For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 408-737-7600 ext. 3468.

General Description

The MAX1450 sensor signal conditioner is optimized for

piezoresistive sensor calibration and temperature compensation. It includes an adjustable current source for

sensor excitation and a 3-bit programmable-gain amplifier (PGA). Achieving a total typical error factor within

1% of the sensor’s inherent repeatability errors, the

MAX1450 compensates offset, full-span output (FSO), offset tempco, FSO tempco, and FSO nonlinearity of silicon

piezoresistive sensors via external trimmable resistors,

potentiometers, or digital-to-analog converters (DACs).

The MAX1450 is capable of compensating sensors that

display close error distributions with a single temperature point, making it ideal for low-cost, medium-accuracy

applications. Although optimized for use with popular

piezoresistive sensors, it may also be used with other

resistive sensor types such as strain gauges.

Customization

Maxim can customize the MAX1450 for unique requirements including improved power specifications. With a

dedicated cell library consisting of more than 90 sensor-specific functional blocks, Maxim can quickly provide customized MAX1450 solutions. Contact the

factory for additional information.

Applications

Piezoresistive Pressure and Acceleration

Transducers and Transmitters

Manifold Absolute Pressure (MAP) Sensors

Automotive Systems

Hydraulic Systems

Industrial Pressure Sensors

Features

♦ 1% Sensor Signal Conditioning

♦ Corrects Sensor Errors Using Coefficients Stored

in External Trimmable Resistors, Potentiometers,

or DACs

♦ Compensates Offset, Offset TC, FSO, FSO TC,

and FSO Linearity

♦ Rail-to-Rail

®

Analog Output

♦ Programmable Current Source for Sensor

Excitation

♦ Fast Signal-Path Settling Time (< 1ms)

