General Description

The MAX1612/MAX1613 manage the bridge battery

(sometimes called a hot-swap or auxiliary battery) in

portable systems such as notebook computers. They

feature a step-up DC-DC converter that boosts 2-cell or

3-cell bridge-battery voltages up to the same level as

the main battery. This voltage boosting technique

reduces the number of cells otherwise required for a 6cell plus diode-OR bridging scheme, reducing overall

size and cost. Another key feature is a trickle-charge

timer that minimizes battery damage caused by constant charging and eliminates trickle-charge current

drain on the main battery once the bridge battery is

topped off.

These devices contain a highly flexible collection of

independent circuit blocks that can be wired together

in an autonomous stand-alone configuration or used in

conjunction with a microcontroller. In addition to the

boost converter and charge timer, there is a micropower linear regulator (useful for RTC/CMOS backup as

well as for powering a microcontroller) and a high-precision low-battery detection comparator.

The two devices differ only in the preset linear-regulator

output voltage: +5.0V for the MAX1612 and +3.3V for

the MAX1613. Both devices come in a space-saving

16-pin QSOP package.

Applications

Notebook Computers

Portable Equipment

Backup Battery Applications

Features

♦ Reduce Battery Size and Cost

♦ Four Key Circuit Blocks

Adjustable Boost DC-DC Converter

NiCd/NiMH Trickle Charger

Always-On Linear Regulator (+28V Input)

Low-Battery Detector

♦ Low 18µA Quiescent Current

♦ Selectable Charging/Discharging Rates

♦ Preset Linear-Regulator Voltage

5V (MAX1612)

3.3V (MAX1613)

