Page 1

查询MAX187ACPA供应商

19-0196; Rev 0; 10/93

EVALUATION KIT MANUAL

FOLLOWS DATA SHEET

+5V, Low-Power, 12-Bit Serial ADCs

__________________General Description

The MAX187/MAX189 serial 12-bit analog-to-digital

converters (ADCs) operate from a single +5V supply

and accept a 0V to 5V analog input. Both parts feature

an 8.5µs successive-approximation ADC, a fast

track/hold (1.5µs), an on-chip clock, and a high-speed

3-wire serial interface.

The MAX187/MAX189 digitize signals at a 75ksps

throughput rate. An external clock accesses data from

the interface, which communicates without external

hardware to most digital signal processors and microcontrollers. The interface is compatible with SPI™,

QSPI™, and Microwire™.

The MAX187 has an on-chip buffered reference, and

the MAX189 requires an external reference. Both the

MAX187 and MAX189 save space with 8-pin DIP and

16-pin SO packages. Power consumption is 7.5mW

and reduces to only 10µW in shutdown.

Excellent AC characteristics and very low power consumption combined with ease of use and small package size make these converters ideal for remote DSP

and sensor applications, or for circuits where power

consumption and space are crucial.

___________________________Applications

Portable Data Logging

Remote Digital Signal Processing

Isolated Data Acquisition

High-Accuracy Process Control

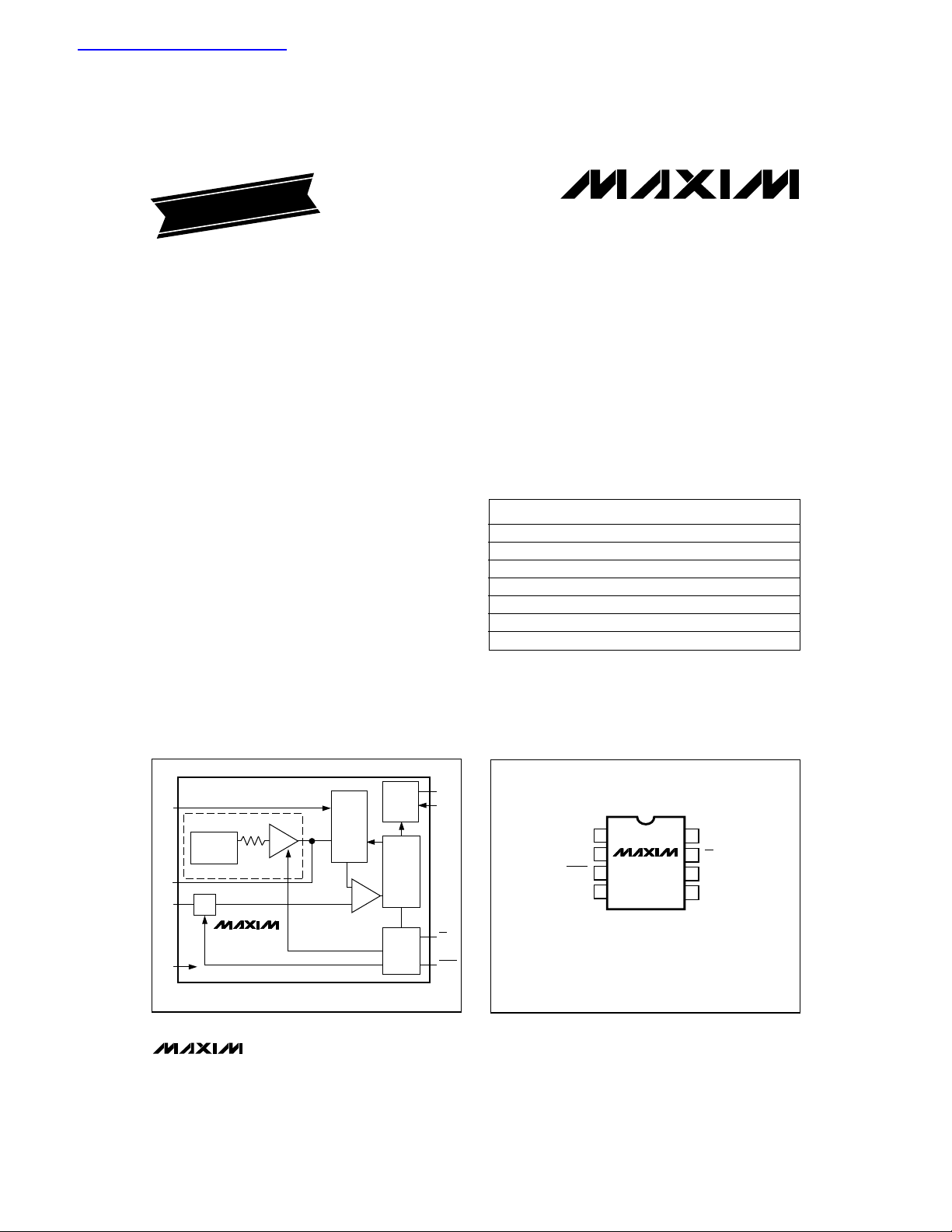

________________Functional Diagram

________________________________Features

♦ 12-Bit Resolution

1

⁄2 LSB Integral Nonlinearity (MAX187A/MAX189A)

♦ ±

♦ Internal Track/Hold, 75kHz Sampling Rate

♦ Single +5V Operation

♦ Low Power: 2µA Shutdown Current

1.5mA Operating Current

♦ Internal 4.096V Buffered Reference (MAX187)

