19-1066; Rev 0; 6/96

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

________________General Description

The MAX1245 12-bit data-acquisition system combines

an 8-channel multiplexer, high-bandwidth track/hold, and

serial interface with high conversion speed and ultra-low

power consumption. It operates from a single +2.375V to

+3.3V supply, and its analog inputs are software configurable for unipolar/bipolar and single-ended/differential

operation.

The 4-wire serial interface directly connects to SPI™,

QSPI™, and Microwire™ devices without external logic.

A serial strobe output allows direct connection to

TMS320-family digital signal processors. The MAX1245

works with an external reference, and uses either the

internal clock or an external serial-interface clock to

perform successive-approximation analog-to-digital

conversions.

This device provides a hard-wired SHDN pin and a

software-selectable power-down, and can be programmed to automatically shut down at the end of a

conversion. Accessing the serial interface powers up

the MAX1245, and the quick turn-on time allows it to be

shut down between conversions. This technique can

cut supply current to under 10µA at reduced sampling

rates.

The MAX1245 is available in a 20-pin DIP package and

an SSOP that occupies 30% less area than an 8-pin DIP.

For supply voltages from +2.7V to +5.25V, use the pincompatible MAX147.

________________________Applications

Portable Data Logging Medical Instruments

Battery-Powered Instruments Data Acquisition

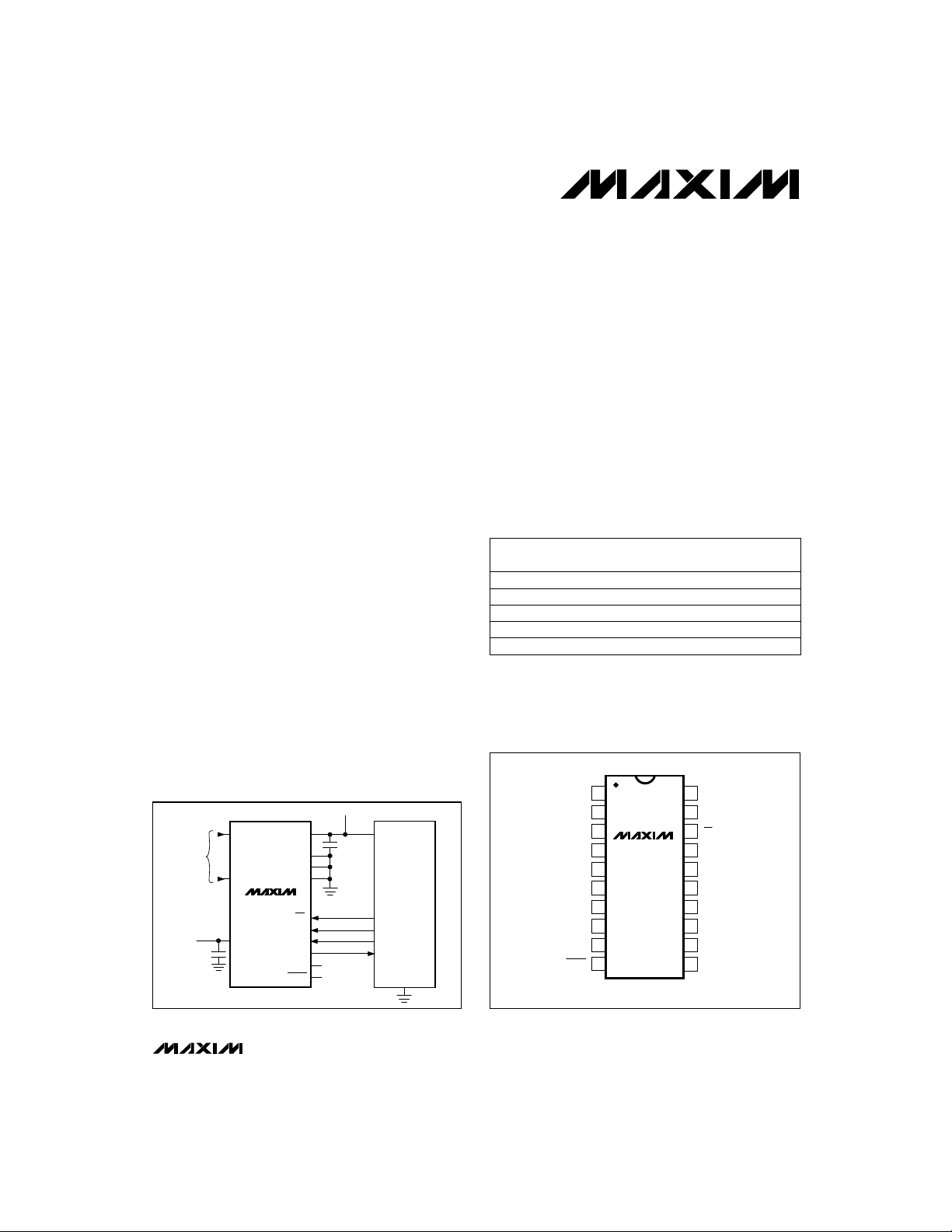

___________T ypical Operating Circuit

+2.5V

+2.048V

ANALOG

INPUTS

+2.048V

0V to

0.1µF

CH0

CH7

VREF

MAX1245

V

DGND

AGND

COM

CS

SCLK

DIN

DOUT

SSTRB

SHDN

DD

0.1µF

V

DD

CPU

I/O

SCK (SK)*

MOSI (SO)

MISO (SI)

V

SS

____________________________Features

♦ Single +2.375V to +3.3V Operation

♦ 8-Channel Single-Ended or 4-Channel

Differential Analog Inputs

♦ Low Power: 0.8mA (100ksps)

10µA (1ksps)

1µA (power-down mode)

♦ Internal Track/Hold, 100kHz Sampling Rate

♦ SPI/QSPI/Microwire/TMS320-Compatible

4-Wire Serial Interface

♦ Software-Configurable Unipolar or Bipolar Inputs

♦ 20-Pin DIP/SSOP Packages

________________Ordering Information

†

PART

MAX1245ACPP

MAX1245BCPP

MAX1245ACAP 0°C to +70°C

MAX1245BCAP 0°C to +70°C 20 SSOP

MAX1245BC/D 0°C to +70°C Dice*

Ordering Information continued at end of data sheet.

†

Contact factory for availability of alternate surface-mount

TEMP. RANGE PIN-PACKAGE

0°C to +70°C

0°C to +70°C

20 Plastic DIP

20 Plastic DIP

20 SSOP

packages.

*

Contact factory for availability.

INL

(LSB)

±1/2

±1

±1/2

±1

±1

___________________Pin Configuration

TOP VIEW

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

COM

1

2

3

4

5

6

7

8

9

10

MAX1245

DIP/SSOP

20

V

DD

19

SCLK

18

CS

17

DIN

16

SSTRB

DOUT

15

DGND

14

13

AGND

V

12

DD

11

VREFSHDN

MAX1245

SPI and QSPI are registered trademarks of Motorola, Inc. Microwire is a registered trademark of National Semiconductor Corp.

________________________________________________________________

Maxim Integrated Products

1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

ABSOLUTE MAXIMUM RATINGS

VDDto AGND, DGND.............................................. -0.3V to +6V

AGND to DGND.................................................... -0.3V to +0.3V

CH0–CH7, COM to AGND, DGND............ -0.3V to (V

VREF to AGND........................................... -0.3V to (V

Digital Inputs to DGND............................................ -0.3V to +6V

Digital Outputs to DGND........................... -0.3V to (V

Digital Output Sink Current.................................................25mA

Continuous Power Dissipation (T

MAX1245

Plastic DIP (derate 11.11mW/°C above +70°C) ......... 889mW

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

= +70°C)

A

DD

DD

DD

+ 0.3V)

+ 0.3V)

+ 0.3V)

