Page 1

EVALUATION KIT AVAILABLE

19-6043; Rev 1; 3/12

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

General Description

The MAX17498A/MAX17498B/MAX17498C devices are

current-mode fixed-frequency flyback/boost converters

with a minimum number of external components. They

contain all the control circuitry required to design wide

input voltage isolated and nonisolated power supplies.

The MAX17498A has its rising/falling undervoltage lockout (UVLO) thresholds optimized for universal offline (85V

AC to 265V AC) applications, while the MAX17498B/

MAX17498C support UVLO thresholds suitable to lowvoltage DC-DC applications.

The switching frequency of the MAX17498A/MAX17498C

flyback converters is 250kHz, while that of the MAX17498B

flyback/boost converter is 500kHz. These frequencies

allow the use of tiny magnetic and filter components,

resulting in compact, cost-effective power supplies. An

EN/UVLO input allows the user to start the power supply

precisely at the desired input voltage, while also functioning as an on/off pin. The OVI pin enables implementation

of an input overvoltage-protection scheme that ensures

that the converter shuts down when the DC input voltage

exceeds the desired maximum value.

The devices incorporate a flexible error amplifier and an

accurate reference voltage (REF) to enable the end user to

regulate both positive and negative outputs. Programmable

current limit allows proper sizing and protection of the

primary switching FET. The MAX17498B supports a maximum duty cycle of 92% and provides programmable

slope compensation to allow optimization of control-loop

performance. The MAX17498A/MAX17498C support a

maximum duty cycle of 49%, and have fixed internal slope

compensation for optimum control-loop performance. The

devices provide an open-drain PGOOD pin that serves as a

power-good indicator and enters the high-impedance state

to indicate that the flyback/boost converter is in regulation. An SS pin allows programmable soft-start time for the

flyback/boost converter. Hiccup-mode overcurrent protection and thermal shutdown are provided to minimize

dissipation under overcurrent and overtemperature fault

conditions. The devices are available in a space-saving,

16-pin (3mm x 3mm) TQFN package with 0.5mm lead

spacing.

Ordering Information appears at end of data sheet.

Typical Application Circuits appears at end of data sheet.

Benefits and Features

S Peak Current-Mode Flyback/Boost Converter

S Current-Mode Control Provides Excellent

Transient Response

S Fixed Switching Frequency

250kHz (MAX17498A/MAX17498C)

500kHz (MAX17498B)

S Flexible Error Amplifier to Regulate Both Positive

and Negative Outputs

S Programmable Soft-Start to Reduce Input Inrush

Current

S Programmable Voltage or Current Soft-Start

S Power-Good Signal (PGOOD)

S Reduced Power Dissipation Under Fault

Hiccup-Mode Overcurrent Protection

Thermal Shutdown with Hysteresis

S Robust Protection Features

Flyback/Boost Programmable Current Limit

Input Overvoltage Protection

S Optimized Loop Performance

Programmable Slope Compensation for

Flyback /Boost Maximizes Obtainable Phase

Margin

S High Efficiency

175mI, 65V Rated n-Channel MOSFET Offers

Typical Efficiency Greater Than 80%

No Current-Sense Resistor

S Optional Spread Spectrum

S Space-Saving, 16-Pin (3mm x 3mm) TQFN

Package

Applications

Front-End AC-DC Power Supplies for Industrial

Applications (Isolated and Nonisolated)

Telecom Power Supplies

Wide Input Range DC Input Flyback/Boost

Industrial Power Supplies

For related parts and recommended products to use with this part,

refer to www.maxim-ic.com/MAX17498A.related.

_________________________________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

ABSOLUTE MAXIMUM RATINGS

IN to SGND ............................................................-0.3V to +40V

EN/UVLO to SGND ......................................... -0.3V to IN + 0.3V

OVI to SGND .............................................. -0.3V to VCC + 0.3V

VCC to SGND .......................................................... -0.3V to +6V

SS, LIM, EA-, EA+, COMP, SLOPE,

REF to SGND ........................................ -0.3V to (VCC + 0.3V)

LX to SGND ........................................................... -0.3V to +70V

PGOOD to SGND .................................................... -0.3V to +6V

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

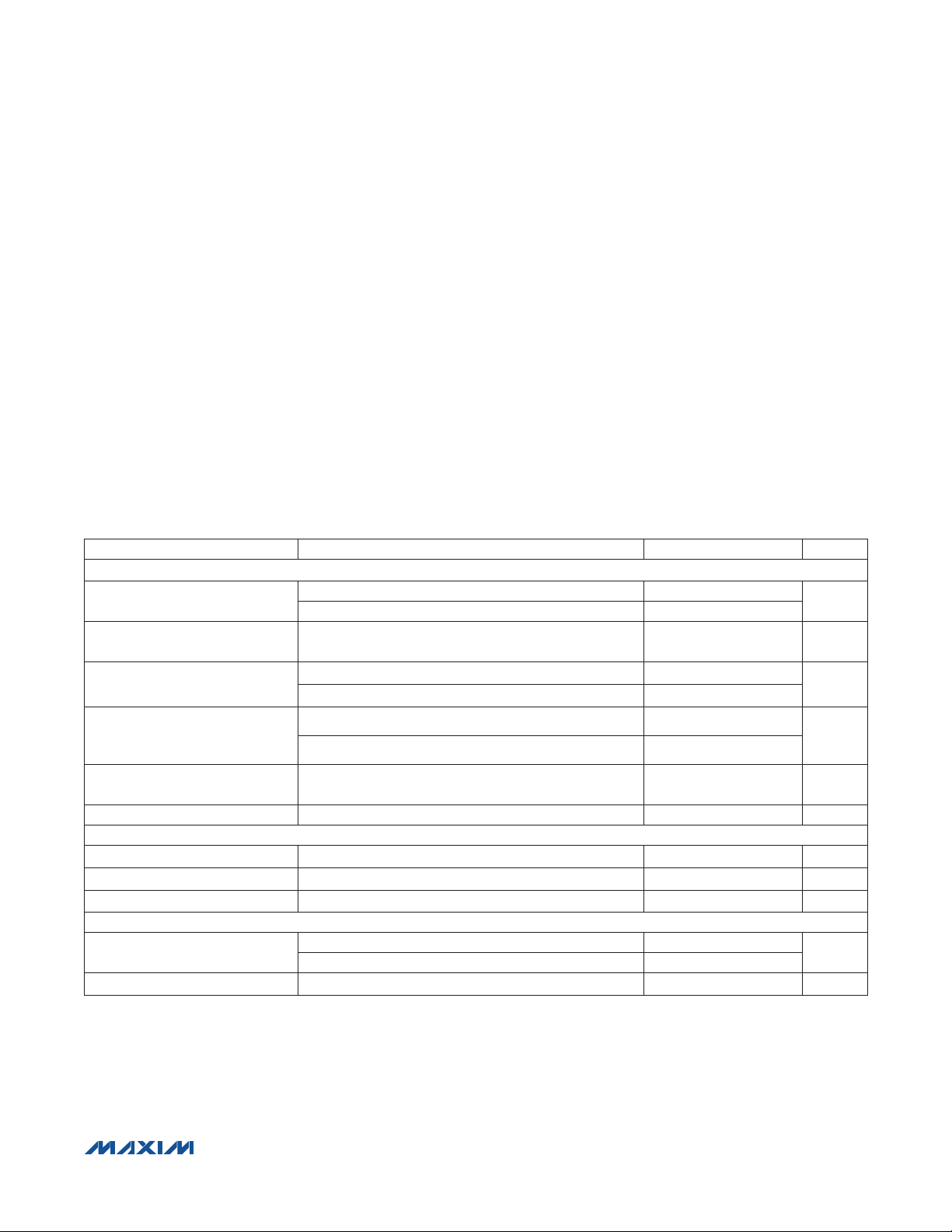

ELECTRICAL CHARACTERISTICS

(VIN = +15V, V

values are at TA = +25°C.) (Note 1)

INPUT SUPPLY (VIN)

IN Voltage Range (VIN)

IN Supply Startup Current Under

UVLO

IN Supply Current (IIN)

IN Boostrap UVLO Rising

Threshold

IN Bootstrap UVLO Falling

Threshold

IN Clamp Voltage EN/UVLO = SGND, IIN = 1mA (MAX17498A) (Note 2) 31 33.5 36 V

LINEAR REGULATOR (VCC)

VCC Output Voltage Range 6V < VIN < 29V, 0mA < I

VCC Dropout Voltage VIN = 4.5V, I

VCC Current Limit VCC = 0V, VIN = 6V 50 100 mA

ENABLE (EN/UVLO)

EN/UVLO Threshold

EN/UVLO Input Leakage Current

EN/UVLO

PARAMETER CONDITIONS MIN TYP MAX UNITS

= +2V, COMP = open, CIN = 1µF, C

MAX17498A 4.5 29

MAX17498B/MAX17498C 4.5 36

I

INSTARTUP

Switching, fSW = 250kHz (MAX17498A/MAX17498C) 1.8 3

Switching, fSW = 500kHz (MAX17498B) 2 3.25

MAX17498A 19 20.5 22

MAX17498B/MAX17498C 3.85 4.15 4.4

Rising 1.18 1.23 1.28

Falling 1.11 1.17 1.21

0V < V

, VIN < UVLO or EN/UVLO = SGND 22 36 µA

= 20mA 160 300 mV

VCC

EN/UVLO

< 1.5V, TA = +25NC

VCC

PGND to SGND .................................................... -0.3V to +0.3V

Continuous Power Dissipation (Single-Layer Board)

