Page 1

19-5821; Rev 1; 2/12

EVALUATION KIT

AVAILABLE

USB Battery Charger Detectors

General Description

The MAX14578E/MAX14578AE are USB charger detectors compliant with USB Battery Charging Revision 1.1.

The USB charger-detection circuitry detects USB standard downstream ports (SDPs), USB charging downstream ports (CDPs), or dedicated charger ports (DCPs),

and controls an external lithium-ion (Li+) battery charger.

The devices implement USB Battery Charging Revision

1.1-compliant detection logic including data contact

detection, D+/D- short detection, charging downstream

port identification, and optional USB dead-battery charging support. Dead-battery charging support features a

45-minute (max) charge timer and weak battery voltage

monitor controlled by I2C communication (MAX14578E

only.) The MAX14578AE features an enable (EN) input

and an LDO output.

In addition, the internal USB switch is compliant to

Hi-Speed USB, full-speed USB, and low-speed USB

signals. The devices feature low on-resistance, low

on-resistance flatness, and very low capacitance. The

devices also feature high-ESD protection up to Q15kV

Human Body Model on the CD+ and CD- pins.

In addition, the MAX14578E/MAX14578AE feature Apple

and Sony charger detection that allows identification of

resistor-divider networks on D+/D-.

The MAX14578E/MAX14578AE are available in both a

12-bump, 0.4mm pitch, 1.3mm x 1.68mm WLP package

and 16-pin TQFN package, and operate over the -40NC

to +85NC extended temperature range.

Features

S Compliant to USB Battery Charging Revision 1.1

S Data Contact Detection for Foolproof Connector

Insertion Detection

S USB Dead-Battery Charging Support

S Charging Downstream Detection

S Apple/Sony Charger Detection

S Dedicated Charger Detection

S China YD/T1591-Compliant Charger Detection

S Internal Switches Isolate the USB Transceiver

During the Charger Detection Process

S V

S Device Status Change Interrupt

S Low Supply Current

S High-ESD Protection on CD+ and CD-

Connection Capable of 28V

BUS

±15kV Human Body Model

±8kV IEC 61000-4-2 Contact Discharge

Applications

DSC and Camcorder

Media Players

Cell Phones

e-Book Readers

Mobile Internet Devices (MIDs)

MAX14578E/MAX14578AE

Ordering Information/Selector Guide

PART I2C

MAX14578EEWC+T Yes No No

MAX14578EETE+T Yes No No

MAX14578AEEWC+T No Yes Yes

MAX14578AEETE+T No Yes Yes

+Denotes a lead(Pb)-free/RoHS-compliant package.

*EP = Exposed Pad.

T = Tape and reel.

_______________________________________________________________ Maxim Integrated Products 1

EN

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

LDO TEMP RANGE PIN-PACKAGE TOP MARK

-40NC to +85NC

-40NC to +85NC

-40NC to +85NC

-40NC to +85NC

12 WLP +ABW

16 TQFN-EP* AJA

12 WLP +ABX

16 TQFN-EP* AJB

Page 2

USB Battery Charger Detectors

ABSOLUTE MAXIMUM RATINGS

(All voltages referenced to GND.)

BAT, INT, SDA, SCL, CE0, CE1, CE2, EN .......... -0.3V to +6.0V

LOUT ........................................... -0.3V to (VB + 0.3V, 6V) (min)

VB ..........................................................................-0.3V to +30V

Switch Disabled or CP_ENA = 1 (Note 1)

CD+, CD- ........................................ -2.1V to (V

TD+, TD- ......................................... -0.3V to (V

Switch Enabled or CP_ENA = 0 (Note 2)

CD+, CD-, TD+, TD- .......................-0.3V to (V

SWPOS

SWPOS

VCCINT

+ 0.3V)

+ 0.3V)

+ 0.3V)

Continuous Current into LOUT ..................................... ±150mA

Continuous Current into Any Other Terminal .................. ±50mA

Continuous Power Dissipation (TA = +70NC)

WLP (derate 13.7mW/NC above +70NC) ................. 1096mW

TQFN (derate 20.8mW/NC above +70NC)..................1667mW

Operating Temperature Range ........................ -40NC to +85NC

Junction Temperature .................................................. +150NC

Storage Temperature Range ......................... -65NC to +150NC

Soldering Temperature (reflow) ......................................+260NC

Note 1: V

Note 2: V

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

SWPOS

VCCINT

= (V

= (V

or 3.3V) (min)

VCCINT

[(VB or 4.2V) (min)]) (max)

BAT,

PACKAGE THERMAL CHARACTERISTICS (Note 3)

WLP

Junction-to-Ambient Thermal Resistance (BJA) ..........73°C/W

Note 3: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial.

