Page 1

General Description

The MAX1253/MAX1254 are stand-alone, 10-channel (8

external, 2 internal) 12-bit system monitor ADCs with

internal reference. A programmable single-ended/differential mux accepts voltage and remote-diode temperature-sensor inputs. These devices independently

monitor the input channels without microprocessor

interaction and generate an interrupt when any variable

exceeds user-defined limits. The MAX1253/MAX1254

configure both high and low limits, as well as the number of fault cycles allowed, before generating an interrupt. These ADCs can also perform recursive data

averaging for noise reduction. Programmable wait intervals between conversion sequences allow the selection

of the sample rate.

At the maximum sampling rate of 94ksps (auto mode,

single channel enabled), the MAX1253 consumes only

5mW (1.7mA at 3V). AutoShutdownTMreduces supply

current to 190µA at 2ksps and to less than 8µA at 50sps.

Stand-alone operation, combined with ease of use in a

small package (16-pin TSSOP), makes the MAX1253/

MAX1254 ideal for multichannel system-monitoring

applications. Low power consumption also makes

these devices a good fit for hand-held and battery-powered applications.

Applications

System Supervision

Remote Telecom Networks

Server Farms

Remote Data Loggers

Features

♦ Monitor 10 Signals Without Processor

Intervention

♦ Eight External Channels Programmable as

Temperature or Voltage Monitors

♦ Intelligent Circuitry for Reliable Autonomous

Measurement

Programmable Digital Averaging Filter

Programmable Fault Counter

♦ Precision Measurements

12-Bit Resolution

±1 LSB INL, ±1 LSB DNL

±0.75°C Temperature Accuracy (typ)

♦ Flexible

Automatic Channel Scan Sequencer with

Programmable Intervals

Programmable Inputs: Single Ended/Differential,

Voltage/Temperature

Programmable Wait State

♦ Internal 2.5V/4.096V Reference

(MAX1253/MAX1254)

♦ Remote Temperature Sensing Up to 10m

(Differential Mode)

♦ Single 3V or 5V Supply Operation

♦ Small 16-Pin TSSOP Package

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

________________________________________________________________ Maxim Integrated Products 1

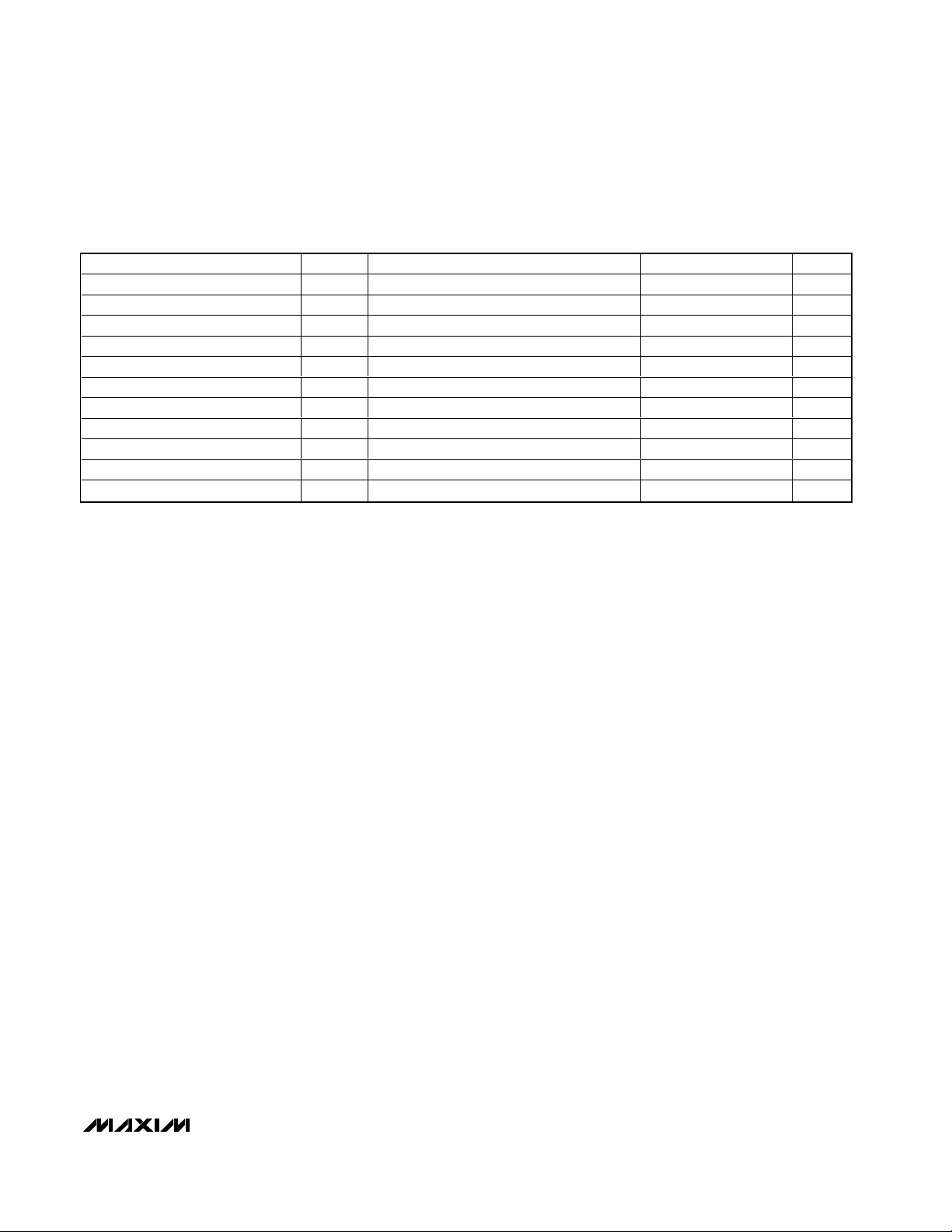

Selector Guide

19-2838; Rev 0; 4/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

*Future product—contact factory for availability.

*Future product—contact factory for availability.

Typical Application Circuit appears at end of data sheet.

AutoShutdown is a trademark of Maxim Integrated Products, Inc.

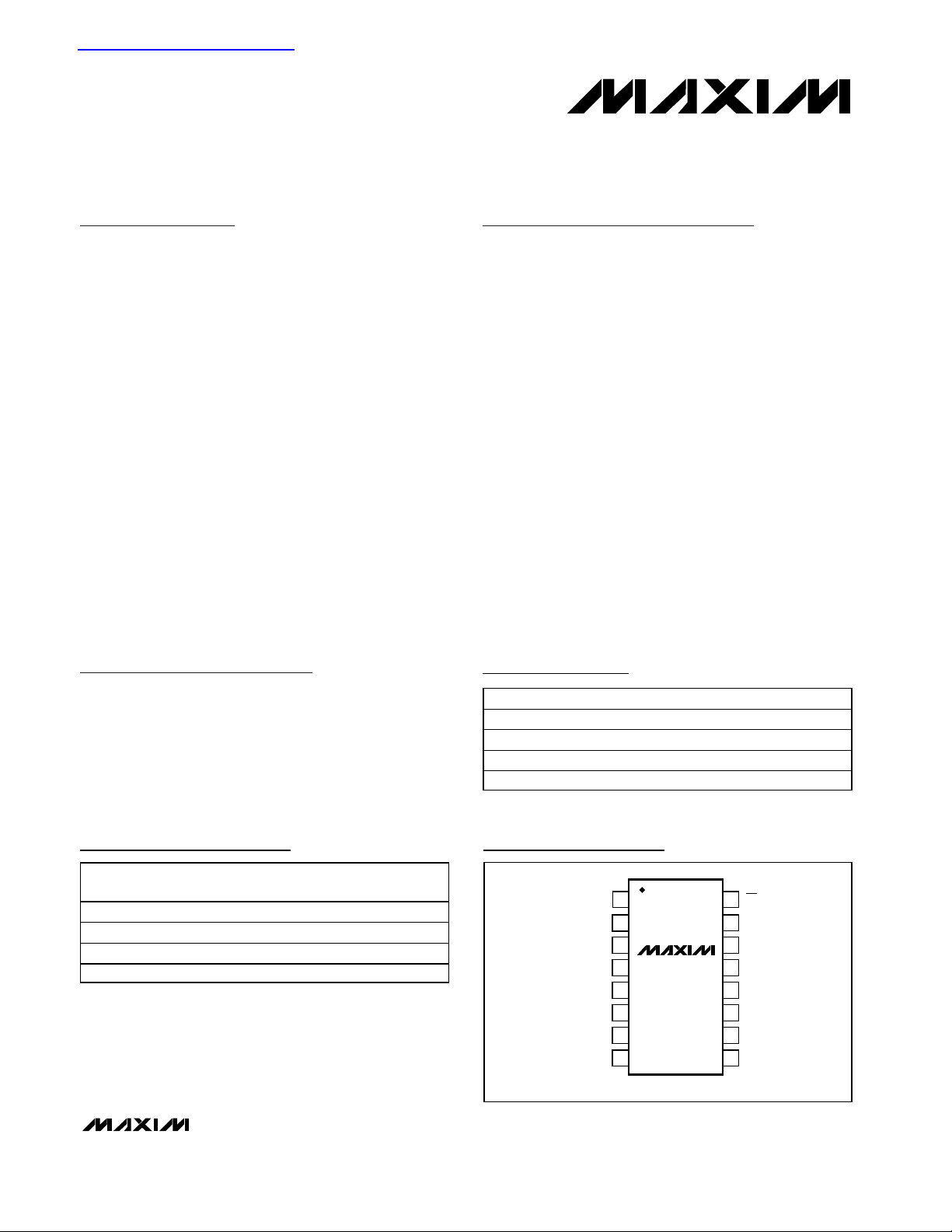

Pin Configuration

Ordering Information

查询MAX1253AEUE供应商

PART INL (LSB)

MAX1253AEUE*

MAX1253BEUE

MAX1254AEUE*

MAX1254BEUE

±1 ±1.0

±1 ±3.0

±1 ±1.0

±1 ±2.5

TEMP

ERROR (°C)

SUPPLY

VOLTAGE (V)

2.7 to 3.6

2.7 to 3.6

4.5 to 5.5

4.5 to 5.5

PART TEMP RANGE PIN-PACKAGE

MAX1253AEUE* -40°C to +85°C

MAX1253BEUE -40°C to +85°C

MAX1254AEUE* -40°C to +85°C

MAX1254BEUE -40°C to +85°C

TOP VIEW

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

1

2

3

4

5

6

7

8

MAX1253

MAX1254

16 TSSOP

16

15

14

13

12

11

10

9

16 TSSOP

16 TSSOP

16 TSSOP

16 TSSOP

CS

SCLK

DIN

V

DD

GND

DOUT

INT

REF

Page 2

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto GND .............................................................-0.3V to +6V

Analog Inputs to GND (AIN0–AIN7, REF) ... -0.3V to (V

DD

+ 0.3V)

Digital Inputs to GND (DIN, SCLK, CS) .... -0.3V to (V

DD

+ 0.3V)

Digital Outputs to GND (DOUT, INT) ........ -0.3V to (V

DD

+ 0.3V)

Digital Outputs Sink Current ............................................. 25mA

Maximum Current into Any Pin .......................................... 50mA

Continuous Power Dissipation (TA= +70°C)

16-Pin TSSOP (derate 8.7mW/°C above +70°C) .........696mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

