Page 1

For price, delivery, and to place orders, please contact Maxim Distribution at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

General Description

The MAX1715 PWM controller provides the high efficiency, excellent transient response, and high DC output accuracy needed for stepping down high-voltage

batteries to generate low-voltage CPU core, I/O, and

chipset RAM supplies in notebook computers.

Maxim’s proprietary Quick-PWM™ quick-response,

constant-on-time PWM control scheme handles wide

input/output voltage ratios with ease and provides

100ns “instant-on” response to load transients while

maintaining a relatively constant switching frequency.

The MAX1715 achieves high efficiency at a reduced

cost by eliminating the current-sense resistor found in

traditional current-mode PWMs. Efficiency is further

enhanced by its ability to drive very large synchronousrectifier MOSFETs.

Single-stage buck conversion allows this device to

directly step down high-voltage batteries for the highest

possible efficiency. Alternatively, two-stage conversion

(stepping down the +5V system supply instead of the

battery) at a higher switching frequency allows the minimum possible physical size.

The MAX1715 is intended for CPU core, chipset,

DRAM, or other low-voltage supplies as low as 1V. The

MAX1715 is available in a 28-pin QSOP package. For

applications requiring VID compliance or DAC control

of output voltage, refer to the MAX1710/MAX1711 data

sheet. For a single-output version, refer to the MAX1714

data sheet.

Applications

Notebook Computers

CPU Core Supply

Chipset/RAM Supply as Low as 1V

1.8V and 2.5V I/O Supply

Features

♦ Ultra-High Efficiency

♦ No Current-Sense Resistor (lossless I

LIMIT

)

♦ Quick-PWM with 100ns Load-Step Response

♦ 1% V

OUT

Accuracy over Line and Load

♦ Dual-Mode Fixed 1.8V/3.3V/Adj or 2.5V/Adj Outputs

♦ Adjustable 1V to 5.5V Output Range

♦ 2V to 28V Battery Input Range

♦ 200/300/420/540kHz Nominal Switching Frequency

♦ Over/Undervoltage Protection

♦ 1.7ms Digital Soft-Start

♦ Drives Large Synchronous-Rectifier FETs

♦ Power-Good Indicator

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

________________________________________________________________ Maxim Integrated Products 1

19-1541; Rev 2; 8/05

Pin Configuration appears at end of data sheet.

Quick-PWM is a trademark of Maxim Integrated Products.

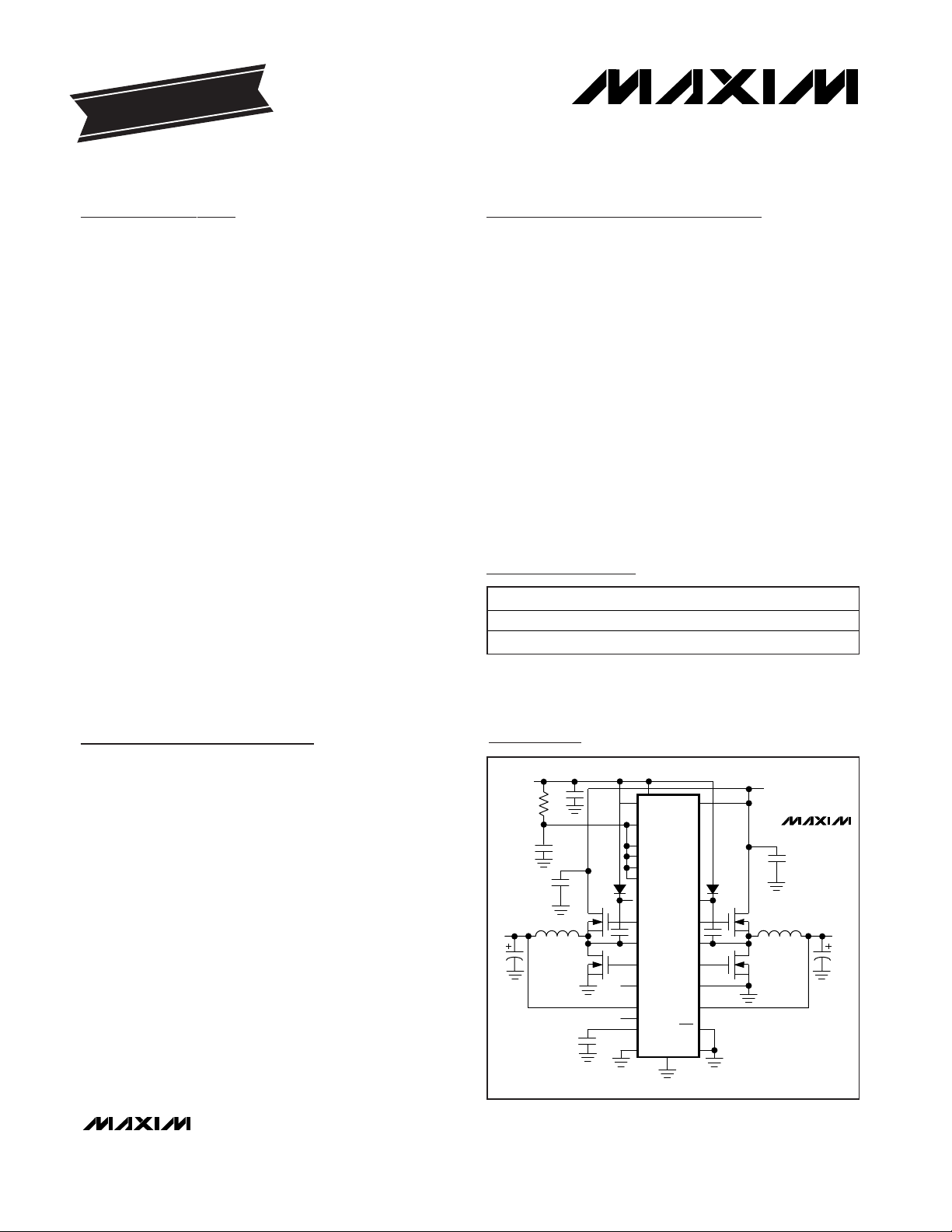

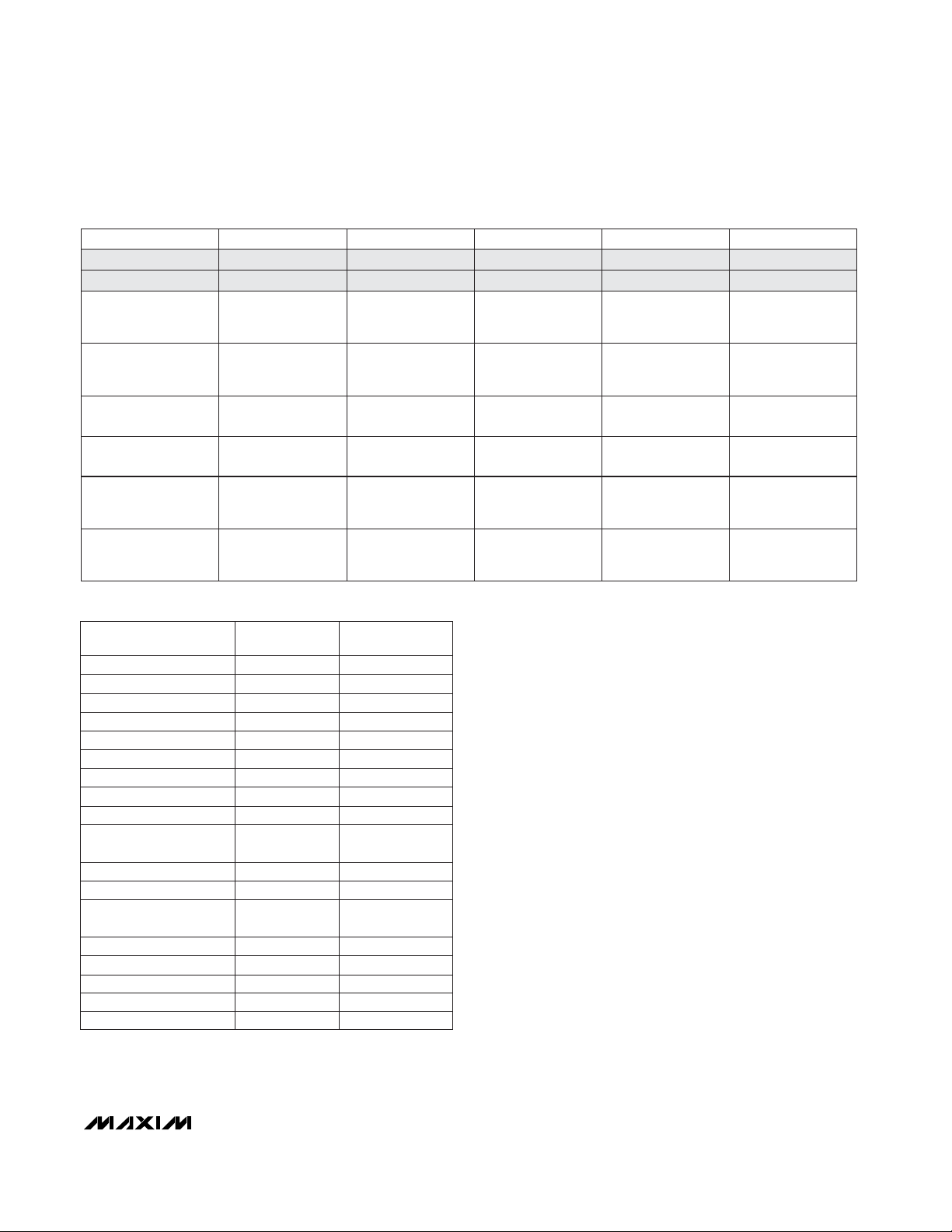

Ordering Information

EVALUATION KIT

AVAILABLE

V

CC

OUTPUT1

1.8V

BATTERY

4.5V TO 28V

ILIM1

ON2

DL1

TON

OUT1

LX1

DH1

FB1 AGND

V

DD

BST1

ILIM2

ON1

REF

DL2

PGND

OUT2

LX2

DH2

FB2

V+

BST2

SKIP

5V INPUT

PGOOD

OUTPUT2

2.5V

MAX1715

Minimal Operating Circuit

PART TEMP RANGE PIN-PACKAGE

MAX1715EEI -40°C to +85°C 28 QSOP

MAX1715EEI+

-40°C to +85°C 28 QSOP

+ Denotes lead-free package.

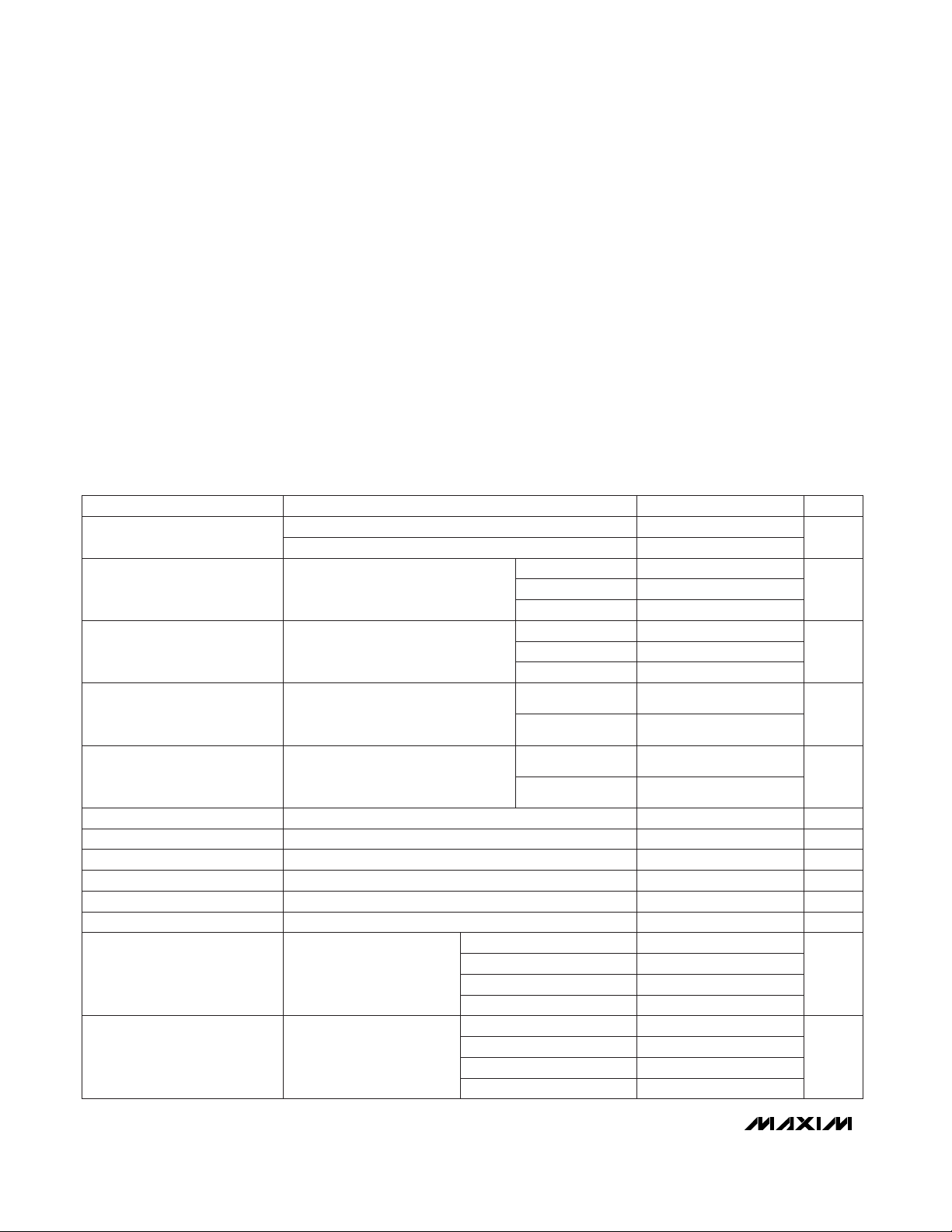

Page 2

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

V+ to AGND..............................................................-0.3 to +30V

