General Description

The MAX17019 is a high-input-voltage quad-output controller (up to 38V). The MAX17019 provides a compact,

low-cost controller capable of providing four independent regulators—a main stage, a 3A

P-P

internal step-

down, a 5A

P-P

internal step-down, and a 2A source/sink

linear regulator. The input voltage is up to 38V. This

makes it an excellent choice for automotive applications.

The internal switching regulators include 5V synchronous

MOSFETs that can be powered directly from a single Li+

cell or from the main 3.3V/5V power stages. Finally, the

linear regulator is capable of sourcing and sinking 2A to

support DDR termination requirements or to generate a

fixed output voltage.

The step-down converters use a peak current-mode,

fixed-frequency control scheme—an easy to implement

architecture that does not sacrifice fast-transient

response. This architecture also supports peak currentlimit protection and pulse-skipping operation to maintain

high efficiency under light-load conditions.

Separate enable inputs and independent open-drain

power-good outputs allow flexible power sequencing. A

soft-start function gradually ramps up the output voltage to reduce the inrush current. Disabled regulators

enter high-impedance states to avoid negative output

voltage created by rapidly discharging the output

through the low-side MOSFET. The MAX17019 also

includes output undervoltage, output overvoltage, and

thermal-fault protection.

The MAX17019 is available in a 48-pin, 6mm x 6mm

thin QFN package.

Applications

Automotive Battery-Powered Devices

Embedded Control Systems

Set-Top Boxes

Features

♦ Fixed-Frequency, Current-Mode Controllers

♦ 5.5V to 38V Input Range (Step-Down)

♦ 1x Step-Down Controller

♦ 1x Internal 5A

P-P

Step-Down Regulator

♦ 1x Internal 3A

P-P

Step-Down Regulator

♦ 1x 2A Source/Sink Linear Regulator with Dynamic

REFIN

♦ Internal BST Diodes

♦ Internal 5V 50mA Linear Regulator

♦ Fault Protection—Undervoltage, Overvoltage,

Thermal, Peak Current Limit

♦ Independent Enable Inputs and Power-Good

Outputs

♦ Voltage-Controlled Soft-Start

♦ High-Impedance Shutdown

♦ 10µA (typ) Shutdown Current

MAX17019

High-Input-Voltage Quad-Output Controller

________________________________________________________________

Maxim Integrated Products

1

MAX17019

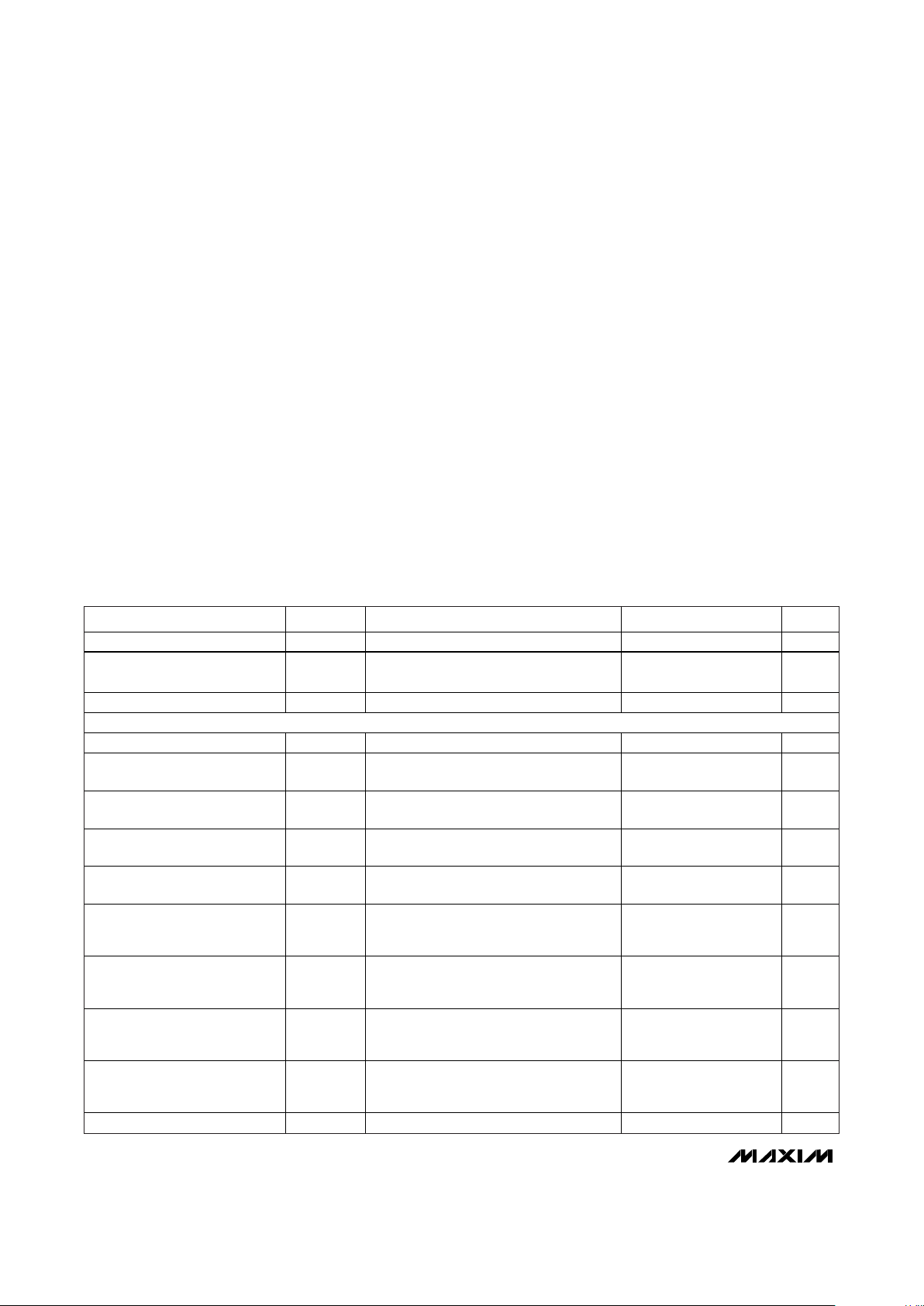

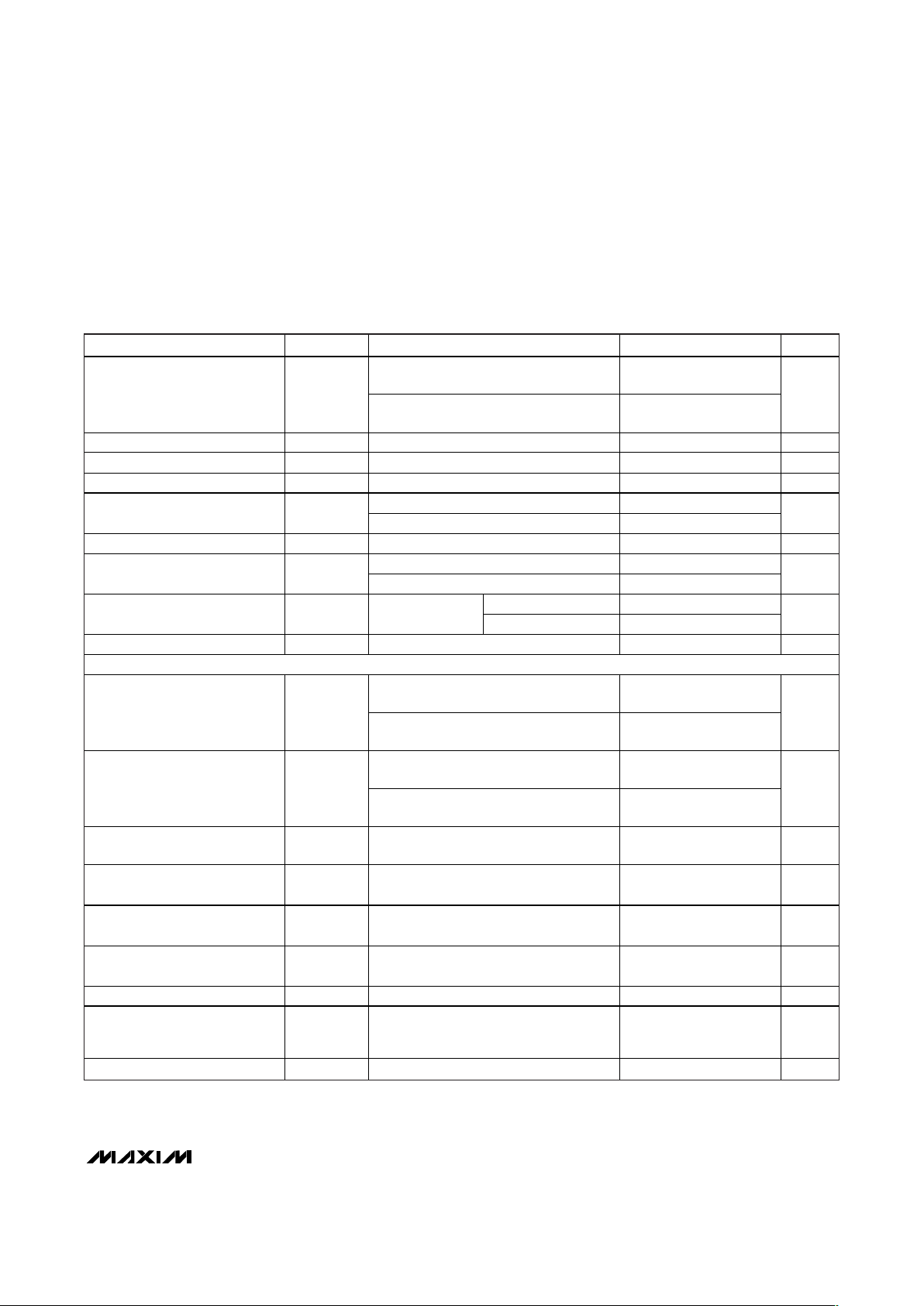

36 35 34 33 32 31 30 29 28 27 26 25

24

23

22

21

20

19

18

17

16

15

14

13

CSPA

CSNA

AGND

REF

FREQ

UP/DN

INA

V

CC

BYP

LDO5

INLDO

SHDN

ONB

SYNC

ONA

INBC

INBC

INBC

INBC

V

DD

POKD

OND

ONC

FBC

37

38

39

40

41

42

43

44

45

46

47

48

1

POKC

BSTC

LXC

LXC

LXC

LXC

OUTD

OUTD

IND

FBD

VTTR

REFIND

FBB

POKB

BSTB

LXB

LXB

LXB

DLA

BSTA

LXA

DHA

POKA

FBA

+

2 3 4 5 6 7 8 9 10 11 12

EXPOSED PAD = PGND

THIN QFN

TOP VIEW

Pin Configuration

19-4225; Rev 0; 8/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Ordering Information

+

Denotes a lead-free/RoHS-compliant package.

*

EP = Exposed pad.

