Page 1

General Description

The MAX13362 is a 24-channel automotive contact monitor designed as an interface between mechanical

switches and low-voltage processors or other logic circuits. The IC operates over a voltage range of 5.5V to

28V, and withstands voltages up to 40V. It protects lowvoltage circuitry from high voltages and reverse battery

conditions. The MAX13362’s low-current operation under

all operating conditions makes it suitable for use in electronic control units (ECUs) that are connected directly to

the automotive battery. It has an adjustable scan mode

that significantly reduces the current drawn in key-off.

The MAX13362 features an SPI™ interface to monitor

the switch status and set the device configuration.

Multiple MAX13362s can be cascaded to support any

multiple of 24 switches.

The MAX13362 is available in a 6mm x 6mm, 40-pin

thin QFN package and operates over the -40°C to

+125°C temperature range.

Applications

Automotive Body Controllers

Automotive Door Modules

Automotive Smart Junction Boxes

Features

♦ 9V to 18V Operating Voltage Range with Full

Performance

♦ Fully Functional Range of 5.5V to 28V

♦ Switch Inputs Withstand 27V

♦ Switch Inputs Withstand Reverse Battery

♦ Ultra-Low Operating Current 100µA (typ) in Scan

Mode

♦ Built-In Switching Hysteresis

♦ Built-In Switch Deglitching

♦ CMOS-Compatible Logic Outputs Down to 3.0V

♦ Interrupt Output to Processor

♦ Configurable Wetting Current (0mA, 5mA, 10mA,

or 15mA) for Each Switch Input

♦ AEC-Q100 Qualified

MAX13362

24-Channel Automotive Switch Monitor

________________________________________________________________

Maxim Integrated Products

1

19-4464; Rev 0; 2/09

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Ordering Information

*

EP = Exposed pad.

+

Denotes a lead(Pb)-free/RoHS-compliant package.

/V Denotes an automotive qualified part.