♦ Accepts Sensor Outputs from 10mV/V to 30mV/V

♦ Fully Analog Signal Path

MAX1450

Low-Cost, 1%-Accurate Signal Conditioner

for Piezoresistive Sensors

________________________________________________________________

Maxim Integrated Products

1

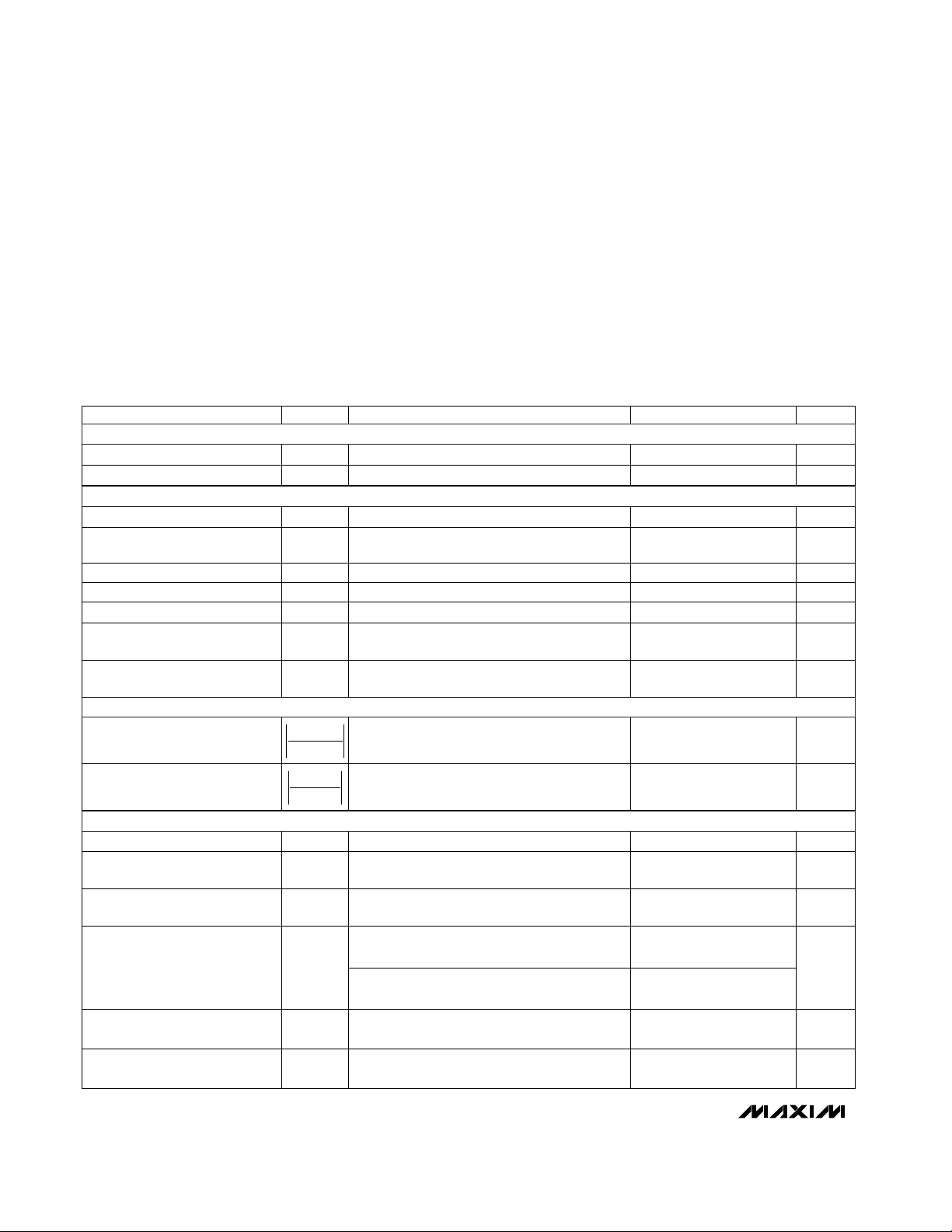

PGA

A = 1

OUT

ISRC

BDRIVE

INP

INM

SOTC

SOFF

OFFTC

OFFSET

BBUF

A2

FSOTRIM

A1

A0

+

-

V

DD

V

SS

CURRENT

SOURCE

V

DD

MAX1450

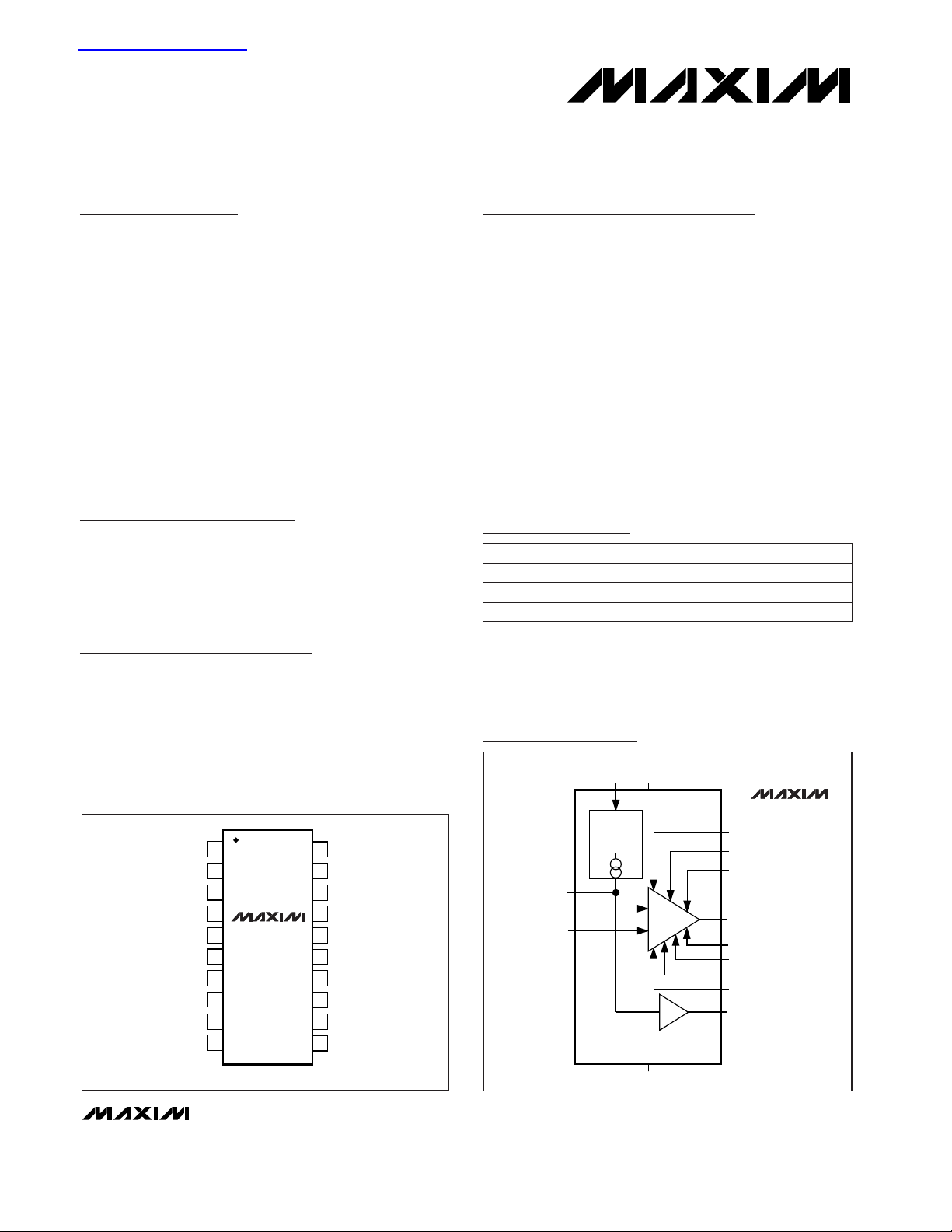

Pin Configuration

19-1365; Rev 0; 5/98

PART

MAX1450CAP

MAX1450C/D

MAX1450EAP -40°C to +85°C

0°C to +70°C

0°C to +70°C

TEMP. RANGE PIN-PACKAGE

20 SSOP

Dice*

20 SSOP

*

Dice are tested at TA = +25°C, DC parameters only.

Functional Diagram

Ordering Information

Rail-to-Rail is a registered trademark of Nippon Motorola, Ltd.

查询MAX1450供应商

TOP VIEW

INP

I.C.

I.C.

SOFF

A1

A0

OFFSET

20

INM

19

V

SS

18

BDRIVE

17

ISRCSOTC

16

I.C.

15

V

DD

OUT

14

A2OFFTC

13

12

I.C.

11

FSOTRIMBBUF

1

2

3

4

MAX1450

5

6

7

8

9

10

SSOP

MAX1450

Low-Cost, 1%-Accurate Signal Conditioner

for Piezoresistive Sensors

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VDD= +5V, VSS= 0, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Supply Voltage, VDDto VSS......................................-0.3V to +6V

All Other Pins ...................................(VSS- 0.3V) to (VDD+ 0.3V)

Short-Circuit Duration, OUT, BBUF, BDRIVE.............Continuous

Continuous Power Dissipation (TA= +70°C)

SSOP (derate 8.00mW/°C above +70°C) ....................640mW

Operating Temperature Range

MAX1450CAP .....................................................0°C to +70°C

MAX1450EAP ..................................................-40°C to +85°C

Storage Temperature Range.............................-65°C to +165°C

Lead Temperature (soldering, 10sec).............................+300°C

TA= +25°C (Note 1)

DC to 10Hz, gain = 39,

sensor impedance = 5kΩ

V

OUT

= (VSS+ 0.25V) to (VDD- 0.25V)

,

TA= +25°C

(Note 5)

(Note 4)

5kΩ load to VSSor V

DD,

TA= +25°C

From VSSto V

DD

63% of final value

(Notes 2, 3)

Eight selectable gains (Table 3)

CONDITIONS

µV

RMS

500Output Noise

mA

-1.0 1.0

(sink) (source)

