Page 1

General Description

The MAX1937/MAX1938/MAX1939 comprise a family of

synchronous, two-phase, step-down controllers capable

of delivering load currents up to 60A. The controllers utilize Quick-PWM™ control architecture in conjunction with

active load-current voltage positioning. Quick-PWM control provides instantaneous load-step response, while

programmable voltage positioning allows the converter

to utilize full transient regulation limits, reducing the output capacitance requirement. The two phases operate

180° out-of-phase with an effective 500kHz switching frequency, thus reducing input and output current ripple, as

well as reducing input filter capacitor requirements.

The MAX1937/MAX1938/MAX1939 are compliant with

AMD Hammer, Intel®‚ Voltage-Regulator Module (VRM)

9.0/9.1, and AMD Athlon™ Mobile VID code specifications (see Table 1 for VID codes). The internal DAC provides ultra-high accuracy of ±0.75%. A controlled VID

voltage transition is implemented to minimize both

undervoltage and overvoltage overshoot during VID

input change.

Remote sensing is available for high output-voltage

accuracy. The MOSFET switches are driven by a 6V

gate-drive circuit to minimize switching and crossover

conduction losses to achieve efficiency as high as

90%. The MAX1937/MAX1938/MAX1939 feature cycleby-cycle current limit to ensure that the current limit is

not exceeded. Crowbar protection is available to protect against output overvoltage.

Applications

Notebook and Desktop Computers

Servers and Workstations

Blade Servers

High-End Switches

High-End Routers

Macro Base Stations

Features

♦ ±0.75% Output Voltage Accuracy

♦ Instant Load-Transient Response

♦ Up to 90% Efficiency Eliminates Heatsinks

♦ Up to 60A Output Current

♦ 8V to 24V Input Range

♦ User-Programmable Voltage Positioning

♦ Controlled VID Voltage Transition

♦ 500kHz Effective Switching Frequency

♦ MAX1937: AMD Hammer Compatible

♦ MAX1938: Intel VRM 9.0/9.1 Compatible

♦ MAX1939: AMD Athlon Mobile Compatible

♦ Soft-Start

♦ Power-Good (PWRGD) Output

♦ Cycle-by-Cycle Current Limit

♦ Output Overvoltage Protection (OVP)

♦ R

DS(ON)

or R

SENSE

Current Sensing

♦ Remote Voltage Sensing

♦ 28-Pin QSOP Package

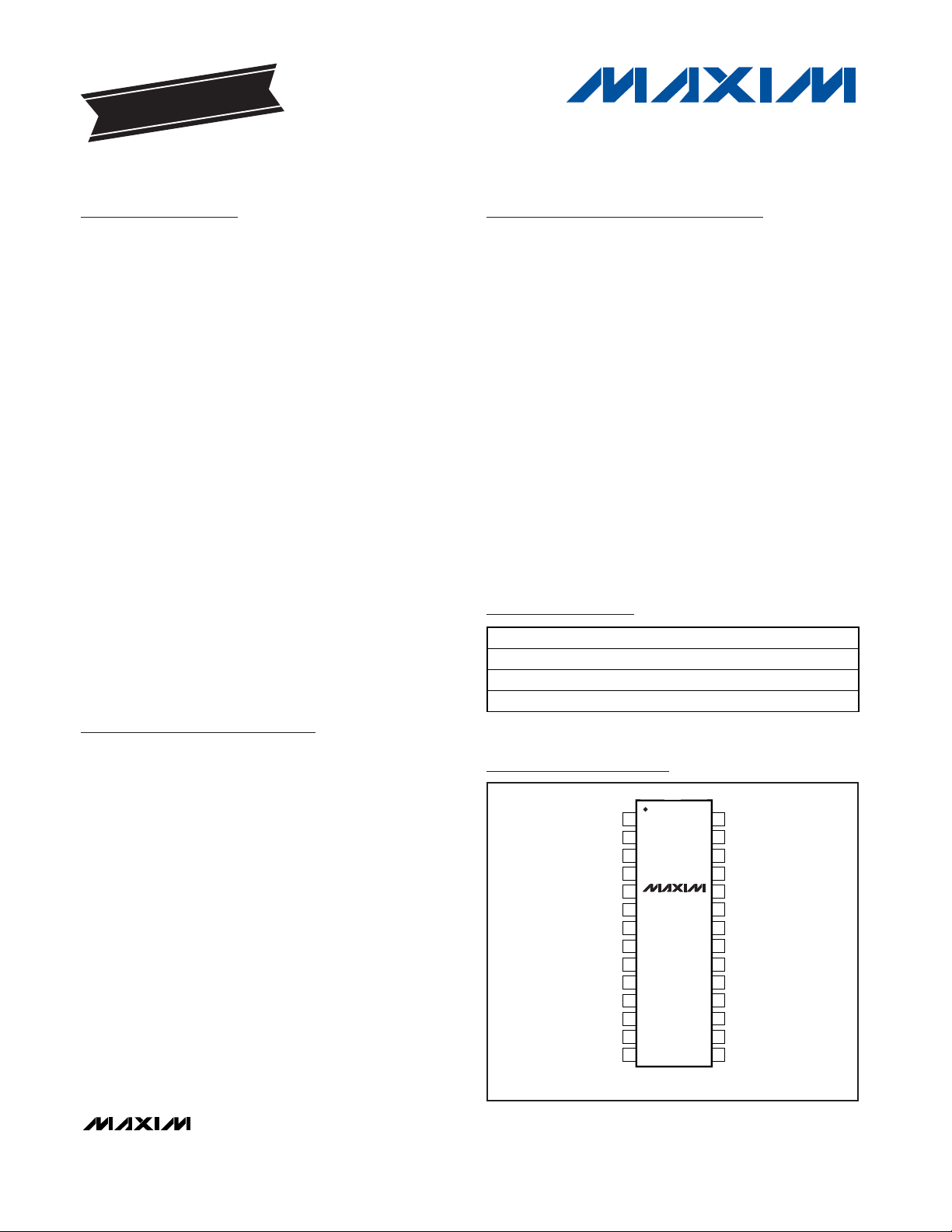

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

________________________________________________________________ Maxim Integrated Products 1

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

V

CC

BST1

DH1

LX1

CS1

DL1

PWRGD

VLG

PGND

DL2

CS2

LX2

DH2

BST2

FB

EN

REF

GNDS

GND

ILIM

V

DD

VPOS

VID4

VID3

VID2

TIME

VID1

VID0

QSOP

TOP VIEW

MAX1937

MAX1938

MAX1939

Pin Configuration

Ordering Information

19-2498; Rev 1; 10/02

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

PART TEMP RANGE PIN-PACKAGE

MAX1937EEI -40°C to +85°C 28 QSOP

MAX1938EEI -40°C to +85°C 28 QSOP

MAX1939EEI -40°C to +85°C 28 QSOP

Quick-PWM is a trademark of Maxim Integrated Products, Inc.

Athlon is a trademark of Advanced Micro Devices, Inc.

Intel is a registered trademark of Intel Corp.

Typical Application Circuits and Functional Diagram appear

at end of data sheet.

Page 2

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCCto GND............................................................-0.3V to +28V

V

DD

, PWRGD, ILIM, FB to GND ...............................-0.3V to +6V

EN, GNDS, VPOS, REF, VID_,

TIME to GND ............................................0.3V to V

VDD

+ 0.3V

PGND to GND .......................................................-0.3V to +0.3V

CS1, CS2 to GND ......................................................-2V to +28V

VLG to GND..............................................................-0.3V to +7V

BST1, BST2 to GND ...............................................-0.3V to +35V

LX1 to BST1..............................................................-7V to +0.3V

LX2 to BST2..............................................................-7V to +0.3V

DH1 to LX1.................................................-0.3V to V

BST1

+ 0.3V

DH2 to LX2.................................................-0.3V to V

BST2

+ 0.3V

DL1, DL2 to PGND ......................................-0.3V to V

VLG

+ 0.3V

Continuous Power Dissipation (T

A

= +70°C)

28-Pin QSOP (derate 20.8mW/°C above +70°C)......860.2mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

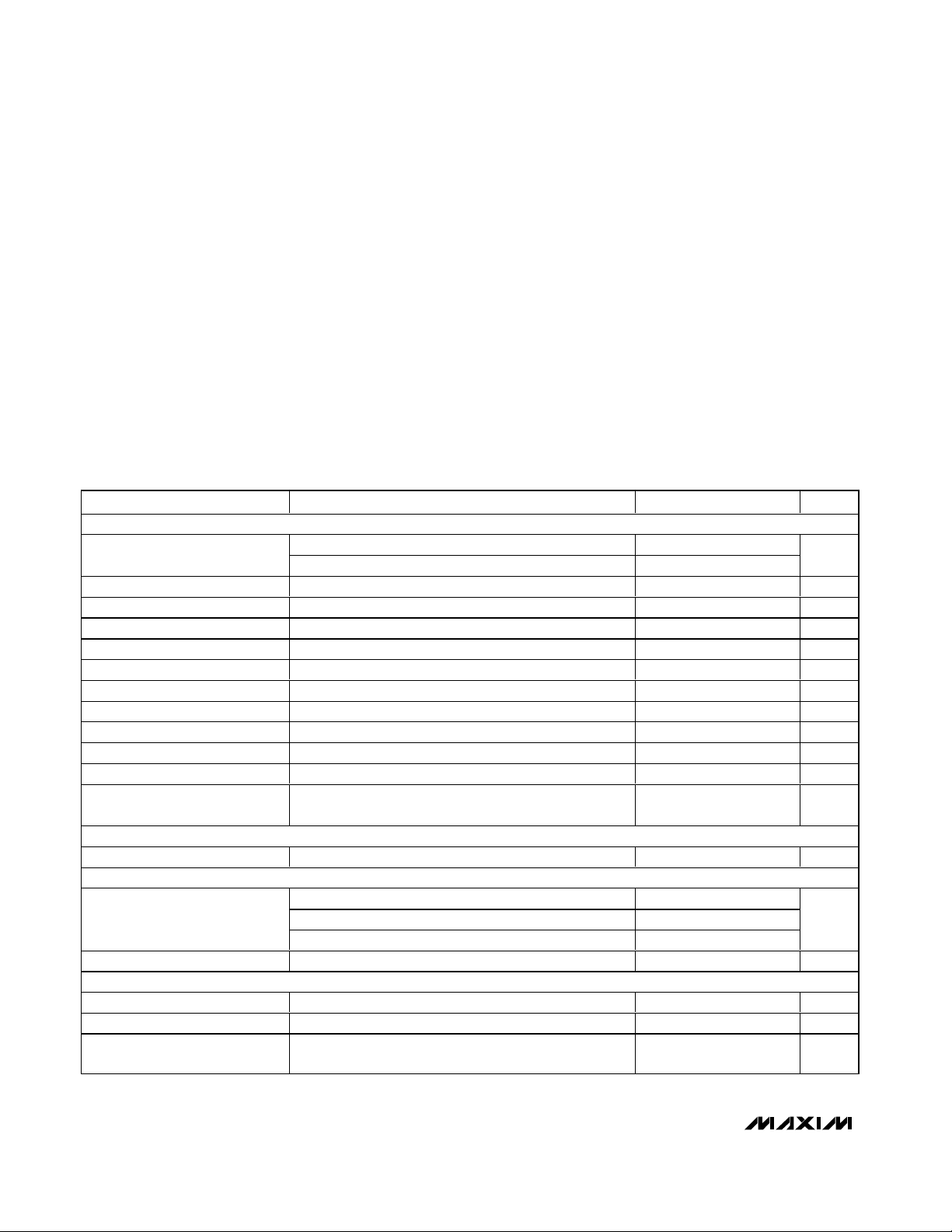

ELECTRICAL CHARACTERISTICS

(VCC= 12V, VEN= V

VDD

= 5V, PGND = GNDS = GND = 0, VID_ = GND, C

VPOS

= 47pF, C

REF

= 0.1µF, V

ILIM

= 1V, TA= 0°C to

+85°C, unless otherwise noted. Typical values are at T

A

= +25°C.)

