Page 1

General Description

The MAX1233/MAX1234 are complete PDA controllers in

5mm × 5mm, 28-pin QFN and TQFN packages. They feature a 12-bit analog-to-digital converter (ADC), low onresistance switches for driving resistive touch screens, an

internal +1.0V/+2.5V or external reference, ±2°C accurate, on-chip temperature sensor, direct +6V battery monitor, keypad controller, 8-bit digital-to-analog converter

(DAC), and a synchronous serial interface. Each of the

keypad controllers’ eight row and column inputs can be

reconfigured as general-purpose parallel I/O pins (GPIO).

All analog inputs are fully ESD protected, eliminating the

need for external TransZorb™ devices.

The MAX1233/MAX1234 offer programmable resolution

and sampling rates. Interrupts from the devices alert the

host processor when data is ready, when the screen is

touched, or a key press is detected. Softwareconfigurable scan control and internal timers give the user

flexibility without burdening the host processor. These

devices consume only 260µA at the maximum sampling

rate of 50ksps. Supply current falls to below 50µA for

sampling rates of 10ksps. The MAX1233/MAX1234 are

guaranteed over the -40°C to +85°C temperature range.

Applications

Personal Digital Assistants

Pagers

Touch-Screen Monitors

Cellular Phones

MP3 Players

Portable Instruments

Point-of-Sale Terminals

Features

♦ ESD-Protected Analog Inputs

±15kV IEC 1000-4-2 Air-Gap Discharge

±8kV IEC 1000-4-2 Contact Discharge

♦ Single-Supply Operation

+2.7V to +3.6V (MAX1233)

+4.75V to +5.25V (MAX1234)

♦ 4-Wire Touch-Screen Interface

♦ Internal +1.0V/+2.5V Reference or External

Reference (+1.0V to AVDD)

♦ SPI™/QSPI™/MICROWIRE™-Compatible 10MHz

Serial Interface

♦ 12-Bit, 50ksps ADC Measures

Resistive Touch-Screen Position and Pressure

Two Auxiliary Analog Inputs

Two Battery Voltages (0.5V to 6V)

On-Chip Temperature

♦ 8-Bit DAC for LCD Bias Control

♦ 4 × 4 Keypad Programmable Controller Offers Up

to Eight GPIO Pins

♦ Automatic Detection of Screen Touch, Key Press,

and End of Conversion

♦ Programmable 8-, 10-, 12-Bit Resolution

♦ Programmable Conversion Rates

♦ AutoShutdown

™

Between Conversions

♦ Low Power

260µA at 50ksps

50µA at 10ksps

6µA at 1ksps

0.3µA Shutdown Current

♦ 28-Pin 5mm × 5mm QFN and TQFN Packages

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

________________________________________________________________

Maxim Integrated Products

1

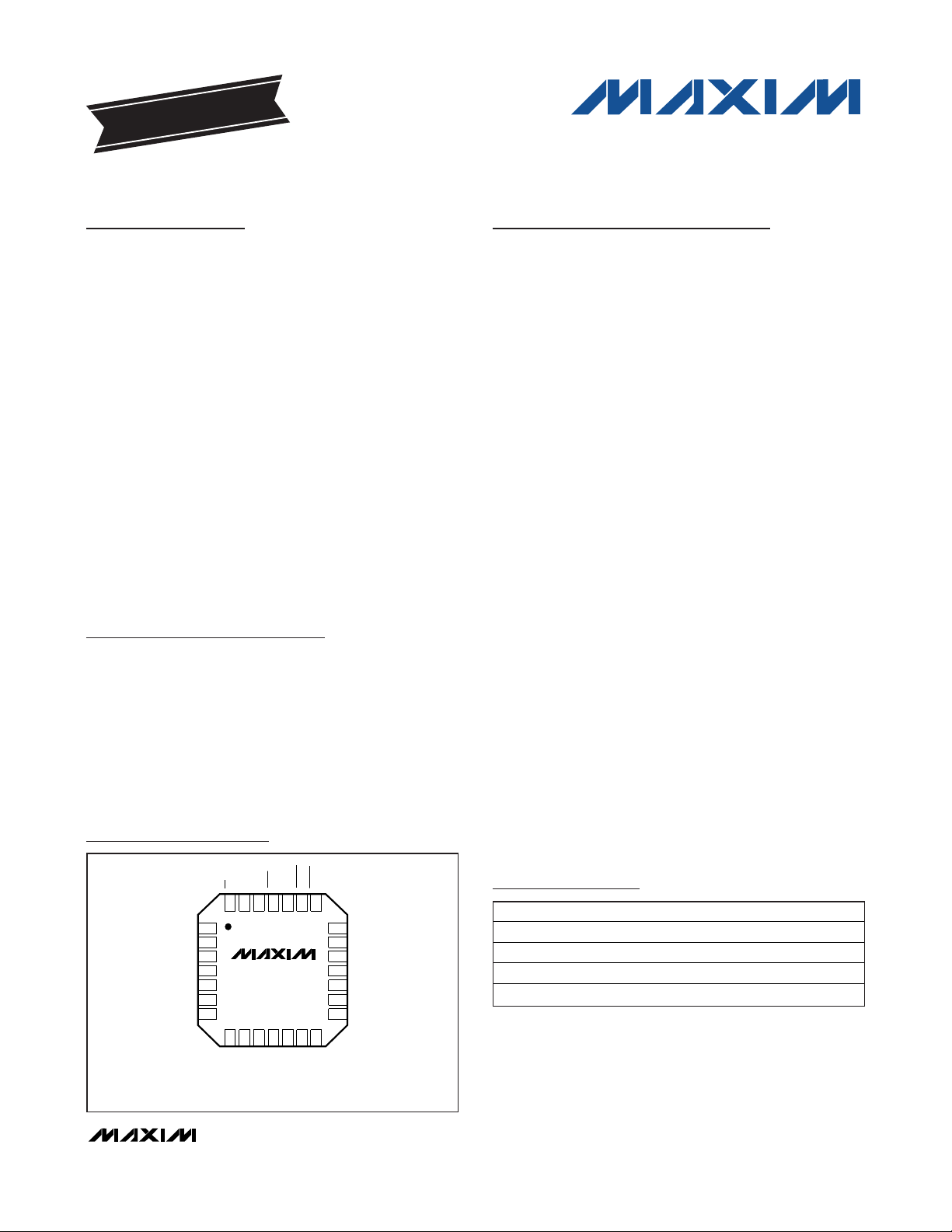

Pin Configuration

Ordering Information

19-2512; Rev 4; 3/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

TransZorb is a trademark of General Semiconductor Industries, Inc.

SPI and QSPI are trademarks of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corp.

AutoShutdown is a trademark of Maxim Integrated Products, Inc.

TOP VIEW

1

DV

DD

2

AV

DD

3

*X+

4

*Y+

5

*X-

6

*Y-

7

GND

*PIN INCLUDES 8kV/15kV ESD PROTECTION.

DIN

DOUT

PENIRQ

BUSY

SCLK

CS

28272625242322

MAX1233

MAX1234

8

9

1011121314

*BAT2

*AUX1

*AUX2

QFN/TQFN

REF

DACOUT

*BAT1

KEYIRQ

R4

21

C4

20

C3

19

C2

18

C1

17

R1

16

R2

15

R3

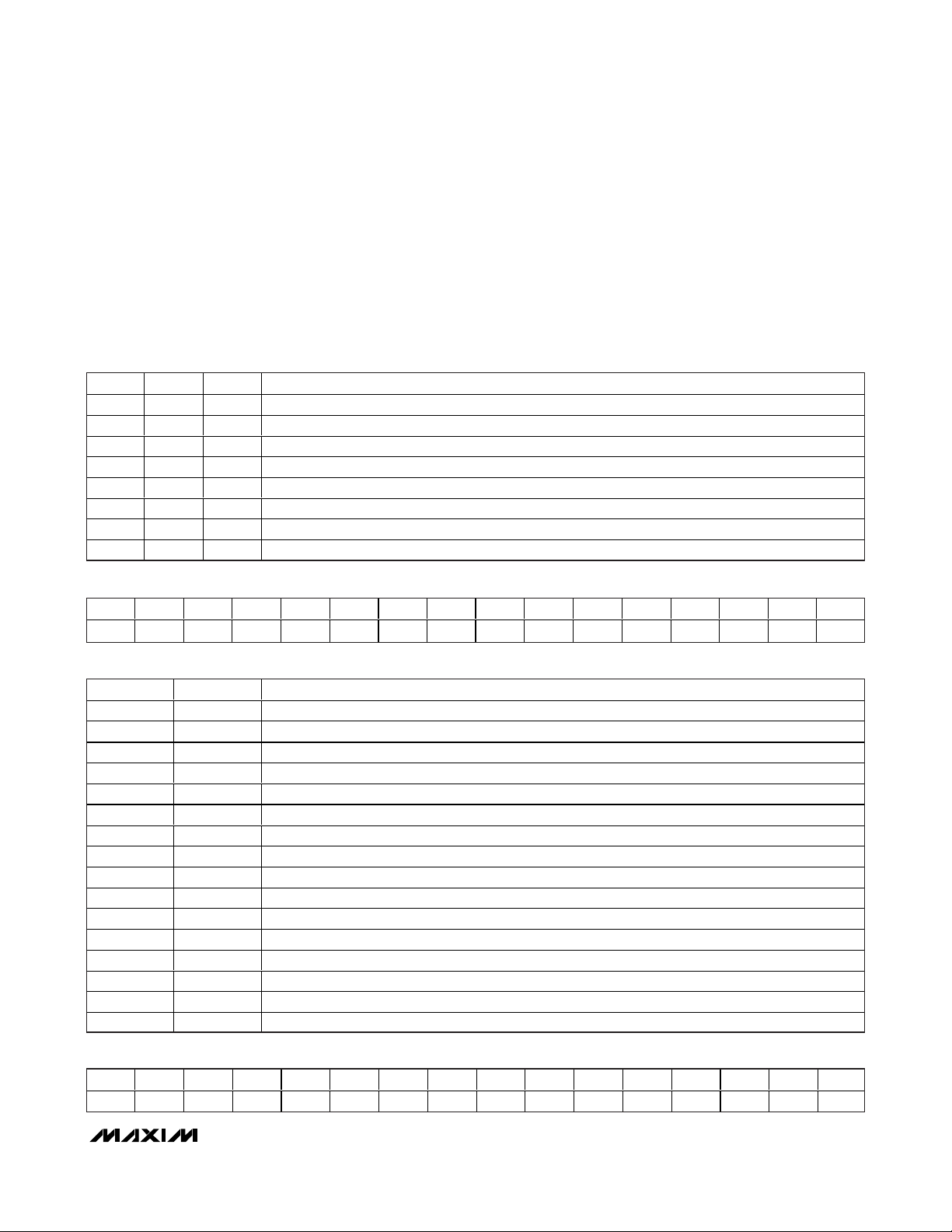

PART TEMP RANGE PIN-PACKAGE

MAX1233EGI -40°C to +85°C 28 QFN (5mm x 5mm)

MAX1233ETI -40°C to +85°C 28 TQFN (5mm x 5mm)

MAX1234EGI -40°C to +85°C 28 QFN (5mm x 5mm)

MAX1234ETI -40°C to +85°C 28 TQFN (5mm x 5mm)

Page 2

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

2 _______________________________________________________________________________________

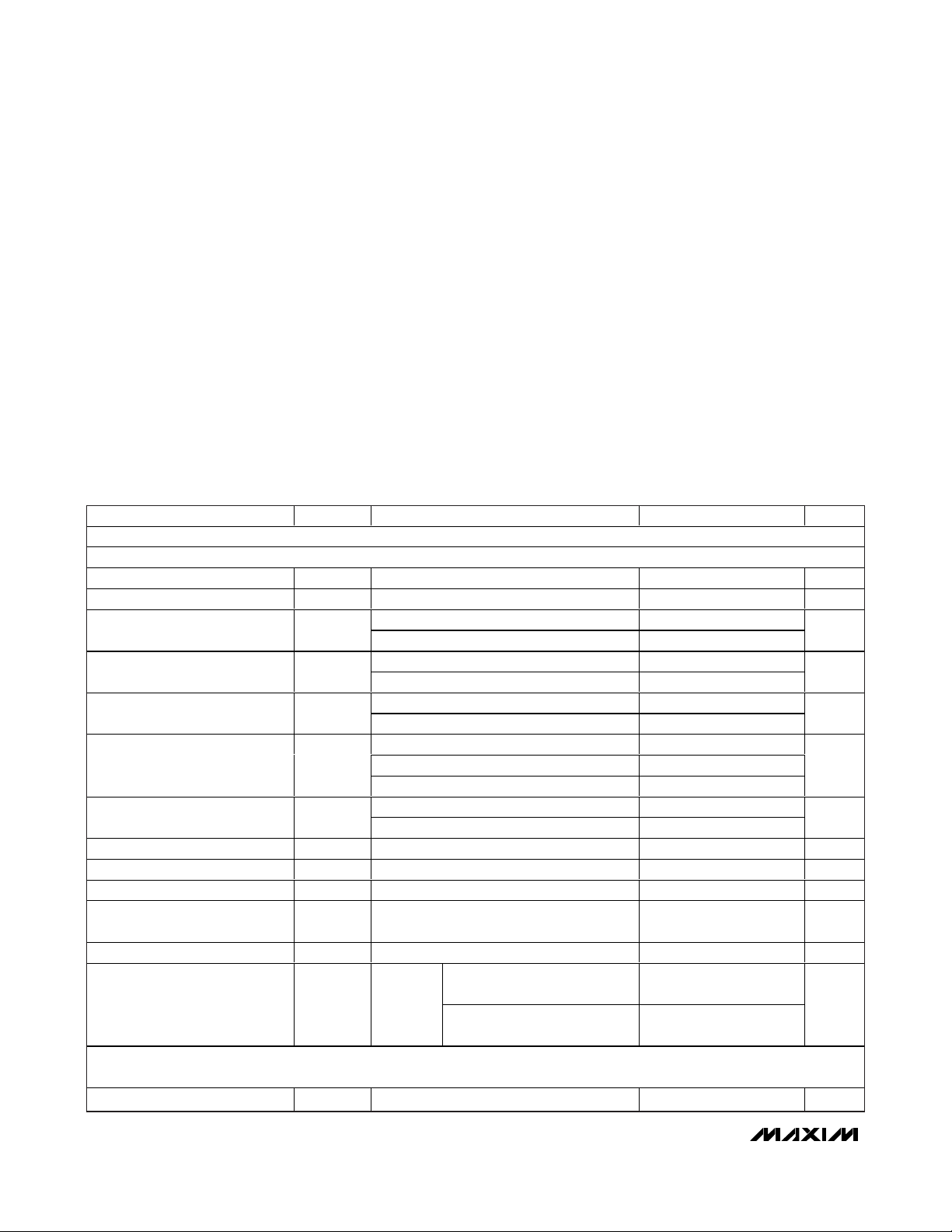

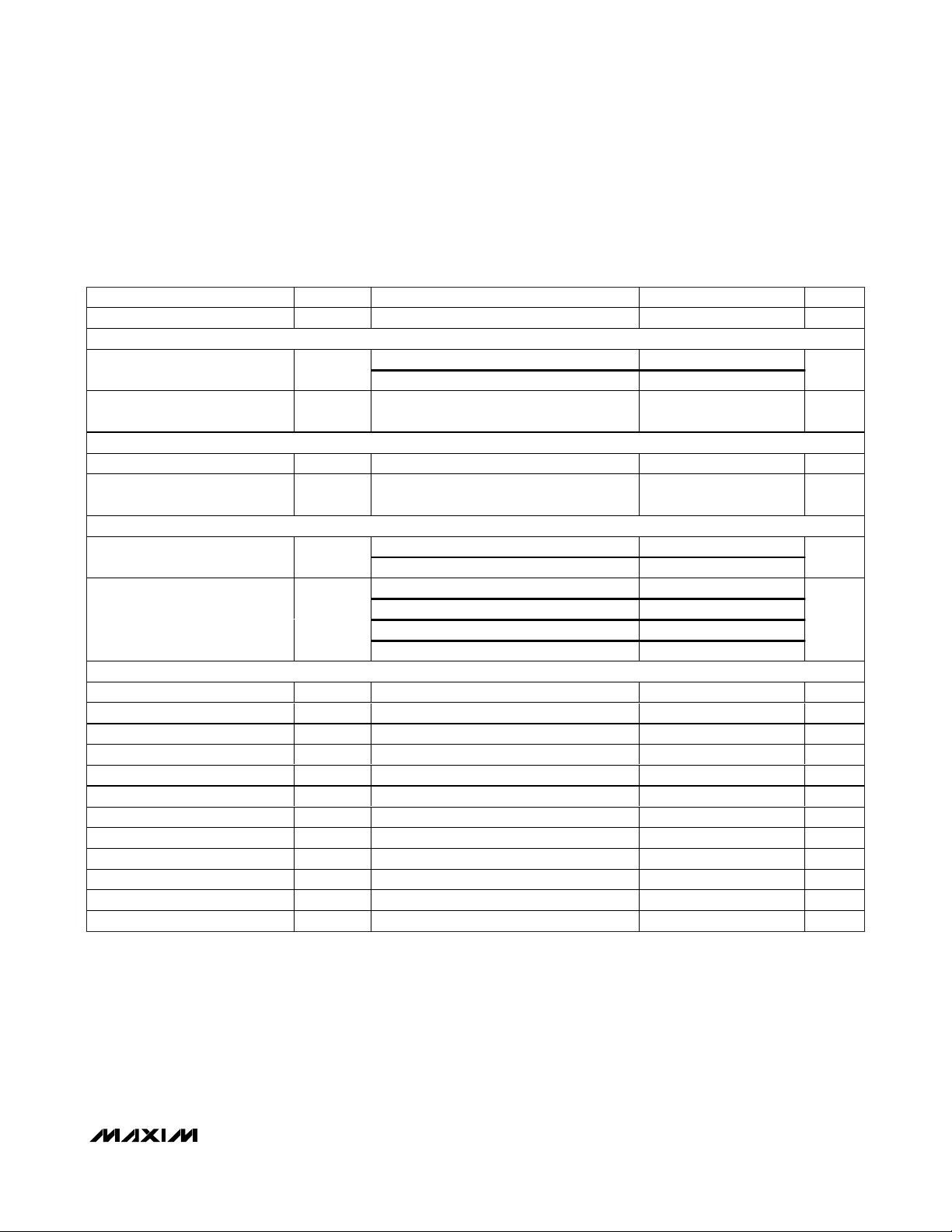

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(DVDD= AVDD= +2.7V to +3.6V (MAX1233), DVDD= AVDD= +4.75V to +5.25V (MAX1234), external reference V

