0.4 ±0.1 +0.4 %FS

Gain Error GE External reference = 1.25V -1.5 ±0.3 +1.5 %FS

ANALOG INPUTS (INA+, INA-, INB+, INB-) (Figure 3)

Differential Input-Voltage Range V

Common-Mode Input-Voltage

Range

Input Resistance R

Input Current I

Input Capacitance

CONVERSION RATE

Maximum Clock Frequency f

Minimum Clock Frequency f

Data Latency Figures 9, 10 9 Cycles

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DIFF

V

CM

IN

C

PAR

C

SAMPLE

CLK

CLK

Differential or single-ended inputs 1.5 V

(Note 2) 0.4 1.4 V

Fixed resistance, common mode, and

differential mode

IN

Differential input resistance, common mode

connected to inputs

Switched capacitance common-mode input

current, each input

Fixed capacitance to ground, each input 0.7

Switched capacitance, each input 1.2

> 100

4

54 µA

100 MHz

50 MHz

P-P

kΩ

pF

Page 3

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(V

AVDD

= V

OVDD

= 1.8V, internal reference, differential clock, V

CLK

= 1.5V

P-P

, f

CLK

= 100MHz, AIN= -0.5dBFS, data output termina-

tion = 50Ω, T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

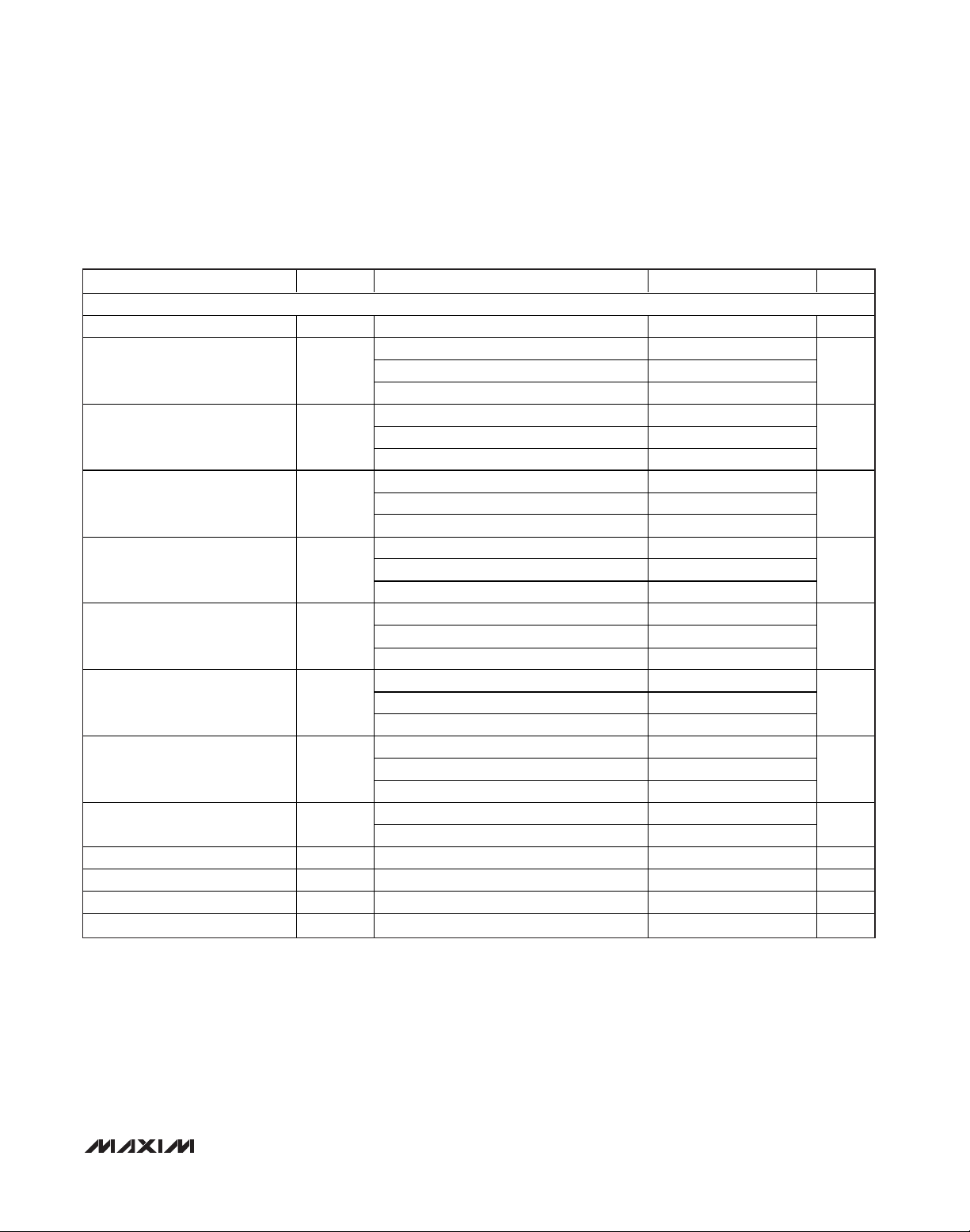

DYNAMIC PERFORMANCE

Small-Signal Noise Floor SSNF fIN = 70MHz, < -35dBFS -49.8 dBFS

Signal-to-Noise Plus Distortion

Ratio

Spurious-Free Dynamic Range

(2nd and 3rd Harmonic)

Spurious-Free Dynamic Range

(4th and Higher Harmonics)

Third Harmonic HD3

Third-Order Intermodulation IM3

Full-Power Bandwidth FPBW R

Aperture Delay t

Aperture Jitter t

Overdrive Recovery Time ±10% beyond full scale 1 Cycles

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

fIN = 3MHz 49.8

fIN = 70MHz 49.0 49.8Signal-to-Noise Ratio SNR

= 175MHz 49.8

f

IN

fIN = 3MHz 49.3

SINAD

SFDR1

SFDR2

AD

AJ

fIN = 70MHz 48.5 49.3

f

= 175MHz 49.3

IN

fIN = 3MHz 77.0

fIN = 70MHz 65.0 77.0

= 175MHz 77.0

f

IN

fIN = 3MHz 69.0

fIN = 70MHz 64.0 69.0

f

= 175MHz 69.0

IN

fIN = 3MHz -78.0

fIN = 70MHz -78.0 -65.0Second Harmonic HD2

= 175MHz -78.0

f

IN

fIN = 3MHz -82.0

fIN = 70MHz -82.0 -65.0

= 175MHz -80.0

f

IN

fIN = 3MHz -72.0

fIN = 70MHz -72.0 -63.0Total Harmonic Distortion THD

= 175MHz -72.0

f

IN

fIN = 70MHz ±1.5MHz, -7dBFS -80

= 175MHz ±2.5MHz, -7dBFS -75

f

IN

= 50Ω differential, -3dB rolloff 850 MHz

SOURCE

850 ps

0.3 ps

dBFS

dB

dBc

dBc

dBc

dBc

dBc

dBc

RMS

Page 4

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

AVDD

= V

OVDD

= 1.8V, internal reference, differential clock, V

CLK

= 1.5V

P-P

, f

CLK

= 100MHz, AIN= -0.5dBFS, data output termina-

tion = 50Ω, T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

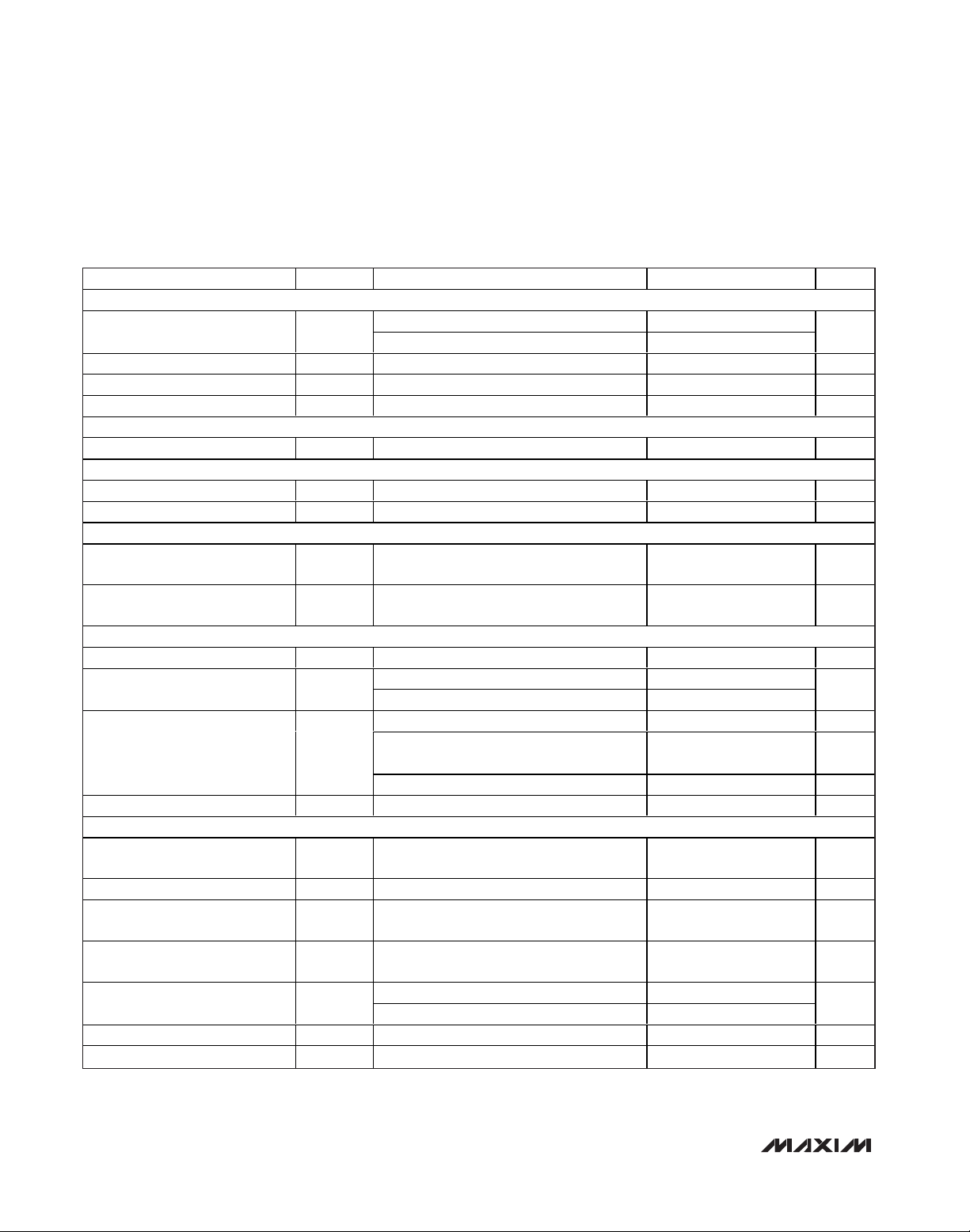

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

INTERCHANNEL CHARACTERISTICS

f

or f

Crosstalk

f

INA

INA

= 70MHz at -1dBFS 95

INB

or f

= 175MHz at -1dBFS 85

INB

dBc

Gain Match fIN = 70MHz ±0.05 dB

Offset Match fIN = 70MHz ±0.1 %FSR

Phase Match fIN = 70MHz ±0.5 D eg r ees

ANALOG OUTPUTS (CMA, CMB)

CMA, CMB Output Voltage V

COM

Default programmable setting 0.85 0.9 0.95 V

INTERNAL REFERENCE

REFIO Output Voltage V

REFOUT

REFIO Temperature Coefficient TC

REF

1.23 1.25 1.27 V

< ±60 ppm/°C

EXTERNAL REFERENCE

REFIO Input-Voltage Range V

REFIO Input Resistance R

REFIN

REFIN

1.25

+5/-10%

10

±20%

V

kΩ

CLOCK INPUTS (CLK+, CLK-)—DIFFERENTIAL MODE

Differential Clock Input Voltage 0.4 to 2.0 V

Differential Input Common-Mode

Voltage

Self-biased 1.20

DC-coupled clock signal 1.0 to 1.4

P-P

V

Differential, default 10 kΩ

Input Resistance R

CLK

Differential, programmable internal

termination selected

100 Ω

Common mode 9 kΩ

Input Capacitance C

CLK

CLOCK INPUTS (CLK+, CLK-)—SINGLE-ENDED MODE (V

Single-Ended Mode Selection

Threshold (V

Allowable Logic Swing (V

CLK-

)

) 0 - V

CLK+

Single-Ended Clock Input High

Threshold (V

CLK+

)

Single-Ended Clock Input Low

Threshold (V

CLK+

)

Input Leakage (CLK+)

Input Leakage (CLK-) V

To ground, each input 3 pF

< 0.1V)

CLK-

0.1 V

AVDD

1.5 V

0.3 V

V

= V

CLK+

= 0V -0.5

V

CLK+

= 0V -150 -50 µA

CLK-

= 1.8V or 3.3V +0.5

AVDD

µA

V

Input Capacitance (CLK+) 3pF

Page 5

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(V

AVDD

= V

OVDD

= 1.8V, internal reference, differential clock, V

CLK

= 1.5V

P-P

, f

CLK

= 100MHz, AIN= -0.5dBFS, data output termina-

tion = 50Ω, T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CLOCK INPUT (SYNC)

Allowable Logic Swing 0 - V

AVDD

Sync Clock Input High Threshold 1.5 V

Sync Clock Input Low Threshold 0.3 V

Input Leakage

= V

SYNC

= 0V -0.5

V

SYNC

= 1.8V or 3.3V +0.5

AVDD

V

Input Capacitance 4.5 pF

DIGITAL INPUTS (SHDN, SPEN)

Allowable Logic Swing 0 - V

AVDD

Input High Threshold 1.5 V

Input Low Threshold 0.3 V

Input Leakage

Input Capacitance C

DIN

V

SHDN/VSPEN

V

SHDN/VSPEN

= V

= 1.8V or 3.3V +0.5

AVDD

= 0V -0.5

3pF

SERIAL-PORT INPUTS (SCLK, SDIN, CS, where SPEN = 0V)—SERIAL-PORT CONTROL MODE

Allowable Logic Swing 0 - V

AVDD

Input High Threshold 1.5 V

Input Low Threshold 0.3 V

V

Input Leakage

Input Capacitance C

DIN

SCLK/VSDIN/VCS

V

SCLK/VSDIN/VCS

SERIAL-PORT INPUTS (SCLK, SDIN, CS, where SPEN = V

V

Input Pullup Current

Input Pulldown Current

Open-Circuit Voltage V

OC

SCLK/VSDIN/VCS

V

SCLK/VSDIN/VCS

V

SCLK/VSDIN/VCS

V

SCLK/VSDIN/VCS

V

= 1.8V 1.35 1.45 1.55

AVDD

V

= 3.3V 2.58 2.68 2.78

AVDD

= V

= 1.8V or 3.3V +0.5

AVDD

= 0V -0.5

)—PARALLEL CONTROL MODE (Figure 5)

