Page 1

General Description

The MAX1856 offers a low-cost solution for generating a

SLIC (ringer and off-hook) power supply. Using standard

off-the-shelf transformers from multiple vendors, the

MAX1856 generates various output voltages: -24V and

-72V (dual output) for both ringer and off-hook supplies for

voice-enabled broadband consumer premises equipment

(CPE), -48V for IP phones and routers, -5V and -15V (single or dual output) for DSL CO line drivers, or negative

voltages as high as -185V for MEMS bias supplies. The

output voltages are adjusted with an external voltage

divider.

Due to its wide operating voltage range, the MAX1856

operates from a low-cost, unregulated DC power supply

for cost-sensitive applications like xDSL, cable modems,

set-top boxes, LMDS, MMDS, WLL, and FTTH CPE. The

MAX1856 provides low audio-band noise for talk battery

and a sturdy output capable of handling the ring trip conditions for ring battery.

The operating frequency can be set between 100kHz and

500kHz with an external resistor in free-running mode. For

noise-sensitive applications, the MAX1856’s operating frequency can be synchronized to an external clock over its

operating frequency range.

The flyback topology allows operation close to 50% duty

cycle, offering high transformer utilization, low ripple current, and less stress on input and output capacitors.

Internal soft-start minimizes startup stress on the input

capacitor, without any external components.

The MAX1856’s current-mode control scheme does not

require external loop compensation. The low-side currentsense resistor provides accurate current-mode control

and overcurrent protection.

Applications

VoIP Ringer and Off-Hook Voltage Generators

Cable and DSL Modems

Set-Top Boxes

Wireless Local Loop

FTTH

LMDS/MMDS

Routers

Industrial Power Supplies

CO DSL Line Driver Supplies

MEMS Bias Supplies

Features

♦ Low-Cost, Off-the-Shelf Transformer

♦ 3V to 28V Input Range

♦ Low Audio-Band Noise on Talk Battery

♦ Effectively Handles Ring Trip Transients

♦ Powers 2-, 4-, or 12-Line Equipment

♦ High Efficiency Extends Battery Life During

Life-Line Support Conditions

♦ Adjustable 100kHz to 500kHz Switching

Frequency

♦ Clock Synchronization

♦ Internal Soft-Start

♦ Current-Mode PWM and Idle Mode™ Control

Scheme

♦ Logic-Level Shutdown

♦ 10-Pin µMAX Package

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

________________________________________________________________ Maxim Integrated Products 1

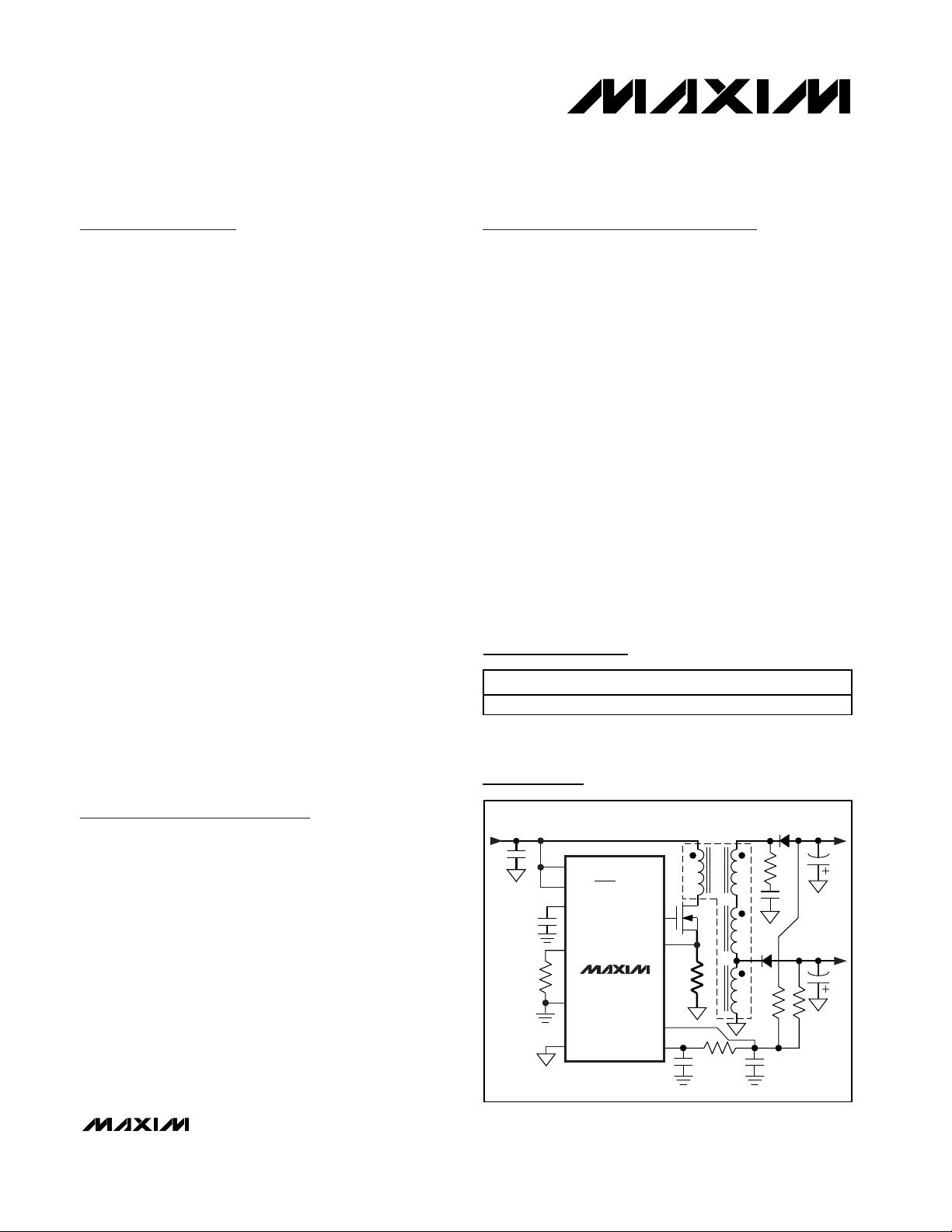

Typical Operating Circuit

Ordering Information

19-1898; Rev 0; 2/01

For price, delivery, and to place orders, please contact Maxim Distribution at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Idle Mode is a trademark of Maxim Integrated Products.

PART TEMP. RANGE PIN-PACKAGE

MAX1856EUB -40°C to +85°C 10 µMAX

INPUT

3V TO 28V

V

CC

SYNC/SHDN

LDO

FREQ

GND

PGND

OUT2

-72V

1

EXT

CS

MAX1856

FB

REF

2

2

2

OUT1

-24V

Page 2

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

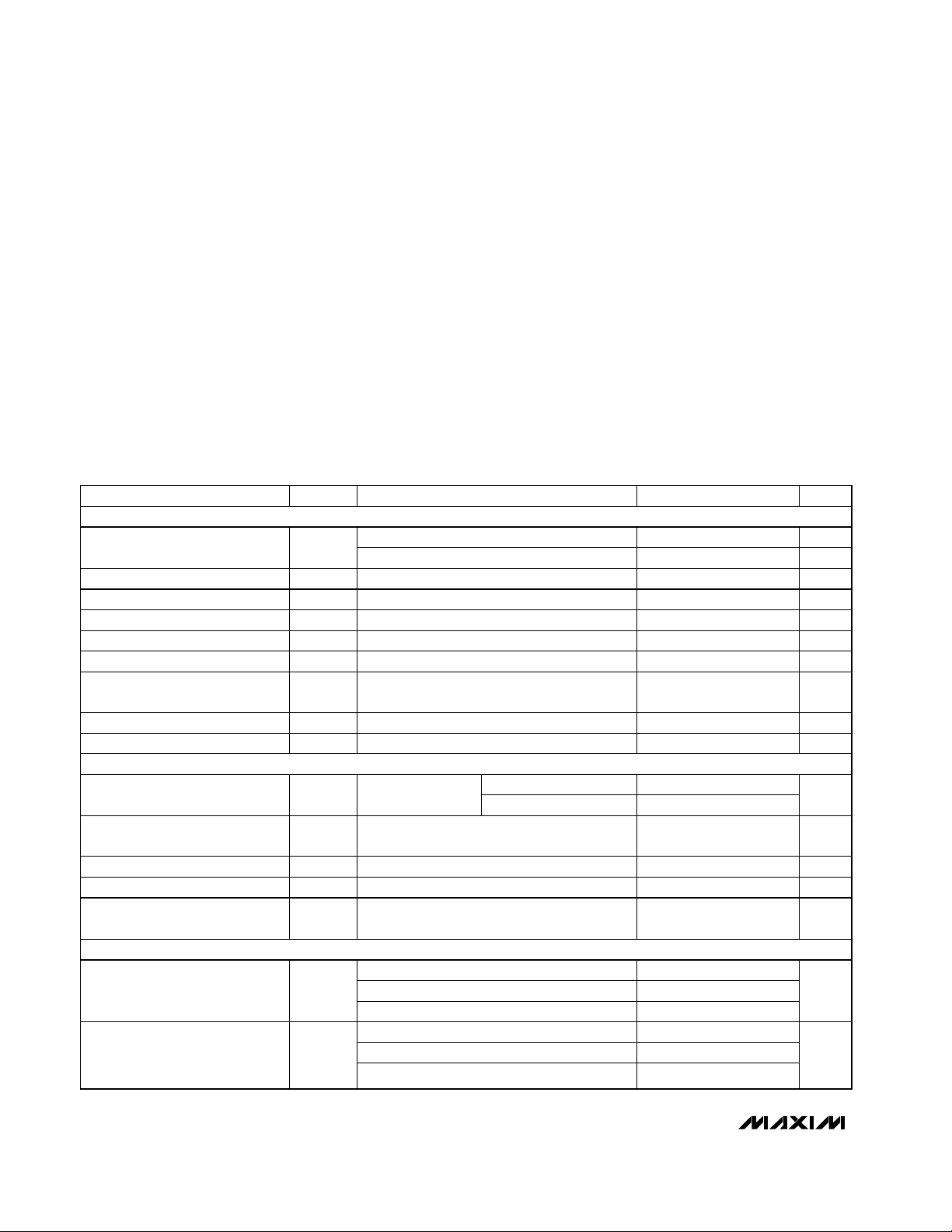

ELECTRICAL CHARACTERISTICS

(VCC= SYNC/SHDN, V

CC

= 5V, V

LDO

= 5V, R

OSC

= 200kΩ, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCC, SYNC/SHDN to GND .....................................-0.3V to +30V