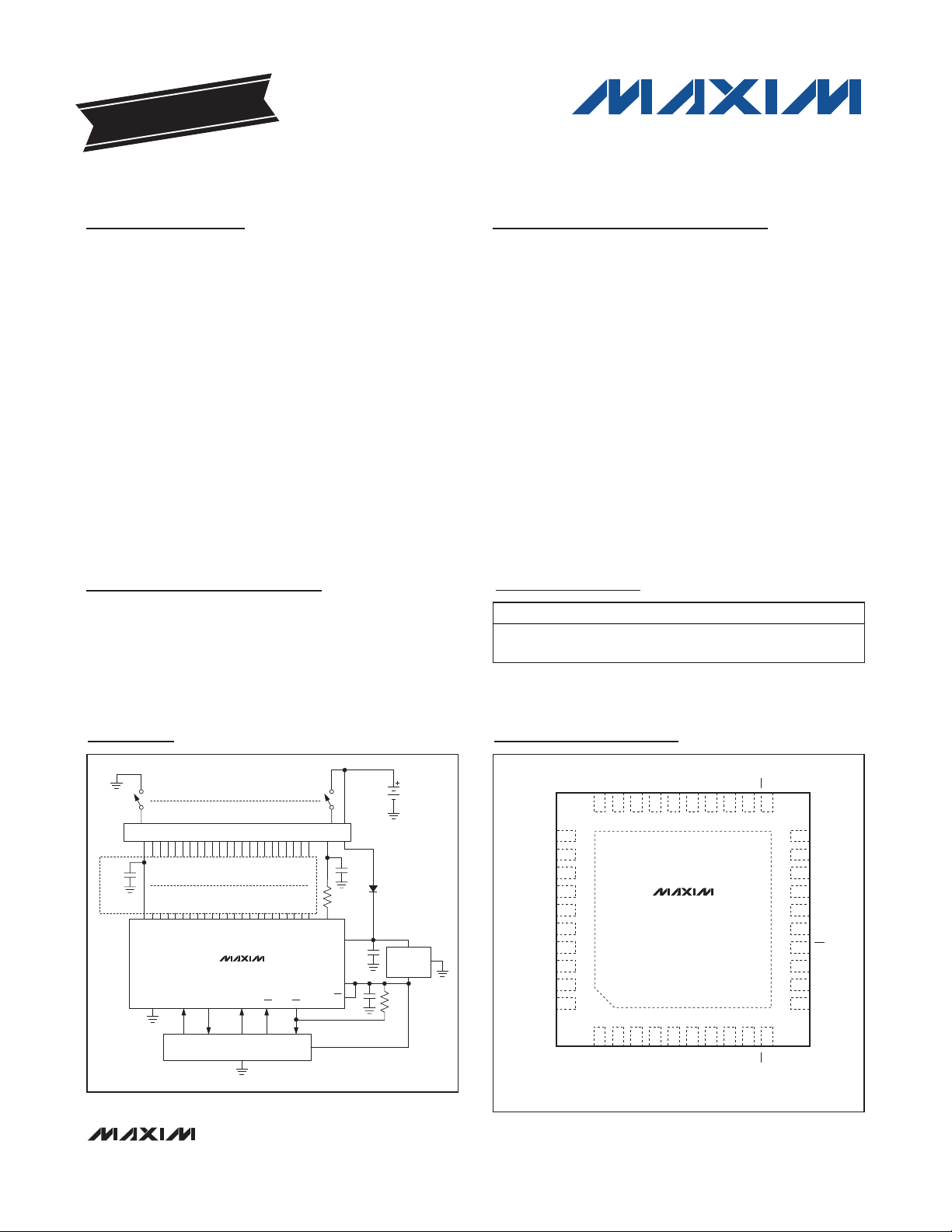

Typical Application Circuit

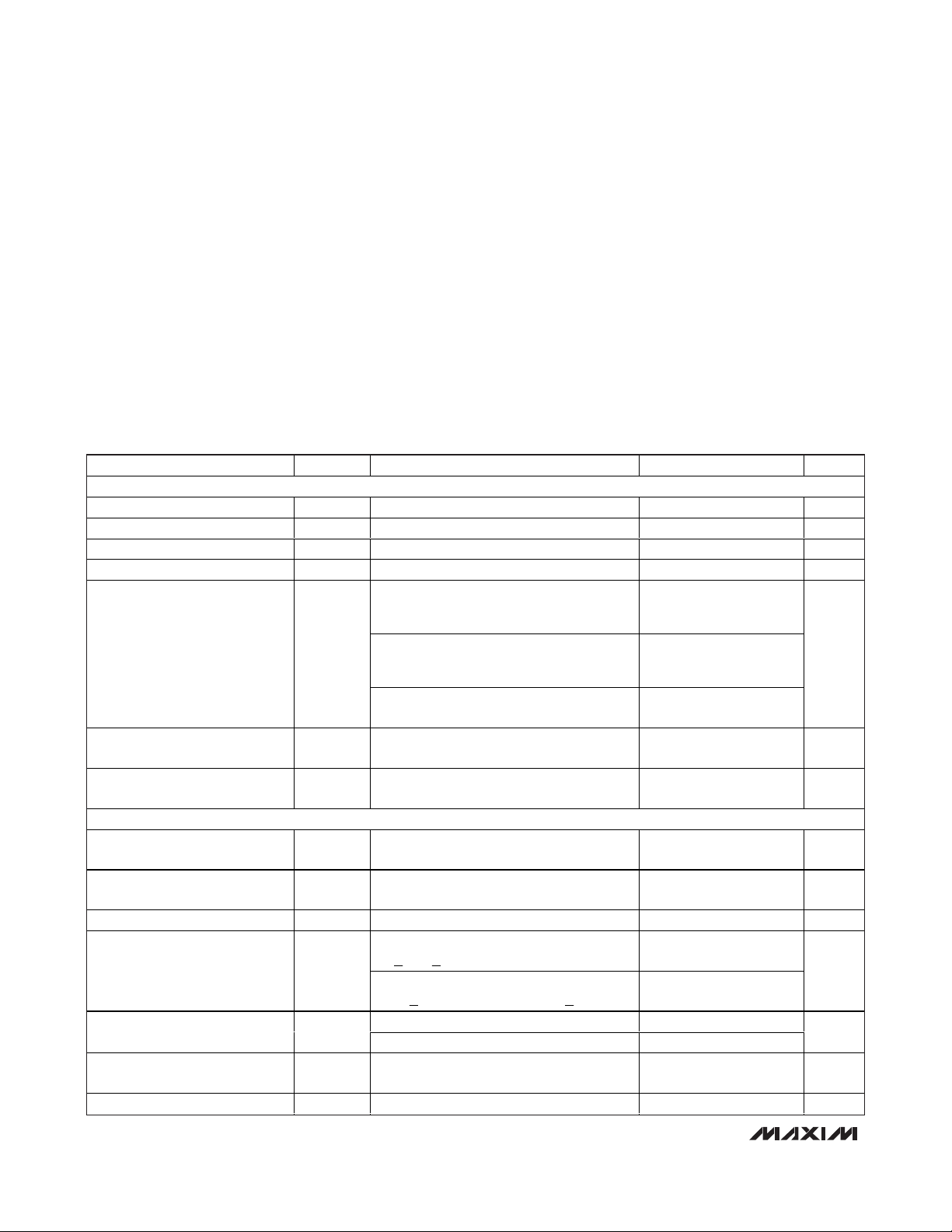

Pin Configuration

SPI is a trademark of Motorola, Inc.

PART TEMP RANGE PIN-PACKAGE

M AX 13362ATL/V + -40°C to +125°C

40 Thin QFN-EP*

(6mm x 6mm)

0.047μF

24 SWITCHES, 1 BATTERY-CONNECTED

ECU CONNECTOR

0.047μF

100Ω

IN1

IN6

IN7

IN9

IN8

IN23

IN21

IN20

IN19

IN22

GND

SDI

IN13

IN14

IN15

IN16

IN17

IN18

SDO CS

MICROCONTROLLER

IN12

MAX13362

/LOGIC CIRCUIT

IN5

IN10

IN11

CLK

IN0

IN4

IN3

IN2

VS

REGULATOR

V

DD

SD

INT

BATTERY

9V TO 18V

IN

OUT

TOP VIEW

IN16

30 N.C.

29 N.C.

31IN7

32IN8

33IN9

34IN10

35IN11

36IN12

37IN13

38IN14

39IN15

40

+

1N.C.

2N.C.

28 IN6

27 IN5

26 IN4

25 IN3

24 IN2

23 IN1

22 IN0

21 SD

MAX13362

3IN17

4IN18

5IN19

6IN20

7IN21

8IN22

9IN23

10INT

THIN QFN

(6mm x 6mm)

20 VS

19 VS

18 GND

17 V

16 GND

15 SDI

14 CS

13 SDO

12 CLK

11 N.C.

DD

Page 2

MAX13362

24-Channel Automotive Switch Monitor

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATING

ELECTRICAL CHARACTERISTICS

(V

DD

= 5V, VVS= 14V, TA= -40°C to +125°C, unless otherwise noted. Typical values are at TA=+25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDD, CLK, SDI, CS to GND ......................................-0.3V to +6V

VS, SD, INT to GND................................................-0.3V to +40V

IN0–IN23 to GND.....................................................-15V to +27V

SDO to GND...............................................-0.3V to (V

DD

+ 0.3V)

ESD Protection, All Pins (HBM)............................................±2kV

ESD Protection on Pins IN0–IN23 to IEC 61000-4-2 Specification

(with added 0.047µF capacitor, and/or 100Ω resistor)....±8kV

Current Into Any Pin..........................................................±20mA

Continuous Power Dissipation (T

A

= +70°C)

(derate 37mW/°C above +70°C)(multilayer board)....2963mW

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature........................................-40°C to +150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

POWER SUPPLY

VDD Operating Supply Range V

VDD Supply Current I

VS Supply Range V

VS Undervoltage Lockout V

Total Supply Current (Flowing

into VS and V

DD

)

VS Supply Current in Shutdown

Mode

VDD Supply Current in Shutdown

Mode

SWITCH INPUTS

Input Voltage Threshold V

Input Hysteresis V

Wetting Current Rise/Fall Time t

Wetting Current I

IN0–IN23 Input Current I

IN0–IN23 Input Leakage Current

in Shutdown

IN4–IN23 Dropout Voltage V

DD

DD

(Note 1) 5.5 28 V

VS

UVLO

t

internal register = 0, 24 channels active, all

switches open, T

I

SUP

t

internal register = 0, 24 channels active, all

switches open

Continuous polling mode, wetting current

set to 5mA

I

SDVS

I

SDVDDVSD

TH

IWETT

VSD = 0, VVS = 14V, all switches open, TA =

+25°C

VVS = 5.5V to 28V, measured with 100Ω

series resistor for high-side switches

VVS = 5.5V to 28V, measured with 100Ω

H

series resistor for high-side switches

Wetting current set to 15mA,

9V

WETT

Wetting current set to 15mA,

(5.5V

IN_

I

LEAKSDVVS

DO15IWETT

V

V

= 64ms, t

POLL

= 64ms, t

POLL

= 0, VVS = 14V, TA = +25°C 0.1 5 µA

< VVS < 18V

< VVS < 9V) or (18V < VVS < 28V)