Output Current Range

V

V

SS +

V

DD -

0.25 0.25

Output Voltage Swing

V/V36 39 44

Minimum Differential Signal

Gain

V/V39 to 221Differential Signal Range Gain

mA2.8 3.5I

DD

Supply Current

mV/V10 to 30

Input-Referred Adjustable

Full-Span Output Range

mV±100

Input-Referred Adjustable Offset

Range

dB90CMRRCommon-Mode Rejection Ratio

ms1Output Step-Response Time

MΩ1.0R

IN

Input Impedance

µV/°C±0.5

Input-Referred Offset

Temperature Coefficient

%V

DD

0.01Amplifier Gain Nonlinearity

UNITSMIN TYP MAXSYMBOLPARAMETER

No load, TA= T

MIN

to T

MAX

V

SS +

V

DD -

0.05 0.05

V4.5 5.0 5.5V

DD

Supply Voltage

At any gain ppm/°C±50

Differential Signal Path

Temperature Coefficient

V/V1.15Offset TC Gain

V/V1.15Offset Gain

∆∆V

V

OUT

OFFSET

∆∆V

V

OUT

OFFTC

GENERAL CHARACTERISTICS

ANALOG OUTPUT (PGA)

ANALOG INPUT (PGA)

SUMMING JUNCTION (Figure 1)

MAX1450

Low-Cost, 1%-Accurate Signal Conditioner

for Piezoresistive Sensors

_______________________________________________________________________________________

3

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +5V, VSS= 0, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

Note 1: Contact factory for high-volume applications requiring less than 1.5mA.

Note 2: All electronics temperature errors are compensated together with the sensor errors.

Note 3: The sensor and the MAX1450 must always be at the same temperature during calibration and use.

Note 4: This is the maximum allowable sensor offset at minimum gain (39V/V).

Note 5: This is the sensor’s sensitivity normalized to its drive voltage, assuming a desired full-span output (FSO) of 4V and a bridge

voltage of 2.5V. Operating at lower bridge excitation voltages can accommodate higher sensitivities.

V

BDRIVE

= 2.5V

No load

(V

BDRIVE

- V

BBUF

) at V

BDRIVE

= 2.5V, no load

CONDITIONS

µA-100 100Current Drive

V

V

SS +

V

DD -

1.3 1.3

Voltage Swing

mV-20 20V

OFS

Offset Voltage

UNITSMIN TYP MAXSYMBOLPARAMETER

∆I

BDRIVE/

∆I

ISRC

(Figure 2)

V

V

SS +

V

DD -

1.3 1.3

V

BDRIVE

Bridge Voltage Swing

mA0.1 0.5 2.0I

BDRIVE

Bridge Current Range

µA/µA13AACurrent-Source Gain

V

V

SS +

V

DD-

1.3 1.3

V

ISRC

Current-Source Input Voltage

Range

BUFFER (BBUF)

CURRENT SOURCE

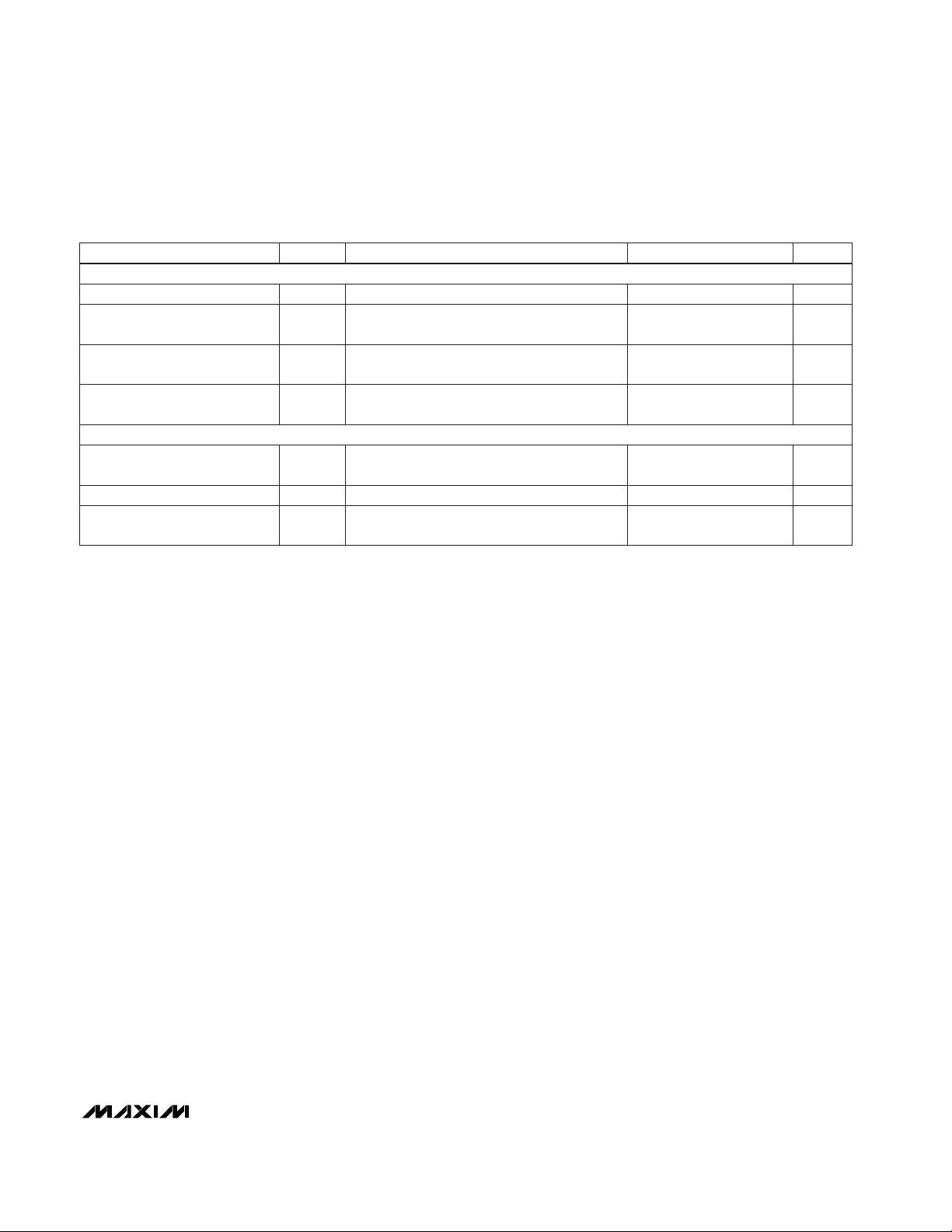

______________ Detailed Description

Analog Signal Path

The MAX1450’s signal path is fully differential and combines the following three stages: a 3-bit PGA with

selectable gains of 39, 65, 91, 117, 143, 169, 195, and

221; a summing junction; and a differential to singleended output buffer (Figure 1).