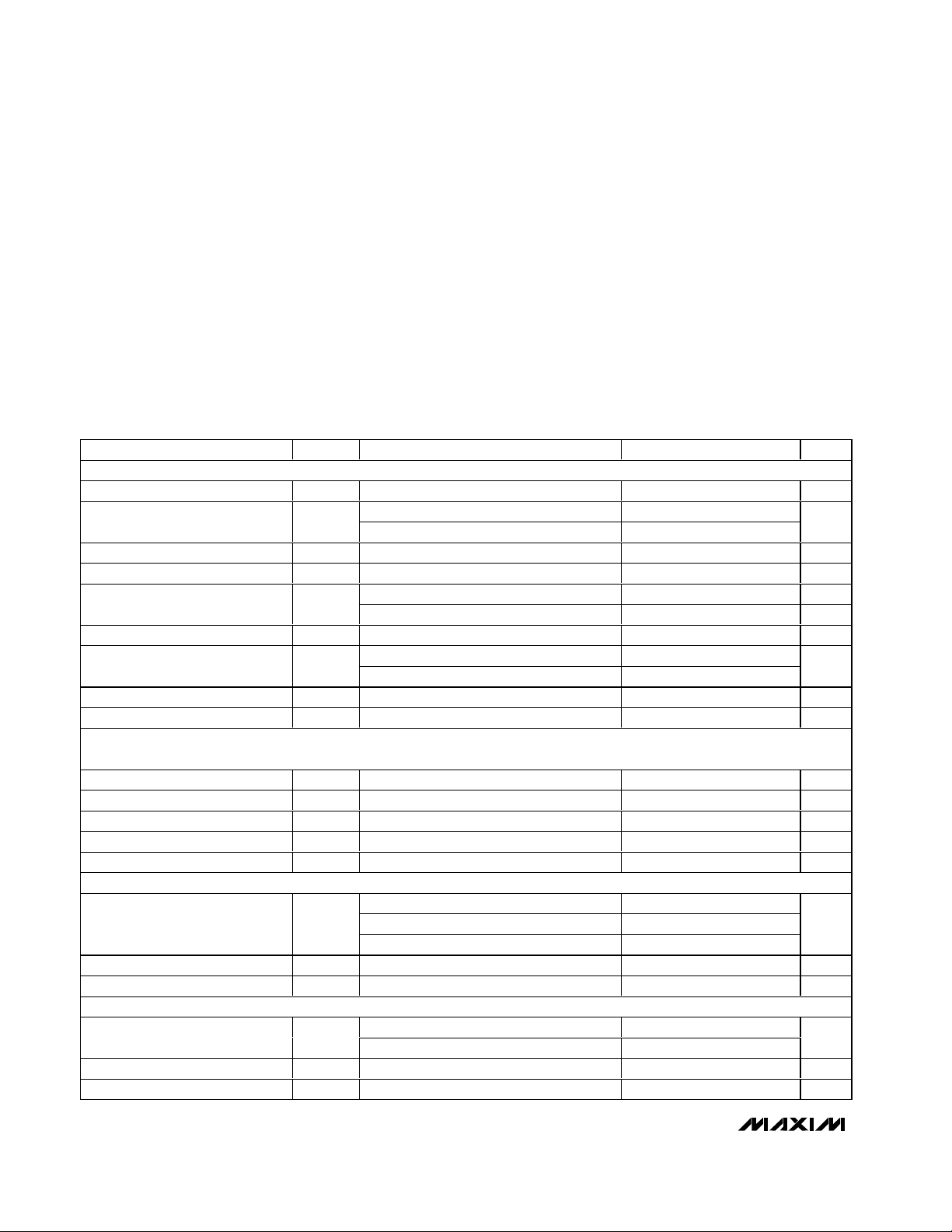

ELECTRICAL CHARACTERISTICS

(VDD= +2.7V to +3.6V (MAX1253), VDD= +4.5V to +5.5V (MAX1254), V

REF

= +2.5V (MAX1253), V

REF

= +4.096V (MAX1254), f

SCLK

= 10MHz (50% duty cycle), TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

DC ACCURACY

Resolution RES 12 Bits

Integral Nonlinearity (Note 1) INL

Differential Nonlinearity DNL No missing codes overtemperature ±1.0 LSB

Offset Error ±4.0 LSB

Gain Error (Note 2)

Offset Error Tempco ±5p p m /°C

Gain and Temperature Coefficient

C hannel - to- C hannel Offset M atchi ng ±0.1 LSB

V DD M oni tor Accur acy Internal reference ±2.5 %

DYNAMIC ACCURACY

(10kHz sine-wave input, 2.5V

Signal-to-Noise Plus Distortion SINAD 70 dB

Total Harmonic Distortion THD Up to the 5th harmonic -76 dB

Spurious-Free Dynamic Range SFDR 72 dB

Full-Power Bandwidth -3dB point 1 MHz

Full Linear Bandwidth S / (N + D) > 68dB 100 kHz

CONVERSION RATE

Single-Channel Throughput Manual trigger, voltage measurement 70 ksps

Power-Up Time t

ANALOG INPUT

Input Voltage Range (Note 5)

Common-Mode Range Differentially configured inputs 0 V

Common-Mode Rejection D i ffer enti all y confi g ur ed i np uts, V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

P-P

(AIN0–AIN7)

(MAX1253), 4.096V

Grade A ±1.0

Grade B ±1.0

External reference ±4.0 LSB

Internal reference 2.0 %FSR

External reference ±2

Internal reference ±30

Voltage measurement, all ref modes 10.6 11.7

CONV

Temp-sensor ref modes 01, 10 46 50.7Conversion Time (Note 3) t

Temp-sensor ref mode 00 73 80

Internal reference (Note 4) 40 45 µs

PU

U ni p ol ar , si ng l e- end ed , or d i ffer enti al i np uts 0 +V

Bipolar, differential inputs -V

(MAX1254), 64ksps, f

P-P

= 10MHz, bipolar input mode)

SCLK

= 0 to V

C M

D D

/ 2 +V

REF

-90 dB

REF

REF

DD

/ 2

LSB

p p m /°C

µs

V

V

Page 3

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

_______________________________________________________________________________________ 3

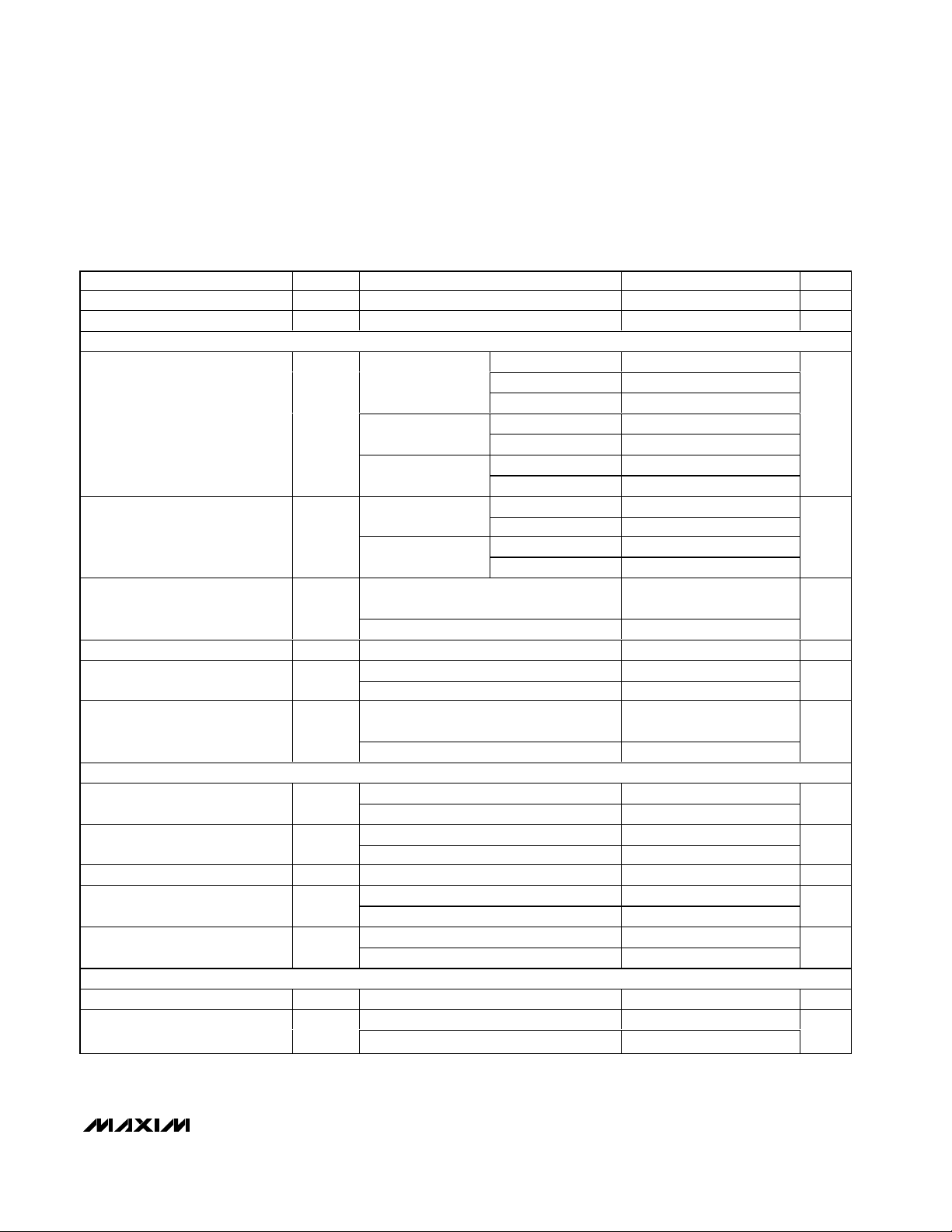

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +2.7V to +3.6V (MAX1253), VDD= +4.5V to +5.5V (MAX1254), V

REF

= +2.5V (MAX1253), V

REF

= +4.096V (MAX1254), f

SCLK

= 10MHz (50% duty cycle), TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

Input Leakage Current On-/off-leakage, VIN = 0 or V

Input Capacitance (Note 6) 18 pF

TEMPERATURE MEASUREMENTS

Internal Sensor Measurement Error

(Note 7)

External Sensor Measurement

Error (Note 8)

Temperature Measurement Noise

Temperature Resolution 0.125 °C/LSB

External Sensor Bias Current

Power-Supply Rejection PSR

INTERNAL REFERENCE

REF Output Voltage V

REF Temperature Coefficient TC

REF Output Resistance 7kΩ

REF Output Noise

REF Power-Supply Rejection Ratio PSRR

EXTERNAL REFERENCE

REF Input Voltage Range V

REF Input Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Grade A

MAX1253

MAX1254

Grade B

MAX1253

Grade B

MAX1254

Differential

Single ended

Differentially configured inputs and internal

sensor

Single-ended configured, external sensor 0.1

Low 4

High 66

Differentially configured inputs and internal

sensor

Single-ended configured, external sensor 0.1

MAX1253 2.456 2.500 2.544

REF

MAX1254 4.024 4.096 4.168

Grade A ±8

REF

Grade B ±30

MAX1253 200

MAX1254 160

MAX1253 -70 -50

MAX1254 -70 -50

REF

V

= +2.5V; f

REF

REF

In power-down ±1

SAMPLE

DD

TA = -20°C to +85°C ±0.5 ±1.0

TA = -40°C to +85°C ±0.75 ±1.5

= +25°C ±0.3

T

A

TA = -40°C to +85°C ±1.2 ±2.5

T

= +25°C ±0.7

A

TA = -40°C to +85°C ±1.2 ±3.0

= +25°C ±0.7

T

A

TA = -40°C to +85°C±2

= +25°C±1

T

A

TA = -40°C to +85°C±5

T

= +25°C±2

A

= 94ksps 15 40

±1 µA

0.3

0.3

p p m /°C

µV

1.0 VDD + 0.05 V

°C

°C

°C

µA

°C/V

V

RMS

dB

µA

Page 4

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

4 _______________________________________________________________________________________

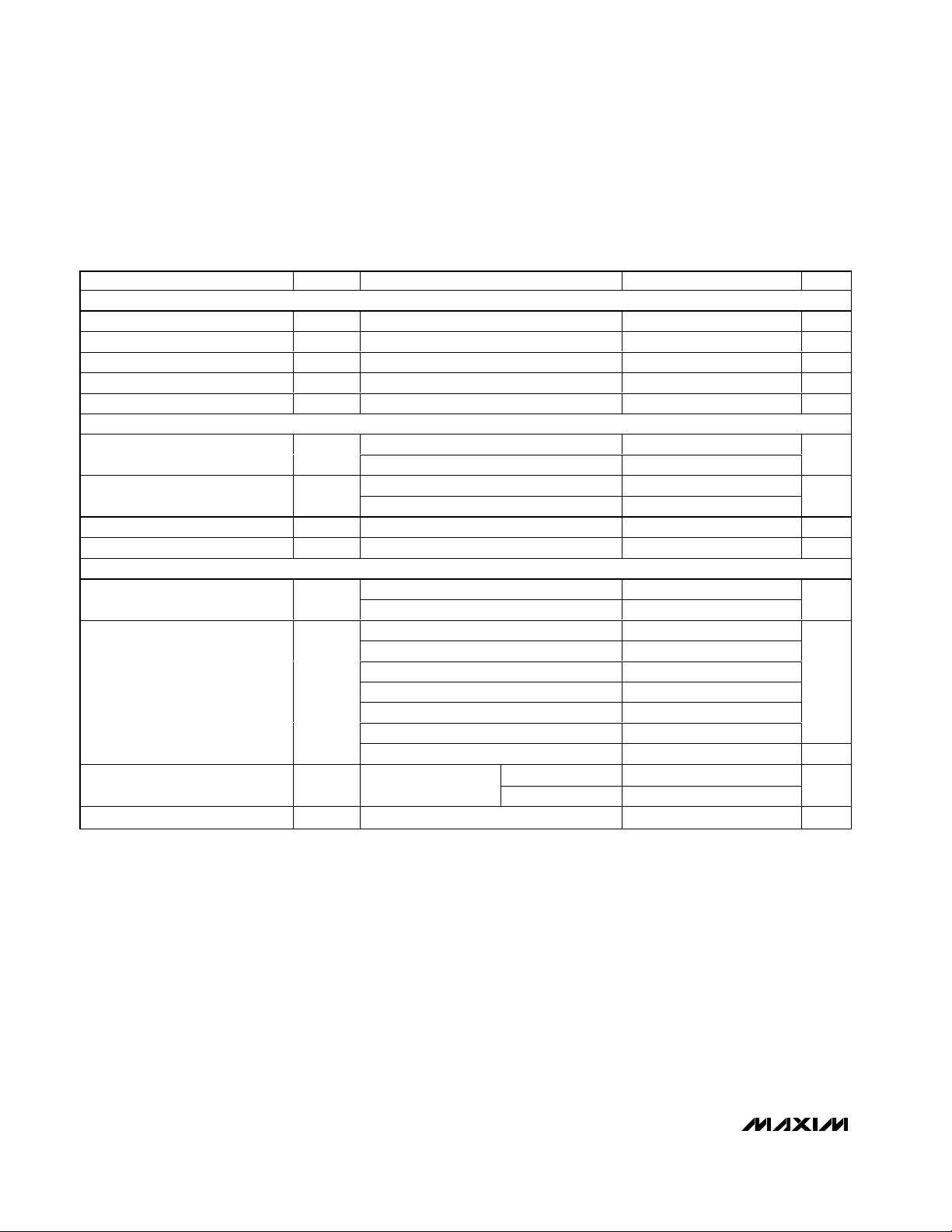

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +2.7V to +3.6V (MAX1253), VDD= +4.5V to +5.5V (MAX1254), V

