19-1158; Rev 0; 12/96

Chemistry-Independent

Battery Chargers

_______________General Description

The MAX1647/MAX1648 provide the power control necessary to charge batteries of any chemistry. In the MAX1647,

all charging functions are controlled via the Intel System

Management Bus (SMBus™) interface. The SMBus 2-wire

serial interface sets the charge voltage and current, and

provides thermal status information. The MAX1647 functions as a level 2 charger, compliant with the Duracell/Intel

Smart Battery Charger Specification. The MAX1648 omits

the SMBus serial interface, and instead sets the charge

voltage and current proportional to the voltage applied to

external control pins.

In addition to the feature set required for a level 2 charger,

the MAX1647 generates interrupts to signal the host when

power is applied to the charger or a battery is installed or

removed. Additional status bits allow the host to check

whether the charger has enough input voltage, and

whether the voltage on or current into the battery is being

regulated. This allows the host to determine when lithiumion batteries have completed charge without interrogating

the battery.

The MAX1647 is available in a 20-pin SSOP with a 2mm

profile height. The MAX1648 is available in a 16-pin SO

package.

________________________Applications

Notebook Computers

Personal Digital Assistants

Charger Base Stations

Phones

____________________________Features

♦ Charges Any Battery Chemistry:

Li-Ion, NiCd, NiMH, Lead Acid, etc.

♦ Intel SMBus 2-Wire Serial Interface (MAX1647)

♦ Intel/Duracell Level 2 Smart Battery Compliant

(MAX1647)

♦ 4A, 2A, or 1A Maximum Battery-Charge Current

♦ 11-Bit Control of Charge Current

♦ Up to 18V Battery Voltage

♦ 10-Bit Control of Voltage

♦ ±0.75% Voltage Accuracy with External ±0.1%

Reference

♦ Up to 28V Input Voltage

♦ Battery Thermistor Fail-Safe Protection

______________Ordering Information

PART

MAX1647EAP

MAX1648ESE

TEMP. RANGE PIN-PACKAGE

-40°C to +85°C

-40°C to +85°C

20 SSOP

16 Narrow SO

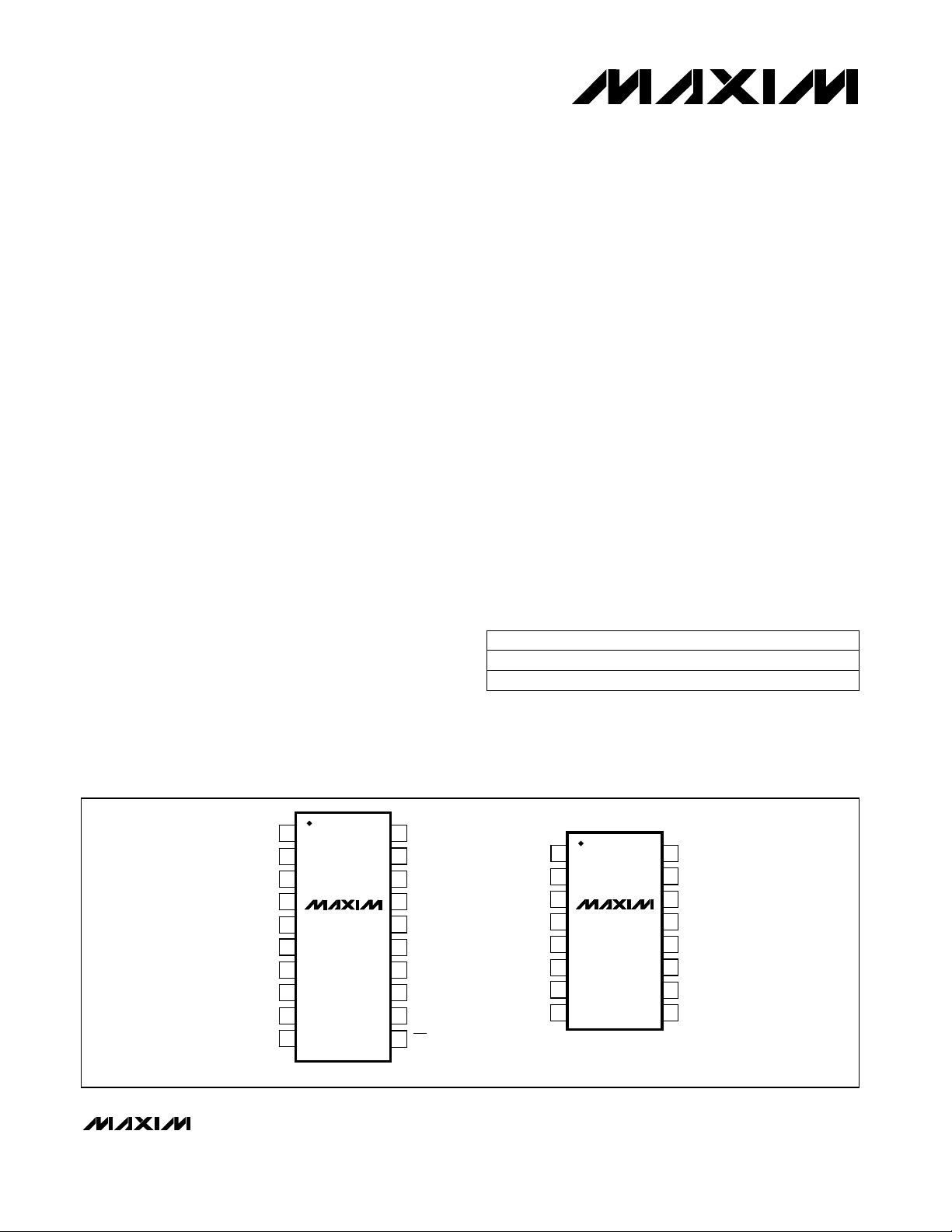

MAX1647/MAX1648

__________________________________________________________Pin Configurations

TOP VIEW

IOUT

DCIN

CCV

CCI

SEL

BATT

REF

1

2

3

VL

4

MAX1647

5

6

CS

7

8

9

10

SSOP

20

BST

16

DCIN

CCV

CCI

BATT

REF

AGND

1

VL

2

3

MAX1648

4

CS

5

6

7

8

SO

LX

19

18

DHI

17

DLO

PGND

16

15

DACV

SDA

14

SCL

13

12

THM

11

INTAGND

BST

LX

15

DHI

14

13

DLO

PGND

12

SETV

11

SETI

10

THM

9

SMBus is a trademark of Intel Corp.

________________________________________________________________

Maxim Integrated Products

1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

Chemistry-Independent

Battery Chargers

ABSOLUTE MAXIMUM RATINGS

DCIN to AGND..........................................................-0.3V to 30V

DCIN to IOUT...........................................................-0.3V to 7.5V

BST to AGND............................................................-0.3V to 36V

BST, DHI to LX............................................................-0.3V to 6V

LX to AGND ..............................................................-0.3V to 30V

THM, CCI, CCV, DACV, REF,

DLO to AGND................................................-0.3V to (VL + 0.3V)

