General Description

The MAX104/MAX106/MAX108 evaluation kits (EV kits)

are designed to simplify evaluation of the devices’ analog-to-digital converters (ADCs). Each EV kit contains

all circuitry necessary to evaluate the dynamic performance of these ultra-high-speed converters, including

the power-supply generation for the PECL termination

voltage (PECLVTT). Since the design combines highspeed analog and digital circuitry, the board layout

calls for special precautions and design features.

Connectors for the power supplies (VCCA/VCCI, VCCD,

VCCO, VEE), SMA connectors for analog and clock

inputs (VIN+, VIN-, CLK+, CLK-), and all digital PECL

outputs simplify connection to the EV kit. The four-layer

board layout (GETek™ material) is optimized for best

dynamic performance of the MAX104 family.

The EV kits come with a MAX104/MAX106/MAX108

installed on the board with a heatsink attached for operation over the full commercial temperature range.

Features

♦ 50Ω Clock and Analog Inputs Through SMA

Coaxial Connectors

♦ ±250mV Input Signal Range

♦ Demultiplexed Differential PECL Outputs

♦ On-Board Generation of PECL Termination

Voltage (PECLV

TT

)

♦ On-Board Generation of ECL Termination Voltage

(ECLV

TT

)

♦ Separate Analog and Digital Power and Ground

Connections with Optimized Four-Layer PCB

♦ Square-Pin Headers for Easy Connection of Logic

Analyzer to Digital Outputs

♦ Fully Assembled and Tested

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

________________________________________________________________

Maxim Integrated Products

1

19-1503; Rev 0; 6/99

Component List

PART

MAX104EVKIT

MAX106EVKIT

0°C to +70°C

0°C to +70°C

TEMP.

RANGE

PIN-

PACKAGE

192 ESBGA

192 ESBGA

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

Ordering Information

Not populated; see text for description of reset input operation.

2R3, R4

DESIGNATION

10kΩ potentiometer 1R2

1N5819 Schottky diode1D1

47pF ±10% ceramic capacitors

(0402)

20

C3–C6, C15, C16,

C22–C25,

C33–C37,

C42–C45, C50

0.01µF ±10% ceramic capacitors

(0603)

30

C2, C7–C12, C14,

C17, C18, C19,

C21, C26–C30,

C32, C41, C47,

C49, C51–C59

10µF ±10%, 16V tantalum caps

AVX TAJD106D016

7

C1, C13, C20, C31,

C40, C46, C48

DESCRIPTIONQTY

MAX108EVKIT*

0°C to +70°C 192 ESBGA

SAMPLING

RATE

1Gsps

600Msps

1.5Gsps

GETek is trademark of GE Electromaterials.

49.9Ω ±1% resistors (0603)38

R5–R38,

R44–R47

DESIGNATION DESCRIPTIONQTY

2-pin headers41

JU2, JU4, JU5,

JUA0- to JUA7-,

JUA0+ to JUA7+,

JUP0- to JUP7-,

JUP0+ to JUP7+,

JUOR+, JUOR-,

JUDR-, JUDR+,

JURO-, JURO+

3-pin headers5JU3, JU6–JU9

SMA connectors (edge mounted)10J1–J10

158Ω ±1% resistors (0603)2R52, R54

243Ω ±1% resistors (0603)2R51, R53

*

Future product—contact factory for availability.

查询MAX104EVKIT供应商

_________________________Quick Start

The EV kit is delivered fully assembled, tested, and

sealed in an antistatic bag. To ensure proper operation,

open the antistatic bag only at a static-safe work area

and follow the instructions below. Do not turn on the

power supplies until all power connections to the

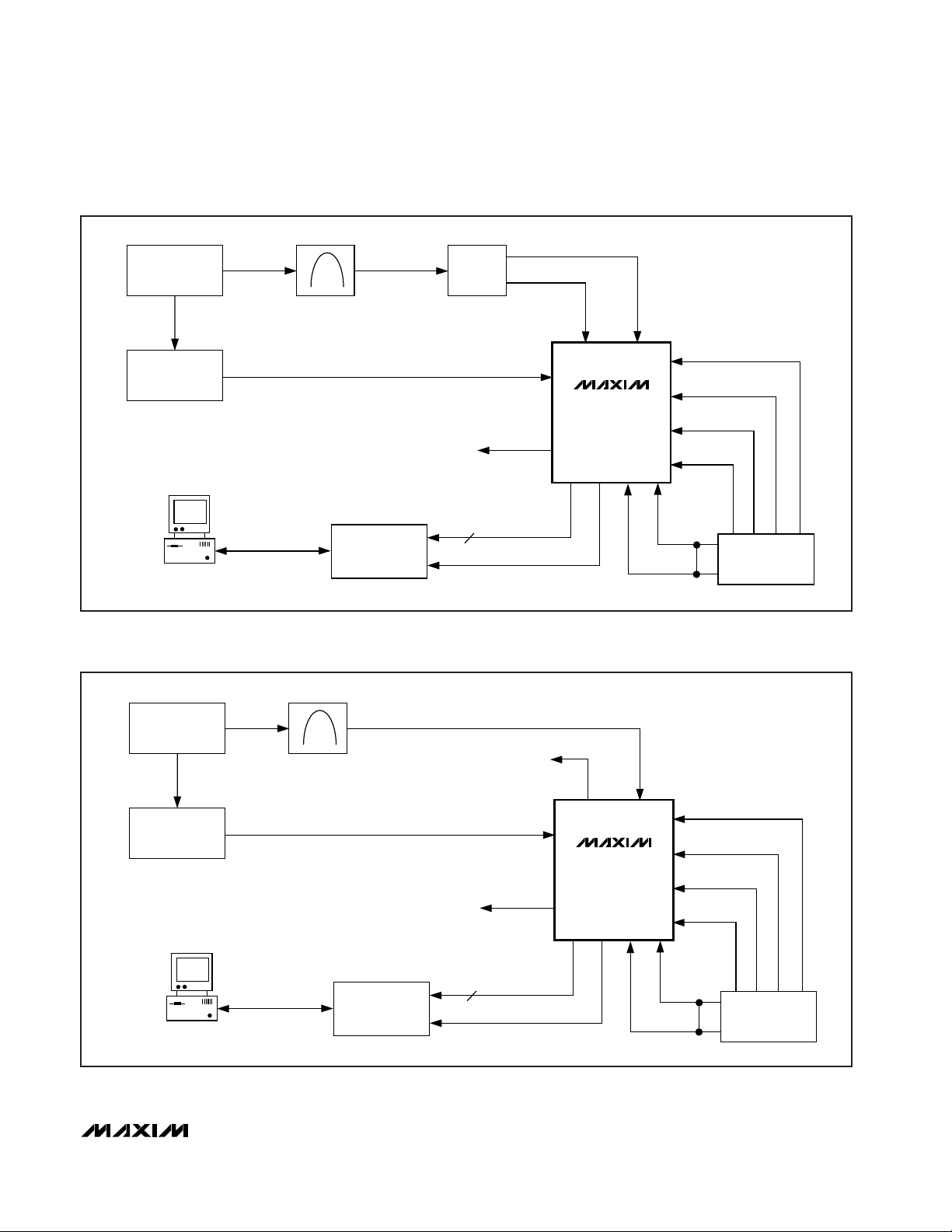

EV kit are established. Figure 1 shows a typical evalu-

ation setup with differential analog inputs and singleended sine- wave (CLK- is 50Ω reverse-terminated to

GNDI) clock drive. Figure 2 shows a typical evaluation

setup with single-ended analog inputs (VIN- is 50Ω

reverse-terminated to GNDI) and a single-ended sinewave clock drive.