♦ 4V to 28V Main Input Voltage Range

♦ Internal Switch Boost Converter

♦ Small 16-Pin QSOP Package

MAX1612/MAX1613

Bridge-Battery Backup Controllers

for Notebooks

________________________________________________________________

Maxim Integrated Products

1

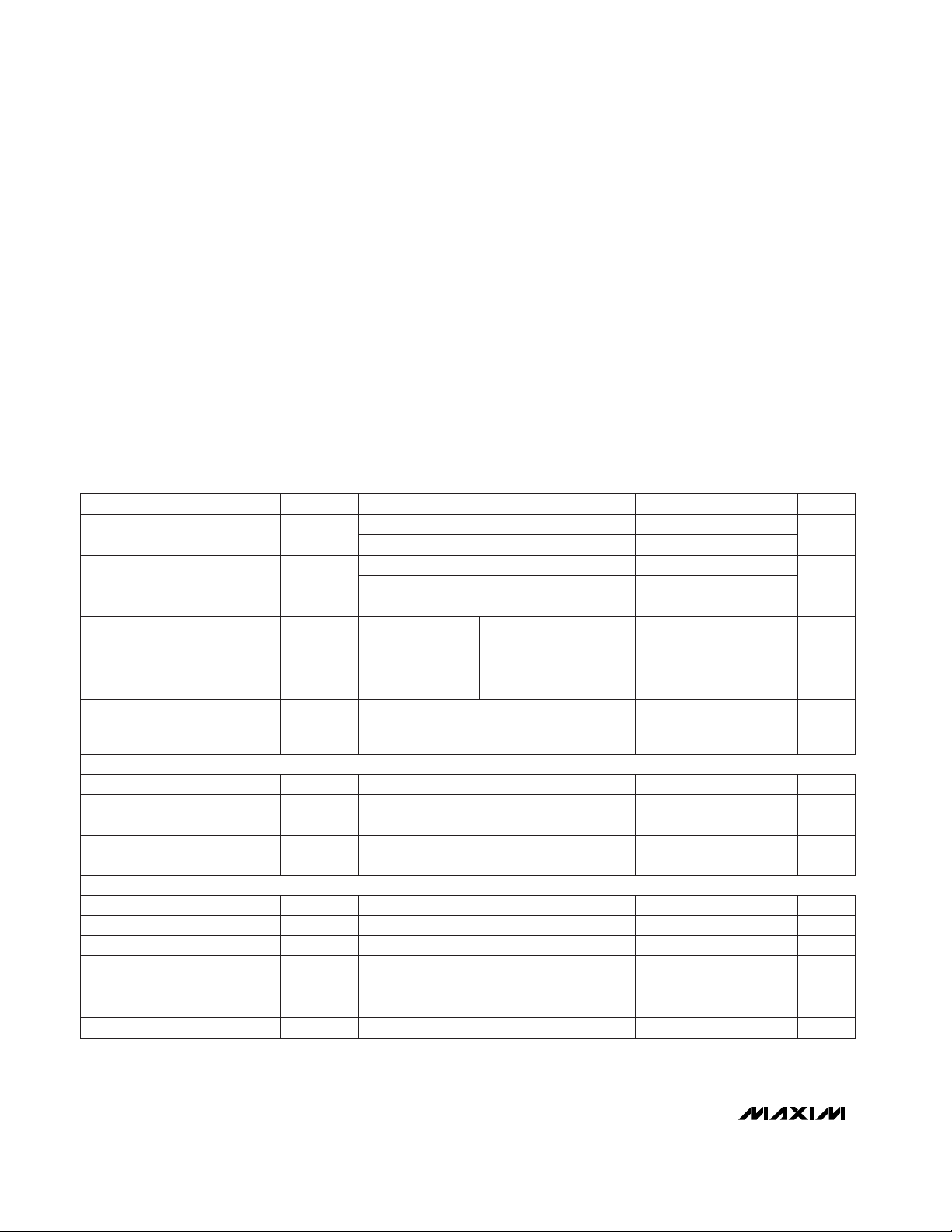

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

ISET LRI

LRO

PGND

CD

CC

GND

LBI

FB

TOP VIEW

MAX1612

MAX1613

QSOP

BBATT

LX

DCMD

LBO

BBON

CCMD

FULL

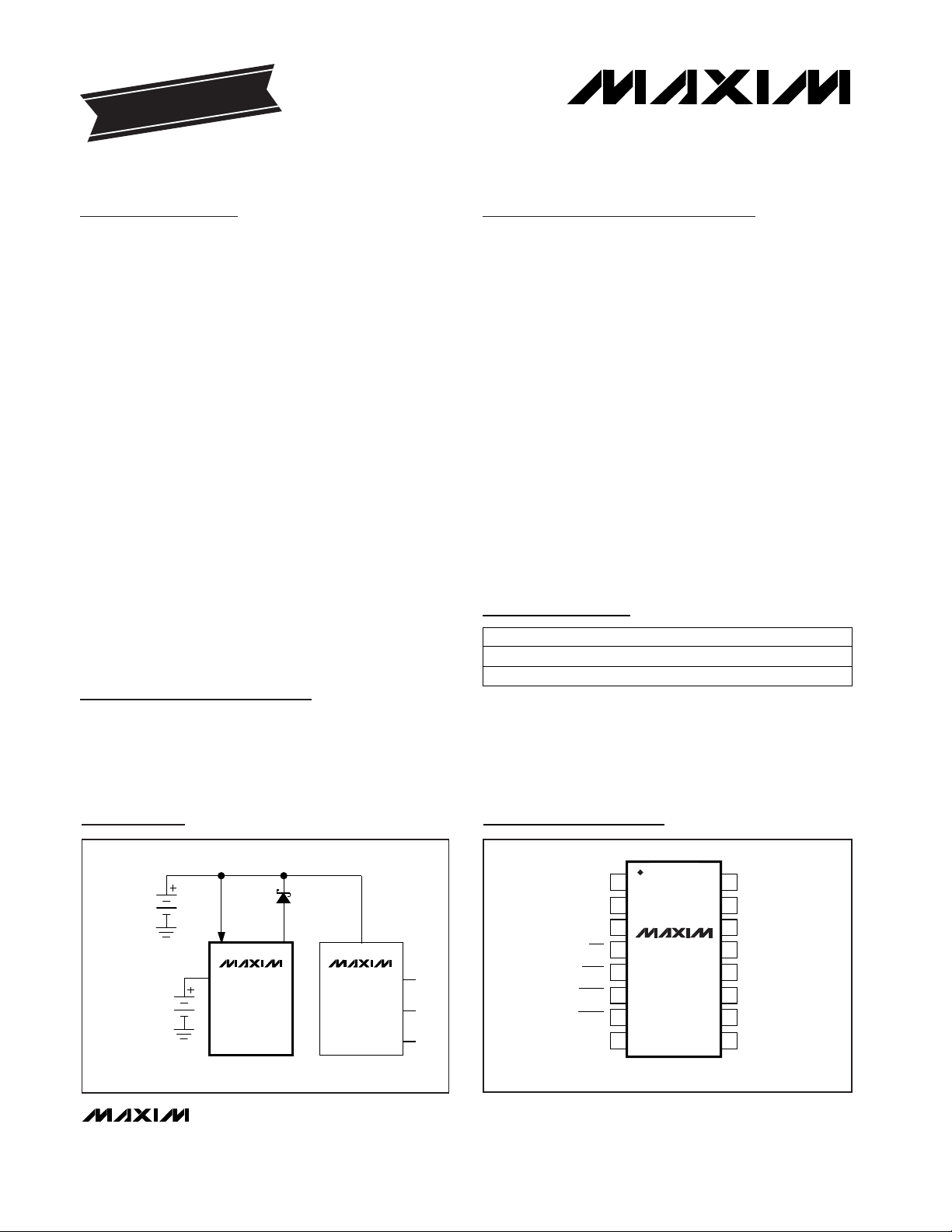

Typical Operating Circuit

19-4785; Rev 0; 11/98

PART

MAX1612EEE

MAX1613EEE

-40°C to +85°C

-40°C to +85°C

TEMP. RANGE PIN-PACKAGE

16 QSOP

16 QSOP

EVALUATION KIT MANUAL

FOLLOWS DATA SHEET

Pin Configuration

Ordering Information

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

MAIN BATTERY

OR

WALL

ADAPTER

AUXILIARY

BRIDGE

BATTERY

LRI

BBATT

MAX1613

APPLICATION

CIRCUIT

DC-DC

OUTPUT

V+

MAX1630MAX1612

DC-DC

CONVERTER

+3.3V

+5V

V

CPU

MAX1612/MAX1613

Bridge-Battery Backup Controllers

for Notebooks

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

LRI

= V

ISET

= 20V, CCMD = DCMD = BBON = LRO, V

BBATT

= 3V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at

T

A

= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

LRI, ISET to GND....................................................-0.3V to +30V

LX to GND ..............................................................-0.3V to +14V

PGND to GND .......................................................-0.3V to +0.3V

BBATT, LRO, CCMD, DCMD, FULL, BBON,

LBO to GND ..........................................................-0.3V to +6V

CC, CD, LBI, FB to GND...........................-0.3V to (V

LRO

+ 0.3V)

FB, LBI, ISET, and BBATT Current......................................50mA

LRO Output Current ...........................................................50mA

Continuous Power Dissipation (T

A

= +70°C)

QSOP (derate 8.30mW/°C above +70°C).................... 667mW

Operating Temperature Range

MAX1612/MAX1613EEE...................................-40°C to +85°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec)............................ +300°C

I

SINK

= 1mA

V

LBO

= V

FULL

= 5.5V

V

BBON

≥ 2V

V

LBI

= 1.9V

MAX1613

MAX1612

V

ISET

= 28V, V

BBATT

= 0

LRO rising hysteresis = 200mV

CCMD = GND, I

ISET

= 10mA, V

BBATT

= 2V,

%loss = [(I

ISET

- I

BBATT

) / I

ISET

) · 100%

V

DCMD

= 0, R

BBON

= 1MΩ to GND

(boost converter on)

5.7V ≤ V

LRI

≤ 28V

(MAX1612)

I

ISET

= 10mA, V

CCMD

= 0, V

BBATT

= 2V

V

ISET

= 0 or 28V, V

BBATT

= 6V

CONDITIONS

LBO, FULL Output Voltage Low

V0.4

LBO, FULL Output Leakage

Current

µA1I

LBO, IFULL

nA

0.2 10

I

LBI

LBI Input Current

V

1.955 2 2.045

V

LBTH

LBI Rising Trip Voltage

V

1.76 1.8 1.84

V

LBTL

LBI Falling Trip Voltage

%

0.1 5

Charge-Switch Loss Current

V

0.5 1 1.3

Charge-Switch On Voltage

µA

-5 5

I

BBATT(LEAK

)BBATT Leakage Current

18 28

I

LRI

4V ≤ V

LRI

≤ 28V

(MAX1613)