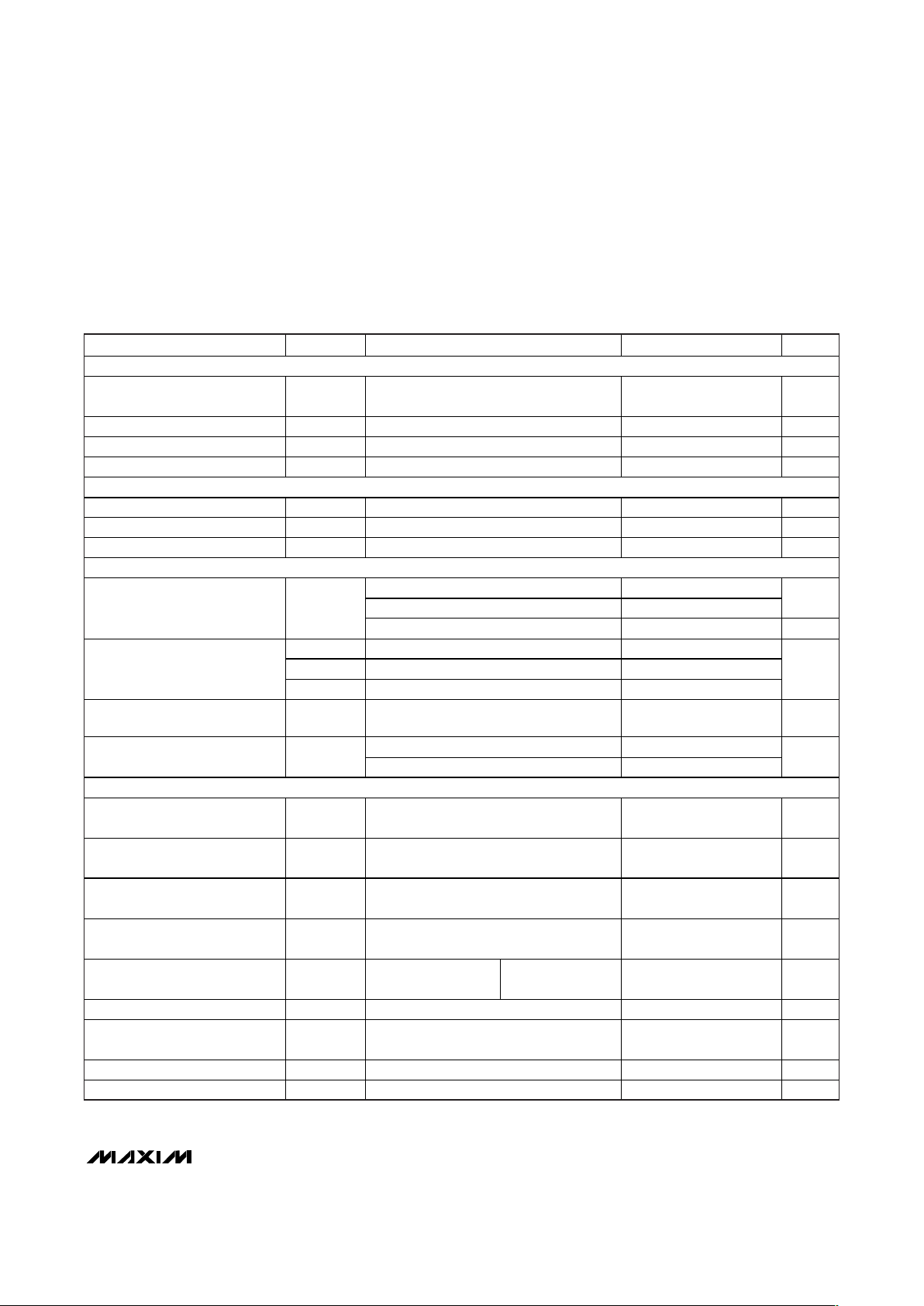

PART TEMP RANGE PIN-PACKAGE

MAX17019ATM+ -40°C to +125°C 48 TQFN-EP*

MAX17019

High-Input-Voltage Quad-Output Controller

2 _______________________________________________________________________________________

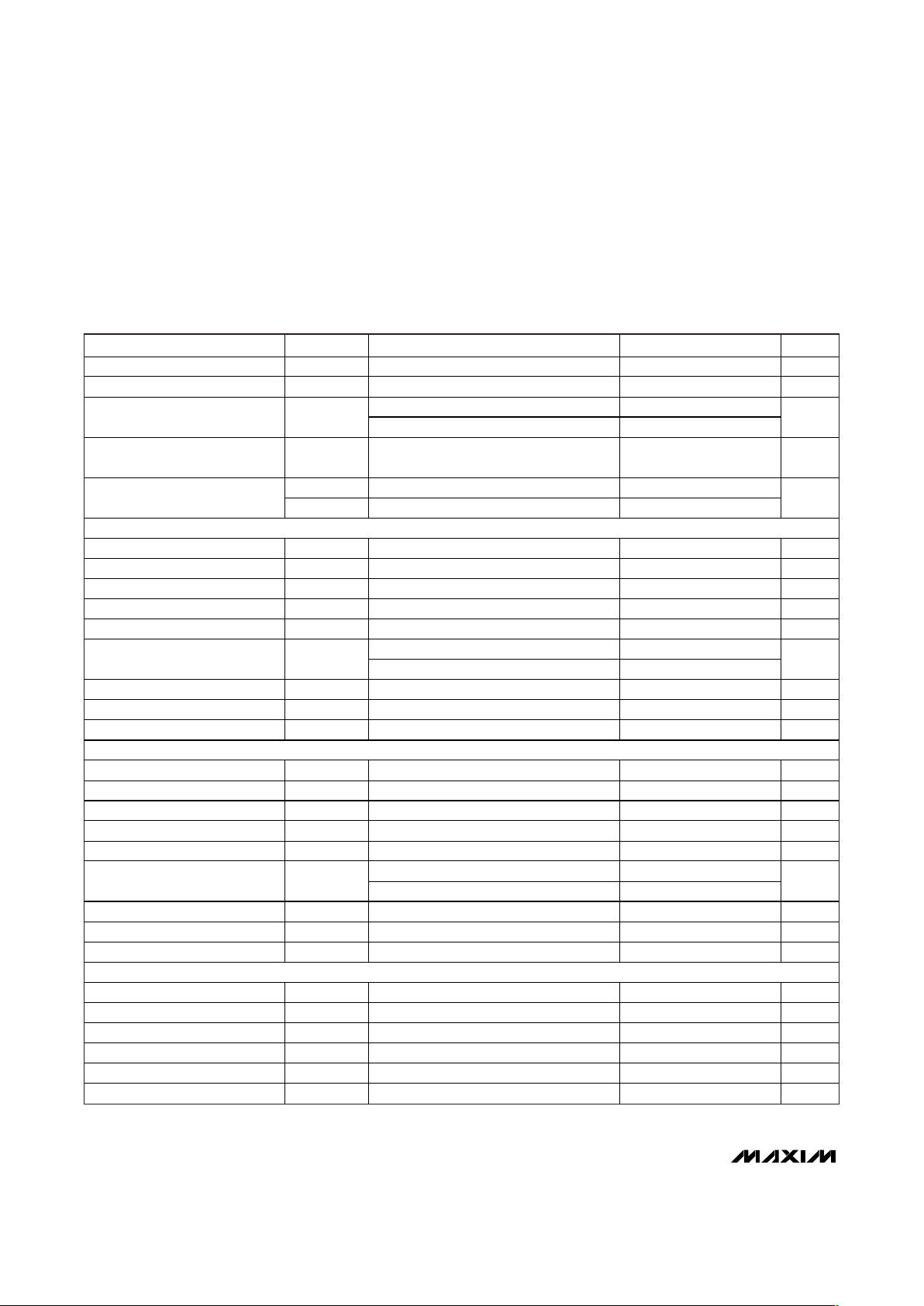

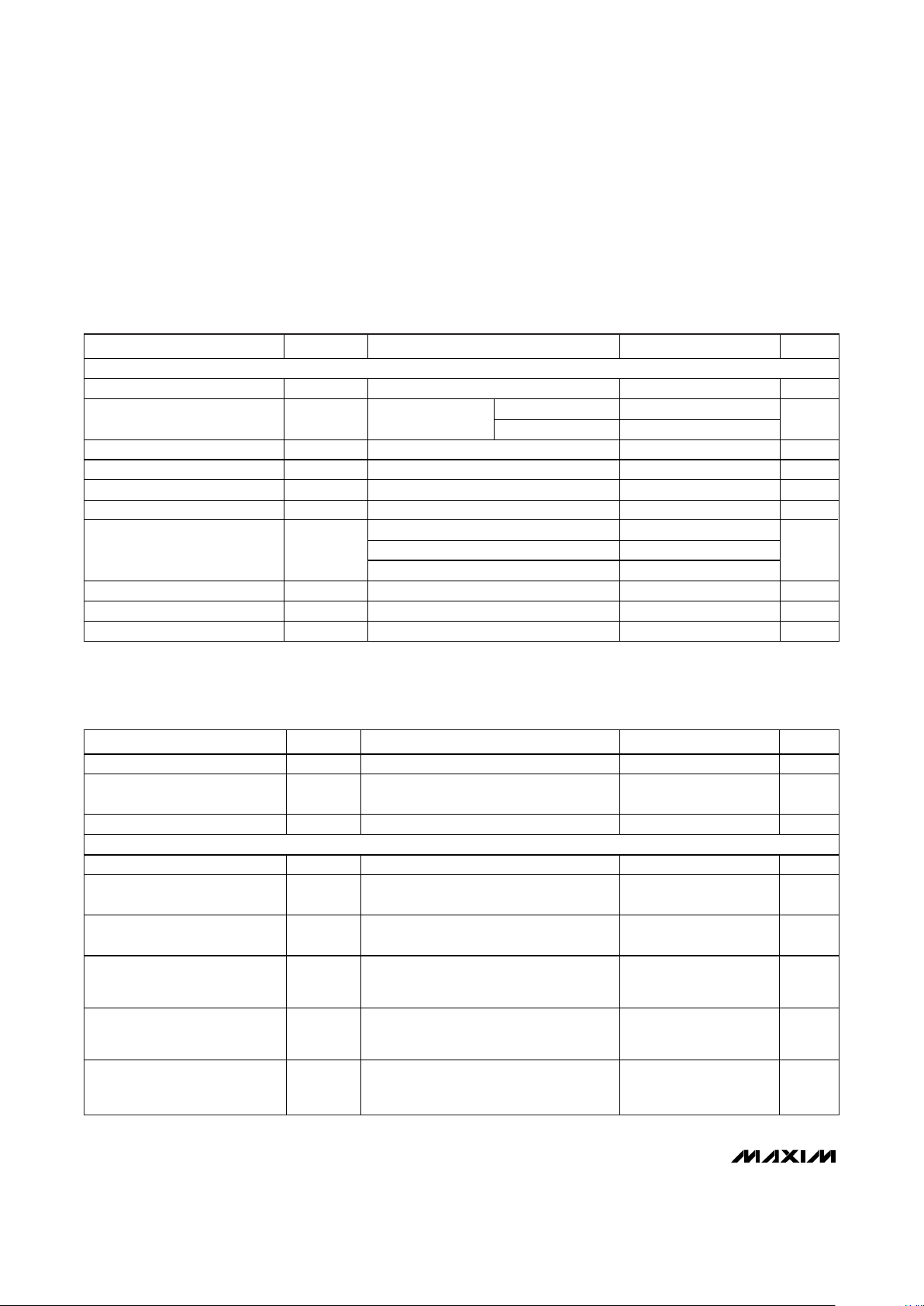

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V

INLDO

= 12V, V

INA

= V

INBC

= VDD= VCC= V

BYP

= V

CSPA

= V

CSNA

= 5V, V

IND

= 1.8V, V

SHDN

= V

ONA

= V

ONB

=

V

ONC

= V

OND

= 5V, I

REF

= I

LDO5

= I

OUTD

= no load, FREQ = GND, UP/DN = VCC, TA= 0°C to +85°C, unless otherwise noted.