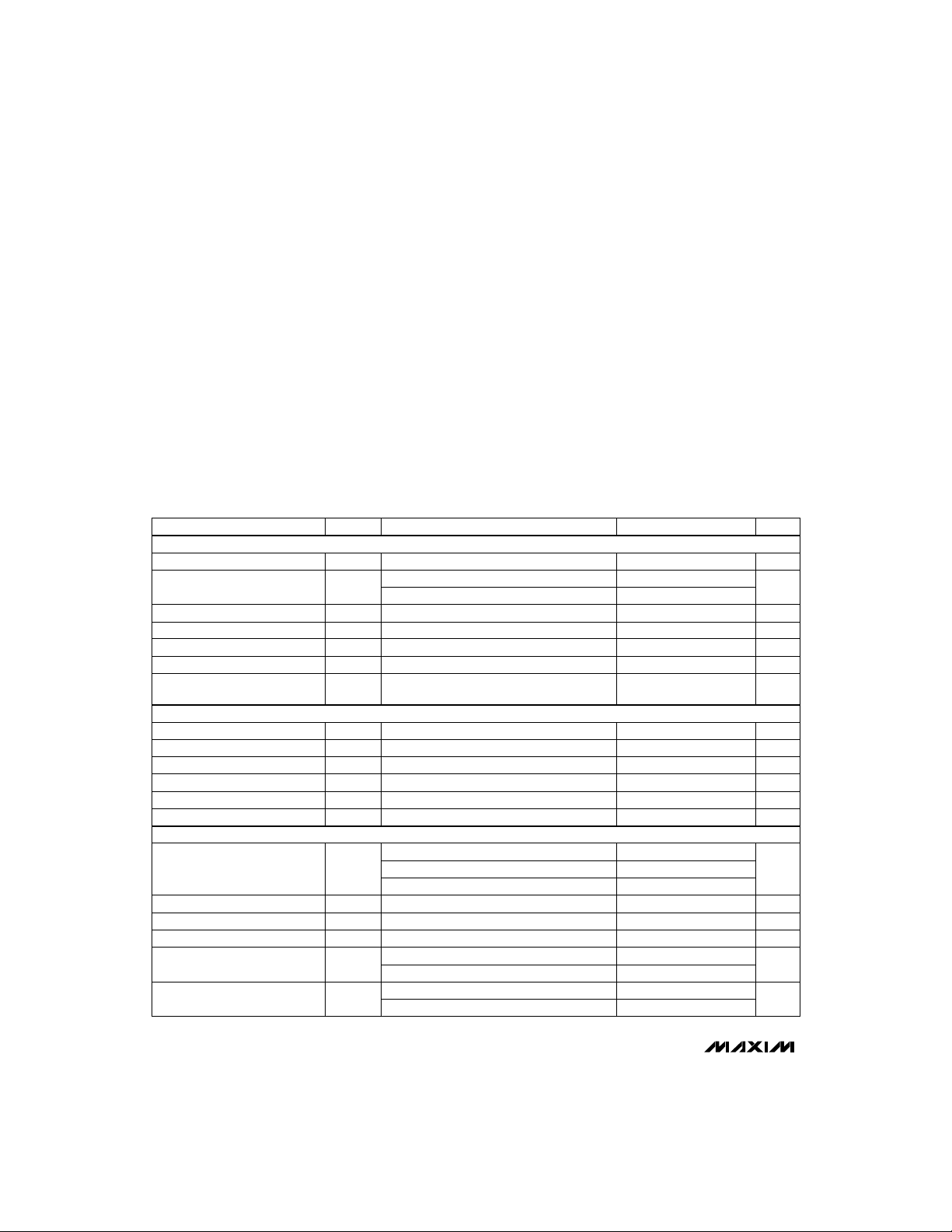

ELECTRICAL CHARACTERISTICS

(VDD= +2.375V to +3.3V, COM = 0V, f

VREF = 2.048V applied to VREF pin, T

DC ACCURACY (Note 1)

Differential Nonlinearity

Offset Error

Channel-to-Channel Offset

Matching

DYNAMIC SPECIFICATIONS (10kHz sine-wave input, 0Vp-p to 2.048Vp-p, 100ksps, 1.5MHz external clock, bipolar input mode)

CONVERSION RATE

Conversion Time (Note 5)

Track/Hold Acquisition Time External clock = 1.5MHz

Internal Clock Frequency

External Clock Frequency

= 1.5MHz, external clock (50% duty cycle), 15 clocks/conversion cycle (100ksps),

CLK

= T

to T

A

INLRelative Accuracy (Note 2)

t

CONV

ACQ

MIN

, unless otherwise noted.)

MAX

MAX1245A

MAX1245B

No missing codes over temperature

Up to the 5th harmonic

50kHz, 2V

-3dB rolloff

Internal clock, SHDN = FLOAT

Internal clock, SHDN = V

External clock = 1.5MHz, 12 clocks/conversion

SHDN = FLOAT

SHDN = V

Data transfer only

p-p

DD

(Note 4)

SSOP (derate 8.00mW/°C above +70°C) ................... 640mW

CERDIP (derate 11.11mW/°C above +70°C).............. 889mW

Operating Temperature Ranges

MAX1245_C_P................................................... 0°C to +70°C

MAX1245_E_P ................................................ -40°C to +85°C

Storage Temperature Range............................ -60°C to +150°C

Lead Temperature (soldering, 10sec)............................ +300°C

CONDITIONS

±0.5

±1.0

5.5 7.5

DD

35 65

8

1.5

0.225

0.1 1.5

0 1.5

UNITSMIN TYP MAXSYMBOLPARAMETER

ppm/°C±0.25Gain Temperature Coefficient

Bits12Resolution

LSB

LSB±1DNL

LSB±0.5 ±4

LSBGain Error (Note 3) ±0.5 ±4

LSB±0.2

dB68SINADSignal-to-Noise + Distortion Ratio

dB-76THDTotal Harmonic Distortion

dB76SFDRSpurious-Free Dynamic Range

dB-85Channel-to-Channel Crosstalk

MHz2.25Small-Signal Bandwidth

MHz1.0Full-Power Bandwidth

µs

µs2.0t

ns40Aperture Delay

ps<50Aperture Jitter

MHz

MHz

2 _______________________________________________________________________________________

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

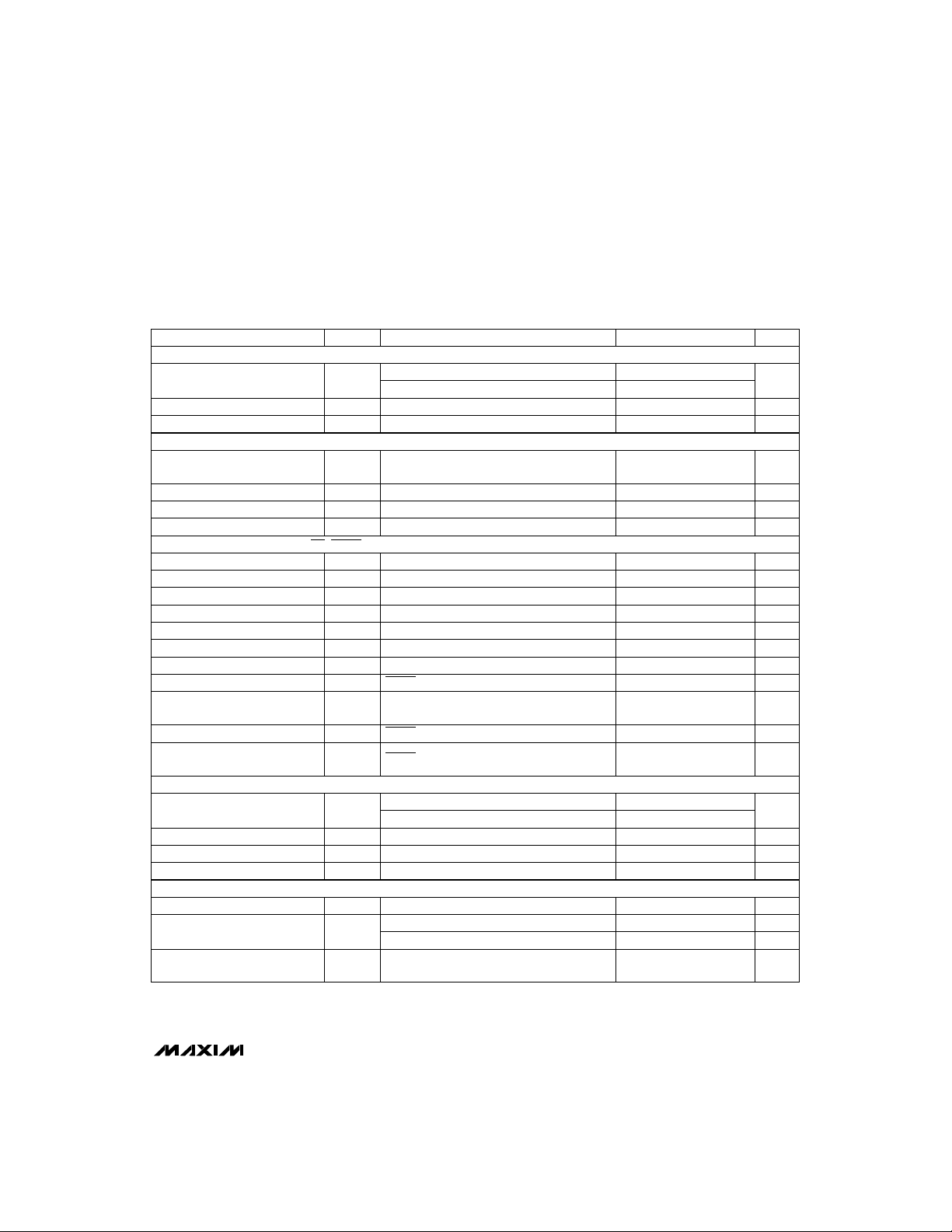

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +2.375V to +3.3V, COM = 0V, f

VREF = 2.048V applied to VREF pin, T

ANALOG/COM INPUTS

Input Voltage Range, SingleEnded and Differential (Note 6)

Multiplexer Leakage Current

EXTERNAL REFERENCE

VREF Input Voltage Range

(Note 8)

DIGITAL INPUTS (DIN, SCLK, CS, SHDN)

DIN, SCLK, CS Input High Voltage

DIN, SCLK, CS Input Low Voltage

DIN, SCLK, CS Input Hysteresis

DIN, SCLK, CS Input Leakage

DIN, SCLK, CS Input Capacitance

SHDN Input High Voltage

SHDN Input Low Voltage

SHDN Input Current

SHDN Input Mid Voltage

SHDN Voltage, Floating

SHDN Maximum Allowed Leakage,

Mid Input

DIGITAL OUTPUTS (DOUT, SSTRB)

Output Voltage Low

Output Voltage High

Three-State Leakage Current

Three-State Output Capacitance

POWER REQUIREMENTS

Positive Supply Voltage

Positive Supply Current

= 1.5MHz, external clock (50% duty cycle), 15 clocks/conversion cycle (100ksps),

CLK

= T

to T

A

INH

INL

HYST

IN

IN

INH

INL

IN

V

IM

FLT

V

OL

OH

L

OUT

DD

I

DD

MIN

, unless otherwise noted.)