PGND to GND .......................................................-0.3V to +0.3V

LDO, FREQ, FB, CS to GND.....................................-0.3V to +6V

EXT, REF to GND......................................-0.3V to (V

LDO

+ 0.3V)

LDO Output Current............................................-1mA to +20mA

LDO Short Circuit to GND ...............................................<100ms

REF Short Circuit to GND ...........................................Continuous

Continuous Power Dissipation (T

A

= +70°C)

10-Pin µMAX (derate 5.6mW/°C above +70°C) ...........444mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PWM CONTROLLER

Operating Input Voltage Range V

FB Input Current I

Load Regulation VCS = 0 to 100mV for 0 to I

Line Regulation Typically 0.0074% per % duty factor on EXT 0.0074 %/%

Current-Limit Threshold V

CS Input Current I

Idle Mode Current-Sense

Threshold

VCC Supply Current (Note 1) I

Shutdown Supply Current SYNC/SHDN = GND, VCC = 28V 3.5 6 µA

REFERENCE AND LDO REGULATOR

LDO Output Voltage V

Undervoltage Lockout

Threshold

REF to FB Voltage (Note 2) V

REF Load Regulation I

REF Undervoltage Lockout

Threshold

OSCILLATOR

Oscillator Frequency f

Maximum Duty Cycle D

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

FB

CS

CS

CC

LDO

V

UVLO

REF

OSC

328V

VCC = V

VFB = -0.05V 1 50 nA

CS = GND 1 µA

VFB = -0.05V, VCC = 3V to 28V 250 400 µA

R

V

R

Rising edge, 1% hysteresis (typ) 1.0 1.1 1.2 V

R

R

R

R

R

R

LDO

LOAD(MAX)

= 400Ω

LDO

falling edge, 1% hysteresis (typ) 2.40 2.50 2.60 V

LDO

= 10kΩ, C

REF

= 0 to 400µA -2 -10 mV

REF

= 100kΩ ±1% 425 500 575

OSC

= 200kΩ ±1% 225 250 275

OSC

= 500kΩ ±1% 85 100 115

OSC

= 100kΩ ±1% 86 90 94

OSC

= 200kΩ ±1% 87 90 93

OSC

= 500kΩ ±1% 86 90 94

OSC

5V ≤ VCC ≤ 28V 4.50 5.00 5.50

3V ≤ V

= 0.22µF 1.225 1.250 1.275 V

REF

≤ 28V 2.65 5.50

CC

2.7 5.5 V

0.013 %/mV

85 100 115 mV

51525mV

V

kHz

%

Page 3

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

_______________________________________________________________________________________ 3

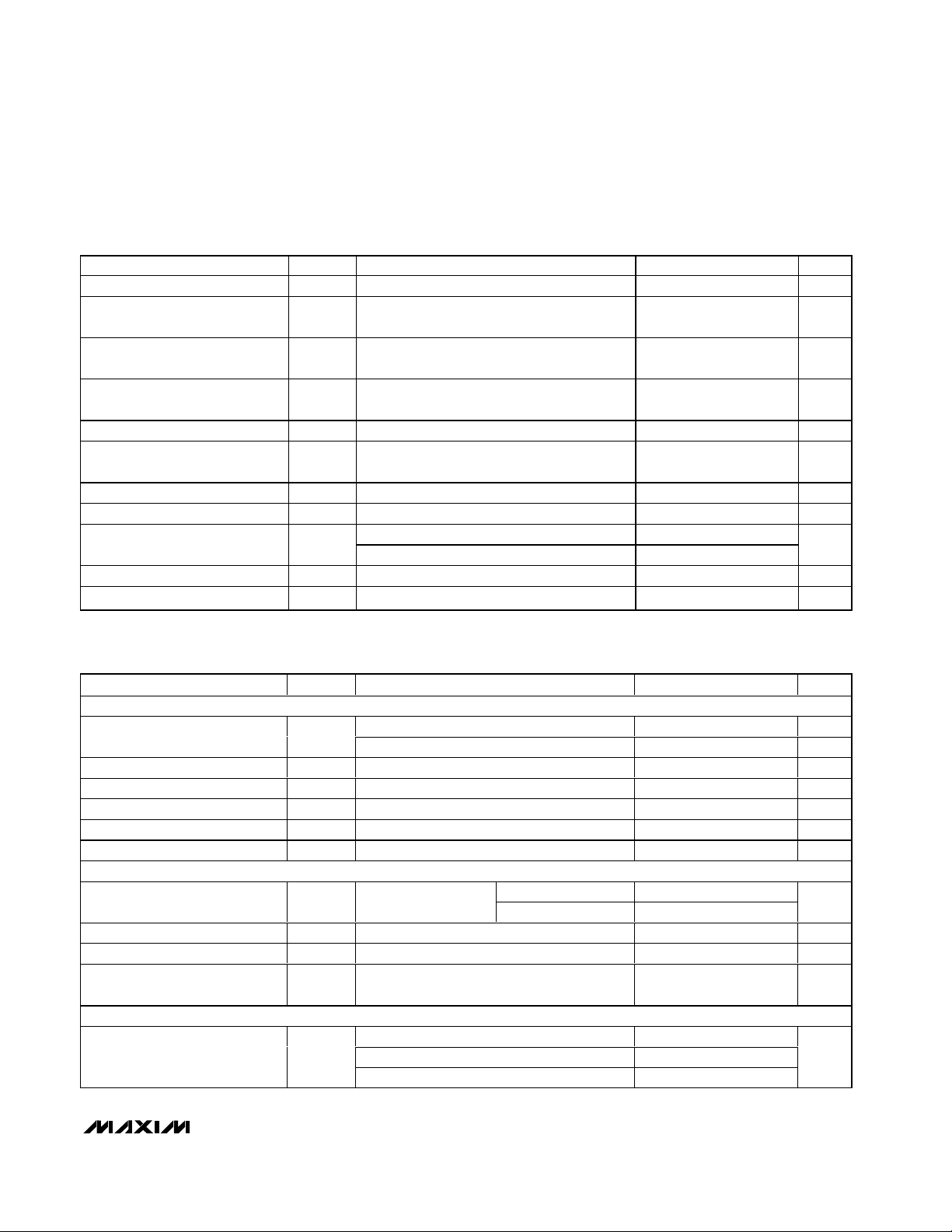

ELECTRICAL CHARACTERISTICS (continued)

(VCC= SYNC/SHDN, V

CC

= 5V, V

LDO

= 5V, R

OSC

= 200kΩ, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

ELECTRICAL CHARACTERISTICS

(VCC= SYNC/SHDN, V

CC

= 5V, V

LDO

= 5V, R

OSC

= 200kΩ, TA= -40°C to +85°C, unless otherwise noted.) (Note 3)

Minimum EXT Pulse Width 290 ns

Minimum SYNC Input Signal

Duty Cycle

Minimum SYNC Input

Low Pulse Width

Maximum SYNC Input

Rise/Fall Time

SYNC Input Frequency Range f

SYNC/SHDN Falling Edge to

Shutdown Delay

SYNC/SHDN Input High Voltage V

SYNC/SHDN Input Low Voltage V

SYNC/SHDN Input Current

EXT Sink/Source Current I

EXT On-Resistance R

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SYNC

t

SHDN

IH

IL

EXT

ON(EXT)

20 45 %

50 200 ns

200 ns

100 500 kHz

50 µs

2.0 V

0.45 V

V

SYNC/SHDN

V

SYNC/SHDN

EXT forced to 2V 1 A

EXT high or low 2 5 Ω

= 5V 0.5 3.0

= 28V 1.5 10

PWM CONTROLLER

Operating Input Voltage Range V

FB Input Current I

Current-Limit Threshold V

CS Input Current I

V

Shutdown Supply Current SYNC/SHDN = GND, VCC = 28V 6 µA

REFERENCE AND LDO REGULATOR

LDO Output Voltage V

REF to FB Voltage (Note 2) V

REF Load Regulation I

REF Undervoltage Lockout

Threshold

OSCILLATOR

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Current (Note 1) I

CC

CC

FB

CS

CS

CC

LDO

REF

OSC

328V

VCC = V

VFB = -0.05V 50 nA

CS = GND 1 µA

VFB = -0.05V, VCC = 3V to 28V 400 µA

R

R

Rising edge, 1% hysteresis (typ) 1.0 1.2 V

R

R

R

LDO

= 400Ω

LDO

= 10kΩ, C

REF

= 0 to 400µA -10 mV

REF

= 100kΩ ±1% 425 575

OSC

= 200kΩ ±1% 222 278Oscillator Frequency f

OSC

= 500kΩ ±1% 85 115

OSC

REF

5V ≤ VCC ≤ 28V 4.50 5.50

3V ≤ V

= 0.22µF 1.22 1.28 V

≤ 28V 2.65 5.50

CC

2.7 5.5 V

85 115 mV

µA

V

kHz

Page 4

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

4 _______________________________________________________________________________________

)

ELECTRICAL CHARACTERISTICS (continued)

(VCC= SYNC/SHDN, V

CC

= 5V, V

LDO

= 5V, R

OSC

= 200kΩ, TA= -40°C to +85°C, unless otherwise noted.) (Note 3)

Note 1: This is the V

CC

current consumed when active, but not switching, so the gate-drive current is not included.

Note 2: The reference output voltage (V

REF

) is measured with respect to FB. The difference between REF and FB is guaranteed to

be within these limits to ensure output voltage accuracy.

Note 3: Specifications to -40°C are guaranteed by design, not production tested.

