General Description

The MAX1667 provides the power control necessary to

charge batteries of any chemistry. All charging functions

are controlled through the Intel System Management Bus

(SMBus™) interface. The SMBus 2-wire serial interface

sets the charge voltage and current and provides thermal

status information. The MAX1667 functions as a Level 2

charger, compliant with the Duracell/Intel Smart Battery

Charger Specification.

In addition to the feature set required for a Level 2 charger, the MAX1667 generates interrupts to signal the host

when power is applied to the charger or when a battery is

installed or removed. Additional status bits allow the host

to check whether the charger has enough input voltage,

and whether the voltage on or current into the battery is

being regulated. This allows the host to determine when

lithium-ion (Li+) batteries have completed the charge without interrogating the battery.

The MAX1667 is available in a 20-pin SSOP with a 2mm

profile height.

________________________Applications

Notebook Computers Charger Base Stations

Personal Digital Assistants Phones

____________________________Features

♦ Charges Any Battery Chemistry: Li+, NiCd,

NiMH, Lead Acid, etc.

♦ SMBus 2-Wire Serial Interface

♦ Compliant with Duracell/Intel Smart Battery

Charger Specification Rev. 1.0

♦ 4A, 3A, or 1A (max) Battery Charge Current

♦ 5-Bit Control of Charge Current

♦ Up to 18.4V Battery Voltage

♦ 11-Bit Control of Voltage

♦ ±1% Voltage Accuracy

♦ Up to +28V Input Voltage

♦ Battery Thermistor Fail-Safe Protection

♦ Greater than 95% Efficiency

♦ Synchronous Rectifier

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

________________________________________________________________

Maxim Integrated Products

1

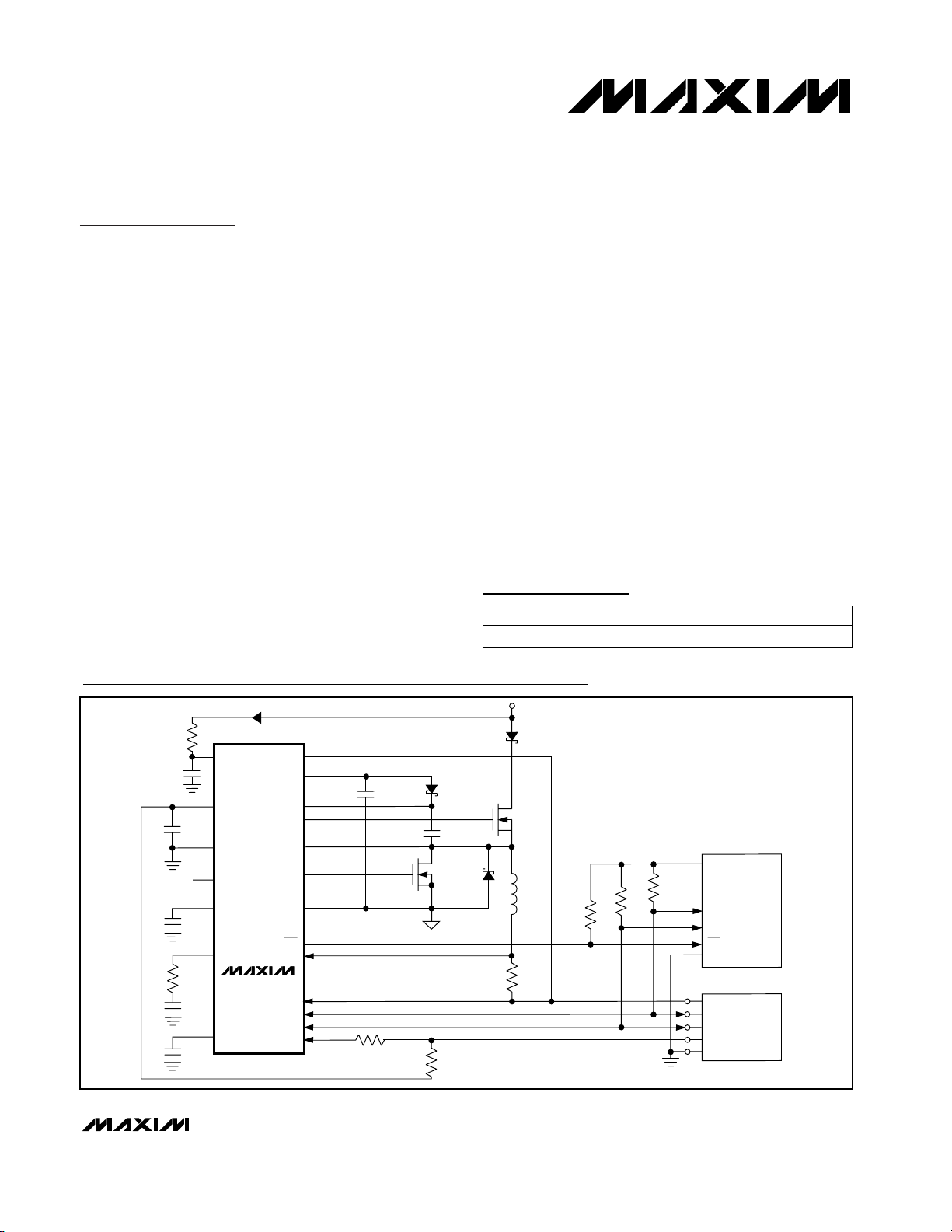

Typical Operating Circuit

PART

MAX1667EAP -40°C to +85°C

TEMP. RANGE PIN-PACKAGE

20 SSOP

Ordering Information

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

SMBus is a trademark of Intel Corp.

19-1488; Rev 0; 7/99

MAX1667

DCIN

REF BST

DHI

LX

DLO

PGND

INT

CS

BATT

SCL

SDA

THM

IOUT

VL

CHARGE SOURCE

AGND

SEL

DACV

CCV

CCI

V

DD

HOST

CONTROLLER

SMART

BATTERY

SCL

SDA

INT

GND

BATT+

R

SENSE

SCL

SDA

TEMP

BATT-

Pin Configuration appears at end of data sheet.

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

2 _______________________________________________________________________________________

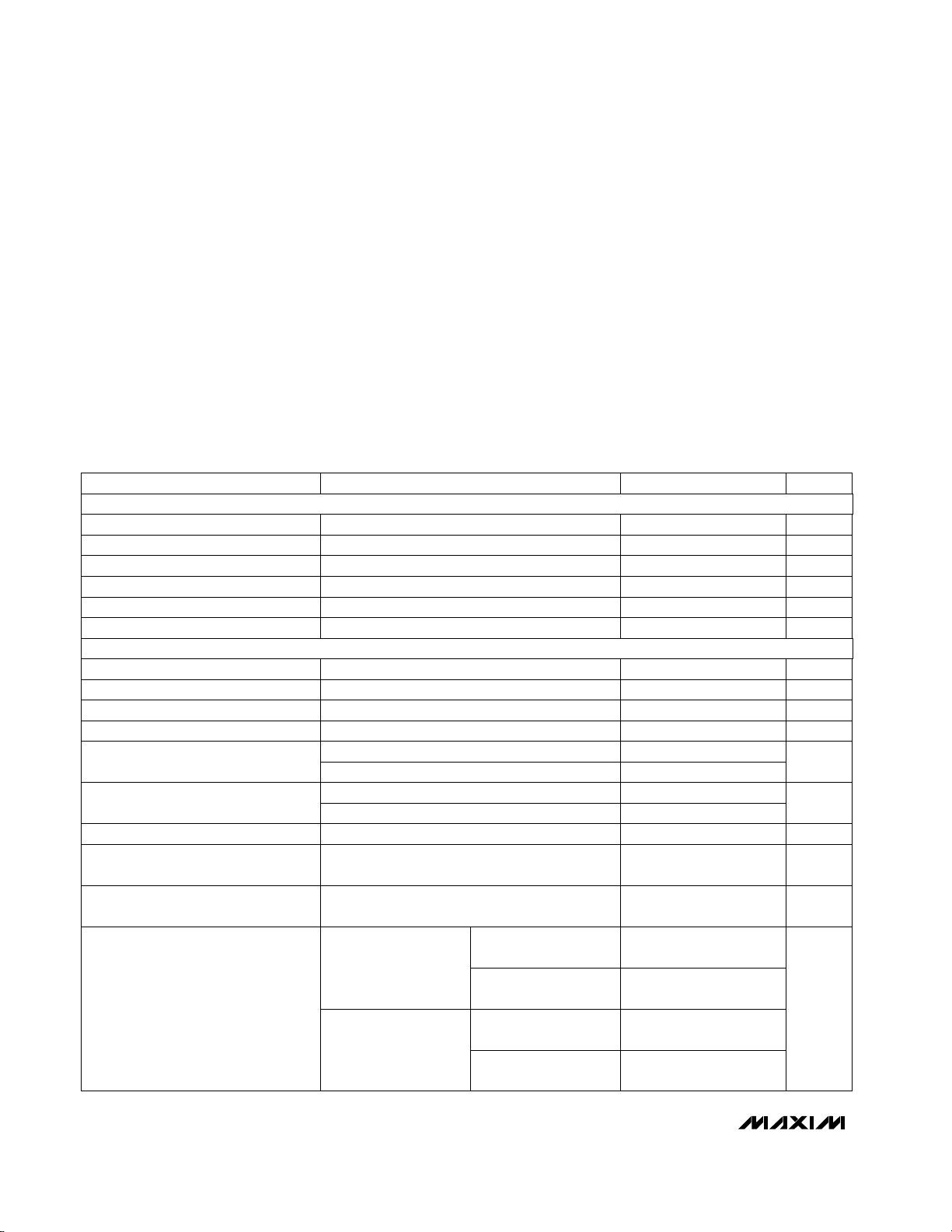

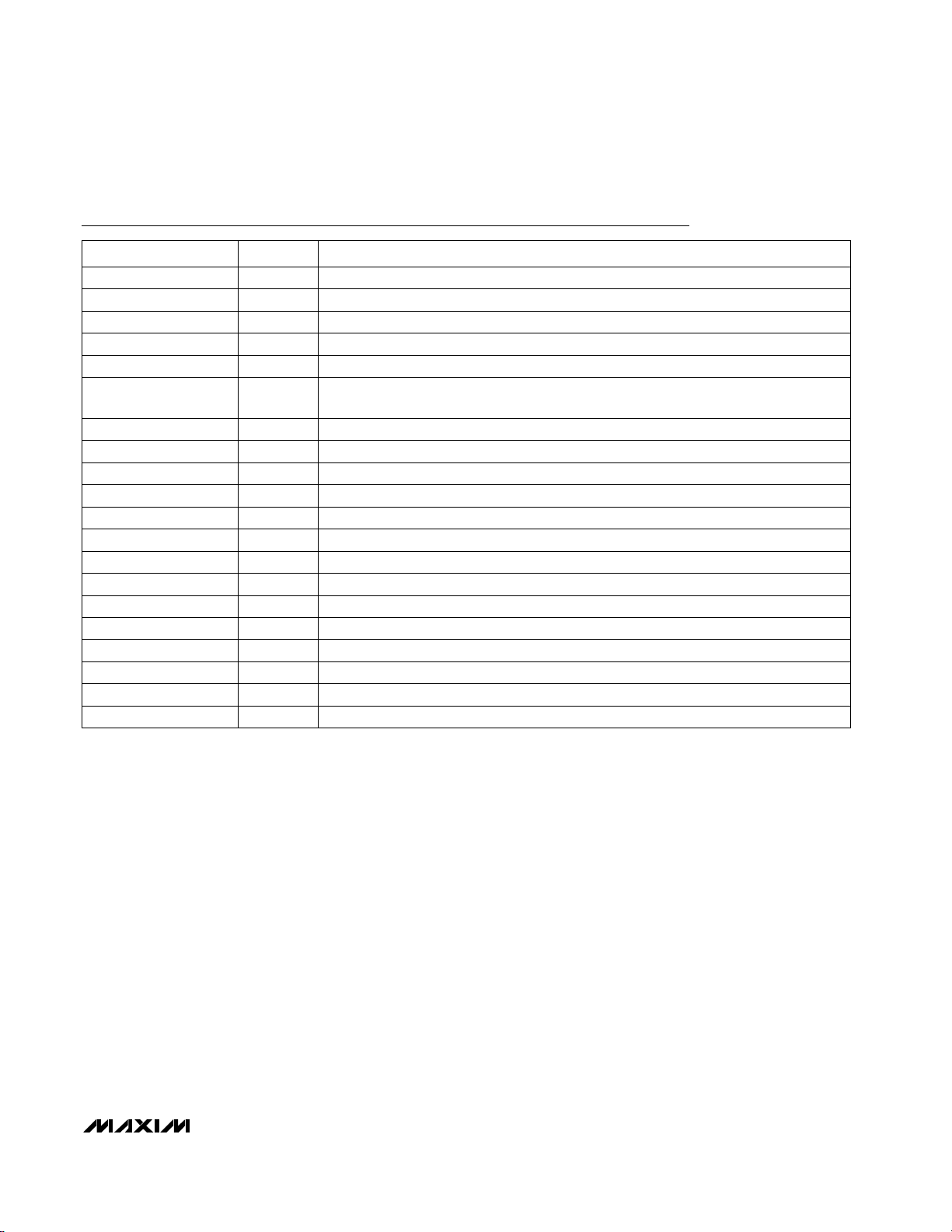

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

DCIN

= 18V, internal reference, 1µF capacitor at REF, 1µF capacitor at VL, TA= 0°C to +85°C, unless otherwise noted. Typical values

are at T

A

= +25°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

DCIN to AGND .......................................................-0.3V to +30V