REF

= 2.5V

(MAX1233), V

REF

= 4.096V (MAX1234); f

SCLK

= 10MHz, f

SAMPLE

= 50ksps, 12-bit mode, 0.1µF capacitor at REF, TA= -40°C to

+85°C, unless otherwise noted. Typical values are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

AVDDto GND............................................................-0.3V to +6V

DV

DD

to AVDD.......................................................-0.3V to +0.3V

Digital Inputs/Outputs to GND .................-0.3V to (DV

DD

+ 0.3V)

X+, Y+, X-, Y-, AUX1, AUX2,

and REF to GND ..................................-0.3V to (AV

DD

+ 0.3V)

BAT1, BAT2 to GND .................................................-0.3V to +6V

Maximum ESD per IEC 1000-4-2 (per MIL STD-883 HBM)

X+, X-, Y+, Y-, AUX1, AUX2, BAT1, BAT2......................±15kV

All Other Pins.....................................................................±2.5kV

Maximum Current into Any Pin............................................50mA

Continuous Power Dissipation (T

A

= +70°C)

28-Pin QFN (derate 28.5mW/°C above +70°C) .................2W

28-Pin TQFN (derate 28.5mW/°C above +70°C) ...............2W

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

DC ACCURACY (Note 1)

Resolution Software-programmable 8/10/12 bit 12 Bits

No Missing Codes 11 Bits

Relative Accuracy (Note 2) INL

Differential Nonlinearity DNL

Offset Error

Total Unadjusted Error TUE

Offset Temperature Coefficient ±0.4 ppm/°C

Gain Temperature Coefficient ±0.4 ppm/°C

Channel-to-Channel Offset ±0.1 LSB

Channel-to-Channel Gain

Matching

Noise Including internal V

Power-Supply Rejection PSR

DYNAMIC SPECIFICATIONS (1kHz SINE WAVE, VIN = 2.5V

= 10MHz)

f

SCLK

Signal-to-Noise Plus Distortion SINAD 69 dB

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ANALOG-TO-DIGITAL CONVERTER

12-bit mode ±0.8 ±2

10-bit and 8-bit modes ±0.5

12-bit mode ±0.8 ±2

10-bit and 8-bit modes ±0.5

12-bit mode ±0.5 ±4

10-bit and 8-bit modes ±0.5

12-bit mode ±0.5 ±4

10-bit mode ±0.5Gain Error (Note 3)

8-bit mode ±0.5

12-bit mode ±2

10-bit and 8-bit modes ±1

Full-scale

input

REF

MAX1233

AV

= DVDD = +2.7V to +3.6V

DD

MAX1234

AV

= DVDD = +5V ±5%

DD

FOR MAX1233, VIN = 4.096V

P-P

±0.1 LSB

50 µV

±0.4

±0.3

FOR MAX1234, 50ksps,

P-P

LSB

LSB

LSB

LSB

LSB

RMS

mV

Page 3

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

_______________________________________________________________________________________ 3

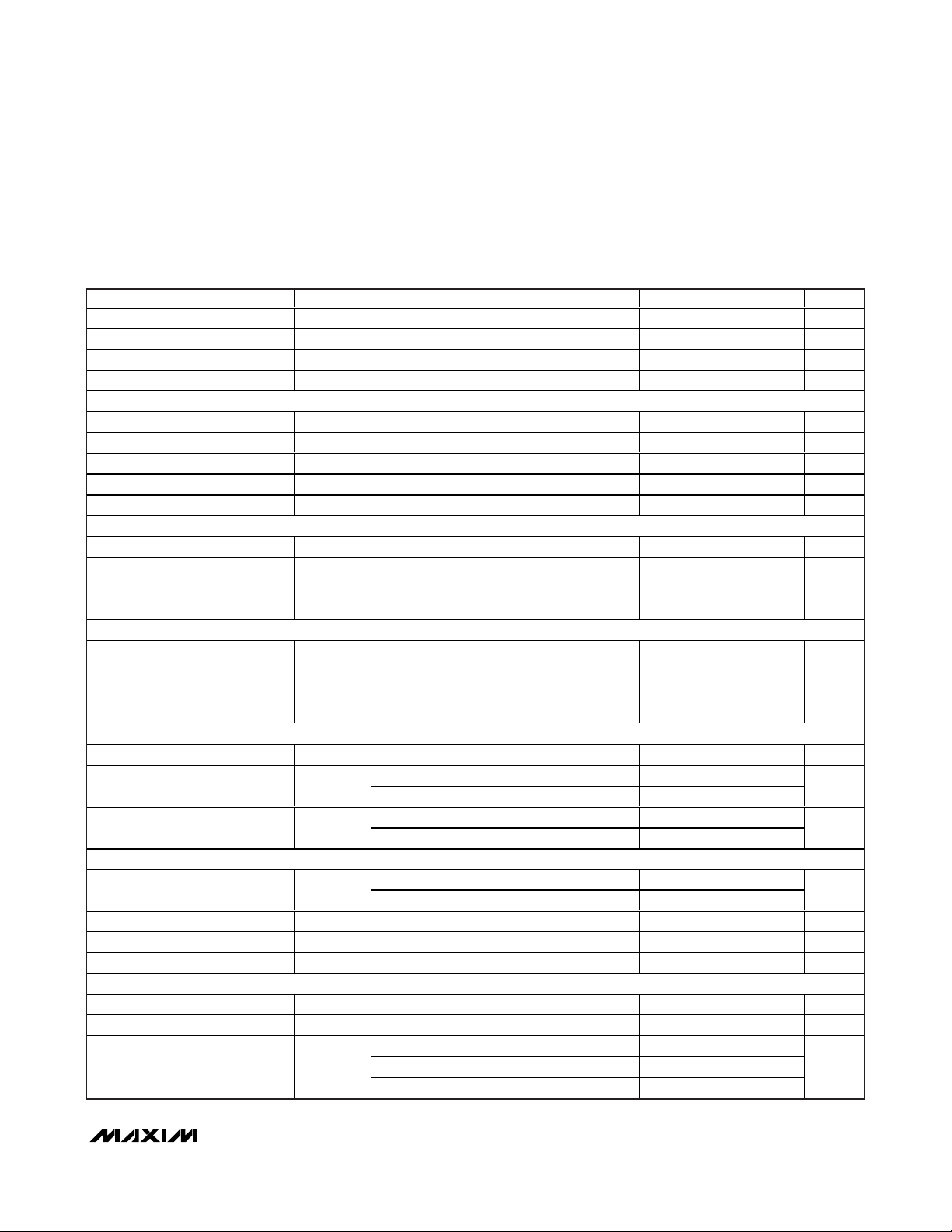

ELECTRICAL CHARACTERISTICS (continued)

(DVDD= AVDD= +2.7V to +3.6V (MAX1233), DVDD= AVDD= +4.75V to +5.25V (MAX1234), external reference V

REF

= 2.5V

(MAX1233), V

REF

= 4.096V (MAX1234); f

SCLK

= 10MHz, f

SAMPLE

= 50ksps, 12-bit mode, 0.1µF capacitor at REF, TA= -40°C to

+85°C, unless otherwise noted. Typical values are at T

A

= +25°C.)

Total Harmonic Distortion THD -84 dB

Spurious-Free Dynamic Range SFDR 84 dB

Full-Power Bandwidth -3dB point 0.5 MHz

Full-Linear Bandwidth SINAD > 67dB 50 kHz

CONVERSION RATE

Internal Oscillator Frequency 8 11.5 MHz

Aperture Delay 30 ns

Aperture Jitter <50 ps

Maximum Serial Clock Frequency f

Duty Cycle 30 70 %

AUXILIARY ANALOG INPUTS (AUX1, AUX2)

Input Voltage Range 0V

Input Leakage Current

Input Capacitance 34 pF

BATTERY MONITOR INPUTS (BAT1, BAT2)

Input Voltage Range 0.5 6.0 V

Input Impedance

Accuracy Internal reference -3 +3 %

TEMPERATURE MEASUREMENT

Temperature Range -40 +85 °C

Resolution

Accuracy

INTERNAL ADC REFERENCE

Reference Output Voltage V

Output Tempco TCV

Reference Output Impedance Normal operation 250 Ω

Reference Short-Circuit Current 18 mA

EXTERNAL ADC REFERENCE (INTERNAL REFERENCE DISABLED, REFERENCE APPLIED TO REF)

Reference Input Voltage Range (Note 6) 1.0 V

Input Impedance CS = GND or V

Input Current

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCLK

REF

REF

Channel not selected or conversion

stopped

Sampling battery 10 kΩ

Battery monitor OFF 1 GΩ

Differential method (Note 4) 1.6

Single measurement method (Note 5) 0.3

Differential method (Note 4) ±3

Single measurement method (Note 5) ±2

2.5V mode, TA = +25°C 2.470 2.500 2.530

1.0V mode, TA = +25°C 0.980 1.000 1.020

V

V

Shutdown/between conversions ±0.1

= +2.5V at 50ksps (MAX1233) 5 10

REF

= +4.096V at 50ksps (MAX1234) 8 15

REF

10 MHz

REF

±0.1 ±1µA

60 ppm/°C

DD

1GΩ

DD

°C

°C

µA

V

V

V

Page 4

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

4 _______________________________________________________________________________________

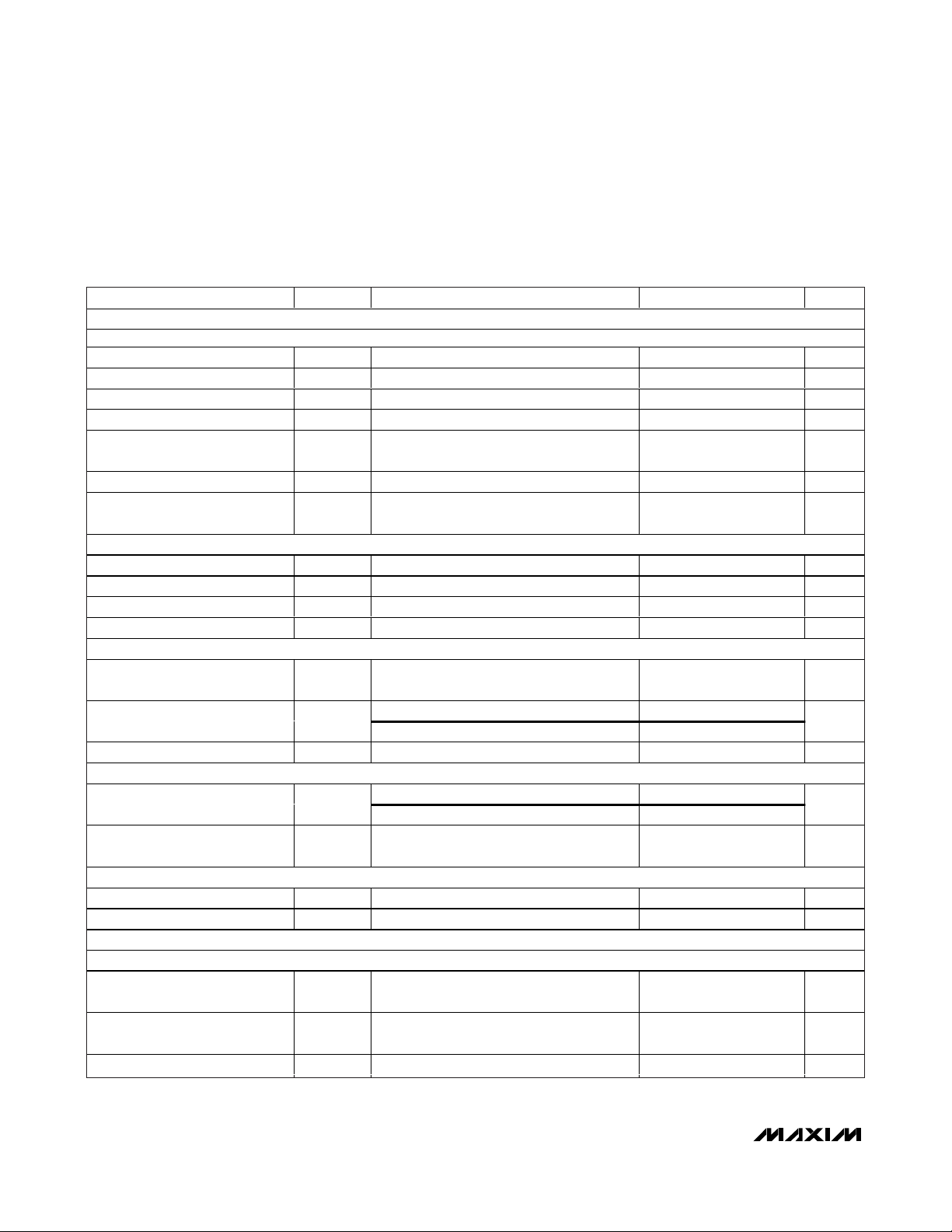

ELECTRICAL CHARACTERISTICS (continued)

(DVDD= AVDD= +2.7V to +3.6V (MAX1233), DVDD= AVDD= +4.75V to +5.25V (MAX1234), external reference V

REF

= 2.5V

(MAX1233), V

REF

= 4.096V (MAX1234); f

SCLK

= 10MHz, f

SAMPLE

= 50ksps, 12-bit mode, 0.1µF capacitor at REF, TA= -40°C to

+85°C, unless otherwise noted. Typical values are at T

A

= +25°C.)

DC ACCURACY

Resolution 8Bits

Integral Linearity Error INL (Note 7) ±1.0 LSB

Differential Linearity Error DNL No missing codes ±1.0 LSB

Offset Error V

Offset Error Temperature

Coefficient

Full-Scale Error Code = 255, no load 5 %

Full-Scale Error Temperature

Coefficient

DYNAMIC PERFORMANCE

Voltage Output Slew Rate Positive and negative 0.4 V/µs

Output Settling Time 0.5LSB; 50kΩ and 50pF load (Note 9) 20 µs

Glitch Impulse Code 127 to 128 40 nV/s

Wake-Up Time From shutdown 50 µs

DAC OUTPUT

Internal DAC Reference V

Output Load Regulation

Output Resistance Power-down mode 1.0 MΩ

On-Resistance

Touch-Detection Internal Pullup

Resistance

Pullup Resistance C4, C3, C2, C1 (Note 11) 0.5 kΩ

Pulldown Resistance R4, R3, R2, R1 (Note 11) 16 kΩ

DIGITAL INPUTS (SCLK, CS, DIN, R_, C_)

Input Voltage Low V

Input Voltage High V

Input Leakage Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

REFDAC

DIGITAL-TO-ANALOG CONVERTER

OS

(Note 8) ±1 ±25 mV

Code = 255, no load ±10 ppm/°C

(Note 10)

Code = 255; 0 to 100µA 0.5

Code = 0; 0 to 100µA 0.5

TOUCH-SCREEN CONTROLLER

Y+, X+ 7

Y-, X- 9

X+ to AV

IL

IH

L

DD

KEYPAD CONTROLLER

DIGITAL INTERFACE

0.85

AV

0.7

DV

1 ppm/°C

✕

DD

✕

DD

✕

0.9

AV

DD

1MΩ

±0.1 ±1µA

0.95

AV

0.3

DV

✕

DD

✕

DD

V

LSB

Ω

V

V

Page 5

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(DVDD= AVDD= +2.7V to +3.6V (MAX1233), DVDD= AVDD= +4.75V to +5.25V (MAX1234), external reference V

REF

= 2.5V

(MAX1233), V

REF

= 4.096V (MAX1234); f

SCLK

= 10MHz, f

SAMPLE

= 50ksps, 12-bit mode, 0.1µF capacitor at REF, TA= -40°C to

+85°C, unless otherwise noted. Typical values are at T

A

= +25°C.)

Note 1: Tested at DVDD= AVDD= +2.7V (MAX1233), DVDD= AVDD= +5V (MAX1234).

Note 2: Relative accuracy is the deviation of the analog value at any code from its theoretical value after the offset and gain errors

have been removed.

Note 3: Offset nulled.

Note 4: Difference between TEMP1 and TEMP2; temperature in °K = (V

TEMP2

- V

TEMP1

) × 2680°K/V. No calibration is necessary.

Note 5: Temperature coefficient is -2.1mV/°C. Determine absolute temperature by extrapolating from a calibrated value.

Note 6: ADC performance is limited by the conversion noise floor, typically 300µV

P-P

. An external reference below 2.5V can

compromise the ADC performance.

Note 7: Guaranteed from code 5 to 255.