= 0, TA = +25°C 2

IN_

= 14V, TA = +25°C (Note 2) 16 30

IN_

= 0 or 14V, VSD = 0, TA = +25°C ±2 µA

= 15mA (Note 3) 2.8 4.0 V

3 5.5 V

0.1 10 µA

3 5.5 V

POLL_ACT

= 1ms; LP bit in

100 170

= +25°C

A

POLL_ACT

= 1ms; LP bit in

100 200

1000

610µA

2.5 3.7 V

0.2 V

5µs

12.7 15 17.25

10.5 15 19.5

µA

mA

µA

Page 3

MAX13362

24-Channel Automotive Switch Monitor

_______________________________________________________________________________________ 3

)

)

ELECTRICAL CHARACTERISTICS (continued)

(V

DD

= 5V, VVS= 14V, TA= -40°C to +125°C, unless otherwise noted. Typical values are at TA=+25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

LOGIC LEVELS

INT Output-Voltage Low V

SDO Output-Voltage Low V

SDO Output-Voltage High V

SDO Leakage Current in HighImpedance Mode

OLSDO

OHSDO

I

SDI, CLK, CS Input-Voltage Low V

SDI, CLK, CS Input-Voltage High V

SD Input Low Voltage V

SD Input High Voltage V

SDI Internal Pulldown Resistor R

CLK Pin Leakage I

CS Pin Leakage I

SD Pin Leakage I

INT Pin Leakage I

LEAKCLKVCLK

LEAKCS

LEAKSDVSD

LEAKINTVINT

THERMAL SHUTDOWN

Thermal Shutdown Threshold T

Thermal Shutdown Hysteresis T

TIMING

Switch Inputs Deglitching Time t

CLK Frequency Range f

Falling Edge of CS to Rising

Edge of CLK Setup Time

t

Falling Edge of CLK to Rising

Edge of CS Setup Time

SDI-to-CLK Falling Edge Setup

Time

SDI Hold Time After Falling Edge

of CLK

Time from Rising Edge of CLK to

SDO Data Valid

Time from Falling Edge of CS to

SDO Low Impedance

Time from Rising Edge of CS to

SDO High Impedance

t

SI(SU)

t

SI(HOLD

t

VALID

t

SO(EN)

t

SDO(DIS

OLINT

LSDO

ILSD

IHSD

PD

SHDN

HYST

GT

CLK

LEAD

t

LAG

Sinking 1mA 0.4 V

Sinking 1mA 0.2 x V

Sourcing 1mA 0.8 x V

VCS = 5V -1 +1 µA

IL

IH

= 5V, TA = +25°C 1 µA

VCS = 5V, TA = +25°C 1 µA

= 5V, TA = +25°C 1 µA

= high impedance, TA = +25°C 1 µA

Temperature rising (Note 4) +150 +165 °C

(Note 4) 0.01 4 MHz

Polling mode, input rise/fall time

< 10ns (Note 4)

Input rise/fall time < 10ns

(Note 4)

(Note 4) 30 ns

(Note 4) 20 ns

C

= 50pF (Note 3) 70 ns

SDO

(Note 4) 55 ns

(Note 4) 55 ns

DD

DD

0.33 x V

D D

0.66 x V

D D

0.8 V

2.4 V

30 50 120 kΩ

15 °C

37 50 63 µs

100 ns

100 ns

V

V

V

V

Page 4

MAX13362

24-Channel Automotive Switch Monitor

4 _______________________________________________________________________________________

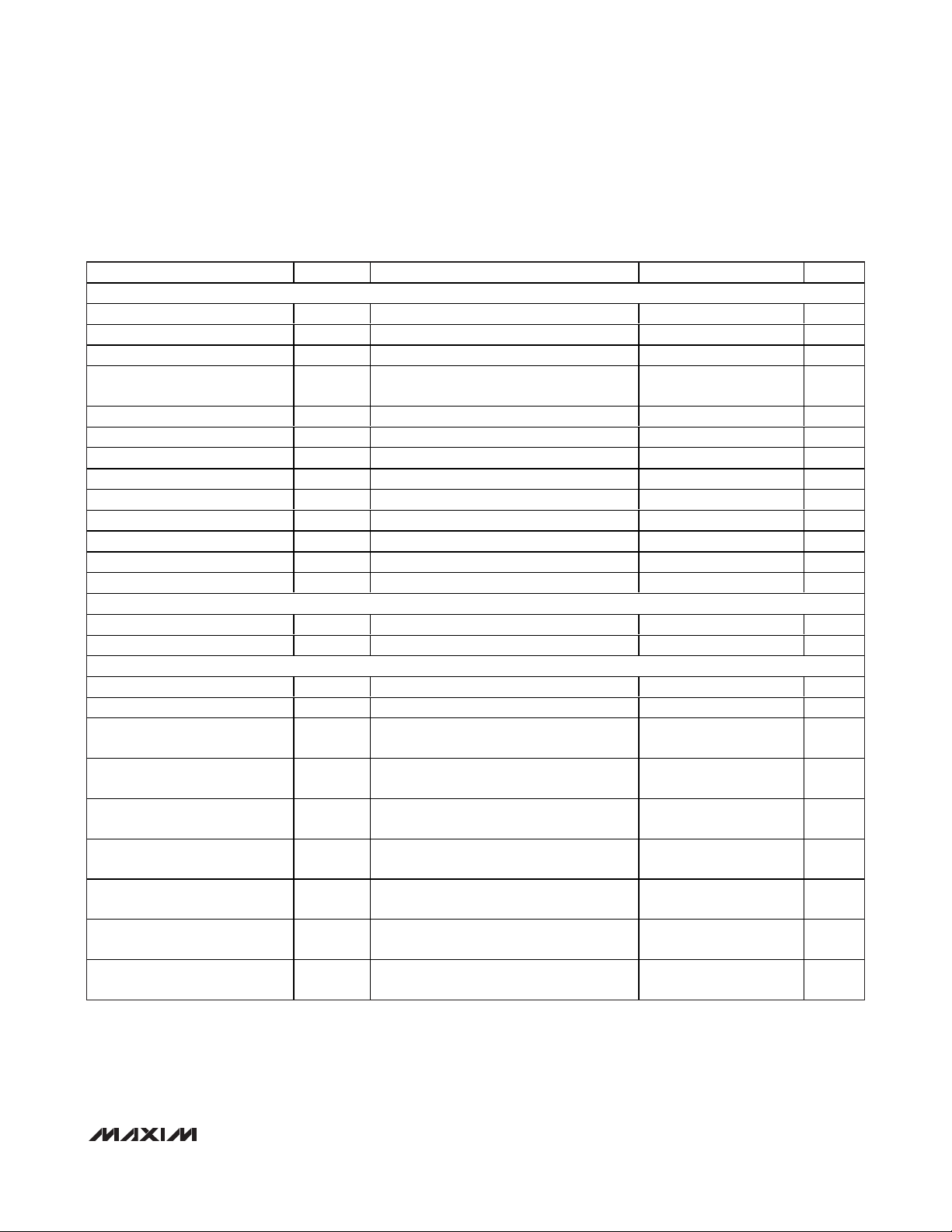

Figure 1. SPI Timing Characteristics

ELECTRICAL CHARACTERISTICS (continued)

