General Description

The MAX1512 is a programmable VCOM-adjustment

solution for thin-film transistor (TFT) liquid-crystal displays

(LCDs). The MAX1512 simplifies the labor-intensive

VCOM-adjustment process and replaces mechanical

potentiometers, which significantly reduces labor costs,

increases reliability, and enables automation.

The MAX1512 attaches to an external resistive voltagedivider and sinks a programmable current to set the

VCOM voltage level. An internal 7-bit digital-to-analog

converter (DAC) controls the sink current. The DAC is

ratiometric relative to AVDD and is guaranteed to be

monotonic over all operating conditions. This VCOM

calibrator IC includes an EEPROM to store the desired

VCOM voltage level. The EEPROM can be programmed

repeatedly, giving TFT LCD manufacturers the flexibility

to calibrate the display panel as many times as the

manufacturing process requires.

The IC features a single-wire interface between the

LCD panel and the programming circuit. The singlewire interface delivers both programming power and

DAC-adjustment commands to minimize changes to

panel connectors and production equipment. The

MAX1512 is available in an 8-pin 3mm x 3mm TDFN

package. A complete evaluation kit is available to simplify evaluation and production development.

Applications

LCD Panels

Notebook Computers

Monitors

LCD TVs

Features

♦ 7-Bit Adjustable Sink-Current Output

♦ Resistor-Adjustable Full-Scale Range

♦ Guaranteed Monotonic Output Over Operating

Range

♦ Single-Wire Adjustment and Programming*

♦ EEPROM Stores VCOM Setting

♦ Interface Enable/Disable Control (CE)

♦ 2.6V to 3.6V Logic Supply-Voltage Operating

Range (V

DD

)

♦ 4.5V to 20V Analog Supply-Voltage Range (V

AVDD

)

♦ V

DD

UVLO Protection

♦ 8-Pin 3mm x 3mm TDFN (0.8mm max)