BST to AGND..........................................................-0.3V to +36V

BST, DHI to LX..........................................................-0.3V to +6V

LX, IOUT to AGND..................................................-0.3V to +30V

THM, CCI, CCV, DACV, REF,

DLO to AGND .............................................-0.3V to (VL + 0.3V)

VL, SEL, INT, SDA, SCL to AGND............................-0.3V to +6V

BATT, CS+ to AGND ..............................................-0.3V to +20V

PGND to AGND.....................................................-0.3V to +0.3V

SDA, INT Current ................................................................50mA

VL Current...........................................................................50mA

Continuous Power Dissipation (T

A

= +70°C)

SSOP (derate 8mW/°C above +70°C) ..........................640mW

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10sec) .............................+300°C

%

-0.8 0.8

ChargingVoltage()

= 0x3130 (12,592mV)

and

0x41A0 (16,800mV)

Voltage Accuracy

mV5ChargingCurrent() = 0x0080 (128mA)

CS to BATT Single-Count

Current-Sense Voltage

V019BATT, CS Input Voltage Range

µA

350 500VL > 5.15V, V

BATT

= 12V

BATT Input Current (Note 1)

15VL < 3.2V, V

BATT

= 12V

Ω58High or lowDLO On-Resistance

Ω47High or lowDHI On-Resistance

mA467.5V < V

DCIN

< 28V, logic inputs = VLDCIN Quiescent Current

V7.5 28DCIN Input Voltage Range

%96.5 97.7In dropoutDHI Maximum Duty Cycle

kHz200 250 300Not in dropoutOscillator Frequency

V5.15 5.4 5.657.5V < V

DCIN

< 28V, no loadVL Output Voltage

mV100I

LOAD

= 0 to 10mAVL Load Regulation

V3.20 4 5.15VL AC_PRESENT Trip Point

4.055 4.096 4.137

UNITSMIN TYP MAXCONDITIONSPARAMETER

µA

170 400VL > 5.15V, VCS= 12V

CS Input Current (Note 1)

15VL < 3.2V, VCS= 12V

mV145 160 175

SEL = VL (4A),

ChargingCurrent() = 0x0F80 (3968mA)

CS to BATT Full-Scale

Current-Sense Voltage

V0 < I

SOURCE

< 500µAREF Output Voltage

TA= +25°C

TA= T

MIN

to T

MAX

-1.0 1.0

TA= +25°C

TA= T

MIN

to T

MAX

-3.0 3.0

-1.0 1.0

ChargingVoltage()

= 0x1060 (4192mV)

and

0x20D0 (8400mV)

SWITCHING REGULATOR

SUPPLY AND REFERENCE

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

_______________________________________________________________________________________ 3

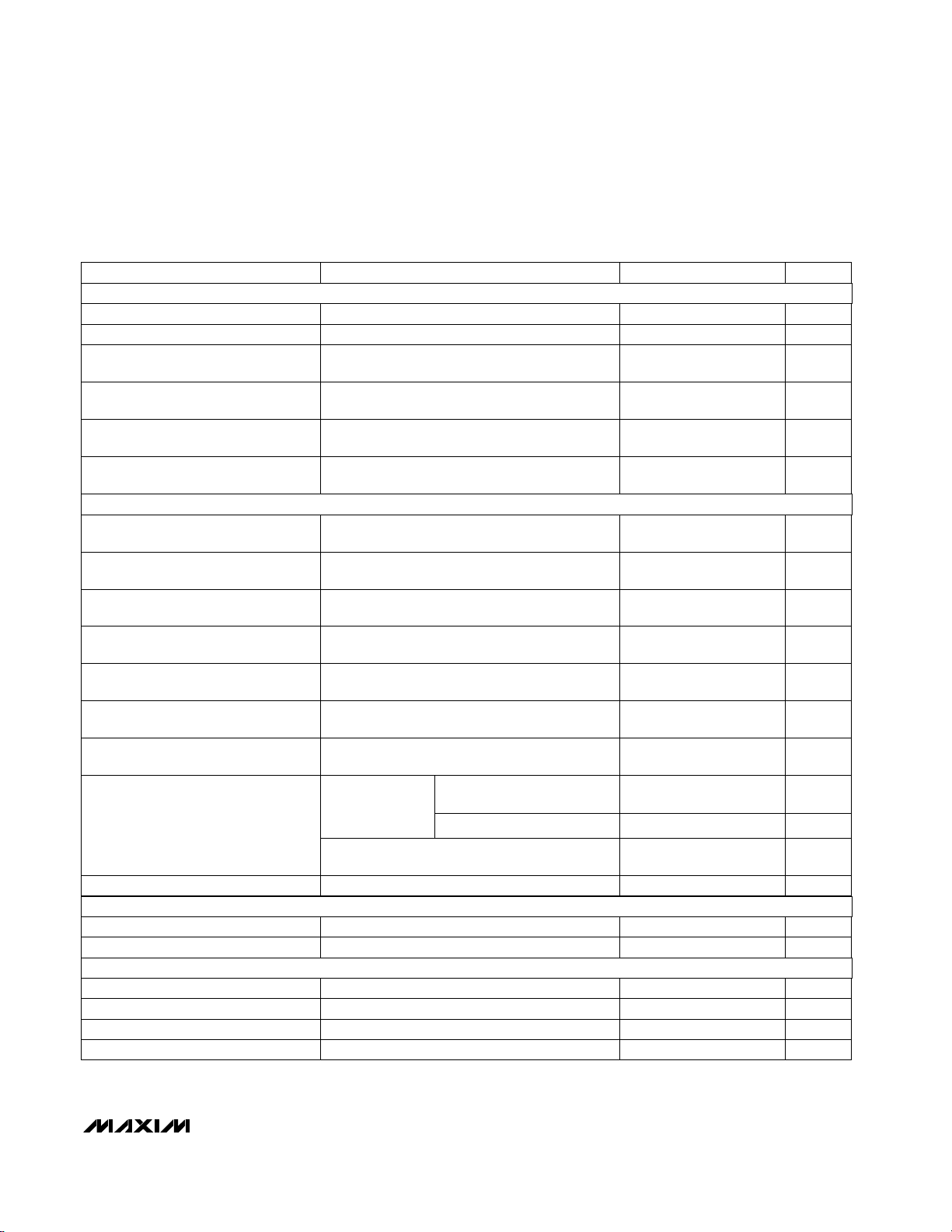

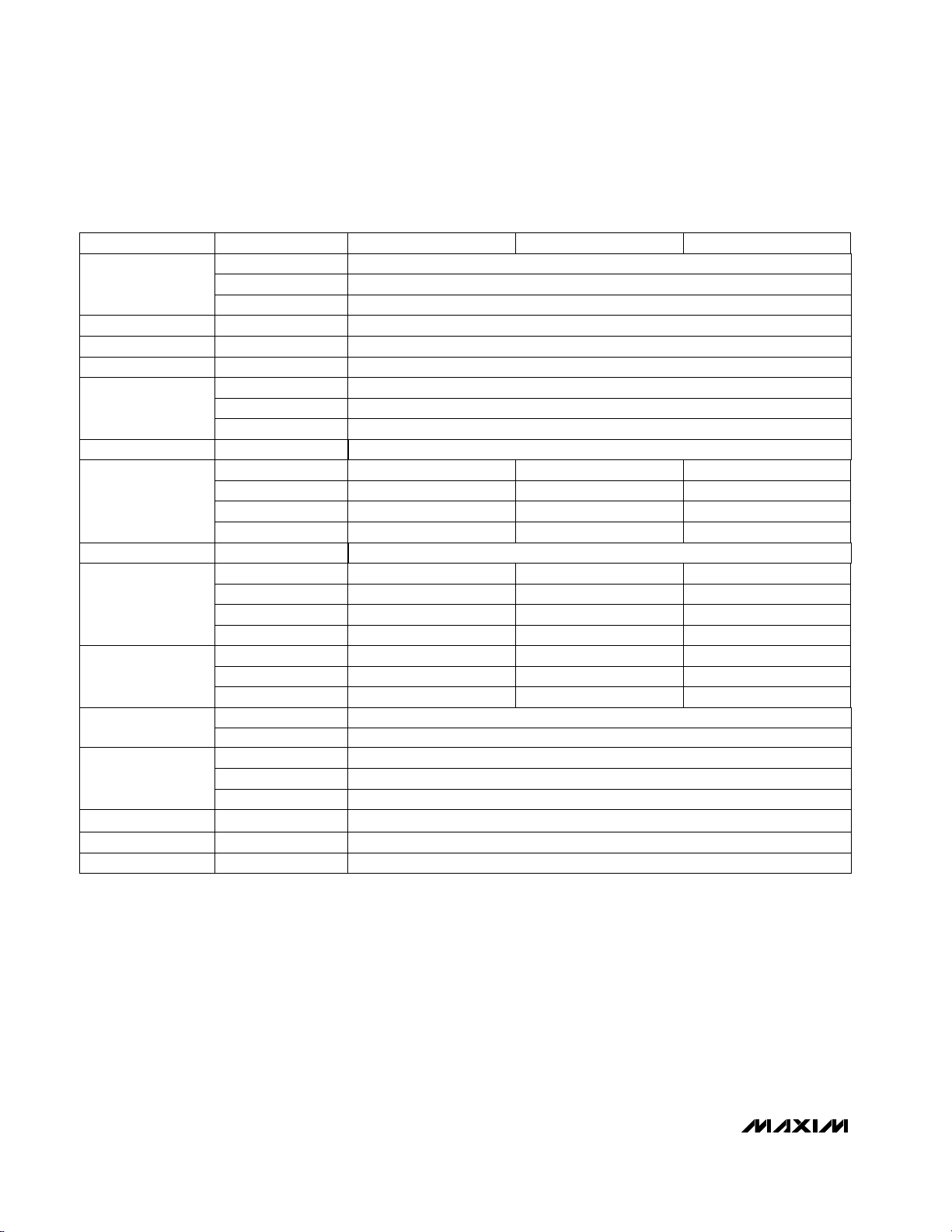

ELECTRICAL CHARACTERISTICS (continued)

(V

DCIN

= 18V, internal reference, 1µF capacitor at REF, 1µF capacitor at VL, TA= 0°C to +85°C, unless otherwise noted. Typical values

are at T

A

= +25°C, unless otherwise noted.)

Note 1: When DCIN is less than 4V, VL is less than 3.2V, causing the battery current to be typically 2µA (CS plus BATT input

current).

Bits11Guaranteed monotonicVDAC Voltage-Setting DAC Resolution

Bits5Guaranteed monotonicCDAC Current-Setting DAC Resolution

mA5

mA579

% of

V

REF

3 4.5 6THM falling

THM THERMISTOR_UR

Underrange Trip Point

% of

V

REF

22 23.5 25THM falling

THM THERMISTOR_HOT

Trip Point

% of

V

REF

74 75.5 77THM falling

THM THERMISTOR_COLD

Trip Point

mA/V0.2GMI Amplifier Transconductance

mA/V1.4GMV Amplifier Transconductance

% of

V

REF

89 91 93THM falling

THM THERMISTOR_OR

Overrange Trip Point

% of

V

DCIN

93 95 97BATT risingBATT POWER_FAIL Threshold

µA±80

GMV Amplifier Maximum

Output Current

µA±200

GMI Amplifier Maximum

Output Current

mV25 80 2001.1V < V

CCI

< 3.5V

CCV Clamp Voltage with

Respect to CCI

UNITSMIN TYP MAXCONDITIONSPARAMETER

mA6V

SDA

= 0.6VSDA Output Low Sink Current

µA-1 1SDA, SCL Input Bias Current

V2.2SDA, SCL Input Voltage High

V0.8SDA, SCL Input Voltage Low

mV25 80 2001.1V < V

CCV

< 3.5V

CCI Clamp Voltage with

Respect to CCV

ChargingCurrent() = 0x0000 10 µA

ChargingCurrent() = 0x0001

to 0x007F (127mA)

V

IOUT

= 17V, ChargingCurrent() = 0x0001

to 0x007F (127mA)

V

DCIN

= 0, V

IOUT

= 20V µA10IOUT Leakage Current

V

IOUT

= 0

IOUT Output Current

% of

V

DCIN

0.5

THM THERMISTOR_OR, _COLD,

_HOT, _UR Trip Point Hysteresis

% of

V

DCIN

1

BATT POWER_FAIL Threshold

Hysteresis

ERROR AMPLIFIERS

TRIP POINTS AND LINEAR CURRENT SOURCES

CURRENT- AND VOLTAGE-SETTING DACs

LOGIC LEVELS

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS

(V

DCIN

= 18V, internal reference, 1µF capacitor at REF, 1µF capacitor at VL, TA= -40°C to +85°C, unless otherwise noted. Typical values

are at T

A

= +25°C. Limits over this temperature range are guaranteed by design.)

