Page 1

查询MAX101供应商

19-1109; Rev 0; 7/96

EVALUATION KIT MANUAL

AVAILABLE

500Msps, 8-Bit ADC with Track/Hold

_______________General Description

The MAX101A ECL-compatible, 500Msps, 8-bit analogto-digital converter (ADC) allows accurate digitizing of

analog signals from DC to 250MHz (Nyquist frequency). Dual monolithic converters, driven by the track/hold

(T/H), operate on opposite clock edges (time interleaved). Designed with Maxim’s proprietary advanced

bipolar processes, the MAX101A contains a high-performance T/H amplifier and two quantizers in an 84-pin

ceramic flat pack.

The innovative design of the internal T/H ensures an

exceptionally wide 1.2GHz input bandwidth and aperture delay uncertainty of less than 2ps, resulting in a

high 7.0 effective bits at the Nyquist frequency. Special

comparator output design and decoding circuitry

reduce out-of-sequence code errors. The probability of

erroneous codes due to metastable states is reduced to

less than 1 error per 1015clock cycles. And, unlike other

ADCs that can have errors resulting in false full-scale or

zero-scale outputs, the MAX101A keeps the error magnitude to less than 1LSB.

The analog input is designed for either differential or

single-ended use with a ±250mV range. Sense pins for

the reference input allow full-scale calibration of the

____________________________Features

♦ 500Msps Conversion Rate

♦ 7.0 Effective Bits Typical at 250MHz

♦ 1.2GHz Analog Input Bandwidth

♦ Less than ±1/2LSB INL

♦ 50Ω Differential or Single-Ended Inputs

♦ ±250mV Input Signal Range

♦ Ratiometric Reference Inputs

♦ Dual Latched Output Data Paths

-15

♦ Low Error Rate, Less than 10

Metastable States

♦ 84-Pin Ceramic Flat Pack

________________________Applications

High-Speed Digital Instrumentation

High-Speed Signal Processing

Medical Systems

Radar/Signal Processing

High-Energy Physics

Communications

input range or facilitate ratiometric use.

Phase adjustment is available to adjust the relative

sampling of the converter halves for optimizing converter performance. Input clock phasing is also available

for interleaving several MAX101As for higher effective

sampling rates.

______________Ordering Information

PART

MAX101ACFR* 0°C to +70°C

*Contact factory for 84-pin ceramic flat pack without heatsink.

TEMP. RANGE PIN-PACKAGE

84 Ceramic Flat Pack

(with heatsink)

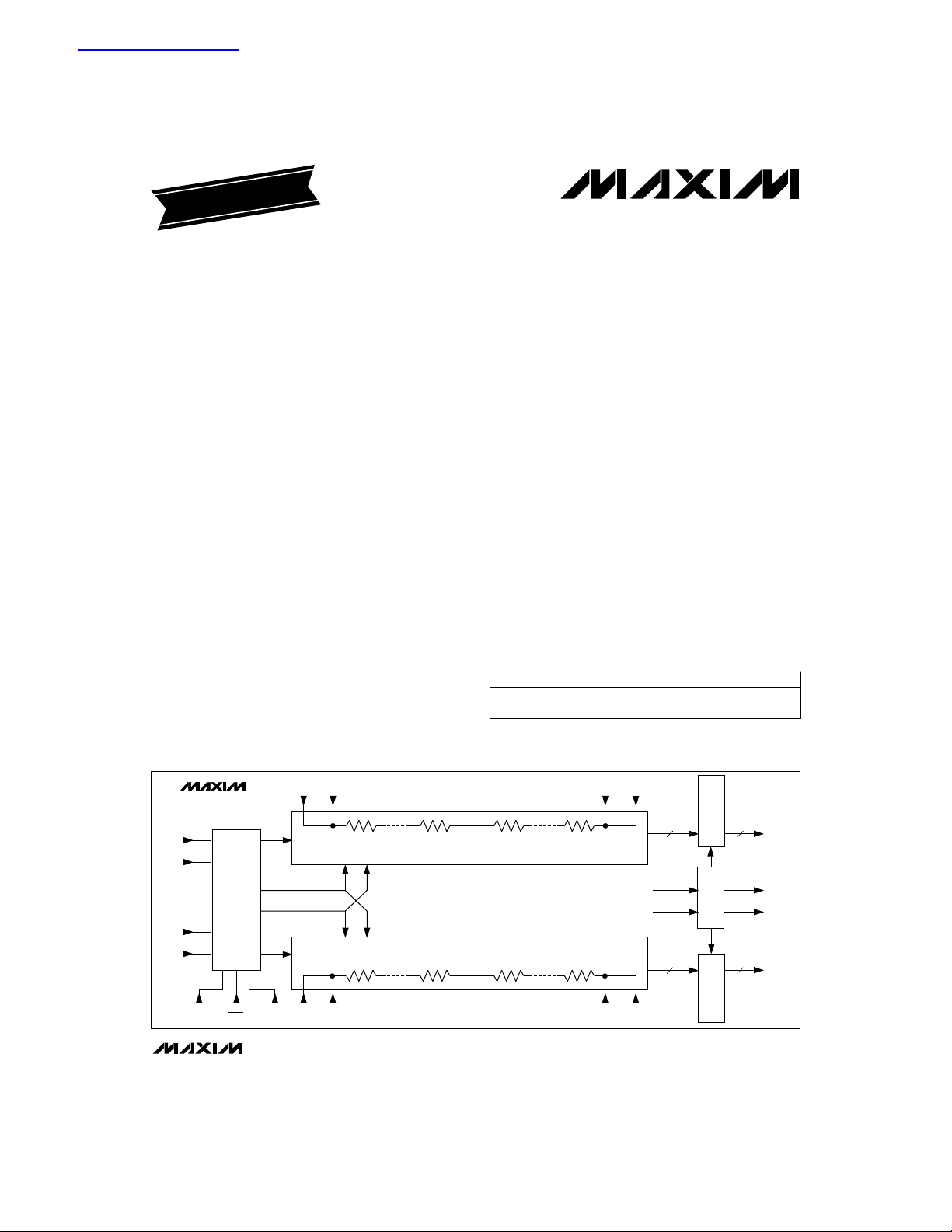

_________________________________________________________Functional Diagram

MAX101A

AIN+

AIN-

CLK

CLK

MAX101A

TRK1

VA

RTVARTS VA

FLASH CONVERTER

(8 -BIT)

TRACK

AND

HOLD

FLASH CONVERTER

(8 -BIT)

PH

VB

TRK1

ADJ

________________________________________________________________

VB

RT

RTS

VA

RBS

RB

8 8

STROBESTROBE

8 8

VB

VB

RB

RBS

Maxim Integrated Products

For the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

L

A

T

C

H

E

S

B

U

F

F

E

R

L

A

T

C

H

E

S

ADATA

DCLK

DCLK

BDATA

1

Page 2

500Msps, 8-Bit ADC with Track/Hold

ABSOLUTE MAXIMUM RATINGS

Supply Voltages (Note 1)

...........................................................................0V to +7V

V

CC

.............................................................................-7V to 0V

V

EE

- VEE.........................................................................+12V

V

CC

Analog Input Voltage.............................................................±2V

Reference Voltage (VA

Reference Voltage (VA

Clock Input Voltage (V

MAX101A

Note 1: The digital control inputs are diode protected. However, limited protection is provided on other pins. Permanent damage

, VBRT)...........................-0.3V to +1.5V

RT

, VBRB)..........................-1.5V to +0.3V

RB

, VIL).....................................-2.3V to 0V

IH

may occur on unconnected units under high-energy electrostatic fields. Keep unused units in supplied conductive carrier or

shunt the terminals together.