MAX

CONDITIONS

Unipolar, COM = 0V

Bipolar, COM = VREF/2

On/off leakage current, VIN= 0V or V

(Note 7)

VREF = 2.048V

VIN= 0V or V

(Note 7)

SHDN = 0V or V

SHDN = open

SHDN = open

I

SINK

I

SINK

I

SOURCE

CS = V

CS = VDD(Note 7)

Operating mode, full-scale input

VDD= 2.375V to 3.3V, full-scale input,

external reference = 2.048V

DD

DD

= 5mA

= 16mA

=0.5mA

DD

DD

0 to VREF

±VREF/2

V

0.5

1.2 10Power-down

DD

50mV

0.4

1.0

VDD/2 VDD/2

- 0.3 + 0.3

MAX1245

UNITSMIN TYP MAXSYMBOLPARAMETER

V

µA±0.01 ±1

pF16Input Capacitance

+

V

µA82 120VREF Input Current

kΩ18 25VREF Input Resistance

µA0.01 10Shutdown VREF Input Current

V2.0V

V0.8V

V0.2V

µA±0.01 ±1I

pF15C

VVDD- 0.4V

V0.4V

µA±4.0I

V

VVDD/2V

nA±80

V

VVDD - 0.375V

µA±0.01 ±10I

pF15C

V2.375 3.3V

mA0.8 1.3

µA

mV±0.3PSRSupply Rejection (Note 9)

_______________________________________________________________________________________ 3

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

TIMING CHARACTERISTICS

(VDD= +2.375V to +3.3V, COM = 0V, TA= T

PARAMETER

Acquisition Time

DIN to SCLK Setup

DIN to SCLK Hold

SCLK Fall to Output Data Valid

MAX1245

CS Fall to Output Enable

CS Rise to Output Disable

CS to SCLK Rise Setup

CS to SCLK Rise Hold

SCLK Pulse Width Low

SCLK Fall to SSTRB ns

CS Fall to SSTRB Output Enable

CS Rise to SSTRB Output Disable

SSTRB Rise to SCLK Rise

Note 1: Tested at V

Note 2: Relative accuracy is the deviation of the analog value at any code from its theoretical value after the full-scale range has

= +2.375V; COM = 0V; unipolar single-ended input mode.

DD

been calibrated.

Note 3: External reference (VREF = +2.048V), offset nulled.

Note 4: Ground “on” channel; sine wave applied to all “off” channels.

Note 5: Conversion time defined as the number of clock cycles multiplied by the clock period; clock has 50% duty cycle.

Note 6: The common-mode range for the analog inputs is from AGND to V

Note 7: Guaranteed by design. Not subject to production testing.

Note 8: ADC performance is limited by the converter’s noise floor, typically 300µVp-p.

Note 9: Measured as

VFS(2.375V) - VFS(3.3V)|.

|

to T

MIN

, unless otherwise noted.)

MAX

CONDITIONS

ACQ

DS

DH

t

Figure 1 ns20 260

DO

Figure 1

DV

Figure 2

TR

CSS

t

CSH

t

CH

CL

Figure 1

SSTRB

External clock mode only, Figure 1

SDV

External clock mode only, Figure 2

STR

Internal clock mode only (Note 7)

SCK

DD

.