Typical values are at T

A

= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

INLDO, SHDN to GND............................................-0.3V to +43V

LDO5, INA, V

DD

, VCCto GND..................................-0.3V to +6V

DHA to LXA .............................................-0.3V to (V

BSTA

+ 0.3V)

ONA, ONB, ONC, OND to GND ...............................-0.3V to +6V

POKA, POKB, POKC, POKD to GND.........-0.3V to (V

CC

+ 0.3V)

REF, REFIND, FREQ, UP/DN,

SYNC to GND ........................................-0.3V to (V

CC

+ 0.3V)

FBA, FBB, FBC, FBD to GND.....................-0.3V to (V

CC

+ 0.3V)

BYP to GND ............................................-0.3V to (V

LDO5

+ 0.3V)

CSPA, CSNA to GND .................................-0.3V to (V

CC

+ 0.3V)

DLA to GND................................................-0.3V to (V

DD

+ 0.3V)

INBC, IND to GND....................................................-0.3V to +6V

OUTD to GND............................................-0.3V to (V

IND

+ 0.3V)

VTTR to GND.............................................-0.3V to (V

BYP

+ 0.3V)

LXB, LXC to GND ....................................-1.0V to (V

INBC

+ 0.3V)

BSTB to GND ....................................(V

DD

- 0.3V) to (V

LXB

+ 6V)

BSTC to GND....................................(V

DD

- 0.3V) to (V

LXC

+ 6V)

BSTA to GND ....................................(V

DD

- 0.3V) to (V

LXA

+ 6V)

REF Short-Circuit Current......................................................1mA

Continuous Power Dissipation (T

A

= +70°C)

Multilayer PCB: 48-Pin 6mm x 6mm

2

TQFN

(T4866-2 derated 37mW/°C above +70°C) ....................2.9W

Operating Temperature Range .........................-40°C to +105°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) ................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Input Voltage Range UP/DN = LDO5, INLDO, INA = LDO5 5.5 38 V

INA Undervoltage Threshold V

INA(UVLO)

UP/DN = LDO5, INA = VCC, rising edge,

hysteresis = 160mV

4.0 4.2 4.4 V

INBC Input Voltage Range 2.3 5.5 V

SUPPLY CURRENTS

V

INLDO

Shutdown Supply Current I

IN(SHDN)VINLDO

= 5.5V to 38V, SHDN = GND 10 15 μA

V

INLDO

Suspend Supply Current I

IN(SUS)

V

INLDO

= 5.5V to 38V, ON_ = GND,

SHDN = INLDO

50 80 μA

VCC Shutdown Supply Current

SHDN = ONA = ONB = ONC = OND =

GND, T

A

= +25°C

0.1 1 μA

VDD Shutdown Supply Current

SHDN = ONA = ONB = ONC = OND =

GND, T

A

= +25°C

0.1 1 μA

INA Shutdown Current I

INA

SHDN = ONA = ONB = ONC = OND =

GND, UP/DN = V

CC

7 10 μA

VCC Supply Current

Main Step-Down Only

ONA = V

CC

, ONB = ONC = OND = GND;

does not include switching losses,

measured from V

CC

210 300 μA

VCC Supply Current

Main Step-Down and Reg ulator B

ONA = ONB = V

CC

, ONC = OND = GND;

does not include switching losses,

measured from V

CC

280 350 μA

VCC Supply Current

Main Step-Down and Reg ulator C

ONA = ONC = V

CC

, ONB = OND = GND;

does not include switching losses,

measured from V

CC

280 350 μA

VCC Supply Current

Main Step-Down and Reg ulator D

ONA = OND = V

CC

, ONB = ONC = GND;

does not include switching losses,

measured from V

CC

2.2 3 mA

INA Supply Current I

INA

ONA = VCC, UP/DN = VCC 40 60 μA

MAX17019

High-Input-Voltage Quad-Output Controller

_______________________________________________________________________________________ 3

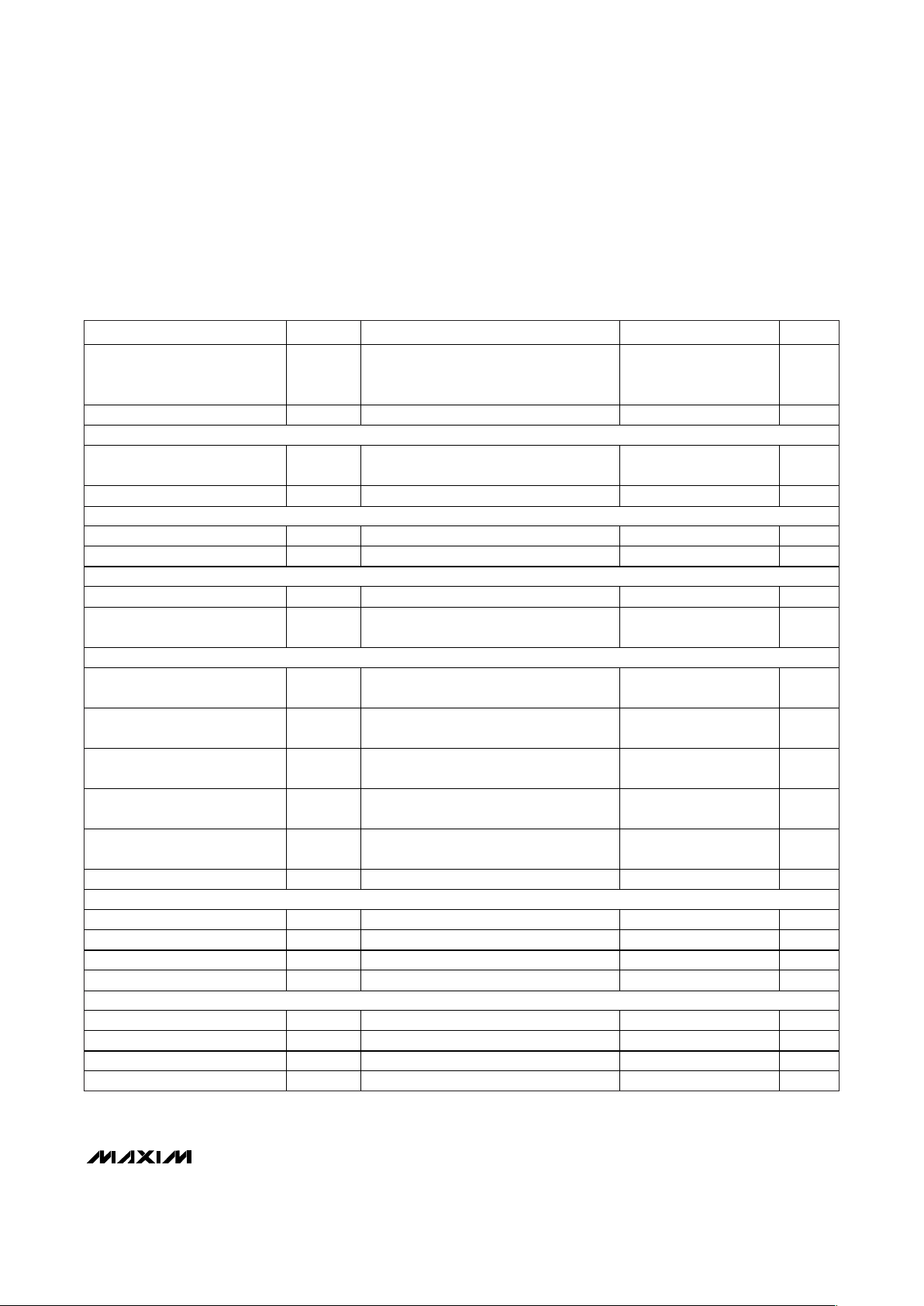

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

5V LINEAR REGULATOR (LDO5)

LDO5 Output Voltage V

LDO5

V

INLDO

= 5.5V to 38V, I

LDO5

= 0 to 50mA,

BYP = GND

4.75 5.0 5.2 V

LDO5 Short-Circuit Current Limit LDO5 = BYP = GND, V

INLDO

= 5.5V 70 160 250 mA

BYP Switchover Threshold V

BYP

Rising edge 4.65 V

LDO5-to-BYP Switch Resistance R

BYP

LDO5 to BYP, V

BYP

= 5V, I

LDO5

= 50mA 1.5 4

1.25V REFERENCE

Reference Output Voltage V

REF

No load 1.237 1.25 1.263 V

Reference Load Regulation V

REF

I

REF

= -1μA to +50μA 3 10 mV

Reference Undervoltage Lockout V

REF(UVLO)

1.0 V

OSCILLATOR

FREQ = VCC 500

FREQ = REF 750

kHz

Oscillator Frequency f

OSC

FREQ = GND 0.9 1.0 1.1 MHz

f

SWA

Regulator A 1/2 f

OSC

f

SWB

Regulator B f

OSC

Switching Frequency

f

SWC

Regulator C 1/2 f

OSC

MHz

Maximum Duty Cycle

(All Switching Regulator s)

D

MAX

90 93.5 %

FREQ = VCC or GND 90

Minimum On-Time

(All Switching Regulator s)

t

ON(MIN)

FREQ = REF 75

ns

REGULATOR A (Main Step-Down)

Output Voltage-Adjust Range Step-down configuration (UP/DN = VCC) 1.0

V

CC

+

0.3

V

FBA Regulation Voltage V

FBA

Step-down configuration (UP/DN = VCC),

V

CSPA

- V

CSNA

= 0 to 20mV, 90% duty cycle

0.968 0.97 1.003 V

FBA Regulation Voltage

(Overload)

V

FBA

Step-down configuration (UP/DN = VCC),

V

CSPA

- V

CSNA

= 0 to 20mV, 90% duty cycle

0.930 1.003 V

FBA Load Regulation V

FBA

Step-down configuration (UP/DN = VCC),

V

CSPA

- V

CSNA

= 0 to 20mV

16 mV

FBA Line Regulation

UP/DN = V

CC

,

0 to 100% duty cycle

Step-down

(UP/DN = V

CC

)

10 16 22 mV

FBA Input Current I

FBA

UP/DN = GND or VCC, TA = +25°C -100 -5 +100 nA

Current-Sense Input CommonMode Range

V

CSA

0

V

CC

+

0.3V

V

Current-Sense Input Bias Current I

CSA

TA = +25°C 40 60 μA

Idle Mode™ Threshold V

IDLEA

4 mV

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

INLDO

= 12V, V

INA

= V

INBC

= VDD= VCC= V

BYP

= V

CSPA

= V

CSNA

= 5V, V

IND

= 1.8V, V

SHDN

= V

ONA

= V

ONB

=

V

ONC

= V

OND

= 5V, I

REF

= I

LDO5

= I

OUTD

= no load, FREQ = GND, UP/DN = VCC, TA= 0°C to +85°C, unless otherwise noted.

Typical values are at T

A

= +25°C.) (Note 1)

Idle Mode is a trademark of Maxim Integrated Products, Inc.

MAX17019

High-Input-Voltage Quad-Output Controller

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

INLDO

= 12V, V

INA

= V

INBC

= VDD= VCC= V

BYP

= V

CSPA

= V

CSNA

= 5V, V

IND

= 1.8V, V

SHDN

= V

ONA

= V

ONB

=

V

ONC

= V

OND

= 5V, I

REF

= I

LDO5

= I

OUTD

= no load, FREQ = GND, UP/DN = VCC, TA= 0°C to +85°C, unless otherwise noted.

Typical values are at T

A

= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Zero-Crossing Threshold V

IZX

1 mV

DHA Gate Driver On-Resistance R

DH

DHA forced high and low 2.5 5

DLA forced high 2.5 5

DLA Gate Driver On-Resistance R

DL

DLA forced low 1.5 3

DHA Gate Driver Source/Sink

Current

I

DH

DHA forced to 2.5V 0.7 A

I

DL(SRC)

DLA forced to 2.5V 0.7

DLA Gate Driver Source/Sink

Current

I

DL(SNK)

DLA forced to 2.5V 1.5

A

REGULATOR B (Internal 3A Step-Down Converter)

FBB Regulation Voltage I

LXB

= 0% duty cycle (Note 2) 0.747 0.755 0.762 V

FBB Regulation Voltage (Overload) V

FBB

I

LXB

= 0 to 2.5A, 0% duty cycle (Note 2) 0.720 0.762 V

FBB Load Regulation V

FBB

/I

LXB ILXB

= 0 to 2.5A -5 mV/A

FBB Line Regulation 0 to 100% duty cycle 7 8 10 mV

FBB Input Current I

FBB

TA = +25°C -100 -5 +100 nA

High-side n-channel 75 150

Internal MOSFET On-Resistance

Low-side n-channel 40 80

m

LXB Peak Current Limit I

PKB

3.0 3.45 4.0 A

LXB Idle-Mode Trip Level I

IDLEB

0.8 A

LXB Zero-Crossing Trip Level I

ZXB

100 mA

REGULATOR C (Internal 5A Step-Down Converter)

FBC Regulation Voltage I

LXC

= 0A, 0% duty cycle (Note 2) 0.747 0.755 0.762 V

FBC Regulation Voltage (Overload) V

FBC

I

LXC

= 0 to 4A, 0% duty cycle (Note 2) 0.710 0.762 V

FBC Load Regulation V

FBC

/I

LXC ILXC

= 0 to 4A -7 mV/A

FBC Line Regulation 0 to 100% duty cycle 12 14 16 mV

FBC Input Current I

FBC

TA = +25°C -100 -5 +100 nA

High-side n-channel 50 100

Internal MOSFET On-Resistance

Low-side n-channel 25 40

m

LXC Peak Current Limit I

PKC

5.0 5.75 6.5 A

LXC Idle-Mode Trip Level I

IDLEC

1.2 A

LXC Zero-Crossing Trip Level I

ZXC

100 mA

REGULATOR D (Source/Sink Linear Regulator and VTTR Buffer)

IND Input Voltage Range V

IND

1 2.8 V

IND Supply Current OND = VCC 10 50 μA

IND Shutdown Current OND = GND, TA = +25°C 10 μA

REFIND Input Range 0.5 1.5 V

REFIND Input Bias Current V

REFIND

= 0 to 1.5V, TA = +25°C -100 +100 nA

OUTD Output Voltage Range V

OUTD

0.5 1.5 V

MAX17019

High-Input-Voltage Quad-Output Controller

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

INLDO

= 12V, V

INA

= V

INBC

= VDD= VCC= V

BYP

= V

CSPA

= V

CSNA

= 5V, V

IND

= 1.8V, V

SHDN

= V

ONA

= V

ONB

=

V

ONC

= V

OND

= 5V, I

REF

= I

LDO5

= I

OUTD

= no load, FREQ = GND, UP/DN = VCC, TA= 0°C to +85°C, unless otherwise noted.