Note 2: Typical thermal resistance, junction-to-case R

=12°C/W, if 200 lineal ft/min airflow is provided. See

R

θJA

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

= 5°C/W and thermal resistance, junction to ambient (MAX101ACFR)

θJC

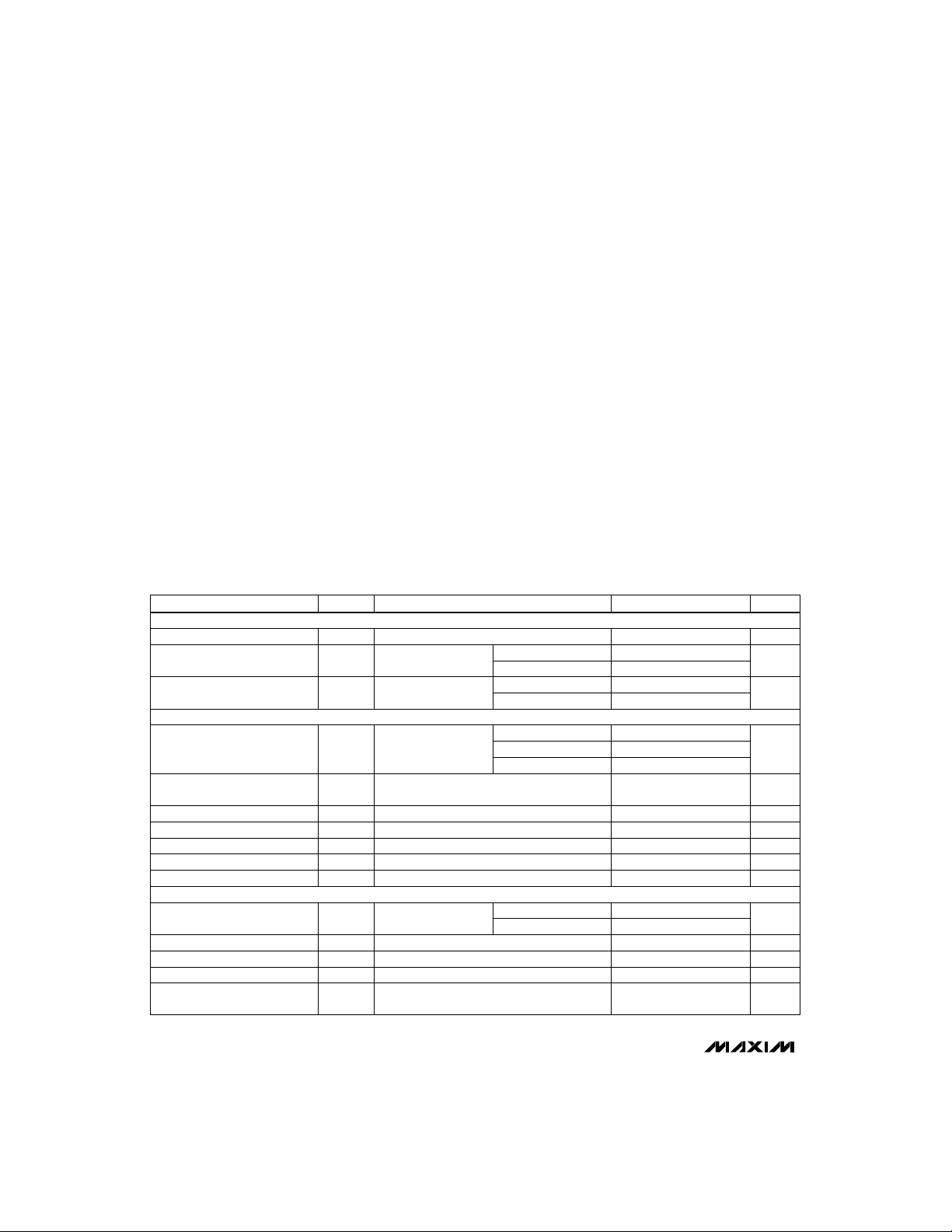

ELECTRICAL CHARACTERISTICS

(VEE= -5.2V, VCC= +5V, RL= 100Ω to -2V, VART, VBRT= 0.95V, VARB, VBRB= -0.95V, TA= +25°C, unless otherwise noted.

to T

T

MIN

ACCURACY

DYNAMIC SPECIFICATIONS

Maximum Conversion Rate

Analog Input Bandwidth

Aperture Width

Aperture Delay

Aperture Jitter

ANALOG INPUT

Input Voltage Range

Input Offset Voltage

Least Significant Bit Size

Input Resistance

Input Resistance

Temperature Coefficient

= 0°C to +70°C.) (Note 3)

MAX

AData, BData

INLIntegral Nonlinearity (Note 4)

AData, BData,

DNLDifferential Nonlinearity

no missing codes

f

= 500MHz,

CLK

ENOBEffective Bits

VIN= 95% full scale

(Note 5)

f

= 125MHz, f

AIN

VIN= 95% full scale (Note 6)

(Note 7)

CLK

3dB

Figure 4

AW

Figure 4 ns1t

AD

Figure 4

AJ

AIN+ to AIN-, Table 2,

V

IN

TA= T

AIN+, AIN-, TA= T

IO

TA= T

AIN+, AIN-, to GND

I

MIN

MIN

to T

to T

DIV10 Input Voltage (VIH, VIL).......................................VEEto 0V

Output Current, (I

<100°C.......................................................................14mA

T

J

100°C < T

Operating Temperature Range...............................0°C to +70°C

<120°C.........................................................12mA

J

OUT(max)

)

Operating Junction Temperature (Note 2)............0°C to +120°C

Storage Temperature Range.............................-65°C to +150°C

Lead Temperature (soldering, 10sec).............................+250°C

Package Information.