1) Connect a -5V power supply capable of providing

-250mA to the pad marked VEE. Connect the supply’s ground to the GNDI pad. Set the current limit

to 500mA or less.

2) Connect a +5V power supply capable of providing

600mA to the VCCI pad. Connect the supply’s

ground to the GNDI pad.

3) Connect a +5V power supply capable of providing

250mA to the VCCD pad. Connect the supply’s

ground to the GNDD pad.

4) Connect a +3.3V or +5V power supply capable of

providing approximately 600mA to the VCCO pad.

Connect the supply’s ground to the GNDD pad.

5) Connect GNDI to GNDD at the power supplies.

6) Connect an RF source with low phase jitter, such as

an HP8662A (up to 1.28GHz) or an HP8663A (up to

2.56GHz), to clock inputs CLK- and CLK+. For single-ended clock inputs, feed a +4dBm (500mV

amplitude) power level from the signal generator

into the CLK+ input and terminate the unused CLKinput with 50Ω to GNDI.

7) Connect a ±225mV (approximately -1dB below FS)

sine-wave test signal to the analog inputs. Use

VIN+ and VIN- through a balun if the test signal is

differential, or either VIN+ or VIN- if the signal is single-ended (see the sections

Single-Ended Analog

Inputs

and

Differential Analog Inputs

in the devices’

data sheets). For best results, use a narrow bandpass filter designed for the frequency of interest to

reduce the harmonic distortion from the signal generator.

8) Connect a logic analyzer, such as an HP16500C

with an HP16517A plug-in card for monitoring all 16

output channels (8 channels for primary and 8

channels for auxiliary outputs) of the device.

9) Connect the logic analyzer clock to the DREADY+

output on the EV kit, and set the logic analyzer to

trigger on the falling edge of the acquisition clock.

Set the logic analyzer’s threshold voltage to the

VCCO supply voltage -1.3V. For example, if VCCO =

+3.3V, the threshold voltage should be set to

+2.0V.

10) Turn on the supplies and signal sources. Capture

the digitized outputs from the ADC with the logic

analyzer and transfer the digital record to a PC for

data analysis.

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

2 _______________________________________________________________________________________

Component List (continued)

Shunts7None

Test points24

VCCO, VCCD,

GNDD, PECLVTT,

GNDA, VCCA,

VCCI, GNDI, VEE,

ECLV

TT

Protective feet4None

Heatsink

International Electronic Research

Corp. BDN09-3CB/A01

1None

MAX104CHC, MAX106CHC, or

MAX108CHC (192-contact ESBGA™)

1U1

LM2991S, low-dropout adjustable

linear regulator

2U3, U4

MAX104EVKIT circuit board1None

MAX104, MAX106, or MAX108 data

sheet

1None

DESIGNATION DESCRIPTIONQTY

ESBGA is a trademark of Amkor/Anam.

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

_______________________________________________________________________________________ 3

MAX104

MAX106

MAX108

EV KIT

BALUN

HP8662/3A

SINE-WAVE SOURCE

PHASE

LOCKED

f

SAMPLE

, + 4dBm

EXTERNAL 50Ω

TERMINATION TO GNDI

HP8662/3A

SINE-WAVE SOURCE

POWER

SUPPLIES

GNDD

+5V ANALOG

VIN+VIN-

CLK+

CLK-

16 DATA

DREADY+

-5V ANALOG

+5V DIGITAL

+3.3V DIGITAL

GNDI

HP16500C

DATA ANALYSIS

SYSTEM

GPIB

PC

BPF

Figure 1. Typical Evaluation Setup with Differential Analog Inputs and Single-Ended Clock Drive

MAX104

MAX106

MAX108

EV KIT

HP8662/3A

SINE-WAVE SOURCE

PHASE

LOCKED

f

SAMPLE

, + 4dBm

EXTERNAL 50Ω

TERMINATION TO GNDI

EXTERNAL 50Ω

TERMINATION

TO GNDI

HP8662/3A

SINE-WAVE SOURCE

POWER

SUPPLIES

GNDD

+5V ANALOG

VIN+VIN-

CLK+

CLK-

16 DATA

DREADY+

-5V ANALOG

+5V DIGITAL

+3.3V DIGITAL

GNDI

HP16500C

DATA ANALYSIS

SYSTEM

GPIB

PC

BPF

Figure 2. Typical Evaluation Setup with Single-Ended Analog Inputs and Single-Ended Clock Drive

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

4 _______________________________________________________________________________________

_______________Detailed Description

Clock Input Requirements

The MAX104/MAX106/MAX108 feature clock inputs

designed for either single-ended or differential operation with very flexible input drive requirements. Each

clock input is terminated with an on-chip, laser-trimmed

50Ω resistor to CLKCOM (clock termination return). The

traces from the SMA inputs to the high-speed data converter are 50Ω microstrip transmission lines.

The CLKCOM termination voltage may be connected

anywhere between ground and -2V for compatibility

with standard ECL drive levels. The side-launched SMA

connectors for the clock signals are located at the

lower left corner of the EV board and are labeled J3

(CLK+) and J4 (CLK-).

An on-board bias generator, located between the analog and clock inputs, creates a -2V termination voltage

(ECLVTT) for operation with ECL clock sources. The

voltage is generated by an LM2991 voltage regulator

operated from the board’s -5V VEEpower supply. To

enable this ECLVTTbias generator, first remove shorting jumper JU2, then move jumper JU3 into its ON

position.

The voltage regulator has a shutdown control that

requires a TTL logic-high level to enter the shutdown

state. This logic level is derived from the +5V analog

supply (VCCI). The EV kits are delivered with the

ECLVTTbias generator turned off and CLKCOM tied to

GNDI (JU2 installed).

