General Description

The MAX17005/MAX17006/MAX17015 are high-frequency multichemistry battery chargers. These circuits feature a new high-frequency current-mode architecture

that significantly reduces component size and cost*.

The charger uses a high-side MOSFET with n-channel

synchronous rectifier. Widely adjustable charge current,

charge voltage, and input current limit simplify the construction of highly accurate and efficient chargers.

The charge voltage and charge current are set with

analog control inputs. The charge current setting can

also be adjusted with a PWM input. High-accuracy current-sense amplifiers provide fast cycle-by-cycle current-mode control to protect against short circuits to the

battery and respond quickly to system load transients.

In addition, the charger provides a high-accuracy analog output that is proportional to the adapter current. In

the MAX17015, this current monitor remains active

when the adapter is absent to monitor battery discharge current.

The MAX17005 charges three or four Li+ series cells,

and the MAX17006 charges two or three Li+ series

cells. The MAX17015 adjusts the charge voltage setting

and the number of cells through a feedback resistordivider from the output. All variants of the charger can

provide at least 4A of charge current with a 10mΩ

sense resistor.

The charger utilizes a charge pump to control an n-channel

adapter selection switch. The charge pump remains

active even when the charger is off. When the adapter

is absent, a p-channel MOSFET selects the battery.

The MAX17005/MAX17006/MAX17015 are available in

a small, 4mm x 4mm x 0.8mm 20-pin, lead-free TQFN

package. An evaluation kit is available to reduce

design time.

Applications

Notebook Computers

Tablet PCs

Portable Equipment with Rechargeable Batteries

Features

♦ High Switching Frequency (1.2MHz)

♦ Controlled Inductor Current-Ripple Architecture

Reduced BOM Cost

Small Inductor and Output Capacitors

♦ ±0.4% Accurate Charge Voltage

♦ ±2.5% Accurate Input-Current Limiting

♦ ±3% Accurate Charge Current

♦ Single-Point Compensation

♦ Monitor Outputs for

±2.5% Accurate Input Current Limit

±2.5% Battery Discharge Current

(MAX17015 only)

AC Adapter Detection

♦ Analog/PWM Adjustable Charge-Current Setting

♦ Battery Voltage Adjustable for 3 and 4 Cells

(MAX17005) or 2 and 3 Cells (MAX17006)

♦ Adjustable Battery Voltage (4.2V to 4.4V/Cell)

♦ Cycle-by-Cycle Current Limit

Battery Short-Circuit Protection

Fast Response for Pulse Charging

Fast System-Load-Transient Response

♦ Programmable Charge Current < 5A

♦ Automatic System Power Source Selection with

n-Channel MOSFET

♦ Internal Boost Diode

♦ +8V to +26V Input Voltage Range

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

________________________________________________________________

Maxim Integrated Products

1

Ordering Information

19-4041; Rev 0; 2/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

+

Denotes a lead-free package.

Pin Configuration and Minimal Operating Circuit appear at

end of data sheet.

*

Patent pending.

PART TEMP RANGE

MAX17005ETP+ -40°C to +85°C

MAX17006ETP+ -40°C to +85° C

MAX17015ETP+ -40°C to +85° C

PINPACKAGE

20 Thin QFN

(4mm x 4mm)

20 Thin QFN

(4mm x 4mm)

20 Thin QFN

(4mm x 4mm)

PKG

CODE

T2044-3

T2044-3

T2044-3

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

2 _______________________________________________________________________________________

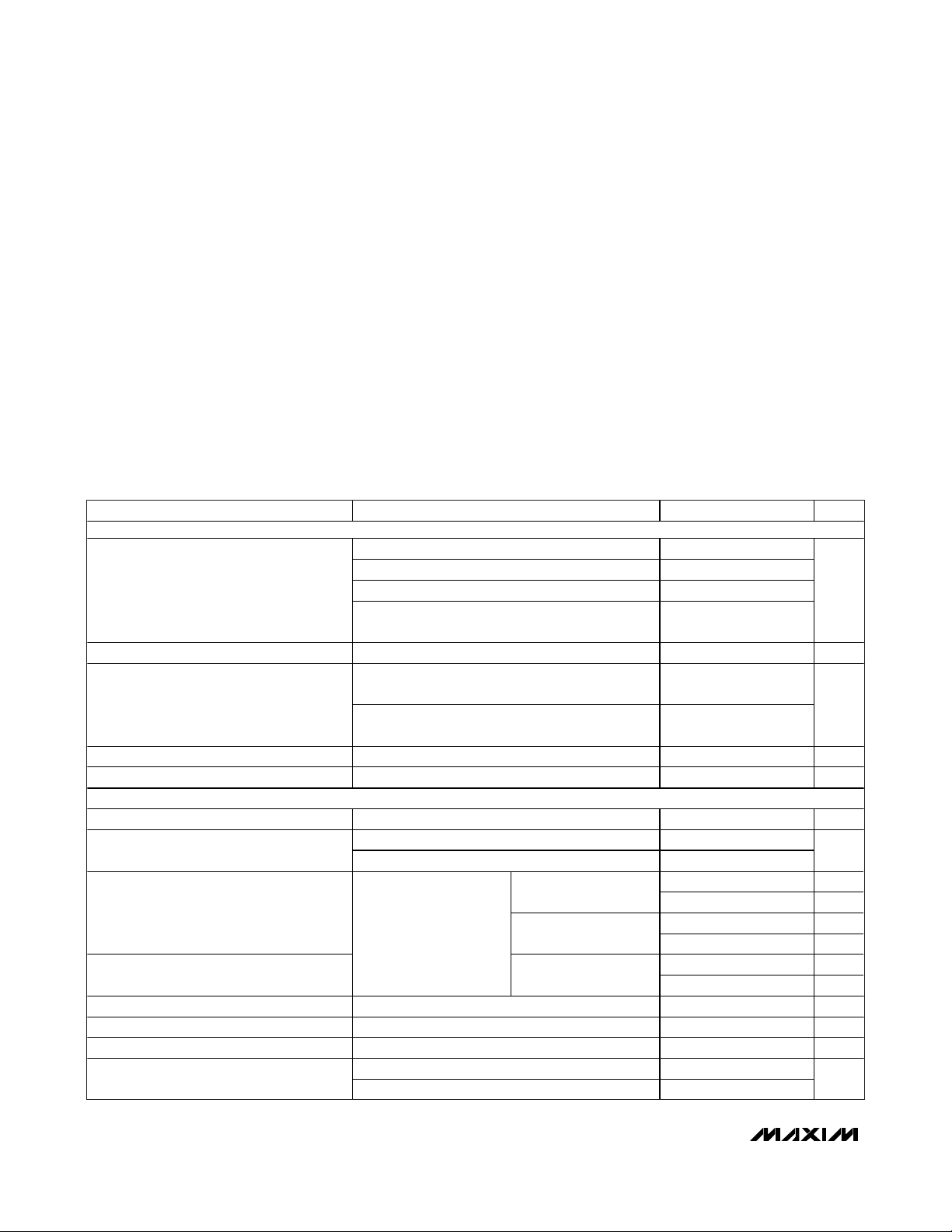

ABSOLUTE MAXIMUM RATINGS

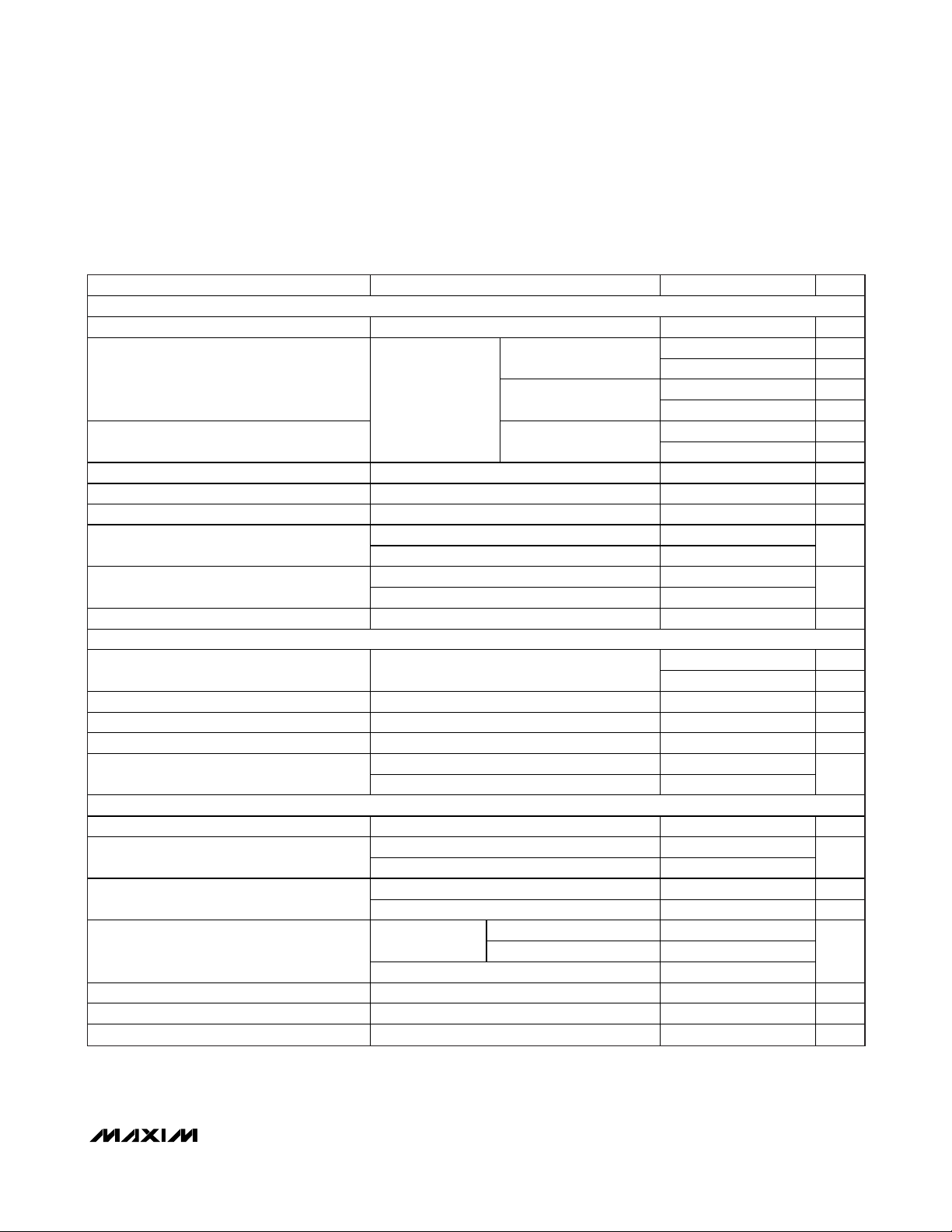

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 19V, V

BATT

= V

CSIP

= V

CSIN

= 16.8V, V

VCTL

= VAA, V

ISET

= 1V, TA= 0°C to +85°C,

unless otherwise noted. Typical values are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

DCIN, CSSP, CSSN, BATT, CSIN, CSIP, ACOK,

LX to AGND .......................................................-0.3V to +30V

BST to LDO.............................................................-0.3V to +30V

CSIP to CSIN, CSSP to CSSN .............................. -0.3V to +0.3V

IINP, FB, ACIN to AGND.............................-0.3V to (V

AA

+ 0.3V)

V

AA

, LDO, ISET, VCTL, CC to AGND .......................-0.3V to +6V

DHI to LX ....................................................-0.3V to (BST + 0.3V)

BST to LX..................................................................-0.3V to +6V

DLO to PGND ............................................-0.3V to (LDO + 0.3V)

PGND to AGND .................................................... -0.3V to +0.3V

Continuous Power Dissipation (T

A

= +70°C)

16-Pin TQFN (derate 16.9mW/°C above +70°C)....1349.1mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