CONDITIONS

TA= T

MIN

to T

MAX

TA= +25°C

CLK

MAX

MAX

TA= T

f

AIN

f

AIN

f

AIN

= 500MHz,

Full scale

Zero scale

to T

MIN

MIN

= 10MHz

= 125MHz

= 250MHz

MAX

to T

MAX

7.6

6.7 7.0

205 290

-290 -205

UNITSMIN TYP MAXSYMBOLPARAMETER

±0.50TA= +25°C

±0.75

±0.75

±0.85

Bits8Resolution

LSB

LSB

Bits7.1

dB44.5SNRSignal-to-Noise Ratio

Msps500f

GHz1.2BW

ps270t

ps2t

mV

mV-23 23V

mV1.65 2.35LSB

Ω49 51R

Ω/°C0.008

2 _______________________________________________________________________________________

Page 3

500Msps, 8-Bit ADC with Track/Hold

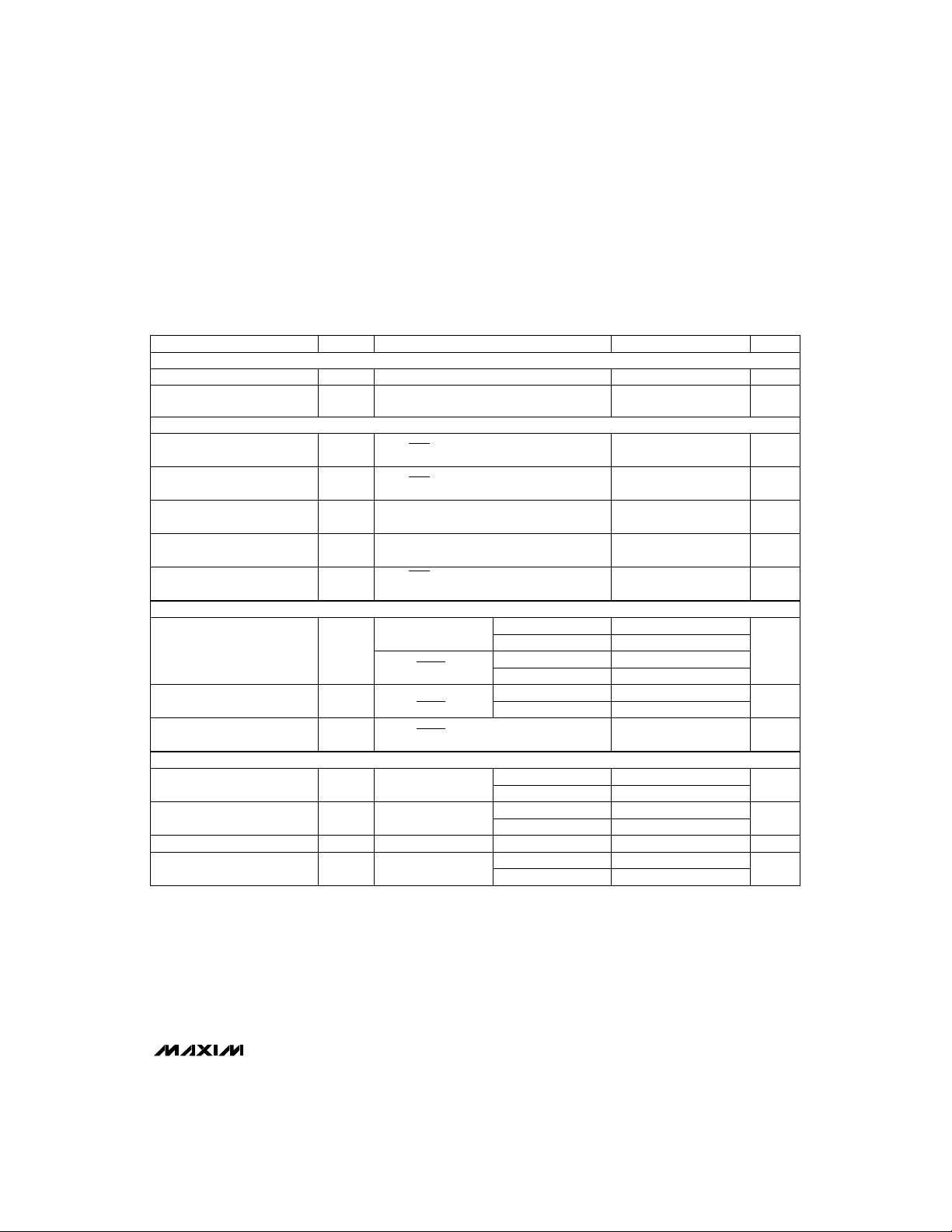

ELECTRICAL CHARACTERISTICS (continued)

(VEE= -5.2V, VCC= +5V, RL= 100Ω to -2V, VART, VBRT= 0.95V, VARB, VBRB= -0.95V, TA= +25°C, unless otherwise noted.

to T

T

MIN

REFERENCE INPUT

Reference String Resistance

Reference String Resistance

Temperature Coefficient

LOGIC INPUTS

Digital Input Low Voltage

Digital Input High Voltage

Digital Input High Current

Input Bias Current I

Clock Input Bias Current I

LOGIC OUTPUTS (Note 8)

Digital Output Low Voltage

Digital Output High Voltage

Digital Output Voltage

POWER REQUIREMENTS

Positive Supply Current

Negative Supply Current

Power-Supply Rejection Ratio PSRR

= 0°C to +70°C.) (Note 3)

MAX

OH

VARTto VA

REF

CLK, CLK, TA= T

IL

CLK, CLK, TA= T

IH

I

DIV10 = 0V, TA= T

IH

PH

B

CLK, CLK = -0.8V (no termination),

CLK

TA= T

= 0V, TA= T

ADJ

MIN

RB

to T

AData, BData

V

OL

DCLK, DCLK

AData, BData,

V

OH

DCLK, DCLK

DCLK, DCLK, TA= T

- V

OL

VCC= 5.0V

I

VCC

VEE= -5.2V

I

VEE

V

= ±0.5V TA= T

INCM

VCC(nom) = ±0.25V

TA= T

MIN

to T

CONDITIONS

to T

MIN

to T

MIN

to T

MIN

to T

MIN

MAX

MIN

MAX

MAX

MAX

MAX

MAX

TA= T

TA= T

MIN

MIN

to T

to T

MAX

MAX

TA= +25°C

TA= T

to T

MAX

MIN

to T

MAX

TA= +25°C

TA= T

MIN

to T

MAX

TA= +25°C

TA= T

MIN

MIN

to T

to T

MAX

MAX

VEE(nom) = ±0.25V

-1.1

1.1 3.1

-40 40

-50 50

-1.95 -1.60TA= +25°C

-1.95 -1.50

-1.3 -1.00TA= +25°C

-1.4 -0.9

-1.02 -0.70

-1.10 -0.60

415 855

910

-895 -500

-935

40VCC(nom) = ±0.25V

40

MAX101A

UNITSMIN TYP MAXSYMBOLPARAMETER

Ω100 190R

Ω/°C0.02

V-1.50V

VV

mA

µA

µA

V

V

mV275 445V

mA

mA

dBCMRRCommon-Mode Rejection Ratio 35

dB

_______________________________________________________________________________________ 3

Page 4

500Msps, 8-Bit ADC with Track/Hold

TIMING CHARACTERISTICS

(VEE= -5.2V, VCC= +5V, RL= 100Ω to -2V, VART, VBRT= 0.95V, VARB, VBRB= -0.95V, TA= +25°C, unless otherwise noted.)

CONDITIONS

Clock Pulse Width Low

Clock Pulse Width High

CLK to DCLK

Propagation Delay

DCLK to A/BData

MAX101A

Propagation Delay

Rise Time

Fall Time

Note 3: All devices are 100% production tested at +25°C and are guaranteed by design for T

Note 4: Deviation from best-fit straight line. See

Note 5: See the

Signal-to-Noise Ratio and Effective Bits

Note 6: SNR calculated from effective bits performance using the following equation: SNR(dB) = 1.76 + 6.02 x effective bits.