µACS Input Current (Note 1) 5VL < 3.2V, VCS= 12V

mV145 160 175

V

SEL

= VL,

ChargingCurrent() = 0x0F80 (128mA)

CS to BATT Full-Scale

Current-Sense Voltage

%

-1.0 1.0

ChargingVoltage() = 0x3130 (12,592mV),

ChargingVoltage() = 0x41A0 (16,800mV)

Voltage Accuracy

µABATT Input Current (Note 1) 5VL < 3.2V, V

BATT

= 12V

Ω58High or lowDLO On-Resistance

Ω47High or lowDHI On-Resistance

mA467.5V < V

DCIN

< 28V, logic inputs = VLDCIN Quiescent Current

%96.5In dropoutDHI Maximum Duty Cycle

kHz200 250 310Not in dropoutOscillator Frequency

V5.15 5.4 5.657.5V < V

DCIN

< 28V, no loadVL Output Voltage

V4.055 4.1370 < I

SOURCE

< 500µAREF Output Voltage

UNITSMIN TYP MAXCONDITIONSPARAMETER

% of

V

REF

88.5 93.5THM falling

THM THERMISTOR_OR

Overrange Trip Point

% of

V

REF

73.5 77.5THM falling

THM THERMISTOR_COLD

Trip Point

V0.5SDA, SCL Input Voltage Low

V2.2SDA, SCL Input Voltage High

µA-1 1SDA, SCL Input Bias Current

% of

V

REF

21.5 25.5THM falling

THM THERMISTOR_HOT

Trip Point

% of

V

REF

2.5 6.5THM falling

THM THERMISTOR_UR

Underrange Trip Point

mA6V

SDA

= 0.6VSDA Output Low Sink Current

%1

THM THERMISTOR_OR, _COLD,

_HOT, _UR Trip Point Hysteresis

-3.0 3.0

ChargingVoltage() = 0x1060 (4192mV),

ChargingVoltage() = 0x20D0 (8400mV)

SUPPLY AND REFERENCE

SWITCHING REGULATOR

TRIP POINTS AND LINEAR CURRENT SOURCES

LOGIC LEVELS

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

_______________________________________________________________________________________ 5

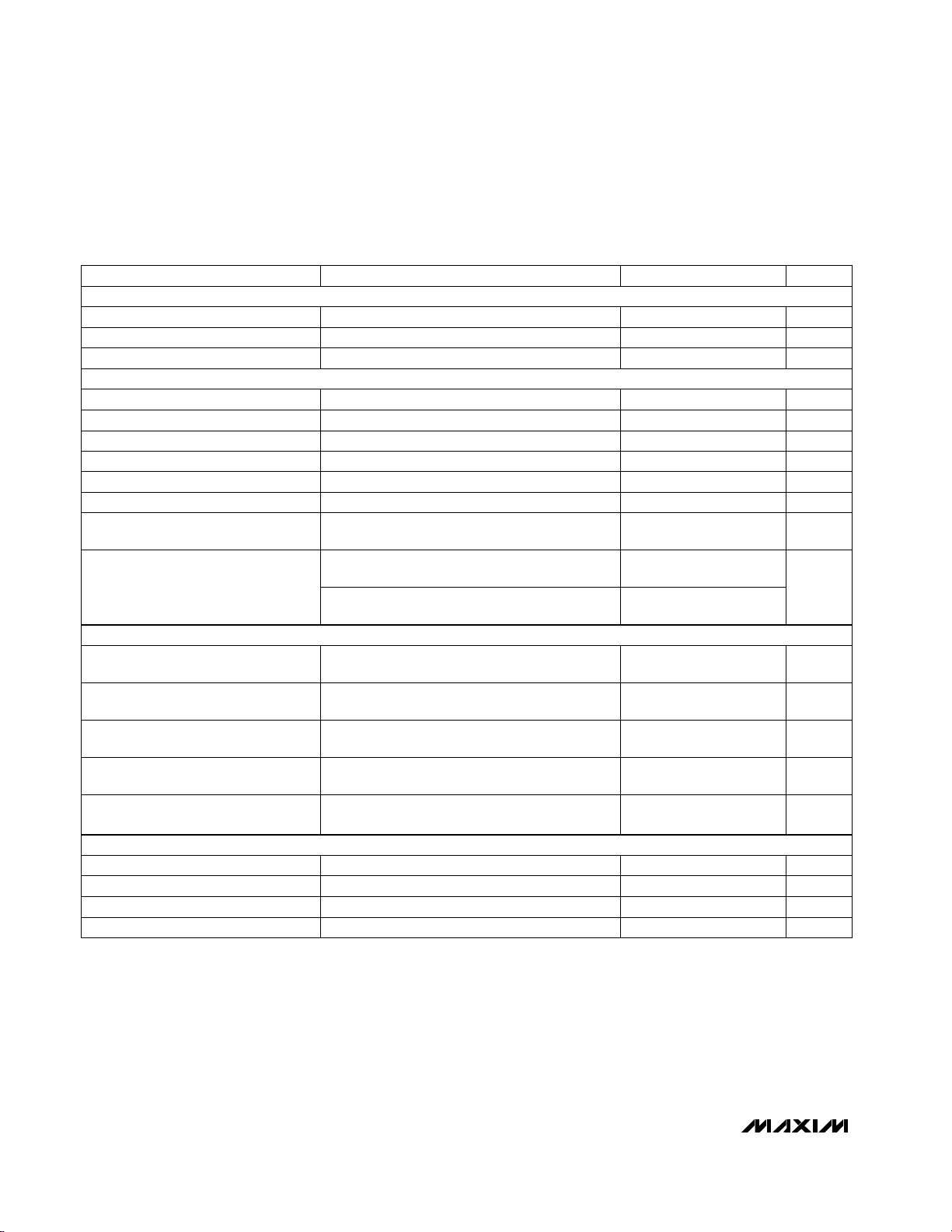

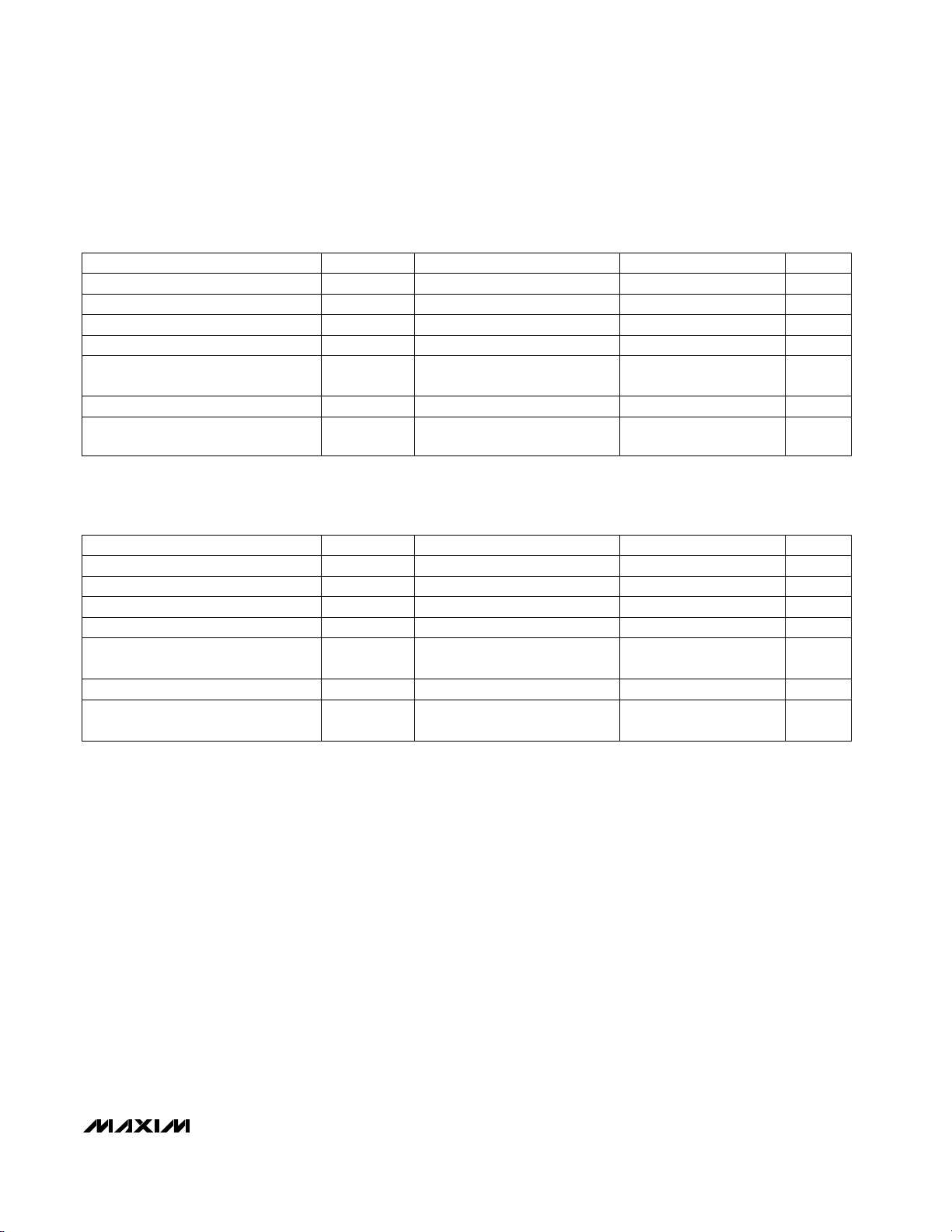

TIMING CHARACTERISTICS (Figures 1 and 2)

(TA= 0°C to +85°C, unless otherwise noted.)

TIMING CHARACTERISTICS (Figures 1 and 2)

(TA= -40°C to +85°C, unless otherwise noted. Limits over this temperature range are guaranteed by design.)

CONDITIONS

µs1t

DV

SCL Falling Edge to SDA Valid,

Master Clocking in Data

ns0t

HD:DAT

SCL Falling Edge to SDA Transition

µs4.7t

SU:STA

Start-Condition Setup Time

µs4.7t

LOW

µs4t

HIGH

SCL Serial-Clock High Period

SCL Serial-Clock Low Period

µs4t

HD:STA

Start-Condition Hold Time

ns250t

SU:DAT

SDA Valid to SCL Rising-Edge

Setup Time, Slave Clocking in Data

UNITSMIN TYP MAXSYMBOLPARAMETER

CONDITIONS

µs4.7t

SU:STA

Start-Condition Setup Time

µs4.7t

LOW

UNITSMIN TYP MAXSYMBOLPARAMETER

SCL Serial-Clock Low Period

µs4t

HD:STA

Start-Condition Hold Time

µs4t

HIGH

SCL Serial-Clock High Period

ns250t

SU:DAT

SDA Valid to SCL Rising-Edge

Setup Time, Slave Clocking in Data

ns0t

HD:DAT

SCL Falling Edge to SDA Transition

µs1t

DV

SCL Falling Edge to SDA Valid,

Master Clocking in Data

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

6 _______________________________________________________________________________________

Figure 2. SMBus Serial-Interface Timing—Acknowledge

t

DV

SLAVE PULLING

SDA LOW

t

DV

MOST SIGNIFICANT BIT

OF DATA CLOCKED

INTO MASTER

ACKNOWLEDGE

BIT CLOCKED

INTO MASTER

RW BIT

CLOCKED

INTO SLAVE

SCL

SDA

START

CONDITION

MOST SIGNIFICANT

ADDRESS BIT (A6)