♦ 3-Wire Serial Interface, Compatible with SPI,

QSPI, and Microwire

♦ Small-Footprint 8-Pin DIP and 16-Pin SO

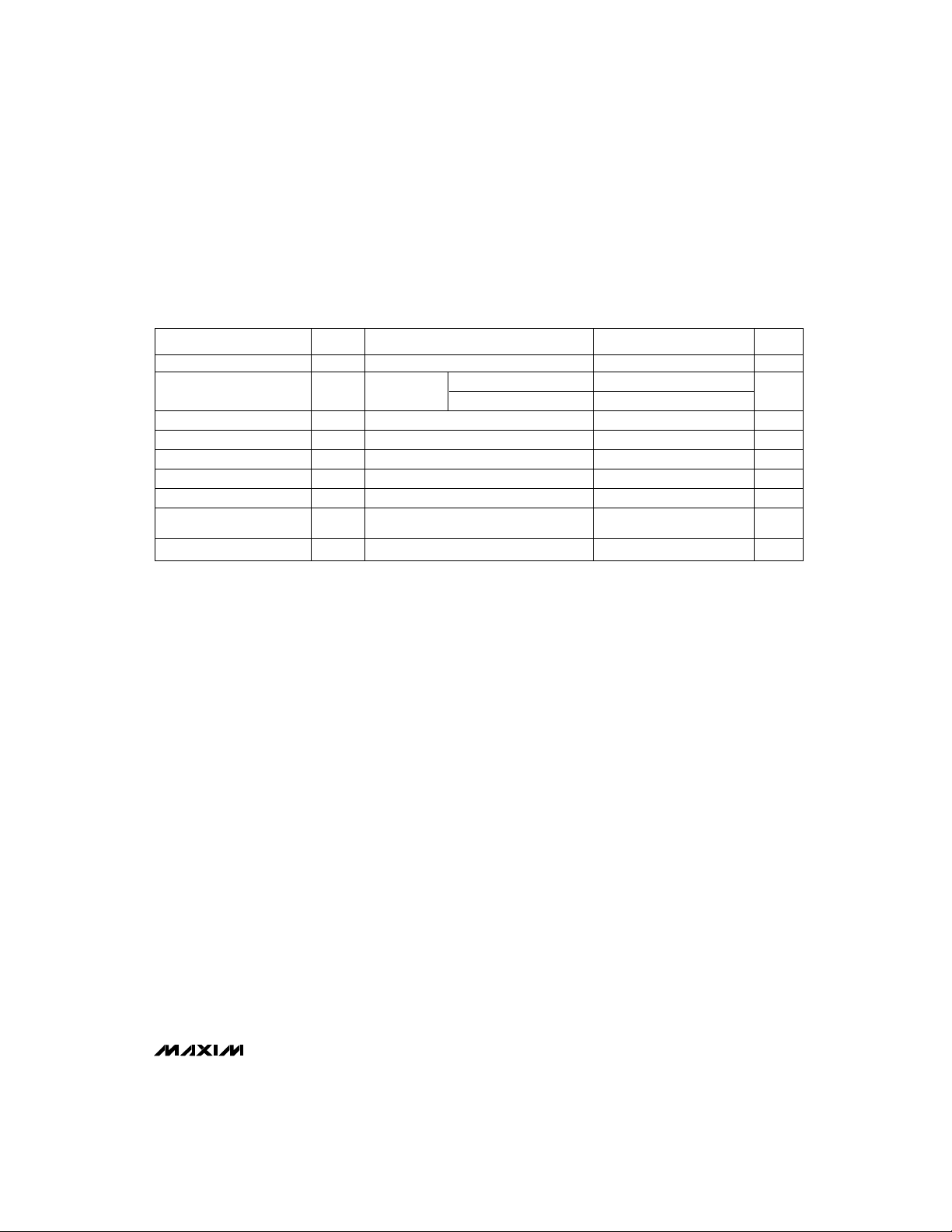

_________________Ordering Information

PART TEMP. RANGE PIN-PACKAGE

MAX187ACPA 0°C to +70°C 8 Plastic DIP ±

MAX187BCPA 0°C to +70°C 8 Plastic DIP ±1

MAX187CCPA 0°C to +70°C 8 Plastic DIP ±2

MAX187ACWE 0°C to +70°C 16 Wide SO ±

MAX187BCWE 0°C to +70°C 16 Wide SO ±1

MAX187CCWE 0°C to +70°C 16 Wide SO ±2

MAX187BC/D 0°C to +70°C Dice* ±1

Ordering Information continued on last page.

* Dice are specified at T

** Contact factory for availability and processing to MIL-STD-883.

= +25°C, DC parameters only.

A

ERROR

(LSB)

1

⁄2

1

⁄2

_________________Pin Configurations

MAX187/MAX189

6

SAR

AND

8

7

3

DOUT

SCLK

CS

SHDN

DAC

OUTPUT

SHIFT

REGISTER

12-BIT

CONTROL

TIMING

5

GND

+2.5V

BANDGAP

REFERENCE

(MAX187 ONLY)

4

REF

2

T/H

AIN

1

V

DD

NOTE: PIN NUMBERS SHOWN ARE FOR 8-PIN DIPs ONLY.

™ SPI and QSPI are trademarks of Motorola. Microwire is a trademark of National Semiconductor.

AV = 1.638

10k

MAX187

MAX189

________________________________________________________________

REF-

(4.096V)

REF+

COMPARATOR

BUFFER ENABLE/DISABLE

TOP VIEW

V

DD

1

AIN

2

SHDN

REF

Pin Configurations continued on last page.

MAX187

3

MAX189

4

DIP

Maxim Integrated Products

Call toll free 1-800-998-8800 for free samples or literature.

8

SCLK

CS

7

DOUT

6

5

GND

1

Page 2

+5V, Low-Power, 12-Bit Serial ADCs

ABSOLUTE MAXIMUM RATINGS

to GND.............................................................-0.3V to +6V

V

DD

AIN to GND................................................-0.3V to (V

REF to GND...............................................-0.3V to (V

Digital Inputs to GND.................................-0.3V to (V

Digital Outputs to GND..............................-0.3V to (V

SHDN

to GND.............................................-0.3V to (V

REF Load Current (MAX187) .........................4.0mA Continuous

REF Short-Circuit Duration (MAX187)................................20sec

DOUT Current..................................................................±20mA

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

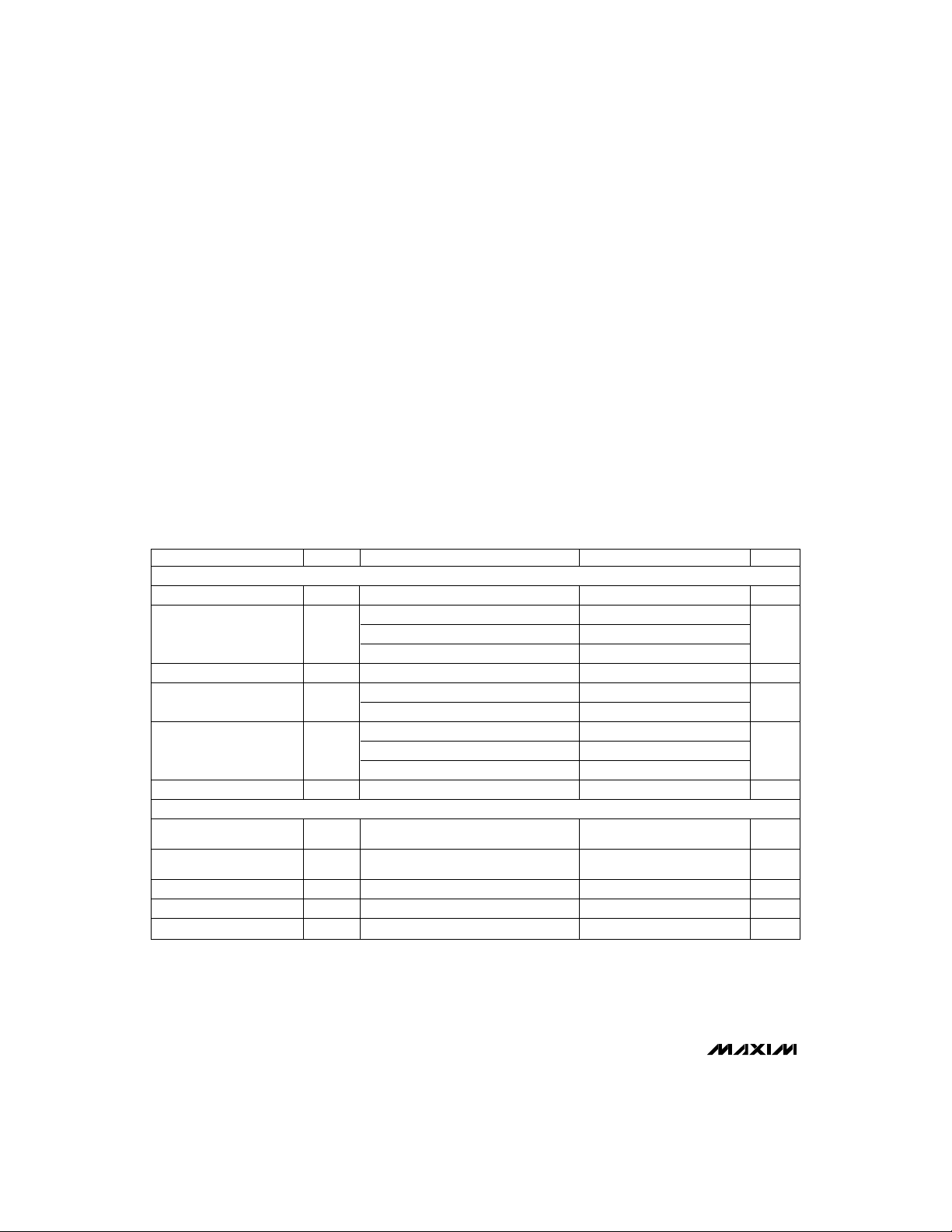

ELECTRICAL CHARACTERISTICS

MAX187/MAX189

(VDD= +5V ±5%; GND = 0V; unipolar input mode; 75ksps, f

reference: V

capacitor at REF pin; T

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DC ACCURACY (Note 1)

Resolution 12 Bits

Relative Accuracy (Note 2) MAX18_B ±1 LSB

Differential Nonlinearity DNL No missing codes over temperature ±1 LSB

Offset Error

Gain Error (Note 3)

Gain Temperature Coefficient External reference, 4.096V ±0.8 ppm/°C

DYNAMIC SPECIFICATIONS

Signal-to-Noise plus

Distortion Ratio

Total Harmonic Distortion

(up to the 5th harmonic)

Spurious-Free Dynamic Range SFDR 80 dB

Small-Signal Bandwidth Rolloff -3dB 4.5 MHz

Full-Power Bandwidth 0.8 MHz

= 4.096V, 4.7µF capacitor at REF pin, or MAX189—external reference: V

REF

= T

to T

A

MIN

; unless otherwise noted.)