Input Capacitance C

DIGITAL OUTPUT (DOUT)

Output Voltage Low V

Output Voltage High V

DIGITAL OUTPUT (BUSY, PENIRQ, KEYIRQ, R_, C_)

Output Voltage Low V

Output Voltage High V

Supply Voltage (Note 12)

Analog and Digital Supply

Current

TIMING CHARACTERISTICS

SCLK Clock Period t

SCLK Pulse Width High t

SCLK Pulse Width Low t

DIN to SCLK Rise Setup t

SCLK Rise to DIN Hold t

SCLK Fall to DOUT Valid t

CS Fall to DOUT Enabled t

CS Rise to DOUT Disabled t

CS Fall to SCLK Rise t

CS Fall to SCLK Ignored t

SCLK Rise to R_/C_ Data Valid t

CS Pulse Width High t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IN

OL

OH

OL

OH

15 pF

I

= 2mA 0.4

SINK

I

= 4mA 0.8

SINK

DV

-

DV

DD

0.5

DD

0.5

-

I

I

I

= 1.5mA

SOURCE

= 0.2mA 0.4 V

SINK

= 0.2mA

SOURCE

POWER REQUIREMENTS

AV

DV

DD

MAX1233 2.7 3 3.6

/

DD MAX1234 4.75 5 5.25

Idle; all blocks shut down 0.5 5

I

AVDD

I

DVDD

Only ADC on; f

+

Only DAC on; no load 150 230

= 20ksps 150 500

SAMPLE

Only internal reference on 670 900

CP

CH

CL

DS

DH

DOV

DV

DOD

CSS

CSH

GPO

CSW

C

= 50pF 40 ns

LOAD

C

= 50pF 45 ns

LOAD

C

= 50pF 40 ns

LOAD

C

= 50pF (Note 13) 230 ns

LOAD

100 ns

40 ns

40 ns

40 ns

0ns

40 ns

0ns

40 ns

V

V

V

V

µA

Page 6

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(DVDD= AVDD= +2.7V to +3.6V (MAX1233), DVDD= AVDD= +4.75V to +5.25V (MAX1234), external reference V

REF

= 2.5V

(MAX1233), V

REF

= 4.096V (MAX1234); f

SCLK

= 10MHz, f

SAMPLE

= 50ksps, 12-bit mode, 0.1µF capacitor at REF, TA= -40°C to

+85°C, unless otherwise noted. Typical values are at T

A

= +25°C.)

Note 8: The offset value extrapolated from the range over which the INL is guaranteed.

Note 9: Output settling time is measured by stepping from code 5 to 255, and from code 255 to 5.

Note 10: Actual output voltage at full scale is 255/256 × V

REFDAC

.

Note 11: Resistance is open when configured as GPIO or in shutdown.

Note 12: AV

DD

and DVDDshould not differ by more than 300mV.

Note 13: When configured as GPIO.

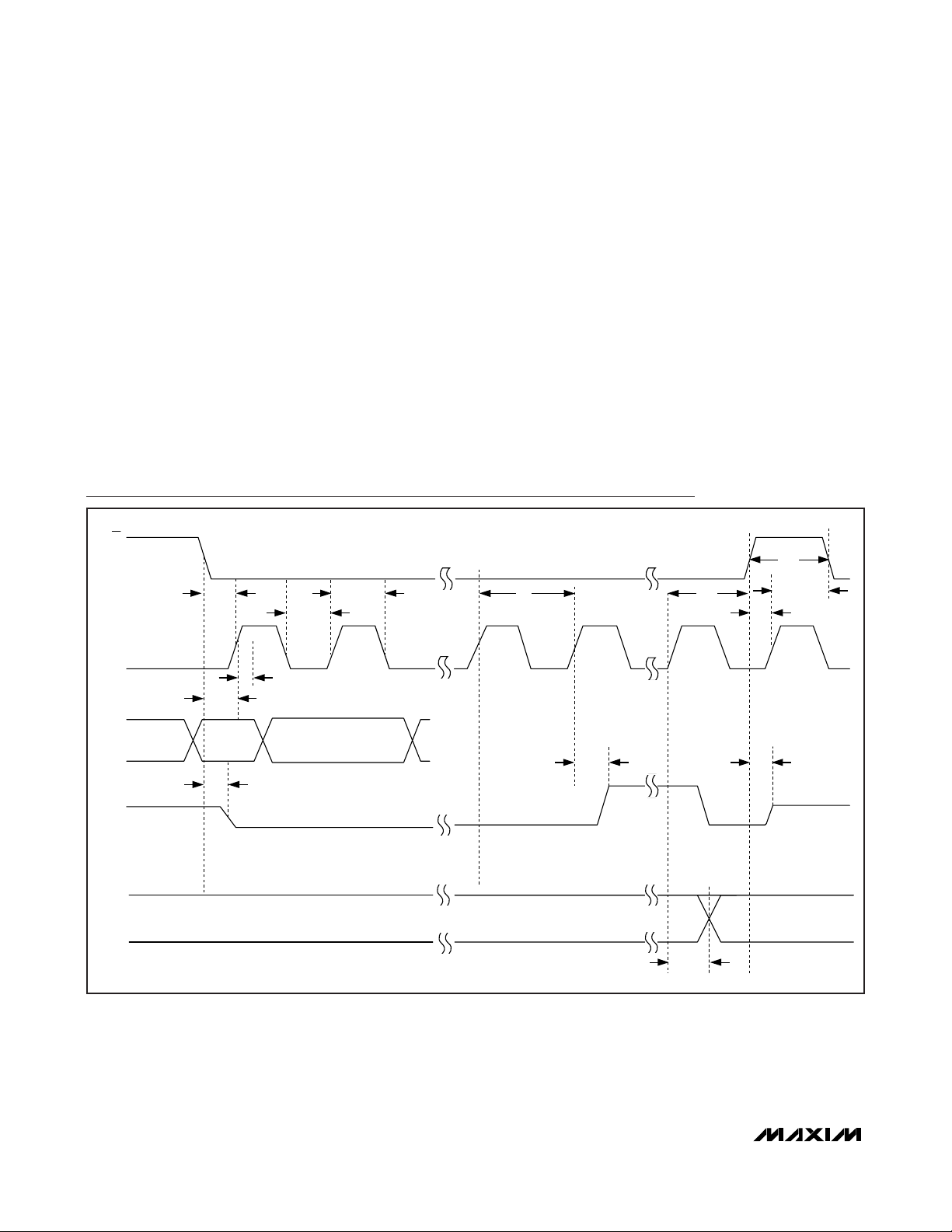

SCLK

DIN

DOUT

NOTE: TIMING NOT TO SCALE.

R_/C_

CS

t

CL

t

DH

t

DV

t

DS

t

CH

t

CSS

t

CP

t

CSH

t

CSW

t

CSH

t

CSS

t

DOD

t

DOV

t

GPO

Timing Diagram

Page 7

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

_______________________________________________________________________________________ 7

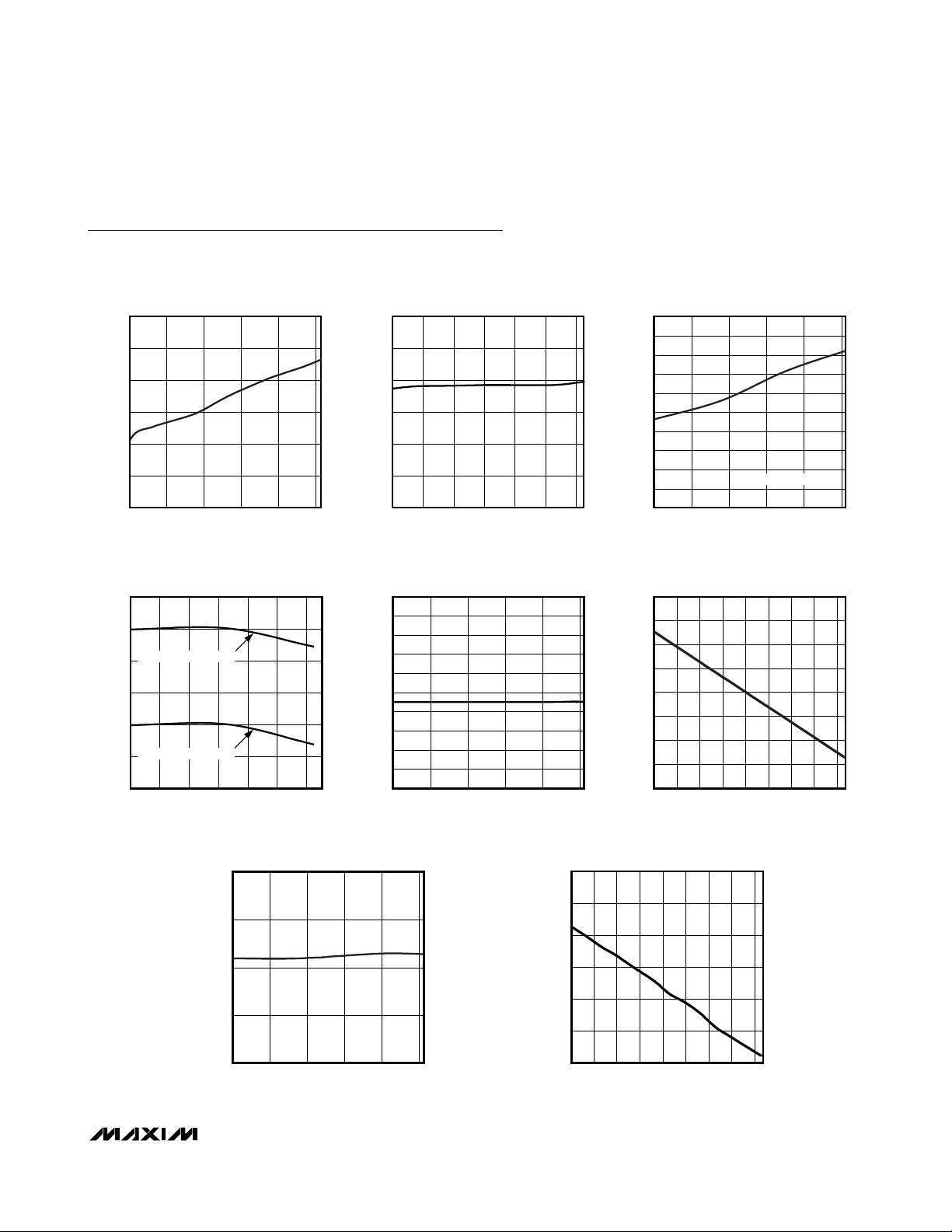

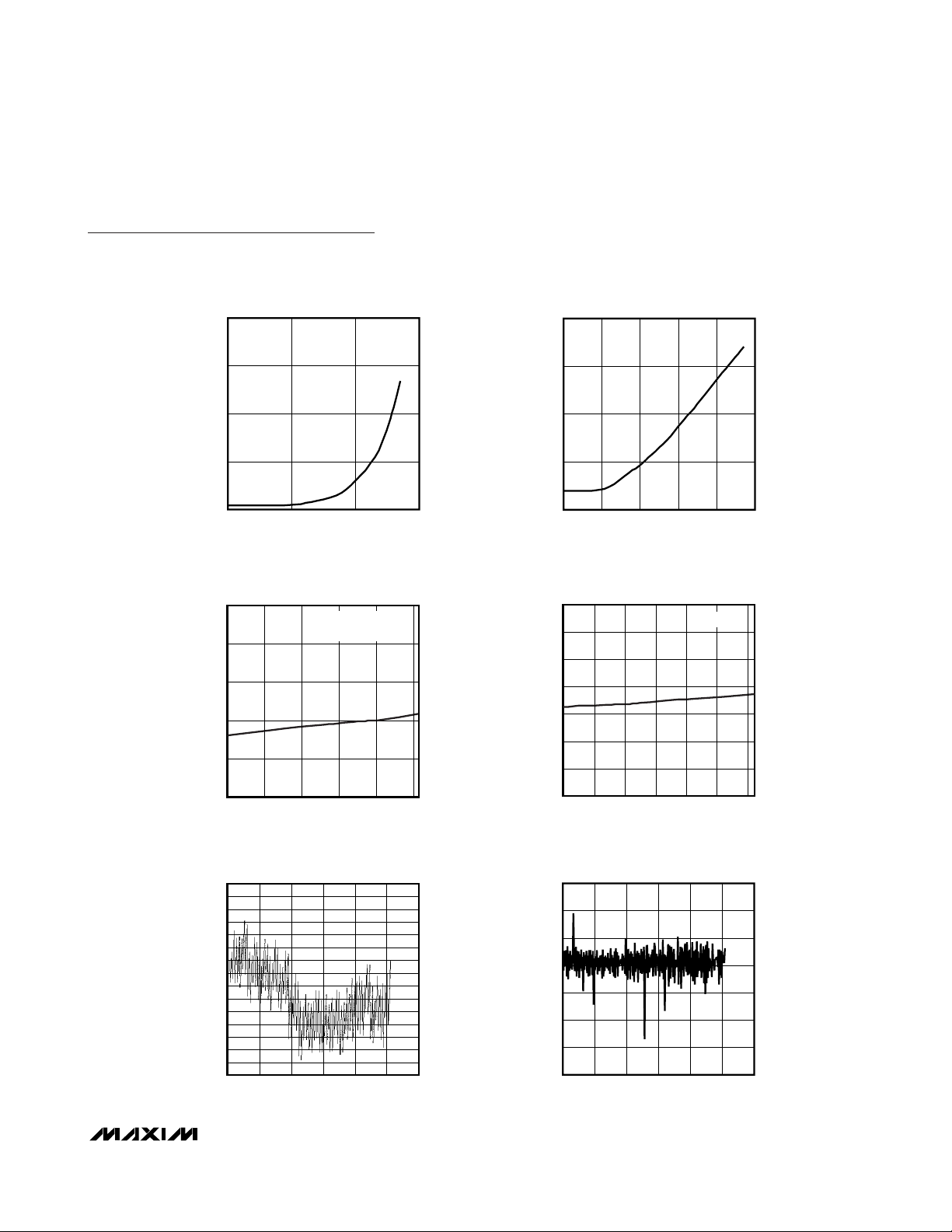

Typical Operating Characteristics

(AV

DD

= DVDD= 3V (MAX1233) or 5V (MAX1234), external V

REF

= +2.5V (MAX1233), external V

REF

= +4.096V (MAX1234), f

SCLK

=

10MHz (50% duty cycle), f

SAMPLE

= 20ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

SHUTDOWN CURRENT

vs. ANALOG SUPPLY VOLTAGE

300

250

200

150

100

SHUTDOWN CURRENT (nA)

50

0

2.7

AVDD (V)

MAX1233/34 toc01

5.24.74.23.73.2

INTERNAL OSCILLATOR FREQUENCY

vs. TEMPERATURE

9.8

9.6

MAX1234, AVDD = +5.0V

9.4

9.2

9.0

MAX1233, AVDD = +3.0V

8.8

INTERNAL OSCILLATOR FREQUENCY (MHz)

8.6

-40

TEMPERATURE (°C)

MAX1233/34 toc04

806040200-20

TEMP2 DIODE VOLTAGE

vs. ANALOG SUPPLY VOLTAGE

0.80

SHUTDOWN CURRENT

vs. TEMPERATURE

300

250

200

150

100

SHUTDOWN CURRENT (nA)

50

0

-40

TEMPERATURE (°C)

806040200-20

10.0

MAX1233/34 toc02

INTERNAL OSCILLATOR FREQUENCY (MHz)

TEMP1 DIODE VOLTAGE

vs. ANALOG SUPPLY VOLTAGE

0.70

0.68

0.66

0.64

0.62

0.60

0.58

0.56

TEMP1 DIODE VOLTAGE (V)

0.54

0.52

0.50

2.7

5.24.74.23.73.2

AVDD (V)

0.80

0.75

MAX1233/34 toc05

0.70

0.65

0.60

0.55

TEMP1 DIODE VOLTAGE (V)

0.50

0.45

0.40

TEMP2 DIODE VOLTAGE

vs. TEMPERATURE

0.90

INTERNAL OSCILLATOR FREQUENCY

vs. ANALOG SUPPLY VOLTAGE

9.8

9.6

9.4

9.2

9.0

8.8

8.6

8.4

8.2

8.0

2.7

TEMP1 DIODE VOLTAGE

vs. TEMPERATURE

-40

TEMPERATURE (°C)

MAX1233/MAX1234

AVDD (V)

8065-25 -10 5 3520 50

MAX1233/34 toc03

5.24.74.23.73.2

MAX1233/34 toc06

0.75

0.70

TEMP2 DIODE VOLTAGE (V)

0.65

0.60

2.7

AVDD (V)

5.24.74.23.73.2

MAX1233/34 toc07

0.85

0.80

0.75

0.70

TEMP2 DIODE VOLTAGE (V)

0.65

0.60

-40

TEMPERATURE (°C)

MAX1233/34 toc08

80655035205-10-25

Page 8

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

8 _______________________________________________________________________________________