CLOCKED INTO SLAVE

A5 CLOCKED

INTO SLAVE

A4 CLOCKED

INTO SLAVE

A3 CLOCKED

INTO SLAVE

t

HIGH

t

LOW

t

HD:STA

t

SU:STA

t

SU:DAT

t

HD:DAT

SCL

SDA

t

SU:DAT

t

HD:DAT

Figure 1. SMBus Serial-Interface Timing—Address

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

_______________________________________________________________________________________

7

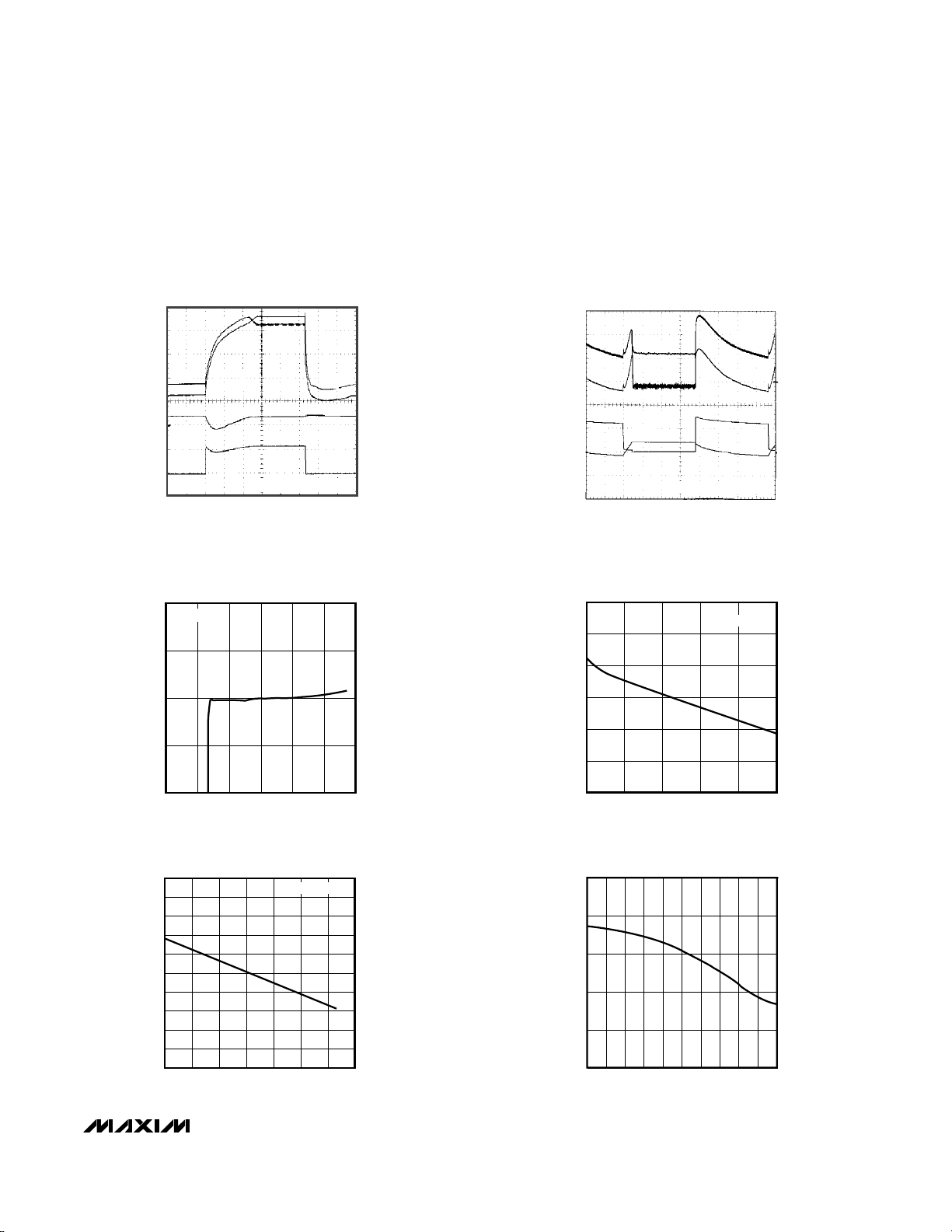

__________________________________________Typical Operating Characteristics

(Circuit of Figure 7, TA = +25°C, unless otherwise noted.)

(VOLTAGE REGULATION WITH CURRENT LIMIT)

10V

5V/div

V

DCIN

ChargingVoltage() = 12,000mV

ChargingCurrent() = 1500mA

CCI

CCV

= 18V

LOAD TRANSIENT

CCV

CCI

CCV

CCI

V

BATT

I

LOAD

AVERAGED MEASUREMENT

500µs/div

CCI

CCV

MAX1667TOC01

200mV/div

1.4V

1A

1A/div

(WITH CHANGE IN REGULATION LOOP)

LOAD TRANSIENT

CCV

CCI

I

LOAD

10V

5V/div

V

= 18V

DCIN

ChargingVoltage() = 12,000mV

ChargingCurrent() = 1500mA

CCI

CCV

V

BATT

AVERAGED MEASUREMENT

1ms/div

MAX1667TOC02

CCV

CCI

50mV/div

2V

1A

500mA/div

VL LINE REGULATION

5.450

NO LOAD

5.425

5.400

VL (V)

5.375

5.350

010155 202530

V

(V)

DCIN

VL vs. TEMPERATURE

5.45

5.44

5.43

5.42

5.41

5.40

VL (V)

5.39

5.38

5.37

5.36

5.35

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

V

DCIN

= 20V

MAX1667 TOC03

MAX1667 TOC05

VL LOAD REGULATION

5.50

5.45

5.40

5.35

VL (V)

5.30

5.25

5.20

0105 152025

LOAD CURRENT (mA)

V

LOAD REGULATION

REF

0 0.80.60.2 0.4 1.0 1.2 1.4 1.6 1.8 2.0

LOAD CURRENT (mA)

(V)

V

4.11

4.10

4.09

REF

4.08

4.07

4.06

V

= 20V

DCIN

MAX1667 TOC04

MAX1667 TOC06

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

8 _______________________________________________________________________________________

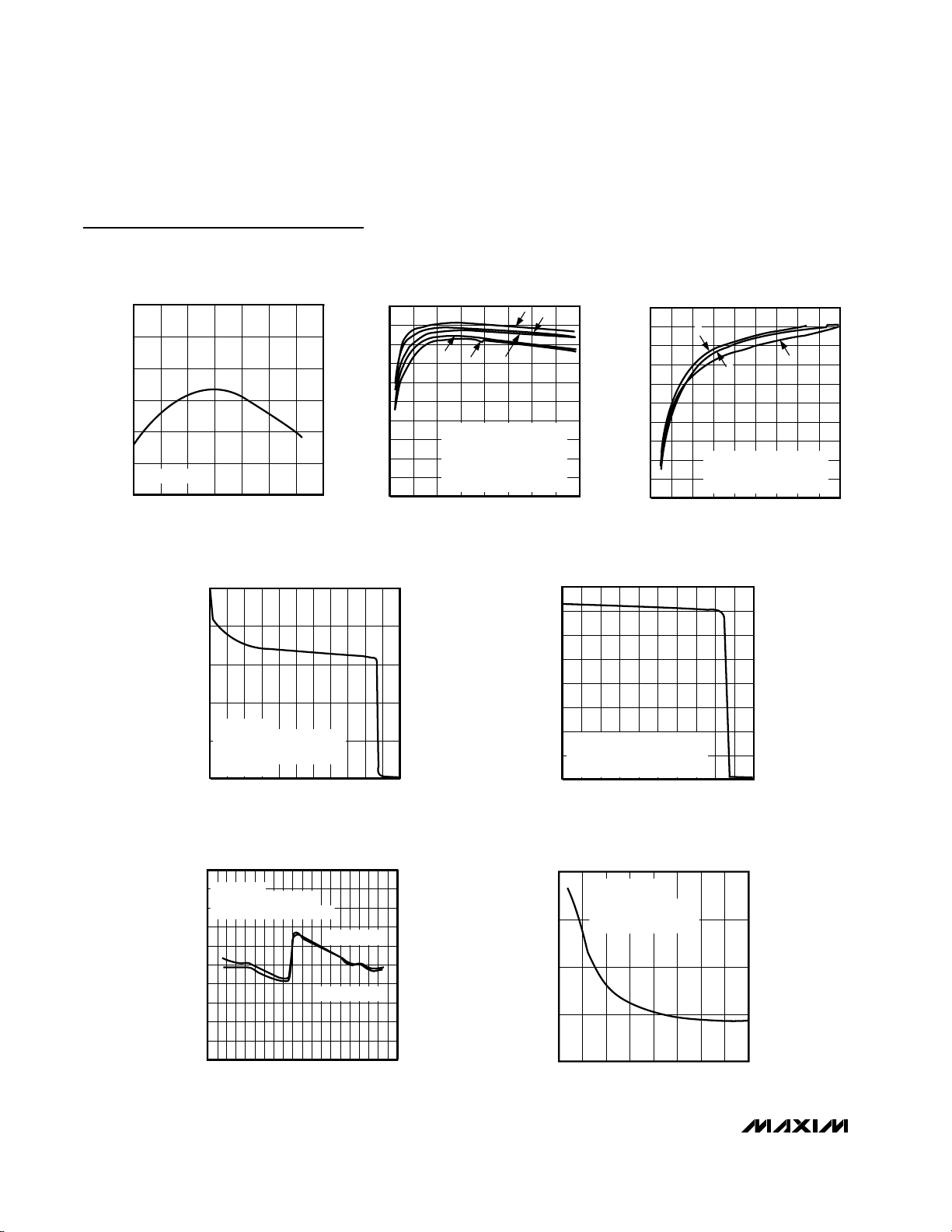

Typical Operating Characteristics (continued)

(Circuit of Figure 7, TA = +25°C, unless otherwise noted.)

100

0.01

10

1.0

0.1

0.001

0 400 800 1200 1600 2000

OUTPUT V-I CHARACTERISTIC

(SWITCHING REGULATOR)

MAX1667 TOC10

LOAD CURRENT (mA)

DROP IN BATT OUTPUT VOLTAGE (%)

V

DCIN

= 20V

ChargingVoltage() = 17,408mV

ChargingCurrent() = 1920mA

V

REF

= 4.096V

0

5

1

3

4

8

02468101214161820

OUTPUT V-I CHARACTERISTIC

(LINEAR SOURCE)

MAX1667 TOC11

V

IOUT

(V)

I

IOUT

(mA)

2

6

7

V

DCIN

= 20V

ChargingVoltage() = 17,408mV

ChargingCurrent() = 1 to 127mA

4.080

4.100

4.085

4.090

4.095

4.110

-40 4020-20 0 60 80 100

V

REF

vs. TEMPERATURE

MAX1667 TOC07

TEMPERATURE (°C)

V

REF

(V)

4.105

V

DCIN

= 20V

50

70

55

60

65

100

0 20001000 3000 4000

EFFICIENCY vs. LOAD CURRENT

(VOLTAGE REGULATION)

MAX1667 TOC08

LOAD CURRENT (mA)

EFFICIENCY (%)

75

80

85

90

95

A: V

DCIN

= 20V, V

BATT

= 17V

B: V

DCIN

= 16V, V

BATT

= 12.75V

C: V

DCIN

= 20V, V

BATT

= 12.75V

D: V

DCIN

= 16V, V

BATT

= 8.5V

E: V

DCIN

= 20V, V

BATT

= 8.5V

A

B

C

E

D

50

70

55

60

65

100

0862 4 10 12 18

EFFICIENCY vs. BATT VOLTAGE

(CURRENT REGULATION)

MAX1667 TOC09

BATT VOLTAGE (V)

EFFICIENCY (%)

75

80

85

90

95

14 16

A: V

DCIN

= 16V, I

LOAD

= 2A

B: V

DCIN

= 20V, I

LOAD

= 2A

C: V

DCIN

= 20V, I

LOAD

= 600mA

A

B

C

BATT VOLTAGE ERROR (%)

BATT VOLTAGE ERROR

vs. ChargingVoltage() CODE

1.0

0.8

V

= 20V

DCIN

MEASURED AT AVAILABLE

0.6

ChargingVoltage() CODES

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

0 4k6k8k2k 10k 12k 14k 18k16k 20k

ChargingVoltage() CODE

I

LOAD

I

LOAD

= 600mA

= 3mA

MAX1667 TOC12

LOAD CURRENT ERROR

15

10

5

BATT CURRENT ERROR (%)

0

-5

V

=20V

DCIN

V

= 12.75V

BATT

MEASURED AT AVAILABLE

ChargingCurrent() CODES

0 1000 2000 3000500 1500 2500 3500 4000

CODE

MAX1667 TOC13

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

_______________________________________________________________________________________ 9

Pin Description

Linear Current-Source Output1 IOUT

Input Voltage for Powering Charger2 DCIN

Voltage-Regulation-Loop Compensation Point4 CCV

IC Power Supply. 5.4V linear-regulator output from DCIN.3 VL

Current-Range Selector. Connecting SEL to VL sets a 4A full-scale current. Leaving SEL

open sets a 3A full-scale current. Connecting SEL to AGND sets a 1A full-scale current.