VL, SEL, INT, SDA, SCL to AGND (MAX1647) ...........-0.3V to 6V

SETV, SETI to AGND (MAX1648)................................-0.3V to 6V

BATT, CS+ to AGND.................................................-0.3V to 20V

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

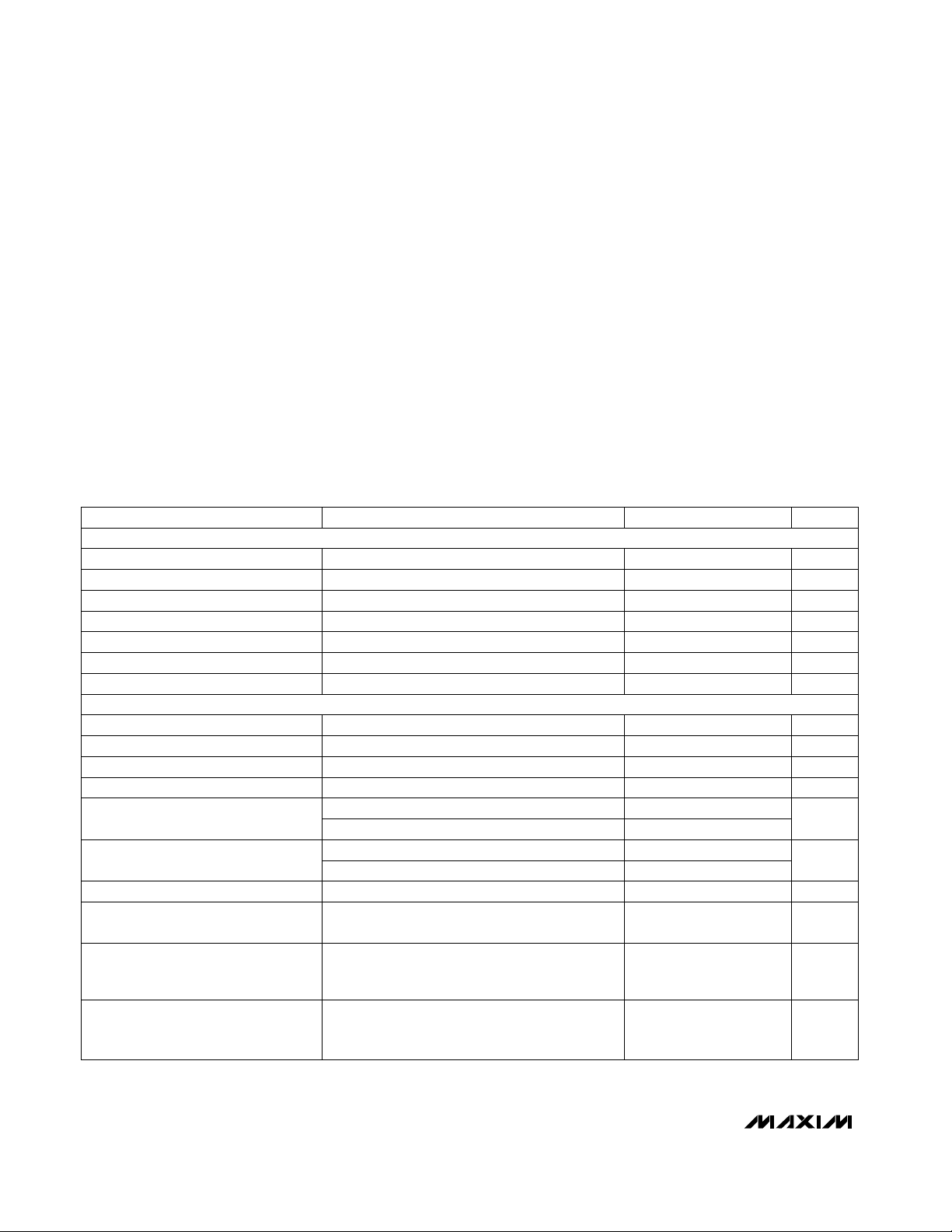

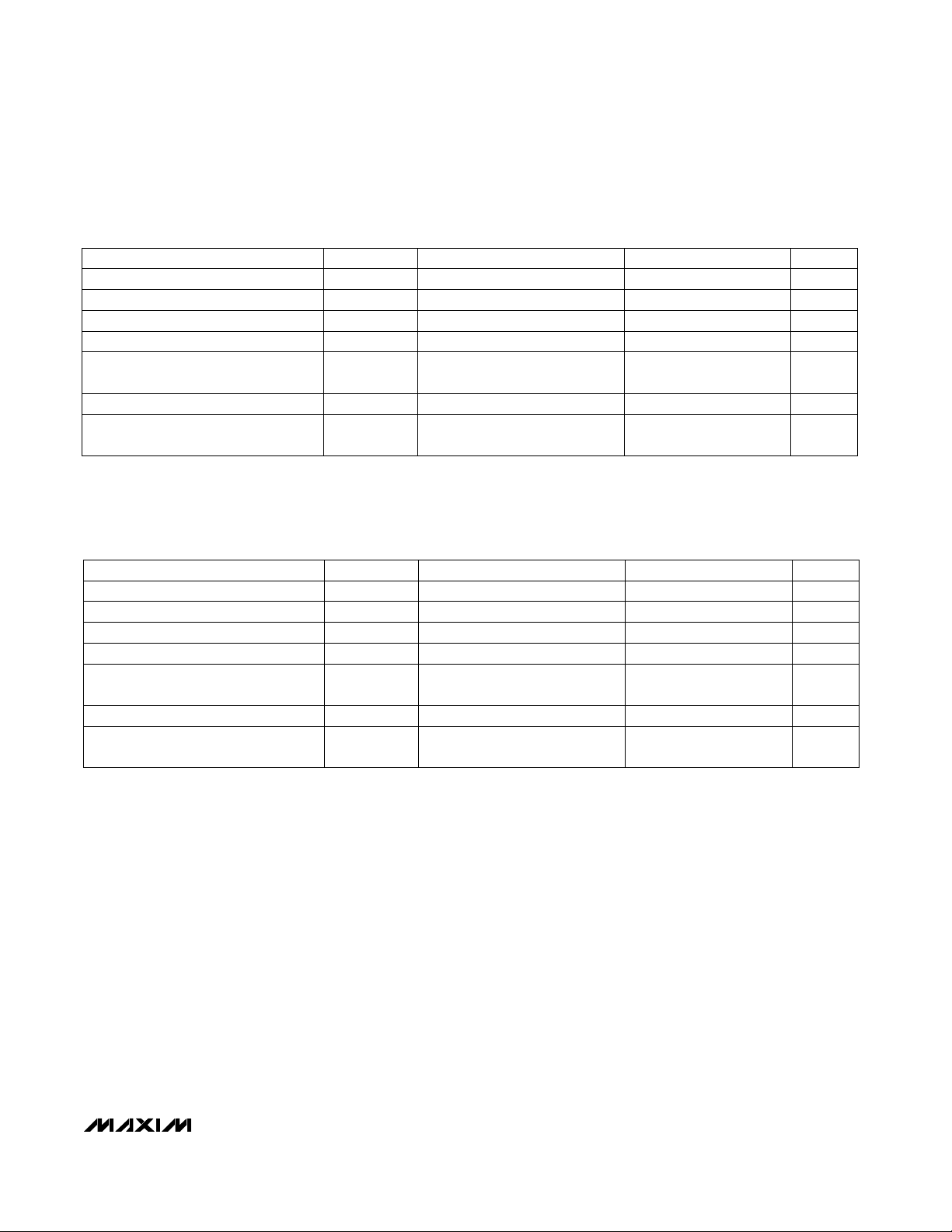

ELECTRICAL CHARACTERISTICS

(V

DCIN

= 18V, V

= 4.096V, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

REF

PGND to AGND.....................................................-0.3V to +0.3V

SDA, INT Current ................................................................50mA

VL Current...........................................................................50mA

Continuous Power Dissipation (T

16-Pin SO (derate 8.7mW/°C above +70°C).................696mW

20-Pin SSOP (derate 8mW/°C above +70°C) ...............640mW

Operating Temperature Range

MAX1647EAP, MAX1648ESE ...........................-40°C to +85°C

Storage Temperature.........................................-60°C to +150°C

Lead Temperature (soldering, 10sec).............................+300°C

= +70°C)

A

MAX1647/MAX1648

SUPPLY AND REFERENCE

LOAD

SWITCHING REGULATOR

BATT Input Current (Note 1)

CS Input Current (Note 1)

CS to BATT Single-Count

Current-Sense Voltage

CS to BATT Full-Scale

Current-Sense Voltage

Voltage Accuracy

MAX1647, SEL = open,

ChargingCurrent( ) = 0x0020

MAX1647, SEL = open,

ChargingCurrent( ) = 0x07F0;

MAX1648, V

MAX1647, ChargingVoltage( ) = 0x1060,

ChargingVoltage( ) = 0x3130; MAX1648,

V

SETV

< 28V, logic inputs = VLDCIN Quiescent Current

DCIN

< 28V, no loadVL Output Voltage

DCIN

= 10mAVL Load Regulation

SOURCE

BATT

BATT

SETI

= 3.15V, V

< 500µAREF Output Voltage

= 12V

= 12V

= 1.024V

SETV

= 1.05V

15VL < 3.2V, V

350 500VL < 5.15V, V

15VL < 3.2V, VCS= 12V

170 400VL < 5.15V, VCS= 12V

-0.65 0.65

UNITSMIN TYP MAXCONDITIONSPARAMETER

V7.5 28DCIN Input Voltage Range

mA467.5V < V

V5.15 5.4 5.657.5V < V

mV100I

V3.20 4 5.15MAX1647VL AC_PRESENT Trip Point

V3.74 3.9 4.070µA < I

µA700REF Overdrive Input Current

kHz200 250 300Oscillator Frequency

%89 93DHI Maximum Duty Cycle

Ω47High or lowDHI On-Resistance

Ω614High or lowDLO On-Resistance

µA

µA

V019BATT, CS Input Voltage Range

mV2.94

mV170 185 200

%

2 _______________________________________________________________________________________

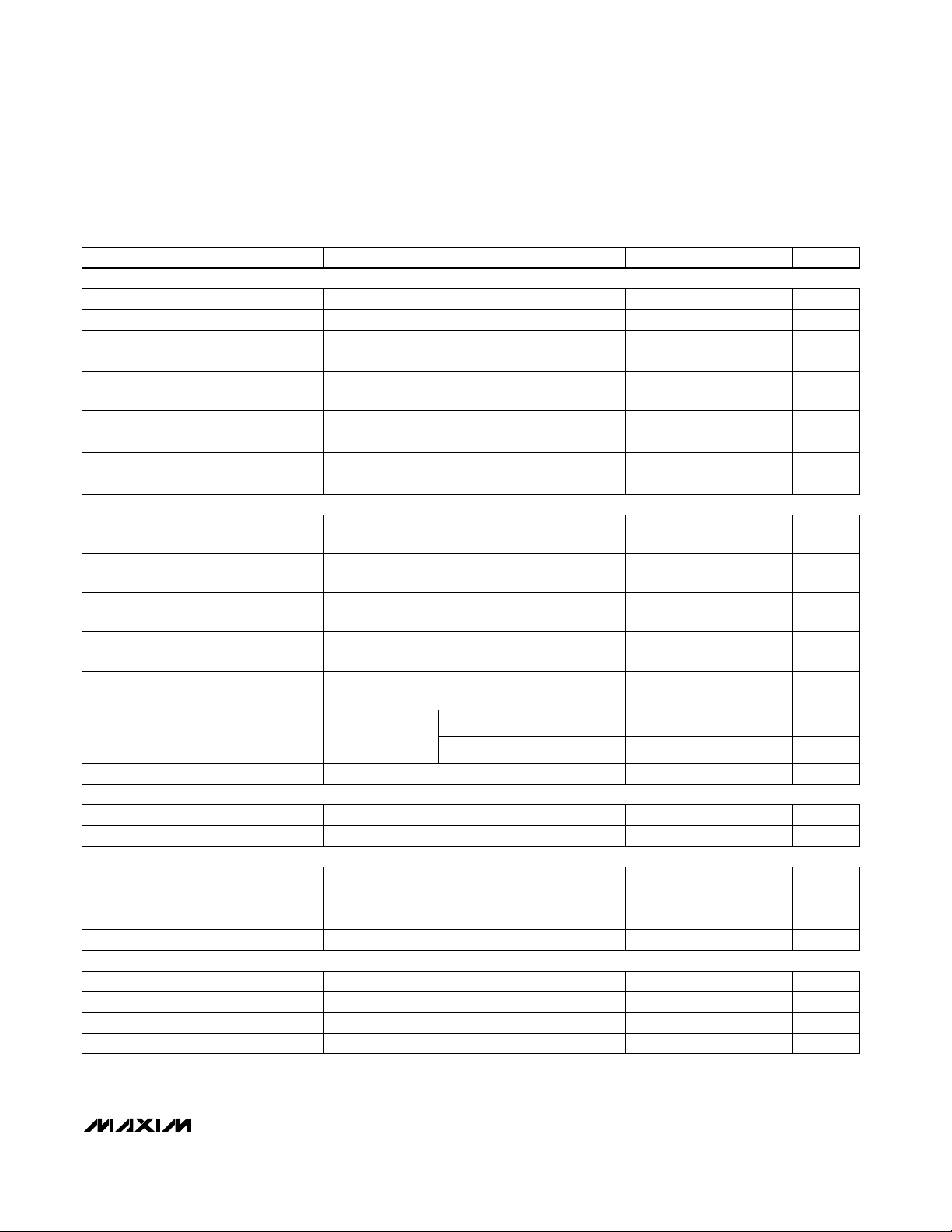

Chemistry-Independent

Battery Chargers

ELECTRICAL CHARACTERISTICS (continued)

(V

= 18V, V

DCIN

ERROR AMPLIFIERS

GMV Amplifier Maximum

Output Current

GMI Amplifier Maximum

Output Current

CCI Clamp Voltage with

Respect to CCV

CCV Clamp Voltage with

Respect to CCI

TRIP POINTS AND LINEAR CURRENT SOURCES

THM THERMISTOR_OR

Over-Range Trip Point

THM THERMISTOR_COLD

Trip Point

THM THERMISTOR_HOT

Trip Point

THM THERMISTOR_UR

Under-Range Trip Point

IOUT Output Current

CURRENT- AND VOLTAGE-SETTING DACs (MAX1647)

SETV, SETI (MAX1648)

LOGIC LEVELS (MAX1647)

Note 1: When DCIN is less than 4V, VL is less than 3.2V, causing the battery current to be typically 2µA (CS plus BATT input

current).