MAX1512

EEPROM-Programmable TFT VCOM Calibrator

________________________________________________________________ Maxim Integrated Products 1

CE

CTL

AVDD

R

SET

OUT

R2

R1

VCOM

SET

GND

V

DD

V

DD

AVDD

MAX1512

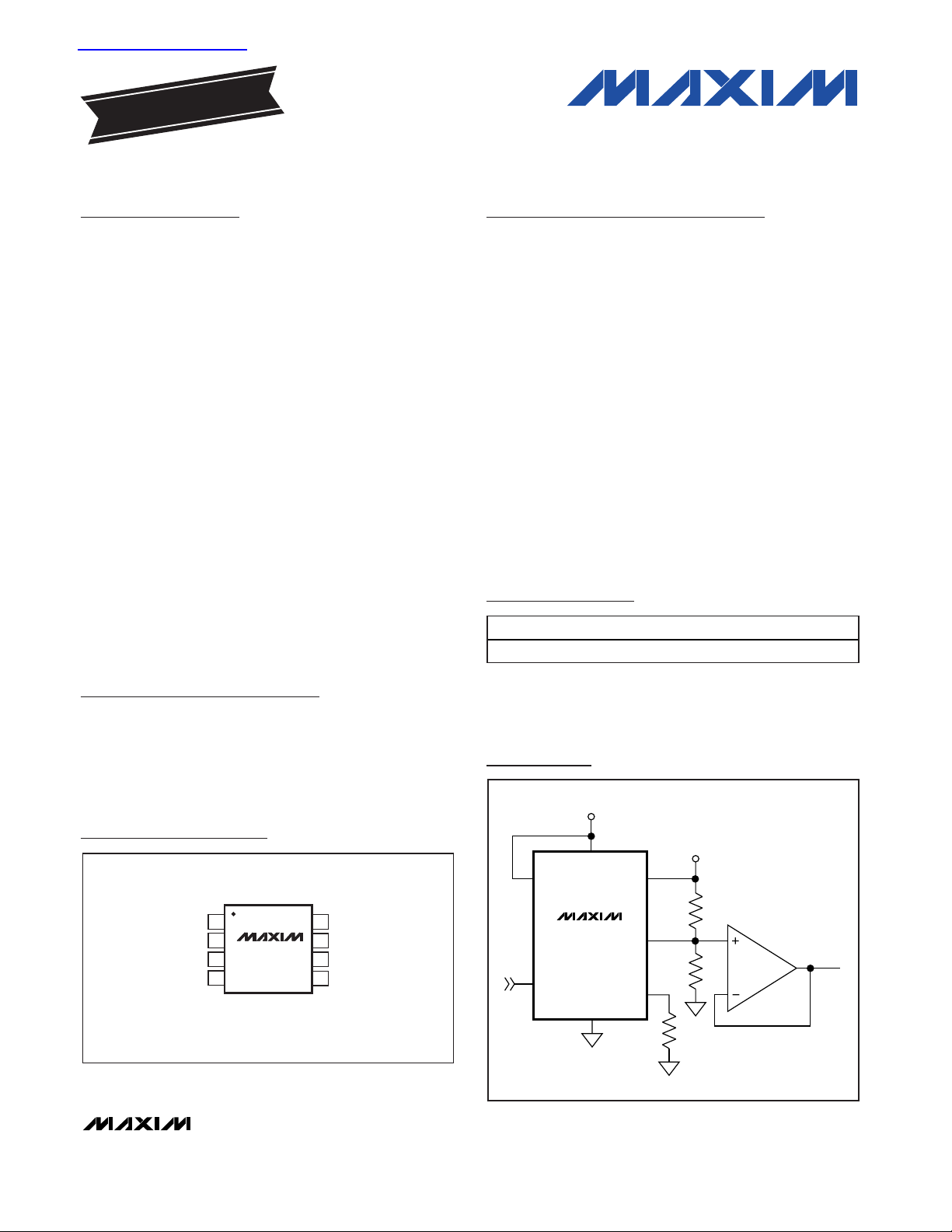

Pin Configuration

Ordering Information

1

2

3

4

8

7

6

5

SET

CE

CTL

V

DD

GND

N.C.

AVDD

OUT

MAX1512

TDFN

TOP VIEW

Typical Operating Circuit

19-2911 Rev 2; 8/04

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

PART

PIN-PACKAGE

MAX1512ETA

8 TDFN 3mm x 3mm

EVALUATION KIT

AVAILABLE

*Patent Pending.

查询MAX1512供应商

TEMP RANGE

-40°C to +85°C

MAX1512

EEPROM-Programmable TFT VCOM Calibrator

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