MAX

MAX18_A ±

MAX18_C ±2

MAX18_A ±1

MAX18_B/C ±3

MAX187 ±3

MAX189A ±1

MAX189B/C ±3

(10kHz sine wave input, 0V to 4.096V

SINAD 70 dB

THD -80 dB

DD

DD

DD

DD

DD

+ 0.3V)

+ 0.3V)

+ 0.3V)

+ 0.3V)

+ 0.3V)

Continuous Power Dissipation (T

8-Pin Plastic DIP (derate 9.09mW/°C above +70°C)..500mW

16-Pin Wide SO (derate 8.70mW/°C above +70°C)...478mW

8-Pin CERDIP (derate 8.00mW/°C above +70°C) ......440mW

Operating Temperature Ranges:

MAX187_C_ _/MAX189_C_ _.............................0°C to +70°C

MAX187_E_ _/MAX189_E_ _..........................-40°C to +85°C

MAX187_MJA/MAX189_MJA .......................-55°C to +125°C

Storage Temperature Range............................-60°C to +150°C

Lead Temperature (soldering, 10sec)............................+300°C

= 4.0MHz, external clock (50% duty cycle); MAX187—internal

CLK

, 75ksps)

p-p

REF

= +70°C)

A

= 4.096V applied to REF pin, 4.7µF

1

⁄2

1

⁄2

LSB

LSB

2 _______________________________________________________________________________________

Page 3

+5V, Low-Power, 12-Bit Serial ADCs

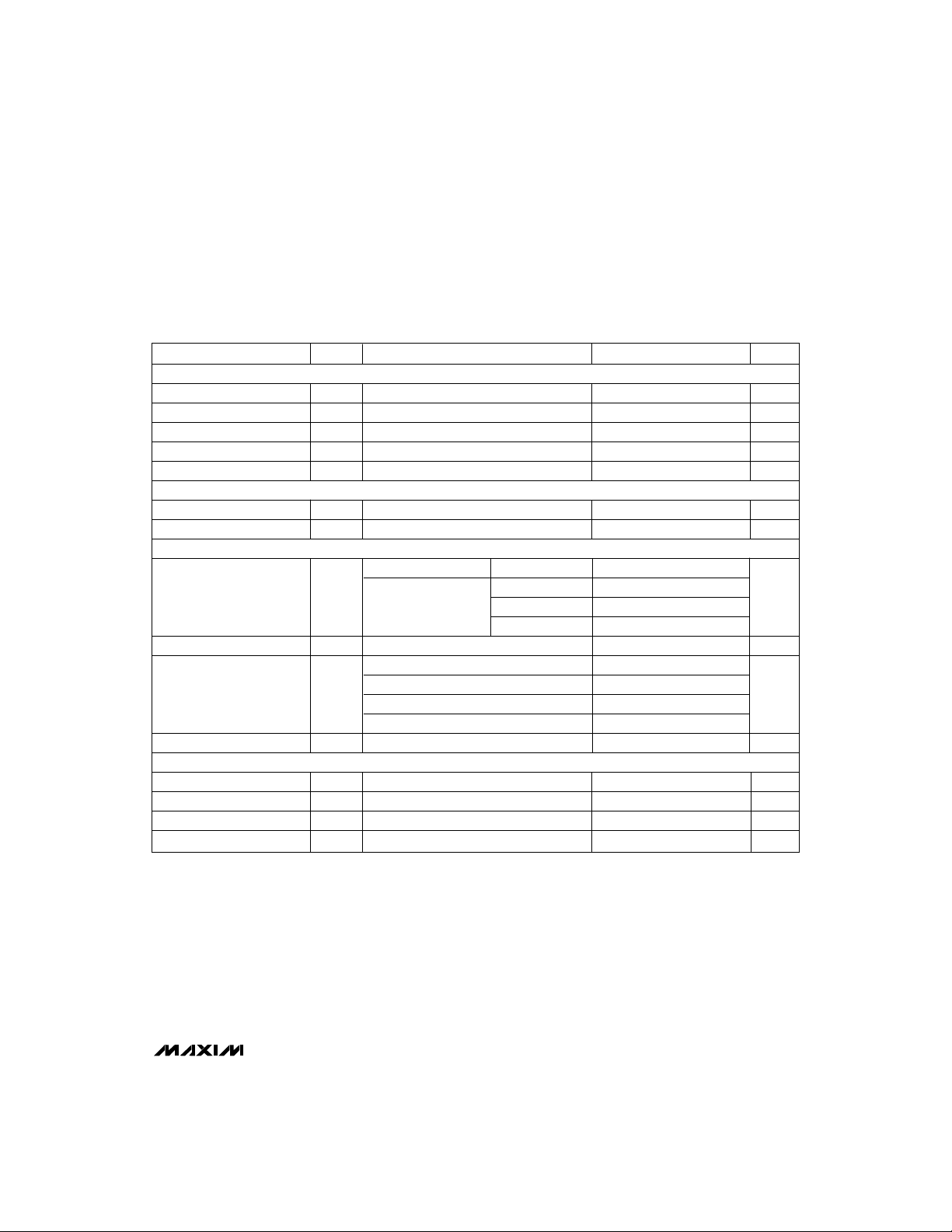

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +5V ±5%; GND = 0V; unipolar input mode; 75ksps, f

reference: V

capacitor at REF pin; T

CONVERSION RATE

Conversion Time t

Track/Hold Acquisition Time t

Throughput Rate External clock, 4MHz, 13 clocks 75 ksps

Aperture Delay t

Aperture Jitter <50 ps

ANALOG INPUT

Input Voltage Range 0 to V

Input Capacitance (Note 4) 16 pF

INTERNAL REFERENCE (MAX187 only, reference buffer enabled)

REF Output Voltage V

REF Short-Circuit Current 30 mA

REF Tempco

Load Regulation (Note 5) 0mA to 0.6mA output load 1 mV

EXTERNAL REFERENCE AT REF (Buffer disabled, V

Input Voltage Range 2.50 V

Input Current 200 350 µA

Input Resistance 12 20 kΩ

Shutdown REF Input Current 1.5 10 µA

= 4.096V, 4.7µF capacitor at REF pin, or MAX189—external reference: V

REF

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

= T

to T

A

MIN

; unless otherwise noted.)

MAX

CONV

ACQ

APR

TA= +25°C 4.076 4.096 4.116

REF

TA= T

MAX187AC/BC ±30 ±50

MAX187AE/BE ±30 ±60

MAX187AM/BM ±30 ±80

MAX187C ±30

MIN

to T

REF

MAX

= 4.0MHz, external clock (50% duty cycle); MAX187—internal

CLK

MAX187_C 4.060 4.132

MAX187_E 4.050 4.140

MAX187_M 4.040 4.150

= 4.096V)

