Page 1

General Description

The MAX1737 is a switch-mode lithium-ion (Li+) battery

charger that charges one to four cells. It provides a

regulated charging current and a regulated voltage

with only a ±0.8% total voltage error at the battery terminals. The external N-channel switch and synchronous

rectifier provide high efficiency over a wide input voltage range. A built-in safety timer automatically terminates charging once the adjustable time limit has been

reached.

The MAX1737 regulates the voltage set point and charging current using two loops that work together to transition smoothly between voltage and current regulation. An

additional control loop monitors the total current drawn

from the input source to prevent overload of the input

supply, allowing the use of a low-cost wall adapter.

The per-cell battery voltage regulation limit is set

between +4.0V and +4.4V and can be set from one to

four by pin strapping. Battery temperature is monitored

by an external thermistor to prevent charging if the battery temperature is outside the acceptable range.

The MAX1737 is available in a space-saving 28-pin

QSOP package. Use the evaluation kit (MAX1737EVKIT)

to help reduce design time.

Applications

Features

♦ Stand-Alone Charger for Up to Four Li+ Cells

♦ ±0.8% Accurate Battery Regulation Voltage

♦ Low Dropout: 98% Duty Cycle

♦ Safely Precharges Near-Dead Cells

♦ Continuous Voltage and Temperature Monitoring

♦ <1µA Shutdown Battery Current

♦ Input Voltage Up to +28V

♦ Safety Timer Prevents Overcharging

♦ Input Current Limiting

♦ Space-Saving 28-Pin QSOP

♦ 300kHz PWM Oscillator Reduces Noise

♦ 90% Conversion Efficiency

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

________________________________________________________________ Maxim Integrated Products 1

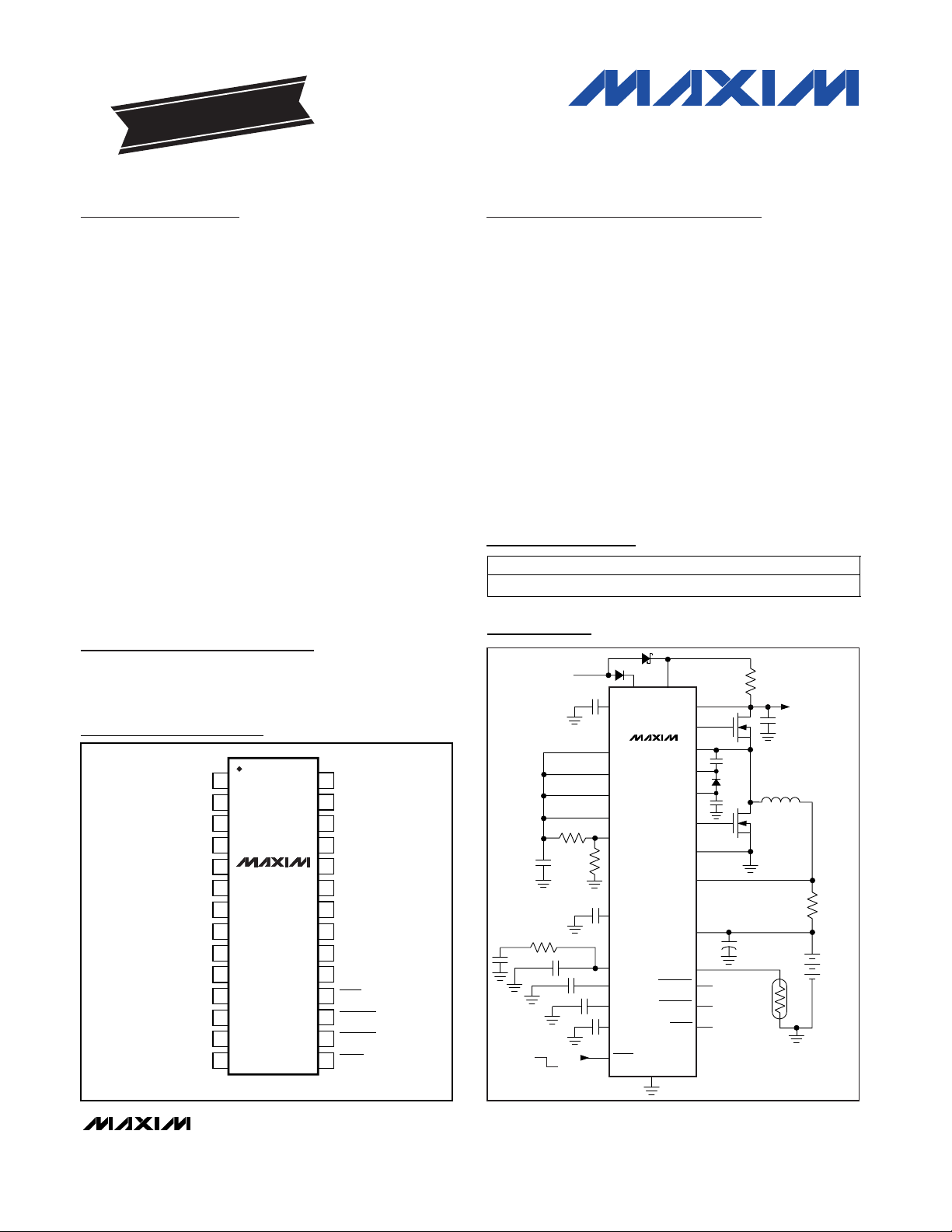

GND

DCIN

CSSP

CSSN

LX

BST

VLO

DLO

PGND

CS

THM

BATT

FASTCHG

FULLCHG

FAULT

SHDN

ON

OFF

TIMER2

TIMER1

Li+

BATTERY

1 TO 4

CELLS

R

S

CCI

CCV

CCS

VADJ

ISETIN

VL

REF

ISETOUT

INPUT SUPPLY

CELL

DHI

SYSTEM

LOAD

MAX1737

19-1626; Rev 3; 5/05

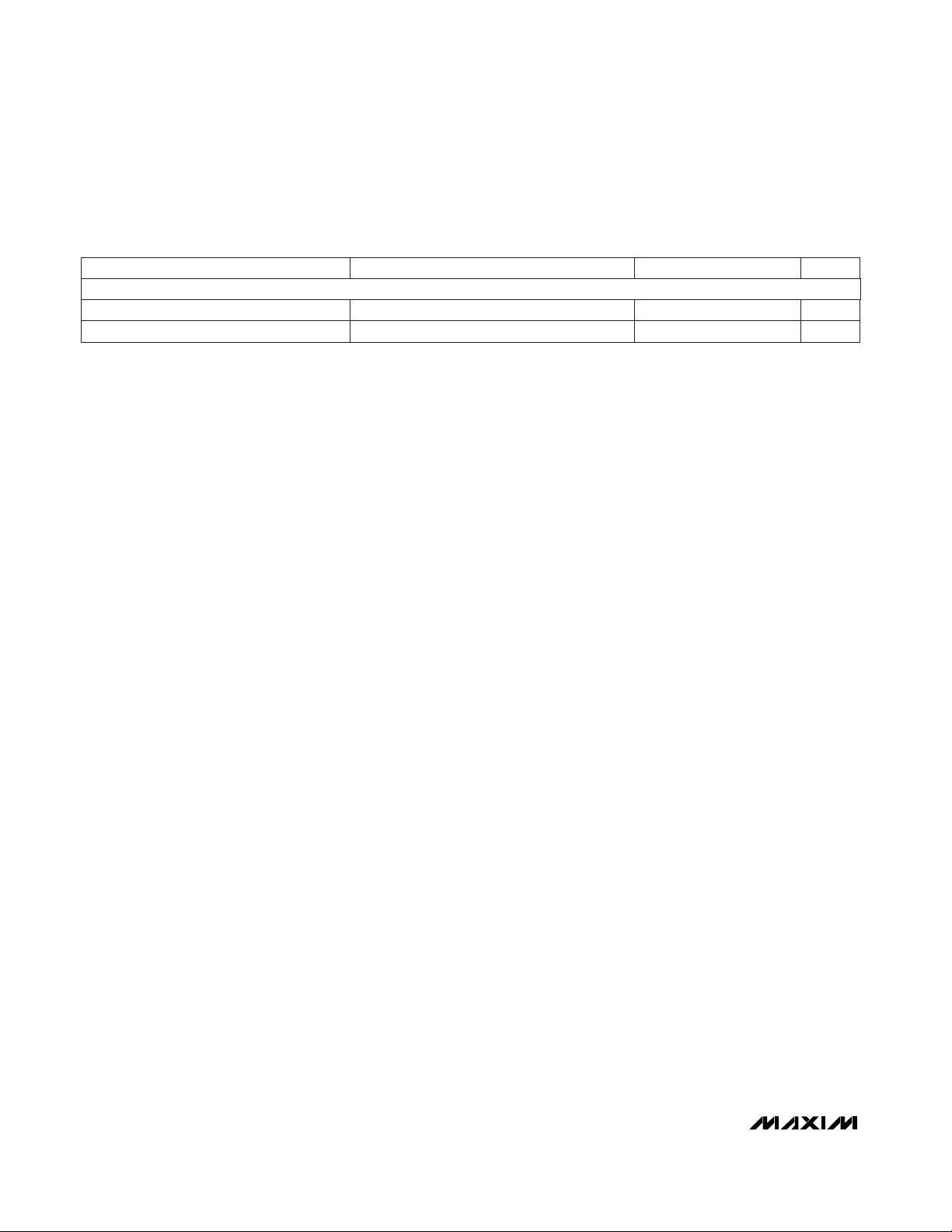

PART

MAX1737EEI -40°C to +85°C

TEMP RANGE PIN-PACKAGE

28 QSOP

EVALUATION KIT

AVAILABLE

Typical Operating Circuit

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DCIN

CSSP

CSSN

DHI

LX

BST

FAULT

VLO

DLO

PGND

CS

SHDN

FULLCHG

FASTCHG

TIMER2

TIMER1

CELL

CCI

CCS

CCV

VADJ

BATT

GND

REF

THM

ISETOUT

ISETIN

VL

QSOP

TOP VIEW

MAX1737

Pin Configuration

Ordering Information

Notebook Computers

Hand-Held Instruments

Li+ Battery Packs

Desktop Cradle Chargers

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

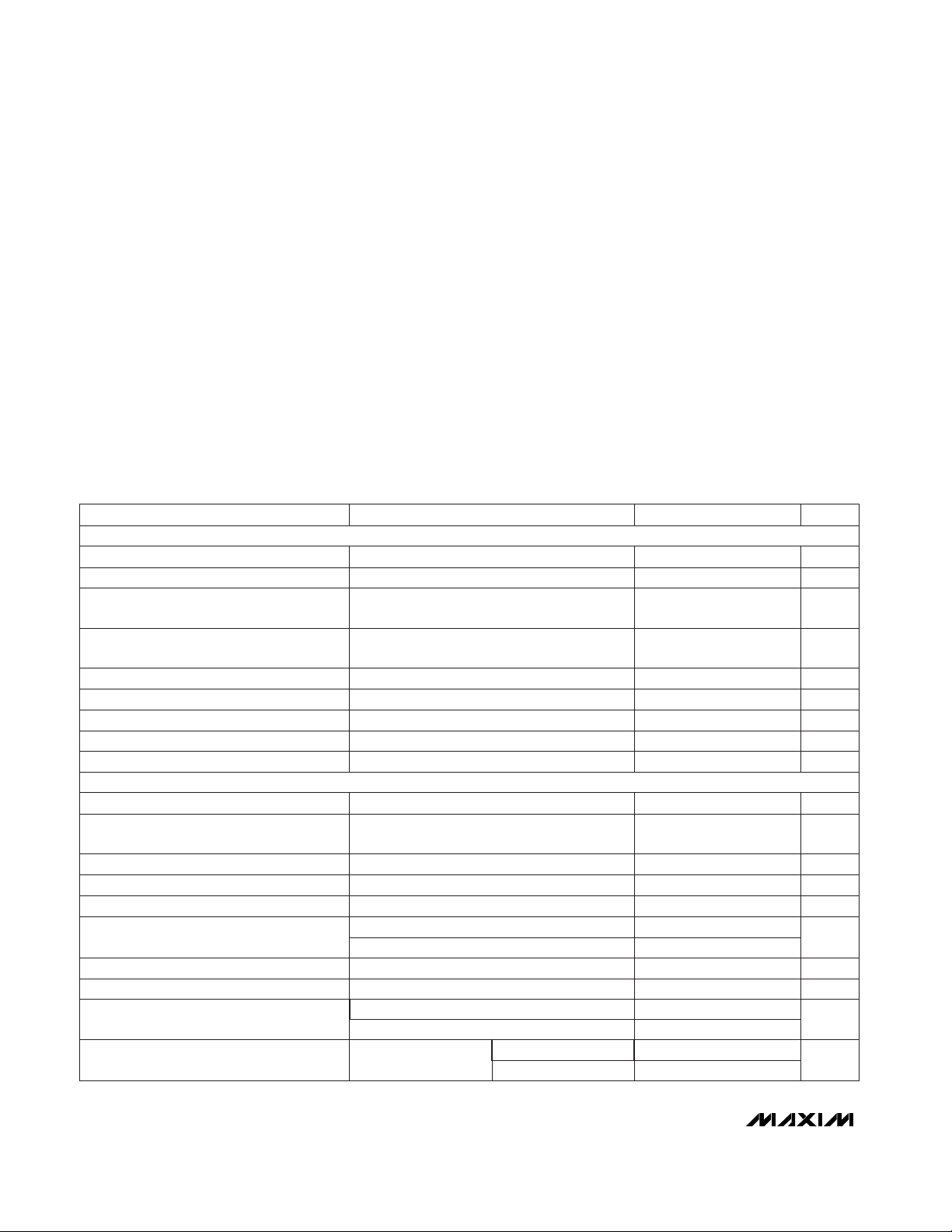

