Page 1

19-5955; Rev 0; 6/11

EVALUATION KIT

AVAILABLE

4-Channel, Automotive Class D Audio Amplifier

General Description

The MAX13301 combines four high-efficiency Class D

amplifiers with integrated diagnostic hardware for reliable automotive audio systems, and delivers up to 80W

at 10% THD+N per channel into 4I when operating from

a 24V supply.

The internal diagnostics evaluate each channel’s output

impedance to check for shorts across the outputs, to the

battery, or to ground. The I2C interface allows the system to query critical device parameters such as device

temperature and output clipping. The device is programmable to four different I2C addresses.

The audio amplifiers feature single-ended analog inputs

with a common negative input. The MAX13301 has a

fixed gain of 26dB.

The Class D amplifier has 10 programmable switching

frequencies between 300kHz and 750kHz.

The BTL outputs are protected against short circuits and

thermal overload. The outputs can be configured as a

2-, 3-, or 4-channel amplifier. The device provides 50V

load-dump protection, and is offered in the thermally

enhanced, 48-pin TSSOP-EPR package operating over

the -40NC to +125NC temperature range.

Applications

Car Stereo

Rear-Seat Entertainment Units

Discrete Amplifier Modules

Active Loudspeaker Systems

Radio Head Units

Mobile Surround Systems

Features

S High Output Power (10% THD+N)

2 x 160W into 2I at 24V

4 x 80W into 4I at 24V

S 2 Channels Can Be Paralleled

S Feedback After the Filter

Improves THD+N

Low Output Impedance

High-Frequency Response

Improved Damping of Complex Loads

Enables Low-Cost Inductors

S 102dB SNR

S Low 0.04% THD+N

S 70dB PSRR

S On-Board Diagnostics

Short-to-Battery/GND

Open/Shorted Load

Tweeter Detect

S Protection and Monitoring Functions:

Short-Circuit Protection

50V Load-Dump Protection

Programmable Clip Detection

DC Offset Detection

Open Battery/GND Tolerant

Thermal-Overload Protection

Thermal Warning Indication

S Four-Address I2C Control Interface

S Low-Power Shutdown Mode

S Up to 90.5% Efficiency

S -40°C to +125°C Ambient Operating Temperature

S 48-Pin TSSOP-EPR (Top Side Exposed Pad) Package

S AEC-Q100 Qualified

MAX13301

Ordering Information

PART PIN-PACKAGE

Typical Operating Circuit appears at end of data sheet.

MAX13301AUM/V+ 48 TSSOP-EPR* 6 to 25.5

Note: The device operates over the -40°C to +125°C operating

temperature range.

/V denotes an automotive qualified part.

+Denotes a lead(Pb)-free/RoHS-compliant package.

*EPR = Top side exposed pad.

_______________________________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

SUPPLY VOLTAGE

RANGE (V)

Page 2

4-Channel, Automotive Class D Audio Amplifier

ABSOLUTE MAXIMUM RATINGS

PVDD to PGND ......................................................-0.3V to +30V

PVDD to PGND (t < 200ms) ..................................-0.3V to +50V

PVDD Ramp Rate ........................................................... 25V/ms

V

, CM to PGND ................................................. -0.3V to +6V

DD5

CP to PGND ........................(V

CHOLD to PVDD .....................................................-0.3V to +6V

OUT_ to PGND, FB_ to PGND ..............-0.3V to (V

VDD to GND ............................................................-0.3V to +6V

REF to GND ............................................................. -0.3V to +6V

MAX13301

SCL, SDA, SYNC to GND ........................................-0.3V to +6V

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

- 0.3V) to (V

PVDD

CHOLD

PVDD

+ 0.3V)

+ 0.3V)

PACKAGE THERMAL CHARACTERISTICS (Notes 1 and 2)

TSSOP

Junction-to-Ambient Thermal Resistance (BJA) ..........60NC/W

Junction-to-Case Thermal Resistance (BJC) .................1NC/W

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial.

Note 2: The 48-pin TSSOP-EPR package has a top side exposed pad for enhanced thermal management. Connect this exposed

pad to an external heatsink to ensure the device is adequately cooled. The maximum power dissipation in the device is a

function of this external heatsink and other system parameters. See the Thermal Information section for more information.

MUTE_CL1, CL0, FLT_OT, EN to GND ...................-0.3V to +6V

IN_ to GND ..............................................................-0.3V to +6V

GND to PGND ......................................................-0.3V to +0.3V

Continuous Power Dissipation (Notes 1 and 2)

TSSOP (derate 16.7mW/NC above 70NC) ...............1333.3mW

Operating Temperature Range ........................ -40NC to +125NC

Junction Temperature Range ........................... -40NC to +150NC

Storage Temperature Range ............................ -65NC to +150NC

Lead Temperature (soldering, 10s) ................................+300NC

Soldering Temperature (reflow) ......................................+240NC

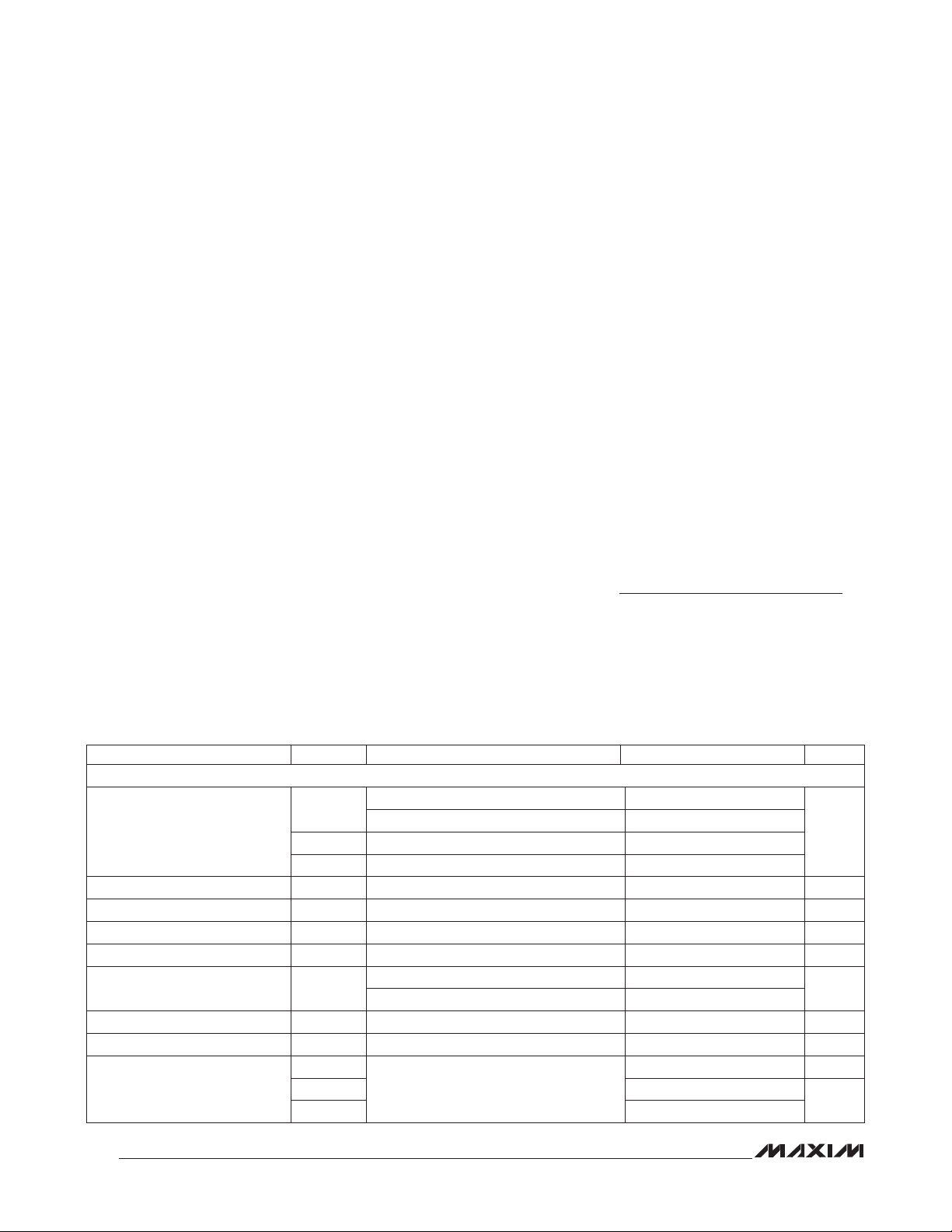

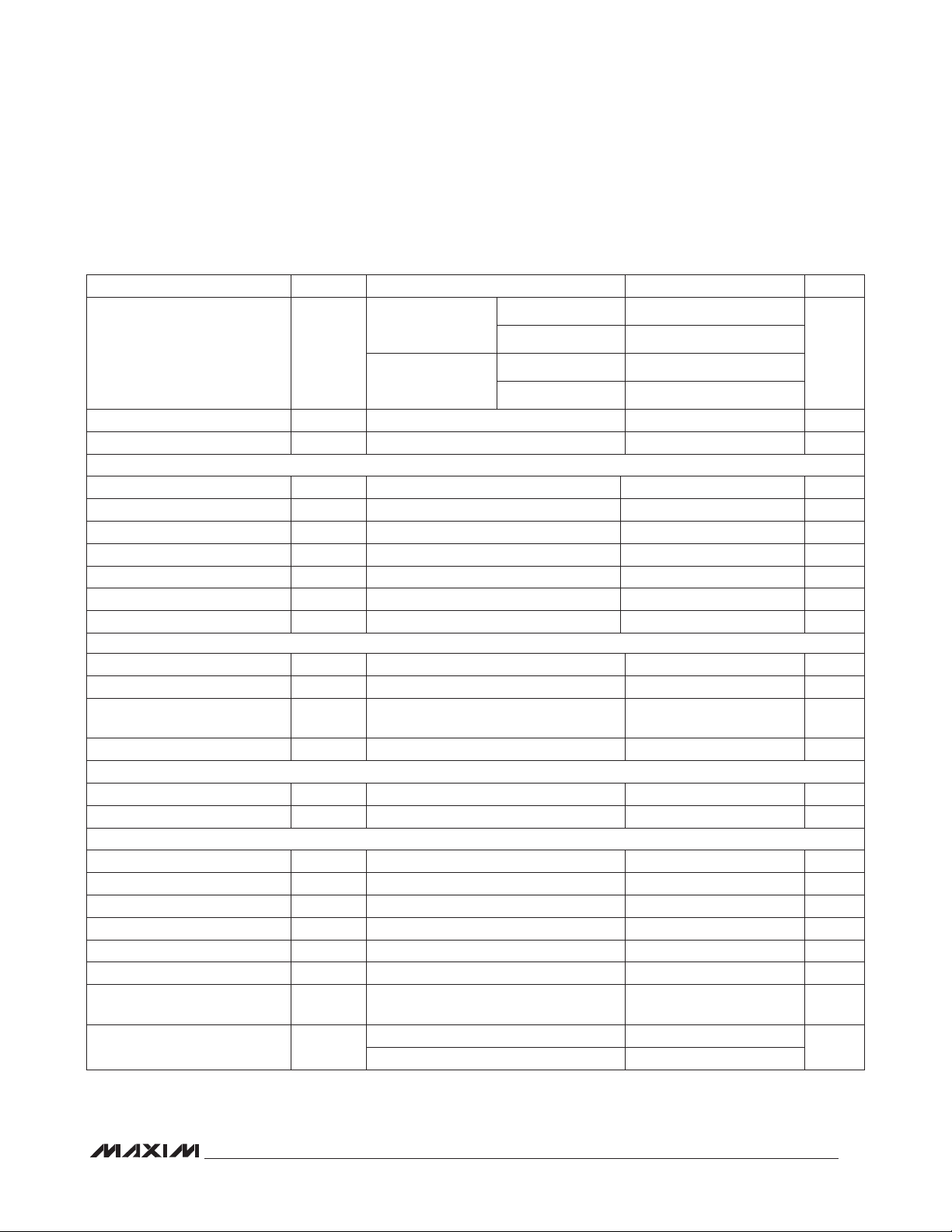

ELECTRICAL CHARACTERISTICS

(V

= 14.4V, VDD = V

PVDD

TA = -40NC to +125NC; typical values are at TA = +25NC, unless otherwise noted.) (Note 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

AMPLIFIER DC CHARACTERISTICS

Supply Voltage Range

PVDD UVLO Threshold Falling 5.2 5.35 5.6 V

PVDD OVLO Threshold Rising 26 27 30 V

PVDD OVLO Response Timing Rising 4 14 55

OUT_ and FB_ Voltage OV active V

VDD UV Threshold

VDD UV Threshold Hysteresis 0.1 0.2 V

VDD UV Threshold Deglitch 1

Quiescent Supply Current

DD5

= 5V, V

GND

V

PVDD

V

DD5

V

I

PVDD

I

VDD5

I

VDD

= V

DD

= 0V, fSW = 500kHz, MAP.COMP[2:0] = (see Table 20 for applicable setting),

PGND

8 25.5

Operational 6

4.75 5 5.5

4.5 5 5.5

Falling 4.2 4.35

Rising 4.5 4.6

RL = J, play mode (CTRL2 = 0x0F)

