Page 1

General Description

The MAX1917 provides a complete power-management solution for DDR memory. It contains a synchronous buck controller and an amplifier to generate

1/2V

DDR

voltage for VTT and VTTR. The VTT and VTTR

voltages are maintained within 1% of 1/2V

DDR

. The

controller operates in synchronous rectification mode to

ensure balanced current sourcing and sinking capability of up to 25A. With a shutdown current of less than

5µA, the MAX1917 is the best choice for low-power

notebook applications, as well as servers and desktop

computers. An all N-FET design optimizes efficiency.

The MAX1917 can also be used for generating V

DDR

and as a general-purpose step-down controller with

variable switching frequency as high as 1MHz with few

additional components.

The MAX1917 uses Maxim’s proprietary Quick-PWM™

architecture for fast transient response up to 96% efficiency, and the smallest external components. Output

current monitoring is achieved without sense resistors

by monitoring the bottom FET’s drain-to-source voltage.

The current-limit threshold is programmable through an

external resistor. The MAX1917 comes in a space-saving 16-pin QSOP package.

Applications

Features

♦ 25A Sourcing and Sinking Current

♦ Automatically Sets VTT to 1/2V

DDR

♦ VTT and VTTR Within 1% of 1/2V

DDR

♦ Smallest Output Capacitors

♦ 4.5V to 14V (or 28V with Resistor-Divider) Input

Voltage Range

♦ 1.5V to 3.6V Input DDR Range

♦ 200kHz/300kHz/400kHz/550kHz Preset Switching

Frequencies

♦ Variable Switching Frequency of Up to 1MHz

♦ Overcurrent Protection Without Current-Sense

Resistor

♦ Internal Soft-Start

♦ VTTR Reference Sources and Sinks Up to 25mA

♦ Quick-PWM Control for Fastest Loop Response

♦ Up to 96% Efficiency

♦ 16-Pin QSOP Package

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

MAX1917

V

IN

(2.5V TO 15V)

POK

VDDR

EN/HSD

POK

DDR

V+

REF

ILIM

FSEL

GND

DH

VL

BST

DL

LX

PGND

VTT

VTTR

V

OUT

VTTR

(4.5V TO 14V)

VL

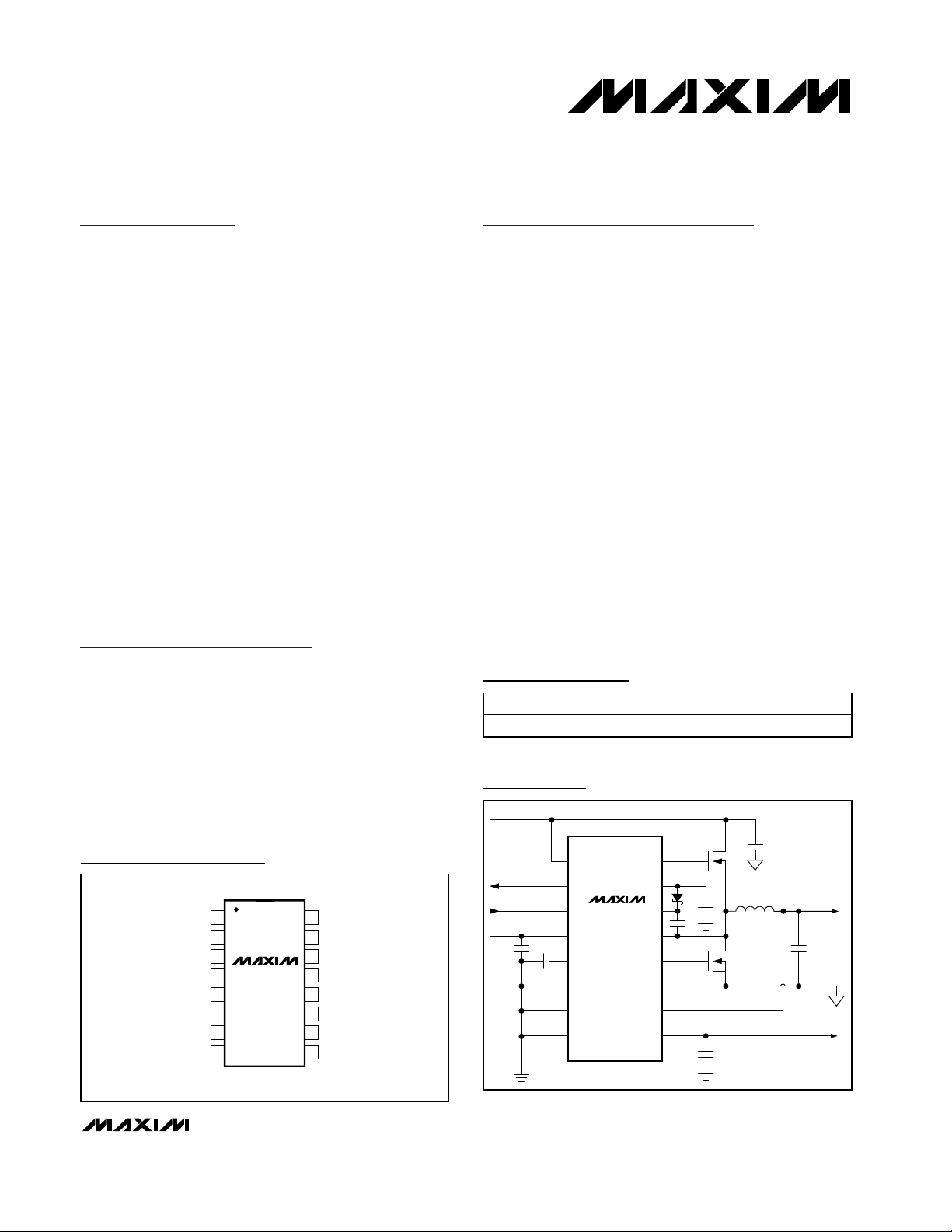

Typical Operating Circuit

19-2335; Rev 1; 6/02

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Pin Configuration

Quick-PWM is a trademark of Maxim Integrated Products, Inc.