TQFN (derate 20.8mW/°C above +70°C)..................1700mW

Operating Temperature Range ........................ -40°C to +125°C

Storage Temperature Range ............................ -65°C to +160°C

Junction Temperature (continuous) ................................+150°C

Lead Temperature (soldering, 10s) ................................+300°C

Soldering Temperature (reflow) ......................................+260°C

= 1µF, TA = TJ = -40°C to +125°C, unless otherwise noted. Typical

V

mA

V

3.65 3.95 4.25 V

< 50mA 4.8 5 5.2 V

VCC

V

-100 0 +100 nA

_________________________________________________________________ Maxim Integrated Products 2

Page 3

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

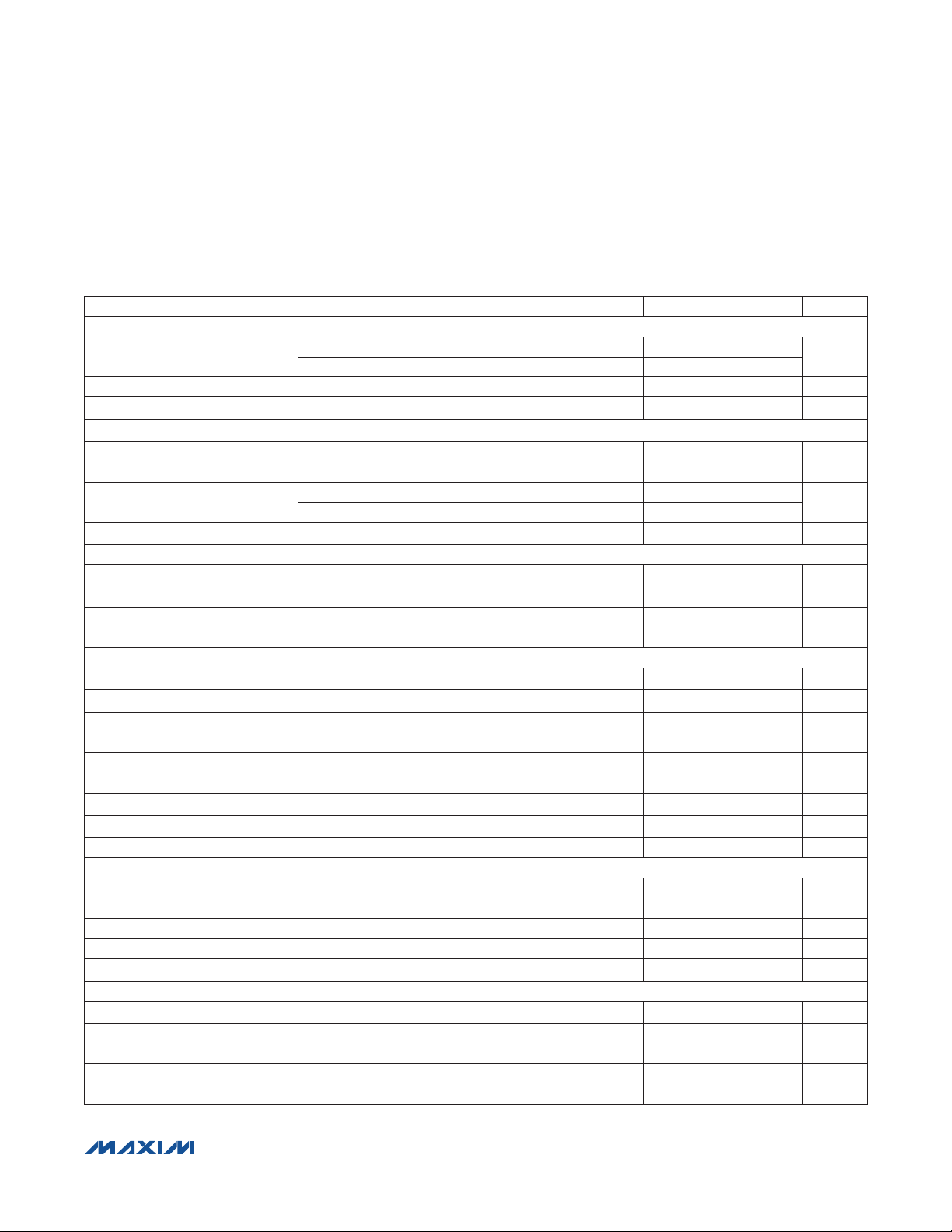

ELECTRICAL CHARACTERISTICS (continued)

(VIN = +15V, V

values are at TA = +25°C.) (Note 1)

OVERVOLTAGE PROTECTION (OVI)

OVI Threshold

OVI Masking Delay 2 µs

OVI Input Leakage Current

SWITCHING FREQUENCY AND MAXIMUM DUTY CYCLE (f

Switching Frequency

Maximum Duty Cycle

Minimum Controllable On Time t

SOFT-START (SS)

SS Set-Point Voltage 1.2 1.22 1.24 V

SS Pullup Current VSS = 400mV 9 10 11 µA

SS Peak Current-Limit-Enable

Threshold

ERROR AMPLIFIER (EA+, EA-, and COMP)

EA+ Input Bias Current

EA- Input Bias Current

Error-Amplifier Open-Loop

Voltage Gain

Error-Amplifier

Transconductance

Error-Amplifier Source Current V

Error-Amplifier Sink Current V

Current-Sense Transresistance 0.45 0.5 0.55

INTERNAL SWITCH

DMOS Switch On-Resistance

(R

DSON

DMOS Peak Current Limit LIM = 100K 1.62 1.9 2.23 A

DMOS Runaway Current Limit LIM = 100K 1.9 2.3 2.6 A

LX Leakage Current

CURRENT LIMIT (LIM)

LIM Reference Current 9 10 11 µA

Peak Switch Current Limit with

LIM Open

Runaway Switch Current Limit

with LIM Open

EN/UVLO

PARAMETER CONDITIONS MIN TYP MAX UNITS

)

= +2V, COMP = open, CIN = 1µF, C

Rising 1.18 1.23 1.28

Falling 1.11 1.17 1.21

0V < V

MAX17498A/MAX17498C 235 250 265

MAX17498B 470 500 530

MAX17498A/MAX17498C 47.5 48.75 50

MAX17498B 90 92 94

ONMIN

V

EA+

V

EA-

V

COMP

COMP

COMP

I

LX

VLX = 65V, TA = +25NC

< 1.5V, TA = +25NC

OVI

= 1.5V, TA = +25NC

= 1.5V, TA = +25NC

= 2V, V

= 2V, EA- < EA+ 80 120 210 µA

= 2V, EA- > EA+ 80 120 210 µA

= 200mA 175 380

= 1V 1.5 1.8 2.1 mS

LIM

= 1µF, TA = TJ = -40°C to +125°C, unless otherwise noted. Typical

VCC

-100 0 +100 nA

SW and DMAX

)

110 ns

1.11 1.17 1.21 V

-100 +100 nA

-100 +100 nA

90 dB

0.1 1 µA

0.39 0.45 0.54 A

0.39 0.5 0.6 A

V

kHz

%

I

mI

_________________________________________________________________ Maxim Integrated Products 3

Page 4

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

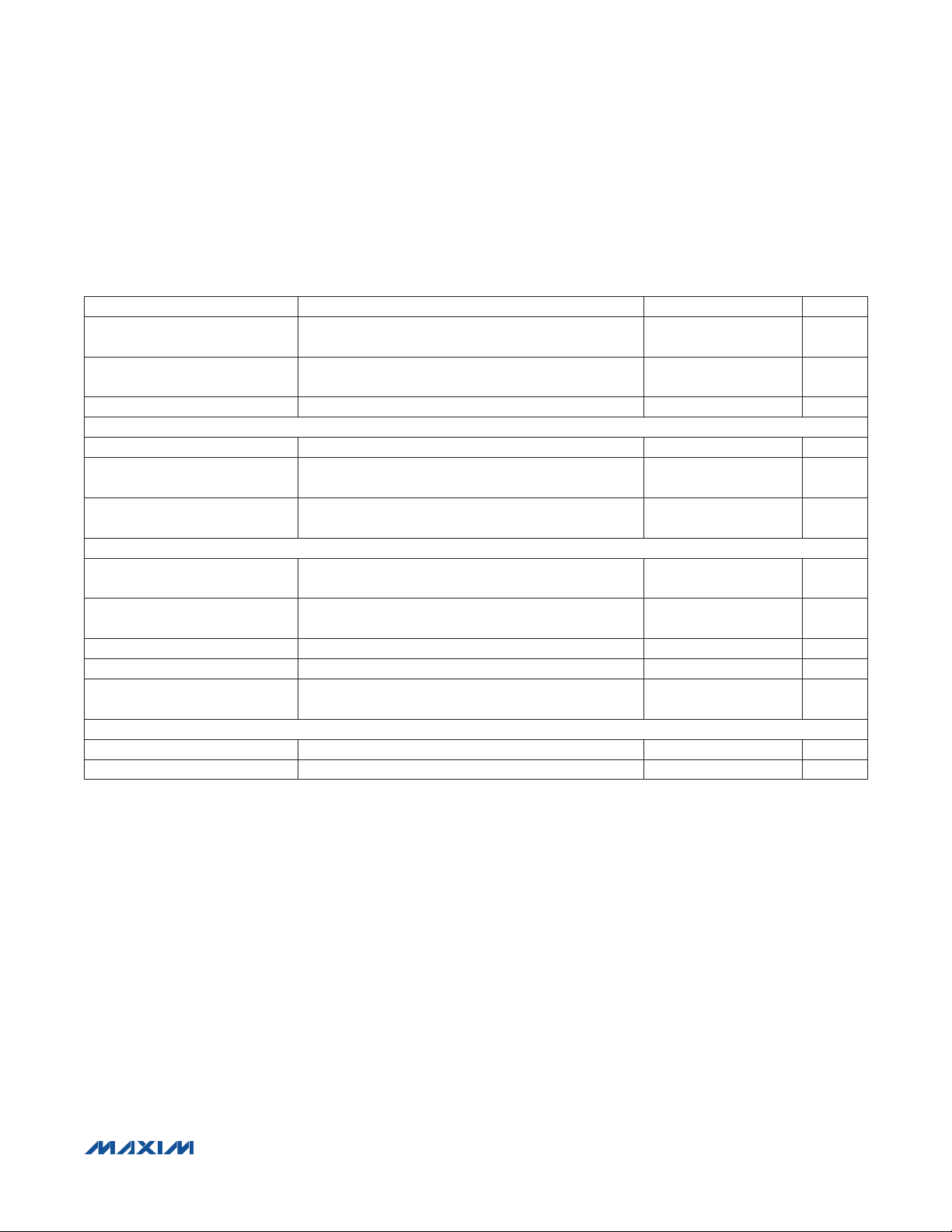

ELECTRICAL CHARACTERISTICS (continued)

(VIN = +15V, V

values are at TA = +25°C.) (Note 1)

Number of Peak Current-Limit

Hits Before Hiccup Timeout

Number of Runaway CurrentLimit Hits Before Hiccup Timeout

Overcurrent Hiccup Timeout 32 ms

SLOPE COMPENSATION (SLOPE)

SLOPE Pullup Current 9 10 11 µA

SLOPE-Compensation Resistor

Range

Default SLOPE-Compensation

Ramp

POWER-GOOD SIGNAL (PGOOD)

PGOOD Output-Leakage

Current (Off State)

PGOOD Output Voltage

(On State)

PGOOD Higher Threshold EA- rising 93.5 95 96.5 %

PGOOD Lower Threshold EA- falling 90.5 92 93.5 %

PGOOD Delay After

EA- Reaches 95% Regulation

THERMAL SHUTDOWN

Thermal-Shutdown Threshold Temperature rising +160

Thermal-Shutdown Hysteresis 20

Note 1: All devices are 100% production tested at TA = +25NC. Limits over temperature are guaranteed by design.

Note 2: The MAX17498A is intended for use in universal input power supplies. The internal clamp circuit at IN is used to prevent the

EN/UVLO

PARAMETER CONDITIONS MIN TYP MAX UNITS

bootstrap capacitor from changing to a voltage beyond the absolute maximum rating of the device when EN/UVLO is low

(shutdown mode). Externally limit the maximum current to IN (hence to clamp) to 2mA (max) when EN/UVLO is low.