PARAMETER CONDITIONS

UNITS

GENERAL

MAX1937 6 24

V

CC

Operating Range

MAX1938/MAX1939 8 24

V

V

DD

Operating Range 4.5 5 5.5 V

VLG Operating Range V

VLG

> V

VDD

4.5 6.5 V

V

CC

Operating Supply Current FB above threshold (no switching) 20 40 µA

V

DD

Operating Supply Current FB above threshold (no switching) 1.4 2.5 mA

VLG Operating Supply Current FB above threshold (no switching) 20 60 µA

V

CC

Shutdown Current EN = GND <1 5 µA

V

DD

Shutdown Current EN = GND, VID_ not connected 50

µA

VLG Shutdown Current EN = GND <1 5 µA

TIME Output Voltage

V

ILIM Input Bias V

ILIM

= 1.5V

nA

VPOS Output Voltage

CS_= GND, VPOS connected to REF through a 75kΩ

resistor

2.0

V

REFERENCE

Reference Voltage -50µA ≤ I

REF

≤ 50µA

V

SOFT-START

MAX1937 1.1 5.5

MAX1938 1.5 6.2 Ramp Period

MAX1939 1.3 6.5

ms

Soft-Start Voltage Step 25 mV

ERROR AMPLIFIER

FB Input Resistance Resistance from FB to GND

kΩ

GNDS Input Bias Current -5 +5 µA

Output Regulation Voltage

Accuracy

%

MIN TYP MAX

1.96 2.00 2.04

-250

1.96

100

+250

2.04

1.987 2.000 2.013

180

-0.75

+0.75

Page 3

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

_______________________________________________________________________________________ 3

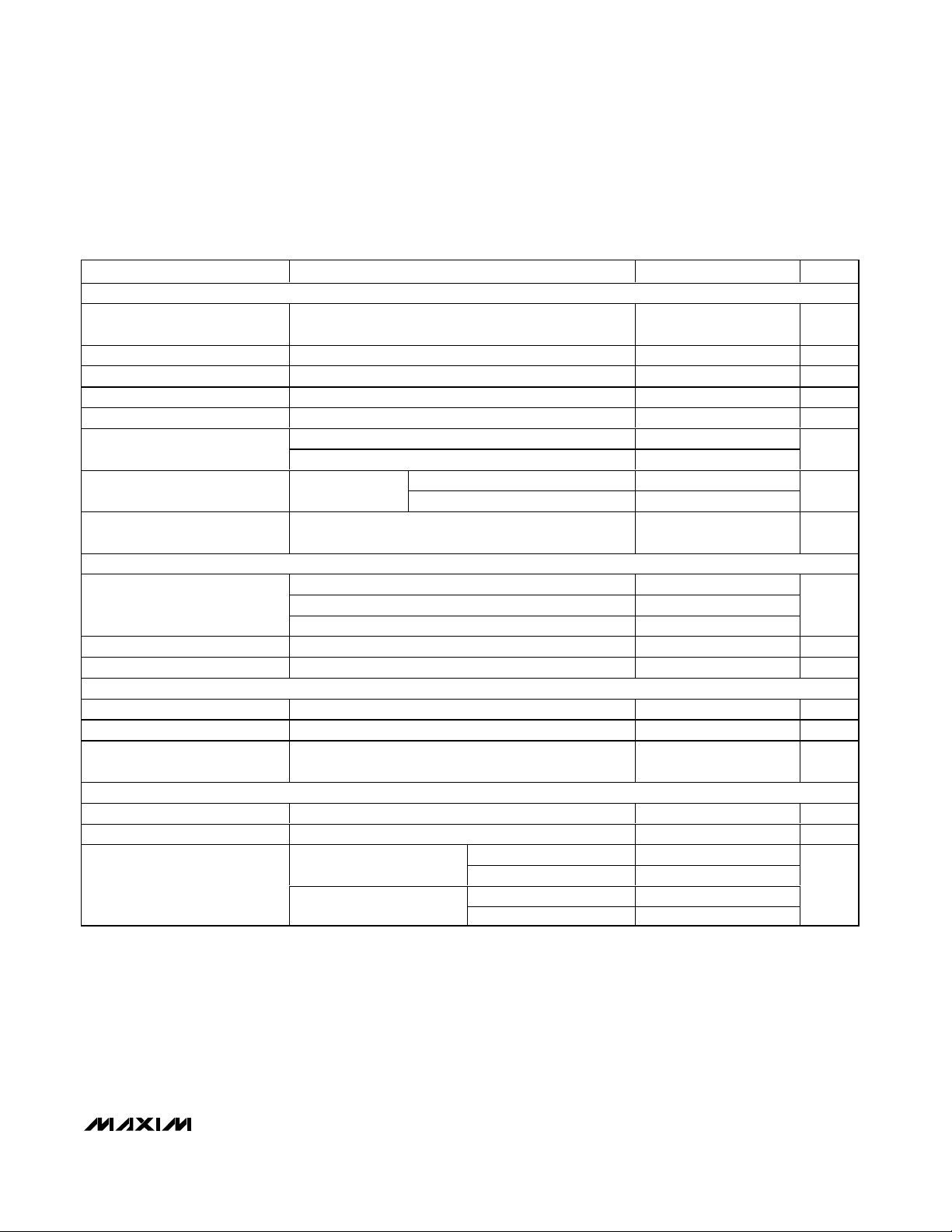

ELECTRICAL CHARACTERISTICS (continued)

(VCC= 12V, VEN= V

VDD

= 5V, PGND = GNDS = GND = 0, VID_ = GND, C

VPOS

= 47pF, C

REF

= 0.1µF, V

ILIM

= 1V, TA= 0°C to

+85°C, unless otherwise noted. Typical values are at T

A

= +25°C.)

PARAMETER CONDITIONS

UNITS

FAULT PROTECTION

V

DD

Undervoltage Lockout

(UVLO) Threshold

Rising or falling V

DD

V

V

DD

UVLO Hysteresis 80 mV

VLG UVLO Threshold Rising or falling VLG

V

VLG UVLO Hysteresis 40 mV

Thermal Shutdown Rising temperature, typical hysteresis = 15°C

°C

Rising edge

Reference UVLO Threshold

Falling edge

V

MAX1937/MAX1938

Output Overvoltage Fault

Threshold

MAX1939

V

Output UVLO Threshold

Rising and falling percentage of the nominal

regulation voltage

65 70 75 %

CURRENT LIMIT

PGND to CS_, V

ILIM

= 1.5V

PGND to CS_, V

ILIM

= 1V 90

Current-Limit Threshold

PGND to CS_, V

ILIM

= 0.5V 45 50 55

mV

CS Input Offset Voltage CS_ = GND -3 +3 mV

CS_ Input Bias Current CS_ = GND -5 +5 µA

VOLTAGE POSITIONING

VPOS Input Offset Voltage -3 +3 mV

VPOS Gain

%/V

VPOS Gain

From CS1, CS2 to FB; V

CS1

, V

CS2

= +13mV, -113mV;

R

VPOS

= 75kΩ

68 75 82 %/V

TIMER AND DRIVERS

On-Time LX1 = LX2 = CS1 = CS2 = GND, V

FB

= 1.5V

ns

Minimum Off-Time DH1 low to DH2 high, and DH2 low to DH1 high

ns

MAX1937/MAX1938 60

DH_ low to DL_ high

MAX1939

60

MAX1937/MAX1938 85

Break-Before-Make Time

DL_ low to DH_ high

MAX1939

70

ns

MIN TYP MAX

4.00 4.25 4.45

4.00 4.25 4.45

160

1.600

1.584

Rising and falling

1.97 2.00 2.03

2.215 2.250 2.285

135 150 165

100 110

From CS_ to FB; V

CS1

, V

= 0, -100mV; R

CS2

VPOS

= 75kΩ 72.5 75.0 77.5

420 525 630

260 325 390

Page 4

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

4 _______________________________________________________________________________________

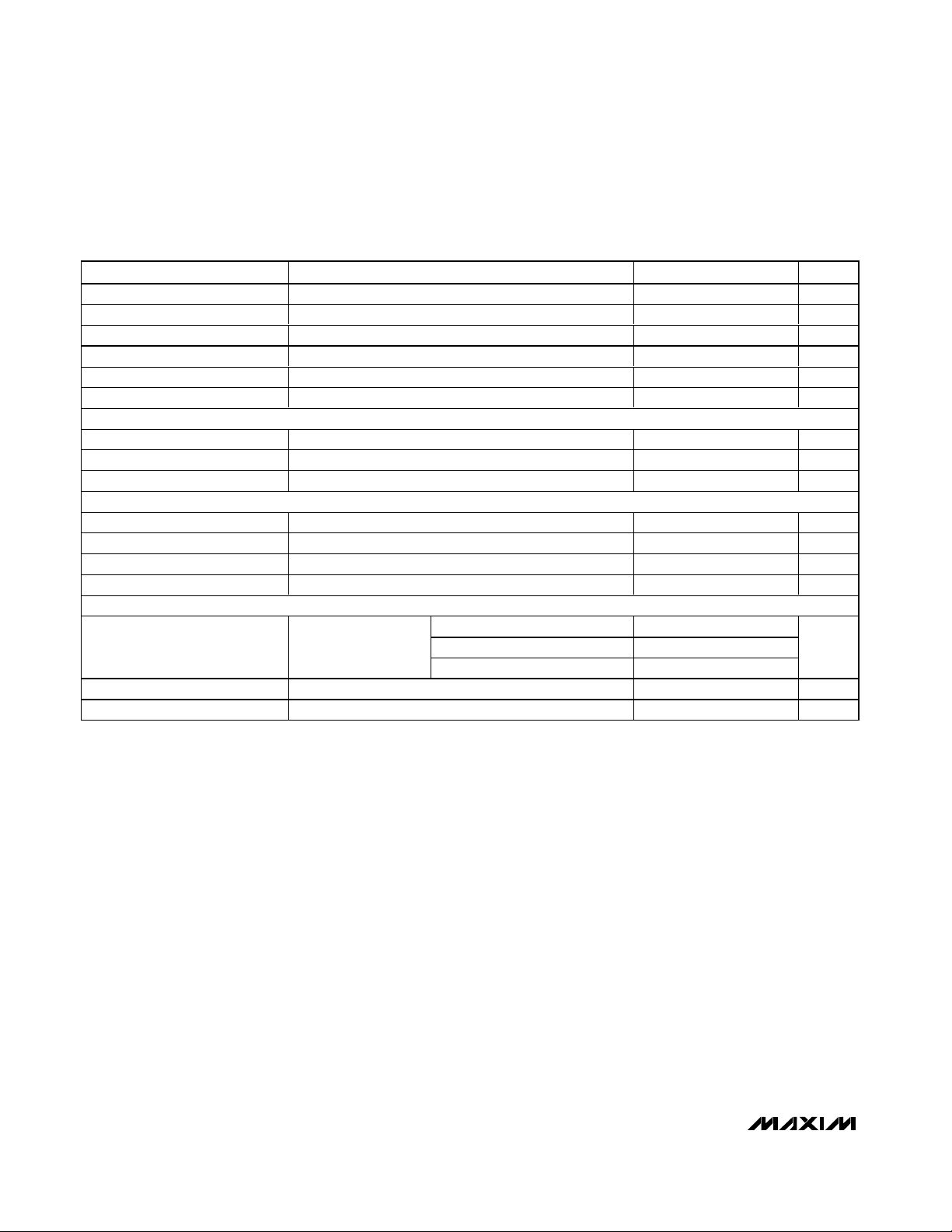

ELECTRICAL CHARACTERISTICS (continued)

(VCC= 12V, VEN= V

VDD

= 5V, PGND = GNDS = GND = 0, VID_ = GND, C

VPOS

= 47pF, C

REF

= 0.1µF, V

ILIM

= 1V, TA= 0°C to

+85°C, unless otherwise noted. Typical values are at T

A

= +25°C.)