DDR Memory Power

Supply

Processor or DSP Core

Supply

AGTL Bus Termination

Supply

Notebook Computers

Desktop Computers

Storage

Networking Systems

PART TEMP RANGE PIN-PACKAGE

MAX1917EEE -40°C to +85°C 16 QSOP

TOP VIEW

1

EN/HSD LX

2

DDR

POK

3

4

VTT

ILIM

5

6

FSEL

7

REF

GND

8

16

15

DH

14

BST

MAX1917EEE

QSOP

13

PGND

12

DL

VL

11

10

V+

9

VTTR

Page 2

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

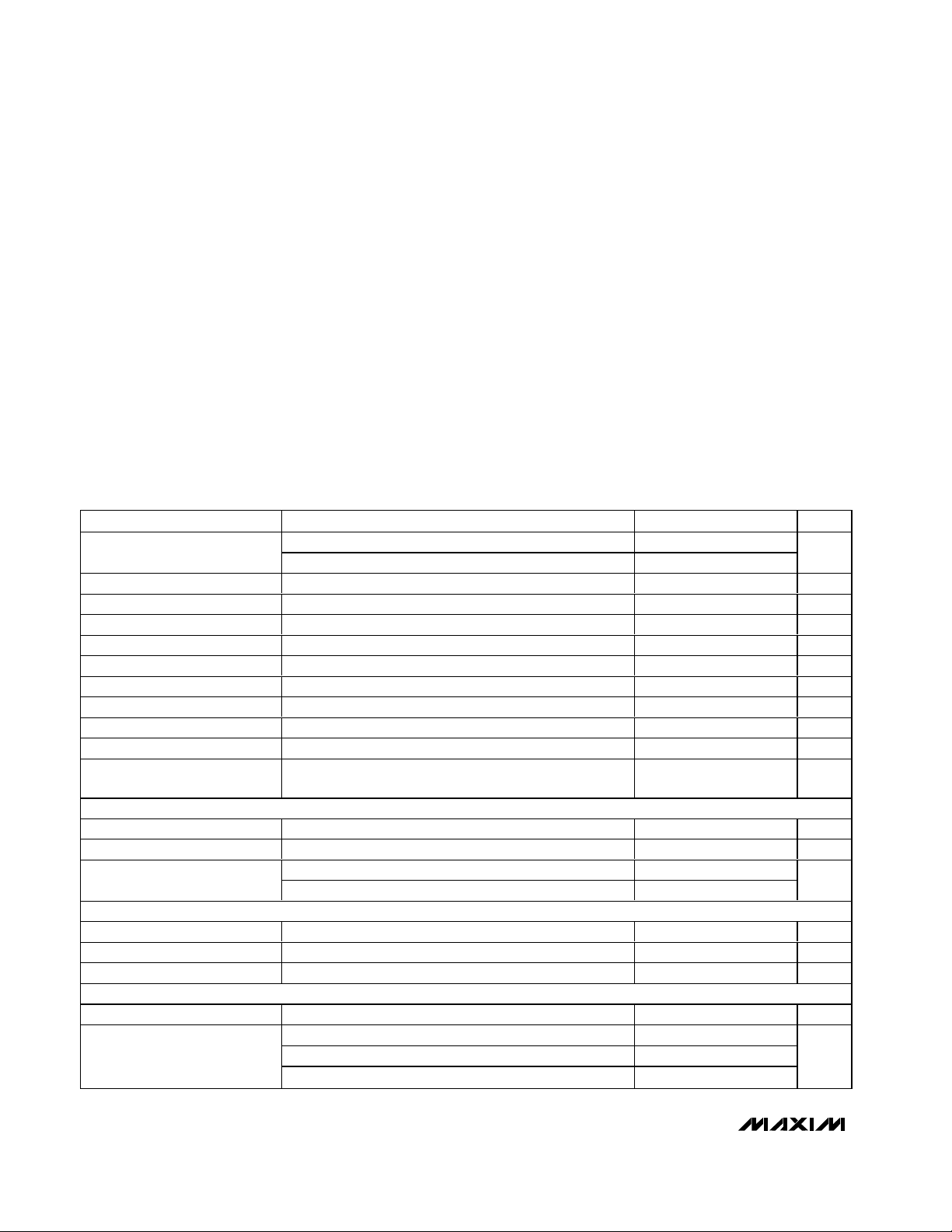

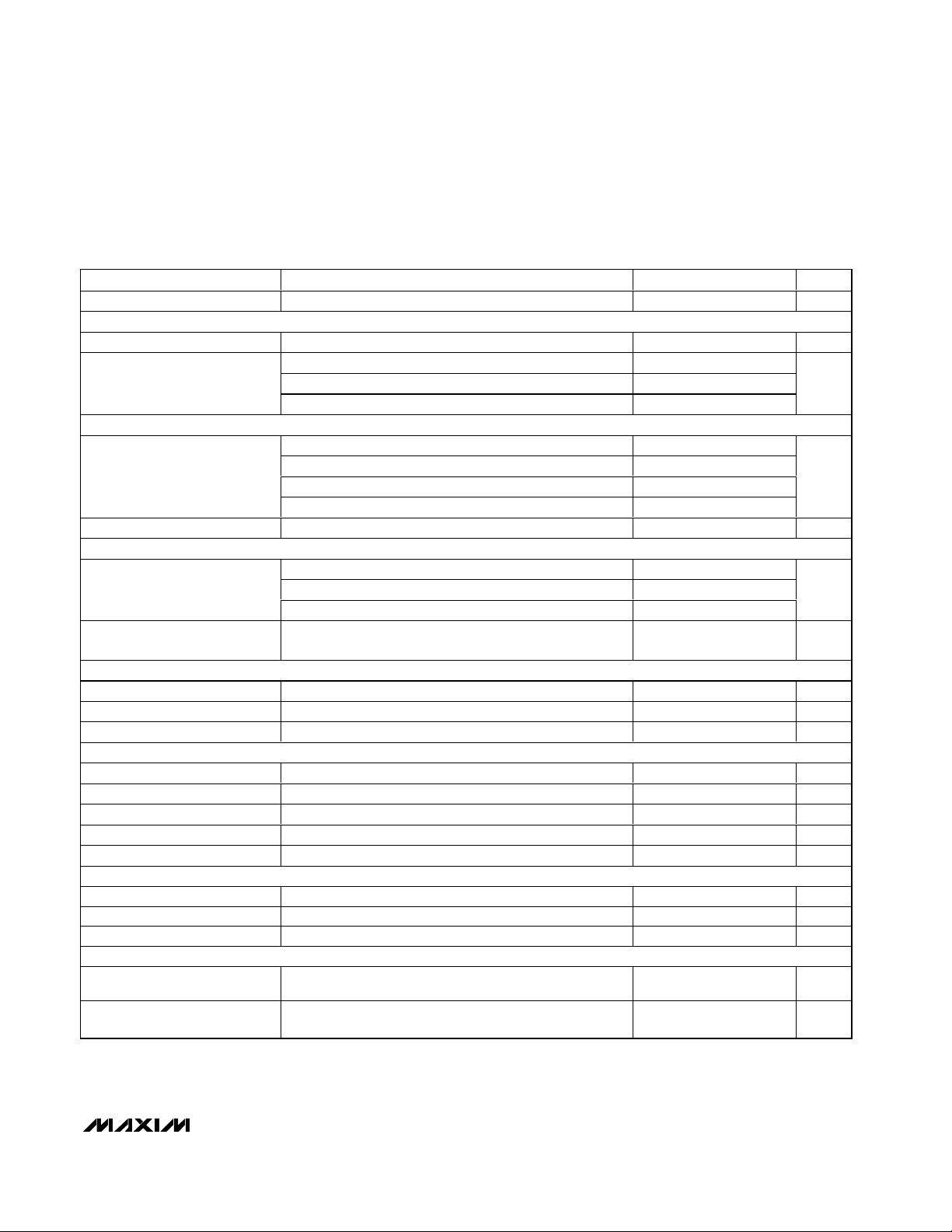

ELECTRICAL CHARACTERISTICS

(V+ = 12V, V

EN/HSD

= V

DDR

= 2.5V, CVL= 4.7µF, C

VTTR

= 1µF, C

REF

= 0.22µF, V

FSEL

= 0, ILIM = VL, PGND = LX = POK = GND,

BST = VL. Specifications are for T

A

= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise specified.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

V+ to GND ..............................................................-0.3V to +15V

EN/HSD to GND .....................................................-0.3V to +16V

VL to GND ................................................................-0.3V to +6V

PGND to GND .......................................................-0.3V to +0.3V

VTT, DDR, POK to GND ...........................................-0.3V to +6V

REF, VTTR, DL, ILIM, FSEL to GND ................-0.3V to VL + 0.3V

LX to PGND ............................................................-0.3V to +30V

BST to GND ............................................................-0.3V to +36V

DH to LX ......................................................-0.3V to V

BST

+ 0.3V

LX to BST..................................................................-6V to +0.3V

REF Short Circuit to GND ...........................................Continuous

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate up to +70°C)..............................667mW

16-Pin QSOP (derating above +70°C).....................8.3mW/°C

Operating Temperature Range

Extended .........................................................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering 10s.) .................................+300°C