(V

DD

= 5V, VVS= 14V, TA= -40°C to +125°C, unless otherwise noted. Typical values are at TA=+25°C.)

Note 1: When V

VS

is above 28V, the wetting current is disabled to limit power dissipation, and the switch inputs are not monitored.

When V

VS

returns, there is a 1ms blanking time before the external switches are polled.

Note 2: This current only flows during the polling active time thus the average value is much lower. For example with a polling time

of 64ms and a polling active time of 1ms the average current on an input when connected to 14V is typically 16µA x 1/64 =

0.25µA.

Note 3: Difference between VS and IN_ voltage when wetting current has dropped to 90% of its nominal value.

Note 4: Guaranteed by design.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Polling Active Time Accuracy t

POLL_ACT

Polling Time Accuracy t

Time from Shutdown to Normal

Operation

POLL

t

START

-20 +20 %

-20 +20 %

0.1 1 ms

CS

t

LEAD

CLK

t

SI(SU)tSI(HOLD)

SDI MSB IN

t

SO(EN)

SDO

MSB OUT LSB OUT

t

VALID

t

LAG

t

SDO(DIS)

Page 5

MAX13362

24-Channel Automotive Switch Monitor

_______________________________________________________________________________________ 5

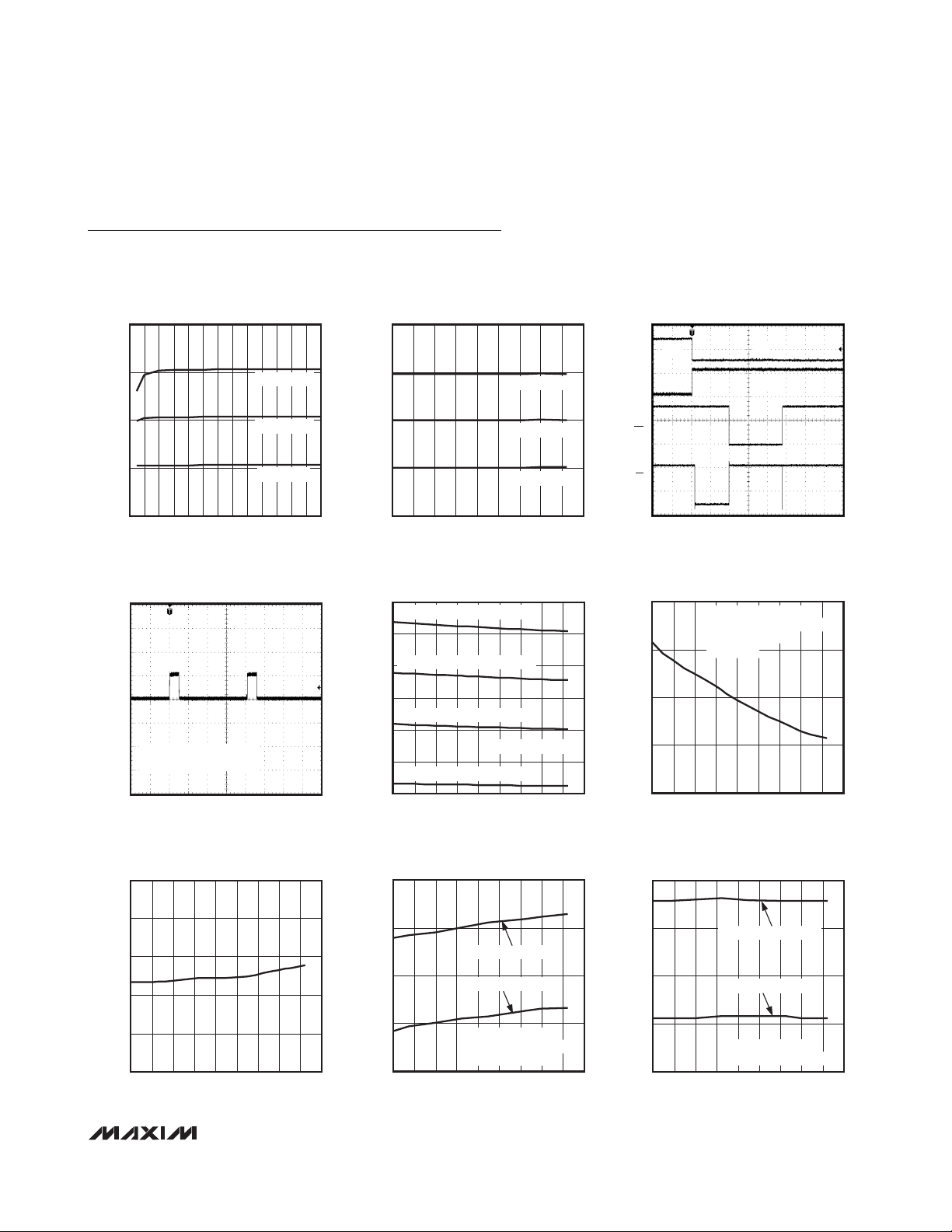

Typical Operating Characteristics

(V

DD

= VSD= 5V, VVS= 14V, TA= +25°C, unless otherwise noted.)

