Page 1

General Description

The MAX16807/MAX16808 are integrated, high-efficiency white or RGB LED drivers. They are designed for

LCD backlighting and other LED lighting applications

with multiple strings of LEDs. The MAX16807/

MAX16808’s current-mode PWM controller regulates

the necessary voltage to the LED array. Depending on

the input voltage and LED voltage range, it can be

used with boost or buck-boost (SEPIC) topologies. The

MAX16807/MAX16808 feature an 8V to 26.5V input voltage range. A wide range of adjustable frequency

(20kHz to 1MHz) allows design optimization for efficiency and minimum board space.

The MAX16807/MAX16808 LED drivers include eight

open-drain, constant-current-sinking LED driver outputs

rated for 36V continuous operation. The LED currentcontrol circuitry achieves ±3% current matching among

strings and enables paralleling of outputs for LED string

currents higher than 55mA. The output-enable pin is

used for simultaneous PWM dimming of all output channels. Dimming frequency range is 50Hz to 30kHz and

dimming ratio is up to 5000:1. The constant-current outputs are single resistor programmable and the LED current can be adjusted up to 55mA per output channel.

The MAX16807/MAX16808 operate either in stand-alone

mode or with a microcontroller (µC) using an industrystandard, 4-wire serial interface. The MAX16808 includes

circuitry that automatically detects open-circuit LEDs.

The MAX16807/MAX16808 include overtemperature

protection, operate over the full -40°C to +125°C temperature range, and are available in a thermally

enhanced, 28-pin TSSOP exposed paddle package.

Features

o Eight Constant-Current Output Channels (Up to

55mA Each)

o ±3% Current Matching Among Outputs

o Paralleling Channels Allows Higher Current per

LED String

o Outputs Rated for 36V Continuous Voltage

o Output-Enable Pin for PWM Dimming (Up to 30kHz)

o One Resistor Sets LED Current for All Channels

o Wide Dimming Ratio Up to 5000:1

o Low Current-Sense Reference (300mV) for High

Efficiency

o 8V to 26.5V Input Voltage or Higher with External

Biasing Devices

o Open LED Detection (MAX16808)

o 4-Wire Serial Interface to Control Individual

Output Channels

Applications

LCD White or RGB LED Backlighting:

LCD TVs, Desktop, and Notebook Panels

Automotive Navigation, Heads-Up,

and Infotainment Displays

Industrial and Medical Displays

Ambient, Mood, and Accent Lighting

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

________________________________________________________________

Maxim Integrated Products

1

19-0655; Rev 1; 4/07

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Pin Configurations appear at end of data sheet.

Ordering Information

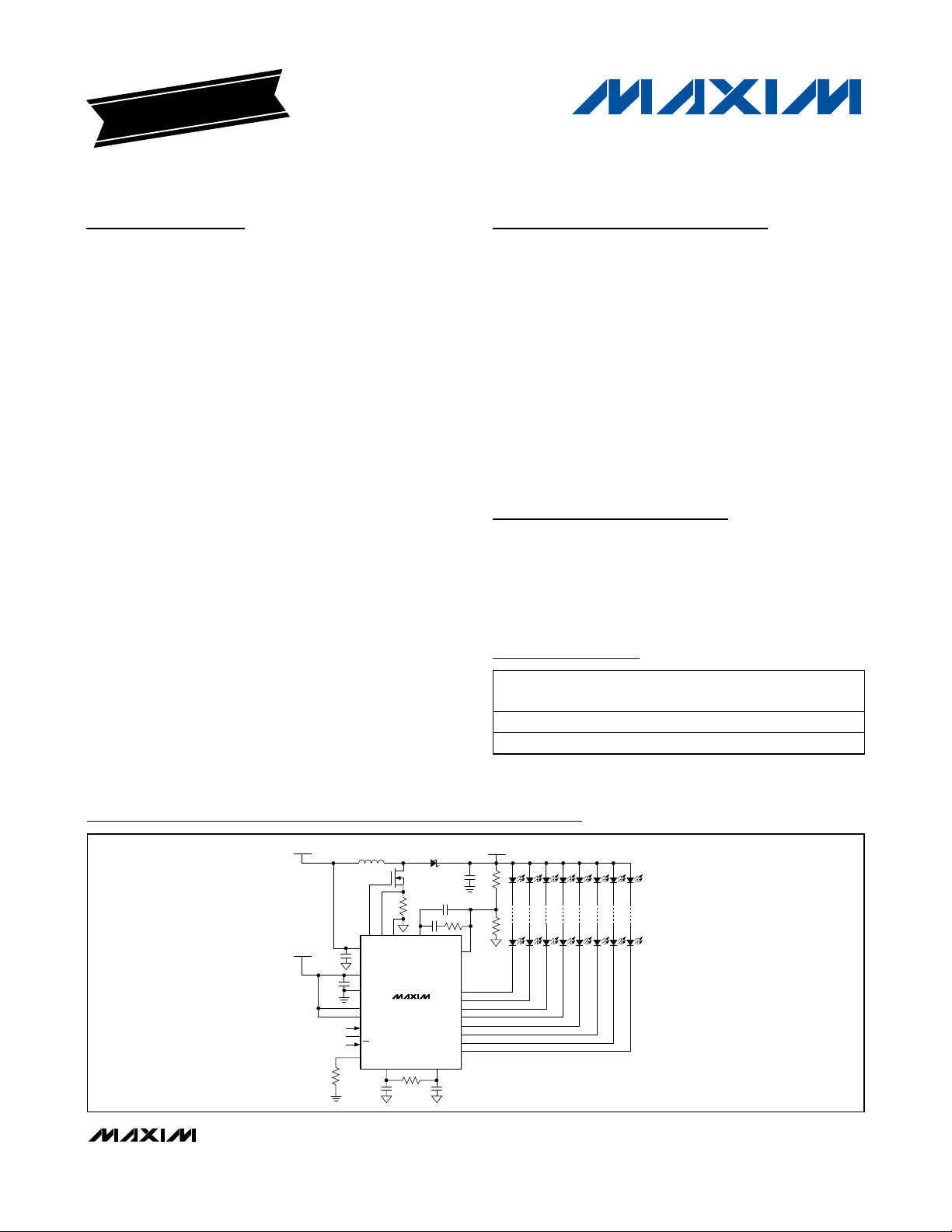

Typical Operating Circuits

+

Denotes a lead-free package.

*

EP = Exposed paddle.

Typical Operating Circuits continued at end of data sheet.