V+ Input Voltage Range

EN/HSD Input Voltage Range Enabled 1.5 15.0 V

DDR Input Voltage Range 0 3.6 V

V+ Supply Current VTT = 2.0V 0.8 1.2 mA

DDR Supply Current 115 250 µA

EN/HSD Supply Current 510µA

VL Supply Current VL = V+ = 5.5V, VTT = 2.0V 0.8 1.2 mA

V+ Shutdown Supply Current EN/HSD = 0V 3 5 µA

DDR Shutdown Supply Current EN/HSD = 0V 1 µA

VL Shutdown Supply Current VL = V+ = 5.5V 3 5 µA

VL Undervoltage Lockout

Threshold

VTT

VTT Input Bias Current V

VTT Feedback Voltage Range 0 1.8 V

VTT Feedback Voltage

Accuracy

REFERENCE

Reference Output Voltage V+ = VL = 4.5V to 5.5V, I

Reference Load Regulation V+ = VL = 5V, I

Reference UVLO V+ = VL = 5V 1.5 1.6 1.7 V

VTTR

VTTR Output Voltage Range 0 1.8 V

VTTR Output Accuracy

PARAMETER CONDITIONS MIN TYP MAX UNITS

VL = V+ 4.5 5.5

Rising edge, hysteresis = 40mV 4.05 4.25 4.40 V

VTT

Overload range, V

Overload range, V

I

VTTR

I

VTTR

I

VTTR

= 2.5V -0.1 0 µA

= 1.8V 49.5 50 50.5

DDR

= 3.6V 49.5 50 50.5

DDR

REF

= 0 to 50µA 10 mV

REF

= -5mA to +5mA 49.5 50 50.5

= -25mA to +25mA, V

= -25mA to +25mA, V

= 0 1.98 2.00 2.02 V

= 1.8V 49 50 51

DDR

= 3.6V 49.5 50 50.5

DDR

5.5 14.0

%V

%V

V

DDR

DDR

Page 3

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

_______________________________________________________________________________________ 3

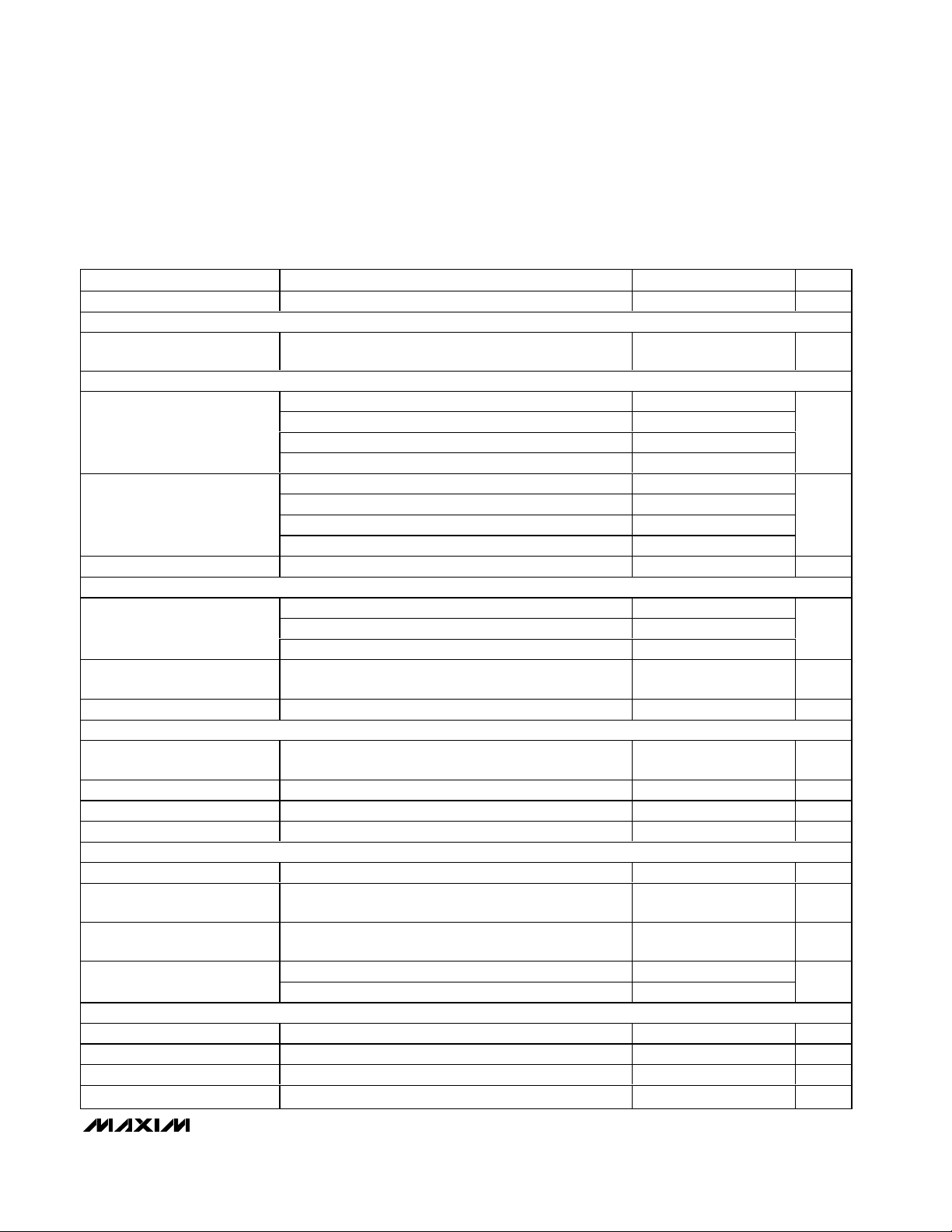

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 12V, V

EN/HSD

= V

DDR

= 2.5V, CVL= 4.7µF, C

VTTR

= 1µF, C

REF

= 0.22µF, V

FSEL

= 0, ILIM = VL, PGND = LX = POK = GND,

BST = VL. Specifications are for T

A

= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise specified.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Thermal Shutdown Rising temperature, typical hysteresis = 15°C +160 °C

SOFT-START

ILIM Ramp Period

OSCILLATOR

Ramps the ILIM trip threshold from 20% to 100%

in 20% increments

1.7 ms

FSEL = VL 200

Oscillator Frequency

FSEL = unconnected 300

FSEL = REF 400

FSEL = GND 550

kHz

FSEL = VL 2.18 2.5 2.83

On Time (Note 1)

FSEL not connected 1.45 1.67 1.89

FSEL = REF 1.09 1.25 1.41

FSEL = GND 0.82 0.91 1.00

µs

Minimum Off Time (Note 1) 350 400 ns

CURRENT LIMIT

Current-Limit Threshold

(Positive Direction)

Current-Limit Threshold

(Negative Direction)

ILIM Input Current 5µA

V

REGULATOR

L

Output Voltage

Line Regulation 5.5V < V+ < 14V, IVL = 10mA 0.2 %

RMS Output Current 35 mA

Bypass Capacitor ESR < 100mΩ 2.2 µF

DRIVER

DH Gate-Driver On-Resistance V

DL Gate-Driver On-Resistance

(Source)

DL Gate-Driver On-Resistance

(Sink)

Dead Time

FSEL LOGIC

Logic Input Current -3 3 µA

Logic GND Level 0.5 V

Logic REF Level FSEL = VREF 1.65 2.35 V

Logic Float Level FSEL floating 3.15 3.85 V

LX to PGND, ILIM = VL 90 100 110

LX to PGND, R

LX to PGND, R

LX to PGND, ILIM = VL, with percentage of positive

current-limit threshold

5.5V < V+ < 14V

1mA < I

BST

DL high state 1.6 3 Ω

DL low state 0.75 1.25 Ω

DL rising 32

DL falling 30

< 35mA

VL

- VLX = 5V 1.4 2.5 Ω

= 100kΩ 40 50 60

ILIM

= 400kΩ 170 200 230

ILIM

-90 -110 -130 %

4.8 5.0 5.2 V

mV

ns

Page 4

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

4 _______________________________________________________________________________________

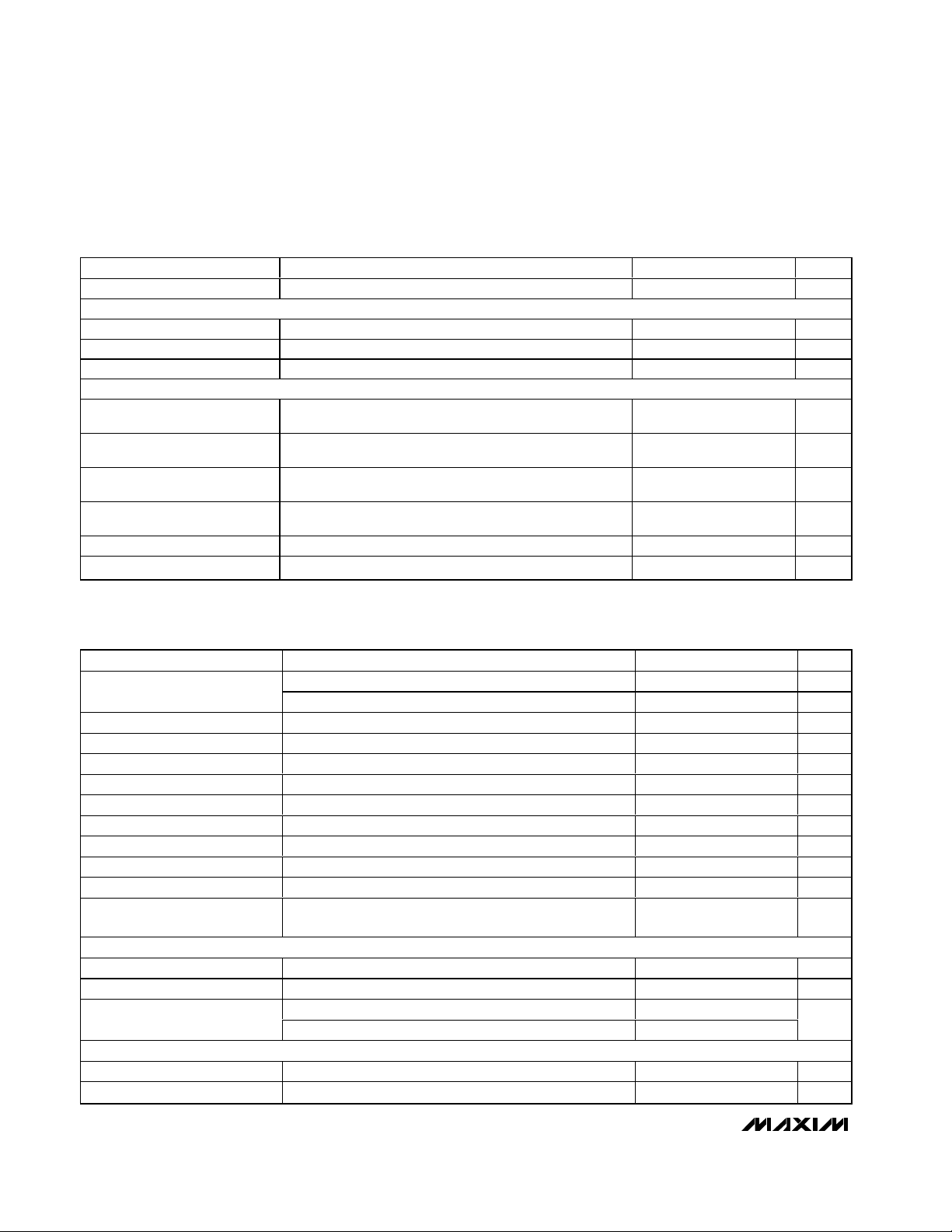

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 12V, V

EN/HSD

= V

DDR

= 2.5V, CVL= 4.7µF, C

VTTR

= 1µF, C

REF

= 0.22µF, V

FSEL

= 0, ILIM = VL, PGND = LX = POK = GND,

BST = VL. Specifications are for T

A

= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise specified.)