WETTING CURRENT vs. VS VOLTAGE

20

15

10

WETTING CURRENT (mA)

5

0

5187109811612

VS VOLTAGE (V)

13 161514 17

WETTING CURRENT

(POLLING MODE)

5mA

I

WETT

I

WETT

I

WETT

MAX13362 toc01

= 15mA

= 10mA

= 5mA

MAX13362 toc04

WETTING CURRENT vs. TEMPERATURE

20

15

10

WETTING CURRENT (mA)

5

0

-40 8020-20 120 14010060

VS SUPPLY CURRENT vs. TEMPERATURE

2600

2200

1800

400

TEMPERATURE (°C)

(CONTINUOUS MODE)

I

= 15mA FOR ALL CHANNELS

WETT

I

= 10mA FOR ALL CHANNELS

WETT

SWITCH STATUS CHANGE

I

WETT

I

WETT

I

WETT

= 15mA

= 10mA

= 5mA

MAX13362 toc02

MAX13362 toc05

(CONTINUOUS MODE)

V

10V

IN0

I

WETT

V

V

0mA

INT

CS

5mA

10ms/div

VS SUPPLY CURRENT vs. TEMPERATURE

(POLLING MODE)

130

120

POLLING TIME = 65.536ms

POLLING ACTIVE TIME = 1.024ms

ALL CHANNELS OPEN

= 5mA

I

WETT

MAX13362 toc03

0V

10V/div

5mA/div

2V/div

2V/div

MAX13362 toc06

4.096ms POLLING TIME

WETTING CURRENT (5mA/div)

512μs POLLING ACTIVE TIME

1ms/div

VS SUPPLY CURRENT vs. TEMPERATURE

(SHUTDOWN MODE)

6.5

6.2

5.9

5.6

SUPPLY CURRENT (μA)

5.3

5.0

-40 -20 20 8040 140100 120

600

TEMPERATURE (°C)

1400

1000

SUPPLY CURRENT (μA)

600

200

3.4

MAX13362 toc07

3.3

3.2

SWITCH THRESHOLD (V)

3.1

3.0

I

= 5mA FOR ALL CHANNELS

WETT

ALL CHANNELS OPEN

I

= 0mA FOR ALL CHANNELS

WETT

400-40 8020-20 120 14010060

TEMPERATURE (°C)

SWITCH THRESHOLD vs. TEMPERATURE

(HIGH SIDE SWITCH)

MAX13362 toc08

SWITCH OPEN TO CLOSE

SWITCH CLOSE TO OPEN

HIGH SIDE SWITCH

15mA WETTING CURRENT

100Ω INCLUDED

-40 140080

20 12040 10060-20

TEMPERATURE (°C)

110

SUPPLY CURRENT (μA)

100

90

-40 140080

20 12040 10060-20

TEMPERATURE (°C)

SWITCH THRESHOLD vs. TEMPERATURE

(LOW-SIDE SWITCH)

3.4

3.3

3.2

SWITCH THRESHOLD (V)

3.1

3.0

-40 140080

SWITCH OPEN TO CLOSE

SWITCH CLOSE TO OPEN

LOW-SIDE SWITCH

15mA WETTING CURRENT

20 12040 10060-20

TEMPERATURE (°C)

MAX13362 toc09

Page 6

MAX13362

24-Channel Automotive Switch Monitor

6 _______________________________________________________________________________________

Pin Description

Typical Operating Characteristics (continued)

(V

DD

= VSD= 5V, VVS= 14V, TA= +25°C, unless otherwise noted.)

SWITCH THRESHOLD vs. VS VOLTAGE

(LOW-SIDE SWITCH)

3.5

SWITCH STATUS CHANGE

(POLLING MODE)

MAX13362 toc11

3.4

3.3

3.2

SWITCH THRESHOLD (V)

3.1

3.0

91811 15

PIN NAME FUNCTION

1, 2, 11,

29, 30

3 IN17 Switch Monitor Input Channel 17. Connect IN17 to a ground-connected switch.

4 IN18 Switch Monitor Input Channel 18. Connect IN18 to a ground-connected switch.

5 IN19 Switch Monitor Input Channel 19. Connect IN19 to a ground-connected switch.

6 IN20 Switch Monitor Input Channel 20. Connect IN20 to a ground-connected switch.

7 IN21 Switch Monitor Input Channel 21. Connect IN21 to a ground-connected switch.

8 IN22 Switch Monitor Input Channel 22. Connect IN22 to a ground-connected switch.

9 IN23

10 INT

12 CLK SPI Serial Clock Input

13 SDO

14 CS

15 SDI

16, 18 GND Ground. Pins 16 and 18 must be connected to ground.

17 V

N.C. No Connection. Not internally connected.

DD

MAX13362 toc10

SWITCH OPEN TO CLOSE

SWITCH CLOSE TO OPEN

12 1713 161410

VS VOLTAGE (V)

10V

V

IN

0V

V

INT

0V

2ms/div

Switch Monitor Input Channel 23. Connect IN23 to a battery-connected or ground-connected switch.

When used for a battery-connected switch, add a 100Ω series protection resistor to the input.

Inter r up t Outp ut. INT i s an op en- d r ai n outp ut that asser ts l ow w hen one or m or e of the i np uts ( IN 0–IN 23)

chang e state and ar e enab l ed for i nter r up ts, or w hen the over tem p er atur e thr eshol d i s exceed ed .

SPI Serial Data Output. SPI data is output on SDO on the rising edges of CLK while CS is held low.

SDO is high impedance when CS is high. Connect SDO to a microcontroller data input or to a

succeeding device in a daisy chain.

SPI Chip-Select Input. Drive CS low to enable clocking of data into and out of the IC. SPI data is

latched into the device on the rising edge of CS.

SPI Serial Data Input. SPI data is latched into the internal shift register on the falling edges of CLK

while CS is held low. SDI has an internal 50kΩ pulldown resistor. Connect SDI to the SDO of a

preceding device in a daisy chain or to the microcontroller data output.

Logic Supply Voltage. Connect VDD to a 3.3V or 5V logic supply. Bypass VDD to GND with at least a

0.1µF capacitor placed as close as possible to V

DD

.

5V/div

2V/div

Page 7

MAX13362

24-Channel Automotive Switch Monitor

_______________________________________________________________________________________ 7

Pin Description (continued)

PIN NAME FUNCTION

Supply Voltage Input. VS should be protected from reverse battery using a series diode. Bypass VS to

19, 20 VS

21 SD

22 IN0

23 IN1

24 IN2

25 IN3

26 IN4 Switch Monitor Input Channel 4. Connect IN4 to a ground-connected switch.

27 IN5 Switch Monitor Input Channel 5. Connect IN5 to a ground-connected switch.

28 IN6 Switch Monitor Input Channel 6. Connect IN6 to a ground-connected switch.

31 IN7 Switch Monitor Input Channel 7. Connect IN7 to a ground-connected switch.

32 IN8 Switch Monitor Input Channel 8. Connect IN8 to a ground-connected switch.

33 IN9 Switch Monitor Input Channel 9. Connect IN9 to a ground-connected switch.

34 IN10 Switch Monitor Input Channel 10. Connect IN10 to a ground-connected switch.

35 IN11 Switch Monitor Input Channel 11. Connect IN11 to a ground-connected switch.

36 IN12 Switch Monitor Input Channel 12. Connect IN12 to a ground-connected switch.

37 IN13 Switch Monitor Input Channel 13. Connect IN13 to a ground-connected switch.

38 IN14 Switch Monitor Input Channel 14. Connect IN14 to a ground-connected switch.

39 IN15 Switch Monitor Input Channel 15. Connect IN15 to a ground-connected switch.

40 IN16 Switch Monitor Input Channel 16. Connect IN16 to a ground-connected switch.

— EP Exposed Pad. Connect EP to GND for enhanced thermal performance.