V

3V TO 5.5V

IN

R

SET

C

IN

C

BYP

L

Q

R

OUT CS AGND COMP

V

CC

V+

PGND

MAX16807

LE

MAX16808

DIN

CLK

DOUT

OE

SET

REF

R

C

REF

D

C

CS

C

C1

RTCT

T

C

T

PA R T

M A X1 6 8 0 7 AU I+ - 40°C to + 125°C 28 TS S O P - E P *U 28M E - 1

M A X1 6 8 0 8 AU I+ - 40°C to + 125°C 28 TS S O P - E P *U 28M E - 1

T EM P

R A N G E

PIN - PA C K A G E

V

OUT

C

OUT

R1

C2

R

C1

R2

FB

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

STAND-ALONE OPERATION

LEDs

PK G

C O D E

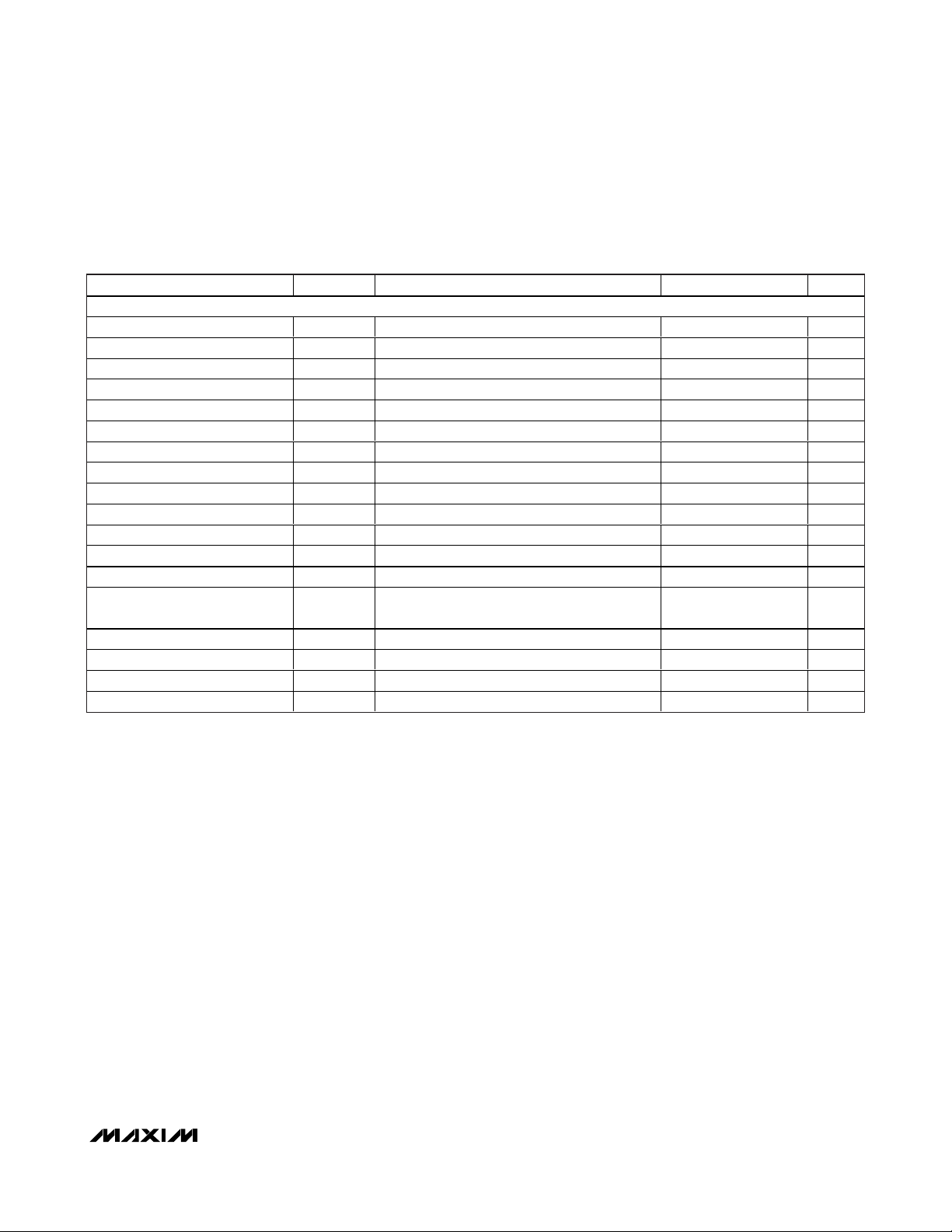

Page 2

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

2 _______________________________________________________________________________________

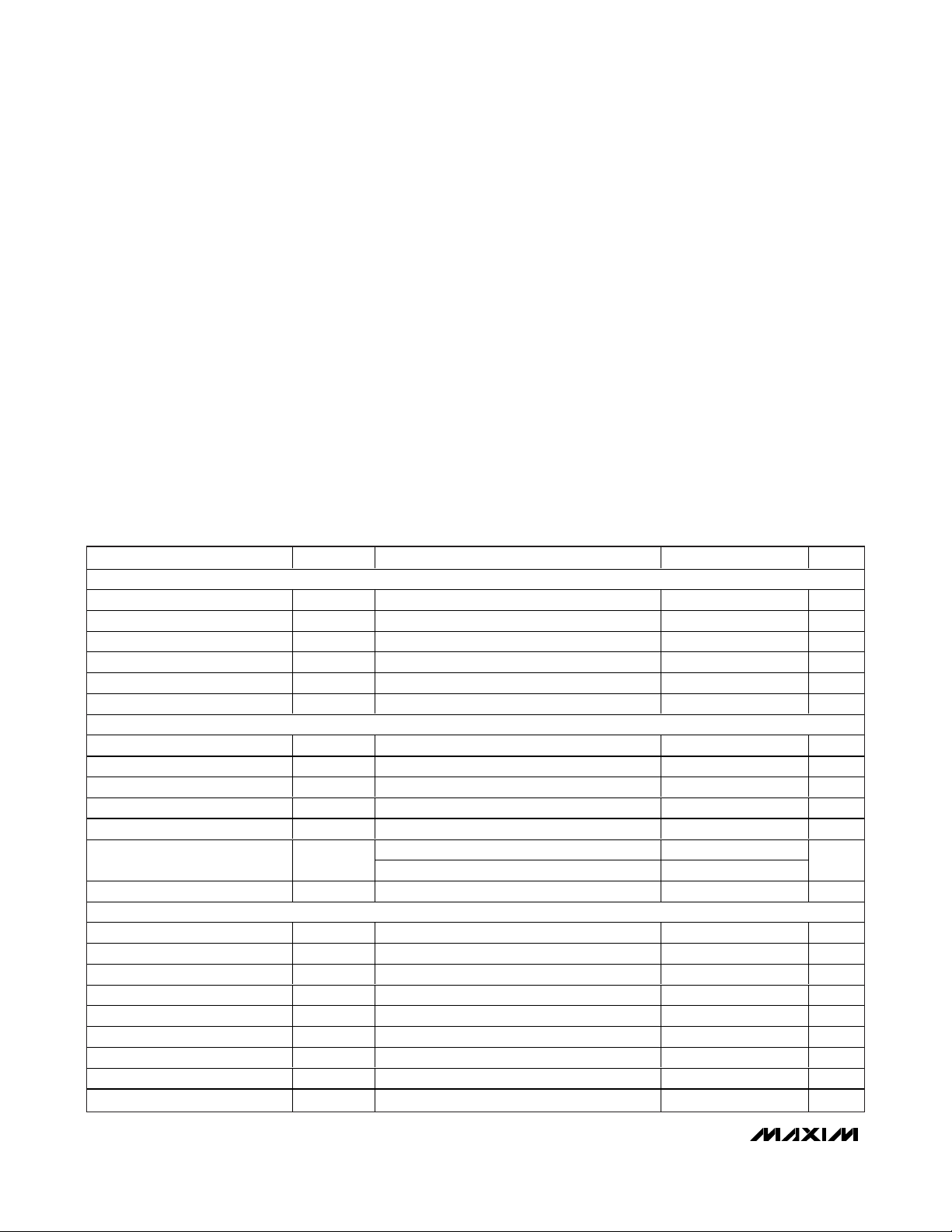

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS (PWM CONTROLLER)

(VCC= +15V, V+ = +3V to +5.5V referenced to PGND, RT= 10kΩ, CT= 3.3nF, REF = open, COMP = open, C

REF

= 0.1µF, VFB= 2V,

CS = AGND, AGND = PGND = 0V; all voltages are measured with respect to AGND, unless otherwise noted. T

J

= TA = -40°C to

+125°C, unless otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCCto AGND..........................................................-0.3V to +30V

Current into V

CC (VCC

> 24V)...........................................±30mA

V+ to PGND..............................................................-0.3V to +6V

OUT to AGND.............................................-0.3V to (V

CC

+ 0.3V)

OUT Current (10µs duration) .................................................±1A

FB, COMP, CS, RTCT, REF to AGND.......................-0.3V to +6V

COMP Sink Current.............................................................10mA

OUT0–OUT7 to PGND............................................-0.3V to +40V

DIN, CLK, LE, OE, SET to PGND..................-0.3V to (V+ + 0.3V)

DOUT Current...................................................................±10mA

OUT0–OUT7 Sink Current...................................................60mA

Total PGND Current ..........................................................480mA

Continuous Power Dissipation (T

A

= +70°C)

28-Pin TSSOP (derate 27mW/°C* above +70°C).......2162mW

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

*

Per JEDEC51 Standard (Multilayer Board).

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

REFERENCE

Output Voltage V

Line Regulation ΔV

Load Regulation ΔV

Total Output-Voltage Variation V

Output Noise Voltage V

Output Short-Circuit Current I

REF

LINE

LOAD

REFT

NOISE

SHORT

OSCILLATOR

Initial Accuracy TJ = +25°C 51 54 57 kHz

Voltage Stability 12V < VCC < 25V 0.2 0.5 %

Temperature Stability 1%

RTCT Ramp Peak-to-Peak 1.7 V

RTCT Ramp Valley 1.1 V

Discharge Current I

Frequency Range f

DIS

OSC

ERROR AMPLIFIER

FB Input Voltage V

Input Bias Current I

Open-Loop Gain A

Unity-Gain Bandwidth f

FB

B(FB)