V

DD

, VCCto AGND..................................................-0.3V to +6V

PGND to AGND or V

CC

to VDD...........................................±0.3V

PGOOD, OUT_ to AGND..........................................-0.3V to +6V

ILIM_, FB_, REF,

SKIP, TON,

ON_ to AGND...........................................-0.3V to (V

DD

+ 0.3V)

DL_ to PGND..............................................-0.3V to (V

DD

+ 0.3V)

BST_ to AGND........................................................-0.3V to +36V

DH1 to LX1 ...............................................-0.3V to (BST1 + 0.3V)

DH2 to LX2 ...............................................-0.3V to (BST2 + 0.3V)

LX1 to BST1..............................................................-6V to +0.3V

LX2 to BST2..............................................................-6V to +0.3V

REF Short Circuit to AGND.........................................Continuous

Continuous Power Dissipation (T

A

= +70°C)

28-Pin QSOP (derate 8.0mW/°C above +70°C).....640mW/°C

Operating Temperature Range ..........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range ............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, 4A components from Table 1, V

CC = VDD

= +5V, SKIP = AGND, V+ = 15V, TA= 0°C to +85°C, unless otherwise

noted.) (Note 1)

I

LOAD

= 0 to 4A, each output %0.4

FB2 = GND

Battery voltage, V+

Input Voltage Range

V+ = 24V, OUT2 = 2V

Load Regulation Error

VCC= 4.5V to 5.5V, V+ = 4.5V to 28V

V+ = 24V, OUT1 = 2V

Adjustable mode, each output

Output 2 Error Comparator

Threshold (DC Output Voltage

Accuracy) (Note 2)

TON = GND

FB_ Input Bias Current

TON = GND

TON = open

V

OUT

_ = AGND

210 247 280

CONDITIONS

V

TON = REF

142 173 205

ms

TON = V

DD

OUT_ Input Resistance

µA

Soft-Start Ramp Time

ΩFB_ = AGND

Rising edge of ON_ to full current limit

2.475 2.5 2.525

V+ = 2V to 28V,

SKIP = V

CC

, TA = +25°C

I

LOAD

= 0 to 4A

V+ = 2V to 28V,

SKIP = V

CC

, TA = +25°C

I

LOAD

= 0 to 4A

ns

154 182 215

V

On-Time (PWM2)

ns

112 136 160

0.99 1.00 1.01

On-Time (PWM1)

V

1.7

0.99 1.00 1.01

300 353 407

1.782 1.8 1.818

-0.1 0.1

TON = open

292 336 380

TON = REF

75k

3.267 3.3 3.333

FB1 = V

CC

FB1 = AGND

FB1 = OUT1

228

FB2 = OUT2

V

1 5.5

Output Voltage Range

%0.2

198 234 270

Line Regulation Error

TON = V

DD

420 484 550

UNITSMIN TYP MAXPARAMETER

Output 1 Error Comparator

Threshold (DC Output Voltage

Accuracy) (Note 2)

4.5 5.5

V

DD,VCC

Output 1 Error Comparator

Threshold (DC Output Voltage

Accuracy) (Note 2)

V+ = 2V to 28V,

SKIP = V

CC

, TA = 0°C to +85°C

I

LOAD

= 0 to 4A

V

0.985 1.00 1.105

1.773 1.8 1.827

3.250 3.3 3.350

FB1 = V

CC

FB1 = AGND

FB1 = OUT1

FB2 = GND

Output 2 Error Comparator

Threshold (DC Output Voltage

Accuracy) (Note 2)

2.463 2.5 2.538

V+ = 2V to 28V,

SKIP = V

CC

, TA = 0°C to +85°C

I

LOAD

= 0 to 4A

V

0.985 1.00 1.105

FB2 = OUT2

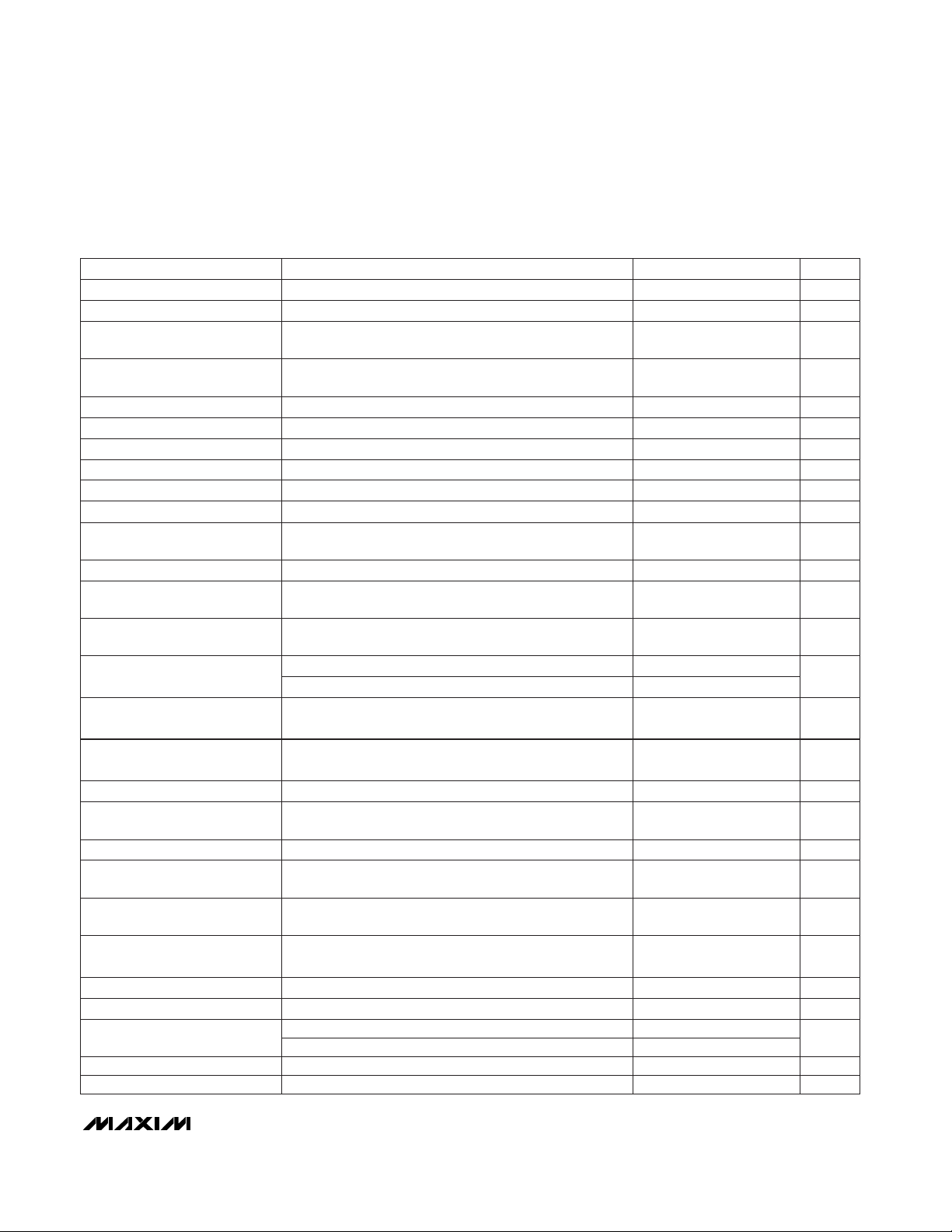

Page 3

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, 4A components from Table 1, V

CC = VDD

= +5V, SKIP = AGND, V+ = 15V, TA= 0°C to +85°C, unless otherwise

noted.) (Note 1)

(Note 3) ns400 500Minimum Off-Time

I

REF

= 0 to 50µA

No external REF load

ON1 = ON2 = 0

V2 0.01Reference Load Regulation

V1.98 2 2.02Reference Voltage

µA<1 5Shutdown Supply Current (V+)

µA<1 5

Shutdown Supply Current

(VCC+ VDD)

Falling edge, hysteresis = 40mV V1.6REF Fault Lockout Voltage

10

PGND - LX_, I

LIM

resistor = 100kΩ

mV

40 50 60

Current-Limit Threshold

(Positive Direction, Adjusted)

PGND - LX_, TA= +25°C, I

LIM

= V

CC

mV-145 -120 -95

Current-Limit Threshold

(Negative Direction)

PGND - LX_, SKIP = AGND

mV-5 3 10

Current-Limit Threshold, Zero

Crossing

Hysteresis = 10°C °C150Thermal Shutdown Threshold

Rising edge, hysteresis = 20mV, PWM disabled below

this level

V4.1 4.4

VCCUndervoltage Lockout

Threshold

BST - LX forced to 5V Ω1.5 5DH Gate Driver On-Resistance

FB1 and FB2 forced above the regulation point µA1100 1600

Quiescent Supply Current

(VCC+ VDD)

µA25 70Quiescent Battery Current (V+)

FB_ forced 2% above trip threshold µs1.5

Overvoltage Fault Propagation

Delay

With respect to error comparator threshold %8.5 10.5 13Overvoltage Trip Threshold

With respect to error comparator threshold %60 70 80Output Undervoltage Threshold

From ON_ signal going high ms10 20 30

Output Undervoltage Lockout

Time

PGND - LX_, I

LIM

= V

CC

mV75 100 125

Current-Limit Threshold

(Positive Direction, Fixed)

ON1 = ON2 = 0

DL, high state Ω1.5 5

DL Gate Driver On-Resistance

(pull-up)

0.6 2.5

A

DH Gate Driver Source/Sink

Current

DH forced to 2.5V, BST_ - LX_ forced to 5V 1

ADL Gate Driver Source Current DL forced to 2.5V 1

ADL Gate Driver Sink Current DL forced to 2.5V 3

nsDead Time

DL rising 35

REF in regulationREF Sink Current

DL, low state

DL Gate Driver On-Resistance

(pull-down)

Ω

µA

CONDITIONS UNITSMIN TYP MAXPARAMETER

PGND - LX_, I

LIM

resistor = 400kΩ 160 200 240

DH rising 26

ON_, SKIP

0.8

VLogic Input High Voltage

ON_, SKIP

2.4

VLogic Input Low Voltage

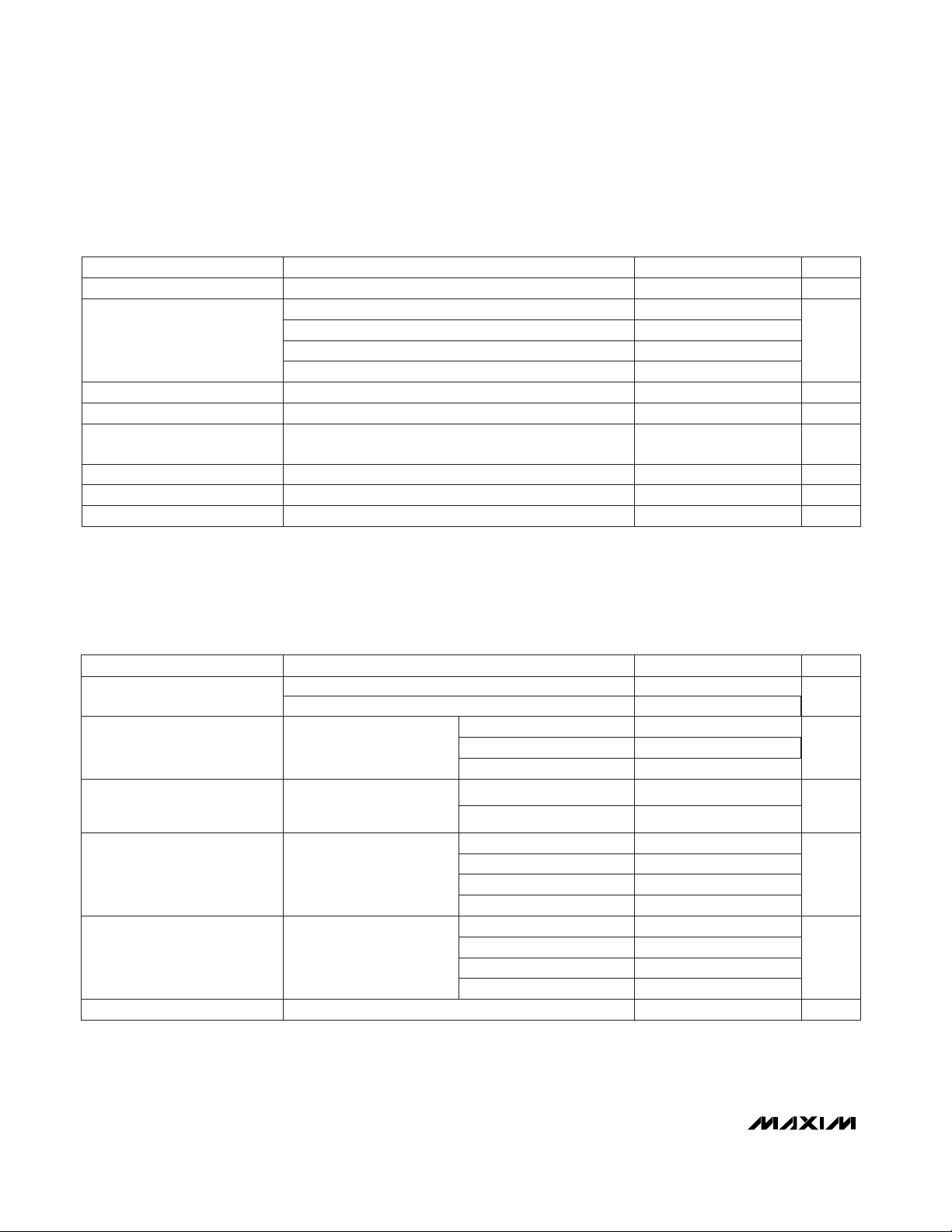

Page 4

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, 4A components from Table 1, V