AVDD

= V

= V

= 0V, V

= 0V, V

= 1.8V 7 12 17

AVDD

= 3.3V 16 21 26

AVDD

= 1.8V -65 -50 -35

AVDD

= 3.3V -105 -90 -75

AVDD

3pF

DIGITAL OUTPUTS (CMOS MODE, 75Ω, D0–D7 (A and B Channel), DCLKA, DCLKB, DORA, DORB)

Output-Voltage Low V

Output-Voltage High V

Three-State Leakage Current I

OL

OH

LEAK

I

= 200µA 0.2 V

SINK

V

I

SOURCE

V

= 200µA

applied +0.5

OVDD

OVDD

- 0.2

GND applied -0.5

V

µA

V

µA

V

µA

µA

µA

V

V

µA

Page 6

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

AVDD

= V

OVDD

= 1.8V, internal reference, differential clock, V

CLK

= 1.5V

P-P

, f

CLK

= 100MHz, AIN= -0.5dBFS, data output termina-

tion = 50Ω, T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

POWER-MANAGEMENT CHARACTERISTICS

Wake-Up Time from Shutdown t

Wake-Up Time from Standby t

WAKE

WAKE

Internal reference, C

= 0.1µF (10τ)5ms

REFIO

Internal reference 15 µs

SERIAL-PORT INTERFACE TIMING (Note 2) (Figure 7)

SCLK Period t

SCLK to CS Setup Time t

SCLK to CS Hold Time t

SDIN to SCLK Setup Time t

SDIN to SCLK Hold Time t

SCLK to SDIN Output Data Delay t

SCLK

CSS

CSH

SDS

SDH

SDD

Serial-data write 10 ns

Serial-data write 0 ns

Serial-data read 10 ns

50 ns

10 ns

10 ns

TIMING CHARACTERISTICS—DUAL BUS PARALLEL MODE (Figure 9), (Default Timing see Table 5)

Clock Pulse-Width High t

Clock Pulse-Width Low t

Clock Duty Cycle tCH/t

Data Delay After Rising Edge of

CLK+

Data to DCLK Setup Time t

Data to DCLK Hold Time t

CH

CL

CLK

t

DD

SETUP

HOLD

CL = 10pF, V

CL = 10pF, V

CL = 10pF, V

CL = 10pF, V

= 1.8V (Note 2) 2.1 4.0 5.8

OVDD

= 3.3V 3.1

OVDD

= 1.8V (Note 2) 8.1 8.7 ns

OVDD

= 1.8V (Note 2) 0.6 1.3 ns

OVDD

TIMING CHARACTERISTICS—MULTIPLEXED BUS PARALLEL MODE (Figure 10), (Default Timing see Table 5)

Clock Pulse-Width High t

Clock Pulse-Width Low t

Clock Duty Cycle tCH/t

Data Delay After Rising Edge of

CLK+

Data to DCLK Setup Time t

Data to DCLK Hold Time t

DCLK Duty Cycle t

MUX Data Duty Cycle t

CH

CL

CLK

t

DD

SETUP

HOLD

DCH/tCLK

CHA/tCLK

CL = 10pF, V

CL = 10pF, V

CL = 10pF, V

CL = 10pF, V

CL = 10pF, V

CL = 10pF, V

= 1.8V (Note 2) 2.1 3.9 5.8

OVDD

= 3.3V 3.1

OVDD

= 1.8V (Note 2) 2.9 3.9 ns

OVDD

= 1.8V (Note 2) 0.4 1.1 ns

OVDD

= 1.8V (Note 2) 41 50 59 %

OVDD

= 1.8V (Note 2) 41 50 59 %

OVDD

TIMING CHARACTERISTICS—SYNCHRONIZATION (Figure 12)

Setup Time for Valid Clock Edge t

Hold-Off Time for Invalid Clock

Edge

Minimum Synchronization Pulse

Width

SUV

t

HO

Edge mode (Note 2) 0.7 ns

Edge mode (Note 2) 0.5 ns

Relative to input clock period 2 Cycles

5.0 ns

5.0 ns

30 to 70 %

ns

5.0 ns

5.0 ns

30 to 70 %

ns

Page 7

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (continued)

(V

AVDD

= V

OVDD

= 1.8V, internal reference, differential clock, V

CLK

= 1.5V

P-P

, f

CLK

= 100MHz, AIN= -0.5dBFS, data output termina-

tion = 50Ω, T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

Note 1: Specifications at ≥ +25°C guaranteed by production test, specifications at < +25°C guaranteed by design and characterization.

Note 2: Guaranteed by design and characterization.

POWER REQUIREMENTS

Analog Supply Voltage V

Digital Output Supply Voltage V

Analog Supply Current I

Analog Power Dissipation P

Digital Output Supply Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Low-level V

AVDD

OVDD

AVDD

OVDD

High-level V

automatically)

Dual channel 63 77

Single channel active 37

Standby mode 9.5 13

Power-down mode 0.65 0.9

Power-down mode, V

Dual channel 113 139

Dual channel, V

Single channel active 67

DA

Standby mode 17 24

Power-down mode 1.2 1.6

Power-down mode, V

Dual-channel mode, CL = 10pF 17

Power-down mode < 0.1

AVDD

(regulator mode, invoked

AVDD

AVDD

= 3.3V 1.6

AVDD

= 3.3V 208

= 3.3V 2.9

AVDD

1.7 1.9

2.3 3.5

1.7 3.5 V

V

mA

mW

mA

Page 8

MAX19506 toc06

FREQUENCY (MHz)

AMPLITUDE (dBFS)

40302010

-80

-70

-60

-50

-40

-30

-20

-10

0

-100

-90

0 50

f

IN1

= 172.50290MHz

f

IN2

= 177.49523MHz

175MHz TWO-TONE FFT PLOT

MAX19506 toc05

FREQUENCY (MHz)

AMPLITUDE (dBFS)

40302010

-80

-70

-60

-50

-40

-30

-20

-10

0

-90

-100

0

50

f

IN1

= 71.501922MHz

f

IN2

= 68.509674MHz

70MHz TWO-TONE FFT PLOT

MAX19506 toc04

FREQUENCY (MHz)

AMPLITUDE (dBFS)

40302010

-80

-70

-60

-50

-40

-30

-20

-10

0

-90

0

50

fIN = 175.099945MHz

A

IN

= -0.492dBFS

SNR = 49.240dB

SINAD = 49.223dB

THD = -73.096dBc

SFDR1 = 76.572dBc

SFDR2 = 69.564dBc

175MHz INPUT FFT PLOT

MAX19506 toc03

FREQUENCY (MHz)

AMPLITUDE (dBFS)

37.525.012.5

-80

-70

-60

-50

-40

-30

-20

-10

0

-90

0

50.0

fIN = 70.0935363MHz

A

IN

= -0.517dBFS

SNR = 49.391dB

SINAD = 49.378dB

THD = -80.148dBc

SFDR1 = 81.688dBc

SFDR2 = 68.992dBc

70MHz INPUT FFT PLOT

MAX19506 toc02

FREQUENCY (MHz)

AMPLITUDE (dBFS)

40302010

-80

-70

-60

-50

-40

-30

-20

-10

0

-90

0

50

fIN = 2.99911499MHz

A

IN

= -0.489dBFS

SNR = 49.348dB

SINAD = 49.326dB

THD = -72.29dBc

SFDR1 = 73.498dBc

SFDR2 = 70.34dBc

3MHz SINGLE-ENDED INPUT FFT PLOT

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

8 _______________________________________________________________________________________

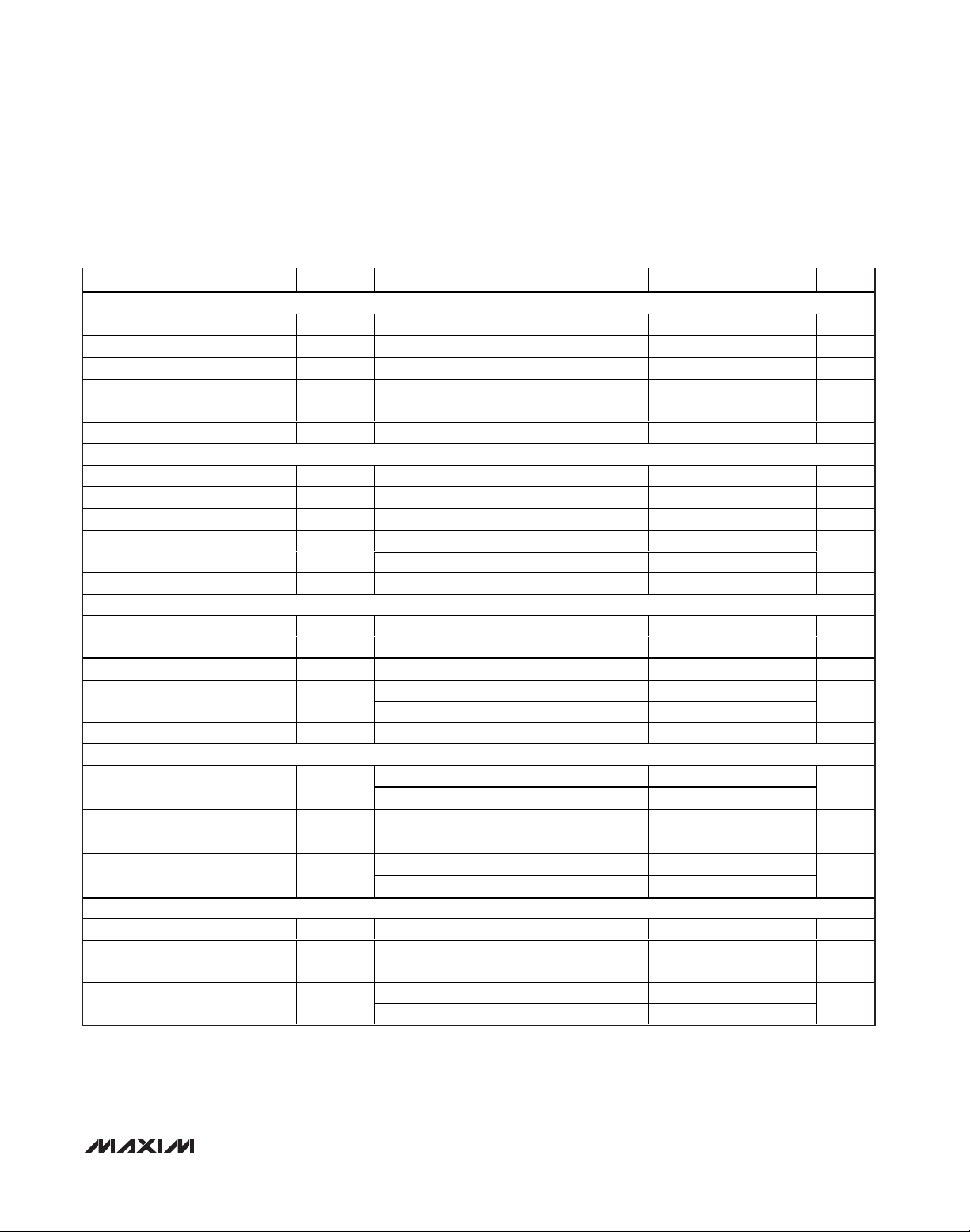

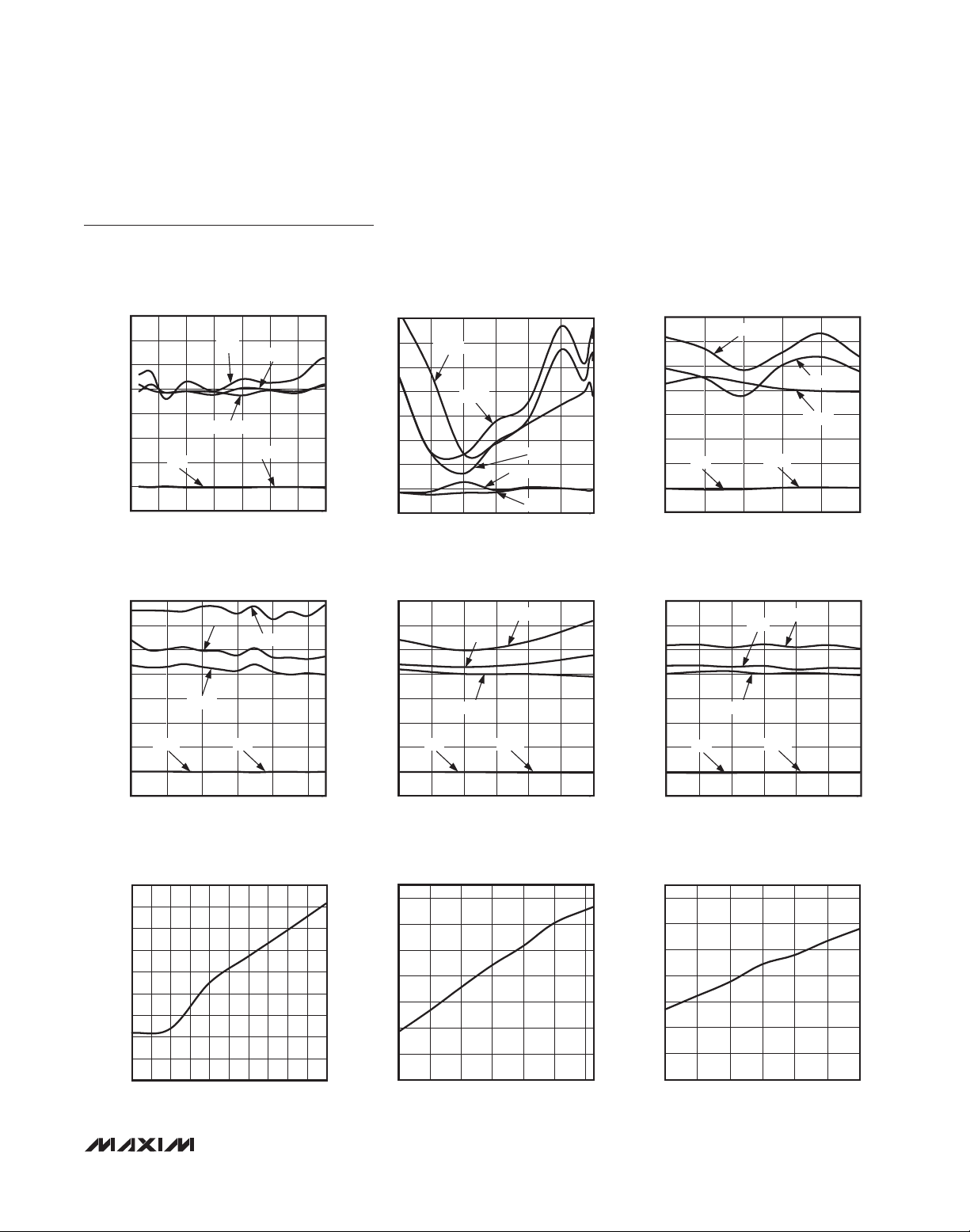

Typical Operating Characteristics

(V

AVDD

= V

OVDD

= 1.8V, internal reference, differential clock, V

CLK

= 1.5V

P-P

, f

CLK

= 100MHz, AIN= -0.5dBFS, data output termina-

tion = 50Ω, T

A

= +25°C, unless otherwise noted.)