TQFN

Junction-to-Ambient Thermal Resistance (BJA) ..........48°C/W

Junction-to-Case Thermal Resistance (BJC) .............. 10°C/W

MAX14578E/MAX14578AE

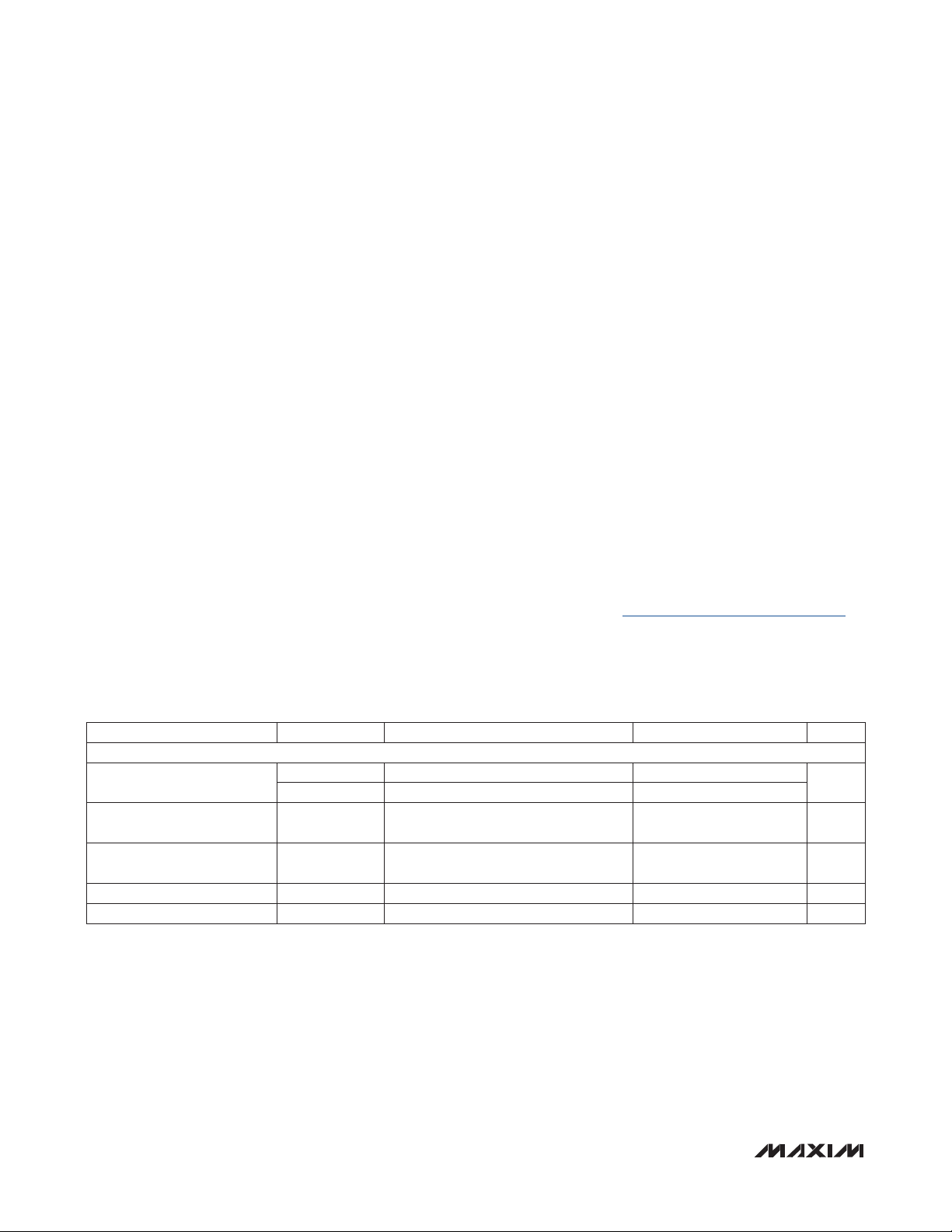

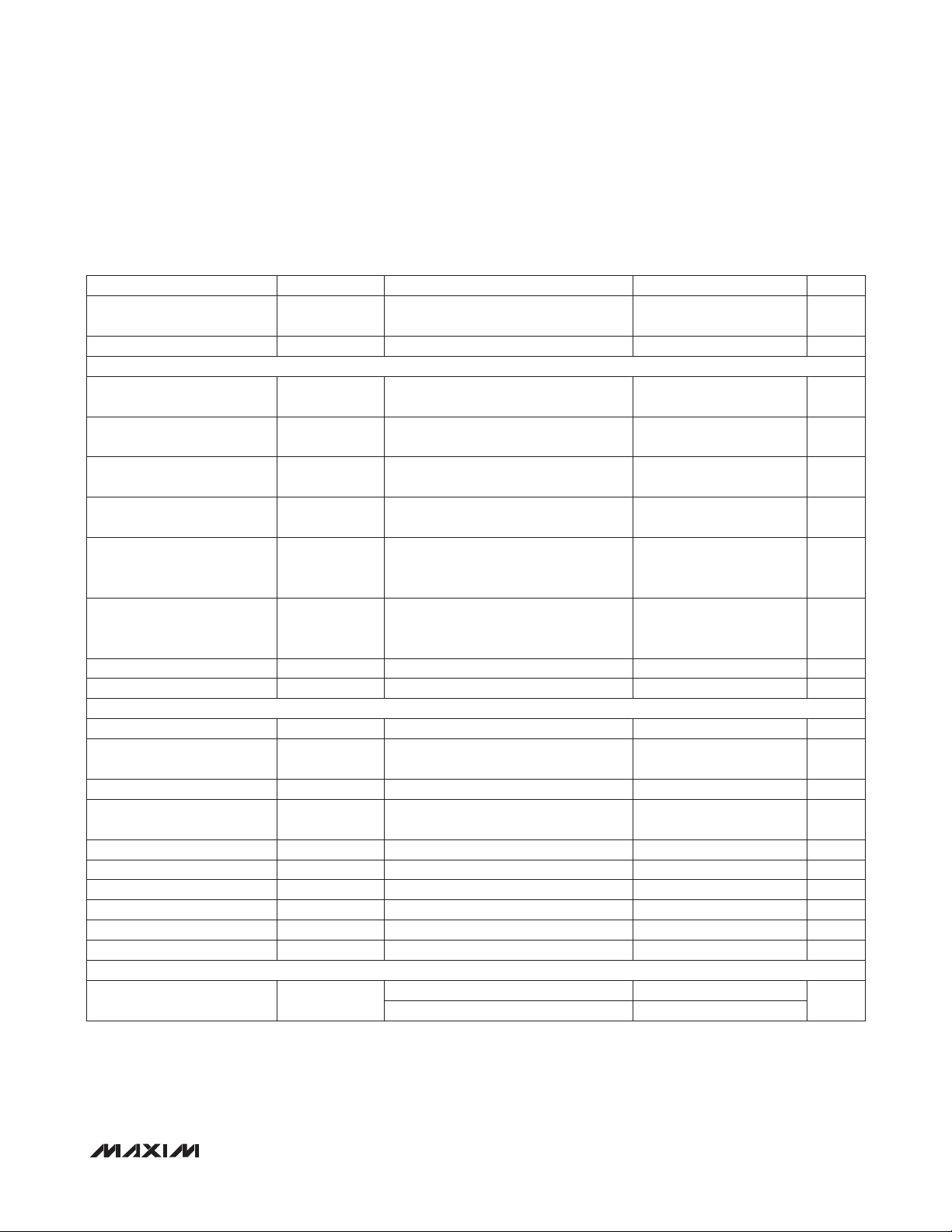

ELECTRICAL CHARACTERISTICS

(V

= +2.8V to +5.5V, VB = +3.5V to +5.5V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at V

BAT

VB = +5.0V, TA = +25NC.) (Note 4)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DC CHARACTERISTICS

Supply Voltage Range

Internal Positive Switch

Regulator

Internal Negative Switch

Regulator

V

UVLO V

BAT

V

UVLO V

BUS

V

BAT

V

B

V

SWPOS

V

SWNEG

BATUVLO

BUSUVLO

2.8 5.5

3.5 28

3.25 3.4 3.6 V

-2.06 -1.90 -1.76 V

V

= 4.2V, VB = 0V 0.90 1.65 2.45 V

BAT

V

= 0V, VB = 5.5V 1.0 1.33 3.30 V

BAT

BAT

= +3.6V,

V

2 ______________________________________________________________________________________

Page 3

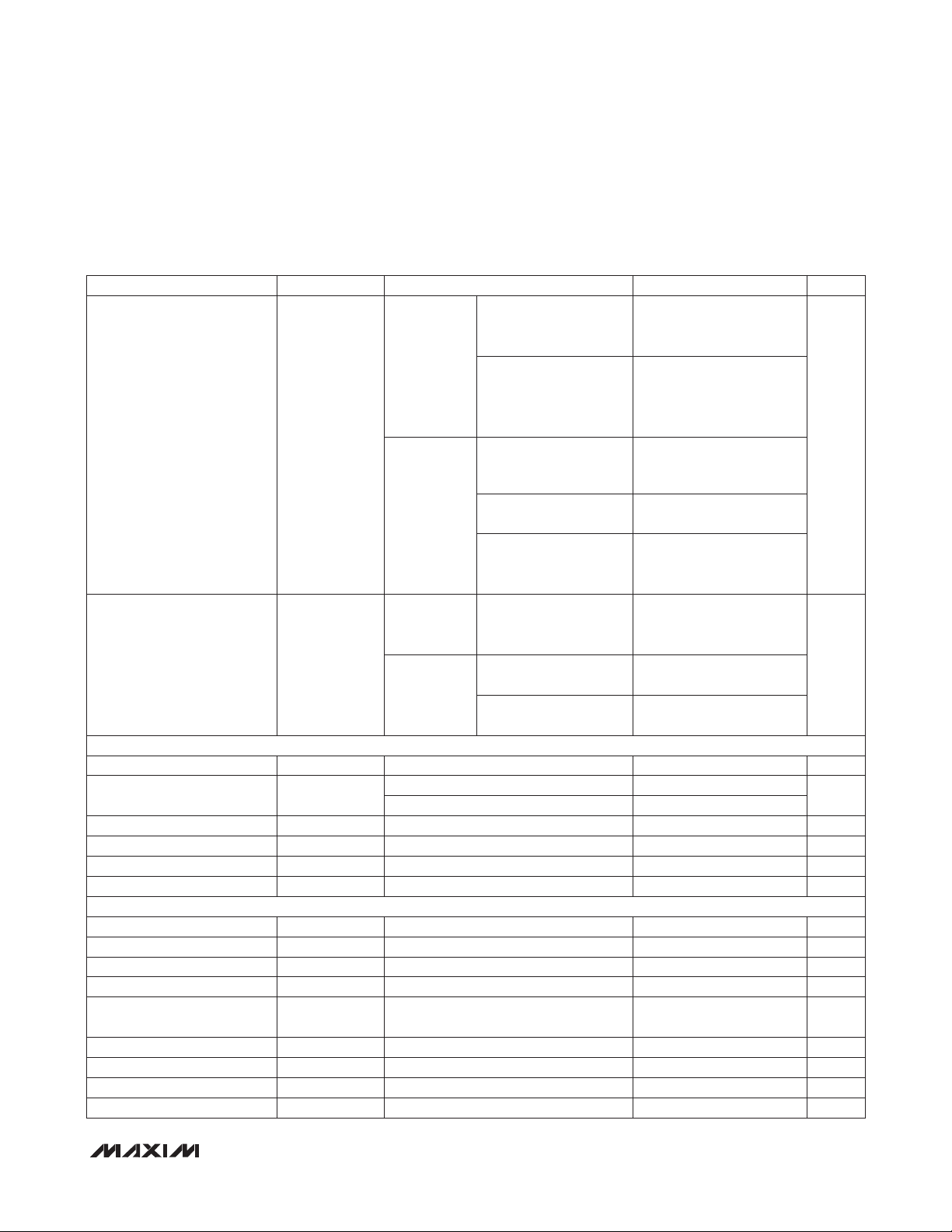

USB Battery Charger Detectors

ELECTRICAL CHARACTERISTICS (continued)

(V

= +2.8V to +5.5V, VB = +3.5V to +5.5V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at V

BAT

VB = +5.0V, TA = +25NC.) (Note 4)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

= +3.6V,

BAT

VB = 0V, CP_ENA = 0,

USBSWC = 0

MAX14578E

BAT Supply Current I

BAT

MAX14578AE

MAX14578E

VB Supply Current I

VB

MAX14578AE

LOUT (LDO OUT) (MAX14578AE ONLY)