Programmable-Gain Amplifier

The analog signal is first fed into a programmable-gain

instrumentation amplifier with a CMRR of 90dB and a

common-mode input range from VSSto VDD. Pins A0,

A1, and A2 set the PGA gain anywhere from 39V/V to

221V/V (in steps of 26).

MAX1450

Low-Cost, 1%-Accurate Signal Conditioner

for Piezoresistive Sensors

4 _______________________________________________________________________________________

NAME FUNCTION

1 INP Positive Sensor Input. Input impedance is typically 1MΩ. Rail-to-rail input range.

PIN

2, 3,

12, 16

I.C. Internally connected. Leave unconnected.

4 SOTC

Offset TC Sign Bit Input. A logic low inverts V

OFFTC

with respect to V

SS.

This pin is internally pulled to V

SS

via a 1MΩ (typical) resistor. Connect to VDDto add V

OFFTC

to the PGA output, or leave unconnected (or

connect to VSS) to subtract V

OFFTC

from the PGA output.

8 OFFTC

Offset TC Adjust. Analog input summed with PGA output and V

OFFSET

. Input impedance is typically 1MΩ.

Rail-to-rail input range.

7 A0

PGA Gain-Set LSB Input. Internally pulled to VSSvia a 1MΩ (typical) resistor. Connect to VDDfor a logic

high or VSSfor a logic low.

6 A1

PGA Gain-Set Input. Internally pulled to VSSvia a 1MΩ (typical) resistor. Connect to VDDfor a logic high or

VSSfor a logic low.

5 SOFF

Offset Sign Bit Input. A logic low inverts V

OFFSET

with respect to VSS. This pin is internally pulled to VSSvia

a 1MΩ (typical) resistor. Connect to VDDto add V

OFFSET

to the PGA output, or leave unconnected (or con-

nect to VSS) to subtract V

OFFSET

from the PGA output.

14 OUT PGA Output Voltage. Connect a 0.1µF capacitor from OUT to VSS.

13 A2

PGA Gain-Set MSB Input. Internally pulled to VSSvia a 11kΩ (typical) resistor. Connect to VDDfor a logic

high or VSSfor a logic low.

11 FSOTRIM Bridge Drive Current-Set Input. The voltage on this pin sets the nominal I

ISRC

. See the

Bridge Drive

section.

10 BBUF

Buffered Bridge-Voltage Output (the voltage at BDRIVE). Use with correction resistor R

STC

to correct for FSO

tempco.

9 OFFSET

Offset Adjust Input. Analog input summed with PGA output and V

OFFTC

. Input impedance is typically

1MΩ. Rail-to-rail input range.

Pin Description

15 V

DD

Positive Supply Voltage Input. Connect a 0.1µF capacitor from VDDto VSS.

20 INM Negative Sensor Input. Input impedance is typically 1MΩ. Rail-to-rail input range.

19 V

SS

Negative Power-Supply Input.

18 BDRIVE Sensor Excitation Current Output. This pin drives a nominal 0.5mA through the bridge.

17 ISRC Current-Source Reference. Connect a 50kΩ (typical) resistor from ISRC to VSS.

Figure 1. Signal-Path Functional Diagram

INP

INM

A2

A1 A0

PGA

OFFTC SOTC

±

Σ

±

OFFSET SOFF

A = 1

OUT

Summing Junction

The second stage in the analog signal path consists of

a summing junction for offset, offset temperature compensation, and the PGA output. The offset voltage

(V

OFFSET

) and offset temperature-compensation volt-

age (V

OFFTC

) add or subtract from the PGA output

depending on their respective sign bits, offset sign

(SOFF), and offset TC sign (SOTC). V

OFFSET

and

V

OFFTC

can range in magnitude from VSSto VDD.

Output Buffer

The final stage in the analog signal path consists

of a unity-gain buffer. This buffer is capable of swinging

to within 250mV of VSSand VDDwhile sourcing/sinking

up to 1.0mA, or within 50mV of the power supplies with

no load.