Page 2

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V

DCIN

= V

CSSN

= V

CSSP

= +18V, SHDN = VL, CELL = GND, V

BATT

= VCS= +4.2V, V

VADJ

= V

REF

/ 2, ISETIN =

ISETOUT = REF, R

THM

= 10kΩ, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

CSSP, CSSN, DCIN to GND ...................................-0.3V to +30V

BST, DHI to GND....................................................-0.3V to +36V

BST to LX..................................................................-0.3V to +6V

DHI to LX ..........................................-0.3V to ((BST - LX) + 0.3V)

LX to GND ...............................................-0.3V to (CSSN + 0.3V)

FULLCHG, FASTCHG, FAULT to GND ..................-0.3V to +30V

VL, VLO, SHDN, CELL, TIMER1, TIMER2, CCI,

CCS, CCV, REF, ISETIN, ISETOUT, VADJ,

THM to GND ........................................................-0.3V to +6V

DLO to GND...............................................-0.3V to (VLO + 0.3V)

BATT, CS to GND ...................................................-0.3V to +20V

PGND to GND, CSSP to CSSN..............................-0.3V to +0.3V

VL to VLO ..............................................................-0.3V to +0.3V

VL Source Current...............................................................50mA

Continuous Power Dissipation (TA= +70°C)

28-Pin QSOP (derate 10.8mW/°C above +70°C)........860mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

VREF Output Voltage

SWITCHING REGULATOR

SUPPLY AND REFERENCE

With 1% VADJ resistors

-1 +1

Absolute Voltage Accuracy

Not including VADJ resistor tolerances

-0.8 +0.8

%

V

VADJ

= REF

V

VADJ

= GND

4.386 4.421 4.453

PARAMETER CONDITIONS MIN TYP MAX UNITS

6.0V < V

DCIN

< 28V

SHDN = GND, V

BATT

= 19V

LX = V

DCIN

= 28V, SHDN = GND

I

REF

= 0 to 1mA

6V < V

DCIN

< 28V

V

CSSN

= V

CSSP

= V

DCIN

= 28V, SHDN = GND

In dropout f

OSC

/ 4, V

CCV

= 2.4V,

V

BATT

= 15V, CELL = VL

6.0V < V

DCIN

< 28V

V

BATT

= 15V, CELL = VL

IVL= 0 to 15mA

µA

0.1 5

BATT, CS Input Current

µA

0.1 10

LX Leakage

Ω

7

DHI, DLO On-Resistance

µA

210

CSSN + CSSP Off-State Leakage

%

97 98

LX Maximum Duty Cycle

kHz

270 300 330

PWM Oscillator Frequency

mA

57

DCIN Quiescent Supply Current

V

628

DCIN Input Voltage Range

mV

614

REF Load Regulation

mV

26

REF Line Regulation

4.179 4.20 4.221

V

0.05 0.155

DCIN to BATT Undervoltage Threshold,

DCIN Falling

V

0.19 0.40

DCIN to BATT Undervoltage Threshold,

DCIN Rising

V

5.10 5.40 5.70

VL Output Voltage

mV

44 65

VL Output Load Regulation

225 500

CELL = SHDN = VL, V

BATT

= 17V

BATT, CS Input Voltage Range

Battery Regulation Voltage (V

BATTR

) CELL = float, GND, VL, or REF (Note 1)

