Page 1

General Description

The MAX1026/MAX1028/MAX1030 are serial 10-bit analog-to-digital converters (ADCs) with an internal reference

and an internal temperature sensor. These devices feature on-chip FIFO, scan mode, internal clock mode, internal averaging, and AutoShutdown™. The maximum

sampling rate is 300ksps using an external clock. The

MAX1030 has 16 input channels, the MAX1028 has 12

input channels, and the MAX1026 has 8 input channels.

All input channels are configurable for single-ended or

differential inputs in unipolar or bipolar mode. All three

devices operate from a +5V supply and contain a 10MHz

SPI™/QSPI™/MICROWIRE™-compatible serial port.

The MAX1030 is available in 28-pin 5mm x 5mm QFN

with exposed pad and 24-pin QSOP packages. The

MAX1026/MAX1028 are only available in QSOP packages. All three devices are specified over the extended

-40°C to +85°C temperature range.

________________________Applications

System Supervision

Data-Acquisition Systems

Industrial Control Systems

Patient Monitoring

Data Logging

Instrumentation

Features

♦ Internal Temperature Sensor (±1°C Accuracy)

♦ 16-Entry First-In/First-Out (FIFO)

♦ Analog Multiplexer with True Differential

Track/Hold

16-, 12-, 8-Channel Single Ended

8-, 6-, 4-Channel True Differential

(Unipolar or Bipolar)

♦ Accuracy: ±1 LSB INL, ±1 LSB DNL, No Missing

Codes Over Temperature

♦ Scan Mode, Internal Averaging, and Internal Clock

♦ Low-Power Single +5V Operation

1.9mA at 300ksps

♦ Internal 4.096V Reference or External Differential

Reference

♦ 10MHz 3-Wire SPI/QSPI/MICROWIRE-Compatible

Interface

♦ Space-Saving 28-Pin 5mm x 5mm QFN Package

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

________________________________________________________________ Maxim Integrated Products 1

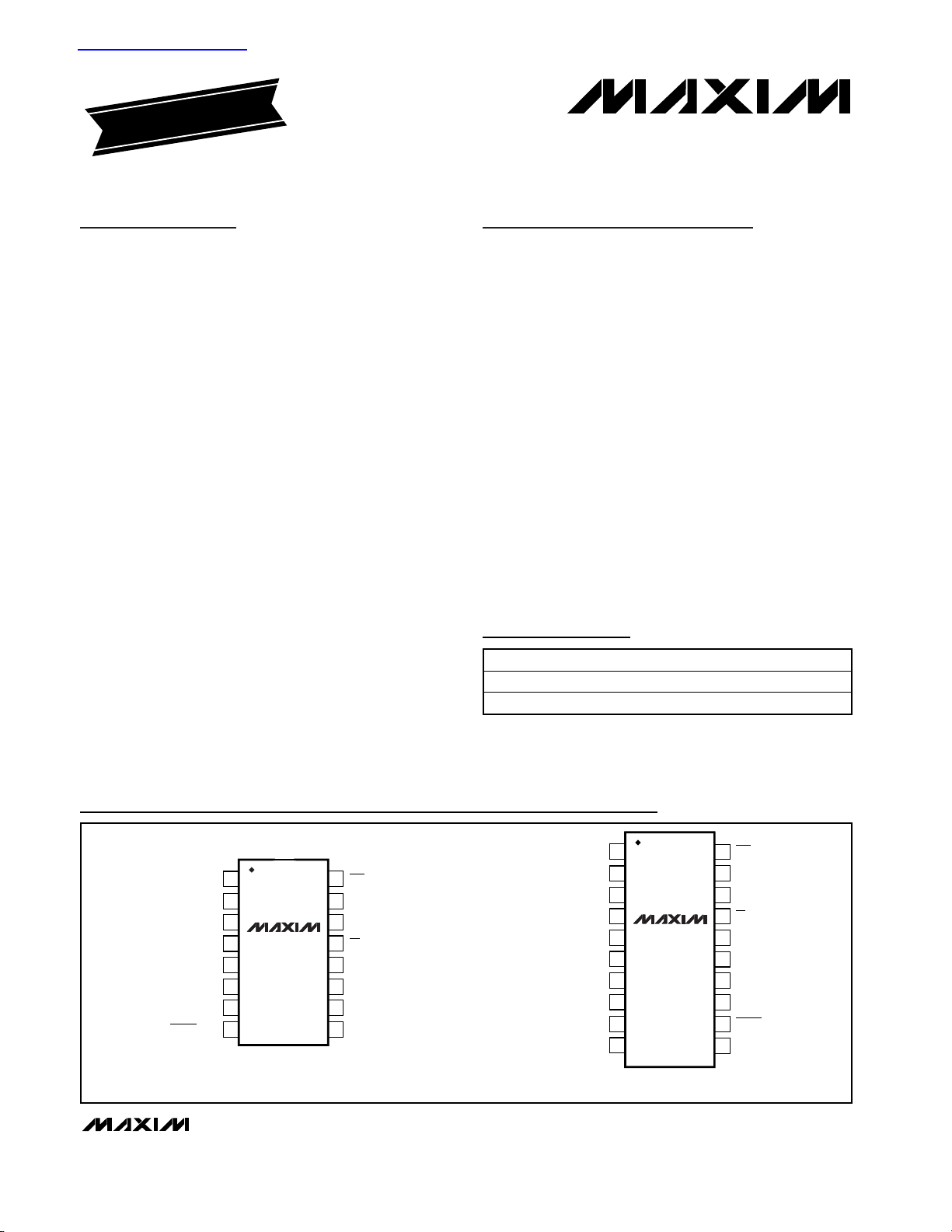

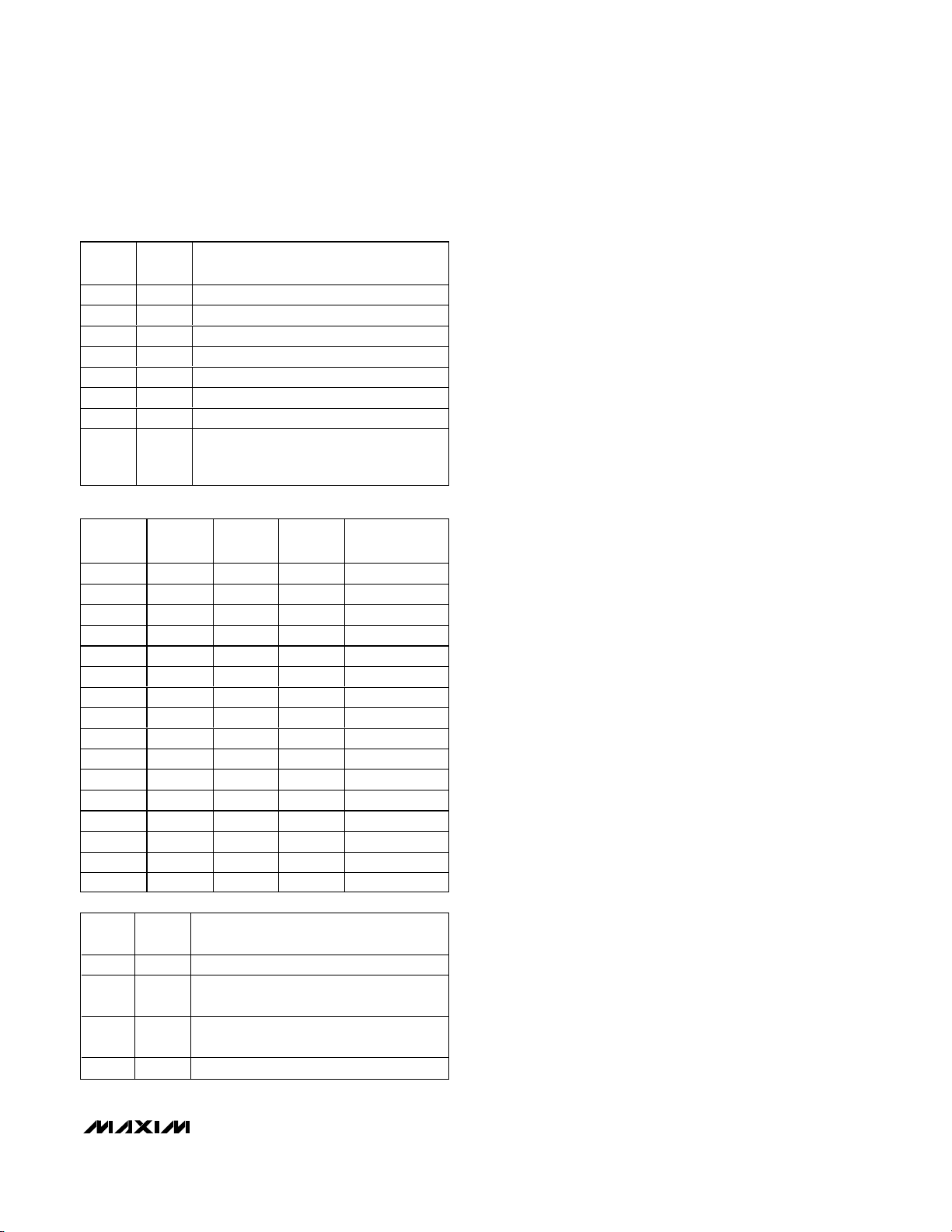

Pin Configurations

19-2853; Rev 1; 7/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Ordering Information

*Future product—contact factory for availability.

Ordering Information continued at end of data sheet.

AutoShutdown is a trademark of Maxim Integrated Products, Inc.

SPI/QSPI are trademarks of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corp.

TOP VIEW

Pin Configurations continued at end of data sheet.

查询MAX1026供应商

PART TEMP RANGE PIN-PACKAGE

MAX1026ACEE-T* 0°C to +70°C 16 QSOP

MAX1026AEEE-T* -40°C to +85°C 16 QSOP

1

AIN0

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

REF-/AIN6

CNVST/AIN7

1

2

3

MAX1026

4

5

6

7

8

QSOP

16

EOC

15

DOUT

14

DIN

13

CS

12

SCLK

V

11

DD

GND

10

REF+

9

AIN1

AIN2

AIN4

AIN5

AIN6

AIN8

2

3

4

MAX1028

5

6

7

8

9

10

QSOP

20

EOC

19

DOUT

18

DIN

17

CSAIN3

16

SCLK

15

V

14

GND

REF+AIN7

13

12

CNVST/AIN11

11

REF-/AIN10AIN9

DD

Page 2

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

2 _______________________________________________________________________________________

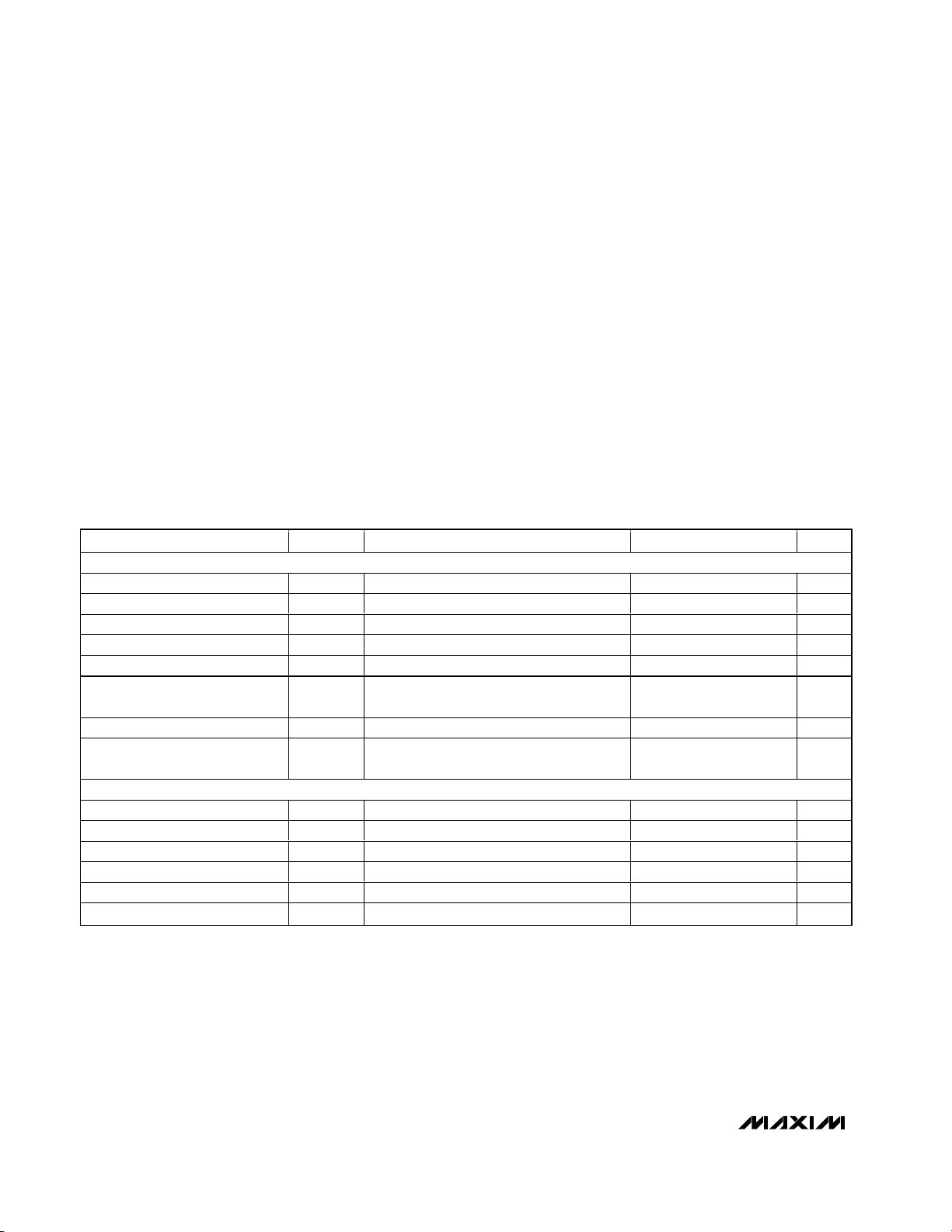

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VDD= +5V ±5%, f

SAMPLE

= 300kHz, f

SCLK

= 4.8MHz (50% duty cycle), V

REF

= 4.096V, TA= T

MIN

to T

MAX

, unless otherwise noted.

