Page 1

EVALUATION KIT AVAILABLE

19-6168; Rev 0; 1/12

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

General Description

The MAX13335E/MAX13336E are high-fidelity stereo

audio input amplifiers designed for automotive applications requiring audio-level detection and/or jack sensing

capability.

The devices feature a dual-channel, low-noise, programmable gain amplifier that accepts fully differential and

quasi-differential input signals with diagnostics capability

controlled through an I2C interface. The devices’ audio

receiver can also pair with the MAX13325/MAX13326

audio transmitter to form a complete differential audio link

in automotive systems.

Each channel of the device features high common-mode

rejection ratio (CMRR) (80dB), enabling the recovery of

audio signals in the presence of large common-mode

noise in automotive environments. An integrated programmable gain amplifier is adjustable from -14dB to

+16dB (MAX13335E) and -22dB to +8dB (MAX13336E)

with zero-crossing detection to provide an optimum

output-signal level and limit zip noise. The external flexible diagnostic inputs can be configured to perform jack

sense functions or to detect short-to-battery, short-toground, open load, and shorts between channels.

The audio inputs are protected against ISO 10605 Q15kV

Air Gap and Q8kV Contact Discharge ESD pulses. Both

devices have a -40NC to +105NC operating temperature

range, and are available in a 16-pin QSOP package.

Features

S +3.3V or +5V Operation

S +28V to -16V Tolerant Inputs

S Wide Common-Mode Input Range (-5V to +11.5V)

S Fully Differential Inputs Up to 7V

S Quasi-Differential Inputs Up to 3.5V

S Audio Presence Detection

S Jack Sense Detection

S Diagnostic Capability

S Programmable Gain with Zero-Crossing Detection

S I2C Control Interface

S Automotive Grade ESD Protection

ISO 10605 ±15kV Air Gap

±8kV Contact Discharge

RMS

RMS

Applications

Radio Head Units

RSA/RSE

Connectivity Modules

Automotive Telematics

Ordering Information appears at end of data sheet.

For related parts and recommended products to use with this part,

refer to www.maxim-ic.com/MAX13335E.related.

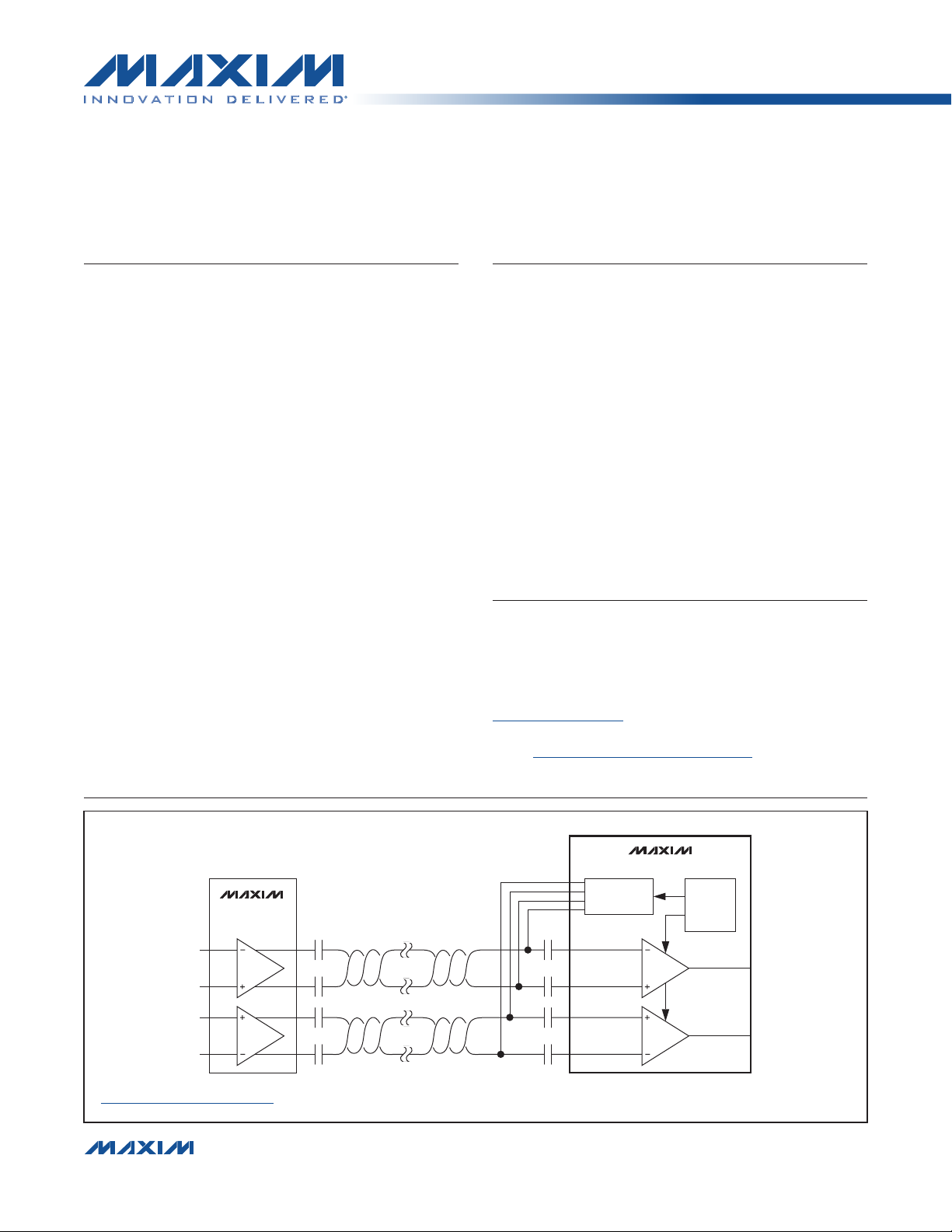

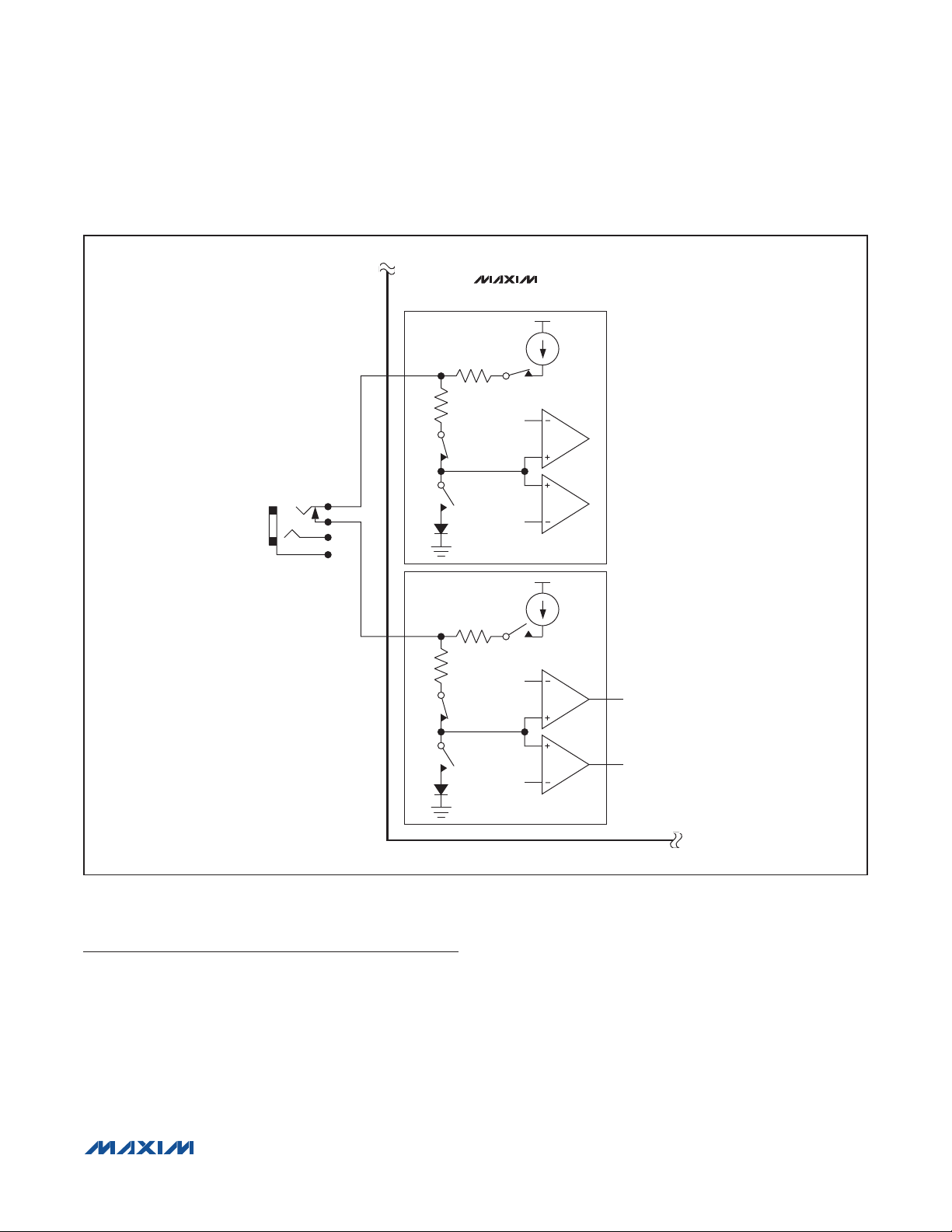

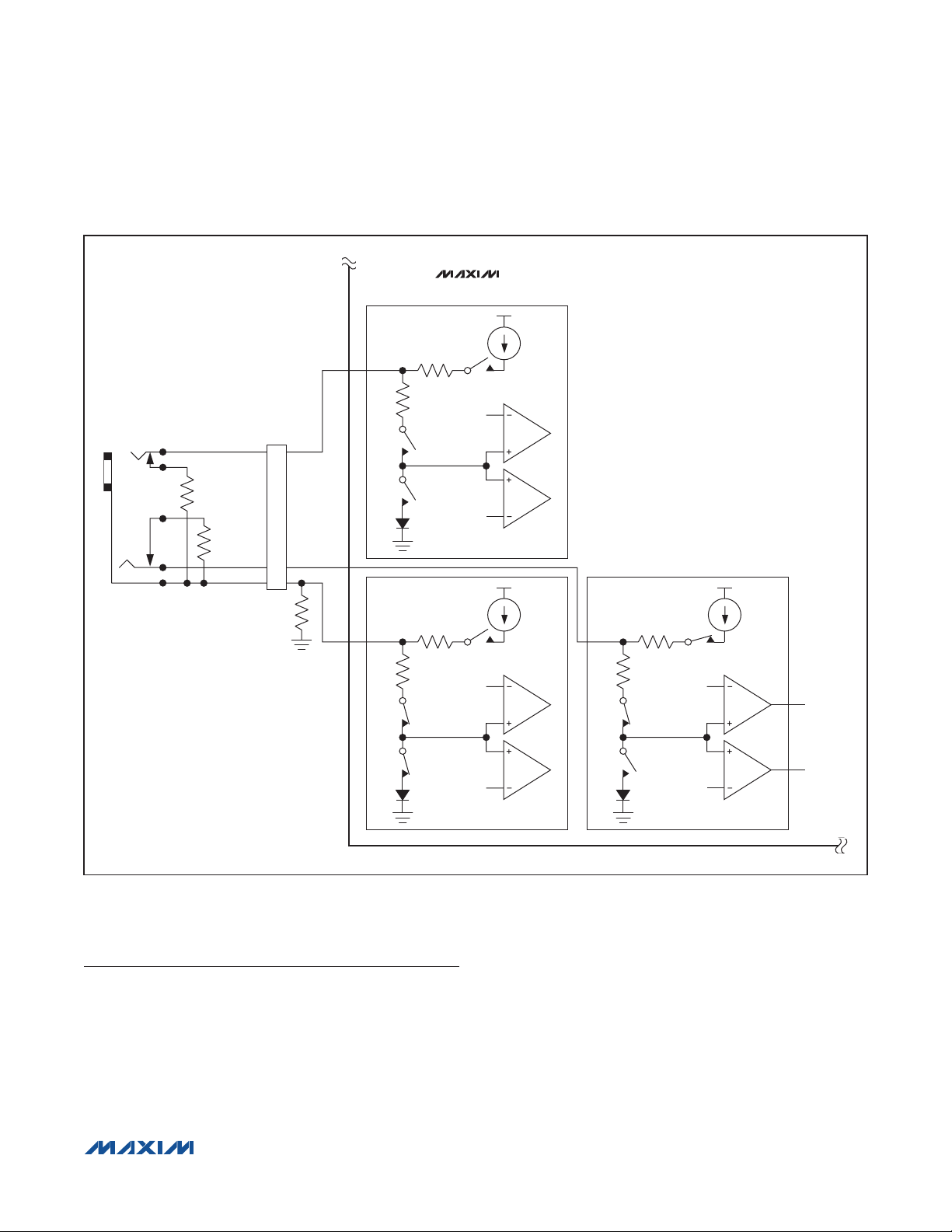

Typical Application Circuits

MAX13335E/MAX13336E

MAX13325

DIAGNOSTICS

MAX13326

PGA

PGA

Typical Application Circuits continued at end of data sheet.

����������������������������������������������������������������� Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

I2C

AND

CONTROL

Page 2

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

ABSOLUTE MAXIMUM RATINGS

VDD to GND ............................................................. -0.3V to +6V

D_ to GND .............................................................. -16V to +28V

INL_, INR_ to GND ................................................. -10V to +15V

OUTR, OUTL to GND ............................... -0.3V to (VDD + 0.3V)

SDA, SCL, INT to GND ............................................ -0.3V to +6V

REF to GND .............................................. -0.3V to (VDD + 0.3V)

Output Short-Circuit Duration ....................................Continuous

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

PACKAGE THERMAL CHARACTERISTICS (Note 1)

QSOP

Junction-to-Ambient Thermal Resistance (BJA) .....103.7NC/W

Junction-to-Case Thermal Resistance (BJC) ...............37NC/W

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial.

Continuous Power Dissipation (TA = +70NC)

QSOP (derate 9.6 mW/NC above +70°C) ................771.5 mW

Operating Junction Temperature Range ......... -40NC to +150NC

Storage Temperature Range ............................ -65NC to +150NC

Lead Temperature (soldering, 10s) ................................+300NC

Soldering Temperature (reflow) ......................................+260NC

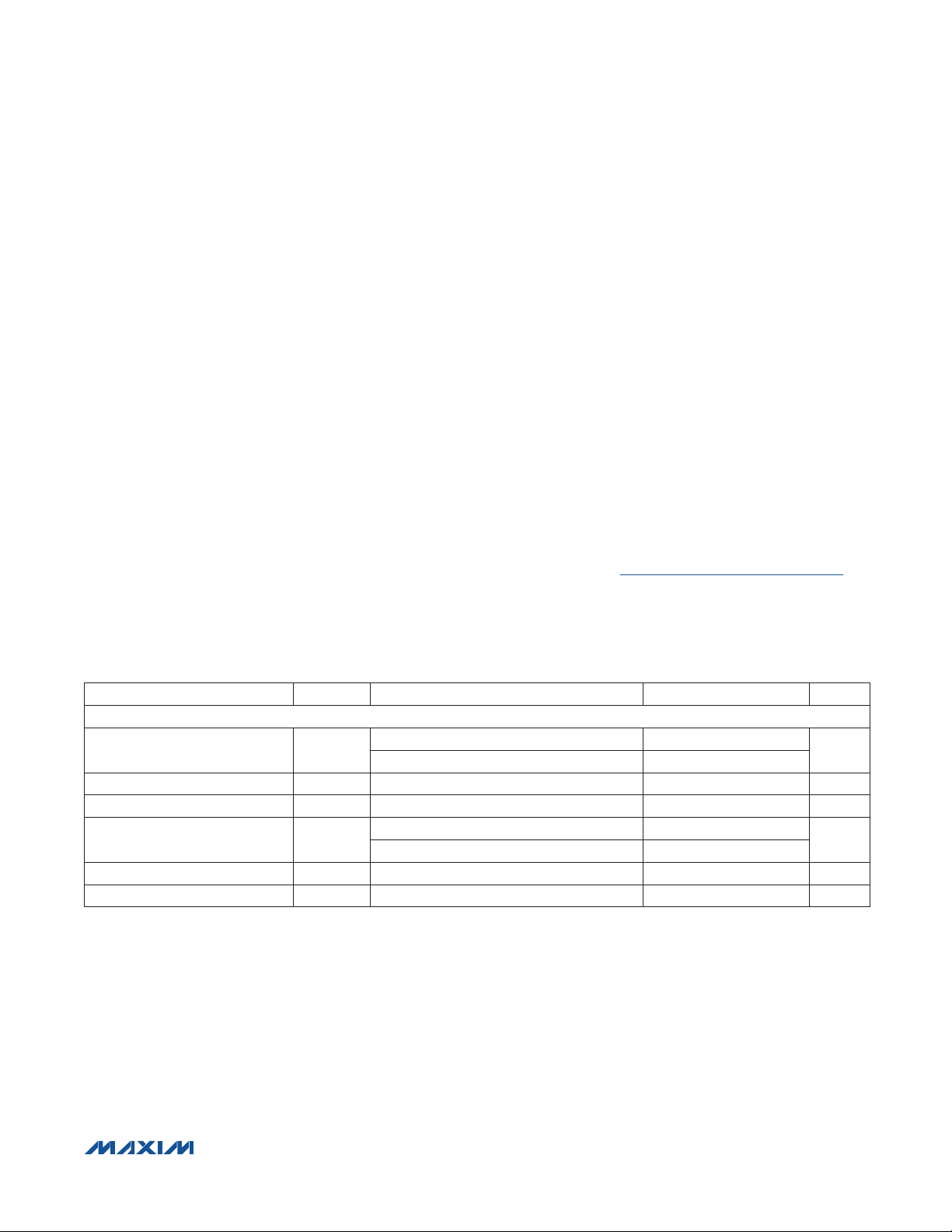

ELECTRICAL CHARACTERISTICS

(VDD = 5V, AV = -6dB, RL = 10kI, f = 20Hz to 20kHz, TA = TJ = -40NC to +105NC, unless otherwise noted. Typical values are at

TA = 25NC under normal conditions, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

GENERAL

V

= 1.68V -5% 3.3 +5%

Supply-Voltage Range V

Quiescent Supply Current I

Shutdown Supply Current I

REF Output Voltage V

Thermal Shutdown T

Thermal Shutdown Hysteresis T

DD

DD

SHDN

REF

SHDN

HYS

REF

V

= 2.5V -5% 5.0 +5%

REF

V

= V

INL_

SHDN bit = 1 6 10

V

= 3.3V -4% 1.68 +4%

DD

V

= 5V -3% 2.5 +3%

DD

(Note 3) +150 °C

(Note 3) 15 °C

= VDD/2 11 mA

INR_

FA

V

V

����������������������������������������������������������������� Maxim Integrated Products 2

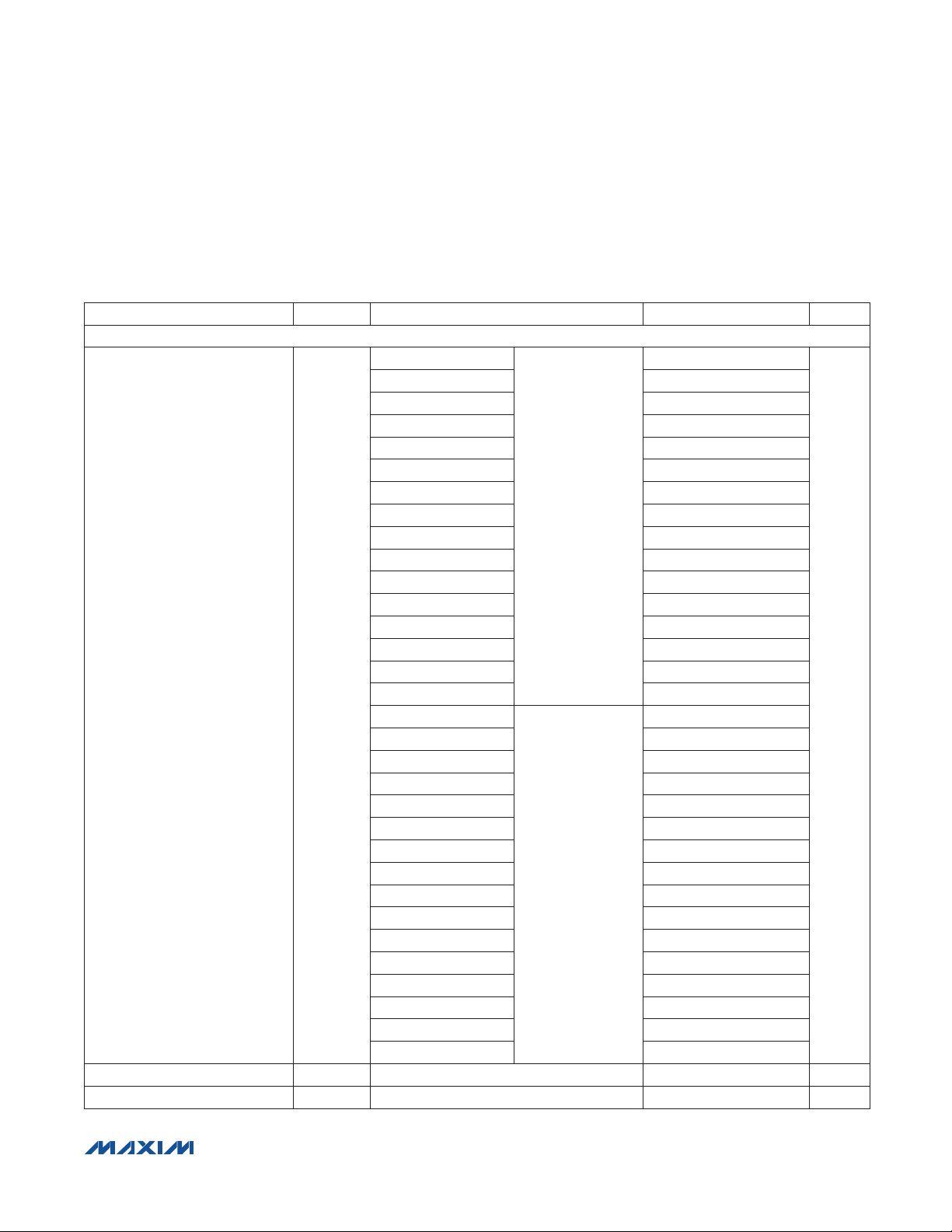

Page 3

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

ELECTRICAL CHARACTERISTICS (continued)

(VDD = 5V, AV = -6dB, RL = 10kI, f = 20Hz to 20kHz, TA = TJ = -40NC to +105NC, unless otherwise noted. Typical values are at

TA = 25NC under normal conditions, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

AMPLIFIERS

Programmable Gain Amp A

Gain Error A

Gain Matching A

V

ERR

MCH

G_[3:0] = 0000

G_[3:0] = 0001 -12

G_[3:0] = 0010 -10

G_[3:0] = 0011 -8

G_[3:0] = 0100 -6

G_[3:0] = 0101 -4

G_[3:0] = 0110 -2

G_[3:0] =0111 0

G_[3:0] =1000 2

G_[3:0] =1001 4

G_[3:0] =1010 6

G_[3:0] =1011 8

G_[3:0] =1100 10

G_[3:0] =1101 12

G_[3:0] =1110 14

G_[3:0] =1111 16

G_[3:0] = 0000

G_[3:0] = 0001 -20

G_[3:0] = 0010 -18

G_[3:0] = 0011 -16

G_[3:0] = 0100 -14

G_[3:0] = 0101 -12

G_[3:0] = 0110 -10

G_[3:0] =0111 -8

G_[3:0] =1000 -6

G_[3:0] =1001 -4

G_[3:0] =1010 -2

G_[3:0] =1011 0

G_[3:0] =1100 2

G_[3:0] =1101 4

G_[3:0] =1110 6

G_[3:0] =1111 8

Within VCM operating range

Within VCM operating range

MAX13335E

MAX13336E

-14

-22

Q0.4

Q0.4

dB

dB

dB

����������������������������������������������������������������� Maxim Integrated Products 3