= 4.096V, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

REF

< 3.5V

CCV

< 3.5V

CCI

86.5 89 91.5MAX1647BATT POWER_FAIL Trip Point

89.5 91 92.5MAX1647

74 75.5 77

22 23.5 25

3 4.5 6MAX1647

MAX1647,

V

= 7.5V,

DCIN

V

= 0V

IOUT

= 0.6VSDA Output Low Sink Current

SDA

ChargingCurrent( ) = 0x001F

ChargingCurrent( ) = 0x0000 10 µA

UNITSMIN TYP MAXCONDITIONSPARAMETER

mA/V1.4GMV Amplifier Transconductance

mA/V0.2GMI Amplifier Transconductance

V

µA±80

µA±200

mV25 80 2001.1V < V

mV25 80 2001.1V < V

% of

DCIN

% of

V

REF

% of

V

REF

% of

V

REF

% of

V

REF

mA25 31 35

V-7.5 -1.0With respect to DCIN voltageIOUT Operating Voltage Range

bits6Guaranteed monotonicCDAC Current-Setting DAC Resolution

bits10Guaranteed monotonicVDAC Voltage-Setting DAC Resolution

µA1SETV Input Bias Current

µA5SETI Input Bias Current

V0 4.2SETV Input Voltage Range

V0 1.024SETI Input Voltage Range

V0.8SDA, SCL Input Low Voltage

V2.8SDA, SCL Input High Voltage

µA-1 1SDA, SCL Input Bias Current

mA6V

MAX1647/MAX1648

_______________________________________________________________________________________ 3

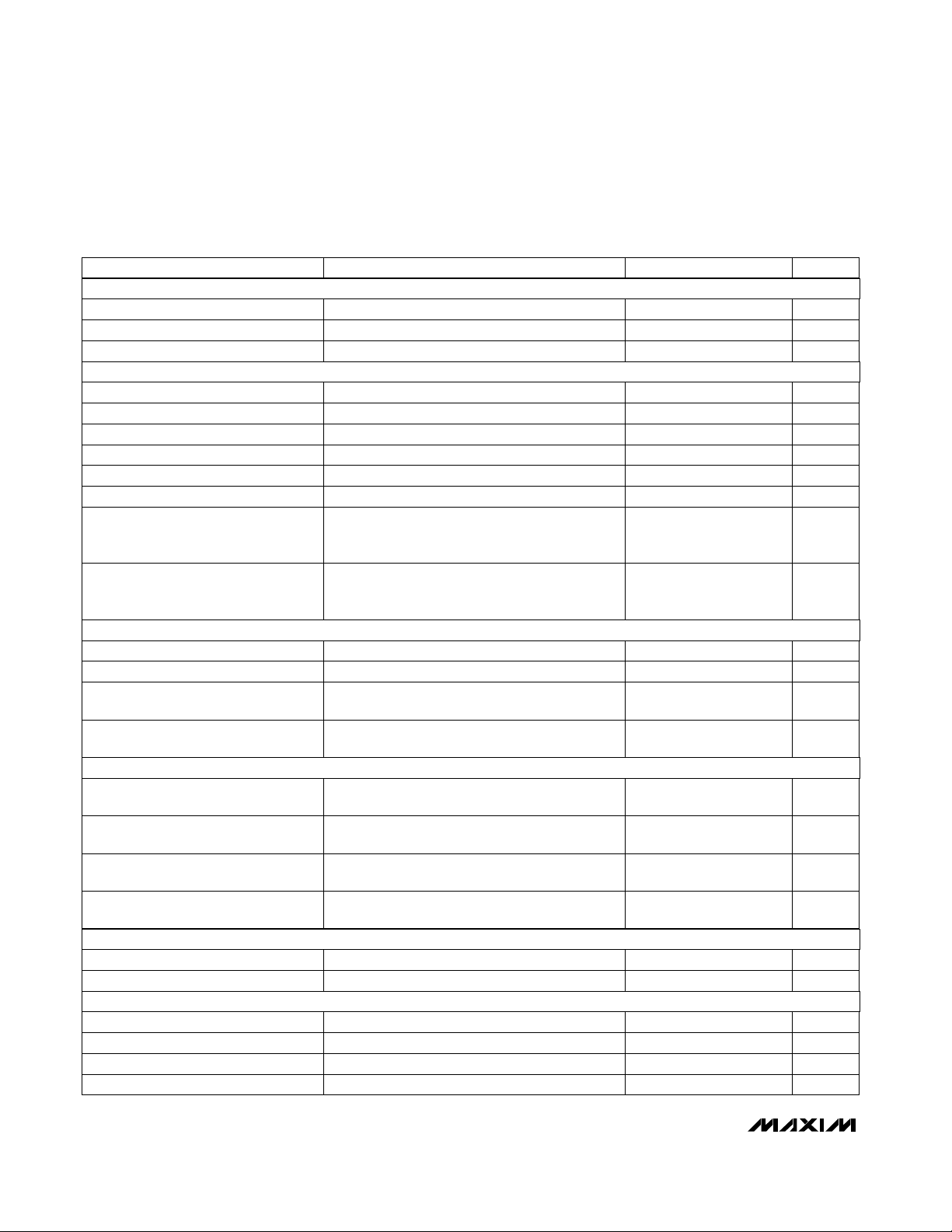

Chemistry-Independent

Battery Chargers

ELECTRICAL CHARACTERISTICS

(V

= 18V, V

DCIN

temperature range are guaranteed by design.)

SUPPLY AND REFERENCE

SWITCHING REGULATOR

MAX1647/MAX1648

CS to BATT Full-Scale

Current-Sense Voltage

Voltage Accuracy

ERROR AMPLIFIERS

GMV Amplifier Maximum

Output Current

GMI Amplifier Maximum

Output Current

TRIP POINTS AND LINEAR CURRENT SOURCES

THM THERMISTOR_OR

Over-Range Trip Point

THM THERMISTOR_COLD

Trip Point

THM THERMISTOR_HOT

Trip Point

THM THERMISTOR_UR

Under-Range Trip Point

SETV, SETI (MAX1648)

LOGIC LEVELS (MAX1647)

= 4.096V, TA= -40°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted. Limits over this

REF

< 28V, logic inputs = VLDCIN Quiescent Current

DCIN

< 28V, no loadVL Output Voltage

DCIN

SOURCE

BATT

MAX1647, SEL = open,

ChargingCurrent( ) = 0x07F0;

MAX1648, V

MAX1647, ChargingVoltage( ) = 0x1060,

ChargingVoltage( ) = 0x3130; MAX1648,

V

SETV

SDA

SETI

= 3.15V, V

= 0.6VSDA Output Low Sink Current

< 500µAREF Output Voltage

= 12V

= 1.024V

SETV

= 1.05V

89.5 91 92.5MAX1647

74 75.5 77

22 23.5 25

3 4.5 6MAX1647

UNITSMIN TYP MAXCONDITIONSPARAMETER

mA/V1.4GMV Amplifier Transconductance

mA/V0.2GMI Amplifier Transconductance

mA467.5V < V

V5.15 5.4 5.657.5V < V

V3.74 3.9 4.070µA < I

kHz200 250 310Oscillator Frequency

%89DHI Maximum Duty Cycle

Ω47High or lowDHI On-Resistance

Ω614High or lowDLO On-Resistance

µABATT Input Current 5VL < 3.2V, V

µACS Input Current 5VL < 3.2V, VCS= 12V

mV160 185 200

%-0.65 0.65

µA±130

µA±320

% of

V

REF

% of

V

REF

% of

V

REF

% of

V

REF

µA1SETV Input Bias Current

µA5SETI Input Bias Current

V0.8SDA, SCL Input Low Voltage

V2.8SDA, SCL Input High Voltage

µA-1 1SDA, SCL Input Bias Current

mA6V

4 _______________________________________________________________________________________

Chemistry-Independent

Battery Chargers

TIMING CHARACTERISTICS—MAX1647

(TA= 0°C to +85°C, unless otherwise noted.)

SCL Serial-Clock High Period

SCL Serial-Clock Low Period

Start-Condition Setup Time

Start-Condition Hold Time

SDA Valid to SCL Rising-Edge

Setup Time, Slave Clocking in Data

SCL Falling Edge to SDA Transition

SCL Falling Edge to SDA Valid,

Master Clocking in Data

HIGH

LOW

SU:STA

HD:STA

SU:DAT

HD:DAT

DV

TIMING CHARACTERISTICS—MAX1647

(TA= -40°C to +85°C, unless otherwise noted. Limits over this temperature range are guaranteed by design.)

CONDITIONS

SCL Serial-Clock High Period

SCL Serial-Clock Low Period

Start-Condition Setup Time

Start-Condition Hold Time

SDA Valid to SCL Rising-Edge

Setup Time, Slave Clocking in Data

SCL Falling Edge to SDA Transition

SCL Falling Edge to SDA Valid,

Master Clocking in Data

HIGH

LOW

SU:STA

HD:STA

SU:DAT

HD:DAT

DV

MAX1647/MAX1648

UNITSMIN TYP MAXSYMBOLPARAMETER CONDITIONS

µs4t

µs4.7t

µs4.7t

µs4t

ns250t

ns0t

µs1t

UNITSMIN TYP MAXSYMBOLPARAMETER

µs4t

µs4.7t

µs4.7t

µs4t

ns250t

ns0t

µs1t

_______________________________________________________________________________________ 5

Chemistry-Independent

Battery Chargers

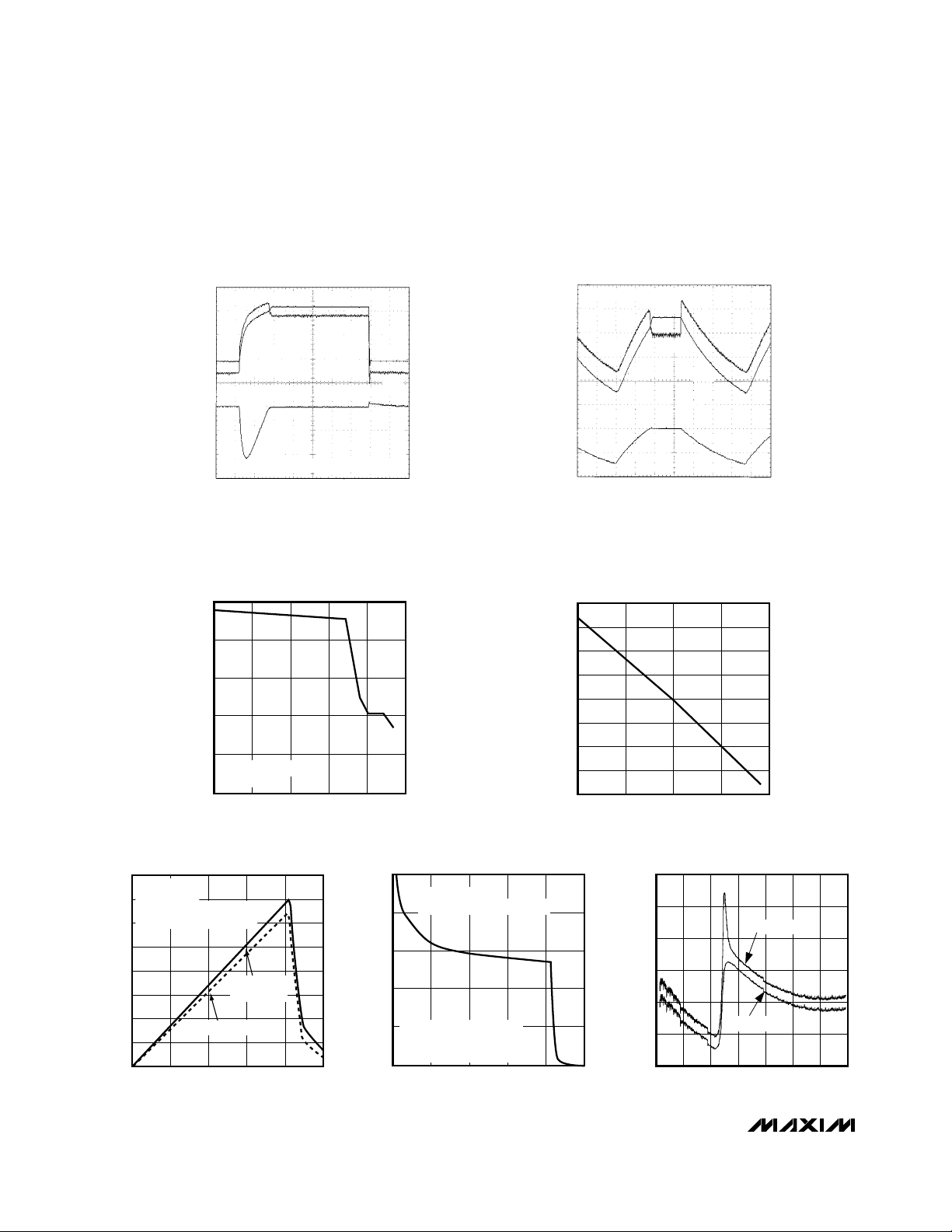

__________________________________________Typical Operating Characteristics

(Circuit of Figure 3, TA = +25°C, unless otherwise noted.)