Note 7: Clock pulse width minimum requirements t

Note 8: Outputs terminated through 100Ω to -2.0V.

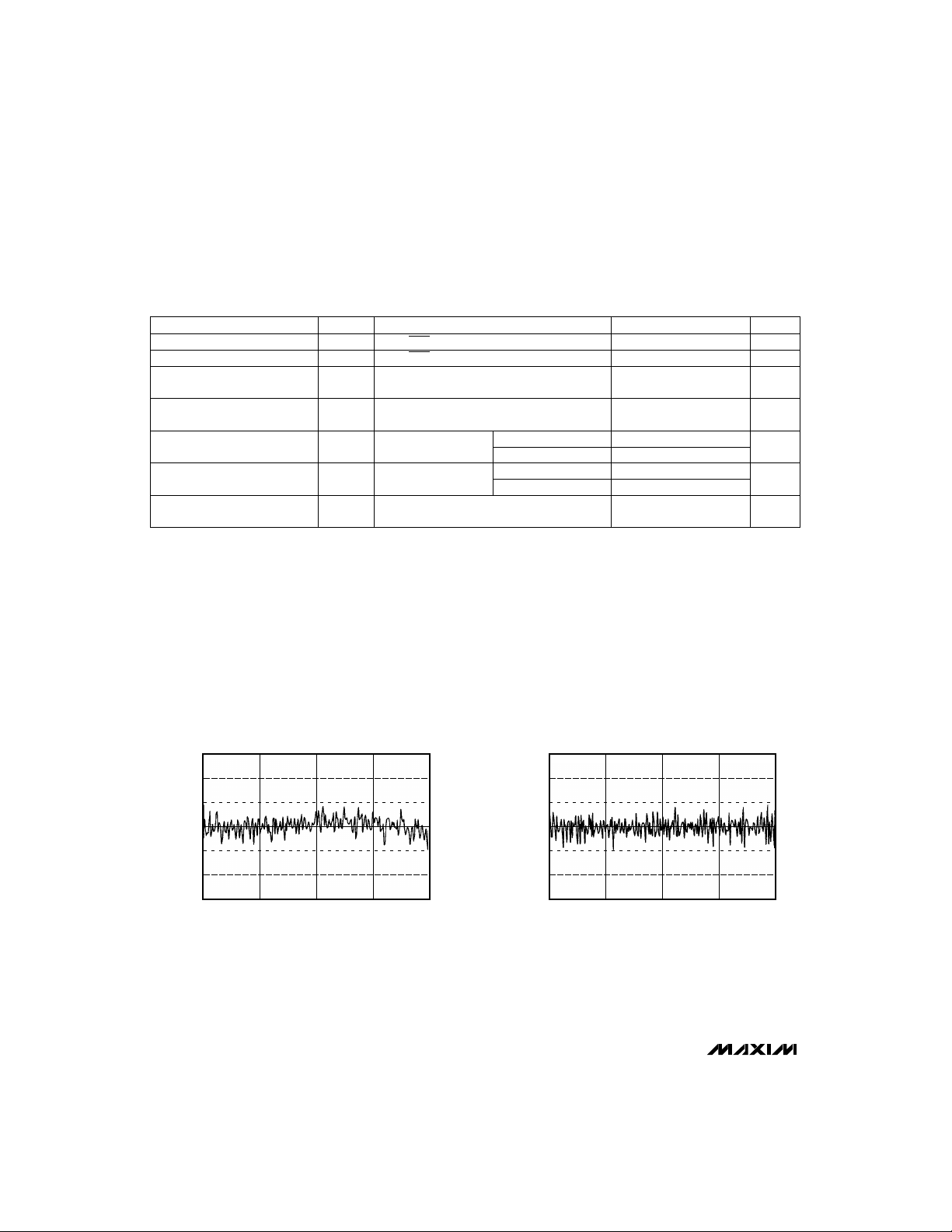

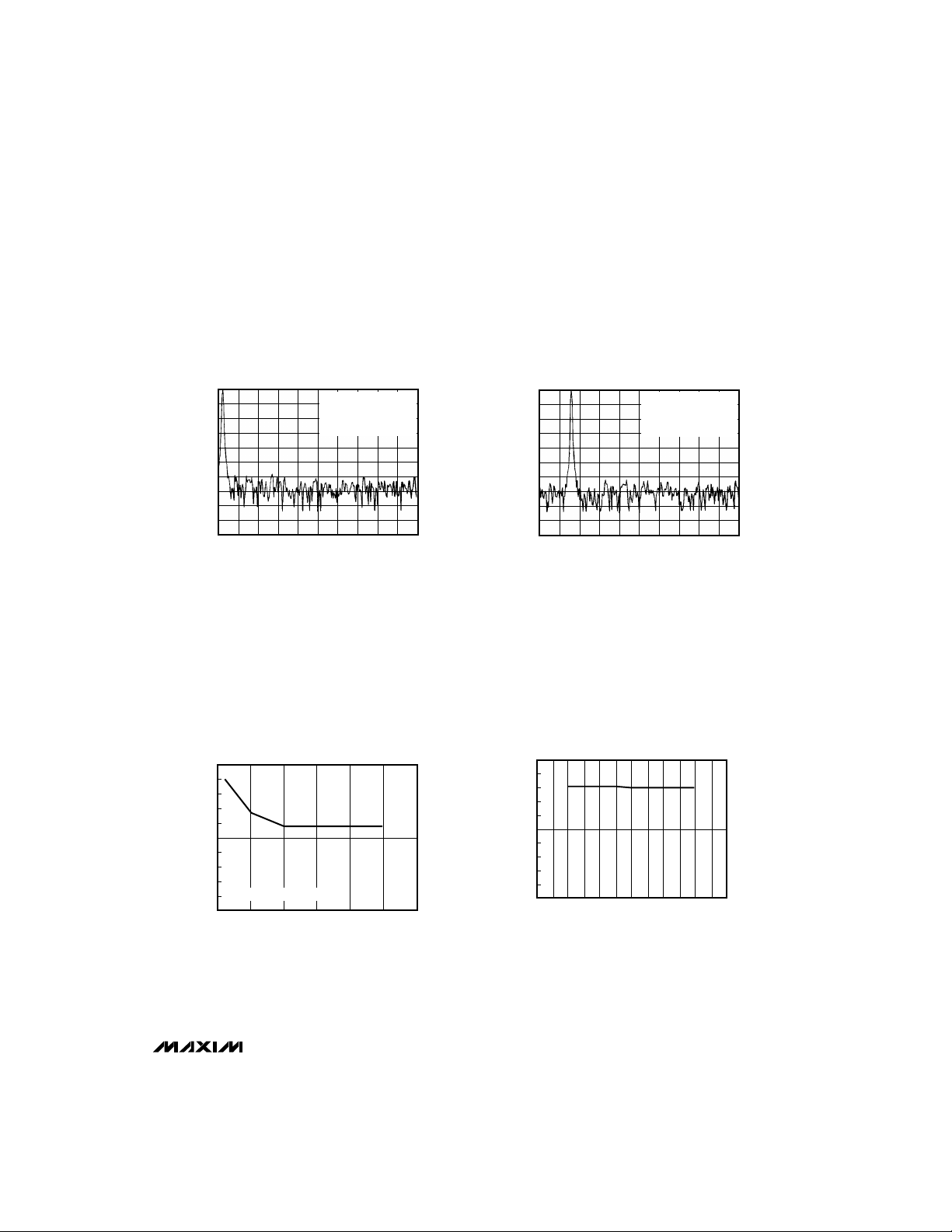

__________________________________________Typical Operating Characteristics

(VEE= -5.2V, VCC= +5V, RL= 100Ω to -2V, VART, VBRT= 0.95V, VARB, VBRB= -0.95V, TA= +25°C, unless otherwise noted.)