VOL

GBW

Power-Supply Rejection Ratio PSRR 12V ≤ VCC ≤ 25V 60 80 dB

COMP Sink Current I

COMP Source Current I

COMP Output-Voltage High V

COMP Output-Voltage Low V

SINK

SOURCE

OH

OL

I

= 1mA, T

REF

12V< V

CC

1mA < I

REF

(Note 2) 4.875 5.125 V

10Hz < f < 10kHz 50 µV

V

= 0V 30 180 mA

REF

V

= 2V, TJ = +25°C 7.9 8.3 8.7

RTCT

V

= 2V, -40oC ≤ TJ ≤ +125°C 7.5 8.3 9.0

RTCT

FB shorted to COMP 2.45 2.50 2.55 V

2V ≤ V

COMP

VFB = 2.7V, V

VFB = 2.3V, V

VFB = 2.3V, R

VFB = 2.7V, R

= +25°C 4.95 5 5.05 V

J

< 25V, I

= 1mA 0.4 4 mV

REF

< 20mA 6 50 mV

20 1000 kHz

-0.01 -0.1 µA

≤ 4V 100 dB

1 MHz

= 1.1V 2 6 mA

COMP

= 5V 0.5 1.2 1.8 mA

COMP

= 15kΩ to AGND 5 5.8 V

COMP

COMP

= 15kΩ to V

REF

0.1 1.1 V

mA

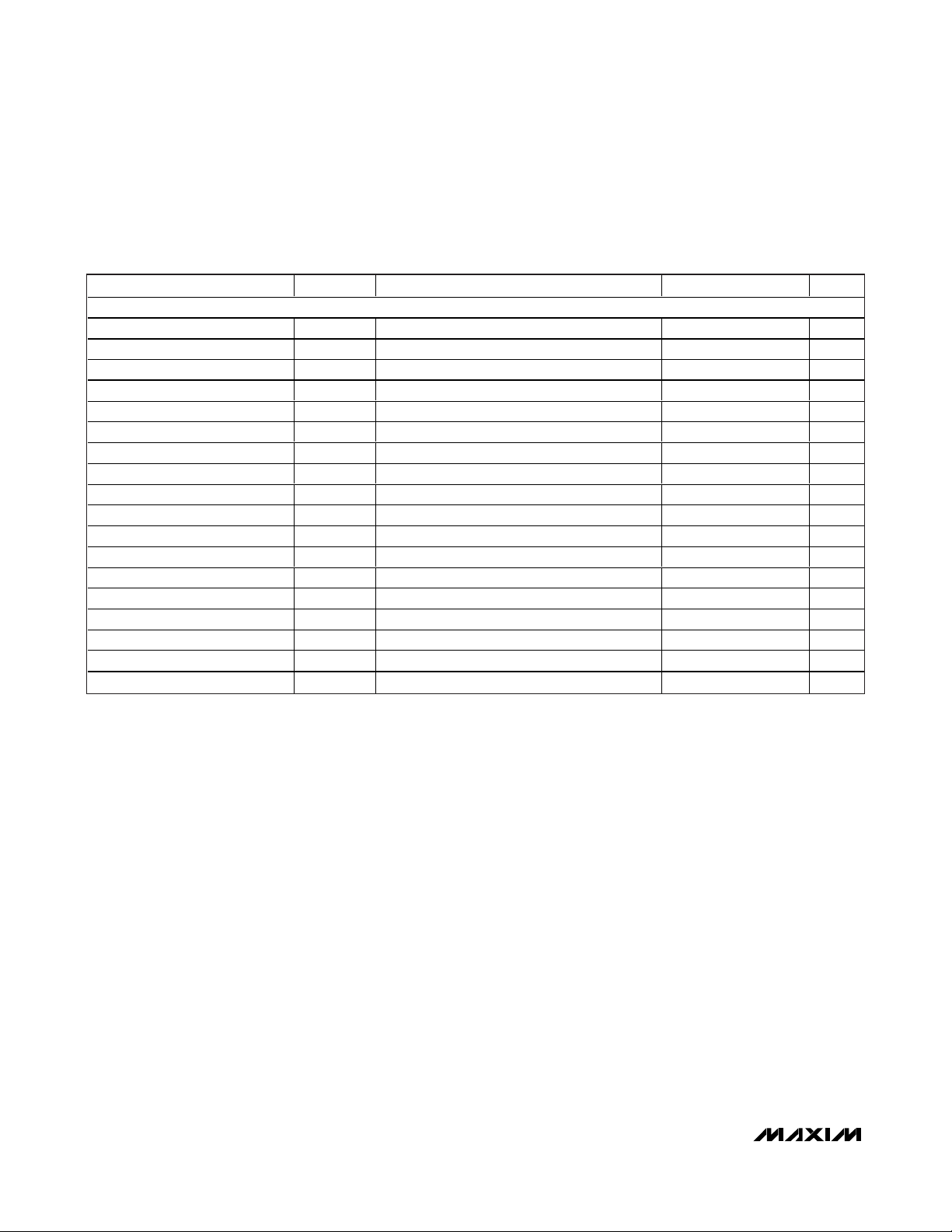

Page 3

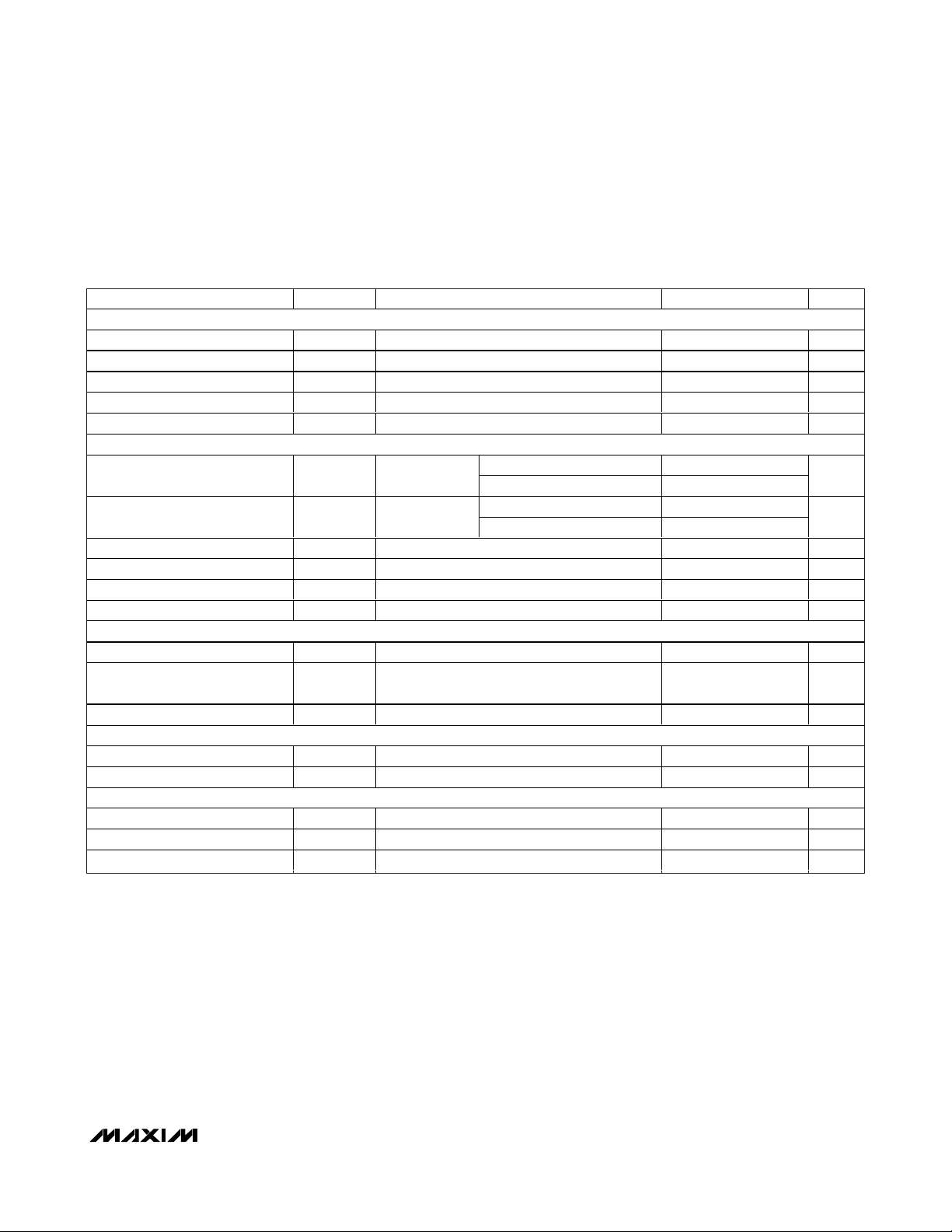

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (PWM CONTROLLER) (continued)

(VCC= +15V, V+ = +3V to +5.5V referenced to PGND, RT= 10kΩ, CT= 3.3nF, REF = open, COMP = open, C

REF

= 0.1µF, VFB= 2V,

CS = AGND, AGND = PGND = 0V; all voltages are measured with respect to AGND, unless otherwise noted. T

J

= TA = -40°C to

+125°C, unless otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CURRENT-SENSE AMPLIFIER

Current-Sense Gain A

Maximum Current-Sense Signal V

Power-Supply Rejection Ratio PSRR 12V ≤ VCC ≤ 25V 70 dB

Current-Sense Input Bias Current I

Current Sense to OUT Delay t

MOSFET DRIVER

OUT Low-Side On-Resistance V

OUT High-Side On-Resistance V

Source Current (Peak) I

Sink Current (Peak) I

Rise Time t

Fall Time t

UNDERVOLTAGE LOCKOUT/STARTUP

Startup Voltage Threshold V

Minimum Operating Voltage After

Turn-On

Undervoltage-Lockout Hysteresis UVLO

PULSE-WIDTH MODULATION (PWM)

Maximum Duty Cycle D

Minimum Duty Cycle D

SUPPLY CURRENT

Startup Supply Current I

Operating Supply Current I

VCC Zener Voltage V

CS

CS_MAX

CS

PWM

RDS_ONL

RDS_ONH

SOURCE

SINK

R

F

CC_START

V

CC_MIN

HYST

MAX

MIN

START

CC

Z

(Notes 3, 4) 2.85 3.00 3.40 V/V

(Note 3) 0.275 0.300 0.325 V

V

= 0V -1 -2.5 µA

COMP

50mV overdrive 60 ns

I

= 200mA

SINK

I

100mA

C

C

C

C

VCC = 7.5V 32 65 µA

VFB = VCS = 0V 3 5 mA

ICC = 25mA 24 26.5 V

=

SOURCE

= 10nF 2 A

LOAD

= 10nF 1 A

LOAD

= 1nF 15 ns

LOAD

= 1nF 22 ns

LOAD

TJ = -40°C to +85°C (Note 2) 4.5 10

= -40°C to +125°C 4.5 12

T

J

TJ = -40°C to +85°C (Note 2) 3.5 7.5

T

= -40°C to +125°C 3.5 10

J

7.98 8.4 8.82 V

7.1 7.6 8.0 V

94.5 96 97.5 %

0.8 V

0%

Ω

Ω

Page 4

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (LED DRIVER)