Typical values are at T

A

= +25°C.) (Note 1)

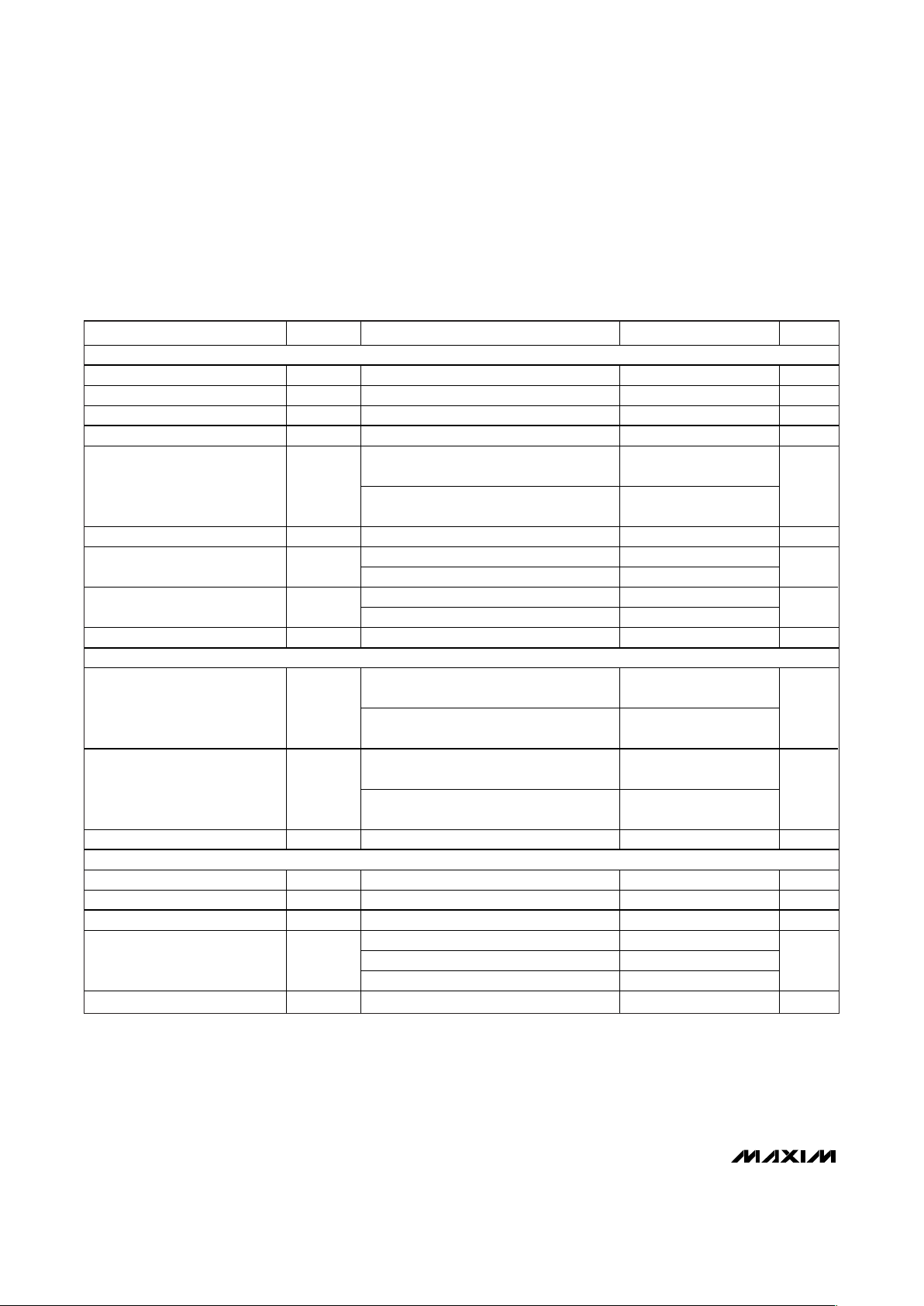

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

FBD

with respect to V

REFIND

, OUTD =

FBD, I

OUTD

= +50μA (source load)

-10 0

FBD Output Accuracy V

FBD

V

FBD

with respect to V

REFIND

,

OUTD = FBD, I

OUTD

= -50μA (sink load)

0 +10

mV

FBD Load Regulation I

OUTD

= ±1A -17 -13 mV/A

FBD Line Regulation V

IND

= 1.0V to 2.8V, I

OUTD

= ±200mA 1 mV

FBD Input Current V

FBD

= 0 to 1.5V, TA = +25°C 0.1 0.5 μA

Source load +2 +4

OUTD Linear-Regulator Current

Limit

Sink load -2 -4

A

Current-Limit Soft-Start Time With respect to internal OND signal 160 μs

High-side on-resistance 120 250

Internal MOSFET On-Resistance

Low-side on-resistance 180 450

m

I

VTTR

= ±0.5mA -10 +10

VTTR Output Accuracy REFIND to VTTR

I

VTTR

= ±3mA -20 +20

mV

VTTR Maximum Current Rating ±5 mA

FAULT PROTECTION

Upper threshold rising edge,

hysteresis = 50mV

9 12 14

SMPS POK and Fault Thresholds

Lower threshold falling edge,

hysteresis = 50mV

-14 -12 -9

%

Upper threshold rising edge,

hysteresis = 50mV

6 12 16

VTT LDO POKD and Fault

Threshold

Lower threshold falling edge,

hysteresis = 50mV

-16 -12 -6

%

POK Propagation Delay t

POK

FB_ forced 50mV beyond POK_ trip

threshold

5 μs

Overvoltage Fault Latch Delay t

OVP

FB_ forced 50mV above POK_ upper

trip threshold

5 μs

SMPS Undervoltage Fault

Latch Delay

t

UVP

FBA, FBB, or FBC forced 50mV below

POK_ lower trip threshold

5 μs

VTT LDO Undervoltage Fault

Latch Delay

t

UVP

FBD forced 50mV below POKD lower

trip threshold

5000 μs

POK Output Low Voltage V

POK

I

SINK

= 3mA 0.4 V

POK Leakage Currents I

POK

V

FBA

= 1.05V, V

FBB

= V

FBC

= 0.8V, V

FBD

=

V

REFIND

+ 50mV (POK high impedance);

POK_ forced to 5V, T

A

= +25°C

1 μA

Thermal-Shutdown Threshold T

SHDN

Hysteresis = 15°C +160 °C

MAX17019

High-Input-Voltage Quad-Output Controller

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

INLDO

= 12V, V

INA

= V

INBC

= VDD= VCC= V

BYP

= V

CSPA

= V

CSNA

= 5V, V

IND

= 1.8V, V

SHDN

= V

ONA

= V

ONB

=

V

ONC

= V

OND

= 5V, I

REF

= I

LDO5

= I

OUTD

= no load, FREQ = GND, UP/DN = VCC, TA= 0°C to +85°C, unless otherwise noted.

Typical values are at T

A

= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

GENERAL LOGIC LEVELS

SHDN Input Logic Threshold Hysteresis = 20mV 0.5 1.6 V

SHDN = 0~16V -2 +2

SHDN Input Bias Current TA = +25°C

SHDN = 17V~38V -2 +150

μA

ON_ Input Logic Threshold Hysteresis = 170mV 0.5 1.6 V

ON_ Input Bias Current TA = +25°C -1 +1 μA

UP/DN Input Logic Threshold 0.5 1.6 V

UP/DN Input Bias Current TA = +25°C -1 +1 μA

High (VCC) VCC- 0.4V

Unconnected/REF 1.65 3.8

FREQ Input Voltage Levels

Low (GND) 0.5

V

FREQ Input Bias Current TA = +25°C -2 +2 μA

SYNC Input Logic Threshold 1.5 3.5 V

SYNC Input Bias Current TA = +25°C -1 +1 μA

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V

INLDO

= 12V, V

INA

= V

INBC

= VDD= VCC= V

BYP

= V

CSPA

= V

CSNA

= 5V, V

IND

= 1.8V, V

SHDN

= V

ONA

= V

ONB

=

V

ONC

= V

OND

= 5V, I

REF

= I

LDO5

= I

OUTD

= no load, FREQ = GND, UP/DN = VCC, TA= -40°C to +125°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Input Voltage Range UP/DN = LDO5, INLDO, INA = LDO5 5.5 24 V

INA Undervoltage Threshold V

INA(UVLO)

UP/DN = LDO5, INA = VCC, ris ing edge,

hysteresis = 160mV

3.9 4.5 V

INBC Input Voltage Range 2.3 5.5 V

SUPPLY CURRENTS

V

INLDO

Shutdown Supply Current I

IN(SHDN)VINLDO

= 5.5V to 38V, SHDN = GND 15 μA

V

INLDO

Suspend Supply Current I

IN(SUS)

V

INLDO

= 5.5V to 38V, ON_ = GND,

SHDN = INLDO

80 μA

INA Shutdown Current I

INA

SHDN = ONA = ONB = ONC = OND = GND,

UP/DN = V

CC

10 μA

VCC Supply C urrent

Main Step-Down Only

ONA = V

CC

, ONB = ONC = OND = GND;

does not include switching losses,

measured from V

CC

350 μA

VCC Supply Current

Main Step-Down and Regulator B

ONA = ONB = V

CC

, ONC = OND = GND;

does not include switching losses,

measured from V

CC

400 μA

VCC Supply Current

Main Step-Down and Regulator C

ONA = ONC = V

CC

, ONB = OND = GND,

does not include switching losses,

measured from V

CC

400 μA

MAX17019

High-Input-Voltage Quad-Output Controller

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

INLDO

= 12V, V

INA

= V

INBC

= VDD= VCC= V

BYP

= V

CSPA

= V

CSNA

= 5V, V

IND

= 1.8V, V

SHDN

= V

ONA

= V

ONB

=

V

ONC

= V

OND

= 5V, I

REF

= I

LDO5

= I

OUTD

= no load, FREQ = GND, UP/DN = VCC, TA= -40°C to +125°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

VCC Supply Current

Main Step-Down and Reg ulator D

ONA = OND = V

CC

, ONB = ONC = GND,

does not include switching losses,

measured from V

CC

3.5 mA

INA Supply Current (Step-Down) I

INA

ONA = VCC, UP/DN = VCC(step-down) 75 μA

5V LINEAR REGULATOR

LDO5 Output Voltage V

LDO5

V

INLDO

= 5.5V to 38V, I

LDO5

= 0 to 50mA,

BYP = GND

4.75 5.25 V

LDO5 Short-Circuit Current Limit LDO5 = BYP = GND, V

INLDO

= 5.5V 55 mA

1.25V REFERENCE

Reference Output Voltage V

REF

No load 1.237 1.263 V

Reference Load Regulation V

REF

I

REF

= -1μA to +50μA 12 mV

OSCILLATOR

Oscillator Frequency f

OSC

FREQ = GND 0.9 1.1 MHz

Maximum Duty Cycle

(All Switching Regulator s)

D

MAX

89 %

REGULATOR A (Main Step-Down)