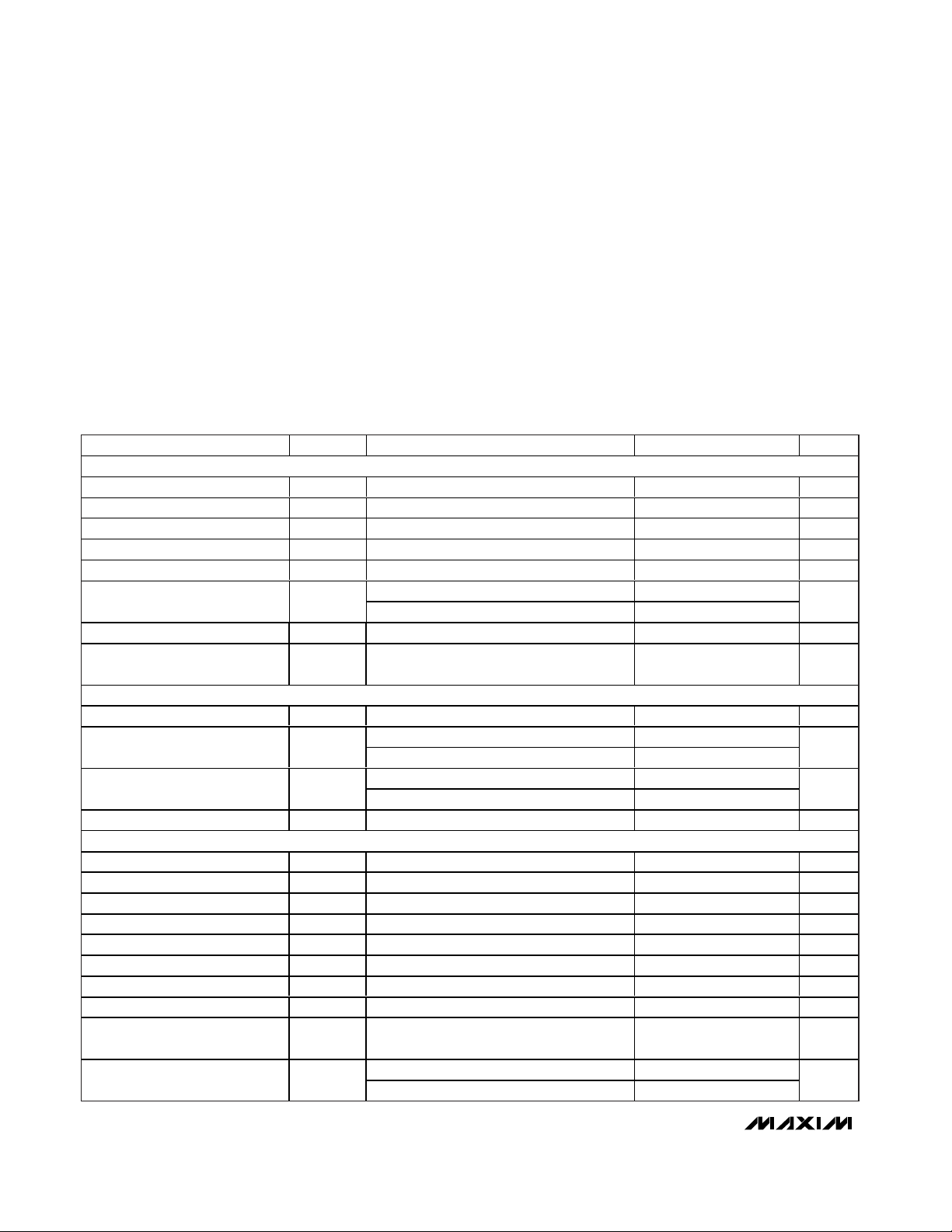

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, VDD= 3V, V

AVDD

= 10V, V

OUT

= 5V, R

SET

= 30.1kΩ, TA= 0°C to +85°C, unless otherwise noted. Typical values

are at T

A

= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDD, SET, CE to GND...............................................-0.3V to +4V

OUT to GND ...........................................................-0.3V to +14V

AVDD to GND.........................................................-0.3V to +24V

CTL to GND ............................................................-0.3V to +16V

Continuous Power Dissipation (T

A

= +70°C) ...............................