CHARGE-VOLTAGE REGULATION

Battery Regulation-Voltage Accuracy

FB Input Bias Curent -1 +1 μA

VCTL Range

VCTL Gain V

VCTL Input Bias Current V

CHARGE-CURRENT REGULATION

ISET Range 0.0 VAA/2 V

ISET Full-Scale Setting

Ful l-Charge Current Accuracy

(CSIP to CSIN)

Trickle Charge-Current Accuracy

Charge-Current Gain Error Based on V

Charge-Current Offset Error Based on V

BATT/CSIP/CSIN Input Voltage Range 0 24 V

ISET Power-Down Mode Threshold

PARAMETER CONDITIONS MIN TYP MAX UNITS

2 cel ls, V

3 cel l s, V

4 cel ls, V

FB accuracy using FB divider (for MAX17015)

(Note 1)

2 cells (for MAX17006), 4 cell s (for MAX17005) 0.0

3 cell s (for MAX17005 and MAX17006)

CELL/VVCTL

VCTL

ISET = 1.4V 80

ISET = 99.9% duty cycle 60

V

BATT

ISET falling 21 26 31

ISET ri sing 33 40 47

VCTL

= VAA(for MAX17005 and MAX17006) 12.549 12.60 12.651

VCTL

VCTL

5.85 6 6.15 V/V

= GND and VCTL = V

= 1V to 16.8V

ISET

ISET

= GND (for MAX17006) 8.3664 8.40 8.4336

= GND (for MAX17005) 16.733 16.80 16.867

= V

VAA

= V

VAA

AA

V

= VAA/4 or ISET

ISET

= 99.9% duty cycle

V

= VAA/6 or ISET

ISET

= 66.7% duty cycle

V

= VAA/80 or ISET

ISET

= 5% duty cycle

/4 and V

/4 and V

ISET

ISET

= V

= V

/80 -2 +2 %

VAA

/80 -1.4 +1.4 mV

VAA

2.0916 2.1 2.1084

V

AA

-0.2

VAA/2

+0.2

-1 +1 μA

58.2 60 61.8 mV

-3 +3 %

38.2 40 41.8 mV

-4.5 +4.5 %

1.4 3 4.6 mV

-52 +52 %

V

AA

/2

V

V

mV

mV

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

_______________________________________________________________________________________ 3

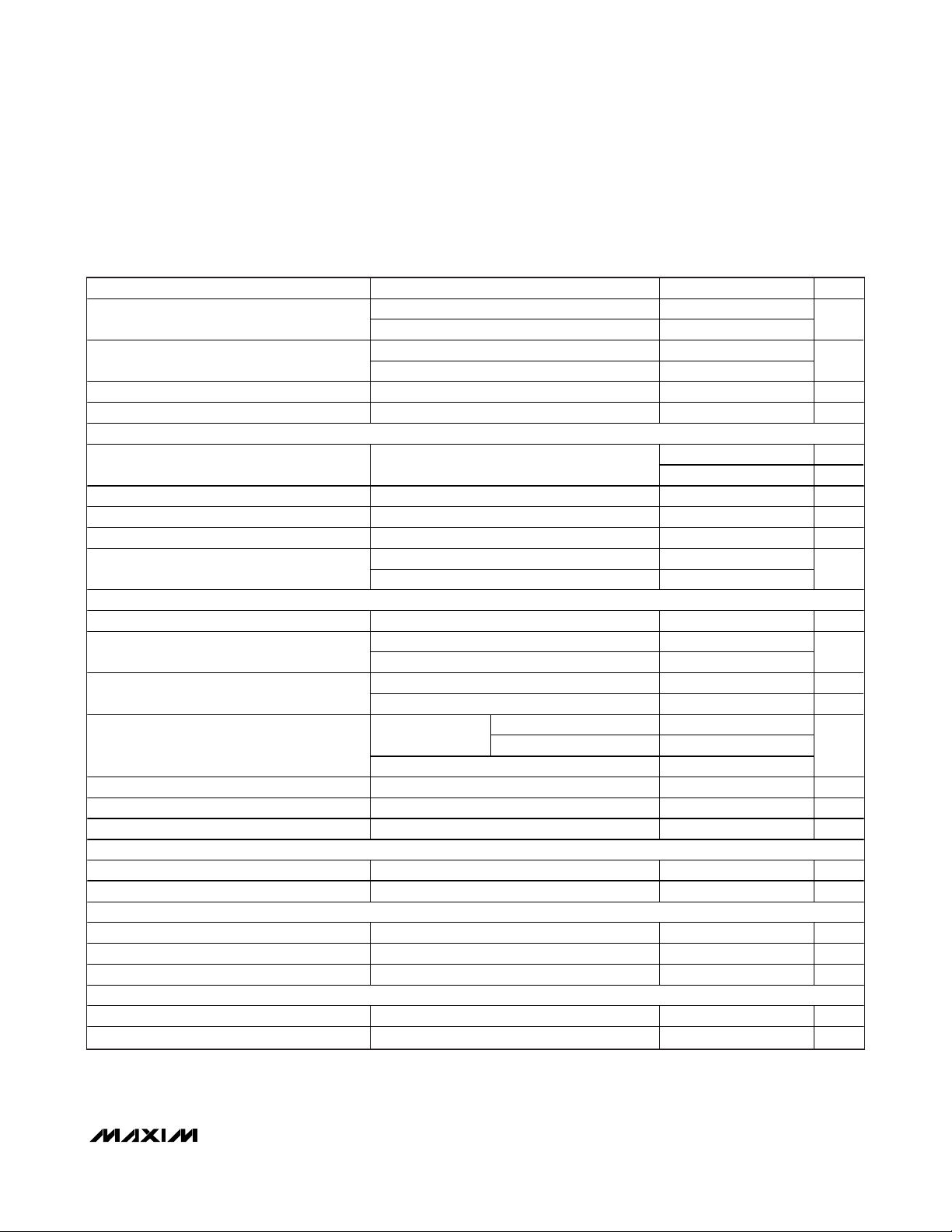

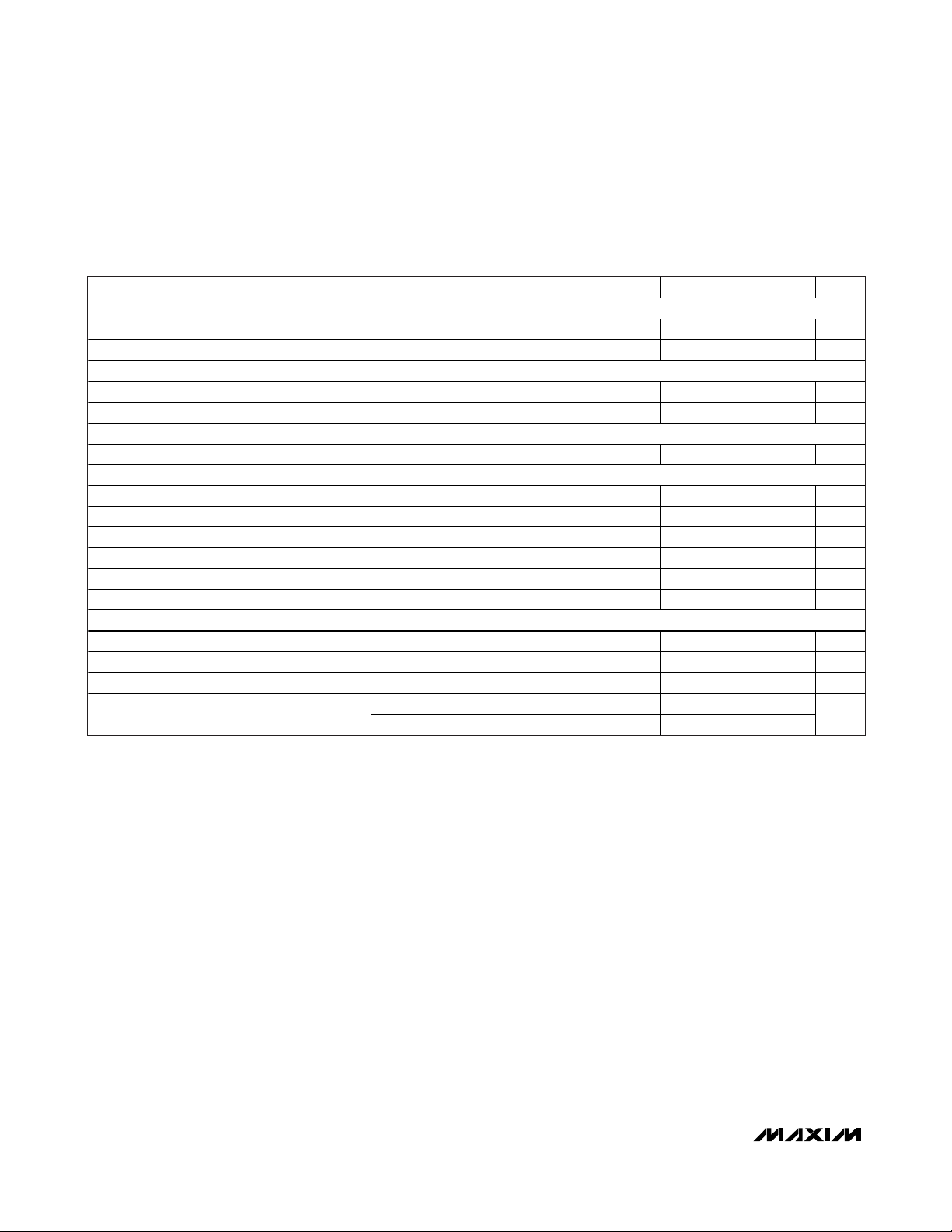

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 19V, V

BATT

= V

CSIP

= V

CSIN

= 16.8V, V

VCTL

= VAA, V

ISET

= 1V, TA= 0°C to +85°C,

unless otherwise noted. Typical values are at T

A

= +25°C.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

ISET Input Bias Current

ISET PWM Threshold

ISET Frequency 0.128 500 kHz

ISET Effective Resolution f

INPUT-CURRENT REGULATION

Input Current-Limit Threshold V

CSSN Input Bias Current Adapter present -0.1 +0.1 μA

CSSP/CSSN Input-Voltage Range 8.0 26.0 V

IINP Transconductance V

IINP Accuracy

SUPPLY AND LINEAR REGULATOR

DCIN Input Voltage Range 8 26 V

DCIN Undervoltage-Lockout (UVLO) Trip-Point

DCIN + CSSP + CSSN Quiescent Current

BATT + CSIP + CSIN + LX Input Current

LDO Output Voltage 8.0V < V

LDO Load Regulation 0 < I

LDO UVLO Threshold 3.2 4.1 5.0 V

REFERENCES

VAA Output Voltage I

VAA UVLO Threshold VAA falling 3.1 3.9 V

ACIN

ACIN Thresho ld 2.058 2.1 2.142 V

ACIN Threshold Hysteresis 10 20 30 mV

ACIN Input Bias Current -1 +1 μA

ACOK

ACOK Sink Current V

ACOK Leakage Current V

V

ISET

CSSN = BATT, V

Ri sing 2.4

Fal ling 0.8

PWM

CSSP

CSSP

V

CSSP

V

CSSP

DCIN falling 7.9 8.1

DCIN rising 8.7 8.9

Adapter present (Note 2) 3 6 mA

Adapter absent (Note 2) 30 50 μA

V

BATT

V

BATT

VAA

ACOK

ACOK

= 3V -0.2 +0.2

=3.2MHz 8 Bits

- V

CSSN

- V

CSSN

- V

CSSN

- V

CSSN

= 16.8V

= 2V to 19V, adapter present (Note 2) 200 500

DCIN

< 40mA 100 200 mV

LDO

= 50μA 4.18 4.20 4.22 V

= 0.4V, V

= 5.5V, V

ISET

= 60mV 2.66 2.8 2.94 μA/mV

= 60mV, V

= 35mV -2.5 +2.5

< 26V, no load 5.15 5.35 5.55 V

ACIN

ACIN

= 5V -0.2 +0.2

= 0V to 4.5V -2.5 +2.5

IINP

Adapter absent (Note 2) 10 20

Charger shutdown (Note 2) 10 20

= 1.5V 6 mA

= 2.5V 1 μA

58.5 60 61.5 mV

-2.5 +2.5 %

μA

V

%

V

μA

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 19V, V

BATT

= V

CSIP

= V

CSIN

= 16.8V, V

VCTL

= VAA, V

ISET

= 1V, TA= 0°C to +85°C,

unless otherwise noted. Typical values are at T

A

= +25°C.)