Typical values are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto GND..............................................................-0.3V to +6V

CS, SCLK, DIN, EOC, DOUT to GND.........-0.3V to (V

DD

+ 0.3V)

AIN0–AIN13, REF-/AIN_, CNVST/AIN_,

REF+ to GND.........................................-0.3V to (V

DD

+ 0.3V)

Maximum Current into Any Pin............................................50mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.3mW/°C above +70°C)...........667mW

20-Pin QSOP (derate 9.1mW/°C above +70°C)...........727mW

24-Pin QSOP (derate 9.5mW/°C above +70°C)...........762mW

28-Pin QFN 5mm x 5mm

(derate 20.8mW/°C above +70°C)..........................1667mW

Operating Temperature Ranges

MAX10__C__.......................................................0°C to +70°C

MAX10__E__....................................................-40°C to +85°C

Storage Temperature Range .............................-60°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10s) .................................+300°C

DC ACCURACY (Note 1)

Resolution RES 10 Bits

Integral Nonlinearity INL ±1.0 LSB

Differential Nonlinearity DNL No missing codes over temperature ±1.0 LSB

Offset Error ±0.5 ±2.0 LSB

Gain Error (Note 2) ±0.5 ±2.0 LSB

Offset Error Temperature

Coefficient

Gain Temperature Coefficient ±0.8 ppm/°C

Channel-to-Channel Offset

Matching

DYNAMIC SPECIFICATIONS (10kHz sine wave input, 4.096VP-P, 300ksps, fSCLK = 4.8MHz)

Signal-to-Noise Plus Distortion SINAD 70 dB

Total Harmonic Distortion THD Up to the 5th harmonic -82 dBc

Spurious-Free Dynamic Range SFDR 80 dBc

Intermodulation Distortion IMD f

Full-Power Bandwidth -3dB point 1 MHz

Full-Linear Bandwidth S / (N + D) > 68dB 25 kHz

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

= 9.9kHz, f

in1

= 10.2kHz 76 dBc

in2

±2

±0.1 LSB

ppm/°C

FSR

Page 3

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

_______________________________________________________________________________________ 3

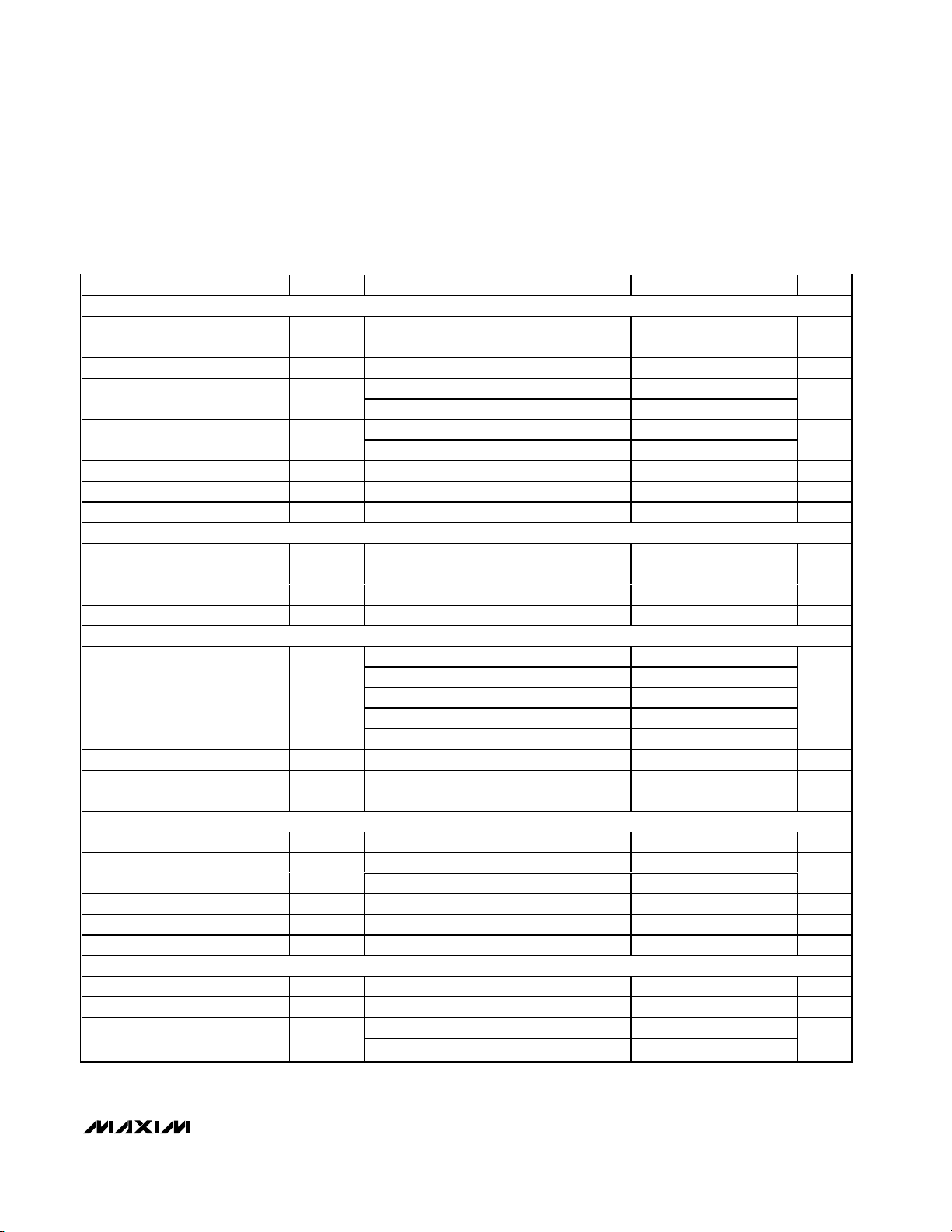

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +5V ±5%, f

SAMPLE

= 300kHz, f

SCLK

= 4.8MHz (50% duty cycle), V

REF

= 4.096V, TA= T

MIN

to T

MAX

, unless otherwise noted.

Typical values are at T

A

= +25°C.)

CONVERSION RATE

Power-Up Time t

Acquisition Time t

Conversion Time t

External Clock Frequency f

SCLK Duty Cycle 40 60 %

Aperture Delay 30 ns

Aperture Jitter <50 ps

ANALOG INPUT

Input Voltage Range

Input Leakage Current V

Input Capacitance During acquisition time (Note 6) 24 pF

INTERNAL TEMPERATURE SENSOR

Measurement Error (Note 7)

Tem p er atur e M easur em ent N oi se 0.1 °C

Temperature Resolution 1/8 °C

Power-Supply Rejection 0.3 °C/V

INTERNAL REFERENCE

REF Output Voltage 4.024 4.096 4.168 V

REF Temperature Coefficient TC

Output Resistance 6.5 kΩ

REF Output Noise 200 µV

REF Power-Supply Rejection PSRR -70 dB

EXTERNAL REFERENCE INPUT

REF- Input Voltage Range V

REF+ Input Voltage Range V

REF+ Input Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

PU

ACQ

CONV

SCLK

REF-

REF+

REF+

External reference 0.8

Internal reference (Note 3) 65

Internally clocked 3.5

Externally clocked (Note 4) 2.7

Externally clocked conversion 0.1 4.8

Data I/O 10

Unipolar 0 V

Bipolar (Note 5) - V

= V

IN

DD

Grade A, TA = +25°C ±0.3

Grade A, TA = -20°C to +85°C ±0.5 ±1

Grade A, TA = T

Grade B, TA = +25°C ±0.7

Grade B, T

Grade A ±8

REF

Grade B ±30

V

REF+

V

REF+

A

= 4.096V, f

= 4.096V, f

= T

to T

MIN

to T

MIN

SAMPLE

SAMPLE

MAX

MAX

= 300ksps 40 100

= 0 ±0.1 ±5

RE F

0 500 mV

1.0 VDD + 50mV V

/ 2 V

±0.01 ±1 µA

±0.75 ±1.5

±1.2 ±3.0

RE F

0.6 µs

REF

/ 2

p p m /° C

µs

µs

MHz

V

°C

RMS

RMS

µA

Page 4

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

4 _______________________________________________________________________________________

Note 1: Tested at VDD= +5V, unipolar input mode.

Note 2: Offset nulled.

Note 3: Time for reference to power up and settle to within 1 LSB.

Note 4: Conversion time is defined as the number of clock cycles multiplied by the clock period; clock has 50% duty cycle.

Note 5: The operational input voltage range for each individual input of a differentially configured pair is from GND to V

DD

. The oper-

ational input voltage difference is from -V

REF

/ 2 to +V

REF

/ 2.

Note 6: See Figure 3 (Input Equivalent Circuit) and the Sampling Error vs. Source Impedance curve in the Typical Operating

Characteristics section.

Note 7: Fast automated test, excludes self-heating effects.

Note 8: Supply current is specified depending on whether an internal or external reference is used for voltage conversions.

Temperature measurements always use the internal reference.

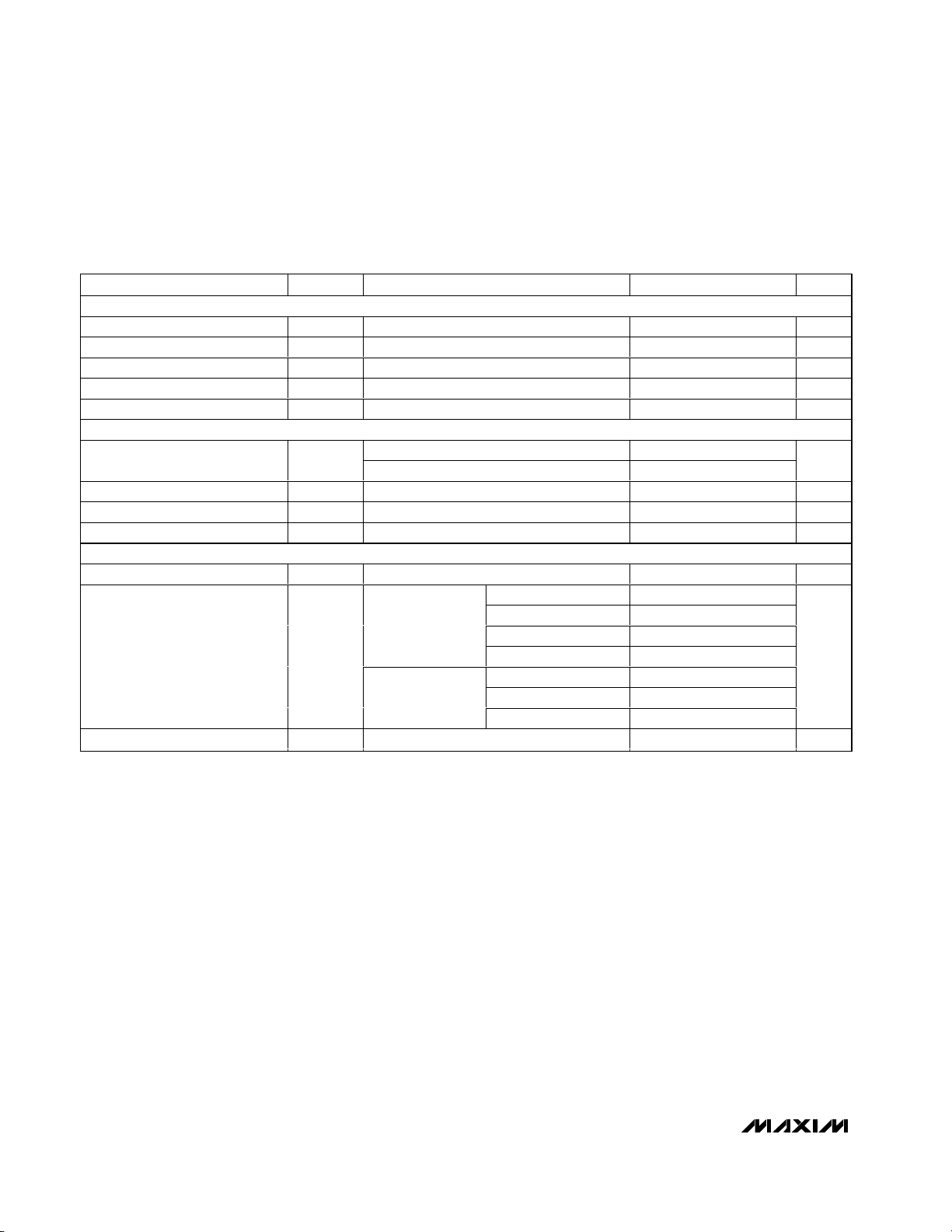

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +5V ±5%, f

SAMPLE

= 300kHz, f

SCLK

= 4.8MHz (50% duty cycle), V

REF

= 4.096V, TA= T

MIN

to T

MAX

, unless otherwise noted.