019

4.167 4.2 4.233

V

V/cell

Battery Regulation Voltage Adjustment

Range

V

CCV

= 2V

3.948 3.979 4.010

V/cell

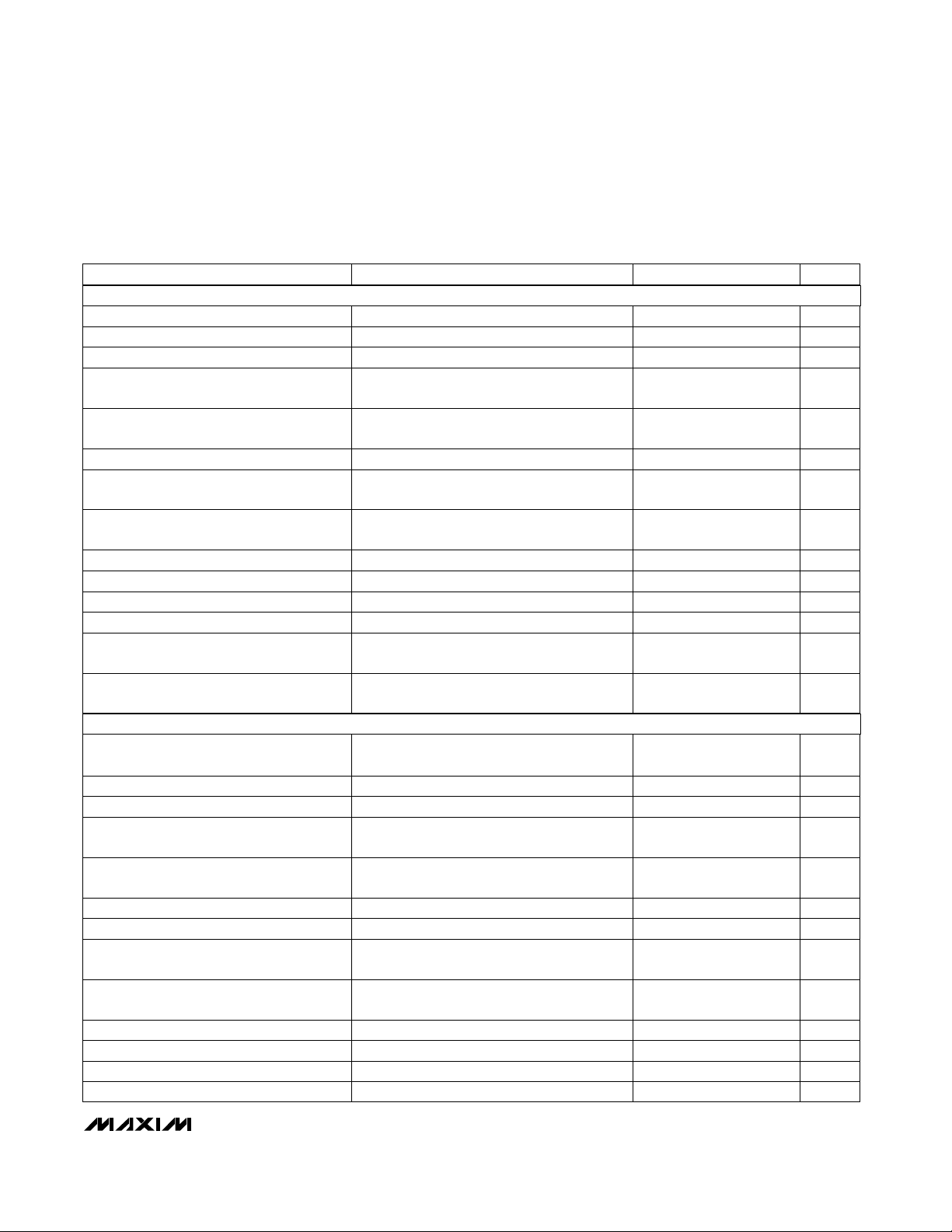

Page 3

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

DCIN

= V

CSSN

= V

CSSP

= +18V, SHDN = VL, CELL = GND, V

BATT

= VCS= +4.2V, V

VADJ

= V

REF

/ 2, ISETIN =

ISETOUT = REF, R

THM

= 10kΩ, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Full-Charge Timer

81 90 100

min

Fast-Charge Timer

81 90 100

min

BATT Overvoltage Threshold (Note 5)

4.55 4.67 4.8

V/cell

BATT Charge Current Full-Charge

Termination Threshold CS-BATT (Note 6)

35 44 55

mV

BATT Recharge Voltage Threshold (Note 7)

94 95 96

% of

V

BATTR

TIMER1, TIMER2 Oscillation Frequency

2.1 2.33 2.6

kHz

Prequalification Timer

6.25 7.5 8.75

min

CCI, CCS Clamp Voltage with Respect

to CCV

25 200

mV

CCV Clamp Voltage with Respect

to CCI, CCS

25 200

mV

THM Trip-Threshold Voltage

1.386 1.4 1.414

V

THM Low-Temperature Current

46.2 49 51.5

µA

THM High-Temperature Current

344 353 362

µA

THM COLD Threshold Resistance (Note 3)

26.92 28.70 30.59

kΩ

THM HOT Threshold Resistance (Note 3)

3.819 3.964 4.115

kΩ

BATT Undervoltage Threshold (Note 4)

2.4 2.5 2.6

V/cell

THM low-temperature or high-temperature

current

V

THM

= 1.4V

V

THM

= 1.4V

Combines THM low-temperature current and

THM rising threshold, V

TRT/ITLTC

Combines THM high-temperature current and

THM rising threshold, V

TRT/ITHTC

CCV Amplifier Transconductance (Note 2)