8-Pin Thin QFN 3mm x 3mm (derate 24.4mW/°C

above +70°C).............................................................1951mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +160°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

SINK-CURRENT ADJUSTMENT

SET Voltage Resolution 7 Bits

SET Differential Nonlinearity Guaranteed monotonic -1 +1 LSB

SET Zero-Scale Error -1 +1 +2 LSB

SET Full-Scale Error -12

LSB

SET Current I

SET

120 µA

To GND, V

AVDD

= 20V 10 200

SET External Resistance (Note 2)

R

SET

To GND, V

AVDD

= 4.5V

kΩ

V

SET

/ V

AVDD

Voltage Ratio DAC full scale

V/V

V

SET

/ V

AVDD

Factory Set Voltage

Ratio

V/V

VDD SUPPLY

VDD Supply Range V

DD

2.6 3.6 V

CE = V

DD

32 55

VDD Supply Current I

DD

CE = GND 12 20

µA

Rising edge 2.2 2.5 2.7

VDD Power-On Reset Threshold

Falling edge 2.1 2.4 2.6

V

VDD Power-On Reset Hysteresis

mV

CONTROL AND PROGRAMMING

CE Input Low Voltage 2.6V < VDD < 3.6V 0.4 V

CE Input High Voltage 2.6V < VDD < 3.6V 1.6 V

CE Startup Time (Note 3) 1 ms

CTL High Voltage 2.6V < VDD < 3.6V

V

CTL Float Voltage 2.6V < VDD < 3.6V

V

CTL Low Voltage 2.6V < VDD < 3.6V

V

CTL Rejected Pulse Width 20 µs

CTL Minimum Pulse Width

µs

CTL Minimum Time Between

Pulses

10 µs

CTL = GND -10

CTL Input Current

CTL = V

DD

10

µA

+12

2.25 45.00

0.05

0.024 0.025 0.026

100

0.70 x V

0.40 x V

0.20 x V

DD

DD

DD

0.82 x V

0.62 x V

0.32 x V

DD

DD

DD

200

MAX1512

EEPROM-Programmable TFT VCOM Calibrator

_______________________________________________________________________________________ 3

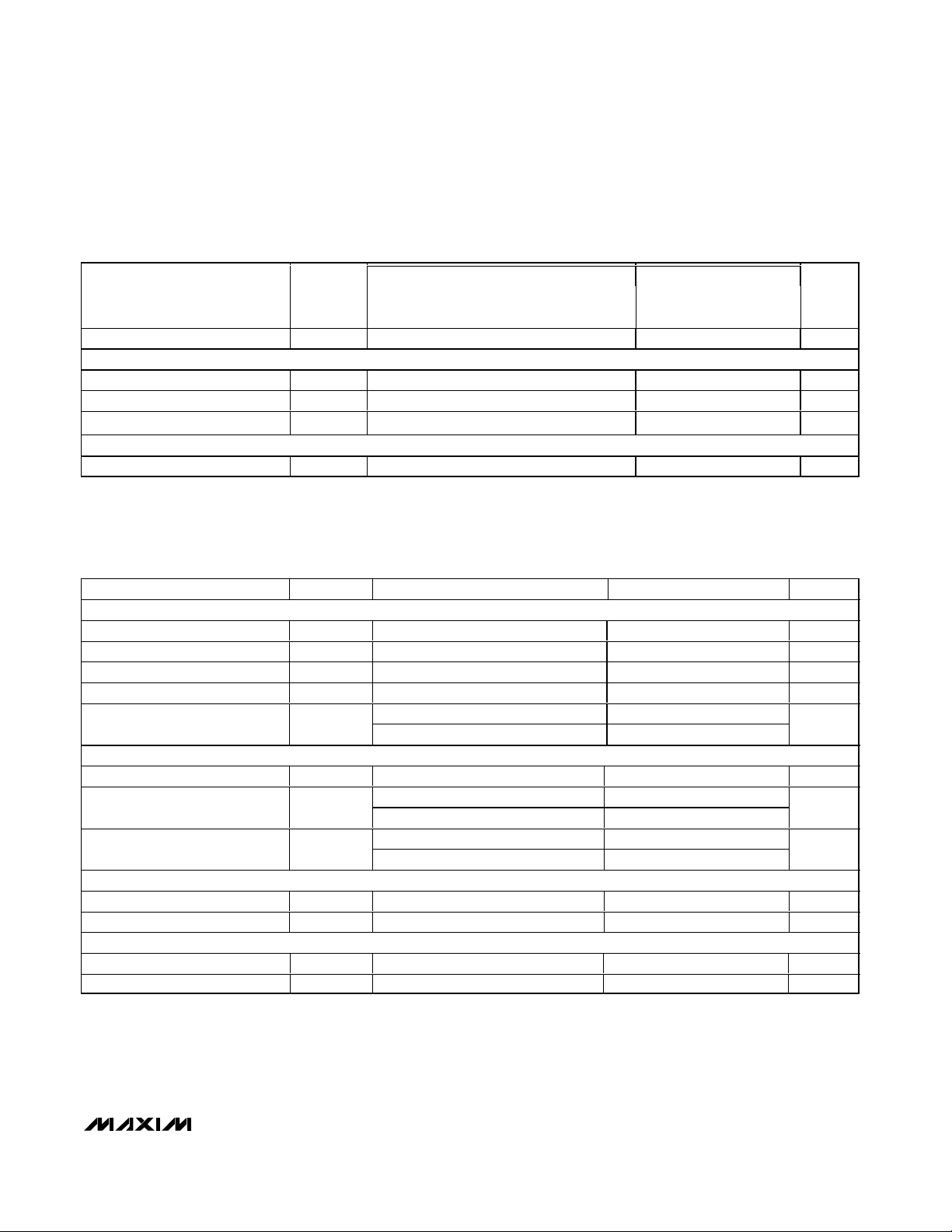

ELECTRICAL CHARACTERISTICS

(VDD= 3V, V

AVDD

= 10V, V

OUT

= 5V, R

SET

= 30.1kΩ, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

Note 1: Limits are 100% production tested at T

A

= +25°C. Limits over the operating temperature range are guaranteed through

correlation using standard quality control (SQC) methods.

Note 2: SET external resistor range is verified at DAC full scale.

Note 3: Guaranteed by design. Not production tested.

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VDD= 3V, V

AVDD

= 10V, V

OUT

= 5V, R

SET

= 30.1kΩ, TA= 0°C to +85°C, unless otherwise noted. Typical values

are at T

A

= +25°C.) (Note 1)

CTL Input Current

CTL = V

DD

10

µA

PARAMETER

CONDITIONS

UNITS

CTL EEPROM Program Voltage V

PP

(Note 3)

V

OUTPUT VOLTAGE

OUT Leakage Current V

DD

= 2.1V 1 nA

OUT Settling Time To ±0.5 LSB error band 20 µs

V

OUT

Voltage Range V

OUT

13 V

AVDD SUPPLY

V

AVDD

Supply Range V

AVDD

4.5

V

SYMBOL

MIN TYP MAX

15.25 15.5 15.75

V

+ 0.5V

SET

SINK-CURRENT ADJUSTMENT

SET Differential Nonlinearity Guaranteed monotonic -1 +1 LSB

SET Zero-Scale Error -1 +2 LSB

SET Full-Scale Error -12 +12 LSB

SET Current I

SET External Resistance (Note 2) R

VDD SUPPLY

VDD Supply Range V

VDD Supply Current I

VDD Power-On Reset Threshold

CONTROL AND PROGRAMMING

CE Input Low Voltage 2.6V < VDD < 3.6V 0.4 V

CE Input High Voltage 2.6V < VDD < 3.6V 1.6 V

AVDD SUPPLY

V

AVDD

AVDD Operating Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SET

SET

DD

DD

To GND, V

To GND, V

= 20V 10 200

AVDD

= 4.5V 2.25 45.00

AVDD

2.6 3.6 V

CE = V

DD

CE = GND 20

120 µA

55

Rising edge 2.2 2.7

Falling edge 2.1 2.6

Supply Range V

AVDD

AVDD

V

= 20V 20 µA

AVDD

4.5 20.0 V

20.0

kΩ

µA

V

MAX1512

EEPROM-Programmable TFT VCOM Calibrator

4 _______________________________________________________________________________________