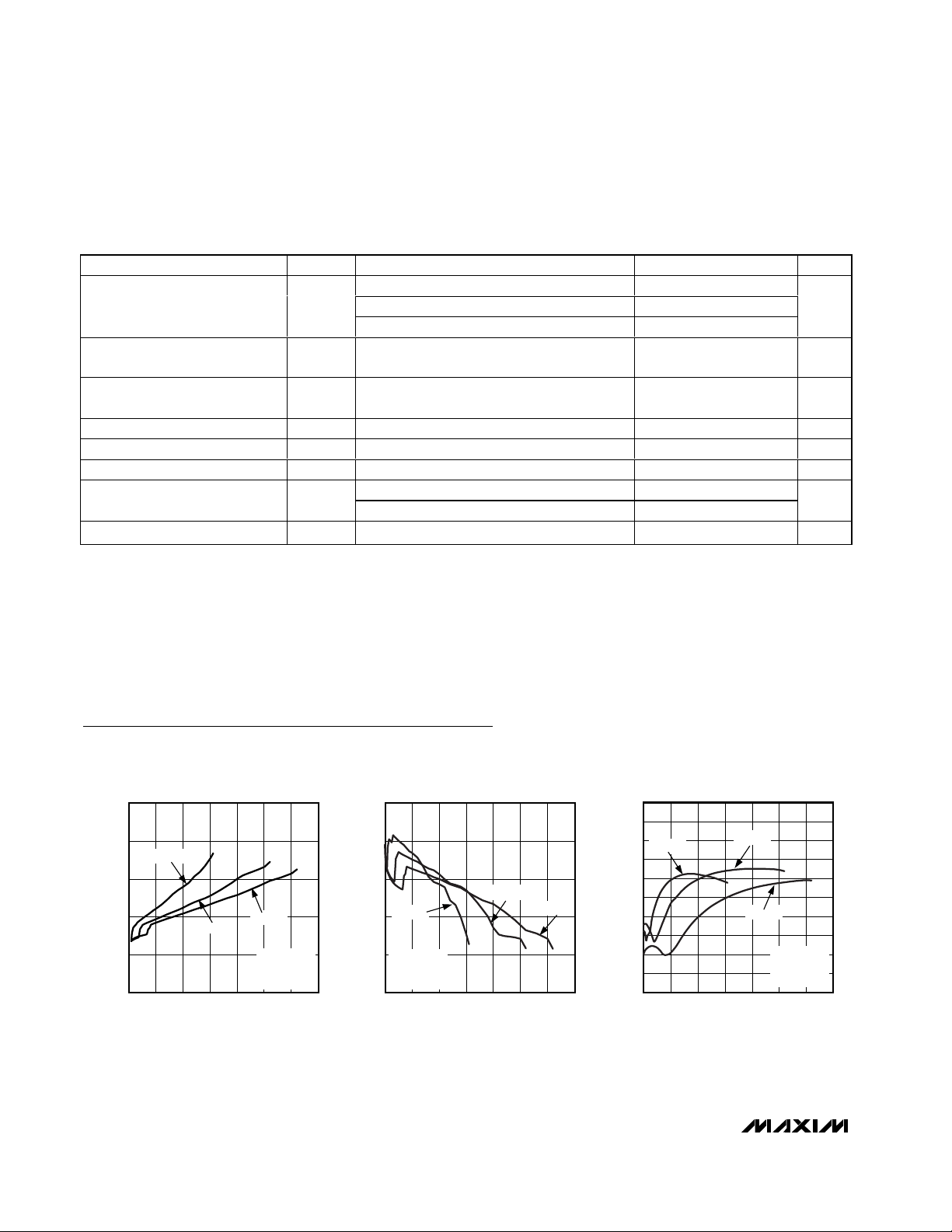

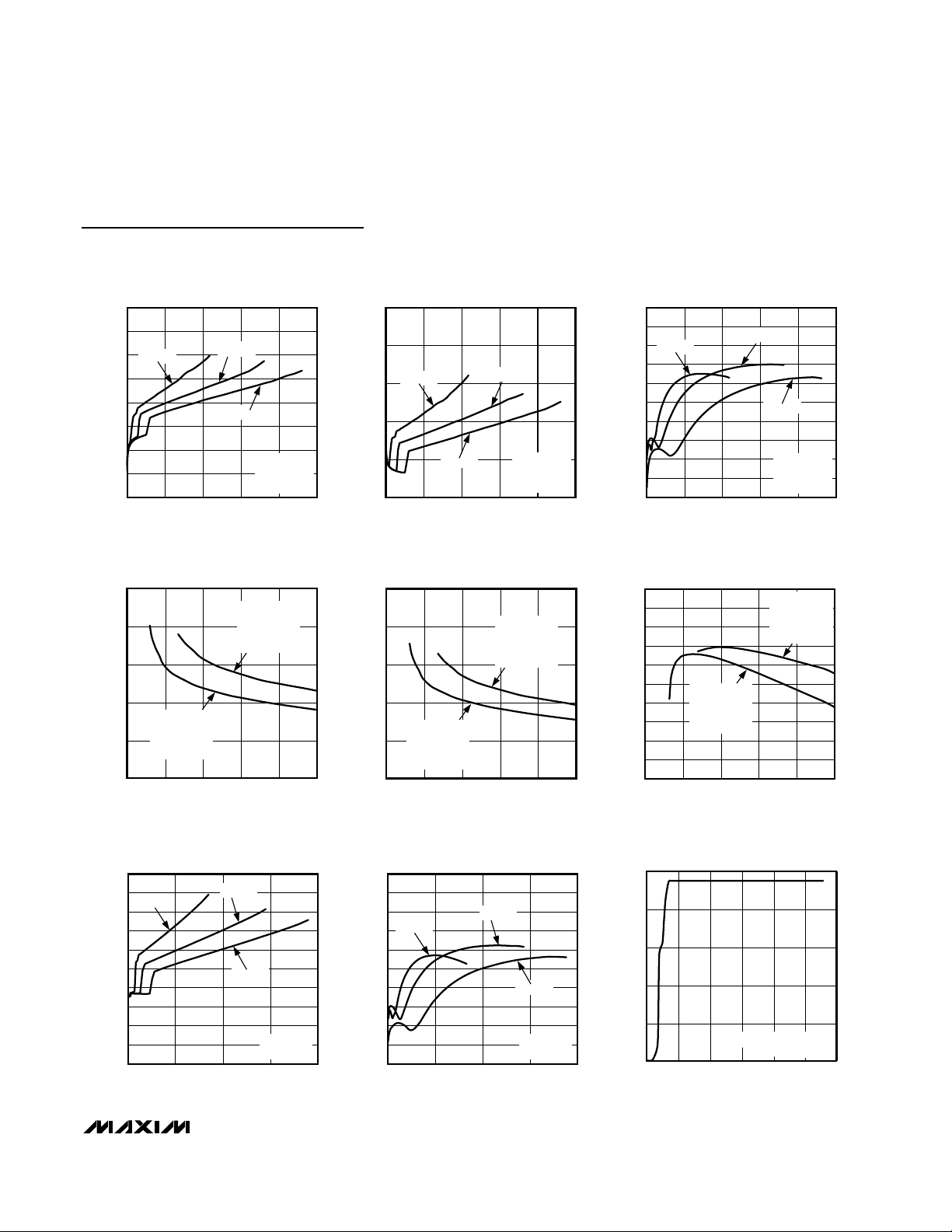

Typical Operating Characteristics

(Circuit of Figure 1, VCC= V

SYNC/SHDN

= 12V, V

OUT1

= -24V, V

OUT2

= -72V, R

OSC

= 200kΩ, unless otherwise noted.)

-24.5

-24.0

-23.0

-23.5

-22.5

-22.0

0 200100 300 400 500 600 700

-24V OUTPUT VOLTAGE

vs. LOAD CURRENT

MAX1856 toc01

I

OUT1

(mA)

V

OUT1

(V)

VIN = 5V

VIN = 12V

VIN = 24V

V

OUT1

= -24V

V

OUT2

= -72V

I

OUT2

= 5mA

-74.5

-74.0

-73.0

-73.5

-72.5

-72.0

0 200100 300 400 500 600 700

-72V CROSS-REGULATION VOLTAGE

vs. LOAD CURRENT

MAX1856 toc02

I

OUT1

(mA)

V

OUT2

(V)

VIN = 5V

VIN = 24V

V

OUT1

= -24V

V

OUT2

= -72V

I

OUT2

= 5mA

VIN = 12V

50

60

70

90

80

100

0 100 200 300 400 500 600 700

EFFICIENCY vs. LOAD CURRENT

(-24V OUTPUT)

MAX1856 toc03

I

OUT1

(mA)

EFFICIENCY (%)

V

OUT1

= -24V

V

OUT2

= -72V

I

OUT2

= 5mA

VIN = 5V

VIN = 24V

VIN = 12V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Minimum SYNC Input Signal

Duty Cycle

Minimum SYNC Input

Low Pulse Width

SYNC Input Frequency Range f

SYNC/SHDN Input High Voltage V

SYNC/SHDN Input Low Voltage V

SYNC/SHDN Input Current

EXT On-Resistance R

SYNC

IH

IL

ON(EXT

R

= 100kΩ ±1% 86 94

OSC

R

= 200kΩ ±1% 87 93Maximum Duty Cycle D

OSC

= 500kΩ ±1% 86 94

R

OSC

V

SYNC/SHDN

V

SYNC/SHDN

= 5V 3.0

= 28V 10

EXT high or low 5 Ω

%

45 %

200 ns

100 500 kHz

2.0 V

0.45 V

µA

Page 5

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

_______________________________________________________________________________________ 5

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VCC= V

SYNC/SHDN

= 12V, V

OUT1

= -24V, V

OUT2

= -72V, R

OSC

= 200kΩ, unless otherwise noted.)