/2 V

PVDD

70

60 72

50 75

V

Fs

V

Fs

FA

mA

2

Page 3

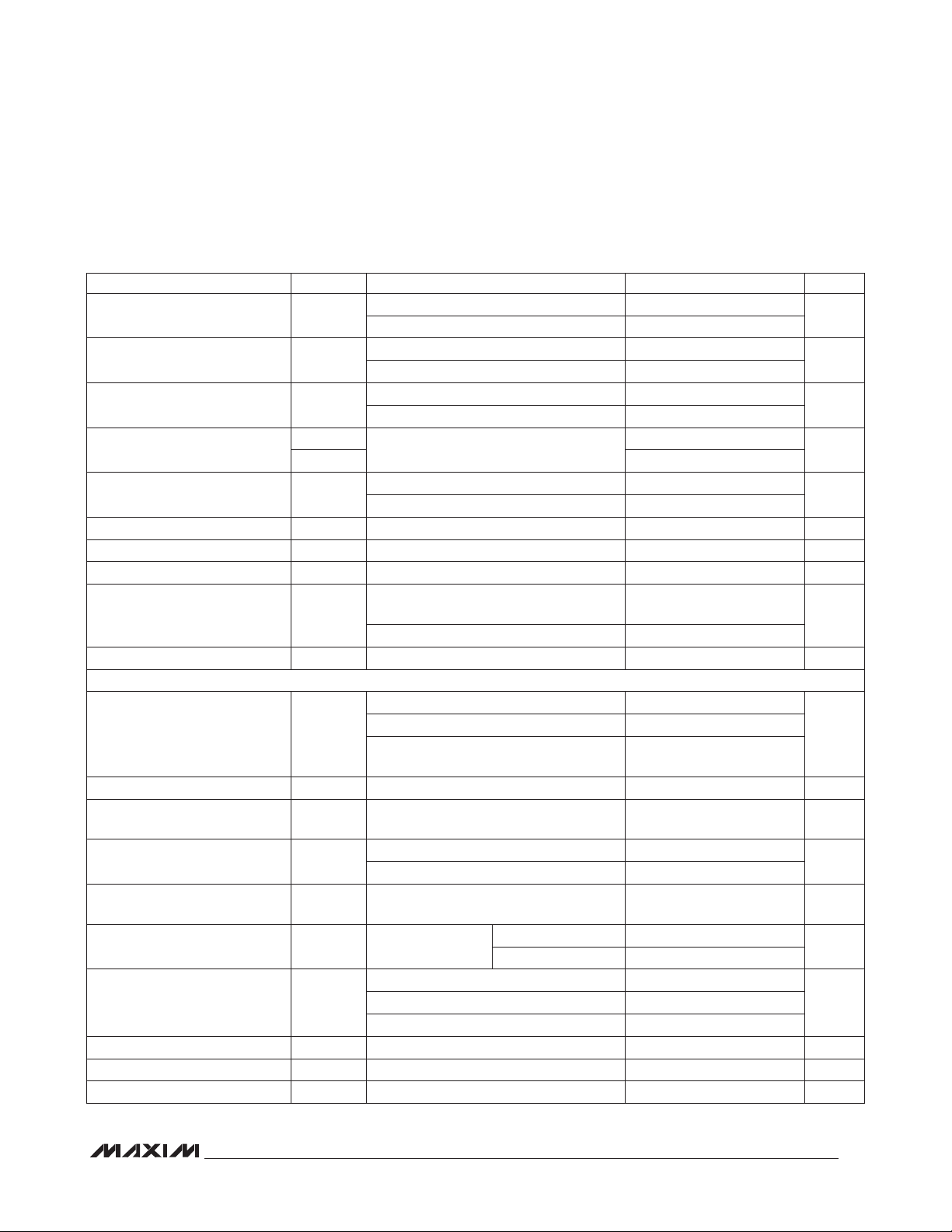

4-Channel, Automotive Class D Audio Amplifier

ELECTRICAL CHARACTERISTICS (continued)

(V

= 14.4V, VDD = V

PVDD

TA = -40NC to +125NC; typical values are at TA = +25NC, unless otherwise noted.) (Note 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

PVDD Shutdown Supply Current

V

Shutdown Supply Current

DD5

VDD Shutdown Supply Current I

Standby Supply Current

Output Leakage

Output Discharge Current CTRL3.DIS = 1 8 mA

R

per Output Excluding wire bond resistance 70

DS(ON)

FB_ Resistance 310

Output Offset V

OUT_ Output Impedance 100

AMPLIFIER AC CHARACTERISTICS

Output Power P

Signal-Path Gain 26 dB

Channel-to-Channel Gain

Tracking

Input Resistance

Mute Attenuation

Precharge Current CTRL1.PRE = 1

Power-Supply Rejection Ratio

REF Voltage C

REF Output Impedance DC 800

Input Voltage Range AC-coupled 1.2 V

DD5

= 5V, V

= V

GND

I

PVDD_

SHDN

I

VDD5_

SHDN

VDD_SHDN

I

VDD5

I

VDD

OS

OUT

= 0V, fSW = 500kHz, MAP.COMP[2:0] = (see Table 20 for applicable setting),

PGND

TA = +25NC, VEN = 0V

TA = T

to +85NC, VEN = 0V

MIN

TA = +25NC, VEN = 0V

TA = T

to +85NC, VEN = 0V

MIN

TA = +25NC, VEN = 0V

TA = T

to +85NC, VEN = 0V

MIN

CTRL2 = 0x20, VEN = 5V

V

= 14.4V 200

OUT_

V

= 0V 1

OUT_

TA = +25NC, mute mode (CTRL2 = 0x00),

no input signal

TA = T

THD+N = 1%, RL = 4I, V

THD+N = 10%, RL = 4I, V

THD+N = 10%, RL = 2I, V

MIN

to T

MAX

PVDD

PVDD

PVDD

= 24V

= 24V

= 24V,

parallel mode

7

17

0.1

2

0.1

2

1

10

15

100

66

80

160

-1 +0.1 +1 dB

IN0+, IN1+, IN2+, IN3+ 20

IN- 5

Guaranteed by design, test is functional

only

90 100 dB

IN- 5 10

IN_+ 1 2

VDD = 4.5V to 5.5V 70

V

= 1V

PVDD

V

= 8V to 25.5V 68

PVDD

REF(MIN)

ripple, 100Hz to 10kHz 60

P-P

= 1µF 2.224 V

FA

FA

FA

mA

FA

mI

kI

mV

mI

W

kI

mA

dB

I

RMS

MAX13301

3

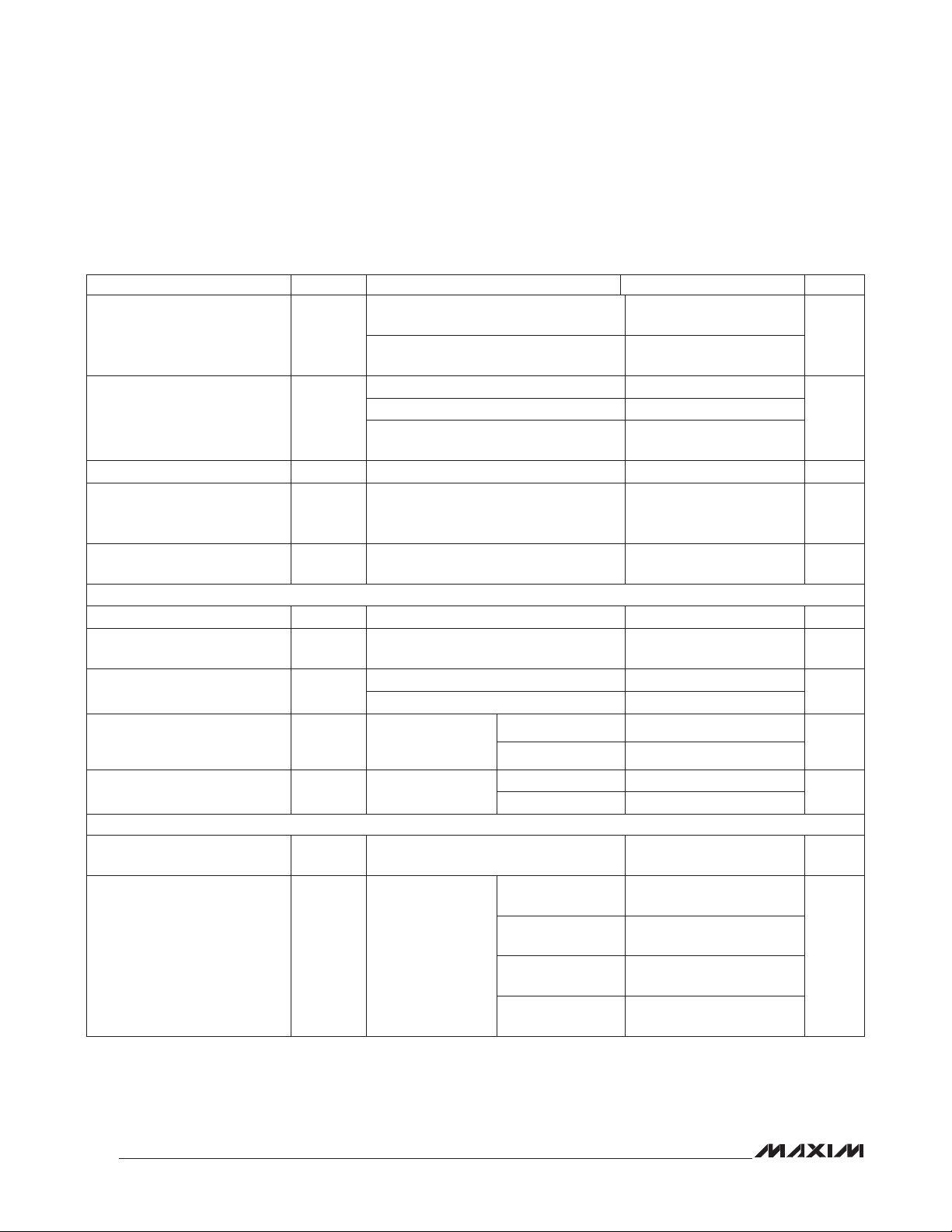

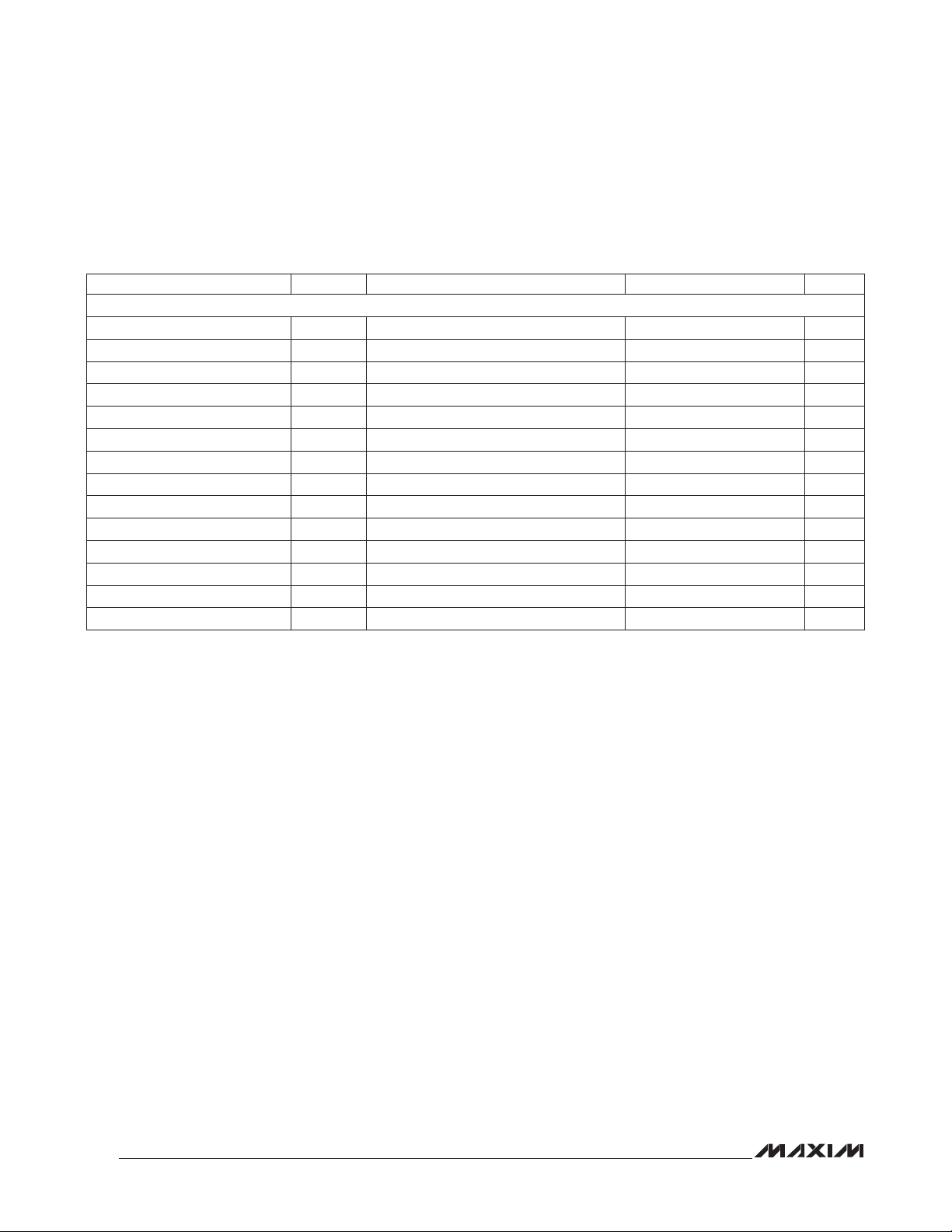

Page 4

4-Channel, Automotive Class D Audio Amplifier

ELECTRICAL CHARACTERISTICS (continued)

(V

= 14.4V, VDD = V

PVDD

TA = -40NC to +125NC; typical values are at TA = +25NC, unless otherwise noted.) (Note 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Total Harmonic Distortion Plus

Noise

MAX13301

Noise N

Crosstalk P

Efficiency

Internal Switching Frequency

Adjust Range

ONE-TIME DIAGNOSTICS

Short-to-Ground Detection CTRL2.STBY = 0, CTRL3.SDET = 1 75

Short-to-PVDD Detection

Threshold

Open-Load Detection

Low-Current Threshold

High-Current Threshold

CONTINUOUS DIAGNOSTICS

Differential Output Offset Voltage

Threshold

Clip-Detect Threshold

DD5

= 5V, V

= V

GND

THD+N

E

= 0V, fSW = 500kHz, MAP.COMP[2:0] = (see Table 20 for applicable setting),

PGND

P

= 10W, RL = 4I, BW = 22Hz to

OUT

20kHz AES17 filter, f = 1kHz

P

= 1W to 10W, RL = 4I, BW = 22Hz

OUT

to 20kHz AES17 filter, f = 1kHz

A-weighted, V

22Hz to 22kHz, V

A-weighted, CTRL5.SS[2:0] = 110,

SSEN = 1, V

= 4W, f = 1kHz to 10kHz 60 dB

OUT_

RL = 4I, P

VDD supplied from a switching power

supply

6 to 15 clock-divider range 300 750 kHz

CTRL2.STBY = 1, CTRL3.SDET = 1 6 V

CTRL3.LDM = 1, power amplifier mode 70 100

CTRL3.LDM = 0, line-driver mode 200 300

15kHz < f < 25kHz,

TA = +25NC,

CTRL3.TW = 1

f < 20Hz,

CTRL3.TW = 0

No audio in play mode 0.56 1.04 1.6 V

RL = 4I

OUT

= 24V 100

PVDD

= 24V 140

PVDD

= 24V

PVDD

= 20W/channel, V

CTRL3.HCL = 0 160 291 500

CTRL3.HCL = 1 200 364 625

CTRL3.HCL = 0 0.65 1.15 1.85

CTRL3.HCL = 1 0.9 1.65 2.15

CTRL1.CLVL[1:0]

= 11

CTRL1.CLVL[1:0]

= 01

CTRL1.CLVL[1:0]

= 10

CTRL1.CLVL[1:0]

= 00

DD5

,

0.04 0.14

0.1

100

88 %

1

3

5

10

%

FV

RMS

I

I

mA

A

%THDN

4

Page 5

4-Channel, Automotive Class D Audio Amplifier

ELECTRICAL CHARACTERISTICS (continued)