REF

= +2.5V (MAX1253), V

REF

= +4.096V (MAX1254), f

SCLK

= 10MHz (50% duty cycle), TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

DIGITAL INPUTS

Input Voltage Low V

Input Voltage High V

Input Hysteresis V

Input Leakage Current I

Input Capacitance C

DIGITAL OUTPUTS

Output Voltage Low V

Output Voltage High V

Tri-State Leakage Current I

Tri-State Output Capacitance C

POWER REQUIREMENTS

Positive Supply Voltage V

Supply Current I

Full Power-Down Supply Current I

Power-Supply Rejection Ratio PSRR Analog inputs at full scale (Note 12) ±0.4 ±1.6 mV/V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

(SCLK, DIN, CS)

(INT, DOUT)

IL

IH

HYST

IN

IN

OL

OH

L

OUT

DD

DD

SHDN

VIN = 0 or V

I

SINK

I

SINK

I

SOURCE

I

SOURCE

CS = V

CS = V

MAX1253 2.7 3.6

MAX1254 4.5 5.5

MAX1253 internal reference (Note 9) 3.3

MAX1253 internal reference (Note 10) 2.9

MAX1253 external reference (Note 10) 2.2

MAX1254 internal reference (Note 9) 5.0

MAX1254 internal reference (Note 10) 4.0

MAX1254 external reference (Note 10) 3.0

Both internal reference, mode 01 (Note 11) 8 µA

Full power-down state

DD

= 8mA, DOUT 0.5

= 2mA, INT 0.5

= 8mA, DOUT VDD - 0.5

= 2mA, INT VDD - 0.5

DD

DD

VDD x 0.7 V

MAX1253 480

MAX1254 860

200 mV

VDD x 0.3 V

±10 µA

2pF

±10 µA

5pF

V

V

V

mA

nA

Page 5

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

_______________________________________________________________________________________ 5

Note 1: Relative accuracy is the deviation of the analog value at any code from its theoretical value after the gain and offset errors

have been calibrated.

Note 2: Offset nulled.

Note 3: In reference mode 00, the reference system powers up for each temperature measurement. In reference mode 01, the ref-

erence system powers up once per sequence of channels scanned. If a sample wait <80µs is programmed, the reference

system is on all the time. In reference mode 10, the reference system is on all the time (see Table 7).

Note 4: No external capacitor on REF.

Note 5: The operational input voltage range for each individual input of a differentially configured pair (AIN0–AIN7) is from GND to

V

DD

.

The operational input voltage difference is from -V

REF

/2 to +V

REF

/2.

Note 6: See Figure 3 and the Sampling Error vs. Input Source Impedance graph in the Typical Operating Characteristics section.

Note 7: Grade A tested at +10°C and +55°C. -20°C to +85°C and -40°C to +85°C specifications guaranteed by design. Grade B

tested at +25°C. T

MIN

to T

MAX

specification guaranteed by design.

Note 8: External temperature measurement mode using an MMBT3904 (Diodes Inc.) as a sensor. External temperature sensing

from -40°C to +85°C; MAX1253/MAX1254 held at +25°C.

Note 9: Performing eight single-ended external channels’ temperature measurements, an internal temperature measurement, and

an internal V

DD

measurement with no sample wait results in a conversion rate of 2ksps per channel.

Note 10: Performing eight single-ended voltage measurements, an internal temperature measurement, and an internal V

DD

measure-

ment with no sample wait results in a conversion rate of 7ksps per channel.

Note 11: Performing eight single-ended voltage measurements, an internal temperature measurement, and an internal V

DD

measure-

ment with maximum sample wait results in a conversion rate of 3ksps per channel.

Note 12: Defined as the shift in the code boundary as a result of supply voltage change. V

DD

= min to max; full-scale input, mea-

sured using external reference.

TIMING CHARACTERISTICS

(VDD= +2.7V to +3.6V (MAX1253), VDD= +4.5V to +5.5V (MAX1254), TA= T

MIN

to T

MAX

, unless otherwise noted.) (Figures 1, 2, and 4)

SCLK Clock Period t

SCLK Pulse Width High Time t

SCLK Pulse Width Low Time t

DIN to SCLK Setup Time t

DIN to SCLK Hold Time t

CS Fall to SCLK Rise Setup t

SCLK Rise to CS Rise Hold t

SCLK Fall to DOUT Valid t

CS Rise to DOUT Disable t

CS Fall to DOUT Enable t

CS Pulse Width High t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CP

CH

CL

DS

DH

CSS

CSH

DOV

DOD

DOE

CSW

CL = 30pF 50 ns

CL = 30pF 40 ns

CL = 30pF 40 ns

100 0.5 ns

45 ns

45 ns

25 ns

0ns

25 ns

50 ns

40 ns

Page 6

SUPPLY CURRENT

vs. SAMPLE RATE

MAX1253/54 toc07

SAMPLE RATE (kHz)

SUPPLY CURRENT (mA)

1010.10.01

0.01

0.1

1

10

0.001

0.001 100

INTERNAL REFERENCE

(MODE 01) MAX1254

9 TEMPERATURE

CHANNELS AND 1

VOLTAGE CHANNEL

9 VOLTAGE

CHANNELS AND

1 TEMPERATURE

CHANNEL

1 VOLTAGE CHANNEL

(V

DD

/2)

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX1253/54 toc08

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (mA)

5.14.73.1 3.5 3.9 4.3

1.4

1.8

2.2

2.6

3.0

3.4

3.8

4.2

1.0

2.7 5.5

EXTERNAL REFERENCE (MODE 00)

9 VOLTAGE CHANNELS AND

1 TEMPERATURE CHANNEL

1 VOLTAGE CHANNEL

(V

DD

/2)

9 TEMPERATURE CHANNELS

AND 1 VOLTAGE CHANNEL

REFERENCE VOLTAGE

vs. TEMPERATURE

MAX1253/54 toc05

TEMPERATURE (°C)

REFERENCE VOLTAGE (V)

6040200-20

2.492

2.494

2.496

2.498

2.500

2.502

2.504

2.506

2.508

2.510

2.490

-40 80

GRADE A

GRADE B

MAX1253

REFERENCE VOLTAGE

vs. TEMPERATURE

MAX1253/54 toc05b

TEMPERATURE (°C)

REFERENCE VOLTAGE (V)

6040200-20

4.0725

4.0750

4.0775

4.0800

4.0825

4.0850

4.0875

4.0900

4.0700

-40 80

GRADE A

MAX1254

GRADE B

SUPPLY CURRENT

vs. SAMPLE RATE

MAX1253/54 toc06

SAMPLE RATE (kHz)

SUPPLY CURRENT (mA)

1010.10.01

0.01

0.1

1

10

0.001

0.001 100

INTERNAL REFERENCE

(MODE 01) MAX1253

9 TEMPERATURE

CHANNELS AND 1

VOLTAGE CHANNEL

(V

DD

/2)

9 VOLTAGE

CHANNELS AND

1 TEMPERATURE

CHANNEL

1 VOLTAGE CHANNEL

(V

DD

/2)

INTERNAL REFERENCE VOLTAGE

vs. SUPPLY VOLTAGE

MAX1253/54 toc04

SUPPLY VOLTAGE (V)

INTERNAL REFERENCE VOLTAGE (V)

5.45.35.1 5.24.7 4.8 4.9 5.04.6

4.077

4.079

4.081

4.083

4.085

4.075

4.5 5.5

MAX1254

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

6 _______________________________________________________________________________________

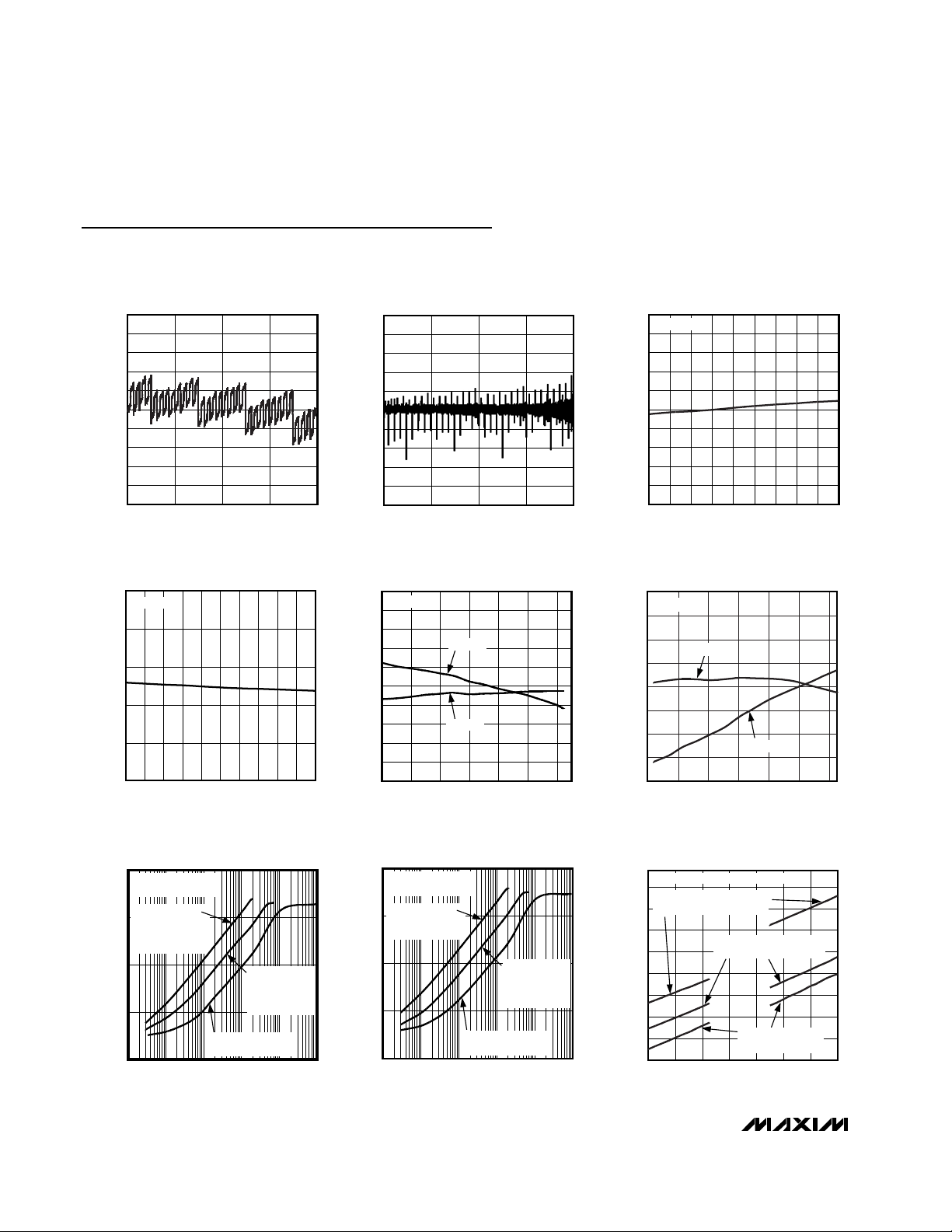

Typical Operating Characteristics

(VDD= +3V, V

REF

= 2.5V (MAX1253); VDD= 5V, V

REF

= 4.096V (MAX1254); f

SCLK

= 10MHz, C

REF

= 0.1µF, TA= +25°C, unless oth-

erwise noted.)