MAX1647

BATT LOAD TRANSIENT

CCI

CCV

0.9A TO 1.9A TO 0.9A

1ms/div

MAX1647/MAX1648

ChargingVoltage( ) = 0x2EE0 = 12000mV

ChargingCurrent( ) = 0xFFFF = MAX VALUE

ACDCIN = 18.0V, SEL = OPEN, R1 = 0.1Ω

R2 = 10kΩ, C1 = 68µF, C2 = 0.1µF, C3 = 47nF

L1 = 22µH, V

= 4.096V

REF

VL VOLTAGE vs. LOAD CURRENT

5.5

5.0

4.5

VL (V)

4.0

3.5

CIRCUIT OF FIGURE 3

= 6.6V

V

DCIN

0

050

10 20 40

LOAD CURRENT (mA)

30

INPUT AND OUTPUT POWER

40

V

= 28V

DCIN

= 12.6V

V

BATT

35

ChargingCurrent( ) = 0xFFFF

ChargingVoltage( ) = 0xFFFF

30

25

20

POWER (W)

15

10

5

0

500

0 2500

CURRENT INTO BATT (mA)

POWER INTO

CIRCUIT

POWER TO BATT

1000 1500

2000

0.001

MAX1647/48-05

0.01

0.1

DROP IN BATT OUTPUT VOLTAGE (%)

100

MAX1647/48-01

V

2.4V

12V

MAX1647/48-03

CCI

V

CCV

200mV/div

V

BATT

1V/div

CCI

CCV

MAX1647

OUTPUT V-I CHARACTERISTIC

BATT NO-LOAD

OUTPUT VOLTAGE = 16.384V

1

10

V

= 28V, V

DCIN

ChargingVoltage( ) = 0xFFFF

ChargingCurrent( ) = 0xFFFF

500 1000 2000

0 2500

= 4.096V

REF

1500

LOAD CURRENT (mA)

1.1A TO 0.9A TO 1.1A

CCV

ChargingVoltage( ) = 0x2EE0 = 12000mV

ChargingCurrent( ) = 0x03E8 = 1000mA

ACDCIN = 18.0V, SEL = OPEN, C1 = 68µF,

C2 = 0.1µF, C3 = 47nF, R1 = 0.1Ω

R2 = 10kΩ, L1 = 22µH, V

INTERNAL REFERENCE VOLTAGE

3.86

3.84

3.82

3.80

(V)

3.78

REF

V

3.76

3.74

3.72

3.70

0 2.0

MAX1647/48-06

MAX1647

BATT LOAD TRANSIENT

CCI

CCV

CCI

2ms/div

REF

0.5 1.0 1.5

LOAD CURRENT (mA)

MAX1647/48-02

CCV

CCI

= 4.096V

OUTPUT VOLTAGE ERROR

0.8

0.6

0.4

0.2

0

OUTPUT VOLTAGE ERROR (%)

-0.2

-0.4

4500 8500 12,500

PROGRAMMED VOLTAGE CODE IN DECIMAL

3mA LOAD

300mA LOAD

2.3V

12V

MAX1647/48-04

V

CCV

V

CCI

100mV/div

V

BATT

5V/div

16,500

MAX1647/48-07

6 _______________________________________________________________________________________

Chemistry-Independent

Battery Chargers

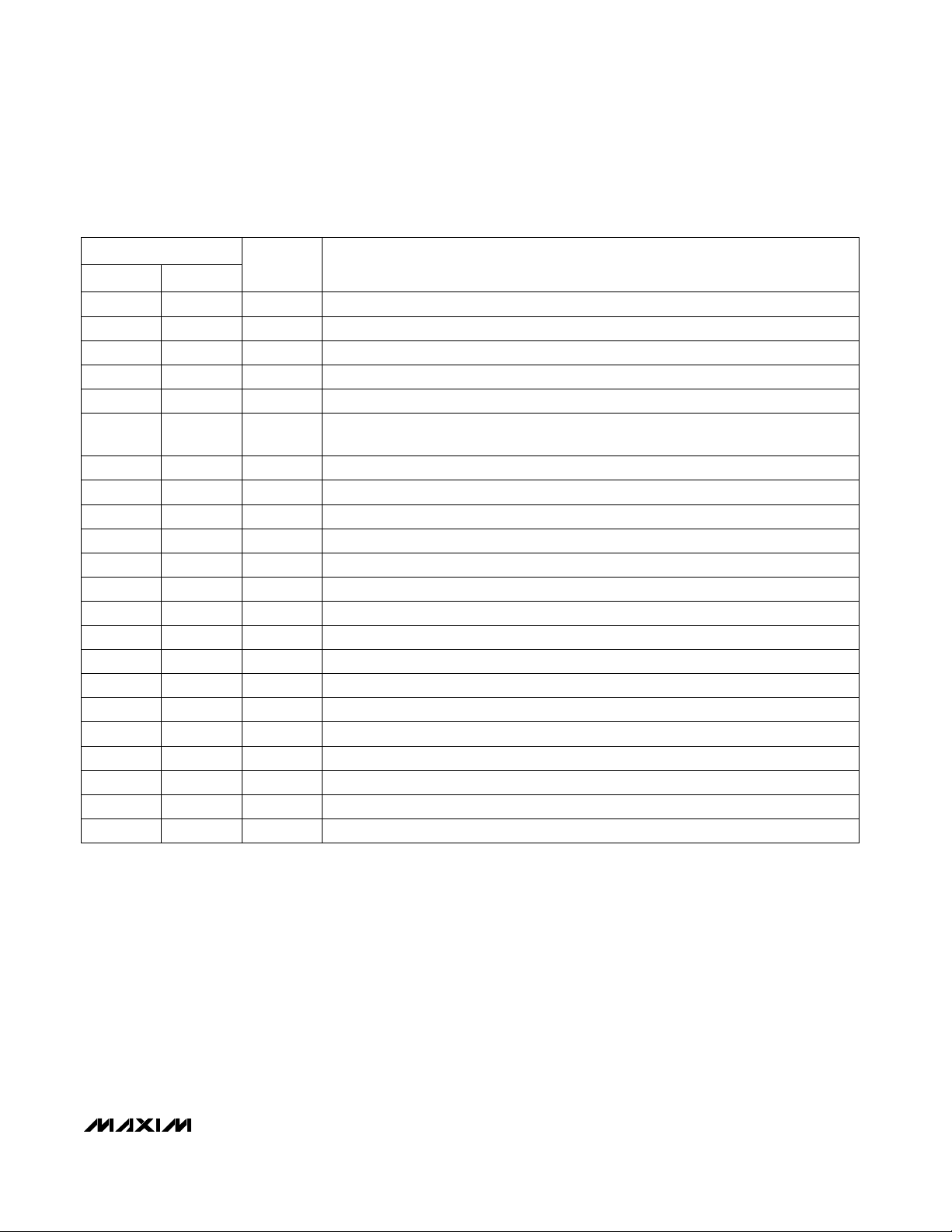

______________________________________________________________Pin Description

PIN

MAX1647 MAX1648

—6 SEL

NAME

INT

Linear Current-Source Output—1 IOUT

Input Voltage for Powering Charger12 DCIN

Chip Power Supply. 5.4V linear regulator output from DCIN.23 VL

Voltage-Regulation-Loop Compensation Point34 CCV

Current-Regulation-Loop Compensation Point45 CCI

Current-Range Selector. Tying SEL to VL sets a 4A full-scale current. Leaving SEL open

sets a 2A full-scale current. Tying SEL to AGND sets a 1A full-scale current.

Current-Sense Positive Input57 CS

Battery Voltage Input and Current-Sense Negative Input68 BATT

3.9V Reference Voltage Output or External Reference Input79 REF

Analog Ground810 AGND

Current-Regulation-Loop Set Point10— SETI

Open-Drain Interrupt Output—11

Voltage-Regulation-Loop Set Point11— SETV

Thermistor Sense Voltage Input912 THM

Serial Clock—13 SCL

Serial Data—14 SDA

Voltage DAC Output—15 DACV

Power Ground1216 PGND

Low-Side Power MOSFET Driver Output1317 DLO

High-Side Power MOSFET Driver Output1418 DHI

Power Connection for the High-Side Power MOSFET Driver1519 LX

Power Connection for the High-Side Power MOSFET Driver1620 BST

FUNCTION

MAX1647/MAX1648

_______________________________________________________________________________________ 7

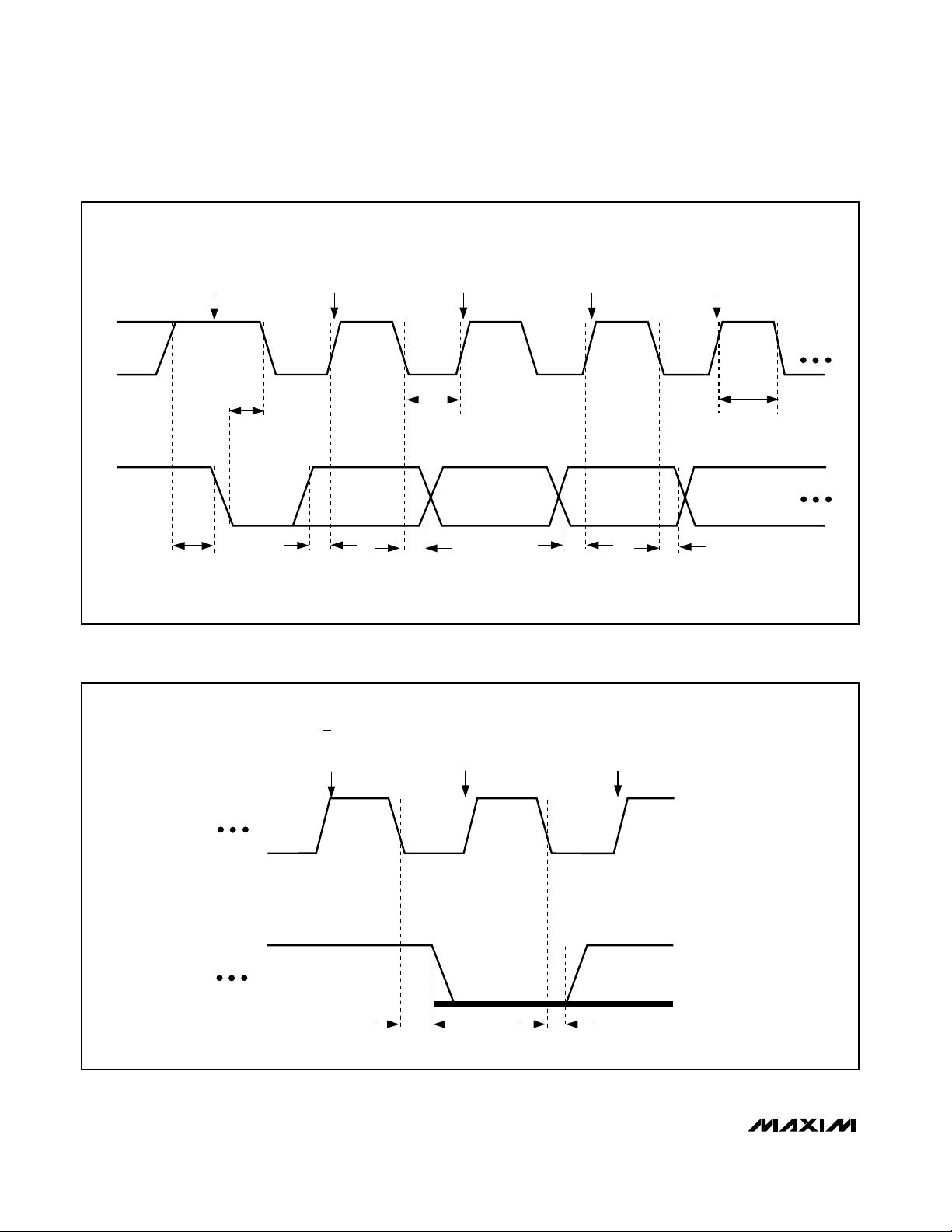

Chemistry-Independent

Battery Chargers

MOST SIGNIFICANT

SCL

START

CONDITION

ADDRESS BIT (A6)

CLOCKED INTO SLAVE

A5 CLOCKED

INTO SLAVE

A4 CLOCKED

INTO SLAVE

A3 CLOCKED

INTO SLAVE

t

HD:STA

SDA

MAX1647/MAX1648

t

SU:STA

Figure 1. SMBus Serial Interface Timing—Address

SCL

t

SU:DAT

RW BIT

CLOCKED

INTO SLAVE

t

HD:DAT

t

LOW

ACKNOWLEDGE

BIT CLOCKED

INTO MASTER

t

SU:DAT

MOST SIGNIFICANT BIT

OF DATA CLOCKED

INTO MASTER

t

HD:DAT

t

HIGH

DV

SLAVE PULLING

SDA LOW

t

DV

SDA

t

Figure 2. SMBus Serial Interface Timing—Acknowledge

8 _______________________________________________________________________________________

Chemistry-Independent

Battery Chargers

MAX1647/MAX1648

4

GND

6

VOUT

MAX874

VIN

2

10

AGND

C4

9

REF

R3

R4

12

THM

MAX1647

5

C3

R2

C2

CCI

4

CCV

IOUT

DCIN

SEL

BST

DHI

DLO

PGND

CS

1

2

6

N.C.