Output Voltage Adjust Range Step-down configuration (UP/DN = VCC) 1.0

V

CC

+

0.3V

V

FBA Regulation Voltage

Step-down configuration,

V

CSPA

- V

CSNA

= 0mV, 90% duty cycle

0.963 1.008 V

FBA Regulation Voltage

(Overload)

V

FBA

Step-down configuration (UP/DN = VCC),

V

CSPA

- V

CSNA

= 0 to 20mV, 90% duty cycle

0.925 1.008 V

FBA Line Regulation Step-down (UP/DN = VCC) 10 33 mV

Current-Sense Input CommonMode Range

V

CSA

0

V

CC

+

0.3V

V

Current-Limit Threshold (Positive) V

ILIMA

17 23 mV

REGULATOR B (Internal 3A Step-Down Converter)

FBB Regulation Voltage I

LXB

= 0A, 0% duty cycle (Note 2) 0.742 0.766 V

FBB Regulation Voltage (Overload) V

FBB

I

LXB

= 0 to 2.5A , 0% duty cycle (Note 2) 0.715 0.766 V

FBB Line Regulation 6 12 mV

LXB Peak Current Limit I

PKB

2.7 4.2 A

REGULATOR C (Internal 5A Step-Down Converter)

FBC Regulation Voltage I

LXC

= 0A, 0% duty cycle (Note 2) 0.742 0.766 V

FBC Regulation Voltage (Overload) V

FBC

I

LXC

= 0 to 4A, 0% duty cycle (Note 2) 0.705 0.766 V

FBC Line Regulation 11 20 mV

LXC Peak Current Limit I

PKC

5.0 6.5 A

MAX17019

High-Input-Voltage Quad-Output Controller

8 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

INLDO

= 12V, V

INA

= V

INBC

= VDD= VCC= V

BYP

= V

CSPA

= V

CSNA

= 5V, V

IND

= 1.8V, V

SHDN

= V

ONA

= V

ONB

=

V

ONC

= V

OND

= 5V, I

REF

= I

LDO5

= I

OUTD

= no load, FREQ = GND, UP/DN = VCC, TA= -40°C to +125°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

REGULATOR D (Source/Sink Linear Regulator and VTTR Buffer)

IND Input Voltage Range V

IND

1 2.8 V

IND Supply Current OND = VCC 70 μA

REFIND Input Range 0.5 1.5 V

OUTD Output Voltage Range V

OUTD

0.5 1.5 V

V

FBD

with respect to V

REFIND

,

OUTD = FBD, I

OUTD

= +50μA (source load)

-12 0

FBD Output Accuracy V

FBD

V

FBD

with respect to V

REFIND

,

OUTD = FBD, I

OUTD

= -50μA (sink load)

0 +12

mV

FBD Load Regulation I

OUTD

= ±1A -20 mV/A

Source load +2 +4

OUTD Linear-Regulator Current

Limit

Sink load -2 -4

A

High-side on-resistance 300

Internal MOSFET On-Resistance

Low-side on-resistance 475

m

VTTR Output Accuracy REFIND to VTTR, I

VTTR

= ±3mA -20 +20 mV

FAULT PROTECTION

Upper threshold rising edge,

hysteresis = 50mV

8 16

SMPS POK and Fault Thresholds

Lower threshold falling edge,

hysteresis = 50mV

-16 -8

%

Upper threshold rising edge,

hysteresis = 50mV

6 16

VTT LDO POKD and Fault

Threshold

Lower threshold falling edge,

hysteresis = 50mV

-16 -6

%

POK Output Low Voltage V

POK ISINK

= 3mA 0.4 V

GENERAL LOGIC LEVELS

SHDN Input Logic Threshold Hysteresis = 20mV 0.5 1.6 V

ON_ Input Logic Threshold Hysteresis = 170mV 0.5 1.6 V

UP/DN Input Logic Threshold 0.5 1.6 V

High (VCC) VCC- 0.4V

Unconnected/REF 1.65 3.8

FREQ Input Voltage Levels

Low (GND) 0.5

V

SYNC Input Logic Threshold 1.5 3.5 V

Note 1: Limits are 100% production tested at TA= +25°C. Maximum and minimum limits are guaranteed by design and

characterization.

Note 2: Regulation voltage tested with slope compensation. Typical value is equivalent to 0% duty cycle. In real applications, the

regulation voltage is higher due to the line regulation times the duty cycle.

MAX17019

High-Input-Voltage Quad-Output Controller

_______________________________________________________________________________________

9

SMPS REGULATOR A EFFICIENCY

vs. LOAD CURRENT

MAX17019 toc01

LOAD CURRENT (A)

EFFICIENCY (%)

10.10.01

55

60

65

70

75

80

85

90

95

100

50

0.001 10

VIN = 20V

VIN = 12V

VIN = 8V

SMPS REGULATOR A OUTPUT VOLTAGE

vs. LOAD CURRENT

MAX17019 toc02

LOAD CURRENT (A)

OUTPUT VOLTAGE (V)

4.54.03.53.02.52.01.51.00.5

4.80

4.85

4.90

4.95

5.00

5.05

4.75

05.0

V

IN

= 20V

VIN = 12V

VIN = 8V

SMPS REGULATOR B EFFICIENCY

vs. LOAD CURRENT

MAX17019 toc03

LOAD CURRENT (A)

EFFICIENCY (%)

10.10.01

55

60

65

70

75

80

85

90

95

100

50

0.001 10

VIN = 3.3V

VIN = 5V

VIN = 2.5V

SMPS REGULATOR B OUTPUT VOLTAGE

vs. LOAD CURRENT

MAX17019 toc04

LOAD CURRENT (A)

OUTPUT VOLTAGE (V)

1.5 2.0 2.51.00.5

1.77

1.82

1.72

03.0

VIN = 3.3V

VIN = 5V

VIN = 2.5V

SMPS REGULATOR C EFFICIENCY

vs. LOAD CURRENT

MAX17019 toc05

LOAD CURRENT (A)

EFFICIENCY (%)

10.10.01

55

60

65

70

75

80

85

90

50

0.001 10

VIN = 3.3V

VIN = 5V

VIN = 2.5V

SMPS REGULATOR C OUTPUT VOLTAGE

vs. LOAD CURRENT

MAX17019 toc06

LOAD CURRENT (A)

OUTPUT VOLTAGE (V)

4.54.03.53.02.52.01.51.00.5

0.99

1.00

1.01

1.02

1.03

1.04

1.05

0.98

05.0

VIN = 3.3V

VIN = 5V

VIN = 2.5V

REGULATOR D VOLTAGE

vs. SOURCE/SINK LOAD CURRENT

MAX17019 toc07

LOAD CURRENT (A)

V

TT

VOLTAGE (V)

1.51.00 0.5-1.0 -0.5-1.5

0.885

0.890

0.895

0.900

0.905

0.910

0.915

0.920

0.925

0.930

0.880

-2.0 2.0

Typical Operating Characteristics

(TA = +25°C, Circuit of Figure 1, unless otherwise noted.)

MAX17019

High-Input-Voltage Quad-Output Controller

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(TA = +25°C, Circuit of Figure 1, unless otherwise noted.)

REG B STARTUP WAVEFORM

(HEAVY LOAD)

MAX17019 toc10

400μs/div

ONB

OUTB

POKB

I

LB

LXB

ONB: 5V/div

OUTB: 2V/div

POKB: 5V/div

I

LB

: 2A/div

LXB: 5V/div

R

LOAD

= 1.01Ω

REG B SHUTDOWN WAVEFORM

MAX17019 toc11

400μs/div

ONB

OUTB

POKB

I

LB

LXB

ONB: 5V/div

OUTB: 2V/div

POKB: 5V/div

I

LB

: 2A/div

LXB: 5V/div

R

LOAD

= 0.8Ω

REG C STARTUP WAVEFORM

(HEAVY LOAD)

MAX17019 toc12

400μs/div

ONC

OUTC

POKC

I

LC

LXC

ONC: 5V/div

OUTC: 1V/div

POKC: 5V/div

I

LC

: 5A/div

LXC: 5V/div

R

LOAD

= 0.25Ω

REG C SHUTDOWN

MAX17019 toc13

100μs/div

ONC

OUTC

POKC

I

LC

LXC

ONC: 5V/div

OUTC: 1V/div

POKC: 5V/div

I

LC

: 5A/div

LXC: 5V/div

R

LOAD

= 0.25Ω

REG A STARTUP WAVEFORM

(HEAVY LOAD)

MAX17019 toc08

400μs/div

ONA

OUTA

POKA

I

LA

LXA

ONA: 5V/div

OUTA: 5V/div

POKA: 5V/div

I

LA

: 5A/div

LXA: 10V/div

R

LOAD

= 1.6Ω

REG A SHUTDOWN WAVEFORM

MAX17019 toc09

400μs/div

ONA

OUTA

POKA

I

LA

LXA

ONA: 5V/div

OUTA: 5V/div

POKA: 5V/div

I

LA

: 5A/div

LXA: 10V/div

R

LOAD

= 2.5Ω

MAX17019

High-Input-Voltage Quad-Output Controller

______________________________________________________________________________________

11

REG A LOAD TRANSIENT (1A TO 3.2A)

MAX17019 toc14

20μs/div

OUTA

I

OUTA

I

LA

LXA

OUTA: 100mV/div

LXA: 10V/div

I

LA

: 2A/div

I

OUTA

: 2A/div

V

INA

= 12V, LOAD TRANSIENT

IS FROM 1A TO 3.2A

REG B LOAD TRANSIENT (0.4A TO 2A)

MAX17019 toc15

20μs/div

OUTB

I

OUTB

I

LB

LXB

OUTB: 50mV/div

LXB: 5V/div

I

LB

: 1A/div

I

OUTB

: 2A/div

V

INBC

= 5V, 0.4A TO 2.0A

LOAD TRANSIENT

REG C LOAD TRANSIENT (0.8A TO 3A)

MAX17019 toc16

20μs/div

OUTC

I

OUTC

I

LC

LXC

OUTC: 50mV/div

LXC: 5V/div

I

LC

: 2A/div

I

OUTC

: 2A/div

V

INBC

= 5V, 0.8A TO 3.0A

LOAD TRANSIENT

REG D LOAD TRANSIENT (SOURCE/SINK)

MAX17019 toc17

20μs/div

I

OUTD

OUTD

OUTD: 20mV/div

I

OUTD

: 1A/div

V

IND

= 1.8V, V

REFIND

= 0.9V,

C

OUT

= 2 x 10μF, LOAD TRANSIENT

IS FROM 1A SOURCING TO 1A SINKING

REG D LOAD TRANSIENT (SINK)

MAX17019 toc18

20μs/div

I

OUTD

OUTD

OUTD: 10mV/div

I

OUTD

: 1A/div

V

IND

= 1.8V, V

REFIND

= 0.9V,

C

OUT

= 2 x 10μF, LOAD TRANSIENT

IS FROM 0 TO 1A SINKING

Typical Operating Characteristics (continued)

(TA = +25°C, Circuit of Figure 1, unless otherwise noted.)

REG D LOAD TRANSIENT (SOURCE)

MAX17019 toc19

20μs/div

I

OUTD

OUTD

OUTD: 10mV/div

I

OUTD

: 1A/div

V

IND

= 1.8V, V

REFIND

= 0.9V,

C

OUT

= 2 x 10μF, LOAD TRANSIENT

IS FROM 0 TO 1A SOURCING

MAX17019

High-Input-Voltage Quad-Output Controller

12 ______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1 POKC

Open-Drain Power-Good Output for the Internal 5A Step-Down Converter. POKC is low if FBC is more than

12% (typ) above or below the nominal 0.75V feedback regulation threshold. POKC is held low during

startup and in shutdown. POKC becomes high impedance when FBC is in regulation.

2 BSTC

Boost Flying Capacitor Connection for the Internal 5A Step-Down Converter. The MAX17019 includes an

internal boost switch/diode connected between VDD and BSTC. Connect to an external capacitor as shown

in Figure 1.

3–6 LXC

Inductor Connection for the Internal 5A Step-Down Converter. Connect LXC to the switched side of the

inductor.

7, 8 OUTD

Source/Sink Linear-Regulator Output. Bypass OUTD with 2x 10μF or greater ceramic capacitors to ground.

Dropout needs additional output capacitance (see the VTT LDO Output Capacitor Selection (C

OUTD

)

section).