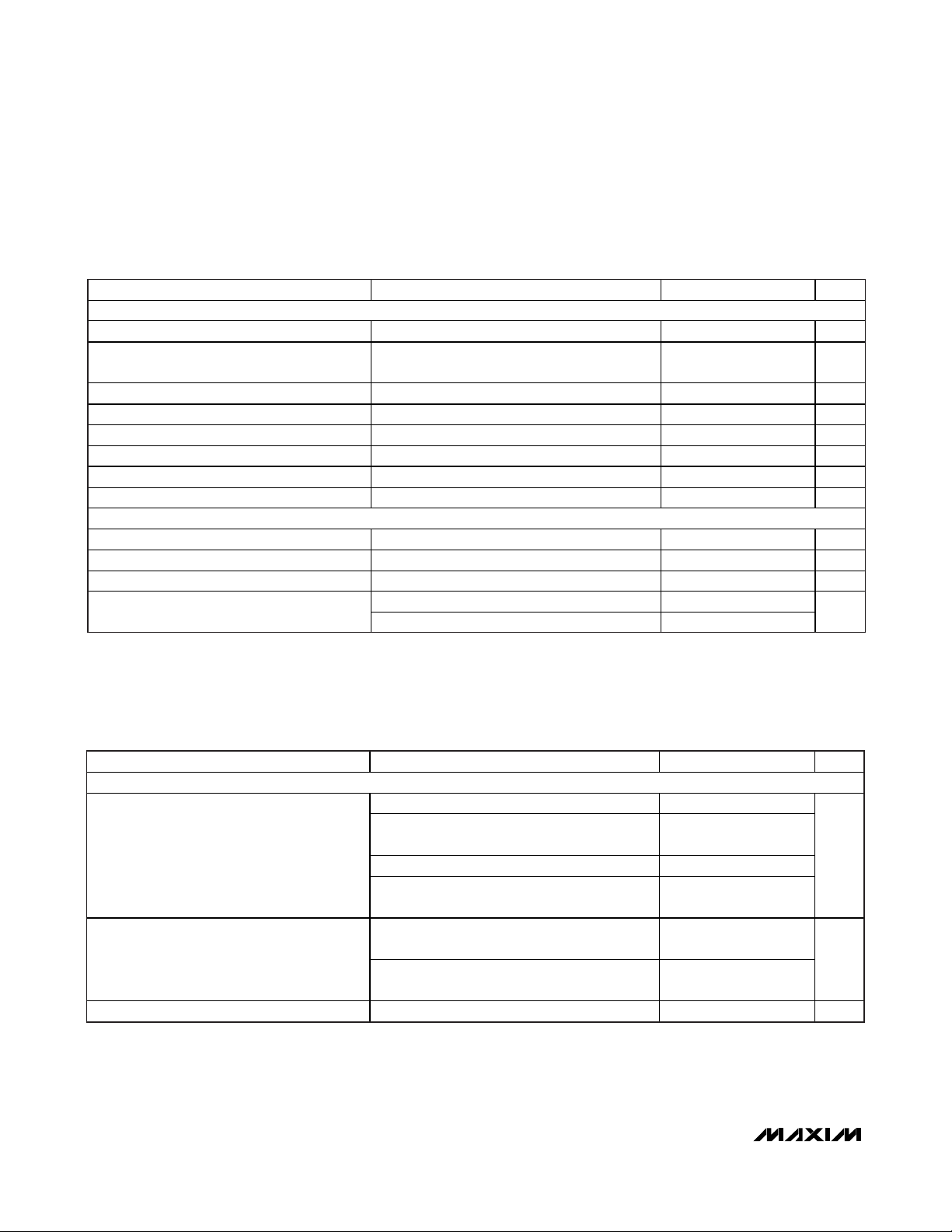

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 19V, V

BATT

= V

CSIP

= V

CSIN

= 16.8V, V

VCTL

= VAA, V

ISET

= 1V, TA= -40°C to +85°C,

unless otherwise noted.)

PARAMETER CONDITIONS MIN TY P MAX UNITS

SWITCHING REGULATOR

DHI Off-Time K Factor V

Sense Voltage for Minimum Discontinuous

Mode Ripple Current

Zero-Cros sing Comparator Threshold V

Cycle-by-Cycle Current-Limit Sense Voltage V

DHI Resistance High I

DHI Resistance Low I

DLO Resistance High I

DLO Resistance Low I

ADAPTER DETECTION

Adapter Absence-Detect Threshold V

Adapter Detect Threshold V

Adapter Switch Charge-Pump Frequency Charger Shutdown 180 200 220 Hz

Adapter Switch Charge-Pump Refresh Pulse

DCIN

V

CSIP

CSIP

CSIP

DLO

DLO

DLO

DLO

DCIN

DCIN

= 19V, V

- V

CSIN

- V

CSIN

- V

CSIN

BATT

= 10V 0.029 0.030 0.041 μs/V

10 mV

10 mV

105 110 115 mV

=10mA 1.5 3

= -10mA 0.8 1.75

= 10mA 3 6

= -10mA 3 7

- V

, V

BATT

- V

BATT,VDCIN

falling +70 +120 +170 mV

DCIN

rising +360 +420 +580 mV

DLO 0.04 0.1 0.20

DHI 0.07 0.15 0.30

μs

PARAMETER CONDITIONS MIN TY P MAX UNITS

CHARGE-VOLTAGE REGULATION

Battery Regulation-Voltage Accuracy

VCTL Range

VCTL Gain V

2 cel ls, V

3 cel ls, V

VCTL

VCTL

= GND (for MAX17006) 8.366 8.433

= V

AA

(for MAX17005 and MAX17006)

4 cel ls, V

= GND (for MAX17005) 16.73 16.86

VCTL

FB accuracy using FB divider (for MAX17015)

(Note 1)

2 cel ls (for MAX17006),

4 cell s (for MAX17005)

3 cell s (for MAX17005 and MAX17006)

CELL/VVCTL

5.85 6.15 V/V

12.549 12.651

2.091 2.108

VAA/2

+ 0.2

0.0

VAA/2

- 0.2

V

AA

V

V

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 19V, V

BATT

= V

CSIP

= V

CSIN

= 16.8V, V

VCTL

= VAA, V

ISET

= 1V, TA= -40°C to +85°C,

unless otherwise noted.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

CHARGE-CURRENT REGULATION

ISET Range 0.0 VAA/2 V

Ful l Charge-Current Accurac y

(CSIP to CSIN)

Trickle Charge-Current Accuracy

Charge-Current Gain Error Based on V

Charge-Current Offset Error Based on V

BATT/CSIP/CSIN Input Voltage Range 0 24 V

ISET Power-Down Mode Threshold

ISET PWM Threshold

ISET Frequency 0.128 500 kHz

INPUT-CURRENT REGULATION

Input Current-Limit Threshold V

CSSN Input Bias Current Adapter present -2 +2 μA

CSSP/CSSN Input-Voltage Range 8.0 26.0 V

IINP Transconductance V

IINP Accuracy

SUPPLY AND LINEAR REGULATOR

DCIN Input-Voltage Range 8 26 V

DCIN UVLO Trip-Point

DCIN + CSSP + CSSN Quiescent Current

BATT + CSIP + CSIN + LX Input Current

LDO Output Voltage 8.0V < V

LDO Load Regulation 0 < I

LDO UVLO Threshold 3.2 5.0 V

V

= 1V to 16.8V

BATT

ISET

ISET

V

ISET

= VAA/4 or

ISET = 99.9% duty cycl e

V

= VAA/6 or

ISET

ISET = 66.7% duty cycl e

V

= VAA/80 or

ISET

ISET = 5% duty cycle

= V

/4 and V

= V

VAA

VAA

/4 and V

ISET

ISET

57.5 62.5 mV

-4.2 +4.2 %

38 42 mV

-5 +5 %

1.4 4.6 mV

-52 +52 %

= V

/80 -2 +2 %

VAA

= V

/80 -1.4 +1.4 mV

VAA

ISET falling 21 31

ISET ris ing 33 47

Ri sing 2.4

Fal ling 0.8

CSSP

CSSP

V

CSSP

V

CSSP

- V

- V

- V

- V

CSSN

= 60mV 2.66 2.94 μA/mV

CSSN

= 60mV, V

CSSN

= 35mV -2.5 +2.5

CSSN

= 0V to 4.5V -2.5 +2.5

IINP

58.2 61.8 mV

-3 +3 %

DCIN falling 7.9

DCIN rising 8.9

Adapter present (Note 2) 6 mA

Adapter absent (Note 2) 50 μA

V

= 16.8V

BATT

V

= 2V to 19V, adapter present (Note 2) 500

BATT

DCIN

< 40mA 200 mV

LDO

Adapter absent (Note 2) 20

Charger shutdown (Note 2) 20

< 26V, no load 5.15 5.55 V

mV

V

%

V

μA

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

DCIN

= V

CSSP

= V

CSSN

= 19V, V

BATT

= V

CSIP

= V

CSIN

= 16.8V, V

VCTL

= VAA, V

ISET

= 1V, TA= -40°C to +85°C,

unless otherwise noted.)

Note 1: Accuracy does not include errors due to external resistance tolerances.

Note 2: Adapter present conditions are tested at V

DCIN

= 19V and V

BATT

= 16.8V. Adapter absent conditions are tested at

V

DCIN

= 16V, V

BATT

= 16.8V.