300t

0t

260t

UNITSMIN TYP MAXSYMBOL

µs2.0t

ns200t

ns0t

ns240t

ns400t

ns200t

ns0

ns300SCLK Pulse Width High

ns

ns240t

ns400t

ns

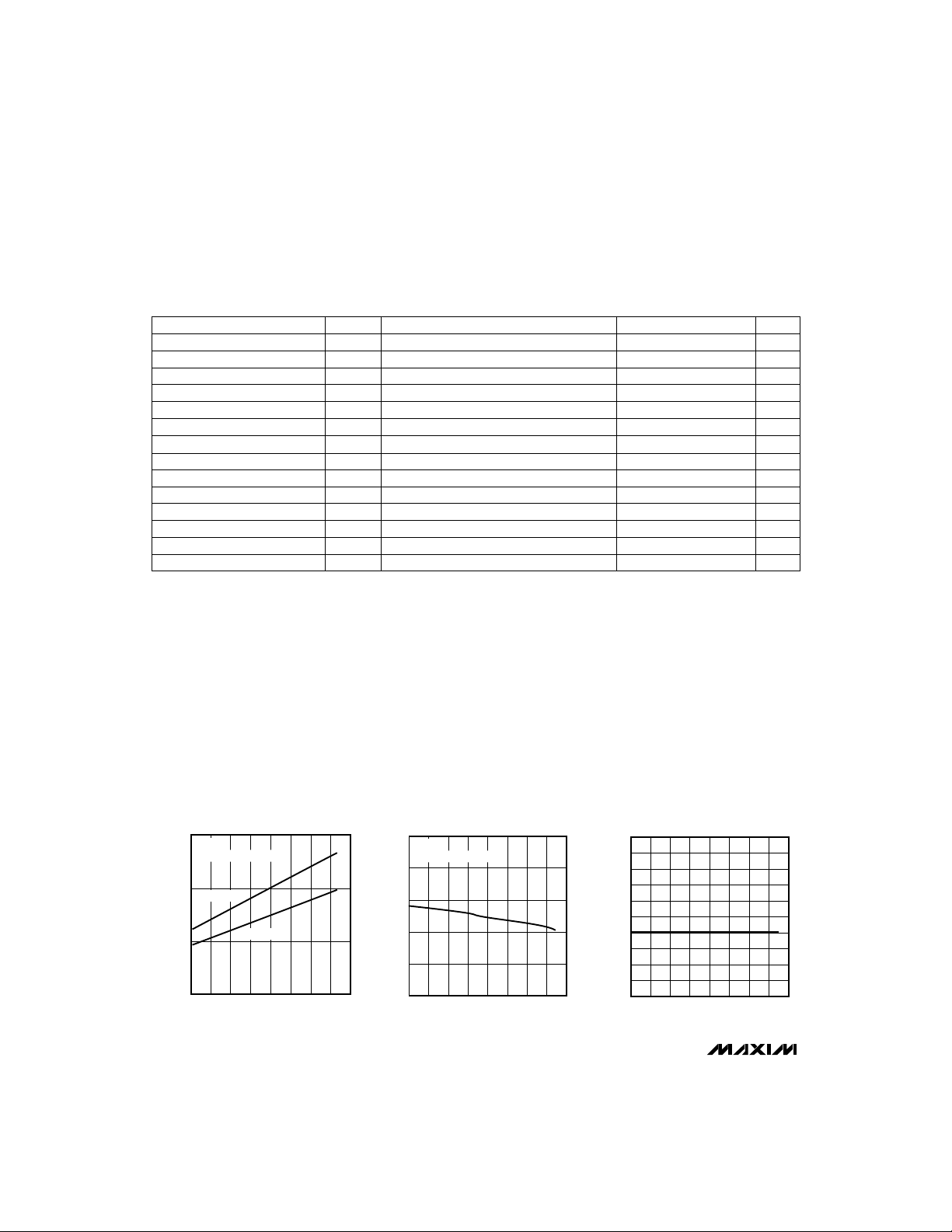

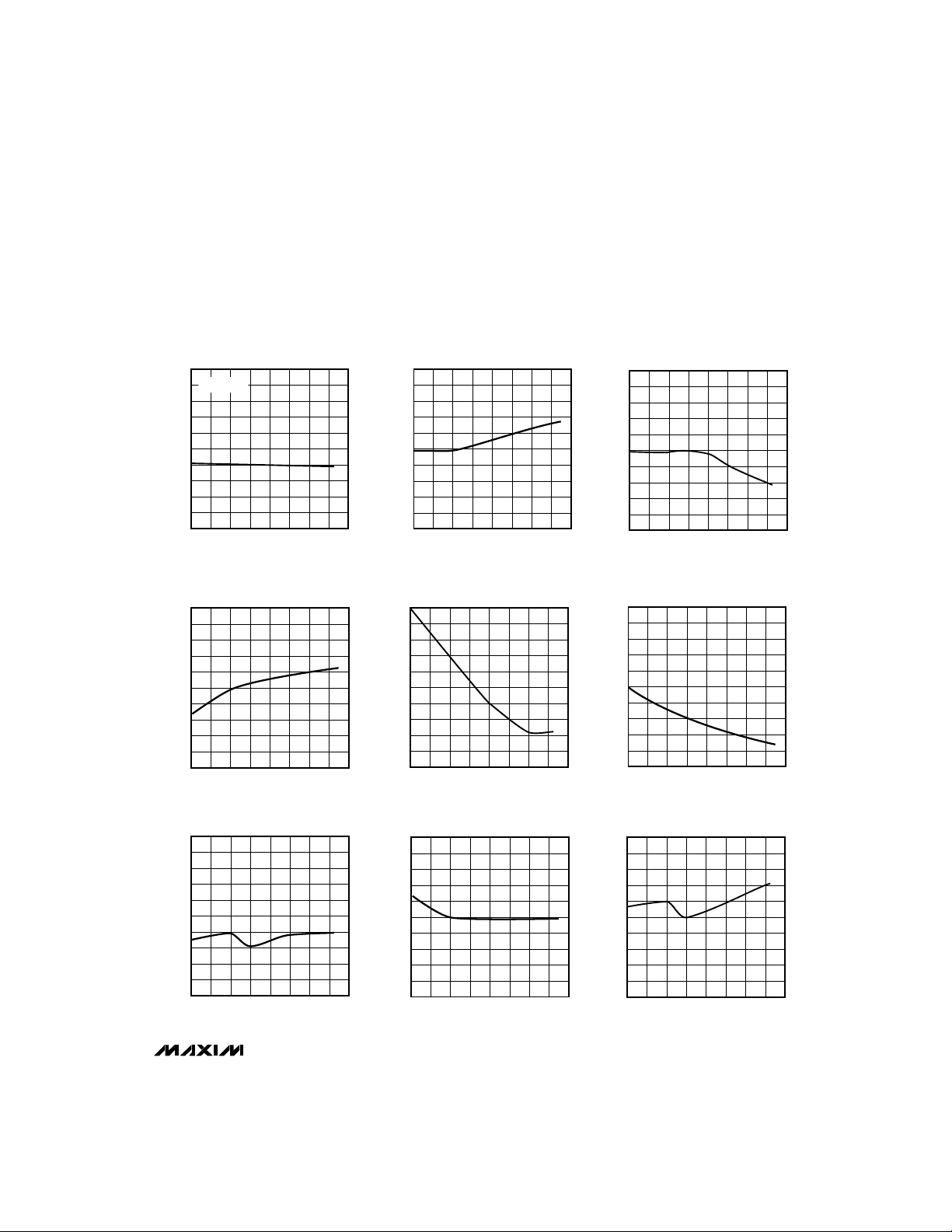

__________________________________________Typical Operating Characteristics

(VDD= 2.5V, VREF = 2.048V, f

SUPPLY CURRENT

1.25

1.00

(mA)

DD

I

0.75

0.50

vs. SUPPLY VOLTAGE

RL = ∞

CODE = 101010100000

C

= 50pF

LOAD

2.625

2.375

C

= 20pF

LOAD

2.875

(V)

V

DD

4 _______________________________________________________________________________________

= 1.5MHz, C

CLK

3.125

3.375

LOAD

0.90

MAX1245-01

0.85

0.80

(mA)

DD

I

0.75

0.70

0.65

-55 -30 70

= 20pF, TA = +25°C, unless otherwise noted.)

SUPPLY CURRENT

vs. TEMPERATURE

RL = ∞

CODE = 101010100000

20 145120-5 45 95

TEMPERATURE (°C)

MAX1245-02

0.50

0.45

0.40

0.35

0.30

0.25

INL (LSB)

0.20

0.15

0.10

0.05

0.00

2.375

INTEGRAL NONLINEARITY

vs. SUPPLY VOLTAGE

2.875

V

(V)

DD

3.3753.1252.625

MAX1245-03

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

____________________________Typical Operating Characteristics (continued)

(VDD= 2.5V, VREF = 2.048V, f

INTEGRAL NONLINEARITY

0.50

0.45

0.40

0.35

0.30

0.25

INL (LSB)

0.20

0.15

0.10

0.05

0

-55 -30 45

vs. TEMPERATURE

VDD = 2.375V

20-5 70 95 145120

TEMPERATURE (˚C)

CHANNEL-TO-CHANNEL OFFSET MATCHING

0

2.375

vs. SUPPLY VOLTAGE

2.875

V

(V)

DD

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

OFFSET MATCHING (LSB)

0.10

0.05

GAIN ERROR

0.50

0.45

0.40

0.35

0.30

0.25

0.20

GAIN ERROR (LSB)

0.15

0.10

0.05

0

vs. TEMPERATURE

-55

-5 45 120

-30 20

TEMPERATURE (˚C)

CLK

3.1252.625

70

= 1.5MHz, C

95

MAX1245-04

MAX1245-07

3.375

MAX1245-10

145

= 20pF, TA = +25°C, unless otherwise noted.)

LOAD

OFFSET vs. SUPPLY VOLTAGE

0.50

0.45

0.40

0.35

0.30

0.25

0.20

OFFSET (LSB)

0.15

0.10

0.05

0

2.375

CHANNEL-TO-CHANNEL OFFSET MATCHING

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

OFFSET MATCHING (LSB)

0.10

0.05

0

-55

-30 45

CHANNEL-TO-CHANNEL GAIN MATCHING

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

GAIN MATCHING (LSB)

0.10

0.05

0

2.375

2.875

V

(V)

DD

vs. TEMPERATURE

20

-5

TEMPERATURE (˚C)

70

vs. SUPPLY VOLTAGE

2.875

2.625

V

(V)

DD

3.1252.625

95

MAX1245-05

3.375

MAX1245-08

145120

MAX1245-11

3.3753.125

OFFSET vs. TEMPERATURE

0.50

0.45

0.40

0.35

0.30

0.25

0.20

OFFSET (LSB)

0.15

0.10

0.05

0

-55 -30

20-5 70 14512095

45

TEMPERATURE (˚C)

GAIN ERROR

0

2.375 2.875 3.3753.1252.625

vs. SUPPLY VOLTAGE

V

(V)

DD

0.50

0.45

0.40

0.35

0.30

0.25

0.20

GAIN ERROR (LSB)

0.15

0.10

0.05

CHANNEL-TO-CHANNEL GAIN MATCHING

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

GAIN MATCHING (LSB)

0.10

0.05

0

-55

vs. TEMPERATURE

-30

-5 45

TEMPERATURE (˚C)