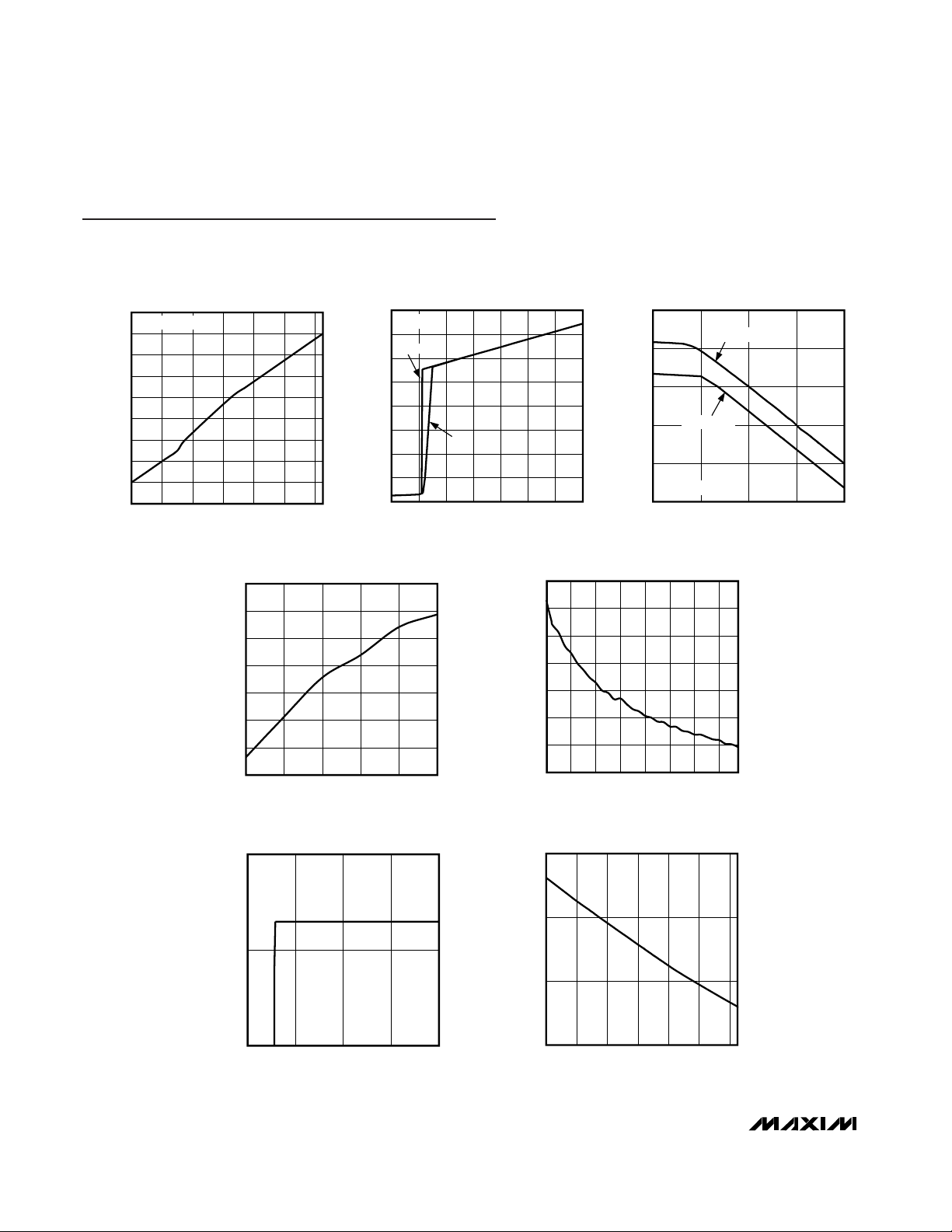

Typical Operating Characteristics

(Circuit of Figure 1, VDD= 3V, V

AVDD

= 10V, V

OUT

= 5V, R

SET

= 24.9kΩ, TA= +25°C, DAC half scale, unless otherwise noted.)

VDD SUPPLY CURRENT

vs. TEMPERATURE

MAX1512 toc01

TEMPERATURE (°C)

V

DD

SUPPLY CURRENT (µA)

806020 400-20

31.6

31.8

32.0

32.2

32.4

32.6

32.8

33.0

33.2

31.4

-40

CE = VDD = 3V

VDD SUPPLY CURRENT vs. V

DD

MAX1512 toc02

VDD (V)

V

DD

SUPPLY CURRENT (µA)

3.43.22.4 2.6 2.8 3.0

5

10

15

20

25

30

35

40

0

2.2 3.6

RISING

FALLING

CE = V

DD

I

OUT

vs. R

SET

MAX1512 toc03

R

SET

(kΩ)

I

OUT

(µA)

100101

1

10

100

1000

10,000

0.1

0.1 1000

V

AVDD

= 20V

V

AVDD

= 4.5V

VDD = V

OUT

= 3V

I

OUT

SINK-CURRENT ERROR vs. V

DD

MAX1512 toc04

VDD (V)

I

OUT

SINK-CURRENT ERROR (LSB)

3.43.23.02.8

2.825

2.830

2.835

2.840

2.845

2.850

2.855

2.820

2.6 3.6

I

OUT

SINK-CURRENT ERROR vs. V

AVDD

MAX1512 toc05

V

AVDD

(V)

I

OUT

SINK-CURRENT ERROR (LSB)

18.516.514.512.510.58.56.5

2.75

2.80

2.85

2.90

2.95

3.00

3.05

2.70

4.5

I

OUT

SINK-CURRENT ERROR vs. V

OUT

MAX1512 toc06

V

OUT

(V)

I

OUT

SINK-CURRENT ERROR (LSB)

1.51.00.5

2.835

0 2.0

2.840

2.830

I

OUT

SINK-CURRENT ERROR

vs. TEMPERATURE

MAX1512 toc07

TEMPERATURE (°C)

I

OUT

SINK-CURRENT ERROR (LSB)

806040200-20

2.8

2.9

3.0

2.7

-40

MAX1512

EEPROM-Programmable TFT VCOM Calibrator

_______________________________________________________________________________________ 5

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VDD= 3V, V

AVDD

= 10V, V

OUT

= 5V, R

SET

= 24.9kΩ, TA= +25°C, DAC half scale, unless otherwise noted.)