PARAMETER CONDITIONS MIN TY P MAX UNITS

REFERENCES

VAA Output Voltage I

VAA UVLO Threshold VAA falling 3.9 V

ACIN

ACIN Thresho ld 2.058 2.142 V

ACIN Threshold Hysteresis 10 30 mV

ACOK

ACOK Sink Current V

SWITCHING REGULATOR

DHI Off-Time K Factor V

Cycle-by-Cycle Current-Limit Sense Voltage V

DHI Resistance High I

DHI Resistance Low I

DLO Resistance High I

DLO Resistance Low I

ADAPTER DETECTION

Adapter Absence-Detect Threshold V

Adapter Detect Threshold V

Adapter Switch Charge-Pump Frequency 180 220 Hz

Adapter Switch Charge-Pump Refresh Pulse

VAA

DLO

DLO

DLO

DLO

DLO 0.04 0.2

DHI 0.07 0.3

= 50μA 4.18 4.22 V

= 0.4V, V

ACOK

= 19V, V

DCIN

- V

CSIP

CSIN

= 10mA 3

= -10mA 1.75

= 10mA 6

= -10mA 7

- V

DCIN

BATT

- V

DCIN

BATT,VDCIN

, V

ACIN

BATT

DCIN

= 1.5V 6 mA

= 10V 0.029 0.041 μs/V

falling +70 +170 mV

rising +320 +620 mV

105 115 mV

μs

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

_______________________________________________________________________________________ 7

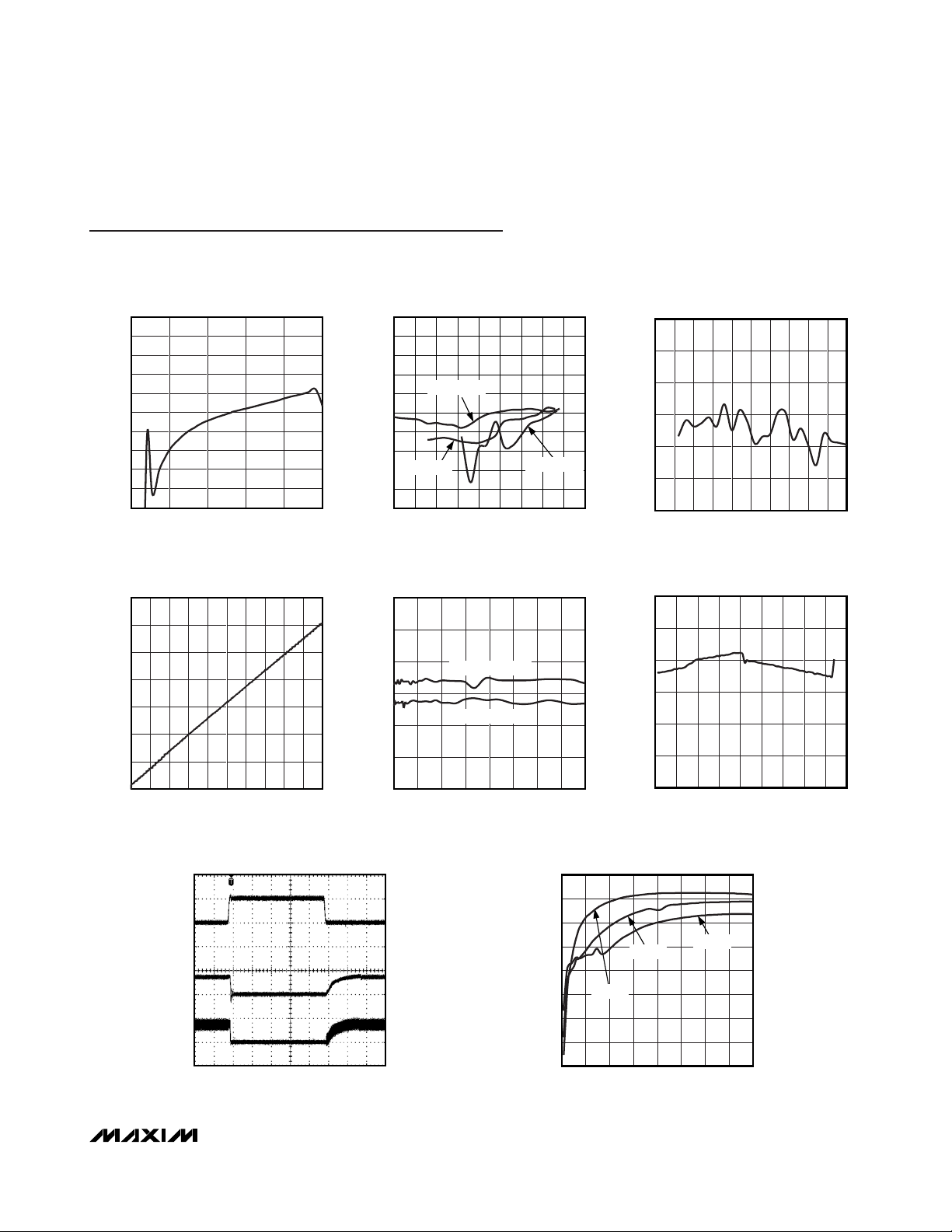

Typical Operating Characteristics

(Circuit of Figure 1, adapter = 19V, battery = 10V, ISET = 1.05V, V

CTL

= GND, TA= +25°C, unless otherwise noted.)

IINP DC ERROR

vs. SYSTEM CURRENT

MAX17005 toc01

SYSTEM CURRENT (A)

IINP ERROR (%)

4312

-8

-6

-4

-2

0

2

4

6

8

10

-10

05

IINP ERROR

vs. SYSTEM CURRENT

MAX17005 toc02

SYSTEM CURRENT (A)

IINP ERROR (%)

4.03.52.5 3.01.0 1.5 2.00.5

-8

-6

-4

-2

0

2

4

6

8

10

-10

04.5

V

BATT

= 16.8V

V

BATT

= 8.4V

V

BATT

= 12.6V

ISET PWM DUTY-CYCLE CHANGE

MAX17005 toc03

DUTY CYCLE

CHARGE-CURRENT ERROR (%)

0.8 0.90.1 0.2 0.3 0.4 0.5 0.6 0.7

0.5

1.0

1.5

2.0

2.5

3.0

0

01.0

ISET PWM DUTY-CYCLE CHANGE

MAX17005 toc04

DUTY CYCLE

CHARGE CURRENT (A)

80 9010 20 30 40 50 60 70

0.5

1.0

1.5

2.0

2.5

3.0

3.5

0

0100

ISET PWM FREQUENCY SWEEP

MAX17005 toc05

FREQUENCY (kHz)

CHARGE-CURRENT ERROR (%)

600 700100 200 300 400 500

0.5

1.0

1.5

2.0

2.5

3.0

0

0 800

DUTY CYCLE = 75%

DUTY CYCLE = 25%

BATTERY VOLTAGE-SETTING ERROR

MAX17005 toc06

VCTL (V)

BATTERY VOLTAGE ERROR (%)

3.0 3.5 4.00.5 1.0 1.5 2.0 2.5

-0.5

-0.4

-0.3

-0.2

-0.1

0

-0.6

04.5

SYSTEM LOAD TRANSIENT

MAX17005 toc07

200μs/div

SYSTEM

CURRENT

5A/div

CHARGING

CURRENT

5A/div

INDUCTOR

CURRENT

5A/div

EFFICIENCY

vs. CHARGE CURRENT

MAX17005 toc08

CHARGE CURRENT (A)

EFFICIENCY (%)

2.5 3.0 3.50.5 1.0 1.5 2.0

70

65

75

80

85

95

90

100

60

04.0

2 CELLS

3 CELLS

4 CELLS

VAA LOAD REGULATION

MAX17005 toc11

LOAD CURRENT (mA)

V

AA

VOLTAGE (V)

0.80.2 0.4 0.6

4.197

4.196

4.198

4.200

4.199

4.201

4.203

4.202

4.205

4.204

4.195

01.0

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

8 _______________________________________________________________________________________

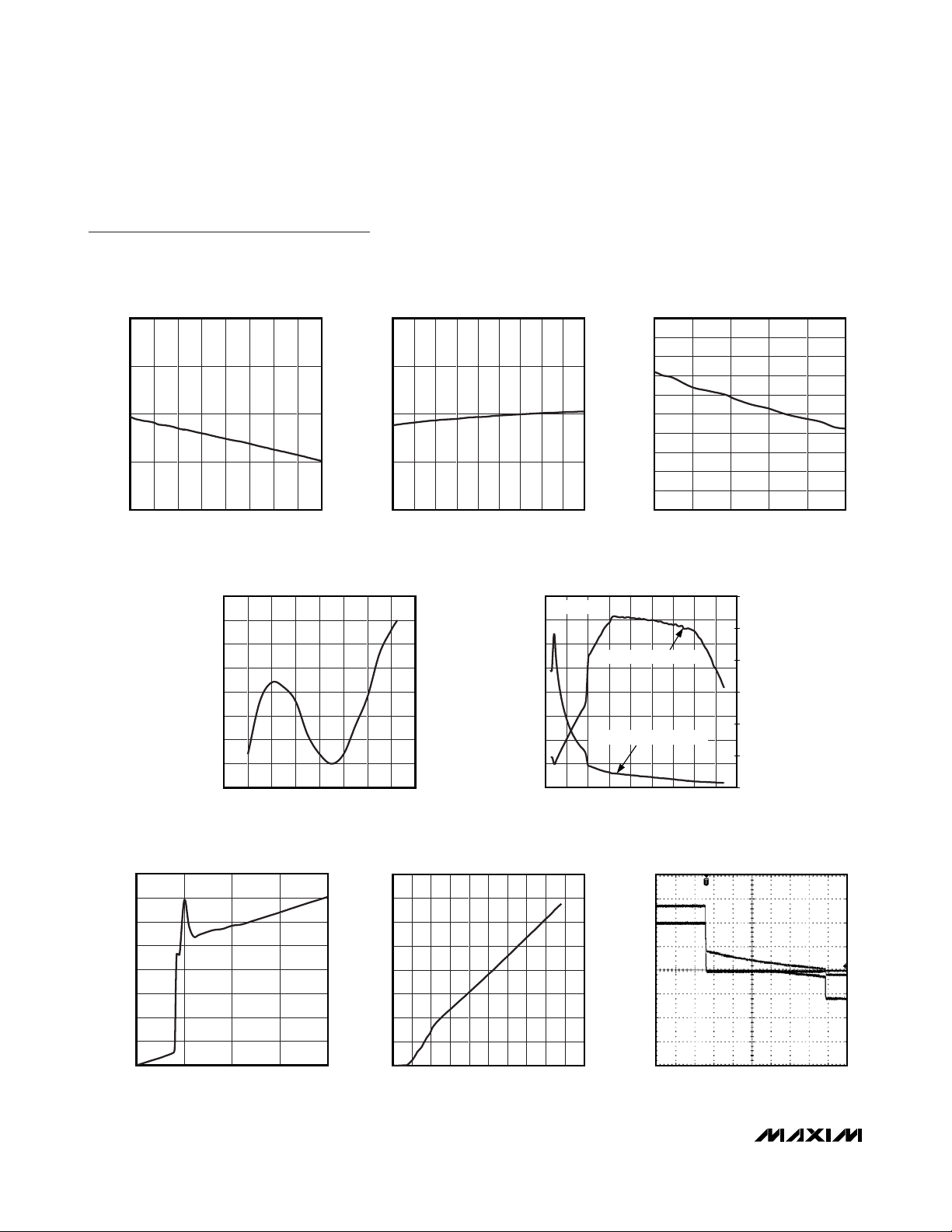

Typical Operating Characteristics (continued)

(Circuit of Figure 1, adapter = 19V, battery = 10V, ISET = 1.05V, V

CTL

= GND, TA= +25°C, unless otherwise noted.)

5.50

5.45

5.40

LDO VOLTAGE (V)

5.35

5.30

040

LDO CURRENT (mA)

3551015202530

MAX17005 toc09

5.50

5.45

5.40

LDO VOLTAGE (V)

5.35

5.30

LDO LOAD REGULATION

LDO LINE REGULATION

826

INPUT VOLTAGE (V)

242210 12 14 16 18 20

HIGH-SIDE MOSFET OFF-TIME AND

4.2005

VAA vs. TEMPERATURE

4.2000

4.1995

4.1990

(V)

4.1985

AA

V

4.1980

4.1975

4.1970

4.1965

-60 100

TEMPERATURE (°C)

60 80-40 -20 0 20 40

MAX17005 toc12

SWITCHING FREQUENCY vs. BATTERY VOLTAGE

1.6 6

VIN = 20V

1.4

1.2

1.0

0.8

0.6

0.4

SWITCHING FREQUENCY (MHz)

0.2

0

HIGH-SIDE MOSFET OFF-TIME

018

MAX17005 toc10

SWITCHING FREQUENCY

BATTERY VOLTAGE (V)

MAX17005 toc13

161410 124682

5

4

3

2

HIGH-SIDE MOSFTE OFF-TIME (μs)

1

0

ADAPTER CURRENT

vs. ADAPTER VOLTAGE

1.6

1.4

1.2

1.0

0.8

0.6

ADAPTER CURRENT (mA)

0.4

0.2

0

020

ADAPTER VOLTAGE (V)

15510

MAX17005 toc14

400

BATTERY LEAKAGE

350

300

250

200

150

100

BATTERY LEAKAGE CURRENT (μA)

50

0

020

BATTERY VOLTAGE (V)

14 16 18682 4 10 12

MAX17005 toc15

ADAPTER REMOVAL

200ms/div

MAX17005 toc16

5.00V

5.00V

5.00V

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

_______________________________________________________________________________________ 9

Pin Description

Dual Mode is a trademark of Maxim Integrated Products, Inc.