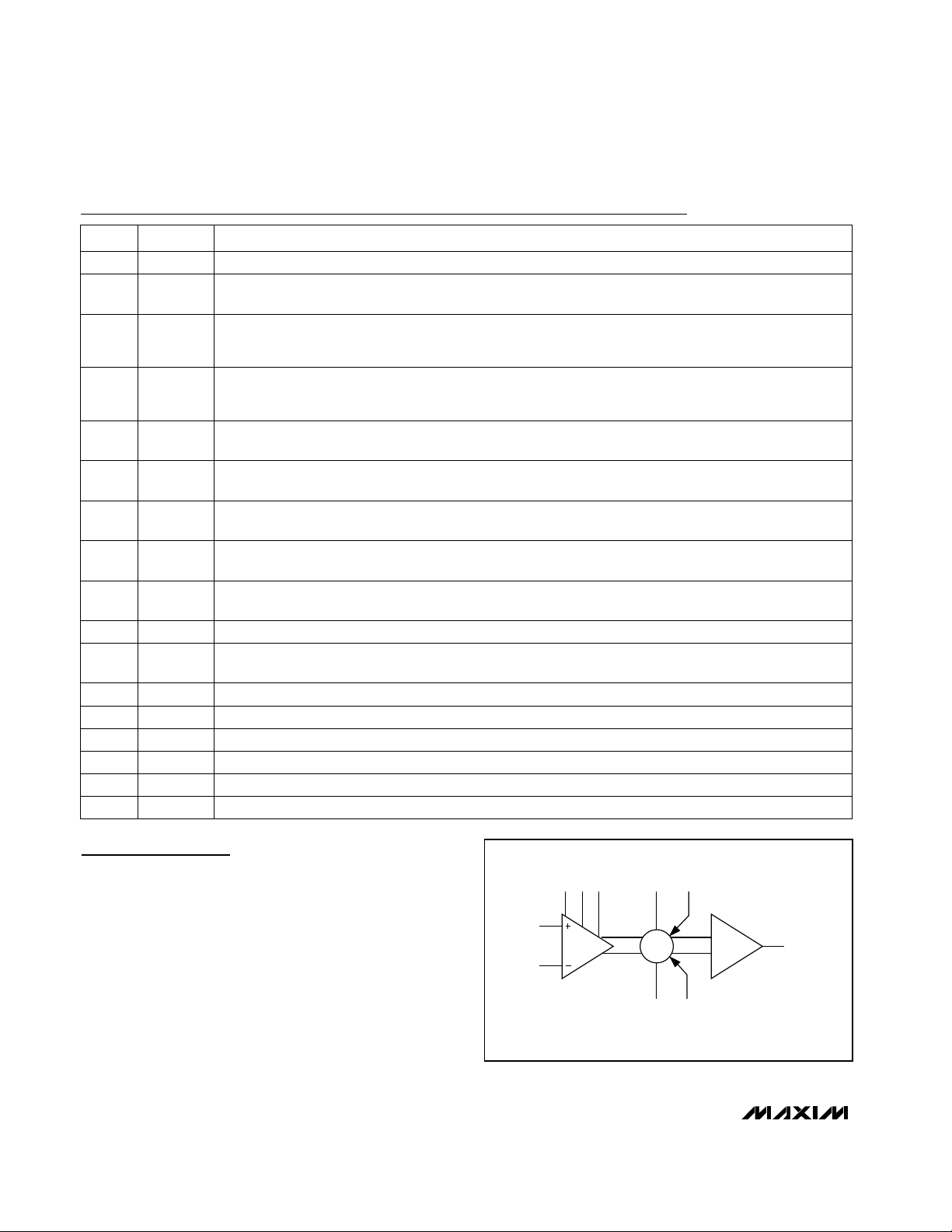

Bridge Drive

Figure 2 shows the functional diagram of the on-chip

current source. The voltage at FSOTRIM, in conjunction

with R

ISRC

, sets the nominal current, I

ISRC

which sets

the FSO (refer to Figure 3 for sensor terminology.) I

ISRC

is additionally modulated by components from the

external resistor R

STC

and the optional resistor R

LIN

.

R

STC

is used to feed back a portion of the buffered

bridge-excitation voltage (V

BBUF

), which compensates

FSO TC errors by modulating the bridge-excitation current over temperature. To correct FSO linearity errors,

feed back a portion of the output voltage to the currentsource reference node via the optional R

LIN

resistor.

Applications Information

Compensation Procedure

The following compensation procedure assumes a pressure transducer with a +5V supply and an output voltage

that is ratiometric to the supply voltage (see

Ratiometric

Output Configuration

section). The desired offset voltage

(V

OUT

at P

MIN

) is 0.5V, and the desired FSO voltage

(V

OUT(PMAX

) - V

OUT(PMIN

)) is 4V; thus the FS output volt-

age (V

OUT

at P

MAX

) will be 4.5V. The procedure requires

a minimum of two test pressures (e.g., zero and full scale)

and two temperatures. A typical compensation procedure

is as follows:

1) Perform Coefficient Initialization

2) Perform FSO Calibration

3) Perform FSO TC Compensation

4) Perform OFFSET TC Compensation

5) Perform OFFSET Calibration

6) Perform Linearity Calibration (Optional)

Coefficient Initialization

Select the resistor values and the PGA gain to prevent

gross overload of the PGA and bridge current source.

These values depend on sensor behavior and require

some sensor characterization data. This data may be

available from the sensor manufacturer. If not, it can be

generated by performing a two-temperature, two-pres-

MAX1450

Low-Cost, 1%-Accurate Signal Conditioner

for Piezoresistive Sensors

_______________________________________________________________________________________ 5

V

DD

I

BDRIVE ≈

13 (I

ISRC

)

V

BDRIVE

I

ISRC

I

ISRC

BBUF

INP

INM

SENSOR

R

ISRC

(EXTERNAL)

BDRIVE

FSOTRIM

BBUF

OUT

A = 1

R

STC

(EXTERNAL)

R

LIN

(OPTIONAL)

(EXTERNAL)

MAX1450

Figure 2. Bridge Drive Circuit

MAX1450

sure sensor evaluation. Note that the resistor values

and PGA gain obtained from this evaluation will represent a starting point. The final compensated transducer

will likely use slightly different values. The required sensor information is shown in Table 1, and can be used to

obtain the values for the parameters shown in Table 2.

Selecting R

ISRC

R

ISRC

programs the nominal sensor excitation current

and is placed between ISRC and VSS. Use a variable

resistor with a nominal starting value of:

where Rb(T1) is the sensor input impedance at temperature T1 (usually +25°C).

Selecting R

STC

R

STC

compensates the FSO TC errors and is placed

between BBUF and ISRC. Use a variable resistor with

a nominal starting value of the following:

This approximation works best for bulk, micromachined,

silicon piezoresistive sensors (PRTs). Negative values

for R

STC

indicate unexpected sensor behavior that cannot be compensated by the MAX1450 without additional external circuitry.

Selecting PGA Gain Setting

Calculate the ideal gain using the following formula,

and select the nearest gain setting from Table 3.

SensorFSO can be derived as follows:

where S is the sensor sensitivity at T1, V

BDRIVE

is the

sensor excitation voltage (initially 2.5V), and ∆P is the

maximum pressure differential.