TOTAL UNADJUSTED ERROR

vs. DAC SETTING

MAX1512 toc08

DAC SETTING

TOTAL UNADJUSTED ERROR (LSB)

112968064483216

1

2

3

4

5

6

7

0

0128

R

SET

= 25kΩ

R

SET

= 100kΩ

INTEGRAL NONLINEARITY

vs. DAC SETTING

MAX1512 toc09

DAC SETTING

INTEGRAL NON-LINEARITY (LSB)

1129664 8032 4816

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0128

R

SET

= 100kΩ

R

SET

= 25kΩ

DIFFERENTIAL NONLINEARITY

vs. DAC SETTING

MAX1512 toc10

DAC SETTING

DIFFERENTIAL NON-LINEARITY (LSB)

1129664 8032 4816

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0128

AVDD POWER-UP RESPONSE

MAX1512 toc11

0

0

V

AVDD

10V/div

40µs/div

V

OUT

1V/div

0

V

DD

2V/div

C

OUT

= 100pF

VDD POWER-UP RESPONSE

MAX1512 toc12

0

4V

5V

40µs/div

10V

0

V

DD

2V/div

V

OUT

V

AVDD

C

OUT

= 100pF

SINGLE LSB STEP-UP RESPONSE

MAX1512 toc13

0

V

OUT

5mV/div

40µs/div

V

CTL

2V

C

OUT

= 100pF

SINGLE LSB STEP-DOWN RESPONSE

MAX1512 toc14

0

V

OUT

5mV/div

40µs/div

V

CTL

2V

C

OUT

= 100pF

MAX1512

EEPROM-Programmable TFT VCOM Calibrator

6 _______________________________________________________________________________________

Detailed Description

The MAX1512 is a solid-state alternative to mechanical

potentiometers used for adjusting the LCD backplane

voltage (VCOM) in TFT LCD displays. The MAX1512

attaches to an external resistive voltage-divider and

sinks a programmable current (I

OUT

), which sets the

VCOM level (Figure 1). An internal 7-bit DAC controls

the sink current and allows the user to increase or

decrease the VCOM level (Figure 2). The DAC is ratiometric relative to AVDD and is monotonic over all operating conditions. The user can store the DAC setting in

an internal EEPROM. On power-up, the EEPROM presets the DAC to the last stored setting. The single-wire

interface between the LCD panel and the programming

circuit adjusts the DAC, programs the EEPROM, and

provides programming power.

The resistive voltage-divider and the AVDD supply set

the maximum value of VCOM. The MAX1512 sinks current from the voltage-divider to reduce the VCOM level.

The external resistor R

SET

sets the full-scale sink cur-

rent and the minimum value of VCOM.

Pin Description

PIN

FUNCTION

1 OUT

Adjustable Sink-Current Output. OUT connects to the resistive voltage-divider between AVDD and GND that

sets the VCOM voltage. I

OUT

lowers the divider voltage by an adjustable amount. See the SET pin

description.

2 AVDD High-Voltage Analog Supply. Connects to the panel source-driver supply rail.

3N.C. No Connect. Not internally connected.

4 GND Ground

5VDDSupply Input. +2.6V to +3.6V input range.

6 CTL

VCOM Adjustment and EEPROM Programming Control. CTL sets the internal DAC code and programs the

EEPROM. A pulse-control method is used to adjust the VCOM level. See the VCOM Adjustment (CTL)

section. To program the DAC setting into the EEPROM as the power-on default, drive CTL to the EEPROM

programming voltage using the correct timing and voltage ramp rates. See the EEPROM Programming

(CTL) section.

7CE

Control Interface Enable. Connect CE to V

DD

to enable the CTL input. Connect CE to GND to disable the

CTL input and reduce the supply current.

8 SET

Full-Scale Sink-Current Adjustment Input. Connect a resistor, R

SET

, from SET to GND to set the full-scale

adjustable sink current. The full-scale adjustable sink current is equal to:

I

OUT

is equal to the current through R

SET

.

Figure 1. Standard Application Circuit

V

R

AVDD

SET

20 ×

NAME

V

DD

3V

AVDD

V

DD

CE

MAX1512

CTL

AVDD

OUT

SET

GND

10V

R

SET

25kΩ

R1

200kΩ

R2

245kΩ

VCOM

5V

MAX1512

EEPROM-Programmable TFT VCOM Calibrator

_______________________________________________________________________________________ 7

Setting the VCOM

Adjustment Range (R

SET

)

The external resistive voltage-divider sets the maximum

value of the VCOM adjustment range. R

SET

sets the

full-scale sink current, I

OUT

, which determines the mini-

mum value of the VCOM adjustment range. Large R

SET

values increase resolution but decrease the VCOM

adjustment range. Calculate R1, R2, and R

SET

using

the following procedure:

1) Choose the maximum VCOM level (V

MAX

), the mini-

mum VCOM level (V

MIN

), and the AVDD supply

voltage (V

AVDD

).