PIN NAME FUNCTION

1 DCIN Charger Bia s Suppl y Input. B ypass DCIN with a 1μF capacitor to PGND.

2 AGND Analog Ground

3 CSIP Output Current-Sense Pos it ive Input. Connect a current-sense resistor from CSIP to CSIN.

4 CSIN Output Current-Sense Negative Input

Input Current-Monitor Output. IINP sources the current proportional to the current sen sed across

5 IINP

6 BATT Battery Voltage Feedback Input

7 ACOK

8 CSSP Input Current Sense for Positive I nput. C onnect a current- sense re sist or from CSSP to CSSN.

9 CSSN Input Current-Sense Negative Input

10 ISET

11 PGND Power Ground Connection for MOSFET Drivers

12 DLO Low-Side Power-MOSFET Driver Output. Connect to low-side n-channel MOSFET gate.

13 LDO

14 BST High-Side Driver Supply. Connect a 0.68μF capac itor from BST to LX.

15 DHI High-Side Power-MOSFET Driver Output. Connect to high-side n-channel MOSFET gate.

16 LX High-Side Dri ver Source Connection. Connect a 0.68μF capacitor from BST to LX.

17 ACIN AC Adapter Detect Input. ACIN is the input to an uncommitted comparator.

18 V

19 CC

20 VCTL

— BP Backside Paddle. Connect the backside paddle to analog ground.

AA

CSSP and CSSN. The transconductance from (CSSP - CSSN) to IINP is 2.8μA/ mV. See the Analog

Input Current-Monitor Output section to configure the current mon itor for a particu lar gain setting.

AC Detect Output. Thi s open-drain output is high impedance when ACIN is lower than V

Connect a 10k pul lup resistor from LDO to ACOK.

Dual Mode™ Input for Setting Maximum Charge Current. ISET can be conf igured either with a

resi stor vo ltage-divider or with a PWM signal from 128Hz to 500 kHz. If there is no clock edge

within 20ms, ISET defaults to analog input mode. Pull ISET to GND to shut down the charger.

In the MAX17015, when the adapter is ab sent, drive ISET above 1V to enable IINP during battery

discharge. When the adapter is reinserted, ISET must be released to the correct control level within

300m s.

Linear Regulator Output. LDO provides the power to the MOSFET drivers. LDO is the output of the 5.4V

linear regulator supplied from DCIN. Bypas s LDO with a 4.7μF ceramic capacitor from LDO to PGND.

4.2V Voltage Reference and Device Power-Supply Input. Bypa ss VAA with a 1μF capacitor to GND.

Voltage Regulation Loop-Compensation Point. Connect 3k and 0.01μF capacitor in serie s from

CC to GND.

Battery Voltage Adjust Input. VCTL sets the number of cell s and adjusts the vo ltage per cell. The

adjustment range is 4.2V to 4.4V per cel l. See the Setting Charge Voltage section.

AA

/2.

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

10 ______________________________________________________________________________________

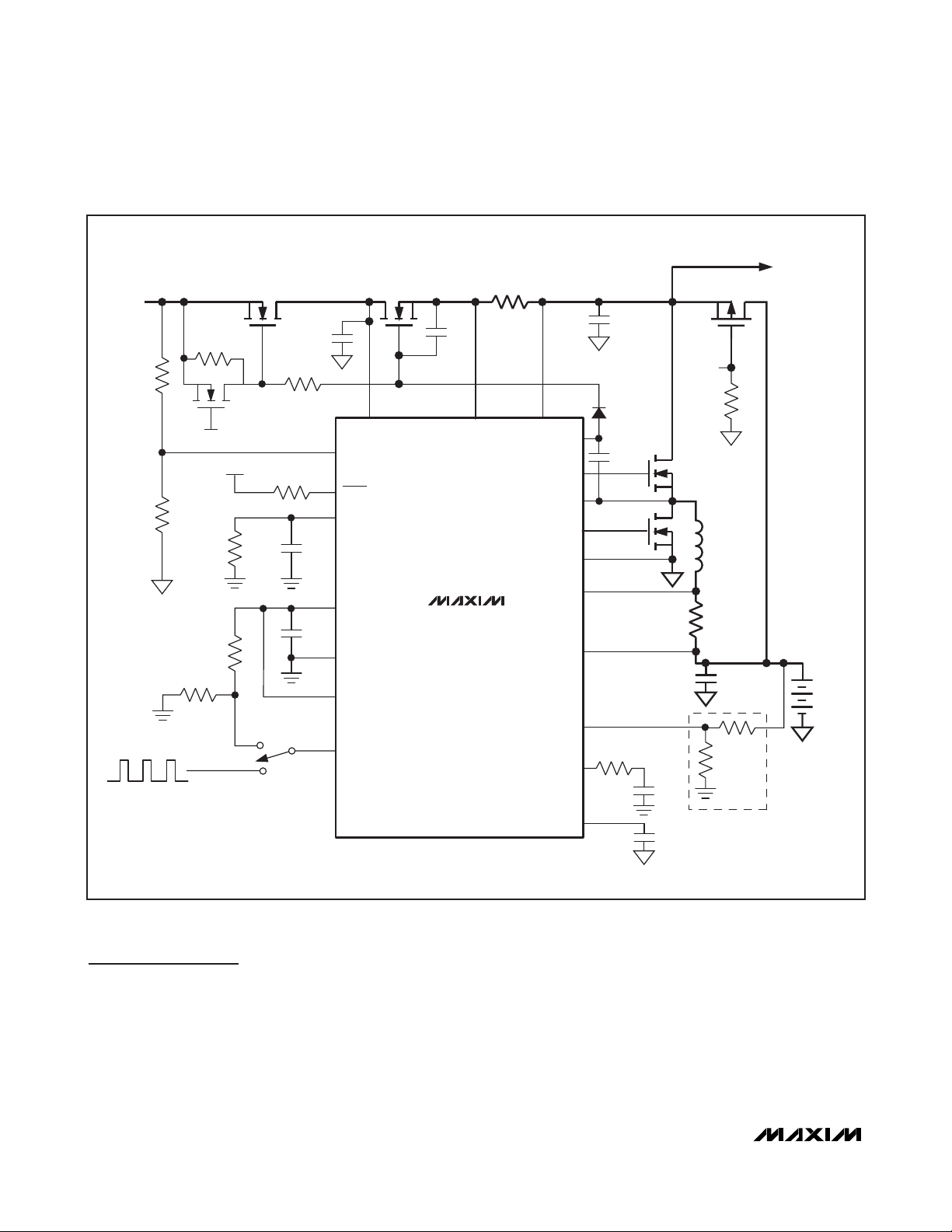

Figure 1. Typical Operating Circuit

Detailed Description

The MAX17005/MAX17006/MAX17015 include all the

functions necessary to charge Li+, NiMH, and NiCd

batteries. An all n-channel synchronous-rectified stepdown DC-DC converter is used to implement a precision constant-current, constant-voltage charger. The

charge current and input current-limit sense amplifiers

have low-input offset errors (250μV typ), allowing the

use of small-valued sense resistors.

The MAX17005/MAX17006/MAX17015 use a new thermally optimized high-frequency architecture. With this

new architecture, the switching frequency is adjusted

to control the power dissipation in the high-side

MOSFET. Benefits of the new architecture include:

reduced output capacitance and inductance, resulting in

smaller printed-circuit board (PCB) area and lower cost.

RS1

ADAPTER

R

R

ACIN1

ACIN2

N4

R9

2MΩ

BATT

22.6kΩ

R3

Q1a

N3

C6

1μF

R4

200kΩ

DCIN

C2

0.1μF

C3

1μF

ACIN

ACOK

IINP

V

AA

GND

VCTL

LDO

R1

R2

10kΩ

C7

0.1μF

MAX17005

MAX17006

MAX17015

15mΩ

CSSP CSSN

BST

DHI

DLO

PGND

CSIP

CSIN

SYSTEM LOAD

Q1b

C

IN

ADAPTER

R6

N2

N1

200kΩ

C

C

L1 = 2μH

= 2 x 4.7μF

IN

= 4.7μF

OUT

L1

RS2

10mΩ

C

OUT

BATTERY

D1

C4

0.68μF

LX

BATT

PWM SIGNAL

ISET

LDO

R5

3kΩ

CC

C5

0.01μF

C1

4.7μF

R7

R8

ONLY FOR MAX17015

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

______________________________________________________________________________________ 11

Figure 2. Functional Diagram

The MAX17005/MAX17006/MAX17015 feature a voltage-regulation loop (CCV) and two current-regulation

loops (CCI and CCS). The loops operate independently

of each other. The CCV voltage-regulation loop monitors BATT to ensure that its voltage never exceeds the

voltage set by VCTL. The CCI battery charge currentregulation loop monitors current delivered to BATT to

ensure that it never exceeds the current limit set by

ISET. The charge current-regulation loop is in control as

long as the battery voltage is below the set point. When

the battery voltage reaches its set point, the voltage-

regulation loop takes control and maintains the battery

voltage at the set point. A third loop (CCS) takes control

and reduces the charge current when the adapter current exceeds the input current limit.

The MAX17005/MAX17006/MAX17015 have singlepoint compensation. The two current loops are internally compensated while the voltage loop is compensated

with a series RC network at CC pin. See the

CC Loop

Compensation

section for the resistor and capacitor

selection. A functional diagram is shown in Figure 2.

CSSP

CSSN

GND

CC

BATT

VCTL

CSA

A = 17.5V/V

V

AA

60mV

CELL

SELECT

LOGIC

BDIV

GMS

GMV

CSI

Gm =

2.8μA/mV

LOWEST

VOLTAGE

CLAMP

IINP

ACIN

V

/2

AA

VCTL + 100mV

BDIV

10mV

LDO

ACOK

IMIN

CCMP

BATT

POWER

FAIL

OVP

DC-DC

CONVERTER

DCIN

5.4V LINEAR

REGULATOR

LEVEL

SHIFT

LDO

4.2V

REFERENCE

HIGH-SIDE

DRIVER

V

LDO

BST

DHI

LX

AA

CSIP

CSA

A = 17.5V/V

CSIN

PWM

FILTER

ISET

GMI

26mV

LOW-SIDE

DRIVER

MAX17005

MAX17006

110mV

CHARGER

SHUTDOWN

IMAX

IZX

10mV

MAX17015

DLO

PGND

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

12 ______________________________________________________________________________________

Setting Charge Voltage

The VCTL input adjusts the battery-output voltage,

V

BATT

, and determines the number of cells. For 3- and

4-cell applications, use the MAX17005; for 2- and 3-cell

applications, use the MAX17006. Use the MAX17015 to

adjust the cell number and set the cell voltage with a

resistive voltage-divider from the output. Based on the

version of the part, the number of cells and the level of

VCTL should be set as in Table 1:

The MAX17005 and MAX17006 support from 4.2V/cell

to 4.4V/cell, whereas the MAX17015 supports minimum

2.1V. The maximum voltage is determined with the

dropout performance of IC. When the required voltage

falls outside the range available with the MAX17005 or

MAX17006, the MAX17015 should be used.

The charge-voltage regulation for the MAX17005 and

MAX17006 is calculated with the following equations:

for 3-cell selection of MAX17005 and MAX17006, 4.2V

> VCTL > 2.4V:

for 2- or 4-cell selection of MAX17006 or MAX17005,

respectively, 0V < VCTL < 1.8V. Connect VCTL to GND

or to VAAfor default 4.2V/cell battery-voltage setting.

For the MAX17015, connect VCTL to GND to set the FB

regulation point to 2.1V. The charge-voltage regulation is

calculated with the following equation:

There are two constraints in choosing R7 and R8. The

resistors cannot be too small since they discharge the

battery, and they cannot be too large because FB pin

consumes less than 1μA of input bias current. Pick R8

to be approximately 10kΩ and then calculate R7.