INTEGRAL NONLINEARITY

0.75

0.50

0.25

vs. OUTPUT CODE

CLK, CLK

PWL

CLK, CLK

PWH

DIV10 = 0, Figures 1 and 2

PD1

DIV10 = 0, Figures 1 and 2

PD2

20% to 80%

t

R

20% to 80% ps

t

F

Divide-by-1 mode See

t

Divide-by-1 mode, Figures 2 and 3, Table 1Pipeline Delay (Latency) 15 15

NPD

Figures 2, 3

Integral Nonlinearity

section in the

and t

PWL

DCLK

DATA

DCLK

DATA

section.

Detailed Description of Specifications

must be observed to achieve stated performance.

PWH

0.7 1.3 1.8t

300

500

300

800

= T

to T

A

MIN

DIFFERENTIAL NONLINEARITY

vs. OUTPUT CODE

MAX101 TOC1

0.75

0.50

0.25

as specified.

MAX

.

UNITSMIN TYP MAXSYMBOLPARAMETER

ns0.9 2.5t

ns0.9 2.5t

ns1.2 2.3 3.4t

ns

ps

Clock

Cycles

MAX101 TOC2

0

INL (LSBs)

-0.25

-0.50

-0.75

0 256

64 192128

OUTPUT CODE

0

DNL (LSBs)

-0.25

-0.50

-0.75

0 256

64 192128

OUTPUT CODE

4 _______________________________________________________________________________________

Page 5

500Msps, 8-Bit ADC with Track/Hold

____________________________Typical Operating Characteristics (continued)

(VEE= -5.2V, VCC= +5V, RL= 100Ω to -2V, VART, VBRT= 0.95V, VARB, VBRB= -0.95V, TA= +25°C, unless otherwise noted.)

FFT PLOT

(f

= 251.4462MHz)

0

-10

-20

-30

-40

-50

(dB)

-60

-70

-80

-90

-100

0 50 75 100 125

AIN

f

= 500MHz

CLK

SER = -44.5dB

NOISE FLOOR = -67.3dB

SPURIOUS = -58.2dB

25

(MHz)

EFFECTIVE BITS vs. ANALOG INPUT

FREQUENCY (f

(f

= 500MHz, VIN = 95% FS)

8

CLK

AIN

0

MAX101 TOC3

)

MAX110 TOC5

-10

-20

-30

-40

-50

(dB)

-60

-70

-80

-90

-100

0 25 37.5 50 62.5

12.5

(f

8

FFT PLOT

(f

= 10.4462MHz)

AIN

f

= 250MHz

CLK

SER = -47.2dB

NOISE FLOOR = -70.5dB

SPURIOUS = -61.8dB

(MHz)

EFFECTIVE BITS vs. CLOCK

FREQUENCY (f

= 10.4462, VIN = 95% FS)

AIN

CLK

)

MAX101 TOC4

MAX110 TOC6

MAX101A

7

EFFECTIVE BITS

RECORD LENGTH = 512

6

7

EFFECTIVE BITS

500

100 150 200 250 300

f

(MHz)

AIN

6

200 300 400 500 600

1000

f

(MHz)

CLK

_______________________________________________________________________________________

5

Page 6

500Msps, 8-Bit ADC with Track/Hold

____________________________Typical Operating Characteristics (continued)

(VEE= -5.2V, VCC= +5V, RL= 100Ω to -2V, VART, VBRT= 0.95V, VARB, VBRB= -0.95V, TA= +25°C, unless otherwise noted.)

-550mV

MAX101A

100mV/div

-1.55V

-4.18ns 5.2ns

-825mV

100mV/div

DATA CLOCK (DCLK)

RISE TIME (360ps), DIV10 = OPEN

BDATA RISE TIME (504ps),

DIV10 = OPEN

MAX101 TOC7

MAX101 TOC9

DATA CLOCK (DCLK) FALL TIME

(315ps), DIV10 = OPEN

-550mV

MAX101 TOC8

100mV/div

-1.55V

-4.18ns 5.2ns

BDATA FALL TIME (827ps),

DIV10 = OPEN

-825mV

MAX101 TOC10

100mV/div

-1.825V

-4.98ns 5.02ns

-1.825V

-4.98ns 5.02ns

6 _______________________________________________________________________________________

Page 7

500Msps, 8-Bit ADC with Track/Hold

______________________________________________________________Pin Description

PIN

1 PAD Internal connection, leave open.

2, 62 CLK

3, 61 CLK

4, 7, 15, 18,

24, 27, 30,

34, 37, 40,

46, 49, 57,

60, 64, 67,

68, 70, 71,

74, 77, 78,

79, 82, 84

5, 59 TRK1

6, 58 TRK1

8, 21, 43,

56, 81

9 VB

10 VB

11 TP4 Internal connection, leave pin open.

12 TP3

13 VB

14 VB

16, 48, 63 N.C.

29 SUB

31 DCLK

33 DCLK

32, 69, 80 V

35

36, 38, 39,

41, 42, 44,

45, 47

28, 26, 25,

23, 22, 20,

19, 17

NAME FUNCTION

Complementary Differential Clock Inputs. Can be driven from standard 10KH ECL with the following

considerations: Internally, pins 2, 62 and 3, 61 are the ends of a 50Ω transmission line. Either end

can be driven with the other end terminated with 50Ω to -2V. See

GND Power-Supply Ground

Phasing inputs (normally left open). See

V

DIV10 Divide by 10 mode. Leave open for normal operation. Selects test mode when grounded.

A7–A0

B7–B0

Positive Power Supply, +5V ±5% nominal

CC

“B” side negative reference voltage input (Note 9)

RB

“B” side negative reference voltage sense (Note 9)

RBS

Internal connection, leave pin open.

“B” side positive reference voltage sense (Note 9)

RTS

“B” side positive reference voltage input (Note 9)

RT

No Connect—no internal connection to these pins.

Circuit Substrate contact. This pin must be connected to VEE.

Complementary Differential Clock Outputs. Used to synchronize following circuitry: Outputs A0–A7

are valid after DCLK’s rising edge. B0–B7 output data are valid after DCLK’s falling edge (see Figure 1

for output timing information).

Negative Power Supply, -5.2V ±5% nominal

EE

AData and BData Outputs. A0 and B0 are the LSBs, and A7 and B7 are the MSBs. AData and BData

outputs conform to ECL logic swings and drive 100Ω transmission lines. Terminate with 100Ω to -2V

(120Ω for Tj > +100°C). See Figures 1–3.