LOUT Current Limit I

LOUT Voltage V

LOUT Debounce Time t

LOUT

LOUT

LOUT_DEB

I

= 10mA, VB = 5.0V 4.87 4.94

LOUT

I

= 0mA, VB = 6.0V 4.0 5.3 5.5

LOUT

VB = 5.0V to V

LOUT Turn-On Time 100

Themal Shutdown +141

Themal Shutdown Hysteresis 20

CHARGER DETECTION

V

V

V

I

DP_SRC

CD+ and CD- Sink Current

RCD Resistance R

TD+ Pulldown Resistor R

TD- Pulldown Resistor R

Charger Detection Weak Sink I

Voltage V

DP_SRC

DAT_REF

LGC

Voltage V

Voltage V

Current I

DP_SRC

DAT_REF

LGC

DP_SRC

I

CD+_SINK

I

CD-_SINK

CD

TD+_DWN

TD-_DWN

WEAK

V

= +4.2V,

BAT

VB = 0V, CP_ENA = 1,

USBSWC = 1,

V

SDA

V

BAT

VB < V

= V

= +3.6V,

SCL

VBRAW

= 1.8V

, VEN =

34.5 59

+3.6V

V

= +4.2V,

BAT

VB = 0V, VEN = 0V

1.3 30

Supply current increase

when VEN = 1.6V,

V

= +4.2V

BAT

1.3 3.5

VB = +5.5V,

CP_ENA = 0,

USBSWC = 0

VB = +5.5V,

VEN = 0V

190 2.95

VB = +5.5V,

VEN = +5.5V

= 4.5V 20 ms

LOUT

0.5 0.7 V

0.25 0.4 V

0.8 2.0 V

6.6 11

50 150

200 330 500

15 20 25

14.25 24.8

= +3.6V,

BAT

1 2.5

FA

1 2.5

87 140

FA

75 125

95 mA

V

Fs

NC

NC

FA

FA

kI

kI

kI

0.18

FA

MAX14578E/MAX14578AE

_______________________________________________________________________________________ 3

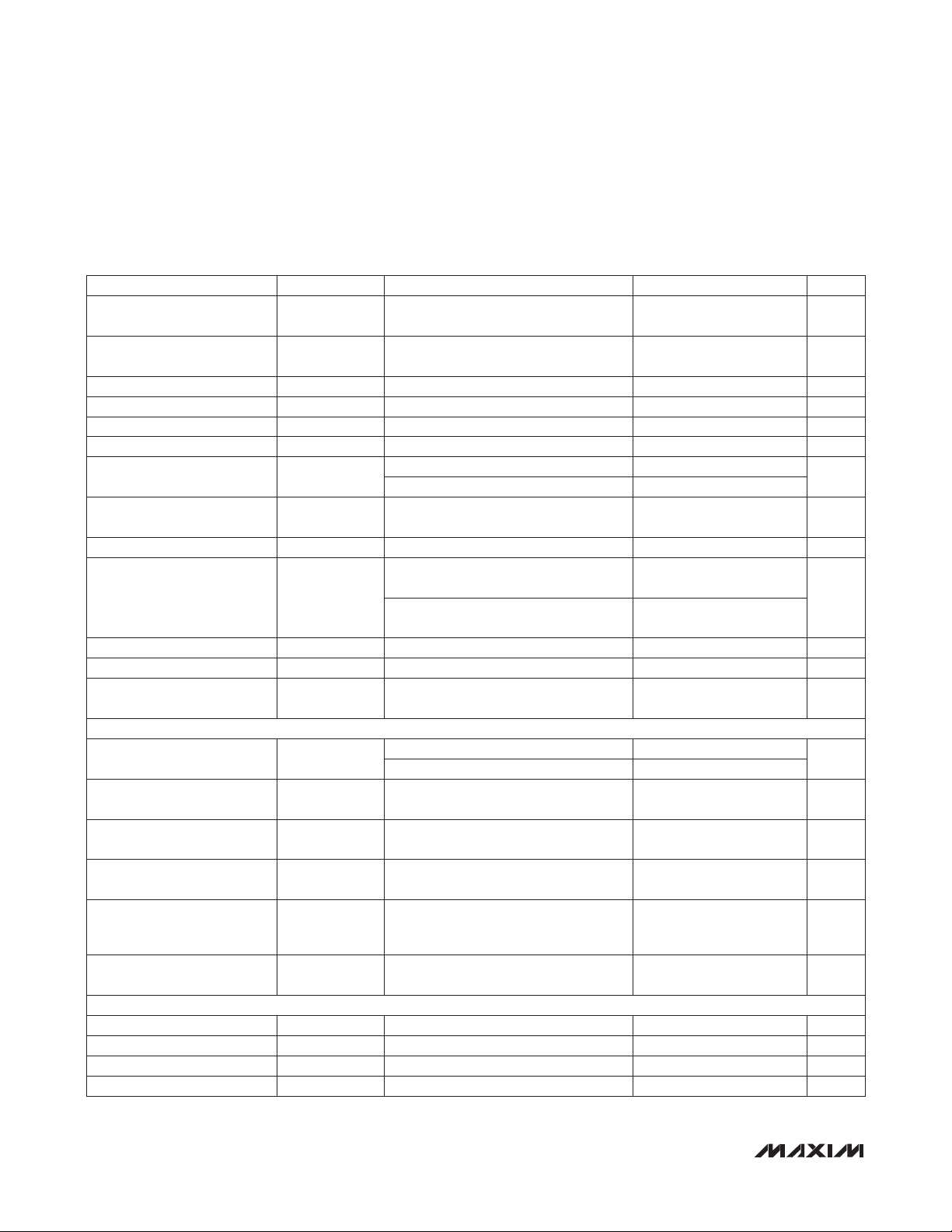

Page 4

USB Battery Charger Detectors

ELECTRICAL CHARACTERISTICS (continued)

(V

= +2.8V to +5.5V, VB = +3.5V to +5.5V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at V

BAT

VB = +5.0V, TA = +25NC.) (Note 4)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

VBUS25 Ratio VBUS25

VBUS47 Ratio VBUS47

VBUS60 Ratio VBUS60 57.5 60.3 63.5 %

DCD M Time t

DCD C Time t

MDEB

CDEB

DCD Timer 2 s

Charger-Detect Source Time t

Charger-Detect-Type

Detection Time

Charger-Detect Delay Time t

VB Attach to CE1 and CE2

Output Time

DP_SRC_ON

t

DP_RES_ON

DP_SRC_HICRNT

t

VBSW

MAX14578E/MAX14578AE

VB Raw-Detect Threshold V

VB-Detect Threshold V

VB-Detect Threshold

Hysteresis

USB ANALOG SWITCHES (CD-, CD+)

Analog-Signal Range V

On- Resistance R

On -Resistance Match

Between Channels

On -Resistance Flatness R

Off-Leakage Current I

On-Leakage Current I

DIGITAL SIGNALS (INT, SCL, SDA, EN, CE0, CE1, CE2)

Input Logic-High V

Input Logic-Low V

Input Leakage Current I

Open-Drain Low V

VBRAW

VBDET

V

VBDET_HYS

DN2, VDP2

ONUSB

DR

ONUSB

FLATUSB

LUSB(OFF)

LUSB(ON)

IH

IL

INLEAK

ODOL

Reference ratio for special charger as a

percentage of V

voltage, VB = 5V

BUS

Reference ratio for special charger as a

percentage of V

voltage, VB = 5V

BUS

24 26 29 %

44 47 50 %

All comparators 20 30 40 ms

All comparators 5 ms

DCHK = 0 40

DCHK = 1 625

120 ms

40 80 ms

From VB > V

(DCHK = 0) to CE1 and/or CE2 change

From VB > V

(DCHK = 1) to CE1 and/or CE2 change

or CHG_TYP_M = 1

VBDET

or CHG_TYP_M = 1

VBDET

520

1450

1.7 2.6 3.5 V

3.2 3.5 3.3 V

38 50 mV

CP_ENA = 0 (MAX14578E) 0 V

CP_ENA = 1 V

V

= +3.0V, I

BAT

V

, V

= 0 to +3.0V

CD-

= +3.0V, I

, V

= +400mV

CD-

= +3.0V, I

, V

= 0 to +3.3V

CD-

= 4.2V, switch open, V

= +0.3V or +2.5V; V

V

V

V

V

V

V

CD+

BAT

CD+

BAT

CD+

BAT

CD-

CD+

CD+

CD+

= I

= I

= I

= 10mA,

CD-

= 10mA,

CD-

= 10mA,

CD-

TD+

CD+

or V

=

TD-

SWNEG

3.3 6

0.06 0.26

=

-360 +360 nA

VCCINT

V

SWPOS

0.5

+2.5V or +0.3V

V

= 4.2V, switch closed, V

BAT

V

= +0.3V or +2.5V

CD-

CD+

or

-360 +360 nA

1.4 V

0.4 V

-1 +1

I

= 1mA 0.4 V

SINK

= +3.6V,

BAT

ms

ms

V

I

I

I

FA

4 ______________________________________________________________________________________

Page 5

USB Battery Charger Detectors

ELECTRICAL CHARACTERISTICS (continued)

(V

= +2.8V to +5.5V, VB = +3.5V to +5.5V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at V

BAT

VB = +5.0V, TA = +25NC.) (Note 4)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Output Logic-High V

Output Logic-Low V

DYNAMIC (Note 5)

OH

OL

I

SOURCE

I

SINK

= 1mA

= 1mA 0.2 V

VIO -

0.2

= +3.6V,

BAT

MAX14578E/MAX14578AE

V

Charge-Pump Delay Time t

Analog-Switch Turn-On Time t

Analog-Switch Turn-Off Time t

Break-Before-Make

Delay Time

Off-Capacitance C

ON

OFF

t

BBM

OFF

CP

CP_ENA from 0 to 1 until switch on 1 ms

MAX14578E, I2C STOP to switch on,

RL = 50I

MAX14578E, I2C STOP to switch off,

RL = 50I

RL = 50I, TA = +25NC

TD-, TD+, applied voltage is 0.5V

P-P

DC bias = 0V, f = 240MHz; CD-, CD+

> 0

,

0.1 1 ms

0.1 1 ms

2 pF

not connected to TD-, TD+

On-Capacitance C

ON

TD-, TD+, applied voltage is 0.5V

DC bias = 0V, f = 240MHz; CD-, CD+

P-P

,

4.5 pF

connected to TD-, TD+; RL = 50I

-3dB Bandwidth BW V

Off-Isolation V

ISO

= 0.5V

CD_

P-P

RL = 50I, f = 20kHz, V

CD_

= 0.5V

P-P

1000 MHz

-60 dB

I2C TIMING SPECIFICATIONS

I2C Max Clock f

Bus Free Time Between STOP

and START Conditions

I2CCLK

t

BUF

1.3

400 kHz

START Condition Setup Time 0.6

Repeat START Condition

Setup Time

START Condition Hold Time t

STOP Condition Setup Time t

Clock Low Period t

Clock High Period t

Data Valid to SCL Rise Time t

Data Hold Time to SCL Fall t

t

SU:STA

HD:STA

SU:STO

LOW

HIGH

SU:DAT

HD:DAT

90% to 90% 0.6

10% of SDA to 90% of SCL 0.6

90% of SCL to 10% of SDA 0.6

10% to 10% 1.3

90% to 90% 0.6

Write setup time 100 ns

Write hold time 0 ns

ESD PROTECTION

CD+, CD-

Human Body Model ±15

IEC 61000-4-2 Contact Discharge ±8

Note 4: All units are 100% production tested at TA = +25NC. Limits over the operating temperature range are guaranteed by

design and not production tested.