PARAMETER CONDITIONS

DH_ On-Resistance in Low State

V

BST1

= V

BST2

= 6V, LX1 = LX2 = GND 1.5 3.0 Ω

DH_ On-Resistance in High State

V

BST_

= 6V, LX_ = GND 1.5 3.0 Ω

DL_ On-Resistance in Low State

0.5 1.7 Ω

DL_ On-Resistance in High State

1.5 3.0 Ω

BST_ Leakage Current V

BST_

= 30V, V

LX_

= 24V 50 µA

LX_ Leakage Current V

BST_

= 30V, V

LX_

= 24V 50 µA

EN AND VID

Low Level Threshold 0.8 V

High Level Threshold 1.6 V

Pullup Resistance Internally pulled up to V

DD

50

kΩ

PWRGD

PWRGD Upper Trip Level

%

PWRGD Lower Trip Level -15

-10 %

Output Low Level 0.4 V

Output High Leakage 1 µA

CONTROLLED VID CHANGE

R

TIME

= 120kΩ

R

TIME

= 47kΩ

On-the-Fly VID Change Slew

Rate

25mV per step

R

TIME

= 470kΩ

µs

VID_ Change Frequency Range

38

kHz

PWRGD Blanking Time V

VDD

= 4.5V to 5.5V

µs

MIN TYP MAX UNITS

10.0 12.5 15.0

100 200

-12.5

6.17 6.67 7.25

2.35 2.63 2.99

23.5 26.3 29.9

380

125 200 350

Page 5

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS

(V

VCC

= 12V, VEN= V

VDD

= 5V, PGND = GNDS = GND, VID_= GND, C

VPOS

= 47pF, C

REF

= 0.1µF, V

ILIM

= 1V, TA= -40°C to +85°C,

unless otherwise noted.) (Note 1)

PARAMETER CONDITIONS

UNITS

GENERAL

MAX1937 6 24

V

CC

Operating Range

MAX1938/MAX1939 8 24

V

V

DD

Operating Range 4.5 5.5 V

VLG Operating Range V

VLG

≥ V

VDD

4.5 6.5 V

V

CC

Operating Supply Current FB above threshold (no switching) 40 µA

V

DD

Operating Supply Current FB above threshold (no switching) 2.5 mA

VLG Operating Supply Current FB above threshold (no switching) 20 60 µA

V

CC

Shutdown Current EN = GND 5 µA

V

DD

Shutdown Current EN = GND, VID_ not connected

µA

VLG Shutdown Current EN = GND 5 µA

TIME Output Voltage

V

ILIM Input Bias V

ILIM

= 1V

nA

VPOS Output Voltage

CS_ = GND, VPOS connected to REF through a 75kΩ

resistor

V

REFERENCE

Reference Voltage -50µA ≤ I

REF

≤ 50µA

V

SOFT-START

MAX1937 1.1 5.5

MAX1938 1.5 6.6 Ramp Period

MAX1939 1.3 7.0

ms

ERROR AMPLIFIER

GNDS Input Bias Current -5 +5 µA

Output Regulation Voltage

Accuracy

-1 +1 %

FAULT PROTECTION

V

DD

UVLO Threshold Rising or falling V

DD

V

VLG UVLO Threshold Rising or falling VLG

V

MAX1937/MAX1938

Output Overvoltage Fault

Threshold

MAX1939

V

Output UVLO Threshold

Rising and falling percentage of the nominal

regulation voltage

65 75 %

CURRENT LIMIT

PGND to CS_, V

ILIM

= 1.5V

PGND to CS_, V

ILIM

= 1V 90

Current-Limit Threshold

PGND to CS_, V

ILIM

= 0.5V 45 55

mV

MIN TYP MAX

1.96

-250

1.96

1.98

100

2.04

+250

2.04

2.02

Rising and falling

4.00

4.00

1.97

2.215

135

4.45

4.45

2.03

2.285

165

110

Page 6

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

VCC

= 12V, VEN= V

VDD

= 5V, PGND = GNDS = GND, VID_= GND, C

VPOS

= 47pF, C

REF

= 0.1µF, V

ILIM

= 1V, TA= -40°C to +85°C,

unless otherwise noted.) (Note 1)

PARAMETER CONDITIONS

UNITS

CS Input Offset Voltage CS_ = GND -5 +5 mV

CS_ Input Bias Current CS_ = GND -5 +5 µA

VOLTAGE POSITIONING

VPOS Input Offset Voltage -5 +5 mV

VPOS Gain

%/V

VPOS Gain

From CS1, CS2 to FB; V

CS1

, V

CS2

= +13mV, -113mV;

R

VPOS

= 75kΩ

68 82 %/V

TIMER AND DRIVERS

On-Time LX1 = LX2 = CS1 = CS2 = GND, V

FB

= 1.5V

ns

Minimum Off-Time DH1 low to DH2 high, and DH2 low to DH1 high

ns

DH_ On-Resistance in Low State

V

BST1

= V

BST2

= 6V, LX1 = LX2 = GND 3 Ω

DH_ On-Resistance in High State

V

BST_

= 6V, LX_ = GND 3 Ω

DL_ On-Resistance in Low State

1.7 Ω

DL_ On-Resistance in High State

3 Ω

BST_ Leakage Current V

BST_

= 30V, V

LX_

= 24V 50 µA

LX_ Leakage Current V

BST_

= 30V, V

LX_

= 24V 50 µA

EN AND VID_

Low Level Threshold 0.8 V

High Level Threshold 1.6 V

Pullup Resistance Internally pulled up to V

DD

50

kΩ

PWRGD

PWRGD Upper Trip Level 10 15 %

PWRGD Lower Trip Level -15 -10 %

Output Low Level 0.4 V

Output High Leakage 1 µA

CONTROLLED VID CHANGE

R

TIME

= 120kΩ

R

TIME

= 47kΩ

On-the-Fly VID Change Slew

Rate

25mV per step

R

TIME

= 470kΩ

µs

VID_ Change Frequency Range

38

kHz

PWRGD Blanking Time V

VDD

= 4.5V to 5.5V

µs

Note 1: Specifications to -40°C are guaranteed by design and not production tested.

MIN TYP MAX

From CS_ to FB; V

CS1

, V

= 0, -100mV; R

CS2

= 75kΩ 72.5

VPOS

420

260

77.5

630

390

200

6.17

2.35

23.5

7.25

2.99

29.9

380

125

350

Page 7

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

_______________________________________________________________________________________ 7

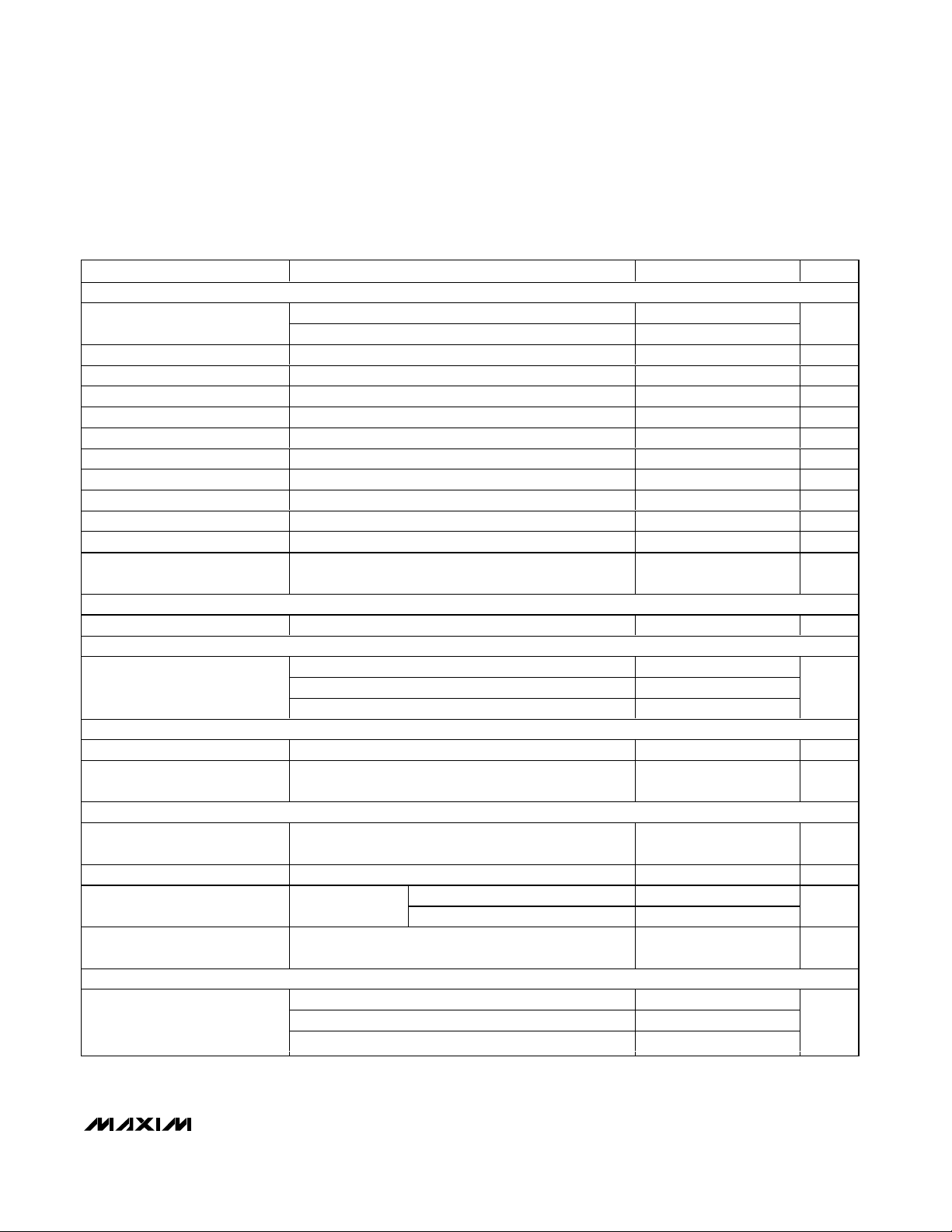

EFFICIENCY vs. LOAD CURRENT

AT 1.45V OUTPUT

MAX1937 toc01

LOAD CURRENT (A)

EFFICIENCY (%)

10

60

70

80

90

50

1 100

VIN = 8V

VIN = 14V

V

IN

= 12V

V

OUT

= 1.45V

50

60

70

80

90

1 10 100

EFFICIENCY vs. LOAD CURRENT

AT 1.85V OUTPUT

MAX1937 toc02

LOAD CURRENT (A)

EFFICIENCY (%)

VIN = 12V

V

IN

= 14V

V

OUT

= 1.85V

V

IN

= 8V

FREQUENCY vs. LOAD CURRENT

MAX1937 toc03

LOAD CURRENT (A)

FREQUENCY (kHz)

5040302010

50

100

150

200

250

300

350

0

060

VIN = 12V

V

OUT

= 1.45V

FREQUENCY vs. INPUT VOLTAGE

MAX1937 toc04

INPUT VOLTAGE (V)

FREQUENCY (kHz)

131211109

175

200

225

250

275

300

325

150

814

I

LOAD

= 46A

V

OUT

= 1.45V

I

LOAD

= 1A

FREQUENCY vs. TEMPERATURE

MAX1937 toc05

TEMPERATURE (°C)

FREQUENCY (kHz)

8060-20 0 20 40

225

230

235

240

245

250

255

260

220

-40 100

VIN = 12V

V

OUT

= 1.45V

I

LOAD

= 10A

VCC INPUT CURRENT

vs. INPUT VOLTAGE

MAX1937 toc06

INPUT VOLTAGE (V)

V

CC

INPUT CURRENT (μA)

131211109

5

10

15

20

25

0

814

V

OUT

= 1.45V

VDD CURRENT vs. VDD VOLTAGE

MAX1937 toc07

V

DD

VOLTAGE (V)

V

DD

CURRENT (mA)

5.35.14.94.7

1.55

1.60

1.65

1.70

1.75

1.80

1.50

4.5 5.5

Typical Operating Characteristics

(VIN= 12V, V

OUT

= 1.45V, TA= +25°C, unless otherwise noted.)