ELECTRICAL CHARACTERISTICS

(V+ = 12V, V

EN/HSD

= V

DDR

= 2.5V, CVL= 4.7µF, C

VTTR

= 1µF, C

REF

= 0.22µF, V

FSEL

= 0, ILIM = VL, PGND = LX = POK = GND,

BST = VL. Specifications are for T

A

= -40°C to +85°C, unless otherwise specified.) (Note 2)

Logic VL Level FSEL = VL VL - 0.4 V

EN/HSD LOGIC

EN/HSD Shutdown Current Max I

Logic High VL = V+ = 4.5V to 5.5V, 100mV hysteresis 1.45 V

Logic Low VL = V+ = 4.5V to 5.5V 0.8 V

POWER-OK OUTPUT

Upper VTT Threshold 110 112 114

Lower VTT Threshold 86 88 90

Upper VTTR Threshold 110 112 114

Lower VTTR Threshold 86 88 90

POK Output Low Level I

POK Output High Leakage V

PARAMETER CONDITIONS MIN TYP MAX UNITS

= 2mA 0.4 V

SINK

POK

for V

EN/HSD

= 5.5V 5 µA

= 0.8V 0.5 3.0 µA

EN/HSD

%V

%V

%V

%V

DDR

2

DDR

2

DDR

2

DDR

2

/

/

/

/

V+ Input Voltage Range

EN/HSD Input Voltage Range Enabled 1.5 15.0 V

DDR Input Voltage Range 0 3.6 V

V+ Supply Current VTT = 2.0V 1.2 mA

DDR Supply Current 250 µA

EN/HSD Supply Current V

VL Supply Current VL = V+ = 5.5V 1.2 mA

V+ Shutdown Supply Current EN/HSD = 0V 5 µA

DDR Shutdown Supply Current EN/HSD = 0V 1 µA

VL Shutdown Supply Current VL = V+ = 5.5V 5 µA

VL Undervoltage Lockout

Threshold

VTT

VTT Input Bias Current V

VTT Feedback Voltage Range 0 1.8 V

VTT Feedback Voltage

Accuracy

REFERENCE

Reference Output Voltage V+ = VL = 4.5V to 5.5V, I

Reference Load Regulation V+ = VL = 5V, I

PARAMETER CONDITIONS MIN TYP MAX UNITS

VL = V+ 4.5 5.5 V

EN/HSD

Rising edge, hysteresis = 40mV 4.05 4.40 V

VTT

Overload range, V

Overload range, V

= 2.5V 10 µA

= 2.5V -0.15 0 µA

= 1.8V 49.5 50.5

DDR

= 3.6V 49.5 50.5

DDR

REF

= 0 to 50µA 10 mV

REF

= 0 1.98 2.02 V

5.5 14.0 V

%V

DDR

Page 5

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 12V, V

EN/HSD

= V

DDR

= 2.5V, CVL= 4.7µF, C

VTTR

= 1µF, C

REF

= 0.22µF, V

FSEL

= 0, ILIM = VL, PGND = LX = POK = GND,

BST = VL. Specifications are for T

A

= -40°C to +85°C, unless otherwise specified.) (Note 2)

Reference UVLO V+ = VL = 5V 1.5 1.7 V

VTTR

VTTR Output Voltage Range 0 1.8 V

OSCILLATOR

PARAMETER CONDITIONS MIN TYP MAX UNITS

On Time (Note 1)

I

VTTR

I

VTTR

I

VTTR

FSEL = VL 2.18 2.83

FSEL not connected 1.45 1.89

FSEL = REF 1.09 1.41

FSEL = GND 0.82 1.00

= -5mA to +5mA 49.5 50.5

= -25mA to +25mA, V

= -25mA to +25mA, V

DDR

DDR

= 1.8V 49 51VTTR Output Accuracy

= 3.6V 49.5 50.5

%V

DDR

µs

Minimum Off Time (Note 1) 400 ns

CURRENT LIMIT

Current-Limit Threshold

(Positive Direction)

Current-Limit Threshold

(Negative Direction)

LX to PGND, ILIM = VL 85 110

LX to PGND, R

LX to PGND, R

LX to PGND, ILIM = VL, with percentage of positive

current-limit threshold

= 100kΩ 35 60

ILIM

= 400kΩ 160 230

ILIM

-90 -130 %

mV

VL REGULATOR

Output Voltage 5.5V < V+

< 14V; 1mA < I

< 35mA 4.8 5.2 V

VL

RMS Output Current 35 mA

Bypass Capacitor ESR < 100mΩ 2.2 µF

FSEL LOGIC

Logic Input Current 3µA

Logic GND Level 0.5 V

Logic REF Level FSEL = VREF 1.65 2.35 V

Logic Float Level FSEL floating 3.15 3.85 V

Logic VL Level FSEL = VL VL - 0.4 V

EN/HSD LOGIC

EN/HSD Shutdown Current I

Logic High VL = V+ = 4.5V to 5.5V, 100mV hysteresis 1.45 V

Logic Low VL = V+ = 4.5V to 5.5V 0.8 V

POWER-OK OUTPUT

Upper VTT Threshold 110 114

Lower VTT Threshold 86 90

EN/HSD

for V

= 0.8V 0.5 3.0 µA

EN/HSD

%V

%V

DDR

/2

DDR

/2

Page 6

Note 1: On Time and Off Time specifications are measured from 50% point to 50% point at the DH pin with LX forced to 0V, BST

forced to 5V, and a 250pF capacitor connected from DH to LX. Actual in-circuit times may differ due to MOSFET switching

speeds.

Note 2: Specifications to -40°C are guaranteed by design and are not production tested.

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 12V, V

EN/HSD

= V

DDR

= 2.5V, CVL= 4.7µF, C

VTTR

= 1µF, C

REF

= 0.22µF, V

FSEL

= 0, ILIM = VL, PGND = LX = POK = GND,

BST = VL. Specifications are for T

A

= -40°C to +85°C, unless otherwise specified.) (Note 2)