CC = VDD

= +5V, SKIP = AGND, V+ = 15V, TA= -40°C to +85°C, unless otherwise

noted.) (Note 1)

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, 4A components from Table 1, V

CC = VDD

= +5V, SKIP = AGND, V+ = 15V, TA= 0°C to +85°C, unless otherwise

noted.) (Note 1)

CONDITIONS

V

CC

level

V

VCC- 0.4

TON Threshold

Float level 3.15 3.85

REF level 1.65 2.35

AGND level 0.5

TON (0 or VCC) µA-3 3Logic Input Current

UNITSMIN TYP MAXPARAMETER

On-Time (PWM1)

112 136 160

ns

FB2 = GND

FB2 = OUT2

V+ = 4.5V to 28V,

SKIP = V

CC

3.234 3.3 3.372FB1 = V

CC

FB1 = AGND

FB1 = OUT1

1.764 1.8 1.836

Minimum Off-Time 400 500 ns(Note 3)

2.45 2.5 2.55

Output 2 Error Comparator

Threshold (DC Output Voltage

Accuracy) (Note 2)

0.98 1.00 1.02

V

PARAMETER MIN TYP MAX UNITS

Input Voltage Range

228

V

4.5 5.5

Output 1 Error Comparator

Threshold (DC Output Voltage

Accuracy) (Note 2)

0.98 1.00 1.02

V

CONDITIONS

Battery voltage, V+

V

DD, VCC

V+ = 2V to 28V,

SKIP = V

CC

On-Time (PWM2)

154 182 215

ns

ON_, SKIP (0 or VCC)

µA-1 1Logic Input Current

Falling edge, FB_ forced 2% below PGOOD trip threshold µs1.5PGOOD Propagation Delay

Measured at FB_, with respect to error comparator

threshold, no load

%-8 -5.5 -4PGOOD Trip Threshold

I

SINK

= 1mA V0.1 0.4PGOOD Output Low Voltage

High state, forced to 5.5V µA1PGOOD Leakage Current

SKIP, to deactivate OVP circuitry

mA-5 -1Logic Input Current

210 247 280

142 173 205

300 353 407

292 336 380

198 234 270

V+ = 24V, OUT2 = 2V

420 484 550

TON = GND

TON = REF

TON = open

TON = V

DD

V+ = 24V, OUT1 = 2V

TON = GND

TON = REF

TON = open

TON = V

DD

Page 5

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

_______________________________________________________________________________________ 5

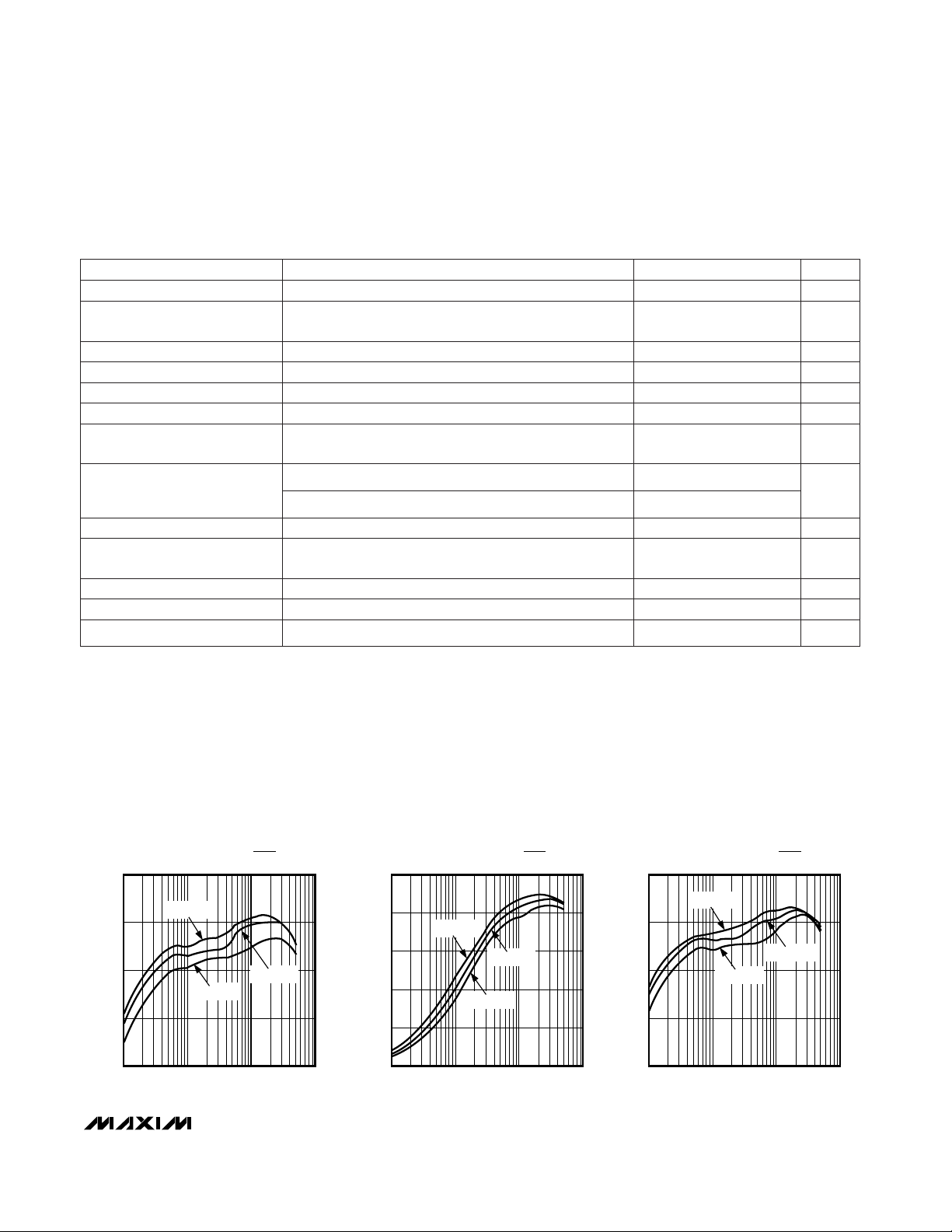

60

0.01 1010.1

90

100

80

70

MAX1715-01

LOAD CURRENT (A)

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

(1.8V, 4A COMPONENTS, SKIP = GND)

V+ = +7V

V+ = +12V

V+ = +20V

0

0.01 1010.1

60

80

100

40

20

MAX1715-02

LOAD CURRENT (A)

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

(1.8V, 4A COMPONENTS, SKIP = V

CC

)

V+ = +7V

V+ = +20V

V+ = +12V

60

0.01 1010.1

90

100

80

70

MAX1715-03

LOAD CURRENT (A)

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

(2.5V, 4A COMPONENTS, SKIP = GND)

V+ = +7V

V+ = +20V

V+ = +12V

Note 1: Specifications to -40°C are guaranteed by design, and not production tested.

Note 2: When the inductor is in continuous conduction, the output voltage will have a DC regulation higher than the trip level by

50% of the ripple. In discontinuous conduction (SKIP = AGND, light load) the output voltage will have DC regulation

higher than the trip level by approximately 1.5% due to slope compensation.

Note 3: On-time and off-time specifications are measured from the 50% point at the DH pin with LX = PGND, V

BST

= 5V. Actual

in-circuit times may differ due to MOSFET switching speeds.

__________________________________________Typical Operating Characteristics

(Circuit of Figure 1, components from Table 1, VIN= +15V, SKIP = AGND, TON = unconnected, TA= +25°C, unless otherwise noted.)

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, 4A components from Table 1, V

CC = VDD

= +5V, SKIP = AGND, V+ = 15V, TA= -40°C to +85°C, unless otherwise

noted.) (Note 1)

Quiescent Battery Current (V+) 25 70 µA

Reference Voltage 1.97 2 2.03 VNo external REF load

Quiescent Supply Current

(VCC+ VDD)

1100 1600 µAFB1 and FB2 forced above the regulation point

PARAMETER MIN TYP MAX UNITSCONDITIONS

Reference Load Regulation 0.01 VI

REF

= 0 to 50µA

Overvoltage Trip Threshold 10 12.5 15 %With respect to error comparator threshold

Output Undervoltage Threshold 60 70 80 %With respect to error comparator threshold

Current-Limit Threshold (positive

direction, fixed)

75 100 125 mVPGND - LX_, I

LIM

= V

CC

Current-Limit Threshold (positive

direction, adjusted)

32 50 62

mV

PGND - LX_, I

LIM

resistor = 100kΩ

PGND - LX_, I

LIM

resistor = 400kΩ 160 200 240

Thermal Shutdown Threshold 150 °CHysteresis = 10°C

Rising edge, hysteresis = 20mV, PWM disabled below

this level

4.1 4.4 V

VCCUndervoltage Lockout

Threshold

Logic Input High Voltage 2.4 V

ON_, SKIP

ON_, SKIP

0.8 VLogic Input Low Voltage

SKIP, to deactivate OVP circuitry

-5 -1 mALogic Input Current

Page 6

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

6 _______________________________________________________________________________________

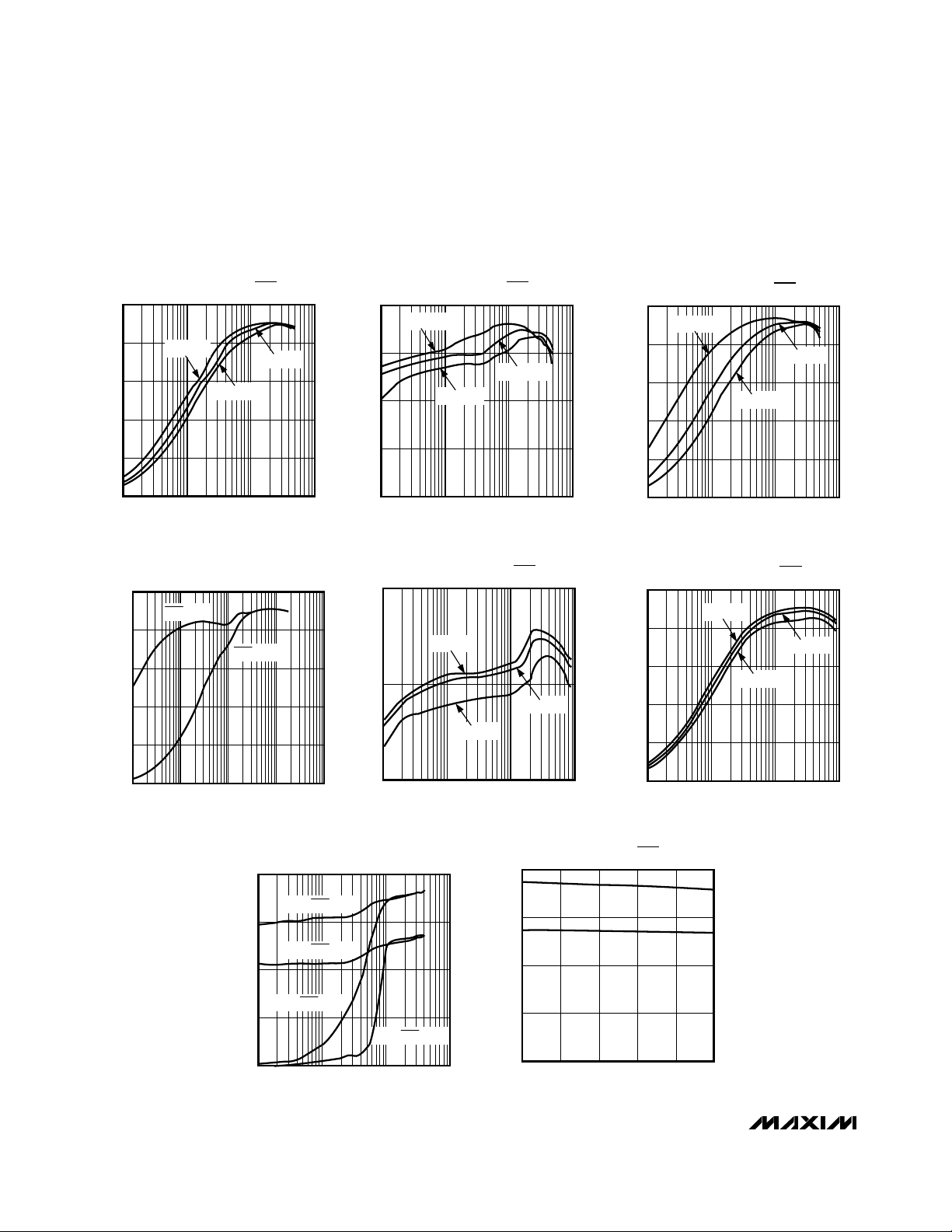

_____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 1, components from Table 1, VIN= +15V, SKIP = AGND, TON = unconnected, TA= +25°C, unless otherwise noted.)