INTEGRAL NONLINEARITY

vs. DIGITAL OUTPUT CODE

MAX1253/54 toc01

OUTPUT CODE

INL (LSB)

307220481024

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0 4096

DIFFERENTIAL NONLINEARITY

vs. DIGITAL OUTPUT CODE

MAX1253/54 toc02

OUTPUT CODE

DNL (LSB)

307220481024

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0 4096

INTERNAL REFERENCE VOLTAGE

vs. SUPPLY VOLTAGE

MAX1253/54 toc03

SUPPLY VOLTAGE (V)

INTERNAL REFERENCE VOLTAGE (V)

3.53.43.2 3.32.9 3.0 3.12.8

2.501

2.502

2.503

2.504

2.505

2.506

2.507

2.508

2.509

2.510

2.500

2.7 3.6

MAX1253

Page 7

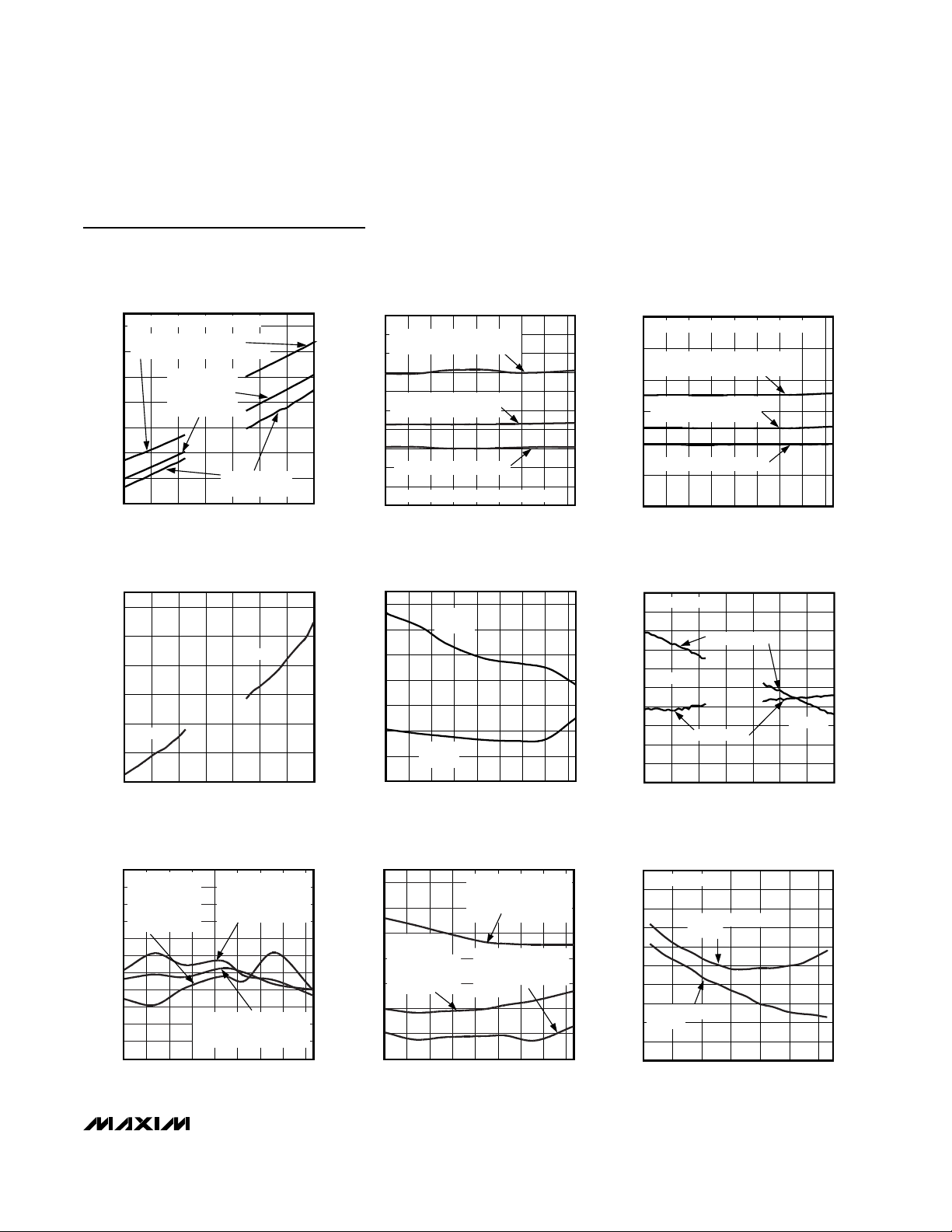

GAIN ERROR vs. TEMPERATURE

MAX1253/54 toc15

TEMPERATURE (°C)

GAIN ERROR (LSB)

80655035205-10-25

0.10

0

0.20

0.40

0.30

0.60

0.50

0.70

0.90

0.80

1.00

-0.10

-40

UNIPOLAR

DIFFERENTIAL

CONFIGURATION

EXTERNAL

REFERENCE MODE

BIPOLAR DIFFERENTIAL

CONFIGURATION

EXTERNAL REFERENCE

MODE

UNIPOLAR SINGLE-ENDED

CONFIGURATION

EXTERNAL REFERENCE MODE

OFFSET ERROR vs. TEMPERATURE

MAX1253/54 toc16

TEMPERATURE (°C)

OFFSET ERROR (LSB)

80655035205-10-25

-0.80

-0.60

-0.40

-0.20

0

0.20

0.40

-1.00

-40

UNIPOLAR

DIFFERENTIAL

CONFIGURATION

EXTERNAL

REFERENCE MODE

BIPOLAR DIFFERENTIAL

CONFIGURATION

EXTERNAL REFERENCE

MODE

UNIPOLAR SINGLE-ENDED

CONFIGURATION

EXTERNAL REFERENCE

MODE

INTERNAL TEMPERATURE SENSOR

TEMPERATURE ERROR

MAX1253/54 toc17

TEMPERATURE (°C)

ERROR (°C)

6040200-20

-0.80

-0.60

-0.40

-0.20

0

0.20

0.40

0.60

0.80

1.00

-1.00

-40 80

MAX1253/MAX1254

GRADE A INTERNAL

SENSOR

GRADE B INTERNAL

SENSOR

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

_______________________________________________________________________________________ 7

Typical Operating Characteristics (continued)

(VDD= +3V, V

REF

= 2.5V (MAX1253); VDD= 5V, V

REF

= 4.096V (MAX1254); f

SCLK

= 10MHz, C

REF

= 0.1µF, TA= +25°C, unless oth-

erwise noted.)

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX1253/54 toc09

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (mA)

5.14.73.1 3.5 3.9 4.3

1.9

2.3

2.7

3.1

3.5

3.9

4.3

1.5

2.7 5.5

INTERNAL REFERENCE (MODE 01)

9 TEMPERATURE CHANNELS

AND VOLTAGE CHANNEL (V

DD

/2)

9 VOLTAGE

CHANNELS AND

1 TEMPERATURE

CHANNEL

1 VOLTAGE

CHANNEL (V

DD

/2)

SUPPLY CURRENT

vs. TEMPERATURE

MAX1253/54 toc10

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

806535 50-10 5 20-25

1.7

1.8

1.9

2.0

2.1

2.2

2.3

2.4

2.5

2.6

1.6

-40

9 TEMPERATURE CHANNELS AND

1 VOLTAGE CHANNEL (V

DD

/2)

9 VOLTAGE CHANNELS AND

1 TEMPERATURE CHANNEL

1 VOLTAGE CHANNEL (VDD/2)

INTERNAL REFERENCE (MODE 01) MAX1253

SUPPLY CURRENT

vs. TEMPERATURE

MAX1253/54 toc11

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

806535 50-10 5 20-25

2.5

3.0

4.0

3.5

4.5

5.0

2.0

-40

9 TEMPERATURE CHANNELS AND

1 VOLTAGE CHANNEL (V

DD

/2)

9 VOLTAGE CHANNELS AND

1 TEMPERATURE CHANNEL

1 VOLTAGE CHANNEL (VDD/2)

INTERNAL REFERENCE (MODE 01) MAX1254

SHUTDOWN SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX1253/54 toc12

SUPPLY VOLTAGE (V)

SHUTDOWN SUPPLY CURRENT (nA)

5.14.74.33.93.53.1

200

300

400

500

600

700

100

2.7 5.5

MAX1253

MAX1254

SHUTDOWN SUPPLY CURRENT

vs. TEMPERATURE

MAX1253/54 toc13

TEMPERATURE (°C)

SHUTDOWN SUPPLY CURRENT (nA)

655035205-10-25

100

200

300

400

500

600

700

0

-40 80

MAX1254

V

DD

= 5V

MAX1253

V

DD

= 3V

GAIN AND OFFSET ERROR

vs. SUPPLY VOLTAGE

MAX1253/54 toc14

SUPPLY VOLTAGE (V)

GAIN AND OFFSET ERROR (LSB)

5.14.73.9 4.33.53.1

-0.80

-0.60

-0.40

-0.20

0

0.20

0.40

0.60

0.80

1.00

-1.00

2.7 5.5

SINGLE ENDED

MAX1253

MAX1254

OFFSET ERROR

GAIN ERROR

Page 8

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VDD= +3V, V

REF

= 2.5V (MAX1253); VDD= 5V, V

REF

= 4.096V (MAX1254); f

SCLK

= 10MHz, C

REF

= 0.1µF, TA= +25°C, unless oth-

erwise noted.)

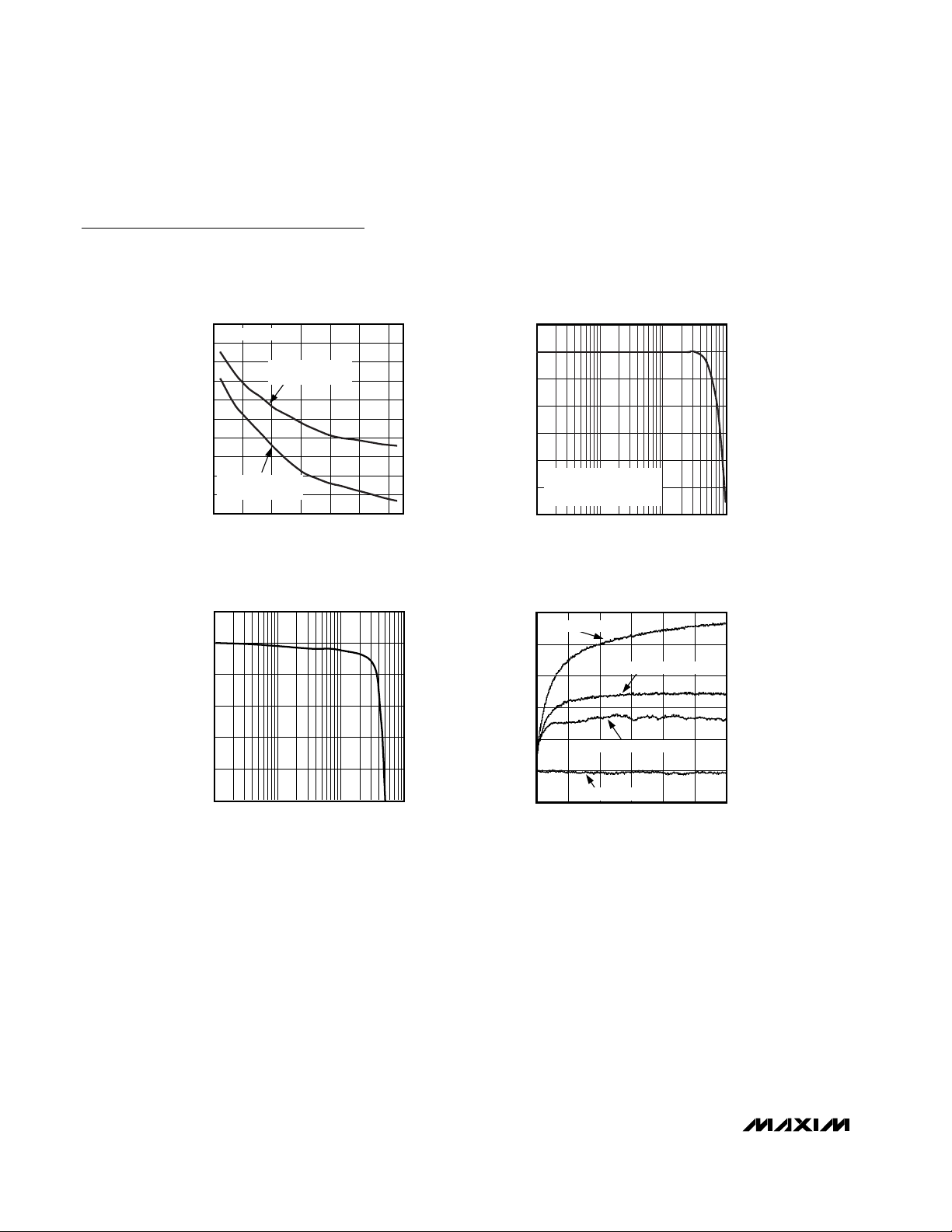

EXTERNAL TEMPERATURE SENSOR

TEMPERATURE ERROR

2.0

MAX1253/MAX1254

1.6

1.2

0.8

0.4

0

ERROR (°C)