6 SEL

Battery Voltage Input and Current-Sense Negative Input8 BATT

Current-Sense Positive Input7 CS

Current-Regulation-Loop Compensation Point5 CCI

+4.096V Reference Voltage Output or External Reference Input9 REF

Open-Drain Interrupt Output11

INT

Analog Ground10 AGND

Thermistor Sense Voltage Input12 THM

Serial Data (need external pull-up resistor)14 SDA

Power Ground16 PGND

Voltage DAC Output Filtering Point15 DACV

Serial Clock (need external pull-up resistor)13 SCL

High-Side Power MOSFET Driver Output18 DHI

Power Connection for the High-Side Power MOSFET Driver20 BST

Power Connection for the High-Side Power MOSFET Driver19 LX

Low-Side Power MOSFET Driver Output17 DLO

FUNCTIONPIN NAME

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

Smart Battery Charging System

A smart battery charging system, at a minimum, consists of a smart battery and smart battery charger compatible with the Smart Battery System specifications

using Intel’s system management bus (SMBus).

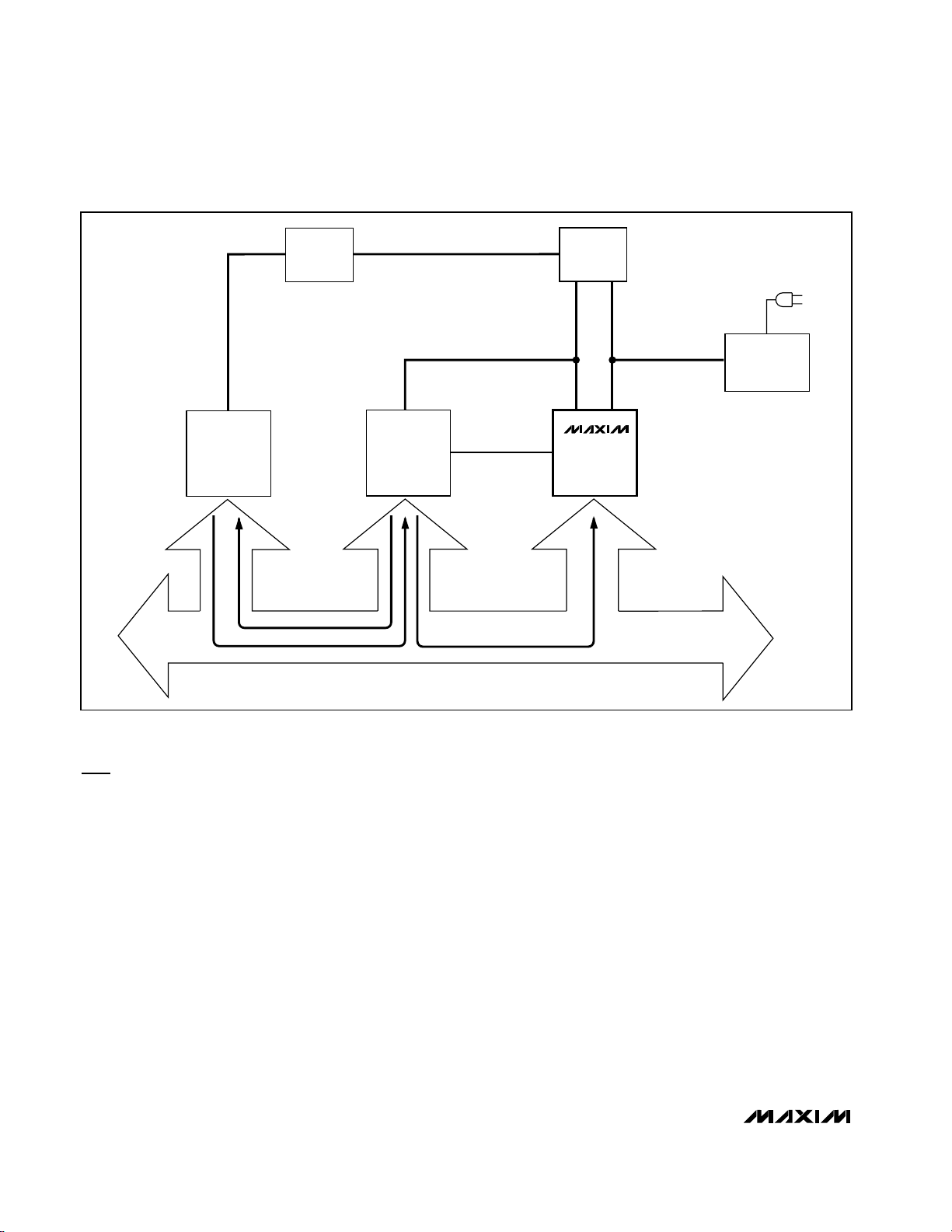

Smart Battery System Block Diagrams

A system may use one or more smart batteries. The

block diagram of a smart battery charging system

shown in Figure 3 depicts a single battery system. This

is typically found in notebook computers, video cameras, cellular phones, and other portable electronic

equipment.

Another possibility is a system that uses two or more

smart batteries. A block diagram for a system featuring

multiple batteries is shown in Figure 4. The smart battery selector is used to connect batteries to either the

smart battery charger or the system, or to disconnect

them, as appropriate. For a standard smart battery, the

following connections must be made: power (the bat-

tery’s positive and negative terminals), SMBus (clock

and data), and safety signal (resistance, typically temperature dependent). Additionally, the system host

must be able to query any battery in the system so it

can display the state of all batteries present in the system.

Figure 4 shows a two-battery system where Battery 2 is

being charged while Battery 1 is powering the system.

This configuration may be used to “condition” Battery

1, allowing it to be fully discharged prior to recharge.

Smart Battery Charger Types

Two types of smart battery chargers are defined: Level

2 and Level 3. All smart battery chargers communicate

with the smart battery using the SMBus; the two types

differ in their SMBus communication mode and in

whether they modify the charging algorithm of the

smart battery as shown in Table 1. Level 3 smart battery chargers are supersets of Level 2 chargers and as

such support all Level 2 charger commands.

SYSTEM

POWER

CONTROL

AC-DC

CONVERTER

(UNREGULATED)

AC

SYSTEM

POWER

SUPPLY

DC (UNREGULATED) / V

BATTERY

SAFETY

SIGNAL

V

BATTERY

DC (UNREGULATED)

V

CC

+12V, -12V

SYSTEM HOST

(SMBus HOST)

SMART BATTERY

CRITICAL EVENTS

CRITICAL EVENTS

CHARGING VOLTAGE/CURRENT

REQUESTS

BATTERY DATA/STATUS REQUESTS

SMART BATTERY

CHARGER

SMBus

MAX1667

Figure 3. Typical Single Smart Battery System

10 ______________________________________________________________________________________

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

______________________________________________________________________________________ 11

Level 2 Smart Battery Charger

The Level 2 or “smart-battery-controlled” smart battery

charger interprets the smart battery’s critical warning

messages, and operates as an SMBus slave device

that responds to ChargingVoltage() and ChargingCurrent() messages sent to it by a smart battery. The

charger is obliged to adjust its output characteristics in

direct response to the messages it receives from the

battery. In Level 2 charging, the smart battery is completely responsible for initiating communication and for

providing the charging algorithm to the charger. The

smart battery is in the best position to tell the smart battery charger how it needs to be charged. The charging

algorithm in the battery may request a static charge

condition or may choose to periodically adjust the

smart battery charger’s output to meet its present

needs. A Level 2 smart battery charger is truly chemistry independent, and since it is defined as an SMBus

slave device only, it is relatively inexpensive and easy

to implement.

Table 1. Charger Type by SMBus Mode

and Charge Algorithm Source

Level 3Level 3Slave/Master

Level 3Level 2

Modified from BatteryBattery

Slave Only

SMBus MODE

CHARGE ALGORITHM SOURCE

Note: Level 1 smart battery chargers are defined in the ver-

sion 0.95a specification. While they can correctly interpret

smart battery end-of-charge messages minimizing overcharge, they do not provide truly chemistry-independent

charging. They are no longer defined by the Smart Battery

Charger specification and are explicitly not compliant with this

and subsequent Smart Battery Charger specifications.

AC-DC

CONVERTER

(UNREGULATED)

AC

DC (UNREGULATED) / V

BATTERY

NOTE: SB 1 POWERING SYSTEM

SB 2 CHARGING

V

CC

+12V, -12V

SYSTEM HOST

(SMBus HOST)

SMART BATTERY

SELECTOR

SMBus

SMBus

SMBus

SAFETY SIGNAL

V

CHARGE

V

BATT

SAFETY

SIGNAL

V

BATT

SAFETY

SIGNAL

SMART BATTERY 1

SMART BATTERY 2

CRITICAL EVENTS

BATTERY DATA/STATUS REQUESTS

SMART BATTERY

CHARGER

SMBus

MAX1667

SYSTEM

POWER

SUPPLY

Figure 4. Typical Multiple Smart Battery System

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

12 ______________________________________________________________________________________

_______________Detailed Description

Output Characteristics

The MAX1667 contains both a voltage-regulation loop

and a current-regulation loop. Both loops operate independently of each other. The voltage-regulation loop

monitors BATT to ensure that its voltage never exceeds

the voltage set point (V0). The current-regulation loop

monitors current delivered to BATT to ensure that it

never exceeds the current-limit set point (I0). The current-regulation loop is in control as long as BATT voltage is below V0. When BATT voltage reaches V0, the

current loop no longer regulates, and the voltage-regulation loop takes over. Figure 5 shows the V-I characteristic at the BATT pin.

Setting V0 and I0

Set the MAX1667’s voltage and current-limit set points

via the Intel SMBus 2-wire serial interface. The

MAX1667’s logic interprets the serial-data stream from

the SMBus interface to set internal digital-to-analog converters (DACs) appropriately. The power-on-reset value

for V0 and I0 is 18.4V and 7mA, respectively. See

Digital

Section

for more information.

_____________________Analog Section

The MAX1667 analog section consists of a currentmode pulse-width-modulated (PWM) controller and two

transconductance error amplifiers—one for regulating

current and the other for regulating voltage. The device

uses DACs to set the current and voltage level, which

are controlled via the SMBus interface. Since separate

amplifiers are used for voltage and current control, both

control loops can be compensated separately for optimum stability and response in each state.

Whether the MAX1667 is controlling the voltage or current at any time depends on the battery’s state. If the

battery has been discharged, the MAX1667’s output

reaches the current-regulation limit before the voltage

limit, causing the system to regulate current. As the battery charges, the voltage rises until the voltage limit is

reached, and the charger switches to regulating voltage.

The transition from current to voltage regulation is done

by the charger and need not be controlled by the host.

Figure 6 shows the MAX1667 block diagram.

Voltage Control

The internal GMV amplifier controls the MAX1667’s output voltage. The voltage at the amplifier’s noninverting

input is set by an 11-bit DAC, which is controlled by a

ChargingVoltage() command on the SMBus (see

Digital

Section

for more information). The battery voltage is fed

to the GMV amplifier through a 5:1 resistive voltage

divider. The set voltage ranges between 0 and 18.416V

with 16mV resolution. This allows up to four Li+ cells in

series to be charged.

The GMV amplifier’s output is connected to the CCV

pin, which compensates the voltage-regulation loop.

Typically, a series-resistor/capacitor combination can

be used to form a pole-zero doublet. The pole introduced rolls off the gain starting at low frequencies. The

zero of the doublet provides sufficient AC gain at midfrequencies. The output capacitor then rolls off the midfrequency gain to below 1 to guarantee stability before

encountering the zero introduced by the output capacitor’s equivalent series resistance (ESR). The GMV

amplifier’s output is internally clamped to between onefourth and three-fourths of the voltage at REF.

Current Control

An internal 7mA linear current source is used in conjunction with the PWM regulator to set the battery

charge current. When the current is set to 0, the voltage

regulator is on but no current is available. A current setting between 1mA and 127mA turns on the linear current source, providing a maximum of 7mA for trickle

charging. For current settings above 127mA, the linear

current source is disabled and the charging current is

provided by the switching regulator set by the 5-bit current-control DAC.

The GMI amplifier’s noninverting input is driven by a 4:1

resistive voltage divider, which is driven by the 5-bit

DAC. With the internal 4.096V reference, this input is

approximately 1.0V at full scale, and the resolution is

31mV. The current-sense amplifier drives the inverting

input to the GMI amplifier. It measures the voltage

Figure 5. Output V-I Characteristic

BATT

VOLTAGE

V0

V0 = VOLTAGE SET POINT

I0 = CURRENT-LIMIT SET POINT

AVERAGE CURRENT

THROUGH THE RESISTOR

I0

BETWEEN CS AND BATT

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

______________________________________________________________________________________ 13

Figure 6. Functional Diagram

REF

THM

AGND

CS

BATT

FROM LOGIC

BLOCK

FROM LOGIC BLOCK

BATT

FROM LOGIC BLOCK

10k 10k

100k

CURRENT-SENSE

LEVEL SHIFT AND

GAIN OF 5.5

5

5-BIT DAC

AGND

4R

R

AGND

30k 3k

REF

11

10k

3R

R

TO LOGIC BLOCK

TO LOGIC BLOCK

REF

11-BIT DAC

10k

500Ω

VOLTAGE_INREG

CURRENT_INREG

THERMISTOR_OR

THERMISTOR_COLD

THERMISTOR_HOT

THERMISTOR_UR

CCI

GMI

CLAMP

GMV

CCV

DACV

LOGIC

BLOCK

CCV_LOW

3/8 REF = ZERO CURRENT

NOTE: APPROX. REF/4 + V

TO 3/4 REF + V

MIN

THRESH

NOTE:

REF/4 TO 3/4 REF

CLAMP

TO REF

(MAX)

AGND

THERM_SHUT

SEL

SCL

SDA

INT

AC_PRESENT

THRESH

FROM LOGIC

BLOCK

7mA

THERMAL

SHUTDOWN

DCIN

5.4V LINEAR

REGULATOR

R

AGND

LEVEL

SHIFT

SUMMING

COMPARATOR

BLOCK

DCIN

MAX1667

IOUT

VL

INTERNAL

4.096V

REFERENCE

AGND

CCV

3R

REF

BST

DRIVER

LX

VL

DRIVER

PGND

REF

DHI

DLO

AGND

TO LOGIC BLOCK

POWER_FAIL

DCIN/4.5

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

14 ______________________________________________________________________________________

across the current-sense resistor (R

SEN

) (which is

between the CS and BATT pins), amplifies it by approximately 5.45, and level shifts it to ground. The full-scale

current is approximately 0.16V/R

SEN

, and the resolution

is 5mV/R

SEN

.