Applications Information

Typical Operating Circuit

section.

.

MAX101A

_______________________________________________________________________________________ 7

Page 8

500Msps, 8-Bit ADC with Track/Hold

_________________________________________________Pin Description (continued)

NAME FUNCTIONPIN

50 VA

51 VA

52 TP1 Internal connection, leave pin open.

MAX101A

53 TP2 Internal connection, leave pin open.

54 VA

55 VA

65 TP5 Internal connection, leave pin open.

66 TP6 Internal connection, leave pin open.

72, 73 AIN+

75, 76 AIN-

83 PH

Note 9: VART, VARB, VBRT, and VBRBshould be adjusted separately from a well bypassed reference circuit to ensure proper

amplitude and offset matching. The sense connections to each of these terminals allows precision setting of the reference

voltage. The reference ladder is similar for both converter halves (check electrical section for values). Any noise on these

terminals will severely reduce overall performance.

Note 10: Good results are obtained by connecting the PH

±1.25V to this input. The time that the “A” T/H bridge samples relative to the time that the “B” T/H bridge samples can be

varied through a ±18ps range.

“A” side positive reference voltage input (Note 9)

RT

“A” side positive reference voltage sense (Note 9)

RTS

“A” side negative reference voltage sense (Note 9)

RBS

“A” side negative reference voltage input (Note 9)

RB

Analog Inputs, internally terminated with 50Ω to ground. Full-scale linear input range is approximately

±250mV. Drive AIN+ and AIN- differentially for best high-frequency performance.

Phase adjustment for T/H. Normally connected to ground. A phase adjustment of approximately ±18ps

ADJ

can be made by varying this pin’s bias point to optimize interleaving between sides A and B (Note 10).

input to ground. Improve performance by applying a voltage between

ADJ

CLK

CLK

DCLK

DCLK

ADATA

BDATA

t

PD2

t

t

PWH

t

PD1

t

PWL

PD2

Figure 1. Output Timing, Normal Mode (DIV10 = OPEN)

8 _______________________________________________________________________________________

Page 9

CLK

DCLK

500Msps, 8-Bit ADC with Track/Hold

N–1

N

N+2 +14 +15 +16 +17

N+1

01 7 8

MAX101A

ADATA

BDATA

t

PD2

t

PD2

NOTE: DATA ARBITRARY ON START-UP FOR SIDE A OR B, SEE

INPUT CLOCK PHASING

Figure 2. Output Timing, Clock to Data, Normal Mode (DIV10 = OPEN)

CLK

DCLK

ADATA

BDATA

N

N+2 N+3 +15 +16 +17

N+1

N-1 N+3

N-2 N N+2

SECTION.

N+1

N

N+5

NOTE: DATA ARBITRARY ON START-UP FOR SIDE A OR B, SEE

Figure 3. Output Timing, Test Mode (DIV10 = GND)

_______________________________________________________________________________________ 9

INPUT CLOCK PHASING

SECTION.

Page 10

500Msps, 8-Bit ADC with Track/Hold

______Definitions of Specifications

Signal-to Noise Ratio and Effective Bits

Signal-to-noise ratio (SNR) is the ratio between the RMS

amplitude of the fundamental input frequency to the

RMS amplitude of all other analog-to-digital (A/D) output signals. The theoretical minimum A/D noise is

caused by quantization error and is a direct result of

the ADC’s resolution: SNR = (6.02N + 1.76)dB, where N

MAX101A

is the number of effective bits of resolution. Therefore, a

perfect 8-bit ADC can do no better than 50dB. The FFT

plots in the

Typical Operating Characteristics

output level in various spectral bands.

Effective bits is calculated from a digital record taken

from the ADC under test. The quantization error of the

ideal converter equals the total error of the device. In

addition to ideal quantization error, other sources of

error include all DC and AC nonlinearities, clock and

aperture jitter, missing output codes, and noise. Noise

on references and supplies also degrades effective bits

performance.

The ADC’s input is sine-wave filtered with an anti-aliasing filter to remove any harmonic content. The digital

record taken from this signal is compared against a

mathematically generated sine wave. DC offsets,

phase, and amplitudes of the mathematical model are

adjusted until a best-fit sine wave is found. After subtracting this sine wave from the digital record, the residual error remains. The RMS value of the error is applied

in the following equation to yield the ADC’s effective

bits.

Effective bits = N - log2—————————-

measured RMS error

ideal RMS error

where N is the resolution of the converter. In this case,

N = 8.

The worst-case error for any device will be at the converter’s maximum clock rate with the analog input near

the Nyquist rate (one-half the input clock rate).

Aperture Width and Jitter

Aperture width is the time the T/H circuit takes to disconnect the hold capacitor from the input circuit (i.e., to

turn off the sampling bridge and put the T/H in hold

mode). Aperture jitter is the sample-to-sample variation

in aperture delay (Figure 4).

Error Rates

Errors resulting from metastable states may occur when

the analog input voltage, at the time the sample is

taken, falls close to the decision point for any one of the

input comparators. The resulting output code for many

show the

CLK

CLK

ANALOG

INPUT

t

AD

SAMPLED

DATA (T/H)

TRACK

T/H

Figure 4. T/H Aperture Timing

typical converters can be incorrect, including false full- or

zero-scale output. The MAX101A’s unique design

reduces the magnitude of this type of error to 1LSB, and

reduces the probability of the error occurring to less than

one in every 10

15

operated at 500MHz, 24 hours a day, this would translate

to less than one metastable state error every 46 days.

Integral nonlinearity is the deviation of the transfer function from a reference line measured in fractions of 1LSB

using a “best straight line” determined by a least

square curve fit.

Differential nonlinearity (DNL) is the difference between

the measured LSB step and an ideal LSB step size

between adjacent code transitions. DNL is expressed

in LSBs and is calculated using the following equation:

DNL(LSB) = ——————————————-

where V

MEAS - 1

is the measured value of the previous

code.

A DNL specification of less than 1LSB guarantees no

missing codes and a monotonic transfer function.

t

AW

t

AJ

TRACKHOLD

APERTURE DELAY (t

APERTURE WIDTH (tAW)

APERTURE JITTER (tAJ)

AD)

clock cycles. If the MAX101A were

Integral Nonlinearity

Differential Nonlinearity

[V

MEAS

- (V

MEAS - 1

)] - LSB

LSB

10 ______________________________________________________________________________________

Page 11

500Msps, 8-Bit ADC with Track/Hold

_______________Detailed Description

Converter Operation

The parallel or “flash” architecture used by the MAX101A

provides the fastest multibit conversion of all common

integrated ADC designs. The basic element of a flash, as

with all other ADC architectures, is the comparator, which

has a positive input, a negative input, and an output. If

the voltage at the positive input is higher than the negative input (connected to a reference), the output will be

high. If the positive input voltage is lower than the reference, the output will be low. A typical n-bit flash consists

of 2n- 1 comparators with negative inputs evenly spaced

at 1LSB increments from the bottom to the top of the reference ladder. For n = 8, there are 255 comparators.