3MHz INPUT FFT PLOT

MAX19506 toc01

FREQUENCY (MHz)

AMPLITUDE (dBFS)

40302010

-80

-70

-60

-50

-40

-30

-20

-10

0

-90

0

50

fIN = 2.99911499MHz

A

IN

= -0.476dBFS

SNR = 49.169dB

SINAD = 49.165dB

THD = -79.250dBc

SFDR1 = 87.836dBc

SFDR2 = 68.557dBc

MAX19506 toc07

DIGITAL OUTPUT CODE

INL (LSB)

19212864

-0.06

-0.08

-0.04

-0.02

0

0.02

0.04

0.06

0.08

0.10

-0.10

0 256

INTEGRAL NONLINEARITY

vs. DIGITAL OUTPUT CODE

MAX19506 toc08

DIGITAL OUTPUT CODE

DNL (LSB)

19212864

-0.06

-0.08

-0.04

-0.02

0

0.02

0.04

0.06

0.08

0.10

-0.10

0 256

DIFFERENTIAL NONLINEARITY

vs. DIGITAL OUTPUT CODE

PERFORMANCE

vs. INPUT FREQUENCY

85

80

75

70

65

SFDR2

60

PERFORMANCE (dBFS)

55

50

45

SNR

0

INPUT FREQUENCY (MHz)

-THD

SFDR1

SINAD

MAX19506 toc09

300200100

400

Page 9

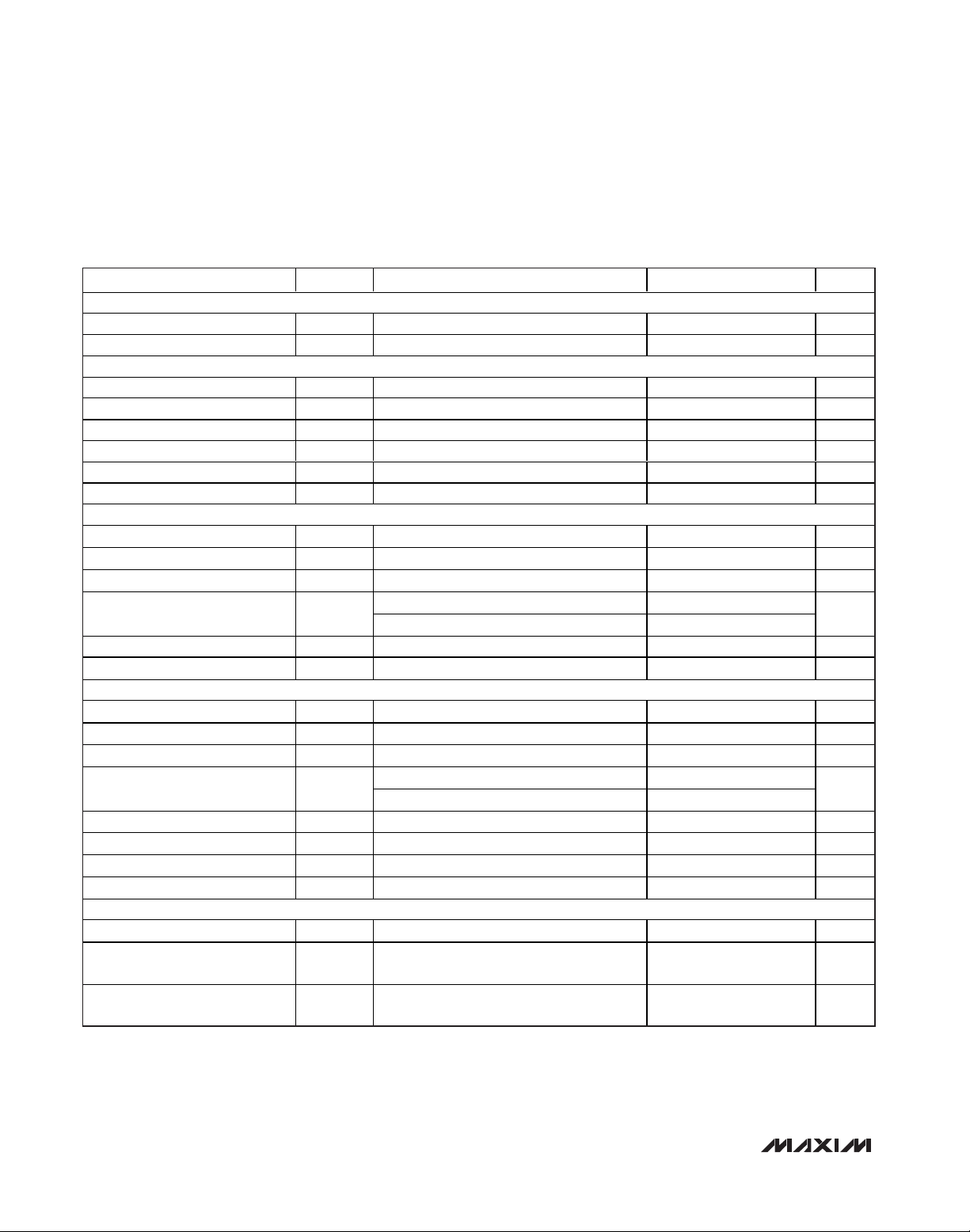

Typical Operating Characteristics (continued)

(V

AVDD

= V

OVDD

= 1.8V, internal reference, differential clock, V

CLK

= 1.5V

P-P

, f

CLK

= 100MHz, AIN= -0.5dBFS, data output termina-

tion = 50Ω, T

A

= +25°C, unless otherwise noted.)

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

_______________________________________________________________________________________

9

SINGLE-ENDED PERFORMANCE

vs. INPUT FREQUENCY

85

80

75

70

65

60

PERFORMANCE (dBFS)

55

50

45

SNR

0

-THD

SFDR1

INPUT FREQUENCY (MHz)

PERFORMANCE

vs. COMMON-MODE VOLTAGE

85

80

75

70

65

60

PERFORMANCE (dBFS)

SINAD

55

50

45

0.35 1.35

-THD

SFDR2

COMMON-MODE VOLTAGE (V)

SNR

SINAD

SFDR1

SFDR2

50 604010 20 30

1.150.950.55 0.75

MAX19506 toc10

70

MAX19506 toc13

PERFORMANCE

vs. ANALOG INPUT AMPLITUDE

85

80

75

70

65

60

PERFORMANCE (dBFS)

55

50

45

SFDR2

SFDR1

-60 0

ANALOG INPUT AMPLITUDE (dBFS)

PERFORMANCE

vs. ANALOG SUPPLY VOLTAGE

85

80

75

70

65

60

PERFORMANCE (dBFS)

55

50

45

1.65 1.90 1.951.70

-THD

SFDR2

SNR

ANALOG SUPPLY VOLTAGE (V)

SFDR1

SINAD

SNR

SINAD

1.851.801.75

-THD

PERFORMANCE

vs. SAMPLING FREQUENCY

85

80

MAX19506 toc11

75

70

65

60

PERFORMANCE (dBFS)

55

50

45

-10-20-50 -40 -30

60 110

SFDR1

SNR

SAMPLING FREQUENCY (Msps)

SINAD

PERFORMANCE

vs. ANALOG SUPPLY VOLTAGE

85

80

MAX19506 toc14

75

70

65

60

PERFORMANCE (dBFS)

55

50

45

SNR

2.3 3.3 3.52.5

-THD

SFDR2

SINAD

ANALOG SUPPLY VOLTAGE (V)

-THD

SFDR2

1009070 80

SFDR1

3.12.92.7

MAX19506 toc12

MAX19506 toc15

ANALOG SUPPLY CURRENT

vs. SAMPLING FREQUENCY

68

66

64

62

60

58

56

54

ANALOG SUPPLY CURRENT (mA)

52

50

60 65 70 75 80 85 90 95 100 105 110

SAMPLING FREQUENCY (MHz)

69

67

MAX19506 toc16

65

63

61

59

ANALOG SUPPLY CURRENT (mA)

57

55

-40-200 20406080

ANALOG SUPPLY CURRENT

vs. TEMPERATURE

TEMPERATURE (°C)

69

MAX19506 toc17

67

65

63

61

59

ANALOG SUPPLY CURRENT (mA)

57

55

1.65 1.70 1.75 1.80 1.85 1.90 1.95

ANALOG SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX19506 toc18

SUPPLY VOLTAGE (V)

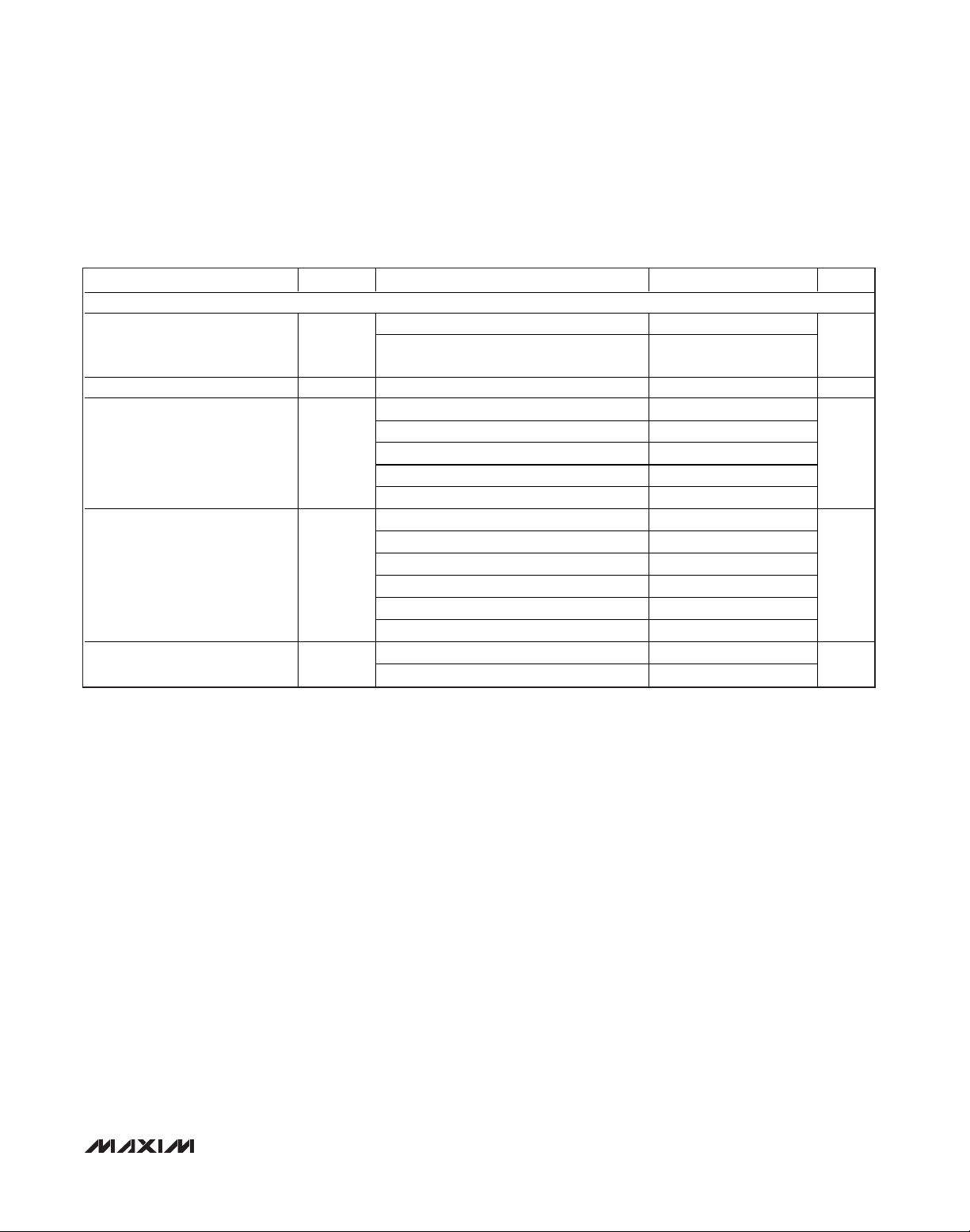

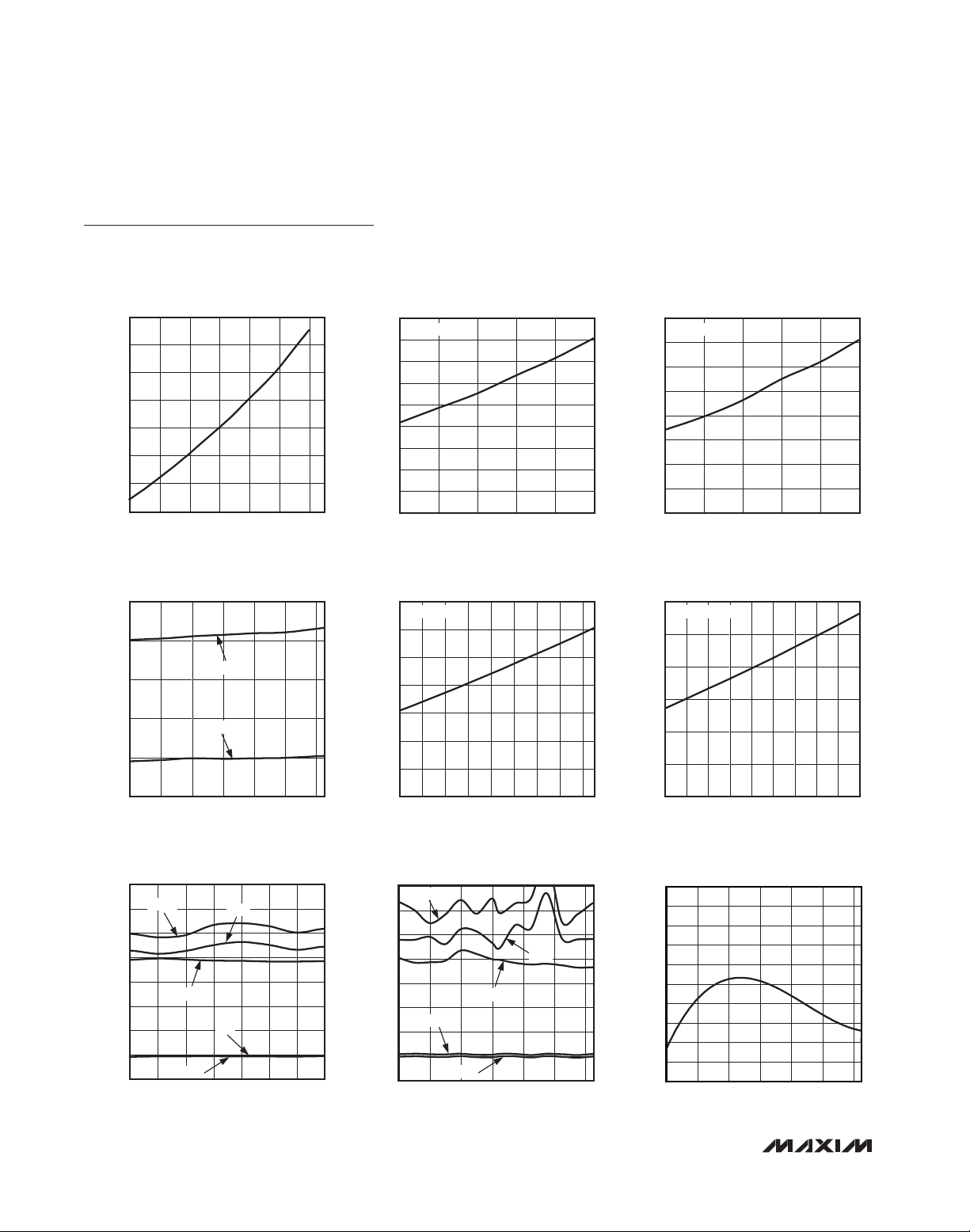

Page 10

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(V

AVDD

= V

OVDD

= 1.8V, internal reference, differential clock, V

CLK

= 1.5V

P-P

, f

CLK

= 100MHz, AIN= -0.5dBFS, data output termina-

tion = 50Ω, T

A

= +25°C, unless otherwise noted.)