-74

-73

-72

-71

-70

0 50 100 150 200 250

-72V OUTPUT VOLTAGE

vs. LOAD CURRENT

MAX1856 toc04

I

OUT2

(mA)

V

OUT2

(V)

V

OUT1

= -24V

V

OUT2

= -72V

I

OUT1

= 5mA

VIN = 5V

VIN = 24V

VIN = 12V

-24.0

-23.8

-23.4

-23.6

-23.2

-23.0

010050 150 200 250

-24V CROSS-REGULATION VOLTAGE

vs. LOAD CURRENT

MAX1856 toc05

I

OUT2

(mA)

V

OUT1

(V)

V

OUT1

= -24V

V

OUT2

= -72V

I

OUT1

= 5mA

VIN = 5V

VIN = 24V

VIN = 12V

50

60

70

80

90

100

010050 150 200 250

EFFICIENCY vs. LOAD CURRENT

(-72V OUTPUT)

MAX1856 toc06

I

OUT2

(mA)

EFFICIENCY (%)

V

OUT1

= -24V

V

OUT2

= -72V

I

OUT1

= 5mA

VIN = 5V

VIN = 24V

VIN = 12V

-24V OUTPUT VOLTAGE

vs. INPUT VOLTAGE

-23.0

V

= -24V

OUT1

= 100mA

I

VIN (V)

V

I

OUT1

OUT2

OUT2

= -72V

= 100mA

-23.2

-23.4

(V)

OUT1

V

-23.6

-23.8

-24.0

V

= -24V

OUT1

= 50mA

I

OUT1

= -72V

V

OUT2

= 50mA

I

OUT2

0105152025

MAX1856 toc07

-72V OUTPUT VOLTAGE

-71.0

-71.4

-71.8

(V)

OUT1

V

-72.2

V

OUT1

= 50mA

I

-72.6

-73.0

OUT1

V

OUT2

= 50mA

I

OUT2

0105152025

vs. INPUT VOLTAGE

V

OUT1

= 100mA

I

OUT1

V

OUT2

= 100mA

I

OUT2

= -24V

= -72V

VIN (V)

100

= -24V

MAX1856 toc08

90

= -72V

80

70

EFFICIENCY (%)

60

50

0105152025

DUAL-OUTPUT EFFICIENCY

vs. INPUT VOLTAGE

V

OUT1

= 100mA

I

OUT1

V

OUT2

= 100mA

I

OUT2

V

= -24V

OUT1

= 50mA

I

OUT1

= -72V

V

OUT2

= 50mA

I

OUT2

VIN (V)

= -24V

= -72V

MAX1856 toc09

-48V OUTPUT VOLTAGE

-46.5

VIN = 5V

-46.9

-47.3

(V)

OUT2

V

-47.7

-48.1

-48.5

0 100 200 300 400

SUPPLY CURRENT

vs. INPUT VOLTAGE

vs. LOAD CURRENT

EFFICIENCY vs. LOAD CURRENT

(-48V OUTPUT)

100

250

VIN = 12V

MAX1856 toc10

90

VIN = 12V

MAX1856 toc11

200

VIN = 5V

80

150

VIN = 24V

70

EFFICIENCY (%)

V

= -48V

OUT

FIGURE 4

I

(mA)

OUT2

60

50

0 100 200 300 400

I

OUT2

(mA)

VIN = 24V

V

OUT

FIGURE 4

= -48V

100

SUPPLY CURRENT (µA)

50

CURRENT INTO VCC PIN

R

0

0105 15202530

OSC

INPUT VOLTAGE (V)

MAX1856 toc12

= 500kΩ

Page 6

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

6 _______________________________________________________________________________________

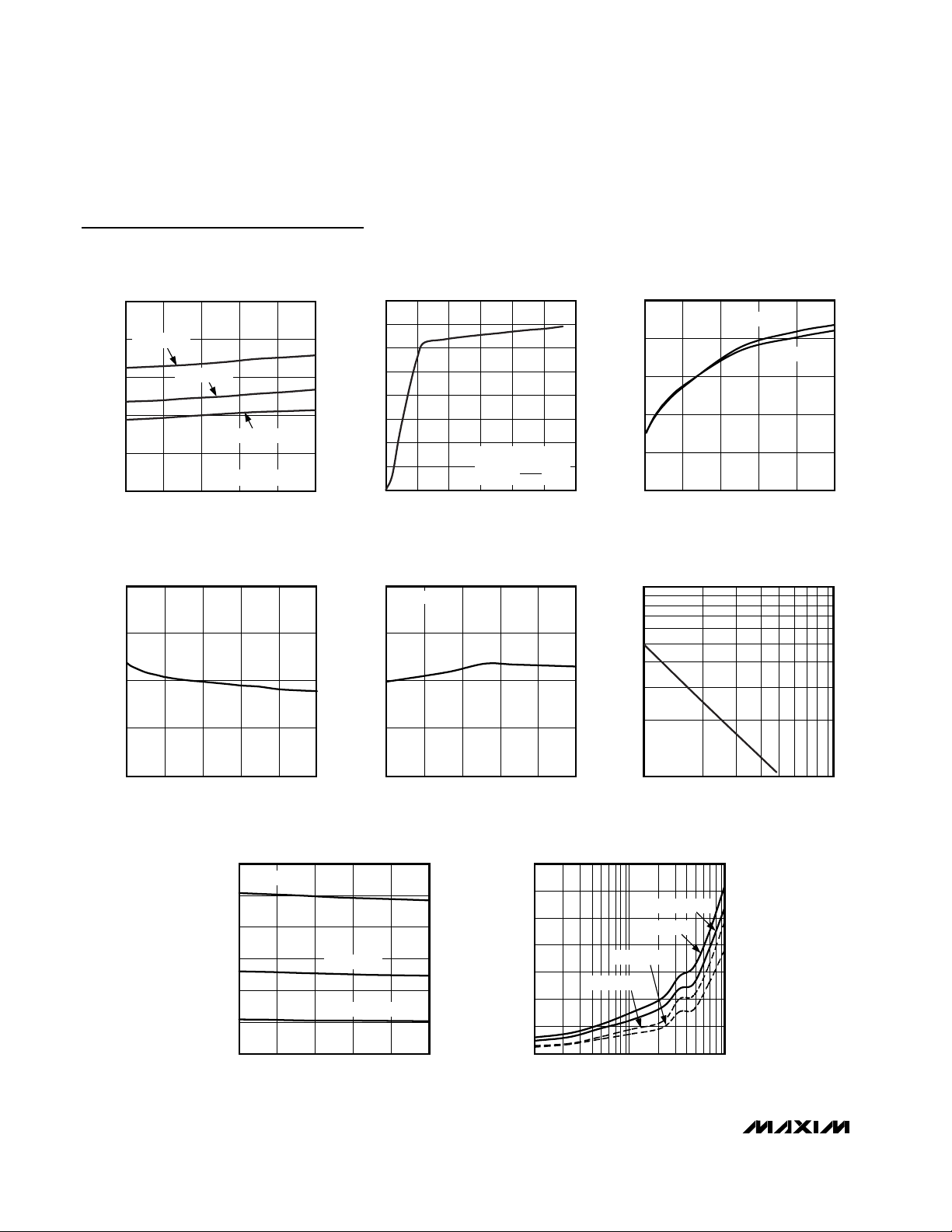

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VCC= V

SYNC/SHDN

= 12V, V

OUT1

= -24V, V

OUT2

= -72V, R

OSC

= 200kΩ, unless otherwise noted.)

1.240

1.250

1.245

1.255

1.260

REFERENCE VOLTAGE

vs. REFERENCE CURRENT

MAX1856 toc16

REFERENCE CURRENT (µA)

V

REF

(V)

0 200100 300 500

400

1.240

1.250

1.245

1.255

1.260

REFERENCE VOLTAGE

vs. TEMPERATURE

MAX1856 toc17

TEMPERATURE (°C)

V

REF

(V)

-40 10-15 35 85

60

NO LOAD

1000

100

100 1000

SWITCHING FREQUENCY vs. R

OSC

MAX1856 toc18

R

OSC

(kΩ)

SWITCHING FREQUENCY (kHz)

0

200

100

400

300

500

600

-40 10-15 35 60 85

SWITCHING FREQUENCY

vs. TEMPERATURE

MAX1856 toc19

TEMPERATURE (°C)

SWITCHING FREQUENCY (kHz)

R

OSC

= 100kΩ

R

OSC

= 200kΩ

R

OSC

= 500kΩ

70

0

0.1 1 10

EXT RISE/FALL TIME

vs. CAPACITANCE

10

MAX1856 toc20

CAPACITANCE (nF)

EXT RISE/FALL TIME (ns)

30

50

60

40

20

t

RISE

, VIN = 5V

t

RISE

, VIN = 3.3V

t

FALL

, VIN = 5V

t

FALL

, VIN = 3.3V

150

190

270

230

310

350

-40 10-15 35 60 85

SUPPLY CURRENT

vs. TEMPERATURE

MAX1856 toc13

TEMPERATURE (°C)

SUPPLY CURRENT (µA)

R

OSC

= 100kΩ

R

OSC

= 200kΩ

R

OSC

= 500kΩ

CURRENT INTO VCC PIN

0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

0105 15202530

SHUTDOWN CURRENT

vs. INPUT VOLTAGE

MAX1856 toc14

INPUT VOLTAGE (V)

SHUTDOWN CURRENT (µA)

CURRENT INTO VCC PIN

R

OSC

= 500kΩ

SYNC/SHDN = GND

0

50

150

100

200

250

0426810

LDO DROPOUT VOLTAGE

vs. LOAD CURRENT

MAX1856 toc15

I

LDO

(mA)

DROPOUT VOLTAGE (V)

VIN = 5V

VIN = 3.3V

Page 7

A. V

OUT

= -48V, I

OUT

= 200mA, 50mV/div

B. I

LP

, 2A/div

CIRCUIT OF FIGURE 4

HEAVY-LOAD SWITCHING WAVEFORM

MAX1856 toc23

-47.2V

-47.0V

-47.1V

2A

0

2.0µs/div

A

B

4A

A. V

OUT

= -48V, I

OUT

= 20mA, 20mV/div

B. I

LP

, 2A/div

CIRCUIT OF FIGURE 4

LIGHT-LOAD SWITCHING WAVEFORM

MAX1856 toc24

-47.80V

-47.72V

-47.76V

2A

0

4µs/div

A

B

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

_______________________________________________________________________________________ 7

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VCC= V

SYNC/SHDN

= 12V, V

OUT1

= -24V, V

OUT2

= -72V, R

OSC

= 200kΩ, unless otherwise noted.)