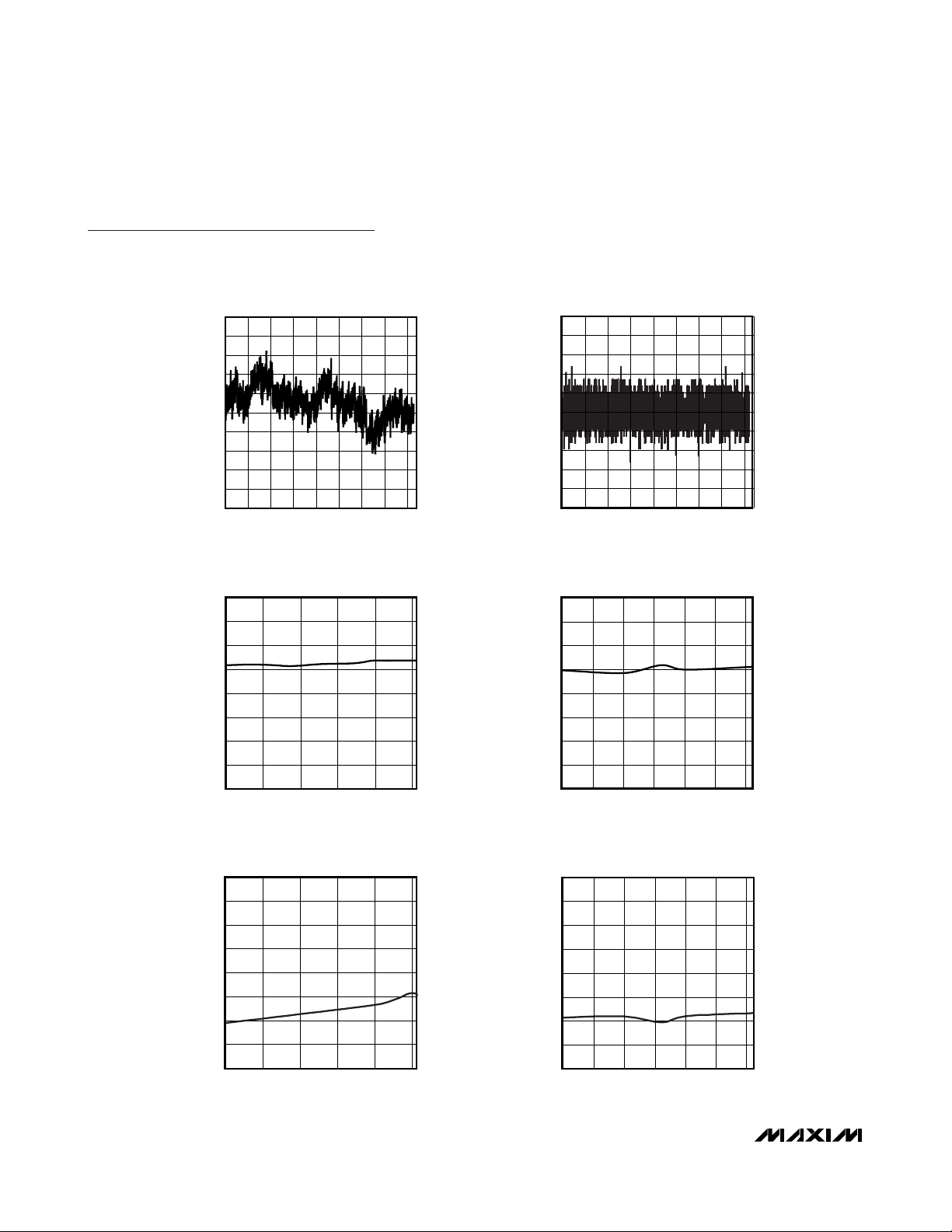

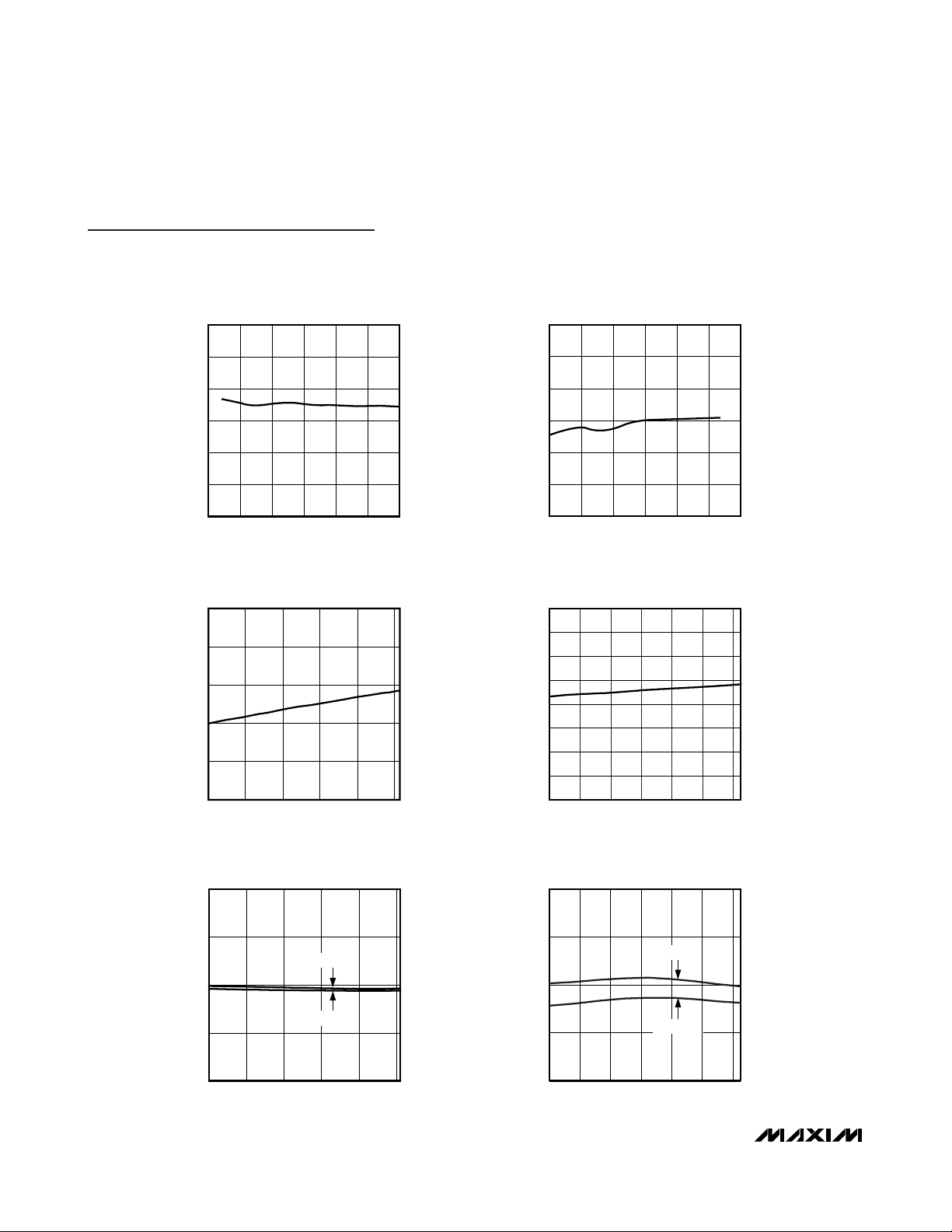

Typical Operating Characteristics (continued)

(AV

DD

= DVDD= 3V (MAX1233) or 5V (MAX1234), external V

REF

= +2.5V (MAX1233), external V

REF

= +4.096V (MAX1234), f

SCLK

=

10MHz (50% duty cycle), f

SAMPLE

= 20ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

ADC DIFFERENTIAL NONLINEARITY

vs. OUTPUT CODE

MAX1233/34 toc10

OUTPUT CODE

DNL (LSB)

400035002500 30001000 1500 2000500

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0

ADC OFFSET ERROR

vs. ANALOG SUPPLY VOLTAGE

MAX1233/34 toc11

AVDD (V)

OFFSET ERROR (LSB)

5.24.73.2 3.7 4.2

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

-2.0

2.7

ADC OFFSET ERROR vs. TEMPERATURE

MAX1233/34 toc12

TEMPERATURE (°C)

OFFSET ERROR (LSB)

8060-20 0 20 40

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

-2.0

-40

ADC GAIN ERROR

vs. ANALOG SUPPLY VOLTAGE

MAX1233/34 toc13

AVDD (V)

GAIN ERROR (LSB)

5.24.73.2 3.7 4.2

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

-2.0

2.7

ADC GAIN ERROR

vs. TEMPERATURE

MAX1233/34 toc14

TEMPERATURE (°C)

GAIN ERROR (LSB)

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

-2.0

8060-20 0 20 40-40

ADC INTEGRAL NONLINEARITY

vs. OUTPUT CODE

MAX1233/34 toc09

OUTPUT CODE

INL (LSB)

400035002500 30001000 1500 2000500

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1.0

-1.0

0

Page 9

MAX1233/MAX1234

-0.050

-0.075

-0.100

-0.025

0

0.025

0.050

0.075

0 100 200 300

DAC INTEGRAL NONLINEARITY vs. CODE

MAX1233/34 toc19

CODE

INL (LSB)

50

150

250

DAC DIFFERENTIAL NONLINEARITY

vs. OUTPUT CODE

MAX1233/34 toc20

OUTPUT CODE

DNL (LSB)

25020015010050

-0.075

-0.500

-0.025

0

0.025

0.050

0.075

-0.100

0 300

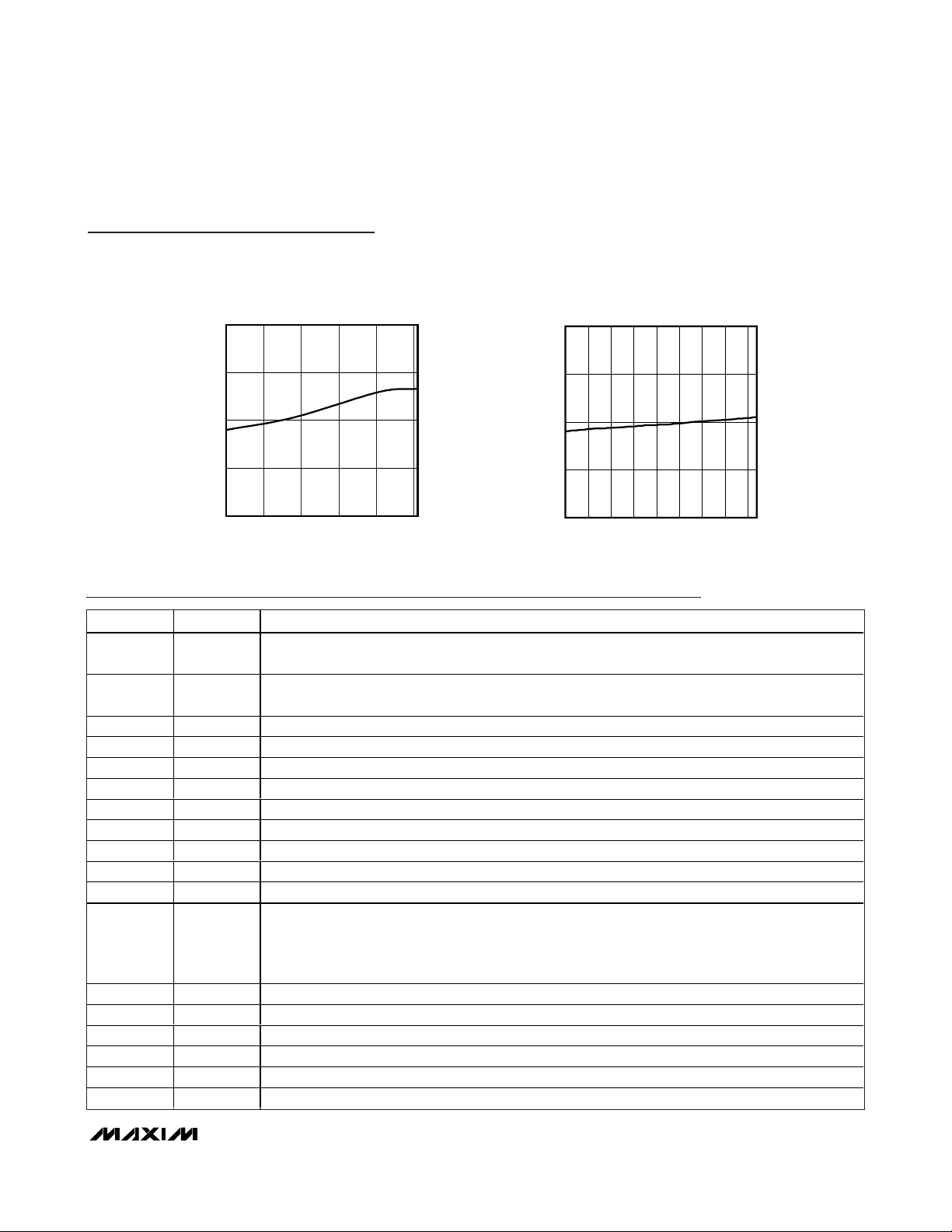

Typical Operating Characteristics (continued)

(AV

DD

= DVDD= 3V (MAX1233) or 5V (MAX1234), external V

REF

= +2.5V (MAX1233), external V

REF

= +4.096V (MAX1234), f

SCLK

=

10MHz (50% duty cycle), f

SAMPLE

= 20ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

_______________________________________________________________________________________ 9

ADC EXTERNAL REFERENCE INPUT

CURRENT vs. SAMPLING RATE

8

MAX1233

= +2.5V

V

REF

6

1000

MAX1233/34 toc15

100

ADC SUPPLY CURRENT

vs. SAMPLING RATE

MAX1233/34 toc16

4

REFERENCE CURRENT (μA)

2

0

100 100k

f

SAMPLE

10k1k

(Hz)

ADC SUPPLY CURRENT

vs. SUPPLY VOLTAGE

250

200

150

100

SUPPLY CURRENT (μA)

50

0

AVDD (V)

EXTERNAL REF

= 20ksps

f

SAMPLE

5.24.74.23.73.22.7

MAX1233/34 toc17

10

SUPPLY CURRENT (μA)

1

0.1

1 100k10 1k

ADC SUPPLY CURRENT

140

120

100

80

60

SUPPLY CURRENT (μA)

40

20

0

f

(Hz)

SAMPLE

vs. TEMPERATURE

TEMPERATURE (°C)

10k100

AVDD = +3V

MAX1233/34 toc18

8060-20 0 20 40-40

Page 10

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

10 ______________________________________________________________________________________

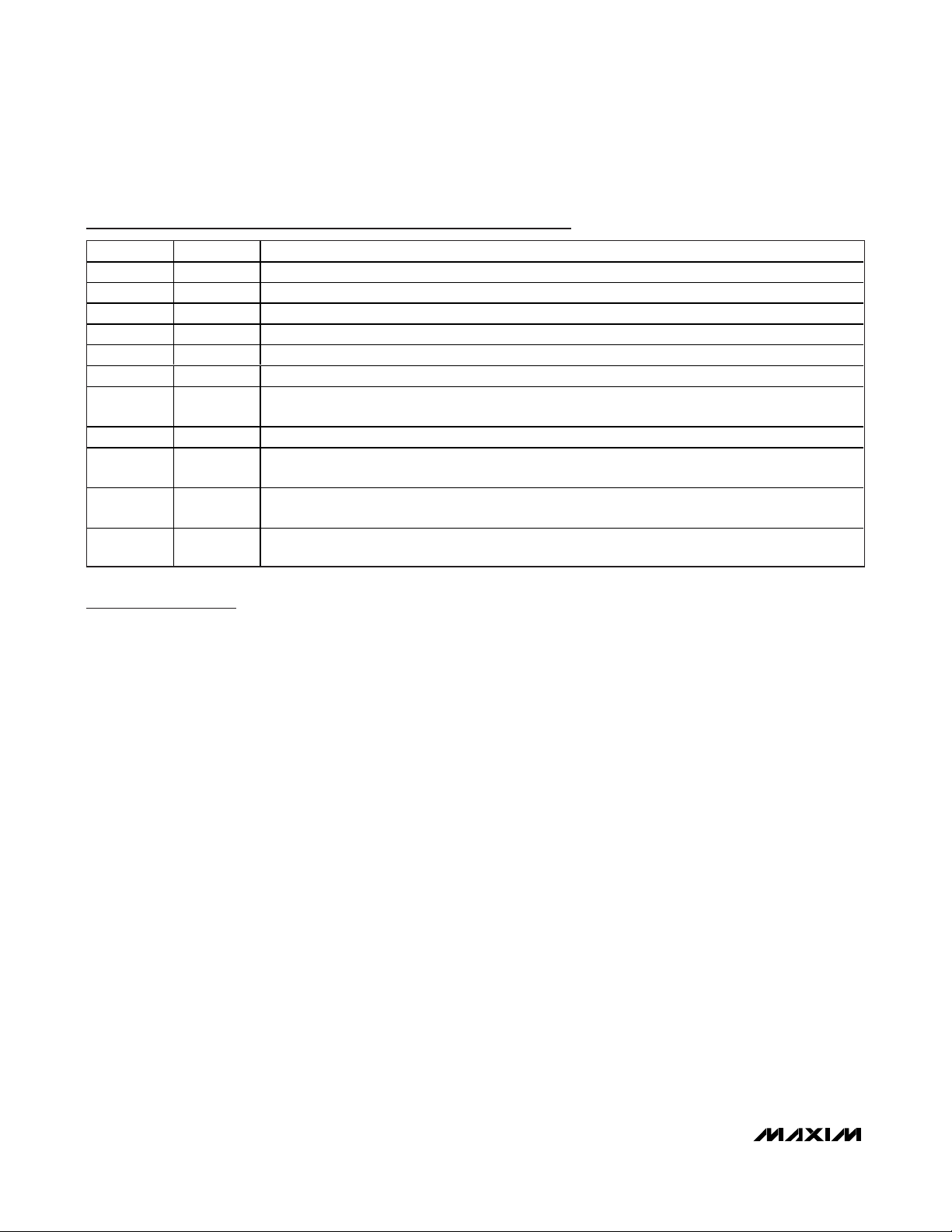

Typical Operating Characteristics (continued)

(AV

DD

= DVDD= 3V (MAX1233) or 5V (MAX1234), external V

REF

= +2.5V (MAX1233), external V

REF

= +4.096V (MAX1234), f

SCLK

=

10MHz (50% duty cycle), f

SAMPLE

= 20ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

DAC FULL-SCALE ERROR

vs. ANALOG SUPPLY VOLTAGE

0.75

MAX1233/34 toc21

1.2

DAC FULL-SCALE ERROR

0.75

vs. TEMPERATURE

MAX1233/34 toc22

1.2

0.50

0.25

0

-0.25

FULL-SCALE ERROR (LSB)

-0.50

-0.75

2.5 4.03.0 3.5 4.5 5.0 5.5

AVDD (V)

DAC SUPPLY CURRENT

vs. ANALOG SUPPLY VOLTAGE

250

200

150

100

DAC SUPPLY CURRENT (μA)

50

0

AVDD (V)

5.24.74.23.73.22.7

0.8

0.4

0

-0.4

FULL-SCALE ERROR (%)

-0.8

-1.2

MAX1233/34 toc23

0.50

0.25

0

-0.25

FULL-SCALE ERROR (LSB)

-0.50

-0.75

-40 20-20 0 40 60 80

TEMPERATURE (°C)

DAC SUPPLY CURRENT

vs. TEMPERATURE

200

175

150

125

100

75

50

DAC SUPPLY CURRENT (μA)

25

0

-40

TEMPERATURE (°C)

0.8

0.4

0

-0.4

FULL-SCALE ERROR (%)

-0.8

-1.2

MAX1233/34 toc24

8060-20 0 20 40

ADC REFERENCE VOLTAGE

vs. TEMPERATURE

TEMPERATURE (°C)

MAX1233/34 toc26

V

= 1.0V

REF

V

= 2.5V

REF

(V)

V

REF

2.550

2.525

2.500

2.475

2.450

ADC REFERENCE VOLTAGE

vs. ANALOG SUPPLY VOLTAGE

V

AVDD (V)

MAX1233/34 toc25

= 1.0V

REF

V

= 2.5V

REF

(V)

REF

V

2.60

2.55

2.50

2.45

2.40

1.020

1.010

(V)

1.000

REF

V

0.990

0.980

5.24.74.23.73.22.7

1.250

1.125

(V)

1.000

REF

V

0.875

0.750

8060-20 0 20 40-40

Page 11

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

______________________________________________________________________________________ 11

Typical Operating Characteristics (continued)

(AV

DD

= DVDD= 3V (MAX1233) or 5V (MAX1234), external V

REF

= +2.5V (MAX1233), external V

REF

= +4.096V (MAX1234), f

SCLK

=

10MHz (50% duty cycle), f

SAMPLE

= 20ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

ADC REFERENCE SUPPLY CURRENT

vs. ANALOG SUPPLY VOLTAGE

MAX1233/34 toc27

AVDD (V)

SUPPLY CURRENT (μA)

4.74.23.73.2

600

650

700

750

550

2.7 5.2

REFERENCE SUPPLY CURRENT

vs. TEMPERATURE

MAX1233/34 toc28

TEMPERATURE (°C)

SUPPLY CURRENT (μA)

600

650

700

750

550

8065-25 -10 5 3520 50-40

PIN NAME FUNCTION

1DV

DD

Positive Digital Supply Voltage, +2.7V to +3.6V for MAX1233, +4.75V to +5.25V for MAX1234. Bypass

with a 0.1µF capacitor. Must be within 300mV of AV

DD

.