Typical values are at T

A

= +25°C.)

DIGITAL INPUTS (SCLK, DIN, CS, CNVST)

Input Voltage Low V

Input Voltage High V

Input Hysteresis V

Input Leakage Current I

Input Capacitance C

DIGITAL OUTPUTS (DOUT, EOC)

Output Voltage Low V

Output Voltage High V

Tri-State Leakage Current I

Tri-State Output Capacitance C

POWER REQUIREMENTS

Supply Voltage V

Supply Current (Note 8) I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Power-Supply Rejection PSR VDD = 4.75V to 5.25V; full-scale input ±0.2 ±1 mV

IL

IH

HYST

IN

OL

L

VIN = 0 or V

I

= 2mA 0.4

SINK

I

= 4mA 0.8

SINK

I

CS = V

CS = V

Internal

reference

External

reference

= 1.5mA VDD - 0.5 V

SOURCE

DD

DD

IN

OH

OUT

DD

DD

DD

During temp sense 2400 3100

f

f

Shutdown 0.2 5

During temp sense 1650 2300

f

Shutdown 0.2 5

= 300ksps 1950 2300

SAMPLE

= 0, REF on 1000 1350

SAMPLE

= 300ksps 1250 1500

SAMPLE

2.0 V

4.75 5.25 V

0.8 V

200 mV

±0.01 ±1.0 µA

15 pF

±0.05 ±1 µA

15 pF

V

µA

Page 5

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

_______________________________________________________________________________________ 5

Note 9: This time is defined as the number of clock cycles needed for conversion multiplied by the clock period. If the internal refer-

ence needs to be powered up, the total time is additive. The internal reference is always used for temperature measurements.

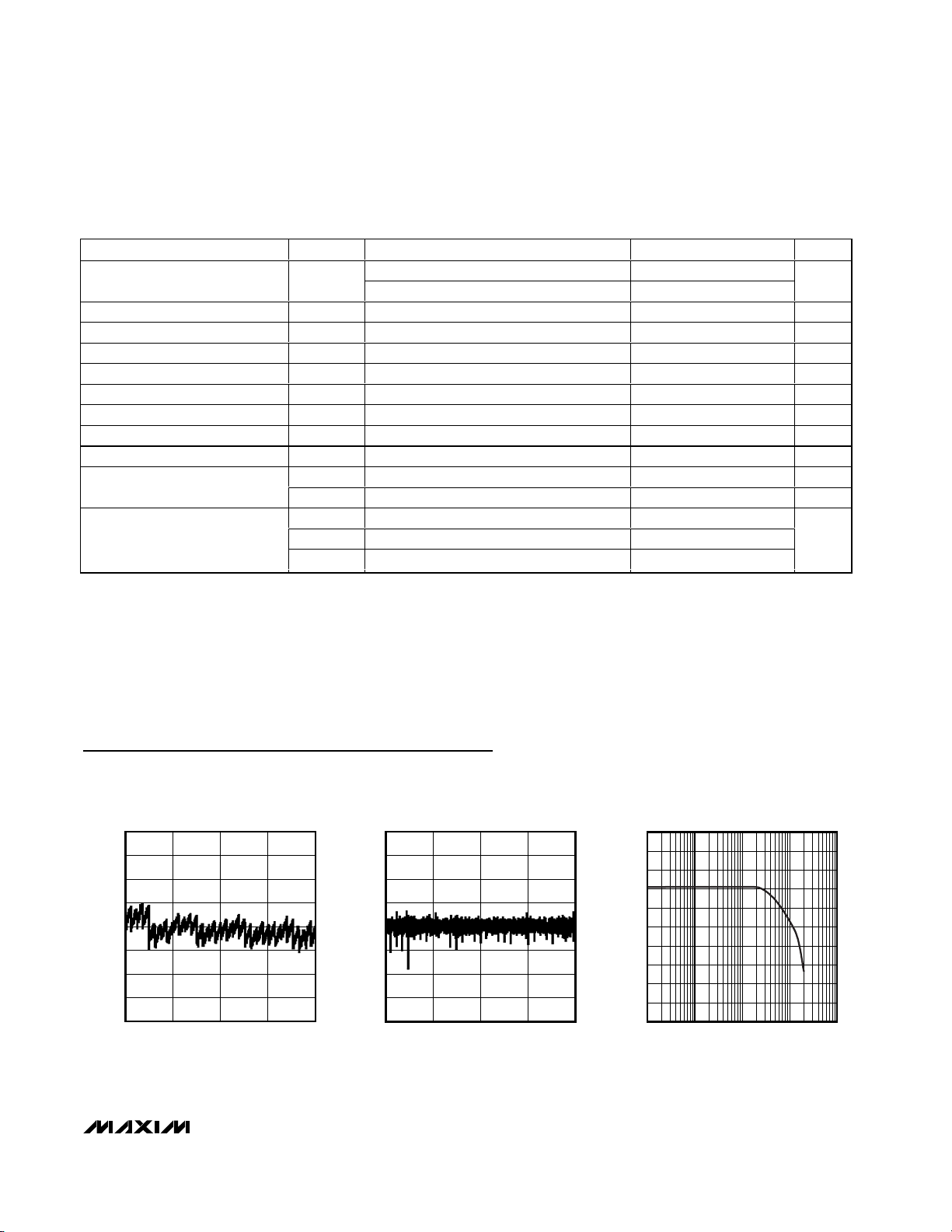

TIMING CHARACTERISTICS (Figure 1)

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0 256 512 768 1024

INTEGRAL NONLINEARITY

vs. OUTPUT CODE

MAX1026/28/30 toc01

OUTPUT CODE

INTEGRAL NONLINEARITY (LSB)

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0 256 512 768 1024

DIFFERENTIAL NONLINEARITY

vs. OUTPUT CODE

MAX1026/28/30 toc02

OUTPUT CODE

DIFFERENTIAL NONLINEARITY (LSB)

SINAD vs. FREQUENCY

MAX1026/28/30 toc03

FREQUENCY (kHz)

SINAD AMPLITUDE (dB)

100101

10

20

30

40

50

60

70

80

90

100

0

0.1 1000

Typical Operating Characteristics

(VDD= +5V, V

REF

= +4.096V, f

SCLK

= 4.8MHz, C

LOAD

= 30pF, TA= +25°C, unless otherwise noted.)

SCLK Clock Period t

SCLK Duty Cycle t

SCLK Fall to DOUT Transition t

CS Rise to DOUT Disable t

CS Fall to DOUT Enable t

DIN to SCLK Rise Setup t

SCLK Rise to DIN Hold t

CS to SCLK Rise Setup t

SCLK Rise to CS Hold t

CNVST Pulse Width

CS or CNVST Rise to EOC

Low (Note 9)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CP

CH

DOT

DOD

DOE

DS

DH

CSS

CSH

t

CSW

Externally clocked conversion 208

Data I/O 100

40 60 %

C

= 30pF 40 ns

LOAD

C

= 30pF 40 ns

LOAD

C

= 30pF 40 ns

LOAD

40 ns

0ns

40 ns

0ns

CKSEL = 00, CKSEL = 01 (temp sense) 40 ns

ns

CKSEL = 01 (voltage conversion) 1.4 µs

t

T S

t

R P

Temp sense 55

Voltage conversion 7

Reference power-up 65

µs

Page 6

4.0494

4.0496

4.0495

4.0498

4.0497

4.0499

4.0500

4.75 4.954.85 5.05 5.15 5.25

INTERNAL REFERENCE VOLTAGE

vs. SUPPLY VOLTAGE

MAX1026/28/30 toc10

SUPPLY VOLTAGE (V)

INTERNAL REFERENCE VOLTAGE (V)

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

6 _______________________________________________________________________________________

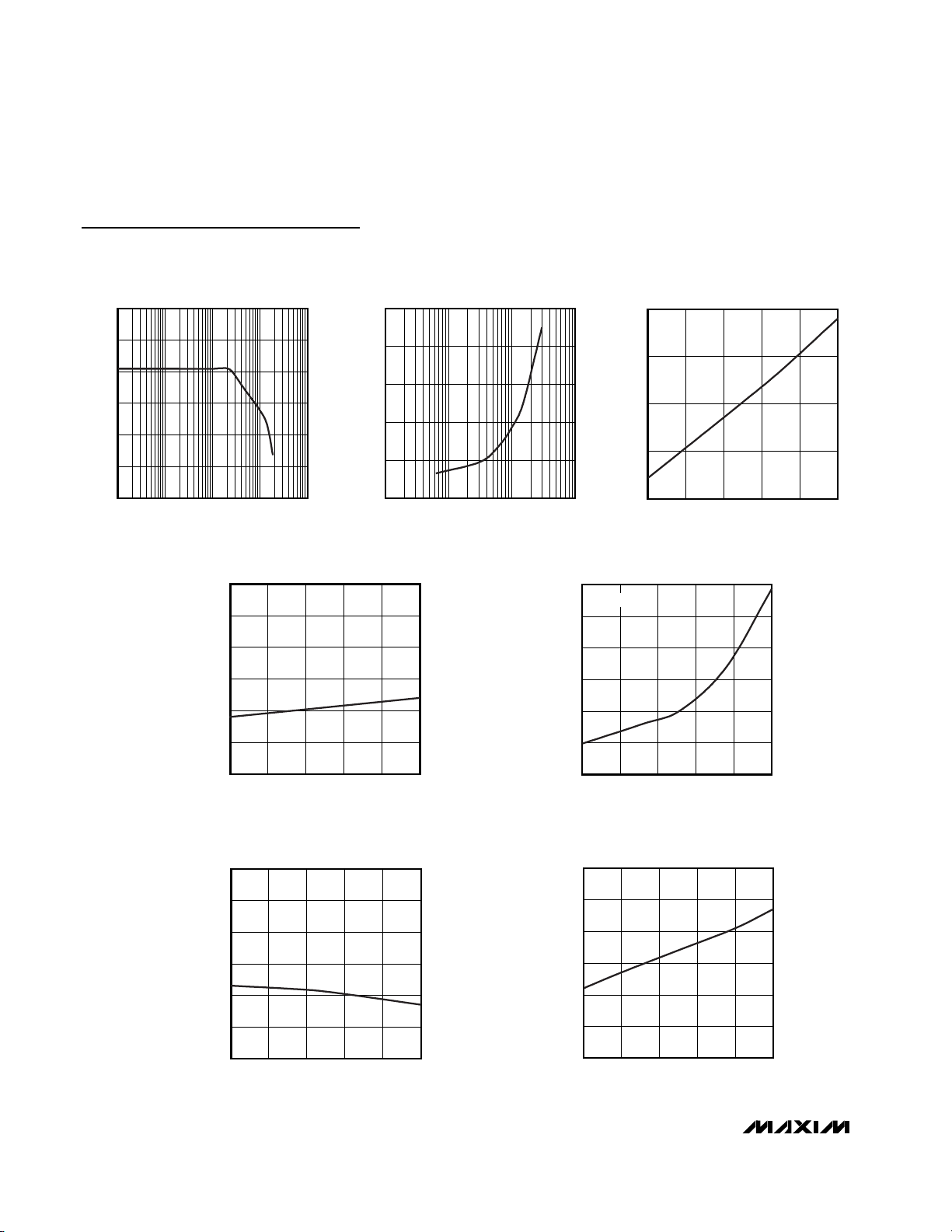

Typical Operating Characteristics (continued)

(VDD= +5V, V

REF

= +4.096V, f

SCLK

= 4.8MHz, C

LOAD

= 30pF, TA= +25°C, unless otherwise noted.)