= +2V, COMP = open, CIN = 1µF, C

MAX17498B 30 150

SLOPE = open 60 mV/µs

V

PGOOD

I

PGOOD

= 5V, TA = +25NC

= 10mA 0 0.4 V

= 1µF, TA = TJ = -40°C to +125°C, unless otherwise noted. Typical

VCC

8 #

1 #

-1 +1 µA

4 ms

kI

NC

NC

_________________________________________________________________ Maxim Integrated Products 4

Page 5

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

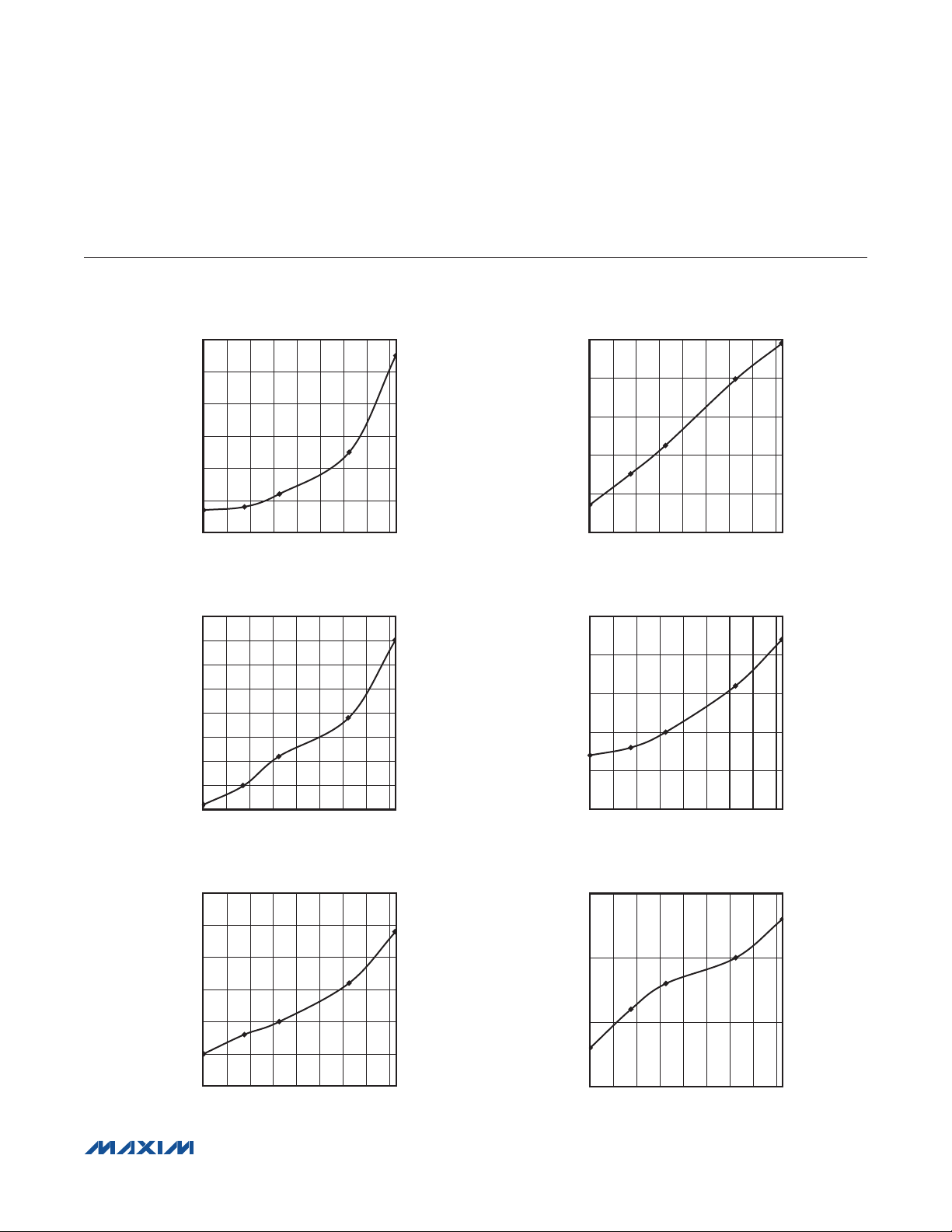

Typical Operating Characteristics

(VIN = +15V, V

EN/UVLO

= +2V, COMP = open, CIN = 1µF, C

BOOTSTRAP UVLO WAKE-UP LEVEL

vs. TEMPERATURE (MAX17498A)

20.26

20.24

20.22

20.20

20.18

20.16

BOOTSTRAP UVLO WAKE-UP LEVEL (V)

20.14

-40

TEMPERATURE (°C)

IN UVLO SHUTDOWN LEVEL

vs. TEMPERATURE

4.015

4.010

4.005

4.000

3.995

3.990

3.985

IN UVLO SHUTDOWN LEVEL (V)

3.980

3.975

-40

TEMPERATURE (°C)

EN/ UVLO FALLING LEVEL

vs. TEMPERATURE

1.170

120100806040200-20

120100-20 0206040 80

MAX17498 toc01

MAX17498 toc03

= 1µF, TA = TJ = -40°C to +125°C, unless otherwise noted.)

VCC

IN UVLO WAKE-UP LEVEL vs. TEMPERATURE

(MAX17498B/MAX17498C)

4.15

4.10

4.05

4.00

IN UVLO WAKE-UP LEVEL (V)

3.95

3.90

TEMPERATURE (°C)

EN/UVLO RISING LEVEL

vs. TEMPERATURE

1.235

1.230

1.225

1.220

EN/UVLO RISING LEVEL (V)

1.215

1.210

TEMPERATURE (°C)

OVI RISING LEVEL

vs. TEMPERATURE

1.225

MAX17498 toc02

120100806040200-20-40

MAX17498 toc04

120100806040200-20-40

1.165

1.160

1.155

1.150

EN/UVLO FALLING LEVEL (V)

1.145

1.140

-40

TEMPERATURE (°C)

120100806040200-20

MAX17498 toc05

1.220

1.215

OVI RISING LEVEL (V)

1.210

-40

120100806040200-20

TEMPERATURE (°C)

_________________________________________________________________ Maxim Integrated Products 5

MAX17498 toc06

Page 6

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

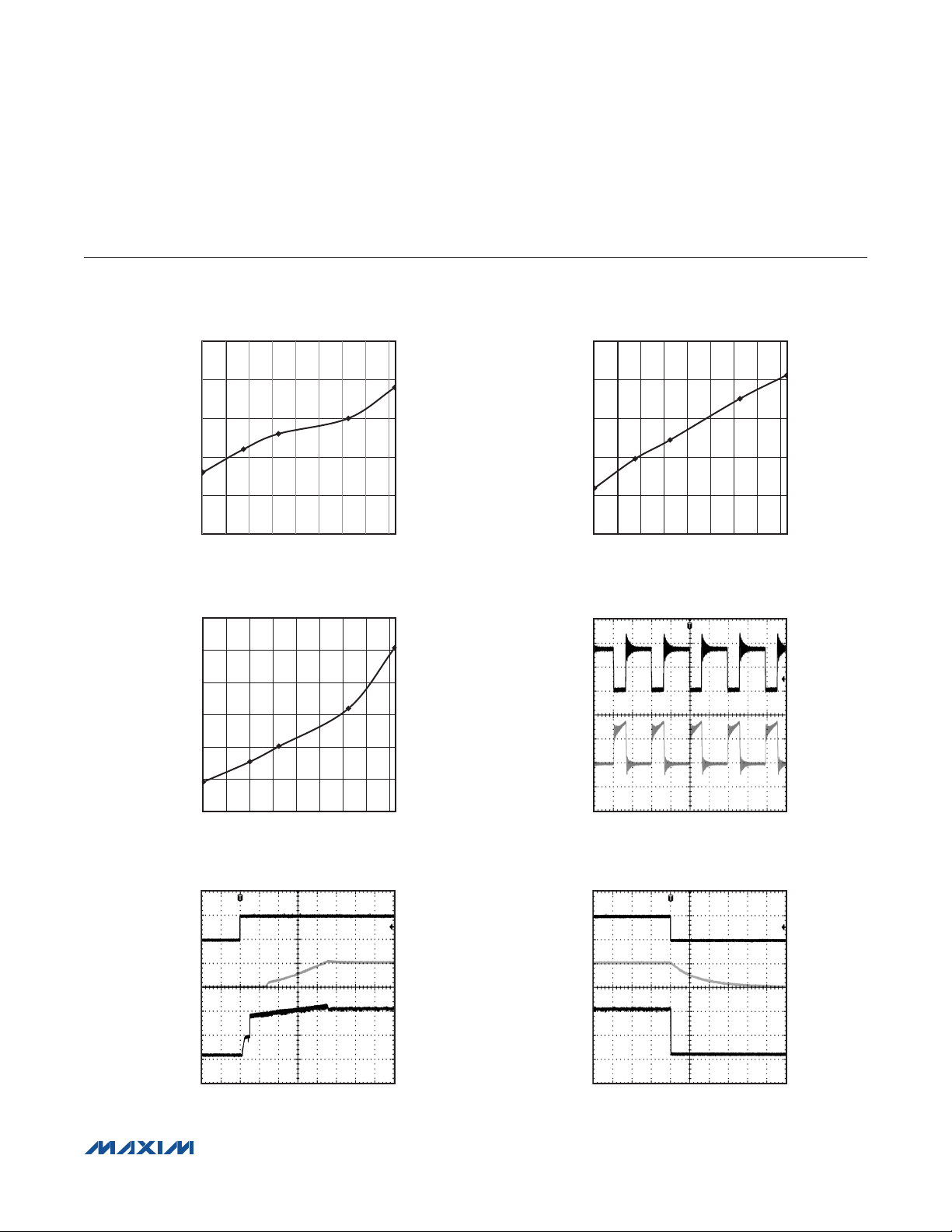

Typical Operating Characteristics (continued)

(VIN = +15V, V

EN/UVLO

1.160

1.155

1.150

1.145

OVI FALLING LEVEL (V)

1.140

1.135

= +2V, COMP = open, CIN = 1µF, C

IN CURRENT DURING SWITCHING

2.6

2.4

2.2

2.0

OVI FALLING LEVEL

vs. TEMPERATURE

TEMPERATURE (°C)

vs. TEMPERATURE

120100806040200-20-40

MAX17498 toc07

MAX17498 toc09

= 1µF, TA = TJ = -40°C to +125°C, unless otherwise noted.)

VCC

IN CURRENT UNDER UVLO

vs. TEMPERATURE

30

28

26

24

IN CURRENT UNDER UVLO (µA)

22

20

TEMPERATURE (°C)

LX AND PRIMARY CURRENT WAVEFORM

MAX17498 toc10

120100806040200-20-40

MAX17498 toc08

V

LX

20V/div

1.8

1.6

IN CURRENT DURING SWITCHING (mA)

1.4

-40

TEMPERATURE (°C)

EN STARTUP WAVEFORM

400µs/div

MAX17498 toc11

120100806040200-20

EN/UVLO

5V/div

V

OUT

5V/div

V

COMP

1V/div

1µs/div

EN SHUTDOWN WAVEFORM

400µs/div

MAX17498 toc12

_________________________________________________________________ Maxim Integrated Products 6

I

PRI

0.5A/div

EN/UVLO

5V/div

V

OUT

5V/div

V

COMP

1V/div

Page 7

MAX17498A/MAX17498B/MAX17498C

08

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

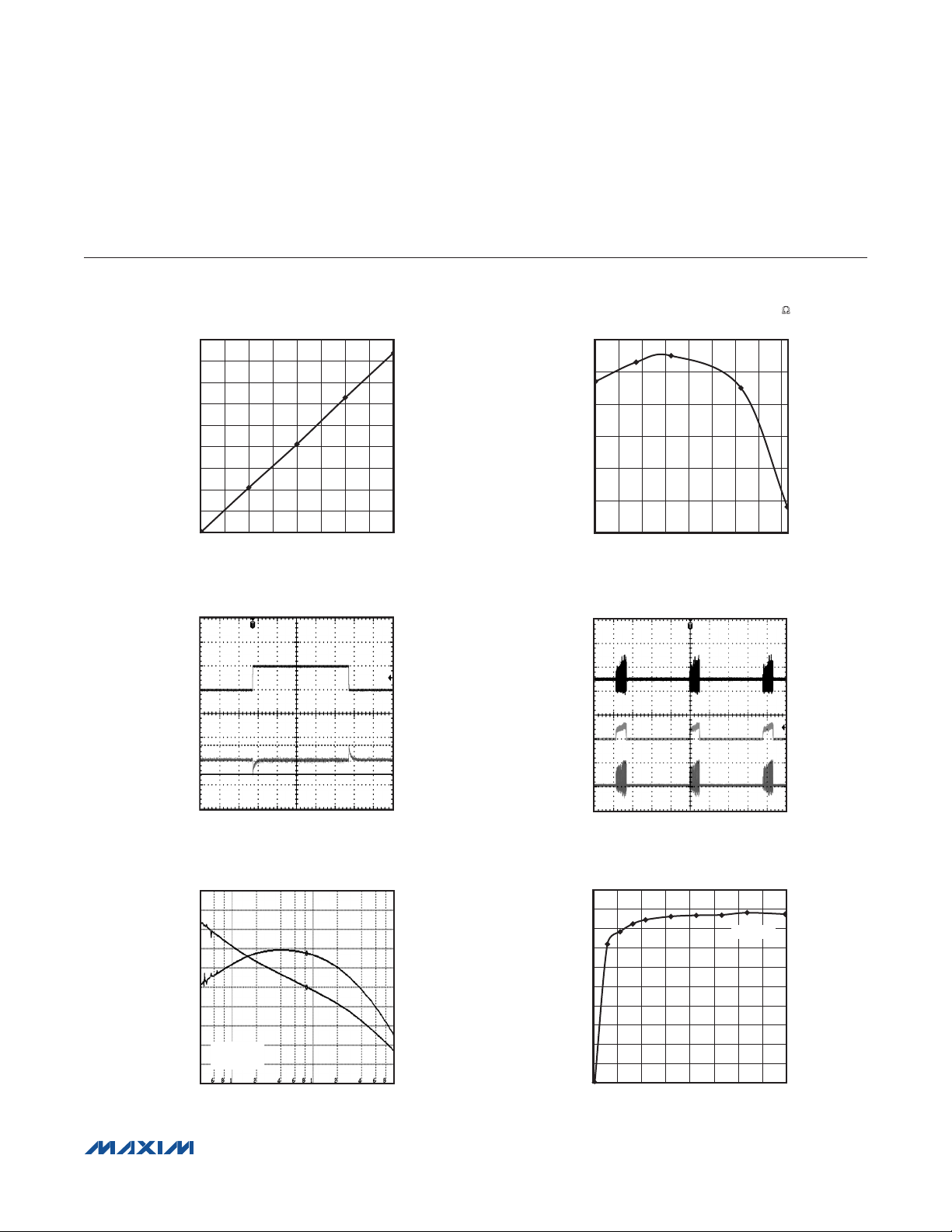

Typical Operating Characteristics (continued)