3

VL

C5

(NOTE 2)

20

18

19

LX

17

16

7

Q1

R6

R5

D2

C7

D5

C9

M1

(NOTE 1)

C1

R7

D4*

DC SOURCE

7.5V–28V

L1

D1

D3

D6

C6

M2

15

C8

= HIGH-CURRENT TRACES (8A MAX)

NOTE 1: C6, M2, D1, AND C1 GROUNDS MUST CONNECT TO

THE SAME RECTANGULAR PAD ON THE LAYOUT.

NOTE 2: C5 MUST BE PLACED WITHIN 0.5cm OF THE MAX1647,

WITH TRACES NO LONGER THAN 1cm CONNECTING

VL AND PGND.

*OPTIONAL (SEE

DACV

NEGATIVE INPUT VOLTAGE PROTECTION

BATT

SCL

SDA

INT

SECTION).

Figure 3. MAX1647 Typical Application Circuit

_______________________________________________________________________________________ 9

R1B

8

13

14

11

-TD C+

SMART BATTERY

STANDARD CONNECTOR

SMBDATA

SMBCLOCK

HOST & LOAD

KINT-

GND

R1A

Chemistry-Independent

Battery Chargers

Table 1a. Component Selection for Figure 3 Circuit (Also Use for Figure 4)

UNITSQTYDESIGNATION

µF47C1

µF0.1C2, C4, C7, C9

nF47C3

µF22C6

D1, D3, D4

D2, D5

MAX1647/MAX1648

D6

µH22L1

M1

M2

Q1

20V, ESR at 250kHz ≤ 0.4Ω

10V, ceramic or low ESRµF1C5

35V

10VnF22C8

3A IDC, 30V Schottky diode,

PD> 0.8W, 1N5821 equivalent

50mA IDC, 40V fast-recovery diode,

1N4150 equivalent

4.3V zener diode,

1N4731 or equivalent

±20%, 3A I

Note: size in L x W x H

R

DS, ON

PD> 0.5W, logic level, N-channel

power MOSFET

R

DS, ON

logic level, N-channel power

MOSFET, 2N7002 equivalent

V

CE, MAX

2N3906 equivalent

SAT

≤ 0.1Ω, V

≤ 10Ω, V

≤ -30V, 50mA I

DSS

DSS

≥ 30V,

≥ 30V,

C, CONT

SOURCE/TYPENOTES

Sprague, 595D476X0020D7T, D case

AVX, TPSE476M020R0150, E case

NIEC, NSQ03A04, FLAT-PAK (SMC)

NIEC, 30VQ04F, TO-252AA (SMD)

Motorola, MBRS340T3, SMC

Motorola, MBRD340T4, DPAK

Diodes Inc., SK33, SMC

IR, 30BQ040, SMC

Sumida, RCH-110/220M, 10mm x 10mm x 10mm

Coiltronics, UP2-220, 0.541" x 0.345" x 0.231"

Coilcraft, DO3340P-223, 0.510" x 0.370" x 0.450"

Coilcraft, DO5022P-223, 0.730" x 0.600" x 0.280"

Motorola, MMSF5N03HD, SO-8

Motorola, MMDF3N03HD, SO-8

Motorola, MTD20N03HDL, DPAK

IR, IRF7201, SO-8

IR, IRF7303, SO-8

IR, IRF7603, Micro8

Siliconix, Si9410DY, SO-8

Siliconix, Si9936DY, SO-8

Siliconix, Si6954DQ, TSSOP-8

Motorola, 2N7002LT1, SOT23

Motorola, MMBF170LT1, SOT23

Diodes Inc., 2N7002, SOT23

Diodes Inc., BS870, SOT23

Zetex, ZVN3306F, SOT23

Central Semiconductor, 2N7002, SOT23

,

IRC, CHP1100R100F13, 2512

±1%, 1WmΩ100R1A

±5%, 1/8WΩ1R1B

±5%, 1/16WkΩ10R2, R4

±1%, 1/16WkΩ10R3

±5%, 1/16WΩ10R5, R7

±5%, 1/8WkΩ10R6

10 ______________________________________________________________________________________

IRC, LR251201R100F, 2512

Dale, WSL-2512/0.1Ω/±1%, 2512

Chemistry-Independent

Battery Chargers

Table 1b. Component Suppliers

Central Semiconductor

IR

Sprague

R3

R4

C3

R2

C2

R8

THM

CCI

CCV

SETI

MAX1648

_______________Detailed Description

FAXPHONEMANUFACTURER

(803) 626-3123(803) 946-0690AVX

(516) 435-1824(516) 435-1110

(847) 639-1469(847) 639-6400Coilcraft

(561) 241-9339(561) 241-7876Coiltronics

(605) 665-1627(605) 668-4131Dale

(310) 322-3332(310) 322-3331

(512) 992-3377(512) 992-7900IRC

(805) 867-2698(805) 867-2555NIEC

(408) 970-3950(408) 988-8000Siliconix

(603) 224-1430(603) 224-1961

(847) 956-0702(847) 956-0666Sumida

(516) 864-7630(516) 543-7100Zetex

C4

REF

VL

DCIN

DHI

BST

LX

DLO

PGND

CS

The MAX1647/MAX1648 contain both a voltageregulation loop and a current-regulation loop. Both

loops operate independently of each other. The voltage-regulation loop monitors BATT to ensure that its

voltage never exceeds the voltage set point (V0). The

current-regulation loop monitors current delivered to

BATT to ensure that it never exceeds the current-limit

set point (I0). The current-regulation loop is in control

as long as BATT voltage is below V0. When BATT voltage reaches V0, the current loop no longer regulates,

and the voltage-regulation loop takes over. Figure 5

shows the V-I characteristic at the BATT pin.

C5

R5

D2

C6

M1

C7

M2

Output Characteristics

D4

DC SOURCE

L1

D1

7.5V–28V

D3

R1

MAX1647/MAX1648

R10

R9

SETV

R11

Figure 4. MAX1648 Typical Operating Circuit

______________________________________________________________________________________ 11

BATT

C1

AGND

BATTERY

T

Chemistry-Independent

Battery Chargers

BATT

VOLTAGE

V0

V0 = VOLTAGE SET POINT

I0 = CURRENT-LIMIT SET POINT

AVERAGE CURRENT

THROUGH THE RESISTOR

I0

BETWEEN CS AND BATT

MAX1647/MAX1648

Figure 5. Output V-I Characteristic

Setting V0 and I0 (MAX1647)

Set the MAX1647’s voltage and current-limit set points

via the Intel System Management Bus (SMBus™) 2-wire

serial interface. The MAX1647’s logic interprets the

serial-data stream from the SMBus interface to set internal digital-to-analog converters (DACs) appropriately.

See the

Set the MAX1648’s voltage- and current-limit set points

(V0 and I0, respectively) using external resistive dividers.

Figure 6b is the MAX1648 block diagram. V0 equals four

times the voltage on the SETV pin. I0 equals the voltage

on SETI divided by 5.5, divided by R1 (Figure 4).

_____________________Analog Section

The MAX1647/MAX1648 analog section consists of a

current-mode PWM controller and two transconductance error amplifiers: one for regulating current and

the other for regulating voltage. The MAX1647 uses

DACs to set the current and voltage level, which are

controlled via the SMBus interface. The MAX1648 eliminates the DACs and controls the error amplifiers directly from SETI (for current) and SETV (for voltage). Since

separate amplifiers are used for voltage and current

control, both control loops can be compensated separately for optimum stability and response in each state.

The following discussion relates to the MAX1647; however, MAX1648 operation can easily be inferred from

the MAX1647.

MAX1647 Logic

Setting V0 and I0 (MAX1648)

section for more information.

Whether the MAX1647 is controlling the voltage or current at any time depends on the battery’s state. If the

battery has been discharged, the MAX1647’s output

reaches the current-regulation limit before the voltage

limit, causing the system to regulate current. As the battery charges, the voltage rises until the voltage limit is

reached, and the charger switches to regulating voltage.

The transition from current to voltage regulation is done

by the charger, and need not be controlled by the host.

Voltage Control

The internal GMV amplifier controls the MAX1647’s output voltage. The voltage at the amplifier’s noninverting

input amplifier is set by a 10-bit DAC, which is controlled

by a ChargingVoltage( ) command on the SMBus (see

the

MAX1647 Logic

battery voltage is fed to the GMV amplifier through a 4:1

resistive voltage divider. With an external 4.096V reference, the set voltage ranges between 0 and 16.38V with

16mV resolution.

This poses a challenge for charging four lithium-ion

cells in series: because the lithium-ion battery’s typical

per-cell voltage is 4.2V maximum, 16.8V is required. A

larger reference voltage can be used to circumvent

this. Under this condition, the maximum battery voltage

no longer matches the programmed voltage. The solution is to use a 4.2V reference and host software.

Contact Maxim’s applications department for more

information.

The GMV amplifier’s output is connected to the CCV

pin, which compensates the voltage-regulation loop.