= 4.096V applied to REF pin, 4.7µF

REF

5.5 8.5 µs

1.5 µs

10 ns

DD

REF

ppm/°C

+ 50mV V

MAX187/MAX189

V

V

_______________________________________________________________________________________ 3

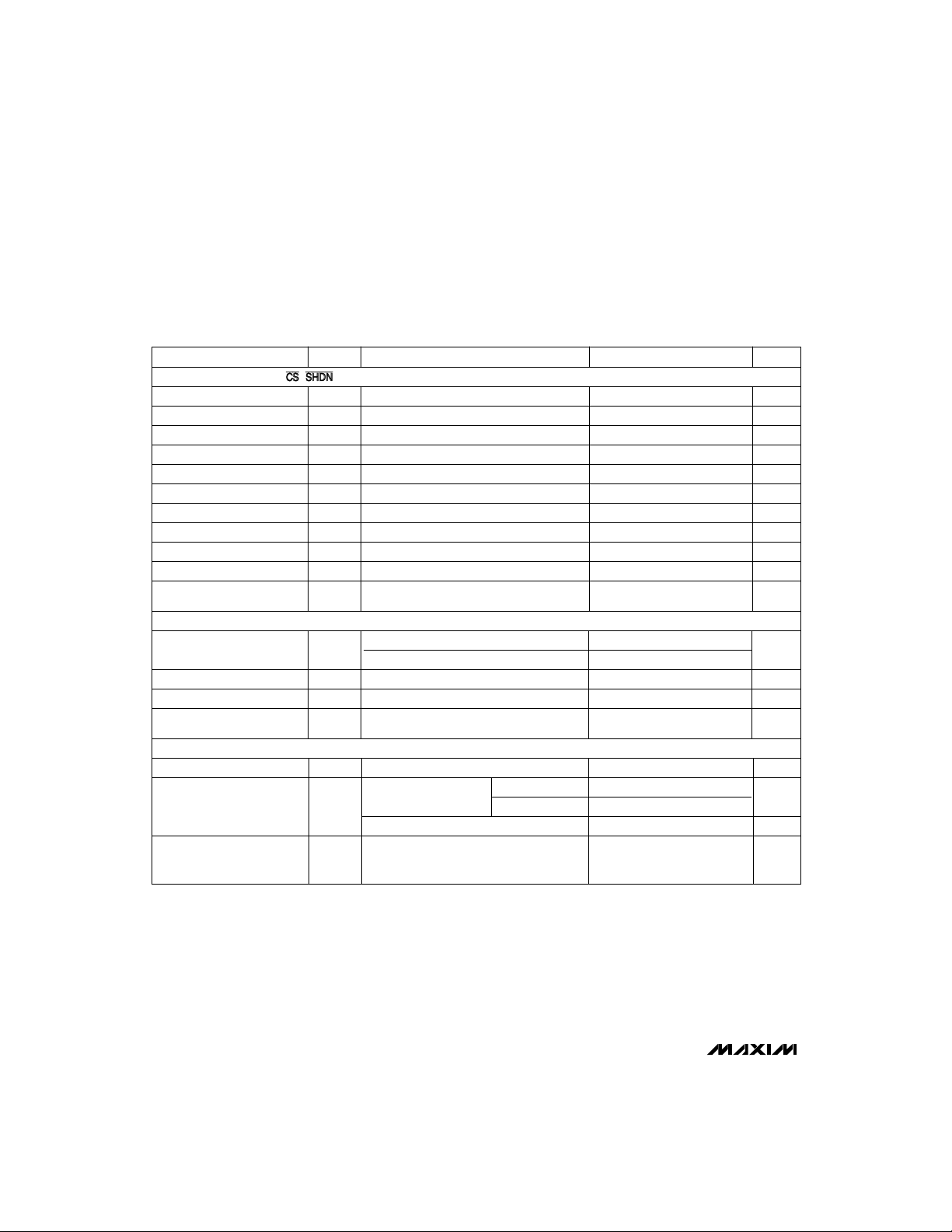

Page 4

+5V, Low-Power, 12-Bit Serial ADCs

SHDN

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +5V ±5%; GND = 0V; unipolar input mode; 75ksps, f

reference: V

capacitor at REF pin; T

= 4.096V, 4.7µF capacitor at REF pin, or MAX189—external reference: V

REF

= T

to T

A

MIN

; unless otherwise noted.)

MAX

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DIGITAL INPUTS (SCLK, CS,

SCLK, CSInput High Voltage V

SCLK, CSInput Low Voltage V

SCLK, CSInput Hysteresis V

SCLK, CSInput Leakage I

SCLK, CSInput Capacitance C

SHDN

MAX187/MAX189

Input High Voltage V

SHDN

Input Low Voltage V

SHDN

Input Current I

SHDN

Input Mid Voltage V

SHDN

Voltage, Floating V

SHDN

Maximum Allowed

Leakage, Mid Input

)

INH

INL

HYST

VIN= 0V or V

IN

(Note 4) 15 pF

IN

INSH

INSL

SHDN

INS

IM

FLT

= VDDor 0V ±4.0 µA

SHDN

= open 2.75 V

SHDN

= open -100 100 nA

DIGITAL OUTPUT (DOUT)

I

= 5mA 0.4

Output Voltage Low V

Output Voltage High V

Three-State Leakage Current I

Three-State Output

Capacitance

C

SINK

OL

I

SINK

OHISOURCE

CS

L

OUT

= 5V ±10 µA

CS

= 5V (Note 4) 15 pF

= 16mA 0.3

= 1mA 4 V

POWER REQUIREMENTS

Supply Voltage V

Supply Current

DD

I

DD

Operating mode

Power-down mode 2 10 µA

DD

= 4.0MHz, external clock (50% duty cycle); MAX187—internal

CLK

MAX187 1.5 2.5

MAX189 1.0 2.0

= 4.096V applied to REF pin, 4.7µF

REF

2.4 V

0.8 V

0.15 V

±1 µA

V

- 0.5 V

DD

0.5 V

1.5 VDD-1.5 V

4.75 5.25 V

V

mA

Power-Supply Rejection PSR

VDD= +5V, ±5%; external reference, 4.096V;

full-scale input (Note 6)

±0.06 ±0.5 mV

4 _______________________________________________________________________________________

Page 5

+5V, Low-Power, 12-Bit Serial ADCs

TIMING CHARACTERISTICS

(VDD= +5.0V ±5%, TA= T

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Track/Hold Acquisition Time t

SCLK Fall to Output Data Valid t

CS

Fall to Output Enable t

CS

Rise to Output Disable t

SCLK Clock Frequency f

SCLK Pulse Width High t

SCLK Pulse Width Low t

CS

SCLK Low to

Setup Time

CS

Pulse Width t

Note 1: Tested at VDD= +5V.

Note 2: Relative accuracy is the deviation of the analog value at any code from its theoretical value after the full-scale range has

Note 3: MAX187—internal reference, offset nulled; MAX189–external +4.096V reference, offset nulled. Excludes reference errors.

Note 4: Guaranteed by design. Not subject to production testing.

Note 5: External load should not change during conversion for specified ADC accuracy.

Note 6: DC test, measured at 4.75V and 5.25V only.

Note 7: To guarantee acquisition time, t

Fall

been calibrated.

time needed for the signal to be acquired.

MIN

to T

, unless otherwise noted.)

MAX

CS

ACQ

C

DO

LOAD

C

DV

LOAD

C

TR

LOAD

SCLK

CH

CL

t

CSO

CS

is the maximum time the device takes to acquire the signal, and is also the minimum