0 ≤ I

LRO

≤ 10mA

4 28

V

5.7 28

V

LRI

Linear-Regulator Input Voltage

Range

µA

0.3 5

I

ISET(LEAK

)ISET Leakage Current

V

2.65 2.97

V

UVLO

Linear-Regulator Output

Undervoltage Lockout

Threshold

V

3.1 3.3 3.5

µA

42 58

Linear-Regulator Quiescent

Current

4.7 5.0 5.3

V

LRO

Linear-Regulator Output Voltage

UNITMIN TYP MAXSYMBOLPARAMETER

Overdrive = 100mV µs

20

t

PD

LBI Comparator Response Time

BATTERY CHARGER

LOW-BATTERY COMPARATOR

MAX1612/MAX1613

Bridge-Battery Backup Controllers

for Notebooks

_______________________________________________________________________________________

3

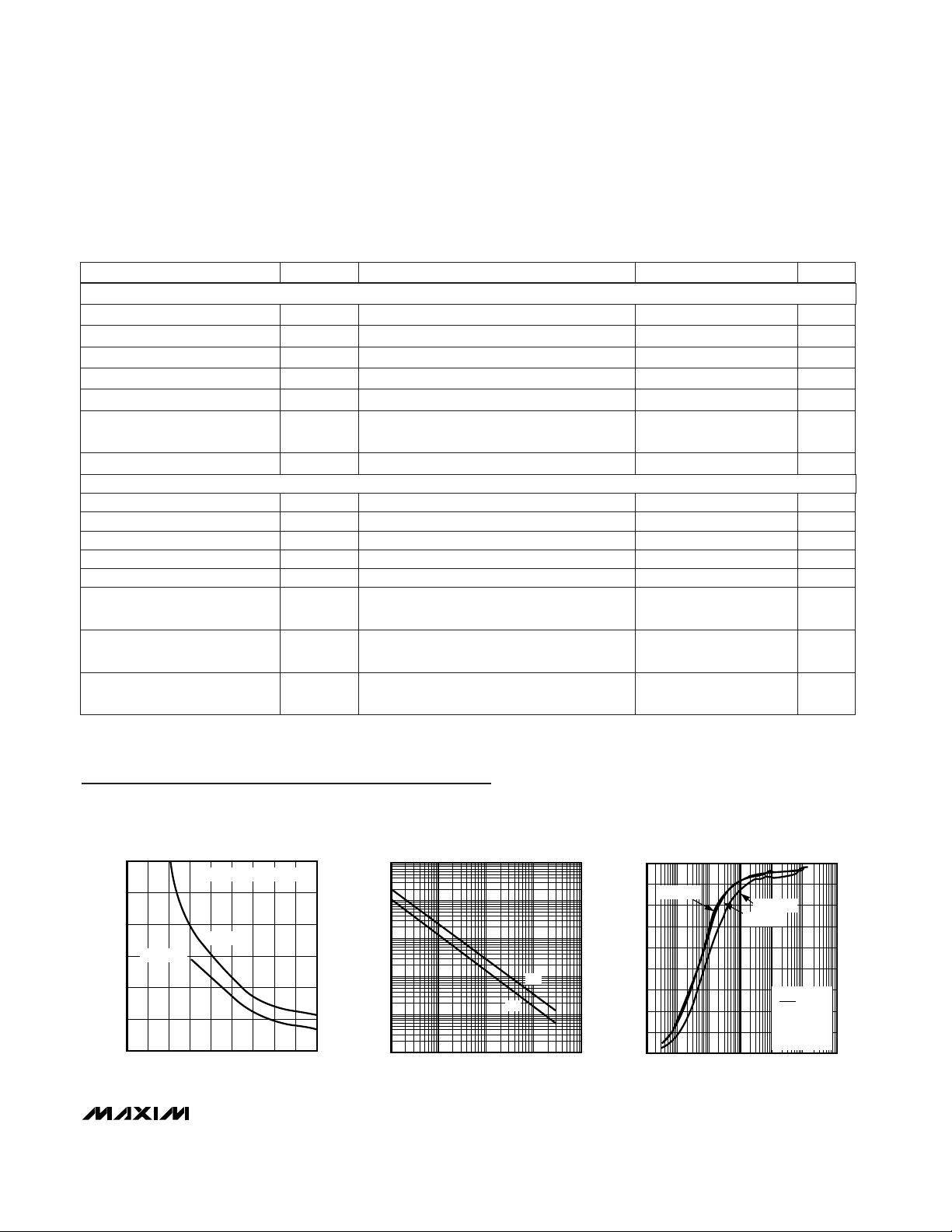

Typical Operating Characteristics

(Circuit of Figure 3, TA = +25°C, unless otherwise noted.)

CONDITIONS UNITMIN TYP MAXSYMBOLPARAMETER

CCMD, DCMD

V

CCMD

= 0, CC = GND

V

DCMD

= 0, CD = GND

Resets the counter

Voltage that allows a new cycle, defined as

(V

BBATT

- VLX) (see

DC-DC Converter

section)

VFB= 2.1V

R

BBON

= 100kΩ to GND

VLX= 12V

CCC= 33nF

ILX= 200mA

CCD= 3.3nF

V

0.8

V

IL

Logic Input Low Level

%

-1 1

CD to CC Current Matching

V

0.4

ISET Logic Input Low Voltage

Hz

60 75.8 95

CC

OSC

CC Oscillator Frequency

Hz

600 758 950

CD

OSC

CD Oscillator Frequency

V

1.95 2.05

V

FB

FB Trip Point

µA

4.35 5.00 5.65

CC Output Current

V2.1

BBON Logic Input Low Voltage

V

-0.2 -0.1 0.2

LX Zero Crossing Trip Threshold

nA

0.15 10

I

FB

FB Input Current

A

0.580 0.835 1.100

I

PEAK

LX Switch Current Limit

µA

0.01 10

LX Off-Leakage

Ω

0.5 1.5

R

DSON

LX On-Resistance

ELECTRICAL CHARACTERISTICS (continued)

(V

LRI

= V

ISET

= 20V, CCMD = DCMD = BBON = LRO, V

BBATT

= 3V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at

T

A

= +25°C.) (Note 1)

CCMD, DCMD

V

2.2

V

IH

Logic Input High Level

V

CCMD

, V

DCMD

= 0 to V

LRO

µA

1

I

(CCMD),

I

(DCMD)

Logic Input Leakage Current

TIMER BLOCK

DC-DC CONVERTER

Note 1: Specifications from 0°C to -40°C are guaranteed by design, not production tested.