GND with a 0.1µF ceramic capacitor placed as close as possible to VS. In addition, bypass VS with a

47µF or greater capacitor.

Shutdown Input. Drive SD low to place the IC into shutdown mode. Drive SD high for normal operation.

SD is battery-voltage compatible.

Switch Monitor Input Channel 0. Connect IN0 to a battery-connected or ground-connected switch.

When used for a battery-connected switch, add a 100Ω series protection resistor to the input.

Switch Monitor Input Channel 1. Connect IN1 to a battery-connected or ground-connected switch.

When used for a battery-connected switch, add a 100Ω series protection resistor to the input.

Switch Monitor Input Channel 2. Connect IN2 to a battery-connected or ground-connected switch.

When used for a battery-connected switch, add a 100Ω series protection resistor to the input.

Switch Monitor Input Channel 3. Connect IN3 to a battery-connected or ground-connected switch.

When used for a battery-connected switch, add a 100Ω series protection resistor to the input.

Page 8

MAX13362

24-Channel Automotive Switch Monitor

8 _______________________________________________________________________________________

Functional Diagram

VS V

DD

IN10

IN11

IN12

IN13

IN14

IN15

IN16

IN17

IN18

IN19

IN20

IN21

IN22

IN23

IN0

IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

IN9

MAX13362

WETTING

CURRENT

CONTROL

1 OF 24

24 OF 24

REF

GENERATOR

SHIFT

REGISTER

+

CONTROL

SDO

CS

CLK

INT

SD

SDI

GND

Page 9

Detailed Description

The MAX13362 is a 24-channel automotive contact

monitor designed as an interface between mechanical

switches and low-voltage microcontrollers or other logic

circuits. It features an SPI interface to monitor individual

switch inputs and to configure interrupt capability, wetting current, switch configuration (battery-connected or

ground-connected), polling time and polling active

time. Any switch status change will cause an interrupt

signal if the switch is interrupt enabled. The MAX13362

has three modes of operation: continuous mode, polling

mode, and shutdown mode.

VDDand VS

VDDis the power-supply input for the logic input/

output circuitry. Connect VDDto a 3V to 5.5V logic-level

supply. Bypass V

DD

to GND with at least a 0.1µF

capacitor placed as close as possible to V

DD

.

VS is the main power-supply input. Bypass VS to GND

with a 0.1µF ceramic capacitor placed as close as possible to VS. In addition, bypass VS with a 47µF or

greater capacitor.

Mechanical Switch Inputs (IN0–IN23)

IN0–IN23 are the inputs for remote mechanical switches. The switch status is indicated by the S0–S23 bits in

the status register, and each switch input can be programmed to assert an interrupt (INT) by writing to the

IE0–IE23 bits in the command register. All switch inputs

are interrupt disabled upon power-up.

The IN4–IN22 inputs are intended for ground-connected switches. The IN0–IN3 and IN23 inputs can be programmed for either ground-connected switches or

battery-connected switches by writing to the LH0–LH3

and LH23 bits (see Table 2). The default configuration

of the IN0–IN3 and IN23 inputs after power-up is for

ground-connected switches.

Wetting Current

The MAX13362 applies a programmable wetting current

to any closed switch to clean switch contacts that are

exposed to adverse conditions. The wetting current for

each switch can be set to 0mA, 5mA, 10mA, or 15mA

by the W_.0 and W_.1 data bits in the command registers (see Table 5) by means of an SPI data transaction.

When using wetting current, special care must be

taken to avoid exceeding the maximum power dissipation of the MAX13362 (see the

Applications Information

section). Disabling the wetting current or limiting the

active-wetting current time reduces power consumption. The default state upon power-up is with wetting

current disabled.

Interrupt Output (

INT

)

INT is an active-low, open-drain output that asserts low

when any of the switch inputs change state and is

enabled for interrupts, or when the overtemperature

threshold is exceeded. An external pullup resistor to

VDDis needed on INT. INT is cleared when CS is driven

low for a read/write operation. However, in polling mode,

any switch state change or overtemperature change

which occurs during an SPI transaction is stored and

causes an additional interrupt after the SPI transaction is

over and CS goes high (shown in Figure 2).

If VDDis absent, the INT output is functional provided

that it is pulled up to a different supply voltage.