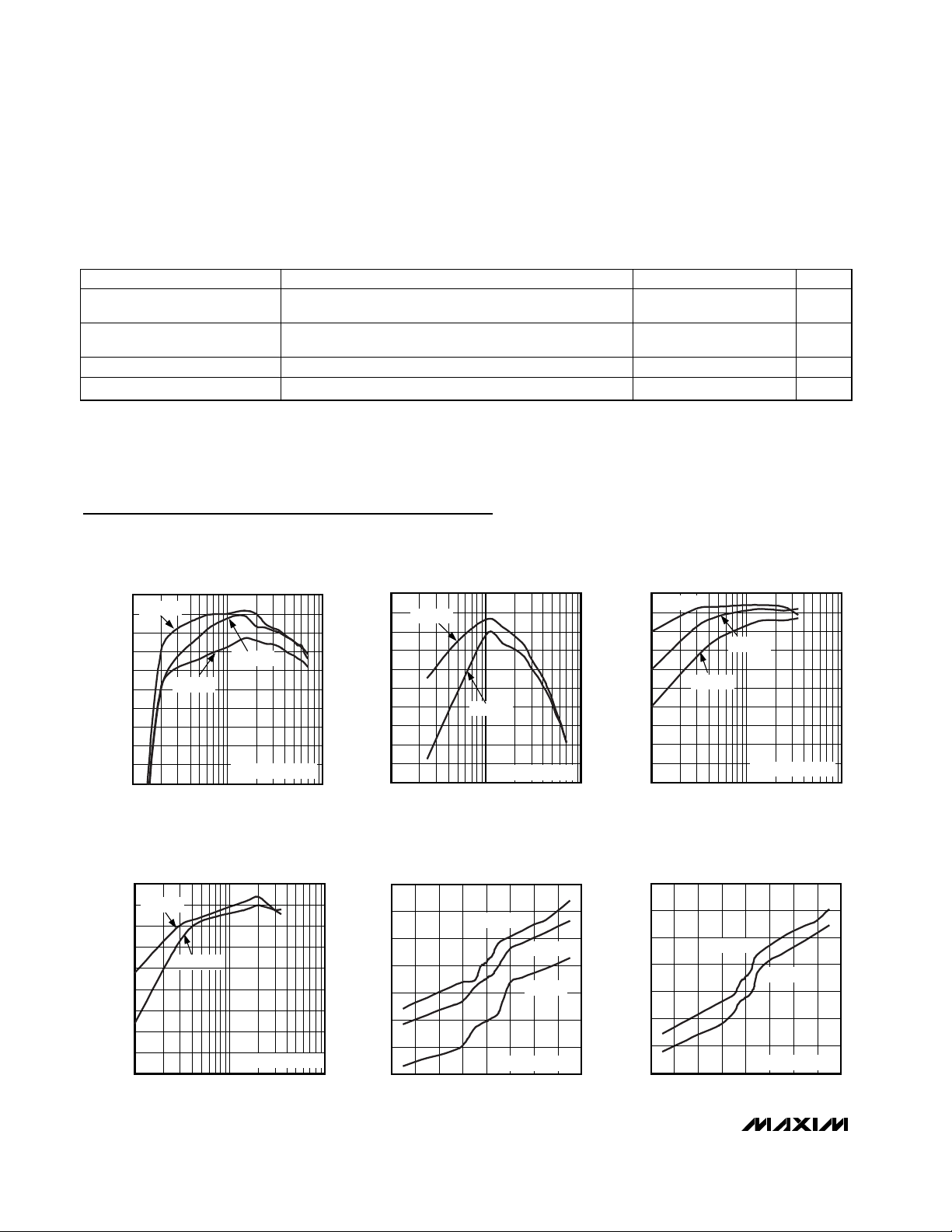

Typical Operating Characteristics

(V+ = 12V, V

OUT

= 1.25V, TA= +25°C, unless otherwise noted.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Upper VTTR Threshold 110 114

Lower VTTR Threshold 86 90

POK Output Low Level I

POK Output High Leakage V

EFFICIENCY vs. LOAD CURRENT

100

VIN = 2.5V

95

90

85

80

75

70

EFFICIENCY (%)

65

60

55

50

0.1 1.0 10.0

= 2mA 0.4 V

SINK

POK

= 5.5V 5 µA

AT 1.25V OUTPUT

96

94

MAX1917 toc01

92

VIN = 5V

VIN = 2V

CIRCUIT OF FIGURE 3

LOAD CURRENT (A)

90

88

86

84

EFFICIENCY (%)

82

80

78

76

0.1 1.0 10.0

EFFICIENCY vs. LOAD CURRENT

AT 0.9V OUTPUT

VIN = 2.5V

VIN = 5V

CIRCUIT OF FIGURE 3

LOAD CURRENT (A)

EFFICIENCY vs. LOAD CURRENT

AT 1.25V OUTPUT

100

VIN = 2.5V

90

MAX1917 toc02

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.1 1.0 10.0

VIN = 5V

VIN = 12V

CIRCUIT OF FIGURE 4

LOAD CURRENT (A)

%V

%V

DDR

/2

DDR

/2

MAX1917 toc03

EFFICIENCY vs. LOAD CURRENT

AT 0.9V OUTPUT

95

90

VIN = 2.5V

85

80

75

70

EFFICIENCY (%)

65

60

55

50

0.1 1.0 10.0

VIN = 5V

CIRCUIT OF FIGURE 4

LOAD CURRENT (A)

MAX1917 toc04

FREQUENCY vs. LOAD CURRENT

AT 1.25V OUTPUT

650

600

550

500

450

FREQUENCY (kHz)

400

350

300

-8 -4 -2-6 02468

VIN = 2.5V

VIN = 5V

VIN = 12V

CIRCUIT OF FIGURE 3

LOAD CURRENT (A)

MAX1917 toc05

FREQUENCY (kHz)

FREQUENCY vs. LOAD CURRENT

AT 0.9V OUTPUT

650

600

550

500

450

400

350

300

-8 -2 0-6-4 2468

VIN = 2.5V

LOAD CURRENT (A)

MAX1917 toc06

VIN = 5V

CIRCUIT OF FIGURE 3

Page 7

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

_______________________________________________________________________________________ 7

Typical Operating Characteristics (continued)

(V+ = 12V, V

OUT

= 1.25V, TA= +25°C, unless otherwise noted.)

FREQUENCY vs. INPUT VOLTAGE

650

600

550

500

450

FREQUENCY (kHz)

400

350

CIRCUIT OF FIGURE 3

300

157391311 15

I

= 7A

OUT

I

= 0.1A

OUT

INPUT VOLTAGE (V)

SHUTDOWN CURRENT

vs. INPUT VOLTAGE

2.5

2.3

2.1

1.9

1.7

1.5

1.3

1.1

SHUTDOWN CURRENT (mA)

0.9

0.7

0.5

13579111315

CIRCUIT OF FIGURE 3

INPUT VOLTAGE (V)

SHUTDOWN CURRENT

vs. INPUT VOLTAGE

CIRCUIT OF FIGURE 6

INPUT VOLTAGE (V)

LOAD REGULATION WITH

DROOP RESISTOR

V

= 2.5V

DDR

VIN = 12V

VIN = 2.5V

LOAD CURRENT (A)

VIN = 5V

540

538

MAX1917 toc07

536

534

532

530

528

FREQUENCY (kHz)

526

524

522

520

1.32

1.31

MAX1917 toc10

1.30

1.29

1.28

1.27

1.26

OUTPUT VOLTAGE (V)

1.25

1.24

1.23

1.22

FREQUENCY vs. TEMPERATURE

I

= 3.5A

LOAD

CIRCUIT OF FIGURE 3

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

LOAD REGULATION WITHOUT

DROOP RESISTOR

V

= 2.5V

DDR

VIN = 5V

VIN = 2.5V

-7 -3 -1-5 1357

LOAD CURRENT (A)

VIN = 12V

4.0

3.5

MAX1917 toc08

3.0

2.5

2.0

SHUTDOWN CURRENT (µA)

1.5

1.0

1.35

1.33

MAX1917 toc11

1.31

1.29

1.27

1.25

1.23

OUTPUT VOLTAGE (V)

1.21

1.19

1.17

1.15

1793 5 11 13 15

-8 -4 -2-6 02468

MAX1917 toc09

MAX1917 toc12

TRANSIENT LOAD RESPONSE

WITHOUT DROOP RESISTOR

OA

CIRCUIT OF FIGURE 3

TRANSIENT LOAD RESPONSE

20µs/div

MAX1917 toc13

V

VTT

50mV/div

I

OUT

5A/div

WITH DROOP RESISTOR

0A

CIRCUIT OF FIGURE 3

20µs/div

MAX1917 toc14

V

VTT

50mV/div

I

OUT

5A/div

POWER-UP WITH V

400µs/div

TRACKING

DDR

MAX1917 toc15

V

OUT

1V/div

V

POK

5V/div

V

DDR

2.5V

V

EN/HSD

10V/div

Page 8

Pin Description

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(V+ = 12V, V

OUT

= 1.25V, TA= +25°C, unless otherwise noted.)

CURRENT LIMIT vs. TEMPERATURE

18

16

14

12

10

CURRENT LIMIT (A)

R

= 402kΩ

ILIM

8

6

R

= 200kΩ

ILIM

4

2

0

-40 100

TEMPERATURE (°C)

INDUCTOR PEAK AND VALLEY CURRENT

vs. INPUT VOLTAGE AT CURRENT LIMIT

18

R

= 400kΩ

ILIM

MAX1917 toc16

806020 400-20

16

14

12

INDUCTOR CURRENT (A)

10

CIRCUIT OF FIGURE 3

8

115

I

VALLEY

I

PEAK

VIN (V)

MAX1917 toc17

13119753

PIN NAME FUNCTION

1 EN/HSD

2 DDR

3 POK

4 VTT VTT Feedback Input. Connect to VTT output.

5 ILIM

6 FSEL Frequency Select. Selects the switching frequency of the MAX1917. See Table 1 for configuration of FSEL.

7 REF Reference Bypass. Connect a 0.22µF or larger capacitor from REF to GND.

8 GND Ground

9 VTTR

10 V+

11 VL

12 DL Low-Side MOSFET Gate Drive. Connect to the gate of the low-side N-channel MOSFET.

13 PGND Power Ground

14 BST

15 DH High-Side MOSFET Gate Drive. Connect to the high-side N-channel MOSFET gate.

16 LX Inductor Switching Node

Enable/High-Side Drain. Connect to the high-side N-FET drain for normal operation. Leave unconnected or

connect to GND for low-power shutdown.

DDR Reference Input. An applied voltage at DDR sets V

VTT

and V

VTTR

to 1/2V

. DDR voltage range is

DDR

from 0 to 3.6V.

