Page 1

General Description

The MAX1020–MAX1023/MAX1057/MAX1058 integrate a

multichannel, 10-bit, analog-to-digital converter (ADC)

and an octal, 10-bit, digital-to-analog converter (DAC) in a

single IC. These devices also include a temperature sensor and configurable general-purpose I/O ports (GPIOs)

with a 25MHz SPI™-/QSPI™-/MICROWIRE™-compatible

serial interface. The ADC is available in 8/12/16 inputchannel versions. The octal DAC outputs settle within

2.0µs, and the ADC has a 300ksps conversion rate.

All devices include an internal reference (2.5V or 4.096V)

providing a well-regulated, low-noise reference for both

the ADC and DAC. Programmable reference modes for

the ADC and the DAC allow the use of an internal reference, an external reference, or a combination of both.

Features such as an internal ±1°C accurate temperature

sensor, FIFO, scan modes, programmable internal

or external clock modes, data averaging, and

AutoShutdown™ allow users to minimize both power consumption and processor requirements. The low glitch

energy (4nV•

s) and low digital feedthrough (0.5nV•s) of

the integrated octal DACs make these devices ideal for

digital control of fast-response closed-loop systems.

The devices are guaranteed to operate with a supply voltage from +2.7V to +3.6V (MAX1021/MAX1023/MAX1057)

and from +4.75V to +5.25V (MAX1020/MAX1022/

MAX1058). The devices consume 2.5mA at 300ksps

throughput, only 22µA at 1ksps throughput, and under

0.2µA in the shutdown mode. The MAX1057/MAX1058

feature 12 GPIOs, while the MAX1020/MAX1021 offer 4

GPIOs that can be configured as inputs or outputs.

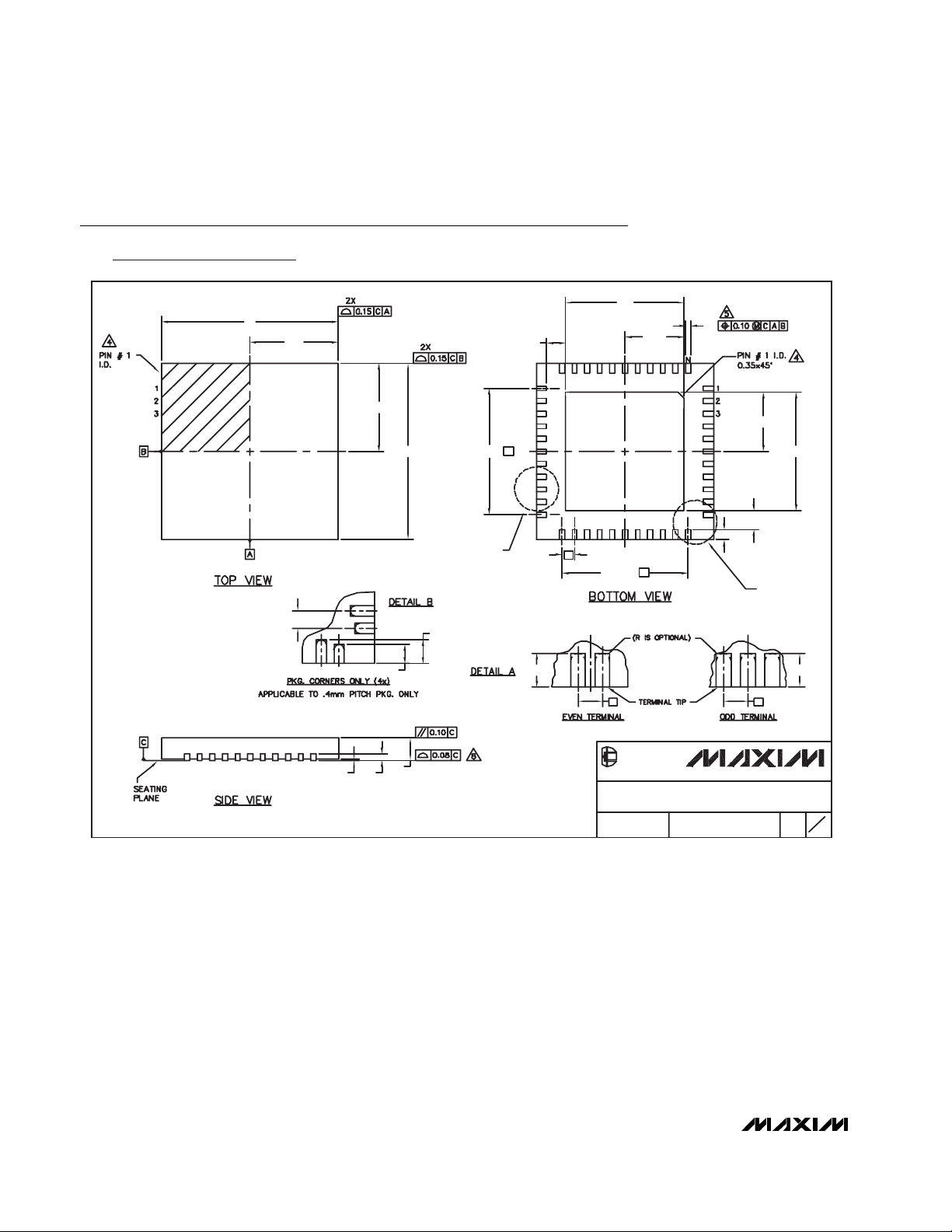

The MAX1057/MAX1058 are available in 48-pin thin QFN

packages. The MAX1020–MAX1023 are available in 36pin thin QFN packages. All devices are specified over the

-40°C to +85°C temperature range.

Applications

Controls for Optical Components

Base-Station Control Loops

System Supervision and Control

Data-Acquisition Systems

Features

♦ 10-Bit, 300ksps ADC

Analog Multiplexer with True-Differential

Track/Hold (T/H)

16 Single-Ended Channels or 8 Differential

Channels (Unipolar or Bipolar)

12 Single-Ended Channels or 6 Differential

Channels (Unipolar or Bipolar)

8 Single-Ended Channels or 4 Differential

Channels (Unipolar or Bipolar)

Excellent Accuracy: ±0.5 LSB INL, ±0.5 LSB DNL

♦ 10-Bit, Octal, 2µs Settling DAC

Ultra-Low Glitch Energy (4nV

•s)

Power-Up Options from Zero Scale or Full Scale

Excellent Accuracy: ±1 LSB INL

♦ Internal Reference or External Single-Ended/

Differential Reference

Internal Reference Voltage 2.5V or 4.096V

♦ Internal ±1°C Accurate Temperature Sensor

♦ On-Chip FIFO Capable of Storing 16 ADC

Conversion Results and One Temperature Result

♦ On-Chip Channel-Scan Mode and Internal

Data-Averaging Features

♦ Analog Single-Supply Operation

+2.7V to +3.6V or +4.75V to +5.25V

♦ 25MHz, SPI/QSPI/MICROWIRE Serial Interface

♦ AutoShutdown Between Conversions

♦ Low-Power ADC

2.5mA at 300ksps

22µA at 1ksps

0.2µA at Shutdown

♦ Low-Power DAC: 1.5µA

♦ Evaluation Kit Available (Order MAX1258EVKIT)

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

________________________________________________________________ Maxim Integrated Products 1

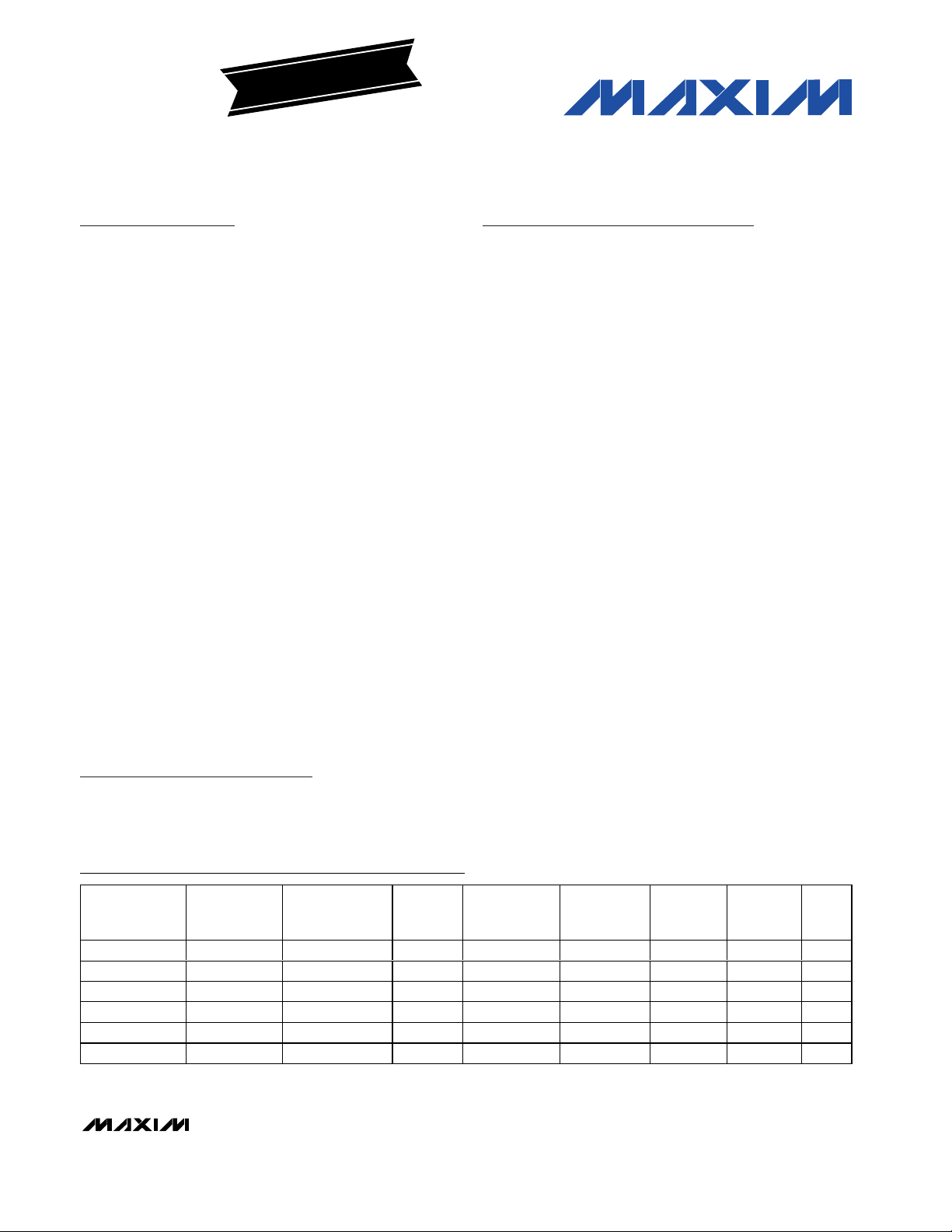

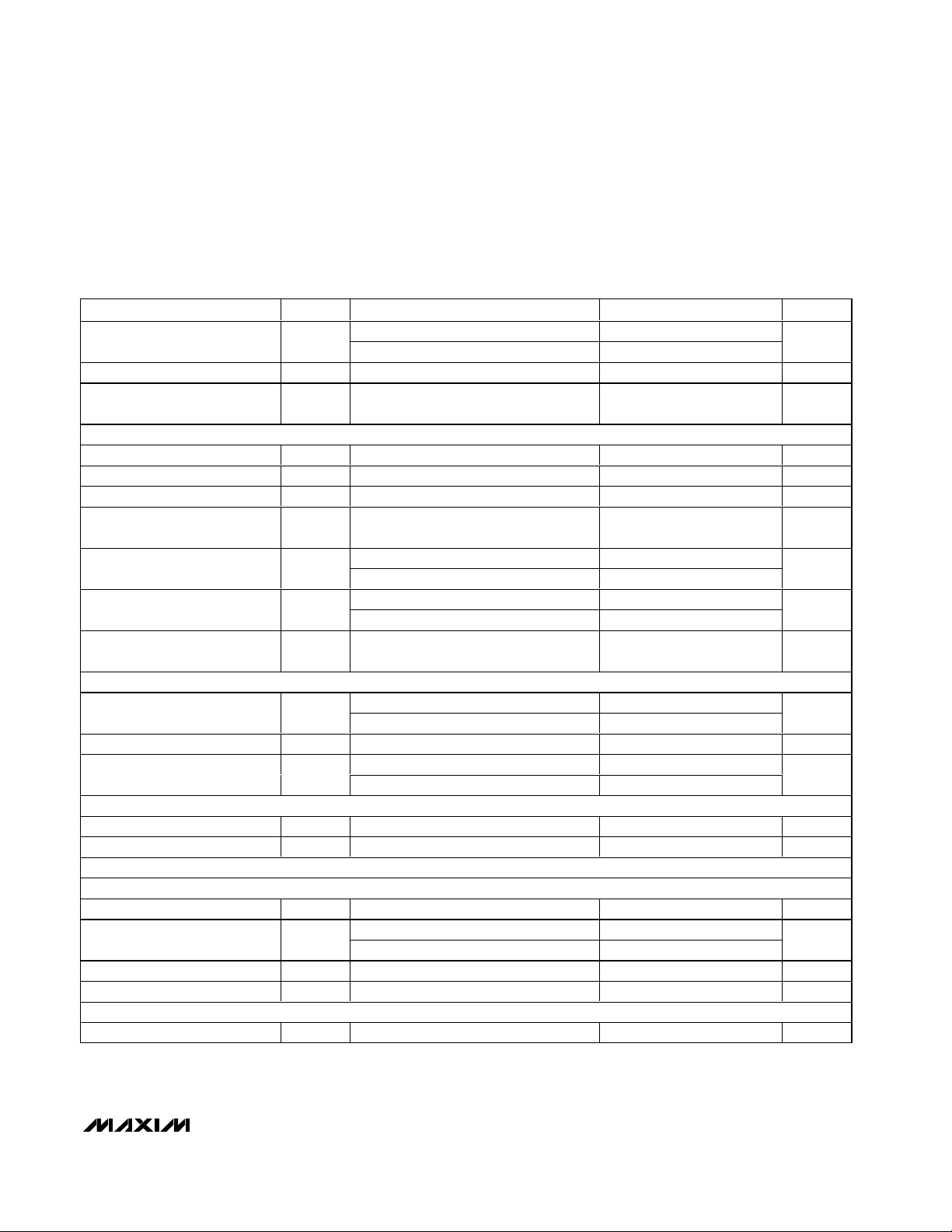

Ordering Information/Selector Guide

19-3280; Rev 2; 8/04

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Pin Configurations appear at end of data sheet.

SPI and QSPI are trademarks of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corp.

AutoShutdown is a trademark of Maxim Integrated Products, Inc.

*Future product—contact factory for availability.

**EP = Exposed pad.

***Number of resolution bits refers to both DAC and ADC.

REF

PART TEMP RANGE PIN-PACKAGE

MAX1020BETX -40°C to +85°C 36 Thin QFN-EP** 4.096 4.75 to 5.25 10 8 8 4

MAX1021BETX* -40°C to +85°C 36 Thin QFN-EP** 2.5 2.7 to 3.6 10 8 8 4

MAX1022BETX* -40°C to +85°C 36 Thin QFN-EP** 4.096 4.75 to 5.25 10 12 8 0

MAX1023BETX* -40°C to +85°C 36 Thin QFN-EP** 2.5 2.7 to 3.6 10 12 8 0

MAX1057BETM -40°C to +85°C 48 Thin QFN-EP** 2.5 2.7 to 3.6 10 16 8 12

MAX1058BETM -40°C to +85°C 48 Thin QFN-EP** 4.096 4.75 to 5.25 10 16 8 12

VOLTAGE

(V)

ANALOG

SUPPLY

VOLTAGE (V)

RESOLUTION

BITS***

ADC

CHANNELS

DAC

CHANNELS

GPIOs

Page 2

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

2 _______________________________________________________________________________________