0

20

40

60

80

100

120

0 105 15 20 25 30 35 40 45

DISCHARGE TIME

vs. OUTPUT CURRENT

MAX612-01

OUTPUT CURRENT (mA)

DISCHARGE TIME (MINUTES)

2 CELLS (SANYO N-50AAA)

V

OUT

= 7V

V

OUT

= 5V

100k

1

0.1 10 1001 1000

OSCILLATOR FREQUENCY

vs. CAPACITANCE

10

MAX1612-02

CAPACITANCE (nF)

OSCILLATOR FREQUENCY (Hz)

100

1k

10k

CD

CC

90

80

70

0

1µ 10µ 1m 10m

100m

100µ 1

EFFICIENCY vs. OUTPUT CURRENT

(BBATT = 3.6V)

MAX612-03

OUTPUT CURRENT (A)

EFFICIENCY (%)

30

20

10

60

50

40

V

OUT

= 7V

V

OUT

= 6V

V

OUT

= 5V

BBATT = 3.6V

R

BBON

= 240kΩ

NOTE: DC-DC

CONVERTER

SUPPLIES V

LRI

MAX1612/MAX1613

Bridge-Battery Backup Controllers

for Notebooks

4 _______________________________________________________________________________________

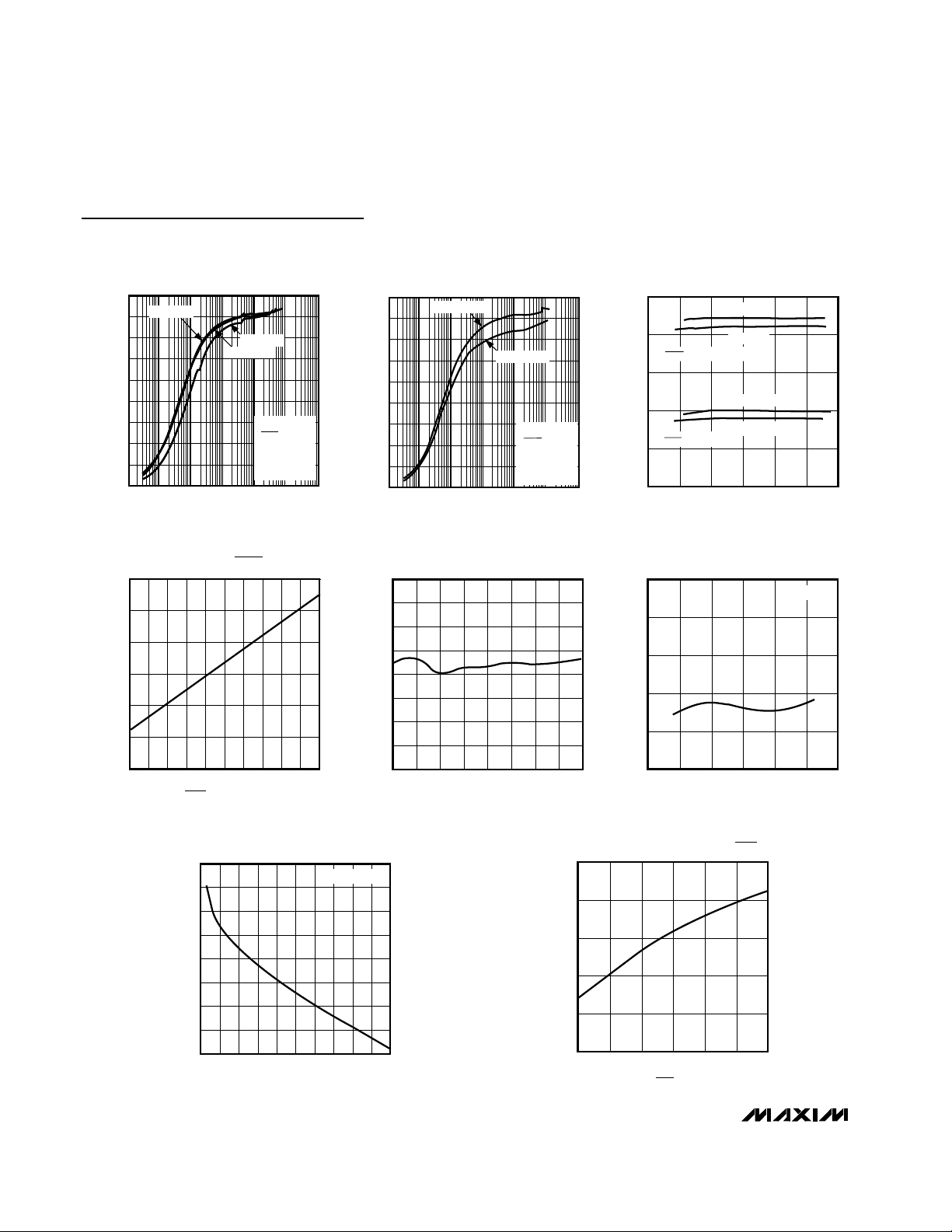

Typical Operating Characteristics (continued)

(Circuit of Figure 3, TA = +25°C, unless otherwise noted.)