Typically, a series-resistor/capacitor combination can

be used to form a pole-zero couplet. The pole introduced rolls off the gain starting at low frequencies. The

zero of the couplet provides sufficient AC gain at midfrequencies. The output capacitor then rolls off the midfrequency gain to below 1, to guarantee stability before

encountering the zero introduced by the output capacitor’s equivalent series resistance (ESR). The GMV

amplifier’s output is internally clamped to between onefourth and three-fourths of the voltage at REF.

section for more information). The

Current Control

The internal GMI amplifier and an internal current

source control the battery current while the charger is

regulating current. Since the regulator current’s accuracy is not adequate to ensure full 11-bit accuracy, an

internal linear current source is used in conjunction with

the PWM regulator to set the battery current. The current-control DAC’s five least significant bits set the

12 ______________________________________________________________________________________

REF

10k 10k

10k

10k

Chemistry-Independent

Battery Chargers

16mA

8mA 4mA 2mA 1mA

DCIN

MAX1647/MAX1648

THM

AGND

CS

BATT

FROM LOGIC

BLOCK

FROM LOGIC BLOCK

BATT

FROM LOGIC BLOCK

100k

CURRENT-SENSE

LEVEL SHIFT AND

GAIN OF 5.5

REF

6

6-BIT DAC

AGND

R

RR

AGND

30k 3k

TO LOGIC BLOCK

TO LOGIC BLOCK

R

10

10-BIT DAC

REF

THERMISTOR_OR

THERMISTOR_COLD

LOGIC

BLOCK

THERMISTOR_HOT

THERMISTOR_UR

500Ω

NOTE: APPROX. REF/4 + V

TO 3/4 REF + V

CCI

R

R

R

VOLTAGE_INREG

CURRENT_INREG

GMI

R

GMV

DACV

CLAMP

CCV

CCV_LOW

3/8 REF = ZERO CURRENT

NOTE: REF/4 TO 3/4 REF

MIN

THERM_SHUT

AC_PRESENT

THRESH

THRESH

CLAMP

TO REF

(MAX)

AGND

5

SEL

SCL

SDA

INT

COMPARATOR

FROM LOGIC

BLOCK

SHUTDOWN

5.4V LINEAR

REGULATOR

R

AGND

SUMMING

BLOCK

THERMAL

DCIN

3R

LEVEL

SHIFT

VL

AGND

CCV

REF

INTERNAL 3.9V

REFERENCE

BST

DRIVER

LX

VL

DRIVER

PGND

IOUT

REF

DHI

DLO

AGND

Figure 6a. MAX1647 Block Diagram

______________________________________________________________________________________ 13

TO LOGIC BLOCK

POWER_FAIL

DCIN/4.5

Chemistry-Independent

Battery Chargers

REF

THM

MAX1647/MAX1648

AGND

CS

BATT

CURRENT-SENSE

LEVEL SHIFT AND

GAIN OF 5.5

BATT

AGND

ON

SETI

R

R

RR

SETV

GMI

GMV

10k

30k

CLAMP

CCI

CCV

10k

3k

MIN

AC_PRESENT

REF / 2 =

ZERO CURRENT

NOT (THERMISTOR_HOT

OR THERMISTOR_COLD)

THERMISTOR_COLD

THERMISTOR_HOT

DCIN

5.4V LINEAR

REGULATOR

SUMMING

COMPARATOR

BLOCK

ON

AC_PRESENT AND

LEVEL

SHIFT

VL

AGND

INTERNAL 3.9V

REFERENCE

BST

DRIVER

LX

VL

DRIVER

PGND

REF

DHI

DLO

Figure 6b. MAX1648 Block Diagram

14 ______________________________________________________________________________________

Chemistry-Independent

Battery Chargers

internal current sources’ state, and the six most significant bits control the switching regulator’s current. The

internal current source supplies 1mA resolution to the

battery to comply with the smart-battery specification.

When the current is set to a number greater than 32,

the internal current source remains at 31mA. This guarantees that battery-current setting is monotonic regardless of current-sense resistor choice and current-sense

amplifier offset.

The GMI amplifier’s noninverting input is driven by a 4:1

resistive voltage divider, which is driven by the 6-bit

DAC. If an external 4.096V reference is used, this input

is approximately 1.0V at full scale, and the resolution is

16mV. The current-sense amplifier drives the inverting

input to the GMI amplifier. It measures the voltage

across the current-sense resistor (R

between the CS and BATT pins), amplifies it by approximately 5.45, and level shifts it to ground. The full-scale

current is approximately 0.2V / R

is 3.2mV / R

The current-regulation-loop is compensated by adding

a capacitor to the CCI pin. This capacitor sets the current-feedback loop’s dominant pole. The GMI amplifier’s

output is clamped to between approximately one-fourth

and three-fourths of the REF voltage. While the current is

in regulation, the CCV voltage is clamped to within

80mV of the CCI voltage. This prevents the battery voltage from overshooting when the DAC voltage setting is

updated. The converse is true when the voltage is in

regulation and the current is not at the current DAC setting. Since the linear range of CCI or CCV is about 1.5V

to 3.5V or about 2V, the 80mV clamp results in a relatively negligible overshoot when the loop switches from

voltage to current regulation or vice versa.

SEN

.

, and the resolution

SEN

) (which is

SEN

PWM Controller

The battery voltage or current is controlled by the current-mode, pulse-width-modulated (PWM), DC-DC converter controller. This controller drives two external

N-channel MOSFETs, which switch the voltage from the

input source. This switched voltage feeds an inductor,

which filters the switched rectangular wave. The controller sets the pulse width of the switched voltage so that

it supplies the desired voltage or current to the battery.

The heart of the PWM controller is the multi-input comparator. This comparator sums three input signals to

determine the pulse width of the switched signal, setting the battery voltage or current. The three signals are

the current-sense amplifier’s output, the GMV or GMI

error amplifier’s output, and a slope-compensation signal, which ensures that the controller’s internal currentcontrol loop is stable.

The PWM comparator compares the current-sense

amplifier’s output to the higher output voltage of either

the GMV or the GMI amplifier (the error voltage). This

current-mode feedback corrects the duty ratio of the

switched voltage, regulating the peak battery current

and keeping it proportional to the error voltage. Since

the average battery current is nearly the same as the

peak current, the controller acts as a transconductance

amplifier, reducing the effect of the inductor on the output filter LC formed by the output inductor and the battery’s parasitic capacitance. This makes stabilizing the

circuit easy, since the output filter changes from a complex second-order RLC to a first-order RC. To preserve

the inner current-control loop’s stability, slope compensation is also fed into the comparator. This damps out

perturbations in the pulse width at duty ratios greater

than 50%.

At heavy loads, the PWM controller switches at a fixed

frequency and modulates the duty cycle to control the

battery voltage or current. At light loads, the DC current

through the inductor is not sufficient to prevent the current from going negative through the synchronous rectifier (Figure 3, M2). The controller monitors the current

through the sense resistor R

the synchronous rectifier turns off to prevent negative

current flow.

; when it drops to zero,

SEN

MOSFET Drivers

The MAX1647 drives external N-channel MOSFETs to

regulate battery voltage or current. Since the high-side

N-channel MOSFET’s gate must be driven to a voltage

higher than the input source voltage, a charge pump is

used to generate such a voltage. The capacitor C7

(Figure 3) charges to approximately 5V through D2

when the synchronous rectifier turns on. Since one side

of C7 is connected to the LX pin (the source of M1), the

high-side driver (DHI) can drive the gate up to the voltage at BST, which is greater than the input voltage,

when the high-side MOSFET turns on.

The synchronous rectifier behaves like a diode, but with

a smaller voltage drop to improve efficiency. A small

dead time is added between the time that the high-side

MOSFET turns off and the synchronous rectifier turns

on, and vice versa. This prevents crowbar currents (currents that flow through both MOSFETS during the brief

time that one is turning on and the other is turning off).

Connect a Schottky rectifier from ground to LX (across

the source and drain of M2) to prevent the synchronous

rectifier’s body diode from conducting. The body diode

typically has slower switching-recovery times, so allowing it to conduct would degrade efficiency.

MAX1647/MAX1648

______________________________________________________________________________________ 15

Chemistry-Independent

Battery Chargers

The synchronous rectifier may not be completely

replaced by a diode because the BST capacitor

charges while the synchronous rectifier is turned on.

Without the synchronous rectifier, the BST capacitor

may not fully charge, leaving the high-side MOSFET

with insufficient gate drive to turn on. However, the synchronous rectifier may be replaced with a small MOSFET, such as a 2N7002, to guarantee that the BST

capacitor is allowed to charge. In this case, most of the

current at high currents is carried by the diode and not

by the synchronous rectifier.

Internal Regulator and Reference

The MAX1647 uses an internal low-dropout linear regulator to create a 5.4V power supply (VL), which powers its

internal circuitry. VL can supply up to 20mA. A portion of

this current powers the internal circuitry, but the remaining current can power the external circuitry. The current

used to drive the MOSFETs comes from this supply,

MAX1647/MAX1648

which must be considered when calculating how much

power can be drawn. To estimate the current required to

drive the MOSFETs, multiply the total gate charge of

each MOSFET by the switching frequency (typically

250kHz). The internal circuitry requires as much as 6mA

from the VL supply. To ensure VL stability, bypass the VL

pin with a 1µF or greater capacitor.

The MAX1647 has an internal ±2% accurate 3.9V reference voltage. An external reference can be used to

increase the charger’s accuracy. Use a 4.096V reference,

such as the MAX874, for compliance with the Intel/

Duracell smart-battery specification. Voltage-setting

accuracy is ±0.65%, so the total voltage accuracy is the

accuracy added to the reference accuracy. For 1% total

voltage accuracy, use a reference with ±0.35% or greater

accuracy. If the internal reference is used, bypass it with

a 0.1µF or greater capacitor.

MAX1647 Logic

The MAX1647 uses serial data to control its operation. The

serial interface complies with the SMBus specification (see

System Management Bus Specification

Architecture Labs; http://www.intel.com/IAL/powermgm.html; Intel Architecture Labs: 800-253-3696).

Charger functionality complies with the Intel/Duracell

Smart Charger Specification for a level 2 charger.

The MAX1647 uses the SMBus Read-Word and WriteWord protocols to communicate with the battery it is

charging, as well as with any host system that monitors

the battery to charger communications. The MAX1647

never initiates communication on the bus; it only

receives commands and responds to queries for status

information. Figure 7 shows examples of the SMBus

Write-Word and Read-Word protocols.

, from Intel

ACK

D10

D11

D12

D13

D14

D15

ACK

ACK

CMD0

CMD1

CMD2

CMD3

CMD4

CMD5

CMD6

CMD7

ACK

START

TIME

D8

D9

D0

D1

D2

D3

D4

D5

D6

D7

W

1

0

0

1

0

0

0

SCL

SDA

BOLD LINE INDICATES THAT

THE MAX1647 PULLS SDA LOW

ChargingMode( ) = 0 x 12

ChargingVoltage( ) = 0 x 15

ChargingCurrent( ) = 0 x 14

AlarmWarning( ) = 0 x 16

ChargerStatus( ) = 0 x 13

ACK

THERMISTOR_OR

THERMISTOR_COLD

THERMISTOR_HOT

THERMISTOR_UR

ALARM_INHIBITED

POWER_FAIL

BATTERY_PRESENT

AC_PRESENT

ACK

1

1

0

0

1

0

0

0

ACK

W

1

0

0

1

0

0

0

WRITE WORD: ChargingMode( ), ChargingVoltage( ), ChargingCurrent( ), AlarmWarning( )

START

SCL

CHARGE_INHIBITED

MASTER_MODE

VOLTAGE_NOTREG

CURRENT_NOTREG

SDA

ACK

LEVEL_2

LEVEL_3

CURRENT_OR

VOLTAGE_OR

ACK

REPEATED

START

Figure 7. Write-Word and Read-Word Examples

R

1

0

0

1

0

0

0

SCL

SDA

READ WORD: ChargersStatus( )

16 ______________________________________________________________________________________

Chemistry-Independent

Battery Chargers

Each communication with the MAX1647 begins with a

start condition that is defined as a falling edge on SDA

with SCL high. The device address follows the start

condition. The MAX1647 device address is 0b0001001

(0b indicates a binary number), which may also be

denoted as 0x12 (0x indicates a hexadecimal number)

for Write-Word commands, or 0x13 in hexadecimal for

Read-Word commands (note that the address is only

seven bits, and the hexadecimal representation uses

R/W as its least significant bit).

ChargerMode( )

The ChargerMode( ) command uses Write-Word protocol. The command code for ChargerMode( ) is 0x12;

thus the CMD7–CMD0 bits in Write-Word protocol

should be 0b00010010. Table 2 describes the functions

of the 16 different data bits (D0–D15). Bit 0 refers to the

D0 bit in the Write-Word protocol (Figure 7).

Whenever the BATTERY_PRESENT status bit is clear,

the HOT_STOP bit is set, regardless of any previous

ChargerMode( ) command. To charge a battery that

has a thermistor impedance in the HOT range (i.e.,

THERMISTOR_HOT = 1 and THERMISTOR_UR = 0),

the host must use the ChargerMode( ) command to

clear HOT_STOP after the battery is inserted. The

HOT_STOP bit returns to its default power-up condition

(‘1’) whenever the battery is removed.