20

MAX1245

MAX1245-06

MAX1245-09

MAX1245-12

1451209570

_______________________________________________________________________________________

5

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

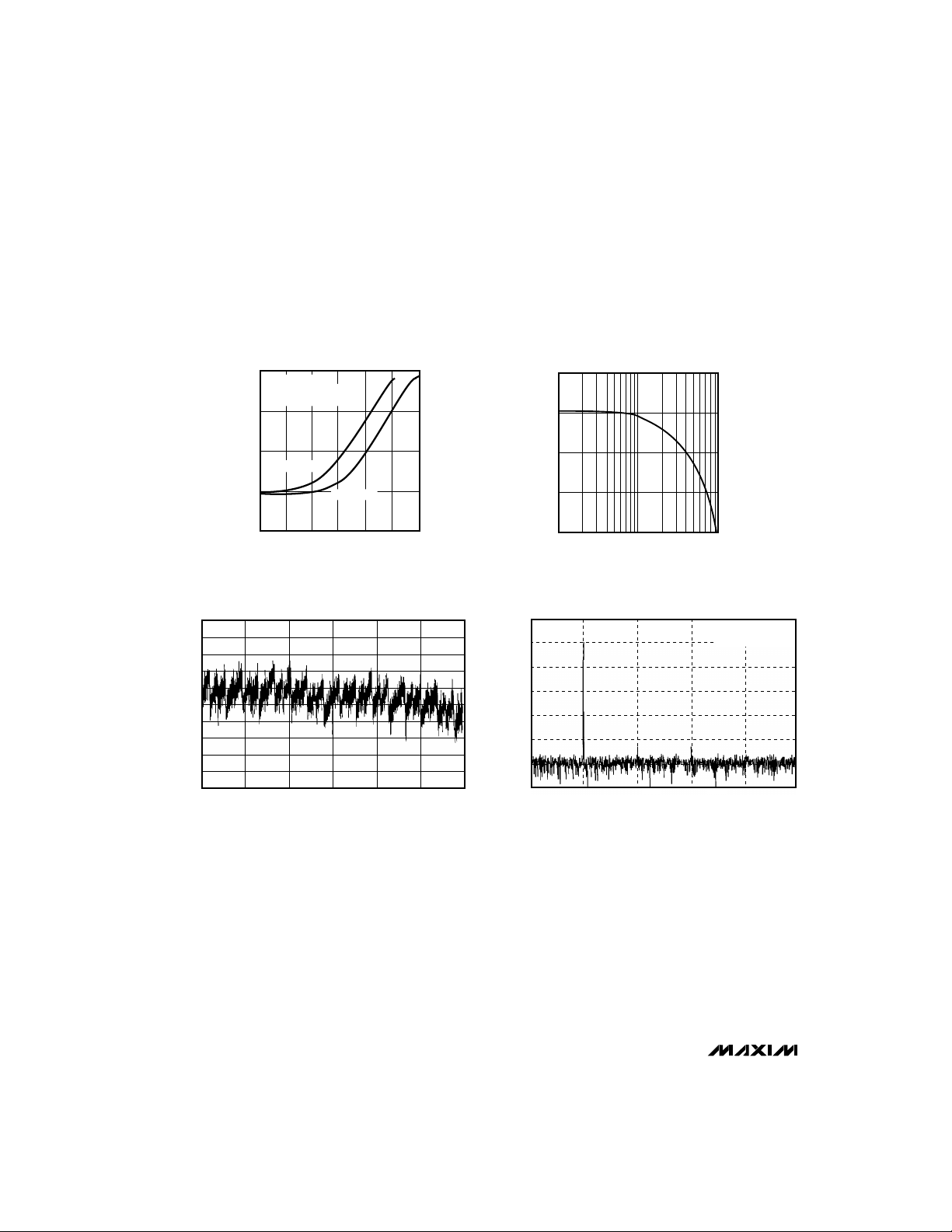

____________________________Typical Operating Characteristics (continued)

(VDD= 2.5V, VREF = 2.048V, f

= 1.5MHz, C

CLK

= 20pF, TA = +25°C, unless otherwise noted.)

LOAD

1000

MAX1245

0.25

0.20

0.15

0.10

0.05

0

INL (BITS)

-0.05

-0.10

-0.15

-0.20

-0.25

100

(µA)

10

DD

I

1

0.1

0

AVERAGE SUPPLY CURRENT

vs. CONVERSION RATE

V

VREF = 2.5V

DD =

CODE = 101010100000

= ∞

R

L

8 CHANNELS

1 CHANNEL

0.1

CONVERSIONS PER CHANNEL PER SECOND (Hz)

101 1k 10k100 100k

MAX1245-13

INTEGRAL NONLINEARITY

2048

DIGITAL CODE

4096

12.0

11.5

11.0

10.5

EFFECTIVE NUMBER OF BITS

10.0

1 10 100

20

0

-20

-40

-60

AMPLITUDE (dB)

-80

-100

-120

0

EFFECTIVE NUMBER OF BITS

vs. INPUT FREQUENCY

MAX1245-14

INPUT FREQUENCY (kHz)

FFT PLOT

f

= 10ksps

TONE

= 100ksps

f

SAMPLE

10 20 30 40 50

FREQUENCY (kHz)

6 _______________________________________________________________________________________

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

______________________________________________________________Pin Description

PIN

1–8 CH0–CH7 Sampling Analog Inputs

9 COM

10

11 VREF External Reference Voltage Input for analog-to-digital conversion

12, 20 V

13 AGND Analog Ground

14 DGND Digital Ground

15 DOUT

16 SSTRB

17 DIN Serial Data Input. Data is clocked in at the rising edge of SCLK.

18

19 SCLK

NAME FUNCTION

Ground reference for analog inputs. Sets zero-code voltage in single-ended mode. Must be stable to

±0.5LSB.

Three-Level Shutdown Input. Pulling SHDN low shuts the MAX1245 down to 10µA (max) supply current;

SHDN

otherwise, the MAX1245 is fully operational. Letting SHDN float sets the internal clock frequency to 1.5MHz.

Pulling SHDN high sets the internal clock frequency to 225kHz. See

DD

Positive Supply Voltage

Serial Data Output. Data is clocked out at the falling edge of SCLK. High impedance when CS is high.

Serial Strobe Output. In internal clock mode, SSTRB goes low when the MAX1245 begins the A/D con-

version and goes high when the conversion is done. In external clock mode, SSTRB pulses high for

one clock period before the MSB decision. High impedance when CS is high (external clock mode).

CS

Active-Low Chip Select. Data will not be clocked into DIN unless CS is low. When CS is high, DOUT is

high impedance.

Serial Clock Input. Clocks data in and out of serial interface. In external clock mode, SCLK also sets

the conversion speed. (Duty cycle must be 40% to 60%.)

Hardware Power-Down

section.

MAX1245

V

DD

DOUT

6k

a) High-Z to V

DGND

and VOL to V

OH

DOUT

C

LOAD

50pF

b) High-Z to VOL and VOH to V

OH

6k

C

LOAD

50pF

DGND

DOUT

OL

6k

DGND

a) VOH to High-Z b) VOL to High-Z

C

50pF

LOAD

Figure 1. Load Circuits for Enable Time Figure 2. Load Circuits for Disable Time

_______________________________________________________________________________________ 7

DOUT

V

DD

6k

C

LOAD

50pF

DGND

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

_______________Detailed Description

The MAX1245 analog-to-digital converter (ADC) uses a

successive-approximation conversion technique and

input track/hold (T/H) circuitry to convert an analog signal to a 12-bit digital output. A flexible serial interface

provides easy interface to microprocessors (µPs). No

external hold capacitors are required. Figure 3 is a

block diagram of the MAX1245.

MAX1245

The sampling architecture of the ADC’s analog comparator is illustrated in the equivalent input circuit (Figure 4). In

single-ended mode, IN+ is internally switched to

CH0–CH7, and IN- is switched to COM. In differential

mode, IN+ and IN- are selected from the following pairs:

CH0/CH1, CH2/CH3, CH4/CH5, and CH6/CH7. Configure

the channels with Tables 2 and 3.

In differential mode, IN- and IN+ are internally switched

to either of the analog inputs. This configuration is

pseudo-differential to the effect that only the signal at

IN+ is sampled. The return side (IN-) must remain stable within ±0.5LSB (±0.1LSB for best results) with

respect to AGND during a conversion. To accomplish

this, connect a 0.1µF capacitor from IN- (the selected

analog input) to AGND.

During the acquisition interval, the channel selected as the

positive input (IN+) charges capacitor C

sition interval spans three SCLK cycles and ends on the

falling SCLK edge after the last bit of the input control

word has been entered. At the end of the acquisition interval, the T/H switch opens, retaining charge on C

sample of the signal at IN+.

Pseudo-Differential Input

. The acqui-

HOLD

HOLD

as a

The conversion interval begins with the input multiplexer

switching C

from the positive input, IN+, to the

HOLD

negative input, IN- (In single-ended mode, IN- is simply

COM). This unbalances node ZERO at the input of the

comparator. The capacitive DAC adjusts during the

remainder of the conversion cycle to restore node ZERO

to 0V within the limits of 12-bit resolution. This action is

equivalent to transferring a charge of 16pF x [(V

(VIN-)] from C

to the binary-weighted capacitive

HOLD

) -

IN

+

DAC, which in turn forms a digital representation of the

analog input signal.

Track/Hold

The T/H enters its tracking mode on the falling clock

edge after the fifth bit of the 8-bit control word has been

shifted in. It enters its hold mode on the falling clock

edge after the eighth bit of the control word has been

shifted in. If the converter is set up for single-ended

inputs, IN- is connected to COM, and the converter

samples the “+” input. If the converter is set up for differential inputs, IN- connects to the “-” input, and the

difference of |IN+ - IN-| is sampled. At the end of the

conversion, the positive input connects back to IN+,

and C

charges to the input signal.

HOLD

The time required for the T/H to acquire an input signal

is a function of how quickly its input capacitance is

charged. If the input signal’s source impedance is high,

the acquisition time lengthens, and more time must be

allowed between conversions. The acquisition time,

t

, is the maximum time the device takes to acquire

ACQ

the signal, and is also the minimum time needed for the

signal to be acquired. It is calculated by:

t

= 9 x (RS+ RIN) x 16pF

ACQ

18

CS

19

SCLK

INPUT

17

DIN

SHDN

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

COM

VREF

10

1

2

3

4

5

6

7

8

9

11

SHIFT

REGISTER

ANALOG

INPUT

MUX

MAX1245

Figure 3. Block Diagram

CONTROL

LOGIC

T/H

IN

INT

CLOCK

CLOCK

12-BIT

SAR

ADC

REF

OUTPUT

SHIFT

REGISTER

OUT

15

16

12, 20

14

13

DOUT

SSTRB

V

DD

DGND

AGND

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

COM

SINGLE-ENDED MODE: IN+ = CHO–CH7, IN- = COM.

DIFFERENTIAL MODE: IN+ AND IN- SELECTED FROM PAIRS OF

CH0/CH1, CH2/CH3, CH4/CH5, AND CH6/CH7.