Page 8

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

8 _______________________________________________________________________________________

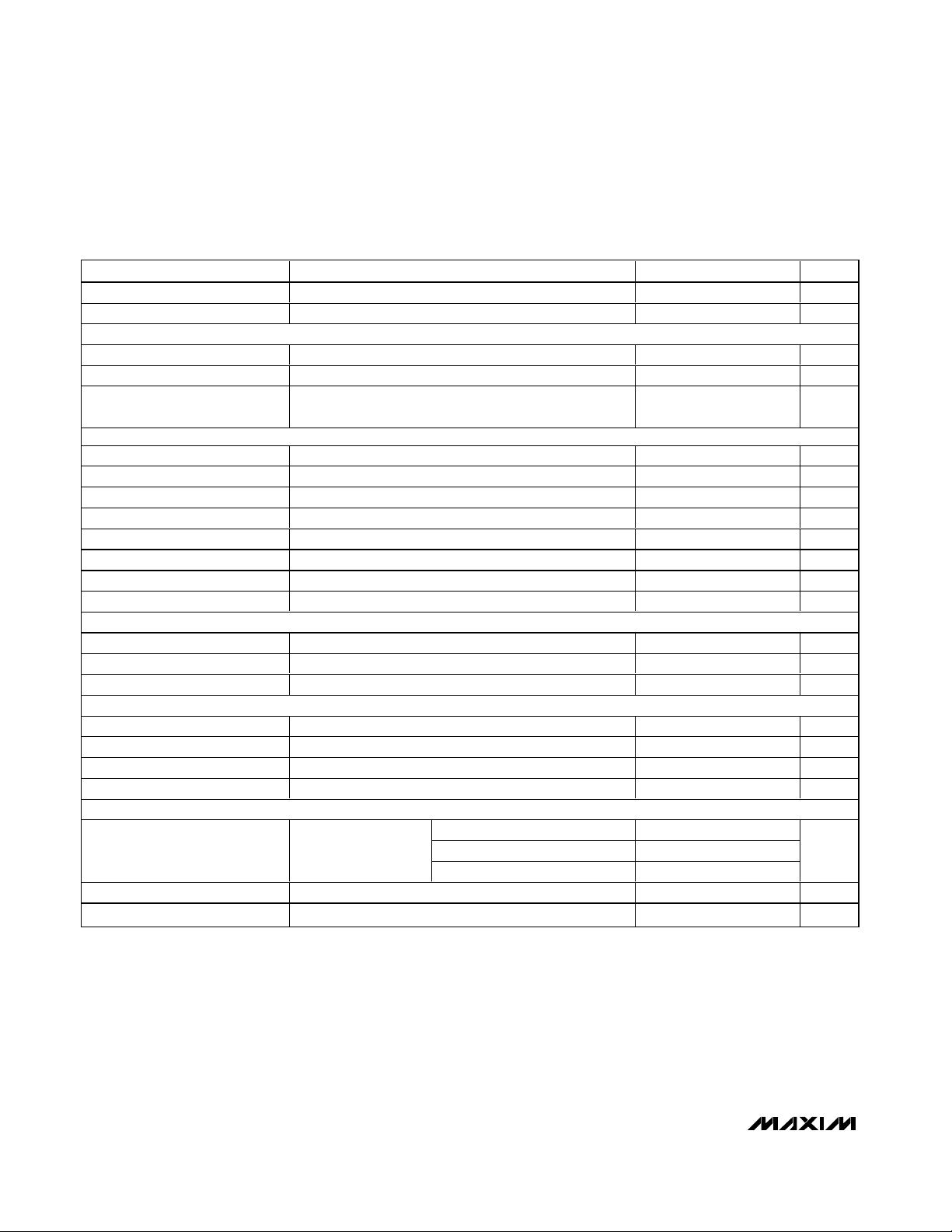

Typical Operating Characteristics (continued)

(VIN= 12V, V

OUT

= 1.45V, TA= +25°C, unless otherwise noted.)

CURRENT SHARING

MAX1937 toc10

LOAD CURRENT (A)

INDUCTOR CURRENTS (A)

40302010

0

5

10

15

20

25

30

-5

050

VIN = 12V

V

OUT

= 1.45V

T

A

= +25°C

CURRENT SHARING

MAX1937 toc11

LOAD CURRENT (A)

INDUCTOR CURRENTS (A)

40302010

0

5

10

15

20

25

30

-5

050

VIN = 12V

V

OUT

= 1.45V

T

A

= +80°C

V

IN

= 12V

V

OUT

= 1.45V

I

OUT

= 0A

0A

OUTPUT INDUCTOR

CURRENTS:

10A/div

OUTPUT RIPPLE

VOLTAGE:

20mV/div

2μs/div

MAX1937 toc12

INDUCTOR CURRENT WAVEFORMS

WITH 0A LOAD

V

IN

= 12V

V

OUT

= 1.45V

I

OUT

= 40A

OUTPUT INDUCTOR

CURRENTS:

10A/div

OUTPUT RIPPLE

VOLTAGE:

20mV/div

2μs/div

MAX1937 toc13

INDUCTOR CURRENT WAVEFORMS

WITH 40A LOAD

0A

OUTPUT VOLTAGE vs. LOAD CURRENT

AT 1.45V OUTPUT

MAX1937 toc09

LOAD CURRENT (A)

V

OUT

40302010

1.375

1.400

1.425

1.450

1.350

050

R

VPOS

= 90.9k

Ω

VIN = 12V

R

VPOS

= 120k

Ω

VDD CURRENT vs. VDD VOLTAGE

IN SHUTDOWN

MAX1937 toc08

VDD VOLTAGE (V)

V

DD

CURRENT (mA)

5.35.14.94.7

35

40

45

50

55

65

60

70

30

4.5 5.5

VID_ NOT CONNECTED

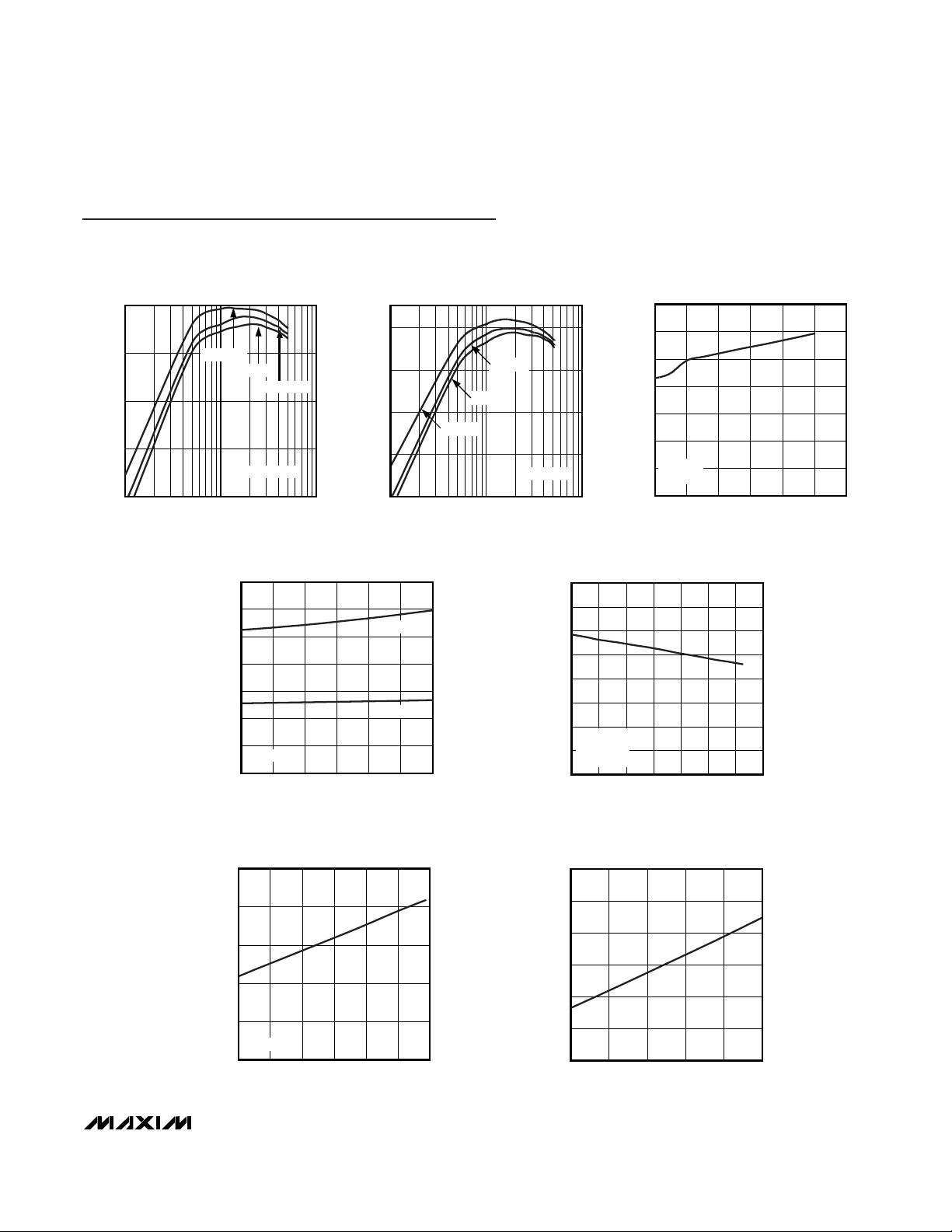

Page 9

ENABLE SIGNAL

OUTPUT VOLTAGE:

0.5V/div

POK SIGNAL

20ms/div

MAX1937 toc18

SHUTDOWN WAVEFORM

WITH 40A LOAD

INDUCTOR CURRENT:

10A/div

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

_______________________________________________________________________________________ 9

CURRENT-SENSE THRESHOLD vs. V

ILIM

MAX1937 toc19

V

ILIM

(V)

CURRENT-SENSE THRESHOLD (mV)

1.31.10.90.7

60

80

100

120

140

160

40

0.5 1.5

VIN = 12V

V

OUT

= 1.45V

TA = +25°C

TA = +80°C

Typical Operating Characteristics (continued)

(VIN= 12V, V

OUT

= 1.45V, TA= +25°C, unless otherwise noted.)

ENABLE SIGNAL

OUTPUT VOLTAGE:

0.5V/div

POK SIGNAL

1ms/div

MAX1937 toc16

SOFT-START WAVEFORMS

WITH 40A LOAD

INDUCTOR CURRENT:

10A/div

ENABLE SIGNAL

OUTPUT VOLTAGE:

0.5V/div

POK SIGNAL

20ms/div

MAX1937 toc17

SHUTDOWN WAVEFORM

WITH NO LOAD

INDUCTOR CURRENT:

10A/div

40μs/div

MAX1937 toc14

LOAD TRANSIENT

1A TO 40A TO 1A

TRANSIENT CONTROL

SIGNAL:

C6

= 47pF

R2

= 91.1kΩ

INDUCTOR CURRENTS:

10A/div

OUTPUT VOLTAGE:

50mV/div

ENABLE SIGNAL

OUTPUT VOLTAGE:

0.5V/div

POK SIGNAL

1ms/div

MAX1937 toc15

SOFT-START WAVEFORMS

WITH NO LOAD

INDUCTOR CURRENT:

10A/div

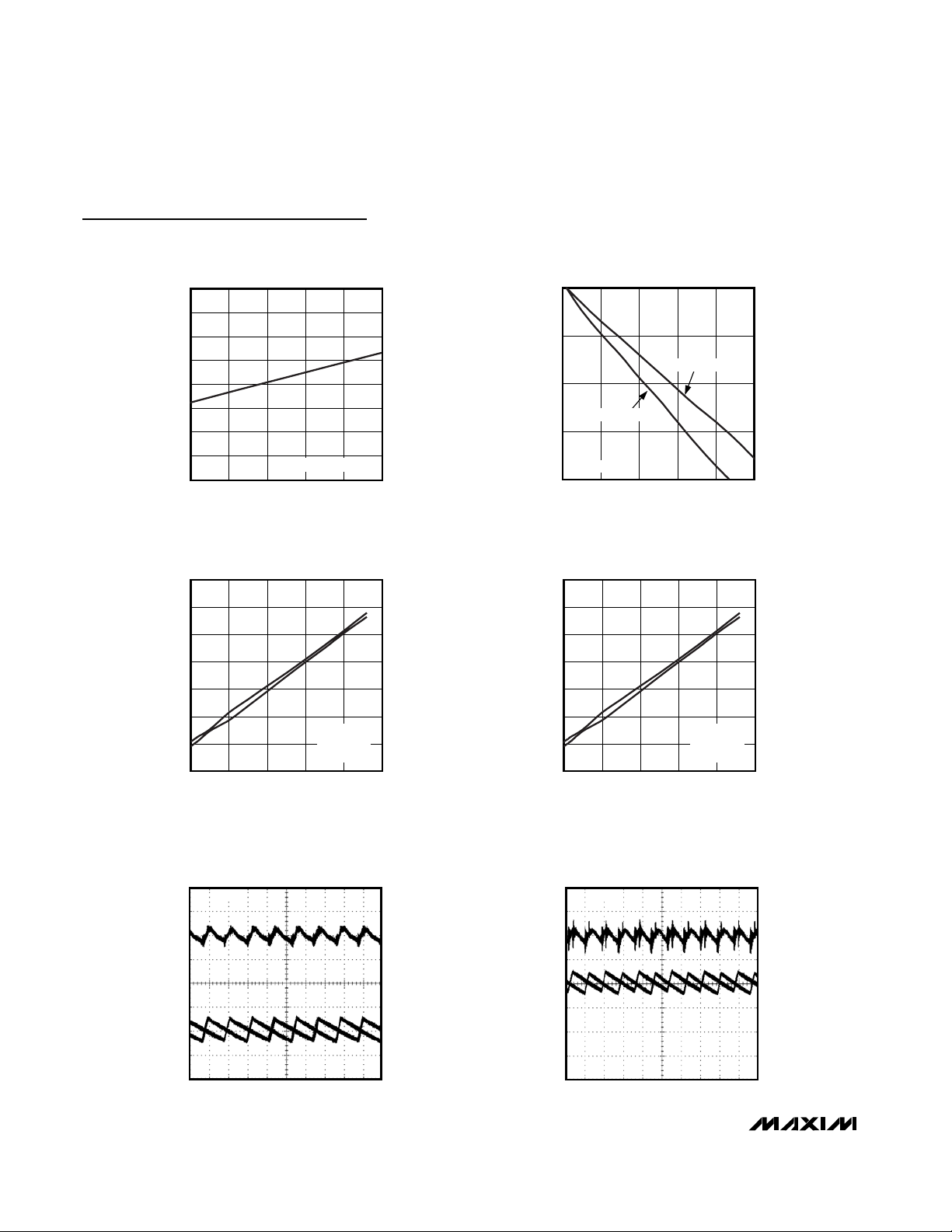

Page 10

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

10 ______________________________________________________________________________________

REFERENCE VOLTAGE vs. TEMPERATURE

MAX1937 toc22

TEMPERATURE (°C)

REFERENCE VOLTAGE (V)

806040200-20

1.992

1.994

1.996

1.998

2.000

1.990

-40 100

VIN = 12V

V

OUT

= 1.45V

NO LOAD

FB VOLTAGE vs. TEMPERATURE

MAX1937 toc23

TEMPERATURE (°C)

FB VOLTAGE (V)

603510-15

0.795

0.800

0.805

0.810

0.790

-40 85

VIN = 12V

NO LOAD

V

OUT

= 0.8V

FB VOLTAGE vs. TEMPERATURE

MAX1937 toc24

TEMPERATURE (°C)

FB VOLTAGE (V)

806040200-20

1.450

1.455

1.460

1.465

1.445

-40 100

VIN = 12V

NO LOAD

V

OUT

= 1.45V

OUTPUT VOLTAGE:

200mV/div

POK SIGNAL

40

μs/div

MAX1937 toc20

VID CODE CHANGE ON-THE-FLY WITH 40A

LOAD 1.2V TO 1.45V TO 1.2V

VID CODE CHANGE

CONTROL SIGNAL

OUTPUT VOLTAGE:

200mV/div

POK SIGNAL

40μs/div

MAX1937 toc21

VID CODE CHANGE ON-THE-FLY WITH 1A

LOAD 1.2V TO 1.45V TO 1.2V

VID CONTROL

SIGNAL

Typical Operating Characteristics (continued)

(VIN= 12V, V

OUT

= 1.45V, TA= +25°C, unless otherwise noted.)

Page 11

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

______________________________________________________________________________________ 11

Pin Description

PIN NAME FUNCTION

1 VID0 Voltage Identification Input Bit 0. See Table 1. Internal 100kΩ pullup resistor to V

DD

.

2 VID1 Voltage Identification Input Bit 1. See Table 1. Internal 100kΩ pullup resistor to V

DD

.

3 TIME Connect to an external resistor (47kΩ to 470kΩ) for VID change slew-rate control.

4 VID2 Voltage Identification Input Bit 2. See Table 1. Internal 100kΩ pullup resistor to V

DD

.

5 VID3 Voltage Identification Input Bit 3. See Table 1. Internal 100kΩ pullup resistor to V

DD

.

6 VID4 Voltage Identification Input Bit 4. See Table 1. Internal 100kΩ pullup resistor to V

DD

.

7 VPOS

Voltage Positioning. Connect a resistor between VPOS and REF to set the output voltage-positioning

droop, or connect directly to REF for no output voltage positioning. Connect a 47pF capacitor from

VPOS to GND.

8 V

DD

IC Analog Power-Supply Input. Connect a 5V supply to V

DD

.

9 ILIM

Current-Limit Threshold per Phase. Connect ILIM to V

DD

to set a default current limit of 120mV, or

connect to a voltage-divider from REF to GND to adjust the current limit. See the Setting the Current

Limit section.

10 GND Ground

11 GNDS

Remote Ground Sense. Connect GNDS to the output ground at the load. For VRM applications, also

connect a 100Ω resistor from GNDS to PGND locally.

12 REF Reference Output. Connect a 0.1µF capacitor from REF to GND.

13 EN Enable Input. Leave unconnected or drive high for normal operation. Drive low for shutdown.

14 FB

Remote Feedback Sense. Connect FB to the output at the load. For VRM applications, also connect

a 100Ω resistor from FB to the output locally.

15 PWRGD

Power-Good Output. Open-drain output is high impedance when the output is in regulation and

pulled low when the output deviates more than 12.5% from the voltage set by the VID code. PWRGD

is also low in shutdown or during any fault condition. To use as a logic output, connect a pullup

resistor from PWRGD to the logic supply.

16 BST2

High-Side MOSFET Gate-Driver Bootstrap Input. Connect 0.22µF or higher value bypass capacitor

from BST2 to LX2. Keep trace length as short as possible. Connect a Schottky diode between BST2

and VLG. See the Selecting a BST Capacitor section.

17 DH2

High-Side MOSFET Gate-Drive Output. Connect to the high-side MOSFET gate. DH2 is pulled low in

shutdown.

18 LX2 Inductor Connection. Connect to the switched side of the inductor.

19 CS2

Negative Current-Sense Input. Connect to a current-sense resistor in series with the low-side

MOSFET, or connect to LX2 to use the low-side MOSFET’s on-resistance for current sensing.

20 DL2

Low-Side MOSFET Gate-Driver Output. Connect to the low-side MOSFET gate. DL2 is pulled low in

shutdown.

21 PGND

Power Ground. Connect to power ground at the point where the current-sense resistors or low-side

MOSFET sources connect. PGND is used as the positive current-sense connection.

Page 12

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

12 ______________________________________________________________________________________

Detailed Description

The MAX1937/MAX1938/MAX1939 is a family of synchronous, two-phase step-down controllers capable of

delivering load currents up to 60A. The controllers use

Quick-PWM control architecture in conjunction with

active load current voltage positioning. Quick-PWM

control provides instantaneous load-step response,

while programmable voltage positioning allows the converter to utilize full transient regulation limits, reducing

the output capacitance requirement. Furthermore, the

two phases operate 180° out-of-phase with an effective

500kHz switching frequency, thus reducing input and

output current ripple, as well as reducing input filter

capacitor requirements.

The MAX1937/MAX1938/MAX1939 are compliant with

the AMD Hammer, Intel VRM 9.0/VRM 9.1, and AMD

Athlon Mobile VID code specifications (see Table 1 for

VID codes). The internal DAC provides ultra-high accuracy of ±0.75%. A controlled VID voltage transition is

implemented to minimize both undervoltage and overvoltage overshoot during VID input change.

Remote sensing is available for high output-voltage

accuracy. The MOSFET switches are driven by with a

6V gate-drive circuit to minimize switching and

crossover conduction losses to achieve efficiency as

high as 90%. The MAX1937/MAX1938/ MAX1939 feature cycle-by-cycle current limit to ensure current limit

is not exceeded. Crowbar protection is available to protect against output overvoltage.

On-Time One-Shot

The heart of the Quick-PWM core is the one-shot that

sets the high-side switch on-time. This fast, low-jitter,

one-shot circuitry varies the on-time in response to the

input and output voltages. The high-side switch on-time

is inversely proportional to the voltage applied to V

CC

and directly proportional to the output voltage. This

algorithm results in a nearly constant switching frequency, despite the lack of a fixed-frequency clock

generator. The benefits of a constant switching frequency are twofold: the frequency selected avoids

noise-sensitive regions, and the inductor ripple current

operating point remains relatively constant, resulting in

easy design methodology and predictable output voltage ripple:

where the constant K is 4µs and V

DROP

is the voltage

drop across the low-side MOSFET’s on-resistance plus

the drop across the current-sense resistor (V

DROP

≈

75mV), if used.

The on-time one-shot has good accuracy at the operating point specified in the Electrical Characteristics. Ontimes at operating points far removed from the

conditions specified in the Electrical Characteristics can

vary over a wide range. For example, the regulators run

slower with input voltages greater than 12V because of

the very short on-times required.

t

KV V

V

ON

OUT DROP

VCC

=

+

()

Pin Description (continued)

PIN NAME FUNCTION

22 VLG

DL_ Driver Power-Supply Input. Connect to a 4.5V to 6.5V supply for powering the low-side MOSFET

gate drive, and the bootstrap circuit for driving the high-side MOSFETs. Ensure that V

VLG

is greater

than or equal to V

VDD

.

23 DL1

Low-Side MOSFET Gate-Driver Output. Connect to the low-side MOSFET gate. DL1 is pulled low in

shutdown.

24 CS1

Negative Current-Sense Input. Connect to a current-sense resistor in series with the low-side

MOSFET or connect to LX1 to use the low-side MOSFET’s on-resistance for current sensing.

25 LX1 Inductor Connection. Connect to the switched side of the inductor.

26 DH1

High-Side MOSFET Gate-Drive Output. Connect to the high-side MOSFET gate. DH1 is pulled low in

shutdown.

27 BST1

High-Side MOSFET Gate-Driver Bootstrap Input. Connect 0.22µF or higher value bypass capacitor

from BST1 to LX1. Keep trace length as short as possible. Connect a Schottky diode between BST1

and VLG. See the Selecting a BST Capacitor section.

28 V

CC

Input Voltage Sense. Connect to the input supply at the high-side MOSFET drain. The voltage

sensed at V

CC

is used to set the on-time.