2AV

DD

Positive Analog Supply Voltage, +2.7V to +3.6V for MAX1233, +4.75V to +5.25V for MAX1234.

Bypass with a 0.1µF capacitor. Must be within 300mV of DV

DD

.

3* X+ X+ Position Input

4* Y+ Y+ Position Input

5* X- X- Position Input

6* Y- Y- Position Input

7 GND Analog and Digital Ground

8* BAT1 Battery Monitoring Input 1. Measures battery voltages up to 6V.

9* BAT2 Battery Monitoring Input 2. Measures battery voltages up to 6V.

10* AUX1 Auxiliary Analog Input 1 to ADC. Measures analog voltages from zero to V

REF

.

11* AUX2 Auxiliary Analog Input 2 to ADC. Measures analog voltages from zero to V

REF

.

12 REF

Voltage Reference Output/Input. Reference voltage for analog-to-digital conversion. In internal

reference mode, the reference buffer provides a 2.5V or 1.0V nominal output. In external reference

mode, apply a reference voltage between 1.0V and AV

DD

. Bypass REF to GND with a 0.1µF

capacitor in the external reference mode only.

13

DAC Voltage Output; 0.9 × AVDD Full Scale

14 R4 Keypad Row 4. Can be reconfigured as GPIO3.

15 R3 Keypad Row 3. Can be reconfigured as GPIO2.

16 R2 Keypad Row 2. Can be reconfigured as GPIO1.

17 R1 Keypad Row 1. Can be reconfigured as GPIO0.

18 C1 Keypad Column 1. Can be reconfigured as GPIO4.

Pin Description

DACOUT

Page 12

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

12 ______________________________________________________________________________________

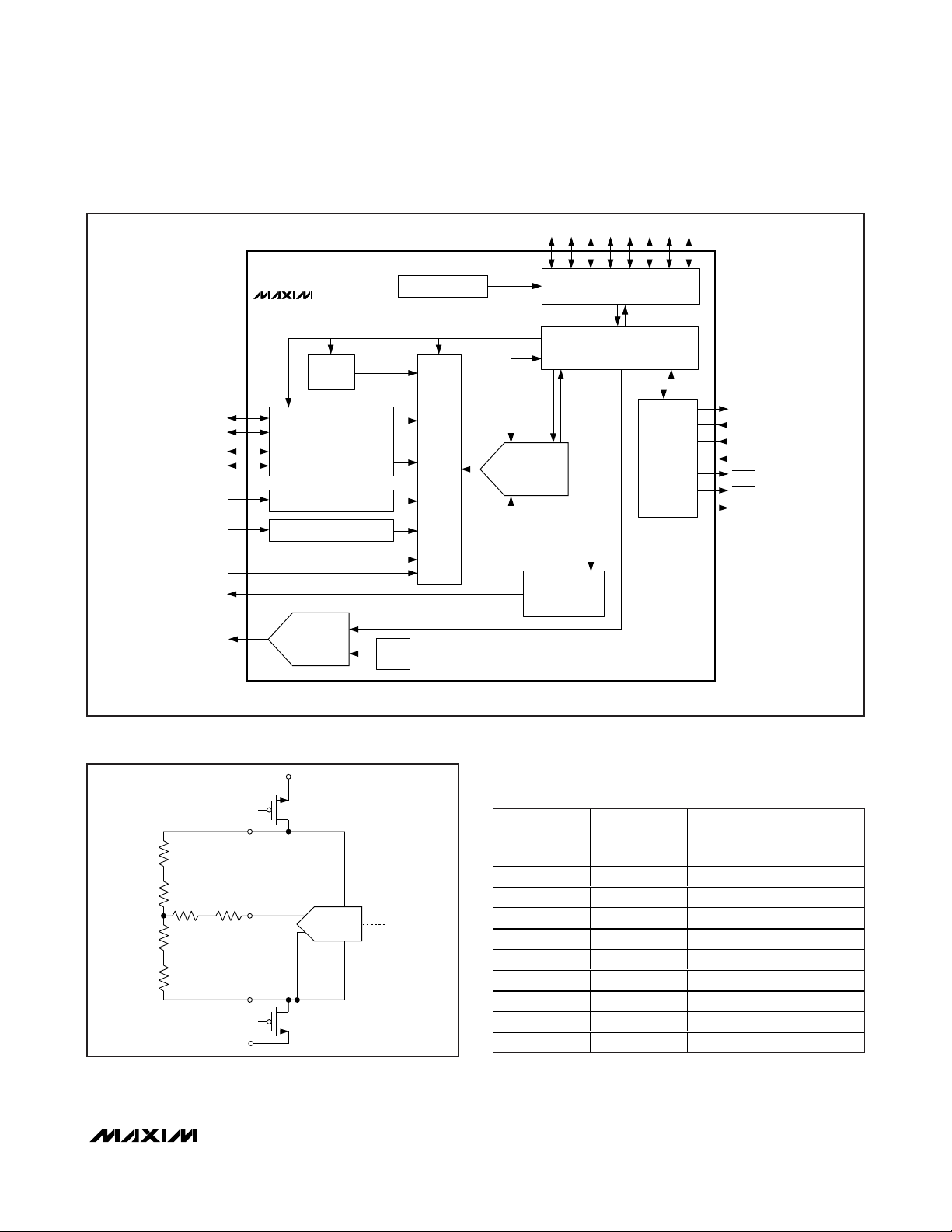

Detailed Description

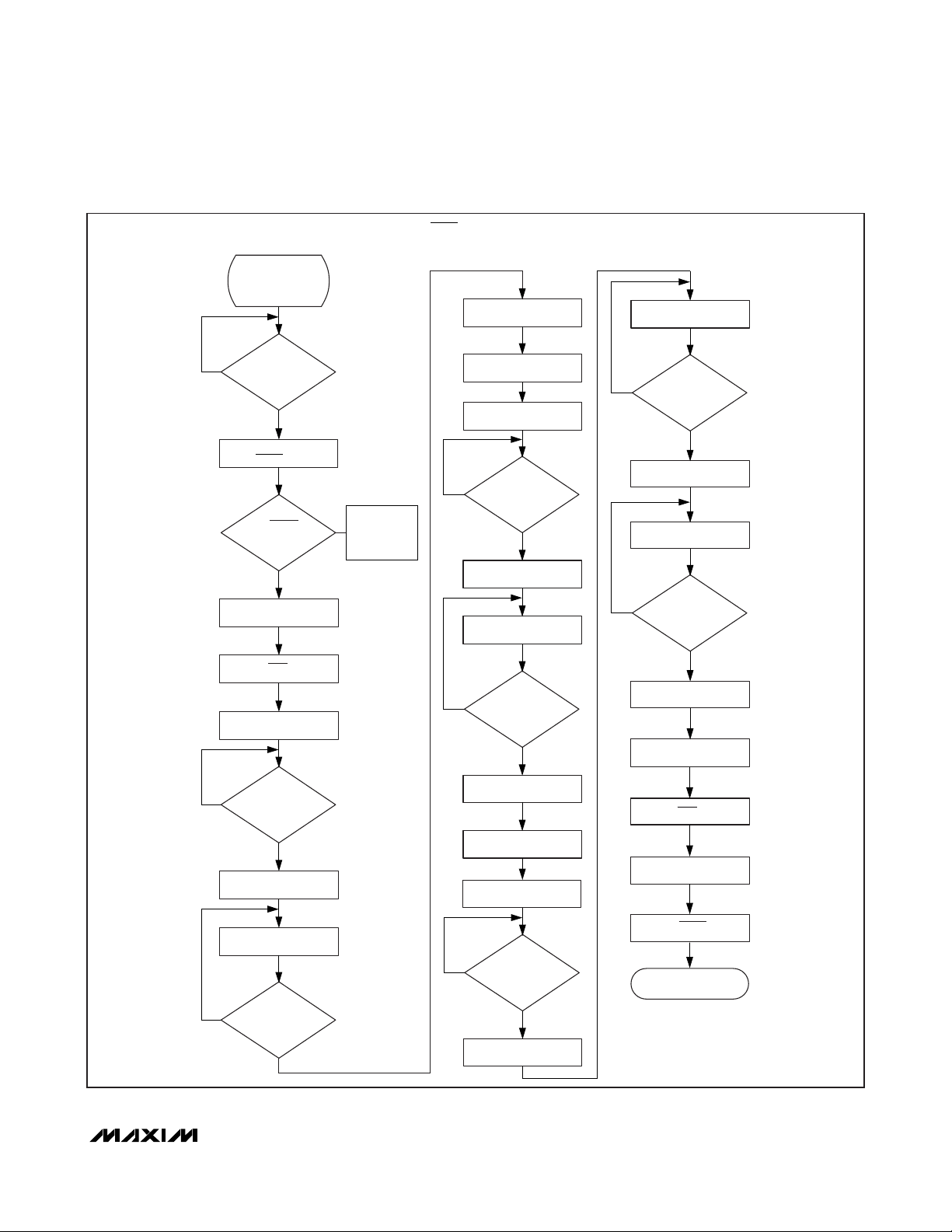

The MAX1233/MAX1234 are 4-wire touch-screen controllers. Figure 1 shows the functional diagram of the

MAX1233/MAX1234. Each device includes a 12-bit sampling ADC, 8-bit voltage output DAC, keypad scanner

that can also be configured as a GPIO, internal clock,

reference, temperature sensor, two battery monitor

inputs, two auxiliary analog inputs, SPI/QSPI/

MICROWIRE-compatible serial interface, and low onresistance switches for driving touch screens.

The 16-bit register inside the MAX1233/MAX1234

allows for easy control and stores results that can be

read at any time. The BUSY output indicates that a

functional operation is in progress. The PENIRQ and

KEYIRQ outputs, respectively, indicate that a screen

touch or a key press has occurred.

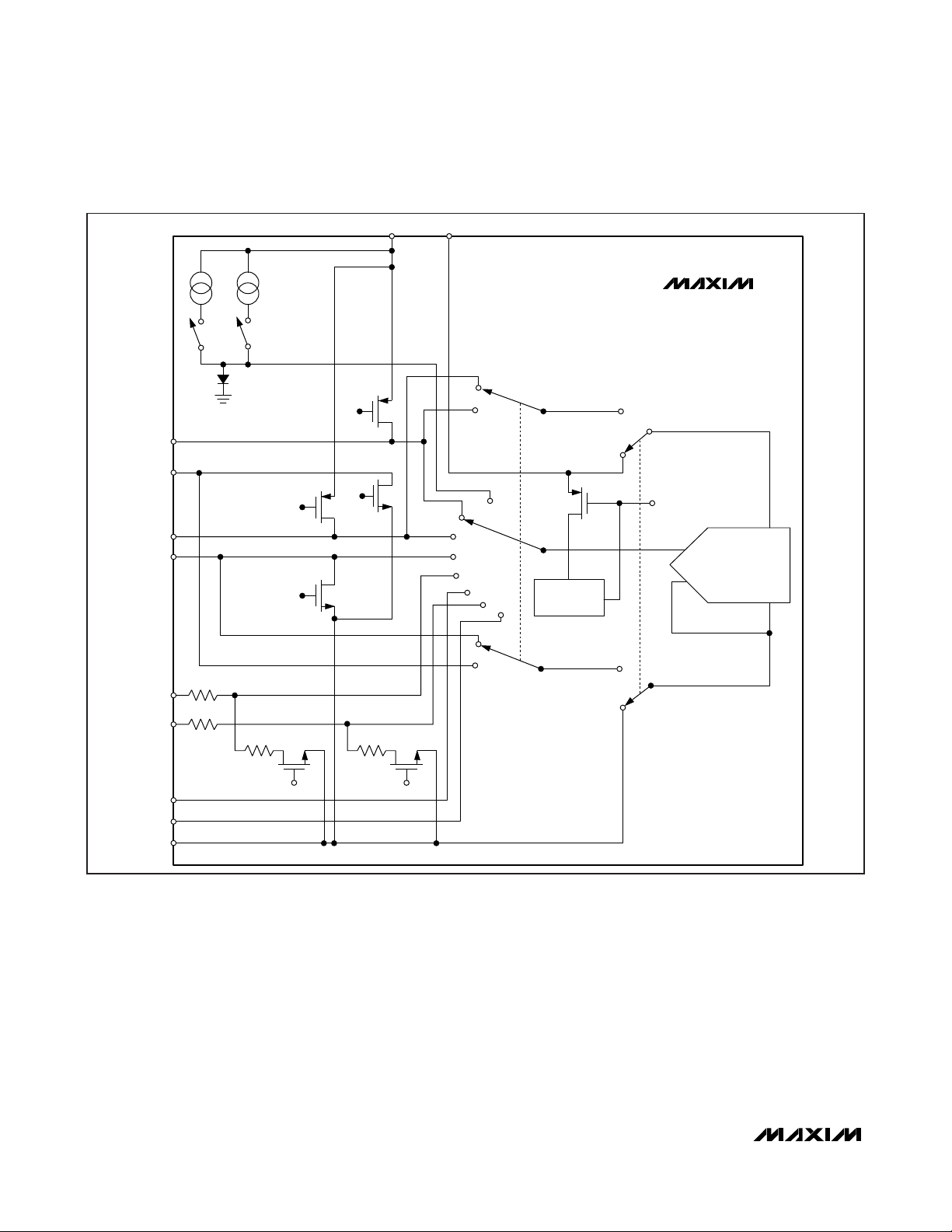

Touch-Screen Operation

The 4-wire touch-screen controller works by creating a

voltage gradient across the vertical or horizontal resistive touch screen connected to the analog inputs of the

MAX1233/MAX1234, as shown in Figure 2. The voltage

across the touch-screen panels is applied through internal MOSFET switches that connect each resistive layer

to AVDDand ground. For example, to measure the Y

position when a pointing device presses on the touch

screen, the Y+ and Y- drivers are turned on, connecting

one side of the vertical resistive layer to AVDDand the

other side to ground. The horizontal resistive layer functions as a sense line. One side of this resistive layer gets

connected to the X+ input, while the other side is left

open or floating. The point where the touch screen is

pressed brings the two resistive layers in contact and

creates a voltage-divider at that point. The data converter senses the voltage at the point of contact through the

X+ input and digitizes it.