Figure 4. Equivalent Input Circuit

12-BIT CAPACITIVE DAC

VREF

INPUT

MUX

–

C

SWITCH

C

HOLD

16pF

TRACK

+

SWITCH

T/H

ZERO

R

IN

12k

HOLD

AT THE SAMPLING INSTANT,

THE MUX INPUT SWITCHES

FROM THE SELECTED IN+

CHANNEL TO THE SELECTED

IN- CHANNEL.

8 _______________________________________________________________________________________

COMPARATOR

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

where RIN= 12kΩ, RS= the source impedance of the

input signal, and t

is never less than 2.0µs. Note

ACQ

that source impedances below 1kΩ do not significantly

affect the AC performance of the ADC. Higher source

impedances can be used if an input capacitor is connected to the analog inputs, as shown in Figure 5. Note

that the input capacitor forms an RC filter with the input

source impedance, limiting the ADC’s signal bandwidth.

Input Bandwidth

The ADC’s input tracking circuitry has a 2.25MHz

small-signal bandwidth, so it is possible to digitize

high-speed transient events and measure periodic signals with bandwidths exceeding the ADC’s sampling

rate by using undersampling techniques. To avoid

high-frequency signals being aliased into the frequency

band of interest, anti-alias filtering is recommended.

Analog Input Protection

Internal protection diodes, which clamp the analog

input to VDDand AGND, allow the channel input pins to

swing from AGND - 0.3V to VDD+ 0.3V without damage. However, for accurate conversions near full scale,

the inputs must not exceed VDDby more than 50mV or

be lower than AGND by 50mV.

If the analog input exceeds 50mV beyond the supplies, do not forward bias the protection diodes of

off channels over two milliamperes, as excessive

current will degrade the conversion accuracy of the

on channel.

To quickly evaluate the MAX1245’s analog perfor-

Quick Look

mance, use the circuit of Figure 5. The MAX1245

requires a control byte to be written to DIN before each

conversion. Tying DIN to VDDfeeds in control bytes of

$FF (HEX), which trigger single-ended unipolar conversions on CH7 in external clock mode without powering

down between conversions. In external clock mode, the

SSTRB output pulses high for one clock period before

the most significant bit of the 12-bit conversion result is

shifted out of DOUT. Varying the analog input to CH7

alters the sequence of bits from DOUT. A total of 15

clock cycles is required per conversion. All transitions

of the SSTRB and DOUT outputs occur on the falling

edge of SCLK.

How to Start a Conversion

A conversion is started by clocking a control byte into

DIN. With CS low, each rising edge on SCLK clocks a

bit from DIN into the MAX1245’s internal shift register.

After CS falls, the first arriving logic “1” bit defines the

MSB of the control byte. Until this first “start” bit arrives,

any number of logic “0” bits can be clocked into DIN

with no effect. Table 1 shows the control-byte format.

The MAX1245 is compatible with Microwire, SPI, and

QSPI devices. For SPI, select the correct clock polarity

and sampling edge in the SPI control registers: set

CPOL = 0 and CPHA = 0. Microwire, SPI, and QSPI all

transmit a byte and receive a byte at the same time.

Using the

Typical Operating Circuit,

the simplest soft-

ware interface requires only three 8-bit transfers to

MAX1245

0V TO

2.048V

ANALOG

0.01µF

INPUT

2.048V

C1

0.1µF

Figure 5. Quick-Look Circuit

_______________________________________________________________________________________ 9

CH7

VREF

MAX1245

V

DGND

AGND

COM

SCLK

DIN

DOUT

SSTRB

SHDN

OSCILLOSCOPE

DD

CS

+2.5V

N.C.

+2.5V

0.1µF

1.5MHz

OSCILLATOR

CH1 CH2

* FULL-SCALE ANALOG INPUT, CONVERSION RESULT = $FFF (HEX)

CH3 CH4

SCLK

SSTRB

DOUT*

+2.375V, Low-Power, 8-Channel,

DIF

DIF

Serial 12-Bit ADC

Table 1. Control-Byte Format

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

(MSB) (LSB)

START SEL2 SEL1 SEL0 UNI/BIP SGL/DIF PD1 PD0

BIT NAME DESCRIPTION

7(MSB) START The first logic “1” bit after CS goes low defines the beginning of the control byte.

MAX1245

6 SEL2 These three bits select which of the eight channels are used for the conversion (Tables 2 and 3).

5 SEL1

4 SEL0

3 UNI/BIP 1 = unipolar, 0 = bipolar. Selects unipolar or bipolar conversion mode. In unipolar mode, an

2 SGL/DIF 1 = single ended, 0 = differential. Selects single-ended or differential conversions. In single-

1 PD1 Selects clock and power-down modes.

0(LSB) PD0 PD1 PD0 Mode

analog input signal from 0V to VREF can be converted; in bipolar mode, the signal can range

from -VREF/2 to +VREF/2.

ended mode, input signal voltages are referred to COM. In differential mode, the voltage

difference between two channels is measured (Tables 2 and 3).

0 0 Power-down (IQ= 1.2µA)

0 1 Unassigned

1 0 Internal clock mode

1 1 External clock mode

Table 2. Channel Selection in Single-Ended Mode (SGL/

SEL2 SEL1 SEL0 CH0 CH1 CH2 CH3 CH4 CH5 CH6 CH7 COM

00 0 + –

10 0 + –

00 1 + –

10 1 + –

01 0 + –

11 0 + –

01 1 +–

11 1 + –

Table 3. Channel Selection in Differential Mode (SGL/

SEL2 SEL1 SEL0 CH0 CH1 CH2 CH3 CH4 CH5 CH6 CH7

00 0 + –

00 1 + –

01 0 + –

01 1 +–

10 0 – +

10 1 – +

11 0 – +

11 1 –+

10 ______________________________________________________________________________________

= 1)

= 0)

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

perform a conversion (one 8-bit transfer to configure the

ADC, and two more 8-bit transfers to clock out the 12-bit

conversion result). See Figure 17 for MAX1245 QSPI

connections.

Simple Software Interface

Make sure the CPU’s serial interface runs in master

mode so the CPU generates the serial clock. Choose a

clock frequency from 100kHz to 1.5MHz.

1) Set up the control byte for external clock mode and

call it TB1. TB1 should be of the format: 1XXXXX11

binary, where the Xs denote the particular channel

and conversion mode selected.

2) Use a general-purpose I/O line on the CPU to pull

CS low.

3) Transmit TB1 and, simultaneously, receive a byte

and call it RB1. Ignore RB1.

4) Transmit a byte of all zeros ($00 HEX) and, simultaneously, receive byte RB2.

5) Transmit a byte of all zeros ($00 HEX) and, simultaneously, receive byte RB3.

6) Pull CS high.

Figure 6 shows the timing for this sequence. Bytes RB2

and RB3 will contain the result of the conversion

padded with one leading zero and three trailing zeros.

The total conversion time is a function of the serial

clock frequency and the amount of idle time between

8-bit transfers. Make sure that the total conversion time

does not exceed 120µs, to avoid excessive T/H droop.

In unipolar input mode, the output is straight binary

Digital Output

(Figure 14). For bipolar inputs, the output is two’s-complement (Figure 15). Data is clocked out at the falling

edge of SCLK in MSB-first format.

Clock Modes

The MAX1245 may use either an external serial clock or

the internal clock to perform the successive-approximation conversion. In both clock modes, the external clock

shifts data in and out of the MAX1245. The T/H acquires

the input signal as the last three bits of the control byte

are clocked into DIN. Bits PD1 and PD0 of the control

byte program the clock mode. Figures 7–10 show the

timing characteristics common to both modes.

External Clock

In external clock mode, the external clock not only shifts

data in and out, it also drives the analog-to-digital conversion. SSTRB pulses high for one clock period after

the control byte’s last bit. Successive-approximation bit

decisions are made and appear at DOUT on each of the

next 12 SCLK falling edges (Figure 6). SSTRB and

DOUT go into a high-impedance state when CS goes

high; after the next CS falling edge, SSTRB outputs a

logic low. Figure 8 shows the SSTRB timing in external

clock mode.

The conversion must complete in some minimum time,

or droop on the sample-and-hold capacitors may

degrade conversion results. Use internal clock mode if

the serial clock frequency is less than 100kHz, or if

serial-clock interruptions could cause the conversion

interval to exceed 120µs.