90

80

70

0

1µ 10µ 1m 10m

100m

100µ 1

EFFICIENCY vs. OUTPUT CURRENT

(BBATT = 2.4V)

MAX612-04

OUTPUT CURRENT (A)

EFFICIENCY (%)

30

20

10

60

50

40

V

OUT

= 7V

V

OUT

= 6V

V

OUT

= 5V

BBATT = 2.4V

R

BBON

= 240kΩ

NOTE: DC-DC

CONVERTER

SUPPLIES V

LRI

90

80

70

0

1µ 10µ 1m 10m

100m

100µ 1

EFFICIENCY vs. OUTPUT CURRENT

(BBATT = 6V)

MAX612-05

OUTPUT CURRENT (A)

EFFICIENCY (%)

30

20

10

60

50

40

BBATT = 3.6V

BBATT = 2.4V

V

OUT

= 6V

R

BBON

= 240kΩ

NOTE: DC-DC

CONVERTER

SUPPLIES V

LRI

0

20

10

40

30

50

0 10 155 20 25 30

QUIESCENT CURRENT

vs. LRI VOLTAGE

MAX612-06

V

LRI

(V)

QUIESCENT CURRENT (µA)

MAX1612

MAX1612

MAX1613

MAX1613

R

BBON

= 100kΩ TO GND

V

BBON

= V

LRO

0

600

400

200

800

1000

1200

5 13117 9 15 17 19 21 23 25

PEAK CURRENT vs. BBON CURRENT

MAX612-07

BBON CURRENT (µA)

PEAK CURRENT (mA)

3.20

3.24

3.22

3.26

3.32

3.30

3.34

3.28

3.36

0 4 6 8 102 12 14 16 18 20

MAX1613

LRO VOLTAGE vs. LOAD CURRENT

MAX612-10

LOAD CURRENT (mA)

V

LRO

(V)

V

LRI

= 20V

-2.0

-1.0

-1.5

0

-0.5

0.5

1.0

1.5

2.0

2.0 3.0 3.52.5 4.0 4.5 5.0 5.5 6.0

BBATT LEAKAGE CURRENT

vs. BBATT INPUT VOLTAGE

MAX612-08

BBATT INPUT VOLTAGE (V)

BBATT LEAKAGE CURRENT (µA)

3.25

3.27

3.31

3.29

3.33

3.35

0 105 15 20 25 30

MAX1613

LRO VOLTAGE vs. LRI VOLTAGE

MAX612-09

V

LRI

(V)

V

LRO

(V)

I

LOAD

= 5mA

100

150

250

200

300

350

120 200160 240 280 320 360

SWITCHING FREQUENCY vs. R

BBON

MAX612-11

R

BBON

(kΩ)

SWITCHING FREQUENCY (kHz)

MAX1612/MAX1613

Bridge-Battery Backup Controllers

for Notebooks

_______________________________________________________________________________________ 5

NAME FUNCTION

1 ISET

Bridge-Battery Charge-Current Input. Connect a current-setting resistor from this input to a voltage

higher than the bridge battery. Maximum current rating is 10mA. Pulling ISET below 0.4V resets the

internal counter.

2 BBATT Bridge-Battery Connection. Bridge-battery charger output.

PIN

3 LX Step-Up DC-DC Converter N-Channel MOSFET Drain. The maximum operating range is 12V.

4

LBO

Open-Drain Low-Battery Detector Output. When V

LBI

falls below 1.8V, LBO sinks current. When

V

LBI

rises above 2.0V, LBO becomes high impedance.

8 FULL

Open-Drain Bridge-Battery Full Indicator Output. When the internal timer reaches all 1sec, FULL

goes high impedance.

7

CCMD

Charge Command Input. When low with DCMD high, the internal switch from ISET to BBATT is

closed, charging the bridge battery. CCMD is inhibited if DCMD is low. The internal timer counts up

at a frequency set by the CC capacitor.

6

DCMD

Discharge Command Input. When low with CCMD high, the internal timer counts down at a

frequency set by the CD capacitor. When both DCMD and CCMD are low, discharge takes

precedence.

5

BBON

Bridge-Battery On Input. When high, the DC-DC converter turns off. When pulled low through an

external resistor, the resistor sets the peak inductor current. The inductor current is approximately

42,000 times the current in the external resistor (R

BBON

).

13 CD

Discharge Oscillator Capacitor Input. This capacitor sets the discharging oscillator frequency,

which determines the maximum time to decrement the counter from all 1s to all 0s. Calculate the

capacitor value as follows: CD (in nF) = 4.3 · discharge time (in hours).

12 CC

Charge Oscillator Capacitor Input. This capacitor programs the charging oscillator frequency,

which sets the time for the internal counter to reach all 1s. Determine the capacitor value by: CC

(in nF) = 4.3 · charge time (in hours).

11 GND Ground

10 LBI

Low-Battery-Detector Input. When LBI falls below 1.8V, LBO goes low and sinks current. When LBI

goes above 2.0V, LBO goes high impedance. Hysteresis is typically 200mV.

9 FB

Feedback Input of Step-Up DC-DC Converter. Regulates to 2V. Connect feedback resistors to set

output voltage (Figure 2).

Pin Description

14 PGND Power Ground and Step-Up DC-DC Converter N-Channel MOSFET Source

15 LRO

5V (MAX1612) or 3.3V (MAX1613) Linear-Regulator Output. Bypass to GND with a 1µF capacitor.

Maximum external load current is 10mA.

16 LRI Linear-Regulator Supply Input

MAX1612/MAX1613

_______________Detailed Description

The MAX1612/MAX1613 manage the bridge battery

(auxiliary battery) in portable systems. These devices

consist of a timer block that monitors the charging

process, a linear regulator for supplying IC power and

external circuitry to the MAX1612/MAX1613, and a DCDC step-up converter that powers the system when the

main battery is removed (Figure 1). The boost DC-DC

converter reduces the number of bridge-battery cells

required to supply the system’s DC-DC converter.

When the main supply is present, the DC-DC converter

is inactive, reducing the drain on the main battery to

only 18µA. However, if the main battery voltage falls (as

detected by the low-battery comparator), the bridge

battery becomes the input source.

The MAX1612/MAX1613 have an internal linear regulator set at +5V (MAX1612) or +3.3V (MAX1613). The linear regulator can deliver a load up to 10mA, making it

capable of powering external components such as a

microcontroller (Figure 4). An undervoltage lockout feature disables the device when the input voltage falls

below the operating range, preventing the DC-DC converter from inadvertently powering up.