120

SFDR vs. FREQUENCY

100

80

60

40

SFDR AMPLITUDE (dB)

20

0

0.1 1000

FREQUENCY (kHz)

MAX1026/28/30 toc04

100101

SUPPLY CURRENT vs. SAMPLING RATE

1200

1000

800

600

SUPPLY CURRENT (µA)

400

200

11000

SAMPLING RATE (ksps)

10010

SHUTDOWN SUPPLY CURRENT

vs. SUPPLY VOLTAGE

0.6

0.5

0.4

0.3

MAX1026/28/30 toc07

0.2

SHUTDOWN SUPPLY CURRENT (µA)

0.1

SUPPLY CURRENT vs. SUPPLY VOLTAGE

1200

1150

MAX1026/28/30 toc05

1100

SUPPLY CURRENT (µA)

1050

1000

4.75 5.25

SUPPLY CURRENT vs. TEMPERATURE

1300

fS = 300ksps

1250

1200

1150

1100

SUPPLY CURRENT (µA)

1050

MAX1026/28/30 toc06

5.155.054.954.85

SUPPLY VOLTAGE (V)

MAX1026/28/30 toc08

0

4.75 4.954.85 5.05 5.15 5.25

SUPPLY VOLTAGE (V)

SHUTDOWN SUPPLY CURRENT

vs. TEMPERATURE

0.6

0.5

0.4

0.3

0.2

SHUTDOWN SUPPLY CURRENT (µA)

0.1

0

-40 10-15 35 60 85

TEMPERATURE (°C)

MAX1026/28/30 toc09

1000

-40 85

TEMPERATURE (°C)

603510-15

Page 7

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

_______________________________________________________________________________________ 7

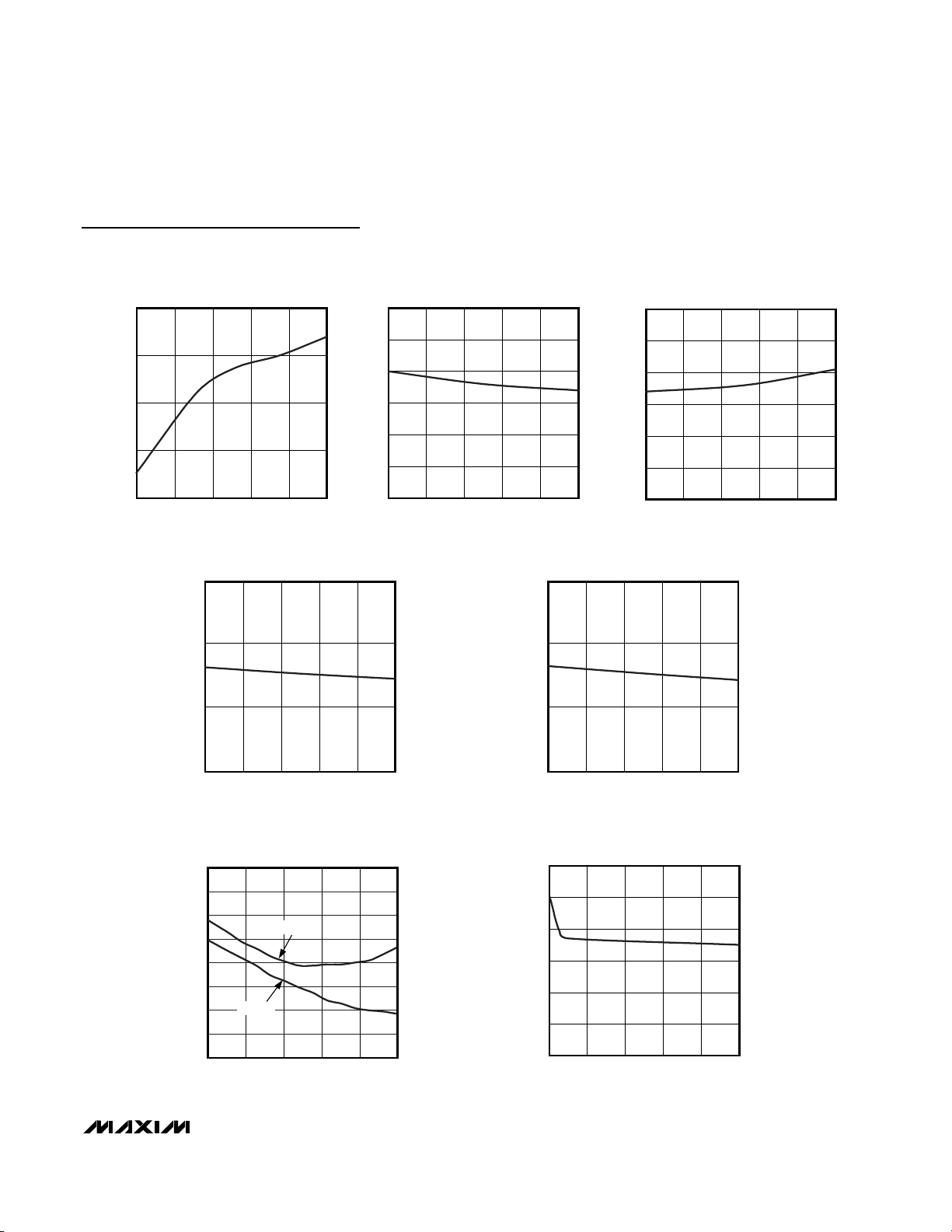

Typical Operating Characteristics (continued)

(VDD= +5V, V

REF

= +4.096V, f

SCLK

= 4.8MHz, C

LOAD

= 30pF, TA= +25°C, unless otherwise noted.)

-1.00

-0.50

0.50

0.25

-0.25

-0.75

0

1.00

0.75

TEMPERATURE SENSOR ERROR

vs. TEMPERATURE

MAX1026/28/30 toc16

TEMPERATURE (°C)

TEMPERATURE SENSOR ERROR (°C)

-40 -15 35 85

6010

GRADE A

GRADE B

-5

-3

-4

-1

-2

0

1

0426810

SAMPLING ERROR

vs. SOURCE IMPEDANCE

MAX1026/28/30 toc17

SOURCE IMPEDANCE (kΩ)

SAMPLING ERROR (LSB)

INTERNAL REFERENCE VOLTAGE

vs. TEMPERATURE

4.051

4.050

4.049

4.048

INTERNAL REFERENCE VOLTAGE (V)

4.047

-40 10-15 356085

0.5

TEMPERATURE (°C)

GAIN ERROR vs. SUPPLY VOLTAGE

0

OFFSET ERROR

vs. SUPPLY VOLTAGE

0.6

0.5

MAX1026/28/30 toc11

0.4

0.3

0.2

OFFSET ERROR (LSB)

0.1

0

4.75 4.954.85 5.05 5.15 5.25

SUPPLY VOLTAGE (V)

MAX1026/28/30 toc14

0.6

0.5

MAX1026/28/30 toc12

0.4

0.3

0.2

OFFSET ERROR (LSB)

0.1

GAIN ERROR vs. TEMPERATURE

0.5

0

0

-40 10-15 35 60 85

OFFSET ERROR

vs. TEMPERATURE

TEMPERATURE (°C)

MAX1026/28/30 toc15

MAX1026/28/30 toc13

GAIN ERROR (LSB)

-0.5

-1.0

4.75 4.85 5.05 5.25

SUPPLY VOLTAGE (V)

GAIN ERROR (LSB)

-0.5

-1.0

5.154.95

-40 -15 35 85

TEMPERATURE (°C)

6010

Page 8

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

8 _______________________________________________________________________________________

Pin Description

MAX1030

QFN

1, 17, 19,

25

2–12, 26,

27, 28

——1–10 — AIN0–9 Analog Inputs

———1–6AIN0–5 Analog Inputs

13 15 ——REF-/AIN14

——11 — REF-/AIN10

——— 7 REF-/AIN6

14 16 ——

——12 —

——— 8

15 17 13 9 REF+ Positive Reference Input. Bypass to GND with a 0.1µF capacitor.

16 18 14 10 GND Ground

18 19 15 11 V

20 20 16 12 SCLK

MAX1030

QSOP

———N.C. No Connection. Not internally connected.

1–14 ——AIN0–13 Analog Inputs

MAX1028 MAX1026 NAME FUNCTION

Negative Input for External Differential Reference/Analog Input 14.

See Table 3 for details on programming the setup register.

Negative Input for External Differential Reference/Analog Input 10.

See Table 3 for details on programming the setup register.

Negative Input for External Differential Reference/Analog Input 6.

See Table 3 for details on programming the setup register.

CNVST/

AIN15

CNVST/

AIN11

CNVST/

AIN7

DD

Active-Low Conversion Start Input/Analog Input 15. See Table 3

for details on programming the setup register.

Active-Low Conversion Start Input/Analog Input 11. See Table 3

for details on programming the setup register.

Active-Low Conversion Start Input/Analog Input 7. See Table 3 for

details on programming the setup register.

Power Input. Bypass to GND with a 0.1µF capacitor.

Serial Clock Input. Clocks data in and out of the serial interface.

(Duty cycle must be 40% to 60%.) See Table 3 for details on

programming the clock mode.

21 21 17 13 CS

22 22 18 14 DIN

23 23 19 15 DOUT

24 24 20 16 EOC End of Conversion Output. Data is valid after EOC pulls low.

Active-Low Chip-Select Input. When CS is low, the serial interface

is enabled. When CS is high, DOUT is high impedance.

Serial Data Input. DIN data is latched into the serial interface on

the rising edge of SCLK.

Serial Data Output. Data is clocked out on the falling edge of

SCLK. High impedance when CS is connected to V

DD

.

Page 9

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

_______________________________________________________________________________________ 9

Detailed Description

The MAX1026/MAX1028/MAX1030 are low-power, serial-output, multichannel ADCs with temperature-sensing

capability for temperature-control, process-control, and

monitoring applications. These 10-bit ADCs have internal track and hold (T/H) circuitry that supports singleended and fully differential inputs. Data is converted

from an internal temperature sensor or analog voltage

sources in a variety of channel and data-acquisition

configurations. Microprocessor (µP) control is made

easy through a 3-wire SPI/QSPI/MICROWIRE-compatible serial interface.

Figure 2 shows a simplified functional diagram of the

MAX1026/MAX1028/MAX1030 internal architecture. The

MAX1026 has eight single-ended analog input channels or four differential channels. The MAX1028 has 12

single-ended analog input channels or six differential

channels. The MAX1030 has 16 single-ended analog

input channels or eight differential channels.