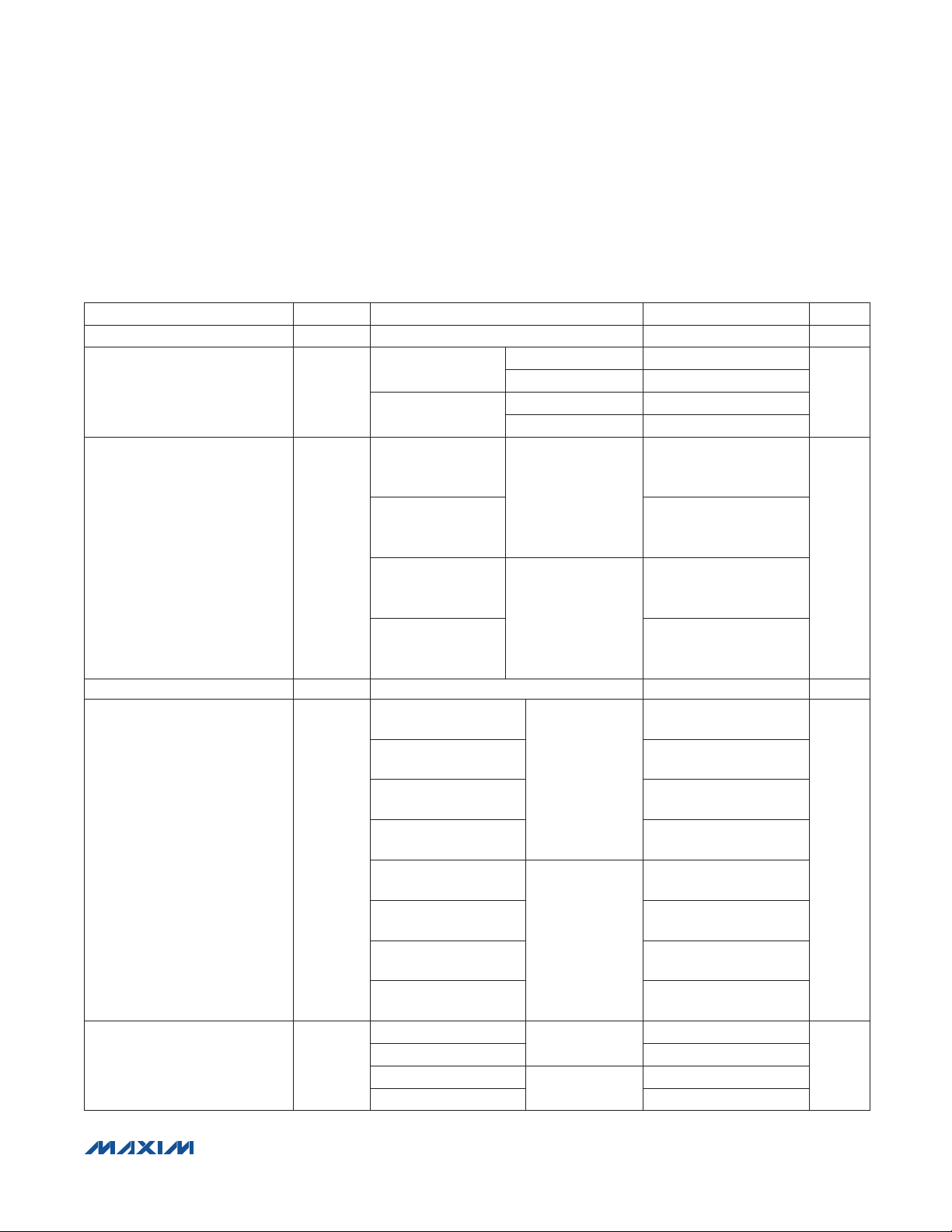

Page 4

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

ELECTRICAL CHARACTERISTICS (continued)

(VDD = 5V, AV = -6dB, RL = 10kI, f = 20Hz to 20kHz, TA = TJ = -40NC to +105NC, unless otherwise noted. Typical values are at

TA = 25NC under normal conditions, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Input Offset Voltage V

Input Impedance R

Common-Mode Rejection Ratio A

Power-Supply Rejection Ratio A

Input Voltage Range V

Input Common-Mode Voltage

Range

IOS

CMRR

PSRR

V

CM

AV = 0dB -10 +10 mV

Differential

IN

Single-ended

Within VCM range,

f = DC, AV = -2dB

(Note 4)

VCM = 2V

f = 20Hz to 20kHz

(Note 3)

Within VCM range,

f = DC, AV = -10dB

(Note 4)

VCM = 2V

f = 20Hz to 20kHz

(Note 3)

f = 1kHz, V

Quasi-differential

source, VDD = 3.3V

Quasi-differential

source, VDD = 5V

Differential source,

V

DD

Differential source,

V

IN

DD

Quasi-differential

source, VDD = 3.3V

Quasi-differential

source, VDD = 5V

Differential source,

V

DD

Differential source,

V

DD

V

DD

V

DD

V

DD

V

DD

,

RMS

,

RMS

RIPPLE

= 3.3V

= 5V

= 3.3V

= 5V

= 3.3V

= 5V -1.8 7.0

= 3.3V

= 5V -5.0 11.5

MAX13335E 13.5 22 33

MAX13336E 19 30 42

MAX13335E 8.5 14 21

MAX13336E 11 17 24

60 80

MAX13335E

60

65 85

MAX13336E

65

= 200mV

(Note 3) -80 dB

P-P

MAX13335E

MAX13336E

MAX13335E

MAX13336E

-1.2 4.6

-3.3 7.6

1.3

2

2.6

4.0

2.3

3.5

4.6

7.0

V

kI

dB

RMS

V

����������������������������������������������������������������� Maxim Integrated Products 4

Page 5

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

ELECTRICAL CHARACTERISTICS (continued)

(VDD = 5V, AV = -6dB, RL = 10kI, f = 20Hz to 20kHz, TA = TJ = -40NC to +105NC, unless otherwise noted. Typical values are at

TA = 25NC under normal conditions, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

-

Output Voltage Range V

Total Harmonic Distortion Plus

Noise

OUT

THD+N f = 1kHz, V

Signal-to-Noise Ratio SNR

Output Noise V

RL = 10kW

V

OUT_

(Note 3)

AV = 0dB, unweighted

N

(Note 3)

= 1.4V

OUT_

RMS

= 1.4V

(Note 3) 0.01 %

RMS

MAX13335E 104.8

MAX13336E 99.4

MAX13335E 8

MAX13336E 15

0.1

Slew Rate SR CL = 300pF (Note 3) 0.5

Maximum Capacitive Load C

Crosstalk A

XTALKVIN

Mute Attenuation A

Shutdown Attenuation A

SHDN

MUTE

No sustained oscillation (Note 3) 300 pF

L

= 2V

MUTE bit = 1, V

SHDN bit = 1, V

(Note 3) -80 dB

RMS

IN

IN

= 2V

= 2V

(Note 3) -80 dB

RMS

(Note 3) -80 dB

RMS

LEVEL SENSE/CLIP DETECTION

Audio Presence Threshold V

Clip-Level Warning

V

V

TAP

TCP

TCN

Output referred 127 200 268 mV

Positive clip warning level 90

Negative clip warning level 10

DIAGNOSTIC I/O

D_[3:0]=0001 40

D_[3:0]=0010 97

D_[3:0]=0011 154

D_[3:0]=0100 210

D_[3:0]=0101 265

D_[3:0]=0110 320

Pullup Current Limit I

IDH

V

D_

= 1.5V

D_[3:0]=0111 375

D_[3:0]=1000 430

D_[3:0]=1001 485

D_[3:0]=1010 540

D_[3:0]=1011 595

D_[3:0]=1100 650

D_[3:0]=1101 705

Pulldown Current I

Trip High Threshold V

Trip Low Threshold V

Switch Diode V

Input Resistance R

IDL

IDH

IDL

DON

DOFF

D_[3:0] = 1110, V

R

= 1kI to 10kI

D_

R

= 1kI to 10kI

D_

D_

< V

CM

D_[3:0] = 1111 0.7 V

Off-state D_[3:0] = 0000, V

D_

< V

CM

32 65

1.94 V

0.92 V

1

DD

0.1

FV

V/Fs

% V

MI

V

dB

RMS

RMS

DD

FA

FA

����������������������������������������������������������������� Maxim Integrated Products 5

Page 6

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

ELECTRICAL CHARACTERISTICS (continued)

(VDD = 5V, AV = -6dB, RL = 10kI, f = 20Hz to 20kHz, TA = TJ = -40NC to +105NC, unless otherwise noted. Typical values are at

TA = 25NC under normal conditions, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Leakage Current I

DLKG

ESD PROTECTION

ISO 10605 Air Gap V

Contact Discharge V

ESD

ESD

DIGITAL INTERFACE

Input Voltage High V

Input Voltage Low V

Input Voltage Hysteresis V

I/O Leakage Current I

Output Low Voltage V

EN to Full Operation Time t

INH

INL

HYS

LKG

OL

SON

I2C TIMING

Output Fall Time t

OF

Pin Capacitance C

Clock Frequency f

SCL Low Time t

SCL High Time t

START Condition Hold Time t

START Condition Setup Time t

Data Hold Time t

Data Setup Time t

SCL

LOW

HIGH

HD:STA

SU:STA

HD:DAT

SU:DAT

Input Rise Time t

Input Fall Time t

STOP Condition Setup Time t

Bus Free Time t

Maximum Bus Capacitance C

SU:STO

BUF

BUS

Note 2: Specifications within minimum and maximum limits are 100% production tested at TA = +25NC and are guaranteed over

the operating temperature range by design and characterization. Actual typical values may vary and are not guaranteed.

Note 3: Guaranteed by bench characterization.

Note 4: A

CMRR

= 20log(δV

IOS

/δVCM).

Off-state D_[3:0] = 0000, V

D_

< V

CM

Q10 FA

2kI/150pF, INL_, INR_ Q15

330I/330pF, INL_, INR_ Q8

SDA, SCL

0.7 x

V

DD

SDA, SCL

0.14 x

V

DD

Q10 FA

100 ms

IN

SDA, SCL

SDA, SCL, INT

SDA, INT, I

C

= 2.2FF (Note 3)

REF

C

= 10pF to 400pF 250 ns

BUS

SINK

= 3mA

1.3

0.6

Repeated START condition 0.6

Repeated START condition 0.6

0 900 ns

100 ns

SCL, SDA 300 ns

R

SCL, SDA 300 ns

F

0.6

Between START and STOP conditions 1.3

Per bus line 400 pF

kV

kV

0.3 x

V

DD

mV

0.4 V

10 pF

400 kHz

V

V

Fs

Fs

Fs

Fs

Fs

Fs

����������������������������������������������������������������� Maxim Integrated Products 6