SensorFSO S x V x P

1.5mV/V psi x 2.5V x 10 psi

0.0375V

BDRIVE

=

=

=

∆

R

R x 500ppm/ C

TCR TCS

65k x 500ppm/ C

2600ppm/ C 2100ppm/ C

65k

STC

ISRC

≈

°

−

≈

°

− −

=

Ω

Ω

o o

R 13 x Rb(T1)

13(5k ) 65k

ISRC

≈

≈ =Ω Ω

Low-Cost, 1%-Accurate Signal Conditioner

for Piezoresistive Sensors

6 _______________________________________________________________________________________

Table 1. Sensor Information

Table 2.Compensation Components/Values

PARAMETER

SENSOR

DESCRIPTION

TYPICAL

VALUE

Rb(T) Input/Output Impedance 5kΩ at +25°C

TCR

Input/Output Impedance

Tempco

2600ppm/°C

S(T) Sensitivity

1.5mV/V psi at

+25°C

TCS Sensitivity Tempco -2100ppm/°C

O(T) Offset

12mV/V at

+25°C

OTC Offset Tempco

-1030 ppmFSO/°C

S(p)

Sensitivity Linearity Error as

% FSO BSLF (Best StraightLine Fit)

0.1% FSO

BSLF

P

MIN

Minimum Input Pressure 0 PSI

P

MAX

Maximum Input Pressure 10 PSI

PARAMETER DESCRIPTION

R

ISRC

Resistor that programs the nominal sensor

excitation current

R

STC

Resistor that compensates FSO TC errors

A

PGA

Programmable-gain amplifier gain

OFFTC

Offset TC correction voltage, including its

respective sign bit

R

LIN

Resistor that corrects FSO linearity errors

(optional)

Figure 3. Typical Pressure-Sensor Output

4.5

FULL-SPAN OUTPUT (FSO)

VOLTAGE (V)

0.5

OFFSET

P

MIN

PRESSURE

P

MAX

FULL-SCALE (FS)

where OUTFSO is the desired calibrated transducer

full-span output voltage, and SensorFSO is the sensor

full-span output voltage at T1.

Determining OFFTC Initial Value

Generally, the OFFTC coefficient can be set to 0V,

since the offset TC errors will be compensated in a later

step. However, sensors with large offset TC errors may

require an initial coarse offset TC adjustment to prevent

the PGA from saturating as the temperature increases

during the compensation procedure. An initial coarse

offset TC adjustment would be required if the magnitude of the sensor offset TC error is more than about

10% of the FSO. If a coarse offset TC adjustment is

required, use the following equation:

which can be approximated by:

where OTC is the sensor offset TC error in ppm of FSO,

∆T is the operating temperature range in °C, and OTC

Correction is the offset TC resistor-divider ratio. For

positive values of OTC correction, connect SOTC to

V

DD

; for negative values, connect SOTC to VSS.

Select the Offset TC resistor divider (R

OTCA

and

R

OTCB

, Figure 4) using the following equation:

where 500kΩ ≥ (R

OTCA

+ R

OTCB

) ≥ 100kΩ. Choose

R

OTCB

= 100kΩ and R

OTCA

= 20kΩ.

Transfer Function

The following transfer function (linearity correction not

included) is useful for data modeling or for developing

compensative algorithms:

(AA = current source gain)

FSO Calibration

Perform FSO calibration at room temperature with a fullscale sensor excitation.

1) At +25°C (or T1), set V

FSOTRIM

to 2.5V. Adjust

R

ISRC

until V

BBUF

= 2.5V.

2) Adjust V

OFFSET

until the room temperature offset

voltage is 0.5V (see

OFFSET Calibration

section).

3) Measure the full-span output (measuredV

FSO

).

4) Calculate V

BIDEAL(25°C)

using the following equation:

Note: If V

BIDEAL(25°C)

is outside the allowable bridge

voltage swing of (VSS+ 1.3V) to (VDD- 1.3V), readjust

the PGA gain setting. If V

BIDEAL(25°C)

is too low,

decrease the PGA gain setting by one step and return

to Step 1. If V

BIDEAL(25°C)

is too high, increase the PGA

gain setting by one step and return to Step 1.

V

V 1

desiredV measuredV

measuredV

BIDEAL(25 C)

FSOTRIM

FSO FSO

FSO

o

=

+

[ ]−[ ]

[ ]

V V x

V x PGA + 1.15 x

V

V

1.15 x V

where V =

V

R

V

R

1

AA x Rb(T)

1

R

OUT BDRIVE

S

OFFTC

DD

OFFSET

BDRIVE

DD

ISRC

DD

STC

STC

=

+

+

+

OTC Correction

R

R R

R

R R

OTCA

OTCA OTCB

OTCA

OTCA OTCB

.

=

+

=

+

0 17

OTC Correction

OTC x FSO x ( T)

TCS x V x 1.15 x ( T)

1

2100 x .5V x 1.15

0.68

BDRIVE

≈

≈

− °

−

=

∆

∆

030 4

2

ppm C x V/

OTC Correction

V

V x 1.15

OUT(T)

BDRIVE(T)