FB regulation error (±0.5% max) and the tolerance of R7

and R8 both contribute to the error on the battery voltage. Use 0.1% feedback resistors for best accuracy.

Setting Charge Current

The voltage at ISET determines the voltage across current-sense resistor RS2. ISET can accept either analog

or digital inputs. The full-scale differential voltage

between CSIP and CSIN is 80mV (8A for RS2 = 10mΩ)

for the analog input, and 60mV (6A for RS2 = 10mΩ) for

the digital PWM input.

When the MAX17005/MAX17006/MAX17015 power up

and the charger is ready, if there is no clock edge within 20ms, the circuit assumes ISET is an analog input,

and disables the PWM filter block. To configure the

charge current, force the voltage on ISET according to

the following equation:

The input range for ISET is from 0 to VAA/2. To shut

down the charger, pull ISET below 26mV.

If there is a clock edge on ISET within 20ms, the PWM

filter is enabled and ISET accepts digital PWM input.

The PWM filter has a DAC with 8-bit resolution that corresponds to equivalent V

CSIP-CSIN

steps.

Table 1. Cell Configuration

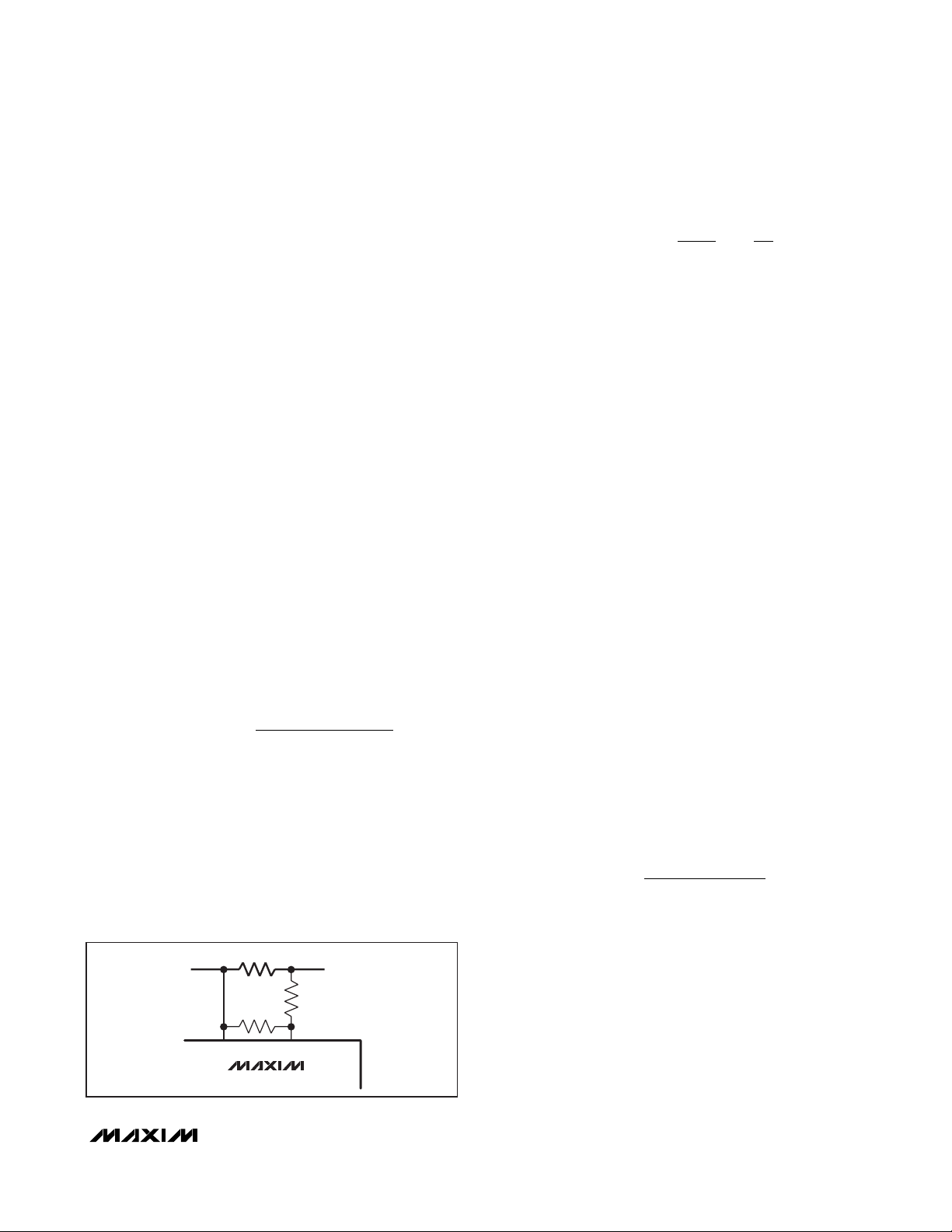

Figure 3. MAX17015 Charge-Voltage Regulation Feedback Network

VERSION NO. OF CELLS LEVEL

MAX170 05 3 2.4V < VCTL < 4.2V

MAX170 05 4 0V < VCTL < 1. 8V

MAX170 06 2 0V < VCTL < 1. 8V

MAX170 06 3 2.4V < VCTL < 4.2V

MAX170 15 Sets FB VCTL = GND or VCTL = V

AA

VV

−

42

.

VV

=+

42

CELL

.

VCTL

6

V

VV

=+426.

CELL

VCTL

CSIN

mV

I

240

=×

CHG

RS

V

ISET

V

2

AA

C

MAX17015

OUT

FB

RR

VV

CHG R EG FB SETPOINT__

=×

+87

R

8

R7

R8

BATTERY

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

______________________________________________________________________________________ 13

The PWM filter accepts the digital signal with a frequency

from 128Hz to 500kHz. Zero duty cycle shuts down the

MAX17005/MAX17006/MAX17015, and 99.5% duty cycle

corresponds to full scale (60mV) across CSIP and CSIN.

Choose a current-sense resistor (RS2) to have a sufficient power-dissipation rating to handle the full-charge

current. The current-sense voltage can be reduced to

minimize the power-dissipation period. However, this

can degrade accuracy due to the current-sense amplifier’s input offset (0.25mV typ). See

Typical Operating

Characteristics

to estimate the charge-current accuracy

at various set points.

Setting Input-Current Limit

The total input current, from a wall adapter or other DC

source, is the sum of the system supply current and the

current required by the charger. When the input current

exceeds the set input-current limit, the controller

decreases the charge current to provide priority to system load current. System current normally fluctuates as

portions of the system are powered up or down. The

input-current-limit circuit reduces the power requirement of the AC wall adapter, which reduces adapter

cost. As the system supply rises, the available charge

current drops linearly to zero. Thereafter, the total input

current can increase without limit.

The total input current is the sum of the device supply current, the charger input current, and the system load current. The total input current can be estimated as follows:

where η is the efficiency of the DC-to-DC converter

(typically 85% to 95%).

In the MAX17005/MAX17006/MAX17015, the voltage

across CSSP and CSSN is constant at 60mV. Choose

the current-sense resistor, RS1, to set the input current

limit. For example, for 4A input current limit, choose

RS1 = 15mΩ. For the input current-limit settings, which

cannot be achievable with standard sense resistor values, use a resistive voltage-divider between CSSP and

CSSN to tune the setting (Figure 4).

To minimize power dissipation, first choose RS1

according to the closest available value. For convenience, choose Ra = 6kΩ and calculate Rb from the

above equation.

Choose a current-sense resistor (RS1) to have a sufficient power rating to handle the full system current. The

current-sense resistor can be reduced to improve efficiency, but this degrades accuracy due to the currentsense amplifier’s input offset (0.15mV typ). See

Typical

Operating Characteristics

to estimate the input current-

limit accuracy at various set points.

Automatic Power-Source Selection

The MAX17005/MAX17006/MAX17015 use an external

charge pump to drive the gate of an n-channel adapter

selection switch (N3 and Q1a). In Figure 1, when the

adapter is present, BST is biased 5V above V

ADAPTER

so that N3 and Q1a are on, and Q1b is off. As long as

the adapter is present, even though the charger is off,

the power stage forces a refresh pulse to the BST

charge pump every 5ms.

When the adapter voltage is removed, the charger

stops generating BST refresh pulses and N4 forces N2

off, Q1b turns on and supplies power to the system

from the battery.

In Figure 1, D1 must have low forward-voltage drop and

low reverse-leakage current to ensure sufficient gate

drive at N3 and Q1a. A 100mA, low reverse-leakage

Schottky diode is the right choice.

Analog Input Current-Monitor Output

Use IINP to monitor the system-input current, which is

sensed across CSSP and CSSN. The voltage at IINP is

proportional to the input current:

where I

INPUT

is the DC current supplied by the AC

adapter, G

IINP

is the transconductance of the sense

amplifier (2.8 mA/V typ), and R

IINP

is the resistor connected between IINP and ground. Typically, IINP has a

0V to 3.5V output voltage range. Leave IINP unconnected when not used.

Figure 4. Input Current-Limit Fine Tuning

II

=+

INPUT LOAD

IV

CHARGE BATTERY

RS1

Ra

×

V

×η

IN

Rb

mV

I

INPUT LIMIT_

60

RS

1

Rb

()=×+

1

Ra

V

I

=

INPUT

RS G R

IINP

××1

IINP IINP

CSSP CSSN

MAX17005/MAX17006/MAX17015

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

14 ______________________________________________________________________________________

IINP can also be used to monitor battery discharge current (see Figure 5). In the MAX17015, when the adapter is

absent, drive ISET above 1V to enable IINP during battery

discharge. When the adapter is reinserted, ISET must be

released to the correct control level within 300ms.

AC Adapter Detection

The MAX17005/MAX17006/MAX17015 include a hysteretic comparator that detects the presence of an AC

power adapter. When ACIN is lower than 2.1V, the

open-drain ACOK output becomes high impedance.

Connect a 10kΩ pullup resistance between LDO and

ACOK. Use a resistive voltage-divider from the

adapter’s output to the ACIN pin to set the appropriate

detection threshold. Select the resistive voltage-divider

so that the voltage on ACIN does not to exceed its

absolute maximum rating (6V).

LDO Regulator and V

AA

An integrated low-dropout (LDO) linear regulator provides a 5.4V supply derived from DCIN, and delivers

over 40mA of load current. Do not use the LDO to

external loads greater than 10mA. The LDO powers the

gate drivers of the n-channel MOSFETs. See the

MOSFET Drivers

section. Bypass LDO to PGND with a

4.7μF ceramic capacitor. VAAis 4.2V reference supplied by DCIN. VAAbiases most of the control circuitry,

and should be bypassed to GND with a 1μF or greater

ceramic capacitor.

Operating Conditions

The MAX17005/MAX17006/MAX17015 have the following

operating states:

• Adapter Present: When DCIN is greater than 8.7V,

the controller detects the adapter. In this condition,

both the LDO and VAAturn on and battery charging

is allowed:

a) Charging: The total MAX17005/MAX17006/

MAX17015 quiescent current when charging is

3mA (max) plus the current required to drive the

MOSFETs.

b) Not Charging: To disable charging drive ISET

below 26mV. When the adapter is present and

charging is disabled, the total adapter quiescent

current is less than 1.5mA and the total battery

quiescent current is less than 60μA. The charge

pump still operates.

• Adapter Absent (Power Fail): When V

DCIN

is less

than V

CSIN

+ 120mV, the DC-DC converter is in

dropout. The charger detects the dropout condition

and shuts down.

The MAX17005/MAX17006/MAX17015 allow charging

under the following conditions:

• DCIN > 7.5V, LDO > 4V, VAA> 3.1V

•V

DCIN

> V

CSIN

+ 420mV (300mV falling hysteresis)

•V

ISET

> 45mV or PWM detected

____________________DC-DC Converter

The MAX17005/MAX17006/MAX17015 employ a synchronous step-down DC-DC converter with an n-channel high-side MOSFET switch and an n-channel

low-side synchronous rectifier. The charger features a

controlled inductor current-ripple architecture, currentmode control scheme with cycle-by-cycle current limit.