The MAX1612/MAX1613 feature an internal counter

intended to track the charging and discharging

process. The counter tracks the charge on the bridge

battery, allowing trickle charge to terminate when the

maximum charge is achieved. The charging rate is

determined by current through the ISET switch, and

limited by the switch’s maximum current specification

as well as by the bridge cell’s charging capability. As

Bridge-Battery Backup Controllers

for Notebooks

6 _______________________________________________________________________________________

N-CHANNEL

PGND

V

CHARGE

V

MAIN

R

ISET

L1

ISETLRI BBATT

V

BBATT

LX

FB

D1

R1

R2

R3

C

OUT

LBI

DISCHARGE

OSCILLATOR

TIMER BLOCK

CHARGE/DISCHARGE

COUNTER

CHARGE

OSCILLATOR

2.0V

REFERENCE

+3.3/+5V

LINEAR REGULATOR

1.8V/2.0V

BBON

R

BBON

DCMDCCMDFULL

CD

CC

C

CD

C

CC

GND

LRO

TO EXTERNAL

LOADS

LBO

TO MAIN

DC-DC

MAX1612

MAX1613

PULSE-

FREQUENCY

MODULATION

CONTROL

BLOCK

Figure 1. Functional Diagram

specifications vary, the counter frequency can be

adjusted to accommodate these variances by adjusting

CCC. Similarly, the discharging oscillator frequency can

be adjusted with the CCDcapacitor. However, the rate

of bridge battery discharge depends on the DC-DC

converter’s load. Decrementing the charge/discharge

counter is used only to estimate the remaining charge

on the bridge battery. The counter increments (or

decrements) based on CCMD and DCMD logic states.

Note that the net charge must exceed the net discharge to compensate for charging efficiency losses.

Figure 3 shows a typical stand-alone application (see

Design Procedure

for details). It reduces the need for

an external microcontroller to manage these functions.

However, if the design requires greater flexibility, a

microcontroller can be used as shown in Figure 4.

DC-DC Converter

The DC-DC step-up converter is a pulse-frequency

modulated (PFM) type. The on-time is determined by

the time it takes for the inductor current to ramp up to

the peak current limit (set via R

BBON

), which in turn is

determined by the bridge battery voltage and the

inductor value. With light load or no load, the converter

is forced to operate in discontinuous-conduction mode

(where the inductor current decays to zero with each

cycle) by a comparator that monitors the LX voltage

waveform. The converter will not start a new cycle until

the voltage at LX goes below the battery voltage. At full

load, the converter operates at the crossover point

between continuous and discontinuous mode. This

“edge of continuous” algorithm results in the minimum

possible physical size for the inductor. At light loads,

the devices pulse infrequently to maintain output regulation (VFB≥ 2V). Note that the LX comparator requires

the DC-DC output voltage to be set at least 0.6V above

the maximum bridge battery voltage.

Timer Block

The MAX1612/MAX1613 have an internal charge/discharge counter that keeps track of the bridge-battery

charging/discharging process. When CCMD is low and

DCMD is high, the internal counter increments until the

FULL pin goes high, indicating that the counter has

reached all 1s. The maximum counter value is 221.

Additional pulses from the CC oscillator will not cause

the counter to wrap around. In the stand-alone application (Figure 3), terminate the charging process automatically by connecting FULL to CCMD. In a microcontroller application, pull CCMD high. The counter

only specifies the maximum time for full charging; it

does not control the actual rate of charging. CCMD

controls the charging switch, and the resistor at ISET

sets the charging rate.

During the discharging process, drive DCMD low in

order to begin decrementing the counter. When the

counter is full, FULL is high. As soon as the counter

decrements just two counts, the FULL pin sinks current,

indicating that the battery is no longer full. The counter

only indicates the relative portion of the charge remaining. The incrementing and decrementing rate depends

on the maximum charge and discharge times set forth

by charging and discharging rates (see the following

equations for CC and CD). Note that the actual discharging is caused by the input current of the step-up

DC-DC converter loading down the bridge battery,

which is controlled via BBON rather than by DCMD.

The CC and CD capacitor values determine the

upcount and downcount rates by controlling the discharging oscillator frequency. Determine the maximum

charge and discharge times as follows:

CCC(nF) = 4.3 · t

HRS

CCD(nF) = 4.3 · t

HRS

where CCCis the charging capacitor, CCDis the discharging capacitor and t

HRS

is the maximum time in

hours for the process. Choose values that allow for

losses in the battery charging and discharging

process, such as battery charging inefficiencies, errors

in charging current value caused by variable main battery voltages, leakage currents, and losses in the

device’s internal switch. For charging, use the standard

charge rate recommended by the battery manufacturer. The maximum charging current is restricted to

the battery specifications. Consult the battery manufacturer’s specifications. Do not set the charging

current above 10mA.

MAX1612/MAX1613

Bridge-Battery Backup Controllers

for Notebooks

_______________________________________________________________________________________ 7

MICROCONTROLLER

I/O

BBON

LRO

GND

250k

1M

MAX1612

MAX1613

2N7002

Figure 2. Reducing BBON Noise Sensitivity

MAX1612/MAX1613

The counter block can be used to estimate the charge

remaining in the battery. For example, if the maximum

expected charge time is 14 hours (CCC= 60nF) and

the maximum expected discharge time is about 2 hours

(CCD= 8.6nF), the battery reaches full charge in 14

hours with the FULL pin going high. If the bridge battery must supply the load for 1 hour, the counter will

decrement down to about half full. Recharging the battery will now require only 7 hours to reach all 1s in the

counter, signaling with FULL going high.

If both DCMD and CCMD are pulled low simultaneously, the counter defaults to the discharge mode. When

the bridge battery is supplying the circuit, it is considered to be in discharge mode (Table 1).

Charge Current Selection (ISET)

A resistor between ISET and a voltage higher than the

bridge battery sets the charging rate. The switch is

open when CCMD is high and is turned on when

CCMD is pulled low (assuming DCMD is high). If the

voltage at ISET falls below 0.4V, the internal counter

resets to all 0s. The internal high-voltage switch has a

typical on-state voltage drop of 1V (Figure 1).

Therefore, the charge current equals:

I

ISET

= [ (V

CHARGE

- V

BBATT

) - 1V] / R

ISET

Linear-Regulator Output (LRO)

The linear-regulator output, LRO, is set at +5.0V for the

MAX1612 and at +3.3V for the MAX1613, with a tolerance of ±6%. For powering external circuitry such as

the microcontroller shown in Figure 4, LRO is guaranteed to deliver up to 10mA while maintaining regulation.

