MAXIM MAX1011 Technical data

Quick Start

The MAX1011 EV kit is fully assembled and tested.

Follow these steps to verify proper board operation. Do

not turn on the power supplies until all connections

to the EV kit are completed.

1) Connect a +5V power supply to the pad marked

VCC. Connect this supply’s ground to the pad

marked GND.

2) Connect a +3.3V power supply to the pad labeled

VCCO. Connect the supply ground to the pad

marked OGND.

3) Connect a +3.7V power supply to the pad marked

VTUNE. Connect the supply ground to the GND

pad.

4) Remove the shunt from jumper JU5. This sets a

250mVp-p full-scale range.

General Description

The MAX1011 evaluation kit (EV kit) simplifies evaluation

of the 90Msps MAX1011 6-bit analog-to-digital converter

(ADC). The kit includes the basic components necessary

to operate the on-chip oscillator as a voltage-controlled

oscillator (VCO). The board can also be easily modified to

accommodate an external clocking source.

Connectors for power supplies, analog inputs, and digital

outputs simplify connections to the device. The PC board

features an optimized layout to ensure the best possible

dynamic performance. The EV kit includes a MAX1011.

Features

♦ 5.85 Effective Number of Bits at 20MHz Analog

Input Frequency

♦ Separate Analog and Digital Power and Ground

Connections with Optimized PC Board Layout

♦ Single-Ended or Differential Analog Input

♦ Square-Pin Header for Easy Connection of Logic

Analyzer to Digital Outputs

♦ User-Selectable ADC Full-Scale Gain Ranges

♦ Fully Assembled and Tested Surface-Mount

Board

Evaluates: MAX1011

MAX1011 Evaluation Kit

________________________________________________________________

Maxim Integrated Products

1

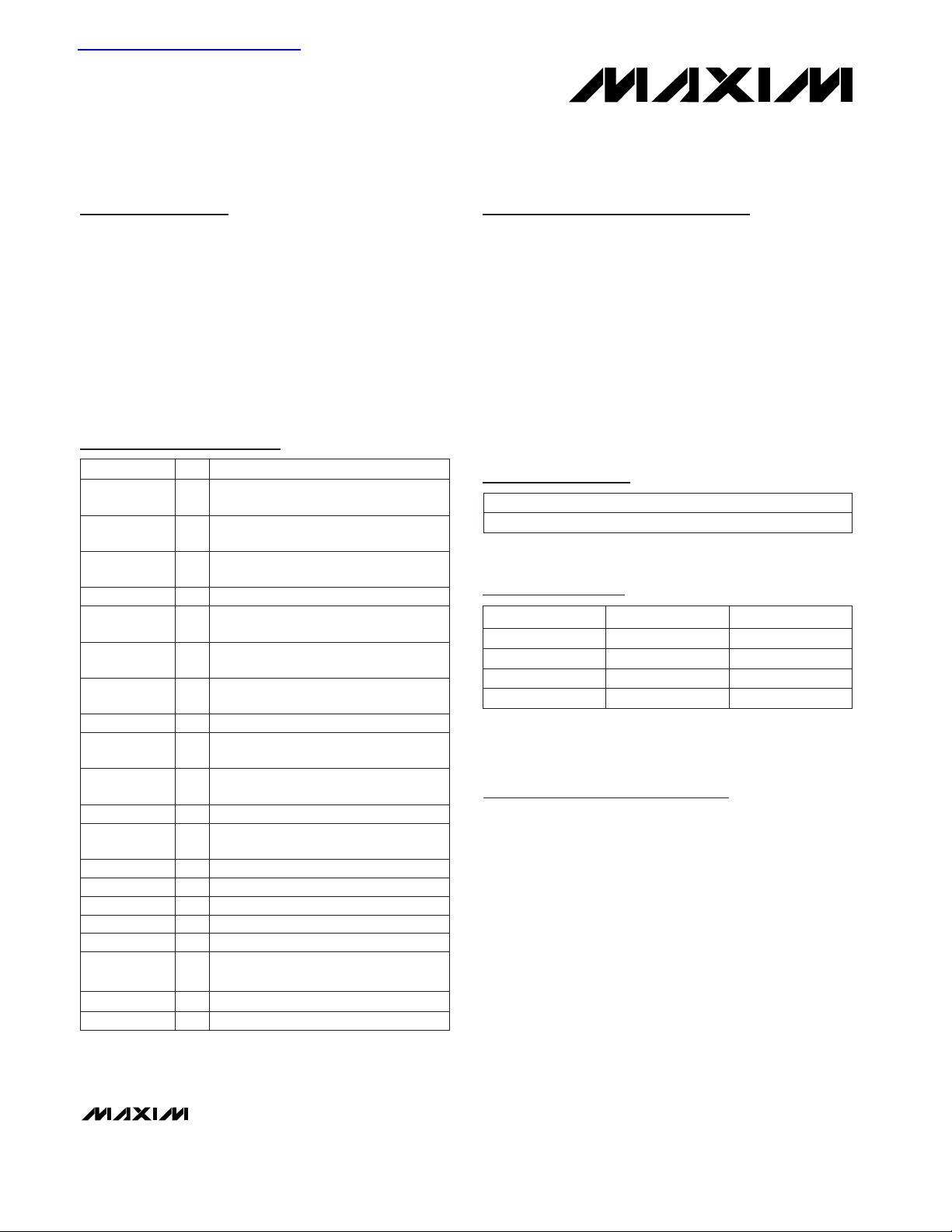

SUPPLIER* PHONE FAX