0.39 0.584 0.80

mS

CCV Amplifier Maximum Output Current

±50

µA

CS to BATT Current-Sense Voltage

30 40 50

mV

CS to BATT Full-Scale Current-Sense

Voltage

185 200 215

mV

CS to BATT Current-Sense Voltage When in

Prequalification State

51015

mV

CS to BATT Hard Current-Limit Voltage

355 385 415

mV

CSSP to CSSN Current-Sense Voltage

10 20 30

mV

CSSP to CSSN Full-Scale

Current-Sense Voltage

90 105 115

mV

CCI Amplifier Transconductance

0.6 1 1.4

mS

CCI Amplifier Output Current

±100

µA

CCS Amplifier Transconductance

1.2 2 2.6

mS

CCS Amplifier Output Current

±100

µA

4.15V < V

BATT

< 4.25V, V

CCV

= 2V

3.5V < V

BATT

< 5V, V

CCV

= 2V

V

ISETOUT

= V

REF

/ 5

V

BATT

= 3V to 17V, CELL = GND or VL

V

BATT

< 2.4V per cell

6V < V

CSSP

< 28V, V

ISETIN

= V

REF

/ 5,

V

CCS

= 2V

6V < V

CSSP

< 28V, V

CCS

= 2V

V

CCI

= 2V

VCS- V

BATT

= 0, 400mV

I

SET

= REF, V

CCS

= 2V

V

CSSP

- V

CSSN

= 0, 200mV

PARAMETER MIN TYP MAX UNITSCONDITIONS

STATE MACHINE

ERROR AMPLIFIERS

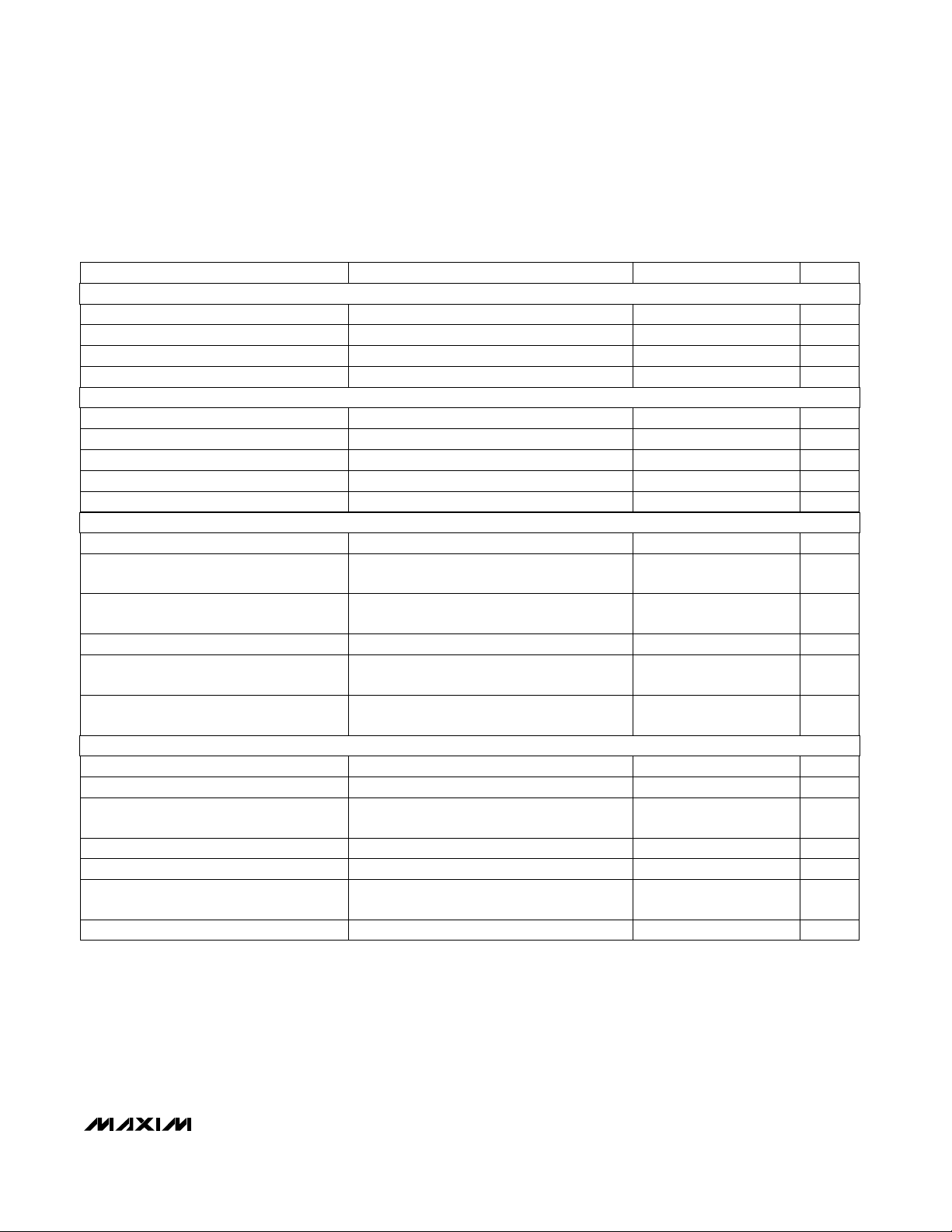

Page 4

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

DCIN

= V

CSSN

= V

CSSP

= +18V, SHDN = VL, CELL = GND, V

BATT

= VCS= +4.2V, V

VADJ

= V

REF

/ 2, ISETIN =

ISETOUT = REF, R

THM

= 10kΩ, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

CELL Input Voltage

0 0.5

1.5 2.5

V

REF

- 0.3 V

REF

+ 0.3

V

VVL- 0.4 V

VL

FASTCHG, FULLCHG, FAULT

Output Low Voltage

0.5

V

FASTCHG, FULLCHG, FAULT Output High

Leakage

1

µA

For 1 cell

For 2 cells

For 3 cells

For 4 cells

I

SINK

= 5mA

FASTCHG, FULLCHG, FAULT = 28V;

SHDN = GND

Top-Off Timer

40.5 45 49.8

min

SHDN Input Voltage High

1.4

V

SHDN Input Voltage Low (Note 8)

0.6

V

VADJ, ISETIN, ISETOUT Input Voltage

Range

0V

REF

V

VADJ, ISETIN, ISETOUT

Input Bias Current

nA

-50 50

SHDN Input Bias Current

-1 1

µA

CELL Input Bias Current

-5 5

µA

ISETIN Adjustment Range

V

REF

/ 5 V

REF

V

ISETOUT Adjustment Range

V

REF

/ 5 V

REF

V

ISETOUT Voltage for I

CHG

= 0

150 220 300

mV

V

VADJ

, V

ISETIN

, V

ISETOUT

= 0 or 4.2V

SHDN = GND or VL

PARAMETER MIN TYP MAX UNITSCONDITIONS

Temperature Measurement Frequency

0.98 1.12 1.32

Hz1nF on TIMER1 and TIMER2

CONTROL INPUTS/OUTPUTS

Page 5

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V

DCIN

= V

CSSN

= V

CSSP

= +18V, SHDN = VL, CELL = GND, V

BATT

= VCS= +4.2V, V

VADJ

= V

REF

/ 2, ISETIN =

ISETOUT = REF, R

THM

= 10kΩ, TA= -40°C to +85°C, unless otherwise noted.) (Note 9)

PARAMETER CONDITIONS MIN MAX UNITS

DCIN Input Voltage Range

VL Output Voltage

REF Output Voltage

REF Line Regulation

PWM Oscillator Frequency

DHI, DLO On-Resistance

BATT, CS Input Voltage Range

Battery Regulation Voltage (V

BATTR

)

Absolute Voltage Accuracy

CS to BATT Current-Sense Voltage

CS to BATT Full-Scale Current-Sense

Voltage

CS to BATT Current-Sense Voltage When in

Prequalification State

CS to BATT Hard Current-Limit Voltage

CSSP to CSSN Current-Sense Voltage

CSSP to CSSN Full-Scale Current-Sense

Voltage

THM Trip-Threshold Voltage

THM Low-Temperature Current

THM COLD Threshold Resistance (Note 3)

BATT Undervoltage Threshold (Note 4)

BATT Overvoltage Threshold (Note 5)

BATT Charge Current Full-Charge

Termination Threshold, CS-BATT (Note 6)

Temperature Measurement Frequency 1nF on TIMER1 and TIMER2

4.55 4.8 V/cell

35 55 mV

0.93 1.37 Hz

6.0V < V

DCIN

< 28V

6V < V

DCIN

< 28V

V

BATT

= 15V, CELL = VL

CELL = float, GND, VL, or REF

Not including V

ADJ

resistor tolerances

V

ISETOUT

= V

REF

/5

V

BATT

= 3V to 17V, CELL = GND or VL

V

BATT

< 2.4V per cell

6V < V

CSSP

< 28V, V

ISETIN

= V

REF

/5,

V

CCS

= 2V

6V < V

CSSP

< 28V, V

CCS

= 2V

THM low-temperature or high-temperature current

V

THM

= 1.4V

Combines THM low-temperature current and

THM rising threshold, V

TRT/ITLTC

260 340 kHz

6 mV

4.166 4.242 V

7 Ω

019V

4.158 4.242 V/cell

-1 1 %

628V

5.1 5.7 V

25 55 mV

180 220 mV

317mV

350 420 mV

535mV

85 115 mV

1.386 1.414 V

46.2 51.5 µA

26.92 30.59 kΩ

2.4 2.6 V/cell

SUPPLY AND REFERENCE

SWITCHING REGULATOR

ERROR AMPLIFIERS

STATE MACHINE

Page 6

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

DCIN

= V

CSSN

= V

CSSP

= +18V, SHDN = VL, CELL = GND, V

BATT

= VCS= +4.2V, V

VADJ

= V

REF

/ 2, ISETIN =

ISETOUT = REF, R

THM

= 10kΩ, TA= -40°C to +85°C, unless otherwise noted.) (Note 9)

Note 1: Battery Regulation Voltage = Number of Cells

× (3.979V + 0.10526 × V

VADJ

).

Note 2: This transconductance is for one cell. Divide by number of cells to determine actual transconductance.

Note 3: See Thermistor section.

Note 4: Below this threshold, the charger reverts to prequalification mode and I

CHG

is reduced to about 5% of full scale.

Note 5: Above this threshold, the charger returns to reset.

Note 6: After full-charge state is complete and peak inductor current falls below this threshold, FULLCHG output switches high.

Battery charging continues until top-off timeout occurs.

Note 7: After charging is complete, when BATT voltage falls below this threshold, a new charging cycle is initiated.

Note 8: In shutdown, charging ceases and battery drain current drops to 5µ A ( max), but internal IC bias current remains on.

Note 9: Specifications to -40°C are guaranteed by design and not production tested.