Page 13

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

______________________________________________________________________________________ 13

While the on-time is set by the input and output voltage,

other factors contribute to the switching frequency. The

on-time guaranteed in the Electrical Characteristics is

influenced by switching delays in the external high-side

MOSFET. Resistive losses in the inductor, both MOSFETs,

output capacitor ESR, and PC board copper losses in

the output and ground, tend to raise the switching frequency at higher output currents. Switch dead-time can

also increase the effective on-time, reducing the

switching frequency. This effect occurs when the

inductor current reverses at light or negative load currents. With reversed inductor current, the inductor’s

V

OUT

(V)

VID4 VID3 VID2 VID1 VID0

MAX1937 MAX1938 MAX1939

00000 1.550 1.850 2.000

00001 1.525 1.825 1.950

00010 1.500 1.800 1.900

00011 1.475 1.775 1.850

00100 1.450 1.750 1.800

00101 1.425 1.725 1.750

00110 1.400 1.700 1.700

00111 1.375 1.675 1.650

01000 1.350 1.650 1.600

01001 1.325 1.625 1.550

01010 1.300 1.600 1.500

01011 1.275 1.575 1.450

01100 1.250 1.550 1.400

01101 1.225 1.525 1.350

01110 1.200 1.500 1.300

01111 1.175 1.475 Shutdown

10000 1.150 1.450 1.275

10001 1.125 1.425 1.250

10010 1.100 1.400 1.225

10011 1.075 1.375 1.200

10100 1.050 1.350 1.175

10101 1.025 1.325 1.150

10110 1.000 1.300 1.125

10111 0.975 1.275 1.100

11000 0.950 1.250 1.075

11001 0.925 1.225 1.050

11010 0.900 1.200 1.025

11011 0.875 1.175 1.000

11100 0.850 1.150 0.975

11101 0.825 1.125 0.950

11110 0.800 1.100 0.925

11111 Shutdown Shutdown Shutdown

Table 1. VID Programmed Output Voltage

Note: In the above table, a zero indicates the VID_ pin is connected to GND or driven low, indicates the VID_ pin is driven high or

not connected.

Page 14

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

14 ______________________________________________________________________________________

EMF causes LX to go high earlier than normal, extending the on-time by a period equal to the DH rising

dead-time.

When the controller operates in continuous mode, the

dead-time is no longer a factor, and the actual switching frequency is:

where V

DROP1

is the sum of the parasitic voltage drops

in the inductor discharge path, including the synchronous rectifier, inductor, and PC board resistances;

V

DROP2

is the sum of the resistances in the charging

path, including the high-side MOSFET, inductor, and

PC board resistances.

Synchronized 2-Phase Operation

The two phases of the MAX1937/MAX1938/MAX1939

operate 180° out-of-phase to reduce input filtering

requirements, reduce electromagnetic interference

(EMI), and improve efficiency. This effectively lowers

cost and saves board space, making the MAX1937/

MAX1938/MAX1939 ideal for cost-sensitive applications.

With dual synchronized out-of-phase operation, the

MAX1937/MAX1938/MAX1939s’ high-side MOSFETs turn

on 180° out-of-phase. The instantaneous input current

peaks of both regulators do not overlap, resulting in

reduced input voltage ripple and RMS ripple current.

This reduces the input capacitance requirement, allowing

fewer or less expensive capacitors, and reduces shielding requirements for EMI. The 180° out-of-phase waveforms are shown in the Typical Operating Characteristics.

Each phase operates with a 250kHz switching frequency. Since the two regulators operate 180° out-of-phase,

an effective switching of 500kHz is seen at the input

and output. In addition to being at a higher frequency

(compared to a single-phase regulator), both the input

and output ripple have lower amplitude.

Phase Overlap

To minimize the crosstalk noise in the two phases, the

maximum duty cycle of the MAX1937/MAX1938/

MAX1939 is less than 50%. To provide a fast transient

response, these devices have a phase-overlap mode

that allows the two phases to operate in phase when a

heavy-load transient is detected. In-phase operation

continues until the output voltage returns to the nominal

output voltage regulation value.

Once regulation is achieved, the controller returns to

180° out-of-phase operation. A minimum current-adaptive phase-selection algorithm is used to determine which

phase is used to start the first out-of-phase cycle. Once

the output voltage returns to the nominal output voltage

regulation value, the subsequent cycle starts with the

phase that has the lowest inductor current. For example,

if the current-sense inputs indicate that phase 2 has

lower inductor current than phase 1, the controller turns

on phase 2’s high-side MOSFET first when returning to

normal operation.

Differential Voltage Sensing and Error

Comparator

The MAX1937/MAX1938/MAX1939 use differential

sensing of the output voltage to achieve the highest

possible accuracy of the output voltage. This allows the

error comparator to sense the actual voltage at the

load, so that the controller can compensate for losses

in the power output and ground lines.

FB and GNDS are used for the differential output voltage

sensing. The controller triggers the next cycle (turn on

the high-side MOSFET) when the error comparator is low

(VFB- V

GNDS

is less than the VID regulation voltage),

V

CS

is below the current-limit threshold, and the mini-

mum off-time one-shot has timed out.

Traces from FB and GNDS should be routed close to

each other and as far away as possible from sources of

noise (such as the inductors and high di/dt traces). If

noise on these connections cannot be prevented, then

use RC filters. To filter FB, connect a 100Ω series resistor

from the positive sense trace to FB, and connect a

1000pF capacitor from FB to GND right at the FB pin. For

GNDS, connect a 100Ω series resistor from the negative

sense trace to GNDS, and connect a 1000pF capacitor

from GNDS to GND at the GNDS pin.

For VRM applications, connect a 10kΩ resistor from FB

to the output locally (on the VRM board), and connect a

10kΩ resistor from GNDS to PGND locally (on the VRM

board). FB and GNDS also connect to the output at the

load (off the VRM board, at the microprocessor). This

provides the benefits of differential output voltage sensing mentioned above and the safety of regulating the

output voltage on the board in case the external sense

connections get disconnected.

External Linear Regulator

A 6V linear regulator (U2) is used to step down the

main supply. The output of this linear regulator is connected to VLG to provide power for the low-side gate

drive and bootstrap circuit. Using 6V for this supply

improves efficiency by providing a stronger gate drive

than a 5V supply. To reduce switching noise on VLG,

f

VV

tV V V

SW

OUT DROP

ON VCC DROP DROP

=

+

+

()

−

1

12

Page 15

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

______________________________________________________________________________________ 15

connect a capacitor (C

VLG

) from VLG to PGND. Place

this capacitor as close as possible to the VLG pin.

The MAX1937/MAX1938/MAX1939 also require an external 5V supply connected to VDD. A diode with a forward

voltage drop of about 1V (D1) is used to stepdown the

6V supply to power the IC, as shown in Figure 1. The

diode connects between the linear regulator output and

the RC filter used to filter the voltage at VDD(R1, C

VDD

,

and C3). In the PC board layout, place C

VDD

as close as

possible to the VDDpin.

High-Side Gate-Drive Supply (BST_)

The drive voltage for the high-side MOSFETs is generated using a bootstrap circuit. The capacitor, C

BST_

,

should be sized properly to minimize the ripple voltage

for switching. The ripple voltage should be less than

200mV. For more information on selecting capacitors

for the BST circuit, see the Selecting a BST Capacitor

section. To minimize the forward voltage drop across

the bootstrap diodes (D2), use Schottky diodes. The

recommended value for the boost capacitors (C

BST_

) is

0.22µF.

R2

100kΩ

V

CC

V

DD

VID4

EN

GNDS

TIME

VPOS

GND

REF

BF

PWRGD

LX2

DH2

ILIM

GNDS

6 × 10μF CERAMIC CAPACITORS

TAIYO YUDEN TMK432BJ106MM

AND 2 × 100μF OS-CON

SANYO 16SP100M

IR: 2 × IRLR7811W

6 × 390μF SP-CAP

PANASONIC EEFUE0D391XR

AND 4 × 1μF CERAMIC CAPACITORS

TAIYO YUDEN LMK212BJ105MG

C

VLG

1μF

C3

2.2μF

C

VDD

0.01μF

VID4

EN

N2

N3

L2

0.66μH

SUMIDA CDEP134-6

IR: 2 × 1RLR7811W

FAIRCHILD

2 × ISL9N303AS3ST

D2

CENTRAL CMPSH-3A

FAIRCHILD

2 × ISL9N303AS3ST

R5

10kΩ

R4

68kΩ

C

REF

0.47μF

C

VPOS

47pF

R3

200kΩ

R1

10Ω

PWRGD

C

OUT

V

OUT

FB

VDD

L1

0.66μH

SUMIDA CDEP134-6

C1

2.2μF

R

VPOS

51.1kΩ

R

TIME

120kΩ

U1

MAX1937

R6

10kΩ

28

8

6

13

VID2

VID3

VID2

VID1

VID0

D1

GND

U2

KA78M06

CENTRAL

CMHD4448

2

3

2

OUTIN

11

VID3

4

5

VID0

VID1

1

2

3

7

12

9

10

11

18

17

14

1

2

2

2

C

BST2

0.22μF

C

BST1

0.22μF

3

DL2

N4

20

CS2

19

PGND

21

VLG

CS1

22

24

DL1

23

BST1

27

LX1

25

DH1

26

BST2

16

1

1

1

1

3

3

N3

2

3

N1

C

IN

INPUT: 8V TO 14V

OUTPUT

0.8V TO 1.55V

46A

3

2

13

V

IN

VDD

1mΩ

R

CS2

1mΩ

R

CS1

C2

2.2μF

V

IN

Figure 1. MAX1937 Application Circuit

Page 16

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

16 ______________________________________________________________________________________

MOSFET Drivers

The DH_ and DL_ drivers are optimized for driving large

high-side (N1 and N2) and larger low-side MOSFETs

(N3 and N4). This is consistent with the low duty-cycle

operation of the controller. The DL_ low-side drive waveform is always the complement of the DH_ high-side

drive waveform, with a fixed dead-time between one

MOSFET turning off and the other turning on to prevent

cross-conduction or shoot-through current.

The internal transistor that drives DL_ low is robust with

a 0.5Ω (typ) on-resistance. This helps prevent DL_ from

being pulled up during the fast rise time of the LX_

node due to capacitive coupling from the drain to the

gate of the low-side synchronous-rectifier MOSFET.

However, some combinations of high-side and low-side

MOSFETs may cause excessive gate-drain coupling,

leading to poor efficiency, EMI, and shoot-through currents. This is often remedied by adding a resistor (typically less than 5Ω) in series with BST_, which increases

the turn-on time of the high-side MOSFET without

degrading the turn-off time.

Current-Limit Circuit

The MAX1937/MAX1938/MAX1939 use either the onresistance of the low-side MOSFETs or a current-sense

resistor to monitor the inductor current. Using the lowside MOSFETs’ on-resistance as the current-sense element provides a lossless and inexpensive solution ideal

for high-efficiency or cost-sensitive applications. The disadvantage to this method is that the on-resistance of

MOSFETs vary from part to part, and overtemperature,

which means it cannot be counted on for high accuracy.

If high accuracy is needed, use current-sense resistors,

which provide an accurate current limit under all conditions but reduce efficiency slightly because of the power

lost in the resistors.

The current-limit circuit employs a “valley” currentsensing algorithm to monitor the inductor current. If the

current-sense signal does not drop below the currentlimit threshold, the controller does not initiate a new

cycle. This limits the maximum value of I

VALLEY

to the

current set by the current-limit threshold (Figure 2).

The current-limit threshold is adjustable over a wide

range, allowing for a range of current-sense resistor

values. The voltage on ILIM sets the current-limit

threshold between PGND and CS_ to 0.1 ✕V

ILIM

. The

10mV to 200mV adjustment range corresponds to ILIM

voltages from 100mV to 2V. The ILIM voltage is set by a

resistor-divider between REF and GND. See the Setting

the Current Limit section for details.

Current Balancing

The DC current balancing between phases depends on

the accuracy of the current-sense elements and the offset of the current-balance amplifier.

The maximum offset of the current-balance amplifier

(V

CBOFFSET

) is ±3mV. The current-balance accuracy

can be calculated from:

Current-balance accuracy = V

CBOFFSET

/ (I

L

✕

RCS)

where ILis the peak inductor current and RCSis the

value of the current-sense resistor.

The current-balance accuracy is most important at full

load. With a load current of 50A (IL= 25A) and 2mΩ

current-sense resistors, the worst-case current-balance

accuracy is:

Current-balance accuracy = 0.003 / (25 ✕0.002) = 6%

If the on-resistance of the low-side MOSFETs is used

for current sensing, the part-to-part variation of the

MOSFET on-resistance is a significant factor in the current balance. The matching between MOSFETs should

be on the order of 15%, worst case. Thus, even if the

current-balance amplifier has no offset, the DC-current

balance could be as bad as 15%. In practice, a little

help is received from the thermal ballasting of the

MOSFETs. That is to say, the positive temperature coefficient of the on-resistance of MOSFETs reduces the

mismatch current between the two phases.