ACQ

= high (Note 7) 1.5 µs

= 100pF

= 100pF 100 ns

= 100pF 100 ns

MAX18_ _C/E 20 150

MAX18_ _M 20 200

5 MHz

100 ns

100 ns

50 ns

500 ns

MAX187/MAX189

ns

_______________________________________________________________________________________ 5

Page 6

+5V, Low-Power, 12-Bit Serial ADCs

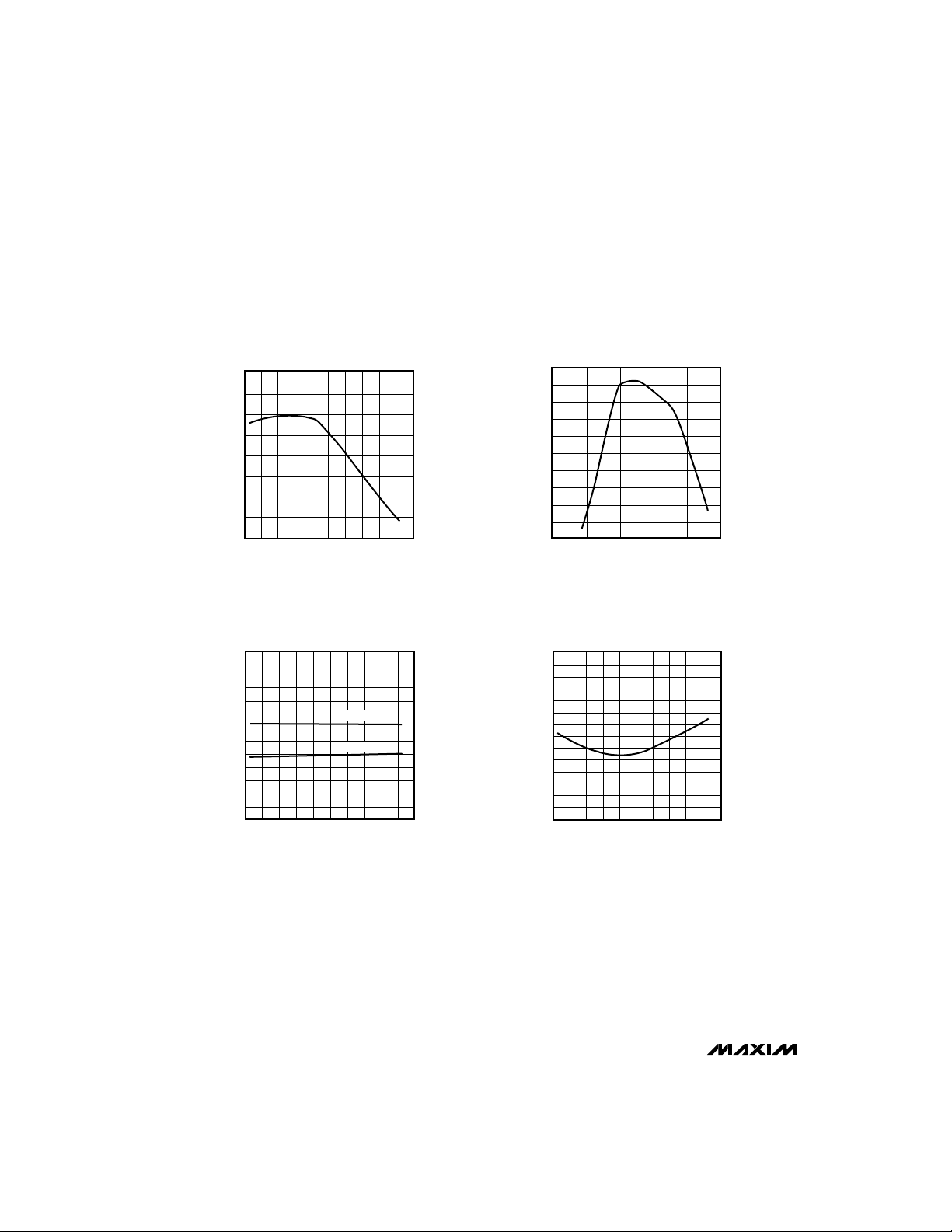

________________________________________________T ypical Operating Characteristics

POWER-SUPPLY REJECTION vs.

0.16

0.14

0.12

0.10

0.08

0.06

0.04

MAX187/MAX189

POWER-SUPPLY REJECTION (mV)

0.02

0

-60 -20 20 60 100 140

SUPPLY CURRENT vs. TEMPERATURE

2.2

1.8

1.4

1.0

SUPPLY CURRENT (mA)

0.6

0.2

-60 -20 20 60 100 140

TEMPERATURE

TEMPERATURE (°C)

MAX187

MAX189

TEMPERATURE (°C)

vs. TEMPERATURE

V

4.090

4.089

4.088

4.087

4.086

4.085

4.084

4.083

4.082

INTERNAL REFERENCE VOLTAGE (V)

4.081

4.080

REF

-60 -20 20 60 140

TEMPERATURE (°C)

SHUTDOWN SUPPLY CURRENT vs.

TEMPERATURE

7

6

5

4

3

2

SHUTDOWN SUPPLY CURRENT (µA)

1

0

-60 -20 20 60 100 140

TEMPERATURE (°C)

100

6 _______________________________________________________________________________________

Page 7

+5V, Low-Power, 12-Bit Serial ADCs

_______________________________________________________________________Pin Description

PIN

DIP WIDE SO

11VDDSupply voltage, +5V ±5%

2 3 AIN Sampling analog input, 0V to V

36SHDN

4 8 REF

5 — GND Analog and digital ground

— 10 AGND Analog ground

— 11 DGND Digital ground

6 12 DOUT Serial data output. Data changes state at SCLK’s falling edge.

715

8 16 SCLK Serial clock input. Clocks data out with rates up to 5MHz.

— 2,4,5,7,9,13,14 N.C. Not internally connected. Connect to AGND for best noise performance.

_______________Detailed Description

The MAX187/MAX189 use input track/hold (T/H) and

successive approximation register (SAR) circuitry to

convert an analog input signal to a digital 12-bit output.

No external hold capacitor is needed for the T/H.

Figures 3a and 3b show the MAX187/MAX189 in their

simplest configuration. The MAX187/MAX189 convert

input signals in the 0V to V

T/H acquisition time. The MAX187’s internal reference

is trimmed to 4.096V, while the MAX189 requires an

external reference. Both devices accept external reference voltages from +2.5V to VDD. The serial interface

requires only three digital lines, SCLK,

and provides easy interface to microprocessors (µPs).

Both converters have two modes: normal and shutdown. Pulling

reduces supply current to below 10µA, while pulling

SHDN

high or leaving it floating puts the device into the

operational mode. A conversion is initiated by

falling. The conversion result is available at DOUT in

SHDN

low shuts the device down and

NAME FUNCTION

Three-level shutdown input. Pulling

CS

down to 10µA (max) supply current. Both MAX187 and MAX189 are fully operational with either

enables the internal reference, and letting

reference and allows for the use of an external reference.

Reference voltage—sets analog voltage range and functions as a 4.096V output

for the MAX187 with enabled internal reference. REF also serves as a +2.5V to

V

input for a precision reference for both MAX187 (disabled internal reference)

DD

and MAX189. Bypass with 4.7µF if internal reference is used, and with 0.1µF if an

external reference is applied.

Active-low chip select initiates conversions on the falling edge. When CSis high,

DOUT is high impedance.

SHDN

high or floating. For the MAX187, pulling

unipolar serial format. A high bit, signaling the end of

conversion (EOC), followed by the data bits (MSB first),

Converter Operation

make up the serial data stream.

The MAX187 operates in one of two states: (1) internal

reference and (2) external reference. Select internal

reference operation by forcing

reference operation by floating

range in 10µs, including

REF

Figure 4 illustrates the sampling architecture of the

ADC’s analog comparator. The full-scale input voltage

depends on the voltage at REF.

CS,

and DOUT,

REFERENCE

Internal Reference

(MAX187 only)

External Reference 0V V

For specified accuracy, the external reference voltage

range spans from +2.5V to VDD.

CS

REF

range

SHDN

low shuts the MAX187/MAX189

SHDN

float disables the internal

SHDN

SHDN

ZERO FULL

SCALE SCALE

0V +4.096V

SHDN

high

high, and external

.

Analog Input

REF

MAX187/MAX189

_______________________________________________________________________________________ 7

Page 8

+5V, Low-Power, 12-Bit Serial ADCs

+5V

3k

DOUT DOUT

3k

DGND

MAX187/MAX189

a. High-Z to VOH and VOL to V

Figure 1. Load Circuits for DOUT Enable Time

DOUT DOUT

3k

DGND

to High-Z

OH

Figure 2. Load Circuits for DOUT Disable Time

C

= 100pF C

LOAD

OH

C

= 100pF C

LOAD

LOAD

DGND

b. High-Z to VOL and VOH to V

+5V

3k

LOAD

DGND

b. VOLto High-Za. V

= 100pF

OL

= 100pF

8 _______________________________________________________________________________________

Page 9

+5V, Low-Power, 12-Bit Serial ADCs

4.7µF

0.1µF

4.7µF

0.1µF

MAX187/MAX189

8

SCLK

7

CS

6

DOUT

5

GND

SERIAL

INTERFACE

ANALOG INPUT

0V TO +5V

SHUTDOWN

INPUT

OFF

4.7µF

1

+5V

ON

V

DD

2

MAX187

AIN

3

SHDN

4

REF

Figure 3a. MAX187 Operational Diagram

12-BIT CAPACITIVE DAC

REF

AIN

C

PACKAGE

GND

TRACK

HOLD

INPUT

C

SWITCH

C

HOLD

-+

16pF

TRACK

5k

R

COMPARATOR

ZERO

IN

HOLD

AT THE SAMPLING INSTANT,

THE INPUT SWITCHES FROM

AIN TO GND.

Figure 4. Equivalent Input Circuit

Track/Hold

In track mode, the analog signal is acquired and stored

in the internal hold capacitor. In hold mode, the T/H

switch opens and maintains a constant input to the

ADC’s SAR section.

During acquisition, the analog input AIN charges

capacitor C

. Bringing CSlow ends the acquisition

HOLD

SCLK

DOUT

GND

8

7

CS

6

5

SERIAL

INTERFACE

ANALOG INPUT

0V TO +5V

SHUTDOWN

INPUT

OFF

REFERENCE

INPUT

0.1µF

1

+5V

ON

V

DD

2

MAX189

AIN

3

SHDN

4

REF

Figure 3b. MAX189 Operational Diagram

interval. At this instant, the T/H switches the input side

of C

resents a sample of the input, unbalancing the node

to GND. The retained charge on C

HOLD

HOLD

rep-

ZERO at the comparator’s input.