SHDN Input Voltage Low (Note 8)

0.6

V

SHDN Input Voltage High

1.4 V

PARAMETER MIN TYP MAX UNITSCONDITIONS

CONTROL INPUTS/OUTPUTS

Page 7

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

________________________________________________________________________________________ 7

0

1.0

0.5

2.5

2.0

1.5

4.0

3.5

3.0

4.5

0 1.00.5 1.5 2.0 2.5

BATTERY VOLTAGE

vs. CHARGING CURRENT

MAX1737 toc01

CHARGING CURRENT (A)

BATTERY VOLTAGE (V)

R18 = 0.1Ω

0

50

25

125

100

75

175

200

150

225

0 1.5 2.00.5 1.0 2.5 3.0 3.5 4.0 4.5

CHARGING CURRENT-SENSE VOLTAGE

vs. ISETOUT VOLTAGE

MAX1737 toc02

ISETOUT VOLTAGE (V)

CHARGING CURRENT-SENSE VOLTAGE (mV)

0

20

40

60

80

100

120

0 1.00.5 1.5 2.0 2.5 3.0 3.5 4.0 4.5

INPUT CURRENT-SENSE VOLTAGE

vs. ISETIN VOLTAGE

MAX1737 toc03

ISETIN VOLTAGE (V)

INPUT CURRENT-SENSE VOLTAGE (mV)

3.95

4.05

4.00

4.15

4.10

4.25

4.20

4.30

4.40

4.35

4.45

0 1.0 1.5 2.00.5 2.5 3.0 3.5 4.0 4.5

VOLTAGE LIMIT vs. VADJ VOLTAGE

MAX1737 toc04

VADJ VOLTAGE (V)

VOLTAGE LIMIT (V)

4.175

4.185

4.180

4.195

4.190

4.200

4.205

-40 20 40-20 0 60 80 100

REFERENCE VOLTAGE

vs. TEMPERATURE

MAX1737 toc05

TEMPERATURE (°C)

REFERENCE VOLTAGE (V)

50

60

70

80

90

100

81216202428

EFFICIENCY vs. INPUT VOLTAGE

MAX1737 toc06

INPUT VOLTAGE (V)

EFFICIENCY (%)

CELL = FLOAT (2 CELLS)

V

BATT

= 7V

R18 = 0.1Ω (I

BATT

= 2A)

4.190

4.194

4.192

4.198

4.196

4.202

4.200

4.204

4.208

4.206

4.210

0 200 300 400100 500 600 700 900800 1000

REFERENCE LOAD REGULATION

MAX1737 toc07

REFERENCE CURRENT (µA)

REFERENCE VOLTAGE (V)

1000

0.1

0.1 1 10

TIMEOUT vs. TIMER1 CAPACITANCE

1

MAX1737 toc08

CAPACITANCE (nF)

TIMEOUT (MINUTES)

10

100

PREQUALIFICATION MODE

TOP-OFF MODE

FULL-CHARGE

MODE

1000

1

0.1 1 10

FAST-CHARGE TIMEOUT

vs. TIMER2 CAPACITANCE

10

MAX1737 toc09

CAPACITANCE (nF)

TIMEOUT (MINUTES)

100

Typical Operating Characteristics

(Circuit of Figure 1, V

DCIN

= +18V, ISETIN = ISETOUT = REF, V

VADJ

= V

REF

/ 2, TA= +25°C, unless otherwise noted.)

Page 8

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

8 _______________________________________________________________________________________

Pin Description

Source Current-Sense Positive Input. See Input Current Regulator section.CSSP27

Power-Supply Input. DCIN is the input supply for the VL regulator. Bypass DCIN to GND with a

0.1µF capacitor. Also used for the source undervoltage sensing.

DCIN28

Synchronous-Rectifier MOSFET Gate-Drive Bias. Bypass VLO to PGND with a 0.1µF capacitor.VLO22

High-Side MOSFET Gate Drive Bias. Connect a 0.1µF or greater capacitor from BST and LX.BST23

Power Inductor Switching Node. Connect LX to the high-side MOSFET source.LX24

High-Side MOSFET Gate-Drive OutputDHI25

Source Current-Sense Negative Input. See Input Current Regulator section.CSSN 26

Shutdown Input. Drive SHDN low to disable charging. Connect SHDN to VL for normal

operation.

SHDN

18

Battery Current-Sense Positive Input. See Charging Current Regulator section.CS19

Power GroundPGND20

Synchronous-Rectifier MOSFET Gate-Drive Output DLO21

Full-Charge Indicator. Open-drain output pulls low when charging with constant voltage in

full-charge state.

FULLCHG

17

Fast-Charge Indicator. Open-drain output pulls low when charging with constant current.

FASTCHG

16

Charge Fault Indicator. Open-drain output pulls low when charging terminates abnormally

(Table 1).

FAULT

15

Timer 2 Adjustment. Connect a capacitor from TIMER2 to GND to set the fast-charge time. See

Timers section.

TIMER214

Voltage Regulation Loop Compensation PointCCV9

Input Source Current Regulation Compensation PointCCS10

Battery-Current Regulation Loop Compensation PointCCI11

Cell-Count Programming Input. See Table 2CELL12

Timer 1 Adjustment. Connect a capacitor from TIMER1 to GND to set the prequalification,

full-charge, and top-off times. See Timers section.

TIMER113

4.2V Reference Voltage Output. Bypass REF to GND with a 1µF or larger ceramic capacitor. REF5

Analog GroundGND6

Battery Voltage-Sense Input and Current-Sense Negative InputBATT7

Voltage Adjust. Use a voltage-divider to set the VADJ voltage between 0 and V

REF

to adjust the

battery regulation voltage by ±5%. See Setting the Voltage Limit section.

VADJ8

Thermistor Input. Connect a thermistor from THM to GND to set a qualification temperature

range. If unused, connect a 10kΩ resistor from THM to ground. See Thermistor section.

THM4

Battery Charging Current Adjust. Use a voltage-divider to set the voltage between 0 and V

REF

.

See Charging Current Regulator section.

ISETOUT3

PIN

Input Current Limit Adjust. Use a voltage-divider to set the voltage between 0 and V

REF

.

See Input Current Regulator section.

ISETIN2

Chip Power Supply. Output of the 5.4V linear regulator from DCIN. Bypass VL to GND with a

2.2µF or larger ceramic capacitor.

VL

1

FUNCTIONNAME

Page 9

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

_______________________________________________________________________________________ 9

Detailed Description

The MAX1737 includes all of the functions necessary to

charge between one and four series Li+ battery cells. It

includes a high-efficiency synchronous-rectified stepdown DC-DC converter that controls charging voltage

and current. It also includes input source-current limiting, battery temperature monitoring, battery undervoltage precharging, battery fault indication, and a state

machine with timers for charge termination.

The DC-DC converter uses an external dual N-channel

MOSFET as a switch and a synchronous rectifier to

convert the input voltage to the charging current or voltage. The typical application circuit is shown in Figure 1.

Figure 2 shows a typical charging sequence and

Figure 3 shows the block diagram. Charging current is

set by the voltage at ISETOUT and the voltage across

R18. The battery voltage is measured at the BATT pin.

The battery regulation voltage is set to 4.2V per cell

and can be adjusted ±5% by changing the voltage at

the VADJ pin. By limiting the adjust range, the voltage

27

26

22

23

25

24

21

20

19

7

4

28

CSSP

DCIN

CSSN

VLO

BST

DHI

LX

DLO

PGND

CS

BATT

THM

REF

ISETIN

VL

SHDN

ISETOUT

VADJ

CELL

GND

CCV

CCI

CCS

TIMER1

TIMER2

R12

Li+

BATTERY

(1 TO 4 CELLS)

L1

R18

22µH

FAULT

FULLCHG

FULL CHARGE

FAST CHARGE

FAULT

FASTCHG

C6

47nF

C13

1nF

C14

1nF

1nF

C5

47nF

C4

C3

1µF

C1

4.7µF

C18

22µF

C19

22µF

SYSTEM

LOAD

INPUT

SUPPLY

C2

0.1µF

C7

0.1µF

C8

0.1µF

R1

10k

R8

D1

D3

D2

R9

0.1µF

16

11

9

6

12

3

8

2

5

18

1

10

13

14

17

15

0.1µF

0.1µF

C15

68µF

C9

0.1µF

C11

0.1µF

C10

0.1µF

MAX1737

++

THERMISTOR

Figure 1. Typical Application Circuit

Page 10

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

10 ______________________________________________________________________________________

accuracy is better than 1% while using 1% setting

resistors.