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

ANALOG SUPPLY CURRENT

vs. SUPPLY VOLTAGE

67.5

67.0

66.5

66.0

65.5

65.0

ANALOG SUPPLY CURRENT (mA)

64.5

64.0

2.3 2.5 2.7 2.9 3.1 3.3 3.5

SUPPLY VOLTAGE (V)

DIGITAL SUPPLY CURRENT

vs. TEMPERATURE

35

30

V

= 3.6V

V

OVDD

OVDD

= 1.8V

25

20

15

DIGITAL SUPPLY CURRENT (mA)

18

V

OVDD

16

MAX19506 toc19

14

12

10

8

6

4

DIGITAL SUPPLY CURRENT (mA)

2

0

60 70 80 90 100 110

35

DUAL BUS

30

MAX19506 toc22

25

20

15

10

DIGITAL SUPPLY CURRENT (mA)

5

DIGITAL SUPPLY CURRENT

vs. SAMPLING FREQUENCY

= 1.8V

SAMPLING FREQUENCY (Msps)

DIGITAL SUPPLY CURRENT

vs. SUPPLY VOLTAGE

40

V

OVDD

35

MAX19506 toc20

30

25

20

15

10

DIGITAL SUPPLY CURRENT (mA)

5

0

60 70 80 90 100 110

30

MULTIPLEXED BUS

25

MAX19506 toc23

20

15

10

DIGITAL SUPPLY CURRENT (mA)

5

DIGITAL SUPPLY CURRENT

vs. SAMPLING FREQUENCY

= 3.6V

MAX19506 toc21

SAMPLING FREQUENCY (Msps)

DIGITAL SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX19506 toc24

10

-40 -20 0 20 6040 80

TEMPERATURE (°C)

PERFORMANCE

vs. CLOCK DUTY CYCLE

85

SFDR1

80

75

70

65

60

PERFORMANCE (dBFS)

55

50

45

30 60 6535

SFDR2

SINAD

CLOCK DUTY CYCLE (%)

-THD

SNR

0

1.8 2.0 2.2 2.4 3.22.8 3.02.6 3.4

SUPPLY VOLTAGE (V)

PERFORMANCE

vs. TEMPERATURE

85

SFDR1

80

MAX19506 toc25

75

70

65

60

PERFORMANCE (dBFS)

55

50

55504540

45

SNR

-40 80-20

SFDR2

SINAD

TEMPERATURE (°C)

-THD

6040200

MAX19506 toc26

0

1.7 1.9 2.1 2.3 3.12.7 2.92.5 3.3 3.5

SUPPLY VOLTAGE (V)

GAIN ERROR vs. TEMPERATURE

0.05

0.04

0.03

0.02

0.01

0

-0.01

GAIN ERROR (%)

-0.02

-0.03

-0.04

-0.05

-40 40200-20 8060

TEMPERATURE (°C)

MAX19506 toc27

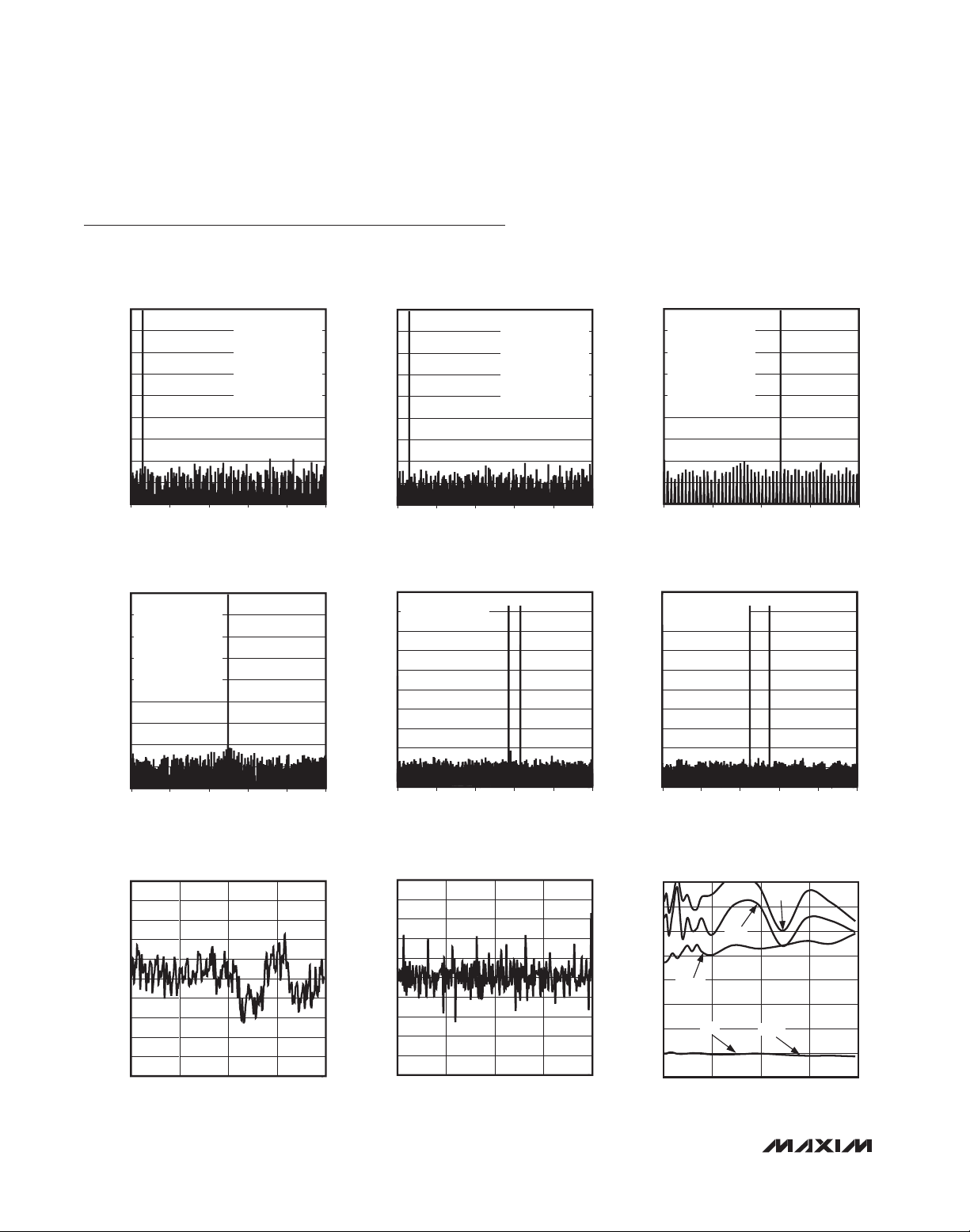

Page 11

Typical Operating Characteristics (continued)

(V

AVDD

= V

OVDD

= 1.8V, internal reference, differential clock, V

CLK

= 1.5V

P-P

, f

CLK

= 100MHz, AIN= -0.5dBFS, data output termina-

tion = 50Ω, T

A

= +25°C, unless otherwise noted.)

COMMON-MODE REFERENCE VOLTAGE

vs. TEMPERATURE

TEMPERATURE (°C)

COMMON-MODE REFERENCE VOLTAGE (V)

MAX19506 toc30

-40 40200-20 8060

0

1.2

0.8

0.4

0.2

1.4

1.0

0.6

1.6

VCM = 1.35V

VCM = 1.2V

VCM = 0.9V

VCM = 0.6V

VCM = 0.75V

VCM = 0.45V

VCM = 1.05V

OFFSET ERROR vs. TEMPERATURE

TEMPERATURE (°C)

OFFSET ERROR (mV)

MAX19506 toc28

-40 40200-20 8060

-0.7

-0.3

-0.1

0

0.1

-0.2

-0.5

-0.6

-0.4

0.2

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________

11

1.2516

1.2495

1.2474

REFERENCE VOLTAGE (V)

1.2453

1.2432

GAIN ERROR vs. SUPPLY VOLTAGE

0.08

0.06

0.04

0.02

0

-0.02

GAIN ERROR (%)

-0.04

-0.06

-0.08

1.6 2.6 3.42.4 3.23.02.82.01.8 3.62.2

REGULATOR MODE

SUPPLY VOLTAGE (V)

REFERENCE VOLTAGE vs. TEMPERATURE

-40 40200-20 8060

TEMPERATURE (°C)

MAX19506 toc31

vs. COMMON-MODE VOLTAGE

90

80

70

60

50

INPUT CURRENT (mA)

40

30

0.4 0.9 1.30.8 1.21.11.00.60.5 1.40.7

COMMON-MODE VOLTAGE (V)

MAX19506 toc29

INPUT CURRENT

MAX19506 toc32

Page 12

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

12 ______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1, 12, 13, 48 AVDD Analog Supply Voltage. Bypass each AVDD input pair (1, 48) and (12, 13) to GND with 0.1µF.

2 CMA Channel A Common-Mode Input-Voltage Reference

3 INA+ Channel A Positive Analog Input

4 INA- Channel A Negative Analog Input

5 SPEN Active-Low SPI Enable. Drive high to enable parallel programming mode.

6 REFIO

7SHDN

8, 21, 22, 32,

33

9 INB+ Channel B Positive Analog Input

10 INB- Channel B Negative Analog Input

11 CMB Channel B Common-Mode Input-Voltage Reference

14 SYNC Clock-Divider Mode Synchronization Input

15 CLK+ Clock Positive Input

16 CLK-

17, 18 GND Ground. Connect all ground inputs and EP (exposed pad) together.

19 DORB Channel B Data Over Range

20 DCLKB Channel B Data Clock

23 D0B Channel B Three-State Digital Output, Bit 0 (LSB)

24 D1B Channel B Three-State Digital Output, Bit 1

25, 36 OVDD Digital Supply Voltage. Bypass each OVDD input to GND with a 0.1µF capacitor.

26 D2B Channel B Three-State Digital Output, Bit 2

27 D3B Channel B Three-State Digital Output, Bit 3

28 D4B Channel B Three-State Digital Output, Bit 4

29 D5B Channel B Three-State Digital Output, Bit 5

30 D6B Channel B Three-State Digital Output, Bit 6

31 D7B Channel B Three-State Digital Output, Bit 7 (MSB)

34 D0A Channel A Three-State Digital Output, Bit 0 (LSB)

35 D1A Channel A Three-State Digital Output, Bit 1

37 D2A Channel A Three-State Digital Output, Bit 2

38 D3A Channel A Three-State Digital Output, Bit 3

39 D4A Channel A Three-State Digital Output, Bit 4

I.C. Internally Connected. Leave unconnected.

Reference Input/Output. To use internal reference, bypass to GND with a > 0.1µF capacitor. See

the Reference Input/Output (REFIO) section for external reference adjustment.

Active-High Power-Down. If SPEN is high (parallel programming mode), a register reset is initiated

on the falling edge of SHDN.

Clock Negative Input. If CLK- is connected to ground, CLK+ is a single-ended logic-level clock

input. Otherwise, CLK+/CLK- are self-biased differential clock inputs.

Page 13

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 13

Detailed Description

The MAX19506 uses a 10-stage, fully differential,

pipelined architecture (Figure 1) that allows for highspeed conversion while minimizing power consumption. Samples taken at the inputs move progressively

through the pipeline stages every half clock cycle.

From input to output the total latency is 9 clock cycles.

Each pipeline converter stage converts its input voltage

to a digital output code. At every stage, except the last,

the error between the input voltage and the digital output code is multiplied and passed on to the next

pipeline stage. Digital error correction compensates for

ADC comparator offsets in each pipeline stage and

ensures no missing codes. Figure 2 shows the

MAX19506 functional diagram.

Analog Inputs and Common-Mode

Reference

Apply the analog input signal to the analog inputs

(INA+/INA- or INB+/INB-), which are connected to the

input sampling switch (Figure 3). When the input sampling switch is closed, the input signal is applied to the

sampling capacitors through the input switch resistance.

The input signal is sampled at the instant the input

switch opens. The pipeline ADC processes the sampled

voltage and the digital output result is available 9 clock

cycles later. Before the input switch is closed to begin

the next sampling cycle, the sampling capacitors are

reset to the input common-mode potential.

Common-mode bias can be provided externally or

internally through 2kΩ resistors. In DC-coupled applications, the signal source provides the external bias and

the bias current. In AC-coupled applications, the input

current is supplied by the common-mode input voltage.

For example, the input current can be supplied through

the center tap of a transformer secondary winding.

Alternatively, program the appropriate internal register

through the serial-port interface to supply the input DC

current through internal 2kΩ resistors (Figure 3). When

the input current is supplied through the internal resistors, the input common-mode potential is reduced by

the voltage drop across the resistors. The commonmode input reference voltage can be adjusted through

programmable register settings from 0.45V to 1.35V in

0.15V increments. The default setting is 0.90V. Use this

feature to provide a common-mode output reference to

a DC-coupled driving circuit.