2) Calculate the R1 / R2 ratio:

3) Calculate the R1 / R

SET

ratio:

4) Choose R

SET

according to the limits shown in the

Electrical Characteristics section and calculate the

values for R1 and R2.

5) The resulting resolution is:

A complete design example is given below:

1) V

MAX

= 5V, V

MIN

= 3V, V

AVDD

= 10V

4) If R

SET

= 24.9kΩ, then R1 = 200kΩ and R2 =

200kΩ

5) Resolution = 15.75mV

3

1

20

53

5

8)

R

R

SET

=×

()

=

-

2

1210

5

1)

R

R

≅ =-1

Re

solutionV=

()

MAX MIN

-V

127

R

R

V

V

SET MAX

1

20

≅

()

×

MAX MIN

-V

R

R

V

V

AVDD

MAX

1

2

1 ≅ -

CE

R

CTL

7

7

CTL

AVDD

R

SET

OUT

R2

R1

19R

DAC

EEPROM

VCOM

SET

GND

V

DD

V

DD

AVDD

MAX1512

CONTROL

INTERFACE

Figure 2. Simplified Functional Diagram

MAX1512

Translating Existing Potentiometer

Circuits

Existing VCOM adjustment circuits using conventional

mechanical potentiometers can be translated into

MAX1512 circuits. Figures 3 and 4 show two common

adjustment circuits and their equivalent MAX1512 circuits.

Interface Enable/Disable (CE)

The MAX1512 control interface can be disabled to

reduce the VDDsupply current. Connect CE to GND to

reduce the typical supply current from 32µA to 12µA.

Connect CE to VDDto enable the control interface.

EEPROM-Programmable TFT VCOM Calibrator

8 _______________________________________________________________________________________

AVDD

R

SET

R

SET

=

OUT

R2

R1

R1 = Ra

R2 = Rb + Rc

Ra × (Rb + Rc)

20 × Rb

VCOM

SET

AVDD

MAX1512

Rb

Ra

VCOM

AVDD

Rc

MECHANICAL

POTENTIOMETER

MAX1512

EQUIVALENT CIRCUIT

Figure 3. Replacement of Mechanical/Potentiometer Circuit

AVDD

R

SET

R

SET

=

OUT

R2

R1

R1 = Rd

R2 = Rf

Rd × (Rd + Re + Rf)

20 × Re

VCOM

SET

AVDD

MAX1512

Re

Rd

VCOM

AVDD

Rf

MECHANICAL

POTENTIOMETER

MAX1512

EQUIVALENT CIRCUIT

Figure 4. Replacement of Mechanical/Potentiometer Circuit

The programming circuit in Figure 5 drives CE high to

enable the CTL input when it is connected. When the

programming circuit is not connected, CE is pulled low

through resistor R

CE

, which disables the CTL input. The

CTL input is relatively immune to noise and brief voltage transients. It can be safely left continuously

enabled if higher supply current is acceptable.

VCOM Adjustment (CTL)

Pulse CTL low for more than 200µs to increment the DAC

setting, which increases the OUT sink current and lowers

the VCOM level by 1 least-significant bit (LSB) (Figure 6).

Similarly, pulse CTL high for more than 200µs to decrement the DAC setting, which decreases the OUT sink current and increases the VCOM level by 1 LSB.

MAX1512

EEPROM-Programmable TFT VCOM Calibrator

_______________________________________________________________________________________ 9

CE

CTL

GND

MAX1512

PROGRAMMING

CIRCUIT

R

CE

V

DD

Figure 5. Optional Circuit to Drive CE

>1ms >200µs >200µs >200µs >10µs <20µs <20µs>200µs

CTL HIGH

V

DD

/2

CTL LOW

CTL

DAC SETTING

CE / V

DD

VCOM

CTL

ENABLED

64 65 64 63

UNDEFINED

FIRST

COUNT

IGNORED

SHORT

COUNTS

IGNORED

VCOM UP

VCOM DOWN

Figure 6. VCOM Adjustment

MAX1512

To avoid unintentional VCOM adjustment, the MAX1512

is guaranteed to reject CTL pulses shorter than 20µs. In

addition, to avoid the possibility of a single false pulse

caused by power-up sequencing between V

DD

and

CTL, the very first pulse is ignored.

EEPROM Programming (CTL)

To program the EEPROM, apply the EEPROM programming waveform through the CTL interface (Figure 7).

The control interface delivers programming power and

DAC adjustment commands on the same wire. This

1-wire approach minimizes the number of connections

from the programming circuit to the LCD panel.