(VIN = +15V, V

EN/UVLO

= +2V, COMP = open, CIN = 1µF, C

PEAK CURRENT LIMIT (I

AT ROOM TEMPERATURE

vs. R

1800

1600

1400

1200

1000

800

600

PEAK CURRENT LIMIT (mA)

400

200

0

LIM

R

AT ROOM TEMPERATURE (kI)

LIM

TRANSIENT RESPONSE FOR 50%

LOAD STEP ON FLYBACK OUTPUT (5V)

)

LIM

706040 5020 3010

MAX17498 toc15

MAX17498 toc13

0

I

LOAD

500mA/div

= 1µF, TA = TJ = -40°C to +125°C, unless otherwise noted.)

VCC

PEAK CURRENT LIMIT AT R

= 100kI

LIM

vs. TEMPERATURE

2.00

1.99

(A)

LIM

1.98

1.97

1.96

PEAK CURRENT LIMIT AT R

1.95

1.94

-40

TEMPERATURE AT GIVEN R

SHORT-CIRCUIT PROTECTION

LIM

(°C)

MAX17498 toc16

120100806040200-20

MAX17498 toc14

V

LX

50V/div

V

OUT

500mV/div

I

PRI

2A/div

2ms/div

V

OUT

200mV/div

10ms/div

EFFICIENCY GRAPH AT 24V INPUT

BODE PLOT - (5V OUTPUT AT 24V INPUT)

BW = 8.3kHz

PM = 63°

LOG (F)

MAX17498 toc17

PHASE

36°/div

GAIN

10dB/div

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

(FLYBACK REGULATOR)

VIN = 24V

LOAD CURRENT (A)

MAX17498 toc18

1.41.20.8 1.00.4 0.60.20

_________________________________________________________________ Maxim Integrated Products 7

Page 8

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

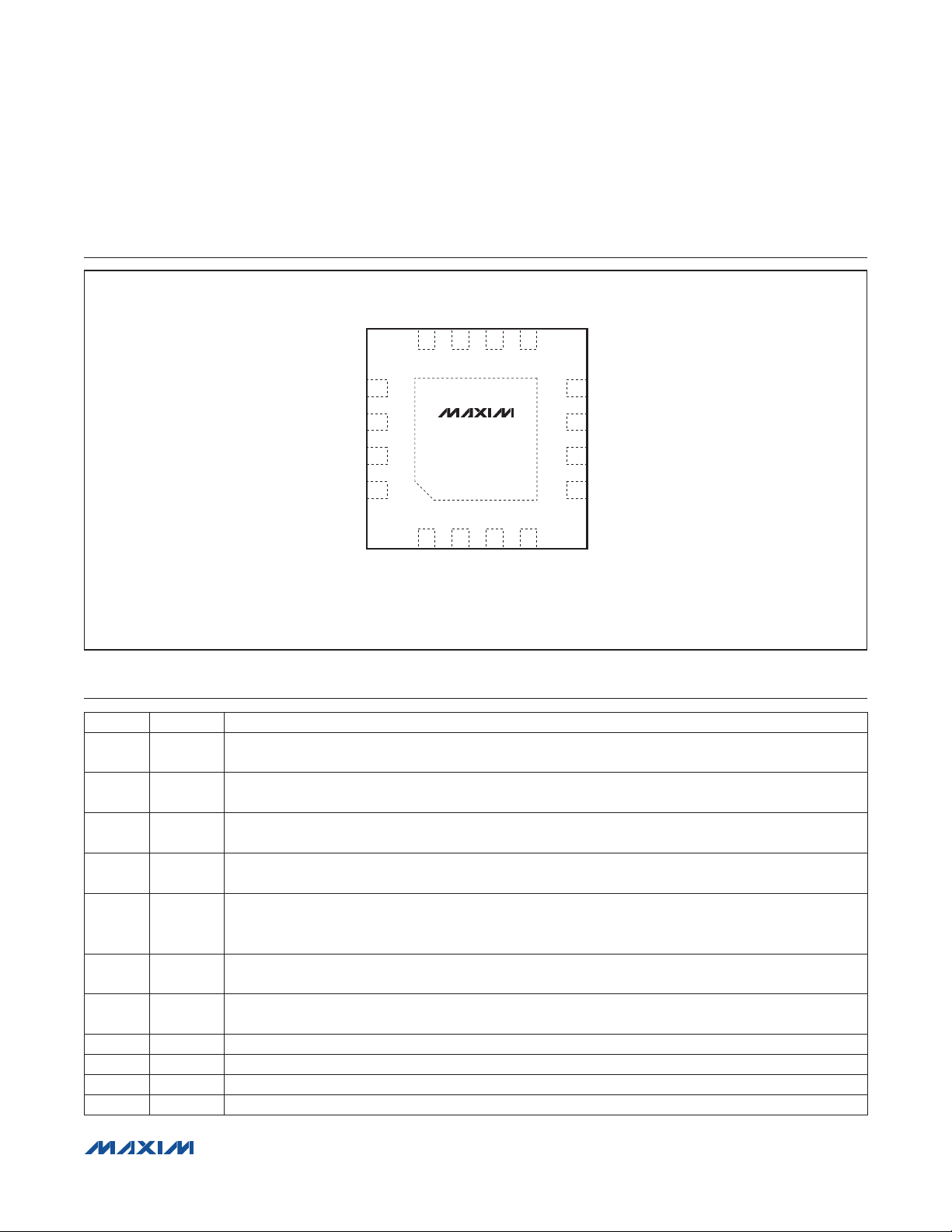

Pin Configuration

TOP VIEW

PGOOD

PGND

13

14

LX

15

16

IN

+

REF

N.C.

12 11 9

12

EN/UVLO

10

MAX17498A

MAX17498B

MAX17498C

EP (SGND)

3

CC

V

TQFN-EP

OVI N.C.

EA+

SS

8

7

COMP

EA-

6

SLOPE

5

4

LIM

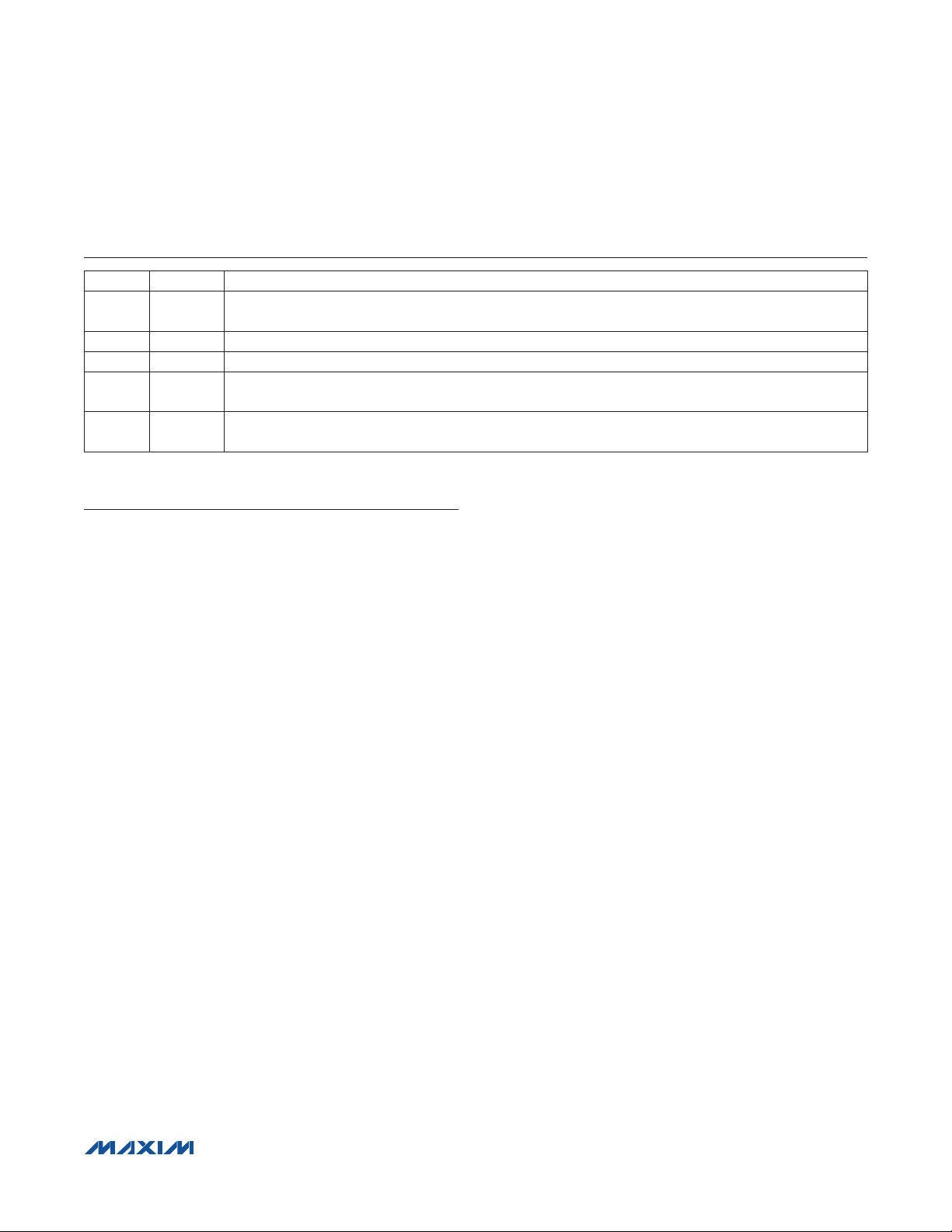

Pin Description

PIN NAME FUNCTION

1 EN/UVLO

2 V

CC

3 OVI

4 LIM

5 SLOPE

6 EA-

7 COMP

8 SS Soft-Start Pin. Connect a capacitor from SS to SGND to set the soft-start time interval.

9 EA+ Noninverting Input of the Flexible Error Amplifier. Connect to SS to use 1.22V as the reference.

10, 12 N.C. No Connection

11 REF Internal 1.22V Reference Output Pin. Connect a 100pF capacitor from REF to SGND.

Enable/Undervoltage-Lockout Pin. Drive to > 1.23V to start the devices. To externally program the UVLO

threshold of the input supply, connect a resistor-divider between input supply EN/UVLO and SGND.

Linear Regulator Output. Connect input bypass capacitor of at least 1µF from VCC to SGND as close as

possible to the IC.