EXITING SHUTDOWN

5V

0

2A

0

0

-20V

-40V

-60V

A. V

SYNC/SHDN

, 2A/div

B. I

LP

C. V

OUT

CIRCUIT OF FIGURE 4

= -48V, R

4ms/div

= 0 TO 5V, 5V/div

= 2.4kΩ, 20V/div

OUT

MAX1856 toc21

A

B

C

5V

0

5V

0

2A

0

200mA

0

-47.1V

-47.6V

-48.1V

ENTERING SHUTDOWN

A. V

B. V

C. I

V

OUT

CIRCUIT OF FIGURE 4

SYNC/SHDN

, 5V/div

EXT

, 2A/div

LP

= -48V, R

= 5V TO 0, 5V/div

= 240Ω

OUT

LOAD TRANSIENT

10µs/div

MAX1856 toc22

MAX1856 toc25

A

B

C

A

B

C

14V

12V

10V

-47V

LINE TRANSIENT

MAX1856 toc26

A

B

A. I

= 20mA TO 200mA, 200mA/div

OUT

, = -48V, 500mV/div

B. V

OUT

, 2A/div

C. I

LP

CIRCUIT OF FIGURE 4

1ms/div

A. V

= 10V TO 14V, 2Vdiv

IN

= -48V, I

B. V

OUT

CIRCUIT OF FIGURE 4

400µs/div

= 200mA, 100mV/div

OUT

RINGER TO TALK-BATTERY CROSSTALK

60

RINGER OUTPUT

MAX1856 toc27

TALK-BATTERY OUTPUT

FREQUENCY (Hz)

40

20

0

-20

(dB)

-40

-60

-80

-100

0 50 100 150 200 250

Page 8

MAX1856

Detailed Description

The MAX1856 current-mode PWM controller uses an

inverting flyback configuration that is ideal for generating the high negative voltages required for SLIC power

supplies. Optimum conversion efficiency is maintained

over a wide range of loads by employing both PWM

operation and Maxim’s proprietary Idle Mode control to

minimize operating current at light loads. Other features

include shutdown, adjustable internal operating frequency or synchronization to an external clock, softstart, adjustable current limit, and a wide (3V to 28V)

input range.

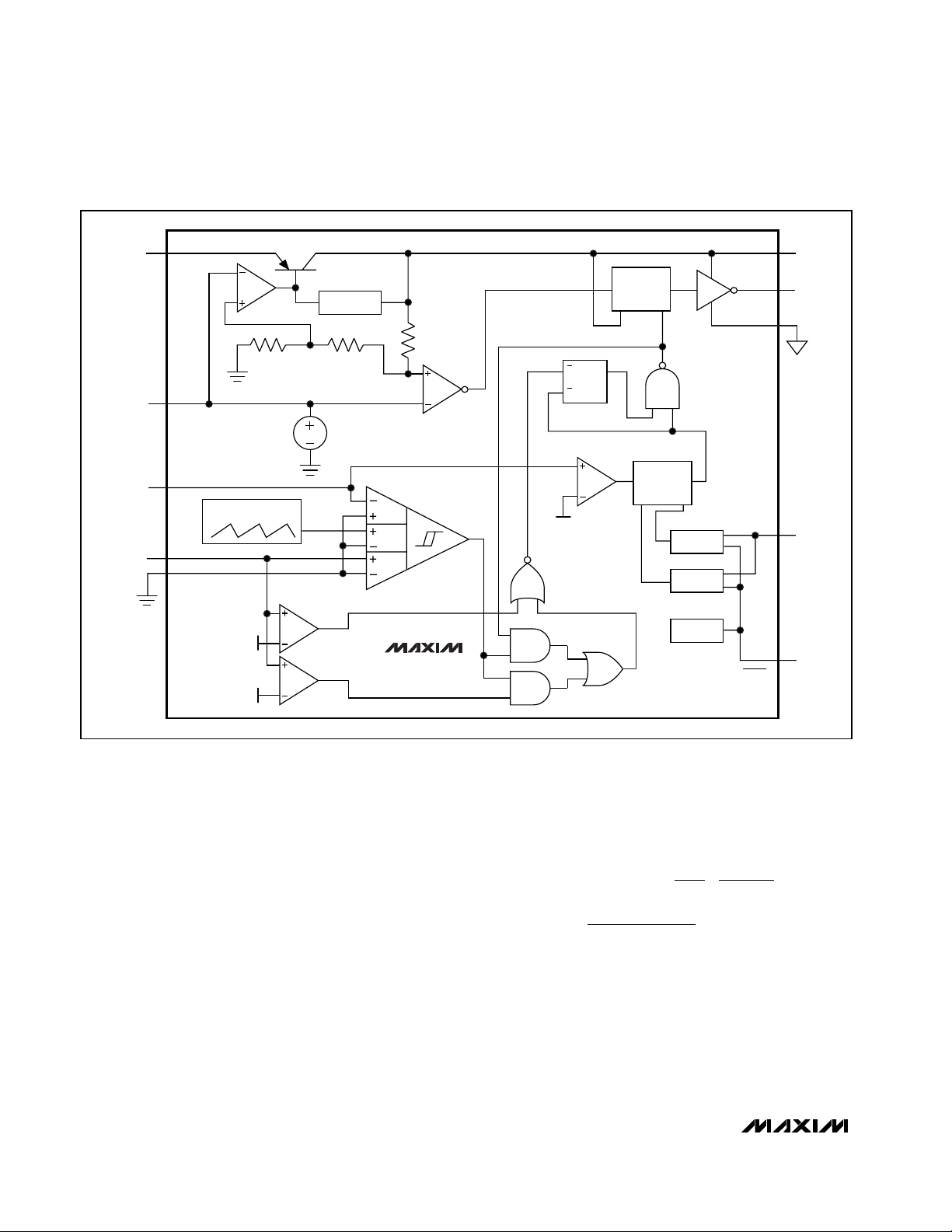

PWM Controller

The heart of the MAX1856 current-mode PWM controller is a BiCMOS multi-input comparator that simultaneously processes the output-error signal, the

current-sense signal, and a slope-compensation ramp

(Figure 2). The main PWM comparator is direct summing, lacking a traditional error amplifier and its associ-

ated phase shift. The direct-summing configuration

approaches ideal cycle-by-cycle control over the output voltage since there is no conventional error amplifier in the feedback path.

In PWM mode, the controller uses fixed-frequency, current-mode operation where the duty ratio is set by the

input-to-output voltage ratio and the transformer’s turn

ratio. The current-mode feedback loop regulates peak

inductor current as a function of the output error signal.

At light loads, the controller enters Idle Mode. During

Idle Mode, switching pulses are provided only as necessary to supply the load, and operating current is minimized to provide the best light-load efficiency. The

minimum-current comparator threshold is 15mV, or

15% of the full-load value (I

MAX

) of 100mV. When the

controller is synchronized to an external clock, Idle

Mode occurs only at very light loads.

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

8 _______________________________________________________________________________________

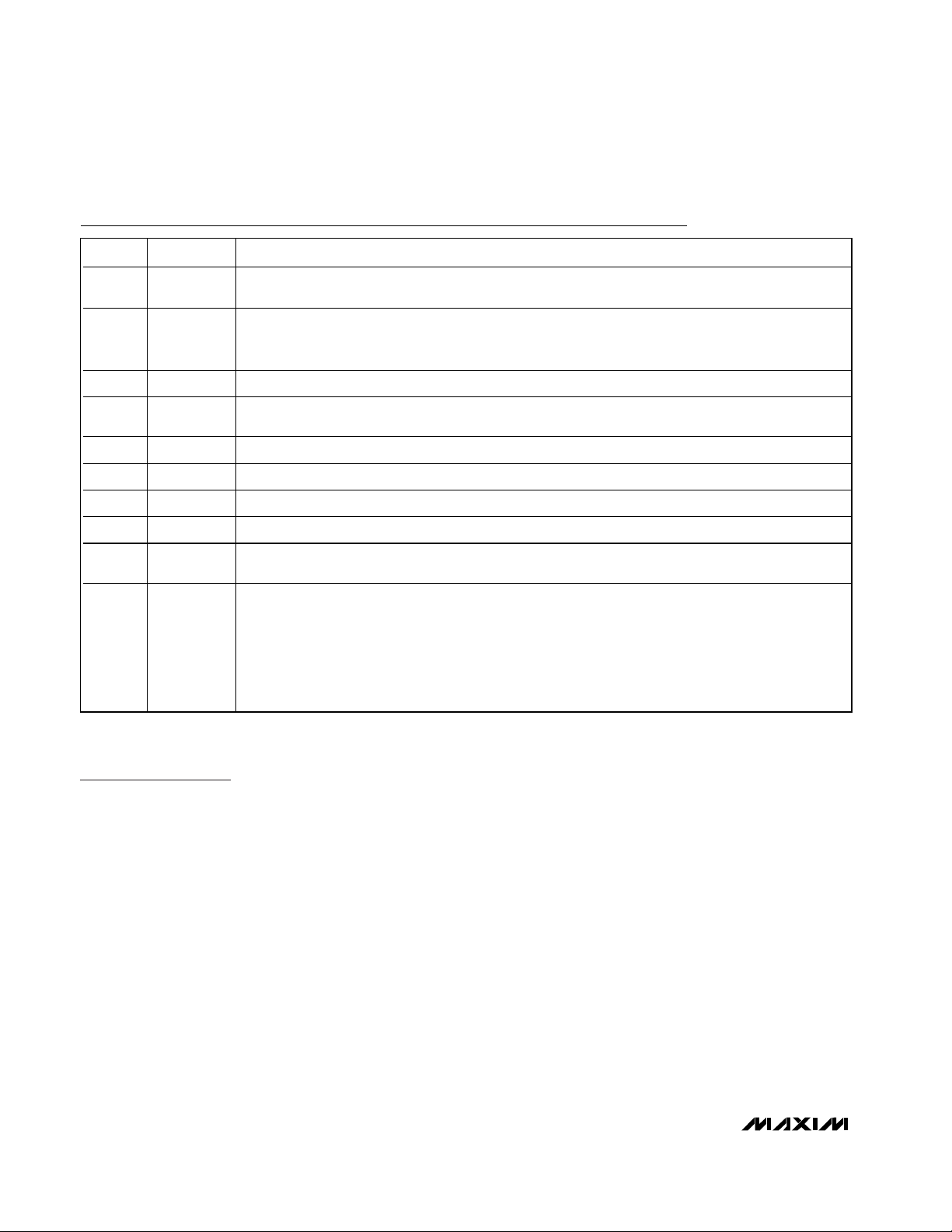

Pin Description

PIN NAME FUNCTION

1LDO

2 FREQ

3 GND Analog Ground

4 REF 1.25V Reference Output. REF can source up to 400µA. Bypass to GND with a 2.2µF ceramic capacitor.

5 FB Feedback Input. The feedback voltage threshold is 0.

6 CS Positive Current-Sense Input. Connect a current-sense resistor (RCS) between CS and PGND.

7 PGND Power Ground

8 EXT External MOSFET Gate-Driver Output. EXT swings from LDO to PGND.

9V

10 SYNC/SHDN

CC

5V Linear Regulator Output. The regulator powers all of the internal circuitry, including the EXT gate

driver. Bypass LDO to GND with a 1µF or greater ceramic capacitor.