ChargingVoltage( )

The ChargingVoltage( ) command uses Write-Word

protocol. The command code for ChargingVoltage( ) is

0x15; thus, the CMD7–CMD0 bits in Write-Word protocol should be 0b00010101. The 16-bit binary number

formed by D15–D0 represents the voltage set point

(V0) in millivolts; however, since the MAX1647 has only

16mV resolution in setting V0, the D0, D1, D2, and D3

bits are ignored. For D15 = D14 = 0:

VOLTAGE_OR = 0 and V0 in Volts = 4 x REF x

()

VDAC

10

2

In equation 1, VDAC is the decimal equivalent of the

binary number represented by bits D13, D12, D11,

D10, D9, D8, D7, D6, D5, and D4 programmed with the

ChargingVoltage( ) command. For example, if D4–D13

are all set, VDAC is the decimal equivalent of

0b1111111111 (1023). If either D15 or D14, or both

D15 and D14, are set, all the bits in the voltage DAC

(Figure 6a) are set, regardless of D13–D0, and the

status register’s VOLTAGE_OR bit is set. For D15 = 1

and/or D14 = 1:

10

VOLTAGE_OR = 1 and V0 in Volts = 4 x REF x

()

2-1

10

2

MAX1647/MAX1648

Table 2. ChargerMode( ) Bit Functions

BIT NAME

ENABLE_POLLING

N/A

BATTERY_PRESENT_MASK

*

Bit position in the D15–D0 data.

N/A = Not available.

______________________________________________________________________________________ 17

BIT

POSITION*

4, 7, 8, 9,

11–15

**

Power-on reset value.

POR

VALUE**

00INHIBIT_CHARGE

—1

—2POR_RESET

—3RESET_TO_ZERO

—

05

16POWER_FAIL_MASK

110HOT_STOP

FUNCTION

0 = Allow normal operation; clear the CHG_INHIBITED status bit.

1 = Turn the charger off; set the CHG_INHIBITED status bit.

Not implemented. Write 0 into this bit.

0 = No change in any non-ChargerMode( ) settings.

1 = Change the voltage and current settings to 0xFFFF and 0x00C0

respectively; clear the THERMISTOR_HOT and ALARM_INHIBITED bits.

Not implemented. Write 0 into this bit.

Not implemented. Write 1 into this bit.

0 = Interrupt on either edge of the BATTERY_PRESENT status bit.

1 = Do not interrupt because of a BATTERY_PRESENT bit change.

0 = Interrupt on either edge of the POWER_FAIL status bit.

1 = Do not interrupt because of a POWER_FAIL bit change.

0 = The THERMISTOR_HOT status bit does not turn the charger off.

1 = THERMISTOR_HOT turns the charger off.

Chemistry-Independent

Battery Chargers

Figure 8 shows the mapping between V0 (the voltageregulation-loop set point) and the ChargingVoltage( )

data.

The power-on reset value for the ChargingVoltage( )

register is 0xFFF0; thus, the first time a MAX1647 is

powered on, the BATT voltage regulates to 16.368V

with V

= 4.096V. Any time the BATTERY_PRESENT

REF

status bit is clear, the ChargingVoltage( ) register

returns to its power-on reset state.

16.368

MAX1647/MAX1648

V

= 4.096V

REF

12.592

ChargingCurrent( )

The ChargingCurrent( ) command uses Write-Word

protocol. The command code for ChargingCurrent( ) is

0x14; thus, the CMD7–CMD0 bits in Write-Word protocol should be 0b00010100. The 16-bit binary number

formed by D15–D0 represents the current-limit set point

(I0) in milliamps. Tying SEL to AGND selects a 1.023A

maximum setting for I0. Leaving SEL open selects a

2.047A maximum setting for I0. Tying SEL to VL selects

a 4.095A maximum setting for I0.

8.400

VOLTAGE SET POINT (V0)

4.192

0

0b000000000000xxxx

0x000x

Figure 8. ChargingVoltage( ) Data to Voltage Mapping

18 ______________________________________________________________________________________

0b000100000110xxxx

0x106x

0b001000001101xxxx

0x20Dx 0x3FFx

ChargingVoltage( ) D15–D0 DATA

0b001100010011xxxx

0x313x

0b001111111111xxxx

0b111111111111xxxx

0xFFFx

Chemistry-Independent

Battery Chargers

Two sources of current in the MAX1647 charge the battery: a binary-weighted linear current source sources

from IOUT, and a switching regulator controls the current

flowing through the current-sense resistor (R1). IOUT

provides a small maintenance charge current to compensate for battery self-discharge, while the switching

regulator provides large currents for fast charging.

IOUT sources from 1mA to 31mA. Table 3 shows the

relationship between the value programmed with the

ChargingCurrent( ) command and IOUT source current.

The CCV_LOW comparator checks to see if the output

voltage is too high by comparing CCV to REF / 4. If

CCV_LOW = 1 (when CCV < REF / 4), IOUT shuts off,

preventing the output voltage from exceeding the voltage

set point specified by the ChargingVoltage( ) register.

VOLTAGE_NOTREG = 1 whenever the internal clamp

pulls down on CCV. (The internal clamp pulls down on

CCV to keep its voltage close to CCI’s voltage.)

Table 3. Relationship Between IOUT Source Current and ChargingCurrent( ) Value

CHARGE_

INHIBITED

(NOTE 1)

ALARM_

INHIBITED

000

000

000

000

000

000

000

000

1x0

x10

xx1

ChargingVoltage( )

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF

x

0x0000–0x000F

x

x

x

ChargingCurrent( )

0x0001–0x001F

0x0001–0x001F

0x0001–0x001F

0x0020–0xFFFF

0x0020–0xFFFF

0x0020–0xFFFF

0x0000

x

x

x

x

CCV_LOW

0

1

1

0

1

1

x

x

x

x

x

VOLTAGE_

NOTREG

x

0

1

x

0

1

x

x

x

x

x

OUTPUT

CURRENT

1mA–31mA

1mA–31mA

MAX1647/MAX1648

IOUT

0mA

31mA

0mA

31mA

0mA

0mA

0mA

0mA

0mA

Note 1: Logical AND of THERMISTOR_HOT, HOT_STOP, NOT(THERMISTOR_UR).

185

SEL = OPEN OR SEL = VL

94

AVERAGE CS - BATT VOLTAGE

IN CURRENT REGULATION (mV)

2.94

0b000001 0b100000 0b111111

CURRENT DAC CODE, DA5–DA0 BITS

Figure 9. Average Voltage Between CS and BATT vs. Current DAC Code

______________________________________________________________________________________ 19

Chemistry-Independent

Battery Chargers

Table 4. Relationship Between Current DAC Code and the ChargingCurrent( ) Value

CHARGE_

INHIBITED

0

0

(NOTE 1)

MAX1647/MAX1648

0

0

Note 1: Logical AND of THERMISTOR_HOT, HOT_STOP, NOT(THERMISTOR_UR).

Note 2: Value of CURRENT_OR bit in the ChargerStatus( ) register.

N/C = No change

ALARM_

INHIBITED

000

000

000

000

000

ChargingVoltage( )

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF 0x0040–0x07DF

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF 0x0020–0x003F

0x0010–0xFFFF

0x0010–0xFFFF

0x0010–0xFFFF 0x0FC0–0x0FFF

0x0010–0xFFFF

0x0010–0xFFFF

x

x x

SEL

open0x0010–0xFFFF 0x0001–0x001F

open

open

open

open0x0010–0xFFFF 0x0800–0xFFFF

ChargingCurrent( )

0V

0V0x0010–0xFFFF 0x0020–0x003F 2 Yes 0000

0V

0V0x0010–0xFFFF 0x03E0–0x03FF

0V

VL

VL

VL

VL0x0010–0xFFFF 0x0080–0x0F9F

VL

VL

VL

xx 0x0000

x

xx x

x

x

0x0001–0x001F

0x0040–0x03DF 4–60 Yes 0000

0x0400–0xFFFF

0x0020–0x003F

0x07E0–0x07FF

0x0001–0x001F

0x0040–0x007F

0x0FA0–0x0FBF

0x0001–0xFFFF 63 Yes 1000

x

x

CURRENT

DAC

CODE

0

62 Yes 0000

62

0 No 0000

1 Yes 000

2–62 Yes

63

63 Yes 1000

0 No 000

1 Yes

1

2–62 Yes 0000

63 Yes 000

63 Yes

0 No 0000

N/C

N/C No N/C1x0

N/C No N/Cx1

N/C No

SW REG

ON?

No

Yes

Yes

Yes

No

(NOTE 2)

0

1

0000

0

0000

0

0000

N/C

N/Cxx1

Table 5. Effect of SEL Pin-Strapping on the ChargingCurrent( ) Data Bits

SEL

Open

*

When SEL = VL, D5 = 1 forces DA0 to be 1 regardless of the D6 bit value.

With the switching regulator on, the current through R1

(Figure 3) is regulated by sensing the average voltage

between CS and BATT. A 6-bit current DAC controls

the current-limit set point. DA5–DA0 denote the bits in

the current DAC code. Figure 9 shows the relationship

between the current DAC code and the average voltage between CS and BATT.

20 ______________________________________________________________________________________

R1

(mΩ)

181AGND

90

45VL

D15

0

0

0

D14

0

0

0

D13

0

0

0

D12

0

0

0

D11

0

0

DA5

D10

0

DA5

DA4

D9

DA5

DA4

DA3

D8

D7

D6

D5

D4

D3

DA4

DA3

DA2

DA3

DA2

DA2

DA1

DA1

DA0

DA1

DA0

I4

I3

I4

I3

*

I4

I3

When the switching regulator is off, DHI is forced to

LX and DLO is forced to ground. This prevents current

from flowing through inductor L1. Table 4 shows the

relationship between the ChargingCurrent( ) register

value and the switching regulator current DAC code.

D2

I2

I2

I2

D1

I1

I1

I1

D0

I0

I0

I0

Chemistry-Independent

Battery Chargers

With SEL = AGND, R1 should be as close as possible to

0.185 / 1.023 = 181mΩ to ensure that the actual output

current matches the data value programmed with the

ChargingCurrent( ) command. With SEL = open, R1

should be as close as possible to 90mΩ. With SEL = VL,

R1 should be as close as possible to 45mΩ. Table 5 summarizes how SEL affects the R1 value and the meaning of

data bits D15–D0 in the ChargingCurrent( ) command.

DA5–DA0 denote the current DAC code bits, and I4–I0

denote the IOUT linear-current source binary weighting

bits. Note that whenever any current DAC bits are set, the

linear-current source is set to full scale (31mA).

The power-on reset value for the ChargingCurrent( )

register is 0x000C. Irrespective of the SEL pin setting,

the MAX1647 powers on with I0 set to 12mA (i.e.,

DA5–DA0, I1, and I0 all equal to zero, and only I3 and

I2 set). Anytime the BATTERY_PRESENT status bit is

clear (battery removed), the ChargingCurrent( ) register

returns to its power-on reset state. This ensures that

upon insertion of a battery, the initial charging current is

12mA.

AlarmWarning( )

The AlarmWarning( ) command uses Write-Word protocol.

The command code for AlarmWarning( ) is 0x16; thus the

CMD7–CMD0 in Write-Word protocol should be

0b00010110. The AlarmWarning( ) command sets the

ALARM_INHIBITED status bit in the MAX1647 if D15, D14,

or D12 of the Write-Word protocol data equals 1. Table 6

summarizes the AlarmWarning( ) command’s function.