The current-regulation loop is compensated by adding a

capacitor to the CCI pin. This capacitor sets the currentfeedback loop’s dominant pole. The GMI amplifier’s output is clamped to between approximately one-fourth

and three-fourths of the REF voltage. While the current is

in regulation, the CCV voltage is clamped to within

80mV of the CCI voltage. This prevents the battery voltage from overshooting when the DAC voltage setting is

updated. The converse is true when the voltage is in

regulation and the current is not at the current DAC setting. Since the linear range of CCI or CCV is about 1.5V

to 3.5V (about 2V), the 80mV clamp results in a relatively

negligible overshoot when the loop switches from voltage to current regulation or vice versa.

PWM Controller

The battery voltage or current is controlled by the current-mode, PWM, DC-DC converter controller. This controller drives two external N-channel MOSFETs, which

switch the voltage from the input source. This switched

voltage feeds an inductor, which filters the switched rectangular wave. The controller sets the pulse width of the

switched voltage so that it supplies the desired voltage

or current to the battery.

The heart of the PWM controller is the multi-input comparator. This comparator sums three input signals to

determine the pulse width of the switched signal, setting the battery voltage or current. The three signals are

the current-sense amplifier’s output, the GMV or GMI

error amplifier’s output, and a slope-compensation signal, which ensures that the controller’s internal currentcontrol loop is stable.

The PWM comparator compares the current-sense

amplifier’s output to the lower output voltage of either

the GMV or the GMI amplifier (the error voltage). This

current-mode feedback corrects the duty ratio of the

switched voltage, regulating the peak battery current

and keeping it proportional to the error voltage. Since

the average battery current is nearly the same as the

peak current, the controller acts as a transconductance

amplifier, reducing the effect of the inductor on the output filter LC formed by the output inductor and the battery’s parasitic capacitance. This makes stabilizing the

circuit easy, since the output filter changes from a complex second-order RLC to a first-order RC. To preserve

the inner current-control loop’s stability, slope compensation is also fed into the comparator. This damps out

perturbations in the pulse width at duty ratios greater

than 50%.

At heavy loads, the PWM controller switches at a fixed

frequency and modulates the duty cycle to control the

battery voltage or current. At light loads, the DC current

through the inductor is not sufficient to prevent the current from going negative through the synchronous rectifier (Figure 7, M2). The controller monitors the current

through the sense resistor R

SEN

; when it drops to zero,

the synchronous rectifier turns off to prevent negative

current flow.

MOSFET Drivers

The MAX1667 drives external N-channel MOSFETs to

regulate battery voltage or current. Since the high-side

N-channel MOSFET’s gate must be driven to a voltage

higher than the input source voltage, a charge pump is

used to generate such a voltage. The capacitor C7

(Figure 7) charges to approximately 5V through D2

when the synchronous rectifier turns on. Since one side

of C7 is connected to the LX pin (the source of M1), the

high-side driver (DHI) can drive the gate up to the voltage at BST (which is greater than the input voltage)

when the high-side MOSFET turns on.

The synchronous rectifier may not be completely

replaced by a diode because the BST capacitor

charges while the synchronous rectifier is turned on.

Without the synchronous rectifier, the BST capacitor

may not fully charge, leaving the high-side MOSFET

with insufficient gate drive to turn on. Use a small MOSFET, such as a 2N7002, to guarantee that the BST

capacitor is allowed to charge. In this case, most of the

current at high currents is carried by the Schottky diode

and not by the synchronous rectifier.

Internal Regulator and Reference

The MAX1667 uses an internal low-dropout linear regulator to create a 5.4V power supply (VL), which powers its

internal circuitry. VL can supply up to 20mA, less than

10mA powers the internal circuitry, and the remaining

current can power the external circuitry. The current

used to drive the MOSFETs comes from this supply,

which must be considered when calculating how much

power can be drawn. To estimate the current required to

drive the MOSFETs, multiply the total gate charge of

each MOSFET by the switching frequency (typically

250kHz). To ensure VL stability, bypass the VL pin with a

1µF or greater capacitor.

The MAX1667 has an internal, accurate 4.096V reference voltage. This guarantees a voltage-setting accuracy of ±1% max. Bypass the reference with a 1µF or

greater capacitor.

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

______________________________________________________________________________________ 15

Figure 7. Typical Application Circuit

AGND

D2

C9

R5

R6

C6

M1

M2

D1

D4*

D3

DC SOURCE

C1

L1

D5

R1

C7

C11

REF

R3

C4

C10

THM

CCI

IOUT

C5

(NOTE 2)

10

1

2

6

3

20

18

19

17

16

7

8

13

14

11

9

12

5

4

15

= HIGH-CURRENT TRACES (8A MAX)

NOTE 1: C6, M2, D1, AND C1 GROUNDS MUST CONNECT TO

THE SAME RECTANGULAR PAD ON THE LAYOUT.

NOTE 2: C5 AND C11 MUST BE PLACED WITHIN 0.5cm OF THE

MAX1667, WITH TRACES NO LONGER THAN 1cm

CONNECTING VL AND PGND.

*OPTIONAL (SEE

NEGATIVE INPUT VOLTAGE PROTECTION

SECTION).

SEE TABLES 2a AND 2b FOR COMPONENT SELECTION AND MANUFACTURERS.

C8

C2

R2

C3

R4

DCIN

MAX1667

SEL

VL

BST

CCV

DACV

LX

DLO

PGND

CS

DHI

(NOTE 1)

SMART BATTERY

STANDARD CONNECTOR

-TD C+

BATT

SCL

SDA

INT

HOST & LOAD

SMBCLOCK

V+

SMBDATA

KINT-

GND

7.5V–28V

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

16 ______________________________________________________________________________________

Table 2a. Component Selection

_____________________Digital Section

SMBus Interface

The MAX1667 uses serial data to control its operation. The

serial interface complies with the SMBus specification (see

System Management Bus Specification

, from the SBS

forum at www.sbs-Forum.org or from Intel Architecture

Labs: 800-253-3696). Charger functionality complies with

the Duracell/Intel Smart Charger Specification for a Level 2

charger.

The MAX1667 uses the SMBus Read-Word and WriteWord protocols to communicate with the battery it is

charging, as well as with any host system that monitors

the battery to charger communications. The MAX1667

acts only as a slave device and never initiates communication on the bus; it receives commands and responds

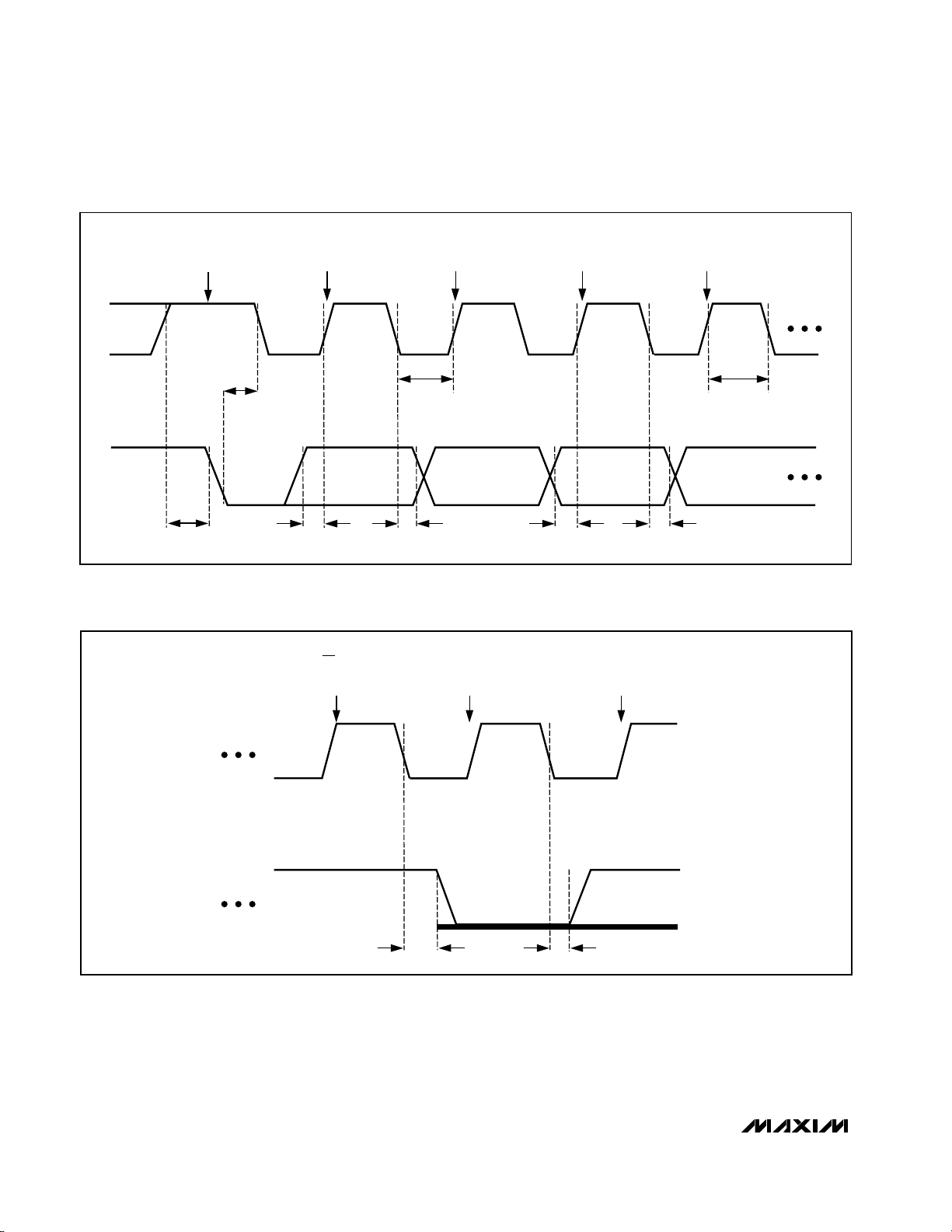

to queries for status information. Figures 8a and 8b show

the SMBus Write-Word and Read-Word protocols.

Each communication with the MAX1667 begins with the

master issuing a START condition, which is a high-tolow transition on SDA while SCL is high (Figure 1).

DESIGNATION MANUFACTURER

M2

Low-Side MOSFET

C8

R1

Sense Resistor

40mΩ ±1%, 1W

2N7002 equivalent

D2, D3 Central

Sprague 594D686X0025R2T

C1

Output Capacitor

TPSE686M020R0150

68µF, 20V, low ESR

IRF7805

M1

High-Side MOSFET

IR IRF7603 IRF7201

R5, R6 33Ω ±5%, 1/16W

R3 10kΩ ±1%, 1/16W

R2, R4 10kΩ ±5%, 1/16W

4A1A 3A

C4, C5, C9, C10 1µF

C2, C7, C11

C3 47nF

0.1µF

C6

Input Capacitor

Sprague 594D226X0035R2T

TPSE226M035R0200

2 x 22µF, 35V, low ESR

D1, D4, D5

Schottky Diodes

Central CMSH3-40 CMSH5-40

MBRS130LT3 MBRS340T3

1N5819 equivalent 1N5821 equivalent

MBRS340T3

1N5821 equivalent

AVX

AVX

Motorola

Motorola MMBF1170LT1

L1

Inductor

33µH, 1A ISAT 33µH, 3A ISAT, 30V 33µH, 4A ISAT, 30V

Sumida CDH74-330 CDRH127-330 CDRH127-270

Coiltronics UP1B-330 UP3B-330

Coilcraft DS3316P-333

FDS6680Fairchild FDN359A FDS4410

Motorola MTSF3N03HD MMDF3N03HD

IRC LR251201R040F

Dale WSL-2512/0.04W/±1%

22nF

Schottky diode, 50mA IDC, 30V, CMPSH-3

NIEC EC31 NSQ03A04 CMSH5-40

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

______________________________________________________________________________________ 17

When the master has finished communicating with the

slave, the master issues a STOP condition, which is a

low-to-high transition on SDA while SCL is high. The

bus is then free for another transmission. Figures 1 and

2 show timing diagrams for signals on the SMBus interface. The address byte, control byte, and data bytes

are transmitted between the START and STOP conditions. Data is transmitted in 8-bit words, and after each

byte either the slave or the master issues an acknowledgment (Figure 2); therefore, nine clock cycles are

required to transfer each byte. The SDA state is allowed

to change only while SCL is low, except for the START

and STOP conditions.