OSC

OSC

when

=

Oscillator Frequency Set Input. A resistor from FREQ to GND sets the oscillator from 100kHz (R

500kΩ) to 500kHz (R

an external clock is connected to SYNC/SHDN.

Input Supply to the Linear Regulator. VCC accepts inputs up to 28V. Bypass to PGND with a 1µF

ceramic capacitor.

Shutdown Control and Synchronization Input. There are three operating modes:

• SYNC/SHDN low: shutdown mode

• SYNC/SHDN high: the DC-to-DC controller operates with the oscillator frequency set at FREQ by

R

OSC

• SYNC/SHDN clocked: the DC-to-DC controller operates with the oscillator frequency set by the SYNC

clock input. The conversion cycles initiate on the rising edge of the input clock signal. However, the

MAX1856 still requires R

= 100kΩ): f

OSC

= 50MΩ-kHz / R

OSC

when SYNC/SHDN is externally clocked.

OSC

. The MAX1856 still requires R

OSC

Page 9

Low-Dropout Regulator (LDO)

All MAX1856 functions, including EXT, are internally

powered from the on-chip, low-dropout 5V regulator.

The regulator input is at VCC, while its output is at LDO.

The VCC-to-LDO dropout voltage is typically 200mV

(300mV max at 12mA), so that when VCCis <5.2V,

V

LDO

is typically VCC- 200mV. When the LDO is in

dropout, the MAX1856 still operates with VCCas low as

3V (as long as the LDO exceeds 2.7V), but with

reduced amplitude FET drive at EXT. The maximum

VCCinput voltage is 28V.

LDO can supply up to 12mA to power the IC, supply

gate charge through EXT to the external FET, and supply small external loads. When driving particularly large

FETs at high switching rates, little or no LDO current

may be available for external loads. For example, when

switched at 500kHz, a large FET with 20nC gate charge

requires 20nC ✕500kHz, or 10mA.

Soft-Start

The MAX1856 features a “digital” soft-start that is preset and requires no external capacitor. Upon startup,

the peak inductor current increments from 1/5th of the

value set by RCS, to the full current-limit value in five

steps over 1024 cycles of f

OSC

or f

SYNC

. Additionally,

the oscillator runs at 1/3 the normal operating frequency (f

OSC

/3) until the output voltage reaches 20% of its

nominal value (V

FB

≤ 1.0V). See the Typical Operating

Characteristics for a scope picture of the soft-start

operation. Soft-start is implemented: 1) when power is

first applied to the IC, 2) when exiting shutdown with

power already applied, and 3) when exiting undervoltage lockout. The MAX1856’s soft-start sequence does

not start until V

LDO

reaches 2.5V.

Design Procedure

The MAX1856 can operate within a wide input voltage

range from 3V to 28V. This allows it to be used with wall

adapters. In applications driven by low-power, low-cost

and low input and output ripple current requirements,

the MAX1856 flyback topology can be used to generate various levels of output voltages and multiple outputs.

Communications over the Internet interface with a standard telephone connection, which includes the

Subscriber Line Interface Circuit (SLIC). The SLIC

requires a negative power supply for the audio and

ringer functions. The circuits discussed here are

designed for these applications. The following design

discussions are related to the standard application cir-

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

_______________________________________________________________________________________ 9

Figure 1. Standard Application Circuit

*INPUT

4.5V TO 24V

*INPUT RANGE LIMITED BY OUTPUT POWER REQUIREMENTS.

SEE MAXIMUM OUTPUT POWER AND TYPICAL OPERATING CHARACTERISTICS.

10Ω

C4

1µF

C

LDO

1µF

R

OSC

200kΩ

R5

9

V

10

SYNC/SHDN

1

LDO

2

FREQ

3

GND

7

PGND

CC

MAX1856

C

(2x) 10µF

25V

8

EXT

6

CS

5

FB

4

REF

IN

R6

100Ω

C5

1nF

R3

5.11kΩ

C

REF

2.2µF

T1

1

M1

R

CS

33mΩ

C

FB

1nF

D1, D2: Central Semiconductor CMR1U-02

M1: International Rectifier IRLL2705

T1: Coiltronics CTX01-14853

D2

2

2

D1

2

R2

681kΩ

R4

470Ω

C3

100pF

R1

174kΩ

OUT2

-72V

C2

100µF

Sanyo

100MV100AX

OUT1

-24V

C1

330µF

Sanyo

35MV330AX

Page 10

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

10 ______________________________________________________________________________________

cuit (Figure 1) converting a +12V input to a -72V output

(maximum load 100mA) and a -24V output (maximum

load 400mA).

Maximum Output Power

The maximum output power the MAX1856 can provide

depends on the maximum input power available and

the circuit’s efficiency:

Furthermore, the efficiency and input power are both

functions of component selection. Efficiency losses can

be divided into three categories: 1) resistive losses

across the transformer, MOSFET’s on-resistance, current-sense resistor, and the ESR of the input and output

capacitors; 2) switching losses due to the MOSFET’s

transition region, the snubber circuit, which also

increases the transition times, and charging the MOSFET’s gate capacitance; and 3) transformer core loss-

es. Typically, 80% efficiency can be assumed for initial

calculations. The input power depends on the current

limit, input voltage, output voltage, inductor value, the

transformer’s turns ratio, and the switching frequency:

where N

P:NS

is the transformer’s turns ratio.

Setting the Operating Frequency

(SYNC/SHDN and FREQ)

The SYNC/SHDN pin provides both external-clock synchronization (if desired) and shutdown control. When

SYNC/SHDN is low, all IC functions are shut down. A

logic high at SYNC/SHDN selects operation at a

Figure 2. Functional Diagram

V

9

CC

REF

4

5

FB

6

CS

3

GND

R3

276kΩ

SLOPE COMP

100mV

15mV

ANTISAT

R2

276kΩ

V

REF

1.25V

I

I

MAX

MIN

X6

X1

X1

MAX1856

R1

552kΩ

1.0V

LDO

1

MUX

01

R

Q

S

MUX

1

0

F

OSC

F

/3

OSC

BIAS

EXT

PGND

FREQ

SYNC/SHDN

8

7

2

10

P EFFICIENCY P

OUT MAX IN MAX() ()

=×

PVD

IN MAX IN

()

NV

=

D

NV NV

P OUT S IN

V

CS

=−

R

CS

P OUT

+

VD

ƒ

2

IN

OSC

L

Page 11

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

______________________________________________________________________________________ 11

100kHz to 500kHz frequency, which is set by a resistor

(R

OSC

) connected from FREQ to GND. The relationship

between f

OSC

and R

OSC

is:

Thus, a 250kHz operating frequency, for example, is

set with R

OSC

= 200kΩ. At higher frequencies, the

magnetic components will be smaller. Peak currents

and, consequently, resistive losses will be lower at the

higher switching frequency. However, core losses, gate

charge currents, and switching losses increase with

higher switching frequencies.

Rising clock edges on SYNC/SHDN are interpreted as

synchronization input. If the sync signal is lost while

SYNC/SHDN is high, the internal oscillator takes over at

the end of the last cycle, and the frequency is returned

to the rate set by R

OSC

. If the signal is lost with

SYNC/SHDN low, the IC waits for 50µs before shutting

down. This maintains output regulation even with intermittent sync signals. When an external sync signal is

used, Idle Mode switchover at the 15mV current-sense

threshold is disabled so that Idle Mode only occurs at

very light loads. Also, R

OSC

should be set for a fre-

quency 15% below the SYNC clock rate:

Setting the Output Voltage

Set the output voltage using two external resistors forming a resistive divider to FB between the output and

REF. First select a value for R3 between 3.3kΩ and

100kΩ. R1 is then given by:

For a dual output as shown in Figure 1, a split feedback

technique is recommended. Since the feedback voltage threshold is 0, the total feedback current is:

Since the feedback resistors are connected to the reference, I

TOTAL

must be <400µA so that V

REF

is guaranteed to be in regulation (see Electrical Characteristics

Table). Therefore, select R3 so the total current value is

between 200µA and 250µA as shown in Figure 1. To

ensure that the MAX1856 regulates both outputs with

the same degree of accuracy over load, select the

feedback resistors (R1 and R2) so their current ratio

(I

R1:IR2

) equals the output power ratio (P

OUT1:POUT2

)

under full load:

Once R3 and the dual feedback currents (I

R1

and IR2)

are determined from the two equations above, use the

following two equations to determine R1 and R2:

Selecting the Transformer

The MAX1856 PWM controller works with economical

off-the-shelf transformers. The transformer selection

depends on the input-to-output voltage ratio, output

current capacity, duty cycle, and oscillator frequency.

Table 1 shows recommended transformers for the typical applications, and Table 2 gives some recommended suppliers.