0

0.01 1010.1

60

80

100

40

20

MAX1715-9

LOAD CURRENT (A)

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

(1.3V, 8A COMPONENTS, SKIP = V

CC

)

V+ = +7V

V+ = +20V

V+ = +12V

0

0.01 1010.1

300

400

200

100

MAX1715-10

LOAD CURRENT (A)

FREQUENCY (kHz)

FREQUENCY vs. LOAD CURRENT

(4A COMPONENTS)

OUT1, SKIP = V

CC

OUT2, SKIP = V

CC

OUT1, SKIP = GND

OUT2, SKIP = GND

400

300

200

100

0

4128 162024

MAX1715-11

SUPPLY VOLTAGE (V)

FREQUENCY (kHz)

FREQUENCY vs. SUPPLY VOLTAGE

(4A COMPONENTS, SKIP = V

CC

)

OUT1

OUT2

100

80

60

40

20

0

0.001 0.1 10.01 10

MAX1715-07

LOAD CURRENT (A)

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

(3.3V, 1.5A COMPONENTS, V

IN

= 5V)

SKIP = V

CC

SKIP = GND

60

0.01 1010.1

80

100

MAX1715-08

LOAD CURRENT (A)

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

(1.3V, 8A COMPONENTS, SKIP = GND)

V+ = +7V

V+ = +20V

V+ = +12V

0

0.01 1010.1

60

80

100

40

20

MAX1715-04

LOAD CURRENT (A)

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

(2.5V, 4A COMPONENTS, SKIP = V

CC

)

V+ = +7V

V+ = +20V

V+ = +12V

60

0.01 1010.1

90

100

80

70

MAX1715-05

LOAD CURRENT (A)

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

(5V, 3A COMPONENTS, SKIP = GND)

V+ = +7V

V+ = +20V

V+ = +12V

0

0.01 1010.1

60

80

100

40

20

MAX1715-06

LOAD CURRENT (A)

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

(5V, 3A COMPONENTS, SKIP = V

CC

)

V+ = +7V

V+ = +20V

V+ = +12V

Page 7

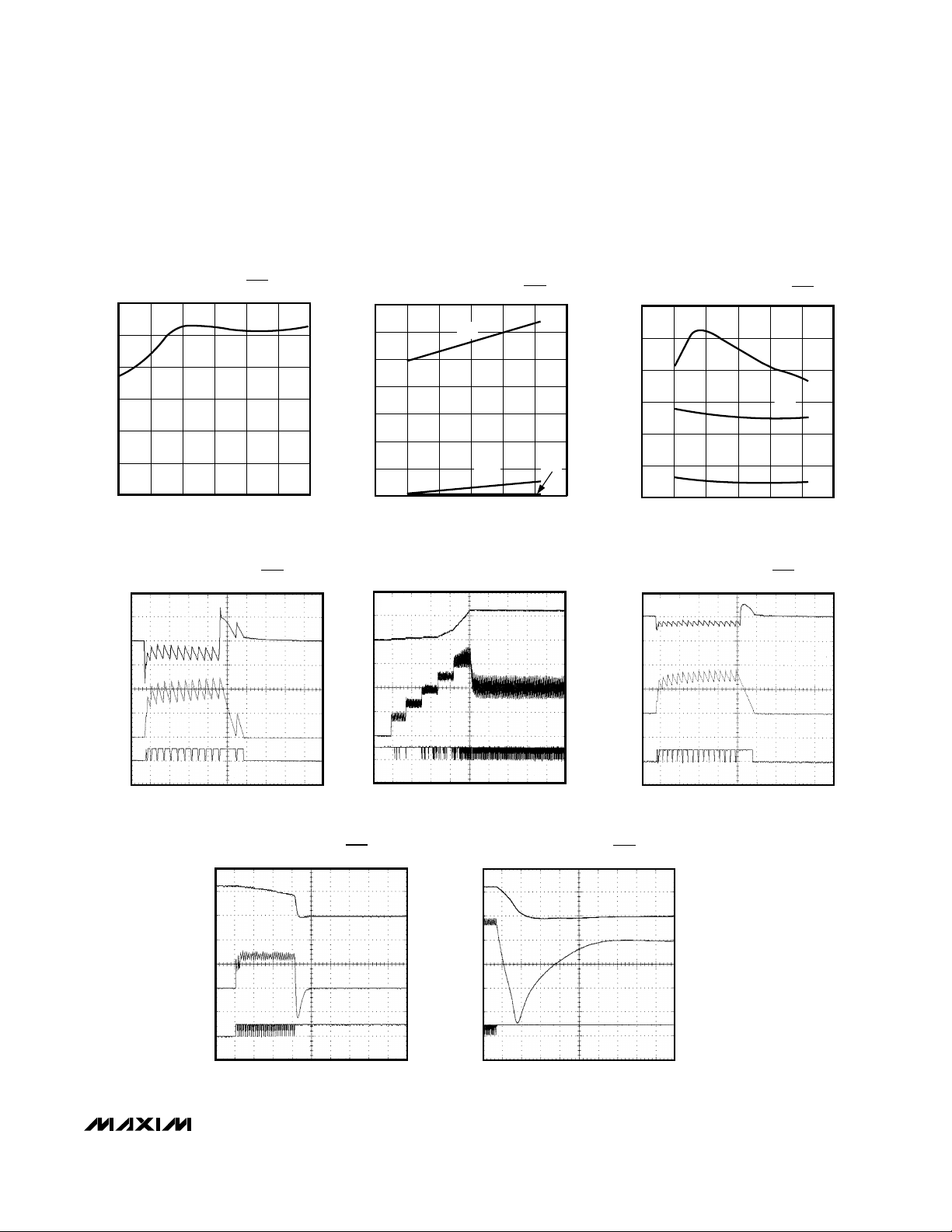

300

200

250

150

100

50

0

-400-20

40

20

60

80

MAX1715-12

TEMPERATURE (°C)

FREQUENCY (kHz)

FREQUENCY vs. TEMPERATURE

(2.5V, 4A COMPONENTS, SKIP = HIGH)

C

A

B

MAX1715-16

A = V

OUT

, 2V/div

B = INDUCTOR CURRENT, 2A/div

C = DL, 10V/div

START-UP WAVEFORM

(2.5V, 4A COMPONENTS, ACTIVE LOAD)

700

500

600

400

300

100

200

0

0105

20

15

25

30

MAX1715-13

INPUT VOLTAGE (V)

SUPPLY CURRENT (μA)

NO-LOAD SUPPLY CURRENT vs. INPUT VOLTAGE

(OUT1 = 1.8V, 4A COMPONENTS;

OUT2 = 2.5V, 4A COMPONENTS; SKIP = GND)

I

DD

I

CC

I

BATT

12

8

10

6

4

2

0

0105

20

15

25

30

MAX1715-14

INPUT VOLTAGE (V)

SUPPLY CURRENT (mA)

NO-LOAD SUPPLY CURRENT vs. INPUT VOLTAGE

(OUT1 = 1.8V, 4A COMPONENTS;

OUT2 = 2.5V, 4A COMPONENTS; SKIP = V

CC

)

I

DD

I

CC

I

IN

C

A

B

MAX1715-17

A = V

OUT

, AC-COUPLED, 100mV/div

B = INDUCTOR CURRENT, 5A/div

C = DL, 10V/div

LOAD-TRANSIENT RESPONSE

(1.3V, 8A COMPONENTS, SKIP = GND)

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

_______________________________________________________________________________________ 7

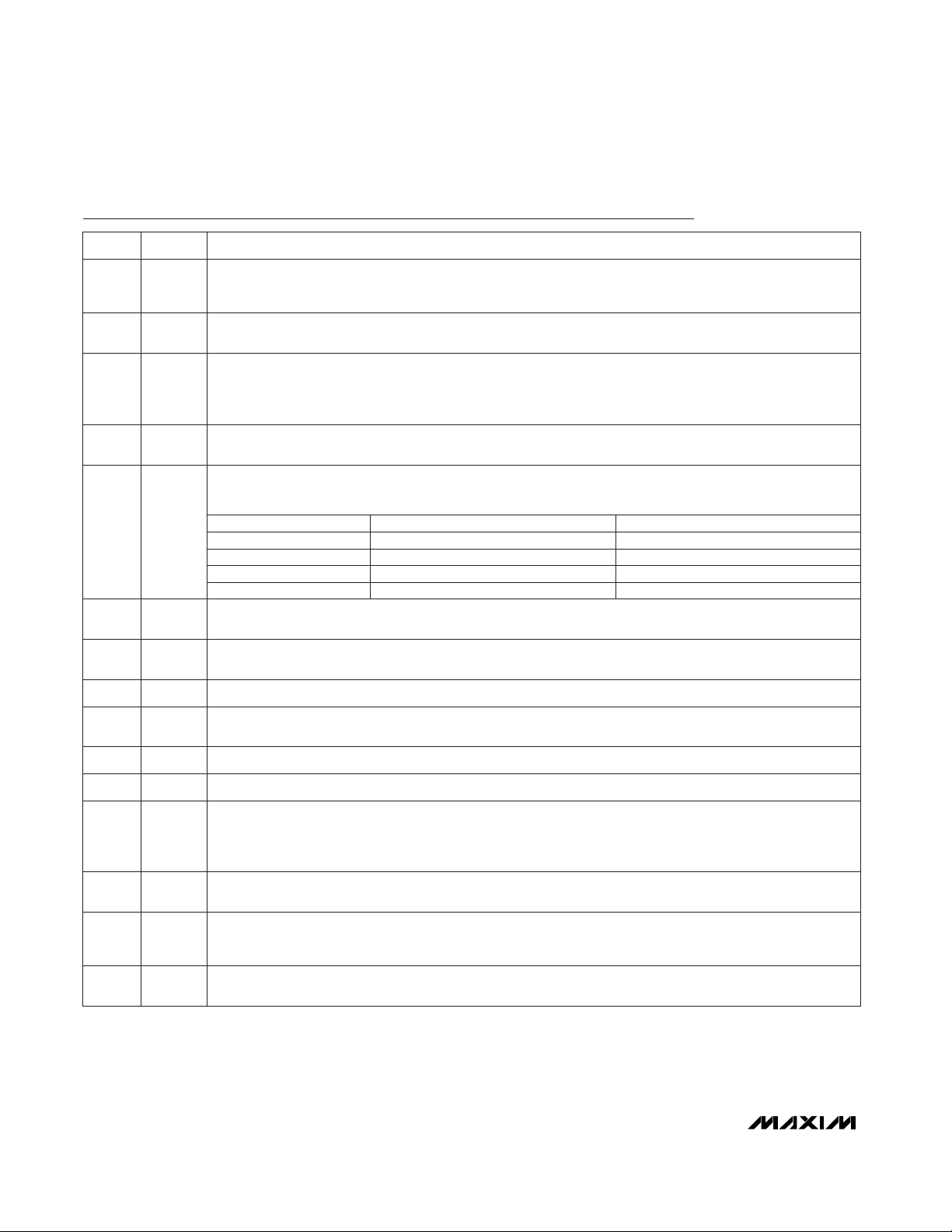

_____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 1, components from Table 1, VIN= +15V, SKIP = AGND, TON = unconnected, TA= +25°C, unless otherwise noted.)

C

A

B

MAX1715-19

A = V

OUT

, 2V/div

B = INDUCTOR CURRENT, 5A/div

C = DL, 10V/div

SHUTDOWN WAVEFORM

(2.5V, 4A COMPONENTS, SKIP = GND)

C

A

B

MAX1715-18

A = V

OUT

, 2V/div

B = INDUCTOR CURRENT, 5A/div

C = DL, 10V/div

OUTPUT OVERLOAD WAVEFORM

(2.5V, 4A COMPONENTS, SKIP = GND)

C

A

B

MAX1715-15

A = V

OUT

, AC-COUPLED, 100mV/div

B = INDUCTOR CURRENT, 2A/div

C = DL, 10V/div

LOAD-TRANSIENT RESPONSE

(2.5V, 4A COMPONENTS, SKIP = GND)

Page 8

170

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

8 _______________________________________________________________________________________

Pin Description

OUT1 ON/OFF Control Input. Drive to AGND to turn OUT1 off. Drive to VCCto turn OUT1 on.

ON110

Feedback Input for OUT1. Connect to AGND for 1.8V fixed output or to VCCfor 3.3V fixed output, or connect

to a resistor-divider from OUT1 for an adjustable output.

FB12

+2.0V Reference Voltage Connection. Bypass to AGND with 0.22µF (min) capacitor. Can supply 50µA for

external loads.

REF9

Output Voltage Connection for the OUT1 PWM. Connect directly to the junction of the external inductor and

output filter capacitors. OUT1 senses the output voltage to determine the on-time and also serves as the

feedback input in fixed-output modes.

OUT11

Pulse-Skipping Control Input. Connect to VCCfor low-noise forced-PWM mode. Connect to AGND to enable

pulse-skipping operation.

SKIP

6

Power-Good Open-Drain Output. PGOOD is low when either FB_ input is more than 5.5% below the normal

regulation point (typ).