(V+ = +3V to +5.5V, AGND = PGND = 0V; all voltages are measured with respect to PGND, unless otherwise noted. TA= TJ= -40°C

to +125°C, unless otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Operating Supply Voltage V+ 3.0 5.5 V

Output Voltage V

Standby Current (Interface Idle, All

Output Ports High Impedance)

Standby Current

(Interface Active, All Output Ports

High Impedance)

OUT_

R

OE = V+, DOUT unconnected

R

DIN, LE = PGND or V+, DOUT unconnected

= 360Ω, DIN, LE, CLK = PGND or V+,

SET

= 360Ω, f

SET

= 5MHz, OE = V+,

CLK

36 V

3.6 4.5 mA

3.8 4.8 mA

Supply Current

(Interface Idle, All Output Ports

Active Low)

INTERFACE (DIN, CLK, DOUT, LE, OE)

Input-Voltage High

(DIN, CLK, LE, OE)

Input-Voltage Low

(DIN, CLK, LE, OE)

Hysteresis Voltage

(DIN, CLK, LE, OE)

Input Leakage Current

(DIN, CLK)

OE Pullup Current to V+ I

LE Pulldown Current to PGND I

Output-Voltage High (DOUT) V

Output-Voltage Low (DOUT) V

OUT_ Output Current I

OUT_ Leakage Current OE = V+ 1 µA

OUT_ Fault Detection Threshold

(MAX16808)

I+

V

V

V

HYST

I

LEAK

OE

OUT_

V

OUTTH

R

= 360Ω, OE = PGND, DIN,

SET

LE = V+, DOUT unconnected

IH

IL

V+ = 5.5V, OE = PGND 0.25 1.5 25.0 µA

V+ = 5.5V, LE = V+ 0.25 1.5 25.0 µA

LE

I

OH

I

OL

0oC ≤ TA ≤ +125°C, V

360Ω

TA = -40°C, V

R

V+ = 5.5V, OE = V+ 0.8 V

= 4mA

SOURCE

= 4mA 0.5 V

SINK

= 1V to 2.5V, R

SET

= 360Ω

= 1V to 2.5V,

OUT

OUT

SET

0.7

x V+

-1 +1 µA

V+

- 0.5V

=

46.5 50 53.5

43 57

17 30 mA

0.8 V

0.3

x V+

V

V

V

mA

Page 5

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

_______________________________________________________________________________________ 5

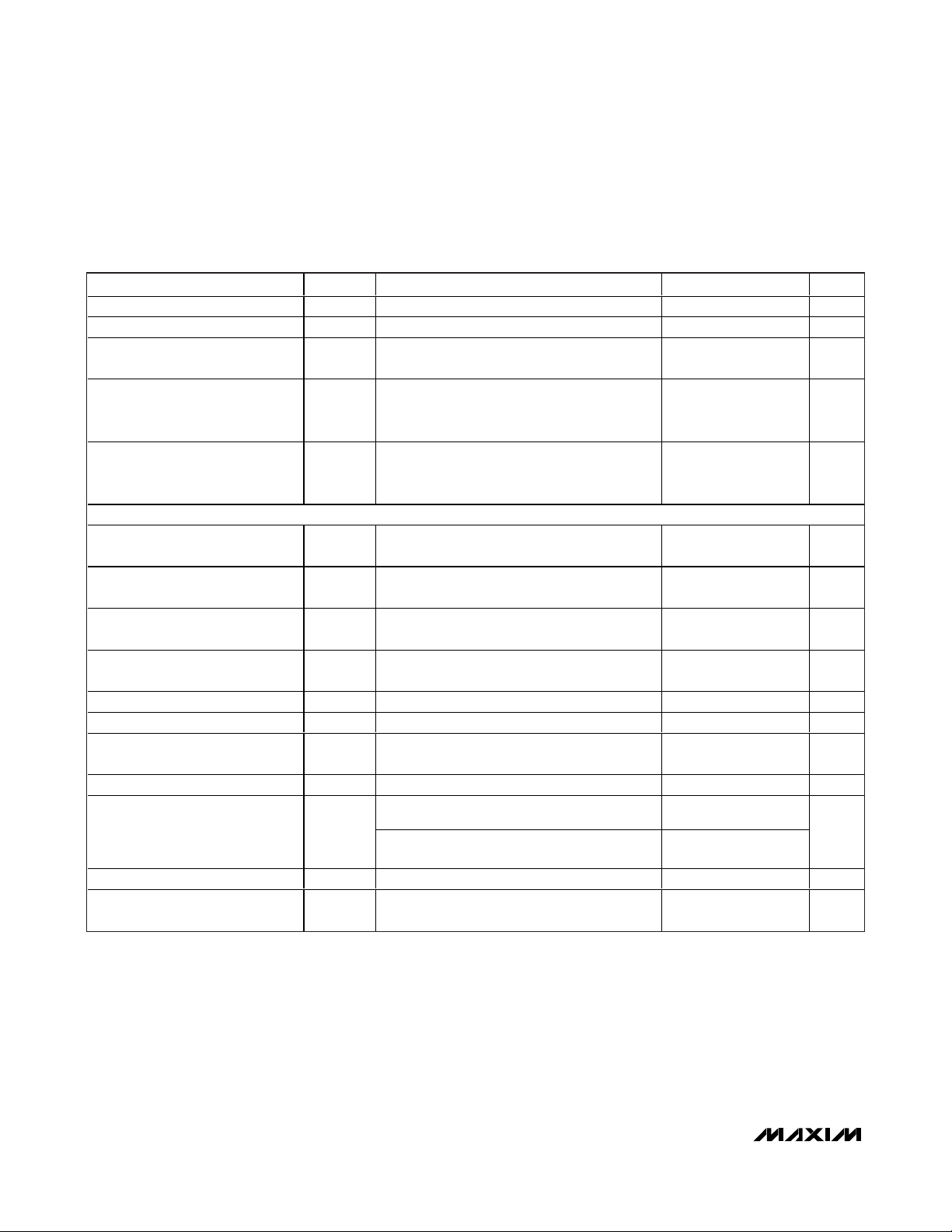

5V TIMING CHARACTERISTICS

(V+ = +4.5V to +5.5V, AGND = PGND = 0V; all voltages are measured with respect to PGND, unless otherwise noted. TA= TJ= -40°C

to +125°C, unless otherwise noted. Typical values are at TA = +25°C.) (Notes 1, 5)

PARAMETER SYMBOL CONDITION MIN TYP MAX UNITS

INTERFACE TIMING CHARACTERISTICS

CLK Clock Period t

CLK Pulse-Width High t

CLK Pulse-Width Low t

DIN Setup Time t

DIN Hold Time t

DOUT Propagation Delay t

DOUT Rise Time t

DOUT Fall Time t

LE Pulse-Width High t

LE Setup Time t

LE Rising to OUT_ Rising Delay t

LE Rising to OUT_ Falling Delay t

CLK Rising to OUT_ Rising Delay t

CLK Rising to OUT_ Falling

Delay

OE Rising to OUT_ Rising Delay t

OE Falling to OUT_ Falling Delay t

OUT_ Turn-On Fall Time t

OUT_ Turn-Off Rise Time t

CH

DH

DO

DR

LW

LRR

LRF

CRR

t

CRF

OER

OEF

CP

CL

DS

DF

LS

C

= 10pF, 20% to 80% 10 ns

DOUT

C

= 10pF, 80% to 20% 10 ns

DOUT

(Note 6) 110 ns

(Note 6) 325 ns

(Note 6) 110 ns

(Note 6) 325 ns

(Note 6) 110 ns

(Note 6) 325 ns

F

R

80% to 20% (Note 6) 210 ns

20% to 80% (Note 6) 130 ns

40 ns

19 ns

19 ns

4ns

8ns

12 50 ns

20 ns

15 ns

Page 6

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

6 _______________________________________________________________________________________

3.3V TIMING CHARACTERISTICS

(V+ = +3V to < +4.5V, AGND = PGND = 0V; all voltages are measured with respect to PGND, unless otherwise noted. TA= TJ= -40°C

to +125°C, unless otherwise noted. Typical values are at TA = +25°C.) (Notes 1, 5)

Note 1: All devices are 100% production tested at TJ= +25°C and +125°C. Limits to -40°C are guaranteed by design.

Note 2: Guaranteed by design, not production tested.

Note 3: Parameter is measured at trip point of latch with V

FB

= 0V.

Note 4: Gain is defined as A = ΔV

COMP

/ ΔVCS, 0.05V ≤ VCS≤ 0.25V.

Note 5: See Figures 3 and 4.

Note 6: A 65Ω pullup resistor is connected from OUT_ to 5.5V. Rising refers to V

OUT_

when current through OUT_ is turned off and

falling refers to V

OUT_

when current through OUT_ is turned on.