9 IND Source/Sink Linear-Regulator Input. Bypass IND with a 10μF or greater ceramic capacitor to ground.

10 FBD

Feedback Input for the Internal Source/Sink Linear Regulator. FBD tracks and regulates to the REFIND

voltage.

11 VTTR Ouput of Reference Buffer. Bypass with 0.22μF for ±3mA of output current.

12 REFIND

Dynamic Reference Input Voltage for the Source/Sink Linear Regulator and the Reference Buffer. The

linear-regulator feedback threshold (FBD) tracks the REFIND voltage.

13 SHDN

Shutdown Control Input. The device enters its 5μA supply current shutdown mode if V

SHDN

is less than

the SHDN input falling-edge trip level and does not restart until V

SHDN

is greater than the SHDN input

rising-edge trip level. Connect SHDN to V

INLDO

for automatic startup of LDO5.

14 INLDO

Input of the Startup Circuitry and the LDO5 Internal 5V Linear Regulator. Bypass to GND with a 0.1μF or

greater ceramic capacitor close to the controller.

In the single-cell step-up applications, the 5V linear regulator is no longer necessary for the 5V bias supply.

Connect BYP and INLDO to the system’s 5V supply to effectively disable the linear regulator.

15 LDO5

5V Internal Linear-Regulator Output. Bypass with 4.7μF or greater ceramic capacitor. The 5V linear

regulator provides the bias power for the gate drivers (V

DD

) and analog control circuitry (VCC). The linear

regulator sources up to 50mA (max guaranteed). When BYP exceeds 4.65V (typ), the MAX17019 bypasses

the linear regulator through a 1.5 bypass switch. When the linear regulator is bypassed, LDO5 supports

loads up to 100mA.

In the single-cell step-up applications, the 5V linear regulator is no longer necessary for the 5V bias supply.

Bypass SHDN to ground and leave LDO5 unconnected. Connect BYP and INLDO to effectively disable the

linear regulator.

16 BYP

Linear-Regulator Bypass Input. When BYP exceeds 4.65V, the controller shorts LDO5 to BYP through a

1.5 bypass switch and disables the linear regulator. When BYP is low, the linear regulator remains active.

The BYP input also serves as the VTTR buffer supply, allowing VTTR to remain active even when the

source/sink linear regulator (OUTD) has been disabled under system standby/suspend conditions.

In the single-cell step-up applications, the 5V linear regulator is no longer necessary for the 5V bias supply.

Bypass LDO5 to ground with a 1μF capacitor and leave this output unconnected. Connect BYP and INLDO

to the system’s 5V supply to effectively disable the linear regulator.

MAX17019

High-Input-Voltage Quad-Output Controller

______________________________________________________________________________________ 13

Pin Description (continued)

PIN NAME FUNCTION

17 V

CC

5V Analog Bias Supply. VCC powers all the analog control blocks (error amplifiers, current-sense amp lifiers,

fault comparators, etc.) and control logic. Connect V

CC

to the 5V system supply with a series 10 resistor,

and bypass to analog ground using a 1μF or greater ceramic capacitor.

18 INA Input to the Circuit in Reg A in Boost Mode. Connect INA to LDO5 in step-down mode (UP/DN = VCC).

19 UP/DN

Converter Configuration Selection Input for Regulator A. When UP/DN is pulled high (UP/DN = V

CC

), regulator A

operates as a step-down converter (Figure 1). When UP/DN is pulled low (UP/DN = GND), regulator A operates

as a low-voltage step-up converter. (Refer to the MAX17017 data sheet for step-up configuration.)

20 FREQ

Trilevel Oscillator Frequency Selection Input:

FREQ = V

CC

: RegA = 250kHz, RegB = 500kHz, RegC = 250kHz

FREQ = REF: RegA = 375kHz, RegB = 750kHz, RegC = 375kHz

FREQ = GND: RegA = 500kHz, RegB = 1MHz, RegC = 500kHz

21 REF

1.25V Reference-Voltage Output. Bypass REF to analog ground with a 0.1μF ceramic capacitor. The

reference sources up to 50μA for external loads. Loading REF degrades output voltage accuracy according

to the REF load-regulation error. The reference shuts down when the system pulls SHDN low in buck mode

(UP/DN = GND).

22 AGND Analog Ground

23 CSNA

Negative Current-Sense Input for the Main Switching Regulator. Connect to the negative terminal of the currentsense resistor. Due to the CSNA bias current requirements, limit the series impedance to less than 10.

24 CSPA

Positive Current-Sense Input for the Main Switching Regulator. Connect to the positive terminal of the currentsense resistor. Due to the CSPA bias current requirements, limit the series impedance to less than 10.

25 FBA Feedback Input for the Main Switching Regulator. FBA regulates to 1.0V.

26 POKA

Open-Drain Power-Good Output for the Main Switching Regulator. POKA is low if FBA is more than 12% (typ)

above or below the nominal 1.0V feedback regulation point. POKA is held low during soft-start and in

shutdown. POKA becomes high impedance when FBA is in regulation.

27 DHA High-Side Gate-Driver Output for the Main Switching Regulator. DHA swings from LXA to BSTA.

28 LXA Inductor Connection of Converter A. Connect LXA to the switched side of the inductor.

29 BSTA

Boost Flying Capacitor Connection of Converter A. The MAX17019 needs an external boost switch/diode

connected between V

DD

and BSTA. Connect to an external capacitor as shown in Figure 1.

30 DLA Low-Side Gate-Driver Output for the Main Switching Regulator. DLA swings from GND to VDD.

31, 32,

33

LXB

Inductor Connection for the Internal 3A Step-Down Converter. Connect LXB to the switched side of the

inductor.

34 BSTB

Boost Flying Capacitor Connection for the Internal 3A Step-Down Converter. The MAX17019 includes an

internal boost switch/diode connected between VDD and BSTB. Connect to an external capacitor as shown

in Figure 1.

35 POKB

Open-Drain Power-Good Output for the Internal 3A Step-Down Converter. POKB is low if FBB is more than

12% (typ) above or below the nominal 0.75V feedback-regulation threshold. POKB is held low during softstart and in shutdown. POKB becomes high impedance when FBB is in regulation.

MAX17019

High-Input-Voltage Quad-Output Controller

14 ______________________________________________________________________________________

Pin Description (continued)

PIN NAME FUNCTION

36 FBB Feedback Input for the Internal 3A Step-Down Converter. FBB regulates to 0.75V.

37 ONB

Switching Regulator B Enable Input. When ONB is pulled low, LXB is high impedance. When ONB is driven

high, the controller enables the 3A internal switching regulator.

38 SYNC External Synchronization Input. Used to override the internal switching frequency.

39 ONA

Switching Regulator A Enable Input. When ONA is pulled low, DLA and DHA are pulled low. When ONA is

driven high, the controller enables the step-up/step-down converter.

40–43 INBC

Input for Regulators B and C. Power INBC from a 2.5V to 5.5V supply. Internally connected to the drain of

the high-side MOSFETs for both regulator B and regulator C. Bypass to PGND with 2x 10μF or greater

ceramic capacitors to support the RMS current.

44 V

DD

5V Bias Supply Input for the Internal Switching Regulator Drivers. Bypass with a 1μF or greater ceramic

capacitor. Provides power for the BSTB and BSTC driver supplies.

45 POKD

Open-Drain Power-Good Output for the Internal Source/Sink Linear Regulator. POKD is low if FBD is more

than 10% (typ) above or below the REFIND regulation threshold. POKD is held low during soft-start and in

shutdown. POKD becomes high impedance when FBD is in regulation.

46 OND

Source/Sink Linear Regulator (Regulator D) and Reference Buffer Enable Input. When OND is pulled low, OUTD

is high impedance. When OND is driven high, the controller enables the source/sink linear regulator.

47 ONC

Switching Regulator C Enable Input. When ONC is pulled low, LXC is high impedance. When ONC is driven

high, the controller enables the 5A internal switching regulator.

48 FBC Feedback Input for the Internal 5A Step-Down Converter. FBC regulates to 0.75V.

EP PGND

Power Ground. The source of the low-side MOSFETs (REG B and REG C), the drivers for all switching

regulators, and the sink MOSFET of the VTT LDO are all internally connected to the exposed pad.

Connect the exposed backside pad to system power ground planes through multiple vias.

Detailed Description

The MAX17019 standard application circuit (Figure 1)

provides a 5V/5A

P-P

main stage, a 1.8V/3A

P-P

VDDQ

and 0.9A/2A VTT outputs for DDR, and a 1.05V/5A

P-P

chipset supply.

The MAX17019 supports four power outputs—one highvoltage step-down controller, two internal MOSFET

step-down switching regulators, and one high-current

source/sink linear regulator. The step-down switching

regulators use a current-mode fixed-frequency architecture compensated by the output capacitance. An internal 50mA 5V linear regulator provides the bias supply

and driver supplies, allowing the controller to power up

from input supplies greater than 5.5V.

Fixed 5V Linear Regulator (LDO5)

An internal linear regulator produces a preset 5V lowcurrent output from INLDO. LDO5 powers the gate drivers for the external MOSFETs, and provides the bias

supply required for the SMPS analog controller, reference, and logic blocks. LDO5 supplies at least 50mA

for external and internal loads, including the MOSFET

gate drive, which typically varies from 5mA to 15mA

per switching regulator, depending on the switching

frequency. Bypass LDO5 with a 4.7μF or greater

ceramic capacitor to guarantee stability under the fullload conditions.

The MAX17019 switch-mode step-down switching regulators require a 5V bias supply in addition to the mainpower input supply. This 5V bias supply is generated

by the controller’s internal 5V linear regulator (LDO5).

This boot-strappable LDO allows the controller to

power up independently. The gate driver V

DD

input

supply is typically connected to the fixed 5V linear regulator output (LDO5). Therefore, the 5V LDO supply

must provide LDO5 (PWM controller) and the gatedrive power during power-up.

MAX17019

High-Input-Voltage Quad-Output Controller

______________________________________________________________________________________ 15

MAX17019

PWR

PWR

C1

4.7μF, 6V

0603

AGND

C2

1.0μF, 6V

0402

LDO5

INA

SHDN

V

DD

UP/DN

ONA

ONB

ONC

V

CC

R1

10Ω

5%, 0402

R9–R12

(4x) 100kΩ

5%, 0402

5V SMPS

OUTPUT

AGND

AGND

C16

0.1μF, 6V

0402

REF

AGND

AGND

AGND

OND

POKA

POKB

POKC

POKD

VTTR

1.8V SMPS

OUTPUT

ON OFF

ON OFF

ON OFF

ON OFF

R3

40.2kΩ

1%, 0402

R5

14.0kΩ

1%, 0402

R14

15.0kΩ

1%, 0402

R2

0Ω

1%, 0402

AGND

R15

0Ω

5%, 0402

R4

10.0kΩ

1%, 0402

R4 4mΩ

5%, 1206

FREQ

R13

15kΩ

1%, 0402

REFIND

AGND

SYNC

C4

0.22μF, 4V

0402

AGND

C13

680pF, 50V

0402

C3

0.1μF, 6V

0402

C5

0.1μF, 6V

0402

C8

0.1μF

PWR

LDO5

C17, C18

(2x) 1μF, 50V

0603

GND

INLDO

BSTA

DHA

PWR

PWR

C19, C20

(2x) 4.7μF, 50V

1206

PWR

C7

1μF, 16V

0402

PWR

C9

10μF, 6V

0805

PWR

C21

22μF, 50V

PWR

2A

C22

150μF

35mΩ, 6V, B2 CASE

PWR

C23

330μF

15mΩ, 2.5V, B2 CASE

5.5V TO 38V

DLA

CSPA

LXA

N

L1

N

H1

L1

3.3μH, 6A, 30mΩ

BSTB

LXB

L2

1μH, 7A, 14mΩ

FBD

CSNA

FBA

BYP

AGND

R6

10.0kΩ

1%, 0402

AGND

C14

1000pF, 50V

0402

FBB

INBC

PWR

C8

1μF, 6V

0402

PWR

C10

10μF, 6V

0805

IND

OUTD

5V

2.0A

1.8V

2.5A

R7

4.02kΩ

1%, 0402

C6

0.1μF, 6V

0402

PWR

C24

330μF

15mΩ, 2.5V, B2 CASE

BSTC

LXC

L3

1μH, 7A, 14mΩ

AGND

R8

10.0kΩ

1%, 0402

R16

1Ω

5%

AGND

C15

2200pF, 50V

0402

FBC

1.05V

4.0A

0.9V

±1A

PWR

C11, C12

(2x) 10μF, 6V

0805

Figure 1. Standard Application Circuit

MAX17019

High-Input-Voltage Quad-Output Controller

16 ______________________________________________________________________________________

MAX17019

SHDN

REFOK

INLDO

LDO5

LDO5

TSDN

SW

DRV

UVLO

CSB

EN

BIAS

EN

BYP

BYP_OK

V

CC

_OK

V

DD

UP/DN

UP/DN = V

CC

[BUCK],

LOW BUCK MODE

REF_OK

ONLDO

V

CC

REF

PGOOD AND

FAULT

PROTECTION

EN

EN

V

CC

OSC

REG A

ANALOG

EN

V

CC

REG D

ANALOG

V

CC

V

CC

V

CC

TSDN

V

CC

REF

SYNC

*ONA (SHDN)

IND

PGND

REG D PWR

OUTD

OND

FBD

REFIND

REFIND

ON_VTTR

VTTR

BYP

ONA

*BUCK REF ENABLED BY SHDN;

BOOST REF ENABLED BY ONA.