PGOOD7

Analog GroundAGND8

Current-Limit Threshold Adjustment for OUT1. The LX1-PGND current-limit threshold defaults to +100mV if

ILIM1 is connected to VCC. Or, connect an external resistor to AGND to adjust the limit. A precision 5µA pull-up

current through R

EXT

sets the threshold from 50mV to 200mV. The voltage on the pin is 10 times the current-

limit voltage. Choose R

EXT

equal to 2kΩ per mV of current-limit threshold (100kΩ to 400kΩ).

ILIM13

Battery Voltage Sense Connection. Connect to the input power source. V+ is used only to set the PWM oneshot timing.

V+4

PIN

On-Time Selection Control Input. This is a four-level input used to determine DH_ on-time. The TON table

below is for VIN= 24V, V

OUT1

= 1.8V, V

OUT2

= 2.5V condition.

TON5

FUNCTIONNAME

OUT2 ON/OFF Control Input. Drive to AGND to turn OUT2 off. Drive to VCCto turn OUT2 on.

ON211

Current-Limit Threshold Adjustment for OUT2. The LX2-PGND current-limit threshold defaults to +100mV if

ILIM2 is connected to VCC. Or, connect an external resistor to AGND to adjust the limit. A precision 5µA pull-up

current through R

EXT

sets the threshold from 50mV to 200mV. The voltage on the pin is 10 times the current-

limit voltage. Choose R

EXT

equal to 2kΩ per mV of current-limit threshold (100kΩ to 400kΩ).

ILIM212

Feedback Input for OUT2. Connect to AGND for 2.5V fixed output, or connect to a resistor-divider from

OUT2 for an adjustable output.

FB213

Output Voltage Connection for the OUT2 PWM. Connect directly to the junction of the external inductor and

output filter capacitors. OUT2 senses the output voltage to determine the on-time and also serves as the

feedback input in fixed-output mode.

OUT214

No Connection. These pins are not connected to any internal circuitry. Connect the N.C. pins to the ground

plane to enhance thermal conductivity.

N.C.

15, 23,

28

AGND

TON

Open

V

CC

REF

235

345

485

620

Frequency (OUT1) (kHz) Frequency (OUT2) (kHz)

460

355

255

170

Page 9

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

_______________________________________________________________________________________ 9

Pin Description (continued)

High-Side Gate Driver Output for OUT1. Swings from LX1 to BST1.DH126

High-Side Gate Driver Output for OUT2. Swings from LX2 to BST2.DH217

Boost Flying Capacitor Connection for OUT1. Connect to an external capacitor and diode according to the

Standard Application Circuit (Figure 1). See MOSFET Gate Drivers (DH_, DL_) section.

BST125

External Inductor Connection for OUT2. Connect to the switched side of the inductor. LX2 serves as the

lower supply voltage rail for the DH2 high-side gate driver and is the positive input to the OUT2 current-limit

comparator.

LX216

Analog-Supply Input. Connect to the system supply voltage, +4.5V to +5.5V, with a 20Ω series resistor.

Bypass to AGND with a 1µF ceramic capacitor.

V

CC

21

Power Ground. Connect directly to the low-side MOSFETs’ sources. Serves as the negative input of the current-sense amplifiers.

PGND22

Low-Side Gate Driver Output for OUT1. DL1 swings PGND to VDD.DL124

Boost Flying Capacitor Connection for OUT2. Connect to an external capacitor and diode according to the

Standard Application Circuit (Figure 1). See MOSFET Gate Drivers (DH_, DL_) section.

BST218

Low-Side Gate-Driver Output for OUT2. DL2 swings from PGND to VDD.DL219

PIN

Supply Input for the DL Gate Drivers. Connect to the system supply voltage, +4.5V to +5.5V. Bypass to

PGND with a minimum 4.7µF ceramic capacitor.

V

DD

20

FUNCTIONNAME

External Inductor Connection for OUT1. Connect to the switched side of the inductor. LX1 serves as the

lower supply voltage rail for the DH1 high-side gate driver.

LX127

Page 10

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

10 ______________________________________________________________________________________

VDD = 5V

BIAS SUPPLY

PINS 15, 23, 28 = N.C.

POWER-GOOD

INDICATOR

MAX1715

V

CC

OUTPUT1

1.8V

V

IN

4.5V TO 28V

D3

CMPSH-3A

ILIM1

ON1

DL1

TON

OUT1

AGND

C3 C4

D1

N2

N4

N3

N1

LX1

DH1

C5

0.1μF

C6

0.1μF

C7

0.22μF

FB1

V

DD

C8

1μF

C1

20

21

25

26

27

24

5

1

9

2

8

10

11

18

17

16

19

22

14

6

13

7

C2

C11

1μF

L1

12

3

L2

BST1

ILIM2

REF

ON1

ON2

DL2

PGND

+5V

100k

OUT2

LX2

DH2

FB2

PGOOD

V+

4

BST2

SKIP

C9

4.7μF

R1

20Ω

OUTPUT2

2.5V

D2

ON/OFF

CONTROLS

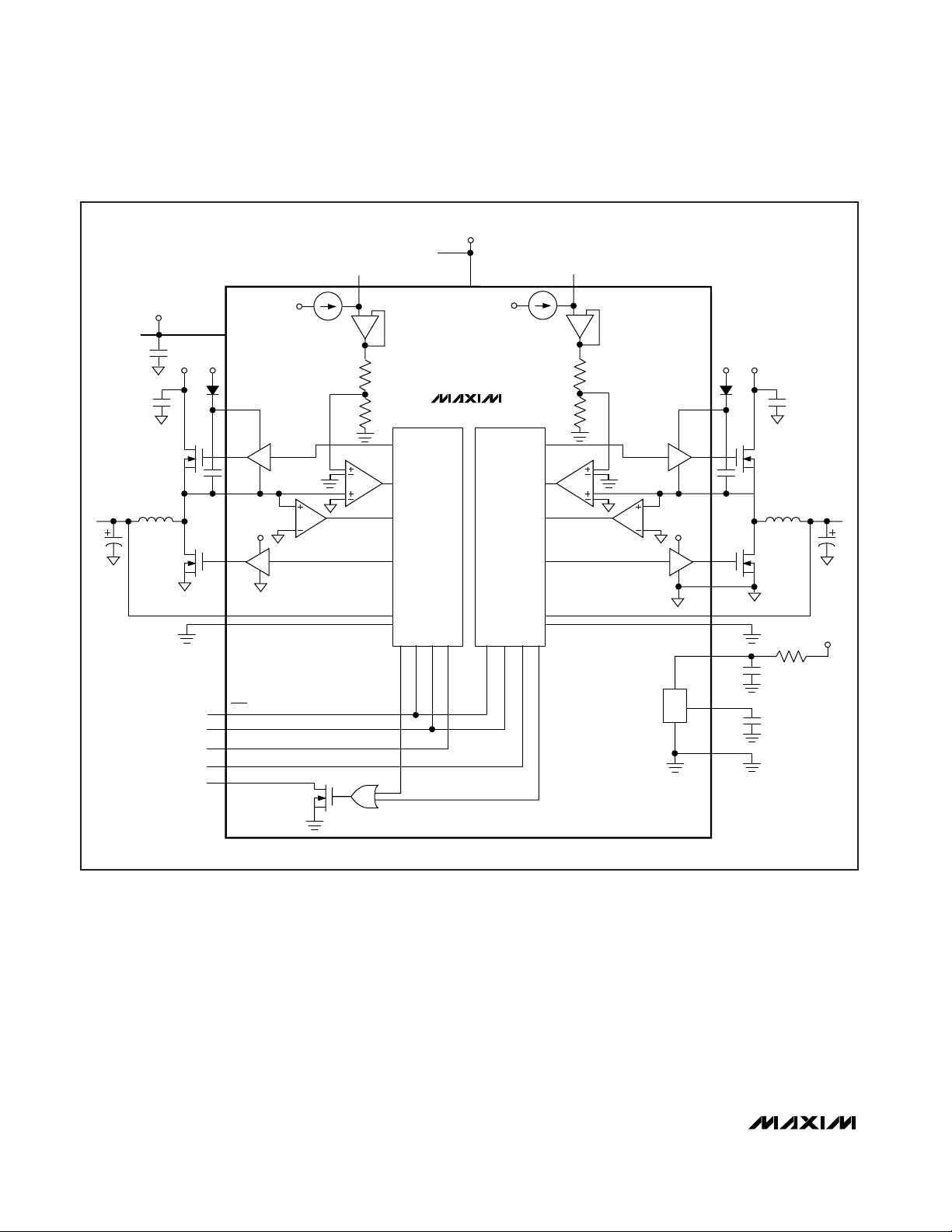

Figure 1. Standard Application Circuit

Standard Application Circuit

The standard application circuit (Figure 1) generates

two low-voltage rails for general-purpose use in notebook computers (I/O supply, fixed CPU core supply,

DRAM supply). This DC-DC converter steps down a

battery or AC adapter voltage to voltages from 1.0V to

5.5V with high efficiency and accuracy.

See Table 1 for a list of components for common applications. Table 2 lists component manufacturers.

Detailed Description

The MAX1715 buck controller is designed for low-voltage power supplies for notebook computers. Maxim’s

proprietary Quick-PWM pulse-width modulator in the

MAX1715 (Figure 2) is specifically designed for handling fast load steps while maintaining a relatively constant operating frequency and inductor operating point

over a wide range of input voltages. The Quick-PWM

architecture circumvents the poor load-transient timing

problems of fixed-frequency current-mode PWMs while

also avoiding the problems caused by widely varying

switching frequencies in conventional constant-on-time

and constant-off-time PWM schemes.

+5V Bias Supply (VCCand VDD)

The MAX1715 requires an external +5V bias supply in

addition to the battery. Typically, this +5V bias supply

is the notebook’s 95% efficient +5V system supply.

Keeping the bias supply external to the IC improves

efficiency and eliminates the cost associated with the

+5V linear regulator that would otherwise be needed to

supply the PWM circuit and gate drivers. If stand-alone

capability is needed, the +5V supply can be generated

with an external linear regulator such as the MAX1615.

Page 11

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

______________________________________________________________________________________ 11

The power input and +5V bias inputs can be connected

together if the input source is a fixed +4.5V to +5.5V

supply. If the +5V bias supply is powered up prior to

the battery supply, the enable signal (ON1, ON2) must

be delayed until the battery voltage is present to ensure

start-up. The +5V bias supply must provide VCCand

gate-drive power, so the maximum current drawn is:

I

BIAS

= ICC+ f (QG1 + QG2) = 5mA to 30mA (typ)

where ICC is 1mA typical, f is the switching frequency,

and QG1 and QG2 are the MOSFET data sheet total

gate-charge specification limits at VGS= 5V.

Free-Running, Constant-On-Time PWM

Controller with Input Feed-Forward

The Quick-PWM control architecture is a pseudo-fixedfrequency, constant-on-time current-mode type with

voltage feed-forward (Figure 3). This architecture relies

on the output filter capacitor’s ESR to act as the current-sense resistor, so the output ripple voltage provides the PWM ramp signal. The control algorithm is

simple: the high-side switch on-time is determined solely by a one-shot whose period is inversely proportional

to input voltage and directly proportional to output voltage. Another one-shot sets a minimum off-time (400ns

typ). The on-time one-shot is triggered if the error comparator is low, the low-side switch current is below the

Table 1. Component Selection for Standard Applications

Table 2. Component Suppliers

4.75V to 5.5V7V to 20V7V to 20VInput Range

100µF, 10V

Sanyo POSCAP

10TPA100M

470µF, 4V Sanyo

POSCAP 4TPB470M

470µF, 4V Sanyo

POSCAP 4TPB470M

C2 Output Capacitor

100µF, 10V

Sanyo POSCAP

10TPA100M

10µF, 25V

Taiyo Yuden

TMK432BJ106KM

10µF, 25V

Taiyo Yuden

TMK432BJ106KM

C1 Input Capacitor

3.3µH

TOKO D73LC

3.1µH

Sumida CDRH125

4.4µH

Sumida CDRH125

L1 Inductor

—Nihon EP10QY03Nihon EP10QY03D2 Rectifier

International Rectifier

1/2 IRF7301

Fairchild

Semiconductor

1/2 FDS6982A

Fairchild

Semiconductor

1/2 FDS6982A

Q2 Low-Side MOSFET

International Rectifier

1/2 IRF7301

Fairchild

Semiconductor

1/2 FDS6982A

Fairchild

Semiconductor

1/2 FDS6982A

Q1 High-Side MOSFET

600kHz345kHz255kHz

Frequency

3.3V at 1.5A1.8V at 4A2.5V at 4ACOMPONENT

[1] 602-994-6430602-303-5454Motorola

[1] 408-986-1442408-986-0424Kemet

[1] 408-721-1635408-822-2181Fairchild Semiconductor

[1] 561-241-9339561-241-7876Coiltronics

[1] 847-639-1469847-639-6400Coilcraft

[1] 516-435-1824516-435-1110Central Semiconductor

[1] 803-626-3123803-946-0690AVX

FACTORY FAX

[Country Code]

USA PHONEMANUFACTURER

[1] 714-960-6492714-969-2491Matsuo

[1] 310-322-3332310-322-3331International Rectifier

[1] 408-573-4159408-573-4150Taiyo Yuden

[1] 603-224-1430603-224-1961Sprague

[1] 408-970-3950

408-988-8000

800-554-5565

Siliconix

[81] 7-2070-1174619-661-6835Sanyo

[81] 3-3494-7414805-867-2555*NIEC (Nihon)

[1] 814-238-0490

814-237-1431

800-831-9172

Murata

[81] 3-3607-5144847-956-0666Sumida

[1] 847-390-4405847-390-4461TDK

*Distributor

7V to 20V

(2) 470µF, 6V Kemet

T510X477108M0

06AS

(2) 10µF, 25V

Taiyo Yuden

TMK432BJ106KM

1.5µH Sumida

CEP125-1R5MC

Motorola

MBRS340T3

Fairchild

Semiconductor

FDS6670A

International

Rectifier IRF7811

255kHz

1.3V at 8A

7V to 20V

330µF, 6V AVX

TPSV337M006R

0060

10µF, 25V

Taiyo Yuden

TMK432BJ106KM

6.8µH

Coiltronics UP2B

Nihon EP10QY03

Fairchild

Semiconductor

1/2 FDS6990A

Fairchild

Semiconductor

1/2 FDS6990A

255kHz

5V at 3A

[1] 708-699-1194800-PIK-TOKOTOKO

Page 12

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

12 ______________________________________________________________________________________

current-limit threshold, and the minimum off-time oneshot has timed out.