Overvoltage Comparator Input. Connect a resistor-divider between the input supply (OVI) and SGND to

set the input overvoltage threshold.

Current-Limit Setting Pin. Connect a resistor between LIM and SGND to set the peak-current limit for

nonisolated flyback converter. Peak-current limit defaults to 500mA if unconnected.

Slope Compensation Input Pin. Connect a resistor between SLOPE and SGND to set slopecompensation ramp. Connect to VCC for minimum slope compensation. See the Programming Slope

Compensation (SLOPE) section.

Inverting Input of the Flexible Error Amplifier. Connect to mid-point of resistor-divider from the positive

terminal output to SGND.

Flexible Error-Amplifier Output. Connect the frequency-compensation network between COMP and

SGND.

_________________________________________________________________ Maxim Integrated Products 8

Page 9

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Pin Description (continued)

PIN NAME FUNCTION

13 PGOOD

14 PGND Power Ground for Converter

15 LX External Transformer/Inductor Connection for the Converter

16 IN

—

EP

(SGND)

Open-Drain Output. PGOOD goes high when EA- is within 5% of the set point. PGOOD pulls low when

EA- falls below 92% of its set-point value.

Internal Linear Regulator Input. Connect IN to the input-voltage source. Bypass IN to PGND with a 1µF

(min) ceramic capacitor.

Exposed Pad. Internally connected to SGND. Connect EP to a large copper plane at SGND potential to

provide adequate thermal dissipation. Connect EP (SGND) to PGND at a single point.

Detailed Description

The MAX17498A offers a bootstrap UVLO wakeup level

of 20V with a wide hysteresis of 15V (min) optimized

for implementing an isolated and nonisolated universal

(85V AC to 265V AC) offline single-switch flyback

converter or telecom (36V to 72V) power supplies. The

MAX17498B/MAX17498C offer a UVLO wakeup level of

4.4V and are well suited for low-voltage DC-DC flyback/

boost power supplies. An internal reference (1.22V)

can be used to regulate the output down to 1.23V in

nonisolated flyback and boost applications. Additional

semi-regulated outputs, if needed, can be generated

by using additional secondary windings on the flyback

converter transformer. A flexible error amplifier and REF

allow the end-user selection between regulating positive

and negative outputs.

The devices utilize peak current-mode control and external compensation for optimizing the loop performance for

various inductors and capacitors. The devices include a

cycle-by-cycle peak current limit and eight consecutive

occurrences of current-limit event trigger hiccup mode,

that protect external components by halting switching for

a period of time (32ms). The devices also include voltage

soft-start for nonisolated designs and current soft-start

for isolated designs to allow monotonic rise of the output

voltage. The voltage or current soft-start can be selected

using the SLOPE pin. See the Block Diagram for more

information.

Input Voltage Range

The MAX17498A has different rising and falling UVLO

thresholds on the IN pin than those of the MAX17498B/

MAX17498C. The thresholds for the MAX17498A are

optimized for implementing power-supply startup

schemes typically used for offline AC-DC power supplies.

The MAX17498A is therefore well suited for operation from the rectified DC bus in AC-DC power-supply

applications typically encountered in front-end industrial

power-supply applications. As such, the MAX17498A

has no limitation on the maximum input voltage as long

as the external components are rated suitably and the

maximum operating voltages of the MAX17498A are

respected. The MAX17498A can successfully be used

in universal input-rectified (85V to 265V AC) bus applications, rectified 3-phase DC bus applications, and telecom (36V to 72V DC) applications.

The MAX17498B/MAX17498C are intended for implementing a flyback (isolated and nonisolated) and

boost converter with an on-board 65V rated n-channel

MOSFET. The IN pin of the MAX17498B/MAX17498C has

a maximum operating voltage of 36V. The MAX17498B/

MAX17498C implement rising and falling thresholds on

the IN pin that assume power-supply startup schemes,

typical of lower voltage DC-DC applications, down to an

input voltage of 4.5V DC. Therefore, flyback converters

with a 4.5V to 36V supply voltage range can be implemented with the MAX17498B/MAX17498C.

Internal Linear Regulator (VCC)

The internal functions and driver circuits are designed

to operate from a 5V Q5% power-supply voltage. The

devices have an internal linear regulator that is powered

from the IN pin and generates a 5V power rail. The output

of the linear regulator is connected to the VCC pin and

should be decoupled with a 2.2µF capacitor to ground

for stable operation. The VCC converter output supplies

the operating current for the devices. The maximum

operating voltage of the IN pin is 29V for the MAX17498A

and 36V for the MAX17498B/MAX17498C.

_________________________________________________________________ Maxim Integrated Products 9

Page 10

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Configuring the Power Stage (LX)

The devices use an internal n-channel MOSFET to implement internal current sensing for current-mode control

and overcurrent protection of the flyback/boost converter. To facilitate this, the drain of the internal nMOSFET is

connected to the source of the external MOSFET in the

MAX17498A high-input-voltage applications. The gate of

the external MOSFET is connected to the IN pin. Ensure

by design that the IN pin voltage does not exceed the

maximum operating gate-voltage rating of the external

MOSFET. The external MOSFET gate-source voltage is

controlled by the switching action of the internal nMOSFET, while also sensing the source current of the external MOSFET. In the MAX17498B/MAX17498C-based

applications, the LX pin is directly connected to either

the flyback transformer primary winding or to the boostconverter inductor.

IN REF

V

EN/UVLO

OVI

CC

5V, 50mA

1.23V

POK

LDO

33V CLAMP

(MAX17498A ONLY)

BG

CHIPEN

V

CS

Maximum Duty Cycle

The MAX17498A/MAX17498C operate at a maximum

duty cycle of 49%. The MAX17498B offers a maximum

duty cycle of 92% to implement both flyback and boost

converters involving large input-to-output voltage ratios

in DC-DC applications.

Power-Good Signal (PGOOD)

The devices include a PGOOD signal that serves as

a power-good signal to the system. PGOOD is an

open-drain signal and requires a pullup resistor to the

preferred supply voltage. The PGOOD signal monitors

EA- and pulls high when EA- is 95% (typ) of its regulation

value (1.22V). For isolated power supplies, PGOOD cannot serve as a power-good signal.

CHIPEN

HICCUP

CLK

10µA

1.17V

V

SUM

V

SLOPE

SSDONEF

V

CS

MAX17498A

MAX17498B

MAX17498C

OSC

SS

LX

1.23V

LIM

SLOPE

10µA

10µA

1.23V

250mV

DECODER

VOLTAGE SS CURRENT SS

LIMINT

V

SUM

COMP

FIXED SLOPE

VARIABLE SLOPE

Figure 1. MAX17498A/MAX17498B/MAX17498C Block Diagram

________________________________________________________________ Maxim Integrated Products 10

RUNAWAY

PEAK

PWM

CONTROL

LOGIC AND

DRIVER

CHIPEN

EA-

8 PEAK OR 1

RUNAWAY

PGOOD

BLOCK

SSDONE

PGND

PGOOD

COMP

EA+

EA-

Page 11

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Soft-Start

The devices implement soft-start operation for the

flyback /boost converter. A capacitor connected to the

SS pin programs the soft-start period for the flyback/

boost converter. The soft-start feature reduces the input

inrush current. These devices allow the end user to select

between voltage soft-start usually preferred in nonisolated applications and current soft-start, which is useful in

isolated applications to get a monotonic rise in the output

voltage. See the Programming Soft-Start of the Flyback/

Boost Converter (SS) section.

Spread-Spectrum Factory Option

For EMI-sensitive applications, a spread-spectrumenabled version of the device can be requested from

the factory. The frequency-dithering feature modulates

the switching frequency by Q10% at a rate of 4kHz.

This spread-spectrum-modulation technique spreads

the energy of switching-frequency harmonics over a

wider band while reducing their peaks, helping to meet

stringent EMI goals.

Applications Information

Startup Voltage and Input Overvoltage-

Protection Setting (EN/UVLO, OVI)

The devices’ EN / UVLO pin serves as an enable /disable

input, as well as an accurate programmable input UVLO

pin. The devices do not commence startup operation

unless the EN/UVLO pin voltage exceeds 1.23V (typ).

The devices turn off if the EN/UVLO pin voltage falls

below 1.17V (typ). A resistor-divider from the input DC

bus to ground can be used to divide down and apply a

fraction of the input DC voltage (VDC) to the EN/UVLO

pin. The values of the resistor-divider can be selected

so that the EN/UVLO pin voltage exceeds the 1.23V (typ)

turn-on threshold at the desired input DC bus voltage. The

same resistor-divider can be modified with an additional

resistor (R

in

addition to the EN/UVLO functionality as shown in

Figure 2. When voltage at the OVI pin exceeds 1.23V (typ),

the devices stop switching and resume switching operations

only if voltage at the OVI pin falls below 1.17V (typ).

For given values of startup DC input voltage (V

) to implement input overvoltage protection

OVI

START

),

and input overvoltage-protection voltage (V

resistor values for the divider can be calculated as follows, assuming a 24.9kI resistor for R

V

R R 1k

= × −Ω

EN OVI

where R

where REN and R

applications, R

is in kI while V

OVI

= + × −Ω

R R R 1k

SUM OVI EN

are in kI. In universal AC input

OVI

might need to be implemented as

SUM

equal resistors in series (R

OVI

V

START

and V

START

V

START

1.23

, R

DC1

DC2

:

OVI

are in volts.

OVI

, R

DC3

voltage across each resistor is limited to its maximum

operation voltage.

R

RRR k

= = = Ω

DC1 DC1 D C1

SUM

3

For low-voltage DC-DC applications based on the

MAX17498B/MAX17498C, a single resistor can be used

in the place of R

, as the voltage across it is

SUM

approximately 40V.

V

DC

R

DC1

R

R

SUM

DC2

R

DC3

EN/UVLO

R

EN

OVI

R

OVI

MAX17498A

MAX17498B

MAX17498C

), the

OVI

) so that

Figure 2. Programming EN/UVLO and OVI

________________________________________________________________ Maxim Integrated Products 11

Page 12

MAX17498A/MAX17498B/MAX17498C

=+×

Rk

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Startup Operation

The MAX17498A is optimized for implementing an offline

single-switch flyback converter and has a 20V IN UVLO

wake-up level with hysteresis of 15V (min). In offline applications, a simple cost-effective RC startup circuit is used.

When the input DC voltage is applied, the startup resistor (R

causing the voltage at the IN pin to increase

) charges the startup capacitor (C

START

),

START

towards the

wake-up IN UVLO threshold (20V typ). During this time,

the MAX17498A draws a low startup

through R

. When the voltage at IN reaches the

START

current of 20µA (typ)

wake-up IN UVLO threshold, the MAX17498A commences switching operations and drives the internal n-channel

MOSFET whose drain is connected to the LX pin. In this

condition, the MAX17998A draws 1.8mA current from

C

, in addition to the current required to switch the

START

gate of the external nMOSFET. Since this current cannot

be supported by the current through R

age on C

starts to drop. When suitably configured,

START

START

, the volt-

as shown in Figure 10, the external nMOSFET is

switched by the LX pin and the flyback/forward converter generates an output voltage (V

to the IN pin through the diode (D2). If V

) bootstrapped

OUT

OUT

exceeds

the sum of 5V and the drop across D2 before the voltage on C

sustained by V

operating with energy from V

falls below 5V, then the IN voltage is

START

, allowing the MAX17498A to continue

OUT

. The large hysteresis

OUT

(15V typ) of the MAX17498A allows for a small startup

capacitor (C

allows the use of a large start resistor (R

). The low startup curent (20µA typ)

START

), thus reducing

START

power dissipation at higher DC bus voltages. Figure 3 shows

the typical RC startup scheme for the MAX17498A.