Power-OK Output. POK is an open-drain output and is logic high when both VTT and VTTR are within 12%

of regulation. POK is pulled low in shutdown.

Current-Limit Threshold Adjustment. Connect a resistor from ILIM to GND to set the current-limit threshold,

or connect ILIM to VL for default setting. See the Setting the Current Limit section.

VTTR Reference Output. Connect a 1µF or larger capacitor from VTTR to GND. VTTR is capable of

sourcing and sinking up to 25mA.

Input Supply Voltage. Supply input for the VL regulator and the VTTR regulator. Bypass with a 0.22µF or

larger capacitor.

Internal Regulator Output. Connect a 2.2µF or larger capacitor from VL to GND. VL can be connected to

V+ if the operating range is 4.5V to 5.5V.

Bootstrapped Supply to Drive High-Side N-Channel MOSFET. Connect a 0.47µF or larger capacitor from

BST to LX.

Page 9

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

_______________________________________________________________________________________ 9

Functional Diagram

DDR

EN/HSD

POK

ON TIME

COMPUTE

TON

TRIG Q

1-SHOT

ILIM

1-SHOT

VTTFSEL

TRIGQ

5µA

S

Q

R

Σ

BST

DH

LX

VL

DL

PGND

5V

REF

2V

REF

MAX1917

VTTR

VTT

V+

VL

REF

GND

Page 10

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

10 ______________________________________________________________________________________

Detailed Description

Internal Linear Regulator (VL)

An internal regulator produces the 5V supply (VL) that

powers the PWM controller, MOSFET driver, logic, reference, and other blocks within the IC. This 5V lowdropout (LDO) linear regulator supplies up to 35mA for

MOSFET gate-drive and external loads. For supply voltages between 4.5V and 5.5V, connect VL to V+. This

bypasses the VL regulator, which improves efficiency,

and allows the IC to function at lower input voltages.

On-Time One-Shot and

Switching Frequency

The heart of the PWM is the one-shot that sets the highside switch on time. This fast, low-jitter, adjustable oneshot includes circuitry that varies the on time in response

to both input and output voltages. The high-side switch

on time is inversely proportional to the input voltage as

measured by the EN/HSD input, and is directly proportional to the VTT output voltage. This algorithm results in

a nearly constant switching frequency despite the lack

of a fixed-frequency clock generator. The switching frequency can be selected to avoid noise-sensitive regions

such as the 455kHz IF band. Also, with a constant

switching frequency, the inductor ripple-current operating point remains relatively constant, resulting in easy

design methodology and predictable output voltage ripple. The general formula for on time (tON) is:

where V

HSD

and V

DDR

are the voltages measured at

EN/HSD and DDR, respectively, and K = 1.7µs. The

value of N depends on the configuration of FSEL and is

listed in Table 1.

The actual switching frequency, which is given by the

following equation, varies slightly due to voltage drop

across the on-resistance of the MOSFETs and the DC

resistance of the output inductor:

where I

O

is the output current, R

DSONH

is the on-resis-

tance of the high-side MOSFET, R

DSONL

is the onresistance of the low-side MOSFET, and RDCis the DC

resistance of the output inductor. The above equation is

valid only when FSEL is connected to ground. The ideal

switching frequency for V

DDR

= 2.5V is about 550kHz.

The switching frequency, which is almost constant,

results in relatively constant inductor ripple current

regardless of input voltage and predictable output voltage ripple. This feature eases design methodology.

Switching frequency increases for positive (sourcing)

load current and decreases for negative (sinking) load

current, due to the changing voltage drop across the

low-side MOSFET, which changes the inductor-current

discharge ramp rate. The on times guaranteed in the

Electrical Characteristics tables are also influenced by

switching delays caused by the loading effect of the

external power MOSFETs.

VTTR Reference

The MAX1917 VTTR output is capable of sourcing or

sinking up to 25mA of current. The V

TTR

output voltage

is one half of the voltage applied to the DDR input.

Bypass VTTR with at least a 1.0µF capacitor.

EN/HSD Function

In order to reduce pin count and package size, the

MAX1917 features a dual-function input pin, EN/HSD.

When EN/HSD is connected to ground, the internal circuitry powers off, reducing current consumption to less

than 5µA typical (circuit of Figure 6). To enable normal

operation, connect EN/HSD to the drain of the high-side

MOSFET. If EN/HSD is not grounded, it becomes an

input that monitors the high-side MOSFET drain voltage

(converter input voltage) and uses that measurement to

calculate the appropriate on time for the converter.

Therefore, EN/HSD must be connected to this node in

order for the controller to operate properly.

Table 1. Configuration of FSEL

.

VIR R

tKN

=×× ×

ON

V

1

HSD

V

DDR

2

s

µ

×+ +

f

=

S

tVIR R

ON IN O DSONL DSONH

DDR O DSONL DC

×+ −

()

()

×0510

()

3

kHz

FSEL CONNECTED

TO

N t

(µs) FREQUENCY (kHz) CONDITION

ON

Ground 1.00 0.91 550 0.5V

REF 1.33 1.25 400 0.5V

Floating 2.00 1.66 300 0.5V

VL 3.00 2.50 200 0.5V

DDR

DDR

DDR

DDR

/ V

/ V

/ V

/ V

HSD

HSD

HSD

HSD

= 0.5

= 0.5

= 0.5

= 0.5

Page 11

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

______________________________________________________________________________________ 11

Voltage Reference

The voltage at REF is nominally 2.00V. Connect a 0.22µF

ceramic bypass capacitor between REF and GND.

Overcurrent Protection

The current-limit circuit employs a unique “valley” current-sensing algorithm that uses the on-state resistance

of the low-side MOSFET as a current-sensing element.

If the current-sense signal is greater than the currentlimit threshold, the PWM is not allowed to initiate a new

cycle. The actual peak current is greater than the current-limit threshold by an amount equal to the inductor

ripple current. Therefore, the exact current-limit characteristic and maximum load capability are a function of

the MOSFET on-resistance, inductor value, and input

voltage. The reward for this uncertainty is robust, lossless overcurrent sensing. There is also a negative current limit that prevents excessive reverse inductor

currents when V

OUT

is sinking current. The negative

current-limit threshold is set to approximately 110% of

the positive current limit, and tracks the positive current

limit when ILIM is adjusted. The current-limit threshold

can be adjusted with an external resistor (R

ILIM

) at ILIM.

A precision 5µA pullup current source at ILIM sets a

voltage drop on this resistor, adjusting the current-limit

threshold from <50mV to >200mV. In the adjustable

mode, the current-limit threshold voltage is precisely

1/10th the voltage seen at ILIM.

Therefore, choose R

ILIM

equal to 2kΩ/mV of the cur-

rent-limit threshold. The threshold defaults to 100mV

when ILIM is connected to VL. The logic threshold for

switchover to the 100mV default value is approximately

V

L

- 1V. The adjustable current limit can accommodate

various MOSFETs. A capacitor in parallel with R

ILIM

can

provide a variable soft-start function.

Carefully observe the PC board layout guidelines to

ensure that noise and DC errors do not corrupt the current-sense signals seen by LX and PGND. The IC must

be mounted close to the low-side MOSFET with short,

direct traces making a Kelvin-sense connection to the

source and drain terminals. See the PC Board Layout

section.

Voltage Positioning

The quick-PWM control architecture responds virtually

instantaneously to transient load changes and eliminates the control loop delay of conventional PWM controllers. As a result, a large portion of the voltage

deviation during a step load change is from the equivalent series resistance (ESR) of the output capacitors.

For DDR termination applications, the maximum

allowed voltage deviation is ±40mV for any output load

transition from sourcing current to sinking current.

Passive voltage positioning adjusts the converter’s output voltage based on its load current to optimize transient response and minimize the required output

capacitance. Voltage positioning is implemented by

connecting a 2mΩ resistor as shown in Figure 1.