If the voltage at the linear-regulator input falls below the

operating range, an undervoltage-lockout feature shuts

down the entire device.

Bridge-Battery Backup Controllers

for Notebooks

8 _______________________________________________________________________________________

DCMD CCMD

COUNTER ISET SWITCH

0 0 Count Down Off

0 1 Count Down Off

1 0 Count Up On

1 1 No Count Off

Table 1. CCMD, DCMD Truth Table

MAX1612

MAX1613

LX

MAIN

BATTERY

22µH

22µF

2.2k

160k

470k

+5V/3.3V

470k

1µF

0.33µF

100µF

ALWAYS-ON

OUTPUT

BRIDGE

BATTERY

442k

SYSTEM

DC-DC

(MAX1630)

20k

200k

BBATT

MBR0530

PGND

ISET

FB

LBI

GNDCDCC

4.7nF

68nF

BBON

DCMD

LBO

CCMD

FULL

LRO

Figure 3. Stand-Alone Application

Low-Battery Comparator (LBI,

LBO

)

The MAX1612/MAX1613 feature a low-battery comparator with a factory-preset 1.8V threshold. This comparator is intended to monitor the main high-voltage

battery. As the voltage falls below 1.8V, the open-drain

LBO output sinks current. With 200mV of hysteresis, the

output will not go high until V

LBI

exceeds 2.0V. LBO

can easily be connected to BBON to start the DC-DC

converter when V

LBI

< 1.8V (stand-alone application,

Figure 3). Figure 4 shows an application using a microcontroller, where LBO alerts the microcontroller to the

falling voltage and pulls BBON low through an external

resistor to start the DC-DC converter while also pulling

DCMD low to start the counter.

BBON

Control Input

The BBON input serves two functions: setting the peak

LX switch current, and enabling the DC-DC converter.

The control signal is normally applied to R

BBON

rather

than at the pin itself. The peak LX switch current is

directly proportional to and 42,000 times greater than

the current through R

BBON

(see

Typical Operating

Characteristics

). The BBON pin is internally regulated

to 2V, so that when the control input is forced low, the

voltage across R

BBON

is 2V.

When driving BBON from external logic, ensure the low

state has minimal noise. Otherwise, drive R

BBON

with

an N-channel FET whose source is returned directly to

GND (Figure 2).

Applications Information

Design Procedure

The following section refers to the Functional Diagram

of Figure 1.

Step 1: Select the output voltage and maximum output

current for the boost DC-DC converter. Generally,

choose an output voltage high enough to run the main

system’s buck DC-DC converters. Assuming the maximum battery capacity is 50mAh (Sanyo 1.2V N-50AAA),

the following equations can help the design process:

I

PEAK

= 2 · I

OUT

· (V

OUT

+ VD) / (V

BBATT

- V

RDSON

)

IIN= 0.5 · I

PEAK

MAX1612/MAX1613

Bridge-Battery Backup Controllers

for Notebooks

_______________________________________________________________________________________ 9

MAX1612

MAX1613

LX

MAIN

BATTERY

15µH

20µF

2.4k

250k

470k 470k

47µF

1µF

BRIDGE

BATTERY

V

CC

MICROCONTROLLER

I/O

I/O

I/O

I/O

I/O

I/O

750k

SYSTEM

DC-DC

(MAX1630)

35.2k

479.1k

BBATT

MBR0530

PGND

ISET

FB

LBI

GNDCDCC

0.01µF

0.1µF

BBON

LRO

LBO

FULL

DCMD

CCMD

0.33µF

2N7002*

*OPTIONAL, TO RESET COUNTER

Figure 4. Microcontroller-Based Application

MAX1612/MAX1613

where I

PEAK

is the peak current, I

OUT

is the load cur-

rent, V

BBATT

is the bridge-battery voltage, VDis the for-

ward drop across D1, V

OUT

is the output voltage, IINis

average current provided by the bridge battery, and

V

RDS(ON)

is the voltage drop across the internal Nchannel power transistor at LX (typically 0.5V). A larger

number of cells reduces the I

PEAK

and, in effect,

reduces the discharge current, thereby extending the

discharge time. The same is true for decreasing the

output voltage or output current. For example, choose

the following values: I

OUT

= 100mA, V

OUT

= 5V, and

V

BBATT

= 2V (two cells). Using the minimum voltage of

1V for each cell, Table 2 summarizes some common

values.

Step 2: To avoid saturation, choose an inductor (L) with

a peak current rating above the I

PEAK

calculated in

Step 1. Use low series resistance (≤ 200mΩ), to optimize efficiency. In this example, a 15µH inductor is

used. See Table 4 for a list of component suppliers.

The “edge-of-continuous” DC-DC algorithm causes the

inductor value to fall out of the peak current equation.

Therefore, the exact inductor value chosen is not critical to the design. However, the switching frequency is

inversely proportional to inductance, so trade-offs of

switching losses versus physical inductor size can be

made by adjusting the inductor value.

where f is the switching frequency, V

OUT

is the output

voltage, V

RDSON

is the voltage across the internal MOS-

FET switch, VDis the forward voltage of D1, I

PEAK

is the

peak current, and V

BBATT

is the bridge battery voltage.

The maximum practical switching frequency is 400kHz.

Step 3: Choose the charging (CCC) and discharging

(CCD) timing capacitors. These capacitors set the frequency that the counter increments/decrements.

CCC(nF) = 4.3 · expected charge time (in hours)

CCD(nF) = 4.3 · expected discharge time (in hours)

For instance, using a charge time of 16 hours and a discharge time of one hour, CCC= 68nF and CCD= 4.3nF.

(Consult battery manufacturers’ specifications for standard charging information, which generally compensates for battery inefficiencies.)

Step 4: Using the peak current calculated in Step 1,

calculate the series resistor (R

BBON

) as follows:

R

BBON

= (V

BBON

· 42,000) / I

PEAK

where V

BBON

= 2V (internally regulated).