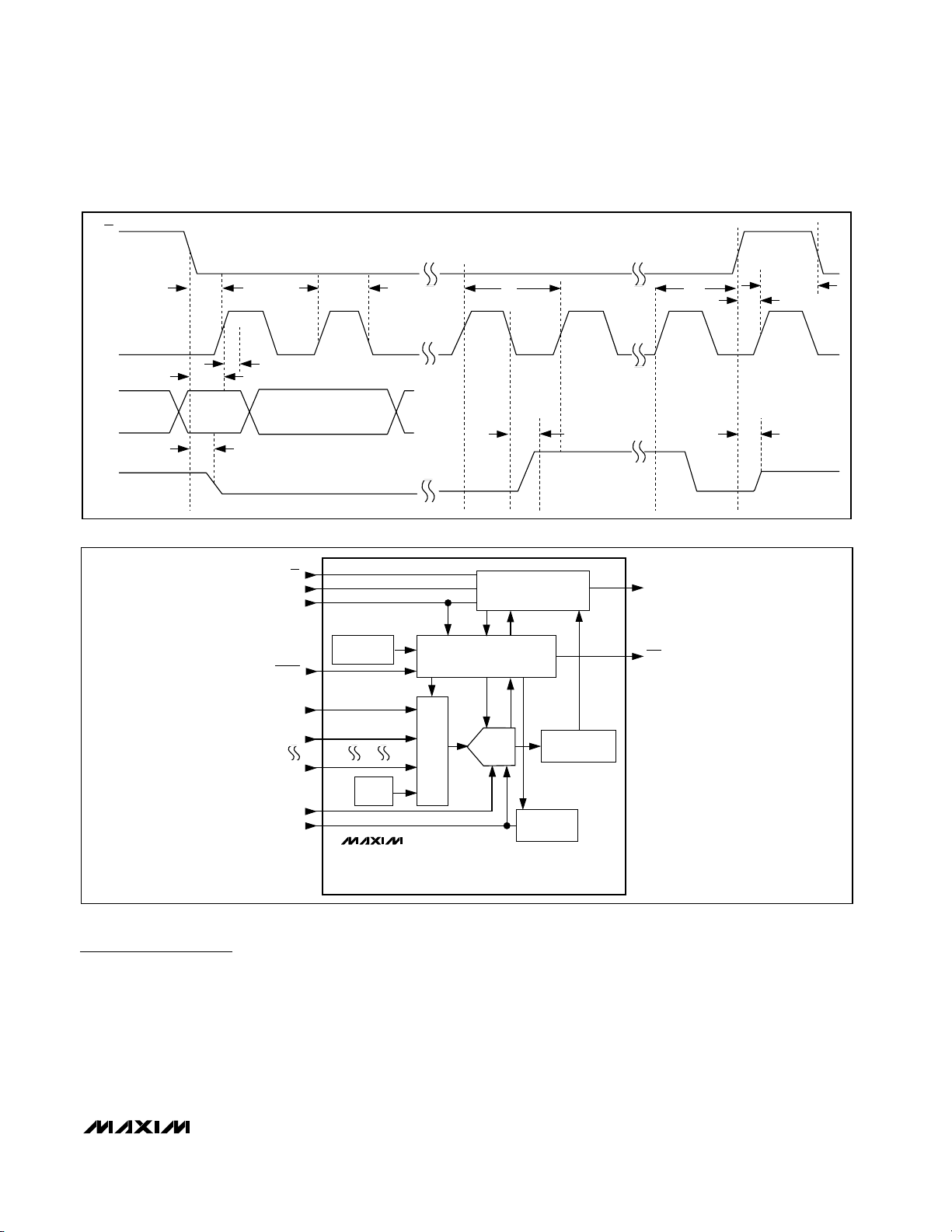

Figure 1. Detailed Serial-Interface Timing Diagram

Figure 2. Functional Diagram

CS

t

CH

SCLK

DIN

DOUT

t

CSS

t

t

DS

DH

t

DOE

CS

DIN

SCLK

OSCILLATOR

CNVST

t

DOT

CONTROL

t

CP

SERIAL

INTERFACE

DOUT

EOC

t

CSH

t

CSH

t

CSS

t

DOD

AIN1

AIN2

AIN15

REFREF+

TEMP

SENSE

MAX1026

MAX1028

MAX1030

T/H

12-BIT

SAR

ADC

ACCUMULATOR

INTERNAL

REFERENCE

FIFO AND

Page 10

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

10 ______________________________________________________________________________________

Converter Operation

The MAX1026/MAX1028/MAX1030 ADCs use a fully differential, successive-approximation register (SAR) conversion technique and an on-chip T/H block to convert

temperature and voltage signals into a 10-bit digital

result. Both single-ended and differential configurations

are supported, with a unipolar signal range for singleended mode and bipolar or unipolar ranges for differential mode.

Input Bandwidth

The ADC’s input-tracking circuitry has a 1MHz smallsignal bandwidth, so it is possible to digitize highspeed transient events and measure periodic signals

with bandwidths exceeding the ADC’s sampling rate by

using undersampling techniques. Anti-alias prefiltering

of the input signals is necessary to avoid high-frequency signals aliasing into the frequency band of interest.

Analog Input Protection

Internal ESD protection diodes clamp all pins to V

DD

and GND, allowing the inputs to swing from (GND -

0.3V) to (VDD+ 0.3V) without damage. However, for

accurate conversions near full scale, the inputs must

not exceed VDDby more than 50mV or be lower than

GND by 50mV. If an off-channel analog input voltage

exceeds the supplies, limit the input current to 2mA.

3-Wire Serial Interface

The MAX1026/MAX1028/MAX1030 feature a serial

interface compatible with SPI/QSPI and MICROWIRE

devices. For SPI/QSPI, ensure the CPU serial interface

runs in master mode so it generates the serial clock

signal. Select the SCLK frequency of 10MHz or less,

and set clock polarity (CPOL) and phase (CPHA) in the

µP control registers to the same value. The MAX1026/

MAX1028/MAX1030 operate with SCLK idling high or

low, and thus operate with CPOL = CPHA = 0 or CPOL

= CPHA = 1. Set CS low to latch input data at DIN on

the rising edge of SCLK. Output data at DOUT is

updated on the falling edge of SCLK. Bipolar true-differential results and temperature sensor results are

available in two’s complement format, while all others

are in binary.

Serial communication always begins with an 8-bit input

data byte (MSB first) loaded from DIN. Send a second

byte, immediately following the setup byte, to write to

the unipolar mode or bipolar mode registers (see

Tables 1, 3, 4, and 5). A high-to-low transition on CS initiates the data input operation. The input data byte and

the subsequent data bytes are clocked from DIN into

the serial interface on the rising edge of SCLK.

Tables 1–7 detail the register descriptions. Bits 5 and 4,

CKSEL1 and CKSEL0, respectively, control the clock

modes in the setup register (see Table 3). Choose

between four different clock modes for various ways to

start a conversion and determine whether the acquisitions are internally or externally timed. Select clock

mode 00 to configure CNVST/AIN_ to act as a conversion start and use it to request the programmed internally timed conversions without tying up the serial bus.

In clock mode 01, use CNVST to request conversions

one channel at a time, controlling the sampling speed

without tying up the serial bus. Request and start internally timed conversions through the serial interface by

writing to the conversion register in the default clock

mode, 10. Use clock mode 11 with SCLK up to 4.8MHz

for externally timed acquisitions to achieve sampling

rates up to 300ksps. Clock mode 11 disables scanning

and averaging. See Figures 4–7 for timing specifications and how to begin a conversion.

These devices feature an active-low, end-of-conversion

output. EOC goes low when the ADC completes the

last-requested operation and is waiting for the next

input data byte (for clock modes 00 and 10). For clock

mode 01, EOC goes low after the ADC completes each

requested operation. EOC goes high when CS or CNVST

goes low. EOC is always high in clock mode 11.

Single-Ended/Differential Input

The MAX1026/MAX1028/MAX1030 use a fully differential ADC for all conversions. The analog inputs can be

configured for either differential or single-ended conversions by writing to the setup register (see Table 3).

Single-ended conversions are internally referenced to

GND (see Figure 3).

In differential mode, the T/H samples the difference

between two analog inputs, eliminating common-mode

DC offsets and noise. IN+ and IN- are selected from

the following pairs: AIN0/AIN1, AIN2/AIN3, AIN4/AIN5,

AIN6/AIN7, AIN8/AIN9, AIN10/AIN11, AIN12/AIN13,

and AIN14/AIN15. AIN0–AIN7 are available on the

MAX1026, MAX1028, and MAX1030. AIN8–AIN11 are

only available on the MAX1028 and MAX1030.

AIN12–AIN15 are only available on the MAX1030. See

Tables 2–5 for more details on configuring the inputs.

For the inputs that can be configured as CNVST or an

analog input, only one can be used at a time. For the

inputs that can be configured as REF- or an analog

input, the REF- configuration excludes the analog input.

Page 11

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

______________________________________________________________________________________ 11

Unipolar/Bipolar

Address the unipolar and bipolar registers through the

setup register (bits 1 and 0). Program a pair of analog

channels for differential operation by writing a 1 to the

appropriate bit of the bipolar or unipolar register.

Unipolar mode sets the differential input range from 0 to

V

REF

. A negative differential analog input in unipolar

mode causes the digital output code to be zero.

Selecting bipolar mode sets the differential input range

to ±V

REF

/ 2. The digital output code is binary in unipolar mode and two’s complement in bipolar mode (see

the transfer function graphs, Figures 8 and 9).

In single-ended mode, the MAX1026/MAX1028/

MAX1030 always operate in unipolar mode. The analog

inputs are internally referenced to GND with a full-scale

input range from 0 to V

REF

.

True Differential Analog Input T/H

The equivalent circuit of Figure 3 shows the

MAX1026/MAX1028/MAX1030s’ input architecture. In

track mode, a positive input capacitor is connected to

AIN0–AIN15 in single-ended mode (and AIN0, AIN2,

AIN4…AIN14 in differential mode). A negative input

capacitor is connected to GND in single-ended mode

(or AIN1, AIN3, AIN5…AIN15 in differential mode). For

external track-and-hold timing, use clock mode 01.

After the T/H enters hold mode, the difference between

the sampled positive and negative input voltages is

converted. The time required for the T/H to acquire an

input signal is determined by how quickly its input

capacitance is charged. If the input signal’s source

impedance is high, the required acquisition time lengthens. The acquisition time, t

ACQ

, is the maximum time

needed for a signal to be acquired, plus the power-up

time. It is calculated by the following equation:

where R

IN

= 1.5kΩ, RSis the source impedance of the

input signal, and t

PWR

= 1µs, the power-up time of the

device. The varying power-up times are detailed in the

explanation of the clock mode conversions.

t

ACQ

is never less than 1.4µs, and any source imped-

ance below 300Ω does not significantly affect the

ADC’s AC performance. A high-impedance source can

be accommodated either by lengthening t

ACQ

or by

placing a 1µF capacitor between the positive and negative analog inputs.

Internal FIFO

The MAX1026/MAX1028/MAX1030 contain a FIFO

buffer that can hold up to 16 ADC results plus one temperature result. This allows the ADC to handle multiple

internally clocked conversions and a temperature measurement, without tying up the serial bus.

If the FIFO is filled and further conversions are requested without reading from the FIFO, the oldest ADC

results are overwritten by the new ADC results. Each

result contains 2 bytes, with the MSB preceded by 4

leading zeros and the LSB followed by 2 sub-bits. After

each falling edge of CS, the oldest available byte of

data is available at DOUT, MSB first. When the FIFO is

empty, DOUT is zero.

The first 2 bytes of data read out after a temperature measurement always contain the temperature result preceded

by 4 leading zeros, MSB first. If another temperature measurement is performed before the first temperature result

is read out, the old measurement is overwritten by the

new result. Temperature results are in degrees Celsius

(two’s complement) at a resolution of 1/8 of a degree. See

the Temperature Measurements section for details on

converting the digital code to a temperature.

Internal Clock

The MAX1026/MAX1028/MAX1030 operate from an internal oscillator, which is accurate within 10% of the

4.4MHz nominal clock rate. The internal oscillator is

active in clock modes 00, 01, and 10. Read out the data

at clock speeds up to 10MHz. See Figures 4–7 for details

on timing specifications and starting a conversion.

txRRxpFt

AQC S IN PWR

=+

()

+924

Figure 3. Equivalent Input Circuit

AIN0-AIN15

(SINGLE ENDED);

AIN0, AIN2,

AIN4…AIN14

(DIFFERENTIAL)

HOLD

GND

(SINGLE ENDED);

AIN1, AIN3,

AIN5…AIN15

(DIFFERENTIAL)

REF

GND

CIN+

CIN-

HOLD

V

DD

DAC

COMPARATOR

+

-

HOLD

/2

Page 12

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

12 ______________________________________________________________________________________

Applications Information

Register Descriptions

The MAX1026/MAX1028/MAX1030 communicate

between the internal registers and the external circuitry

through the SPI/QSPI-compatible serial interface. Table

1 details the registers and the bit names. Tables 2–7

show the various functions within the conversion register, setup register, averaging register, reset register,

unipolar register, and bipolar register.

Conversion Time Calculations

The conversion time for each scan is based on a number of different factors: conversion time per sample,

samples per result, results per scan, if a temperature

measurement is requested, and if the external reference is in use.

Use the following formula to calculate the total conversion time for an internally timed conversion in clock

modes 00 and 10 (see the Electrical Characteristics

section as applicable):

total conversion time = t

cnv

x n

avg

x n

result

+ t

TS

+ t

RP

where:

t

cnv

= t

acq

(max) + t

conv

(max)

n

avg

= samples per result (amount of averaging)

n

result

= number of FIFO results requested; determined

by number of channels being scanned or by NSCAN1,

NSCAN0

tTS= time required for temperature measurement; set

to zero if temp measurement is not requested

t

RP

= internal reference wake-up; set to zero if the internal reference is already powered up or if the external

reference is being used

In clock mode 01, the total conversion time depends on

how long CNVST is held low or high, including any time

required to turn on the internal reference. Conversion

time in externally clocked mode (CKSEL1, CKSEL0 = 11)

depends on the SCLK period and how long CS is held

high between each set of eight SCLK cycles.