The MAX1737 includes a state machine that controls

the charging algorithm. Figure 4 shows the state diagram. Table 1 lists the charging state conditions. When

power is applied or SHDN is driven high, the part goes

into the reset state where the timers are reset to zero to

prepare for charging. From the reset state, it enters the

prequalification state. In this state, 1/20 of the fastcharge current charges the battery, and the battery

temperature and voltage are measured. If the voltage is

above the undervoltage threshold and the temperature

is within the limits, then it will enter the fast-charge

state. If the battery voltage does not rise above the

undervoltage threshold before the prequalification timer

expires, the charging terminates and the FAULT output

goes low. The prequalification time is set by the

TIMER1 capacitor (C

TIMER1

). If the battery is outside

the temperature limits, charging and the timer are suspended. Once the temperature is back within limits,

charging and the timer resume.

In the fast-charge state, the FASTCHG output goes low,

and the batteries charge with a constant current (see

the Charging Current Regulator section). If the battery

voltage reaches the voltage limit before the fast timer

expires, the part enters the full-charge state. If the fastcharge timer expires before the voltage limit is

reached, charging terminates with a fault indication.

The fast-charge time limit is set by the TIMER2 capaci-

tor (C

TIMER2

). If the battery temperature is outside the

limits, charging pauses and the timers are suspended

until the temperature returns to within the limits.

In the full-charge state, the FULLCHG output goes low

and the batteries charge at a constant voltage (see the

Voltage Regulator section). When the charging current

drops below 10% of the charging current limit, or if the

full-charge timer expires, the state machine enters the

top-off state. In the top-off state, the batteries continue

to charge at a constant voltage until the top-off timer

expires, at which time it enters the done state. In the

done state, charging stops until the battery voltage

drops below the recharge-voltage threshold. It then

enters the reset state to start the charging process

again. In the full-charge or the top-off state, if the battery temperature is outside the limits, charging pauses

and the timers are suspended until the battery temperature returns to within limits.

Voltage Regulator

Li+ batteries require a high-accuracy voltage limit while

charging. The MAX1737 uses a high-accuracy voltage

regulator (±0.8%) to limit the charging voltage. The battery regulation voltage is nominally set to 4.2V per cell

and can be adjusted ±5% by setting the voltage at the

VADJ pin between reference voltage and ground. By

limiting the adjust range of the regulation voltage, an

overall voltage accuracy of better than 1% is maintained while using 1% resistors. CELL sets the cell

count from one to four series cells (see Setting the

Battery Regulation Voltage section).

An internal error amplifier (GMV) maintains voltage regulation (Figure 3). The GMV amplifier is compensated

at CCV. The component values shown in Figure 1 provide suitable performance for most applications.

Individual compensation of the voltage regulation and

current regulation loops allows for optimal compensation of each.

Charging Current Regulator

The charging current-limit regulator limits the charging

current. The current is sensed by measuring the voltage across the current-sense resistor (R18, Figure 1)

placed between the BATT and CS pins. The voltage on

the ISETOUT pin also controls the charging current.

Full-scale charging current is achieved by connecting

ISETOUT to REF. In this case, the full-scale currentsense voltage is 200mV from CS to BATT.

When choosing the charging current-sense resistor,

note that the voltage drop across this resistor causes

further power loss, reducing efficiency. However,

adjusting ISETOUT to reduce the voltage across the

FAST-

CHARGE

STATE

OPENDRAIN

LOW

OPENDRAIN

LOW

BATTERY

CURRENT

BATTERY

VOLTAGE

FASTCHG

OUTPUT

FULLCHG

OUTPUT

FULL-

CHARGE

STATE

TOP-OFF

STATE

DONE

CHARGE I = 1C

BATTERY

INSERTION

OR SHDN HIGH

TRANSITION TO

VOLTAGE MODE

(APPROX 85% CHARGE)

FULL-CHARGE TIMER

TIMES OUT OR

BATTERY CURRENT

DROPS TO C/10

(APPROX 95% CHARGE)

TOP-OFF TIMER

TIMES OUT, END OF ALL

CHARGE FUNCTIONS

Figure 2. Charge State and Indicator Output Timing for a

Typical Charging Sequence

Page 11

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

______________________________________________________________________________________ 11

current-sense resistor may degrade accuracy due to

the input offset of the current-sense amplifier.

The charging-current error amplifier (GMI) is compensated at CCI. A 47nF capacitor at CCI provides suitable performance for most applications.

Input Current Regulator

The total input current (from a wall cube or other DC

source) is the sum of system supply current plus the

battery-charging current. The input current regulator

limits the source current by reducing charging current

when input current exceeds the set input current limit.

System current normally fluctuates as portions of the

system are powered up or put to sleep. Without input

PWMCOMP

ON

BST

CCI

DHI

LX

DLO

VLO

PGND

CCV

CCS

LO

PWMCMP

ILIMIT

LOWILIM

OSC

160ns

160ns

PWMOSC

REF/42

REF/2

REF/2.6

CCI

GND

CCS

LVC

GMS

GND

GND

R

GND

R

R/9

3R

DHI

DLO

GATE

CONTROL

CCV

SW+

SW-

CS+

CS-

EA+

EA-

GMI

10x

CSS

GMV

GND

GND

R

R

R/2

R/2R/2R

R

9R

CELL

CELL

REF

VADJ

3R

ISETOUT

ISETIN

REF/42

STOP

SLOPE

COMP

BATT

SAW

PREQ

BATT

SHDN

CS

CSSN

CSSP

ONE

TWO

THREE

FOUR

5x

CSI

MAX1737

Figure 3. PWM Controller Block Diagram

Page 12

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

12 ______________________________________________________________________________________

current regulation, the input source must be able to

supply the maximum system current plus the maximum

charger input current. By using the input current limiter,

the current capability of the AC wall adapter may be

lowered, reducing system cost.

Input current is measured through an external sense

resistor at CSSP and CSSN. The voltage at ISETIN also

adjusts the input current limit. Full-scale input current is

achieved when ISETIN is connected to REF, setting the

full-scale current-sense voltage to 100mV.

When choosing the input current-sense resistor, note

that the voltage drop across this resistor adds to the

power loss, reducing efficiency. Reducing the voltage

across the current-sense resistor may degrade input

current limit accuracy due to the input offset of the

input current-sense amplifier.

The input current error amplifier (GMS) is compensated

at CCS. A 47nF capacitor at CCS provides suitable performance for most applications.

PWM Controller

The PWM controller drives the external MOSFETs to

control the charging current or voltage. The input to the

PWM controller is the lowest of CCI, CCV, or CCS. An

internal clamp limits the noncontrolling signals to within

200mV of the controlling signal to prevent delay when

switching between regulation loops.

SHUTDOWN

FASTCHG = HIGH

FULLCHG = HIGH

FAULT = HIGH

RESET

FASTCHG = HIGH

FULLCHG = HIGH

FAULT = HIGH

PREQUAL

FASTCHG = LOW

FULLCHG = HIGH

FAULT = HIGH

FAULT

FASTCHG = HIGH

FULLCHG = HIGH

FAULT = LOW

FAST CHARGE

FASTCHG = LOW

FULLCHG = HIGH

FAULT = HIGH

FULL CHARGE

FASTCHG = HIGH

FULLCHG = LOW

FAULT = HIGH

DONE

FASTCHG = HIGH

FULLCHG = HIGH

FAULT = HIGH

TOP-OFF

FASTCHG = HIGH

FULLCHG = HIGH

FAULT = HIGH

TEMP

OK

TEMP

OK

TEMP

OK

TEMP

OK

TEMP

NOT OK

TOP-OFF

TIMEOUT

I

CHARGE

< I

MIN

OR

FULL-CHARGE

TIMEOUT

ONCE PER

SECOND

ONCE PER

SECOND

TEMP

QUAL

V

BATT

> 2.5V

V

BATT

< 0.95 × V

BATTR

V

BATT

< 0.95 × V

BATTR

V

DCIN

< BATT

V

BATT

< UNDERVOLTAGE

THRESHOLD

V

BATT

= BATTERY

REGULATION VOLTAGE (V

BATTR

)

FAST-CHARGE

TIMEOUT

PREQUAL

TIMEOUT

TEMP

NOT OK

TEMP

NOT OK

SHUTDOWN IS

ENTERED FROM ALL STATES

WHEN SHDN IS LOW.