-0.4

-0.8

-1.2

EXTERNAL SENSOR,

SINGLE-ENDED INPUT

-1.6

-2.0

-40 80

EXTERNAL SENSOR,

DIFFERENTIAL INPUT

TEMPERATURE (°C)

SAMPLING ERROR

vs. INPUT SOURCE IMPEDANCE

1

0

-1

MAX1253/54 toc18

6040200-20

MAX1253/54 toc20

TEMPERATURE ERROR vs. INTERCONNECT

CAPACITANCE (EXTERNAL SENSOR)

1

0

-1

-2

-3

TEMPERATURE (°C)

-4

EXTERNAL DIODE

DIFFERENTIAL TEMPERATURE

-5

MEASUREMENT MODE

-6

1

10 100

INTERCONNECT CAPACITANCE (pF)

TURN ON THERMAL TRANSIENT,

CONTINUOUS CONVERSION

V

0.625

IN A TSSOP SOCKET

0.500

0.375

DD

SOLDER ON A 2in ✕ 2in PWB

MAX1253/54 toc19

1000

= 3.0V

MAX1253/54 toc21

-2

-3

SAMPLING ERROR (LSB)

-4

-5

10 10,000

SOURCE IMPEDANCE (Ω)

1000100

0.250

0.125

TEMPERATURE SHIFT (°C)

0

-0.125

030

IN AN OIL BATH

EXTERNAL BJT

252015105

TIME (s)

Page 9

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

_______________________________________________________________________________________ 9

Pin Description

PIN

NAME

FUNCTION

1

Analog Voltage Input/Temperature Input Channel 0 or Positive Differential Input Relative to AIN1

2

Analog Voltage Input/Temperature Input Channel 1 or Negative Differential Input Relative to AIN0

3

Analog Voltage Input/Temperature Input Channel 2 or Positive Differential Input Relative to AIN3

4

Analog Voltage Input/Temperature Input Channel 3 or Negative Differential Input Relative to AIN2

5

Analog Voltage Input/Temperature Input Channel 4 or Positive Differential Input Relative to AIN5

6

Analog Voltage Input/Temperature Input Channel 5 or Negative Differential Input Relative to AIN4

7

Analog Voltage Input/Temperature Input Channel 6 or Positive Differential Input Relative to AIN7

8

Analog Voltage Input/Temperature Input Channel 7 or Negative Differential Input Relative to AIN6

9

Positive Reference Input in External Mode. Bypass REF with a 0.1µF capacitor to GND when in external mode.

When using the internal reference, REF must be left open.

10

Interrupt Output. Push-pull or open drain with selectable polarity. See Table 9 and the INT Interrupt Output section.

11

Serial Data Output. DOUT transitions on the falling edge of SCLK. High impedance when CS is at logic high.

12

Ground

13

Positive Power Supply. Bypass with a 0.1µF capacitor to GND.

14

Serial Data Input. DIN data is latched into the serial interface on the rising edge of the SCLK.

15

Serial Clock Input. Clocks data in and out of the serial interface (duty cycle must be 40% to 60%).

16

Active-Low Chip-Select Input. When CS is low, the serial interface is enabled. When CS is high, DOUT is high

impedance, and the serial interface resets.

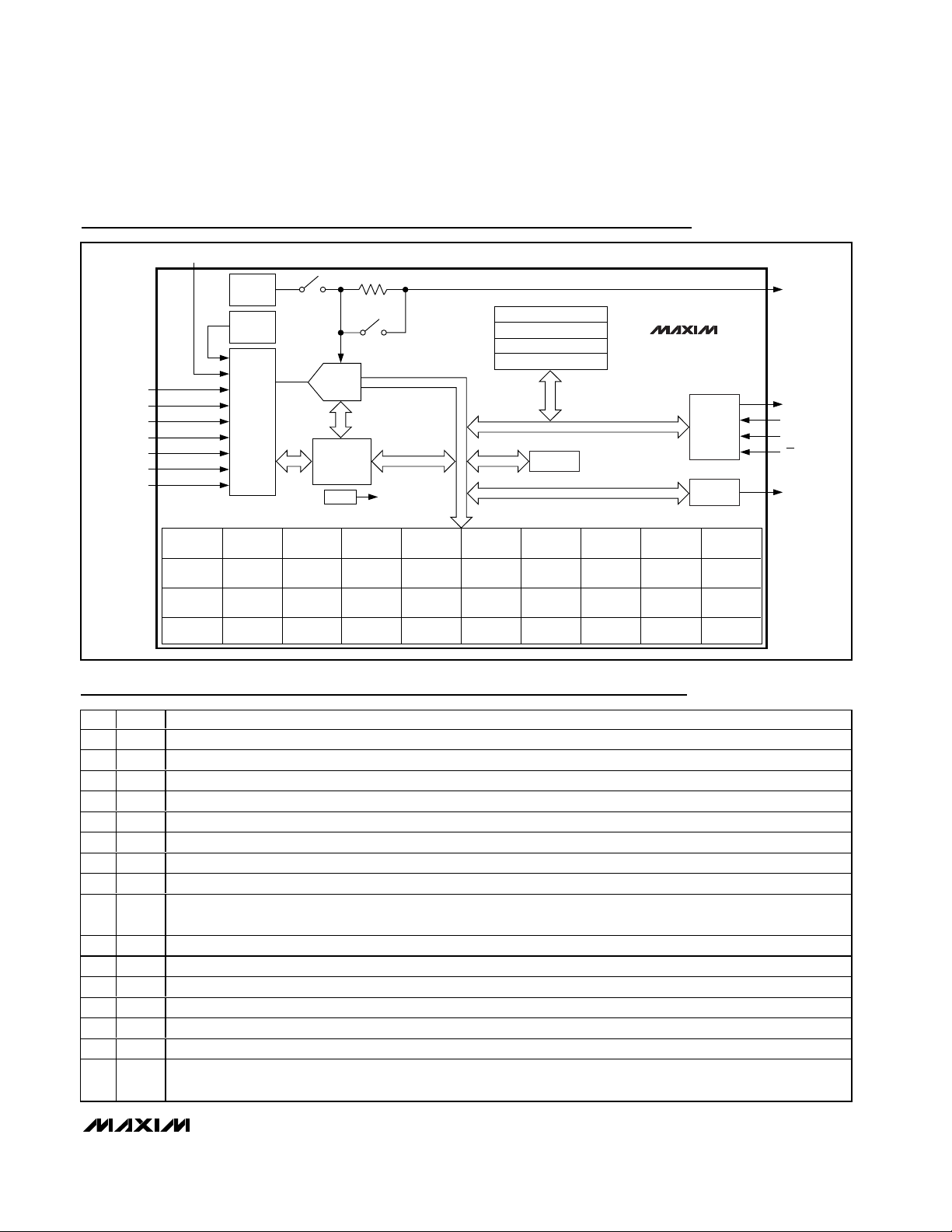

Block Diagram

V

DD

REFERENCE

INPUT CHANNEL REGISTER

INPUT CONFIGURATION REGISTER

STEP-UP REGISTER

ALARM REGISTER

AIN3

ACCUMULATOR

THRESHOLD

THRESHOLD

CHANNEL

CONFIGURATION

ACCUMULATOR

UPPER

LOWER

CONFIGURATION

AVERAGING

AIN4

UPPER

THRESHOLD

LOWER

THRESHOLD

CHANNEL

AIN5

ACCUMULATOR

UPPER

THRESHOLD

LOWER

THRESHOLD

CHANNEL

CONFIGURATION

MAX1253

MAX1254

AIN6

ACCUMULATOR

UPPER

THRESHOLD

LOWER

THRESHOLD

CHANNEL

CONFIGURATION

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

INTERNAL TEMP

ACCUMULATOR

UPPER

THRESHOLD

LOWER

THRESHOLD

CHANNEL

CONFIGURATION

TEMP

SENSOR

MUX

/2

V

DD

ACCUMULATOR

UPPER

THRESHOLD

LOWER

THRESHOLD

CHANNEL

CONFIGURATION

ADC WITH

CONVERSION

CONTROL

AIN0

ACCUMULATOR

UPPER

THRESHOLD

LOWER

THRESHOLD

CHANNEL

CONFIGURATION

12-BIT

T/H

SCAN

AND

POR

ACCUMULATOR

THRESHOLD

THRESHOLD

CHANNEL

CONFIGURATION

AIN1

UPPER

LOWER

POWER-

GOOD

AIN2

ACCUMULATOR

UPPER

THRESHOLD

LOWER

THRESHOLD

CHANNEL

CONFIGURATION

REF

DOUT

SERIAL

INTERFACE

DIGITAL

COMPARATOR

AIN7

ACCUMULATOR

UPPER

THRESHOLD

LOWER

THRESHOLD

CHANNEL

CONFIGURATION

DIN

SCLK

CS

INT

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

REF

INT

DOUT

GND

V

DD

DIN

SCLK

CS

Page 10

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

10 ______________________________________________________________________________________

Figure 1. Load Circuits for DOUT Enable Time and SCLK to

DOUT Delay Time

Figure 2. Load Circuit for DOUT Disable Time

Detailed Description

The MAX1253/MAX1254 are precision-monitoring integrated circuit systems specifically intended for standalone operation. They can monitor diverse types of

inputs, such as those from temperature sensors and

voltage signals from pressure, vibration, and acceleration sensors, and digitize these input signals. The digital values are then compared to preprogrammed

thresholds and, if the thresholds are exceeded, the

processor is alerted by an interrupt signal. No interaction by the CPU or microcontroller (µC) is required until

one of the programmed limits is exceeded (Figures 3

and 4).

Voltages on all the inputs are converted to 12-bit values

sequentially and stored in the current data registers.

Note that eight of these inputs are external and two are

internal. One of the internal inputs monitors the V

DD

voltage supply, while the other monitors the internal IC

temperature. AIN0 to AIN7 can be configured as either

single ended (default) or differential. In addition, these

inputs can be configured for single-ended or differential temperature measurements. In the temperature

configuration, the device provides the proper bias necessary to measure temperature with a diode-connected

transistor sensor. The user enables which inputs are

measured (both external and internal) and sets the

delay between each sequence of measurements during the initial setup of the device.

The values stored in the current data registers are compared to the user-preprogrammed values in the threshold registers (upper and lower thresholds) and, if

exceeded, activate the interrupt output and generate an

alarm condition. If desired, the device can be programmed to average the results of many measurements

before comparing to the threshold value. This reduces

the sensitivity to external noise in the measured signal.

In addition, the user can set the number of times the

threshold is exceeded (fault cycles) before generating

an interrupt. This feature reduces falsely triggered

alarms caused by undesired, random spurious impulses.

When the fault cycle criterion is exceeded, an alarm

condition is created. The device writes the fault condition into the alarm register to indicate the alarmed input

channel.

Converter Operation

The MAX1253/MAX1254 ADCs use a fully differential

successive-approximation register (SAR) conversion

technique and an on-chip track-and-hold (T/H) block to

convert temperature and voltage signals into a 12-bit

digital result. Both single-ended and differential configurations are supported with a unipolar signal range for

single-ended mode and bipolar or unipolar ranges for

differential mode. Figure 5 shows the equivalent input

circuit for the MAX1253/MAX1254. Configure the input

channels according to Tables 5 and 6 (see the Input

Configuration Register section).

In single-ended mode, the positive input (IN+) is connected to the selected input channel and the negative

input (IN-) is connected to GND. In differential mode,

IN+ and IN- are selected from the following pairs:

AIN0/AIN1, AIN2/AIN3, AIN4/AIN5, and AIN6/AIN7.

Once initiated, voltage conversions require 10.6µs (typ)

to complete.