Conversion Register

Select active analog input channels, scan modes, and

a single temperature measurement per scan by writing

to the conversion register. Table 2 details channel

selection, the four scan modes, and how to request a

temperature measurement. Request a scan by writing

to the conversion register when in clock mode 10 or 11,

or by applying a low pulse to the CNVST pin when in

clock mode 00 or 01.

A conversion is not performed if it is requested on a

channel that has been configured as CNVST or REF-.

Do not request conversions on channels 8–15 on the

MAX1026 and channels 12–15 on the MAX1028. Set

CHSEL3:CHSEL0 to the lower channel’s binary value. If

the last two channels are configured as a differential

pair and one of them has been reconfigured as CNVST

or REF-, the pair is ignored.

Select scan mode 00 or 01 to return one result per single-ended channel and one result per differential pair

within the requested range, plus one temperature result if

selected. Select scan mode 10 to scan a single input

channel numerous times, depending on NSCAN1 and

NSCAN0 in the averaging register (Table 6). Select scan

mode 11 to return only one result from a single channel.

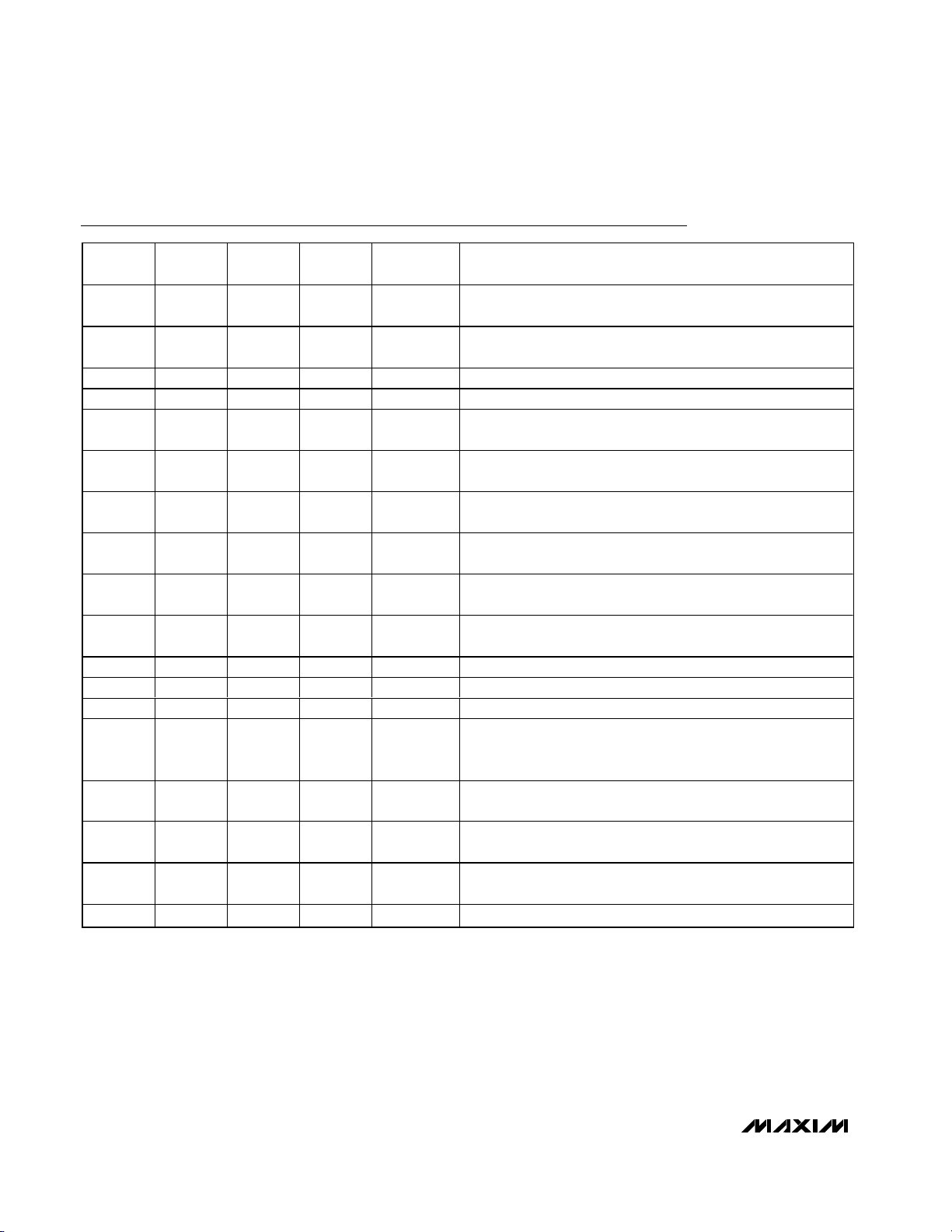

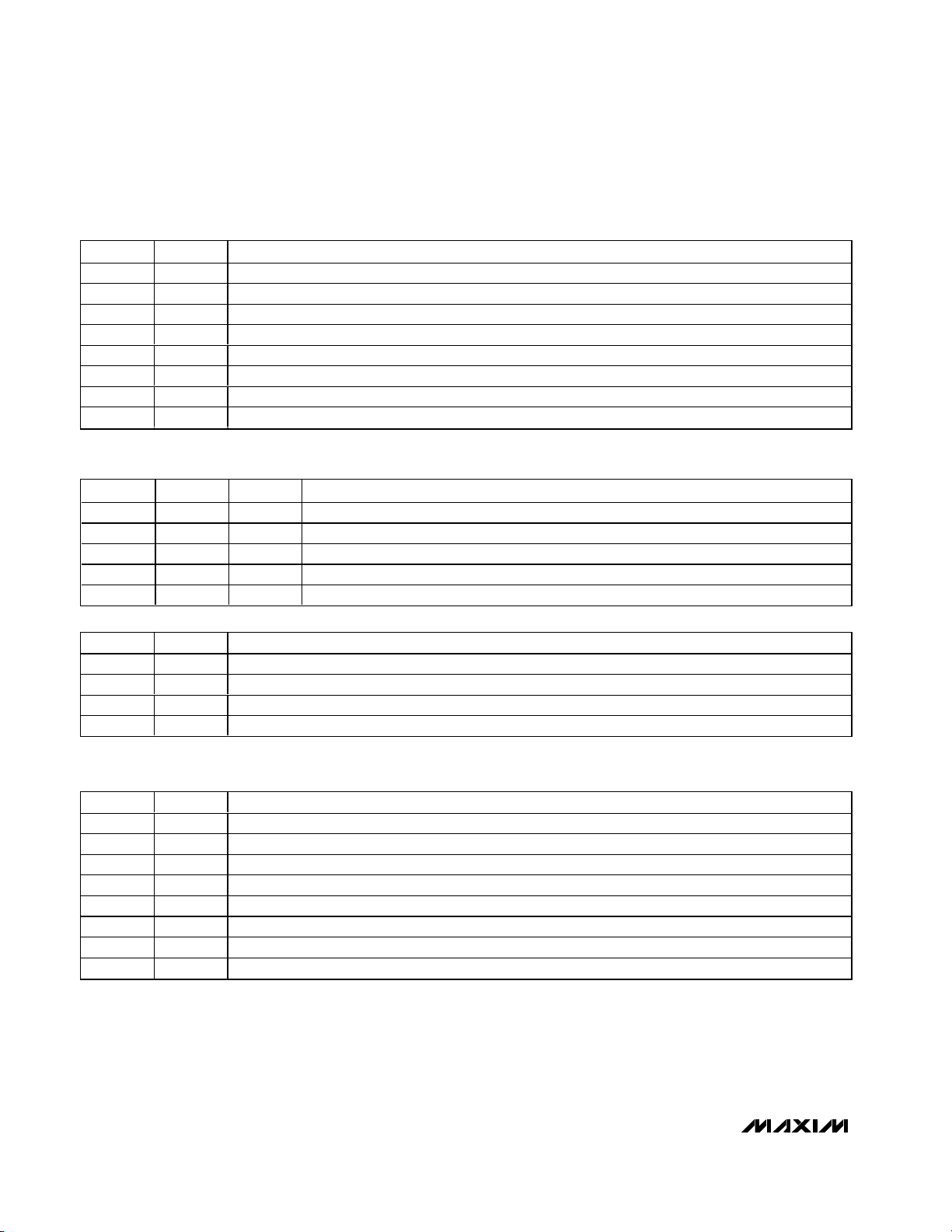

Table 1. Input Data Byte (MSB First)

*Unipolar/bipolar channels 8–15 are only valid on the MAX1028 and MAX1030.

**Unipolar/bipolar channels 12–15 are only valid on the MAX1030.

X = Don’t care.

REGISTER NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

Conversion 1 CHSEL3 CHSEL2 CHSEL1 CHSEL0 SCAN1 SCAN0 TEMP

Setup 0 1 CKSEL1 CKSEL0 REFSEL1 REFSEL0 DIFFSEL1 DIFFSEL0

Averaging 0 0 1 AVGON NAVG1 NAVG0 NSCAN1 NSCAN0

Reset 0 0 0 1 RESET XXX

Unipolar mode (setup) UCH0/1 UCH2/3 UCH4/5 UCH6/7 UCH8/9* UCH10/11* UCH12/13** UCH14/15**

Bipolar mode (setup) BCH0/1 BCH1/2 BCH4/5 BCH6/7 BCH8/9* BCH10/11* BCH12/13** BCH14/15**

Page 13

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

______________________________________________________________________________________ 13

Setup Register

Write a byte to the setup register to configure the clock,

reference, and power-down modes. Table 3 details the

bits in the setup register. Bits 5 and 4 (CKSEL1 and

CKSEL0) control the clock mode, acquisition and sampling, and the conversion start. Bits 3 and 2 (REFSEL1

and REFSEL0) control internal or external reference use.

Bits 1 and 0 (DIFFSEL1 and DIFFSEL0) address the

unipolar mode and bipolar mode registers and configure

the analog input channels for differential operation.

Unipolar/Bipolar Registers

The final 2 bits (LSBs) of the setup register control the

unipolar/bipolar mode address registers. Set bits 1 and

0 (DIFFSEL1 and DIFFSEL0) to 10 to write to the unipolar mode register. Set bits 1 and 0 to 11 to write to the

bipolar mode register. In both cases, the setup byte

must be followed immediately by 1 byte of data written

to the unipolar register or bipolar register. Hold CS low

and run 16 SCLK cycles before pulling CS high. If the

last 2 bits of the setup register are 00 or 01, neither the

unipolar mode register nor the bipolar mode register is

written. Any subsequent byte is recognized as a new

input data byte. See Tables 4 and 5 to program the

unipolar and bipolar mode registers.

If a channel is configured as both unipolar and bipolar,

the unipolar setting takes precedence. In unipolar

mode, AIN+ can exceed AIN- by up to V

REF

. The output format in unipolar mode is binary. In bipolar mode,

either input can exceed the other by up to V

REF

/ 2. The

output format in bipolar mode is two's complement.

Averaging Register

Write to the averaging register to configure the ADC to

average up to 32 samples for each requested result,

and to independently control the number of results

requested for single-channel scans.

Table 2 details the four scan modes available in the conversion register. All four scan modes allow averaging as

long as the AVGON bit, bit 4 in the averaging register, is

set to 1. Select scan mode 10 to scan the same channel

multiple times. Clock mode 11 disables averaging.

Reset Register

Write to the reset register (as shown in Table 7) to clear

the FIFO or to reset all registers to their default states.

Set the RESET bit to 1 to reset the FIFO. Set the reset

bit to zero to return the MAX1026/MAX1028/MAX1030

to the default power-up state.

Table 2. Conversion Register*

*See below for bit details.

BIT

NAME

— 7 (MSB) Set to 1 to select conversion register.

CHSEL3 6 Analog input channel select.

CHSEL2 5 Analog input channel select.

CHSEL1 4 Analog input channel select.

CHSEL0 3 Analog input channel select.

SCAN1 2 Scan mode select.

SCAN0 1 Scan mode select.

TEMP 0 (LSB)

CHSEL3 CHSEL2 CHSEL1 CHSEL0

SCAN1 SCAN0

0 0 Scans channels 0 through N.

01

10

1 1 No scan. Converts channel N once only.

BIT FUNCTION

Set to 1 to take a single temperature

measurement. The first conversion result

of a scan contains temperature information.