For any input voltage, all the comparators with negative

inputs connected to the reference ladder below the

input voltage will have outputs of 1 and all comparators

with negative inputs above the input voltage will have

outputs of 0. Decode logic is provided to convert this

information into a parallel n-bit digital word (the output)

corresponding to the number of LSBs (minus 1) that the

input voltage is above the bottom of the ladder.

The comparators contain latch circuitry and are

clocked. This allows the comparators to function as

described previously when, for example, clock is low.

When clock goes high (samples) the comparator will

latch and hold its state until the clock goes low again.

The MAX101A uses a monolithic, dual-interleaved parallel quantizer chip with two separate 8-bit converters.

These converters deliver results to the A and B output

latches on alternate negative edges of the input clock.

Track/Hold

As with all ADCs, if the input waveform is changing

rapidly during the conversion, the effective bits and

SNR will decrease. The MAX101A has an internal

track/hold (T/H) that increases attainable effective-bits

performance and allows more accurate capture of analog data at high conversion rates.

The internal T/H circuit provides two important circuit

functions for the MAX101A:

1) Its nominal voltage gain of 4 reduces the input driving signal to ±250mV differential (assuming a

±0.95V reference).

2) It provides a differential 50Ω input that allows easy

interface to the MAX101A.

Table 1. Output Mode Control

DCLK*

DIV10

* Input clocks (CLK, CLK) = 500MHz for all above combinations. In

(MHz)

OPEN 250

GND 50

all modes, the output clock DCLK will be a 50% duty-cycle signal.

MODE

Normal

Divide

by 2

Test

Divide

by 10

DESCRIPTION

AData and BData valid on opposite DCLK edges (AData on rise,

BData on fall).

AData and BData valid on opposite DCLK edges (AData on rise,

BData on fall). Data sampled at

input CLK rate but 4 out of every

5 samples discarded.

Data Flow

The MAX101A’s internal T/H amplifier samples the analog input voltage for the ADC to convert. The T/H is split

into two sections that operate on alternate negative

clock edges. The input clock, CLK, is conditioned by

the T/H and fed to the A/D section. The output clock,

DCLK, used for output data timing, will be divided by 2

or 10 from the input clock (Table 1). This results in an

output data rate of 250Mbps on each output port in normal mode and 50Mbps in test mode. The differential

inputs, AIN+ and AIN-, are tracked continuously

between data samples. When a negative strobe edge is

sensed, one-half of the T/H goes into hold mode (Figure

4). When the strobe is low, the just-acquired sample is

presented to the ADC’s input comparators. Internal processing of the sampled data takes an additional 15

clock cycles before it is available at the outputs, AData

and BData. See Figures 1–3 for timing.

__________Applications Information

Although the normal operating range is ±250mV, the

MAX101A can be operated with up to ±500mV on each

input with respect to ground. This extended input level

includes the analog signal and any DC common-mode

voltage.

To obtain full-scale digital output with differential

input drive, a nominal +250mV must be applied

between AIN+ and AIN-. That is, AIN+ = +125mV and

AIN- = -125mV (with no DC offset). Mid-scale digital

output code occurs when there is no voltage difference

across the analog inputs. Zero-scale digital output

code, with differential -250mV drive, occurs when AIN+

= -125mV and AIN- = +125mV. Table 2 shows how the

output of the converter stays at all ones (full scale)

when over-ranged or all zeros (zero scale) when underranged.

Analog Input Ranges

MAX101A

______________________________________________________________________________________ 11

Page 12

500Msps, 8-Bit ADC with Track/Hold

Table 2. Input Voltage Range

INPUT

Differential 0 0 1 0 0 0 0 0 0 0 mid scale

MAX101A

Single

Ended

* An offset VIO, as specified in the DC electrical parameters, will

be present at the input. Compensate for this offset by adjusting

the reference voltage. Offsets may be different between side A

and side B.

AIN+

(mV)

+125 -125 1 1 1 1 1 1 1 1 full scale

-125 +125 0 0 0 0 0 0 0 0 zero scale

+250 0 1 1 1 1 1 1 1 1 full scale

-250 0 0 0 0 0 0 0 0 0 zero scale

For single-ended operation:

1) Apply a DC offset to one of the analog inputs, or

leave one input open. (Both AIN+ and AIN- are terminated internally with 50Ω to analog ground.)

2) Drive the other input with a ±250mV + offset to

obtain either full- or zero-scale digital output. If a DC

common-mode offset is used, the total voltage swing

allowed is ±500mV (analog signal plus offset with

respect to ground).

The ADC’s reference resistor is a Kelvin-sensed, resistor string that sets the ADC’s LSB size and dynamic

operating range. Normally, the top and bottom of this

string are driven with an external buffer amplifier. It will

need to supply approximately 19mA due to the 100Ω

minimum resistor string impedance. A ±0.95V reference voltage is normally applied to inputs VART, VBRT,

VARB, and VBRB. The reference inputs VA

VB

, and VB

RTS

RBS

voltages to increase precision.

An RC network at the ADC’s reference terminals is

needed for best performance. This network consists of

a 33Ω resistor connected in series with the buffer output that drives the reference. A 0.47µF capacitor must

be connected near the resistor at the buffer’s output

(see

Typical Operating Circuit

capacitor combination should be located within 0.5

inches of the MAX101A package. Any noise on these

pins will directly affect the code uncertainty and

degrade the ADC’s effective-bits performance.

AIN-

(mV)

0 0 1 0 0 0 0 0 0 0 mid scale

OUTPUT

CODE

Reference

allow Kelvin sensing of the applied

RTS

). This resistor and

MSB to

LSB

, VA

RBS

POSITIVE

REFERENCE

VA

RT

PARASITIC

RESISTANCE

VA

RTS

R

TO

COMPARATORS

R

R

R

,

R

VA

RBS

PARASITIC

RESISTANCE

VA

RB

NEGATIVE

REFERENCE

Figure 5. Reference Ladder

12 ______________________________________________________________________________________

Page 13

500Msps, 8-Bit ADC with Track/Hold

All input and output clock signals are differential. The

input clocks, CLK and CLK, are the primary timing signals for the MAX101A. CLK (pins 2, 62) and CLK (pins

3, 61) are fed to the internal circuitry through an internal

50Ω transmission line. One set of CLK, CLK inputs

should be driven and the other pair terminated by 50Ω

to -2V. Either set of inputs can be used as the driven

inputs (input lines are balanced) for easy circuit connection. A minimum pulse width (t

CLK and CLK (Figures 1–3).

For best performance and consistent results, use a lowphase-jitter clock source for CLK and CLK. Phase jitter

larger than 2ps from the input clock source reduces the

converter’s effective bits performance and causes

inconsistent results. The clock supplied to the

MAX101A is internally divided by two, reshaped, and

buffered. This divided clock becomes the internal signal used as strobes for the converters.

DCLK and DCLK are output clock signals derived from

the input clocks and are used for external timing of the

AData and BData outputs. (AData is valid after the rising edge of DCLK, and BData is valid after the falling

edge.) They are fixed at one-half the rate of the input

clocks in normal mode (Table 1). The MAX101A is

characterized to work with 500MHz maximum input

clock frequencies. See

Typical Operating Circuit

) is required for

PWL

.