MAX1245

CS

SCLK

DIN

SSTRB

DOUT

A/D STATE

Figure 6. 24-Clock External-Clock-Mode Conversion Timing (Microwire and SPI Compatible, QSPI Compatible with f

14 8 12 16 20 24

SEL2 SEL1 SEL0

START

RB1

IDLE

______________________________________________________________________________________ 11

UNI/

SGL/

BIP

DIF

ACQUISITION

(SCLK = 1.5MHz)

t

ACQ

PD1 PD0

2.0µs

B11

MSB

RB2

B10 B9 B8 B7 B6 B5 B4 B3 B2 B1

CONVERSION

RB3

LSB

B0

FILLED WITH

ZEROS

IDLE

CLK

≤

1.5MHz)

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

CS

t

t

CSH

SCLK

MAX1245

DIN

DOUT

CSS

t

DS

t

DV

Figure 7. Detailed Serial-Interface Timing

CS

SSTRB

SCLK

• • •

t

t

t

DH

• • •

t

SDV

• • •

• • •

CH

CL

• • •

• • •

t

DO

• • •

t

SSTRB

• • •

t

SSTRB

• • •

• • • • •

t

CSH

t

TR

t

STR

PD0 CLOCKED IN

Figure 8. External-Clock-Mode SSTRB Detailed Timing

In internal clock mode, the MAX1245 generates its own

Internal Clock

conversion clock internally. This frees the µP from the

burden of running the SAR conversion clock and allows

the conversion results to be read back at the processor’s convenience, at any clock rate from zero to

1.5MHz. SSTRB goes low at the start of the conversion

and then goes high when the conversion is complete.

SSTRB will be low for a maximum of 7.5µs (SHDN =

FLOAT), during which time SCLK should remain low for

best noise performance.

An internal register stores data when the conversion is

in progress. SCLK clocks the data out of this register at

any time after the conversion is complete. After SSTRB

goes high, the next falling clock edge produces the

MSB of the conversion at DOUT, followed by the

remaining bits in MSB-first format (Figure 9). CS does

not need to be held low once a conversion is started.

Pulling CS high prevents data from being clocked into

the MAX1245 and three-states DOUT, but it does not

adversely affect an internal clock-mode conversion

already in progress. When internal clock mode is

12 ______________________________________________________________________________________

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

MAX1245

CS

SCLK

DIN

SSTRB

DOUT

A/D STATE

14 8

2 3 5 6 7 9 10 11 19 21 22 23

SEL2 SEL1 SEL0

START

IDLE

Figure 9. Internal Clock Mode Timing

CS • • •

t

CSH

SSTRB • • •

SCLK • • •

PD0 CLOCK IN

DOUT • • •

UNI/

SGL/

BIP

DIF

ACQUISITION

(SCLK = 1.5MHz)

PD1 PD0

2.0µs

t

SSTRB

t

CONV

CONVERSION

7.5µs MAX

(SHDN = FLOAT)

t

CONV

12

B11

B10 B9 B2 B1

MSB

IDLE

t

SCK

18

20

FILLED WITH

B0

ZEROS

LSB

t

CSS

24

t

DO

NOTE: FOR BEST NOISE PERFORMANCE, KEEP SCLK LOW DURING CONVERSION.

Figure 10. Internal Clock Mode SSTRB Detailed Timing

selected, SSTRB does not go into a high-impedance

state when CS goes high.

Figure 10 shows the SSTRB timing in internal clock

mode. In this mode, data can be shifted in and out of

the MAX1245 at clock rates exceeding 1.5MHz, provided that the minimum acquisition time, t

ACQ

, is kept

above 2.0µs.

Data Framing

The falling edge of CS does not start a conversion on

the MAX1245. The first logic high clocked into DIN is

interpreted as a start bit and defines the first bit of the

control byte. A conversion starts on the falling edge of

______________________________________________________________________________________ 13

SCLK, after the eighth bit of the control byte (the PD0

bit) is clocked into DIN. The start bit is defined as:

The first high bit clocked into DIN with CS low any

time the converter is idle; e.g., after V

is applied.

DD

OR

The first high bit clocked into DIN after bit 5 of a conversion in progress is clocked onto the DOUT pin.

is toggled before the current conversion is com-

If CS

plete, then the next high bit clocked into DIN is recognized as a start bit; the current conversion is terminated,

and a new one is started.

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

The fastest the MAX1245 can run is 15 clocks per conversion with CS held low between conversions. Figure 11a

shows the serial-interface timing necessary to perform a

conversion every 15 SCLK cycles in external clock mode.

If CS is low and SCLK is continuous, guarantee a start bit

by first clocking in 16 zeros.

Most microcontrollers require that conversions occur in

multiples of eight SCLK clocks; 16 clocks per conversion

will typically be the fastest that a microcontroller can

MAX1245

drive the MAX1245. Figure 11b shows the serial-interface timing necessary to perform a conversion every 16

SCLK cycles in external clock mode.

__________ Applications Information

When power is first applied, and if SHDN is not pulled

low, internal power-on reset circuitry activates the

MAX1245 in internal clock mode, ready to convert with

SSTRB = high. After the power supplies have stabilized, the internal reset time is 10µs, and no conversions should be performed during this phase. SSTRB is

high on power-up and, if CS is low, the first logical 1 on

CS

SCLK

DIN

DOUT

SSTRB

1

S CONTROL BYTE 0

Power-On Reset

8181

B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

CONVERSION RESULT 0

DIN will be interpreted as a start bit. Until a conversion

takes place, DOUT shifts out zeros.

Power-Down

The MAX1245’s automatic power-down mode can save

considerable power when operating at speeds below

the maximum sampling rate. Figure 13 shows the average supply current as a function of the sampling rate.

You can save power by placing the converter in a lowcurrent shutdown state between conversions.

Select power-down via bits 1 and 0 of the DIN control

byte with SHDN high (Tables 1 and 4). Pull SHDN low at

any time to shut down the converter completely. SHDN

overrides bits 1 and 0 of the control byte (Table 5).

Power-down mode turns off all chip functions that draw

quiescent current, reducing IDDtypically to 1.2µA.

Figures 12a and 12b illustrate the various power-down

sequences in both external and internal clock modes.

Software Power-Down

Software power-down is activated using bits PD1 and PD0

of the control byte. As shown in Table 4, PD1 and PD0

CONTROL BYTE 1S

B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

CONVERSION RESULT 1

CONTROL BYTE 2S

Figure 11a. External Clock Mode, 15 Clocks/Conversion Timing

CS

SCLK

DIN

DOUT

Figure 11b. External Clock Mode, 16 Clocks/Conversion Timing

14 ______________________________________________________________________________________

S CONTROL BYTE 0

B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0 B11 B10 B9 B8

CONVERSION RESULT 0

CONTROL BYTE 1S

CONVERSION RESULT 1

• • •

• • •

• • •

• • •

+2.375V, Low-Power, 8-Channel,

SHDN

Serial 12-Bit ADC

MAX1245

CLOCK

MODE

SHDN

DIN

DOUT

MODE

SETS EXTERNAL

CLOCK MODE

XXXX

SX

11 S 00

12 DATA BITS

POWERED UP

EXTERNAL

XXXXX XXXXX

Figure 12a. Timing Diagram Power-Down Modes, External Clock

CLOCK

MODE

DIN

DOUT

SSTRB

MODE

SX

XXXX

SETS INTERNAL

CLOCK MODE

10 S 00

DATA VALID

CONVERSION

POWERED UP

EXTERNAL

SETS SOFTWARE

POWER-DOWN

12 DATA BITS

INTERNAL

XXXXX

SETS EXTERNAL

CLOCK MODE

S11

SOFTWARE

POWER-DOWN

SETS

POWER-DOWN

CONVERSION

POWERED UP

DATA VALID

POWER-DOWN

VALID

DATA

SOFTWARE

INVALID

DATA

HARDWARE

POWER-

DOWN

POWERED UP

S

POWERED UP

Figure 12b. Timing Diagram Power-Down Modes, Internal Clock

Table 4. Software Power-Down and

Clock Mode

PD1 PD0 DEVICE MODE

1 1 External Clock

1 0 Internal Clock

0 1 Unassigned

0 0 Power-Down

______________________________________________________________________________________ 15

Table 5. Hard-Wired Power-Down and

Internal Clock Frequency

STATE MODE FREQUENCY

1 Enabled 225kHz

Floating Enabled 1.5MHz

0 Power-Down N/A

DEVICE INTERNAL CLOCK

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

Table 6. Full Scale and Zero Scale

UNIPOLAR MODE BIPOLAR MODE

Full Scale Zero Scale

VREF + COM COM

MAX1245

also specify the clock mode. When software shutdown is

asserted, the ADC continues to operate in the last specified clock mode until the conversion is complete. Then the

ADC powers down into a low quiescent-current state. In

internal clock mode, the interface remains active and conversion results can be clocked out after the MAX1245 has

entered a software power-down.

The first logical 1 on DIN is interpreted as a start bit, and

powers up the MAX1245. Following the start bit, the data

input word or control byte also determines clock mode

and power-down states. For example, if the DIN word

contains PD1 = 1, the chip remains powered up. If PD0 =

PD1 = 0, a power-down resumes after one conversion.

Hardware Power-Down

Pulling SHDN low places the converter in hardware

power-down. Unlike the software power-down mode, the

conversion is not completed; it stops coincidentally with

SHDN being brought low. SHDN also controls the clock

frequency in internal clock mode. Letting SHDNfloat sets

the internal clock frequency to 1.5MHz. When returning

to normal operation with SHDN floating, there is a t

delay of approximately 2MΩ x CL, where CLis the

capacitive loading on the SHDN pin. Pulling SHDN high

sets the internal clock frequency to 225kHz. This feature

eases the settling-time requirement for the reference

voltage.