NOTE: If the regulator’s shutdown logic level is not

present (VCCI on first) before the VEEsupply is

turned on, the regulator will momentarily turn on

until the VCCI supply is energized. If JU2 is installed,

this will momentarily short the regulator’s output to

ground. The regulator is short-circuit protected so

no damage will result. The regulator is further protected by limiting the V

EE

supply current to 500mA.

Single-Ended Clock Inputs

(Sine-Wave Drive)

To obtain the lowest jitter clock drive, AC- or DC-couple

a low-phase-noise sine-wave source into a single clock

input. Clock amplitudes of up to 1V (2Vp-p or +10dBm)

can be accommodated with CLKCOM connected to

GNDI.

The dynamic performance of the data converter is

essentially unaffected by clock-drive power levels from

-10dBm to +10dBm (100mV to 1V clock signal ampli-

tude). The dynamic performance specifications are

measured with a single-ended clock drive of +4dBm

(500mV clock signal amplitude). To avoid saturation of

the input amplifier stage, limit the clock power level to a

maximum of +10dBm.

Differential Clock Inputs (ECL Drive)

The MAX104/MAX106/MAX108 clock inputs may also

be driven with standard ground-referenced ECL logic

levels by using the on-board ECLVTT-2V bias generator as described above. It is also possible to drive the

clock inputs with positive supply referenced (PECL)

levels if the clock inputs are AC-coupled. With AC-coupled clock inputs, the CLKCOM termination voltage

should be grounded. Single-ended DC-coupled ECL

drive is possible as well, if the undriven clock input is

tied to the ECL VBBvoltage (-1.3V nominal).

Analog Input Requirements

The analog inputs to the ADC on the EV board are provided by two side-launch SMA connectors located on

the middle left side of the EV kit. They are labeled J1

(VIN+) and J2 (VIN-). The analog inputs are terminated

on-chip with precision laser-trimmed 50Ω NiCr resistors

to GNDI. Although the analog (and clock) inputs are

ESD protected, good ESD practices should always be

observed. The traces from the SMA inputs to the device

are 50Ω microstrip transmission lines. The analog

inputs can be driven either single-ended or differential.

Optimal performance is obtained with differential input

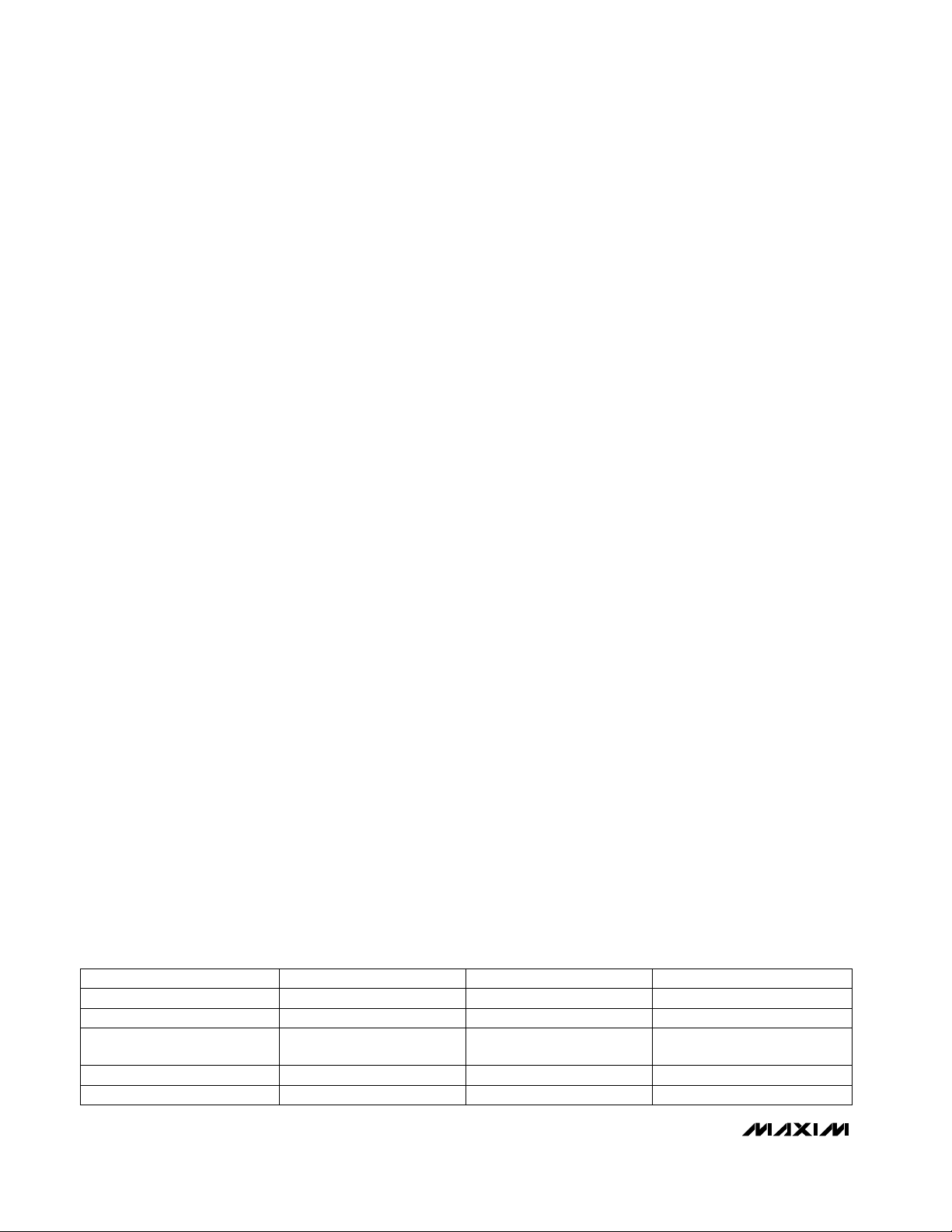

drive due to reduction of even-order harmonic distortion. Table 1 represents single-ended input drive, and

Table 2 displays differential input drive.

Table 1. Input Setup and Output Code Results for Single-Ended Analog Inputs

0V+250mV - 1LSB

0V+250mV

VIN+ VIN-

0

1

OVERRANGE BIT

11111111

11111111 (full scale)

OUTPUT CODE

00V-250mV + 1LSB

0

00000001

01111111

toggles 10000000

0V0V

00V-250mV 00000000 (zero scale)

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

_______________________________________________________________________________________ 5

Internal Reference

The MAX104 family features an on-chip +2.5V precision

bandgap reference, which can be used by shorting

jumper JU5 to connect REFOUT with REFIN. If

required, REFOUT can also source up to 2.5mA to supply other peripheral circuitry.