(V

= 14.4V, VDD = V

PVDD

TA = -40NC to +125NC; typical values are at TA = +25NC, unless otherwise noted.) (Note 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Short-to-Ground/PVDD

Level 1 Output Current Limit I

Level 2 Output Current Limit I

THERMAL PROTECTION

Thermal Warning Range 1 Guaranteed monotonic 110

Thermal Warning Range 2 Guaranteed monotonic 120

Thermal Warning Range 3 Guaranteed monotonic 130

Thermal Warning Range 4 Guaranteed monotonic 140

Thermal Shutdown Level Guaranteed monotonic 150 165

Thermal Warning Hysteresis 5

Thermal Shutdown Hysteresis 15

CHARGE PUMP

Switching Frequency fCP = f

Soft-Start Time 100

Charge-Pump Output

Impedance

Output Voltage V

INTERNAL OSCILLATOR

SYNC I/O Frequency Range 2x switching frequency 0.6 1.5 MHz

Frequency Spread-spectrum disabled 17.1 18 18.9 MHz

DIGITAL INTERFACE (SCL, SDA, ADDR, CL0, MUTE_CL1, EN, SYNC, FLT_OT)

SYNC High CTRL1.CM[1:0] = 01, I

SYNC Low CTRL1.CM[1:0] = 01, I

Input Voltage High V

Input Voltage Low V

Input Voltage Hysteresis 300 mV

Input Leakage Current

Output Low Voltage

Pulldown Current

DD5

= 5V, V

GND

LIM1

LIM2

INH

INL

= V

= 0V, fSW = 500kHz, MAP.COMP[2:0] = (see Table 20 for applicable setting),

PGND

OUT__ shorted

to ground/PVDD,

CTRL1.CL_TH = 1

OUT__ shorted

to ground/PVDD,

CTRL1.CL_TH = 0

CTRL3.HCL = 0 5.5 7 A

CTRL3.HCL = 1 7 8.75 A

SW

Guaranteed by FET R

measurement

SDA, SCL, CL0, MUTE_CL1, FLT_OT

SDA, CL0, MUTE_CL1, I

FLT_OT

MUTE_CL1

EN 10 18

CTRL3.HCL = 0 1.03

CTRL3.HCL = 1 1.28

CTRL3.HCL = 0 3.09

CTRL3.HCL = 1 3.86

300 750 kHz

DS(ON)

SOURCE

SINK

= 3mA 4.5 V

= 3mA 0.4 V

2.0 V

= 3mA,

SINK

1.8

+ 5 V

PVDD

5 13

NC

NC

NC

NC

NC

NC

NC

Fs

I

0.8 V

Q10 FA

0.4 V

FA

MAX13301

A

5

Page 6

4-Channel, Automotive Class D Audio Amplifier

ELECTRICAL CHARACTERISTICS (continued)

(V

= 14.4V, VDD = V

PVDD

TA = -40NC to +125NC; typical values are at TA = +25NC, unless otherwise noted.) (Note 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I2C TIMING

Output Fall Time t

Pin Capacitance 10 pF

Clock Frequency f

MAX13301

SCL Low Time t

SCL High Time t

START Condition Hold Time t

START Condition Setup Time t

Data Hold Time t

Data Setup Time t

Input Rise Time t

Input Fall Time t

STOP Condition Setup Time t

Bus Free Time t

Maximum Bus Capacitance C

Note 3: All units are 100% production tested at TA = +25NC. All temperature limits are guaranteed by design.

DD5

= 5V, V

= V

GND

OF

SCL

LOW

HIGH

HD:STA

SU:STA

HD:DAT

SU:DAT

R

F

SU:STO

BUF

BUS

= 0V, fSW = 500kHz, MAP.COMP[2:0] = (see Table 20 for applicable setting),

PGND

C

= 10pF to 400pF 250 ns

BUS

400 kHz

1.3

0.6

Repeated START condition 0.6

Repeated START condition 0.6

0 900 ns

100 ns

SCL, SDA 300 ns

SCL, SDA 300 ns

0.6

Between START and STOP conditions 1.3

Per bus line 400 pF

Fs

Fs

Fs

Fs

Fs

Fs

6

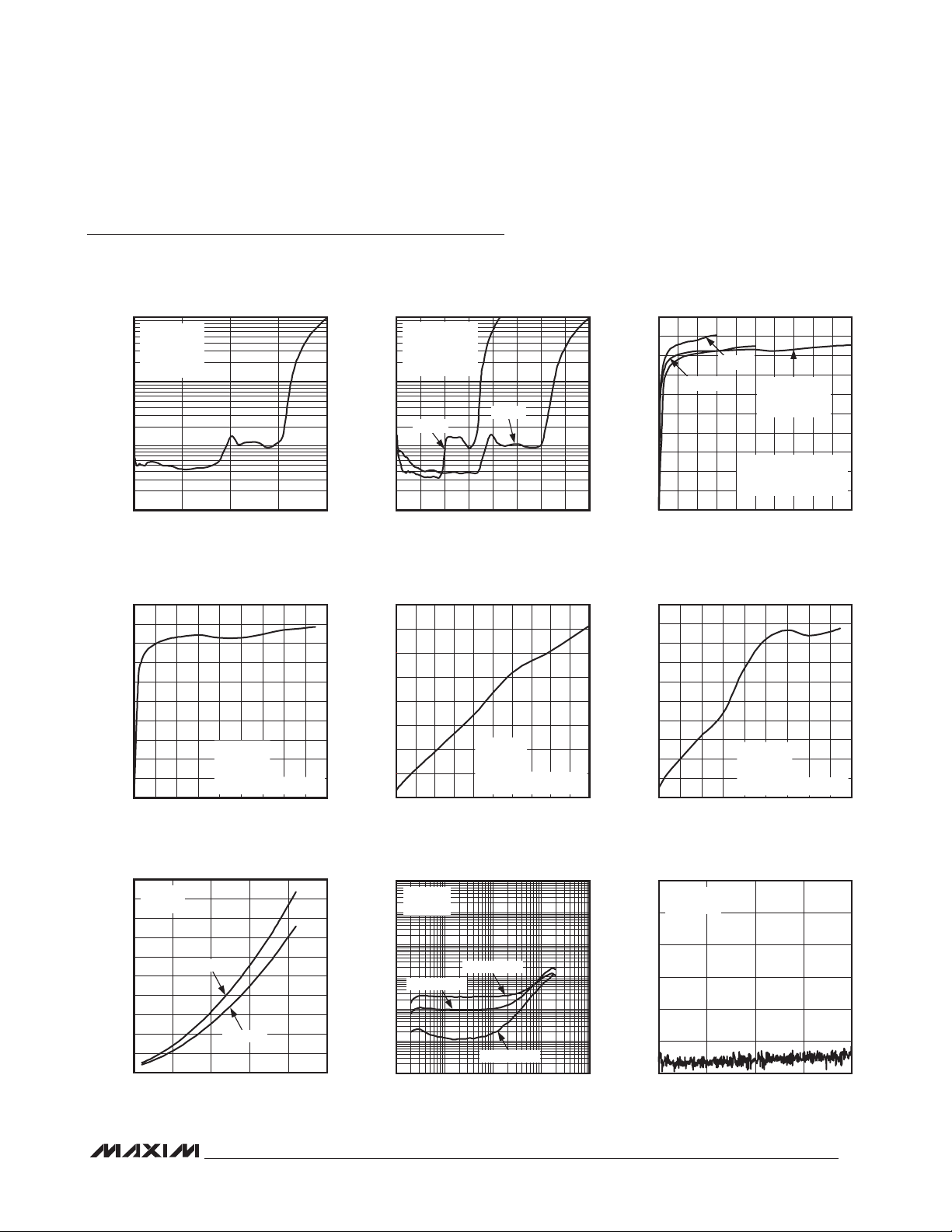

Page 7

4-Channel, Automotive Class D Audio Amplifier

Typical Operating Characteristics

(V

= 24V, VDD = V

PVDD

TA = +25NC, unless otherwise noted.)

THD+N vs. OUTPUT POWER

10

f = 1kHz

BW = 22Hz TO

20kHz AES17

R

= 4I

L

1

THD+N (%)

0.1

0.01

0 80

OUTPUT POWER (W)

DD5

= 5V, V

604020

GND

= V

MAX13301 toc01

= 0V, fSW = 500kHz, MAP.COMP[2:0] = 011, see Table 32 for LC filter value,

PGND

EFFICIENCY vs. OUTPUT POWER

PER CHANNEL

RL = 4I

RL = 2I

OUTPUT POWER PER CHANNEL (W)

2-CHANNEL

PARALLEL MODE

R

= 1I

L

fIN = 1kHz

10% THD+N

BW = 22Hz TO 20kHz AES17

10

1

THD+N (%)

0.1

0.01

THD+N vs. OUTPUT POWER

f = 1kHz

BW = 22Hz TO

20kHz AES17

PARALLEL MODE

RL = 2I

RL = 4I

OUTPUT POWER (W)

140120100806040200 160

MAX13301 toc02

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

908010 20 30 50 6040 700 100

MAX13301

MAX13301 toc03

EFFICIENCY vs. OUTPUT POWER

PER CHANNEL

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0 90

OUTPUT POWER PER CHANNEL (W)

fIN = 1kHz

RL = 4I

10% THD+N

BW = 22Hz TO 20kHz AES1

OUTPUT POWER vs. SUPPLY VOLTAGE

100

RL = 4I

90

fIN = 1kHz

80

70

60

50

40

30

20

OUTPUT POWER PER CHANNEL(W)

10

0

10% THD+N

1% THD+N

10 15 20 255 30

V

(V)

PVDD

POWER DISSIPATION vs. OUTPUT POWER

PER CHANNEL

40

35

MAX13301 toc04

30

25

20

15

POWER DISSIPATION (W)

10

5

807050 6020 30 4010

0

OUTPUT POWER PER CHANNEL (W)

RL = 2I

f

= 1kHz

IN

10% THD+N

BW = 22Hz TO 20kHz AES17

MAX13301 toc05

45405 10 15 25 3020 350 50

CROSSTALK

-40

P

= 4W

OUT

R

= 4I

L

-50

MAX13301 toc07

-60

-70

OUT0 TO OUT2

CROSSTALK (dB)

-80

-90

-100

0.01 100

OUT0 TO OUT3

OUT0 TO OUT1

FREQUENCY (kHz)

1010.1

MAX13301 toc08

POWER DISSIPATION vs. OUTPUT POWER

PER CHANNEL

50

45

40

35

30

25

20

15

POWER DISSIPATION (W)

10

5

0

0 90

OUTPUT POWER PER CHANNEL (W)

fIN = 1kHz

RL = 4I

10% THD+N

BW = 22Hz TO 20kHz AES17

OUTPUT FREQUENCY SPECTRUM

0

MUTE MODE

R

= 4I

L

-20

-40

-60

AMPLITUDE (dBV)

-80

-100

-120

0 20

FREQUENCY (kHz)

MAX13301 toc06

807050 6020 30 4010

MAX13301 toc09

15105

7

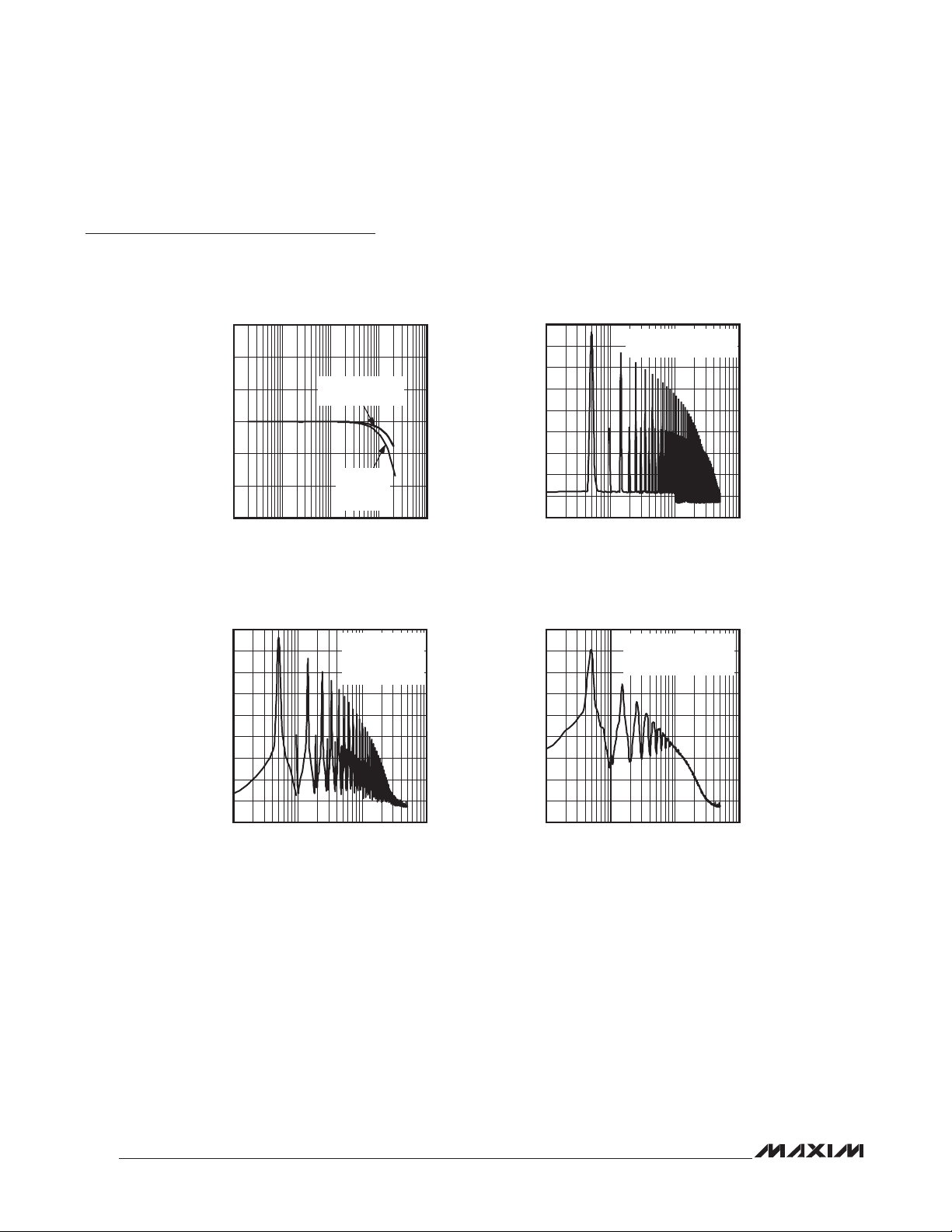

Page 8

4-Channel, Automotive Class D Audio Amplifier

Typical Operating Characteristics (continued)

(V

= 24V, VDD = V

PVDD

TA = +25NC, unless otherwise noted.)