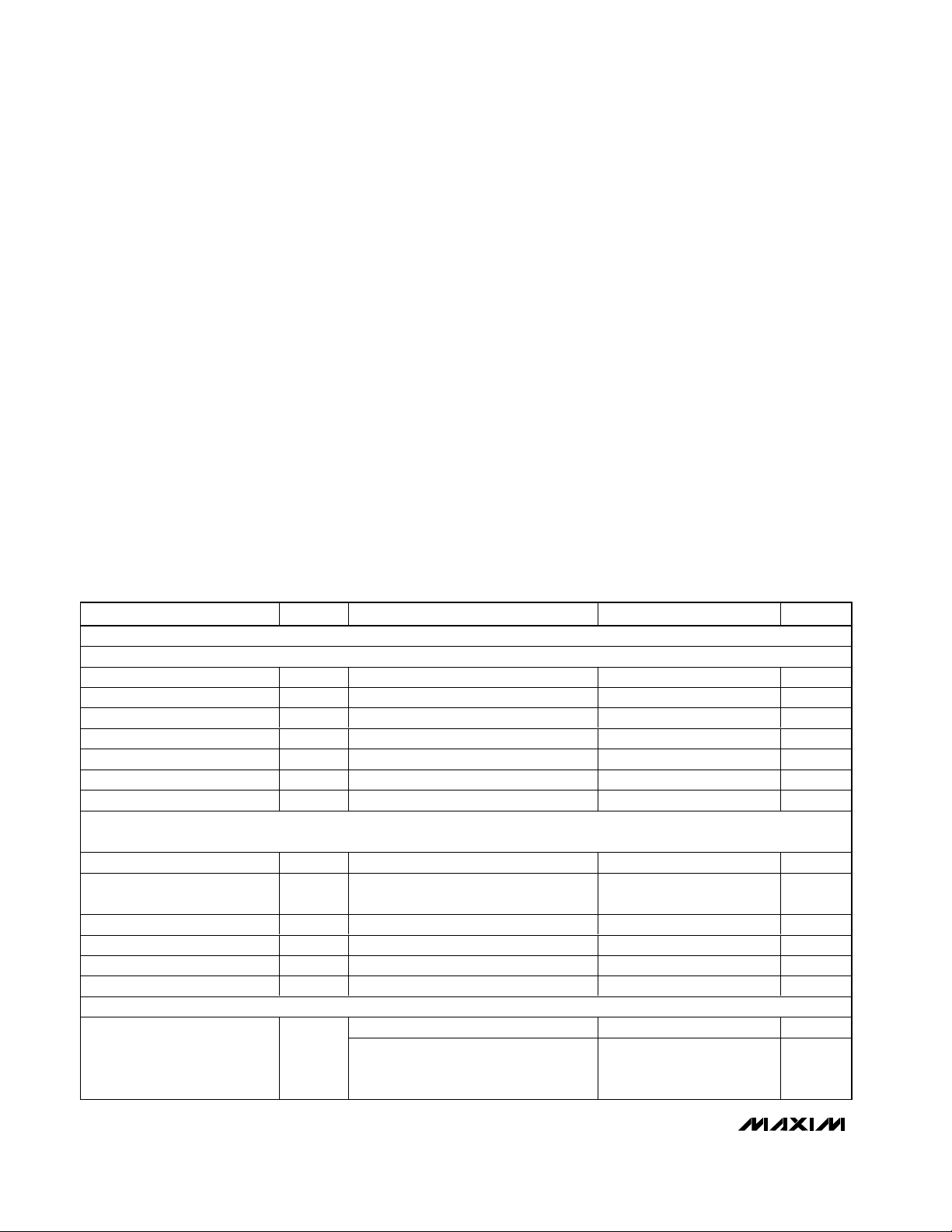

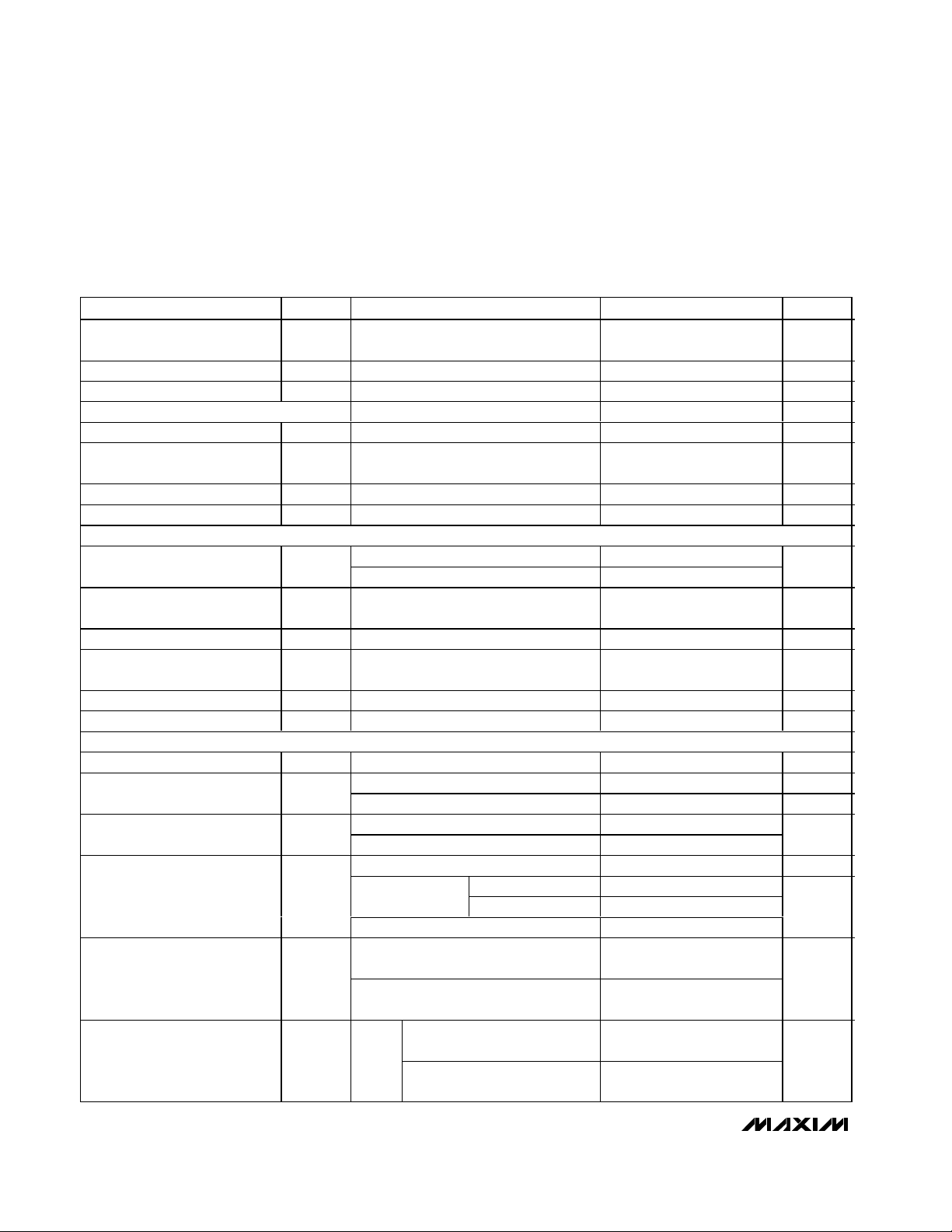

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(AVDD= DVDD= 2.7V to 3.6V (MAX1021/MAX1023/MAX1057), external reference V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD=

DV

DD

= 4.75V to 5.25V (MAX1020/MAX1022/MAX1058), external reference V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

SCLK

= 4.8MHz

(50% duty cycle), T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057),

AV

DD

= DVDD= 5V (MAX1020/MAX1022/MAX1058), TA= +25°C. Outputs are unloaded, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

AVDDto AGND .........................................................-0.3V to +6V

DGND to AGND.....................................................-0.3V to +0.3V

DV

DD

to AVDD.......................................................-3.0V to +0.3V

Digital Inputs to DGND.............................................-0.3V to +6V

Digital Outputs to DGND .........................-0.3V to (DV

DD

+ 0.3V)

Analog Inputs, Analog Outputs and REF_

to AGND...............................................-0.3V to (AV

DD

+ 0.3V)

Maximum Current into Any Pin (except AGND, DGND, AV

DD

,

DV

DD

, and OUT_) ...........................................................50mA

Maximum Current into OUT_.............................................100mA

Continuous Power Dissipation (T

A

= +70°C)

36-Pin Thin QFN (6mm x 6mm)

(derate 26.3mW/°C above +70°C)......................2105.3mW

48-Pin Thin QFN (7mm x 7mm)

(derate 26.3mW/°C above +70°C)......................2105.3mW

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range .............................-60°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10s) .................................+300°C

Note: If the package power dissipation is not exceeded, one output at a time may be shorted to AVDD, DVDD, AGND, or DGND

indefinitely

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DC ACCURACY (Note 1)

Resolution 10 Bits

Integral Nonlinearity INL ±0.5 ±1.0 LSB

Differential Nonlinearity DNL ±0.5 ±1.0 LSB

Offset Error ±0.25 ±2.0 LSB

Gain Error (Note 2) ±0.025 ±2.0 LSB

Gain Temperature Coefficient ±1.4 ppm/°C

Channel-to-Channel Offset ±0.1 LSB

DYNAMIC SPECIFICATIONS (10kHz sine wave input, VIN = 2.5V

(MAX1020/MAX1022/MAX1058), 300ksps, f

Signal-to-Noise Plus Distortion SINAD 61 dB

Total Harmonic Distortion

(Up to the Fifth Harmonic)

Spurious-Free Dynamic Range SFDR 66 dBc

Intermodulation Distortion IMD f

Full-Linear Bandwidth SINAD > 70dB 100 kHz

Full-Power Bandwidth -3dB point 1 MHz

CONVERSION RATE (Note 3)

Power-Up Time t

ADC

= 4.8MHz)

SCLK

THD -70 dBc

= 9.9kHz, f

in1

External reference 0.8 µs

PU

Internal reference (Note 4) 218

P-P

= 10.2kHz 72 dBc

in2

(MAX1021/MAX1023/MAX1057), VIN = 4.096V

P-P

C onver si on

C l ock

C ycl es

Page 3

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

_______________________________________________________________________________________ 3

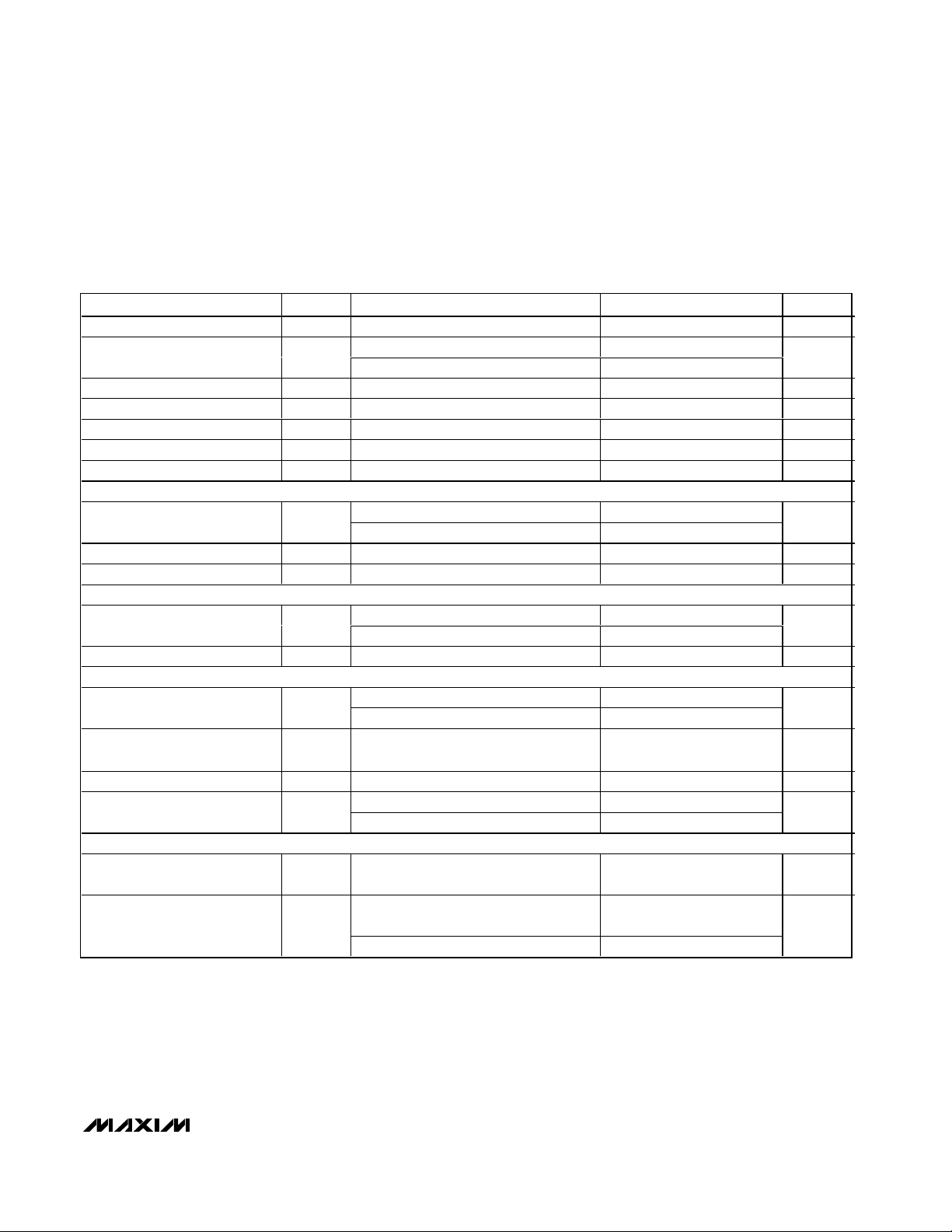

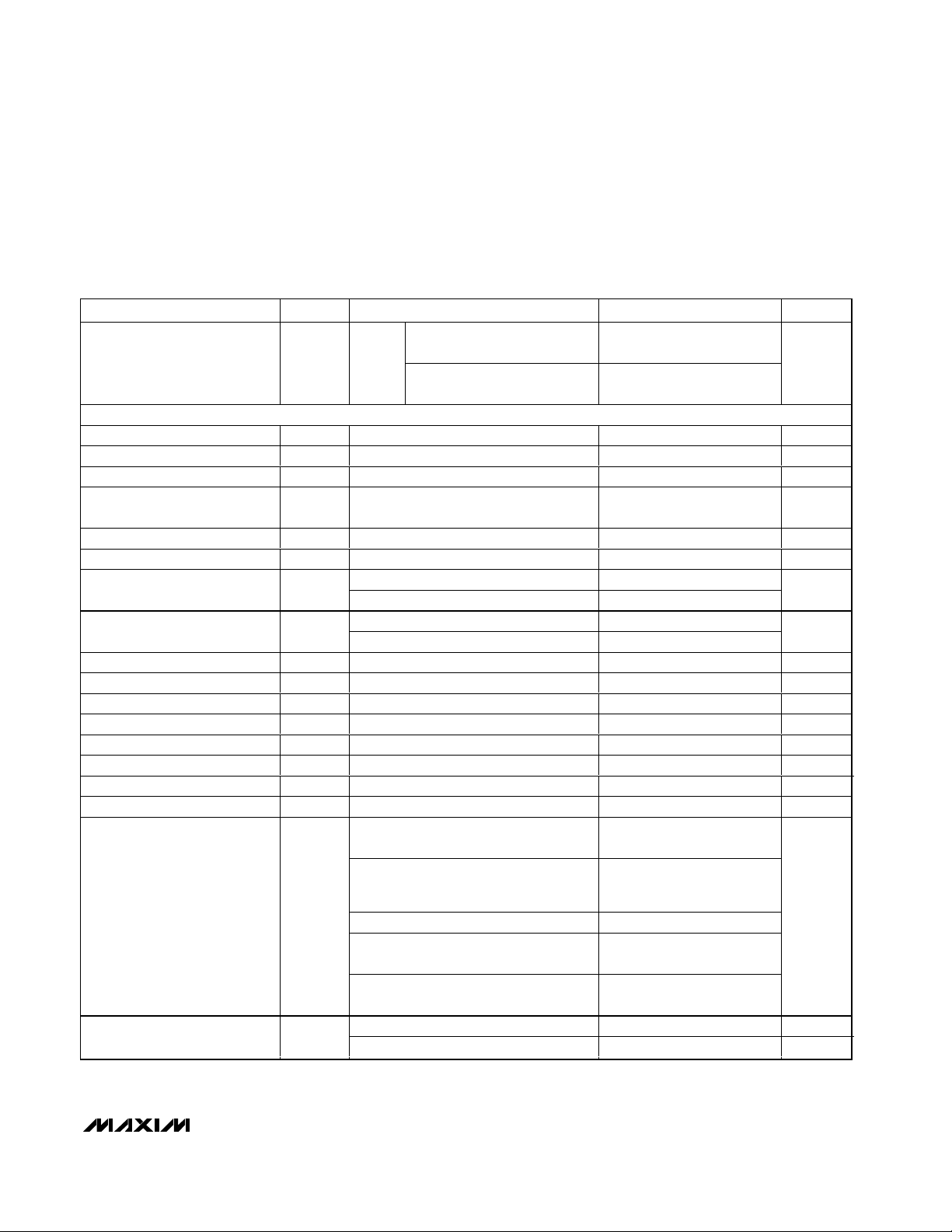

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= DVDD= 2.7V to 3.6V (MAX1021/MAX1023/MAX1057), external reference V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD=

DV

DD

= 4.75V to 5.25V (MAX1020/MAX1022/MAX1058), external reference V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

SCLK

= 4.8MHz

(50% duty cycle), T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057),

AV

DD

= DVDD= 5V (MAX1020/MAX1022/MAX1058), TA= +25°C. Outputs are unloaded, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Acquisition Time t

Conversion Time t

Internal Clock Frequency Internally clocked conversion 4.3 MHz

External Clock Frequency f

Duty Cycle 40 60 %

Aperture Delay 30 ns

Aperture Jitter <50 ps

ANALOG INPUTS

Input Voltage Range (Note 6)

Input Leakage Current ±0.01 ±1 µA

Input Capacitance 24 pF

INTERNAL TEMPERATURE SENSOR

Measurement Error (Notes 5, 7)

Temperature Resolution 1/8 °C/LSB

INTERNAL REFERENCE

REF1 Output Voltage (Note 8)

REF1 Voltage Temperature

Coefficient

REF1 Output Impedance 6.5 kΩ

REF1 Short-Circuit Current

EXTERNAL REFERENCE

REF1 Input Voltage Range V

REF2 Input Voltage Range

(Note 4)