To use an external reference, remove the shorting

jumper on JU5 and connect the new reference voltage

source to the REFIN side of JU5. Leave the REFOUT

side of JU5 floating. Connect the ground of the external

reference to GNDI on the EV kit. REFIN accepts an

input voltage range of +2.3V to +2.7V.

CAUTION: With an external reference connected,

JU5 must not be installed at any time to avoid damaging the internal reference with the external reference supply.

Offset Adjust

The devices also provide a control input (VOSADJ) to

eliminate any offset from additional preamplifiers driving the ADC. The VOSADJ control input is a selfbiased voltage divider from the internal +2.5V precision

reference. Under normal-use conditions, the control

input is left floating.

The EV kits include a 10kΩ potentiometer that is biased

from the ADC’s +2.5V reference. The wiper of the

potentiometer connects to the VOSADJ control input

through JU4. To enable the offset-adjust function, install

a shorting jumper on JU4 and adjust potentiometer R2

while observing the resulting offset in the reconstructed

digital outputs. The offset-adjust potentiometer offers

about ±5.5LSB of adjustment range. The EV kits are

shipped from the factory without a shorting jumper

installed on JU4.

Primary and Auxiliary

PECL Outputs

All PECL outputs on the EV kits are powered from the

VCCO power supply, which may be operated from any

voltage between +3.0V to +5.0V for flexible interfacing

with either +3.3V or +5V systems. The nominal VCCO

supply voltage is +3.3V.

The PECL outputs are standard open-emitter types and

require external 50Ω termination resistors to the

PECLV

TT

voltage for proper biasing. The termination

resistors are located at the far end of each 50Ω

microstrip transmission line, very close to the square

pin headers for the logic analyzer interface. Every EV

board is delivered with the PECL termination resistors

installed on the back side of the board. Each output

links to a 0.100 inch square 2-pin header to ease the

connection to a high-speed logic analyzer such as

Hewlett Packard’s HP16500C.

To capture the digital data from the device in demultiplexed 1:2 format, each of the 16 channels from the

logic analyzer is connected to the eight primary (P0 to

P7) and eight auxiliary (A0 to A7) outputs. The ADC

provides differential PECL outputs, but most logic analyzers (such as the HP16500C) have single-ended

acquisition pods. Connect all single-ended logic analyzer pods to the same phase (either “+” or “-”) of the

PECL outputs.

Data Ready (DREADY) Output

The clock pod from the logic analyzer should be connected to the DREADY+ output at JUDR+ on the EV

kits. Since both the primary and auxiliary outputs

change on the rising edge of DREADY+, set the logic

analyzer to trigger on the falling edge. The DREADY

and data outputs are internally time-aligned, which

places the falling edge of DREADY+ in the approximate

center of the valid data window, resulting in the maximum setup and hold time for the logic analyzer. Set the

logic analyzer’s threshold voltage to VCCO - 1.3V. For

example, if VCCO is +3.3V, the threshold voltage

should be set to +2.0V. The sample offset (trigger

delay) of the logic analyzer should be set to 0ps under

these conditions.

It is also possible to use the DREADY- output for the

acquisition clock. Under this condition, set the logic

analyzer to trigger on the rising edge of the clock.

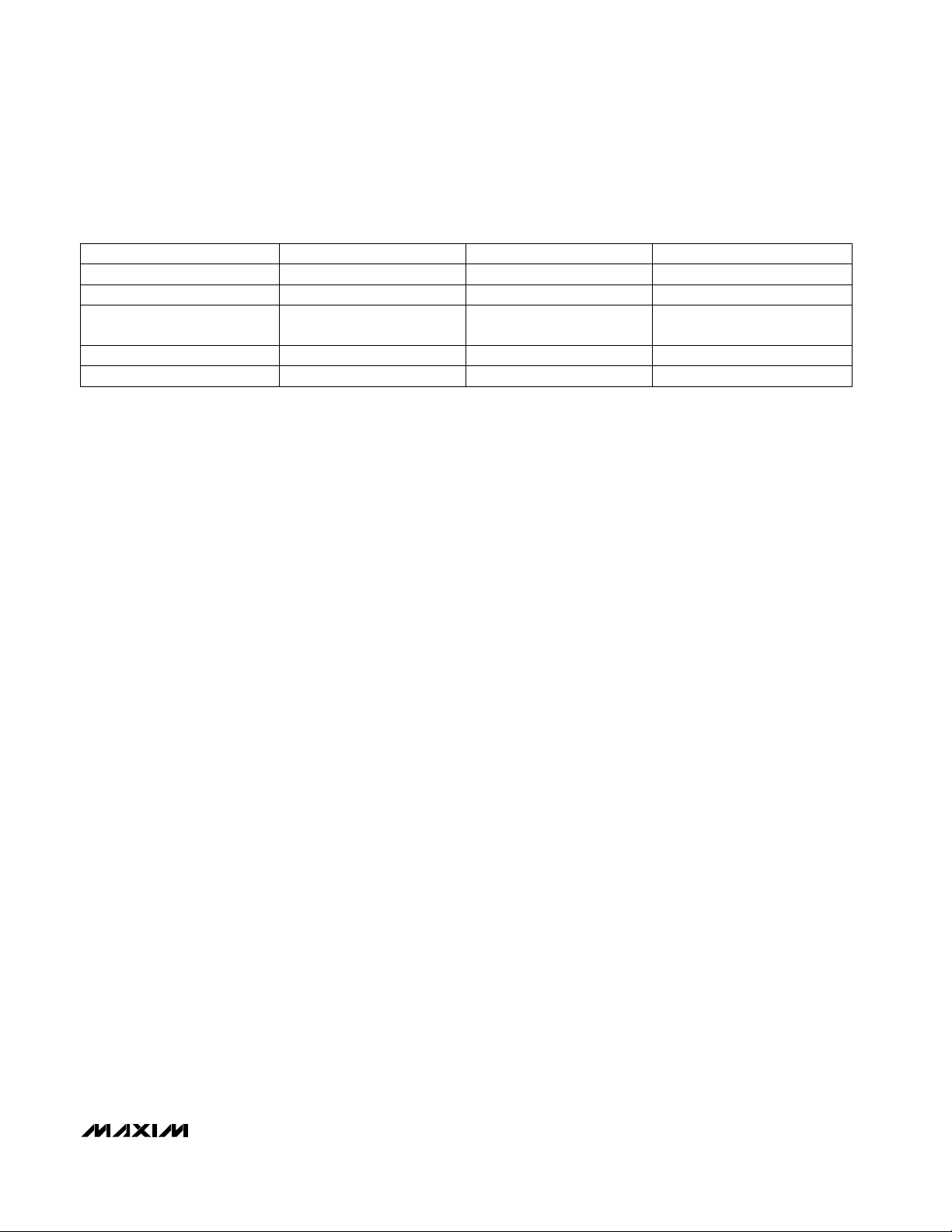

Table 3 summarizes the digital outputs and their functions.