DD5

= 5V, V

GND

= V

= 0V, fSW = 500kHz, MAP.COMP[2:0] = 011, see Table 32 for LC filter value,

PGND

3

2

MAX13301

1

0

RESPONSE (dB)

-1

-2

-3

SPREAD-SPECTRUM MODULATION WIDEBAND

0

-10

-20

-30

-40

-50

AMPLITUDE (dBV)

-60

-70

-80

-90

FREQUENCY RESPONSE

= 1W AND 10W

P

OUT

R

= 4I

L

P

= 30W

OUT

R

= 2I

L

C2 = 1µF

0.01 100

FREQUENCY (kHz)

1010.1

OUTPUT SPECTRUM

CTRL5 = 0x09

MEASURED AT

OUT__ WITH -20dB

ATTENUATION

0.1 100

FREQUENCY (MHz)

101

MAX13301 toc10

MAX13301 toc12

FIXED-FREQUENCY MODULATION WIDEBAND

OUTPUT SPECTRUM

0

-10

-20

-30

-40

-50

AMPLITUDE (dBV)

-60

-70

-80

-90

0.1 100

MEASURED AT OUT__

WITH -20dB ATTENUATION

101

FREQUENCY (MHz)

SPREAD-SPECTRUM MODULATION WIDEBAND

OUTPUT SPECTRUM

0

-10

-20

-30

-40

-50

AMPLITUDE (dBV)

-60

-70

-80

-90

0.1 100

WITH -20dB ATTENUATION

FREQUENCY (MHz)

CTRL5 = 0xB9

MEASURED AT OUT__

101

MAX13301 toc11

MAX13301 toc13

8

Page 9

4-Channel, Automotive Class D Audio Amplifier

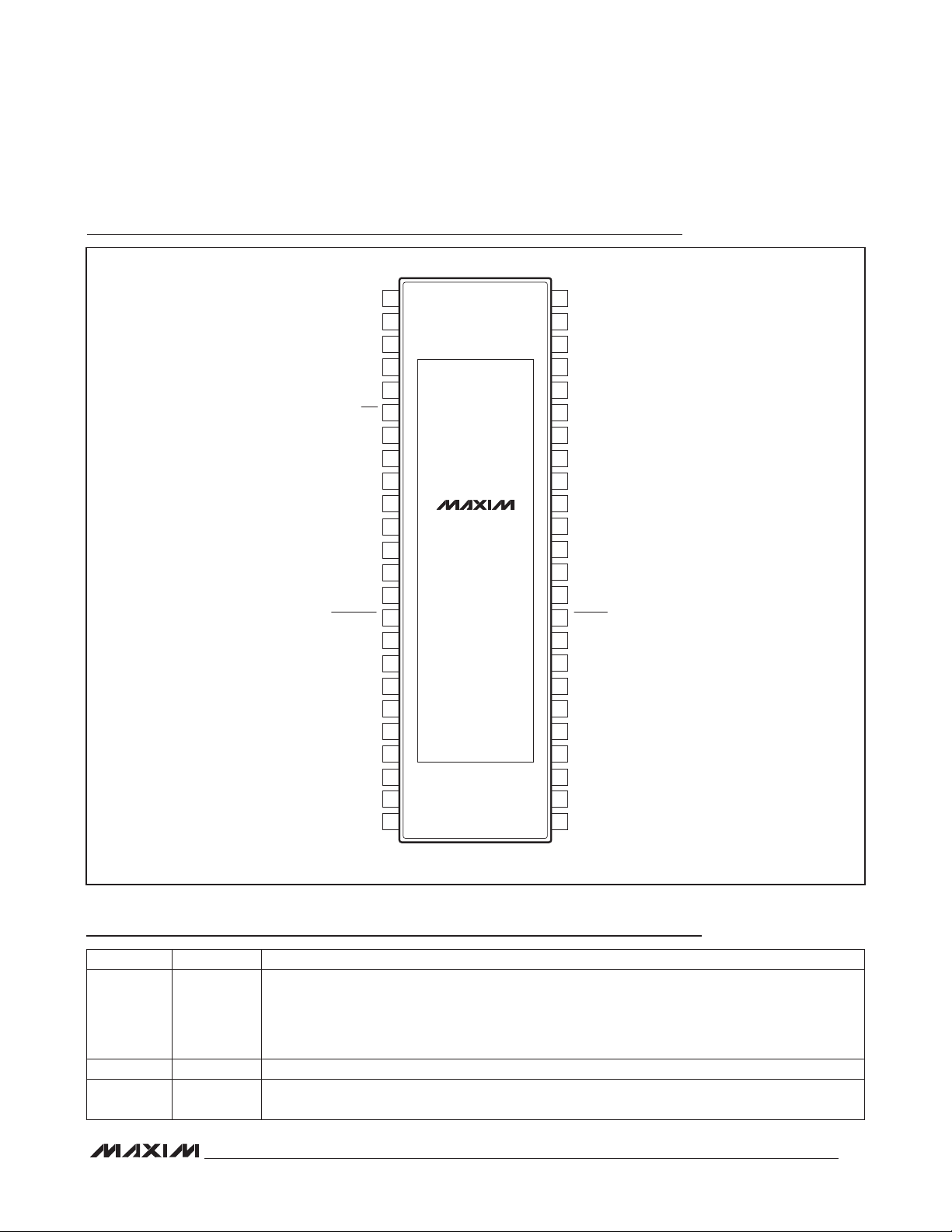

Pin Configuration

TOP VIEW

PVDD

FB2+

FB2-

FB3-

CL0

OUT3+

PGND

PGND

PGND

OUT2+

OUT2-

MUTE_CL1

IN-

GND

V

IN0+

IN1+

REF

PVDD

+

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

DD

19

20

21

22IN2+

23IN3+

24

MAX13301

EPR

48

PVDD

47

CP

46

CHOLD

45

CMFB3+

V

44

DD5

PGND

43

OUT1+

42

OUT1-OUT3-

41

PGND

40

PGNDPGND

39

PGND

38

PGND

37

OUT0+

36

OUT0-

35

FLT_OT

34

FB0+

33

FB0-

32

FB1+

31

FB1-

30

SDA

29

SCL

28

EN

27

SYNC

26

PVDD

25

MAX13301

TSSOP

Pin Description

PIN NAME FUNCTION

Audio Output Power-Supply Input. Bypass each PVDD to its PGND pair locally with 0.1FF and 4.7FF

ceramic capacitors. Each PVDD/PGND pair consists of one PVDD and two PGNDs. The PVDD/

1, 24, 25, 48 PVDD

2 FB2+

3 FB2-

PGND pairs are 1 and 9-10, 48 and 39-40, 24 and 11-12, and 25 and 37-38. Bypassing PVDD

locally minimizes the area of di/dt loops. An additional 1000FF, low-ESR electrolytic capacitor

should be placed from 1 and 48 to PGND and 24 and 25 to PGND.

Output 2 Positive Feedback. Connect to the LC filter’s positive output through a 150I ±1% resistor.

Output 2 Negative Feedback. Connect to the LC filter’s negative output through a 150I ±1%

resistor.

9

Page 10

4-Channel, Automotive Class D Audio Amplifier

Pin Description (continued)

PIN NAME FUNCTION

4 FB3+

5 FB3-

6

MAX13301

7 OUT3+ Channel 3 Power Amplifier Positive Output

8 OUT3- Channel 3 Power Amplifier Negative Output

9–12,

37–40, 43

13 OUT2+ Channel 2 Power Amplifier Positive Output

14 OUT2- Channel 2 Power Amplifier Negative Output

15

16 IN-

17 GND Analog Ground

18 V

19 IN0+

20 IN1+

21 REF

22 IN2+

23 IN3+

26 SYNC

27 EN

28 SCL I2C Serial-Clock Input

29 SDA I2C Serial-Data Input and Output

30 FB1-

31 FB1+

32 FB0-

33 FB0+

CL0

PGND Audio Output Power Ground

MUTE_CL1

DD

Output 3 Positive Feedback. Connect to the LC filter’s positive output through a 150I ±1% resistor.

Output 3 Negative Feedback. Connect to the LC filter’s negative output through a 150I ±1%

resistor.

Active-Low Open-Drain Clip 0 Output. CL0 is configurable to provide clipping indication for outputs

0 and 1 or for all four outputs.

Mute Input or Active-Low Open-Drain Clip 1 Output. MUTE_CL1 is configurable as a mute input or

as an open-drain clip indicator output. When configured as an input, drive MUTE_CL1 low to mute

all four outputs. As an output, MUTE_CL1 provides clipping indication for outputs 2 and 3. This

pin also selects the low bit of the I2C address and is latched upon the rising edge of the EN pin.

MUTE_CL1 has an internal 5FA pulldown.

Common Audio Negative Input. IN- has 5kI of input resistance. Bypass to analog ground with 2µF

or 4 x C

5V Analog Power-Supply Input. Bypass with a 2.2FF or larger ceramic capacitor to GND. V

provides power to the analog and digital circuitry.

Channel 0 Audio Input. IN0+ has 20kI of input resistance. Connect a series capacitor of at least

0.47FF to IN0+.

Channel 1 Audio Input. IN1+ has 20kI of input resistance. Connect a series capacitor of at least

0.47FF to IN1+.

2.2V Reference Output. Bypass REF to GND with a 1FF ceramic capacitor.

Channel 2 Audio Input. IN2+ has 20kI of input resistance. Connect a series capacitor of at least

0.47FF to IN2+.

Channel 3 Audio Input. IN3+ has 20kI of input resistance. Connect a series capacitor of at least

0.47FF to IN3+.

Sync I/O. In master mode, SYNC outputs a clock signal that is synchronized to that of the

modulator. In slave mode, SYNC is a clock input and serves as the clock source for the modulator.

Enable Input. Connect EN to VDD for normal operation. Connect EN to GND to place the device in a

low-power mode. There is an internal 10µA pulldown on EN.

Output 1 Negative Feedback. Connect to the LC filter’s negative output through a 150I ±1%

resistor.

Output 1 Positive Feedback. Connect to the LC filter’s positive output through a 150I ±1% resistor.

Output 0 Negative Feedback. Connect to the LC filter’s negative output through a 150I ±1%

resistor.

Output 0 Positive Feedback. Connect to the LC filter’s positive output through a 150I ±1% resistor.

IN_+

.

DD

10

Page 11

4-Channel, Automotive Class D Audio Amplifier

Pin Description (continued)

PIN NAME FUNCTION

34

FLT_OT

35 OUT0- Channel 0 Power Amplifier Negative Output

36 OUT0+ Channel 0 Power Amplifier Positive Output

41 OUT1- Channel 1 Power Amplifier Negative Output

42 OUT1+ Channel 1 Power Amplifier Positive Output

44 V

DD5

45 CM Charge-Pump Capacitor Negative Terminal

46 CHOLD

47 CP Charge-Pump Capacitor Positive Terminal

— EPR

Active-Low Open-Drain Fault and Overtemperature Output. FLT_OT provides indication of faults,

overtemperature, and thermal shutdown status.

5V Power-Supply Input. Bypass with a 0.1FF capacitor to PGND. V

provides power to the gate

DD5

drivers and charge pump.

Charge-Pump Output. Connect a 1FF capacitor from CHOLD to PVDD.

Top Side Exposed Pad. Connect this exposed pad to an external heatsink to ensure the device is

adequately cooled. The maximum power dissipation in the device is a function of this external

heatsink and other system parameters. See the Thermal Information section for more information.

The top side exposed pad is electrically isolated from the die.