PARAMETERS SYMBOL CONDITIONS MIN TYP MAX UNITS

INTERFACE TIMING CHARACTERISTICS

CLK Clock Period t

CLK Pulse-Width High t

CLK Pulse-Width Low t

DIN Setup Time t

DIN Hold Time t

DOUT Propagation Delay t

DOUT Rise Time t

DOUT Fall Time t

LE Pulse-Width High t

LE Setup Time t

LE Rising to OUT_ Rising Delay t

LE Rising to OUT_ Falling Delay t

CLK Rising to OUT_ Rising Delay t

CLK Rising to OUT_ Falling Delay t

OE Rising to OUT_ Rising Delay t

OE Falling to OUT_ Falling Delay t

OUT_ Turn-On Fall Time t

OUT_ Turn-Off Rise Time t

CP

CH

CL

DS

DH

DO

DR

DF

LW

LS

LRR

LRF

CRR

CRF

OER

OEF

F

R

C

DOUT

C

DOUT

(Note 6) 140 ns

(Note 6) 350 ns

(Note 6) 140 ns

(Note 6) 350 ns

(Note 6) 140 ns

(Note 6) 350 ns

80% to 20% (Note 6) 275 ns

20% to 80% (Note 6) 150 ns

= 10pF, 20% to 80% 12 ns

= 10pF, 80% to 20% 12 ns

52 ns

24 ns

24 ns

4ns

8ns

12 70 ns

20 ns

15 ns

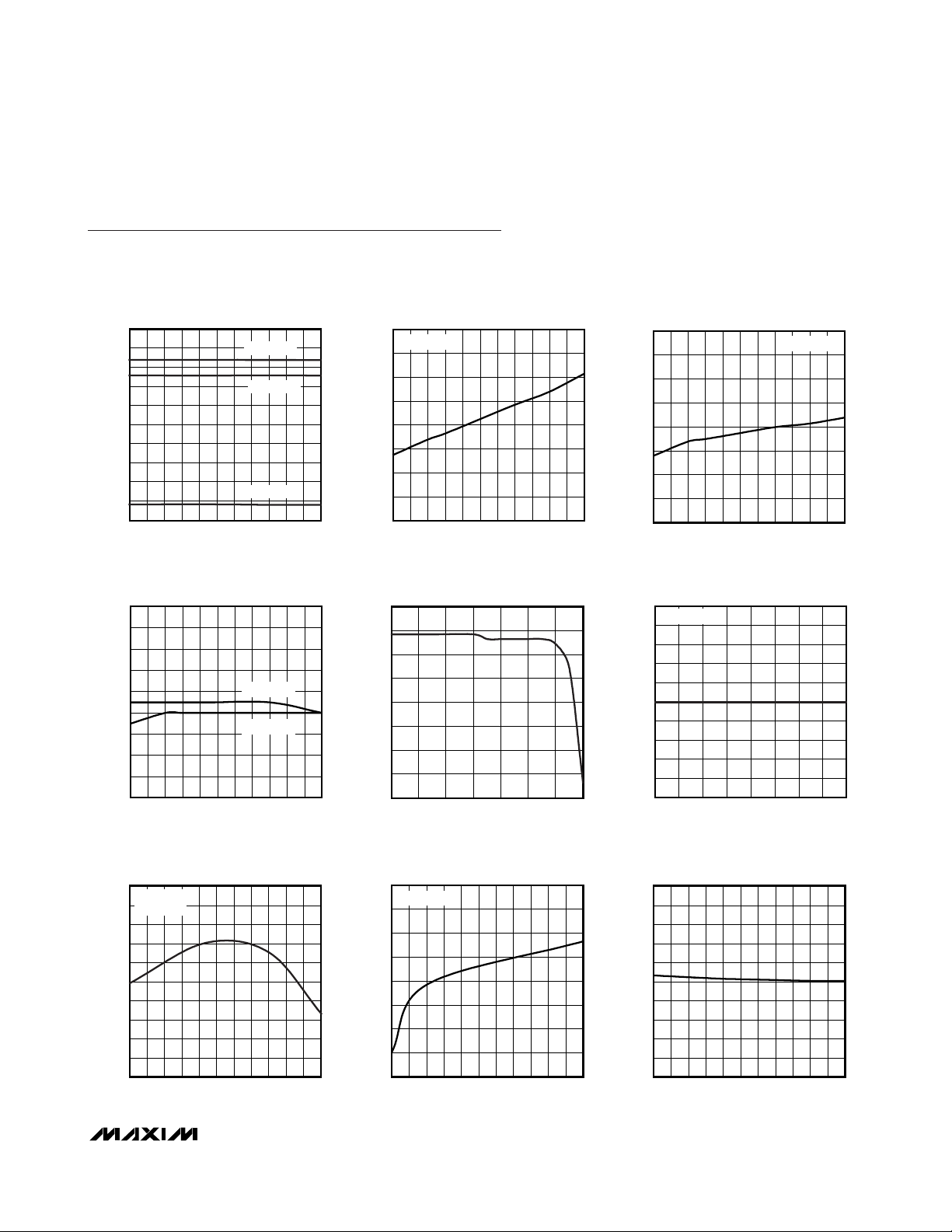

Page 7

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

_______________________________________________________________________________________

7

)

(°C)

V

(V)

Typical Operating Characteristics

(VCC= +15V, V+ = 3V to 5.5V, RT= 10kΩ, CT= 3.3nF, V

REF

= COMP = open, C

REF

= 0.1µF, VFB= 2V, CS = AGND = PGND = 0V.

Typical values are at TA= +25°C, unless otherwise noted.)

BOOTSTRAP UVLO vs. TEMPERATURE

10

9

8

7

6

(V)

5

CC

V

4

3

2

1

0

-40 125

TEMPERATURE (°C)

VCC RISING

VCC FALLING

HYSTERESIS

1109565 80-10 5 20 35 50-25

MAX16807 toc01

41

VCC = 7.5V

39

37

35

(μA)

33

CC

I

31

29

27

25

-40 -10 5 20-25 35 50 9580 11065 125

REFERENCE VOLTAGE

5.08

vs. TEMPERATURE

5.06

5.04

5.02

I

5.00

(V)

REF

V

4.98

4.96

4.94

4.92

4.90

-40 -10 5 20-25 35 50 9580 11065 125

TEMPERATURE (°C)

REF

I

REF

= 1mA

= 20mA

MAX16807 toc04

(V)

V

REF

vs. REFERENCE LOAD CURRENT

5.05

5.00

4.95

4.90

4.85

4.80

4.75

4.70

4.65

02010 30 40 50 60 70

STARTUP CURRENT

vs. TEMPERATURE

TEMPERATURE (°

REFERENCE VOLTAGE

I

(mA)

REF

OPERATING SUPPLY CURRENT

vs. TEMPERATURE AFTER STARTUP

5.1

4.9

MAX16807 toc02

4.7

4.5

(mA)

4.3

CC

I

4.1

3.9

3.7

3.5

-40 -10 5 20-25 35 50 9580 11065 125

C

5.000

I

REF

4.998

4.996

MAX16807 toc05

4.994

4.992

4.990

REF

4.988

4.986

4.984

4.982

4.980

10 14 1612 18 20 22 24 26

= fSW = 300kHz)

(f

OSC

TEMPERATURE

REFERENCE VOLTAGE

vs. SUPPLY VOLTAGE

= 1mA

VCC (V)

CT = 560pF

MAX16807 toc03

MAX16807 toc06

OSCILLATOR FREQUENCY (f

vs. TEMPERATURE

550

RT = 3.65kΩ

540

= 560pF

C

T

530

520

510

500

490

480

OSCILLATOR FREQUENCY (kHz)

470

460

450

-40 -10 5-25 203550658095110125

TEMPERATURE (°C)

OSC

)

OSCILLATOR RT/CT DISCHARGE CURRENT

vs. TEMPERATURE

8.04

V

= 2V

RT/CT

8.02

MAX16807 toc07

8.00

7.98

7.96

7.94

DISCHARGE CURRENT (mA)

T

7.92

/C

T

R

7.90

7.88

-40 -10 5 20-25 35 50 9580 11065 125

TEMPERATURE (°C)

MAX16807 toc08

CURRENT-SENSE TRIP THRESHOLD

vs. TEMPERATURE

0.40

0.38

0.36

0.34

0.32

0.30

0.28

CS THRESHOLD (V)

0.26

0.24

0.22

0.20

-40 -10 5 20-25 35 50 9580 11065 125

TEMPERATURE (°C)

MAX16807 toc09

Page 8

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VCC= +15V, V+ = 3V to 5.5V, RT= 10kΩ, CT= 3.3nF, V

REF

= COMP = open, C

REF

= 0.1µF, VFB= 2V, CS = AGND = PGND = 0V.

Typical values are at TA= +25°C, unless otherwise noted.)