Table 2. Input Setup and Output Code Results for Differential Analog Inputs

0-125mV + 0.5LSB+125mV - 0.5LSB

1

OVERRANGE BIT

11111111

11111111 (full scale)-125mV+125mV

OUTPUT CODE

0+125mV - 0.5LSB-125mV + 0.5LSB

0

00000001

01111111

toggles 10000000

0V0V

0+125mV-125mV 00000000 (zero scale)

VIN+ VIN-

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

6 _______________________________________________________________________________________

Demultiplexer Settings

Demultiplexed DIV2 Mode

This mode reduces the output data rate to one-half the

sample clock rate. The demultiplexed outputs are presented in dual 8-bit format with two consecutive samples in the primary and auxiliary output ports on the rising edge of the data ready clock. To activate this

mode, jumpers JU7 (DEMUXEN), JU8 (AUXEN2), and

JU9 (AUXEN1) have to be in the ON position, and

DIVSELECT (JU6) must be set to position 2.

NOTE: Each EV kit is shipped with jumpers JU7,

JU8, and JU9 installed in the ON position and JU6

set to 2.

Non-Demultiplexed DIV1 Mode

It is also possible to operate the ADC in a non-demultiplexed mode. In this mode, the internal demultiplexer is

disabled and the sampled data is presented to the primary output port only. To consume less power, the auxiliary port can be shut down by two separate inputs

(AUXEN1 and AUXEN2). To enter this mode, place

jumpers JU7 (DEMUXEN), JU8 (AUXEN2), and JU9

(AUXEN1) in the OFF position. The position of the DIVSELECT (JU6) jumper is a don’t care. To save additional

power, remove all the 50Ω pull-down resistors (R5–R20)

on the auxiliary output port. It is not necessary to

remove the resistors; however, both the true and complementary PECL outputs will pull up to the VOHlevel.

Table 3. PECL Outputs and Functions

JUA0+ to JUA7+,

JUA0- to JUA7-

A0+ to A7+,

A0- to A7-

JUP0+ to JUP7+,

JUP0- to JUP7-

P0+ to P7+,

P0- to P7-

JUOR+, JUOR-OR+, ORJUDR+, JUDR-DREADY+, DREADY-

PECL OUTPUT

SIGNALS

EV KIT JUMPER

LOCATION

Auxiliary Port Differential Outputs from LSB to

MSB. A “+” indicates the true value; a “-”

denotes the complementary outputs.

Primary Port Differential Outputs from LSB to

MSB. A “+” indicates the true value; a “-”

denotes the complementary outputs.

Overrange’s True and Complementary Outputs.

Data-Ready PECL Output Latch Clock. Output

data changes on the rising edge of DREADY+.

FUNCTION

Demux Reset Input Signals. Resets the internal

demux when asserted.

Reset Outputs—for resetting additional external

demux devices.

J5, J6 (SMA connectors)RSTIN+, RSTIN-

JURO+, JURO-RSTOUT+, RSTOUT-

DEMUXEN (JU7)

•

OFF ON

AUXEN2 (JU8)

•

OFF ON

AUXEN1 (JU9)

•

OFF ON

DIVSELECT (JU6)

•

24

•

•

•

•

DEMUXEN (JU7)

•

OFF ON

AUXEN2 (JU8)

•

OFF ON

AUXEN1 (JU9)

•

OFF ON

DIVSELECT (JU6)

X

2

X = Leave open or don’t care

•

•

•

X

X

4

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

_______________________________________________________________________________________ 7

Decimation DIV4 Mode

In this special decimated, demultiplexed output mode,

the ADC discards every other input sample and outputs

data at one-quarter the input sampling rate. This mode

is useful for system debugging at the resulting slower

output data rates, and may be required to capture data

successfully when testing the MAX108. To activate the

EV board’s DIV4 mode, jumpers JU7 (DEMUXEN), JU8

(AUXEN2), and JU9 (AUXEN1) have to be in the ON

position, and DIVSEL has to be in position 4. Since

every other sample at the input is discarded, the converter’s effective sample rate will be f

SAMPLE

/2.

Overrange Operation

A single differential PECL overrange output bit (OR+,

OR-) is provided for both primary and auxiliary demultiplexed outputs. The operation of the overrange bit

depends on the status of the internal demultiplexer. In

demultiplexed DIV2 mode and decimation DIV4 mode,

the OR bit will flag an overrange condition if either the

primary or auxiliary port contains an overranged sample (Table 4). In non-demultiplexed DIV1 mode, the OR

port will flag an overrange condition only when the primary output port contains an overranged sample.

Reset Operation Requirements

A detailed description of the reset circuitry and its operation is located in each device’s data sheet. To use the

reset input function, install two 50Ω pull-down resistors

at positions R3 and R4 on the back side of the EV

board. These resistors are connected to the on-board

PECLVTTtermination generator. The RSTIN logic levels

are compatible with standard PECL levels referenced

from the VCCO power supply.

The signals associated with the demultiplexer reset

operation and the control of this section are listed in

Table 5. Consult the data sheet for a more detailed

description of the demultiplexer reset function, including timing diagrams.

Reset Inputs

The reset circuitry accepts differential PECL inputs referenced to the same VCCO power supply that powers

the ADC’s PECL outputs. The reset input side-launched

SMA connectors are located at the lower left side of the

EV kits and are labeled RSTIN+ and RSTIN-.

For applications that do not require a synchronizing

reset, the reset inputs must be left open and resistors

R3 and R4 removed. In this case, they will self-bias to a

proper level with internal 50kΩ resistors and a 20µA

current source. This combination creates a -1V voltage

difference between RSTIN+ and RSTIN- to disable the

internal reset circuitry. When driven with PECL logic

levels terminated with 50Ω to VCCO - 2V, the internal

biasing network can easily be overdriven. The EV kits

are shipped with these resistor positions open to allow

the internal self-bias circuitry to disable the reset control input.

NOTE: Do not install the 50Ω RSTIN termination

resistors R3 and R4 unless the RSTIN input is driven with valid PECL logic levels. If the RSTIN inputs

are open circuited with the 50Ω resistors installed,

intermittent resetting of the internal demultiplexer

will occur and unpredictable operation will result.

Table 4. Selection Table for

Demultiplexer Operation

DIV22ON

DIV1

DEMUX

MODE

Primary OR auxiliary

port

Only primary port

active (auxiliary port

off)

XOFF

OVERRANGE BIT

OUTPUT MODE

DIV44ON

Primary OR auxiliary

port

DEMUXEN DIVSELECT

X = Don’t care

DEMUXEN

OFF ON

•

•

AUXEN2

OFF ON

•

•

AUXEN1

OFF ON

•

•

DIVSELECT

24

•

•

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

8 _______________________________________________________________________________________

Reset Outputs

With a single device, no synchronizing reset is required

since the order of the samples in the output ports is

unchanged regardless of the phase of the DREADY

(DREADY+, DREADY-) clock (as described in the data

sheets). DREADY+ (jumper JUDR+) and DREADY(jumper JUDR-) can be found in the middle of the PECL

output arc in the right center of the EV board.