ACQ

CONV

CLK

TC

REF1

V

REF2

(Note 5) 0.6 µs

Internally clocked 3.5

Externally clocked 2.7

Externally clocked conversion (Note 5) 0.1 4.8 MHz

Unipolar 0 V

Bipolar -V

TA = +25°C ±0.7

T

= T

A

MAX1021/MAX1023/MAX1057 2.482 2.50 2.518

MAX1020/MAX1022/MAX1058 4.066 4.096 4.126

REF

V

REF

V

REF

REF mode 11 (Note 4) 1

REF mode 01 1

REF mode 11 0 1

to T

MIN

MAX

= 2.5V 0.39

= 4.096V 0.63

/ 2 V

REF

±1.0 ±3.0

±30 ppm/°C

AV

AV

REF

REF

DD

0.05

DD

0.05

/ 2

+

+

µs

V

°C

V

mA

V

V

Page 4

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

4 _______________________________________________________________________________________

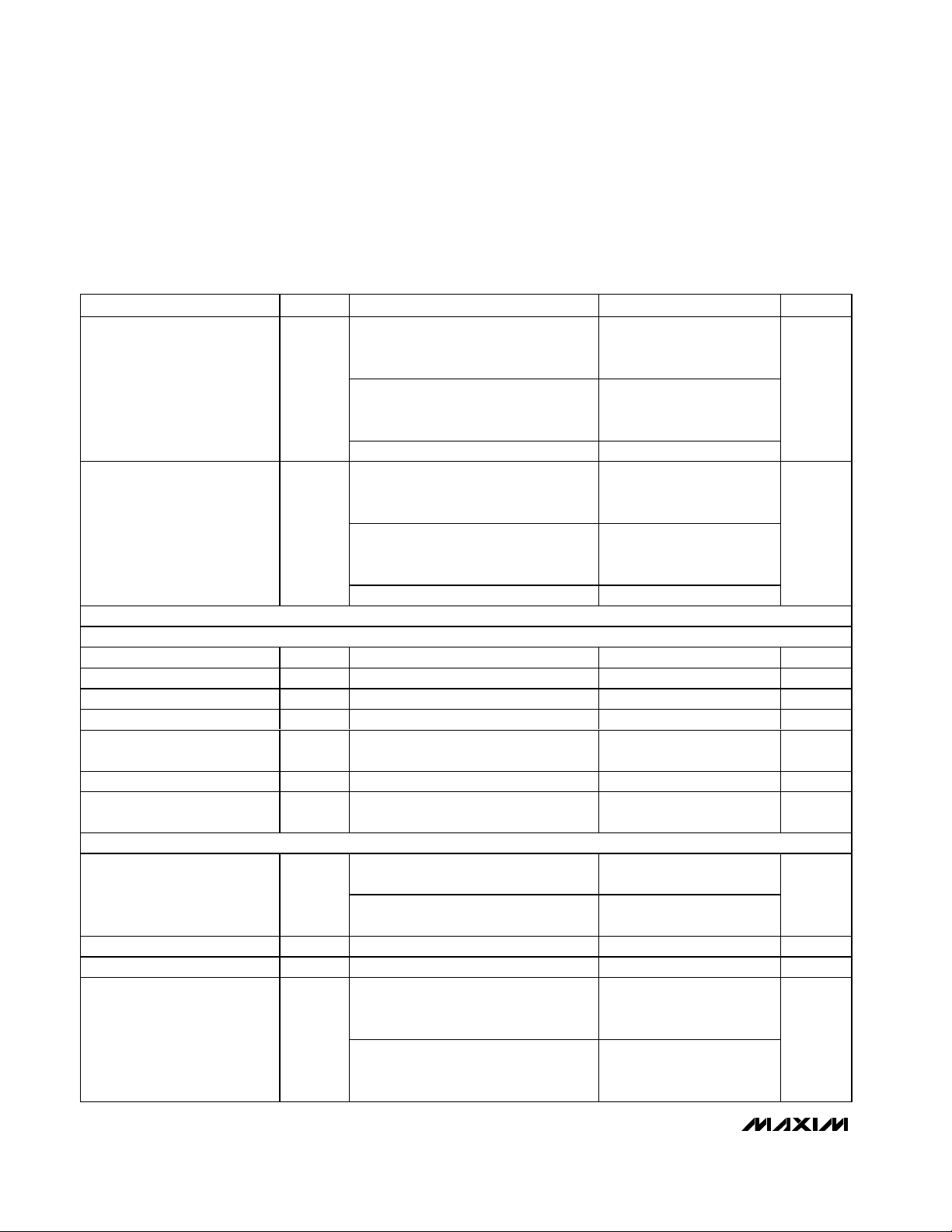

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= DVDD= 2.7V to 3.6V (MAX1021/MAX1023/MAX1057), external reference V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD=

DV

DD

= 4.75V to 5.25V (MAX1020/MAX1022/MAX1058), external reference V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

SCLK

= 4.8MHz

(50% duty cycle), T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057),

AV

DD

= DVDD= 5V (MAX1020/MAX1022/MAX1058), TA= +25°C. Outputs are unloaded, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

REF1 Input Current (Note 9) I

REF2 Input Current I

DC ACCURACY (Note 10)

Resolution 10 Bits

Integral Nonlinearity INL ±0.5 ±1 LSB

Differential Nonlinearity DNL Guaranteed monotonic ±0.5 LSB

Offset Error V

Offset-Error Drift ±10

Gain Error GE (Note 8) ±1.25 ±10 LSB

Gain Temperature Coefficient ±8

DAC OUTPUT

Output-Voltage Range

DC Output Impedance 0.5 Ω

Capacitive Load (Note 11) 1 nF

Resistive Load to AGND R

V

= 2.5V

REF

(MAX1021/MAX1023/MAX1057),

REF1

REF2

OS

L

f

V

(MAX1020/MAX1022/MAX1058),

f

Acquisition between conversions ±0.01 ±1

V

(MAX1021/MAX1023/MAX1057),

f

V

(MAX1020/MAX1022/MAX1058),

f

Acquisition between conversions ±0.01 ±1

(Note 8) ±3 ±10 mV

No load 0.02

10kΩ load to either rail 0.1

AVDD = 2.7V, V

(MAX1021/MAX1023/MAX1057),

gain error < 1%

AVDD = 4.75V, V

(MAX1020/MAX1022/MAX1058),

gain error < 2%

SAMPLE

= 4.096V

REF

SAMPLE

= 2.5V

REF

SAMPLE

= 4.096V

REF

SAMPLE

= 300ksps

= 300ksps

= 300ksps

= 300ksps

REF

REF

DAC

= 2.5V

= 4.096V

25 80

40 80

25 80

40 80

AV

DD

0.02

AV

DD

0.1

2000

500

-

-

µA

µA

ppm of

FS/°C

ppm of

FS/°C

V

Ω

Page 5

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= DVDD= 2.7V to 3.6V (MAX1021/MAX1023/MAX1057), external reference V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD=

DV

DD

= 4.75V to 5.25V (MAX1020/MAX1022/MAX1058), external reference V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

SCLK

= 4.8MHz

(50% duty cycle), T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057),

AV

DD

= DVDD= 5V (MAX1020/MAX1022/MAX1058), TA= +25°C. Outputs are unloaded, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Wake-Up Time (Note 12)

From power-down mode, AVDD = 5V 25

From power-down mode, AV

DD

1kΩ Output Termination Programmed in power-down mode 1 kΩ

100kΩ Output Termination

At wake-up or programmed in

power-down mode

DYNAMIC PERFORMANCE (Notes 5, 13)

Output-Voltage Slew Rate SR Positive and negative 3 V/µs

Output-Voltage Settling Time t

To 1 LSB, 400 - C00 hex (Note 7) 2 5 µs

S

Digital Feedthrough Code 0, all digital inputs from 0 to DV

Major Code Transition Glitch

Impulse

Output Noise (0.1Hz to 50MHz)

Output Noise (0.1Hz to 500kHz)

Between codes 2047 and 2048 4 nV

From V

REF

Using internal reference 720

From V

REF

Using internal reference 320

DAC-to-DAC Transition

Crosstalk

INTERNAL REFERENCE

REF1 Output Voltage (Note 8)

REF1 Temperature Coefficient TC

REF1 Short-Circuit Current

MAX1021/MAX1023/MAX1057 2.482 2.50 2.518

MAX1020/MAX1022/MAX1058 4.066 4.096 4.126

REF

V

= 2.5V 0.39

REF

V

= 4.096V 0.63

REF

EXTERNAL-REFERENCE INPUT

REF1 Input Voltage Range V

REF1 Input Impedance R

REF1

REF1

REF modes 01, 10, and 11 (Note 4) 0.7 AV

DIGITAL INTERFACE

DIGITAL INPUTS (SCLK, DIN, CS, CNVST, LDAC)

Input-Voltage High V

Input-Voltage Low V

Input Leakage Current I

Input Capacitance C

DV

IH

IL

L

IN

= 2.7V to 5.25V 2.4 V

DD

DV

= 3.6V to 5.25V 0.8

DD

DV

= 2.7V to 3.6V 0.6

DD

DIGITAL OUTPUT (DOUT) (Note 14)

Output-Voltage Low V

OL

I

= 2mA 0.4 V

SINK

= 2.7V 21

100 kΩ

DD

0.5 nV•s

660

260

0.5 nV

±30

70 100 130 kΩ

±0.01 ±10 µA

15 pF

DD

µV

µV

ppm/°C

µs

•s

P-P

P-P

•s

V

mA

V

V

Page 6

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= DVDD= 2.7V to 3.6V (MAX1021/MAX1023/MAX1057), external reference V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD=

DV

DD

= 4.75V to 5.25V (MAX1020/MAX1022/MAX1058), external reference V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

SCLK

= 4.8MHz

(50% duty cycle), T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057),

AV

DD

= DVDD= 5V (MAX1020/MAX1022/MAX1058), TA= +25°C. Outputs are unloaded, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Output-Voltage High V

OHISOURCE

= 2mA

Tri-State Leakage Current ±10 µA

Tri-State Output Capacitance C

OUT

DIGITAL OUTPUT (EOC) (Note 14)

Output-Voltage Low V

Output-Voltage High V

I

OL

OHISOURCE

= 2mA 0.4 V

SINK

= 2mA

Tri-State Leakage Current ±10 µA

Tri-State Output Capacitance C

OUT

DIGITAL OUTPUTS (GPIO_) (Note 14)

I

= 2mA 0.4

GPIOB_, GPIOC_ OutputVoltage Low

GPIOB_, GPIOC_ OutputVoltage High

GPIOA_ Output-Voltage Low I

GPIOA_ Output-Voltage High I

SINK

I

= 4mA 0.8

SINK

I

SOURCE

SINK

SOURCE

= 2mA

= 15mA 0.8 V

= 15mA

Tri-State Leakage Current ±10 µA

Tri-State Output Capacitance C

OUT

POWER REQUIREMENTS (Note 15)

Digital Positive-Supply Voltage DV

Digital Positive-Supply Current DI

Analog Positive-Supply Voltage AV

Analog Positive Supply Current A

DD

Idle, all blocks shut down 0.2 4 µA

DD

Only ADC on, external reference 1 mA

MAX1021/MAX1023/MAX1057 2.7 3.6

DD

MAX1020/MAX1022/MAX1058 4.75 5.25

Idle, all blocks shut down 0.2 1 µA

f

= 300ksps 2.8 4.2

Only ADC on,

IDD

external reference

SAMPLE

= 100ksps 2.6

f

SAMPLE

All DACs on, no load, internal reference 1.5 4.0

AVDD = 2.7V

REF1 Positive-Supply Rejection PSRR

MAX1021/MAX1023/MAX1057

AV

= 4.75V

DD

MAX1020/MAX1022/MAX1058

MAX1021/MAX1023/MAX1057

= 2.7V to 3.6V

AV

DD

M AX 1020/M AX 1022/M AX 1058

= 4.75V to 5.25V

AV

D D

DAC Positive-Supply Rejection PSRD

Output

code =

FFFhex

DV

-

DD

0.5

15 pF

DV

-

DD

0.5

15 pF

DV

-

DD

0.5

DV

-

DD

0.8

15 pF

2.70 AV

-77

-80

±0.1 ±0.5

±0.1 ±0.5

DD

V

V

V

V

V

V

V

mA

dB

mV

Page 7

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= DVDD= 2.7V to 3.6V (MAX1021/MAX1023/MAX1057), external reference V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD=

DV

DD

= 4.75V to 5.25V (MAX1020/MAX1022/MAX1058), external reference V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

SCLK

= 4.8MHz

(50% duty cycle), T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057),

AV

DD

= DVDD= 5V (MAX1020/MAX1022/MAX1058), TA= +25°C. Outputs are unloaded, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ADC Positive-Supply Rejection PSRA

Fullscale

input

MAX1021/MAX1023/

MAX1057 AV

M AX 1020/M AX 1022/

M AX 1058 AV

= 2.7V to 3.6V

DD

= 4.75V to 5.25V

D D

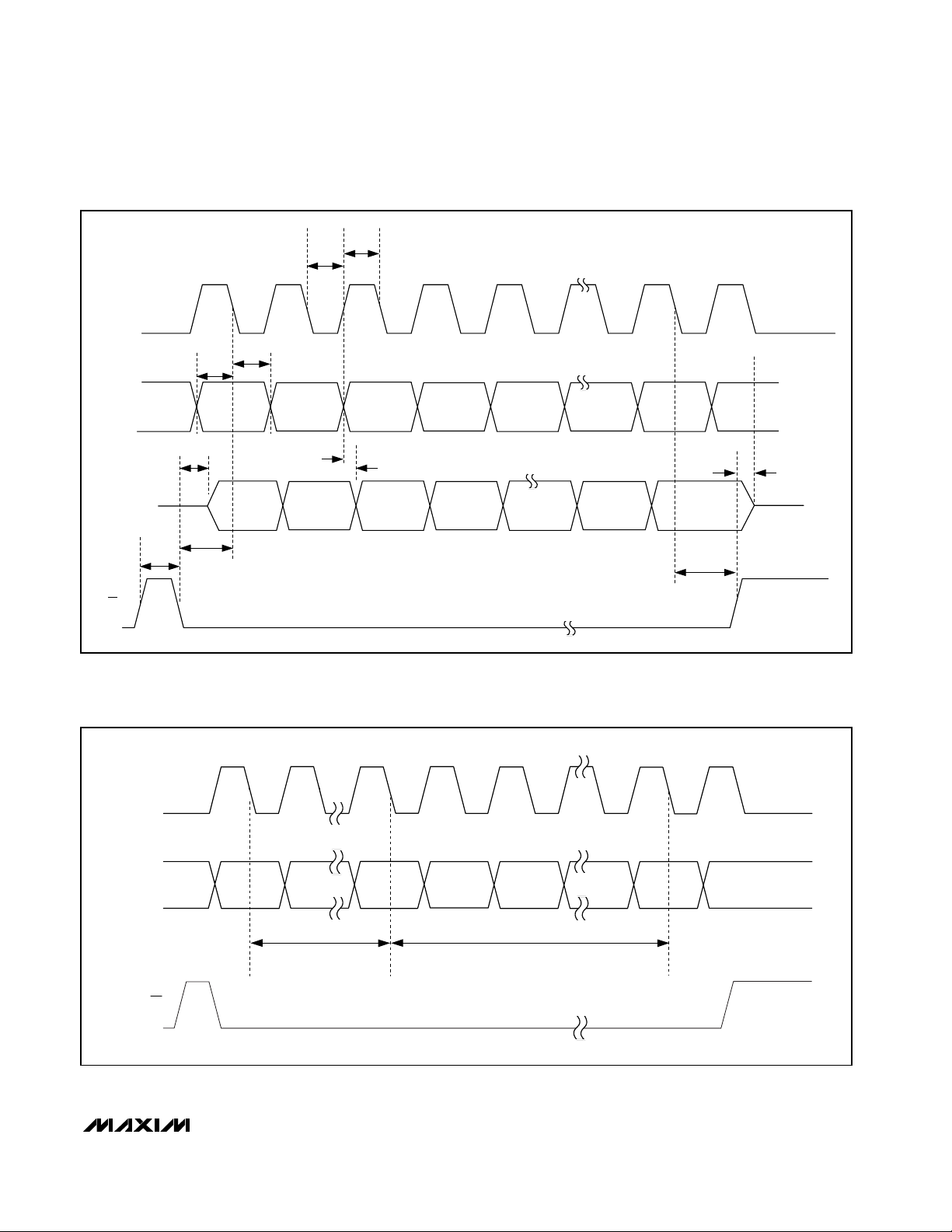

TIMING CHARACTERISTICS (Figures 6–13)

SCLK Clock Period t

SCLK Pulse-Width High t

SCLK Pulse-Width Low t

GPIO Output Rise/Fall After

CS Rise

GPIO Input Setup Before CS Fall t

LDAC Pulse Width t

SCLK Fall to DOUT Transition

(Note 16)

SCLK Rise to DOUT Transition

(Notes 16, 17)

CS Fall to SCLK Fall Setup Time t

S C LK Fal l to CS Ri se S etup Ti m et

DIN to SCLK Fall Setup Time t

DIN to SCLK Fall Hold Time t

CS Pulse-Width High t

CS Rise to DOUT Disable t

CS Fall to DOUT Enable t

EOC Fall to CS Fall t

CP

CH

CL

t

GOD

GSU

LDACPWL

t

DOT

t

DOT

CSS

CSH

DS

DH

CSPWH

DOD

DOE

RDS

40/60 duty cycle 16 ns

60/40 duty cycle 16 ns

C

= 20pF 100 ns

LOAD

C

= 20pF, SLOW = 0 1.8 12.0

LOAD

C

= 20pF, SLOW = 1 10 40

LOAD

C

= 20pF, SLOW = 0 1.8 12.0

LOAD

C

= 20pF, SLOW = 1 10 40

LOAD

C

= 20pF 25 ns

LOAD

C

= 20pF 1.5 25.0 ns

LOAD

CKSEL = 01 (temp sense) or CKSEL =

10 (temp sense), internal reference on

CKSEL = 01 (temp sense) or CKSEL =

10 (temp sense), internal reference

initially off

CS or CNVST Rise to EOC Fall t

DOV

CKSEL = 01 (voltage conversion) 8

CKSEL = 10 (voltage conversion),

internal reference on

CKSEL = 10 (voltage conversion),

internal reference initially off

CNVST Pulse Width t

CSW

CKSEL = 00, CKSEL = 01 (temp sense) 40 ns

CKSEL = 01 (voltage conversion) 1.4 µs

40 ns

20 ns

10 ns

10 ns

50 ns

30 ns

±0.06 ±0.5

mV

±0.06 ±0.5

0ns

ns

ns

0ns

0ns

55

120

µs

8

80

Page 8

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

8 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= DVDD= 2.7V to 3.6V (MAX1021/MAX1023/MAX1057), external reference V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD=

DV

DD

= 4.75V to 5.25V (MAX1020/MAX1022/MAX1058), external reference V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

SCLK

= 4.8MHz

(50% duty cycle), T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057),

AV

DD

= DVDD= 5V (MAX1020/MAX1022/MAX1058), TA= +25°C. Outputs are unloaded, unless otherwise noted.)