On-Time One-Shot (TON)

The heart of the PWM core is the one-shot that sets the

high-side switch on-time for both controllers. This fast,

low-jitter, adjustable one-shot includes circuitry that

varies the on-time in response to battery and output

voltage. The high-side switch on-time is inversely proportional to the battery voltage as measured by the V+

input, and proportional to the output voltage. This algorithm results in a nearly constant switching frequency

despite the lack of a fixed-frequency clock generator.

The benefits of a constant switching frequency are

twofold: first, the frequency can be selected to avoid

noise-sensitive regions such as the 455kHz IF band;

second, the inductor ripple-current operating point

remains relatively constant, resulting in easy design

methodology and predictable output voltage ripple.

The on-times for side 1 are set 15% higher than the

2V

REF

AGND

REF

OUT2

FB2

20Ω

PGND

V

DD

OUTPUT2

2.5V

DL2

V

CC

V

DD

LX2

ZERO

CROSSING

CURRENT

LIMIT

PWM

CONTROLLER

(SEE FIGURE 3)

DH2

BST2

R

I

LIM_

V

DD

V

CC

V+

V+

V+

OUT1

FB1

SKIP

TON

ON1

ON2

OUTPUT1

1.8V

5V INPUT

DL1

V

DD

LX1

ZERO

CROSSING

CURRENT

LIMIT

DH1

9R

R

I

LIM_

BATTERY

4.5V TO 28V

5μA

BST1

V

DD

V

DD

V

CC

V

DD

V+

PWM

CONTROLLER

(SEE FIGURE 3)

MAX1715

5μA

9R

P

GOOD

Figure 2. Functional Diagram

Page 13

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

______________________________________________________________________________________ 13

REF

-6%

FROM

OUT

REF

FROM ZERO-CROSSING COMPARATOR

ERROR

AMP

TOFF

TON

REF

+12%

REF

-30%

FEEDBACK

MUX

(SEE FIGURE 9)

x2

OVP/UVLO

LATCH

TO DL DRIVER

TO DH DRIVER

ON-TIME

COMPUTE

TON

1-SHOT

FROM ILIM

COMPARATOR

1-SHOT

TRIG

IN

2V TO 28V

TRIG

Q

Q

S

R

FB_

OUT_

Q

S1

Q

S2 TIMER

TON

V+

S

R

Q

TO PGOOD

OR GATE

Figure 3. PWM Controller (one side only)

X = Don’t care

ON1

ON2 SKIP MODE COMMENTS

0 0 X SHUTDOWN Low-power shutdown state. DL = VDD. Clears fault latches.

0 1 X OUT1 Disable Disable OUT1. DL1 = VDD. Clears OUT1 fault latches.

1 0 X OUT2 Disable Disable OUT2. DL2 = VDD. Clears OUT2 fault latches.

X X <-0.3V No Fault Disables the output overvoltage and undervoltage fault circuitry.

1 1 V

DD

RUN (PWM)

Low Noise

Low-Noise operation with no automatic PWM/PFM switchover. Fixed-frequency PWM

action is forced regardless of load. Inductor current reverses at light load levels. I

DD

draw <1.5mA (typ) plus gate-drive current.

Table 3. Operating Mode Truth Table

1 1 AGND

RUN

(PFM/PWM)

Normal operation with automatic PWM/PFM switchover for pulse-skipping at light loads.

I

DD

<1.5mA (typ) plus gate drive current.

Page 14

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

14 ______________________________________________________________________________________

nominal frequency setting (200kHz, 300kHz, 420kHz, or

540kHz), while the on-times for side 2 are set 15%

lower than nominal. This is done to prevent audio-frequency “beating” between the two sides, which switch

asynchronously for each side:

On-Time = K (V

OUT

+ 0.075V) / V

IN

where K is set by the TON pin-strap connection and

0.075V is an approximation to accommodate for the

expected drop across the low-side MOSFET switch.

One-shot timing error increases for the shorter on-time

settings due to fixed propagation delays; it is approximately ±12.5% at 540kHz and 420kHz nominal settings

and ±10% at the two slower settings. This translates to

reduced switching-frequency accuracy at higher frequencies (Table 5). Switching frequency increases as a

function of load current due to the increasing drop

across the low-side MOSFET, which causes a faster

inductor-current discharge ramp. The on-times guaranteed in the Electrical Characteristics are influenced by

switching delays in the external high-side power MOSFET.

Two external factors that influence switching-frequency

accuracy are resistive drops in the two conduction

loops (including inductor and PC board resistance) and

the dead-time effect. These effects are the largest contributors to the change of frequency with changing load

current. The dead-time effect increases the effective

on-time, reducing the switching frequency as one or

both dead times. It occurs only in PWM mode (SKIP =

high) when the inductor current reverses at light or negative load currents. With reversed inductor current, the

inductor’s EMF causes LX to go high earlier than normal, extending the on-time by a period equal to the

low-to-high dead time.

For loads above the critical conduction point, the actual

switching frequency is:

where V

DROP

1 is the sum of the parasitic voltage drops

in the inductor discharge path, including synchronous

rectifier, inductor, and PC board resistances; VDROP2

is the sum of the resistances in the charging path; and

tONis the on-time calculated by the MAX1715.

Automatic Pulse-Skipping Switchover

In skip mode (SKIP low), an inherent automatic

switchover to PFM takes place at light loads. This

switchover is effected by a comparator that truncates

the low-side switch on-time at the inductor current’s

zero crossing. This mechanism causes the threshold

between pulse-skipping PFM and nonskipping PWM

operation to coincide with the boundary between continuous and discontinuous inductor-current operation

(also known as the “critical conduction” point). For a

battery range of 7V to 24V, this threshold is relatively

constant, with only a minor dependence on battery voltage.

where K is the on-time scale factor (Table 5). The loadcurrent level at which PFM/PWM crossover occurs,

I

LOAD(SKIP)

, is equal to 1/2 the peak-to-peak ripple current, which is a function of the inductor value (Figure 4).

For example, in the standard application circuit with

V

OUT1

= 2.5V, VIN= 15V, and K = 2.96µs (see Table

5), switchover to pulse-skipping operation occurs at

I

LOAD

= 0.7A or about 1/6 full load. The crossover point

occurs at an even lower value if a swinging (soft-saturation) inductor is used.

The switching waveforms may appear noisy and asynchronous when light loading causes pulse-skipping

I

KV

2L

V-V

V

LOAD(SKIP)

OUT_

IN OUT

IN

≈

×

⎛

⎝

⎜

⎞

⎠

⎟

f

VV

tV V

OUT DROP

ON IN DROP

=

+

+

()

1

2

Good operating point for

compound buck designs

or desktop circuits.

+5V input540

420 3-cell Li+ notebook

Useful in 3-cell systems

for lighter loads than the

CPU core or where size is

key.

Considered mainstream

by current standards.

4-cell Li+ notebook 300

200 4-cell Li+ notebook

Use for absolute best

efficiency.

COMMENTS

TYPICAL

APPLICATION

NOMINAL

FREQUENCY

(kHz)

Table 4. Frequency Selection Guidelines

Table 5. Approximate K-Factor Errors

TON

SETTING

MIN V

IN

AT V

OUT

= 2V (V)

SIDE 1 K

FACTOR

(µs)

V

CC

2.6 4.24

OPEN 2.9 2.96

REF 3.2 2.08

GND 3.6 1.63

APPROX

K-FACTOR

ERROR (%)

±10

±10

±12.5

±12.5

SIDE 2 K

FACTOR

(µs)

5.81

4.03

2.81

2.18

Page 15

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

______________________________________________________________________________________ 15

operation, but this is a normal operating condition that

results in high light-load efficiency. Trade-offs in PFM

noise vs. light-load efficiency are made by varying the

inductor value. Generally, low inductor values produce

a broader efficiency vs. load curve, while higher values

result in higher full-load efficiency (assuming that the

coil resistance remains fixed) and less output voltage

ripple. Penalties for using higher inductor values

include larger physical size and degraded load-transient response (especially at low input voltage levels).

DC output accuracy specifications refer to the trip level of

the error. When the inductor is in continuous conduction,

the output voltage will have a DC regulation higher than

the trip level by 50% of the ripple. In discontinuous conduction (SKIP = AGND, light-loaded), the output voltage

will have a DC regulation higher than the trip level by

approximately 1.5% due to slope compensation.

Forced-PWM Mode (

SSKKIIPP

= high)

The low-noise, forced-PWM mode (SKIP = high) disables the zero-crossing comparator, which controls the

low-side switch on-time. This causes the low-side gatedrive waveform to become the complement of the highside gate-drive waveform. This in turn causes the

inductor current to reverse at light loads as the PWM

loop strives to maintain a duty ratio of V

OUT/VIN

. The

benefit of forced-PWM mode is to keep the switching

frequency fairly constant, but it comes at a cost: the noload battery current can be 10mA to 40mA, depending

on the external MOSFETs.

Forced-PWM mode is most useful for reducing audiofrequency noise, improving load-transient response,

providing sink-current capability for dynamic output

voltage adjustment, and improving the cross-regulation

of multiple-output applications that use a flyback transformer or coupled inductor.

Current-Limit Circuit (ILIM)

The current-limit circuit employs a unique “valley” currentsensing algorithm that uses the on-state resistance of the

low-side MOSFET as a current-sensing element. If the

current-sense signal is above the current-limit threshold,

the PWM is not allowed to initiate a new cycle (Figure 5).

The actual peak current is greater than the current-limit

threshold by an amount equal to the inductor ripple current. Therefore, the exact current-limit characteristic and

maximum load capability are a function of the MOSFET

on-resistance, inductor value, and battery voltage. The

reward for this uncertainty is robust, lossless overcurrent

sensing. When combined with the undervoltage protection circuit, this current-limit method is effective in almost

every circumstance.

There is also a negative current limit that prevents excessive reverse inductor currents when V

OUT

is sinking current. The negative current-limit threshold is set to

approximately 120% of the positive current limit, and

therefore tracks the positive current limit when ILIM is

adjusted.

The current-limit threshold is adjusted with internal 5µA

current source and an external resistor at ILIM. The

current-limit threshold adjustment range is from 50mV

to 200mV, corresponding to resistor values of 100kΩ to

400kΩ. In the adjustable mode, the current-limit threshold voltage is precisely 1/10 the voltage seen at ILIM.

The threshold defaults to 100mV when ILIM is connected to V

CC

. The logic threshold for switchover to the

100mV default value is approximately VCC- 1V.

The adjustable current limit accommodates MOSFETs

with a wide range of on-resistance characteristics (see

Design Procedure).

Carefully observe the PC board layout guidelines to

ensure that noise and DC errors don’t corrupt the current-sense signals seen by LX and PGND. Mount or

Figure 4. Pulse-Skipping/Discontinuous Crossover Point

INDUCTOR CURRENT

I

LOAD

= I

PEAK

/2

ON-TIME0 TIME

-I

PEAK

L

V

BATT -VOUT

Δi

Δt

=

Figure 5. ‘‘Valley’’ Current-Limit Threshold Point

INDUCTOR CURRENT

I

LIMIT

I

LOAD

0 TIME

-I

PEAK

Page 16

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

16 ______________________________________________________________________________________

place the IC close to the low-side MOSFET with short,

direct traces, making a Kelvin sense connection to the

source and drain terminals.

MOSFET Gate Drivers (DH, DL)

The DH and DL drivers are optimized for driving moderate-size, high-side and larger, low-side power

MOSFETs. This is consistent with the low duty factor

seen in the notebook CPU environment, where a large

V

BATT

- V

OUT

differential exists. An adaptive dead-time

circuit monitors the DL output and prevents the highside FET from turning on until DL is fully off. There must

be a low-resistance, low-inductance path from the DL

driver to the MOSFET gate for the adaptive dead-time

circuit to work properly. Otherwise, the sense circuitry

in the MAX1715 will interpret the MOSFET gate as “off”

while there is actually still charge left on the gate. Use

very short, wide traces measuring 10 to 20 squares (50

to 100 mils wide if the MOSFET is 1 inch from the

MAX1715).

The dead time at the other edge (DH turning off) is

determined by a fixed 35ns (typ) internal delay.