Note 5: Guaranteed by design; not production tested.

Fs

Fs

Fs

Fs

Fs

Fs

Fs

Fs

kV

_______________________________________________________________________________________ 5

Page 6

USB Battery Charger Detectors

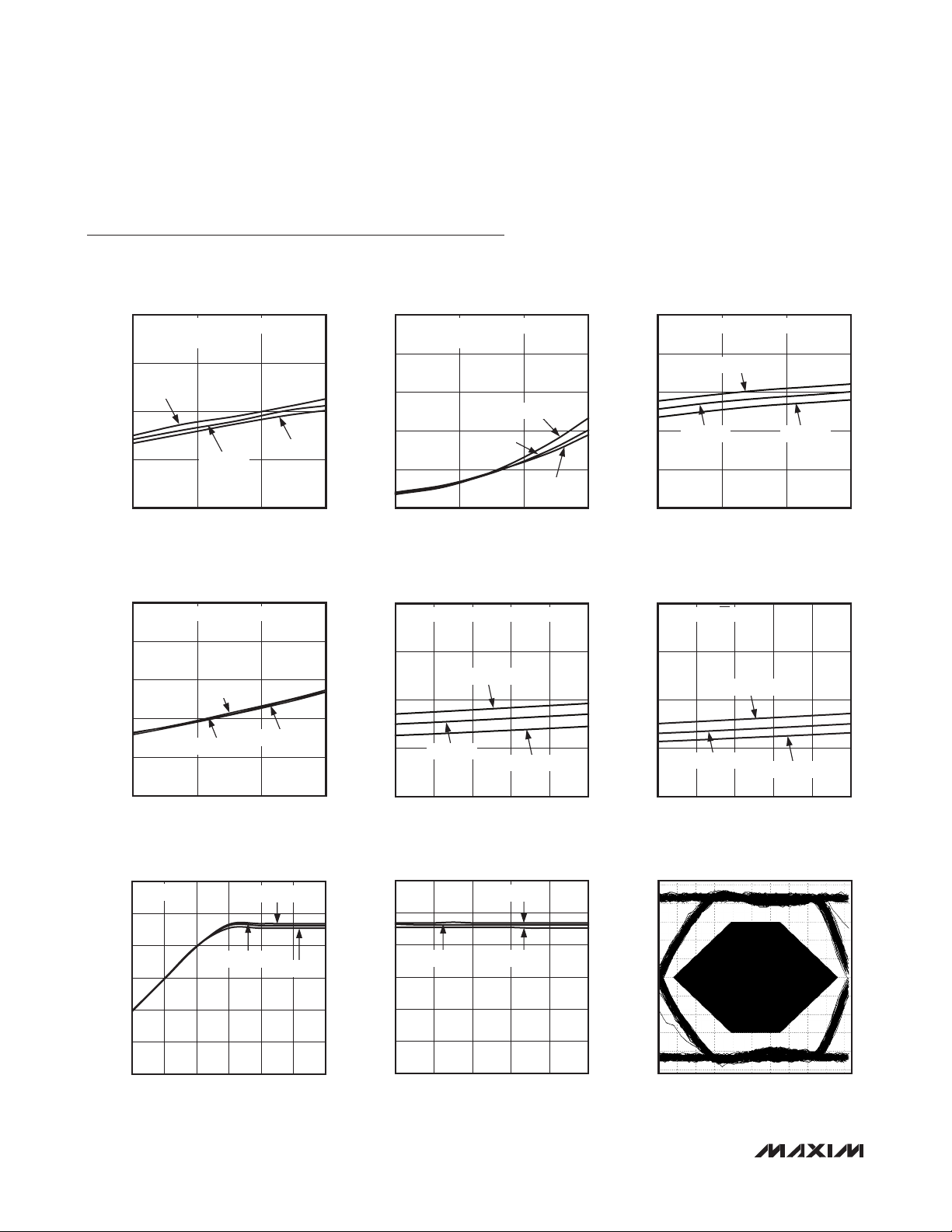

01

Typical Operating Characteristics

(V

= +4.2V, VB = +5.0V, C

BAT

= 1FF, CVB = 1FF, unless otherwise noted.)

BAT

BAT SUPPLY CURRENT

vs. SUPPLY VOLTAGE

2.0

VB = 0V, CP_ENA = 0, USBSWC = 0

= V

V

1.5

1.0

BAT SUPPLY CURRENT (µA)

0.5

0

2.8 4.3

= 0V

SDA

SCL

TA = +85°C

BAT SUPPLY VOLTAGE (V)

TA = +25°C

3.83.3

TA = -40°C

MAX14578E toc01

BAT SUPPLY CURRENT (µA)

BAT SUPPLY CURRENT

vs. SUPPLY VOLTAGE

25

VB = 0V, CP_ENA = 0, USBSWC = 1

MAX14578E/MAX14578AE

20

15

10

BAT SUPPLY CURRENT (µA)

5

TA = +25°C

TA = +85°C

TA = -40°C

MAX14578E toc04

SUPPLY CURRENT (µA)

V

BAT SUPPLY CURRENT INCREASE

vs. SUPPLY VOLTAGE

10

VB = 0V, CP_ENA = 0, USBSWC = 0

= V

V

8

6

4

2

0

2.8 4.3

= 1.8V

SDA

SCL

BAT SUPPLY VOLTAGE (V)

TA = +25°C

VB SUPPLY CURRENT

vs. SUPPLY VOLTAGE (MAX14578E)

200

V

= +3.6V, CP_ENA = 0, USBSWC = 0

BAT

150

TA = +85°C

100

B

50

TA = +25°C

TA = +85°C

TA = -40°C

3.83.3

TA = -40°C

50

40

MAX14578E toc02

30

20

BAT SUPPLY CURRENT (µA)

10

0

2.8 4.3

200

MAX14578E toc05

150

100

SUPPLY CURRENT (µA)

B

V

50

BAT SUPPLY CURRENT

vs. SUPPLY VOLTAGE

VB = 0V, CP_ENA = 1, USBSWC = 0

TA = +85°C

TA = +25°C

BAT SUPPLY VOLTAGE (V)

TA = -40°C

3.83.3

VB SUPPLY CURRENT

vs. SUPPLY VOLTAGE (MAX14578AE)

V

= +3.6V, EN = HIGH

BAT

TA = +85°C

TA = +25°C

TA = -40°C

MAX14578E toc03

MAX14578E toc06

0

2.8 4.3

BAT SUPPLY VOLTAGE (V)

3.83.3

LOUT VOLTAGE REGULATION (MAX14578AE)

6.0

I

= 1mA

LOUT

5.5

5.0

4.5

LOUT VOLTAGE (V)

4.0

3.5

3.0

4.0 7.0

VB SUPPLY VOLTAGE (V)

TA = +85°C

TA = +25°C

TA = -40°C

0

4.5 5.5

VB SUPPLY VOLTAGE (V)

5.35.14.94.7

LOUT LOAD REGULATION (MAX14578AE)

6.0

VB = 6V

5.5

MAX14578E toc07

5.0

4.5

LOUT VOLTAGE (V)

4.0

3.5

6.56.05.55.04.5

3.0

TA = +25°C TA = -40°C

LOUT CURRENT (mA)

TA = +85°C

MAX14578E toc08

8642

0

0

0.5

0.4

0.3

0.2

0.1

0

-0.1

-0.2

DIFFERENTIAL SIGNAL (V)

-0.3

-0.4

-0.5

6 ______________________________________________________________________________________

4.5 5.5

VB SUPPLY VOLTAGE (V)

ANALOG-SWITCH EYE DIAGRAM

0

TIME (x 10-9s)