Note 1: Tested at DV

DD

= AVDD= +3.6V (MAX1021/MAX1023/MAX1057), DVDD= AVDD= +5.25V (MAX1020/MAX1022/MAX1058).

Note 2: Offset nulled.

Note 3: No bus activity during conversion. Conversion time is defined as the number of conversion clock cycles multiplied by the

clock period.

Note 4: See Table 5 for reference-mode details.

Note 5: Not production tested. Guaranteed by design.

Note 6: See the ADC/DAC References section.

Note 7: Fast automated test, excludes self-heating effects.

Note 8: Specified over the -40°C to +85°C temperature range.

Note 9: REFSEL[1:0] = 00 or when DACs are not powered up.

Note 10: DAC linearity, gain, and offset measurements are made between codes 115 and 3981.

Note 11: The DAC buffers are guaranteed by design to be stable with a 500pF load.

Note 12: Time required by the DAC output to power up and settle within 1 LSB in the external reference mode.

Note 13: All DAC dynamic specifications are valid for a load of 1nF and 10kΩ.

Note 14: Only one digital output (either DOUT, EOC, or the GPIOs) can be indefinitely shorted to either supply at one time.

Note 15: All digital inputs at either DV

DD

or DGND. DVDDshould not exceed AVDD.

Note 16: See the Reset Register section and Table 9 for details on programming the SLOW bit.

Note 17: Clock mode 11 only.

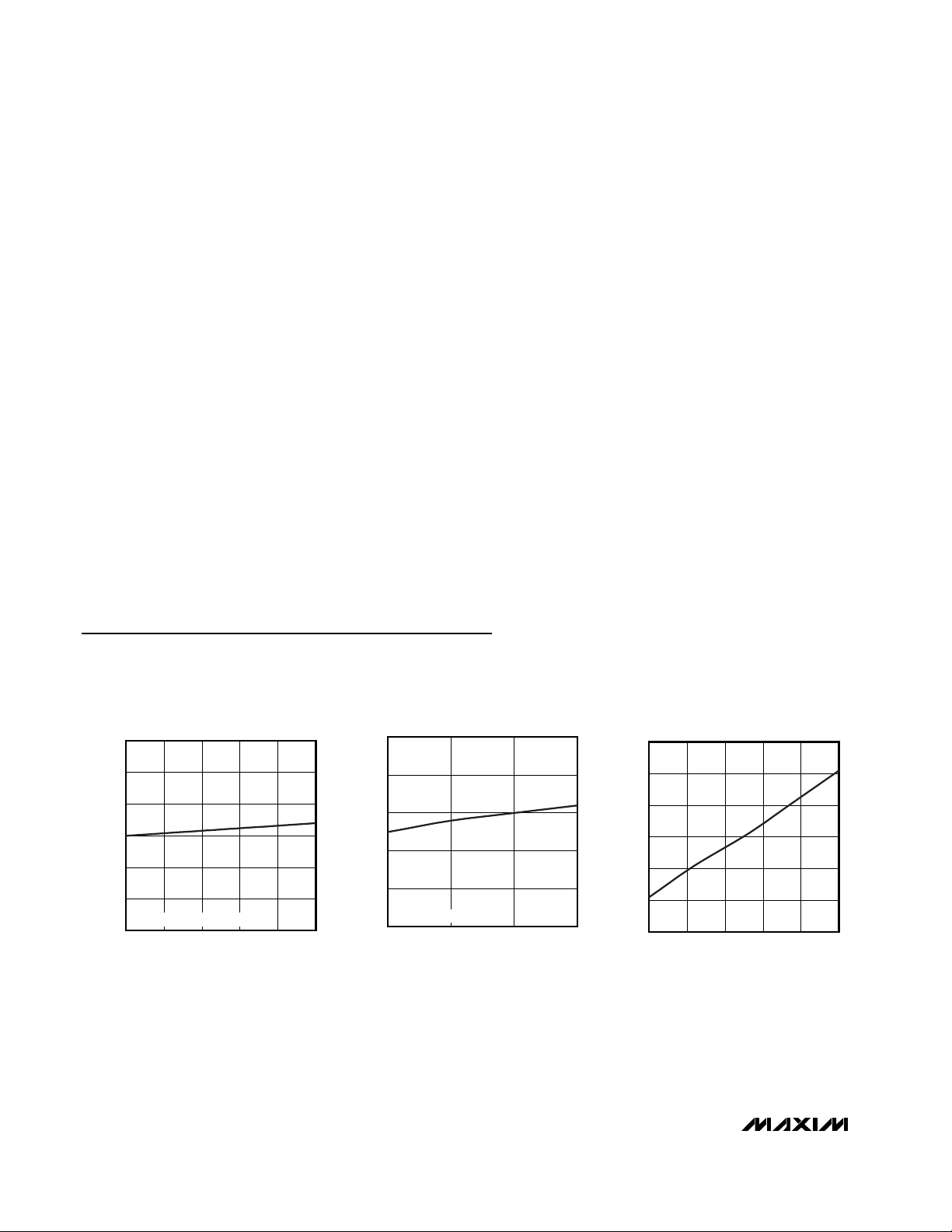

SHUTDOWN CURRENT

vs. ANALOG SUPPLY VOLTAGE

MAX1020 toc01

SUPPLY VOLTAGE (V)

SHUTDOWN CURRENT (µA)

5.155.054.954.85

0.05

0.10

0.15

0.20

0.25

0.30

0

4.75 5.25

MAX1020/MAX1022/MAX1058

SHUTDOWN CURRENT

vs. ANALOG SUPPLY VOLTAGE

MAX1020 toc02

SUPPLY VOLTAGE (V)

SHUTDOWN CURRENT (µA)

3.33.0

0.12

0.14

0.16

0.18

0.20

0.10

2.7 3.6

MAX1021/MAX1023/MAX1057

SHUTDOWN CURRENT

vs. TEMPERATURE

MAX1020 toc03

TEMPERATURE (°C)

SHUTDOWN CURRENT (µA)

603510-15

0.1

0.2

0.3

0.4

0.5

0.6

0

-40 85

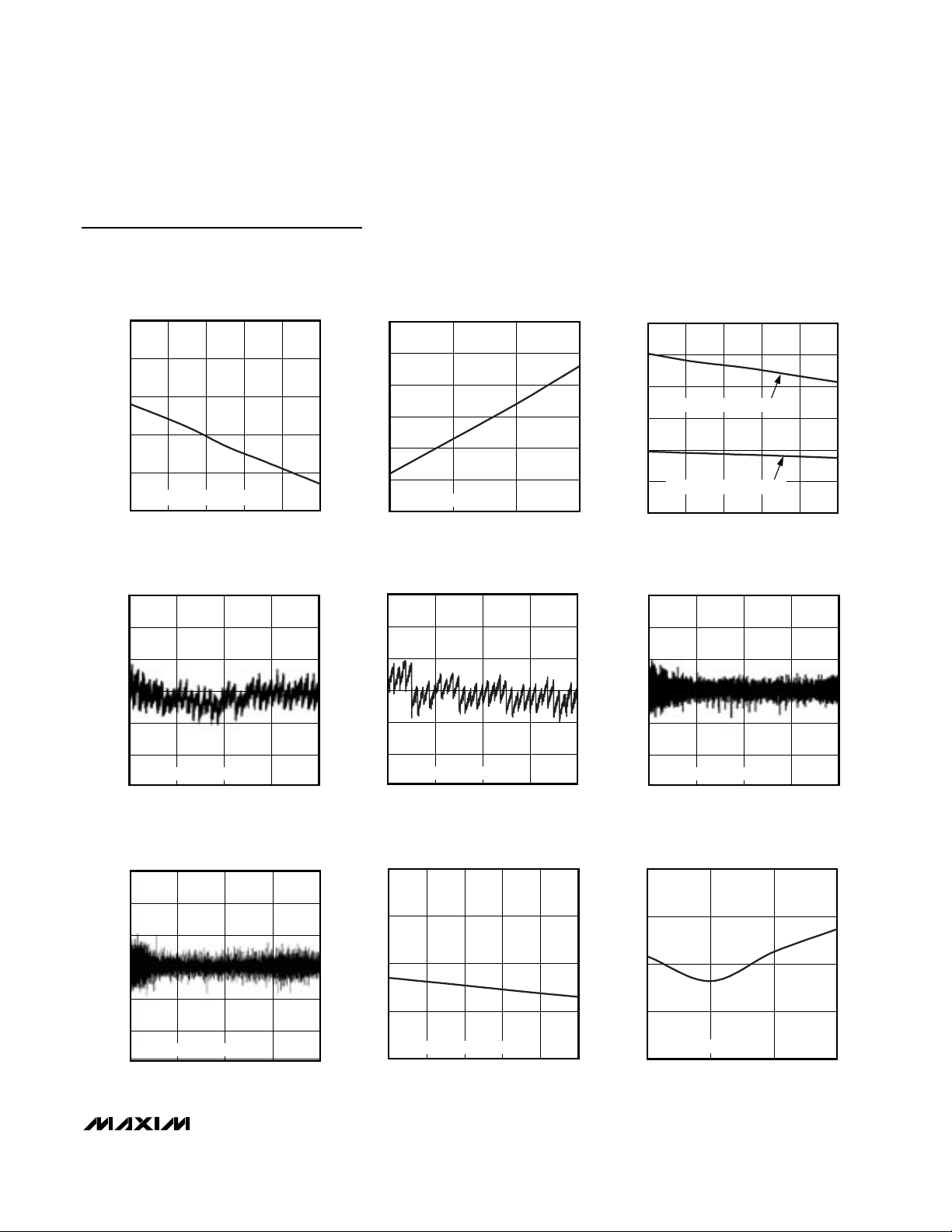

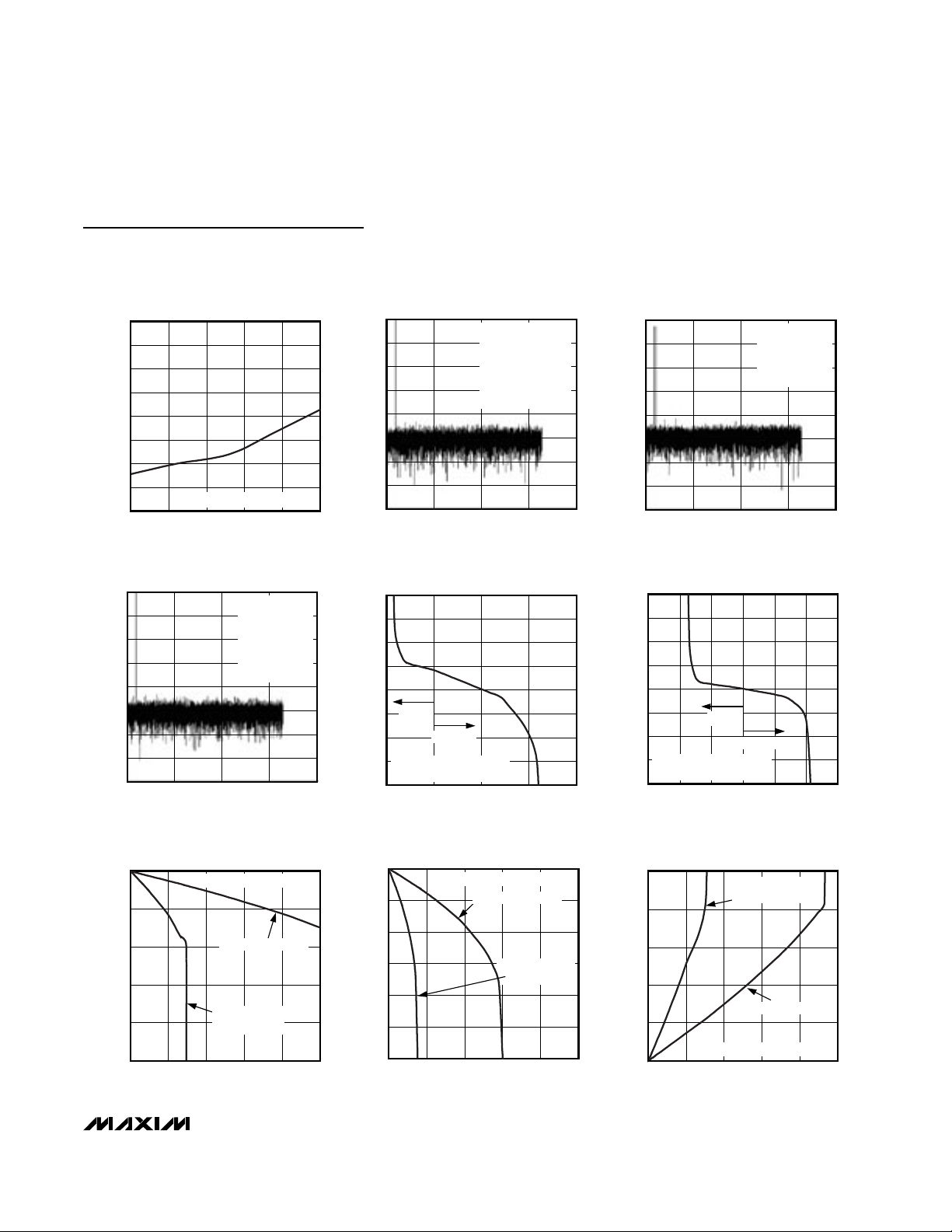

Typical Operating Characteristics

(AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057), external V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD= DVDD= 5V

(MAX1020/MAX1022/MAX1058), external V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