The internal pull-down transistor that drives DL low is

robust, with a 0.5Ω typical on-resistance. This helps

prevent DL from being pulled up during the fast risetime of the inductor node, due to capacitive coupling

from the drain to the gate of the low-side synchronousrectifier MOSFET. However, for high-current applications, you might still encounter some combinations of

high- and low-side FETs that will cause excessive gatedrain coupling, which can lead to efficiency-killing,

EMI-producing shoot-through currents. This is often

remedied by adding a resistor in series with BST,

which increases the turn-on time of the high-side FET

without degrading the turn-off time (Figure 6).

POR, UVLO, and Soft-Start

Power-on reset (POR) occurs when VCCrises above

approximately 2V, resetting the fault latch and soft-start

counter and preparing the PWM for operation. V

CC

undervoltage lockout (UVLO) circuitry inhibits switching

and forces the DL gate driver high (to enforce output

overvoltage protection) until VCCrises above 4.2V,

whereupon an internal digital soft-start timer begins to

ramp up the maximum allowed current limit. The ramp

occurs in five steps: 20%, 40%, 60%, 80%, and 100%;

100% current is available after 1.7ms ±50%.

A continuously adjustable analog soft-start function can

be realized by adding a capacitor in parallel with the

ILIM external resistor. This soft-start method requires a

minimum interval between power-down and power-up

to discharge the capacitor.

Power-Good Output (PGOOD)

The output voltage is continuously monitored for undervoltage by the PGOOD comparator. In shutdown, softstart, and standby modes, PGOOD is actively held low.

After digital soft-start has terminated, PGOOD is

released if both the outputs are within 5.5% of the error

comparator threshold. The PGOOD output is a true

open-drain type with no parasitic ESD diodes. Note

that the PGOOD undervoltage detector is completely

independent of the output UVP fault detector.

Output Overvoltage Protection (OVP)

The overvoltage protection circuit is designed to protect against a shorted high-side MOSFET by drawing

high current and blowing the battery fuse. The output

voltage is continuously monitored for overvoltage. If the

output is more than 10.5% above the trip level of the

error amplifier, OVP is triggered and the circuit shuts

down. The DL low-side gate-driver output is then

latched high until SHDN is toggled or V

CC

power is

cycled below 1V. This action turns on the synchronousrectifier MOSFET with 100% duty and, in turn, rapidly

discharges the output filter capacitor and forces the

output to ground. If the condition that caused the overvoltage (such as a shorted high-side MOSFET) persists, the battery fuse will blow. DL is also kept high

continuously when VCCUVLO is active, as well as in

shutdown mode (Table 3).

Note that DL latching high causes the output voltage to

go slightly negative, due to energy stored in the output

LC at the instant OVP activates. If the load can’t tolerate being forced to a negative voltage, it may be desirable to place a power Schottky diode across the output

to act as a reverse-polarity clamp (Figure 1).

BST

+5V

V

IN

5Ω

DH

LX

MAX1715

Figure 6. Reducing the Switching-Node Rise Time

Page 17

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

______________________________________________________________________________________ 17

Overvoltage protection can be defeated through the

SKIP test mode (Table 3).

Output Undervoltage Protection (UVP)

The output undervoltage protection function is similar to

foldback current limiting, but employs a timer rather

than a variable current limit. If the MAX1715 output voltage is under 70% of the nominal value 20ms after coming out of shutdown, the PWM is latched off and won’t

restart until VCCpower is cycled or SHDN is toggled.

No-Fault Test Mode

The over/undervoltage protection features can complicate the process of debugging prototype breadboards

since there are (at most) a few milliseconds in which to

determine what went wrong. Therefore, a test mode is

provided to totally disable the OVP, UVP, and thermal

shutdown features, and clear the fault latch if it has

been set. The PWM operates as if SKIP were grounded

(PFM/PWM mode).

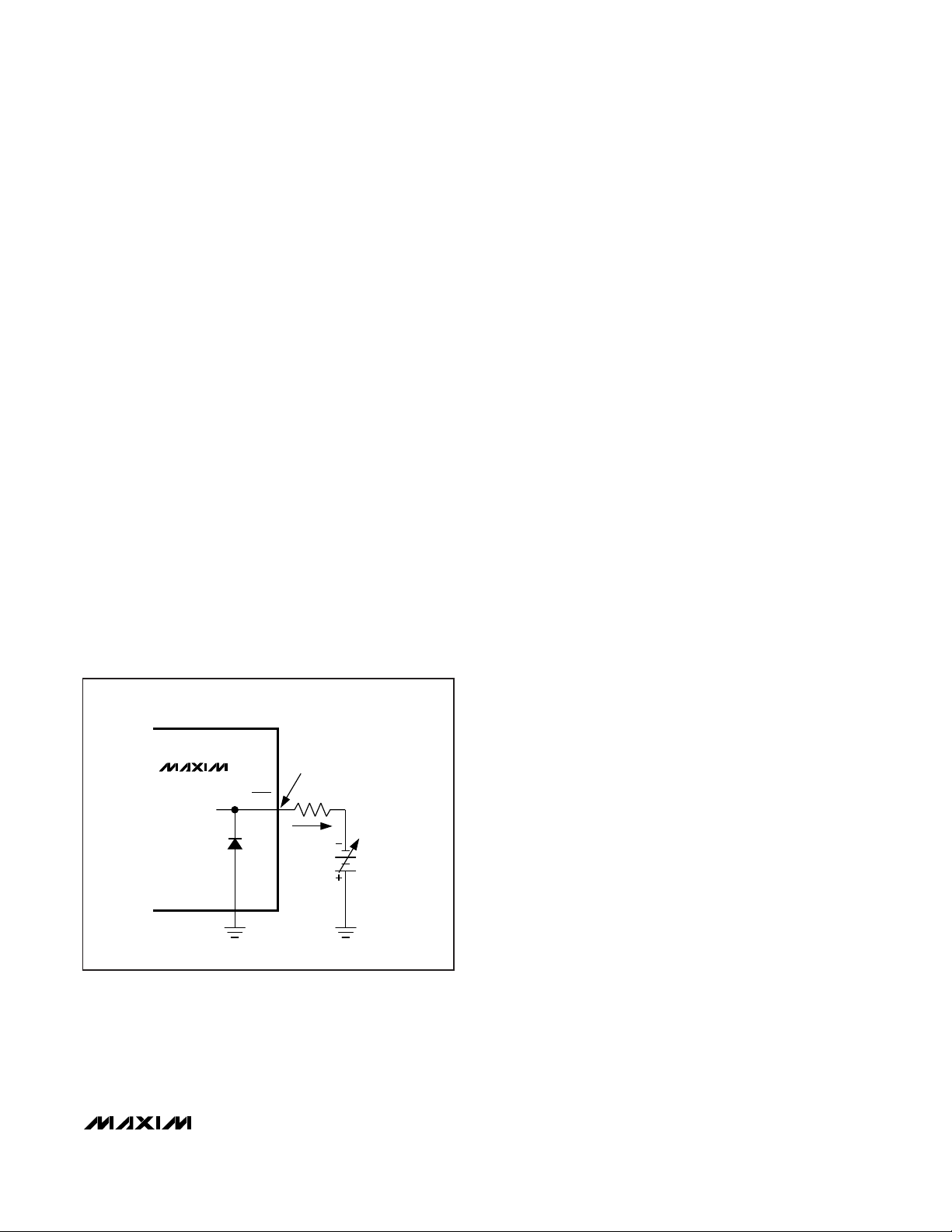

The no-fault test mode is entered by sinking 1.5mA

from SKIP through an external negative voltage source

in series with a resistor (Figure 7). SKIP is clamped to

AGND with a silicon diode, so choose the resistor value

equal to (V

FORCE

- 0.65V) / 1.5mA.

__________________Design Procedure

Firmly establish the input voltage range and maximum

load current before choosing a switching frequency

and inductor operating point (ripple-current ratio). The

primary design trade-off lies in choosing a good switching frequency and inductor operating point, and the following four factors dictate the rest of the design:

1) Input voltage range. The maximum value (V

IN(MAX)

)

must accommodate the worst-case high AC adapter

voltage. The minimum value (V

IN(MIN)

) must account

for the lowest battery voltage after drops due to connectors, fuses, and battery selector switches. If

there is a choice at all, lower input voltages result in

better efficiency.

2) Maximum load current. There are two values to

consider. The peak load current (I

LOAD(MAX)

) determines the instantaneous component stresses and filtering requirements, and thus drives output

capacitor selection, inductor saturation rating, and

the design of the current-limit circuit. The continuous

load current (I

LOAD

) determines the thermal stresses

and thus drives the selection of input capacitors,

MOSFETs, and other critical heat-contributing components. Modern notebook CPUs generally exhibit

I

LOAD

= I

LOAD(MAX)

· 80%.

3) Switching frequency. This choice determines the

basic trade-off between size and efficiency. The

optimal frequency is largely a function of maximum

input voltage, due to MOSFET switching losses that

are proportional to frequency and V

IN

2

. The optimum frequency is also a moving target, due to rapid

improvements in MOSFET technology that are making higher frequencies more practical (Table 4).

4) Inductor operating point. This choice provides

trade-offs between size vs. efficiency. Low inductor

values cause large ripple currents, resulting in the

smallest size, but poor efficiency and high output

noise. The minimum practical inductor value is one

that causes the circuit to operate at the edge of critical conduction (where the inductor current just

touches zero with every cycle at maximum load).

Inductor values lower than this grant no further sizereduction benefit.

The MAX1715’s pulse-skipping algorithm initiates

skip mode at the critical conduction point. So, the

inductor operating point also determines the loadcurrent value at which PFM/PWM switchover occurs.

The optimum point is usually found between 20%

and 50% ripple current.

APPROXIMATELY

-0.65V

1.5mA

V

FORCE

SKIP

AGND

MAX1715

Figure 7. Disabling Over/Undervoltage Protection (Test Mode)

Page 18

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

18 ______________________________________________________________________________________

The inductor ripple current also impacts transientresponse performance, especially at low VIN- V

OUT

differentials. Low inductor values allow the inductor

current to slew faster, replenishing charge removed

from the output filter capacitors by a sudden load step.

The amount of output sag is also a function of the maximum duty factor, which can be calculated from the ontime and minimum off-time:

where

where minimum off-time = 400ns typ (see Table 5).

Inductor Selection

The switching frequency (on-time) and operating point

(% ripple or LIR) determine the inductor value as follows:

Example: I

LOAD(MAX)

= 8A, VIN= 7V, V

OUT

= 1.6V, f =

300kHz, 35% ripple current or LIR = 0.35:

Find a low-loss inductor having the lowest possible DC

resistance that fits in the allotted dimensions. Ferrite

cores are often the best choice; although powdered

iron is inexpensive and can work well at 200kHz. The

core must be large enough not to saturate at the peak

inductor current (I

PEAK

):

I

PEAK

= I

LOAD(MAX)

+ [(LIR / 2) ✕I

LOAD(MAX)

]

Determining the Current Limit

The minimum current-limit threshold must be great

enough to support the maximum load current when the

current limit is at the minimum tolerance value. The valley of the inductor current occurs at I

LOAD(MAX)

minus

half of the ripple current; therefore:

I

LIMIT(LOW)

> I

LOAD(MAX)

- (LIR / 2) I

LOAD(MAX)

where I

LIMIT(LOW)

= minimum current-limit threshold

voltage divided by the R

DS(ON)

of Q2. For the

MAX1715, the minimum current-limit threshold (100mV

default setting) is 90mV. Use the worst-case maximum

value for R

DS(ON)

from the MOSFET Q2 data sheet, and

add some margin for the rise in R

DS(ON)

with tempera-

ture. A good general rule is to allow 0.5% additional

resistance for each °C of temperature rise.

Examining the 8A circuit example with a maximum

R

DS(ON)

= 12mΩ at high temperature reveals the fol-

lowing:

I

LIMIT(LOW)

= 90mV / 12mΩ = 7.5A

7.5A is greater than the valley current of 6.6A, so the

circuit can easily deliver the full-rated 8A using the

default 100mV nominal ILIM threshold.

Output Capacitor Selection

The output filter capacitor must have low enough effective series resistance (ESR) to meet output ripple and

load-transient requirements, yet have high enough ESR

to satisfy stability requirements. Also, the capacitance

value must be high enough to absorb the inductor

energy going from a full-load to no-load condition without tripping the overvoltage protection circuit.

In CPU V

CORE

converters and other applications where

the output is subject to violent load transients, the output capacitor’s size depends on how much ESR is

needed to prevent the output from dipping too low

under a load transient. Ignoring the sag due to finite

capacitance:

In non-CPU applications, the output capacitor’s size

depends on how much ESR is needed to maintain an

acceptable level of output voltage ripple:

The actual microfarad capacitance value required

relates to the physical size needed to achieve low ESR,

as well as to the chemistry of the capacitor technology.

Thus, the capacitor is usually selected by ESR and voltage rating rather than by capacitance value (this is true

of tantalums, OS-CONs, and other electrolytics).

When using low-capacity filter capacitors such as

ceramic or polymer types, capacitor size is usually

determined by the capacity needed to prevent VSAG

and VSOAR from causing problems during load transients. Also, the capacitance must be great enough to

prevent the inductor’s stored energy from launching the

output above the overvoltage protection threshold.

Generally, once enough capacitance is added to meet

the overshoot requirement, undershoot at the rising

load edge is no longer a problem (see the VSAG equation in the Design Procedure).