5.35.14.94.7

MAX14578E toc09

2.01.81.4 1.60.4 0.6 0.8 1.0 1.20.2

Page 7

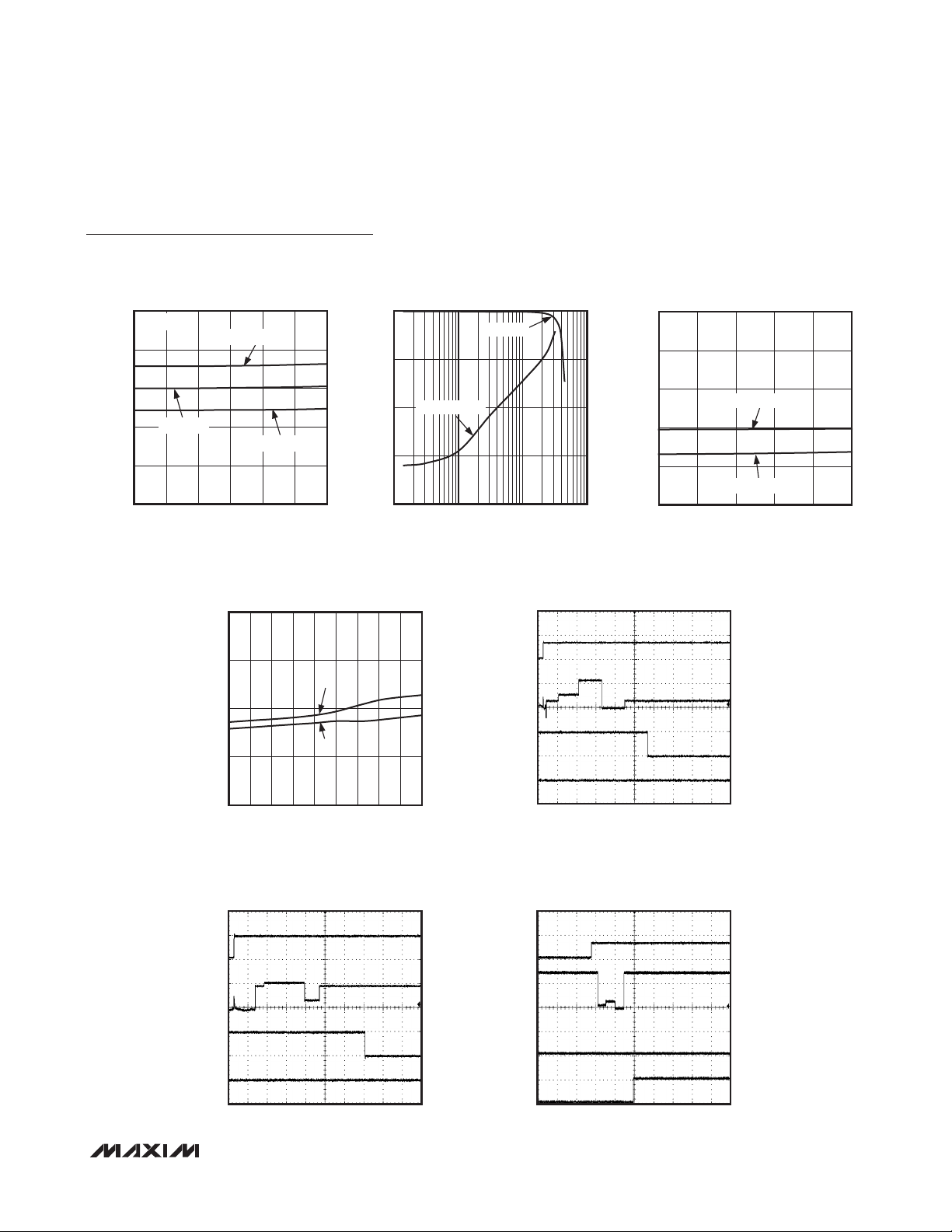

USB Battery Charger Detectors

Typical Operating Characteristics (continued)

(V

= +4.2V, VB = +5.0V, C

BAT

= 1FF, CVB = 1FF, unless otherwise noted.)

BAT

MAX14578E/MAX14578AE

CD+/CD- ON-RESISTANCE

VOLTAGE

vs. V

5

= 10mA

I

CD_

4

3

TA = +25°C

2

CD+/CD- ON-RESISTANCE (Ω)

1

0

0 3.0

CD_

V

VOLTAGE (V)

CD_

2.0

1.5

1.0

TA = +85°C

MAX14578E toc10

-20

-40

TA = -40°C

2.52.01.51.00.5

-60

CD+/CD- FREQUENCY RESPONSE (dB)

-80

LOGIC-INPUT THRESHOLD

vs. SUPPLY VOLTAGE

V

IH

CD+/CD- FREQUENCY RESPONSE

0

ON-LOSS

OFF-ISOLATION

0.01 10,000

FREQUENCY (MHz)

1001

CE_ vs. V

USB CHARGING DOWNSTREAM PORT, USB COMPLIANT

(USB_CPL = 1, USBSWC = 0, V

MAX14578E toc13

CD+/CD- LEAKAGE CURRENT

50

40

MAX14578E toc11

30

20

10

CD+/CD- LEAKAGE CURRENT (nA)

0

-40 85

CONNECTION (MAX14578E)

BUS

TD+

MAX14578E toc14

vs. TEMPERATURE

ON-LEAKAGE

OFF-LEAKAGE

TEMPERATURE (°C)

= 3V)

V

B

5V/div

V

CD+

0.5V/div

MAX14578E toc12

603510-15

V

V

0.5

LOGIC-INPUT THRESHOLD (V)

0

2.8 5.5

BAT SUPPLY VOLTAGE (V)

CE_ vs. V

BUS

IL

CONNECTION (MAX14578E)

APPLE 1A CHARGER, USB COMPLIANT

(USB_CPL = 1, USBSWC = 0, V

20ms/div

5.24.94.64.34.03.73.43.1

= 3V)

TD+

MAX14578E toc15

V

B

5V/div

V

CD+

2V/div

V

CE2

5V/div

V

CE1

5V/div

40ms/div

CE_ vs. V

CONNECTION (MAX14578AE)

BUS

USB CHARGING DOWNSTREAM PORT

(V

= 3V)

TD+

100ms/div

MAX14578E toc16

CE2

5V/div

V

CE1

5V/div

V

B

5V/div

V

CD+

2V/div

V

CE2

5V/div

V

CE1

5V/div

_______________________________________________________________________________________ 7

Page 8

USB Battery Charger Detectors

Pin/Bump Configurations

TOP VIEW

(BUMP SIDE DOWN)

A

B

C

() MAX14578AE ONLY.

MAX14578E/MAX14578AE

2413

+

CD+ CD- V

SCL

GND

(EN)

TD+ TD- BAT CE2

SDA

(CE0)

B

WLP

INT

(LOUT)

CE1

TOP VIEW

SDA

(CEO)

SCL

(EN)

TD-

N.C.

() MAX14578AE ONLY.

*CONNECT EP TO GND.

CE2

12 10 9

11

13

14

15

16

MAX14578E

MAX14578AE

+

13

2

TD+

N.C. CE1

TQFN

N.C.

(LOUT_SNS)

N.C.

EP*

INT

4

(LOUT)

CD+

V

8

B

BAT

7

CD-

6

GND

5

Pin/Bump Description

MAX14578E/MAX14578AE

TQFN-EP WLP TQFN-EP WLP

1 C1 1 C1 TD+ USB Transceiver D+ Connection

2, 3, 10, 16 — 2, 3, 16 — N.C. No Connection. Not internally connected.

4 A1 4 A1 CD+ USB Connector D+ Connection

5 B1 5 B1 GND Ground

6 A2 6 A2 CD- USB Connector D- Connection

7 C3 7 C3 BAT

8 A3 8 A3 V

9 A4 — —

— — 9 A4 LOUT

— — 10 — LOUT_SNS Connect Externally to LOUT (MAX14578AE, TQFN Only)

11 B4 11 B4 CE1 Charger-Enable Control 1, Open-Drain Output

12 C4 12 C4 CE2 Charger-Enable Control 2, Open-Drain Output

13 B3 — — SDA

— — 13 B3 CE0 Charger-Enable Control 0, Open-Drain Output

— — 14 B2

PIN

NAME FUNCTIONMAX14578E MAX14578AE

Battery Connection Input. Connect a 1FF capacitor as close as

possible between BAT and GND.

USB Connector V

as close as possible between VB and GND for Q15kV ESD

B

Connection. Connect a 1FF capacitor

BUS

protection.

INT

Active-Low Interrupt Request, Open-Drain Output

+5.3V USB Transceiver V

Power Output. Connect a 1FF

BUS

capacitor as close as possible between LOUT and GND.

I2C Serial-Data Input/Output. Connect SDA to an external pullup

resistor.

Active-Low Enable Input. Drive EN low to enable the charger ID

EN

detection and close the USB switches after charger detection is

complete.

8 ______________________________________________________________________________________

Page 9

USB Battery Charger Detectors

Pin/Bump Description (continued)

PIN

MAX14578E MAX14578AE

TQFN-EP WLP TQFN-EP WLP

14 B2 — — SCL

15 C2 15 C2 TD- USB Transceiver D- Connection

— — — — EP

MAX14578E Functional Diagram/Typical Application Circuit

NAME FUNCTION

I2C Serial-Clock Input. Connect SCL to an external pullup

resistor.

Exposed Pad (TQFN Only). EP is internally connected to

GND. Connect to a large ground plane to maximize thermal

performance. Not intended as an electrical connection point.