CLK

= 4.8MHz (50% duty cycle), f

SAMPLE

= 300ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

Page 9

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

_______________________________________________________________________________________ 9

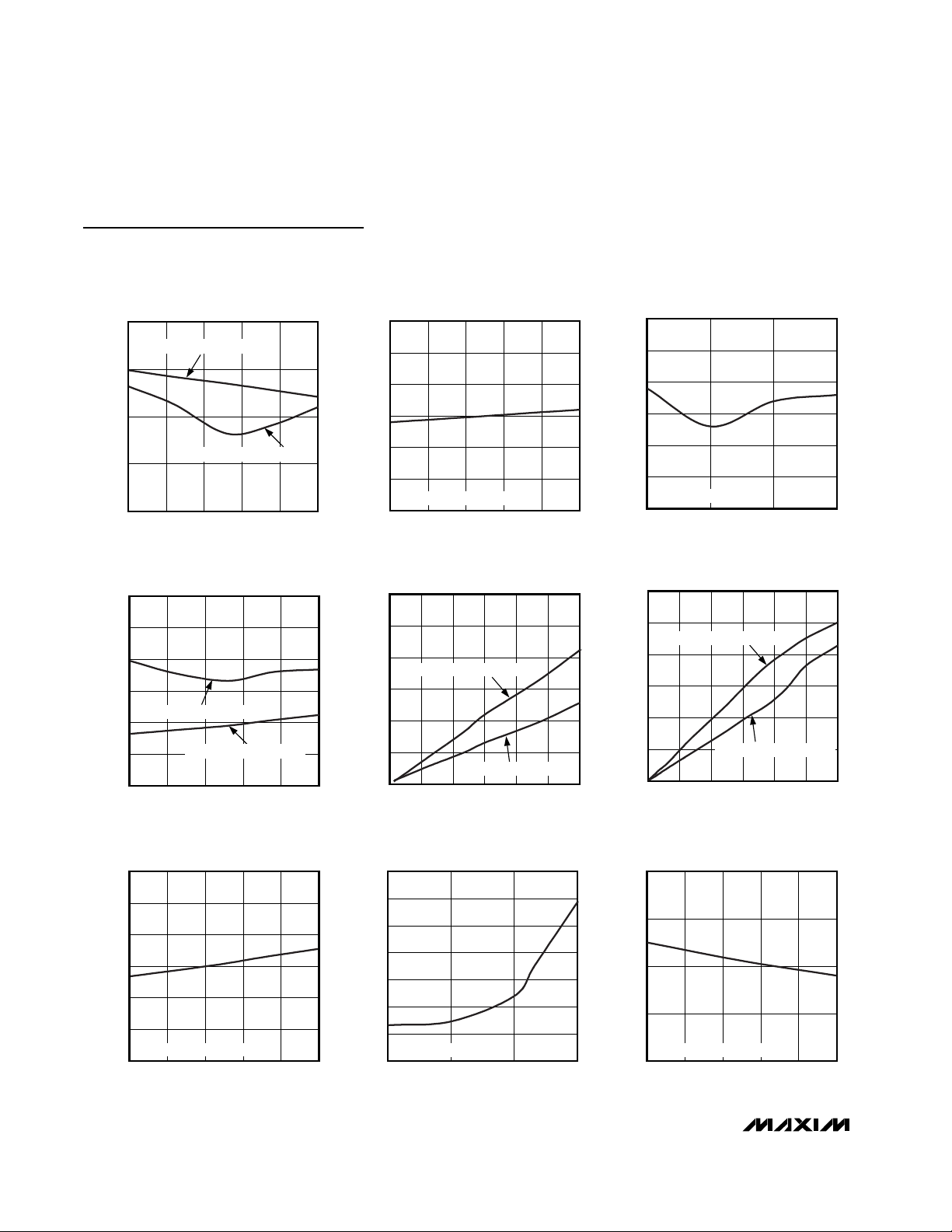

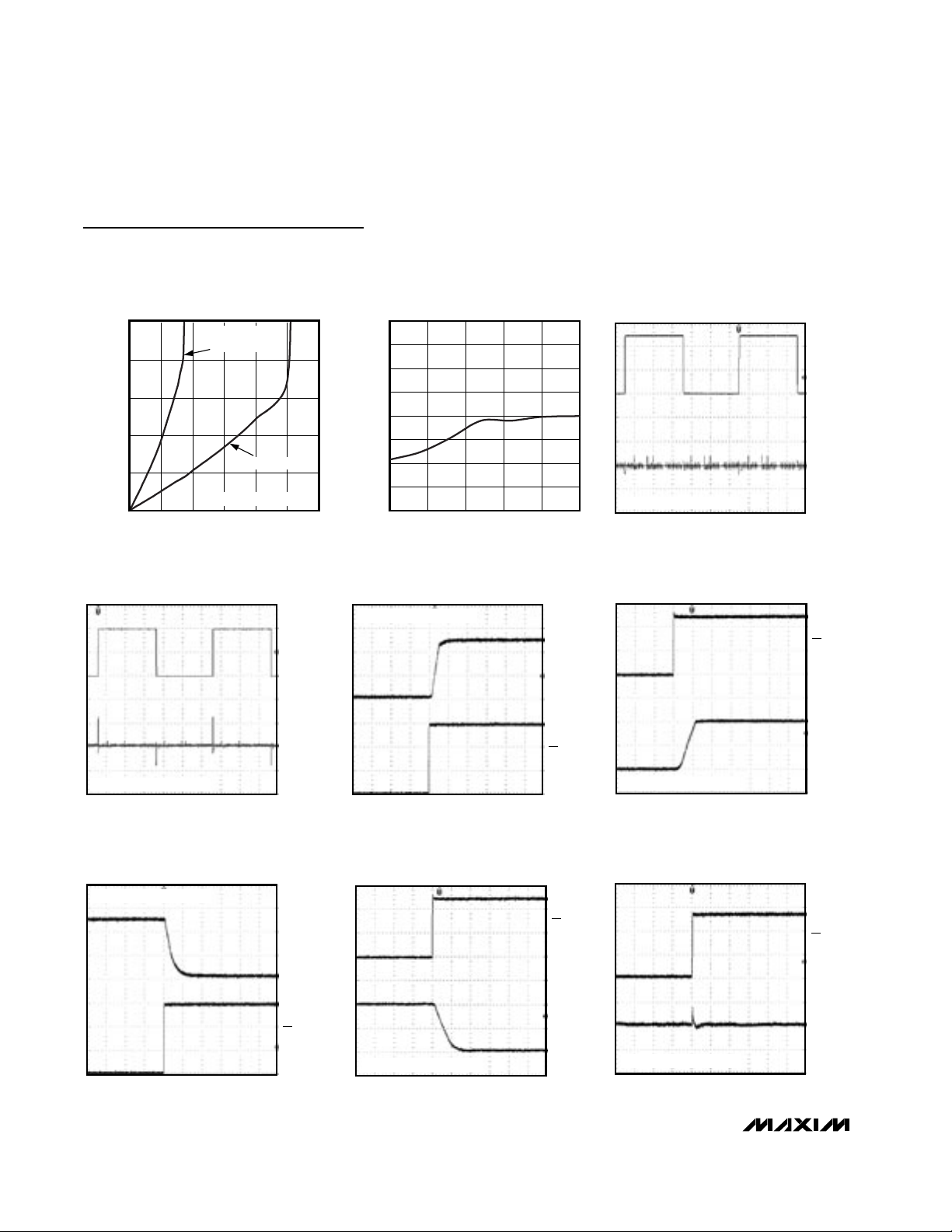

Typical Operating Characteristics (continued)

(AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057), external V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD= DVDD= 5V

(MAX1020/MAX1022/MAX1058), external V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

CLK

= 4.8MHz (50% duty cycle), f

SAMPLE

= 300ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

INTERNAL OSCILLATOR FREQUENCY

4.5

4.4

4.3

4.2

4.1

INTERNAL OSCILLATOR FREQUENCY (MHz)

MAX1020/MAX1022/MAX1058

4.0

4.75 5.25

vs. ANALOG SUPPLY VOLTAGE

SUPPLY VOLTAGE (V)

5.155.054.954.85

ADC INTEGRAL NONLINEARITY

vs. OUTPUT CODE

0.3

0.2

0.1

INTERNAL OSCILLATOR FREQUENCY

vs. ANALOG SUPPLY VOLTAGE

4.90

4.85

MAX1020 toc04

4.80

4.75

4.70

4.65

INTERNAL OSCILLATOR FREQUENCY (MHz)

MAX1021/MAX1023/MAX1057

4.60

2.7 3.6

ADC INTEGRAL NONLINEARITY

vs. OUTPUT CODE

0.3

0.2

MAX1020 toc07

0.1

INTERNAL OSCILLATOR FREQUENCY

vs. TEMPERATURE

5.0

4.8

MAX1020 toc05

4.6

MAX1021/MAX1023/MAX1057

4.4

4.2

4.0

INTERNAL OSCILLATOR FREQUENCY (MHz)

3.33.0

SUPPLY VOLTAGE (V)

MAX1020/MAX1022/MAX1058

3.8

-40 85

TEMPERATURE (°C)

ADC DIFFERENTIAL NONLINEARITY

vs. OUTPUT CODE

0.3

0.2

MAX1020 toc08

0.1

MAX1020 toc06

603510-15

MAX1020 toc09

0

-0.1

INTEGRAL NONLINEARITY (LSB)

-0.2

MAX1020/MAX1022/MAX1058

-0.3

0 1024

OUTPUT CODE

ADC DIFFERENTIAL NONLINEARITY

vs. OUTPUT CODE

0.3

0.2

0.1

0

-0.1

DIFFERENTIAL NONLINEARITY (LSB)

-0.2

MAX1021/MAX1023/MAX1057

-0.3

0 1024

OUTPUT CODE

0

-0.1

INTEGRAL NONLINEARITY (LSB)

-0.2

MAX1021/MAX1023/MAX1057

-0.3

768512256

0 1024

OUTPUT CODE

768512256

ADC OFFSET ERROR

vs. ANALOG SUPPLY VOLTAGE

-0.4

MAX1020 toc10

-0.5

-0.6

OFFSET ERROR (LSB)

-0.7

MAX1020/MAX1022/MAX1058

-0.8

768512256

4.75 5.25

SUPPLY VOLTAGE (V)

5.155.054.954.85

MAX1020 toc11

0

-0.1

DIFFERENTIAL NONLINEARITY (LSB)

-0.2

MAX1020/MAX1022/MAX1058

-0.3

0 1024

OUTPUT CODE

ADC OFFSET ERROR

vs. ANALOG SUPPLY VOLTAGE

0

-0.5

-1.0

OFFSET ERROR (LSB)

-1.5

MAX1021/MAX1023/MAX1057

-2.0

2.7 3.6

SUPPLY VOLTAGE (V)

3.33.0

768512256

MAX1020 toc12

Page 10

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057), external V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD= DVDD= 5V

(MAX1020/MAX1022/MAX1058), external V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

CLK

= 4.8MHz (50% duty cycle), f

SAMPLE

= 300ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

ADC OFFSET ERROR

vs. TEMPERATURE

0

MAX1020/MAX1022/MAX1058

-0.5

-1.0

OFFSET ERROR (LSB)

-1.5

-2.0

-40 85

MAX1021/MAX1023/MAX1057

603510-15

TEMPERATURE (°C)

ADC GAIN ERROR

vs. TEMPERATURE

1.00

vs. ANALOG SUPPLY VOLTAGE

0.050

MAX1020 toc13

0.025

0

-0.025

GAIN ERROR (LSB)

-0.050

MAX1020/MAX1022/MAX1058

-0.075

4.75 5.25

ADC EXTERNAL REFERENCE

INPUT CURRENT vs. SAMPLING RATE

60

ADC GAIN ERROR

ADC GAIN ERROR

vs. ANALOG SUPPLY VOLTAGE

0.50

0.45

MAX1020 toc14

0.40

0.35

GAIN ERROR (LSB)

0.30

0.25

MAX1021/MAX1023/MAX1057

0.20

5.155.054.954.85

SUPPLY VOLTAGE (V)

2.7 3.6

SUPPLY VOLTAGE (V)

ANALOG SUPPLY CURRENT

vs. SAMPLING RATE

3.0

MAX1020 toc15

3.33.0

0.75

0.50

0.25

MAX1021/MAX1023/MAX1057

GAIN ERROR (LSB)

0

-0.25

-0.50

-40 85

MAX1020/MAX1022/MAX1058

603510-15

TEMPERATURE (°C)

ANALOG SUPPLY CURRENT

vs. ANALOG SUPPLY VOLTAGE

2.8

2.7

2.6

2.5

2.4

SUPPLY CURRENT (mA)

2.3

MAX1020/MAX1022/MAX1058

2.2

4.75 5.25

SUPPLY VOLTAGE (V)

5.155.054.954.85

50

MAX1020 toc16

40

30

20

10

ADC EXTERNAL REFERENCE INPUT CURRENT (µA)

0

2.6

2.5

MAX1020 toc19

2.4

2.3

2.2

SUPPLY CURRENT (mA)

2.1

2.0

1.9

MAX1020/MAX1022/MAX1058

MAX1021/MAX1023/MAX1057

0 300

SAMPLING RATE (ksps)

25020015010050

ANALOG SUPPLY CURRENT

vs. ANALOG SUPPLY VOLTAGE

MAX1021/MAX1023/MAX1057

2.7 3.6

SUPPLY VOLTAGE (V)

3.33.0

2.5

MAX1020 toc17

2.0

1.5

1.0

ANALOG SUPPLY CURRENT (mA)

0.5

0

0 300

2.7

MAx1020 toc20

2.6

2.5

2.4

ANALOG SUPPLY CURRENT (mA)

MAX1020/MAX1022/MAX1058

2.3

-40 85

MAX1020/MAX1022/MAX1058

ANALOG SUPPLY CURRENT

MAX1020 toc18

MAX1021/MAX1023/MAX1057

25020015010050

SAMPLING RATE (ksps)

vs. TEMPERATURE

MAX1020 toc21

603510-15

TEMPERATURE (°C)

Page 11

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

______________________________________________________________________________________ 11

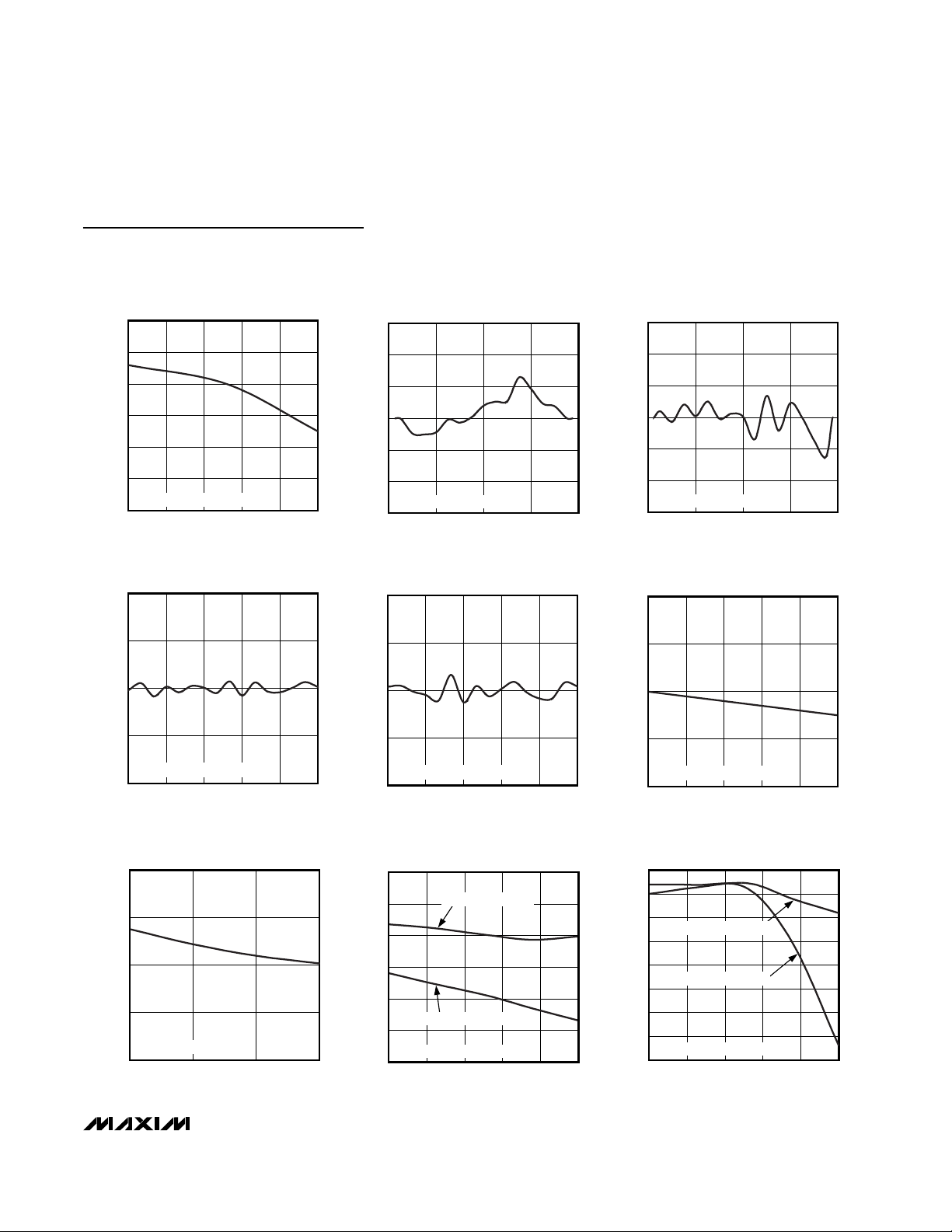

Typical Operating Characteristics (continued)

(AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057), external V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD= DVDD= 5V

(MAX1020/MAX1022/MAX1058), external V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

CLK

= 4.8MHz (50% duty cycle), f

SAMPLE

= 300ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

2.16

2.15

2.14

2.13

2.12

ANALOG SUPPLY CURRENT (mA)

2.11

2.10

ANALOG SUPPLY CURRENT

vs. TEMPERATURE

MAX1021/MAX1023/MAX1057

-40 85

TEMPERATURE (°C)

603510-15

DAC DIFFERENTIAL NONLINEARITY

vs. OUTPUT CODE

0.10

0.05

DAC INTEGRAL NONLINEARITY

0.3

0.2

MAX1020 toc22

0.1

0

-0.1

INTEGRAL NONLINEARITY (LSB)

-0.2

MAX1020/MAX1022/MAX1058

-0.3

0 1024

DAC DIFFERENTIAL NONLINEARITY

vs. OUTPUT CODE

0.10

MAX1020 toc25

0.05

DAC INTEGRAL NONLINEARITY

vs. OUTPUT CODE

OUTPUT CODE

0.3

0.2

MAX1020 toc23

0.1

0

-0.1

INTEGRAL NONLINEARITY (LSB)

-0.2

MAX1021/MAX1023/MAX1057

-0.3

768512256

0 1024

vs. OUTPUT CODE

OUTPUT CODE

DAC FULL-SCALE ERROR

vs. ANALOG SUPPLY VOLTAGE

0.04

MAX1020 toc26

0.03

MAX1020 toc24

768512256

MAX1020 toc27

0

-0.05

DIFFERENTIAL NONLINEARITY (LSB)