TIMING RESISTANCE

OUT IMPEDANCE vs. TEMPERATURE

vs. OSCILLATOR FREQUENCY

MAX16807 toc10

(Ω)

DS_ON

R

5.0

I

4.8

4.6

4.4

4.2

4.0

3.8

3.6

3.4

3.2

3.0

2.8

2.6

2.4

2.2

2.0

-40 125

1000

CT = 1nF

100

(kΩ)

10

T

R

CT = 10nF

CT = 4.7nF

1

CT = 3.3nF

CT = 2.2nF

0.1

10k 10M

CT = 560pF

CT = 220pF

1M100k

FREQUENCY (Hz)

CT = 100pF

(R

DS_ON

= 100mA

SOURCE

TEMPERATURE (°C)

PMOS DRIVER)

OUT IMPEDANCE vs. TEMPERATURE

(R

I

SINK

DS_ON

= 200mA

TEMPERATURE (°C)

10

9

MAX16807 toc11

1109565 80-10 5 20 35 50-25

8

7

6

(Ω)

5

DS_ON

R

4

3

2

1

0

-40 -10 5 20-25 35 50 9580 11065 125

NMOS DRIVER)

MAX16807 toc12

PROPAGATION DELAY FROM CURRENT-LIMIT

COMPARATOR TO OUT vs. TEMPERATURE

100

90

80

70

60

50

40

30

PROPAGATION DELAY (ns)

20

10

0

-40 -10 5 20-25 35 50 9580 11065 125

TEMPERATURE (°C)

MAX16807 toc13

ERROR-AMPLIFIER OPEN-LOOP GAIN

140

120

100

80

60

GAIN (dB)

40

20

0

-20

0.01

SUPPLY CURRENT

vs. OSCILLATOR FREQUENCY

7.0

CT = 100pF

6.5

6.0

5.5

5.0

(mA)

4.5

CC

I

4.0

3.5

3.0

2.5

2.0

20 220 320 420120 520 620 720 920820 1020

TA = +125°C

TA = -40°C

FREQUENCY (kHz)

AND PHASE vs. FREQUENCY

GAIN

FREQUENCY (Hz)

MAX16807 toc14

PHASE

1M100k1k 10k10 1001

SUPPLY CURRENT vs. SUPPLY VOLTAGE

(INTERFACE IDLE, ALL OUTPUTS OFF, R

2.00

MAX16807 toc16

1.95

1.90

SUPPLY CURRENT (mA)

1.85

1.80

COMP VOLTAGE LEVEL TO TURN

OFF DEVICE vs. TEMPERATURE

10

-15

-40

-65

-90

-115

-140

-165

-190

100M

10M

TA = +125°C

3.0 5.5

SUPPLY VOLTAGE (V)

2.3

2.2

2.1

2.0

(V)

1.9

COMP

V

1.8

PHASE (DEGREES)

1.7

1.6

1.5

TA = +85°C

TA = -40°C

-40 -10 5 20-25 35 50 9580 11065 125

TEMPERATURE (°C)

= 720Ω)

SET

TA = +25°C

5.04.54.03.5

VCC = 15V

MAX16807 toc15

MAX16807 toc17

Page 9

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

_______________________________________________________________________________________

9

_______________________________________________________________________________________

9

Typical Operating Characteristics (continued)

(VCC= +15V, V+ = 3V to 5.5V, RT= 10kΩ, CT= 3.3nF, V

REF

= COMP = open, C

REF

= 0.1µF, VFB= 2V, CS = AGND = PGND = 0V.

Typical values are at TA= +25°C, unless otherwise noted.)

SUPPLY CURRENT vs. SUPPLY VOLTAGE

(INTERFACE IDLE, ALL OUTPUTS OFF, R

3.70

TA = +125°C

3.65

3.60

SUPPLY CURRENT (mA)

3.55

3.50

3.0 5.5

TA =-40°C

SUPPLY VOLTAGE (V)

TA = +85°C

SUPPLY CURRENT vs. SUPPLY VOLTAGE

(INTERFACE IDLE, ALL OUTPUTS ON, R

25

22

19

16

SUPPLY CURRENT (mA)

13

10

3.0 4.03.5 4.5 5.0 5.5

TA = +125°C

TA = -40°C

SUPPLY VOLTAGE (V)

TA = +85°C

TA = +25°C

= 360Ω)

SET

TA = +25°C

5.04.54.03.5

SET

= 360Ω)

MAX16807 toc18

MAX16807 toc20

SUPPLY CURRENT vs. SUPPLY VOLTAGE

(INTERFACE IDLE, ALL OUTPUTS ON, R

20

TA = +125°C

17

14

11

SUPPLY CURRENT (mA)

8

5

3.0 4.03.5 4.5 5.0 5.5

TA = -40°C

SUPPLY VOLTAGE (V)

TA = +85°C

TA = +25°C

= 720Ω)

SET

MAX16807 toc19

OUT_ CURRENT vs. OUT_ VOLTAGE

= 720Ω, V+ = 3.3V)

(R

30

25

20

15

10

OUT_ CURRENT (mA)

5

0

0 1.0 1.50.5 2.0 2.5 3.0

SET

MAX16807 toc21

TA = -40°C

TA = +25°C

TA = +85°C

TA = +125°C

OUT_ VOLTAGE (V)

OUT_ CURRENT vs. OUT_ VOLTAGE

= 360Ω, V+ = 3.3V)

(R

60

50

40

30

20

OUT_ CURRENT (mA)

10

0

SET

MAX16807 toc22

TA = -40°C

TA = +25°C

TA = +85°C

TA = +125°C

0 1.0 1.50.5 2.0 2.5 3.0

OUT_ VOLTAGE (V)

OUT_ CURRENT vs. OUT_ VOLTAGE

= 720Ω, V+ = 5.0V)

(R

30

25

20

15

10

OUT_ CURRENT (mA)

5

0

0 1.0 1.50.5 2.0 2.5 3.0

SET

TA = -40°C

TA = +25°C

TA = +85°C

TA = +125°C

OUT_ VOLTAGE (V)

MAX16807 toc23

Page 10

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VCC= +15V, V+ = 3V to 5.5V, RT= 10kΩ, CT= 3.3nF, V

REF

= COMP = open, C

REF

= 0.1µF, VFB= 2V, CS = AGND = PGND = 0V.

Typical values are at TA= +25°C, unless otherwise noted.)

48

49

50

51

52

3.0 4.03.5 4.5 5.0 5.5

OUT_ CURRENT vs. SUPPLY VOLTAGE V+

(R

SET

= 360Ω, V

OUT

= 2V)

MAX16807 toc26

SUPPLY VOLTAGE (V)

OUT_ CURRENT (mA)

TA = +125°C

TA = -40°C

TA = +25°C

TA = +85°C

OUT_ CURRENT vs. SET RESISTANCE

(V+ = 5.0V)

MAX16807 toc27

R

SET

(kΩ)

OUT_ CURRENT (mA)

4321

10

20

30

40

50

0

05

0

20

10

40

30

50

60

OUT_ CURRENT vs. OUT_ VOLTAGE

(R

SET

= 360Ω, V+ = 5.0V)

MAX16807 toc24

OUT_ VOLTAGE (V)

OUT_ CURRENT (mA)

0 1.0 1.50.5 2.0 2.5 3.0

TA = +25°C

TA = -40°C

TA = +85°C

TA = +125°C

24.0

24.5

25.0

25.5

26.0

3.0 4.03.5 4.5 5.0 5.5

OUT_ CURRENT vs. SUPPLY VOLTAGE V+

(R

SET

= 720Ω, V

OUT

= 2V)

MAX16807 toc25

SUPPLY VOLTAGE (V)

OUT_ CURRENT (mA)

TA = +125°C

TA = -40°C

TA = +25°C

TA = +85°C

Page 11

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

______________________________________________________________________________________ 11

Detailed Description

The MAX16807/MAX16808 LED drivers include an

internal switch-mode controller that can be used as

boost or buck-boost (SEPIC) converters to generate the

voltage necessary to drive the multiple strings of LEDs.

These devices incorporate an integrated low-side driver, a programmable oscillator (20kHz to 1MHz), an

error amplifier, a low-voltage (300mV) current sense for

higher efficiency, and a 5V reference to power up

external circuitry (see Figures 1a, 1b, and 1c).

The MAX16807/MAX16808 LED drivers include a 4-wire

serial interface and a current-mode PWM controller to

generate the necessary voltage for driving eight opendrain, constant-current-sinking output ports. The drivers

use current-sensing feedback circuitry (not simple current mirrors) to ensure very small current variations over

the full allowed range of output voltage (see the

Typical

Operating Characteristics

). The 4-wire serial interface

comprises an 8-bit shift register and an 8-bit transparent latch. The shift register is written through a clock

input, CLK, and a data input, DIN, and the data propagates to a data output, DOUT. The data output allows

multiple drivers to be cascaded and operated together.

The contents of the 8-bit shift register are loaded into

the transparent latch through a latch-enable input, LE.

The latch is transparent to the shift register outputs

when high and latches the current state on the falling

edge of LE. Each driver output is an open-drain, constant-current sink that should be connected to the cath-

Pin Description

PIN NAME FUNCTION

1, 13, 28 N.C. No Connection. Not internally connected. Leave unconnected.

2 AGND Analog Ground

3 OUT MOSFET Driver Output OUT. Connects to the gate of the external n-channel MOSFET.

4V

5 REF 5V Reference Output. Bypass REF to AGND with a 0.1µF ceramic capacitor.

6–9 OUT4–OUT7 LED Driver Outputs. OUT4–OUT7 are open-drain, constant-current-sinking outputs rated for 36V.

10 OE

11 DOUT

12 SET LED Current Setting. Connect R

14 V+ LED Driver Positive Supply Voltage. Bypass V+ to PGND with a 0.1µF ceramic capacitor.

15, 16 PGND Power Ground

17 DIN Serial-Data Input

18 CLK Serial-Clock Input

19 LE

20–23 OUT0–OUT3 LED Driver Outputs. OUT0–OUT3 are open-drain, constant-current-sinking outputs rated for 36V.

24 COMP Error-Amplifier Output

25 FB Error-Amplifier Inverting Input

26 CS PWM Controller Current-Sense Input

27 RTCT

—EP

CC

Power-Supply Input. Bypass VCC to AGND with a 0.1µF ceramic capacitor or a parallel combination

of a 0.1µF and a higher value ceramic capacitor.