AVX (803) 946-0690 (803) 626-3123

Component Suppliers

Component List

Ordering Information

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

For small orders, phone 408-737-7600 ext. 3468.

Coilcraft (847) 639-6400 (847) 639-1469

M/A-COM (617) 564-3100 (617) 564-3050

Sprague (603) 224-1961 (603) 224-1430

*

Please indicate that you are using the MAX1011 when contacting these component suppliers.

PART

MAX1011EVKIT 0°C to +70°C

TEMP. RANGE IC PACKAGE

24 QSOP

DESIGNATION QTY DESCRIPTION

C1, C3,

C5

3

0.01µF, 10V min, 10% ceramic

capacitors

C2, C7,

C8

3 47pF, 10V min, 5% ceramic capacitors

C4 1

0.22µF, 10V min, 10% ceramic

capacitor

C6 1 5pF, 10V min, 10% ceramic capacitor

C9, C10 2

0.1µF, 10V min, 10% ceramic

capacitors

D1 1

Varactor diode

M/A-COM MA4ST079CK-287, SOT23

JU1, JU2, JU6 3 0Ω resistors

JU3, JU4 2 2-pin headers

JU5 1 3-pin header

C11, C12 2

10µF, 10V min, 20% tantalum caps

AVX TAJC106K016

J1 1 14-pin connector

R2, R3 2 47kΩ, 5% resistors

R4, R5 2 49.9Ω, 1% resistors

None 1

MAX1011CEG

IN+, IN- 2 BNC connectors

Clock

Overdrive

0 Not Supplied

MAX1011 circuit board

None 1 Shunt for JU5

U1 1

R1 1 10kΩ, 5% resistor

L1 1

220nH inductor

Coilcraft 1008CS-221XKB

19-1335; Rev 0a; 2/98

查询MAX1011EVKIT供应商

Evaluates: MAX1011

5) Connect a 250mVp-p, 20MHz sine-wave source to

the analog input at BNC J3. The analog input is terminated in 50Ω (R4).

6) Connect a logic analyzer to connector J1 to monitor

the digital outputs.

7) Turn on all power supplies and signal sources.

8) Observe the digitized analog input signals with the

logic analyzer.

_______________Detailed Description

EV Kit Jumpers

The MAX1011 EV kit contains several jumpers that control board and part options. The following sections

describe the different jumpers and their purposes.