Transformer Turns Ratio

The transformer turns ratio is a function of the input-tooutput voltage ratio and maximum duty cycle. Under

steady-state conditions, the change in flux density during the on-time must equal the return change in flux

density during the off-time (or flyback period):

For example, selecting a 50% duty cycle for the standard application circuit (Figure 1) and a +12V input

voltage, the -72V output requires a 1:6 turns ratio, and

the -24V output requires a 1:2 turns ratio. Therefore, a

transformer with a 1:2:2:2 turns ratio was selected.

Primary inductance

The average input current at maximum load can be calculated as:

where η = efficiency. For V

OUT

= -24V, I

OUT(MAX)

=

400mA, and V

IN(MIN)

= 10.8V as shown in Figure 1, this

R

OSC

=

M kHz

50 Ω

ƒ

OSC

×

kHz

()

R

OSC SYNC

()

M kHz

×

50

=

Ω

ƒ

OSC

kHz

.()

085

RR

13=

V

OUT

V

REF

III

=+=

TOTAL R R

12

V

REF

3

R

VI

I

OUT OUT

R

1

=

I

VI

R

OUT OUT

2

11

22

V

OUT

I

==

R

1

12

R

1

and I

V

OUT

R

2

2

R

VtNVt

IN ONPOUT OFF

=

N

S

I

IN DC

VI

=

()

OUT OUT MAX

η

V

IN MIN

()

()

Page 12

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

12 ______________________________________________________________________________________

gives 1.11A for 80% efficiency. With a duty cycle of

52.5%, the average switch current (I

SW(AVG)

) is 2.114A.

Choosing a primary inductance ripple current ∆ILto be

40% of the average switch current, the primary inductance is given by:

Selecting f

OSC

= 250kHz and ∆IL= 0.4 x I

SW(AVG)

=

0.846A, the primary inductance value is 27µH, and the

peak primary current for this example is therefore 2.5A.

Core Selection

The transformer in a flyback converter is a coupled

inductor with multiple windings on the same magnetic

core. Flyback topologies operate by storing energy in

the transformer magnetics during the on-time and

transferring this energy to the output during the offtime.

Core selection depends on the core’s power-handling

capability. The required output power is first considered. For example, the standard application circuit

requires 9.6W. Assuming a typical 80% efficiency, the

transformer must support 12W of power. The core

material’s properties, the core’s shape, and the size of

the air gap determine the core’s power rating. Since the

equations relating these properties to the power capability are involved, manufacturers simply provide charts

giving “Power vs. Frequency” for different core sizes.

For the standard application circuit (f

OSC

= 250kHz),

the EFD15 core from Coiltronics meets the criteria.

Once the core is chosen, the number of turns in the primary is given by:

where A

L

is the inductance factor. Ensure that the num-

ber of ampere-turns (NPI

SAT

) is below the saturation

limit. A significant portion of the total energy is stored in

the air gap. Therefore, the larger the air gap, the lower

the ALvalue and the larger the number of ampere-turns

at which saturation starts. Some manufacturers define

saturation as the current at which the inductance

decreases by 30%.

Current-Sense Resistor Selection

Once the peak inductor current is determined, the current-sense resistor (RCS) is determined by:

Kelvin-sensing should be used to connect CS and

PGND to R

CS

. Connect PGND and GND together at the

ground side of RCS.

Due to inductive ringing after the MOSFET turns on, a

lowpass filter may be required between R

CS

and CS to

prevent the noise from tripping the current-sense comparator. Connect a 100Ω resistor between CS and the

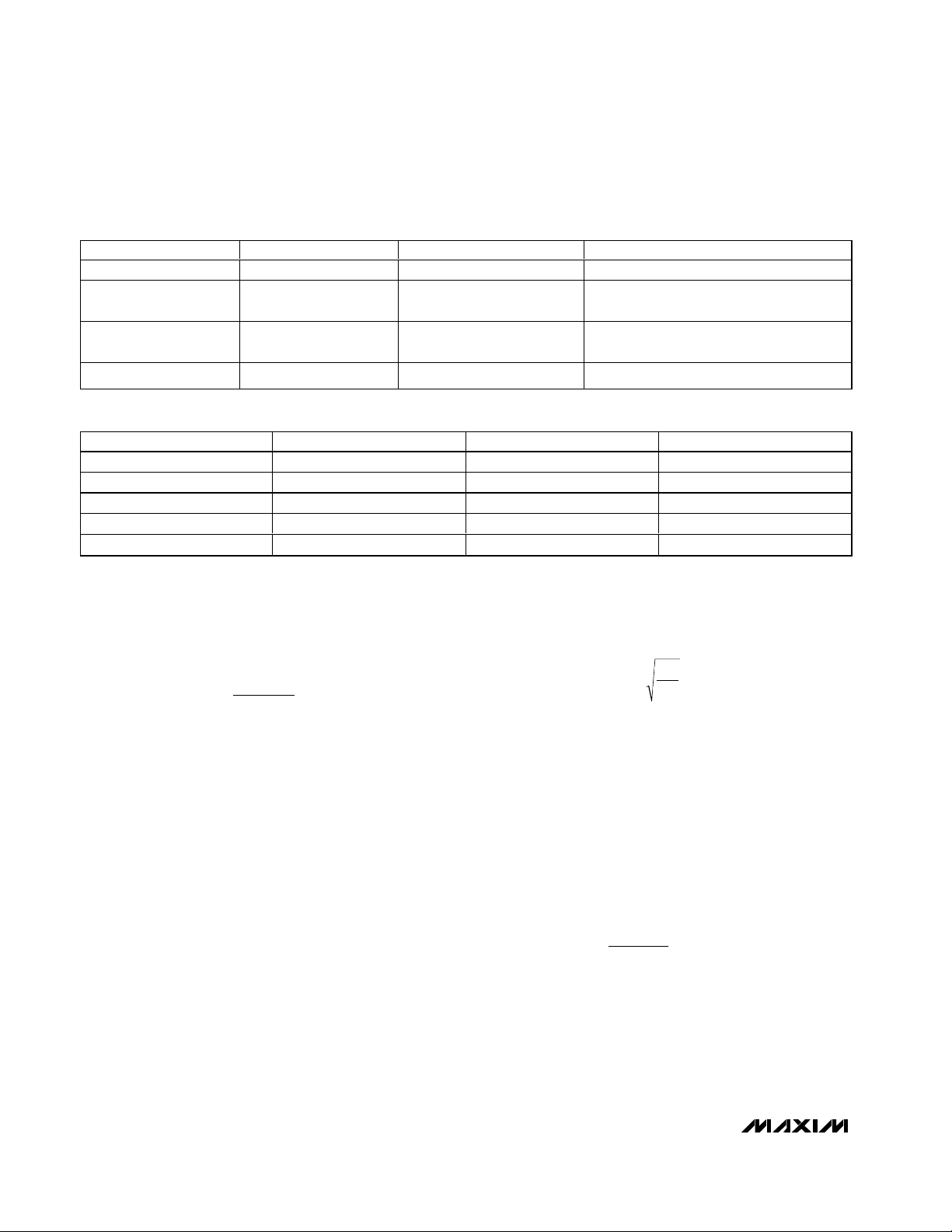

Table 1. Transformer Selection for Standard Applications

Table 2. Transformer Suppliers

INPUT VOLTS (V) OUTPUT VOLTS (V) OUTPUT CURRENT (mA) TRANSFORMER (VENDOR)

5 -48 100 VP3-0055 (Coiltronics)

12 -48 100

12 -24 and -72 400 or 100

12 -95 and -30 320 and 150 CTX03-15220 (Coiltronics)

CTX01-14853 (Coiltronics), or

ICA-0635 (ICE Components)

CTX01-14853 (Coiltronics), or

ICA-0635 (ICE Components)

Coilcraft 847-639-6400 847-639-1469 www.coilcraft.com

Coiltronics 888-414-2645 561-241-9339 www.coiltronics.com

ICE Components 800-729-2099 703-257-7547 www.icecomponents.com

Pulse Engineering 858-674-8100 858-674-8262 www.pulseeng.com

TDK 847-390-4461 847-390-4405 www.tdk.com

VENDOR USA PHONE USA FAX INTERNET

VD

P

=

∆ƒ

IN

I

L OSC

L

L

N

P

=

P

A

L

V

CS MIN

R

CS

()

==

I

LPEAK

mV I

/85

LPEAK

Page 13

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

______________________________________________________________________________________ 13

high side of RCS, and connect a 1000pF capacitor

between CS and GND.

Power MOSFET Selection

The MAX1856 drives a wide variety of N-channel power

MOSFETs (NFETs). Since the LDO limits the EXT output

gate drive to no more than 5V, a logic-level NFET is

required. Best performance, especially with input voltages below 5V, is achieved with low-threshold NFETs

that specify on-resistance with a gate-to-source voltage

(VGS) of 2.7V or less. When selecting an NFET, key

parameters include:

1) Total gate charge (Q

G

)

2) Reverse transfer capacitance or charge (C

RSS

)

3) On-resistance (R

DS(ON)

)

4) Maximum drain-to-source voltage (V

DS(MAX)

)

5) Minimum threshold voltage (V

TH(MIN)

)

At high switching rates, dynamic characteristics (parameters 1 and 2 above) that predict switching losses

may have more impact on efficiency than R

DS(ON)

,

which predicts DC losses. QGincludes all capacitance

associated with charging the gate. In addition, this

parameter helps predict the current needed to drive the

gate at the selected operating frequency. The continuous LDO current for the FET gate is:

For example, the IRLL2705 has a typical Q

G

of 17nC

(at VGS= 5V); therefore, the I

GATE

current at 500kHz is

8.5mA.

The switching element in a flyback converter must have

a high enough voltage rating to handle the input voltage plus the reflected secondary voltage, as well as

any spikes induced by leakage inductance. The reflected secondary voltage is given by:

where V

DIODE

is the voltage drop across the output

diode. For a 10% variation in input voltage and a 30%

safety margin, this gives a required 33V voltage rating

(VDS) for the switching MOSFET in Figure 1. The

IRLL2705 with a VDSof 55V was chosen.