V

DD

100nA

DOUT

100nA

a) V

OL

GND

TO V

C

= 100pF

LOAD

OH

DOUT

C

= 100pF

LOAD

GND

b) HIGH-Z TO VOL AND VOH TO V

OL

DOUT

100nA

GND

TO HIGH-Z

a) V

OH

C

V

100nA

DOUT

GND

b) VOL TO HIGH-Z

LOAD

= 100pF

DD

C

= 100pF

LOAD

Page 11

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

______________________________________________________________________________________ 11

During the acquisition interval, IN+ and IN- charge both

a positive (CHOLDP) and a negative (CHOLDN) sampling capacitor. After completing the acquisition interval, the T/H switches open, storing an accurate sample

of the differential voltage between IN+ and IN-. This

charge is then transferred to the ADC and converted.

Finally, the conversion result is transferred to the current data register.

Temperature conversions require 46µs (typ) and measure the difference between two sequential voltage

measurements (see the Temperature Measurement

section for a detailed description).

Fully Differential Track/Hold (T/H)

The T/H acquisition interval begins with the rising edge

of CS (for manually triggered conversions) and is internally timed to 1.5µs (typ). The accuracy of the input signal sample is a function of the input signal’s source

impedance and the T/H’s capacitance. In order to

achieve adequate settling of the T/H, limit the signal

source impedance to a maximum of 1kΩ.

Input Bandwidth

The ADC’s input tracking circuitry has a 1MHz smallsignal bandwidth. To avoid high-frequency signals

aliasing into the frequency band of interest, anti-alias

prefiltering of the input signals is recommended.

Analog Input Protection

Internal protection diodes, which clamp the analog

inputs to VDDand GND, allow the channel input pins to

swing from (GND - 0.3V) to (VDD+ 0.3V) without damage. However, for accurate conversions near full scale,

the inputs must not exceed VDDby more than 50mV or

be lower than GND by 50mV. If the analog input range

must exceed 50mV beyond the supplies, limit the input

current.

Single Ended/Differential

The MAX1253/MAX1254 use a fully differential ADC for

all conversions. Through the input configuration register, the analog inputs can be configured for either differential or single-ended conversions. When sampling

signal sources close to the MAX1253/MAX1254, singleended conversion is generally sufficient. Single-ended

conversions use only one analog input per signal

source, internally referenced to GND.

Figure 3. Simplified Alarm Block Diagram of the MAX1253/MAX1254

V

DD

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

MUX

TEMP

SENSE

12-BIT

ADC WITH T/H

INPUT REGISTERS

CURRENT DATA

UPPER THRESHOLD

LOWER THRESHOLD

# FAULT CYCLES

AVERAGE

CONFIGURATION/

STATUS

REGISTERS

SCAN AND

CONVERSION

CONTROL

DIGITAL

COMPARATOR

SERIAL

INTERFACE

INT

DIN

DOUT

SCLK

CS

Page 12

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

12 ______________________________________________________________________________________

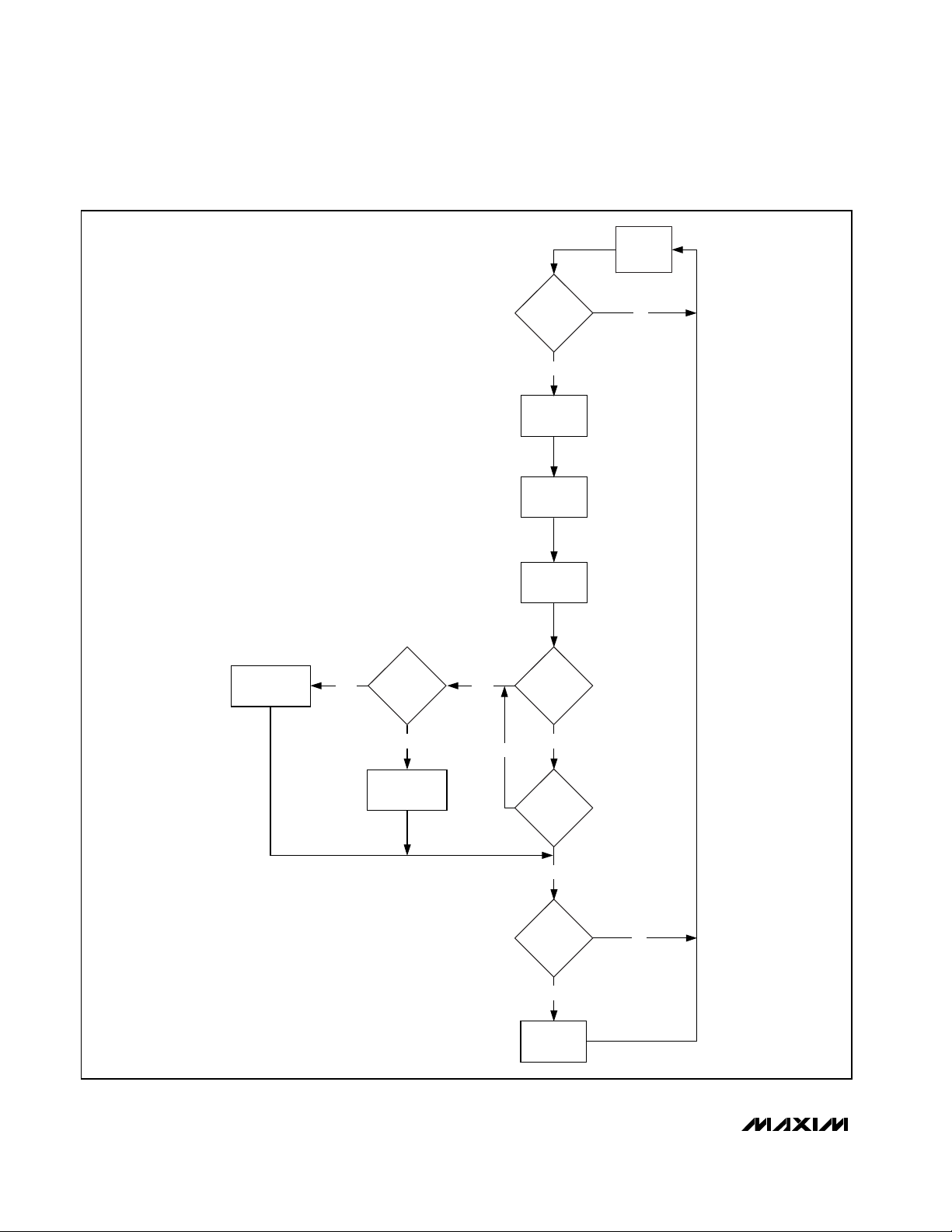

Figure 4. Alarm Flowchart

IS CHANNEL

ENABLED?

YES

SAMPLE

CHANNEL

CONVERT

CHANNEL

AVERAGE

CONVERTED

CHANNEL DATA

INCREMENT

CHANNEL

COUNTER

NO

INCREMENT

FAULT COUNTER

YES

SAME FAULT

AS PREVIOUS?

NO

RESET FAULT

COUNTER

YES

YES

IS

AVG DATA

> UPPER?

NO

IS

AVG DATA

< LOWER?

NO

IS

FAULT CNT

>

FAULT REG?

YES

SET ALARM

REGISTER

NO

Page 13

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

______________________________________________________________________________________ 13

In differential mode, the T/H samples the difference

between two analog inputs, eliminating common-mode

DC offsets and noise. See the Input Configuration

Register section and Tables 5 and 6 for more details on

configuring the analog inputs.

Unipolar/Bipolar

When performing differential conversions, the input

configuration register (Tables 5 and 6) also selects

between unipolar and bipolar operation. Unipolar mode

sets the differential input range from 0 to V

REF.

A negative differential analog input in unipolar mode causes

the digital output code to be zero. Selecting bipolar

mode sets the differential input range to ±V

REF

/2. The

digital output code is straight binary in unipolar mode

and two’s complement in bipolar mode (see the

Transfer Function section).

In single-ended mode, the MAX1253/MAX1254 always

operate in unipolar mode. The analog inputs are internally referenced to GND with a full-scale input range

from 0 to V

REF.

Digital Interface

The MAX1253/MAX1254 digital interface consists of

five signals: CS, SCLK, DIN, DOUT, and INT. CS,

SCLK, DIN, and DOUT comprise an SPI™-compatible

serial interface (see the Serial Digital Interface section).

INT is an independent output that provides an indication that an alarm has occurred in the system (see the

INT Interrupt Output section).

Serial Digital Interface

The MAX1253/MAX1254 feature a serial interface compatible with SPI, QSPI™, and MICROWIRE™ devices.

For SPI/QSPI, ensure that the CPU serial interface runs

in master mode so it generates the serial clock signal.

Select a serial clock frequency of 10MHz or less, and

set clock polarity (CPOL) and phase (CPHA) in the µP

control registers to the same value, one or zero. The

MAX1253/MAX1254 support operation with SCLK idling

high or low, and thus operate with CPOL = CPHA = 0 or

CPOL = CPHA = 1.

Figure 5. Single-Ended/Differential Input Equivalent Input Circuit

SPI and QSPI are trademarks of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corp.

V

DD

T

CHOLDP CHOLD

8-TO-1

DIFFERENTIAL

MUX

TEMP

DIFFERENTIAL INPUT EQUIVALENT INPUT CIRCUIT

H

CHOLDN

T

TT

HH

V

AZ

ADC

V

DD

T

8-TO-1

DIFFERENTIAL

MUX

TEMP

SINGLE-ENDED INPUT EQUIVALENT INPUT CIRCUIT

H

T

H

V

AZ

ADC

Page 14

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

14 ______________________________________________________________________________________

Clock pulses on SCLK shift data into DIN on the rising

edge of the SCLK and out of DOUT on the falling edge

of SCLK.

Data transfers require a logic low on CS. A high-to-low

transition of CS marks the beginning of a data transfer. A

logic high on CS at any time resets the serial interface.

See Figure 6 and the Timing Characteristics table for

detailed serial-interface timing information.

Input Data Format

Serial communications always begin with an 8-bit command word, serially loaded from DIN. A high-to-low

transition on CS initiates the data input operation. The

command word and the subsequent data bytes (for

write operations) are clocked from DIN into the

MAX1253/MAX1254 on the rising edges of SCLK. The

first rising edge on SCLK, after CS goes low, clocks in

the MSB of the command word (see the Command

Word section). The next seven rising edges on SCLK

complete the loading of the command word into the

internal command register. After the 8-bit command

word is entered, transfer 0 to 20 bytes of data, depending on the command. Table 2 shows the number of

data bytes for each command.

Output Data Format

Output data from the MAX1253/MAX1254 is clocked

onto DOUT on the falling edge of SCLK. Single-ended

and unipolar differential measurements are output in

straight binary MSB first, with two 8-bytes-per-conversion result, and the last 4 bits padded with zeros. For

temperature and bipolar differential voltage measurements, the output is two’s complement binary in the

same 2-byte format. The MSB of the output data from a

read command transitions at DOUT after the falling

edge of the 8th SCLK clock pulse following the CS

high-to-low transition. Table 2 shows the number of

bytes to be read from DOUT for a given read command.

Command Word

The command word (Table 1) controls all serial communications and configuration of the MAX1253/

MAX1254, providing access to the 44 on-chip registers.

The first 4 MSBs of the command word specify the

command (Table 2), while the last 4 bits provide

address information.

The first rising edge on SCLK, after CS goes low, transfers the command word MSB into DIN. The next seven

rising edges on SCLK shift the remaining 7 bits into the

internal command register (see the Serial Digital

Interface section).

Figure 6. Detailed Serial Interface Timing Diagram

Table 1. Command Word

B7 (MSB) B6 B5 B4 B3 B2 B1 B0 (LSB)

Command B3

Address B0

CS

SCLK

DIN

DOUT

HIGH-Z

t

CSS

t

DS

t

DH

t

DOE

t

t

CH

CL

t

CP

t

DOV

t

CSH

t

CSW

t

DOD

HIGH-Z

Command B2 Command B1 Command B0 Address B3 Address B2 Address B1

Page 15

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

______________________________________________________________________________________ 15

Manually Triggered Conversion

(Command Code = 0000)

Before beginning a manual conversion, ensure the

scan mode bit in the setup register is zero, because a

logic 1 disables manual conversions. The address bits

in a Manually Triggered Conversion command select

the input channel for conversion (see Table 3). When

performing a differential conversion, use the even channel address (AIN0, AIN2, AIN4, AIN6); the command is

ignored if odd channel addresses (AIN1, AIN3, AIN5,

AIN7) are used for a differential conversion.

After issuing a Manually Triggered Conversion command, bring CS high to begin the conversion. To obtain

a correct conversion result, CS must remain high for a

period longer than the reference power-up time (if in

power-down mode) plus the conversion time for the

selected channel configured conversion type (voltage

or temperature). The conversion’s result can then be

read at DOUT by issuing a Read Current Data Register

for Selected Channel command, addressing the converted channel. See Table 3 for channel addresses.