MAX13301

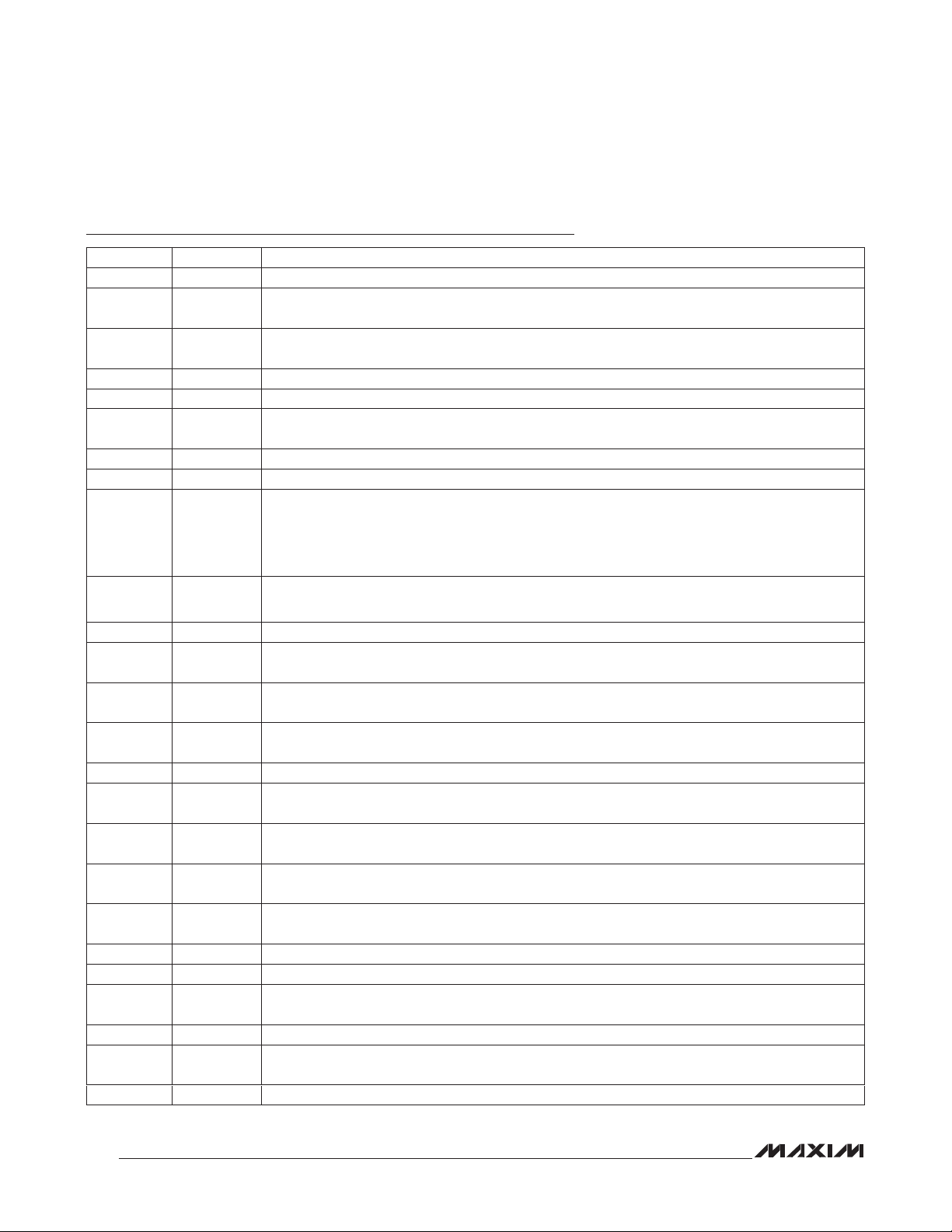

Functional Diagram

V

DD5

PGND

IN_+

IN-

V

GND

REF

SCL

SDA

CLO

MUTE_CL1

FLT_OT

SYNC

OSC

DD

EN

ANALOG

AUDIO

INTERFACE

I2C CONTROL

INTERFACE

REGISTERS

AND

SYSTEM

CONTROL

ANALOG

MODULATOR

AND

DIAGNOSTICS

V

DD5

GATE

DRIVER 0

LPF

LPF

V

DD5

GATE

DRIVER 3

MAX13301

CLASS D

OUTPUT

STAGE 0

AND DIAGS

FEEDBACK

DIFF. AMP

FEEDBACK

DIFF. AMP

CLASS D

OUTPUT

STAGE 3

AND DIAGS

CHARGE

PUMP

PVDD

OUT0+

OUT0-

PGND

FB0+

FB0-

FB3+

FB3-

PVDD

OUT3+

OUT3-

PGND

CP

CM

CHOLD

11

Page 12

4-Channel, Automotive Class D Audio Amplifier

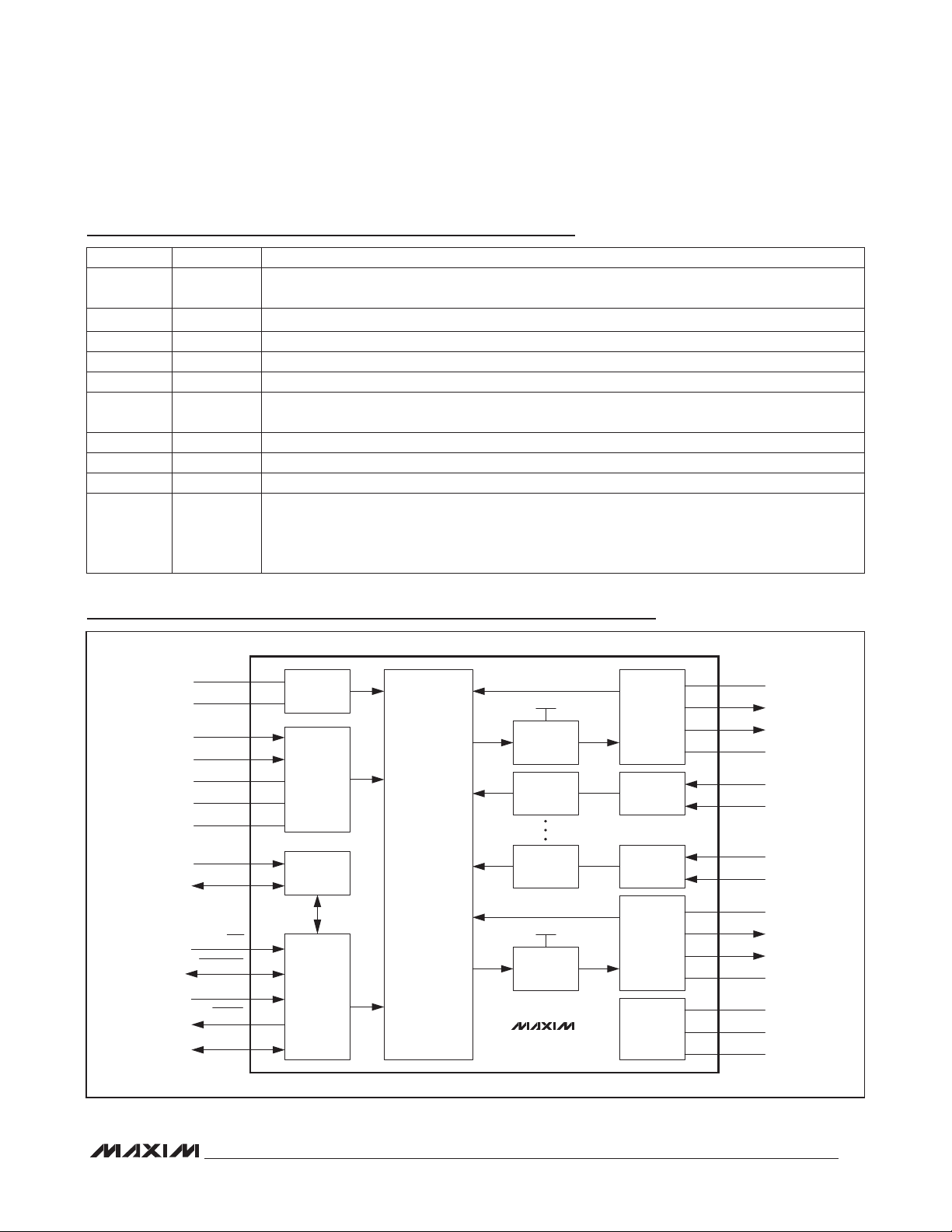

2

C COMP

I

MAX13301

AUDIO IN

PWM LOGIC

TRIANGLE WAVE

REF

REF

PWM

COMPARATOR

REF

I2C COMP

ERROR

AMPLIFIER

REF

3-BIT ADC

FEED-

FORWARD

OSC

PVDD

REF

PREAMPLIFIER

Figure 1. Detailed Block Diagram of the MAX13301 Audio Path

Detailed Description

The MAX13301 4-channel, Class D audio power amplifiers is specifically designed for automotive applications.

Integrated feedback from the LC filter’s output improves

the THD+N by reducing the distortion, providing Class

AB performance while achieving efficiency up to 90.5%.

The devices also support spread-spectrum modulation

for AM radio compatibility.

Description of Operation

The device emulates current-mode controllers with digital

feed-forward (Figure 1). The internal oscillator creates an

18MHz square wave. The I2C controls a clock divider that

divides down this high-frequency clock to a usable frequency. The resulting square wave is integrated to create

12

a triangle wave. A 3-bit ADC converts the PVDD voltage

into a code that adjusts the resistors used in the trianglewave integrator. The triangle-wave amplitude becomes

progressively larger as PVDD increases. The triangle

wave is fed into the PWM comparator.

The two differential amplifiers provide both analog and

digital feedback. The feedback is summed with the output of the preamplifier at the error amplifier. The output

of the error amplifier is an AC replica of the inductor current (emulated current mode) and the triangle wave is

therefore the slope compensation. The PWM comparator

controls the full-bridge operation, turning on and off each

FET pair (double-edge modulation). To ensure that the

devices switch at the desired frequency, it is important

to ensure that the triangle wave is greater than the error-

Page 13

4-Channel, Automotive Class D Audio Amplifier

amplifier ramp. The design equation that must be met to

ensure constant frequency is as follows:

Error-Amplifier Ramp < 2/3 Triangle-Wave Ramp

The error-amplifier ramp is fixed by the gain of the differential amplifiers used in the feedback loop and by

the error-amplifier compensation capacitor programmed

through I2C. To ensure the design equation for fixed frequency is met, the error-amplifier compensation capacitor tracks the integrator capacitor used to generate the

triangle wave.

For optimal noise shaping, the error-amplifier capacitor should be set to a small value. This results in a

broadband spectrum where the error amplifier pushes

the noise created by the clock jitter and PWM sampling above the audio range. However, there is a limit.

Because the triangle-wave capacitor tracks the erroramplifier capacitor, small capacitor values can clip

the triangle wave as it runs out of supply. This effect is

aggravated at high PVDD voltages by the ADC action

that decreases the integrator resistor at higher supply

voltages. Tables 20 and 21 are lookup tables to facilitate choosing the optimal setting for the error-amplifier

capacitance (MAP.COMP[2:0]).

It is possible to change this setting instantaneously while

playing music, but if there is no music, a slight audible

click is heard at the speakers. Systems that monitor

the input voltage can take advantage of this instantaneous programmability and use a smaller error-amplifier

capacitor at lower PVDD voltages. Higher switching

frequencies also allow the use of a smaller integrator

capacitor, and thus help improve the noise performance

of the amplifier.

Do not set the error-amplifier capacitor to a value less

than 18pF. Doing so results in extreme distortion, as the

triangle wave clips. The MAP.COMP[2:0] settings that

result in this behavior are listed as reserved (Table 19).

Advantage of Feedback After the Filter

High-fidelity audio amplifiers require very low output

impedance. The device achieves this by using a dual-

feedback approach. The digital feedback (feedback

MAX13301

from OUT__ outputs) emulates current-mode enabling on

chip compensation. The analog feedback (FB__ inputs)

significantly reduces the output impedance of the amplifier and at the same time, compensates for the nonideal

characteristics of the output filter. If the characteristics

of the speaker and/or output filter change with age or

temperature, the analog feedback compensates accordingly. Further inductor matching is less critical because

the inductors are inside the feedback loop. Because the

inductors are inside the feedback loop, the loop can

dampen out any LC ringing that might occur when the

amplifier is used as a line driver. The analog feedback is

differential so it does not help with common-mode ringing. Thus, the Zobel (RC) networks are required on each

speaker connection to damp any common-mode ringing

associated with the LC output filter and speaker.

Operating Modes

Configure the device for one of three states of activity:

normal, standby, or shutdown.

Normal

In normal mode, the device is ready for play. Placing

the device in standby reduces power consumption while

keeping fault monitors and the I2C interface on to communicate fault conditions. In shutdown, the device is

completely disabled and draws minimal current from the

battery.

To reset the device and clear all register contents to their

reset values, set CTRL5.RST to 1. After reset, this bit is

automatically cleared back to 0.

Standby

In standby, all circuitry is disabled except the fault monitors and the I2C interface. The I2C registers retain their

content and are still interactive. To place the device in

standby, set the CTRL2.STBY bit to 1. In standby, the

device draws 11mA from all power-supply inputs.

Before exiting standby, always set the CTRL1.CL_TH (current-limit threshold setting) bit to 1. After exiting standby,

clear CTRL1.CL_TH back to 0.

Table 1. Operating Modes

MODE EN CTRL2.STBY I2C FAULT MONITORS ALL OTHER CIRCUITRY

Normal High 0 Enabled On On

Standby High 1 Enabled On Off

Shutdown Low X Off Off Off

X = Don’t care

13

Page 14

4-Channel, Automotive Class D Audio Amplifier

Shutdown

In shutdown, all circuitry including the fault monitors and

I2C interface is disabled to reduce power consumption

and extend battery life. Connect EN to logic-high for normal operation. Connect EN to GND to place the device in a

low-power shutdown mode. In shutdown, the devices draw

17mA (typ) from the battery.

Clock Source

The device supports fixed-frequency modulation with an

MAX13301

internal or external clock. The modulation mode is selected through CTRL1.CM[1:0] (operating mode select bits).

Master Configuration

In master mode, 10 modulation frequencies are available in fixed-frequency modulation mode. Program

CTRL0.MDIV[3:0] (master clock-divide ratio bits) for the

desired frequency.

Slave Configuration

Configuring the device as a slave allows an external

clock source to provide the switching frequency. In this

case, apply the external clock signal at SYNC at double

the desired switching frequency.

Fixed-Frequency Modulation Mode

The devices supports a fixed-frequency modulation

mode with 10 different selectable frequencies between

300kHz and 750kHz. The frequency is selectable through

the I2C interface. The frequency spectrum consists of the

fundamental switching frequency and its associated

harmonics (see the wideband output spectrum graphs in

the Typical Operating Characteristics). For applications

where exact spectrum placement of the switching fundamental is important, program the switching frequency so

that the harmonics do not fall within a sensitive frequency

band.

Spread Spectrum

The device features a unique spread-sprectrum mode

that flattens the wideband spectral components, improving EMI emissions that can be radiated by the speaker

and cables. This feature is only available in master clock

mode and is enabled by setting the CTRL5.SS[2:0] and

CTRL5.SSEN bits. In spread-spectrum mode, the switching frequency vaies linearly by up to 7% depending on

CTRL5.SS[2:0] setting. The modulation scheme remains

the same, but the period of the triangle waveform

changes from cycle to cycle. Instead of a large amount

of spectral energy present at multiples of the switching

frequency, the energy is now spread over a bandwidth

that increases with frequency. Above a few megahertz,

the wideband spectrum looks like white noise for EMI

purposes. A proprietary amplifier topology ensures this

does not significantly increase the noise floor in the

audio bandwidth.

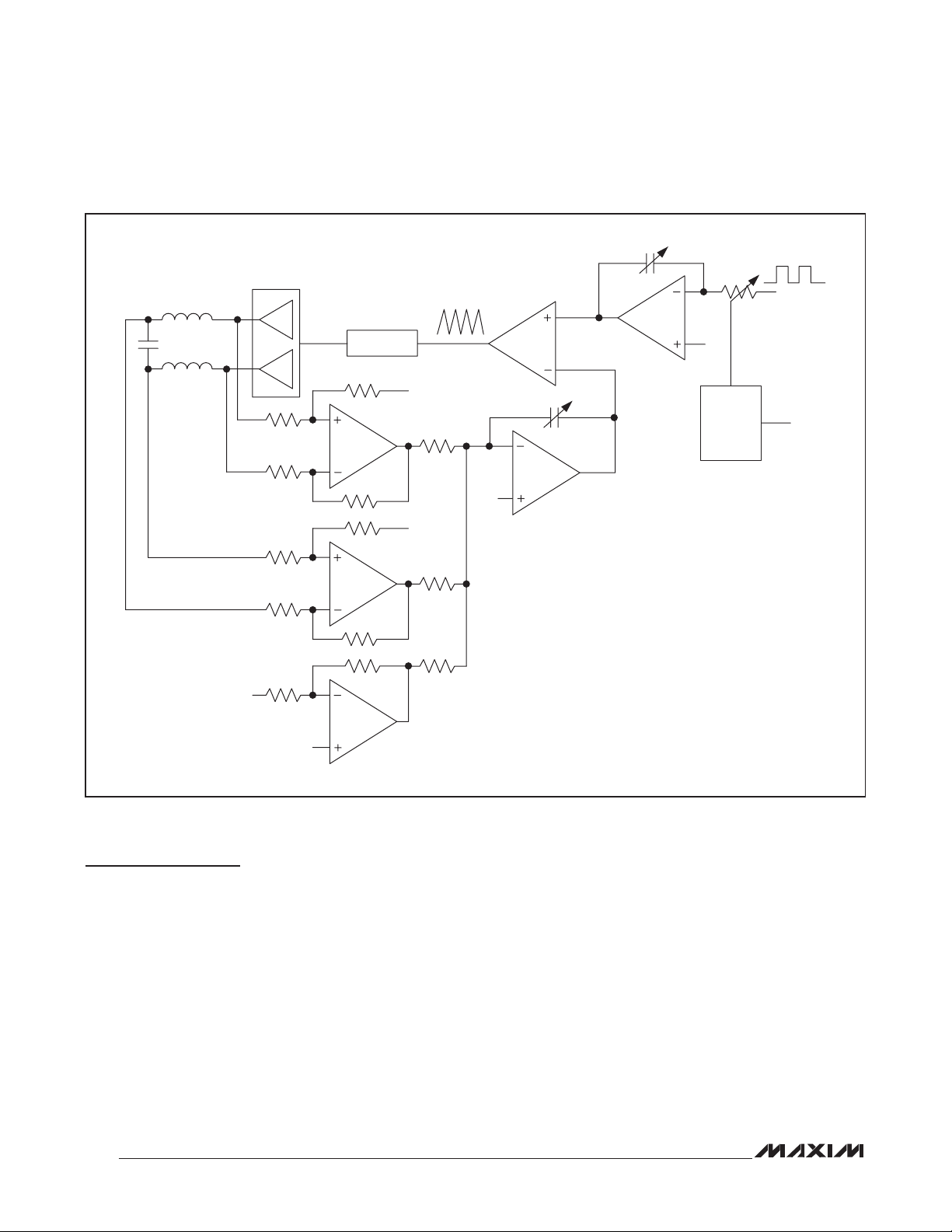

Efficiency

The high efficiency of a Class D amplifier is due to the

switching operation of the output stage transistors. In a

Class D amplifier, the output transistors act as currentsteering switches and consume negligible additional

power. Any power loss associated with the Class D

output stage is mostly due to the I2R loss of the MOSFET

on-resistance and quiescent current overhead. The

theoretical best efficiency of a linear amplifier is 78% at

peak output power. Under normal operating levels (typical music reproduction levels), the efficiency falls below