The MAX1667 7-bit address is preset to 0b0001001.

The eighth bit indicates a Write-Word (W = 0) or a

Read-Word (R = 1) command. This can also be denoted by the hexadecimal number 0x12 for a Write-Word

command or a 0x13 for a Read-Word command.

The following commands use the Write-Word protocol

(Figure 8a): ChargerMode(), ChargingVoltage(),

ChargingCurrent(), and AlarmWarning(). The

ChargerStatus command uses the Read-Word protocol

(Figure 8b).

ChargerMode()

The ChargerMode() command uses Write-Word protocol

(Figure 8a). The command code for ChargerMode() is

0x12 (0b00010010). Table 3 describes the functions of

the 16 data bits (D0–D15). Bit 0 refers to the D0 bit in the

Write-Word protocol.

Whenever the BATTERY_PRESENT status bit (bit 14) of

ChargerStatus() is clear, the HOT_STOP bit is set,

regardless of any previous ChargerMode() command.

To charge a battery that has a thermistor impedance

in the HOT range (i.e., THERMISTOR_HOT = 1 and

THERMISTOR_UR = 0), the host must use the

ChargerMode() command to clear HOT_STOP after the

battery is inserted. The HOT_STOP bit returns to its

default power-up condition (‘1’) whenever the battery is

removed.

ChargingVoltage()

The ChargingVoltage() command uses Write-Word protocol (Figure 8a). The command code for ChargingVoltage()

is 0x15 (0b00010101). The 16-bit binary number formed

by D15–D0 represents the voltage set point (V0) in millivolts; however, since the MAX1667 has only 16mV of resolution in setting V0, the D0, D1, D2, and D3 bits are

ignored.

The maximum voltage delivered by the MAX1667 is

18.416V, corresponding to a ChargingVoltage() value of

0x47F0. This is also the floating voltage set by the

power-on reset (POR). ChargingVoltage() values above

0x47F0 deliver the floating voltage and set the VOLTAGE_OR status bit. Any time the BATTERY_PRESENT

status bit is clear, the ChargingVoltage() register

returns to its POR state.

Figure 9 shows the mapping between V0 (the voltageregulation-loop set point) and the ChargingVoltage()

data.

ChargingCurrent()

The ChargingCurrent() command uses Write-Word protocol (Figure 8a). The command code for ChargingCurrent()

is 0x14 (0b00010100). The 16-bit binary number formed

by D15–D0 represents the current-limit set point (I0) in

milliamps (Table 4). Connecting SEL to AGND selects a

0.896A maximum setting for I0. Leaving SEL open selects

a 2.944A maximum setting for I0. Connecting SEL to VL

selects a 3.968A maximum setting for I0.

Two sources of current in the MAX1667 charge the battery: a linear current source begins from IOUT, and a

switching regulator controls the current flowing through

the current-sense resistor (R1). IOUT provides a tricklecharge current to compensate for battery self-discharge,

while the switching regulator provides large currents for

fast charging.

IOUT sources 7mA, while the switching regulator

sources from 128mA to 3968mA with a 5-bit resolution

(LSB = 5.12mV / RSENSE = 128mA with a 40mΩ sense

resistor). In Table 4, DA4–DA0 denotes the bits in the

current DAC code. Table 5 shows the relationship

between the value programmed with the ChargingCurrent() command and IOUT source current. The

CCV_LOW comparator checks to see if the output volt-

Table 2b. Component Suppliers

847-639-1469847-639-6400Coilcraft

516-435-1824516-435-1110

803-626-3123803-946-0690AVX

Central Semiconductor

561-241-9339561-241-7876Coiltronics

FAXPHONEMANUFACTURER

512-992-3377512-992-7900IRC

310-322-3332310-322-3331

605-665-1627605-668-4131Dale

IR

805-867-2698805-867-2555NIEC

603-224-1430603-224-1961

408-970-3950408-988-8000Siliconix

Sprague

847-956-0702847-956-0666Sumida

516-864-7630516-543-7100Zetex

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

18 ______________________________________________________________________________________

age is too high by comparing CCV to REF/4. If

CCV_LOW = 1 (when CCV < REF/4), IOUT shuts off.

This prevents the output voltage from exceeding the

voltage set point specified by the ChargingVoltage()

register. VOLTAGE_NOTREG = 1 whenever the internal

clamp pulls down on CCV. (The internal clamp pulls

down on CCV to keep its voltage close to CCI’s voltage.)

With the switching regulator on, the current through R1

(Figure 7) is regulated by sensing the average voltage

between CS and BATT. Figure 10 shows the relationship between the ChargingCurrent() data and the average voltage between CS and BATT.

When the switching regulator is off, DHI is forced to

LX and DLO is forced to ground. This prevents current

from flowing through inductor L1. Table 6 shows the

relationship between the ChargingCurrent() register

value and the switching regulator current DAC code

(DA4–DA0).

To ensure that the actual output current matches the

data value programmed with the ChargingCurrent()

command, R1 should be as close as possible to 40mΩ.

The SEL pin setting affects the full-scale current but not

the step size. ChargingCurrent() values above the full-

scale setting set the CURRENT_OR status bit. Note that

whenever any current DAC bits are set, the linear-current source is turned off.

The power-on reset value for the ChargingCurrent() register is 0x0007. Any time the BATTERY_PRESENT status

bit is clear (battery removed), the ChargingCurrent()

register returns to its power-on reset state. This ensures

that upon insertion of a battery, the initial charging current is 7mA.

AlarmWarning()

The AlarmWarning() command uses Write-Word protocol

(Figure 8a). The command code for AlarmWarning() is

0x16 (0b00010110). The AlarmWarning() command sets

the ALARM_INHIBITED status bit. The MAX1667 responds

to the following alarms: OVER_CHARGED_ALARM (D15),

TERMINATE_CHARGE_ALARM (D14), and OVER_TEMP_

ALARM (D12). Table 7 summarizes the AlarmWarning()

command’s function. The ALARM_INHIBITED status bit

remains set until BATTERY_PRESENT = 0 (battery

removed), a ChargerMode() command is written with the

POR_RESET bit set, or a new ChargingVoltage() or

ChargingCurrent() is written.

—7–9N/A

05

—4N/A

BATTERY_PRESENT_MASK

—

11–15

(MSB)

N/A Not implemented. Write 1 into this bit.

110HOT_STOP

Not implemented. Write 1 into this bit.

0 = Interrupt on either edge of the BATTERY_PRESENT status bit.

1 = Do not interrupt because of a BATTERY_PRESENT bit change.

Not implemented. Write 1 into this bit.

0 = The THERMISTOR_HOT status bit does not turn the charger off.

1 = THERMISTOR_HOT turns the charger off.

0 = No change in any non-ChargerMode() settings.

1 = Change the voltage and current settings to 0xFFFF and 0x0007

respectively; clear the THERMISTOR_HOT and ALARM_INHIBITED bits.

Not implemented. Write 0 into this bit.

0 = Allow normal operation; clear the CHG_INHIBITED status bit.

1 = Turn the charger off; set the CHG_INHIBITED status bit.

Not implemented. Write 0 into this bit.

FUNCTION

—2POR_RESET

—1

0

0

(LSB)

INHIBIT_CHARGE

ENABLE_POLLING

—3RESET_TO_ZERO

POR

VALUE**

BIT

POSITION*

BIT NAME

Table 3. ChargerMode() Bit Functions

16POWER_FAIL_MASK

0 = Interrupt on either edge of the POWER_FAIL status bit.

1 = Do not interrupt because of a POWER_FAIL bit change.

*

Bit position in the D15–D0 data. **Power-on reset value.

N/A = Not applicable

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

______________________________________________________________________________________ 19

ChargerStatus()

The ChargerStatus() command uses Read-Word protocol (Figure 8b). The command code for ChargerStatus()

is 0x13 (0b00010011). The ChargerStatus() command

returns information about thermistor impedance and the

MAX1667’s internal state. The Read-Word protocol

returns D15–D0. Table 8 describes the meaning of the

individual bits. The latched bits, THERMISTOR_HOT

and ALARM_INHIBITED, are cleared whenever BATTERY_PRESENT = 0 or ChargerMode() is written with

POR_RESET = 1.

Interrupts and the

Alert-Response Address

An interrupt is triggered (INT goes low) whenever power

is applied to DCIN, the BATTERY_PRESENT bit changes,

or the POWER_FAIL bit changes. BATTERY_PRESENT

and POWER_FAIL have interrupt masks that can be set

or cleared via the ChargerMode() command. INT stays

low until the interrupt is cleared. There are two methods

for clearing the interrupt: issuing a ChargerStatus() command, and using a modified Receive Byte protocol with a

0x19 (0b0011001) Alert-Response address. The

MAX1667 responds to the Alert-Response address with

its address (0x13) left justified as the most significant bits

of the returned byte.

__________Applications Information

Negative Input Voltage Protection

In most portable equipment, the DC power to charge

batteries enters through a two-conductor cylindrical

power jack. It is easy for the end user to add an

adapter to switch the DC power’s polarity. Polarized

capacitor C6 would be destroyed if a negative voltage

were applied. Diode D4 in Figure 7 prevents this from

happening.

Figure 8. SMBus a) Write-Word and b) Read-Word Protocols

0MSB LSB

1b7 bits

W

SLAVE

ADDRESS

S

1b

ACK S

MSB LSB

1b8 bits

ACK

COMMAND

BYTE

1b

ACK

1MSB LSB

1b7 bits

R

SLAVE

ADDRESS

MSB LSB

1b8 bits

ACK

LOW

DATA

BYTE

P

MSB LSB

1b8 bits

NACK

HIGH

DATA

BYTE

Preset to

0b0001001

D7 D0 D15 D8

ChargerMode() = 0x12

ChargingCurrent() = 0x14

ChargerVoltage() = 0x15

AlarmWarning() = 0x16

Preset to

0b0001001

Preset to

0b0001001

D7 D0 D15 D8

ChargerStatus() =

0x13

1b

ACK S

MSB LSB

1b8 bits

ACK

COMMAND

BYTE

0MSB LSB

1b7 bits

W

SLAVE

ADDRESS

S

MSB LSB

1b7 bits

ACK

LOW

DATA

BYTE

P

MSB LSB

1b8 bits

ACK

HIGH

DATA

BYTE

a) Write-Word Format

b) Read-Word Format

Legend:

S = Start Condition or Repeated Start Condition P = Stop Condition

ACK = Acknowledge (logic low) NACK = NOT Acknowledge (logic high)

W = Write Bit (logic low) R = Read Bit (logic high)

MASTER TO SLAVE

SLAVE TO MASTER

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

20 ______________________________________________________________________________________

Figure 9. ChargingVoltage() Data to Voltage Mapping

18.416V

16.368V

V

REF

= 4.096V

DCIN > 20V

0V

0b000000000000xxxx

0x000x

0x20Dx 0x47Fx

0b001000001101xxxx

0b010010100000xxxx

0x313x

0b001100010011xxxx

0xFFFx

0b111111111111xxxx

0x106x

0b000100000110xxxx

4.192V

12.592V

ChargingVoltage() D15–D0 DATA

VOLTAGE SET POINT (V0)

8.400V

Figure 10. Average Voltage Between CS and BATT vs. Code

Figure 11. Typical Thermistor Characteristics

1000

100

10

RESISTANCE (kΩ)

1

0.1

-40

-50 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110

TEMPERATURE (°C)

160 SEL = VL

115

AVERAGE CS-BATT VOLTAGE

IN CURRENT REGULATION (mV)

35

5

0x0080

A:

B:

C:

0x0380 0x0B80 0x0F80 0xFFFF

(128) (896)

0b00001

0b00111 0b10111 0b11111

A: ChargingCurrent( ) CODE (D15–D0)

B: EQUIVALENT DECIMAL CODE

C: CURRENT DAC CODE (DA4–DA0)

(2944) (3968) (65535)

SEL = OPEN

SEL = GND

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

______________________________________________________________________________________ 21

If reverse-polarity protection for the DC input power is

not necessary, diode D4 can be omitted. This eliminates

the power lost due to the voltage drop on diode D4.