Pin Description (continued)

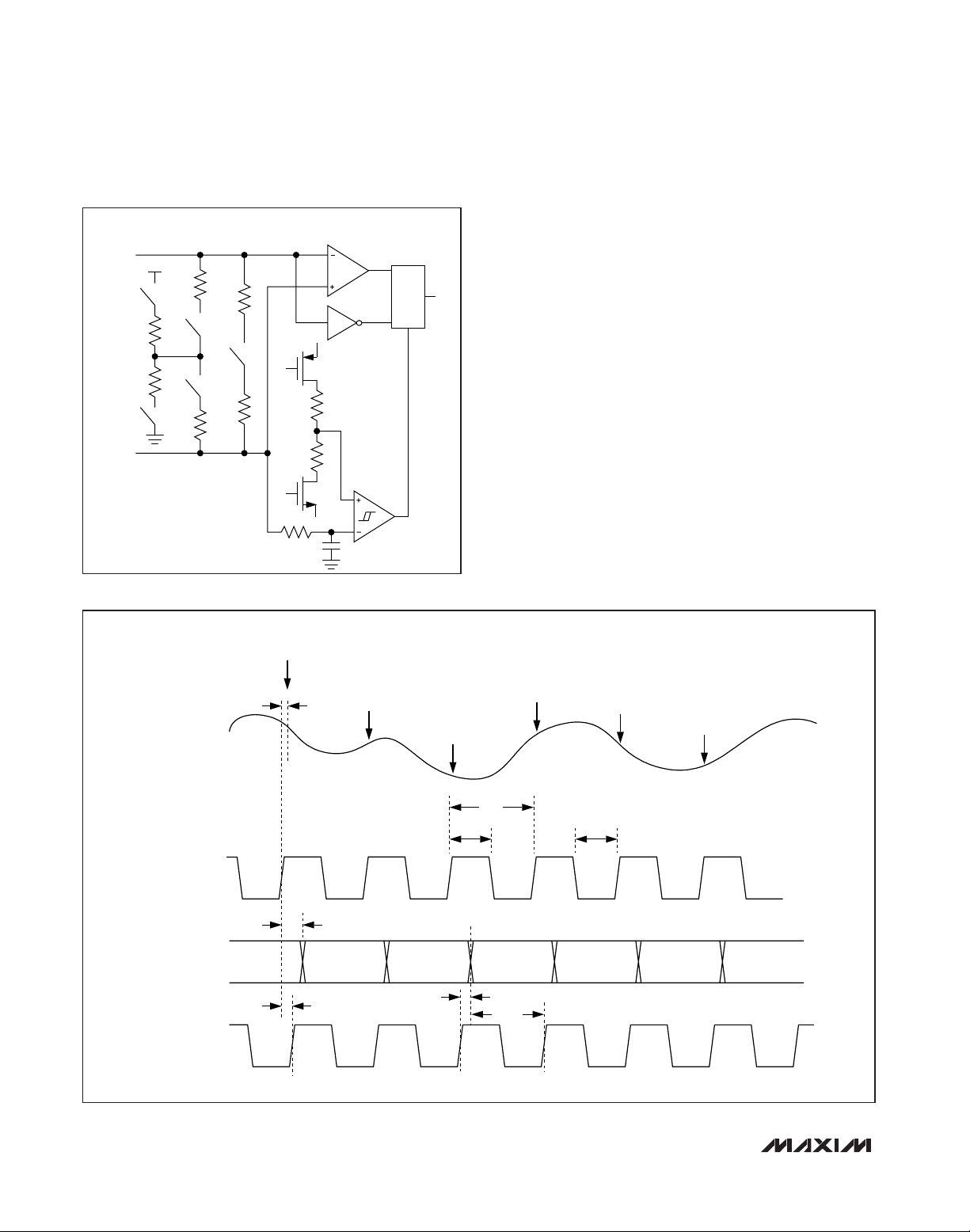

Figure 1. Pipeline Architecture—Stage Blocks

PIN NAME FUNCTION

40 D5A Channel A Three-State Digital Output, Bit 5

41 D6A Channel A Three-State Digital Output, Bit 6

42 D7A Channel A Three-State Digital Output, Bit 7 (MSB)

43 DORA Channel A Data Over Range

44 DCLKA Channel A Data Clock

45 SDIN/FORMAT SPI Data Input/Format. Serial-data input when SPEN is low. Output data format when SPEN is high.

46 SCLK/DIV Serial Clock/Clock Divider. Serial clock when SPEN is low. Clock divider when SPEN is high.

47 CS/OUTSEL

—EP

Serial-Port Select/Data Output Mode. Serial-port select when SPEN is low. Data output mode

selection when SPEN is high.

Exposed Pad. Internally connected to GND. Connect to a large ground plane to maximize thermal

performance.

MAX19506

FLASH

ADC

IN_+

IN_-

STAGE 1 STAGE 9

STAGE 2

DIGITAL ERROR CORRECTION

+

Σ

−

DAC

D0_ THROUGH D7_

x2

STAGE 10

END OF PIPELINE

Page 14

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

14 ______________________________________________________________________________________

Figure 2. Functional Diagram

Figure 3. Internal Track-and-Hold (T/H) Circuit

CLOCK

MAX19506

INA+

INA-

CMA

REFIO

CMB

INB+

INB-

T/H

T/H

PIPELINE

ADC

REFERENCE

AND BIAS

SYSTEM

PIPELINE

ADC

DIGITAL

ERROR

CORRECTION

INTERNAL

REFERENCE

GENERATOR

DIGITAL

ERROR

CORRECTION

DATA

AND

OUTPUT

FORMAT

CLOCK

OUTPUT

DRIVERS

D0A–D7A

DORA

DCLKA

OVDD

(1.8V TO 3.3V)

D0B–D7B

DORB

DCLKB

CLK+

CLK-

SYNC

CS

SCLK

SDIN

SPEN

CMA

INA+

2kΩ

2kΩ

INA-

CLOCK

DIVIDER

SERIAL PORT

AND

CONTROL REGISTERS

DUTYCYCLE

EQUALIZER

1.8V INTERNAL

INTERNAL CONTROL

AVDD

*V

COM

AVDD

C

PAR

0.7pF

C

PAR

0.7pF

REGULATOR

AND

POWER CONTROL

R

SWITCH

120Ω

R

SWITCH

120Ω

C

SAMPLE

1.2pF

C

SAMPLE

1.2pF

AVDD

(1.8V OR

2.5V TO 3.3V)

SHDN

GND

SAMPLING CLOCK

*V

PROGRAMMABLE FROM 0.45V TO 1.35V. SEE COMMON-MODE REGISTER (08h).

COM

MAX19506

Page 15

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 15

Reference Input/Output (REFIO)

REFIO adjusts the reference potential, which, in turn,

adjusts the full-scale range of the ADC. Figure 4 shows

a simplified schematic of the reference system. An

internal bandgap voltage generator provides an internal

reference voltage. The bandgap potential is buffered

and applied to REFIO through a 10kΩ resistor. Bypass

REFIO with a 0.1µF capacitor to GND. The bandgap

voltage is applied to a scaling and level-shift circuit,

which creates internal reference potentials that establish the full-scale range of the ADC. Apply an external

voltage on REFIO to trim the ADC full scale. The allowable adjustment range is +5/-15%. The REFIO-to-ADC

gain transfer function is:

VFS= 1.5 x [V

REFIO

/1.25] Volts

Programming and Interface

There are two ways to control the MAX19506 operating

modes. Full feature selection is available using the SPI

interface, while the parallel interface offers a limited set

of commonly used features. The programming mode is

selected using the SPEN input. Drive SPEN low for SPI

interface; drive SPEN high for parallel interface.

Parallel Interface

The parallel interface offers a pin-programmable interface with a limited feature set. Connect SPEN to AVDD

to enable the parallel interface. See Table 1 for pin

functionality; see Figure 5 for a simplified parallel-interface input schematic.

BANDGAP

REFERENCE

BUFFER

1.250V

REFIO

INTERNAL GAIN—BYPASS REFIO

EXTERNAL GAIN CONTROL—DRIVE REFIO

SCALE AND

LEVEL SHIFT

INTERNAL REFERENCE

(CONTROLS ADC GAIN)

10kΩ

0.1µF

EXTERNAL BYPASS

Figure 4. Simplified Reference Schematic

36kΩ

156kΩ

CS

SCLK

SDIN

AVDD

29/32 AVDD

DECODER

TO

CONTROL

LOGIC

23/32 AVDD

3/32 AVDD

Figure 5. Simplified Parallel-Interface Input Schematic

Table 1. Parallel-Interface Pin Functionality

X = Don’t care.

SPEN SDIN/FORMAT SCLK/DIV CS/OUTSEL DESCRIPTION

0 SDIN SCLK CS

1 0 X X Two’s complement

1 AVDD X X Offset binary

1 Unconnected X X Gray code

1 X 0 X Clock divide-by-1

1 X AVDD X Clock divide-by-2

1 X Unconnected X Clock divide-by-4

1 X X 0 CMOS (dual bus)

1 X X AVDD MUX CMOS (channel A data bus)

1 X X Unconnected MUX CMOS (channel B data bus)

SPI interface active. Features are programmed through the

serial port (see the Serial Programming Interface section).

Page 16

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

16 ______________________________________________________________________________________

Serial Programming Interface

A serial interface programs the MAX19506 control registers through the CS, SDIN, and SCLK inputs. Serial

data is shifted into SDIN on the rising edge of SCLK

when CS is low. The MAX19506 ignores the data presented at SDIN and SCLK when CS is high.

CCSS

must

transition high after each read/write operation. SDIN

also serves as the serial-data output for reading control

registers. The serial interface supports two-byte transfer

in a communication cycle. The first byte is a control

byte, containing the address and read/write instruction,

written to the MAX19506. The second byte is a data

byte and can be written to or read from the MAX19506.

Figure 6 shows a serial-interface communication cycle.

The first SDIN bit clocked in establishes the communi-

cation cycle as either a write or read transaction (0 for

write operation and 1 for read operation). The following

7 bits specify the address of the register to be written or

read. The final 8 SDIN bits are the register data. All

address and data bits are clocked in or out MSB first.

During a read operation, the MAX19506 serial port drives read data (D7) into SDIN after the falling edge of

SCLK following the 8th rising edge of SCLK. Since the

minimum hold time on SDIN input is zero, the master

can stop driving SDIN any time after the 8th rising edge

of SCLK. Subsequent data bits are driven into SDIN on

the falling edge of SCLK. Output data in a read operation is latched on the rising edge of SCLK. Figure 7

shows the detailed serial-interface timing diagram.

R/W A6 A4A5 A2A3 A0A1 D7 D6 D4D5 D2D3 D0D1

R/W

0 = WRITE

1 = READ

CS

SCLK

SDIN

ADDRESS

DATA

WRITE OR READ

CS

t

CSS

t

CSH

t

SDD

t

SDS

t

SDH

t

SCLK

SCLK

SDIN

WRITE READ

Figure 6. Serial-Interface Communication Cycle

Figure 7. Serial-Interface Timing Diagram

Page 17

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 17

Table 2. Register 0Ah Status Byte

Table 3. User-Programmable Registers

Register address 0Ah is a special-function register.

Writing data 5Ah to register 0Ah initiates a register

reset. When this operation is executed, all control regis-

ters are reset to default values. A read operation of register 0Ah returns a status byte with information

described in Table 2.

The SHDN input (pin 7) toggles between any two

power-management states. The Power Management

register defines each power-management state. In the

default state, SHDN = 1 shuts down the MAX19506 and

SHDN = 0 returns to full power.

User-Programmable Registers

Power Management (00h)

BIT NO. VALUE DESCRIPTION

7 0 Reserved

6 0 Reserved

5 0 or 1 1 = ROM read in progress

4 0 or 1 1 = ROM read completed and register data is valid (checksum is OK)

3 0 Reserved

2 1 Reserved

1 0 or 1 Reserved

0 0 or 1 1 = Duty-cycle equalizer DLL is locked

ADDRESS POR DEFAULT FUNCTION

00h 00000011 Power management

01h 00000000 Output format

02h 00000000 Digital output power management

03h 10110110 Data/DCLK timing

04h 00000000 C H A d ata outp ut ter m i nati on contr ol

05h 00000000 C H B d ata outp ut ter m i nati on contr ol

06h 00000000 C l ock d i vi d e/d ata for m at/test p atter n

07h Reserved Reserved—do not use

08h 00000000 Common mode

0Ah — Software reset

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

HPS_SHDN1 STBY_SHDN1 C H B_ON _S H D N 1C H A_O N _S H D N 1 HPS_SHDN0 STBY_SHDN0 CHB_ON_SHDN0 C H A_O N _S H D N 0

Page 18

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

18 ______________________________________________________________________________________

Control Bits:

Output Format (01h)

In addition to power management, the HPS_SHDN1

and HPS_SHDN0 activate an A+B adder mode. In this

mode, the results from both channels are averaged.

The MUX_CH bit selects which bus the (A+B)/2 data is

presented.

*

HPS_SHDN0, STBY_SHDN0, CHA_ON_SHDN0, and CHB_ON_SHDN0 are active when SHDN = 0.

**

HPS_SHDN1, STBY_SHDN1, CHA_ON_SHDN1, and CHB_ON_SHDN1 are active when SHDN = 1.

X = Don’t care.

Note: When HPS_SHDN_ = 1 (A+B adder mode), CHA_ON_SHDN_, and CHB_ON_SHDN_ must BOTH equal 0 for power-down or

standby.

Bit 7, 6, 5 Set to 0 for proper operation

Bit 4 BIT_ORDER_B: Reverse CHB output bit order

0 = Defined data bus pin order (default)

1 = Reverse data bus pin order

Bit 3 BIT_ORDER_A: Reverse CHA output bit order

0 = Defined data bus pin order (default)

1 = Reverse data bus pin order

Bit 2 MUX_CH: Multiplexed data bus selection

0 = Multiplexed data output on CHA (CHA data presented first, followed by CHB data) (default)

1 = Multiplexed data output on CHB (CHB data presented first, followed by CHA data)

Bit 1 MUX: Digital output mode

0 = Dual data bus output mode (default)

1 = Single multiplexed data bus output mode

MUX_CH selects the output bus

Bit 0 Set to 0 for proper operation

HPS_SHDN0 STBY_SHDN0 CHA_ON_SHDN0 CHB_ON_SHDN0 SHDN INPUT = 0*

HPS_SHDN1 STBY_SHDN1 CHA_ON_SHDN1 CHB_ON_SHDN1 SHDN INPUT = 1**

X 0 0 0 Complete power-down

0 0 0 1 Channel B active, channel A full power-down

0 0 1 0 Channel A active, channel B full power-down

0 X 1 1 Channels A and B active

0 1 0 0 Channels A and B in standby mode

0 1 0 1 Channel B active, channel A standby

0 1 1 0 Channel A active, channel B standby

1 1 0 0 Channels A and B in standby mode

1 X X 1 Channels A and B active, output is averaged

1 X 1 X Channels A and B active, output is averaged

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

0 0 0 BIT_ORDER_B BIT_ORDER_A MUX_CH MUX 0

Page 19

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 19

Digital Output Power Management (02h)

Bit 7–4 Don’t care

Bit 3, 2 PD_DOUT_1, PD_DOUT_0: Power-down digital output state control

00 = Digital output three state (default)

01 = Digital output low

10 = Digital output three state

11 = Digital output high

Bit 1 DIS_DOR: DOR driver disable

0 = DOR active (default)

1 = DOR disabled (three state)

Bit 0 DIS_DCLK: DCLK driver disable

0 = DCLK active (default)

1 = DCLK disabled (three state)

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

X X X X PD_DOUT_1 PD_DOUT_0 DIS_DOR DIS_DCLK

Page 20

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

20 ______________________________________________________________________________________

Data/DCLK Timing (03h)

Bit 7 DA_BYPASS: Data aligner bypass

0 = Nominal

1 = Bypasses data aligner delay line to minimize output data latency with respect to the input clock.