30%, whereas the device exhibits > 80% efficiency

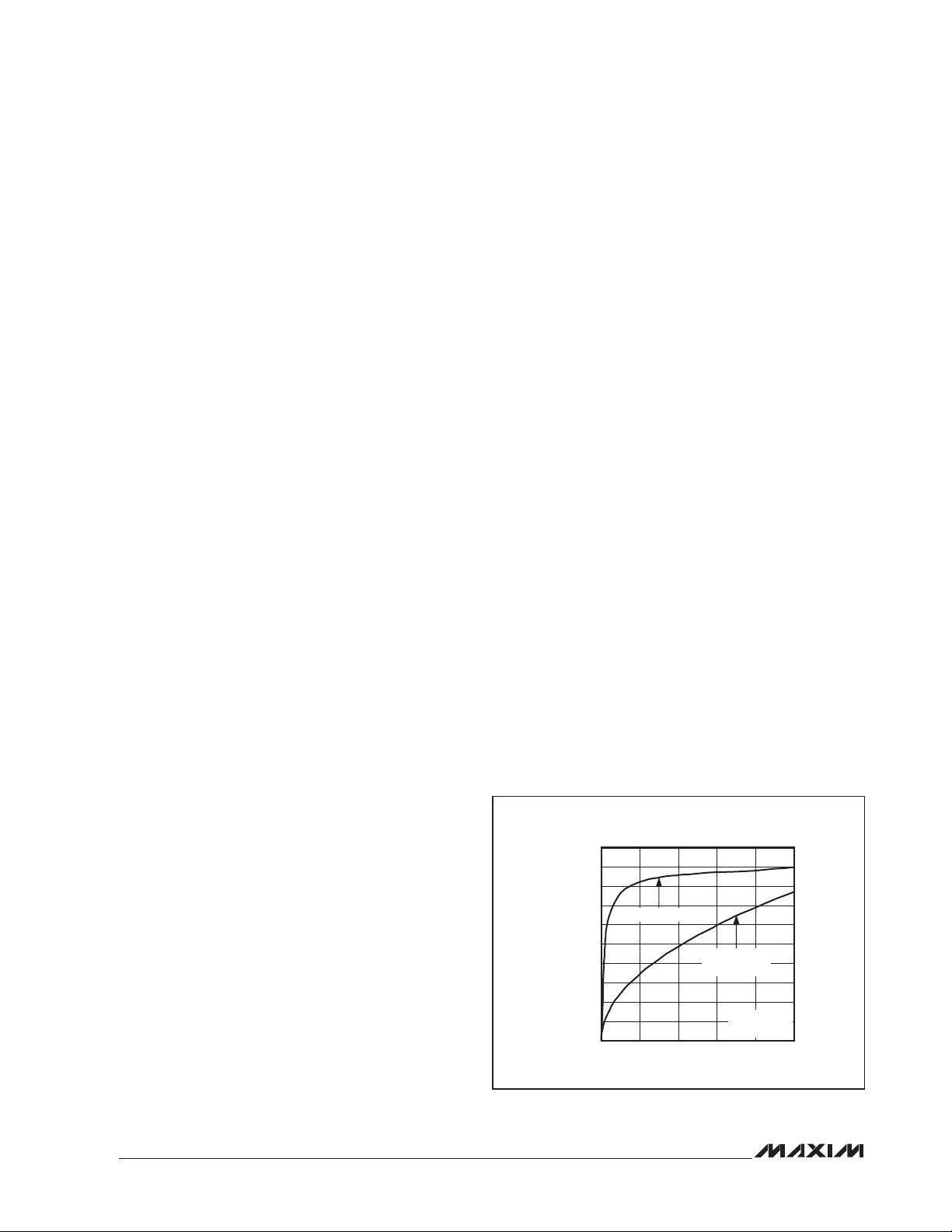

under the same conditions (Figure 2).

Current Limit

The current limit of the outputs is selectable between 7A

(typ) and 8.75A (typ) through the CTRL3.HCL bit.

When the current limit is exceeded, the affected output

is latched off and its corresponding overcurrent indicator bit OSTAT0.OC[3:0] is set to 0. The device does

not attempt to activate the output until instructed by

the microcontroller to do so. After eliminating the cause

of the current limit, reactivate the output by setting

OSTAT0.OC[3:0] to 1.

Short to either ground or battery causes the output to be

latched off and its corresponding OSTAT0.OC[3:0] bit

to be set to 0. After removing the short, reactivate the

output by setting OSTAT0.OC[3:0] to 1.

MAX13301 EFFICIENCY vs.

IDEAL CLASS AB AMPLIFIER EFFICIENCY

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

Figure 2. Efficiency vs. Output Power of Class AB Amplifier

and the MAX13301

MAX13301

IDEAL CLASS AB

AMPLIFIER

V

= 14.4V

PVDD

RL = 4I

0 25

OUTPUT POWER PER CHANNEL (W)

2015105

14

Page 15

4-Channel, Automotive Class D Audio Amplifier

The device has real-time current limit for shorted outputs,

outputs shorted to battery, outputs shorted to ground,

and outputs shorted to adjacent channels.

For shorted outputs, the devices enter cycle-by-cycle

current limit. In a BTL configuration, current flows

diagonally through two of the four FETs at any instant

in time. If the current in either of these FETs reaches

the current-limit threshold, then both turn off and the

other pair of diagonal FETs turns on for a fixed time.

This creates distortion, as the music clips. The internal

logic of the device counts the cycle-by-cycle currentlimit events, and if too many happen in a fixed amount

of time, the devices latch off the faulted channel. Current

limit is programmable with the I2C. When CTRL3.HCL

= 1, the peak current is limited to 8.75A (typ). With

CTRL3.HCL = 0, peak current is limited to 7A (typ).

Short-to-battery and short-to-ground take advantage

of the diagonal flow of current in a full bridge to detect

fault conditions. The load current during normal operation should be equal in the two diagonal FETs that are

actively conducting current. When an output is shorted

to battery or ground, the current is no longer equal and

the degree of mismatch is a measure of the severity of

the fault. If the mismatch threshold is exceeded in any

channel, that channel is immediately shut down and an

overcurrent fault is reported. The level of mismatch is

programmable through I2C. When CTRL1.CL_TH = 0,

the mismatch threshold is 3.09A with CTRL3.HCL = 0 and

3.86A with CTRL3.HCL = 1. When CTRL1.CL_TH = 1, the

mismatch threshold is 1.03A with CTRL3.HCL = 0 and

1.28A with CTRL3.HCL = 1. The lower setting is preferred in that it can detect a misconfigured speaker. For

example, the lower setting issues a fault if a 4I speaker

is incorrectly connected between one of the outputs

and ground. At startup, when a large snubber capacitor

is present, the higher setting is sometimes required to

avoid false trips. When the bridge starts switching, both

snubber capacitors must be charged to half the battery.

The charging current mimics a short to ground. Following

the startup procedure is the best way to avoid issues

with overcurrent faults.

Mute/Precharging

The device features a clickless/popless mute mode.

When muted, the volume at the speaker is reduced to an

inaudible level. To mute the device, configure MUTE_CL1

as a mute input by setting MAP.MCLP (clip output mapping bit) to 0. Then drive the mute input low. Use the mute

function during system power-up and power-down to

ensure optimum click-and-pop performance.

It is also advisable to set CTRL1.PRE (precharge bit) to

1 after taking the device out of standby mode to precharge the input DC-blocking capacitors. This action

should be part of any startup routine. Precharging the

DC-blocking capacitors enhances click-and-pop performance. Capacitors that are 0.47µF/2µF in series with the

inputs take about 1ms to be charged.

Output Configuration

The four FETs forming the full-bridge output of each

channel can be programmed into one of four states:

high-impedance (default), forced overvoltage, mute, and

play through the CTRL2.MD01_[1:0] (channels 0 and 1

output mode) and CTRL2.MD23_[1:0] (channels 2 and

3 output mode) bits. Channels 0 and 1 and channels 2

and 3 always share the same configuration.

In high-impedance mode, all four FETs are turned off. In

forced overvoltage state, each half-bridge output is regulated to 1/2 V

to switch but the volume is kept to an inaudible level. In

play mode, the FETs switch normally.

. In mute mode, the outputs continue

PVDD

I2C Interface

The device features an I2C, 2-wire serial interface consisting of a serial-data line (SDA) and a serial-clock line

(SCL). SDA and SCL facilitate communication between

the device and the master at clock rates up to 400kHz.

When the device is used on an I2C bus with multiple

devices, the VDD supply must stay powered on to ensure

proper I2C bus operation. The master, typically a microcontroller, generates SCL and initiates data transfer

on the bus. Figure 3 shows the 2-wire interface timing

diagram.

A master device communicates to the IC by transmitting

the proper address followed by the data word. Each

transmit sequence is framed by a START (S) or repeated

START (Sr) condition, and a STOP (P) condition. Each

word transmitted over the bus is 8 bits long and is always

followed by an acknowledge clock pulse.

The SDA line operates as both an input and an opendrain output. A pullup resistor, greater than 500I, is

required on the SDA bus. The SCL line operates as

an input only. A pullup resistor, greater than 500I, is

required on SCL if there are multiple masters on the bus,

or if the master in a single-master system has an opendrain SCL output. Series resistors in line with SDA and

SCL are optional. The SCL and SDA inputs suppress

noise spikes to ensure proper device operation even on

a noisy bus.

MAX13301

15

Page 16

4-Channel, Automotive Class D Audio Amplifier

SDA

t

t

SU:DAT

t

HD:DAT

t

F

SCL

MAX13301

t

HD:STA

START

CONDITION

t

LOW

t

HIGH

t

R

Figure 3. 2-Wire Serial-Interface Timing Diagram

S PSr

SDA

SCL

Figure 4. START, STOP, and Repeated START Conditions

Bit Transfer

One data bit is transferred during each SCL cycle. The

data on SDA must remain stable during the high period

of the SCL pulse. Changes in SDA while SCL is high are

control signals (see the START and STOP Conditions sec-

tion). SDA and SCL idle high when the I2C bus is not busy.

STOP and START Conditions

A master device initiates communication by issuing a

START condition. A START condition is a high-to-low

transition on SDA with SCL high. A STOP condition is a

low-to-high transition on SDA while SCL is high (Figure 4).

A START condition from the master signals the beginning

of a transmission to the device. The master terminates

transmission and frees the bus by issuing a STOP condition. The bus remains active if a repeated START condition is generated instead of a STOP condition.

t

SU:STA

REPEATED

CONDITION

START

t

HD:STA

t

SP

t

SU:STO

CONDITION

Early STOP Condition

The device recognizes a STOP condition at any point during data transmission, except if the STOP condition occurs

in the same high pulse as a START condition.

Each time the device is enabled, the state of the

MUTE_CL1 input is latched and determines the device’s

slave address. Table 2 shows the two possible hardware-defined slave addresses of the devices.

Once the device is enabled, it is programmable to one of

four I2C slave addresses through CTRL4.ADDR[1:0] (I2C

slave address setting bits), as shown in Table 3. When

initially setting the slave address, use the default slave

address as discussed in the previous paragraph and

shown in Table 2. After setting the slave address, set the

CTRL5.ADDR_DEF (I2C slave address definition bit) to 1.

For subsequent reads and writes, use the new softwaredefined address. These slave addresses are unique

device IDs.

The address is defined as the 7 most significant bits

(MSBs) followed by the R/W bit. Set the R/W bit to 1 to

configure the device to read mode. Set the R/W bit to 0

to configure the device to write mode. The address is

the first byte of information sent to the device after the

START condition.

BUF

STOP

CONDITION

Slave Address

START

16

Page 17

4-Channel, Automotive Class D Audio Amplifier

Table 2. Default Slave Address

MUTE_CL1

Low 1 1 0 1 1 0 1 X 0xDA 0xDB

High 1 1 0 1 1 0 0 X 0xD8 0xD9

A6 A5 A4 A3 A2 A1 A0

R/W

Table 3. I2C Programmable Slave Address

CTRL4.

ADDR[1:0]

00 1 1 0 1 1 0 0 X 0xD8 0xD9

01 1 1 0 1 1 1 0 X 0xDC 0xDD

10 1 1 0 1 1 0 1 X 0xDA 0xDB

11 1 1 0 1 1 1 1 X 0xDE 0xDF

A6 A5 A4 A3 A2 A1 A0

R/W

WRITE READ

WRITE READ

MAX13301

Acknowledge

The acknowledge bit (ACK) is a clocked 9th bit that the

device uses to handshake receipt each byte of data

(Figure 5). The device pulls down SDA during the master-generated 9th clock pulse. The SDA line must remain

stable and low during the high period of the acknowledge clock pulse. Monitoring ACK allows for detection

of unsuccessful data transfers. An unsuccessful data

transfer occurs if a receiving device is busy or if a system

fault has occurred. In the event of an unsuccessful data

transfer, the bus master can reattempt communication.