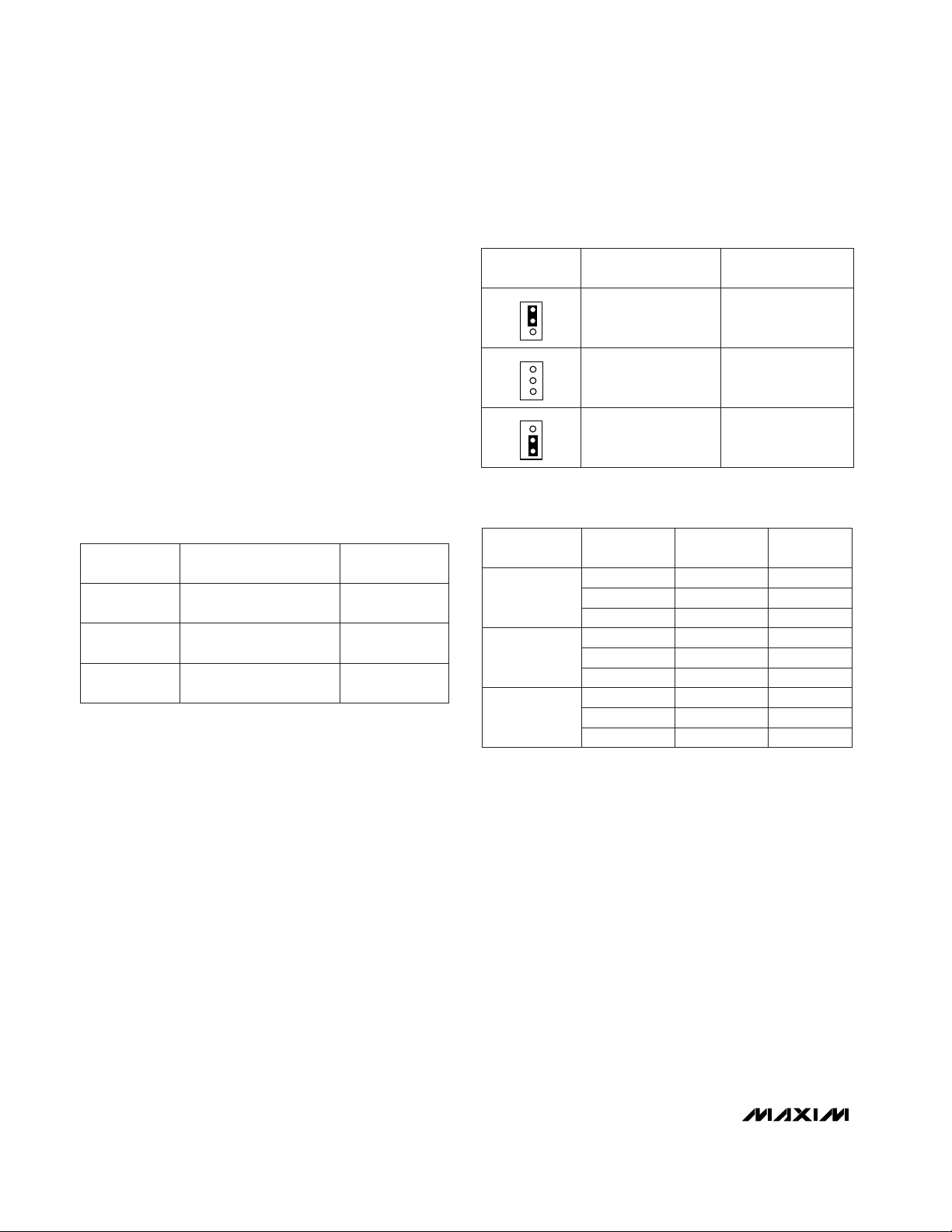

Table 1 lists the jumpers on the EV kit and their default

positions.

Analog Supply Power Requirements

The MAX1011 requires a +5V at approximately 37mA for

the analog VCCsupply. 0Ω resistors are installed at

jumper sites JU1, JU2, and JU6 and can be removed to

sense device power-supply currents with an ammeter.

Digital Outputs Supply

The MAX1011 requires +3.3V for the V

CCO

supply. The

current requirement from the power supply is a function

of the sampling clock and analog input frequencies, as

well as the capacitive loading on the digital outputs.

With 15pF loads and a 20MHz analog input frequency

sampled at 90Msps, the current draw is approximately

8.5mA.

Analog Inputs

The analog inputs to the ADC are provided through

BNC connectors IN+, and IN-. The connectors are terminated with 49.9Ω to ground and are AC coupled to

the converter’s analog inputs, which are internally selfbiased at 2.35V DC. A typical application circuit drives

the IN+ noninverting analog input using AC-coupled

signals. The nominal 20kΩ input resistance of the ana-

log inputs, plus the 0.1µF AC-coupling capacitor value,

sets the low-frequency corner at approximately 80Hz.

You can drive the analog inputs either single-ended or

differentially using AC- or DC-coupled inputs. Either the

inverting or the noninverting input can be driven singleended. If the inverting input is driven, then the digital

output codes are inverted (complemented). Refer to the

MAX1011 data sheet for typical circuits.

ADC Gain Selection

The single GAIN-select pin on the MAX1011 controls

the full-scale input range. Jumper JU5 is used to manually select the desired gain range as shown in Table 2.

The EV kits are shipped with the mid-gain range selected (jumper pins open).

Table 3 lists the possible input-drive combinations

for the mid-gain (250mVp-p) full-scale range selection.