In hold mode, the capacitive DAC adjusts during the

remainder of the conversion cycle to restore node

ZERO to 0V within the limits of a 12-bit resolution. This

action is equivalent to transferring a charge from

C

to the binary-weighted capacitive DAC, which in

HOLD

turn forms a digital representation of the analog input

signal. At the conversion’s end, the input side of C

switches back to AIN, and C

signal again.

charges to the input

HOLD

HOLD

The time required for the T/H to acquire an input signal

is a function of how quickly its input capacitance is

charged. If the input signal’s source impedance is

high, the acquisition time lengthens and more time

must be allowed between conversions. Acquisition time

is calculated by:

t

= 9 (RS+ RIN) 16pF,

ACQ

where RIN= 5kΩ, RS= the source impedance of the

input signal, and t

impedances below 5kΩ do not significantly affect the

is never less than 1.5µs. Source

ACQ

AC performance of the ADC.

_______________________________________________________________________________________ 9

Page 10

+5V, Low-Power, 12-Bit Serial ADCs

The ADCs’ input tracking circuitry has a 4.5MHz small-

Input Bandwidth

signal bandwidth, and an 8V/µs slew rate. It is possible

to digitize high-speed transient events and measure

periodic signals with bandwidths exceeding the ADC's

sampling rate by using undersampling techniques. To

avoid aliasing of unwanted high-frequency signals into

the frequency band of interest, an anti-alias filter is recommended. See the MAX274/MAX275 continuous-time

filters data sheet.

Input Protection

Internal protection diodes that clamp the analog input

allow the input to swing from GND - 0.3V to VDD+ 0.3V

without damage. However, for accurate conversions

near full scale, the input must not exceed VDDby more

than 50mV, or be lower than GND by 50mV.

MAX187/MAX189

If the analog input exceeds the supplies by more than

50mV beyond the supplies, limit the input current to

2mA, since larger currents degrade conversion

accuracy.

Driving the Analog Input

The input lines to AIN and GND should be kept as short

as possible to minimize noise pickup. Shield longer

leads. Also see the

Input Protection

section

.

Because the MAX187/MAX189 incorporate a T/H, the

drive requirements of the op amp driving AIN are less

stringent than those for a successive-approximation

ADC without a T/H. The typical input capacitance is

16pF. The amplifier bandwidth should be sufficient to

handle the frequency of the input signal. The MAX400

and OP07 work well at lower frequencies. For higherfrequency operation, the MAX427 and OP27 are practical choices. The allowed input frequency range is limit-

ed by the 75ksps sample rate of the MAX187/MAX189.

Therefore, the maximum sinusoidal input frequency

allowed is 37.5kHz. Higher-frequency signals cause

aliasing problems unless undersampling techniques

are used.

Reference

The MAX187 can be used with an internal or external reference, while the MAX189 requires an external reference.

Internal Reference

The MAX187 has an on-chip reference with a buffered

temperature-compensated bandgap diode, lasertrimmed to +4.096V ±0.5%. Its output is connected to

REF and also drives the internal DAC. The output can

be used as a reference voltage source for other components and can source up to 0.6mA. Decouple REF

with a 4.7µF capacitor. The internal reference is

enabled by pulling the

SHDN

pin high. Letting

SHDN

float disables the internal reference, which allows the

use of an external reference, as described in the

External Reference

section.

External Reference

The MAX189 operates with an external reference at the

REF pin. To use the MAX187 with an external reference,

disable the internal reference by letting

SHDN

float. Stay

within the voltage range +2.5V to VDDto achieve specified accuracy. The minimum input impedance is 12kΩ

for DC currents. During conversion, the external reference must be able to deliver up to 350µA DC load current and have an output impedance of 10Ω or less. The

recommended minimum value for the bypass capacitor

is 0.1µF. If the reference has higher output impedance

or is noisy, bypass it close to the REF pin with a 4.7µF

capacitor.

COMPLETE CONVERSION SEQUENCE

CS

t

SHDN

DOUT

CONVERSION 0 CONVERSION 1

Figure 5. MAX187/MAX189 Shutdown Sequence

10 ______________________________________________________________________________________

WAKE

POWERED UPPOWERED DOWNPOWERED UP

Page 11

SHDN

10000

+5V, Low-Power, 12-Bit Serial ADCs

MAX187/MAX189

3.0

1000

MAX187

100

10

SUPPLY CURRENT (µA)

1

0.1 1 10 100 1000 10000

Figure 6. Average Supply Current vs. Conversion Rate

*REF CONNECTED TO V

CONVERSIONS PER SECOND

MAX189*

DD

100000

____________________Serial Interface

Initialization After Power-Up and

When power is first applied, it takes the fully discharged 4.7µF reference bypass capacitor up to 20ms

to provide adequate charge for specified accuracy.

With

SHDN

not pulled low, the MAX187/MAX189 are

now ready to convert.

To start a conversion, pull CSlow. At

the T/H enters its hold mode and a conversion is initiated. After an internally timed 8.5µs conversion period,

the end of conversion is signaled by DOUT pulling

high. Data can then be shifted out serially with the

external clock.

Using

Power consumption can be reduced significantly by

shutting down the MAX187/MAX189 between conversions. This is shown in Figure 6, a plot of average supply current vs. conversion rate. Because the MAX189

uses an external reference voltage (assumed to be present continuously), it "wakes up" from shutdown more

quickly, and therefore provides lower average supply

currents. The wakeup-time, t

SHDN deasserted to the time when a conversion may

be initiated. For the MAX187, this time is 2µs. For the

MAX189, this time depends on the time in shutdown

(see Figure 7) because the external 4.7µF reference

bypass capacitor loses charge slowly during shutdown

(see the specifications for shutdown, REF Input Current

= 10µA max).

Starting a Conversion

CS’s

falling edge,

to Reduce Supply Current

is the time from

WAKE,

2.5

2.0

(ms)

1.5

WAKE

t

1.0

0.5

0

0.0001 0.001 0.01 0.1 1 10

TIME IN SHUTDOWN (sec)

Figure 7. t

vs. Time in Shutdown (MAX187 only)

WAKE

External Clock

The actual conversion does not require the external

clock. This frees the µP from the burden of running the

SAR conversion clock, and allows the conversion result

to be read back at the µP’s convenience at any clock

rate from 0MHz to 5MHz. The clock duty cycle is unrestricted if each clock phase is at least 100ns. Do not

run the clock while a conversion is in progress.

Timing and Control

Conversion-start and data-read operations are controlled by the CSand SCLK digital inputs. The timing

diagrams of Figures 8 and 9 outline the operation of the

serial interface.

A CSfalling edge initiates a conversion sequence: The

T/H stage holds input voltage, the ADC begins to convert, and DOUT changes from high impedance to logic

low. SCLK must be kept inactive during the conversion.

An internal register stores the data when the conversion

is in progress.

End of conversion (EOC) is signaled by DOUT going

high. DOUT’s rising edge can be used as a framing

signal. SCLK shifts the data out of this register any time

after the conversion is complete. DOUT transitions on

SCLK’s falling edge. The next falling clock edge produces the MSB of the conversion at DOUT, followed by

the remaining bits. Since there are 12 data bits and one

leading high bit, at least 13 falling clock edges are

needed to shift out these bits. Extra clock pulses occurring after the conversion result has been clocked out,

and prior to a rising edge of CS, produce trailing 0s at

DOUT and have no effect on converter operation.

______________________________________________________________________________________ 11

Page 12

+5V, Low-Power, 12-Bit Serial ADCs

CS

SCLK

DOUT

INTERFACE IDLE

A/D

TRACK

STATE

MAX187/MAX189

MINIMUM

CYCLE TIME

CONVERSION

IN PROGRESS

CONVERSION

0

CONV

EOC

EOC

0µs8.5µs (t

)

Figure 8. MAX187/MAX189 Interface Timing Sequence

CS

t

CS0

SCLK

t

CONV

DOUT

t

DV

t

APR

14 8 12

B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

CLOCK OUTPUT DATA

TRACK

12 × 0.250µs = 3.25µs

TOTAL = 12.25µs

…

t

CH

…

t

DO

…

t

CL

B2 B1 B0

TRAILING

ZEROS

0µs

IDLE

CONV. 1

0.5µs

(tCS)

t

CS

t

TR

INTERNAL

T/H

(TRACK)

(HOLD) (TRACK)

…

Figure 9. MAX187/MAX189 Detailed Serial-Interface Timing

12 ______________________________________________________________________________________

Page 13

OUTPUT CODE

11…111

11…110

11…101

+5V, Low-Power, 12-Bit Serial ADCs

20

FULL-SCALE

TRANSITION

0

-20

-40

fS = 75ksps

f

= 10kHz

T

T

= +25°C

A

MAX187/MAX189

FS = +4.096V

FS

1LSB =

4096

00…011

00…010

00…001

00…000

012 FS

Figure 10. MAX187/MAX189 Unipolar Transfer Function,

4.096V = Full Scale

3

FS - 3/2LSBINPUT VOLTAGE (LSBs)

Minimum cycle time is accomplished by using DOUT’s

rising edge as the EOC signal. Clock out the data with

13 clock cycles at full speed. Raise CSafter the conversion’s LSB has been read. After the specified minimum

time, t

next conversion.