S

SDA

SCL

Figure 5. Acknowledge Condition

1 2 8 9

Write Data Format

A write to the device includes transmission of a START condition, the slave address with the write bit set to 0, one byte

of data to register address, one byte of data to the command register, and a STOP condition. Figure 6 illustrates

the proper format for one frame.

Read Data Format

A read from the device includes transmission of a START

condition, the slave address with the write bit set to 0, one

byte of data to register address, restart condition, the slave

address with read bit set to 1, one byte of data to the command register, and a STOP condition. Figure 6 illustrates

the proper format for one frame.

ACKNOWLEDGE

SLAVE ADDRESS

S A A P

(WRITE ADDRESS)

SLAVE ADDRESS

S A A Sr

(WRITE ADDRESS)

S = START CONDITION, A = ACKNOWLEDGE, NA = NOT ACKNOWLEDGE

Sr = REPEATED START CONDITION, P = STOP CONDITION

Figure 6. Data Format of I2C Interface Write Mode Read Mode

REGISTER

ADDRESS

REGISTER

ADDRESS

DATA

SLAVE ADDRESS

(READ ADDRESS)

A

A DATA NA

P

17

Page 18

4-Channel, Automotive Class D Audio Amplifier

Register Map

Table 4. Register Map

REGISTER BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0 ADDRESS R/W

CTRL0 — — MDIV3 MDIV2 MDIV1 MDIV0 TW1 TW0 0x00 R/W 0x24

CTRL1 — CL_TH CLVL1 CLVL0 — PRE CM1 CM0 0x01 R/W 0x00

CTRL2 — — STBY — MD23_1 MD23_0 MD01_1 MD01_0 0x02 R/W 0x20

CTRL3 TW RDET SDET DIS — HCL — LDM 0x03 R/W 0x00

MAX13301

CTRL4 — — ADDR1 ADDR0 — — — — 0x04 R/W 0xC0

CTRL5 SSEN RST SS2 SS1 SS0 PAR1 PAR0 ADDR_DEF 0x05 R/W 0x01

MAP COMP2 COMP1 COMP0 OTWM LCTM MCLP OTM FLTM 0x06 R/W 0x40

STAT —

OSTAT0

OSTAT1

OSTAT2

OSTAT3 — — — VER

OC3 OC2 OC1 OC0 CLIP3 CLIP2 CLIP1 CLIP0

LDOK3 LDOK2 LDOK1 LDOK0 LOAD3 LOAD2 LOAD1 LOAD0

SBAT3 SBAT2 SBAT1 SBAT0 SGND3 SGND2 SGND1 SGND0

OT OTW OV UV OC CPUV CLIP

VOS3 VOS2 VOS1 VOS0

0x07 R —

0x08 R —

0x09 R —

0x0A R —

0x0B R —

Table 5. Control Register 0

CTRL0

BIT # 7 6 5 4 3 2 1 0

NAME

POR

— — MDIV3 MDIV2 MDIV1 MDIV0 TW1 TW0

0 0 1 0 0 1 0 0

POWER-ON

RESET (POR)

Table 6. Control Register 0 Bit Description

BIT BIT DESCRIPTION

Master Clock-Divide Ratio. In master mode, the modulation and charge-pump frequencies are each set

to 4.5MHz/(MDIV[3:0]). The device is in standby mode for MDIV[3:0] ≤ 3. The valid operating frequencies

are 750kHz, 642.9kHz, 562.5kHz, 500kHz, 450kHz, 409.1kHz, 375kHz, 346.2kHz, 321.4kHz, and 300kHz.

MDIV[3:0]

TW[1:0]

18

Switching frequencies below 450kHz compromises noise, as a larger integrator and triangle-wave capacitor

trim setting is required.

In slave mode, the modulation and charge-pump frequency are always set to f

frequency of the clock signal applied to the SYNC input.

Thermal Warning Threshold. This threshold determines the temperature at which the status bit STAT.OTW

asserts.

00 = Junction temperature exceeds 110NC.

01 = Junction temperature exceeds 120NC.

10 = Junction temperature exceeds 130NC.

11 = Junction temperature exceeds 140NC.

SYNC

/2, where f

SYNC

is the

Page 19

4-Channel, Automotive Class D Audio Amplifier

Table 7. Control Register 1

CTRL1

BIT # 7 6 5 4 3 2 1 0

NAME

POR

Table 8. Control Register 1 Bit Description

BIT BIT DESCRIPTION

CL_TH

CLVL[1:0]

PRE

CM[1:0]

— CL_TH CLVL1 CLVL0 — PRE CM1 CM0

0 0 0 0 0 0 0 0

Selects the current threshold for the real-time short-to-ground and short-to-battery detection diagnostics.

Set this bit to 0 before exiting high-Z mode to prevent false triggering of short-to-ground and short-to-battery

faults during startup. Set this bit to 1 after the device has entered mute or play mode.

0 = High threshold

1 = Normal threshold

Clip Level. The clip level provides an indication of the amount of total harmonic distortion in the output signal.

00 = THD exceeds 10%

10 = THD exceeds 5%

01 = THD exceeds 3%

11 = THD exceeds 1%

Precharge. Use PRE to precharge the input DC-blocking capacitors. Set this bit to 1 as part of the startup

procedure. A 2FF capacitor for IN- and 0.47FF input blocking capacitors require a 1ms precharge to avoid

startup pop.

0 = Disable precharging

1 = Enable precharging

Clock Mode. Before selecting the operating mode, three-state all outputs.

00 = Master fixed frequency, switching frequency set by the master clock-divide ratio (CTRL0.MDIV[3:0])

bits, SYNC output disabled

01 = Master fixed frequency, switching frequency set by the master clock-divide ratio (CTRL0.MDIV[3:0])

bits, SYNC output enabled

10 = Reserved

11 = Slave fixed frequency, SYNC input enabled

MAX13301

19

Page 20

4-Channel, Automotive Class D Audio Amplifier

Table 9. Control Register 2

CTRL2

BIT # 7 6 5 4 3 2 1 0

NAME

POR

Table 10. Control Register 2 Bit Description

MAX13301

BIT BIT DESCRIPTION

STBY

MD23_[1:0]

MD01_[1:0]

— — STBY — MD23_1 MD23_0 MD01_1 MD01_0

0 0 1 0 0 0 0 0

Standby Mode. Wait 50ms after exiting standby mode to allow the charge pump and reference to stabilize

before entering mute or play mode.

0 = Normal mode

1 = Standby mode. The charge pump, preamplifier, and modulator are disabled. Fault monitors and I2C are

still active.

Channels 2 and 3 Output Mode. Channels 2 and 3 are always in the same configuration. MD23_[1:0]

determines the state of outputs 2 and 3.

00 = High-Z

01 = Mute

10 = Forced overvoltage. In this state, both differential outputs are charged to 1/2 V

11 = Play

Channels 0 and 1 Output Mode. Channels 0 and 1 are always in the same mode. MD01_[1:0] determines

the state of outputs 0 and 1.

00 = High-Z

01 = Mute

10 = Force overvoltage. In this state, both differential outputs are charged to 1/2 V

11 = Play

PVDD

PVDD

.

.

20

Page 21

4-Channel, Automotive Class D Audio Amplifier

Table 11. Control Register 3

CTRL3

BIT # 7 6 5 4 3 2 1 0

NAME

POR

Table 12. Control Register 3 Bit Description

BIT BIT DESCRIPTION

TW

RDET

TW RDET SDET DIS — HCL — LDM

0 0 0 0 0 0 0 0

Tweeter-Detect Current Threshold Setting

0 = The current threshold at which OSTAT1.LOAD[3:0] (load indicator bit) asserts is set equal to the shortedload current threshold (see the Electrical Characteristics table). Use this setting when running shorted-load

diagnostic.

1 = The current threshold at which OSTAT1.LOAD[3:0] asserts is set equal to the tweeter detect current

threshold. This threshold is approximately 25% of the default value to facilitate tweeter detection. Use this

setting when the running tweeter diagnostic or for detecting the presence of a speaker.

Open-Load Diagnostic Enable. Upon detecting an open load on any of the outputs, the corresponding

OSTAT1.LDOK[3:0] (load OK indicator bit) asserts. Always perform short-to-ground and short-to-battery

diagnosis before entering RDET mode. If a short-to-battery is detected, do not enter RDET mode. After

performing the short-to-battery test, discharge both outputs by setting CTRL3.DIS to 1 for 200µs, then reset

CTRL3.DIS back to 0. Failure to follow this procedure can result in a loud pop at the speaker.

Because the results are not latched, read LDOK[3:0] before clearing RDET. Wait a minimum of 200µs before

reading these status bits. RDET can only be set after three-stating all four outputs. When performing the

open-load diagnostic, set the CTRL3.SDET (short-to-ground/battery enable) bit to 0.

0 = Disable open-load diagnostic

1 = Enable open-load diagnostic

MAX13301

SDET

DIS

HCL

LDM

Short-to-Ground/Battery Diagnostic Enable. Upon detecting a short-to-ground or battery on any of the outputs,

the corresponding OSTAT2.SBAT[3:0] (short-to-battery) and OSTAT2.SGND[3:0] (short-to-ground) bits assert.

Because the results are not latched, read OSTAT2.SBAT[3:0] and OSTAT2.SGND[3:0] before clearing SDET.

Wait a minimum of 200µs before reading these status bits. Before setting SDET to 1, three-state all four outputs and set the CTRL3.DIS (discharge output enable) bit to 1 and then reset back to 0. Before performing

the short-to-ground/battery diagnostic, set the CTRL3.RDET (open-load diagnostic enable) bit to 0. To test for

short-to-ground, set CTRL2.STBY to 0, and to test for short-to-battery, set CTRL2.STBY to 1.

0 = Disable short-to-ground/battery diagnostic

1 = Enable short-to-ground/battery diagnostic

Discharge Output Enable. Set DIS to 1 to discharge all outputs with 15mA current sources. Use DIS to discharge all outputs before performing the short-to-ground/battery diagnostic (SDET) to avoid a loud pop on

the speaker. DIS can only be set to 1 after three-stating all four outputs.

0 = Output discharge is disabled.

1 = Output discharge is enabled.

Current-Limit Level. HCL sets the current-limit threshold of the outputs during normal operation.

0 = 7A (typ) current limit

1 = 8.75A (typ) current limit

Line-Driver Mode. Use LDM to set the load resistance threshold required to assert the OSTAT1.LDOK[3:0]

(load-okay indicator bit). Any load with a resistance greater than the threshold is interpreted as an open

output.

0 = Line-driver mode, OSTAT1.LDOK[3:0] = 1 if RL > 300I

1 = Power amplifier mode, OSTAT1.LDOK[3:0] = 1 if RL > 100I

21

Page 22

4-Channel, Automotive Class D Audio Amplifier

Table 13. Control Register 4

CTRL4

BIT # 7 6 5 4 3 2 1 0

NAME

POR

Table 14. Control Register 4 Bit Description

MAX13301

BIT BIT DESCRIPTION

ADDR[1:0]

— — ADDR1 ADDR0 — — — —

1 1 0 0 X X X X

I2C Slave Address Setting. Use ADDR[1:0] to set the slave address of the device. After setting the slave

address, set CTRL5.ADDR_DEF (I2C slave address definition bit) to 1 to make the new address effective.

00 = Slave address set to 1101100 R/W

01 = Slave address set to 1101110 R/W

10 = Slave address set to 1101101 R/W

11 = Slave address set to 1101111 R/W

22

Page 23

4-Channel, Automotive Class D Audio Amplifier

Table 15. Control Register 5

CTRL5

BIT # 7 6 5 4 3 2 1 0

NAME

POR

Table 16. Control Register 5 Bit Description

BIT BIT DESCRIPTION

SSEN

RST

SS[2:0]

PAR[1:0]

SSEN RST SS2 SS1 SS0 PAR1 PAR0 ADDR_DEF

0 0 0 0 0 0 0 1

Spread-Spectrum Modulation Enable.

0: Spread-spectrum disabled; SSEN = 1 and SS[2:0] > 0: Spread-spectrum enabled

Reset. Setting RST to 1 resets the device. In reset, all register bits are reset to their POR values. RST is automatically cleared back to 0 after device reset.

0 = Not in reset

1 = Reset

Spread-Spectrum Modulation Control. Spread-spectrum modulation is enabled when SSEN = 1 and SS[2:0]

> 0, once enabled the switching frequency varies from +2% to +7% (see Table 17).

Parallel Mode. The four outputs can be paralleled in one of four ways. To parallel outputs, connect the positive outputs together and connect the negative outputs together. In parallel mode, only the feedback inputs

corresponding to the slaved input IN0+ or IN2+ are used. Connect the other feedback inputs to ground.

00 = 4-channel output

01 = 2.1-channel output. Outputs 0 and 1 are paralleled and slaved to input IN0+. Channels 2 and 3 are

unaffected.

10 = 2.1-channel output. Outputs 2 and 3 are paralleled and slaved to input IN2+. Channels 0 and 1 are

unaffected.

11 = 2-channel output. Outputs 0 and 1 are paralleled and slaved to input IN0+. Outputs 2 and 3 are paralleled and slaved to input IN2+.

MAX13301

I2C Slave Address Definition. This bit determines whether the I2C slave address is hardware or softwaredefined.

ADDR_DEF

0 = Slave address is defined by CTRL4.ADDR[1:0] (I2C slave address setting bits).

1 = Slave address is set to the default address as defined by the state of the MUTE_CL1 input when the

enable input EN is pulled high.

Table 17. Spread-Spectrum Modulation Table

SSEN SS2 SS1 SS0 SPREAD (%)

0 X X X Disabled

1 0 0 0 0

1 0 0 1 2

1 0 1 0 3

1 0 1 1 4

1 1 0 0 5

1 1 0 1 6

1 1 1 0 7

1 1 1 1 Reserved

23

Page 24

4-Channel, Automotive Class D Audio Amplifier

Table 18. Mapping Register

MAP

BIT # 7 6 5 4 3 2 1 0

NAME

POR

Table 19. Mapping Register Bit Description

MAX13301

BIT BIT DESCRIPTION

COMP[2:0]

OTWM

LCTM

MCLP

OTM

FLTM

COMP2 COMP1 COMP0 OTWM LCTM MCLP OTM FLTM

0 1 0 0 0 0 0 0

Integrator and Triangle-Wave Capacitor Trim. A smaller integrator capacitor pushes noise out of the audio

band yielding the lowest noise. If distortion rises at high output powers, lower switching frequencies, or

higher PVDD voltages then use a larger capacitor setting. See Table 20 for choosing minimum capacitor

settings based on PVDD and the switching frequency. Larger capacitor values can be used.

If all 4 channels of the amplifier are used to drive subwoofers, the capacitor settings can be relaxed

because a smaller capacitor setting helps to eliminate high-frequency noise (greater than 10kHz). Systems

with multiple tweeters benefit the most from proper COMP[2:0] selection. Lower switching frequencies are

possible when this high-frequency noise is not a concern as with systems that lack tweeters.