On the EV kits, the reset output 2-pin headers for

RSTOUT+ (jumper JURO+) and RSTOUT- (jumper

JURO-) are located above the reset input SMA connectors on the lower left side of the board.

Power Supplies

The EV kits feature separate analog and digital power

supplies and grounds for best dynamic performance. The

power-supply connectors are located at the top of the

board and require the power supplies listed in Table 6.

To simplify use of the EV kits and reduce the number of

power sources required to drive the EV board, VCCA

and VCCI, as well as GNDA and GNDI, are connected

together by shorting straps SP1 and SP2. To separate

the supplies, cut the traces at SP1 and SP2. Be sure to

observe the absolute maximum voltage difference of

±0.3V between the supplies if separate supplies are

used. This may require back-to-back Schottky diodes

between VCCA and VCCI to prevent violation of the

absolute maximum ratings during power-up/down.

The EV kits are tested with the V

CC

A and VCCI supplies

shorted by SP1 and SP2. There is no measurable difference in the parts’ dynamic performance with the supplies separated, therefore Maxim recommends leaving

the supplies connected together.

CAUTION: There are no connections between

GNDA/GNDI and GNDD on the EV kits. These

grounds must be referenced together at the power

supply to the board, or damage to the device may

result!

Referencing analog (GNDA/GNDI) and digital (GNDD)

grounds together at a single point avoids ground loops

and reduces noise pickup from the digital signals or

power lines.

To avoid a possible latchup condition when disassembling an application, a high-speed Schottky diode (D1,

1N5819) was added between V

EE

and GNDI. This

diode prevents the substrate (which is connected to

VEE) from forward biasing and possibly causing a

latchup condition when the VEEconnector is opened.

Board Layout

Each EV kit is a four-layer board design, optimized for

high-speed signals. The board is constructed from lowloss GETek core material, which has a relative dielectric constant of 3.9 (εr= 3.9). The GETek material used

for the EV board offers improved high-frequency and

thermal properties over standard FR4 board material.

All high-speed signals are routed with 50Ω microstrip

Table 6. Power-Supply and Ground Requirements and Location

J11VCCD = +5V

J17VEE= -5V

J13, J15VCCA = VCCI = +5V

POWER SUPPLY

EV KIT JUMPER

LOCATION

GNDD

GNDI

GNDA/GNDI

GROUND

REFERENCE

J12

J16

J14, J16

EV KIT JUMPER

LOCATION

J18VCCO = +3.0V to +5V J12GNDD

Table 5. Demultiplexer Operation and Reset Control Signals

JURO+, JURO-

JUDR+, JUDR-DREADY+, DREADY-

RSTOUT+, RSTOUT- Reset Output—for resetting additional external demux devices.

Data-Ready PECL Output. Output data changes on the rising edge of

DREADY+.

Master ADC Timing Signal. The ADC samples on the rising edge of CLK+.J3, J4CLK+, CLK-

FUNCTION

J5, J6RSTIN+, RSTIN- Demux Reset Input Signal. Resets the internal demux when asserted.

SIGNAL NAME

EV KIT JUMPER

LOCATION

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

_______________________________________________________________________________________ 9

transmission lines. The line width for 50Ω microstrip is

18 mils with a ground plane height of 10 mils, which is

a standard GETek core thickness. Figure 3 shows a

cross-section of the EV kit layer profile.

The board also features a de-embedding fixture formed

from two lengths of microstrip transmission line connected between SMA connectors J9-10 and J7-8,

located on the right edge of the board. The 1.50-inch

line length difference between the two paths exactly

matches the line length of the microstrip connecting the

analog inputs. By measuring the power-loss difference

between the two paths at the frequency of interest, it is

possible to estimate the attenuation of the analog

inputs caused by PCB losses. Figure 4 shows the measured attenuation vs. frequency for the microstrip lines

connecting the analog inputs.

Special Layout Considerations

A special effort was made in the board layout to separate the analog and digital portions of the circuit. 50Ω

microstrip transmission lines are used for the analog

and clock inputs as well as for the high-speed PECL

digital outputs. The analog and clock transmission lines

are formed on the top side of the board, while the digital transmission lines are located on the back side of

the board. This reduces coupling of the high-speed

digital outputs to the analog inputs. The analog and

clock inputs provide on-chip, laser-trimmed 50Ω termi-

nation resistors for the best VSWR performance.

Wherever large ground or power planes are used, care

was taken to ensure that the analog planes were not

overlapping with any digital planes. This eliminates the

possibility of capacitively coupling digital noise through

the circuit board to sensitive analog areas.

Table 7. EV Kit PCB Layers

LAYER #1 (TOP)

18 MILS

50Ω

1 oz. Cu

LAYER #2

18 MILS

50Ω

10 MIL GETek CORE

GETek PREPREG AS NEEDED

10 MIL GETek CORE

LAYER #3

LAYER #4 (BOTTOM)

Figure 3. EV Kit Layer Profile for 50ΩMicrostrip Design

0

-0.05

-0.10

-0.15

-0.20

-0.25

-0.30

-0.35

-0.40

-0.45

-0.50

1 500 1500 2500

BOARD LOSS vs. INPUT FREQUENCY

ANALOG INPUT FREQUENCY (MHz)

AMPLITUDE (dB)

Figure 4. Analog Input Attenuation from PCB Losses

VEE, PECLVTT(VCCO - 2V), GNDD

VCCA, VCCO, GNDI, digital 50Ω microstrip lines, 50Ω termination resistorsLayer IV, bottom layer

Layer III, power plane

Components, jumpers, connectors, test pads, VCCO, GNDD, GNDI, analog 50Ω

microstrip lines, de-embedding fixtures

Layer I, top layer

Ground for analog 50Ω microstrips, GNDA, GNDD, GNDI, VCCDLayer II, ground plane

LAYER DESCRIPTION

Evaluate: MAX104/MAX106/MAX108

All differential digital outputs are properly terminated

with 50Ω termination resistors on both phases of the

output, even though most logic analyzers are single

ended. By terminating both sides of the differential outputs, the AC current in the VCCO and GNDD supplies is

reduced. This also reduces coupling of the ADC outputs back to the analog inputs and preserves the

excellent SNR performance of the converter.