, CScan be pulled low again to initiate the

ACQ

Output Coding and Transfer Function

The data output from the MAX187/MAX189 is binary,

and Figure 10 depicts the nominal transfer function.

Code transitions occur halfway between successive

integer LSB values. If V

= +4.096V, then

REF

1 LSB = 1.00mV or 4.096V/4096.

_____________Dynamic Performance

High-speed sampling capability and a 75ksps throughput make the MAX187/MAX189 ideal for wideband signal processing. To support these and other related

applications, Fast Fourier Transform (FFT) test techniques are used to guarantee the ADC’s dynamic frequency response, distortion, and noise at the rated

throughput. Specifically, this involves applying a lowdistortion sine wave to the ADC input and recording the

digital conversion results for a specified time. The data

is then analyzed using an FFT algorithm that determines its spectral content. Conversion errors are then

seen as spectral elements outside of the fundamental

-60

AMPLITUDE (dB)

-80

-100

-120

-140

0 18.75 37.5

Figure 11. MAX187/MAX189 FFT plot

FREQUENCY (kHz)

input frequency. ADCs have traditionally been evaluated by specifications such as Zero and Full-Scale Error,

Integral Nonlinearity (INL), and Differential Nonlinearity

(DNL). Such parameters are widely accepted for specifying performance with DC and slowly varying signals,

but are less useful in signal-processing applications,

where the ADC’s impact on the system transfer function

is the main concern. The significance of various DC

errors does not translate well to the dynamic case, so

different tests are required.

Signal-to-Noise Ratio and

Effective Number of Bits

Signal-to-noise plus distortion (SINAD) is the ratio of the

fundamental input frequency’s RMS amplitude to the

RMS amplitude of all other ADC output signals. The

input bandwidth is limited to frequencies above DC and

below one-half the ADC sample (conversion) rate.

The theoretical minimum ADC noise is caused by quantization error and is a direct result of the ADC’s resolution: SINAD = (6.02N + 1.76)dB, where N is the number

of bits of resolution. An ideal 12-bit ADC can, therefore,

do no better than 74dB. An FFT plot of the output

shows the output level in various spectral bands. Figure

11 shows the result of sampling a pure 10kHz sine

wave at a 75ksps rate with the MAX187/MAX189.

______________________________________________________________________________________ 13

Page 14

+5V, Low-Power, 12-Bit Serial ADCs

12.2

12.0

11.8

11.6

11.4

11.2

11.0

10.8

EFFECTIVE BITS

10.6

10.4

10.2

MAX187/MAX189

1 10 100 1000

INPUT FREQUENCY (kHz)

(UNDERSAMPLED)

Figure 12. Effective Bits vs. Input Frequency

The effective resolution (effective number of bits) the

ADC provides can be determined by transposing the

above equation and substituting in the measured

SINAD: N = (SINAD - 1.76)/6.02. Figure 12 shows the

effective number of bits as a function of the input frequency for the MAX187/MAX189.

Total Harmonic Distortion

If a pure sine wave is sampled by an ADC at greater

than the Nyquist frequency, the nonlinearities in the

ADC’s transfer function create harmonics of the input

frequency present in the sampled output data.

Total Harmonic Distortion (THD) is the ratio of the RMS

sum of all the harmonics (in the frequency band above

DC and below one-half the sample rate, but not including the DC component) to the RMS amplitude of the

fundamental frequency. This is expressed as follows:

THD = 20log

√ V

+ V

2

2

+ V

3

4

V

1

+ … V

2

N

2

2

where V1is the fundamental RMS amplitude, and V

through VNare the amplitudes of the 2nd through Nth

harmonics. The THD specification in the

Characteristics

includes the 2nd through 5th

Electrical

harmonics.

a. SPI

b. QSPI

c. MICROWIRE

Figure 13. Common Serial-Interface Connections to the

2

MAX187/MAX189

SCK

MISO

SCK

MISO

I/O

+5V

CS

SCLK

DOUT

MAX187

SS

CS

+5V

MAX189

CS

SCLK

DOUT

MAX187

SS

I/O

SK

SI

MAX189

CS

SCLK

DOUT

MAX187

MAX189

14 ______________________________________________________________________________________

Page 15

+5V, Low-Power, 12-Bit Serial ADCs

____________Applications Information

The MAX187/MAX189 serial interface is fully compatible

with SPI, QSPI, and Microwire standard serial

interfaces.

If a serial interface is available, set the CPU’s serial

interface in master mode so the CPU generates the serial clock. Choose a clock frequency up to 2.5MHz.

1. Use a general-purpose I/O line on the CPU to pull

low. Keep SCLK low.

2. Wait the for the maximum conversion time specified

before activating SCLK. Alternatively, look for a

DOUT rising edge to determine the end of

conversion.

3. Activate SCLK for a minimum of 13 clock cycles. The

first falling clock edge will produce the MSB of the

DOUT conversion. DOUT output data transitions on

SCLK

DOUT

Connection to Standard Interfaces

1ST BYTE READ 2ND BYTE READ

CS

t

CONV

HI-Z

MSB D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 LSB

CS

SCLK’s falling edge and is available in MSB-first format. Observe the SCLK to DOUT valid timing characteristic. Data can be clocked into the µP on SCLK’s

rising edge.

CS

4. Pull

high at or after the 13th falling clock edge. If

CS

remains low, trailing zeros are clocked out after

the LSB.

5. With

CS

= high, wait the minimum specified time, tCS,

before launching a new conversion by pulling

CS

low. If a conversion is aborted by pulling CShigh

before the conversions end, wait for the minimum

acquisition time, t

, before starting a new

ACQ

conversion.

Data can be output in 1-byte chunks or continuously, as

shown in Figure 8. The bytes will contain the result of

the conversion padded with one leading 1, and trailing

0s if SCLK is still active with CS kept low.

HI-Z

MAX187/MAX189

EOC

Figure 14. SPI/Microwire Serial Interface Timing (CPOL = CPHA = 0)

SCLK

CS

t

CONV

HI-Z

DOUT

EOC

Figure 15. QSPI Serial Interface Timing (CPOL = CPHA = 0)

______________________________________________________________________________________ 15

MSB D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 LSB

HI-Z

Page 16

+5V, Low-Power, 12-Bit Serial ADCs

When using SPI or QSPI, set CPOL = 0 and CPHA = 0.

SPI and Microwire

Conversion begins with a CSfalling edge. DOUT goes

low, indicating a conversion in progress. Wait until

DOUT goes high or the maximum specified 8.5µs conversion time. Two consecutive 1-byte reads are

required to get the full 12 bits from the ADC. DOUT output data transitions on SCLK’s falling edge and is

clocked into the µP on SCLK’s rising edge.

The first byte contains a leading 1 and 7 bits of conversion result. The second byte contains the remaining 5

bits and 3 trailing 0s. See Figure 13 for connections

and Figure 14 for timing.

Set CPOL = CPHA = 0. Unlike SPI, which requires two

MAX187/MAX189

1-byte reads to acquire the 12 bits of data from the

ADC, QSPI allows the minimum number of clock cycles

necessary to clock in the data. The MAX187/MAX189

require 13 clock cycles from the µP to clock out the

+5V ON THIS SIDE OF

BARRIER MUST BE ISOLATED POWER

MAX187

1

2

4

V

AIN

REF

GND

DD

SHDN

SCLK

DOUT

3

7

CS

8

6

3k

470Ω

ANALOG

INPUT

0.1µF

SIGNAL

GROUND

+5V

10µF

4.7µF5

3k

QSPI

12 bits of data with no trailing 0s (Figure 15). The maximum clock frequency to ensure compatibility with QSPI

is 2.77MHz.

Opto-Isolated Interface,

Serial-to-Parallel Conversion

Many industrial applications require electrical isolation

to separate the control electronics from hazardous

electrical conditions, provide noise immunity, or prevent excessive current flow where ground disparities

exist between the ADC and the rest of the system.

Isolation amplifiers typically used to accomplish these

tasks are expensive. In cases where the signal is eventually converted to a digital form, it is cost effective to

isolate the input using opto-couplers in a serial link.