Page 7

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

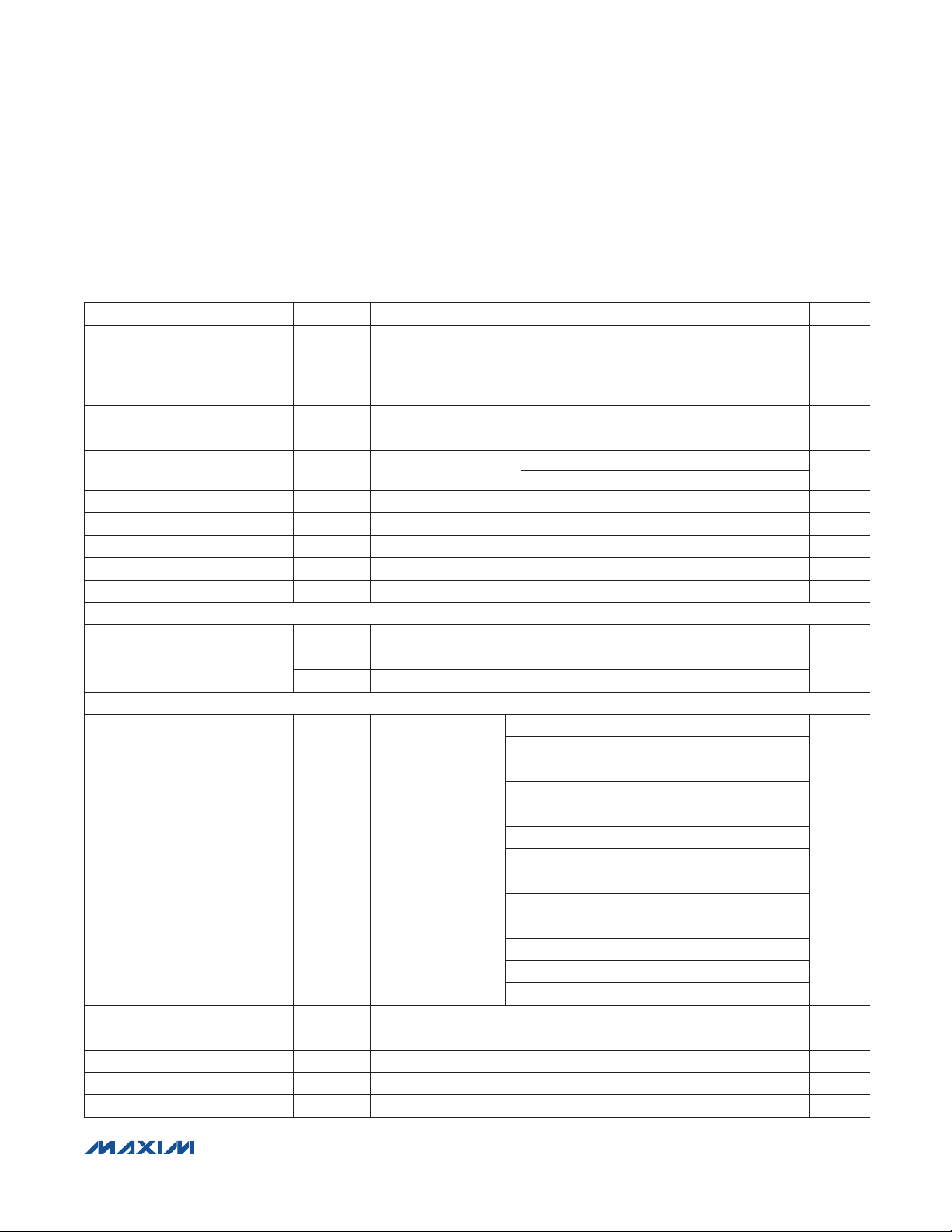

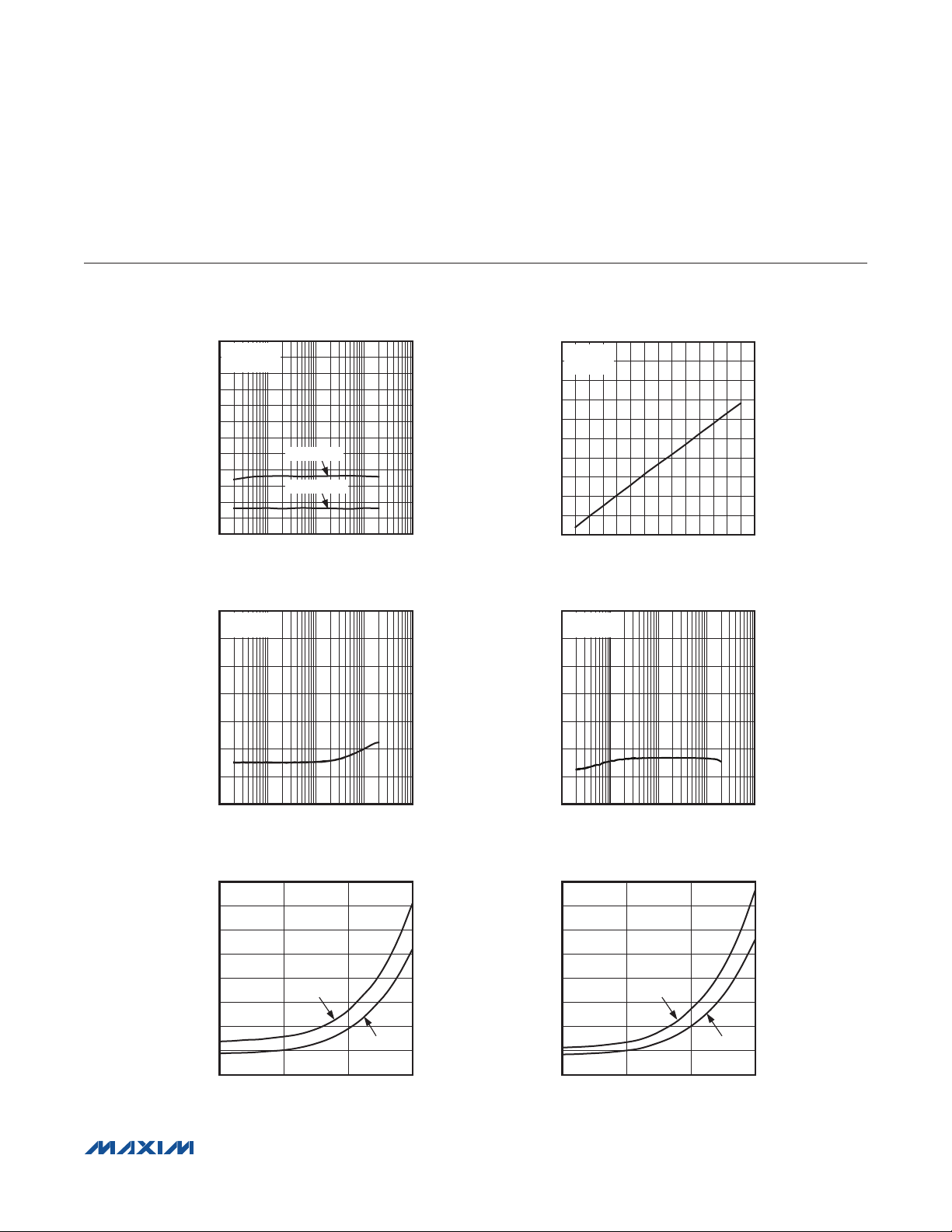

Typical Operating Characteristics

(VDD = 5V, AV = -6dB, R

0.1

0.01

THD+N (%)

0.001

0.0001

0.01 100

10

1

0.1

THD+N (%)

0.01

= 10kI, BW = 20Hz to 20kHz, T

L

THD+N vs. FREQUENCY

V

= 2V

IN_

RMS

MAX13336E

MAX13335E

1010.1

FREQUENCY (kHz)

THD+N vs. OUTPUT VOLTAGE

MAX13335E

= 5V

V

DD

= -18dB

A

V

f = 6kHz

= +25NC, unless otherwise noted.)

A

THD+N vs. OUTPUT VOLTAGE

10

MAX13336E

= 5V

V

DD

= -22dB

A

V

MAX13335E toc01

1

0.1

THD+N (%)

0.01

0.001

0.0001

0 0.5

THD+N vs. OUTPUT VOLTAGE

10

MAX13336E

= 5V

V

DD

AV = -6dB

MAX13335E toc03

1

0.1

THD+N (%)

0.01

OUTPUT VOLTAGE (V

f = 6kHz

f = 6kHz

f = 100Hz, 1kHz

0.40.30.20.1

)

RMS

MAX13335E toc02

MAX13335E toc04

0.001

f = 100Hz AND 1kHz

0.0001

0 0.5

OUTPUT VOLTAGE (V

THD+N vs. OUTPUT VOLTAGE

10

MAX13335E

1

0.1

THD+N (%)

0.01

0.001

0.0001

0 2.0

f = 6kHz

f = 100Hz

OUTPUT VOLTAGE (V

RMS

f = 1kHz

1.51.00.5

RMS

0.40.30.20.1

)

MAX13335E toc05

)

0.001

f = 100Hz AND 1kHz

0.0001

0 2.4

OUTPUT VOLTAGE (V

THD+N vs. OUTPUT VOLTAGE

10

MAX13336E

= 5V

V

DD

= 8dB

A

V

1

0.1

THD+N (%)

0.01

0.001

0.0001

0 2.4

OUTPUT VOLTAGE (V

f = 6kHz

f = 100Hz, 1kHz

RMS

RMS

2.01.61.20.80.4

)

MAX13335E toc06

2.01.61.20.80.4

)

����������������������������������������������������������������� Maxim Integrated Products 7

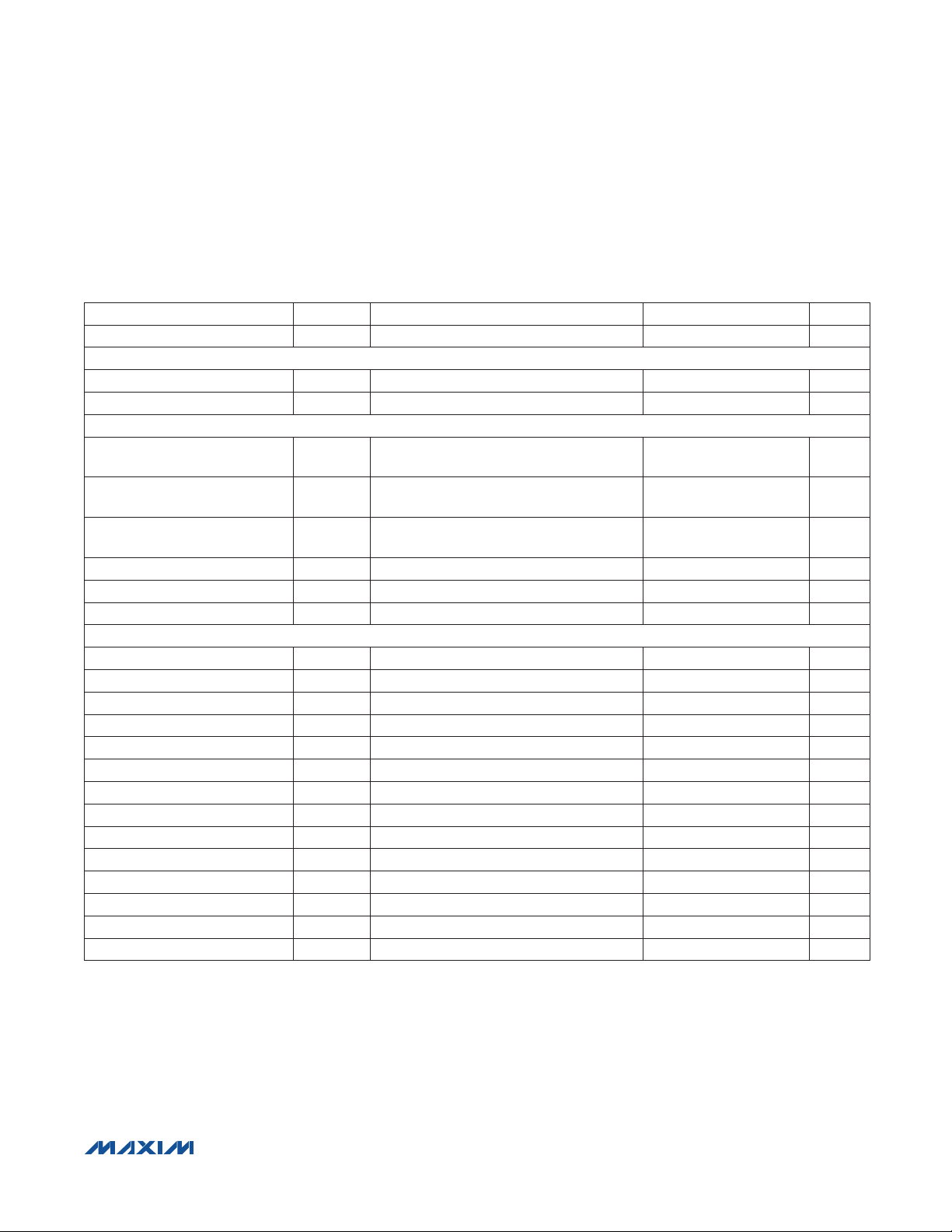

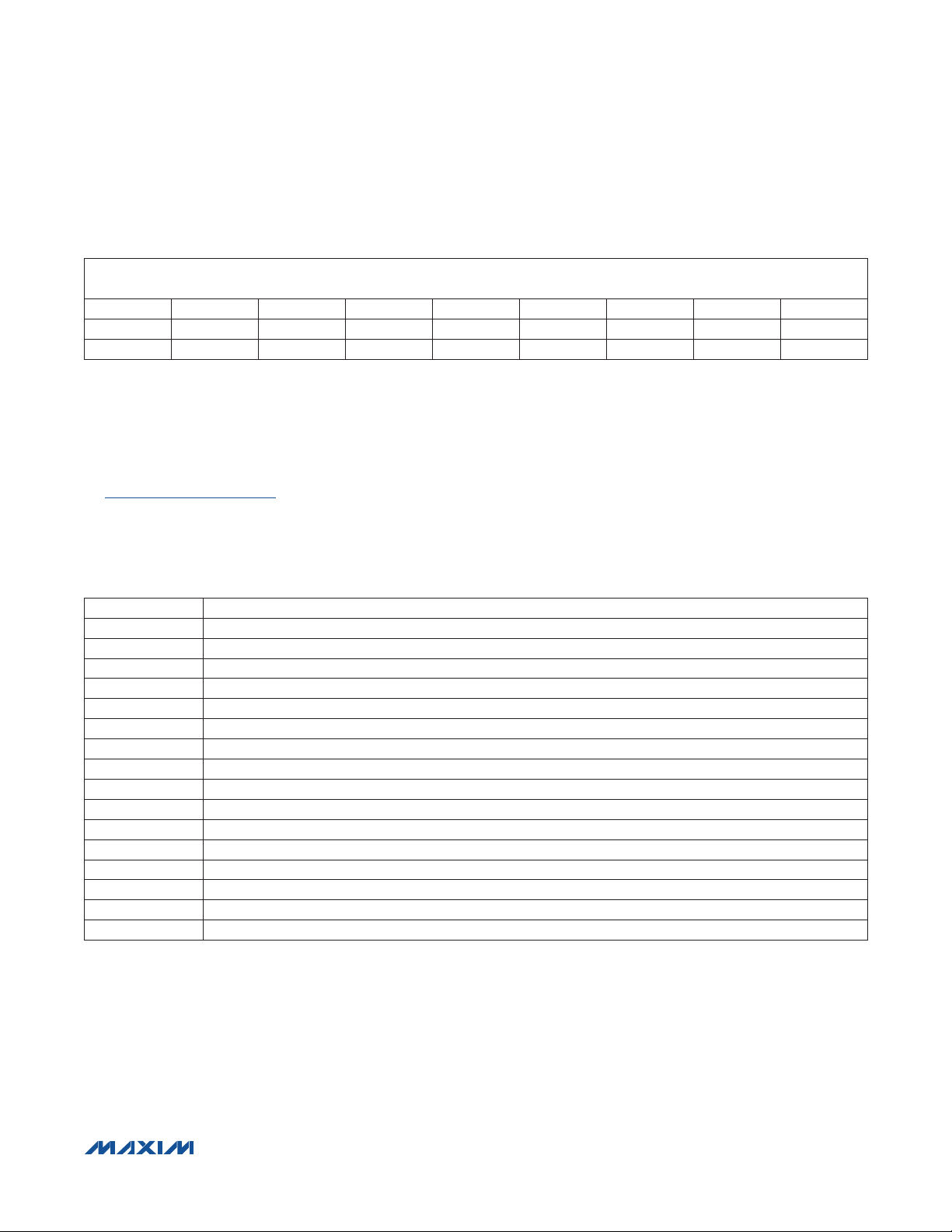

Page 8

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Typical Operating Characteristics (continued)

(VDD = 5V, AV = -6dB, R

0.1

THD+N (%)

0.01

0.001

0.0001

-80

-90

-100

-110

-120

CMRR (dB)

-130

-140

-150

= 10kI, BW = 20Hz to 20kHz, T

L

THD+N vs. OUTPUT VOLTAGE

10

MAX13335E

= 5V

V

DD

= +12dB

A

V

1

f = 6kHz

f = 100Hz AND 1kHz

RMS

1.51.00.5

)

0 2.0

OUTPUT VOLTAGE (V

CROSSTALK vs. FREQUENCY

V

= 2V

IN_

RMS

OUTR TO OUTL

OUTL TO OUTR

0.01 100

FREQUENCY (kHz)

1010.1

= +25NC, unless otherwise noted.)