The PECL digital outputs are arranged in an arc to match

the line lengths between the ADC outputs and the logic

analyzer connectors. The lengths of the 50Ω microstrip

lines are matched to within 0.050 inch to minimize layoutdependent data skew between the bits. The propagation

delay on the EV board is about 134ps per inch.

ESBGA Device Pad Design

An excellent reference on the assembly and design of

PCBs with BGA devices is “

Application Notes on

Surface Mount Assembly of Amkor/Anam BGA

Packages

.” This publication is available from

Amkor/Anam, 1900 S. Price Road, Chandler AZ, 85248,

phone: (602) 821-5000.

As described in the above applications note, there are

two possibilities for defining PCB pads for mounting

BGA devices: solder mask defined (SMD) and nonsolder mask defined (non-SMD, copper defined). The EV

kits’ design employs nonsolder mask defined pads.

Figure 5 shows the layout of each of these pad types.

The non-SMD (Figure 5b) pad has a solder-mask opening that is larger than the copper land area. This means

that the size of the mounting pad is controlled by the

copper etch quality control. The SMD pad (Figure 5a)

has a solder-mask opening that is smaller than the copper land area. This means that the solder-mask alignment and etch quality will control the pad dimensions.

Since the edges of the copper do not need to extend

under the solder mask as with the SMD pad, the pad

can either be made larger or can provide more line

routing space between adjacent pads. There is room to

route a single 50Ω microstrip trace (18 mils wide)

between the BGA mounting pads on the EV kits. The

copper land diameter is 25 mils, while the solder mask

opening is 30 mils.

Die Temperature Measurement

It is possible to determine the die temperature of the

ADC under normal operating conditions by observing

the currents I

CONST

and I

PTAT

. These are two nominally

100µA currents designed to be equal at 27°C. The currents are derived from the internal precision +2.5V

bandgap reference of the ADC. Their test pads (J21

and J22) are labeled ICONST and IPTAT and are located just above the analog inputs.

The simplest method of determining die temperature is

to measure each current with an ammeter referenced to

GNDI, as described in the data sheets. The die temperature in °C is then calculated by the expression:

T 300

I

I

273

DIE

PTAT

CONST

=

−

⋅

MAX104/MAX106/MAX108 Evaluation Kits

10 ______________________________________________________________________________________

Figure 5a. BGA PCB Pad Designs (SMD Pad) Figure 5b. BGA PCB Pad Designs (Non-SMD Pad)

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

______________________________________________________________________________________ 11

C1

10µF

C7

0.01µF

C2

0.01µF

C3

47pF

C4

47pF

C6

47pF

C5

47pF

V

CC

D

J11

J12

GNDD

C20

10µF

C21

0.01µF

C9

0.01µF

C22

47pF

C23

47pF

C25

47pF

C24

47pF

V

CC

I

J15

J16

GNDI

C13

10µF

C14

0.01µF

C8

0.01µF

C15

47pF

C16

47pF

V

CC

A

J13

GNDA

J14

C40

10µF

C41

0.01µF

C11

0.01µF

C42

47pF

C43

47pF

C45

47pF

C44

47pF

V

CC

O

J18

R53

243Ω

R54

158Ω

U4

LM2991

GND

OUT

IN

ADJ

1

2

3

5

4

J19

PECLV

TT

C46

10µF

C47

0.01µF

GNDD

SP2

SP1

V

EE

GNDD

J17

J20

GNDI

D1

C31

10µF

R51

243Ω

R52

158Ω

U3

LM2991

ADJ IN

OUT

GND

4

2

5

3

1

GNDI

3

1

2

V

CC

I

ON OFF

JU3

GNDI

C37

47pF

C32

0.01µF

C10

0.01µF

C33

47pF

C34

47pF

C35

47pF

C36

47pF

C48

10µF

C49

0.01µF

C50

47pF

ECLV

TT

ON/OFF

ON/OFF

GNDD

Figure 6. MAX104/MAX106/MAX108 EV Kits Schematic

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

12 ______________________________________________________________________________________

VCCO

V

TT

GNDD

C12

0.01µF

C51

0.01µF

VCCO

V

TT

GNDD

C29

0.01µF

C58

0.01µF

VCCO

NOTE: THESE JUMPERS FORM

THE DE-EMBEDDING FIXTURE.

J7

J9

J8

J10

V

TT

GNDD

C18

0.01µF

C53

0.01µF

VCCO

V

TT

GNDD

C17

0.01µF

C52

0.01µF

EXAMPLE FOR PECL OUTPUT

JUMPER AND TERMINATION.

(EACH OUTPUT ON THE EV KIT

IS TERMINATED LIKE THIS.)

VCCO

V

TT

GNDD

GNDD

PECLV

TT

JUOR+

R28

49.9Ω

C30

0.01µF

C59

0.01µF

VCCO

V

TT

GNDD

C28

0.01µF

C57

0.01µF

VCCO

V

TT

GNDD

C27

0.01µF

C58

0.01µF

VCCO

V

TT

GNDD

C26

0.01µF

C55

0.01µF

VCCO

V

TT

GNDD

C19

0.01µF

C54

0.01µF

JUOR+

JUORJUP7+

JUP7JUP6+

JUP6JUP5+

JUP5JUP4+

JUP4JUP3+

JUP3JUP2+

JUP2JUP1+

JUP1JUP0+

JUP0JUA7+

JUA7JUA6+

JUA6JUA5+

JUA5JUA4+

JUA4JUA3+

JUA3JUA2+

JUA2JUA1+

JUA1JUA0+

JUA0JUDRJUDR+

JUROJURO+

R28

R29

R30

R38

R37

R36

R35

R34

R33

R32

R31

R27

R26

R25

R24

R23

R22

R21

R20

R19

R18

R17

R16

R15

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5

R44

R45

R46

R47

JUMPER

TERMINATION

RESISTOR TO V

TT

JUOR+

Figure 6. MAX104/MAX106/MAX108 EV Kits Schematic (continued)

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

______________________________________________________________________________________ 13

MAX104

MAX106

MAX108

U1

JUOR+

JUORJUP7+

JUP7JUP6+

JUP6JUP5+

JUP5JUP4+

JUP4JUP3+

JUP3JUP2+

JUP2JUP1+

JUP1JUP0+

JUP0JUA7+

JUA7JUA6+

JUA6JUA5+

JUA5JUA4+

JUA4JUA3+

JUA3JUA2+

JUA2JUA1+

JUA1JUA0+

JUA0-

JUDRJUDR+

JUROJURO+

OR+

ORP7+

P7P6+

P6P5+

P5P4+

P4P3+

P3P2+

P2P1+

P1P0+

P0A7+

A7A6+

A6A5+

A5A4+

A4A3+

A3A2+

A2A1+

A1A0+

A0-

OFF

ON

JU7

GNDD

1

2

3

VCCD

D17

E18

V12

U12

V14

U14

V16

U16

N18

N17

L18

L17

H18

H17

F18

F17

B14

C14

B12

C12

V13

U13

V15

U15

P18

P17

M18

M17

J18

J17

G18

G17

B15

C15

B13

C13

DIVSEL

DEMUXEN

24

JU5

GNDD

1

2

3

VCCD

GNDD

V11

U11

K18

K17

RSTOUT+

RSTOUT-

DREADY+

DREADY-

GNDI

P2

T.P.