Table 2. Command Description

DATA BYTES AFTER

COMMAND WORD

COMMAND

WORD

DIN

BYTES

COMMAND DESCRIPTION

0000#### 0 0 Manually Trigged Conversion

0001xxxx 0 3 Read Alarm Register

0010#### 0 2 Read Current Data Register for Selected Channel

0011#### 0 20 Read Current Data Register for All Channels

0100#### 0 5 Read Configuration Register for Selected Channel

0101xxxx 0 5 Read Global Configuration Registers

0110xxxx N/A N/A Reserved

0111xxxx 0 0 Reset

1000#### 0 0 Clear Alarm/Fault for Selected Channels

1001xxxx 0 0 Clear Alarm/Fault for All Channels

1010#### 2 0 Write Current Data Register for Selected Channel

1011xxxx 20 0 Write Current Data Registers for All Channels

1100#### 5 0 Write Configuration Registers for Selected Channel

1101xxxx 5 0 Write Global Configuration Registers

1110xxxx N/A N/A Reserved

1111xxxx N/A N/A Reserved

#### = Channel address code, see Table 3.

xxxx = These bits are ignored for this command.

Table 3. Channel Address

BYTES TO

FROM DOUT

ADDRESS IN COMMAND INPUT

0000 Internal temperature

0001 VDD

0010 AIN0

0011 AIN1

0100 AIN2

0101 AIN3

0110 AIN4

0111 AIN5

1000 AIN6

1001 AIN7

1010 Reserved

1011 Reserved

1100 Reserved

1101 Reserved

1110 Reserved

1111 Reserved

Page 16

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

16 ______________________________________________________________________________________

Read Alarm Register

(Command Code 0001)

The Read Alarm Register command, 0001, outputs the

current status of the alarm register (see Table 11). The

address bits in this command are ignored. The alarm

register is 24 bits long and outputs in 3 bytes. Table 12

illustrates the encoding of the alarm register.

After receiving an interrupt, read the alarm register to

determine the source of the interrupt (see the Alarm

Register section).

Read Current Data Register for Selected

Channel (Command Code 0010)

The Read Current Data Register for Selected Channel

command, 0010, outputs the data in the current data

register of the selected channel. The address bits following this command select the input channel to be

read (see Table 3). The current data register is a 12-bit

register. It takes 2 bytes to read its value. See the

Output Data Format and Current Data Registers sections for more details. See Table 3 for channel addresses. Also, see Figure 7.

Read Current Data Register for All

Channels (Command Code 0011)

The Read Current Data Registers for All Channels command, 0011, outputs the data in the current data registers of all 10 channels starting with the internal

temperature sensor, then the VDDmonitor, followed by

AIN0 to AIN7. The address bits following this command

are ignored. It takes 20 bytes to read all of the 10 channels’ current data registers.

Read Configuration Register for Selected

Channel (Command Code 0100)

The Read Configuration Register for Selected Channel

command, 0100, outputs the configuration data of the

channel selected by the address bits (see Table 3).

The first register that shifts out is the upper threshold

register (2 bytes), followed by the lower threshold register (2 bytes), ending with the channel configuration register (1 byte), all MSB first. It takes 5 bytes to read all

three registers. See the Channel Registers section for

more details.

Figure 7. Serial Register Read Timing

CS

SCLK

DIN

DOUT

C3 C2 C1 C0 A2 A1 A0

A3

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Page 17

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

______________________________________________________________________________________ 17

Read Global Configuration Register

(Command Code 0101)

The Read Global Configuration Register command,

0101, outputs the global configuration registers. The

address bits following this command are ignored.

When the MAX1253/MAX1254 receive a read global

configuration register command, they output 5 bytes of

data: 2 bytes from the channel enable register, 2 bytes

from the input configuration register, and 1 byte from

the setup register, all MSB first. See the Global

Configuration Registers section for more details.

RESET (Command Code 0111)

The RESET command, 0111, resets the device. This

command returns the MAX1253/MAX1254 to their

power-on reset state, placing the device into shutdown

mode. The address bits in the command are ignored.

See the Power-Up/Reset Defaults Summary section for

more details.

Clear Channel Alarm for Selected Channel

(Command Code 1000)

The Clear Channel Alarm command, 1000, clears the

alarm bits in the alarm register and resets the fault

counter for the addressed channel. See the Alarm

Register section for more details. See Table 3 for channel addresses.

Clear Alarm Register for All Channels

(Command Code 1001)

The Clear Alarm Register for All Channels command,

1001, clears the entire alarm register and resets the

fault counters for the internal TEMP sensor, the V

DD

monitor, and the AIN0–AIN7 channels. The address bits

in the command are ignored. See the Alarm Register

section for more details.

Write Current Data Register for Selected

Channel (Command Code 1010)

The Write Current Data Register for Selected Channel

command, 1010, writes to the addressed channel’s current data register. This command sets an initial condition when using the averaging filter option (see the

Averaging section). This command can also be used for

testing the thresholds, fault counters, and alarm functions (Figure 8). See Table 3 for channel addresses.

Write Current Data Register for All

Channels (Command Code 1011)

The Write Current Data Register for All Channels command, 1011, writes to the current data registers of all

channels sequentially, starting with the internal temperature sensor, then the VDDmonitor, followed by channels AIN0 to AIN7. The address bits are ignored. Use

this command for testing and setting initial conditions

when using the averaging filter option (see the

Averaging section).

Figure 8. Serial Register Write Timing

CS

SCLK

DIN

DOUT

C3 C2 C1 C0 A2 A1 A0 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

HIGH-Z

A3

HIGH-Z

Page 18

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

18 ______________________________________________________________________________________

Write-Selected Channel Configuration

Registers (Command Code 1100)

The Write-Selected Channel Configuration Register command, 1100, writes to the three channel configuration

registers for the addressed channel (see Table 3). The

first register to be written is the upper threshold (2 bytes),

followed by the lower threshold (2 bytes), ending with the

channel configuration register (1 byte), all MSB first.

Writing to the configuration registers resets the alarm register bits and the fault counters for the addressed channel. See the Channel Registers section for more details.

Write Global Configuration Registers

(Command Code 1101)

The Write Global Configuration Registers command,

1101, writes to three registers: the channel-enable register (2 bytes), the input configuration register (2 bytes),

and the setup register (1 byte). The command address

bits are ignored. See the Global Configuration

Registers section for more details.

Global Configuration Registers

The global configuration registers consist of the channel-enable register, the input configuration register, and

the setup register. These registers hold configuration

data common to all channels.

Channel-Enable Register

The channel-enable register (Table 4) controls which

channels are converted while in automatic scan mode.

The register contents are ignored for manual conversion commands. Each input channel has a corresponding bit in the channel-enable register. A logic high

enables the corresponding analog input channel for

conversion, while a logic low disables it. In differential

configuration, the bits for odd channels are ignored. At

power-up and after a RESET command, the register

contents default to 111111111111b (all channels

enabled).

Input Configuration Register

The input configuration register (Table 5) stores the

configuration code for each channel as a 3-bit per

channel-pair code (see Table 6), selecting from five

input signal configurations: single-ended unipolar voltage, single-ended temperature, differential unipolar

voltage, differential bipolar voltage, and differential

temperature. Table 5 shows the input configuration register format, and Table 6 shows the 3-bit encoding for

channel configuration. At power-up and after a RESET

command, the register contents defaults to

000000000000b (all inputs single ended).

Table 4. Channel-Enable Register Format

B11

(MSB)

B10 B9 B8 B7 B6 B5 B4 B3 B2 B1

B0

(LSB)

TEMP

VDD AIN0 AIN1 AIN2 AIN3 AIN4 AIN5 AIN6 AIN7 Res Res

Table 5. Input Configuration Register Format

B11

(MSB)

B10 B9 B8 B7 B6 B5 B4 B3 B2 B1

B0

(LSB)

AIN0 and AIN1 configuration

AIN6 and AIN7 configuration

Table 6. Channel Configuration Coding (3 Bits/Channel Pair)

CODE

AIN0, AIN2, AIN4, AIN6 CONFIGURATION AIN1, AIN3, AIN5, AIN7 CONFIGURATION

000 Single-ended input (power-up state) Single-ended input (power-up state)

001 Single-ended input Single-ended, external temperature sensor input

010 Single-ended, external temperature sensor input Single-ended input

011 Single-ended, external temperature sensor input Single-ended, external temperature sensor input

100 Differential unipolar encoded, positive input Differential unipolar encoded, negative input

101 Differential bipolar encoded, positive input Differential bipolar encoded, negative input

110

Differential external temperature sensor, negative input

111 Reserved Reserved

AIN2 and AIN3 configuration AIN4 and AIN5 configuration

Differential external temperature sensor, positive input

Page 19

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

______________________________________________________________________________________ 19

Setup Register

The 8-bit setup register (Table 7) holds configuration

data common to all input channels. At power-up and

after a RESET command, this register defaults to

00000000b.

Setup Register: Sample Wait Bits (B7, B6, B5)

These 3 bits in the setup register (Table 8) set the wait

time between conversion scans. The following are

examples of how the MAX1253/MAX1254 begin a sample sequence (see the Setup Register: Reference

Selection Bits (B1, B0) section).

Operating in reference mode 00 (external reference for

voltage conversions, internal reference for temperature

conversions):

1) Convert the first-enabled channel. If this channel is a

temperature measurement, power up the internal reference (this takes 20µs for each enabled temperature measurement in reference mode 00).

2) Sequence to the next-enabled channel until all channels have been converted.

3) Wait the sample wait period.

4) Repeat the procedure.

Operating in reference mode 01 (internal reference for all

conversions, can be powered down between scans):

1) Power up the internal reference, if powered down

(this takes 40µs).

2) Convert the first-enabled channel, starting with the

internal temperature sensor, if enabled.

3) Sequence to the next-enabled channel until all

enabled channels have been converted.

4) Wait the sample wait time, and enter internal reference power-down mode if this period is greater than

80µs.

5) Repeat the above steps.

Operating in reference mode 10 (internal reference for

all conversions, continuously powered up):

1) Convert the first-enabled channel.

2) Sequence to the next-enabled channel until all

enabled channels have been converted.

3) Wait the sample wait time.

4) Repeat the procedure.

Use the sample wait feature to reduce supply current

when measuring slow-changing analog signals. This

power savings occurs when reference mode 00 or 01 is

used in combination with wait times longer than 80µs.

With reference mode 10 or wait times of less than 80µs,

the internal reference system remains powered up, minimizing any power savings. See the Computing Data

Throughput section. Table 8 shows the B7, B6, B5 wait

time encoding.

Setup Register: Interrupt Control (B4, B3)

Bits B3 and B4 in the setup register configure INT and

how it responds to an alarm event (see the Alarm

Register section). Table 9 shows the available INT

options.

Table 7. Setup Register Format

B7 (MSB) B6 B5 B4 B3 B2 B1 B0 (LSB)

Sample wait bits

Interrupt

active

Interrupt

polarity

Scan

mode

Reference

source B1

Reference

source B2

Table 8. Wait Time Encoding

Table 9. Interrupt Control

B7, B6, B5 WAIT TIME (ms)

000 0

001 0.080

010 0.395

011 1.310

100 4.970

101 19.600

110 78.200

111 312.000

BIT FUNCTION

Output

B4

driver type

Output

B3

polarity

BIT

STATE

1 Driven high or low at all times

High-Z when inactive, driven (high

0

or low) when active

1Acti ve = hig h, i nacti ve = low or hig h- Z

0Acti ve = l ow , inacti ve = hig h or hig h- Z

INT OPERATION

Page 20

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

20 ______________________________________________________________________________________

Setup Register: Scan Mode Bit (B2)

The scan mode bit selects between automatic scanning and manual conversion mode.

When set (B2 = 1), the MAX1253/MAX1254 enter automatic scanning mode and convert every enabled channel starting with the internal temperature sensor,

followed by the V

DD

monitor, then sequencing through

AIN0 to AIN7.

After converting all the enabled channels, the

MAX1253/MAX1254 enter a wait state set by the sample wait bits in the setup register. After completing the

sample wait time, the scan cycle repeats.

When B2 = 0, the MAX1253/MAX1254 are in manual

mode and convert only the selected channel after

receiving a Manually Triggered Conversion command

(see the Manually Triggered Conversion (Command

Code 0000) section). Whether in automatic scanning

mode or manual mode, a Read Current Data Register

for Selected Channel command outputs the last-completed conversion result for the addressed channel at

DOUT.

Setup Register: Reference Selection Bits (B1, B0)

The MAX1253/MAX1254 can be used with an internal

or external reference. Select between internal and

external reference modes through bits B1 and B0 of the

setup register (see Table 10).