Voltage Positioning (VPOS)

During a load transient, the output voltage instantly

changes by the ESR of the output capacitors times the

change in load current (ΔV

OUT

= -ESR

COUT

✕

ΔI

LOAD

).

Conventional DC-DC converters respond by regulating

the output voltage back to its nominal state after the

load transient occurs (Figure 3). However, the CPU

requires that the output voltage remain within a specific

voltage band. Dynamically positioning the output voltage allows the use of fewer output capacitors and

reduces power consumption under heavy load.

For a conventional (nonvoltage-positioned) circuit, the

total output voltage deviation from light load to full load

and back to light load is:

V

P-P1

= 2 ✕(ESR

COUT

✕

ΔI

LOAD

) + V

SAG

+ V

SOAR

where V

SAG

and V

SOAR

are defined in the Output

Capacitor Selection section. Setting the converter to

regulate at a lower voltage when under load allows a

larger voltage step when the output current suddenly

decreases. The total voltage change for a voltage-positioned circuit is:

V

P-P2

= (ESR

COUT

✕

ΔI

LOAD

) + V

SAG+VSOAR

Page 17

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

______________________________________________________________________________________ 17

The maximum allowable voltage change during a transient is fixed by the supply range of the CPU (V

P-P1

=

V

P-P2

). This means that the voltage-positioned circuit

tolerates twice the ESR in the output capacitors.

Because the ESR specification is achieved by paralleling several capacitors, fewer capacitors are needed for

the voltage-positioned circuit. Figure 4 shows transient

response regions.

An additional benefit of voltage positioning is reduced

power consumption at high-load currents. Because the

output voltage is lower under heavy load, the CPU

draws less current. The result is lower power dissipation in the CPU.

Voltage Reference (REF)

A 2V reference is provided on the MAX1937/MAX1938/

MAX1939 through the REF pin. REF is capable of

sourcing or sinking up to 50µA. In addition to providing

a reference for the IC, REF is used for setting the current limit and voltage positioning. Connect a 0.47µF

capacitor from REF to GND. This capacitor should be

placed as close as possible to the REF pin.

A UVLO is provided for the reference voltage. The reference voltage must rise above 1.600V to activate the

controller. The controller is disabled if the reference

voltage falls below 1.584V.

Enable Input (EN) and Soft-Start

When EN is low, DL_ and DH_ are held low (turning off

the MOSFETs), leaving LX_ high impedance. In addition, the reference is turned off and PWRGD is pulled

low. In shutdown, total current consumption is about

50µA (typ).

In the case of shutdown by VID code, only DL_ and

DH_ are held low. The rest of the controller is enabled.

When EN is driven high, the startup sequence begins.

Once the reference voltage rises above its 1.6V UVLO

threshold, the controller begins switching and starts to

ramp up the output voltage. The output voltage is

ramped up in 25mV steps every 50µs until the output

reaches the nominal output voltage.

Fault Conditions

The MAX1937/MAX1938/MAX1939 contain internal circuitry to protect themselves and surrounding circuitry

from damage from output overvoltage and output

undervoltage conditions. When either of these conditions occurs, DH_ is pulled low, DL_ is driven high, and

PWRGD is pulled low. These pins remain in this state

until either power is cycled on VDDor EN is toggled

high-low-high.

Setting the Output Voltage (VID_)

An internal DAC is used to set the output regulation

voltage. A 5-bit code on inputs VID0–VID4 is used to

specify the output voltage. Some codes disable the

output. There is an internal 100kΩ pullup resistor to

VDD on each of the VID_ inputs. Connecting VID_ to

GND sets the bit to logic low (0); connecting VID_ to

VDD or leaving it unconnected sets the bit to logic high

(1). Use external pullup resistors to speed the low-tohigh logic transition, or for lower logic voltages. See

Table 1 for a list of codes and corresponding output

regulation voltages for each of the parts.

The VID_ codes for the MAX1937 comply with AMD

Hammer code. The VID_ codes on the MAX1938 are

INDUCTOR CURRENT

TIME

I

PEAK

I

LOAD

I

VALLEY

Figure 2. Inductor Current Waveform

B

1.4V

1.4V

A

A. CONVENTIONAL CONVERTER (50mV/div)

B. VOLTAGE-POSITIONED OUTPUT (50mV/div)

VOLTAGE POSITIONING THE OUTPUT

Figure 3. Voltage-Positioning and Nonvoltage-Positioning

Waveforms

Page 18

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

18 ______________________________________________________________________________________

set for Intel VRM 9.0/9.1 and AMD Athlon. The

MAX1939 is set for AMD Athlon Mobile.

VID_ Change Slew Rate (TIME)

The MAX1937/MAX1938/MAX1939 allow the VID_ code

to be changed while the converter is operating (on-thefly). The slew rate at which the output voltage is changing is controlled through TIME. The slew rate is

adjusted externally by connecting a 47kΩ to 470kΩ

resistor (R

TIME

) from TIME to GND. To set the slew rate,

select the R

TIME

resistor using the following equation:

where SR is the slew rate of the output voltage in V/µs.

The output voltage is stepped up or down in 25mV

steps until it reaches the voltage set by the new VID

code.

Power-Good Output (PWRGD)

PWRGD is an open-drain output that is pulled low when

the output voltage deviates more than 12.5% from its

regulation voltage (set by VID_ inputs). PWRGD is

pulled low in shutdown, input UVLO, and during startup. Any fault condition forces PWRGD low until the fault

is cleared, and the IC is reset by cycling power at V

DD

or momentarily toggling EN. For logic-level output voltages, connect an external pullup resistor between

PWRGD and the logic power supply. A 100kΩ resistor

works well in most applications.

Design Procedure

Output Inductor Selection

For most applications, an inductor value of 0.5µH to

1µH is recommended. The inductance is set by the

desired amount of inductor current ripple (LIR). A larger

inductance value minimizes output ripple current and

increases efficiency, but slows transient response. For

the best compromise of size, cost, and efficiency, a LIR

of 30% to 40% is recommended (LIR = 0.3 to 0.4). The

inductor value is found from:

where f

sw

is the actual switching frequency of a phase.

The selected inductor should have the lowest possible

equivalent DC resistance and a saturation current

greater than the peak inductor current (I

PEAK

). I

PEAK

is

found from:

Output Capacitor Selection

The output capacitor must have low enough ESR to

meet output ripple and load-transient requirements.

Also, the capacitance value must be high enough to

absorb the inductor energy going from a full-load to a

no-load condition without tripping the OVP circuit.

In CPU core power supplies and other applications

where the output is subject to large load transients, the

output capacitor’s size typically depends on how much

ESR is needed to prevent the output from dipping too

low under a load transient. Ignoring the sag due to

finite capacitance:

R

ESR

= V

STEP(MAX)

/ ΔI

LOAD(MAX)

The actual capacitance value required relates to the

physical size needed to achieve low ESR, as well as to

the chemistry of the capacitor technology. Thus, the

capacitor is usually selected by ESR and voltage rating

rather than by capacitance value (this is true of OSCONs, SP capacitors, POSCAPs, and other electrolytic

capacitors). Generally, ceramic capacitors are not recommended for bulk output capacitance but make

excellent high-frequency decoupling capacitors.

Once enough capacitance is added to meet the overshoot requirement, undershoot at the rising load edge

II

LIR

PEAK LOAD MAX

=×+

⎛

⎝

⎜

⎞

⎠

⎟

()

1

2

L

VVV

V f I LIR

OUT IN OUT

IN SW LOAD MAX

=

×−

()

×× ×

()

R

SR

TIME

=

521

()Ω

V

OUT

ESR VOLTAGE STEP

(I

STEP

x R

ESR

)

CAPACITIVE SOAR

(dV/dt = I

OUT/COUT

)

RECOVERY

CAPACITIVE SAG

(dV/dt = I

OUT/COUT

)

I

LOAD

Figure 4. Transient Response Regions

Page 19

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

______________________________________________________________________________________ 19

(V

SAG

) is no longer a problem. The amount of overshoot

from stored inductor energy can be calculated as:

where I

PEAK

is the peak inductor current.

The undershoot at the rising load edge of a load transient is calculated from:

where ΔI

LOAD

is the change in load current, and K is

4µs.

To ensure stability, make sure that the zero frequency

created by the output capacitance, and the ESR of the

output capacitor do not exceed 50kHz. The zero frequency is found from:

Currently, aluminum electrolytic, Sanyo POSCAP, and

Panasonic SP capacitors have ESR zero frequencies

well below 50kHz. When using ceramic capacitors, it

might be necessary to use a series resistance to

ensure that the ESR zero is below 50kHz.

Input Capacitor Selection

The input capacitor reduces peak currents drawn from

the power source and reduces noise and voltage ripple

on the input caused by the circuit’s switching. The input

capacitor must meet the ripple current requirement

(I

RMS

) imposed by the switching currents as defined by

the following equation:

I

RMS

has a maximum value when the input voltage

equals twice the output voltage (VIN= 2V

OUT

), so

I

RMS(MAX)

= I

LOAD

/ 2. For most applications, nontantalum capacitors (ceramic, aluminum electrolytic, polymer, or OS-CON) are preferred at the input because of

their robustness with high inrush currents typical of sys-

tems that may be powered from very low impedance

sources.

Multiple smaller value capacitors can be used in parallel to satisfy the ESR and capacitance requirements.

Selecting a BST Capacitor

The BST capacitors must be large enough to handle

the gate-charging requirements of the high-side

MOSFETs. For most applications, 0.22µF ceramic

capacitors are recommended.

BST capacitors are needed to keep the voltage on the

BST_ pins from dropping too much when the high-side

MOSFET gates are charged. A capacitor value that

prevents V

BST

_ from dropping more than 100mV to

200mV is adequate. The capacitance needed for the

BST_ capacitor is calculated from:

where QGHis the total gate charge of the high-side

MOSFET and ΔV

BST_

is the amount that the voltage on

the BST_ pin drops when the gate is charged. If using

multiple MOSFETs in parallel, use the sum of all the

gate charges for QGH.

Setting the Current Limit

Current limit sets the maximum value of the inductor

“valley” current. I

VALLEY

is calculated from the following

equation:

The current-limit threshold (I

LIMIT

) must be set higher

than the valley current:

The current-limit threshold is set by the voltage at ILIM

and the value of the current-sense resistors:

where V

ILIM

is the voltage on the ILIM pin (0.1V to 2V)

and RCSis the value of the current-sense resistor. If the

on-resistance of the low-side MOSFET is used for current sensing, then the maximum value of the on-resistance (overtemperature and part-to-part variation) must

be used for R

CS

.

I

V

R

LIMIT

ILIM

CS

=

×10

II

LIMIT VALLEY

>

I

I

LIR

VALLEY

LOAD MAX

=×−

⎛

⎝

⎜

⎞

⎠

⎟

()

2

1

2

C

Q

V

BST

GH

BST__

=

Δ

I

I

VVV

V

RMS

LOAD

OUT IN OUT

IN

=

×−

()

2

f

ESR C

zESR

COUT OUT

=

××

1

2π

V

LI

VK

V

t

CV

VV K

V

t

SAG

LOAD

OUT

IN

OFF MIN

OUT OUT

IN OUT

IN

OFF MIN

=

×Δ ×

×

+

⎡

⎣

⎢

⎤

⎦

⎥

×××

−×

⎡

⎣

⎢

−

2

2

()

()

()

V

IL

CV

SOAR

PEAK

OUT OUT

=

×

××

2

2

Page 20

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

20 ______________________________________________________________________________________

V

ILIM

is set from 0.5V to 2V by connecting ILIM to a

resistor-divider from REF to GND. Select resistors R3

and R4 such that the current through the divider is at

least 5µA:

A typical value for R3 is 200kΩ; then solve for R4 using:

Setting the Voltage Positioning

Voltage positioning dynamically changes the outputvoltage set point in response to the load current. When

the output is loaded, the signals fed back from the current-sense inputs adjust the output voltage set point,

thereby decreasing power dissipation. The load-transient response of this control loop is extremely fast yet

well controlled, so the amount of voltage change can

be accurately confined within the limits stipulated in the

microprocessor power-supply guidelines. To understand the benefits of dynamically adjusting the output

voltage, see the Voltage Positioning (VPOS) section.