R

Vp p

LIR I

ESR

LOAD MAX

≤

×-

()

R

V

I

ESR

DIP

LOAD MAX

≤

()

L

1.6V (7 - 1 6)

7 300kHz 0.33 8A

1.6 H =

×

×××

=μ

L =

V(V- V)

V f LIR I

OUT IN OUT

IN LOAD(MAX)

×× ×

DUTY

K (V + 0.075V) V

K (V + 0.075V) V + min off -time

OUT IN

OUT OUT

=

V

IL

C DUTY V V

SAG

LOAD MAX

F IN MIN OUT

=

×

××

()

()

()

()

Δ

-

2

2

Page 19

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

______________________________________________________________________________________ 19

The amount of overshoot due to stored inductor energy

can be calculated as:

where I

PEAK

is the peak inductor current.

Output Capacitor Stability Considerations

Stability is determined by the value of the ESR zero relative to the switching frequency. The point of instability

is given by the following equation:

where:

For a typical 300kHz application, the ESR zero frequency must be well below 95kHz, preferably below 50kHz.

Tantalum and OS-CON capacitors in widespread use

at the time of publication have typical ESR zero frequencies of 15kHz. In the design example used for

inductor selection, the ESR needed to support 50mVp-p

ripple is 50mV/3.5A = 14.2mΩ. Three 470µF/4V Kemet

T510 low-ESR tantalum capacitors in parallel provide

15mΩ max ESR. Their typical combined ESR results in

a zero at 14.1kHz, well within the bounds of stability.

Don’t put high-value ceramic capacitors directly across

the fast feedback inputs (FB_ to AGND) without taking

precautions to ensure stability. Large ceramic capacitors can have a high-ESR zero frequency and cause

erratic, unstable operation. However, it’s easy to add

enough series resistance by placing the capacitors a

couple of inches downstream from the junction of the

inductor and FB_ pin (see the All-Ceramic-Capacitor

Application section).

Unstable operation manifests itself in two related but

distinctly different ways: double-pulsing and fast-feedback loop instability.

Double-pulsing occurs due to noise on the output or

because the ESR is so low that there isn’t enough voltage ramp in the output voltage signal. This “fools” the

error comparator into triggering a new cycle immediately after the 400ns minimum off-time period has

expired. Double-pulsing is more annoying than harmful,

resulting in nothing worse than increased output ripple.

However, it can indicate the possible presence of loop

instability, which is caused by insufficient ESR.

Loop instability can result in oscillations at the output

after line or load perturbations that can trip the overvoltage protection latch or cause the output voltage to fall

below the tolerance limit.

The easiest method for checking stability is to apply a

very fast zero-to-max load transient (refer to the

MAX1715 EV kit manual) and carefully observe the output voltage ripple envelope for overshoot and ringing. It

can help to simultaneously monitor the inductor current

with an AC current probe. Don’t allow more than one

cycle of ringing after the initial step-response under- or

overshoot.

Input Capacitor Selection

The input capacitor must meet the ripple current

requirement (IRMS) imposed by the switching currents.

Nontantalum chemistries (ceramic, aluminum, or OSCON) are preferred due to their resistance to power up

surge currents.

Power MOSFET Selection

Most of the following MOSFET guidelines focus on the

challenge of obtaining high load-current capability

(>5A) when using high-voltage (>20V) AC adapters.

Low-current applications usually require less attention.

For maximum efficiency, choose a high-side MOSFET

(Q1) that has conduction losses equal to the switching

losses at the optimum battery voltage (15V). Check to

ensure that the conduction losses at the minimum

input voltage don’t exceed the package thermal limits

or violate the overall thermal budget. Check to ensure

that conduction losses plus switching losses at the

maximum input voltage don’t exceed the package ratings or violate the overall thermal budget.

Choose a low-side MOSFET (Q2) that has the lowest

possible R

DS(ON)

, comes in a moderate to small package (i.e., SO-8), and is reasonably priced. Ensure that

the MAX1715 DL gate driver can drive Q2; in other

words, check that the gate isn’t pulled up by the highside switch turning on due to parasitic drain-to-gate

capacitance, causing cross-conduction problems.

Switching losses aren’t an issue for the low-side MOSFET since it’s a zero-voltage switched device when

used in the buck topology.

MOSFET Power Dissipation

Worst-case conduction losses occur at the duty factor

extremes. For the high-side MOSFET, the worst-case-

I I

VV-V

V

RMS LOAD

OUT IN OUT

IN

=

()

⎛

⎝

⎜

⎜

⎞

⎠

⎟

⎟

f

RC

ESR

ESR F

=

×× ×

1

2 π

f

f

ESR

=

π

ΔV

LI

2

2CV

PEAK

OUT

≈

Page 20

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

20 ______________________________________________________________________________________

power dissipation (PD) due to resistance occurs at

minimum battery voltage:

Generally, a small high-side MOSFET is desired in

order to reduce switching losses at high input voltages.

However, the R

DS(ON)

required to stay within package

power-dissipation limits often limits how small the MOSFET can be. Again, the optimum occurs when the

switching (AC) losses equal the conduction (R

DS(ON)

)

losses. High-side switching losses don’t usually

become an issue until the input is greater than approximately 15V.

Switching losses in the high-side MOSFET can become

an insidious heat problem when maximum AC adapter

voltages are applied, due to the squared term in the

CV2F switching loss equation. If the high-side MOSFET

you’ve chosen for adequate R

DS(ON)

at low battery

voltages becomes extraordinarily hot when subjected

to V

IN(MAX)

, reconsider your choice of MOSFET.

Calculating the power dissipation in Q1 due to switching losses is difficult since it must allow for difficult

quantifying factors that influence the turn-on and turnoff times. These factors include the internal gate resistance, gate charge, threshold voltage, source

inductance, and PC board layout characteristics. The

following switching loss calculation provides only a

very rough estimate and is no substitute for breadboard evaluation, preferably including a verification

using a thermocouple mounted on Q1:

where C

RSS

is the reverse transfer capacitance of Q1

and I

GATE

is the peak gate-drive source/sink current

(1A typ).

For the low-side MOSFET, Q2, the worst-case power

dissipation always occurs at maximum battery voltage:

The absolute worst case for MOSFET power dissipation

occurs under heavy overloads that are greater than

I

LOAD(MAX)

but are not quite high enough to exceed

the current limit and cause the fault latch to trip. To protect against this possibility, you must “overdesign” the

circuit to tolerate:

I

LOAD

= I

LIMIT(HIGH)

+ (LIR / 2) ✕I

LOAD(MAX)

where I

LIMIT(HIGH)

is the maximum valley current

allowed by the current-limit circuit, including threshold

tolerance and on-resistance variation. This means that

the MOSFETs must be very well heatsinked. If short-circuit protection without overload protection is enough, a

normal I

LOAD

value can be used for calculating com-

ponent stresses.

Choose a Schottky diode (D1) having a forward voltage

low enough to prevent the Q2 MOSFET body diode

from turning on during the dead time. As a general

rule, a diode having a DC current rating equal to 1/3 of

the load current is sufficient. This diode is optional and

can be removed if efficiency isn’t critical.

_________________Application Issues

Dropout Performance

The output voltage adjust range for continuous-conduction operation is restricted by the nonadjustable

500ns (max) minimum off-time one-shot. For best

dropout performance, use the slowest (200kHz) ontime setting. When working with low input voltages, the

duty-factor limit must be calculated using worst-case

values for on- and off-times. Manufacturing tolerances

and internal propagation delays introduce an error to

the TON K-factor. This error is greater at higher frequencies (Table 5). Also, keep in mind that transient

response performance of buck regulators operated

close to dropout is poor, and bulk output capacitance

must often be added (see the VSAG equation in the

Design Procedure).

Dropout design example: VIN= 3V min, V

OUT

= 2V, f

= 300kHz. The required duty is (V

OUT

+ VSW) / (VINVSW) = (2V + 0.1V) / (3.0V - 0.1V) = 72.4%. The worstcase on-time is (V

OUT

+ 0.075) / V

IN

✕

K = 2.075V / 3V

✕

3.35µs-V ✕90% = 2.08µs. The IC duty-factor limitation

is:

which meets the required duty.

Remember to include inductor resistance and MOSFET

on-state voltage drops (VSW) when doing worst-case

dropout duty-factor calculations.

All-Ceramic-Capacitor Application

Ceramic capacitors have advantages and disadvantages. They have ultra-low ESR and are noncombustible, relatively small, and nonpolarized. They are

also expensive and brittle, and their ultra-low ESR characteristic can result in excessively high ESR zero frequencies (affecting stability). In addition, their relatively

low capacitance value can cause output overshoot

DUTY

t

tt

2.08 s

2.08 s 500ns

80.6%

ON(MIN)

ON(MIN) OFF(MAX)

=

+

=

+

=

μ

μ

PD(Q2)

1 - V

V

I R

OUT

IN MAX

LOAD

2

DS ON

=

⎛

⎝

⎜

⎜

⎞

⎠

⎟

⎟

×

()

()

PD(Q1 switching)

CV fI

I

RSS IN(MAX)

2

LOAD

GATE

=

×××

PD(Q1 resistance)

V

V

I R

OUT

IN MIN

LOAD

2

DS ON

=

⎛

⎝

⎜

⎜

⎞

⎠

⎟

⎟

×

()

()

Page 21

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

______________________________________________________________________________________ 21

when going abruptly from full-load to no-load conditions, unless there are some bulk tantalum or electrolytic capacitors in parallel to absorb the stored energy in

the inductor. In some cases, there may be no room for

electrolytics, creating a need for a DC-DC design that

uses nothing but ceramics.

The all-ceramic-capacitor application of Figure 8

replaces the standard tantalum output capacitors with

ceramics. This design relies on having a minimum of

5mΩ parasitic PC board trace resistance in series with

the capacitor to reduce the ESR zero frequency. This

small amount of resistance is easily obtained by locating the MAX1714A circuit 2 or 3 inches away from the

CPU, and placing all the ceramic capacitors close to

the CPU. Resistance values higher than 5mΩ just

improve the stability (which can be observed by examining the load-transient response characteristic as

shown in the Typical Operating Characteristics). Avoid

adding excess PC board trace resistance, as there’s an

efficiency penalty; 5mΩ is sufficient for a 7A circuit:

Output overshoot (ΔV) determines the minimum output

capacitance requirement. In this example, the switching frequency has been increased to 600kHz and the

inductor value has been reduced to 0.5µH (compared

to 300kHz and 2µH for the standard 8A circuit) to minimize the energy transferred from inductor to capacitor

during load-step recovery. The overshoot must be calculated to avoid tripping the OVP latch. The efficiency

penalty for operating at 540kHz is about 2% to 3%,

depending on the input voltage.

An optional 1Ω resistor is placed in series with OUT.

This resistor attenuates high-frequency noise in some

bands, which causes double pulsing.

Fixed Output Voltages

The MAX1715’s Dual Mode™ operation allows the

selection of common voltages without requiring external

components (Figure 9). Connect FB to AGND for a

fixed +2.5V output or to VCCfor a +3.3V output, or connect FB directly to OUT for a fixed +1.0V output.

Setting V

OUT

with a Resistor-Divider

The output voltage can be adjusted with a resistordivider if desired (Figure 8). The equation for adjusting

the output voltage is:

where VFBis 1.0V and R2 is about 10kΩ.

Two-Stage (5V-Powered) Notebook

CPU Buck Regulator

The most efficient and overall cost-effective solution for

stepping down a high-voltage battery to a very low output voltage is to use a single-stage buck regulator

that’s powered directly from the battery. However, there

may be situations where the battery bus can’t be routed

near the CPU, or where space constraints dictate the

smallest possible local DC-DC converter. In such

cases, the 5V-powered circuit of Figure 10 may be

appropriate. The reduced input voltage allows a higher

V V 1

R1

R2

OUT FB

=+

⎛

⎝

⎜

⎞

⎠

⎟

R

1

2FC

ESR

OUT

≥

MAX1715

TO ERROR

AMP1

TO ERROR

AMP2

OUT2

FB2

0.2V

0.2V

2V

FB1

FIXED

2.5V

FIXED

1.8V

FIXED

3.3V

OUT1

Figure 9. Feedback Mux

DL

AGND

OUT

PGND

DH

1/2

FB

V

BATT

V

OUT

R1

R2

MAX1715

Figure 8. Setting V

OUT

with a Resistor-Divider

Dual Mode is a trademark of Maxim Integrated Products.

Page 22

MAX1715

Ultra-High Efficiency, Dual Step-Down

Controller for Notebook Computers

22 ______________________________________________________________________________________

switching frequency and a much smaller inductor

value.

PC Board Layout Guidelines

Careful PC board layout is critical to achieving low

switching losses and clean, stable operation. This is

especially true for dual converters, where one channel

can affect the other. The switching power stages require

particular attention (Figure 11). Refer to the MAX1715

EV kit data sheet for a specific layout example.

If possible, mount all of the power components on the

top side of the board with their ground terminals flush

against one another. Follow these guidelines for good

PC board layout:

• Isolate the power components on the top side from

the sensitive analog components on the bottom side

with a ground shield. Use a separate PGND plane

under the OUT1 and OUT2 sides (called PGND1 and

PGND2). Avoid the introduction of AC currents into

the PGND1 and PGND2 ground planes. Run the

power plane ground currents on the top side only, if

possible.

• Use a star ground connection on the power plane to

minimize the crosstalk between OUT1 and OUT2.

• Keep the high-current paths short, especially at the

ground terminals. This practice is essential for stable, jitter-free operation.

• Tie AGND and PGND together close to the IC. Do

not connect them together anywhere else. Carefully