The ALARM_INHIBITED status bit remains set until

BATTERY_PRESENT = 0 (battery removed) or a

ChargerMode() command is written with the POR_RESET

bit set. As long as ALARM_INHIBITED = 1, the MAX1647

switching regulator and IOUT current source remain off.

ChargerStatus( )

The ChargerStatus( ) command uses Read-Word protocol. The command code for ChargerStatus( ) is 0x13;

thus, the CMD7–CMD0 bits in Write-Word protocol

should be 0b00010011. The ChargerStatus( ) command returns information about thermistor impedance

and the MAX1647’s internal state. The Read-Word

protocol returns D15–D0 (Figure 7). Table 7 describes

the meaning of the individual bits. The latched bits,

THERMISTOR_HOT and ALARM_INHIBITED, are

cleared whenever BATTERY_PRESENT = 0 or

ChargerMode( ) is written with POR_RESET = 1.

Interrupts and the Alert-Response

Address

An interrupt is triggered (INT goes low) whenever power

is applied to DCIN, the BATTERY_PRESENT bit changes,

or the POWER_FAIL bit changes. BATTERY_PRESENT

and POWER_FAIL have interrupt masks that can be set

or cleared via the ChargerMode( ) command. INT stays

low until the interrupt is cleared. There are two methods

for clearing the interrupt: issuing a ChargerStatus( ) command, and using the Receive Byte protocol with a 0x19

Alert-Response address. The MAX1647 responds to the

Alert-Response address with the 0x89 byte.

__________Applications Information

Using the MAX1647

with Duracell Smart Batteries

The following pseudo-code describes an interrupt routine that is triggered by the MAX1647 INT output going

low. This interrupt routine keeps the host informed of

any changes in battery-charger status, such as DCIN

power detection, or battery removal and insertion.

DOMAX1647:

{ This is the beginning of the routine that handles

MAX1647 interrupts. }

{ Check the status of the MAX1647. }

TEMPWORD = ReadWord( SMBADDR = 0b00010011

= 0x13, COMMAND = 0x13 )

{ Check for the normal power-up case without a battery

installed. THERMISTOR_OR = 1, BATTERY_PRESENT =

0. Use 0b1011111011111111 = 0xBEFF as the mask. }

IF (TEMPWORD OR 0xBEFF) = 0xBFFF THEN GOTO

NOBATT:

{ Check to see if the battery is installed. BATTERY_

PRESENT = 1. Use 0b1011111111111111 = 0xBFFF as

the mask. }

MAX1647/MAX1648

Table 6. Effect of the AlarmWarning( ) Command

AlarmWarning( ) WRITE-WORD PROTOCOL DATA

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

1

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

1

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

1

x

x

x

x

x

x

x

x

x

x

x

______________________________________________________________________________________ 21

RESULT

x

Set ALARM_INHIBITED

x

Set ALARM_INHIBITED

x

Set ALARM_INHIBITED

Chemistry-Independent

Battery Chargers

IF (TEMPWORD OR 0xBEFF) = 0xFFFF THEN GOTO

HAVEBATT:

GOTO ENDINT:

HAVEBATT:

{ A battery is installed. Turn the battery’s broadcast

mode off to monitor the charging process. Using the

BatteryMode( ) command, make sure the CHARGER_

MODE bit is set. }

WriteWord(SMBADDR = 0b00010110 = 0x16,

COMMAND = 0X03, DATA = 0x4000)

GOTO ENDINT:

NOBATT:

{ Notify the system that AC power is present, but no battery is present. }

GOTO ENDINT:

ENDINT:

{ This is the end of the interrupt routine. }

The following pseudo-code describes a polling routine

that queries the battery for its desired charge voltage and

MAX1647/MAX1648

charge current, checks to make sure that the requested

charge current and charge voltage are valid, and

instructs the MAX1647 to comply with the request.

DOPOLLING:

{ This is the beginning of the polling routine. }

{ Ask the battery what voltage it wants using the bat-

tery’s ChargingVoltage( ) command. }

TEMPVOLTAGE = ReadWord( SMBADDR =

0b00010111 = 0x17, COMMAND = 0x15 )

{ Ask the battery what current it wants using the battery’s ChargingCurrent( ) command. }

TEMPCURRENT = ReadWord( SMBADDR =

0b00010111 = 0x17, COMMAND = 0x14 )

{ Now the routine can check that the TEMPVOLTAGE

and TEMPCURRENT values make sense and that the

battery is not malfunctioning. }

{ With valid TEMPVOLTAGE and TEMPCURRENT values, instruct the MAX1647 to comply with the request. }

WriteWord( SMBADDR = 0b00010010 = 0x12 ,

COMMAND = 0x15, DATA = TEMPVOLTAGE )

WriteWord( SMBADDR = 0b00010010 = 0x12 ,

COMMAND = 0x14, DATA = TEMPCURRENT )

ENDPOL:

{ This is the end of the polling routine. }

Negative Input Voltage Protection

In most portable equipment, the DC power to charge

batteries enters via a two-conductor cylindrical power

jack. It is easy for the end user to add an adapter to

switch the DC power’s polarity. Polarized capacitor C6

would be destroyed if a negative voltage were applied.

Diode D4 in Figure 3 prevents this from happening.

If reverse-polarity protection for the DC input power is

not necessary, diode D4 can be omitted. This eliminates

the power lost due to the voltage drop on diode D4.

Selecting External Components for the

MAX1647 4A Application

The MAX1647 can be configured to charge at a maximum current of 4A (instead of 2A, as shown in Figure 3)

by changing the external power components and tying

SEL to REF. The following paragraphs discuss the selection requirements for each component in Figure 3 that

must be changed to accommodate the 4A application.

Diode D4 in Figure 3 has to support both the charge

current and the current required to operate the host

load (i.e., what the batteries normally power when not

charging). This means that the continuous current flowing through D4 exceeds 4A. One possible choice for

D4 is the Motorola MBRD835L 8A Schottky barrier

diode in a DPAK surface-mount package. Care must

be taken in thermal management of the circuit board

when using the 4A application circuit, by mounting D4

on a three-square-inch piece of copper.

Motorola’s MBRD835L can also be used for D3. The

Siliconix Si4410DY is a good choice for M1 and M2 in the

4A application. Changing M2 from a 2N7002 (Table 1) to

a Si4410DY increases the power dissipated by the

MAX1647’s 20-pin SSOP.

High-current inductors are difficult to find in surface-mount

packages. Low-cost solutions use toroidal powdered-iron

cores with exposed windings of heavy-gauge wire. The

Coiltronics CTX20-5-52 20µH 5A inductor provides a highefficiency solution.

R1A must also dissipate more power in the 4A application circuit than in the circuit of Figure 3. R1A’s value

decreases to 50mΩ in the 4A application. IRC’s

LR2512-01-R050-F meets this requirement with a 1W

maximum power-dissipation rating.

22 ______________________________________________________________________________________

Chemistry-Independent

Battery Chargers

Table 7. ChargerStatus( ) Bit Descriptions

NAME

CHARGE_INHIBITED

MASTER_MODE

VOLTAGE_NOTREG

CURRENT_NOTREG

LEVEL_2

LEVEL_3

CURRENT_OR

VOLTAGE_OR

THERMISTOR_OR

THERMISTOR_COLD

THERMISTOR_HOT

THERMISTOR_UR

BIT

POSITION

0

1

2

3

4

5

6

7

8

9

10

11 No

LATCHED?

Yes

N/A

No

No

N/A

N/A

No

No

No

No

Yes

0 = Ready to charge a smart battery

1 = Charger is off; IOUT current = 0mA; DLO = PGND; DHI = LX

Always returns ‘0’

0 = BATT voltage is limited at the voltage set point (BATT = V0).

1 = BATT voltage is less than the voltage set point (BATT < V0).

0 = Current through R1 is at its limit (I

1 = Current through R1 is less than its limit (I

Always returns 1

Always returns 0

0 = ChargingCurrent( ) value is valid for MAX1647.

1 = ChargingCurrent( ) value exceeds what MAX1647 can actually deliver.

0 = ChargingVoltage( ) value is valid for MAX1647.

1 = ChargingVoltage( ) value exceeds what MAX1647 can actually deliver.

0 = THM voltage < 91% of REF voltage

1 = THM voltage > 91% of REF voltage

0 = THM voltage < 75% of REF voltage

1 = THM voltage > 75% of REF voltage

This bit reports the state of an internal SR flip-flop (denoted THERMISTOR_HOT

flip-flop). The THERMISTOR_HOT flip-flop is set whenever THM is below 23%

of REF. It is cleared whenever BATTERY_PRESENT = 0 or ChargerMode( ) is

written with POR_RESET = 1.

0 = THM voltage > 5% of REF voltage

1 = THM voltage < 5% of REF voltage

DESCRIPTION

= I0).

BATT

BATT

MAX1647/MAX1648

< I0).

ALARM_INHIBITED 12 Yes

POWER_FAIL 13 No

BATTERY_PRESENT 14 No

AC_PRESENT 15 No

*

Bit position in the D15-D0 data

N/A = Not applicable

______________________________________________________________________________________ 23

This bit reports the state of an internal SR flip-flop (denoted ALARM_INHIBITED

flip-flop). The ALARM_INHIBITED flip-flop is set whenever the AlarmWarning( )

command is written with D15, D14, or D12 set. The ALARM_INHIBITED flip-flop

is cleared whenever BATTERY_PRESENT = 0 or ChargerMode( ) is written with

POR_RESET = 1.

0 = BATT voltage < 89% of DCIN voltage

1 = BATT voltage > 89% of DCIN voltage

0 = No battery is present (THERMISTOR_OR = 1).

1 = A battery is present (THERMISTOR_OR = 0).

0 = VL voltage < 4V

1 = VL voltage > 4V

___________________Chip Information

TRANSISTOR COUNT: 3612

SUBSTRATE CONNECTED TO AGND

Chemistry-Independent

Battery Chargers

HE

e

MAX1647/MAX1648

A

B

D

D

e

A1

A

0.101mm

0.004in.

A1

B

C

L

SSOP

SHRINK

SMALL-OUTLINE

PACKAGE

C

DIM

A

A1

B

C

α

0°-8°

L

D

E

H

α

DIM

D

D

D

D

D

DIM

A

A1

B

C

E

e

H

L

INCHES

MIN

0.068

0.002

0.010

0.004

0.205

e

0.301

L

0.025

PINS

14

16

20

24

28

MIN

0.053

0.004

0.014

0.007

0.150

0.228

0.016

MAX

0.078

0.008

0.015

0.008

SEE VARIATIONS

0.209

0.311

0.037

0˚

INCHES

MIN

0.239

0.239

0.278

0.317

0.397

INCHES MILLIMETERS

MAX

0.069

0.010

0.019

0.010

0.157

0.244

0.050

8˚

MAX

0.249

0.249

0.289

0.328

0.407

MILLIMETERS

MIN

1.73

0.05

0.25

0.09

5.20

7.65

0.63

MIN

1.35

0.10

0.35

0.19

3.80

5.80

0.40

MAX

1.99

0.21

0.38

0.20

0.65 BSC0.0256 BSC

0˚

MILLIMETERS

MIN

6.07

6.07

7.07

8.07

10.07

5.38

7.90

0.95

8˚

MAX

6.33

6.33

7.33

8.33

10.33

21-0056A

MAX

1.75

0.25

0.49

0.25

4.00

1.270.050

6.20

1.27

PINS

Narrow SO

HE

SMALL-OUTLINE

PACKAGE

(0.150 in.)

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

24

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

© 1996 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

© 1996 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

DIM

D

D

D

INCHES MILLIMETERS

MIN

MAX

8

0.189

0.197

14

0.337

0.344

16

0.386

0.394

MIN

4.80

8.55

9.80

MAX

5.00

8.75

10.00

21-0041A

Loading...

Loading...