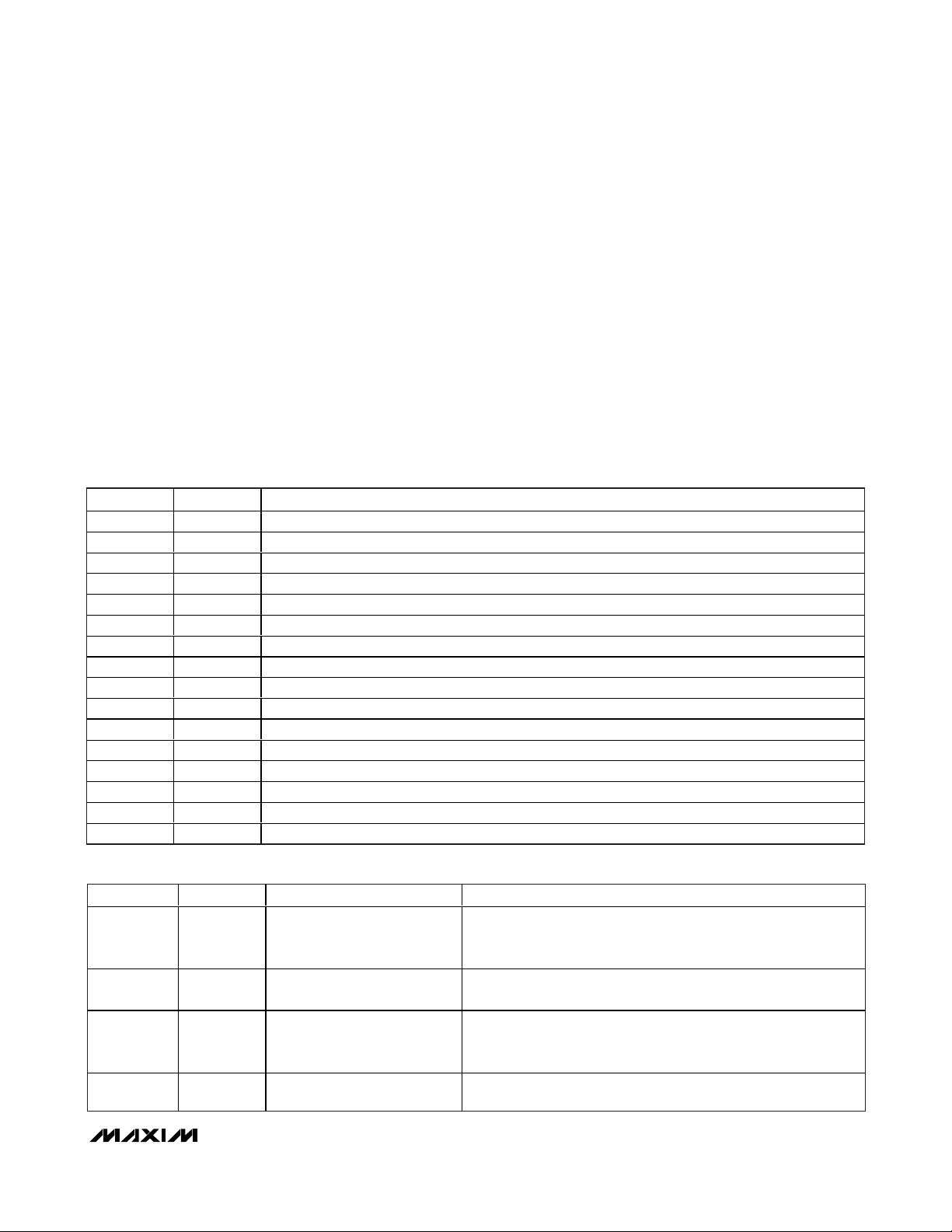

12-Bit ADC

Analog Inputs

Figure 3 shows a block diagram of the ADC’s analog

input section including the input multiplexer, the differential input, and the differential reference. The input multiplexer switches between X+, X-, Y+, Y-, AUX1, AUX2,

BAT1, BAT2, and the internal temperature sensor.

The time required for the T/H to acquire an input signal

is a function of how quickly its input capacitance is

charged. If the input signal’s source impedance is high,

the acquisition time lengthens, and more time must be

allowed. The acquisition time (t

ACQ

) is the maximum

time the device takes to acquire the input signal to 12bit accuracy. Configure t

ACQ

by writing to the ADC

control register. See Table 1 for the maximum input signal source impedance (R

SOURCE

) for complete settling

during acquisition.

Accommodate higher source impedances by placing a

0.1µF capacitor between the analog input and GND.

Input Bandwidth

The ADC’s input-tracking circuitry has a 0.5MHz smallsignal bandwidth. To avoid high-frequency signals

being aliased into the frequency band of interest, antialias filtering is recommended.

Pin Description (continued)

*

ESD protected: ±8kV Contact, ±15kV Air.

PIN NAME FUNCTION

19 C2 Keypad Column 2. Can be reconfigured as GPIO5.

20 C3 Keypad Column 3. Can be reconfigured as GPIO6.

21 C4 Keypad Column 4. Can be reconfigured as GPIO7.

22 KEYIRQ Active-Low Keypad Interrupt. KEYIRQ is low when a key press is detected.

23 PENIRQ Active-Low Pen Touch Interrupt. PENIRQ is low when a screen touch is detected.

24 DOUT Serial Data Output. Data is clocked out at SCLK falling edge. High impedance when CS is high.

25 BUSY

26 DIN Serial Data Input. Data is clocked in on the rising edge of SCLK.

27 SCLK

28 CS

—EP

Active-Low Busy Output. BUSY goes low and stays low during each functional operation. The host

controller should wait until BUSY is high again before using the serial interface.

Serial Clock Input. Clocks data in and out of the serial interface and sets the conversion speed (duty

cycle must be 30% to 70%).

Active-Low Chip Select. Data is not clocked into DIN unless CS is low. When CS is high, DOUT is

high impedance.

Exposed Pad. Internally connected to GND. Connect to a large ground plane to maximize thermal

performance. Not intended as an electrical connection point.

Page 13

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

______________________________________________________________________________________ 13

Figure 1. Block Diagram

Figure 2. Touch-Screen Measurement

Table 1. Maximum Input Source

Impedance

*X+

*Y+

*BAT1

*BAT2

*AUX1

*AUX2

REF

DACOUT

C1 C2 C3 C4 R1 R2 R3 R4

INTERNAL

REFERENCE

2.5V/1.0V

KEYPAD CONTROLLER

AND GPIO

REGISTERS AND

SCAN STATE

CONTROL

SERIAL

DATA

I/O

DOUT

SCLK

DIN

CS

PENIRQ

KEYIRQ

BUSY

OSCILLATOR

MAX1233

MAX1234

TEMP

SENSOR

*X-

*Y-

X/Y SWITCHES

BATTERY MONITOR

BATTERY MONITOR

8-BIT

DAC

REF

DAC

MUX

12-BIT

ADC

*ESD PROTECTED

+AV

FORCE LINE

Y+

SENSE LINE

X+

FORCE LINE

Y-

GND

DD

SENSE

LINE

ACQUISITION

TIME (µs)

1.5 8 2.6

1.5 10 2.0

+REF

+IN

-IN

-REF

1.5 12 1.5

5.0 8 23

5.0 10 19

5.0 12 15

95 8 560

95 10 470

95 12 400

RESOLUTION

(BITS)

MAXIMUM R

SOURCE

FOR

COMPLETE SETTLING

DURING ACQUISITION (kΩ)

Page 14

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

14 ______________________________________________________________________________________

Analog Input Protection

Internal protection diodes that clamp the analog input

to AVDDand GND allow the analog input pins to swing

from GND - 0.3V to AVDD+ 0.3V without damage.

Analog inputs must not exceed AV

DD

by more than

50mV or be lower than GND by more than 50mV for

accurate conversions. If an off-channel analog input

voltage exceeds the supplies, limit the input current to

50mA. All analog inputs are also fully ESD protected

to ±8kV, using the Contact-Discharge method and

±15kV using the Air-Gap method specified in IEC1000-4-2.

Reference for ADC

Internal Reference

The MAX1233/MAX1234 offer an internal voltage reference for the ADC that can be set to +1.0V or +2.5V. The

MAX1233/MAX1234 typically use the internal reference

for battery monitoring, temperature measurement, and for

Figure 3. Simplified Diagram of Analog Input Section

TEMP1

TEMP2

X+

X-

Y+

Y-

+AV

DD

V

REF

MAX1233

MAX1234

REF ON/OFF

CONVERTER

+REF

-

REF

2.5V/1.0V

REFERENCE

+IN

-IN

7.5kΩ

V

BAT1

7.5kΩ

V

BAT2

AUX1

AUX2

GND

2.5kΩ

BATTERY

ON

2.5kΩ

BATTERY

ON

Page 15

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

______________________________________________________________________________________ 15

measurement of the auxiliary inputs. Figure 4 shows the

on-chip reference circuitry of the MAX1233/MAX1234.

Set the internal reference voltage by writing to the RFV

bits in the ADC control register (see Tables 4, 5, and 12).

The MAX1233/MAX1234 can accept an external reference connected to REF for ADC conversion.

External Reference

The MAX1233/MAX1234 can accept an external reference connected to the REF pin for ADC conversions.

The internal reference should be disabled (RES1 = 1)

when using an external reference. At a conversion rate

of 50ksps, an external reference at REF must deliver up

to 15µA of load current and have 50Ω or less output

impedance. If the external reference has high output

impedance or is noisy, bypass it close to the REF pin

with a 0.1µF capacitor.

Selecting Internal or External Reference

Set the type of reference being used by programming

the ADC control register. To select the internal reference, clock zeros into bits [A/D3:A/D0] and a zero to bit

RES1, as shown in the

Control Registers

section. To

change to external reference mode, clock zeros into

bits [A/D3:A/D0] and a one to bit RES1. See Table 13

for more information about selecting an internal or

external reference for the ADC.

Reference Power Modes

Auto Power-Down Mode (RES1 = RES0 = 0)

The MAX1233/MAX1234 are in auto power-down mode

at initial power-up. Set the RES1 and RES0 bits to zero

to use the MAX1233/MAX1234 in the auto power-down

mode. In this mode, the internal reference is normally

off. When a command to perform a battery measure-

ment, temperature measurement, or auxiliary input

measurement is written to the ADC control register, the

device powers on the internal reference, waits for the

internal reference to settle, completes the requested

scan, and powers down the internal reference. The reference power delay depends upon the ADC resolution

selected (see Table 8). Do not bypass REF with an

external capacitor when performing scans in auto

power-down mode.

Full-Power Mode (RES1 = 0, RES0 = 1)

In the full-power mode, the RES1 bit is set LOW and

RES0 bit is set HIGH. In this mode, the device is powered up and the internal ADC reference is always ON.

The MAX1233/MAX1234 internal reference remains fully

powered after completing a scan.

Internal Clock

The MAX1233/MAX1234 operate from an internal oscillator, which is accurate to within 20% of the 10MHz

specified clock rate. The internal oscillator controls the

timing of the acquisition, conversion, touch-screen settling, reference power-up, and keypad debounce times.

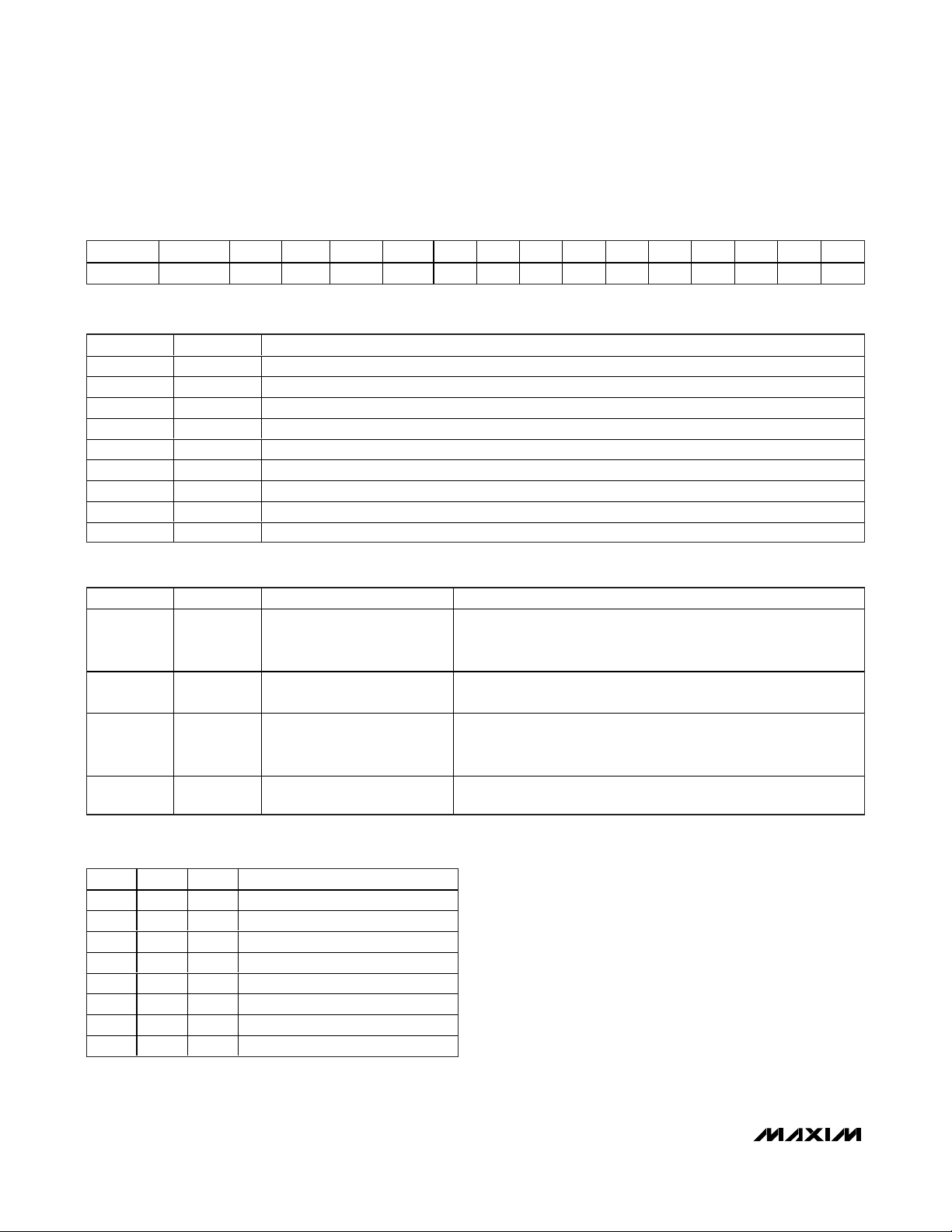

8-Bit DAC

The MAX1233/MAX1234 have a voltage-output, true 8-bit

monotonic DAC with less than 1LSB integral nonlinearity

error and less than 1LSB differential nonlinearity error. It

requires a supply current of only 150µA (typ) and provides a buffered voltage output. The DAC is at midscale

code at power-up and remains there until a new code is

written to the DAC register. During shutdown, the DAC’s

output is pulled to ground with a 1MΩ load.

The internal DAC can be used in various system applications such as LCD/TFT-bias control, automatic tuning

(VCO), power amplifier bias control, programmable

threshold levels, and automatic gain control (AGC).

The 8-bit DAC in the MAX1233/MAX1234 employs a

current-steering topology as shown in Figure 5. At the

core of this DAC is a reference voltage-to-current converter (V/I) that generates a reference current. This current is mirrored to 255 equally weighted current

sources. DAC switches control the outputs of these current mirrors so that only the desired fraction of the total

current-mirror currents is steered to the DAC output.

The current is then converted to a voltage across a

resistor, and the output amplifier buffers this voltage.

DAC Output Voltage

The 8-bit DAC code is binary unipolar with 1LSB =

(V

REF

/256). The DAC has a full-scale output voltage of

(0.9 × AV

DD

- 1LSB).

Figure 4. Block Diagram of the Internal Reference

+1.25V

BANDGAP

3R

2R

2x

REF PIN

OPTIONAL

Page 16

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

16 ______________________________________________________________________________________

Output Buffer

The DAC voltage output is an internally buffered unitygain follower that slews at up to ±0.4V/µs. The output

can swing from zero to full scale. With a 1/4FS to 3/4FS

output transition, the amplifier output typically settles to

1/2LSB in less than 5µs when loaded with 10kΩ in parallel with 50pF. The buffer amplifier is stable with any

combination of resistive loads >10kΩ and capacitive

loads <50pF.

Power-On Reset

All registers of the MAX1233/MAX1234 power up at a

default zero state, except the DAC data register, which

is set to 10000000, so the output is at midscale.

Keypad Controller and GPIO

The keypad controller is designed to interface a matrixtype 4 rows × 4 columns (16 keys or fewer) keypad to a

host controller. The KEY control register controls keypad

interrupt, keypad scan, and keypad debounce times.

The KeyMask and ColumnMask registers enable masking of a particular key or an entire column of the keypad

when they are not in use. The MAX1233/MAX1234 offer

two keypad data registers. KPData1 is the pending register. KPData2 holds keypad scan results of only the

unmasked keys. If 12 or fewer keys are being monitored,

one or more of the row/column pins of the

MAX1233/MAX1234 can be software programmed as

GPIO pins.

Touch-Screen Detection

Touch-screen detection can be enabled or disabled by

writing to the ADC control register as shown in Table 4.

Touch-screen detection is disabled at initial power-up.

Once touch-screen detection is enabled, the Y- driver

is on and the Y- pin is connected to GND. The X+ pin is

internally pulled to AVDDthrough a 1MΩ resistor as

shown in Figure 6. When the screen is touched, the X+

pin is pulled to GND through the touch screen and a

touch is detected.

When the 1MΩ pullup resistor is first connected, the X+

pin can be floating near ground. To prevent false touch

detection in this case, the X+ pin is precharged high for

0.1µs using the 7Ω PMOS driver before touch detection

begins.

Key-Press Detection

Key-press detection can be enabled or disabled by

writing to the keypad control register as shown in Table

17. Key-press detection is disabled at initial power-up.

Once key-press detection is enabled, the C_ pins are

internally connected to DV

DD

and the R_ pins are internally pulled to GND through a 16kΩ resistor. When a

key is pressed, the associated row pin is pulled to

DVDDand the key press is detected. Figure 7 shows

the key-press detection circuitry.

Interrupts

PEN Interrupt Request (PENIRQ)

The PENIRQ output can be used to alert the host controller of a screen touch. The PENIRQ output is normally

high and goes low after a screen touch is detected.