Rising clock to data transition is approximately 6ns with DTIME = 000b settings (default)

Bit 6 DLY_HALF_T: Data and DCLK delayed by T/2

0 = Normal, no delay (default)

1 = Delays data and DCLK outputs by T/2

Disabled in MUX data bus mode

Bit 5, 4, 3 DCLKTIME_2, DCLKTIME_1, DCLKTIME_0: DCLK timing adjust (controls both channels)

000 = Nominal

001 = +T/16

010 = +2T/16

011 = +3T/16

100 = Reserved, do not use

101 = -1T/16

110 = -2T/16 (default)

111 = -3T/16

Bit 2, 1, 0 DTIME_2, DTIME_1, DTIME_0: Data timing adjust (controls both channels)

000 = Nominal

001 = +T/16

010 = +2T/16

011 = +3T/16

100 = Reserved, do not use

101 = -1T/16

110 = -2T/16 (default)

111 = -3T/16

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

DA_BYPASS DLY_HALF_T DCLKTIME_2 DCLKTIME_1 DCLKTIME_0 DTIME_2 DTIME_1 DTIME_0

Page 21

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 21

CHA Data Output Termination Control (04h)

Bit 7, 6 Don’t care

Bit 5, 4, 3 CT_DCLK_2_A, CT_DCLK_1_A, CT_DCLK_0_A: CHA DCLK termination control

000 = 50Ω (default)

001 = 75Ω

010 = 100Ω

011 = 150Ω

1xx = 300Ω

Bit 2, 1, 0 CT_DATA_2_A, CT_DATA_1_A, CT_DATA_0_A: CHA data output termination control

000 = 50Ω (default)

001 = 75Ω

010 = 100Ω

011 = 150Ω

1xx = 300Ω

CHB Data Output Termination Control (05h)

Bit 7, 6 Don’t care

Bit 5, 4, 3 CT_DCLK_2_B, CT_DCLK_1_B, CT_DCLK_0_B: CHB DCLK termination control

000 = 50Ω (default)

001 = 75Ω

010 = 100Ω

011 = 150Ω

1xx = 300Ω

Bit 2, 1, 0 CT_DATA_2_B, CT_DATA_1_B, CT_DATA_0_B: CHB data output termination control

000 = 50Ω (default)

001 = 75Ω

010 = 100Ω

011 = 150Ω

1xx = 300Ω

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

X X CT_DCLK_2_A CT_DCLK_1_A CT_DCLK_0_A CT_DATA_2_A CT_DATA_1_A CT_DATA_0_A

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

X X CT_DCLK_2_B CT_DCLK_1_B CT_DCLK_0_B CT_DATA_2_B CT_DATA_1_B CT_DATA_0_B

Page 22

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

22 ______________________________________________________________________________________

Clock Divide/Data Format/Test Pattern (06h)

Reserved (07h)—Do not write to this register

Bit 7 TEST_PATTERN: Test pattern selection

0 = Ramps from 0 to 255 (offset binary) and repeats (subsequent formatting applied) (default)

1= Data alternates between D[7:0] = 01010101, DOR = 1, and D[7:0] = 10101010,

DOR = 0 on both channels

Bit 6 TEST_DATA: Data test mode

0 = Normal data output (default)

1 = Outputs test data pattern

Bit 5, 4 FORMAT_1, FORMAT_0: Data numerical format

00 = Two’s complement (default)

01 = Offset binary

10 = Gray code

11 = Two’s complement

Bit 3 TERM_100: Select 100Ω clock input termination

0 = No termination (default)

1 = 100Ω termination across differential clock inputs

Bit 2 SYNC_MODE: Divider synchronization mode select

0 = Slip mode (Figure 11) (default)

1 = Edge mode (Figure 12)

Bit 1, 0 DIV1, DIV0: Input clock-divider select

00 = No divider (default)

01 = Divide-by-2

10 = Divide-by-4

11 = No divider

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

TEST_PATTERN TEST_DATA FORMAT_1 FORMAT_0 TERM_100 SYNC_MODE DIV1 DIV0

Page 23

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 23

Common Mode (08h)

Software Reset (0Ah)

Bit 7 CMI_SELF_B: CHB connect input common-mode to analog inputs

0 = Internal common-mode voltage is NOT applied to inputs (default)

1 = Internal common-mode voltage applied to analog inputs through 2kΩ resistors

Bit 6, 5, 4 CMI_ADJ_2_B, CMI_ADJ_1_B, CMI_ADJ_0_B: CHB input common-mode voltage adjustment

000 = 0.900V (default)

001 = 1.050V

010 = 1.200V

011 = 1.350V

100 = 0.900V

101 = 0.750V

110 = 0.600V

111 = 0.450V

Bit 3 CMI_SELF_A: CHA connect input common-mode to analog inputs

0 = Internal common-mode voltage is NOT applied to inputs (default)

1 = Internal common-mode voltage applied to analog inputs through 2kΩ resistors

Bit 2, 1, 0 CMI_ADJ_2_A, CMI_ADJ_1_A, CMI_ADJ_0_A: CHA input common-mode adjustment

000 = 0.900V (default)

001 = 1.050V

010 = 1.200V

011 = 1.350V

100 = 0.900V

101 = 0.750V

110 = 0.600V

111 = 0.450V

Bit 7–0 SWRESET: Write 5Ah to initiate software reset

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

CMI_SELF_B CMI_ADJ_2_B CMI_ADJ_1_B CMI_ADJ_0_B CMI_SELF_A CMI_ADJ_2_A CMI_ADJ_1_A CMI_ADJ_0_A

Page 24

Clock Inputs

The input clock interface provides for flexibility in the

requirements of the clock driver. The MAX19506

accepts a fully differential clock or single-ended logiclevel clock. For differential clock operation, connect a

differential clock to the CLK+ and CLK- inputs. In this

mode, the input common mode is established internally

to allow for AC-coupling. The differential clock signal

can also be DC-coupled if the common mode is constrained to the specified 1V to 1.4V clock input common-mode range. For single-ended operation, connect

CLK- to GND and drive the CLK+ input with a logiclevel signal. When the CLK- input is grounded (or

pulled below the threshold of the clock mode detection

comparator) the differential-to-single-ended conversion

stage is disabled and the logic-level inverter path is

activated.

Clock Divider

The MAX19506 offers a clock-divider option. Enable

clock division either by setting DIV0 and DIV1 through

the serial interface; see the Clock Divide/Data

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

24 ______________________________________________________________________________________

Figure 8. Simplified Clock Input Schematic

DCLK

DATA, DOR

SAMPLE CLOCK

n n+1

SAMPLE ON RISING EDGE

n+2 n+4 n+5

n-9 n-8n-10 n-7 n-6 n-5 n-4

t

CLK

t

SETUP

t

CH

t

DD

t

DC

t

HOLD

t

CL

DUAL-BUS OUTPUT MODE

SAMPLE CLOCK IS THE DERIVED CLOCK FROM (CLK+ - CLK-)/CLOCK DIVIDER, IN_ = IN_+ - IN_-.

SAMPLING

INSTANT

SAMPLING

INSTANT

SAMPLING

INSTANT

SAMPLING

INSTANT

SAMPLING

INSTANT

SAMPLING

INSTANT

IN_

t

AD

n+3

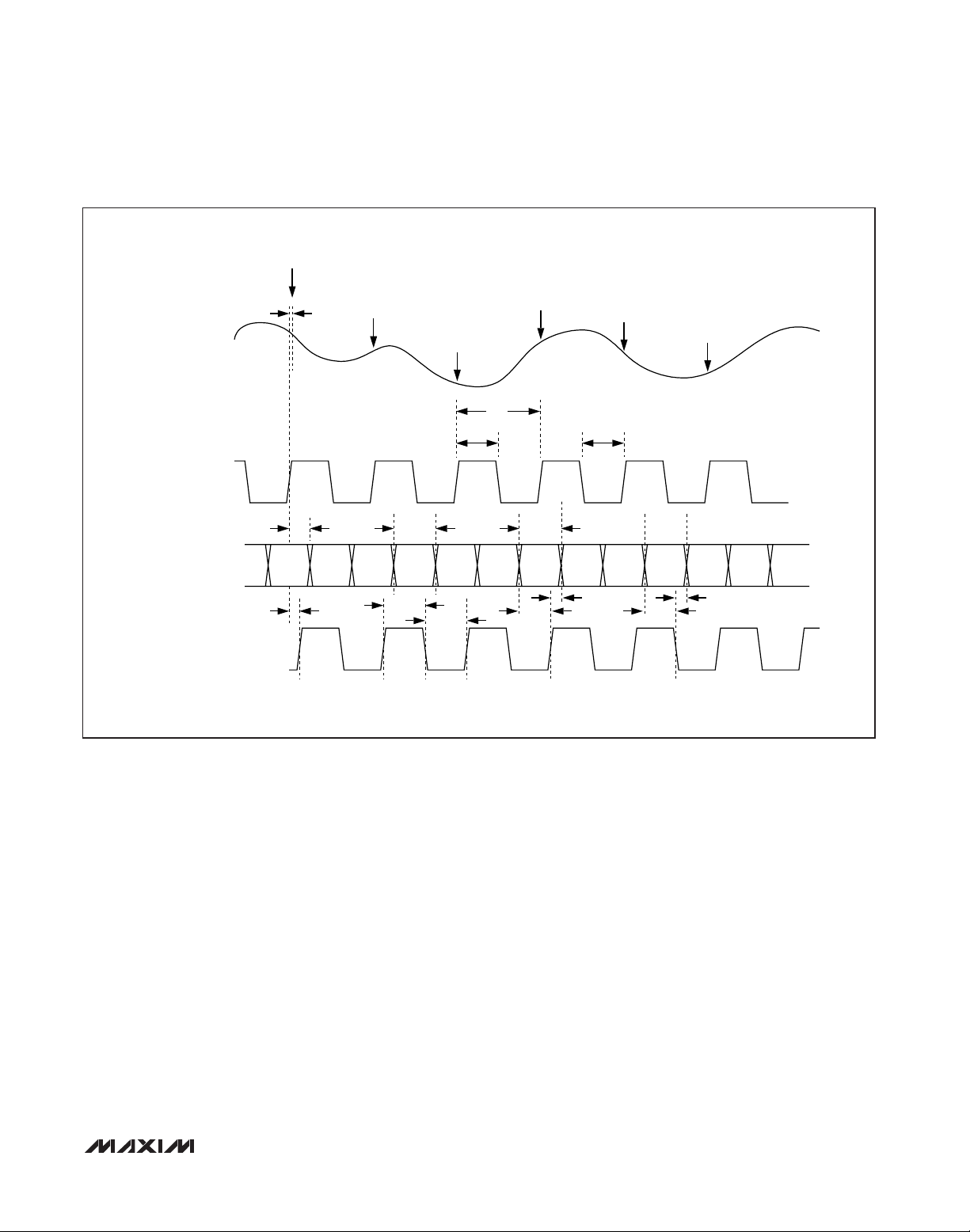

Figure 9. Dual-Bus Output Mode Timing

100Ω

TERMINATION

CLK+

AVDD

10kΩ

20kΩ

CLK-

GND

SELF-BIAS TURNED OFF FOR

SINGLE-ENDED CLOCK

OR POWER-DOWN.

(PROGRAMMABLE)

5kΩ

50Ω

50Ω

5kΩ

SELECT

THRESHOLD

2:1 MUX

Page 25

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 25

Format/Test Pattern register (06h) for clock-divider

options, or in parallel programming configuration (SPEN

= 1) by using the DIV input.

System Timing Requirements

Figures 9 and 10 depict the relationship between the

clock input and output, analog input, sampling event,

and data output. The MAX19506 samples on the rising

edge of the sampling clock. Output data is valid on the

next rising edge of DCLK after a nine-clock internal

latency. For applications where the clock is divided, the

sample clock is the divided internal clock derived from:

[(CLK+ - CLK-)/DIVIDER]

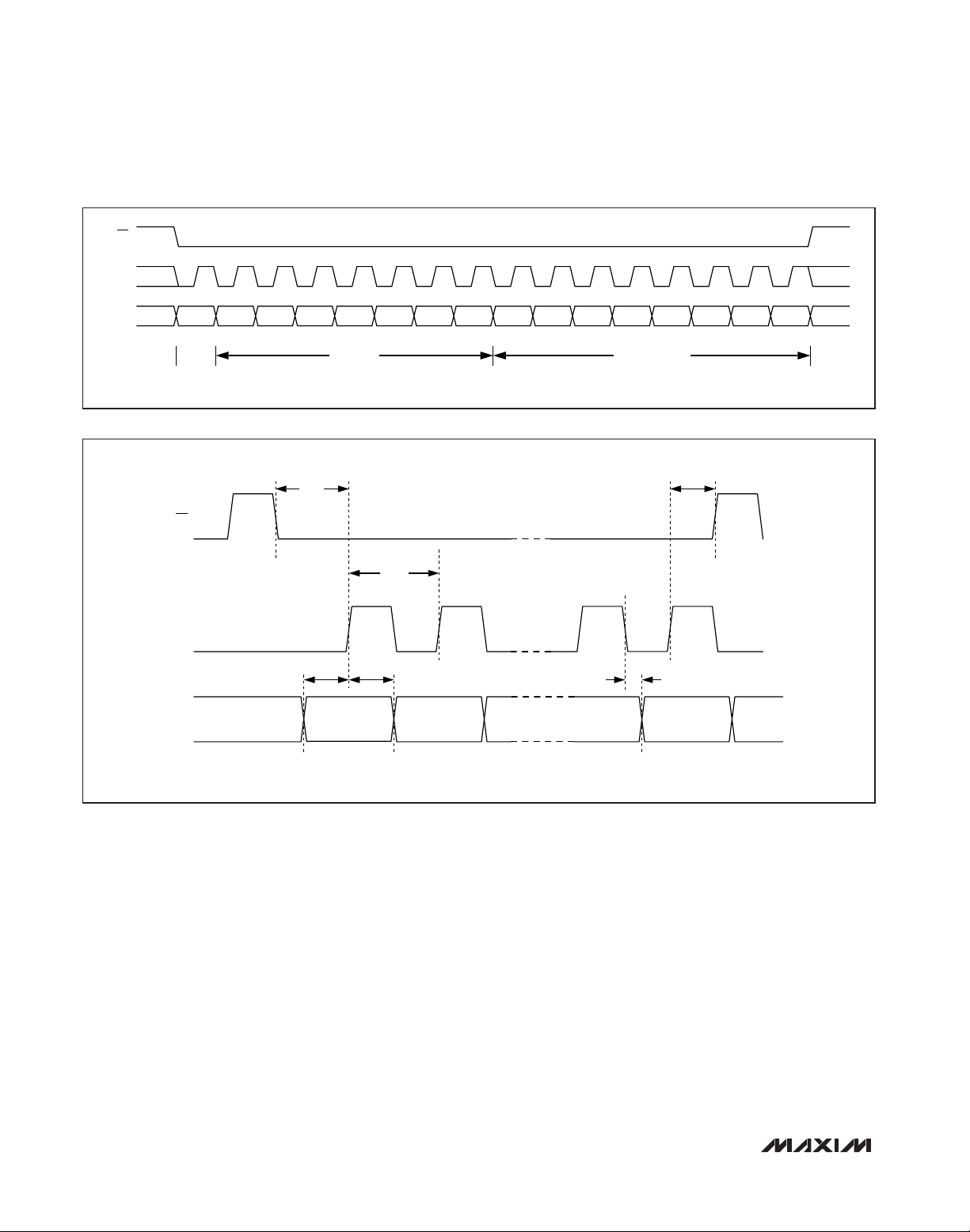

Synchronization

When using the clock divider, the phase of the internal

clock can be different than that of the FPGA, microcontroller, or other MAX19506s in the system. There are

two mechanisms to synchronize the internal clock: slip

synchronization and edge synchronization. Select the

synchronization mode using SYNC_MODE (bit 2) in the

Clock Divide/Data Format/Test Pattern register (06h)

and drive the SYNC input high to synchronize.