+SSDA ONLY USED IN STEP-UP MODE. SSDA = HIGH IN STEP-DOWN MODE.

ONB

ONC

OND

POKX

FAULTX

ONX

V

CC

OK

UVLO

INBC_OK

INA

V

CC

BSTA

DHA

DLA

V

DD

CSPA

CSNA ONA

FBA

REG B

ANALOG

FBB

SSDA+

LXA

BSTB

V

DD

EN

EN

LXB

INBC

CSC

REG C

ANALOG

FBC

BSTC

V

DD

EN

LXC

INBC

INBC

ONB

INBC_OK

ONC

INBC_OK

FB

-

+

Figure 2. MAX17019 Block Diagram

MAX17019

High-Input-Voltage Quad-Output Controller

______________________________________________________________________________________ 17

LDO5 Bootstrap Switchover

When the bypass input (BYP) exceeds the LDO5 bootstrap-switchover threshold for more than 500μs, an

internal 1.5Ω (typ) p-channel MOSFET shorts BYP to

LDO5, while simultaneously disabling the LDO5 linear

regulator. This bootstraps the controller, allowing power

for the internal circuitry and external LDO5 loading to

be generated by the output of a 5V switching regulator.

Bootstrapping reduces power dissipation due to driver

and quiescent losses by providing power from a

switch-mode source, rather than from a much-less-efficient linear regulator. The current capability increases

from 50mA to 100mA when the LDO5 output is

switched over to BYP. When BYP drops below the bootstrap threshold, the controller immediately disables the

bootstrap switch and reenables the 5V LDO.

Reference (REF)

The 1.25V reference is accurate to ±1% over temperature

and load, making REF useful as a precision system reference. Bypass REF to GND with a 0.1μF or greater ceramic capacitor. The reference sources up to 50μA and sinks

5μA to support external loads. If highly accurate specifications are required for the main SMPS output voltages,

the reference should not be loaded. Loading the reference slightly reduces the output voltage accuracy

because of the reference load-regulation error.

SMPS Detailed Description

Fixed-Frequency, Current-Mode

PWM Controller

The heart of each current-mode PWM controller is a

multi-input, open-loop comparator that sums multiple

signals: the output voltage-error signal with respect to

the reference voltage, the current-sense signal, and the

slope compensation ramp (Figure 3). The MAX17019

uses a direct-summing configuration, approaching

ideal cycle-to-cycle control over the output voltage

without a traditional error amplifier and the phase shift

associated with it.

Frequency Selection (FREQ)

The FREQ input selects the PWM mode switching frequency. Table 1 shows the switching frequency based

on the FREQ connection. High-frequency (FREQ =

GND) operation optimizes the application for the smallest component size, trading off efficiency due to higher

switching losses. This might be acceptable in ultraportable devices where the load currents are lower.

Low-frequency (FREQ = 5V) operation offers the best

overall efficiency at the expense of component size and

board space.

FB_

REF

CSH_

CSL_

SLOPE COMPENSATION

V

L

I1

R1 R2

TO PWM

LOGIC

OUTPUT DRIVER

UNCOMPENSATED

HIGH-SPEED

LEVEL TRANSLATOR

AND BUFFER

I2 I3 V

BIAS

Figure 3. PWM Comparator Functional Diagram

MAX17019

High-Input-Voltage Quad-Output Controller

18 ______________________________________________________________________________________

Light-Load Operation Control

The MAX17019 uses a light-load pulse-skipping operating mode for all switching regulators. The switching

regulators turn off the low-side MOSFETs when the current sense detects zero inductor current. This keeps the

inductor from discharging the output capacitors and

forces the switching regulator to skip pulses under

light-load conditions to avoid overcharging the output.

Idle-Mode Current-Sense Threshold

When pulse-skipping mode is enabled, the on-time of

the step-down controller terminates when the output

voltage exceeds the feedback threshold and when the

current-sense voltage exceeds the idle-mode currentsense threshold. Under light-load conditions, the ontime duration depends solely on the idle-mode

current-sense threshold. This forces the controller to

source a minimum amount of power with each cycle. To

avoid overcharging the output, another on-time cannot

begin until the output voltage drops below the feedback threshold. Since the zero-crossing comparator

prevents the switching regulator from sinking current,

the MAX17019 switching regulators must skip pulses.

Therefore, the controller regulates the valley of the output ripple under light-load conditions.

Automatic Pulse-Skipping Crossover

In skip mode, an inherent automatic switchover to PFM

takes place at light loads. This switchover is affected by

a comparator that truncates the low-side switch on-time

at the inductor current’s zero crossing. The zero-crossing

comparator senses the inductor current during the offtime. For regulator A, once V

CSPA

- V

CSNA

drops below

the 1mV zero-crossing current-sense threshold, the comparator turns off the low-side MOSFET (DLA pulled low).

For regulators B and C, once the current through the lowside MOSFET drops below 100mA, the zero-crossing

comparator turns off the low-side MOSFET.

The minimum idle-mode current requirement causes

the threshold between pulse-skipping PFM operation

and constant PWM operation to coincide with the

boundary between continuous and discontinuous

inductor-current operation (also known as the critical

conduction point). The load-current level at which

PFM/PWM crossover occurs (I

LOAD(SKIP)

) is equivalent

to half the idle-mode current threshold (see the

Electrical Characteristics

table for the idle-mode thresholds of each regulator). The switching waveforms can

appear noisy and asynchronous when light loading

causes pulse-skipping operation, but this is a normal

operating condition that results in high light-load efficiency. Trade-offs in PFM noise vs. light-load efficiency

are made by varying the inductor value. Generally, low

inductor values produce a broader efficiency vs. load

curve, while higher values result in higher full-load efficiency (assuming that the coil resistance remains fixed)

and less output voltage ripple. Penalties for using higher inductor values include larger physical size and

degraded load-transient response (especially at low

input-voltage levels).

Table 1. FREQ Table

REG A AND REG C REG B

SWITCHING

FREQUENCY

SOFT-START TIME

STARTUP

BLANKING

TIME

SWITCHING

FREQUENCY

SOFT-START

TIME

STARTUP

BLANKING

TIME

PIN

SELECT

f

SWA

AND f

SWC

REG A: 1200/f

SWA

REG C: 900/f

SWC

1500/f

SWA

f

SWB

1800/f

SWB

3000/f

SWB

LDO5 250kHz

REG A: 4.8ms

REG C: 3.6ms

6ms 500kHz 3.6ms 6ms

REF 375kHz

REG A: 3.2ms

REG C: 2.4ms

4ms 750kHz 2.4ms 4ms

GND 500 kH z

REG A: 2.4ms

REG C: 1.8ms

3ms 1MHz 1.8ms 3ms

SYNC 0.5 x f

SYNC

— — f

SYNC

— —

MAX17019

High-Input-Voltage Quad-Output Controller

______________________________________________________________________________________ 19

SMPS POR, UVLO, and Soft-Start

Power-on reset (POR) occurs when VCCrises above

approximately 1.9V, resetting the undervoltage, overvoltage, and thermal-shutdown fault latches. The POR circuit also ensures that the low-side drivers are pulled low

until the SMPS controllers are activated. The V

CC

input

undervoltage lockout (UVLO) circuitry prevents the

switching regulators from operating if the 5V bias supply

(VCCand VDD) is below its 4.2V UVLO threshold.

Regulator A Startup

Once the 5V bias supply rises above this input UVLO

threshold and ONA is pulled high, the main step-down

controller (regulator A) is enabled and begins switching. The internal voltage soft-start gradually increments

the feedback voltage by 10mV every 12 switching

cycles. Therefore, OUTA reaches its nominal regulation

voltage 1200/f

SWA

after regulator A is enabled (see the

REG A Startup Waveform (Heavy Load) graph in the

Typical Operating Characteristics

).

Regulator B and C Startup

The internal step-down controllers start switching and

the output voltages ramp up using soft-start. If the bias

supply voltage drops below the UVLO threshold, the

controller stops switching and disables the drivers (LX_

becomes high impedance) until the bias supply voltage

recovers.

Once the 5V bias supply and INBC rise above their

respective input UVLO thresholds (SHDN must be

pulled high to enable the reference), and ONB or ONC

is pulled high, the respective internal step-down controller (regulator B or C) becomes enabled and begins

switching. The internal voltage soft-start gradually

increments the feedback voltage by 10mV every 24

switching cycles for regulator B or every 12 switching

cycles for regulator C. Therefore, OUTB reaches its

nominal regulation voltage 1800/f

SWB

after regulator B

is enabled, and OUTC reaches its nominal regulation

voltage 900/f

SWC

after regulator C is enabled (see the

REG B Startup Waveform (Heavy Load) and REG C

Startup Waveform (Heavy Load) graphs in the

Typical

Operating Characteristics

).

SMPS Power-Good Outputs (POK)

POKA, POKB, and POKC are the open-drain outputs of

window comparators that continuously monitor each

output for undervoltage and overvoltage conditions.

POK_ is actively held low in shutdown (SHDN = GND),

standby (ONA = ONB = ONC = GND), and soft-start.

Once the soft-start sequence terminates, POK_

becomes high impedance as long as the output remains

within ±8% (min) of the nominal regulation voltage set

by FB_. POK_ goes low once its corresponding output

drops 12% (typ) below its nominal regulation point, an

output overvoltage fault occurs, or the output is shut

down. For a logic-level POK_ output voltage, connect an

external pullup resistor between POK_ and LDO5. A

100kΩ pullup resistor works well in most applications.

SMPS Fault Protection

Output Overvoltage Protection (OVP)

If the output voltage rises above 112% (typ) of its nominal regulation voltage, the controller sets the fault latch,

pulls POK_ low, shuts down the respective regulator,

and immediately pulls the output to ground through its

low-side MOSFET. Turning on the low-side MOSFET

with 100% duty cycle rapidly discharges the output

capacitors and clamps the output to ground. However,

this commonly undamped response causes negative

output voltages due to the energy stored in the output

LC at the instant the OVP occurs. If the load cannot tolerate a negative voltage, place a power Schottky diode

across the output to act as a reverse-polarity clamp. If

the condition that caused the overvoltage persists

(such as a shorted high-side MOSFET), the input

source also fails (short-circuit fault). Cycle VCCbelow

1V or toggle the respective enable input to clear the

fault latch and restart the regulator.

Output Undervoltage Protection (UVP)

Each MAX17019 includes an output UVP circuit that

begins to monitor the output once the startup blanking

period has ended. If any output voltage drops below

88% (typ) of its nominal regulation voltage, the UVP

protection immediately sets the fault latch, pulls the

respective POK output low, forces the high-side and

low-side MOSFETs into high-impedance states (DH =

DL = low), and shuts down the respective regulator.

Cycle VCCbelow 1V or toggle the respective enable

input to clear the fault latch and restart the regulator.