MOSFET Drivers

The DH and DL drivers are optimized for driving moderate-size, high-side and larger, low-side power

MOSFETs and are optimized for 2.5V and 5V input voltages. The drivers are sized to drive MOSFETs that can

deliver up to 25A output current. An adaptive deadtime circuit monitors the DL output and prevents the

Figure 2. Increasing the On Time of the High-Side MOSFET

Figure 1. Using a Resistor for Voltage Positioning

V

POK

V+

MAX1917

DDR

EN/HSD

REF

ILIM

FSEL

GND

VL

BST

DH

LX

DL

PGND

VTT

VTTR

4 x 270µF

IN

R

2mΩ

BST

PGND

VTT

VTTR

VL

R

BST

DH

LX

DL

POK

V+

MAX1917

DDR

DRP

V

OUT

2V

VTTR

EN/HSD

REF

ILIM

FSEL

GND

Page 12

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

12 ______________________________________________________________________________________

high-side FET from turning on until DL is fully off. There

must be a low-resistance, low-inductance path from the

DL driver to the MOSFET gate in order for the adaptive

dead-time circuit to work properly. Otherwise, the

sense circuitry in the MAX1917 interprets the MOSFET

gate as off while there is actually still charge left on the

gate. Use very short, wide traces measuring 10

squares to 20 squares (50mils to 100mils wide if the

MOSFET is 1in from the MAX1917). The dead time at

the other edge (DH turning off) is determined by a fixed

35ns (typ) internal delay. The internal pulldown transistor that drives DL low is robust, with a 0.5Ω (typ) on-

resistance. This helps prevent DL from being pulled up

during the fast rise time of the inductor node, due to

capacitive coupling from the drain to the gate of the

massive low-side synchronous-rectifier MOSFET. Some

combinations of high- and low-side FETs may be

encountered that cause excessive gate-drain coupling,

which can lead to efficiency-killing, EMI-producing

shoot-through currents. This can often be remedied by

adding a resistor (R

BST

) in series with BST, which

increases the turn-on time of the high-side FET without

degrading the turn-off time (Figure 2).

Figure 3. Typical Application Circuit for 1.25V at 7A Output

Typical Application Circuits

R2

5.1kΩ

MAX1917

V+

V

DDR

SHDN

POK

2N7002K

VL

R3

20kΩ

5.5V TO 14V

C9

0.47µF/25V

0.47µF/10V

Q3

3

POK

10

V+

2

DDR

1

EN/HSD

C8

7

REF

5

VL

ILIM

6

FSEL

8

GND

BST

PGND

VTT

VTTR

VL

2.5V

V

V

OUT

PGND

VTTR

IN

11

VL

DH

LX

DL

D1

CMPSH-3

14

C4

0.47µF

15

10V

16

12

13

4

9

C7

1µF/6.3V

C3

4.7µF

10V

2.5V

Q1

IRF7463

0.68µH/9A

Q2

IRF7463

C2

2 x 330µF

6V

L1

6 x 270µF

C1

1µF

6.3V

1.25V AT 7A

C6

2V

C5

2 x 10µF

6.3V

OUTPUT CAPACITORS ARE SELECTED TO COMPLY WITH JEDEC SPECIFICATIONS.

Page 13

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

______________________________________________________________________________________ 13

Typical Application Circuits (continued)

Figure 5. Typical Application Circuit for 1.25V at 3.5A Output

Figure 4. Typical Application Circuit for 1.25V at 7A Output Using Voltage Positioning

R2

5.1kΩ

MAX1917

VL

BST

DH

LX

DL

PGND

VTT

VTTR

V+

V

DDR

SHDN

POK

2N7002K

Q3

VL

R3

20kΩ

5.5V TO 14V

C9

0.47µF/25V

0.47µF/10V

VL

3

POK

10

V+

2

DDR

1

EN/HSD

C8

7

REF

5

ILIM

6

FSEL

8

GND

R2

5.1kΩ

MAX1917

VL

BST

DH

LX

DL

PGND

VTT

VTTR

V+

V

DDR

SHDN

POK

Q3

2N7002K

VL

R3

20kΩ

5.5V TO 14V

C9

0.47µF/25V

0.47µF/10V

VL

3

POK

10

V+

2

DDR

1

EN/HSD

C8

7

REF

5

ILIM

6

FSEL

8

GND

VL

11

D1

CMPSH-3

14

C4

0.47µF

15

10V

16

12

13

4

9

C7

1µF/6.3V

OUTPUT CAPACITORS ARE SELECTED TO COMPLY WITH JEDEC SPECIFICATIONS

VL

11

D1

CMPSH-3

14

C4

0.22µF

15

10V

16

12

13

4

9

C7

1µF/6.3V

C3

4.7µF

10V

2.5V

C3

2.2µF

10V

2.5V

Q1

IRF7463

0.68µH/9A

Q2

IRF7463

Q1

IRF7811W

Q2

IRF7811W

C2

2 x 330µF

6V

L1

C2

330µF

6V

L1

1.0µH/5A

3 x 270µF

C6

2V

C1

1µF

6.3V

1.25V AT 7A

2mΩ

C1

1µF

6.3V

1.25V AT 3.5A

C5

10µF

6.3V

2.5V

C6

4 x 270µF

2V

2.5V

V

V

OUT

PGND

VTTR

V

PGND

VTTR

V

OUT

IN

IN

OUTPUT CAPACITORS ARE SELECTED TO COMPLY WITH JEDEC SPECIFICATIONS.

Page 14

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

14 ______________________________________________________________________________________

Figure 7. Circuit to Generate a Fixed 2.5V at 12A Output with a Wide Input Voltage Range

Figure 6. Typical Application Circuit Using P/N-Channel MOSFETs for EN to Minimize the Supply Current from VINin Shutdown Mode

Typical Application Circuits (continued)

R2

10kΩ

VL

SHDN

V

20kΩ`

POK

V+

DDR

R3

Q3

Si1029X

5.5V TO 14V

C9

0.47µF/25V

VL

C8

0.47µF/10V

VL

3

POK

10

V+

2

MAX1917

DDR

1

EN/HSD

7

REF

5

ILIM

6

FSEL

8

GND

11

VL

BST

DH

LX

PGND

VTT

VTTR

D1

CMPSH-3

14

C4

0.22µF

10V

15

16

12

DL

13

4

9

C7

1µF/10V

OUTPUT CAPACITORS ARE SELECTED TO COMPLY WITH JEDEC SPECIFICATIONS.

C3

2.2µF

10V

2.5V

Q1

IRF7811W

1.0µH/5A

Q2

IRF7811W

C2

330µF

6V

L1

3 x 270µF

C6

2V

C1

1µF

6.3V

1.25V AT 3.5A

C5

10µF

6.3V

2.5V

V

V

OUT

PGND

VTTR

IN

SHDN

2N7002K

5V

R3

20kΩ

POK

C9

0.22µF

25V

C8

R6

0.47µF/10V

Q3

3

POK

10

V+

2

DDR

1

EN/HSD

7

REF

5

VL

ILIM

6

FSEL

8

GND

R2

5.1kΩ

MAX1917

BST

PGND

VTT

VTTR

4.5V TO 15V

11

VL

DH

LX

D1

CMPSH-3

14

C4

0.47µF

15

10V

16

C3

4.7µF

10V

2.5V

12

DL

Q1

IRF7822

0.75µH/24A

Q2

IRF7822

C2

4 x 330µF

6V

L1

13

4

C1

1µF

25V

R4

15kΩ

0.1%

R5

10kΩ

0.1%

C6

3 x 560µF

4V

2.5V AT 12A

C5

1µF

6.3V

9

V

OUT

PGND

V

IN

OUTPUT CAPACITORS ARE SELECTED TO COMPLY WITH JEDEC SPECIFICATIONS

Page 15

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

______________________________________________________________________________________ 15

Design Procedure

Firmly establish the input voltage range and maximum

load current before choosing a switching frequency

and inductor operating point (ripple current ratio). The

primary design trade-off is in choosing a good switching frequency and inductor operating point, and the following four factors dictate the rest of the design:

1) Input Voltage Range. The maximum value

(V

IN(MAX)

) must accommodate the worst-case high

input voltage. The minimum value (V

IN(MIN)

) must

account for the lowest input voltage after drops due

to connectors, fuses, and battery selector switches.

If there is a choice at all, lower input voltages result

in better efficiency.

2) Maximum Load Current. There are two values to

consider. The peak load current (I

LOAD(MAX)

)

determines the instantaneous component stresses

and filtering requirements, and thus drives output

capacitor selection, inductor saturation rating, and

the design of the current-limit circuit. The continuous load current (I

LOAD

) determines the thermal

stresses and thus drives the selection of input

capacitors, MOSFETs, and other critical heat-contributing components.

3) Switching Frequency. This determines the basic

trade-off between size and efficiency. The optimal

frequency is largely a function of maximum input

voltage, due to MOSFET switching losses that are

proportional to frequency and V

IN

2

. The optimum

frequency is also a moving target, due to rapid

improvements in MOSFET technology that are making higher frequencies more practical.

4) Inductor Operating Point. This provides trade-offs

between size and efficiency. Low inductor values

cause large ripple currents, resulting in the smallest

size but poor efficiency and high output noise. The

minimum practical inductor value is one that causes

the circuit to operate at the edge of critical conduction (where the inductor current just touches zero

with every cycle at maximum load). Inductor values

lower than this grant no further size-reduction benefit.

The inductor ripple current also impacts transientresponse performance, especially at low V

IN

- V

OUT

differentials. Low inductor values allow the inductor

current to slew faster, replenishing charge removed

from the output filter capacitors by a sudden load step.