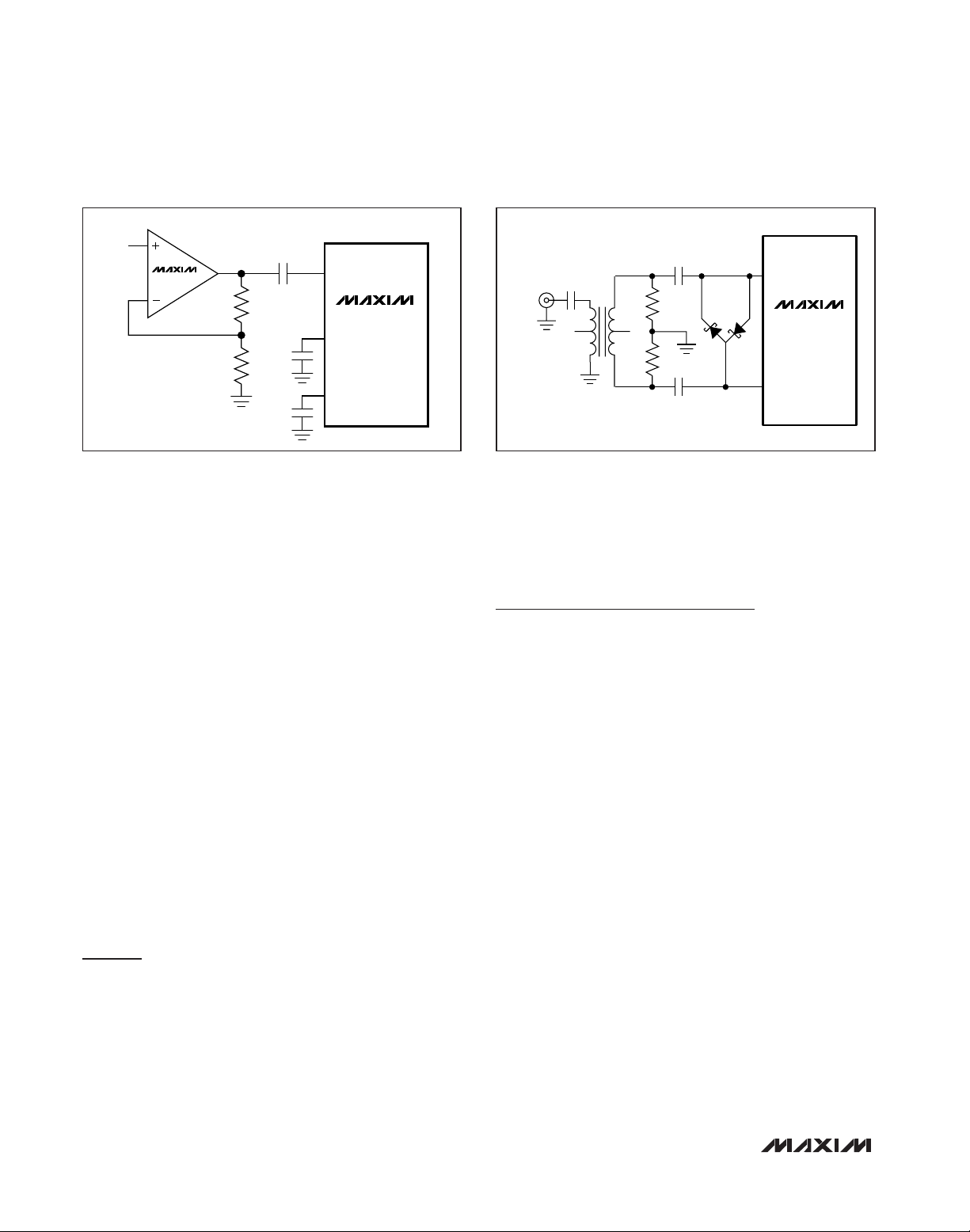

Slip Synchronization Mode, SYNC_MODE = 0

(default): On the third rising edge of the input clock

(CLK) after the rising edge of SYNC (provided set-up

and hold times are met), the divided output is forced to

skip a state transition (Figure 11).

Edge Synchronization Mode, SYNC_MODE = 1: On

the third rising edge of the input clock (CLK) after the

rising edge of SYNC (provided set-up and hold times

are met), the divided output is forced to state 0. A divided clock rising edge occurs on the fourth (/2 mode) or

fifth (/4 mode) rising edge of CLK, after a valid rising

edge of SYNC (Figure 12).

DCLK

DATA, DOR

SAMPLE CLOCK

n-9

CHA CHB

n-9 n-8

CHA CHB

n-8

CHB

n-10 n-7

CHA CHB

n-7 n-6

CHA CHB

n-6 n-5

CHA CHB

n-5 n-4

CHA CHB

n-4

MUX OUTPUT MODE

IN_

SAMPLING

INSTANT

SAMPLING

INSTANT

SAMPLING

INSTANT

SAMPLING

INSTANT

SAMPLING

INSTANT

SAMPLING

INSTANT

t

AD

n n+1 n+2 n+4 n+5n+3

t

CH

t

CL

SAMPLE ON RISING EDGE

t

DC

t

DD

t

CHA

t

DCH

t

SETUP

t

HOLD

t

HOLD

t

DCL

t

SETUP

t

CHB

SAMPLE CLOCK IS THE DERIVED CLOCK FROM (CLK+ - CLK-)/CLOCK DIVIDER, IN_ = IN_+ - IN_-.

MUX_CH (BIT 2, OUTPUT FORMAT 01h) DETERMINES THE OUTPUT BUS AND WHICH CHANNEL DATA IS PRESENTED.

t

CLK

Figure 10. Multiplexed Output Mode Timing

Page 26

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

26 ______________________________________________________________________________________

Figure 11. Slip Synchronization Mode

t

SYNC

2x INPUT CLK

HO

t

SUV

1234

= SET-UP TIME FOR VALID CLOCK EDGE.

t

SUV

= HOLD-OFF TIME FOR INVALID CLOCK EDGE.

t

HO

DIVIDE-BY-2 SLIP SYNCRONIZATION

SLIP

(1) (0) (1) (0) (1) (0) (1) (0) (1) (0)(0)(0)

1x DIVIDED CLK

(STATE)

(1) (0) (1) (0) (1) (0) (1)(1) (0)(1) (0) (1)

t

HO

t

SUV

DIVIDE-BY-4 SLIP SYNCHRONIZATION

SYNC

1234

4x INPUT CLK

1x DIVIDED CLK

(STATE)

5

SLIP

(3)(0) (1) (2) (3) (0) (1) (2) (3) (0) (1) (2) (3)

(0) (1) (2) (3) (0) (1) (2) (3) (0)(1) (2) (3) (0)

(1) (2) (3) (0) (1) (2) (3) (0) (1)(2) (3) (0) (1)

(2) (3) (0) (1) (2) (3) (0) (1)(3) (0) (1) (2) (2)

Page 27

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 27

SYNC

Figure 12. Edge Synchronization Mode

2x INPUT CLK

1x DIVIDED CLK

(STATE)

t

HO

t

SUV

= SET-UP TIME FOR VALID CLOCK EDGE.

t

SUV

= HOLD-OFF TIME FOR INVALID CLOCK EDGE.

t

HO

1234

(1) (0) (1) (0) (1) (0) (1) (0) (1) (0) (1)(0)(0)

t

HO

t

SUV

DIVIDE-BY-2 EDGE SYNCRONIZATION

FORCE TO 0

(1) (0) (1) (0) (1) (0) (1) (0) (1)(1) (0)(1) (0)

DIVIDE-BY-4 EDGE SYNCHRONIZATION

SYNC

1234

4x INPUT CLK

1x DIVIDED CLK

(STATE)

5

FORCE TO 0

(0) (1) (2) (3)(0) (1) (2) (3) (0) (1) (2) (3) (0) (1)

(0) (1) (2) (3) (0) (1) (2) (3) (0) (1)(1) (2) (3) (0)

(0) (1) (2) (3) (0) (1) (2) (3) (0) (1)(2) (3) (0) (1)

(0) (1) (2) (3) (0) (1) (2) (3) (0) (1)(3) (0) (1) (2)

Page 28

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

28 ______________________________________________________________________________________

Digital Outputs

The MAX19506 features a dual CMOS, multiplexable,

reversible data bus. In parallel programming mode,

configure the data outputs (D0_–D7_) for offset binary,

two’s complement, or gray code using the FORMAT

input. Select multiplexed or dual-bus operation using the

OUTSEL input. See the Output Format register (01h) for

details on output formatting using the SPI interface. The

SPI interface offers additional flexibility where D0_–D7_

are reversed, so the LSB appears at D7_ and the MSB

at D0_. OVDD sets the output voltage; set OVDD

between 1.8V and 3.3V. The digital outputs feature programmable output impedance from 50Ω to 300Ω. Set

the output impedance for each bus using the CH_ Data

Output Termination Control registers (04h and 05h).

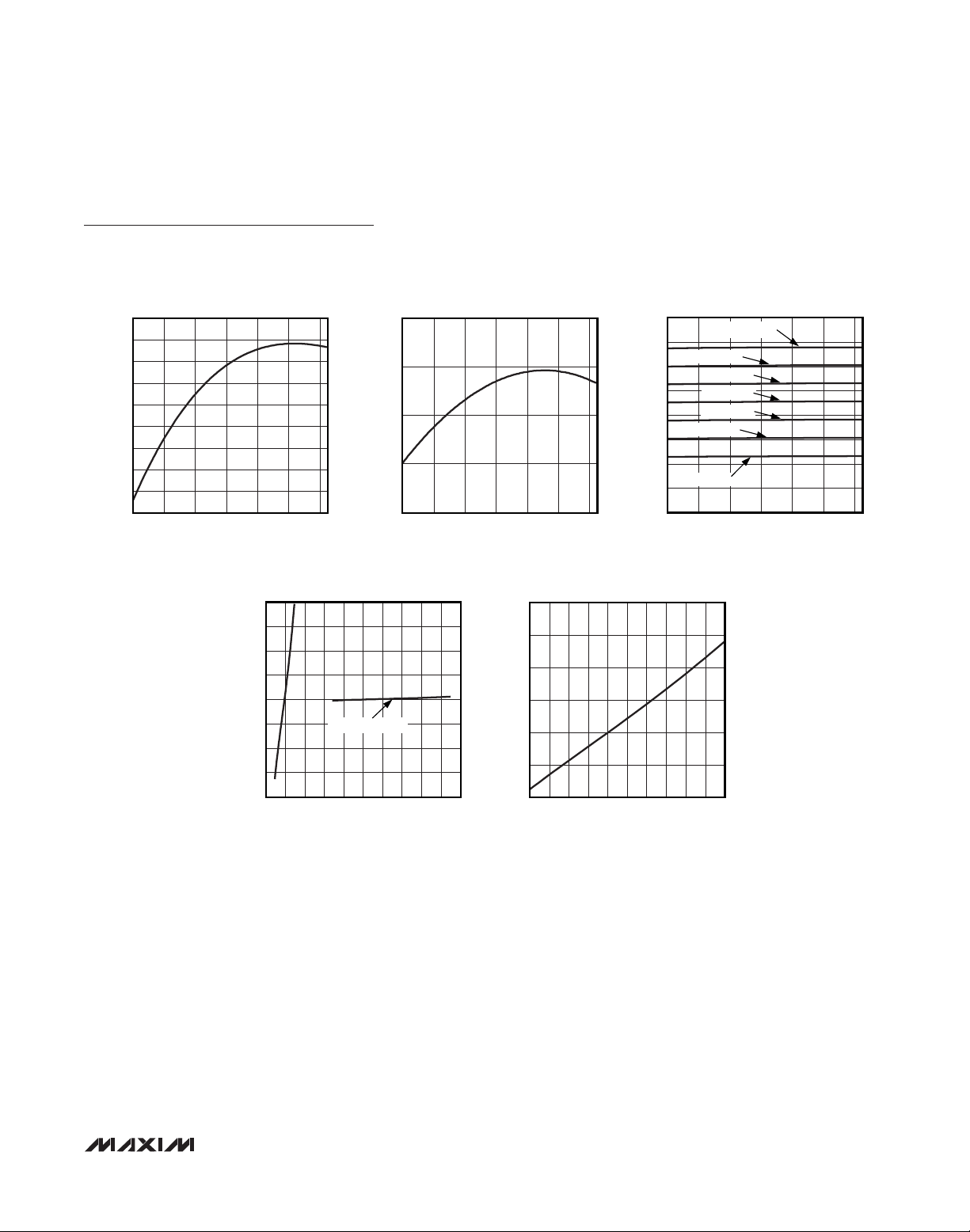

Programmable Data Timing

The MAX19506 provides programmable data timing control to allow for optimization of timing characteristics to

meet the system timing requirements. The timing adjustment feature also allows for ADC performance improvements by shifting the data output transition away from

the sampling instant. The data timing control signals are

summarized in Table 4. The default settings for timing

adjustment controls are given in Table 5. Many applications will not require adjustment from the default settings.

The effects of the data timing adjustment settings are

illustrated in Figures 13 and 14. The x axis is sampling

rate and the y axis is data delay in units of clock period.

The solid lines are the nominal data timing characteristics for the 14 available states of DTIME and

DLY_HALF_T. The heavy line represents the nominal

data timing characteristics for the default settings. Note

that the default timing adjustment setting for the

MAX19506 100Msps ADC results in an additional period of data latency.

Tables 6 and 7 show the recommended timing control

settings versus sampling rate.

The nominal data timing characteristics versus sampling rate for these recommended timing adjustment

settings are shown in Figures 15 and 16.

When DA_BYPASS = 1, the DCLKTIME delay setting

must be equal to or less than the DTIME delay setting,

as shown in Table 8.

Power Management

The SHDN input (pin 7) toggles between any two powermanagement states. The Power Management register

(00h) defines each power-management state. In default

state, SHDN = 1 shuts down the MAX19506 and SHDN

= 0 returns to full power. Use of the SHDN input is not

required for power management. For either state of

SHDN, complete power-management flexibility is provided, including individual ADC channel power-management control, through the Power Management register

(00h). The available reduced-power modes are shutdown and standby. In standby mode, the reference and

duty-cycle equalizer circuits remain active for rapid

wake-up time. In standby mode, the externally applied

clock signal must remain active for the duty-cycle equalizer to remain locked. Typical wake-up time from standby mode is 15µs. In shutdown mode, all circuits are

turned off except for the reference circuit required for the

integrated self-sensing voltage regulator. If the regulator

is active, there is additional supply current associated

with the regulator circuit when the device is in shutdown.

Typical wake-up time from shutdown mode is 5ms,

which is dominated by the RC time constant on REFIO.

Table 4. Data Timing Controls

Table 5. Data Timing Control Default

Settings

DATA TIMING CONTROL DESCRIPTION

DA_BYPASS

DLY_HALF_T

DTIME<2:0> Allows adjustment of data output delay in T/16 increments, where T is the sample clock period.

DCLKTIME<2:0>

Data aligner bypass. When this control is active (high), data and DCLK delay is reduced by

approximately 3.4ns (relative to DA_BYPASS = 0).

When this control is active, data output is delayed by half clock period (T/2). This control does not

delay data output if MUX mode is active.