The MAX187 is ideal in this application because it

includes both T/H amplifier and voltage reference,

operates from a single supply, and consumes very little

power (Figure 16).

CS/START

14

SER

11

SCK

12

RCK

10

SCLR

14

SER

11

SCK

12

RCK

10

SCLR

SCLK/INPUT CLOCK

QH

QG

74HC595

QF

QE

QD

QC

QB

QA

13 8

9

QH′

QH

QG

74HC595

QF

QE

QD

QC

QB

QA

13 8

6N136

8

7

6

5

6N136

8

7

6

5

6N136

1

2

3

4

+5V

1

200Ω

2

3

4

74HC04

1

200Ω

2

3

4

8

7

6

5

74HC04

8.2k

+5V

7

6

5

4

3

2

1

15

16

7

6

5

4

3

2

1

15

16

D11 (MSB)

D10

D9

D8

+5V

0.1µF

D7

D6

D5

D4

D3

D2

D1

D0(LSB)

+5V

0.1µF

Figure 16. 12-Bit Isolated ADC

16 ______________________________________________________________________________________

Page 17

+5V, Low-Power, 12-Bit Serial ADCs

The ADC results are transmitted across a 1500V isolation barrier provided by three 6N136 opto-isolators.

Isolated power must be supplied to the converter and

the isolated side of the opto-couplers. 74HC595 threestate shift registers are used to construct a 12-bit parallel data output. The timing sequence is identical to the

timing shown in Figure 8. Conversion speed is limited

by the delay through the opto-isolators. With a 140kHz

clock, conversion time is 100µs.

The universal 12-bit parallel data output can also be

used without the isolation stage when a parallel interface is required. Clock frequencies up to 2.9MHz are

possible without violating the 20ns shift-register setup

time. Delay or invert the clock signal to the shift registers beyond 2.9MHz.

Layout, Grounding, Bypassing

For best performance, use printed circuit boards. Wirewrap boards are not recommended. Board layout

should ensure that digital and analog signal lines are

separated from each other. Do not run analog and digital (especially clock) lines parallel to one another, or

digital lines underneath the ADC package.

Figure 17 shows the recommended system ground

connections. A single-point analog ground (“star”

ground point) should be established at GND, separate

from the logic ground. All other analog grounds should

be connected to this ground. The 16-pin versions also

have a dedicated DGND pin available. Connect DGND

to this star ground point for further noise reduction. No

other digital system ground should be connected to

this single-point analog ground. The ground return to

the power supply for this ground should be low impedance and as short as possible for noise-free operation.

High-frequency noise in the VDDpower supply may

affect the ADC’s high-speed comparator. Bypass this

supply to the single-point analog ground with 0.01µF

and 4.7µF bypass capacitors. Minimize capacitor lead

lengths for best supply-noise rejection. If the +5V

power supply is very noisy, a 10Ω resistor can be connected as a lowpass filter to attenuate supply noise

(Figure 17).

SUPPLIES

+5V GND

R* = 10Ω

4.7µF

0.01µF

DD

MAX187

MAX189

*OPTIONAL

Figure 17. Power-Supply Grounding Condition

DGNDAGNDV

DGND+5V

DIGITAL

CIRCUITRY

MAX187/MAX189

______________________________________________________________________________________ 17

Page 18

+5V, Low-Power, 12-Bit Serial ADCs

__Ordering Information (continued)

PART TEMP. RANGE PIN-PACKAGE

MAX187AEPA -40°C to +85°C 8 Plastic DIP ±

MAX187BEPA -40°C to +85°C 8 Plastic DIP ±1

MAX187CEPA -40°C to +85°C 8 Plastic DIP ±2

MAX187AEWE -40°C to +85°C 16 Wide SO ±

MAX187BEWE -40°C to +85°C 16 Wide SO ±1

MAX187CEWE -40°C to +85°C 16 Wide SO ±2

MAX187AMJA -55°C to +125°C 8 CERDIP** ±

MAX187BMJA -55°C to +125°C 8 CERDIP** ±1

MAX189ACPA 0°C to +70°C 8 Plastic DIP ±

MAX187/MAX189

MAX189BCPA 0°C to +70°C 8 Plastic DIP ±1

MAX189CCPA 0°C to +70°C 8 Plastic DIP ±2

MAX189ACWE 0°C to +70°C 16 Wide SO ±

MAX189BCWE 0°C to +70°C 16 Wide SO ±1

MAX189CCWE 0°C to +70°C 16 Wide SO ±2

MAX189BC/D 0°C to +70°C Dice* ±1

MAX189AEPA -40°C to +85°C 8 Plastic DIP ±

MAX189BEPA -40°C to +85°C 8 Plastic DIP ±1

MAX189CEPA -40°C to +85°C 8 Plastic DIP ±2

MAX189AEWE -40°C to +85°C 16 Wide SO ±

MAX189BEWE -40°C to +85°C 16 Wide SO ±1

MAX189CEWE -40°C to +85°C 16 Wide SO ±2

MAX189AMJA -55°C to +125°C 8 CERDIP** ±

MAX189BMJA -55°C to +125°C 8 CERDIP** ±1

* Dice are specified at TA= +25°C, DC parameters only.

**Contact factory for availability and processing to MIL-STD-883.

ERROR

(LSB)

1

⁄2

1

⁄2

1

⁄2

1

⁄2

1

⁄2

1

⁄2

1

⁄2

1

⁄2

____Pin Configurations (continued)

V

N.C.

AIN

N.C.

N.C.

SHDN

N.C.

REF

DD

1

2

3

MAX187

4

MAX189

5

6

7

8

Wide SO

SCLK

16

CS

15

N.C.

14

N.C.

13

DOUT

12

DGND

11

AGND

10

N.C.

9

18 ______________________________________________________________________________________

Page 19

+5V, Low-Power, 12-Bit Serial ADCs

___________________Chip Topography

MAX187/MAX189

AIN

SHDN

V

DD

0.117"

(2.97mm)

REF

SCLK

AGND

CS

0.151"

(3.84mm)

DOUT

DGND

AGND

MAX187/MAX189

TRANSISTOR COUNT: 2278;

SUBSTRATE CONNECTED TO VDD.

______________________________________________________________________________________ 19

Page 20

+5V, Low-Power, 12-Bit Serial ADCs

________________________________________________________________Package Information

INCHES MILLIMETERS

DIM

A2

A

A1

L

D

e

B

MAX187/MAX189

D1

D

A

e

B

A1

0.101mm

0.005in.

B1

A3

DUAL-IN-LINE

C

E

E1

0°-15°

eA

eB

P PACKAGE

PLASTIC

L

0°- 8°

A

A1

A2

A3

B

B1

C

C

D1

E

E1

e

eA

eB

L

DIM

PINS

D

D

D

DIM

A

A1

B

C

E

e

H

L

MAX

MIN

–

0.015

0.125

0.055

0.016

0.045

0.008

0.050

0.600

0.525

0.100

0.600

–

0.120

INCHES MILLIMETERS

MIN

24

1.230

28

1.430

40

2.025

INCHES MILLIMETERS

MIN

0.093

0.004

0.014

0.009

0.291

0.050

0.394

0.016

0.200

–

0.175

0.080

0.020

0.065

0.012

0.090

0.625

0.575

–

–

0.700

0.150

MAX

0.104

0.012

0.019

0.013

0.299

0.419

0.050

MAX

1.270

1.470

2.075

MIN

–

0.38

3.18

1.40

0.41

1.14

0.20

1.27

15.24

13.34

2.54

15.24

–

3.05

31.24

36.32

51.44

MIN

2.35

0.10

0.35

0.23

7.40

10.00

0.40

MIN

1.27

MAX

5.08

–

4.45

2.03

0.51

1.65

0.30

2.29

15.88

14.61

–

–

17.78

3.81

MAX

32.26

37.34

52.71

MAX

2.65

0.30

0.49

0.32

7.60

10.65

1.27

DIM

HE

W PACKAGE

SMALL

OUTLINE

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

D

D

D

D

D

MIN

MAX

MIN

0.398

0.447

0.496

0.598

0.697

0.413

0.463

0.512

0.614

0.713

16

18

20

24

28

10.10

11.35

12.60

15.20

17.70

MAX

10.50

11.75

13.00

15.60

18.10

21-0042A

INCHES MILLIMETERS

PINS

© 1993 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Loading...

Loading...