The controller’s off-time (t

OFF

) is adjusted to keep the

high-side MOSFET junction temperature constant. In

this way, the controller switches faster when the highside MOSFET has available thermal capacity. This

allows the inductor current ripple and the output-voltage ripple to decrease so that smaller and cheaper

components can be used. The controller can also operate in discontinuous conduction mode for improved

light-load efficiency.

Figure 5. Current-Monitoring Design Battery Discharge

Q1a

RS1

15mΩ

C7

10nF

CSSP CSSN

MAX17015

BST

DHI

SYSTEM LOAD

C

IN

ADAPTER

R6

50kΩ

D1

C4

0.1μF

N1

LX

Q1b

BATTERY

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

______________________________________________________________________________________ 15

The operation of the DC-to-DC controller is determined

by the following five comparators as shown in the functional diagram in Figures 2 and 6:

• The IMIN comparator triggers a pulse in discontinuous mode when the accumulated error is too high.

IMIN compares the control signal (LVC) against

10mV (referred at V

CSIP

- V

CSIN

). When LVC is less

than this threshold, DHI and DLO are both forced

low. Indirectly, IMIN sets the peak inductor current

in discontinuous mode.

• The CCMP comparator is used for current-mode

regulation in continuous-conduction mode. CCMP

compares LVC against the inductor current. The

high-side MOSFET on-time is terminated when the

CSI voltage is higher than LVC.

• The IMAX comparator provides a secondary cycleby-cycle current limit. IMAX compares CSI to

110mV (corresponding to 11A when RS2 = 10mΩ).

The high-side MOSFET on-time is terminated when

the current-sense signal exceeds 11A. A new cycle

cannot start until the IMAX comparator’s output

goes low.

• The ZCMP comparator provides zero-crossing detection during discontinuous conduction. ZCMP compares the current-sense feedback signal to 1A (RS2

= 10mΩ). When the inductor current is lower than

the 1A threshold, the comparator output is high,

and DLO is turned off.

• The OVP comparator is used to prevent overvoltage

at the output due to battery removal. OVP compares BATT against the VCTL. When BATT is

100mV/cell above the set value, the OVP comparator output goes high, and the high-side MOSFET

on-time is terminated. DHI and DLO remain off until

the OVP condition is removed.

SET POINT + 100mV

Figure 6. DC-DC Converter Functional Diagram

CSI

BDIV

OVP

IMAX

11A

CCMP

LVC

IMIN

1A

ZCMP

1A

CSSP

CSIN

OFF-TIME

COMPUTE

R

S

Q

Q

OFF-TIME

ONE SHOT

DH DRIVER

DL DRIVER

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

16 ______________________________________________________________________________________

CC, CCI, CCS, and LVC Control Blocks

The MAX17005/MAX17006/MAX17015 control input

current (CCS control loop), charge current (CCI control

loop), or charge voltage (CC control loop), depending

on the operating condition. The three control loops, CC,

CCI, and CCS are brought together internally at the

lowest voltage clamp (LVC) amplifier. The output of the

LVC amplifier is the feedback control signal for the

DC-DC controller. The minimum voltage at the CC, CCI,

or CCS appears at the output of the LVC amplifier and

clamps the other control loops to within 0.3V above the

control point. Clamping the other two control loops

close to the lowest control loop ensures fast transition

with minimal overshoot when switching between different control loops (see the

Compensation

section). The

CCS and CCI loops are compensated internally, and

the CC loop is compensated externally.

Continuous-Conduction Mode

With sufficiently large charge current, the MAX17005/

MAX17006/MAX17015s’ inductor current never crosses

zero, which is defined as continuous-conduction mode.

The controller starts a new cycle by turning on the highside MOSFET and turning off the low-side MOSFET.

When the charge-current feedback signal (CSI) is

greater than the control point (LVC), the CCMP comparator output goes high and the controller initiates the

off-time by turning off the high-side MOSFET and turning on the low-side MOSFET. The operating frequency

is governed by the off-time and is dependent upon

V

CSIN

and V

DCIN

.

The on-time can be determined using the following

equation:

where:

The switching frequency can then be calculated:

At the end of the computed off-time, the controller initiates a new cycle if the control point (LVC) is greater

than 10mV (V

CSIP

- V

CSIN

referred), and the charge

current is less than the cycle-by-cycle current limit.

Restated another way, IMIN must be high, IMAX must

be low, and OVP must be low for the controller to initiate a new cycle. If the peak inductor current exceeds

IMAX comparator threshold or the output voltage

exceeds the OVP threshold, then the on-time is terminated. The cycle-by-cycle current limit effectively protects against overcurrent and short-circuit faults.

If during the off-time the inductor current goes to zero,

the ZCMP comparator output pulls high, turning off the

low-side MOSFET. Both the high- and low-side

MOSFETs are turned off until another cycle is ready to

begin. ZCOMP causes the MAX17005/MAX17006/

MAX17015 to enter into the discontinuous conduction

mode (see the

Discontinuous Conduction

section).

Discontinuous Conduction

The MAX17005/MAX17006/MAX17015 can also operate

in discontinuous conduction mode to ensure that the

inductor current is always positive. The MAX17005/

MAX17006/MAX17015 enter discontinuous conduction

mode when the output of the LVC control point falls below

10mV (referred at V

CSIP

- V

CSIN

). For RS2 = 10mΩ, this

corresponds to a peak inductor current of 1A.

In discontinuous mode, a new cycle is not started until

the LVC voltage rises above IMIN. Discontinuous mode

operation can occur during conditioning charge of

overdischarged battery packs, when the charge current has been reduced sufficiently by the CCS control

loop, or when the charger is in constant-voltage mode

with a nearly full battery pack.

Compensation

The charge voltage, charge current, and input currentlimit regulation loops are compensated separately. The

charge current and input current-limit loops, CCI and

CCS, are compensated internally, whereas the charge

voltage loop is compensated externally at CC.

t

ON

I

RI PPLE

f

LI

×

=

SW

RI PPLE

VV

DCIN BATT

Vt

BATT OFF

=

=

tt

+

ON OFF

−

×

L

1

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

______________________________________________________________________________________ 17

CC Loop Compensation

The simplified schematic in Figure 7 is sufficient to

describe the operation of the controller’s voltage loop,

CC. The required compensation network is a pole-zero

pair formed with CCCand RCC. The zero is necessary

to compensate the pole formed by the output capacitor

and the load. R

ESR

is the equivalent series resistance

(ESR) of the charger output capacitor (C

OUT

). RLis the

equivalent charger output load, where RL= ΔV

BATT

/

ΔI

CHG

. The equivalent output impedance of the GMV

amplifier, R

OGMV

, is greater than 10MΩ. The voltage-

amplifier transconductance, GMV = 0.125μA/mV. The

DC-DC converter transconductance is dependent upon

charge current-sense resistor RS2:

where A

CSI

= 20, and RS2 = 10mΩ in the typical appli-

cation circuits, so GM

OUT

= 5A/V.

The loop transfer function is given by:

The poles and zeros of the voltage-loop transfer function

are listed from lowest frequency to highest frequency in

Table 2.

Near crossover, CCCis much lower impedance than

R

OGMV

. Since CCCis in parallel with R

OGMV, CCC

dominates the parallel impedance near crossover. Additionally,

RCCis much higher impedance than CCCand dominates

the series combination of RCCand CCC, so:

C

OUT

is also much lower impedance than RLnear

crossover so the parallel impedance is mostly capacitive and:

Table 2. CC Loop Poles and Zeros

f

RC

PCV

OGMV CC

_

=

×

1

2π

f

RC

ZCV

CC CC

_

=

×

1

2π

f

RC

POUT

LOUT

_

=

×

1

2π

f

RC

ZOUT

ESR OUT

_

=

×

1

2π

Figure 7. CC Loop Diagram

BATT

GM

OUT

R

ESR

R

C

OUT

CC

GMV

R

CC

C

CC

R

OGMV

VCTL

L

GM =

OUT

CSI ×

1

2ARS

LTF R GMV R

=×××

GM

OUT L OGMV

sC R

+×

(1 ))( )

×

OUT ESR

()()

11

+× + ×

sC R sC R

CC O GMV OUT L

1

+×

sC R

CC CC

RsCR

×+ ×

()

OGMV CC CC

1

sC R

+×

()

1

CC OGMV

R

≅

CC

R

L

sC R sC

()11+×

OUT L OUT

≅

NAME EQUATION DESCRIPTION

CCV Pole Lowest frequency pole created by CCVand GMV’s finite output resistance.

Voltage-loop compensation zero. If this zero is at the same frequency or lower

CCV Zero

Output

Pole

Output

Zero

than output pole f

response near the crosso ver frequency. Choose C

lea st one decade below crosso ver to ensure adequate phase margin.

Output pole formed with the effective load resi stance R

capacitance C

of the system or the crossover frequency.

Output ESR Zero. This zero can keep the loop from crossing unit y gain if

is less than the desired crossover frequency; therefore, choose a

f

Z_OUT

capacitor with an ESR zero greater than the crossover frequency.

OUT

, the loop-transfer function approximate s a single-pole

P_OUT

. RLinfluences the DC gain but does not affect the stability

to place thi s zero at

CV

and the output

L

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

18 ______________________________________________________________________________________

If R

ESR

is small enough, its associated output zero has

a negligible effect near crossover and the loop-transferfunction can be simplified as follows:

Setting LTF = 1 to solve for the unity-gain frequency

yields:

For stability, choose a crossover frequency lower than

1/10 the switching frequency (f

OSC)

. For example,

choose a crossover frequency of 50kHz and solve for

RCCusing the component values listed in Figure 1 to

yield R

CC

= 3kΩ:

GMV = 0.125μA/mV

GM

OUT

= 5A/V

C

OUT

= 4.7μF

f

OSC_CV

= 600kHz

RL = 0.2Ω

f

CO_CV

= 50kHz

To ensure that the compensation zero adequately cancels the output pole, select f

Z_CV

≤ f

P_OUT

:

CCC≥ (RL/RCC) x C

OUT

CCC≥ 300pF (assuming 2 cells and 2A maximum

charge current).

Figure 8 shows the Bode plot of the voltage-loopfrequency response using the values calculated above.

MOSFET Drivers

The DHI and DLO outputs are optimized for driving

moderate-sized power MOSFETs. The MOSFET drive

capability is the same for both the low-side and highsides switches. This is consistent with the variable duty

factor that occurs in the notebook computer environment where the battery voltage changes over a wide

range. There must be a low-resistance, low-inductance

path from the DLO driver to the MOSFET gate to prevent shoot-through. Otherwise, the sense circuitry in the

MAX17005/MAX17006 interpret the MOSFET gate as

“off” while there is still charge left on the gate. Use very

short, wide traces measuring 10 to 20 squares or fewer

(1.25mm to 2.5mm wide if the MOSFET is 25mm from

the device). Unlike the DLO output, the DHI output uses

a 50ns (typ) delay time to prevent the low-side MOSFET

from turning on until DHI is fully off. The same considerations should be used for routing the DHI signal to the

high-side MOSFET.

The high-side driver (DHI) swings from LX to 5V above

LX (BST) and has a typical impedance of 1.5Ω sourcing

and 0.8Ω sinking. The strong high-side MOSFET driver

eliminates most of the power dissipation due to switching losses. The low-side driver (DLO) swings from LDO

to ground and has a typical impedance of 3Ω sinking

and 3Ω sourcing. This helps prevent DLO from being

pulled up when the high-side switch turns on due to

capacitive coupling from the drain to the gate of the

low-side MOSFET. This places some restrictions on the

MOSFETs that can be used. Using a low-side

MOSFET with smaller gate-to-drain capacitance can

prevent these problems.