MAX1020/MAX1022/MAX1058

-0.10

1023 1038

OUTPUT CODE

DAC FULL-SCALE ERROR

vs. ANALOG SUPPLY VOLTAGE

-0.50

-0.55

-0.60

-0.65

DAC FULL-SCALE ERROR (LSB)

MAX1021/MAX1023/MAX1057

-0.70

2.7 3.6

SUPPLY VOLTAGE (V)

3.33.0

0

-0.05

DIFFERENTIAL NONLINEARITY (LSB)

MAX1021/MAX1023/MAX1057

1035103210291026

-0.10

1023 1038

OUTPUT CODE

1035103210291026

DAC FULL-SCALE ERROR

vs. TEMPERATURE

2.0

1.5

MAx1020 toc28

1.0

0.5

0

DAC FULL-SCALE ERROR (LSB)

-0.5

MAX1020/MAX1022/MAX1058

-1.0

-40 85

INTERNAL REFERENCE

EXTERNAL REFERENCE = 4.096V

603510-15

TEMPERATURE (°C)

0.02

0.01

DAC FULL-SCALE ERROR (LSB)

MAX1020/MAX1022/MAX1058

0

4.75 5.25

0

-0.25

MAX1020 toc29

-0.50

EXTERNAL REFERENCE = 2.500V

-0.75

-1.00

-1.25

-1.50

DAC FULL-SCALE ERROR (LSB)

-1.75

MAX1021/MAX1023/MAX1057

-2.00

-40 85

5.155.054.954.85

SUPPLY VOLTAGE (V)

DAC FULL-SCALE ERROR

vs. TEMPERATURE

MAX1020 toc30

INTERNAL REFERENCE

603510-15

TEMPERATURE (°C)

Page 12

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

12 ______________________________________________________________________________________

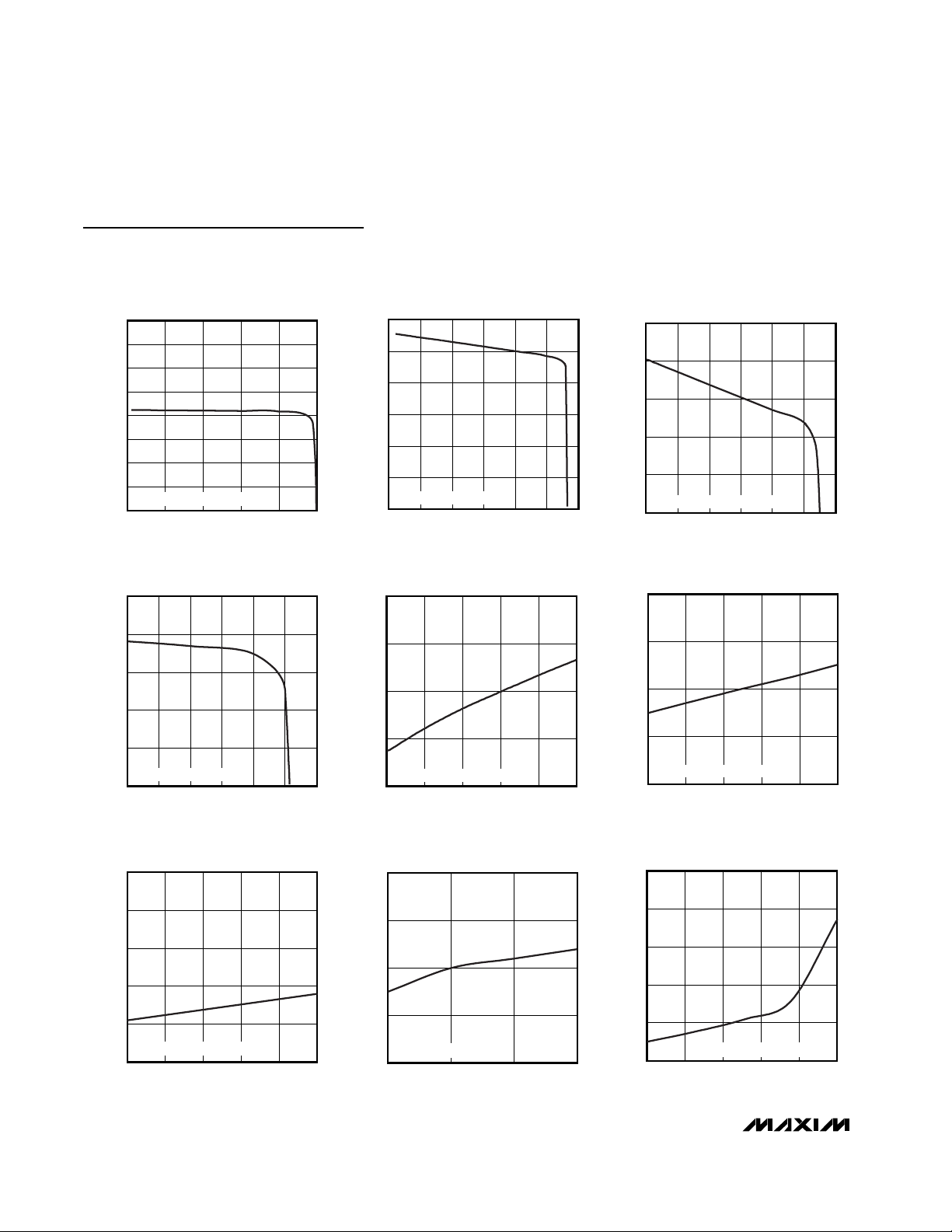

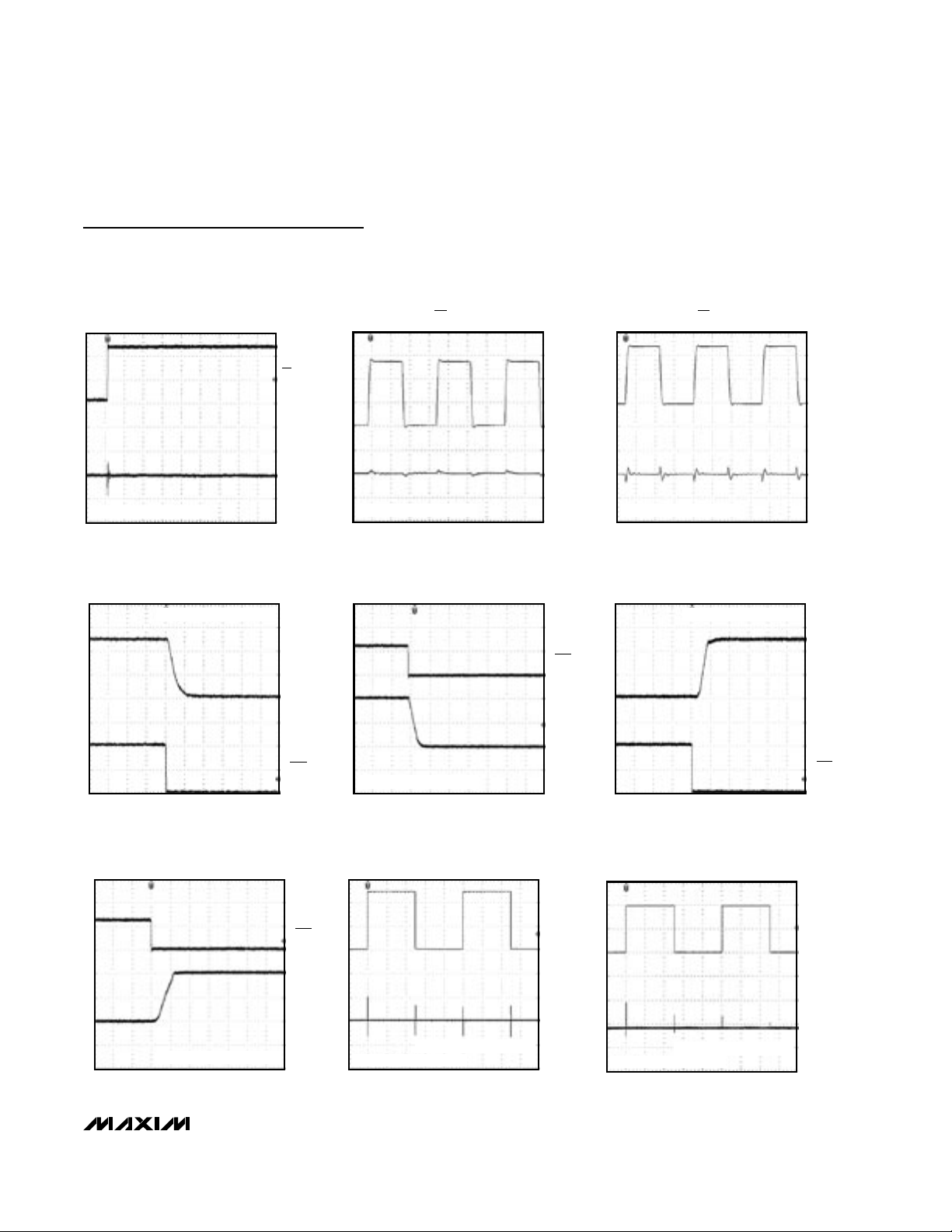

Typical Operating Characteristics (continued)

(AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057), external V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD= DVDD= 5V

(MAX1020/MAX1022/MAX1058), external V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

CLK

= 4.8MHz (50% duty cycle), f

SAMPLE

= 300ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

1.00

0.75

0.50

0.25

0

-0.25

-0.50

DAC FULL-SCALE ERROR (LSB)

-0.75

-1.00

DAC FULL-SCALE ERROR

vs. REFERENCE VOLTAGE

MAX1020/MAX1022/MAX1058

05

REFERENCE VOLTAGE (V)

431 2

DAC FULL-SCALE ERROR

DAC FULL-SCALE ERROR

vs. REFERENCE VOLTAGE

0

-0.5

MAX1020 toc31

-1.0

-1.5

-2.0

DAC FULL-SCALE ERROR (LSB)

-2.5

MAX1021/MAX1023/MAX1057

-3.0

0 3.0

INTERNAL REFERENCE VOLTAGE

vs. LOAD CURRENT

1

4.12

DAC FULL-SCALE ERROR

vs. LOAD CURRENT

1

MAX1020 toc32

0

-1

-2

DAC FULL-SCALE ERROR (LSB)

-3

MAX1020/MAX1022/MAX1058

2.0 2.51.50.5 1.0

REFERENCE VOLTAGE (V)

-4

030

LOAD CURRENT (mA)

INTERNAL REFERENCE VOLTAGE

vs. TEMPERATURE

2.52

vs. TEMPERATURE

MAX1020 toc33

252015105

0

-1

-2

DAC FULL-SCALE ERROR (LSB)

-3

MAX1021/MAX1023/MAX1057

-4

0 3.0

LOAD CURRENT (mA)

ADC REFERENCE SUPPLY CURRENT

vs. ANALOG SUPPLY VOLTAGE

43.0

42.8

42.6

42.4

42.2

ADC REFERENCE SUPPLY CURRENT (µA)

MAX1020/MAX1022/MAX1058

42.0

4.75 5.25

SUPPLY VOLTAGE (V)

5.155.054.954.85

MAX1020 toc34

4.11

4.10

4.09

INTERNAL REFERENCE VOLTAGE (V)

MAX1020/MAX1022/MAX1058

2.52.01.51.00.5

4.08

-40 85

TEMPERATURE (°C)

603510-15

ADC REFERENCE SUPPLY CURRENT

vs. ANALOG SUPPLY VOLTAGE

25.8

MAX1020 toc37

25.7

25.6

25.5

ADC REFERENCE SUPPLY CURRENT (µA)

MAX1021/MAX1023/MAX1057

25.4

2.7 3.6

SUPPLY VOLTAGE (V)

3.33.0

MAX1020 toc35

2.51

2.50

2.49

INTERNAL REFERENCE VOLTAGE (V)

MAX1021/MAX1023/MAX1057

2.48

-40 85

ADC REFERENCE SUPPLY CURRENT

50

MAX1020 toc38

48

46

44

42

ADC REFERENCE SUPPLY CURRENT (µA)

40

-40 85

MAX1020 toc36

603510-15

TEMPERATURE (°C)

vs. TEMPERATURE

MAX1020 toc39

MAX1020/MAX1022/MAX1058

603510-15

TEMPERATURE (°C)

Page 13

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

______________________________________________________________________________________ 13

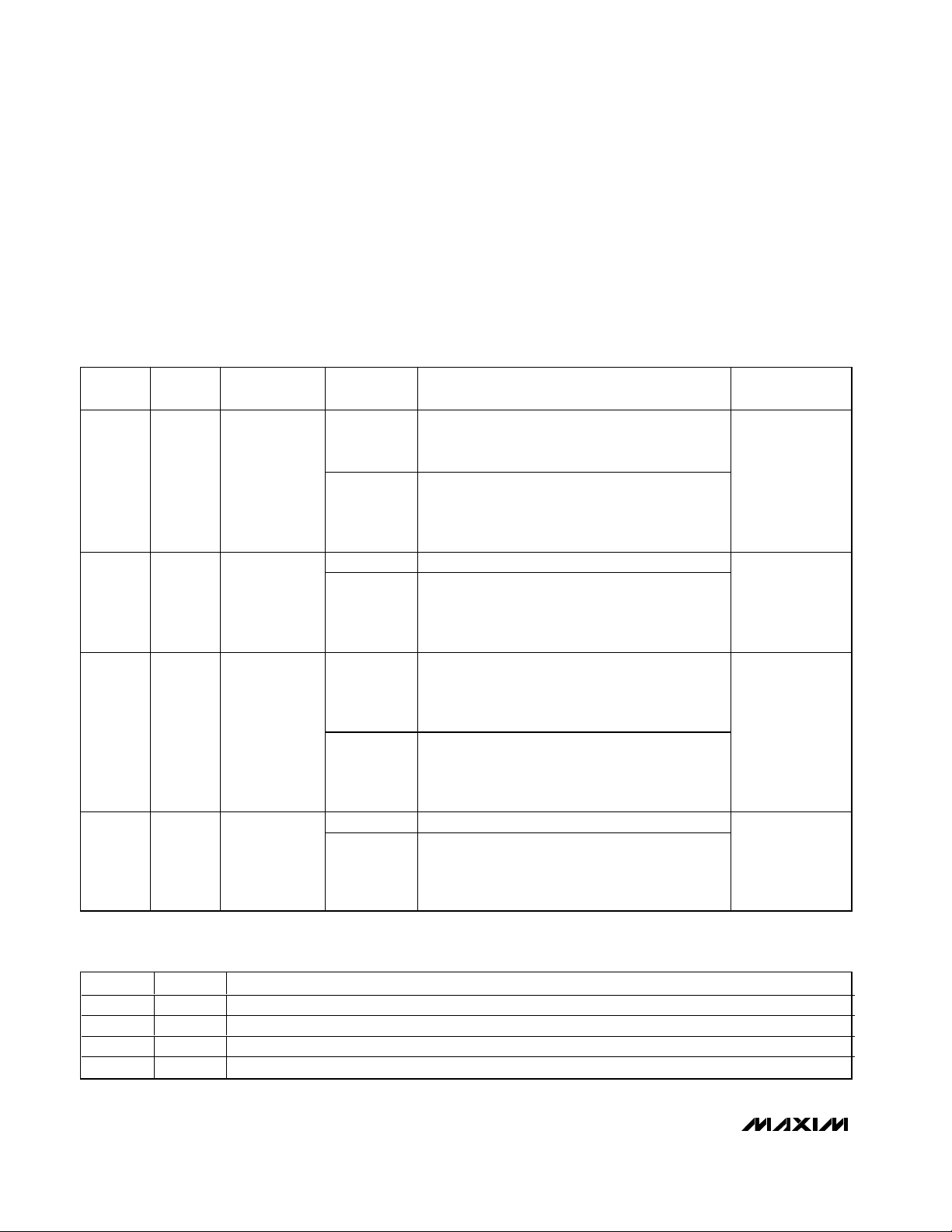

Typical Operating Characteristics (continued)

(AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057), external V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD= DVDD= 5V

(MAX1020/MAX1022/MAX1058), external V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

CLK

= 4.8MHz (50% duty cycle), f

SAMPLE

= 300ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

ADC REFERENCE SUPPLY CURRENT

27.00

26.75

26.50

26.25

26.00

25.75

25.50

25.25

ADC REFERENCE SUPPLY CURRENT (µA)

25.00

-40 85

vs. TEMPERATURE

MAX1021/MAX1023/MAX1057

TEMPERATURE (°C)

6035-15 10

ADC CROSSTALK PLOT

0

-20

-40

-60

-80

-100

AMPLITUDE (dB)

-120

-140

-160

0 200

ANALOG INPUT FREQUENCY (kHz)

f

= 5.24288MHz

CLK

= 10.080kHz

f

IN1

= 8.0801kHz

f

IN2

SNR = 61.11dBc

THD = 73.32dBc

ENOB = 9.86 BITS

SFDR = 86.34dBc

15010050

GPIO OUTPUT VOLTAGE

vs. SOURCE CURRENT

5

4

3

2

GPIO OUTPUT VOLTAGE (V)

1

0

0 100

MAX1020/MAX1022/MAX1058

GPIOA0–A3 OUTPUTS

GPIOB0–B3,

C0–C3 OUTPUTS

SOURCE CURRENT (mA)

80604020

0

-20

MAX1020 toc40

-40

-60

-80

-100

AMPLITUDE (dB)