=

∆

∆

A

OUTFSO

SensorFSO

4V

0.0375V

106V/V

PGA

≈

≈ =

MAX1450

Low-Cost, 1%-Accurate Signal Conditioner

for Piezoresistive Sensors

_______________________________________________________________________________________ 7

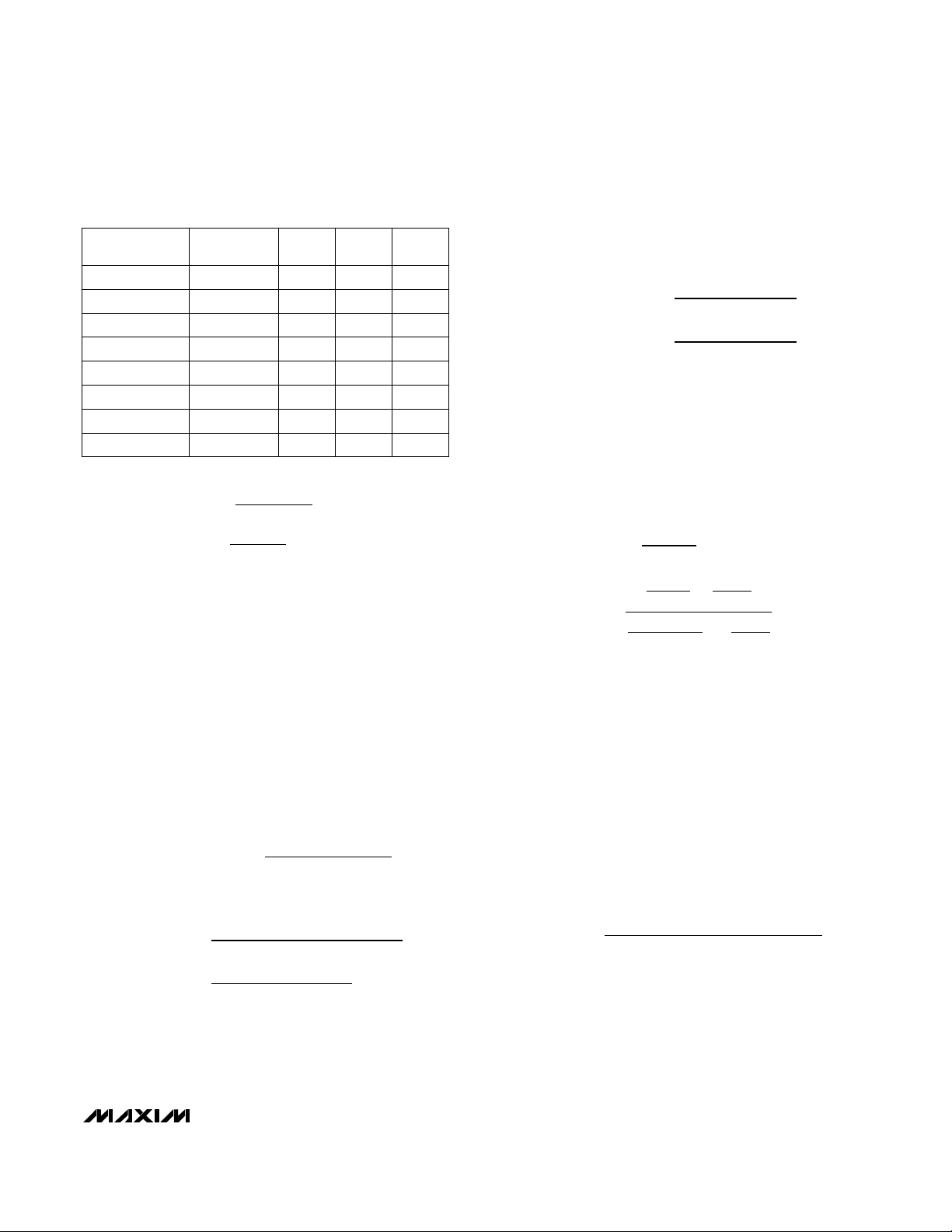

Table 3. PGA Gain Settings

PGA GAIN (V/V) PGA VALUE A2 A1 A0

39 0 0 0 0

65 1 0 0 1

91 2 0 1 0

117 3 0 1 1

143 4 1 0 0

169 5 1 0 1

195 6 1 1 0

221 7 1 1 1

MAX1450

5) Set V

FSOTRIM

= V

BIDEAL(25°C)

. Adjust R

ISRC

until

V

BBUF

= V

BIDEAL(25°C)

.

6) Readjust V

OFFSET

until the offset voltage is 0.5V (see

OFFSET Calibration

section).

FSO TC Compensation

Correct linear span TC by connecting BBUF to ISRC

through a resistor (R

STC

). The value of R

STC

depends

on the required correction coefficient, which is sensor

dependent, but typically around 100kΩ for most silicon

PRTs. The following procedure results in FSO TC calibration:

1) Measure the full-span output at T2.

2) Use the equation from Step 4 of the

FSO Calibration

section to determine V

BIDEAL(T2)

. While at T2, adjust

R

STC

until V

BBUF

= V

BIDEAL(T2)

.

3) Do not adjust V

OFFSET

or V

OFFTC

.

OFFSET TC Compensation

Connect OFFTC to a resistor divider between BBUF

and VSS. The divided-down V

BBUF

is then fed into

OFFTC and the appropriate polarity (designating

whether V

OFFTC

should be added or subtracted from

the PGA output) is selected with SOTC.

1) At T2, remeasure the offset at V

OUT

.

2) Use the following equation to determine the magnitude of V

OFFTC(T2)

, and adjust R

OTCA

accordingly. If

V

OFFTC

is negative, connect SOTC to VSS. If V

OFFTC

is positive, connect SOTC to VDD. After OTC calibration, the output may be saturated; correct this condition during OFFSET calibration. In most cases

Current OFFTC will be 0. However, if a coarse

OFFTC adjustment was performed, the coefficient

must be inserted in the equation below.

where Current OFFTC is the voltage at pin OFFTC.

Note that the magnitude of V

OFFTC

is directly proportional to the gain of the PGA. Therefore, if the PGA gain

changes after performing the offset TC calibration, the

offset TC must be recalibrated.

V

V V

V V x 1.15

Current OFFTC

OFFTC

OFFSET(T1) OFFSET(T2)

BDRIVE(T1) BDRIVE(T2)

=

−

−

( )

+

Low-Cost, 1%-Accurate Signal Conditioner

for Piezoresistive Sensors

8 _______________________________________________________________________________________

R

STC

R

FSOB

R

FSOA

V

DD

V

DD

R

ISRC

0.1µF

R

LIN

(OPTIONAL)

PGA

A = 1

CURRENT

SOURCE

OUT

OUT

ISRC

BDRIVE

INP

INM

SOTC

OFFSET

OFFTC

SOFF

BBUF

A2

A1

A0

V

DD

V

DD

FSOTRIM

V

SS

MAX1450

R

OTCA

R

OTCB

R

OFFA

R

OFFB

V

DD

V

DD

0.1µF

0.1µF

SENSOR

V

DD

Figure 4. Basic Ratiometric Output Configuration

OFFSET Calibration

Accomplish offset calibration by applying a voltage to the

OFFSET pin (SOFF determines the polarity of V

OFFSET

).