Drive levels are referenced to the open-circuit,

common-mode voltage of the analog inputs (typically

MAX1011 Evaluation Kit

2 _______________________________________________________________________________________

Open

Offset-correction

amplifier enabled

JU3, JU4

Shorted with 0Ω

resistors

Power-supply currentsense ports

JU1, JU2,

JU6

DEFAULT

POSITION

FUNCTIONJUMPER(S)

Open

ADC full-scale range

selection

JU5

Mid-gain, 250mVp-p

OPEN

Low-gain, 500mVp-pGND

ADC GAIN RANGE

MAX1011 GAIN

CONTROL PIN

JU5 SETTING

High-gain, 125mVp-pV

CC

INPUT DRIVE

Single-Ended

Noninverting

0

+125mV

IN+

-125mV

Open Circuit

Open Circuit

IN-

Open Circuit

100000

111111

OUTPUT

CODE

000000

Open Circuit

Open Circuit

Open Circuit

0

+125mV

-125mV

Single-Ended

Inverting

011111

000000

111111

0

+62.5mV

-62.5mV

0

-62.5mV

+62.5mV

Differential

100000

111111

000000

JU5

1

2

3

JU5

1

2

3

JU5

1

2

3

Table 1. EV Kit Jumpers and Default

Positions

Table 2. Gain-Selection Jumper JU5

Settings

Table 3. Typical Input-Drive Requirements

for Mid-Gain

Evaluates: MAX1011

MAX1011 Evaluation Kit

_______________________________________________________________________________________ 3

2.35V) if DC coupled, or to ground if AC coupling is

used. If the low-gain (500mVp-p) range is selected, the

input-drive requirements are twice those listed in Table

3. If the high-gain (125mVp-p) range is selected, the

input-drive requirements are half those listed in Table 3.

Offset-Correction Amplifier

The offset-correction amplifier included on the

MAX1011 is usually enabled in a typical AC-coupled

application circuit. For DC-coupled applications, the

amplifier must be disabled by installing shorting blocks

on jumpers JU3 and JU4. These jumpers short device

pins OCC+ (pin 2) and OCC- (pin 3) to ground and disable the amplifier. The MAX1011 EV kit is configured

with the offset-correction amplifier enabled (jumpers

open) and AC-coupled analog inputs.