A

POWER-SUPPLY REJECTION RATIO

vs. FREQUENCY

-60

V

= 200mV

RIPPLE

MAX13335E toc07

-70

-80

-90

PSRR (dB)

-100

-110

-120

0.01 100

GAIN MATCHING vs. FREQUENCY

-5.80

V

= 2V

IN_

-5.85

MAX13335E toc09

-5.90

-5.95

-6.00

-6.05

GAIN (dB)

-6.10

-6.15

-6.20

-6.25

-6.30

0.01 100

RMS

P-P

MAX13335E toc08

OUTR

OUTL

1010.1

FREQUENCY (kHz)

MAX13335E toc10

OUTR

OUTL

1010.1

FREQUENCY (kHz)

SUPPLY CURRENT vs. TEMPERATURE

12.0

11.8

11.6

11.4

11.2

11.0

10.80

SUPPLY CURRENT (mA)

10.60

10.40

10.20

-50 125

TEMPERATURE (°C)

VDD = 5V

VDD = 3.3V

MAX13335E toc11

1007525 500-25

SHUTDOWN CURRENT vs. TEMPERATURE

8

VDD = V

= V

SCL

7

6

5

4

3

SHUTDOWN CURRENT (µA)

2

1

0

-50 125

SDA

VDD = 5V

VDD = 3.3V

TEMPERATURE (°C)

MAX13335E toc12

10075-25 0 25 50

����������������������������������������������������������������� Maxim Integrated Products 8

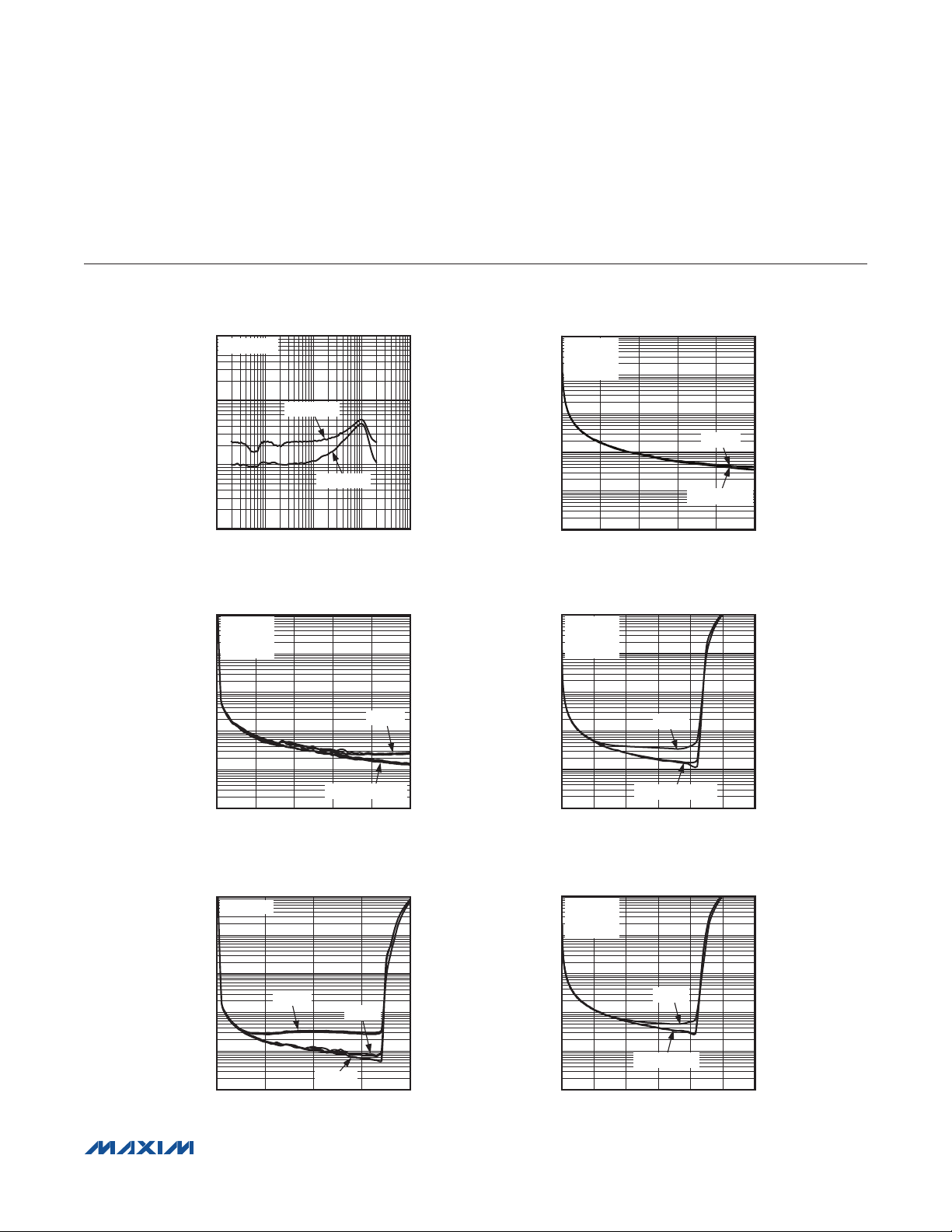

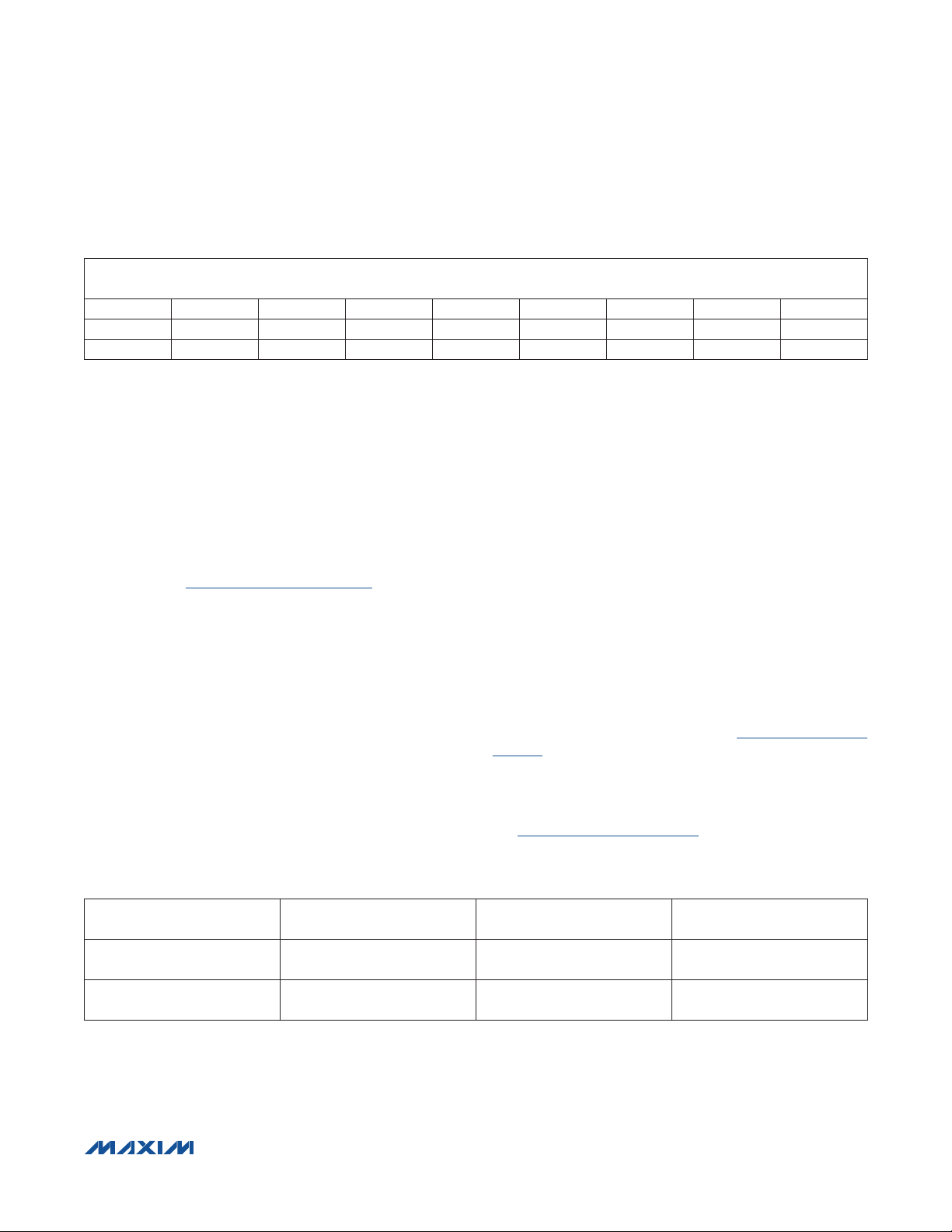

Page 9

MAX13335E/MAX13336E

01

01

01

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Typical Operating Characteristics (continued)

(VDD = 5V, AV = -6dB, R

0

-10

-20

-30

-40

-50

-60

CMRR (dB)

-70

-80

-90

-100

-110

-120

0.01 100

0

-20

-40

-60

-80

= 10kI, BW = 20Hz to 20kHz, T

L

COMMON-MODE REJECTION RATIO

vs. FREQUENCY

MAX13336E

= 2V

V

IN_

RMS

LEFT CHANNEL

RIGHT CHANNEL

1010.1

FREQUENCY (kHz)

MUTE ATTENUATION vs. FREQUENCY

V

= 2V

IN_

RMS

MUTE = 1

= +25NC, unless otherwise noted.)

A

DIAGNOSTIC CURRENT SOURCE vs. D_[3:0]

1000

VDD = 5V

900

= 1.5V

V

D_

(µA)

D_

I

800

700

600

500

400

300

200

100

0

MAX13335E toc13

SHUTDOWN ATTENUATION vs. FREQUENCY

0

V

= 2V

IN_

SHDN = 1

MAX13335E toc15

-20

-40

-60

-80

RMS

D_[3:0] (dec)

MAX13335E toc14

131210 113 4 5 6 7 8 91 2

4

MAX13335E toc16

-100

MUTE ATTENUATION (dB)

-120

-140

0.01 100

FREQUENCY (kHz)

1010.1

OUTPUT NOISE vs. GAIN SETTING

40

MAX13336E

35

)

30

RMS

25

20

15

OUTPUT NOISE (µV

10

5

0

NONWEIGHTED

G_[3:0] (dec)

A-WEIGHTED

105

5

����������������������������������������������������������������� Maxim Integrated Products 9

MAX13335E toc17

-100

SHUTDOWN ATTENUATION (dB)

-120

-140

0.01 100

FREQUENCY (kHz)

OUTPUT NOISE vs. GAIN SETTING

40

MAX13335E

35

)

30

RMS

25

20

15

OUTPUT NOISE (µV

10

5

0

NONWEIGHTED

A-WEIGHTED

105

G_[3:0] (dec)

1010.1

MAX13335E toc18

5

Page 10

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Pin Configuration

TOP VIEW

1

2

3

4

5

6

7

8

+

MAX13335E

MAX13336E

16

REF

15

V

DD

OUTL

14

GND

13

OUTR

12

INT

11

SDA

10

SCL

9

D0

D1

INL+

INL-

INR-

INR+

D2

D3

QSOP

PIN NAME FUNCTION

1 D0 Diagnostic I/O 0. I/O pin used for jack sense and diagnostics.

2 D1 Diagnostic I/O 1. I/O pin used for jack sense and diagnostics.

3 INL+ Noninverting Left-Channel Audio Input

4 INL- Inverting Left-Channel Audio Input

5 INR- Inverting Right-Channel Audio Input

6 INR+ Noninverting Right-Channel Audio Input

7 D2 Diagnostic I/O 2. I/O pin used for diagnostics.

8 D3 Diagnostic I/O 3. I/O pin used for diagnostics.

9 SCL I2C Serial-Clock Input

10 SDA I2C Serial-Data Input and Output

11

INT

Active-Low, Open-Drain Interrupt Request Output

12 OUTR Right-Channel Audio Output

13 GND Ground

14 OUTL Left-Channel Audio Output

15 V

DD

16 REF

Supply Input

VDD/2 Reference Output. Bypass REF to GND with a 2.2FF capacitor.