This voltage is generated by a resistor-divider between

VDDand VSS(R

OFFA

and R

OFFB

in Figure 4). To calibrate

the offset, set V

OFFSET

to 0 and perform a minimum pressure input reading at room temperature. If the output voltage (V

OFFZERO

) is greater than 0.5V, connect SOFF to

VSS; if V

OFFZERO

is less than 0.5V, connect SOFF to VDD.

Adjust V

OFFSET

until V

OUT

= 0.5V.

Note that the magnitude of V

OFFSET

is directly proportional to the gain of the PGA. Therefore, if the PGA gain

changes after performing the offset calibration, the offset

must be recalibrated.

Linearity Calibration (optional)

Correct pressure linearity by using feedback from the

output voltage (V

OUT

) to ISRC to modulate the current

source. If a bridge current is constant with applied

pressure, sensor linearity remains unaffected. If, with a

constant bridge current, the output voltage is nonlinear

with applied pressure (e.g., increasing faster than the

pressure), use pressure linearity correction to linearize

the output.

Performing linearity corrections through the use of a

transfer function is not practical, since a number of

required system variables cannot easily be measured

with a high enough degree of accuracy. Therefore, use a

simple empirical approach. Figure 5 shows the uncompensated pressure linearity error of a silicon PRT. The

magnitude of this error is usually well below 1% of span.

Curves A, B, C, D, E, and F in Figure 5 represent increasing amounts of linearity error corrections, corresponding

to decreasing values in the resistance of R

LIN

. To correct

pressure linearity errors, use the following equation to

determine the appropriate range for R

LIN

:

where S(p) is the sensitivity linearity error as % best

straight-line fit (BSLF). Ideally, this variable resistor

should be disconnected during temperature error compensation. If this is not possible, set it to the maximum

available value.

First measure the magnitude of the uncorrected error

(R

LIN

= maximum value), then choose an arbitrary

value for R

LIN

(approximately 50% of maximum value).

Measuring the new linearity error establishes a linear

relationship between the amount of linearity correction

and the value of R

LIN

.

Note that if pressure linearity correction is to be performed, it must occur after temperature compensation

is completed. A minor readjustment to the FSO and

OFFSET will be required after linearity correction is performed. If pressure linearity correction is not required,

remove R

LIN

.

Ratiometric Output Configuration

Ratiometric output configuration provides an output that

is proportional to the power-supply voltage. When used

with ratiometric A/D converters, this output provides

digital pressure values independent of supply voltage.

Most automotive and some industrial applications

require ratiometric outputs.

The MAX1450 has been designed to provide a highperformance ratiometric output with a minimum number

of external components (Figure 4).

Sensor Calibration and

Compensation Example

Calibration and compensation requirements for a sensor

involve conversion of a sensor-specific performance

into a normalized output curve. Table 4 shows an

example of the MAX1450’s capabilities.

A repeatable piezoresistive sensor with an initial offset

of 30mV and FSO of 37.5mV was converted into a compensated transducer (using the piezoresistive sensor

with the MAX1450) with an offset of 0.5V and an FSO of

4.0V. The temperature errors, which were on the order

of -17% for the offset TC and -35% for the FSO TC, were

reduced to about ±1% FSO. The graphs of Figure 6

show the outputs of the uncompensated sensor and the

compensated transducer.

R

R x R

R R x S p

LIN

ISRC STC

ISRC STC

≈

+

( )

( )

2

MAX1450

Low-Cost, 1%-Accurate Signal Conditioner for

Piezoresistive Sensors

_______________________________________________________________________________________ 9

B

C

D

E

F

PRESSURE

LINEARITY

ERROR

UNCOMPENSATED ERROR

(R

LIN

REMOVED)

OVERCOMPENSATED ERROR

(R

LIN

TOO SMALL)

A

Figure 5. Effect of R

LIN

on Linearity Corrections

MAX1450

Low-Cost, 1%-Accurate Signal Conditioner

for Piezoresistive Sensors

10 ______________________________________________________________________________________

-20

-10

10

0

20

30

-50 0 50 100 150

UNCOMPENSATED SENSOR ERROR

TEMPERATURE (°C)

ERROR (% SPAN)

OFFSET

FSO

-0.8

-0.6

0.4

-0.2

-0.4

0

0.2

0.6

0.8

-50 0 50 100 150

COMPENSATED TRANSDUCER ERROR

TEMPERATURE °(C)

ERROR (% SPAN)

OFFSET

FSO

Figure 6. Comparison of an Uncalibrated Sensor and a Temperature-Compensated Transducer

TRANSISTOR COUNT: 1364

SUBSTRATE CONNECTED TO V

SS

Chip Information

Typical Uncompensated Input (Sensor) Typical Compensated Transducer Output

Offset ..........................................................................±80% FSO

FSO..................................................................................15mV/V

Offset TC......................................................................-17% FSO

Offset TC Nonlinearity.....................................................1% FSO

FSO TC.........................................................................-35% FSO

FSO TC Nonlinearity........................................................1% FSO

Temperature Range...........................................-40°C to +125°C

V

OUT

...................................................Ratiometric to VDDat 5.0V

Offset at +25°C ......................................................0.500V ±5mV

FSO at +25°C .........................................................4.000V ±5mV

Offset Accuracy Over Temp. Range.............±60mV (1.5% FSO)

FSO Accuracy Over Temp. Range ...............±60mV (1.5% FSO)

Table 4. MAX1450 Calibration and Compensation

MAX1450

Low-Cost, 1%-Accurate Signal Conditioner for

Piezoresistive Sensors

______________________________________________________________________________________ 11

Package Information

SSOP.EPS

MAX1450

Low-Cost, 1%-Accurate Signal Conditioner

for Piezoresistive Sensors

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

12

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1998 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

NOTES

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...