SELECTED

CHANNEL (N)

0 0 0 0 AIN0

0 0 0 1 AIN1

0 0 1 0 AIN2

0 0 1 1 AIN3

0 1 0 0 AIN4

0 1 0 1 AIN5

0 1 1 0 AIN6

0 1 1 1 AIN7

1 0 0 0 AIN8

1 0 0 1 AIN9

1 0 1 0 AIN10

1 0 1 1 AIN11

1 1 0 0 AIN12

1 1 0 1 AIN13

1 1 1 0 AIN14

1 1 1 1 AIN15

SCAN MODE (CHANNEL N IS

SELECTED BY BITS CHSEL3–CHSEL0)

Scans channels N through the highest

numbered channel.

S cans channel N r ep eated l y. The aver ag i ng

r eg i ster sets the num b er of r esul ts.

Page 14

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

14 ______________________________________________________________________________________

Table 3. Setup Register*

*See below for bit details.

BIT NAME BIT FUNCTION

— 7 (MSB) Set to zero to select setup register.

— 6 Set to 1 to select setup register.

CKSEL1 5 Clock mode and CNVST configuration. Resets to 1 at power-up.

CKSEL0 4 Clock mode and CNVST configuration.

REFSEL1 3 Reference mode configuration.

REFSEL0 2 Reference mode configuration.

DIFFSEL1 1 Unipolar/bipolar mode register configuration for differential mode.

DIFFSEL0 0 (LSB) Unipolar/bipolar mode register configuration for differential mode.

CKSEL1 CKSEL0 CONVERSION CLOCK ACQUISITION/SAMPLING CNVST CONFIGURATION

0 0 Internal Internally timed

0 1 Internal Externally timed through CNVST CNVST

1 0 Internal Internally timed AIN15/11/7

1 1 External (4.8MHz max) Externally timed through SCLK AIN15/11/7

CNVST

REFSEL1 REFSEL0 VOLTAGE REFERENCE AutoShutdown REF- CONFIGURATION

0 0 Internal

0 1 External single ended Reference off; no wake-up delay. AIN14/10/6

1 0 Internal

1 1 External differential Reference off; no wake-up delay. REF-

DIFFSEL1 DIFFSEL0 FUNCTION

0 0 No data follows the setup byte. Unipolar mode and bipolar mode registers remain unchanged.

0 1 No data follows the setup byte. Unipolar mode and bipolar mode registers remain unchanged.

1 0 One byte of data follows the setup byte and is written to the unipolar mode register.

1 1 One byte of data follows the setup byte and is written to the bipolar mode register.

Reference off after scan; need

wake-up delay.

Reference always on; no wake-up

delay.

AIN14/10/6

AIN14/10/6

Page 15

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

______________________________________________________________________________________ 15

Power-Up Default State

The MAX1026/MAX1028/MAX1030 power up with all

blocks in shutdown, including the reference. All registers

power up in state 00000000, except for the setup register, which powers up in clock mode 10 (CKSEL1 = 1).

Temperature Measurements

The MAX1026/MAX1028/MAX1030 perform temperature measurements with an internal diode-connected

transistor. The diode bias current changes from 68µA

to 4µA to produce a temperature-dependent bias voltage difference. The second conversion result at 4µA is

subtracted from the first at 68µA to calculate a digital

value that is proportional to absolute temperature. The

output data appearing at DOUT is the above digital

code minus an offset to adjust from Kelvin to Celsius.

The reference voltage used for the temperature measurements is derived from the internal reference source

to ensure a resolution of 1/8 of a degree.

Output Data Format

Figures 4–7 illustrate the conversion timing for the

MAX1026/MAX1028/MAX1030. The 10-bit conversion

result is output in MSB-first format with 4 leading zeros

and 2 trailing sub-bits. The 12-bit temperature measurement is output with 4 leading zeros. DIN data is

latched into the serial interface on the rising edge of

SCLK. Data on DOUT transitions on the falling edge of

SCLK. Conversions in clock modes 00 and 01 are initiated by CNVST. Conversions in clock modes 10 and 11

are initiated by writing an input data byte to the conversion register. Data is binary for unipolar mode and two’s

complement for bipolar mode.

Table 4. Unipolar Mode Register (Addressed Through Setup Register)

Table 5. Bipolar Mode Register (Addressed Through Setup Register)

BIT NAME BIT FUNCTION

UCH0/1 7 (MSB) Set to 1 to configure AIN0 and AIN1 for unipolar differential conversion.

UCH2/3 6 Set to 1 to configure AIN2 and AIN3 for unipolar differential conversion.

UCH4/5 5 Set to 1 to configure AIN4 and AIN5 for unipolar differential conversion.

UCH6/7 4 Set to 1 to configure AIN6 and AIN7 for unipolar differential conversion.

UCH8/9 3 Set to 1 to configure AIN8 and AIN9 for unipolar differential conversion (MAX1028/MAX1030 only).

UCH10/11 2 Set to 1 to configure AIN10 and AIN11 for unipolar differential conversion (MAX1028/MAX1030 only).

UCH12/13 1 Set to 1 to configure AIN12 and AIN13 for unipolar differential conversion (MAX1030 only).

UCH14/15 0 (LSB) Set to 1 to configure AIN14 and AIN15 for unipolar differential conversion (MAX1030 only).

BIT NAME BIT FUNCTION

BCH0/1 7 (MSB) Set to 1 to configure AIN0 and AIN1 for bipolar differential conversion.

BCH2/3 6 Set to 1 to configure AIN2 and AIN3 for bipolar differential conversion.

BCH4/5 5 Set to 1 to configure AIN4 and AIN5 for bipolar differential conversion.

BCH6/7 4 Set to 1 to configure AIN6 and AIN7 for bipolar differential conversion.

BCH8/9 3 Set to 1 to configure AIN8 and AIN9 for bipolar differential conversion (MAX1028/MAX1030 only).

BCH10/11 2 Set to 1 to configure AIN10 and AIN11 for bipolar differential conversion (MAX1028/MAX1030 only).

BCH12/13 1 Set to 1 to configure AIN12 and AIN13 for bipolar differential conversion (MAX1030 only).

BCH14/15 0 (LSB) Set to 1 to configure AIN14 and AIN15 for bipolar differential conversion (MAX1030 only).

Page 16

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

16 ______________________________________________________________________________________

Table 6. Averaging Register*

Table 7. Reset Register

*See below for bit details.

BIT NAME BIT FUNCTION

— 7 (MSB) Set to zero to select averaging register.

— 6 Set to zero to select averaging register.

— 5 Set to 1 to select averaging register.

AVGON 4 Set to 1 to turn averaging on. Set to zero to turn averaging off.

NAVG1 3 Configures the number of conversions for single-channel scans.

NAVG0 2

NSCAN1 1 Single-channel scan count. (Scan mode 10 only.)

NSCAN0 0 (LSB) Single-channel scan count. (Scan mode 10 only.)

AVGON NAVG1 NAVG0 FUNCTION

0 x x Performs 1 conversion for each requested result.

1 0 0 Performs 4 conversions and returns the average for each requested result.

1 0 1 Performs 8 conversions and returns the average for each requested result.

1 1 0 Performs 16 conversions and returns the average for each requested result.

1 1 1 Performs 32 conversions and returns the average for each requested result.

Configures the number of conversions for single-channel scans.

NSCAN1 NSCAN0 FUNCTION (APPLIES ONLY IF SCAN MODE 10 IS SELECTED)

0 0 Scans channel N and returns 4 results.

0 1 Scans channel N and returns 8 results.

1 0 Scans channel N and returns 12 results.

1 1 Scans channel N and returns 16 results.

BIT NAME BIT FUNCTION

— 7 (MSB) Set to zero to select reset register.

— 6 Set to zero to select reset register.

— 5 Set to zero to select reset register.

— 4 Set to 1 to select reset register.

RESET 3 Set to zero to reset all registers. Set to 1 to clear the FIFO only.

x 2 Reserved. Don’t care.

x 1 Reserved. Don’t care.

x 0 (LSB) Reserved. Don’t care.

Page 17

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

______________________________________________________________________________________ 17

Internally Timed Acquisitions and

Conversions Using

CNVST

Performing Conversions in Clock Mode 00

In clock mode 00, the wake up, acquisition, conversion,

and shutdown sequences are initiated through CNVST

and performed automatically using the internal oscillator. Results are added to the internal FIFO to be read

out later. See Figure 4 for clock mode 00 timing.

Initiate a scan by setting CNVST low for at least 40ns

before pulling it high again. The MAX1026/MAX1028/

MAX1030 then wake up, scan all requested channels,

store the results in the FIFO, and shut down. After the

scan is complete, EOC is pulled low and the results are

available in the FIFO. Wait until EOC goes low before

pulling CS low to communicate with the serial interface.

EOC stays low until CS or CNVST is pulled low again. A

temperature measurement result, if requested, precedes all other FIFO results.

Do not initiate a second CNVST before EOC goes low;

otherwise, the FIFO can become corrupted.

Externally Timed Acquisitions and

Internally Timed Conversions with

CNVST

Performing Conversions in Clock Mode 01

In clock mode 01, conversions are requested one at a

time using CNVST and performed automatically using

the internal oscillator. See Figure 5 for clock mode 01

timing.

Setting CNVST low begins an acquisition, wakes up the

ADC, and places it in track mode. Hold CNVST low for

at least 1.4µs to complete the acquisition. If the internal

reference needs to wake up, an additional 65µs is

required for the internal reference to power up. If a temperature measurement is being requested, reference

power-up and temperature measurement are internally

timed. In this case, hold CNVST low for at least 40ns.

Set CNVST high to begin a conversion. After the con-

version is complete, the ADC shuts down and pulls

EOC low. EOC stays low until CS or CNVST is pulled

low again. Wait until EOC goes low before pulling CS or

CNVST low.

If averaging is turned on, multiple CNVST pulses need

to be performed before a result is written to the FIFO.

Once the proper number of conversions has been performed to generate an averaged FIFO result, as specified by the averaging register, the scan logic

automatically switches the analog input multiplexer to

the next-requested channel. If a temperature measurement is programmed, it is performed after the first rising

edge of CNVST following the input data byte written to

the conversion register. The result is available on DOUT

once EOC has been pulled low.

Figure 4. Clock Mode 00

CNVST

CS

SCLK

DOUT

EOC

SET CNVST LOW FOR AT LEAST 40ns TO BEGIN A CONVERSION. X = DON'T CARE.

(UP TO 514 INTERNALLY CLOCKED ACQUISITIONS AND CONVERSIONS)

MSB1

LSB1 MSB2

Page 18

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

18 ______________________________________________________________________________________

Internally Timed Acquisitions and

Conversions Using the Serial Interface

Performing Conversions in Clock Mode 10

In clock mode 10, the wake-up, acquisition, conversion,

and shutdown sequences are initiated by writing an

input data byte to the conversion register, and are performed automatically using the internal oscillator. This

is the default clock mode upon power-up. See Figure 6

for clock mode 10 timing.

Initiate a scan by writing a byte to the conversion register. The MAX1026/MAX1028/MAX1030 then power up,

scan all requested channels, store the results in the

FIFO, and shut down. After the scan is complete, EOC

is pulled low and the results are available in the FIFO. If

a temperature measurement is requested, the temperature result precedes all other FIFO results. EOC stays

low until CS is pulled low again.

Figure 5. Clock Mode 01

Figure 6. Clock Mode 10

CNVST

(ACQUISITION1)

CS

SCLK

DOUT

EOC

DIN

CS

SCLK

(CONVERSION1)

REQUEST MULTIPLE CONVERSIONS BY SETTING CNVST LOW FOR EACH CONVERSION. X = DON'T CARE.

(ACQUISITION2)

(CONVERSION2)

MSB1

(CONVERSION BYTE)

(UP TO 514 INTERNALLY CLOCKED ACQUISITIONS AND CONVERSIONS)

DOUT

MSB1

LSB1

LSB1

MSB2

MSB2

EOC

THE CONVERSION BYTE BEGINS THE ACQUISITION. CNVST IS NOT REQUIRED. X = DON'T CARE.

Page 19

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

______________________________________________________________________________________ 19

Externally Clocked Acquisitions and

Conversions Using the Serial Interface

Performing Conversions in Clock Mode 11

In clock mode 11, acquisitions and conversions are initiated by writing to the conversion register and are performed one at a time using the SCLK as the conversion

clock. Scanning and averaging are disabled, and the

conversion result is available at DOUT during the conversion. See Figure 7 for clock mode 11 timing.

Initiate a conversion by writing a byte to the conversion

register followed by 16 SCLK cycles. If CS is pulsed

high between the eighth and ninth cycles, the pulse

width must be less than 100µs. To continuously convert

at 16 cycles per conversion, alternate 1 byte of zeros

between each conversion byte.