Thermal-Fault Protection

The MAX17019 features a thermal fault-protection circuit. When the junction temperature rises above

+160°C, a thermal sensor activates the fault latch, pulls

all POK outputs low, and shuts down all regulators.

Toggle SHDN to clear the fault latch and restart the

controllers after the junction temperature cools by 15°C.

MAX17019

High-Input-Voltage Quad-Output Controller

20 ______________________________________________________________________________________

VTT LDO Detailed Description

VTT LDO Power-Good Output (POKD)

POKD is the open-drain output of a window comparator

that continuously monitors the VTT LDO output for

undervoltage and overvoltage conditions. POKD is

actively held low when the VTT LDO is disabled (OND

= GND) and in soft-start. Once the startup blanking

time expires, POKD becomes high impedance as long

as the output remains within ±6% (min) of the nominal

regulation voltage set by REFIND. POKD goes low once

its corresponding output drops or rises 12% (typ)

beyond its nominal regulation point or the output is shut

down. For a logic-level POKD output voltage, connect

an external pullup resistor between POKD and LDO5. A

100kΩ pullup resistor works well in most applications.

VTT LDO Fault Protection

LDO Output OVP

If the output voltage rises above 112% (typ) of its nominal regulation voltage, the controller sets the fault latch,

pulls POKD low, shuts down the source/sink linear regulator, and immediately pulls the output to ground

through its low-side MOSFET. Turning on the low-side

MOSFET with 100% duty cycle rapidly discharges the

output capacitors and clamps the output to ground.

Cycle VCCbelow 1V or toggle OND to clear the fault

latch and restart the linear regulator.

LDO Output UVP

Each MAX17019 includes an output UVP circuit that

begins to monitor the output once the startup blanking

period has ended. If the source/sink LDO output voltage

drops below 88% (typ) of its nominal REFIND regulation

voltage for 5ms, the UVP sets the fault latch, pulls the

POKD output low, forces the output into a highimpedance state, and shuts down the linear regulator.

Cycle VCCbelow 1V or toggle OND to clear the fault

latch and restart the regulator.

SMPS Design Procedure

(Step-Down Regulators)

Firmly establish the input voltage range and maximum

load current before choosing a switching frequency

and inductor operating point (ripple-current ratio). The

primary design trade-off lies in choosing a good switching frequency and inductor operating point, and the following four factors dictate the rest of the design:

• Input voltage range. The maximum value (V

IN(MAX)

)

must accommodate the worst-case, high ACadapter voltage. The minimum value (V

IN(MIN)

) must

account for the lowest battery voltage after drops

due to connectors, fuses, and battery selector

switches. If there is a choice at all, lower input voltages result in better efficiency.

• Maximum load current. There are two values to con-

sider. The peak load current (I

LOAD(MAX)

) determines

the instantaneous component stresses and filtering

requirements and thus drives output capacitor selection, inductor saturation rating, and the design of the

current-limit circuit. The continuous load current

(I

LOAD

) determines the thermal stresses and thus

drives the selection of input capacitors, MOSFETs,

and other critical heat-contributing components.

• Switching frequency. This choice determines the

basic trade-off between size and efficiency. The

optimal frequency is largely a function of maximum

input voltage, due to MOSFET switching losses that

are proportional to frequency and V

IN

2

.

• Inductor operating point. This choice provides

trade-offs between size vs. efficiency and transient

response vs. output ripple. Low inductor values provide better transient response and smaller physical

size, but also result in lower efficiency, higher output

ripple, and lower maximum load current due to

increased ripple currents. The minimum practical

inductor value is one that causes the circuit to operate at the edge of critical conduction (where the

inductor current just touches zero with every cycle at

maximum load). Inductor values lower than this

grant no further size-reduction benefit. The optimum

operating point is usually found between 20% and

50% ripple current. When pulse skipping (light

loads), the inductor value also determines the loadcurrent value at which PFM/PWM switchover occurs.

Step-Down Inductor Selection

The switching frequency and inductor operating point

determine the inductor value as follows:

Find a low-loss inductor having the lowest possible DC

resistance that fits in the allotted dimensions. Most

L

VVV

Vf I LIR

OUT IN OUT

IN SW LOAD MAX

=

()

-

()

MAX17019

High-Input-Voltage Quad-Output Controller

______________________________________________________________________________________ 21

inductor manufacturers provide inductors in standard

values, such as 1.0μH, 1.5μH, 2.2μH, 3.3μH, etc. Also

look for nonstandard values, which can provide a better

compromise in LIR across the input voltage range. If

using a swinging inductor (where the no-load inductance decreases linearly with increasing current), evaluate the LIR with properly scaled inductance values. For

the selected inductance value, the actual peak-to-peak

inductor ripple current (ΔI

INDUCTOR

) is defined by:

Ferrite cores are often the best choice, although soft saturating molded core inductors are inexpensive and can

work well at 500kHz. The core must be large enough not

to saturate at the peak inductor current (I

PEAK

):

SMPS Output Capacitor Selection

The output filter capacitor selection requires careful

evaluation of several different design requirements—

stability, transient response, and output ripple voltage—that place limits on the output capacitance and

ESR. Based on these requirements, the typical application requires a low-ESR polymer capacitor (lower cost

but higher output-ripple voltage) or bulk ceramic

capacitors (higher cost but low output-ripple voltage).

SMPS Loop Compensation

Voltage positioning dynamically lowers the output voltage in response to the load current, reducing the loop

gain. This reduces the output capacitance requirement

(stability and transient) and output power dissipation

requirements as well. The load-line is generated by sensing the inductor current through the high-side MOSFET

on-resistance, and is internally preset to -5mV/A (typ) for

regulator B and -7mV/A (typ) for regulator C. The loadline ensures that the output voltage remains within the

regulation window over the full-load conditions.

The load line of the internal SMPS regulators also provides the AC ripple voltage required for stability. To

maintain stability, the output capacitive ripple must be

kept smaller than the internal AC ripple voltage, and

crossover must occur before the Nyquist pole—(1 +

duty)/(2fSW)—occurs. Based on these loop requirements, a minimum output capacitance can be determined from the following:

where R

DROOP

is 2R

SENSE

for regulator A, 5mV/A for

regulator B, or 7mV/A for regulator C as defined in the

Electrical Characteristics

table, and fSWis the switching

frequency selected by the FREQ setting (see Table 1).

Additionally, an additional feedback pole—capacitor

from FB to analog ground (CFB)—might be necessary to

cancel the unwanted ESR zero of the output capacitor.

In general, if the ESR zero occurs before the Nyquist

pole, then canceling the ESR zero is recommended:

If:

Then:

where RFBis the parallel impedance of the FB resistive

divider.

SMPS Output Ripple Voltage

With polymer capacitors, the effective series resistance

(ESR) dominates and determines the output ripple voltage. The step-down regulator’s output ripple voltage

(V

RIPPLE

) equals the total inductor ripple current

(ΔI

INDUCTOR

) multiplied by the output capacitor’s ESR.

Therefore, the maximum ESR to meet the output ripple

voltage requirement is:

where fSWis the switching frequency. The actual capacitance value required relates to the physical case size

needed to achieve the ESR requirement, as well as to

the capacitor chemistry. Thus, polymer capacitor selection is usually limited by ESR and voltage rating rather

than by capacitance value. Alternatively, combining

ceramics (for the low ESR) and polymers (for the bulk

capacitance) helps balance the output capacitance vs.

output ripple-voltage requirements.

R

Vf L

VV V

V

ESR

IN SW

IN OUT OUT

RI PPLE

≤

()

⎡

⎣

⎢

⎢

⎤

⎦

⎥

⎥

-

C

C ESR

R

FB

OUT

FB

>

⎛

⎝

⎜

⎞

⎠

⎟

ESR

D

fC

SW OUT

>

+

⎛

⎝

⎜

⎞

⎠

⎟

1

4π

C

fR

V

V

V

V

OUT

SW DROOP

REF

OUT

OUT

>

⎛

⎝

⎜

⎞

⎠

⎟

⎛

⎝

⎜

⎞

⎠

⎟

+

1

2

1

IIN

⎛

⎝

⎜

⎞

⎠

⎟

II

I

PEAK LOAD MAX

INDUCTOR

=+

⎛

⎝

⎜

⎞

⎠

⎟

()

Δ

2

ΔI

VVV

Vf L

INDUCTOR

OUT IN OUT

IN SW

=

()

-

MAX17019

High-Input-Voltage Quad-Output Controller

22 ______________________________________________________________________________________

Internal SMPS Transient Response

The load-transient response depends on the overall

output impedance over frequency, and the overall

amplitude and slew rate of the load step. In applications with large, fast load transients (load step > 80% of

full load and slew rate > 10A/μs), the output capacitor’s

high-frequency response—ESL and ESR—needs to be

considered. To prevent the output voltage from spiking

too low under a load-transient event, the ESR is limited

by the following equation (ignoring the sag due to finite

capacitance):

where V

STEP

is the allowed voltage drop, ΔI

LOAD(MAX)

is

the maximum load step, and R

PCB

is the parasitic board

resistance between the load and output capacitor.

The capacitance value dominates the midfrequency

output impedance and dominates the load-transient

response as long as the load transient’s slew rate is

less than two switching cycles. Under these conditions,

the sag and soar voltages depend on the output

capacitance, inductance value, and delays in the transient response. Low inductor values allow the inductor

current to slew faster, replenishing charge removed

from or added to the output filter capacitors by a sudden load step, especially with low differential voltages

across the inductor. The sag voltage (V

SAG

) that occurs

after applying the load current can be estimated by the

following:

where D

MAX

is the maximum duty factor (see the

Electrical Characteristics

table), T is the switching peri-

od (1/f

OSC

), and ΔT equals V

OUT/VIN

x T when in PWM

mode, or L x I

IDLE

/(VIN- V

OUT

) when in pulse-skipping

mode. The amount of overshoot voltage (V

SOAR

) that

occurs after load removal (due to stored inductor energy) can be calculated as:

When using low-capacity ceramic filter capacitors,

capacitor size is usually determined by the capacity

needed to prevent V

SOAR

from causing problems during

load transients. Generally, once enough capacitance is

added to meet the overshoot requirement, undershoot at

the rising load edge is no longer a problem.

Input Capacitor Selection

The input capacitor must meet the ripple current

requirement (I

RMS

) imposed by the switching currents.

The I

RMS

requirements of an individual regulator can be

determined by the following equation:

The worst-case RMS current requirement occurs when

operating with VIN= 2V

OUT

. At this point, the above

equation simplifies to I

RMS

= 0.5 x I

LOAD.

However, the

MAX17019 uses an interleaved fixed-frequency architecture, which helps reduce the overall input RMS current on the INBC input supply.

For the MAX17019 system (INA) supply, nontantalum

chemistries (ceramic, aluminum, or OS-CON) are preferred due to their resistance to inrush surge currents

typical of systems with a mechanical switch or connector

in series with the input. For the MAX17019 INBC input

supply, ceramic capacitors are preferred on input due to

their low parasitic inductance, which helps reduce the

high-frequency ringing on the INBC supply when the

internal MOSFETs are turned off. Choose an input

capacitor that exhibits less than +10°C temperature rise

at the RMS input current for optimal circuit longevity.

BST Capacitors

The boost capacitors (C

BST

) must be selected large

enough to handle the gate charging requirements of

the high-side MOSFETs. For these low-power applications, 0.1μF ceramic capacitors work well.

Regulator A Power-MOSFET Selection

Most of the following MOSFET guidelines focus on the

challenge of obtaining high load-current capability

when using high-voltage (> 20V) AC adapters. Lowcurrent applications usually require less attention.

The high-side MOSFET (NH) must be able to dissipate

the resistive losses plus the switching losses at both

V

IN(MIN)

and V

IN(MAX)

. Ideally, the losses at V

IN(MIN)

should be roughly equal to the losses at V

IN(MAX)

, with

lower losses in between. If the losses at V

IN(MIN)

are

significantly higher, consider increasing the size of NH.

Conversely, if the losses at V

IN(MAX)

are significantly

higher, consider reducing the size of NH. If VINdoes

not vary over a wide range, maximum efficiency is

achieved by selecting a high-side MOSFET (NH) that

has conduction losses equal to the switching losses.

Choose a low-side MOSFET (NL) that has the lowest

possible on-resistance (R