-120

-140

-160

0 200

ANALOG INPUT FREQUENCY (kHz)

DAC OUTPUT LOAD REGULATION

vs. OUTPUT CURRENT

2.08

2.07

MAX1020 toc43

2.06

2.05

2.04

2.03

SINKING

DAC OUTPUT VOLTAGE (V)

2.02

2.01

2.00

-30 90

SOURCING

DAC OUTPUT = MIDSCALE

MAX1020/MAX1022/MAX1058

OUTPUT CURRENT (mA)

GPIO OUTPUT VOLTAGE

vs. SOURCE CURRENT

3.0

2.5

MAX1020 toc46

2.0

1.5

1.0

GPIO OUTPUT VOLTAGE (V)

0.5

0

0 100

SOURCE CURRENT (mA)

ADC FFT PLOT

f

SAMPLE

f

ANALOG_)N

= 5.24288MHz

f

CLK

SINAD = 61.21dBc

SNR = 61.21dBc

THD = 73.32dBc

SFDR = 81.25dBc

= 32.768kHz

= 10.080kHz

15010050

MAX1020 toc41

ADC IMD PLOT

0

-20

-40

-60

-80

-100

AMPLITUDE (dB)

-120

-140

-160

0 200

ANALOG INPUT FREQUENCY (kHz)

DAC OUTPUT LOAD REGULATION

vs. OUTPUT CURRENT

1.29

1.28

MAX1020 toc44

1.27

1.26

1.25

1.24

DAC OUTPUT VOLTAGE (V)

1.23

1.22

DAC OUTPUT = MIDSCALE

MAX1021/MAX1023/MAX1057

1.21

60300

-30 30

SINKING

SOURCING

-10

OUTPUT CURRENT (mA)

GPIO OUTPUT VOLTAGE

vs. SINK CURRENT

MAX1021/MAX1023/MAX1057

GPIOA0–A3 OUTPUTS

GPIOB0–B3, C0–C3

OUTPUTS

80604020

1500

MAX1020 toc47

1200

900

600

GPIO OUTPUT VOLTAGE (mV)

300

0

0 100

GPIOB0–B3, C0–C3

GPIOA0–A3 OUTPUTS

MAX1020/MAX1022/MAX1058

SINK CURRENT (mA)

f

= 5.24288MHz

CLK

= 9.0kHz

f

IN1

= 11.0kHz

f

IN2

= -6dBFS

A

IN

IMD = 78.0dBc

15010050

OUTPUTS

MAX1020 toc42

MAX1020 toc45

20100-20

MAX1020 toc48

80604020

Page 14

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

14 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057), external V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD= DVDD= 5V

(MAX1020/MAX1022/MAX1058), external V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

CLK

= 4.8MHz (50% duty cycle), f

SAMPLE

= 300ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

1500

1200

900

600

GPIO OUTPUT VOLTAGE (mV)

300

0

GPIO OUTPUT VOLTAGE

vs. SINK CURRENT

GPIOB0–B3, C0–C3

OUTPUTS

GPIOA0–A3 OUTPUTS

MAX1021/MAX1023/MAX1057

060

SINK CURRENT (mA)

40 50302010

TEMPERATURE SENSOR ERROR

1.00

0.75

MAX1020 toc49

0.50

0.25

0

-0.25

-0.50

TEMPERATURE SENSOR ERROR (°C)

-0.75

-1.00

-40 85

DAC-TO-DAC CROSSTALK

vs. TEMPERATURE

MAX1020 toc50

6035-15 10

TEMPERATURE (°C)

= 10kΩ, C

R

LOAD

MAX1021/MAX1023/MAX1057

LOAD

100µs

= 100pF

MAX1020 toc51

V

OUTA

1V/div

V

OUTB

10mV/div

AC-COUPLED

DAC-TO-DAC CROSSTALK

= 10kΩ, C

R

LOAD

MAX1020/MAX1022/MAX1058

100µs

LOAD

= 100pF

MAX1020 toc52

V

OUTA

2V/div

V

OUTB

10mV/div

AC-COUPLED

DYNAMIC RESPONSE FALL TIME

= 10kΩ, C

R

LOAD

MAX1021/MAX1023/MAX1057

1µs

LOAD

= 100pF

MAX1020 toc55

V

OUT

1V/div

CS

1V/div

DYNAMIC RESPONSE RISE TIME

= 10kΩ, C

R

LOAD

MAX1021/MAX1023/MAX1057

1µs

LOAD

= 100pF

DYNAMIC RESPONSE FALL TIME

= 10kΩ, C

R

LOAD

MAX1020/MAX1022/MAX1058

1µs

LOAD

= 100pF

MAX1020 toc53

MAX1020 toc56

V

OUT

1V/div

CS

1V/div

CS

2V/div

V

OUT

2V/div

DYNAMIC RESPONSE RISE TIME

= 10kΩ, C

R

LOAD

MAX1020/MAX1022/MAX1058

MAJOR CARRY TRANSITION

= 10kΩ, C

R

LOAD

MAX1021/MAX1023/MAX1057

1µs

1µs

LOAD

LOAD

= 100pF

MAX1020 toc54

= 100pF

MAX1020 toc57

CS

2V/div

V

OUT

2V/div

CS

1V/div

V

OUT

10mV/div

AC-COUPLED

Page 15

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

______________________________________________________________________________________ 15

Typical Operating Characteristics (continued)

(AVDD= DVDD= 3V (MAX1021/MAX1023/MAX1057), external V

REF

= 2.5V (MAX1021/MAX1023/MAX1057), AVDD= DVDD= 5V

(MAX1020/MAX1022/MAX1058), external V

REF

= 4.096V (MAX1020/MAX1022/MAX1058), f

CLK

= 4.8MHz (50% duty cycle), f

SAMPLE

= 300ksps, C

LOAD

= 50pF, 0.1µF capacitor at REF, TA= +25°C, unless otherwise noted.)

MAJOR CARRY TRANSITION

= 10kΩ, C

R

LOAD

MAX1020/MAX1022/MAX1058

= 100pF

LOAD

1µs

MAX1020 toc58

CS

2V/div

V

OUT

20mV/div

AC-COUPLED

NEGATIVE FULL-SCALE SETTLING TIME

R

LOAD

= 10kΩ, C

MAX1021/MAX1023/MAX1057

LOAD

= 100pF

MAX1020 toc61

V

OUT

1V/div

DAC DIGITAL FEEDTHROUGH (R

= 100pF, CS = HIGH, DIN = LOW)

C

LOAD

MAX1021/MAX1023/MAX1057

200ns

NEGATIVE FULL-SCALE SETTLING TIME

= 10kΩ, C

R

LOAD

LOAD

= 10kΩ,

MAX1020 toc59

SCLK

1V/div

V

OUT

100mV/div

AC-COUPLED

DAC DIGITAL FEEDTHROUGH (R

= 100pF, CS = HIGH, DIN = LOW)

C

LOAD

MAX1020/MAX1022/MAX1058

200ns

LOAD

POSITIVE FULL-SCALE SETTLING TIME

LOAD

= 100pF

MAX1020 toc62

V

LDAC

2V/div

R

LOAD

= 10kΩ, C

MAX1021/MAX1023/MAX1057

LOAD

= 100pF

= 10kΩ,

MAX1020 toc60

MAX1020 toc63

SCLK

2V/div

V

OUT

100mV/div

AC-COUPLED

V

OUT_

1V/div

1µs

POSITIVE FULL-SCALE SETTLING TIME

R

LOAD

= 10kΩ, C

MAX1020/MAX1022/MAX1058

1µs

LOAD

= 100pF

MAX1020 toc64

V

LDAC

1V/div

V

LDAC

2V/div

V

OUT_

2V/div

MAX1020/MAX1022/MAX1058

2µs

ADC REFERENCE FEEDTHROUGH

= 10kΩ, C

R

LOAD

ADC REFERENCE SWITCHING

MAX1021/MAX1023/MAX1057

200µs

LOAD

= 100pF

MAX1020 toc65

V

OUT_

2V/div

V

REF2

1V/div

V

DAC-OUT

10mV/div

AC-COUPLED

1µs

ADC REFERENCE FEEDTHROUGH

= 10kΩ, C

R

LOAD

ADC REFERENCE SWITCHING

MAX1020/MAX1022/MAX1058

200µs

LOAD

= 100pF

MAX1020 toc66

V

LDAC

1V/div

V

REF2

2V/div

V

DAC-OUT

2mV/div

AC-COUPLED

Page 16

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

16 ______________________________________________________________________________________

Pin Description

MAX1020/

MAX1021

MAX1022/

MAX1057/

NAME FUNCTION

1, 2 — —

General-Purpose I/O A0, A1. GPIOA0, A1 can sink and source 15mA.

334 EOC

Active-Low End-of-Conversion Output. Data is valid after the falling edge

of EOC.

447 DV

DD

Digital Positive-Power Input. Bypass DVDD to DGND with a 0.1µF

capacitor.

558 DGND Digital Ground. Connect DGND to AGND.

669 DOUT

Serial-Data Output. Data is clocked out on the falling edge of the SCLK

clock in modes 00, 01, and 10. Data is clocked out on the rising edge of

the SCLK clock in mode 11. It is high impedance when CS is high.

7710 SCLK

Serial-Clock Input. Clocks data in and out of the serial interface. (Duty

cycle must be 40% to 60%.) See Table 5 for details on programming the

clock mode.

8811 DIN

Serial-Data Input. DIN data is latched into the serial interface on the

falling edge of SCLK.

9–12,

16–19

9–12,

16–19

22–25

OUT0–OUT7 DAC Outputs

13 13 18 AV

DD

Positive Analog Power Input. Bypass AVDD to AGND with a 0.1µF

capacitor.

14 14 19 AGND Analog Ground

15, 23, 32,

33

32

— N.C. No Connection. Not internally connected.

20 20 26 LDAC

Active-Low Load DAC. LDAC is an asynchronous active-low input that

updates the DAC outputs. Drive LDAC low to make the DAC registers

transparent.

21 21 27 CS

Active-Low Chip-Select Input. When CS is low, the serial interface is

enabled. When CS is high, DOUT is high impedance.

22 22 28 RES_SEL

Reset Select. Select DAC wake-up mode. Set RES_SEL low to wake up

the DAC outputs with a 100kΩ resistor to GND or set RES_SEL high to

wake up the DAC outputs with a 100kΩ resistor to V

REF

. Set RES_SEL

high to power up the DAC input register to FFFh. Set RES_SEL low to

power up the DAC input register to 000h.

24, 25 — —

G ener al - P ur p ose I/O C 0, C 1. G P IO C 0, C 1 can si nk 4m A and sour ce 2m A.

MAX1023

2, 15, 24, 32

MAX1058

GP IOA0, G P IOA1

12–15,

GP IOC 0, G P IOC 1

Page 17

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

______________________________________________________________________________________ 17

Pin Description (continued)

MAX1020/

MAX1021

MAX1022/

MAX1057/

NAME FUNCTION

26 26 35 REF1

Reference 1 Input. Reference voltage; leave unconnected to use the

internal reference (2.5V for the MAX1021/MAX1023/MAX1057 or 4.096V

for the MAX1020/MAX1022/MAX1058). REF1 is the positive reference in

ADC external differential reference mode. Bypass REF1 to AGND with a

0.1µF capacitor in external reference mode only. See the ADC/DAC

References section.

27–31, 34

——AIN0–AIN5 Analog Inputs

35 — — REF2/AIN6

Reference 2 Input/Analog-Input Channel 6. See Table 5 for details on

programming the setup register. REF2 is the negative reference in the

ADC external differential reference.

36 — — CNVST/AIN7

Active-Low Conversion-Start Input/Analog Input 7. See Table 5 for details

on programming the setup register.

—1—

Active-Low Conversion-Start Input/Analog Input 11. See Table 5 for

details on programming the setup register.

—

23, 25,

27–31,

— AIN0–AIN9 Analog Inputs

—36—REF2/AIN10

Reference 2 Input/Analog-Input Channel 10. See Table 5 for details on

programming the setup register. REF2 is the negative reference in the

ADC external differential reference.

—— 1

Active-Low Conversion-Start Input/Analog Input 15. See Table 5 for

details on programming the setup register.

——

Gener al - P ur p ose I/O A0–A3. GP IOA0–GP IOA3 can si nk and sour ce 15m A.

——

20, 21

General-Purpose I/O B0–B3. GPIOB0–GPIOB3 can sink 4mA and

source 2mA.

——29–32

General-Purpose I/O C0–C3. GPIOC0–GPIOC3 can sink 4mA and

source 2mA.

——

33, 34,

36–47

AIN0–AIN13 Analog Inputs

——48 REF2/AIN14

Reference 2 Input/Analog-Input Channel 14. See Table 5 for details on

programming the setup register. REF2 is the negative reference in the

ADC external differential reference.

——— EP

Exposed Paddle. Must be externally connected to AGND. Do not use as

a ground connect.

MAX1023

33, 34, 35

MAX1058

2, 3, 5, 6 GPIOA0–GPIOA3

16, 17,

CNVST/AIN11

CNVST/AIN15

GPIOB0–GPIOB3

GP IOC 0–GP IOC 3

Page 18

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

18 ______________________________________________________________________________________

Detailed Description

The MAX1020–MAX1023/MAX1057/MAX1058 integrate

a multichannel, 10-bit ADC and an octal, 10-bit DAC in

a single IC. These devices also include a temperature

sensor and configurable GPIOs with a 25MHz SPI/QSPI-/MICROWIRE-compatible serial interface. The

ADC is available in 8/12/16 input-channel versions. The

octal DAC outputs settle within 2.0µs, and the ADC has

a 300ksps conversion rate.

All devices include an internal reference (2.5V or

4.096V) providing a well-regulated, low-noise reference

for both the ADC and DAC. Programmable reference

modes for the ADC and DAC allow the use of an internal reference, an external reference, or a combination

of both. Features such as an internal ±1°C accurate

temperature sensor, FIFO, scan modes, programmable

internal or external clock modes, data averaging, and

AutoShutdown allow users to minimize both power consumption and processor requirements. The low glitch

energy (4nV•

s) and low digital feedthrough (0.5nV•s) of

the integrated octal DACs make these devices ideal for

digital control of fast-response closed-loop systems.

The devices are guaranteed to operate with a supply

voltage from +2.7V to +3.6V (MAX1021/MAX1023/

MAX1057) and from +4.5V to +5.5V (MAX1020/

MAX1022/MAX1058), they consume 25mA at 300ksps

throughput, only 22µA at 1ksps throughput, and under

0.2µA in the shutdown mode. The MAX1057/MAX1058

feature 12 GPIOs, while the MAX1020/MAX1021 offer 4

GPIOs that can be configured as inputs or outputs.

Figure 1 shows the MAX1057/MAX1058 functional dia-

gram. The MAX1020/MAX1021 only include the GPIO

A0, A1, GPIO C0, C1 block. The MAX1022/MAX1023

exclude the GPIOs. The output-conditioning circuitry

takes the internal parallel data bus and converts it to a

serial data format at DOUT, with the appropriate wakeup timing. The arithmetic logic unit (ALU) performs the

averaging function.

SPI-Compatible Serial Interface

The MAX1020–MAX1023/MAX1057/MAX1058 feature a

serial interface that is compatible with SPI and

MICROWIRE devices. For SPI, ensure the SPI bus master (typically a microcontroller (µC)) runs in master

mode so that it generates the serial clock signal. Select

the SCLK frequency of 25MHz or less, and set the

clock polarity (CPOL) and phase (CPHA) in the µC con-

trol registers to the same value. The MAX1020–

MAX1023/MAX1057/MAX1058 operate with SCLK idling

high or low, and thus operate with CPOL = CPHA = 0 or

CPOL = CPHA = 1. Set CS low to latch any input data

at DIN on the falling edge of SCLK. Output data at

DOUT is updated on the falling edge of SCLK in clock

modes 00, 01, and 10. Output data at DOUT is updated

on the rising edge of SCLK in clock mode 11. See

Figures 6–11. Bipolar true-differential results and temperature-sensor results are available in two’s complement format, while all other results are in binary.

A high-to-low transition on CS initiates the data-input

operation. Serial communications to the ADC always

begin with an 8-bit command byte (MSB first) loaded

from DIN. The command byte and the subsequent data

bytes are clocked from DIN into the serial interface on

the falling edge of SCLK. The serial-interface and fastinterface circuitry is common to the ADC, DAC, and

GPIO sections. The content of the command byte

determines whether the SPI port should expect 8, 16, or

24 bits and whether the data is intended for the ADC,

DAC, or GPIOs (if applicable). See Table 1. Driving CS

high resets the serial interface.

The conversion register controls ADC channel selection, ADC scan mode, and temperature-measurement

requests. See Table 4 for information on writing to the

conversion register. The setup register controls the

clock mode, reference, and unipolar/bipolar ADC configuration. Use a second byte, following the first, to

write to the unipolar-mode or bipolar-mode registers.

See Table 5 for details of the setup register and see

Tables 6, 7, and 8 for setting the unipolar- and bipolarmode registers. Hold CS low between the command

byte and the second and third byte. The ADC averaging register is specific to the ADC. See Table 9 to

address that register. Table 11 shows the details of the

reset register.

Begin a write to the DAC by writing 0001XXXX as a

command byte. The last 4 bits of this command byte

are don’t-care bits. Write another 2 bytes (holding CS

low) to the DAC interface register following the command byte to select the appropriate DAC and the data

to be written to it. See the DAC Serial Interface section

and Tables 10, 20, and 21.