Output Mode Control (DIV10)

When DIV10 is grounded, it enables the test mode,

where the input incoming clock is divided by ten. This

reduces the output data and clock rates by a factor of

5, allowing the output clock duty cycle to remain at

50%. The clock to output phasing remains the same

and four out of every five sampled input values are discarded.

When left open, this input (DIV10) is pulled low by internal circuitry and the converter functions in its normal

mode.

CLK and DCLK

Layout, Grounding, and Power Supplies

A +5V ±5% supply as well as a -5.2V ±5% supply is

needed for proper operation. Bypass the VEEand V

supply pins to GND with high-quality 0.1µF and 0.001µF

ceramic capacitors located as close to the package as

possible. Connect all ground pins to a ground plane to

optimize noise immunity and device accuracy. Turn on

the fan before connecting the power supplies. See

Package Information

for the required airflow.

CC

Phase Adjust

This control pin affects the point in time that one-half of

the converter samples the input signal relative to the

other half. PH

but can be adjusted over a ±1.25V range that typically

provides a ±18ps adjustment between the “A” side T/H

bridge strobe and the “B” side T/H bridge strobe.

is normally connected to ground (0V),

ADJ

Interleaving (Input Clock Phasing)

To interleave two MAX101As it is necessary to know on

which positive edge of the input clock data will change.

At power-up, the clock edge from which AData and

BData are synchronized is undetermined. The converter can work from a specific input clock edge, as

described in the following paragraph.

TRK1 and TRK1 are differential inputs that are used in

addition to the normal input clock (CLK) to set data

phasing. A signal at one-half the input clock rate with

the proper setup and hold times (setup and hold typically 300ps) is applied to these inputs. Choose AData

by applying a logic “1” to TRK1 (“0” to TRK1) before

CLK’s negative transition. Choose BData by applying a

logic “0” to TRK1 before CLK’s negative edge (“1” to

TRK1). Voltages at the TRK1 input between ±50mV are

interpreted as logic “1” and voltages between -350mV

and -500mV are interpreted as logic “0”.

MAX101A

______________________________________________________________________________________ 13

Page 14

500Msps, 8-Bit ADC with Track/Hold

____________________________________________________________Pin Configuration

TOP VIEW

MAX101A

ADJ

GND

PH

848382

EE

GND

GND

V

VCCGND

8180797877

GND

AIN76

AIN-

75

AIN+

AIN+

GND

74

72

73

GND

71

70

GND

EE

V

69

GND

GND

686766

TP6

TP5

GND

65

64

VB

VB

PAD

CLK

CLK

GND

TRK1

TRK1

GND

V

VB

RBS

TP4

TP3

RTS

VB

GND

N.C.

GND

V

1

2

3

4

5

6

7

8

CC

9

RB

10

11

12

13

14

RT

15

16

17

B0

18

19

B1

20

B2

21

CC

2425262728

22

23

B7

B6

B5

B4

B3

GND

GND

MAX101A

29

SUB

30

GND

31

DCLK

32

EE

V

33

DCLK

34

GND

35

DIV10

38

37

36

A7

GND

40

39

A6

A5

GND

63

N.C.

62

CLK

61

CLK

60

GND

59

TRK1

58

TRK1

57

GND

56

V

CC

55

VA

RB

54

VA

RBS

53

TP2

52

TP1

51

VA

RTS

50

VA

RT

49

GND

48

N.C.

47

A0

46

GND

45

A1

44

A2

43

V

CC

42

41

A4

A3

Ceramic Flat Pack

14 ______________________________________________________________________________________

Page 15

500Msps, 8-Bit ADC with Track/Hold

___________________________________________________Typical Operating Circuit

+5V

1

+VS

VOUT

GND

MX580LH

WATKINS-JOHNSON

SMRA 89-1 (2x)

0.01µF

2

3

0.01µF

500Ω

1.2k

2k

500Ω

1.2k

500Ω

1.2k

2k

500Ω

1.2k

MC100E116

2.5V

2k

2k

1

/2 MAX412

0.47µF

0.01µF

0.01µF

20k

10k

0.01µF

0.01µF

20k

10k

50Ω

20k

1

/2 MAX412

0.47µF

1

/2 MAX412

0.47µF

50Ω

20k

1

/2 MAX412

0.47µF

-2V

-2V

4, 7, 15, 18, 24, 27, 30, 34,

37, 40, 46, 49, 57, 60, 64, 67, 68,

70, 71, 74, 77, 78, 79, 82, 84

33Ω20Ω

CMPSH-3

50Ω

33Ω20Ω

CMPSH-3

72, 73

75, 76

33Ω20Ω

CMPSH-3

50Ω

33Ω20Ω

CMPSH-3

50Ω

50Ω

8, 21, 43, 56, 81

50

51

54

55

14

13

10

9

62

2

61

3

VA

VA

AIN+

AIN-

VB

VB

VA

VA

VB

VB

CLK

CLK

RT

RTS

RBS

RB

RT

RTS

RBS

RB

GND

+5V

V

CC

MAX101A

SUB VEE

0.1µF

0.001µF

ADATA

DCLK

DCLK

BDATA

PH

ADJ

29 32, 69, 80

-5.2V

33

31

83

0.001µF

MC100E151

D>Q

Q

8

8

+1.25V

-1.25V

D>Q

Q

MC100E151

D>Q

Q

D>Q

Q

PHASE

0.1µF

MAX101A

______________________________________________________________________________________ 15

Page 16

500Msps, 8-Bit ADC with Track/Hold

________________________________________________________Package Information

PIN FIN HEATSINK

FORCED CONVECTION PARAMETERS

23

21

MAX101A

19

17

15

(°C/W)

JA

θ

13

11

45° Angle*

9

7

0 100 200 300 400 500

*DIRECTION OF AIRFLOW ACROSS HEATSINK

0° Angle*

VELOCITY (ft /min)

MAX100-insertB

E1

E

E2

e

PIN #1

C

5°–6°

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

© 1996 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

S

0.060±.005(7x)

D1

D

D2

b

A2 A1

A

D3

0.075±.020(6x)

EQUAL SPACES

84-PIN CERAMIC FLAT

PACK WITH HEAT SINK

E3

0.060±.005

MILLIMETERS INCHES

DIM

MIN MAX MIN MAX

A

17.272

A1

A2

b

C

D

D1

D2

D3

e

E

E1

E2

E3

S

18.288

1.041

1.270

3.048

3.302

0.406

0.508

0.228

0.279

29.184

29.794

44.196

44.704

25.298

25.502

28.448

28.829

1.270 BSC 0.050 BSC

29.184

29.794

44.196

44.704

25.298

25.502

28.194

28.702

1.930

2.184

0.680

0.041

0.120

0.016

0.009

1.149

1.740

0.996

1.120

1.149

1.740

0.996

1.110

0.076

0.720

0.050

0.130

0.020

0.011

1.173

1.760

1.004

1.135

1.173

1.760

1.004

1.130

0.086

Loading...

Loading...