Figure 5. DAC Current-Steering Topology

Figure 6. Touch-Screen Detection Block Diagram

+AV

DD

V

REF

1MΩ

SW1 SW2

SW255

OUT

S1

TOUCH-SCREEN

TOUCH

SCREEN

X+

Y+

X-

Y-

S2

DETECTOR

PENIRQ

Page 17

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

______________________________________________________________________________________ 17

Figure 7. Key-Press Detection Circuitry

Figure 8a. Timing Diagram for Touch-Initiated Screen Scan

Figure 8b. Timing Diagram for Host-Initiated Screen Scan

SIMPLIFIED KEYPAD CIRCUITRY

DRIVERS PULL HIGH

OR GO THREE-STATE

C1 C2 C3 C4

R1

TO KEYPAD

WAKEUP AND

DEBOUNCE

LOGIC

X+

PENIRQ

BUSY

KEYPAD

R2

R3

R4

X+

PENIRQ

BUSY

CS

DOUT

TOUCHSCREEN

DATA

DATA

READ

CS

DIN

DOUT

DATA

READ

TOUCHSCREEN

DATA

Page 18

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

18 ______________________________________________________________________________________

PENIRQ returns high only after a touch-screen scan is

completed. PENIRQ does not go low again until one of

the touch-screen data registers is read. Figures 8a and

8b show the timing diagrams for the PENIRQ pin.

Keypad Interrupt Request (KEYIRQ)

The KEYIRQ output can be used to alert the host controller of a key press. The KEYIRQ output is normally

high and goes low after a key press is detected.

KEYIRQ returns high only after a key-press scan is

completed. KEYIRQ does not go low again until one of

the key-press data registers is read. Figures 9a and 9b

show the timing diagrams for the KEYIRQ pin.

Busy Indicator (

BUSY

)

BUSY informs the host processor that a scan is in

progress. BUSY is normally high and goes low and

stays low during each functional operation. The host

controller should wait until BUSY is high again before

using the serial interface.

Digital Interface

The MAX1233/MAX1234 interface to the host controller

through a standard 3-wire serial interface at up to

10MHz. DIN and CS are the digital inputs to the

MAX1233/MAX1234. DOUT is the serial data output.

Data is clocked out at the SCLK falling edge and is

high impedance when CS is high. When performing an

ADC scan, CS must de-assert high before the end of

the first conversion, otherwise the conversion results

will not be stored. PENIRQ and KEYIRQ communicate

interrupts from the touch-screen and keypad controllers

to the host processor when a screen touch or a key

press is detected. BUSY informs the host processor that

a scan is in progress. In addition to these digital I/Os, the

row and column pins of the keypad controller can be

programmed as GPIO pins.

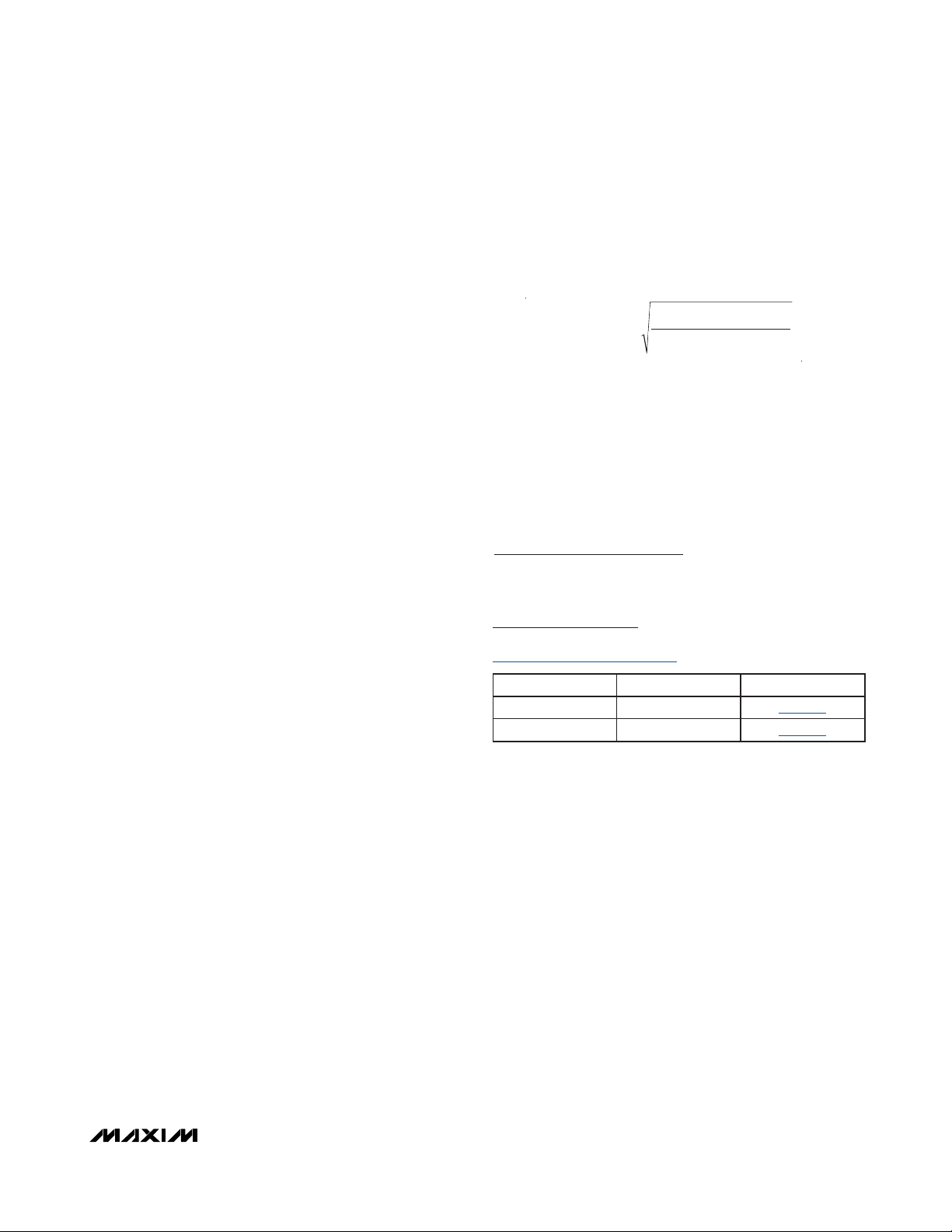

Communications Protocol

The MAX1233/MAX1234 are controlled by reading from

and writing to registers through the 3-wire serial interface. These registers are addressed through a 16-bit

command that is sent prior to the data. The command

is shown in Table 2.

The first 16 bits after the falling edge of CS contain the

command word. The command word begins with an

R/W bit, which specifies the direction of data flow on

the serial bus. Bits 14 through 7 are reserved for future

use. Bit 6 specifies the page of memory in which the

desired register is located. The last 6 bits specify the

address of the desired register. The next 16 bits of data

are read from or written to the address specified in the

command word. After 32 clock cycles, the interface

automatically increments its address pointer and continues reading or writing until the rising edge of CS, or

until it reaches the end of the page.

Figure 9a. Timing Diagram for Key-Press-Initiated Debounce

Scan

Figure 9b. Timing Diagram for Host-Initiated Keypad

Debounce Scan

Table 2. Command Word Format

R_

KEYIRQ

BUSY

CS

DOUT

R_

KEYIRQ

BUSY

CS

DIN

DOUT

TOUCHSCREEN

DATA

TOUCHSCREEN

DATA

DATA

READ

DATA

READ

BIT15

BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1

MSB

R/W RES RES RES RES RES RES RES RES PAGE ADD5 ADD4 ADD3 ADD2 ADD1 ADD0

BIT0

LSB

Page 19

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

______________________________________________________________________________________ 19

Table 3. Register Summary

Note: All other registers are reserved and should always be 0. Power-on reset state is DAC data at midscale (0x0080), all other reg-

isters are 0.

WRITE

COMMAND

0x000B 0x800B DAC data 0 0 0 0 0 0 0 0 DA7 DA6 DA5 DA4 DA3 DA2 DA1 DA0

0x000F 0x800F GPIO data GPD7 GPD6 GPD5 GPD4 GPD3 GPD2 GPD1 GPD0 0 0 0 00000

0x0040 0x8040 ADC control P EN STS ADSTS A/D3 A/D2 A/D1 A/D0 RES1 RES0 AVG1 AVG0 CNR1 CNR0 ST2 ST1 ST0 RFV

0x0041 0x8041 KEY control KEYSTS1 KEYSTS0 DB N2 D BN 1 DB N0 H LD 2 H LD 1 H LD 0 0 0 0 00000

0x0042 0x8042 DAC control DAPD 0 0 0 0 0 0 0 0 0 0 00000

0x004E 0x804E GPIO pullup PU7 PU6 PU5 PU4 PU3 PU2 PU1 PU0 0 0 0 00000

0x004F 0x804F GPIO control GP7 GP6 GP5 GP4 GP3 GP2 GP1 GP0 OE7 OE6 OE5 OE4 OE3 OE2 OE1 OE0

0x0050 0x8050 KPKeyMask KM15 KM14 KM13 KM12 KM11 KM10 KM9 KM8 KM7 KM6 KM5 KM4 KM3 KM2 KM1 KM0

0x0051 0x8051 KPColumnMask CM4 CM3 CM2 CM1 0 0 0 0 0 0 0 00000

READ

(HEX)

REGISTER

NAME

BIT15 BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

COMMAND

(HEX)

— 0x8000 X 0 0 0 0 X11 X10 X9 X8 X7 X6 X5 X4 X3 X2 X1 X0

— 0x8001 Y 0 0 0 0 Y11 Y10 Y9 Y8 Y7 Y6 Y5 Y4 Y3 Y2 Y1 Y0

— 0x8002 Z1 0 0 0 0 Z1_11 Z1_10 Z1_9 Z1_8 Z1_7 Z1_6 Z1_5 Z1_4 Z1_3 Z1_2 Z1_1 Z1_0

— 0x8003 Z2 0 0 0 0 Z2_11 Z2_10 Z2_9 Z2_8 Z2_7 Z2_6 Z2_5 Z2_4 Z2_3 Z2_2 Z2_1 Z2_0

— 0x8004 KPD K15 K14 K13 K12 K11 K10 K9 K8 K7 K6 K5 K4 K3 K2 K1 K0

— 0x8005 BAT1 0 0 0 0 B1_11 B1_10 B1_9 B1_8 B1_7 B1_6 B1_5 B1_4 B1_3 B1_2 B1_1 B1_0

— 0x8006 BAT2 0 0 0 0 B2_11 B2_10 B2_9 B2_8 B2_7 B2_6 B2_5 B2_4 B2_3 B2_2 B2_1 B2_0

— 0x8007 AUX1 0 0 0 0 A1_11 A1_10 A1_9 A1_8 A1_7 A1_6 A1_5 A1_4 A1_3 A1_2 A1_1 A1_0

— 0x8008 AUX2 0 0 0 0 A2_11 A2_10 A2_9 A2_8 A2_7 A2_6 A2_5 A2_4 A2_3 A2_2 A2_1 A2_0

— 0x8009 TEMP1 0 0 0 0 T1_11 T1_10 T1_9 T1_8 T1_7 T1_6 T1_5 T1_4 T1_3 T1_2 T1_1 T1_0

— 0x800A TEMP2 0 0 0 0 T2_11 T2_10 T2_9 T2_8 T2_7 T2_6 T2_5 T2_4 T2_3 T2_2 T2_1 T2_0

— 0x8010 KPData1 K1_15 K1_14 K1_13 K1_12 K1_11 K1_10 K1_9 K1_8 K1_7 K1_6 K1_5 K1_4 K1_3 K1_2 K1_1 K1_0

— 0x8011 KPData2 K2_15 K2_14 K2_13 K2_12 K2_11 K2_10 K2_9 K2_8 K2_7 K2_6 K2_5 K2_4 K2_3 K2_2 K2_1 K2_0

Page 20

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

20 ______________________________________________________________________________________

In order to read the entire first page of memory, for

example, the host processor must send the

MAX1233/MAX1234 the command 0x8000

H

. The

MAX1233/MAX1234 then begin clocking out 16-bit data

starting with the X-data register. In order to write to the

second page of memory, the host processor sends the

MAX1233/MAX1234 the command 0x0040H. The succeeding data is then written in 16-bit words beginning

with the ADC control register. Figures 10a and 10b show

a complete write and read operation, respectively,

between the processor and the MAX1233/MAX1234.

Memory Map

The MAX1233/MAX1234s’ internal memory is divided

into two pages—one for data and one for control, each

of which contains thirty-two 16-bit registers.

Control Registers

Table 3 provides a summary of all registers and bit

locations of the MAX1233/MAX1234.

ADC Control Register

The ADC measures touch position, touch pressure, battery voltage, auxiliary analog inputs, and temperature.

The ADC control register determines which input is

selected and converted. Tables 4 and 5 show the format and bit descriptions for the ADC control register.

Figure 10a. Timing Diagram of Write Operation

Figure 10b. Timing Diagram of Read Operation

Table 4. ADC Control Register (Write 0x0040/Read 0x8040)

SCLK

CS

DIN

D15 IS READ/WRITE BIT

D15

LOW FOR WRITE

D15–D0 COMMAND WORD

WRITE OPERATION

D0

D15

D15–D0 DATA WORD

D0

THREE-

DOUT

STAT E

TIMING NOT TO SCALE.

SCLK

CS

DIN

DOUT

THREE-STATE

D15 D14

D15–D0 COMMAND

WORD

READ OPERATION

D0

D15

D0

D15

DATA WORD DATA WORD

THREE-

STAT E

D0

THREE-STATE

BIT15 BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

PENSTS ADSTS A/D3 A/D2 A/D1 A/D0 RES1 RES0 AVG1 AVG0 CNR1 CNR0 ST2 ST1 ST0 RFV

Page 21

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

______________________________________________________________________________________ 21

Bits 14-15: Pen Interrupt Status and

ADC Status Bits

These bits are used to control or monitor ADC scans.

Bits 10-13: ADC Scan Select

These bits control which input to convert and which converter mode is used. The bits are identical regardless of a

read or write. See Table 7 for details about using these bits.

Bits 8-9: ADC Resolution Control

These bits specify the ADC resolution and are identical

regardless of read or write. Table 8 shows how to use

these bits to set the resolution.

Bits 6-7: Converter Averaging Control

These bits specify the number of data averages the

converter performs. Table 9 shows how to program for

the desired number of averages. When averaging is

used, ADSTS and BUSY indicate the converter is busy

until all conversions needed for the averaging finish.

These bits are identical, regardless of read or write.

Bits 4-5: ADC Conversion Rate Control

These bits specify the internal conversion rate, which

the ADC uses to perform a single conversion, as shown

in Table 10. Lowering the conversion rate also reduces

power consumption. These bits are identical, regardless of read or write.

Table 5. ADC Control Register Bit Descriptions (Write 0x0040/Read 0x8040)

Table 6. ADSTS Bit Operation

BIT NAME DESCRIPTION

15 (MSB) PENSTS Read: pen interrupt status; Write: sets interrupt initiated touch-screen scans

14 ADSTS Read: ADC status; Write: stops ADC

13 A/D3 Selects ADC scan functions

12 A/D2 Selects ADC scan functions

11 A/D1 Selects ADC scan functions

10 A/D0 Selects ADC scan functions

9 RES1 Controls ADC resolution

8 RES0 Controls ADC resolution

7 AVG1 Controls ADC result averaging

6 AVG0 Controls ADC result averaging

5 CNR1 Controls ADC conversion rate

4 CNR0 Controls ADC conversion rate

3 ST2 Controls touch-screen settling wait time

2 ST1 Controls touch-screen settling wait time

1 ST0 Controls touch-screen settling wait time

0 (LSB) RFV Chooses 1.0V or 2.5V reference

PENSTS ADSTS READ FUNCTION WRITE FUNCTION

00

10

01

11

No screen touch detected;

scan or conversion in progress

Screen touch detected;

scan or conversion in progress

No screen touch detected;

data available

Screen touch detected;

data available

Performs one scan and waits to detect a screen touch. Upon

detection, issues an interrupt and waits until told to scan by the

host controller.

Stops any ongoing scan and waits to detect a screen touch. Upon

detection, issues an interrupt and performs a scan.

Stops any ongoing scan and waits to detect a screen touch. Upon

detection, issues an interrupt and waits until told to scan by the

host controller.

Stops any ongoing scan and powers down the screen touch

detection circuit. No screen touches are detected in this mode.

Page 22

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

22 ______________________________________________________________________________________

Table 7. ADC Scan Select (Touch Screen, Battery, Auxiliary Channels, and Temperature)

Table 8. ADC Resolution Control

*

Applicable only for temperature, battery, or auxiliary

measurements in auto power-up reference mode.

Table 9. ADC Averaging Control

Table 10. ADC Conversion Rate Control

A/D3 A/D2 A/D1 A/D0 FUNCTION

0000

0 0 0 1 Measures X/Y touch position and returns results to the X and Y data registers.

0010

0 0 1 1 Measures X touch position and returns results to the X data register.

0 1 0 0 Measures Y touch position and returns results to the Y data register.

0 1 0 1 Measures Z1/Z2 touch pressure and returns results to the Z1 and Z2 data register.

0 1 1 0 Measures Battery Input 1 through a 4:1 divider and returns results to the BAT1 data register.

0 1 1 1 Measures Battery Input 2 through a 4:1 divider and returns results to the BAT2 data register.

1 0 0 0 Measures Auxiliary Input 1 and returns results to the AUX1 data register.

1 0 0 1 Measures Auxiliary Input 2 and returns results to the AUX2 data register.

1 0 1 0 Measures temperature (single ended) and returns results to the TEMP1 data register.

1011

1 1 0 0 Measures temperature (differential) and returns results to the TEMP1 and TEMP2 data registers.

1 1 0 1 Turns on Y+, Y- drivers. No measurement is performed.

1 1 1 0 Turns on X+, X- drivers. No measurement is performed.

1 1 1 1 Turns on Y+, X- drivers. No measurement is performed.