Write to the GPIOs (if applicable) by issuing a command byte to the appropriate register. Writing to the

MAX1020/MAX1021 GPIOs requires 1 additional byte

Page 19

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

______________________________________________________________________________________ 19

Figure 1. MAX1057/MAX1058 Functional Diagram

SCLK

CS

DIN

DOUT

EOC

AIN0

AIN13

REF2/

AIN14

CNVST/

AIN15

GPIOB0–

GPIOA0–

GPIOB3

GPIOA3

USER-PROGRAMMABLE

I/O

OSCILLATOR

TEMPERATURE

SENSOR

CNVST

T/H

CONTROL

REF2

LOGIC

10-BIT

SAR

ADC

GPIOC0–

GPIOC3

GPIO

CONTROL

SPI

PORT

FIFO AND

ALU

AV

DD

ADDRESS

DV

DD

MAX1057

MAX1058

INPUT

REGISTER

INPUT

REGISTER

INPUT

REGISTER

INPUT

REGISTER

INPUT

REGISTER

INPUT

REGISTER

INPUT

REGISTER

INPUT

REGISTER

DAC

REGISTER

DAC

REGISTER

DAC

REGISTER

DAC

REGISTER

DAC

REGISTER

DAC

REGISTER

DAC

REGISTER

DAC

REGISTER

10-BIT

DAC

10-BIT

DAC

10-BIT

DAC

10-BIT

DAC

10-BIT

DAC

10-BIT

DAC

10-BIT

DAC

10-BIT

DAC

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

OUTPUT

CONDITIONING

OUTPUT

CONDITIONING

OUTPUT

CONDITIONING

OUTPUT

CONDITIONING

OUTPUT

CONDITIONING

OUTPUT

CONDITIONING

OUTPUT

CONDITIONING

OUTPUT

CONDITIONING

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

REF1

INTERNAL

REFERENCE

LDAC

AGND

DGND

RES_SEL

Page 20

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

20 ______________________________________________________________________________________

Table 1. Command Byte (MSB First)

X = Don’t care.

*Only applicable on the MAX1020/MAX1021/MAX1057/MAX1058.

following the command byte. Writing to the MAX1057/

MAX1058 requires 2 additional bytes following the

command byte. See Tables 12–19 for details on GPIO

configuration, writes, and reads. See the GPIO

Command section. Command bytes written to the

GPIOs on devices without GPIOs are ignored.

Power-Up Default State

The MAX1020–MAX1023/MAX1057/MAX1058 power up

with all blocks in shutdown (including the reference). All

registers power up in state 00000000, except for the

setup register and the DAC input register. The setup

register powers up at 0010 1000 with CKSEL1 = 1 and

REFSEL1 = 1. The DAC input register powers up to

FFFh when RES_SEL is high and it powers up to 000h

when RES_SEL is low.

10-Bit ADC

The MAX1020–MAX1023/MAX1057/MAX1058 ADCs

use a fully differential successive-approximation register (SAR) conversion technique and on-chip track-andhold (T/H) circuitry to convert temperature and voltage

signals into 10-bit digital results. The analog inputs

accept both single-ended and differential input signals.

Single-ended signals are converted using a unipolar

transfer function, and differential signals are converted

using a selectable bipolar or unipolar transfer function.

See the ADC Transfer Functions section for more data.

ADC Clock Modes

When addressing the setup, register bits 5 and 4 of the

command byte (CKSEL1 and CKSEL0, respectively)

control the ADC clock modes. See Table 5. Choose

between four different clock modes for various ways to

start a conversion and determine whether the acquisitions are internally or externally timed. Select clock

mode 00 to configure CNVST/AIN_ to act as a conversion start and use it to request internally timed conversions, without tying up the serial bus. In clock mode 01,

use CNVST to request conversions one channel at a

time, thereby controlling the sampling speed without

tying up the serial bus. Request and start internally

timed conversions through the serial interface by writing to the conversion register in the default clock mode,

10. Use clock mode 11 with SCLK up to 4.8MHz for

externally timed acquisitions to achieve sampling rates

up to 300ksps. Clock mode 11 disables scanning and

averaging. See Figures 6–9 for timing specifications on

how to begin a conversion.

These devices feature an active-low, end-of-conversion

output. EOC goes low when the ADC completes the

last requested operation and is waiting for the next

command byte. EOC goes high when CS or CNVST go

low. EOC is always high in clock mode 11.

Single-Ended or Differential Conversions

The MAX1020–MAX1023/MAX1057/MAX1058 use a

fully differential ADC for all conversions. When a pair of

inputs are connected as a differential pair, each input is

connected to the ADC. When configured in singleended mode, the positive input is the single-ended

channel and the negative input is referred to AGND.

See Figure 2.

In differential mode, the T/H samples the difference

between two analog inputs, eliminating common-mode

DC offsets and noise. IN+ and IN- are selected from

the following pairs: AIN0/AIN1, AIN2/AIN3, AIN4/AIN5,

AIN6/AIN7, AIN8/AIN9, AIN10/AIN11, AIN12/AIN13,

AIN14/AIN15. AIN0–AIN7 are available on all devices.

AIN0–AIN11 are available on the MAX1022/MAX1023.

REGISTER NAME BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

Conversion 1 CHSEL3 CHSEL2 CHSEL1 CHSEL0 SCAN1 SCAN0 TEMP

Setup 0 1 CKSEL1 CKSEL0 REFSEL1 REFSEL0 DIFFSEL1 DIFFSEL0

ADC Averaging 0 0 1 AVGON NAVG1 NAVG0 NSCAN1 NSCAN0

DAC Select 0 0 0 1 XXXX

Reset 0 0 0 0 1 RESET SLOW FBGON

GPIO Configure* 0 0 000011

GPIO Write* 0 0 000010

GPIO Read* 0 0 000001

No Operation 0 0 000000

Page 21

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

______________________________________________________________________________________ 21

AIN0–AIN15 are available on the MAX1057/MAX1058.

See Tables 5–8 for more details on configuring the

inputs. For the inputs that are configurable as CNVST,

REF2, and an analog input, only one function can be

used at a time.

Unipolar or Bipolar Conversions

Address the unipolar- and bipolar-mode registers

through the setup register (bits 1 and 0). See Table 5 for

the setup register. See Figures 3 and 4 for the transferfunction graphs. Program a pair of analog inputs for differential operation by writing a one to the appropriate bit

of the bipolar- or unipolar-mode register. Unipolar mode

sets the differential input range from 0 to V

REF1.

A negative differential analog input in unipolar mode causes

the digital output code to be zero. Selecting bipolar

mode sets the differential input range to ±V

REF1

/ 2. The

digital output code is binary in unipolar mode and two’s

complement in bipolar mode.

In single-ended mode, the MAX1020–MAX1023/

MAX1057/MAX1058 always operate in unipolar mode.

The analog inputs are internally referenced to AGND

with a full-scale input range from 0 to the selected reference voltage.

Analog Input (T/H)

The equivalent circuit of Figure 2 shows the ADC input

architecture of the MAX1020–MAX1023/MAX1057/

MAX1058. In track mode, a positive input capacitor is

connected to AIN0–AIN15 in single-ended mode and

AIN0, AIN2, and AIN4–AIN14 (only positive inputs) in

differential mode. A negative input capacitor is connected to AGND in single-ended mode or AIN1, AIN3,

and AIN5–AIN15 (only negative inputs) in differential

mode. For external T/H timing, use clock mode 01.

After the T/H enters hold mode, the difference between

the sampled positive and negative input voltages is

converted. The input capacitance charging rate determines the time required for the T/H to acquire an input

signal. If the input signal’s source impedance is high,

the required acquisition time lengthens.

Any source impedance below 300Ω does not significantly affect the ADC’s AC performance. A high-impedance source can be accommodated either by

lengthening t

ACQ

(only in clock mode 01) or by placing

a 1µF capacitor between the positive and negative analog inputs. The combination of the analog-input source

impedance and the capacitance at the analog input creates an RC filter that limits the analog input bandwidth.

Input Bandwidth

The ADC’s input-tracking circuitry has a 1MHz smallsignal bandwidth, making it is possible to digitize highspeed transient events and measure periodic signals

with bandwidths exceeding the ADC’s sampling rate by

using undersampling techniques. Anti-alias prefiltering

of the input signals is necessary to avoid high-frequency signals aliasing into the frequency band of interest.

Analog-Input Protection

Internal electrostatic-discharge (ESD) protection diodes

clamp all analog inputs to AV

DD

and AGND, allowing

the inputs to swing from (AGND - 0.3V) to (AVDD+

0.3V) without damage. However, for accurate conversions near full scale, the inputs must not exceed AV

DD

by more than 50mV or be lower than AGND by 50mV. If

an analog input voltage exceeds the supplies, limit the

input current to 2mA.

Internal FIFO

The MAX1020–MAX1023/MAX1057/MAX1058 contain a

first-in/first-out (FIFO) buffer that holds up to 16 ADC

results plus one temperature result. The internal FIFO

allows the ADC to process and store multiple internally

clocked conversions and a temperature measurement

without being serviced by the serial bus.

If the FIFO is filled and further conversions are requested without reading from the FIFO, the oldest ADC

results are overwritten by the new ADC results. Each

result contains 2 bytes, with the MSB preceded by four

leading zeros and the LSB followed by 2 sub-bits. After

each falling edge of CS, the oldest available pair of

bytes of data is available at DOUT, MSB first. When the

FIFO is empty, DOUT is zero.

Figure 2. Equivalent Input Circuit

AIN0–AIN15

(SINGLE-ENDED),

AIN0, AIN2,

AIN4–AIN14

(DIFFERENTIAL)

AGND

(SINGLE-ENDED),

AIN1, AIN3,

AIN5–AIN15

(DIFFERENTIAL)

ACQ

HOLD

ACQ

HOLD

AV

DD

REF1

AGND

CIN+

CIN-

/ 2

DAC

ACQ

COMPARATOR

HOLD

Page 22

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

22 ______________________________________________________________________________________

The first 2 bytes of data read out after a temperature

measurement always contain the 12-bit temperature

result, preceded by four leading zeros, MSB first. If

another temperature measurement is performed before

the first temperature result is read out, the old measurement is overwritten by the new result. Temperature

results are in degrees Celsius (two’s complement), at a

resolution of 8 LSB per degree. See the Temperature

Measurements section for details on converting the digital code to a temperature.

10-Bit DAC

In addition to the 10-bit ADC, the MAX1020–MAX1023/

MAX1057/MAX1058 also include eight voltage-output,

10-bit, monotonic DACs with less than 4 LSB integral

nonlinearity error and less than 1 LSB differential nonlinearity error. Each DAC has a 2µs settling time and

ultra-low glitch energy (4nV•s). The 10-bit DAC code is

unipolar binary with 1 LSB = V

REF

/ 4096.

DAC Digital Interface

Figure 1 shows the functional diagram of the MAX1057/

MAX1058. The shift register converts a serial 16-bit

word to parallel data for each input register operating

with a clock rate up to 25MHz. The SPI-compatible digital interface to the shift register consists of CS, SCLK,

DIN, and DOUT. Serial data at DIN is loaded on the

falling edge of SCLK. Pull CS low to begin a write

sequence. Begin a write to the DAC by writing

0001XXXX as a command byte. The last 4 bits of the

DAC select register are don’t-care bits. See Table 10.

Write another 2 bytes to the DAC interface register following the command byte to select the appropriate DAC

and the data to be written to it. See Tables 20 and 21.

The eight double-buffered DACs include an input and a

DAC register. The input registers are directly connected to the shift register and hold the result of the most

recent write operation. The eight 10-bit DAC registers

hold the current output code for the respective DAC.

Data can be transferred from the input registers to the

DAC registers by pulling LDAC low or by writing the

appropriate DAC command sequence at DIN. See

Table 20. The outputs of the DACs are buffered through

eight rail-to-rail op amps.

The MAX1020–MAX1023/MAX1057/MAX1058 DAC out-

put-voltage range is based on the internal reference or

an external reference. Write to the setup register (see

Table 5) to program the reference. If using an external

voltage reference, bypass REF1 with a 0.1µF capacitor

to AGND. The MAX1021/MAX1023/MAX1057 internal

reference is 2.5V. The MAX1020/MAX1022/MAX1058

internal reference is 4.096V. When using an external

reference on any of these devices, the voltage range is

0.7V to AVDD.

DAC Transfer Function

See Table 2 for various analog outputs from the DAC.

DAC Power-On Wake-Up Modes

The state of the RES_SEL input determines the wake-up

state of the DAC outputs. Connect RES_SEL to AVDDor

AGND upon power-up to be sure the DAC outputs

wake up to a known state. Connect RES_SEL to AGND

to wake up all DAC outputs at 000h. While RES_SEL is

low, the 100kΩ internal resistor pulls the DAC outputs to

AGND and the output buffers are powered down.

Connect RES_SEL to AVDDto wake up all DAC outputs

at FFFh. While RES_SEL is high, the 100kΩ pullup

resistor pulls the DAC outputs to V

REF1

and the output

buffers are powered down.

DAC Power-Up Modes

See Table 21 for a description of the DAC power-up

and power-down modes.

GPIOs

In addition to the internal ADC and DAC, the

MAX1057/MAX1058 also provide 12 general-purpose

input/output channels, GPIOA0–GPIOA3, GPIOB0–

Table 2. DAC Output Code Table

DAC CONTENTS

MSB LSB

11 1111 1111

10 0000 0001

+

10 0000 0000

01 0111 0111

00 0000 0001

V

ANALOG OUTPUT

1023

1024

513

1024

511

1024

1024

+

V

=

1

REF

V

+

REF

+

V

REF

512

REF

1024 2

+

V

REF

+

V

REF

00 0000 0000 0

Page 23

MAX1020–MAX1023/MAX1057/MAX1058

10-Bit, Multichannel ADCs/DACs with FIFO,

Temperature Sensing, and GPIO Ports

______________________________________________________________________________________ 23

GPIOB3, and GPIOC0–GPIOC3. The MAX1020/MAX1021

include four GPIO channels (GPIOA0, GPIOA1, GPIOC0,

GPIOC1). Read and write to the GPIOs as detailed in

Table 1 and Tables 12–19. Also, see the GPIO Command

section. See Figures 11 and 12 for GPIO timing.

Write to the GPIOs by writing a command byte to the

GPIO command register. Write a single data byte to the

MAX1020/MAX1021 following the command byte. Write

2 bytes to the MAX1057/MAX1058 following the command byte.

The GPIOs can sink and source current. The

MAX1057/MAX1058 GPIOA0–GPIOA3 can sink and

source up to 15mA. GPIOB0–GPIOB3 and GPIOC0–

GPIOC3 can sink 4mA and source 2mA. The MAX1020/

MAX1021 GPIOA0 and GPIOA1 can sink and source up

to 15mA. The MAX1020/MAX1021 GPIOC0 and GPIOC1

can sink 4mA and source 2mA. See Table 3.

Clock Modes

Internal Clock

The MAX1020–MAX1023/MAX1057/MAX1058 can

operate from an internal oscillator. The internal oscillator is active in clock modes 00, 01, and 10. Figures 6,

7, and 8 show how to start an ADC conversion in the

three internally timed conversion modes.

Read out the data at clock speeds up to 25MHz

through the SPI interface.

External Clock

Set CKSEL1 and CKSEL0 in the setup register to 11 to

set up the interface for external clock mode 11. See

Table 5. Pulse SCLK at speeds from 0.1MHz to

4.8MHz. Write to SCLK with a 40% to 60% duty cycle.

The SCLK frequency controls the conversion timing.

See Figure 9 for clock mode 11 timing. See the ADC

Conversions in Clock Mode 11 section.

ADC/DAC References

Address the reference through the setup register, bits 3

and 2. See Table 5. Following a wake-up delay, set

REFSEL[1:0] = 00 to program both the ADC and DAC

for internal reference use. Set REFSEL[1:0] = 10 to program the ADC for internal reference. Set REFSEL[1:0] =

10 to program the DAC for external reference, REF1.

When using REF1 or REF2/AIN_ in external-reference

mode, connect a 0.1µF capacitor to AGND. Set REFSEL[1:0] = 01 to program the ADC and DAC for external-reference mode. The DAC uses REF1 as its external

reference, while the ADC uses REF2 as its external reference. Set REFSEL[1:0] = 11 to program the ADC for

external differential reference mode. REF1 is the positive reference and REF2 is the negative reference in the

ADC external differential mode.

When REFSEL [1:0] = 00 or 10, REF2/AIN_ functions as

an analog input channel. When REFSEL [1:0] = 01 or 11,

REF2/AIN_ functions as the device’s negative reference.

Temperature Measurements

Issue a command byte setting bit 0 of the conversion

register to one to take a temperature measurement.

See Table 4. The MAX1020–MAX1023/MAX1057/

MAX1058 perform temperature measurements with an

internal diode-connected transistor. The diode bias current changes from 68µA to 4µA to produce a temperature-dependent bias voltage difference. The second

conversion result at 4µA is subtracted from the first at

68µA to calculate a digital value that is proportional to

absolute temperature. The output data appearing at

DOUT is the digital code above, minus an offset to

adjust from Kelvin to Celsius.

The reference voltage used for the temperature measurements is always derived from the internal reference

source to ensure that 1 LSB corresponds to 1/8 of a

degree Celsius. On every scan where a temperature