External Reference

An external reference is required for the MAX1245. The

reference voltage range is 1V to VDD.

At VREF, the input impedance is a minimum of 18kΩ for

DC currents. During a conversion, the reference must

be able to deliver up to 250µA DC load current and

have an output impedance of 10Ω or less. If the reference has higher output impedance or is noisy, bypass

it close to the VREF pin with a 0.1µF capacitor.

Transfer Function

Table 6 shows the full-scale voltage ranges for unipolar

and bipolar modes using a 2.048V reference.

The external reference must have a temperature coefficient

of 4ppm/°C or less to achieve accuracy to within 1LSB over

the commercial temperature range of 0°C to +70°C.

RC

Positive Zero Negative

Full Scale Scale Full Scale

VREF/2

+ COM + COM

(µA)

DD

I

Figure 13. Average Supply Current vs. Conversion Rate

Figure 14 depicts the nominal, unipolar input/output

(I/O) transfer function, and Figure 15 shows the bipolar

input/output transfer function. Code transitions occur

halfway between successive-integer LSB values.

Output coding is binary, with 1LSB = 500µV (2.048V /

4096) for unipolar operation and 1LSB = 500µV

[(2.048V / 2 - -2.048V / 2) / 4096] for bipolar operation.

For best performance, use printed circuit boards.

Wire-wrap boards are not recommended. Board layout

should ensure that digital and analog signal lines are

separated from each other. Do not run analog and digital (especially clock) lines parallel to one another, or

digital lines underneath the ADC package.

Figure 16 shows the recommended system ground

connections. A single-point analog ground (“star”

ground point) should be established at AGND, separate from the logic ground. Connect all other analog

grounds and DGND to the star ground. No other digital

system ground should be connected to this ground.

The ground return to the power supply for the star

COM

AVERAGE SUPPLY CURRENT

1000

100

10

0.1

vs. CONVERSION RATE

V

VREF = 2.5V

DD =

CODE = 101010100000

= ∞

R

L

8 CHANNELS

1

0.1

CONVERSIONS PER CHANNEL PER SECOND (Hz)

1 CHANNEL

101 1k 10k100 100k

-VREF/2

MAX1245-13

Layout, Grounding, and Bypassing

16 ______________________________________________________________________________________

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

OUTPUT CODE

FULL-SCALE

11 . . . 111

11 . . . 110

11 . . . 101

00 . . . 011

00 . . . 010

00 . . . 001

00 . . . 000

0

(COM)

123

TRANSITION

INPUT VOLTAGE (LSBs)

FS = VREF + COM

ZS = COM

1LSB =

FS - 3/2LSB

VREF

4096

FS

Figure 14. Unipolar Transfer Function, Full Scale (FS) = VREF

+ COM, Zero Scale (ZS) = COM

ground should be low impedance and as short as possible for noise-free operation.

High-frequency noise in the VDDpower supply may

affect the high-speed comparator in the ADC. Bypass

the supply to the star ground with 0.1µF and 4.7µF

capacitors close to pin 20 of the MAX1245. Minimize

capacitor lead lengths for best supply-noise rejection. If

the +2.5V power supply is very noisy, a 10Ω resistor

can be connected as a lowpass filter (Figure 16).

OUTPUT CODE

VREF

FS

+ COM

=

ZS = COM

-FS = + COM

1LSB =

- FS

2

-VREF

2

VREF

4096

( VREF/2)

INPUT VOLTAGE (LSBs)

COM

≤

+FS - 1LSB

011 . . . 111

011 . . . 110

000 . . . 010

000 . . . 001

000 . . . 000

111 . . . 111

111 . . . 110

111 . . . 101

100 . . . 001

100 . . . 000

Figure 15. Bipolar Transfer Function, Full Scale (FS) = VREF /

2 + COM, Zero Scale (ZS) = COM

SUPPLIES

+2.5V

+2.5V

GND

MAX1245

R* = 10Ω

DD

* OPTIONAL

AGNDV

MAX1245

DGND+2.5VDGNDCOM

DIGITAL

CIRCUITRY

Figure 16. Power-Supply Grounding Connection

______________________________________________________________________________________ 17

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

+3V

+2.5V

0.1µF

MAX1245

ANALOG

INPUTS

1

CH0

2

CH1

CH2

3

4

CH3

MAX1245

5

CH4

6

CH5

7

CH6

8

CH7

9

COM

10

SHDN

V

SCLK

DIN

SSTRB

DOUT

DGND

AGND

V

VREF

20

DD

19

18

CS

17

16

15

14

13

12

DD

11

Figure 17. MAX1245 QSPI Connections

High-Speed Digital Interfacing with QSPI

The MAX1245 can interface with QSPI using the circuit in

Figure 17 (f

= 1.5MHz, CPOL = 0, CPHA = 0). This

SCLK

QSPI circuit can be programmed to do a conversion on

each of the eight channels. The result is stored in memory

without taxing the CPU, since QSPI incorporates its own

micro-sequencer.

Because the maximum external clock frequency is

1.5MHz, the MAX1245 is QSPI compatible up to 1.5MHz.

4.7µF

(POWER SUPPLIES)

SCK

PCS0

MOSI

MISO

0.1µF

+2.048V

MC683XX

(GND)

CLOCK CONNECTIONS NOT SHOWN

18 ______________________________________________________________________________________

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

Figure 18 shows an application circuit to interface the

TMS320LC3x-to-MAX1245 Interface

MAX1245 to the TMS320 in external clock mode. The timing diagram for this interface circuit is shown in Figure 19.

Use the following steps to initiate a conversion in the

MAX1245 and to read the results:

1) The TMS320 should be configured with CLKX

(transmit clock) as an active-high output clock and

CLKR (TMS320 receive clock) as an active-high

input clock. CLKX and CLKR on the TMS320 are

tied together with the MAX1245’s SCLK input.

2) The MAX1245’s CS pin is driven low by the TMS320’s

XF_ I/O port, to enable data to be clocked into the

MAX1245’s DIN.

3) An 8-bit word (1XXXXX11) should be written to the

MAX1245 to initiate a conversion and place the

device into external clock mode. Refer to Table 1 to

select the proper XXXXX bit values for your specific

application.

4) The MAX1245’s SSTRB output is monitored via the

TMS320’s FSR input. A falling edge on the SSTRB

output indicates that the conversion is in progress

and data is ready to be received from the

MAX1245.

5) The TMS320 reads in one data bit on each of the

next 16 rising edges of SCLK. These data bits represent the 12-bit conversion result followed by four

trailing bits, which should be ignored.

6) Pull CS high to disable the MAX1245 until the next

conversion is initiated.

XF

CLKX

TMS320LC3x

CLKR

DX

DR

FSR

Figure 18. MAX1245-to-TMS320 Serial Interface

CS

SCLK

DIN

DOUT

SSTRB

MAX1245

MAX1245

CS

SCLK

DIN

SSTRB

DOUT

Figure 19. TMS320 Serial-Interface Timing Diagram

START SEL2 SEL1 SEL0 UNI/BIP SGL/DIF PD1 PD0

______________________________________________________________________________________ 19

MSB B10 B1 LSB

HIGH

IMPEDANCE

HIGH

IMPEDANCE

+2.375V, Low-Power, 8-Channel,

Serial 12-Bit ADC

__Ordering Information (continued)

†

PIN-PACKAGETEMP. RANGEPART

INL

(LSB)

___________________Chip Information

TRANSISTOR COUNT: 2554

±1/220 Plastic DIP-40°C to +85°CMAX1245AEPP

±120 Plastic DIP-40°C to +85°CMAX1245BEPP

±1/220 SSOP-40°C to +85°CMAX1245AEAP

MAX1245

†

Contact factory for availability of alternate surface-mount

±120 SSOP-40°C to +85°CMAX1245BEAP

packages.

________________________________________________________Package Information

INCHES

DIM

MIN

A

0.068

A1

0.002

B

0.010

C

0.004

HE

α

C

L

D

E

e

H

L

α

SEE VARIATIONS

0.205

0.301

0.025

0˚

MAX

0.078

0.008

0.015

0.008

0.209

0.311

0.037

8˚

MILLIMETERS

MIN

1.73

0.05

0.25

0.09

5.20

0.65 BSC0.0256 BSC

7.65

0.63

0˚

MAX

1.99

0.21

0.38

0.20

5.38

7.90

0.95

8˚

PINS

14

16

20

24

28

INCHES

MIN

0.239

0.239

0.278

0.317

0.397

DIM

e

SSOP

A

SHRINK

SMALL-OUTLINE

B

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

A1

D

PACKAGE

D

D

D

D

D

MAX

0.249

0.249

0.289

0.328

0.407

MILLIMETERS

MAX

MIN

6.33

6.07

6.33

6.07

7.33

7.07

8.33

8.07

10.33

10.07

21-0056A

© 1996 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Loading...

Loading...