Design Procedure

MOSFET Selection

Choose the n-channel MOSFETs according to the maximum required charge current. The MOSFETs must be

able to dissipate the resistive losses plus the switching

losses at both V

DCIN(MIN)

and V

DCIN(MAX)

.

For the high-side MOSFET, the worst-case resistive

power losses occur at the maximum battery voltage

and minimum supply voltage:

Figure 8. CC Loop Response

R

LTF GM

=×

OUT

sC

CC

OUT

G

MV

fGMG

CO CV OUT MV

=××

_

R

CC

×2π

C

OUT

R

CC

π

=

×

GMV GM

Cf

×2

OUT CO CV

×

_

OUT

k

≅

Ω

3

80

60

0

40

-45

20

MAGNITUDE (dB)

0

-20

-40

0.1 1M

MAG

PHASE

FREQUENCY (Hz)

PHASE (DEGREES)

-90

-135

100k10k1k100101

PD HighSide

()

COND

V

BATT MAX

V

DCIN MIN

()

()

=×

I

CHG

2

××R

DS ON()

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

______________________________________________________________________________________ 19

Generally, a low gate charge high-side MOSFET is preferred to minimize switching losses. However, the

R

DS(ON)

required to stay within package power dissipation often limits how small the MOSFET can be. The

optimum occurs when the switching losses equal the

conduction losses. High-side switching losses do not

usually become an issue until the input is greater than

approximately 15V. Calculating the power dissipation in

N1 due to switching losses is difficult since it must

allow for difficult quantifying factors that influence the

turn-on and turn-off times. These factors include the

internal gate resistance, gate charge, threshold voltage, source inductance, and PCB layout characteristics. The following switching-loss calculation provides

only a very rough estimate and is no substitute for

breadboard evaluation, preferably including a verification using a thermocouple mounted on N1:

where t

TRANS

is the drivers transition time and can be

calculated as follows:

I

GSRC

and I

GSNK

are the peak gate-drive source/sink

current (3Ω sourcing and 0.8Ω sinking, typically). The

MAX17005/MAX17006/MAX17015 control the switching

frequency as shown in the

Typical Operating

Characteristics

.

The following is the power dissipated due to high-side

n-channel MOSFET’s output capacitance (C

RSS

):

The following high-side MOSFET’s loss is due to the

reverse-recovery charge of the low-side MOSFET’s

body diode:

Ignore PD

QRR

(HighSide) if a Schottky diode is used

parallel to a low-side MOSFET.

The total high-side MOSFET power dissipation is:

Switching losses in the high-side MOSFET can become

an insidious heat problem when maximum AC adapter

voltages are applied. If the high-side MOSFET chosen

for adequate R

DS(ON)

at low-battery voltages becomes

hot when biased from V

DCIN(MAX)

, consider choosing

another MOSFET with lower parasitic capacitance.

For the low-side MOSFET (N2), the worst-case power

dissipation always occurs at maximum input voltage:

The following additional loss occurs in the low-side

MOSFET due to the body diode conduction losses:

The total power low-side MOSFET dissipation is:

These calculations provide an estimate and are not a

substitute for breadboard evaluation, preferably

including a verification using a thermocouple mounted

on the MOSFET.

Inductor Selection

The selection of the inductor has multiple trade-offs

between efficiency, transient response, size, and cost.

Small inductance is cheap and small, and has a better

transient response due to higher slew rate; however, the

efficiency is lower because of higher RMS current. High

inductance results in lower ripple so that the need of the

output capacitors for output voltage ripple goes low.

The MAX17005/MAX17006/MAX17015 combine all the

inductor trade-offs in an optimum way by controlling

switching frequency. High-frequency operation permits

the use of a smaller and cheaper inductor, and consequently results in smaller output ripple and better transient response.

The charge current, ripple, and operating frequency

(off-time) determine the inductor characteristics. For

optimum efficiency, choose the inductance according

to the following equation:

where k = 35ns/V.

1

()=× × × ×

2

PD HS t V I f

SW TRA NS CSSP CHG SW

t

TRANS

⎛

11

=+

⎜

II

⎝

GSRC GSNK

⎞

QQ

×+

()

GD GS

⎟

⎠

2

PD HS

CRSS

()≈

VCf

××

CSSP RSS SW

2

QV f

××

2

RR CSSP SW

2

PD HS

()=

QRR

PD HS PD HS PD HS

() () ()≈+

TOTAL COND SW

() ()++PD HS PD HS

CRSS QRR

PD LS

COND

()

⎛

V

=−

⎜

V

⎝

BATT MIN

CSSP MAX

⎞

()

×1

⎟

⎠

()

I

CH

R2×

GGDSON

()

PD LS I V

() . .=× ×005 04

BDY PEAK

PD LS PD LS PD LS

() () ()≈+

TOTAL COND BDY

L

=

4

ILIR

××

CHG MAX

kV

×

IN

2

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

20 ______________________________________________________________________________________

For optimum size and inductor current ripple, choose

LIR

MAX

= 0.4, which sets the ripple current to 40% the

charge current and results in a good balance between

inductor size and efficiency. Higher inductor values

decrease the ripple current. Smaller inductor values

save cost but require higher saturation current capabilities and degrade efficiency.

Inductor L1 must have a saturation current rating of at

least the maximum charge current plus 1/2 the ripple

current (ΔIL):

I

SAT

= I

CHG

+ (1/2) ΔIL

The ripple current is determined by:

Input Capacitor Selection

The input capacitor must meet the ripple current

requirement (I

RMS

) imposed by the switching currents.

Nontantalum chemistries (ceramic, aluminum, or

OS-CON) are preferred due to their resilience to powerup and surge currents:

The input capacitors should be sized so that the temperature rise due to ripple current in continuous conduction does not exceed approximately 10°C. The

maximum ripple current occurs at 50% duty factor or

V

DCIN

= 2 x V

BATT

, which equates to 0.5 x I

CHG

. If the

application of interest does not achieve the maximum

value, size the input capacitors according to the worstcase conditions.

Output Capacitor Selection

The output capacitor absorbs the inductor ripple current and must tolerate the surge current delivered from

the battery when it is initially plugged into the charger.

As such, both capacitance and ESR are important

parameters in specifying the output capacitor as a filter

and to ensure the stability of the DC-to-DC converter

(see the

Compensation

section.) Beyond the stability

requirements, it is often sufficient to make sure that the

output capacitor’s ESR is much lower than the battery’s

ESR. Either tantalum or ceramic capacitors can be

used on the output. Ceramic devices are preferable

because of their good voltage ratings and resilience to

surge currents. Choose the output capacitor based on:

Choose k

CAP-BIAS

is a derating factor of 2 for typical 25V-

rated ceramic capacitors.

For fSW= 800kHz, I

RIPPLE

= 1A, and to get ΔV

BATT

=

70mV, choose C

OUT

as 4.7μF.

If the internal resistance of battery is close to the ESR of

the output capacitor, the voltage ripple is shared with

the battery and is less than calculated.

Applications Information

Setting Input Current Limit

The input current limit should be set based on the current capability of the AC adapter and the tolerance of

the input current limit. The upper limit of the input current threshold should never exceed the adapter’s minimum available output current. For example, if the

adapter’s output current rating is 5A ±10%, the input

current limit should be selected so that its upper limit is

less than 5A × 0.9 = 4.5A. Since the input current-limit

accuracy of the MAX17005/MAX17006/MAX17015 is

±3%, the typical value of the input current limit should

be set at 4.5A/1.03 ≈ 4.36A. The lower limit for input

current must also be considered. For chargers at the

low end of the spec, the input current limit for this

example could be 4.36A × 0.95 or approximately 4.14A.

Layout and Bypassing

Bypass DCIN with a 0.1μF ceramic to ground (Figure 1).

N1 and N2 protect the MAX17005/MAX17006/

MAX17015 when the DC power source input is reversed.

Bypass VAA, CSSP, and LDO as shown in Figure 1.

Good PCB layout is required to achieve specified noise

immunity, efficiency, and stable performance. The PCB

layout designer must be given explicit instructions—

preferably, a sketch showing the placement of the

power switching components and high current routing.

Refer to the PCB layout in the MAX17005/MAX17006/

MAX17015 evaluation kit for examples. A ground plane

is essential for optimum performance. In most applications, the circuit is located on a multilayer board, and

full use of the four or more copper layers is recommended. Use the top layer for high-current connections, the bottom layer for quiet connections, and the

inner layers for an uninterrupted ground plane.

Use the following step-by-step guide:

1) Place the high-power connections first, with their

grounds adjacent:

a) Minimize the current-sense resistor trace lengths,

and ensure accurate current sensing with Kelvin

connections.

b) Minimize ground trace lengths in the high-current

paths.

Δ=

2

×ILkV

IN

L

4

II

RMS CHG

⎛

VVV

×−

BATT DCIN BATT

=

⎜

×

⎜

⎝

()

V

DCIN

⎞

⎟

⎟

⎠

C

=

OUT

fV

××

SW BATT

I

RI PPLE

8 Δ

k

×

CAP BIAS

−

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

______________________________________________________________________________________ 21

c) Minimize other trace lengths in the high-current

paths.

d) Use > 5mm wide traces in the high-current

paths.

e) Connect CINto high-side MOSFET (10mm max

length).

f) Minimize the LX node (MOSFETs, rectifier cath-

ode, inductor (15mm max length)). Keep LX on

one side of the PCB to reduce EMI radiation.

Ideally, surface-mount power components are flush

against one another with their ground terminals

almost touching. These high-current grounds are

then connected to each other with a wide, filled

zone of top-layer copper, so they do not go through

vias. The resulting top-layer subground plane is

connected to the normal inner-layer ground plane

at the paddle. Other high-current paths should also

be minimized, but focusing primarily on short

ground and current-sense connections eliminates

about 90% of all PCB layout problems.

2) Place the IC and signal components. Keep the

main switching node (LX node) away from sensitive

analog components (current-sense traces and V

AA

capacitor). Important: the IC must be no further than

10mm from the current-sense resistors. Quiet connections to V

AA

and CC should be returned to a separate ground (GND) island. There is very little current

flowing in these traces, so the ground island need not

be very large. When placed on an inner layer, a sizable ground island can help simplify the layout

because the low-current connections can be made

through vias. The ground pad on the backside of the

package should also be connected to this quiet

ground island.

3) Keep the gate drive traces (DHI and DLO) as short

as possible (L < 20mm), and route them away from

the current-sense lines and VAA. These traces

should also be relatively wide (W > 1.25mm).

4) Place ceramic bypass capacitors close to the IC.

The bulk capacitors can be placed further away.

Place the current-sense input filter capacitors under

the part, connected directly to the GND pin.

5) Use a single-point star ground placed directly

below the part at the PGND pin. Connect the power

ground (ground plane) and the quiet ground island

at this location.

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

22 ______________________________________________________________________________________

Pin Configuration

Chip Information

TRANSISTOR COUNT: 12,990

PROCESS: BiCMOS

Minimal Operating Circuit

ADAPTER

SYSTEM

ADAPTER

DCIN

BATT

LDO

V

AA

GND

IINP

VCTL

ISET

CSSP CSSN

MAX17005

MAX17006

MAX17015

ACOK

BST

DHI

LX

DLO

PGND

CSIP

CSIN

BATT

CC

ACIN

TOP VIEW

BST

DHI

15 14 12 11

DLO

LDO

13

PGND

BATTERY

ISET

IINP

10

CSSN

9

8

CSSP

ACOK

7

BATT

6

ACIN

V

VCTL

CC

LX

16

17

EXPOSED PADDLE

1 2

DCIN

MAX17005

MAX17006

MAX17015

3

CSIP

AGND

45

CSIN

18

AA

19

20

THIN QFN

4mm x 4mm

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

______________________________________________________________________________________ 23

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

24L QFN THIN.EPS

MAX17005/MAX17006/MAX17015

1.2MHz Low-Cost,

High-Performance Chargers

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

Loading...

Loading...