SHDN HIGH

V

DCIN

> V

BATT

Figure 4. State Diagram

Page 13

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

______________________________________________________________________________________ 13

Table 1. Charging State Conditions

From initial power on

or

From done state if battery voltage <

recharge voltage threshold

or

V

DCIN

- V

BATT

< 100mV or V

BATT

> bat-

tery overvoltage threshold

Timers reset, charging current = 0,

FASTCHG = high, FULLCHG = high,

FAULT = high

Reset

Fault

From prequalification state if prequalification timer expires

or

From fast-charge state if fast-charge

timer expires

Charging current = 0,

FASTCHG = high, FULLCHG = high,

FAULT = low

Over/Under Temperature

From fast-charge state or full-charge

state if battery temperature is outside of

limits

Charge current = 0, timers suspended,

FASTCHG = no change, FULLCHG = no change,

FAULT = no change

Done From top-off state if top-off timer expires

Recharge voltage threshold ≤ battery voltage ≤ battery

regulation voltage, charging current = 0, FASTCHG =

high, FULLCHG = high, FAULT = high

Top-Off

(Constant Voltage)

From full-charge state if full-charge timer

expires or charging current ≤ 10% of

current limit

Battery voltage = battery regulation voltage, charging

current ≤ 10% of current limit, timeout = 45min typ

(C

TIMER1

= 1nF), FASTCHG = high, FULLCHG = high,

FAULT = high

Full Charge

(Constant Voltage)

From fast-charge state if battery

voltage = battery regulation voltage

Battery voltage = battery regulation voltage, charging

current ≤ current limit,

timeout = 90min typ (C

TIMER1

= 1nF),

FASTCHG = high, FULLCHG = low, FAULT = high

ENTRY CONDITIONS STATE CONDITIONS

Prequalification

From reset state if input power,

reference, and internal bias are within

limits

Battery voltage ≤ undervoltage threshold, charging

current = C/20, timeout = 7.5min typ (C

TIMER1

= 1nF),

FASTCHG = low, FULLCHG = high, FAULT = high

Fast Charge

(Constant Current)

From prequalification state if battery

voltage > undervoltage threshold

Undervoltage threshold ≤ battery voltage ≤ battery regulation voltage, charging current = current limit,

timeout = 90min typ (C

TIMER2

= 1nF),

FASTCHG = low, FULLCHG = high, FAULT = high

STATE

Page 14

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

14 ______________________________________________________________________________________

The current-mode PWM controller uses the inductor

current to regulate the output voltage or current, simplifying stabilization of the regulation loops. Separate

compensation of the regulation circuits allows each to

be optimally stabilized. Internal slope compensation is

included, ensuring stable operation over a wide range

of duty cycles.

The controller drives an external N-channel MOSFET

switch and a synchronous rectifier to step the input

voltage down to the battery voltage. A bootstrap

capacitor drives the high-side MOSFET gate to a voltage higher than the input source voltage. This capacitor (between BST and LX) is charged through a diode

from VLO when the synchronous rectifier is on. The

high-side MOSFET gate is driven from BST, supplying

sufficient voltage to fully drive the MOSFET gate even

when its source is near the input voltage. The synchronous rectifier is driven from DLO to behave like a diode,

but with a smaller voltage drop for improved efficiency.

A built-in dead time (50ns typ) between switch and synchronous rectifier turn-on and turn-off prevents crowbar

currents (currents that flow from the input voltage to

ground due to both the MOSFET switch and synchronous rectifier being on simultaneously). This dead time

may allow the body diode of the synchronous rectifier

to conduct. If this happens, the resulting forward voltage and diode recovery time will cause a small loss of

efficiency and increased power dissipation in the synchronous rectifier. To prevent the body diode from conducting, place an optional Schottky rectifier in parallel

with the drain and source of the synchronous rectifier.

The internal current-sense circuit turns off the synchronous rectifier when the inductor current drops to zero.

Timers

The MAX1737 includes safety timers to terminate

charging and to ensure that faulty batteries are not

charged indefinitely. TIMER1 and TIMER2 set the timeout periods.

TIMER1 controls the maximum prequalification time,

maximum full-charge time, and the top-off time. TIMER2

controls the maximum fast-charge time. The timers are

set by external capacitors. The typical times of 7.5 minutes for prequalification, 90 minutes for full charge, 45

minutes for top-off, and 90 minutes for fast charge are

set by using a 1nF capacitor on TIMER1 and TIMER2

(Figure 1). The timers cannot be disabled.

Charge Monitoring Outputs

FASTCHG, FULLCHG, and FAULT are open-drain outputs that can be used as LED drivers. FASTCHG indi-

cates the battery is being fast charged. FULLCHG

indicates the charger has completed the fast-charge

cycle (approximately 85% charge) and is operating in

voltage mode. The FASTCHG and FULLCHG outputs

can be tied together to indicate charging (see Figure 2).

FAULT indicates the charger has detected a charging

fault and that charging has terminated. The charger can

be brought out of the FAULT condition by removing and

reapplying the input power, or by pulling SHDN low.

Thermistor

The intent of THM is to inhibit fast-charging the cell

when it is too cold or too hot (+2.5°C ≤ TOK≤ +47.5°C),

using an external thermistor. THM time multiplexes two

sense currents to test for both hot and cold qualification.

The thermistor should be 10kΩ at +25°C and have a

negative temperature coefficient (NTC); the THM pin

expects 3.97kΩ at +47.5°C and 28.7kΩ at +2.5°C.

Connect the thermistor between THM and GND. If no

temperature qualification is desired, replace the thermistor with a 10kΩ resistor. Thermistors by

Philips/BCcomponents (2322-640-63103), Cornerstone

Sensors (T101D103-CA), and Fenwal Electronics (140103LAG-RB1) work well.

Shutdown

When SHDN is pulled low, the MAX1737 enters the

shutdown mode and charging is stopped. In shutdown,

the internal resistive voltage-divider is removed from

BATT to reduce the current drain on the battery to less

than 1µA. DHI and DLO are low. However, the internal

linear regulator (VLO) and the reference (REF) remain

on. The status outputs FASTCHG, FULLCHG, and

FAULT are high impedance. When exiting shutdown

mode, the MAX1737 goes back to the power-on reset

state, which resets the timers and begins a new charge

cycle.

Source Undervoltage Shutdown

(Dropout)

If the voltage on DCIN drops within 100mV of the voltage on BATT, the charger resets.

Table 2. Cell-Count Programming

4VL

3REF

2

1GND

CELL COUNT (N)CELL

Float

Page 15

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

_______________________________________________________________________________________ 15

Design Procedure

Setting the Battery Regulation Voltage

VADJ sets the per-cell voltage limit. To set the VADJ

voltage, use a resistor-divider from REF to GND. A

GND-to-VREF change at VADJ results in a ±5% change

in the battery limit voltage. Since the full VADJ range

results in only a 10% change on the battery regulation

voltage, the resistor-divider’s accuracy need not be as

high as the output voltage accuracy. Using 1% resistors for the voltage-dividers results in no more than

0.1% degradation in output voltage accuracy. VADJ is

internally buffered so that high-value resistors can be

used. Set V

VADJ

by choosing a value less than 100kΩ

for R8 and R9 (Figure 1) from VADJ to GND. The percell battery termination voltage is a function of the battery chemistry and construction; thus, consult the

battery manufacturer to determine this voltage. Once

the per-cell voltage limit battery regulation voltage is

determined, the VADJ voltage is calculated by the

equation:

where V

BATTR

is N x the cell voltage. CELL is the programming input for selecting cell count N. Table 2

shows how CELL is connected to charge one to four

cells.

Setting the Charging Current Limit

A resistor-divider from REF to GND sets the voltage at

ISETOUT (V

ISETOUT

). This voltage determines the

charging current during the current-regulation fastcharge mode. The full-scale charging current (I

FSI

) is

set by the current-sense resistor (R18, Figure 1)

between CS and BATT. The full-scale current is I

FSI

=

0.2V / R18.

The charging current I

CHG

is therefore:

In choosing the current-sense resistor, note that the drop

across this resistor causes further power loss, reducing

efficiency. However, too low a value may degrade the

accuracy of the charging current.

Setting the Input Current Limit

A resistor-divider from REF to GND can set the voltage

at ISETIN (V

ISETIN

). This sets the maximum source current allowed at any time during charging. The source

current (I

FSS

) is set by the current-sense resistor (R12,

Figure 1) between CSSP and CSSN. The full-scale

source current is I

FSS

= 0.1V / R12.

The input current limit (IIN) is therefore:

Set ISETIN to REF to get the full-scale current limit.