Pin Description

���������������������������������������������������������������� Maxim Integrated Products 10

Page 11

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Detailed Description

The MAX13335E/MAX13336E are designed to operate

with the MAX13325/MAX13326 dual automotive audio

line drivers to form a complete differential audio link

in automotive systems. In addition, the MAX13335E/

MAX13336E can operate as an auxiliary input audio

amplifier with jack sense function.

Signal Path

The devices can be configured to operate with quasi-differential (up to 3.5V

input signals. Both input channels feature high 80dB CMRR

(typ). An integrated programmable gain amplifier with zerocrossing detection controlled through the I2C interface provides adjustable gain from -14dB to +16dB (MAX13335E)

or -22dB to +8dB (MAX13336E) in +2dB increments. Zerocrossing detection can be enabled to limit the zip noise

during a gain transition by delaying the gain change until a

zero-crossing event occurs on the input signal.

The devices can monitor the inputs for the presence of

audio, clip detection, and change-of-state in the jack sense.

An active-low, open-drain interrupt request output can be

configured through the I2C interface to report the presence

of audio, clip detection, and change-of-state in the jack

sense. The internal status register also latches the status

change of those parameters until an I2C read is performed.

D_

R

D_

Figure 1. Diagnostic I/O Port

) and fully differential (up to 7V

RMS

Interrupt Output

40µA TO

705µA

V

IDH

V

IDL

DH_

DL_

I2C INTERFACE

RMS

)

Thermal Shutdown

Thermal shutdown protects the device when the junction

temperature exceeds +150NC (typ). The device resumes

operation when the junction temperature drops below the

thermal shutdown hysteresis of 15NC (typ). The internal

status register latches the status change of the TSD bit

until an I2C read is performed.

Diagnostics

The devices feature four similar diagnostic I/O ports.

When configured correctly, they are capable of performing jack sense detection, short-to-ground, short-tobattery, open-load, and shorts between channels. Each

diagnostic I/O port contains a programmable current

source, a voltage sense, and a diode to ground.

The principle behind the diagnosis is simply forcing a

current into the load attached to the I/O port and sensing

the voltage to check if it is greater or smaller than the

two predefined low/high thresholds. These can be easily

accessed by a microcontroller through the I2C interface.

The procedure usually starts with stepping up the current

source from the minimum to maximum range.

1) If the sensed voltage is consistently below the low

threshold, a short-to-ground event is determined.

2) However, if the sensed voltage is consistently above

the high threshold, there is a possibility of either a

short-to-battery or an open-load event. In order to differentiate between them, the I/O port should be tested

again with a voltage-sense-only configuration (i.e.,

with the current source switched off). If the sensed

voltage remains above the high threshold, a short-tobattery event has occurred. Otherwise, an open-load

event is detected.

3) In some current source range, if the sensed voltage

is between the high and low thresholds, this could

indicate that the load is present.

A valid readout of the status might require some amount

of delays (to be inserted by the microcontroller) due to

the settling time needed to charge/discharge any external capacitive load on the I/O port.

The diode is useful in the case of sensing an unconnected load or short between channels. Here, one end

of the load can be forced to ground by the diode and

the usual procedure described above can be applied to

detect various events. It is, however, advisable to test the

I/O port for a short-to-battery condition prior to turning on

the diode as it could risk damaging the device.

���������������������������������������������������������������� Maxim Integrated Products 11

Page 12

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

See the Applications Information section for various

examples on how the diagnostic can be set up to detect

different events.

Applications Information

Serial Interface

Writing to the device using I2C requires that first the master send a START condition (S) followed by the device’s

I2C address. After the address, the master sends the

address of the register that is to be programmed. The

master then ends communication by issuing a STOP condition (P) to relinquish control of the bus, or a repeated

START condition (Sr) to communicate to another I2C

slave (Figure 2).

Bit Transfer

Each SCL rising edge transfers one data bit. The data

on SDA must remain stable during the high portion of the

SCL clock pulse (Figure 3). Changes in SDA while SCL

SDA

t

t

F

t

LOW

SU:DAT

t

R

t

F

is high are read as control signals (see the START and

STOP Conditions section). When the serial interface is

inactive, SDA and SCL idle high.

START and STOP Conditions

A master device initiates communication by issuing a

START condition (S) which is a high-to-low transition on

SDA with SCL high. A START condition from the master

signals the beginning of a transmission to the device.

The master terminates transmission by a STOP condition (P) (see the Acknowledge Bit section). A STOP

condition is a low-to-high transition on SDA while SCL is

high (Figure 4). The STOP condition frees the bus. If a

repeated START condition (Sr) is generated instead of a

STOP condition, the bus remains active. When a STOP

condition or incorrect slave ID is detected, the device

internally disconnects SCL from the serial interface until

the next START or repeated START condition, minimizing digital noise and feedthrough.

t

t

HD:STA

t

SP

R

t

BUF

SCL

t

HD:STA

t

HD:DAT

t

HIGH

t

SU:STA

t

SU:STO

Figure 2. I2C Timing

START

SDA

SCL

DATA LINE

STABLE;

DATA VALID

CHANGE OF

DATA ALLOWED

CONDITION

SDA

SCL

Figure 3. Bit Transfer Figure 4. START/STOP Conditions

���������������������������������������������������������������� Maxim Integrated Products 12

SPSrS

STOP

CONDITION

Page 13

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Acknowledge Bit

The acknowledge bit (ACK) is a clocked 9th bit that the

device uses to handshake the receipt of each byte of

data when in write mode. The device pulls down SDA

during the entire master-generated 9th clock pulse if

the previous byte is successfully received (Figure 5).

Monitoring ACK allows for detection of unsuccessful

data transfers. An unsuccessful data transfer occurs

if a receiving device is busy or if a system fault has

occurred. In the event of an unsuccessful data transfer,

the bus master could retry communication. The master must pull down SDA during the 9th clock cycle to

acknowledge receipt of data when the device is in read

mode. An acknowledge must be sent by the master

after each read byte to allow data transfer to continue.

S

SDA

SCL

18

A not-acknowledge is sent when the master reads the

final byte of data from the device, followed by a STOP

condition.

Slave Address

The device is programmable to one of the four I2C slave

addresses (Table 2). The power-on default I2C slave address

of the device for read/write is 0xD0/0xD1 (1101000R/W). The

I2C slave address of the device can be selected by writing

to Control Register 1 (0x03) while INT is pulled low externally

during the I2C write duration (Figure 6).

Single Byte-Write Operation

For a single byte-write operation, send the slave address

as the first byte followed by the register address and then

a single data byte (Figure 7).

NOT ACKNOWLEDGE

ACKNOWLEDGE

9

Figure 5. Acknowledge and Not-Acknowledge Bits

CONTROL REGISTER 1 (0x03) PROGRAM I

SDA 11 11100 00000

SCL

INT

Figure 6. I2C Slave Address Programming

S S7 S6 S5 S4 S3 S2 S1 ACK

SLAVE ADDRESS

B7 B6 B5 B4 B3 B2 B1 B0 ACK P

DATA 1

Figure 7. A Single Byte-Write Operation

���������������������������������������������������������������� Maxim Integrated Products 13

R/W

= 0

2

C ADDRESSCURRENT I2C ADDRESS

00000000 ACK ACK ACKI2C1 I2C1I2C0 I2C0

C7 C6 C5 C4 C3 C2 C1 C0 ACK

REGISTER ADDRESS

Page 14

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Burst-Write Operation

For a burst-write operation, send the slave address as

the first byte followed by the register address and then

the data bytes (Figure 8).

Single Byte-Read Operation

For a single byte-read operation, send the slave address

with read bit set as the first byte followed by the register

address. Then send a repeated START condition followed by the slave address. After the slave sends the

S S7 S6 S5 S4 S3 S2 S1 ACK

SLAVE ADDRESS

B7 B6 B5 B4 B3 B2 B1 B0 ACK B7 B6 B5 B4 B3 B2 B1 B0 ACK

DATA 1

Figure 8. A Burst-Write Operation

R/W

= 0

ACK B7 B6 B5 B4 B3 B2 B1 B0 ACK P

data byte, send a not-acknowledge followed by a STOP

condition (Figure 9).

Burst-Read Operation

For a burst-read operation, send the slave address with

a write as the first byte followed by the register address.

Then send a repeated START condition followed by the

slave address. The slave sends data bytes until a notacknowledge condition is sent (Figure 10).

R7 R6 R5 R4 R3 R2 R1 R0 ACK

REGISTER ADDRESS

DATA 2

DATA N

S S7 S6 S5 S4 S3 S2 S1 ACK B7 B6 B5 B4 B3 B2 B1 B0 ACK

SLAVE ADDRESS REGISTER ADDRESS

Sr

S7 S6 S5 S4 S3 S2 S1 ACK B7 B6 B5 B4 B3 B2 B1 B0 NACK P

SLAVE ADDRESS DATA

NOTE: SHADED ITEM IS FROM THE MASTER.

Figure 9. A Single Byte-Read Operation

S S7 S6 S5 S4 S3 S2 S1 ACK B7 B6 B5 B4 B3 B2 B1 B0 ACK

SLAVE ADDRESS REGISTER ADDRESS

Sr S7 S6 S5 S4 S3 S2 S1 ACK B7 B6 B5 B4 B3 B2 B1 B0 ACK

SLAVE ADDRESS DATA 1

NOTE: SHADED ITEMS ARE FROM THE MASTER.

Figure 10. A Burst-Read Operation

���������������������������������������������������������������� Maxim Integrated Products 14

R/W

= 0

R/W

= 1

R/W

= 0

R/W

= 1

ACK B7 B6 B5 B4 B3 B2 B1 B0 NACK P

DATA N

Page 15

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Register Map

NAME REG BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0 R/W POR SETTINGS

STAT0 00 DH3 DL3 DH2 DL2 DH1 DL1 DH0 DL0 R 0x00

STAT1 01 APD CLD JSD TSD — ID2 ID1 ID0 R 0x00

CTRL0 02 API CLI JSI — — ZEN MUTE SHDN

CTRL1 03 — — — — — — I2C1 I2C0

DIAG0 04 D1[3] D1[2] D1[1] D1[0] D0[3] D0[2] D0[1] D0[0]

DIAG1 05 D3[3] D3[2] D3[1] D3[0] D2[3] D2[2] D2[1] D2[0]

GAIN 06 GL3 GL2 GL1 GL0 GR3 GR2 GR1 GR0

R/W

R/W

R/W

R/W

R/W

Status Register 0 (STAT0)

ADDRESS: 0x00

MODE: R

BIT 7 6 5 4 3 2 1 0

NAME

POR

DH3 DL3 DH2 DL2 DH1 DL1 DH0 DL0

0 0 0 0 0 0 0 0

0x00

0x00

0x00

0x00

0x00

The bits in Status Register 0 are updated to reflect the states of the upper (DH_) and lower (DL_) comparator’s threshold

when voltage sensing is enabled for the corresponding diagnostic I/O. Combinations of DH_ and DL_ can be used to

decode the fault on the I/O port.

Bits 7, 5, 3, 1: DH� (Diagnostic Upper Comparator Threshold V

IDH

)

0 = Below upper threshold

1 = Above upper threshold

Bits 6, 4, 2, 0: DL� (Diagnostic Lower Comparator Threshold V

IDL

)

0 = Below lower threshold

1 = Above lower threshold

Table 1. Interpretation of Diagnostic Status Bits

DH� DL� CONDITION

0 0 Short-to-ground (or disabled)

0 1 No fault

1 0 Invalid (not used)

1 1 Short-to-battery if current source is disabled (i.e., D_[3:0] = 1110)

1 1 Open-load if current source is enabled (i.e., D_[3:0] = 0001 to 1101)

���������������������������������������������������������������� Maxim Integrated Products 15

Page 16

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Status Register 1 (STAT1)

ADDRESS: 0x01

MODE: R

BIT 7 6 5 4 3 2 1 0

NAME

POR

Bit 7: APD (Audio Presence Status Bit)

0 = Audio not present.

1 = Audio presence detected. INT asserts low.

Bit 6: CLD (Clip Detection Status Bit)

0 = No clipping detected.

1 = Clip warning. INT asserts low.

Bit 5: JSD (Jack Sense Status Bit)

0 = Jack removed. INT asserts low.

1 = Jack inserted. INT asserts low.

Note: INT asserts low whenever jack sense changes state.

Bit 4: TSD (Thermal Shutdown Status Bit)

0 = Within safe operating range.

1 = Overheating detected. INT pin asserts low.

Bit 3: No Function

Bit 2 to 0: ID� (Die ID)

001 = MAX13335E

010 = MAX13336E

Note: Reading of Status Register 1 (REG = 0x01) releases INT and resets bits APD, CLD, JSD, and TSD back to zero.