The amount of output sag is also a function of the maximum duty factor, which can be calculated from the on

time and minimum off time:

Output Inductor Selection

The switching frequency (on time) and operating point

(% ripple or LIR) determine the inductor value as follows:

Example: I

LOAD(MAX)

= 7A, V

OUT

= 1.25V, f = 550kHz,

50% ripple current or LIR = 0.5:

Find a low-loss inductor having the lowest possible DC

resistance that fits in the allotted dimensions. Ferrite

cores are often the best choice, although powdered

iron is inexpensive and can work well at 200kHz. The

core must be large enough not to saturate at the peak

inductor current:

(I

PEAK

): I

PEAK

= I

LOAD(MAX)

+ (LIR / 2) (I

LOAD(MAX)

)

Output Capacitor Selection

The output filter capacitor must have low enough ESR

to meet output ripple and load-transient requirements,

yet have high enough ESR to satisfy stability requirements. Also, the capacitance value must be high

enough to absorb the inductor energy going from a

positive full-load to negative full-load condition or vice

versa without incurring significant over/undershoot. In

DDR termination applications where the output is subject to violent load transients, the output capacitor’s

size depends on how much ESR is needed to prevent

the output from dipping too low under a load transient.

Ignoring the sag due to finite capacitance:

In DDR applications, V

DIP

= 40mV, the output capacitor’s size depends on how much ESR is needed to

maintain an acceptable level of output voltage ripple:

2

IL

∆

()

LOAD MAX

V

SAG

=

×× × −

C DUTY V V

2

f IN MIN OUT

()

L

=

L

550 0 5 7

kHz A

f LIR I

125

V

OUT

××

V

.

××

.

R

ESR

R

≤

ESR

V

DIP

≤==Ω

I

LOAD MAX

()

V

PP

−

×

LIR I

LOAD MAX

()

×

()

()

LOAD MAX

()

065 068

=µ µ

..

mV

40

A

14

mV

9

=

×

.

05 7

kHz

HH=

()

.

m

285

=Ω

.

m

257

A

Page 16

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

16 ______________________________________________________________________________________

The actual microfarad capacitance value required

relates to the physical size needed to achieve low ESR,

as well as to the chemistry of the capacitor technology.

As a result, the capacitor is usually selected by ESR

and voltage rating rather than by capacitance value

(this is true of tantalums, OS-CONs, POSCAPs, and

other electrolytics).

Input Capacitor Selection

The input capacitor must meet the ripple current

requirement (I

RMS

) imposed by the switching currents.

Nontantalum chemistries (ceramic, aluminum, or OSCON) are preferred due to their superior surge current

capacity:

Setting the Current Limit

The minimum current-limit threshold must be great

enough to support the maximum load current when the

current limit is at the minimum tolerance value. The valley of the inductor current occurs at I

LOAD(MAX)

minus

half of the ripple current. For example:

I

LIMIT(LOW)

> I

LOAD(MAX)

- (LIR / 2) ✕ I

LOAD(MAX)

where I

LIMIT(LOW)

= minimum current-limit threshold

voltage divided by the R

DS(ON)

of Q2. For the

MAX1917, the minimum current-limit threshold (100mV

default setting) is 50mV. Use the worst-case maximum

value for R

DS(ON)

from the MOSFET Q2 data sheet, and

add some margin for the rise in R

DS(ON)

with temperature. A good general rule is to allow 0.5% additional

resistance for each °C of temperature rise.

When adjusting the current limit, use a 1% tolerance

R

ILIM

resistor to prevent a significant increase of errors

in the current-limit tolerance.

Setting the Voltage Positioning

The droop resistor, R

DRP

, in series with the output

inductor before the output capacitor, sets the droop

voltage, V

DRP

. Choose R

DRP

such that the output voltage at the maximum load current, including ripple, is

just above the lower limit of the output tolerance:

R

DRP

introduces some power dissipation, which is

given by:

PD(DRP) = R

DRP

✕ I

OUT(MAX)

2

R

DRP

should be chosen to handle this power dissipation.

MOSFET Power Dissipation

Worst-case conduction losses occur at the duty-factor

extremes. For the high-side MOSFET, the worst-case

power dissipation due to resistance occurs at minimum

input voltage:

PD(Q1) = (V

OUT

/ V

IN(MIN)

) ✕ (I

LOAD

2

) ✕ (R

DS(ON)

)

Generally, a small high-side MOSFET is desired in order

to reduce switching losses at high input voltages.

However, the R

DS(ON)

required to stay within package

power-dissipation limits often limits how small the

MOSFET can be. Again, the optimum occurs when the

switching (AC) losses equal the conduction (R

DS(ON)

)

losses. Calculating the power dissipation in Q1 due to

switching losses is challenging because it must allow for

difficult-to-quantify factors that influence the turn-on and

turn-off times. These factors include the internal gate

resistance, gate charge, threshold voltage, source

inductance, and PC board layout characteristics. The following switching loss calculation provides only a very

rough estimate and is no substitute for breadboard evaluation, preferably including a check using a thermocouple mounted on Q1:

where C

RSS

is the reverse transfer capacitance of Q1

and I

GATE

is the peak gate-drive source/sink current.

For the low-side MOSFET, Q2, the worst-case power

dissipation always occurs at maximum input voltage:

PD(Q2) = (1 - V

OUT

/ V

IN(MAX)

) ✕ I

LOAD

2

✕ R

DS(ON)

II

RMS LOAD

VVV

OUT IN OUT

=×

×−

()

V

IN

R

VVV

OUT TYP OUT MIN RIPPLE

<

DRP

−−

() ()

I

()

OUT MAX

/2

PD SWITCHING

()

CV fI

×××

RSS IN MAX LOAD

=

2

()

I

GATE

Page 17

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

______________________________________________________________________________________ 17

The absolute worst case for MOSFET power dissipation

occurs under heavy overloads that are greater than or

equal to I

LOAD(MAX)

. To protect against this condition,

design the circuit to tolerate:

I

LOAD

= I

LIMIT(HIGH)

+ (LIR / 2) (I

LOAD

(MAX))

where I

LIMIT(HIGH)

is the maximum valley current

allowed by the current-limit circuit, including threshold

tolerance and on-resistance variation. If short-circuit

protection without overload protection is enough, a normal I

LOAD

value can be used for calculating compo-

nent stresses.

Control IC Power Dissipation

MAX1917 has on-chip MOSFETs drivers (DH and DL)

that dissipate the power loss due to driving the external

MOSFETs. Power dissipation due to a MOSFET driver is

given by:

where QGHand QGLare the total gate charge of the

high-side and low-side MOSFETs, respectively. Select

the switching frequency and V+ correctly to ensure the

power dissipation does not exceed the package power

dissipation requirement.

Applications Information

PC Board Layout

Careful PC board layout is critical to achieving low

switching losses and clean, stable operation. The

switching power stage requires particular attention. If

possible, mount all of the power components on the top

side of the board with their ground terminals flush

against one another. Follow these guidelines for good

PC board layout:

1) Keep the high-current paths short, especially at the

ground terminals. This practice is essential for stable, jitter-free operation.

2) Connect GND and PGND together as close to the

IC as possible.

3) Keep the power traces and load connections short.

This practice is essential for high efficiency. The

use of thick copper PC boards (2oz vs. 1oz) can

enhance full-load efficiency by 1% or more.

Correctly routing PC board traces is a difficult task

that must be approached in terms of fractions of

centimeters, where a single mΩ of excess trace

resistance causes a measurable efficiency penalty.

4) LX and PGND connections to Q2 for current limiting

must be made using Kelvin-sense connections in

order to guarantee the current-limit accuracy. With

8-pin SO MOSFETs, this is best done by routing

power to the MOSFETs from outside using the top

copper layer, while tying in PGND and LX inside

(underneath) the 8-pin SO package.

5) When trade-offs in trace lengths must be made, it is

preferable to allow the inductor charging path to be

made longer than the discharge path. For example,

it is better to allow some extra distance between the

input capacitors and the high-side MOSFET than to

allow distance between the inductor and the lowside MOSFET or between the inductor and the output filter capacitor.

6) Ensure that the VTT feedback connection to C

OUT

is short and direct. In some cases, it may be desirable to deliberately introduce some trace length

(droop resistance) between the FB inductor node

and the output filter capacitor.

7) VTT feedback sense point should also be as close

as possible to the load connection.

8) Route high-speed switching nodes away from sensitive analog nodes (DDR, EN/HSD, REF, ILIM).

9) Make all pin-strap control input connections (ILIM,

etc.) to GND or VL close to the chip, and do not

connect to PGND.

Chip Information

TRANSISTOR COUNT: 2708

PROCESS: BiCMOS

PVfQQ I

=+

×× +

()

DR S GH GL VTTR

()

()

+

Page 18

MAX1917

Tracking, Sinking and Sourcing, Synchronous Buck

Controller for DDR Memory and Termination Supplies

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

18 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2002 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages.)

QSOP.EPS

Loading...

Loading...