If reference mode 00 is requested, or if an external reference is selected but a temperature measurement is

being requested, wait 65µs with CS high after writing the

conversion byte to extend the acquisition and allow the

internal reference to power up. To perform a temperature

measurement, write 24 bytes (192 cycles) of zeros after

the conversion byte. The temperature result appears on

DOUT during the last 2 bytes of the 192 cycles.

Partial Reads and Partial Writes

If the first byte of an entry in the FIFO is partially read

(CS is pulled high after fewer than eight SCLK cycles),

the second byte of data that is read out contains the

next 8 bits (not b7–b0). The remaining bits are lost for

that entry. If the first byte of an entry in the FIFO is read

out fully, but the second byte is read out partially, the

rest of the entry is lost. The remaining data in the FIFO

is uncorrupted and can be read out normally after taking CS low again, as long as the 4 leading bits (normally zeros) are ignored. Internal registers that are written

partially through the SPI contain new values, starting at

the MSB up to the point that the partial write is stopped.

The part of the register that is not written contains previously written values. If CS is pulled low before EOC

goes low, a conversion cannot be completed and the

FIFO is corrupted.

Transfer Function

Figure 8 shows the unipolar transfer function for singleended or differential inputs. Figure 9 shows the bipolar

transfer function for differential inputs. Code transitions

occur halfway between successive-integer LSB values.

Output coding is binary, with 1 LSB = V

REF

/ 1024V for

unipolar and bipolar operation, and 1 LSB = 0.125°C

for temperature measurements.

Layout, Grounding, and Bypassing

For best performance, use PC boards. Do not use wirewrap boards. For the QFN package, connect its

exposed pad to GND. Board layout should ensure that

digital and analog signal lines are separated from each

other. Do not run analog and digital (especially clock)

signals parallel to one another or run digital lines underneath the MAX1026/MAX1028/MAX1030 package. Highfrequency noise in the VDDpower supply can affect

performance. Bypass the VDDsupply with a 0.1µF

capacitor to GND, close to the VDDpin. Minimize

capacitor lead lengths for best supply-noise rejection. If

the power supply is very noisy, connect a 10Ω resistor in

series with the supply to improve power-supply filtering.

Figure 7. Clock Mode 11

DIN

(ACQUISITION1)

CS

SCLK

DOUT

EOC

EXTERNALLY TIMED ACQUISITION, SAMPLING AND CONVERSION WITHOUT CNVST. X = DON'T CARE.

(CONVERSION BYTE)

MSB1

LSB1

(ACQUISITION2)

MSB2

(CONVERSION1)

Page 20

MAX1026/MAX1028/MAX1030

Definitions

Integral Nonlinearity

Integral nonlinearity (INL) is the deviation of the values

on an actual transfer function from a straight line. This

straight line can be either a best-straight-line fit or a line

drawn between the end points of the transfer function,

once offset and gain errors have been nullified. INL for

the MAX1026/MAX1028/MAX1030 is measured using

the end-point method.

Differential Nonlinearity

Differential nonlinearity (DNL) is the difference between

an actual step width and the ideal value of 1 LSB. A

DNL error specification of less than 1 LSB guarantees

no missing codes and a monotonic transfer function.

Aperture Jitter

Aperture jitter (tAJ) is the sample-to-sample variation in

the time between the samples.

Aperture Delay

Aperture delay (tAD) is the time between the rising

edge of the sampling clock and the instant when an

actual sample is taken.

Signal-to-Noise Ratio

For a waveform perfectly reconstructed from digital

samples, signal-to-noise ratio (SNR) is the ratio of the

full-scale analog input (RMS value) to the RMS quanti-

zation error (residual error). The ideal, theoretical minimum analog-to-digital noise is caused by quantization

error only and results directly from the ADC’s resolution

(N bits):

SNR = (6.02 x N + 1.76)dB

In reality, there are other noise sources besides quantization noise, including thermal noise, reference noise,

clock jitter, etc. Therefore, SNR is calculated by taking

the ratio of the RMS signal to the RMS noise, which

includes all spectral components minus the fundamental, the first five harmonics, and the DC offset.

Signal-to-Noise Plus Distortion

Signal-to-noise plus distortion (SINAD) is the ratio of the

fundamental input frequency’s RMS amplitude to the

RMS equivalent of all other ADC output signals:

SINAD (dB) = 20 x log (Signal

RMS

/ Noise

RMS

)

Effective Number of Bits

Effective number of bits (ENOB) indicates the global

accuracy of an ADC at a specific input frequency and

sampling rate. An ideal ADC error consists of quantization noise only. With an input range equal to the fullscale range of the ADC, calculate the effective number

of bits as follows:

ENOB = (SINAD - 1.76) / 6.02

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

20 ______________________________________________________________________________________

Figure 9. Bipolar Transfer Function, Full Scale (±FS) = ±V

REF

/ 2

Figure 8. Unipolar Transfer Function, Full Scale (FS) = V

REF

OUTPUT CODE

FULL-SCALE

11 . . . 111

11 . . . 110

11 . . . 101

00 . . . 011

00 . . . 010

00 . . . 001

00 . . . 000

0

(COM)

123

INPUT VOLTAGE (LSB)

TRANSITION

FS = V

ZS = V

1 LSB =

FS - 3/2 LSB

REF

COM

V

1024

FS

+ V

REF

COM

011 . . . 111

011 . . . 110

000 . . . 010

000 . . . 001

000 . . . 000

111 . . . 111

111 . . . 110

111 . . . 101

100 . . . 001

100 . . . 000

*V

COM

OUTPUT CODE

V

REF

+

V

=

COM

2

-V

REF

2

V

REF

1024

COM*

INPUT VOLTAGE (LSB)

≥ V

REF

FS

ZS = COM

-FS =

1 LSB =

- FS

/ 2

+FS - 1 LSB

Page 21

Total Harmonic Distortion

Total harmonic distortion (THD) is the ratio of the RMS

sum of the first five harmonics of the input signal to the

fundamental itself. This is expressed as:

where V1 is the fundamental amplitude, and V2–V5 are

the amplitudes of the first five harmonics.

Spurious-Free Dynamic Range

Spurious-free dynamic range (SFDR) is the ratio of the

RMS amplitude of the fundamental (maximum signal

component) to the RMS value of the next-largest distortion component.

THD 20 x log V V V V / V

2

2

3

2

4

2

5

2

1

= +++

()

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

______________________________________________________________________________________ 21

Ordering Information (continued)

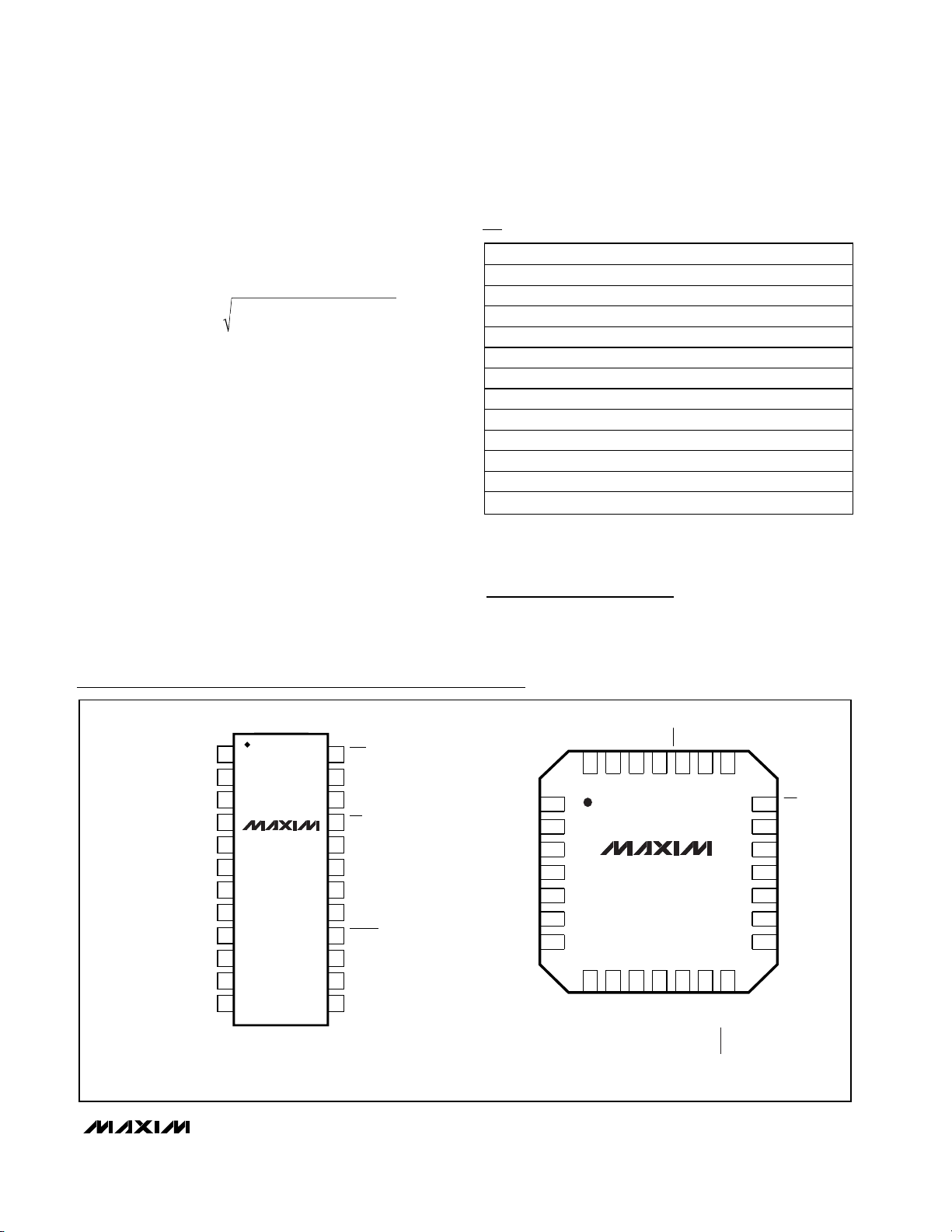

Pin Configurations (continued)

TOP VIEW

*Future product—contact factory for availability.

**EP = Exposed paddle (connect to GND).

Chip Information

TRANSISTOR COUNT: 30,889

PROCESS: BiCMOS

PART TEMP RANGE PIN-PACKAGE

MAX1026BCEE-T 0°C to +70°C 16 QSOP

MAX1026BEEE-T -40°C to +85°C 16 QSOP

MAX1028ACEP-T* 0°C to +70°C 20 QSOP

MAX1028AEEP-T* -40°C to +85°C 20 QSOP

MAX1028BCEP-T 0°C to +70°C 20 QSOP

MAX1028BEEP-T -40°C to +85°C 20 QSOP

MAX1030ACEG-T* 0°C to +70°C 24 QSOP

MAX1030AEEG-T* -40°C to +85°C 24 QSOP

MAX1030BCEG-T 0°C to +70°C 24 QSOP

MAX1030BEEG-T -40°C to +85°C 24 QSOP

MAX1030BCGI-T* 0°C to +70°C 28 QFN-EP**

MAX1030BEGI-T* -40°C to +85°C 28 QFN-EP**

AIN1

AIN0

N.C.

EOC

DOUT

AIN0

AIN1

AIN2

AIN4

AIN5

AIN6

AIN8

AIN9

AIN10

1

2

3

4

MAX1030

5

6

7

8

9

10

11

12

24

EOC

23

DOUT

22

DIN

21

CSAIN3

20

SCLK

19

V

18

GND

17

REF+AIN7

16

CNVST/AIN15

15

REF-/AIN14

14

AIN13

13

AIN12AIN11

28

27

26

25

1

N.C.

2

AIN3

3

AIN4

8

AIN9 AIN2

9

AIN10

MAX1030

10

11

AIN11

AIN12

DD

AIN5

AIN6

AIN7

AIN8

4

5

6

7

QSOP

QFN

24

12

AIN13

DIN

23

22

13

14

REF-/AIN14

CNVST/AIN15

CS

21

SCLK

20

N.C.

19

18

V

DD

17

N.C.

16

GND

15

REF+

Page 22

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

22 ______________________________________________________________________________________

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

QSOP.EPS

PACKAGE OUTLINE, QSOP .150", .025" LEAD PITCH

21-0055

E

1

1

Page 23

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

______________________________________________________________________________________ 23

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

32L QFN.EPS

PACKAGE OUTLINE, 16,20,28,32L QFN,

5x5x0.90 MM

21-0091

1

I

2

Page 24

MAX1026/MAX1028/MAX1030

10-Bit 300ksps ADCs with FIFO,

Temp Sensor, Internal Reference

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2003 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

PACKAGE OUTLINE, 16,20,28,32L QFN,

5x5x0.90 MM

21-0091

I

2

2

Loading...

Loading...