R

resistors in series (R

might need to be implemented as equal, multiple

START

V

DC

R

IN1

IN1

, R

IN2

, and R

) to share the

IN3

V

DC

V

OUT

D1

C

OUT

applied high DC voltage in offline applications so that

the voltage across each resistor is limited to the maximum

continuous operating-voltage rating. R

START

and C

START

can be calculated as:

C I µF

START IN

Q ft

×

GATE sw SS

10

6

10

where IIN is the supply current drawn at the IN pin

in mA, Q

is the gate charge of the external

GATE

nMOSFET used in nC, fSW is the switching frequency

of the converter in Hz, and tSS is the soft-start time

programmed for the flyback/forward converter in ms.

See the Programming Soft-Start of the Flyback/Boost

Converter (SS) section.

where C

V 10 50

( )

START

START

= Ω

is the startup capacitor in µF.

−×

START

1C

+

START

For designs that cannot accept power dissipation in the

startup resistors at high DC input voltages in offline applications, the startup circuit can be set up with a current

source instead of a startup resistor as shown in Figure 4.

V

DC

R

R

START

IN1

R

IN2

R

IN3

IN

V

DC

V

OUT

D1

C

OUT

R

R

START

IN2

V

V

OUT

R

C

D2

START

IN3

C

VCC

MAX17498A

IN

V

CC

LDO

LX

OUT

C

START

R

ISRC

D2

C

VCC

IN

V

CC

MAX17498A

LX

LDO

Figure 3. MAX17498A RC-Based Startup Circuit Figure 4. MAX17498A Current Source-Based Startup Circuit

________________________________________________________________ Maxim Integrated Products 12

Page 13

MAX17498A/MAX17498B/MAX17498C

=+×

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

V

DC

IN

C

Figure 5. MAX17498B/MAX17498C Typical Startup Circuit with

IN Connected Directly to DC Input

R

Z

Z

D1

6.3V

Figure 6. MAX17498B/MAX17498C Typical Startup Circuit with

Bias Winding to Turn Off Q1 and Reduce Power Dissipation

IN

LDO

IN

MAX17498B

MAX17498C

Q1

IN

C

IN

C

VCC

IN

V

CC

The startup capacitor (C

C I µF

START IN

V

CC

C

VCC

LX Np Ns

V

DC

D2

NB

MAX17498B

MAX17498C

LDO

START

Qft

GATE SW SS

LX Np

) can be calculated as:

×

6

10

10

V

OUT

D1

C

OUT

V

OUT

D1

C

OUT

Ns

where IIN is the supply current drawn at the IN pin in mA,

Q

is the gate charge of the external MOSFET used

GATE

in nC, fSW is the switching frequency of the converter in

kHz, and tSS is the soft-start time programmed for the

flyback converter in ms.

Resistors R

and R

SUM

RM

SUM

RM

can be calculated as:

ISRC

V

START

= Ω

10

V

BEQ1

= Ω

ISRC

70

The IN UVLO wakeup threshold of the MAX17498B/

MAX17498C is set to 3.9V (typ) with a 200mV hysteresis, optimized for low-voltage DC-DC applications

down to 4.5V. For applications where the input DC

voltage is low enough (e.g., 4.5V to 5.5V DC) that the

power loss incurred to supply the operating current of

the MAX17498B/MAX17498C can be tolerated, the IN

pin is directly connected to the DC input, as shown in

Figure 5. In the case of higher DC input voltages (e.g., 16V

to 32V DC), a startup circuit, such as that shown in Figure 6,

can be used to minimize power dissipation in the startup

circuit. In this startup scheme, the transistor (Q1)

supplies the switching current until a bias winding NB

comes up. The resistor (RZ) can be calculated as:

R 9 (V 6.3) k=× −Ω

Z INMIN

where V

is the minimum input DC voltage.

INMIN

Programming Soft-Start of the

Flyback/Boost Converter (SS)

The soft-start period in the voltage soft-start scheme of

the devices can be programmed by selecting the value

of the capacitor connected from the SS pin to GND.

The capacitor CSS can be calculated as:

C 8.13 t nF= ×

SS SS

where tSS is expressed in ms.

The soft-start period in the current soft-start scheme

depends on the load at the output and the soft-start

capacitor.

Programming Output Voltage

The devices incorporate a flexible error amplifier that

allows regulating to both the positive and negative

outputs. The positive output voltage of the converter

can be programmed by selecting the correct values

for the resistor-divider connected from V

OUT

, the flyback /boost output to ground, with the midpoint of the

divider connected to the EA- pin (Figure 7). With RB

selected in the range of 20kI to 50kI, RU can be

calculated as:

V

R R 1k

= × −Ω

UB

OUT

1.22

where RB is in kI.

________________________________________________________________ Maxim Integrated Products 13

Page 14

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

The negative output voltage of the converter can be

programmed by selecting the correct values for the

resistor-divider connected from V

, the flyback /boost

OUT

output to REF with the midpoint of the divider connected

to the EA+ pin (Figure 8). With R1 selected in the range

of 20kI to 50kI, R2 can be calculated as:

V

R2 R1 k

=×Ω

OUT

1.22

where R1 is in kI.

Current-Limit Programming (LIM)

The devices include a robust overcurrent-protection

scheme that protects the device under overload and

short-circuit conditions. For the flyback/boost converter, the devices include a cycle-by-cycle peak

current limit that turns off the driver whenever the

current into the LX pin exceeds an internal limit that is

programmed by the resistor connected from the LIM

pin to GND. The devices include a runaway current limit

that protects the device under high-input-voltage shortcircuit conditions when there is insufficient output voltage

available to restore the inductor current built up during the on period of the flyback/boost converter. Either

eight consecutive occurrences of the peak currentlimit event or one occurrence of the runaway current limit

trigger a hiccup mode that protects the converter by

immediately suspending switching for a period of time

(t

RSTART

). This allows the overload current to decay due

to power loss in the converter resistances, load, and

the output diode of the flyback/boost converter before

soft-start is attempted again. The resistor at the LIM pin

for a desired current limit (IPK) can be calculated as:

R 50 I k=×Ω

LIM PK

where IPK is expressed in amperes.

For a given peak current-limit setting, the runaway

current limit is typically 20% higher. The peak currentlimit-triggered hiccup operation is disabled until the end

of soft-start, while the runaway current-limit-triggered hiccup operation is always enabled.

Programming Slope Compensation (SLOPE)

Since the MAX17498A/MAX17498C operate at a maximum duty cycle of 49%, in theory they do not require slope

compensation for preventing subharmonic instability that

occurs naturally in continuous-mode peak current-modecontrolled converters operating at duty cycles greater

than 50%. In practice, the MAX17498A/MAX17498C

require a minimum amount of slope compensation to

provide stable, jitter-free operation. The MAX17498A/

V

OUT

R

U

MAX17498A

EA-

MAX17498B

R

B

Figure 7. Programming the Positive Output Voltage

EA-

R

EA-

Figure 8. Programming the Negative Output Voltage

MAX17498C

MAX17498A

MAX17498B

MAX17498C

REF

EA+

V

OUT

R1

R2

MAX17498C allow the user to program this default value

of slope compensation simply by con

necting the SLOPE

pin to VCC. It is recommended that discontinuous-mode

designs also use this minimum amount of slope compensation to provide noise immunity and jitter-free operation.

The MAX17498B flyback/boost converter can be

designed to operate in either discontinuous mode or

to enter into the continuous-conduction mode at a specific heavy-load condition for a given DC input voltage.

In the continuous-conduction mode, the flyback/boost

converter needs slope compensation to avoid subharmonic instability that occurs naturally over all specified

load and line conditions in peak current-mode-controlled

converters operating at duty cycles greater than 50%.

A minimum amount of slope signal is added to the

sensed current signal even for converters operating

below 50% duty to provide stable, jitter-free operation.

The SLOPE pin allows the user to program the necessary

slope compensation by setting the value of the resistor

(R

) connected from SLOPE pin to ground.

SLOPE

R 0.5 S k=×Ω

SLOPE E

where the slope (SE) is expressed in millivolts per microsecond.

________________________________________________________________ Maxim Integrated Products 14

Page 15

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Error Amplifier, Loop Compensation,

and Power-Stage Design

of the Flyback/Boost Converter

The flyback/boost converter requires proper loop compensation to be applied to the error-amplifier output to achieve

stable operation. The goal of the compensator design is to

achieve the desired closed-loop bandwidth and sufficient

phase margin at the crossover frequency of the open-loop

gain-transfer function of the converter. The error amplifier

provided in the devices is a transconductance amplifier. The

compensation network used to apply the necessary loop

compensation is shown in Figure 9.

The flyback/boost converter can be used to implement

the following converters and operating modes:

• Nonisolated flyback converter in discontinuous-

conduction mode (DCM flyback)

• Nonisolated flyback converter in continuous-

conduction mode (CCM flyback)

• Boost converter in discontinuous-conduction mode

(DCM boost)

• Boost converter in continuous-conduction mode

(CCM boost)

Calculations for loop-compensation values (RZ, CZ, and CP)

for these converter types and design procedures for powerstage components are detailed in the following sections.

DCM Flyback

Primary-Inductance Selection

In a DCM flyback converter, the energy stored in the

primary inductance of the flyback transformer is ideally

delivered entirely to the output. The maximum primaryinductance value for which the converter remains in

discontinuous mode at all operating conditions can be

calculated as:

V D 0.4

L

PRIMAX

R

Z

C

Z

Figure 9. Error-Amplifier Compensation Network

( )

≤

(V V ) I f

C

P

××

INMIN MAX

+× ×

OUT D OUT SW

COMP

MAX17498A

MAX17498B

MAX17498C

2

where D

is 0.35 for the MAX17498A/MAX17498C and

MAX

0.7 for the MAX17498B, VD is the voltage drop of the output rectifier diode on the secondary winding, and fSW is

the switching frequency of the power converter. Choose

the primary inductance value to be less than L

PRIMAX

.

Duty-Cycle Calculation

The accurate value of the duty cycle (D

selected primary inductance (L

) can be calculated

PRI

NEW

) for the

using the following equation:

2.5 L (V V ) I f

× × +× ×

D

NEW

=

PRI OUT D OUT SW

V

INMIN

Turns-Ratio Calculation (Ns/Np)

Transformer turns ratio (K = Ns/Np) can be calculated as:

(V V ) (1 D )

+ ×−

OUT D MAX

K

=

VD

×

INMIN MAX

Peak /RMS-Current Calculation

The transformer manufacturer needs RMS current values

in the primary and secondary to design the wire diameter

for the different windings. Peak current calculations are

useful in setting the current limit. Use the following equations to calculate the primary and secondary peak and

RMS currents.

Maximum primary peak current:

I

PRIPEAK

VD

=

×

INMIN NEW

Lf

×

PRI SW

Maximum primary RMS current:

D

II

PRIRMS PRIPEAK

= ×

NEW

3

Maximum secondary peak current:

I

I

SECPEAK

PRIPEAK

=

K

Maximum secondary RMS current:

II

SECRMS PRIPEAK

= ×

I Lf

SECPEAK PRI SW

××

3V V

( )

+

OUTF D

For current-limit setting, the peak current can be

calculated as:

I I 1.2= ×

LIM PRIPEAK

Primary RCD Snubber Selection

Ideally, the external n-channel MOSFET experiences

a drain-source voltage stress equal to the sum of the

input voltage and reflected voltage across the primary

________________________________________________________________ Maxim Integrated Products 15

Page 16

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

winding during the off period of the nMOSFET. In practice, parasitic inductances and capacitors in the circuit,

such as leakage inductance of the flyback transformer,

cause voltage overshoot and ringing. Snubber circuits

are used to limit the voltage overshoots to safe levels

within the voltage rating of the external nMOSFET. The

snubber capacitor can be calculated using the following

equation:

22

2

C

SNUB

2L I K

×× ×

LK PRIPEAK

=

V

OUT

where LLK is the leakage inductance that can be

obtained from the transformer specifications (usually 1%

to 2% of the primary inductance).