Short CSSP and CSSN to DCIN if the input source current limit is not used.

In choosing the current-sense resistor, note that the

drop across this resistor causes further power loss,

reducing efficiency. However, too low a resistor value

may degrade input current limit accuracy.

Inductor Selection

The inductor value may be changed to achieve more or

less ripple current. The higher the inductance, the

lower the ripple current will be; however, as the physical size is kept the same, higher inductance typically

will result in higher series resistance and lower saturation current. A good trade-off is to choose the inductor

so that the ripple current is approximately 30% to 50%

of the DC average charging current. The ratio of ripple

current to DC charging current (LIR) can be used to

calculate the optimal inductor value:

where f is the switching frequency (300kHz).

The peak inductor current is given by:

Capacitor Selection

The input capacitor absorbs the switching current from

the charger input and prevents that current from circulating through the source, typically an AC wall cube.

Thus, the input capacitor must be able to handle the

input RMS current. Typically, at high charging currents,

the converter will operate in continuous conduction (the

inductor current does not go to 0). In this case, the

RMS current of the input capacitor may be approximated by the equation:

where I

CIN

= the input capacitor RMS current, D =

PWM converter duty ratio (typically V

BATT

/ V

DCIN

), and

I

CHG

= battery charging current.

II

CIN CHG

DD

2

≈−

II

LIR

PEAK CHG

=+

1

2

L

VV V

VfILIR

BATT DCIN MAX BATT

DCIN MAX CHG

=

−

×× ×

()

()

()

II

V

V

IN FSS

ISETIN

REF

=

II

V

V

CHG FSI

ISETOUT

REF

=

V

9.5 V

N

(9.0 V )

ADJ

BATTR

REF

=

×

−×

Page 16

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

16 ______________________________________________________________________________________

The maximum RMS input current occurs at 50%

duty cycle, so the worst-case input ripple current is

0.5 × I

CHG

. If the input to output voltage ratio is such

that the PWM controller will never work at 50% duty

cycle, then the worst-case capacitor current will occur

where the duty cycle is nearest 50%.

The impedance of the input capacitor is critical to preventing AC currents from flowing back into the wall cube.

This requirement varies depending on the wall cube’s

impedance and the requirements of any conducted or

radiated EMI specifications that must be met. Aluminum

electrolytic capacitors are generally the least costly, but

are usually a poor choice for portable devices due to

their large size and low equivalent series resistance

(ESR). Tantalum capacitors are better in most cases, as

are high-value ceramic capacitors. For equivalent size

and voltage rating, tantalum capacitors will have higher

capacitance and ESR than ceramic capacitors. This

makes it more critical to consider RMS current and

power dissipation when using tantalum capacitors.

The output filter capacitor is used to absorb the inductor ripple current. The output capacitor impedance

must be significantly less than that of the battery to

ensure that it will absorb the ripple current. Both the

capacitance and ESR rating of the capacitor are important for its effectiveness as a filter and to ensure stability of the PWM circuit. The minimum output capacitance

for stability is:

where C

OUT

is the total output capacitance, V

REF

is the

reference voltage (4.2V), V

BATT

is the maximum battery

voltage (typically 4.2V per cell), and V

DCIN(MIN)

is the

minimum source input voltage.

The maximum output capacitor ESR allowed for stability

is:

where R

ESR

is the output capacitor ESR and RCSis the

current-sense resistor from CS to BATT.

Setting the Timers

The MAX1737 contains four timers: a prequalification

timer, fast-charge timer, full-charge timer, and top-off

timer. Connecting a capacitor from TIMER1 to GND

and TIMER2 to GND sets the timer periods. The

TIMER1 input controls the prequalification, full-charge,

and top-off times, while TIMER2 controls fast-charge

timeout. The typical timeouts for a 1C charge rate are

set to 7.5 minutes for the prequalification timer, 90 minutes for the fast-charge timer, 90 minutes for the fullcharge timer, and 45 minutes for the top-off timer by

connecting a 1nF capacitor to TIMER1 and TIMER2.

Each timer period is directly proportional to the capacitance at the corresponding pin. See the Typical

Operating Characteristics.

Compensation

Each of the three regulation loops—the input current

limit, the charging current limit, and the charging voltage limit—can be compensated separately using the

CCS, CCI, and CCV pins, respectively.

The charge-current loop error amp output is brought

out at CCI. Likewise, the source-current error amplifier

output is brought out at CCS; 47nF capacitors to

ground at CCI and CCS compensate the current loops

in most charger designs. Raising the value of these

capacitors reduces the bandwidth of these loops.

The voltage-regulating loop error amp output is brought

out at CCV. Compensate this loop by connecting a

capacitor in parallel with a series resistor-capacitor

(RC) from CCV to GND. Recommended values are

shown in Figure 1.

Applications Information

MOSFET Selection

The MAX1737 uses a dual N-channel external power

MOSFET switch to convert the input voltage to the

charging current or voltage. The MOSFET must be

selected to meet the efficiency and power-dissipation

requirements of the charging circuit, as well as the temperature rise of the MOSFETs. The MOSFET characteristics that affect the power dissipation are the

drain-source on-resistance (R

DS(ON)

) and the gate

charge. In general, these are inversely proportional.

To determine the MOSFET power dissipation, the operating duty cycle must first be calculated. When the

charger is operating at higher currents, the inductor

current will be continuous (the inductor current will not

drop to 0A) and, in this case, the high-side MOSFET

duty cycle (D) can be approximated by the equation:

and the synchronous-rectifier MOSFET duty cycle (D′)

will be 1 - D or:

′

≈−D

VV

V

DCIN BATT

DCIN

D

V

V

BATT

DCIN

≈

R

RV

V

ESR

CS BATT

REF

<

×

C

V

V

V

VfR

OUT

REF

BATT

DCIN MIN

BATT CS

>

+

××

1

()

Page 17

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

______________________________________________________________________________________ 17

For the high-side switch, the worst-case power dissipation due to on-resistance occurs at the minimum source

voltage V

DCIN(MIN)

and the maximum battery voltage

V

BATT(MAX)

, and can be approximated by the equation:

The transition loss can be approximated by the equation:

where tTRis the MOSFET transition time. So the total

power dissipation of the high-side switch is P

TOT

= P

R

+ PT.

The worst-case synchronous-rectifier power occurs at

the minimum battery voltage V

BATT(MIN)

and the maxi-

mum source voltage V

DC(MAX)

, and can be approxi-

mated by:

There is a brief dead time where both the high-side

switch and synchronous rectifier are off. This prevents

crowbar currents that flow directly from the source voltage to ground. During the dead time, the inductor current will turn on the synchronous-rectifier MOSFET body

diode, which may degrade efficiency. To prevent this,

connect a Schottky rectifier across the drain source of

the synchronous rectifier to stop the body diode from

conducting. The Schottky rectifier may be omitted, typically degrading the efficiency by approximately 1% to

2%, causing a corresponding increase in the low-side

synchronous-rectifier power dissipation.

VL and REF Bypassing

The MAX1737 uses an internal linear regulator to drop

the input voltage down to 5.4V, which powers the internal circuitry. The output of the linear regulator is the VL

pin. The internal linear regulator may also be used to

power external circuitry as long as the maximum current

and power dissipation of the linear regulator are not

exceeded. The synchronous-rectifier MOSFET gate driver (DLO) is powered from VLO. An internal 12Ω resistor

from VL to VLO provides the DC current to power the

gate driver. Bypass VLO to PGND with a 0.1µF or

greater capacitor.

A 4.7µF bypass capacitor is required at VL to ensure

that the regulator is stable. A 1µF bypass capacitor is

also required between REF and GND to ensure that the

internal 4.2V reference is stable. In both cases use a

low-ESR ceramic capacitor.

Chip Information

TRANSISTOR COUNT: 5978

P

VV

V

RI

DL

DCIN MAX BATT MIN

DCIN MAX

DS ON CHG

≈

−

××

() ()

()

()

2

P

VIft

T

DCIN CHG TR

≈

×××

3

P

V

V

RI

R

BATT MAX

DCIN MIN

DS ON CHG

≈××

()

()

()

2

Page 18

MAX1737

Stand-Alone Switch-Mode

Lithium-Ion Battery-Charger Controller

QSOP.EPS

E

1

1

21-0055

PACKAGE OUTLINE, QSOP .150", .025" LEAD PITCH

Note: The MAX1737EEI is a 28-pin QSOP and does not have a heat slug.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 18

© 2005 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

Loading...

Loading...