APD CLD JSD TSD — ID2 ID1 ID0

0 0 0 0 0 — — —

���������������������������������������������������������������� Maxim Integrated Products 16

Page 17

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Control Register 0 (CTRL0)

ADDRESS: 0x02

MODE: R/W

BIT 7 6 5 4 3 2 1 0

NAME

POR

Bit 7: API (Audio Presence Interrupt Enable Bit)

0 = Disable

1 = Enable*

*Bit automatically resets to 0 when an audio presence interrupt occurs.

Bit 6: CLI (Clip Warning Interrupt Enable Bit)

0 = Disable

1 = Enable*

*Bit automatically resets to 0 when a clip warning interrupt occurs.

Bit 5: JSI (Jack Sense Interrupt Enable Bit)

The JSI bit can be set only after D1[3:0] and D0[3:0] in Diagnostic register 0 (DIAG0) has been programmed.

0 = Disable

1 = Enable*

*Bit automatically resets to 0 when a jack sense interrupt occurs.

Bits 4 and 3: No Function (0 should be written during write access.)

Bit 2: ZEN (Zero-Crossing Enable Bit)

Enabling zero-crossing detection loads the new PGA gain settings at the signal zero crossing to avoid zip noise.

0 = Disable

1 = Enable

Bit 1: MUTE (Mute Enable Bite)

0 = Play mode

1 = Mute mode

Bit 0 : SHDN (Shutdown Enable Bit)

0 = Normal mode

1 = Shutdown mode

API CLI JSI — — ZEN MUTE SHDN

0 0 0 0 0 0 0 0

���������������������������������������������������������������� Maxim Integrated Products 17

Page 18

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Control Register 1 (CTRL1)

ADDRESS: 0x03

MODE: R/W

BIT 7 6 5 4 3 2 1 0

NAME

POR

Bits 7 to 2: No Function (0 should be written during write access.)

Bits 1 and 0: I2C�

The I2C1 and I2C0 bits determine the I2C slave address of the device. The I2C slave address is changed by writing to

CTRL1 while INT is pulled low (e.g., by an external microcontroller) for the duration of the I2C write cycle.

Table 2. I2C Address

— — — — — — I2C1 I2C0

0 0 0 0 0 0 0 0

A7 A6 A5 A4 A3 A2 (I2C1) A1 (I2C0)

1 1 0 1 0 0 0 — 0xD1 0xD0

1 1 0 1 0 0 1 — 0xD3 0xD2

1 1 0 1 0 1 0 — 0xD5 0xD4

1 1 0 1 0 1 1 — 0xD7 0xD6

A0 (R/W)

READ WRITE

Diagnostic Register 0 (DIAG0)

ADDRESS: 0x04

MODE: R/W

BIT 7 6 5 4 3 2 1 0

NAME

POR

D1[3] D1[2] D1[1] D1[0] D0[3] D0[2] D0[1] D0[0]

0 0 0 0 0 0 0 0

���������������������������������������������������������������� Maxim Integrated Products 18

Page 19

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Diagnostic Register 1 (DIAG1)

ADDRESS: 0x05

MODE: R/W

BIT 7 6 5 4 3 2 1 0

NAME

POR

The Diagnostic registers, DIAG0 and DIAG1, program the state of the four diagnostic I/O ports D_. The diagnostic ports

can be programmed to operate in one of the four states:

1) Setting D_[3:0] = 0000 disables the corresponding diagnostic I/O.

2) Setting D_[3:0] = 0001 to 1101 enables the internal current source (40FA to 705FA) and voltage sensing. The voltage sensing utilizes a window comparator with an upper threshold of 1.94V and a lower threshold of 0.92V (see the

Diagnostic Configurations section).

3) Setting D_[3:0] = 1110 enables voltage sensing only.

4) Setting D_[3:0] = 1111 enables the internal diode to ground.

Table 3. Diagnostic I/O Port States

D3[3] D3[2] D3[1] D3[0] D2[3] D2[2] D2[1] D2[0]

0 0 0 0 0 0 0 0

D�[3:0] FUNCTION

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

Diagnostic output disabled.

Enables the 40FA current source and voltage sense.

Enables the 97FA current source and voltage sense.

Enables the 154FA current source and voltage sense.

Enables the 210FA current source and voltage sense.

Enables the 265FA current source and voltage sense.

Enables the 320FA current source and voltage sense.

Enables the 375FA current source and voltage sense.

Enables the 430FA current source and voltage sense.

Enables the 485FA current source and voltage sense.

Enables the 540FA current source and voltage sense.

Enables the 595FA current source and voltage sense.

Enables the 650FA current source and voltage sense.

Enables the 705FA current source and voltage sense.

Enable voltage sense. The current source is disabled.

Enables the diode. The current source and voltage sense are disabled.

���������������������������������������������������������������� Maxim Integrated Products 19

Page 20

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Gain Register (GAIN)

ADDRESS: 0x06

MODE: R/W

BIT 7 6 5 4 3 2 1 0

NAME

POR

Bits 7 to 0: G�

The Gain register sets the gain of the internal programmable gain amplifier (AV) for the left (GL[3:0]) and right (GR[3:0])

channels. The gain of the programmable gain amplifier (AV) is determined by the following transfer function:

GL3 GL2 GL1 GL0 GR3 GR2 GR1 GR0

0 0 0 0 0 0 0 0

Gain(AV) = -14dB + (G_[3:0] x 2)dB (for MAX13335E)

Gain(AV) = -22dB + (G_[3:0] x 2)dB (for MAX13336E)

Diagnostic Configurations

The device’s diagnostics can be configured for local jack

sense, remote jack sense, and differential drive connections (see the Typical Application Circuits). Diagnostic

registers DIAG0 and DIAG1 configure the diagnostic I/O

ports D_ as a current-source output with voltage sensing

enabled, a voltage sensing input, or a diode to GND.

When voltage sensing is enabled, the current states of

the internal window comparator are updated to status

register STAT0. A valid readout of the STAT0 register

might require some amount of delays (to be inserted by

the microcontroller) between configuring the diagnostic

and reading the status register due to the settling time

needed to charge/discharge the external capacitive load

on the D_ pins.

Local Jack Sense

The device is configured for jack sense function when the

jack is localized to the same module. In this application

example, the diagnostic I/O D1 is configured as a 97FA

current-source output and D0 is configured for voltage

sensing. When a plug is not inserted, the internal spring

contact of the jack shorts D1 to D0. The 97FA current

source from D1 pulls D0 to VDD resulting in DH0 = 1.

When a plug is inserted, the internal spring contact of

the jack is forced open and disconnects D1 from D0. This

results in D0 going low and hence DH0 = 0.

Remote Jack Sense Detection

When the jack is remotely located, the device can be

used for additional fault detection of the wiring harness

used for the connection. See the Typical Application

Circuits.

For fully differential applications, the device can be configured to detect faults in the wiring harness as shown in

the Typical Application Circuits.

Table 4. Local Jack Sense Diagnostic Configuration

CONFIGURATION FUNCTION COMPARATOR OUTPUT STATUS

D1[3:0] = 0010

D0[3:0] = 1110

D1[3:0] = 0010

D0[3:0] = 1110

Source 97FA

Source off

Source 97FA

Source off

DH0 = H Device not plugged in

DH0 = L Device plugged in

Differential Connection

���������������������������������������������������������������� Maxim Integrated Products 20

Page 21

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

MAX13335E/MAX13336E

D1[3:0] ≥ 0010

97µA

D1

V

IDH

L

V

IDL

R

C

D0[3:0] = 1110

40µA TO

D0

705µA

Figure 11. Diagnostic Setup for Local Jack Sense

Audio Presence Detection

When the device is used in an auxiliary input amplifier, it can detect if audio is present at the inputs so the

downstream DSP does not have to continuously convert

the analog signal to digital in order to monitor the audio

stream. This can save two ADC inputs as the auxiliary

input can be muxed with another audio stream that is

mutually exclusive. To do this, perform the following steps:

V

IDH

DH0

DL0

V

IDL

1) Set the gain in the GAIN register based on the

required input audio level where the APD threshold is

exceeded. The threshold is set to 200mV

RMS

/G_[3:0].

2) Set API bit in the CTRL0 register to enable the APD

interrupt.

When the input audio level exceeds 200mV

RMS

/G_[3:0]

the INT pin is asserted. The microcontroller can read

back the STAT0 register to check for APD = 1.

���������������������������������������������������������������� Maxim Integrated Products 21

Page 22

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

MAX13335E/MAX13336E

D1[3:0] = 0000

40µA TO

705µA

40µA TO

705µA

D3[3:0] = 1101

705µA

1kΩ-10kΩ

1kΩ-10kΩ

CONNECTOR

0-10kΩ

D1

V

IDH

L

V

IDL

R

D3

C

D2[3:0] = 1111

D2

Figure 12. Diagnostic Setup for Remote Jack Sense

Low-Power Standby

with Jack Sense

When the device is used as an auxiliary amplifier, there

is the option to put the device into a low-power standby

mode while waiting for a plug to be inserted into the jack.

To do this, perform the following steps:

1) Connect D0 to the R (or L) of the jack.

2) Connect R

resistor to ground.

SENSE

(or L

) of the jack with a 50I

SENSE

V

IDH

V

IDL

V

IDH

V

IDL

3) Set the SHDN bit to 1 in the CTRL0 register to power

down the amplifier.

4) Set D0[3:0] = 0001 to source 40FA out of the D0 pin.

5) Enable the JSI bit in the CTRL0 register.

When a plug is inserted, the DH0 comparator trips and subsequently asserts the interrupt INT pin. The microcontroller

can read back the STAT0 register to check for DH0 = 1

and follow up by setting SHDN to 0.

In the standby state, the typical current consumption is

reduced to 290FA.

DH3

DL2

���������������������������������������������������������������� Maxim Integrated Products 22

Page 23

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

ESD Guide

For maximum protection against IEC 61000-4-2 and ISO

10605 ESD pulses, a 1kI or larger resistor is recommended on every diagnostic D_ pin before the input

AC-coupling capacitor. Additionally, a suitable ESD

diode must be connected from the DC-blocking ceramic

capacitor to ground. The ESD diode can be connected

1nF

1nF

1nF

1nF

1kΩ

2.2µF

1kΩ

2.2µF

1kΩ

2.2µF

on either side of the DC-blocking capacitor; however,

depending on application requirements, the IC side

may allow for a lower clamping voltage, which results

in a smaller ESD device. If the input source is always

DC biased to V

/2, then a unidirectional ESD device

BAT

can be used when clamping on the input side of the

DC-blocking capacitor. See Figure 13.

MAX13335E/MAX13336E

D3

20Ω

20Ω

20Ω

20Ω

INL-

INL+

INR+

INR-

D2

D1

D0

DIAGNOSTICS

PGA

PGA

I2C

AND

CONTROL

1kΩ

2.2µF

Figure 13. ESD Protection Technique Against IEC 61000-4-2 and ISO 10605 Pulses

���������������������������������������������������������������� Maxim Integrated Products 23

Page 24

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

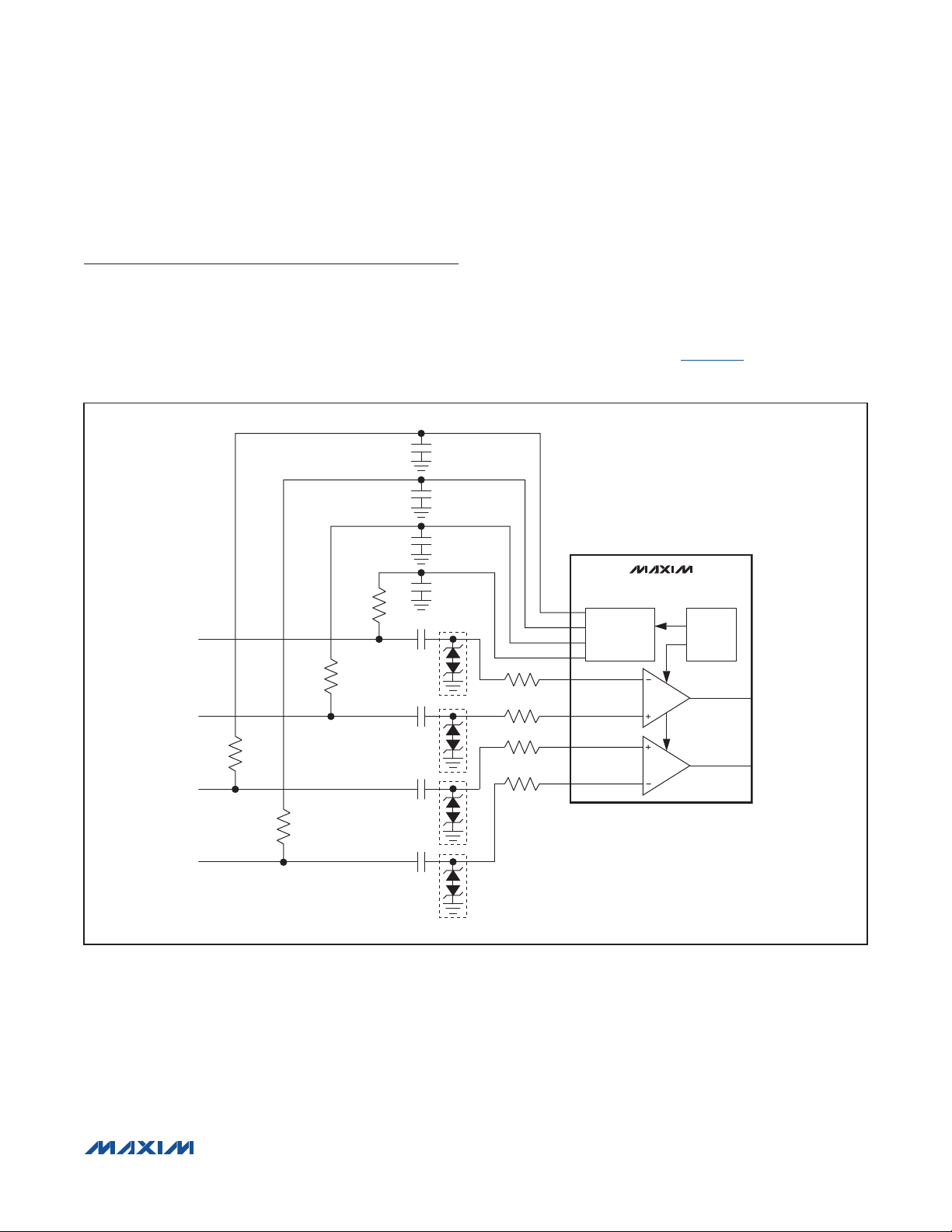

Typical Application Circuits (continued)