The power to be dissipated in the snubber resistor is

calculated using the following formula:

P 0.833 L I f= ×× ×

SNUB LK PRIPEAK SW

2

The snubber resistor can be calculated based on the

following equation:

R

SNUB

6.25 V

×

=

PK

SNUB

OUT

×

2

2

The voltage rating of the snubber diode is:

V

V V 2.5

DSNUB INMAX

= +×

OUT

K

Output-Capacitor Selection

X7R ceramic output capacitors are preferred in industrial

applications due to their stability over temperature. The

output capacitor is usually sized to support a step load

of 50% of the maximum output current in the application

so that the output-voltage deviation is contained to 3% of

the output-voltage change. The output capacitance can

be calculated as:

OUT

t ()

RESPONSE

where I

is the load step, t

STEP

time of the controller, DV

∆

V

OUT

0.33 1

≅+

ff

C SW

RESPONSE

is the allowable output-

OUT

is the response

×

It

STEP RESPONSE

=

C

voltage deviation, and fC is the target closed-loop crossover frequency. fC is chosen to be 1/10 the switching

frequency (fSW). For the flyback converter, the output

capacitor supplies the load current when the main switch

is on, and therefore, output-voltage ripple is a function of

load current and duty cycle. Use the following equation

to calculate the output-capacitor ripple:

2

∆=

V

where I

OUT

D I KI

× −×

COUT

NEW PRIPEAK OUT

× ××

2I f C

PRIPEAK SW OUT

is load current and D

is the duty cycle at

NEW

minimum input voltage.

Input-Capacitor Selection

The MAX17498A is optimized to implement offline

AC-DC converters. In such applications, the input capacitor must be selected based on either the ripple due

to the rectified line voltage, or based on holdup-time

requirements. Holdup time can be defined as the time

period over which the power supply should regulate its

output voltage from the instant the AC power fails. The

MAX17498B/MAX17498C are useful in implementing

low-voltage DC-DC applications where the switchingfrequency ripple must be used to calculate the input

capacitor. In both cases, the capacitor must be sized to

meet RMS current requirements for reliable operation.

Capacitor Selection Based on Switching Ripple

(MAX17498B/MAX17498C): For DC-DC applications,

X7R ceramic capacitors are recommended due to their

stability over the operating temperature range. The ESR

and ESL of a ceramic capacitor are relatively low, so

the ripple voltage is dominated by the capacitive component. For the flyback converter, the input capacitor

supplies the current when the main switch is on. Use the

following equation to calculate the input capacitor for a

specified peak-to-peak input switching ripple (V

D I 1 0.5 D

× −×

NEW PRIPEAK NEW

=

C

IN

××

2f V

SW IN_RIP

( )

IN_RIP

2

):

Capacitor Selection Based on Rectified Line-Voltage

Ripple (MAX17498A): For the flyback converter, the

input capacitor supplies the input current when the diode

rectifier is off. The voltage discharge (V

IN_RIP

), due to the

input average current, should be within the limits specified:

0.5 I D

××

PRIPEAK NEW

fV

RIPPLE IN_RIP

×

where f

C

=

IN

, the input AC ripple frequency equal to the

RIPPLE

supply frequency for half-wave rectification, is two times

the AC supply frequency for full-wave rectification.

________________________________________________________________ Maxim Integrated Products 16

Page 17

MAX17498A/MAX17498B/MAX17498C

=+×

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Capacitor Selection Based on Hold-Up Time

Requirements (MAX17498A):

(P

HOLDUP

time (t

fails (V

the converter can regulate the output voltages (V

the input capacitor (CIN) is estimated as:

The input capacitor RMS current can be calculated as:

MOSFET selection criteria includes the maximum drain

voltage, peak/RMS current in the primary, and the

maximum allowable power dissipation of the package

without exceeding the junction temperature limits. The

voltage seen by the MOSFET drain is the sum of the

input voltage, the reflected secondary voltage on the

transformer primary, and the leakage inductance spike.

The MOSFET’s absolute maximum VDS rating must be

higher than the worst-case drain voltage:

The drain current rating of the external MOSFET is

selected to be greater than the worst-case peak

current-limit setting.

Secondary-diode-selection criteria includes the maximum reverse voltage, average current in the secondary,

reverse recovery time, junction capacitance, and the

maximum allowable power dissipation of the package.

The voltage stress on the diode is the sum of the output

voltage and the reflected primary voltage.

The maximum operating reverse-voltage rating must be

higher than the worst-case reverse voltage:

The current rating of the secondary diode should be

selected so that the power loss in the diode (given as

the product of forward-voltage drop and the average

diode current) should be low enough to ensure that the

junction temperature is within limits. This necessitates

that the diode current rating be in the order of 2 x I

that needs to be delivered during hold-up

)

HOLDUP

INFAIL

V V 2.5

DSMAX INMAX

), DC bus voltage at which the AC supply

), and the minimum DC bus voltage at which

3P t

C

I

INCRMS

V 1.25 (K V V )= ×× +

SECDIODE INMAX OUT

××

=

IN

(V V )

0.6 V D

=

For a given output power

HOLDUP HOLDUP

22

INFAIL INMIN

−

××

INMIN MAX

fL

SW PRI

External MOSFET Selection

( )

×

VV

OUT D

2

+

K

Secondary-Diode Selection

INMIN

OUT

),

to 3 x I

time less than 50ns, or Schottky diodes with low junction

capacitance.

The loop compensation values are calculated as:

where:

fSW is the switching frequency of the devices and can

be obtained from the Electrical Characteristics section.

. Select fast-recovery diodes with a recovery

OUT

Error-Amplifier Compensation Design

2

×

SW

f

P

××

2L f

PRI SW

I

OUT

OUT OUT

1

Rf

ZP

1

Rf

Z SW

OUT OUT

= ×

R 450

Z

0.1 f

1 VI

+ ××

=

f

P

π× ×

VC

=

C

Z

π× ×

=

C

P

π× ×

CCM Flyback

Transformer Turns-Ratio Calculation (K = Ns/Np)

The transformer turns ratio can be calculated using the

following formula:

V V (1 D )

+ ×−

( )

OUT D MAX

K

=

VD

where D

input (0.35 for MAX17498A/MAX17498C and 0.7 for

MAX17498B).

Calculate the primary inductance based on the ripple:

where D

DC input voltage (V

The output current, down to which the flyback converter

should operate in CCM, is determined by selection of

the fraction A in the above primary inductance formula.

For example, A should be selected as 0.15 so that the

converter operates in CCM down to 15% of the maximum

is the duty cycle assumed at minimum

MAX

V V (1 D ) K

( )

L

NOM

D

PRI

NOM

OUT D NOM

=

, the nominal duty cycle at nominal operating

INNOM

=

V V VK

INNOM OUT D

×

INMIN MAX

Primary-Inductance Calculation

+ ×− ×

2I f

× ×β×

OUT SW

), is given as:

V VK

+×

( )

OUT D

+ +×

( )

________________________________________________________________ Maxim Integrated Products 17

Page 18

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

output load current. Since the ripple in the primary current

waveform is a function of duty cycle and is maximum-atmaximum DC input voltage, the maximum (worst-case)

load current, down to which the converter operates in

CCM, occurs at maximum operating DC input voltage.

VD is the forward drop of the selected output diode at

maximum output current.

Peak/RMS-Current Calculation

RMS current values in the primary and secondary are

needed by the transformer manufacturer to design the

wire diameter for the different windings. Peak current

calculations are useful in setting the current limit. Use the

following equations to calculate the primary and secondary peak and RMS currents.

Maximum primary peak current:

I

PRIPEAK

×

OUT

= +

1D 2L f

− ××

MAX PRI SW

VD

×

INMIN MAX

IK

Maximum primary RMS current:

2

I

∆

2

II I I

PRIRMS PRIPEAK PRIPEAK PRI

where DI

= + − ×∆

is the ripple current in the primary current

PRI

PRI

( )

3

D

×

MAX

waveform, and is given by:

I

∆=

VD

PRI

×

INMIN MAX

Lf

×

PRI SW

Maximum secondary peak current:

Primary RCD Snubber Selection

The design procedure for primary RCD snubber selection

is identical to that outlined in the DCM Flyback section.

Output-Capacitor Selection

X7R ceramic output capacitors are preferred in industrial

applications due to their stability over temperature. The

output capacitor is usually sized to support a step load

of 50% of the maximum output current in the application

so that the output-voltage deviation is contained to 3% of

the output-voltage change. The output capacitance can

be calculated as:

OUT

t ()

RESPONSE

where I

is the load step, t

STEP

time of the controller, DV

∆

V

OUT

0.33 1

≅+

ff

C SW

RESPONSE

is the allowable output-

OUT

is the response

×

It

STEP RESPONSE

=

C

voltage deviation, and fC is the target closed-loop

crossover frequency. fC is chosen to be less than 1/5 the

worst-case (lowest) RHP zero frequency (f

). The right

RHP

half-plane zero frequency is calculated as:

2

MAX OUT

2

f

ZRHP

(1 D ) V

=

2D LI K

−×

×π× × × ×

MAX PRI OUT

For the CCM flyback converter, the output capacitor supplies the load current when the main switch is on, and

therefore, the output-voltage ripple is a function of load

current and duty cycle. Use the following equation to

estimate the output-voltage ripple:

I

I

SECPEAK

PRIPEAK

=

K

Maximum secondary RMS current:

2

I

∆

2

1D

×−

SEC

3

MAX

( )

II I I

SECRMS SECPEAK SECPEAK SEC

where DI

= + − ×∆

is the ripple current in the secondary current

SEC

waveform, and is given by:

I

∆=

SEC

VD

×

INMIN MAX

L fK

××

PRI SW

Current-limit setting the peak current can be calculated as:

I I 1.2= ×

LIM PRIPEAK

________________________________________________________________ Maxim Integrated Products 18

ID

×

V

∆=

COUT

OUT MAX

fC

×

SW OUT

Input-Capacitor Selection

The design procedure for input-capacitor selection is

identical to that outlined in the DCM Flyback section.

External MOSFET Selection

The design procedure for external MOSFET selection is

identical to that outlined in the DCM Flyback section.

Secondary-Diode Selection

The design procedure for secondary-diode selection is

identical to that outlined in the DCM Flyback section.

Page 19

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Error-Amplifier Compensation Design

In the CCM flyback converter, the primary inductance

and the equivalent load resistance introduces a right

half-plane zero at the following frequency:

2

MAX OUT

2

f

ZRHP

(1 D ) V

=

2D LI K

−×

×π× × × ×

MAX PRI OUT

The loop-compensation values are calculated as:

f

RHP

2

200 I

×

R1

= ×+

Z

OUT

(1 D ) 5 f

−×

MAX P

where fP, the pole due to output capacitor and load, is

given by:

(1 D ) I

+×

f

=

P

MAX OUT

2C V

×π× ×

OUT OUT

The above selection sets the loop-gain crossover

frequency (fC, where the loop gain equals 1) equal to 1/5

the right half-plane zero frequency:

f

ZRHP

f5≤

C

With the control-loop zero placed at the load pole frequency:

C

=

Z

1

2R f

π× ×

ZP

With the high-frequency pole placed at 1/2 the switching

frequency:

C

=

P

1

Rf

π× ×

Z SW

DCM Boost

In a DCM boost converter, the inductor current returns to

zero in every switching cycle. Energy stored during the

on time of the main switch is delivered entirely to the load

in each switching cycle.

Inductance Selection

The design procedure starts with calculating

the boost converter’s input inductor so that it operates in DCM at all operating line and load conditions.

The critical inductance required to maintain DCM

operation is calculated as:

2

2

where V

V V V 0.4

−× ×

( )

L

IN

INMIN

OUT INMIN INMIN

≤

IV f

××

OUT OUT SW

is the minimum input voltage.