MAX14578E/MAX14578AE

USB

TRANSCEIVER

PROCESSOR

AUDIO CODEC/

AMPLIFIER

V

CC

ID

D-

D+

INT

BATTERY

1µF

V

B

MAX14578E

V

IO

INT

SCLSCL

SDASDA

BAT

USB CHARGER DETECTION

CONTROL

LOGIC

CE1

CE2

V

V

IO

IO

PMIC/

CHARGER

GND

1µF

CD-TD-

CD+TD+

V

BUS

GND

D-

D+

ID

MICRO-B

USB

CONNECTOR

_______________________________________________________________________________________ 9

Page 10

USB Battery Charger Detectors

MAX14578AE Functional Diagram/Typical Application Circuit

BATTERY

MAX14544

V

CC

USB

TRANSCEIVER

PROCESSOR

MAX14578E/MAX14578AE

AUDIO CODEC/

AMPLIFIER

ID

D-

D+

EN

BATTERY

LOUT

1µF 1µF

EN

BAT

1µF

CE2

V

IO

LDO

MAX14578AE

USB CHARGER DETECTION

CONTROL

LOGIC

CE1 CE0

IUSB DCM USUS

SWITCH MODE CHARGER

MAX8903/MAX8934

MAX8677

CHG

V

B

V

BUS

CD-TD-

CD+TD+

GND

V

CC

GND

D-

D+

ID

MICRO-B

USB

CONNECTOR

10 _____________________________________________________________________________________

Page 11

USB Battery Charger Detectors

Table 1. Register Map

ADDRESS NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

0x00 DEVICE ID VENDOR_ID CHIP_REV

0x01

0x02 INTERRUPT CHG_TYP VBCOMP DBCHG DCD_T CHGRUN RFU

0x03

0x04

Table 2. Detailed Register Map

FIELD NAME READ/WRITE BIT DEFAULT DESCRIPTION

DEVICE ID (I2C ADDRESS = 0x00)

VENDOR_ID Read Only [7:4] 0010 Vendor Identification

CHIP_REV Read Only [3:0] 0001 Chip Revision

CONTROL 1 (I2C ADDRESS = 0x01)

INTPOL Read/Write 7 0

CONTROL

1

CONTROL

2

CONTROL

3

INTPOL INTEN USBSWC CP_ENA LOW_POW DCHK CHG_TYP_M USB_CHGDET

DCD_EN DB_EXIT DB_IDLE SUS_LOW CE_FRC CE

RFU RFU RFU CDP_DET USB_CPL SFOUT_EN SFOUTASRT DCD_EXIT

Interrupt Polarity

0 = Active low

1 = Active high

MAX14578E/MAX14578AE

INTEN Read/Write 6 0

USBSWC Read/Write 5 0

CP_ENA Read/Write 4 0

LOW_POW Read/Write 3 1

DCHK Read/Write 2 0

CHG_TYP_M Read/Write 1 0

Interrupt Enable. If interrupt is disabled, pending interrupts

are not cleared and the INT pin deasserts. INTEN is a

global setting to mask all interrupts.

0 = Interrupt disabled

1 = Interrupt enabled

Opens/Closes USB Switch

0 = Switch open

1 = Switch closed

Charge-Pump Enable

0 = Charge pump disabled

1 = Charge pump enabled

Low-Power Mode

0 = Low-power mode disabled; oscillator/bandgap always on

1 = Low-power mode enabled; oscillator/bandgap turned

off under the following conditions: no V

and CP_ENA = 0

Charger-Type Source-Detection Time

0 = DCHK, t

1 = DCHK, t

Charger-Type Manual-Detection Enable. Set CHG_TYP_M

to 1 to force the internal logic to open the USB switches

and perform a charger-type detection. After the detection

state matching completes, this bit resets to 0.

0 = Charger detection disabled

1 = Force a manual charge detection

DP_SRC_ON

DP_SRC_ON

= 40ms

= 625ms

, USBSWC = 0,

BUS

______________________________________________________________________________________ 11

Page 12

USB Battery Charger Detectors

Table 2. Detailed Register Map (continued)

FIELD NAME READ/WRITE BIT DEFAULT DESCRIPTION

Charger-Detection-Enable Start. Charger detection starts

USB_CHGDET Read/Write 0 1

INTERRUPT (I2C ADDRESS = 0x02)

CHG_TYP Read Only [7:5] 000

VBCOMP Read Only 4 0

MAX14578E/MAX14578AE

DBCHG Read Only 3 0

with any change in VB.

0 = Charger detection disabled

1 = Charger detection enabled

Output of USB Charger Detection

000 = Nothing attached

001 = USB cable attached

010 = Charging dowstream port: current depends on USB

operating speed

011 = Dedicated charger: current up to 1.8A

100 = Special charger: 500mA max

101 = Special charger: current up to 1A

110 = RFU

111 = Dead-battery charging: 100mA max

Output of VB Comparator. Changes in VBCOMP triggers

interrupt.

0 = VB < V

1 = VB R V

Dead-Battery Charger Mode. If DBCHG = 1, the 45-minute

timer is running.

0 = Not in dead-battery charge mode

1 = In dead-battery charge mode

VBDET

VBDET

Data-Contact Detection (DCD) Time Wait. DCD_T

DCD_T Read Only 2 0

CHGRUN Read Only 1 0

RFU Read Only 0 0 Reserved

CONTROL 2 (I2C ADDRESS = 0x03)

DCD_EN Read/Write 7 1

12 _____________________________________________________________________________________

generates an interrupt after a 0-to-1 transition.

0 = Data contact detection not running

1 = Data contact detection running for > 2s

Charger-Detection State Machine Running. For information

only—no interrupt generated.

0 = Charger detection not running

1 = Charger detection running (DCD, dead battery, D+/Dshort)

DCD Enable. If DCD_EN = 1, D+/D- is tested for a short

after DCD passes. If DCD_EN = 0, DCD is skipped and

D+/D- short detection begins when V

CHG_TYP_M = 1. If DCD is stuck (DCD_T) = 1, setting

DCD_EN = 0 bypasses DCD and D+/D- short detection

begins.

0 = Disabled

1 = Enabled

BUS

is connected or

Page 13

USB Battery Charger Detectors

Table 2. Detailed Register Map (continued)

FIELD NAME READ/WRITE BIT DEFAULT DESCRIPTION

Exit Dead-Battery Charge Mode. If DBCHG = 1, setting

DB_EXIT to 1 stops the 45-minute timer, sets DBCHG to 0,

DB_EXIT Read/Write 6 0

DB_IDLE Read/Write 5 0

SUS_LOW Read/Write 4 0 (1)*

CE_FRC Read/Write 3 0

and leaves CHG_EN = 1. DB_EXIT is automatically reset to

0 if V

0 = Do not exit dead-battery mode

1 = Exit dead-battery mode

Dead-Battery Idle Mode. DB_IDLE = 1 in dead-battery

mode to forces the USB switch to close. DB_IDLE is

automatically reset when the USB switch is closed.

0 = Dead-battery mode off or test completed

1 = Dead-battery mode on or test still needed

Suspend Mode Selection

0 = When the charger is disabled, CE1 = CE2 = 1

1 = When the charger is disabled, CE1 = CE2 = 0

CE Outputs Force Enable

0 = CE outputs follow the charger-detection finite state

machine (FSM)

1 = CE outputs follow the CE[2:0] register regardless of the

result from the charger-detection FSM

reaches the dead-battery threshold.

BAT

MAX14578E/MAX14578AE

CE Outputs (CE2, CE1, CE0). If CE_FRC = 0, registers are

CE Read/Write [2:0] 000

CONTROL 3 (I2C ADDRESS = 0x04)

RFU Read/Write [7:5] 000 Reserved

CDP_DET Read/Write 4 0

USB_CPL Read/Write 3 1 (0)*

SFOUT_EN Read/Write 2 0 (1)*

SFOUTASRT Read/Write 1 1

DCD_EXIT Read/Write 0 1

Note: CP_ENA, DCHK, USB_CHGDET, DCD_EN, SUS_LOW, CE_FRC, CE, USB_CPL, SFOUT_EN, SFOUTASRT, and DCD_EXIT

can be configured to have different default values. Contact the factory for more information.

*Default value for MAX14578AE only.

set by the result of charger FSM. If CE_FRC = 1, registers

are set by I2C command only.

0 = Normal detection

1 = Resistive detection

USB Compliance

0 = Device is not USB compliant

1 = Device is USB compliant

LOUT Enable

0 = LOUT off

1 = LOUT on as per SFOUTASRT

LOUT Assert Timing

0 = LOUT asserts when the charger-detection FSM

completes

1 = LOUT asserts after valid V

Exit Charger-Type-Detection Routine After DCD_T is Set to 1

0 = Disabled

1 = Enabled

voltage detection

BUS

______________________________________________________________________________________ 13

Page 14

USB Battery Charger Detectors

Detailed Description

The MAX14578E/MAX14578AE are USB charger detectors compliant with USB Battery Charging Revision 1.1.

The USB charger-detection circuitry detects USB standard downstream ports (SDPs), USB charging downstream ports (CDPs), or dedicated charger ports (DCPs),

and controls an external lithium-ion (Li+) battery charger.

The MAX14578E features I2C communication, while the

MAX14578AE features an EN pin and an LDO output pin.

The internal USB switch is compliant to Hi-Speed USB,

full-speed USB, and low-speed USB signals. Both devices feature low on-resistance, low on-resistance flatness,

and very low capacitance.