VOSADJ

ICONST

IPTAT

VIN+

VINCLK+

CLKCLKCOM

RSTIN+

RSTIN-

V

CC

A

V

CC

I

V

CC

D

AUXEN1

AUXEN2

V

CC

O

F1

E1

E2

L1

J1

T1

P1

R1

V10

U10

A9

B5

B10

R19

D18

A12

VEEVEEVEEVEEGNDA

REFOUT

REFIN

GNDR

GNDI

U2

A8

A1

C6

B6

ICONST

REFOUT

1

R2

10k

GNDI

2

3

J5

R3*

49.9Ω

J6

R4*

49.9Ω

V

TT

GNDI

GNDI

J4

GNDI

V

TT

J3

GNDI

J2

GNDI

J1

GNDI

V

CLKCOM

JU2

GNDI

IPTAT

JU4

J21

J22

VCCA

*NOT INSTALLED

VCCI

VCCD

SP1

1

32

ON

OFF

JU9

1

32

ON

OFF

JU8

VCCO

GNDD

GNDD

GNDD

V

EE

GNDI

SP2

JU5

REFOUT

GNDA

F3

B11

C7

B3

E3

GNDD

GNDD

Figure 6. MAX104/MAX106/MAX108 EV Kits Schematic (continued)

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

14 ______________________________________________________________________________________

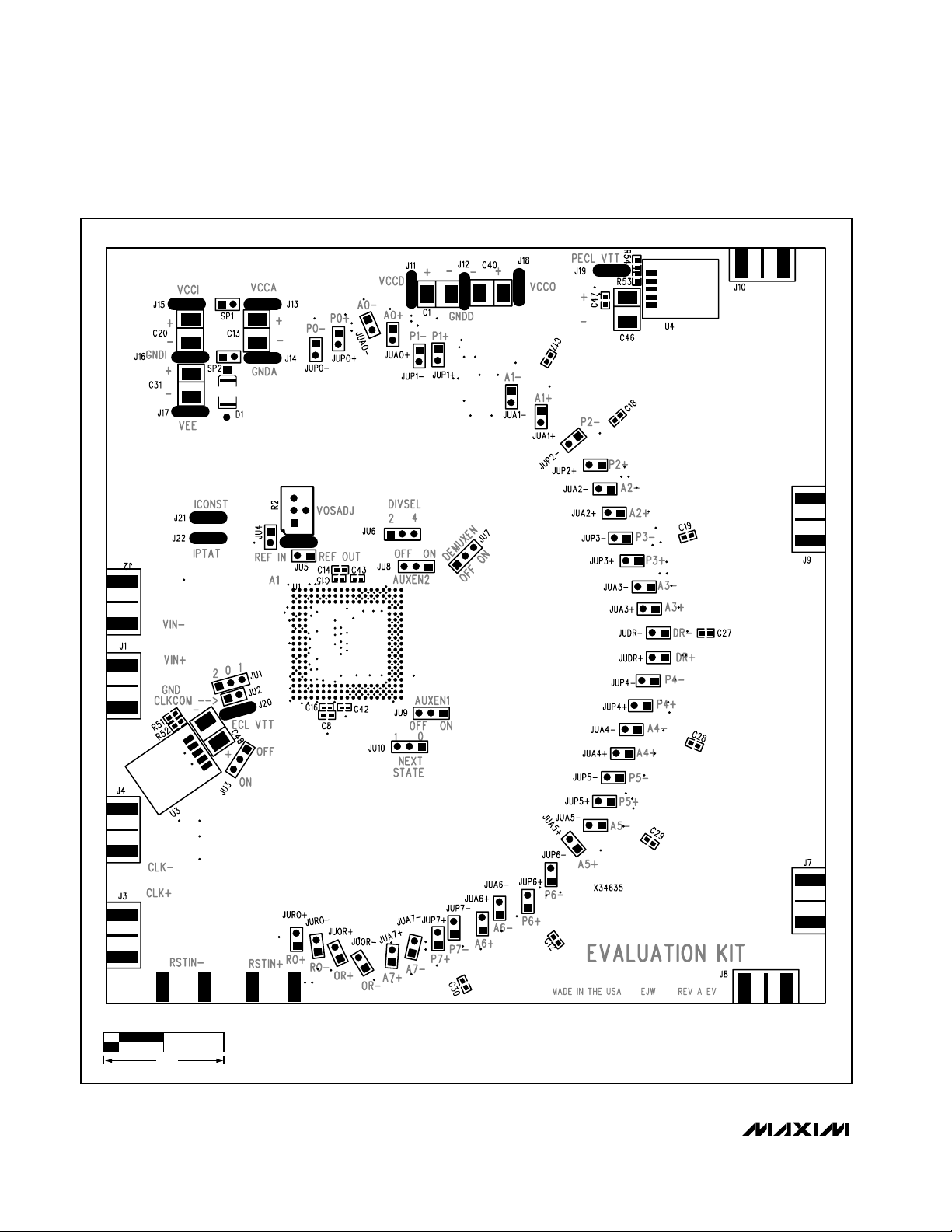

Figure 7. MAX104/MAX106/MAX108 EV Kits Component Placement Guide—Component Side (Layer I)

1.0"

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

______________________________________________________________________________________ 15

Figure 8. MAX104/MAX106/MAX108 EV Kits Component Placement Guide—Solder Side (Layer IV)

1.0"

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

16 ______________________________________________________________________________________

Figure 9. MAX104/MAX106/MAX108 EV Kits PC Board Layout—Component Side (Layer I)

1.0"

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

______________________________________________________________________________________ 17

Figure 10. MAX104/MAX106/MAX108 EV Kits PC Board Layout—GND Plane (Layer II)

1.0"

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

18 ______________________________________________________________________________________

Figure 11. MAX104/MAX106/MAX108 EV Kits PC Board Layout—Power Plane (Layer III)

1.0"

Evaluate: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

______________________________________________________________________________________ 19

Figure 12. MAX104/MAX106/MAX108 EV Kits PC Board Layout—Solder Side (Layer IV)

1.0"

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1999 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Evaluates: MAX104/MAX106/MAX108

MAX104/MAX106/MAX108 Evaluation Kits

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1999 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

NOTES

Loading...

Loading...