Provides adjustment of DCLK delay in T/16 increments, where T is the sample clock period. When

DTIME and DCLKTIME are adjusted to the same setting, the rising edge of DCLK occurs T/8 prior

to data transitions.

DATA TIMING

CONTROL

DA_BYPASS 1 Data aligner disabled

DLY_HALF_T 0 No delay

DTIME<2:0> 110 -2T/16 (1.25ns at 100Msps)

DCLKTIME<2:0> 110 -2T/16 (1.25ns at 100Msps)

DEFAULT DESCRIPTION

Page 29

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 29

Figure 15. Recommended Data Timing (V

OVDD

= 1.8V)

Figure 16. Recommended Data Timing (V

OVDD

= 3.3V)

Table 6. Recommended Timing Adjustments (V

OVDD

= 1.8V)

Figure 13. Default Data Timing (V

OVDD

= 1.8V)

FACTORY-DEFAULT NOMINAL DATA

Figure 14. Default Data Timing (V

OVDD

= 3.3V)

TIMING vs. SAMPLE RATE

2.0

V

= 1.8V

OVDD

DA_BYPASS = 1

1.5

1.0

0.5

DATA DELAY (T FRACTIONAL PERIOD)

RECOMMENDED DATA TIMING

vs. SAMPLE RATE

2.0

V

= 1.8V

OVDD

MAX19506 fig13

+11/16

+9/16

+7/16

+5/16

+3/16

+1/16

-1/16

-3/16

+10/16

+8/16

+6/16

+2/16

0

-2/16

DA_BYPASS = 1

1.5

1.0

0.5

DATA DELAY (T FRACTIONAL PERIOD)

MAX19506 fig15

+11/16

+9/16

+7/16

+5/16

+3/16

+1/16

-1/16

-3/16

+10/16

+8/16

+6/16

+2/16

0

-2/16

0

50 100

90807060

SAMPLING RATE (Msps)

FACTORY-DEFAULT NOMINAL DATA

TIMING vs. SAMPLE RATE

2.0

V

= 3.3V

OVDD

DA_BYPASS = 1

1.5

1.0

0.5

DATA DELAY (T FRACTIONAL PERIOD)

MAX19506 fig14

+11/16

+9/16

+7/16

+5/16

+3/16

+1/16

-1/16

-3/16

+10/16

+8/16

+6/16

+2/16

0

-2/16

0

50 100

90807060

SAMPLING RATE (Msps)

SAMPLING RATE (Msps) V

0

50 100

SAMPLING RATE (Msps)

RECOMMENDED DATA TIMING

vs. SAMPLE RATE

2.0

V

= 3.3V

OVDD

DA_BYPASS = 1

1.5

1.0

0.5

DATA DELAY (T FRACTIONAL PERIOD)

0

50 100

SAMPLING RATE (Msps)

= 1.8V

OVDD

90807060

90807060

FROM TO DA_BYPASS DLY_HALF_T DTIME<2:0> DCLKTIME<2:0>

50 56 1 0 000 000

56 68 1 0 101 101

68 80 1 0 110 110

80 92 1 0 111 111

92 100 1 1 011 011

MAX19506 fig16

+11/16

+9/16

+7/16

+5/16

+3/16

+1/16

-1/16

-3/16

+10/16

+8/16

+6/16

+2/16

0

-2/16

Page 30

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

30 ______________________________________________________________________________________

Integrated Voltage Regulator

The MAX19506 includes an integrated self-sensing linear voltage regulator on the analog supply (AVDD). See

Figure 17. When the applied voltage on AVDD is below

2V, the voltage regulator is bypassed, and the core

analog circuitry operates from the externally applied

voltage. If the applied voltage on AVDD is higher than

2V, the regulator bypass switches off, and voltage regulator mode is enabled. When in voltage regulation

mode, the internal-core analog circuitry operates from a

stable 1.8V supply voltage provided by the regulator.

The regulator provides an output voltage of 1.8V over a

2.3V to 3.5V AVDD input-voltage range. Since the

power-supply current is constant over this voltage

range, analog power dissipation is proportional to the

applied voltage.

Power-On and Reset

The user-programmable register default settings and

other factory-programmed settings are stored in nonvolatile memory. Upon device power-up, these values

are loaded into the control registers. This operation

occurs after application of supply voltage to AVDD and

application of an input clock signal. The register values

are retained as long as AVDD is applied. While AVDD is

applied, the registers can be reset, which will overwrite

all user-programmed registers with the default values.

This reset operation can be initiated by software command through the serial-port interface or by hardware

control using the SPEN and SHDN inputs. The reset

time is proportional to the ADC clock period and

requires 85µs at 100Msps. Table 9 summarizes the

reset methods.

Table 7. Recommended Timing Adjustments (V

OVDD

= 3.3V)

Table 8. Allowed Settings of DCLKTIME and DTIME for DA_BYPASS = 1

Table 9. Reset Methods

SAMPLING RATE (Msps) V

FROM TO DA_BYPASS DLY_HALF_T DTIME<2:0> DCLKTIME<2:0>

50 73 1 0 000 000

73 88 1 0 101 101

88 100 1 0 110 110

DTIME<2:0> ALLOWED DCLKTIME<2:0> SETTINGS

111 (-3T/16) 111 (-3T/16)

110 (-2T/16) 110 (-2T/16); 111 (-3T/16)

101 (-1T/16) 101 (-1T/16); 110 (-2T/16); 111 (-3T/16)

000 (nominal) 000 (nominal); 101 (-1T/16); 110 (-2T/16); 111 (-3T/16)

001 (+1T/16) 001 (+1T/16); 000 (nominal); 101 (-1T/16); 110 (-2T/16); 111 (-3T/16)

010 (+2T/16) 010 (+2T/16); 001 (+1T/16); 000 (nominal); 101 (-1T/16); 110 (-2T/16); 111 (-3T/16)

011 (+3T/16) 011 (+3T/16); 010 (+2T/16); 001 (+1T/16); 000 (nominal); 101 (-1T/16); 110 (-2T/16); 111 (-3T/16)

= 3.3V

OVDD

RESET MODE DESCRIPTION

Power-On Reset

Software Reset Write data 5Ah to address 0Ah to initiate register reset.

Hardware Reset A register reset is initiated by the falling edge on the SHDN pin when SPEN is high.

Upon power-up (AVDD supply voltage and clock signal applied), the POR (power-on-reset) circuit initiates a

register reset.

Page 31

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 31

Applications Information

Analog Inputs

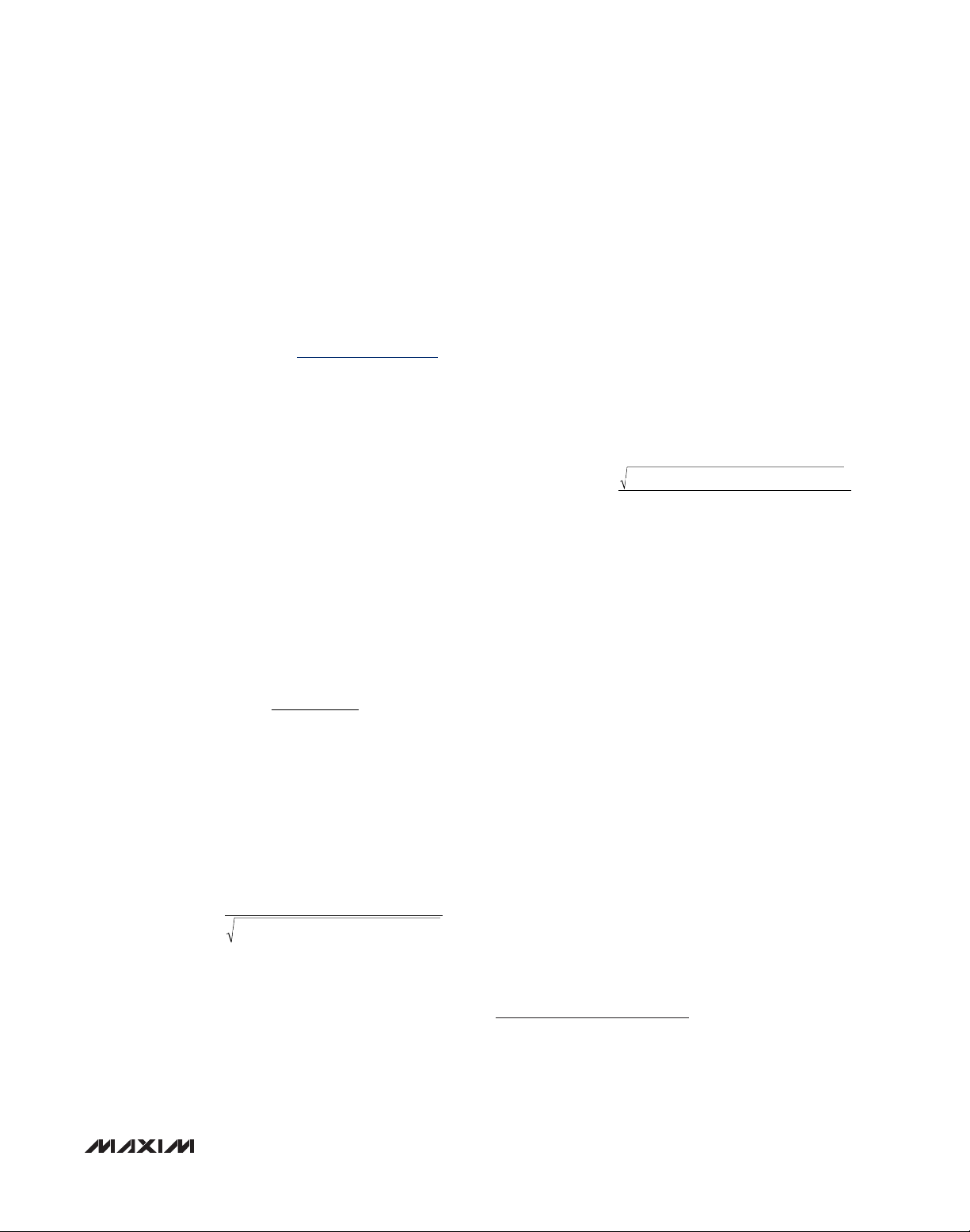

Transformer-Coupled Differential Analog Input

The MAX19506 provides better SFDR and THD with

fully differential input signals than a single-ended input

drive. In differential input mode, even-order harmonics

are lower as both inputs are balanced, and each of the

ADC inputs only require half the signal swing compared

to single-ended input mode.

An RF transformer (Figure 18) provides an excellent

solution for converting a single-ended signal to a fully

differential signal. Connecting the center tap of the

transformer to CM_ provides a common-mode voltage.

The transformer shown has an impedance ratio of 1:1.4.

Alternatively, a different step-up transformer can be

selected to reduce the drive requirements. A reduced

signal swing from the input driver can also improve the

overall distortion. The configuration of Figure 18 is good

for frequencies up to Nyquist (f

CLK

/2).

Figure 17. Integrated Voltage Regulator

(PINS 1, 12, 13, 48)

Figure 19. Transformer-Coupled Input Drive for Input Frequencies Beyond Nyquist

Figure 18. Transformer-Coupled Input Drive for Input

Frequencies Up to Nyquist

AVDD

REGULATOR

REFERENCE

GND

IN_+

0.1µF

V

IN

1

5

N.C. N.C.

3

MINI-CIRCUITS

ADT1-1WT

T1

36.5Ω

0.5%

6

2

4

36.5Ω

0.5%

0.1µF

MAX19506

CM_

IN_-

IN

2.3V TO 3.5V

ENABLE

OUT

1.8V

INTERNAL

ANALOG

CIRCUITS

V

IN

0.1µF

N.C.

1

6

T1

5

2

3

4

MINI-CIRCUITS

ADT1-1WT

N.C.

75Ω

0.5%

75Ω

0.5%

1

5

N.C.

3

MINI-CIRCUITS

ADT1-1WT

6

T2

2

N.C.

4

110Ω

0.5%

0.1µF

110Ω

0.5%

IN_+

MAX19506

CM_

IN_-

Page 32

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

32 ______________________________________________________________________________________

The circuit of Figure 19 also converts a single-ended

input signal to a fully differential signal. Figure 19 utilizes an additional transformer to improve the commonmode rejection allowing high-frequency signals beyond

the Nyquist frequency. A set of 75Ω and 110Ω termina-

tion resistors provide an equivalent 50Ω termination to

the signal source. The second set of termination resistors connect to CM_ providing the correct input common-mode voltage.

Single-Ended AC-Coupled Input Signal

Figure 20 shows a single-ended, AC-coupled input

application. The MAX4108 provides high speed, high

bandwidth, low noise, and low distortion to maintain the

input signal integrity. Bias voltage is applied to the

inputs through internal 2kΩ resistors. See Common

Mode register 08h for further details.

DC-Coupled Input

The MAX19506’s wide common-mode voltage range

(0.4V to 1.4V) allows DC-coupled signals. Ensure that the

common-mode voltage remains between 0.4V and 1.4V.

Clock Input

Figure 21 shows a single-ended-to-differential clock

input converting circuit.

Grounding, Bypassing, and

Board-Layout Considerations

The MAX19506 requires high-speed board-layout

design techniques. Locate all bypass capacitors as

close as possible to the device, preferably on the same

side as the ADC, using surface-mount devices for minimum inductance. Bypass AVDD, OVDD, REFIO, CMA,

and CMB with 0.1µF ceramic capacitors to GND.

Multilayer boards with ground and power planes

produce the highest level of signal integrity. Route highspeed digital signal traces away from the sensitive analog traces of either channel. Make sure to isolate the

analog input lines to each respective converter to minimize channel-to-channel crosstalk. Keep all signal lines

short and free of 90° turns.

Definitions

Integral Nonlinearity (INL)

INL is the deviation of the measured transfer function

from a best-fit straight line. Worst-case deviation is

defined as INL.

Differential Nonlinearity (DNL)

DNL is the difference between the measured transfer

function step width and the ideal value of 1 LSB. A DNL

error specification of less than 1 LSB guarantees no

missing codes and a monotonic transfer function. DNL

deviations are measured at each step of the transfer

function and the worst-case deviation is defined as DNL.

Offset Error

Offset error is a parameter that indicates how well the

actual transfer function matches the ideal transfer function at midscale. Ideally, the midscale transition occurs

at 0.5 LSB above midscale. The offset error is the

amount of deviation between the measured midscale

transition point and the ideal midscale transition point.

Gain Error

Gain error is a figure of merit that indicates how well the

slope of the measured transfer function matches the

slope of the ideal transfer function based on the specified full-scale input-voltage range. The gain error is

defined as the relative error of the measured transfer

function and is expressed as a percentage.

Figure 20. Single-Ended, AC-Coupled Input Drive

Figure 21. Single-Ended-to-Differential Clock Input

V

IN

MAX4108

100Ω

100Ω

0.1µF

0.1µF

IN_+

MAX19506

CM_

0.1µF

CLKIN

IN_-

0.1µF

49.9Ω

49.9Ω

0.01µF

CLK+

MAX19506

0.01µF

CLK-

Page 33

MAX19506

Dual-Channel, 8-Bit, 100Msps ADC

______________________________________________________________________________________ 33

Small-Signal Noise Floor (SSNF)

SSNF is the integrated noise and distortion power in the

Nyquist band for small-signal inputs. The DC offset is