Input Sources and Routing

The typical Micro/Mini-USB connector has five signal

lines: USB power, two USB signal lines (D-, D+), ID line,

and ground. The USB power on the Micro/Mini-USB connector connects to VB on the MAX14578E/MAX14578AE.

The two USB signal lines, D- and D+, connect to CD- and

CD+.

MAX14578E/MAX14578AE

The MAX14578E/MAX14578AE support Hi-Speed

(480Mbps), full-speed (12Mbps), and low-speed USB

(1.5Mbps) signal levels. The USB channel is bidirectional

and has low 3.3I (typ) on-resistance and 4.5pF (typ)

on-capacitance. The low on-resistance is stable as the

analog input signals are swept from ground to V

for low signal distortion.

USB (CD-, CD+)

SWPOS

LOUT features a 100mA (typ) current limit to protect the

device in the event of a short circuit.

Interrupts

The MAX14578E generates an interrupt for any change in

VBCOMP, and when DBCHG or DCD_T transitions from

0 to 1. The INTEN bit in the CONTROL 1 register (0x01)

enables interrupt output. When INTEN is set to zero, all

interrupts are masked but not cleared. A read to the

INTERRUPT register (0x02) is required to clear interrupts.

Detection Debounce

To avoid multiple interrupts at the insertion of an accessory and for added noise/disturbance protection, a

30ms (typ) debounce timer is present that requires an

inserted or removed state hold for the debounce time

before it sends an interrupt.

Low-Power Modes

The MAX14578E has two I2C bits in the CONTROL 1

register (0x01) dedicated to low-power operation:

LOW_POW and CP_ENA.

LOW_POW sets low-power mode. In low-power mode,

the internal oscillator is turned off under the following

conditions: no V

When enabled, all switches are high impedance (note

that no negative rail voltage can be applied).

CP_ENA controls the charge pump required for proper

operation of the analog switches. When set to disable,

no negative rail voltage can be applied. A factory default

sets CP_ENA = 0 automatically.

, USBSWC = 0, and CP_ENA = 0.

BUS

LOUT LDO Output (MAX14578AE Only)

The LOUT LDO provides a 5.3V (typ) output, used to

power a USB transceiver. Most USB transceivers are

powered from a 3.3V or higher voltage that is difficult to

derive from a Li+ battery. One solution is to power the

transceivers from the USB V

can rise as high as +28V in a fault condition. The LOUT

pin provides a voltage-limited supply that protects the

USB transceiver from these high voltages. When V

rises above 9.0V (typ), the MAX14578AE detects an

overvoltage fault and LOUT goes to 0V. Additionally,

14 _____________________________________________________________________________________

power; however, V

BUS

BUS

BUS

The MAX14578E includes internal logic to detect if a valid

USB charger is connected. When a valid V

applied to VB or when CHG_TYP_M in the CONTROL 1

register is set to 1, the MAX14578E/MAX14578AE begin

the charger-type-detection sequence (see Figure 1).

During the charger-type-detection sequence, the CDand CD+ switches are open, and once the sequence

completes, the switches return to their previous state.

Figure 2 shows a timing diagram for an example charger-type-detection sequence.

USB Charger Detection

voltage is

BUS

Page 15

USB Battery Charger Detectors

DORMANT

CE_ = HI-Z

V

> V

B

VB < V

VBDET

DCD

BEGIN DCD TEST

VBDET

MAX14578E: USB_CHGDET = 1

MAX14578AE: V

= 0V

EN

NOT DCD COMPLIANTDCD COMPLIANT

MAX14578E/MAX14578AE

D+/D- SHORT TEST

DCP/CDP TEST

() MAX14578AE ONLY.

Figure 1. Charger-Type-Detection Sequence

V

B

DCD START

ENABLE STANDARD DOWNSTREAM

PORT DETECTION

CHARGER CONFIGURATION

(USB SWITCH CLOSED)

CONFIGURE CE_

t

MDEB

t

DP_SRC_ON

SPECIAL CHARGER

SONY CHARGER TEST

APPLE CHARGER TEST

VB < V

VBDET

t

MDEBtMDEBtMDEB

COMPARATORS

ENABLE CHARGING DOWNSTREAM

PORT DETECTION

LOUT ENABLE (MAX14578AE)

(SFOUTASRT = 0)

Figure 2. Charger-Detection Timing

______________________________________________________________________________________ 15

ENABLE

CHGRUN

V

DCD PASS D+/D- SHORT DEDICATED CHARGER

VBDET

CHG_TYP = 011

Page 16

USB Battery Charger Detectors

STANDARD USB

HOST CHARGING

DOWNSTREAM PORT

V

PU

LOAD

3.6V

HLPU

300kΩ

D+

HPD

14.25kΩ TO 24.8kΩ

V

PU

LOAD

3.6V

HLPU

300kΩ

D-

HPD

14.25kΩ TO 24.8kΩ

MAX14578E/MAX14578AE

Figure 3. Standard USB Host/Charging Downstream Port, Apple Charger, Sony Charger, and Dedicated Charger

Figure 3 shows D+/D- terminations for a standard USB

host/charging downstream port, an Apple charger, a

Sony charger, and a dedicated charger.

APPLE CHARGER

V

BUS

5.0V

ADPPU

75.0kΩ

D+

ADPPD

49.9kΩ

V

BUS

5.0V

ADMPU

43.2kΩ (FOR 1A)

75.0kΩ (FOR 0.5A)

D-

ADMPD

49.9kΩ

SONY CHARGER

V

BUS

5.0V

D+

V

BUS

5.0V

D-

SDPPU

5.1kΩ

SDPPD

10kΩ

SDPPU

5.1kΩ

SDPPD

10kΩ

DEDICATED CHARGER

D+

D-

Charger-Enable Control Outputs

The MAX14578E/MAX14578AE feature digital open-drain

outputs—CE0 (MAX14578AE only), CE1, and CE2—to

control an external charger autonomously. See Table 3.

V

5.0V

BUS

2MΩ

(MIN)

2MΩ

(MIN)

Table 3. Charger-Enable Control Outputs

SUS_LOW

EN

0 1 X X 1 1 1

1 1 X X 0 0 1

0 0 000 X 1 1 1

1 0 000 X 0 0 1

0 0 110 X 1 1 1

1 0 110 X 0 0 1

X 0 001 0 1 0 0

0 0 001 1 1 1 1

1 0 001 1 0 0 1

X 0 010 X 0 1 0

X 0 011 X 0 1 0

X 0 100 X 1 0 0

X 0 101 X 0 1 0

X 0 111 X 0 0 0

Note: When CE_FRC = 1, CE[2:0] are set by an I2C command.

X = Don’t care.

16 _____________________________________________________________________________________

CHG_TYP USB_CPL CE2 CE1 CE0

Page 17

USB Battery Charger Detectors

I2C Serial Interface (MAX14578E)

Serial Addressing

The MAX14578E operates as a slave device that sends

and receives data through an I2C-compatible 2-wire

interface. The interface uses a serial-data line (SDA) and

a serial-clock line (SCL) to achieve bidirectional communication between master(s) and slave(s). A master (typically a microcontroller) initiates all data transfers to and

from the MAX14578E and generates the SCL clock that

synchronizes the data transfer. The SDA line operates as

both an input and an open-drain output. A pullup resistor is required on SDA. The SCL line operates only as an

input. A pullup resistor is required on SCL if there are

multiple masters on the 2-wire interface, or if the master

SDA

t

SCL

t

LOW

t

SU:DAT

HIGH

t

HD:DAT

t

SU:STA

in a single-master system has an open-drain SCL output.

Each transmission consists of a START condition (Figure

4) sent by a master, followed by the MAX14578E 7-bit

slave address plus a R/W bit, a register address byte,

one or more data bytes, and finally a STOP condition.

START and STOP Conditions

Both SCL and SDA remain high when the interface is not

busy. A master signals the beginning of a transmission

with a START (S) condition by transitioning SDA from

high to low while SCL is high (see Figure 5). When the

master has finished communicating with the slave, it

issues a STOP (P) condition by transitioning SDA from

low to high while SCL is high. The bus is then free for

another transmission.

t

R

t

t

HD:STA

t

SU:STO

BUF

MAX14578E/MAX14578AE

t

HD:STA

START

CONDITION

t

R

Figure 4. I2C Interface Timing Details

SDA

SCL

S

START

CONDITION

Figure 5. START and STOP Conditions

REPEATED

START CONDITION

STOP

CONDITION

CONDITION

START

CONDITION

P

STOP

______________________________________________________________________________________ 17

Page 18

USB Battery Charger Detectors

Bit Transfer

One data bit is transferred during each clock pulse

(Figure 6). The data on SDA must remain stable while

SCL is high.

Acknowledge

The acknowledge bit is a clocked 9th bit that the

recipient uses to handshake receipt of each byte of

data (Figure 7). Thus, each byte transferred effectively

requires nine bits. The master generates the 9th clock

pulse, and the recipient pulls down SDA during the

acknowledge clock pulse. The SDA line is stable low

during the high period of the clock pulse. When the

master is transmitting to the MAX14578E, it generates

the acknowledge bit because the MAX14578E is the

SDA

SCL

MAX14578E/MAX14578AE

DATA LINE STABLE;

DATA VALID

CHANGE OF DATA

ALLOWED

recipient. When the MAX14578E is transmitting to the

master, the master generates the acknowledge bit

because the master is the recipient.