To apply the EEPROM programming waveform, carefully

ramp CTL from midscale (V

DD

/ 2) to the programming

voltage, V

PP

, in 7.5ms as shown in Figure 7. If the ramp

is generated digitally, use at least 45 steps to achieve

the required 320mV ramp resolution. During the ramp

time, VCOM adjustment is disabled and the EEPROM

cells are biased in preparation for programming. After

reaching VPP, hold CTL at VPPfor 1ms. During the

EFPROM program time, the EEPROM stores the DAC

setting. Next, drive CTL to ground in less than 1ms and

hold for at least 200µs. Finally, drive CTL to V

DD

/ 2 to

complete the write cycle. The EEPROM is factory set to

half scale. Follow the EEPROM Programming Spec-

ifications in Table 1 to guarantee reliable EEPROM programming. Violating the specifications can damage the

EEPROM or affect data retention.

A complete evaluation kit is available to simplify evaluation and production development.

EEPROM-Programmable TFT VCOM Calibrator

10 ______________________________________________________________________________________

Table 1. EEPROM Programming Specifications

PARAMETER SYMBOL MIN TYP MAX UNITS

CTL Programming Voltage V

PP

15.25 15.5 15.75 V

CTL Programming Ramp T1 7.0 7.5 8.0 ms

EEPROM Program Time T2 0.9 1.0 1.1 ms

VPP Fall Time T3 10 1000 µs

Done Hold Time T4 200 µs

Figure 7. EEPROM Programming

CTL VOLTAGE

V

PP

/ 2

V

DD

0

T1

T2 T4T3

TIME

Applications Information

The VCOM adjustment and the EEPROM programming

must be performed with an external programming circuit. Refer to the MAX1512 evaluation kit for a complete

programming circuit solution.

Use a circuit similar to the conceptual diagram shown

in Figure 8 to drive CTL. The accuracy of the programming voltage (V

PP

) is critical for proper MAX1512 data

retention. The use of a comparator is recommended to

verify the correct programming voltage has been

reached. A complete design example of a CTL programming circuit is presented in the MAX1512 evaluation kit data sheet.

Electrostatic Discharge (CTL)

The CTL pin is exposed at the LCD panel connector and

is subject to electrostatic discharge (ESD). Often an RC

filter is used to improve an input’s resilience to ESD. If a

filter is added between the LCD panel connector and

CTL, ensure that the RC time constant is short enough to

avoid interfering with CTL pulses or the EEPROM programming timing. An RC time constant less than 200µs

does not interfere with EEPROM programming.

Leakage Current (CTL)

The CTL pin is internally biased to V

DD

/ 2, but it is sensitive to leakage currents above 0.1µA. When CTL is

not driven, avoid leakage currents around the CTL pin.

Otherwise, reinforce the V

DD

/ 2 set point with an exter-

nal resistive voltage-divider.

Layout Information

Use the following guidelines for good layout:

• Place the VCOM buffer and the R1/R2 voltage-

divider close to the OUT pin (Figure 1). Keep the

VCOM buffer and the R1/R2 voltage-divider close

to each other.

• Place R

SET

close to SET.

• In noisy environments, bypass capacitors may be

desired on VDDand/or V

AVDD

. Keep any bypass

capacitors close to the IC with short connections to

the pins.

Refer to the MAX1512 evaluation kit for an example of

proper board layout.

MAX1512

EEPROM-Programmable TFT VCOM Calibrator

______________________________________________________________________________________ 11

DAC

0 TO 2.5V

µC

USER

INTERFACE

CTL

MAX1512

REF

0 TO 15.5V

V

PP

VERIFY

Figure 8. Conceptual Programming Circuit

MAX1512

EEPROM-Programmable TFT VCOM Calibrator

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

12 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2004 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

D

N

PIN 1

INDEX

AREA

COMMON DIMENSIONS

MIN. MAX.

SYMBOL

A0.700.80

D2.903.10

E2.903.10

A1 0.00 0.05

L

0.20

0.25 MIN.k

A2 0.20 REF.

E

DETAIL A

L

A

NUMBER OF LEADS SHOWN ARE FOR REFERENCE ONLY

0.40

E2

C

L

e

C

L

L

e

PACKAGE OUTLINE, 6, 8, 10 & 14L,

TDFN, EXPOSED PAD, 3x3x0.80 mm

21-0137

6, 8, &10L, DFN THIN.EPS

1

F

2

PACKAGE VARIATIONS

PKG. CODE

T833-1

T1033-1

N D2 E2 e

2.30±0.101.50±0.106T633-1 0.95 BSC MO229 / WEEA

1.50±0.10

2.30±0.108

1.50±0.10

2.30±0.1010

1.70±0.10 2.30±0.1014T1433-1

1.70±0.10

0.65 BSC

0.50 BSC

0.40 BSC

0.40 BSC

JEDEC SPEC

MO229 / WEEC

MO229 / WEED-3

- - - - 0.20±0.03 2.40 REFT1433-2 14 2.30±0.10

b

0.40±0.05

[(N/2)-1] x e

1.90 REF

1.95 REF0.30±0.05

2.00 REF0.25±0.05

2.40 REF0.20±0.03- - - -

PACKAGE OUTLINE, 6, 8, 10 & 14L,

TDFN, EXPOSED PAD, 3x3x0.80 mm

21-0137

2

F

2

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...