Diode Selection

The MAX1856’s high switching frequency demands a

high-speed rectifier. Schottky diodes are recommended for most applications because of their fast recovery

time and low forward voltage. Ensure that the diode’s

average current rating exceeds the peak secondary

current, using the diode manufacturer’s data or approximating it with the following formula:

where N = N

s/NP

is the secondary-to-primary turns

ratio. Additionally, the diode’s reverse breakdown voltage must exceed V

OUT

plus the reflected input voltage

plus the leakage inductance spike. For high output voltages (50V or above), Schottky diodes may not be practical because of this voltage requirement. In these

cases, use a faster ultra-fast recovery diode with adequate reverse-breakdown voltage.

Capacitor Selection

Output Filter Capacitor

The output capacitor (C

OUT

) does all the filtering in a fly-

back converter. Typically, C

OUT

must be chosen based

on the output ripple requirement. The output ripple is

due to the variations in the charge stored in the output

capacitor with each pulse and the voltage drop across

the capacitor’s equivalent series resistance (ESR)

caused by the current into and out of the capacitor. The

ESR-induced ripple usually dominates, so output capacitor selection is actually based upon the capacitor’s

ESR, voltage rating, and ripple current rating.

Input Filter Capacitor

The input capacitor (CIN) in flyback designs reduces

the current peaks drawn from the input supply and

reduces noise injection. The value of CINis largely

determined by the source impedance of the input supply. High source impedance requires high input capacitance, particularly as the input voltage falls. Since

inverting flyback converters act as “constant-power”

loads to their input supply, input current rises as the

input voltage falls. Consequently, in low-input-voltage

designs, increasing C

IN

and/or lowering its ESR can

add as much as 5% to the conversion efficiency.

Bypass Capacitors

In addition to C

IN

and C

OUT

, three ceramic bypass

capacitors are also required with the MAX1856. Bypass

REF to GND with 2.2µF or more. Bypass LDO to GND

with 1µF or more. And bypass VCCto GND with 1µF or

more. All bypass capacitors should be located as close

to their respective pins as possible.

Compensation Capacitor

Output ripple voltage due to C

OUT

ESR affects loop

stability by introducing a left half-plane zero. A small

capacitor connected from FB to GND forms a pole with

IQ

GATE G OSC

=׃

II

D PK OUT

()

=+

1

NV

V

OUT

×

IN

∆

I

L

+

2

N

V

REFLECT

N

P

=+

VV

()

N

S

OUT DIODE

Page 14

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

14 ______________________________________________________________________________________

the feedback resistance that cancels the ESR zero. The

optimum compensation value is:

where R1 and R3 are feedback resistors (Figure 3). If

the calculated value for C

FB

results in a nonstandard

capacitance value, values from 0.5CFBto 1.5CFBwill

also provide sufficient compensation.

Snubber Design

The MAX1856 uses a current-mode controller that

employs a current-sense resistor. Immediately after

turn-on, the MAX1856 uses a 100ns current-sense

blanking period to minimize noise sensitivity. However,

when the MOSFET turns on, the secondary inductance

and the output diode’s parasitic capacitance form a

resonant circuit that causes ringing. Reflected back

through the transformer to the primary side, these oscillations appear across the current-sense resistor and

last well beyond the 100ns blanking period. As shown

in Figure 1, a series RC snubber circuit at the output

diode increases the damping factor, allowing the ringing to settle quickly. Applications with dual output voltages require only one snubber circuit on the higher

voltage output.

The diode’s parasitic capacitance can be estimated

using the diode’s reverse voltage rating (V

RRM

), current

capability (IO), and recovery time (tRR). A rough

approximation is:

For the CMR1U-02 Central Semiconductor diode used

in Figure 1, the capacitance is roughly 172pF. A value

less than this (100pF) was chosen since the output

snubber only needs to dampen the ringing, so the initial

turn-on spike that occurs during the 100ns blanking

period is still present. Larger capacitance values

require more charge, thereby increasing the power dissipation.

The snubber’s time constant (t

SNUB

) must be smaller

than the 100ns blanking time. A typical RC time constant of 50ns was chosen for Figure 1:

When a MOSFET with a transformer load is turned off,

the drain will fly to a high voltage as a result of the energy stored in the transformer’s leakage inductance.

During the switch on-time, current is established in the

leakage inductance (L

L

) equal to the peak primary cur-

rent (I

PEAK

). The energy stored in the leakage induc-

tance is:

When the switch turns off, this energy is transferred to

the MOSFET’s parasitic capacitance, causing a voltage

spike at the MOSFET’s drain. For the IRLL2705 MOSFET, the capacitance value (C

DS

) is 130pF. If all of the

leakage inductance energy transfers to this capacitance, the drain would fly up to:

The leakage inductance is (worst case) 1% of the primary inductance value. For a 0.27µH leakage inductance and a 2.5A peak current, the voltage reaches

114V at the MOSFET’s drain, which is much higher than

the MOSFET’s rated breakdown voltage. This causes

the parasitic bipolar transistor to turn on if the dv/dt at

the drain is high enough. Note that the inductive spike

adds on to the sum of the input voltage and the reflected secondary voltage already present at the drain of

the transistor (see Power MOSFET Selection).

A series combination RC snubber (R7 and C6 in Figure

3) across the MOSFET (drain to source) reduces this

spike. The energy stored in the leakage inductance

transfers to the snubber capacitor (C6) as electrostatic

energy. Therefore, C6 must be large enough to guarantee the voltage spike will not exceed the breakdown

voltage, but not so large as to result in excessive power

dissipation:

Typically, a 30% safety margin is chosen so that V

C6

is

at most equal to about 70% of the MOSFET’s VDSrating. For example, the V

DSS

is 55V for the IRLL2705, so

this gives a value of 1000pF for C9. The amount of

energy stored in snubber capacitor C6 has to discharge through series resistor R7 in the snubber network. During turn-off, the drain voltage rises in a time

period (tf) characteristic of the MOSFET used, which is

22ns for the IRLL2705. The RC time constant should

therefore equal this time. Hence:

1

CC

=

FB OUT

21313( )/( )

ESR

COUT

×+

RR RR

C

DIODE

=

It

ORR

V

RRM

t

SNUB

R

4

==

C

50

ns

3

3

C

L PEAK

2

2

LI

E

=

L

V

COSS

LI

=

L PEAK

C

DS

2

LI

C

6

=

L PEAK

2

V

6

C

2

Page 15

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

______________________________________________________________________________________ 15

This gives a value of about 22Ω for R7. However, this

snubber adds capacity to the MOSFET output, and this

in turn increases the dissipation in the MOSFET during

turn-on.

The selection of the input and output snubbers is an

interactive process. The design procedures above provide initial component recommendations, but the actual

values depend on the layout and transformer winding

practices used in the actual application.

Applications Information

Voice-over-IP CPE systems have +5V or +12V available

from which the talk battery voltage and the ringer voltage must be generated. The examples given below are

circuits using these supply voltages to generate the

negative power supplies needed in such applications.

Low Input Voltage

IP phones and routers require -48V. For cost-sensitive

applications, this needs to be used from an available

+5V supply. The circuit in Figure 4 is an example of

such a circuit using an off-the-shelf transformer from

Coiltronics and ICE components.

SLIC Power Supply with Split Feedback

Telephones in broadband systems use low-power-consuming SLICs that reduce the power drain by providing

the option of using two voltages for loop supervision.

The load on each output is dependent on the number

of lines on- or off-hook. The higher voltage is used to

generate ring battery voltage when the subscriber is onhook, while a second lower voltage is used to generate

talk battery voltage when off-hook is detected. The actual value of these two voltages can be adjusted based on

system requirements and the specific SLIC used. The

design given here specifically addresses the supply

requirements for the AMD79R79 SLIC device with onchip ringing. The input voltage is 12V nominal, and the

output voltages are -24V at 400mA and -72V at 100mA.

The transformer turns ratio is 1:2:2:2, where 24V appears

across each secondary winding. The -72V output is

derived from the -24V output by stacking the secondary

windings in series as shown in Figure 1. A split feedback

is used, using resistors R1, R2, and R3. This allows for

accurate regulation of both outputs (see Typical

Operating Characteristics).

Figure 3. Feedback Compensation and Snubber Circuits

INPUT

3V TO 28V

R5

9

V

CC

10

C4

C

LDO

R

OSC

t

ƒ

R

=

C76

SYNC/SHDN

1

LDO

2

FREQ

3

GND

7

PGND

MAX1856

EXT

CS

FB

REF

C

IN

M1

8

R6

6

C5

5

R3

4

C

REF

T1

R7

C6

R

CS

C

FB

D1

R4

C3

R1

OUTPUT

C1

Page 16

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

16 ______________________________________________________________________________________

Figure 4. -48V Output Application Circuit

INPUT

4.5V TO 24V

10Ω

C4

1µF

C

LDO

1µF

R

OSC

200kΩ

C

R5

9

V

CC

10

SYNC/SHDN

MAX1856

1

LDO

2

FREQ

3

GND

7

PGND

(2x) 10µF

25V

EXT

CS

FB

REF

IN

8

R6

100Ω

6

C5

1nF

5

R3

8.66kΩ

4

C

REF

2.2µF

T1

1

4

M1

R

CS

33mΩ

C

FB

1nF

D1: Central Semiconductor CMR1U-02

M1: International Rectifier IRLL2705

T1: ICE Components ICA-0635

D1

R4

220Ω

C3

330pF

R1

332kΩ

OUTPUT

-48V

C1

100µF

Sanyo

100MV100AX

Page 17

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

______________________________________________________________________________________ 17

Pin Configuration

Chip Information

TRANSISTOR COUNT: 1538

PROCESS: BiCMOS

TOP VIEW

LDO

FREQ

GND

1

2

MAX1856

3

4

5

µMAX

10

9

8

7

6

SYNC/SHDN

V

CC

EXT

PGNDREF

CSFB

Page 18

MAX1856

Wide Input Range, Synchronizable,

PWM SLIC Power Supply

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 18

© 2001 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

10LUMAX.EPS

Loading...

Loading...