Active-Low Output Enable Input. Drive OE low to PGND to enable the OUT0–OUT7. Drive OE high to

disable OUT0–OUT7.

Serial-Data Output. Data is clocked out of the 8-bit internal shift register to DOUT on CLK’s rising

edge.

from SET to PGND to set the LED current.

SET

Latch-Enable Input. Data is loaded transparently from the internal shift register(s) to the output

latch(es) while LE is high. Data is latched into the output latch(es) on LE’s falling edge, and retained

while LE is low.

PWM Controller Timing Resistor/Capacitor Connection. A resistor R

capacitor C

Exposed Paddle. Connect to the ground plane for improved power dissipation. Do not use as the

only ground connection for the part.

from RTCT to AGND set the oscillator frequency.

T

from RTCT to REF and a

T

Page 12

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

12 ______________________________________________________________________________________

ode of a string of LEDs connected in series. The constant-current capability is up to 55mA per output, set

for all 8 outputs by an external resistor, R

SET

. The

devices can operate in a stand-alone mode (see the

Typical Operating Circuits

.)

The MAX16808 includes circuitry that automatically

detects open-circuit LEDs. Fault status is loaded into the

serial-interface shift register when LE goes high and is

automatically shifted out on DOUT when the next data

transmission is shifted in. The number of channels can be

expanded by using the MAX6970 and MAX6971 family in

conjunction with the MAX16807 and MAX16808.

Figure 1a. Internal Block Diagram (MAX16807)

AGND

CS

FB

COMP

MAX16807

VEA

REFERENCE

2.5V

DELAY

300mV

REG_OK

I

LIM

PREREG

2R

5V

R

THERMAL

SHUTDOWN

CPWM

CLK

UVLO

EN_REF

BG

SNS

OSC

V

DD

5V REG

VOLTAGE

DIVIDER

Q

VOLTAGE-

DIVIDER

26.5V

V

CC

S

Q

R

V

REF

OUT

RTCT

CC

CLK

DIN

LE

OE

THERMAL

SHUTDOWN

D0 D1 D2 D3 D4 D5 D6 D7

D0 D1 D2 D3 D4 D5 D6 D7

D0 D1 D2 D3 D4 D5 D6 D7

OUT0

SERIAL-TO-PARALLEL SHIFT REGISTER

CONSTANT-CURRENT SINK

OUT1

OUT2

OUTPUT LATCHES

OUT3

OUT4

OUT5

OUT6

OUT7

POWER-ON

RESET

V+

CURRENT

REFERENCE

PGND

DOUT

V+

SET

Page 13

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

______________________________________________________________________________________ 13

Figure 1b. Internal Block Diagram (MAX16808)

AGND

COMP

CLK

CLK

UVLO

EN_REF

BG

SNS

OSC

V

DD

5V REG

VOLTAGE

DIVIDER

Q

VOLTAGE-

DIVIDER

V

CC

26.5V

REF

V

CC

S

Q

R

OUT

RTCT

MAX16808

REFERENCE

2.5V

DELAY

300mV

CS

FB

VEA

REG_OK

I

LIM

PREREG

5V

THERMAL

SHUTDOWN

CPWM

2R

R

SERIAL-TO-PARALLEL SHIFT REGISTER

DIN

LE

OE

THERMAL

SHUTDOWN

D0 D1 D2 D3 D4 D5 D6 D7

D0 D1 D2 D3 D4 D5 D6 D7

D0 D1 D2 D3 D4 D5 D6 D7

OUT0

OUT1

OUTPUT LATCHES

CONSTANT-CURRENT SINK

OPEN LED FAULT DETECTION

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

POWER-ON

RESET

V+

CURRENT

REFERENCE

PGND

DOUT

V+

SET

Page 14

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

14 ______________________________________________________________________________________

Switch-Mode Controller

Current-Mode Control Loop

The advantages of current-mode control over voltagemode control are twofold. First, there is the feed-forward characteristic brought on by the controller’s ability

to adjust for variations in the input voltage on a cycleby-cycle basis. Second, the stability requirements of

the current-mode controller are reduced to that of a single pole system unlike the double pole in the voltagemode control scheme. The MAX16807/MAX16808 use

a current-mode control loop where the output of the

error amplifier is compared to the current-sense voltage

(VCS). When the current-sense signal is lower than the

inverting input of the CPWM comparator, the output of

the comparator is low and the switch is turned on at

each clock pulse. When the current-sense signal is

higher than the inverting input of the CPWM comparator, the output is high and the switch is turned off.

Undervoltage Lockout (UVLO)

The turn-on supply voltage for the MAX16807/

MAX16808 is 8.4V (typ). Once V

CC

reaches 8.4V, the

reference powers up. There is a 0.8V of hysteresis from

the turn-on voltage to the UVLO threshold. Once V

CC

reaches 8.4V, the MAX16807/MAX16808 operate with

V

CC

down to 7.6V (typ). Once VCCgoes below 7.6V,

the device is in UVLO. When in UVLO, the quiescent

supply current into VCCfalls back to 32µA (typ), and

OUT and REF are pulled low.

MOSFET Driver

OUT drives an external n-channel MOSFET and swings

from AGND to VCC. Ensure that VCCremains below the

absolute maximum VGSrating of the external MOSFET.

OUT is a push-pull output with the on-resistance of the

pMOS typically 3.5Ω and the on-resistance of the

nMOS typically 4.5Ω. The driver can source 2A and

sink 1A typically. This allows for the MAX16807/

MAX16808 to quickly turn on and off high gate-charge

MOSFETs. Bypass V

CC

with one or more 0.1µF ceramic

capacitors to AGND, placed close to the V

CC

pin. The

average current sourced to drive the external MOSFET

depends on the total gate charge (QG) and operating

frequency of the converter. The power dissipation in the

MAX16807/MAX16808 is a function of the average output drive current (I

DRIVE

). Use the following equation to

calculate the power dissipation in the device due to

I

DRIVE

:

I

DRIVE

= (QGx fSW)

PD = (I

DRIVE

+ ICC) x V

CC

where ICCis the operating supply current. See the

Typical Operating Characteristics

for the operating

supply current at a given frequency.

Error Amplifier

The MAX16807/MAX16808 include an internal error

amplifier. The inverting input is at FB and the noninverting input is internally connected to a 2.5V reference.

Set the output voltage using a resistive divider between

output of the converter V

OUT

, FB, and AGND. Use the

following formula to set the output voltage:

where V

FB

= 2.5V.

Oscillator

The oscillator frequency is programmable using an

external capacitor and a resistor at RTCT (see RTand

CTin the

Typical Operating Circuits

). RTis connected

from RTCT to the 5V reference (REF), and CTis connected from RTCT to AGND. REF charges CTthrough

RTuntil its voltage reaches 2.8V. CTthen discharges

through an 8.3mA internal current sink until CT’s voltage

reaches 1.1V, at which time CTis allowed to charge

through RTagain. The oscillator’s period is the sum of

the charge and discharge times of CT. Calculate the

charge time as follows:

tC= 0.57 x RTx C

T

where tCis in seconds, RT in ohms (Ω), and CTin

Farads (F).

The discharge time is then:

tD= (RTx CTx 1000) / [(4.88 x RT) - (1.8 x 1000)]

Figure 1c. OUT_ Driver Internal Diagram

V+

68W/L

1.23

R

1.23V

EST

W/L

995R

R

PGNDSET

OUT_

R

1

⎞

1

xV

⎟

⎠

R

2

V

OUT FB

⎛

=+

⎜

⎝

Page 15

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

______________________________________________________________________________________ 15

where tDis in seconds, RT in ohms (Ω), and CTin

Farads (F).

The oscillator frequency is then:

Reference Output

REF is a 5V reference output that can source 20mA.

Bypass REF to AGND with a 0.1µF capacitor.

Current Limit

The MAX16807/MAX16808 include a fast current-limit

comparator to terminate the on cycle during an overload or a fault condition. The current-sense resistor,

RCS, connected between the source of the external

MOSFET and AGND, sets the current limit. The CS

input has a voltage trip level (VCS) of 0.3V. Use the following equation to calculate RCS:

I

P-P

is the peak current that flows through the MOSFET.

When the voltage produced by this current (through the

current-sense resistor) exceeds the current-limit comparator threshold, the MOSFET driver (OUT) turns the

switch off within 60ns. In most cases, a small RC filter is

required to filter out the leading-edge spike on the sense

waveform. Set the time constant of the RC filter at 50ns.

Buck-Boost (SEPIC) Operation

Figure 2 shows a buck-boost application circuit using

the MAX16807/MAX16808 in a stand-alone mode of

operation. SEPIC topology is necessary when the total

forward voltage of the LEDs in a string is such that

V

OUT

can be below or above VIN.