Peak /RMS-Current Calculation

To set the current limit, the peak current in the inductor

can be calculated as:

I I 1.2

= ×

LIM PK

where I is given by:

PK

×− ×

2 (V V ) I

=

I

PK

L

is the minimum value of the input inductor, taking

INMIN

into account tolerance and saturation effects. f

OUT INMIN OUT

Lf

×

INMIN SWMIN

SWMIN

is

the minimum switching frequency for the MAX17498B

from the Electrical Characteristics section.

Output-Capacitor Selection

X7R ceramic output capacitors are preferred in industrial

applications due to their stability over temperature. The

output capacitor is usually sized to support a step load

of 50% of the maximum output current in the application

so that the output-voltage deviation is contained to 3% of

the output-voltage change. The output capacitance can

be calculated as:

OUT

t ()

RESPONSE

where I

is the load step, t

STEP

time of the controller, DV

∆

V

OUT

0.33 1

≅+

ff

C SW

RESPONSE

is the allowable output-

OUT

is the response

×

It

STEP RESPONSE

=

C

voltage deviation, and fC is the target closed-loop crossover frequency. fC is chosen to be 1/10 the switching

frequency (fSW). For the boost converter, the output

capacitor supplies the load current when the main switch

is on, and therefore, the output-voltage ripple is a function of duty cycle and load current. Use the following

equation to calculate the output-capacitor ripple:

I LI

××

V

∆=

COUT

OUT IN PK

VC

×

INMIN OUT

________________________________________________________________ Maxim Integrated Products 19

Page 20

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Input-Capacitor Selection

The value of the required input ceramic capacitor can

be calculated based on the ripple allowed on the input

DC bus. The input capacitor should be sized based

on the RMS value of the AC current handled by it.

The calculations are:

3.75 I

×

C

=

IN

V f (1 D )

× ×−

INMIN SWMIN MAX

OUT

The capacitor RMS can be calculated as:

I

I

CIN_RMS

PK

=

23

×

Error-Amplifier Compensation Design

The loop-compensation values for the error amplifier can

now be calculated as:

G G 10

××

C G 10 nF

DC M

= = ×

Z DC

2f

×π×

SW

( )

where GDC, the DC gain of the power stage, is given as:

2

G

DC

where V

and I

OUT

× − ×× ×

8 (V V ) f V L

=

R

INMIN

is the maximum load current:

OUT INMIN SW OUT IN

(2V V ) I

V C (V V )

OUT OUT OUT INMIN

=

Z

I C (2V V )

OUT Z OUT INMIN

−×

OUT INMIN OUT

×× −

×× −

2

is the minimum operating input voltage

C ESR

×

C

OUT

=

P

R

Z

Slope Compensation

In theory, the DCM boost converter does not require

slope compensation for stable operation. In practice, the

converter needs a minimum amount of slope for good

noise immunity at very light loads. The minimum slope is

set for the devices by connecting the SLOPE pin to the

VCC pin.

Output-Diode Selection

The voltage rating of the output diode for the boost

converter ideally equals the output voltage of the

boost converter. In practice, parasitic inductances and

capacitances in the circuit interact to produce voltage overshoot during the turn-off transition of the

diode that occurs when the main switch turns on. The

diode rating should therefore be selected with the

necessary margin to accommodate this extra voltage

stress. A voltage rating of 1.3 x V

provides the

OUT

necessary design margin in most cases.

The current rating of the output diode should be selected

so that the power loss in the diode (given as the product

of forward-voltage drop and the average diode current)

is low enough to ensure that the junction temperature

is within limits. This necessitates that the diode current

rating be in the order of 2 x I

OUT

to 3 x I

. Select fast-

OUT

recovery diodes with a recovery time less than 50ns or

Schottky diodes with low junction capacitance.

Internal MOSFET RMS Current Calculation

The voltage stress on the internal MOSFET, whose drain

is connected to LX, ideally equals the sum of the output

voltage and the forward drop of the output diode. In

practice,

voltage overshoot and ringing occur due to the

action of circuit parasitic elements during the turn-off

transition. The maximum rating of the devices’ internal

n-channel MOSFET is 65V, making it possible to design

boost converters with output voltages up to 48V and sufficient margin for voltage overshoot and ringing. The RMS

current into LX is useful in estimating the conduction loss

in the internal nMOSFET, and is given as:

3

I Lf

××

I

LX_RMS

PK INS SW

=

3V

×

INMIN

where IPK is the peak current calculated at the lowest

operating input voltage (V

INMIN

).

CCM Boost

In a CCM boost converter, the inductor current does

not return to zero during a switching cycle. Since the

MAX17498B implements a nonsynchronous boost converter, the inductor current enters DCM operation at load

currents below a critical value equal to 1/2 the peak-topeak ripple in the inductor current.

Inductor Selection

The design procedure starts with calculating the boost

converter’s input inductor at nominal input voltage for a

ripple in the inductor current equal to 30% of the maximum input current:

V D (1 D)

××−

=

IN

0.3 I f

IN

××

OUT SW

L

where D is the duty cycle calculated as:

V VV

+−

OUT D IN

D

=

VV

+

OUT D

VD is the voltage drop across the output diode of the

boost converter at maximum output current.

________________________________________________________________ Maxim Integrated Products 20

Page 21

MAX17498A/MAX17498B/MAX17498C

×−

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Peak/RMS-Current Calculation

To set the current limit, the peak current in the inductor

and internal nMOSFET can be calculated as:

V D (1 D ) I

× ×−

I

PK

I 1.2 for D 0.5

= +× ≥

PK MAX

D

, the maximum duty cycle, is obtained by substitut-

MAX

ing the minimum input operating voltage (V

equation above for duty cycle. L

OUT MAX MAX OUT

= +

0.25 V I

L f (1 D)

INMIN SWMIN

L f (1 D)

INMIN SWMIN

1.2 for D 0.5

×≥

×

OUT OUT

MAX

×−

INMIN

) in the

INMIN

is the minimum

value of the input inductor taking into account tolerance

and saturation effects. f

is the minimum switch-

SWMIN

ing frequency for the MAX17498B from the Electrical

Characteristics section.

Output-Capacitor Selection

X7R ceramic output capacitors are preferred in industrial

applications due to their stability over temperature. The

output capacitor is usually sized to support a step load

of 50% of the maximum output current in the application,

such that the output-voltage deviation is contained to 3%

of the output-voltage change. The output capacitance

can be calculated as:

C

where I

is the load step, t

STEP

response time of the controller, DV

=

OUTF

t ()

RESPONSE

∆

V

OUT

0.33 1

≅+

ff

C SW

RESPONSE

is the allowable

OUT

is the

×

It

STEP RESPONSE

output-voltage deviation, and fC is the target closedloop crossover frequency. fC is chosen to be 1/10 the

switching frequency (fSW). For the boost converter, the

output capacitor supplies the load current when the main

switch is on, and therefore, the output-voltage ripple is a

function of duty cycle and load current. Use the following

equation to calculate the output-capacitor ripple:

ID

×

V

∆=

COUT

OUT MAX

Cf

×

OUT SW

Input-Capacitor Selection

The input ceramic capacitor value required can be calculated based on the ripple allowed on the input DC bus.

The input capacitor should be sized based on the RMS

value of the AC current handled by it. The calculations are:

3.75 I

×

C

=

IN

V f (1 D )

INMIN SW MAX

OUT

× ×−

The input-capacitor RMS current can be calculated as:

I

∆

I

CIN_RMS

LIN

=

23

×

where:

V D (1 D )

× ×−

I for D 0.5

∆= <

LIN MAX

OUT MAX MAX

Lf

I for D 0.5

∆= ≥

LIN MAX

Lf

×

INMIN SWMIN

0.25 V

×

OUT

×

INMIN SWMIN

Error-Amplifier Compensation Design

The loop-compensation values for the error amplifier can

now be calculated as:

2

OUT OUT MAX

IL

OUTMAX IN

VC

OUT OUT

=

2I R

××

C

=

P

π× ×

×

×

OUTMAX Z

1

fR

SW Z

where I

R

=

Z

OUTMAX

203 V C (1 D )

× × ×−

is the maximum load current:

C

Z

Slope-Compensation Ramp

The slope required to stabilize the converter at duty

cycles greater than 50% can be calculated as:

0.41(V V )

S V per µs

=

E

−

OUT INMIN

L

IN

where LIN is in µH.

________________________________________________________________ Maxim Integrated Products 21

Page 22

MAX17498A/MAX17498B/MAX17498C

=+ ++

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Output-Diode Selection

The design procedure for output-diode selection is identical to that outlined in the DCM Boost section.

Internal MOSFET RMS Current Calculation

The voltage stress on the internal MOSFET, whose drain

is connected to LX, ideally equals the sum of the output

voltage and the forward drop of the output diode. In

practice, voltage overshoot and ringing occur due to the

action of circuit parasitic elements during the turn-off

transition. The maximum rating of the internal n-channel

MOSFET of the devices is 65V, making it possible to

design boost converters with output voltages up to

48V and sufficient margin for voltage overshoot and

ringing. The RMS current into LX is useful in estimating the

conduction loss in the internal nMOSFET, and is given as:

ID

×

I

LXRMS

where D

input voltage and I

is the duty cycle at the lowest operating

MAX

OUT

OUT MAX

=

(1 D )

−

MAX

is the maximum load current.

Thermal Considerations

It should be ensured that the junction temperature of the

devices does not exceed +125°C under the operating conditions specified for the power supply. The power dissipated in the devices to operate can be calculated using the

following equation:

P VI= ×

IN IN IN

where VIN is the voltage applied at the IN pin and IIN is

operating supply current.

The internal n-channel MOSFET experiences conduction

loss and transition loss when switching between on and

off states. These losses are calculated as:

P IR

CONDUCTION LXRMS DSONLX

P 0.5 V I t t f

TRANSITION INMAX PK R F SW

=× × × +×

= ×

2

( )

where tR and tF are the rise and fall times of the internal

nMOSFET in CCM operation. In DCM operation, since

the switch current starts from zero, only tF exists and the

transition-loss equation changes to:

P 0.5 V I t f= × × ××

TRANSITION INMAX PK F SW

Additional loss occurs in the system in every switching cycle due to energy stored in the drain-source

capacitance of the internal MOSFET being lost when

the MOSFET turns on and discharges the drain-source

capacitance voltage to zero. This loss is estimated as:

P 0.5 C V f=×× ×

CAP DS DSMAX SW

The total power loss in the devices can be calculated

from the following equation:

P PP P P

LOSS IN CONDUCTION TRANSITION CAP

The maximum power that can be dissipated in the

devices is 1666mW at +70°C temperature. The powerdissipation capability should be derated as the temperature rises above +70°C at 21mW/°C. For a multilayer

board, the thermal-performance metrics for the package

are given below:

48°C / W

θ=

JA

10°C / W

θ=

JC

The junction-temperature rise of the devices can be

estimated at any given maximum ambient temperature

(T

If the application has a thermal-management system

that ensures that the exposed pad of the devices is

maintained at a given temperature (T

proper heatsinks, then the junction-temperature rise of

the devices can be estimated at any given maximum

ambient temperature from the following equation:

) from the following equation:

AMAX

TT P= +θ ×

JMAX AMAX JA LOSS

( )

2

EPMAX

) by using

________________________________________________________________ Maxim Integrated Products 22

TT P= +θ ×

JMAX EPMAX JC LOSS

( )

Page 23

MAX17498A/MAX17498B/MAX17498C

AC-DC and DC-DC Peak Current-Mode Converters

for Flyback/Boost Applications

Layout, Grounding and Bypassing

All connections carrying pulsed currents must be very

short and as wide as possible. The inductance of these

connections must be kept to an absolute minimum

due to the high di/dt of the currents in high-frequency

switching power converters. This implies that the loop