MAX13362

24-Channel Automotive Switch Monitor

_______________________________________________________________________________________ 9

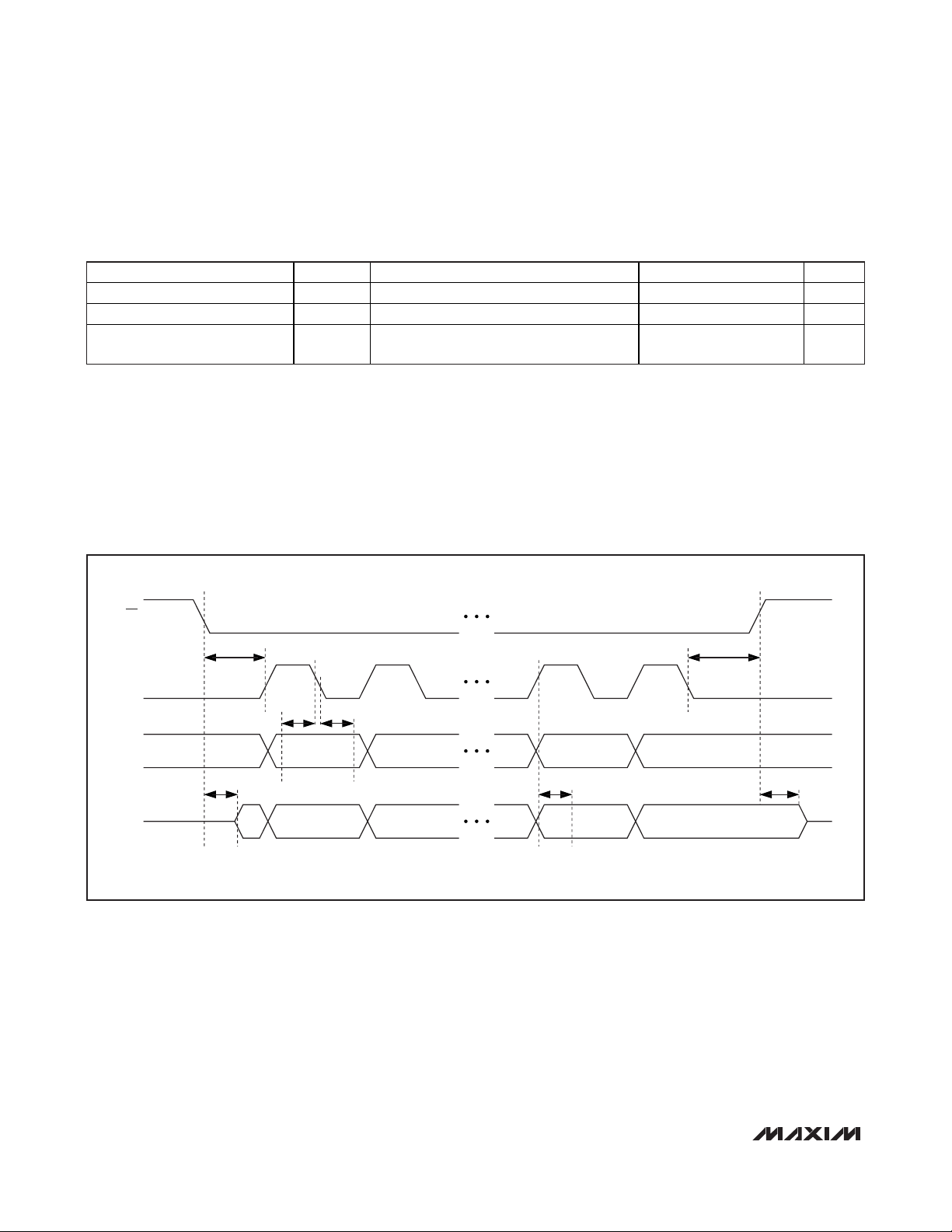

Figure 2. Switch State Change During the SPI transaction

CS

CLK

INT

SWITCH STATUS CHANGE

NEW INTERRUPT

Page 10

MAX13362

Serial Peripheral Interface

(

CS

, SDO, SDI, CLK)

The MAX13362 operates as a serial peripheral interface

(SPI) slave device. An SPI master accesses and programs the MAX13362 by reading/writing the control

registers. The control registers are 32 bits wide, have 2

command bits (or register addresses) and 30 data bits

(see Table 1). Figure 3 shows the read/write sequence

through SPI. The SPI logic counts the number of bits

clocked into the IC (using a modulo-32 counter so that

daisy chaining is possible) and enables data latching

only if exactly 32 bits (or an integer multiple thereof)

have been clocked in.

Status Register

The status register contains the status of the switches

connected to IN0–IN23. The status register also contains an overtemperature warning bit, a power-on-reset

bit and a device type bit (see Table 1). The status register is accessed by the SPI-compatible interface.

24-Channel Automotive Switch Monitor

10 ______________________________________________________________________________________

Figure 3. SPI Read/Write Sequence

Table 1. Bit Description

CS

CLK

SDI

SDO

RSTDTZ

NOTE: X = UNUSED, Z = HIGH IMPEDANCE.

D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11

T S0 S8S7S6S5S4S3S2S1 S9 S10

D12CB0 CB1 D0

S19

S20 S21 S22 S23 x x xx x

D24D13 D14 D15 D16 D17 D18 D19 D20 D21 D22 D23 D29D25 D26 D27 D28

ZS11 S12 S13 S14 S15 S16 S17 S18

BIT NAME BIT DESCRIPTION

CB0, CB1 Command bits. Select the internal register to which data bits D0–D29 are to be written.

D0–D29 Data bits.

S0–S23 Switch state bit. 0 = switch open, 1 = switch closed.

T Overtemperature bit. When overtemperature occurs, this bit is set to 1. It is reset on the rising edge of CS.

RST

DT Device type. 0 = reserved for future use, 1 = MAX13362.

Power-on-reset bit. It indicates whether the IC has had a power-on-reset since the last SPI read. 0 = device has

been reset. RST is set to 1 on the rising edge of CS.

Page 11

Command Register

Three 32-bit command registers are used to configure

the MAX13362 for various modes of operation and are

accessed by the SPI-compatible interface (see Table 2).

LH_: Switch Configuration for IN0–IN3 and IN23

The LH0–LH3 and LH23 bits set the switch configuration

for IN0–IN3 and IN23, respectively. Set LH_ to 0 to configure the input channel to ground connected. Set LH_

to1 to configure the input channel to battery connected.

The default configuration after power-on is LH_ = 0,

ground connected.

P0–P3: Polling Time

P0–P3 are used to set the polling time as shown in Table 3.

PA0–PA2: Polling Active Time

PA0–PA2 are used to set the polling active time as

shown in Table 4.

MAX13362

24-Channel Automotive Switch Monitor

______________________________________________________________________________________ 11

Table 3. Polling Time Setting

Table 2. Command Register Map

*

Default POR Value.

*

Default POR value.

Table 4. Polling-Active Time Setting

D29 D28 D27 D26 D25 D24 D23 D22 D21 D20 D19 D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 CB1 CB0

X

PA2 PA1 PA0

LP

XP3P2P1P0

LH2

LH3 LH2 LH1 LH0 IE23 IE22 IE21 IE20 IE19 IE18 IE17 IE16 IE15 IE14 IE13 IE12 IE11 IE10 IE9 IE8 IE7 IE6 IE5 IE4 IE3 IE2 IE1 IE0 X 1 0

3

P3 P2 P1 P0 POLLING TIME (ms)

0 0 0 0 Continuous*

0 0 0 1 4.096

0 0 1 0 4.096

0 0 1 1 4.096

0 1 0 0 4.096

0 1 0 1 4.096

0 1 1 0 8.192

0 1 1 1 16.384

1 0 0 0 32.768

1 0 0 1 65.536

1010 131

1 0 1 1 262.1

1 1 0 0 524.3

1 1 0 1 1049

1 1 1 0 2097

1 1 1 1 4194

W23.0W22.0W21.0W20.0W19.0W18.0W17.0W16.0W15.0W14.0W13.0W12.0W11.0W10.0W9.0W8.0W7.0W6.0W5.0W4.0W3.0W2.0W1.0W0.