LOCAL JACK SENSE CONNECTION

L

R

C

2.2µF

2.2µF

2.2µF

2.2µF

INL-

INL+

INR+

INR-

D3

D2

D1

D0

ESD PROTECTION

ESD PROTECTION

3.3V OR 5V

1µF

V

DD

40µA TO

705µA

V

IDH

V

IDL

X4

MAX13335E/MAX13336E

D_[3:0]

DH_

DL_

PGA

PGA

2

C

I

AND

CONTROL

AUDIO

PRESENCE

DETECT

2kΩ 2kΩ 2kΩ

SDA

SCL

INT

OUTL

OUTR

EXTERNAL ESD PROTECTION COMPONENTS ARE NOT SHOWN.

���������������������������������������������������������������� Maxim Integrated Products 24

REFGND

10µF

Page 25

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

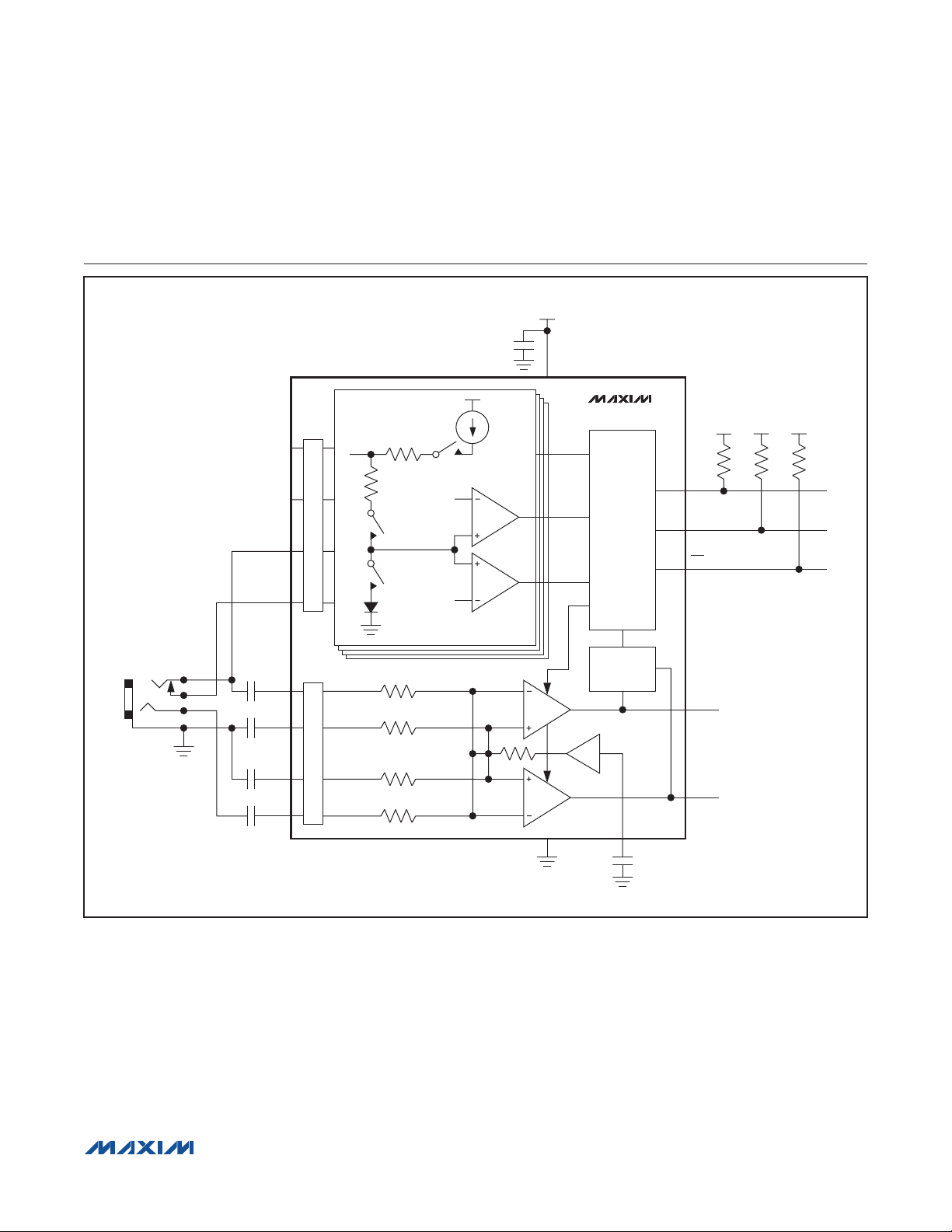

Typical Application Circuits (continued)

REMOTE JACK SENSE CONNECTION

L

CONNECTOR

R

C

2.2µF

2.2µF

2.2µF

2.2µF

INL-

INL+

INR+

INR-

D3

D2

D1

D0

ESD PROTECTION

ESD PROTECTION

3.3V OR 5V

1µF

V

DD

40µA TO

705µA

V

IDH

V

IDL

X4

MAX13335E/MAX13336E

D_[3:0]

DH_

DL_

PGA

PGA

2

C

I

AND

CONTROL

AUDIO

PRESENCE

DETECT

2kΩ 2kΩ 2kΩ

SDA

SCL

INT

OUTL

OUTR

EXTERNAL ESD PROTECTION COMPONENTS ARE NOT SHOWN.

���������������������������������������������������������������� Maxim Integrated Products 25

REFGND

10µF

Page 26

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

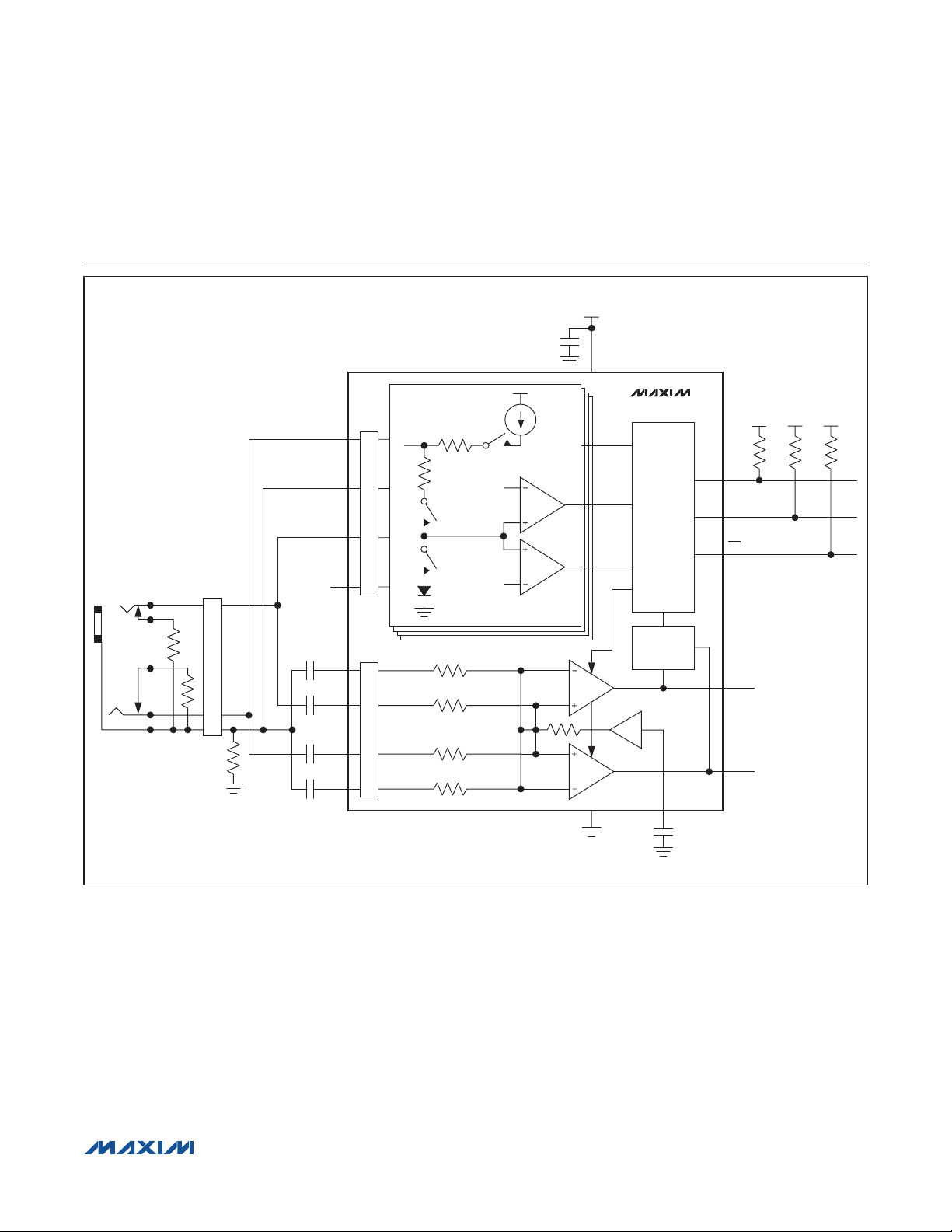

Typical Application Circuits (continued)

DIFFERENTIAL CONNECTION

2.2µF

L-

2.2µF

L+

2.2µF

R+

2.2µF

R-

INL-

INL+

INR+

INR-

D3

D2

D1

D0

ESD PROTECTION

ESD PROTECTION

3.3V OR 5V

1µF

V

DD

40µA TO

705µA

V

IDH

V

IDL

X4

MAX13335E/MAX13336E

D_[3:0]

DH_

DL_

PGA

PGA

2

C

I

AND

CONTROL

AUDIO

PRESENCE

DETECT

2kΩ 2kΩ 2kΩ

SDA

SCL

INT

OUTL

OUTR

EXTERNAL ESD PROTECTION COMPONENTS ARE NOT SHOWN.

���������������������������������������������������������������� Maxim Integrated Products 26

REFGND

10µF

Page 27

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

PART TEMP RANGE GAIN RANGE (dB) OPTIONS PIN-PACKAGE

MAX13335EGEE/V+

MAX13336EGEE/V+

/V denotes an automotive qualified part.

+Denotes a lead(Pb)-free/RoHS-compliant package.

-40NC to +105NC

-40NC to +105NC

MAX13335E/MAX13336E

-14 to +16

-22 to +8

Ordering Information

Differential VIN up to

4V

;

quasi-differential VIN

Differential VIN up to

quasi-differential VIN

RMS

up to 2V

7V

RMS

up to 3.5V

RMS

;

RMS

16 QSOP

16 QSOP

PROCESS: BCD

Chip Information

Package Information

For the latest package outline information and land patterns

(footprints), go to www.maxim-ic.com/packages. Note that a

“+”, “#”, or “-” in the package code indicates RoHS status only.

Package drawings may show a different suffix character, but

the drawing pertains to the package regardless of RoHS status.

PACKAGE

TYPE

16 QSOP E16+1

PACKAGE

CODE

OUTLINE

NO.

21-0055 90-0167

LAND

PATTERN NO.

���������������������������������������������������������������� Maxim Integrated Products 27

Page 28

MAX13335E/MAX13336E

Dual Automotive Differential Audio Receivers

with I2C Control and Diagnostics

Revision History

REVISION

NUMBER

0 1/12 Initial release —

REVISION

DATE

DESCRIPTION

PAGES

CHANGED

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time. The parametric values (min and max limits) shown in the Electrical

Characteristics table are guaranteed. Other parametric values quoted in this data sheet are provided for guidance.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 28

©

2012 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...