000 = 43pF

001 = 37pF

010 = 31pF

011 = 25pF

100 = 18pF

101 = Reserved

110 = Reserved

111 = Reserved

Overtemperature Warning Mapping Bit

0 = STAT.OTW (overtemperature warning bit) is unmapped to the FLT_OT open-drain output.

1 = STAT.OTW is mapped to FLT_OT when MAP.OTM = 1.

Low-Current Threshold Mapping Bit. The current thresholds used in tweeter and shorted load diagnostics

are lower than the current limit. When the threshold is exceeded in running either diagnostic,

OSTAT1.LOAD[3:0] (load indicator bit) asserts. Hardware indication is also possible by using LCTM to map

OSTAT1.LOAD[3:0] to the CL0 and MUTE_CL1 outputs.

0 = OSTAT1.LOAD[3:0] (load indicator bit used for tweeter and shorted load diagnostics) is unmapped to

the CL0 and MUTE_CL1 outputs.

1 = OSTAT1.LOAD[3:0] is mapped to the CL0 and MUTE_CL1 outputs. Use this setting only when running

tweeter or shorted load diagnostic.

Clip Output Mapping. MCLP determines which open-drain outputs (CL0 and MUTE_CL1) are used to indicate clipping on an audio output. CL0 is always used as a clip indicator, while MUTE_CL1 is configurable

as a clip indicator output or as a mute input.

0 = CL0 provides clip indication for all audio outputs; MUTE_CL1 is configured as a mute input.

1 = CL0 provides clip indication for audio outputs 0 and 1; MUTE_CL1 is configured as a clip indicator output for audio outputs 2 and 3.

Overtemperature Shutdown Map

0 = STAT.OT (overtemperature shutdown bit) is unmapped to the open-drain FLT_OT output.

1 = STAT.OT is mapped to the FLT_OT output.

Fault Mapping Bit

0 = Faults are unmapped to the open-drain FLT_OT output.

1 = Any fault condition (as indicated by the status bits OV, UV, OC) causes FLT_OT to assert low.

24

Page 25

4-Channel, Automotive Class D Audio Amplifier

Table 20. COMP[2:0] Setting Lookup Table

fSW/V

PVDD

300k 100 100 100 011 011 010 001

320k 100 100 100 011 011 010 010

346k 100 100 100 100 011 010 010

375k 100 100 100 100 011 011 010

409k 100 100 100 100 100 011 011

450k 100 100 100 100 100 011 011

475k 100 100 100 100 100 100 011

500k 100 100 100 100 100 100 011

530k 100 100 100 100 100 100 011

562k 100 100 100 100 100 100 100

600k 100 100 100 100 100 100 100

643k 100 100 100 100 100 100 100

675k 100 100 100 100 100 100 100

700k 100 100 100 100 100 100 100

725k 100 100 100 100 100 100 100

750k 100 100 100 100 100 100 100

< 8V

8V to

9.5V

9.5V to

12.65V

12.65V to

15.6V

15.6V to

18.65V

18.65V to

21.1V

> 21.1V

MAX13301

Table 21. Status Register

STAT

BIT # 7 6 5 4 3 2 1 0

NAME

—

OT OTW OV UV OC CPUV CLIP

Table 22. Status Register Bit Description

BIT BIT DESCRIPTION

Overtemperature Shutdown. The device goes into thermal shutdown when the junction temperature exceeds

OT

OTW

OV

UV

+150NC.

0 = Device is in thermal shutdown.

1 = Device is not in thermal shutdown.

Overtemperature Warning. OTW asserts when the junction temperature exceeds the thermal warning threshold programmed in CTRL0.TW[1:0].

0 = Junction temperature is greater than the programmed thermal warning threshold.

1 = Junction temperature is less than the programmed thermal warning threshold.

Overvoltage Indicator

0 = V

Characteristics table.

1 = V

Undervoltage Indicator

0 = V

Characteristics table.

1 = V

is greater than the PVDD overvoltage lockout (OVLO) threshold as defined in the Electrical

PVDD

is less than the OVLO threshold.

PVDD

is less than the PVDD undervoltage lockout (UVLO) threshold as defined in the Electrical

PVDD

is greater than the UVLO threshold.

PVDD

25

Page 26

4-Channel, Automotive Class D Audio Amplifier

Table 22. Status Register Bit Description (continued)

BIT BIT DESCRIPTION

General Overcurrent Indicator. OC asserts when there is an overcurrent condition on any of the outputs

such as a short-to-ground/battery. To identify which output(s) is experiencing an overcurrent condition, read

OC

MAX13301

CPUV

CLIP

Table 23. Status Register 0

BIT # 7 6 5 4 3 2 1 0

NAME

the OSTAT0.OC[3:0] (overcurrent indicator bit).

0 = An overcurrent condition exists on one or more of the outputs.

1 = No overcurrent condition.

Charge-Pump Undervoltage Indicator. CPUV asserts when the voltage on the hold capacitor of the charge

pump (C

0 = Undervoltage on C

1 = Adequate voltage on C

General Clip Indicator. CLIP asserts when any of the outputs is clipping. To identify which output(s) is clipping, read the OSTAT0.CLIP[3:0] (clip indicator) bits.

0 = One or more outputs are clipping.

1 = None of the outputs are clipping.

OC3 OC2 OC1 OC0 CLIP3 CLIP2 CLIP1 CLIP0

) falls below 3.87V. It deasserts once the voltage rises above 4.1V.

HOLD

HOLD

HOLD

OSTAT0

Table 24. Status Register 0 Bit Description

BIT BIT DESCRIPTION

Overcurrent Indicator. An overcurrent condition such as a short-to-ground/battery on any of the outputs

causes the corresponding OC[3:0] bit to latch to 0. Write a 1 to this bit to clear it. Reset also clears this bit.

OC[3:0]

CLIP[3:0]

An overcurrent indicator is available for each output: OC3 is for output 3, OC2 is for output 2, etc.

0 = There is an overcurrent condition on the output.

1 = There is no overcurrent condition on the output.

Clip Indicator. CLIP[3:0] is a real-time clip indicator for each output. This bit asserts only during the times

when an overdriven output is actually clipping. A clip indictor is available for each output: CLIP3 is for output

3, CLIP2 is for output 2, etc.

0 = Output is clipping.

1 = Output is not clipping.

26

Page 27

4-Channel, Automotive Class D Audio Amplifier

Table 25. Status Register 1

OSTAT1

BIT # 7 6 5 4 3 2 1 0

NAME

Table 26. Status Register 1 Bit Description

LDOK[3:0]

LOAD[3:0]

LDOK3 LDOK2 LDOK1 LDOK0 LOAD3 LOAD2 LOAD1 LOAD0

BIT BIT DESCRIPTION

Load Okay Indicator. When running the open-load diagnostic, LDOK[3:0] = 1 if the load resistance

is greater than the resistance threshold set by CTRL3.LDM (line driver mode bit), indicating that the

output is properly loaded and not open. A load okay indicator is available for each output: LDOK3 is

for output 3, LDOK2 is for output 2, etc.

0 = Output is loaded.

1 = Output is open.

Load Indicator. When running shorted load or tweeter diagnostic, LOAD[3:0] asserts if there is a

short across the load or if a tweeter is connected. See the Shorted-Load Diagnostic and Tweeter

Diagnostic sections for information on the use of LOAD[3:0] in performing load diagnostics.

LOAD[3:0] is available for each output: LOAD3 is for output 3, LOAD2 is for output 2, etc.

0 = Load threshold exceeded.

1 = Load threshold not exceeded.

MAX13301

Table 27. Status Register 2

OSTAT2

BIT # 7 6 5 4 3 2 1 0

NAME

SBAT3 SBAT2 SBAT1 SBAT0 SGND3 SGND2 SGND1 SGND0

Table 28. Status Register 2 Bit Description

BIT BIT DESCRIPTION

Short-to-Battery Indicator. When running a short-to-ground/battery diagnostic, SBAT[3:0] provides indication of any short-to-battery for each output. Use SBAT[3:0] to ensure that there is no short-to-battery before

SBAT[3:0]

SGND[3:0]

turning on the device. This indicator is available for each output: SBAT3 is for output 3, SBAT2 is for output

2, etc.

0 = Output is shorted to the battery.

1 = Output is not shorted to the battery.

Short-to-Ground Indicator. When running a short-to-ground/battery diagnostic, SGND[3:0] provides indication of any short-to-ground for each output. Use SGND[3:0] to ensure that there is no short-to-ground

before turning on the device. This indicator is available for each output: SGND3 is for output 3, SGND2 is

for output 2, etc.

0 = Output is shorted to ground.

1 = Output is not shorted to ground.

27

Page 28

4-Channel, Automotive Class D Audio Amplifier

Table 29. Status Register 3

OSTAT3

BIT # 7 6 5 4 3 2 1 0

NAME

Table 30. Status Register 3 Bit Description

BIT BIT DESCRIPTION

MAX13301

VER

VOS[3:0]

Table 31. Fault Conditions

Overvoltage All

Undervoltage (PVDD) Normal, Standby

Charge-Pump Undervoltage Normal I2C High-Z All No

Overtemperature Shutdown Normal, Standby

Overtemperature Warning Normal

Open Load Normal I2C None No

Shorted Load Normal I2C High-Z Channel Yes

Short-to-Ground/Battery Normal

Clip Output Normal

Overcurrent Normal

DC Offset Normal, No Music I2C None No

— — — VER

Version Indicator.

0 = Reserved

1 = MAX13301

Offset Voltage Indicator. VOS[3:0] indicates whether an offset voltage exists between the differential outputs.

Read this bit in play mode after precharge with no signal on the input. This bit is not latched and is not a

valid indicator of offset when an input signal is present. An offset voltage indicator is available for each output: VOS3 is for output 3, VOS2 is for output 2, etc.

0 = The differential offset voltage between OUT_+ and OUT_- exceeds Q1V (typ).

1 = The differential offset voltage between OUT_+ and OUT_- is within Q1V (typ).

FAULT MONITORING STATE REPORTING METHOD ACTION LATCHED

I2C, CL0, MUTE_CL1

VOS3 VOS2 VOS1 VOS0

I2C, FLT_OT

I2C, FLT_OT

I2C, FLT_OT

I2C, FLT_OT

I2C, FLT_OT

I2C, FLT_OT

OUT_ to 1/2 V

High-Z All No

High-Z All No

High-Z Channel Yes

High-Z Channel Yes

PVDD

None No

None No

No

Fault Detection

The device integrates fault detection and protection

circuitry. Table 31 lists all fault events that each device

can encounter, the modes in which they are detected,

the method with which they are reported, the devices'

response to them, and whether they cause the outputs

to latch into a high-impedance state.

Load Diagnostics

The device incorporates built-in diagnostics to detect

external wire harness faults that can occur during installation or over time. Load diagnostics include short circuit

to ground or battery, shorted or open speaker, and

open tweeter. Load diagnostics can be run at any time

28

when the device is in normal mode (i.e., not in standby

mode) with the outputs three-stated. The presence of

any of these faults is indicated by software through the

status registers and by hardware through the CL0 and

MUTE_CL1 open-drain outputs if the status bits have

been mapped to the outputs.

Short-to-Ground/Battery Diagnostic

The diagnostic for short-to-battery and ground is done

with CTRL3.SDET = 1. None of the results are latched

so the OSTAT2 register must be read while running this

diagnostic to get a valid status.

If the load is present, a short on either of the differential

outputs results in a short on the other output. Therefore,

Page 29

4-Channel, Automotive Class D Audio Amplifier

the status register only indicates which channel’s output

is shorted and not which of its differential outputs is shorted. The I2C status register can indicate, for example, that

output 1 is shorted to battery, but it cannot differentiate

between an OUT1+ and OUT1- short-to-battery.

Before running the short-to-ground/battery diagnostic,

perform steps 1 to 3 of the shutdown procedure outlined in the Startup and Shutdown section. Before set-

ting CTRL3.SDET to 1, discharge the output by setting CTRL3.DIS to 1 for 200µs and reset CTRL3.DIS

to 0. Run the short-to-ground/battery diagnostic by

setting CTRL3.SDET (short-to-ground/battery diagnostic enable bit) to 1. To test for short-to-ground, set

CTRL2.STBY to 0; to test short-to-battery, set

CTRL2.STBY to 1. With CTRL2.STBY = 0, 6V is developed

at each output. An output voltage > 6V is interpreted as

a short-to-battery. An output voltage < 150mV is interpreted as a short to ground. Results of the diagnostic

are reported in the OSTAT2.SBAT[3:0] (short-to-battery indicator) and OSTAT2.SGND[3:0] (short-to-ground

indicator) bits. Wait a minimum of 200Fs after setting

CTRL3.SDET for valid results. After running the short-toground/battery diagnostic, clear the CTRL3.SDET bit to 0.

Because no latch is set, a short-to-ground or battery

does not prevent the device from powering up. Therefore,

the microcontroller can enable the device into a short

although it is discouraged. Should the device be enabled

into a short, the real-time overcurrent latches the shorted

channel off. The device offers real-time protection for

short-to-battery, short-to-ground, and shorted load to prevent damage to the device.

Open-Load Diagnostic

This diagnostic detects an open between OUT_+ and

OUT_- of > 100I or > 300I, depending on the value of

CTRL3.LDM (line driver mode bit).

Before running the open-load diagnostic, perform steps

1 to 3 of the shutdown procedure outlined in the Startup

and Shutdown section. Run the open-load diagnostic test by setting CTRL3.RDET (open-load diagnostic

enable bit) to 1, and in the same command, discharge the output capacitors by setting CTRL3.DIS

(discharge bit) to 1. During the diagnostic, all low-side

FETs of the negative outputs (OUT_-) are turned on,

while all other FETs are turned off. The device sources

a 2mA current from OUT_+ to OUT_-. If a load is not

present, OUT_+ swings high and is interpreted as an

open output. Results of the diagnostic are reported in

OSTAT1.LDOK[3:0] (load OK indicator bit). Wait

a minimum of 200Fs for valid results after setting

MAX13301

CTRL3.RDET. After running the open-load diagnostic,

clear CTRL3.RDET and CTRL3.DIS to 0.

Shorted-Load Diagnostic

This diagnostic detects shorted loads on any of the

outputs. To detect shorted loads, the device should be

in play mode. Set CTRL3.TW (tweeter-detect current

threshold setting bit) to 0 and apply a low-frequency

(typically < 20Hz) sinusoidal signal to all the inputs.

The device compares the load current to the shortedload current threshold. If the load current exceeds the

threshold, the corresponding OSTAT1.LOAD[3:0] (load

indicator bit) is set to 1, indicating that there is a shorted

load. The shorted-load current threshold depends on the

programmed current limit as set by the CTRL3.HCL. See

the High-Current Threshold parameter in the Electrical

Characteristics table.