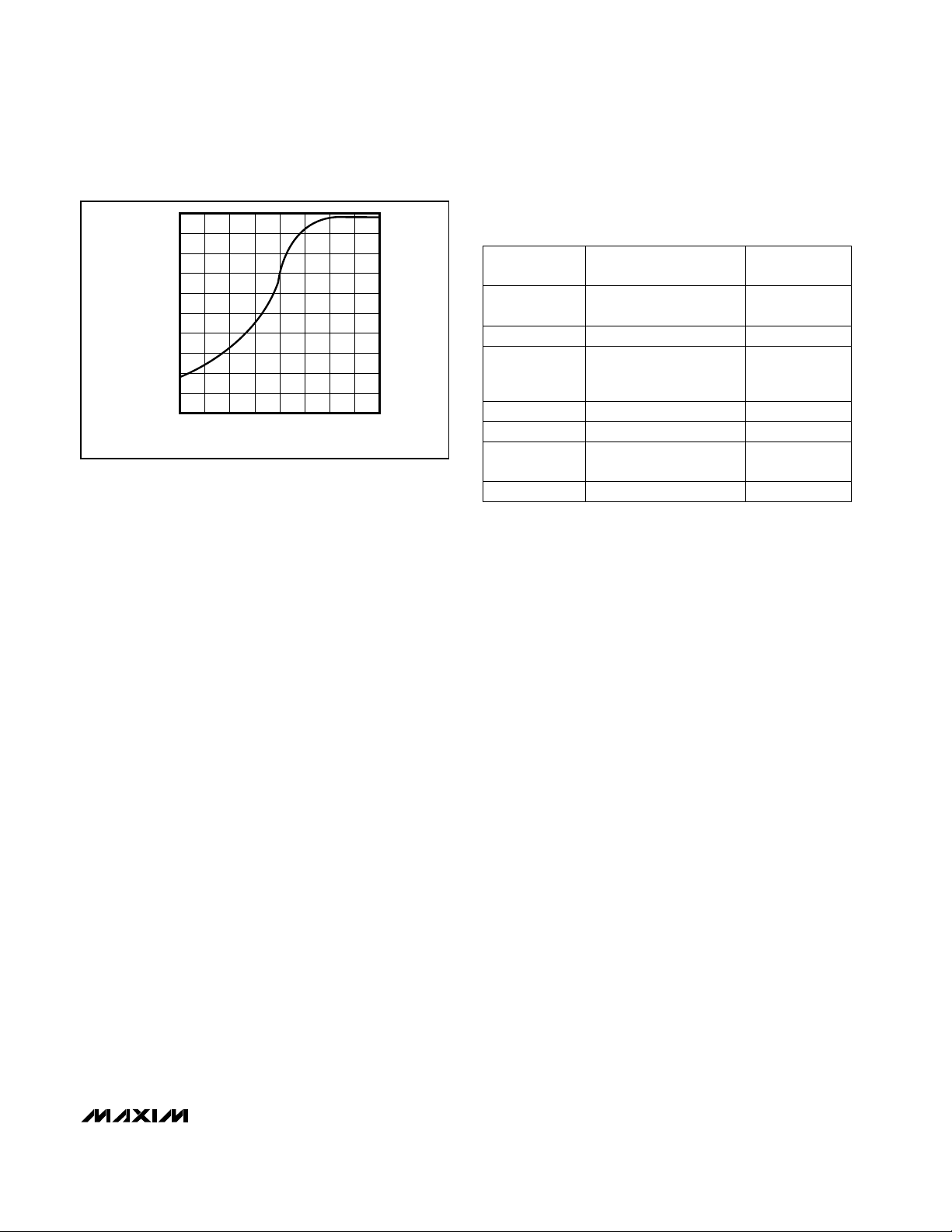

Voltage-Controlled-Oscillator Operation

The EV kit includes a voltage-controlled-oscillator

(VCO) circuit to set the analog-to-digital converter

(ADC) sampling rate using an external resonant tank

and a varactor diode. A voltage applied to the VTUNE

pad changes the varactor diode’s capacitance to

adjust the tank’s resonant frequency, which sets the

oscillator’s sampling frequency. VTUNE voltage can be

varied from 0V to a maximum of 8V.

The EV kit is designed so that a nominal VTUNE control

voltage of about 3.7V sets the ADC sampling rate to

90Msps. The VTUNE control voltage should be well filtered, as any noise on the supply contributes to jitter in

the internal oscillator and degrades the converter’s

dynamic performance. Figure 1 shows the VTUNE

control-voltage typical frequency-adjustment range for

the MAX1011 EV kit (for VCO mode, refer to schematic

in Figure 2).

External Clock Operation

The MAX1011 EV kit can be converted to drive the ADC

from an external clock source. This involves removing

the external resonator components from the VCO circuit

and adding a few new components. Table 4 lists the EV

kit changes required to convert the board to accept an

external clock source. The resulting schematic is

shown in Figure 3.

The new 49.9Ω value of R3 shown in Figure 3 provides

proper termination for a 50Ω external signal generator.

AC-coupling capacitor C7 couples the external clock

signal to the MAX1011 oscillator circuitry at TNK+ (pin

7). R2 and C8 ensure that the impedance at both ports

of the oscillator is balanced. After all modifications are

complete, connect an external clock source to the BNC

connector on the EV kit marked CLOCK OVERDRIVE

(J2). The recommended clock amplitude is 1Vp-p; however, the ADC operates correctly with as little as

300mVp-p or up to 1.25Vp-p on CLOCK OVERDRIVE.

The external clock source should have low-phase noise

for best dynamic performance. A low-phase-noise

sine-wave oscillator serves this purpose well. A squarewave clock source is not necessary to drive the

MAX1011. The device contains sufficient gain to amplify even a low-level-input sine wave to drive the ADC

comparators, while ensuring excellent dynamic performance.

60

70

65

80

75

90

85

95

105

100

110

0 2 31 4 5 6 7 8

MAX1011 Fig01

VTUNE CONTROL VOLTAGE (V)

FREQUENCY (MHz)

Figure 1. MAX1011 Oscillator Frequency vs. VTUNE Control

Voltage

D1 RemoveVaractor diode

R1

R2, R3

L1

Replace with

49.9Ω resistors

47kΩ resistors

Remove

Remove

220nH inductor

10kΩ resistor

Replace with

0.01µF capacitors

MODIFICATION

Add

Remove

C6

C7, C8

Clock Overdrive

(J2)

COMPONENT

47pF capacitors

DESCRIPTION

Clock input BNC

connector

5pF capacitor

Table 4. External Clock Source EV Kit

Modifications

Loading...

Loading...