Thermistor Characterization

Figure 11 represents the expected electrical behavior

of a 103ETB-type thermistor (nominally 10kΩ at +25°C

±5% or better) to be used with the MAX1667. The

graph is typical of the suggested thermistor’s characteristics.

THERMISTOR_OR bit is set only when the thermistor

value is > 100kΩ. This indicates that the thermistor is

open.

THERMISTOR_COLD bit is set only when the thermistor

value is > 30kΩ. The thermistor indicates a cold battery.

THERMISTOR_HOT bit is set only when the thermistor

value is < 3kΩ.

THERMISTOR_UR bit is set only when the thermistor

value is < 500Ω.

Multiple bits may be set depending on the values of the

thermistor (e.g., a 450Ω thermistor will cause both the

THERMISTOR_HOT

and

the THERMISTOR_UR bits to

be set). The thermistor may be replaced by fixed-value

resistors in battery packs that do not require the thermistor as a secondary fail-safe indicator. In this case, it

is the responsibility of the battery pack to manipulate

the resistance to obtain correct charger behavior.

Table 4. ChargingCurrent() Bit Functions

2048

DA4

1024

DA3

512

DA2

256

DA1

128

DA0

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

WEIGHT IN mA

(R

SENSE

= 40mΩ)

FUNCTION

BIT POSITION

3968*

FS* IOUT**

7**

x

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF

0x0000–0x000F

ChargingVoltage()

0x0000

0x0001–0x0007

0x0001–0x0007

0x0008–0x007F

0x0001–0x0007

000

x

ChargingCurrent()

x

1

0

0

1

x

CCV_LOW

x

0

x

x

1

x

VOLTAGE_

NOTREG

0

0

7

7

7

0

000

000

I

OUT

OUTPUT

CURRENT (mA)

0x0010–0xFFFF

000

000

x

x0x0010–0xFFFF

x

x

0x0010–0xFFFF

0x0008–0x007F

x

0x0080–0xFFFF

x

x

000

0x0008–0x007F

1

x

x

x

x

1

1

x

x

x

x

0

7

0

0

0

0

0

0

0

100

0

000

xx1

x10

000

ALARM_

INHIBITED

(Note 1)

CHARGE_

INHIBITED

Table 5. Relationship Between IOUT Source Current and ChargingCurrent() Value

*

When SEL = VL, values above 0x0F80 set the output current to 3.968A.

When SEL = OPEN, values above 0x0B80 set the output current to 2.944A.

When SEL = GND, values above 0x0380 set the output current to 0.896A.

**

Values below 0x0080 set the output current to 7mA.

Note 1: THERMISTOR_HOT and HOT_STOP and NOT (THERMISTOR_UR).

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

22 ______________________________________________________________________________________

0x000F–0xFFFF 0x0000–0x007F

0x0000–0x000F

ChargingVoltage()

0 No000

x

ChargingCurrent()

0x000F–0xFFFF 0x0100–0x037F

0x000F–0xFFFF

2–6 Yes

N/A

SEL = GND

CURRENT DAC CODE

000

0x0080–0x00FF

No

SEL = GND

SW REG ON?

1 Yes000

0x000F–0xFFFF 0x0400–0x047F

0x000F–0xFFFF

7 Yes000

0x0380–0x03FF

0x000F–0xFFFF 0x0B80–0x0BFF

0x000F–0xFFFF

7 Yes

7

000

0x0480–0x0B7F

Yes

7 Yes000

000

0x000F–0xFFFF 0x0C80

0x000F–0xFFFF

70Yes

0

000

0

0x0C00–0x0C7F

0x000F–0xFFFF 0x1000–0xFFFF

0x000F–0xFFFF

7 Yes

7

000

0x0F80–0x0FFF

Yes

7 Yes000

x x

x

N/A Nox1

ALARM_INHIBITED

0

(Note 1)

CHARGE_INHIBITED

x

x

N/AxNo

N/A Noxx1

100

000

Table 6. Relationship Between Current DAC Code and the ChargingCurrent() Value

x

x

1

x

1

x

x

x

x

1

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

AlarmWarning() DATA BITS

Set ALARM_INHIBITED

Set ALARM_INHIBITED

Set ALARM_INHIBITED

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

RESULT

Table 7. Effect of the AlarmWarning() Command

0

0

0

SEL = GND

CURRENT_OR

0

1

1

0

1

1

1

1

1

N/A

N/A

N/A

0

2–6

N/A

SEL = OPEN

CURRENT DAC CODE

1

8

23

7

9–22

23

23

23

23

N/A

N/A

N/A

No

Yes

No

SEL = OPEN

SW REG ON?

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

0

0

0

SEL = OPEN

CURRENT_OR

0

0

0

0

0

1

1

1

1

N/A

N/A

N/A

0

2–6

N/A

SEL = VL

CURRENT DAC CODE

1

8

23

7

9–22

25–30

31

24

31

N/A

N/A

N/A

No

Yes

No

SEL = VL

SW REG ON?

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

0

0

0

SEL = VL

CURRENT_OR

0

0

0

0

0

0

1

0

0

N/A

N/A

N/A

Note 1: THERMISTOR_HOT and HOT_STOP and NOT (THERMISTOR_UR).

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

______________________________________________________________________________________ 23

Table 8. ChargerStatus() Bit Descriptions

DESCRIPTION

0 = Ready to charge a smart battery

1 = Charger is off; IOUT current = 0mA; DLO = PGND; DHI = LX

0 = VL voltage < 4V

1 = VL voltage > 4V

Always returns ‘0’

0 = THM voltage > 5% of REF voltage

1 = THM voltage < 5% of REF voltage

No11

This bit reports the state of an internal SR flip-flop (denoted ALARM_INHIBITED

flip-flop). The ALARM_INHIBITED flip-flop is set whenever the AlarmWarning()

command is written with D15, D14, or D12 set. The ALARM_INHIBITED flip-flop

is cleared whenever BATTERY_PRESENT = 0, or ChargerMode() is written with

POR_RESET = 1, or ChargingVoltage() or ChargingCurrent() is written.

LATCHED?

Yes

No

N/A

BIT

POSITION

0

15

1

AC_PRESENT

0 = No battery is present (THERMISTOR_OR = 1).

1 = A battery is present (THERMISTOR_OR = 0).

Yes

No14

12

BATTERY_PRESENT

0 = BATT voltage < 89% of DCIN voltage

1 = BATT voltage > 89% of DCIN voltage

ALARM_INHIBITED

No13

THERMISTOR_UR

Always returns 0

0 = ChargingCurrent() value is valid for MAX1667.

1 = ChargingCurrent() value exceeds what MAX1667 can actually deliver.

0 = ChargingVoltage() value is valid for MAX1667.

1 = ChargingVoltage() value exceeds what MAX1667 can actually deliver.

N/A

No

No

5

6

7

0 = THM voltage < 91% of REF voltage

1 = THM voltage > 91% of REF voltage

0 = THM voltage < 75% of REF voltage

1 = THM voltage > 75% of REF voltage

This bit reports the state of an internal SR flip-flop (denoted THERMISTOR_HOT

flip-flop). The THERMISTOR_HOT flip-flop is set whenever THM is below 23%

of REF. It is cleared whenever BATTERY_PRESENT = 0 or ChargerMode() is

written with POR_RESET = 1.

No

No

Yes

8

9

10

THERMISTOR_OR

THERMISTOR_COLD

THERMISTOR_HOT

LEVEL_3

CURRENT_OR

VOLTAGE_OR

POWER_FAIL

0 = BATT voltage is limited at the voltage set point (BATT = V0).

1 = BATT voltage is less than the voltage set point (BATT < V0).

Always returns 1

0 = Current through R1 is at its limit (I

BATT

= I0).

1 = Current through R1 is less than its limit (I

BATT

< I0).

No

N/A

No

2

4

3

VOLTAGE_NOTREG

LEVEL_2

NAME

CHARGE_INHIBITED

CURRENT_NOTREG

MASTER_MODE

*

Bit position in the D15–D0 data

N/A = Not applicable

PC Board Layout Considerations

Good PC board layout is required to achieve specified

noise, efficiency, and stable performance. The PC

board layout artist must be given explicit instructions,

preferably a pencil sketch showing the placement of

power-switching components and high-current routing.

Refer to the PC board layout in the MAX1667 evaluation

kit manual for examples. A ground plane is essential for

optimum performance. In most applications, the circuit

will be located on a multilayer board, and full use of the

four or more copper layers is recommended. Use the

top layer for high-current connections, the bottom layer

for quiet connections (REF, CCV, CCI, DACV, GND),

and the inner layers for an uninterrupted ground plane.

Use the following step-by-step guide:

1) Place the high-power components (C1, C6, M1, M2,

D1, L1, and R1) first, with their grounds adjacent:

•

Minimize current-sense resistor trace lengths

and

ensure accurate current sensing with Kelvin connections (Figure 12).

•

Minimize ground trace lengths

in the high-current

paths.

•

Minimize other trace lengths

in the high-current

paths:

— Use > 5mm-wide traces.

— Connect CIN to high-side MOSFET drain: 10mm

max length.

— Connect rectifier diode cathode to low side.

— MOSFET: 5mm max length.

— LX node (MOSFETs, rectifier cathode, induc-

tor): 15mm max length.

Ideally, surface-mount power components are butted

up to one another with their ground terminals almost

touching. These high-current grounds are then connected to each other with a wide, filled zone of

top-layer copper so they do not go through vias. The

resulting top-layer subground plane is connected to the

normal inner-layer ground plane at the output ground

terminals, which ensures that the IC’s analog ground is

sensing at the supply’s output terminals without interference from IR drops and ground noise. Other high-current paths should also be minimized, but focusing

primarily on short ground and current-sense connections eliminates about 90% of all PC board layout problems.

2) Place the IC and signal components. Keep the main

switching nodes (LX nodes) away from sensitive

analog components (current-sense traces and REF

capacitor). Place the IC and analog components on

the opposite side of the board from the powerswitching node. Important: The IC must be no further than 10mm from the current-sense resistors.

Keep the gate-drive traces (DH, DL, and BST) shorter than 20mm and route them away from CSH, CSL,

and REF. Place ceramic bypass capacitors close to

the IC. The bulk capacitors can be placed further

away.

3) Use a single-point star ground where the input

ground trace, power ground (subground plane), and

normal ground plane meet at the supply’s output

ground terminal. Connect both IC ground pins and

all IC bypass capacitors to the normal ground plane.

Upgrading from MAX1647 to MAX1667

The MAX1667 is a pin- and software-compatible

upgrade to the MAX1647, with the following functional

differences:

1) The PWM duty cycle has been extended to 97%.

2) The internal reference has been changed to

+4.096V with 1% accuracy over line, load, and temperature.

3) The internal voltage DAC has been changed to allow

a program voltage of 18,416mV. Up to four Li+ cells

can be charged.

4) The linear current source (IOUT) has been reduced

to 7mA and turns off when the switching regulator is

on.

5) An internal diode has been added to the IOUT pin to

prevent reverse current from BATT when the DC

source is removed.

6) The internal current DAC was changed from 6-bit to

5-bit resolution.

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

24 ______________________________________________________________________________________

Figure 12. Kelvin Connections for the Current-Sense Resistors

HIGH-CURRENT PATH

SENSE RESISTOR

MAX1667

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

______________________________________________________________________________________ 25

7) The SEL pin digitally limits the output current to 4A,

3A, or 1A without a change in sense resistor value

between the three modes.

8) The single count current-sense voltage has been

changed to 5mV. R1 required is now 40mΩ.

9) After the AlarmWarning() message, the charger is

not locked off. Subsequent ChargingVoltage() or

ChargingCurrent() commands allow the MAX1667

to resume the charge.

10) The Alert-Response address is 0x13 (0b00010011).

When upgrading a MAX1647 design, follow these recommended or required changes (part numbers refer to

Figure 3 of the MAX1647 data sheet):

1) Change R1 to 40mΩ (required).

2) Remove diodes D5 and D6, transistor Q1, and resis-

tor R6. Connect IOUT directly to BATT (recommended).

3) Remove the external +4.096V reference (recom-

mended).

4) Remove D6 (recommended). When doing this, also

place a small-signal diode in series with R7 and connect it directly to the DC source (see D3 and R5 on

Figure 3 of the MAX1647 data sheet).

Pin Configuration

TRANSISTOR COUNT: 6378

SUBSTRATE CONNECTED TO AGND

Chip Information

TOP VIEW

1

IOUT

DCIN

CCV

CCI

SEL

CS

BATT

REF

2

3

VL

4

MAX1667

5

6

7

8

9

10

SSOP

20

19

18

17

16

15

14

13

12

11

BST

LX

DHI

DLO

PGND

DACV

SDA

SCL

THM

INTAGND

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

26 ______________________________________________________________________________________

________________________________________________________Package Information

SSOP.EPS

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

______________________________________________________________________________________ 27

NOTES

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

28

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

© 1999 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

MAX1667

Chemistry-Independent,

Level 2 Smart Battery Charger

NOTES

Loading...

Loading...