Figure 2. Buck-Boost (SEPIC) Configuration

f

OSC

1

tt

=+

()

CD

V

IN

L1

C1

Q

D

C

L2

V

=

CS

I

PP

−

R

CS

V

OUT

OUT

R1

LEDs

OUT CS AGND COMP

V

CC

V+

PGND

DIN

LE

CLK

DOUT

OE

SET

REF

C

REF

3V TO 5.5V

C

IN

C

BYP

EXTERNAL

CLOCK INPUT

EXTERNAL

DIM INPUT

R

SET

R

CS

MAX16807

MAX16808

R

T

C

C2

C

C1

R

C1

R2

FB

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

RTCT

C

T

Page 16

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

16 ______________________________________________________________________________________

LED Driver

4-Wire Interface

The MAX16807/MAX16808 also operate in a standalone mode (see the

Typical Operating Circuits

). For

use with a microcontroller, the MAX16807/MAX16808

feature a 4-wire serial interface using DIN, CLK, LE, OE

inputs and DOUT as a data output. This interface is

used to write the LED channels’ data to the MAX16807/

MAX16808. The serial-interface data word length is 8

bits, D0–D7. See Figure 3.

The functions of the five interface pins are as follows:

DIN is the serial-data input, and must be stable when it

is sampled on the rising edge of CLK. Data is shifted in

MSB first. This means that data bit D7 is clocked in first,

followed by 7 more data bits, finishing with the LSB, D0.

CLK is the serial-clock input that shifts data at DIN into

the MAX16807/MAX16808’s 8-bit shift register on its rising edge.

LE is the latch enable input of the MAX16807/

MAX16808 that transfers data from the 8-bit shift register to its 8-bit output latch (transparent latch). The data

is latched on the falling edge of LE (Figure 4). The

fourth input (OE) provides output-enable control of the

output drivers. When OE is driven high, the outputs

(OUT0–OUT7) are forced to high impedance without

altering the contents of the output latches. Driving OE

low enables the outputs to follow the state of the output

latches. OE is independent of the operation of the serial

interface operation. Data can be shifted into the serialinterface shift register and latched, regardless of the

state of OE. DOUT is the serial-data output that shifts

data out from the MAX16807/MAX16808’s 8-bit shift

register on the rising edge of CLK. Data at DIN propagates through the shift register and appears at DOUT

eight clock cycles later. Table 1 shows the 4-wire serial-interface truth table.

Table 1. 4-Wire Serial-Interface Truth Table

L = Low Logic Level

H = High Logic Level

X = Don’t Care

P = Present State (Shift Register)

R = Previous State (Latched)

SERIAL

DATA

INPUT

DIN

CLOCK

INPUT

SHIFT REGISTER CONTENTS

CLK D0 D1 D2 … Dn-1 Dn LE D0 D1 D2 … Dn-1 Dn OE D0 D1 D2 … Dn-1 Dn

LOAD

INPUT

LATCH CONTENTS

BLANKING

INPUT

OUTPUT CONTENTS

CURRENT AT OUT_

H H R0 R1 … Rn-2 Rn-1

L L R0 R1 … Rn-2 Rn-1

X R0 R1 R2 … Rn-1 Rn

X X X … X X L R0 R1 R2 … Rn-1 Rn

P0 P1 P2 … Pn-1 Pn H P0 P1 P2 … Pn-1 Pn L P0 P1 P2 … Pn-1 Pn

XXX…X X H LLL… L L

Page 17

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

______________________________________________________________________________________ 17

LED Fault Detection (MAX16808)

The MAX16808 includes circuitry that detects open-circuit LEDs automatically. An open-circuit fault occurs

when an output is sinking current less than approximately 50% of the programmed current flows. Open circuits are checked just after the falling edge of OE. The

fault data is latched on the rising edge of LE and is

shifted out when new LED data is loaded into the output latches from the shift register. If one or more output

ports are detected with an open-circuit fault, the D6

and D5 bits of DOUT go high. If no open-circuit faults

are detected, D6 and D5 are set to low. The data in the

other 6 bit positions in DOUT are not altered. Fault status is shifted out on DOUT for the first two rising edges

of the clock after the falling edge of LE (see Figure 5).

LE is normally taken high after all 8 bits of new LED

Figure 3. 4-Wire Serial-Interface Timing Diagram

Figure 4. LE and CLK to OUT_ Timing

Figure 5. Fault Timing

CLK

DOUT

DIN

LE

t

t

CL

CH

t

DH

t

DS

D7

t

OE

OEW

t

CP

D0

t

DO

t

LW

t

LS

D7

OUT_

LE

OUT_

LE

OUT_

CLK

OUT_

t

LRF

t

LRR

t

CRF

t

OEF

t

f

80%

20%

t

OER

t

r

OE

CLK

OUT_

t

CRR

LE

CLK

DOUT

D5

D6

D7

FAULT STATUS BITS

D4

Page 18

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

18 ______________________________________________________________________________________

data have been clocked into the shift register(s), and

then DOUT outputs data bit D7. A typical fault-detecting application tests all the shifted out data. Bits D0–D4

and D7 are checked against the originally transmitted

data to check data-link integrity. Bits D5 and D6 are

checked first to see that they contain the same data

(validating the status), and second, whether faults are

reported or not by the actual logic level.

Selecting External Component

R

SET

to Set LED Output Current

The MAX16807/MAX16808 use an external resistor,

R

SET

, to set the LED current for outputs OUT0–OUT7.

The minimum allowed value of R

SET

is 330Ω, which

sets the output currents to 55mA. The maximum

allowed value of R

SET

is 5kΩ (I

OUT_

= 3.6mA) and max-

imum allowed capacitance at SET is 100pF.

Use the following formula to set the output current:

where I

OUT_

is the desired output current in milliamps

and the value for R

SET

is in ohms.

Overtemperature Cutoff

The MAX16807/MAX16808 contain an internal temperature sensor that turns off all outputs when the die temperature exceeds +165°C. The outputs are enabled again

when the die temperature drops below +140°C. Register

contents are not affected, so when a driver is overdissipating, the external symptom is the load LEDs cycling on

and off as the driver repeatedly overheats and cools,

alternately turning itself off and then back on again.

Stand-Alone Operation

In stand-alone operation, the MAX16807/MAX16808

does not use the 4-wire interface (see the

Typical

Operating Circuits

). Connect DIN and LE to V+ provide

at least 8 external clock pulses to CLK to enable 8 outputs. This startup pulse sequence can be provided

either using an external clock or the PWM signal. The

external clock can also be generated using the signal

at RTCT and an external comparator.

LED Dimming

PWM Dimming

All the output channels can be dimmed simultaneously

by applying a PWM signal (50Hz to 30kHz) to OE. This

allows for a wide range of dimming up to a 5000:1 ratio.

Each channel can be independently turned on and off

using a 4-wire serial interface. The dimming is proportional to the PWM duty cycle.

LED Current Amplitude Adjustment

Using an analog or digital potentiometer as R

SET

allows

for LED current amplitude adjustment and linear dimming.

Computing Power Dissipation

Use the following equation to estimate the upper limit

power dissipation (PD) for the MAX16807/MAX16808:

where:

V+ = supply voltage

I+ = operating supply current

DUTY = PWM duty cycle applied to OE

V

OUTi

= MAX16807/MAX16808 port output voltage

when driving load LED(s)

I

OUTi

= LED drive current programmed by R

SET

PD = power dissipation.

PCB Layout Guidelines

Careful PCB layout is critical to achieve low switching

losses and clean, stable operation. Use a multilayer

board whenever possible for better noise immunity.

Protect sensitive analog grounds by using a star

ground configuration. Minimize ground noise by connecting AGND, PGND, the input bypass-capacitor

ground lead, and the output-filter ground lead to a single point (star ground configuration). Also, minimize

trace lengths to reduce stray capacitance, trace resistance, and radiated noise. The trace between the output voltage-divider and the FB pin must be kept short,

as well as the trace between AGND and PGND.

R

=

SET

18 000

I

,

_

OUT

i

i

∑

==0

7

OUTi CC CC

OUTi

⎤

⎥

⎥

⎦

PD DUTY x V x I V x I V x I

( ) ( )

=+++

⎡

⎢

⎢

⎣

+

Page 19

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

______________________________________________________________________________________ 19

Pin Configuration

Chip Information

PROCESS: BiCMOS

TOP VIEW

N.C.

AGND

OUT

OUT4

+

1

2

3

4

MAX16807

CC

MAX16808

REF

5

6

7

TSSOP-EP

28

N.C.

27

RTCT

26

CS

25

FBV

24

COMP

23

OUT3

OUT2OUT5

22

218 OUT1OUT6

209 OUT0OUT7

1910 LEOE

1811 CLKDOUT

1712 DINSET

1613 PGNDN.C.

1514 PGNDV+

Page 20

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

20 ______________________________________________________________________________________

Typical Operating Circuits (continued)

V

IN

3V TO 5.5V

C

IN

C

BYP

R

SET

L

Q

R

CS

OUT CS AGND COMP

V

CC

V+

PGND

REF

MAX16807

MAX16808

R

T

LE

DIN

CLK

DOUT

OE

SET

C

REF

D

C

C1

RTCT

C

T

V

OUT

C

OUT

C

C2

R

C1

FB

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

R1

R2

STAND-ALONE OPERATION

LEDs

Page 21

MAX16807/MAX16808

Integrated 8-Channel LED Drivers with

Switch-Mode Boost and SEPIC Controller

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

21

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Heaney

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

Revision History

Pages changed at Rev 1: 1, 21

XX XX

TSSOP 4.4mm BODY.EPS

PACKAGE OUTLINE, TSSOP, 4.40 MM BODY,

EXPOSED PAD

21-0108

1

E

1

Loading...

Loading...