Configures the ADC reference as selected by RES [1:0] bits as shown in Table 13. No measurement

is performed.

Measures X/Y touch position and Z1/ Z2 touch pressure and returns results to the X, Y, Z1, and Z2

data registers.

Measures Battery Input 1, Battery Input 2, Auxiliary Input 1, Auxiliary Input 2, and temperature

(differential), and returns results to the appropriate data registers.

RES1 RES0

0 0 8 bit 31

0 1 8 bit 31

1 0 10 bit 37

1 1 12 bit 44

ADC

RESOLUTION

INTERNALLY TIMED

REFERENCE POWER-UP

DELAY* (µs)

CNR1 CNR0 FUNCTION

00

01

10

11

3.5µs/sample

(1.5µs acquisition, 2µs conversion)

3.5µs/sample

(1.5µs acquisition, 2µs conversion)

10µs/sample

(5µs acquisition, 5µs conversion)

100µs/sample

(95µs acquisition, 5µs conversion)

AVG1 AVG0 FUNCTION

0 0 No data averages (default)

0 1 4 data averages

1 0 8 data averages

1 1 16 data averages

Page 23

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

______________________________________________________________________________________ 23

Bits 1-3: Touch-Screen Settling Time Control

These bits specify the time delay from pen-touch detection to a conversion start. This allows the selection of the

appropriate settling time for the touch screen being used.

Table 11 shows how to set the settling time. These bits

are identical, regardless of read or write.

Bit 0: ADC Internal Reference Voltage Control

This bit selects the ADC internal reference voltage,

either +1.0V or +2.5V. This bit is identical, regardless of

read or write. The reference control bit is shown in

Table 12.

Internal ADC Reference Power-Down Control

The ADC control register controls the power setting of

the internal ADC reference. Zeros must be written to

bits A/D3–A/D0 to control internal reference power-up

followed by the appropriate logic at the RES1 and RES0

bits. Table 13 shows the internal ADC reference powerdown control.

DAC Control Register

The MSB in this control register determines the powerdown control of the on-board DAC. Table 14 shows the

DAC control register. Writing a zero to bit 15 (DAPD)

powers up the DAC, while writing a 1 powers down the

DAC. Table 15 describes the DAC control register contents, while Table 16 shows the DAC power-down bit.

Keypad Control Registers

The keypad control register, keypad mask register, and

keypad column mask control register control the keypad scanner in the MAX1233/MAX1234. The keypad

control register (Table 17) controls scanning and

debouncing, while the keypad mask register (Table 22)

and the keypad column mask control register (Table 24),

Table 11. Touch-Screen Settling Time

Control*

*

Applicable only for X, Y, Z1, and Z2 measurements.

Table 13. Internal ADC Reference Auto Power-Up Control

Table 12. ADC Reference Control Bit

Table 14. DAC Control Register (Write 0x0042/Read 0x8042)

BIT

DESCRIPTION

15 (MSB)

DAC powered down

[14:0]

0 Reserved

Table 15. DAC Control Register

Descriptions

DAPC FUNCTION

0 DAC powered up

1 DAC powered down

Table 16. DAC Power-Down Bit

ST2 ST1 ST0 SETTLING TIME

0 0 0 Settling time: 0µs

0 0 1 Settling time: 100µs

0 1 0 Settling time: 500µs

0 1 1 Settling time: 1ms

1 0 0 Settling time: 5ms

1 0 1 Settling time: 10ms

1 1 0 Settling time: 50ms

1 1 1 Settling time: 100ms

NAME

DAPD

RFV FUNCTION

0 +1.0V reference

1 +2.5V reference

[A/D3:A/D0] RES1 RES0

0000 0 0 Internal

0000 0 1 Internal Always powered up

0000 1 0 External Always powered down

0000 1 1 External Always powered down

A DC R EF ER EN C E

SOURCE

Power up, wait for reference to settle, and power down again for

each temperature, battery, or auxiliary scan (auto power-up mode)

ADC REFERENCE POWER MODE

BIT15 BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

DAPD000000000000000

Page 24

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

24 ______________________________________________________________________________________

Table 19. KEYSTS1/KEYSTS0 Functions

Table 20. Keypad Debounce Time Control

Table 18. Keypad Control Register Bit Descriptions (Write 0x0041/Read 0x8041)

Table 17. Keypad Control Register (Write 0x0041/Read 0x8041)

BIT15 BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

KEYSTS1 KEYSTS0 DBN2 DBN1 DBN0 HLD2

BIT NAME DESCRIPTION

15 (MSB) KEYSTS1 Read: keypad interrupt status; Write: set interrupt initiated keypad scans

14 KEYSTS0 Read: keypad scan status; Write: stop keypad scan

13 DBN2 Keypad debounce time control

12 DBN1 Keypad debounce time control

11 DBN0 Keypad debounce time control

10 HLD2 Keypad hold time control

9 HLD1 Keypad hold time control

8 HLD0 Keypad hold time control

[7:0] 0 Reserved

KEYSTS1 KEYSTS0 READ FUNCTION WRITE FUNCTION

00

No button press detected;

scan or debounce in progress

HLD HLD

Scans keypad once and waits to detect a button press. Upon

detection, issues an interrupt and waits for the host’s instruction

before scanning.

00000000

10

01

11

Button press detected;

scan or debounce in progress

No button press detected;

data available

Button press detected;

data available

DBN2 DBN1 DBN0 FUNCTION (ms)

0 0 0 Debounce time: 2

0 0 1 Debounce time: 10

0 1 0 Debounce time: 20

0 1 1 Debounce time: 50

1 0 0 Debounce time: 60

1 0 1 Debounce time: 80

1 1 0 Debounce time: 100

1 1 1 Debounce time: 120

Stops any ongoing scan and waits to detect a button press. Upon

detection, issues an interrupt and scans the keypad.

Stops any ongoing scan and waits to detect a button press. Upon

detection, issues an interrupt and waits for the host’s instruction

before scanning.

Stops any ongoing scan and powers down the button press

detection circuit. No button presses are detected in this mode.

Page 25

Table 21. Keypad Hold Time Control

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

______________________________________________________________________________________ 25

allowing certain keys to be masked from detection.

Tables 18–21 show the programmable bits of the keypad

control register. Tables 23, 24, and 25 show the programmable bits of the keypad mask registers. The

Keypad

Controller and GPIO

section provides more details.

GPIO Control Register

The GPIO control register and the GPIO pullup register

allow the keypad controller’s row and column inputs to be

configured as up to eight parallel I/O pins. Tables 26 and

27 show the GPIO control register layout and control register descriptions. Tables 28 and 29 show the GPIO pullup

disable register and associated descriptions. For more

information, see the

Applications Information

section.

Table 22. Keypad Key Mask Register Bit Descriptions (Write 0x0050/Read 0x8050)

Table 24. Keypad Column Mask Register (Write 0x0051/Read 0x8051)

Table 23. Keypad Key Mask Register Bit Descriptions (Write 0x0050/Read 0x8050)

HLD2 HLD1 HLD0 FUNCTION

0 0 0 If a button is held, wait 100µs before beginning next debounce scan

0 0 1 If a button is held, wait 1 debounce time before beginning the next debounce scan

0 1 0 If a button is held, wait 2 debounce times before beginning the next debounce scan

0 1 1 If a button is held, wait 3 debounce times before beginning the next debounce scan

1 0 0 If a button is held, wait 4 debounce times before beginning the next debounce scan

1 0 1 If a button is held, wait 5 debounce times before beginning the next debounce scan

1 1 0 If a button is held, wait 6 debounce times before beginning the next debounce scan

1 1 1 If a button is held, wait 7 debounce times before beginning the next debounce scan

BIT15 BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

KM15 KM14 KM13 KM12 KM11 KM10 KM9 KM8 KM7 KM6 KM5 KM4 KM3 KM2 KM1 KM0

BIT NAME DESCRIPTION

15 KM15 Mask status register data update on individual key for row 4, column 4

14 KM14 Mask status register data update on individual key for row 3, column 4

13 KM13 Mask status register data update on individual key for row 2, column 4

12 KM12 Mask status register data update on individual key for row 1, column 4

11 KM11 Mask status register data update on individual key for row 4, column 3

10 KM10 Mask status register data update on individual key for row 3, column 3

9 KM9 Mask status register data update on individual key for row 2, column 3

8 KM8 Mask status register data update on individual key for row 1, column 3

7 KM7 Mask status register data update on individual key for row 4, column 2

6 KM6 Mask status register data update on individual key for row 3, column 2

5 KM5 Mask status register data update on individual key for row 2, column 2

4 KM4 Mask status register data update on individual key for row 1, column 2

3 KM3 Mask status register data update on individual key for row 4, column 1

2 KM2 Mask status register data update on individual key for row 3, column 1

1 KM1 Mask status register data update on individual key for row 2, column 1

0 KM0 Mask status register data update on individual key for row 1, column 1

BIT15 BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

CM4CM3CM2CM1000000000000

Page 26

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

26 ______________________________________________________________________________________

Data Registers

The data results from conversions or keypad scans are

held in the data registers of the MAX1233/MAX1234.

During power-up, all of these data registers with the

exception of the DAC data register default to 0000

H

.

The DAC register defaults to 1000

H

.

Analog Input Data Registers

Table 30 shows the format of the X, Y, Z1, Z2, BAT1,

BAT2, AUX1, AUX2, TEMP1, and TEMP2 data registers.

The data format for these registers is right justified

beginning with bit 11. Data written through the serial

interface to these registers is not stored.

Keypad Data Registers

Table 31 shows the formatting of the keypad data registers, while Tables 32, 33, and 34 provide individual register bit descriptions. These registers have the same

format as the keypad mask register. Each bit represents one key on the keypad. Table 35 shows a map of

a 16-key keypad. Data written through the serial interface to these registers is not stored.

Table 26. GPIO Control Register (Write 0x004F/Read 0x804F)

Table 27. GPIO Control Register Bit Descriptions (Write 0x004F/Read 0x804F)

Table 28.GPIO Pullup Disable Register (Write 0x004E/Read 0x804E)

Table 29. GPIO Pullup Disable Register

Descriptions

Table 25. Keypad Column Mask Register Bit Descriptions (Write 0x0051/Read 0x8051)

BIT NAME DESCRIPTION

15 CM4 Mask interrupt, status register, and pending register data update on all keys in column 4

14 CM3 Mask interrupt, status register, and pending register data update on all keys in column 3

13 CM2 Mask interrupt, status register, and pending register data update on all keys in column 2

12 CM1 Mask interrupt, status register, and pending register data update on all keys in column 1

[11:0] 0 Reserved

BIT15 BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

GP7 GP6 GP5 GP4 GP3 GP2 GP1 GP0 OE7 OE6 OE5 OE4 OE3 OE2 OE1 OE0

BIT NAME

15 GP7 C4 pin becomes GPIO pin 7 C4 pin remains keypad column 4

14 GP6 C3 pin becomes GPIO pin 6 C3 pin remains keypad column 3

13 GP5 C2 pin becomes GPIO pin 5 C2 pin remains keypad column 2

12 GP4 C1 pin becomes GPIO pin 4 C1 pin remains keypad column 1

11 GP3 R4 pin becomes GPIO pin 3 R4 pin remains keypad row 4

10 GP2 R3 pin becomes GPIO pin 2 R3 pin remains keypad row 3

9 GP1 R2 pin becomes GPIO pin 1 R2 pin remains keypad row 2

8 GP0 R1 pin becomes GPIO pin 0 R1 pin remains keypad row 1

[7:0] [OE7:OE0] GPIO pin configured as an output GPIO pin configured as an input

10

DESCRIPTION

BIT15 BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

PU7PU6PU5PU4PU3PU2PU1PU000000000

BIT NAME DESCRIPTION

[15:8] [PU7:PU0]

[7:0] 0 Reserved: always write as zero.

1: P ul l up d i sab l ed . Op en col l ector outp ut.

0: Pullup enabled.

Page 27

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

______________________________________________________________________________________ 27

Table 30. Analog Inputs Data Register Format

Table 31. Keypad Data Registers

Table 32. Keypad Data Register Descriptions

READ

COMMAND

0x8000 X 0000X11X10X9X8X7X6X5X4X3X2X1X0

0x8001 Y 0000Y11Y10Y9Y8Y7Y6Y5Y4Y3Y2Y1Y0

0x8002 Z1 0000Z1_11Z1_10Z1_9Z1_8Z1_7Z1_6Z1_5Z1_4Z1_3Z1_2Z1_1Z 1_0

0x8003 Z1 0000Z2_11Z2_10Z2_9Z2_8Z2_7Z2_6Z2_5Z2_4Z2_3Z2_2Z2_1Z 2_0

0x8005 BATT1 0000B1_11B1_10B1_9B1_8B1_7B1_6B1_5B1_4B1_3B1_2B1_1B1_0

0x8006 BATT2 0000B2_11B2_10B2_9B2_8B2_7B2_6B2_5B2_4B2_3B2_2B2_1B2_0

0x8007 AUX1 0000A1_11A1_10A1_9A1_8A1_7A1_6A1_5A1_4A1_3A1_2A1_1A1_0

0x8008 AUX2 0000A2_11A2_10A2_9A2_8A2_7A2_6A2_5A2_4A2_3A2_2A2_1A2_0

0x8009 TEMP1 0000T1_11T1_10T1_9T1_8T1_7T1_6T1_5T1_4T1_3T1_2T1_1T1_0

0x800A TEMP2 0000T2_11T2_10T2_9T2_8T2_7T2_6T2_5T2_4T2_3T2_2T2_1T2_0

READ

COMMAND

0x8004 KPD K15 K14 K13 K12 K11 K10 K9 K8 K7 K6 K5 K4 K3 K2 K1 K0

0x8010

0x8011

REGI STER

NAME

REGISTER

NAME

KPData1

(column

m askabl e)

KPData2

(key

m askabl e)

BIT15 BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

BIT15 BIT14 BIT13 BIT12 BIT11 BIT10 BIT9 BIT8 BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

K1_15 K1_14 K1_13 K1_12 K1_11 K1_10 K1_9 K1_8 K1_7 K1_6 K1_5 K1_4 K1_3 K1_2 K1_1 K1_0

K2_15 K2_14 K2_13 K2_12 K2_11 K2_10 K2_9 K2_8 K2_7 K2_6 K2_5 K2_4 K2_3 K2_2 K2_1 K2_0

BIT NAME DESCRIPTION

15 K15 Keypad scan result for row 4, column 4. Can only be masked by column mask.

14 K14 Keypad scan result for row 3, column 4. Can only be masked by column mask.

13 K13 Keypad scan result for row 2, column 4. Can only be masked by column mask.

12 K12 Keypad scan result for row 1, column 4. Can only be masked by column mask.

11 K11 Keypad scan result for row 4, column 3. Can only be masked by column mask.

10 K10 Keypad scan result for row 3, column 3. Can only be masked by column mask.

9 K9 Keypad scan result for row 2, column 3. Can only be masked by column mask.

8 K8 Keypad scan result for row 1, column 3. Can only be masked by column mask.

7 K7 Keypad scan result for row 4, column 2. Can only be masked by column mask.

6 K6 Keypad scan result for row 3, column 2. Can only be masked by column mask.

5 K5 Keypad scan result for row 2, column 2. Can only be masked by column mask.

4 K4 Keypad scan result for row 1, column 2. Can only be masked by column mask.

3 K3 Keypad scan result for row 4, column 1. Can only be masked by column mask.

2 K2 Keypad scan result for row 3, column 1. Can only be masked by column mask.

1 K1 Keypad scan result for row 2, column 1. Can only be masked by column mask.

0 K0 Keypad scan result for row 1, column 1. Can only be masked by column mask.

Page 28

MAX1233/MAX1234

±15kV ESD-Protected Touch-Screen

Controllers Include DAC and Keypad Controller

28 ______________________________________________________________________________________

Table 33. Keypad Data Register 1 (Pending Register) Descriptions

Table 34. Keypad Data Register 2 (Status Register) Descriptions

BIT NAME DESCRIPTION

15 K1_15 Keypad scan result for row 4, column 4. Can only be masked by column mask.

14 K1_14 Keypad scan result for row 3, column 4. Can only be masked by column mask.

13 K1_13 Keypad scan result for row 2, column 4. Can only be masked by column mask.

12 K1_12 Keypad scan result for row 1, column 4. Can only be masked by column mask.

11 K1_11 Keypad scan result for row 4, column 3. Can only be masked by column mask.

10 K1_10 Keypad scan result for row 3, column 3. Can only be masked by column mask.

9 K1_9 Keypad scan result for row 2, column 3. Can only be masked by column mask.

8 K1_8 Keypad scan result for row 1, column 3. Can only be masked by column mask.

7 K1_7 Keypad scan result for row 4, column 2. Can only be masked by column mask.

6 K1_6 Keypad scan result for row 3, column 2. Can only be masked by column mask.

5 K1_5 Keypad scan result for row 2, column 2. Can only be masked by column mask.

4 K1_4 Keypad scan result for row 1, column 2. Can only be masked by column mask.

3 K1_3 Keypad scan result for row 4, column 1. Can only be masked by column mask.

2 K1_2 Keypad scan result for row 3, column 1. Can only be masked by column mask.

1 K1_1 Keypad scan result for row 2, column 1. Can only be masked by column mask.

0 K1_0 Keypad scan result for row 1, column 1. Can only be masked by column mask.

BIT NAME DESCRIPTION

15 K2_15 Keypad scan result for row 4, column 4. Can be masked by key mask or column mask.

14 K2_14 Keypad scan result for row 3, column 4. Can be masked by key mask or column mask.

13 K2_13 Keypad scan result for row 2, column 4. Can be masked by key mask or column mask.

12 K2_12 Keypad scan result for row 1, column 4. Can be masked by key mask or column mask.

11 K2_11 Keypad scan result for row 4, column 3. Can be masked by key mask or column mask.