W23.1W22.1W21.1W20.1W19.1W18.1W17.1W16.1W15.1W14.1W13.1W12.1W11.1W10.1W9.1W8.1W7.1W6.1W5.1W4.1W3.1W2.1W1.1W0.

NO OPERATION (NO DATA WRITTEN) 11

PA2 PA1 PA0 POLLING ACTIVE TIME (µs)

000 64

001 128

010 256

0 1 1 512*

1 0 0 1024

1 0 1 2048

1 1 0 4096

1 1 1 4096

X00

0

X01

1

Page 12

MAX13362

IE_: Interrupt Enable

The IE_ bit programs the switch input channel, IN_, to

be interrupt-enabled or interrupt-disabled (0 = interrupt

disabled, 1 = interrupt enabled). The default value after

power-on is 0.

W_.0 and W_.1: Wetting Current

W_.0 and W_.1 bits set the corresponding switch

channel-wetting current as shown in Table 5.

LP: Low Quiescent Current Bit

In polling mode, when LP is set to 0, the IC is operating

with the lowest quiescent current. The channels that are

not enabled to interrupt have their wetting current disabled and are not monitored. The first pulse of wetting

current after the switch is closed and sampled is 5mA

unless the wetting current for that channel is set to

0mA. The default value of LP after power-on is 0. When

LP is 1, all channels are monitored and the wetting current for each channel is set to the value determined by

W_.0 and W_.1. If the MAX13362 is in continuous

mode, LP is ignored.

Operating Modes

The MAX13362 features three modes of operation: continuous mode, polling mode, and shutdown mode. In

continuous mode, the wetting currents (if enabled) are

continuously applied to the closed switches. In polling

mode, the wetting currents are applied to the closed

switches for a preset duration to reduce the power consumption. In shutdown mode, all switch inputs are high

impedance and all circuitry is shutdown.

Continuous Mode Operation (P0–P3 = 0)

In continuous mode, reading of the switch status is initiated by a falling edge on CS. The microcontroller initiates a low pulse on CS to update the MAX13362 switch

status register. If INT remains high, no action needs be

taken by the microcontroller. If INT goes low, the microcontroller may perform a read operation to read the

updated switch status. On the rising edge of CS, INT is

updated. To get correct data, the microcontroller must

wait 10µs before initiating a switch status read operation. (See Figure 4.)

Polling-Mode Operation

In polling mode (see Figure 5), each switch input is

sampled for a programmable polling active time set by

the PA0–PA2 bits between 64µs and 4ms (see Table 4).

Sampling is repeated at a period set by the P0–P3 bits

(from 4ms to continuous, see Table 3). All switch inputs

are sampled simultaneously at the end of the polling

active time. Wetting currents (if enabled) are applied to

closed switches during the polling active time.

Therefore, the polling mode reduces the current consumption from the VS power supply to some value

dependent on the polling time chosen.

24-Channel Automotive Switch Monitor

12 ______________________________________________________________________________________

*

Default POR value.

Table 5. Wetting Current Setting

Figure 4. Continuous Mode Operation

Figure 5. Switch Sampling in Polling Mode

W_.1 W_.0 WETTING CURRENT (mA)

00 0*

01 5

10 10

11 15

CS

SWITCH

STATUS

CHANGE

INT

INT UPDATED, PERFORM READ OPERATION

POLLING TIME

POLLING

GROUND-CONNECTED

SWITCH-INPUT

INT

ACTIVE TIME

SWITCH

POSITION

SAMPLED

SWITCH OPEN

POLLING ACTIVE TIME

SWITCH

POSITION

SAMPLED

Page 13

Any switch position change (if the switch is interruptenabled) is signaled through the active-low open-drain

INT output. The INT output is cleared when CS goes

low.

Shutdown Mode

In shutdown mode, all switch inputs are high impedance and the external switches are no longer monitored, reducing current consumption on VS to 6µA

(typ). The IC resets upon entering shutdown mode and

the contents of the command registers are lost.

Therefore, any setting other than power-on-reset

defaults needs to be reprogrammed after exiting from

the shutdown mode.

Applications Information

Overtemperature Protection

If the IC junction temperature exceeds +165°C, an

interrupt signal is generated and the wetting currents

are disabled to reduce the on-chip power dissipation.

During an overtemperature event, the last switch status

is retained in internal memory and the switch status is

not updated. The interrupt output is cleared when CS

goes high, but the overtemperature bit T in the output

word remains for as long as the overtemperature condition persists. When the junction temperature drops by

15°C, the wetting currents are re-enabled and there is a

1ms blanking time before the switches can be polled.

Reverse-Battery Tolerance

The IN0–IN23 switch inputs withstand up to -15V DC

voltage without damage. A reverse-battery diode is

needed to protect VS as shown in the

Typical

Application Circuit

. SD can be controlled from a bat-

tery-level source but should be protected against

reverse battery in the application.

Wetting Current and Power Dissipation

The maximum power dissipation happens when all

switch inputs configured with 15mA continuous wetting

current are all closed. Assuming the battery voltage is

14V, the corresponding power dissipated by the IC is

24 x 14V x 15mA = 5040mW. This exceeds the

absolute maximum power dissipation of 2963mW. In

polling mode, the wetting currents are pulsed at the

programmed polling time to reduce the total power dissipated in the IC.

ISO 7637 Pulse Immunity

VS, SD, and IN0–IN23 are potentially exposed to ISO

7637 pulses. Bypass VS with a 0.1µF and a 47µF

capacitor. The VS and SD voltage must be limited

below 40V during load dump. Bypass IN0–IN23 with at

least 0.047µF capacitors at the ECU connector. When

IN0–IN3 or IN23 inputs are used with battery-connected

switches, a 100Ω series resistor is needed. These

external components allow VS, SD, and IN0–IN23 to

withstand ISO 7637 pulses in the application circuit.

Mechanical Switch Characteristics

The MAX13362 is designed to operate with switches

that have the following characteristics:

1) Minimum resistance value with switch open (due to

leakage): 10kΩ.

2) Maximum resistance value with switch closed:

100Ω.

Chip Information

PROCESS: BiCMOS

MAX13362

24-Channel Automotive Switch Monitor

______________________________________________________________________________________ 13

Page 14

MAX13362

24-Channel Automotive Switch Monitor

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

14

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2009 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

40 TQFN-EP T4066+5

21-0141

Package Information

For the latest package outline information and land patterns, go to www.maxim-ic.com/packages.

Loading...

Loading...