Slave Address

The MAX14578E has a 7-bit long slave address. The bit

following a 7-bit slave address is the R/W bit, which is

low for a write command and high for a read command.

The slave address is 01011001 for read commands and

01011000 for write commands. See Figure 8.

Bus Reset

The MAX14578E resets the bus with the I2C START

condition for reads. When the R/W bit is set to 1, the

MAX14578E transmits data to the master, thus the master is reading from the device.

Figure 6. Bit Transfer

SCL

SDA

BY

TRANSMITTER

SDA

BY

RECEIVER

Figure 7. Acknowledge

SDA

SCL

Figure 8. Slave Address

0

MSB

START

CONDITION

S

CLOCK PULSE FOR

ACKNOWLEDGE

1 2 8 9

1

01 00

1 R/W

ACK

LSB

18 _____________________________________________________________________________________

Page 19

USB Battery Charger Detectors

MAX14578E/MAX14578AE

0101 001

S

REGISTER 0x01 WRITE DATA

d7 d6 d5 d4 d2 d1d3

Figure 9. Format for I2C Write

0101 001

S

REGISTER 0x01 WRITE DATA

ADDRESS = 0x58

ADDRESS = 0x58

0 = WRITE

0A A

Pd0 A

0 = WRITE

0A A

0000 0010

0000 0010

REGISTER ADDRESS = 0x01

S = START BIT

P = STOP BIT

A = ACK

N = NACK

d_ = DATA BIT

REGISTER ADDRESS = 0x01

REGISTER 0x02 WRITE DATA

d7 d6 d5 d4 d2 d1 d0d3 A

Figure 10. Format for Writing to Multiple Registers

Format for Writing

A write to the MAX14578E comprises the transmission

of the slave address with the R/W bit set to zero, followed by at least one byte of information. The first byte

of information is the register address or command byte.

The register address determines which register of the

MAX14578E is to be written by the next byte, if received.

If a STOP (P) condition is detected after the register

address is received, the MAX14578E takes no further

action beyond storing the register address (Figure 9).

Any bytes received after the register address are data

bytes. The first data byte goes into the register selected

by the register address, and subsequent data bytes go

into subsequent registers (Figure 10). If multiple data

bytes are transmitted before a STOP condition, these

d7 d6 d5 d4 d2 d1d3 d0

A/N

P

bytes are stored in subsequent registers because the

register addresses autoincrements.

Format for Reading

The MAX14578E is read using the internally stored register address as an address pointer, the same way the

stored register address is used as an address pointer

for a write. The pointer autoincrements after each data

byte is read using the same rules as for a write. Thus, a

read is initiated by first configuring the register address

by performing a write (Figure 11). The master can now

read consecutive bytes from the MAX14578E, with the

first data byte being read from the register address

pointed by the previously written register address. Once

the master sends a NACK, the MAX14578E stops sending valid data.

______________________________________________________________________________________ 19

Page 20

USB Battery Charger Detectors

ADDRESS = 0x58

0101 0001

S P

ADDRESS = 0x59

0101 0011

S d7 d6 d5 d4 d2 d1 d0d3

Figure 11. Format for Reads (Repeated START)

0 = WRITE

A

1 = READ

A

Table 4. CE_ Outputs for Different Charger Control

CE_

OUTPUTS

(CE0) 1 0 0 0 — EN

SUS_LOW = 0

MAX14578E/MAX14578AE

SUS_LOW = 1

() MAX14578AE only.

CE1 1 0 0 1 EN1 —

CE2 1 0 1 0 EN2 —

CE_

OUTPUTS

(CE0) 1 0 0 0 USUS USUS

CE1 0 0 0 1 PEN1 DCM

CE2 0 0 1 0 PEN2 IUSB

OFF 100mA 500mA I

OFF 100mA 500mA I

REGISTER ADDRESS = 0x01

0000 0010

REGISTER 0x00 READ DATA

SET

SET

MAX8606,

MAX8856

MAX8934,

MAX8677

A/N

A/N

MAX8814,

MAX8845

MAX8903

P

Applications Information

be made in choosing pullup resistor values. Every device

connected to the bus introduces some capacitance even

Charger Control

The MAX14578E charger-enable control outputs are

ideal for autonomous external charger control. Table 4

shows example connections for various Maxim chargers.

Hi-Speed USB

Hi-Speed USB requires careful PCB layout with 45I

single-ended/90I differential controlled-impedance

matched traces of equal lengths.

Power-Supply Bypassing

Bypass VB and BAT with 1FF ceramic capacitors to GND

as close as possible to the device.

Choosing I2C Pullup Resistors

I2C requires pullup resistors to provide a logic-high level

to data and clock lines. There are trade-offs between

power dissipation and speed, and a compromise must

20 _____________________________________________________________________________________

when device is not in operation. I2C specifies 300ns rise

times to go from low to high (30% to 70%) for fast-mode,

which is defined for a clock frequency up to 400kHz (see

the I2C Serial Interface (MAX14578E) section for details).

To meet the rise time requirement, choose pullup resistors so that tR = 0.85 x R

PULLUP

x C

transition time becomes too slow, the setup and hold

times may not be met and waveforms may not be recognized.

Extended ESD Protection

ESD-protection structures are incorporated on all pins

to protect against electrostatic discharges up to ±2kV

(Human Body Model) encountered during handling and

assembly. The CD- and CD+ pins are further protected

against ESD up to ±15kV (Human Body Model) and

Q8kV IEC 61000-4-2 Contact Discharge without damage.

< 300ns. If the

BUS

Page 21

USB Battery Charger Detectors

MAX14578E/MAX14578AE

HIGH-

VOLTAGE

DC

SOURCE

R

C

1MΩ

CHARGE-CURRENT-

LIMIT RESISTOR

C

S

100pF

R

D

1.5kΩ

DISCHARGE

RESISTANCE

STORAGE

CAPACITOR

DEVICE

UNDER

TEST

HIGH-

VOLTAGE

DC

SOURCE

R

C

50MΩ TO 100MΩ

CHARGE-CURRENT-

LIMIT RESISTOR

C

S

150pF

R

D

330Ω

DISCHARGE

RESISTANCE

STORAGE

CAPACITOR

Figure 12. Human Body ESD Test Model Figure 14. IEC 61000-4-2 ESD Test Model

I

(AMPS)

I

PEAK

100%

90%

36.8%

10%

(AMPS)

0

0

PEAK-TO-PEAK RINGING

I

r

(NOT DRAWN TO SCALE)

TIME

t

RL

t

DL

tR = 0.7ns TO 1ns

PEAK

100%

90%

10%

30ns

60ns

DEVICE

UNDER

TEST

t

Figure 13. Human Body Current Waveform Figure 15. IEC 61000-4-2 ESD Generator Current Waveform

The VB input withstands up to ±15kV (HBM) if bypassed

with a 1FF ceramic capacitor close to the pin. The ESD

structures withstand high ESD both in normal operation

and when the devices are powered down. After an ESD

event, the MAX14578E/MAX14578AE continue to function without latchup.

ESD Test Conditions

ESD performance depends on a variety of conditions.

Contact Maxim for a reliability report that documents test

setup, test methodology, and test results.

The IEC 61000-4-2 standard covers ESD testing and

performance of finished equipment. However, it does not

specifically refer to integrated circuits. The MAX14578E/

MAX14578AE assist in designing equipment to meet IEC

61000-4-2 without the need for additional ESD-protection

components.

The major difference between tests done using the

Human Body Model and IEC 61000-4-2 is higher peak

current in IEC 61000-4-2, because series resistance is

IEC 61000-4-2

lower in the IEC 61000-4-2 model. Hence, the ESD with-

Human Body Model

Figure 12 shows the Human Body Model, and Figure 13

shows the current waveform it generates when discharged into a low-impedance state. This model consists of a 100pF capacitor charged to the ESD voltage of

stand voltage measured to IEC 61000-4-2 is generally

lower than that measured using the Human Body Model.

Figure 14 shows the IEC 61000-4-2 model, and Figure

15 shows the current waveform for IEC 61000-4-2 ESD

Contact Discharge test.

interest that is then discharged into the device through

a 1.5kI resistor.

______________________________________________________________________________________ 21

Page 22

USB Battery Charger Detectors

Chip Information

PROCESS: BiCMOS

MAX14578E/MAX14578AE

Package Information

For the latest package outline information and land patterns

(footprints), go to www.maxim-ic.com/packages. Note that a

“+”, “#”, or “-” in the package code indicates RoHS status only.

Package drawings may show a different suffix character, but

the drawing pertains to the package regardless of RoHS status.

PACKAGE

TYPE

12 WLP W121A1+1

16 TQFN T1633+5

PACKAGE

CODE

OUTLINE

NO.

21-0449

21-0136 90-0032

LAND

PATTERN NO.

Refer to

Application

Note 1891

22 _____________________________________________________________________________________

Page 23

USB Battery Charger Detectors

Revision History

MAX14578E/MAX14578AE

REVISION

NUMBER

0 3/11 Initial release —

1 2/12

REVISION

DATE

DESCRIPTION

Added TQFN package, corrected MAX14578E Functional Diagram/Typical

Operating Circuit, and corrected default values for MAX14578AE in Table 2

PAGES

CHANGED

1, 2, 8, 9, 13,

22

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 23

©

2012 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...