Step 5: Resistors R1, R2, and R3 set the DC-DC converter’s output voltage and the low-battery comparator

trip value. The sum of R1, R2, and R3 must be less than

2MΩ, to minimize leakage errors. Choose resistor R1 =

750kΩ for the example. Calculate R2 and R3 as follows:

R2 = [ V

OUT

(R3) - 2 (R1) - 2 (R3) ] / (2 - V

OUT

)

R3 = (R1 + R2) / [ (V

TRIP

/ 1.8) - 1]

Bridge-Battery Backup Controllers

for Notebooks

10 ______________________________________________________________________________________

V

OUT

(V)

V

BBATT

(V)

AVERAGE

I

PEAK

(mA)

I

IN

(mA)

MINIMUM

DISCHARGE TIME

(MINUTES)

6 4 300 150 20

6 2 600 300 10

5 2 500 250 12

4.5 2 450 225 13.2

6 3 400 200 15

5 3 333 167 18

4.5 3 300 150 20

5 4 250 125 24

Table 2. Summary of Common Values for

Designing with the MAX1612/MAX1613

Note:

In this table, I

OUT

= 100mA and battery capacity = 50mAh.

Table 3. Component List

INDUCTORS CAPACITORS RECTIFIERS BATTERY

Sumida CD43

or CD54 series

Sprague 595D

series, AVX

TPS series

Motorola

MBR0530,

NIEC

EC10QS03L

Sanyo

N-50AAA

SUPPLIER PHONE FAX

AVX USA: 207-287-5111 USA: 207-283-1941

Motorola

USA: 408-749-0510

800-521-6274

—

NIEC

USA: 805-867-2555

Japan: 81-3-3494-7411

USA: 805-867-2556

Japan: 81-3-3494-7414

Sumida

USA: 708-956-0666

Japan: 81-3-3607-5111

USA: 708-956-0702

Japan: 81-3-3607-5144

Table 4. Component Suppliers

Sanyo

USA: 619-661-6835

Japan: 81-7-2070-6306

USA: 619-661-1055

Japan: 81-7-2070-1174

f

=

L(I )

(V V ) (V V V )

1

PEAK

− − −

BBATT RDSON OUT BBATT D

(V V V )

− −

OUT RDSON D

where V

OUT

is the DC-DC converter’s output voltage

and V

TRIP

is the voltage level the main battery must fall

below to trip the low-battery comparator. For example,

for a +5V boost DC-DC output, a 4.75V main battery

trip level is feasible. For this case, R1 = 750kΩ, R2 =

26kΩ, and R3 = 474kΩ.

Step 6: Select a resistor value to set the charging current. The resistor value at ISET limits the current

through the switch for bridge-battery charging. There is

a voltage drop across the high-voltage switch (see

Electrical Characteristics

) with a typical value of 1V.

The maximum charge current through the internal highvoltage switch is 10mA.

R

ISET

= (V

CHARGE

- V

SWITCH

- V

BBATT

) / I

CHARGE

where V

CHARGE

is the charging supply voltage,

V

SWITCH

is the drop across the high-voltage internal

switch, V

BBATT

is the bridge battery voltage, and

I

CHARGE

is the charge current (in amperes).

Stand-Alone Application

To reduce cost and save space, the MAX1612/

MAX1613 can be operated in a stand-alone configuration, which eliminates the need for a microcontroller. A

stand-alone configuration could also reduce the workload of an existing microcontroller in the system, thus

allowing these unused I/Os to be used for other applications.

Figure 3 shows the MAX1612/MAX1613 operating without the microcontroller by using the low-battery detector to monitor the main battery. If the main battery is too

low, LBO pulls BBON and DCMD low to start the DCDC step-up converter and allow the bridge battery to

discharge. If the bridge battery requires charging,

FULL pulls CCMD low to start the battery charging

process. If both CCMD and DCMD are low, discharging takes precedence and the bridge battery keeps the

boost DC-DC converter active.

Microcontroller-Based Application

The MAX1612/MAX1613 are also suited to operate in a

microcontroller-based system. A microcontroller-based

application provides more flexibility by allowing for separate, independent control of the charging process, the

DC-DC converter, and the counter. Independent control can be beneficial in situations where other subsystems are operating, so that automatic switchover of

power might create some timing issues. If necessary, a

microcontroller can be used to reset the counter by taking ISET low. Another advantage of a microcontrollerbased system is the ability to stop charging the bridge

battery during a fault condition.

Figure 4 shows an example of how the MAX1612/

MAX1613 can be interfaced to a MAX1630 to deliver

the input voltage to the main DC-DC converter. In this

example, the microcontroller monitors the main battery’s status and switches over to the bridge battery

when V

MAIN

falls below a specified trip level (see

Design Procedure

). When V

MAIN

falls below the LBI

threshold, LBO goes low. This signals the microcontroller, via an I/O, to switch over to the bridge battery as

the input source to the system main DC-DC converter.

In this application, the microcontroller also initiates the

bridge-battery charging process. When CCMD goes

low with DCMD high, the battery is charged through the

internal switch. The counter increments until it overflows

and FULL goes high, indicating a full charge. The

microcontroller I/O can read and write the appropriate

states to control the execution and timing of the entire

process.

If the main DC-DC is supplied by the main source, the

MAX1612/MAX1613’s step-up converter turns off, minimizing power consumption. The device typically draws

only 18µA of quiescent current under this condition.

MAX1612/MAX1613

Bridge-Battery Backup Controllers

for Notebooks

______________________________________________________________________________________ 11

Table 5. Surface-Mount Inductor Information

MANUFACTURER

AND PART

INDUCTANCE

(µH)

RESISTANCE

(Ω)

RATED CURRENT

(A)

HEIGHT

(mm)

Sumida CD54-100 10 0.100 1.44 4.5

Sumida CD43-8R2 8.2 0.132 1.26 3.2

Sumida CD43-150 15 0.235 0.92 3.2

Sumida CD54-150 15 0.140 1.30 4.5

Sumida CD54-220 22 0.180 1.11 4.5

MAX1612/MAX1613

Bridge-Battery Backup Controllers

for Notebooks

12 ______________________________________________________________________________________

Package Information

TRANSISTOR COUNT: 3543

Chip Information

QSOP.EPS

Loading...

Loading...