The amount of output voltage change is adjusted by an

external gain resistor (R

VPOS

). Connect R

VPOS

between

REF and VPOS. The output voltage changes in response

to the load current as follows:

where V

VID

is the programmed output voltage set by

the VID code (Table 1), and the voltage-positioning

transconductance (g

m(VPOS)

) is typically 20µS. RCSis

the value of the current-sense resistor connected from

CS_ to PGND. If the on-resistance of the low-side

MOSFETs is used instead of current-sense resistors for

current sensing, then use the maximum on-resistance

of the low-side MOSFETs for RCSin the equation

above.

MOSFET Power Dissipation

Power dissipation in the high-side MOSFET is worst at

high duty cycles (maximum output voltage, minimum

input voltage). Two major factors contribute to the highside power dissipation, conduction losses, and switching losses. Conduction losses are because of current

flowing through a resistance, and can be calculated

from:

where R

DS(ON)

is the on-resistance of the high-side

MOSFET and V

IN

is the input voltage. To minimize con-

duction losses, select a MOSFET with a low R

DS(ON)

.

Switching losses are also a major contributor to power

dissipation in the high-side MOSFET. Switching losses

are difficult to precisely calculate and should be measured in the circuit. To estimate the switching losses,

use the following equation:

where I

PEAK

and I

VALLEY

are the maximum peak and

valley inductor currents, t

FALL

and t

RISE

are the fall and

rise times of the high-side MOSFET, and fSWis the

switching frequency (about 250kHz).

The total power dissipated in the high-side MOSFET is

then found from:

P

D(HS)

= P

D(HS)COND

+ P

D(HS)SW

The power dissipation in the low-side MOSFET is highest at low duty cycles (high input voltage, low output

voltage), and is mainly because of conduction losses:

Switching losses in the low-side MOSFET are small

because of its voltage being clamped by the body

diode. Switching losses can be estimated from:

where I

LOADMAX/2

is the maximum average inductor

current, tDTis the time/cycle that the low-side MOSFET

conducts through its body diode, and VDFis the forward voltage drop across the body diode.

The total power dissipation in the low-side MOSFET is:

P

D(LS)

= P

D(LS)COND

+ P

D(LS)SW

IC Power Dissipation

During normal operation, power dissipation in the controller is mostly from the gate drivers. This can be calculated from the following equation:

P

GATE

= 2 ✕V

VLG

✕

f

SW

✕

( QGH+ QGL)

P

I

tVf

DLSSW

LOADMAX

DT DF SW()

≅×××

2

P

V

V

I

R

D LS COND

OUT

IN

LOADMAX

DS ON() ( )

=−

⎛

⎝

⎜

⎞

⎠

⎟

××1

4

2

PItIt

Vf

D HS SW PEAK fall VALLEY rise

IN SW

()

()≅×+ ×

×

2

P

VI R

V

D HS COND

OUT

LOADMAX

DS ON

IN

()

()

=

××

×

2

4

VVg R

IR

OUT VID m VPOS VPOS

OUT CS

=− × ×

×

⎛

⎝

⎜

⎞

⎠

⎟

()

2

RR

V

V

ILIM

ILIM

43

2

=×

−

RR k3 4 400 +≤ Ω

Page 21

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

______________________________________________________________________________________ 21

where fSWis approximately 250kHz, QGHis the gate

charge of the high-side MOSFET, and QGLis the gate

charge of the low-side MOSFET. The values used for

the gate charge are at the gate drive voltage (V

VLG

).

The “2” in the above equation is due to the two phases

of the converter. If multiple MOSFETs are used in parallel, add the gate charges of each MOSFET to find the

total gate charge used in the above equation.

Make sure that the maximum power dissipation of the IC

is not exceeded (see the Absolute Maximum Ratings).

Applications Information

PC Board Layout Guidelines

A properly designed PC board layout is important in any

switching DC-DC converter circuit. If possible, mount

the MOSFETs, inductor, input/output capacitors, and

current-sense resistor on the top side of the PC board.

Connect the ground for these devices close together on

a power ground plane. Make all other ground connections to a separate analog ground plane. Connect the

analog ground plane to power ground at a single point.

To help dissipate heat, place high-power components

(MOSFETs, inductor, and current-sense resistor) on a

large PC board area, or use a heat sink. Keep high cur-

rent traces short and wide to reduce the resistance in

these traces. Also make the gate-drive connections (DH_

and DL_) short and wide, measuring 10 to 20 squares

(50mils to 100mils wide if the MOSFET is 1in from the

controller IC).

Use Kelvin sense connections for the current-sense

resistors.

Place the REF capacitor, the V

DD

capacitor, and the

BST_ diode and capacitor as close as possible to the IC.

If the IC is far from the input capacitors, bypass VCCto

GND with an additional 0.1µF or greater ceramic capacitor close to the VCCpin.

For an example PC board layout, refer to the MAX1937

or MAX1938 evaluation kit.

Chip Information

TRANSISTOR COUNT: 6243

PROCESS: BiCMOS

Page 22

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

22 ______________________________________________________________________________________

CONTROL

LOGIC

ON-TIME

COMPUTE

CURRENT

BALANCE

CURRENT

LIMIT

UVLO/

OVLO

VCC

CS1

CS2

CS1

CS2

FB

VLG

BST1

DH1

LX1

VLG

DL1

PGND

BST2

DH2

LX2

DL2

DL2

DL2

ON-TIME

ONE-SHOT

BIAS

ENABLE/

SHUTDOWN

MIN OFF

TIME

ONE-SHOT

VDD

PWRGD

VPOS

REF

FB

2V

GNDS

ERROR AMP

VID DAC

GND VID0–VID4 TIME ILIM

∑

REF - 12.5%

REF + 12.5%

EN

g

m

∑

Functional Diagram

Page 23

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

______________________________________________________________________________________ 23

R2

100kΩ

V

CC

V

DD

VID4

EN

GNDS

TIME

VPOS

GND

REF

BF

PWRGD

LX2

DH2

ILIM

GNDS

10 × 10μF CERAMIC CAPACITORS

TAIYO YUDEN TMK432BJ106MM

AND 4 × 330μF

SANYO 25MV330WX

6 × 560μF/4V OS-CAN CAPACITORS

SANYO SP560M

AND 2 × 1μF CERAMIC CAPACITORS

TAIYO YUDEN: LMK212BJ105MG

CVLG

1μF

C3

2.2μF

C

VDD

0.01μF

VID4

EN

N2

N3

L2

0.5μH

BI TECHNOLOGIES HM73-40R50

IR: 2 × 1RLR7811W

FAIRCHILD

2 × 1SL9N303AS3ST

D2

CENTRAL CMPSH-3A

FAIRCHILD

2 × 1SL9N303AS3ST

R5

10kΩ

R4

82.5kΩ

C

REF

0.47μF

C

VPOS

47pF

R3

200kΩ

R1

10Ω

PWRGD

V

OUT

FB

VDD

L1

0.5μH

BI TECHNOLOGIES HM73-40R50

C1

2.2μF

R

VPOS

51.1kΩ

R

TIME

120kΩ

U1

MAX1938

R6

10kΩ

28

8

6

13

VID2

VID3

VID2

VID1

VID0

D1

GND

U2

KA78M06

CENTRAL

CMHD4448

2

3

2

OUTIN

11

VID3

4

5

VID0

VID1

1

2

3

7

12

9

10

11

18

17

14

1

2

2

2

C

BST2

0.22μF

CBST1

0.22μF

3

DL2

N4

20

CS2

19

PGND

21

VLG

CS1

22

24

DL1

23

BST1

27

LX1

25

DH1

26

BST2

16

1

1

1

1

3

3

N3

2

3

N1

C

IN

INPUT: 8V TO 14V

OUTPUT

0.8V TO 1.55V

60A

3

2

13

V

IN

VDD

1mΩ

R

CS2

1mΩ

R

CS1

C2

2.2μF

V

IN

IR: 3X1RLR7811W

IR: 3 × 1RLR7811W

MAX1938 Typical Application Circuit

Page 24

MAX1937/MAX1938/MAX1939

Two-Phase Desktop CPU Core Supply

Controllers with Controlled VID Change

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2002 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2002 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

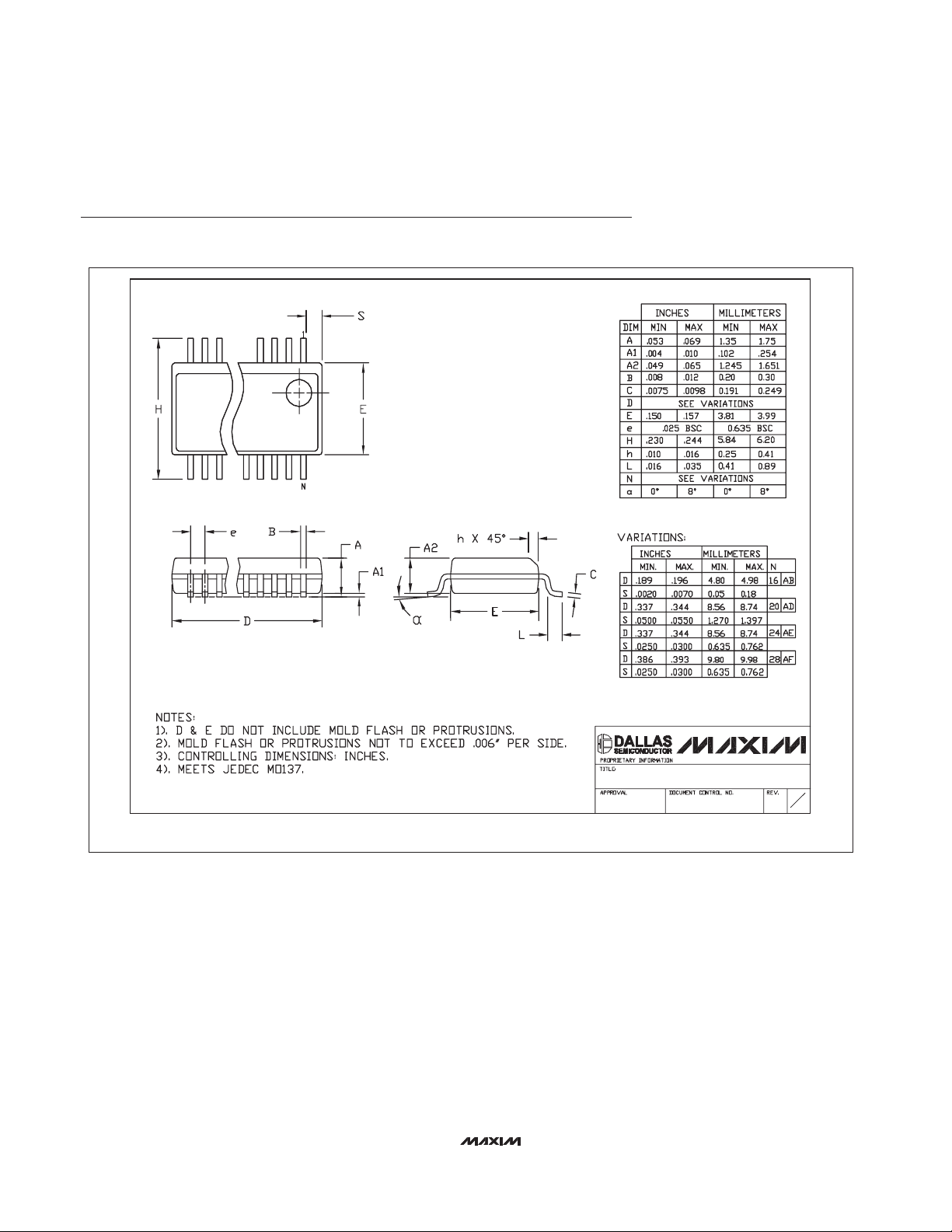

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages.)

QSOP.EPS

F

1

1

21-0055

PACKAGE OUTLINE, QSOP .150", .025" LEAD PITCH

Loading...

Loading...