Alarm Register

The alarm register (Table 11) holds the current alarm status for all of the monitored signals. This 24-bit register

can only be read and cleared. The alarm register has 2

bits for each external input channel, 2 for the onboard

temperature sensor, and 2 for the V

DD

monitor (see

Table 12). At power-up, these bits are logic low, indicating no alarms at any input. When any bit in the alarm register is set, INT becomes active and remains active until

all alarm bits are cleared. After a fault counter exceeds

the set threshold, the alarm register bits for that particular

channel are updated to indicate an alarm.

To clear the interrupt, reset the active alarm bit with the

Clear Alarm Register command, Clear Channel Alarm

command, a RESET command, or by writing a new

configuration to the faulting channel. The alarm register

defaults to 000000 hex.

Table 11 illustrates how the alarm register stores the

information on which channel a fault has occurred. The

alarm code for each bit pair is shown in Table 12.

Channel Registers

Each channel (internal temperature sensor, VDDmonitor, and AIN0 to AIN7) has registers to hold the conversion result (current data register) and channel-specific

configuration data. The channel-specific configuration

registers include: the upper threshold register, the

lower threshold register, and the channel configuration

register. In differential mode, only the registers for the

even channel of the differential input pair are used. The

channel-specific configuration registers for the odd

channel of a differential channel pair are ignored.

Table 10. Reference Selection

Table 11. Alarm Register Format

B23/B22

B1/B0

TEMP

V

DD

AIN0 AIN1 AIN2 AIN3 AIN4 AIN5 AIN6 AIN7 Res Res

Table 12. Alarm Register Coding

(2 Bits/Channel)

B1 B0 REFERENCE MODE

Voltage measurements use external reference,

while temperature measurements use the internal

00

01

10

1 1 Reserved.

reference. A 20µs reference startup delay is

added prior to each temperature measurement

in this mode. This is the default mode after

power-up and after a software RESET.

All measurements use the internal reference. A

40µs reference startup delay is added prior to

starting the scanning of enabled channels,

allowing the internal reference to stabilize.

Note:

reference is continuously powered when in

automatic scan mode.

All measurements use the internal reference. By

selecting this mode, the reference is powered up

immediately when CS goes high after writing this

configuration. Once the reference system is

powered up, no further delay is added.

For sample wait times less than 80µs, the

CODE DESCRIPTION

00 No alarm (power-up state)

01 Input is below lower threshold

10 Input is above upper threshold

00 Reserved

B21/B20 B19/B18 B17/B16 B15/B14 B13/B12 B11/B10 B9/B8 B7/B6 B5/B4 B3/B2

Page 21

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

______________________________________________________________________________________ 21

Channel Configuration Register

Each channel has a channel configuration register

(Table 13) defining the number of consecutive faults to

be detected before setting the alarm bits and generating an interrupt, as well as controlling the digital averaging. At power-up and after a RESET command, the

register defaults to 00 hex (no averaging, alarm on first

fault).

Fault Bits

The value stored in the fault bits (B7–B4) in the channel

configuration register sets the number of faults that

must occur for that channel before generating an interrupt. Encoding of the fault bits is straight binary with

valves 0 to 15. A fault occurs in a channel when the

value in its current data register is outside the range

defined by the channel’s upper and lower threshold

registers. For example, if the number of faults set by the

fault bits is N, an interrupt is generated when the number of consecutive faults (see note below) reach (N +

1). The fault bits default to 0 hex at power-up.

Note: Consecutive faults are those happening in consecutive conversion scans for the same channel. If a

fault occurs and the next scan finds the input within the

normal range defined by the thresholds, the fault

counter resets. If the next counter finds the input signal

outside the opposite threshold, rather than the previous

one, the fault counter also resets. The fault counter

increments only when counting consecutive faults

exceeding the same threshold (Figure 4).

Averaging

The averaging calculated by the data-acquisition algorithm of the MAX1253/MAX1254 improves the input signal-to-noise ratio (SNR) by reducing the signal

bandwidth digitally. The formula below describes the

filter implemented in the MAX1253/MAX1254:

current value = [(N - 1) / N] x past value +

[(present value) / N]

where N = number of samples indicated in Table 14.

The averaging bits (B3–B0) in the channel configuration

register can set the N factor to any value in Table 14.

The output of the filter-running algorithm is continuously

available in the current data register. The starting value

used by the algorithm is the initial state of the current

data register. The current data register is reset to midscale (800 hex) at power-up or after a RESET command, but it can be loaded with a more appropriate

initial value to improve the filter settling time.

At power-up or after a RESET command, the B3–B0

bits of the channel configuration register are set to 0

hex, corresponding to a number of averaged N = 1, no

averaging. See Table 13 and the Write-Selected

Channel Configuration Registers section for programming details. See Table 14 for N encoding.

As in all digital filters, truncation can be a cause of significant errors. In the MAX1253/MAX1254, 24 bits of

precision are maintained in the digital averaging function, maintaining a worst-case truncation error of well

below an LSB. The worst-case truncation error in the

MAX1253/MAX1254 is given by the following:

where N = number of conversions averaged.

Therefore, the worst truncation error when averaging

256 samples is 0.0623 LSBs.

Table 13. Channel Configuration Register Format

B7 (MSB) B6 B5 B4 B3 B2 B1 B0 (LSB)

Fault B3 Fault B2 Fault B1 Fault B0 Ave B3 Ave B2 Ave B1 Ave B0

Table 14. Conversion Average Encoding

CODE N

0000 1, no averaging

0001 2

0010 4

0011 8

0100 16

0101 32

0110 64

0111 128

1000 256

1001 512

1010 1024

1011 2048

1100 Reserved

1101 Reserved

1110 Reserved

1111 Reserved

worst case truncation error

N

-=1

LSBs-

4096

Page 22

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

22 ______________________________________________________________________________________

Upper Threshold Register

A conversion result greater than the value stored in the

upper threshold register results in a fault, increasing

the internal fault counter by one. When the fault count

exceeds the value stored in fault bits B7–B4 of the

channel configuration register, the channel’s alarm bits

in the alarm register are set, resulting in an interrupt on

INT.

The upper threshold register data format must be the

same as the input channel. When the input channel is

configured for single-ended or differential unipolar voltage measurements, data stored in the upper threshold

register is interpreted as straight binary. For input channels configured for temperature measurements or as

differential bipolar voltage inputs, the upper threshold

register data is interpreted as two’s complement. Load

the register with FFF hex to disable upper threshold

faults in unipolar mode, and 7FF hex in temperature or

bipolar mode. The power-up/reset default is FFF hex.

See the Command Word section on how to read/write

to the upper threshold registers.

Lower Threshold Register

Conversion results lower than the value stored in the

lower threshold register increment the internal fault

counter. Considerations about channel configuration

register fault bits B7–B4, INT interrupts, and data format are the same as for the upper threshold register.

Set the register to 000 hex to disable lower threshold

faults in unipolar mode, or to 800 hex in temperature or

bipolar mode. The power-up/reset default is 000 hex.

See the Command Word section on how to read/write

to the lower threshold registers.

Current Data Registers

The current data register holds the last conversion

result or the digitally averaged result, when enabled

(see the Averaging section). The current data registers

default to 800 hex at power-up/reset and can be read

from and written to through the serial interface. See the

Command Word section on how to read/write to the

current data registers.

INT Interrupt Output

INT provides an indication that an alarm has occurred

in the system. It can be programmed (see Table 9) to

operate as a push-pull digital output or as an opendrain output (requiring either a pullup or a pulldown

resistor) for wired-OR interrupt lines. Bits B3 and B4 in

the setup register configure INT and determine its

response to an alarm event.

When an internal fault counter exceeds the threshold

stored in the fault bits (B7–B4) of the corresponding chan-

nel configuration register, the alarm bits for that particular

channel are updated to indicate an alarm. When any bit in

the alarm register is set, the INT output becomes active,

and stays active until all alarm bits are cleared. See the

Alarm Register section for more information.

Servicing Interrupts at INT

After detecting an interrupt on INT, the µC’s interrupt

routine should first read the alarm register to find the

source of the alarm and reset the alarm bits by using

any of the methods described in the Alarm Register

section. Then it can continue with any other action

required by the application to react to the alarm.

Note: Multiple alarm conditions can be present. The

INT remains active until all alarm conditions have been

cleared.

Performing Conversions

At power-up or after a RESET command, the

MAX1253/MAX1254 default to shutdown mode with all

channels enabled, set for single-ended voltage measurements, and with the scan mode set to manual. Start

a conversion by issuing a manually triggered conversion command with the address bits of the channel

selected (see the Manual Conversion section for more

details) or by setting automatic scan mode. To place

the MAX1253/MAX1254 in automatic scan mode, set

scan mode bit B2 in the setup register to logic 1.

In automatic scan mode, the MAX1253/MAX1254 convert all enabled channels starting with the internal temperature sensor, followed by the V

DD

monitor, then by

AIN0 to AIN7. As the scan sequence progresses, the

analog inputs are converted and the resulting values

are stored for each channel into its current data register. Once the scan cycle completes, the MAX1253/

MAX1254 wait a period determined by the sample wait

bits (B7, B6, B5) in the setup register and then repeat

the scan cycle.

After configuring the MAX1253/MAX1254 with automatic scan mode enabled, the devices do not require any

intervention from the system µC until an alarm is triggered. All conversion and monitoring functions can

continue running indefinitely.

Manual Conversion

In manual mode (scan mode bit in the setup register

set to zero, the default after power-up/reset), the

MAX1253/MAX1254 convert individual channels with

the Manually Triggered Conversion command.

Assuming that, either by power-up/RESET defaults or

by previous initialization, the channel to be addressed

is both enabled and configured for the type of signal to

be acquired (voltage/temperature, single ended/differ-

Page 23

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

______________________________________________________________________________________ 23

ential, or unipolar/bipolar), carry out the following steps

to execute a manual conversion. See Figure 9 for manual conversion timing:

1) Disable autoscan (set up register scan mode bit to

zero), if necessary.

2) Pull CS low.

3) Initiate a conversion by issuing a Manually Triggered

Conversion command (0000, followed by the

address bits of the channel to be converted).

4) Pull CS high to start the conversion.

5) Maintain a logic high on CS to allow for reference

power-up (if the reference mode requires it) and

conversion time.

6) Pull CS low.

7) Issue a Read Current Data Register for SelectedChannel command (0010, followed by the same

address of the channel in the Manually Triggered

Conversion command).

Voltage Measurements

Every voltage measurement (internal VDDor external

input channel) requires 10.6µs to complete. If the internal reference needs to power up (reference mode =

01), an additional 40µs is required every time the

MAX1253/MAX1254 come out of automatic shutdown

mode after a sample wait period greater than 80µs.

Monitoring V

DD

This internal acquisition channel samples and converts

the supply voltage, VDD.

V

DD

value can be calculated from the digitized data

with the following equation:

The reference voltage must be larger than 1/2VDDfor

the operation to work properly. VDDmonitoring requires

10.6µs (typ) per measurement.

Temperature Measurement

The MAX1253/MAX1254 perform temperature measurement by measuring the voltage across a diode-connected transistor at two different current levels. The

following equation illustrates the algorithm used for

temperature calculations:

where:

V

HIGH

= sensor-diode voltage with high current flowing

(I

HIGH

)

V

LOW

= sensor-diode voltage with low current flowing

(I

LOW

)

q = charge of electron = 1.602 ✕ 10

-19

coulombs

k = Boltzman constant = 1.38 ✕ 10

-23

J/K

n = ideality factor (slightly greater than 1)

Figure 9. Manual Conversion Timing Without Reading Data

2

V x current data register content x

DD

(__ _ )

=

temperature V V x

=

()-

HIGH LOW

V

4096

q

k

I

nxln

High

I

LOW

REF

CS

SCLK

C3

DIN

DOUT

C2 C1 C0 A2 A1 A0

t

PU+CONV

C3 C2 C1 C0 A2 A1 A0A3A3

Page 24

MAX1253/MAX1254

Stand-Alone, 10-Channel, 12-Bit System Monitors

with Internal Temperature Sensor and V

DD

Monitor

24 ______________________________________________________________________________________

The temperature measurement process is fully automated in the MAX1253/MAX1254. All steps are

sequenced and executed by the MAX1253/MAX1254

each time an input channel (or an input channel pair)

configured for temperature measurement is scanned.

The resulting 12-bit, two’s complement number represents the sensor temperature in degrees Celsius, with

1 LSB = +0.125°C.

The MAX1253/MAX1254 support both single-ended

and differential temperature measurements.

Applications Information

Setting Up the

MAX1253/MAX1254 Subsystem

The MAX1253/MAX1254 are autonomous subsystems,